Page 1

Dual Function Live Sound Console

USER GUIDE

Publication AP4512

Page 2

Limited One Year Warranty

This product has been manufactured in the UK by ALLEN & HEATH and is warranted to be

free from defects in materials or workmanship for period of one year from the date of

purchase by the original owner.

To ensure a high level of performance and reliability for which this equipment has been

designed and manufactured, read this User Guide before operating.

In the event of a failure, notify and return the defective unit to ALLEN & HEATH or its

authorised agent as soon as possible for repair under warranty subject to the following

conditions :

1. The equipment has been installed and operated in accordance with the instructions in

this User Guide

2. The equipment has not been subject to misuse either intended or accidental, neglect, or

alteration other than as described in the User Guide or Service Manual, or approved by

ALLEN & HEATH.

3. Any necessary adjustment, alteration or repair has been carried out by ALLEN &

HEATH or its authorised agent.

4. The defective unit is to be returned carriage prepaid to ALLEN & HEATH or its

authorised agent with proof of purchase.

5. Units returned should be packed to avoid transit damage.

In certain territories the terms may vary. Check with your ALLEN & HEATH agent for any

additional warranty which may apply.

ML3000 User Guide AP4512 Issue 2

Copyright © 2003 Allen & Heath Limited. All rights reserved

This product complies with the European Electromagnetic

Compatibility directives 89/336/EEC & 92/31/EEC and the

European Low Voltage Directives 73/23/EEC & 93/68/EEC.

This product has been tested to EN55103 Parts 1 & 2 1996 for use in Environments

E1, E2, E3, and E4 to demonstrate compliance with the protection requirements in the

European EMC directive 89/336/EEC. During some tests the specified performance

figures of the product were affected. This is considered permissible and the product

has been passed as acceptable for its intended use.

Allen & Heath has a strict policy of ensuring all products are tested to the latest safety

and EMC standards. Customers requiring more information about EMC and safety

issues can contact Allen & Heath.

NOTE: Any changes or modifications to the console not approved by Allen & Heath

could void the compliance of the console and therefore the users authority to operate it.

Manufactured in the United Kingdom by Allen & Heath Limited

Kernick Industrial Estate, Penryn, Cornwall, TR10 9LU, UK

http://www.allen-heath.com

2 ML3000 User Guide

Page 3

Introduction

This user guide presents a quick reference to the ML3000. We recommend that you read this fully

before starting. Included is information on installing, connecting and operating the console, panel

drawings, system block diagram and technical specification. For further information on the basic

principles of audio system engineering, please refer to one of the specialist publications available

from bookshops and audio equipment dealers.

Whilst we believe the information in this guide to be reliable we do not assume responsibility for

inaccuracies. We also reserve the right to make changes in the interest of further product

development.

We are able to offer further product support through our world-wide network of approved dealers

and service agents. You can also access our Web site on the Internet for information on our

product range, assistance with your technical queries or simply to chat about matters audio. To

help us provide the most efficient service please keep a record of your console serial number, and

date and place of purchase to be quoted in any communication regarding this product. The serial

number is located on the rear panel.

Contents

Important Safety Instructions .............................. 4

Mains Plug Wiring Instructions............................ 5

General Precautions ............................................ 5

Quick Start Reference Sheet ............................... 6

ML3000 Key Features ......................................... 9

System Block Diagram ...................................... 10

Technical Specifications.................................... 12

Installation Details.............................................. 13

Connecting the Power Supply .......................... 14

Earthing.............................................................. 15

Rear Panel Connections.................................... 16

Audio Connector Types and Wiring .................. 18

Gain Structure.................................................... 19

Control Layout and Description ........................ 20

Using LCRplus™................................................ 26

Stereo Input and EQ.......................................... 28

Using the Dual Inputs ........................................ 29

Group / Aux Fader and Rotary Masters ............ 30

Configuring Groups and Auxes......................... 31

Main Mix Masters............................................... 32

Using the Engineers Wedge Monitor ................ 32

Matrix ................................................................. 33

VCA Groups....................................................... 34

Assigning VCA and Mute Groups ..................... 36

Mute Groups and Snapshot Memories............. 37

Headphones / Local Monitor / 2-Track ............. 38

Oscillator / Noise Generator.............................. 39

Talkback ............................................................ 40

Mono Input and EQ ........................................... 20

Channel Group / Auxiliary Sends ...................... 22

Channel Internal Link Options........................... 23

Main Mix and Input Faders................................ 24

Channel Main Mix and Fader ............................ 26

ML3000 User Guide 3

Meterpod ........................................................... 41

MIDI/RS232........................................................ 42

Operating System and Technical Support........ 45

User Notes (blank page) ................................... 46

Cue Sheet .......................................................... 47

Page 4

Important Safety Instructions

WARNINGS - Read the following before proceeding :

CAUTION

ATTENTION: RISQUE DE CHOC ELECTRIQUE – NE PAS OUVRIR

Read instructions: Retain these safety and operating instructions for future reference. Adhere to

all warnings printed here and on the console power unit. Follow the operating

instructions printed in this user guide and the power unit user guide.

Do not remove covers: Operate the power unit with its covers correctly fitted. Refer any service work

to competent technical personnel only.

Power sources: Connect the power unit to a mains power only of the type described in this

User Guide and marked on the rear panel. Use the power cord with sealed

mains plug appropriate for your local mains supply as provided with the

console. If the provided plug does not fit into your outlet consult your service

agent for assistance.

Power cord routing: Route the power cord so that it is not likely to be walked on, stretched or

pinched by items placed upon or against it.

Grounding: Do not defeat the grounding and polarisation means of the power cord plug.

Do not remove or tamper with the ground connection in the power cord.

WARNING: This equipment must be earthed.

Water and moisture: To reduce the risk of fire or electric shock do not expose the power unit or

console to rain or moisture or use it in damp or wet conditions. Do not place

containers of liquids on it which might spill into any openings.

Ventilation: Do not obstruct the ventilation slots or position the console or power unit

where the air flow required for ventilation is impeded. If the console is to be

operated in a flightcase ensure that it is constructed to allow adequate

ventilation.

Heat and vibration: Do not locate the power unit in a place subject to excessive heat or direct

sunlight as this could be a fire hazard. Locate the console and its power unit

away from any equipment which produces heat or causes excessive

vibration.

Servicing: Switch off the equipment and unplug the power cord immediately if it is

exposed to moisture, spilled liquid, objects fallen into the openings, the power

cord or plug become damaged, during lightening storms, or if smoke, odour

or noise is noticed. Refer servicing to qualified technical personnel only.

Installation: Install the console in accordance with the instructions printed in this User

Guide. Do not connect the output of power amplifiers directly to the console.

Use audio connectors and plugs only for their intended purpose.

4 ML3000 User Guide

Page 5

Important Mains Plug Wiring Instructions.

The power unit is supplied with a moulded mains plug fitted to the AC mains

power lead. Follow the instructions below if the mains plug has to be

replaced.

The mains lead wires are coloured in accordance with the following code:

TERMINAL

L

LIVE BROWN BLACK

N

NEUTRAL BLUE WHITE

E

EARTH GND GREEN & YELLOW GREEN

The wire which is coloured Green and Yellow must be connected to the

terminal in the plug which is marked with the letter E or with the Earth symbol.

This appliance must be earthed.

The wire which is coloured Blue must be connected to the terminal in the plug

which is marked with the letter N.

The wire which is coloured Brown must be connected to the terminal in the

plug which is marked with the letter L.

Ensure that these colour codes are followed carefully in the event of the plug

being changed.

General Precautions

WIRE COLOUR

European USA/Canada

Damage : To prevent damage to the controls and cosmetics avoid placing heavy

objects on the control surface, scratching the surface with sharp objects, or

subjecting the console to rough handling and vibration.

Environment : Protect from excessive dirt, dust, heat and vibration when operating and

storing. Avoid tobacco ash, smoke, drinks spillage, and exposure to rain and

moisture. If the console becomes wet, switch off and remove mains power

immediately. Allow to dry out thoroughly before using again.

Radiation : To avoid induced noise and interference pickup do not operate the console

close to strong sources of electromagnetic radiation such as power supplies,

video monitors, lighting cables and dimmers.

Cleaning : Avoid the use of chemicals, abrasives or solvents. The control panel is best

cleaned with a soft brush and dry lint-free cloth. Stubborn marks can be

removed using a cloth dampened with isopropyl alcohol. Do not leave

marking tape stuck to the console for long periods of time as the adhesive

can degrade and leave a sticky residue. The faders, switches and

potentiometers are lubricated for life. The use of electrical lubricants on these

parts is not recommended. Refer to the power unit user guide for instructions

on cleaning its ventilation filters.

Transporting : The console should be transported in the original packing or purpose built

foam lined flightcase. Protect the control surface from damage during transit.

The console is a large and heavy item. To avoid injury ensure adequate man

power and precaution when lifting or moving the console.

ML3000 User Guide 5

Page 6

g

Using LCRplus™

PAN and BLEND = Two controls

adjust the balance between L, R

and C.

MAIN MIX = Routes the channel to

the main L,R,C mix.

=

BLEND

+

LCR

BLEND

LR

PAN

CLR

PAN

RL

=

L R

MONO PA

MAIN

MIX

1-2

C

3-4

LRC

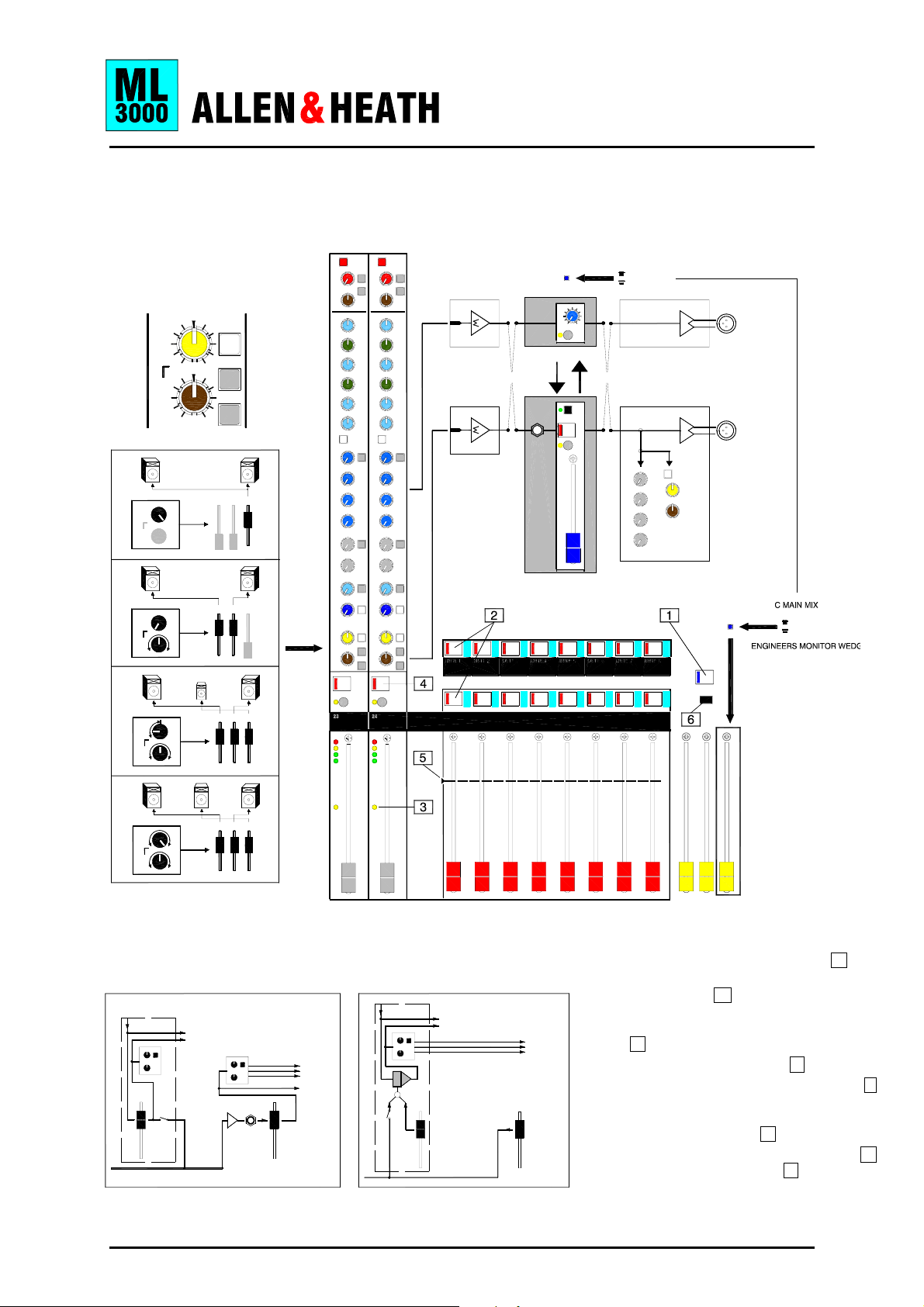

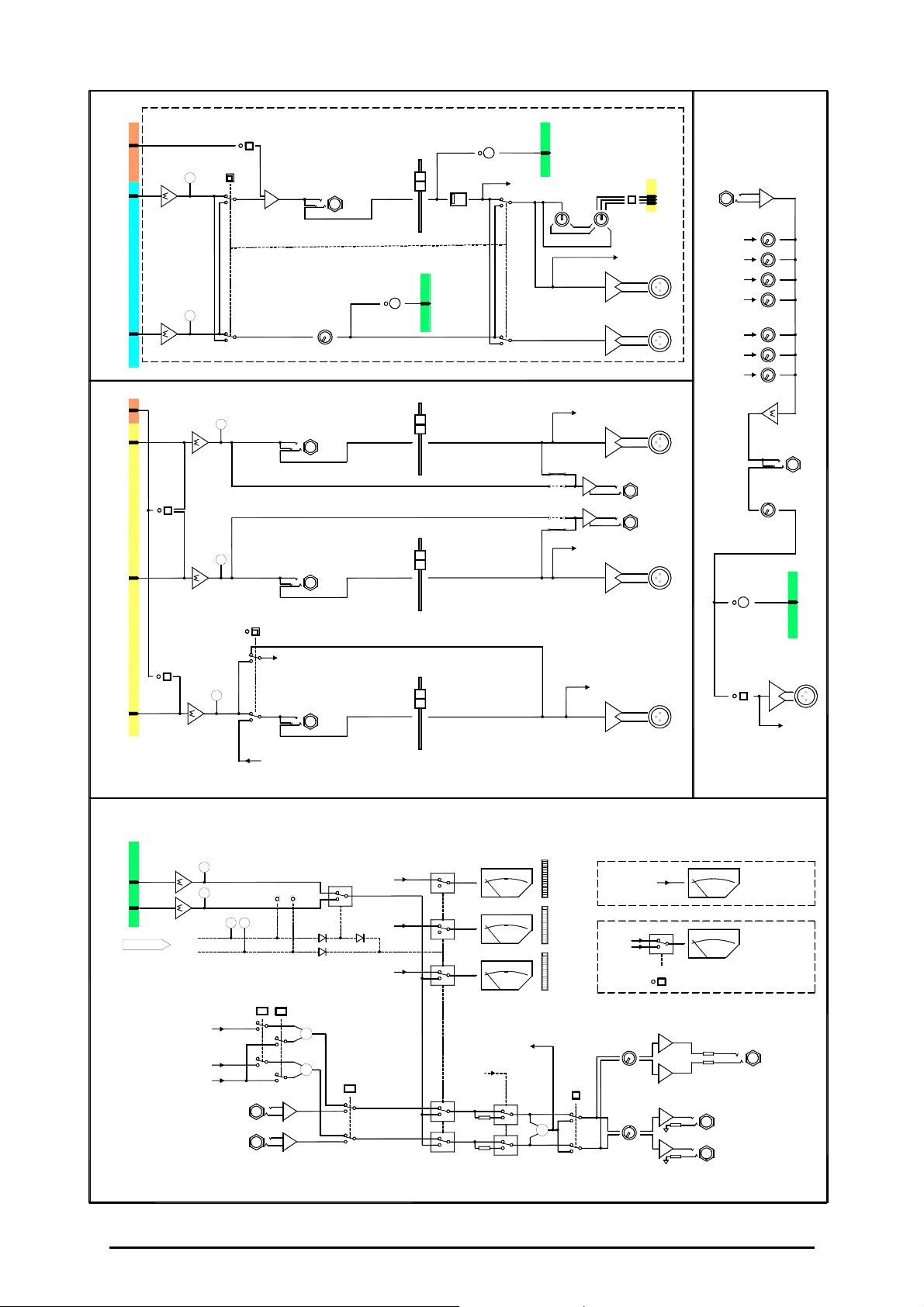

QUICK START REFERENCE SHEET

Copy this sheet to keep with the console for guest user reference.

FRONT -OF-HOUSE or MONITOR Mode

Configure the AUX1-4 and WEDGE underpanel mode switches using

a pen or pointed object.

mode

AUX MIX

GROUP MIX

AUX

LEV

OO

+6

AFL

AUX 1-4 MASTERS

INSERT

TB

MUTE

AFL

FOH

MONITOR

AUX OUT

REVERSEREVERSE

GROUP OUT

1

2

3

4

MIX

BLEND

PAN

SUBGROUP

MATRIX

#

AUDIO GROUP MASTERS

MUTE GROUP MASTERS

M

M

A

S

T

E

R

M

U

T

E

M

A

A

S

S

T

T

E

E

R

R

VCA GROUP MASTERS

M

M

U

U

T

T

E

E

BLEND

PAN

BLEND

PAN

STEREO PA

CLR

RL

STEREO+FILL

CLR

RL

LRC

LRC

PAN

ROUTE

M

A

S

T

E

R

M

U

T

E

LCR

BLEND

CLR

PAN

RL

LRC

How VCA Groups Work:

No audio passes through a VCA group. The channel signal routes direct to the

main mix. A VCA replaces the channel fader. The VCA is controlled by a

voltage from the channel fader and any VCA group master fader assigned to it.

ASSIGN

CHANNEL

PAN

VCA

+

DC

CHANNEL

FADER

PRE-FADE SENDS

POST-FADE SENDS

DIRECT TO MIX

VCA GROUP

DC VOLTAGE

L

MAIN MIX

R

C

MASTER

FADER

CHANNEL

PAN

CHANNEL

FADER

ASSIGN

AUDIO GROUP

PRE-FADE SENDS

POST-FADE SENDS

SUBGROUP

PAN

INSERT

AUDIO BUSS

VIA GROUP TO MIX

MASTER

FADER

L

MAIN MIX

R

C

MATRIX SEND

VCA groups affect the channel post-fade sends. They do not affect the pre-fade

sends. Use VCA groups for level control. Use audio groups when you need to

insert si

nal processing or feed the matrix.

mode

M

M

M

A

A

S

S

T

T

E

E

R

R

M

M

U

U

T

T

E

E

M

A

A

S

S

T

T

E

E

R

R

ASSIGN

M

M

U

T

E

C

U

T

VIEW

E

FOH

MONITOR

How to Assign VCA/Mute Groups:

To assign groups press the ASSIGN key 1 . The

blue LED flashes.

Press the MUTE key 2 of the group you want to

assign. Its LED flashes.

Check its current assignments on the channel VCA

LEDs 3 .

Edit using the channel MUTE keys 4 .

When you have finished press the ASSIGN key 1

again to exit.

For normal operation start with the VCA master

fader at its unity gain position 5 .

To view groups press the group MUTE key 2

while holding down the VIEW key 6 .

Note: In normal operating mode channel VCA

LEDs which are lit show channels assigned to one

or more VCA groups.

6 ML3000 User Guide

Page 7

g

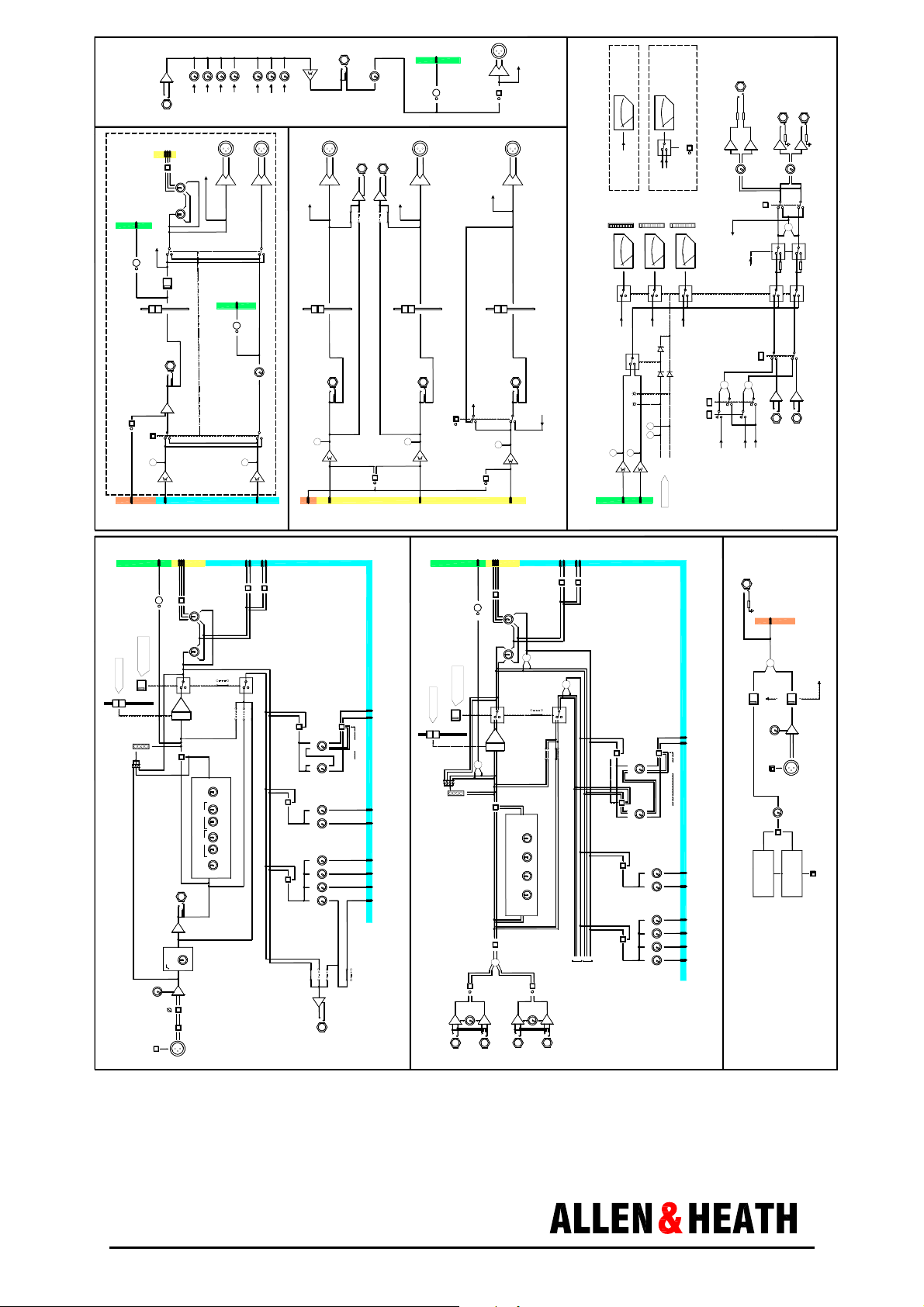

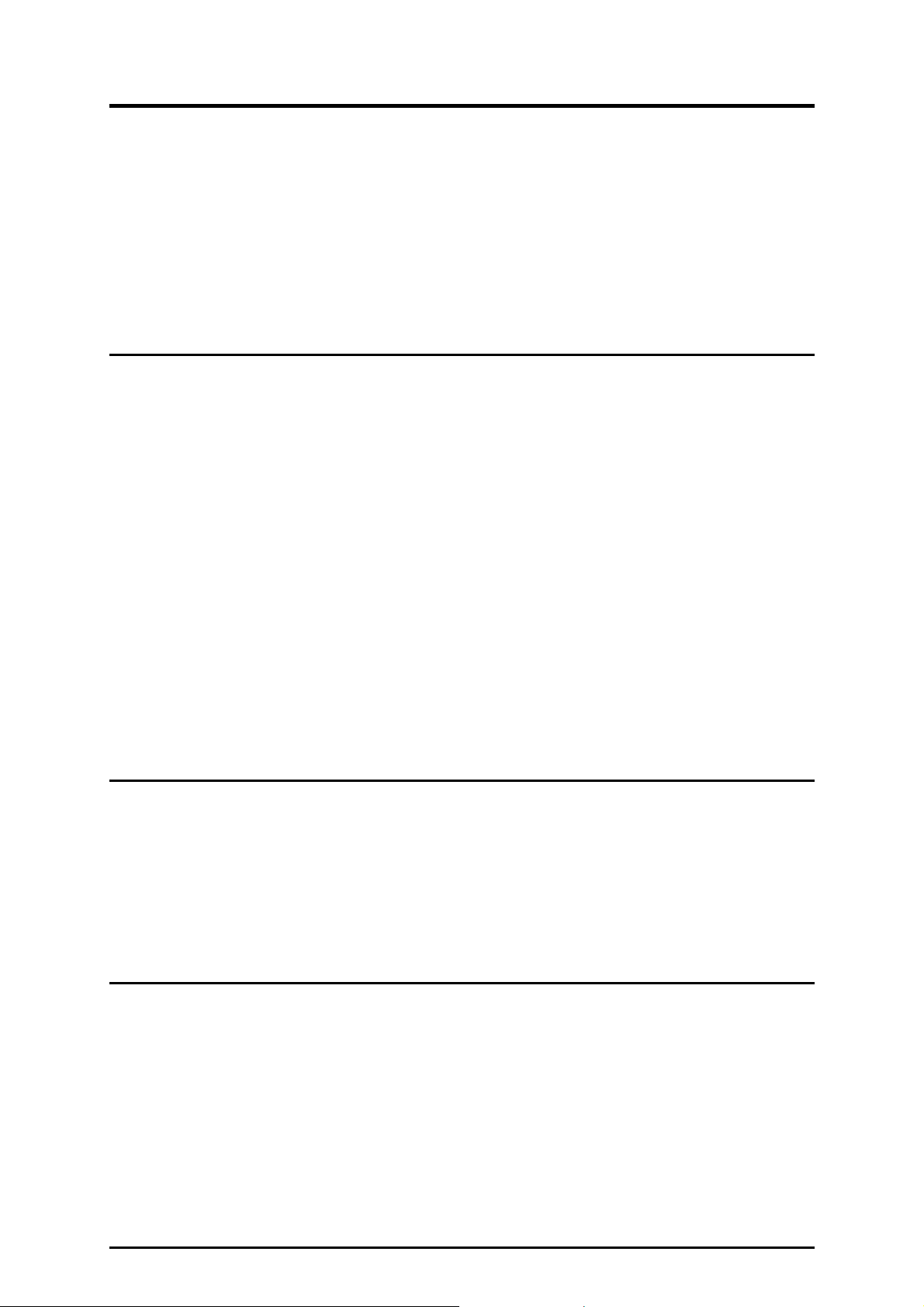

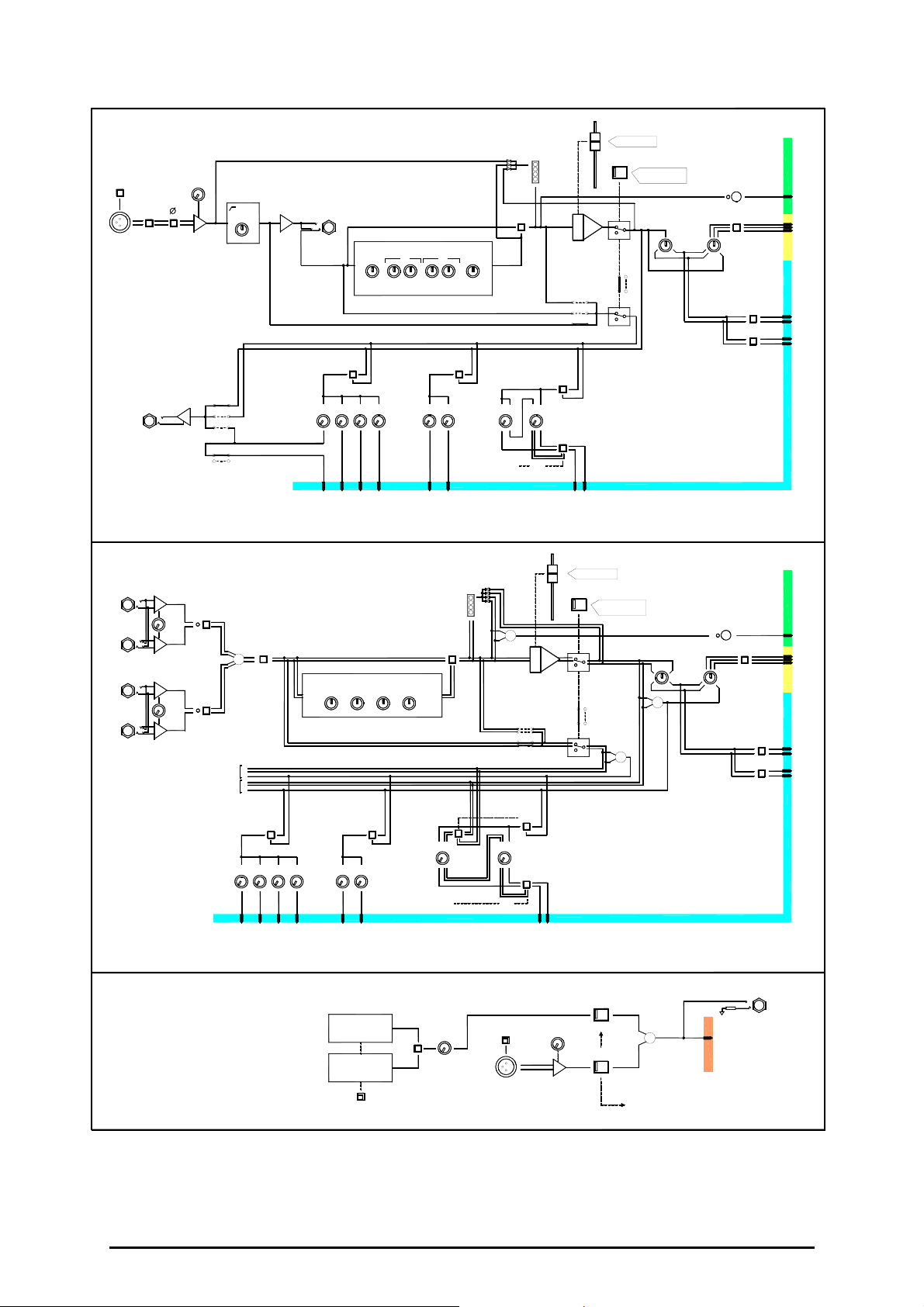

ML3000 BLOCK DIAGRAM

-

+

C

L

MATRIX

AFL

AFL

FADER

GRP 1

GRP 2

EXT.IN

L MIX

R MIX

C MIX

MIX

MAIN

BLEND

LCR+

PAN

TO VU METER

MUTE

GRP 3

GRP OUT

(1-4 ONLY)

GRP TO MTX

BAL

L RLR C

R

GRP 4

AUX OUT

BAL

AFL

AFL

INSERT

LEVEL

OUT

LEFT

BAL

L

FADER

OUT

2TRK

L

R

PRE-INSERT

PRE-INSERT

POST-FADE

POST-FADE

FADER

AFL

AFL

OUT

RIGHT

BAL

R

OUT

MATRIX

BAL

ON

OUT

CENTRE

BAL

C METER

FADER

METERS 1-4

METERS 5-8

GRP

L METERS

L

METER SELECT

AUX

MATRIX

R METERS

C METERS

C

R

HEADPHONES

L

R

PHONES

WEDGE MON

LOCAL

MONITOR

L

R

LOCAL

MONO

+

TB DIM

INSERT

GRP 1-4

AUX 5-8

TB ENABLE

MODE

(1-4 ONLY)

TB

SNAPSHOTS

MUTE GROUPS

VCA GROUPS

MUTE

FADER

PEAK

METER

GAIN

+48V

MONO CHANNEL

S YSTEM BLOCK DIAGRAM

Problems ?

The channel is routed but there is no audio. If it is assigned to a VCA group check that the group fader is up.

The audio groups do not work. Check the setting of the fader master 1-4 mode switches.

Press MODE to reverse GRP and AUX master control sections

SL

MIX

GRP

PFL

L MIX

R MIX

C MIX

MIX

PFL

LCR+

PAN BLEND

L RLRC

VCA

EQ IN

4 BAND EQUALISER

INSERT

HPF

FILTER

FREQ

-

+

PAD

INPUT

MASTER

AUX 1-4

SL

MIX

AUX

GRP 1

GRP 2

1-2

3-4

ASSIGN

GROUP

POST-MUTE

PRE-FADE AUX

OPTION LINKS

PRE-EQ

POST-EQ

PRE-INSERT

HM

LF LM HF

LEFT

INSERT

SL

L MIX

TB

L MIX

GRP 3

GRP 4

PRE

STEREO

AUX8

AUX7

PRE

AUX6

AUX5

AUX4

AUX3

PRE

AUX2

AUX1

(AUX1 ONLY)

PRE-FADE

POST-TRIM

POST-FADE

OPTION LINKS

DIRECT OUT

DIRECT OUT

RIGHT

INSERT

SL

R MIX

TB

R MIX

AUX8

AUX7

PAN

LEV 7-8

AUX 6

AUX 5

AUX 4

AUX 3

AUX 2

AUX 1

VCA GROUPS

FADER

STEREO CHANNEL

CENTRE

INSERT

C

WEDGE mode

TB

PFL

L MIX

R MIX

MIX

MAIN

PFL

LCR+

BAL BLEND

SNAPSHOTS

MUTE GROUPS

MUTE

VCA

+

METER

PEAK

EQ IN

MONO

+

ON

GAIN

-

+

+

R

L/M

INPUT ST1(3)

WEDGE MON

SL

C MIX

C MIX

C MIX

L RLRC

4 BAND EQUALISER

GRP 1

GRP 2

GRP 3

GRP 4

1-2

3-4

ASSIGN

GROUP

+

+

POST-MUTE

PRE-EQ

PRE-FADE AUX

OPTION LINKS

POST-EQ

LM HM HF

LF

LRMLR

ON

-

+

L/M

PRE-FADE

GAIN

-

+

R

INPUT ST2(4)

MONITOR

M

POST-FADE

PFL AFL

SL

SL

SL

SL

AFL MIX

PFL MIX

AFL

PFL

PRE

STEREO

AUX10

AUX9

PRE

AUX4 AUX5 AUX6

AUX3

PRE

AUX2

AUX1

C

LR

MONITOR SOURCE

PFL

AFL

PAFL LOGIC

AUX8

AUX7

PAN

7-8 LEV

AUX 6

AUX 5

AUX 4

AUX 3

AUX 2

AUX 1

The PAN control does not work. Check the setting of the BLEND control.

The console takes a lon

time to power up. Check the rear panel slide switch. RS232 takes longer to boot than MIDI.

2TRK

+

+

-

-

+

+

R

L

IN

2TRK

C

L

R

TB/OSC OUT

TB

+

DIM

OSC/NOISE TO TB

TRIM

+48V

TRIM

MONITOR DIM

TALK TO TB

-

+

TB MIC

OSC/NOISE/TALKBACK

PINK NOISE

Disable

1kHz OSC

www.allen-heath.com email: support@allen-heath.com

ML3000 User Guide 7

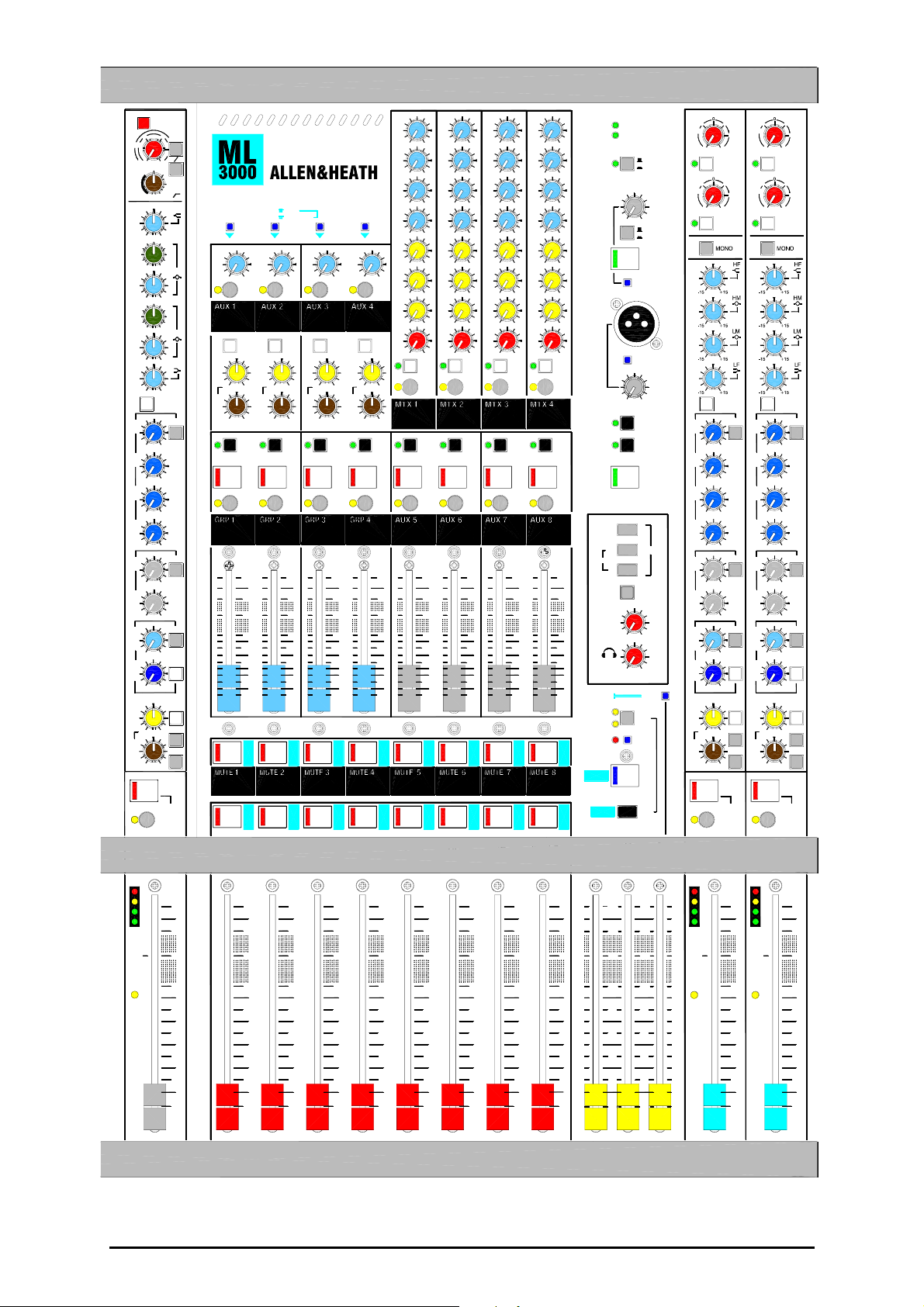

Page 8

GAIN

AUX

LCR

BLEND

PAN

700

45

AUX

1

AUX

2

AUX

3

AUX

4

AUX

5

AUX

6

7

7-8

LEV

AUX

8

PAN

+48V

0

20

10- 10

50

20

-15 +15

2.5k

1k

500Hz 15k

-15

180

80

35Hz

-15

-15

OO

OO

OO

OO

OO

OO

OO

OO

=

+

LR

=

L

GROUP ASSIGN

60 40

400HzOFF

EQ IN

PFL

+15

+15

+15

+6

+6

40

100

1k

+6

+6

+6

+6

+6

+6

C

R

MUTE

4k

250

PAD

20dB

200

HPF

6k

400

PRE

PRE

PRE

STEREO

MAIN

MIX

1-2

3-4

O

HF

GRP/AUX

reverse reverse

HM

OO +6

AFL AFL

LM

LF

BLEND

PAN

LCR

+

LR C

LR

MAIN

MIX MIX

=

LCR

BLEND

=

PAN

TB TB TB TB TB TB TB TB

MUTE MUTE MUTE MUTE

AFL

10

5

0

5

10

20

30

OO

M

A

S

T

E

R

M

U

T

E

FOH

mode

MONITOR

GRP/AUX GRP/AUX GRP/AUX

reverse reverse

LEVLEVLEVLEV

OO +6

OO +6

AFL AFL

MAIN

MAIN

MIX MIX

=

=

+

+

LCR

LR C

=

LR

AFL

10

5

5

10

20

30

OO

M

A

S

T

E

R

M

U

T

E

LCR

BLEND

PAN

0

BLEND

CLR

=

PAN

RL

AFL

10

5

0

5

10

20

30

OO

M

A

S

T

E

R

M

U

T

E

OO +6

=

+

=

1

1

1

1

OO +6

OO +6

OO +6

OO +6

OO +6

OO +6

OO +6

OO +6

OO +6

+6OO

ON ON

AFL

LEV

2

3

4

L

R

C

OO +6

OO +6

OO +6

OO +6

OO +6

OO +6

OO +6

+6OO

AFL

2

2

2

OO +6

OO +6

OO +6

OO +6

OO +6

OO +6

OO +6

3

3

OO +6

4

4

OO +6

L

L

OO +6

R

R

OO +6

C

C

OO +6

LEV

LEV

+6OO

+6OO

ON

ON

AFL

AFL

3

4

L

R

C

LEV

MAIN

CLR

RL

POWER

METERS

OSC/NOISE

TRIM

MIC IN

TALKBACK

TRIM

Disable

+48V

TB TO LR

AUX 5-8

MTX 1-4

maxmin

PINK NOISE

1kHz OSC

OSC/NOISE

TO TB

maxmin

TB TO C

MUTE MUTE MUTE

MUTE

AFL

AFL AFL AFL AFL

TALK

TO TB

2TRK

LR

SOURCE

LCR

LOCAL

MONITOR

PHONES

MIDI

RS232

SLAVE

mode

C

C MAIN MIX

LISTEN WEDGE

MONO

MIDI

CH1-16

100

100

WEDGE

mode

10

10

10

10

10

5

5

5

5

5

0

0

0

0

0

5

5

5

5

10

10

10

20

20

30

30

OO

OO

M

M

A

A

S

S

T

T

E

E

R

R

10

20

20

30

30

OO

OO

M

A

S

T

E

R

5

10

20

30

OO

M

M

A

A

S

S

T

T

E

E

R

R

ASSIGN

Assign MUTE and VCA groups:

Select using GRP MUTE

M

M

M

U

U

T

T

E

E

M

U

U

T

T

E

E

M

U

T

E

Assign using CH MUTES

VIEW

Press and Hold with GRP MUTE

View on channels

DUMP

GAIN

GAIN

BAL

AUX

AUX

AUX

AUX

AUX

AUX

AUX

LEV

AUX

PAN

LCR

BLEND

1

2

3

4

5

6

7

7-8

8

-3

18

-6

ST1

ON

-3

18

-6

ST2

ON

EQ IN

+6OO

+6OO

OO +6

OO +6

OO +6

OO +6

+6OO

+6OO

=

+

=

LR

GROUP ASSIGN

PFL

3

3

CLR

MUTE

10

10

PRE

PRE

PRE

STEREO

MAIN

MIX

1-2

3-4

GAIN

GAIN

BLEND

BAL

AUX

1

AUX

2

AUX

3

AUX

4

AUX

5

AUX

6

AUX

7

7-8

LEV

AUX

8

PAN

LCR

-3

-6

ST3

ON

-3

-6

ST4

ON

EQ IN

OO +6

OO +6

OO +6

OO +6

=

+

=

LR

GROUP ASSIGN

PFL

+6OO

+6OO

18

18

+6OO

+6OO

CLR

MUTE

3

10

3

10

PRE

PRE

PRE

STEREO

MAIN

MIX

1-2

3-4

GROUP

ASSIGNED

PK

+6

10

0

SIG

5

0

5

10

20

30

40

OO

10

10

10

10

10

10

10

10

5

5

5

5

5

5

5

5

0

0

0

0

0

0

0

0

5

5

5

5

5

5

5

5

10

10

10

10

10

10

10

10

20

20

20

20

20

20

20

20

30

30

30

30

30

30

30

30

40

40

40

40

40

40

40

40

OO

OO

OO

OO

OO

OO

OO

OO

10

10

5

5

0

0

5

5

10

10

20

20

30

30

40

40

OO

OO

GROUP

ASSIGNED

PK

+6

0

SIG

PK

+6

10

5

0

5

10

20

30

40

OO

GROUP

ASSIGNED

10

0

SIG

5

0

5

10

20

30

40

OO

8 ML3000 User Guide

Page 9

ML3000 Key Features

The Allen & Heath ML3000 is a small footprint, affordable VCA equipped dual function live sound

console providing many of the features of its larger brothers the ML4000 and ML5000. It can be

quickly configured for front-of-house (FOH) or stage monitor mixing. As one console suitable for

both applications it is equally well suited to installation, rental and touring. It offers an IO capability

and feature set that satisfies the latest requirements of live sound engineering, in particular the

growing number of inputs and outputs for multi-speaker house and monitor systems, demands of

stereo in-ear monitoring, 3 speaker LCR imaging, advanced grouping and automation. The design

ensures on-the-road durability, a clear layout for easy walk up and go operation, and nocompromise audio performance.

Inputs and Outputs

• 4 Standard frame sizes: 24+2, 32+2, 40+2, 48+2 (mono + dual stereo channels)

• Optional ‘B’ versions: 20+6, 28+6, 36+6, 44+6 (mono + dual stereo channels)

• 24, 32, 40, 48 mono mic/line inputs with inserts and direct outputs

• 2 dual stereo line inputs standard (6 optional)

• Sys-Link option to link consoles for more channels

• Main Left, Right and Centre outputs with inserts, Centre configurable as the engineers monitor

• 4 Groups, 8 Auxes: Group/Aux 1-4 and Aux 5-8 with faders and inserts, Aux 1-4 with rotaries

• Aux 7/8 configurable as mono or stereo with level and pan controls

• 8x4 Matrix

• 2-Track monitor input and recording send

• Stereo headphones and local monitors

• Talkback mic input

• Talkback/Oscillator output

Groups and Automation

• 8 VCA groups with mutes

• 4 audio groups with LCRplus™ sub grouping

• 8 mute groups

• MIDI accessible snapshot memories

• MIDI mute on/off, snapshot recall and dump in/out control

Processing and Control

• 4-Band 2 sweep mono EQ, 4-band fixed frequency stereo EQ

• Sweepable high pass filter

• LCRplus™ 3 speaker imaging system

• Protected mode switching to configure the console for FOH or monitor application

• PFL override AFL override selected monitor source

• Assignable talkback

• 1kHz tone and pink noise generator for system line-up and testing

• Full console monitoring and extensive metering with LED bars and illuminated VU

ML3000 User Guide 9

Page 10

MONO CHANNEL

PAD

GAIN

+

-

DIRECT OUT

OPTION LINKS

POST-FADE

PRE-FADE

POST-TRIM

+48V

INPUT

DIRECT OUT

HPF

FILTER

FREQ

(AUX1 ONLY)

INSERT

AUX1

LF LM HF

PRE

AUX2

AUX3

AUX4

AUX 1

AUX 2

AUX 3

4 BAND EQUALISER

AUX 4

AUX5

FADER

VCA

POST-MUTE

VCA GROUPS

MUTE

MUTE GROUPS

SNAPSHOTS

PFL

PAN BLEND

LCR+

L RLRC

MIX

GROUP

ASSIGN

1-2

3-4

PFL

L MIX

R MIX

C MIX

GRP 1

GRP 2

GRP 3

GRP 4

METER

PEAK

EQ IN

HM

PRE-FADE AUX

OPTION LINKS

POST-EQ

PRE-EQ

PRE-INSERT

PRE

PRE

AUX6

AUX7

AUX8

STEREO

LEV 7-8

PAN

AUX8

AUX 5

AUX 6

AUX7

STEREO CHANNEL

L/M

INPUT ST1(3)

L/M

INPUT ST2(4)

+

ON

GAIN

+

R

-

+

ON

GAIN

+

R

-

PRE-FADE

POST-FADE

+

AUX1

FADER

VCA

POST-MUTE

AUX8

AUX7

TRIM

+

-

VCA GROUPS

MUTE

MUTE GROUPS

SNAPSHOTS

OSC/NOISE TO TB

DIM

TALK TO TB

BAL BLEND

L RLRC

+

+

+

LCR+

PFL

MAIN

MIX

GROUP

ASSIGN

1-2

3-4

PFL

L MIX

R MIX

C MIX

GRP 1

GRP 2

GRP 3

GRP 4

TB/OSC OUT

TB

METER

PEAK

+

AUX9

7-8 LEV

EQ IN

AUX10

PAN

PRE-FADE AUX

OPTION LINKS

POST-EQ

PRE-EQ

PRE

STEREO

MONO

4 BAND EQUALISER

LF

LM HM HF

L

R

M

L

R

M

PRE

AUX2

AUX3

AUX4 AUX5 AUX6

AUX 1

AUX 2

AUX 3

AUX 4

PRE

AUX 5

AUX 6

OSC/NOISE/TALKBACK

PINK NOISE

1kHz OSC

TRIM

+48V

TB MIC

Disable

MONITOR DIM

10 ML3000 User Guide

Page 11

ML3000 BLOCK DIAGRAM

GRP

AUX

L MIX

R MIX

TB

MIX

MIX

TB

TB

TB ENABLE

MODE

(1-4 ONLY)

SL

Press MODE to reverse GRP and AUX master control sections

SL

SL

L MIX

R MIX

SL

WEDGE mode

GRP 1-4

AUX 5-8

INSERT

AUX 1-4

MASTER

LEFT

INSERT

RIGHT

INSERT

AFL

FADER

FADER

FADER

AFL

MUTE

AFL

TO VU METER

POST-FADE

PRE-INSERT

PRE-INSERT

POST-FADE

AFL

BLEND

PAN

LCR+

L RLR C

BAL

BAL

L

BAL

R

BAL

MAIN

MIX

(1-4 ONLY)

GRP TO MTX

GRP OUT

AUX OUT

L

R

L MIX

R MIX

C MIX

LEFT

OUT

2TRK

OUT

RIGHT

OUT

MATRIX

EXT.IN

GRP 1

GRP 2

GRP 3

GRP 4

L

R

C

AFL

+

-

LEVEL

INSERT

AFL

C MIX

AFL

PFL

PAFL LOGIC

AFL MIX

PFL MIX

TB

C MIX

SL

C

WEDGE MON

CENTRE

INSERT

FADER

C METER

BAL

CENTRE

OUT

BAL

ON

OUT

MATRIX

MONITOR

TB DIM

L METERS

R METERS

C METERS

WEDGE MON

L

LOCAL

MONITOR

R

L

R

METERS 1-4

METERS 5-8

HEADPHONES

GRP

AUX

MATRIX

METER SELECT

PHONES

MONO

+

LOCAL

PFL

AFL

SL

SL

SL

MONITOR SOURCE

L

IN

R

LR

PFL AFL

C

+

-

+

-

+

+

SL

L

R

C

2TRK

L

R

C

2TRK

ML3000 User Guide 11

Page 12

Technical Specifications

0dBu = 0.775 Vrms, +4dBu = 1.23 Vrms

Operating Levels

Channels......................................... 0dBu Headroom +21dB

Mix .................................................. -2dBu Headroom +23dB

Max XLR output .............................. +23dBu

Frequency Response Referred to 1kHz at +4dBu

Mic to main output (+40dB)............. 20Hz to 70kHz +0/-0.5dB

Line to main output (0dB)................ 20Hz to 22kHz +0/-0.5dB

Distortion @1kHz 0dBu

THD+noise ...................................... < 0.01%

CMRR Common mode rejection @1kHz

Mic (+40dB)..................................... > 85dB

Mic + Pad (0dB) .............................. > 50dB

Crosstalk Referred to driven channel @1kHz

Channel to channel ......................... < -95dB

Mute shutoff .................................... < -85dB

Fader shutoff................................... < -85dB

Noise Performance Measured rms 22Hz to 22kHz unweighted

Mic EIN with 150 ohm source ......... -128dB

Residual output noise ..................... < -98dBu

Mix noise, nothing routed................ < -95dBu

Mix noise, 24 channels routed ........ < -88dBu

Metering

Reading 0................. 0dBu at XLR outputs

LED meters .............. Peak reading, 3 colours

VU meters ................ Ave reading, Illuminated moving coil

Peak indicators ........ 5dB before clip, multi-point sensing

Input meters ............. 4 bar LED (signal, 0, +6, peak)

Group/Mtx meters .... VU

L,R,C meters............ VU and 16 bar LED

Lamp Connectors x3

Connector ....................................... XLR-F 4pin

Rating.............................................. 12V 400mA max

Channel Filters

Slope ............................................... 12dB/oct high pass

Frequency ....................................... Off to 400Hz

Mono Equaliser

HF................. +/-15dB, 12kHz shelf

HM................ +/-15dB, 500Hz to 15kHz bell Q=1.9

LM ................+/-15dB, 35Hz to 1kHz bell Q=1.9

LF .................+/-15dB, 60Hz shelf

Stereo Equaliser

HF................. +/-15dB, 12kHz shelf

HM................ +/-15dB, 2.5kHz bell Q=1.6

LM ................+/-15dB, 250Hz bell Q=1.6

LF .................+/-15dB, 60Hz shelf

Power Supply Model RPS11

Case........................... External 3U rack or floor mount

Type ........................... Linear, convection cooled

Mains Voltage ............ 100,120,220,230 V.AC selectable

Mains Frequency........ 50/60Hz

Power consumption.... 300W

Dimensions Width.............. Depth ...... .....Height

24 Channel 1141 (45”) ...... 640 (25.2”)....252 (9.9”)

32 Channel 1396 (55”) ...... 640.......... .....252

40 Channel 1651 (65”) ...... 640.......... .....252

48 Channel 1906 (75”) ...... 640.......... .....252

RPS11 psu 483 (19”) ........ 229 (9”)... .....134 (3U)

RPSD2 483 (19”) ........ 180 (7”)... ..... 45 (1U)

Weights 24 Channel..... 34 kg (75 lbs)

32 Channel..... 41 kg (90 lbs)

40 Channel..... 48 kg (106 lbs)

48 Channel..... 55 kg (121 lbs)

RPS11 psu..... 9.5 kg (21 lbs)

RPSD2........... 6kg (13 lbs)

INPUTS:

Mic (Pad out)................ XLR.................balanced, pin2+........ 2k ohm..............variable -60 to -10dBu ........ Max +11dBu

Mic/Line (Pad in) .......... ........................ ................................. >10k ohm..........variable -40 to +10dBu ....... Max +31dBu

Stereo ST1-12.............. TRS jack ......... balanced, tip+........... >20k ohm..........variable -18 to +6dBu ......... Max +27dBu

2-Track......................... TRS jack .........balanced, tip+ .......... >20k ohm..........+4dBu ................................. Max +25dBu

Matrix Ext In ................. TRS jack .........balanced, tip+........... >20k ohm..........0dBu ................................... Max +21dBu

INSERTS:

Input ............................. TRS jack .........unbalanced, tip send, ring return.........0dBu ................................... Max +21dBu

Output .......................... TRS jack......... unbalanced, tip send, ring return.........-2dBu.................................. Max +21dBu

Matrix ........................... TRS jack......... unbalanced, tip send, ring return.........-2dBu.................................. Max +21dBu

OUTPUTS:

L,R,C............................ XLR.................balanced, pin2+........ <75 ohm............0dBu ................................... Max +23dBu

Grp 1-4......................... XLR.................balanced, pin2+........ <75 ohm............0dBu ................................... Max +23dBu

Aux 1-8......................... XLR................. balanced, pin2+........ <75 ohm............0dBu ................................... Max +23dBu

Matrix 1-4 ..................... XLR................. balanced, pin2+ ........ <75 ohm............0dBu ................................... Max +23dBu

Direct out...................... TRS jack ......... ground comp, tip+ .... <50 ohm............0dBu ................................... Max +21dBu

2-Track......................... TRS jack .........ground comp, tip+ .... <50 ohm............0dBu ................................... Max +21dBu

TB/Osc out ................... TRS jack .........imp balanced, tip+ .... <50 ohm............0dBu ...................................Max +21dBu

Local Monitor ............... TRS jack.........imp balanced, tip+ .... <50 ohm ............0dBu ...................................Max +21dBu

Headphones................. TRS jack ......... tip left, ring right........ for stereo headphones >30 ohms

12 ML3000 User Guide

Page 13

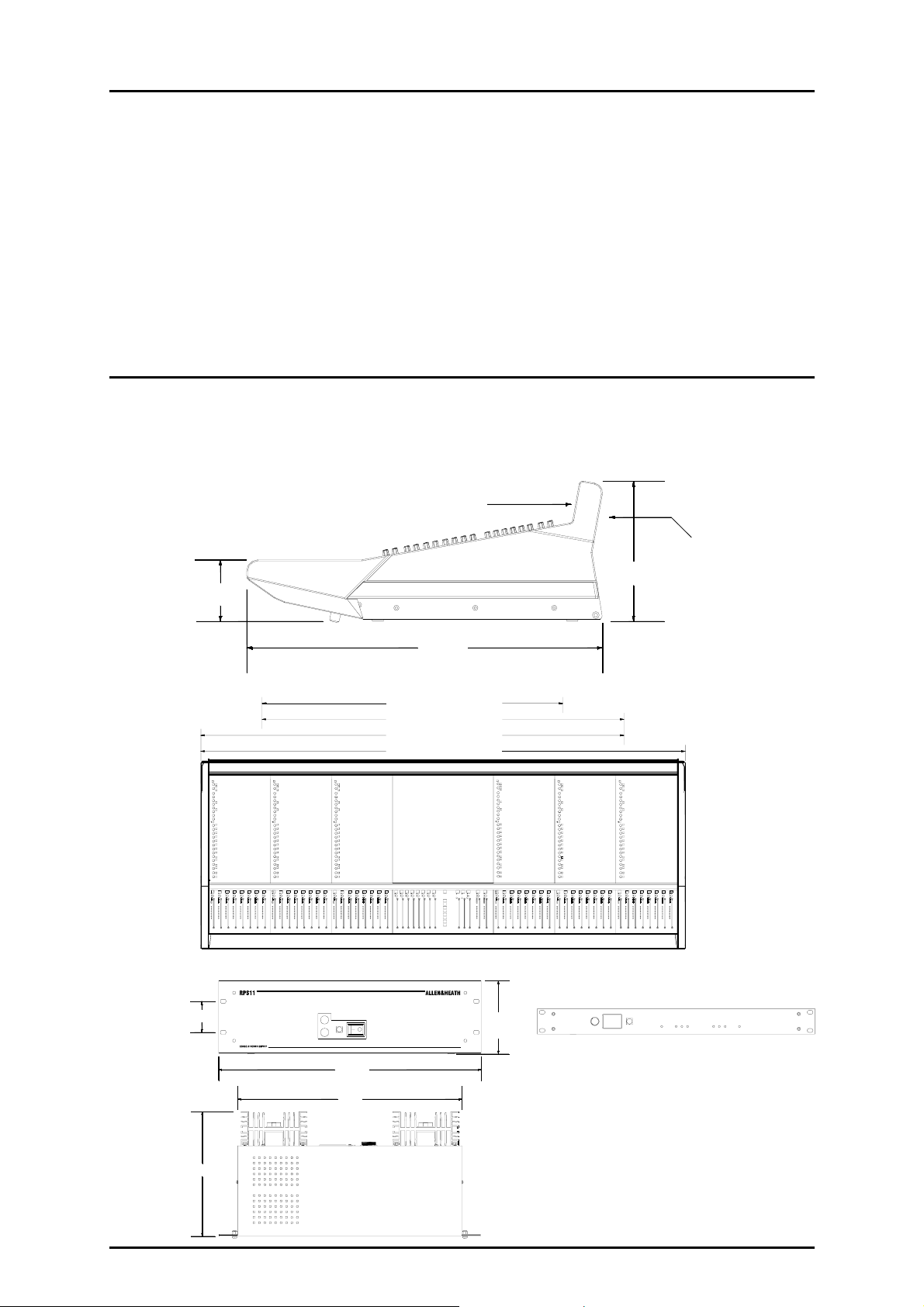

The Range

p

• ML3000-24 24 mono, 2 stereo inputs

• ML3000-32 32 mono, 2 stereo inputs

• ML3000-40 40 mono, 2 stereo inputs

• ML3000-48 48 mono, 2 stereo inputs

• ML3000-24B 20 mono, 6 stereo inputs

• ML3000-32B 28 mono, 6 stereo inputs

• ML3000-40B 36 mono, 6 stereo inputs

• ML3000-48B 44 mono, 6 stereo inputs

Installation Details

Weights 24 Channel 34 kg (75 lbs)

32 Channel 41 kg (90 lbs)

40 Channel 48 kg (106 lbs)

48 Channel 55 kg (121 lbs)

RPS11 psu 9.5 kg (21 lbs)

PHONES SOCKET

110

• RPS11 3U Power Supply Unit

• RPSD2 Power Supply Combiner

• 002-223 2.8 metre DC power lead

• AP2725 RPS11 Power Supply User Guide

• AP2263 RPSD2 combiner User Guide

• AP4511 ML3000 Service Manual

• AL4061 Gooseneck lamp 18”

LAMP SOCKETS

252

FC 57

482.6

417

640

ML3000-24 = 1141

ML3000-32 = 1396

ML3000-40 = 1651

ML3000-48 = 1906

134

(3U)

Refer to the power supply user guide

for safety and installation instructions.

Heed all warnings printed in the user

guide and on the power unit.

229

Refer to the RPSD2 user guide for

instructions on linking two RPS11

power supplies for redundant supply

backu

.

ML3000 User Guide 13

Page 14

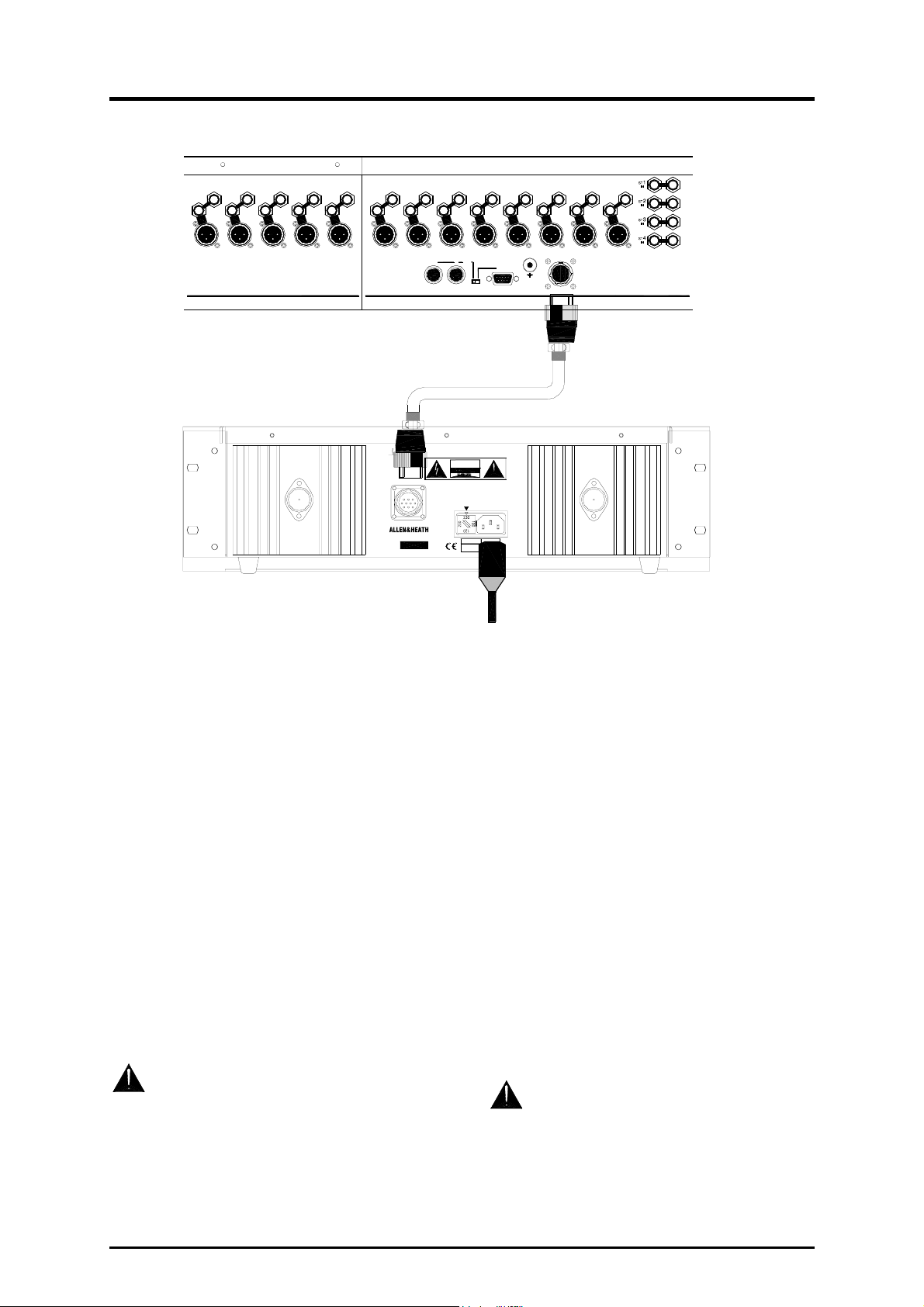

Connecting the Power Supply

DIRECT OUT

INSERT

INPUT

DIRECT OUT

INSERT

INPUT

DIRECT OUT

INSERT

INPUT

DIRECT OUT

INSERT

INPUT

DIRECT OUT

INSERT

INPUT

DIRECT OUT DIRECT OUT DIRECT OUT

INSERT

INSERT

INPUT

INPUT

OUT IN MIDI

WARNING: THIS APPARATUS MUST BE EARTHED.

WARNING: TO REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT EXPOSE THIS APPARATUS TO RAIN OR MOISTURE

DC OUT

PIN CONNECTIONS

1 = +16V 5A

3 = - 16V 5A

4 = CHASSIS 0V

5 = AUDIO 0V

10 = +48V 0.2A

Pins 2,6,7,8,9 =

not connected

Made in the UK by

RPS11

CONSOLE POWER SUPPLY

SERIAL No:

AVIS: RISQUE DE CHOC ELECTRIQUE - NE PAS OUVRIR.

CAUTION: FOR CONTINUED PRO TECTION AGAINST RISK OF FIRE REPLACE FUSE

WITH SAME TYPE AND RATING.

ATTENTION: REMPLACER LE FUSIBLE AVEC UN DES MEMES CARACTERISTIQUES.

INSERT

INPUT

SELECT

DC CABLE

CAUTION

NO USER SERVICEABLE PARTS INSIDE

AC MAINS IN ~

FUSE TYPE AC SUPPLY

T 3.15A 20mm 220 - 240V~

T 5.0A 20mm 100 - 120V~

DIRECT OUT

INSERT

INPUT

RS232

47-63Hz

320VA MAX

300W MAX

MAINS CABLE

DIRECT OUT

DIRECT OUTDIRECT OUT DIRECT OUT

INSERT

INPUT

DC POWER IN

INSERT

INPUT

INSERT

INPUT

CHASSIS

RL

RLL

INSERT

R

INPUT

RL

The ML3000 console range is supplied with the

RPS11 power supply unit. A second RPS11 may

be connected through the optional RPSD2

combiner unit as a redundant (backup) supply.

Before connecting please read the IMPORTANT

SAFETY INSTRUCTIONS printed at the front of this

user guide and the warnings printed on the rear of

the power supply. Also read the user guide

provided with the power supply. Heed all

instructions regarding the installation and ventilation

requirements of the unit.

Connecting Mains Power

Check that the correct mains lead with moulded

plug suitable for your territory has been supplied

with your console. The RPS11 accepts mains

voltages 100, 120, 220, 230V AC by setting the

position of the rear panel fuse carrier.

WARNING: Make sure the power

supply voltage is correctly set to match your

local mains voltage. Refer to the power supply

user guide.

Make sure that the IEC mains plug is pressed fully

into the MAINS INPUT socket.

Connecting the DC Cable

Plug the cable into the power supply DC OUT

socket. First align the locating lugs, press the plug

into the socket, and screw on the locking ring to

hold it firmly in place. Plug and secure the other

end into the console DC POWER IN socket.

If you are using a second ‘redundant’ supply as a

backup then connect as described in the RPSD2

user guide.

Turning the Console On or Off

First check that the mains and DC leads are

correctly plugged in and secured. Turn on the

power supply using its front panel mains switch.

The console must be connected to the power

supply before turning it on.

To avoid loud pops in the speakers make sure that

the connected power amplifiers are turned off

before switching the console on or off.

WARNING: To avoid damage to the

speakers always switch the power amplifiers on

last and off first.

The console meters pulse briefly on power up. This

is normal.

14 ML3000 User Guide

Page 15

Earthing

The connection to earth (ground) in an audio system is important for two reasons:

SAFETY - To protect the operator from high voltage shock, and

1.

2.

AUDIO PERFORMANCE - To minimise the effect of earth (ground) loops

which result in audible hum and buzz, and to shield the audio signals from interference.

For safety it is important that all equipment earths are connected to mains earth so that

exposed metal parts are prevented from carrying high voltage which can injure or even

kill the operator. It is recommended that the engineer check the continuity of the safety

earth from all points in the system including microphone bodies, guitar strings,

connector cases, equipment panels and so on.

The same earth is also used to shield audio cables from external interference such as

the hum fields associated with power transformers, lighting dimmer buzz, and computer

radiation. Problems arise when the signal sees more than one path to mains earth. An

earth loop results causing current to flow between the different earth paths. This

condition is usually detected as a mains frequency audible hum or buzz.

To ensure safe and trouble-free operation we recommend the following:

Use a clean mains outlet for the audio system. Keep the audio

equipment mains feed separate from that powering ‘dirty’ equipment such as air

conditioning and lighting systems, motors and vending machines.

Use star point earthing. It is best to install a ‘star point’ system where the

individual earths to the equipment racks and equipment areas are separately run from a

solid central reference earth point.

Have your mains system checked by a qualified electrician. If the

supply earthing is solid to start with you are less likely to experience problems.

Do not remove the earth connection from the console mains plug.

The console chassis is connected to mains earth through the power cable to ensure

your safety. Audio 0V is connected to the console chassis internally. If problems are

encountered with earth loops operate the audio ‘ground lift’ switch on the power supply

or connected equipment, or disconnect the cable screens at one end, usually at the

destination.

Avoid induced interference. To prevent interference pickup keep audio cables

away from mains power units, cables and distribution boards, motors, lighting and

computer cables and equipment, and any other heavy duty electrical equipment. Where

this cannot be avoided cross the audio and ‘dirty’ equipment cables at right angles to

minimise interference.

Use low impedance sources such as microphones and line level equipment

rated at 200 ohms or less to reduce susceptibility to interference. The console outputs

are designed to operate at very low impedance to minimise interference problems.

Use balanced connections where possible as these provide further

immunity by cancelling out interference that may be picked up on long cable runs. To

connect an unbalanced source to a balanced console input, link the cold input (XLR pin

3 or jack ring) to 0V earth (XLR pin 1 or jack sleeve) at the console. To connect a

balanced console output to an unbalanced destination, link the cold output to 0V earth at

the console.

Use good quality cables and connectors and check for correct wiring and

reliable solder joints. Allow sufficient cable loop to prevent damage through stretching.

If you are not sure ... Contact your service or local Allen & Heath agent for advice.

ML3000 User Guide 15

Page 16

Rear Panel Connections

D

DIRECT OUT DIRECT OUT

INSERT

INPUT

INSERT

INPUT

OUT

IN MIDI

CHANNEL INPUT XLR input for mic or line level

signals. Pin 2 hot. Phantom power is fed to pins 2

and 3 through 6k8 series resistors when the front

panel +48V switch is pressed.

unbalanced sources or cables to the XLR inputs

when phantom power is selected. To avoid loud

clicks always turn the channel off by pressing

the MUTE switch when switching +48V on or off

and when plugging or unplugging microphones.

INSERT TRS jack socket for combined insert send

and return. Tip = send, ring = return, sleeve =

ground. The insert is post-HPF and pre-EQ. Use

this to insert line level processors such as

compressors into the channel signal path. The

channel signal is interrupted when you plug into the

INSERT socket. With nothing plugged in the signal

is passed through switching contacts in the socket.

DIRECT OUT TRS jack providing the post-fade

channel signal as standard. You can reconfigure

the output as pre-fader or as post-fader with the

AUX 1 send control as a level trim by repositioning

internal jumper links. The output is 0dBu ground

compensated line level for connection to balanced

or unbalanced equipment.

ST1-4 IN. Each provides two balanced stereo

inputs on TRS jacks. These can be selected

independently or mixed together into the stereo

channel. They accept line level signals such as CD,

2-track players and effects processors.

RL

RLL

R

RL

+IN

SELECT

DIRECT OUT

INSERT

INPUT

RS232

DIRECT OUT DIRECT OUT

INSERT

INPUT

CHASSIS

INSERT

INPUT

DC POWER IN

DIRECT OUTDIRECT OUT

INSERT

INPUT

INSERT

INPUT

WARNING: Do not connect

2

XLR

1

1

33

- OUT

- IN

RL RL

OUT

MTX FADER FADERFADER

INSERTINSERT

Made in the UK by

INSERT INSERT

INSERT

XLR

INSERT

CONNECTIONS

2

+OUT

RL

OUT

INSERT

MTX MTX

INSERTLINE IN/OUT

SEND

TIPTIP

TIP

TIP +

RINGRING -

RINGRING

RETURN

Serial No.

MTX

INSERT

INSERT

MAIN OUTPUTS. Line level balanced XLR outputs

for the Auxes 1-8, Groups 1-4, Matrix 1-4, L, R and

C main mix. Pin 2 hot. These outputs can provide

up to +23dBu maximum and are suited to driving

line level equipment operating at nominal 0dBu or

+4dBu. The C output is available as the engineers

wedge monitor feed when the front panel mode

switch is selected.

Note: The GRP and AUX signals always remain

on their respective connectors regardless of the

setting of the front panel REVERSE switches.

OUTPUT INSERTS. Each of the L,R,C, Matrix 1-4

and 8 small fader paths has a pre master fader

insert point. These are TRS jack sockets for

combined insert send and return. Tip = send, ring =

return, sleeve = ground. Insert line level processors

such as compressors, limiters, delays and so on

into the output signal paths. The output signal is

interrupted when you plug into the INSERT socket.

With nothing plugged in the signal is passed

through switching contacts in the socket.

Note: Fader paths 1-4 may be Group or Aux

depending on the position of the front panel mode

switches. This lets you use inserts 1-4 for groups or

auxes according to your application.

DC POWER IN A heavy duty 10-pin connector

with locking ring connects to the console power

supply unit. A chassis ground terminal post is

provided for situations requiring earth strapping

between equipment.

WARNING: Use only the DC power

cable type as provided with the console. Refer

to the power supply user guide.

IN

FADER

INSERT INSERT

FADER

FADERFADER

INSERT

INPUTS

FADER

INSERT

16 ML3000 User Guide

Page 17

UTS

DIRECT OUT

DIRECT OUT DIRECT OUT

DIRECT OUT

DIRECT OUTDIRECT OUT DIRECT OUT DIRECT OUT

DIRECT OUT

DIRECT OUT

DIRECT OUT

DIRECT OUT

DIRECT OUT

DIRECT OUT

DIRECT OUT

DIRECT OUT

INSERT

INPUT

MASTER

( from slave )

SLAVE

( to master )

INSERT

INPUT

SYS-LINK LOGIC

INSERT

INPUT

INSERT

INPUT

OUTPUT

INSERT

INPUT

SYS-LINK ( option )

AUDIO OUTPUT ( to master )

INSERT

INPUT

OUTPUT

MATRIX 1-4 EXT INPUT 0dBu line level balanced

TRS jacks to connect external signals into the

matrix. Each matrix has its own input. There are

no level trims for these inputs.

LOCAL MONITOR OUT Impedance balanced

stereo monitor output on TRS jacks. These can

connect to a stereo amplifier/speaker system for

local monitoring.

2-TRACK IN / OUT Line level TRS jacks to

connect to a 2-track recorder such as MiniDisc, tape

or DAT. Connect OUT to the recorder input, and IN

to the recorder output. The connections are

balanced. Link ring (cold) to sleeve (ground) when

connecting to unbalanced equipment.

TB/OSC OUT Impedance balanced TRS line level

output providing talkback, 1kHz oscillator or pink

noise when selected. Use this to patch the test

signal into console channels or other equipment.

MIDI Two standard opto-isolated 5-pin sockets for

MIDI IN and OUT. The small slide switch selects

either the MIDI or RS232 connection. For normal

console operation it is recommended that the switch

is set to MIDI. The power up boot routine is quicker

in this position than RS232.

RS232 9-pin D-connector to connect to the serial

port of a PC for loading new console operating

software, archiving the settings or controlling the

snapshot memories. To enable RS232 set the slide

switch to the RS232 position. Set it to the MIDI

position when RS232 is not needed.

BA

INSERT

INPUT

INSERT

INPUT

INSERT

INPUT

INSERT

INPUT

INSERT

INPUT

INSERT

INPUT

INSERT

INPUT

INPUT A

INSERT

INPUT

SYS-LINK ( option )

AUDIO INPUT ( from slave )

INSERT

INPUT

INPUT B

LAMP 4-pin XLR for plugging in a gooseneck lamp

to illuminate the control surface. Three lamp

sockets are provided along the back of the

meterpod. The right angled Littlite type is

recommended. The 4-pin XLR prevents any

confusion with the 3-pin audio connections.

SYS-LINK EXPANDER OPTION The console is

provided with blanking plates fitted as standard.

The ML3000 Sys-Link option kit is available from

Allen & Heath. It is fitted by removing the base,

blanking plates, and plugging in the circuit cards

provided. Fitting instructions come with the kit.

Two pairs of 37-pin and a pair of 9-pin D-connector

sockets allow two consoles to connect together as

master and slave to expand the number of channels

in the mix. These provide access to all the mix

busses and P/AFL system. They are balanced and

operate at –2dBu line level.

Two ML3000 consoles may be linked as

master/slave. Alternatively the ML3000 may be

connected as a slave to an ML4000 or ML5000

console.

Two 37-way audio and one 9-way logic cables are

required. The audio outputs of the slave console

plug into the master audio inputs. The slave

console SLAVE logic connector plugs into the

master console MASTER logic connector.

The Sys-Link connections conform to the Allen &

Heath Sys-Link II standard. You can connect to a

console fitted with Sys-Link I using special adapter

cables. Contact Allen & Heath for details.

Refer to the Sys-Link fitting instructions for further

details on this option.

INSERT

INPUT

ML3000 User Guide 17

Page 18

Audio Connector Types and Wiring

SYS-LINK II

BA

4 nc

3 nc

2 nc

13 GRP 4+

12 AUX 1+

11 AUX 2+

10 AUX 3+

9 AUX 4+

8 AUX 5+

7 AUX 6+

6 PFL+54 nc

3 PFL DC

2 AFL DC

1 0V (PAFL)

14 GRP 3+

15 GRP 2+

16 GRP 1+

17 R+

18 L+

19 0V (CHS)

L- 37

R- 36

AUX 1- 31

AUX 2- 30

AUX 3- 29

GRP 4- 32

GRP 3- 33

GRP 2- 34

GRP 1- 35

24

nc 23

nc 22

PFL- 25

AUX 4- 28

AUX 5- 27

AUX 6- 26

19 0V (CHS)

nc 21

C- 37

nc 20

141516

17 AFL L+

18 C+

13

12 AUX 7+

11 AUX 8+109

8 nc

7 nc

6 nc

28

272625

35

34

AFL L- 36

29

33

32

AUX 7- 31

AUX 8- 30

24

1 nc

5 nc

nc 23

nc 22

nc 21

nc 20

18 ML3000 User Guide

Page 19

Gain Structure

How the levels between the different signal stages

are set up is referred to as the gain structure. For

best performance it is important that the connected

source signals are matched to the ‘normal operating

level’ of the console. Similarly the levels of the

connected amplifiers and destination equipment

should be correctly matched to the console outputs.

If set too high then the signal peaks will be clipped

resulting in distortion, and if set too low then the

signal-to-noise performance will be degraded

resulting in excessive background hiss and noise.

Using the Meters. The ML3000 provides metering

of inputs and outputs. For best results operate the

console with the LED bar meters averaging around

‘0’ allowing the loudest moments to reach ‘+6’.

Reduce the gain if the red peak LEDs start to flash.

Note that the peak leds light 5dB before actual

clipping to warn that you are nearing distortion and

should reduce gain. The LED bar meters have a

peak response with fast attack and slow release so

that fast musical transients are accurately

displayed. The VU meters have a slower attack so

that the average levels are better displayed. Both

types of metering are useful in live sound mixing.

Matching a Source to the Console. Start by

turning down the channel fader and send levels to

prevent unexpected loud volumes reaching the

main speakers and monitors. Adjust the GAIN

control for an average ‘0’ reading on the channel

meter. Press PFL to listen to the signal using

headphones, local or wedge monitor, and to view its

level on the main LED and VU meters. Once the

gain is correctly set you can raise the levels to bring

the channel into the mix. Note that you may need

to adjust the gain if you make significant changes to

the EQ. Make sure that any equipment inserted

into the channel is set to operate around 0dBu line

level. It is best to first set the gain with inserted

signal processors such as compressors switched to

bypass.

CHANNEL

FADER

VCA GROUPS

Matching the Console to Destination Equipment.

The console produces a standard XLR output level

of 0dBu for a meter reading of ‘0’. It can produce a

maximum of +23dBu and is therefore well suited to

driving equipment operating at nominal 0dBu or

+4dBu while providing plenty of headroom. If you

are connecting directly to a sensitive power

amplifier it is advisable to turn down its input trim

control if the normal console level is too high.

Simply turning down the console output faders

degrades the output stage noise performance and

reduces the resolution of the fader movement. The

output faders are best operated around ‘-10’ to ‘0’

for loudest average volume required. This allows

plenty of additional headroom if you need it.

Terminology. The normal operating level is the

optimum signal level for best console performance,

indicated by ‘0’ meter readings and resulting in the

0dBu output level. The channels operate at 0dBu

and the mix stages at –2dBu for extended

headroom. Headroom is the extra level available

above normal to allow for loud peaks before the

signal becomes clipped resulting in audible

distortion. The signal-to-noise ratio (SNR) is the

difference measured in dB between normal level

and residual noise floor (hiss) produced by the

console electronics. The dynamic range is the

sum of headroom and SNR representing the

maximum signal range possible from quietest to

loudest.

Using the VCA Groups. Assigning a channel to

one or more VCA groups lets those group faders

control the level of its VCA element. Each fader

provides up to +10dB boost. Note that the channel

VCA allows a maximum combined fader boost of

+10dB. Any more is simply ignored. It is best to

operate the VCA group faders around their nominal

‘0’ position. You can also use a VCA group to

reduce the overall level of a hot mix without having

to adjust all the channel faders.

Final word… A little care with setting gain

structure throughout the signal chain will give you

the very best performance and most manageable

control of the mix.

OUTPUT

VU

+30

+20

+10

0dBu

-10

-20

-30

-40

-50

-60

-90

INPUT

GAIN

INSERT

0dBu

EQUALISER

+/-15dB+60/-10 dB

VCA

DIR OUT

0dBu

PAN/BLEND

LRLR

-3dB law

MIXCHANNEL

MIX HEADROOM

MIX

INSERT

C

+23dB

FADER

CLIPPING LEVEL

OUTPUT

DYNAMIC RANGE

113dB

NOISE FLOOR

+23dBu

HEADROOM

+23dB

0dBu

SNR-2dBu

signal-to-noise

-90dB

-90dBu

ML3000 User Guide 19

Page 20

MONO INPUT and EQ

+48V. Switches +48VDC to the channel input XLR

for powering microphones or DI boxes that need

phantom power. The power is current limited

GAIN

+48V

0

20

10- 10

20

50

40

60 40

100

400HzOFF

PAD

20dB

200

O

HPF

HF

through 6800 ohm resistors to pins 2 and 3.

WARNING Do not connect unbalanced

sources or cables to inputs with phantom power

selected. To avoid loud clicks always mute the

channel before switching +48V on or off and

when plugging or unplugging microphones.

GAIN. Adjusts the input sensitivity to match the

connected source to the internal 0dBu operating

level of the channel. Provides a variable 50dB

range from +10 to +60dB gain. The gain should be

set so that the channel meter averages ‘0’ with

-15 +15

2.5k

1k

700

500Hz 15k

4k

6k

HM

loudest moments lighting ‘+6’. Reduce gain if the

red peak meter lights.

PAD. Attenuates the input signal by 20dB for

connection to high level microphone or line sources.

When pad is selected the gain control adjusts from

–10dB attenuation to +40dB gain.

-15

80

45

35Hz

180

+15

250

1k

400

LM

POLARITY. Reverses the polarity of the input

signal. This is used to correct reverse wired cables

or sources, and can be effective in reducing

phasing problems between microphones or acoustic

feedback between the microphone and

-15

+15

LF

loudspeakers.

+10

OFF 400Hz

+5

0dB

-5

-10

-15

-20

-25

-30

-35

-40

10

HIGH PASS FILTER

-15

+15

EQ IN

HPF FREQUENCY. Adjusts the cut off frequency

of the high pass filter from off to 400Hz to reduce

low frequency source noise. The filter attenuates

frequencies below cut off by 12dB per octave.

Using the Filter

Adjust the cut off frequency to clean up sources that

do not have much bass content, for example drum

kit overheads (set to 400Hz), reduce proximity

popping on vocals (set around 150Hz), reduce

handling noise and stage rumble, or protect the

speakers from very low frequency energy (set

around 20 to 50Hz). Turn the filter off by setting the

control fully anti-clockwise to preserve full sub

energy for low frequency sounds such as kick drum,

bass and special effects.

10k1kHz100 30k

20 ML3000 User Guide

Page 21

EQUALISER. The channel equaliser provides

adjustment of 4 independent frequency bands.

+20

+15

+10

0dB

HF EQ

+5

-5

-10

-15

-20

10

10k1kHz100 30k

Each has cut/boost and the mids have frequency

sweep controls. HF and LF are shelving. HM and

LM are peak/dip to affect the chosen band of

frequencies.

HF The high frequency band has a shelving

response that cuts or boosts the higher (treble)

frequencies by up to 15dB. The shelf turning point

frequency is 12kHz.

HM The higher mid band has a bell shaped

peak/dip response that cuts or boosts the higher

mid frequencies by up to 15dB. The centre

frequency can be adjusted from 500Hz to 15kHz.

+20

+15

+10

0dB

HM EQ

500Hz 15kHz

+5

-5

-10

-15

-20

10k1kHz100 30k10

LM The lower mid band is similar to the high mid

but provides adjustment from 35Hz to 1kHz.

LF The low frequency band has a shelving

response that cuts or boosts the lower (bass)

frequencies by up to 15dB. The shelf turning point

frequency is 60Hz.

EQ IN. Switches the equaliser in or out.

Using the Equaliser

+20

+15

+10

0dB

+20

+15

+10

0dB

35Hz 1kHz

+5

-5

-10

-15

-20

+5

-5

-10

-15

-20

LM EQ

LF EQ

The channel equaliser can be used to creatively

enhance or correctively improve the tonal quality of

the sound. For example, to brighten up a guitar so

that it stands out in the mix, to cut back the

boominess of the kick drum while enhancing the

snap of the beater, or to notch out a ringing

frequency associated with the position of a mic on

stage to help increase its gain before feedback.

Before using the equaliser make sure you choose

the best microphones for the job and place them to

capture each sound accurately. Check and adjust

10k1kHz100 30k10

the channel HPF to filter out unwanted low

frequencies where necessary. If you are working

with the full frequency range make sure the HPF

sweep control is set fully anti-clockwise to turn it off.

Start with the EQ set flat and apply only as much

boost or cut as is needed. The HM and LM bands

have an extended frequency range to overlap the

HF and LF shelves. This allows tighter and more

precise two point control of bass and treble where

needed.

Use the in/out switch to compare the original and

equalised sound. The equaliser has a flat response

and therefore no effect when all the cut/boost

10k1kHz100 30k10

controls are set to their centre detented position.

ML3000 User Guide 21

Page 22

GROUP / AUXILIARY SENDS

These controls send the channel signal to the audio

groups 1-4 and aux sends 1-8. The layout is the

same for both the mono and stereo channels. For

the stereo channels the left and right signals are

AUX

1

PRE

combined to feed the mono auxes.

AUX

2

AUX

3

AUX

4

AUX

5

AUX

6

AUX

7

7-8

LEV

AUX

8

PAN

LCR

BLEND

OO

+6

much channel signal is sent to the mono auxiliary

outputs 1-4. The 0dB position is marked at 3

o’clock. An extra +6dB boost is available. These

sends together with their rotary master controls are

AUX SEND 1-4. These rotary controls adjust how

OO

+6

usually used to feed the effects devices in FOH

mode. In MONITOR mode they would usually

provide monitor sends.

OO

+6

AUX SEND 5-6. These rotary controls adjust how

much channel signal is sent to the mono auxiliary

outputs 5-6. The 0dB position is marked at 3

o’clock. An extra +6dB boost is available. These

+6

OO

PRE

sends together with their fader master controls are

used for effects or monitor sends.

OO

+6

AUX SEND 7-8. These rotary controls adjust how

much channel signal is sent to the mono/stereo

auxiliary outputs 7-8. They function according to

the position of the STEREO switches described

below. An extra +6dB boost is available.

OO

+6

PRE

STEREO. This configures aux 7-8 for mono or

stereo operation. In the up position they become

independent mono sends. In the down position

OO

+6

STEREO

they become a stereo pair with separate level and

pan controls. For the stereo channels the left and

right signals are combined to provide mono feeds

when the switch is in the up position. When

OO

+6

pressed they are routed in stereo to the pair of

auxes.

=

+

MAIN

MIX

PRE. Switches the channel pre-fade signal to the

auxiliary outputs. Aux 1-4 is switched as a group of

four, aux 5-6 and 7-8 are switched in pairs. In the

up position the source is post-fade. When pressed

the source is pre-fade. The pre-fade source follows

PAN

LR

1-2

C

=

3-4

the setting of the internal jumper links.

L R

ROUTING SWITCHES. These route the channel

signal to the audio groups in pairs 1-2 and 3-4. The

signal is post-fader and follows the pan control.

Mono or stereo groups can be created using the

pan control. The LCRplus blend control does not

affect the signal routed to the groups.

22 ML3000 User Guide

Page 23

Internal Link Options

Several link options are available to satisfy user

preferences. These require removal of the console

base panels and replugging of 2way jumpers on the

circuit boards. It is not necessary to remove

assemblies from the console. To avoid damage to

the internal assemblies this work should be carried

out by competent technical personnel.

Pre-fade Source. The source for the pre-fade aux

sends may be changed by repositioning jumper

links on each mono and stereo channel. The

default factory setting is pre-insert, pre-EQ, postmute. This is usually preferred when mixing

monitors from front-of-house. Select the source as

pre-insert, pre-EQ, or post-EQ by setting one

jumper. Select pre or post mute by setting another.

Set pairs of links on the stereo channels to affect

left and right signals.

Direct Output Source. The default factory setting

is post-fade. This can be changed to pre-fade.

Pre-fade follows the source as described above.

An additional option sources the output from the

AUX1 send control. This provides a post-fade

direct output with level trim. If preferred, the

channel feed to the AUX1 buss can be disabled so

that adjusting the direct output level does not feed

the aux mix as well. Select the source as pre-fade,

post-fade, or post-fade with AUX1 trim by setting its

jumper. Set another jumper to turn the AUX1 feed

to the rotary master on or off as required.

FADER

CONNECTORS

FADER

CONNECTORS

MONO CHANNEL

AUX1>ON

AUX1>OFF

AUX1>DIR

POST-FADE

PRE-FADE

POST-EQ

PRE-EQ

PRE-INSERT

POST-MUTE

PRE-MUTE

AUX1 TO

ROTARY MASTER

DIR OUT SOURCE

PRE-FADE SOURCE

PRE-FADE MUTE

STEREO CHANNEL

POST-EQ

PRE-EQ R

POST-EQ

PRE-EQ L

POST-MUTE

PRE-MUTE

PRE-FADE SOURCE

RIGHT

PRE-FADE SOURCE

LEFT

PRE-FADE MUTE

Using the GRP/AUX Sends

Configure the Aux 1-4 underpanel mode switches

above the master controls according to the number

of fader controlled audio groups you need. This is

typically fewer on a VCA equipped console where it

is determined by the number of group processors

you want to insert or the number of groups needed

to feed the matrix, rather than the group level

control required. The remaining output faders can

be configured as masters for the related aux sends.

The associated groups swap with these auxes and

are available on their rotary masters.

Audio Groups. These let you route channels to

independent outputs, mix into the matrix, or insert a

common signal processor to affect more than one

signal, for example a compressor on a vocal group.

Four groups are available. Route the channel

signal by pressing one or both group switches. For

mono groups set the PAN control to odd or even

according to the group you wish to feed. For stereo

position the PAN control according to the stereo

image required.

Effects Sends. Use post-fade aux sends to feed

effects processors such as reverb. This ensures

that the balance between the dry and effect signals

is always maintained regardless of channel fader

position. The output of the processor should be

returned to the mix through another channel,

typically a stereo input.

Monitor Sends. Use aux sends to provide

independent monitor mixes to the performers, MD,

backstage crew and so on. These may feed stage

wedges, side fills, hotspot speakers, headphones

and in-ear monitors, and may be mono or stereo.

Aux 5-8 have full featured fader masters. For

similar aux 1-4 control with faders, meters and

inserts configure the master section underpanel

mode switches as required.

Select pre-fade when mixing monitors from front-ofhouse so that the main mix does not affect the

monitors. However, you may prefer to set some

channels post-fade, for example to avoid backstage

pickup when working with radio microphones.

Select post-fade when using the console for

dedicated monitor mixing so that the channel fader

becomes the master for that signal to all mixes.

A stereo monitor may be configured by selecting the

channel STEREO switches. This provides separate

level and pan controls and is ideal for in-ear

monitoring.

Special Sends. The aux sends can be used for

any application where an independent mix is

required. Select pre or post-fade and mono or

stereo as required.

ML3000 User Guide 23

Page 24

MAIN MIX and INPUT FADERS

This section applies to both the mono and stereo

channels.

=

LCR

BLEND

+

MAIN

MIX

LR

PAN

PK

+6

0

SIG

GROUP

ASSIGNED

C

=

L

R

MUTE

GROUP ASSIGN

PFL

1-2

3-4

MAIN MIX. A single switch routes the channel

signal to the 3 output main mix. Its balance and

image within the L, R and C outputs is determined

by the BLEND and PAN controls.

BLEND. Adjusts the balance between the LR and

C outputs. Fully anti-clockwise all the signal routes

to the LR outputs and none to C. At the detented

centre position the signal routes equally to the LR

and C outputs. Fully clockwise all signal routes to

the C output and none to LR. The control has a

3dB attenuation at centre position.

BLEND does not affect the group routing.