Page 1

345 Bayview Avenue

Amityville, New York 11701

For Sales and Repairs 1-800-ALA-LOCK

For Technical Service 1-800-645-9440

Publicly traded on NASDAQ Symbol: NSSC

© ALARM LOCK 2007

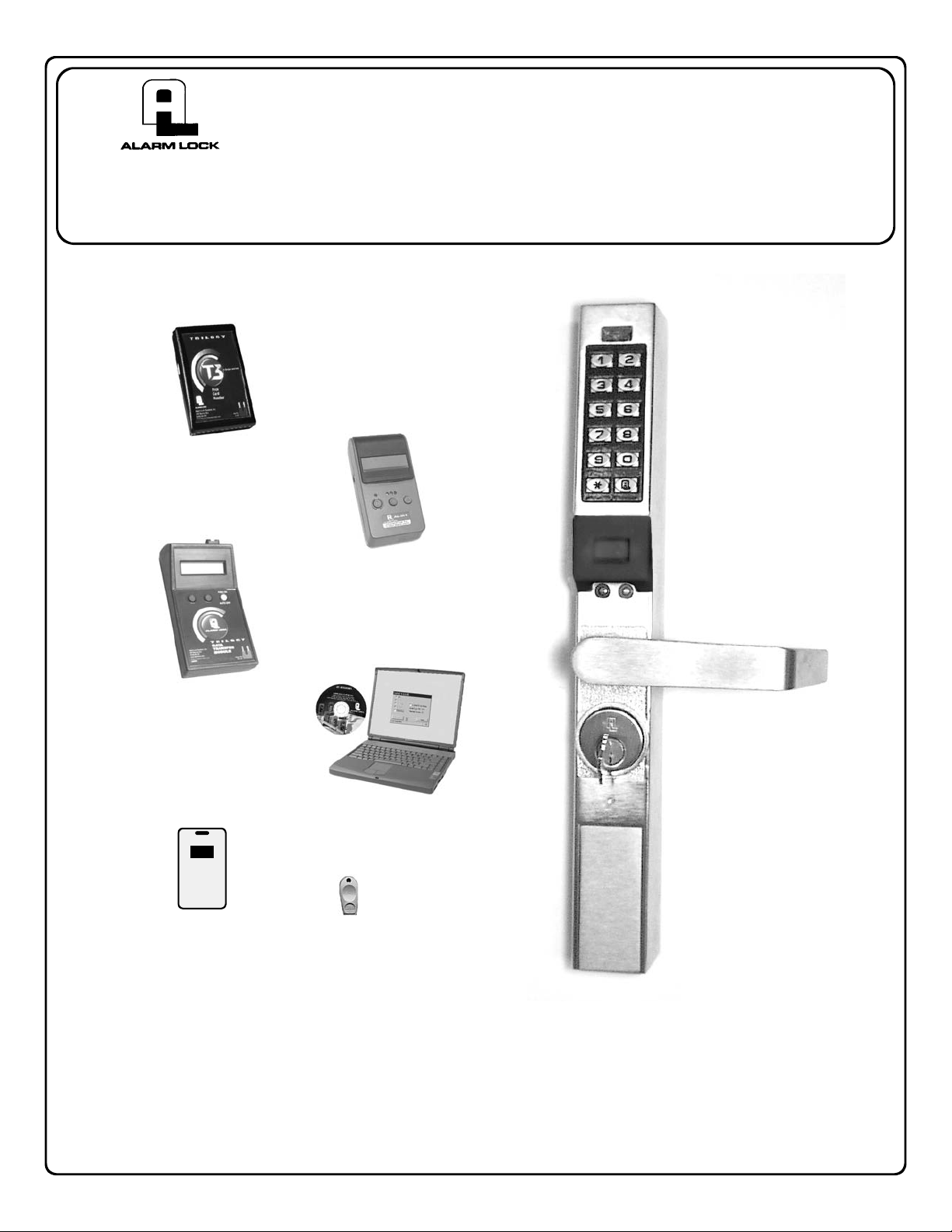

AL-PRE PROXCARD®

READER / ENROLLER

PDL1300

Programming Instructions

OI312A 6/07

AL-IR1 PRINTER

AL-DTM

DATA TRANSFER

MODULE

DL-WINDOWS PROGRAMMING

SOFTWARE

HID

HID CORPORATION

PROXCARD®

PROXKEY®

KEYFOB

PDL1300

PDL Trilogy Series

Stand-Alone Access Control Systems

with ProxCard

®

Access

1

Page 2

PDL1300 SERIES LOCK

THE ALARM LOCK TRILOGY PDL1300 SERIES STAND-ALONE ACCESS CONTROL SYSTEM IS A STATE-OF-THE-

A

RT MICROPROCESSOR-BASED PROGRAMMABLE KEYPAD-ENTRY AND PROXIMITY SECURITY LOCK.

PDL1300

Your new PDL1300 Alarm Lock Trilogy electronic digital lock is a mortise-based

manually programmable narrow stile entry trim for Adams Rite

4900 deadlatch locks, and 1850, 1950, 4070, MS1850S and MS1950S series

deadbolts for narrow stile aluminum doors*. The PDL1300 features an HID compatible ProxCard

®

reader*, and a real-time clock/calendar that automatically adjusts for Daylight Saving Time and allows for automated programming of events.

Features three methods of programming: (1) all features can be programmed

manually through the keypad; (2) you can transfer programming instructions directly from your laptop or desktop PC using DL-Windows software and a special

AL-PCI cable; and (3) data can be transferred from your PC to your PDL lock via

the AL DTM handheld Data Transfer Module. In addition, data can be retrieved

from the lock in one of three ways (1) through an infrared printer; (2) directly from

the lock to the PC; or (3) through an AL-DTM to your PC.

*Adams Rite Manufacturing Co., Pomona, CA. www.adamsrite.com

ProxCard® and ProxKey® are trademarks of the HID© Corporation.

All products, product names and services described in this manual are for identification purposes only and may be trademarks of their respective companies.

®

4710, 4730 and

Table of Contents

PDL Series Lock Features ................................. 3

Supported Products ........................................... 4

Lock Design Overview ....................................... 5

Terminology Used in this Manual ..................... 6

Programming Levels .......................................... 8

Conventions Used in this Manual ..................... 9

LED and Sounder Indicators ............................. 9

Product Communication Examples ................. 10

Wiring and Power Up .......................................... 11

Quick Start ............................................................ 12

Programming Functions Overview ...................15

Programming Functions .....................................16-27

Groups and Scheduled Group 1 Examples .....28

Programming Record Sheet ...............................30

User Code Record Sheet ....................................31-32

Schedule Record Sheet ......................................33-34

Glossary ................................................................35

Warranty ................................................................ 36

Testing the Codes Entered ................................ 14

2

Page 3

PDL Series Lock Features

Audit Trail

• 40,000 Event Capacity

• Entries Logged with Time and Date

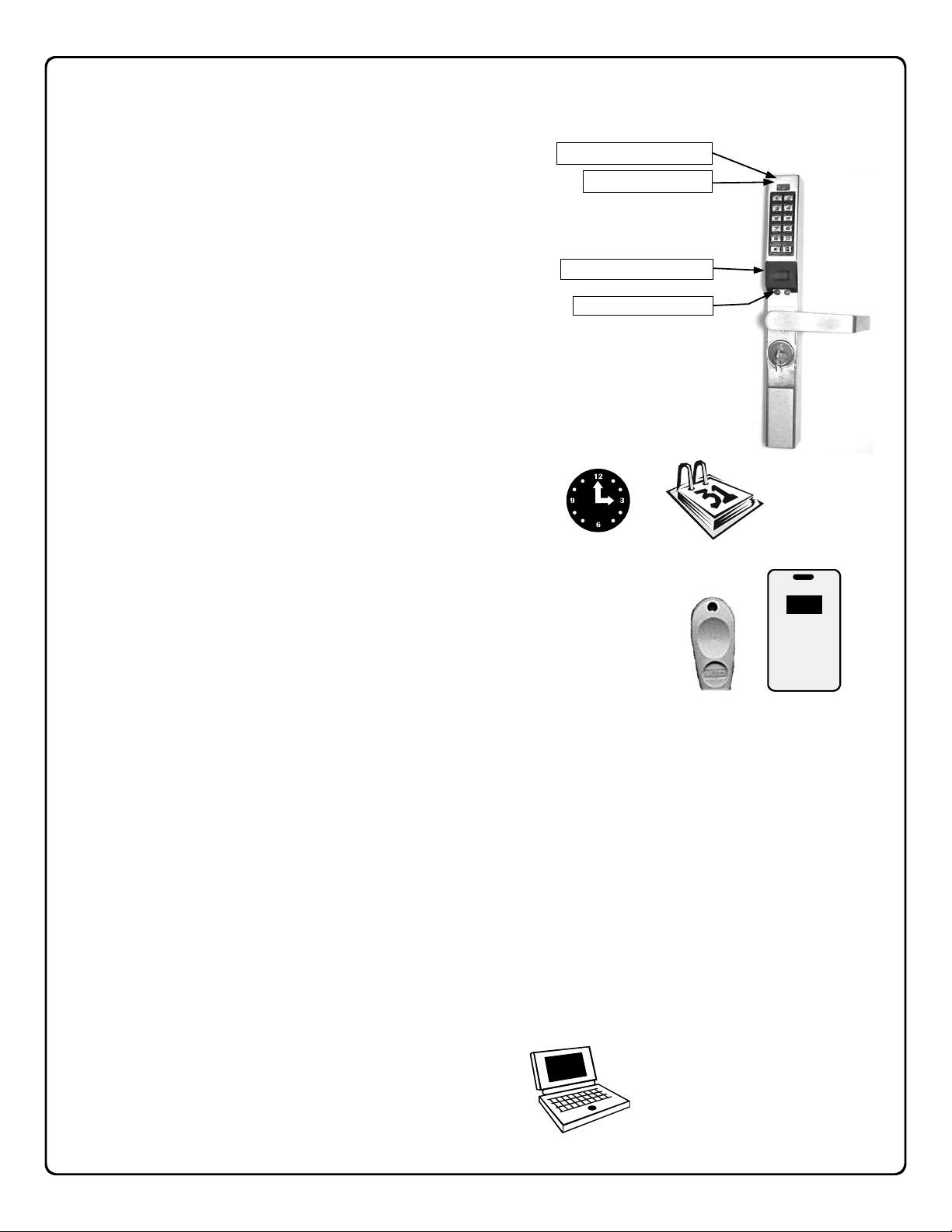

Infrared LED (for Printer)

Two-Color Status LED

• Critical Programming Events Logged

• Printable using the AL-IR1 Hand-Held Printer (see page 23, Function 55)

• Uploadable using Alarm Lock's DL-Windows software (see page 23, Function 58)

• Transferable to AL-DTMs

Lock Features

• Metal Key Override for all cylindrical locks

ProxCard / Keyfob Reader

PC / AL-DTM Interface

• Keypad Lockout (see page 24, Functions 60-61)

• Non-Volatile (Fixed) Memory

• Real-Time Clock (within one second accuracy)

(see page 21, Functions 43-44)

• Visual and Audible Keypad Feedback (see page 9)

• Battery Status Monitor (see page 9)

Scheduling

• 500 Scheduled Events (see pages 25-29)

• Automated Unlock/Lock

• Enable/Disable Users (see page 17, Function 3)

• Enable/Disable Groups (see page 18)

• Four "Quick Schedules" (contains 4 most common schedules) (see page 26)

• Real-time clock and calendar (see page 20-21)

• Programmable Timeout Functions (see page 17-21)

HID

HID CORPORATION

User Access Methods

• Keypad Entered User Codes (see pages 12-13, 16)

• ProxCard

• User Code and ProxCard

• Batch Enroll - Quickly and easily enroll multiple ProxCards

(see page 13)

Note: ProxCards

references to the ProxCard

®

and ProxKey® Keyfob (see page 13)

®

®

(For highest security) (see page 13)

and ProxKey® Keyfobs both function identically. Keyfobs can be substituted for all

®

in this manual.

®

and ProxKey® keyfobs without the use of a PC.

User Features

• 2000 Users (see pages 12-13, 16)

• 6 Pre-defined Administration User Levels including Master, Installer, Manager, Supervisor, Print-Only and

Basic User Codes (see page 8)

• User Code Lengths from 3-6 digits

• Service Code (“One-Time-Only” Code) (see page 7)

• User Lockout Mode (see page 17, Function 6)

• Users Assignable to 4 Groups (see page 28)

Keypad and Computer Programming

• All programming may be performed manually from the keypad, or from a PC using Alarm Lock's DLWindows Software (see page 5)

3

Page 4

Supported Products

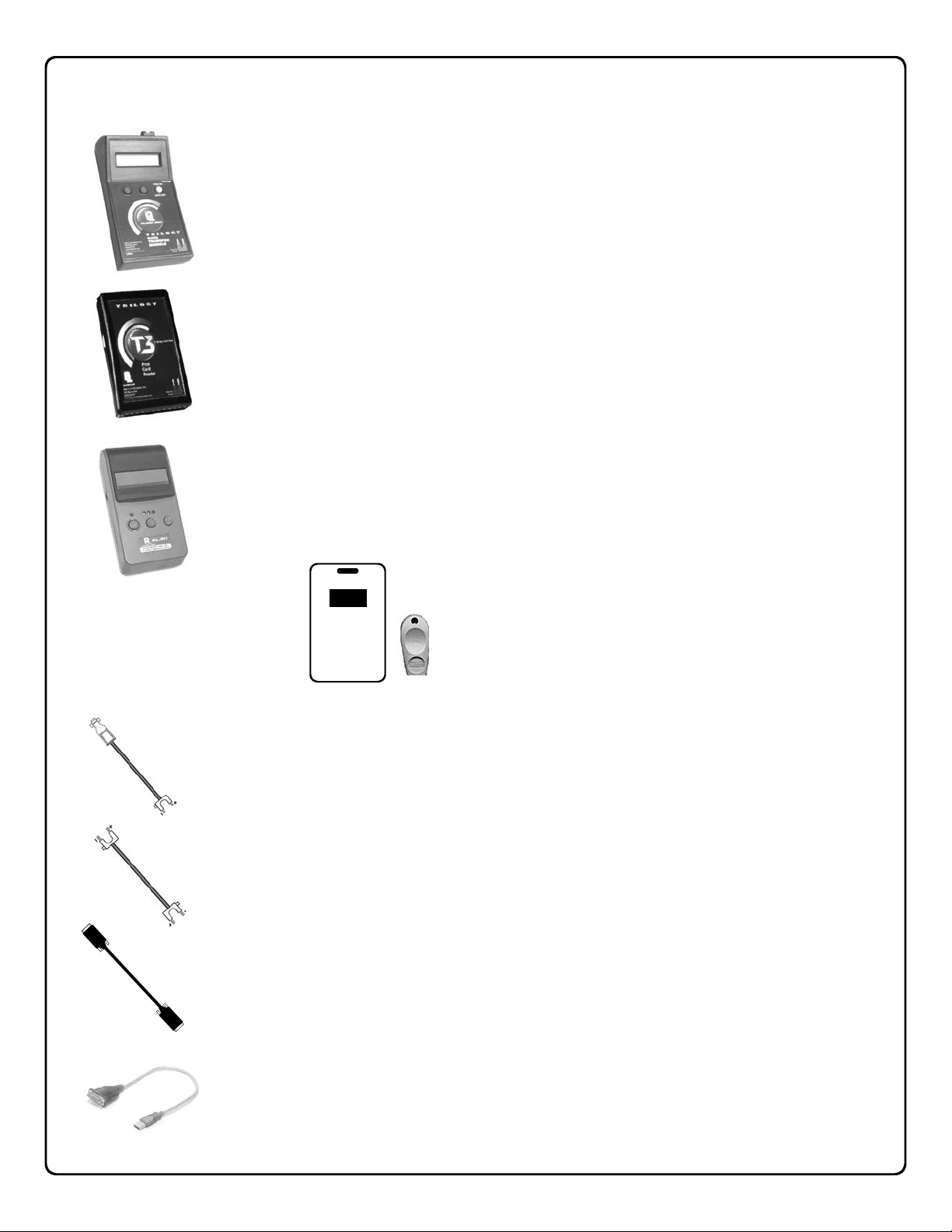

Data Transfer Module (AL-DTM)

An AL-DTM can be used to transfer Lock Programs (and other data) between DL-Windows and locks. When

computers cannot be transported or when electrical power is not available, the hand-held AL-DTM device acts as

a go-between--it allows the transfer of lock data from the computer (through the AL-DT M) and to the lock, or in

reverse (from the lock through the AL-DTM back to the computer).

Prox Card Reader/Enroller (AL-PRE)

An AL-PRE is used to quickly enroll multiple ProxCards

need to manually type User Codes. Use the supplied 9-pin DB9 to DB9 serial cable to connect the AL-PRE to

your computer’s serial COM port. Compatible with most HID ProxCards

®

and ProxKey® keyfobs into DL-Windows without the

®

and ProxKey® keyfobs (37 bits or

less). For PDL series locks only.

Infrared Printer (AL-IR1)

An AL-IR1 printer is used to print Audit Trails and User Code lists without the need for a PC. Its infrared

reader means no cable connection to the lock is needed.

HID

HID CORPORATION

ProxCard® / ProxKey® Keyfob

Compatible with most HID ProxCards

and ProxKey

Note: ProxCard® and ProxKey® are trademarks of the

®

keyfobs (37 bits or less).

HID© Corporation.

®

AL-PCI Cable

An ALARM LOCK AL-PCI cable is required to communicate between your computer’s RS-232 serial communications port (COM 1-4) and the AL-DTM or lock. One end of the AL-PCI cable is designed to be used

on a 9-pin serial Com Port. If your computer has a 25-pin Com Port only, a 25-pin to 9-pin adapter must be

used. The other end of the AL-PCI cable features a 2-pin banana plug connector which is polarity sensitive-

-the TAB (marked “GND”) side must be plugged into the lock’s black (left) terminal.

Double-ended Mini Banana Plug Connector

After you create the program in DL-Windows and transfer the program from your computer to an AL-DTM,

transfer the program from the AL-DTM to the lock(s) via a double-ended mini banana plug.

DB9 to DB9 Serial Cable

Enroll ProxCards quickly into DL-Windows, then transfer this new ProxCard

®

data from the computer to

the AL-PRE via this 9-pin DB9 to DB9 serial cable. Once the data is in the AL-PRE, you can transfer the

data to the lock via the double-ended mini banana plug (see above), thus avoiding the need to use an AL-

PCI cable for this process.

USB to RS-232 Cable

If your computer does not have a serial COM port (DB-9 male) available, you can plug your ALPCI2 cable into a special USB to RS-232 cable. Order part PCI-USB for the USB to RS-232

cable only, or ALPCI2-U for both the USB to RS-232 cable and an AL-PCI2 cable).

4

Page 5

Lock Design Overview

Why Use Software inside a Lock?

With ordinary door locks, the need to make physical copies of metal keys and distributing them can be a huge organizational and

financial task -- and what will you do if someone causes a security breach by simply losing their key?

The answer lies in the advantage of software. Software (also called "firmware") is not "hard" or "fixed" like hardware is. Software

is "soft" -- flexible and changeable to your needs. Software exists inside your Alarm Lock™ series lock, and can be programmed

(and re-programmed again and again) to suit your changing requirements. No more metal keys to distribute...instead, distribute

User Codes -- and delete them from the software when needed. (A User Code is the software equivalent of a metal key--it is a

series of numbers the User enters into the door lock keypad to unlock the lock).

Preparing to Program your Lock

The keypad contains 12 buttons, numbers 1 through 9 plus zero, a star button (:) and a special "AL" button (;). These 12

buttons are all you need to program your lock. In addition to manually programming your lock (using only the keypad), you can

also program your lock using a computer program called DL-Windows. DL-Windows is not needed--but it makes programming

faster and easier. This guide will show you how to program your lock manually, without DL-Windows. (For more information about

DL-Windows, see User Guide OI237).

Programming your lock begins after you unpack it from the box -- there is a specific procedure outlined in "Quick Start" (page 12)

in which you "wake up" the lock to prepare it for programming. This "Quick Start" procedure shows you all the steps required to

get your lock to start working. To begin programming, you must first enter something called "Program Mode".

What is Program Mode?

With hardware, hand tools can be used to make fixes or changes. With software, however, changes are made using the keypad.

The software has only two "modes"--"Normal Mode" and "Program Mode". When you want to make changes to the lock program,

you enter "Program Mode". When you finish programming and wish to put the lock into use, you exit Program Mode to enter

"Normal Mode".

You enter Program Mode using the keypad--by pressing the Master Code of the lock that was set at the factory. The Master Code

is basically a secret passcode that allows you to enter Program Mode. But since all locks are identical and leave the factory with

the same Master Code, the factory Master Code is therefore not very secret--and should be changed to your own personal Master

Code. This way, only YOU can enter Program Mode and make changes to the lock programming.

Once the new Master Code is set , then you can continue with the Quick Start procedure and set the weekday, date and time. After this, you can start entering User Codes for people to use. All changes to the lock are organized by their Function Number.

Want to change the date? Use Function Number 38. Want to add a User Code? Use Function Number 2. Some Functions you

will use often, and others you may never need.

Notice that when you program your lock, programming tends to follow a consistent 5-step pattern: (1) Enter Program Mode

(2) Press ; followed by the Function # (3) Press ; and enter data (4) Press : to end (5) Exit Program Mode.

Turn the page and learn about the special terminology used with your lock. Once that is clear, use the Quick Start procedure on

page 12 to help you get up and running.

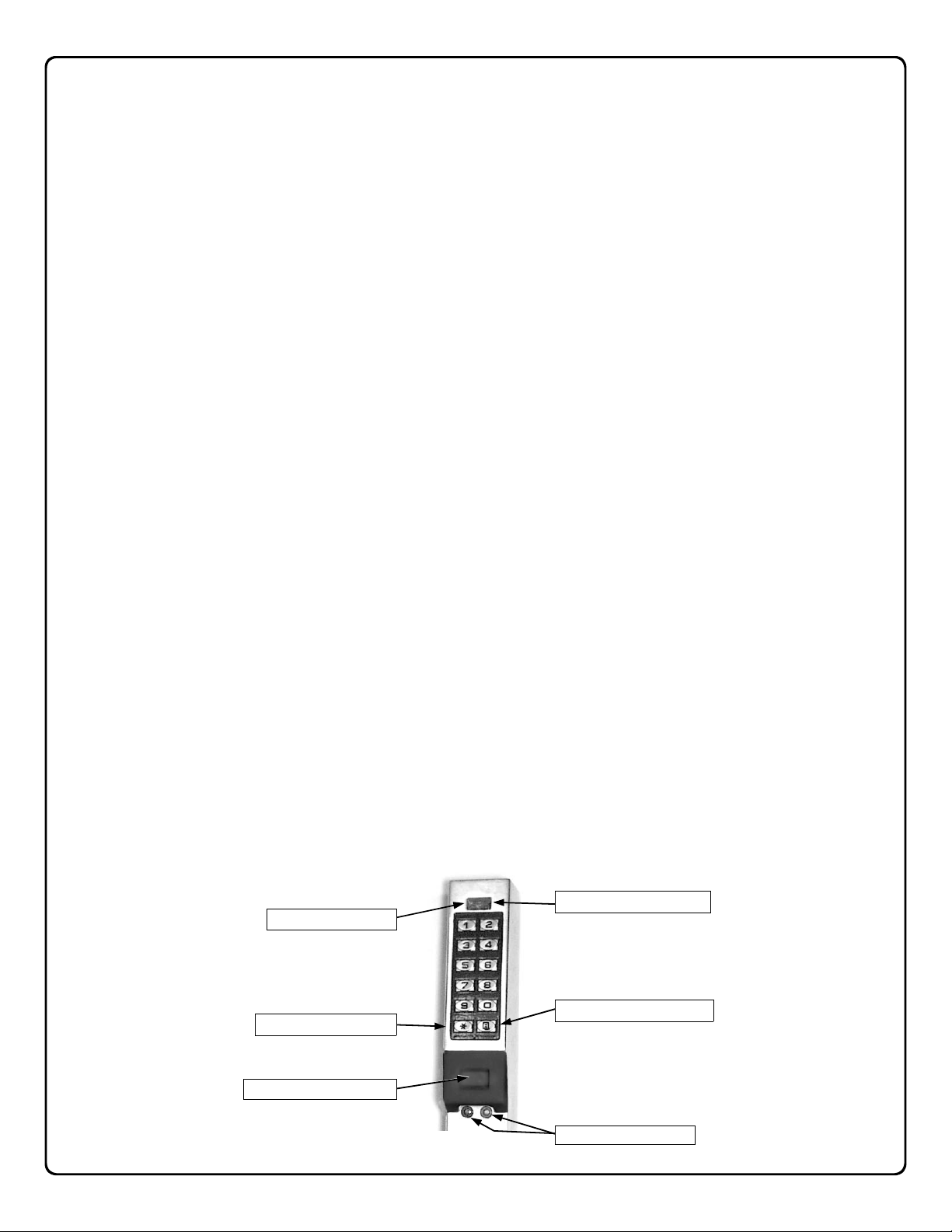

Two-Color Status LED

"STAR" (:) Key

ProxCard / Keyfob Reader

Infrared LED (for Printer)

Special "AL" (;) Key

PC / AL-DTM Interface

5

Page 6

Terminology Used in this Manual

What is a Lock Program?

A Lock Program contains the instructions that a lock uses to perform its various functions. You can use the keypad to create a

Lock Program stored within the lock. You can also use DLWindows (defined below) to create a Lock Program on your computer, and then transfer and store the Program in the circuitry contained inside the lock itself. The Lock Program is essentially a

computer database file that maintains feature settings, schedules,

audit trails, etc. Using DL-Windows, Lock Programs can be created with default information, edited on your PC, and then sent to

(and even received from) locks.

The Lock Program consists of 4 areas: User Codes, Features,

Time Zones, and Schedules, all defined below:

What are User Codes?

Also called User Access Codes or PIN Codes, User Codes are

numbers the User enters into the lock keypad to unlock the lock.

The User Codes are part of the Lock Program, and the Lock Program is stored in the lock circuitry awaiting the Users to key in their

User Codes.

What are Features?

Your lock is designed to support several options and functions.

Using the keypad or DL-Windows software (the Programmable

Features window), you can select the features you wish to activate, such as if the lock will automatically adjust for Daylight Saving Time in the spring and autumn, or if the lock sounder should be

disabled or enabled.

What is a TimeZone?

Events (recorded lock activities) can be programmed to occur at

certain times. It is these times (for example, “every Tuesday at

5pm”) that are referred to as TimeZones. TimeZones can be created manually through the keypad. In DL-Windows, you can use

the Schedule-TimeZone screen to create these TimeZones, and

once created, you can link events to these TimeZones.

What is a Schedule?

Your lock can be programmed to maintain a schedule in which

certain events can occur automatically. For example, you can program the lock to allow Groups of Users (with their User Codes)

access ONLY during specific business hours. With another example, you can program another lock to UNLOCK at 9am, LOCK at

noon for lunch, UNLOCK at 1pm, and LOCK again at 5pm--every

weekday. As you can see, many different combinations of Schedules can be created to suit the needs of the Users. First you create TimeZones (see above). Next you create events and link them

to your TimeZones (also using the Schedule-TimeZone screen in

DL-Windows). When finished, you can view (in DL-Windows) your

schedule in the Schedule View screen.

What is a User?

A User is a person who is authorized to simply use or make certain

programming changes to the lock. This User can be anyone--from

a one-time visitor (who will almost certainly have no authority to

make changes) to the owner of the building in which the lock is

installed (who will probably wish to have total authority to make

changes). The PDL Series locks can hold up to 2000 Users in its

programming memory, and each User possesses a pre-defined

level of authority--a Programming Level--as to their ability to use

or make changes to the lock.

What is a Programming Level?

The Programming Level defines the range of programming tasks a

User is allowed to perform. The higher the Level, the more programming tasks the User is allowed (with Master allowing ALL

tasks).

Note: Since the Programming Level is closely associated with the

type of User and their abilities, a User who holds a certain Programming Level is sometimes referred to by their “User Type”.

For example, PDL Series locks can hold up to 2000 Users in its

programming memory, and each User is associated with a User

Number (see definition of "User Number" below) and therefore a

specific Programming Level, as follows:

Master: Always associated with User Number 1. Is always en-

abled and can program all functions. (Abbreviated as

Programming Level = M).

Installer: Always associated with User Numbers 2 and 3. Can

program all functions except changing the Master Code.

(Abbreviated as Programming Level = 4).

Manager: Always associated with User Numbers 4, 5, and 6.

Can program all functions except functions relating to lock

configuration. (Abbreviated as Programming Level = 3).

Supervisor: Always associated with User Numbers 7, 8 and 9.

Can only program functions relating to day to day operation.

(Abbreviated as Programming Level = 2).

Print Only Users: Always associated with User Numbers 10 &

11. Restricted to print event logs only. No other programming

ability allowed. (Abbreviated as Programming Level = 1).

Basic Users: Always associated with User Number 12 and higher

(except 297-300). No programming ability allowed. Most

Users are Basic Users, who are given their own personal User

Codes and are only allowed to simply unlock the lock when

desired.

Programming Levels are hierarchical--higher levels are allowed to

do anything the levels below them can do. For example, if you are

a Manager, you are allowed to do anything that Supervisors, Print-

Only Users and Basic Users can do in addition to those tasks allowed for Managers (Level 3).

What is the Minimum Required Program Level?

This Programming Level abbreviation is the minimum program-

ming level required to access the particular Function. (The higher

the level number, the more programming tasks the User is allowed, with Master allowing all tasks). Programming Levels for the

PDL1300 are abbreviated as follows: M = Master, 4 = Installer, 3 =

Manager, 2 = Supervisor, 1 = Print Only Users

What is a User Number?

(User Number = Location Number = User Location = Slot in Lock)

User Numbers are used and are significant within each individual

lock only. The User Number determines the Programming Level

for each User. For example, PDL Series locks can hold up to

2000 Users in its programming memory. This memory can be

thought of as simply a numbered list from 1 through 2000. Each

entry in the list is represented by a User Number. Therefore,

where a User is located in this list--their User Location--is a commonly used description of their User Number. Because of their

similarities, a User Number, User Location and Location Number

can be used interchangeably. In some DL-Windows screens, the

word "Slot" is also used. They all mean the same thing.

Since User Numbers are fixed, knowing a User Number will specify the associated Programming Level, and will in turn indicate a

6

Page 7

Terminology Used in this Manual (cont'd)

User’s programming abilities. For example, User Number 1 is

always the Master, who can perform all programming tasks.

Programming Levels are hierarchical--higher levels are allowed to

do anything the levels below them can do. For example, if you

are User 2, you are allowed to do anything that Users 3 through

2000 can do (except for Users 297-300--see below).

Who are Users 297-300?

Users assigned to User Numbers 297, 298, 299 and 300 have

special abilities, as follows:

User 297: Quick Enable User 300

User 297 possesses the unique ability to enable the User Code

associated with User 300. User 297 does this by first entering

their own User 297 User Code into the lock keypad. When User

300 subsequently enters their User 300 User Code, the lock allows access (for one time) and then the User 300 User Code

becomes disabled.

For example, you wish to allow one-time access to a temporary

worker. Simply enter the User 297 User Code into the lock keypad. Later, when the temporary worker enters the User 300

User Code into the lock keypad, the User 300 User Code allows

access (for one time only) and then becomes disabled. Later, if

you wish to grant the temporary worker re-access, simply reenter the User 297 User Code and the User 300 User Code will

be re-enabled (again for one time only).

User 298: Quick PC Access Code

Entering the User Code for User 298 enables that User to send

data to or from the lock. Therefore, User 298 can activate what

is the equivalent of Function 58 in Program Mode (see page 23),

without the need to enter Program Mode nor the need to know

the Master Code of the lock. An AL-PCI cable with a PC is required.

User 299: AL-DTM Code

This is the only User Code that will initiate data transfer with the

AL-DTM--and without allowing the User to pass through the door

(the User Code for User 299 is not an Access Code). An AL-

PCI cable and an AL-DTM (first programmed by the computer

via DL-Windows) is required.

User 300: One-Time Only Service Code

This is a One-Time Only Service User Code enabled by User

297. For example, User Code 300 is sometimes used for guard

tour duties. See User 297: Quick Enable User 300 above.

What is a Group?

With many lock applications, it is convenient for large numbers of

similar Users to be grouped together. Placing Users into Groups

(by assigning them specific User Numbers) allows large numbers

of Users to be controlled all at once rather than individually-saving time and effort. Groups are controlled via schedules, and

a typical example involves enabling or disabling a Group at a certain time. Default Group associations are specified in the tables

on page 8. For example, if you wish to add a User to Group 1,

assign this User a User Number between 51 and 100. These

default Group associations can be changed if needed to allow

Groups larger than the default number of 50 (by using keypad

Function 35). (See page 18 for some Group function examples).

What is DL-Windows?

DL-Windows is a computer program that allows you to program

your ALARM LOCK T3 Security Lock. You do not need DLWindows to program your lock, but it makes programming much

faster and easier. With DL-Windows, you can quickly create Lock

Programs (programs that make the lock perform its many functions) add multiple Users (who have access), add ProxCards

ProxKey

®

keyfobs, retrieve event logs, and create Schedules. The

benefit of DL-Windows is that it allows you to set up all lock programming in advance (on your computer), and then later send the

information to the locks at your convenience.

®

and

7

Page 8

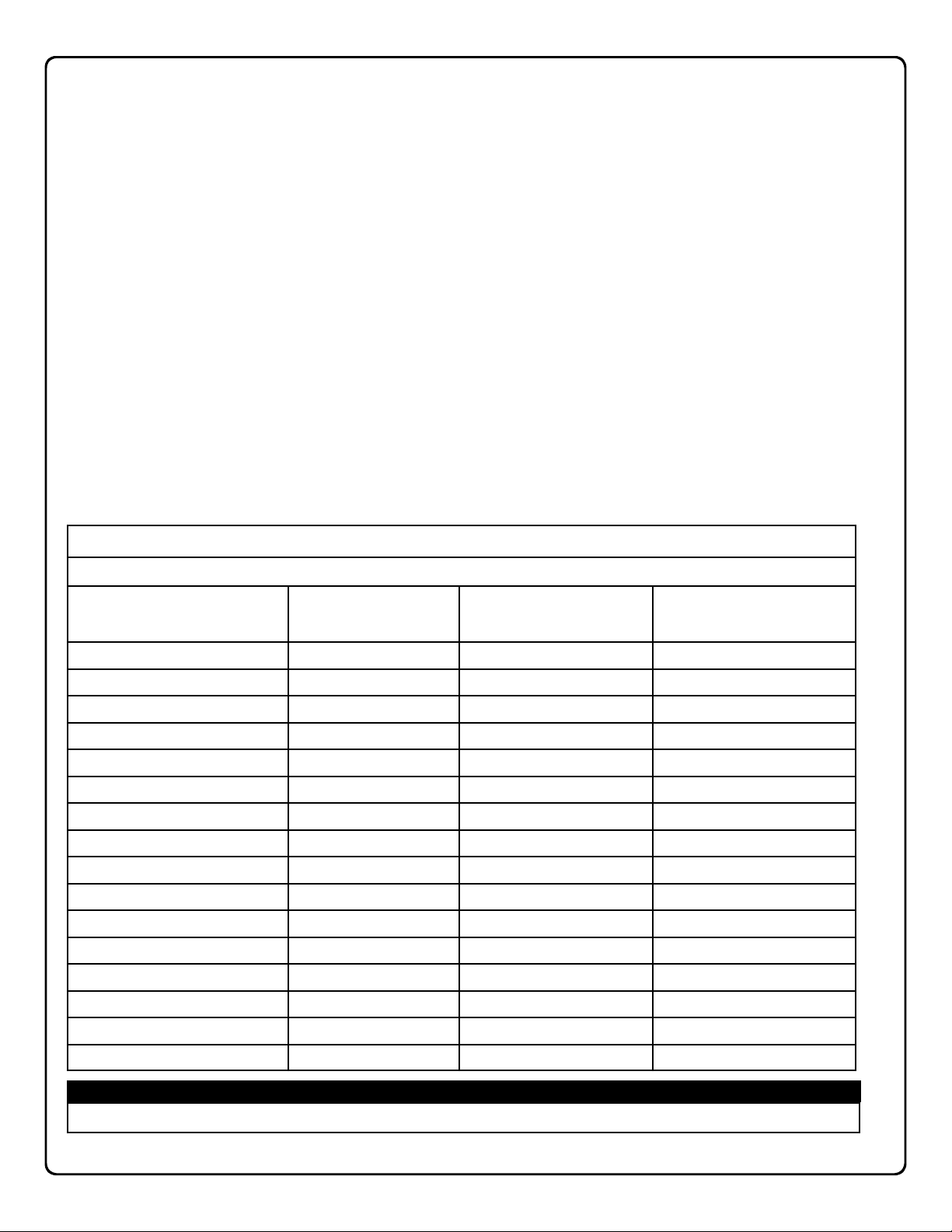

Programming Levels

The Programming Level defines the range of programming

tasks a User is allowed to perform. The higher the Level, the

more programming tasks the User is allowed (with Master

allowing ALL tasks).

Note: Since the Programming Level is closely associated

with the type of User and their abilities, a User who holds a

certain Programming Level is sometimes referred to by their

“User Type”.

For example, PDL Series locks can hold up to 2000 Users in

its programming memory, and each User is associated with a

User Number (see definition of "User Number" in the previous

"Terminology" section) and therefore a specific Programming

Level, as follows:

Master: Always associated with User number 1. Is always

enabled and can program all functions. (Abbreviated as

Programming Level = M).

Installer: Always associated with Users 2 and 3. Can pro-

gram all functions except changing the Master Code.

Lock Defaults for PDL1300

Users added will default to a Group association and a Programming Level as follows:

USER TYPE USER NUMBER GROUP DEFAULT

(Abbreviated as Programming Level = 4).

Manager: Always associated with Users 4, 5, and 6. Can

program all functions except functions relating to lock

configuration. (Abbreviated as Programming Level = 3).

Supervisor: Always associated with Users 7, 8 and 9. Can

only program functions relating to day to day operation.

(Abbreviated as Programming Level = 2).

Print Only Users: Always associated with Users 10 & 11.

Restricted to print audit trails only. No other programming

ability allowed. (Abbreviated as Programming Level = 1).

Basic Users: Always associated with User number 12 and

higher (except 297-300). No programming ability allowed.

Programming Levels are hierarchical--higher levels are allowed to do anything the levels below them can do. For example, if you are a Manager, you are allowed to do anything

that Supervisors, Print-Only Users and Basic Users can do in

addition to those tasks allowed for Managers (Level 3).

MINIMUM PROGRAM

ASSOCIATION

LEVEL (See page 6)

Master Code 1 - M

Installer Codes 2 & 3 none 4

Manager Codes 4 - 6 none 3

Supervisor Codes 7 - 9 none 2

Print Only Codes 10 - 11 none 1

Basic User Codes 12 - 50 none none

Basic User Codes Group 1 51 - 100 1 none

Basic User Codes Group 2 101 - 150 2 none

Basic User Codes Group 3 151 - 200 3 none

Basic User Codes Group 4 201 - 250 4 none

Basic User Codes 251 - 296 none none

Quick Enable User 300 Code 297 none none

Quick PC Access Code 298 none none

AL-DTM Code 299 none none

Service Code 300 none none

Basic User Codes 301-2000 none none

NOTES:

User 299 is a Non-Pass Code. This is the only code that will initiate data transfer with the AL-DTM.

8

Page 9

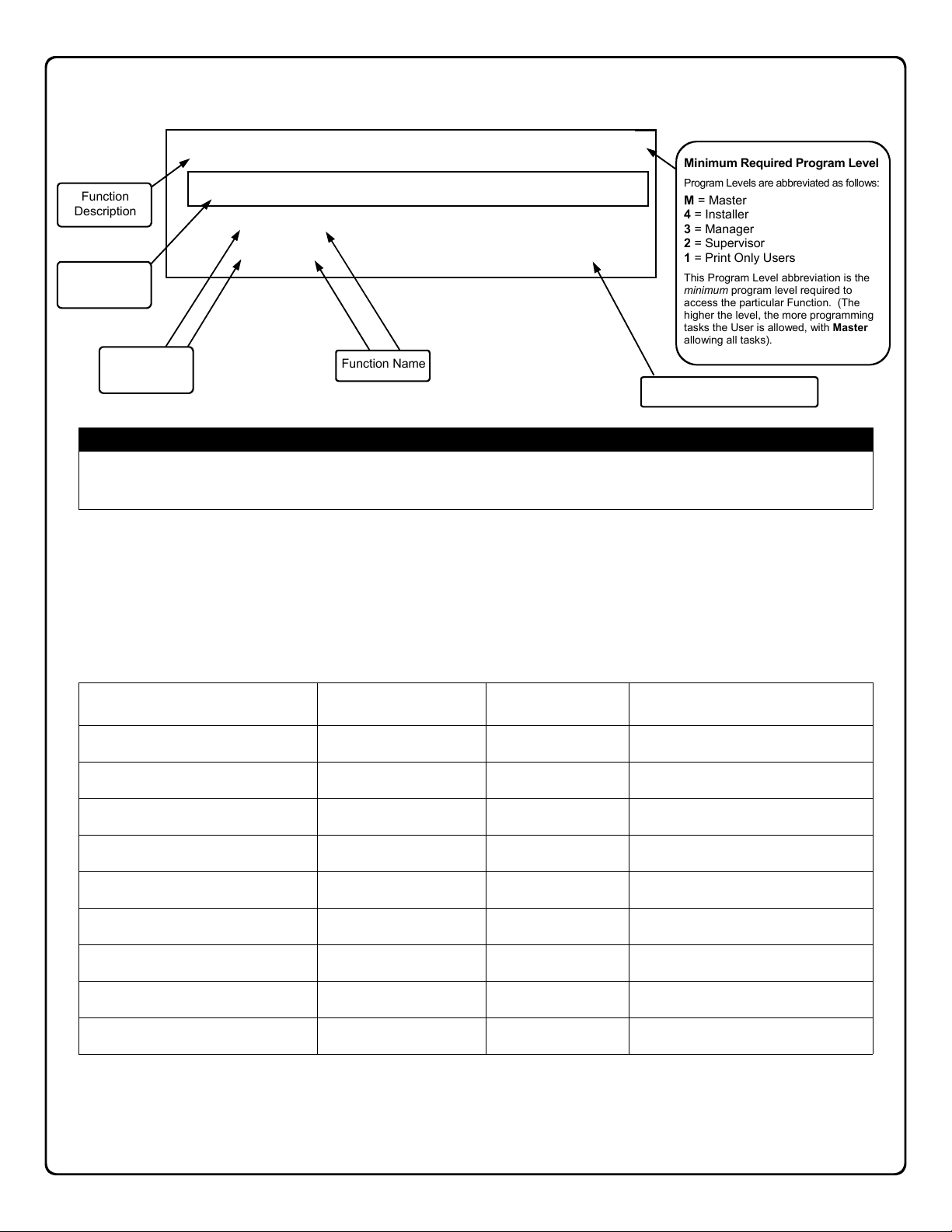

Conventions Used in this Manual

2

Minimum Required Program Level

Program Levels are abbreviated as follows:

M = Master

4 = Installer

3 = Manager

2 = Supervisor

1 = Print Only Users

This Program Level abbreviation is the

minimum program level required to

access the particular Function. (The

higher the level, the more programming

tasks the User is allowed, with Master

allowing all tasks).

Programming Key Sequence.

Function

Description

Programming

Information

Function

Number

Enabling/Disabling Users (By User Number)

User Number must be between 2 and 2000.

NOTE: Will Enable/Disable users even if the user is assoc iated with an enabled group.

3. Disable User

4. Enable User ; 4 ; [ _ _ _ ] :

Function Name

; 3 ; [ _ _ _ ] :

General Program Mode Information

If a wrong key is pressed during code entry, hold any key continuously until the error sound is heard (7 short beeps), this will clear the entry. Re-enter the key

sequence again.

All program sequences are followed by the : key; 2 short beeps indicate a successful program sequence.

LED and Sounder Indicators

The PDL Series locks provide visual and audible keypad feedback. With a fully charged battery, the LED and sounder feedback is as follows:

ACTIVITY LED SOUNDER COMMENTS

Keypress 1 RED Flash 1 Beep Normal Operation

Access Granted 3 GREEN Flashes 3 Beeps

Invalid Code 6 RED Flashes 6 Beeps Re-enter User Code

Successful Program Entry 2 GREEN Flashes 2 Beeps When in Program Mode

Unsuccessful Program Entry 7 RED Flashes 7 Beeps When in Program Mode

Exit Program Mode 2 Red, 2 Green Flashes 10 Beeps

Valid but Disabled Code 1 Green, 4 Red Flashes 1 long, 5 short beeps Code exists in memory, but disabled

Low Battery Red and Green Flash during

Non-fatal memory or clock error

has been detected

key presses

Red and Green Flash Sequence of 7 Beeps

Long Beep See page 11 before changing batteries

Repeated 4 Times

Under this condition, unexpected operation

is possible. Remove power and restart.

9

Page 10

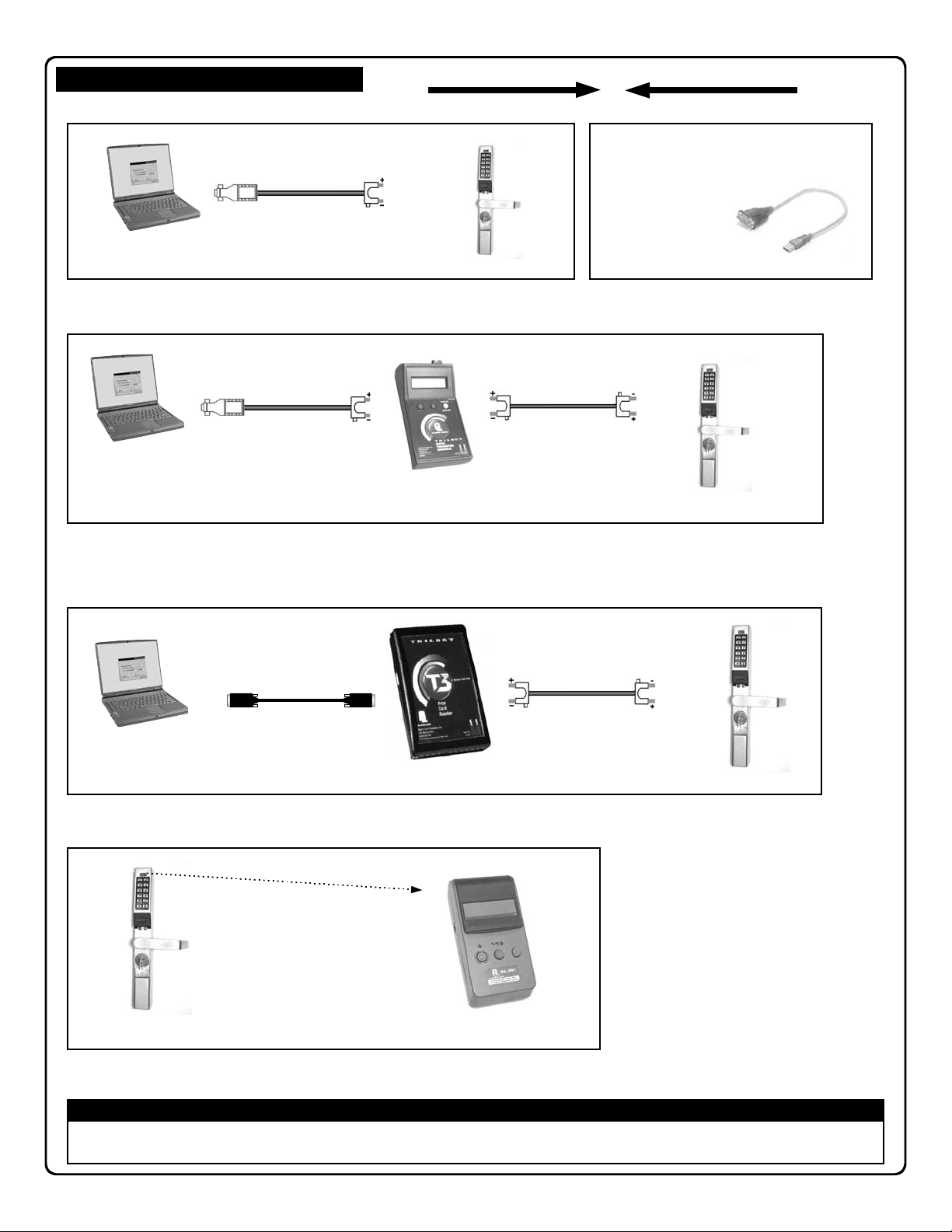

Product Communication Examples

Send to lock

AL-PCI CABLE

CONNECT TO S ERIAL PORT

(COM 1-4)

NOTE: OBSERVE TAB DIRECTION WHEN

INSERTING CABLE INTO LOCK

IBM COMPATA BLE

LAPTOP OR DESKTOP PC

PDL1300 LOCK

Scenario 1 Create the program in DL-Windows on your computer, then transfer the program from the computer directly to the lock via an

AL-PCI cable. You must always enter the User 298 User Code to send or receive data Using DL-Windows.

AL-PCI CABLE

CONNECT TO S ERIAL PORT

IBM COMPATA BLE

LAPTOP OR DESKTOP PC

(COM 1-4)

NOTE: OBSERVE TAB DIRECTION WHEN

INSERTING CABLE INTO LOCK

AL-DTM DATA

TRANSFER

MODULE

DOUBLE-ENDED MINI BANANA

PLUG CONNECTOR

NOTE: OBSERVE TAB DIREC-

TION WHEN INSERTING CABLE

INTO AL-DTM AND LOCK

If your computer does not have a serial COM port

(DB-9 male) available, you can plug your AL-PCI2

cable into a special USB to RS-232 cable. Order

part PCI-USB for the

USB to RS-232 cable

only, or ALPCI2-U for

both the USB to RS-232

cable and an AL-PCI2

cable).

Receive from lock

PDL1300 LOCK

Scenario 2 Create the program in DL-Windows and transfer the program from your computer to an AL-DTM (via an AL-PCI cable)…

then transfer the program from the AL-DTM to the lock(s) (via a double-ended mini banana plug). The hand-held AL-DTM is useful

because you do not have to transport (or find electricity for) your computer. Data can also flow in reverse, from the lock, through

the AL-DTM, back to the computer for examination.

IBM COMPATABLE

LAPTOP OR DESKTOP PC

CONNECT DB9 CABLE

TO COMPUTER S ERIAL

PORT (COM 1-4)

DB9 to DB9 Serial

Cable (supplied)

AL-PRE PROXCARD READER/

ENROLLER

DOUBLE-ENDED MINI BANANA

PLUG CONNECTOR

NOTE: OBSERVE TAB DIREC-

TION WHEN INSERTING CABLE

INTO AL-PRE AND LOCK

PDL1300 LOCK

Scenario 3 Enroll ProxCards® quickly into DL-Windows, then transfer this new ProxCard® data from the computer through the AL-PRE

to the lock (thus avoiding the need to use an AL-PCI cable). For PDL series locks only.

PDL1300 LOCK

AL-IR1

INFRARED PRINTER

Scenario 4 Use the AL-IR1 Infrared printer to print your lock’s audit trail (event log), User Code list, clock settings and software

version. No cable required.

NOTE:

The AL-PCI cable is designed to be used on a 9 pin serial COM port. If your computer has a 25 pin COM port, a 25 pin to 9 pin adapter must be used.

Warning: Polarity MUST be observed when connecting cables to the lock. The tab (-) must plug into the negative (black) hole.

10

Page 11

Wiring and Power Up

WIRING

See the Installation Manual for more information.

Batteries:

Use only 3.0 volt Lithium Type 123 batteries (or equivalent). Two (2) batteries of this type are needed.

BATTERY REPLACEMENT

When a valid code is entered and the batteries are weak,

the red & green LED's will light and the sounder will sound

for 4 seconds. Replace with two (2) 3.0 volt Lithium Type

123 batteries. Always replace weak batteries as soon as

possible.

CAUTION: Do not press any keys while batteries are

disconnected or you may erase the real-time clock

settings.

1. Insert key in cylinder and turn counterclockwise to al-

low access to the battery compartment screw. With the

supplied 5/64" Allen wrench, loosen the battery cover

screw only until the battery cover is able to slide off.

2. Pull out the battery pack and quickly replace both

batteries - within 1 minute.

3. If you do not hear the 3 beeps when power is re-

applied, all programming and settings have been retained, and the lock is ready for use. Go to step 5.

4. If you do hear 3 beeps when power is re-applied, do

not press any keys for 15 seconds. After the 15

second period, the LED will flash red 6 times and 6

beeps will sound. Reset the clock using functions 38, 39

and 40.

5. Slide the battery cover back in place and tighten the

screw.

POWER UP

• When applying power to the lock for the first time, stop

and follow the procedure outlined in "Quick Start, First

Time Start Up" on page 12.

• When power is re-applied to a lock that was already

operational, proceed as follows:

1. Disconnect battery pack connector.

2. With battery power disconnected, press and hold

down ; for 10 seconds to ensure discharge of all

capacitors.

3. Re-connect battery pack (lock will sound 3 short

beeps). If beeps are not heard, then restart at step 1.

4. Do not press any keys for 15 seconds.

5. After 15 seconds, the LED will flash red 6 times and 6

beeps will sound.

The lock is now ready for use. The pre-existing program is

loaded from fixed memory. Reset the clock using functions

38, 39 and 40 if necessary.

ERASE ALL PROGRAMMING

RESTORE FACTORY DEFAULT (original "out of box" set-

tings that were set at the factory will be loaded).

1. Enter the current Master Code (if not known, proceed

directly to ALTERNATIVE METHOD, below). Wait for

the green light and press ; until multiple beeps are

heard. You are now in Program Mode.

2. Press ; 99 ; 000 :.

3. Listen for 6 beeps. The lock will re-lock. All settings and

programming have been erased. Proceed directly to

page 12, Quick Start, and follow the procedure "Enter

Program Mode and Change Factory Master Code".

ALTERNATIVE METHOD

Note: This method requires the lock first be removed from

the door.

1. Insert key in cylinder and turn counterclockwise to allow access to the battery compartment screw. With the

supplied 5/64" Allen wrench, loosen the battery cover

screw only until the battery cover is able to slide off.

2. Disconnect the battery pack.

3. Remove the back plate by unscrewing the two Phillips

head screws. Note: Some models have four Phillips

head screws. Be careful not to damage the motor drive

wires.

4. Locate jumper header JP1 near the top of the printed

circuit board and install the jumper (provided) across pins

1 and 2 of JP1.

5. Press and hold down ; for 10 seconds (to ensure

all power is drained from the lock) and release.

6. Connect the batteries and--within 5 seconds--press

and hold ;. After hearing 6 additional beeps, re-

lease ;. If you do not hear these 6 additional

beeps, you must start over at step 2. Failure to follow

this exact procedure can result in erratic lock behavior.

7. Test by pressing the default Master Code of

123456 (a beep will sound

and the lock will unlock).

8. Remove the jumper from JP1 pins 1 and 2 and place

jumper on 1 pin for storage.

9. Carefully reinstall the back plate STRAIGHT onto the

lock body. Be careful not to pinch or damage the motor

drive wires. While inserting the back plate, be sure the

rear pin of the tailpiece inserts into the spindle hole-check this alignment after installation by pushing on the

spring-loaded tailpiece to verify that it smoothly moves

up and down. Replace the two (or four) Phillips head

screws to secure the back plate. Note: It may be nec-

essary to tighten the battery screw previously loosened

in step 1.

10. Re-mount the lock on the door. With the battery

back inside its compartment, slide the battery cover

back in place and tighten the screw.

All settings and programming have been erased. Pro-

ceed directly to page 12, Quick Start, and follow the

procedure "Enter Program Mode and Change Fac-

tory Master Code".

11

Page 12

Quick Start

First Time Start Up

1. Unpack the lock.

2. With the batteries disconnected, hold down the ; key for 10 seconds and release.

3. Connect the batteries and listen for 3 beeps.

4. Wait 15 seconds, and listen for 6 additional beeps (LED will flash twice). The lock is ready to program when it

unlocks.

Important Note: When entering any key sequence below, do not pause more than 25 seconds between any key

presses--otherwise you must start again.

Enter Program Mode and Change Factory Master Code

1. Press the default Master Code: 1 2 3 4 5 6.

If the lock should fail to unlock using this Master Code, proceed directly to

ERASE ALL PROGRAMMING--

RESTORE FACTORY DEFAULT on the previous page and then perform this Quick Start procedure again.

2. Wait for the green light and press ; until multiple beeps are heard. You are now in Program Mode.

Note: The lock will beep every 6 seconds as a reminder that you are in Program Mode.

3. Enter a new personal 6-digit Master Code number by pressing the following keys:

; 1 ; [

same).

(For example, if you want your new Master Code to be “664433”. Press:

; 1 ; 664433 ; 664433 :).

Now that the Master Code has been changed, there is no need to change it again (unless you want to). Since you are

still in Program Mode, you can now proceed directly below and program various functions. Note: Programming any

Function, such as setting the clock, follows a consistent 5-step pattern: (1) Enter Program Mode (2) Press ;

[Function #] (3) Press ; and enter data (4) Press : to end (5) Exit Program Mode.

Note: There is a 3 minute Program Mode timeout if no keys are pressed when in Program Mode. A steady tone will

sound for the final 15 seconds of the 3 minute timeout period as a warning. To remain in Program Mode, press any

key.

new Master Code] ; [new Master Code] : (the second set of digits must be exactly the

Set the Weekday

1. Enter Program Mode (if not in already).

2. Press ; 40 ; [number of weekday] :. (Use 1= Sunday, 7 = Saturday).

(For example - Friday - press ; 40 ; 6 :).

Set the Date

1. Enter Program Mode (if not in already).

2. Press ; 38 ; [MMDDYY] :.

(For example - May 10, 2002 - press ; 38 ; 051002 :).

Set the Time

1. Enter Program Mode (if not in already. If you just finished the above procedure, you are still in Program Mode).

2. Press ; 39 ; [HHMM] :. (Use 24-hour military format, where PM adds 12 hours).

(For example - 2:30pm - press ; 39 ; 1430 :).

Enter User Codes

1. Enter Program Mode (if not in already).

2. Press ; 2 ; [User Number] ; [new User Code] :.

(For example, John Smith is designated as User 21. You want him to use the code of “232323” to unlock the door.

12

Page 13

Quick Start (cont’d)

Program the lock by pressing: ; 2 ; 21 ; 232323 :).

3. Repeat step 2 for each new user.

Delete a User Code

1. Enter Program Mode (if not in already).

2. Press ; 2 ; [User Number] :.

The lock will flash a green LED and beep continuously for 6 seconds. When the red LED flashes, the User Code is de-

leted.

3. Repeat step 2 for each new User.

User Code Conflicts

Care should be taken not to program a new User Code which matches the first digits of any other User Code (only the

User Code with the least number of digits will be recognized). Example: If User Codes 123 and 123456 are both

entered in the system, only code 123 would be recognized, unless the ENTER Key has been enabled (see Function 69,

see page 25). In addition, an error will sound if you try to program a new User Code that matches the first digits of the

Master Code.

WARNING: When attempting to change an existing Master Code, it is HIGHLY recommended that you enable all

Groups (see Function 23 on page 18), exit Program Mode, and enter the new anticipated Master Code to verify

that the anticipated sequence does not currently open the lock. If the lock does not open, the anticipated Master Code can be used as the new Master Code; if the lock opens, the anticipated Master Code already exists in

the lock (as a User Code), and the anticipated Master Code should NOT be used. Always repeat this procedure

with any new anticipated Master Codes.

Enroll ProxCards at the Lock

If you wish to enroll only one ProxCard (“Single Enrolling”) or many (“Batch Enrolling”), the process is basically the

same.

1. Enter Program Mode (if not in already).

2. Press ; 2 ; [User Number] :. (Enter the User Number you wish to match with the first ProxCard).

3. Lock will beep continuously. Place a new Prox Card in front of the Prox reader (under the lock keypad). When the

lock beeps three times, the card has been enrolled.

4. Press ; to end the process. To return to normal operation, exit Program Mode (see below).

(For example, you wish to enroll two ProxCards for User 14 and User 15 respectively. Press ; 2 ; 1

4 :. and place the first card in front of the reader (hear 3 beeps) and then within 10 seconds, place the sec-

ond card in front of the reader (hear 3 beeps)).

You can continue entering cards in this way, automatically incrementing the User number with each presentation of a

ProxCard. When finished, press ;.

Note: Batch Enrolling will not program Users 297 through 300, as these are Special Function User Codes. After a

ProxCard for User 296 has been Batch Enrolled, the next card presented will enroll as User 301.

High Security Access (ProxCard & User Code Access)

Program the lock for High Security Access for User Number 15, with a ProxCard and a User Code of 7452 required for

access:

1. Enter Program Mode (if not in already).

2. Press ; 2 ; 1 5 :.

3. Lock will beep continuously. Place a new Prox Card in front of the Prox reader (under the lock keypad). When the

lock beeps three times, the card has been enrolled.

4. Press ; 2 ; 1 5 ; 7 4 5 2 :.

In order for User 15 to open the Lock, a User Code must be entered and a ProxCard must be presented to the PDL1300

Lock. User may enter code or present card in either order to open the lock. The sounder will beep for up to 10 seconds,

waiting for the User to enter their User Code and present their card.

13

Page 14

Delete a High Security Access Code

Note: Deleting a ProxCard associated with a User number will also delete the User Code programmed for that User

Number. Delete the ProxCard by not presenting any card for enrollment, as follows:

1. Enter Program Mode (if not in already).

2. Press ; 2 ; _ :. (Enter the User Number matched to the ProxCard you want to delete).

3. Lock will beep continuously. Do not present ANY card during this step. Wait until lock stops beeping, about 10 seconds.

4. Press ; to end

Exit Program Mode

Hold Down any key for 3 seconds. Program Mode exit is confirmed by several beeps. You are now in normal operation.

Re-enter Program Mode

If you wish to re-enter Program Mode, key-in your new 6-digit Master Code, and press ;.

You are now ready to mount and install your PDL series lock and give out your User Codes. Before installation, it is suggested you test and verify that all User Codes entered are active (see below).

Testing the Codes Entered

Verifying Basic Keypad User Codes

Test a valid User Code:

VALID CODE - The Green LED will flash momentarily and the sounder will beep a few times after a valid code is entered.

INVALID CODE - The RED LED will flash several times and the sounder will beep several times after an invalid code is entered.

Use Function 2 to re-program the code.

Verifying Prox Card and Keyfob Access

Test a programmed ProxCard

Present the Programmed ProxCard® (or Keyfob ) to the Prox reader in front of the lock.

VALID CARD - The Green LED will flash momentarily and the sounder will beep a few times after a valid card or keyfob has

been presented to the lock.

INVALID CARD - The RED LED will flash several times and the sounder will beep several times after an invalid ProxCard

Keyfob has been presented to the lock. Use Function 2 to re-program the code.

Verifying High Security Access (ProxCard + User Code)

Test ProxCard® programmed for High Security Access. A ProxCard® and User Code are both required for access.

1. Enter the User Code for the User Number programmed for High Security Access. The sounder will beep slowly for up to 10

seconds.

2. Present the ProxCard

User may enter User Code or present the ProxCard

seconds, waiting for the User to enter User Code or to present the ProxCard

Note: Do not present the ProxCard

®

or ProxKey® Keyfob:

®

programmed for the same User Number.

®

in either order to open the lock. The sounder will beep for up to 10

®

/ Keyfob and enter the User Code simultaneously.

®

/ Keyfob.

®

or

14

Page 15

Programming Functions--Overview

Function 1 Change Master Code

Function 2 Add/Delete/Change User Codes

Function 3 User Disable (By User Number)

Function 4 User Enable (By User Number)

Function 5 User Enable with Timeout

Function 6 Enable Total User Lockout

Function 7 Disable Total User Lockout

Function 8 Reserved

Function 9 Enable User 300 (Service Code)

Function 10 Erase All Users Except the

Master Code

Function 11 Reserved

Function 12 Clear All Schedules and Timeout

Functions

Function 13 Clear All Timeout Functions

Function 14 - 17 Group 1-4 Disable

Function 18 Disable All Groups

Function 19 - 22 Group 1-4 Enable

Function 23 Enable All Groups

Function 24 Reserved

Function 25 - 28 Group Disable with Timeout

Function 29 Disable All Groups with Timeout

Function 30 - 33 Group Enable with Timeout

See page 16

See page 16

See page 17

See page 17

See page 17

See page 17

See page 17

--

See page 17

See page 17

--

See page 18

See page 18

See page 18

See page 18

See page 18

See page 18

--

See page 19

See page 19

See page 19

Function 48 Enable Passage Mode

Function 49 Disable Passage Mode

Function 50 Return Lock to Normal Passage

Mode Schedule

Function 51 Passage Mode Configuration

Function 52 - 54 Pass Time

Function 55 Print Audit Trail

Function 56 Print User Code List

Function 57 Print Clock Settings and Software

Version

Function 58 Upload/Download PC Data

Function 59 Reserved

Function 60 Number of Attempt Before

Lockout

Function 61 Set the Attempts Lockout Time

Function 62 - 66 Reserved

Function 67 Add System Options

Function 68 Delete All System Options added

by Function 67

Function 69 - 70 Enable/Disable Enter Key

Function 71 Reserved

Function 72 - 73 Scheduled Enable/Disable

Passage Mode

Function 74 - 77 Schedule Enable Group 1 - 4

See page 22

See page 22

See page 22

See page 22

See page 22

See page 23

See page 23

See page 23

See page 23

--

See page 24

See page 24

--

See page 24

See page 24

See page 25

--

See page 25

See page 25

Function 34 Disable All Groups with Timeout

Function 35 Group Add/Delete Association

Function 36 - 37 Reserved

Function 38 Set Date

Function 39 Set Time

Function 40 Set Weekday

Function 41 Daylight Saving Time Start Date

Function 42 Daylight Saving Time End Date

Function 43 Speed Up Clock

Function 44 Slow Down Clock

Function 45 - 46 Passage Mode Enable/Disable

Function 47 Timed Passage Mode

See page 19

See page 19

--

See page 20

See page 20

See page 20

See page 20

See page 20

See page 21

See page 21

See page 21

See page 21

Function 78 Schedule Enable All Groups

Function 79 - 82 Schedule Disable Group 1 - 4

Function 83 Schedule Disable All Groups

Function 84 - 87 Quick Schedules - Enable Group

Function 88 Passage Mode

(Open Time Window)

Function 89 Passage Mode

(Close Time Window)

Function 90-91 Reserved

Function 92 Enable Group 4

(Open Time Window)

Function 93 Enable Group 4

(Close Time Window)

Function 94 - 98 Reserved

Function 99 Clear All Lock Programming

See page 25

See page 25

See page 25

See page 26

See page 26

See page 26

--

See page 27

See page 27

--

See page 27

15

Page 16

USERS

Programming Functions

1. New Master Code (User Number 1)

; 1 ; [ _ _ _ _ _ _ ] ; [ _ _ _ _ _ _ ] :

(New Master Code) (Confirm New Master Code)

• Master Code must be 6 digits-only.

• Master Code is Keypad Code Access only.

• Factory Default = 123456

• See "Lock Design Overview" on page 5 for more information about Master Codes.

2. Add/Delete/Change User Codes 2-2000

; 2 ; [ _ _ _ _ ] * ; [ _ _ _ _ _ _ ] :

(User Number) (User Code)

• User Number must be between 2 and 2000.

• To delete a code/card, leave the User Code blank and wait for the rapid beeping to stop, then

to avoid erroneously enrolling Proximity Cards, press and hold : for three seconds to exit

Programming Mode. If more programming is desired, re-enter Programming Mode.

• User Code must be 3-6 digits.

• Each User Code can be thought of as a person. As long as each person possesses their own

unique User Code, you can control access to the lock by adding or deleting User Codes. See

"Terminology Used in this Manual" on page 6 for more information.

Lock Defaults for PDL1300

See page 8. Users added will default to a Group association and a Programming Level as follows:

USER TYPE USER NUMBER GROUP DEFAULT

ASSOCIATION

Master 1 -

M

3

* To program proximity card,

press

: and present the card.

MINIMUM PROGRAM

LEVEL (see page 6)

M (All Programming Abilities)

Installers 2 & 3 none

Managers 4 - 6 none

Supervisors 7 - 9 none

Print Only Users 10 - 11 none

Basic Users 12 - 50 none none

Basic Users in Group 1 51 - 100 1 none

Basic Users in Group 2 101 - 150 2 none

Basic Users in Group 3 151 - 200 3 none

Basic Users in Group 4 201 - 250 4 none

Basic Users 251 - 296 none none

Quick Enable User 300 297 none none

Quick PC Access 298 none none

AL-DTM Code 299 none none

Service User 300 none none

Basic Users 301-2000 none none

User 299 is a Non-Pass Code. This is the only code that will initiate data transfer with the AL-DTM.

4 (Also 3, 2, 1)

3 (Also 2, 1)

2 (Also 1)

1

16

Page 17

Programming Functions (cont'd)

USERS (Continued)

User Enable/Disable (By User Number)

• User Number must be between 2 and 2000.

NOTE: Will Enable/Disable Users even if the User is associated with an enabled Group. Use Feature 3 to disable a specific User

Number and their associated User Code. If the disabled User Code is entered, the lock will flash 1 Green and 4 Red Flashes

(with 1 long and 5 short beeps) indicating that the User Code exists in memory, but is disabled. Function 4 will "undo" Function 3.

3. Disable User

4. Enable User

5. User Enable with Timeout

(Enter Timeout, XXX Hours)

(This Function enabled through keypad only)

; 3 ; [ _ _ _ _ ] :

; 4 ; [ _ _ _ _ ] :

; 5 ; [ _ _ _ _ ] ; [ _ _ _ _ ] :

(User Number) (XXX Hours)

(User Number)

(User Number)

• With Function 5, User Numbers must be between 2-2000, hours must be between 1-999.

• Function 5 can temporarily override a disabled User (disabled using Function 3 above).

• Since this is a temporary feature, Function 5 can only be enabled using the keypad.

• Example: Brian, User Number 1157, rarely works at the office, but when he does, enable him for his 8 hour work day by entering

Program Mode and pressing: ; 5 ; 1157 ; 008 :.

• NOTE: Up to 4 Timeout Functions may be pending at any one time. An error beep will sound when attempting to program more

than 4 Timeout Functions.

User Lockout Mode

2

2

Prevents all User Codes (Except User 1 Code) from operating the lock. Note: No other programming

functions or schedules will re-enable Users. Users must

Note: Does not change the User enable/disable status. Note: If the lock is currently in Passage Mode

(door "unlocked") and Function 6 is programmed, the lock will remain in Passage Mode.

6. Enable Total User Lockout Mode

(This Function enabled through keypad only)

7. Disable Total User Lockout Mode

(This Function enabled through keypad only)

be re-enabled with Function 7.

; 6 :

; 7 :

8. Reserved

9. Enable User 300 (Service Code)

Service Code is a One-Time-Only Code. Once it is used, it is disabled until enabled again.

NOTE: User Number 297 is used to reset Service Code Use. See "Terminology Used in

this Manual" on page 7 for more information and examples regarding special Users 297-300.

10. Erase All Users Except the Master Code (User 1)

(This Function enabled through keypad only)

Erases all User Codes except the Master Code (User 1).

• Function 10 can only be performed using the keypad.

; 9 :

; 1 0 ; 0 0 0 :

M

2 2

M

11. Reserved

17

Page 18

Programming Functions (cont'd)

CLEAR FUNCTIONS

12. Clear All Schedules and Timeout Functions

Function 12 clears all programmed Schedules and all Timeout Functions. (To clear All Timeout Functions only, see

Function 13 below). Function 12 will clear all of the following: All Schedule Functions 72 through 93, Timeout Functions

5, 25 through 34 and Function 47. Note: Function 12 also resets Passage Mode and any disabled Groups. After using

Function 12, your Scheduled/Timeout features must be manually re-programmed.

NOTE: Up to 4 Timeout Functions may be pending at any one time. An error beep will sound when attempting to

program more than 4 Timeout Functions. This Function only disables the timeout; the event associated with the timeout

will remain

13. Clear All Timeout Functions

(This Function enabled through keypad only)

Function 13 clears all Timeout Functions. (To clear All Schedules and Timeout Functions, see Function 12 above).

Function 13 will clear all of the following: All Timeout Functions 5, 25-34 and Function 47. After using Function 12, your

Scheduled/Timeout features must be manually re-programmed.

NOTE: Up to 4 Timeout Functions may be pending at any one time. An error beep will sound when attempting to

program more than 4 Timeout Functions. This Function only disables the timeout; the event associated with the timeout

will remain

Important: It is the responsibility of the lock programmer to verify the proper lock/unlock conditions and Group conditions

after programming the lock with Function 12 and 13.

GROUPS

; 1 3 ; 0 0 0 :

; 1 2 ; 0 0 0 :

3

3

Group Enable/Disable

Enter the functions below to Enable/Disable Groups. Functions 14 - 23 will each override

existing scheduled events. Therefore, Functions 14 - 23 are temporary, take effect immediately, and are always overridden by future scheduled events that already exist within

the lock programming.

14. Disable Group 1

15. Disable Group 2

16. Disable Group 3

17. Disable Group 4

18. Disable All Groups

19. Enable Group 1

20. Enable Group 2

21. Enable Group 3

22. Enable Group 4

; 1 4 :

; 1 5 :

; 1 6 :

; 1 7 :

; 1 8 :

; 1 9 :

; 2 0 :

; 2 1 :

; 2 2 :

2

PRIORITY ORDER

1. Disabled Users

2. Enabled Groups

3. Disabled Groups

4. Enabled Users

The Priority Order details which Function will

take effect before ("have priority over") others.

For example, as per the list above, Enabled

Users have the lowest priority, and other Functions can affect the status of these Users. Disabling a Group (Functions 14-18) will take priority over the Enabled Users in that Group,

disabling them. Enabling Groups (Functions

19-23) will take priority over those tasks lower

in the list, and finally disabling a User (Function

3) takes priority over all other tasks listed.

24. Reserved

18

23. Enable All Groups

; 2 3 :

Page 19

Programming Functions (cont'd)

GROUPS

NOTE:

Clear All Timeout Functions by entering Function 13.

Group Enable/Disable with Timeout (Enter Timeout, XXX Hours)

(Functions 25-34 are enabled through the keypad only)

• Hours must be between 1-999. Enter the functions below to Enable/Disable Groups for the amount of time entered in hours.

NOTE: Only 4 Timeout Functions are allowed at any one time. An error beep will sound when attempting to program more than

4 Timeout Functions. Functions 25 - 34 will each override existing scheduled events. Therefore, Functions 25 - 34 are temporary, take effect immediately, and are always overridden by future scheduled events that already exist within the lock

programming. NOTE: Functions 25-34 are enabled through the keypad only.

• Example: All 15 members of the Accounting Department are members of Group 4, and a schedule programmed in the

department's door lock reflects their normal working hours of 9 AM through 5 PM, Monday through Friday. But one day a

special event occurs, and all Accounting Department members are requested to stay an extra hour until 6 PM. Therefore,

at 5 PM, the manager (wishing to temporarily enable Group 4 users for an extra hour) enters Program Mode and

presses: ; 33 ; 001 :. Likewise, if the manager wished to send his department home

early at 3 PM, the manager could enter ; 28 ; 002 :.

25. Timed Disable Group 1

26. Timed Disable Group 2

27. Timed Disable Group 3

28. Timed Disable Group 4

; 2 5 ; [ _ _ _ ] :

(XXX Hours)

; 2 6 ; [ _ _ _ ] :

(XXX Hours)

; 2 7 ; [ _ _ _ ] :

(XXX Hours)

; 2 8 ; [ _ _ _ ] :

(XXX Hours)

2

29. Timed Disable All Groups

30. Timed Enable Group 1

31. Timed Enable Group 2

32. Timed Enable Group 3

33. Timed Enable Group 4

34. Timed Enable All Groups

35. Group Add/Delete Association

; 2 9 ; [ _ _ _ ] :

(XXX Hours)

; 3 0 ; [ _ _ _ ] :

(XXX Hours)

; 3 1 ; [ _ _ _ ] :

(XXX Hours)

; 3 2 ; [ _ _ _ ] :

(XXX Hours)

; 3 3 ; [ _ _ _ ] :

(XXX Hours)

; 3 4 ; [ _ _ _ ] :

(XXX Hours)

; 3 5 ; [ _ _ _ ] ; [ _ _ _ _ ] :

(User Number) (Groups)

As per the chart on page 8, the lock's default programming from the factory associates certain User Numbers with certain

Groups. To override these default Group associations, Function 35 manually associates (or disassociates) a selected

User with a selected Group. During programming, Groups not selected are then disassociated from the User. Function

35 is helpful when the number of Users you wish to add to a Group outgrows the number of User Numbers defaulted to a

Group (50); or if an existing User joins a department and you wish to simply add them to a Group.

• User Number must be between 2 and 2000; Groups 1-4 (to associate with User) may be selected.

Add Example: To associate User 67 with Groups 1, 2 and 4;

Enter: ; 3 5 ; 6 7 ; 1 2 4 :

Delete Example: To remove all Group associations for User 67;

Enter: ; 3 5 ; 6 7 :

NOTE: If a User is associated with more than one Group, all associated Groups would have to be disabled before the User is disabled.

3

36 - 37. Reserved

19

Page 20

CLOCK SETTINGS

Programming Functions (cont'd)

38. Set Date

• Use Month Day Year format - MMDDYY - Single digit months and days are entered with a preceding zero.

; 3 8 ; [ _ _ _ _ _ _ ] :

(Date)

3

• Enter ONLY the last two digits of the year.

For Example: March 8, 2002; Enter:

; 3 8 ; 0 3 0 8 0 2 :

39. Set Time

• Time must be 4 digits

; 3 9 ; [ _ _ _ _ ] :

(Time)

3

• Use 24 Hour Format (add 12 hours to program PM time)

For Example: To set time to 8:25PM;

Enter: ; 3 9 ; 2 0 2 5 :

For Example: To set time to 8:25AM;

Enter: ; 3 9 ; 0 8 2 5 :

40. Set Weekday

; 4 0 ; [ _ ] :

(Day)

• For day enter: 1 for Sunday, 2 for Monday, 3 for Tuesday, 4 for Wednesday, 5 for Thursday, 6 for Friday and 7 for Saturday.

For Example: To set day to Sunday;

Enter: ; 4 0 ; 1 :

3

41. Daylight Saving Time Start Date

; 4 1 ; [ M M W D ] :

(DST Starting M onth, Month, Week, Day)

The manner in which Daylight Saving Time (DST) is observed varies with location, therefore the DST adjustment is fully flexible to

accommodate these regional differences. Function 41 allows the entry of a DST Start Date (month, day and week), and Function 42

allows the entry of a DST End Date (month, day and week). DST begins and ends at 2AM on the programmed date. Enter ;

4 1 ; 0 0 0 : to disable DST. All locks leave the factory with DST enabled and pre-programmed to the

following start and end dates (for the USA beginning 2007):

• Default DST Start Date: March, Week 2, Sunday ("Second Sunday in March")

• Default DST End Date: November, Week 1, Sunday ("First Sunday in November")

To program the DST start date using the keypad, press: ; 4 1 ; [ M M W D ] : where "M M W D" represents:

• "M M" = Two digits of the month (01 through 12 = January through December. Single digit months are entered with a

preceding zero).

• "W" = Single digit for "week of the month" (valid entries are 1-5 where "1" is the first week, "2" is the second week, "3" is the

third week, "4" is the fourth week and "5" is the last week of the month.

• "D" = Day of the week (valid entries are 1-7: 1 for Sunday, 2 for Monday, 3 for Tuesday, 4 for Wednesday, 5 for Thursday, 6

for Friday and 7 for Saturday).

Example: To set the default start date of "second Sunday in March", press:

; 4 1 ; [ 0 3 2 1 ] : (03 = "March", 2 = "2

42. Daylight Saving Time End Date

; 4 2 ; [ M M W D ] :

nd

week", 1 = Sunday).

(DST Ending Month, Month, Week, Day)

4

End date of Daylight Saving Time (month, week, day). Enter ; 4 2 ; 0 0 0 : to disable DST.

See Function 41 for full explanation.

20

4

Page 21

CLOCK ADJUST

Clock Adjust

Programming Functions (cont'd)

Number of seconds to adjust (speed up/slow down) the clock each day must be between 0-55 seconds.

Note: Repeated use of these Functions are not "cumulative" (this means, for example,

if the clock has already been set to speed up 10 seconds per day, and then is found to

need an additional 10 seconds, then program 20 seconds using Function 43).

Example 1: Clock is losing 13 seconds every day, enter:

; 4 3 ; 1 3 :.

This example assumes that the Clock Adjust setting was at the factory default of zero.

Function 57 can be used to print the current Clock Adjust setting.

Example 2: Clock is gaining 13 seconds every day, enter:

; 4 4 ; 1 3 :.

This example assumes that the Clock Adjust setting was at the factory default of zero.

Function 57 can be used to print the current Clock Adjust setting.

Example 3: To set the clock adjust setting back to the factory default of zero, enter

:

; 4 3 : or ; 4 4 :

43. Speed Up Clock

(This Function enabled through keypad only)

44. Slow Down Clock

(This Function enabled through keypad only)

; 4 3 ; [ _ _ ] :

(seconds)

; 4 4 ; [ _ _ ] :

(seconds)

4

Clock Accuracy

The internal oscillator is factory calibrated to an accuracy of ±5 minutes/year. Changes in ambient temperature may affect accuracy. If necessary, the accuracy of the internal clock may be adjusted by first updating the correct time via Function 39. After an interval

of about 1 month, re-set the correct time via Function 39

and then print an Audit Log via Function 55. Because

the Audit Log displays both the "New Clock Time" and

the "Old Clock Time", a daily accuracy (in seconds) can

be determined by taking the difference in seconds between the "Old" and "New" times divided by the number

of days between the two Function 39 entries. Note:

Because the minimum available adjustment is 1 second

per day, the inaccuracy of the clock must exceed about 6

minutes per year before adjustment is necessary.

PASSAGE MODE

Passage Mode Enable/Disable - Schedule will Override

• Function 45 allows passage through the door without the need for a User Code. Re-Lock using Function 46.

• Programmed Schedules will override the state of the lock when Functions 45 and 46 are used. If it is required that

programmed schedules do not

cause of the temporary nature of these features, Functions 45-47 can only be enabled using the keypad.

45. Enable Passage Mode

(This Function enabled through keypad only)

46. Disable Passage Mode

(This Function enabled through keypad only)

47. Timed Passage Mode

(This Function enabled through keypad only)

• Hours must be between 1 - 999.

Function 47 allows passage through the door without the need for a User Code for the programmed amount of time.

• For example, if you wish your office door lock to be unlocked (unlocked = "Passage Mode") for the next 3 hours,

enter Program Mode and press: ; 47 ; 003 :

override Passage Mode, enable/disable Passage Mode using Functions 48/49. Note: Be-

; 4 5 :

; 4 6 :

; 4 7 ; [ _ _ _ ] :

(XXX Hours)

2

2

21

Page 22

Programming Functions (cont'd)

PERMANENT PASSAGE MODE

Passage Mode Enable/Disable - Schedule will not Override

• Function 48 allows passage through the door without the need for a User Code. Re-Lock using Function 49.

• Programmed Schedules will not override the state of the lock using functions 48 and 49. If it is required that programmed

schedules override Passage Mode, Enable/Disable Passage Mode using Functions 45/46. Use Function 50 to "undo" Functions 48 and/or 49, and therefore return the lock to all pre-existing scheduled functions. Note: Functions 48-50 can only be

enabled using the keypad. Warning: Function 49 will inhibit all scheduled Passage Mode events.

48. Enable Permanent Passage Mode

(This Function enabled through keypad only)

49. Disable Permanent Passage Mode

(This Function enabled through keypad only)

50. Return Lock to Normal Passage

; 4 8 :

; 4 9 :

; 5 0 :

Mode Schedule

(This Function enabled through keypad only)

(Locks will lock or unlock depending on the current schedule). Use Function 50 to "undo" Functions 48 and/

or 49, and therefore return the lock to all pre-existing scheduled functions.

NOTE:

51. Passage Mode Configuration

• Mode 1 (Normal): Passage Mode must be enabled/disabled using Function 45 and 46. Mode 1 (Normal) is the factory default.

• Mode 2: Group 2 toggles Passage Mode.

• Mode 3: Group 2 enables, Group 3 disables Passage Mode. Disable Passage Mode has priority if User is a member of both

With Mode 2, each time any member of Group 2 enters their User Code, they will toggle Passage Mode. For example, if Passage

See Scheduled functions 72 and 73 for Scheduled Passage Mode.

; 5 1 ; [ _ ] :

(Mode)

Groups 2 and 3.

Mode is enabled, and a Group 2 User enters their User Code, Passage Mode will be disabled. If a few seconds later they enter

their User Code again, Passage Mode will be enabled. With Mode 3, Group 2 members will always enable Passage Mode, and

Group 3 members will always disable Passage Mode. For example, if Passage Mode is already enabled, and a Group 2 User enters their User Code, the Passage Mode status will not be changed due to the Function 51 Mode 3 configuration. If Passage Mode

is already enabled, and a Group 3 User enters their User Code, Passage Mode will become disabled.

2

4

PASS TIME

Pass Time

The Pass Time is the length of time the lock stays unlocked after a valid User Code is

entered. When the Pass Time expires, the lock will re-lock automatically. Use the

functions below to change the Pass Time to 3, 10 or 15 seconds. The Pass Time is

defaulted to 3 seconds.

52. Set Pass Time to 3 Sec.

53. Set Pass Time to 10 Sec.

54. Set Pass Time to 15 Sec.

22

; 5 2 :

; 5 3 :

; 5 4 :

4

Page 23

Programming Functions (cont'd)

PRINTER

Hold the printer's infrared reader in front of the lock’s infrared LED as shown in Figure 1 and Figure 2 below.

If the printer has been idle for some time, press the paper feed button to wake up the printer.

Infrared

LED

PDL1300 to Printer

- Side View

Figure 1

55. Print Audit Trail

Hold the printer over the lock's infrared sensor as shown in Figure 1 and Figure 2 above.

Twenty (20) events will print at a time; press 1 for more events, or 9 to quit. To abort

printing, press any key for 3 seconds (three short beeps will sound).

56. Print User Code List

Hold the printer over the lock's infrared sensor as shown in Figure 1 and Figure 2 above.

To abort printing, press any key for 3 seconds (three short beeps will sound).

; 5 5 :

; 5 6 :

Infrared

LED

Infrared

Reader

Place Infrared Reader (on

printer) in front of the Infrared LED (on the lock)

Figure 2

1

3

57. Print Clock Settings, Software

Version and Door Number

; 5 7 :

Hold the printer over the lock's infrared sensor as shown in Figure 1 and Figure 2 above.

DOWNLOADING

58. Upload/Download PC Data

For use with DL-WINDOWS software, refer to OI237. AL-PCI interface cable is needed.

; 5 8 :

59. Reserved

1

3

23

Page 24

LOCKOUT

Programming Functions (cont'd)

60. Number of Attempts Before Lockout

• Number of attempts before lockout must be 1-9 attempts.

• The number of attempts is reduced by half every time the keypad is locked out without a

successful code entry (default is 6 attempts).

• The attempt count is reset each time a valid code is entered.

61. Set the Attempts Lockout Time

• Lockout Time must be 1-60 seconds.

How long the keypad is locked-out after a series of unsuccessful attempts

(default is 18 seconds).

; 6 0 ; [ _ ] :

(Number of Attempts)

4

; 6 1 ; [ _ _ ] :

(Lockout Time)

4

62-66. Reserved

SYSTEM OPTIONS

67. Add System Options

Use Function 67 to program one or more System Options numbered 24-28, detailed below:

• 24. ONE TIME ACCESS FOR GROUP 3 USERS - Allows the creation of multiple 'one time only' User Codes. When this feature is

activated, an entry by a Group 3 User will allow entry only once, then the User will become disabled. Note: When the User

Code is entered for the first time and access is granted, the Event Log will read "Entry" followed by "User Disabled". If the User

Code is entered a second time, access will be denied, and the Event Log will read "User Denied Access".

To use this new feature, proceed as follows:

1. Enable the Feature. Enter Program Mode and enter the key sequence ; 6 7 ; 2 4 : .

2. Assign the selected User Codes to Group 3. For example, to assign User Number 15 to Group 3, press: ; 3

5 ; 1 5 ; 3 :.

As with all Function 67 System Options, this feature can be disabled by entering the following key sequence: ; 6

7 ; 0 0 0 :

; 6 7 ; [ _ _ ] :

(Option Number)

4

• 25. DISABLE SOUNDER - Program to turn off the lock sounder. The lock will not sound under any circumstances.

• 26. FIVE (5) SECOND DELAYED ENTRY - Program to add a 5-second pause before unlocking with a valid User Code. Note: This

feature delays User Codes 12 and higher only (except 297, 298 and 299).

• 27. FIFTEEN (15) SECOND DELAYED ENTRY - Program to add a 15-second pause before unlocking with a valid User Code.

Note: This feature delays User Codes 12 and higher only (except 297, 298 and 299).

• 28. FORTY-FIVE (45) SECOND DELAYED ENTRY - Program to add a 45-second pause before unlocking with a valid User Code.

Note: This feature delays User Codes 12 and higher only (except 297, 298 and 299).

NOTE: Enter ; 6 7 ; 0 0 0 : to delete all Features added by Function 67 (identical to Function 68).

68. Delete All System Options added by Function 67.

Enter ; 6 8 ; 0 0 0 : to delete all System Options added by Function 67.

; 6 8 ; 0 0 0 :

24

4

Page 25

Enter Key

Programming Functions (cont'd)

ENTER KEY

• When this function is enabled, the User must press : after any valid User Code entry. Therefore,

this Function allows User Codes to be subsets of other User Codes.

Examples:

1 2 3 : can be a valid user code;

1 2 3 4 : can be a valid user code within the same lock.

1 2 3 4 5 6 :

69. Enable : as Enter Key

70. Disable : as Enter Key

(Hold ;) for Master User Code to enter Program Mode.

; 6 9 :

; 7 0

:

71. Reserved

SCHEDULES

NOTE:

Clear All Schedule and Timeout Functions by entering Function 12.

To set the time, see Function 39.

Scheduled Passage and Group

Use the functions below to enable Passage Mode and enable/disable Groups at the time programmed.

• For day enter: 1 for Sunday, 2 for Monday, 3 for Tuesday, 4 for Wednesday, 5 for Thursday, 6 for

Friday, 7 for Saturday, 8 for Monday to Friday, 9 for Saturday and Sunday, and 0 for all days of week.

Passage

Mode

72. Schedule Enable Passage

Mode ("Unlock")

; 7 2 ; [ _ ] ; [ _ _ _ _ ] :

(Day) (Time)

4

3

Groups

73. Schedule Disable Passage

Mode ("Lock")

74. Schedule Enable Group 1

75. Schedule Enable Group 2

76. Schedule Enable Group 3

77. Schedule Enable Group 4

78. Schedule Enable All Groups

79. Schedule Disable Group 1

80. Schedule Disable Group 2

81. Schedule Disable Group 3

82. Schedule Disable Group 4

83. Schedule Disable All Groups

; 7 3 ; [ _ ] ; [ _ _ _ _ ] :

(Day) (Time)

; 7 4 ; [ _ ] ; [ _ _ _ _ ] :

(Day) (Time)

; 7 5 ; [ _ ] ; [ _ _ _ _ ] :

(Day) (Time)

; 7 6 ; [ _ ] ; [ _ _ _ _ ] :

(Day) (Time)

; 7 7 ; [ _ ] ; [ _ _ _ _ ] :

(Day) (Time)

; 7 8 ; [ _ ] ; [ _ _ _ _ ] :

(Day) (Time)

; 7 9 ; [ _ ] ; [ _ _ _ _ ] :

(Day) (Time)

; 8 0 ; [ _ ] ; [ _ _ _ _ ] :

(Day) (Time)

; 8 1 ; [ _ ] ; [ _ _ _ _ ] :

(Day) (Time)

; 8 2 ; [ _ ] ; [ _ _ _ _ ] :

(Day) (Time)

; 8 3 ; [ _ ] ; [ _ _ _ _ ] :

(Day) (Time)

25

Page 26

Programming Functions (cont'd)

QUICK SCHEDULES

Quick Schedules - Enable Group

For your convenience, your lock comes pre-programmed with Quick Schedules, which, when programmed, enable Groups for

popular blocks of time. Group members will be enabled during the blocks of time defined below, but will still need to enter their

User Codes into the keypad to unlock the lock.

• Group number must be 1-4; enter the number of the Group that is to be enabled for the time specified by the Quick

Schedules below.

Note: These Quick Schedules can only be programmed through the keypad (not through DL-Windows), and existing Quick

Schedules will be over-written by schedules downloaded from DL-Windows. Therefore, after downloading any DL-Windows

schedules, be sure to re-program your Quick Schedules into your Lock Program.

84. Business Quick Schedule

7AM-5PM, Monday - Friday

(This Function enabled through keypad only)

85. Day Quick Schedule

7AM-5PM, All days

(This Function enabled through keypad only)

86. Evening Quick Schedule

3PM-1AM, All days

(This Function enabled through keypad only)

87. Night Quick Schedule

11PM-9AM, All days

(This Function enabled through keypad only)

; 8 4 ; [ _ ] :

(Group)

; 8 5 ; [ _ ] :

(Group)

; 8 6 ; [ _ ] :

(Group)

; 8 7 ; [ _ ] :

(Group)

3

SCHEDULES GROUP 1 ACTIVATED