Page 1

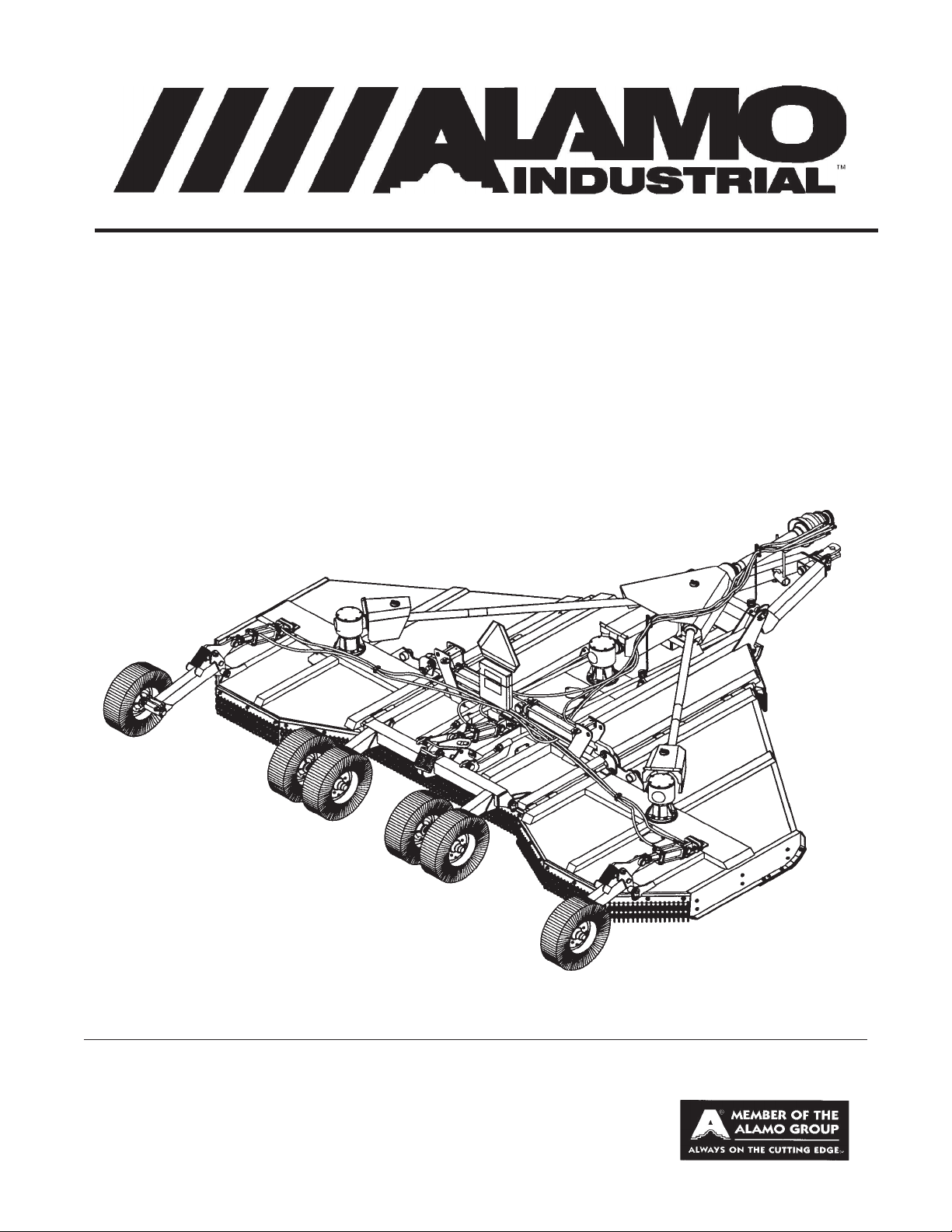

ST15 & ST10 Stingray

ARCHIVE BOOK

15 ' Flex Wing - 4 Gearbox Model

S/N ST15-C31200557203 (Jan. 2002 )

to

S/N ST15-Current

COMPLETE PARTS

LISTING

ALAMO INDUSTRIAL

1502 E. Walnut

Seguin, Texas 78155

830-372-3551

© 2004 Alamo Group Inc.

Archive Book

Part No.

02980337

2004 Edition Rev 01-09

Page 2

Alamo Industrial (Terrain King)

15 foot Flex Wing Mowers

Model - 3 Gearbox 15 ft. / Flex Wing Mowers

Production Date

Start.........to.... End Start s/n...............to..... End s/n

530................ May 1968.......... Nov. 1973* TK530-07195..................TK530-21446*

CP180........... Dec. 1973......... Mar. 1976

X-3................ Apr. 1975.......... Apr. 1978

TK15.............May 1978.......... Sep. 1982

TK15HD........Oct. 1982..........May 1987

A315..............Mar. 1990..........Sep. 1990

* End of Production for this Model

* CP180-31188................. CP180-34724*

* X-3-33388.......................X-3-36782*

* TK15-36783....................TK15-39979*

* TK15HD-39980...............TK15HD-46051*

* A315-01001.................... A315-10080*

Serial Number

Model - 4 Gearbox 15 ft. Flex Wing Mowers

Production Date

Start.........to.... End Start s/n...............to..... End s/n

Serial Number

TK15-IV........ Mar. 1985..........May. 1987* TK15-IV-42840............... TK15-IV-46051*

AG15-IV........ Jun. 1987..........Mar. 2002

A415..............Jun. 1990.......... Dec. 2002

ST15.............Jan 2002........... Current ST15-C31200557203..... ST15-Current

* End of Production for this Model

* AG15-IV-01001............... AG15-IV-04643*

* A415-01001.................... A415-14000*

Archive Manual Part Numbers

TK530........................ 02980262 TK15-IV.........................00761652

CP180........................ 02980263 AG15-IV........................ 00761652

X-3.............................. 02980264 A315.............................. 02980317

TK15.......................... 02980265 A415.............................. 02980316

TK 15HD.....................02980265 ST15.............................. 02980337

Page 3

INDEX - ST15 & ST10

ITEM PAGE NO.

AXLE ASY.

Center Axle:

ST15-C31200557203 (Jan. 2002) to ST15-Current.................................... 26

Wing Axle

ST15-C31200557203 (Jan. 2002) to ST15-Current.................................... 18, 19

BLADE CARRIERS & BLADES:

ST15-C31200557203 (Jan. 2002) to ST15-Current.................................... 48, 49, 50

CHAIN GUARDS:

Front:

ST15-C31200557203 (Jan. 2002) to ST15-Current.................................... 64 thru 69

Rear:

ST15-C31200557203 (Jan. 2002) to ST15-Current.................................... 64 thru 69

COUNTER WEIGHT: (10 foot Model)

ST15-C31300557203 (Jan. 2002) to ST15-Current.................................... 20

CONTROL / LEVEL LIFT ROD:

ST15-C31200557203 (Jan. 2002) to ST15-Current.................................... 27

DECK COMPONENT:

Center Section:

ST15-C31200557203 (Jan. 2002) to ST15-C31200789311 (Oct. 2003).... 14, 15

ST15-C31200790311 (Nov. 2003) to ST15-Current....................................16, 17

Wing Section:

ST15-C31200557203 (Jan. 2002) to ST15-Current.................................... 18, 19

Skirt Assembly ST10:

ST15-C31300557203 (Jan. 2002) to ST15-Current.................................... 20, 21

DRIVELINE ASY:

PTO, Cat 5 C/V:

ST15-C31200557203 (Jan. 2002) to ST15-Current................................... 32, 33

INTERMEDIATE:

ST15-C31200557203 (Jan. 2002) to ST15-Current.................................... 35

WING:

ST15-C31200557203 (Jan. 2002) to ST15-Currentt................................... 34

SLIP CLUTCH:

Intermediate Driveline & Wing Driveleine:

ST15-C31200557203 (Jan. 2002) to ST15-Current.................................... 36, 37

GEARBOX ASY:

Divider:

ST15-C31200557203 (Jan. 2002) to ST15-Current.................................... 38, 39

Center:

ST15-C31200557203 (Jan. 2002) to ST15-Current.................................... 40, 41

Right & Right Wing:

ST15-C31200557203 (Jan. 2002) to ST15-Current.................................... 42 thru 45

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

Index - 3

Page 4

INDEX - ST15 & ST10

ITEM PAGE NO.

GEARBOX SHIELDS

ST15-C31200557203 (Jan. 2002) to ST15-Current..................................... 46, 47

HITCH ASY (OPTIONAL PRECISION HITCH)

ST15-C31200557203 (Jan. 2002) to ST15-Current..................................... 24

HYDRAULICS

Schematic - Axle Lift Cylinders

ST15-C31200557203 (Jan. 2002) to ST15-C31200789311 (Oct. 2003)..... 52, 53

ST15-C31200790311 (Nov. 2003) to ST15-Current.....................................54, 55

Schematic - Wing Lift & Fold Cylinders

ST15-C31200557203 (Jan. 2002) to ST15-C31200789311 (Oct. 2003)..... 58

ST15-C31200790311 (Nov. 2003) to ST15-Current.....................................59

Schematic - Control Valve:

ST15-C31200557203 (Jan. 2002) to ST15-Current..................................... 62

Wing Lift Cyl:

ST15-C31200557203 (Jan. 2002) to ST15-C31200789311 (Oct. 2003)..... 60

ST15-C31200790311 (Nov. 2003) to ST15-Current.....................................61

Axle Lift Cyl:

ST15-C31200557203 (Jan. 2002) to ST15-C31200789311 (Oct. 2003)..... 56

ST15-C31200790311 (Nov. 2003) to ST15-Current.....................................57

Attachments:

Axle Lift:

ST15-C31200557203 (Jan. 2002) to ST15-Current..................................... 18, 63

Wing Lift:

ST15-C31200557203 (Jan. 2002) to ST15-Current..................................... 18, 63

Valve Mnt:

ST15-C31200557203 (Jan. 2002) to ST15-Current..................................... 62

INDEX / INTRODUCTION

Index ............................................................................................................ 3 thru 5

Introduction................................................................................................... 6 & 13

PARKING JACK

ST15-C31200557203 (Jan. 2002) to ST15-Current..................................... 25

SAFETY CHAIN

Safety Chain................................................................................................. 70

SAFETY SECTION

Safety Section...............................................................................................7 thru 12

SKID SHOES

ST15-C31200557203 (Jan. 2002) to ST15-Current..................................... 16 thru 20

TONGUE:

Tongue:

ST15-C31200557203 (Jan. 2002) to ST15-Current..................................... 22, 23

Precision Hitch: (Optional)

ST15-C31200557203 (Jan. 2002) to ST15-Current..................................... 24

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

Index - 4

Page 5

INDEX - ST15 & ST10

ITEM PAGE NO.

TIRE, WHEEL & HUBS

ST15-C31200557203 (Jan. 2002) to ST15-Current..................................... 28 thru 31

TRANSPORT LIGHT ASY:

ST15-C31200557203 (Jan. 2002) to ST15-Current..................................... 71

WINCH & STAND

ST15-C31200557203 (Jan. 2002) to ST15-Current..................................... 51

WHEEL HUB

ST15-C31200557203 (Jan. 2002) to ST15-Current..................................... 28 thru 31

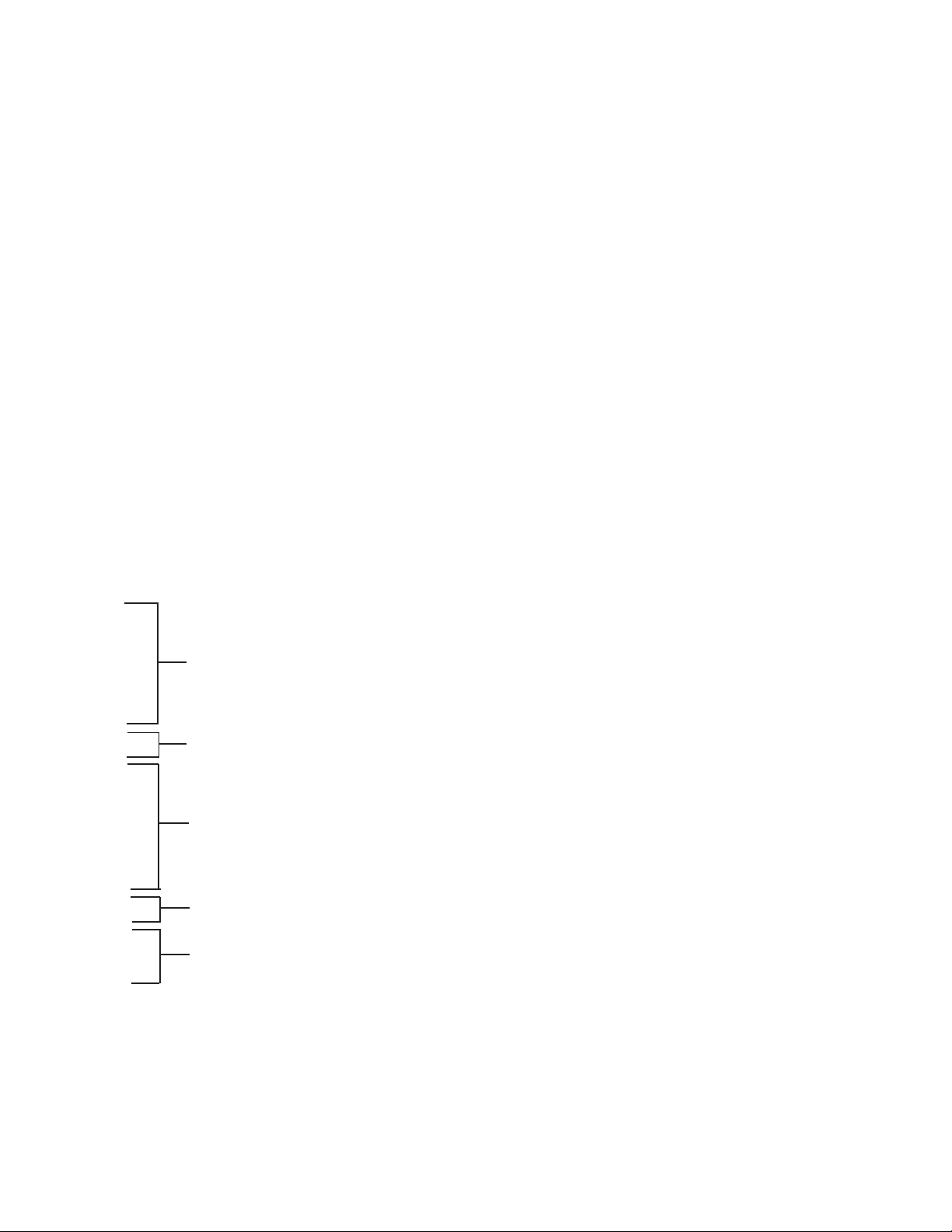

Serial Number Identification Codes

ST15 (C312) & ST10 (C313)

12 Digit Serial Number Break Down

C

3

1

2

0

0

5

5

7

2

0

3

1 st. thru 4 th. digits designate model (C312 = ST15 and C313 = ST10)

5 th. digit designates decade years (example 0=2000 thru 2009 or 1=2010 thru

2019 or 2=2020 thru 2029 & etc.)

6 th. thru 9 th. digit means it was the 557 th unit built that year

10 th. digit is year of the decade (example 2=2002 or 3=2003 & etc.)

11th. thru 12 th. digit is month of the year (example 03=March or 04=April & etc.)

Summary: This serial number means, C312 = ST15, 0 = 1 st. decade of century,

0557 = Five hundred and fifty seventh unit built this year, 2 = the year of the decade

(2002),

03 = the month of the year (March)

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

Index - 5

Page 6

ST15 & ST10

ARCHIVE BOOK

INTRODUCTION

The ST15 / ST10 Archive Book is a complete listing of Parts from the first Unit to the

Present. The Production Dates, Serial Numbers, Special Notes and Descriptions are

furnished to help find Replacement Parts. Dimension (if listed) are for Identification of

Parts and MAY NOT be to Manufacturing Specification, Your measurements may vary

some from dimensions listed. Some Parts may be changed and be different than parts

listed. Some Modification may be required when replacing older parts. Match S/N's listed

in this Book with the S/N's listed at the top of each Parts Page. See Index page for serial

number code break down. The ST15 S/N will start with prefix C312 and ST10 prefix is

C313, the first 4 digits of the 12 digit S/N designates the model.

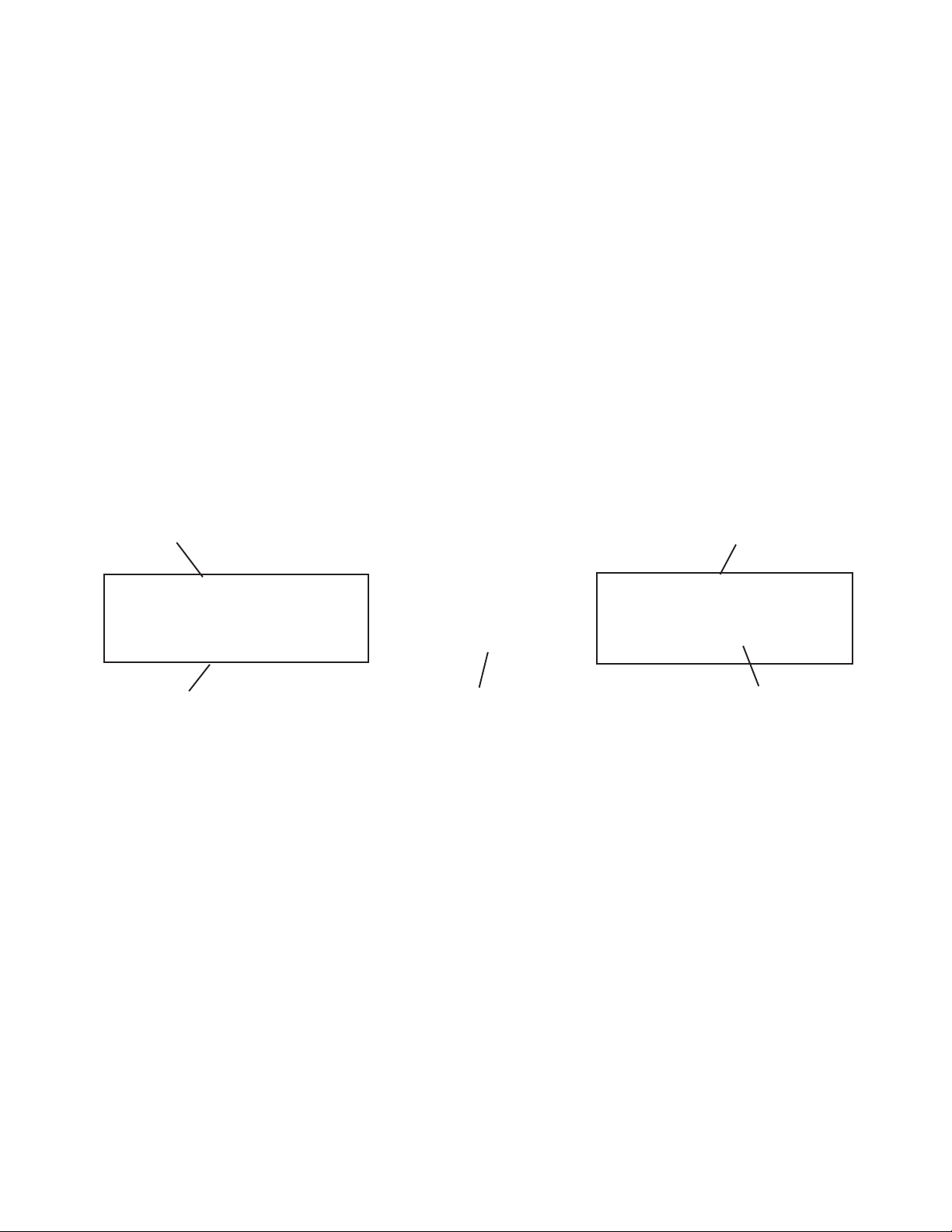

PAGE EXAMPLE

Beginning Production Date

Dec. 2002

to

Current

Ending Production Date Componets Listed This Page

For ordering parts the following instructions are offered to help eliminate delay

1. The purchase order must include the Name, Address (Ship to Street Address) of the

Person / Organization ordering the parts. Who / How Parts should be Billed. Name

and Phone Number of a Contact Person at your end.

2. The Purchase Order must list clearly the correct Part Number of Part. Quantity of

each Part wanted, Complete and correct Description of each Part. All Parts will be

shipped as requested depending on availability and/or reasonability of request

carrier / method.

3. Alamo Industrial reserves the right to substitute parts where applicable and change

prices Without prior notice. Alamo Industrial also reserves the right to Ship Parts the

most Reasonable way as determined by Alamo Industrial.

4. Some Parts are unlisted items, which are special production items not normally

stocked or built for a limited / special use, These parts may be subject to special

handling or cannot be priced till ordered. Always Request a quotation for such Parts

before sending a purchase order.

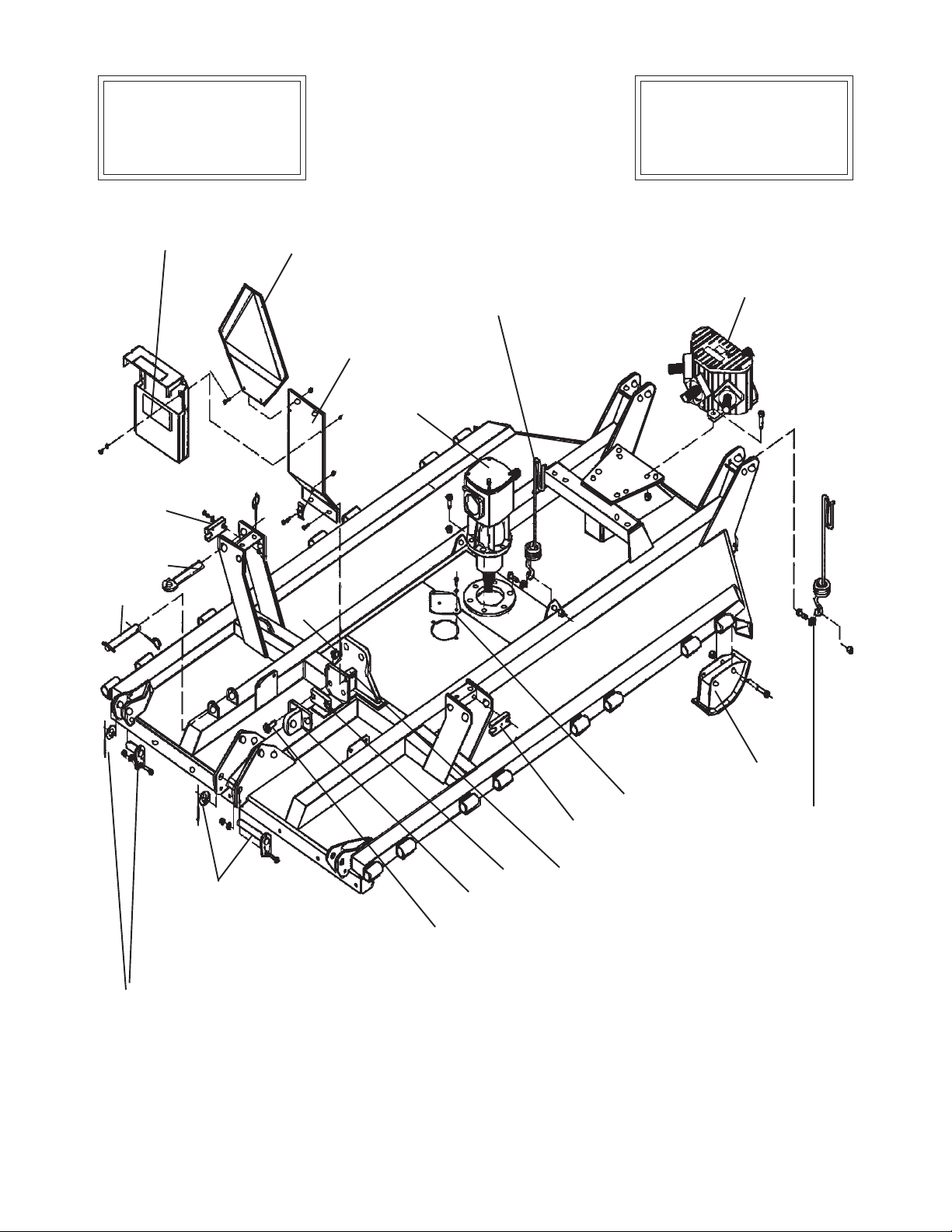

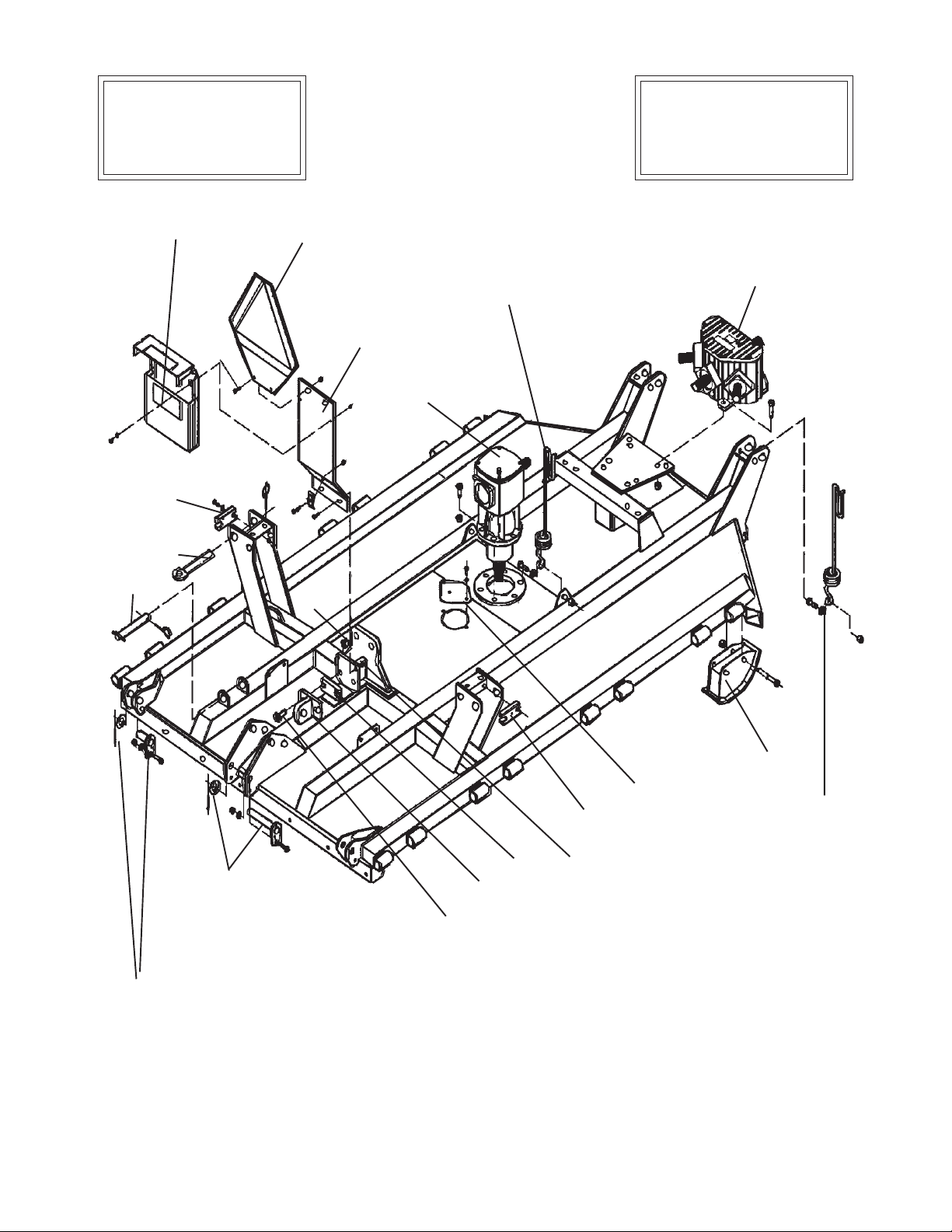

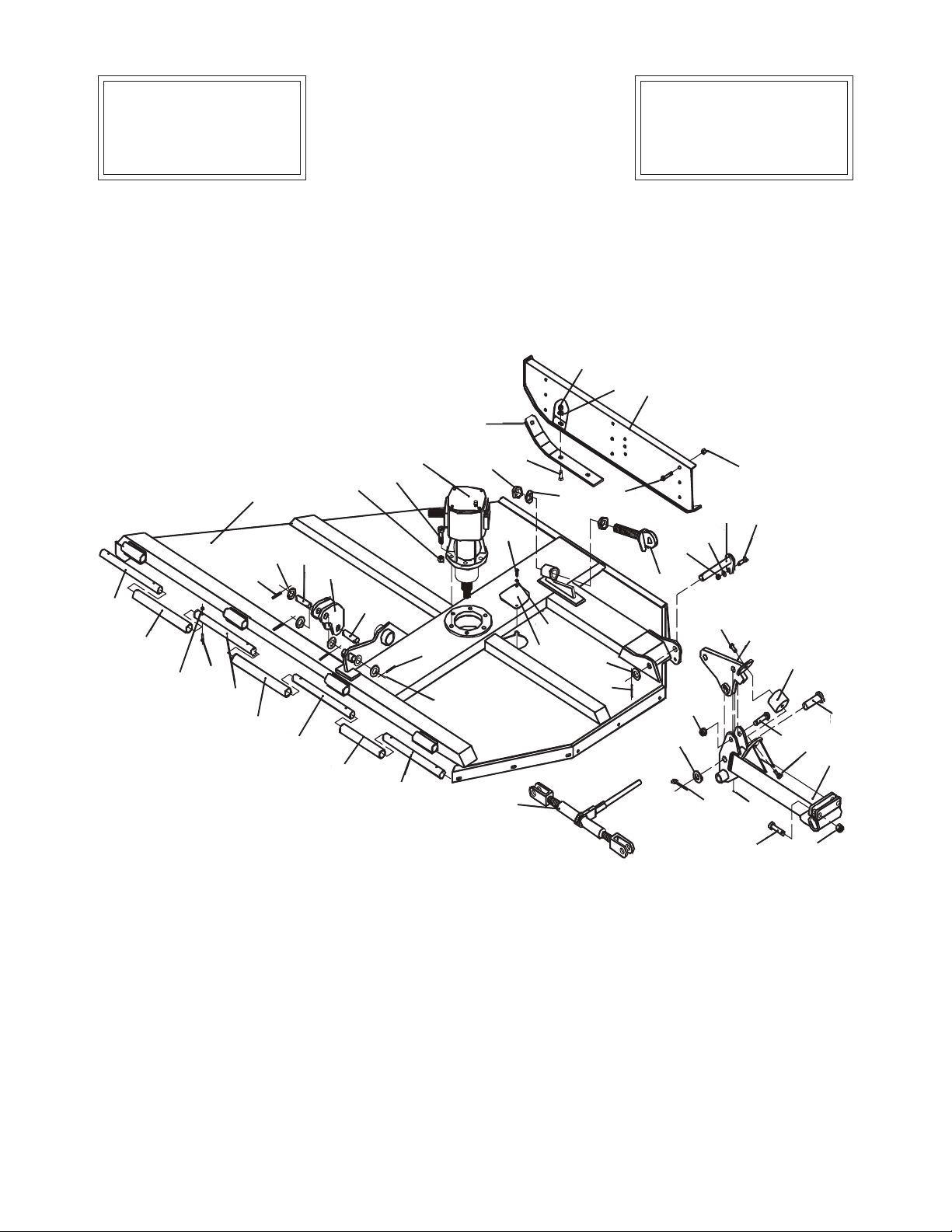

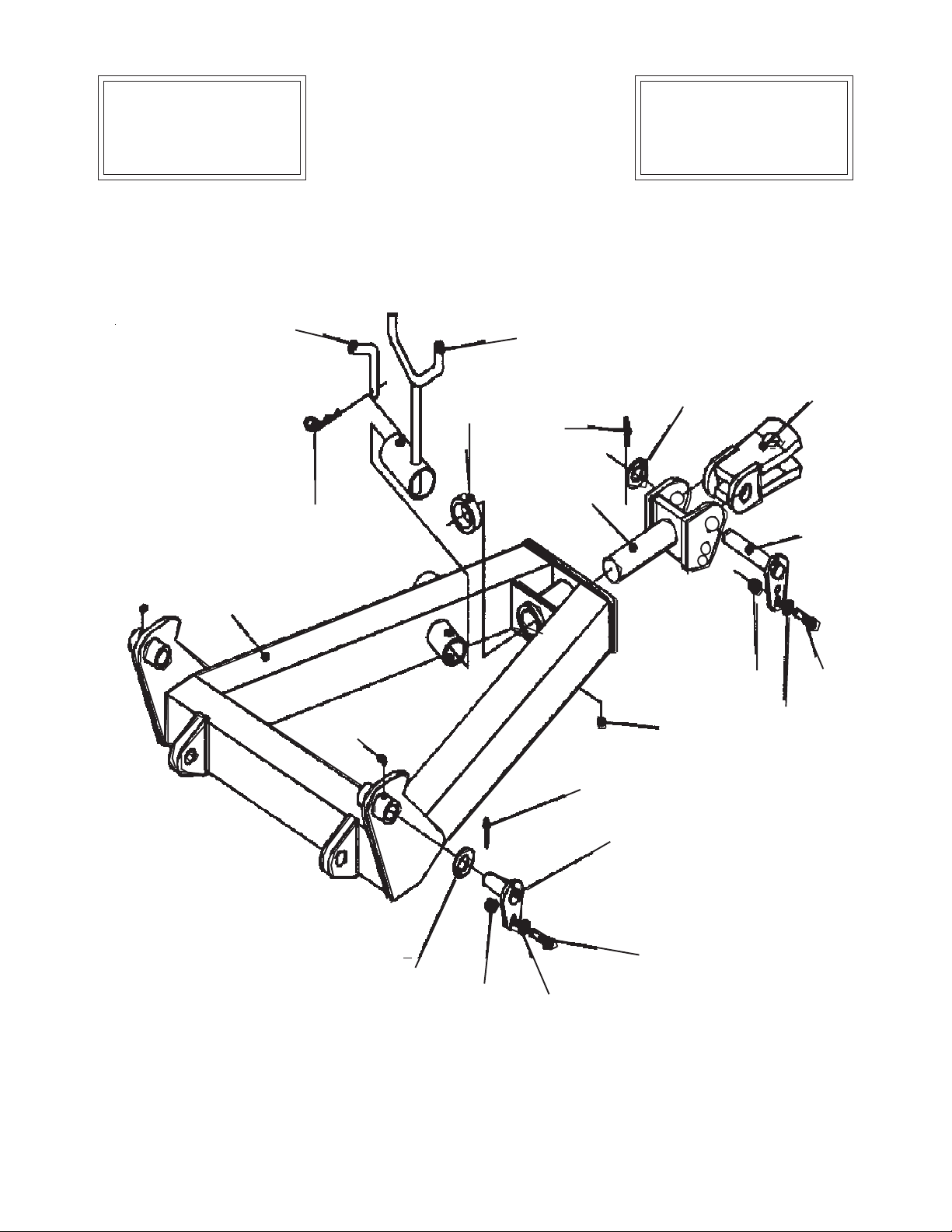

FRAME

ASSEMBLY

Beginning S/N

S/N ST15-C31200557203

to

S/N ST15-Current

Ending S/N

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

Index - 6

Page 7

SAFETY

SECTION

© 2004 Alamo Group Inc.

Safety Section - 7

Page 8

SAFETY

Read these assembly instructions through completely and understand them

before proceeding with the assembly of the equipement.

A safe and careful operator is the best operator. Safety is of primary importance to the manufacturer and should be to the owner/operator. Most accidents can be avoided by being aware of

your equipment, your surroundings, and observing certain precautions. The first section of this

manual includes a list of Safety Messages that, if followed, will help protect the operator and

bystanders from injury or death. Read and understand these Safety Messages before assembling, operating or servicing this Implement. This equipment should only be operated by those

persons who have read the Manual, who are responsible and trained, and who know how to do

so safely and responsibly.

The Safety Alert Symbol combined with a Signal Word, as seen below, is used throughout this

manual and on decals which are attached to the equipment. The Safety Alert Symbol means:

“ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!” The Symbol and Signal

Word are intended to warn the owner/operator of impending hazards and the degree of possible

injury faced when operating this equipment..

Practice all usual and customary safe working precautions and

above all---remember safety is up to YOU. Only YOU can prevent

serious injury or death from unsafe practices.

CAUTION! The lowest level of Safety Message; warns of possible injury. Decals

located on the Equipment with this Signal Word are Black and Yellow.

WARNING! Serious injury or possible death! Decals are Black and Orange.

DANGER! Imminent death/critical injury. Decals are Red and White. (SG-1)

© 2004 Alamo Group Inc.

Safety Section - 8

Page 9

SAFETY

PELIGRO!

Si no lee Ingles, pida ayuda a alguien que si lo lea para que le

traduzca las medidas de seguridad. (SG-3)

READ, UNDERSTAND, and FOLLOW the following Safety

Messages. Serious injury or death may occur unless care is

taken to follow the warnings and instructions stated in the Safety

Messages. Always use good common sense to avoid hazards.

(SG-2)

PELIGRO!

Si no lee Ingles, pida ayuda a alguien que

si lo lea para que le traduzca las medidas

de seguridad. (SG-3)

INSTRUCTIVO!

!LEA EL INSTRUCTIVO!

!

LEA EL

WARNING!

WARNING!

DANGER!

WARNING!

Perform service, repairs and lubrication according to the maintenance section. Ensure the unit

is properly lubricated as specified in the lubrication schedule and all bolts and nuts are properly

torqued. Failure to properly service, repair and maintain this Implement in good operating

condition could cause component failure and possible serious injury or even death. (SG-35)

Operate this Equipment only with a Tractor equipped with an

approved roll-over-protective system (ROPS). Always wear seat

belts. Serious injury or even death could result from falling off the

tractor--particularly during a turnover when the operator could be

pinned under the ROPS. (SG-7)

Never work under the Implement, the framework, or any lifted component unless the Implement is securely supported or blocked up to

prevent sudden or inadvertent falling which could cause serious injury

or even death. (SG-14)

Use caution and wear protective gloves when handling sharp objects such as blades, knives,

and other cutting edges. Be alert to worn component surfaces which have sharp edges. Sharp

surfaces can inflict severe laceration injuries if proper hand protection is not worn. (SG-37)

© 2004Alamo Group Inc.

Safety Section - 9

Page 10

SAFETY

WARNING!

WARNING!

WARNING!

Many of the parts are heavy and require lifting assistance. Do not try to

lift the heavy parts by yourself. Get help from another employee or from

an overhead crane.

The operator and all support personnel should wear hard hats,

safety shoes, safety glasses, and proper hearing protection at all

times for protection from injury including injury from items thrown by

the equipment. (SG-16)

Always wear safety shoes with steel toes when working on this equipment.

It is recommended that the safety shoes have metatarsal guards.

WARNING!

DANGER! Always disconnect the wire leads from the mower valve solenoid before

DANGER!

When welding use Welding hood with the appropriate OSHA required

protective lens, welding apron, and welding gloves.

performing service on the Tractor or Mower. Use caution when working

on the Tractor or Mower. Tractor engine must be stopped before

working on Mower or Tractor. The Mower Blades could inadvertently be

turned on without warning and cause immediate dismemberment, injury

or death. (SBM-12)

Never run the tractor engine in a closed building or without adequate

ventilation. The exhaust fumes can be hazardous to your health.

(SG-23)

Safety Section - 10

© 2004 Alamo Group Inc.

Page 11

SAFETY

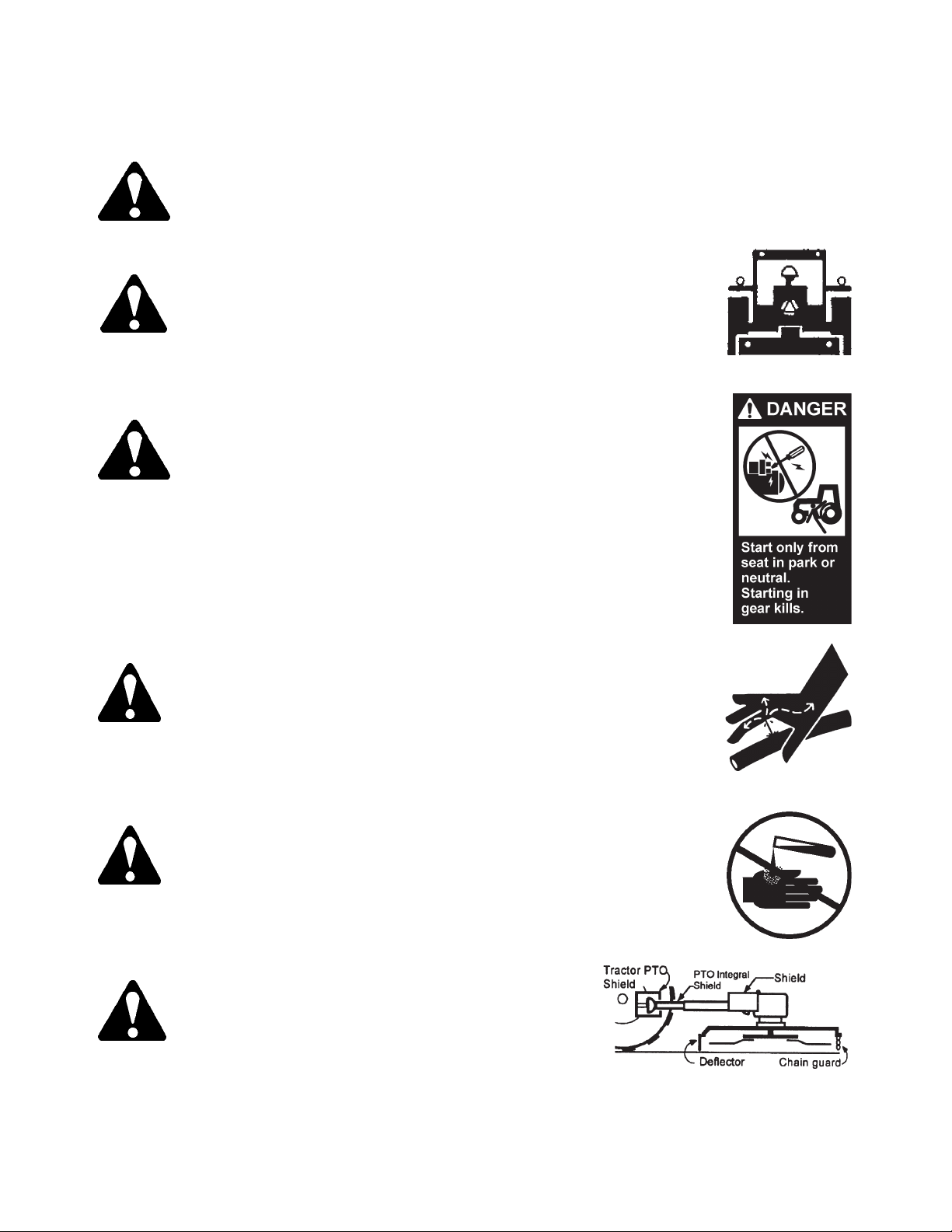

DANGER!

WARNING!

DANGER!

Before starting the mower make sure the area is clear and the floor has

been swept. The mower blade can throw objects several hundred feet.

Thrown objects could damge property or cause severe bodily injuries even

death.

Make certain that the “Slow Moving Vehicle” (SMV) sign is installed in

such a way as to be clearly visible and legible. When transporting the

Equipment use the Tractor flashing warning lights and follow all local traffic

regulations. (SG-6)

Start tractor only when properly seated in the Tractor seat. Starting a

tractor in gear can result in injury or death. Read the Tractor operators

manual for proper starting instructions. (SG-13)

DANGER!

WARNING!

DANGER! All Safety Shields, Guards and Safety devices including

Do not operate this Equipment with hydraulic oil leaking. Oil is

expensive and its presence could present a hazard. Do not check for

leaks with your hand! Use a piece of heavy paper or cardboard. Highpressure oil streams from breaks in the line could penetrate the skin

and cause tissue damage including gangrene. If oil does penetrate the

skin, have the injury treated immediately by a physician knowledgeable and skilled in this procedure. (SG-15)

Always read carefully and comply fully with the manufacturers instructions when handling oil, solvents, cleansers, and any other chemical

agent. (SG-22)

(but not limited to) - the Deflectors, Chain Guards, Steel

Guards, Gearbox Shields, PTO integral shields , and

Retractable Door Shields should be used and maintained in good working condition. All safety devices

should be inspected carefully at least daily for missing

or broken components. Missing, broken, or worn items

must be replaced at once to reduce the possibility of

injury or death from thrown objects, entanglement, or

blade contact. (SGM-3)

© 2004Alamo Group Inc.

Safety Section - 11

Page 12

SAFETY

DANGER!

DANGER! Operate the Tractor and/or Implement controls only while properly seated

WARNING!

NEVER use drugs or alcohol immediately before or while operating the

Tractor and Implement. Drugs and alcohol will affect an operator’s

alertness and coordination and therefore affect the operator’s ability to

operate the equipment safely. Before operating the Tractor or Implement, an operator on prescription or over-the-counter medication must

consult a medical professional regarding any side effects of the medication that would hinder their ability to operate the Equipment safely.

NEVER knowingly allow anyone to operate this equipment when their

alertness or coordination is impaired. Serious injury or death to the

operator or others could result if the operator is under the influence of

drugs or alcohol. (SG-27)

in the Tractor seat with the seat belt securely fastened around you.

Inadvertent movement of the Tractor or Implement may cause serious

injury or death. (SG-29)

Engine Exhaust, some of its constituents, and certain vehicle

components contain or emit chemicals known to the state of

California to cause cancer and birth defects or other

reproductive harm. (SG-30)

WARNING!

WARNING!

WARNING!

WARNING!

Battery posts, terminals and related accessories contain lead

and lead compounds, chemicals known to the state of California to cause cancer and birth defects or other reproductive

harm. Wash Hands after handling. (SG-31)

Use extreme caution when getting onto the Implement to perform repairs, maintenance and

when removing accumulated material. Only stand on solid flat surfaces to ensure good footing.

Use a ladder or raised stand to access high spots which cannot be reached from gound level.

Slipping and falling can cause serious injury or death. (SG-33)

Avoid contact with hot surfaces including hydraulic oil tanks, pumps, motors, valves and hose

connections. Relieve hydraulic pressure before performing maintenance or repairs. Use

gloves and eye protection when servicing hot components. Contact with a hot surface or fluid

can cause serious injury from burns or scalding. (SG-34)

Avoid contact with hot surfaces of the engine or muffler. Use gloves and eye protection when

servicing hot components. Contact with a hot surface or fluid can cause serious injury from

burns or scalding. (SG-38)

© 2004 Alamo Group Inc.

Safety Section - 12

Page 13

ST15 / ST10

Flex Wing Rotary

ARCHIVE BOOK

ST15 Archive Book

This is a complete listing of Parts from the first Unit to the Present (or end of model

production). The Production Dates, Serial Numbers, Special Notes and Descriptions are

furnished to help find Replacement Parts. Dimension (if listed) are for Identification of Parts

and MAY NOT be to Manufacturing Specification, Your measurements may vary some

from dimensions listed. Some Parts may be changed and be different than parts listed.

Some Modification may be required when replacing older parts. Match S/N' and Ship

Dates if available.

ID The ST15 (Jan 2002 to Current)

The ST10 & ST15 was built from Jan. 2002 (s/n

Current) .

Serial Numbers:

See The Index Pages for an explanation on of how to identify your unit by the 12 digit serial number

code, The Serial number code shows manufacturing production date of your unit.

Gearboxes:

The best way to ID the ST10 & ST15 (Stingray Model) is by the Gearboxes, This is a 4 Gearbox

Model (Divider and Center Blade Gearbox two separate gearboxes). The Divider gearbox has a 1-3/

8" X 21 Spline Output Shafts. The Blade Gearbox (Center & Wings) has a long section of the Housing

that protrudes below where it bolts to the deck. The Blade Gearbox has a Dip-Stick type top Plug. The

Blade Carrier Retaining Nut used a Cone Shaped Washer which no other model has to this time.

Blade Carriers:

The Blade Carriers are a Round Shaped Pan Weldment. The Blade Bolts are a Shouldered Blade

Bolt, and a bushing is used with the Blade Bolt. This was not the only 4 gearbox model that had a Shoulder

Blade Bolt but is the only model to use a bushing with the Shoulder Bolt.

Driveline Options:

There were no Driveline size options, There was a Cat IV (4) Wing Drivelines and a Cat V (5)

PTO Driveline used on this model. Some parts will not interchange between drivelines. See Part numbers

for interchangeable parts.

ST15-C31200557203) to Current (s/nST-

Axles:

The axles are Independent from center to wings. The type Hydraulic Axle lift is a Phasing (Slave)

Cylinder system, the Hydraulic lift of the mower is done by using 3 hydraulic Cylinders mounted one in

the center and one on each wing. The Cylinders are connected together into one Hydraulic flow in series.

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

13

Page 14

Jan. 2002

to

Oct. 2003

37,38,39

DECK COMPONENTS

Center Section

ST15 / ST10

32,33

ST15-C31200557203

to

ST15-C31200789311

9,21,22

20,23

23,36

21,24,25,

26,40,41

27

3,4,31

2,5,6

34,35

10,11,12,13,14,15,

10,12,13,14,15,16

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

17

18

14

19

9

25

4,7,8

28,29,30

2,4,5,6

Page 15

Jan. 2002

to

Oct. 2003

DECK COMPONENTS

Center Section

ST15-C31200557203

ST15-C31200789311

ST15 / ST10

Item Part No. Qty. Description

1 02978500 1 Center Section Asy

2 02978501 2 Hose Organizer

3 00755082 6 Bolt

4 000944 16 Lock Nut

5 00008300 2 Bolt

6 15B1200 2 Flat Washer

7 02978502 2 Skid Mount Asy

8 02975147 4 Bolt

9 02978503 2 Wing Lift Spacer Plate

10 02891800 2 Bolt

11 02978504 1 Retainer Pin, Long Center Pin

12 15B800 3 Flat Washer

13 00001800 3 Lock Nut

14 15B1600 3 Flat Washer

15 01408S 3 Roll Pin

16 02978505 2 Retainer Pin, Outer Pins

17 02959332 2 Bolt

18 02978506 1 Cylinder Lug Adj. Asy.

19 02978507 1 Spacer Plate

02978508 1 Spacer Plate

20 02978509 2 Wing Lock Pin,

21 02957042 4 Bolt

22 15B600 4 Flat Washer

23 02978510 3 Lynch Pin

24 02978511 1 Slow Moving Vehicle Sign Stand

25 00015800 8 Lock Nut

26 00753642 2 Bolt

27 00037200 2 Lock Nut

28 02978512 1 Bolt Access Cover Plate

29 00012101 2 Lock Washer

30 10180500 2 Bolt

31 02978513 1 Gearbox Asy, CW, 540 RPM

02978971 1 Gearbox Asy, CW, 1000 RPM

32 10180500 2 Bolt

33 02978915 1 SMV Sign

34 02978514 1 Gearbox Asy, Divider, 540 RPM

02978968 1 Gearbox Asy, Divider,1000 RPM

35 00753753 4 Bolt

36 02978515 1 Transport Lock Pin

37 02978516 1 Operator / Parts Manual Box

38 00024100 2 Flat Washer

39 10058000 2 Bolt

40 02962363 2 Lock Nut

41 02978638 1 Hose Clamp

to

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

15

Page 16

Nov. 2003

to

Current

37,38,39

DECK COMPONENTS

Center Section

ST15 / ST10

32,33

ST15-C31200790311

to

ST15-Current

9,21,22

20,23

23,36

21,24,25,

26,40,41

27

3,4,31

2,5,6

34,35

10,11,12,13,14,15,

10,12,13,14,15,16

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

17

16

18

19

9

25

4,7,8

28,29,30

2,4,5,6

Page 17

Nov. 2003

to

Current

DECK COMPONENTS

Center Section

ST15-C31200790311

ST15-Current

ST15 / ST10

Item Part No. Qty. Description

1 02978500 1 Center Section Asy

2 02978501 2 Hose Organizer

3 00755082 6 Bolt

4 000944 16 Lock Nut

5 00008300 2 Bolt

6 15B1200 2 Flat Washer

7 02978502 2 Skid Mount Asy

8 02975147 4 Bolt

9 02978503 2 Wing Lift Spacer Plate

10 02891800 2 Bolt

11 02978504 1 Retainer Pin, Long Center Pin

12 15B800 3 Flat Washer

13 00001800 3 Lock Nut

14 15B1600 3 Flat Washer

15 01408S 3 Roll Pin

16 02978505 2 Retainer Pin, Outer Pins

17 03200369 2 Bolt, (Light Truck Tire)

02959332 2 Bolt, (Laminated & Aircraft Tire)

18 02978506 1 Cylinder Lug Adj. Asy.

19 02978507 1 Spacer Plate, (Light Truck Tire)

02978508 1 Spacer Plate, (Laminated & Aircraft Tire)

20 02978509 2 Wing Lock Pin,

21 02957042 4 Bolt

22 15B600 4 Flat Washer

23 02978510 3 Lynch Pin

24 02980471 1 Slow Moving Vehicle Sign Stand

25 00015800 8 Lock Nut

26 00753642 2 Bolt

27 00037200 2 Lock Nut

28 02978512 1 Bolt Access Cover Plate

29 00012101 2 Lock Washer

30 10180500 2 Bolt

31 02978513 1 Gearbox Asy, CW, 540 RPM

02978971 1 Gearbox Asy, CW, 1000 RPM

32 10180500 2 Bolt

33 03200347 1 SMV Sign

34 02978514 1 Gearbox Asy, Divider, 540 RPM

02978968 1 Gearbox Asy, Divider,1000 RPM

35 00753753 4 Bolt

36 02978515 1 Transport Lock Pin

37 02978516 1 Operator / Parts Manual Box

38 00024100 2 Flat Washer

39 10058000 2 Bolt

40 02962363 2 Lock Nut

41 02978638 1 Hose Clamp

to

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

17

Page 18

Jan. 2002

to

Current

DECK COMPONENTS

Wing Section

ST15 / ST10

17

16

18

ST15-C31200557203

to

ST15-Current

38

13

12

1

11

20

14

19

37

21

17

22

18

89

7

2

10

9

32

3

5

4

2

7

33

8

7

8

3

2

17

35

8

28

36

25

24

26

23

36

27

6

2

2

15

30

31

29

28

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

18

Page 19

Jan. 2002

to

Current

DECK COMPONENTS

Wing Section

ST15-C31200557203

to

ST15-Current

ST15 / ST10

Item Part No. Part No. Qty. Description

R-Wing L-Wing

1 02978517 ------------- 1 Wing Asy, R-Wing (Shown)

------------- 02978532 1 Wing Asy, L-Wing (Not Shown

2 02978518 02978518 4 Hinge Pin

3 02978519 02978519 2 Hinge Spacer Tube

4 00749017 00749017 8 Lock Nut

5 10121000 10121000 8 Bolt

6 02978520 02978520 1 Hinge Spacer Tube

7 01408S 01408S 5 Roll Pin

8 15B1600 15B1600 6 Flat washer

9 02978521 02978521 2 Pin

10 02978522 02978522 2 Floating lug

11 000944 000944 6 Lock Nut

12 00755082 00755082 6 Bolt

13 02978523 ------------- 1 Gearbox, CCW R-Wing

------------ 02978533 1 Gearbox, CW L-Wing

14 2A381312 2A381312 3 Plow Bolt

16 02978525 02978525 1 Skid Shoe, L or R Wing

17 00001800 00001800 10 Lock Nut

18 15B800 15B800 10 Flat Washer

19 02978795 02978795 1 Lock Washer

20 331212C 331212C 2 Half Nut

21 02978526 02978526 1 Retainer Pin

22 02892000 02892000 1 Bolt

23 02978527 02978527 1 Clevis Pin

24 02959332 02959332 1 Bolt

25 02978528 02978528 1 Wheel Suspension Plate, Standard

26 00751035 00751035 1 Rubber Sandwich

27 02978529 02978529 1 Wing Wheel Standard Asy.

28 00037200 00037200 5 Lock Nut

29 03200269 03200269 2 Bolt

30 00755153 00755153 1 Cotter Pin

31 001291 001291 1 Grease Nipple, Self tap

32 02978512 02978512 1 Bolt Access Cover Plate

33 00012101 00012101 2 Lock Washer

34 10180500 10180500 2 Bolt

35 02978530 02978530 1 Wing Adj. Assy.

36 00011800 00011800 2 Bolt

37 02776600 02776600 6 Bolt

38 02978531 ------------- 1 Adjustable Side Mount, R-Wing

------------- 02978534 1 Adjustable Side Mount, L-Wing

Note: Qty Shown above is for one Wing, double qty of parts for both wings w/ the exception

of items 1, 13 & 38 which must be used on a specific wing.

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

19

Page 20

Jan. 2002

to

Current

14

SKIRT ASY

ST10

8

ST15-C31200557203

to

ST15-Current

1,3,7

2,3,7

4

10

1,3,7,11

5

19

12

13

9

16

21,23

17,18,20,22

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

3,7,15

20

Page 21

Jan. 2002

to

Current

SKIRT ASY

ST10

Item Part No. Qty. Description

1 02891800 2 Bolt

2 02892000 2 Bolt

3 15B800 9 Flat washer

4 02978551 1 Chain guard, double

5 250-145 2 Bolt

7 00001800 9 Lock nut

8 02978552 1 Hinge pin

9 02030300 4 Lock nut

10 02978553 1 Skirt Assy, 10' Unit Only

11 02978554 1 Hinge pin

12 02978555 2 Counter weight

13 15B1600 4 Flat washer

14 00755305 2 Bolt

15 2A381312 5 Plow bolt,

16 02978556 1 Skirt skid

17 00015800 3 Lock nut

18 02978557 3 Chain, 11 links

19 02975147 4 Bolt

20 15B600 3 Flat washer

21 15B1200 4 Flat washer

22 00752675 3 Bolt

23 000944 4 Lock nut

ST15-C31200557203

ST15-Current

to

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

21

Page 22

Jan. 2002

to

Current

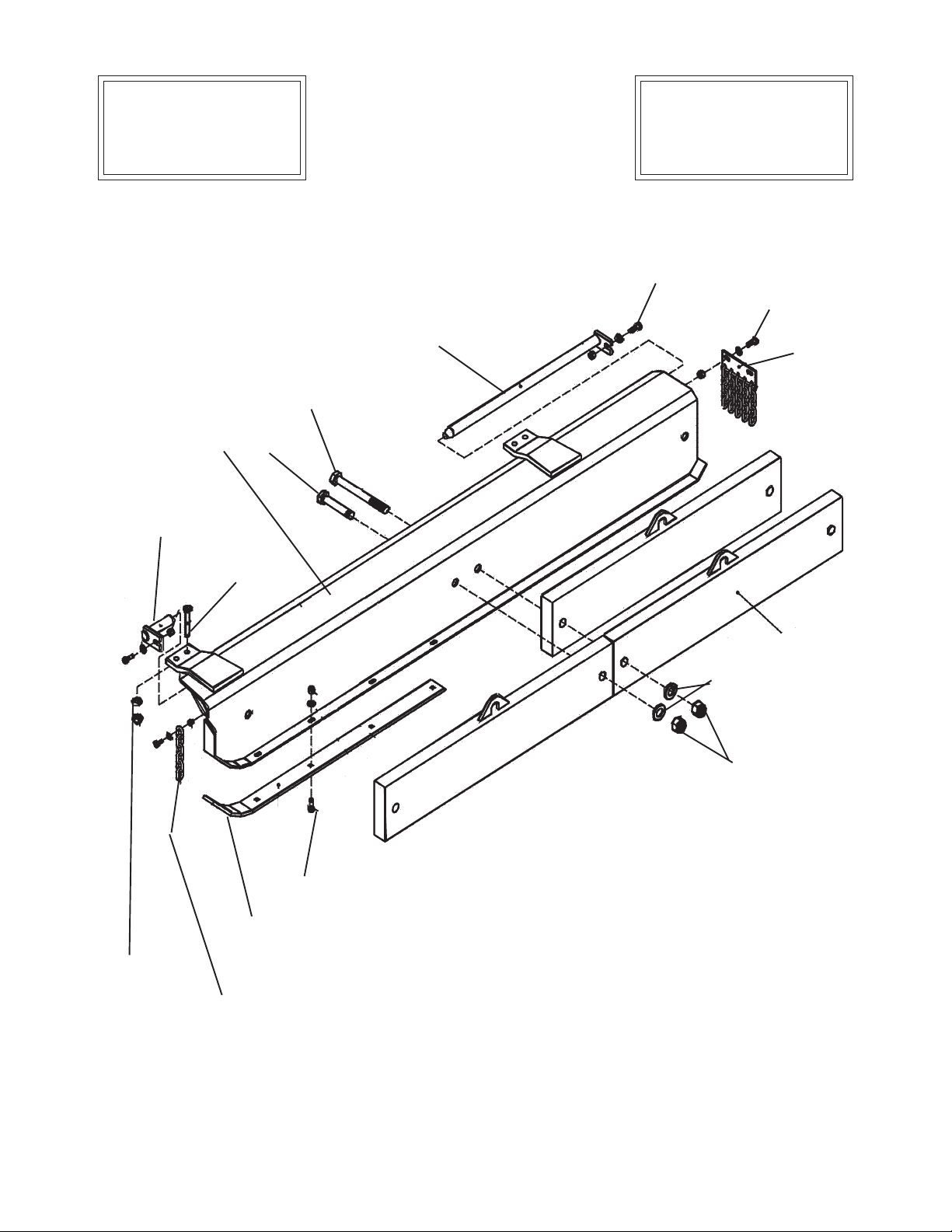

TONGUE ASY.

ST15 / ST10

15 14

ST15-C31200557203

to

ST15-Current

1

3

5

2

4

16

13

9

10

8

9

7

6

2

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

11

12

1

8

7

22

Page 23

Jan. 2002

to

Current

TONGUE ASY.

ST15-C31200557203

ST15 / ST10

Item Part No. Qty. Description

1 15B1600 3 Flat Washer

2 01408S 3 Roll Pin

3 02978536 1 Hitch Clevis, Standard Clevis

4 02978537 1 Pivoting Hitch Asy.

5 02978538 1 Pivot Hitch Weld Sleeve

6 02891800 1 Bolt

7 15B800 3 Flat Washer

8 00001800 3 Lock Nut

9 001291 6 Grease Fitting

10 02978539 1 Hitch Frame Assy.

11 02978540 2 Retaining Pin

12 02892000 2 Bolt

13 02978547 1 Retaining Pin

14 02978548 1 PTO Storage Support

15 02978549 1 Bent Hitch Pin

16 02978550 1 Hitch Pin Clip

to

ST15-Current

Note: Item # 3 is the standard Tongue Hitch Clevis , there is an Optional Hitch Clevis

offered called Precision Hitch Kit # 02978611. See Parts break down for this optional

hitch.

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

23

Page 24

Jan. 2002

to

Current

PRECISION HITCH

OPTION

ST15 / ST10

2, 12

ST15-C31200557203

to

ST15-Current

3

Tractor Draw Bar

1

7

10

11

4

6

5

6

8

13

9

Iten Part No. Qty. Description

1 00752405 2 Bolt

2 02892000 1 Bolt

3 02010800 1 Bolt

4 02978608 1 Drawbar Clevis Top

5 02978609 1 Hitch Tongue

6 00003500 3 Grease Nipple

7 02978610 1 Spacer

8 02978612 1 Drawbar Clevis Base

9 02978796 1 Lock Nut

10 02978613 1 Clamp Bar

11 00037200 2 Lock Nut

12 00001300 1 Lock Washer

13 00036900 1 Cotter Pin

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

02978611 -- Precision Hitch Kit (Optional)

24

Page 25

Jan. 2002

to

Current

PARKING JACK

ST15 / ST10

ST15-C31200557203

to

ST15-Current

14

15

16

1

3

6

2

7

4

5

8

10

9

11

12

13

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

Item Part No. Qty Description

02979699 -- Parking Jack Asy.

1 02979700 1 Cover

2 02979701 2 Bushing

3 02979702 2 Gear

4 02979703 2 Carriage Bolt

5 40010000 2 Cotter Pin

6 02979704 1 Dowel

7 02979705 1 Handle

8 00024000 1 Nut

9 02979706 1 Body

10 02979707 1 Pin

11 02979708 1 Bearing

12 02979709 1 Washer

13 02979710 2 Nut

14 02979711 1 Dowel

15 02979712 1 Screw

16 02979713 1 Leg

25

Page 26

Jan. 2002

to

Current

AXLE - CENTER

ST15 / ST10

1

ST15-C31200557203

to

ST15-Current

7

6

5

4

2

3

8

7

9

Item Part No. Qty. Description

1 00755153 3 Cotter Pin

2 15B1600 2 Flat Washer

3 02978527 1 Clevis Pin

4 02978542 2 Compression Spring

5 02959332 1 Bolt

6 02978543 1 Suspension Top Plate

7 00037200 5 Lock Nut

8 02978546 1 Center Section Wheel Standard

9 03200269 4 Bolt

12

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

26

Page 27

7

Jan. 2002

to

Current

CONTRL ROD

ST15 / ST10

4

ST15-C31200557203

to

ST15-Current

1

2

2

3

6

2

1

5

8

2

Item Part No. Qty Description

1 00755153 3 Cotter Pin

2 15B1600 13 Flat Washer

3 02978535 2 Clevis Pin

4 02978541 2 Lift Rod

5 02978544 2 Leveling Rod Lug

6 00059500 2 Nut

7 23511000 2 Half Nut

8 02978545 2 Clevis Pin

Note: Qty listed is for two control rods, left & Right side.

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

27

Page 28

Jan. 2002

to

Current

20

19

TIRES & WHEELS

ST15 / ST10

1

23

3

2

4

5

6

ST15-C31200557203

to

ST15-Current

7

8

10

24

26

21

25

22

21

18

25

26

17

16

15

14

9

11

12

13

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

28

Page 29

Jan. 2002

to

Current

TIRES & WHEELS

ST15 / ST10

Item Part No. Qty. Description

1 02978573 1 Spindle, w/ #9, 15, 16, Double End

1 02978574 1 Spindle, w/ #9, 15, 16, Single End

2 02978575 1 Seal

3 02978576 1 Bearing

4 02978577 1 Race

5 001291 1 Grease Fitting

6 02978578 1 Hub, w/ Bearing Cups

7 02978579 1 Race

8 02978580 1 Bearing

9 000163 1 Cotter Pin

10 02978930 1 Wheel 15”

11 02978931 1 Valve Stem

12 02978932 1 Tire

13 00749171 5 Wheel Bolt

14 02978581 1 Dust Cap

15 5E12160 1 Castle Nut

16 02978582 1 Machine Bushing

17 10180500 5 Bolt

18 02978797 1 Tire, Solid Laminated, Complete

19 00012101 5 Lockwasher

20 00013901 5 Nut

21 02978798 2 Wheel Half, 6 x 9, 5 Bolt

22 02978799 1 Tire, Solid Laminated, 6 x 9

23 02978583 1 Hub, Includes #2-8 & 14 1

23 02978584 1 Bearing Kit, Includes #2, 3, 4, 7, 8, 14, 16

24 02978800 1 Aircraft Tire 22 x 6.6 x 10 Complete

02978801 Tube & Liner For #02978800

25 00001300 5 Lockwasher

26 00749171 5 Bolt

ST15-C31200557203

to

ST15-Current

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

29

Page 30

Jan. 2002

to

Current

TIRES & WHEELS

ST15 / ST10

ST15-C31200557203

to

ST15-Current

WHEEL ATTACHMENT

Laminated Tire and Wheels:

Attach the wheels to the hubs. If puncture-proof, Laminated Tires and Wheels are used,

be sure the flat side of the nut is against the Wheel. Tighten wheel bolts to 85 ft/lbs. Note

direction of travel and curvature of rubber segments in tire and install as shown below to

give longest tire life.

Note Segment

Place Flat Side of Lug

Nut against Wheel

Segmented Tire

Direction of travel

Curvature

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

30

Page 31

Jan. 2002

to

Current

TIRES & WHEELS

ST15 / ST10

ST15-C31200557203

to

ST15-Current

Adjust the Spindle for Trailing Width,

Adjust Center axle Spindles for Width:

When the Spindles a re installed and mower is being readied for use. The Spindles in the

Center Axle need to be adjusted to give the desired trailing width, this determines where

the Wheels runn inline with the mower and the wheel track width. this will need to be done

once and should not change unless it is unbolted and moved.

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

31

Page 32

Jan. 2002

to

Current

PTO DRIVELINE

540 RPM Cat V

ST15 / ST10

ST15-C31200557203

to

ST15-Current

6,9

1,2

17

3

1,2

16

8

7

4

5

10

12

14,15

25

24

23

26

18

20

19

11

21

13

27

22

28

Item Part No. Qty. Description

02978692 1 Driveline Asy. (540)

1 02978663 3 Grease Fitting

2 02978664 2 Universal Joint

3 02978665 1 Double Yoke

4 02978666 1 Shield support

5 02978667 1 Grease Fitting

6 02978668 1 Yoke, w/ QD Collar

7 02978669 1 Yoke & Sleeve Asy.

8 02978670 1 Shaft Asy, Outer

9 02978671 1 QD Collar Kit, Plastic

02978672 1 QD Collar Kit, Steel

10 02978673 1 Shaft, Splined

11 02978674 1 Roll Pin

12 02978675 1 Yoke, Inner

13 02978676 1 Universal Joint

NOTE: This is a Cat 5 Driveline used on 540 RPM Model and Some parts will not interchange

wth the Cat 4 used on the 1000 RPM Model. Check part numbers for intrchangable parts.

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

Item Part No. Qty. Description

14 02978677 1 Yoke

15 02978678 2 Bolt & Nut

16 02978679 1 Male Shaft Asy.

17 02978680 1 Cone Asy.

18 02978681 1 Bearing

19 02978682 1 Retaining Collar

20 02978683 1 Outer Cone

21 02978684 1 Shield, Outer

22 02978685 1 Shield, Inner

23 02978709 6 Bolt, Wing D/L

24 02978687 1 Inner Cone

25 02978688 1 Retaining Collar

26 02978689 6 Screw

27 02978690 1 Safety Chain

28 02978691 1 Shield Asy, Complete

32

Page 33

Jan. 2002

to

Current

PTO DRIVELINE

1000 RPM Cat IV

ST15 / ST10

ST15-C31200557203

to

ST15-Current

6,9

1,2

17

3

1,2

16

8

7

4

5

10

12

14,15

25

24

23

26

18

20

19

11

21

13

27

22

28

Item Part No. Qty. Description

02978949 1 Driveline Asy. (1000)

1 02978663 3 Grease Fitting

2 02978950 2 Universal Joint

3 02978951 1 Double Yoke

4 02978952 1 Shield support

5 02978667 1 Grease Fitting

6 02978953 1 Yoke, w/ QD Collar

7 02978954 1 Yoke & Sleeve Asy.

8 02978955 1 Shaft Asy, Outer

9 02978671 1 QD Collar Kit, Plastic

02978672 1 QD Collar Kit, Steel

10 02978956 1 Shaft, Splined

11 02978957 1 Roll Pin

12 02978958 1 Yoke, Inner

13 02978696 1 Universal Joint

NOTE: This is a Cat 4 Driveline used on 1000 RPM Model and Some parts will not interchange

wth the Cat 5 used on the 540 RPM Model. Check part numbers for intrchangable parts.

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

Item Part No. Qty. Description

14 02978959 1 Yoke

15 02978678 2 Bolt & Nut

16 02978960 1 Male Shaft Asy.

17 02978961 1 Cone Asy.

18 02978962 1 Bearing

19 02978707 1 Retaining Collar

20 02978963 1 Outer Cone

21 02978964 1 Shield, Outer

22 02978965 1 Shield, Inner

23 02978709 6 Bolt, Wing D/L

24 02978966 1 Inner Cone

25 02978713 1 Retaining Collar

26 02978689 6 Screw

27 02978690 1 Safety Chain

28 02978967 1 Shield Asy, Complete

33

Page 34

Jan. 2002

to

Current

WING DRIVELINE

Cat IV (540 or 1000)

ST15 / ST10

2

5

ST15-C31200557203

to

ST15-Current

1

12

10

9

67

14

5

11

4

15

8

18

3

17

20

22

21

19

16

Item Part No. Qty. Description

02978693 1 Driveline Asy. Wing

1. 02978705 1 Driveline Half Asy.

Clamp Yoke End

2. 02978706 1 Driveline Half Asy,

Clutch End

3 02978694 4 Bolt & Nut

4 02978695 1 Cllamp Yoke

5 02978696 2 Universal Joint

6 02978697 1 Yoke, Outer

7 02978698 1 Roll pin

8 02978699 1 Shield Support

9 02978700 1 Tube, Outer

10 02978701 1 Tube, Inner

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

Item Part No. Qty. Description

11 02978702 1 Roll Pin

12 02978703 1 Yoke, Inner

13 02978667 1 Grease Fitting

14 02978704 1 Clutch Asy

15 02978663 2 Grease Fitting

16 02978707 1 Retaining Collar

17 02978708 1 Outer Cone

18 02978709 6 Bolt

19 02978710 1 Shield Asy, Outer

20 02978711 1 Shield Asy, Inner

21 02978712 1 Clutch Cone

22 02678713 1 Retaining Collar

34

Page 35

Jan. 2002

to

Current

INTERMEDIATE

DRIVELINE

Cat IV (540 or 1000)

ST15 / ST10

3

5

ST15-C31200557203

to

ST15-Current

4

3

7

6

12

8

9

Item Part No. Part No. Qty. Description

540 RPM 1000 RPM

02978714 -------------- -- Driveline Asy, 540 RPM

------------- 02978993 -- Driveline Asy, 1000 RPM

1 02978694 02978694 1 Bolt & Nut

2 02978695 02978695 1 Clamp Yoke

3 02978696 02978696 2 Universal Joint (X-Kit)

4 02978716 02978716 1 Yoke, Pin Yoke

5 02978715 02978715 1 Yoke, Slip Yoke

6 02978717 02978717 1 Splined shaft

7 02978718 02978718 1 Spring Dowel Pin

8 02978663 02978663 2 Grease Fitting

9 02978704 ------------- 1 Slip Clutch Asy, 540 RPM

------------ 02978974 1 Slip Clutch Asy, 1000 RPM

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

35

Page 36

Jan. 2002

4

4

4

4

4

4

4

4

4

4

4

3

3

3

3

3

to

Current

8

SLIP CLUTCH

ST15-C31200557203

to

Cat IV (540 RPM)

ST15-Current

ST15 / ST10

3

10

5

6

7

2

4

2

23

23

1

9

9

23

23

23

23

23

23

23

23

23

1-1/4"

2

2

2

2

2

Iten Part No. Qty. Description

02978704 - Clutch Asy, Center or Wing 540 RPM

1 02978694 1 Bolt & nut

2 02978719 8 Spring

3 02978720 1 Flanged yoke

4 02978721 1 Bushing

5 00754202 2 Lining ring

6 02978723 1 Flange hub, 1 3/8x21

7 02978724 1 Inner plate

8 02978725 1 Pressure plate

9 02978726 8 Bolt & nut

NOTE: To adjust this Slip Clutch tighten Bolts, (item 9) untill Springs, (item 2) are a

compressed length of 1-1/4" as shown in drawing above. When tightening use an

alternating pattern in a cris-cross pattern.

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

36

Page 37

Jan. 2002

4

4

4

4

4

4

4

4

4

4

4

3

3

3

3

3

3

to

Current

8

SLIP CLUTCH

ST15-C31200557203

to

Cat IV (1000 RPM)

ST15-Current

ST15 / ST10

3

10

5

6

7

2

4

2

23

1

9

23

23

23

23

23

23

23

23

23

23

2

2

2

9

1-1/4"

Item Part No. Part No Qty. Description

Center Wings

02978974 ------------- - Slip Clutch Asy, Center 1000 RPM

------------ 02878704 -- Slip Clutch Asy. Wing 1000 RPM

1 02978694 02978694 1 Bolt & nut

2 02978975 02978719 8 Spring

3 02978976 02978720 1 Flanged yoke

4 02978977 02978771 1 Bushing

5 02978978 00754202 2 Lining ring

6 02978979 02978723 1 Flange hub, 1 3/8x21

7 ------------- ------------ n/a Not used on Asy # 02978974 at all

------------- 02978724 1 Inner Plate used on Wings Only

8 02978991 02978725 1 Pressure Plate

9 02978980 02978726 8 Bolt & nut

2

2

2

NOTE: To adjust this Slip Clutch tighten Bolts, (item 9) untill Springs, (item 2) are a

compressed length of 1-1/4" as shown in drawing above. When tightening use an

alternating pattern in a cris-cross pattern.

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

37

Page 38

Jan. 2002

to

Current

GEARBOX ASY.

DIVIDER

ST15 / ST10

ST15-C31200557203

to

ST15-Current

3

1

2

4

5

6

6

24

23

21

7

20

15

16

17

22

1-3/8" X 21 Spline

7

8

9

10

11

12

9

13

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

19

18

17

38

16

15

8

9

10

11

12

9

13

14

Page 39

Jan. 2002

to

Current

GEARBOX ASY.

ST15-C31200557203

DIVIDER

ST15-Current

ST15 / ST10

Item Part No. Part No. Qty. Description

540 RPM 1000 RPM

02978514 ----------- -- Gearbox Asy, Divider, 540 RPM

------------- 02978968 - Gearbox Asy, Divider 1000 RPM

1 02978727 02978727 1 Oil Filler Plug,

2 02978728 02978728 1 Cover

3 02978729 02978729 6 Bolt

4 02978730 02978730 6 Spring washer

6 02978731 02978731 2 Plug, Oil Level

7 02978732 02978732 2 Shaft, 1-3/8" X 21 Spline

8 02978733 02978733 2 Oil seal

9 02978734 02978734 4 Bearing

10 02978735 02978735 2 Internal Circlip

12 02978736 ------------- 2 Gear, 540 RPM

------------- 02978969 2 Gear, 1000 RPM

13 02978737 02978737 2 Shim Kit

14 02978738 02978738 1 Casing

15 02978739 0297839 2 Internal Circlip

16 02978740 02978740 2 Seal

17 02978741 02978741 2 Shim

18 02978742 02978742 1 Bearing

19 02978743 02978743 1 Shaft

20 02978744 02978743 1 Shoulder ring

21 02978742 02978742 1 Bearing

22 02978746 ------------- 1 Gear, 540 RPM

------------- 02978970 1 Gear, 1000RPM

23 000944 000944 4 Lock Nut

24 00753753 00753753 4 Bolt

to

NOTE: Gearbox Gear ratio 1000 RPM is 1.35 in : 1 out and a 540 RPM is 1 in : 1.35 out.

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

39

Page 40

Jan. 2002

to

Current

GEARBOX ASY.

CENTER DECK

ST15 / ST10

ST15-C31200557203

to

ST15-Current

17

5

21

1920

18

2

6

2

6

4

16

3

15

14

7

9

8

5

13

12

11

25

* Item 24, Coned Washer must install w/ Cone down as shown

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

1

10

23

24

26

22

40

Page 41

Jan. 2002

to

Current

GEARBOX ASY.

CENTER DECK

ST15-C31200557203

ST15-Current

ST15 / ST10

Item Part No. Part No. Qty Description

540 RPM 1000 RPM

02978513 ------------ - Gearbox Asy, 540 RPM

------------- 02978971 - Gearbox Asy, 1000 RPM

1 02978747 02978747 1 Casing

2 02978748 02978748 2 Bearing

3 02978733 02978733 1 Seal

4 02978749 02978749 1 Shaft, Input

5 02978750 02978750 2 Snap Ring

6 02978751 02978751 2 Shim

7 02978752 02978752 1 Cotter Pin

8 02978753 02978753 1 Nut

9 02978754 ------------- 1 Gear, 540 RPM

------------- 02978972 1 Gear, 1000 RPM

10 02978758 02978758 1 Shaft

11 02978755 02978755 1 Sealing lid

12 02978756 02978756 1 Seal

13 02978757 02978757 1 Bearing

14 02978759 02978759 1 Bearing

15 02978760 02978760 1 Shim

16 02978761 02978761 1 Shim

17 02978762 02978462 1 Cap

18 02978763 02978763 4 Bolt

19 02978764 02978764 1 Plug

20 02978765 02978765 1 Cover

21 02978766 ------------ 1 Gear, 540 RPM

------------- 02978973 1 Gear, 1000 RPM

22 02978571 02978571 1 Nut, Slotted

23 02978569 02978569 1 Flatwasher

24 02978769 02978769 1 Washer, Disc Spring (Coned)

25 02978770 02978770 1 Splined Hub (Ref Only - weld on part)

26 02978572 02978572 1 Cotter pin

to

NOTE: Gearbox Gear ratio 1000 RPM is 1.2 in : 1 out and a 540 RPM is 1 in : 1.5 out.

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

41

Page 42

Jan. 2002

to

Current

GEARBOX ASY.

RIGHT WING DECK

ST15 / ST10

ST15-C31200557203

to

ST15-Current

17

5

21

1920

18

2

6

2

6

4

16

3

15

14

7

9

8

5

13

12

11

25

* Item 24, Coned Washer must install w/ Cone down as shown

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

1

10

23

24

26

22

42

Page 43

Jan. 2002

to

Current

GEARBOX ASY.

RIGHT WING DECK

ST15 / ST10

Item Part No. Qty Description

02978523 - Gearbox Asy, 540 or 1000 RPM

1 02978747 1 Casing

2 02978748 2 Bearing

3 02978733 1 Seal

4 02978749 1 Shaft, Input

5 02978750 2 Snap Ring

6 02978751 2 Shim

7 02978752 1 Cotter Pin

8 02978753 1 Nut

9 02978772 1 Gear, 540 or 1000 RPM

10 02978758 1 Shaft

11 02978755 1 Sealing lid

12 02978756 1 Seal

13 02978757 1 Bearing

14 02978759 1 Bearing

15 02978760 1 Shim

16 02978761 1 Shim

17 02978762 1 Cap

18 02978763 4 Bolt

19 02978764 1 Plug

20 02978765 1 Cover

21 02978773 1 Gear, 540 or 1000 RPM

22 02978571 1 Nut, Slotted

23 02978569 1 Flatwasher

24 02978769 1 Washer, Disc Spring (Coned)

25 02978770 1 Splined Hub (Ref Only - weld on part)

26 02978572 1 Cotter pin

ST15-C31200557203

to

ST15-Current

NOTE: Gearbox Gear ratio 540 or 1000 RPM is the same, 1 in : 1.35 out, the gear ratio

between the 540 & 1000 RPM output will be determined by the Gear ratio of the divider

Gearbox. Right and Left Wing Gearboxes use the same components, it is where the Input

gear (item 21) & Top Cover (item 20) is installed that makes them different.

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

43

Page 44

Jan. 2002

to

Current

GEARBOX ASY.

LEFT WING DECK

ST15 / ST10

ST15-C31200557203

to

ST15-Current

17

5

16

19

18

2

6

20

21

2

6

4

3

7

5

15

14

9

8

13

12

23

11

25

24

26

22

* Item 24, Coned Washer must install w/ Cone down as shown

1

10

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

44

Page 45

Jan. 2002

to

Current

GEARBOX ASY.

LEFT WING DECK

ST15 / ST10

Item Part No. Qty Description

02978533 - Gearbox Asy, 540 or 1000 RPM

1 02978747 1 Casing

2 02978748 2 Bearing

3 02978733 1 Seal

4 02978749 1 Shaft, Input

5 02978750 2 Snap Ring

6 02978751 2 Shim

7 02978752 1 Cotter Pin

8 02978753 1 Nut

9 02978772 1 Gear, 540 or 1000 RPM

10 02978758 1 Shaft

11 02978755 1 Sealing lid

12 02978756 1 Seal

13 02978757 1 Bearing

14 02978759 1 Bearing

15 02978760 1 Shim

16 02978761 1 Shim

17 02978762 1 Cap

18 02978763 4 Bolt

19 02978764 1 Plug

20 02978765 1 Cover

21 02978773 1 Gear, 540 or 1000 RPM

22 02978571 1 Nut, Slotted

23 02978569 1 Flatwasher

24 02978769 1 Washer, Disc Spring (Coned)

25 02978770 1 Splined Hub (Ref Only - weld on part)

26 02978572 1 Cotter pin

ST15-C31200557203

to

ST15-Current

NOTE: Gearbox Gear ratio 540 or 1000 RPM is the same, 1 in : 1.35 out, the gear ratio

between the 540 & 1000 RPM output will be determined by the Gear ratio of the divider

Gearbox. Right and Left Wing Gearboxes use the same components, it is where the Input

gear (item 21) & Top Cover (item 20) is installed that makes them different.

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

45

Page 46

Jan. 2002

to

Current

6

9

20

GEARBOX SHIELDS

ST15 / ST10

6

9

4

16

15

8

ST15-C31200557203

to

ST15-Current

1

4

22

7

2

21

22

5

14

7

2

2

22

23

18

12

11

22

7

2

10

8

4

17

9

16

6

19

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

46

Page 47

Jan. 2002

to

Current

GEARBOX SHIELDS

ST15 / ST10

Item Part No. Qty. Description

1 02978599 1 Center Section Shield Asy.

2 00011700 17 Lockwasher

4 02978510 3 Lynch Pin

5 02978600 1 Splitter Shield Mount

6 02978601 3 Shield Hinge Pin

7 02972026 15 Bolt

8 02978602 2 Splitter Shield Rest Bracket

9 40010000 6 Cotter Pin

10 02978514 1 Splitter Gearbox, 540 RPM

02978968 1 Splitter Gearbox, 1000 RPM

11 02978603 1 CenterGearbox Pivot Shield Mount

12 00015800 4 Lock Nut

13 15B600 4 Flatwasher

14 00059900 4 Bolt

15 02978604 1 Left Wing Gearbox Pivot Shield

16 02978605 2 Wing Gearbox Pivot Mount

17 02978606 1 Right Wing Gearbox Shield

18 02978513 1 540 RPM Gearbox, CW

02978971 1 1000 RPM Gearbox, CW

19 02978523 1 540 & 1000 RPM Gearbox, CCW

20 02978533 1 540 & 1000 RPM Gearbox, CW

21 00035900 2 Bolt

22 00023500 17 Flat washer

23 02978607 1 Shaft Cover Plastic, 10' Units Only

ST15-C31200557203

ST15-Current

to

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

47

Page 48

Jan. 2002

to

Current

BLADE CARRIERS

ST15 / ST10

ST15-C31200557203

to

ST15-Current

Left Wing

CW Rotation

7

6

Center Section

CW Rotation

7

1

6

3

2

8

4

12

5

13

15

14

11

8

10

2

Right Wing

CCW Rotation

4

9

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

48

Page 49

Jan. 2002

to

Current

BLADE CARRIERS

ST15 / ST10

Item Part No. Qty. Description

1 02978558 1 Blade Carrier & Pan,Center, (w/ item 3 & 6)

2 02978559 2 Blade Carrier & Pan, Wing, (w/ item 4)

3 02978560 1 Pan Only, Center Section Only

4 02978561 2 Pan Only, Left or Right Wing

5 02978562 2 Pan Reinforcements, Center Pan Only

6 02978563 6 Bushing, Blade Bolt

7 02978796 6 Locknut, f/ Blade Bolt

8 02978564 2 Blade, CW - Wing

9 02978565 2 Blade, CCW - Wing

10 02978566 2 Blade, CW - Center

11 02978567 6 Blade Bolt

02978568 6 Blade Bolt & Nut ( w/ item 7)

12 02978569 3 Flatwasher

13 02978570 3 Washer

14 02978571 3 Nut, Slotted

15 02978572 3 Cotter Pin

ST15-C31200557203

to

ST15-Current

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

49

Page 50

Jan. 2002

to

Current

BLADE CARRIER

ROTATION

ST15 / ST10

ST15 (15')

Center

Section

ST15-C31200557203

to

ST15-Current

Left

Wing

Right

Wing

ST10 (10')

Center

Section

Right

Wing

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

50

Page 51

Jan. 2002

to

Current

WINCH & STAND

ST15 / ST10

1

ST15-C31200557203

to

ST15-Current

10

5

11

2

3

4

5

8

7

15

14

14

9

6

12

13

Item Part N0. Qty Description

02978897 -- Winch & Stand Kit (Optional)

1 02978933 1 Winch, 1600 lb., 5.1:1 ratio

2 00753642 3 Bolt

3 15B600 3 Flat Washer

4 02978934 1 Cable

5 00015800 5 Lock Nut

6 02978935 1 Winch Lift Stand

7 02978936 1 Winch Lift Lug, Right

8 02978937 1 Winch Lift Lug, Left

9 02776600 4 Bolt

10 00001800 4 Lock Nut

11 10180500 2 Bolt

NOTE: Items 12 through 15 are not included in Winch Kit # 02978897, they are already on the Wing

Section of mower as part of Wing Axle. See Deck Components Section for these parts

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

51

Page 52

Jan. 2002

to

Oct. 2003

AXLE LIFT CYL.

SCHEMATIC

ST15 / ST10

ST15-C31200557203

to

ST15-C31200789311

14

13

7

21

7

10

11

23

14

7

18

20

19

19

4

22

1

17

4

18

3

13

24

25

21

9

2

14

7

13

21

13

14

14

8

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

52

Page 53

Jan. 2002

to

Oct. 2003

AXLE LIFT CYL.

ST15-C31200557203

SCHEMATIC

ST15-C31200789311

ST15 / ST10

Item Part No. Qty. Description

1 02978633 1 Hose Asy.

2 02978636 1 Cylinder Asy. Large Bore

3 02978637 1 Hose Assembly

4 02978638 6 Hose Clamp, Metal

7 02978616 5 Elbow

8 02978639 1 Cylinder Asy. Medium Bore

9 02978640 1 Hose Asy.

10 02978641 1 Cylinder Asy. Small Bore

11 02978642 1 Hose Asy.

13 00755153 6 Cotter Pin

14 02978527 6 Clevis Pin

17 02957042 1 Bolt

18 15B600 3 Flat Washer

19 00015800 3 Locknut

20 02978643 1 Elbow

21 02978655 3 Stroke Control Asy.

22 02978618 1 Restrictor

23 262-004 1 Roll Pin

24 C502-193 1 Cylinder Pin (Center)

25 C502-194 1 Cylinder Pin Sleeve

to

NOTE: These are Phasing (Slave) Cylinders and must be connected as shown, Large Bore

Cylinder, Medium Bore Cylinder and then Small Bore Cylinder. The Cylinders will have to be

free of Air, this means cylinders must be bled and remain an air tight system to prevent air

from entering cylinders. See Operators manual for procedures to connect these cylinders.

See drawing below shownig how oil is bypassed through the Cylinder to the next Cylinder

when Cylinders are stroked completly out.

Oil Flow

In

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

Cylinder Rod

Oil Flow

Out

Rephasing

Groove

Piston

53

Page 54

Nov. 2003

to

Current

AXLE LIFT CYL.

SCHEMATIC

ST15 / ST10

ST15-C31200790311

to

ST15-Current

14

13

7

21

7

10

11

23

14

7

18

20

19

19

4

22

1

17

4

18

3

13

24

25

21

9

2

14

7

13

21

13

14

14

8

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

54

Page 55

Nov. 2003

to

Current

AXLE LIFT CYL.

ST15-C31200790311

SCHEMATIC

ST15 / ST10

Item Part No. Qty. Description

1 02978633 1 Hose Asy.

2 02980479 1 Cylinder Asy. Large Bore

3 02978637 1 Hose Assembly

4 02978638 6 Hose Clamp, Metal

7 02978616 5 Elbow

8 02980480 1 Cylinder Asy. Medium Bore

9 02978640 1 Hose Asy.

10 02980481 1 Cylinder Asy. Small Bore

11 02978642 1 Hose Asy.

13 00755153 6 Cotter Pin

14 02978527 6 Clevis Pin

17 02957042 1 Bolt

18 15B600 3 Flat Washer

19 00015800 3 Locknut

20 02978643 1 Elbow

21 02978655 3 Stroke Control Asy.

22 02978618 1 Restrictor

23 262-004 1 Roll Pin

24 C502-193 1 Cylinder Pin (Center)

25 C502-194 1 Cylinder Pin Sleeve

to

ST15-Current

NOTE: These are Phasing (Slave) Cylinders and must be connected as shown, Large Bore

Cylinder, Medium Bore Cylinder and then Small Bore Cylinder. The Cylinders will have to be

free of Air, this means cylinders must be bled and remain an air tight system to prevent air

from entering cylinders. See Operators manual for procedures to connect these cylinders.

See drawing below shownig how oil is bypassed through the Cylinder to the next Cylinder

when Cylinders are stroked completly out.

Oil Flow

In

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

Cylinder Rod

Oil Flow

Out

Rephasing

Groove

Piston

55

Page 56

Jan. 2002

to

Oct. 2003

AXLE LIFT CYL.

ST15 / ST10

ST15-C31200557203

to

ST15-C31200789311

9

1

3

10

4

10

10

2

10

10

10

8

7

5

6

Item Part No. Part No. Part No. Qty Description

L-Wing R-Wing Center

1. 02978641 ------------ ------------- 1 Cyl. Asy. 3" Bore X 5" Stroke

------------- 02978657 ------------ 1 Cyl. Asy. 3-1/4" Bore X 5" Stroke

------------- ------------ 02978660 1 Cyl. Asy. 3-1/2" Bore X 5" Stroke

2. 02978650 02978657 02978661 1 Cyl. Barrell

3. 02978652 02978659 02978662 1 Piston

4. 02978653 02978653 02978653 1 Rod

5. 02978654 02978654 02978654 1 Rod Clevis

6. 02957042 02957042 02957042 1 Bolt

7. 00015800 00015800 00015800 1 Locknut

8. 02978655 02978655 02978655 1 Stroke Control Asy.

9. 02030300 02030300 02030300 1 Locknut

10. 02978656 02978689 02978990 1 Seal Kit

NOTE: These are Phasing Cylinders and must be connected in the correct

order to work correctly. Seal Kit components not available as single parts.

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

56

Page 57

Nov. 2003

to

Current

AXLE LIFT CYL.

ST15 / ST10

5

ST15-C31200790311

to

ST15-Current

3

2

1

11

4

8

7

Item Part No. Part No. Part No. Qty Description

L-Wing R-Wing Center

6

12

10

9

02980481 ------------ ------------- 1 Cyl. Asy. 3" Bore X 5" Stroke

------------- 02980480 ------------ 1 Cyl. Asy. 3-1/4" Bore X 5" Stroke

------------- ------------ 02980479 1 Cyl. Asy. 3-1/2" Bore X 5" Stroke

1. 02980482 02980489 02980494 1 Cyl. Barrell

2. 02980476 02980476 02980476 1 Piston Nut

3. 02980483 02980490 02980495 1 Piiston

4. 02980484 02980491 02980496 1 Wear Ring

5. 02980485 02980492 02980497 1 Seal Kit

6. 02980475 02980493 02980498 1 Gland

7. 02980486 02980486 02980486 1 Rod

8. 02978655 02978655 02978655 1 Stroke Control Asy.

9. 02980487 02980487 02980487 1 Jam Nut

10. 00750940 00750940 00750940 1 Nut

11. 00016200 00016200 00016200 1 Bolt

12. 02980488 02980488 02980488 1 Clevis End

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

57

Page 58

Jan. 2002

to

Nov. 2003

5

HYD SCHEMATIC

WING LIFT CYL.

ST15-C31200557203

to

ST15-C312007890311

ST15 / ST10

4

3

4

2

8

1

7

7

3

2

8

5

6

1

Item Part No. Qty Description

1 02978614 2 Cylinder Asy. 3" Bore x 12" Stroke

2 02978615 2 Breather, Filter

3 02978616 2 Elbow

4 02978617 2 Hose Asy.

5 02978618 2 Restrictor

6 02978527 2 Clevis Pin

7 00755153 2 Cotter Pin,

8 15B1600 2 Flatwasher

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

58

Page 59

Nov. 2003

to

Current

5

HYD SCHEMATIC

WING LIFT CYL.

ST15-C31200790311

to

ST15-Current

ST15 / ST10

4

3

4

2

8

1

7

7

3

2

8

5

6

1

ITEM PART NO. QTY. DESCRIPTION

1 02980472 2 Cylinder 3 x 12

2 02978615 2 Breather, filter

3 02978616 2 Elbow

4 02978617 2 Hose assembly

5 02978618 2 Restrictor

6 02978527 2 Clevis pin

7 00755153 2 Cotter pin,

8 15B1600 2 Flat washer

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

59

Page 60

Jan. 2002

to

Oct. 2003

WING LIFT CYL.

ST15 / ST10

ST15-C3120055203

to

ST15-C31200789311

5

1

3

6

4

6

6

6

6

2

6

Item Part No. Qty. Description

1 02978645 1 Barrel Weldment

2 02978646 1 Cylinder Head

3 02978647 1 Piston

4 02978648 1 Rod

5 02030300 1 Locknut

6 02978649 1 Seal Kit

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

02978614 -- Cylinder Asy. 3" Bore X 12" Stroke

60

Page 61

Nov. 2003

to

Current

2

WING LIFT CYL.

ST15 / ST10

ST15-C31200790311

to

ST15-Current

6

5

4

3

1

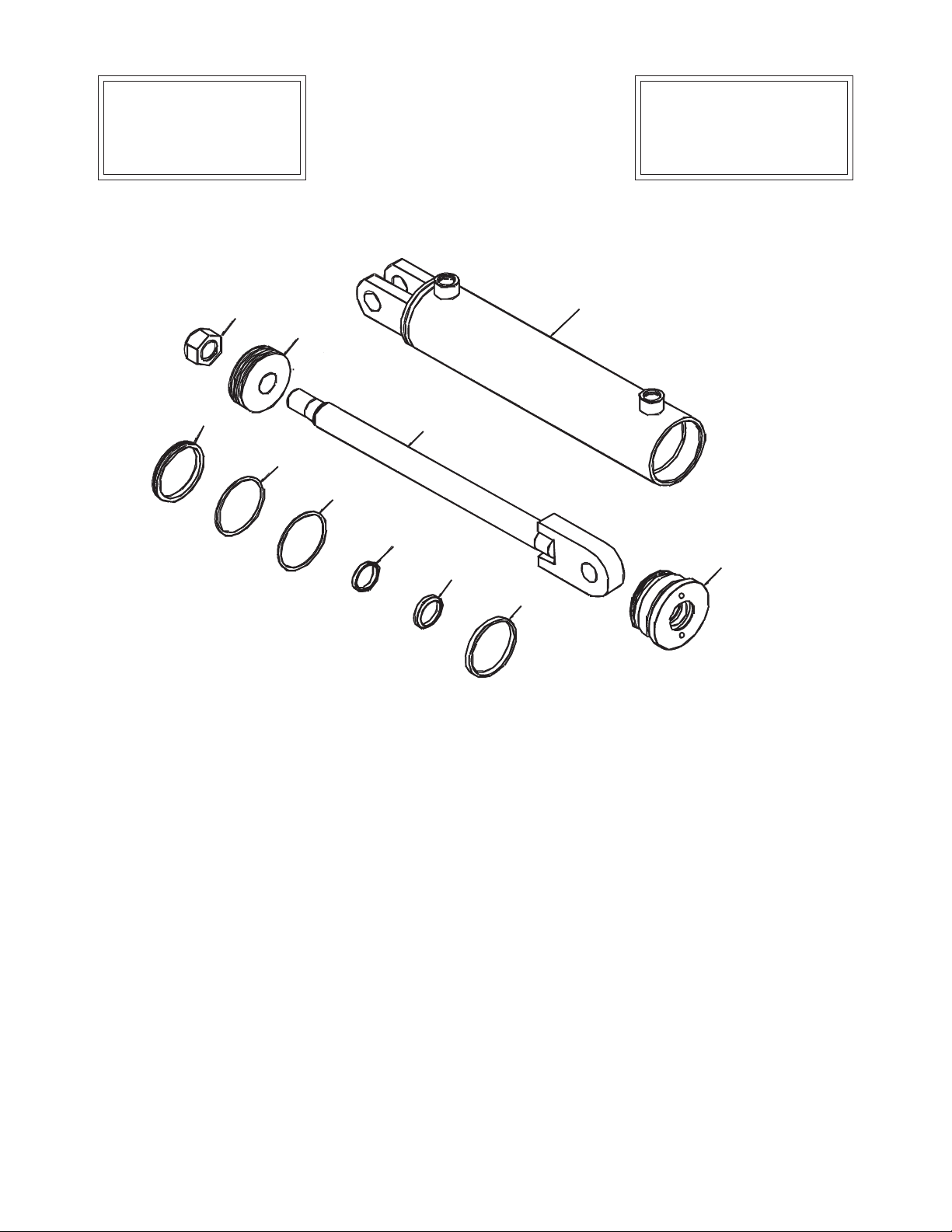

Item Part No. Qty. Description

02980472 -- Cylinder Asy. 3" Bore X 12" Stroke

1. 02980473 1 Rod

2. 02980474 1 Barrel

3. 02980475 1 Gland

4. 02980476 1 Piston Nut

5. 02980479 1 Piston

6. 02980478 1 Seal Kit

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

61

Page 62

Jan. 2002

to

Current

HYD. VALVE

ST15 / ST10

ST15-C31200557203

to

ST15-Current

11

4

Wing Lift Cylinders

7

3

9

11

1

1

2

10

6

2

5

Three Spool

8

Valve

11

Axle Lift Cylinders

Item Part No. Qty Qty Description

02978898 1 -- Spool Valve Kit, ST 15

02978938 -- 1 Spool Valve Kit, ST 10

1 02978939 7 5 Elbow

2 02978940 2 2 Reducer

3 02978941 1 1 Elbow

4 02978615 2 1 Breather, Filter

5 02978942 1 1 Hose Asy.

6 02978943 1 1 Hose Asy.

7 02978944 2 1 Hose Asy.

8 02978945 1 1 Hose Asy.

9 02978946 1 1 Hose Asy.

10 02978947 1 1 Valve, 3 spool

11 02978618 3 2 Restrictor

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

ST15 ST10

62

Page 63

Jan. 2002

to

Current

Trailing Nut

WING CYL. ADJUST

ST15 / ST10

Leading Nut

ST15-C31200557203

to

ST15-Current

Wing Adjust

Weldment

WING AXLE & CYLINDER LEVELING

The Wing Cylinder attachments may need adjusting to level the Wing Axle to the

Center section Axle. These parts are listed in the Deck Component Secton

of parts manual.

Leveling will rquire that the mower is placed on a level surface with the full weight

of the mower on the tractor Draw Bar. The Cylinders must be connected and Bled. Lower

the Wings into the mowing position.

Locate the front to rear leveling rods (Control Rods), these are the rods that run from

center Axle to the Tongue. Adjust the control rods to level the mower from front to rear (on

the center section deck). Tightening (shortening) these control rods will raise the front.

Lengthening thes control rods will lower the front. Mower work best when the front is approx

1" lower than the rear. IMPORTANT that these control rods are tighten equal to where the

carry equal load. This can be check by tapping rod with ahammer and listening to the tone.

A loose control rod will have a dull sound compared to the tight one, tighten till they both

sound the same.

Adjust the Wing Axle Cylinder attachemnt. This will level the Wings with the center

section Left to Right. The Wing Adjus Weldment shown above is used for this. The Trailing

Nut and the Leading Nut will have to be moved together, as one is loosened the other will

have to moved. Moving adjust Weldment out will raise the wing and moving it in will lower

the Wing. When done make sure that both Nuts are tightened down.

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

63

Page 64

DOUBLE CHAIN

12

12

12

12

12

12

12

12

12

12

5

12

12

CHAIN GUARDS

ST15 / ST10

1. Only Double Chain Guards are available.

2. 9 Link sections of Chains are used and are hung by the 5 th link

to form the double Chain Guard. (See illustration below)

3. The Cables are laced through the Bottom Link of the Chain and

then a Cable Clamp is placed at each end of the Cable. (See

illustration below).

4. Front Center Section is in 3 pieces, 1 center (19 Chains) and 2 outer

(16 Chains ea.)

5. The Front Wings are 2 pieces (29 Chains ea.) on each wing, same

LH or RH. There are two Chain Sections that bolt to a lug on the outer

side of each wing.

6. The Rear Center is in 2 pieces (24 Chains ea.)which are both the

same LH or RH Center.

7. The Rear Wings use 3 pieces, The center and inner Wing piece are

the same (19 Chains ea.), the outer for the wings is different (18

Chains)

8. The Chains are held in with a steel rod that is welded to the chain

guard bracket. to change or install chain sections these rods should

be replaced and rewelded.

9 Link Chain Section

is hung by inserting

Chain Guard

Bracket

Mower

Deck

the 5 th. Link

Retaining Bolt

Retaining Rod

23456789012345678901234

9 Link Chain

(Welded to

Bracket)

Section

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

64

Page 65

Jan. 2002

to

Current

1

CHAIN GUARDS

Front & Rear

ST15-C31200557203

to

ST15-Current

ST15 / ST10

3

2

2

1

1

1

6

5

5

4

4

5

5

FRONT & REAR DOUBLE CHAIN GUARD ASSEMBLIES

Item Part No. Qty. Description

1. 02978586 4 Chain Guard Asy. Front Wing

2. 02978587 2 Chain Guard Asy. Front Center Outer

3. 02978588 1 Chain Guard Asy. Front Center Middle

4. 02978589 2 Chain Guard Asy. Rear Center

5. 02978590 4 Chain Guard Asy. Rear Wing Inner & Middle

6. 02978591 2 Chain Guard asy. Rear Wing Outer

6

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

65

Page 66

Jan. 2002

0

12

12

6

to

Current

CHAIN GUARDS

Front Center Section

ST15-C31200557203

to

ST15-Current

Insert 5 th. Link

234567890123456789012345

ST15 / ST10

5,6,7

1

2

2345678901234567890123456789012123456789012345678901234567890121234567890123456789

3,4

5,6,7

1A

2

3,4

FRONT CENTER SECTION DOUBLE CHAIN GUARDS

Item Part No. Qty. Qty Qty Description

Mid-cntr L-cntr R-cntr

1. 02978588 1 -- -- Center Middle Chain Guard Asy. Dble Chain

1A 02978587 -- 1 1 Center Outer Chain Guard Asy. Dble Chain

2. 02978592 16 19 19 Chain Link Section, 9 Links

3. 02978595 1 -- -- Cable, 22" Long

02978594 -- 1 1 Cable, 26-3/4"" Long

4. 02978598 2 2 2 Cable Clamp

5. 02776600 6 6 6 Bolt

6. 15B800 6 6 6 Flat Washer

7. 00001800 6 6 6 Locknut

Qty. Shown above is all three pieces used on front center section LH, RH and Center.

Only Double Chains Available, Cables are an Option

Front Center section used a three piece Chain Guard

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

66

Page 67

Jan. 2002

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

to

Current

Insert 5 th. Link

CHAIN GUARDS

Front Wing Section

ST15 / ST10

ST15-C31200557203

to

ST15-Current

Outer Edge of

each Wing

8

1

3

2

9,10,11

5,6,7

4

FRONT WING DOUBLE CHAIN GUARDS

Item Part No. Qty. Description

1. 02978586 2 Front Wing Chain Guard Asy. Dble Chain

2. 02978592 58 Chain Link Section, 9 Links (29 per Asy)

3. 02978593 2 Cable, 73" Long

4. 02978598 4 Cable Clamp

5. 02776600 8 Bolt

6. 15B800 8 Flat Washer

7. 00001800 8 Locknut

8. 02978592 2 Chain Link, (Bolts To Outer Wing Deck)

9. 00758068 1 Bolt

10. 15B600 2 Flat Washer

11. 00015800 1 Locknut

Qty. Shown above is for one Wing, Double Qty. for both wings

Only Double Chains Available, Cables are an Option

Each Front Wing used a two piece Chain Guard (Total 4 pieces f/ Both Wings)

ST15 (Archive Book) 01/04

© 2004 Alamo Group Inc.

67

Page 68

Jan. 2002

1

to

Current

Insert 5 th. Link

CHAIN GUARDS

Rear Center Section

ST15 / ST10

1

ST15-C31200557203

to