Page 1

SWINGTRIM

SICKLE BAR

BOOM MOWER

Published 03/09 Part No. 00763548C

OPERATOR’S MANUAL

This Operator's Manual is an integral part of the safe operation of this machine and must

be maintained with the unit at all times. READ,

and Operation Instructions contained in this manual before operating the equipment. C01-

Cover

UNDERSTAND, and FOLLOW the Safety

ALAMO INDUSTRIAL®

1502 E. Walnut

Seguin, Texas 78155

830-372-3551

Email: parts@alamo-industrial.com

©2009 Alamo Group Inc.

$0.00

Page 2

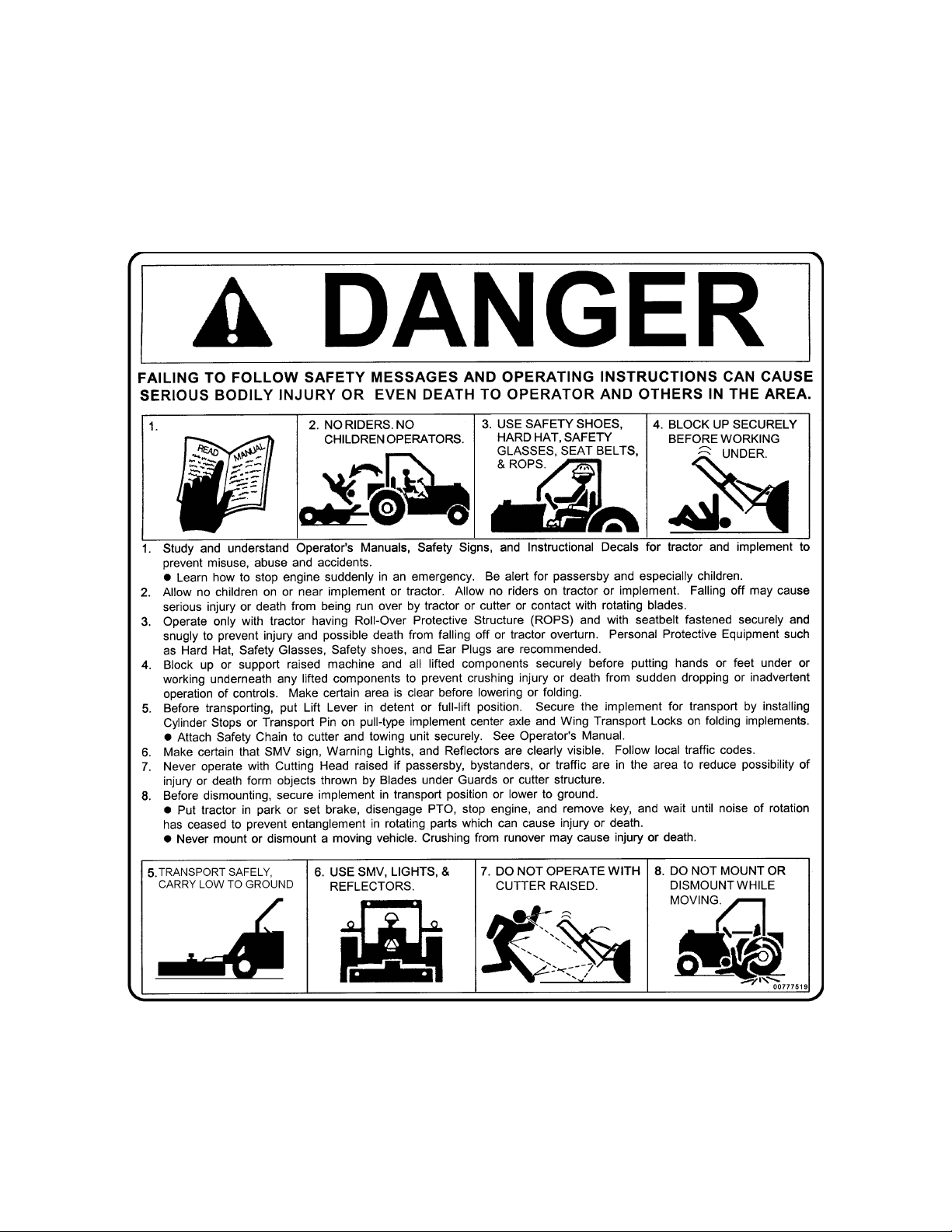

To the Owner/Operator/Dealer

All implements with moving parts are potentially hazardous. There is no substitute for a cautious, safe-minded

operator who recognizes the potential hazards and follows reasonable safety practices. The manufacturer has

designed this implement to be used with all its safety equipment properly attached to minimize the chance of

accidents.

BEFORE YOU START!!Read the safety messages on the implement and shown in your manual. Observe the

rules of safety and common sense!

WARRANTY INFORMATION:

Read and understand the complete Warranty Statement found in this Manual. Fill out the Warranty Registration

Form in full and return it to within 30 Days. Make certain the Serial Number of the Machine is recorded on the

Warranty Card and on the Warranty Form that you retain.

Page 3

In order to reduce accidents and enhance the safe operation of mowers, Alamo Industrial, in cooperation

with other industry manufacturers has developed the AEM/FEMA Industrial and Agricultural Mower

Safety Practices video and guide book.

The video will familiarize and instruct mower-tractor operators in safe practices when using industrial

and agricultural mowing equipment. It is important that Every Mower Operator be educated in the operation of their mowing equipment and be able to recognize the potential hazards that can occur while operating a mower. This video, along with the mower operator’s manual and the warning messages on the

mower, will significantly assist in this important education.

Your Authorized Alamo Industrial Dealer may have shown this video and presented you a DVD Video

when you purchased your mower. If you or any mower operator have not seen this video, Watch the

Video, Read this Operator ’s Manual, and Complete the Video Guidebook before operating your new

mower. If you do not understand any of the instructions included in the video or operator’s manual or if

you have any questions concerning safety of operation, contact your supervisor, dealer or Alamo Indus-

trial.

If you would like a VHS video tape of the video, please email AEMVideo@alamo-group.com or Fax

AEM VHS Video at (830) 372-9529 or mail in a completed copy of the form on the back of this page to

AEM VHS Video 1502 E Walnut Street, Seguin, TX 78155. and request the VHS video version. Please

include your name, mailing address, mower model and serial number.

Every operator should be trained for each piece of equipment (Tractor and Mower), understand the

intended use, and the potential hazards before operating the equipment.

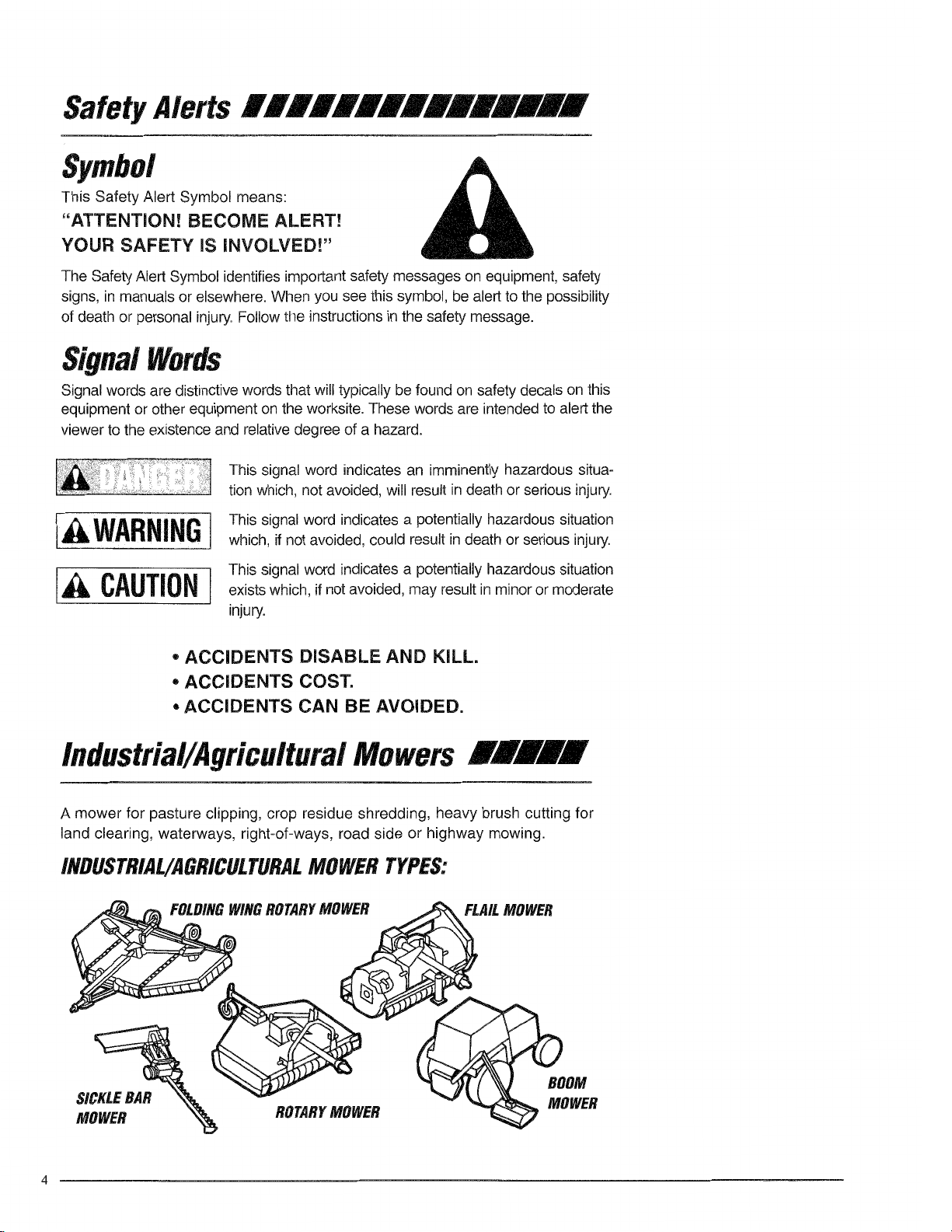

Page 4

Alamo Industrial Division is willing to provide

one (1) AEM Mower Safety Practices Video

Please Send Me: VHS Format – AEM/FEMA Mower Operator Safety Video

DVD Format – AEM/FEMA Mower Operator Safety Video

Mower Operator’s Manual

AEM Mower Operator’s Safety Manual

Requester Name Phone:

Requester Address:

City

State

Zip Code

Mower Model: Serial Number:

Date Purchased: Dealer Salesperson:

Dealership Name: Dealership Location:

Mail to:

AEM Video Services

1502 E Walnut street

Seguin, TX 78155

Or Fax to:

(830) 372-9529

Or Email to:

AEMVideo@alamo-group.com

Page 5

TABLE OF CONTENTS

SAFETY SECTION ..............................................................................................................1-1

Safety Messages ...................................... ... ... .... ... ... ....................................... ... ... ... .... ... ..................................1-2

Decal Location .................................................................................................................................................1-11

Decal Description .............................................................................................................................................1-13

Federal Laws and Regulations ........................................................................................................................ 1-17

INTRODUCTION SECTION .................................................................................................2-1

ASSEMBLY SECTION ........................................................................................................3-1

TRACTOR SELECTION ....................................................................................................................................3-2

ATTACHMENT TO TRACTOR ........................................................ ... ... ... .... ... ... ... ... .... .....................................3-2

COUPLING UP HYDRAULICS .......................................................................................................................... 3-3

REMOVAL FROM THE TRACTOR ...................................................................................................................3-3

STORAGE .........................................................................................................................................................3-3

OPERATION SECTION .......................................................................................................4-1

Standard Equipment and Specifications ............................................................................................................4-3

OPERATOR REQUIREMENTS .........................................................................................................................4-4

TRACTOR REQUIREMENTS ............................................................................................................................4-5

ROPS and Seat Belt ................................. ... ... .... ... ... ....................................... ... ... ... .... ... ... ...............................4-5

Operator Thrown Object Protection ...................................................................................................................4-5

Tractor Lighting and SMV Emblem ................. ...................................................................................................4-6

Tractor Horsepower ...........................................................................................................................................4-6

3-Point Hitch ......................................................................................................................................................4-6

Hydraulics .......................................................................................................................................................... 4-7

Front End Weight ...............................................................................................................................................4-7

Power Take Off (PTO) .......................................................................................................................................4-7

GETTING ON AND OFF THE TRACTOR .........................................................................................................4-8

Boarding the Tractor ..........................................................................................................................................4-8

Dismounting the Tractor .....................................................................................................................................4-8

STARTING THE TRACTOR ........................... .... ... ... ....................................... ... ... ... .... ... ... ... .... ... .....................4-9

CONNECTING THE IMPLEMENT TO TRACTOR ................ ... ... .... ... ... ... .......................................... .............4-10

PRE-OPERATION INSPECTION AND SERVICE ...........................................................................................4-11

Tractor Pre-Operation Inspection/Service ........................................................................................................4-12

Boom Unit Pre-Operation Inspection and Service ...........................................................................................4-12

OPERATING THE IMPLEMENT ......................... ... ... ... ... .... ... .......................................... ................................4-18

Machine Controls ............................................................................................................................................. 4-18

Arm Controls ...... ... .... ...................................... .... ... ... ....................................... ... ... ... .... ...................................4-19

Forward Speed ................................................................................................................................................4-20

Highway Working ............................................................................................................................................. 4-20

Unclogging Cutterbar, Checks or Adjustments ............................................................. ... ... ... .... ... ... ... .............4-20

Breakaway .......................................................................................................................................................4-20

Swingover ........................................................................................................................................................4-20

DRIVING THE TRACTOR AND IMPLEMENT .................................................................................................4-21

Starting the Tractor ..........................................................................................................................................4-23

Brake and Differential Lock Setting ..................................................................................................................4-23

Driving the Tractor and Boom ...................... .................................................................... ................................4-24

OPERATING THE TRACTOR AND IMPLEMENT ...........................................................................................4-25

Page 6

Foreign Debris Hazards/Overhead Obstructions .............................................................................................4-26

Operating Speed and Ground Speed .......................... ... .... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ................4-26

Operating the Attached Head ..........................................................................................................................4-27

Shutting Down the Implement ..........................................................................................................................4-28

TRACTOR, BOOM, AND ATTACHED HEAD STORAGE ...............................................................................4-28

DISCONNECTING THE IMPLEMENT .............................................................................................................4-29

TRANSPORTING THE TRACTOR AND IMPLEMENT ...................................................................................4-29

Transporting on Public Roadways ............ ... ... .... ... ... ... ... .......................................... .......................................4-30

Hauling the Tractor and Implement .... .... ... ... ... .... ... ... ... ... ....................................... ... .... ... ... ... .... ......................4-33

TROUBLESHOOTING GUIDE ........................................................................................................................4-34

MAINTENANCE SECTION ..................................................................................................5-1

LUBRICATION .......................... .......................................................... ...............................................................5-2

FASTENERS .....................................................................................................................................................5-2

CUTTERBAR .....................................................................................................................................................5-3

Adjusting the Knife Guides .................................................................................................................................5-3

Sharpening the Knife .........................................................................................................................................5-4

HYDRAULIC RAMS .............. .... ... ....................................... ... ... ... .... ... ... ............................................................5-5

Ram Seal Replacement- General Information ...................................................................................................5-5

To Change Seals on Angle, Reach and 40 MM Dia Lift Ram ............................................................................5-5

To Change Seals on 50 MM Dia Lift Ram .........................................................................................................5-5

HYDRAULIC SYSTEM (Pump and Tank Kit) .....................................................................................................5-6

Oil Requirements ............... ... .... ...................................... .... ... ... ... .... ... ...............................................................5-6

Oil Supply .............. ....................................... ... .... ... ... ....................................... ... ... ... .........................................5-7

Filtration Maintenance ........... .... ... ... ....................................... ... ... .... ... ... ... .... ... ... ... ... .........................................5-7

Hydraulic Pumps (If Fitted) ................................................................................................................................5-7

Cylinder Rod Maintenance .................................................................................................................................5-7

CONTROL VALVE .............................................................................................................................................5-8

Non Return Valve ............ ... ... .... ... ....................................... ... ... ... .... ... ... ... .........................................................5-9

Replacing Spool “O” Rings ................................................................................................................................5-9

Main Relief Valve ...............................................................................................................................................5-9

HYDRAULIC HOSES ... ... ... ... .... ... ....................................... ... ... ... .... ... ... ... .......................................................5-10

Hose Replacement ..........................................................................................................................................5-10

Hose Warranty .................................................................................................................................................5-10

HOSE CONNECTIONS ...................................................................................................................................5-11

STORAGE .......................................................................................................................................................5-12

PROPER TORQUE VALUES FOR FASTENERS ........................................................................ ... ... ... .... ... ...5-12

Page 7

SAFETY SECTION

© 2009 Alamo Group Inc.

Safety Section 1-1

Page 8

SAFETY

Safety Messages

A careful operator is the best operator. Safety is of primary importance to the manufacturer and should be to

the owner/operator . Most accident s ca n be avo ided by bein g aware of yo ur equipm ent, your surroun dings, and

observing certain precautions. The first section of this manual includes a list of Safety Messages that, if

followed, will help protect the operator and bystanders from injury or death. Read and understand these Safety

Messages before assembling, operating or servicing this Implement. This equipment should only be operated

by those persons who have read the manual, who are responsible and trained, and who know how to do so

responsibly.

The Safety Alert Symbol combined with a Signal Word, as seen below, is used throughout this

manual and on decals which are attached to the equipment. The Safety Alert Symbol means:

“ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!” The Symbol and Signal Word

are intended to warn the owner/operator of impending hazards and the degree of possible injury

faced when operating this equipment.

SAFETY

Practice all usual and customary safe working precautions and above all---remember safety is

up to YOU

. Only YOU can prevent serious injury or death from unsafe practices.

Indicates an imminently hazardous situation that, if not avoided, WILL result in DEATH OR

VERY SERIOUS INJURY.

Indicates an imminently hazardous situation that, if not avoided, COULD result in DEATH

OR SERIOUS INJURY.

Indicates an imminently hazardous situation that, if not avoided, MAY result in MINOR

INJURY.

Identifies special instructions or procedures that, if not strictly observed, could result in

damage to, or destruction of the machine, attachments or the environment.

NOTE: Identifies points of particular interest for more efficient and convenient operation or

repair.

(SG-1)

READ, UNDERSTAND, and FOLLOW the following Safety Messages. Serious injury or

death may occur unless care is taken to follow the warnings and instructions stated in the

Safety Messages. Always use good common sense to avoid hazards.

Si no lee ingles, pida ayuda a alguien que si lo lea para que le traduzca las

medidas de seguridad.

(SG-3)

(SG-2)

SWINGTRIM 03/09 Safety Section 1-2

© 2009 Alamo Group Inc.

Page 9

SAFETY

N

til

d

ever operate the Tractor or Implement un

you have read an

completely understand this Manual, the Tractor Operator’s Manual, and

each of the Safety Messages found in the Manual or on the Tractor and

Implement. Learn how to stop the tractor engine suddenly in an

emergency. Never allow inexperienced or untrained personnel to

operate the Tractor and Implement without supervision. Make sure the

operator has fully read and understood the manuals prior to operation.

(SG-4)

Always maintain the safety signs in good readable condition. If th e safety signs are missing,

damaged, or unreadable, obtain and install replacement safety signs immediately.

(SG-5)

Make certain that the “Slow Moving Vehicle” (SMV) sign is installed in

such a way as to be clea rly visible and legible. When transporti ng the

Equipment use the Tractor flashing warning lights and follow all local

traffic regulations.

(SG-6)

Operate this Equipment only with a Tractor equipped with an approved rollover-protective system (ROPS). Always wear seat belts. Serious injury or

even death could result from falling of f the tractor --particularly during a turnover

when the operator could be pinned under the ROPS.

(SG-7)

SAFETY

Do not modify or alter this Implement. Do not permit anyone to modify or alter this

Implement, any of its components or any Implement function.

(SG-8)

BEFORE leaving the tractor seat, always engage the brake and/or set

the tractor transmission in parking gear, disengage the PTO, stop the

engine, remove the key, and wait for all moving parts to stop. Place the

tractor shift lever into a low range or parking gear to prevent the tractor

from rolling. Never dismount a Tractor that is moving or while the engine

is running. Operate the Tractor contr ols from the tractor seat only.

(SG-9)

Never allow children or other persons to ride on the Tractor or Implement.

Falling off can result in serious injury or death.

(SG-10)

SWINGTRIM 03/09 Safety Section 1-3

© 2009 Alamo Group Inc.

Page 10

SAFETY

SAFETY

Never allow children to operate, ride on, or come close to the Tractor or

Implement. Usually, 16-17 year-old children who are mature and

responsible can operate the implement with adult supervision, if they

have read and understand the Operator’s Manuals, been trained in

proper operation of the tractor and Implement, and are physically large

enough to reach and operate the controls easily.

Do not mount or dismount the Tractor while the tractor is moving. Mount

the Tractor only when the Tractor and all moving parts are completely

stopped.

(SG-12)

Start tractor only when properly seated in the Tractor seat. Starting a

tractor in gear can result in injury or death. Read the Tractor operators

manual for proper starting instructions.

(SG-13)

(SG-11)

Never work under the Implement, the framework, or any lifted

component unless the Implement is securely supported or blocked up

to prevent sudden or inadvertent falling which could cause serious

injury or even death.

(SG-14)

Do not operate this Equipment with hydraulic oil or fuel leaking. Oil

and fuel are explosive and their presence could present a hazard. Do

not check for leaks with your hand! High-pressure oil streams from

breaks in the line could penetrate the skin and cause tissue damage

including gangrene. To check for a hose leak, SHUT the unit ENGINE

OFF and remove all hydraulic pressure. Wear oil imp ene trab le glo ves ,

safety glasses and use Cardboard to check for evidence of oil leaks. If

you suspect a leak, REMOVE the HOSE and have it tested at a Dealer.

If oil does penetrate the skin, have the injury treated immediately by a

physician knowledgeable and skilled in this procedure.

(SG-15)

The operator and all support personnel should wear hard hats, safety

shoes, safety glasses, and proper hearing protection at all times for

protection from injury including injury from items that may be thrown by

the equipment.

(SG-16)

SWINGTRIM 03/09 Safety Section 1-4

© 2009 Alamo Group Inc.

Page 11

SAFETY

PROLONGED EXPOSURE TO LOUD NOISE MAY CAUSE

PERMANENT HEARING LOSS! Tractors with or without an Implement

attached can often be noisy enough to cause permanent hearing loss.

We recommend that you always wear hearing protection if the noise in

the Operator’s position exceeds 80db. Noise over 85db over an

extended period of time will cause severe hearing loss. Noise over 90db

adjacent to the Operator over an extended period of time will cause

permanent or total hearing loss. NOTE: Hearing loss from loud noise

[from tractors, chain saws, radios, a nd other such sources close to the

ear] is cumulative over a lifetime without hope of natural recovery.

Transport only at speeds where you can maintain control of the

equipment. Serious accidents and injuries can result from operating this

equipment at high speeds. Understand the Tractor and Implement and

how it handles before transporting on streets and highways. Make sure the Tractor steering

and brakes are in good condition and operate properly.

Before transporting the Tractor and Implement, determine the proper transport speeds for

you and the equipment. Make sure you abide by the following rules:

Test the tractor at a slow speed and increase the speed slowly. Apply the Brakes smoothly

to determine the stopping characteristics of the Tractor and Implement. As you increase

the speed of the Tractor the stopping distance increases. Determine the maximum

transport speed not to exceed 20 mph (30 kph) for transporting this equipment.

(SG-I7)

SAFETY

Test the equipment at a slow speed in turns. Increase the speed through the turn only after

you determine that the equipment can be operated at a higher speed. Use extreme care

and reduce your speed when turning sharply to prevent the tractor and implement from

turning over. Determine the maximum turning speed for you and this equipment before

operating on roads or uneven ground.

Only transport the Tractor and Implement at the speeds which allow you to properly control

the equipment.

Be aware of the operating conditions. Do not operate the Tractor with weak or faulty brakes

or worn tires. When operating down a hill or on wet or rain slick roads, the braking distance

increases: use extreme care and reduce your speed. When operating in traffic always use

the Tractor’s flashing warning lights and r educe your speed. Be aware of traf fic around you

and watch out for the other guy.

Never attempt to lubricate, adjust, or remove material from the Implement while it is in

motion or while tractor engine is running.

(SG-19)

(SG-20)

SWINGTRIM 03/09 Safety Section 1-5

© 2009 Alamo Group Inc.

Page 12

SAFETY

Al

ith th

Periodically inspect all moving parts for wear and replace when

necessary with authorized service parts. Look for loose fasteners, worn

or broken parts, and leaky or loose fittings. Make sure all pins have

cotter pins and washers. Serious injury may occur from not maintaining

this machine in good working order.

(SG-21)

SAFETY

ways read carefully and comply fully w

e manufacturer’s

instructions when handling oil, solvents, cleansers, and any other

chemical agent.

(SG-22)

Never run the Tractor engine in a closed building or without adequate ventilation. The

exhaust fumes can be hazardous to your health.

(SG-23)

KEEP AWAY FROM ROTATING ELEMENTS to prevent entanglement

and possible serious injury or death.

(SG-24)

Never allow children to play on or around T ractor or Imple ment. Children can slip or fa ll of f

the Equipment and be injured or killed. Children can cause the Implement to shift or fall

crushing themselves or others.

(SG-25)

Do not exceed the rated PTO speed for the Implement. Excessive PTO speeds can cause

Implement driveline or blade failures resulting in serious injury or death.

(SG-26)

SWINGTRIM 03/09 Safety Section 1-6

© 2009 Alamo Group Inc.

Page 13

SAFETY

NEVER use drugs or alcohol immediately before or while operating the

Tractor and Implement. Drugs and alcohol will affect an operator’s

alertness and coordination and therefore affect the operator’s ability to

operate the equipment safely. Before operating the Tractor or

Implement, an operator on prescription or over-the-counter medication

must consult a medical professional regarding any side effects of the

medication that would hinder their ability to operate the Equipment safely.

NEVER knowingly allow anyone to operate this equipment when their

alertness or coordination is impaired. Serious injury or death to the

operator or others could result if the operator is under the influence of

drugs or alcohol.

Operate the Tractor and/or Implement control s only while properly seated in the Tractor seat

with the seat belt securely fastened around you. Inadvertent movement of the Tractor or

Implement may cause serious injury or death.

Mow only in conditions where you have clear visibility in daylight or with adequate artificial

lighting. Never mow in darkness or foggy conditions where you cannot clearly see at least

100 yards(90 m) in front and to the sides of the tractor and mower. Make sure that you can

clearly see and identify passersby, steep slopes, ditches, drop-offs, overhead obstructions,

power lines, debris and foreign objec ts. If you are unab le to clear ly see thes e type of ite ms

discontinue mowing.

(SG-27)

(SG-29)

(SGM-1)

SAFETY

There are obvious and hidden potential hazards in the operation of this

Mower. REMEMBER! This machine is often operated in heavy brush

and in heavy weeds. The Blades of this Mower can throw objects if

shields are not properly installed and maintained. Serious injury or even

death may occur unless care is taken to insure the safety of the operator,

bystanders, or passersby in the area. Do not operate this machine with

anyone in the immediate area. Stop mowing if anyone is within 100 yards

of mower.

(SGM-02)

All Safety Shields, Guards and Safety devices including (but not limited to) - the Deflectors, Chain Guards, Steel Guards, Gearbox

Shields, PTO integral shields, and Retractable Door Shields should

be used and maintained in good working condition. All safety

devices should be inspected carefully at least daily for missing or

broken components. Missing, broken, or worn items must be

replaced at once to reduce the possibility of injury or death from

thrown objects, entanglement, or blade contact.

(SGM-3)

SWINGTRIM 03/09 Safety Section 1-7

© 2009 Alamo Group Inc.

Page 14

SAFETY

Ext

h

M

M

SAFETY

The rotating parts of this machine have been designed and tested for rugged use.

However, the blades could fail upon impact with heavy, solid objects such as metal guard

rails and concrete structures. Such impact could cause the broken objects to be thrown

outward at very high velocities. To reduce the possibility of property damage, serious

injury, or even death, never allow the cutting blades to contact such obstacles.

reme care should be taken when operating near loose objects suc

as gravel, rocks, wire, and other debris. Inspect the area before

mowing. Foreign objects should be removed from the site to prevent

machine damage and/or bodily injury or even death. Any objects that

cannot be removed must be clearly mark ed and carefully a vo ide d b y th e

operator. Stop mowing immediately if blades strike a foreign object.

Repair all damage and make certain rotor or blade carrier is balanced

before resuming mowing.

(SGM-05)

any varied objects, such as wire, cable, rope, or chains, can become entangled in the

operating parts of the mower head. These items could then swing outside the housing at

greater velocities than the blades. Such a situation is extremely hazardous and could result

in serious injury or even death. Inspect the cutting area for such objects before mowing.

Remove any like object from the site. Never allow the cutting blades to contact such items.

(SGM-06)

(SGM-4)

ow at the speed that you can safely operate and control the tractor and mower. The

correct mowing speed depends on terrain condition and grass type, density, and height of

cut. Normal ground speed range is from 2 to 5 mph(3-8 kph). Use slow mowing speeds

when operating on or near steep slopes, ditches, drop-offs, overhead obstructions, power

lines, or when debris and foreign objects are to be avoided.

(SGM-07)

Avoid mowing in reverse direction when possible. Check to make sure there are no

persons behind the mower and use extreme care when mowing in reverse. Mow only at a

slow ground speed where you can safely operate and control the tractor and mower.

Never mow an area that you have not inspected and removed debris or foreign material.

(SGM-08)

Do not put hands or feet under mower decks. Blade Contact can result

in serious injury or even death. Stay away until all motion has stopped

and the decks are securely blocked up.

(SGM-09)

Replace bent or broken blades with new blades. NEVER ATTEMPT TO STRAIGHTEN,

WELD, OR WELD HARDFACING ON BLADES SINCE THIS WILL LIKELY CRACK OR

OTHERWISE DAMAGE THE BLADE WITH SUBSEQUENT FAILURE AND POSSIBLE

SERIOUS INJURY FROM THROWN BLADES.

(SGM-10)

SWINGTRIM 03/09 Safety Section 1-8

© 2009 Alamo Group Inc.

Page 15

SAFETY

r

Rotary Mowers are capable under adverse conditions of throwing

objects for great distances (300 feet or more) and causing serious injury

or death. Follow safety messages carefully.

STOP MOWING IF PASSERSBY ARE WITHIN 100 YARDS UNLESS:

-Front and Rear Deflectors, Chain Guards, or Bands are installed and in good, workable

condition;

-Mower sections or Wings are running close to and parallel to the ground without exposed

Blades;

-Passersby are outside the existing thrown-object zone;

-All areas have been thoroughly inspected and all foreign material such as rocks, cans,

glass, and general debris has been removed.

NOTE: Where there are grass and weeds high enough to hide debris that could be struck

by the blades, the area should be: inspected and large debris removed, mowed at an

intermediate height, inspected, closely with any remaining debris being removed, and

mowed again at desired final height. (This will also reduce power required to mow, reduce

wear and tear on the Mower drivetrain, spread cut material better, reduce streaking, and

make the final cut more uniform).

Do not let the Blades turn when the Mower Deck is raised for any

reason, including clearance or for turning. Raising the Mower deck

exposes the Cutting Blades which creates a potentially serious hazard

and could cause serious injury or even death from objects thrown from

the Blades.

Never leave the Tractor and Implement unattended while the Implement is in the lifted

position. Accidental operation of lifting lever or a hydraulic failure may cause sudden drop

of unit with injury or death by crushing. To properly park the implement when disconnecting

it from the tractor , lower the stan d and put the retaining pin securely in place, or pu t a secure

support under the A-Frame. Lower the implement carefully to th e ground. Do no t put hands

or feet under lifted components.

(SRM-01)

(SRM-07)

(S3PT-1)

SAFETY

Be particularly careful when transporting the Implement with the Tractor. Turn curves or go

up hills only at a low speed and using a gradual steering angle. Rear mounted implements

move the center of gravity to the rear and remove weight from the front wheels. Make

certain, by adding front ballast, that at least 20% of the tractor’s weight is on the front wheels

to prevent rearing up, loss of steering control or Tractor tip-over. Slow down on rough o

uneven surfaces to prevent lo ss of steering control which could result in property damage

or possible injury. Do not transport unless 3-Point lift lever is fully raised and in the latched

transport position. Dropping implement in transport can cause serious damage to the

tractor and/or Implement and possibly cause the operator or others to be injured or killed.

(S3PT-02)

SWINGTRIM 03/09 Safety Section 1-9

© 2009 Alamo Group Inc.

Page 16

SAFETY

SAFETY

There are obvious and hidden potential hazards in the operation of this Implement as in all

power-driven or pulled equipment. REMEMBER! This machine is often operated in rough

terrain conditions that include tall grass, weeds, gullies, holes, slopes, hidden obstructions

and the like. Serious injury or even death may occur unless care is taken to assure the

safety of the operator and bystanders in the area. Do not operate this machine with anyone

in the immediate area.

Make sure the PTO shield, integral driveline shields, and input shields

are is installed when using PTO-driven equipment. Always replace any

shield if it is damaged or missing.

Relieve hydraulic pressure prior to doing any maintenance or repair work

on the Implement. Place the Implement on the ground or securely

blocked up, disengage the PTO, and turn off the tractor engine. Push

and pull the Remote Cylinder lever in and out several times prior to

starting any maintenance or repair work.

The rotating parts of this machine co ntinue to rot ate ev en after the PT O has been turned of f.

The operator should remain in his seat for 60 seconds after the brake has been set, the

PTO disengaged, the tractor turned off, and all evidence of rotation has ceased.

(S3PT-07)

(S3PT-8)

(S3PT-09)

(S3PT-10)

“Wait a minute...Save a life!”

Always disconnect the main PTO Driveline from the Tractor before performing service on

the Implement. Never work on the Implement with the tractor PT O dr iveline connecte d and

running. Rotating Parts, Blades or Drivelines could turn without warning and cause

immediate entanglement, injury or death.

(S3PT-11)

This Implement is wider than the Tractor. Be careful when operating or transporting this

equipment to prevent the Implement from running into or striking sign posts, guar d rails,

concrete abutments or other solid objects. Such an impact could cause the Implement and

Tractor to pivot violently resulting in loss of steering control, serious injury, or even death.

Never allow the Implement to contact obstacles.

(S3PT-12)

In addition to the design and configuration of this Implement, including Safety Signs and Safety Equipment,

hazard control and accident prevention are dependent upon the awareness, concern, prudence, and proper

training of personnel involved in the operation, transport, maintenance, and storage of the machine. Refer

also to Safety Messages and operation instruction in each of the appropriate sections of the Tractor and

Equipment Manuals. Pay close attention to the Safety Signs affixed to the Tractor and Equipment.

(SG-18)

SWINGTRIM 03/09 Safety Section 1-10

© 2009 Alamo Group Inc.

Page 17

SAFETY

PARTS INFORMATION

Alamo Industrial mowers use balanced and matched system components for blade carriers, blades,

cuttershafts, knives, knife hangers, rollers, drivetrain components, and bearings. These parts are made and

tested to Alamo Industrial specifications. Non-genuine "will fit" parts do not consistently meet these

specifications. The use of “will fit” parts may reduce mower performance, void mower warranties, and present

a safety hazard. Use genuine Alamo Industrial mower parts for economy and safety.

SEE YOUR ALAMO DEALER

(SPAM -1 )

Decal Location

NOTE: Alamo Industrial supplies safety decals on this product to promote safe operation. Damage to the

decals may occur while in shipping, use, or reconditioning. Alamo Industrial cares about the safety of its

customers, operators, and bystanders, and will replace the safety decals on this product in the field, free of

charge (Some shipping and handling charges may apply). Contact your Alamo Industrial dealer to order

replacement decals.

SAFETY

SWINGTRIM 03/09 Safety Section 1-11

© 2009 Alamo Group Inc.

Page 18

SAFETY

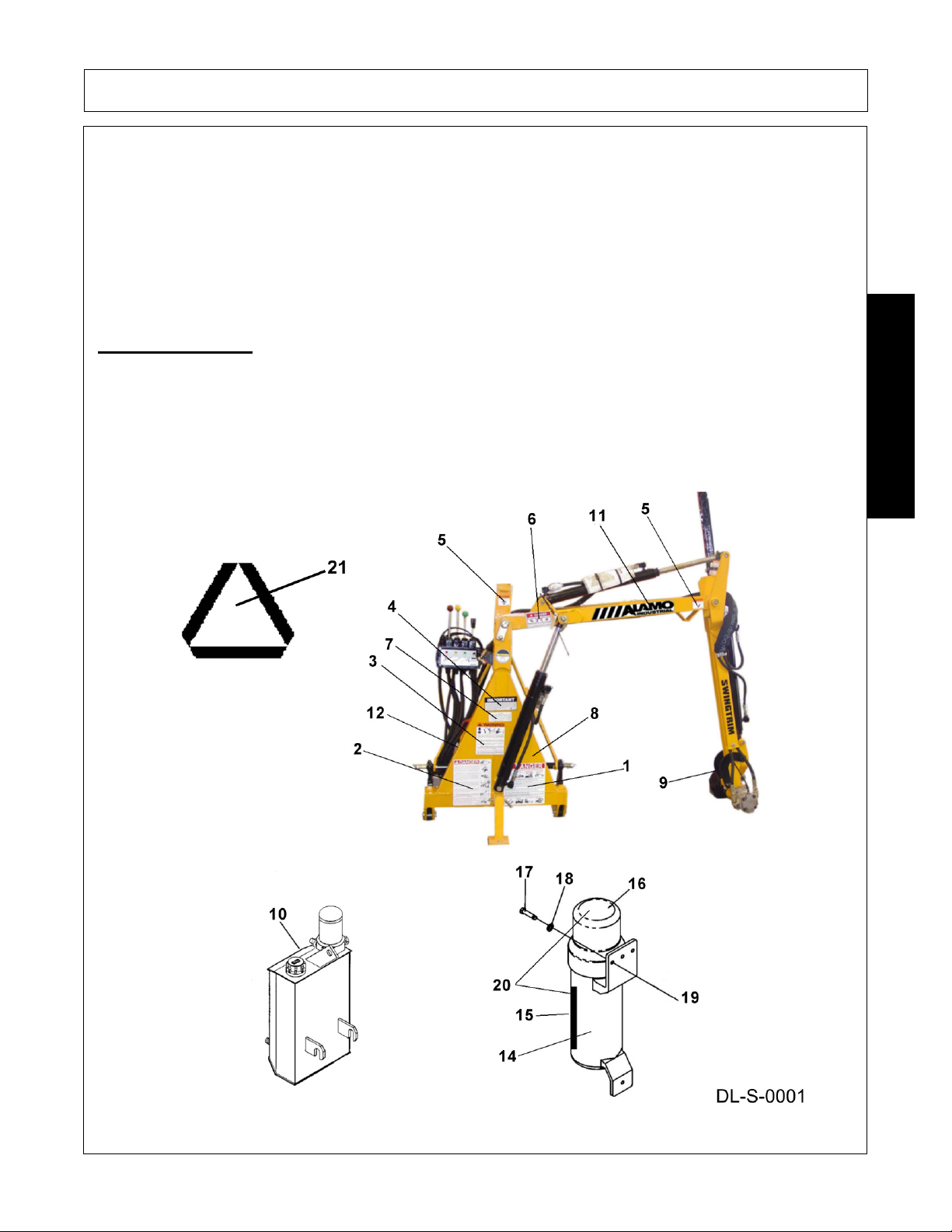

ITEM PART NO. QTY TYPE DESCRIPTION

1. 02967827 1 DANGER Multiple Hazard Rotary

2. 02958241 1 DANGER Multiple Hazard Boom

3. 02965262 1 WARNING Oil/Leak Penetration

4. 0292510 1 IMPORTANT Use Genuine Alamo Industrial Parts

5. 02962764 2 DANGER Pinch Points/Scissors

6. 02962765 1 DANGER Multiple Hazard/Crushing

7. 02965093 1 ATTENTION Do Not Over Speed Engine

8. 00763977 1 NOTICE Operator’s Manual Shipped with Equipment

9. 3688303 1 DANGER Keep Away Sharp Blades

10. 03200437 1 WARNING Pressurized Tank

SAFETY

11. 001651 2 LOGO NAME Alamo Industrial

12. 001650 1 LOGO Alamo Industrial

13. NFS 1 SER PLT Swing Trim Serial Plate

14. 00763548C 1 Alamo Industrial Operator’s Manual

15. 02977046 1 AEM Mower Safety Manual

16. 00776031 1 Canister, Operator’s Manual

17. 10058000 4 Bolt

18. 00024100 4 Flatwasher

19. 0295924 3 Locknut

20. 00776583 1 NOTICE Canister Manual Inside

21. 03200347 * REFLCTR SMV Sign * Supplied by Tractor Manufacturer. Replace if missing from Tractor.

SWINGTRIM 03/09 Safety Section 1-12

© 2009 Alamo Group Inc.

Page 19

SAFETY

Decal Description

DANGER! - Multi Hazard - Failure to follow Safety

Messages and Operating Instructions can cause

serious bodily injury or even death to Operator and

Others in area.

P/N 02967827

DANGER! - Multi-Hazard Boom. Take precautions

while transporting and operating Boom Unit.

SAFETY

P/N 02958241

WARNING! Failure to INSPECT and REPAIR or

REPLACE Hoses may allow worn Hoses to rupture

SUDDENLY and VIOLENTLY with resulting serious

BODILY INJURY from SCALDING or FIRE with

resulting BURN INJURY or DEATH.

P/N 02965262

IMPORTANT - Use only Genuine Alamo Industr ial

replacement parts.

P/N 02925100

SWINGTRIM 03/09 Safety Section 1-13

© 2009 Alamo Group Inc.

Page 20

WARNING! Pinch Points

P/N 02962764

DANGER! Crushing and Pinch Points.

Moving machiney parts can pinch or crush or fallwhich may cause injury or death.

SAFETY

SAFETY

P/N 02962765

INFORMATION - To prevent premature hydraulic

component failure, do not over speed the engine.

When using the mower attachment, operate tractor

at the engine speed which will deliver 540 PTO

RPM on Tachometer. Over speeding the engine

and pump when operating the mower will overheat

and rapidly ruin the oil which will decrease the life

of the hydraulic components.

P/N 02965093

Operator's Manual (with repair parts) and warranty

was attached to this implement during final

inspection.

P/N 00763977

SWINGTRIM 03/09 Safety Section 1-14

© 2009 Alamo Group Inc.

Page 21

DANGER! Keep Away Sharp Blades.

SAFETY

3688303

WARNING: Pressurized Tank

03200437

ALAMO INDUSTRIAL LOGO

SAFETY

P/N 001651

ALAMO NAME LOGO.

P/N 001650

SWINGTRIM 03/09 Safety Section 1-15

© 2009 Alamo Group Inc.

Page 22

Read Operator’s Manual! The operator’s manual is

located inside this canister. If the manual is

missing order one from your dealer.

P/N 00776031

Slow Moving Vehicle Decal. Keep SMV reflector

clean and visible. DO NOT transport or operate

without the SMV.

SAFETY

SAFETY

P/N 03200347

SWINGTRIM 03/09 Safety Section 1-16

© 2009 Alamo Group Inc.

Page 23

SAFETY

Federal Laws and Regulations

This section is intended to explain in broad terms th e concept and effect of federal laws and regulations

concerning employer and employee equipment operators. This section is not intended as a legal

interpretation of the law and should not be considered as such.

Employer-Employee Operator Regulations

U.S. Public Law 91-596 (The Williams-Steiger Occupational and Health Act of 1970) OSHA

This Act Seeks:

“...to assure so far as possible every working man and woman in the nation safe and healthful working

conditions and to preserve our human resources...”

DUTIES

Sec. 5 (a) Each employer(1) shall furnish to each of his employees employment and a place of employment which are free from

recognized hazards that are causing or are likely to cause death or serious physical harm to his employees;

(2) shall comply with occupational safety and health standards promulgated under this Act.

(b) Each employee shall comply with occupational safety and health standards and all rules, regulations and

orders issued pursuant to this Act which are applicable to his own actions and conduct.

OSHA Regulations

OSHA regulations state in part: “At the time of initial assignment and at least annually thereafter, the employer

shall instruct every employee in the safe operation and servicing of all equipment with which the employee is,

or will be involved.”

Employer Responsibilities:

SAFETY

To ensure employee safety during Tractor and Implement operation, it is the employer’s responsibility to:

1. Train the employee in the proper and safe operation of the Tractor and Implement.

2. Require that the employee read and fully understand the Tractor and Implement Operator’s manual.

3. Permit only qualified and properly trained employees to operate the Tractor and Implement.

4. Maintain the Tractor and Implement in a safe operational condition and maintain all shields and guards on the

equipment.

5. Ensure the Tractor is equipped with a functional ROPS and seat belt and require that the employee ope rator

securely fasten the safety belt and operate with the ROPS in the raised position at all times.

6. Forbid the employee operator to carry additional riders on the Tractor or Implement.

7. Provide the required tools to maintain the Tractor and Implement in a good safe working condition and provide the

necessary support devices to secure the equipment safely while performing repairs and service.

8. Require that the employee operator stop operation if bystanders or passersby come within 25 feet.

Child Labor Under 16 Years of Age

Some regulations specify that no one under the age of 16 may operate power machinery. It is your

responsibility to know what these regulations are in your own area or situation. (Refer to U.S. Dept. of

Labor, Employment Standard Administration, Wage & Home Division, Child Labor Bulletin #102.)

SWINGTRIM 03/09 Safety Section 1-17

© 2009 Alamo Group Inc.

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Page 58

Page 59

Page 60

Page 61

Page 62

Page 63

Page 64

Page 65

Page 66

Page 67

Page 68

Page 69

INTRODUCTION SECTION

© 2009 Alamo Group Inc.

Introduction Section 2-1

Page 70

INTRODUCTION

This Swingtrim Sickle Bar is designed with care and built with quality materials by skilled workers. Proper

assembly, maintenance, and operating practices, as described in this manual, will help the owner/operator get

years of satisfactory service from the machine.

The purpose of this manual is to familiarize, and instruct. T he Assembly Section instru ct s the owner/opera tor in

the correct assembly of the Implement using standard and optional equipment. The Parts Listing section is

designed to familiarize the owner/operator with replaceable parts on the Implement. This section provides

exploded assembly drawings of each mower component illustrating each piece and the corresponding part

number.

Careful use and timely service saves extensive repairs and costly downtime losses. The Operation and

Maintenance Sections of the manual train the owner/operator how to work the Implement correctly and attend

to appropriate maintenance. The Trouble Shooting Guide helps diagnose difficulties with implement and offers

solution to the problems.

Safety is of primary importance to the owner/opera tor an d to the ma nufa ctur er. The first section of this manual

includes a list of Safety Messages, that, if followed, will help protect the operator and bystanders from injury or

death. Many of the Safety Messages will be repeated throughout the manual. The owner/operator/dealer

INTRODUCTION

should know these Safety Messages before as sembly and be aware of the hazards of operating this mo wer

during assembly, use, and maintenance. The Safety Alert Symbol combined with a Signal Word, as seen

below, is intended to warn the owner/operator of impe nding hazards and the degre e of possible injury faced

when operating this machine.

Indicates an imminently hazardous situation that, if not avoided, WILL result in DEATH OR

VERY SERIOUS INJURY.

Indicates an imminently hazardous situation that, if not avoided, COULD result in DEATH

OR SERIOUS INJURY.

Indicates an imminently hazardous situation that, if not avoided, MAY result in MINOR

INJURY.

Identifies special instructions or procedures that, if not strictly observed, could result in

damage to, or destruction of the machine, atta ch me n ts or the en vir on m en t.

SWINGTRIM 03/09 Introduction Section 2-2

© 2009 Alamo Group Inc.

Page 71

INTRODUCTION

INTRODUCTION

The sickle bar boom is designed for medium-duty work. They can cut grass and weeds, around waterways,

under fences and other hard-to-reach areas.

For Non-Agricultural use, OSHA, ASAE, SAE, and ANSI standards require the use of Chain

Guards, Deflectors, or Solid Skirts at all times. The Mower manufacturer strongly

recommends the use of Chain Guards, Deflectors, or Solid Skirts for Agricultural purposes

as well to reduce the risk of property damage, serious bodily injury, or even death from

objects thrown out by or from contact with the Cutting Blades.

Mower Orientation: Front and rear, and left and right are determined by the normal direction

of travel (the same as your automobile).

At least 20% of the tractor ’s total weight must be on the front tires with the Mower lifted to

provide adequate traction for safe steering under good con ditions. Slow down on hills, rough

terrain, and curves.

Front and rear, and left and right are determined by the normal direction of travel (the same as on your

automobile).

SWINGTRIM 03/09 Introduction Section 2-3

© 2009 Alamo Group Inc.

Page 72

INTRODUCTION

Attention Owner/Operator

BEFORE OPERATING THIS MACHINE:

1. Carefully read the Operator’s Manual, completely understand the Safety Messages and instructions, and

know how to operate correctly both the Implement and Power Unit.

2. Fill out the Warranty Card in full. Be sure to answer all questions, including the Serial Number of the

Implement. Mail promptly using the return envelope included with the Operator’s Manual.

NOTE: Warranties are honored only if completed “Owner Registration and Warranty” forms are received by

Alamo Group within thirty days of delivery of the mower.

3. Record the Implement Model and Serial Numbers on the Warranty page at the end of the Operator’s

Manual. Keep this as part of the permanent maintenance file for the Implement.

INTRODUCTION

SWINGTRIM 03/09 Introduction Section 2-4

© 2009 Alamo Group Inc.

Page 73

ASSEMBLY SECTION

© 2009 Alamo Group Inc.

Assembly Section 3-1

Page 74

ASSEMBLY

TRACTOR SELECTION

The SWINGTRIM is specifically designed to be fitted to all tractors with Category I linkage facility and a

minimum weight inclusive of ballast to manufacturers specifications, of 650 kg (1430 lbs.).

Check chains/stabilizer bars must be available to hold the machine firmly in position during transport and

operation.

The tractor selected must have a relief valve setting between 2000 PSI (110 Bar) and 3000 PSI (210 Bar).

In addition to tractors which operate on a “closed center” hydraulic principle e.g. John Deere are unsuitable.

Ballast Weight

Irrespective of the size of the tractor it must be stable while operating the Swingtrim under all conditions. Due

regard must be paid to operating on slopes and front end ballast as well as rear wheel weights to

counterbalance the overhang of the cutterbar should be added as appropriate.

ATTACHMENT TO TRACTOR

1. Unbolt the upper halves of the yoke and fit them on either side of the tractor’s top hitch bracket with the 3/

ASSEMBLY

4” UNF nut and bolt provided. If the tractor has only one top hitch position the bolt will replace the existing

top hitch pin. If more than one location is available, mount the yokes through an alternative position as it

will make it easier to put the machine on and take it off the tractor.

2. Do not tighten the nut at this stage.

3. Attach the machine to the three-point linkage and raise to give 200-250 MM (8”-10”) clearance under the

lowest part of the frame.

4. Rebolt the yoke halves together. It may be necessary to raise or lower the machine on the linkage to

achieve hole alignment. Adjust the top link until the main frame is vertical.

5. Tighten the nut and bo lt se cu ring th e u ppe r yoke just enou gh to eliminate any sideways movement. Do not

overtighten and squeeze the top hi tc h br ac kets.

6. Tighten the check chains/stabilizer bars.

7. Release its holding chain and position the contr ol va lve to su it the tr actor an d oper ator. This is achieved by

a combination of height adjustments in the mounting bar attachment and by bending the mounting bar

itself.

8. Turn the parking leg upside down and pin in position.

SWINGTRIM 03/09 Assembly Section 3-2

© 2009 Alamo Group Inc.

Page 75

ASSEMBLY

COUPLING UP HYDRAULICS

Consult the tractor’s handbook for correct installation of the supply and return connection.

Note that if the tractor is equipped with one or more quick release hydraulic couplings the Swingtrim supply

and return hydraulic components may need to be rearranged to facilitate fitting to a variety of tractors.

The motor drain line must always be returned to a low pressure position i.e. Transmission plug.

Where no specific return connection is available and the transmission filter plug has to be used, an adaptor

must be fitted which then allows the motor return and the motor drain to utilize a common return location.

Run up the machine and operate through its complete range of movements including the operation of the

cutterbar drive. Check the tractor’s transmission oil level and top up if necessary.

You are now ready to proceed to the work site.

ASSEMBLY

REMOVAL FROM THE TRACTOR

1. Select a firm level site.

2. Replace the stand leg to the park position with foot down.

3. Position the arms so that the motor is level with the bottom of the frame.

4. Raise tractor linkage to take the weight off the yoke. Where a common top link an d yoke position is us ed,

the yoke must be unbolted in the middle. If different top link locations are used, the yoke may be unbolted

at the top.

5. Lower the machine to the ground and disconnect the three point linkage. Remove top halves of the yoke if

still attached to the tractor.

6. Use chain to tie the hydraulic control valve back to the main arm. This will make it easier for subsequent

coupling up.

7. Blank off hose ends or loop the hoses and join with coupling is available.

STORAGE

If the machine is to be left standing for an extended period of time, lightly coat the exposed portions of the ram

rods with grease. Subsequently, this grease which becomes contaminated with dust and grit should be wiped

off before the rams are next moved.

Liberally grease the cutterbar and replace the finger and knife guard. Remember to take caution and keep

fingers away from the knife.

If the machine is to be stored outside, lay a piece of tarpaulin or canvas over the control valve. Do not use a

plastic bag which could lead to rapid corrosion.

SWINGTRIM 03/09 Assembly Section 3-3

© 2009 Alamo Group Inc.

Page 76

Page 77

OPERATION SECTION

© 2009 Alamo Group Inc.

Operation Section 4-1

Page 78

OPERATION

ALAMO INDUSTRIAL SWINGTRIM

OPERATING INSTRUCTIONS

Alamo Industrial swingtrims are manufactured with quality material by skilled workers. The implement is

designed for cutting hedges, grass and weeds, around waterways, under fences and other hard-to-reach

areas. The implement is equipped with protective deflectors to prevent objects being thrown from the

implement by the blades, however , no shieldin g is 100% ef fective. All shields, gu ards, and deflecto rs equipped

on the mower must be maintained in good operational condition.

It is the operator’s responsibility to be knowledgeable of all potential operating hazards and to take every

reasonable precaution to ensure oneself, others, animals, and property are not injured or damaged by the

implement, tractor, or a thrown object. Do not operate the mower if passersby, pets, livestock, or property are

within 100 yards of the unit.

This section of the Operator’s Manual is designed to familiarize, instruct, and educate safe and proper

implement use to the operator. Pictures contained in this section are intended to be used as a visual aid to

assist in explaining the operation of a swingtrim and are not specific to any model. Some pictures may sho w

shields removed for picture clarity. NEVER operate implement without all shields in place and in good

operational condition. The operator must be familiar with the mower and tractor and all associated safety

OPERATION

practices before operating the mower and tractor. Proper operation of the mower, as detailed in this manual,

will help ensure years of safe and satisfactory use of the mower.

IMPORTANT: To avoid mower damage, retorque all bolts after the first 10 hours of operation. Refer to the

Torque Chart at the end of the Maintenance Section to ensure bolts are properly tightened.

READ AND UNDERSTAND THE ENTIRE OPERATING INSTRUCTIONS AND SAFETY SECTION OF THIS

MANUAL AND THE TRACTOR MANUAL BEFORE ATTEMPTING TO USE THE TRACTOR AND

IMPLEMENT. If you do not understand any of the instructions, contact your nearest authorized dealer for a

full explanation. Pay close attention to all safety signs and safety messages contained in this manual and

those affixed to the implement and tractor. OPS-U- 0001

READ, UNDERSTAND, and FOLLOW

death may occur unless care is taken to follow the warnings and instructions stated in the

Safety Messages. Always use good common sense to avoid hazards.

Si no lee ingles, pida ayuda a alguien que si lo lea para que le traduzca las

medidas de seguridad.

the following Safety Messages. Serious injury or

(SG-2)

(SG-3)

SWINGTRIM 03/09 Operation Section 4-2

© 2009 Alamo Group Inc.

Page 79

OPERATION

1. Standard Equipment and Specifications

Standard Specifications

CAT I Three Point Hitch

Boom reach: 11’ Up, 14’ Out, 6’ Down

Double Swing

Main Boom Arm is 2-3/4” Tubing

Dipper Arm is 2-1/4” Tubing

Mechanical Breakaway

Tractor-Supplied Hydraulics or Optional Tank Kit

4’ or 5’ Sickle Bar Head

Sickle bar angling range of 250 degrees

Cutting Capacity: 1/2” diameter

OPERATION

SWINGTRIM 03/09 Operation Section 4-3

© 2009 Alamo Group Inc.

Page 80

OPERATION

2. OPERATOR REQUIREMENTS

Safe operation of the unit is the responsibility of a qualified operator. A qualified operator has read and

understands the implement and tractor Operator’s Manuals and is experienced in implement and tractor

operation and all associated safety practices. In addition to the safety messages contained in this manual,

safety signs are affixed to the implement and tractor. If any part of the operation and safe use of this

equipment is not completely understood, consult an authorized dealer for a complete explanation.

If the operator cannot read the manuals for themselves or does not completely und erst and the operation of th e

equipment, it is the responsibility of the supervisor to read and explain the manuals, safety practices, and

operating instructions to the operator.

Safe operation of equipment requires that the operator wear approved Personal Protective Equipment (PPE)

for the job conditions when attaching, operating, servicing, and repairing the equipment. PPE is designed to

provide operator protection and includes the following safety wear:

PERSONAL PROTECTIVE EQUIPMENT (PPE)

• Protective Eye Glasses, Goggles, or Face

OPERATION

Shield

•Hard Hat

• Steel Toe Safety Footwear

• Gloves

• Hearing Protection

• Close Fitting Clothing

• Respirator or Filter Mask (depends on

operating conditions) OPS-U- 0002

NEVER use drugs or alcohol immediately before or while operating the

Tractor and Implement. Drugs and alcohol will affect an operator’s

alertness and coordination and therefore affect the operator’s ability to

operate the equipment safely. Before operating the Tractor or

Implement, an operator on prescription or over-the-counter medication

must consult a medical professional regarding any side effects of the

medication that would hinder their ability to operate the Equipment safely.

NEVER knowingly allow anyone to operate this equipment when their

alertness or coordination is impaired. Serious injury or death to the

operator or others could result if the operato r is under the influence of

drugs or alcohol.

SWINGTRIM 03/09 Operation Section 4-4

© 2009 Alamo Group Inc.

(SG-27)

Page 81

OPERATION

3. TRACTOR REQUIREMENTS

In addition to tractor horsepower and size required to o perate th e m ower un it, th e trac tor m ust also be prope rly

equipped to provide operator protection, to alert approaching vehicle drivers of the tractor ’s presence, and to

ensure tractor stability when mowing with the boom fully extended.

Tractor Requirements and Capabilities

• ASAE approved Roll-Over Protective Structure (ROPS) or ROPS cab and seat belt.

• Tractor Safety Devices.....................Slow Moving Vehicle (SMV) emblem, lighting, PTO master shield

• Tractor Horsepower-Minimum..........15 HP

• Tractor Weight .. ... ... ... ... .... ... ... ... .... ...1210 lbs.

• Hitch.................................................Cat I Three-point Hitch

• Hydraulics.........................................Uses tractor’s open center hydraulic system

• Power Take Off.................................540 RPM

3.1 ROPS and Seat Belt

The tractor must be equipped with a Roll-Over-Protective-Structure (ROPS) (tractor cab or roll-bar) and seat

belt to protect the operator from falling o ff the tractor, especially during a roll over where the driver could be

crushed and killed. Only operate the tractor with the ROPS in the raised position and seat belt fast ened.

Tractor model not equipped with a ROPS and seat belt should have these life saving features installed by an

authorized dealer. OPS-U- 0003

OPERATION

Operate this Equipment only with a Tractor equipped with an approved rollover-protective system (ROPS). Always wear seat belts. Serious injury or

even death could result from falling of f the tractor --particularly during a turnover

when the operator could be pinned under the ROPS.

3.2 Operator Thrown Object Protection

The tractor must be equipped with protective

equipment to shield the operator from falling and

thrown objects. For cab tractors, the tractor must

be equipped with an operator safety screen on its

right side or the right side windows must be fitted

with a shatter proof safety window. For non-cab

tractors, the tractor must be equipped with a

ROPS and operator protective safety cage that

provides protection to the right and above the

operator seat. DO NOT remove the ROPS from

non-cab tractors to equip a safety cage.

OPS-B- 0001_A

(SG-7)

SWINGTRIM 03/09 Operation Section 4-5

© 2009 Alamo Group Inc.

Page 82

Never operate the Tractor and Mower Unit without an OPS (Operators

Protective Structure) or Cab to prevent injury from objects thrown from

ground or from overhead trimming. Stop mowing if workers or

passersby are with in 100 yards.

3.3 T ractor Lighting and SMV Emblem

If the tractor will be operated near or traveled on a

public roadway it must be equipped with proper

warning lighting and a Slow Moving Vehicle (SMV)

emblem which are clearly visible from the rear of

the unit. Most tractor’s have different settings for

operating and transporting lighting. Refer to the

tractor operator’s manual for using the tractor’s

light switch and operating the turn signals.

OPS-B- 0017

OPERATION

OPERATION

(SBM-9)

3.4 Tractor Horsepower

The horsepower required to operate the mower depends on ma ny factors including veget ation to be cut, ter rain

condition, operator experience, and condition of the mower a nd tractor. For most mowing condition, the

Swingtrim sickle bar requires a tractor with at least 15 HP. Operating the mower with a tractor that does not

have adequate power may damage the tractor engine.

3.5 3-Point Hitch

Swingtrim sickle bar can attach to tractors with a

CAT I three-point hitch. Refer to the tractor

operator’s manual for the category of the tractor

used. If the hitch does not conform to ASAE Cat I

or II dimensions, the mower may not fit or raise

properly. Consult an authorized dealer for possible

modification procedures to mount nonconforming

hitches.

Use the correct hitch pins for the hitch ca tegory

being used. For a Cat I hitch, 7/8” lower and 3/4”

upper diameter hitch pins are used.

CAT I Implement / Hitch Specification

Width from outside to outside A-frame......26 7/8”

Quick Hitch width inside lug to lug ...........27 1/8”

Height from bottom hitch pin to top pin...........18”

Lower pin diameter........................................7/8”

Upper pin diameter .......................................3/4”

Lynch pin diameter ....................................15/32”

SWINGTRIM 03/09 Operation Section 4-6

© 2009 Alamo Group Inc.

Page 83

OPERATION

3.6 Hydraulics

The Swingtrim uses the tractor’s open center hydraulics with a rating of 3.8 to 5.6 gallons per minute, with

remote outlet. Hydraulic controls shall be provided for boom lift, dipper, and sickle bar tilt for full operator

control. The mower’s hydraulic system shall be protected from overload by an automatic relief valve.

3.7 Front End Weight

A minimum of 20% total tractor weight must be maintained on the tractor front end at all times. Front end

weight is critical to maintain steering control and to prevent the tractor from rearing up while driving. If the

front end is too light, add weight until a minimum of 20% total weight is reached on the front tires. Front

weights and weight carriers can be purchased through an authorized tractor dealership. OPS-U- 0005

3.8 Power Take Off (PTO)

Depending on the unit, the mower is designed to operate at a PTO speed of 540 or 1000 RPM. Most tractors

operate at either 540, or a combination of 540 and 1000 RPM PTO speeds. The operating speed of the

mower and tractor can be determined by the number of splines on the driveline yoke and PTO output shaft.

Those operating at 540 RPM will have a 6-spline shaft and those operating at 1000 RPM will have a 21-spline

shaft or a 1-3/4” 20 spline shaf t. Refer to the tr actor owner’s manual for in structions to chan ge PT O spee ds on

models that operate at more than one speed.

OPERATION

If operating an older model tractor where the tractor’s transmission and PTO utilize one master clutch, an

over-running clutch must be used between the PTO output shaft and the driveline of the mower. An

authorized tractor dealer can provide the over-running clutch and its installation if needed. OPS-U- 0006

DO NOT use a PTO adapter to attach a non-matching Implement driveline to a Tractor

PTO. Use of an adapter can double the operating speed of the Implement resulting in

excessive vibration, thrown objects, and blade and implement failure. Adapter use will also

change the working length of the driveline exposing unshielded driveline areas. Serious

bodily injury and/or equipment failure can result from using a PTO adapter. Consult an

authorized dealer for assistance if the Implement driveline does not match the Tractor PTO.

(S3PT-14)

Never operate the Tractor and Mower if the Implement input driveline is directly connected

to the Tractor transmission. Tractor braking distances can be substantially increased by

the momentum of the rotating Mower blades driving the Tractor transmission even though

the Tractor clutch has been dise nga ge d. Install an over running clutch between the Tractor

PTO and the Mower driveline to prevent this potentially dangerous situation.

(S3PT-16)

SWINGTRIM 03/09 Operation Section 4-7

© 2009 Alamo Group Inc.

Page 84

OPERATION

4. GETTING ON AND OFF THE TRACTOR

Before getting onto the tractor, the operator must read and completely understand the implement and tractor

operator manuals. If any part of either manual is not completely understood, consult an authorized dealer for

a complete explanation. OPS-U- 0007

Do not mount or dismount the Tractor while the tractor is moving. Mount

the Tractor only when the Tractor and all moving parts are completely

stopped.

4.1 Boarding the Tractor

Use both hands and equipped handrails and steps for support when boarding the tractor. Never use control

levers for support when mounting the tractor. Seat yourself in the operator’s seat and secure the seat belt

around you.

Never allow passengers to ride on the tractor or attached equipment. Ride rs can easily fall off and be

OPERATION

seriously injured or killed from falling off and being ran over. It is the operator’s responsibility to forbid all extra

riders at all times. OPS-U- 0008

(SG-12)

Never allow children or other persons to ride on the Tractor or Implement.

Falling off can result in serious injury or death.

Never allow children to operate or ride on the Power Unit or Implement.

(SPU-17)

(SG-10)

4.2 Dismounting the Tractor

Before dismounting, park the tractor and implement on a reasonably level surface, apply the parking brake,

idle the engine down, disengage the PTO, and lower the implement to the ground. Shut down the tractor

engine according to the operator’s manual, remove the key, and wait for all motion to completely stop. Never

leave the seat until the tractor, its engine and all moving parts have come to a complete stop.

Use hand rails and steps when exiting the tractor. Be careful of your step and use extra caution when mud,

ice, snow or other matter has accu mu la te d o n t he steps or hand rails. Use all handrails and ste ps for supp or t

and never rush or jump off the tractor. OPS-U- 0009

SWINGTRIM 03/09 Operation Section 4-8

© 2009 Alamo Group Inc.

Page 85

OPERATION

BEFORE leaving the tractor seat, always engage the brake and/or set

the tractor transmission in parking gear, disengage the PTO, stop the

engine, remove the key, and wait for all moving parts to stop. Place the

tractor shift lever into a low range or parking gear to prevent the tractor

from rolling. Never dismount a Tractor that is moving or while the engine

is running. Operate the Tractor contr ols from the tractor seat only.

(SG-9)

5. STARTING THE TRACTOR

The operator must have a complete understanding of the placement, function, and operational use of all

tractor controls before starting the tractor. Review the tractor operator’s manual and consult an authorized

dealer for tractor operation instructions if needed.

Essential Tractor Controls:

• Locate the ignition key/switch

• Locate the engine shut off control

• Locate the hydraulic control levers

• Locate the light control lever

• Locate the brake pedals and clutch

• Locate the PTO control

• Locate the 3 point hitch control lever

• Locate the boom operating controls (joystick or valve bank)

Before starting the tractor ensure the following:

• Conduct all pre-start operation inspection and service according to the tractor operator’s manual.

• Make sure all guards, shields, and other safety devices are securely in place.

• The parking brake is on.

• The tractor transmission levers are in park or neutr al.

• The boom operating controls are in the neutral and off position.

• The PTO control lever is disengaged.

• The hydraulic remote control levers are in the neutral position.

OPERATION

Refer to the tractor owner’s manual for tractor starting procedures. Only start the tractor while seated and

belted in the tractor operator’s seat. Never bypass the ignition switch by short circuiting the starter solenoid.

After the tractor engine is running, avoid accidental contact with the tractor transmission to prevent sudden

and unexpected tractor movement. OPS-B- 0003

Never run the Tractor engine in a closed building or without adequate ventilation. The

exhaust fumes can be hazardous to your health.

SWINGTRIM 03/09 Operation Section 4-9

© 2009 Alamo Group Inc.

(SG-23)

Page 86

OPERATION

OPERATION

Start tractor only when properly seated in the Tractor seat. Starting a

tractor in gear can result in injury or death. Read the Tractor operators

manual for proper starting instructions.

Avoid contact with hot surfaces including hydraulic oil tanks, pumps, motors, valves and

hose connections. Relieve hydraulic pressure before performing maintenance or repairs.

Use gloves and eye protection when servicing hot components. Contact with a hot surface

or fluid can cause serious injury from burns or scalding.

Always shut the Tractor completely down, place the transmission in park, and set the

parking brake before you or anyone else attempts to connect or disconnect the Implement

and Tractor hitches.

Periodically inspect all moving parts for wear and replace when

necessary with authorized service parts. Look for loose fasteners, worn

or broken parts, and leaky or loose fittings. Make sure all pins have

cotter pins and washers. Serious injury may occur from not maintaining

this machine in good working order.

(S3PT-15)

(SG-13)

(SG-34)

(SG-21)

All Safety Shields, Guards and Safety devices including (but not

limited to) - the Deflectors, Chain Guards, Steel Guards,

Gearbox Shields, PTO integral shields , and Retractable Door

Shields should be used and maintained in good working condition. All safety

devices should be inspected carefully at least daily fo r missing or broken

components. Missing, broken, or worn items must be replaced at once to reduce

the possibility of injury or death from thrown objects, entanglement, or blade

contact.

(SBM-18)

6. CONNECTING THE IMPLEMENT TO TRACTOR

1. Unbolt the upper halves of the yoke and fit them either side of the tractor’s top hitch bracket with the 3/4”

UNF nut and bolt provided. If the tractor has only one top hitch position, the bolt will replace the existing

top hitch pin. If more than one location is available mount the yokes through an alternative position as it will

make it easier to put the machine on and take it off the tractor.

2. Do not tighten the nut at this stage.

SWINGTRIM 03/09 Operation Section 4-10

© 2009 Alamo Group Inc.

Page 87

OPERATION

3. Attach the machine to the three point linkage and raise to give 200-250 mm (8”-10”) clearance under the lowest part of the frame.

4. Rebolt the yoke halves together. It may be necessary to raise or lower the machine on the linkage to achieve hole alignment. Adjust the top link until the main frame is vertical.