查询3213供应商

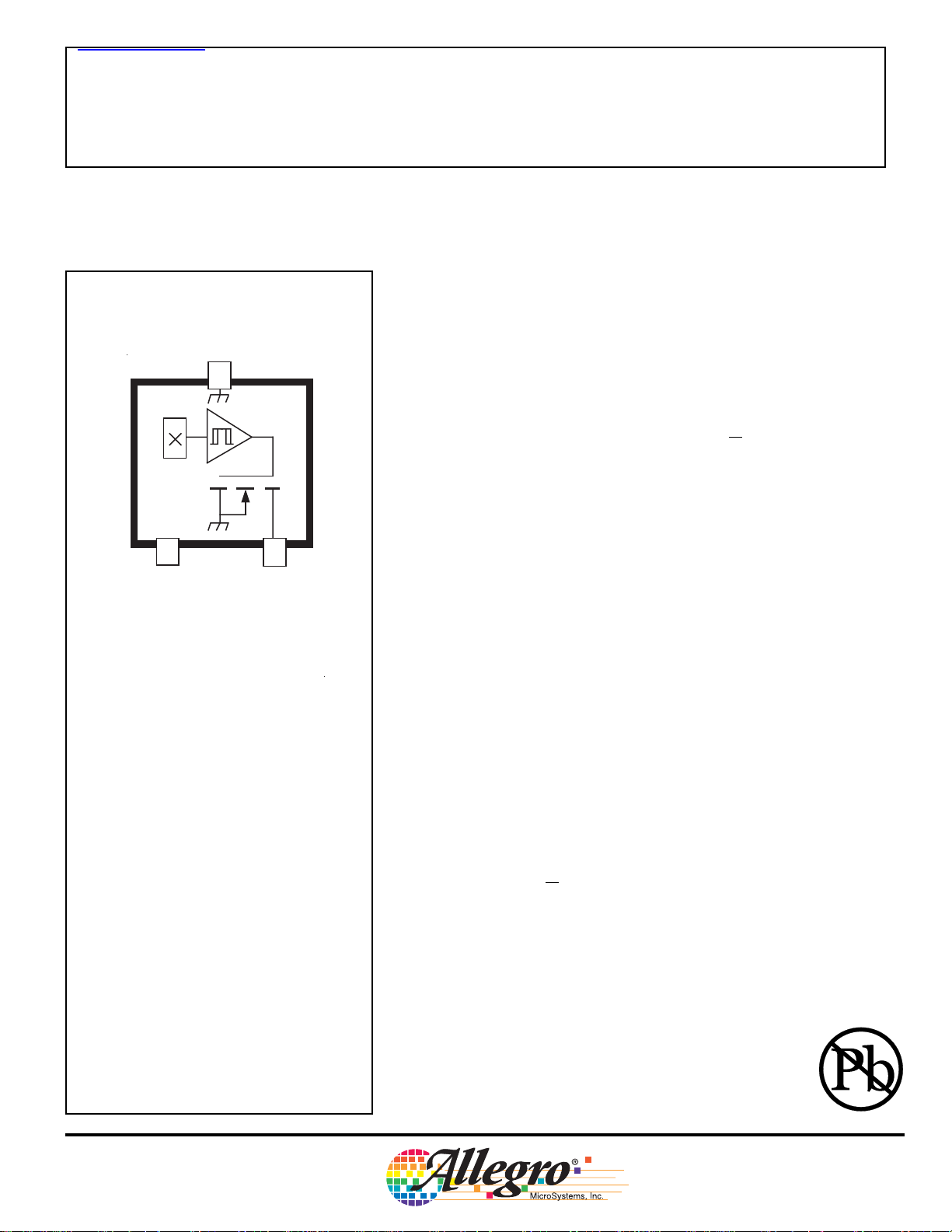

Package Designator ‘LH’ Pinning

(SOT23W)

3

V

DD

12

SUPPLY

Pinning is shown viewed from branded side.

ABSOLUTE MAXIMUM RATINGS

at TA = +25°C

Supply Voltage, VDD .............................. 6 V

Magnetic Flux Density, B .......... Unlimited

Output Off Voltage, V

Output Current, I

Junction Temperature, TJ ................ +170°C

Operating Temperature Range, TA

Suffix 'E' ...................... -40°C to +85°C

Suffix 'L' ................... -40°C to +150°C

Storage Temperature Range,

TS .............................. -65°C to +170°C

Caution: These CMOS devices have input

static protection (Class 3) but are still susceptible to damage if exposed to extremely

high static electrical charges.

GROUND

OUT

........................... 1 mA

OUT

OUTPUT

Dwg. PH-016-1

...................... 6 V

3213

AND

3214

MICROPOWER, ULTRA-SENSITIVE

HALL-EF FECT SWITCHES

The A3213xx and A3214xx integrated circuits are ultra-sensitive, pole

in de pen dent Hall-effect switches with a latched digital output. They are

es pe cial ly suited for operation in battery-operated, hand-held equip ment such

as cellular and cordless tele phones, pagers, and palmtop com put ers. A 2.4 volt

to 5.5 volt operation and a unique clocking scheme reduce the average op er at ing power requirements – the A3213xx to 825 µW, the A3214xx to 14 µW

(typical at 2.75 V)! Except for operating duty cycle and average operating

current, the A3213xx and A3214xx are identical.

Unlike other Hall-effect switches, either a north or south pole of suf fi cient

strength will turn the output on; in the absence of a magnetic field, the output

is off. The polarity independence and minimal power requirement allows

these devices to easily replace reed switches for superior reliability and ease of

manufacturing, while eliminating the requirement for signal conditioning.

Improved stability is made possible through chopper stabilization (dy nam ic offset cancellation), which reduces the residual offset voltage normally

caused by device overmolding, temperature de pen den cies, and thermal stress.

These devices include on a single silicon chip a Hall-voltage generator,

small-signal amplifier, chopper sta bi li za tion, a latch, and a MOSFET output.

Advanced BiCMOS processing is used to take advantage of low-voltage and

low-power requirements, component matching, very low input-offset errors,

and small component geometries.

Range 'E' devices are rated for operation over a tem per a ture range of

-40°C to +85°C; range 'L' devices are rated for operation over a tem per a ture

range of -40°C to +150°C. Two package styles provide a mag net i cal ly op ti mized pack age for most ap pli ca tions. ‘LH’ is a min ia ture low-profile surfacemount package, ‘UA’ is a three-lead SIP for through-hole mounting. Each

package is available in a lead (Pb) free version (suffix, –T) , with a 100% matte

tin plated leadframe.

FEATURES

■ Micropower Operation

■ Operate With North or South Pole

■ 2.4 V to 5.5 V Battery Operation

■ Chopper Stabilized

Superior Temperature Stability

Extremely Low Switch-Point Drift

Insensitive to Physical Stress

■ ESD Protected to 5 kV

■ Sol id-State Reliability

■ Small Size

■ Easily Manufacturable With Magnet Pole Independence

Data Sheet

27622.62F

3213

AND

3214

MICROPOWER,

ULTRA-SENSITIVE

HALL-EFFECT SWITCHES

Product Selection Guide

Part Number Pb-free Packing* Mounting

A3213ELHLT –

A3213ELHLT-T Yes

A3213EUA –

A3213EUA-T Yes

A3213LLHLT –

A3213LLHLT-T Yes

A3213LUA –

A3213LUA-T Yes

A3214ELHLT –

A3214ELHLT-T Yes

A3214EUA –

A3214EUA-T Yes

A3214LLHLT –

A3214LLHLT-T Yes

A3214LUA –

A3214LUA-T Yes

*Contact Allegro for additional packing options.

7-in. reel

3000 pieces/reel

Bulk

500 pieces/bag

7-in. reel

3000 pieces/reel

Bulk

500 pieces/bag

7-in. reel

3000 pieces/reel

Bulk

500 pieces/bag

7-in. reel

3000 pieces/reel

Bulk

500 pieces/bag

Surface Mount

SIP through hole

Surface Mount

SIP through hole

Surface Mount

SIP through hole

Surface Mount

SIP through hole

Ambient, T

(ºC)

–40 to 85

–40 to 150

–40 to 85

–40 to 150

A

DC

(%)

25 460

0.10 11

I

DDAVG(TYP)

(µA)

2

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

3213

AND

3214

MICROPOWER,

ULTRA-SENSITIVE

HALL-EFFECT SWITCHES

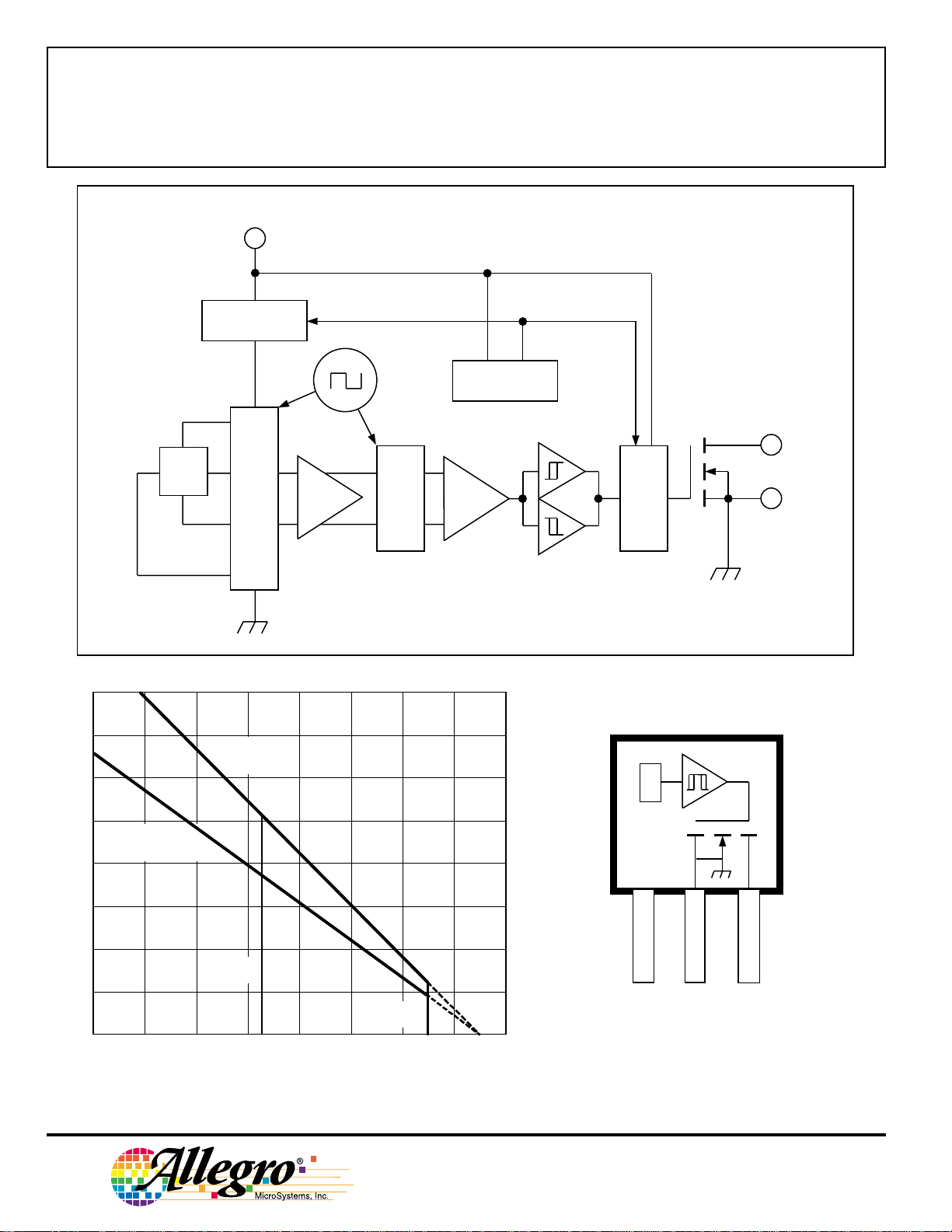

FUNCTIONAL BLOCK DIAGRAM

SUPPLY

SWITCH

X

TIMING

LOGIC

OUTPUT

& HOLD

DYNAMIC

SAMPLE

OFFSET CANCELLATION

800

700

600

500

400

300

200

100

ALLOWABLE PACKAGE POWER DISSIPATION in MILLIWATTS

0

PACKAGE

SUFFIX "LH"

R

θJA

= 228°C/W

20 60 100 140

40 80 120 180

PACKAGE

SUFFIX "UA"

R

θJA

= 165°C/W

TEMP.

CODE "E"

AMBIENT TEMPERATURE in °°°°C

TEMP.

CODE "L"

160

Dwg. GH-046-9

NOTE – Allowable package power dissipation will not be exceeded

unless Absolute Maximum Ratings (page 1) are exceeded.

LATCH

GROUND

Dwg. FH-020-5

Package Designator ‘UA’ Pinning

(SIP)

X

V

DD

1

SUPPLY

32

GROUND

Dwg. PH-016

OUTPUT

Pinning is shown viewed from branded side.

3

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2003 Allegro MicroSystems, Inc.

3213

AND

3214

MICROPOWER,

ULTRA-SENSITIVE

HALL-EFFECT SWITCHES

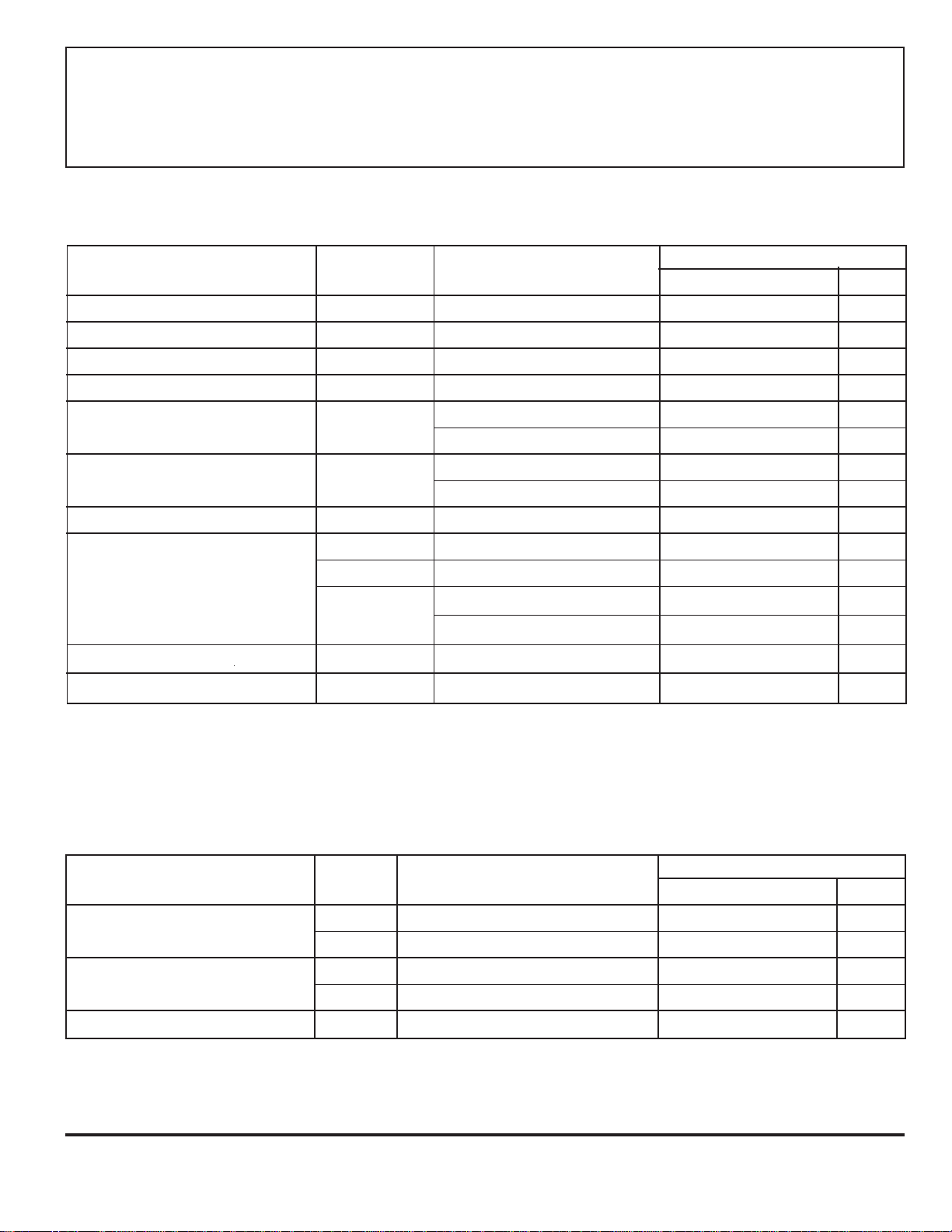

ELECTRICAL CHARACTERISTICS: unless otherwise noted

over operating voltage and temperature range.

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Supply Voltage Range V

Output Leakage Current I

Output On Voltage V

Awake Time t

Period t

DD

OFF

OUT

awake

period

Operating

V

OUT

I

OUT

A3213xx – 240 360 µs

A3214xx – 60 90 ms

Duty Cycle d.c. A3213xx – 25 – %

A3214xx – 0.10 – %

Chopping Frequency f

Supply Current I

C

DD(EN)

I

DD(DIS)

I

DD(AVG)

Chip awake (enabled) – – 2.0 mA

Chip asleep (disabled) – – 8.0 µA

A3213xx – 460 850 µA

A3214xx – 11 22 µA

1)

= 5.5 V, B

RPN

< B < B

RPS

2.4 3.0 5.5 V

– <1.0 1.0 µA

= 1 mA, VDD = 3.0 V – 100 300 mV

–6090µs

– 340 – kHz

ESD, Human Body Model – Per CDF-AEC-Q100-002 5.0 – – kV

ESD, Machine Model – Per JESD22-A115 350 – – V

NOTES: 1. Operate and release points will vary with supply voltage.

= operate point (output turns ON); B

2. B

OPx

= release point (output turns OFF).

RPx

3. Typical Data is at TA = +25°C and VDD = 3.0 V and is for design information only.

MAGNETIC CHARACTERISTICS: over operating voltage and temperature range.

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Operate Points B

Release Points B

Hysteresis B

OPS

B

OPN

RPS

B

RPN

hys

NOTES: 1. As used here, negative flux densities are defined as less than zero (algebraic convention) and -50 G is less than +10 G.

2. B

= operate point (output turns ON); B

OPx

3. Typical Data is at TA = +25°C and VDD = 3.0 V and is for design information only.

4. 1 gauss (G) is exactly equal to 0.1 millitesla (mT).

South pole to branded side – 42 70 G

North pole to branded side -70 -48 – G

South pole to branded side 10 32 – G

North pole to branded side – -38 -10 G

|B

- B

OPx

= release point (output turns OFF).

RPx

|–10–G

RPx

www.allegromicro.com

4

3213

AND

3214

MICROPOWER,

ULTRA-SENSITIVE

HALL-EFFECT SWITCHES

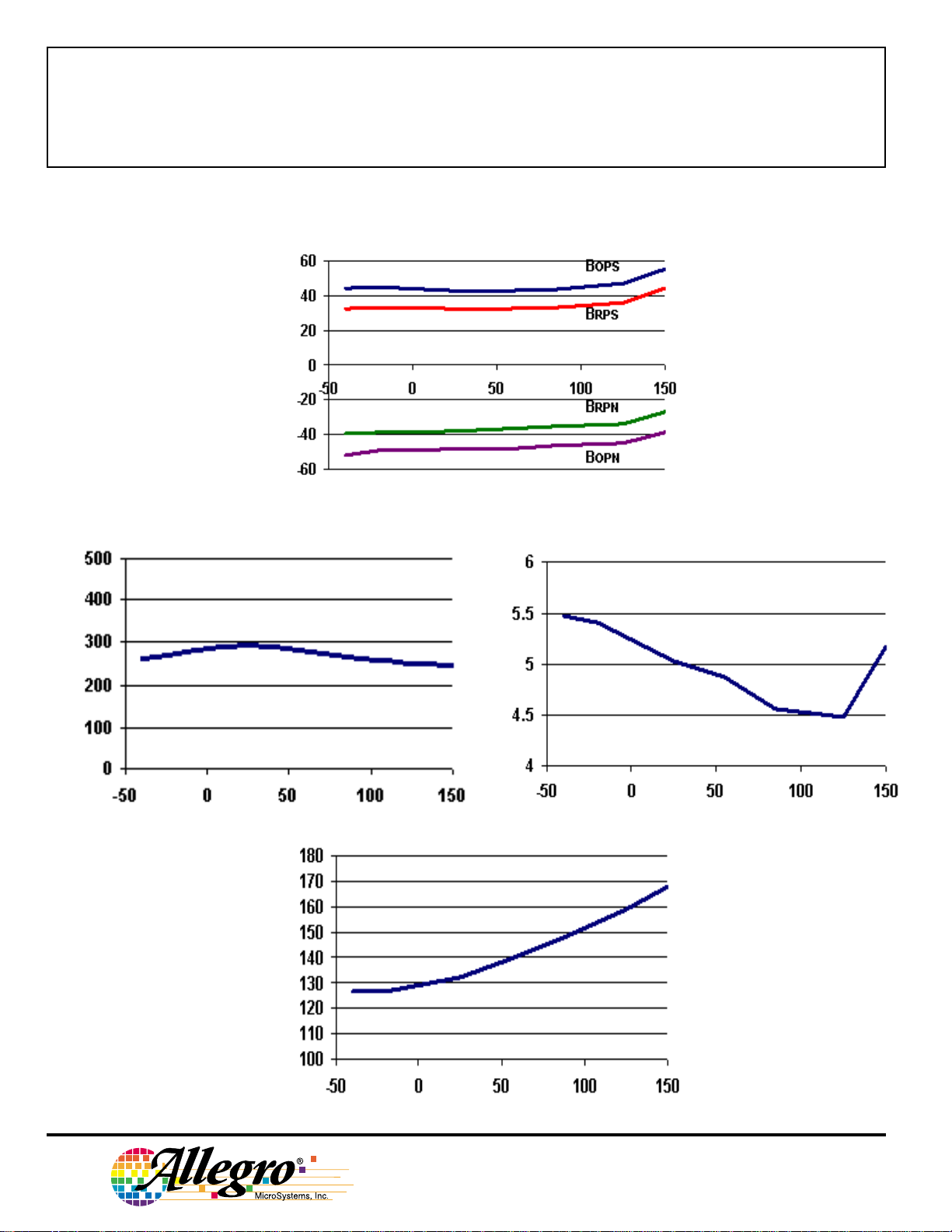

TYPICAL OPERATING CHARACTERISTICS

as a function of temperature (VDD = 3 V)

SWITCH POINTS, B (G)

A3213xx A3214xx

A)

µ

(

DD

I

AVG, SUPPLY CURRENT,

TEMPERATURE, T

(°C)

A

TEMPERATURE, T

A)

µ

(

DD

I

AVG, SUPPLY CURRENT,

(°C)

A

TEMPERATURE, T

(°C)

A

(mV)

OUT

V

OUTPUT ON VOLTAGE,

TEMPERATURE, T

5

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

(°C)

A

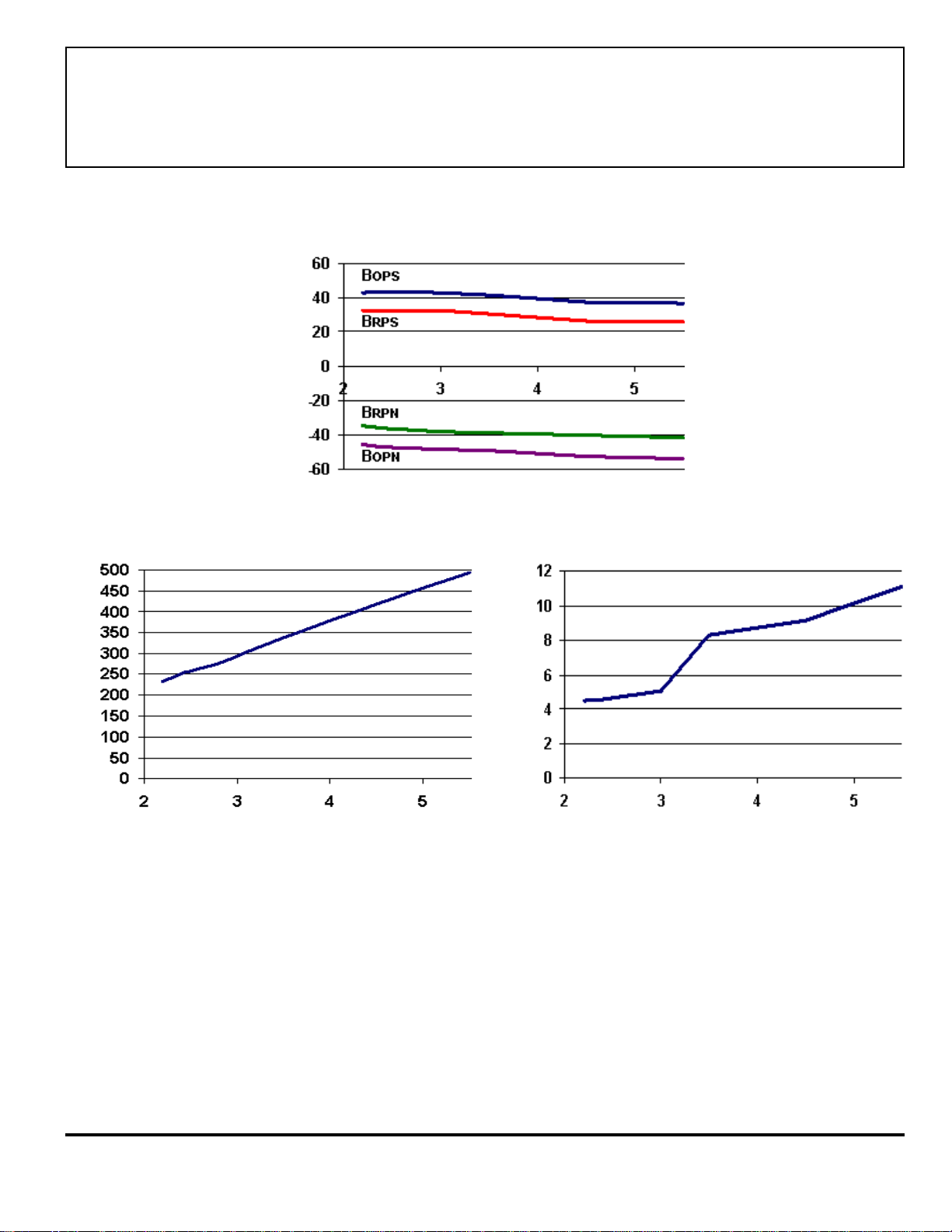

HALL-EFFECT SWITCHES

TYPICAL OPERATING CHARACTERISTICS

as a function of supply voltage (T

SWITCH POINTS, B (G)

SUPPLY VOLTAGE, VDD (V)

= 25°C)

A

3213

AND

3214

MICROPOWER,

ULTRA-SENSITIVE

A3213xx A3214xx

A)

µ

(

DD

I

AVG, SUPPLY CURRENT,

SUPPLY VOLTAGE, VDD (V)

A)

µ

(

DD

I

AVG, SUPPLY CURRENT,

SUPPLY VOLTAGE, VDD (V)

www.allegromicro.com

6

3213

AND

3214

MICROPOWER,

ULTRA-SENSITIVE

HALL-EFFECT SWITCHES

FUNCTIONAL DESCRIPTION

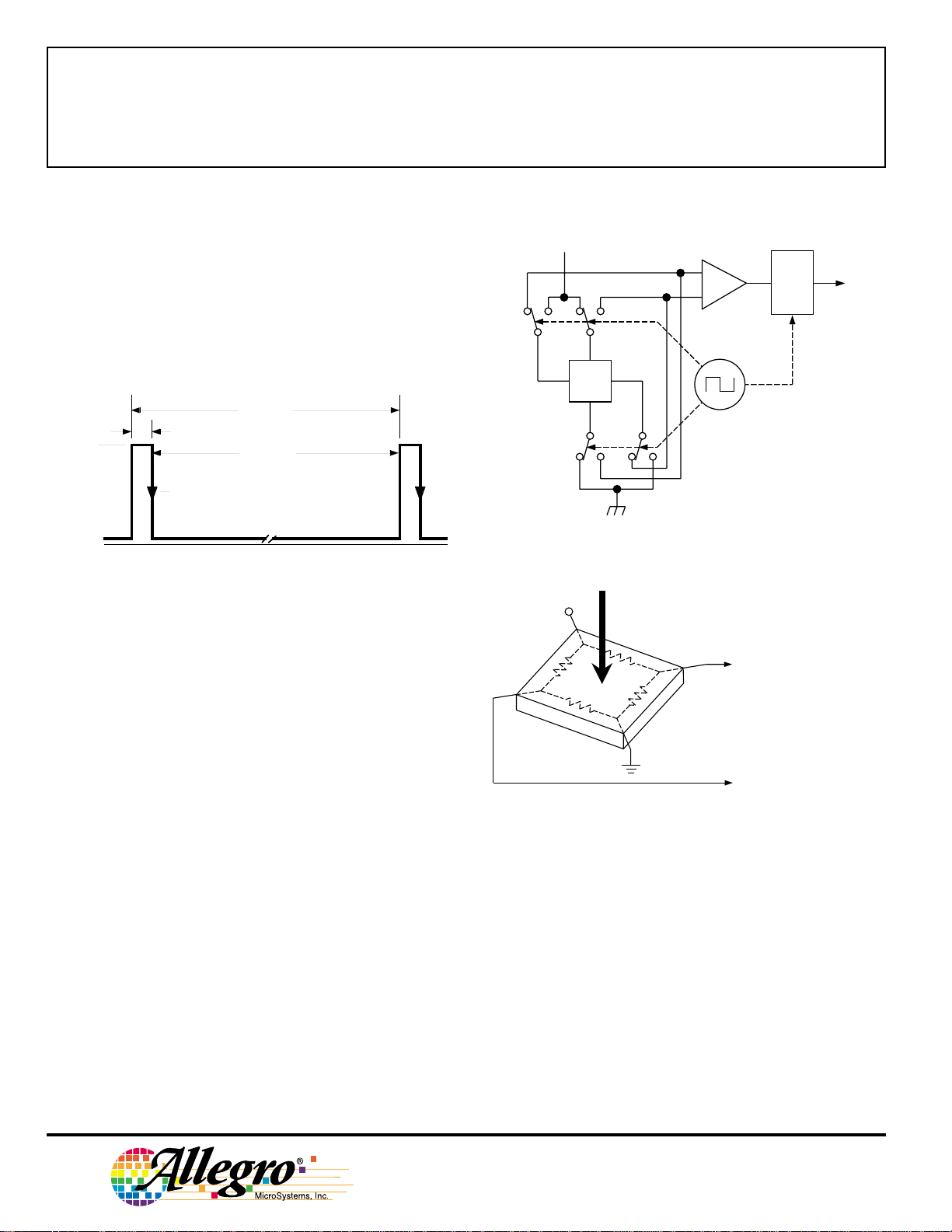

Low Average Power. Internal timing circuitry activates the

sensor for 60 µs and deactivates it for the remainder of the

period (240 µs for the A3213xx and 60 ms for the A3214xx).

A short "awake" time allows for stabilization prior to the

sensor sampling and data latching on the falling edge of the

timing pulse. The output during the "sleep" time is latched in

the last sampled state. The supply current is not affected by

the output state.

PERIOD

I

DD(EN)

I

DD(DIS)

0

60 µs - "AWAKE"

"SLEEP"

SAMPLE &

OUTPUT LATCHED

Dwg. WH-017-1

Chopper-Stabilized Technique. The Hall element can be

considered as a resistor array similar to a Wheatstone bridge.

A large portion of the offset is a result of the mismatching of

these resistors. These devices use a proprietary dynamic offset

cancellation technique, with an internal high-frequency clock

to reduce the residual offset voltage of the Hall element that is

normally caused by device overmolding, temperature dependencies, and thermal stress. The chopper-stabilizing technique

cancels the mismatching of the resistor circuit by changing the

direction of the current flowing through the Hall plate using

CMOS switches and Hall voltage measurement taps, while

maintaing the Hall-voltage signal that is induced by the

external magnetic flux. The signal is then captured by a

sample-and-hold circuit and further processed using low-offset

bipolar circuitry. This technique produces devices that have an

extremely stable quiescent Hall output voltage, are immune to

thermal stress, and have precise recoverability after temperature cycling. This technique will also slightly degrade the

device output repeatability. A relatively high sampling

frequency is used in order that faster signals can be processed.

More detailed descriptions of the circuit operation can be

found in Technical Paper STP 97-10, Monolithic Magnetic

Hall Sensor Using Dynamic Quadrature Offset Cancellation

and Technical Paper STP 99-1, Chopper-Stabilized Amplifiers

With A Track-and-Hold Signal Demodulator.

+V

& HOLD

SAMPLE

X

Dwg. EH-012-1

B

+V

—

HALL

VOLTAGE

+

Dwg. AH-011-2

Operation. The output of this device switches low (turns on)

when a magnetic field perpendicular to the Hall sensor exceeds

the operate point B

(or is less than B

OPS

). After turn-on,

OPN

the output is capable of sinking up to 1 mA and the output

voltage is V

the release point B

. When the magnetic field is reduced below

OUT(ON)

(or increased above B

RPS

RPN

), the device

output switches high (turns off). The difference in the magnetic operate and release points is the hysteresis (B

) of the

hys

device. This built-in hysteresis allows clean switching of the

output even in the presence of external mechanical vibration

and electrical noise.

As used here, negative flux densities are defined as less

than zero (algebraic convention) and -50 G is less than +10 G.

7

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

5 V

MAX

B

OPN

Allegro

OUTPUT OFF

B

OPS

3213

AND

3214

MICROPOWER,

ULTRA-SENSITIVE

HALL-EFFECT SWITCHES

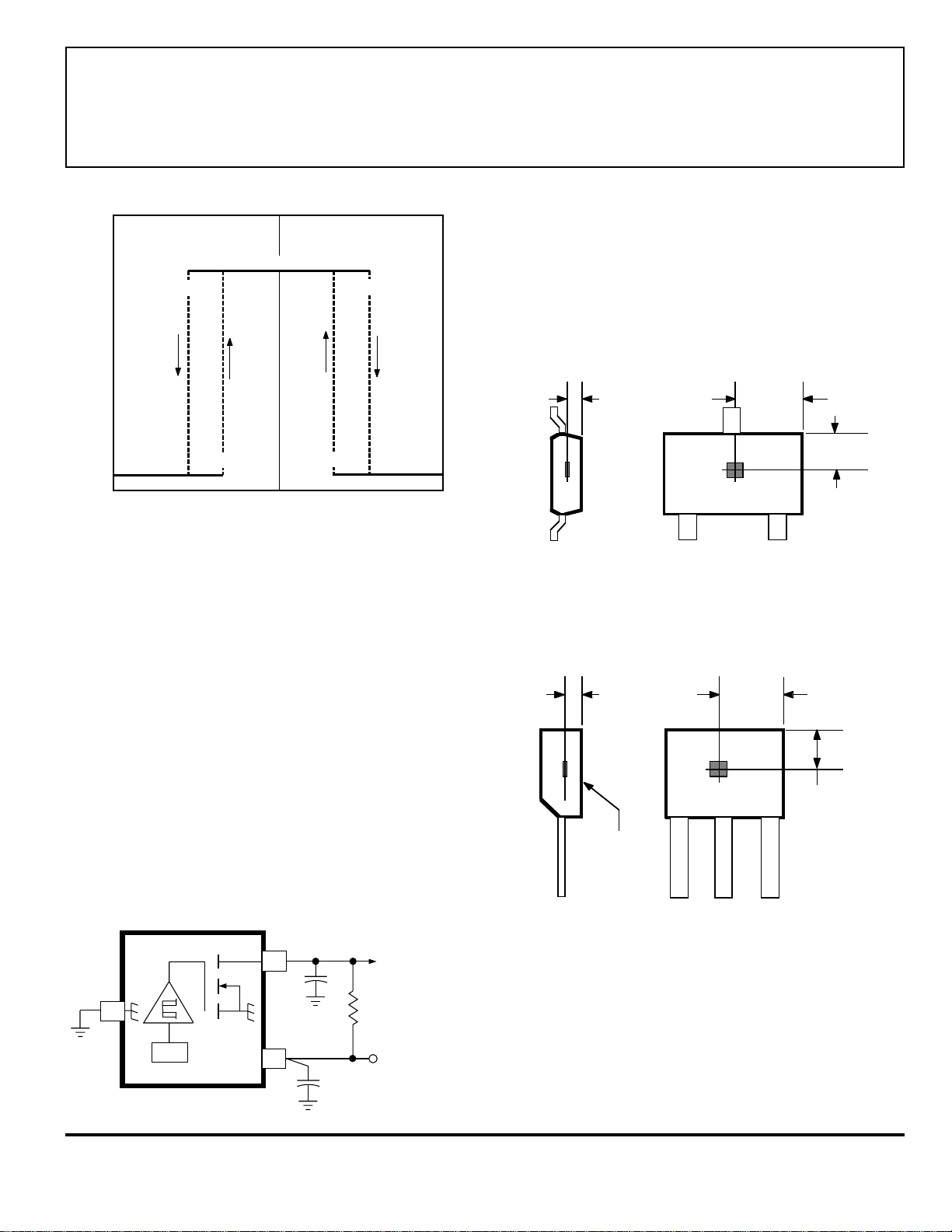

SENSOR LOCATIONS

Package Designator ‘LH’

OUTPUT VOLTAGE

B

RPN

0

-B

0

MAGNETIC FLUX

B

RPS

OUTPUT ON

+B

Dwg. GH-043-1

Applications. Allegro's pole-independent sensing technique

allows for operation with either a north pole or south pole

magnet orientation, enhancing the manufacturability of the

device. The state-of-the-art technology provides the same

output polarity for either pole face.

It is strongly recommended that an external bypass

capacitor be connected (in close proximity to the Hall sensor)

between the supply and ground of the device to reduce both

external noise and noise generated by the chopper-stabilization

technique. This is especially true due to the relatively high

impedance of battery supplies.

The simplest form of magnet that will operate these

devices is a bar magnet with either pole near the branded

surface of the device. Many other methods of operation are

possible. Extensive applications information on magnets and

Hall-effect sensors is also available in the Allegro Electronic

Data Book AMS-702 or Application Note 27701, or at

ACTIVE AREA DEPTH

0.011"

0.28 mm

NOM

Package Designator ‘UA’

ACTIVE AREA DEPTH

0.0195"

0.50 mm

NOM

BRANDED

SURFACE

3

A

1 2

2.07 mm

A

1

2

0.059"

1.51 mm

0.046"

0.85 mm

Dwg. MH-025-1

0.081"

0.053"

1.33 mm

3

www.allegromicro.com

3

X

www.allegromicro.com

Dwg. MH-011-12

2

10 pF

1

DD

V

0.1 µF

OUTPUT

50 kΩ

SUPPLY

(3 V BATTERY)

Dwg. EH-013-2

8

3213

7

AND

3214

MICROPOWER,

ULTRA-SENSITIVE

HALL-EFFECT SWITCHES

PACKAGE DESIGNATOR ‘LH’

(SOT23W, fits SC-59A solder-pad layout)

0.083

0.073

0.022

REF

0.006

0.000

0.122

0.114

0.020

0.012

12

Dimensions in Inches

(for reference only)

3

0.118

0.106

GAUGE PLANE

SEATING PLANE

0.037

BSC

0.045

0.0079

0.0050

0.032

0° TO 8°

0.010

BSC

Dwg. MA-010-3D in

0.010

MIN

0.55

REF

0.15

0.00

2.10

1.85

Dimensions in Millimeters

3.10

2.90

0.50

0.30

3

12

(controlling dimensions)

3.00

2.70

GAUGE PLANE

SEATING PLANE

0° TO 8°

0.95

BSC

1.13

0.20

0.127

0.87

0.25

BSC

0.25

MIN

Dwg. MA-010-3D mm

0.039

0.028

3

1.00

0.70

3

0.094

12

12

0.03

Dwg. MA-011-3 in

Dwg. MA-011-3 mm

NOTES: 1. Tolerances on package height and width represent allowable mold offsets. Dimensions given are

measured at the widest point (parting line).

2. Exact body and lead configuration at vendor’s option within limits shown.

3. Height does not include mold gate flash.

4. Where no tolerance is specified, dimension is nominal.

5. Add "LT" to part number for tape and reel.

9

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

2.40

0.95

Dimensions in Inches

Dwg. MH-014E mm

4.17

4.04

1.57

1.47

0.44

0.35

1.27

BSC

45°

16.26

15.24

0.48

0.36

2.16

MAX

45°

0.79

123

3.10

2.97

SEE NOTE

(controlling dimensions)

0.164

0.159

HALL-EFFECT SWITCHES

PACKAGE DESIGNATOR ‘UA’

Dimensions in Millimeters

3213

AND

MICROPOWER,

ULTRA-SENSITIVE

(for reference only)

3214

0.062

0.058

45°

0.031

0.0173

0.0138

0.0189

0.0142

Dwg. MH-014E in

SEE NOTE

45°

0.122

0.117

0.640

0.600

0.085

123

MAX

0.050

BSC

NOTES: 1. Tolerances on package height and width represent

allowable mold offsets. Dimensions given are

measured at the widest point (parting line).

2. Exact body and lead configuration at vendor’s option

within limits shown.

3. Height does not include mold gate flash.

4. Recommended minimum PWB hole diameter to clear

transition area is 0.035" (0.89 mm).

5. Where no tolerance is specified, dimension is nominal.

6. Supplied in bulk pack (500 pieces per bag).

Radial Lead Form (order A321xxUA-LC)

123

0.620"

0.500"

(15.7 mm

12.7 mm)

0.108"

(2.74 mm)

www.allegromicro.com

0.100"

(2.5 mm)

Dwg. MH-026

NOTE: Lead-form dimensions are the nominals produced on the

forming equipment. No dimensional tolerance is implied

or guaranteed for bulk packaging (500 pieces per bag).

10

3213

AND

3214

MICROPOWER,

ULTRA-SENSITIVE

HALL-EFFECT SWITCHES

11

The products described herein are manufactured under one or more

of the following U.S. patents: 4,761,569; 5,619,137; 5,621,319. In

addition, a patent is pending for Allegro's magnetic pole-independent

feature. Allegro has several foreign counterpart patents as well.

Allegro has not licensed any of these patents to any third party.

Allegro MicroSystems, Inc. reserves the right to make, from time to

time, such departures from the detail specifications as may be required

to permit improvements in the performance, reliability, or

manufacturability of its products. Before placing an order, the user is

cautioned to verify that the information being relied upon is current.

Allegro products are not authorized for use as critical components

in life-support appliances, devices, or systems without express written

approval.

The information included herein is believed to be accurate and

reliable. However, Allegro MicroSystems, Inc. assumes no responsibility for its use; nor for any infringements of patents or other rights of

third parties that may result from its use.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Loading...

Loading...