Page 1

Data

Sheet

for

Accurus®

300VS,

400VS, 600DS,

800CS

&

Cart

Customer

Model/Platform

NOTE:

Test

Check

2.1.1

Throughout

Any

Equipment:

one

of

the

CONSOLE

2.1.1.1 O Tubing

2.12

2.1.3

2.14

21.5

2.1.6

2.17

2.1.8

2.2.1

CART

Is

there

2.1.2.1

CPU

2.1.3.1

LCD

Is

system

214.3

FRONT

PRESSURE

2.1.6.3

2.1.6.4

CT

No

2.1.6.7

SYSTEM

21.710]

ILLUMINATOR

2.1.8.4

2.1.8.5

LATCH

2.2.1.2

2.2.1.3

2.2.1.4

2.2.1.5

2.2.2

2.2.3

SYSTEM

222.60]

2.2.2.7]

SYSTEM

2.2.3.1

2.2.3.2

this

N/A’s

must

EQUIPMENT

following:

INSPECTION

INSPECTION

an

Accurus

L]

Console

BATTERY

LJCPU

BACKLIGHT

below

CILCD

PANEL

SOURCE

No

Is

pressure

Skip

section

Record

COOLING

Verify

DO

verity

SEAL

Latch

Lİ

Hub

Connectors

Fan

POWER

System

Global

REL & ERROR

Record

XS4

PLATFORM

Data

Sheet

be

explained

and

Manifolds

Cart?

Secured

REPLACEMENT

PCB

battery

REPLACEMENT

s/n

IACL001377?

backlight

TOUCHSCREEN

TEST

audible

pressure

source

2.1.6

low

pressure

Cooling

“BULB

“Bulb

(install

REPLACEMENT

Seal

Roller

Filter

ON

TEST

successfully

arrows

system

software

either

fill

in

the

Preventive

(complete

2.1.1.2

L]

No,

Skip

to

Cart

replacement

lamps

or

2.1.5.2]

leaks

adjustable

[Yes

threshold

Fan

Operation.

FAILURE”

Failure”

ONLY

new

CI

口

keys,

LOG

Message.

bulbs.

/

ACCURUS

Footswitch

Receptacles

completed

Standby

REL,

İİ

in

the

requested

notes

section

Maintenance

section

2.1,

2.1

L]

Filter 2.1.1.3

section

2.1.2.2

has

-

HOT

O

Ne.

Skip

LCD

replacement

are

present.

between

Complete

+

2.1.8.6

2.2

boot-up

Switch

Record

any

Work

of

CALIBRATION

or

then

proceed

PREVENTIVE

2.1.2.

[Lower

been

completed

CATHODE

section

Inspect

90-120

section

C1

Bulb

CONSOLE

sequence.

and

listed

Order

No.

data

or

place a “

this

document.

to

2.2)

MAINTENANCE

L]

CPC

LJ

Yes.

Complete

Compartment

in

less

ONLY

2.1.4

has

been

completed

and

clean

the

psi?

2.1.6

psi

(78 - 83)

is

properly

SERVICE

INSPECTION

Power

Cord.

O

Covers

cassette

eject

Error/Fault

S/N

mark

NUMBER

fittings

section

Door

than

two

O

Yes.

in

front

panel

aligned.

FUNCTIONAL

and

panels

are

backlit.

numbers

2.2.3.3

in

the

bracketed

Service

(start

Call/Installation/Upgrade

at

section

2.1.2

Opens & Closes

(2)

years.

Complete

less

section

than

three

Touchscreen.

TEST

L]

Clear

space,

CALIBRATION

2.2}

2.1.4

(3)

years.

error

log.

(

).

DUE

DATE

Form

ITCDOC-000255,

T

Version

1.0,

Page 1 of

4

E982T22S0+

Parent

Document:

ITCSOP-000578

эчеочзтеен

39

Supercedes:

PEF:60

S0578-01

80

90

REY

Page 2

2.2.4

2.2.5

2.2.6

2.2.7

2.2.8

2.2.9

2.2.10

2.2.11

2.2.12

2.2.13

2.2.14

2.2.15

DIATHERMY

2.2.4.1

2.2.4.3

2.2.4.4 - 2.2.4.5

MEASUREMENT

Frequency

Scope

2.2.4.6

2.2.4.7]

2.2.4.8

PRESSURE

2.2.5.1

Location

Press/Vac

Press/Vac

Press/Vac

Manifold

Manifold

Manifold

2.1.5.2

FOOTPEDAL

22610

GLOBAL

2.2.7.3

CASSETTE

2.2.8.1

2.2.8.2

TOUCH

2.2.9.2]

EXTRUDE

2.2.10.3

MAX

LIMIT

200

400

600

REFLUX

22.11.10

221120

FLUID

2.2.12.3 0 Verify

CASSETTE

2.2.13.3

VGFI

TEST

YGFI

2.2.143[]

BACKUP

2.2.15.2

Data

TEST

DIATHERMY

2)

Audible

Measure

Amplitude

LJ

With

Diathermy

Diathermy

Voltage

LI]

Feedback

REGULATORS

Measure

TP3

<62

TEST

Verify

DEFAULTS

UU

Verify

INSERT

1]

Verify

1)

Verify

SCREEN

Verify

(VACUUM)

Measure

PRESET

TEST

Verify

Verify

LEVEL

SENSOR

SENSOR

Lİ

Using

PRESET

022

070

120

verify

PRESSURE

Measure

2.2.14.2

Sheet

and

faotpedal

Global

Cassette

Cassette

TEST

LOAD

tone

when

and

linearity

Reading

record

Test

Port

ΤΡΙ

TP2

TP3

psi

with

AND

Display

EJECT

Loading

Unloading

for

VERIFICATION

record

power

the

T2

icon

KEY

Touchscreen

MODE

and

record

the

aspiration

aspiration

Sensor

the

Actual

and

#1

#2

TEST

Operation

RECOGNITION

sensor

test

Measure

Display

record

backup

Accurus®

footpedal

is

the

following:

set

to

0,

increases

from

following:

clamped.

changes

TEST

Default

icons

TEST

following:

Reflux

Reflux

Values

Sequence

Sequence

and

handpiece

ACCEPTABLE

(5-BAR

pincher,

pincher,

as

stated

-

MODEL

tool,

verify

and

record

Stability.

pressure

300VS,

Cautery

pressed.

ACCEPTABLE

the

amplitude

2.8 - 4.24

Test

323 - 357

38.9 - 42.5

with

Vdc

Acceptable

82 — 93

Psi

(5-Bar

correspondingly

LEDs

191 — 209

387 — 413

583 — 617

Pressure

cassette

the

ACCEPTABLE

+

select

hammer

hammer

in

Table

800CS

sensor

following:

18—

65-75

113 — 127

3.

400VS,

Load

RANGE

KHz

Vrms

is < 0.7

Vrms.

each

increment

(3.96 - 4.04)

Range

Pressure

27-33

54 — 60

RANGE

sequence.

sequence.

ONLY

Psi

Psi

to

footpedal

function.

is

N/A)

recognition.

RANGE

26

600DS,

Select

treadle

of

Is

ohm

10.

N/A)

and

RECORD

-

-

-

RECORD

+

+

+

mmHg

800CS

(75.0

+/-

RECORD

switches.

mmHg

mmHg

mmHg

MEASURED

mmHg

mmHg

mmHg

(25-35)

&

4.0)

MEASURED

Record

+

+

+

MEASURED

Cart

Work

KHz

Vrms

Measured

pst

psi

psi

VALUE

VALUE

Order

VALUE

Value

No.

Form

ITCDOC-000255,

Version

1.0,

Page 2 of

EsBcTLESO+F

4

Parent

Document:

ITCSOP-000578

эчеэочзтеен

39

Supercedes:

8€+:60

S0578-01

80 90

REH

Page 3

2.2.16

2.2.17

2.2.18

22.19

2.2.20

2.2.21

2.2.22,

STEPS

2.2.23

2.2.24.

Data

ILLUMINATOR

2.2.16.4

D)

Sheet

TEST

Verify

2.2.16,5 C Verify

PROBE

2.2.17.5/2.2.17.12

2.2.17.7/2.2.17.14

2.2.17.18/2.2.18.23

2.2.17.10

2.2.17.25/

2.2.17.27/2.2.17.36

SCISSORS

2.2.18.2

MPC

2.2.19.1

2.2.19.5

2.2.19.6

2.2.19.7

VFC

2.2.20.2

2.2.20.3

2.2.20.5

2.2.20.6

XS3 & XS4

XS3 & XS4

FRAGMATOME

2.2.21.1

2.2.21.2

2.2.21.7,

2.2.21.12,

REMOTE

Does

22.22.10

2.2.23 — 2.2.25

VA

2.2.23.6

CONTINUOUS

2.2.24.1 口 Verify

2.2.24.2

DRIVE

Verify

SCISSORS — X83

MPC

Verify

Verify

Verify

TEST — DOES NOT

VFC

MAX

LIMIT

40

80

LI

VFC

MAX

LIMIT

600

400

200

L]

Is

D)

2.2.21.8

the

Accurus®

MAX

Record

0]

TESTS

XS4

PROBE

2.2.17.34

DRIVE

pressure

LOAD

peak

hold

voltage

INJECT:

Verify

EXTRACT:

Verify

PLATFORM

PLATFORM

the

customer's

口

Yes

Complete

Customer's

LİFragmatome

2.2.21.13

CONTROL

Verify

APPLY

measured

REFLUX

Verify

MODELS

MODEL

pedal

pedal

TEST

have a remote

that

that

that

for

Accurus®

ILLUM 1 operation.

ILLUM 2 operation.

XS2 & XS3

MODELS

Verify

Verify

VERIFICATION:

DRIVE

is

20

&XS4

EXCEPT

EXCEPT

300VS

TESTS

"CLOSE"

"CLOSE"

+/- 2 +,

ONLY

ONLY — ACCURUS

2.2.16.9 0 Bulb

PLATFORMS

300VS-

300VS

output

>29 psi

output

>29

psi

MPC

Test

voltage

voltage

with

hold

disabled

APPLY

Measure

77 — 83

control

Measure

583 - 617

control

ONLY

ONLY

handpiece

Handpiece

[1]

Fragmatome

the

ONLY

vacuum

continuous

continuous

TO

and

ACCEPTABLE

(5-BAR

of

pressure 0 -

and

ACCEPTABLE

(5-BAR

of

vacuum.

2.2.20.100]

2.2.20,110]

section

2.2.21

tunes.

Proportional

control?)

Remote

TO

Control

MODEL

reading

reflux

reflux

300VS

record

the

RANGE

38-42

Pressure

record

RANGE

Pressure

387 - 413

191 — 209

available? 口 Ne

and

2.2.21.4,

Pulse

functions

No

is

600DS

-

pincher

pincher

300VS,

Verify

Verify

+

psi

+.

(18-22).2.2.18.4

Load

Vde

Vde

following:

select

is

80

psi.

the

following:

select

Verify

Verify

record

handpiece

2.2.21.5 口 Fragmatome

functions

Skip

capable

of

or

800CS

mmHg

momentarily

remains

400VS,

is

properly

output > to

output > to

N/A)

(0-70

is

N/A) | -

pressure

pressure

Skip

2.2,21.10 O Fragmatome

section

selecting

23

Verify output

psi

“OPEN”

gsi."OPEN"

L]

(10.0 — 11.6)

(1.0

— 1.4)

for

5-BAR

RECORD

-

and

leakage

steps

2.2.21.2 - 2.2.21.13

s/n

2.2.22 O ves

(387 - 413)

retracts.

retracted.

600DS,

aligned.

23

psi

+

psi

+.

is

>29

output

output

MultiCut

Vde

(0—

RECORD

+

+

Pressure

mmHg

-

vacuum

modes

mmHg

mmHg

is < 10

and

psi.

psi.

psi+

$9

<15

output

ohm

0.1)

MEASURED

psi

psi

select)

MEASURED

readings

psi.

Momentary

Complete

changing

800CS

psi.

psi

+___psi.

psi

+___psi

pulses.

(4.0

+/-

VALUE

VALUE

on

LCD

functions

Fixed

functions

section

preset

&

0.2)

(actual).

2.2,22

values:

Cart

Work

_

、

Order

No.

x

Form

ITCDOC-000255,

g'd

Version

1.0,

Page 3 of

E982T2250+

4

Parent

Document:

ITCSOP-000578

эчеочЗзтеен

39

Supercedes:

РЕФ:

БО

$0578-01

BO

90

REY

Page 4

2.2.25

2.2.26

2.2.27

2.2.28

Data

PHACO

2.2.25.2 Ú Verify

Record

Record

Record

2.2.25.4 I Verify

2.2.25.5

222570

2.2.25.8

ACCURUS

Is

2.2.26.1

2.2.26.4

Handpiece

Handpiece

Handpiece

there

an

(7

0]

[|]

22.26.71)

Does

the

Accurus

C]

Yes.

STP

ACCURUS

2.2.27.1

VV

ACCURUS

Does

2.2.28.1

Pole

the

[]

Max

Accurus®

1]

Sheet

that

s/n

s/n

s/n

that

Verify

Verify

pulsed

JI

Verify

that

CART

VISUAL

Accurus

CART

CART

Cart?

Casters

Mayo

Tray

Cable

Cleats

Cart

is

Completed

FUNCTIONAL

Check

here

(113

to

REMOTE CONTROL

have a remote

Verify

Remote

that

117)

for

Accurus®

Phaco

Handpiece

detents I and

U/S

power

is

U/S

power

U/S

pulse

rate

INSPECTION

[7]

No.

STP

2.2.26.2

2.2.26.5(]

have a Manual

O

No.

TESTS

if

ceiling

height

control?

Control

raises

tunes

2 are

felt.

linear

while

and

linear

varies

from 1 to

(if

applicable)

is

Completed

C]

Cables

VGFVAVGFI

IV

Pole?

Continue

prohibits

cmH;0.

VERIFICATION

Lİ

and

lowers

300VS,

Is

Is

Is

in

footswitch

vacuum.

L]

Pole

to

step

maximum

I/V

Pole

No.

STP

I/V

400VS, 600DS,

this a customer

this 2 customer

this a customer

position

15

pps.

Yes

Complete

2.2.26.3 ] Drawers

2.2.26.6

2:2.27

of

115

Min

Complete

Pole.

Section

O]

cmH,O.

(5 to 9)

Lİ

handpiece?

handpiece?

handpiece?

3.

2.2.26

Writing

Record

Yes.

Complete

800CS & Cart

[]

Ne O Yes

[]

No

LU)

Yes

D]

No

CJ

Yes

Tablet

Max

allowed.

<mH,O

section

2.2.28

Work

Order

No.

_____

Test

Performed

Notes:

Was

By

(PRINT)

system

tested

using

5-BAR

pressure

selection? O ne

Signature Date

Lİ

Yes-

N/A

listed

for

all

pressures

exceeding

450

mmHg.

above

70psi and

vacuums

Form

ITCDOC-000255,

pod

Version

1.0,

Page 4 of

E982T2250+

4

Parent

Document:

ITCSOP-000578

еэчеэчзтеен

39

Supercedes:

Ebb:60

50578-01

80 90

REY

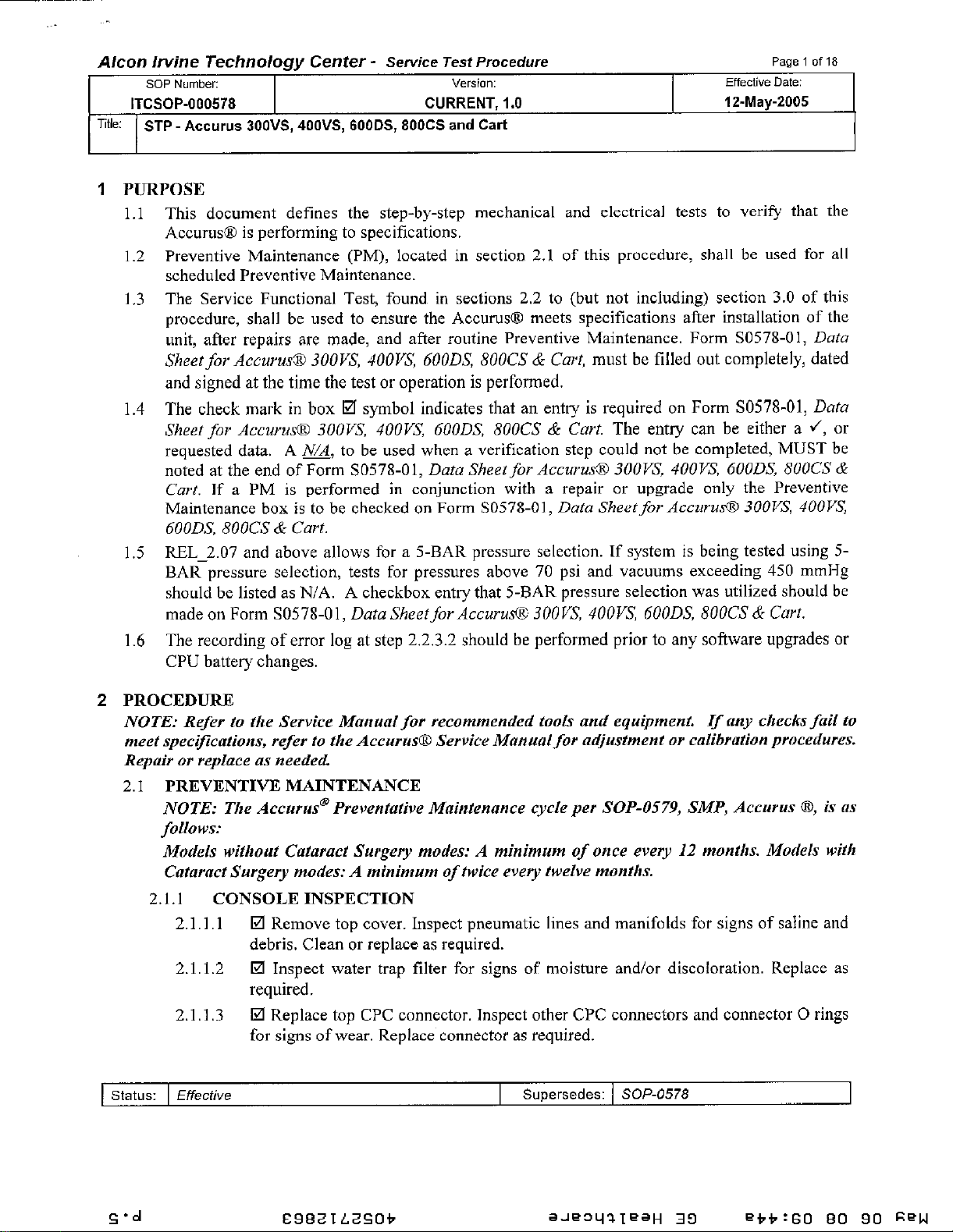

Page 5

Alcon

Title: | STP-

1

SOP

ITCSOP-000578

PURPOSE

1.1

1.2

1.3

14

1.5

1.6

Irvine

Technology

Number:

Accurus

This

document

Accurus®

Preventive

scheduled

The

Service

procedure,

after

unit,

Sheet

for

and

signed

The

check

Sheet

for

requested

noted

at

Cart.

If a PM

Maintenance

600DS,

REL

2.07

BAR

pressure

should

made

The

CPU

be

on

recording

battery

Center - Service

300VS,

is

Maintenance

Preventive

shall

repairs

Accurus®

at

mark

Accurus®

data. A N/A,

the

800CS & Cart.

and

listed

Form

400VS, 600DS,

defines

performing

Maintenance.

Functional

be

used

made,

are

300VS,

the

time

the

in

box

300VS,

end

of

Form

is

performed

box

is

to

be

above

selection,

S0578-01,

of

allows

as

N/A. A checkbox

error

log

changes.

CURRENT,

800CS

the

step-by-step

to

specifications.

(PM),

Test,

to

test

WI

to

S0578-01,

tests

Data

located

found

ensure

and

400VS,

or

operation

symbol

400VS,

be

used

in

checked

for a 5-BAR

for

Sheet

at

step

the

after

600DS,

indicates

when a verification

Data

conjunction

on

pressures

for

2.2.3.2

Test

Procedure

Version:

and

Cart

mechanical

in

section

in

sections

Accurus®

routine

800CS & Cart,

is

performed.

that

600DS,

Form

entry

800CS & Cart.

Sheet

S0578-01, Data

pressure

above

that

Accurus®

should

1.0

and

electrical

2.1

of

this

2.2

to

(but not

meets

Preventive

specifications

Maintenance.

must

an

entry

is

step

could

for

Accurus®

with a repair

Sheet

selection.

70

psi

and

5-BAR

be

pressure

300VS, 400VS,

performed

procedure,

including)

be

filled

required

The

entry

not

300VS,

or

upgrade

for

Accurus®

If

system

vacuums

selection

600DS,

prior

to

Effective

tests

on

be

400VS,

any

12-May-2005

to

verify

shall

be

section

after

installation

S0578-01,

Form

out

completely,

Form

50578-01,

can

be

completed,

600DS,

only

is

being

exceeding

was

utilized

800CS & Cart.

software

Page 1 of

Date:

that

used

for

3.0

of

of

Data

dated

Data

either a Y,

MUST

800CS

the

Preventive

300VS,

tested

450

400VS,

using

mmHg

should

upgrades

18

the

all

this

the

or

be

&

5-

be

or

2

PROCEDURE

NOTE:

meet

Repair

2.1

Refer

specifications,

or

replace

PREVENTIVE

NOTE:

follows:

Models

Cataract

2.1.1

2.1.1.1

21.12

2.1.1.3

|

Status: | Effective

to

the

as

The

Accurus®

without

Surgery

CONSOLE

MW

debris.

M1

required.

MM

for

Service

refer

needed.

to

Manual

the

Accurus®

MAINTENANCE

Preventative

Cataract

Surgery

modes: A minimum

INSPECTION

Remove

Inspect

Replace

signs

top

Clean

water

top

of

wear.

cover.

or

replace

CPC

for

recommended

Service

Maintenance

modes: A minimum

of

twice

trap

Inspect

filter

pneumatic

as

required.

for

connector.

Replace

connector

tools

Manual

for

cycle

per

of

every

twelve

lines

signs

of

moisture

Inspect

other

as

required.

|

Supersedes: | SOP-0578

and

equipment.

adjustment

SOP-0579, SMP,

once

every

months.

and

manifolds

and/or

CPC

connectors

If

any

checks

or

calibration

12

months.

for

signs

discoloration.

and

procedures.

Accurus

Models

of

Replace

connector O rings

fail

®,

saline

to

is

as

with

and

as

gcd

E982T2250+

SJEDUJTESH

39

Pbb:6O

BO 90

REH

Page 6

Alcon

Title: | STP - Accurus

irvine

SOP

ITCSOP-000578

Technology

Number:

2.12

VISUAL

NOTE:

Accurus®

2.1.2.1

2.1.2.2 M Check

2.13

REPLACEMENT

2.1.3.1 M Replace

2.14

2.1.5

REPLACEMENT

2.1.4.1

2.142

2.1.4.3

INSPECT

2.1.5.1

2.1.5.2.

2.1.6

PRESSURE

2.1.6.1

2.1.6.2

2.1.6.3

2.1.64

2.1.6.5

2.1.6.6

2.1.6.7

2.1.6.8

Center - Service

300VS,

M

clamps.

system

previous

M

IACL001377

M

Display

Replace

less

Look

necessary.

M1

based

Plug

Set

psi.

M

on

and

Power

Decrease

System

advisory

air

WM

pressure/vacuum

removed

Set

400VS, 600DS,

INSPECTION

If

system

300VS,

Check

to

to

date

two

Does

Has

it

have

than

the

been

the

three

AND

for

cracks

Inspect

and

window

SOURCE

unit

into

pressure

Verify

Ifa

Form

there

regulated,

S0578-01,

proceed

On

system.

air

Advisory

“Press 5 bar

pressure”

Using

air

blue

from

source

does

400VS,

ensure

ensure

OF

the

of

years,

OF

system

and

been

backlight

years

CLEAN

cleaner.

standard

source

to

step

source

appears,

screen.

Pressure

CURRENT,

800CS

OF

ACCURUS

NOT

have a Cart,

600DS,

that

Accurus®

that

the

CPU

BATTERY

battery

per

manufacture

then,

skip

LCD

BACKLIGHT

use a LCD

below)?

three

replaced?

years

lamps

from

If

date

THE

or

other

physical

clean,

as

necessary,

TEST

outlet

Regulator

are

no

leaks

adjustable

Data

Sheet

2.1.7.

Pressure

“Please

metric

manifold

adjust

for low

select

tubing,

Verify

Regulator

Test

Procedure

Version:

1.0

and

Cart

CART

indicate

800CS & Cart,

console

lower

compartment

instruction

or

the

CPU

to

step

2.1.4.

display

yes,

complete

or

more

since

If

yes,

proceed

per

instruction

of

this

PM).

FRONT

PANEL

damage

touchscreen

and

connect

to

120

psi,

by

confirming

90-120

“Standard”.

assy.

low

psi

for

Accurus®

Regulator

supply

pressure

connect

Slowly

pressure

back

to

(if

applicable)

on

and

is

attached

door

in

the

Accurus

battery

LAMPS

with

step

2.1.4.

the

LCD

to

next

in

the

TOUCHSCREEN

to

the

footswitch

or

the

highest

no

audible

pressure

(to

source

operation

pressure

increase

threshold

90

source

300VS, 400VS,

about

pressure

to

120

Form

proceed

replacement

(Hot

hot-cathode

Accurus

front

with

pressure

psi.

S0578-01,

to

to

the

opens

and

Service

Cathode

If

no,

skip

backlight

step.

If

no,

Service

panel

damp

to

rear

of

pressure

hissing

is

not

60-70

or

meter

is

psi)

from

press

Standard

to

until

approximately

Page 2 of

step

2.1.3.

cart

Effective

12-May-2005

Date:

Data

with

closes.

Manual

has

occurred

LCDs

lamps

proceed

step

2.1.4.

lamps

Manual

only)

(systems

or

to

step

touchscreen,

cloth

or

non-ammonia

unit.

available

is

present.

available,

600DS,

until

90

to

85

psi

System

below

indicate

800CS & Cart,

unit

120

psi”.

and

test

Advisory

78-83

18

Sheet

for

two

knob

unless

in

the

LCD

2.1.5.

(must

the

the

s/n

replace

120

displays

If

the

increase

port

on

psi.

be

if

so

is

|

Status: | Effective

gcd

E982T2250+

|

Supersedes: | SOP-0578

ΘΩΒΟΙΗΣΤΕΘΗ

39

eS+:60

80 90

Рен

Page 7

Alcon

Title: | STP - Accurus

Irvine

SOP

ITCSOP-000578

Technology

Number:

300VS,

Center - Service

400VS,

600DS,

800CS

Test

Procedure

Version:

CURRENT,

and

Cart

1.0

Page 3 of

Effective

12-May-2005

Date:

18

2.1.7

2.1.8

SYSTEM

2.1.7.1

2.1.7.1.1

2.1.7.1.2

ILLUMINATOR

MM

2.1.8.1 | Ensure

2.1.8.2

2.183

Press

Remove

2.1.8.4 M Verify

Out

2.1.8.5

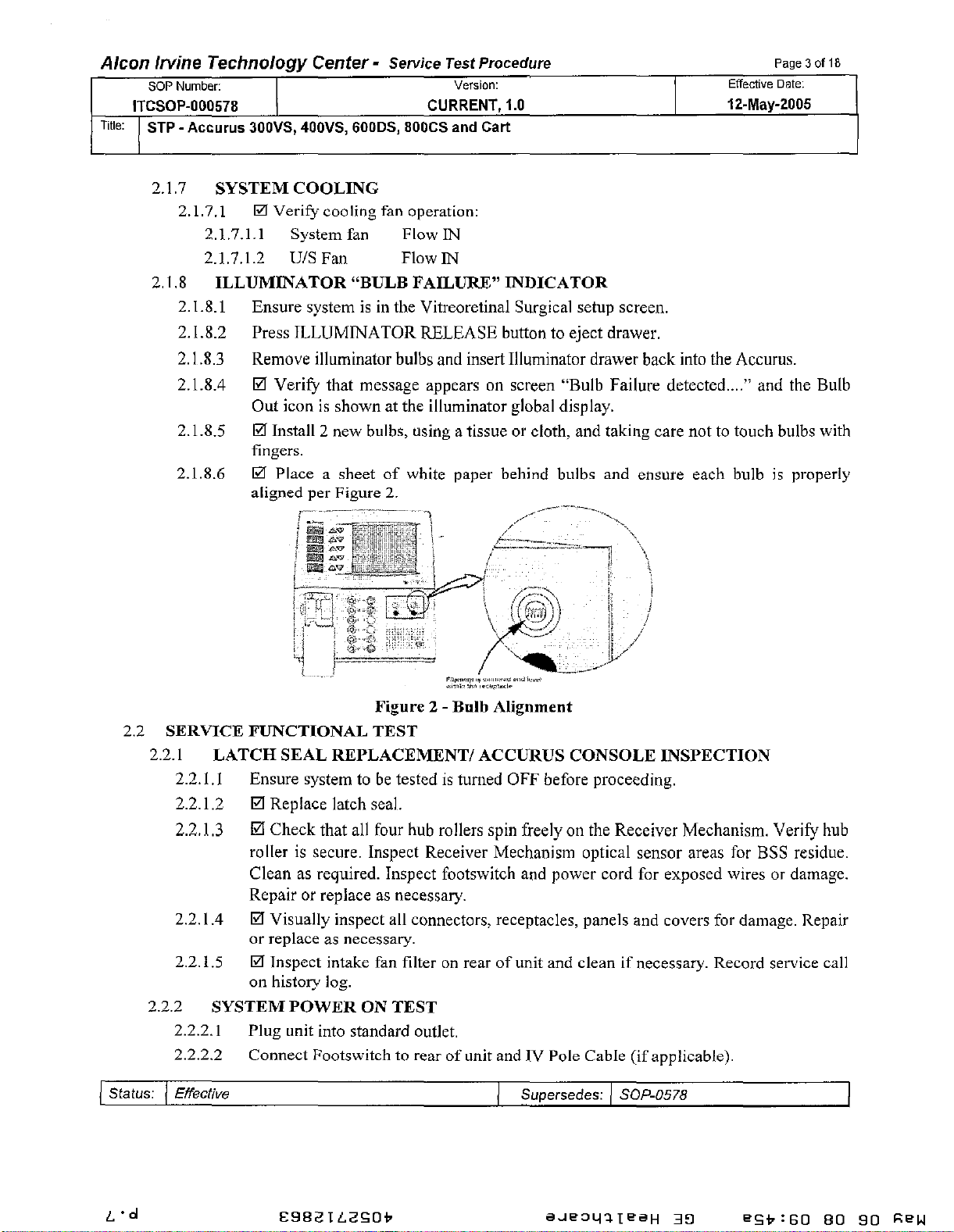

2.1.8.6

HM

fingers.

M

aligned

COOLING

Verify

cooling

System

U/S

Fan

system

fan

“BULB

is

ILLUMINATOR

illuminator

that

message

icon

is

shown

Install 2 new

Place a sheet

per

bulbs,

Figure

fan

operation:

Flow

Flow

IN

FAILURE”

in

the

Vitreoretinal

RELEASE

bulbs

and

appears

at

the

illuminator

using a tissue

of

white

2.

IN

paper

INDICATOR

Surgical

button

insert

I!luminator

on

screen

global

or

behind

to

eject

“Bulb

display.

cloth,

bulbs

setup

drawer.

drawer

Failure

and

taking

and

screen.

back

detected....”

care

ensure

into

the

not

each

Accurus.

and

to

touch

bulb

the

bulbs

js

properly

Bulb

with

22

SERVICE

22.1

LATCH

2.2.1.1

22.12

22,13

22.14

2.2.1.5

222

|

Status: | Effective

SYSTEM

2.2.2.1

2.2.2.2

FUNCTIONAL

SEAL

Ensure

1

M

roller

Clean

Repair

Ы

or

ΠΜ

on

Plug

Connect

system

Replace

Check

Visually

replace

Inspect

history

that

is

secure.

as

required.

or

replace

POWER

unit

into

Footswitch

Figure 2 -

TEST

REPLACEMENT/

to

be

tested

latch

seal.

all

four

Inspect

Inspect

as

necessary.

inspect

as

intake

log.

all

necessary.

fan

filter

ON

TEST

standard

to

Bulb

ACCURUS

is

turned

hub

rollers

Receiver

footswitch

connectors,

on

rear

outlet.

rear

of

unit

Alignment

CONSOLE

OFF

before

spin

freely

Mechanism

and

receptacles,

of

unit

and

IV

Supersedes: ] SOP-0578

proceeding.

on

the

optical

power

and clean

Pole

cord

panels

Cable

INSPECTION

Receiver

Mechanism.

sensor

for

exposed

and

covers

if

necessary.

(if

applicable).

areas

for

Record

for

BSS

wires

damage.

Verify

residue.

or

damage.

Repair

service

hub

call

L*d

EI8ZIZAZSOb еэчеочзтеен

39

ES+:60

80 90

ReW

Page 8

Alcon

Title: | STP - Accurus

Irvine

SOP

ITCSOP-000578

Technology

Number:

300VS,

Center

400VS,

Service

-

600DS,

CURRENT,

800CS

Procedure

Test

Version:

and

Cart

1.0

18

of

4

Page

Date:

Effective

12-May-2005

2223

2.2.2.4

2.2.2.5

2.2.2.6

2227

Connect

Power

Verify

MM

Verify

Procedure

M

Verify

backlit.

2.2.3

System

REL/

2.2.3.1 M Record

locations:

2.2.3.1.1

223,12

223.13

2232

2233

M

XS4

this

note

800CS & Cart.

the

Order

M

XS4

pressure

On

system.

that

that

Selection

that

Error

XS2:

Procedure

XS3:

XS4:

“Options,

ONLY

window.

section

Service

notes.

ONLY

source.

“Accurus*”

all

Global

Screen

all

Global

Log

system

Surgery

of

Management

With

When

Form

Upon

software

Setup

About.”

error

After

logo

is

displayed

Display

is

displayed

Arrow

REL

Selection

the

S0578-01,

processing

recording

Screen

Screen

“About”

log

appears,

Software

Error/Fault

segments

Keys,

Standby

number.

window

record

Data

call

completion,

system

during

light

at

the

end

This

displayed,

any

Sheet

for

(Dispatch,

numbers,

entire

(all

8*s)

of

boot

Switch

can

listed

Accurus®

list

select

boot-up

and

press

Error/Fault

these

period.

during

up.

Cassette

be

found

the

lower

300VS,

error/fault

Siebel,

boot

“Clear

up

Eject

in

the

left

numbers

400VS,

$2000,

Log”.

and

that

Switch

following

portion

onto

600DS,

numbers

etc.)

Work

the

are

of

the

into

224

DIATHERMY

2.2.4.1 M Prior

2.2.4.2

2243

2244

2245

2.2.4.6 M Set

2247

2.2.4.8 M Ensure

|

Status: | Effective

to

load

box

resistance.

to

any

jacks

is

75.0

+/-

Insert

75

ohm

of

load

box.

MW

Press

Left

MH

Verify

M

Verify

frequency

Vrms

Diathermy

Vrms.

M

While

increments

of

10.

DMM

to

verify

to

read

Figure 3 for

reading

TEST

using

the

cautery

Ensure

(open).

4.0

Set

Vertical

Verify

ohms.

load

box

Diathermy

switch

is

is

38.9 - 42.5.

power

continuing

of

10’s

up

Diathermy

DC

voltage

location

to

be

3.96-4.04

test

that

the

into

Diathermy

power

on

from

323-357

to

0.

to

depress

to

100.

Verify

power

is

and

reference).

vde.

load,

perform

the

banana

resistance

output

to

100.

footswitch

KHz.

Fully

depress

Footswitch,

increase

set

for

connect

to

Press

|

Supersedes: | SOP-0578

plugs

across

and

foot

of

100%

MP9(+)

Left

the

following

of

the

the

two

jacks.

Connect

verify

pedal

increase

2.8 - 4.24

and

load

and

vertical

Test

test

an

audible

and

power

Vrms

box

MP7(-)

switch

procedure

Load

are

not

points

verify

of

the

Oscilloscope

tone

is

amplitude: < 0.7

on

front

for

each

is

still

connected.

on

COAG

on

footswitch

to

verify

connected

Test

Load

to

output

heard

panel

increment

PCB

(refer

the

in

Set

and

|

gcd

ES8cTLeSOr

SABSIUITESH

39

eS+:60

80 90

FEW

Page 9

Alcon

Tile: | STP - Ассигиз

Irvine

SOP

Number:

ITCSOP-000578

Technology

300VS,

Center - Service

400VS, 600DS,

800GS

Test

Version:

CURRENT,

and

Procedure

1.0

Cart

Page 5 of

Effective Date:

12-May-2005

18

2249

Remove

setting

225

2.2.6 | FOOTPEDAL

22.7

PRESSURE

2.2.5.1

22.52

2.2.5.3

2.2.6.1

GLOBAL

2.2.7,1

М

pressure/vacuum

listed

Cart.

M

and

Install

EI

Verify

pressed.

Install

NOTE:

restarted

of

Lo

REGULATORS

Using

on

While

ensure

top

While

that

DEFAULTS

top

If,

Diathermy

44.

|

Figure 3 -

blue

metric

manifold

Form

S0578-01, Data

measuring

that

pressure

cover.

observing

cover.

at

TEST

the

after

step

The

icon

AND

Remaining

this

2.2.2.

load

box

tubing,

assy

TP3

(57psi),

does

not

remaining

the

footpedal

changes

KEY

tests

step,

removal

and

Scopemeter.

COAG

Sheet

PCB

connect

and

verify

for

Accurus®

clamp

go

tests

appropriately

off

above

should

icon,

TEST

will

be

performed

of

top

Set

pressure

readings

T2

tubing

62

psi.

be

performed

press

as

cover

Diathermy

meter

are

within

300VS,

400VS,

for a minimum

with

footpedal

the

treadle

with

top

is

required,

preset

to

the

600DS,

top

cover

treadle

and

cover

on.

the

to

the

default

test

ports

on

specifications

of

800CS

30

&

seconds

on.

and

switches.

each

STP

switch

must

is

be

2.2.7.2

[

Status: | Effective

6

'd

Connect

EIBCTLECSOF

plug

fitting

to

VGFI/

F/AX

port.

Refer

to

Figure 4 for

Supersedes: | SOP-0578

SYPOUITESH

39

port

location.

E9+:60

80 90

REM

Page 10

Alcon

Title:

SOP

ITCSOP-000578

| STP - Accurus

Irvine

Number:

Technology

300VS,

Center

400VS,

-

600DS,

Service

CURRENT,

800CS

Procedure

Test

Version:

and

Cart

1.0

6

Page

Effective

12-May-2005

Date:

of

18

2.2.73 M

Arrows

22.8

2.2.8.]

GLOBAL

ILLUM

ILLUM

NOTE:

VGFI

FAX

DIATH

CASSETTE

E

loading

1)

2)

3)

4)

2.2.8.2 M Press

1)

2)

2.2.8.3

Reinsert

Verify

|

2

Insert

Cassette

Tubing

Pumps

Vacuum

Tubing

Cassette

Figure 4 -

all

Global

when

each

function

Turn

ON

Global

DEFAULTS

REL

4.51

Table 1 -

INSERT/EJECT

posterior

sequence:

latches

loads

onto

runs

(clockwise).

check

eject key.

cassette.

Verify

unloads

ejects

o

scissors()

STOP-

inactive)

VGFI&

Display

(press

AND

030

035

050

080

080

Global

test

cassette

into

mechanism.

hub

passes.

the

from

hub

from

mechanism.

mor

O)

ASCURUS

mew(

)

O

Αυτα

COCK

FIAX

O

Connectors

Default

is

selected.

icon)

ABOVE

Display

into

roller.

following

roller.

o

0

0 o ο

0

©

0

0

ο

O

1

ο

L

values

to

display

Default

receiver

unloading

Us-FRAG

O

MPC

SPARE

O

ФЕ

O

DIATHERMY

HANDPIECE

LEDs

in

default

REL

Values

mechanism.

sequence:

(14)

Table | are

value.

DEFAULTS

4.03

AND

022

035

044

080

080

Verify

adjustable

BELOW

the

with

the

following

Status: | Effective

nr*g

ES8cTLeSOr

Supersedes: | SOP-0578

SABSIUITESH

39

es+:60

80 90

Fey

Page 11

Alcon

Title: | STP - Accurus

Irvine

SOP

ITGSOP-000578

Technology

Number:

300VS,

Service

Center

400VS, 600DS,

-

CURRENT,

800CS

Procedure

Test

Version:

and

Cart

1.0

18

of

7

Page

Effective

12-May-2005

Date:

2.2.9

TOUCH

2.2.9.1

Select

NOTE:

2.2.9.2 E Press

corresponding

NOTE:

VENTED

FLUID?

SCREEN

TEST/HANDPIECE

SURGERY

CONTINUE

Press

each

icon

result

Diathermy

GAS

roce,

INFUSION

(VGFI)

AIR

EXCHANGE]

DIATHERMY

ILLUMINATOR

παπα...

P|

1—T

VITREOUS

FRAGMENTATION

mode.

on

for

is

|

Г]

Г]

Г]

(VIT)

when

screen

each

icon

activated

r>uoro

SURGICAL

{FRAG}

SCISSORS’

LED

System

as

indicated

as

shown

through

"ACTUAL

VALUE

TEST

Information

in

Figure 5 -

in

Table

the

footswitch.

RD

QD

VISCOUS

EXTRUDE

message

2.

exit

FLUID

CONTROL

appears

Touch

(VFC}

screen.

on

Screen.

Verify

ICON

GLOBAL

Surgical

MAX

LIMIT | Increments/decrements

CUT

RATE | Increments/decrements

2.2.10

2.2.10.1

2.2.10.2

2.2.10.3

|

Status: | Effective

RESULT

|

Icon

through

lights

Mode

except

EXTRUDE

turns

blue;

footswitch),

(except

change

for

Illumination 1 &

occurs,

EXIT,

(VACUUM)

Insert

Posterior

Connect

next

Lİ

meter

Sheet

vacuum / pressure

to

it).

Press

(measured)

for

Accurus®

Figure 5 -

Global

display

an

audible

icon

turns

and

corresponding

mmHg

cpm

Table

MODE

test

cassette.

footswitch

and

300VS,

brightens

key

2).

blue,

value

value

2-Touch

fully

DOWN.

LCD

400VS,

Touch

(all

press

tone

an

audible

handpiece

and

an

and

an

audible

Screen

TEST

Select

meter

EXTRUDE:

to

(actual)

600DS,

]

Screen

globals

audible

aspiration

Verify

at

the

Supersedes: | SOP-0578

except

is

heard,

key

LED

key

Test

and

press

and/or

key

press

press

tone

High

connector

vacuum

settings

800CS & Cart.

listed

Diathermy,

corresponding

Asp# 1 and 2 LED

tone

tone

mode.

reading

voice

confirmation

is

heard.

is

heard.

#2

(with

on

vacuum / pressure

on

Form

activate

Diathermy

handpiece

is

lights,

illuminated

$0578-01, Data

LED

heard

LED

TT

а

E982T2250+

SJEDUJTESH

39

eLb:60

80 90

REH

Page 12

Alcon

Tile: | STP - Accurus

Irvine

SOP

ITCSOP-000578

Technology

Number:

300VS,

Center

400VS,

-

600DS,

Service

Test

CURRENT,

800CS

Procedure

Version:

and

Cart

1.0

18

of

8

Page

Effective

12-May-2005

Date:

2.2.11

2212

REFLUX

2.2.11.1

2.2.11.2

2.2.11.3 M Select

FLUID

2.2.12.1

22.122

22.123

TEST

#.

1

2

3

4

5

6

7

8

9

TEST

WActivate

pincher

Step 1 Bottom

Step2

Step3

Step

Repeat

System

the

reflux

aspiration

LEVEL

Press

Select

tool

in

Note:

insertion

El

Wait

failed

tool

using

and

verify

NOTE:

removing

ACTION

Block/Open

Block

Open

Block / Open

Block

Open

Block

Block

Open

the

right

and

hammer

Middle

Top

4

Middle

ten

test

Advisory

function

line.

VIT

mode

SENSOR

EJECT

key

Extrude.

slot

while

Placement

into

Receiver

until the

vacuum

test....... ” appears

the

narrow

proper

S1 = Bottom

tool

in

52

SI

Sl

SI

SI

Open

SI

SI

heel

sequence

Out

Out

In/Out

and

and

times

“Apply

will

be

and repeat

TEST

and

remove

Insert

Sensor

testing

level

of

Sensor

Mechanism

loading

end

operation

Sensor,

sensor

slot

RESULT

Pump

Pump

Pump

53 | Pump

Pump

Pump

54 | Pump

Pump

Pump

Table 3 -

switch

as

bottom

ensure

vacuum

locked

step

test

Test

sensors.

Test

sequence

over

of

the

or

press

Runs

Stops

Runs

Runs

Stops

runs

Runs

Stops

runs

Fluid

and

follows:

retract

that

to

out

2.2.11.1.

cassette.

Tool

Tool

to

has

on

the

left

sensors

S4 = Top

approximately

approximately

Msg:

(Message

approximately

Level

verify

proper

in

activations

ten

after

enable

until a vacuum

initiate

screen

“Eject”

additional

wide-end

in

completed.

Level

as

“Draining

into

Cassette

loading

select

Sensors

listed

Sensor.

to

stop

15

removed)

15

Sensors

operation

Reflux

is

applied

Cassette

ID

Sensor

sequence.

When

in

15

cassette.

system

OK

to

in

Table

Ensure

the

pump

seconds

seconds

seconds

of

aspiration

reflux

the

pulses”

to

the

ID

sensor

simulates

advisory

continue.

the

Receiver

3.

pump

from

please

wait”

#2

reflux

locked

is

appears

corresponding

slot.

Place

Mechanism

stops

running.

out.

and

Leave

cassette

“Cassette

the

other

before

2.2.12.4

|

Status: | Effective

21'd

Remove

E982T2250+

sensor

tools

and

press

Eject

key

if

necessary.

Supersedes: | SOP-0578

SJEDUJTESH

39

eLb:60

80 90

REH

Page 13

Alcon

Title

SOP

ITCSOP-000578

| STP - Accurus

Irvine

Number:

Technology

300VS,

Center - Service

400VS,

600DS,

800CS

Test

Version:

CURRENT,

and

Procedure

1.0

Cart

Page 9 of

Effective

12-May-2005

Date:

18

2213

2.2.13.1

2.2.13.2

22133

M

COMBINED

ONLY

Press

Insert

slot.

“Cassette

does

portion

M

Verify

“Exit”

the

Refer

NOT

of

PROCEDURE

to

return

narrow

to

that

type

end

Figure 8 for

the

cassette

does

display.

the

slot,

LEFT

ASPIRATION

to

of

not

NOTE:

the

advisory

|

CONT

the

“Procedure

the

sensor

Cassette

latch

match

If

IRR

PINCHER

(Anterior)

CASSETTE

test

ID

sensor

moves

surgical

the

sensor

should

ASPIRATION

display.

RIGHT

RECOGNITION

Selection”

tool

into

slot

reference.

to

the

down

mode.

Please

test

TOP

PINGHER

REFLUX

HAMMER

BOTTOM

PINGHER

CASSETTE

LATCH

LEVEL

SENSORS

CASSETTE

SENSORS

CHAMBER

LED

tool

screen.

the

top

position

insert

covers

(4}

ID

(3)

Select

of

the

and

the

the

MODEL

“Combined”.

Cassette

that

correct

center

ID

the

cassette.”

or

800CS

sensor

advisory

bottom

|

Status:

22.14

2.2.14.1

22142

22.143

2.2.144

2.2.15

2.2.15.1

|

Effective

WGFI

TEST

Connect

WM

Select

meter

800CS & Cart.

BM

Verify

mmHg.

Remove

BACKUP

Ensure

connector

Figure 8 -

vacuum / pressure

global

as

listed

Actual

vacuum / pressure

PRESSURE

a

preset

until

icon

on

Form

Display

above

message

Receiver

meter

to

for

VGFI.

S0578-01, Data

35mmHg

appears

Measure

Stability: + 1

meter

and

is

on

|

HUB

ROLLER

Mechanism

VGFI

infusion

and

Sheet

mmHg

tubing.

selected.

screen:

Supersedes:

port

with

record output

for

Accurus®

at

120

mmHg,

Allow

air

|

SOP-0578

to

tubing.

on

vacuum / pressure

300VS,

free

400VS,

70

mmHg

flow

from

600DS,

and

22

VGFI

ET'd

E982T2250+

SJEDUJTESH

39

eLb:60

80 90

REH

Page 14

Alcon

Title:

|

Irvine

SOP

ITCSOP-000578

STP

Technology

Number:

-

Accurus

300VS,

Center

400VS,

Service

-

600DS,

CURRENT,

800CS

Procedure

Test

Version:

and

Cart

1.0

Page

Effective

12-May-2005

Date:

10

of

18

2.2.15.1.1

2.2.15.2 M Connect

mmHg.

2.2.16

ILLUMINATOR

WARNING!

OUTPUT

IN

FRONT

2.2.16.1

2.2.16.2

2.2.16.3

2.2.16.4

2.2.16.5

2.2.16.6

2.2.16.7

Turn

Using

intensity

Using

that

M Turn

and

M

Tum

Press

and

2.2.16.8

2.2.16.9

2.2.17

22.171

Re-insert

then

M4

PROBE

interfacing

on

Service

XS2 & XS3

NOTE:

Accurus®

22.17.2

XS2/XS3

VIT

female

2.2.173

22.174

2.2.17.s I Press

2.2.17.6

Connect

Scopemeter

Set

Channel 1 positive

Connect

connector.

2.2.17.7 @ Press

“Check

icons

VGFVF/AX

will

stay

vacuum / pressure

TEST

:

DO

NOT

REFLECTION

OF

THE

ILLUMINATOR.

ON

ILLUM

UP

arrow.

increases

Down

intensity

fan

Repeat

OFF

arrow

decreases

OFF

ILLUM

is

running.

steps

ILLUM

2.2.16.1

Illuminator

ILLUM 2 icons

illuminator

turn

OFF.

Verify

Ensure

bulb

DRIVE

with

either

Checklist.

PROBE

If

system

alignment

TEST - NOTE:

300VS, 400VS, 600DS,

PROBE

mode,

Scopemeter

Innovit

CPC

connector

Phono

Channel

footswitch

to

tri-lumen

footswitch

active

LOOK

ON A WHITE

1.

Verify

Adjust

as

the

key.

Adjust

as

1.

and

2,

Verify

Release

cannot

drawer.

ILLUM 1 &

the

DPM

DRIVE

is

model

DRIVE

probe.

to

Jack/BNC

1.

measure

(+),

DC,

and

verify

test

tubing

and

verify

setup...”

and

Global

meter

DIRECTLY

left

illuminator

intensity

preset

value

intensity

the

preset

Turn

ON

2.2.14.4

illuminator

button.

per

Verify

be

selected.

Verify

Figure

This

INI

or

Probe

TESTS

300VS,

TEST

Select

top

connector.

Cable

1:1

voltage

Time

10ms.

peak

with

female

peak

Press

30

mmHg

displays

to

VGFI

go

OFF.

port.

INTO

SHEET

from

000

is

raised.

from

value

ILLUM 2 and

for

ILLUM

ports

that

ILLUM 1 &

ILLUM 2 icons

2,

if

not

test

Drive

USING

indicate

OF

port

is

on

to

HI3

HI3

is

lowered.

2.

are

off

illuminator

ILLUM 2 ports

already

can

be

Test

SCOPEMETER

on

Form

800CS & Cart,

USING

1200

between

output

output

SCOPEMETER

cpm.

Connect

DPM

at

100mV/DIV.

pulse

CPC

connector

pulse

Connect

other

is

is

icon

on

Verify

LIGHT

PAPER

and

fan

on

Global

to

000

on

verify

and

right

fan

drawer

can

be

selected.

performed

performed

Box.

Indicate

S0578-01,

and

proceed

tri-lumen

end

IIE - HI

(100

>23

psi.

to

>23

psi.

screen.

pressure

SOURCES,

VGFI

and

reading:

OBSERVE

HELD 2 - 4 INCHES

is

running.

display.

Global

illuminator

Verify

display.

port

stops.

ejects

and

ILLUM

light

momentarily,

during

using a Scopemeter

to

-

Insert

to

the

LEVEL

mV = 10

the

second

PM.

test

method

AND

DPM

Data

step

2.2.17.16.

cassette,

test

DPM

OUT

Sheet

tubing

Il

"INPUT"

port

PSD;

from

the

F/AX

30 + 5

that

Verify

is

on

I

used

III

for

select

with

to

trigger

top

[

status:

prd

|

Effective

€E982T2750+

|

Supersedes:

|

SAPBIUITESH

SOP-0578

49

eB+:60

80 90

Fe

Page 15

Alcon

Title:

SOP

ITCSOP-000578

| STP - Accurus

Irvine

Number:

Technology

300VS,

Center - Service

400VS,

600DS,

800CS

Test

Procedure

Version:

CURRENT,

and

Cart

1.0

Page

Effective Date:

12-May-2005

11

of

18

2.2.17.8

2.2.17.9

2.2.17.10

2.2.17.11

2.2.17.12

2.2.17.13

2.2.17.14

2.2.17.15

2.2.17.16

2.2.17.17

2.2.17.18

2.2.17.19

DRIVE

2.2.17.20

2.2.1721

%S2/XS3

cassette,

Connect

other end

Connect

Scopemeter

Set

Channel 1 positive

MI

Press

Connect

connector.

Mi

Press

MODEL

—Select

Connect

other

Connect

Scopemeter

trigger

Bİ

Press

MODEL

selected

Connect

other

Connect

Scopemeter

PROBE

select

VIT

tri-lumen

to

Phono

the

Probe

test

Jack/BNC

Channel

Scopemeter

to

(+),

footswitch

tri-lumen

footswitch

300VS

VIT

tri-lumen

end

to

%4”

mode

the

DPM

Phono

test

XS2/XS3

and

test

Channel

Channel | positive

footswitch

300VS

TEST

preset

tri-lumen

end

to

the

Phono

and

XS2/XS3

BOX - Select

value

test

Probe

Jack/BNC

Channel

DRIVE

mode,

Innovit

tubing

Drive

1.

measure

DC,

and

verify

tubing

and

verify

Accurus

tubing

III

"INPUT"

Jack

1.

Set

(+),

verify

tubing

Drive

1.

TEST

test

Time

ONLY - ACCURUS

from

USING

probe.

with

female

box

"PRESSURE"

Cable

1:1

between

voltage

10ms.

peak

output

with

female

peak

output

probe.

with

Verify

female

DPM

Scopemeter

DC,

Time

output

is

>29

PROBE

Select

CPC

at

pulse

CPC

pulse

CPC

HI

to

20ms.

psi.

ONLY - ACCURUS

VIT

mode

and

with

test

Cable

female

box

CPC

"PRESSURE"

between

DRIVE

1200

cpm.

connector

Port.

Probe

Drive

500mV/DIV

is

>23

connector

is

>23

PROBE

800

cpm

connector

LEVEL

measure

PROBE

Accurus

connector

Port.

Probe

Drive

TEST

to

top

connector,

Box

(500mV=10psi);

psi.

to

the

second

psi.

TEST

is

the

selected

to

top

connector.

OUT

(100

1:1

voltage

TEST

probe.

to

top

Box

Verify

connector.

BOX - Insert

"OUTPUT"

from

USING

DPM

preset

mV=10

at

100m V/DIV;

USING

"OUTPUT"

800

PROBE

cpm

Connect

and

trigger

the

top

III

value.

Connect

PSI)

to

is

the

Connect

and

2.2.17.22

2.2.17.23 E Press

2.2.17.24

2.2.17.25

2.2.17.26

2.2.17.27

|

Status: | Effective

ST

Set

Scopemeter

to

Channel 1 positive

footswitch

XS 4 PROBE

NOTE:

DPM

II

step

2.2.17.28

XS4

PROBE

Connect

other

end

Connect

Scopemeter

EI8ZIAZSOb

DRIVE

This

test

or

Probe

DRIVE

tri-lumen

to

the

DPM

Phono

Jack/BNC

Channel

can

test

measure

(+),

DC,

and

verify

TESTS

be

performed

Drive

Test

TESTS

tubing

IU

"INPUT"

1.

1:1

Time

peak

Box.

USING

with

Cable

voltage

at

500mV/DIV

10ms.

output

If

female

between

]

pulse

is

>29

using a Scopemeter

the

Probe

DPM

CPC

Supersedes: | SOP-0578

еэчеочзтеен

Drive

HI

connector

DPM

II - HI

(500mV=10psi);

psi.

interfacing

Test

Box

is

to

top

connector.

LEVEL

39

with

used,

OUT

E8+:60

trigger

either

proceed

Connect

port

the

to

to

|

80

90

REM

Page 16

Alcon

Title:

Irvine

SOP

ITCSOP-000578

| STP - Accurus

Technology

Number:

300VS,

Center - Service

400VS, 600DS,

800CS

Test

Version:

CURRENT,

and

Procedure

1.0

Cart

Page

12

of

18

Effective

12-May-2005

Date:

2.2.17.28

2.2.17.29

2.2.17.30 Ы Press

2.2.17.31

Set

Scopemeter

Channel 1 positive

Insert

cassette,

peak)

and

for

waveform

Connect

connector.

2.2.17.32

Select

Accurus

22.17.33 M Press

peak)

and

to

measure

(+),

select

footswitch

<9

and

psi for

example.

tri-lumen

test

2500

footswitch

<15

Biçemepp

A

ーー

psi

for

20000

and

131

Nİ

DC,

Accurus

verify

the

"open"

tubing

probe.

verify

the

"open"

IE

DPM

>

1:1

voltage

Time

10ms.

1500

output

pressure

with

female

Set cut

output

pressure

Shown”

Scate

DIY...

probe.

is

rate

to

is

og

pst:

avs

at

100mV/DIV,

Set

cut

>29

psi for

(initial

CPC

connector

2500

>29

psi

(initial

|

MANE

rate

to

"Close"

waveform

for

"Close"

waveform

(100

1500

pressure

start).

to

the

pressure

start).

mV = 10

(top

Refer

second

(top

PSI);

trigger

waveform

to

Figure

from

the

waveform

9

top

2.2.1734

2.2.17.35

XS4

Connect

other

2.2.17.36

2.2.17.37

2.2.17.38

22.17.39 M Press

2.2.17.40

|

Status: | Effective

Connect

Scopemeter

Set

Channel 1 positive

Insert

peak)

for

Connect

connector.

:

RT

Figure 9 -

PROBE

tri-lumen

end

to

the

Phono

Channel

Scopemeter

cassette,

footswitch

and

<9

waveform

tri-lumen

Probe

Drive

METER

Probe

DRIVE

test

Probe

Jack/BNC

1.

to

measure

(+),

select

Accurus

and

psi

for

the

example.

test

er

Test

Drive

TESTS

tubing

Drive

test

DC,

Time

verify

"open"

tubing

2

Test

USING

with

box

Cable

1:1

voltage

10ms.

1500

output

pressure

with

female

30]

>»

EXTmW

Waveform

PROBE

female

CPC

DRIVE

connector

"PRESSURE"

between

probe.

is

>29

Probe

at

500mV/DIV

Set cut

psi for

(initial

CPC

connector

Supersedes:

:

“

Example

TEST

Port.

Drive

rate

to

1500

"Close"

waveform

to

|

SOP-0578

BOX

to

top

connector.

Box

"OUTPUT"

(500mV=10psi);

pressure

peak).

the

(top

Refer

second

from

Connect

and

trigger

waveform

to

Figure

the

9

top

|

9T

E98d1I4dG0# BS4E9YITESH

19

e6+:60

80 90

REM

Page 17

Alcon

Title: | STP - Accurus

Irvine

SOP

Technology

Number:

ITCSOP-000578

300VS,

Center ~ Service

400VS,

6000$,

800CS

Test

Procedure

Version:

CURRENT,

and

Cart

1.0

Page

13

of

Effective Date:

12-May-2005

18

2.2.17.41

2.2.17.42 M Press

2.2.18

2.2.18.1

Select

peak)

SCISSORS DRIVE

Select

CPC

2.2.18.2 M Depress

footswitch

2.2.18.3 Select

2.2.184

2.2.19

2.2.19.1 M Prior

2.2.19.2

2.2.19.3

2.2.19.4

2.2.19.5 M Press

M

the

MPC

SCISSORS

load

is

Note:

connected

Connect

Connect

Time

Sensitivity:

Trigger

Select

Observe

Depress

footswitch

4.0

Release

Accurus

footswitch

and

<15

Scissors

connector

footswitch.

fully

Multi-Cut

footswitch.

TEST — XS3

to

using

box

resistance.

+/- 0.2

MPC

Base:

MPC

ohms.

load

to

the

MPC

Load

MPC

Load

50

SV/DIV

Delay:

Mode,

Right

waveform

footswitch.

volts

2500

probe.

and

verify

psi for

the

TEST

Mode,

to

Scissors

Proportional

Verify

depressed.

submode.

Verify

is

pressed.

the

MPC

Verify

resistance

Accurus.

Box,

Box

ms/DIV

-2DIV

Cut

Rate

Horizontal

on

Scopemeter

Set

Scopemeter

Set cut

"open"

rate

output

pressure

connector

proportional

pulses

Remove

&XS4

load

the

PN

to

Scopemeter

Switch

PERON

tri-lumen

ONLY

box,

resistance

verification

995-2020-073,

Trigger

Coupling:

to

450

cpm,

on

per 6 and

to

to

2500.

is

>29

psi

(initial

submode.

and

attach

of

pressure

tubing.

perform

across

to

set

as

Level:

DC

then

footswitch

verify

read

DC

for

"Close"

waveform

Connect

to

is

in

the

the

is

performed

MPC

tri-tumen

vacuum / pressure

default

are

delivered

following

two

test

drive

output

follows:

2VVertical

select

Vacuum.

to

activate

peak

reading

voltage.

pressure

start).

tubing

setting

continuously

procedure

points

with

on

MPC

drive

to

(top

with

meter.

20 + 2

to

of

the

load

box

Front

at

be

10.8 + 0.8

waveform

female

psi

with

while

verify

the

Test

Load

NOT

Panel.

450

cpm.

V.

2.2.19.6

Status: | Effective

¿1

cd

WM

Activate

mode.

E982T2250+

Figure 6 -

and

Observe

O | 2

hold

hold

40

oo 80

Ti

MULTICUT

MPC

Left

Horizontal

voltage

100

MODE

(4500pm)

Scissors

on

Voltmeter

|

to

be

msec

on

1.2 +

footswitch

0.2

VDC.

120

142 160

Waveform

switch

Superseges: | SOP-0578

еэчеочзтеен

39

to

enable

MPC

E6+:60

Hold

80 90

|

REY

Page 18

Alcon

Title: | STP - Accurus

Irvine

SOP

ITCSOP-000578

Technology

Number:

300VS,

Center - Service

400VS,

600DS,

800CS

Test

Version:

CURRENT,

and

Procedure

1.0

Cart

Page

Effective

12-May-2005

Date:

14

of

18

2.2.19.7 M Disable

verify

2.2.20

VEC

2.2.20.1

TEST

Use

metet

22202

MI

Set

on

01,

2.2.20.3 E With

position.

2.2.204

2.2.20.5

Release Footswitch.

İM

Set

on

vacuum / pressure

Sheet

2.2.206 Ы With

DOWN

NOTE:

PLATFORMS.

2.2.20.7

2.2.20.7.1

TEST

2.2.20.7.2

2.2.20.8

22.209

Set

Plug

22.20.10 M Slowly

readings

FUNCTION

INJECT

ASP

NOTE:

2.2.20.11

2.2.20.12

2.2.21

2.2.21.1

Mi

Keep

seconds.

Remove

FRAGMATOME

M

handpiece

300VS,

customer’s

HOLD

that

voltage

-DOES

VFC

test

to

VFC

Meter

to

vacuum / pressure

Data

Sheet

MAX

Verify

mode

drops

NOT

tubing

connector.

read

psi

meter

for

Accurus®

LIMIT

pedal

control

Select

meter

to

read

mmHg.

meter

for

Accurus®

MAX

position.

STEPS

SETUP/MODE

XS3:

EXCLUSIVE.

EXIT,

XS4:

MAX

ASP

Select

and

Select

LIMITs:

port.

press

on

LCD

Aspiration

footswitch

Verify

tubing

300VS,

LIMIT

Verify

2.2.20.7 - 2220.11

OPTIONS,

Press

YES

to

“DUAL”.

PRESSURE = 80

Meter

should

Footswitch

(actual

MAX

80

psi

250

mmHg

will

in

pressure

and

Vacuum/Pressure

TEST

This

test

is

performed

is

not

available,

400VS,

600DS,

handpiece

by

releasing

to 0 +

0.1

VDC.

APPLY

with

and

TO

female

Select

VFC:

press

MODEL

CPC

footswitch

(measured)

300VS,

at

80

psi,

slowly

of

pressure: 0 to

VFC:

EXTRACT

Press

footswitch

(measured)

400VS,

at

600

pedal

SELECTION:

up

return

display)

LIMIT

activate

fully

down

leakage

indicate

600DS,

mmHg,

control

MEMORY,

arrow

to

INJECT

still

be

to

full

as

follows:

LCD

80

250

at

mid,

position;

is < 10

using

so

attached

the

800CS & Cart,

is

available,

indicate

Left

Remove

connector

INJECT

and

LCD

400VS,

of

to

psi,

DOWN

+3

Meter.

on

600DS,

press

mode.

and

LCD

800CS & Cart.

slowly

vacuum: 0 to

APPLY

change

mode.

VACUUM

to

ACTUAL

pst

mmHg + 10

pedal

Monitor

psi.

customer’s

Form

and

so

Horizontal

MPC

switch

Load

300VS

to

connect

mode.

fully

DOWN.

(actual)

footswitch

80

psi

fully

DOWN.

as

press

as

800CS & Cart.

(0-70psi

listed

footswitch

600

mmHg

ONLY

CONTINUE,

EXCLUSIVE

=

250

VFC

port.

position.

DISPLAY

mmHg

down

Verify

position.

vacuum/pressure

handpiece.

S0578-01, Data

FSR.

Continue

on

Form

S0578-01,

on

footswitch

box

and