Page 1

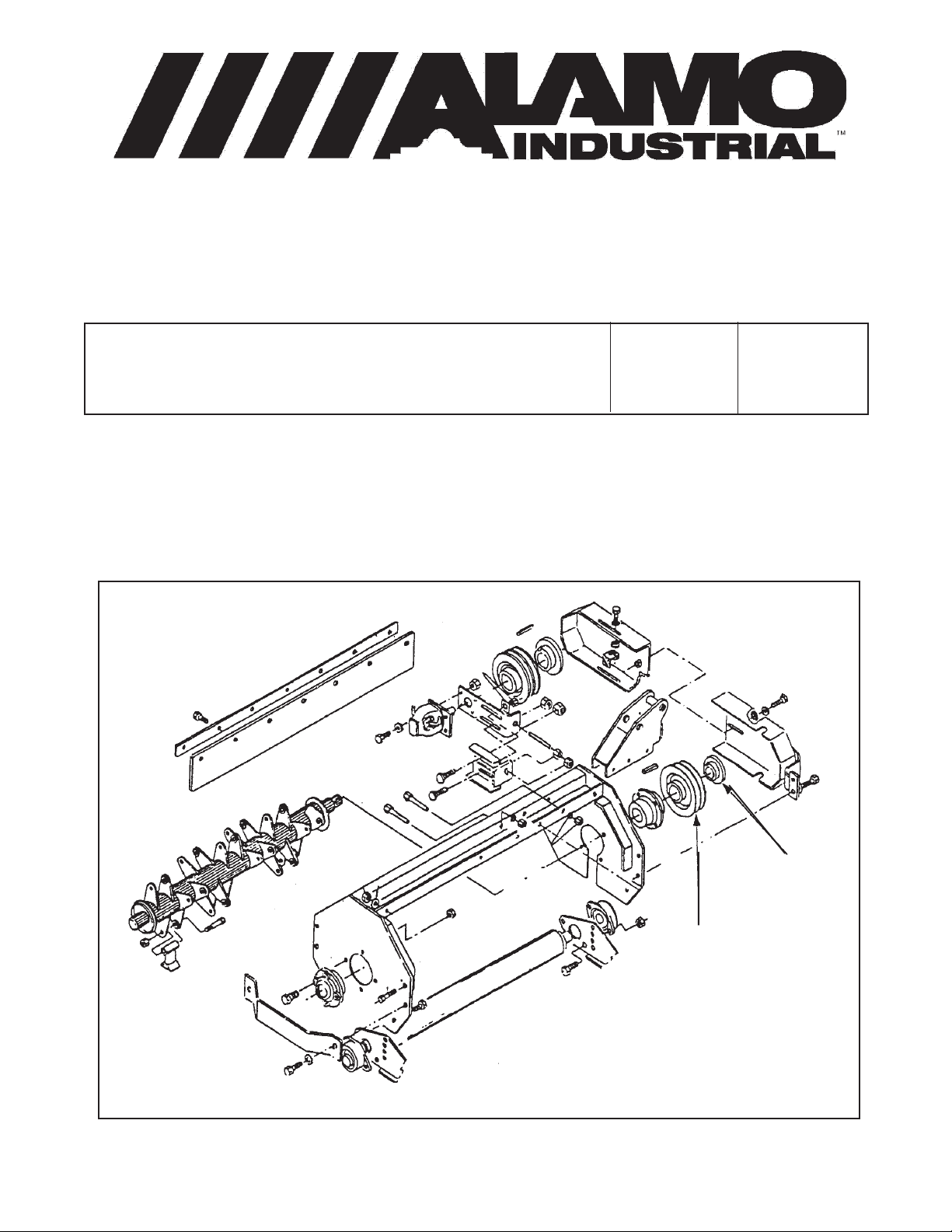

BOOM ARM MOWER

INFORMATION

&

™

SERVICE

BULLETINS

Alamo Industrial

P. O. Drawer 549

Seguin, Texas 78155

830-379-1480

Manual P/N 02980501

(08/05)

2005 Edition

© 2005 Alamo Group Inc.

Page 2

Page 3

INFORMA TION & SERVICE

BULLETINS INTRODUCTION

This Book is divided into two Sections

Section One - Technical Information Bulletins

1. Technical Information Bulletins: Information Bulletins are listed by Bulletin Number (Date).

Example the oldest Bulletin will be listed first and the most recent bulletin will be listed last.

Bulletin No. 021002 = first & second digits are the month, the third & fourth digits are the day

of the month and the fifth & sixth digits are the year this means, the bulletin was written on Feb,

10, 2002. If more than one bulletin was written on that day the a dash with a number will added,

example -1, -2 etc.

2. Authorize Repairs: Technical Information Bulletins do not authorize any repairs to be made

under warranty or any other circumstance unless specifically instructed to do so.

3. Bulletin Reference: Some Technical Information Bulletins will refer to the corresponding

Service Bulletins for repairs and some are for information only.

4. Bulletin Instructions: Technical Information Bulletins should have all the instructions as to

what you need, but may not have all the information needed to make an installation complete.

In some cases it may be required to refer to other manuals for more complete information, this

should be suggested in the Technical Information Bulletin.

5. All Technical Information Bulletins printed in this Manual will void any previously printed Bulletins.

Any changes in these bulletins are the final version as of the date of this manual.

Section Two - Service Bulletins

1. Service Bulletin No: Service Bulletins are listed by Bulletin Number (Date). Example the

oldest Bulletin will be listed first and the most recent bulletin will be listed last. Bulletin No. 021004

= first & second digits are the Year, the third & fourth digits are the day of the month and the fifth

& sixth digits are the month, this means the bulletin was written on Apr, 10, 2002. If more than

one bulletin was written on that day the a dash with a number will added, example -1, -2 etc.

2. Repairs: Service Bulletins are intended to authorize only the repairs listed on It to be made

under warranty or any other circumstance unless specifically instructed to do so.

3. Parts: This is the Rate at which compensation will be allowed under warranty for repair parts.

4. Labor: This is the amount of labor (hours) that are allowed to make this repair under warranty.

5. Parts Disposition: Service Bulletins list the disposition of any parts that are removed during the

repair. If listed removed parts must be held awaiting return to factory if instructed to do so.

6. Termination Date: Service bulletins show a termination date, this is the date that the Bulletin

will be discontinued, Any repairs must be made and all warranty applications filed by the listed

date.

7. All Service Bulletins printed in this Manual will void any previously printed Bulletins. Any

changes in these bulletins are the final version as of the date of this manual.

© 2005 Alamo Group Inc.

Page 4

INDEX

Machete

Section 1

Technical Information Bulletins

Bulletin No. (Old No.) Page Date Description

----------......................... 1-1................-----------....Information Bulletins Introduction

012095..........................1-2................01/20/95.... Flail Axe Head Pulley Fastener Change

092895 .........................1-4................09/28/95.... Push Pull Switch Adjusting

121495..........................1-6................12/14/95.... Repair Cracks in Deck, Rotary Head

010896..........................1-8................01/08/96.... Motor Start Switch Circuit

020596..........................1-9................02/05/96.... New Piston Pump Control Change

032596..........................1-10..............03/25/96.... Blade Bar Seal Protector, Rotary Head

040896..........................1-12..............04/08/96.... Oil Leaking from New Hydraulic Cylinders

042996..........................1-13..............04/29/96.... New Holland Tractor Dead Battery Problem

010397..........................1-14..............01/03/97.... Crack in Main Frames / Stiffener Installation

012097..........................1-16..............01/20/97.... Tube Clamp Location Modification

031097..........................1-17..............03/10/97.... Valve Block to Motor O-Ring Kit

032697...(032697A)...... 1-18..............03/26/97.... Bushing Drivers Available

041797-1(041797A1).... 1-20..............04/17/97.... Hitch Post Re-Design Update Kit

041797-2(041797A2).... 1-22..............04/17/97.... Cylinder & Linkage Redesign Kit

060197...(060197A)...... 1-24..............06/01/97.... Tilt Link Arm Stop Modification

061897...(061897A)...... 1-25..............06/18/97.... Blade Bar Leaf Redesign (Rotary Head)

071797...(071797A)...... 1-26..............07/17/97.... Joystick Power Supply Cut Off Switch

100397..........................1-27..............10/03/97.... Cyl, Link Arm, Turning Arm, Hitch Post Pins

112097..........................1-28..............11/20/97.... Cyl, Link Arm, Turning Arm, Hitch Post Pins

120697..........................1-30..............12/06/97.... Tilt Function, Lock Valve Installation

041398..........................1-32..............04/13/98.... Erratic Boom Movement, Radio Interference

020199..........................1-33..............02/01/99.... TS Tractor Hood to Frame Interference

031000..........................1-34..............03/10/00.... TS Tractor Fuel Filter Change (New Holland)

032200-1.......................1-35..............03/22/00.... Valve, Pressure Side Filter Installation

080300..........................1-36..............08/03/00....

080400..........................1-37..............08/04/00.... Pressure Filter Maintenance Procedure

012501..........................1-38..............01/25/01.... Control Valve Relocation Information

040901..........................1-39..............04/09/01.... Rebuilt Parts Availability Change Notice

041001-1.......................1-40..............04/10/01.... Valve, Pressure Side Filter Installation (Apitech)

041001-2.......................1-41..............04/10/01.... Valve, Pressure Filter Maintenance Instruction

041101..........................1-42..............04/11/01.... Buzz Bar Head Drive Coupler Change

101802..........................1-43..............10/18/02.... Spindle Bearing Lubrication Change

121802..........................1-44..............12/18/02.... Hydraulic Oil Recommendation Change

021803..........................1-45..............02/18/03.... Warranty Repairs with Rebuilt Parts Change

041503..........................1-46..............04/15/03.... John Deere 6000 Tier II Crankshaft Pulley Change

102103..........................1-48..............10/21/03.... Lexan Shield Availability Non-Cab Tractors

011304......................... 1-50..............01/13/04....Driveline Update Kit

Spindle Oil Filler Kit (Rotary Head)

© 2005 Alamo Group Inc.

INDEX - 1

Page 5

INDEX

Machete

Section 2

Service Bulletins

Bulletin No. (Old No.) Page Date Description

----------......................... 2-1............... -----------....Service Bulletin Introduction

951611... (950011) .......2-2................11/16/95.... Joystick Replacement

952911-1 (950014)....... 2-3................11/29/95.... Motor To Spindle Bolt Replacement

952911-2 (950013)....... 2-4................11/29/95.... King Post Pin Replacement

962503-1 (960001)....... 2-6................03/25/96.... Rear Flap Bracket Update (Rotary Head)

962503-2 (960002)....... 2-8................03/25/96.... Lower Crossmember Installation Update

962703....(960003)........2-9................03/27/96.... LH Frame Rail Gusset Reinforcement Update

962310....(960008)........2-10..............10/23/96.... Lack of Joystick Proportional Movement Control

960511....(960009)........2-11..............11/05/96.... Tilt Cyl. Function Restrictor Installation

971903....(970001A)..... 2-12..............03/19/97.... Turning Arm - King Pin Up-Dates

972103....(970002A)..... 2-14..............03/21/97.... Boom Hinge Point Pin Up-Dates

971404....(970004A)..... 2-16..............04/14/97.... Lift & Dipper Cyl. Function Restrictor Installation

973107....(970008A)..... 2-17............. 07/31/97.... Upper King Pin Bushing Slipping

970108....(970009A)..... 2-18............. 08/01/97.... Blade Bolt Inspection / Recall

990303....(990002A)..... 2-19............. 03/03/99.... Lower Crossmember Reinforcement Kit

992704... (990003A)..... 2-20............. 04/27/99.... New Holland T6640 & T7740 A/C Service Notice

991911... (990005A)..... 2-21............. 11/19/99.... New Holland TS Tractor Inspection Service Notice

991012....(990005A)..... 2-22............. 12/10/99.... Turning Arm Pin Update Kit

002908....(200004)........2-24............. 08/29/00....Dipper Boom Re-Reinforcement Plate Installation

000510....(200006)........2-25............. 10/05/00....Control Valve Pressure Filter Installation

010607....(200102)........2-26............. 07/06/01....Motor Drive Coupler Redesign, Buzz Bar Head

021202....(021202)........2-27............. 02/12/02....Motor Drive Coupler Up-Date, Buzz Bar Head

030702....(1020703)......2-28............. 02/07/03....Blade Bolt Inspection and / or Replacement

050504..........................2-29............. 05/05/04.... Blade Carrier Retaining Bolts

083005-1.......................2-30..............08/30/05.... P um p Port Plug Replacement

© 2005 Alamo Group Inc.

INDEX - 2

Page 6

NOTES

© 2005 Alamo Group Inc.

Page 7

SECTION 1

TECHNICAL

INFORMATION

BULLETINS

(This Book is divided into two Sections)

Section One - Technical Information Bulletins

1. Technical Information Bulletins: Information Bulletins are listed by Bulletin Number (Date).

Example the oldest Bulletin will be listed first and the most recent bulletin will be listed last.

Bulletin No. 021002 = first & second digits are the month, the third & fourth digits are the day

of the month and the fifth & sixth digits are the year this means, the bulletin was written on Feb,

10, 2002. If more than one bulletin was written on that day the a dash with a number will added,

example -1, -2 etc.

2. Authorize Repairs: Technical Information Bulletins do not authorize any repairs to be made

under warranty or any other circumstance unless specifically instructed to do so.

3. Bulletin Reference: Some Technical Information Bulletins will refer to the corresponding

Service Bulletins for repairs and some are for information only.

4. Bulletin Instructions: Technical Information Bulletins should have all the instructions as to

what you need, but may not have all the information needed to make an installation complete.

In some cases it may be required to refer to other manuals for more complete information, this

should be suggested in the Technical Information Bulletin.

5. All Technical Information Bulletins printed in this Manual will void any previously printed Bulletins.

Any changes in these bulletins are the final version as of the date of this manual.

MACHETE

© 2005 Alamo Group Inc.

1-1

Page 8

TECHNICAL INFORMATION BULLETIN No. 012095

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: All Boom Mowers using Flail Axe Head

Bulletin No:

012095

Date:

Jan. 20, 1995

Pulley Fastening to Cutter Shaft of Flail Axe Head:

Subject:

A new method has been devised to secure the pulley to the cuttershaft. A new pulley, P/N

02968712 and a QD Pulley Hub P/N 00724670 has replaced the old pulley with setscrew, washer,

lockwasher and bolt. The new pulley and hub are a keyed, taper lock design which will provide a better

fit and longer service life for the shaft.

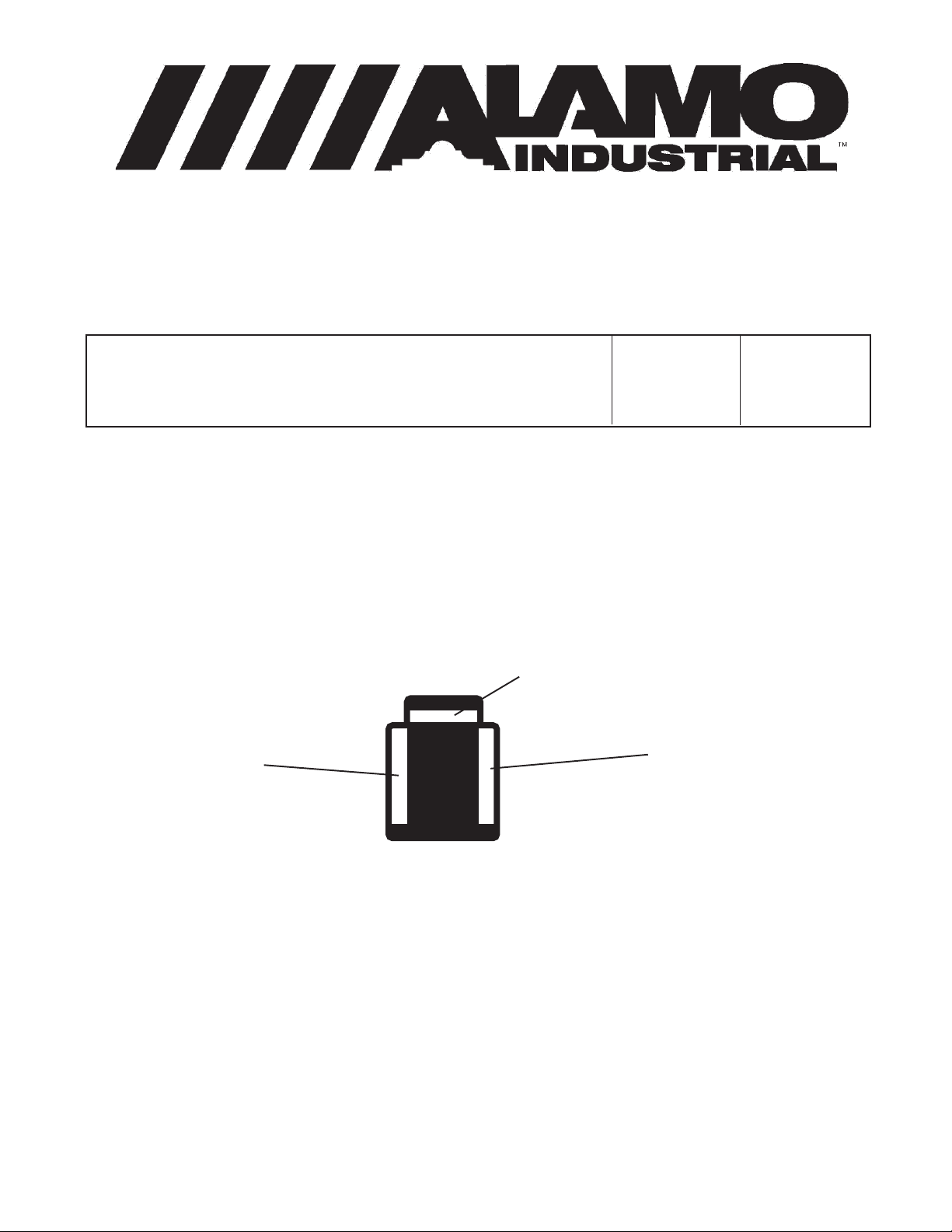

Hub P/N

00724670

Pulley P/N

02968712

Figure 1

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-2

Page 9

NOTES

MACHETE

© 2005 Alamo Group Inc.

1-3

Page 10

TECHNICAL INFORMATION BULLETIN No. 092895

Alamo Industrial Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models:

All Hydraulic mowers using the 02964028 Push-Pull Switch

Bulletin No:

092895

Date:

Sep. 28, 1995

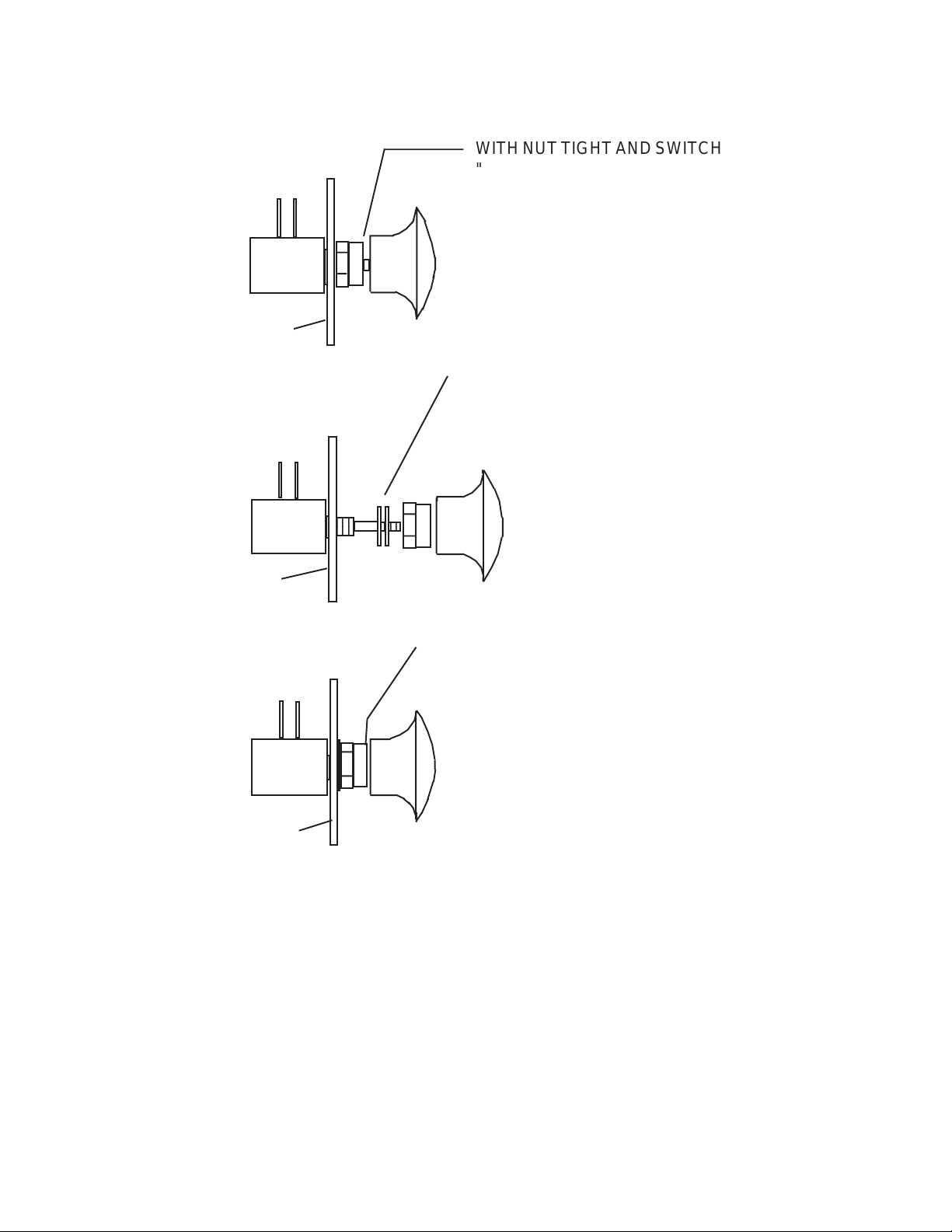

Failures of the mower push-pull switch:

Alamo has recently received reports of failures of the referenced switch. The failures

modes are:

(a) Knob pulls off rod.

(b) Rod and Knob pulls out of switch body.

Test performed on numerous switches indicates that the (b) failures are due to excessive

force being applied to the knob when shutting off the mower. Specifically, the knobs are usually

roughly slapped to turn the mower off. After internal parts of the switch are damaged, the rod can

then be pulled out easily. The (a) failures are due to the knobs not being securely tightened.

To prevent these failures from occurring, or to replace a damaged switch, use the following

procedure to adjust the travel of the switch. (See attached diagram).

1. Install the switch body in the holder and tighten the nut.

2. Screw the Knob on the rod to the bottom of the thread, but do not overtighten. It

will probably be necessary to hold the rod with pliers to get the knob tight, if you do

use caution not to score the rod with the pliers.

3. Measure the distance (if any) between the knob and the nut. Record the

measurement.

4. If a Gap exists between the knob and the nut, remove the knob.

5. Remove the nut and install the same thickness of flat washers that was

measured in step 3. Install and tighten the nut> DO NOT install more washers

than needed to take up the space. Flat Washer Part No. 00023500 or equivalent can

be used.

6. Install the Knob, using Locktite or similar thread locking compound. Thread the

knob on the rod all the way. Test to make sure that when the switch is "Off" (with

rod pushed in) that the knob can not travel further into the switch.

MACHETE

© 2005 Alamo Group Inc.

Continued Next Page

1-4

Page 11

Information Bulletin 092895 Continued from previous Page

4

4

WITH NUT TIGHT AND SWITCH

"OFF". MEASURE THIS GAP IF ANY

MOUNT PLATE

IF GAP EXIST, INSTALL WASHERS OR

SHIMS TO EQUAL GAP MEASURED IN

STEP 3

23

23

MOUNT PLATE

KNOB SHOULD LIGHTLY CONTACT

NUT WHEN PROPERLY ADJUSTED

MOUNT PLATE

TECHNICAL INFORMATION BULLETIN

No. 092895

Contact:

Alamo Industrial

Technical Services Department

1502 East Walnut

Seguin, Texas 78155

Ph; 830-372-2708 Fax; 830-372-9603

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-5

Page 12

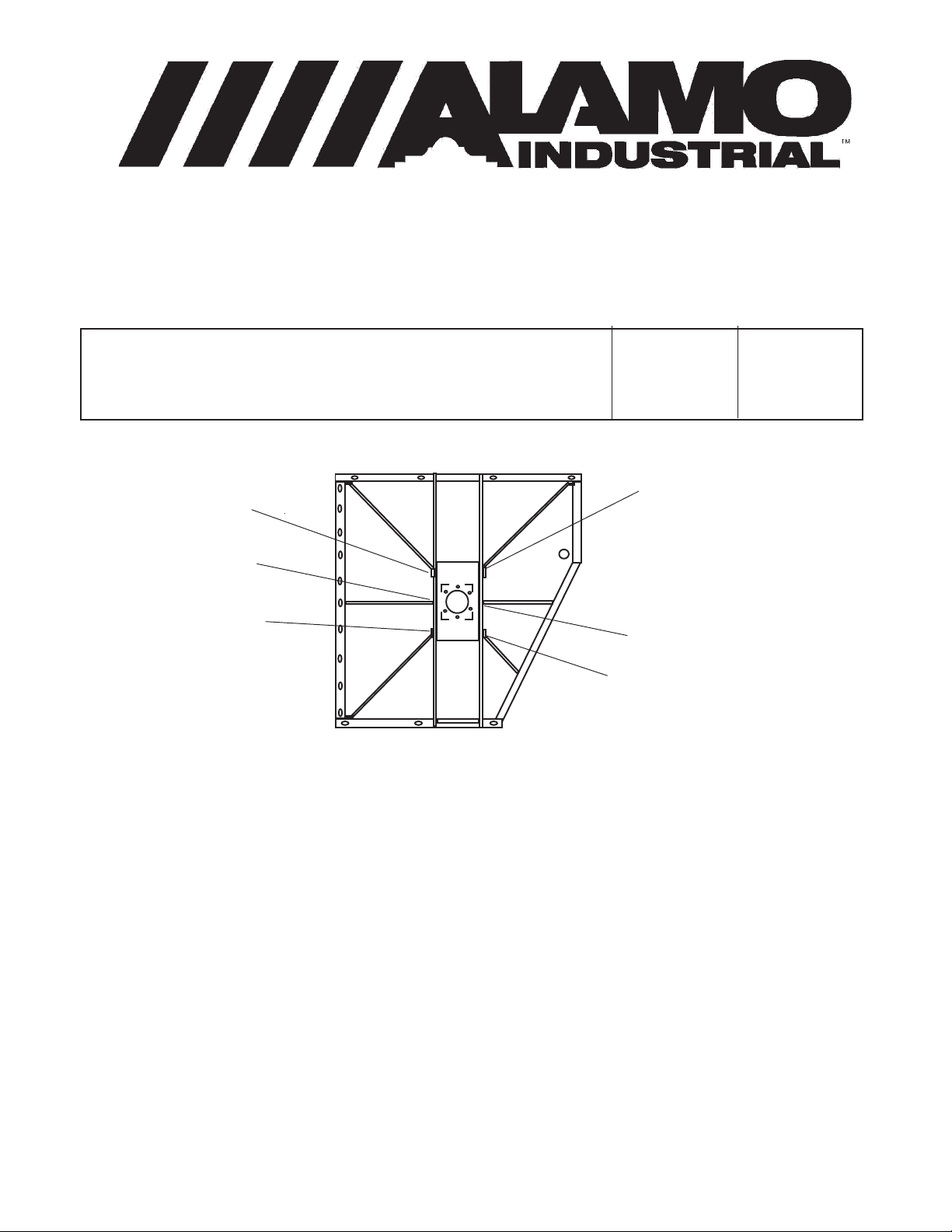

TECHNICAL INFORMATION BULLETIN No. 121495

Alamo Industrial Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models:

Machete Boom Axe, Versa Boom, A-Boom, Slopemower

& Rear Mount Booms.

Repair Procedure for Welding Cracks in Boom Heads:

A

A

A

If cracks appear in the welds at points "A" as shown above, use the following procedures to

repair head.

Bulletin No:

121495

A

A

A

Date:

Dec. 14, 1995

Parts Needed:

Part No. Qty Description

02970111 2 90° Gusset

02970112 4 48° Gusset

Welding Procedure:

1. Grind a groove at the site of the crack and clean the area to be welded.

2. Weld the crack making a 100% weld.

3. After repairing the cracks, prepare the sites for installation of the gussets.

4. Position the reinforcing bar gusset part no. 02970111 if 90° or part no. 02970112 if 48° over

the X-Bar as shown in drawing next page. Weld with a 1/4" fillet weld on the bottom and an

edge weld on top. DO NOT weld the ends.

5. Clean and paint the area.

6. Reassemble any parts that were removed.

Continued Next Page

MACHETE

© 2005 Alamo Group Inc.

1-6

Page 13

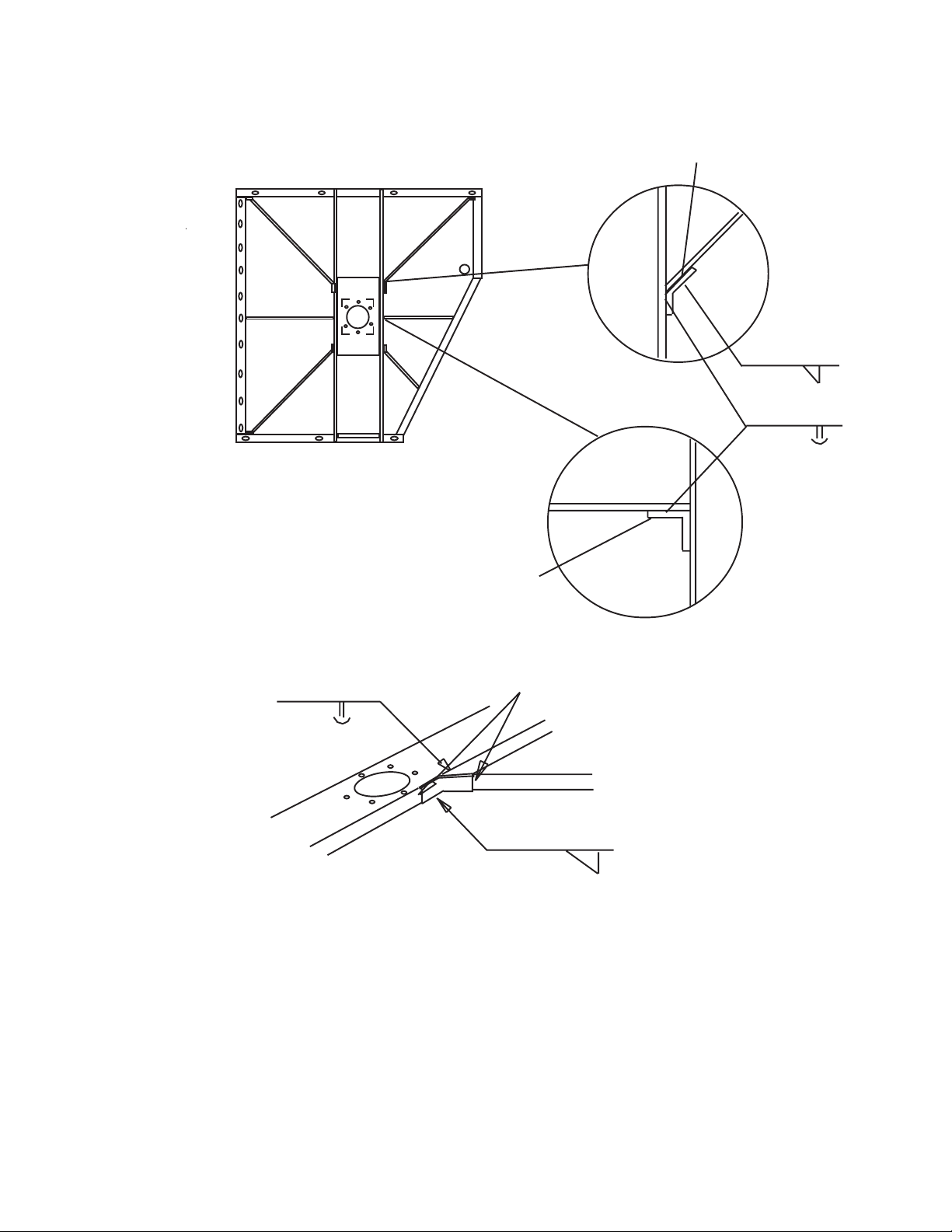

Information Bulletin 121495 Continued from previous Page

48° Gusset

1/4"

1/4"

90° Gusset

Note; Do Not weld ends

1/4"

1/4"

TECHNICAL INFORMATION BULLETIN

No. 121495

Contact:

Alamo Industrial

Technical Services Department

1502 East Walnut

Seguin, Texas 78155

Ph; 830-372-2708 Fax; 830-372-9603

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-7

Page 14

TECHNICAL INFORMATION BULLETIN No. 010896

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: All Machete Boom Mowers

Bulletin No:

010896

Date:

Jan. 8, 1996

Trouble shooting improper operation of motor starting circuit:

The correct operation of the motor is for the operator to pull out the Main Motor Switch and

then momentarily press the Motor Start Button. the Motor will advance to full operating speed and will

continue to run while the Main Motor Switch is in the OUT position.

If the harness is wired wrong, the motor will start as soon as the Motor Start Switch is pulled

out without pressing the Motor Start Button.

A

C

Pull

Circuit

B

Hold

Circuit

The above illustration is the female connector of the motor wire harness

Corrective Action:

Using needle nosed pliers, push the B and C connectors out of the back of the plug and

reinstall them in the opposite positions, or cut the two wires to the B and C connectors and splice

them back together reversing them.

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-8

Page 15

TECHNICAL INFORMATION BULLETIN No. 020596

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: Machete Boom Mowers MB21 & MB24

Bulletin No:

020596

Date:

Feb. 5, 1996

New Piston Pump used on Machete:

A new Pump is being used on all Machete Boom Mowers. The new pump utilizes a solenoid

valve and manifold (New Parts) to control pump swashplate movement instead of the former (Old

Parts) electric solenoid, Spool valve and adjustable linkage. All other parts of the pump remain the

same. The new parts provide for more positive trouble free operation of the pump and do not require

adjustment.

There will be a harness adapter required to connect the new two wire connector to the old

three wire harness. Adapter and instructions are included in replacement parts. When the former (old

part number is ordered, all the new parts will be provided.

New Parts

Old Parts

Former Part No. Description Replacing Part No.s Description

02967192 Pump Assembly 02969527 Pump Assembly

02970201 Decal, Joystick

02970205 Adapter, Wire Harness

02970224 Insert, Instruction Sheet

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-9

Page 16

TECHNICAL INFORMATION BULLETIN No. 032596

Alamo Industrial Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: Machete Boom MB21 & MB24

Bulletin No:

032596

Date:

Mar. 25, 1996

New Seal Protector Added to Blade Bar Assembly:

A few machines have experienced operational problems such as failure of the blade bar to rotate

when the mower is engaged or a slight loss of power at the blades. Sometimes it is assumed that the

spindle has seized and the spindle is replaced without investigating further.

The problem is usually found to be that the spindle end cap cover is binding on the spindle

housing, creating sufficient drag on the shaft to result in the symptoms described above. This condition

is a result of material (Vines, Wire, etc.) wrapping around the cover and forcing it to contact and drag

against the spindle housing, causing no damage to internal components of the spindle.

A new seal protector has been designed to aid in preventing material from wrapping around the

seal cover area. While nothing can completely prevent material from getting to the seal cover, the new

seal protector should greatly reduce the probability of spindle seizures due to these causes.

If a machine is operating or is going to operate in an application in which material is likely to wrap

around spindle, the following parts can be ordered and installed. The old seal protector (# 02968868)

which is on the spindle will be removed and discarded. The Old Part No. 02968868 will be ordered but

the new Seal Protector Part No. 02970459 will be shipped with installation instructions. If only the new

Seal protector is ordered the instruction sheet will not be shipped.

Part No. Qty Description

02968868 1 Cover, End Cap (Seal Protector)

The new seal protector will have to be welded to the upper blade bar as shown on the next page

and the old seal protector which is on the spindle will be discarded. Make sure that the Blade bar

retaining bolts are properly torqued when reattaching to spindle and that components are good

condition.

Continued Next Page

MACHETE

© 2005 Alamo Group Inc.

1-10

Page 17

Information Bulletin 032596 Continued from previous Page

Weld 4 places

3/16"

Seal Protector Ring

# 02970459

1" long

Note: Center ring on blade bar

to allow clearence for spindle.

Blade Bar Asy

# 02782300

Old Seal Protector,

# 02968868 Cover,

End Cap is

no longer used

TECHNICAL INFORMATION BULLETIN

No. 032596

Contact:

Alamo Industrial

Technical Services Department

1502 East Walnut

Seguin, Texas 78155

Ph; 830-372-2708 Fax; 830-372-9603

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-11

Page 18

TECHNICAL INFORMATION BULLETIN No. 040896

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: All Models using Single Acting Hydraulic Cylinder

Bulletin No:

040896

Date:

Apr. 8, 1996

Oil Leaking from new single Acting Hydraulic Cylinders:

There have been numerous cases of the dealers and customers replacing single acting

hydraulic cylinders on new machines due to oil leakage out of the vent plug in the cylinder.

In many of these instances, no defect could be found in the cylinders. Further investigation

has revealed that he manufacture of our cylinders is leaving oil in the cylinders after their testing. The

Oil is left to help protect the interior of the cylinders during storage. When the cylinders are fully

actuated, they are forcing this oil out the vent plug, causing what appears to be a leaking cylinder

through the vent plug. Even the oil is cleaned off the cylinder after testing there is enough oil still inside

the cylinder to bleed out when used.

If you have a New Cylinder that appears to be leaking from the vent plug, The oil should be

cleaned off and unit ran for a few days to a week to determine if the Cylinder is leaking, or if it is the

oil that was left in the cylinder to protect it. It has been found that in some cases it has taken as much

as a week for this to appear that it is not leaking.

If after running and cycling the cylinder during operation and the cylinder continues to leak then

the necessary repair should be performed.

Cylinders that are attracting dust around them is not considered to be leaking. This dust

collecting around them is considered normal.

All Cylinder that are returned as leaking will be pressure tested for leakage to determine the

condition of the Cylinder and its components.

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-12

Page 19

TECHNICAL INFORMATION BULLETIN No. 042996

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: All New Holland Tractors with Alamo Industrial Mounted

Booms

Bulletin No:

042996

Date:

Apr. 29, 1996

Dead Batteries on New tractors:

There have been several reports recently of dealers receiving machines with dead batteries,

some of which could not be satisfactorily recharged. Please see the attached copy of a tag which

is coming with the new tractors.

The "small electrical discharge" being mentioned amounts to a constant drain on the battery.

If the battery cable (+ Post) is left connected for a long enough time with the tractor inactive, the battery

will become sulfated (permanently damaged) and will not accept a charge. Sulfated batteries are not

warranted through the battery manufacturer.

At present, the only alternative to removing the battery cable would to be install a battery

disconnect switch in the negative cable, which would allow the battery to be easily isolated. These

switches are available at most major tractor dealers. USE CAUTION when installing any thing on

battery cables, disconnect the positive cable before installing disconnect switch and make sure after

switch is installed that it is "OFF" before reconnecting Positive Cable.

ATTENTION ! BATTERY CARE

Your new Tractor has electronics which cause a very small electrical demand on the battery. If the

tractor in not in use for an extended period, disconnect battery to avoid damage by excessive discharge.

Recharge Battery if voltage is less than 12.3V (S.G. less than 1.140)

Lataa Akku uudelleen, jos jannite on alle 12.3V (ominaispaino alle 1.140)

Ricaricare la batteria se il voltaggio e inferiore a 12.3V (G.S. inferiore a 1.140)

Batteria recarregavel se a voltagem for inferior a 12.3V (Gravidade especifca inferior a 1.140)

Laddt de batterijweer op wanneer de voltage lager is dan 12.3V (S.G. Minder dan 1.140)

Recharger la batterie si la tension est inferieure a 12.3V (Densite inferieure a 1.140)

Batterie wieder aufladen. wenn spanning unter 12.3V (Spez gewicht unter 1.1.40 IST)

Recarcar la bateria si el voltage es inferior a 12.3V (S.G. inferior a 1.1.40)

Batteriet ma lades opp hvis spenningen er mindre enn 12.3V (Spesifikk vekt under 1.1.40)

_

+

Part No. 82001815

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-13

Page 20

TECHNICAL INFORMATION BULLETIN No. 010397

Alamo Industrial Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: Machete Boom MB21 & MB24

Cracks in Main Frame:

There have been some cracks

in the main frame of some machete

mowers

If a crack should develop (See

Figure 1), use the following procedure to

make repairs untill a permanent repair is

developed. NOTE: This repair will aloow

the machine to continue operating while

a long term correction for the problem is

being developed.

1. Grind out old weld (crack) and

weld the crack, Do not use an excessive high repair weld as you will need to

grind repair weld down smooth.

Crack

develops

here

Figure 1

Bulletin No:

010397

Date:

Jan. 3, 1997

2. Prepare a piece of 1/2" X 6"

HRFB cut to length (See Figure 2). The

bottom should rest against the King

Post frame and the top should be with in

2" of the top of the frame, this will

determine the height of the repair plate

(See Figure 3). Bevel the bottom side of

the plate that is towards the frame to

allow for the old weld. This will be evedent

if you test fit the repair plate.

3. Place the stiffener repair plate

against the vertical memeber of frame

(as shown in figure 3) and tack weld into

position, Make sure repair plate is flat

against the frame.

MACHETE

© 2005 Alamo Group Inc.

Taper the Top

Bevel the side

towards frame to

clear old weld

Figure 2

Continued Next Page

1-14

Page 21

Information Bulletin 010397 Continued from previous Page

4. Weld the plate as described in figure 3

5. After welding is complete, clean weld and immeadiate area . Paint the are around the repair

and areound any area where the paint was damaged from making this repair.

1/4" fillet weld across the top

Stiffener plate 1/2" X 6" HRFB,

cut to fit as shown

Skip weld up sides

1/4" fillet weld across

bottom and sides

Figure 3

TECHNICAL INFORMATION BULLETIN

No. 010397

Contact:

Alamo Industrial

Technical Services Department

1502 East Walnut

Seguin, Texas 78155

Ph; 830-372-2708 Fax; 830-372-9603

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-15

Page 22

TECHNICAL INFORMATION BULLETIN No. 012097

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: Machete, MB21 & MB24

Bulletin No:

012097

Date:

Jan. 20, 1997

Interference between Tube Clamps and Main Frame:

It is possible that the boom hydraulic tube clamps may contact the main frame when boom

is raised to its highest position. This condition effects only machines with certain frames. If you have

a machine that has this interference problem use the procedures described in this bulletin to correct

the problem. (See Figure 1).

25"

To prevent interference of the

hydraulic pipe clamps with the

frame move the clamps to this

new 25" distance

Figure 1

If the parts on your unit are damaged, loosen the six bolts that hold the three tubes. Cut the

bracket away from the boom. Relocate the bracket on the boom so it clears the frame. Weld in place

and paint. Tighten the six bolts. Total time to perform this modification will be approximately 1.5 hours

time or less. If parts are required there is a kit that can be installed, the Kit # 02971938.

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-16

Page 23

TECHNICAL INFORMATION BULLETIN No. 031097

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: Machete, MB21 & MB24

&

Brahma Side Mount models

Valve Block O-Ring Replacement Kit available:

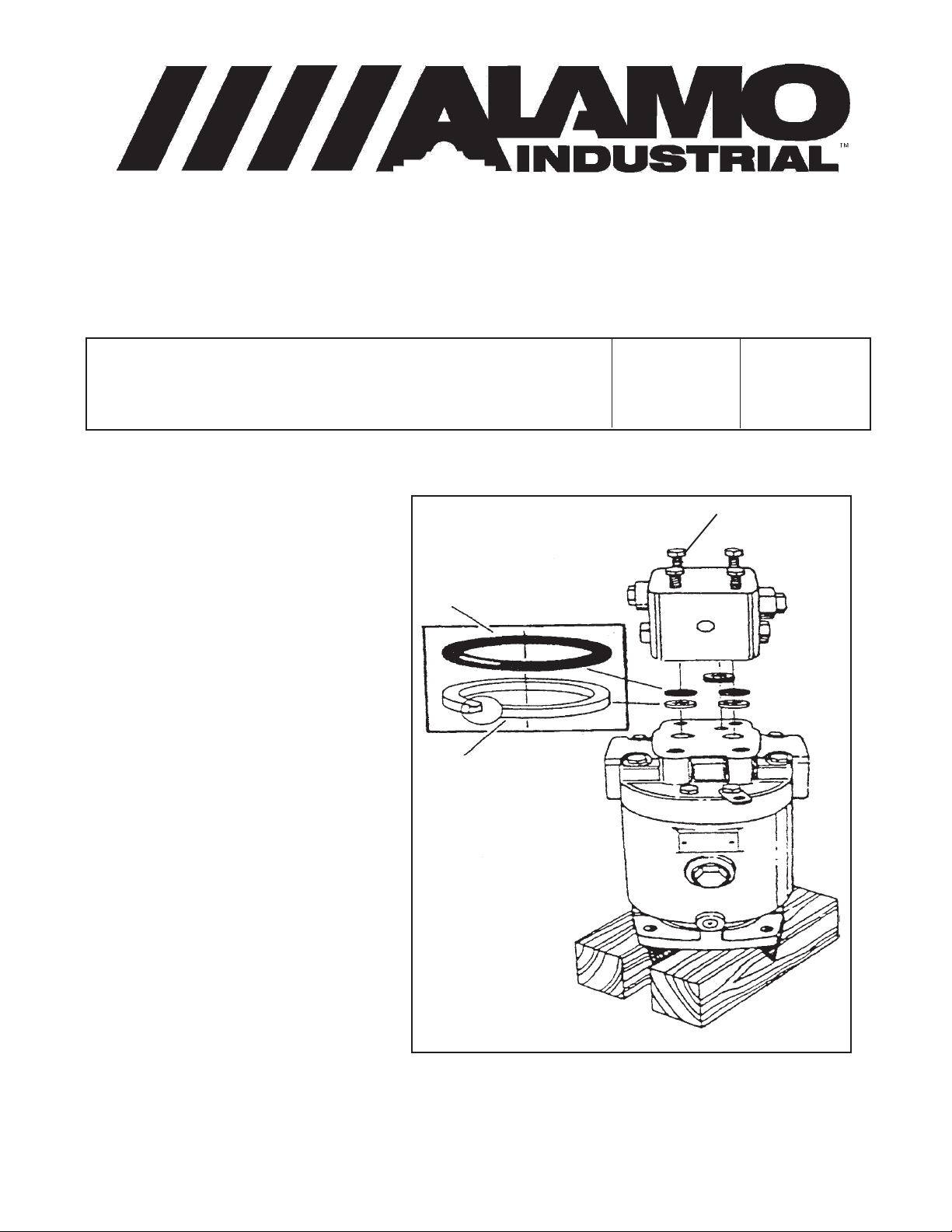

A kit (Kit # 02972094) to replace

the O-Ring and Back-up Rings which

are located between the valve block and

the motor housing on the piston motors

# 02977193 used on the Brahma rotary

and Machete boom mounted cutters is

available. The Valve block must be removed when the motor is replaced as it

is attached to the support plate. This

causes an occasional failure of the seals.

Install O-Rings and Back-up

Rings on the valve block. The High Pressure Ports require an O-Ring and Backup Ring. The O-Ring goes on first

(against valve block) , then the Back-up

ring (against motor) as shown (See

Figure 1). Install the Square-Cut Ring in

the Low Pressure Drain Port of the

valve block.

O-Ring

Back-up Ring

Bulletin No:

031097

Date:

Mar. 10, 1997

Valve Block

Retaining Bolts

When installing the valve block

the retaining bolts to the motor they

must be torqued to 35 ft. lbs. in an

alternating pattern.

Figure 1

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-17

Page 24

TECHNICAL INFORMATION BULLETIN No. 032697

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: Machete, MB21 & MB24

Bulletin No:

032697

Date:

Mar. 26, 1997

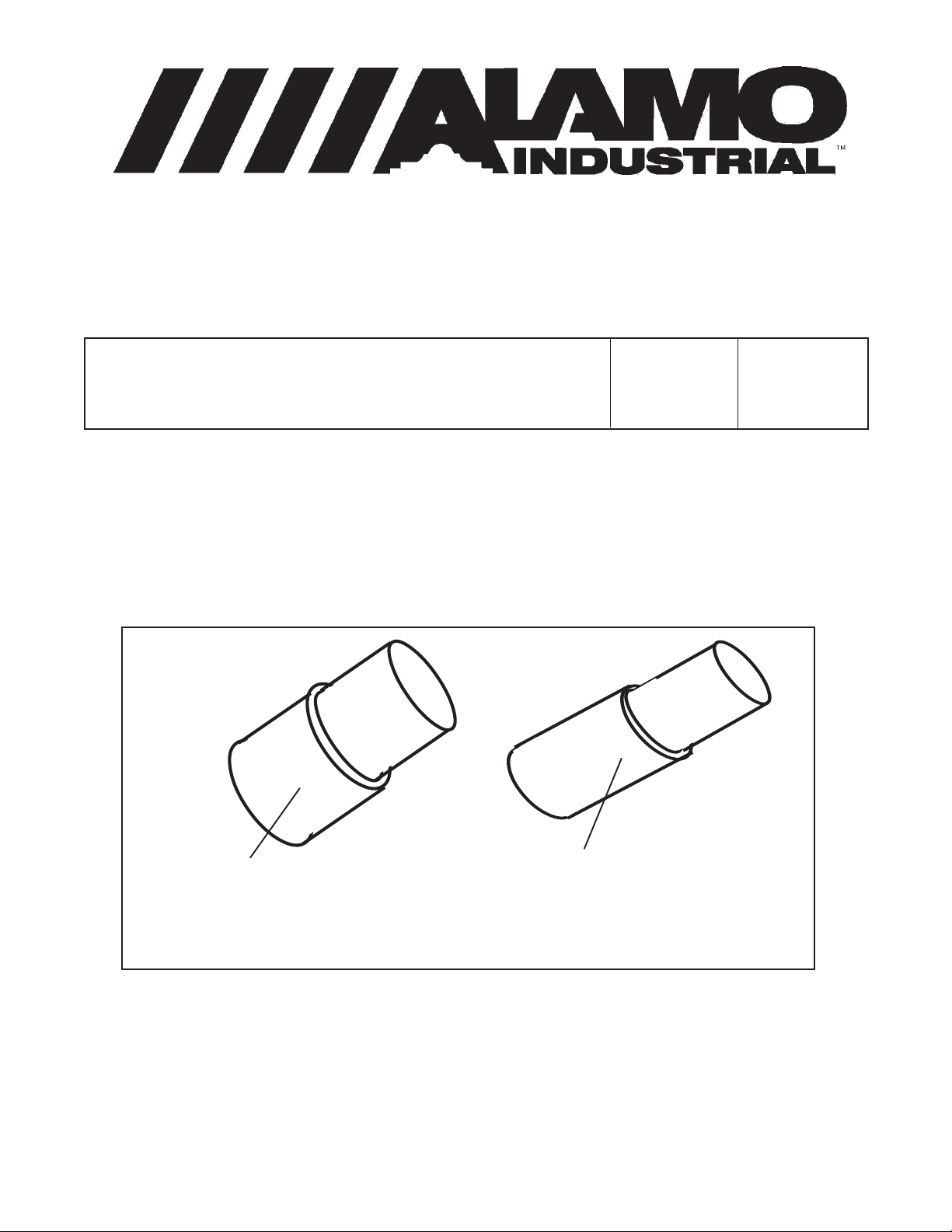

King Pin and Boom Pin Bushing Drivers Available:

It is now possible to obtain the proper bushing driver to facilitate the installation of all bushings

on the Machete Boom Assembly. The Large Driver (P/N 02972281) is used to install the King Pin

Bushings in the frame, while the Small Driver (P/N 02972282) should be used to install all the

bushings in the boom. These tools may be used to install bushings on several other Alamo Industrial

Models such as Slope Mowera and A-Booms. The proper use of the installation tools will help to

prevent damage to the bushing surfaces during installation.

# 02972281 for driving

2-1/2" ID Bushings

# 02972282 for driving

1-1/2" ID Bushings

Figure 1

Note: Replaces / Same as Bulletin No. 032697A

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-18

Page 25

NOTES

MACHETE

© 2005 Alamo Group Inc.

1-19

Page 26

TECHNICAL INFORMATION BULLETIN No. 041797-1

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: Machete, MB21 & MB24

Bulletin No:

041797-1

Date:

Apr. 17, 1997

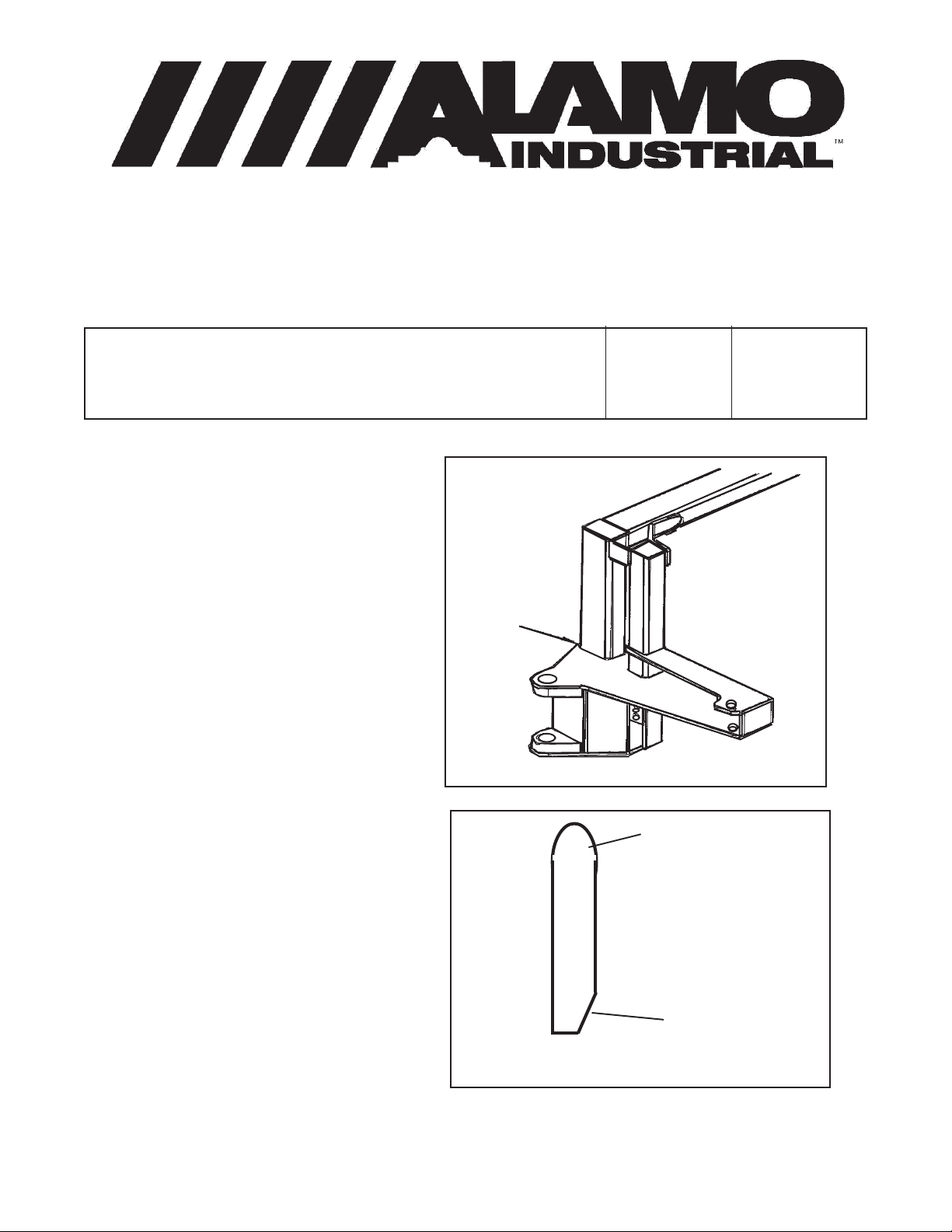

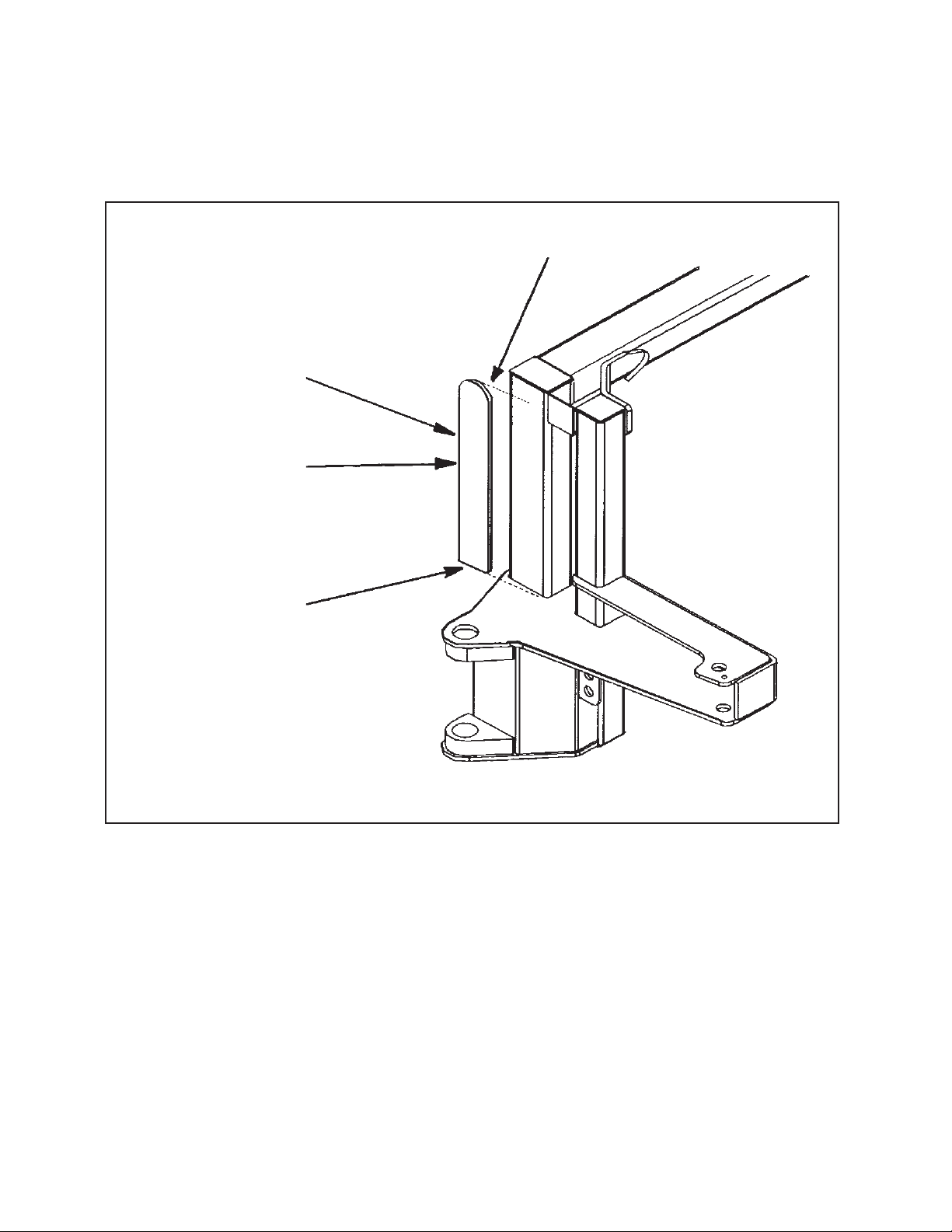

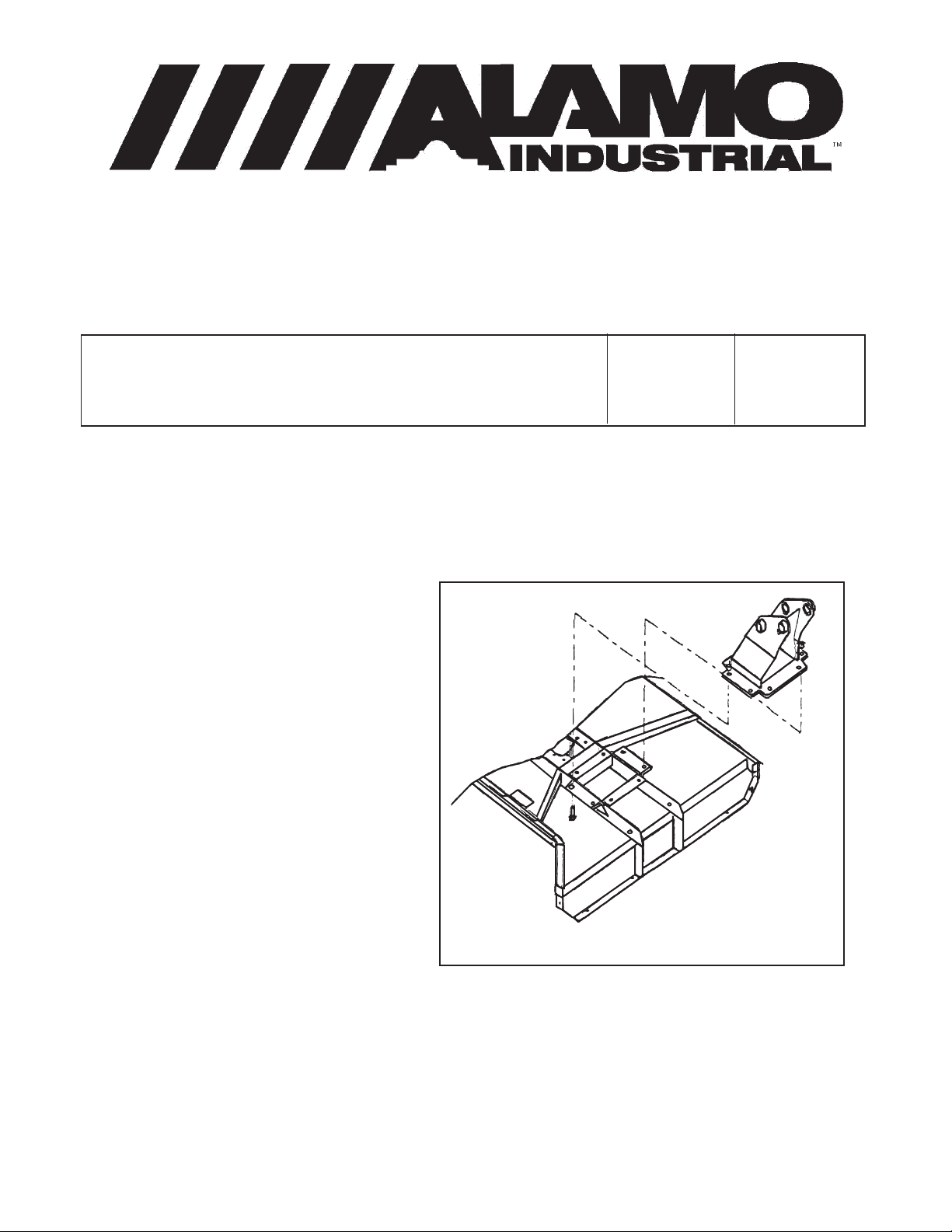

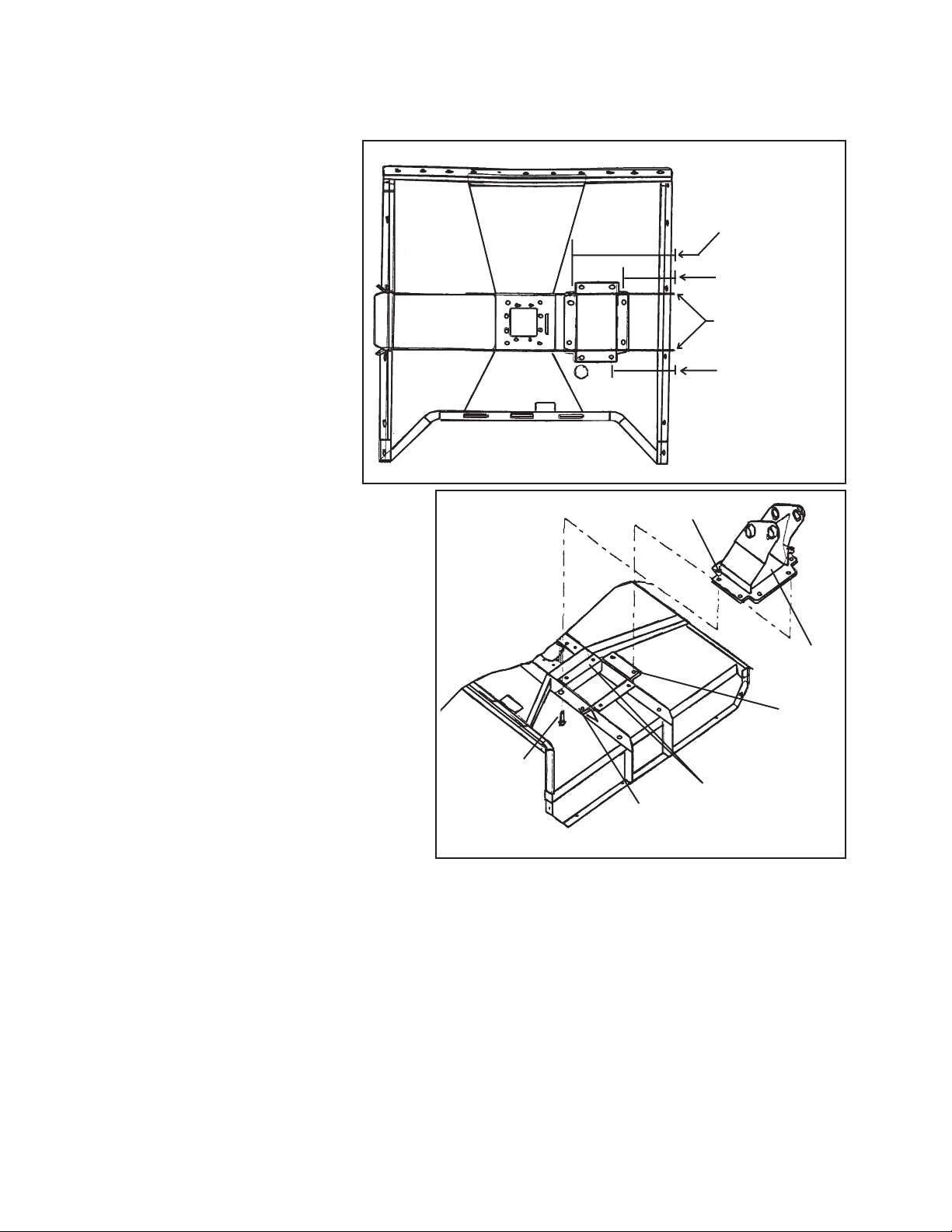

Hitch Post Replacement Kits:

Hitch Post replacement kits are now available for Machete Boom models MB21 & MB24. The

new design utilizes an 8 bolt flange design which requires angle braces to be welded to the cutter

head. If you are experiencing problems with the original hitch post, it could be replaced with the new

design. Install the new Hitch Post using the following procedure.

Important ! Any warranty repairs must be done in accordance with warranty policy and

service bulletin SB No. 970002A only.

Hitch Post Replacement Kits:

(Qty use 1 each)

Part No. Description

02972231 Hitch Post Kit

02967691 Pin Kit

02967687 Pin Kit

02972232 Instruction Sheet

Note: Instruction Sheet is included in Kit.

Repair Procedures:

1. Remove Head from Boom by follow-

ing cutting head removal & install instructions in the Operators Parts manual. If you do

not have this manual it is recommended you

obtain one before proceeding with this repair.

Figure 1

New 8 Bolt Flange

Hitch Post and Deck

Shown

2. Remove the old Hitch Post from the head. Clean all debris and Oil off of deck. Clean the paint

off around the area where the new flange will be welded.

3. Place angles (02971946 & 02972111) on rotary head as shown in Figure 2 and Figure 3. All

measurements are to be taken from the edge of the 3/8" X 3" ribs running across the rotary head.

Continued Next Page

MACHETE

© 2005 Alamo Group Inc.

1-20

Page 27

Information Bulletin 041797-1 Continued from previous Page

4. After aligning the Angles to Deck (See Figure 2) tack weld them in place. Recheck all

measurements and alignments, then weld in flanges in place.

5. Clean all welds and area

around welds, remove weld

slag, burnt paint and etc. Repaint complete area around

flanges to prevent rust.

24-1/16" center

of hole to edge

6.

(02971928) to welded angles as

shown in Figure 3 using hardware furnished with kit. Install the

Lock nut on top of the Hitch post

and the bolt heads down coming

up through the flanges, this will

give the maximum strength to the

bolts and Hitch components.

7. Reinstall Head to Boom

by following cutting head removal & install

instructions in the Operators Parts manual.

If you do not have this manual it is recommended you obtain one before proceeding

with the reinstall of head.

Hitch Post Kit # 02972231 includes -

Part No. Qty Description

02971928 1 Hitch Post

02972111 2 Angle

02971946 2 Angle

02892100 8 Bolt

00037200 8 Locknut

02972232 1 Instruction Sheet

Pin Kit # 02967691 includes -

02971756 1 Pin, Chrome

02971746 1 Bushing

02970595 1 Bolt

00015800 1 Locknut

02971904 1 Instruction Sheet

Pin Kit # 02967687 includes -

02971720 1 Pin Weldment

02971701 1 Nut, Slotted

02971702 1 Flat Washer

165020 1 Cotter Pin

Attach new Hitch Post

Figure 2

00037200 Nut (8)

02892100

Bolt (8)

Figure 3

02971946

Flange (1)

02972111

Flange (2)

Note: Replaces / Same as Bulletin

No. 041797A1

12-1/16" center

of hole to edge

Reference Ribs

14--9/16" center

of hole to edge

02971928

Hitch Post (1)

02971946

Flange (1)

TECHNICAL INFORMATION BULLETIN

No. 041797-1

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-21

Page 28

TECHNICAL INFORMATION BULLETIN No. 041797-2

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: Machete, MB21 & MB24

Bulletin No:

041797-2

Date:

Apr. 17, 1997

Cylinder & Linkage Pin Replacement Kits:

Boom cylinder pin replacement kits for all Machete MB21 & MB24 mowers are now available.

The new design utilizes a Boss and Bolt arrangement to replace the original tear drop and bolt design.

Each kit contains all the necessary parts along with a detailed instruction sheet regarding the correct

replacement procedure for the pins. Likewise, if new pins are ordered in the future, the original part

numbers will be automatically replaced with the new design being shipped to you. Welding and painting

will be required.

If you are experiencing problems with the original pin design. Order the new kit and replace the

pins with the new design. Instruction Sheet # 02971904 will be sent with each kit ordered. This

instruction sheet will show detailed instructions on how to install the following kits.

If replacing these as warranty, follow all warranty procedures in accordance with warranty

guide and Service Bulletins which apply to this application only.

Kit Numbers:

Kit No. Q tyDescription Kit No. Q t y Description

02967685 1 Pin Kit, Dipper Cyl. Rod End 02967691 2 Pin Kit, Head Tilt Linkage

02967673 1 Pin Kit, Swing Cyl. Barrel End 02967694 1 Pin Kit, Tilt Cyl. Rod End

02967677* 1 Pin Kit, Lift Cyl. Rod End 02967683 1 Pin Kit, Tilt Cyl. Barrel End

02967677* 1 Pin Kit, Dipper Cyl. Barrel End 02967675 1 Pin Kit, Swing Cyl. Rod End

02967679 1 Pin Kit, Lift Cyl. Barrel End

02967681 1 Pin Kit, Link Arm to Dipper

02967694 1 Pin Kit, Link Arm to Linkage

02966791 1 Pin Kit, Linkage Asy to Hitch Post.

02868803 a/r Pin Bushing

Note: there is also a Turning Arm Upgrade Kit which

includes a new 1 piece king pin, All Bushings and

Turning arm (Kit # 02972211) which is not shown

here.

Bolt & Nut

New

Pin

Weld on Boss

Figure 1

Continued Next Page

MACHETE

© 2005 Alamo Group Inc.

1-22

Page 29

Information Bulletin 041797-2 Continued from previous Page

Weld

Weld

Weld

Weld

Weld

Weld

Weld

Figure 2

Note: Replaces / Same as Bulletin No. 041797A2

TECHNICAL INFORMATION BULLETIN

No. 041797-2

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-23

Page 30

TECHNICAL INFORMATION BULLETIN No. 060197

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: Machete, MB21 & MB24

Bulletin No:

060197

Date:

Jun. 1, 1997

Tilt Link Arm Stop:

Some Machete models may exhibit interference between the head tilt cylinder and the cutter

motor support plate. This can result in a bent head tilt cylinder rod, a damaged cylinder gland cap, or

a damaged cutter motor housing.

In order to avoid possible damage, a stop should be fabricated and installed which will limit the

head tilt retraction before interference occurs.

A stop made from 1/2" X 2-1/4" HRFB X 6-1/2" long should be welded to head tilt link arm

weldment as shown in figure 1. This will require welding and painting.

To locate the proper angle position of the new stop, carefully retract the head until the cutter

motor support plate and the head tilt cylinder has a clearance of 1". Use caution, do not damage cylinder

when retracting the head. Place the new stop plate in the head tilt link weldment and lay it flat on the

dipper arm. Mark this position, and weld the stop in place as shown in Figure 1. It is important that the

stop is installed so that it flatly contacts the dipper when retracted in order to avoid point loading on the

boom. Extend and retract the cylinder to ensure proper installation.

Existing Formed Gusset

1/4" Weld

Existing Formed Stop

Figure 1

Do Not Weld

on this side

New Stop

Position the New Stop

so that it contacts the

existing Formed

Gusset

Note: Replaces / Same as Bulletin No. 060197A

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-24

Page 31

TECHNICAL INFORMATION BULLETIN No. 061897

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: Machete, MB21 S/N 01001 - 01071, 03507 & 02684

& MB24 S/N 01001 - 01040 & 03459

Bulletin No:

061897

Date:

Jun. 18, 1997

New Thick Blade Bar & Larger Bolts:

Early October 1996, in order to ensure an extended service life, a new blade bar was introduced

which featured larger blade bar leaf bolts (from 7/8" to 1-1/4") and a thicker bottom leaf. As a result,

longer mounting bolts (from 3-1/2" to 4") are required to ensure adequate thread engagement into the

spindle shaft.

When ordering a replacement blade bar using the original number, the new blade bar design

will automatically be sent. However, the 4 longer mounting bolts may not be included.

Therefore, when ordering a replacement blade bar, ensure that the proper length mounting

bolts (P/N 02964861 which is a 4" Bolt) are also replaced. DO NOT attempt to mount the new style blade

bar using the old shorter bolts. The best way is to always check the replacement bottom leaf thickness

as compared to the bottom leaf that was removed. If the replacement is thicker then the new longer

bolts will be needed. Another way to determine which one you have check the Leaf retaining bolt size.

Blade Leaf Bar Bolts (Torque

1-1/4" bolts to 2000 ft. lbs.)

Blade Bar Mounting Bolts

(Torque to 400 ft lbs.)

Figure 1

Note: Replaces / Same as Bulletin No. 061897A

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-25

Page 32

TECHNICAL INFORMATION BULLETIN No. 071797

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: Machete, MB21 S/N 01001 - 01108

& MB24 S/N 01001 - 01045

Bulletin No:

071797

Date:

Jul. 17, 1997

Joystick Power Cut Off Switch:

A Joystick Supply Cut Off Switch (Master Switch) can be added to the Machete in order to

eliminate the possibility of damage caused by the joystick moving while roading the machine over rough

terrain. Inadvertent movement of the controller can result in uncontrolled movement of the boom which

may result in damage to the boom rest, the tractor or other areas.

Parts needed:

Part No. Qty Description

02964028 1 Push Pull Switch, (or a locally purchased switch)

------------- 2 12 or 14 gauge wire butt connectors (furnished by installer)

------------- a/r 14 gauge wire cut to length, preferably red wire (furnished by installer)

Procedure:

1. Turn off the tractor ignition and remove the key (disable tractor to where it can only be started

when you want it started). Set parking Brake.

2. Find the RED Voltage supply wire which supplies electrical power to the Joystick.

3. Locate a suitable mounting position within easy reach of the operator, and run the two wires

from the new switch to the red power supply wire. Cutting the existing power supply wire connect the

two butt connector from the switch to the cut power supply, see drawing.

4. Operate the machine to ensure that the joystick functions will not work when switch is "OFF"

and will when switch is "ON"

Hook terminal Connector

Butt connectors to tractor starter solenoid

Master Switch

Swing

Lift

Ground (Black)

Tractor starter solenoid (brown)

Joystick connector Plug

Dipper

Switched Voltage

Tilt

Door

Butt

connectors

2 pin connector for pump solenoid

Supply (Red)

Note: Replaces / Same as Bulletin No. 071797A

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-26

Page 33

TECHNICAL INFORMATION BULLETIN No. 100397

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: Machete, MB21 S/N 01001 - 01108

& MB24 S/N 01001 - 01045

Bulletin No:

100397

Date:

Oct. 3, 1997

Cylinder, Link Arm, Turning Arm & Hitch Post Pin Update Kit:

Parts Required to update a Machete Boom Mower to the current Pin Design. In an effort to

remedy some of the confusion which exists in regards to what is required to update the Machete Boom

Mowers, the following list has been prepared. If all the listed parts are installed in accordance with the

related Service and Technical Bulletins, along with the instructions provided with each individual kit. The

mower will be updated to the way the current models are built.

Parts Required:

(Main Pin Replacement Kit, See Service Bulletin No. 970002A)

Part No. Qty Description Part No. Qty Description

02967689 1 Pin Kit, Main Pin at Turning Arm 02967693 1 Pin Kit, Dipper to Lift Arm

02967687 1 Pin Kit, Dipper to Hitch Post

(Cylinder Pin Kits, See Technical Information Bulletin No. 041797-2)

Part No. Qty Description Part No. Qty Description

02967679 1 Pin Kit, Lift Cyl. Barrel End 02967677* 1 Pin Kit, Lift Cyl. Rod End

02967683 1 Pin Kit, Tilt Cyl. Barrel End 02967681 1 Pin Kit, Tilt Cyl. Rod End

02967677* 1 Pin Kit, Dipper Cyl. Barrel End 02967685 1 Pin Kit, Dipper Cyl. Rod End

02967679 1 Pin Kit, Swing Cyl. Barrel End 02967675 1 Pin Kit, Swing Cyl. Rod End

02967681 1 Pin Kit, Hitch Post Link Arm to Dipper

02967694 1 Pin Kit, Hitch Post Link Arm to Linkage Asy.

02967691 1 Pin Kit, Linkage Asy. to Hitch Post

02968803 10 Pin Bushing

(Mower Head Hitch Post Replacement Kit, See Technical Information Bulletin No. 041797-1)

Part No. Qty Description

02972231 1 Hitch Post Replacement Kit

(Turning Arm - King Pin Replacement Kit, See Service Bulletin No. 970008A)

Part No. Qty Description

02972211 1 Turning Arm - King Post Replacement Kit

(Lift, Dipper and Head Tilt Drop Restrictions See Service Bulletin No. 970004A & 960009)

Part No. Qty Description Part No. Qty Description

02972159 3 Straight Adapters 02969398 3 .055" Orifice Plates

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-27

Page 34

TECHNICAL INFORMATION BULLETIN No. 112097

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: Machete, MB21 S/N 01001 - 01108

& MB24 S/N 01001 - 01045

Bulletin No:

112097

Date:

Nov. 20, 1997

Update Kits Combined (Kit P/N 02973216):

Includes - Hitch Post Kit , Cyl. Pin Kits, Hinge Pin Kit Turning Arm Pin Kit and Lift &

Dipper Drop Restrictors

Confusion regarding parts to necessitate the update of the MB21 & MB24 foot Machete mowers

has required that all of the parts required for the update be located under one single Kit number in order

to ensure that all of the new designed parts are installed. The parts delivered under this new Kit number

will include all of the parts necessary to fulfill the requirements of the following Service and Technical

information Bulletins:

Technical Information Bulletin 041797-1 Apr. 17, 1997 Hitch Post Replacement

Technical Information Bulletin 041797-2 Apr. 17, 1997 Cyl. Mount Pin Replacement

Service Bulletin 970001A Mar. 19, 1997 Turning Arm - King Pin Replacement

Service Bulletin 970002A Mar. 21, 1997 Hinge Pin Replacement

Service Bulletin 970004A Apr. 14, 1997 Lift & Dipper drop Restrictors.

Therefore, if a Machete mower manufactured with in a serial number within the above listed

range still requires the above listed updates, all the necessary parts can be obtained by ordering the

above listed single kit number 02973216. Complete instructions will be sent along with the parts in

addition to the instructions in the individual Bulletins. Likewise, If individual kits are necessary they can

be ordered using the individual kit numbers as listed in the above bulletins.

DO NOT order the above listed Kit (P/N 02973216) if some updates have been done and some

haven't because you will end up with more parts than needed. Do not make any repairs or order any

parts until you have reviewed all the above listed Bulletins concerning these updates.

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-28

Page 35

NOTES

MACHETE

© 2005 Alamo Group Inc.

1-29

Page 36

TECHNICAL INFORMATION BULLETIN No. 120697

Alamo Industrial Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: MacheteBoom MB21 & MB24

Bulletin No:

120697

Date:

Dec. 6, 1997

Lock Valve Installation Instructions:

Instructions for installing a lock valve on the tilt function of an Alamo Industrial Model Machete

Boom product manufactured before May 1, 1997.

The nominal leak down rate for the cutter head tilt section of the electrically controlled positioning

valve is one inch of rod travel in four minutes. If your machine exhibits a leak down rate substantially

greater than this, it typically indicates excessive valve component wear due to contaminated oil in the

tractor. Refer to the Tractor's Operator / Maintenance guide concerning Oil & Filter change intervals to

eliminate contamination possibilities.

If the cutter head tilt cylinder leak down is greater than one inch of rod travel in four minutes and

this is considered excessive, a lock valve may be added to the tilt function of the boom machine. Alamo

Industrial has developed a cure for this and can provide (at a nominal charge) all the parts for a lock out

vale for the tilt function. The Lock valve will only work on the tilt function of the Boom Machine due to the

design of the hydraulic System. The only parts that must be provided by the installer are two, twelve inch

pieces of 18 gauge wire. Each wire needs to have a # 8 ring connector on one end and a wire splice

connector on the other end.

The drawings on the next page shows the details of the parts and their assembly. The Lock Valve

must be installed in the "C-1" port of the cutter head tilt section

The following parts are required to make this modification:

Part No. Qty Description

02972180 1 Straight Hydraulic Adapter (available from Alamo Industrial)

001654 1 Hydraulic Fitting, 90° Elbow (available from Alamo Industrial)

02972208 1 Solenoid Valve Assembly (available from Alamo Industrial)

------------- 2 18 gauge wire, 12" long each (furnished by installer)

------------- 2 # 8 ring connectors (furnished by installer)

------------- 2 18 gauge splice connectors (furnished by installer)

NOTE; Installation of this Lock valve will not be covered under warranty.

MACHETE

© 2005 Alamo Group Inc.

1-30

Continued Next Page

Page 37

Information Bulletin 120697 Continued from previous Page

Electrical connection:

Identify the plus (+) lead running to the solenoid for the tilt function. This solenoid is located across

the valve from the fitting you installed. Remove approximately 2 " of the outer plastic covering from the

wires coming from the solenoid. Splice one of the 18 gauge wires you provided into one of the wires.

Connect the other end of that wire to a lug on the solenoid. It makes a difference which wire runs to which

connector. Insulate any exposed wires with electrical tape.

Note orientation

of notch in plate

To Valve

Very Important ! DO NOT use

Solenoids as handles

Wire connector Lugs

Door

Tilt

Dipper

Lift

Swing

"C-1"

Port

Steps to take to install the tilt cylinder lock valve

Hydraulic Connections

1. Remove the tilt section hose from the "C-1" Port

2. Assemble the parts as shown above.

3. Attach the hose to the fitting on Lock valve, Test and run.

"C-2"

Port

TECHNICAL INFORMATION BULLETIN

No. 120697

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-31

Page 38

TECHNICAL INFORMATION BULLETIN No. 041398

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: All Machete Boom , MB21 & MB24

All Slope Mowers

Bulletin No:

041398

Date:

Apr. 13, 1998

Eleminate Erratic Boom movement:

(which utilize the joystick operated proportional valve system)

Procedures to eliminate erratic boom operation caused by microwave interference from

customer installed two-way radios.

There have been some scattered reports in regards to erratic or unexpected movement of one

or more of the proportionally controlled boom functions of the joystick control system during the

operation of the customer installed two-way radios.

Specifically, the Swing , Lift or Dipper functions may operate at a speed of one foot of movement

every 10 to 20 seconds, depending on the function and direction, when the radio microphone is keyed.

Research and experiments with machines in the field has revealed that this phenomenon is the

reception of the signal transmitted by the radio passing through the variable controls of the boom control

system. Specifically, the wire harness of the control system acts much like a receiving antenna and

receives the radio signal which sends a false signal through harness.

Elimination of the interference may be obtained with the use of at least of three possible options:

1. Remove the radio from the tractor completely.

2. Install a reflecting plate under the Antenna. A reflecting plate is simply a thin, flat piece of metal

which provides the proper amount of impedance to essentialy reflect the signal emanating down from

the antenna and prevent interference with the valve electronics and tractor functions. Since the

installation requires a fairly large (at least 36" square) area, the specially designed reflecting or "ground

plane tape" can be used in place of the metal sheet for easier installation. this tape is available at most

electronics or radio equipment sources.

3. Utilize a ground plane antenna. These specially designed antenna utilize the standard central

radial element and at least two other radials set at 45° angles to the central one. These radials must

be cut to specific lengths depending on the frequency of the system. Only a professional radio installer

or retailer should be consulted in regard to the avaialbility and proper installation of these antenna.

The installation, operation, and resulting effects to the tractor or any attachment due to the

addition of a radio system to any machine is the responsibility of the machine owner and the radio

installer. Only trained, profesional radio installers should be utilized.

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-32

Page 39

TECHNICAL INFORMATION BULLETIN No. 020199

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: All Machete Boom , MB21 & MB24

All A-Boom Mowers utilizing the New Holland

TS Series Tractors

Bulletin No:

020199

Date:

Feb. 1, 1999

Hood to Frame Interference on TS Series Tractors:

On some occasions, it has been reported that the initial mount kit designs involving the

installation of the current A-Boom or Machete Boom mowers to New Holland TS90, 100 or 110 tractors

allowed the main frame cross over / cooling tube to interfere with the movement of the hood. This

interference would not allow the hood to open to provide access to the required maintenance points

of the tractor engine.

To compensate, the hood was required to be completely removed to perform the required

maintenance procedures.

A spacer kit which lifts the frame to provide clearance between the hood and the cross / cooling

tube enough to allow the hood to open to the first position is now available for all of the affected tractors.

The kit components should be installed per the instructions provided in the kit. likewise, all

required hood components such as hinges, shocks & etc. should also be installed

Part Numbers required:

Figure 1

A-Boom: 2 WD kit No. 02974715

4 WD kit No. 02974739

Machete: 2 WD kit No. 02974351

4 WD Kit No. 02974741

NOTE: Claims for compensation for warrantable repairs should be

filed in accordance with the Alamo Industrial warranty Guide procedures. This

Bulletin does not authorized warranty

repairs for this procedure.

Spacers

Existing Mount Tubes

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-33

Page 40

TECHNICAL INFORMATION BULLETIN No. 031000

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: Models mounted on New Holland TS Series Tractors

Bulletin No:

031000

Date:

Mar. 10, 2000

New Holland TS Series Fuel Filter:

New Holland ships TS100 Tractors to Alamo Industrial with a # 87801634 fuel filter installed.

New Holland has circulated a service bulletin stating that a longer or taller filter is the

replacement part for the fuel filter and the filter should be changed at the recommended time.

Alamo Industrial TS Series mount kit components will interfere with the longer / taller filters.

Please continue using the # 87801634 filter when replacing the fuel filter on the TS Series

tractors equipped with the Alamo Industrial products. Alamo Industrial attachments do not stress or

"Work" the tractor engines in a manner that would be considered extreme service. The part #

87801434 fuel filter will provide adequate protection when the engine of a TS Series New Holland

tractor is powering Alamo Industrial Side or Boom Mounted products.

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-34

Page 41

TECHNICAL INFORMATION BULLETIN No. 032200-1

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: All Machete Boom , MB21 & MB24

Bulletin No:

032200-1

Date:

Mar. 22, 2000

New Oil Filter Kit P/N 02976069:

Detailed investigation of recent valve failures revealed that in the vast majority of the

incidences, the failures are attributable to contamination within the tractor hydraulic systems which

supply pressure to the control valve. Failure normally take the form of one or more inoperative or

poorly operating functions. Repair may involve the replacement of the electronic controller for the

section or, in severe cases, the replacement of the entire valve. Particulate contamination in the form

of small gear metal or brass particles created during break-in and operation and are not removed

during required maintenance of the tractor can enter the valve, this creates leakage due to wear or

clogging of passageways.

In response, an in-line pressure filter and fitting kit (Kit P/N 02976069) has been developed

for installation in the pressure line which delivers oil to the valve. The kit provides all the necessary

fittings, hardware and instructions to facilitate the correct installation.

Installation of the Filter Kit will greatly reduce the

possibility of the occurrence of failures within the Machete

control valve due to particulate contamination. This contamination may result from poor maintenance of the tractor

hydraulic system or other hydraulic system performance

characteristics or problems.

Visual Indicater - Bypass

O-Ring

Filter Head

O-Ring

An indicator located on the top of the filter housing

will indicate when the filter is bypassing thus requiring the

replacement of the filter element. The element is a canister

insert which is easily replaced by unscrewing the cannister.

In accordance with the published Warranty Policy,

failures proven to be the result of contamination of the

system oil due to poor maintenance, performance or repair

of the supply (Tractor) system will not be compensated

under Alamo Industrial Warranty.

Filter Element

O-Ring

Back Up Ring

Filter Bow

l

Figure 1

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-35

Page 42

TECHNICAL INFORMATION BULLETIN No. 080300

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: All Machete, A-Boom, Versa, Rear Mount, Slopemower,

Brahma, EKII, Hydro 60, Hydro 72 & Hydro 15

All Hydraulic powered Rotary Mower heads that utilize the

# 02960553B, 02960553C and 02968859A Spindle Assemblies.

Bulletin No:

080300

Date:

Aug. 3, 2000

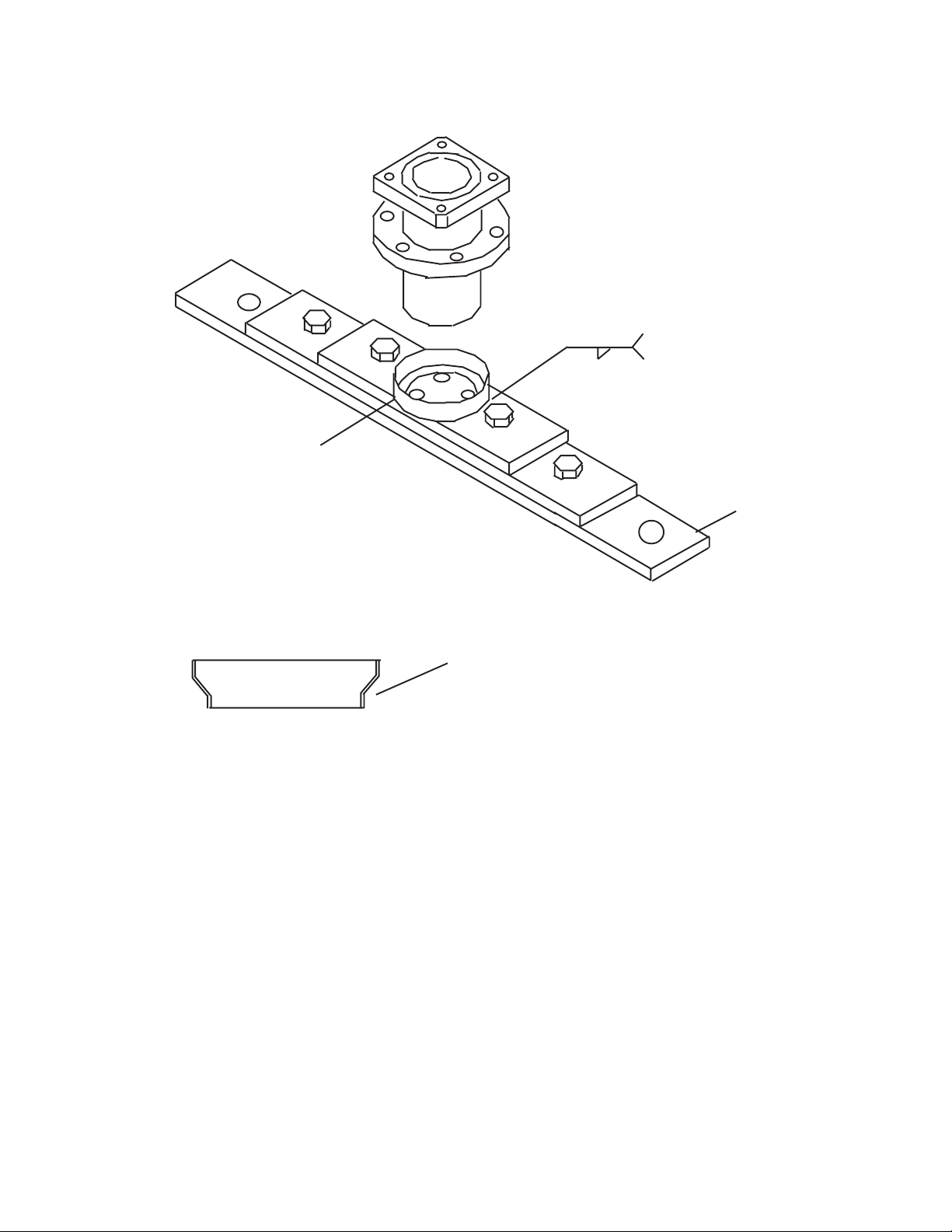

Spindle Oil Filler Kit P/N 02976501:

A Spindle oil filler kit has been developed to provide accurate an easy fill of oil into the spindles

used on all hydraulic powered mowers. The Oil filler Kit P/N 02976501 is available through Alamo

Industrial Parts dept.

Installation requires the replacement of the fill plug with the female quick connect fitting. To

fill the spindle. attach the hose and oil bottle to the spindle by utilizing the quick connect fittings. remove

the vent plug and pump in the oil untill oil is seen at the vent plug opening. reinstall the vent plug and

remove the bottle at the quick connect fitting. The female quick disconnect is designed to be left on

the spindle in place of the fill plug.

Utilization of this spindle fill kit should decrease maintance time and failures by providing

accurate oil fill of the spindle assembly.

Hose (with clamp)

Female Quick Connect

Spindle Assembly

Vent

Fill Plug (Removed)

Oil tank

Figure 1

(with Hand Pump)

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-36

Page 43

TECHNICAL INFORMATION BULLETIN No. 080400

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: All Machete, A-boom, Versa Boom, Slopemower.

Boom Mowers which utilize the Joystick operated control valve

with the 02976069 oil Filter Kit installed.

Bulletin No:

080400

Date:

Aug. 4, 2000

Filter Maintenance Procedure:

The following Procedure should be followed to provide the correct maintenance of the

02976066 Filter assembly use as standard on the machete moddel boom and any mower using

Joystick controlled hydraulic system, and filter as optional equipment.

When to Change Filter:

Inspect the visual indicator when the system is operating at normal operating temperature

and under normal flow conditions. When red starts to enter the indicator window, change the element.

This will occur prior to bypass by the filter.

Element Service Procedure:

1. Shut System down a disable tractor so it

cannot be started. Let Oil cool to a safe

temperature.

2. Place a suitable container under the filter to

catch any spillage.

3. Unscrew the filter bowl using the wrench flats

at the bottom of bowl. Remove the bowl and

drain the oil into the container.

4. Pull the element (P/N 02976067) off the adapter

an discard it.

5. Remove the head to bowl seal and discard.

Clean the seal area with a lint free cloth. Install

the new seals as shown taking care not to cut

the new seals.

6. Install the new element onto the element

adapter boss.

7. Thoroughly clean the filter bowl and fill approximately one half full with clean oil.

8. Screw the Bowl onto the head. Torque the

bowl to 30 ft. lbs.

9. Operate the system to expel any trapped air

and check for leaks.

10. Check and fill the tractor oil level as required.

O-Ring

Back Up

Ring

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-37

Page 44

TECHNICAL INFORMATION BULLETIN No. 012501

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: Machete Boom Mowers

S/N MB21- 01572 & Up

S/N MB21-01245 & Up

Bulletin No:

012501

Date:

Jan 25, 2001

Control Valve Relocation:

The 2001 Machete will reflect a change in the way some of the components are mounted to

the tractor. New Machete units received from the factory, or assembled by dealer after S/N MB2101572 & UP or MB24-01245 & Up will have the control valve in a new location. It will no longer be

mounted on the frame. The Control Valve will be located under the front pump cover in the front of

the tractor. This change was made to better protect the Valve and its components from debris and

other possible damage.

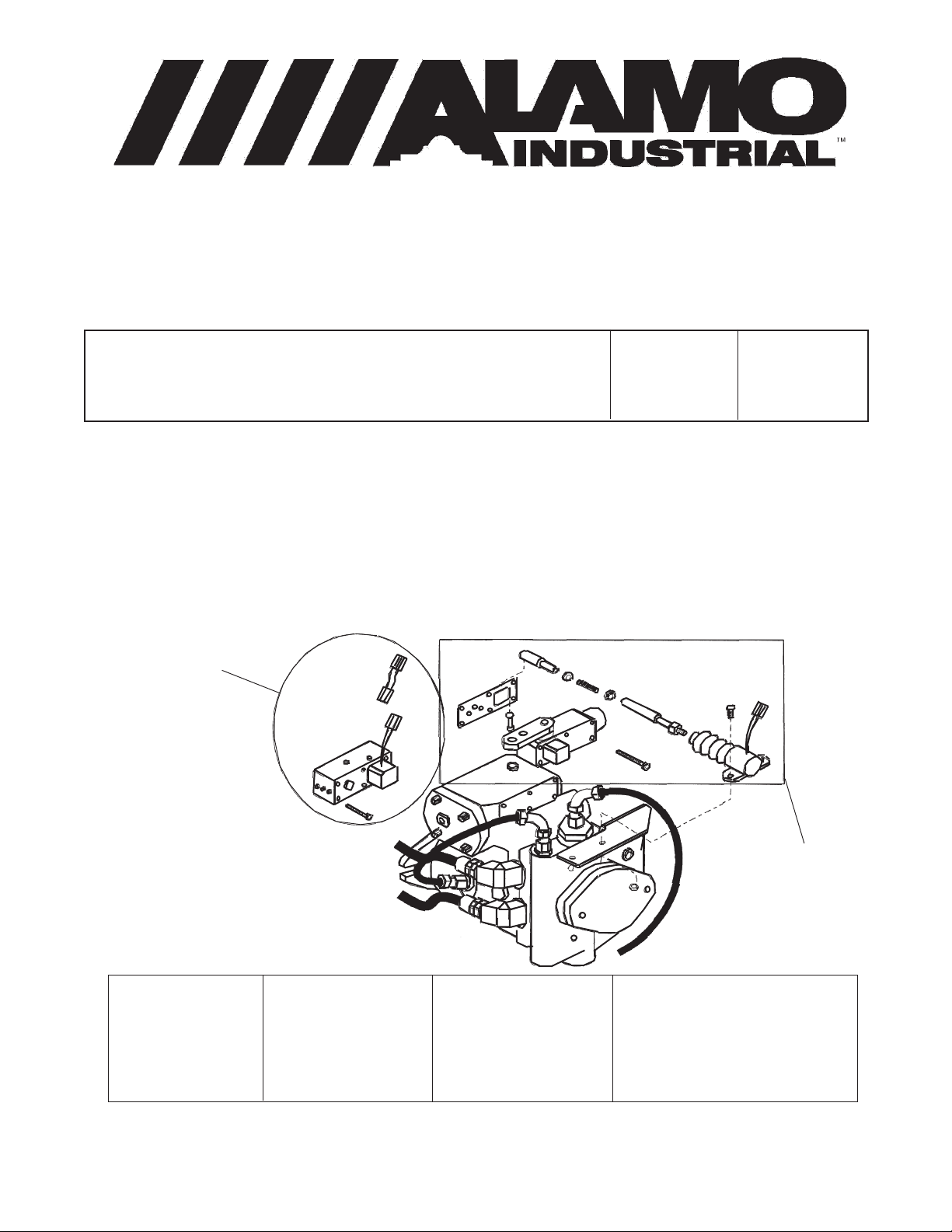

As you can see in figure 1,

the valve is fastened to a plate

that is mounted to the units hydraulic tank. The Pressure Filter

was relocated to a bracket on top

of the tank. Both the Pressure

Filter and the Pump Filter are

accessible and can be changed

with minimal effort. Sepaarate

hose exstension were used to

extend the hose reach to the front

of the tractor. If a hose connection is not easily accessible, then

the valve and mounting plate can

be unfastened an arranged to allow for romm when servicing.

Pump Fiter

Pressure Fiter

Control

Valve

These Changes were

made to better protect the valve

and its components. These

changes will only be seen on the

new units after Jan. 2001 and is

not intended for units already in

use.

Figure 1

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-38

Page 45

TECHNICAL INFORMATION BULLETIN No. 040901

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: All Alamo Industrial Products are affected.

Bulletin No:

040901

Date:

Apr. 9, 2001

Change in the availability of rebuilt components:

This bulletin has been published to inform you of a change in the availability of rebuilt parts.

In the past, rebuilt components such as pumps and motors were available for use as spare parts.

That will no longer be the case. The major factor in this decision was the lack of cores that are returned

from the customer.

Since Alamo Industrial will no longer offer rebuilt parts an effort will be made to offer customers

a complete parts listing of all components that are needed as service repairs. The most common

service parts are pumps and motors will now be available for order through Alamo Industrial

Customer Service Department. Likewise, a parts breakdown with Alamo Industrial part numbers will

be provided. The Eaton Pumps and Motors, Danfoss Control Valves will be the first components

available with such a parts breakdown.

It is Our intention to provide a better and more reliable service parts system. This transition

will better suit customer, and provide more timely and efficient parts delivery.

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-39

Page 46

TECHNICAL INFORMATION BULLETIN No. 041001-1

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: Machete Boom, MB21-01109 & Down

MB24-01046 & Down

Bulletin No:

041001-2

Date:

Apr. 10, 2001

Filter Kit to Update Control Valve System (Kit P/N 02977366):

There is now available for purchase, a filter kit for Machete units that utilize the Apitech valve.

The Apitech valve was the control valve used before the now current Danfoss valve. You can

differentiate the type valve in two ways. The first is by serial number. The Machete units PRE-Date

the following serial numbers, utilize the Apitech Valve: MB21-01109 & Down, MB24-01046 & Down.

The second way is by visually inspecting the unit. The Apitech valve will have electronic Solenoids

on both the pressure and return sides of the valve, as well as electronic connections on each

solenoid. The Danfoss Control Valve only has electronic connectors on one side. Install the Filter as

described by the Assembly Drawing ( Drawing P/N 02977367) that you will receive when you order

the Filter Kit (Kit P/N 02977366) for the Machete Unit

When to Change Filter:

Inspect the visual indicator when the system is operating at normal operating temperature

and under normal flow conditions. When red starts to enter the indicator window, change the element.

This will occur prior to bypass by the filter.

Element Service Procedure:

1. Shut System down a disable tractor so it cannot be started. Let Oil cool to a safe temperature.

2. Place a suitable container under the filter to catch any spillage.

3. Unscrew the filter bowl using the wrench flats at the bottom of bowl. Remove the bowl and

drain the oil into the container.

4. Pull the element (P/N 02976067) off the adapter an discard it.

5. Remove the head to bowl seal and discard. Clean the seal area with a lint free cloth. Install

the new seals as shown taking care not to cut the new seals.

6. Install the new element onto the element adapter boss.

7. Thoroughly clean the filter bowl and fill approximately one half full with clean oil.

8. Screw the Bowl onto the head. Torque the bowl to 30 ft. lbs.

9. Operate the system to expel any trapped air and check for leaks.

10. Check and fill the tractor oil level as required.

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-40

Page 47

TECHNICAL INFORMATION BULLETIN No. 041001-2

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: Machete Boom, MB21-01109 & Down

MB24-01046 & Down

Bulletin No:

041001-1

Date:

Apr. 10, 2001

Filter Maintenance Procedure:

The following Procedure should be followed to provide the correct maintenance of the

02976066 Filter assembly use as standard on the machete moddel boom and any mower using

Joystick controlled hydraulic system, and filter as optional equipment.

When to Change Filter:

Inspect the visual indicator when the system is operating at normal operating temperature

and under normal flow conditions. When red starts to enter the indicator window, change the element.

This will occur prior to bypass by the filter.

Element Service Procedure:

1. Shut System down a disable tractor so it

cannot be started. Let Oil cool to a safe

temperature.

2. Place a suitable container under the filter to

catch any spillage.

3. Unscrew the filter bowl using the wrench flats

at the bottom of bowl. Remove the bowl and

drain the oil into the container.

4. Pull the element (P/N 02976067) off the adapter

an discard it.

5. Remove the head to bowl seal and discard.

Clean the seal area with a lint free cloth. Install

the new seals as shown taking care not to cut

the new seals.

6. Install the new element onto the element

adapter boss.

7. Thoroughly clean the filter bowl and fill approximately one half full with clean oil.

8. Screw the Bowl onto the head. Torque the

bowl to 30 ft. lbs.

9. Operate the system to expel any trapped air

and check for leaks.

10. Check and fill the tractor oil level as required.

O-Ring

Back Up

Ring

This document does not authorize the repair or replacement of parts under warranty

MACHETE

© 2005 Alamo Group Inc.

1-41

Page 48

TECHNICAL INFORMATION BULLETIN No. 041101

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models: All Alamo Industrial Products using the

Buzz Bar Head are affected.

Buzz Bar Drive Coupling Design change:

There has been a design

change to the drive coupler

assembly for the Buzz bar

Cutting Head. If a flexible coupler, Alamo Industrial P/N

02974245 (for Machete) or P/

N 02974246 (for A-Boom &

Slopemower), are ordered they

will be a different design. The

new flexible coupler design will

be molded rubber with metal

inserts. The new molded rubber version will directly replace

the machined design using the

same part number. An installation drawing, that describes

the assembly in detail, will be

shipped if a new coupler is

ordered. this bulletin is to inform you of the design change