Page 1

SERIES 20000

Return to the Browser Screen

SERVICE MANUAL

™*

LEGACY

®

ALCON SURGICAL

a division of Alcon Laboratories, Inc.

15800 Alton Parkway

Irvine, California 92618-3818 U.S.A.

Telephone: 949/753-1393

800/832-7827

FAX: 949/753-6614

906-2000-501 F, ASSEMBLY

906-2000-001 F, TEXT ONLY

* Reg. U.S. Pat. & TM Off.

©

2002, 1999, 1998, 1997, 1994 Alcon Laboratories, Inc.

Page 2

SERIES 20000

™*

LEGACY

IMPORTANT NOTICE

Equipment improvement is an on-going process and, as such, changes may be made to the equipment after this

manual is printed. Accordingly, Alcon Surgical makes no warranties, expressed or implied, that the information

contained in this service manual is complete or accurate. It is understood that if this manual is used to perform service

on the equipment by other than trained personnel, the user assumes all risks in the use of this manual.

CAUTION

Federal law restricts this device to sale by or on the order of a physician.

Pay close attention to warnings and cautions in this manual. Warnings are written to protect individuals from bodily

injury. Cautions are written to protect the instrument from damage.

®

UNIVERSAL PRECAUTIONS:

Universal precautions shall be observed by all people who come in contact with the instrument and/or accessories to

help prevent their exposure to blood-borne pathogens and/or other potentially infectious materials. In any circumstance, wherein the exact status of blood or body fluids/tissues encountered are unknown, it shall be uniformly

considered potentially infectious and handled accordingly. This is in accordance with OSHA guidelines.

Comments or corrections concerning this manual should be addressed to:

Alcon Surgical

Technical Services Group

PO BOX 19587

Irvine, CA, USA 92623-9587

All rights reserved. No part of this manual may be reproduced, transmitted, or stored in a retrieval system, in any form

or by any means; photocopying, electronic, mechanical, recording, or otherwise; without prior written permission

from Alcon Surgical.

*Registered in the U.S. Patent and Trademark Office.

**MACKOOL is a trademark of Richard J. Mackool, M.D.,

ii 906-2000-501

Page 3

SERIES 20000

™*

LEGACY

®

SERVICE MANUAL

SERIES 20000

™*

LEGACY

®

906-2000-501

MANUAL REVISION RECORD

DATE REVISION REVISED PAGE NUMBERS

08/94 A Initial release

11/94 B Change of binder

12/97 C ECN 33181 - i, iii

7/98 D ECN 34142- Removed Service Test Procedure from Section Four. All pages,

except engineering drawings in Sections Six & Seven, changed to update trademarks and area codes.

11/99 E ECN 99200934

General update and edit to cover all configurations of the STTL:

Section One - updated with information from latest Operator's Manual;

Section Two - added Steerable I/A, and updated remaining theory and block diagrams;

Section Three - added disassembly procedures for various LCD's and new handpiece

connector panel;

Section Five - updated supplies, tools, and spares tables, expanded tables for fault,

warning, and advisory messages, updated troubleshooting table, added system

configuration table;

Sections Six and Seven - updated all drawings and parts lists;

Section Eight - added service information for the VideOverlay Parameters System.

05/2002 F ECN 20022436

General update and edit to cover all configurations of the STTL:

Section One - updated with information from latest Operator's Manual.

Section Two - added NeoSonix™* information and new phaco block diagram.

Section Three - added notes for upgraded systems.

Section Four - removed this section (Service Test Procedure) and renumbered

subsequent sections.

Section Five - renumbered to Section Four, updated supplies, tools, and spares tables,

added POST codes for new CPU, updated system configuration table.

Sections Six and Seven - renumbered to Sections Five and Six, updated all drawings and

parts lists, added drawings for new configurations.

Section Eight - renumbered to Section Seven.

906-2000-501 iii

Page 4

SERIES 20000

TABLE OF CONTENTS

TOPIC PAGE #

SECTION ONE - GENERAL INFORMATION

About This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Reference Documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Receiving Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Unpacking and Setting Up the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Cautery, Diathermy, Coagulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Electronic System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

System Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Cassette Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Connector Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Other Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Audible Tones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Remote Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Modes and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Irrigation (Irr) Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Hydrosonics™* (Hydro) Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

AdvanTec Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Ultrasound (U/S) Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Irrigation/Aspiration (I/A) Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Vitrectomy (Vit) Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Coagulation (Coag) Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Custom Mode (for software versions 3.01 and below) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Custom Mode (for software versions 3.12 and above) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

Test Mode (for software versions 3.01 and below). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-37

Test Mode (for software versions 3.12 and above) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-38

Footswitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-40

Handpiece and Tip Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-44

Irrigation Handpiece and Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-44

Ultraflow™* I/A Handpieces and Tips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-44

Reusable I/A Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-45

Ultrasonic Handpiece In U/S Bimodal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-45

Ultrasonic Handpieces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-45

Hydrosonics™* Handpiece and Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-46

ATIOP Handpiece . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-47

Coagulation Handpieces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-47

Steerable I/A Handpiece . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-48

Steerable I/A Tip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-48

Consumable Pak Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-49

Error Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-51

System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-52

™*

LEGACY

®

SECTION TWO - THEORY OF OPERATION

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Common Interface Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Subsystem Kernel Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

iv 906-2000-501

Page 5

SERIES 20000

™*

LEGACY

®

TABLE OF CONTENTS

TOPIC PAGE #

Host System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

CPU PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Multifunction PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Footswitch Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

IV Pole PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Video PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Front Panel Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Front Panel Controller PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Display PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Remote Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Remote Control PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Fluidics Subsystem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Fluidics Controller PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Transducer PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Cassette Type PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Fluidics Backplane PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Anterior Pneumatic Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Anterior Vit Drive PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Anterior Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Phaco Subsystem (software V3.01 and below) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Phaco Controller PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

U/S Driver PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Cautery PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Phaco Subsystem (software V3.12 and above) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

NeoSonix™* Controller PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

Cautery PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Steerable I/A System (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

SECTION THREE - PARTS LOCATION AND DISASSEMBLY

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Skins Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

STTL Disassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

SECTION FOUR - MAINTENANCE AND TROUBLESHOOTING

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Recommended Supplies (Table 4-1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Recommended Tools (Table 4-2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Recommended Spares (Table 4-3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

System Configurations (Table 4-4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Legacy System Fault Messages (Table 4-5). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Legacy System Warning Messages (Table 4-6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Legacy System Advisory Messages (Table 4-7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Troubleshooting (Table 4-8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Maintenance Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

1 Replacing CPU PCB Lithium Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

2 Installing or Upgrading System Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

3 Cleaning the Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

4 Cautery Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

906-2000-501 v

Page 6

SERIES 20000

TABLE OF CONTENTS

TOPIC PAGE #

Power On Self-Test (Post) Error Codes for CPU PCB's PN 200-1592-001 and

200-1845-001 (Table 4-9) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Power On Self-Test (Post) Error Codes for CPU PCB PN 200-2290-001 (Table 4-10) . . . . . . . . . . . . . 4-26

SECTION FIVE - SCHEMATICS

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

SECTION SIX - PARTS LISTS AND DRAWINGS

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

SECTION SEVEN - ADDITIONAL INFORMATION

VideOverlay Parameters System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

LIST OF ILLUSTRATIONS

TITLE PAGE #

™*

LEGACY

®

Figure 1-1 The Series 20000™* Legacy®. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Figure 1-2 STTL Packing Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Figure 1-3 Icons used with the STTL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

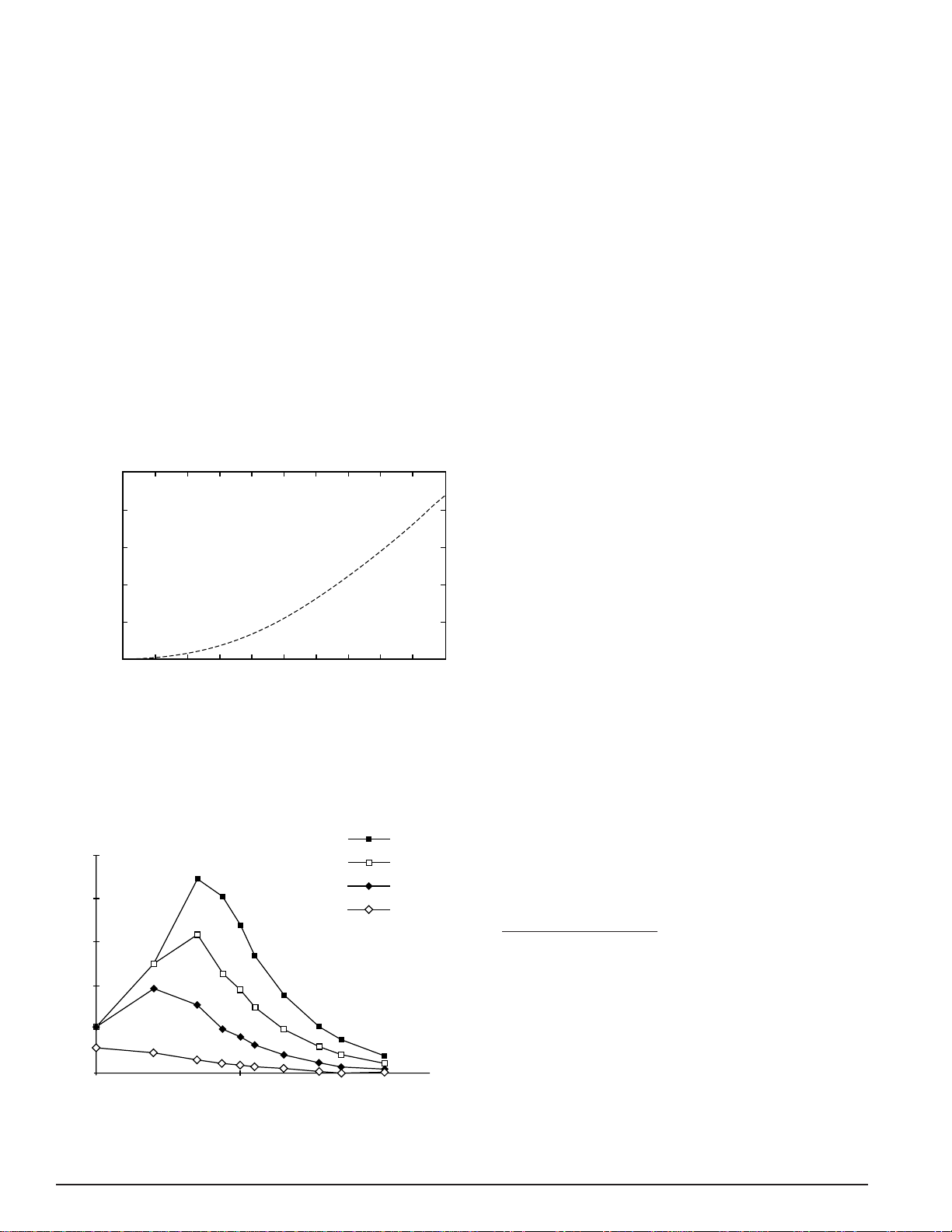

Figure 1-4 Coagulation Power Through 75 Ohm Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Figure 1-5 Coagulation Power vs. Load Impedance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Figure 1-6 Front Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Figure 1-7 Cassette Housing and Connector Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Figure 1-8 Series 20000™* Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Figure 1-9 Remote Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Figure 1-10 Remote Control Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Figure 1-11 Modes and Submodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Figure 1-12 Irrigation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Figure 1-13 Footswitch Functions - Hydrosonics™*. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Figure 1-14 AdvanTec Visco Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Figure 1-15 Footswitch Functions - AdvanTec . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Figure 1-16 Footswitch Functions - U/S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Figure 1-17 Footswitch Functions - I/A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Figure 1-18 Footswitch Functions - Vitrectomy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Figure 1-19 Footswitch Functions - Coag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Figure 1-20 Priming is in Progress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Figure 1-21 Custom: Program (V3.01 and below) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Figure 1-22 Special I/V Pole Setup (V3.01 and below) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Figure 1-23 Special Functions: Aspiration (V3.01 and below) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Figure 1-24 Custom: Sound (V3.01 and below). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

Figure 1-25 Custom: Footswitch (V3.01 and below) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

Figure 1-26 Custom Mode (V3.12 and above) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

Figure 1-27 Custom: Program (V3.12 and above) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

Figure 1-28 Metrics Screen (V3.12 and above) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

Figure 1-29 Special IV Pole Setup (V3.12 and above). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

Figure 1-30 Special Functions: Aspiration (V3.12 and above) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

Figure 1-31 Special Functions: Occlusion (V3.12 and above) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

Figure 1-32 Custom: Sound (V3.12 and above) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

vi 906-2000-501

Page 7

SERIES 20000

™*

LEGACY

®

LIST OF ILLUSTRATIONS

TITLE PAGE #

Figure 1-33 Custom: Footswitch (V3.12 and above) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

Figure 1-34 Custom: Footswitch:Procedure (V3.12 and above) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

Figure 1-35 Accurus

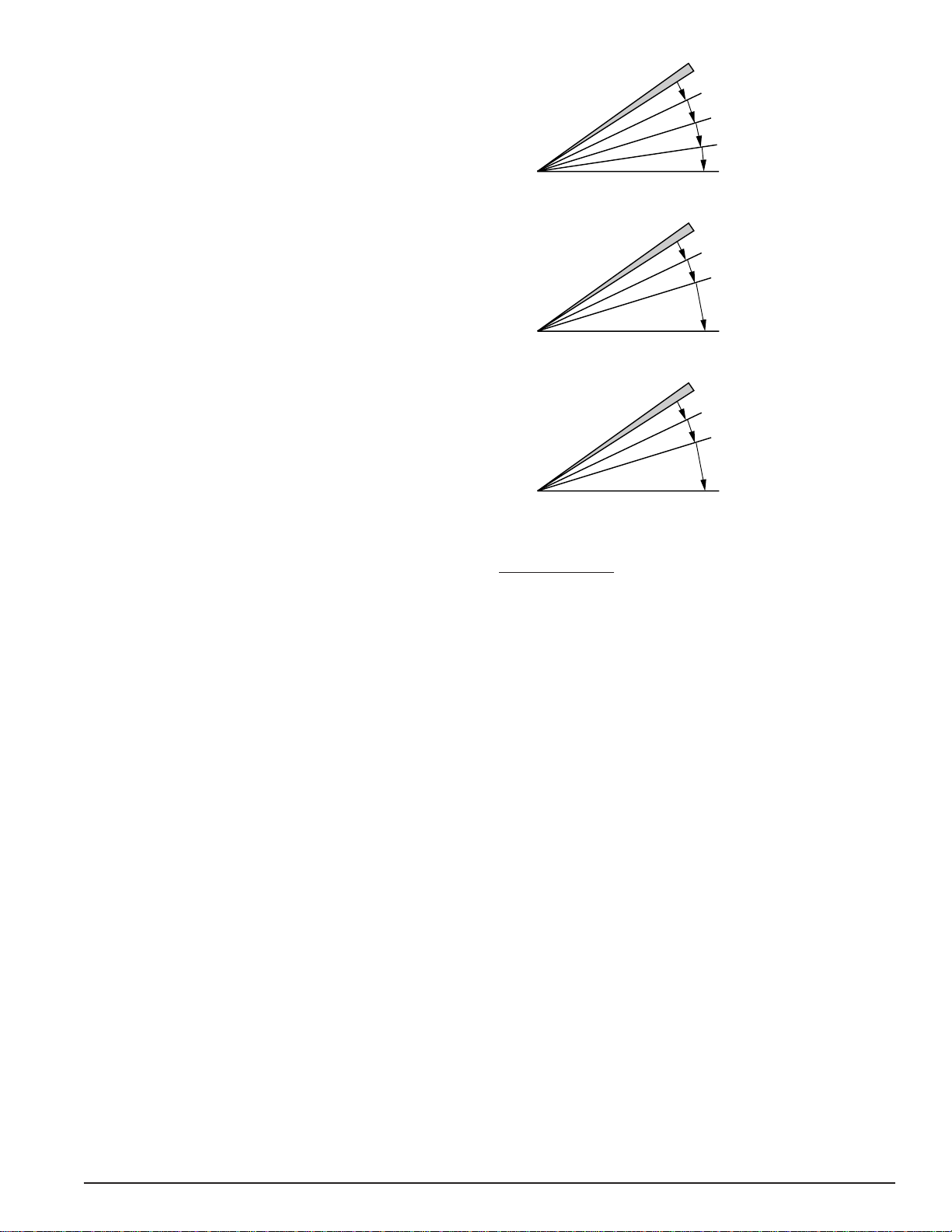

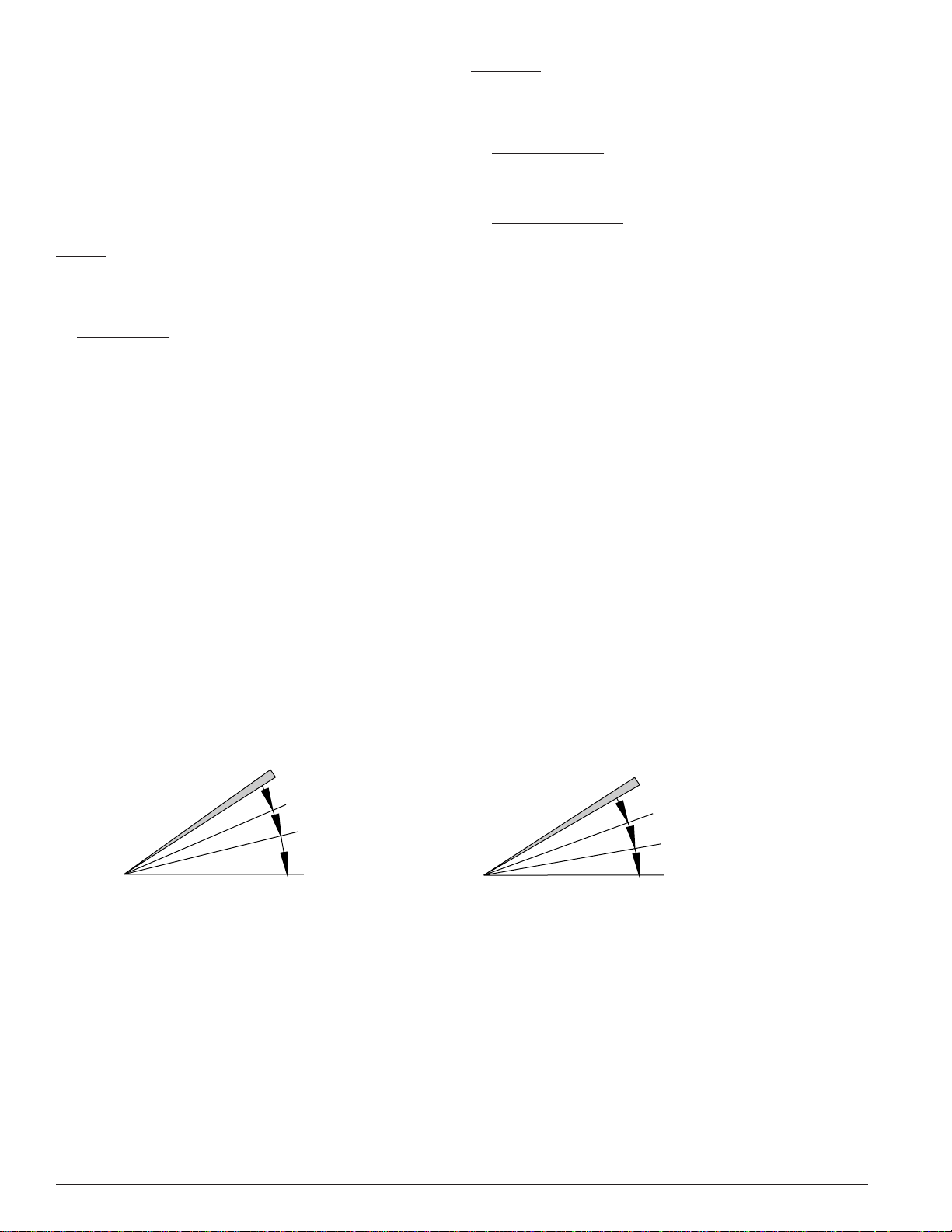

Figure 1-36 Footpedal Travel By Mode of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-41

Figure 1-37 Irrigation Handpiece and Tips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-44

Figure 1-38 Ultraflow™* Handpiece and .3mm Tips (Handpiece Shown with Straight Tip). . . . . . . 1-44

Figure 1-39 Ultraflow™* O-Ring Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-44

Figure 1-40 Ultraflow™* SP Handpiece (Handpiece Shown with .3 mm 45˚ Tip). . . . . . . . . . . . . . . 1-44

Figure 1-41 Reusable I/A Tips And Threaded Tip Adaptor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-45

Figure 1-42 Ultrasonic Handpiece (375-40) with Infusion Sleeve and Bubble Suppression Insert. . . 1-45

Figure 1-43 Hydrosonics™* Handpiece . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-46

Figure 1-44 NeoSonix™* Handpiece. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-46

Figure 1-45 ATIOP Handpiece. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-47

Figure 1-46 4 Inch Nadler Coaptation, 0.4 mm Tip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-47

Figure 1-47 Disposable Bipolar Brush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-47

Figure 1-48 Coagulation Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-47

Figure 1-49 Steerable I/A Handpiece . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-48

Figure 1-50 Steerable I/A Tip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-48

Figure 1-54 Handpiece Tip Styles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-49

®

/Legacy® Footswitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-40

Figure 2-1 Subsystem Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Figure 2-2 System Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Figure 2-3 CPU-Subsystem Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-4 Subsystem Kernal Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Figure 2-5 Host Subsystem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Figure 2-6 Fluidics Flow Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Figure 2-7 Stepper Motor Control Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Figure 2-8 Vit Air Flow Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Figure 2-9 Steerable I/A Control Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

Figure FO-1 Multifunction PCB Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Figure FO-2 Footswitch Interface Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

Figure FO-3 IV Pole Interface Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

Figure FO-4 Video PCB Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

Figure FO-5 Front Panel Subsystem Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

Figure FO-6 Fluidics Subsystem Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

Figure FO-7 Phaco Subsytem Block Diagram (V3.01 and below) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

Figure FO-8 Phaco Subsytem Block Diagram (V3.12 and above) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

Figure 3-1 STTL Skins Location Diagram (Front View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Figure 3-2 STTL Skins Location Diagram (Rear View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Figure 3-3 Exploded View of the STTL Front Panel Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Figure 3-4 Removal of Backlights from LCD PN 088-032 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Figure 3-5 Location of LCD Backlights on LCD PN 200-1836-001 . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Figure 3-6 Location of LCD Backlights on LCD PN 200-1721-001 . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Figure 3-7 Connector Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Figure 3-8 Series 20000™* Footswitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Figure 3-9 STTL Parts Location (Front View). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Figure 3-10 STTL Parts Location (Rear View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Figure 3-11 STTL PCB Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

906-2000-501 vii

Page 8

SERIES 20000

™*

LIST OF ILLUSTRATIONS

TITLE PAGE #

Figure 4-1 24 mm Custom Wrench Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Figure 4-2 Lithium Battery on CPU PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Figure 4-3 Disk Insertion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Figure 7-1Rear Panel - Videoverlay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Figure 7-2RCA to SVHS Adaptor Cables Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Figure 7-3Standard Interconnect (Using RCA To SVHS Adaptor Cables). . . . . . . . . . . . . . . . . . . . 7-3

Figure 7-4Super VHS High-Resolution Setup (Using Customer-Supplied SVHS Video Cables). . . 7-5

Figure 7-5VideOverlay Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

LIST OF TABLES

TITLE PAGE #

Table 1-1 Series 20000™* Legacy® Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Table 1-2 Audible Tones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Table 1-3 Footpedal Travel in Enhanced Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

Table 1-4 Various Memory Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

Table 1-5 Acceptable Pre-Occlusion/Occlusion Combinations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

Table 1-6 Footpedal Travel in Enhanced Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

Table 1-7 Operation by Mode and Footpedal Position for Software Versions 3.01 and Below . . . . 1-42

Table 1-8 Operation by Mode and Footpedal Position for Software Versions 3.12 and Above. . . . 1-43

LEGACY

®

Table 2-1 U/S Driver PCB Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Table 2-2 U/S Enable Logic (Low=0, High=1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Table 2-3 NeoSonix™* Controller PCB Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

Table 2-4 U/S Enabling Logic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

Table 3-1 Skins Removal Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Table 4-1 Recommended Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Table 4-2 Recommended Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Table 4-3 Recommended Spares . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Table 4-4 System Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

®

Table 4-5 Legacy

System Fault Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Table 4-6 Legacy® System Warning Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Table 4-7 Legacy® System Advisory Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Table 4-8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Table 4-9 Power On Self-Test (Post) Error Codes for CPU PCB's PN 200-1592-001 and

200-1845-001 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Table 4-10 Power On Self-Test (Post) Error Codes for CPU PCB PN 200-2290-001 . . . . . . . . . . . . 4-26

Table 7-1 VideOverlay Display Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

viii 906-2000-501

Page 9

SERIES 20000

™*

LEGACY

®

SECTION ONE

GENERAL INFORMATION

Alcon Surgical’s SERIES 20000™* LEGACY

®

(STTL) is a sophisticated ophthalmic surgical instrument

manufactured to be durable, reliable, safe and easy to

operate. This state-of-the-art instrument has been

developed to be user friendly; it combines hardware that

is easy to install and maintain along with computer

software that increases the effectivity of the user.

ABOUT THIS MANUAL...

This manual covers all configurations of the Legacy

®

and is divided into eight sections as follows:

Section One-General Information

This section gives a general description of the STTL

features and components. Also included is an unpacking

and installation procedure.

Section Two-Theory of Operation

This section gives a detailed description of how the

STTL operates starting at the system level and working

down to the PCB (Printed Circuit Board) level. Detailed

block diagrams are provided at the end of this section.

Section Three-Parts Location and Disassembly

This section contains parts location diagrams along with

field level disassembly procedures.

Section Four-Maintenance & Troubleshooting

This section contains system maintenace procedures and

troubleshooting information.

Figure 1-1 The Series 20000™* Legacy

Section Five-Schematics

This section contains the system interconnect diagram,

PCB assembly drawings, and schematic diagrams.

Section Six-Parts Lists and Drawings

This section contains parts lists, engineering

documentation for each major assembly, and cable

drawings.

Section Seven-Additional Information

This section contains information on accessories or

optional equipment that may require service.

®

906-2000-501 1-1

Page 10

SERIES 20000

™*

LEGACY

®

REFERENCE DOCUMENTS

Although this manual provides the necessary information

for maintaining optimum performance of the STTL, it

does not contain all of the operating procedures or

functional descriptions contained in the Operator's

Manual. In addition, the Warnings and Cautions in the

Operator's Manual also apply for this Service Manual.

The Operator's Manual supplements information

provided in this manual and should be available on-site

with the system.

If you have any questions or require additional

information, please contact your local Service

Representative or the Technical Services Department at:

ALCON SURGICAL

15800 Alton Parkway

Irvine, CA 92618

(949) 753-1393

(800) 832-7827

If you are located outside the United States, please

contact your local authorized Alcon Surgical distributor.

CAUTION

Federal Law restricts this device to sale by or on the

order of a physician.

RECEIVING INSPECTION

The system was inspected mechanically and electrically

prior to shipment. If the shipping container appears

damaged, ask that the carrier’s agent be present when the

system is unpacked. The system should be inspected for

external damage (i.e. scratches, dents, or broken parts).

If damage is discovered or if the system fails any of the

functional tests notify the carrier and an Alcon Surgical

representative. Retain the shipping container and

packing material for the carrier’s inspection. As

necessary, file a claim with the carrier or, if insured

separately, with the insurance company.

UNPACKING AND SETTING UP THE SYSTEM

1 Cut and remove the binding straps.

2 Remove the outer sleeve and rails from the shipping

carton (see Figure 1-2 for packing configuration).

3 Remove the accessory box, foam inserts, and

footswitch. Inspect for signs of damage.

4 Carefully tip the shipping carton so as to place the

system in an upright position .

END USER LICENSE AGREEMENT:

This product contains software licensed from Microsoft

Corporation.

5 Roll the system out of the container, remove the

antistatic cover, and inspect the system for signs of

shipping damage.

6 Unwrap the footswitch and plug it into the

appropriate connector on the rear panel.

7 Release the tray arm and pull it out of the storage

position. Remove the instrument tray and remote

control from the accessory box. Open the remote

control back cover and install the batteries.

8 Snap the instrument tray into position on the tray

arm. Place the remote control in the recessed area of

the instrument tray.

9 Release the 115 VAC power cord from the Rear

Panel and plug into a functioning 115 VAC

receptacle but do not turn on the AC Power Switch

or the Stand-by Switch until instructed to do so.

10 Perform the STTL Service Test Procedure.

1-2 906-2000-501

Page 11

SERIES 20000

™*

LEGACY

®

Figure 1-2 STTL Packing Configuration

906-2000-501 1-3

Page 12

SERIES 20000

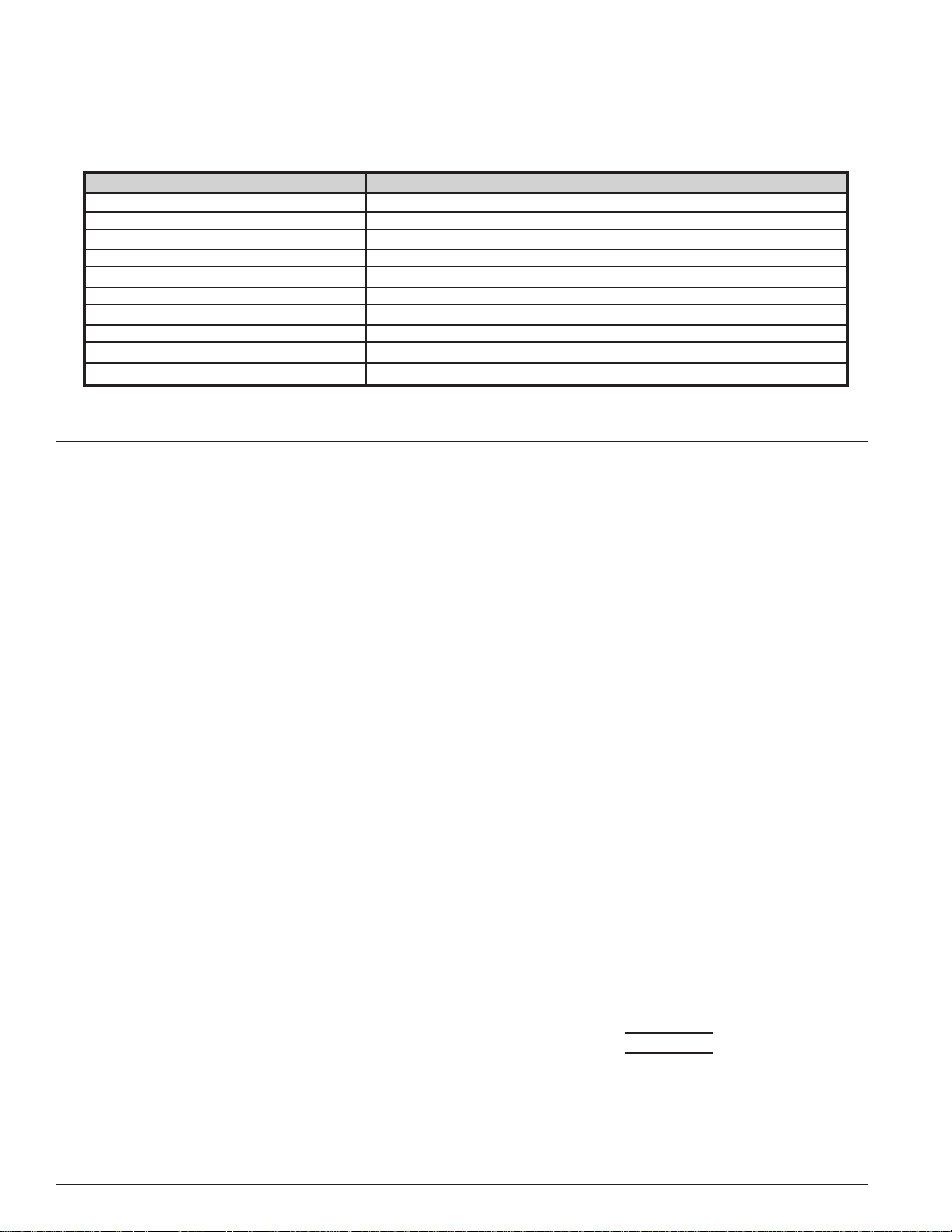

TABLE 1-1. SERIES 20000™* LEGACY® PERFORMANCE SPECIFICATIONS

™*

LEGACY

®

ELECTRICAL

The system will auto-select between the following

voltage:

100 Vac nominal ( 88-110 Vac), 47-63 Hz, single ø

120 Vac nominal (102-132 Vac), 47-63 Hz, single ø

220 Vac nominal (176-242 Vac), 47-63 Hz, single ø

240 Vac nominal (204-270 Vac), 47-63 Hz, single ø

Maximum power ........................................ ≤ 523 Watts

LEAKAGE CURRENT

< 100 µA @120 VAC, per NFPA99

< 500 µA @264 VAC, per IEC-60601-1,

Edition 2 (includes power cord)

(includes power cord)

VOLTAGE NO-LOAD

+5V ............................................................. +5.10 ± .05

+12V ......................................................... +12.00 ± .12

+15V ......................................................... +15.00 ± .15

-15V ........................................................... -15.00 ± .15

+24V ......................................................... +24.00 ± .24

+85V ......................................................... +85.00 ± .85

VOLTAGE UNDER LOAD

+5V ............................................................. +5.10 ± .10

+12V ......................................................... +12.00 ± .20

+15V ......................................................... +15.00 ± .15

-15V ........................................................... -15.00 ± .20

+24V ......................................................... +24.00 ± .24

+85V ......................................................... +85.00 ± .85

IV POLE

Bottle height at retraction ............................. .2 cm ± 1

Bottle height when fully raised (without IV

pole extension) ............................................ 78 cm ± 1

Bottle height at power-up (default) .............. 65 cm ± 1

IV Pole Speed........................................ 10 ± 2 cm/sec

VACUUM ACCURACY

ACTUAL VACUUM DISPLAYED VACUUM

0 mmHg.................................................... 0 ± 2 mmHg

50 mmHg ............................................. 50 ± 2.5 mmHg

200 mmHg.......................................... 200 ± 10 mmHg

400 mmHg.......................................... 400 ± 20 mmHg

500 mmHg.......................................... 500 ± 25 mmHg

VACUUM OCCLUSION

VACUUM SETTING OCCLUSION RANGE

5 mmHg @ 5 cc/min................................. 0-10 mmHg

22 mmHg @ 25 cc/min............................. 7-27 mmHg

48 mmHg @ 25 cc/min........................... 43-53 mmHg

66 mmHg @ 25 cc/min........................... 61-71 mmHg

102 mmHg @ 25 cc/min....................... 92-112 mmHg

400 mmHg @ 25 cc/min..................... 385-415 mmHg

RESIDUAL VACUUM

With irrigation line occluded at the white HP connection

and waiting 3 seconds after the footswitch is released.

VACUUM METER READING

46 mmHg .......................................... 5 mmHg vacuum

400 mmHg...................................... 15 mmHg vacuum

DIMENSIONS

Height .............................................55 inches (138 cm)

Width ................................................20 inches (51 cm)

Depth................................................23 inches (57 cm)

WEIGHT

Unpacked ...................................... 200 pounds (90 kg)

Packed......................................... 275 pounds (125 kg)

ENVIRONMENTAL LIMITATIONS

Altitude

Operating............................8,000 feet (2438 meters)

Non-Operating............... 40,000 feet (12,191 meters)

Temperature

Operating...................... 10°C to 35°C (50°F to 95°F)

Non-Operating.......... -40°C to 75°C (-40°F to 167°F)

Humidity

Operating...................10% to 95% w/o condensation

Non-Operating........... 10% to 95% w/o condensation

ANTERIOR VIT PUMP

Pressure @ 10 CPM ...................... ≥30 psi (pressure)

Vacuum @ 10 CPM.................. ≥450 mmHg (vacuum)

Cut Rate .............................................. 10 to 400 CPM

ULTRASONIC HANDPIECE STROKE

U/S 375-40 ......................... 3.0 to 4.0 mils (maximum)

Hydrosonic.............................................. 1.0 to 1.6mils

NeoSonix™* .............................................. ± 2 degrees

COAGULATION

Frequency............................................... 300-400 KHz

Power @ 100% power using a

75 ohm non-inductive load ...................... 20 ± .5 watts

VIDEO

• 640 x 480 pixel VGA

• 256 Color Active Matrix LCD Screen

1-4 906-2000-501

Page 13

SERIES 20000

™*

LEGACY

®

Coagulation

(Coag)

Custom

Hydrosonics

(Hydro) (V3.01 and below)

Advantec (V3.12 and above)

B

BF

Type B equipment, providing a particular

degree of protection, i.e., basic insulation.

(Phaco/Fragmentation) Protection class I.

Type BF equipment, providing both the

attributes of basic insulation and "floated"

isolation. (Bipolar Coagulation)

Dangerous Voltage

CAUTION: Consult accompanying documents.

!

Equipotential ground connection.

Irrigation/Aspiration

(I/A)

Alternating current.

Stand-by state for a part of equipment.

ON (POWER)

OFF (POWER)

Footswitch.

Irrigation

(Irr)

Ultrasonic

(U/S)

Vitrectomy

(Vit)

Figure 1-3 ICONS USED WITH THE STTL - Icons identifying modes, functions, etc., that are used with the

STTL are identified in this chart.

906-2000-501 1-5

Page 14

SERIES 20000

™*

LEGACY

®

CAUTERY, DIATHERMY, COAGULATION

In the past, some of Alcon Surgical’s products have

referred to the feature “Cautery.” The STTL uses the

word “Coagulation” in place of Cautery, based on the

following definitions:

• Cautery - cutting and burning method associated with

two hot wires passing a current between them; cutting

away skin; halting bleeding.

• Diathermy - introducing an electric field into a body

part to produce heat.

• Coagulation - an isolated bipolar current supplied to

conductors (e.g. forceps). Current passes between

these electrodes, halting bleeding. (Abbreviated

“Coag” in some of the text of this operator’s manual.)

25

20

ELECTRONIC SYSTEM

The STTL is a multi microprocessor-controlled system

with associated memory and input/output (I/O) circuitry.

The system communicates via the Front Panel. An

automatic self-test is initiated each time the system is

turned on. This test performs a variety of checks

including the following:

• Tests the Central Processing Unit (CPU)

• Tests the RAM and ROM memory, and the I/O

circuits

• Initializes the system

• Defaults to:

IRR: Footswitch mode (V3.01 and below)

Advantec: Visco mode (V3.12 and above)

When the system successfully completes the self-test, it

automatically goes into the default mode. If the system

fails the self-test, an error message is displayed. Voice

confirmation verifies all mode selections.

15

POWER

THROUGH

75 OHM

LOAD

(WATTS)

10

05

00

00 10 20 30 40 50 60 70 80 90 100

% DISPLAYED VOLTAGE

Figure 1-4 COAGULATION POWER THROUGH 75

OHM LOAD

NOTE: Unloaded output voltage is roughly 145V

peak to peak.

100% VOLTAGE

25

20

15

10

POWER (WATTS)

5

75% VOLTAGE

50% VOLTAGE

25% VOLTAGE

SYSTEM DESIGN

Front Panel

The front control panel (see Figure 2-1) has a flat,

non-glare surface located on the front of the main

chassis. It contains a graphics display, a touch screen, up

and down arrows, mode buttons, bottle height, U/S time

displays, and a Test button.

The buttons are located both on the sides and on the

bottom of the screen. There are two basic push-type

buttons on the front panel: (1) Those that control up and

down arrows: press and hold until the adjustment is

complete and (2) Those that are momentary buttons: a

single push-and-release activates the function. The

momentary buttons and the up/down arrows emit an

audible signal to indicate key activation.

1.

Standby Power Switch - This is a two-position,

rocker-type switch used to turn secondary power

(part of equipment) ON and OFF. It is located to the

right of the speaker on the front of the machine. This

switch is used to turn the system ON/OFF

between surgeries.

0

10 100 1000

LOAD (LOG OHMS)

Figure 1-5 COAGULATION POWER VS. LOAD

IMPEDANCE

1-6 906-2000-501

Page 15

SERIES 20000

™*

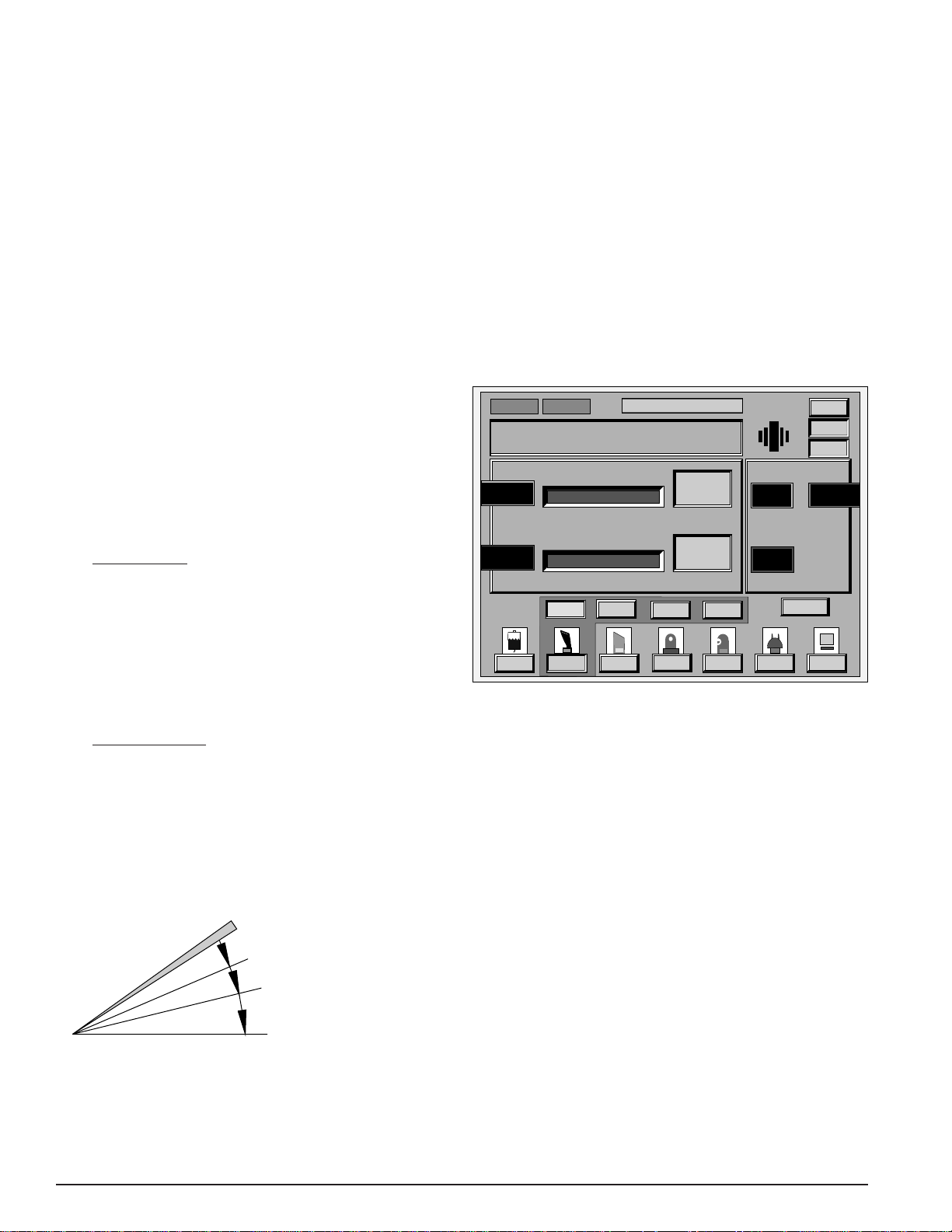

9. GRAPHICS DISPLAY

AND TOUCH SCREEN

8. REMOTE CONTROL SENSOR

7. BOTTLE HEIGHT DISPLAY

AND ADJUSTMENT ARROWS

3. PARAMETER

ADJUSTMENT ARROWS

6. U/S TIME DISPLAY

AND RESET BUTTON

LEGACY

®

Not Tuned

U/S Power

Vac Level

Phaco

AdvanTec

DR. ALCON

StdCas

mmHg

Pulse

U/S

%

BiModal

3

A.P. 0%P.E. L.

375-40 kHz

0

Actual

0

Actual

Burst

Vit

I/A

Panel

0

Surgeon

Asp Rate

20

cc/min

Max Limit

Pulse Rate

pps

15

Max Limit

Memory

Coag

Custom

3. PARAMETER

ADJUSTMENT ARROWS

Not Primed

Vent Rmt Bat LoReflux Occlusion

U/S: Pulse

65

Max Limit

66

Max Limit

Irr

5. TEST BUTTON

Priming/Tuning/Charging

Status

Status Window

Actual Display Bar

and Actual Value

Primary

Parameter #1

Primary

Parameter #2

Cassette Status

and Cassette Type

Not Primed

Vent Rmt Bat LoReflux Occlusion

Not Tuned

U/S: Pulse

U/S Power

65

Max Limit

Vac Level

66

Max Limit

StdCas

Doctor Name

and Memory Selected

DR. ALCON

375-40 kHz

%

Actual

mmHg

Actual

0

0

2. PRIMARY MODE

SELECTION BUTTONS

1. STANDBY POWER SWITCH

4. SPEAKER

Handpiece ID

and Handpiece Icon

Footswitch Status

3

A.P. 0%P.E.L.

0

cc/min

pps

Panel

Surgeon

Asp Rate

20

Max Limit

Pulse Rate

15

Max Limit

Control Keys

Secondary

Parameter #1

Secondary

Parameter #2

Submode Keys

Phaco

Pulse

BiModal

Burst

Memory

Memory Key

Touch Keys/Icons

Mode Keys

AdvanTec

Irr

U/S

I/A

Vit

Coag

Custom

Figure 1-6 FRONT CONTROL PANEL (Display for software versions 3.12 and above shown)

906-2000-501 1-7

Page 16

SERIES 20000

™*

LEGACY

®

2. Primary Mode Selection Buttons - These seven

push-buttons allow selection of operating modes.

They are single-condition (press to turn on) and also

allow the operator to scroll through the sub modes.

(Access to modes is also available by pressing the

associated symbol on the touch screen, or on the

remote control, or by activating the heel switch on

the footswitch if programmed.)

• IRR - Used to select one of three Irrigation

submodes (footswitch, free flow, and continuous

irrigation). Irrigation: Footswitch is the default

submode.

• HYDRO (V3.01 and below) - Used to activate

the HydroSonics™* mode which allows the

surgeon to use the Auto HydroSonics™*

handpiece.

• AdvanTec (V3.12 and above) – Used to activate

the NeoSonix™* or 375/40 handpiece to perform

a phacoemulsification procedure. There are four

submodes within the mode: Visco, Phaco, Pulse,

and Burst. Phaco is the default submode.

• U/S - Used to activate the 375/40 handpiece

while performing phacoemulsification

procedures. There are four submodes of the U/S

mode: Phaco, Pulse, BiModal, and Burst. US:

Phaco is the default submode.

• I/A - Used to activate the Irrigation/Aspiration

system. There are three submodes of the I/A

mode: Min, Max, and CapVac. I/A Max is the

default submode.

• VIT - Used to activate the Vitrectomy mode,

which operates the ATIOP handpiece. There are

two sub modes: ATIOP and I/A Cutter.

VIT: ATIOP is the default submode.

• COAG - Used to activate the Coagulation mode

which uses bipolar coagulation to drive the

Alcon brush and forceps.

• CUSTOM - Used to program the following

operational settings: program, sound, voice,

language, footswitch and remote.

Parameter Adjustment Arrows - Used to adjust

3.

primary and secondary parameters.

4.

Speaker - Emits audible tones from below the

movable display screen.

5.

Test Button - Used to access various functions such

as Priming, Tuning, Charging, Fill, and Clean. The

TEST key is not available when in the Custom and

Coag modes.

U/S Time Display and Reset Button - Records the

6.

cumulative amount of time U/S power is applied

during surgery. Time is given in minutes, to one

decimal place, to a maximum of 30 minutes. U/S

power elapsed time is retained until the Reset button

is pressed, a new U/S or NeoSonix™* handpiece is

plugged in, or until the system is turned off. The U/S

Time Reset Button resets U/S Time (displayed in the

U/S Time Display) and Average U/S Power

(displayed in the Status window) to zero.

Bottle Height Display and Adjustment Arrows -

7.

Display the height of the irrigation bottle in the

display window; bottle height is measured from the

drip chamber to the level of the patient's eye.

Below the display are up and down arrows which

raise and lower the irrigation bottle, allowing

irrigation pressure to be adjusted. Adjustments can

also be made from the left and right dual pivot

switches on the footswitch, as well as from the

remote control. The irrigation pole is positioned at

65 cm±1 at power up.

NOTE: Bottle height is measured from the center

of drip chamber to the patient's eye level. The

patient's eye level is normally set to be even with

the center of the cassette mechanism. In those

cases where the patient's eye level is required to

be different from that of the cassette mechanism,

a patient eye level adjustment must be registered

in the Custom mode.

Remote Control Sensor - Receives remote control

8.

inputs. It is located at the top left of the unit above

the bottle height display; no operator interface is

required.

9.

Graphics Display and Touch Screen - This display

screen serves as the operator's control center. The

system operating status is displayed here, and its

touch screen is used to input operator commands (see

Figure 2-2).

Mode Keys, Touch Keys/Icons, Submode Keys Displays the active mode and submode (if

applicable). When activated, continuous irrigation

flashes above the Irr key/icon. To select mode/

submode, press the desired icon.

Primary Parameters - Displays up to two primary

parameters for a selected mode (along with the

graphical representation of the data), including

maximum limits. When primary parameters are not

displayed this area is used for user prompts, user

1-8 906-2000-501

Page 17

SERIES 20000

™*

LEGACY

®

display, and user data input. Maximum limits can be

adjusted for each parameter by using the up/down

arrows.

Secondary Parameters - Displays up to four

additional parameters for a selected mode, along with

the maximum limit value. Maximum limits can be

adjusted for each parameter by using the up/down

arrows.

Actual Display Bar and Actual Value - Linear values

in selected modes, controlled with the footpedal, are

represented here with a sliding bar display and

numeric readout.

Status Window - Alerts the operator to the system's

normal operating status:

• Modes and Submodes (if applicable) - Blue

background/white text displayed during normal

operation unless other information needs to be

presented.

• General Messages - Text may be displayed to

signify that a normal operation, or step in a

sequence, is being carried out. For example, the

routine steps in the priming/tuning sequence

(e.g., “Vacuum Check”).

• Faults - Displayed on a red background to signify

the most critical of conditions. The system shuts

down and remains inoperable until the fault is

corrected.

• Errors - These are displayed on a yellow

background to signify a condition which must be

given attention, such as “Vacuum Reading Error”

or other hardware failures. Errors must be

acknowledged by the user by pressing a Continue

key. Operation of the machine may continue in

the presence of and/or after the acknowledgment

of specific error conditions.

• Advisories - These are displayed on a green

background to signify a specific condition which

requires operator intervention, such as “Please

insert cassette.”

• Handpiece Identification - These are displayed to

signify the type of U/S handpiece installed, such

as a "375-40."

®

• Kelman

Steerable I/A Identification - This will

display Steerable I/A if the Steerable I/A system

is installed and selected.

Each word illuminates in the text window in a

specific color:

• Vent - Appears in fuchsia when the venting

system opens and the footpedal goes from

position 2 to position 1.

• Reflux - Appears in red when the footswitch

reflux function is operational.

• Occlusion - Appears in black when the aspiration

line becomes occluded, the system has reached

the preset vacuum limit, and the pump stops.

• Cassette Type - Indicates active cassette ("Std

®

Cas, Max Vac

, Attache") in white on black, as

long as a valid cassette is inserted.

• Bottle Height Offset – Numerical value in

centimeters which takes into account the offset

due to presence of I.V. pole extender and patient

eye level located above or below tray level.

• Rmt Bat Lo - Appears in white on black when

remote control battery is low.

• A.P. % - Average U/S Power is calculated from

the average U/S power that was applied over

time, based on instantaneous power levels. The

average power accounts for varying levels of

stroke as well as the off time between the power

pulses for the Visco, Pulse, and Burst submodes.

Average U/S Power is reset simultaneously with

the U/S Time display.

Priming/Tuning/Charging - “Not Primed” is backlit

in red when the system turns on. Upon successful

completion of priming, “Primed” is backlit in green.

“Not Tuned” is backlit in red when the system is

turned on. Upon successful completion of tuning,

“Tuned” is backlit in green (in AdvanTec and U/S

modes). If the Steerable I/A option is installed and

selected, "Not Charged" is backlit in red when the

system is turned on. Upon successful charging of the

Steerable I/A system, "Charged" is backlit in green.

Cassette Status and Cassette Type - Icon appears

when cassette insertion is not detected. Upon

insertion icon disappears and cassette type is

displayed in the Status Window.

Doctor Name and Memory Selected - Current

doctor’s memory & memory number selected.

Selection made by pressing the Memory Key.

Handpiece ID and Handpiece Icon - The handpiece

ID is displayed in the Status Window to identify the

type of U/S handpiece installed. Its icon appears

when a handpiece is not connected, not connected

properly, or there is a handpiece identification error

(in AdvanTec and U/S modes).

Footswitch Indicator - Displays the footpedal

position (backlit numbers from zero to three) in

different colors; also indicates when the reflux and

other footswitch functions are activated.

906-2000-501 1-9

Page 18

SERIES 20000

™*

LEGACY

®

Control Keys - Indicates the type of control of

Aspiration Flow Rate, Vacuum Limits, U/S Burst

Width and Off Time, and U/S Power Level. The

surgeon can toggle between linear control of

parameters via the footswitch (Surgeon, SrgAsp,

SrgVac, Linear or Fixed) and the presets of the front

panel (Panel).

Memory Key - Used to recall preprogrammed

settings. When the memory key (or heel switch of the

Accurus

®

/Legacy® footswitch, if installed and

programmed to do so) is pressed, a memory menu

temporarily appears over the secondary parameters

window. Four programmed memory selections, plus

a default setting selection, are available. The

currently selected doctor name and memory number

is displayed at the top of the screen.

Cassette Housing

The cassette housing is located on the upper left side of

the system (see Figure 1-7). Two factors contribute to

fast and easy installation of the cassette: the cassette

housing contains all the connections required for the

disposable fluidics Cassette Pak set, and the cassette was

designed with an auto-load feature.

Connector Panel

The Connector Panel is located to the right of the cassette

housing (see Figure 1-7). The following connections are

provided:

• Two self-locking “smart” electrical connections on

systems with software V3.01 and below. On V3.12

and above the lower connection is capped off. The

connector is active and can be used as a troubleshooting tool under service supervision. To gain

access to the connector pry the cap away using a

small screwdriver.

• One pneumatic male luer connector for the Steerable

I/A system (if installed).

• Two receptacles for bipolar coagulation handpieces

to accommodate dual safety banana-type connectors

(Coag)

• One female luer lock pneumatic connection for the

ATIOP (Vit) and the HydroSonics™* (V3.01 and

lower) handpieces.

Additionally, there is one unlabeled connector for future

expansion. Colors and symbols near the connectors

facilitate handpiece identification.

Rear Panel

The rear panel (see Figure 1-8) contains various

connectors and outlets used for interconnections and

power input. A floppy disk drive, located on the

connector panel, allows the system to be upgraded.

Power Supply Panel - located on the bottom right of

1.

the instrument.

• AC power input - connects to electrical outlet in

the wall.

• Main power switch - connects AC power to

power supply. This switch is used for overnight

storage of the system.

• Fuse box - holds two fuses. Refer to label on

back of system to identify size and type.

Rear Connector Panel - located near middle of the

2.

instrument.

• Floppy Disk Slot.

• Parallel - 25-pin D connector port.

• Serial 1 and 2 - 9-pin D connector ports.

• PH1 and 2.

Footswitch Connector - For connecting either the

3.

Series 20000™*, Accurus®/Legacy®, or ATFSLegacy® footswitch to the unit.

4.

Footswitch bracket - Used to hold the footswitch

when not in use. Located on the rear panel, to the left

of the cord wrap.

5.

Cord Wrap - Used to store both the footswitch cord

and the power supply cord. Located on the far right

HUB ROLLER

LATCHING

MECHANISM

CASSETTE

HOUSING

U/S

U/S

Str I/A

Coag

Coag

Vit

CONNECTOR

PANEL

STEERABLE I/A

CONNECTOR

IS OPTIONAL

of the rear panel, directly above the power supply.

Figure 1-7 CASSETTE HOUSING AND

CONNECTOR PANEL

1-10 906-2000-501

Page 19

SERIES 20000

™*

LEGACY

®

Other Features

6.

Tiltable, Rotatable Front Panel - Allows easy

maneuverability during setup and surgery.

Tray Assembly - Provides a movable instrument tray

7A.

within the sterile field. There is a curved metal rod on

the tray arm for a sterile bag pouch. The tray is

capable of accommodating a variety of positions in

the operating room environment: right, left, front and

rear of the surgeon as well as the front of the bed.

Autoclavable Instrument Tray - Fits over the tray

7B.

assembly. It is slotted in order to hold six handpieces

and the remote control.

Handles (2) - One handle is located on the front and

8.

another is located on the back of the unit. Handles

should always be used to move the unit. For greater

safety and control, the unit should be pulled, not

pushed.

AUTOCLAVABLE

INSTRUMENT TRAY

(7B)

9. Storage Drawer - Located on the right side of the

unit, it can be used to store handpieces and

accessories.

Locking Wheel Mechanism - Locks are located on

10.

the two front wheels only. The wheels should always

be locked when the unit is in use, and unlocked when

being moved.

IV Pole - The bottle of irrigating fluid is hung from

11.

the hook on top of this pole. Used to raise and lower

the bottle height.

Fan Filter - Located underneath unit, the fan filter

12.

removes particles from incoming air used for cooling

components.

Equipotential Ground Connector - For Service

13.

personnel use.

TILTABLE,

ROTATABLE

FRONT PANEL

(6)

I/V POLE

(11)

TRAY ASSEMBLY

(7A)

STORAGE DRAWER

(9)

FOOTSWITCH BRACKET

(4)

LOCKING WHEEL

MECHANISM

(10)

FAN FILTER

(12)

Figure 1-8 SERIES 20000™* REAR VIEW

EQUIPOTENTIAL GROUND

CONNECTOR

(13)

REAR HANDLE

(8)

REAR

CONNECTOR

PANEL

(2)

CORD WRAP

(5)

POWER SUPPLY

PANEL

(1)

FOOTSWITCH

CONNECTOR

(3)

906-2000-501 1-11

Page 20

Audible Tones

Ten different and clearly distinguishable audible

frequencies, in conjunction with multiple tones, are

produced by the STTL.

TONE TYPE

VACUUM TONE CONTINUOUS WHEN ASPIRATION ACTIVE

COAGULATION CONTINUOUS WHEN COAGULATION ACTIVE

REFLUX CONTINUOUS WHEN REFLUX ACTIVE

ASPIRATION OCCLUSION INTERMITTENT SINGLE BEEP WHEN OCCLUDE DURING ASPIRATION ONLY

U/S OCCLUSION INTERMITTENT DOUBLE BEEP WHEN OCCLUDE DURING U/S

FTSW. IRRIGATION TONE INTERMITTENT

FRONT PANEL SWITCH ACTIVATION INTERMITTENT

CONTINUOUS IRRIGATION ONE BEEP FOR ACTIVATION, TWO FOR DEACTIVATION

FAULT BELL CHIME

CASSETTE NOT DETECTED SHORT WHISTLE

Table 1-2 AUDIBLE TONES

SERIES 20000

™*

LEGACY

®

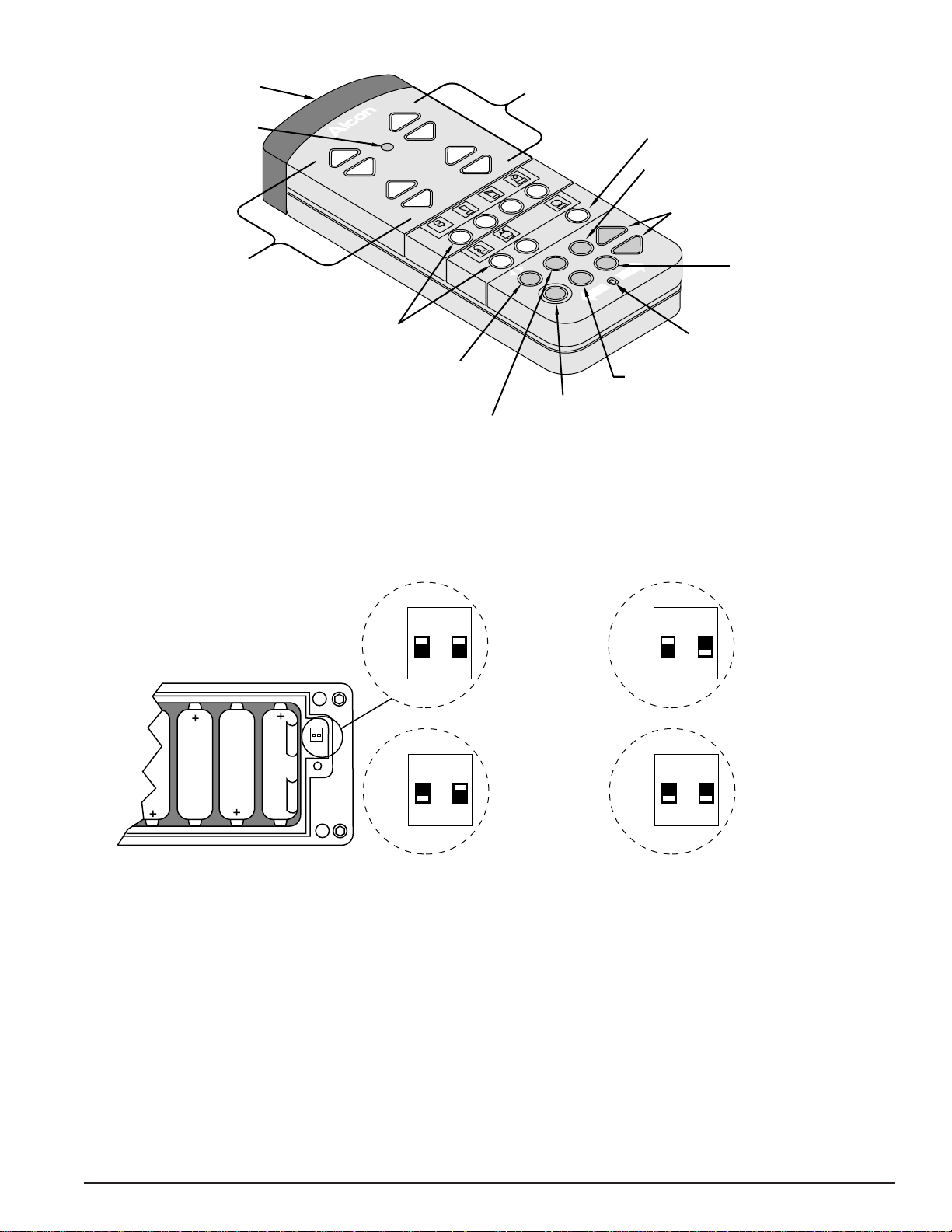

REMOTE CONTROL

The Series 20000™* remote control (see Figure 1-9) is

wireless and can, therefore, be used in one of three ways:

It can be laid into the articulated arm and tray assembly

and operated through the sterile drape supplied in the

disposable pak. This offers the Scrub Nurse or assistant

access to the controls from the sterile field. A sterile,

sealed pouch (available in the remote control aseptic

transfer packaging) can also be utilized to maintain the

sterile field if the remote is used in a hand-held manner.

The circulator could also operate the remote in a nonsterile manner. Programmability and custom user

setup features are functions which are not accessible

from the remote control.

The error message, “RMT BAT LO” is displayed in the

text window on the front panel when the remote batteries

are low. (The battery compartment on the back holds four

AA batteries; to replace batteries, loosen the captive

screw on the compartment door with a standard

screwdriver.)

The controls on the remote control have been arranged to

approximate the respective controls on the console’s front

panel. The Test button has a raised area around it; this

differentiates it from the other buttons in order to ensure

that the test function is not accidentally actuated. All

controls are backlit by heat actuation; i.e., illumination in

low ambient light is activated when the sensor detects

heat from the hand.

On systems with software V3.01 and below: There are

three inactive keys for future expansion: one marked

SCROLL, one marked ENTER, and one undesignated.

On systems with software V3.12 and above: The Forward

and Reverse buttons functionality can be customized

using the Custom Footswitch screen.

The remote control can be configured to operate on one

of four channels (A, B, C, or D). This feature allows four

remote controls to independently control four systems

operating in the same room or area. Remote controls are

factory preset to channel A. To change channels, access

the switch located in the battery compartment (see Figure

1-10). For proper remote operation, the system must be

set to the same channel as the remote. Once the correct

channel is selected on the system, no other steps are

needed to save it into memory.

To ensure proper operation when two or more remote

controls are being used in the same room or area, adjust

each system including remote control to separate

channels.

NOTE: Label the remote controls and the units, if

necessary.

CAUTION

Do not sterilize the remote control as it will damage

the unit.

1-12 906-2000-501

Page 21

SERIES 20000

™*

LEGACY

®

IR Transmitter

Photo Sensor

®

SURGICAL

Secondary Parameter Adjustment Keys

Custom (Program / Exit / Stop)

Memory

Bottle Height Adjustment Arrows

BO

TTLE HEIG

HT

Forward

Y

R

O

M

E

M

L

O

R

T

N

O

C

Primary Parameter Adjustment Keys

T

S

E

T

Primary Mode Keys

Toggle between secondary parameters

in AdvanTec Mode

Reverse

Heat Sensor

(hand proximity sensor)

Test

Control Mode

(Surgeon / Panel / SrgAsp / SrgVac)

Figure 1-9 REMOTE CONTROL (Remote Control for software versions 3.12 and above shown)

S1

O N

S1

1 2

S1

Figure 1-10 REMOTE CONTROL SWITCHES

O N

1

O N

1

2

2

Channel A

Channel B

S1

S1

O N

1

O N

1

Channel C

2

Channel D

2

906-2000-501 1-13

Page 22

SERIES 20000

™*

LEGACY

®

MODES AND FUNCTIONS

The STTL has seven basic operational modes or

functions, some with submodes (see Figure 1.11). Each

allows for the appropriate adjustment of the power,

aspiration, and vacuum settings. These settings can be put

into one of 96 (V3.01 and below) or 384 (V3.12 and

above) memory programs and, consequently, be available

for future use without having to re-program the

instrument.

The operating modes are selectable from the unit’s front

panel controls or from the remote control unit. The

functions within an operating mode are controlled by the

operating position of the footpedal. Mode changes will

result in voice confirmation. (The user has the ability to

turn this feature off via the Custom menus.) An audible

beeper-tone is generated to indicate a change in the

operating mode and to alert the operator of certain

conditions such as an occluded line. Additionally, a

varied pitch tone is generated to audibly indicate vacuum

levels; the pitch increases as the vacuum level increases.

The volume of the audible variable-pitch tone is

adjustable via the Custom menus.

the front panel settings are controlling the system the

word Panel is illuminated; if the footswitch is controlling

the system the word Surgeon, Srg Asp, or Srg Vac is

illuminated.

Coagulation during test states, except for tuning, is

available in Panel control modality.

When a mode button is pressed, the symbol becomes

animated and the selected sub mode is highlighted. The

titles of the selected mode and submode are displayed in

the text window.

The following sections provide an overview of each

mode and, where applicable, the differences between

operating in the various control modes.

Irrigation (Irr) Mode

Irrigation operates on a gravity-feed principle from the

IV bottle, through the cassette irrigation valve to

handpiece. The irrigation valve is normally closed when

cassette is inserted. Bottle height is measured from the

patient's eye to mid-drip chamber.

The operating mode/function is displayed in the mode

display window. The primary modes of operation are

Irrigation (IRR), Advantec (V3.12 and above)

HydroSonics™* (V3.01 and below), Ultrasonics (U/S),

Irrigation/Aspiration (I/A), Vitrectomy (Vit), and

Coagulation (Coag). Preset (default) operating

parameters for the selected mode are programmed into

the system, or new operating parameters can be set by

using the front panel or remote.

Depending on the operating mode, the system can be set

up to automatically operate at the preset limits displayed

on the front panel displays, or to provide linear control of

one of the operating parameters from the footswitch. The

controlling factor is determined by the control mode

switches (Panel/Surgeon/Srg Asp/Srg Vac). In general, if

Legacy

Modes and Submodes

Irr CustomCoagVit

Irrigation

• FootSw

• FreeFlow

• Cont Irr

Figure 1-11 MODES AND SUBMODES

(V3.12 and above)

Ultrasonic and

NeoSoniX®

• Visco

• Phaco

• Pulse

• Burst

Hydro

(V3.01 and above)

Ultrasonic

• Phaco

• Pulse

• BiModal

• Burst

Irrigation and

Aspiration

• Min

• Max

• Cap Vac

Irrigation pressure is increased or decreased by raising or

lowering the irrigation bottle. Default height is 65 cm

above the tray; maximum bottle height of 78 cm (above

the tray) of BSS

®

results in maximum irrigation pressure.

When an IV Pole Extension is installed, the maximum

bottle height is 110 cm above the tray. In the event of

power loss, bottle position is maintained; however, if the

unit is turned off using the Standby switch, the IV Pole is

automatically retracted to its storage position.

The Irrigation mode is automatically entered when the

system is initially turned on, when self-test has been

successfully completed, or when the IRR mode button is

pressed (if the machine has been operating in another

mode). At any time the Irrigation mode is re-entered the

system will default to Irrigation: Footswitch.

I/AU/SAdvanTec

Vitrectomy

• I/A Cut

• ATIOP

Coagulation See Custom

mode later in

this section of

the manual.

1-14 906-2000-501

Page 23

SERIES 20000

™*

LEGACY

®

In the Irrigation mode, Panel and Surgeon functions are

not available; therefore, they are not illuminated.

Irrigation mode has three sub modes:

• Irrigation: Footswitch - entered when system is turned

on (default) or by pressing the IRR mode button when

operating in another mode. The mode display window

reads Irrigation: FootSwitch. Irrigation is provided in

footpedal positions 1, 2, and 3.

• Irrigation: Free Flow - entered by pressing Free Flow

icon or irrigation button. The mode display window

reads Irrigation: FreeFlow. Free flow irrigation

continues until the IRR button is pressed twice to

change to Irrigation: Footswitch or until another mode

is selected (except when continuous irrigation option

is turned on).

• Continuous Irrigation - Continuous Irrigation is

available as a floating sub mode for U/S, I/A, and Vit

modes to allow for continuous irrigation of the eye

during surgery. It maintains irrigation of the anterior

chamber independent of footpedal position (i.e., even

in position 0). It is described as a floating mode as it

can start from Irrigation and go to any allowable

mode. Exiting from U/S, I/A, or Vit modes shuts

Continuous Irrigation off allowing leak-free exchange

of irrigation and aspiration lines to handpieces.

2. When enabled, toggling the footswitch's right

horizontal switch in footpedal position 0 opens and

closes the irrigation valve to provide continuous

irrigation in a similar manner.