Page 1

ONE

I

NI

VISION

TI

SYSTEM

Manufacturer:

Alcon

6201

Fort

U.S.A.

Produced

Alcon

15800

Irvine,

U.S.A.

Telephone:

FAX:

Laboratories,

South

Worth,

Freeway

Texas

By:

Laboratories,

Alton

Parkway

California

Service

Inc.

76134-2099

Inc.

92618-3818

949/753-1393

800/832-7827

949/753-6614

Manual

CE»)

Directive

93/42/EEC

8065750238

906-2100-001

B,

CAT / REF / PART

B,

TEXT

ONLY

NO.

©

2006

Alcon,

Inc.

Page 2

Infiniti™*

Vision

System

8065750238

Service

Manual

January

March

2006

2004

A

B

MANUAL

20042116 - Initial

20060029 - Several

here.

eral

pages

instructions.

to

adjust

replaced

updated.

REVISION

Environmental

added

power

with

Schematics

for

Footswitch

supply

current

RECORD

release

of

service

small

updates

Considerations

System

data.

updated.

parts

added

Assembly

Access

added

to

manual.

to

manual.

added.

and

to

Maintenance

Labels

Sub-Assembly

Spare

Drawings

Larger

Parts

section.

updates

updated.

list.

and

Parts

listed

Sev-

Removal

Instructions

Error

Codes

Lists

SmartPhaco

SmartPhaco

*

Registered

ii

This

is a

registered

is

licensed

in

the

U.S.

END

USER

product

contains

trademark

from

Micro

Medical

Patent & Trademark

LICENSE

software

of

Micro Medical

.

licensed

Devices,

Office.

AGREEMENT:

from

Microsoft

Devices,

Inc.

Inc.

Corporation.

;

ray

чи

8065750238

Page 3

TABLE

OF

CONTENTS

ECTI

AboutthisManual.........................

Reference

Receiving

Unpacking

General

Information

Warnings

Infiniti***

E - GENERAL

Documents.

Inspection.

and

Setting

......................

and

Cautions

Vision

Systern

I

Up

the

System

...

----------

Description

ATI

.

Console

RearPanel....................

Footswitch.

Remote

Handpieces,

Fluidic

Infiniti™ * AquaLase®

Consumable

Front

Display

Setup

Screen

Surgery

し

し

Control. に に に に し に に に に

Tips,

and

Infusion

ManagementSystem.....................

Balanced

Pak

Configurations.

Panel

and

Touch

and

its

Functions.....................................................

Screen

and

its

Functions

に に に に に に に

Sleeves

Salt

........................,.............,............

Screen.

ани

トト

トト

トト

..............................................

Solution

...................................................

1...

K..

нана

トト

トー

トー

Bottle.

...................................

eee

еее

トト て トト

4...

еее

νωνω

ε ο εκ

κε ο ενω

ie

иен

инете

レト て に て て に に て トト

0. に に

ーー

PAGE

0

K

6

νερο κ κο

νε οκ

νεο

tenet

εκ

κκ ωχ

εν

κκ κ νο

nee

ων

sseueeeressssreees

ить

e

cena

tte

ete

トト

トー

トー

トト

トト

トス

ーー

トー レー トー

レー トー て ーー

バー

てこ

レー

4

11

12

12

νν κν

13

1.4

1.8

ον 1.14

1.15

1.17

1.18

ーー

1.23

1.27

1.33

1.34

1.34

バー

1.37

1.38

1.53

SECTION

Itroductfon,

System

Infiniti

Power

"Host

Infiniti™*

Eootswitch

IV

PoleModuleTheory

Fluidics

Pneumatic

U/S

Module

SECTION

Sub-Assembiy

Removal

System

TWO - THEORY

issues

OvervieW

"#

System

Distribution

Theory

Display

Module

Module

Module

Theory

THREE - PARTS

of

Panels

Access

OF

OPERATION

Theory.

Theory . に に に に に に に

に

に に に

Theory

.........................................................

Theory.

に し に

«νε

ーー トト に に に に トト

に に

レレ に に

レー に レト

инь

トー

に に に トト

トト

............... 0 öneren

Theory

Theory

..............................,..,..4444

Locations

from

Infiniti™*

and

Subassembly

ユー に に

に に に に に に し ーー

LOCATION

.........................

ーー に ーー に ドー

Console

Removal

トド

に に に

に に に に に に に

に に に に に

に に

に に に トト

AND

DISASSEMBLY

.............,.............................

.................,..........................

トト

анна

トー

トー

トト

トト

トト に トト

トー

トト

トト て て

トレ

レレ に トート ト トト

トト

ーー

トー

0

iie

トー て トト て て

トト

トー

トト

K

トレ

44e

トー

トト

ーーー て ーー

トト レト て て し し て て て て て ーー

re

トト

レレ

ーー

レー

レー トー

バーーーー

ニー

PAGE

k

ーー

トーーーー

PAGE

Levi

#

2.1

21

2.2

2.3

2.4

2.6

2.5

2.10

2.13

2.16

2.19

#

3.1

3.1

3.3

8065750238

iii

Page 4

ON F INT

SECT

GeneralInformatlon

ServiceTestProcedure......................

Maintenance

Equipment

Problem

Advisories,

Malfunction

Conditions

Warnings,

FIVE

Table

of

Contents

TON

SIX

-

MAINTENANCE

,,

Procedures

....................,,.............,...,,,....,......2....4

.....................,.,,.........,,.,

and

Faults............,..................,...................

-

ATI

.............,..........,..................

-

PARTS

LE

DR

TableofContents........................

SECT.

E

-ADDITIONAL

TR

ΕΜ.

1.1

LESHOOTI

<.

eee

eee

É

4,444...

K

K

K

K

PAGE

K

K

ennne

PAGE

eee.

PAGE

PAGE

ο

ν

4.1

4.1

4.3

4.7

4.9

4.13

5.1

6.1

#

#

#

#

Infiniti™

*

VideOverlay

Overview...................

Standard

Setup

に

System

に

に

に

に

.

...............................,....................

imera

に

レレ

に

に

に

トート

に に トレ

ーー

トー

トト

トト

トト

トレ

て

て

て

て

て

レレ

レー

て

てこ

ーー

こてこて

に て て

てこ

て

ーーーーー

71

74

7.2

iv

8065750238

Page 5

Page 6

Page 7

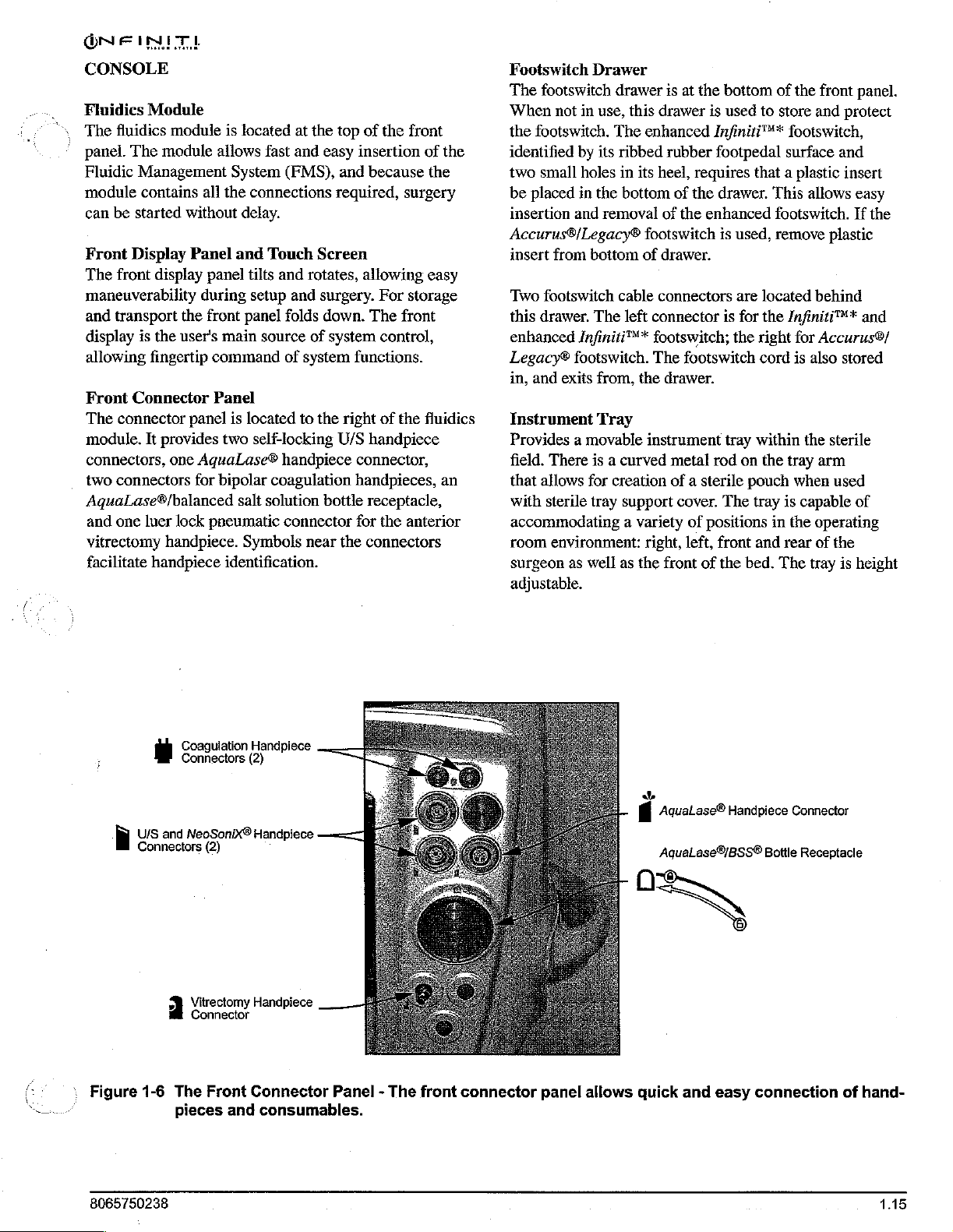

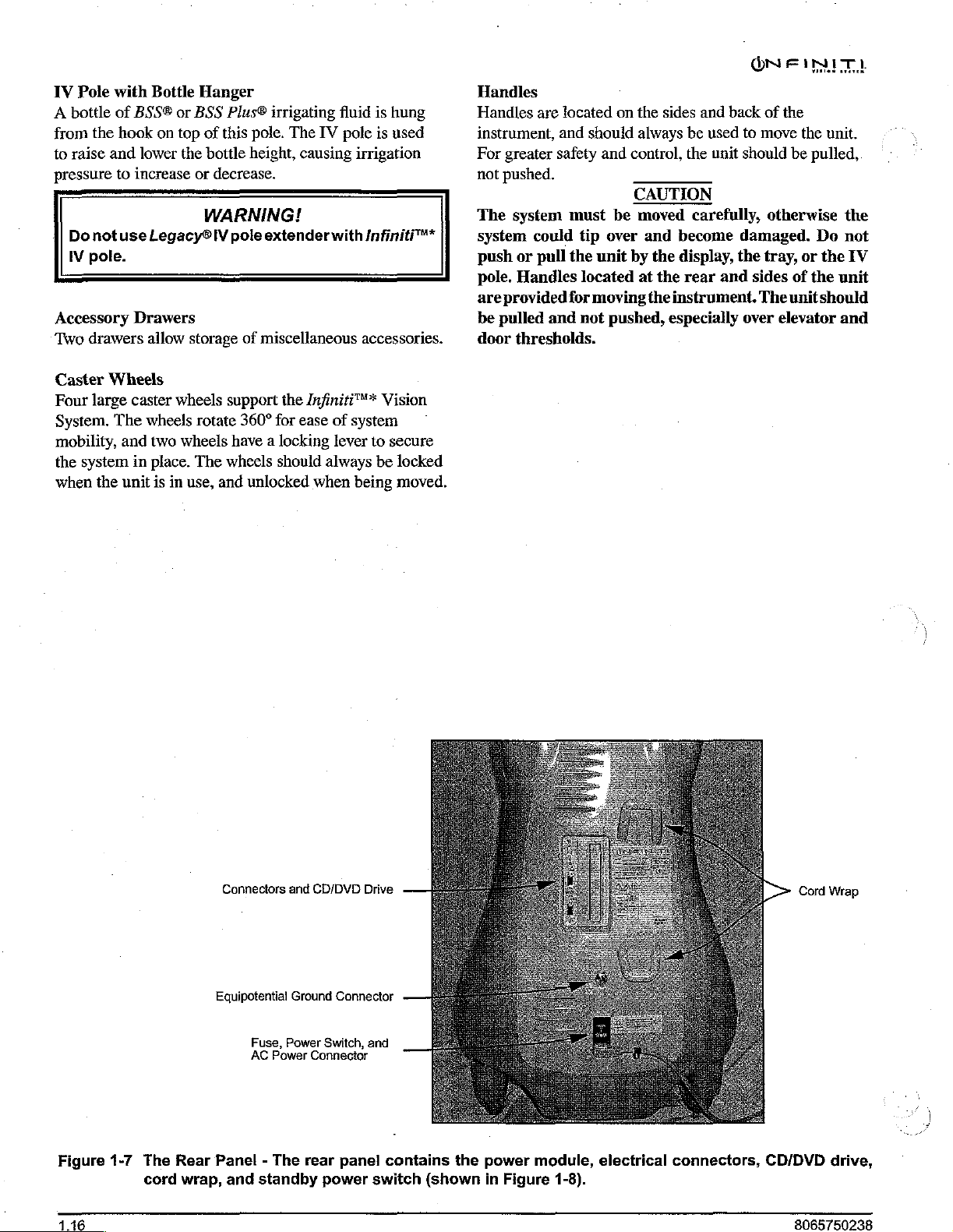

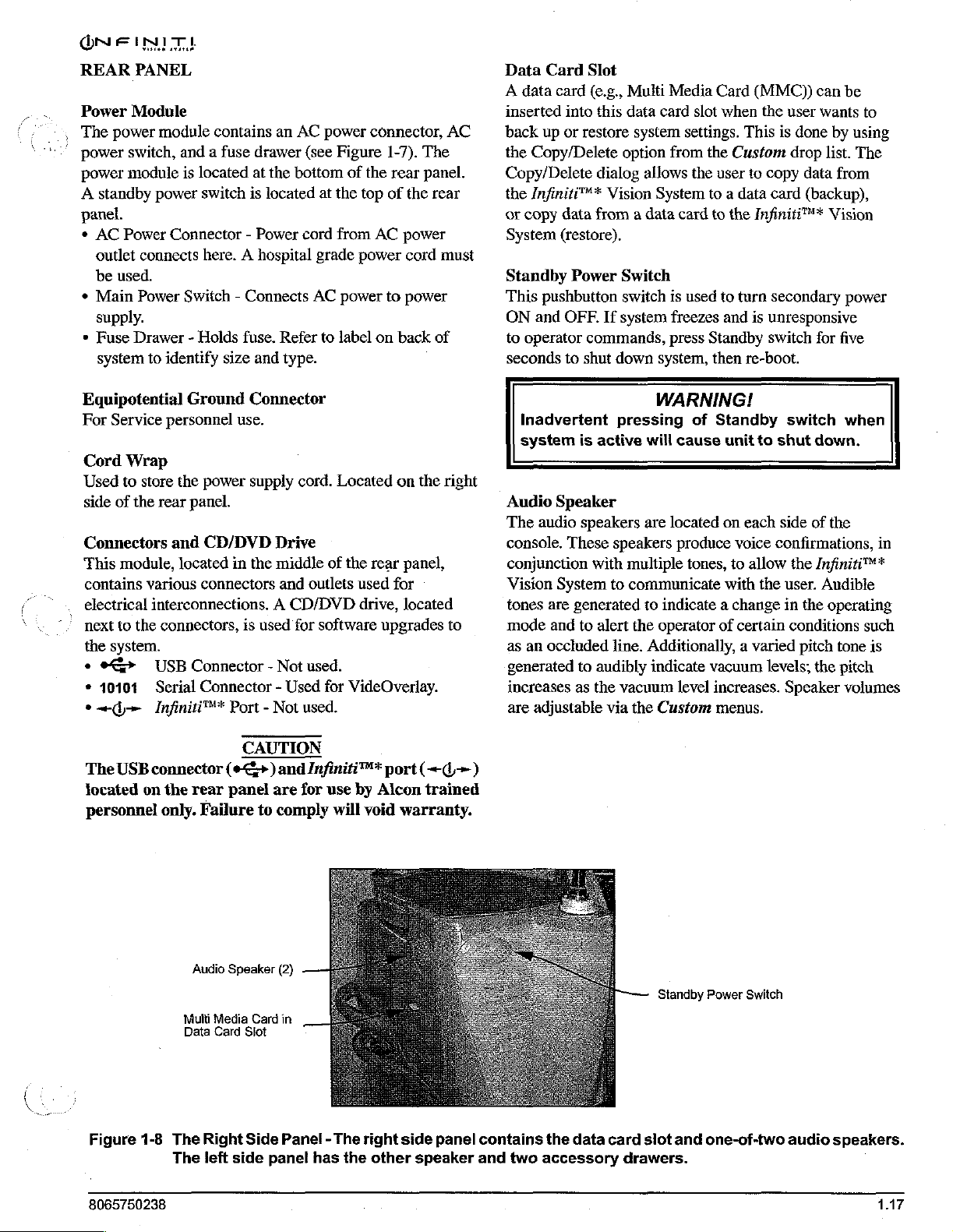

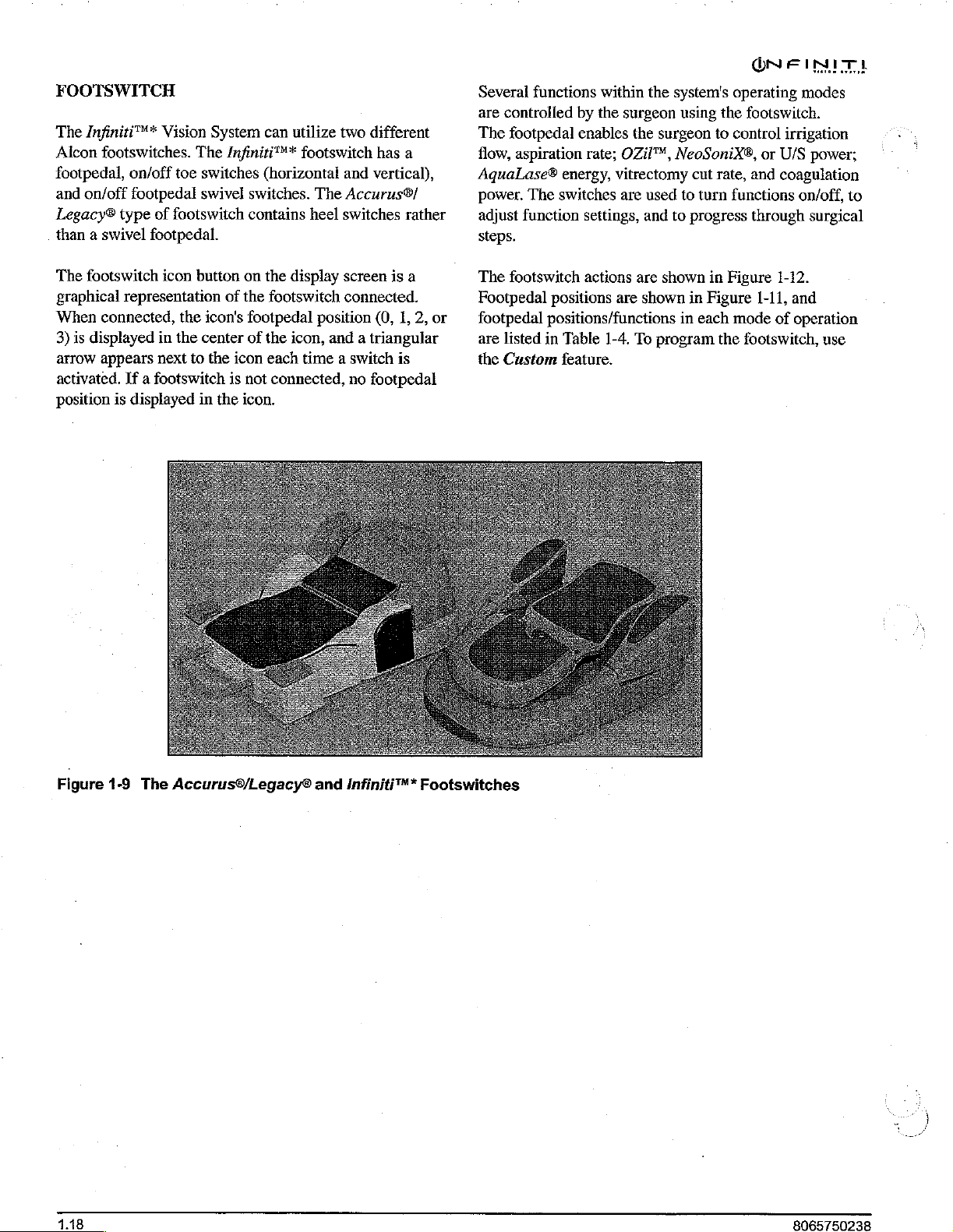

Figure

Figure

Figure

Figure

TABLE#

7-1

7-2

7-3

7-4

Ooo

VideOverlayFrontPanel.................. 기 이 의 기

VideOverlay

”Wall

OutletAdapters. し し し に に に に に に に

VideOverlay

TITLE

Rear

Panel

.....................................,.........

Connection

Diagram

LIST

OF

に に に に に に に トト

トト

トト トト

.............................,.........

TABLES

トト

의 가

기가 가 기시

トト

トト

トット

이시기 아 이 게

レレ

トッ

レー

세가 기 이이 이 이 이 TA

7.2

てこ

ーー

トー

7.3

7.3

PAGE

+

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

1-1

1-2

1-3

1-4

1-5

1-6

1-7

1-8

4-1

4-2

4-3

4-4

4-5

Guidance

Guidance

Recommended

Communications

Table

Programming

Parameters

Abbreviations

Specifications

Recommended

Spare

Voltage

ProblemConditions

ErrorCodes

and

Manufacturer's

and

Manufacturer's

Separation

Equipment

of

Footpedal

the

Footswitch

in

Surgery

Used

.............................................usss...

Tools

Parts

Specifications.

....................

Distances

Positions

Controls

with

the

and

Test

Declaration - Electromagnetic

Declaration - Electromagnetic

Between

and

the

Infiniti™*

..........................................

Treadle.

Infinitit"*

Supplies

...................................

Area

...................................,

Vision

...................................

Portable

Vision

System

Emissions

Immunity

and

Mobile

System

.....................

................

.........

.........

RF

teen

................................................

.......................

iii

emer

eee

enone

1.5

1.6

17

1.20

1.43

1.55

1.58

1.59

4.1

4.2

4.6

49

4.13

8065750238

vil

Page 8

IMPORTANT

NOTICE

Equipment

equipment

or

implied,

understood

personnel,

In

order

and

provide

servicing

in-depth,

and

correction

persons

this

equipment,

Alcon

arising

improvement

after

that

that

the

to

protect

of

extensive

other

will

not

from

this

the

information

if

this

user

assumes

the

its

customers

this

equipment

training

of

problems

than

Alcon-trained

patients,

assume

repairs

Federal

is

an

on-going

manual

by

law

is

printed.

contained

manual

goodwill

responsibility

any

is

used

all

risks

associated

with a high

be

performed

in

the

that

may

and

other

third

restricts

process

Accordingly,

to

perform

in

the

quality

servicing

arise

service

party.

third

for

this

device

personnel

parties

the

and,

Alcon

in

this

service

service

use

of

this

with

Alcon,

of

service,

by

Alcon-trained

of

the

equipment,

with

the

equipment.

may

to

significant

effect

of

CAUTION

to

sale

as

such,

makes

manual

on

manual.

and

its

Alcon

service

expose

the

repairs,

by

or

changes

no

is

complete

the

equipment

products,

strongly

personnel.

including

Any

those

risk

of

damages,

on

the

order

may

be

made

warranties,

or

by

other

maintain

recommends

Such

training

servicing

persons,

serious

of

subsequent

injury

or

personal

of a physician.

to

the

expressed

accurate.

Alcon’s

in

this

and/or

It is

than

trained

that

personnel

the

diagnosis

equipment

injuries

standards,

all

receive

by

users

of

death.

.

WARNINGS

Pay

close

attention

individuals

from

UNIVERSAL

Universal

and/or

infectious

encountered

accordingly.

Comments

precautions

accessories

materials.

are

This

or

Alcon

Technical

PO

BOX

Irvine,

All

rights

reserved.

system,

without

in

any

prior

written

AND

CAUTIONS

to

warnings

bodily

injury.

PRECAUTIONS

shall

to

help

prevent

In

any

unknown,

is

in

corrections

Laboratories,

Services

it

accordance

concerning

Group

19587

CA,

USA

92623-9587

No

part

form

or

by

any

permission

and

cautions

Cautions

be

observed

circumstance,

shall

be

Inc.

of

this

means;

from

are

by

their

exposure

wherein

uniformly

with

OSHA

this

manual

manual

may

photocopying,

Alcon.

in

this

manual.

written

all

to

people

to

blood-borne

the

considered

guidelines.

should

be

reproduced,

electronic,

Warnings

protect

who

come

exact

status

potentially

be

addressed

are

written

the

instrument

in

contact

pathogens

of

blood

infectious

to:

transmitted,

mechanical,

to

protect

from

damage.

with

the

instrument

and/or

or

or

other

body

fluids/tissues

and

stored

recording,

potentially

handled

in a retrieval

or

otherwise;

Page 9

ONFINITI

Alcon’s

surgical

easy

four

OZil™

handpieces.

user

and

effectivity

The

incision

system

in

with

(inflated)

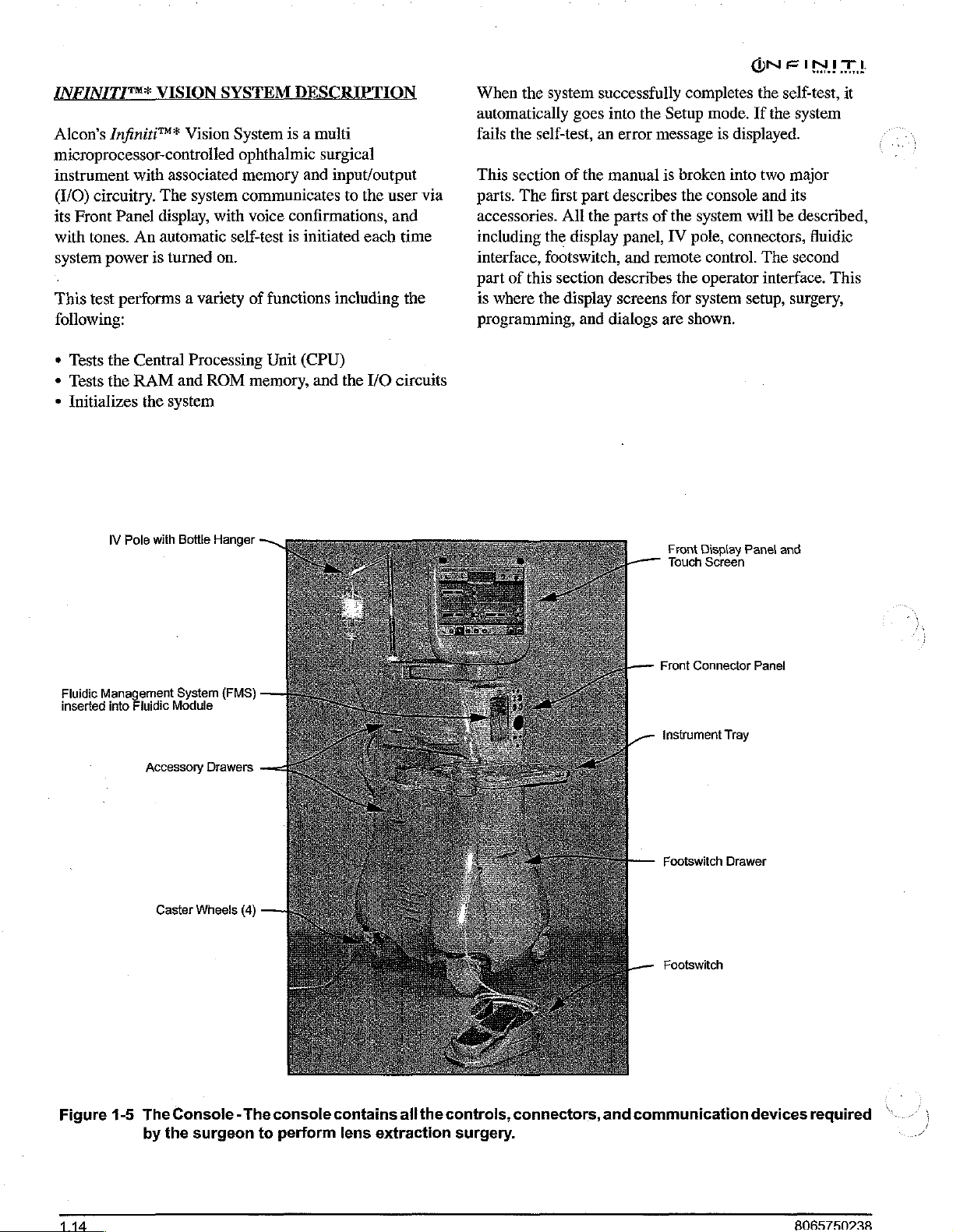

Infiniti™ * Vision

instrument

to

operate.

modes

torsional,

friendly,

maintain

Infiniti™ * Vision

cataract

allows

the

eye,

balanced

designed

The

Infiniti™ * Vision

for

cataract

NeoSoniX®,

This

instrument

combining

along

with

of the user.

lens

extraction

the

surgeon

while

replacing

salt

solution.

eye

chamber

System

to

lens

extraction

has

hardware

software

System

to

emulsify

aspirated

This

volume.

is

be

reliable,

and

high

been

that

that

is

intended

surgical

fluid

process

Using

an

ophthalmic

safe,

and

System

using

performance

developed

is

increases

and

provides

AguaLase®,

to

be

easy

to

install

the

for

use

in

small

procedures.

aspirate

and

lens

the

material

U/S

This

lens

maintains a stable

system

controls

the

surgeon

handpiece

of

BSS®

controls

irrigation

rate,

ABOUT

This

Section

This

Vision

is

an

Section

This

Infiniti™*

level

Board)

the

tip,

or

include a footswitch

flow,

and

coagulation

THIS

manual

One - General

section

System

unpacking

Two - Theory

section

and

working

level.

end

of

regulates

the

BSS

aspiration

is

the

rate

of

Plus®

power.

MANUAL

divided

aspiration,

irrigation

rate,

into

Information

gives a general

features

and

and

installation

of

gives a detailed

Vision

this

System

down

to

Detailed block

section.

amount

to

enable

phaco

seven

of

vacuum,

solution.

power,

sections

description

components.

procedure.

Operation

description

operates

the

starting

PCB

diagrams

power

(Printed

the

surgeon

of

are

Also

of

applied

vitrectomy

as

the

how

at

provided

to

the

and

the

flow

The

system

to

control

cut

follows:

Infiniti™*

included

the

the

system

Circuit

at

Section

This

field

Section

This

troubleshooting

Section

This

PCB

Section

This

documentation

drawings.

Section

This

optional

Three - Parts

section

level

section

contains

disassembly

Four - Maintenance & Troubleshooting

contains

information.

Five - Schematics

section

assembly

section

section

contains

drawings,

Six - Parts

contains

for

Seven - Additional

contains

equipment

Location

parts

location

procedures.

system

the

system

and

Lists

and

parts

lists,

each

major

information

that

may

and

Disassembly

diagrams

maintenace

interconnect

schematic

Drawings

diagrams.

engineering

assembly,

Information

on

accessories

require

service.

along

procedures

diagram,

and

cable

or

with

and

Figure

8065750238

1-1

The

Infiniti™*

Vision

System

11

Page 10

REFERENCE

DOCUMENTS

RECEIVING

INSPECTION

Although

for

Vision

procedures

the

Cautions

service

information

available

If

you

information,

representative

Alcon

15800

Irvine,

(949)

(800)

If

you

contact

this

manual

maintaining

System,

or

functional

operator's

in

the

manual.

manual.

provided

on-site

have

any

please

or

Laboratories

Alton

Parkway

CA

92718

753-1393

832-7827

are

located

your

local

provides

optimum

it

does

performance

not

descriptions

In

addition,

operator's

The

with

questions

manual

operator's

in

this

the

system.

or

contact

the

Technical

outside

the

authorized

the

contain

manual

manual,

require

your

local

Services

United

Alcon

necessary

of the

ail

of

the

operating

contained

the

Warnings

also

apply

supplements

and

should

additional

service

Department

States,

please

distributor.

information

Infiniti™*

in

and

for

this

be

at:

The

system

prior

to

shipment.

damaged,

the

for

parts).

any

Alcon

and

necessary,

separately,

ask

system

external

of

is

If

damage

the

functional

representative.

packing

file a claim

with

was

inspected

If

that the

unpacked.

damage

is

material

the

insurance

mechanically

the

shipping

carrier’s

(i.e.

agent

The

system

scratches,

discovered

tests

notify

Retain

for the

with

the

carrier’s

the

carrier

company.

container

be

should

dents,

or

if

the

the

carrier

shipping

inspection.

or,

and

electrically

appears

present

system

be

or

and

broken

when

inspected

fails

an

container

if

insured

As

Federal

order

Law

of a physician.

CAUTION

restricts

this

device

to

sale

by

or

on

the

Page 11

ONFINITI

UNPACKING

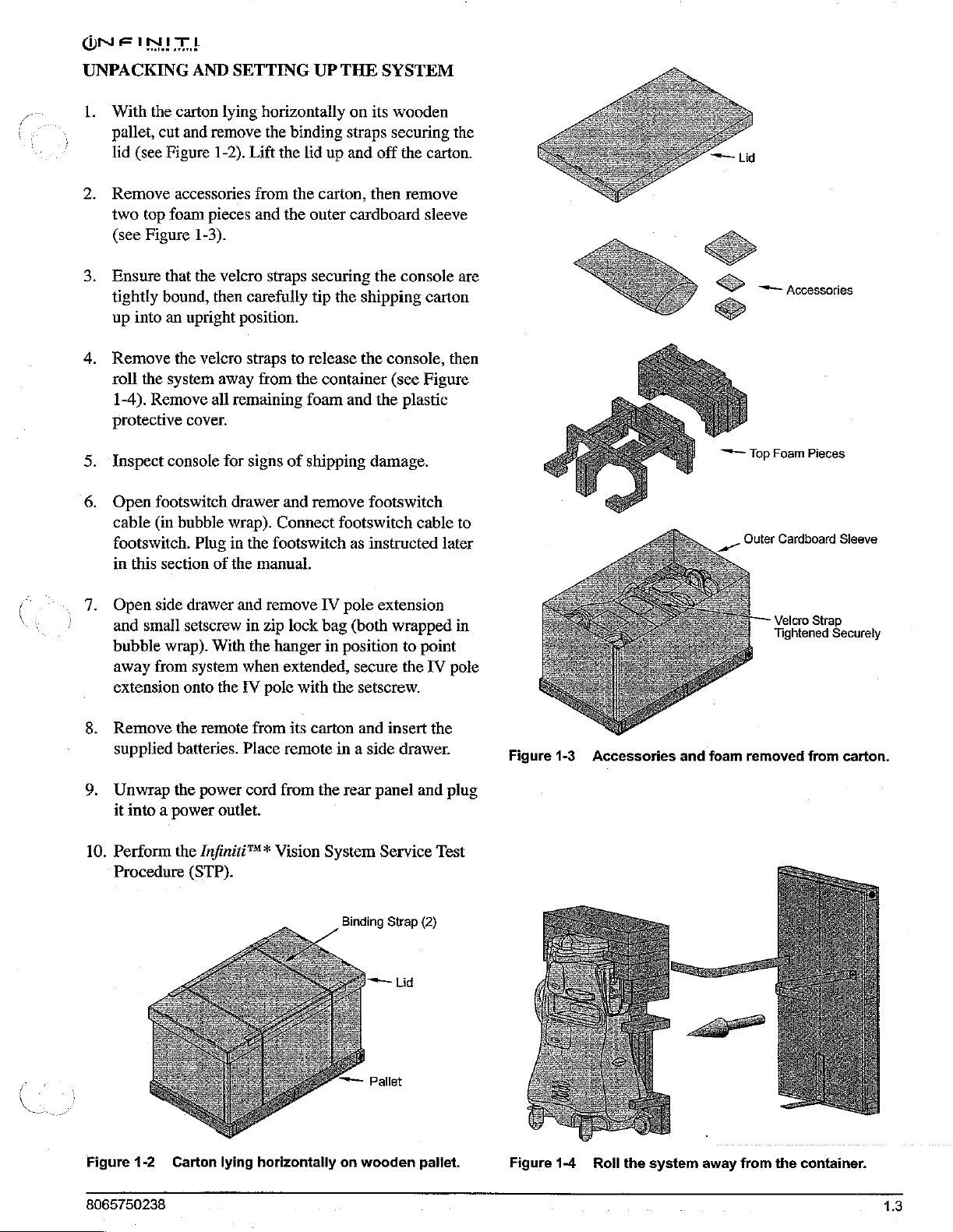

1.

2.

3.

4.

5.

6.

With

the

carton

pallet,

lid

Remove

two

(see

Ensure

tightly

up

Remove

roll

protective

‘Inspect

Open

cable

footswitch.

(see

top

Figure

into

the

1-4).

in

this

cut

and

Figure

accessories

foam

that the

bound,

an

upright

the

system

Remove

cover.

console

footswitch

(in

bubble

section

AND

remove

1-2).

pieces

1-3).

velcro

then

velcro

away

all

Plug

of

SETTING

lying

horizontally

the

Lift the

from

and

straps

carefully

position.

straps

from

remaining

for

signs

drawer

wrap).

in

the

the

manual.

Connect

footswitch

UP

binding

lid

up

the

carton,

the

outer

securing

tip

to

release

the

container

foam

of

shipping

and

remove

THE

SYSTEM

on

its

wooden

straps

securing

and

off the

then

remove

cardboard

the

console

the

shipping

the

console,

(see

and

the

plastic

damage.

footswitch

footswitch

as

instructed

carton.

sleeve

carton

then

Figure

cable

later

the

are

to

x

gi

>

<

—

~~

per

E,

Top

Outer

-

Accessories

Foam

Pieces

Cardboard

Sleeve

Č

`

7.

i

8.

9.

10.

Open

side

drawer

and

small

setscrew

bubble

away

extension

Remove

supplied

Unwrap

it

Perform

Procedure

wrap).

from

onto

the

batteries.

the

into a power

the

(STP).

and

in

With

the

system

when

the

TV

remote

power

Infiniti™*

from

Place

cord

outlet.

remove

zip

lock

hanger

extended,

pole

with

its

remote

from

Vision

IV

pole

bag

(both

in

position

the

carton

in

the

rear

System

Binding

extension

wrapped

to

secure

a

the

setscrew.

and

insert

side

drawer.

panel

Service

Strap

point

IV

the

and

plug

Test

(2)

in

pole

Figure

1-3.

Accessories

and

foam

Velcro

Tightened

removed

Strap

Securely

from

carton.

Figure

8065750238.

1-2

Carton

lying

horizontally

—™—

on

Pallet

wooden

pallet.

Figure

1-4

Roll

the

system

away

from

the

container.

13

Page 12

ONFINI

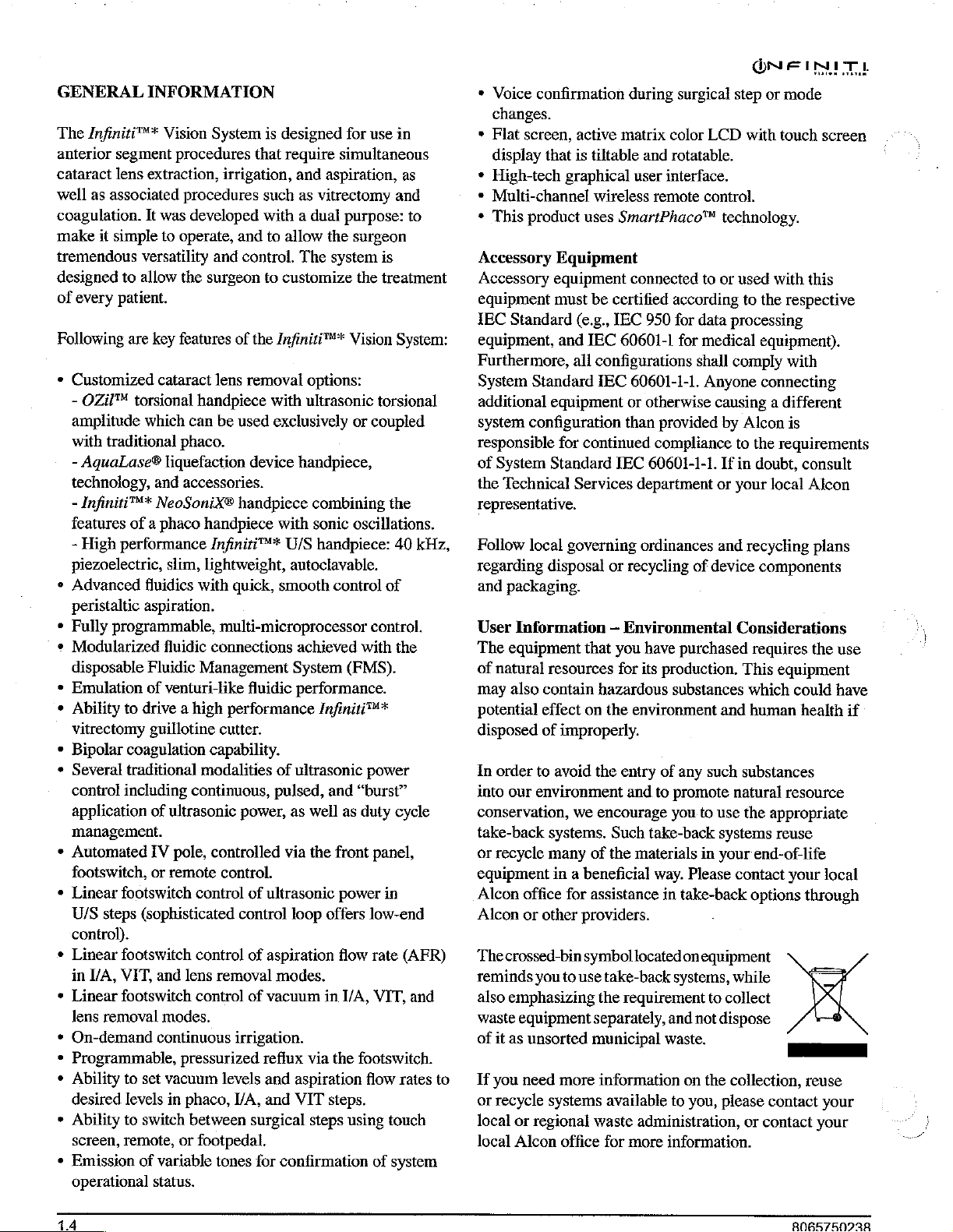

GENERAL

The

Injiniti™*

anterior

cataract

well

coagulation.

make

tremendous

designed

of

Following

*

segment

lens

as

associated

it

simple

versatility

to

allow

every

patient.

are

Customized

-

OZil™

torsional

amplitude

with

traditional

-

AquaLase®

It

which

technology,

-

Infiniti™*

features

-

High

of a phaco

performance

piezoelectric,

+

Advanced

peristaltic

+

Fully

+

Modularized

fluidics

aspiration.

programmable,

disposable

*

Emulation

»

Ability

of

to

drive a high

vitrectomy

¢

Bipolar

¢

Several

control

coagulation

traditional

including

application

management.

*

Automated

footswitch,

*

Linear

U/S

control).

¢

Linear

in

¢

Linear

lens

*

On-demand

¢

Programmable,

*

Ability

desired

*

Ability

screen,

*

Emission

Operational

footswitch

steps

footswitch

I/A,

VIT,

footswitch

removal

to

levels

to

remote,

(sophisticated

set

switch

of

INFORMATION

Vision

extraction,

was

to

key

cataract

and

NeoSoniX®

fluidic

Fluidic

venturi-like

guillotine

of

IV

or

and

modes.

continuous

vacuum

variable

status.

System

procedures

irrigation,

procedures

developed

operate,

and

and

the

surgeon

features

of

lens

handpiece

can

be

used

phaco.

liquefaction

accessories.

handpiece

Infiniti™*

slim,

lightweight,

with

quick,

multi-microprocessor

connections

Management

performance

cutter.

capability.

modalities

continuous,

ultrasonic

pole,

controlled

remote

control.

control

control

lens

removal

control

irrigation.

pressurized

levels

in

phaco,

I/A,

between

or

footpedal.

tones

is

designed

that

require

and

such

as

with a dual

to

allow

control.

the

The

to

customize

Infiniti™*

removal

with

exclusively

device

handpiece,

handpiece

with

U/S

autoclavable.

smooth

achieved

System

fluidic

performance.

of

ultrasonic

pulsed,

power,

as

via the

of

ultrasonic

control

loop

of

aspiration

modes.

of

vacuum

reflux

and

aspiration

and

VIT

surgical

for

confirmation

for

use

simultaneous

aspiration,

vitrectomy

purpose:

the

surgeon

system

the

Vision

options:

ultrasonic

torsional

or

coupled

combining

sonic

oscillations.

handpiece:

control

control.

with

(FMS).

Infiniti™*

power

and

“burst”

well

as

duty

front

panel,

power

offers

low-end

flow

rate

in

I/A,

VIT,

via the

footswitch.

flow

steps.

steps

using

of

in

as

and

to

is

treatment

System:

the

40

kHz,

of

the

cycle

in

(AFR)

and

rates

to

touch

system

»

Voice

confirmation

during

changes.

»

Fiat

screen,

display

+

High-tech

+

Multi-channel

*

This

product

Accessory

Accessory

equipment

IEC

Standard

equipment,

Furthermore,

System

additional

system

configuration

responsible

of

System

the

Technical

active

that

is

graphical

uses

Equipment

equipment

must

(e.g.,

and

IEC

ali

Standard

equipment

for

continued

Standard

Services

matrix

tiltable

user

wireless

SmartPhaco™

connected

be

certified

IEC

60601-1

configurations

TEC

60601-1-1.

or

than

TEC

department

representative.

Follow

regarding

and

User

The

of

may

potential

disposed

In

into

conservation,

take-back

or

equipment

Alcon

Alcon

Thecrossed-bin

reminds

also

waste

of

local

governing

disposal

ordinances

or

recycling

packaging.

Information — Environmental

equipment

natural

also

order

to

our

environment

recycle

that

resources

contain

effect

of

hazardous

on

improperly.

avoid

the

we

encourage

systems.

many

of

you

for

its

the

environment

entry

and

Such

the

materials

in a beneficial

office

for

assistance

or

other

providers.

you

to

emphasizing

equipment

it

as

unsorted

symbol

use

located

take-back

the

requirement

separately,

municipal

P

If

you

need

more

information

or

recycle

local

local

systems

or

regional

Alcon

waste

office

available

administration,

for

more

surgical

color

LCD

and

rotatable.

interface.

remote

control.

to

according

950

for

data

for

medical

shall

Anyone

otherwise

provided

compliance

60601-1-1.

of

have

purchased

production.

substances

of

any

such

to

promote

you

to

take-back

in

way.

Please

in

take-back

on

equipment

systems,

to

and

not

waste.

on

the

to

you,

information.

step

or

mode

with

touch

screen

technology.

or

used

with

this

to

the

respective

processing

equipment).

comply

with

connecting

causing a different

by

Alcon

is

to

the

requirements

If

in

doubt,

consult

or

your

local

Alcon

and

recycling

device

components

plans

Considerations

This

and

requires

which

human

the

use

equipment

could

have

health

substances

natural

use

systems

your

contact

resource

the

appropriate

reuse

end-of-life

your

options

through

local

while

collect

dispose

m-

collection,

please

or

reuse

contact

contact

your

your

if

Page 13

ONE

Universal

Universal

who

IMT!

Precautions

precautions

come

in

accessories

pathogens

In

any

or

body

be

uniformly

handled

and/or

circumstance,

fluids/tissues

in

accordance

guidelines.

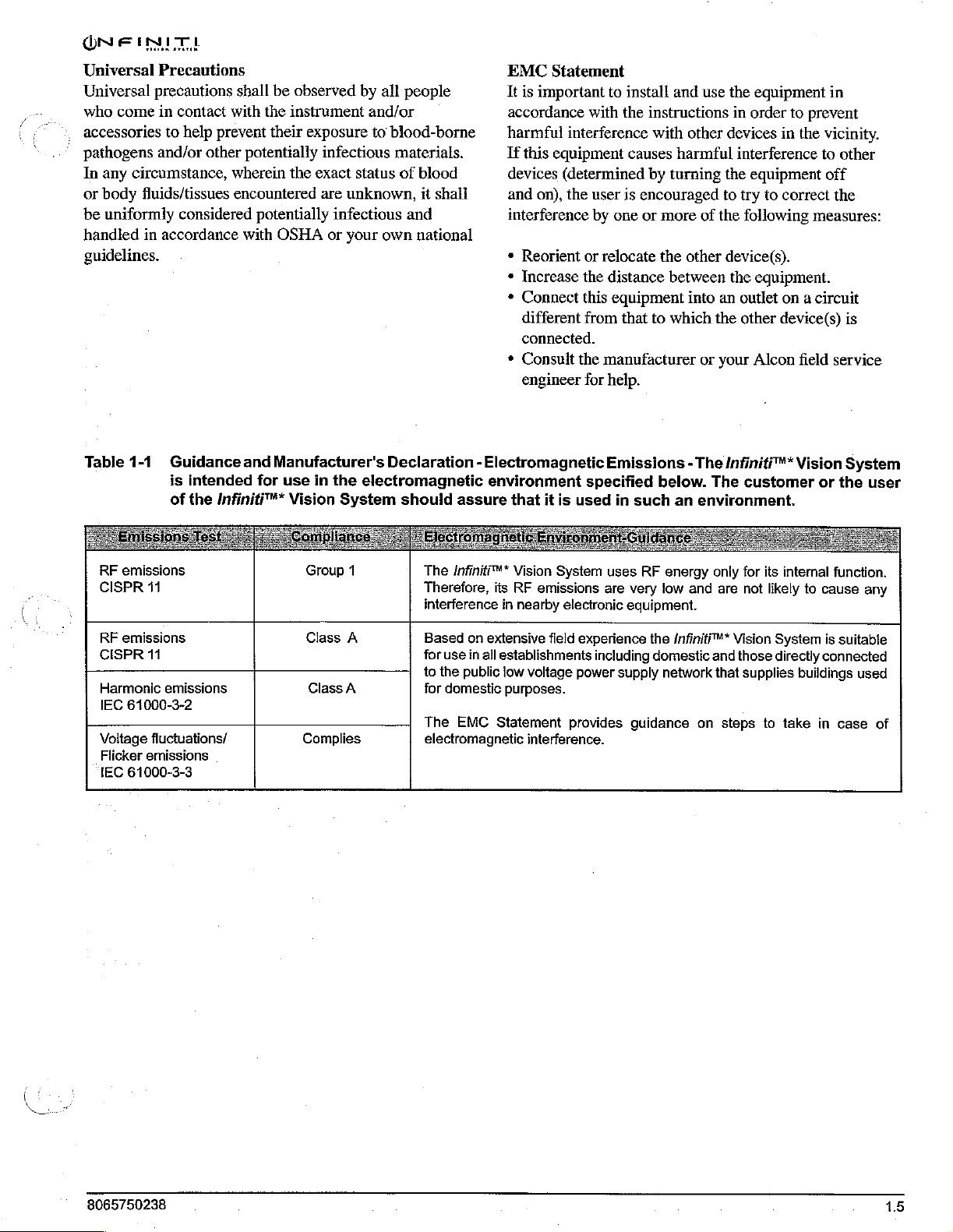

Table

1-1

contact

to

help

prevent

other

considered

Guidance

is

intended

of

the

Infiniti™*

shall

be

observed

with

the

instrument

their

potentially

wherein

encountered

the

potentially

with

OSHA

and

Manufacturer's

for

use

Vision

by

and/or

exposure

to’

infectious

exact

status

are

unknown,

infectious and

or

your

in

the

electromagnetic

System

EMC

Statement

all

people

It is

important

accordance

blood-borne

materials.

of

blood

it

shall

harmful

If

this

equipment

devices

and

on),

interference

(determined

the

interference

own

national

*

Reorient

*

Increase

+

Connect

different

the

this

connected.

*

Consult

the

engineer

Declaration - Electromagnetic

environment

should

assure

that

it

is

used

to

instal!

with

the

instructions

with

causes

by

user

is

encouraged

by

one

or

more

or

relocate

the

distance

equipment

from

that

to

manufacturer

for

help.

Emissions - The

specified

in

below.

such

and

use

other

harmful

turning

of

other

between

into

which

the

or

your

The

an

environment.

the

equipment

in

order

to

devices

in

interference

the

equipment

to

try

to

correct

the

following

device(s).

the

equipment.

an

outlet

on a circuit

other

device(s)

Alcon

Infiniti™*

customer

in

prevent

the

vicinity.

to

other

off

the

measures:

field

service

Vision

or

the

is

System

user

RF

emissions

CISPR

RF

emissions

CISPR

Harmonic

IEC

61000-3-2

Voltage

Flicker

EC

61000-3-3

11

11

emissions

fluctuations/

emissions

Group

1

Class

A

Class

A

Complies

The

Infiniti™*

Therefore,

interference

Based

for

use

to

the

for

domestic

The

electromagnetic

its

in

on

extensive

in

all

establishments

public

low

purposes.

EMC

Statement

Vision

System

RF

emissions

nearby

electronic

field

experience

voltage

interference.

power

provides

uses

RF

are

very

eguipment.

the

including

supply

guidance

energy

low

and

Infiniti™*

domestic

network

on

only

are

Vision

and

that

steps

for

its

internal

not

likely

System

those

directly

supplies

to

take

function.

to

cause

is

suitable

connected

buildings

in

case

any

used

of

8065750238

15

Page 14

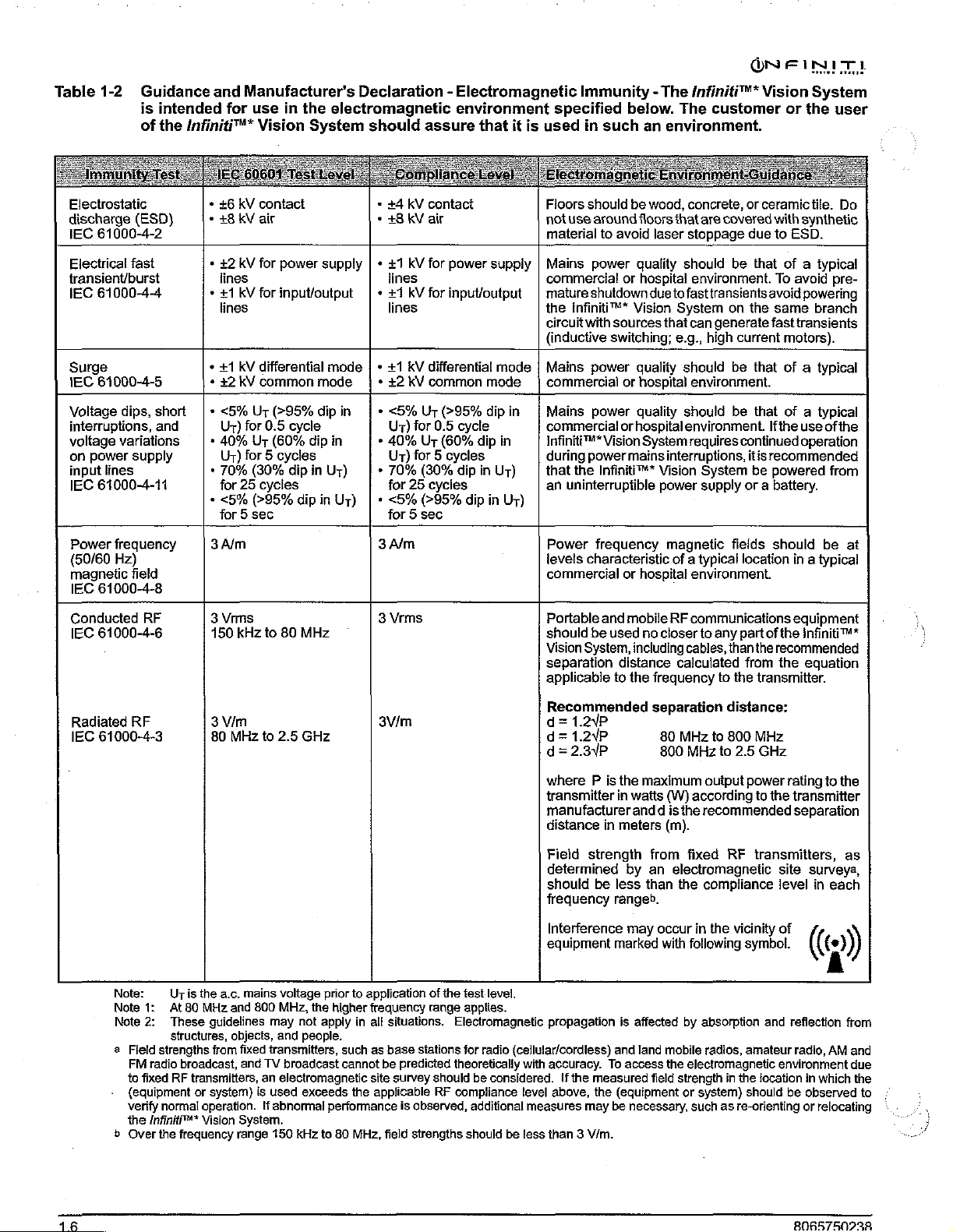

Table

1-2

Electrostatic

discharge

IEC

Electrical

transient/burst

IEC

Surge

IEC

Voltage

interruptions,

voltage

on

input

IEC

Power

(50/60

magnetic

IEC

Conducted

IEC

(ESD)

61000-4-2

fast

61000-4-4

61000-4-5

dips,

variations

power

supply

lines

61000-4-11

frequency

Hz)

field

61000-4-8

61000-4-6

Guidance

is

intended

of

the

Infiniti™*

short

and

RF

and

Manufacturer's

for

use

Vision

*

+6

KV

*

*

*

+

*

*

+

»

*

3A/m

3

150

contact

+8

kV

air

+2

kV

for

lines

#1

kV

for

lines

+1

kV

differential

+2

KV

common

<5%

Ur

Ur)

for

0.5

40%

Ur

Ur)

for 5 cycles

70%

(30%

for

25

cycles

<5%

(>95%

for 5 sec

Vins

kHz

to

(>95%

(60%

Declaration - Electromagnetic

in

the

electromagnetic

System

power

input/output | +

mode

dip

cycle

dip

dip

in

dip

in

80

MHz

should

ㆍ

・

supply | +

mode | +

{| + +2 KV

in

in

Uy)

Uy)

*

*

*

3A/m

3

assure

+4

KV

contact

は 8

kV

ar

+1

kV

for

lines

+7

kV

for

lines

+1

kV

differential

common

<5%

Ur

Ur)

for

0.5

40%

Ur

Ur)

for 5 cycles

70%

(30%

for

25

cycles

<5%

(>95%

for 5 sec

Vrms

environment

that

power

supply | Mains

input/output | mature

mode | Mains

mode | commercial

(>95%

dip

cycle

(60%

dip

in

dip

in

Ur)

dip

in

Ur)

it

in

is

specified

used

Floors

not

use

material

commercial

the

circuit

(inductive

Mains

commercial

Infiniti™*

during

that

an

uninterruptible

Power

levels

commercial

Portable

should

Vision

separation

applicable

Immunity - The

below.

in

such

an

should

be

around

to

power

shutdown

Infiniti™*

with

power

power

power

the

Infiniti™*

freguency

characteristic

and

be

System,

wood,

floors

avoid

laser

quality

or

hospital

due

Vision

sources

switching;

quality

or

hospital

quality

or

hospital

Vision

System

mains

Vision

or

hospital

mobile

used

no

closer

including

distance

to

the

frequency

power

Q@NF

Infiniti™*

The

customer

environment.

concrete,

that

stoppage

should

environment.

to

fast

System

that

can

e.g.,

should

environment.

should

environment.

requires

interruptions,

magnetic

of a typical

environment.

RF

communications

to any

cables,

calculated

or

are

covered

due

be

transients

on

the

generate

high

current

be

be

continued

System

supply

itis

be

or a battery.

fields

location

part

than

from

to

the

INIT)

Vision

ceramictile.

that

that

that

the

transmitter.

System

or

the

with

synthetic

to

ESD.

of a typical

To

avoid

avoid

powering

same

branch

fast

transients

motors).

of a typical

of a typical

Ifthe

use

of

operation

recommended

powered

should

of

recommended

be

in a typical

eguipment

the

infiniti™*

the

equation

user

Do

pre-

the

from

at

Radiated

IEC

RF

61000-4-3

Note:

Note

1:

Note

2:

a

Field

FM

radio

to

fixed

{equipment

verify

the

Infiniti™*

b

Over

3

Vim

80

MHz

Uris

the

a.c,

At

80

These

structures,

strengths

broadcast,

RF

transmitters,

or

normal

the

frequency

mains

MHz

and

guidelines

objects,

from

fixed

and

system)

operation.

Vision

System.

range

to

2.5

GHz

voltage

800

MHz,

the

may

not

and

people.

transmitters,

TV

broadcast

an

electromagnetic

is

used

exceeds

!f

abnormal

150

kHz

3V/m

prior

to

application

higher

apply

to

frequency

in

all

such

as

cannot

site

the

applicable

performance

80

MHz,

be

of

the

range

situations.

base

stations

predicted

survey

should

RF

is

observed,

field

strengths

test

Electromagnetic

for

theoretically

compliance

level.

applies.

radio

(cellular/cordless)

be

considered.

additional

should

be

Recommended

d=

1.2YP

d=

1.2YP

d=2.3YP

where P is

transmitter

manufacturer

distance

Field

determined

should

frequency

Interference

equipment

in

strength

be

separation

the

maximum

in

watts

and d is

meters

from

by an

less

than

rangeb.

may

marked

80

MHz

800

MHz

(W)

according

the

(m).

fixed

electromagnetic

the

occur

in

with

following

propagation

with

accuracy.

level

above,

measures

less

than 3 V/m.

If

the

and

To

measured

the

(equipment

may

be

is

affected

land

mobile

access

field

necessary,

by

the

electromagnetic

strength

or

such

distance:

to

800

MHz

to

2.5

GHz

output

power

RF

the

vicinity

symbol.

amateur

in

the

should

as

re-orienting

to

transmitters,

and

location

recommended

compliance

absorption

radios,

system)

rating

the

transmitter

separation

site

surveya,

level

in

of

(인

reflection

radio,

environment

in

which

be

observed

or

relocating

to

the

as

each

from

AM

and

due

the

to

ン

ミュ

Page 15

ONFINITI

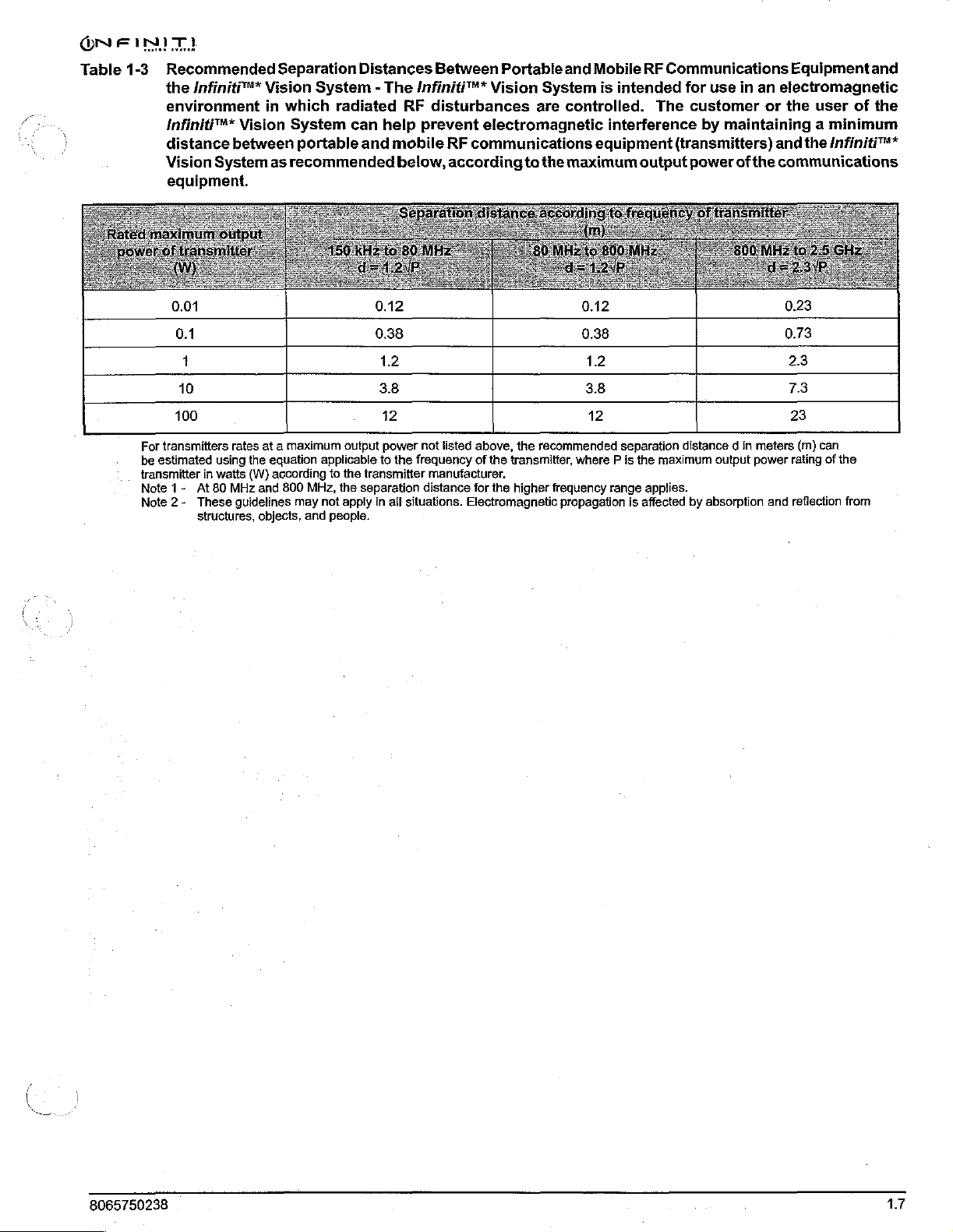

Table

1-3

Recommended

the

Infiniti™*

environment

infiniti™*

distance

Vision

equipment.

10

100

For

transmitters

be

estimated

transmitter

Note

1-

Note

At

2-

These

structures,

between

System

rates

using

in

watts

80

MHz

Separation

Vision

in

which

Vision

System

as

recommended

at a maximum

the

equation

(W)

according

and

guidelines

800

objects,

System - The

radiated

can

portable

output

applicable

to

the

MHz,

the

may

not

apply

and

people.

Distances

help

and

3.8 3.8

12 12

Between

Infiniti™*

RF

disturbances

prevent

mobile

below,

Portable

Vision

electromagnetic

RF

communications

according

to

are

the

System

power

not

listed

above,

the

to

the

in

all

situations.

frequency

transmitter

separation

of

manufacturer.

distance

the

for

Electromagnetic

recommended

transmitter,

the

higher

frequency

and

Mobile

is

intended

controlled.

interference

equipment

maximum

separafion

where P is

propagation

range

is

RF

Communications

for

The

customer

(transmitters)

output

power

distance d in

the

maximum

applies.

affected

by

Equipment

use

in

an

electromagnetic

or

the

user

by

maintaining a minimum

and

the

of

the

communications

7.3

23

meters

(m)

output

power

absorption

and

can

rating

reflection

and

of

the

Infiniti™*

of

the

from

8065750238

17

Page 16

WARNINGS

Most

of

these

manual;

greater

please

the

however,

detail

contact

Technical

The

Infiniti"

be

serviced

engineer.

lead

to

Good

clinical

irrigation,

applicable

eye.

Ensure

any

phase

AND

CAUTIONS

warnings

here.

your

Services

by a factory-trained

Access

injury.

practice

aspiration

for

that

the

of

operation.

are

for

easy

If

additional

local

Department.

Vision

by

flow,

each

handpiece

tubings

Alcon

dictates

stated

elsewhere

reference

information

service

System

untrained

testing

reflux,

are

not

in

this

they

are

repeated

is

required,

representative,

battery

and

prior

occluded

can

Alcon

personnel

service

for

adequate

operation

to

entering

during

There

or

Infiniti™*

all

engineer.

in

WARNINGS!

only

can

as

:

are

no

service

Do

not

use

IV

pole.

Keep

clear

prevent

trapped

moves

height

Keep

from

clothing

during

adjustment.

clear

stored

user

Vision

issues

Legacy®

of

skin,

in

the

of

position

from

serviceable

System

to

the

hair,

power

display

being

console

your

factory-trained

pole

IV

pole

and/or

IV

pole

mechanism.

on/off,

base

to

prevent

trapped

components

or

footswitch.

extender

when

clothing

when

with

it

is

priming,

raising

skin,

at

the

base.

inside

Alcon

Infiniti™*

in

motion

from

The

and

hair,

the

Refer

service

to

being

IV

pole

bottle

display

and

/or

Do

notexceed

ml).

Excessive

drain

bag

in a hazardous

Inadvertent

handpiece

condition

Inadvertent

system

If

the

handpiece

tuning, there

through

imbalance.

or

collapsing

If

the

Infiniti™*

-

240V

range

should

phase

be

circuit.

maximum

maximum

actuation

is in

that

pressing

is

active

is a potential

the

handpiece

This,

of

in

used

pressure

capacity

condition

the

eye

may

result

will

cause

test

chamber

in

turn,

the

anterior

Vision

System

the

United

on a center-tapped,

capacity

can

resultfrom

and

for

the

of

Prime

can

in

patient

of

Standby

unit

of

and

may

may

chamber.

States

of

drain

bag

(500

exceeding

potentially

patient.

or

Tune

create a hazardous

injury.

switch

to

shut

is

collapsed

low

irrigation

result

cause a shallowing

is

used

or

result

while

when

down.

after

flow

in a fluidic

at

the

220V

Canada,

240V

single

a

it

A

gualified

inspection

twelve

+

*

*

In

Alcon

A

continuity

to

(for

be

standards,

do

Services.

Use

provided

decreased

mobile

this

months:

Warning

Power

Fuses

case

ensure

Cord

of a deficiency,

Technical

qualified

they

example:

recorded,

not

use

of

accessories

RF

medical

technician

of

the

Labels

Services.

technician

for

leakage

are

within

EN60601-1/1EC601-1).

and

if

or

50%

the

system;

may

result

immunity

communications

electrical

must

following

do

current

the

they

are

above

and

cables

in

increased

of

the

equipment.

perform

components

not

use

must

every

applicable

above

initial

call

Alcon

system.

equipment

the

system;

check

twelve

standards

Values

the

applicable

measurement,

Technical

other

than

emissions

Portable

can

a

visual

every

:

ground

months

must

those

and

affect

call

or

1.8

Page 17

ÓN

EIDE

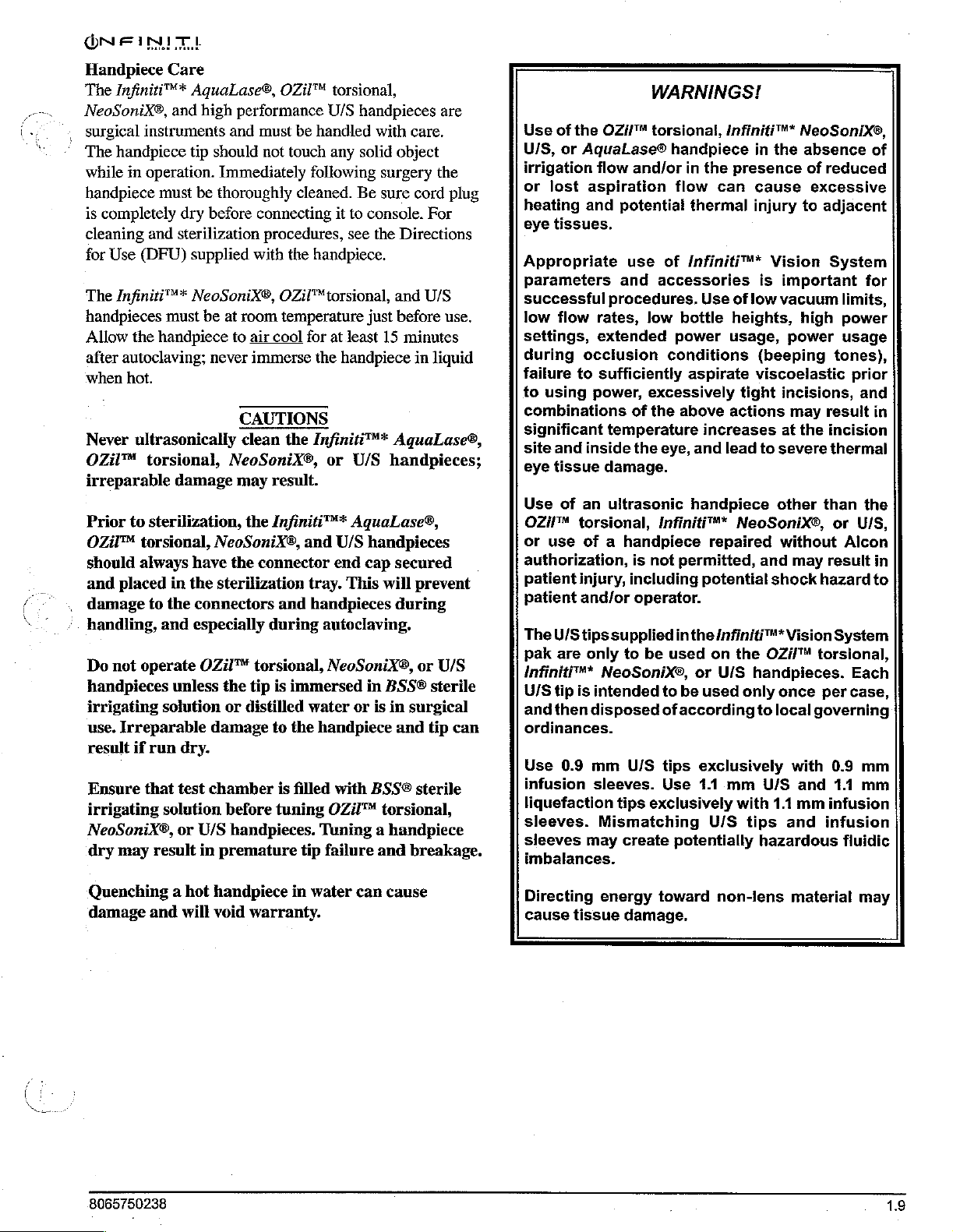

Handpiece

The

Infiniti™*

NeoSoniX®,

.

surgical

The

handpiece

while

in

handpiece

is

completely

cleaning

for

Use

The

Infiniti™*

handpieces

Allow

the

after

autoclaving;

when

hot.

Never

OZil™

irreparable

Prior

OZil™

should

and

damage

handling,

Do

handpieces

irrigating

use.

result

Ensure

irrigating

NeoSoniX®,

dry

ultrasonically

to

placed

not

Irreparable

if

may

Care

AquaLase®,

and

high

instruments

operation.

must

dry

and

sterilization

(DFU)

must

handpiece

torsional,

damage

sterilization,

torsional,

always

in

to

the

and

operate

unless

solution

run

dry.

that

test

solution

or

result

and

tip

should

Immediately

be

thoroughly

before

supplied

NeoSoniX®,

be

at

to

never

NeoSoniX®,

NeoSoniX®,

have

the

the

sterilization

connectors

especially

OZil™

the

or

damage

chamber

before

U/S

handpieces.

in

premature

OZil™

performance

must

be

handled

not

touch

following

cleaned.

connecting

procedures,

with

the

handpiece.

OZil™

room

temperature

air

cool

immerse

CAUTIONS

clean

may

the

connector

torsional,

tip

distilled

for

the

the

Infiniti™*

result.

Infiniti™*

and

tray.

and

handpieces

during

is

immersed

water

to

the

is

filled

tuning

tip

torsional,

U/S

handpieces

with

any

solid

surgery

Be

sure

it

to

console.

see

the

torsional, and

just

at

Jeast

15

handpiece

AquaLase®,

or

U/S

handpieces;

AquaLase®,

U/S

handpieces

end

cap

This

will

autoclaving.

NeoSoniX®,

in

BSS®

or

is

in

handpiece

with

BSS®

OZil™

Tuning a handpiece

failure

torsional,

and

are

care.

object

the

cord plug

For

Directions

U/S

before

secured

during

and

use.

minutes

in

liquid

prevent

or

U/S

sterile

surgical

tip

sterile

breakage.

can

Use

of

the

U/S,

or

AquaLase®

irrigation

or

lost

aspiration

heating

eye

Appropriate

Parameters

successful

low

settings,

during

failure

to

combinations

significant

site

eye

Use

OZiMm

or

authorization,

patient

patient

The

pak

Infiniti

U/S

andthen

ordinances.

Use

infusion

liquefaction

sleeves.

sleeves

imbalances.

and

tissues.

flow

occlusion

to

using

power,

and

inside

tissue

of

an

torsional,

use

of a handpiece

injury,

and/or

U/Stips

are

only

"*

tip

is

intended

disposed

0.9

mm

sleeves.

may

WARNINGS!

OZi/™

flow

rates,

extended

sufficiently

damage.

NeoSoniX®,

Mismatching

torsional,

handpiece

and/or

potential

use

of

and

accessories

procedures.

low

conditions

excessively

of

the

temperature

the

eye,

ultrasonic

Infiniti™*

is

not

including

operator.

supplied

to

be

used

to

ofaccording

U/S

tips

Use

tips

exclusively

create

potentially

Infiniti™*

in

the

presence

flow

can

thermal

Infiniti™*

Use

of

bottle

power

above

permitted,

inthe

be

heights,

usage,

aspirate

tight

actions

increases

and

lead

handpiece

NeoSoniX®,

repaired

potential

/nfiniti™*

on

the

or

U/S

used

only

exclusively

1.1

mm

with

U/S

NeoSonix®,

in

the

absence

of

cause

injury

is

low

(beeping

viscoelastic

to

and

handpieces.

to

U/S

tips

hazardous

excessive

to

Vision

important

vacuum

high

power

incisions,

may

at

the

severe

other

without

may

shock

Vision

OZi/™

once

local

governing

with

and

1.1

mm

and

of

reduced

adjacent

System

for

limits,

power

usage

tones),

prior

and

result

than

result

hazard

torsional,

per

infusion

in

incision

thermal

the

or

UIS,

Alcon

in

to

System

Each

case,

0.9

mm

11

mm

infusion

fluidic

Quenching a hot

damage

8065750238

and

will

handpiece

void

warranty.

in

water

can

cause

Directing

cause

energy

tissue

toward

damage.

non-lens

material

may

1.9

Page 18

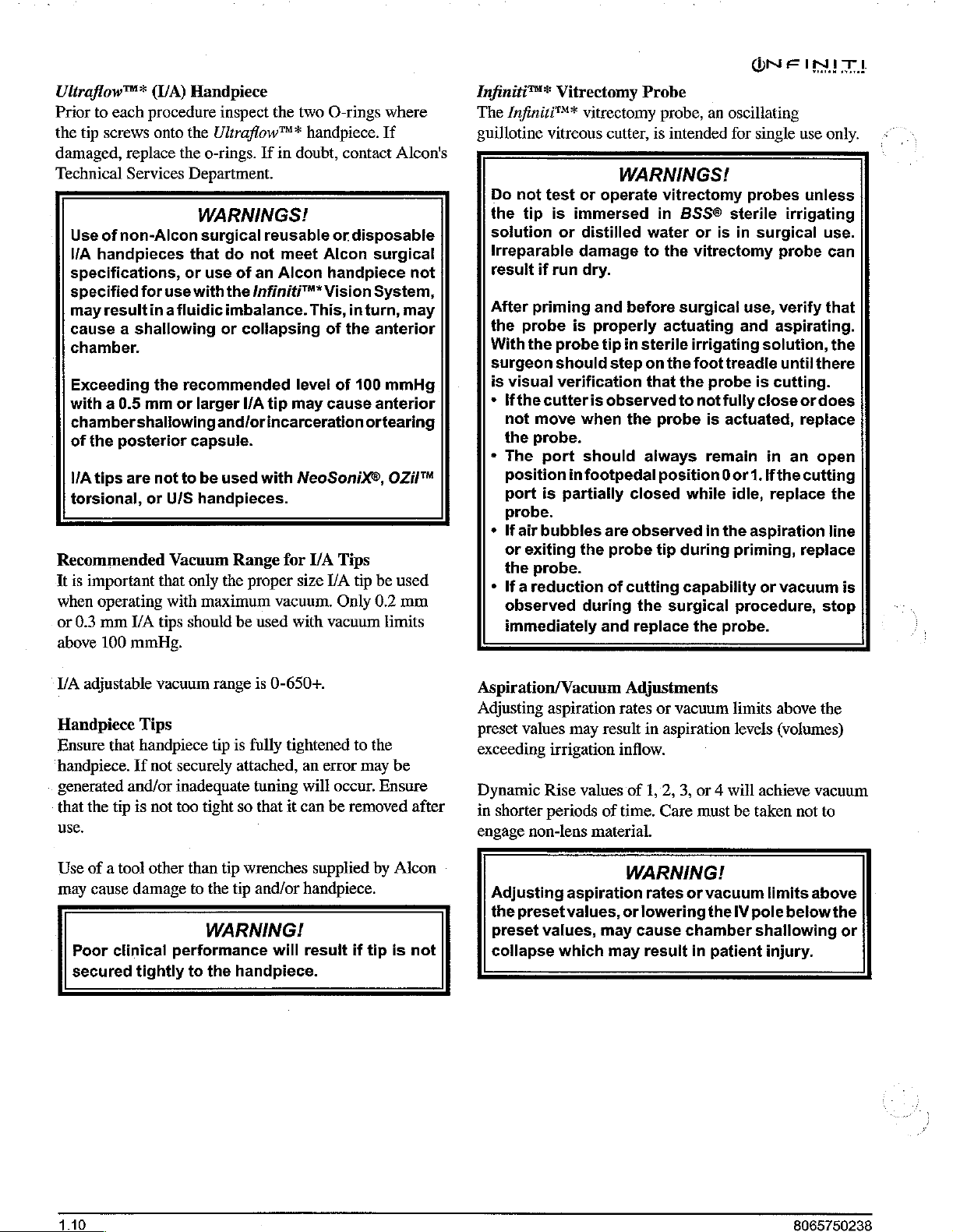

Uliraflow™*

Prior

to

the

tip

screws

damaged,

Technical

Use

of

VA

handpieces

specifications,

specified

may

resultin a fluidic

cause a shallowing

chamber.

Exceeding

with a 0.5

chamber

of

the

VA

tips

torsional,

Recommended

It

is

important

when

operating

or

0.3

mm

above

100

(U/A)

each

procedure

onto

replace

Services

non-Alcon

for

use

the

mm

shallowing

posterior

are not

or

U/S

Vacuum

that

with

WA

tips

mmHg.

Handpiece

inspect

the

Ultraflow™*

the

o-rings.

Department.

WARNINGS!

surgical

that

do

or

use

with

the

imbalance.

or

recommended

or

larger

and/orincarceration

capsule.

to

be

used

handpieces.

only

the

maximum

should

the

If

in

reusable

not

of

an

Infiniti™*

collapsing

I/A tip

with

Range

proper

vacuum.

be

used

two

handpiece.

doubt,

meet

Alcon

Alcon

Vision

This,

level

may

NeoSonix®,

for

VA

size

with

O-rings

contact

or

disposable

surgical

handpiece

System,

inturn,

of

the

anterior

of

100

cause

I/A

vacuum

anterior

ortearing

Tips

tip

be

Only

0.2

where

If

Alcon's

not

may

mmHg

OZiI™

used

mm

limits

Infiniti™*

The

guillotine

Do

the

solution

Irreparable

result

After

the

With

surgeon

is

*

*

*

*

Vitrectomy

Infiniti™*

vitreous

not

test

tip

is

immersed

or

if

run

priming

probe

visual

Ifthe

not

the

The

position

port

probe.

If

air

or

exiting

the

Ifa

observed

immediately

is

the

probe

should

verification

cutteris

move

probe.

port

in

is

partially

bubbles

probe.

reduction

Probe

vitrectomy

cutter,

WARNINGS!

or

operate

distilled

damage

dry.

and

properly

when

should

footpedal

the

during

to

before

tip

in

sterile

step

on

that

observed

the

always

closed

are

observed

probe

of

cutting

the

and

replace

probe,

is

in

water

probe

position 0 or

tip

an

intended

vitrectomy

BSS®

or

is

the

vitrectomy

surgical

actuating

irrigating

the

foot

the

probe

to

not

is

remain

while

in

during

capability

surgical

the

oscillating

for

single

use

probes

sterile

in

surgical

use,

and

treadle

is

fully

close

actuated,

1.

idle,

the

aspiration

priming, replace

procedure,

probe.

unless

irrigating

probe

verify

aspirating.

solution,

until

there

cutting.

ordoes

replace

in

an

open

Ifthe

cutting

replace

or

vacuum

only.

use.

can

that

the

the

line

is

stop

V/A

adjustable

Handpiece

Ensure

handpiece.

generated

that

use.

Use

may

the

of a tool

cause

Poor

secured

that

and/or

tip

clinical

vacuum

Tips

handpiece

If

not

securely

inadequate

is

not too

other

than

damage

tightly

to

performance

to

range

is

tip

is

fully

attached,

tuning

tight

so

that

tip

wrenches

the

tip

and/or

WARNING!

the

handpiece.

0-650+.

tightened

an

will

it

can

supplied

handpiece.

will

resuit

to

error

occur.

be

removed

if

the

may

Ensure

by

tip

be

after

Alcon

is

not

Aspiration/Vacuum

Adjusting

preset

values

exceeding

Dynamic

in

shorter

engage

non-lens

Adjusting

the

preset

preset

collapse

aspiration

may

result

irrigation

Rise

values

periods

values,

of

material.

aspiration

values,

may

which

may

Adjustments

rates

or

vacuum

in

aspiration

inflow.

of

1,2,

3,

time.

Care must

WARNING!

rates

or

or

lowering

cause

result

chamber

in

limits

levels

or 4 will

be

vacuum

the

IV

pole

patient

above

(volumes)

achieve

taken

shallowing

injury.

not

limits

belowthe

vacuum

above

the

to

or

Page 19

Presurgical

Presurgical

outlined

error

message

front

panel,

manual.

When

fluid

is

be

jeopardized.

testing

prior

Ensure

any

phase

Footswitch

Never

pick

Damage

High

Altitudes

Vitrectomy

Consult

Occlusion

\

Two

different

tones

during

or

at its

stopped

the

I/A

during

power

tone

type

a

occlusion

or

The

that

value.

the

8065750238

aspiration

or

is a lower,

of

higher,

AquaLase®

I/A

the

The

phaco

The

phaco

flow.

use

may

Use

AquaLase®

flow

aspiration

potential

Check-out

check-out

in

the

Operating

or

advisory

refer

to

If

the

problem

filling

to

Alcon

preset

to

occlusion

occlusion

occlusion

vacuum

Use

of

and/or

handpiece

weak

or

absent,

for

adequate

entering

that

the

of

operation.

up

or

move

may

result.

cutting

Technical

Tones

occlusion

occlusion)

limit,

avoid

exceeding

tone,

only

AquaLase®

intermittent

tone,

intermittent

occurs

during

magnitude.

has

I/A

occlusion

occlusion

occlusion

of

high

lead

to

the

NeoSonixX®,

handpiece

in

flow

thermal

Tests

tests

must

Instructions

message

the

Troubleshooting

persists,

WARNINGS!

test

good

Good

clinical

irrigation

the

eye.

tubings

performance

and

magnitude). The

double

and

reached

tone

WARNINGS!

U/S

thermal

the

can

injury

are not

the

footswitch

Service

tones

(intermittent

indicate

aspiration

the

sounds

(in

the

phaco

presence

when

the

absence

single

phaco

beep,

application

occlusion

its

tone

can

cannot

bell

indicates

settings

injury.

OZil™

in

the

cause

to

be

performed

section.

is

displayed

DO

NOT

chamber,

fluidics

practice

and

aspiration

occluded

by

may

vary

for

additional

that

the

flow

limit.

The

occlusion

of

YA

beep.

occlusion

and

sounds

of

ultrasonic

tones

maximum

be

turned

be

turned

and/or

torsional,

absence

of

reduced

excessive

adjacent

as

If

an

on

section

response

the

at

vacuum

is

ultrasonic

The

no

eye

of

PROCEED.

if

stream

dictates

during

cable.

high

altitudes.

information.

beeping

is

reduced

first

type,

occurs

occlusion

second

tone,

is

when

power

indicate

allowed

off,

while

off.

aspiration

prolonged

U/S,

of

irrigation

or

heating

tissues.

the

this

of

will

the

flow

near

or

preset

or

lost

and

Vacuum

A

to

that

reduced

Coagulation

Listed

using

*

+

*

*

*

*

*

+

*

Tone

vacuum

the

A

little

OZ が torsional,

in

presence

cause

injury

Do

ml).

drain

in a hazardous

To

only

used

performance

components

To

always

surgical

Interference

frequency

the

Accessories

cables

damage

Operation

extraocular

The

always

Skin-to-skin

and

by

When

and

simultaneously

electrodes

surgical

not

In

frequency

tone

is

amount

little

moderate

to

the

not

Excessive

below

the

ensure

approved

(See

reduce

operation

lowest

body

insertion

physiological

recommended.

all

of

to

no

flow

in

volume,

to

no

flow

absence

of

reduced

excessive

to

adjacent

exceed

bag

maximum

Function

are

Coagulation

safe

cables

your

can

or

the

risk

be

taken

equipment.

produced

surgical

of

should

should

HF

cases,

particularly

to

the

insulation.

of

the

uses

power

be

selected

contact

of

the

of

(high

should

electrodes.

monitoring

current-limiting

provided.

vacuum. A high

is

maximum

pressure

condition

general

operation

Alcon

Alcon-endorsed

when

other

coagulation

only.

patient)

dry

frequency)

on

The

is

occuring.

but not

high

of

be

level

monitoring

be

turned

WARNINGS!

vacuum

occuring.

U/S,

irrigation

heating

eye

capacity

function:

and

representative).

guaranteed

of

accidental

operating

by

equipment

electronic

be

for

the

(for

gauze.

the

placed

Needle

Use

or

AquaLase®

or

lost

and

tissues.

capacity

can

for

precautions

of

the

accessories

the

operation

checked

be

checked

step

in

coagulation

intended

example between

should

surgical

equipment

same

patient,

as

monitoring

systems

devices

pitch

will

vary

vacuum

This

off.

tone

flow

aspiration

result

and

the

coagulation

only

components.

burns,

high-frequency

may

equipment.

regularly;

be

far

incorporating

can

tone

can

may

of

the

NeoSonix®,

handpiece

and/or

potential

of

drain

from

exceeding

potentially

patient.

to

be

followed

must

be

Coagulation

when

using

caution

of

high-

adversely

electrode

for

possible

is

limited

step

should

purpose.

the

avoided,

equipment

are

any

monitoring

as

possible

electrodes

are

recommended.

relative

indicate

be

indicate

in

the

flow

can

thermal

bag

(500

result

when

function,

Alcon

should

influence

to

arms

for

example

used

from

the

are

high

1.11

Page 20

+

The

cables

positioned

or

other

*

Temporarily

so

that

*

The

such

avoided

region

are

sucked

e

Non-flammable

disinfection

+

Flammable

or

as

evaporate

materials,

saturated

produced

+

Do

with

devices.

implanted

devices

that

defibrillatory

and

with

manufacturers

*

Failure

circuitry)

of

The

Infiniti™*

the

effects

Cautery,

The

InfinitiTM*

“Coagulation”

following

Coagulation - an

conductors

electrodes,

some

of

to

in

leads

unused

they

are

use

of

flammable

as

nitrous

if a surgical

of the

thorax

away.

wherever

agents

solvents

before

for

with

in

normal

not

use

pacemakers