Page 1

User Manual

RFID Systems

Bulletin Number 56RF

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation® sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

) describes some

WARNING: WARNING: ??????????ARNING: ?????Identifies information about practices or circumstances that can

cause an explosion in a hazardous environment, which may lead to personal injury or death, property damage, or economic

loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Preface

Introduction

RFID Components

Electrical Installation

Who Should Use this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Abbreviations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

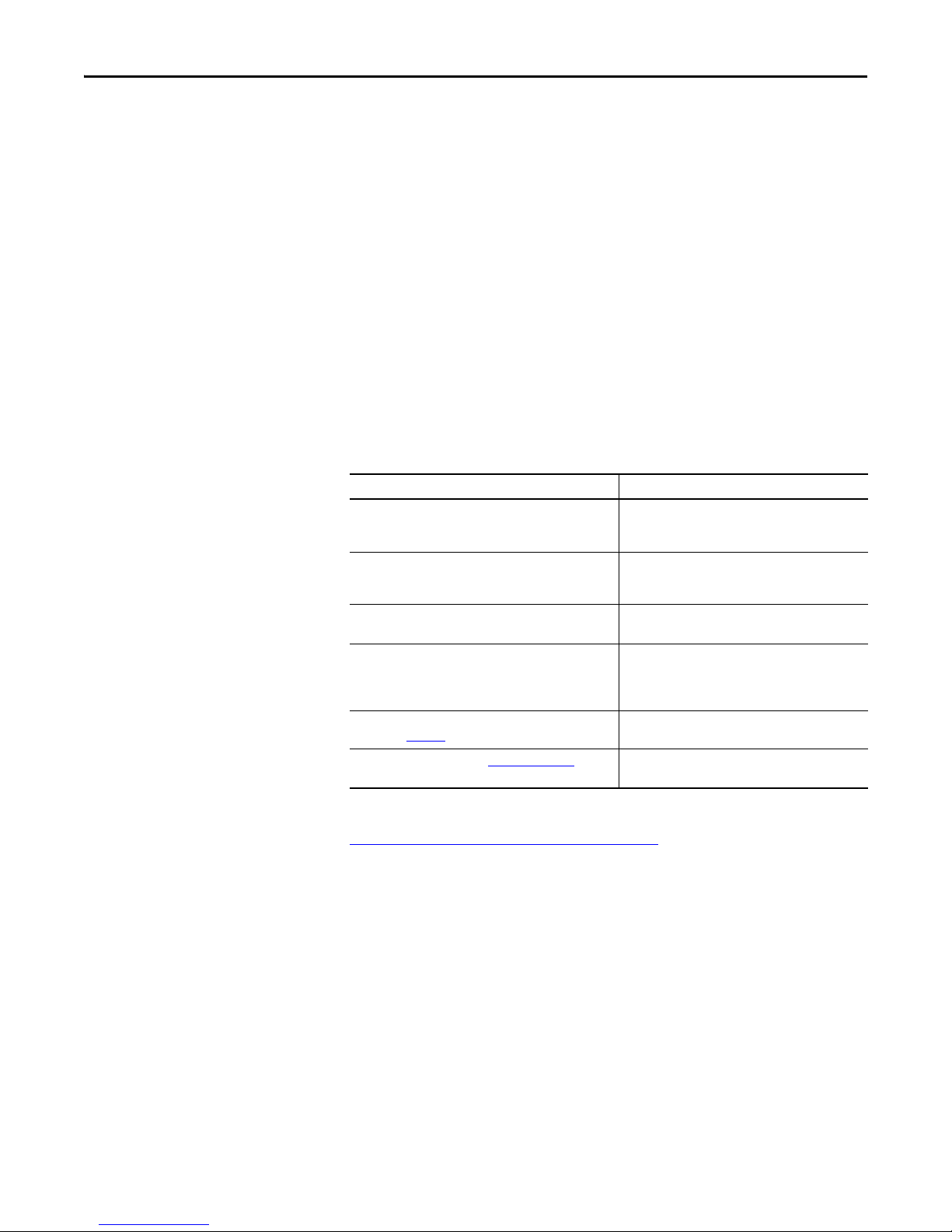

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

What is RFID?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

International Standard Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Backward Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Interface Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Transceivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

RFID Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Handheld Reader/Writer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Component Catalog Number Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Cable Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Auxiliary Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Power Connection Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

EtherNet/IP Addressing

Mechanical Installation

Add Your RFID Interface Block

to an RSLogix 5000 Program

Star Topology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Linear Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Device Level Ring (DLR) Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Setting the Network Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Fundamental IP Addresses: 192.168.1.xxx. . . . . . . . . . . . . . . . . . . . . . . . . . 38

Advanced IP Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Change IP Address from One Advanced Address to another Advanced

Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

IP Address 888. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Fastening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Spacing Between Transceivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Spacing Next to Metal Surfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Transceiver Field Maps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

General Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Module Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Connection Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Module Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Internet Protocol Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Port Configuration Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 3

Page 4

Table of Contents

RSLogix 5000 Controller Tags

Commands Summary

RSLogix 5000 Code Examples

Configuration Image Table and Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Input Image Table and Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Input Channel Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Output Image Table and Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Output Channel Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Commands Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Main Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Example Command Routines - Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Clear Multiple Bytes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Get Multiple Block Security Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Get System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Get Version Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Lock AFI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Lock Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Lock DSFID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Read Byte Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Multi-Tag Block Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Read Multiple Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Read Single Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Read Transceiver Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Write AFI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Write Byte Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Write DSFID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Write Multiple Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Multi-Tag Block Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Write Single Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Continuous Read Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Stop Continuous Read. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Teach Continuous Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

SLC Code Examples

MicroLogix 1400 Code

Examples

RFID Tag Speed

4 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

Read Byte Routine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Read Byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Write Byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Read Multiple Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Write Multiple Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Input Image Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Output Image Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Continuous Read Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Teach Continuous Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Page 5

Table of Contents

RFID Interface Block Web Page

Appendix A — Error Codes for

RFID Interface Block

Appendix B — CIP Information

Home . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Network Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

EtherNet Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

I/O Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Device Identity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Device Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Product Codes and Name Strings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

CIP Explicit Connection Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

CIP Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Identity Object Class Code 0x0001. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Assembly Object Class Code 0x0004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Reading the Input Image Table of a 56RF-IN-IPD22 with a

MicroLogix1400. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Writing to the Output Image Table of a 56RF-IN-IPD22 with a

MicroLogix 1400. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Reading the Input Image Table of a 56RF-IN-IPD22 with a SLC-5/05 . .

141

Class 1 Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Exclusive Owner Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Input Only Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Listen Only Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Class 3 Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Discrete Input Point Object Class Code 0x0008 . . . . . . . . . . . . . . . . . . . 145

Discrete Output Point Object Class Code 0x0009 . . . . . . . . . . . . . . . . . 146

Appendix C — Install the AOP

(Add-On Profile)

Appendix D — Troubleshooting

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 5

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .153

Page 6

Table of Contents

Notes:

6 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

Page 7

Preface

Read this preface to familiarize yourself with the rest of the manual. It provides

information concerning:

• who should use this manual

• the purpose of this manual

• related documentation

• conventions used in this manual

Who Should Use this Manual

Purpose of this Manual

Abbreviations

Use this manual if you are responsible for designing, installing, programming, or

troubleshooting control systems that use the 56RF RFID products.

You should have a basic understanding of electrical circuitry and familiarity with

relay logic. If you do not, obtain the proper training before using this product.

This quick start guide assumes you have some familiarity with RSLogix software.

It provides an example of the steps needed to get a 56RF RFID system set up and

functioning. The reader should refer to appropriate user manuals for other

details. This manual:

• explains how to install and wire an example RFID system

• install and setup the module in an RSLogix 5000 program

• set up a simple program to receive and transmit data to an RFID tag

AFI – Application Family Identifier

AOP – Add On Profile

DFSID – Data Storage Format Identifier

DHCP – Dynamic Host Configuration Protocol

DNS – Domain Name Server

DOS – Disk Operating System

EAS – Electronic Article Surveillance

FE – Functional Earth

IEC – International Electrotechnical Commission

INT – signed, two byte integer

ISO – International Organization for Standardization

JTC – Joint Technical Committee

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 7

Page 8

Preface

MACID – Media Access Control Identification

QD – Quick Disconnect

RFID – Radio Frequency Identification

SB – Sub-committee

SINT – signed, single byte integer

UID – Unique Identifier

UUID – Universally Unique Identifier

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

EtherNet/IP Modules in Logix5000 Control Systems User

Manual, publication ENET-UM001

Getting Results with RSLogix 5000, publication

9399-RLD300GR

Allen-Bradley Industrial Automation Glossary, AG-7.1 A glossary of industrial automation terms and

EtherNet/IP Embedded Switch Technology Application

Guide, publication ENET-AP005

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Product Certifications website, http://www.ab.com

A manual on how to use EtherNet/IP modules with

Logix5000 controllers and communicate with various

devices on the EtherNet network.

Information on how to install and navigate RSLogix

5000. The guide includes troubleshooting information

and tips on how to use RSLogix 5000 effectively.

abbreviations.

A manual on how to install, configure, and maintain

linear and Device-level Ring (DLR) networks using

Rockwell Automation EtherNet/IP devices with

embedded switch technology.

Provides general guidelines for installing a Rockwell

Automation industrial system.

Provides declarations of conformity, certificates, and

other certification details.

You can view or download publications at

http:/www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales office.

8 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

Page 9

Introduction

Chapter 1

What is RFID?

RFID stands for Radio Frequency Identification. It is a method for

communicating information from one point to another point by the use of

electromagnetic waves (i.e., radio waves). It has unique characteristics that make it

attractive for use in industrial systems.

For example, you have a shipping carton that must be loaded with various goods

to meet a customer’s specific purchase order. You can attach a tag to the carton.

Prior to attaching the tag , you fill the tag with the specific items that the customer

wants. Then, as the carton moves to the filling stations, each station places the

required objects, only if needed, into the carton. If the tag does not require

something, the station is skipped.

Each filling station has an RFID transceiver. The transceiver reads and writes to

the tag. When the tag approaches the RFID transceiver, the transceiver reads the

contents of the tag. Based on the information received, the packaging process

adds items (or skips this step) and then writes to the tag that the item(s) was

added. The carton moves to the next filling station.

This is a common use of RFID technology. What makes the Bulletin 56RF

product line unique is its conformance to the open international standards:

ISO15693 and ISO18000-3 M1.

International Standard

Compliance

ISO/IEC 15693 is an ISO standard for what are called vicinity tags. The tags,

commonly referred to as ICODE tags, can be read from a greater distance than

proximity tags and closed couple tags. ISO/IEC 15693 systems operate at the

13.56 MHz frequency, and offer maximum read distance of 3.3…4.9 ft

(1…1.5m), depending on the transceiver. Library applications with very large

antennas are capable of these distances. Most industrial applications are less than

8 in. (20.3cm) for a read/write range.

The ICODE compatible tags permit users to use lower cost tags than proprietary

systems currently provide. Users have the ability to use tag configuration options

from multiple vendors.

ISO/IEC 15693 forms part of a series of International Standards that specify

non-contact tags. The tags can be attached to objects, like cartons, bags, and

valuable items, which can then be tracked while in the vicinity of a reading device.

ISO/IEC 15693-2:2006 defines the power and communications interface

between the vicinity card and the reading device. Other parts of ISO/IEC 15693

define the physical dimensions of the card and the commands interpreted by the

card and reader.

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 9

Page 10

Chapter 1 Introduction

Power is coupled to the tag by an AC field produced in the transceiver. The

powering field has a frequency of 13.56 MHz and is one of the industrial,

scientific and medical (ISM) frequencies available for worldwide use. When

sufficient power is received by the tag, it is able to respond to commands sent

from the coupler. The coupler sends commands to the card by modulating the

powering field and by using a modulation system known as pulse position

modulation, whereby the position of a single pulse relative to a known reference

point codes the value of a nibble or byte of data. This allows the card to draw the

maximum energy from the field almost continuously. Tags, which have no power

source, can be energized at ranges of up to 3.3 ft (1 m) from a coupler that can

only transmit power within the limits permitted by international radio frequency

(RF) regulations.

A tag only responds when it receives a valid command that selects a single tag

from a possible collection of cards within range of the coupler. This process of

collision detection and selection, also known as anti-collision, is made possible by

detecting the unique identification number encoded into every tag.

Anticollision, and the commands used, are defined in ISO/IEC 15693-3. The

tag responds to the transceiver by drawing more or less power from the field and

generates one or two sub-carriers of around 450 kHz. These are switched on and

off to provide special-encoded data that are then detected by the transceiver.

Backward Compatibility

The Bulletin 56RF RFID system will be offered initially on EtherNet/IP and is

backward compatible with the previous offering of Bul. 56RF ICODE products.

The transceivers and interface blocks are a matched pair so they cannot be

interchanged. However, the tags can be interchanged with either system if they

are ICODE tags. Both systems can read and write these tags seamlessly.

10 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

Page 11

Introduction Chapter 1

ETHERNET/IP

NS

MS

LINK

56RF

Interface Block

Personal

Computer

L35E

CompactLogix

1783-US05T

Ethernet/IP

Switch

56RF

Transceiver

56RF

Tag

56RF

Transceiver

Tracked

Object

2

3

4

5

1

P

W

R

1783-US05T

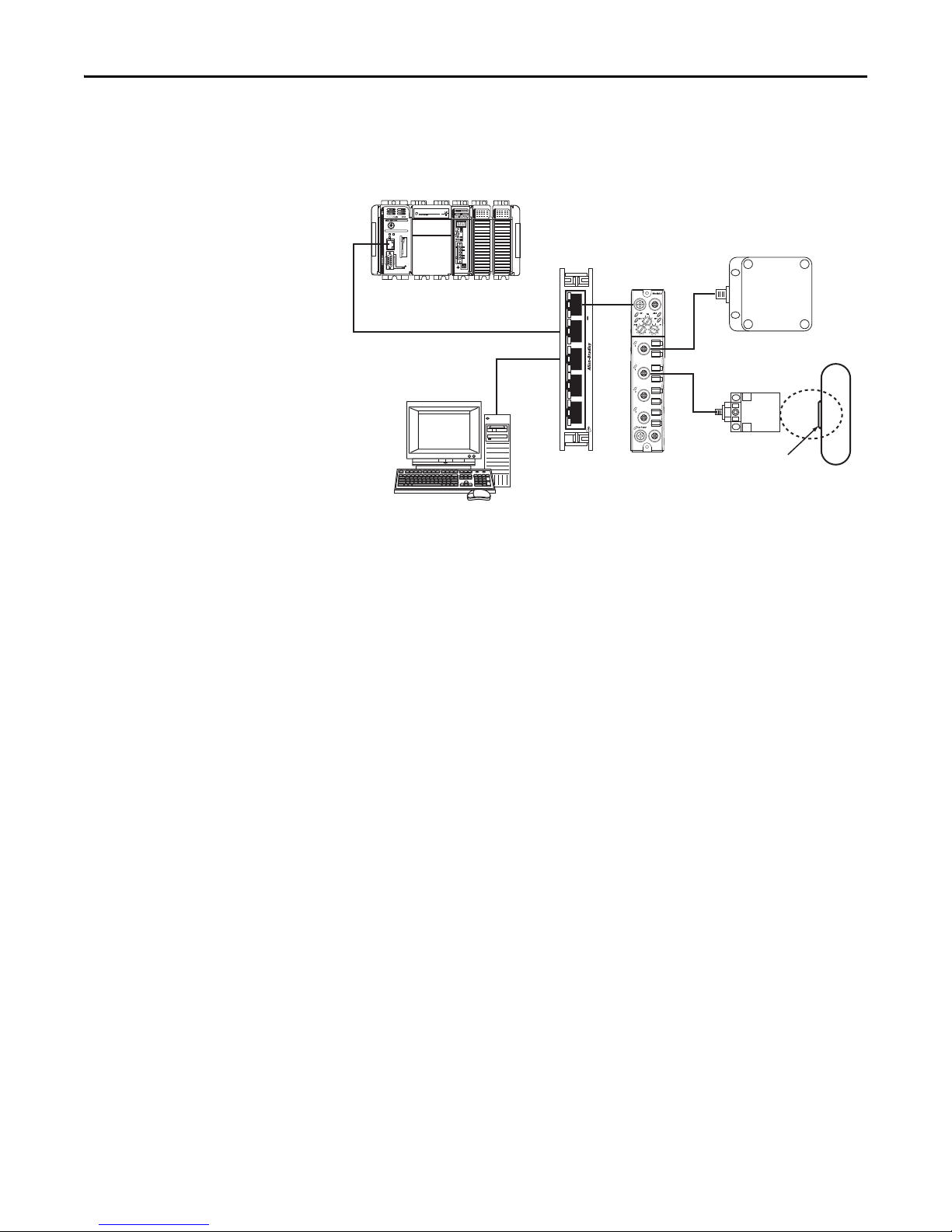

System Setup

The figure below shows a simple RFID system. This user manual describes the

setup, installation, and programming required to get this system running.

Figure 1 - RFID System

Tags are attached to objects that need to be tracked. The tags hold important

information about the object. An RF transceiver reads and/or writes information

to the tags when the tag moves within the transmission envelope of the

transceiver (dotted ellipse). The physical size of the transceiver is directly related

to the size of the transmission field. The larger the transceiver, the longer and

wider the antenna field is. Please see transceiver instruction sheets for antenna

field sizes.

The transceivers are connected to a special RFID EIP interface block. The

distribution block has an EtherNet connection to an EtherNet switch. An L35E

CompactLogix controller and a personal computer also have EtherNet

connections to the EtherNet switch.

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 11

Page 12

Chapter 1 Introduction

Notes:

12 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

Page 13

Chapter 2

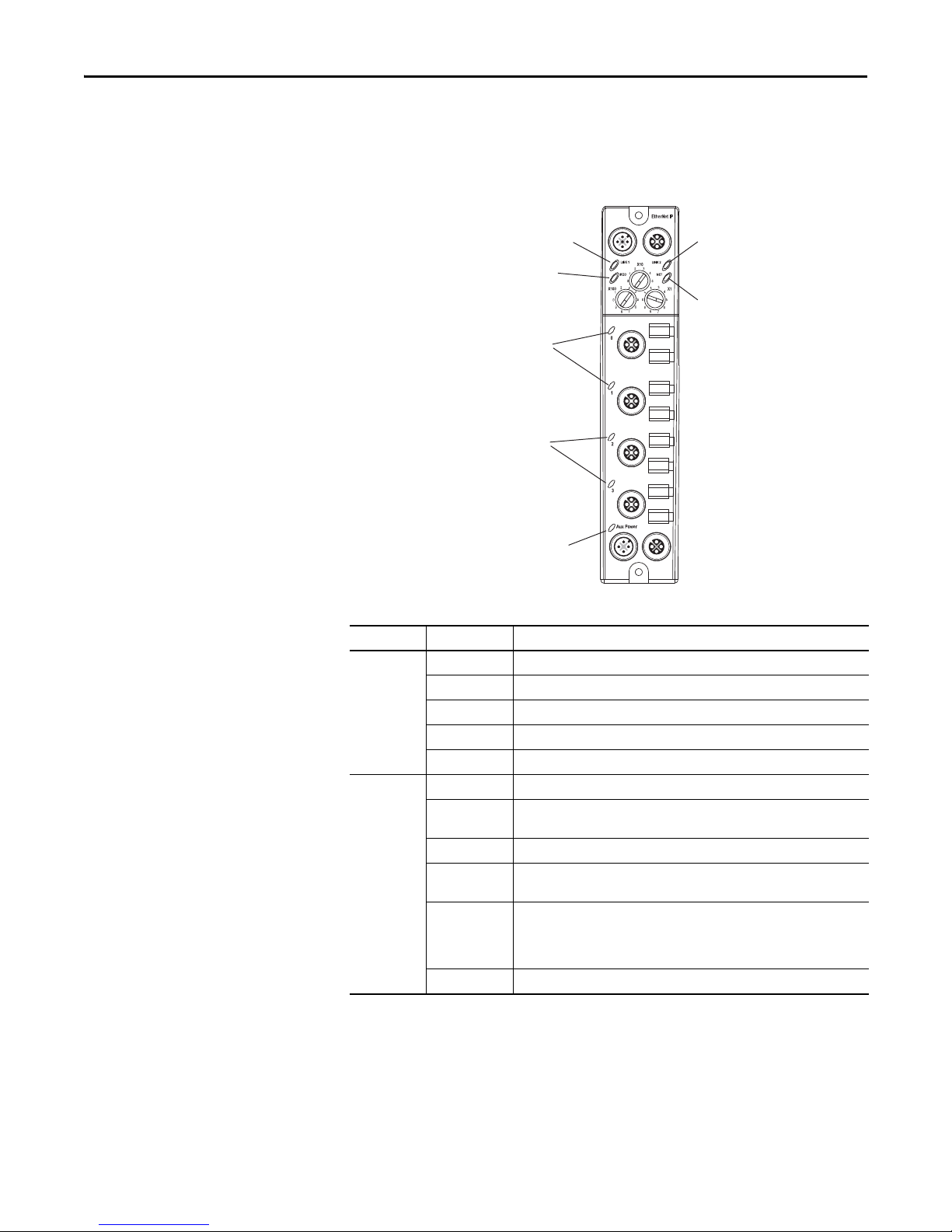

Functional Earth (1)

Status LEDs

Ethernet/IP D-Code

M12 Connector

5-Pin Male

Ethernet/IP D-Code

M12 Connector

5-Pin Female

Auxiliary Power

M12 4-Pin

Female

M12 Output Connector (IPS12, IPD22)

M12 Input Connector (IPD22A)

Female

M12 Input Connector

5-Pin Female

M12 RFID

Transceiver Interface

(IPD22, IPD22A)

5-Pin Female

M12 RFID

Transceiver Interface

5-Pin Female

Auxiliary Power

M12 4-Pin

Male

Node Address Switches

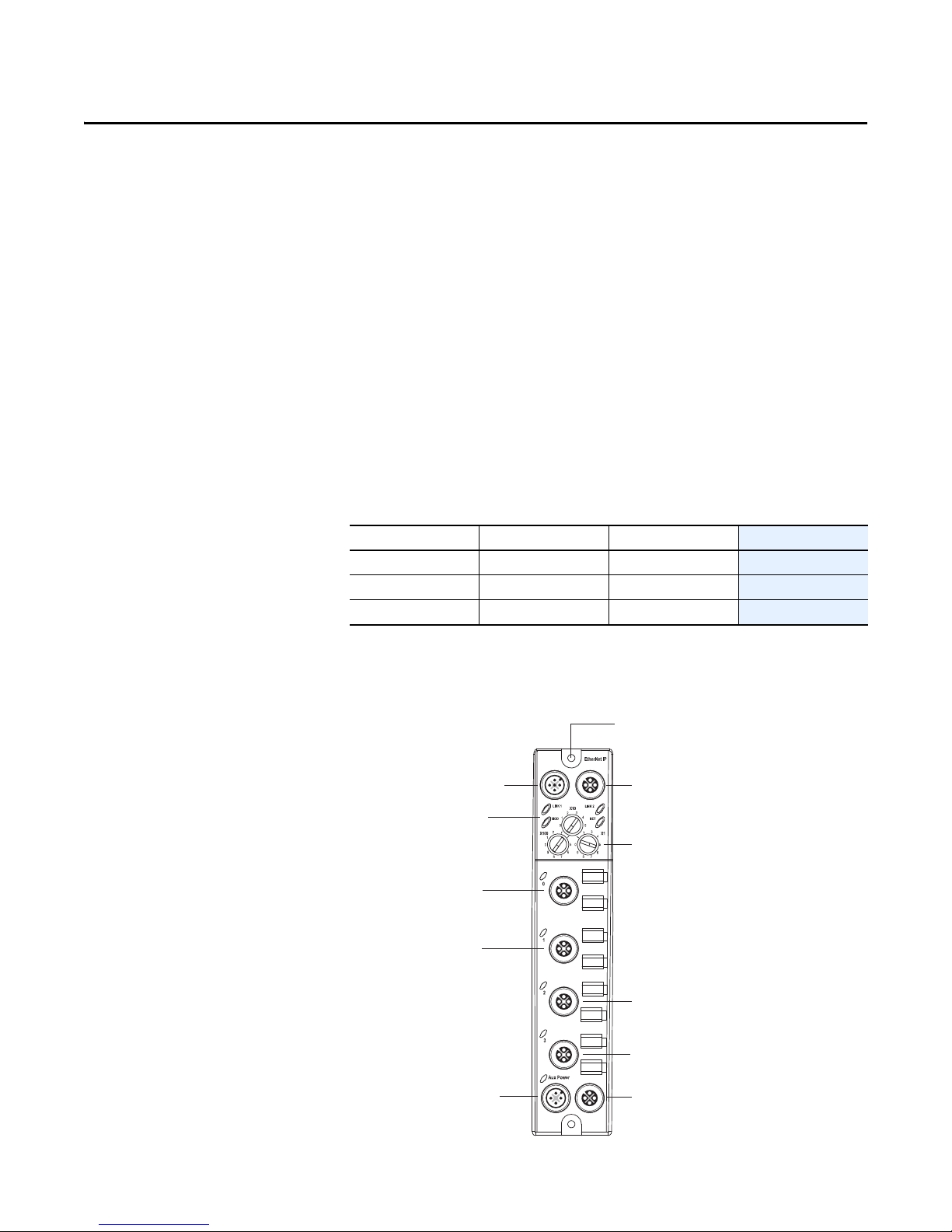

RFID Components

This chapter covers the three key components that make up the RFID system:

• the interface block

• the transceiver

• the tags

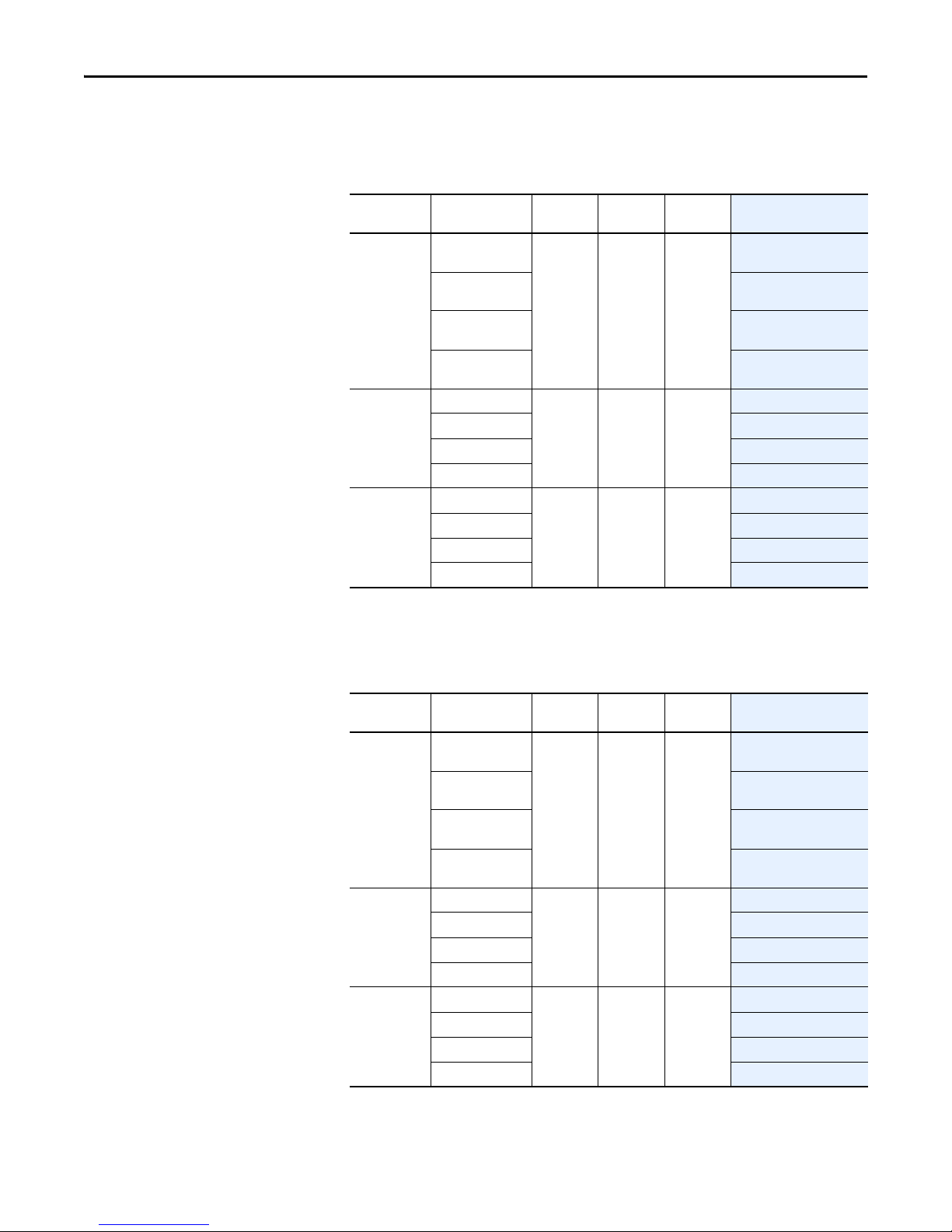

Interface Block

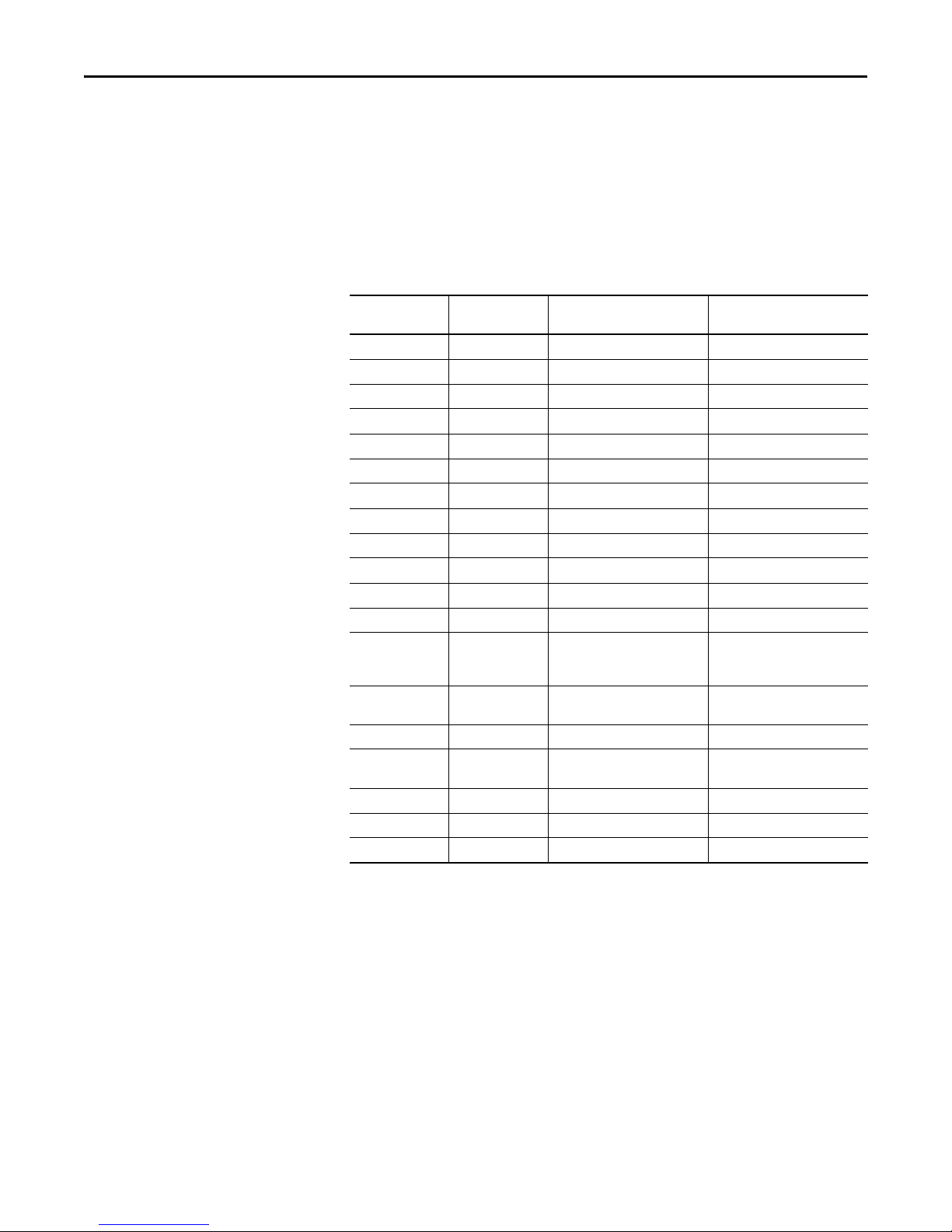

Three different interface blocks are available from which to choose. The table

below shows the type of ports for each catalog number.

Table 1 - Type of Ports

Transceiver Po rts Inpu t Ports Out put Ports Cat. No.

11156RF-IN-IPS12

211

22056RF-IN-IPD22A

56RF-IN-IPD22

The figure below identifies the connections for the EtherNet/IP, RF transceivers,

input devices, output devices, and power.

Figure 2 - Connections

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 13

Page 14

Chapter 2 RFID Components

MOD

Link 1

Link 2

Standard Input/Output

Transceiver Ports

Auxiliary Power

NET

LED Indicators

When the indicator is flashing, all flashes are 0.25 s ON and 0.25 s OFF.

This block has the seven different indicators.

Figure 3 - LED Indicators

Table 2 - LED Indicators

LED Name LED State Indicates

Off No link

Green 100 Mbps

Link1 and

Link2

MOD (Module)

Flashing green 100 Mbps/active

Yellow 10 Mbps

Flashing yellow 10 Mbps/active

Off There is no power applied to the block.

Flashing red/

Device in self-test

green

Green The block is operating in a normal condition.

Flashing green Standby. The device is not communicating with the interface block. Normal state

when only power has been applied to the transceiver.

Flashing red Recoverable fault. Most often occurs when data is corrupted between interface

block and transceiver. CRC failures etc. Recommended solution is to remove

electrical noise near cabling or reduce baud rate between transceiver and

interface block.

Red The transceiver has an unrecoverable fault; may need replacing.

14 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

Page 15

LED Name LED State Indicates

Off There is no power or no IP address.

NET (Network)

Standard I/O

Aux Power

RFID Port

Flashing red/

green

Green The block is operating in a normal condition.

Flashing green Standby. The device is not communicating with the interface block. Normal state

Flashing red Connection timeout. Most often occurs when data is corrupted between

Red Duplicate IP address. The transceiver has an unrecoverable fault; may need

Off Outputs inactive

Yellow Outputs active

Flashing green Outputs are idled and not faulted.

Flashing red Output faulted

Red Outputs forced off

Off No power is applied.

Solid green The applied voltage is within specifications.

Solid yellow The input power is out of specification.

Off No power

Flashing green No tag present, but communicating

Green Communicating

Flashing red No transceiver connected

Amber Tag present

Device in self-test

when only power has been applied to the transceiver.

interface block and transceiver. CRC failures etc. Recommended solution is to

remove electrical noise near cabling or reduce baud rate between transceiver and

interface block.

replacing.

Inputs inactive

Inputs active

Inputs faulted

Inputs unrecoverable fault

RFID Components Chapter 2

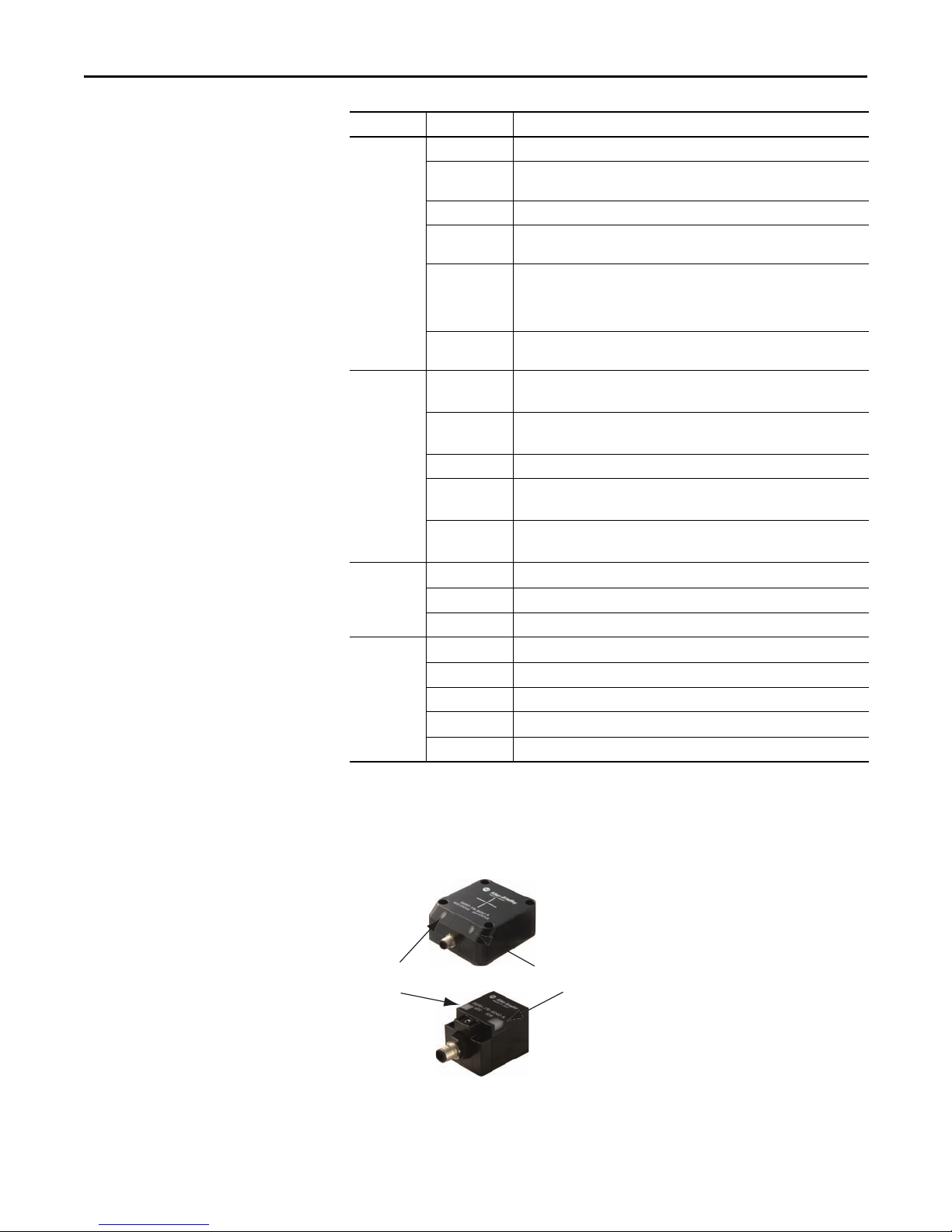

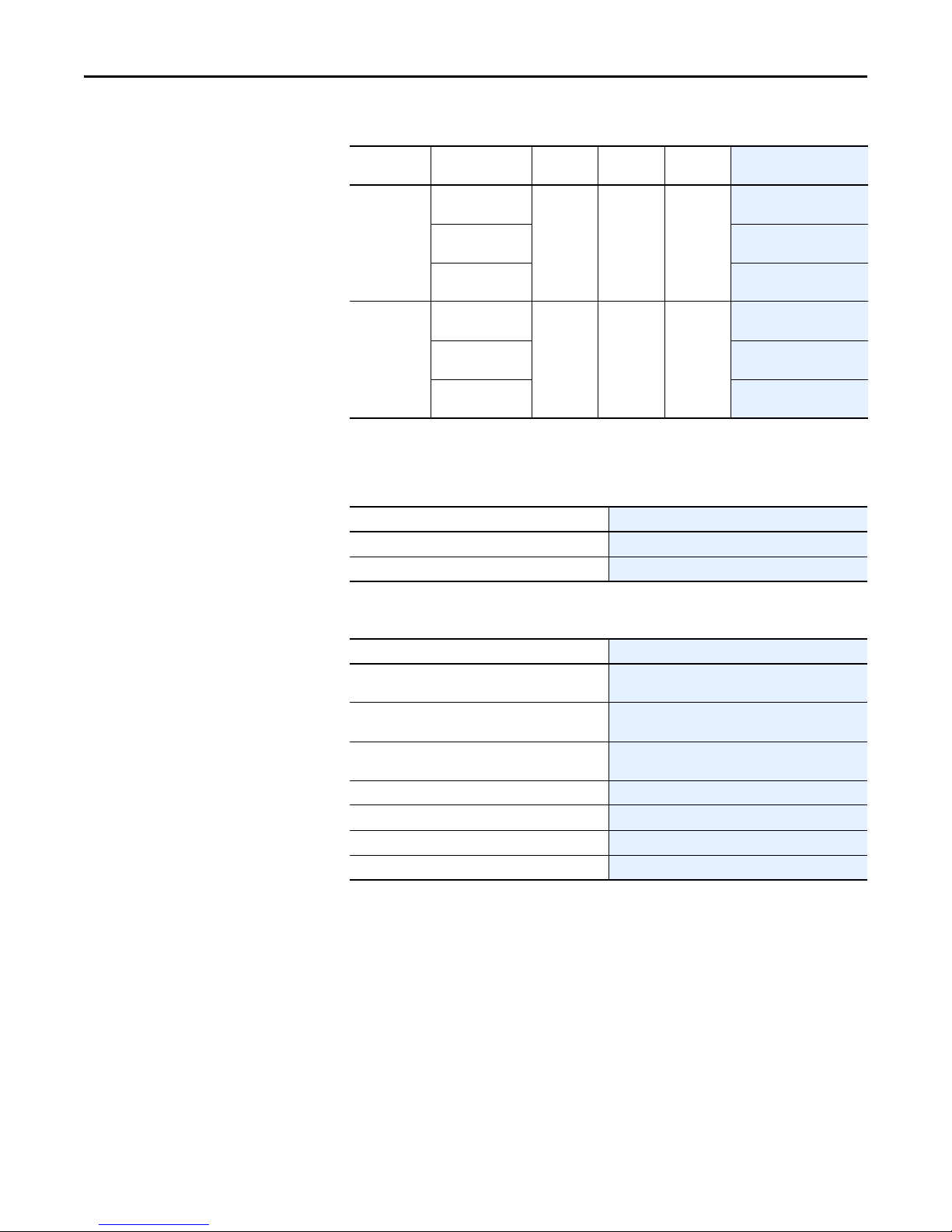

Transceivers

LED Indicators

Figure 4 - Indicators

Power

Module

Status

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 15

Operation

Read/Write

Status

Page 16

Chapter 2 RFID Components

Table 3 - LE Ds

LED Name LED State Indicates

Off There is no power applied to the block.

Module Status

Read/Write

Status

Green The block is operating in a normal condition.

Red The transceiver has an unrecoverable fault; may need replacing.

Off There is no power applied to the device.

Green The EIP interface block is communicating with the transceiver, but no tag is

present. No errors received.

Amber A tag is present within the antenna field.

Red A communication error has occurred. Examples are: bad read/write, corrupt CRC

Note: If a read/write command is not completed while the tag is within the

field, an error will occur.

Transceiver Power Up Sequence

1. Both LEDs OFF.

2. Power status turns green. R/W status turns green for 0.25 seconds.

RFID Tags

3. R/W status turns red for 0.25 seconds.

4. R/W status turns off for 3…5 seconds.

5. R/W status turns amber for 0.5 seconds.

6. R/W status turns green.

RF tags come in many shapes and sizes. In general, the bigger the tag, the longer

the sensing distance from the transceiver. Ta b l e 4

summarizes the size of the

memory for each type of tag.

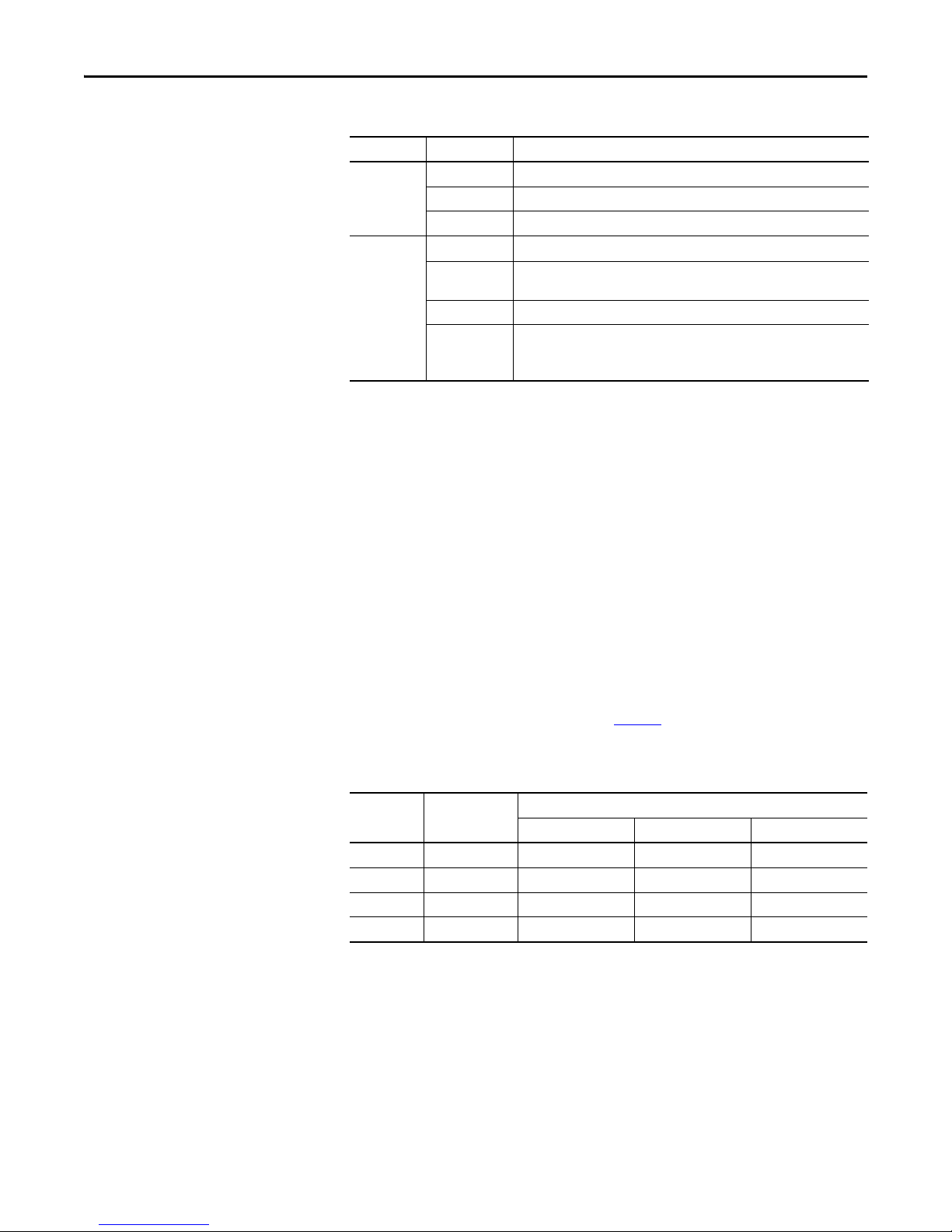

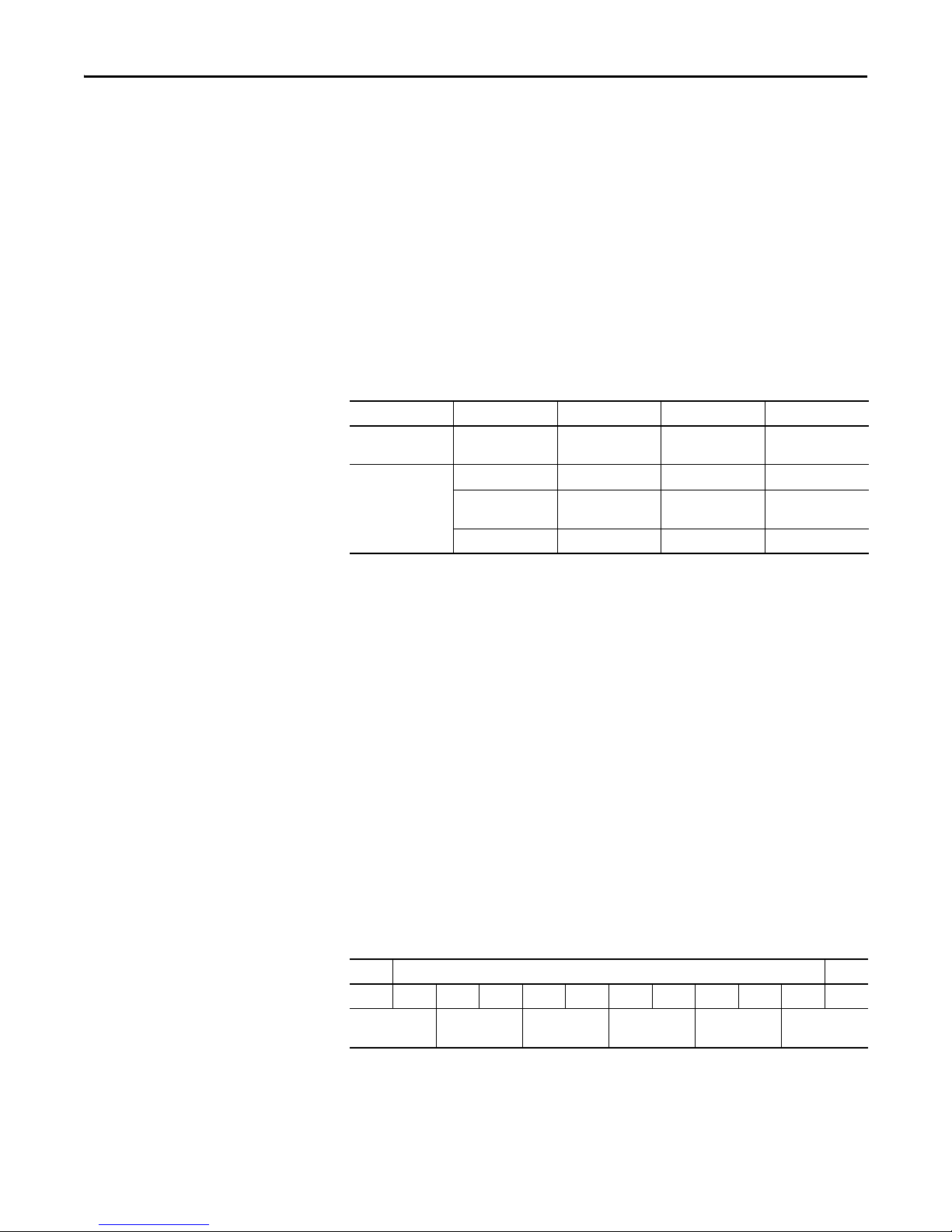

Table 4 - Me mory

Tag Type Total Tag

Memory

SLI 128 B 112 B 28 4

SLI-S 256 B 160 B 40 4

SLI-L 64 B 32 B 8 4

FRAM 2048 B 2 kB 250 8

User Memory

No. of Bytes No. of Blocks Bytes per Block

16 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

Page 17

RFID Components Chapter 2

Tag Memory Structure

Universally Unique Identifier (UUID)

Each tag has a different 64-bit hexadecimal UUID that is programmed during

the production process according to ISO/IEC15693-3 and cannot be changed

afterwards.

The numbering of the 64 bits is done according to ISO/IEC 15693-3 starting

with the least significant bit (LSB) 1 and ending with the most significant bit

(MSB) 64. This is in contrast to the general used bit numbering within a byte

(starting with LSB 0).

Byte 5 (bit 41…48) is the tag type. Byte 6 (bit 49…56) is the manufacturer code,

which coincides with the number of bytes/block.

The table below shows the RFID tags offered by Rockwell Automation and their

structure.

Table 5 - Tag Struc ture

Byte 76543210

Name UID 7 UID 6 UID 5 UID 4 UID 3 UID 2 UID 1 UID 0

Bit 64…57 56…49 48…41 40…1

SLIE00401Unique Serial Number

SLI-S E0 04 02 Unique Serial Number

Val ue

SLI-L E0 04 03 Unique Serial Number

FRAM E0 08 01 Unique Serial Number

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 17

Page 18

Chapter 2 RFID Components

Application Family Identifier (AFI)

The AFI represents the type of application targeted. AFI is coded on one byte,

which constitutes two nibbles of 4 bits each. The most significant nibble of AFI

is used to code one specific or all application families, as defined in the table

below. The least significant nibble of AFI is used to code one specific or all

application sub-families. Sub-family codes different from 0 are proprietary.

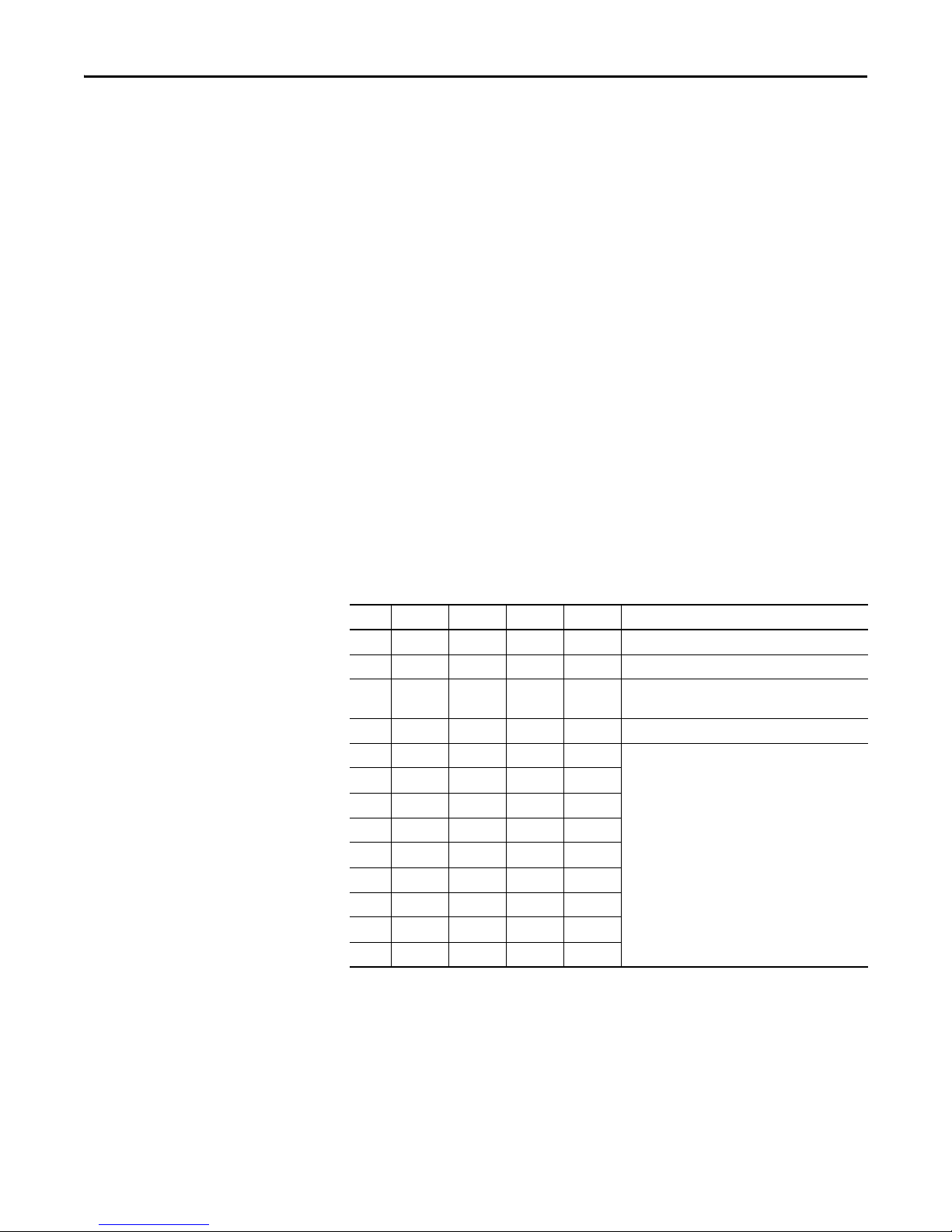

Table 6 - AFI Examples

AFI Most

Significant Nibble

0 0 All families and subfamilies No applicative preselection

X 0 All sub-families of family X Wide applicative preselection

X Y Only the Yth sub-family of family X —

0 Y Proprietary sub-family Y only —

1 0, Y Transport Mass transit, bus, airline

2 0, Y Financial IEP, banking, retail

3 0, Y Indentification Access control

4 0, Y Telecommunication Public telephony, GSM

50, YMedical —

6 0, Y Multimedia Internet service

70, YGaming —

8 0, Y Data storage Portable files

9 0, Y EAN-UCC (European Article

A 0, Y Data Identifiers as defined in ISO/

B 0, Y UPU Managed by ISO/IEC JTC 1/SC 31

C 0, Y IATA (International Air Transport

D 0, Y Reser ved for Future Use Managed by ISO/IEC JTC 1/SC 17

E 0, Y Reserved for Future Use Managed by ISO/IEC JTC 1/SC 17

F 0, Y Reserved for Future Use Managed by ISO/IEC JTC 1/SC 17

AFI Least

Significant Nibble

Meaning Examples/Notes

Managed by ISO/IECJTC 1/SC 31

Numbering-Uniform Code Council)

system for application indentifiers

Managed by ISO/IEC JTC 1/SC 31

IEC 15418

Managed by ISO/IEC JTC 1

Association)

18 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

X = ‘1’ to ‘F’, Y = ‘1’ to ‘F’

Page 19

RFID Components Chapter 2

Data Storage Format Identifier (DSFID)

The DSFID indicates how data is structured in the tag memory. It may be

programmed and locked by the respective commands. It is coded on one byte. It

allows for instant knowledge on the logical organization of the data.

Electronic Article Surveillance (EAS)

EAS is a technology typically used to prevent shoplifting in retail establishments.

An EAS detection system will detect active tags and set off an alarm.

EAS status is 1 bit data (LSB side), which is stored in the system area of a tag. The

initial value is “1”. EAS bit “1” means goods-monitoring status, and EAS bit “0”

means that goods-monitoring status is cleared.

Smart Label Integrated Circuit (SLI)

SLI tags use an EEPROM (electrically erasable programmable read only

memory) to store data. The 1024 bit EEPROM memory is divided into

32blocks. Each block consists of 4 bytes (1block= 32 bits). Bit 0 in each byte

represents the least significant bit (LSB) and bit 7 the most significant bit (MSB),

respectively.

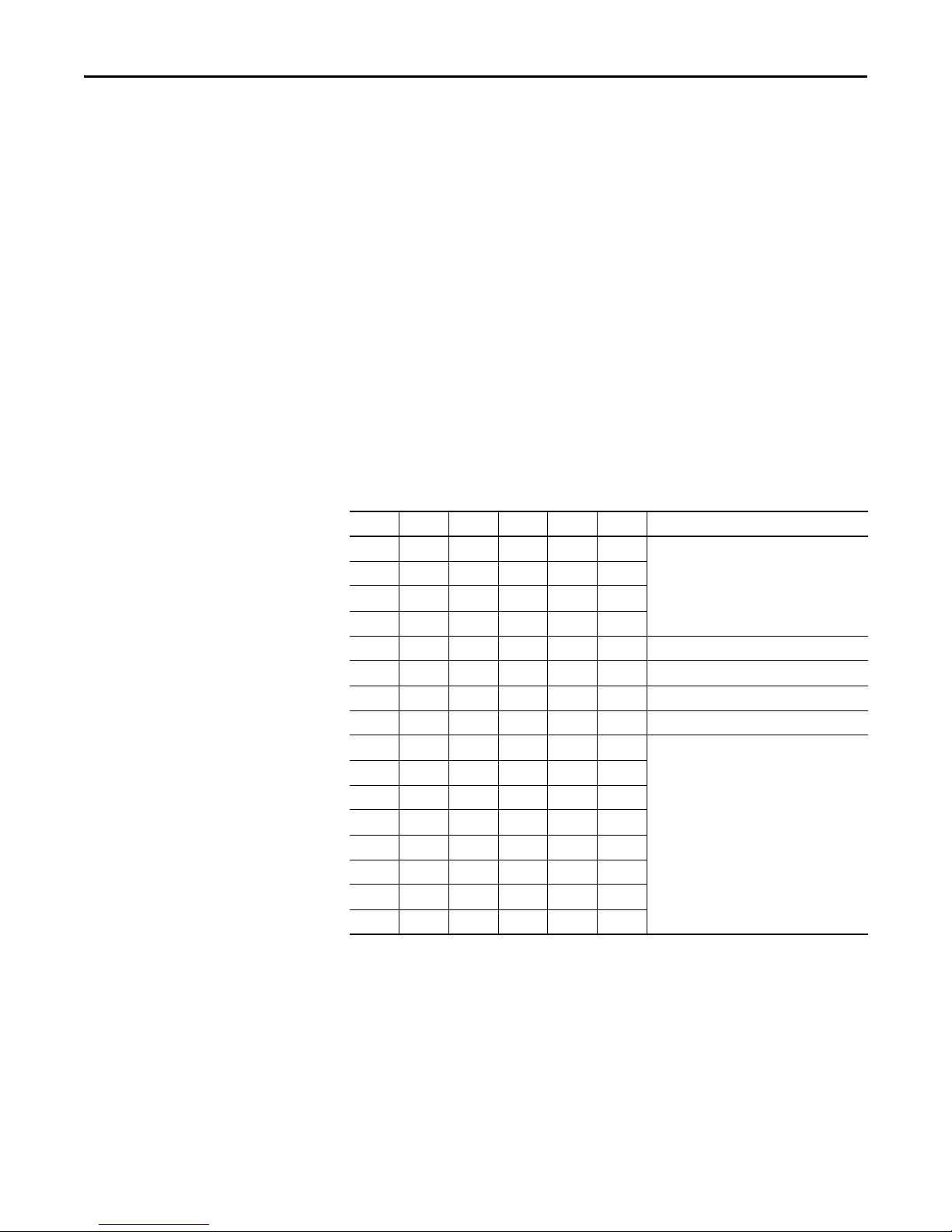

Table 7 - SL I Tags

Block Byte 0 Byte 1 Byte 2 Byte 3 Description

-4 UID0 UID1 UID2 UID3 Unique identifier (lower bytes)

-3 UID4 UID5 UID6 UID7 Unique identifier (higher bytes)

-2 Internally

used

-1 00 00 00 00 Write access conditions

0User Data

1

2

:

:

:

22

23

27

EAS AFI DSFID EAS, AFI, DSFID

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 19

Page 20

Chapter 2 RFID Components

IMPORTANT

SLI

EAS Function

The LSB of Byte 1 in Block -2 holds the EAS bit (Electronic Article Surveillance

mode active – the label responds to an EAS command)

Table 8 - EAS

Block -2, Byte 1

MSB LSB

XXXXXXXe

EAS: e = 1 (EAS enabled) e = 0 (EAS disabled)

Changing of the EAS Configuration must be done in secure environment. The

label must not be moved out of the communication field of the antenna during

writing. We recommend to put the label close to the antenna and not to

remove it during the operation.

Application Family Identifier

The ICODE system offers the feature to use an Application Family Identifier

(AFI) at the inventory command and the two custom commands inventory read

and fast inventory read (this allows for example the creation of label families).

This 8-bit value is located at Byte 2 in Block -2 as shown in the following figure

and is only evaluated if the AFI flag is set in the reader command.

Table 9 - AFI

Block -2, Byte 2

MSB LSB

XXXXXXXX

Data Storage Format Identifier

The Data Storage Format Identifier (DSFID) is located at Byte 3 in Block -2.

Table 10 - DSFID

Block -2, Byte 3

MSB LSB

XXXXXXXX

20 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

Page 21

RFID Components Chapter 2

IMPORTANT

Write Access Conditions

The Write Access Condition bits in block -1 determine the write access

conditions for each of the 28 user blocks and the special data block. These bits

can be set only to 1 with a lock command (and never be changed back to 0), i.e.

already write protected blocks can never be written to from this moment on.

In block -2 each byte can be individually locked.

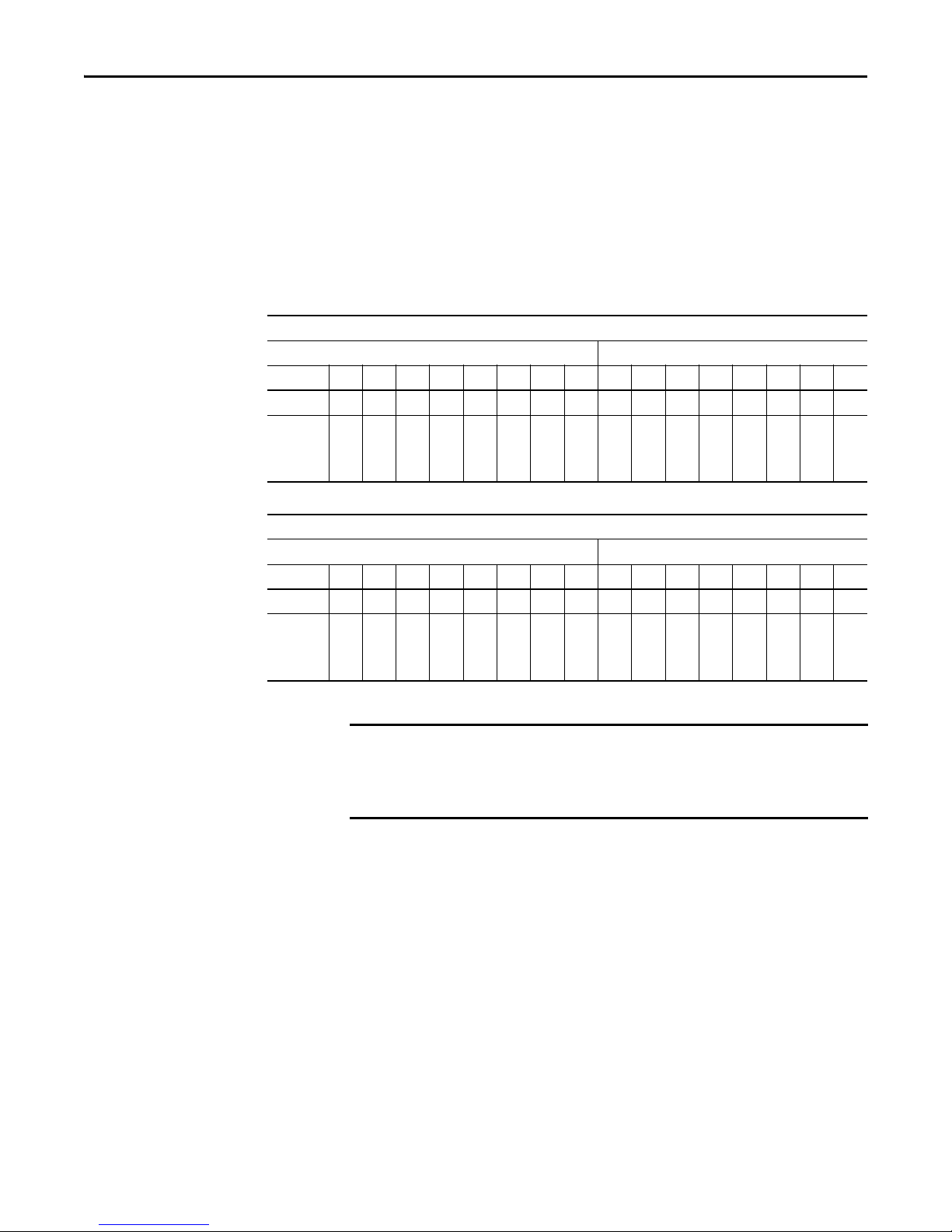

Table 11 - Write Access

Block -1

Byte 0 Byte 1

MSBLSBMSBLSB

Conditon 0000000000000000

Write

Access for

Block

Number

3210-2

(3)

-2

(2)

-2

(1)

-2

1110987654

(0)

Block -1

Byte 2 Byte 3

MSBLSBMSBLSB

Conditon 0000000000000000

Write

Access for

Block

Number

19 18 17 16 15 14 13 12 27 26 25 24 23 22 21 20

Changing of the Write Access conditions must be done in secure environment.

The label must not be moved out of the communication field of the antenna

during writing. We recommend to put the label close to the antenna and not to

remove it during operation.

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 21

Page 22

Chapter 2 RFID Components

Smart Label IC – Secure (SLI-S)

The 2048 bit EEPROM memory is divided into 64 blocks. A block is the

smallest access unit. Each block consists of 4 bytes (1block=32 bits). Four

blocks are summed up to one page for password protection. Bit 0 in each byte

represents the least significant bit (LSB) and bit 7 the most significant bit (MSB),

respectively.

The memory is divided into two parts:

• Configuration Area: This memory area stores all required information,

such as UID, EPC data, write protection, access control information,

passwords, etc. Direct access to this memory area is not possible.

•User Memory: This memory area stores user data. Direct read/write

access to this part of the memory is possible depending on the related

security and write protection conditions.

The table below shows the memory organization of an SLI-S tag.

Table 12 - SLI-S Memory Organization

Page Block Byte 0 Byte 1 Byte 2 Byte 3 Description

-6 -24 Configuration area for internal use

-23

-22

-21

::::::

::::::

::::::

::::::

-1 -4

-3

-2

-1

00 User Memory

1

2

3

::::::

::::::

936

37

38

39

10 pages

4 blocks per page

4 bytes per block

Total: 160 bytes

22 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

Page 23

RFID Components Chapter 2

Smart Label IC – Lean (SLI-L)

The SLI-L is used in applications that require smaller memory size. The 512 bit

EEPROM memory is divided into 16 blocks. A block is the smallest access unit.

Each block consists of 4 bytes (1block=32 bits). Four blocks are summed up to

one page. Bit 0 in each byte represents the least significant bit (LSB) and bit 7 the

most significant bit (MSB), respectively.

The memory is divided into two parts:

• Configuration Area: This memory area stores all required information,

such as UID, write protection, passwords, etc. Direct access to this

memory area is not possible.

•User Memory: This memory area stores user data. Direct read/write

access to this part of the memory is possible depending on the related write

protection conditions.

The table below shows the memory organization of an SLI-L tag.

Table 13 - SLI-L Memory Organization

Page Block Byte 0 Byte 1 Byte 2 Byte 3 Description

-2 -8 Configuration area for internal use

-7

-6

-5

-1 -4

-3

-2

-1

00 User Memory

1

2

3

4

5

6

7

2 pages

4 blocks per page

4 bytes per block

Total: 32 bytes

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 23

Page 24

Chapter 2 RFID Components

Ferroelectric Random Access Memory (FRAM)

FRAM is a non-volatile memory that uses ferroelectric film as a capacitor for

storing data. FRAM offers high speed access, high endurance in write mode, low

power consumption, non-volatility, and excellent tamper resistance. The FRAM

tags have 2000 bytes for use as user area and 48 bytes for use as system area.

The FRAM tag memory areas consist of a total of 256 blocks (250 blocks of user

area and 6 blocks of system area). Each block can store 64 bits (8 bytes) of data.

The block is the unit used for the writing and reading of FRAM data. The

memory configuration of FRAM is shown below.

Table 14 - FRAM Memory Configuration

Area Block No. Details Data Read Data Write

User area

(2000 bytes)

System a rea

(48 bytes)

00

to F9

H

H

FA

H

FB

H

FC

to FF

H

H

User area Yes Yes

UUID (64 bits) Yes No

AFI, DSFID, EAS,

security status

Block security status Yes No

Yes Lim it ed

Blocks 00H…F9H are user area. The user area is defined as an area that can be

accessed when the corresponding block address is specified. On the other hand,

Blocks FA

…FFH are system area. The system area is defined as an area that can

H

be accessed only with a specific command.

The system area consists of six blocks and contains UUID, AFI, DSFID, EAS

bits, and security status (can write or cannot write) data for individual block.

UID is fixed and cannot be updated. AFI, DSFID, and EAS bits are written at

the factory, and can be updated and locked (disable to write) with commands

(only EAS bit cannot be locked) .

As shown in above, FA

status information on individual user areas. The configuration of FB

blocks is shown below. FB

the security status data of AFI and DSFID. Blocks FC

holds the UUID, and FCH…FFH hold the security

H

…FFH

H

block is used for EAS status, AFI and DSFID data,

H

…FFH contain security

H

status data.

Table 15 - Structure of FB

MSB LSB

64 57 56 33 32 25 24 17 16 9 8 1

EAS Status Reserved for

future use

H

DSFID Lock

Status

AFI Lock Status DSFID AFI

24 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

Page 25

RFID Components Chapter 2

Handheld Reader/Writer

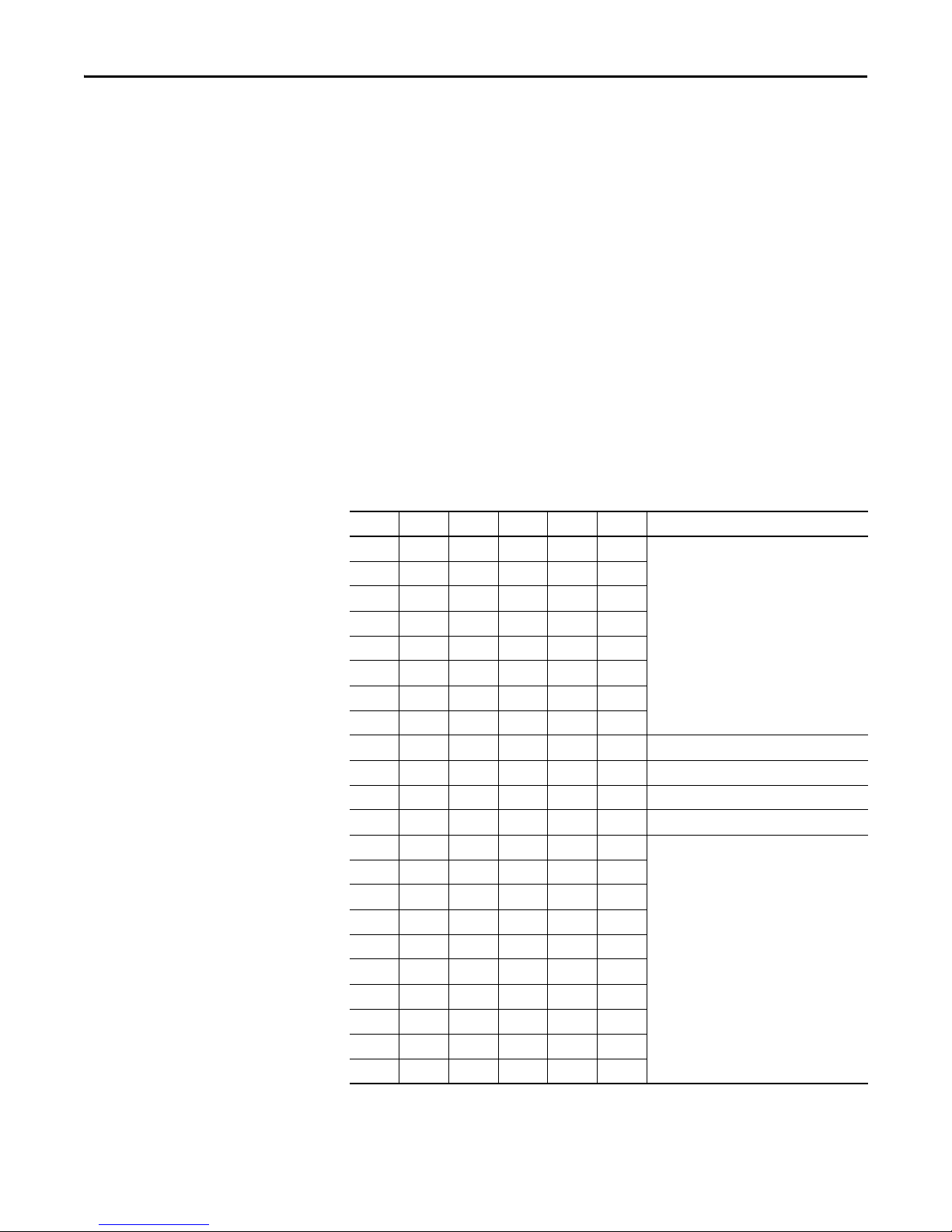

Table 16 - Structure of FCH to FF

MSB LSB

FC

3F 3E 3D 3C 3B 3A 39 03 02 01 00

H

7F 7E 7D 7C 7B 7A 79 43 42 41 40

FD

H

FE

BF BE BD BC BB BA B9 83 82 81 80

H

FF

Reserved for future use (6 bits) F9 C3 C2 C1 C0

H

H

The security status of the user area is stored in the block security status bit in

system area blocks of FC

…FFH per bit in each block. A user area is unlocked

H

when the corresponding block security status bit is 0; it is locked (disable to write

state) when the corresponding block security status bit is 1.

EAS bit is a single bit, and it is used for setting EAS status. It is possible to read/

write data of two blocks at one time in the user area (if Read Multiple Blocks

Unlimited command is used, up to 256 blocks can be accessed at one time) .

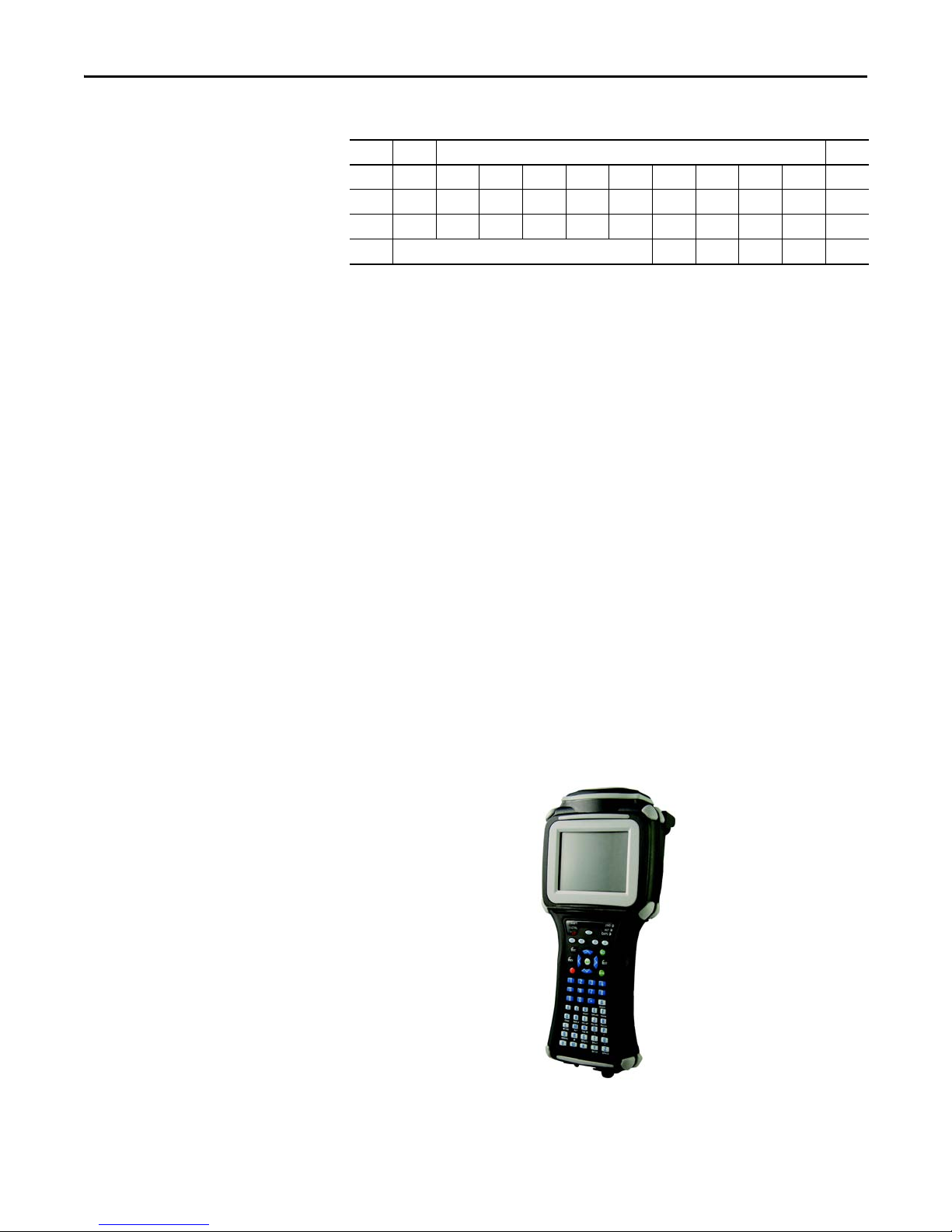

The RFID ICODE handheld interface provides a portable solution for reading/

writing values to the tag data area. The handheld interface is a touch-screen

operated computer with an attached RFID antenna and software that allows

reading, writing, and saving tag RFID tag data. Each handheld interface comes

with multiple connectivity methods, such as wireless, Bluetooth, and USB, which

allow tag data to be transferred to/from a computer. The RFID ICODE

handheld interface is IP65 rated for harsh industrial and outdoor environments.

It is the ideal accessory for system setup, field service, fleet management, time and

attendance, and any other application where transceiver mobility is required.

For more information on the RFID ICODE handheld interface, refer to

Publication 57RF-UM001.

Figure 5 - Handheld Interface

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 25

Page 26

Chapter 2 RFID Components

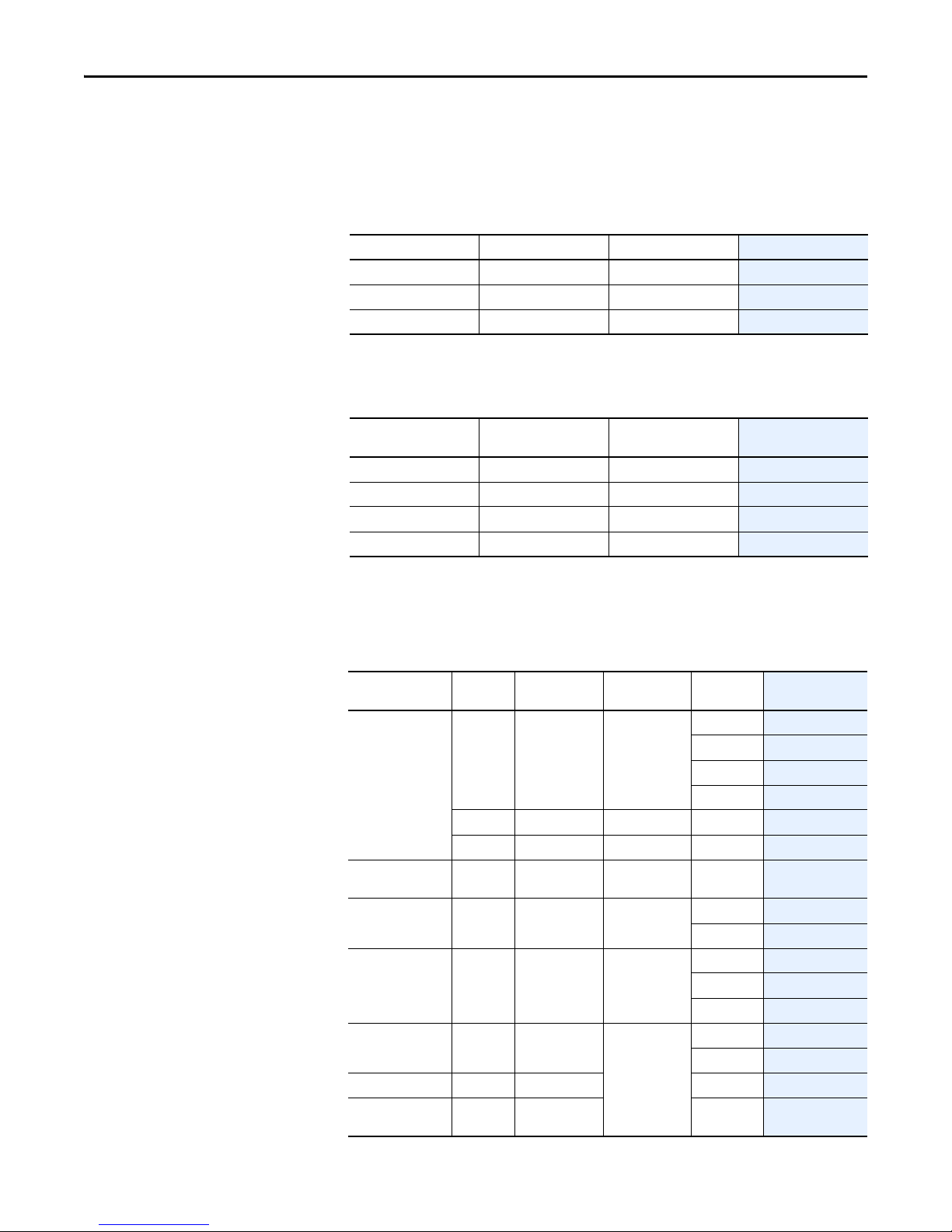

Component Catalog Number

Table

The following tables show the catalog numbers for the components in the

Bul.56RF product family.

EtherNet/IP Interface Blocks

Transceiver Po rts Inpu t Ports Out put Ports Cat. No.

11156RF-IN-IPS12

21156RF-IN-IPD22

220

56RF-IN-IPD22A

Transceivers

Dimensions [mm] Recommended Sensing

Distance [mm] ➊

Rectangular (80x90) 100 168 56RF-TR-8090

Square (40x40) 50 85

Cylindrical M30 35 60 56RF-TR-M30

Cylindrical M18 18 30 56RF-TR-M18

Max. Sensing Distance

[mm] ➊

Cat. No.

56RF-TR-4040

➊ Range reference for a 50 mm diamete r tag.

Tag s

Outline Type Total Memory

SLI 128 112

Disc

SLI-S 64 32 16 56RF-TG-16-64B

SLI-L 256 160 10 56RF-TG-10-256B

Disc – High Impact

Resistant

Disc – Mount on

Metal

Disc – FRAM FRAM 2048 2 kB

Label SLI 128

Smart Cards SLI 128 54 x 86

Square – High

Temperature

SLI 128 112 35

SLI 128 112

SLI 128 50 x 50

Size [B]

User Memory

Size [B]

112

Dimensions

[mm]

16

20 56RF-TG-20

30 56RF-TG-30

50

20

50

20

30

50 56RF-TG-50-2KB

54 x 86

50 x 50

56RF-TG-16

56RF-TG-50

56RF-TG-35HIR

56RF-TG-20MOM

56RF-TG-50MOM

56RF-TG-20-2KB

56RF-TG-30-2KB

56RF-TG-5486

56RF-TG-5050

56RF-TG-5486SC

56RF-TG-50HT

Cat. No.

26 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

Page 27

Accessories

Transceiver

RFID Components Chapter 2

Style Connector Type No. of Pins Shield Wire Size

Female straight to

male straight

Female straight to

DC Micro (M12)

Patch cords

DC Micro (M12)

Cordset s

M12 Terminal

Chambers

➊ Available in 0.3, 1, 2, 5, or 10 m lengths.

➋ Available in 2, 5, or 10 m lengths.

male right angle

Female right angle

to male straight

Female right angle

to male right angle

Female straight

Female right angle 889D-R5FC-J ➋

Male straight 889D-M5FC-J ➋

Male right angle

Female straight

Female right angle 871A-TR5-D1

Male straight

Male right angle 871A-TR5-DM1

4Shielded22

4Shielded22

4 — 18…22

[AWG]

Cat. No.

889D-F5FCDM-J ➊

889D-F5FCDE-J ➊

889D-R5FCDM-J ➊

889D-R5FCDE-J ➊

889D-F5FC-J ➋

889D-E5FC-J ➋

871A-TS5-D1

871A-TS5-DM1

Auxiliary Power

Style Connector Type No. of Pins Shield Wire Size

Female straight to

male straight

Female straight to

DC Micro (M12)

Patch cords

DC Micro (M12)

Cordset s

M12 Terminal

Chambers

➌ Available in 0.3, 1, 2, 5, or 10 m lengths.

➍ Available in 2, 5, or 10 m lengths.

male right angle

Female right angle

to male straight

Female right angle

to male right angle

Female straight

Female right angle

Male straight

Male right angle

Female straight

Female right angle 871A-TR4-D

Male straight

Male right angle

4 Unshielded 22

4 Unshielded 22

4—22

[AWG]

Cat. No.

889D-F4ACDM-➌

889D-F4ACDE-➌

889D-R4ACDM-➌

889D-R4ACDE-➌

889D-F4AC-➍

889D-R4AC-➍

889D-M4AC-➍

889D-E4AC-➍

871A-TS4-D

871A-TS4-DM

871A-TR4-DM

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 27

Page 28

Chapter 2 RFID Components

EtherNet/IP

Style Connector Type No. of Pins Shield Wire Size

Male straight to

male straight

M12 D Code

Patch cords

M12 D Code

Patch cords

➊ Available in lengths of 0.3, 1, 2, 5, 10, 15 m in increments of 5 m up to 75 m.

Male straight to

male right angle

Male right angle to

male right angle

Male straight to

male straight

Male straight to

male right angle

Male right angle to

male right angle

4 Unshielded 24

4Shielded26

[AWG]

Handheld Interface

Description

RFID Handheld Interface, 52-Key Directional Pad 57RF-HH-56A

RFID Handheld Interface, 45-Key Pad

Cat. No.

1585D-M4TBDM-➊

1585D-M4TBDE-➊

1585D-E4TBDE-➊

1585D-M4UBDM-➊

1585D-M4UBDE-➊

1585D-E4UBDE-➊

Cat. No.

57RF-HH-56B

Handheld Accessories

Description

Domestic single position charging cradle with cable,

USB cable, stylus

Domestic wall mount power supply, serial cable,

USB cable, stylus

International power supply kit, serial cable,

USB cable, stylus

Battery pack, rechargeable

Serial cable, 15 ft, RS-232 57RF-HH-56CA

64 MB CompactFlash card 1784-CF64

128 MB CompactFlash card

Cat. No.

57RF-HH-56US1

57RF-HH-56US2

57RF-HH-56IN

57RF-HH-56BAT

1784-CF128

28 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

Page 29

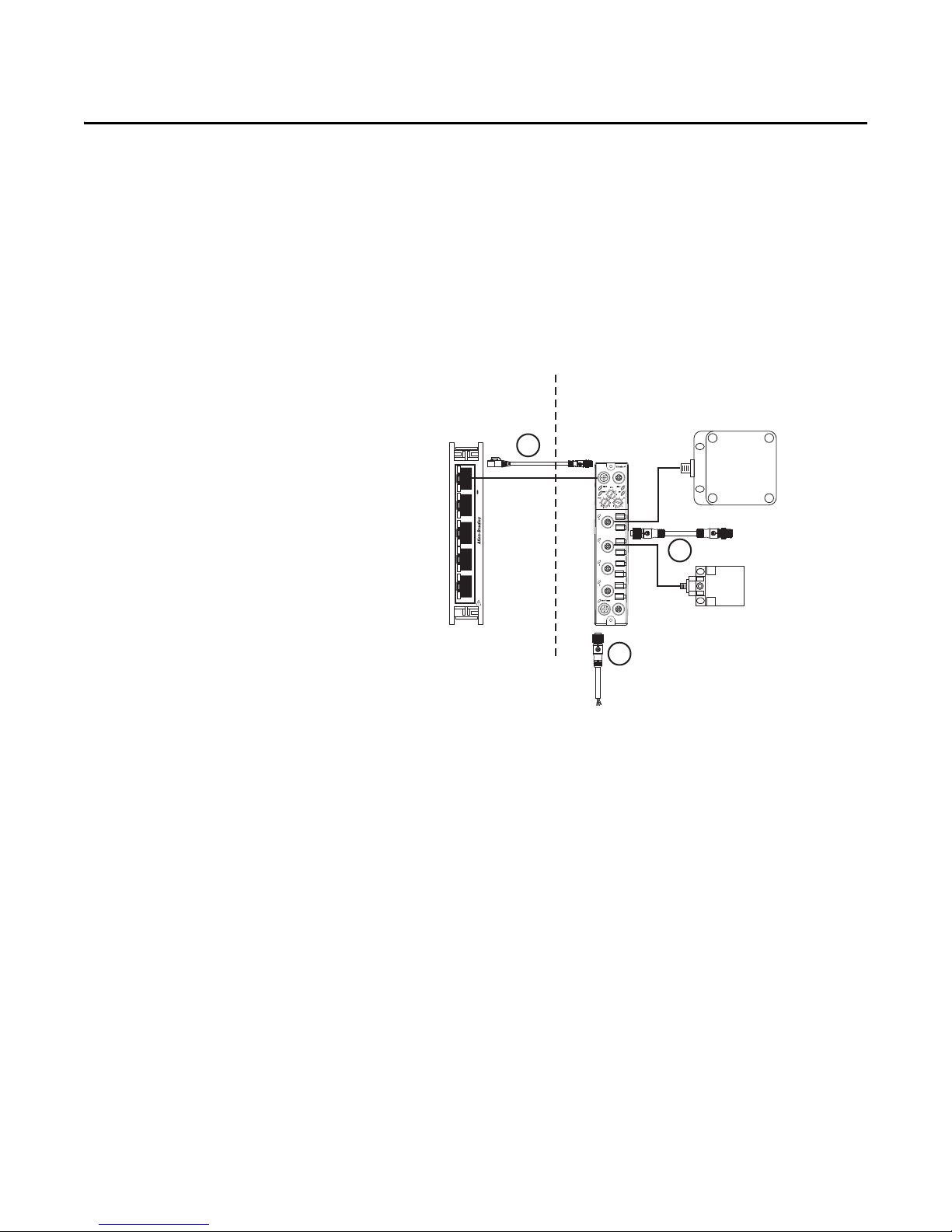

Electrical Installation

Chapter 3

Cable Overview

The EtherNet/IP switch must be mounted inside a control panel. The Bul. 56RF

EIP interface block and Bul. 56RF transceivers can be mounted on the machine.

Figure 6 - Transceiver Mounting

Mounted

in a Cabinet

Mounted

on the Machine

1

1

P

W

R

2

3

4

5

1783-US05T

2

3

1783-US05T

Ethernet/IP Switch

56RF

Interface Block

56RF

Transceivers

Three types of cables are needed.

1. This is an EtherNet cable, RJ45 to M12-QD patchcord.

2. This is a 5-pin M12 to 5-pin M12 patchcord. The cable includes a shield

that connects to the functional earth point on the interface block.

3. This is a 4-pin female micro QD cordset that connects power to the

interface block.

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 29

Page 30

Chapter 3 Electrical Installation

IMPORTANT

Auxiliary Power Connection

Attach a micro-style 4-pin female to the micro-style 4-pin male receptacle as

shown below. The female side is used to daisy chain the power to another device.

The power connection is limited to 4 A. When the daisy chain approach is used,

the maximum number of interface blocks that can be connected is determined by

the total power consumed by each block.

Power must be connected to the male connector first. Do not connect power to

the female connector and leave the male connector exposed. The pins in the

male connector will have 24V DC potential for short circuit.

The pin connections for the aux power connectors are shown below:

2 Module Power +

1 Output Power +

Module Power - 3

4 Output Power -

Male

Module Power + 2

Output Power + 1

Output Power - 4

3 Module Power -

Female

The power for the output port is separate from the power to the remaining

portions of the interface block. This allows the output device to be turned off,

while maintaining power to the transceivers, the input port, and the EtherNet/IP

connection. When the output is connected to the safety related portion of the

machine control system, an actuator can be turned off, while diagnostic

information is still available to the machine control system.

30 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

Page 31

Electrical Installation Chapter 3

56RF Interface Blocks

1606-XL120D

889D-F4AC-5

889D-R4AC-5

889D-R4ACDE-5

889D-F4ACDM-5

1606-XLDNET8

DC 24V/8 A

898N-43PB-N4KF

889D-R4AENM-D2

889N-F4AFNU-20F

889D-F4AENM-D2

56RF Interface Blocks

898N-43PB-N4KF

889N-F4AF-20F

889D-R4AENM-D2

Power Connection Options

Each interface block is limited to 4 A total consumption.

Example 1: Daisy Chain the Power Connections

This example allows for a simple and easy way to distribute power to the RFID

system. This approach is preferred when the total current of the RFID system is

less than 4 A.

Figure 7 - Power Option 1

Example 2: System Needs More Than 4 A

If multiple blocks are required on a machine and the current consumption

exceeds 4 A, then a combination of mini-style and micro-style connections can

be used to distribute the power. In the example below, mini-style cordsets,

patchcords and tees are used to set up the power. A mini-to-micro style patchcord

connects each Bul. 56RF interface block with the tee. In this example, the power

supply is a Cat. No. 1606-XLDNET8, which can supply up to 8 A to the RFID

system.

Figure 8 - Power Option 2

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 31

Page 32

Chapter 3 Electrical Installation

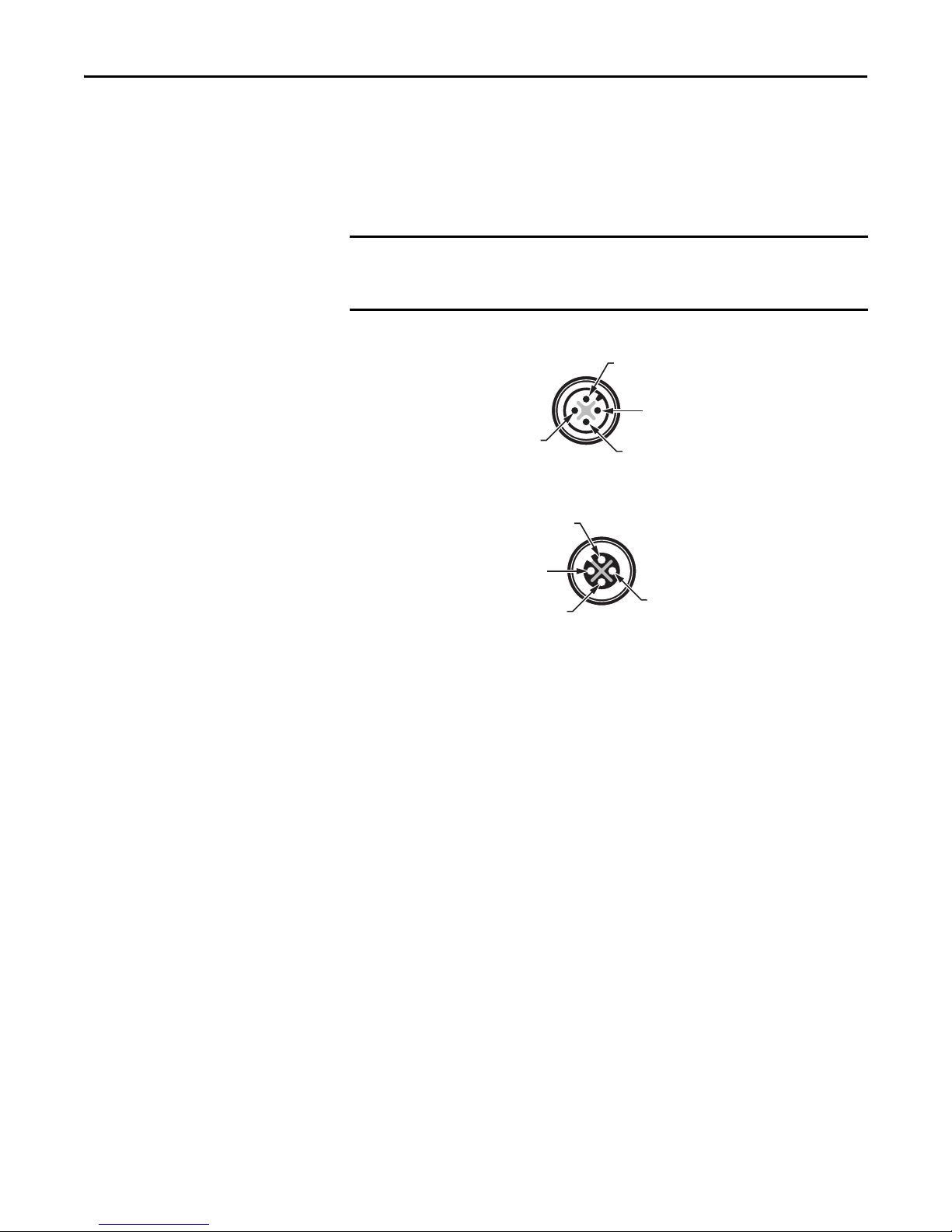

Transceiver Connection

The M12 QD female connector for the transceivers is shown below. Pin 5 is the

cable shield connection and is connected only at the block to functional earth

(FE).

2

1

3

5

4

Pin Function

124V DC power

2 Data +

3 24V common

4 Data -

5 Shield/FE

Digital Input Connection

The female M12 QD input connector is shown below.

2

1

3

5

4

Pin Function

124V DC power

2 Not used

3 24V common

4 Digital input

5 Shield/FE

Digital Output Connection

The female M12 QD output connector is shown below.

2

1

3

5

4

Pin Function

1 Not used

2 Not used

3 24V common

4 Digital output

5 Shield/FE

32 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

Page 33

Electrical Installation Chapter 3

4

2

31

5

EtherNet I/P Connection

The D-Code M12 connector on the interface block is shown in the figure below.

Pin Function

1Tx+

2Rx+

3Tx-

4Rx-

5 Connector shell connected to FE

Use the Cat. No. 1585D-M4DC-H (polyamide small body unshielded) or the

Cat. No. 1585D-M4DC-SH (zinc die-cast large body shielded) mating

connectors for the D-Code M12 female network connector.

Use two twisted pair Cat 5E UTP or STP cables.

D-Code M12 Pin Wire Color Signal 8-Way Modular

1 White-Orange Tx+ 1

2 White-Green Rx+ 3

3Orange Tx- 2

4Green Rx- 6

RJ45 Pin

The 56RF interface block encoders can be connected in either of three network

topologies: star, linear or Device Level Ring (DLR).

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 33

Page 34

Chapter 3 Electrical Installation

Notes:

34 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

Page 35

EtherNet/IP Addressing

RFID

Transceivers

RFID

Interface

Block

RFID

Transceivers

RFID

Interface

Block

Chapter 4

Star Topology

The star structure consists of a number of devices connected to central switch.

When this topology is used, only one EtherNet connection can be made to the

Bul. 56RF interface block – this connection is made to the Link 1 connector. The

Link 2 connection must remain unused.

Figure 9 - Star Topology

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 35

Page 36

Chapter 4 EtherNet/IP Addressing

RFID

Interface

Block

RFID

Transceivers

RFID

Interface

Block

RFID

Transceivers

Linear Topology

The linear topology uses the embedded switching capability to form a

daisychain style network that has a beginning and an end. Linear topology

simplifies installation and reduces wiring and installation costs, but a break in the

network disconnects all devices downstream from the break. When this topology

is used, both EtherNet connections are used. The network connection to Link 1

or Link 2 does not matter.

Figure 10 - Linear Topology

36 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

Page 37

EtherNet/IP Addressing Chapter 4

RFID

Interface

Block

RFID

Transceivers

RFID

Transceivers

RFID

Interface

Block

Device Level Ring (DLR)

Topology

A DLR network is a single-fault tolerant ring network intended for the

interconnection of automation devices. DLR topology is advantageous as it can

tolerate a break in the network. If a break is detected, the signals are sent out in

both directions. When this topology is used, both EtherNet connections are

used. The network connection to Link 1 or Link 2 does not matter.

Rockwell Automation recommends that you use no more than 50 nodes on a

single DLR, or linear, network. If your application requires more than 50 nodes,

we recommend that you segment the nodes into separate, but linked, DLR

networks.

With smaller networks:

• there is better management of traffic on the network.

• the networks are easier to maintain.

• there is a lower likelihood of multiple faults.

Additionally, on a DLR network with more than 50 nodes, network recovery

times from faults are higher. The maximum cable length between devices cannot

exceed 100 m (328 ft).

For more information on setting up and configuring a DLR network, please refer

to ENET-AP005.

Figure 11 - DLR Topology

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 37

Page 38

Chapter 4 EtherNet/IP Addressing

Setting the Network Address

Fundamental IP Addresses:

192.168.1.xxx

Before using the Bul. 56RF interface block in an EtherNet/IP network, configure

it with an IP address, subnet mask, and optional Gateway address. This chapter

describes these configuration requirements and the procedures for providing

them. The address can be set in one of three ways:

• Use the Network Address switches.

• Use the Rockwell BootP/DHCP utility (version 2.3 or greater), which

ships with RSLogix™ 5000.

• Use RSLinx® software.

IP network addresses have a format of xxx.xxx.xxx.xxx. The user must know what

values are being used for the network. If your network has the fundamental

192.168.1.xxx scheme, then you can simply use the three network address

switches. If your network is something other than 192.168.1.xxx, you must use

advanced tools, such as the BootP/DHCPserver, to assign an IP address. After

the address is set, you can use RSLinx to change the address.

If your network scheme is 192.168.1.xxx, then you can adjust the network

address switches to set the IP address. Remove the covers of the three network

address screws. Use a small blade screwdriver to rotate the switches. Line up the

small notch on the switch with the number setting you wish to use. Valid settings

range from 001…254

When the switches are set to a valid number, the IP address of the interface block

is 192.168.1.xxx (where xxx represents the number set on the switches). Cycle the

power and the valid setting becomes effective immediately.

The example below shows an address setting of 192.168.1.123.

The subnet mask of the interface block is automatically set to 255.255.255.0 and

the gateway address is set to 0.0.0.0. When the interface block uses the network

address set on the switches, the interface block does not have a host name

assigned to it or use a Domain Name Server (DNS).

38 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

Page 39

EtherNet/IP Addressing Chapter 4

Advanced IP Addresses

The following steps show how to change the IP address from the fundamental

192.168.1.xxx to an advanced address. This assumes the Bul. 56RF interface

block was already set up with an IP address using the network address switches.

The examples below show the change process using specific addresses. The user is

not limited to these addresses; the user can select any address that meets their

needs. In the example below, we change from 192.168.1.115 to 192.168.2.115.

1. Set address switches to 888 and cycle the power.

On the Bul. 56RF interface block, the address switches had previously

been to 115. Set the address switch settings to 888. Cycle the power and

wait until the MOD indicator is blinking red. The MOD indicator blinks

red once, green once, then solid red for a short while, then blinks green

once, and finally blinks red continuously (about once each second). This

takes about 10 seconds after power is restored. The interface block is reset

to its factory setting.

2. Set the address switches to 999 and cycle the power.

On the Bul. 56RF interface block, set the address switch settings to 999.

Cycle the power and wait until the MOD indicator is solid green. The

MOD indicator blinks red once, green once, solid red for a short while and

finally turns solid green. This takes about 10 seconds after power is

restored. The interface block IP address is reset.

3. Use BootP/DHCP Server to set new address

Use the Rockwell BootP/DHCP Server utility to assign a valid address to

the interface block. From the Start button, select Programs >

RockwellSoftware > BOOTP-DHCP Server > BOOTP-DHCP Server.

When power is restored, the interface block repeatedly broadcasts its

MACID and requests an IP address. The BOOTP-DHCP server displays

the MACID in the Request History panel.

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 39

Page 40

Chapter 4 EtherNet/IP Addressing

IMPORTANT

Double-click on one of the EtherNet Address (MAC) of the device. The New

Entry dialog appears showing the EtherNet Address (MAC) of the device.

Type in the IP Address, Hostname and Description and click OK. The

Hostname and Description are optional fields; they can be left blank.

The device is added to the Relation List, displaying the EtherNet Address

(MAC) and corresponding IP Address, Hostname, and Description.

When the address is assigned to the Bul. 56RF interface block, 1) the Status

message is updated, and 2) the IP address appears in the Request History

window.

40 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

Wait for the Status message to show “Sent 192.168.2.115 to EtherNet

address 00:00:BC:E5:D0:1D.” This may take a few seconds to 30

seconds.

4. At this point, the IP addresses of other devices should be changed.

Page 41

EtherNet/IP Addressing Chapter 4

5. Change the Network Adaptor to 192.168.2.1.

Open the network connections of the host computer. Highlight the Internet

Protocol (TCP/IP) connection. Click Prop erties. In the IP Address field, set the

IP Address to 192.168.2.1. Click OK. Click Close to close the Local Area

Connection window (this window must be closed to apply the new address).

6. Disable DHCP.

Click on (only once) the interface block in the Relation List to highlight it. Then

click Disable BOOTP/DHCP. This instructs the Bul. 56RF interface block to

retain the IP Address at the next power cycle.

Wait for the Status message to show that the command was successfully sent. If

not, repeat this step.

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 41

Page 42

Chapter 4 EtherNet/IP Addressing

Click File > Save As to save the relationship, if desired.

Cycle the power to the Bul. 56RF interface block. You should no longer see the

Bul. 56RF interface block appear in the Request History panel.

From a DOS prompt, you can ping the new address. The response should be 4

packets sent, 4 packets received and 0 lost.

Change IP Address from One

Advanced Address to another

Advanced Address

The easiest way to change the IP Address from one non-simple address to another

non-simple address is to use RSLinx. In this case, the three network switches on

the Bul. 56RF interface block are set to 999, and the address has been previously

set using the BootP/DHCP server. The example below shows how to change the

IP address from 192.168.2.115 to 192.168.3.115.

Open RSLinx.

1. Click on the RS-Who icon.

2. Expand the EtherNet connection.

42 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

3. Right click on the RFID Adaptor.

4. Click Module Configuration.

Page 43

EtherNet/IP Addressing Chapter 4

The Configuration window appears.

1. Click on the Port Configuration tab.

2. Set the Network Configuration Type to Static (if not already done).

3. Change the IP Address to the new address. In this example, the address will

be changed form 192.168.2.115 to 192.168.3.115.

Click Ye s to confirm the change.

Click OK to close the configuration window.

RSLinx places an X over the RFID adaptor because it can no longer

communicate with it.

Use the same steps to change the IP address of the other devices on the network.

Change the Network adaptor address to 192.168.3.1.

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 43

Page 44

Chapter 4 EtherNet/IP Addressing

Close and re-open the RSWho window. The older addresses are not available and

the new addresses (192.168.3.115 and 192.168.3.214) appear.

Note: If DHCP is not disabled, the Bul. 56RF interface block will show two

requests in the DHCP Server at each power up.

In the picture below, power was cycled to the Bul. 56RF interface block at

7:45:16, 7:47:47, 7:49:06 and again at 10:56:00. Each time power was applied,

the Bul. 56RF interface block notified the BootP/DHCP server of its IP

Address. This indicates that DHCP has not been disabled. If DHCP is disabled,

the Bul. 56RF interface block would show nothing.

IP Address 888

44 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

Address 888 is used to reset the interface block to the factory defaults. Rotate the

address switches to 888 and cycle the power. The interface block clears out the

current assigned IP Address.

The MOD indicator blinks the following pattern: blinks red once, green once,

then solid red, then blinks green once, and final blinks continuous red about once

each second. The reset process takes about 10 seconds.

Page 45

Chapter 5

(300 mm) or more

Square Transceiver

(600 mm) or more

Rectangular Transceiver

(300 mm) or more

(600 mm) or more

Mechanical Installation

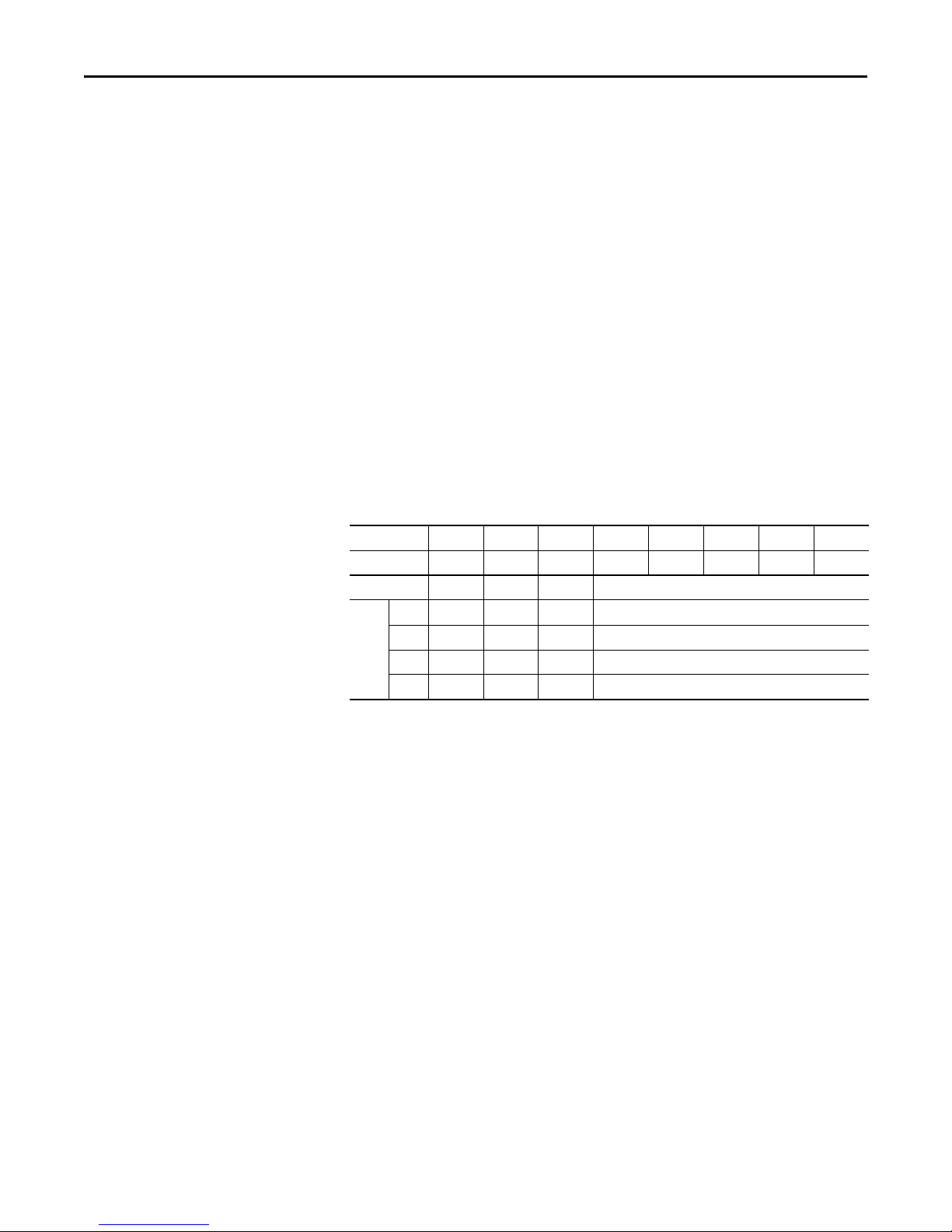

Each of the transceivers has a similar but unique RF field that it generates.

Fastening

Spacing Between

Transceivers

Attach the transceiver to the flat plate with M5 screws. The tightening torque

must be 1.5 N•m for the M5 screw.

Installing more than one transceiver causes radio frequency interference and may

result in the difficulty of the tag communication. Keep a sufficient distance

between the transceivers as shown in Figure 12

Figure 12 - Spacing Between Transceivers

.

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 45

Page 46

Chapter 5 Mechanical Installation

(30 mm)

or more

Metal

(50 mm)

or more

Metal

Square Transceiver Rectangular Transceiver

Spacing Next to Metal

Surfaces

For the square transceiver, the communication distance will drop significantly

when the distance between the transceiver and any surrounding metal is 30mm

(1.2 in.) or less. For the rectangular transceiver, the communication distance will

drop significantly when the distance between the transceiver and any

surrounding metal is 50mm (2 in.) or less.

Figure 13 - Tranceiver Spacing with Metal Surfaces

Transceiver Field Maps

The transceiver has a three-dimensional RF field emanating from its sensing

surface. The field consists of a main center lobe and a secondary side lobe.

The RF tags must enter the RF field once, stay long enough to complete the read

and write cycles, and then to leave the field smoothly and efficiently.

Ideally, the RFID tag should pass through the widest section of the main lobe.

This maximizes the time the transceiver has for reading and writing. Avoid the

top of the field, and avoid the side lobes.

The preferred direction of travel is for the tag to pass across the RFID sensor

surface. The tag can also approach the sensor surface directly and then move away

directly backwards or to the side.

Figure 14

shows the field map of the 65mm x 65mm transceiver.

46 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

Page 47

Figure 14 - 65 x 65 mm Transceiver

Referenced for a 50 mm disc tag

Misalignment (mm)

Sensing Distance [mm]

0

50

100

150

Side Lobe

Side Lobe

ON

OFF

RFID Tag

Preferred

Direction of Travel

OFF

Ideal

Sensing

Range

Acceptable

Sensing

Range

OFF

0

-150

-100

0510010505-

RFID Tag

Alternate

Direction of Travel

100

RFID Tag

Mechanical Installation Chapter 5

Alternate

Direction of Travel

FFOFFO

RFID Tag

Preferred

Direction of Travel

50

Side Lobe

Sensing Distance [mm]

0

-80

OFF

0

Misalignment (mm)

Ideal

Acceptable

ON

Side Lobe

Sensing

Sensing

Range

Range

080404-

Referenced for a 50 mm disc tag

The field map for the 80 mm x 90 mm transceiver, shown in Figure 15, is very

similar.

Figure 15 - 80 x 90 mm Transceiver

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 47

Page 48

Chapter 5 Mechanical Installation

Notes:

48 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

Page 49

Add Your RFID Interface Block to an

RSLogix5000 Program

1. Open RSLogix 5000.

2. Click File>New.

Chapter 6

3. Enter the new controller information.

4. Right click on the EtherNet port of the controller.

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 49

Page 50

Chapter 6 Add Your RFID Interface Block to an RSLogix5000 Program

5. Click New Module.

6. Select the desired 56RF module and click OK.

50 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

Page 51

Add Your RFID Interface Block to an RSLogix5000 Program Chapter 6

TIP

General Tab

The general panel describes the device, its definition and its IP address.

1. Make the four changes shown below and click Apply.

a. Enter a name for the module. In this example, the name is RFID_1. You

may have multiple modules, so be sure to give it a brief but descriptive

name. The name that you assign to the module appears in the

Controller Organizer navigation pane. The name will also appear in the

description of the tags, which are described below.

b. Enter a description of the module or its function.

c. Set the EtherNet Address for the module. In this example, the address is

192.168.1.115. The 115 reflects the address of the three rotary switches

on the Bul. 56RF interface block.

d. The Data Format can be left as SINT (preferred) or changed to INT

(for compatibility with non-Rockwell RFID tags).

A SINT is a signed single byte integer, which can represent numbers from 255…255 in decimal format (-F…FF in hexadecimal format). An INT is a

signed two byte integer, which can represent numbers from -65535…65535

in decimal format (-FFFF…FFFF in hexadecimal format).

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 51

Page 52

Chapter 6 Add Your RFID Interface Block to an RSLogix5000 Program

EtherNet Address

When the controller is offline, the EtherNet address can be set. The user has three

options.

1. When a Private Network is used, click on the Private Network radio

2. When multiple networks exist, the user may elect to set the address to

button. Enter a value for the last octet between 1…254. Be sure not to

duplicate the address of an existing device. In preceding example, the

address of the RFID block is 192.168.1.115.

some other value. When offline, simply click the IP Address radio button

and enter the desired address.

3. Click the Host Name radio button and type in the name of the host. In the

example below, the Host name is QPACK4.

52 Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011

Page 53

Add Your RFID Interface Block to an RSLogix5000 Program Chapter 6

Module Definition

Connection Tab

The user should not have to make changes to the default values. If necessary,

changes can be made by clicking the Change button.

The user can change the Series, Revision, Electronic Keying, Connection and

Data Format. Click the down arrow on the Data Format field and select SINT.

Click OK to accept the changes (or Cancel to retain the original settings). Click

Help for more info.

You should not have to change any settings here.

• Requested Packet Interval – Specify the number of milliseconds between

requests for information from the controller to the RFID block. The block

may provide data on a shorter interval, but if no data is received, the

controller asks the RFID block for a status update. Minimum setting is 2.

Maximum setting is 750.

•Inhibit Module – When checked, the RFID block is not polled for

information, and any information provided will be ignored by the

controller.

• Major Fault on Controller If Connection Fails While In Run Mode –

Check this box if a connection failure should be considered a major fault.

• Use Unicast Connection over EtherNet/IP –Unicast connections are

point-to-point connections. Multicast connections are considered one-tomany. Unicast reduces the amount of network bandwidth used.

•Module Fault – Fault messages will appear in this box.

Rockwell Automation Publication 56RF-UM001A-EN-P - October 2011 53

Page 54

Chapter 6 Add Your RFID Interface Block to an RSLogix5000 Program

Module Info

The Module Info tab contains read only data that is populated when the

controller goes on-line (a program is downloaded to or uploaded from the