Allen-Bradley 836P-N2NFGA14A-D4, 836P-N3NMGA14A-D4, 836P-N2NMGB50A-D4, 836P-N2NMGA60A-D4, 836P-N2NMGB20A-D4 Installation Manual

...Page 1

Installation Instructions

Original Instructions

Non-display Solid-state Pressure Transmitter

Catalog Numbers

Topi c Page

Summary of Changes 1

Specifications 1

Dimensions [mm (in.)] 3

Wirin g Diagr ams 3

Mating Cables 3

Process Connection 3

Commissioning 3

Types of Sealing 4

Dismounting and Disposal 4

836P-N2x, 836P-N3x

Summary of Changes

Updated ratings for ambient temperature, medium temperature, and

storage temperature in Specifications

on page 1.

Safety Considerations

• Read this document for information on installation, handling,

mounting, general product specifications, and operation of this

product. These installation instructions contain important

information on handling the instrument.

• Working safety requires that all safety instructions and work

instructions are observed.

• Observe the relevant local accident prevention regulations and

general safety regulations for the range of use of the instrument.

• The installation instructions are part of the product and must

be kept in the immediate vicinity of the instrument and readily

accessible to skilled personnel at any time.

• Skilled personnel must have carefully read and understood the

installation instructions, before any work begins.

• The Bulletin 836P-N pressure transmitter measures and

monitors absolute and gauge pressures. The device has been

safely built with state-of-the-art technology and meets the

applicable requirements and EC directives. It can, however, be a

source of danger if used incorrectly or for anything other than

the designated use.

• Qualified individuals are required for installation and

commissioning. Failure to comply results in personal injury or

equipment damage.

• During mounting, make sure that the sealing faces at the

instrument and the measuring point are clean and undamaged.

• Safety Installation Considerations: Before installation,

commissioning, and operation, be sure that the appropriate

pressure transmitter has been selected in terms of measuring

range, design, and specific measuring conditions.

Qualified Personnel

Qualified personnel are understood to be personnel who, based on their

technical training, knowledge of measurement and control technology,

and on their experience and knowledge of the country-specific

regulations, current standards and directives, are capable of

implementing the work that is described and independently recognize

potential hazards.

Specifications

Output Signals

Signal Load

4…20 mA ≤ power supply -8V/0.02 A

Power Supply

Power Supply Total Current Consumption

8…30V DC Signal current, maximum 25 mA

IMPORTANT The power supply for the pressure transmitter must be made

via an energy limited electrical circuit in accordance with

section 9.3 of UL/EN/IEC 61010-1, or an LPS per UL/EN/IEC

60950-1,or class 2 in accordance with UL-1310/UL1585(NEC

or CEC). The voltage supply must be suitable for operation

above 2,000 m (6561.66 ft) and should the pressure

transmitter be used at this altitude.

Page 2

Non-display Solid-state Pressure Transmitter

Specifications (Continued)

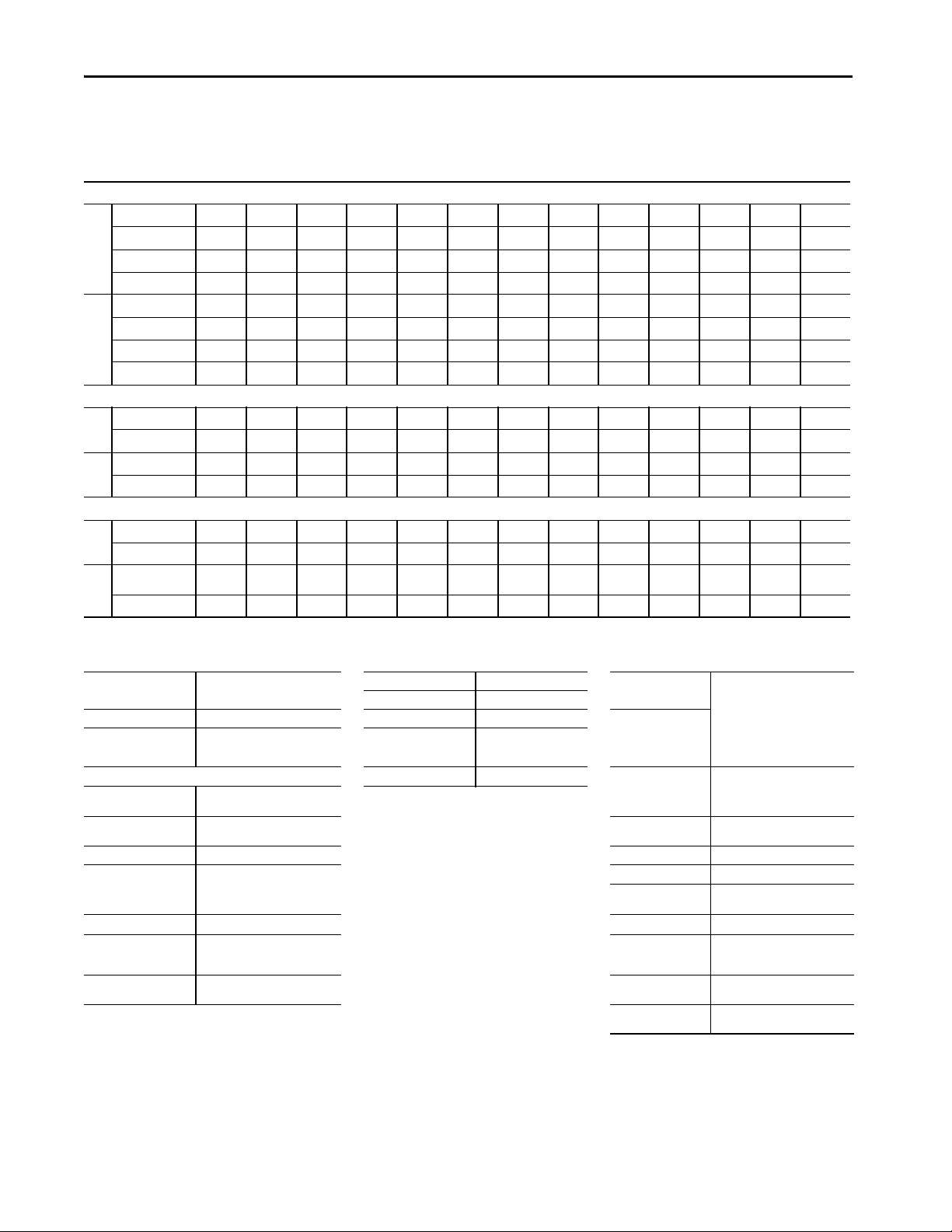

Measuring Ranges

Gauge Pressure

Measuring Range 0…1 0…1.3 0…2 0…2.5 0…4 0…6 0…9 0…13 0…17 0…20

Overpressure Limit 2 2.6 4 5 8 12 18 26 34 40

bar

Measuring Range 0…24 0…34 0…68 0…99 0…137 0…206 0…344 0…399 0…551 0…689

Overpressure Limit 48 68 136 198 274 412 688 798 1,102 1,378

Measuring Range 0…14.5 0…20 0…30 0…36.2 0…60 0…100 0…145 0…200 0…250 0…300

Overpressure Limit 29 40 60 72 120 200 290 400 500 600

psi

Measuring Range 0…362 0…500 0…1000 0…1450 0…2000 0…3000 0…5000 0…5800 0…8000 0…10,000

Overpressure Limit 724 1000 2000 2900 4000 6000 10,000 10,600 16,000 20,000

Absolute Pressure

Measuring Range 0…1 0…1.3 0…2 0…2.5 0…4 0…6 0…9 0…13 0…17 0…20

bar

Overpressure Limit 2 2.6 4 5 8 12 18 26 34 40

Measuring Range 0…14.5 0…20 0…30 0…36.2 0…60 0…100 0…145 0…200 0…250 0…300

psi

Overpressure Limit 29 40 60 72 120 200 290 400 500 600

Vacuum and +/- Measuring Range

Measuring Range -1…1 -1…1.3 -1…2 -1…2.5 -1…4 -1…6 -1…9 -1…13 0…17 0…20

bar

Overpressure Limit 2 2.6 4 5 8 12 18 26 34 40

Measuring Range

psi

Overpressure Limit 29 40 60 72 120 200 290 400 500 600

-30 in

Hg…14.5

-30 in

Hg…20

-30 in

Hg…30

-30 in

Hg…36.2

-30 in

Hg…60

-30 in

Hg…100

-30 in

Hg…145

-30 in Hg…

200

-30 in

Hg…250

-30 in

Hg…300

Performance Characteristics Reference Operation Conditions (per IEC 61298-1) O perating Conditions: Environment

Load

Settling time < 4 ms Humidity 45…75% r. h.

Switch on time < 15 ms Mounting position As required

Analog signal 4…20 mA:

(Power supply -8V)/0.02 A

Accuracy D ata

mBar models: nonrepeatability measuring range

mBar models range of measure

Signal noise ≤ ± 0.3% of span Humidity 45… 75 % r. h.

Temperature error at 0…80 °C

(32…176 °F) in rate

temperature range

Long-te rm drift ≤ ± 0.1% of span Short circuit resistance Analog + vs. Analog -

Range of measure

Non-linearity ≤ ± 0.5% of span Vibration resistance

≤ 0.1 bar ≤ 0.2% span

≤ 0.1% of span

≤ 0.1 bar: ≤ 0.2% of span

≤ 0.1 bar: ≤ 0.1% of span

Typical: 1.0% of span

Maximum: 2.5% of span

≤ 0.1 bar: ≤ ± -0.5% of span

≤ 0.4 bar: ≤ ± -0.2% of span

> 0.4 bar: ≤ ± -0.1% of span

Temperature 15…25 °C (59…77 °F)

Atmospheric pressure 860…1060 mbar

Power supply 24V DC

Vacuum resistance 10 mbar

Ambient temperature range

Medium temperature

Storage temperature -40…+70 °C (-40…+158 °F)

Service life 10 million load cycles

Shock resistance

Reverse polarity protection Analog + vs. Analog -

Ingress protection (per

IEC60529)

1/4 in. NPT:

-30…+100 °C (-22…+212 °F)

G 1/4 in.:

-30…+100 °C (-22…+212 °F)

G 1/2 in.:

-30…+100 °C (-22…+212 °F)

SAE 7/16-20 UNF:

-20…+100 °C (-4…+212 °F)

(0.145 psi)

abs

500 g (17.64 oz)

(IEC 60068-2-27, mechanical)

10 g (0.35 oz)

(IEC 60068-2-6, under resonance)

IP67 – M12x1 4 pin

2 Rockwell Automation Publication 836P-IN002B-EN-P - December 2017

Page 3

Dimensions [mm (in.)]

21.3

(0.84)

13

(0.51)

27

(1.06)

29.5 (1.16) dia.

G1/4B

EN837

2

(0.08)

Wiring Diagrams

20

(0.79)

12

(0.47)

7/16-20 UNF

SAE J514

O-ring BOSS

G 1/2 B

EN837

3

(0.12)

G 1/2 B EN837

G 1/4 BSPP

7/16-20 UNF

1/4 in. NPT Female 1/4 in. NPT Male Process Connection

29

(1.14) dia.

M12x1

29 (1.14) dia.

M12 x 1

(0.47)

12

Non-display Solid-state Pressure Transmitter

27

(1.06)

33 (1.3)

ca./approx.

13 (0.51)

1/4 in.

NPT

25 (0.98)

± 0.1 dia.

27

(1.06)

14

(0.55)

33

(1.3) dia.

20

(0.79)

1/4 in. NPT

4…20 mA

(+)

14

4…20 mA

23

(-)

Mating Cables Process Connection

889D-F4AC-2 (M12x1 connector)

889D-R4AC-2 (M12x1 right angle connector)

Measuring Cell Piezoresistive measuring cell and metallic measuring diaphragm

Application

Process connection

Measurement and monitoring of absolute and gauge pressures

Thread

− 1/4 NPT female

− 1/4 NPT male

− G1/4 BSPP male

G 1/2B

SAE 7/16-20 UNF O-ring BOSS

Commissioning

Making the Mechanical Connection

ATT EN TI ON : Before commissioning, the pressure transmitter must be subjected to a visual inspection.

• Fluid leakage is indicative of damage.

• Only use the pressure transmitter if it is in perfect condition concerning safety.

• While mounting, make sure that the sealing faces at the instrument and the measuring point are clean and undamaged.

• Only screw or unscrew the instrument via the spanner flats and to the prescribed torque with an appropriate tool. The correct torque

depends on the dimensions of the process connection and the gasket used (form/material). When screwing or unscrewing the pressure

transmitter, do not use the housing as contact surface.

• Be careful not to cross-thread.

• Max torque is 50 N·m (442.54 lb·in).

Rockwell Automation Publication 836P-IN002B-EN-P - December 2017 3

Page 4

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Types of Sealing

Rockwell Automation Support

For technical support, visit http://www.rockwellautomation.com/support/overview.page.

per EN 837 per DIN 3852-E

NPT

Parallel Thread Tapered Thread (NPT)

Correct sealing of the process connections with parallel threads at the sealing face must be made using suitable flat gaskets and sealing rings.

The sealing of the tapered threads (for example, NPT thread) is made by providing the thread with additional sealing material such as, PTFE tape

(EN 837-2).

Dismounting and Disposal

ATT EN TI ON : Residual media in the dismounted pressure transmitter can result in a risk to persons, the environment, and equipment. Take sufficient

precautionary measures.

Dismounting: Only disconnect the pressure transmitter once the system has been depressurized.

Disposal: Incorrect disposal can put the environment at risk.

Dispose of instrument and packaging materials in an environmentally compatible way and in accordance with the country-specific waste disposal

regulations.

Waste Electrical and Electronic Equipment (WEEE)

At the end of life, this equipment should be collected separately

from any unsorted municipal waste.

Rockwell Automation maintains current product environmental information on its website at

http://www.rockwellautomation.com/rockwellautomation/about-us/sustainability-ethics/product-environmental-compliance.page

Allen-Bradley, Rockwell Automation, and Rockwell Software are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

.

Publication 836P-IN002B-EN-P - December 2017 14142258.02

Supersedes Publication 836P-IN002A-EN-P - October 2015 Copyright © 2017 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

10001930278 Ver 01

Loading...

Loading...