Allen-Bradley 842E-SIP1BA, 842E-SIP6BA, 842E-SIP3BA, 842E-SIP4BA, 842E-SIP2BA User Manual

...Page 1

User Manual

Original Instructions

EtherNet/IP™Absolute Encoder

Catalog Numbers 842E-SIP1BA. 842E-SIP2BA, 842E-SIP3BA, 842E-SIP4BA, 842E-SIP5BA, 842E-SIP6BA, 842E-SIP7BA,

842E-SIP8BA, 842E-SIP9BA, 842E-SIP10BA, 842E-SIP11BA, 842E-SIP12BA, 842E-MIP1BA, 842E-MIP2BA, 842E-MIP3BA,

842E-MIP4BA, 842E-MIP5BA, 842E-MIP6BA, 842E-MIP7BA, 842E-MIP8BA, 842E-MIP9BA, 842E-MIP10BA, 842E-MIP11BA,

842E-MIP12BA

Page 2

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are

required to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may

be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Page 3

Table of Contents

Preface

About This Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Purpose of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Common Techniques Used in This Manual . . . . . . . . . . . . . . . . . . . . . . .6

Chapter 1

Safety Authorized Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Correct Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

General Safety Notes and Protective Measures . . . . . . . . . . . . . . . . . . . . .8

Environmental Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Chapter 2

Encoder Overview Overview of the Encoder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

What Is an Encoder?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

What Are the Different Kinds of Encoders? . . . . . . . . . . . . . . . . . . .9

842E Encoder Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Configurable Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

The Electronic Data Sheet File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operating Principle of the Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

The 842E-SIP-xxx EtherNet/IP Is a Single-turn Encoder . . . . . 11

The 842E-MIP-xxxEtherNet/IP Is a Multi-turn Encoder . . . . . 11

Scalable Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

842E EtherNet/IP Is Firmware-flash Gradable Using

Control Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Special Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

EtherNet/IP Overview Use of the Common Industrial Protocol . . . . . . . . . . . . . . . . . . . . . . . . 13

Rockwell Automation Publication 842E-UM001C-EN-P - September 2016 3

Chapter 3

TCP/IP and UDP/IP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

MAC Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Communication Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Understanding the Producer/Consumer Model . . . . . . . . . . . . . . . . . 15

Specifying the Requested Packet Interval . . . . . . . . . . . . . . . . . . . . . . . . 16

EtherNet/IP Topologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Star Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Linear Topology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Device Level Ring Topology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Endless Shaft Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Enabling Endless Shaft Functionality. . . . . . . . . . . . . . . . . . . . . . . . 18

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

CIP Object Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Position Sensor Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Page 4

Table of Contents

Identity Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Assembly Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

I/O Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Config . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Chapter 4

Installation Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Shaft Rotation Direction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Mounting with a Solid Shaft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Mounting with a Hollow Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Electrical Wiring Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Preset Push Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Network Address Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Configuring the Encoder for Your

EtherNet/IP Network

Configuring the 842 E Encoder

Using RSLogix 5000®

Chapter 5

Setting the IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Assigning the Last Octet in an IP Address Scheme of 192.168.1.xxx

Using the Network Address Switches . . . . . . . . . . . . . . . . . . . . . . 43

Assigning the IP Address Using BootP/DHCP . . . . . . . . . . . . . . 44

Chapter 6

Example: Installing the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Configuring the Encoder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Installing the Add-on Profile in RSLogix 5000. . . . . . . . . . . . . . . . . . . 49

General Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Ethernet Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Module Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Connection Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Module Info Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Configuration Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Internet Protocol Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Network Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Default Encoder Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Preset Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

RSLogix 5000 Controller Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4 Rockwell Automation Publication 842E-UM001C-EN-P -September 2016

Page 5

Table of Contents

Chapter 7

Diagnostics and Troubleshooting Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Self-test Via EtherNet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Warnings, Alarms, and Errors Via EtherNet/IP. . . . . . . . . . . . . . . . . . 65

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Appendix A

Installing the Add-on Profile Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Performing the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Appendix B

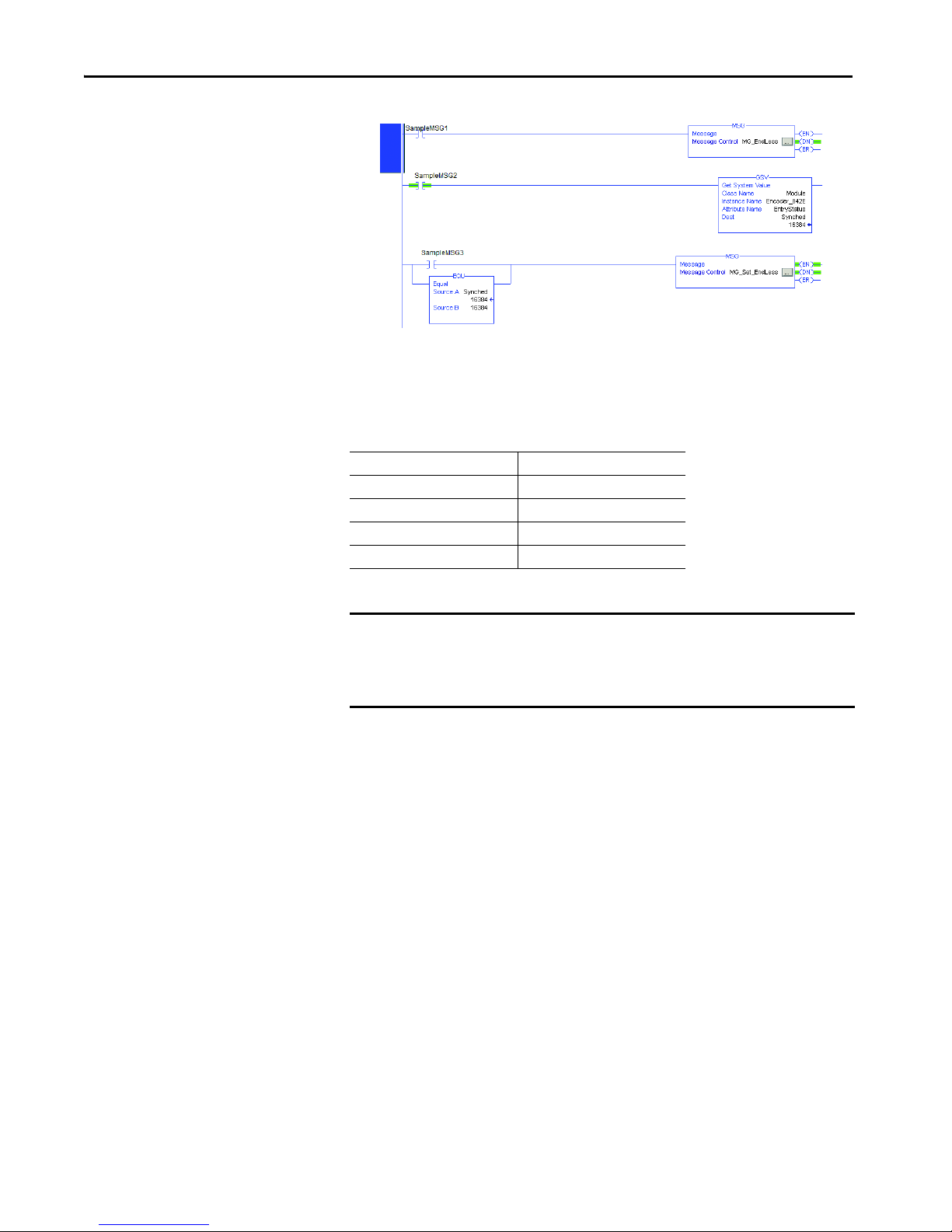

RSLogix 5000® Sample Code Linear Scaling Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Installing Your Project. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Using an Explicit Message Configuration to Set Preset

Encoder Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Using an Explicit Message Configuration to Read Preset

Encoder Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Using an Explicit Message Configuration to Obtain the Encoder

Run-time in Seconds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Rockwell Automation Publication 842E-UM001C-EN-P - September 2016 5

Page 6

Table of Contents

Notes:

6 Rockwell Automation Publication 842E-UM001C-EN-P -September 2016

Page 7

Preface

About This Document

Who Should Use This Manual

Purpose of This Manual

Read this section to familiarize yourself with the rest of the manual. It provides

information concerning:

• Who should use this manual

•The purpose of this manual

• Related documentation

• Conventions that are used in this manual

Use this manual if you are responsible for designing, installing, programming,

or troubleshooting control systems that use 842E EtherNet/IP encoder.

You should have a basic understanding of electrical circuitry and familiarity

with relay logic. If you do not, obtain the proper training before using this

product.

This manual is a reference guide for the 842E EtherNet/IP encoders. It

describes the procedures that you use to install, wire, and troubleshoot your

encoder. This manual:

• Gives you an overview of the 842E EtherNet/IP encoders

• Explains how to install and wire your encoder

Related Documentation

Common Techniques Used in

This Manual

The following documents contain additional information concerning

Rockwell Automation® products. To obtain a copy, contact your local

Rockwell Automation® office or Allen-Bradley distributor.

Resource Description

Installation Instructions

842E EtherNet/IP Multi-turn Encoders

EtherNet/IP Modules in Logix5000™ Control

Systems User Manual, publication ENET-UM001

Getting Results with RSLogix 5000®,

publication 9399-RLD300GR

Allen-Bradley® Industrial Automation Glossary,

AG-7. 1

Pub. # 10000169360

A manual on how to use EtherNet/IP modules with

Logix5000™ controllers and communicate with various devices

on the Ethernet network

Information on how to install and navigate RSLogix 5000®. The

guide includes troubleshooting information and tips on how to

use RSLogix 5000® effectively.

A glossary of industrial automation terms and abbreviations

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not procedural steps.

• Numbered lists provide steps or hierarchical information.

• Italic type is used for emphasis.

Rockwell Automation Publication 842E-UM001C-EN-P - September 2016 7

Page 8

Preface

Notes:

8 Rockwell Automation Publication 842E-UM001C-EN-P -September 2016

Page 9

Authorized Personnel

Chapter 1

Safety

This chapter deals with your own safety and the safety of the equipment

operators.

Read this chapter carefully before working with the 842E EtherNet/IP encoder

or the machine or system in which the 842E EtherNet/IP encoder is used.

ATT EN TI ON : Only authorized personnel can install, commission, and service

the 842E EtherNet/IP encoder.

Only trained and authorized Rockwell Automation® service personnel can make

repairs to the 842E EtherNet/IP encoder.

Correct Use

The following qualifications are necessary for the various tasks:

Activity Qualification

Mounting Basic technical training

Knowledge of the current safety regulations in the workplace

Electrical installation and

replacement

Commissioning, operation, and

configuration

Practical electr ical training

Knowledge of current electrical safety regulations

Knowledge on the use and operation of devices in the related application (for

example, industrial robots, storage, and conveyor technology)

Knowledge on the current safety regulations and the use and operation of

devices in the related application

Knowledge of automation systems (for example, Rockwell Automation®

ControlLogix® controller)

Knowledge of EtherNet/IP

Knowledge of the usage of automation software (for example, Rockwell

Automation RSLogix™)

The 842E EtherNet/IP Absolute Encoder is an instrument that is

manufactured in accordance with recognized industrial regulations. It also

meets the quality requirements as per ISO 9001:2008 and of an environment

management system as per ISO 14_001:2009.

Rockwell Automation Publication 842E-UM001C-EN-P - September 2016 9

An encoder is a device for mounting that cannot be used independently of its

foreseen function. For this reason, an encoder is not equipped with immediate

safety devices. As per statutory regulations, the operator of the system provides

considerations for the safety of personnel and systems. Due to its design, the

842E EtherNet/IP can only be operated within an EtherNet/IP network. It is

Page 10

Chapter 1 Safety

General Safety Notes and

Protective Measures

necessary to comply with the EtherNet/IP specifications and guidelines for

installing an EtherNet/IP network. If any modifications are made to the 842E

EtherNet/IP encoder, any warranty claim against Rockwell Automation is

rendered void.

ATT EN TI ON : Observe the following procedures to confirm the correct and

proper use of the 842E EtherNet/IP encoder.

Qualified personnel with knowledge of electronics, precision mechanics, and

control system programming install and maintain the encoder. It is necessary to

comply with the related standards for the technical safety stipulations.

All persons who install, operate, or maintain the device have to meet the safety

regulations:

• The operating instructions must always be available and must always be

followed.

• Unqualified personnel are not allowed to be present in the vicinity of the

system during installation.

• The system is to be installed in accordance with all applicable safety

regulations and the mounting instructions.

• All work safety regulations of the applicable countries are to be followed

during installation.

• Failure to follow all applicable health and safety regulations results in

personal injury or damage to the system.

• The current and voltage sources in the encoder are designed in accordance

with all applicable technical regulations.

Environmental Protection

10 Rockwell Automation Publication 842E-UM001C-EN-P - September 2016

Note the following information on disposal.

Assembly Material Disposal

Packaging Cardboard Waste paper

Shaft Stainless steel Scrap metal

Flange Aluminum Scrap metal

Housing Aluminum Die-cast Scrap metal

Electronic assemblies Various Hazardous waste

Page 11

Chapter 2

Encoder Overview

The 842E family of encoders uses EtherNet/IP technology to provide its data

to a programmable controller. These encoders include an embedded

EtherNet/IP switch to connect additional EtherNet/IP capable products in

series and/or support a Device Level Ring (DLR) topology for Ethernet media

redundancy.

The 842E is an ultra-high resolution encoder in single-turn and multi-turn

versions. These encoders have 18-bit single-turn resolution. The multi-turn has

an additional 12 bits for counting the number of revolutions.

Overview of the Encoder

What Is an Encoder?

Encoders can electronically monitor the position of a rotating shaft to measure

information such as speed, distance, RPM, and position. Rockwell

Automation® offers various light- and heavy-duty incremental and absolute

encoders. Our accessories help you easily install and efficiently use our

encoders.

What Are the Different Kinds of Encoders?

Incremental

A simple and cost-effective solution for a wide variety of applications,

incremental encoders electronically monitor the position or speed of a rotating

shaft. Encoder feedback is compatible with programmable controllers,

numerical controllers, motion controllers, and other position systems.

Rockwell Automation® offers light-duty and heavy-duty incremental encoders

for different shaft loads. Ruggedized incremental encoders are available with an

enclosure rating of NEMA Type 4 and IP66. Incremental encoders are also

available in solid and hollow shaft models for various mounting options.

Applications include: machine tools, packaging machinery, motion controls,

robotics, and DC drives.

Rockwell Automation Publication 842E-UM001C-EN-P - September 2016 11

Absolute

An absolute encoder has a unique digital output for each shaft position. The

use of absolute encoders assures that true position is always available, regardless

of power interruptions to the system. Absolute encoders can be single-turn or

multi-turn.

Page 12

Chapter 2 Encoder Overview

Multi-turn units assign a unique digital output for each shaft position across

multiple shaft rotations and have high-resolution capability. Rockwell

Automation absolute encoders are available with an enclosure rating of NEMA

Type 4 and IP66, and various mounting options. Applications include steel

mills, overhead cranes, punch presses, transfer lines, oil rigs, wind mills,

machine tools, and packaging.

Sine-cosine

A sine-cosine encoder is a position transducer, which uses two sensors, each 90°

out of phase from each other. Sine-cosine encoders are able to be used directly

by the drive or squared to provide a conventional A quad B digital signal.

Therefore, the sine-cosine encoder can be used as an absolute, sine-cosine, or

incremental feedback device.

Single-turn vs. Multi-turn

Absolute encoders are either single-turn or multi-turn. Single-turn encoders are

used if the absolute position of the shaft for one revolution is required. Multiturn encoders are used if the absolute position is required for multiple shaft

revolutions.

842E Encoder Features

The 842E EtherNet/IP encoder features include:

• Support for the encoder profile 22h (0x22) defined in the Common

Industrial Protocol (CIP

• Compatibility with star, linear, and Device Level Ring topology

• Robust nickel code disk for harsh ambient conditions

• Configurable resolution per revolution: 1 to 262,144

• High precision and availability

• Ball bearings are spaced 30 mm (1.18 in.) apart for longer life

• Face mount flange and servo flange/blind hollow shaft and through

hollow shaft

• 18-bit single turn resolution

• 30-bit total resolution multi-turn resolution

• Endless shaft

•ControlFLASH™ update compatible

IMPORTANT A Series A encoder cannot be updated to a Series B. A Series B encoder must

be purchased to update future firmware. Series A does not have

ControlFLASH update capability.

™), according to IEC 61784-1

12 Rockwell Automation Publication 842E-UM001C-EN-P - September 2016

Page 13

Encoder Overview Chapter 2

Configurable Parameters

The Electronic

Data Sheet File

Operating Principle of the

Encoder

The EtherNet/IP technology allows for certain encoder parameters to be

configured over the network.

•Count direction

•Counts per revolution

• Preset value

•Velocity output

• IP addressing

The electronic data sheet (EDS) file contains all information that is related to

the measuring-system-specific parameters and the operating modes of the 842E

EtherNet/IP encoders. The EDS file is integrated using the EtherNet/IP

network configuration tool to configure and place in operation the 842E

EtherNet/IP encoder

For more information, go to www.rockwellautomation.com/resources/eds/

and search on “842E.”

The 842E EtherNet/IP encoder acquires the position of rotating axes and

outputs the position in the form of a unique digital numeric value. Optical

acquisition of the rotary position value is from an internal coded disk.

The 842E-SIP-xxx EtherNet/IP Is a Single-turn Encoder

Single-turn encoders are used if the absolute position of the shaft for one

revolution is required.

The 842E-MIP-xxxEtherNet/IP Is a Multi-turn Encoder

Multi-turn encoders are used if the absolute position is required for multiple

shaft revolution.

Scalable Resolution

The steps per revolution and the total resolution can be scaled and adapted to

the related application.

The steps per revolution can be scaled in integers from 1…262,144. The total

n

resolution of the 842E-MIP Multi-turn EtherNet/IP encoder must be 2

the steps per revolution. This restriction is not relevant if the round axis or

endless shaft functionality is activated.

times

Rockwell Automation Publication 842E-UM001C-EN-P - September 2016 13

Page 14

Chapter 2 Encoder Overview

Special Features

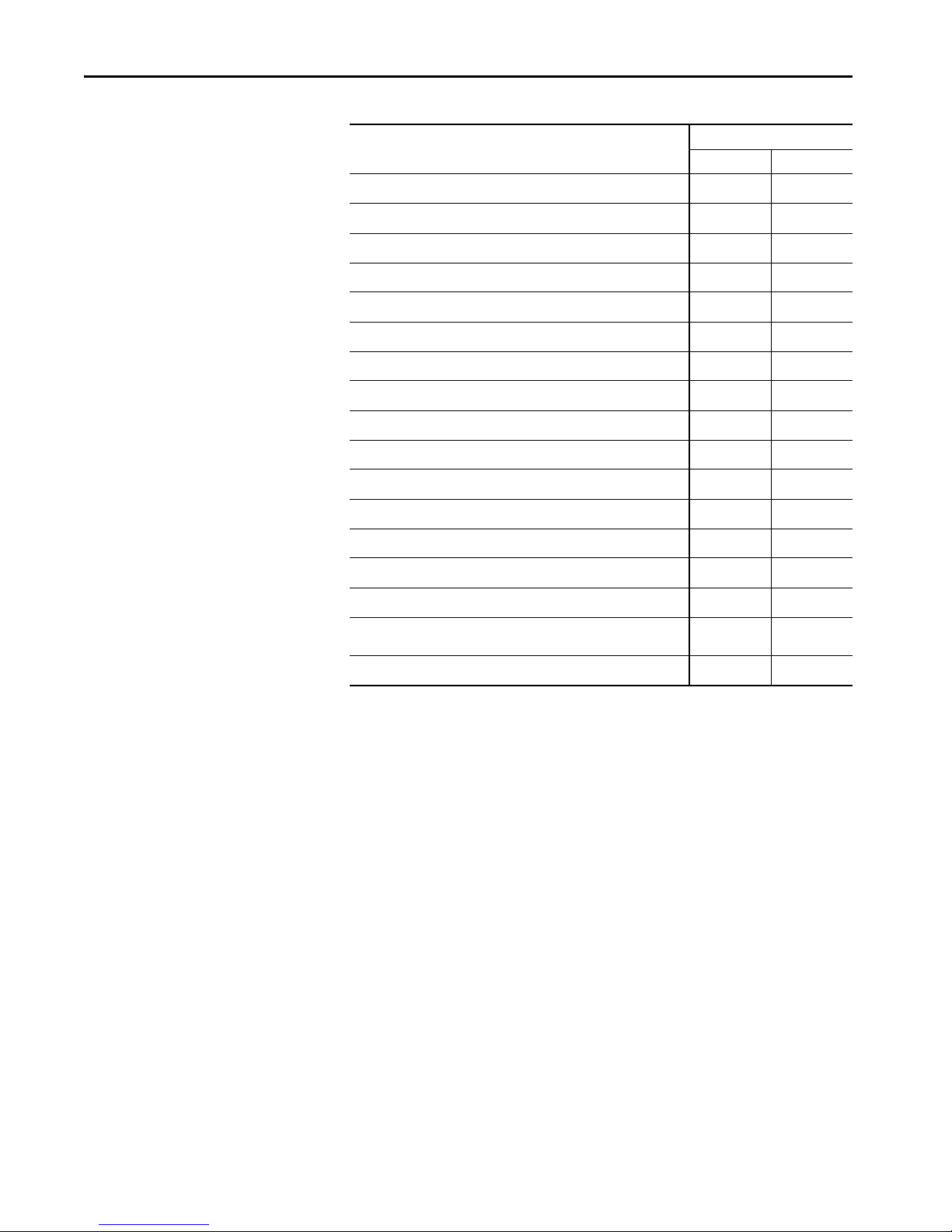

Properties Encoder

Single-turn Multi-turn

Absolute Encoder in 60 mm (2.36 in.) design

Robust nickel code disk for harsh environment

High precision and reliability

Ball bearings are spaced 30 mm (1.18 in.) apart

High level of resistance to vibration

Optimal rotational accuracy

Compact design

Face mount flange, servo flange and blind

Hollow shaft

ControlFLASH upgradable

18-bit single-turn resolution (1 to 262,144 steps)

30-bit total resolution

12-bit multi-turn resolution (1…4,096 revolutions)

Round axis functionality/endless shaft functionality

■■

■■

■■

■■

■■

■■

■■

■■

■■

■■

■■

■

■

■

EtherNet/IP interface (as per IEC 61784-1)

Supports the encoder profile 22h defined in the CIP (Common Industrial

Protocol)

Device Level Ring (DLR)

■■

■■

■■

14 Rockwell Automation Publication 842E-UM001C-EN-P - September 2016

Page 15

Chapter 3

IP

UDP

TCP

HTTPFTP CIP

Ethernet

Process layer

Communication

layers

Explicit messagin

Implicit messagin

Physical layer

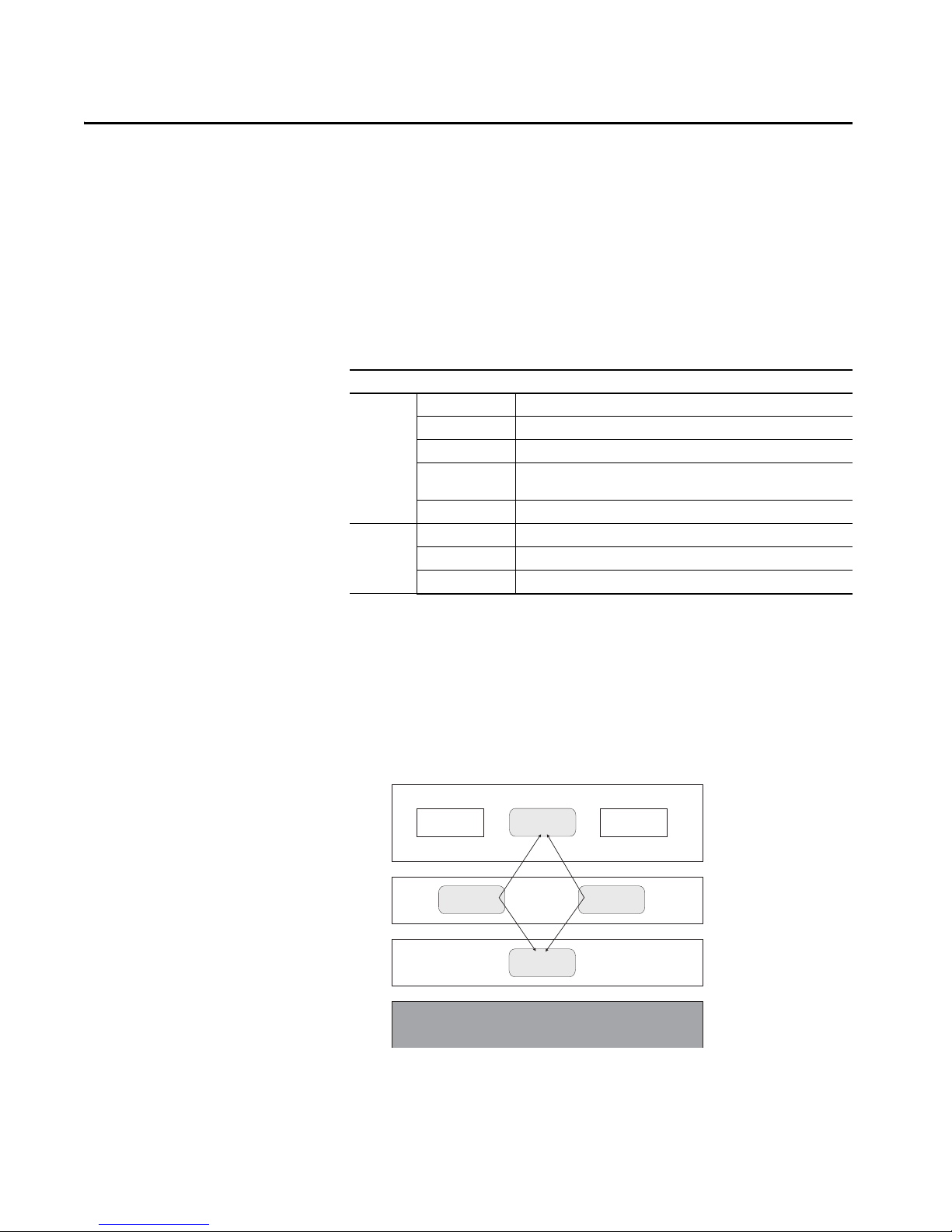

EtherNet/IP Overview

Ethernet Industrial Protocol (EtherNet/IP) is a frame-based computer

networking technology for local industrial area networks. It follows the seven

layers of the Open Systems Interconnection model:

OSI Model

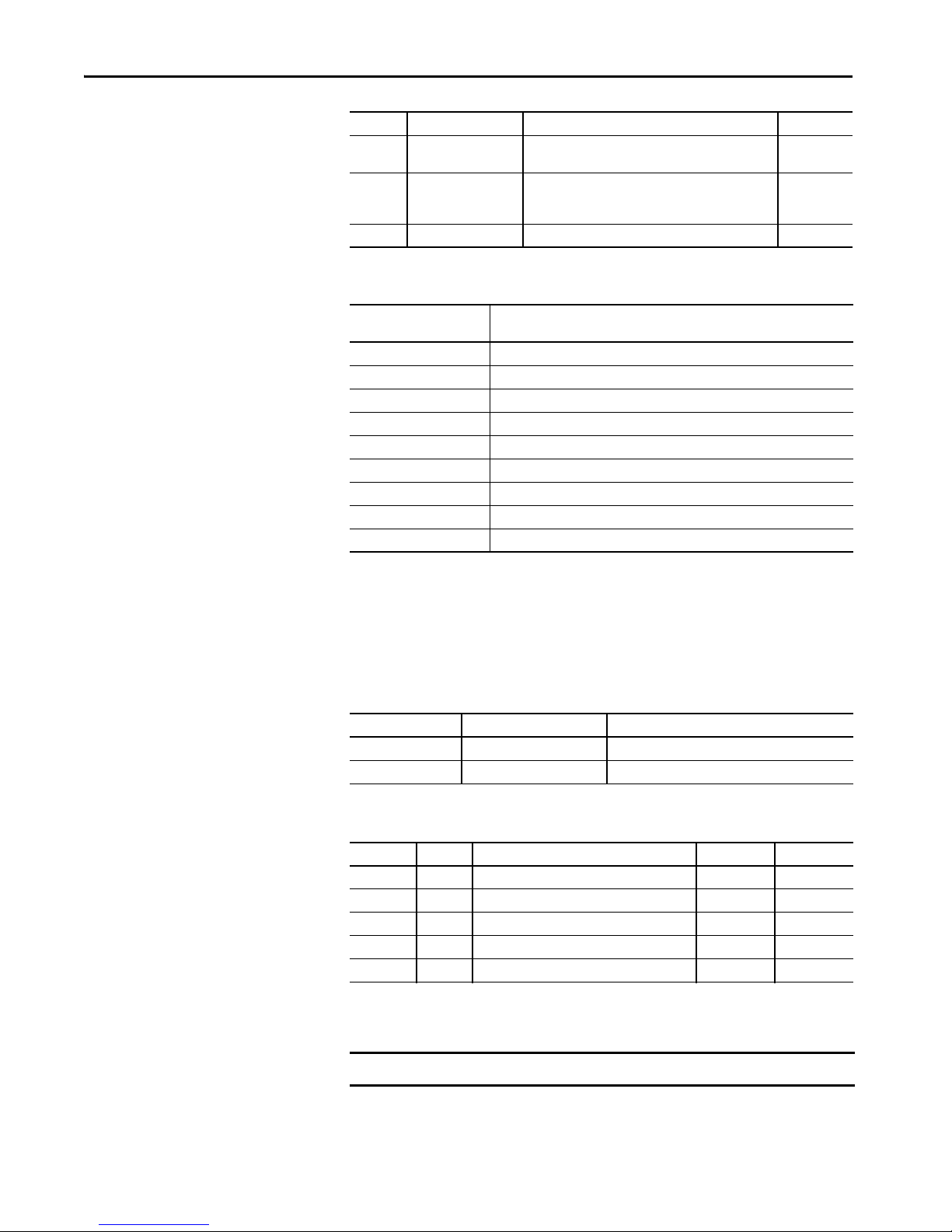

Host Layers Layer Function

7. Application Network process to application

6. Presentation Data, encryption

Media

Layers

5. Session Inter-host communication

4. Transport Flow control, TCP/UDP

3. Network Internet protocol, logical addressing

2. Data Link Physical addressing

1. Physical Media, signal and binary transmission, peer-to-peer, multicast, unicast

Explicit and implicit messaging

Use of the Common

Industrial Protocol

EtherNet/IP implements the Common Industrial Protocol (CIP), the

application layer protocol specified for EtherNet/IP.

EtherNet/IP uses the CIP on the process layer. The 842E encoder meets the

requirements of the EtherNet/IP protocol according to IEC 61784-1 and the

requirement of the encoder profile.

g

Figure 1

g

Rockwell Automation Publication 842E-UM001C-EN-P - September 2016 15

Page 16

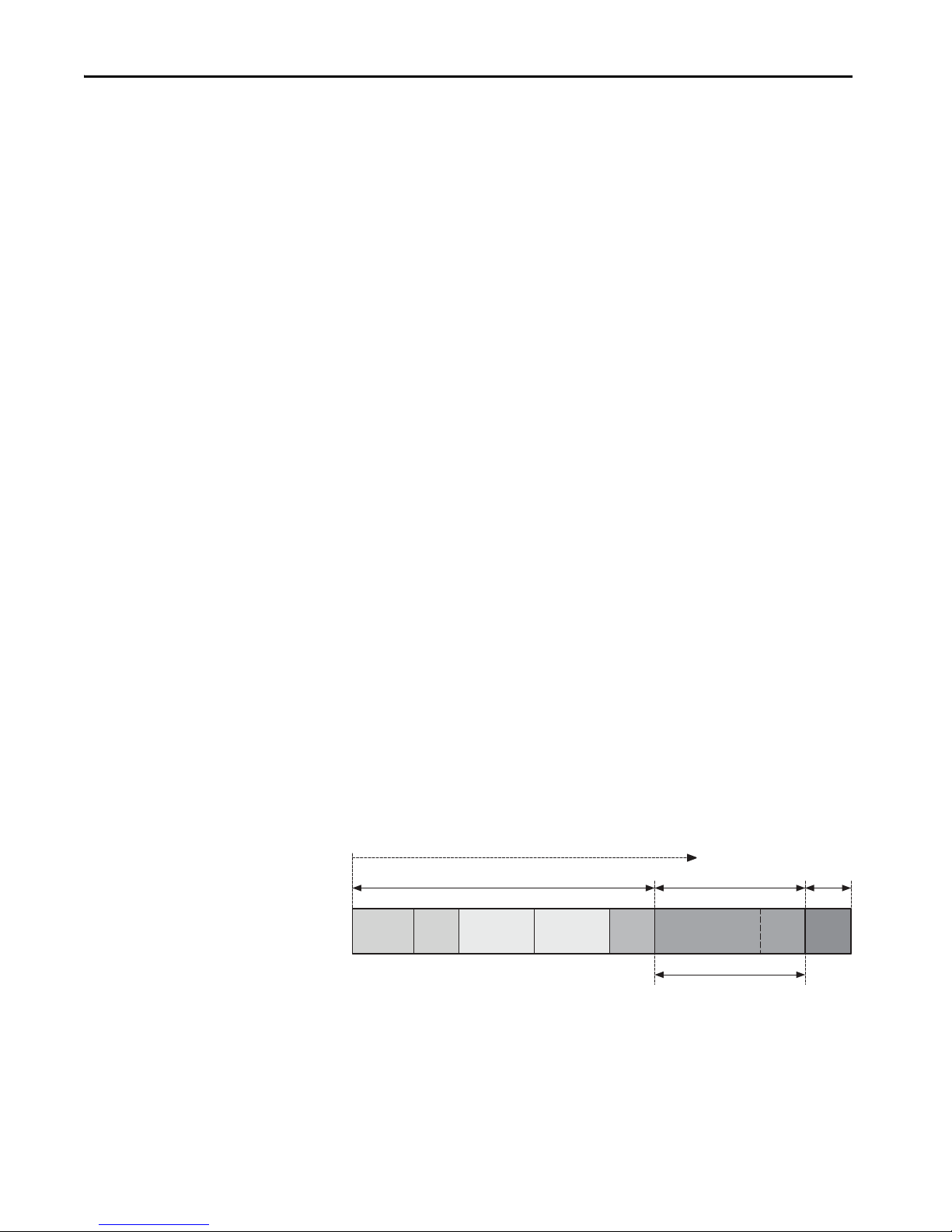

Chapter 3 EtherNet/IP Overview

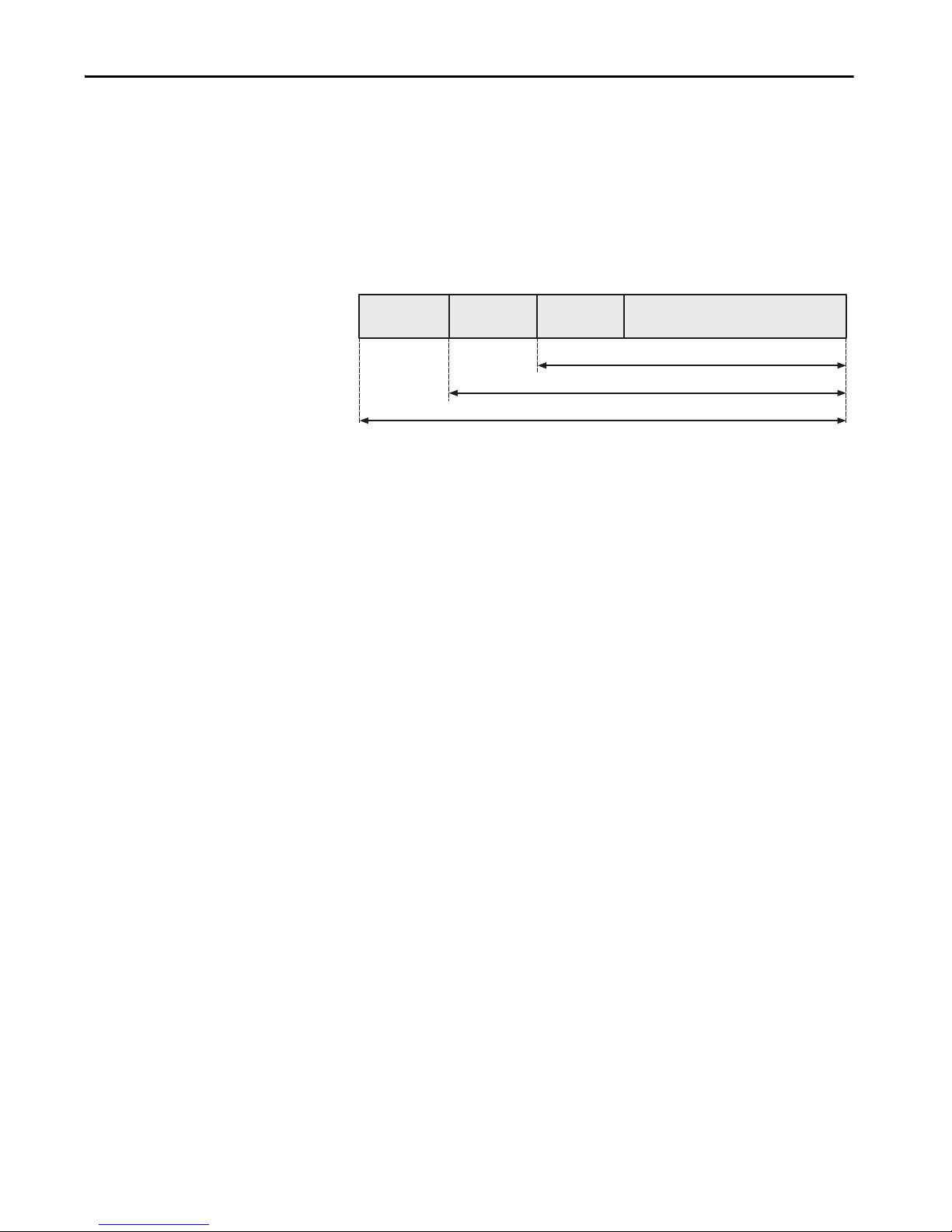

Transmission sequence

Data field

Trailer

Header

Destination

Address

Source

Address

46...1500 Byte

The encoder is an I/O adapter in the EtherNet/IP. It receives and sends explicit

and implicit messages either cyclic or on request (polled).

TCP/IP and UDP/IP

EtherNet/IP uses TCP/IP or UDP/IP for communication. (TCP is

transmission control protocol and UDP is user datagram protocol.)

Implicit messaging is used for real-time communication between a

programmable logic controller (PLC) and the encoder in EtherNet/IP. With

implicit messaging a connection is established between exactly two devices

within the CIP protocol. Implicit messaging uses UDP/IP via port 2222.

Explicit Messaging is used in EtherNet/IP for communication that does not

need to take place in real time. Explicit Messaging uses TCP/IP; it is used, for

example, to transfer parameters from the PLC to the encoder.

MAC ID

Devices that originate or use data on the network have factory-assigned media

access control (MAC) addresses for unique identification. The MAC ID

(MAC ID) consists of 6 bytes. The first three bytes identify the manufacturer.

The last three bytes are unique to the device. An example of a MAC ID is

00:00:BC:C9: D7:14.

Communication Frame

EtherNet/IP is based on the standard Ethernet frame. The frame contains the

Ethernet header, the Ethernet data, and the Ethernet trailer. The MAC IDs of

the receiver (destination address) and of the source (source address) are

contained in the Ethernet header.

16 Rockwell Automation Publication 842E-UM001C-EN-P - September 2016

Figure 2

Page 17

EtherNet/IP Overview Chapter 3

IP header TCP/UDP header CIP header CIP data

CIP protocol

IP datagram

TCP segment or UDP datagram

The Ethernet data field consists of several nested protocols:

• The IP datagram is transported in the user data of the Ethernet data

field.

• The TCP segment or the UDP datagram is transported in the user data

of the IP datagram.

• The CIP protocol is transported in the user data of the TCP segment or

the UDP datagram.

Figure 3

CIP is a message-based protocol that implements a relative path to send a

message from the “producing” device in a system to the “consuming” devices.

Understanding the

Producer/Consumer Model

The producing device contains the path information that steers the message

along the proper route to reach its consumers. Because the producing device

holds this information, other devices along the path simply pass this

information; they do not need to store it.

The Producer/Consumer model has two significant benefits:

• You do not need to configure routing table in the bridging modules,

which greatly simplifies maintenance and module replacement.

• You maintain full control over the route taken by each message, which

enables you to select alternative paths for the same end device.

The CIP “Producer/Consumer” networking model replaces the old source/

destination (“master/slave”) model. The Producer/Consumer model reduces

network traffic and increases speed of transmission. In traditional I/O systems,

controllers poll input modules to obtain their input status. In the CIP system,

the controller does not poll the input modules. Instead, they produce their data

either upon a change of state or periodically. The frequency of update depends

upon the options that are chosen during configuration and where on the

network the input module resides. The input module, therefore, is a producer

of input data and the controller is a consumer of the data.

Rockwell Automation Publication 842E-UM001C-EN-P - September 2016 17

The controller can also produce data for other controllers to consume. The

produced and consumed data is accessible by multiple controllers and other

devices over the EtherNet/IP network. This data exchange conforms to the

Producer/Consumer model.

Page 18

Chapter 3 EtherNet/IP Overview

Specifying the Requested

Packet Interval

EtherNet/IP Topologies

The requested packet interval (RPI) is the update rate that is specified for a

particular piece of data on the network. This value specifies how often to

produce the data for that device. For example, if you specify an RPI of 50 ms, it

means that every 50 ms the device sends its data to the controller or the

controller sends its data to the device.

RPIs are only used for devices that exchange data. For example, a

ControlLogix® EtherNet/IP bridge in the same chassis as the controller does

not require an RPI because it is not a data-producing member of the system; it

is used only as a bridge to remote modules.

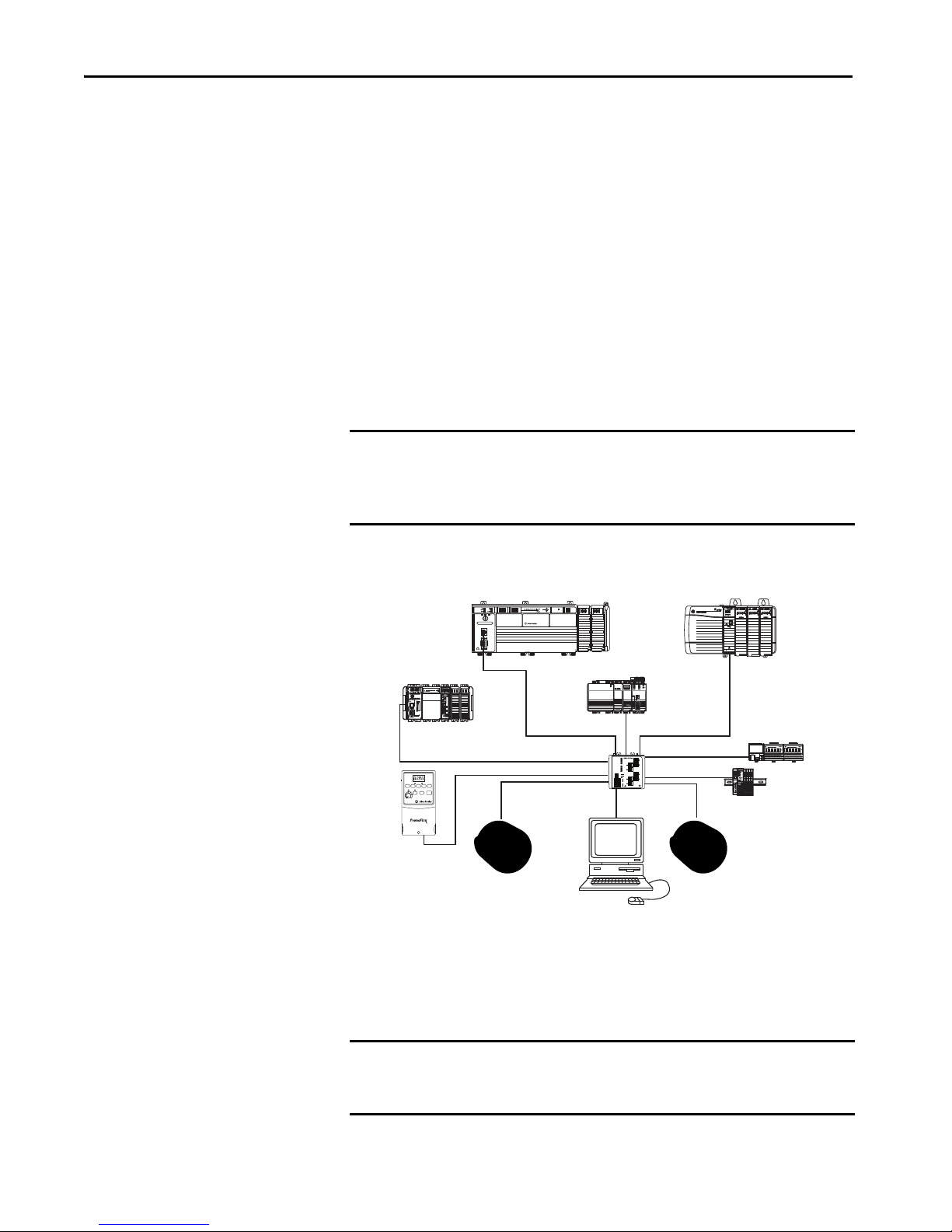

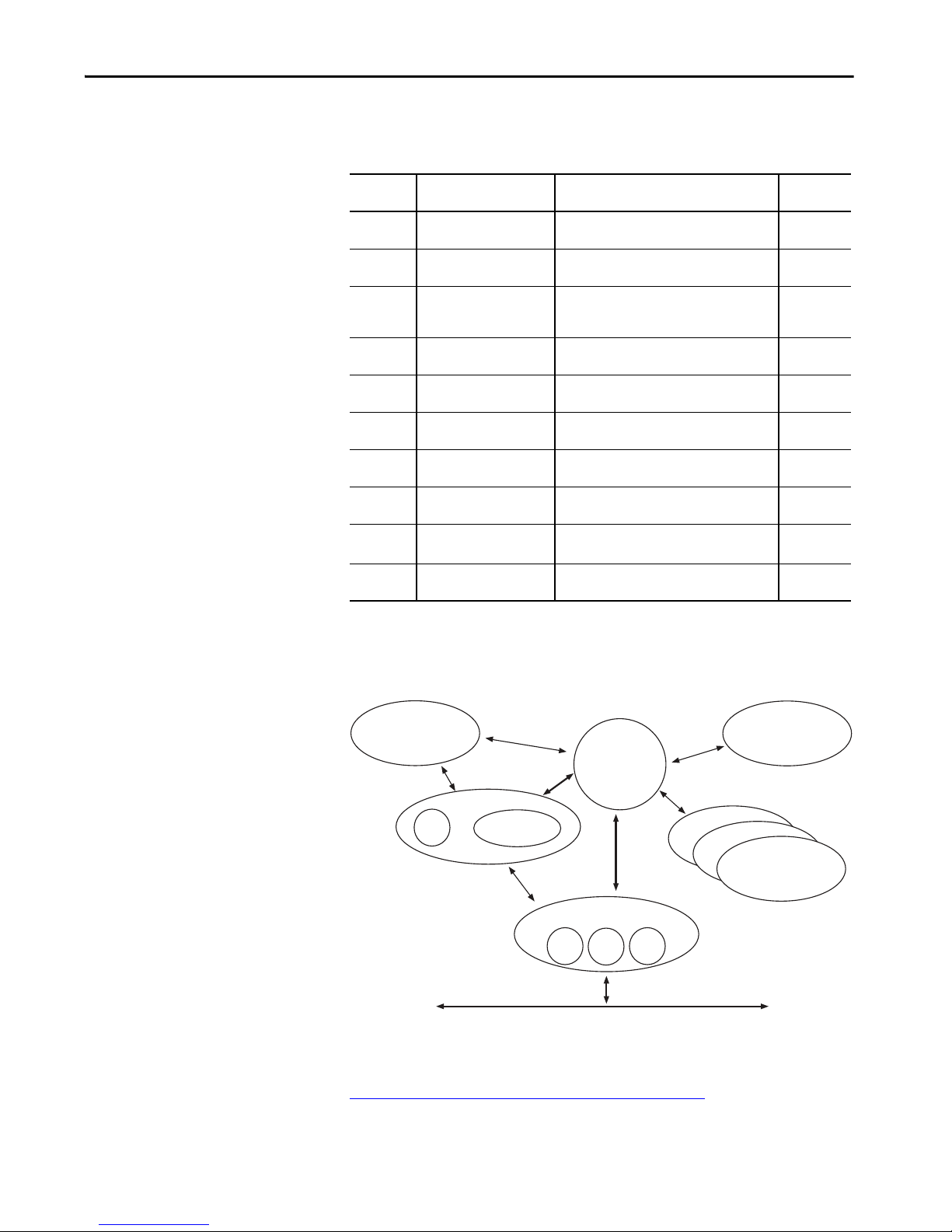

The 842E encoders can be connected in any of three network topologies: star,

linear, or Device Level Ring (DLR).

IMPORTANT Rockwell Automation recommends that you use no more than 50 nodes on

one DLR or linear network. If your application requires more than 50 nodes,

we recommend that you segment the nodes into separate, but linked, DLR or

linear networks.

Star Topology

Figure 4

The star structure consists of a number of devices that are connected to a

central switch.

18 Rockwell Automation Publication 842E-UM001C-EN-P - September 2016

IMPORTANT When this topology is used, make the Ethernet connection on the 842E

encoder to the Link 1 connection. The Link 2 Ethernet connection must

remain unused.

Page 19

EtherNet/IP Overview Chapter 3

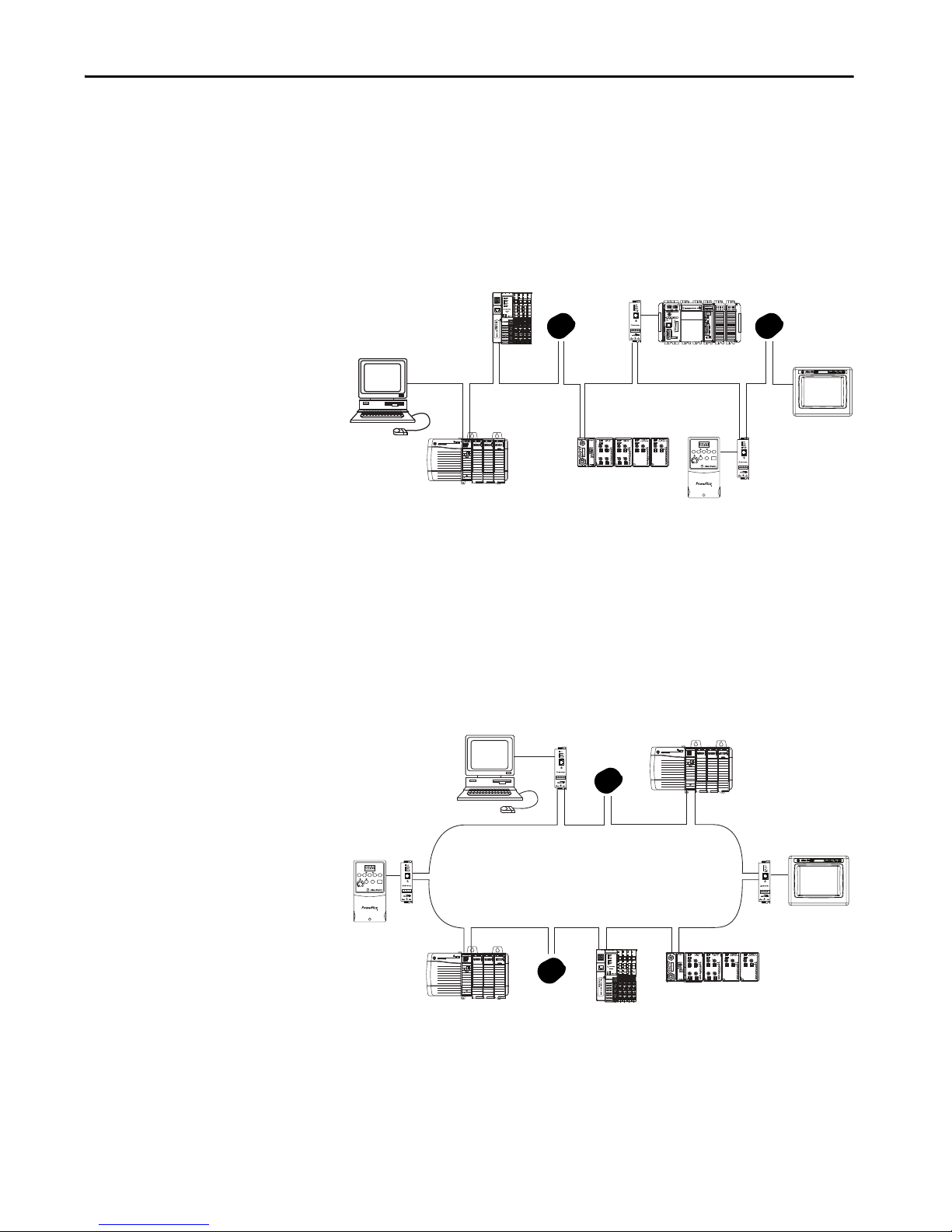

Linear Topology

The linear topology uses the embedded switching capability to form a daisychain style network that has a beginning and an end. Linear topology simplifies

installation and reduces wiring and installation costs, but a break in the

network disconnects all devices downstream from the break. When this

topology is used, both Ethernet connections on the encoder are used. For the

network connection use Link 1, Link 2, or both.

Figure 5

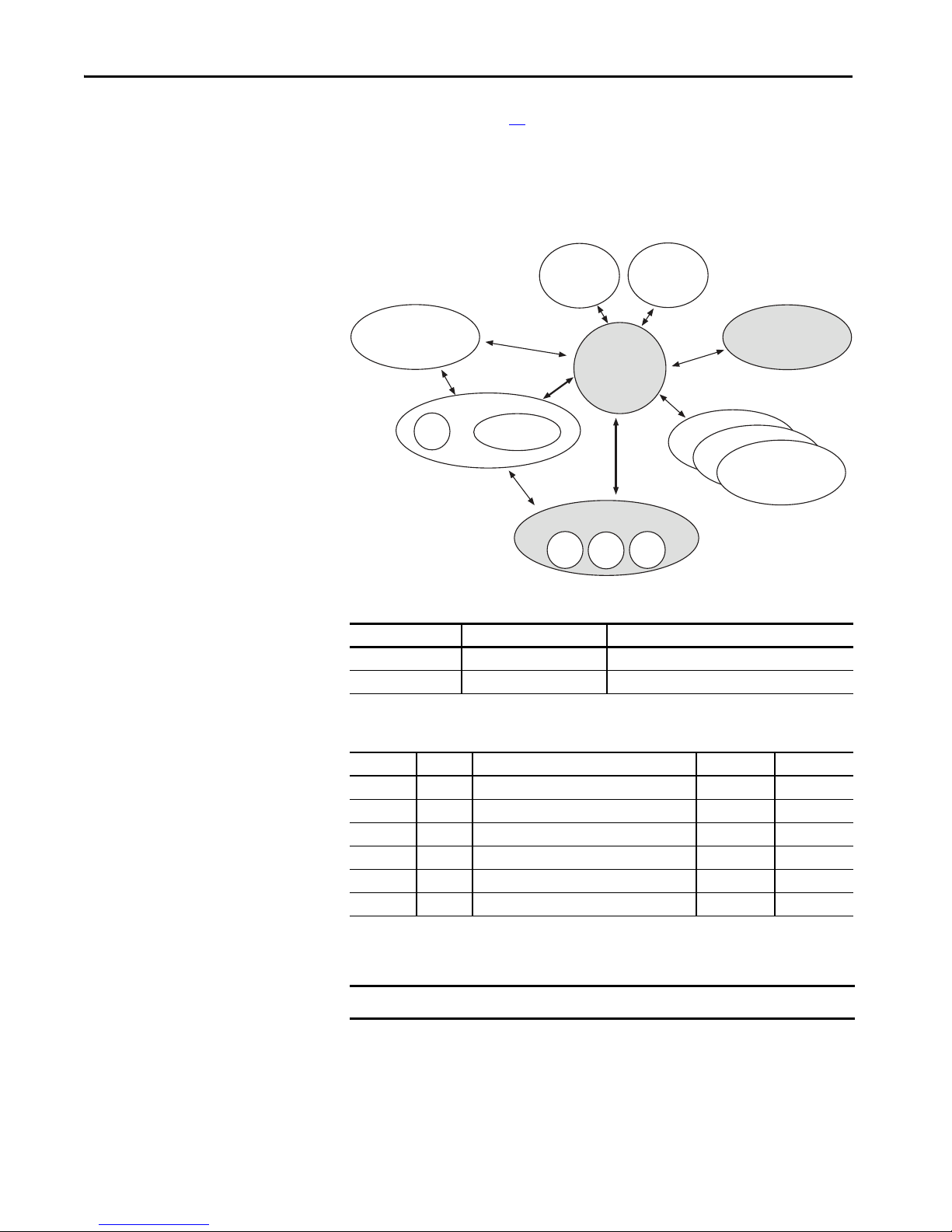

Device Level Ring Topology

A DLR network is a single-fault-tolerant ring network that is intended for the

interconnection of automation devices. DLR topology is advantageous as it

can tolerate a break in the network. If a break is detected, the signals are sent

out in both directions. With this topology, use both the Link 1 and Link 2

Ethernet connections on the 842E encoder.

Rockwell Automation Publication 842E-UM001C-EN-P - September 2016 19

Figure 6

Page 20

Chapter 3 EtherNet/IP Overview

Endless Shaft Functionality

The endless-shaft feature is not supported for the single-turn encoder. This

functionality is applicable only for the multi-turn Ethernet encoders and

accessible only via messaging (not the AOP).

The round axis functionality or endless shaft functionality removes the

n

restriction that the total resolution must be 2

times the steps per revolution.

The shaft is considered an endless shaft.

The steps per revolution are not configured directly. Instead the nominator

and divisor for the number of revolutions are defined. The total measuring

range can be scaled from 1…1,073,741,824 as an integer.

The encoder supports the function for round axes. During this process, the

steps per revolution are set as a fraction. As a result, the total resolution does

n

not have to be configured to 2

times the steps per revolution and can also be a

decimal number. The output position value is adjusted with the zero point

correction, the counting direction set and the gearbox parameters entered.

Number of revolutions, nominator for the round axis functionality: The

nominator can be scaled from 1…2,048 as an integer. The default factory

setting for the nominator is 2,048.

Number of revolutions, divisor for the round axis functionality: The divisor

can be scaled from 1…65,535 as an integer. The default factory setting for the

divisor is 1.

Example:

A rotary table for a filling system is to be controlled. The number of filling

stations define the steps per revolution. There are nine filling stations. For the

precise measurement of the distance between two filling stations, 1000 steps

are required.

The transmission ratio of the rotary table gearing defines the number of

revolutions (= 12.5). The total resolution is then 9 × 1,000 = 9,000 steps to be

realized in 12.5 revolutions of the encoder. This ratio cannot be realized via the

n

steps per revolution and the total resolution, as the total resolution is not 2

times the steps per revolution. The application problem can be solved using the

round axis functionality. The steps per revolution are ignored here. The total

resolution and the nominator and divisor for the number of revolutions are

configured. 9,000 steps are configured as the total resolution. For the

nominator for the number of revolutions, 125 is configured, 10 as the divisor

(125/10 = 12.5). After 12.5 revolutions (that is after one complete revolution

of the rotary table), the encoder reaches the total resolution of 9,000.

20 Rockwell Automation Publication 842E-UM001C-EN-P - September 2016

Page 21

EtherNet/IP Overview Chapter 3

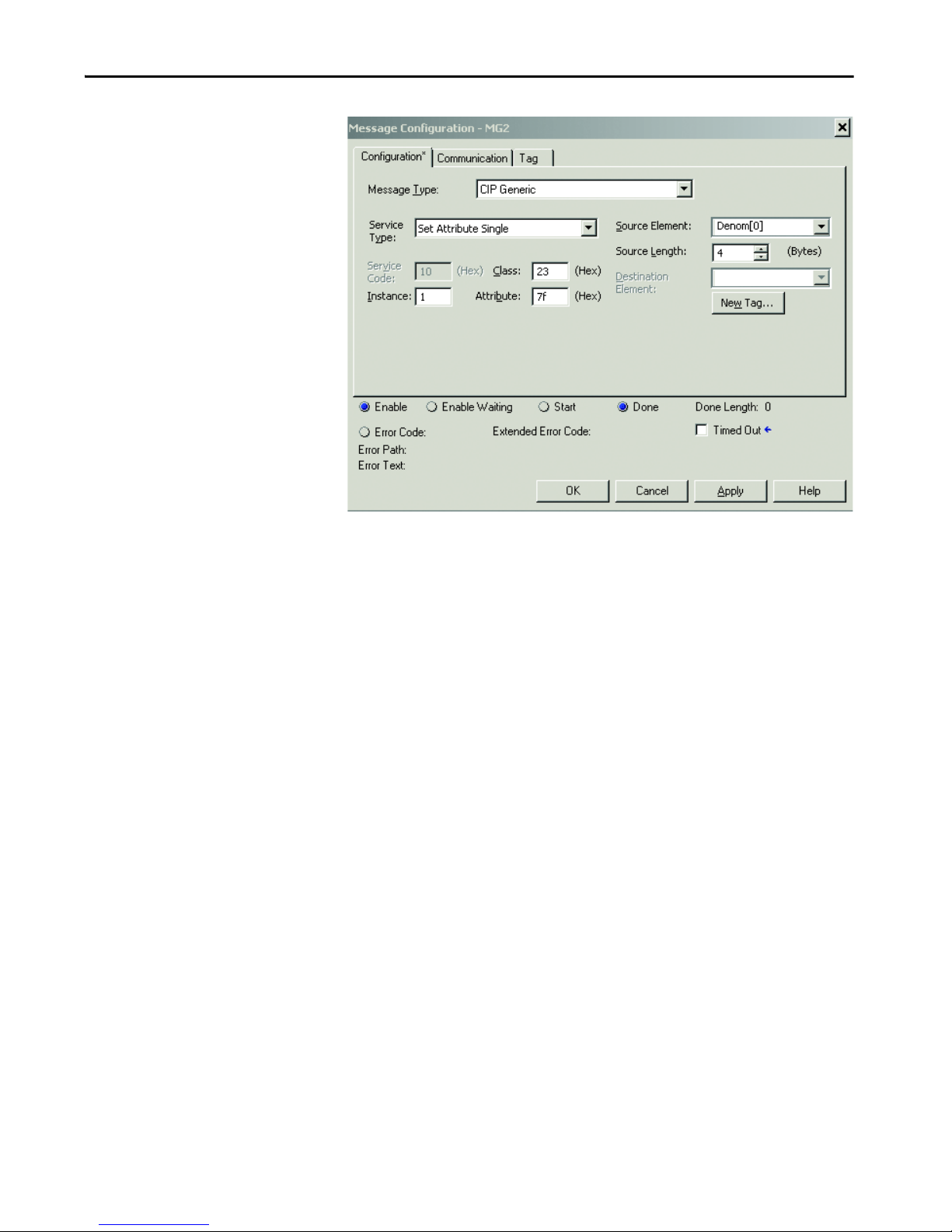

Enabling Endless Shaft Functionality

CIP message instructions must be used to configure the endless shaft

functionality. The following attributes must be set for the functionality to be

enabled.

• Attribute ID 0Eh, Scaling must be set to 1.

• Attribute ID 11 h, Total resolution must be set to between 1 …

536,870,912.

• Attribute ID 7Dh, Round axis functionality must be set to 1.

• Attribute ID 7Eh, Nominator (CNR_N) must be set to 1 … 2,048.

• Attribute ID 7Fh, Divisor (CNR_D) must be set to between 1 …

65,535.

Attribute 14 (e hex) Scaling function control

Rockwell Automation Publication 842E-UM001C-EN-P - September 2016 21

Figure 7

Attribute 125 (7d hex) Endless shaft functionality

Page 22

Chapter 3 EtherNet/IP Overview

Figure 8

Attribute 126 (7e hex) Nominator

22 Rockwell Automation Publication 842E-UM001C-EN-P - September 2016

Figure 9

Attribute 127 (7f hex) Divisor

Page 23

EtherNet/IP Overview Chapter 3

Figure 10

Attribute 17 (11 hex) Total measuring range

Figure 11

Rockwell Automation Publication 842E-UM001C-EN-P - September 2016 23

Update your logic to verify that the encoder is in the RUNNING state before

executing the message instruction to set the endless shaft attribute. Otherwise

the attribute will not be maintained upon power cycle.

Page 24

Chapter 3 EtherNet/IP Overview

Figure 12

Features

Attribute 14 (e hex) Scaling Function Control (SFC)

Attribute 125 (7d hex) Endless Shaft Functionality (ESF)

Attribute 126 (7e hex Nominator (CNR_N)

Attribute 127 (7f hex)– Divisor (CNR_D)

Attribute 17 (11 hex) Total Measuring Range (CMR)

CIP Object Model

IMPORTANT Don’t make online scaling changes through the module profile unless the

encoder device is inhibited. When you execute online changes, an error

message is displayed; “Failed to modify properties. Failed to send

configuration data to the module.” Consequently changes are ignored.

EtherNet/IP uses an object model for network communication wherein all

functions and data of a device are defined. The important terms are as follows:

Class: A class contains related objects of a device, which is organized in

instances.

Instance: An instance consists of different attributes that describe the

properties of the instance. Different instances of a class have the same services,

the same behavior, and the same attributes. They can, however, have different

values.

Attribute: The attributes represent the data that a device provides over

EtherNet/IP. The attributes include the current values of, for example, a

configuration or an input. Typical attributes are configuration and status

information.

24 Rockwell Automation Publication 842E-UM001C-EN-P - September 2016

Service: Services are used to access classes or the attributes of a class or to

generate specific events. These services execute defined actions such as reading

the attributes.

Page 25

EtherNet/IP Overview Chapter 3

23h Position Sensor

02h Message

Router

01h Identity

F6h

06h Connection Manager

04h Assembly

F4h

F5h

Network

The 842E EtherNet/IP encoder supports the following classes of the encoder

profile:

Class Code Object Class Description Number of

0x01 Identity object Contains information on the node within the

0x02 Message router object Processes all messages and routes them to the

0x04 Assembly object

(I/O-assembly class)

0x06 Connection manager object Contains connection-specific attributes for

0x23 Position sensor object Administrates device-specific data like position

0x47 Device Level Ring (DLR) object Contains the configuration and status information

0x48 QoS object Contains mechanisms that are used to treat traffic

0xF4 Port object Contains implemented port types port numbers

0xF5 TCP/IP interface object Contains all attributes for configuring the TCP/IP

0xF6 Ethernet link object Contains connection-specific attributes like

network

appropriate objects

Assembles attributes (data) of various objects to

one object

Used for I/O messages

triggering, transport, and connection type

and counting direction

of the DLR protocol

streams with different relative priorities

and port names

interface

transmission rate, MAC ID, or duplex mode

Instances

1

1

7

1

1

1

1

1

1

3

Table 1 - Supported Classes

Position Sensor Object

Figure 13

The Class Instance Attributes for the position sensor object are provided in

Class Services of the Position Sensor Object

on page 34.

Rockwell Automation Publication 842E-UM001C-EN-P - September 2016 25

Page 26

Chapter 3 EtherNet/IP Overview

23h Position Sensor

02h Message

Router

01h Identity

F6h

06h Connection Manager

04h Assembly

F4h

F5h

Network

48h QoS

47h DLR

See Appendix B on page 75 for an example of how to use the position sensor

object to create an explicit message in RSLogix 5000®.

Identity Object

The device information and device parameters are opened via the instances.

Figure 14 - Connections for the Identity Object

Service Code Service Description

01h Get_Attribute_All Returns the values of all attributes

0Eh Get_Attribute_Single Returns the values of one attribute

Table 2 - Class Services of the Identity Object

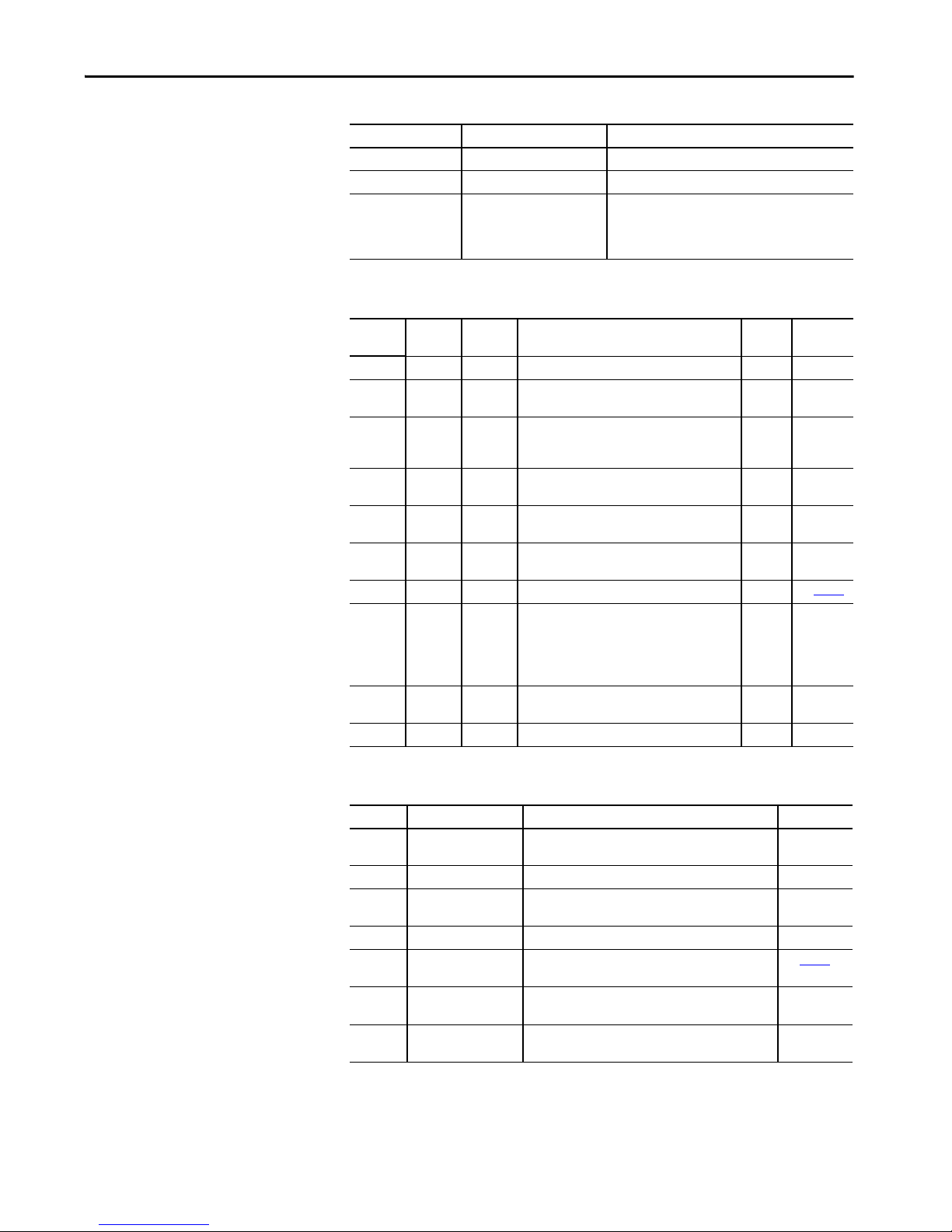

Attribute ID Access Description Data Type Default Value

1 Get Object revision index UINT 0001h

2 Get Highest instance number within the class UINT 0001h

3 Get Number of object instances in this class UINT 0001h

4 Get Optional attribute list STRUCT —

6 Get Highest existing class attribute ID UINT 0007h

7 Get Highest implemented instance attribute UINT 0075h

Table 3 - Class Attributes of the Identity Object

IMPORTANT Class attribute 5 is not implemented.

26 Rockwell Automation Publication 842E-UM001C-EN-P - September 2016

Page 27

EtherNet/IP Overview Chapter 3

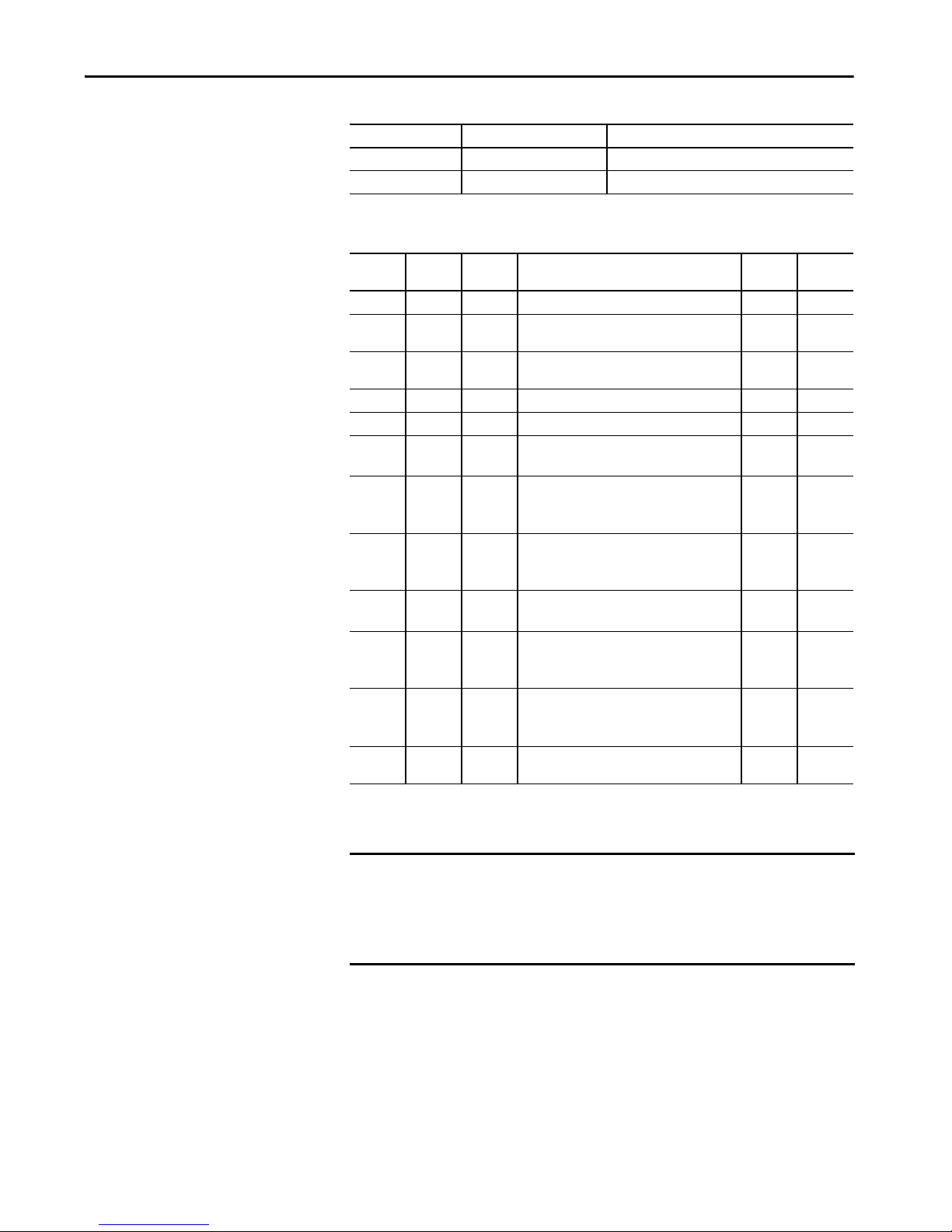

Service Code Service Description

01h Get_Attribute_All Returns the values of all attributes

0Eh Get_Attribute_Single Returns the values of one attribute

05h Reset Resets the device:

0 = The device is reinitialized (power on).

1 = The device is reinitialized (power on) and reset to

the factory settings.

Table 4 - Instance Services of the Identity Object

Attribute IDAccess Name Description Data

01h Get Vendor ID Manufacturer ID UINT

02h Get Device

Typ e

03h Get Product

Code

04h Get Revision Contains the firmware revision number in the

Get Major

Revision

Get Minor

Revision

05h Get Status Device status flags WORD See Tab le 6

06h Get Serial

Number

07h Get Product

Name

68 h Get Vendor Firmware revision in the FPGA (for example, 1.2.0) UDINT 00010200h

Device profile

22 h = Encoder

Vendor-specific product code

03h = Single-turn

04h = Multi-turn

format XX.XX

First part of the revision number, for example, 01

(depending on the release)

Last part of the revision number, for example, 02

(depending on the release)

Serial number in the format YY.WW.xxx

Y = Year

W = Week

x = Sequential number

For example, 0E.34.0001 (depending on release)

Product name Short_

Type

UINT 0022h

UINT

STRUCT

UINT 01h

UINT 02h

UDINT 0E340001h

String

Default

Value

AFx60AEth/IP

Table 5 - Instance Attributes of the Identity Object

Rockwell Automation Publication 842E-UM001C-EN-P - September 2016 27

Bit Name Description Default Value

0 Owned 0 = No connection to the master

1 — Reserved 0

2 Configured 0 = Device with standard configuration

3 — Reserved 0

4…7 Extended Device

Status field

8 Minor Recoverable

Status

9 Minor Unrecoverable

Status

1 = Connection to the master established

1 = No standard configuration

Vendor-specific status bits See Tab le 7

0 = No error

1 = Recoverable error (device not in error status)

0 = No error

1 = Recoverable error (device not in error status)

0

0

0

0

Table 6 - Bits of the Instance Attribute “Status”

Page 28

Chapter 3 EtherNet/IP Overview

Bit Name Description Default Value

10 Major Recoverable

Status

11 Major Unrecoverable

Status

12…15 — Reserved 0000

0 = No serious error

1 = Serious error that can be reset (device in error status)

0 = No serious error

1 = Serious error that cannot be reset (device in error

status)

0

0

Table 6 - Bits of the Instance Attribute “Status”

Assembly Object

Possible Combinations

Bit 4…7

0000 Device in self-test

0001 Firmware update in progress

0010 At least one connection error

0011 No I/O connection established

0100 Configuration in nonvolatile memory (EEPROM) failed

0101 Serious error, bit 10, or bit 11 = 1

0110 At least one connection in the “Run” operating mode

0111 At least one connection exists, all in “Idle” operating mode

1000…1111 Reserved

Description

Table 7 - Bits 4 of 7 of the Instance Attribute “Status”

The Assembly Object allows assembling of data attributes of other objects in

one single object. The 842E EtherNet/IP encoder supports only static

assemblies of attributes. For this reason, the number of instances is fixed.

Service Code Service Description

01h Get_Attribute_All Returns the values of all attributes

0Eh Get_Attribute_Single Returns the values of one attribute

28 Rockwell Automation Publication 842E-UM001C-EN-P - September 2016

Table 8 - Class Services of the Assembly Object

Attribute ID Access Description Data Type Default Value

1 Get Object revision index UINT 0002h

2 Get Highest instance number within the class UINT 006Ah

3 Get Number of object instances in this class UINT 0007h

6 Get Highest existing class attribute ID UINT 0007h

7 Get Highest implemented instance attribute UINT 0004h

Table 9 - Class Attributes of the Assembly Object

IMPORTANT Class attributes 4 and 5 are not implemented.

Page 29

EtherNet/IP Overview Chapter 3

Service Code Service Description

01h Get_Attribute_All Returns the values of all attributes

0Eh Get_Attribute_Single Returns the values of one attribute

Table 10 - Instance Services of the Assembly Object

Instance Attribute IDAccess Description Bits Bytes

1 3 Get Position value 32 4

2 3 Get Position value

Warning and alarm flags

3 3 Get Position value

Vel oci ty

4…5——— ——

100 3 Get Configuration data 224 28

101 3 Get Error

Position value

102 3 Get Error

Position value

Warning and alarm flags

103 3 Set/Get Error

Position value

Vel oci ty

101WS 3 Get Error

Position value

102WS 3 Get Error

Position value

Warning and alarm flags

103WS 3 Set/Get Error

Position value

Vel oci ty

110 3 Set/Get Dummy instance for the configuration data of a

“Listen-only” connection

32

8

32

32

32

32

32

32

8

32

32

32

32

32

32

32

8

32

32

32

00

5

8

8

9

12

8

9

12

Rockwell Automation Publication 842E-UM001C-EN-P - September 2016 29

Table 11 - Instance Attributes of the Assembly Object

IMPORTANT • Instances 4 and 5 from the encoder profile 22 h are not implemented.

• The instances 100 to 110 are manufacturer-specific assemblies.

• If the instances 101, 102, and 103 are used, then configuration assembly

100 is activated. If the instances 101WS, 102WS, and 103WS are used,

then configuration assembly 100 is not activated.

Page 30

Chapter 3 EtherNet/IP Overview

23 h Position Sensor

02h Message

Router

01h Identity

F6h

06h Connection Manager

04h Assembly

F4h

F5h

Network

48 h QoS

47 h DLR

I/O

I/O

I/O Assembly

The I/O data are retrieved/output via instances.

Figure 15 - Connections for the Configuration Assembly

Instance ByteBit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0

1 0 Position value (least significant byte)

1Position value

2Position value

3 Position value (most significant byte)

2 0 Position value (least significant byte)

1Position value

2Position value

3 Position value (most significant byte)

4 Warning Alarm

3 0 Position value (least significant byte)

1Position value

2Position value

3 Position value (most significant byte)

4 Velocity value (least significant byte)

5 Velocity value

6 Velocity value

7 Velocity value (most significant byte)

Table 12 - Data Format of the Attributes of the I/O Assembly

30 Rockwell Automation Publication 842E-UM001C-EN-P - September 2016

Page 31

EtherNet/IP Overview Chapter 3

Instance ByteBit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0

101/101WS 0 Fault header (least significant byte, see Table XX on page XXX)

1Fault header

2Fault header

3 Fault header (most significant byte)

4 Position value (least significant byte)

5Position value

6Position value

7 Position value (most significant byte)

102/102WS 0 Fault header (least significant byte, see Table XX on page XXX)

1Fault header

2Fault header

3 Fault header (most significant byte)

4 Position value (least significant byte)

5Position value

6Position value

7 Position value (most significant byte)

8 Warning Alarm

103/103WS 0 Fault header (least significant byte, see Table XX on page XXX)

1Fault header

2Fault header

3 Fault header (most significant byte)

4 Position value (least significant byte)

5Position value

6Position value

7 Position value (most significant byte)

8 Velocity value (least significant byte)

9 Velocity value

10 Velocity value

11 Velocity value (most significant byte)

Rockwell Automation Publication 842E-UM001C-EN-P - September 2016 31

Table 12 - Data Format of the Attributes of the I/O Assembly

Page 32

Chapter 3 EtherNet/IP Overview

Config

23h Position Sensor

02h Message

Router

01h Identity

F6h

06h Connection Manager

04h Assembly

F4h

F5h

Network

48h QoS

47h DLR

Figure 16 - Connections for the Configuration Assembly

32 Rockwell Automation Publication 842E-UM001C-EN-P - September 2016

Page 33

EtherNet/IP Overview Chapter 3

Instance ByteBit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0

100 0 Not used

1 Not used

2 Not used

3 Not used

4 Steps per revolution CPR (least significant byte)

5CPR

6CPR

7 CPR (most significant byte)

8 Total resolution CMR (least significant byte)

9CMR

10 CMR

11 CMR (most significant byte)

12 Not used cw/ccw

13 Not used sc f

14 Not used raf

1

2

15 Not used

16 Nominator for the number of revolutions CNR_N (least significant byte)

17 CNR_N

18 CNR_N

19 CNR_N (most significant byte)

20 Divisor for the number of revolutions CNR_D (lease significant byte)

21 CNR_D

22 CNR_D

23 CNR_D (most significant byte)

24 Velocity measuring unit (least significant byte)

25 Velocity measuring unit (most significant byte)

26 Not used

27 Not used

Rockwell Automation Publication 842E-UM001C-EN-P - September 2016 33

Table 13 - Data Format for the Attributes for the Configuration Assembly

IMPORTANT • The structure of the configuration assembly is fixed.

• During the initialization of the encoder, it reads the data from the control

system.

1

Scaling function

2

Round axis functionality

Page 34

Chapter 3 EtherNet/IP Overview

Position Sensor Object

Instance Service Name Description

0x05 Reset Restart with all EEPROM parameters of the encoder, restart with the factory

0x0E Get_Attribute_Single Returns value of attribute

0x15

(21dec)

0x16

(22dec)

Restore Restore all parameter values from the non-volatile storage, customer

Save Save parameters to the non-vol atile storage

defaults

00: Restart Objec t– read all EEPROM parameters

01: set and save factory defaults and restart object– read all EEPROM

parameter

defaults

Table 14 - Class Services of the Position Sensor Object

Num

Required/

(dec)

Optional

1Required

(implemented)

2 Implemented Get Max instance INT Max. instance number of an

3 Implemented Get Number of

6 Implemented Get Maximum ID

7 Implemented Get Maximum ID

100 Get NV

Access

Name Data type Description Default

Rule

Get Revision INT Object revision no 0x00 02

0x00 01

0x00 01

0x00 7A

842eaa.bb

dd.mm.yy

(1)

instances

number class

attribute s

number

instance

attribute s

Encoder

firmware

version

object in this class

INT Number of object instances in

INT Highest implemented class ID 0x00 64

INT Highest implemented

ARRAY

of bytes

this class

instance attribute ID

aa.bb: major revision

minor revision

dd.mm.yy: day.month.year

Table 15 - Class Attributes of the Position Sensor Object

(1) Nonvolatile

Instance Services of the position sensor object are automatically populated in

the explicit message instruction configuration

Instance Service name Description

0x0E Get_Attribute_Single Returns value of attribute

0x10 Set_Attribute_Single Sets value of attribute

Table 16 - Instance Services of the Position Sensor Object

34 Rockwell Automation Publication 842E-UM001C-EN-P - September 2016

Page 35

EtherNet/IP Overview Chapter 3

Attribute ID

(dec)

1 1 Get V Number of attributes INT Number of supported attributes in this

Attribute ID

(hex)

Access

rule

NV /

(1)

Name Data type Description Min. / Max.

(2)

V

(default)

0x0039

class

2 2 Get V Attribute list ARRAY

List of supported attributes –

of byte

10 A Get V Position value signed DINT Current position value (32 Bits) none

11 B Get NV Position sensor type

(see following table, encoder ID)

12 C Set NV Direction counting toggle, code

sequence (CS)

INT Device Type

0x01: Single-turn absolute encoder

0x02: Multi-turn absolute encoder

BOOL Definition of direction of incrementing

counts (10)

Min 0x00 01

Max 0x00 02

(0x00 02)

(0: CW)

0: CW

1:CCW

13 D Set NV Commissioning diagnostic

control (encoder position test)

14 E Set NV Scaling function control (SFC) BOOL ON: 1 calc. value (from 16+42)

BOOL ON: 1 Encoder diagnostics possible

OFF: 0 No diagnostics implemented

(OFF: 0)

(OFF: 0)

OFF: 0 phys. resolution [steps]

15 F Set NV Position format ENG

UNIT

Format of position value

(for example, arcsec or steps)

(0x1001)

Engineering unit: 0x1001 (counts)

16 10 Set NV Counts per range DINT Number of requested steps per

revolution.

Min 0x00 00 00 01

Max 0x00 04 00 00

(0x00 04 00 00)

17 11 Set NV Total measuring range DINT Total resolution Min / Max

0x00 00 00 01 /

n

* Attr.16

Max. 2

18 12 Set NV Position measuring increment DINT Minimum resolution in steps (is always

(0x00 00 00 01)

0x00 01)

19 13 Set NV Preset value DINT The preset value is set to the current

position value

Min / Max

0x00 00 00 00 /

Attr.17 - 1

(0x00 00 00 00)

21 15 Get V Position status register BYTE State of the software limit switch

(0x00)

Bit 0: Out of range

Bit 1: Range overflow

Bit: 2: Range underflow

Bit 3…7 reserved

22 16 Set NV Position low limit DINT Lower limit for position 0x00 00 00 00

23 17 Set NV Position high limit DINT Upper limit for position 0x3F FF FF FF

24 18 Get V Velocity value DINT Current velocity (32 Bits) Format (25) and (26)

25 19 Set NV Velocity format ENG

INT

Format of velocity value

0x1F04 counts/s

(0x1F0F)

0x1F0E revs/s

0x1F0F revs/min

26 1A Set NV Velocity resolution DINT Minimum resolution of velocity value

(0x00 00 00 01)

(24)

27 1B Set NV Minimum velocity setpoint DINT Minimum velocity setpoint for setting

(0x00 00 00 00)

warning flag (47)

28 1C Set NV Maximum velocity setpoint DINT Maximum velocity setpoint for setting

(0x3F FF FF FF)

warning flag (47)

29 1D Get V Acceleration value DINT Current acceleration (32 Bits) Format (30) and (31)

Table 17 - Instance Attributes of the Position Sensor Object

Rockwell Automation Publication 842E-UM001C-EN-P - September 2016 35

Page 36

Chapter 3 EtherNet/IP Overview

NV /

Attribute ID

(dec)

Attribute ID

(hex)

Access

rule

(1)

30 1E Set NV Acceleration format ENG

Name Data type Description Min. / Max.

(2)

V

Format of acceleration value

UNIT

0x0810: cps/s

(default)

(0x0810)

0x0811: rpm/s

0x0812: rps/s

31 1F Set NV Acceleration resolution DINT Minimum resolution of acceleration

(0x00 00 00 01)

value

32 20 Set NV Minimum acceleration setpoint DINT Minimum acceleration setpoint (0x00 00 00 00)

33 21 Set NV Maximum acceleration setpoint DINT Maximum acceleration setpoint 0x3F FF FF FF

41 29 Get V Operating status BYTE Operating status encoder

Bit 0: Direct. 0 (inc.) 1 (dec.)

Bit 1: Scaling 0 (off) 1 (on)

Bit: 2…4 Reserved

Bit: 5: Diag. 0 (off) 1 (on)

Bit 6…7 manuf. spec.

42 2A Get NV Physical resolution span (PRS) DINT Number of steps per rev

(0x00 04 00 00)

(single-turn part)

43 2B Get NV Physical resolution

number of spans

INT Number of revolutions

(multi-turn part)

(0x00 01) single-turn

(0x10 00) multi-turn

44 2C Get V Alarms WORD Flags for alarms (errors)

45 2D Get NV Supported alarms WORD Information on supported alarms 0x3003

46 2E Get V Alarm flag BOOL Indication of set alarm 0: OK

1: Alarm error

47 2F Get V Warnings WORD Flags for warnings

48 30 Get NV Supported warnings WORD Information on supported warnings 0x673C

49 31 Get V Warning flag BOOL Indication of set warning 0: OK

1: Warning Flag

50 32 Get NV Operating time DINT Storage of operating time counter

0

[0,1h], the format of the counter is

second.

51 33 Get NV Offset value DINT Offset value is calculated when using

0x00 00 00 00

preset function

100 64 Get V Temperature value INT Current temperature value

-40…100°C or -40…212°F

Accuracy of the temperature sensor is

0xF0 60

0x27 10

(-4000… +10000)

about ± 5 °C (±9 °F).

101 65 Set NV Temperature value format ENG

UNIT

Format of temp erature value

°C or °F (Fahrenheit)

(0x1200)

0x1200: °C

0x1201: °F

102 66 Set NV Temperature resolution DINT Minimum resolution of temperature

(0x00000001)

value

[°C/100] or [(°F)/100]

103 67 Set NV Minimum temperature value

setpoint

INT Minimum temperature setpoint

(-40…100°C, -40…212°F)

0xF0 60

(-4000)

104 68 Set NV Maximum temperature value

105 69 Get V Fault header

Table 17 - Instance Attributes of the Position Sensor Object

36 Rockwell Automation Publication 842E-UM001C-EN-P - September 2016

setpoint

(see Sensor error table)

INT Maximum temperature setpoint

(-40…100°C, -40…212°F)

DINT Flags of encoder sensor errors and

warnings

0x27 10 (+10000)

or 0x52D0

(+21200)

0x00 00 00 00

Page 37

EtherNet/IP Overview Chapter 3

NV /

Attribute ID

(dec)

Attribute ID

(hex)

Access

rule

(1)

106 6A Set NV Slave sign of life DINT Flags for encoder functionalities

Name Data type Description Min. / Max.

(2)

V

(default)

0x0000500

(Bit field):

Bit 0: Slave sign of life (on/off )

Bit 1…7: not used

Bit 8…15: UpdateFactor (1…127)

Bit 16…31: not used

107 6B Get NV Encoder motion time DINT Storage of the motion time. This

0

counter is incrementing if the encoder

is in rotation [sec].

108 6C Get NV Encoder operating time [second] DINT Storage of the operating time. This

0

counter is incrementing if the encoder

is powered on [sec].

109 6D Get NV Max velocity

RA [cnts/ms]

110 6E Get NV Max acceleration [cnts/(ms)2] DINT Storage of the maximum acceleration

DINT Storage of the maximum velocity of

the encoder in operational state.

0

0

of the encoder in operational state.

111 6F Get NV Max temp [°C/100] DINT Storage of the maximum temperature

2000

of the encoder in operational state

112 70 Get NV Min temp [°C/100] DINT Storage of the minimum temperature

2000

of the encoder in operational state

113 71 Get NV Number of startups DINT Storage of the number of startups

0

(power-on) cycles

114 72 Get V light-emitting diode current

value [µ A]

INT Current light-emitting diode current

[µA]

200…25.000

(0)

Range: 200…25.000

115 73 Get NV Max current value [µA] INT Max. light-emitting diode current [µA] 1.500

116 74 Get NV Min current value [µA] INT Min. light-emitting diode current [µA] 1.500

117 0X75 Get V Direction change counter UDINT Direction change counter, this counter

0

is incrementing if the encoder is

changing the direction, for example,

cw to ccw or ccw to cw.

118 0x76 Get V Rotation counter-forward UDINT Rotation counter (0) (forward

0

counter), this counter increments if the

encoder was moving from standstill to

a positive direction (cw).

119 0x77 Get V Rotation counter-backwards UDINT Rotation counter (1) (backwards

0

counter), this counter increments if the

encoder was moving from standstill to

a negative direction (ccw).

120 0x78 Get V Power supply voltage (mV) UINT Current supply voltage (mV)

Range: 9.500…30.500

9,500

30,500

(24,000)

121 0x79 Get V Maximum power supply voltage

(V)

UINT Maximum power supply voltage, this

value is stored to the EEPROM data.

0

33

(0)

122 0x7A Get V Preset offset value DINT Vendor-specific attribute:

(00000000)

Offset value is calculated when using

the preset function.

125 0x7D Set NV Endless shaft functionality BOOL Encoder scaling with endless shaft

(0)

(only with a multi-turn). 0: OFF,

1: ON

126 0x7E Set NV Number of rotations, nominator UDINT This parameter is used if the parameter

“endless shaft functionality” is set

(1:ON)

1

2,048

(2,048)

Table 17 - Instance Attributes of the Position Sensor Object

Rockwell Automation Publication 842E-UM001C-EN-P - September 2016 37

Page 38

Chapter 3 EtherNet/IP Overview

Attribute ID

(dec)

Attribute ID

(hex)

Access

rule

NV /

(1)

Name Data type Description Min. / Max.

(2)

V

127 0x7F Set NV Number of rotations, divisor UDINT This parameter is used if the parameter

“endless shaft functionality” is set

(1:ON)

128 0x80 Set NV Velocity filter integration time UDINT Velocity filter taps, integration time.

Value is stored in EEPROM.

129 0x81 Set NV Velocity filter bandwidth UDINT Controls the bandwidth of the l ow pass

filter that is applied to the raw velocity

signal from feedback. EEPROM

parameter:

0: attribute disabled

1…1000: recommended bandwidth

(Hz)

130 0x82 Set NV Accele ration filter integration

time

UDINT Acceleration filter taps, integration

time

131 0x83 Set NV Acceleration filter bandwidth UDINT Controls the bandwidth of the low pass

filter that is applied to the raw

acceleration signal from feedback.

132 0x84 Set NV Velocity hysteresis UDINT Get and set the hysteresis of the

velocity

133 0x85 Set NV Acceleration hysteresis UDINT Get and set the hysteresis of the

acceleration

(1) You can do a Get of all Set values, as shown in Appendix B, page 75

. It is always good programming practice to do a Get after setting a value to verify the Set command was

successful.

(2) Nonvolatile/volatile

(default)

1

65,535

(1)

0

128

(1)

0

1000

(100)

0

128

(1)

0

1000

(100)

0

3ffffff

(0)

0

3FFFFFF

(0)

Table 17 - Instance Attributes of the Position Sensor Object

38 Rockwell Automation Publication 842E-UM001C-EN-P - September 2016

Page 39

Installation

Chapter 4

Mechanical

This chapter describes how to install the 842E EtherNet/IP Encoder.

Also refer to the installation sheet provided in the box, Publication No.

100000169360.

Shaft Rotation Direction

When you view the encoder from the shaft side, the shaft rotation is clockwise

(CW) or counterclockwise (CCW), as shown.

Figure 1

Rockwell Automation Publication 842E-UM001C-EN-P - September 2016 39

Mounting with a Solid Shaft

1. Be sure to select the proper size flexible coupling clamp to mate to the

encoder shaft, for example, 845–FC–*–*. See our website at http://

ab.rockwellautomation.com/Motion-Control/Encoders for encoder

accessories.

ATT EN TI ON : Do not rigidly connect the encoder shaft to the machine. A rigid

connection causes premature failure of the encoder or machine bearings.

Always use a flexible coupling.

2. To determine the encoder mounting hole locations, use the dimension

drawings in the installation instructions (see “Related Documentation”

on page 7

3. Slide the flexible coupling onto the shaft, but do not tighten the set

screws.

).

Page 40

Chapter 4 Installation

4. Mount the encoder and tighten with three size M4 mounting screws

(not supplied).

5. Center the flexible coupling and tighten the set screws.

6. Rotate the machine slowly and verify that the flexible coupling is not

deforming beyond specifications.

7. Align machine to its mechanical zero or home position.

8. Remove the screw cover on the back of the encoder and press the preset

push button to change the preset value to the current shaft position

value. (The factory preset value is zero.)

9. Replace the screw cover.

Mounting with a Hollow Shaft

IMPORTANT Be sure that the mating shaft is chamfered and grease-free.

1. Loosen the screw on the clamping ring with a 2.5 mm (0.098 in.) star

driver.

2. Slide the encoder onto the mating shaft until the flex mount rests on the

machine surface.

ATT EN TI ON : The encoder slides freely onto the shaft; if not, do not force.

Check the shaft for interferences such as gouges, burrs, rust, or size.

3. Hold encoder firmly and mark the two mounting holes. (If mounting

holes exist, proceed to Step 6.)

4. Slide the encoder off. To accept M4 (or equivalent) screws, drill, and tap

the marked holes.

5. Slide the encoder back onto the shaft until the flex mount rests on the

machine surface.

6. Attach the encoder with two M4 (or equivalent) screws.

IMPORTANT Do not stress the flex mount while tightening the screws.

7. Tighten the clamping ring screw to 1.1 Nm (10 in–lb).

40 Rockwell Automation Publication 842E-UM001C-EN-P - September 2016

8. Align machine to its mechanical zero or home position.

9. Remove the screw cover on the back of the encoder and press the preset

push button to change the preset value to the current shaft position

value. (The factory preset value is zero.)

10. Replace the screw cover.

Page 41

Electrical

Net

Mod

Link 1

Link 2

Encoder

Network

Address

Switches

x1

x10

x100

Reset

Button

Power Connec tion

Link 2 Connection

Network Address

Switches

Link 1 Connection

Preset Push Button

Installation Chapter 4

Mechanical Specifications

Face mount flange 10 x 19 mm (0.39 x 0.75 in.)

Servo flange 6 x 10 mm (0.24 x 0.39 in.)

Blind hollow shaft 8, 10, 12, 15 mm and 1/4, 1/2, 3/8, 5/8 in.

ATT EN TI ON : Switch off the power supply. The machine/system could

unintentionally start while you are connecting the devices.

Confirm that the entire machine/system is disconnected during the electrical

installation.

ATT EN TI ON : Commissioning requires a thorough check by authorized

personnel.

Before you operate a system that is equipped with the 842E EtherNet/IP

absolute encoder, make sure that the system is checked and released by

authorized personnel.

Read more in Chapter 1, Safety.

Electrical Wiring Instructions

Three electrical connections are on the back of the housing.

A 4-pin M12 connector is used for the power supply connection.

Two 4-pin M12 connectors are used for the Ethernet connection. The Link 1

connection is used for star networks. For ring networks, use both the Link 1

and Link 2 connectors. In a linear network, use Link 1, Link 2, or both

connectors.

Rockwell Automation Publication 842E-UM001C-EN-P - September 2016 41

Figure 2

Page 42

Chapter 4 Installation

Pin Assignments

Pin Signal Mating Cable

Wire Color

1 Versus Brown Supply voltage 10…30V DC

2WhiteDo not use

3 GND Blue 0V DC (ground)

4BlackDo not use

Table 1 - Voltage Supply

Pin Signal Mating Cable

Wire Color

1TxD+White orangeEthernet

2 RxD+ White green Ethernet

3 TxD– Orange Ethernet

4RxD–Green Ethernet

Table 2 - Ethernet Link Connections – Link 1 and Link 2

Function

Function

Preset Push Button

ATT EN TI ON : Pressing the preset push button results in a change of position

reading.

The change in position causes unexpected motion, which could result in

personal injury or damage to the product or equipment.

IMPORTANT Press the preset button briefly, no longer than one second.

To preset the position of the encoder, remove the screw cover from the back of

the encoder and briefly press the Preset button inside (see figure on page 41

and “Preset Function” on page 62

).

Network Address Switches

You can use the three Network Address switches to set the IP address of the

encoder (see Figure 3 on page 47

42 Rockwell Automation Publication 842E-UM001C-EN-P - September 2016

and “Setting the IP address” on page 45).

Page 43

Electrical Specifications

Operating voltage 10…30V DC

Power consump tion 3 W

Load current 200 mA

Resolution per revolution 262,144

Revolutions 4,096

Repeat accuracy ±0.002°

Error limit ±0.03°

Code direction CW or CCW programmable

Interface EtherNet/IP per IEC 61784-1

Transmission speed 100 MBits/s

Duplex Full or half

Installation Chapter 4

Rockwell Automation Publication 842E-UM001C-EN-P - September 2016 43

Page 44

Chapter 4 Installation

Notes:

44 Rockwell Automation Publication 842E-UM001C-EN-P - September 2016

Page 45

Chapter 5

Configuring the Encoder for Your EtherNet/IP

Network

Setting the IP Address

The 842E encoder is shipped with the network address switches set to 888. Use

one of these two methods to assign an IP address.

1. To set the last octet of the IP address (192.168.1.xxx) use the network

address switches (see Figure 2 on page 41

2. Use the network address switches to enable BOOTP / DHCP and use a

BOOTP utility or DHCP server to assign the IP address of the unit on

powerup.

) on the encoder.

Assigning the Last Octet in an IP Address Scheme of 192.168.1.xxx

Using the Network Address Switches

1. Set the three network address switches to 999.

2. Cycle power to the encoder.

3. Set the three network address switches to a valid address of 001 – 254.

4. Cycle power to the encoder.

5. The encoder powers up with the IP address set to 192.168.1.xxx, where

xxx is the position of the three network address switches.

Rockwell Automation Publication 842E-UM001C-EN-P - September 2016 45

Network Address Switches Set to 123

x100

Figure 1

x10

x1

Page 46

Chapter 5 Configuring the Encoder for Your EtherNet/IP Network

Assigning the IP Address Using BOOTP/DHCP:

Verify that the encoder MAC ID is in the relationship list in the BOOTP

Utility or DHCP server before attempting to assign the encoder an IP address.

1. Set the three network address switches to 999 and cycle power.

2. Set the three network address switches to 000 and cycle power.

3. The encoder powers up and request an IP address from a BOOTP/

DHCP server.

4. If the encoder MAC ID is in the relationship list, the BOOTP/DHCP

server assigns the associated IP address to the corresponding MAC ID.

46 Rockwell Automation Publication 842E-UM001C-EN-P - September 2016

Figure 2

Setting of

Network Address Switches Function

001…254 Sets last octet of the IP address to the value indicated (xxx in 192.168.1.xxx)

888 Restores all factory default settings in the encoder and clears its IP address

999 Clears the encoder IP address

Table 1 - Function of Network Address Switch Settings

ATT EN TI ON : Disable DHCP after the new network address is set (see next

step).