Page 1

HDE-2 SERIES

ZERO TURN MOWERS

MODELS:

HDE2049KT2, HDE2249FS2, HDE2549PS2

HDE2255FS2, HDE2555KP2, HDE2555PS2

HDE2261FS2, HDE2561KP2, HDE2561PS2

Published: 04/18

Manual Number 50080017

©2018 Alamo Group Inc.

Page 2

Page 3

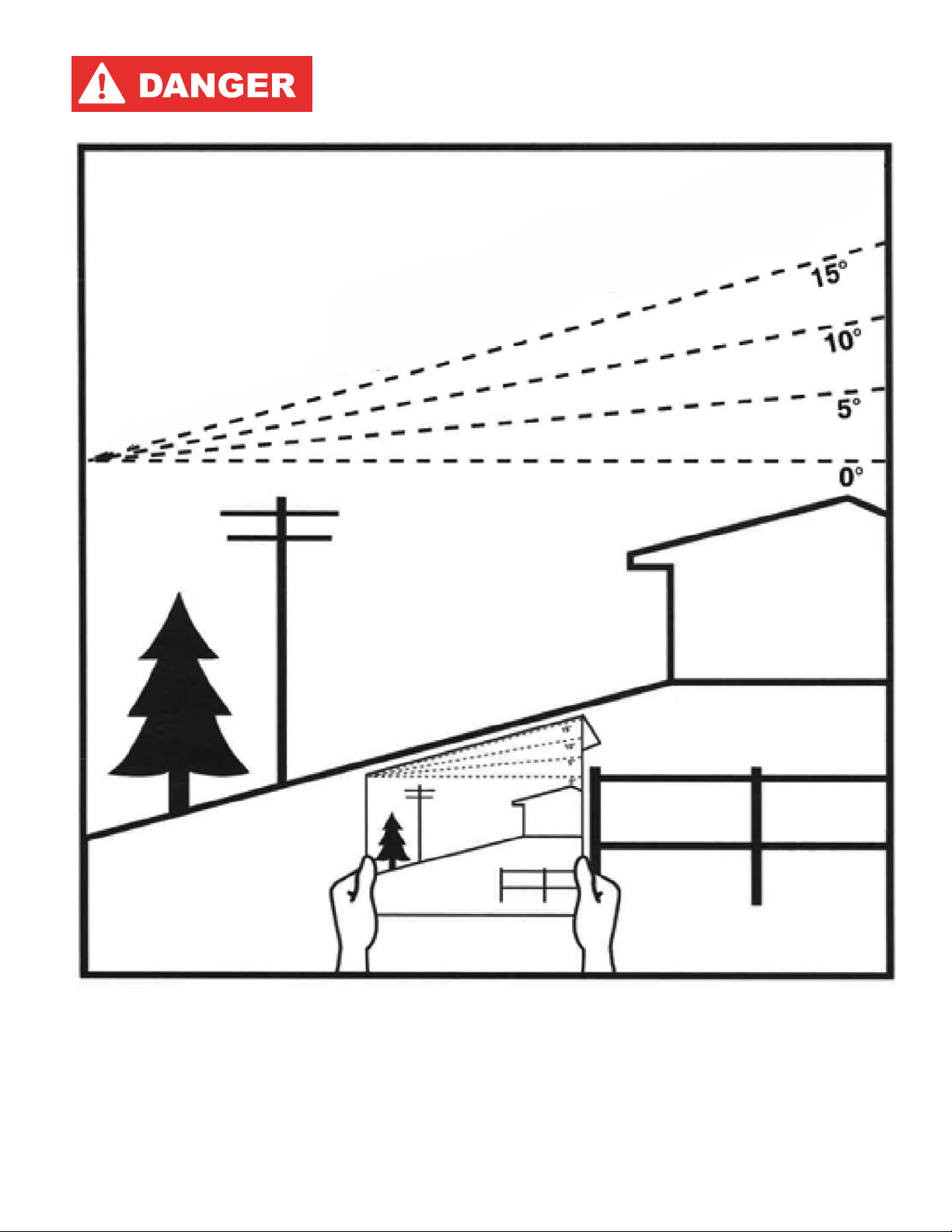

SLOPE INDICATOR

This page may be copied for personal use

outside of this manual.

Operating of this Zero Turn Mower on a Slope Exceeding 15 Degrees is unsafe and can cause upset or loss of traction resulting

in serious injury or death.

q

w

E

q Fold along the dashed line to measure the slope being checked.

w Align this edge with a vertical reference point, a tree, building, power pole, etc.

e Shows example of how to compare the slope with the folded edge.

Page 4

Page 5

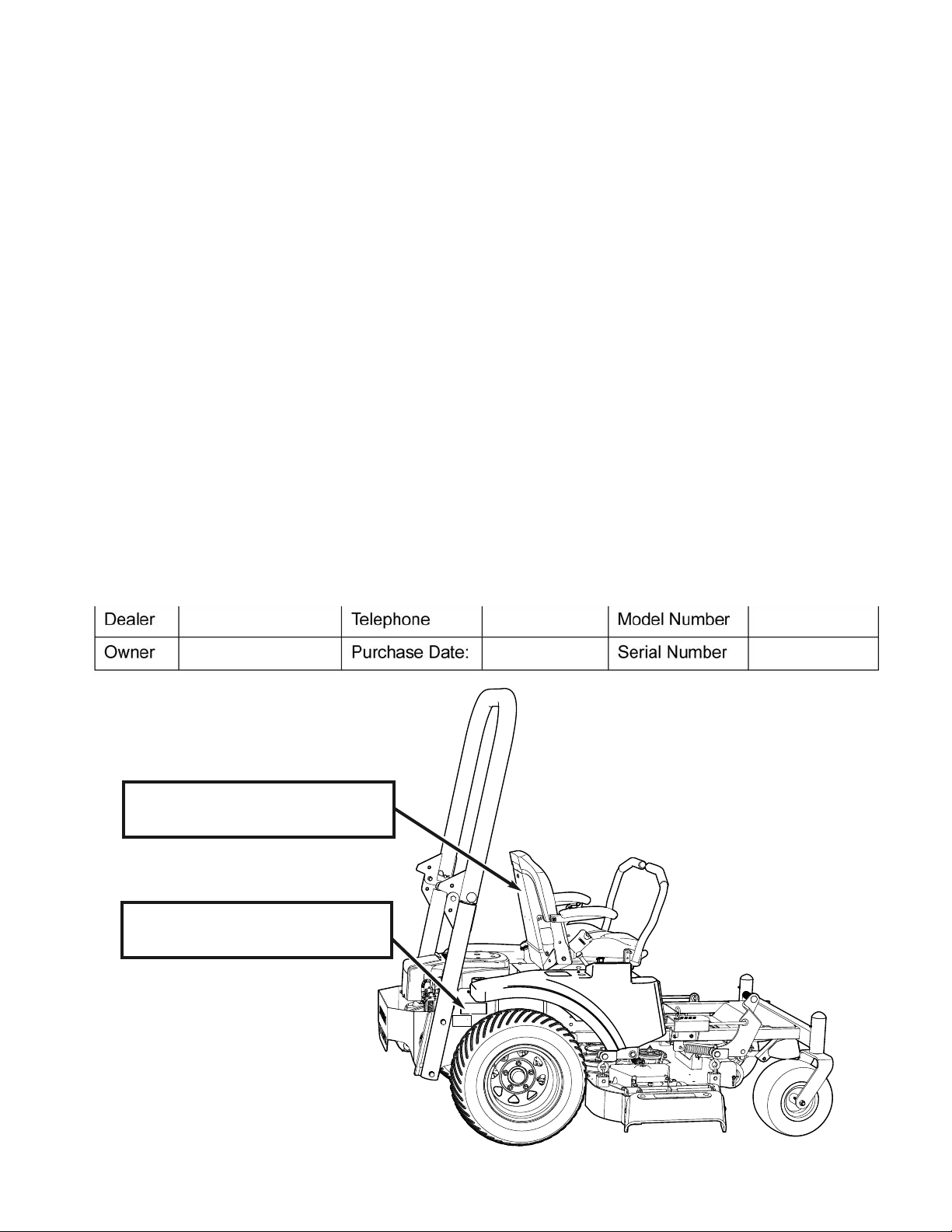

To the Owner/Operator/Dealer

This Operator's Manual is an integral part of the safe operation of this Zero Turn Mower and must be maintained with

the Zero Turn Mower at all times. A Manual holder is provided on the Zero Turn Mower where this manual can be

properly stored. If you lose or damage this manual a free replacement manual can be obtained from an authorized

Bush Hog dealer or by down loading the manual from the Bush Hog website www.bushhog.com

BEFORE YOU START! READ, UNDERSTAND, and FOLLOW the information provided in this manual and the Engine

manual carefully to learn how to operate and service your Zero Turn Mower properly. Failure to do so could result in

personal injury to you and bystanders. All Zero Turn Mowers with moving parts are potentially hazardous. Every effort

has been made to ensure that the Zero Turn Mower is safe but operators must avoid engaging in unsafe practices

and follow the written instructions provided. The manufacturer has designed this Zero Turn Mower to be used with

all its safety equipment properly attached to minimize the chance of accidents.

SAFETY FIRST. Completely read and understand the safety section of this manual before operating this equipment.

Do not allow anyone to operate this equipment who has not fully read and understood this manual. Contact your

Dealer to explain any instructions that you do not fully understand.

The care you give your Bush Hog Zero Turn Mower will greatly determine your satisfaction with its performance and

its service life. Carefully read and follow the instructions in this manual to provide you with a thorough understanding

of your new Zero Turn Mower and its intended use and service requirements.

All references made in this manual to right, left, front, rear, top or bottom are as viewed facing the direction of forward

travel with the Zero Turn Mower.

Replacement Parts information is located in a separate Parts Manual. Bush Hog parts are made and tested to Bush

Hog specifications. Non-genuine “will fit” parts do not consistently meet these specifications. The use of “will fit” parts

may reduce Zero Turn Mower performance, void warranties, and present a safety hazard. Use genuine Bush Hog

Zero Turn Mower parts for economy and safety. For future reference, record your Bush Hog product model number

and serial number.

This unit is Approved for use on U.S. Forest Service Lands.

Serial Number located on right

hand side on the frame.

Manual Holder located on back

of seat.

Page 6

LIMITED WARRANTY

Bush Hog warrants to the original purchaser of any new Bush Hog HDE Series Zero Turn Mower purchased from an Authorized Bush Hog Dealer. This shall warranty that the Zero Turn Mower is free from defects in material and workmanship.

Non-Commercial Warranty is for a period of Three, (3) years from the date of retail sale. (Third year parts only.)

Commercial Warranty is for a period of One, (1) year or 400 Hours from date of retail sale.

Limited Lifetime Deck Weldment Warranty (Original Purchaser).

Engine Warranty is through the engine manufacturer.

The obligation of Bush Hog under these warranties are limited to repair or replacement of defective parts.

Replacement or repair parts installed in the equipment covered by this limited warranty are warranted for ninety (90) days

from the date of purchase of such part or the expiration of the applicable new equipment warranty period, whichever comes

later.

Warranted parts shall be provided at no cost to the user through an Authorized Bush Hog Dealer during regular hours of operation. Bush Hog reserves the right to inspect any equipment or parts which are claimed to have been defective in material

or workmanship.

DISCLAIMER OF IMPLIED WARRANTIES & CONSEQUENTIAL DAMAGES

Bush Hog’s obligation under this limited warranty, to the extent allowed by law, is in lieu of all warranties, implied or expressed,

INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE and any

liability for incidental and consequential damages with respect to the sale or use of the items warranted. Such incidental and

consequential damages shall include but not be limited to: transportation charges other than normal freight charges; cost of

installation other than cost approved by Bush Hog; duty; taxes; charges for normal service or adjustment; loss of crops or

any other loss of income; rental of substitute equipment, expenses due to loss, damage, detention or delay in the delivery

of equipment or parts resulting from acts beyond the control of Bush Hog.

THIS LIMITED WARRANTY SHALL NOT APPLY:

1. To vendor items which carry their own warranties, such as engines, tires, and tubes.

2. If the unit has been subjected to misapplication, abuse, misuse, negligence, fire or other accident.

3. If parts not made or supplied by Bush Hog have been used in connection with the unit, if, in the sole judgement of Bush

Hog such use affects its performance, stability or reliability.

4. If the unit has been altered or repaired outside of an authorized Bush Hog dealership in a manner which, in the sole

judgement of Bush Hog, affects its performance, stability or reliability.

5. To normal maintenance service and normal replacement items such as hydrostatic oil, worn blades, or to normal deterioration of such things as belts and exterior finish due to use or exposure.

6. To expendable or wear items such as belts, springs and any other items that in the company’s sole judgement is a wear

item.

NO EMPLOYEE OR REPRESENTATIVE OF BUSH HOG IS AUTHORIZED TO CHANGE THIS LIMITED WARRANTY IN

ANY WAY OR GRANT ANY OTHER WARRANTY UNLESS SUCH CHANGE IS MADE IN WRITING AND SIGNED BY

BUSH HOG’S SERVICE MANAGER, 2501 GRIFFIN AVE., SELMA, ALABAMA 36703.

Record the model number, serial number and date

purchased. This information will be helpful to your

dealer if parts or service are required.

MODEL NUMBER

SERIAL NUMBER

DATE OF RETAIL SALE

Make Certain that the retailing dealer has

registered your warranty information with

Bush Hog at time of purchase.

Page 7

DEALER PREPARATION CHECK LIST

For NEW ZERO TURN RIDING MOWER

BEFORE DELIVERING MACHINE - The following check list should be completed.

Use the Operator's Manual as a guide. Engine has been serviced.

Ground Cable connected to Battery Negative Pole.

Zero Turn Mower start code communicated to Owner.

Low oil pressure light checked for operation.

Operator interlock switches checked for operation.

Assembly completed.

All fittings lubricated.

Hydraulic Reservoirs filled to Cold Fill Line with oil.

All shields in place and in good condition.

Roll-over Protective Structure is raised to the upright position and pinned out. This may require

the upper ROPS to be rocked forward to align the Pin-Out Holes.

Retractable seat belt functions property.

All fasteners torqued to specifications given in Torque Chart.

All decals in place and readable. (See decal page.)

Overall condition good (i.e. paint, welds)

Parking brake checked and adjusted, if necessary.

Steering checked and adjusted, if necessary.

Check tire pressure.

Warranty information has been registered on line with Bush Hog.

Operator's manual has been delivered to owner and he has been instructed on the safe and

proper use of the Zero Turn Mower.

Dealer's Signature ____________________________________

Purchaser's Signature ____

___________________________________

THIS CHECKLIST TO REMAIN IN OWNER'S MANUAL

It is the responsibility of the dealer to complete the procedures listed

above before delivery of this Zero Turn Mower to the customer.

Page 8

Page 9

HDE SERIES ZERO TURN MOWER

TABLE OF CONTENT

SAFETY (SECTION 1)

General Safety Instructions and Practices............................................................................1-1

Important Safety Considerations and Precautions ..............................................................1-2

Safety Instructions and Recommendations ..........................................................................1-2

OPERATOR SAFETY................................................................................................................1-3

MOWER OPERATION SAFETY................................................................................................1-3

Ground Speed When Mowing ..................................................................................................................................1-3

ACCIDENT PATTERNS TO AVOID...........................................................................................1-4

Contact With The Rotating Blades............................................................................................................................1-4

Mower Thrown Objects.............................................................................................................................................1-4

Grass Discharge Chute ............................................................................................................................................1-4

Over Turning.............................................................................................................................................................1-4

Mower Running Over Victim.....................................................................................................................................1-4

Child Safety ..............................................................................................................................................................1-4

Fuel and Grass Fires ................................................................................................................................................1-4

MOWER BLADE CONTACT HAZARDS...................................................................................1-5

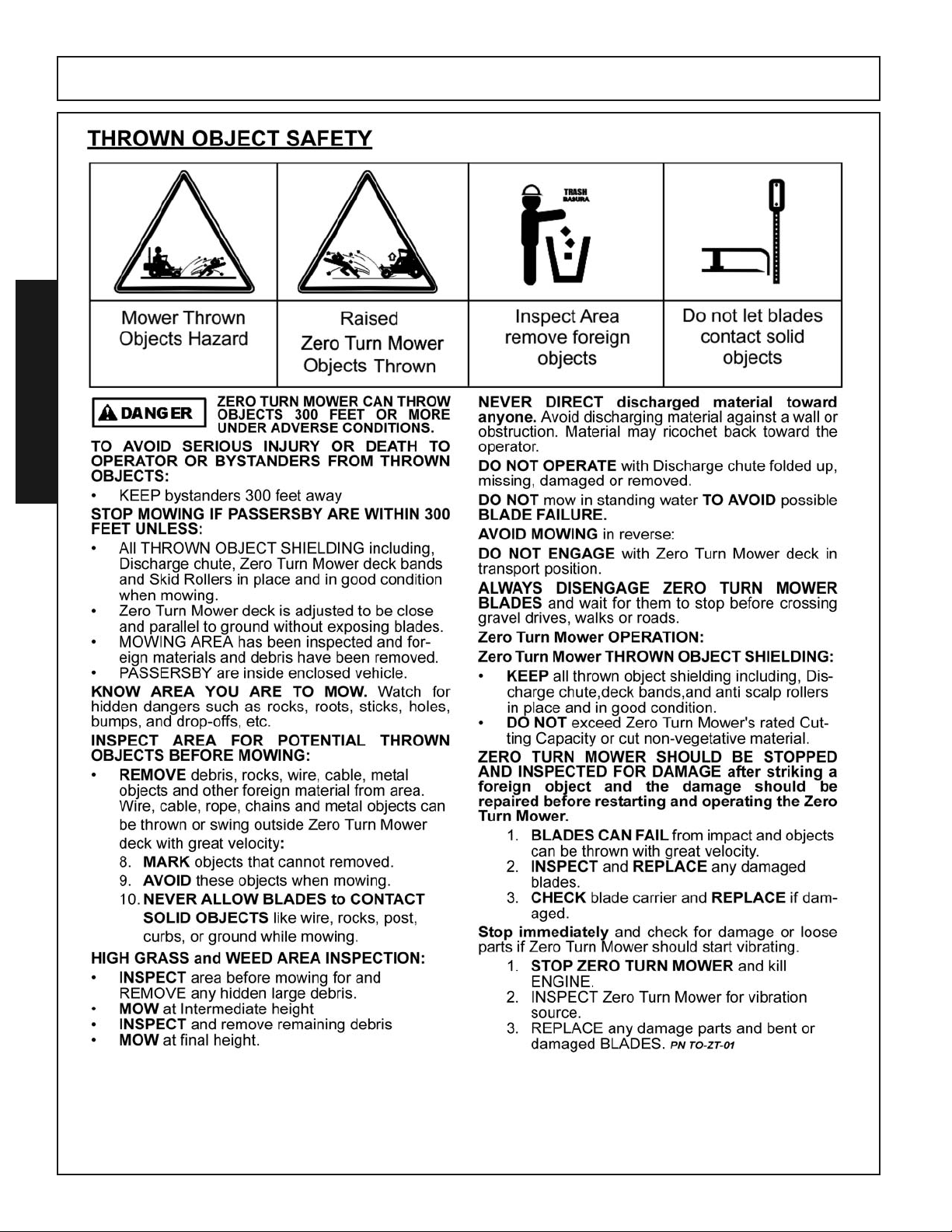

THROWN OBJECT SAFETY ....................................................................................................1-6

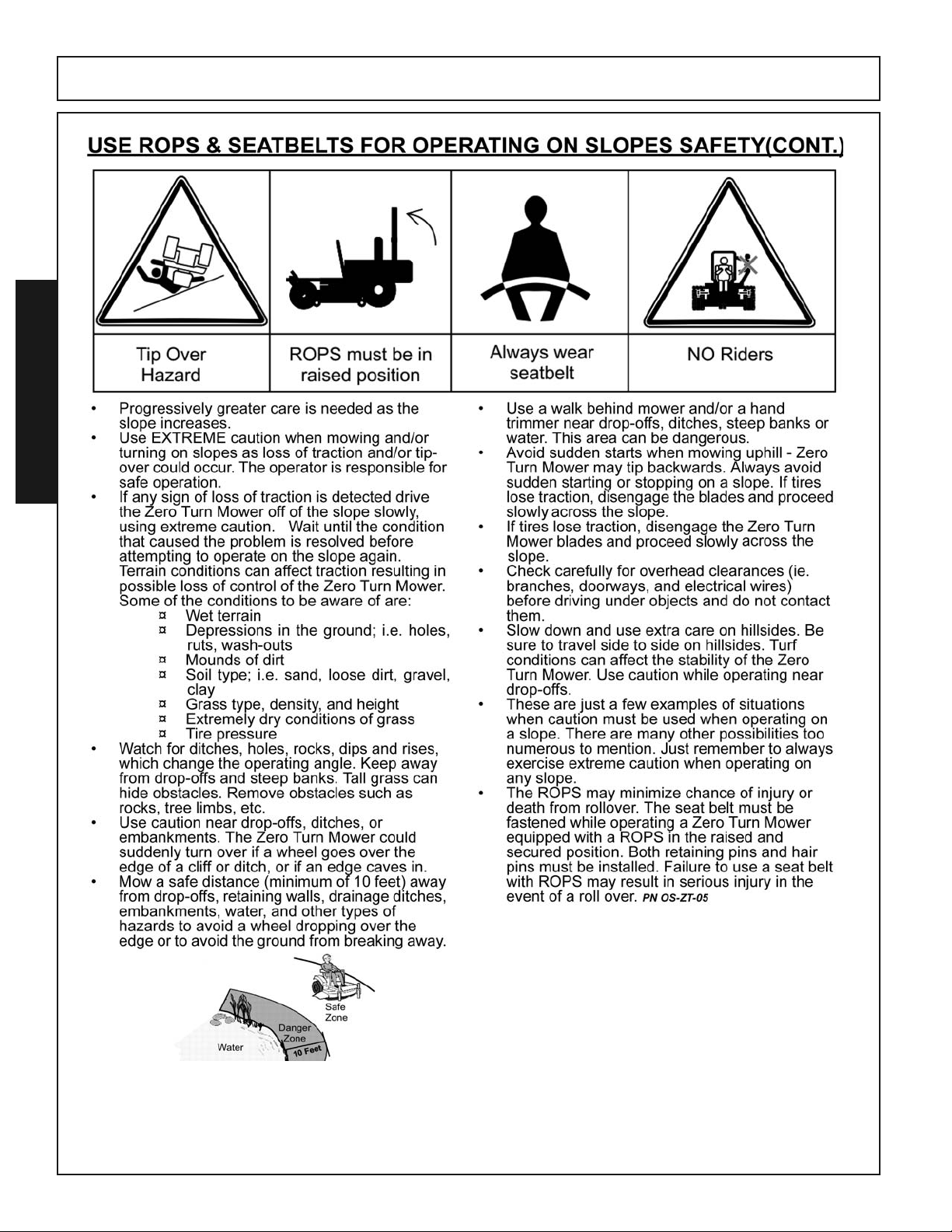

USE ROPS & SEATBELTS FOR OPERATING ON SLOPES SAFETY...........................1-7 / 1-8

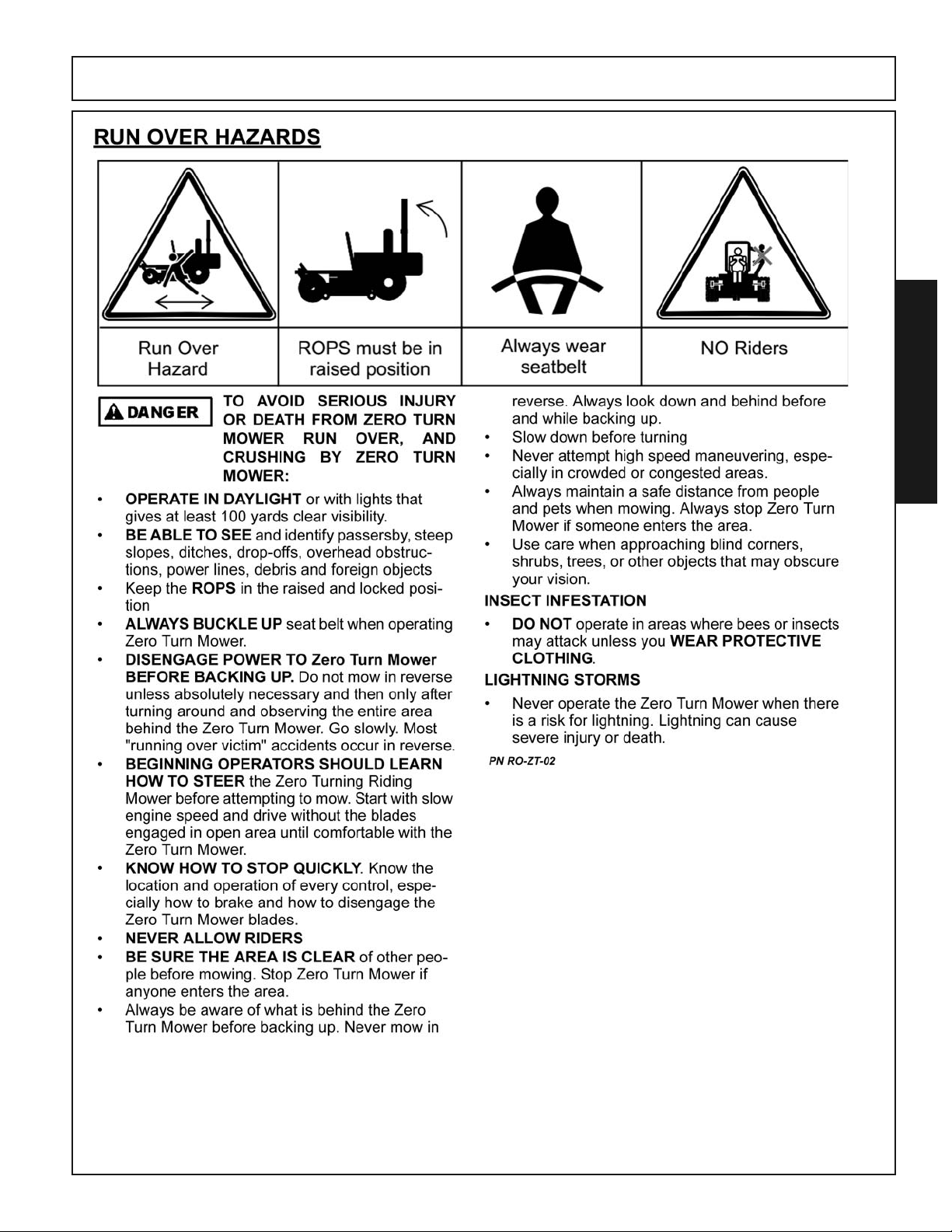

RUN OVER HAZARDS..............................................................................................................1-9

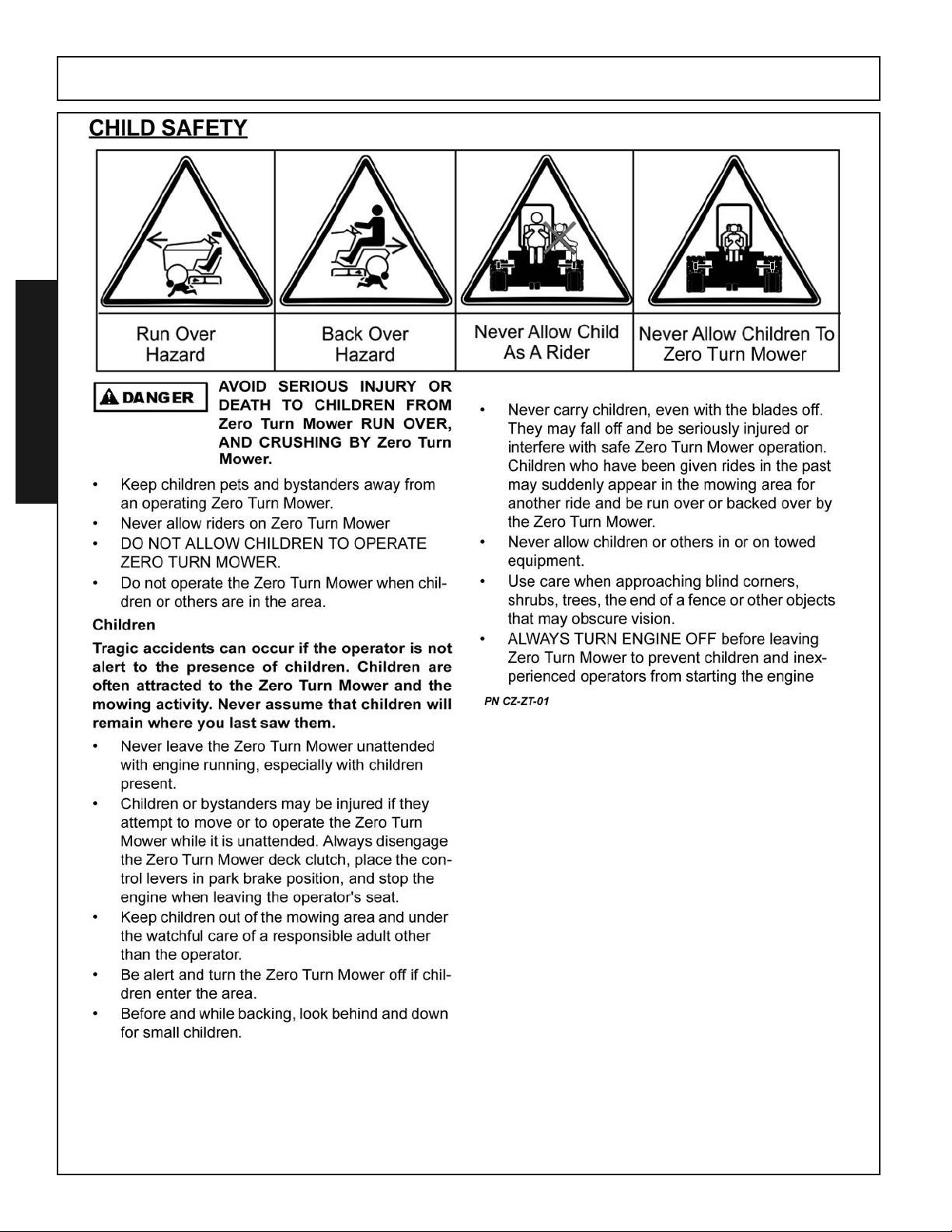

CHILD SAFETY.......................................................................................................................1-10

FUEL & FIRE SAFETY..................................................................................................1-11 / 1-12

MAINTENANCE SERVICE AND STORAGE SAFETY.................................................1-13 / 1/14

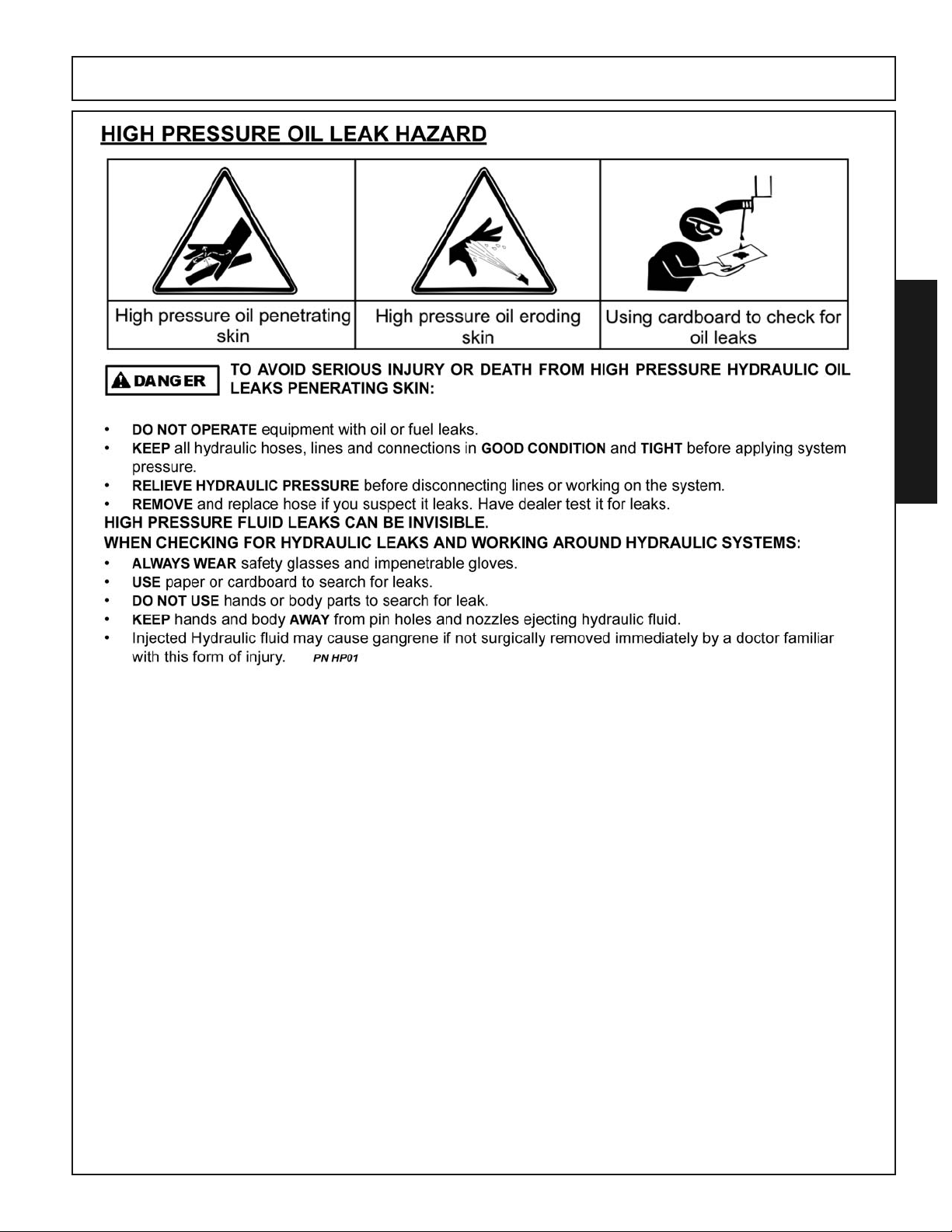

HIGH PRESSURE OIL LEAK HAZARD .................................................................................1-15

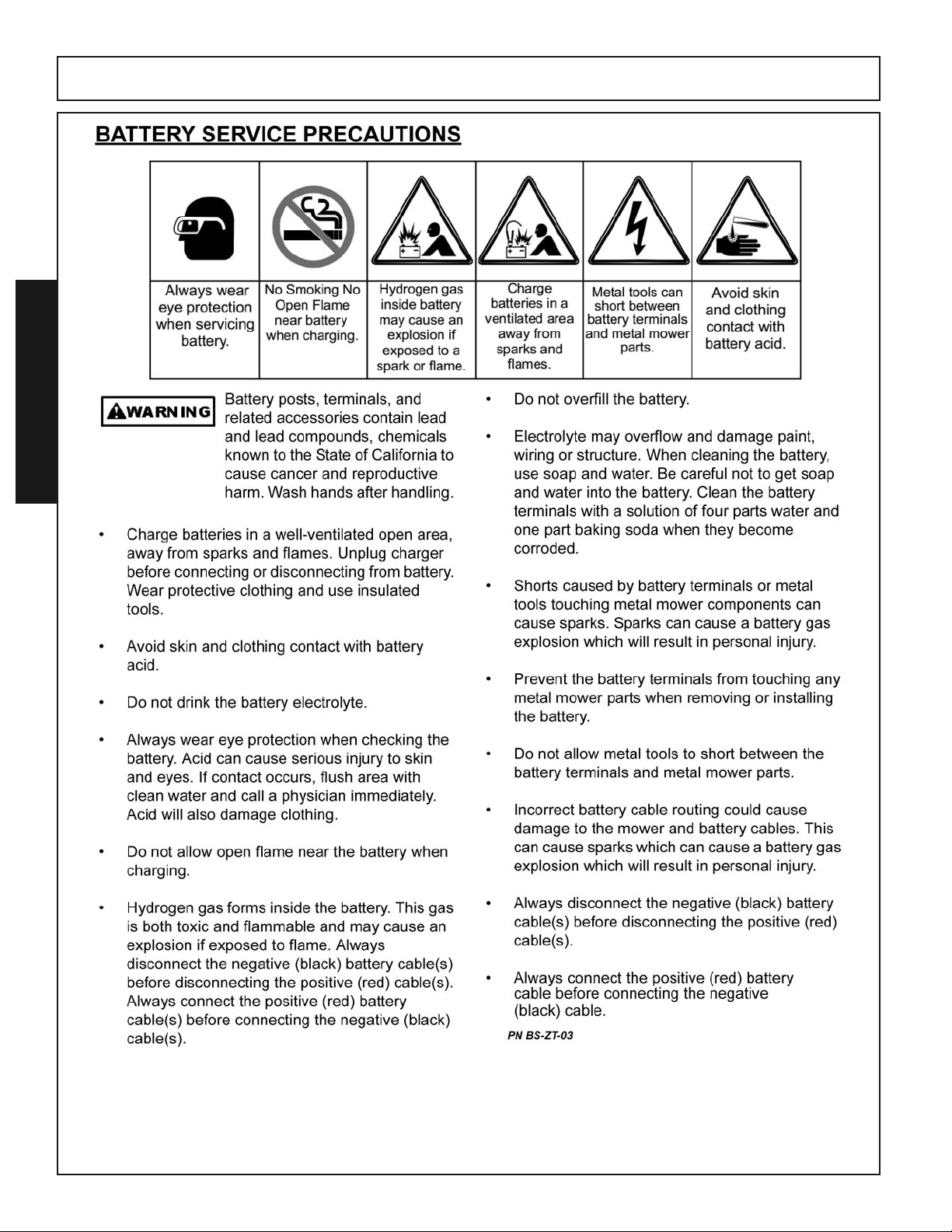

BATTERY SERVICE PRECAUTIONS.....................................................................................1-16

DRIVING AND TRANSPORTING ON PUBLIC ROADS.........................................................1-17

PARTS INFORMATION ...........................................................................................................1-18

SAFETY DECAL LOCATIONS (MOWER DECK)...................................................................1-19

SAFETY DECAL LOCATIONS (POWER UNIT) .....................................................................1-20

SAFETY DECAL PICTORIALS.....................................................................................1-21 / 1/23

FEDERAL LAWS and REGULATIONS ..................................................................................1-24

INTRODUCTION (SECTION 2)

INTRODUCTION ...............................................................................................................2-1 / 2-2

SPECIFICATIONS .....................................................................................................................2-3

CONTROLS (SECTION 3)

CONTROL LOCATIONS...........................................................................................................................................3-1

CONTROL PANEL....................................................................................................................................................3-2

IGNITION SWITCH ..................................................................................................................................................3-3

PERSONALIZING YOUR KEY CODE .....................................................................................................................3-3

CHOKE and THROTTLE..........................................................................................................................................3-3

STEERING CONTROL LEVERS .............................................................................................................................3-4

SPEED TRACKING ADJUSTMENTS.......................................................................................................................3-4

PARKING BRAKE.....................................................................................................................................................3-5

PTO SWITCH ...........................................................................................................................................................3-5

CUTTING HEIGHT CONTROLS ..............................................................................................................................3-5

FUEL TANK and FILLER NECK ...............................................................................................................................3-6

SEAT ADJUSTMENT CONTROLS ..........................................................................................................................3-6

TRANSAXLE BYPASS CONTROLS ........................................................................................................................3-7

Page 10

OPERATION (SECTION 4)

TRAINING ...............................................................................................................4-1

BEFORE STARTING ..................................................................................................................4-1

Starting the Engine ....................................................................................................................................................4-1

Shutting Down the Engine .........................................................................................................................................4-1

STEERING..................................................................................................................................4-2

To Move Forward or Backwards ................................................................................................................................4-2

To Turn Left................................................................................................................................................................4-2

To Turn Right..............................................................................................................................................................4-2

To Perform a Zero Turn..............................................................................................................................................4-2

OPERATING THE MOWER........................................................................................................4-2

ROPS and SEAT BELTS............................................................................................................4-3

MOWING ON SLOPES and HILLS............................................................................................4-3

MOWING NEAR WATER, DITCHES, and EMBANKMENTS ....................................................4-4

MOWING TIPS............................................................................................................................4-4

AFTER MOWING is COMPLETED ............................................................................................4-4

MOVING THE MACHINE MANUALLY.......................................................................................4-5

WEAK or DISCHARGED BATTERY..........................................................................................4-5

Jumper Cable Usage .................................................................................................................................................4-5

Starting Engine ..........................................................................................................................................................4-5

Removing Jumper Cables..........................................................................................................................................4-5

TRANSPORTING (SECTION 5)

TRANSPORTING THE MACHINE .............................................................................................5-1

Preparing to Transport ...............................................................................................................................................5-1

Loading the Machine..................................................................................................................................................5-1

Tie Down Points.........................................................................................................................................................5-1

Unloading the Machine ..............................................................................................................................................5-2

MAINTENANCE (SECTION 6)

RECOMMENDED REGULAR MAINTENANCE SCHEDULE ....................................................6-1

LUBRICATION............................................................................................................................6-2

Lubrication Points on Power Unit...............................................................................................................................6-2

Lubrication Points on Mower Deck ............................................................................................................................6-2

ENGINE MAINTENANCE...................................................................................................6-2 / 6-3

SERVICING the BATTERY.........................................................................................................6-4

Keep Battery Terminal Clean - Cleaning Battery Terminals .......................................................................................6-4

Replacing the Battery.................................................................................................................................................6-4

SAFETY SYSTEM ......................................................................................................................6-5

PARKING BRAKE ......................................................................................................................6-5

Parking Brake Adjustment..........................................................................................................................................6-5

TIRE PRESSURE .......................................................................................................................6-5

CASTER WHEELS .....................................................................................................................6-6

ANTI SCALP ROLLERS.............................................................................................................6-6

MOWER DECK V-BELT .............................................................................................................6-7

Mower Deck Belt Removal.........................................................................................................................................6-7

Mower Deck Belt Installation......................................................................................................................................6-7

Adjusting the Mower Deck Belt ..................................................................................................................................6-7

Page 11

PUMP BELT INSTALLATION.....................................................................................................6-9

CUTTING BLADE MAINTENANCE ...........................................................................................6-9

Blade Removal...........................................................................................................................................................6-9

Inspect Blades ...........................................................................................................................................................6-9

Sharpening Blades...................................................................................................................................................6-10

Installing Blades.......................................................................................................................................................6-10

ADJUSTING the MOWER DECK.............................................................................................6-10

Leveling the Deck ....................................................................................................................................................6-10

TRANSAXLE MAINTENANCE.................................................................................................6-11

Fluid and Filter Change Procedure ..........................................................................................................................6-11

Purging Procedures .................................................................................................................................................6-12

CONSOLE MAINTENANCE ...........................................................................................6-13- 6-15

General Care ...........................................................................................................................................................6-14

Bypass or Failed Safety Interlock Switch Detection.................................................................................................6-14

Service Alerts ...........................................................................................................................................................6-14

Alarms......................................................................................................................................................................6-14

Console Diagnostic Codes.......................................................................................................................................6-15

Spark Arrestor Maintenance ....................................................................................................................................6-16

STORAGE (SECTION 7)

WINTER STORAGE ...................................................................................................................7-1

Preparing the Machine for Storage ............................................................................................................................7-1

New Season Preparation ...........................................................................................................................................7-1

TROUBLE SHOOTING (SECTION 8) .....................................................................8-1

TECHNICAL DATA (SECTION 9)

MAIN WIRING HARNESS .........................................................................................................................................9-1

MAIN WIRING HARNESS SCHEMATIC ...................................................................................................................9-2

ENGINE ADAPTOR HARNESS for BRIGGS & STRATTON ENGINE ......................................................................9-3

ENGINE ADAPTOR HARNESS for KAWASAKI ENGINES.......................................................................................9-4

ENGINE ADAPTOR HARNESS for KOHLER ENGINES ..........................................................................................9-5

TORQUE SPECIFICATIONS .....................................................................................................................................9-6

SERVICE and MAINTENANCE RECORDS ..............................................................................................................9-7

Page 12

Page 13

SAFETY

SECTION 1

Page 14

Page 15

SAFETY

SAFETY

HDE-2 ZT 04/18 Safety Section 1-1

© 2018 Alamo Group Inc.

Page 16

SAFETY

SAFETY

HDE-2 ZT 04/18 Safety Section 1-2

© 2018 Alamo Group Inc.

Page 17

SAFETY

SAFETY

HDE-2 ZT 04/18 Safety Section 1-3

© 2018 Alamo Group Inc.

Page 18

SAFETY

SAFETY

HDE-2 ZT 04/18 Safety Section 1-4

© 2018 Alamo Group Inc.

Page 19

SAFETY

SAFETY

HDE-2 ZT 04/18 Safety Section 1-5

© 2018 Alamo Group Inc.

Page 20

SAFETY

SAFETY

HDE-2 ZT 04/18 Safety Section 1-6

© 2018 Alamo Group Inc.

Page 21

SAFETY

SAFETY

HDE-2 ZT 04/18 Safety Section 1-7

© 2018 Alamo Group Inc.

Page 22

SAFETY

SAFETY

HDE-2 ZT 04/18 Safety Section 1-8

© 2018 Alamo Group Inc.

Page 23

SAFETY

SAFETY

HDE-2 ZT 04/18 Safety Section 1-9

© 2018 Alamo Group Inc.

Page 24

SAFETY

SAFETY

HDE-2 ZT 04/18 Safety Section 1-10

© 2018 Alamo Group Inc.

Page 25

SAFETY

SAFETY

HDE-2 ZT 04/18 Safety Section 1-11

© 2018 Alamo Group Inc.

Page 26

SAFETY

SAFETY

HDE-2 ZT 04/18 Safety Section 1-12

© 2018 Alamo Group Inc.

Page 27

SAFETY

SAFETY

HDE-2 ZT 04/18 Safety Section 1-13

© 2018 Alamo Group Inc.

Page 28

SAFETY

SAFETY

HDE-2 ZT 04/18 Safety Section 1-14

© 2018 Alamo Group Inc.

Page 29

SAFETY

SAFETY

HDE-2 ZT 04/18 Safety Section 1-15

© 2018 Alamo Group Inc.

Page 30

SAFETY

SAFETY

HDE-2 ZT 04/18 Safety Section 1-16

© 2018 Alamo Group Inc.

Page 31

SAFETY

SAFETY

© 2018 Alamo Group Inc.

HDE-2 ZT 04/18 Safety Section 1-17

Page 32

SAFETY

HDE-2 ZT 04/18 Safety Section 1-18

SAFETY

© 2018 Alamo Group Inc.

Page 33

SAFETY

SAFETY

© 2018 Alamo Group Inc.

HDE-2 ZT 04/18 Safety Section 1-19

Safety Decal Location Mower Deck

ITEM PART NO. QTY. DESCRIPTION

1 D914 2 Danger Decal - Rotating Blades

2 D646 2 Warning Decal - Shield Missing Decal

3 D916 1 Danger Decal - Do Not Mow without Discharge Chute in Place

4 D917 1 Danger Decal - Thrown Object Hazard

5 D918 2 Warning Decal - Keep Shields In Place

6 50077946 1 Installation Decal, Mower Belt

7 D943 1 Not a Step Decal

e

r

w

Under

Shield

t

u

q

y

t

w

Under

Shield

q

Page 34

SAFETY

SAFETY

© 2018 Alamo Group Inc.

HDE-2 ZT 04/18 Safety Section 1-20

Safety Decal Location Power Unit

ITEM PART NO. QTY. DESCRIPTION

1 D859 1 Warning - Use Genuine Bush Hog Parts

2 D919 1 Warning - Crushing Hazard

3 D920 1 Instruction - Maintain ROPS (English)

4 D921 1 Warning - Hot Surface

5 D922 1 Instruction - Maintain ROPS (Spanish)

6 D923 1 Warning - Crushing Hazard

7 D924 1 Caution - Hearing Protection

8 D925 1 Caution - Avoid Equipment Fires (Spanish)

9 D926 1 Danger - Avoid Injury to Children

10 D927 1 Caution - Help Avoid Bodily Injury (Spanish)

11 D928 1 Caution - Help Avoid Bodily Injury (English)

12 D929 1 Danger - Avoid Tip-Over

13 D931 1 Caution - Avoid Equipment Fires (English)

14 D951 1 Caution - Gas Fueling Decal

15 50079856 2 Tracking Adjust Decal

t

q

1%

r

e

w

o

y

u

CAUTION

Ÿ Shut off engine before

fueling.

Ÿ 1HYHU¿OOIXHOWDQN

indoors or when

engine is hot.

Ÿ :LSHXSDOOVSLOOHGIXHO

EHIRUHVWDUWLQJHQJLQH

Ÿ 'RQRWVPRNHZKLOH

refueling.

ATENCIÓN

Ÿ $SDJXHHOPRWRUDQWHVGH

UHDEDVWHFLPLHQWRGH

FRPEXVWLEOH

Ÿ 1XQFDOOHQHHOWDQTXHGH

FRPEXVWLEOHHQLQWHULRUHVR

FXDQGRHOPRWRUHVWpFDOLHQWH

Ÿ /LPSLHWRGRHOFRPEXVWLEOH

GHUUDPDGRDQWHVGHDUUDQFDU

el motor.

Ÿ 1RIXPHVPLHQWUDVUHSRVWDV

FRPEXVWLEOH

1$

D951

1@

i

1#

1)

1!

Page 35

SAFETY

SAFETY

© 2018 Alamo Group Inc.

HDE-2 ZT 04/18 Safety Section 1-21

Safety Decal Pictorials

Page 36

HDE-2 ZT 04/18 Safety Section 1-22

Safety Decal Pictorials

SAFETY

SAFETY

© 2018 Alamo Group Inc.

Page 37

SAFETY

SAFETY

© 2018 Alamo Group Inc.

Safety Decal Pictorials

HDE-2 ZT 04/18 Safety Section 1-23

CAUTION

Ÿ Shut off engine before

fueling.

Ÿ 1HYHU¿OOIXHOWDQN

indoors or when

engine is hot.

Ÿ :LSHXSDOOVSLOOHGIXHO

EHIRUHVWDUWLQJHQJLQH

Ÿ 'RQRWVPRNHZKLOH

refueling.

ATENCIÓN

Ÿ $SDJXHHOPRWRUDQWHVGH

UHDEDVWHFLPLHQWRGH

FRPEXVWLEOH

Ÿ 1XQFDOOHQHHOWDQTXHGH

FRPEXVWLEOHHQLQWHULRUHVR

FXDQGRHOPRWRUHVWpFDOLHQWH

Ÿ /LPSLHWRGRHOFRPEXVWLEOH

GHUUDPDGRDQWHVGHDUUDQFDU

el motor.

Ÿ 1RIXPHVPLHQWUDVUHSRVWDV

FRPEXVWLEOH

D951

Page 38

SAFETY

SAFETY

© 2018 Alamo Group Inc.

HDE-2 ZT 04/18 Safety Section 1-24

Page 39

INTRODUCTION

SECTION 2

Page 40

Page 41

INTRODUCTION

INTRODUCTION

HDE-2 ZT 04/18 Introduction Section 2-1

© 2018 Alamo Group Inc.

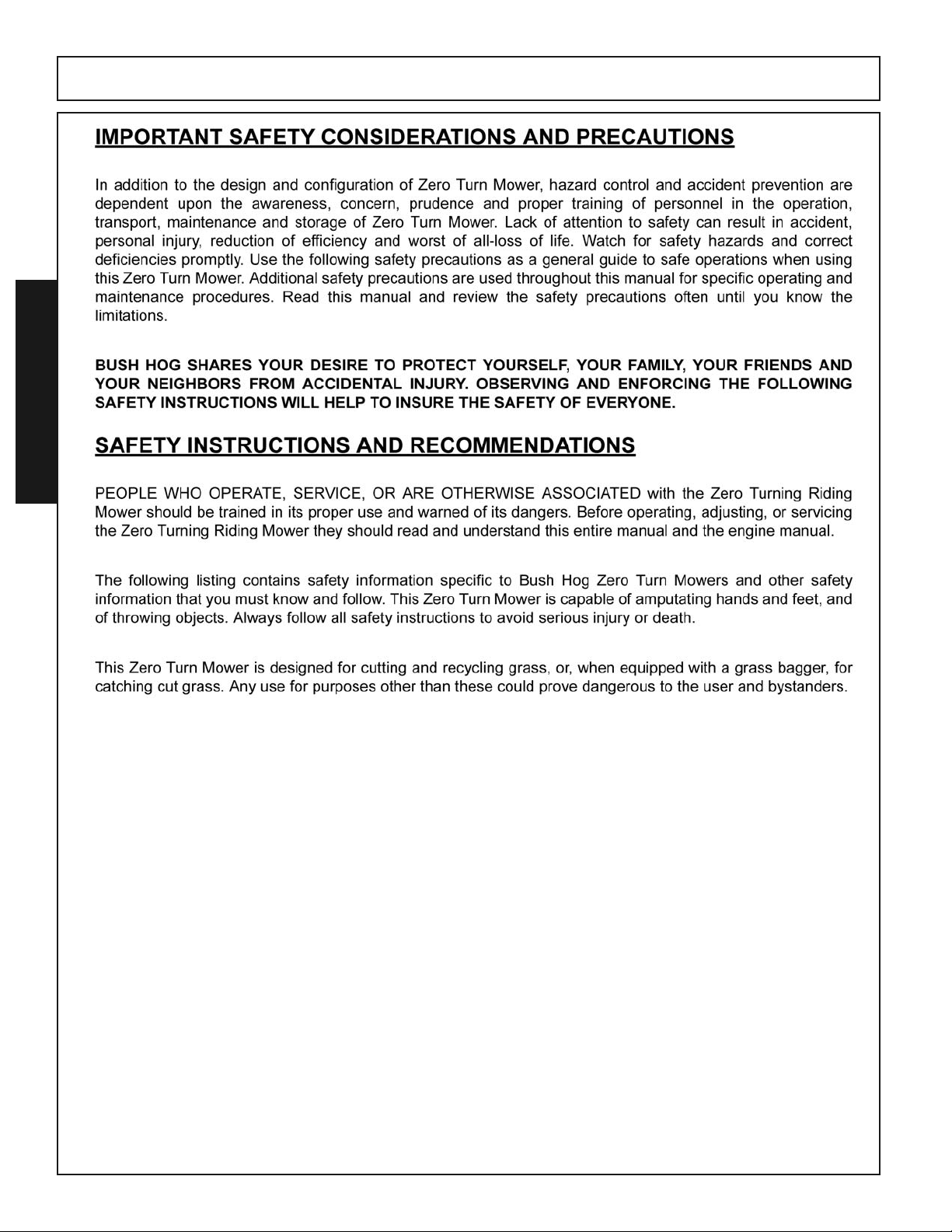

We are pleased to have you as a Bush Hog customer. Your Bush Hog Zero Turn Riding Mower

has been carefully designed with care and built with quality materials by skilled workers to give

maximum service with minimum down time. This manual is provided to give you the necessary

operating and maintenance instructions for keeping your Zero Turn Mower in top operating condition. Careful use and timely service saves extensive repairs and costly down time losses.

Please read this manual thoroughly. Understand what each control is for and how to use it. No

shielding is 100% effective in preventing thrown objects. The possibility of injury and property

damage from this hazard can be substantially reduced by selecting proper shielding, maintaining

the Zero Turn Mower and shielding in good operational condition, inspecting the area for foreign

debris before mowing, and operating the Zero Turn Mower at a minimum cutting height, Keep

unprotected persons at a minimum distance of 300 feet from the Zero Turn Mower at all times

during operation. Safety is of primary importance to the owner/operator and to the manufacturer.

Observe all safety precaution decals on the Zero Turn Mower and noted throughout the manual

for safe operation of Zero Turn Mowers. If any assistance or additional information is needed,

contact your authorized Bush Hog dealer. The owner/operator/dealer should know and understand the Safety Messages before assembly and be aware of the hazards of operating this Zero

Turn Mower during assembly, use, and maintenance. The Safety Alert Symbol combined with

a Signal Word, as seen below, is intended to warn the owner/operator of impending hazards

and the degree of possible injury faced when operating this Zero Turn Mower.

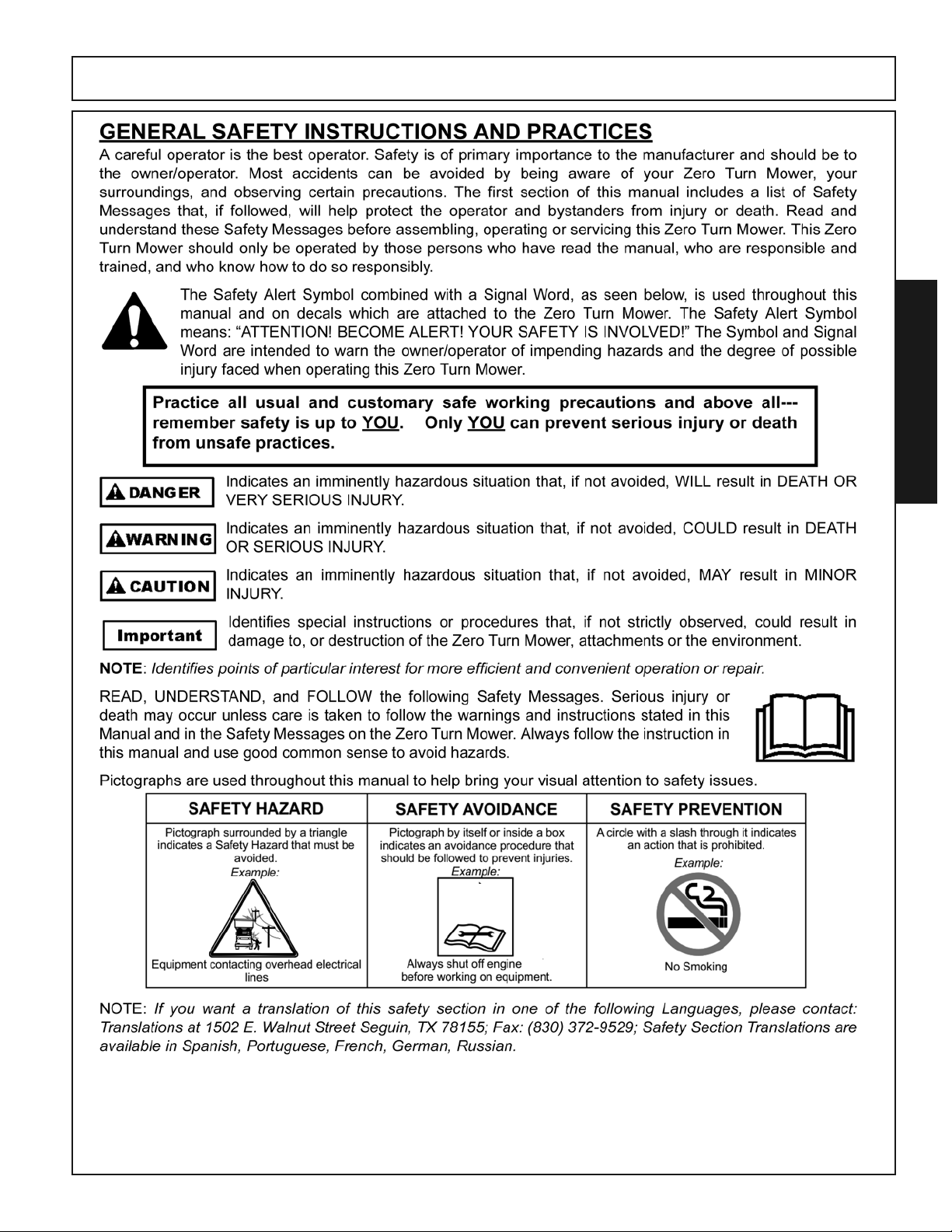

! DANGER

! WARNING

! CAUTION

IMPORTANT!

Indicates an imminently hazardous situation that, if not avoided, WILL result

in DEATH OR VERY SERIOUS INJURY.

Indicates an imminently hazardous situation that, if not avoided, COULD result in DEATH OR SERIOUS INJURY.

Indicates an imminently hazardous situation that, if not avoided, MAY result

in MINOR INJURY.

Identifies special instructions or procedures that, if not strictly observed, could

result in damage to, or destruction of the Zero Turn Mower, attachments or

the environment.

Page 42

INTRODUCTION

INTRODUCTION

HDE-2 ZT 04/18 Introduction Section 2-2

© 2018 Alamo Group Inc.

The Bush Hog Zero Turn is intended for use on lawns and other frequently

maintained areas where a smooth, even cut is desired and superior maneuverability is needed. The Power Unit consists of a Briggs & Stratton,

Kawasaki, or Kohler twin cylinder engine. The engine has a pressurized oil

lubrication system with spin-on type filter, fused electronic ignition, electric

start and the Zero Turn has a 8 gallon fuel system.

Two hydrostatic transaxles are used for propelling and steering. The

Transaxles are belt driven by the engine output shaft. One lever for each

drive controls both speed and direction. This independent control of each

drive wheel coupled with continuously variable speed selection gives the Zero Turn mower exceptional maneuverability.

The Zero Turn Mower Deck is available in 49”, 55” or 61” cutting widths. The Zero Turn Mower

has three cutting blades, driven by an electromagnetic clutch through a single v-belt.

Front, rear, left and right are determined by the normal direction of travel, the same as driving an

automobile.

Page 43

INTRODUCTION

INTRODUCTION

HDE-2 ZT 04/18 Introduction Section 2-3

© 2018 Alamo Group Inc.

SPECIFICATIONS

HDE Series Zero Turn Mower

MODEL ENGINE CUTTING WIDTH

HDE2049KT2.......................................20 HP Kohler 7000 Series KT715.............................................. 49” Deck

HDE2249FS2.......................................22 HP Kawasaki FS651..............................................................49” Deck

HDE2549PS2.......................................25 HP Briggs and Stratton Pro Series ........................................49’’ Deck

HDE2255FS2.......................................22 HP Kawasaki FS651..............................................................55” Deck

HDE2555KP2.......................................25 HP Kohler 7000 Series+ PRO Filtration.................................55” Deck

HDE2555PS2.......................................25 HP Briggs and Stratton Pro Series ........................................55” Deck

HDE2261FS2.......................................22 HP Kawasaki FS651..............................................................61” Deck

HDE2561KP2.......................................25 HP Kohler 7000 Series+ PRO Filtration.................................61” Deck

HDE2561PS2.......................................25 HP Briggs and Stratton Pro Series ........................................61” Deck

CONTROLS.........................................Electronic Control Module with Keyless Start, System Monitoring and

Soft Start PTO Engage

PTO......................................................Electromagnetic Clutch rated at 175 FT/LBS

FUEL CAPACITY.................................8 Gallons (87 Octane Unleaded Gasoline)

TRANSAXLES.....................................(2) Hydro-Gear ZT3100 Hydrostats

TIRES ..................................................Front - 13 x 6.5 - 6

Rear - 23 x 10.5 - 12 (Selection of Turf Tire or Bar Tire)

TREAD WIDTH....................................50”

HEIGHT to TOP OF SEAT BACK .......47” Non Suspension Seat / 51” Full Suspension Seat

STEERING...........................................Dampened Twin Lever, Adjustable Fore, Aft and Vertical

SPEED.................................................Infinitely Variable 0-8 mph Forward, 0-4 mph Reverse

DECK SPECIFICATIONS

CUTTING WIDTHS..............................49” .......................55” .......................61”

OVERALL WIDTH (CHUTE DOWN)...63” .......................69” .......................75”

BLADES (Standard) ...........................(3) 17” Uplift.........(3) 19” Uplift .........(3) 21” Uplift

CUTTING HEIGHTS ............................1-1/2” to 5” Adjustable in 1/4” Increments

DECK CONSTRUCTION.....................7 Gauge reinforced steel

SAFETY

Integrated Operator Presence Controls

2-7/8” Round Tube ROPS

Seat Belts

Page 44

Page 45

CONTROLS

SECTION 3

Page 46

Page 47

CONTROLS

CONTROLS

HDE-2 ZT 04/18 Controls Section 3-1

© 2018 Alamo Group Inc.

CONTROL LOCATIONS

1. Transaxle Bypass Linkage

2. Fuel Cap

3. Steering Control Levers

4. Parking Brake Lever

5. Deck Lift Pedal

6. Deck Height Adjust Pin

7. Seat Adjusting Lever

8. Start/Stop Button

9. Mower PTO Switch

10. Engine Throttle Control

11. Choke

12. Tracking Adjusting Control

t

y

u

i

o

1)

1!

1@

1@

q

w

e

r

Under Engine

Under

Armrest

Under

Armrest

Page 48

CONTROLS

CONTROLS

HDE-2 ZT 04/18 Controls Section 3-2

© 2018 Alamo Group Inc.

CONSOLE

qwe

r

t

y

u

io

1)

1!

ITEM DESCRIPTION FUNCTION

q

Engine Start/Stop Button Powers Engine ON / Powers Engine OFF.

w Key Code Buttons Powers up Console by entering Key Code and enables specific functions

as starting /stopping engine, engaging PTO.

e OK to Start Indicator Light Glows Green when safe to start engine, Red when unsafe.

r PTO Indicator LED Glows Red to indicate PTO is engaged.

t Steering Lever Indicator LED Glows Reds when Steering Levers are not in Neutral position during startup

y Parking Brake LED Glows Red if Parking Brake not set during startup.

u Operator Position Indicator Glows Red if Operator is not in seat.

i Low Oil Indicator LED Alerts Operator when Engine oil is low.

o Fuel Level Indicator LED Alerts Operator when Fuel is low.

1) PTO Switch Engages /Disengages Mower Blades.

1! LCD Display Indicates Hours, Service Alerts, Engine RPM, and Voltage.

Page 49

CONTROLS

CONTROLS

HDE-2 ZT 04/18 Controls Section 3-3

© 2018 Alamo Group Inc.

Ignition Switch

Choke and Throttle

The Ignition Switch is keyless and is the Red Button on

the Console located on the right hand side of the Zero

Turn Mower. This controls starting and stopping the engine.

A 4 digit code must be entered before the engine can be started.

This code will be supplied by the dealer at the time

the purchaser takes ownership of the Zero Turn

Mower. A code is programmed at the factory for use until

the owner changes it to his personal code.

It is recommended that the owner personalize the

code as soon as possible after taking ownership of

the Zero Turn Mower.

See Personalizing Your Key Code.

PERSONALIZING YOUR KEY CODE

1. Record your new Key Code (1-12 digits) for safe keeping. NOTE: Only a dealer service call can reset a for-

gotten code.

2. Engine must be stopped and console unlocked (using

the original code that comes with the Zero Turn

Mower) and the PTO Switch down (OFF).

3. Hold KEY CODE BUTTONS 1 & 2 simultaneously for

three seconds until the display shows “CHNGE”

“CODE” followed by a blank screen.

4. Enter the new key code into the console. If more than

12 digits are used the display shows “FULL”

NOTE: The display always shows the 5 most recently

entered digits.

5. After entering the new code, pull the PTO Switch up.

If the new code is unusable, the display will show

“BAD” “CODE”. If this occurs push the PTO switch

down and return to step 1 and try a different code.

NOTE: If user does not enter a code and pulls the PTO

switch up the display shows “EMPTY” “CODE”.

IGNITION

SWITCH

CHOKE

The Choke provides a richer fuel mixture to the engine

to assist on cold starts. Pull the choke up to engage and

once the engine starts push down to disengage.

THROTTLE

The Throttle controls the engine speed and blade speed

when blades are engaged. To increase the engine and

blade speeds push the Throttle forward and to decrease

the speeds push the throttle toward the back. For best

mowing performance run the engine at full throttle and

control your ground speed with the Steering levers.

THROTTLE

LEVER

CHOKE

6. If the new code is usable, the console prompts the

user to re-enter the code again by displaying: ENTER”

“CODE” “AGAIN”. Re-enter the code used in step 4,

then push the PTO switch down

.

7. The console confirms that the two key codes entered

in step 4 and 6 match. If they do match, the console

saves the new unlock code and displays “SAVED”

“CODE” before returning to the previous display

mode. If they do not match the console displays “NO”

“MATCH” and the user must return to step 1.

NOTE: If no input is received for 10 seconds the console displays”TIME” “OUT” before returning to the

previous display mode, retaining the previous unlock

code.

RECORD YOUR PERSONALIZED KEY CODE HERE

IMPORTANT!

Page 50

CONTROLS

CONTROLS

HDE-2 ZT 04/18 Controls Section 3-4

© 2018 Alamo Group Inc.

Steering Control Levers

Steering Control Levers control the direction and speed

of the Zero Turn Mower in both forward and reverse

travel. Turning is controlled by pushing one lever forward

and pulling the opposite lever backward or to the neutral

position.

Moving the levers forward equally will cause the Zero

Turn Mower to travel forward in a straight line. Moving

the levers backward equally causes the Zero Turn

Mower to travel in reverse. The further the levers are

moved forward or backward increases the speed of

travel in that direction.

THE ZERO TURN MOWER WILL

TURN VERY RAPIDLY IF ONE

STEERING LEVER IS MOVED MUCH FURTHER

FORWARD THAN THE OTHER.

NOTE: These maneuvers should be done with extra

care at a slow speed when turning.

Moving the right hand lever forward and the left hand

lever to the neutral position turns the Zero Turn Mower

left.

Moving the left hand lever forward and the right hand

lever to the neutral position turns the Zero Turn Mower

to the right

Moving the right hand lever forward and the left hand

lever backward the Zero Turn Mower will achieve a zero

turn to the left.

Moving the left hand lever forward and the right hand

lever backward achieves a zero turn to the right.

! WARNING

Speed Tracking Adjusting

The Speed Tracking Adjustment Screws, located on the

panels under the seat arm rest on each side, allow the

operator to adjust the forward speed of each Steering

Control Lever so the Zero Turn travels in a straigt line

when both Steering Levers are pushed all the way forward.

To adjust the forward speed, turn the knobs counter

clockwise to increase the forward speed and colckwise

to decrease the forward speed.

Test drive the mower to determine if speed tracking adjustments are required. Push the steering control levers

all the way forward, if the mower steers to the right or left

adjustments are needed.

● If mower steers to the right, adjust the tracking adjustment on the left side of the mower to decrease the

speed of the left drive axle speed.

● If mower steers to the left, adjust the tracking adjustment on the right side of the mower to decrease the

speed of the right drive axle speed.

NOTE: After tracking speed adjustments are com-

pleted the steering handles may need to be adjusted

to the operators preferred position for comfort and

best operation of the mower.

Page 51

CONTROLS

CONTROLS

HDE-2 ZT 04/18 Controls Section 3-5

© 2018 Alamo Group Inc.

The Parking Brake is located on the left side of the Zero

Turn Mower. To set the brake pull the lever up and push

down to release. When engaging the brake the Zero Turn

Mower must be completely motionless. Always set the

Parking Brake before dismounting the Zero Turn Mower

and always release the brake before putting the Zero

Turn Mower into operation.

NOTE: If the Parking Brake is not set in the Park position when starting, the engine will not start and the

Parking Brake LED will be lit on the console. Release

the brake after the engine has started.

NOTE: Applying the parking brake while in forward

or reverse travel and the Steering Levers in the operating position will stop the engine and could do

possible damage to the Hydrostat Drives.

Parking Brake

Parking Brake

Lever

PTO Switch

The PTO Switch is located on the Console and is Yellow

in color.

To engage the Zero Turn mower blades pull the PTO

Switch switch up and to disengage push the switch down.

NOTE: The PTO Switch should only be engaged when

the engine is running and the steering levers are in

the Neutral position. The Zero Turn Mower will not

start if the PTO Switch is pulled up prior to starting

the Zero Turn Mower. It must always be in the OFF

(Down) position to start.

The Cutting Height is controlled by selecting the desired

height and pushing the Foot Control Pedal all the way

forward and placing the Height Adjusting Pin in the desired cutting height. Release the pressure on the foot

control until it stops at the set cutting height.

PTO

Switch

Cutting Height Controls

IMPORTANT: To maintain an even cutting

height, all tires must have equal air pressure

of 15 psi /103kPa / 1bar.

Height

Adjusting

Pin

Foot

Control

Pedal

IMPORTANT: Always raise the Zero Turn

Mower Deck to the highest position and disengage blades when transporting.

Page 52

CONTROLS

CONTROLS

HDE-2 ZT 04/18 Controls Section 3-6

© 2018 Alamo Group Inc.

Seat Adjustment Controls

NON-SUSPENSION SEAT

The Non-Suspension Seat can be adjusted forward or

backward to fit the operators need. The adjusting lever is

located under the front right hand side of the seat. Move

the lever to the left as seen from the driver in the seat to

move the seat backward or forward.

Move Lever

to left to

adjust.

1

2

3

4

NON-SUSPENSION SEAT

FULL SUSPENSION SEAT

FULL SUSPENSION SEAT

1. The Weight Adjustment Knob lets you set a personalized suspension setting.

The Fuel Tank is located under the operators seat and

the Filler Neck is located on the left hand side toward the

rear of the seat. The Fuel Cap is tethered to the tank to

avoid dropping when refueling the Zero Turn Mower.

Gasoline is highly flammable. The engine and exhaust system become

very hot during operation.

Allow engine and exhaust system to cool down before refueling the Zero Turn Mower.

Use CAUTION and only fill outdoors.

Fill to the bottom of the filler neck (DO NOT OVER FILL).

Do not fuel the Zero Turn Mower near an open flame.

Clean away any spilled fuel after re-fueling and before

re-starting the Zero Turn Mower.

Check the gas fill cap often for damage to gasket. If damaged replace the fill cap.

The engine is designed to operate on 87 Octane unleaded gasoline.

Damage to the engine may occur if E85 Alcohol based

fuel or Methanol fuel is used.

Fuel Tank and Filler Neck

Filler

Neck

&

Fuel

Cap

! WARNING!

Page 53

HDE-2 ZT 04/18 Controls Section 3-7

© 2018 Alamo Group Inc.

The Transaxle Bypass Linkages must be pulled out

when pushing or pulling the Zero Turn Mower without engine power. The linkages are located at the rear of the

Zero Turn Mower under the engine plate. The linkages

must be pulled out and locked in order to relieve hydraulic pressure so the Zero Turn Mower can be moved.

Refer to Moving the Zero Turn by Hand in the Opera-

tion Section.

NOTE: The Tansaxle Bypass Linkages must be disengaged in order for the Zero Turn Mower to move forward

or backward under its engine power.

The Bypass Linkage is located close

to the muffler. To prevent burn injury,

turn the engine off and allow the engine and muffler to

cool down before handling the Bypass Linkage.

Transaxle Bypass Control

Transaxle Bypass Linkages

! CAUTION

2. The Backrest Angle Adjustment Knob.

3. Arm Rest Height adjustment (raise arm rest to access

adjustment knobs).

4. Seat Slide allows 6” of fore and aft adjustment.

The seat is shaped to increase air flow so that you stay

more comfortable on hot days

CONTROLS

CONTROLS

Page 54

Page 55

OPERATION

SECTION 4

Page 56

Page 57

OPERATION

OPERATION

HDE-2 ZT 04/18 Operation Section 4-1

© 2018 Alamo Group Inc.

If you are unfamiliar with the oper-

ation of a Zero Turn Mower, READ

the Safety Section and the Controls Section before

Operating.

IMPORTANT!

Training

Zero Turn Mowers are more maneuverable than conventional riding mowers because of the unique steering capabilities.

Before attempting to operate this Zero Turn Mower under

it’s own power, the Operation Section should be reviewed

entirely.

After reviewing the Operation Section, board the Zero

Turn Mower (Always from the left side or front only,

never from the right hand side). Begin slowly by practicing on a smooth, hard, level surface such as concrete

or asphalt before moving to turf.

Choose an area where no people, vehicles or other obstacles are present.

Do not move the Steering Levers too aggressively to the

most forward or rearward positions during your initial operation. Moving to turf before being completely comfortable with the maneuverability of this Zero Turn Mower

could cause turf damage.

Before Starting

1.Read the Safety and Controls sections before starting

the Zero Turn Mower.

2.Do a maintenance check before starting. See Maintenance Schedule in the Maintenance Section.

3.Check Fuel for a sufficient amount to perform the task

at hand.

4.Adjust the Operators Seat to desired position (See Seat

Adjustment Controls).

5. Raise the Zero Turn mower deck to the transport position (highest cutting setting).

6.The following Control settings must be applied before

the engine will start.

• PTO Control Switch must be down (Off position).

• Parking Brake must be set (Up position).

• Both Steering control Levers must be in the Neutral

Lock position.

• Operator must be in the seat.

Starting the Engine

1. Operator sitting in seat. NOTE; The Seat is

equipped with an operator presence switch and the

unit will not start if operator is not sitting in the seat!

2. Raise the Zero Turn mower deck to the transport position (highest cutting setting).

3. The PTO Switch must be disengage.

4. Engage the Parking Brake.

5. Steering Levers in the Neutral Lock position.

6. Move Throttle Control to middle position.

7. Pull Choke Up. (On cold starts)

8. Enter Console Un-Lock Code.

9. Press Start/Stop Button after the Green light is on.

If the engine fails to start after 5 seconds release the

Starter Button wait 10 seconds and retry.

10. When engine starts release Starter Button and push

the Choke Knob down.

NOTE: When engine is running, engine RPM shows

in the LED Display. When engine is shut down total

usage Hours displayed.

11. Allow the engine to run at a moderate speed for a

short time before beginning to mow.

Shutting Down the Engine

The Engine can be shut down at any

time by simply pushing the

Start/Stop Button, however this should not be done with

Zero Turn mower deck engaged and forward or reverse

travel in progress. This should be done only in an emergency procedure.

NOTE: The engine will shut down during operation

if the operator leaves the seat.

Proper Shutdown is achieved as follows:

1. Disengage the Zero Turn Mower deck by pushing the

PTO Switch down.

2. Bring the engine down to idle speed.

2. Place the Steering Levers in the Neutral Lock position.

3. Set the Parking Brake.

4. Depress the Start/Stop switch.

IMPORTANT!

Page 58

OPERATION

OPERATION

HDE-2 ZT 04/18 Operation Section 4-2

© 2018 Alamo Group Inc.

Steering

Direction of travel and speed are controlled by the Steering Control Levers. The right hand lever controls the right

wheel and the left hand lever controls the left wheel.

All procedures listed below should be

performed slowly and with caution

until the operator is confident in their ability to operate

this Zero Turn Mower SAFELY.

Begin with the operator sitting in the seat and adjust the

seat so the operator feels comfortable with the steering

controls and can easily raise and lower the deck with the

Foot Control Pedal.

Begin by bringing the engine to idle speed. Release the

Parking Brake. Move the Steering Levers inward from

the Neutral Lock position to the Neutral position.

To Move Forward or Backwards

Pushing the Steering Lever forward equally causes the

Zero Turn Mower to travel forward in a straight line. The

further forward the Levers are pushed the travel speed

will increase.

Pulling the levers backward equally causes the Zero

Turn Mower to travel in reverse and speed increases the

further back they are pulled.

To Turn Left

To negotiate a left hand turn while moving forward pull

the left hand lever backward toward the neutral position

slowing the left wheel causing the Zero Turn Mower to

turn left.

To Turn Right

To negotiate a right hand turn while moving forward pull

the right hand lever backward toward the neutral position

slowing the right wheel causing the Zero Turn Mower to

turn right.

To Perform a Zero Turn

Bring both Steering Levers to the neutral position until

the Zero Turn Mower slows or stops.

Pushing the Left Lever slightly forward and pulling the

Right Lever slightly backward negotiates a Right Hand

Zero Turn.

Pushing the Right Lever slightly forward and pulling the

Left Lever slightly backward negotiates a Left Hand Zero

Turn.

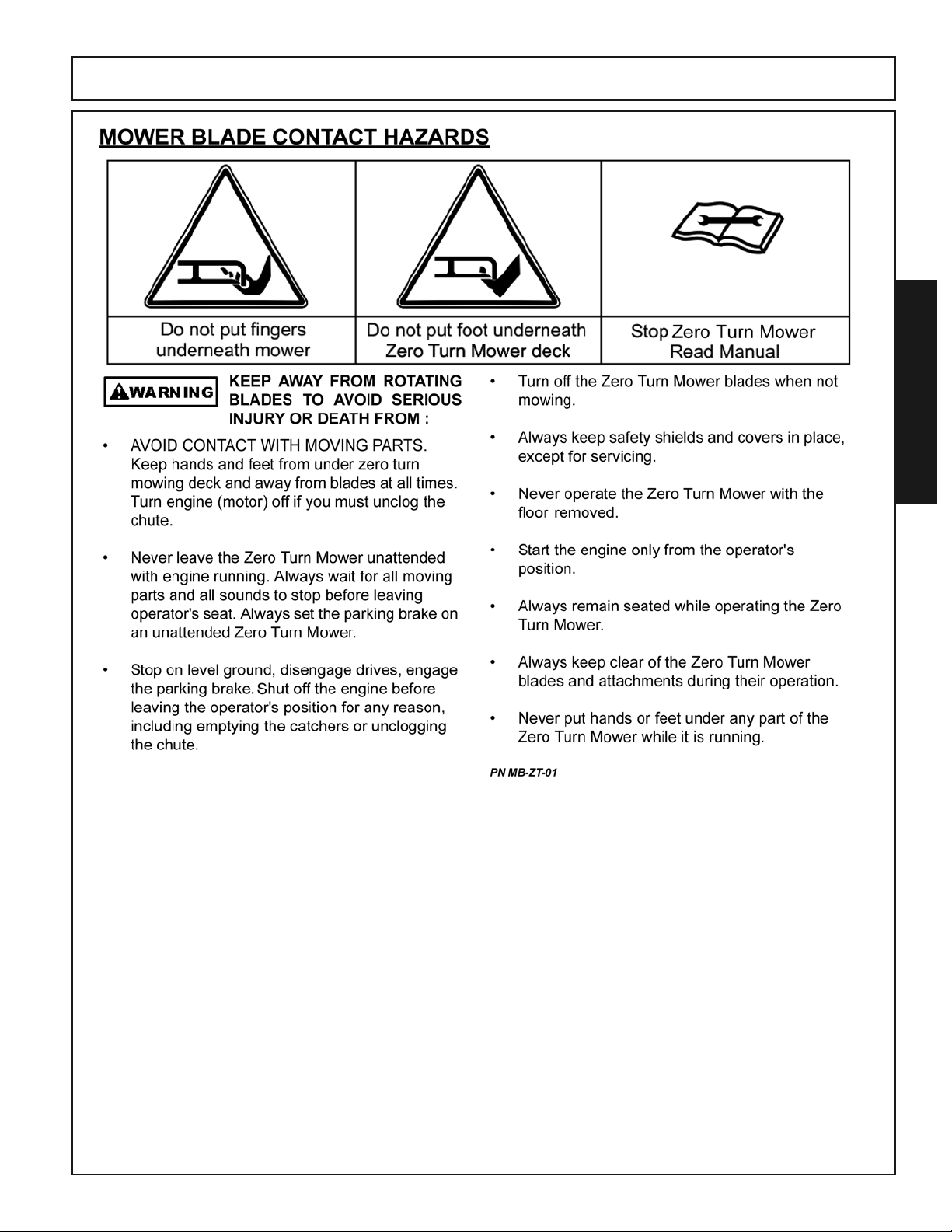

Operating the Mower

The Mowing Height is controlled by the Foot Control

Pedal and a Height Adjusting Pin.

Mowing Height is adjustable from 1-1/2” to 5” in 1/4” increments.

NOTE: Mowing Height Adjustment should only be made

with the Zero Turn Mower deck blades disengaged.

To adjust the Mowing Height, place the right foot against

the knurled shaft on the Foot Control Pedal and push forward. Place the Height Adjusting Pin in the desired cutting height hole. Release pressure on the Foot Control

Pedal.

When the mowing height has been established, start the

Zero Turn Mower, pull the PTO Switch up to engage the

blades. Engine should be at full throttle when engaging

the blades.

When engaging the blades make sure

no one is near to the Zero Turn

Mower.

Be sure the area to be mowed has been cleared of all

debris that could be thrown by the rotating blades causing injury to bystanders and damage to the Zero Turn

Mower.

Best mowing results are achieved when the engine

is at full throttle and ground speed is controlled by

the Steering Levers.

When mowing is completed, disengage the Zero Turn

Mower deck blades by pushing the PTO Switch down.

Raise the Zero Turn Mower by pushing the Foot Control

Pedal and place the Height Adjusting Pin in the 5” hole

for transporting to the next location.

! CAUTION

Foot Control

Pedal

Height

Adjusting

Pin

!WARNING

Page 59

OPERATION

OPERATION

HDE-2 ZT 04/18 Operation Section 4-3

© 2018 Alamo Group Inc.

ROPS and Seat Belts

This Zero Turn Mower is equipped with a ROPS (Roll

Over Protective System) and Seat Belts for the Operator’s safety.

The ROPS should always be raised and locked and Seat

Belt used when the Zero Turn Mower is in use.

Ensure the seat is secured to the Zero Turn Mower.

If the ROPS must be lowered for

clearance, do not wear the seat

belt. There is no protection from a

rollover when the ROPS is lowered. Raise the ROPS and

lock in the up position as soon as clearance allows.

Seat

Belt

ROPS

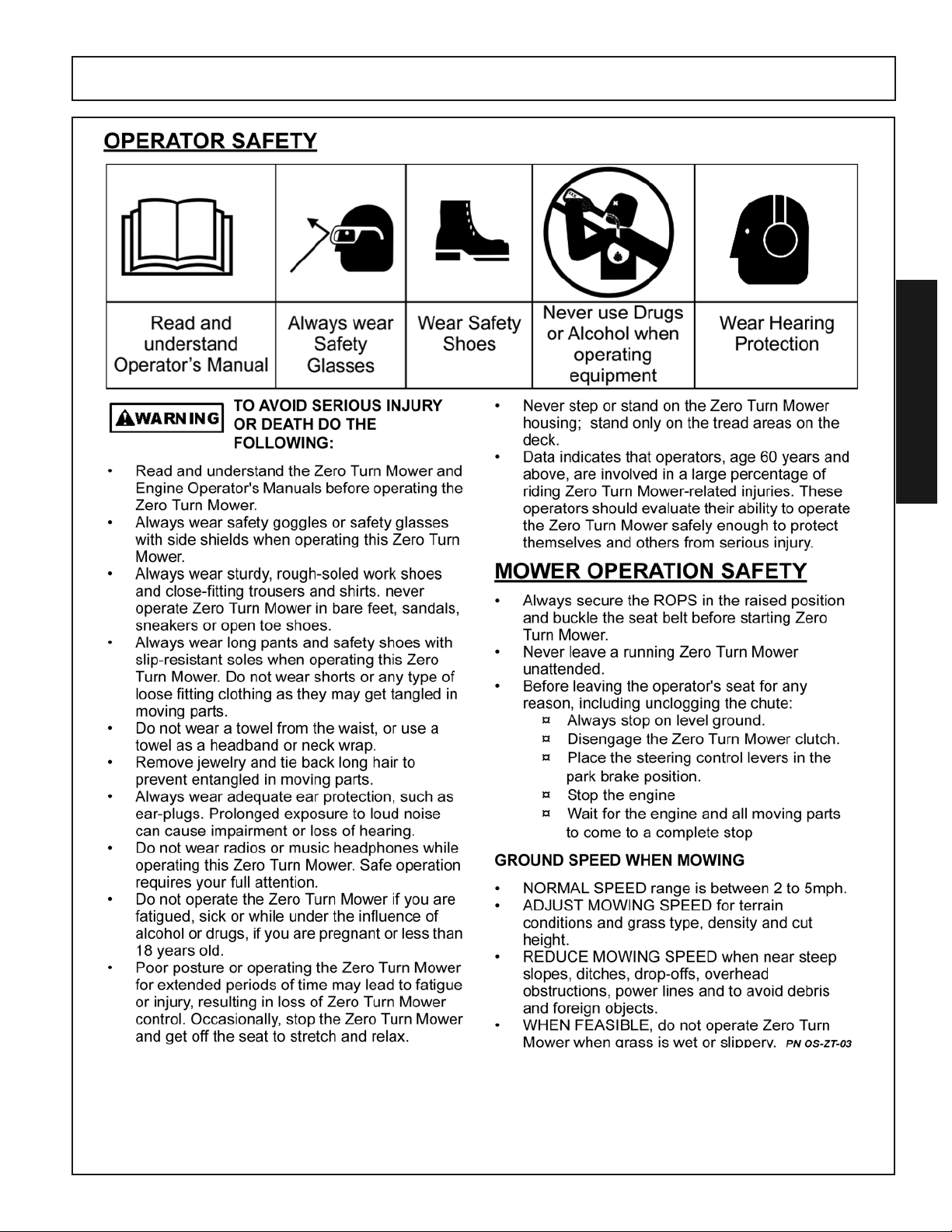

Mowing on Slope and Hills

Operating this Zero Turn Mower

on a Slope Exceeding 15 Degrees

is unsafe and can cause upset or

loss of traction resulting in serious injury or death.

Refer to the Slope Indicator page in the front of this

manual to determine if a Slope or Hill is too DANGEROUS to operate this Zero Turn Mower on!

Refer to SAFETY SECTION: Using ROPS & Seat Belts

For Operating on Slopes Safety.

To avoid tipover, drive across slopes, not up an

down. If machine stops going uphill, stop blades and

back down slowly.

Mowing on wet grass can cause

sliding and result in loss of control!

1. Reduce speed to slowest speed possible before starting up or down hills.

2. Avoid stopping or changing speed on hills.

3. If you must stop, place the steering levers in the neutral lock position and engage parking brake.

4. To Restart movement release the parking brake. Move

the Steering Levers out of Neutral Lock position and

push forward equally to regain forward motion.

5. Make turns slowly if operator must turn on a slope or

hill.

! DANGER

! CAUTION

! DANGER

Page 60

OPERATION

OPERATION

HDE-2 ZT 04/18 Operation Section 4-4

© 2018 Alamo Group Inc.

Mowing Tips

Before mowing check the area to

be mowed for debris that can be

removed. Objects that are fixed

and cannot be removed, flag the object so a collision

does not occur.

●Start by setting the Zero Turn Mower at the desired cut-

ting height so desired result is attained. The

average

lawn should be cut to a height of 2-1/2’’

during cool seasons and 3” during hot months. For healthier, better looking lawns mow often after moderate growth

has occurred.

●Grass over 6” in height should be mowed twice. Make

the first cut relatively high and then mow a second time

at desired height.

●Mowing results are best when the engine is a full throt-

tle (blades spin faster) and the travel speed is

low. If

grass is low, travel speed can increase without affecting

mowing results.

●Avoid mowing when grass is damp or wet. The mowing

results can be poor and cause the wet grass to clump

under the deck and stick to the underside of the mow-

ing deck, resulting in an uneven cut.

After Mowing is Completed

●After the Zero Turn Mower is shut down and the engine

has cooled, use compressed air to clean the top surfaces of the Zero Turn Mower deck and frame. If compressed air is not available a leaf blower can be used.

●Avoid using water on top surfaces around engine and

electrical components.

●Raise the Zero Turn Mower deck to its highest position

and hose the underside of the Zero Turn Mower deck

to remove any build up of grass clippings.

Mowing Near Water, Ditches, and

Embankments

Operating this Zero Turn Mower

near water where drop offs are

present is unsafe. Wheels dropping over the edge

can cause rollover or loss of traction resulting in serious injury or death by drowning.

Refer to SAFETY SECTION: Using ROPS & Seat Belts

For Operating on Slopes Safety.

●Watch for ditches, holes, rocks, dips and rises that can

change the operating angle. Keep away from drop offs

and steep banks. Tall grass can hide these obstacles.

●Use caution near drop offs, ditches, or embankments.

The Zero Turn Mower can suddenly turn over if a wheel

goes over an edge of a ditch, drop off, embankment, or

an edge caves in.

●Mow a safe distance from water’s edge (Ponds or

Lakes). A Danger Zone of 10 feet should be observed.

! DANGER

! CAUTION

! CAUTION

Page 61

OPERATION

OPERATION

HDE-2 ZT 04/18 Operation Section 4-5

© 2018 Alamo Group Inc.

Moving Machine Manually

NOTE: Do not push, pull, or tow this Zero Turn Mower

without first releasing the hydraulic pressure in the Integrated Transaxles.

To release the hydraulic pressure from the Transaxles,

pull the two Bypass Linkages out and down to lock them

in position in the keyhole slot.

The linkages must be returned to the original position

before the Zero Turn Mower is placed back in service,

otherwise the Zero Turn Mower will not move.

The linkages are located at the rear of the Zero Turn

Mower under the engine plate.

The Bypass Linkage is located

under the Zero Turn Mower close to

the muffler. To prevent burn injury DO NOT attempt ac-

cess to the Bypass Linkages from the top. Turn the

engine off and allow the engine and muffler to cool down

and access the Bypass Linkages from the underside

below the muffler before handling the Bypass Linkage.

Weak or Discharged Battery

If the battery is weak and will not start the engine, it

should be recharged using a battery charger.

Replace the battery if it will not hold a charge after

recharging.

The minimum capacity battery for this Zero Turn Mower

is a 12 Volt / 350 cranking amp Lawn and Garden.

Lead-acid Batteries generate explosive gases. Keep sparks, flames and

smoking materials away from batteries. Always wear eye

protection when Jump Starting batteries.

Jumper Cable Usage

1. Attach each end of the RED cable ends to the POSITIVE (+) terminals on each battery. Care should be

taken not to short against the Zero Turn Mowers

frame.

2. Connect one end of the BLACK (-) to the Fully

charged battery.

3. Connect the other end of the BLACK (-) cable to a

good CHASSIS GROUND on the Zero Turn Mowers

frame.

Starting the Engine

4. Operator sitting in seat. NOTE; The Seat is equipped

with an operator presence switch and will not start if

operator is not sitting in the seat!

5. Raise the Zero Turn Mower deck to the transport po-

sition (highest cutting setting).

6. Disengage the PTO Switch.

7. Engage the Parking Brake.

8. Steering Levers in the Neutral Lock position.

9. Move Throttle Control to middle position.

10. Pull Choke Up. (On cold starts)

11. Enter Console Un-Lock Code.

12. Press Start/Stop Button.

Removing Jumper Cables

13. Disconnect the BLACK cable from the chassis

ground first then from the Zero Turn Mowers battery.

14. Remove the RED cable from the Zero Turn Mowers

battery and then the jumper battery.

Transaxle Bypass Linkages

! CAUTION

! CAUTION

Page 62

Page 63

TRANSPORTING

SECTION 5

Page 64

Page 65

TRANSPORTING

TRANSPORTING

HDE-2 ZT 04/18 Transporting Section 5-1

© 2018 Alamo Group Inc.

Transporting the Zero Turn Mower

Transport Zero Turn Mower on a heavy duty trailer that

is adequate to handle the size and weight of the Zero

Turn Mower. Be sure the trailer has all the necessary

brakes, lighting and reflective markings required by law.

Never drive this Zero Turn Mower

on public streets or roadways.

Driving this Zero Turn Mower on streets or roadways

without proper lighting, turn signals, reflective markings or a Slow Moving Vehicle Placard can lead to se-

rious injury or death by collision with other vehicles.

Preparing to Transport

1. Connect the trailer to the towing vehicle. Connect all

trailer safety chains and lighting harness to tow vehicle.

2. Connect trailer brakes if applicable.

Loading the Zero Turn Mower

Extreme CAUTION should be

used when loading and unloading the Zero Turn Mower. Avoid sudden acceleration

and deceleration while driving on the ramp and

trailer bed. This could cause loss of control and tip-

over.

Do not use narrow individual

ramps on each side to load this

Zero Turn Mower.

Only use a full width ramp that is wider than the Zero

Turn Mowers width.

The ramp should be 4 times longer than the

height of the trailer to prevent angles above

15 degrees.

! WARNING

! CAUTION

Trailer Height

4 Times

Trailer

Height

Loading the Zero Turn Mower at a steeper angle than

15 degrees can cause possible tip over or loss of

traction resulting in injury or death. Mower components may hang up on the transition from the ramp

to the trailer bed.

When loading the Zero Turn Mower on a trailer, back the

Zero Turn Mower up the ramp and center the weight of

the Zero Turn Mower over the trailer axles.

After the Zero Turn Mower is loaded on the trailer shut

the engine off and apply the parking brake

.

Tie Down Points

Do not rely strictly on the parking brake to transport on a

trailer! Use of the tie down

points are required for safe transport.

Four (4) tie down points are located on the Zero Turn

Mower for safe transport. Two located on the front and

two at the rear. Use tie down straps, chains or ropes to

secure the Zero Turn Mower to the trailer at the four tie

down locations.

Sudden stops or acceleration can cause the Zero Turn

Mower to skid in the bed of the trailer possibly over turning the Zero Turn Mower or ejecting the Zero Turn Mower

from the trailer causing injury or death to bystanders and

damage to surrounding vehicles.

BACK ZERO TURN MOWER UP

RAMP ONTO TRAILER

! DANGER

FRONT TIE

DOWN POINT

LOCATIONS

REAR TIE DOWN POINT

LOCATIONS

IMPORTANT!

Page 66

TRANSPORTING

TRANSPORTING

HDE-2 ZT 04/18 Transporting Section 5-2

© 2018 Alamo Group Inc.

Unloading the Zero Turn Mower

Extreme CAUTION should be

used when loading and unloading the Zero Turn Mower. Avoid sudden acceleration

and deceleration while driving on the ramp and trailer

bed. This could cause loss of control and tip-over.

1. Park the trailer on a level surface, then lower the

ramp. NOTE: If unloading must be done on a slope,

position the trailer so the ramp extends up the slope

not exceeding a 15 degree angle.

2. Release the tie down straps.

3. Board the Zero Turn Mower, start the engine.

4. Release the park brake and slowly drive forward off

the trailer.

DRIVE ZERO TURN MOWER

FORWARD DOWN THE RAMP

! CAUTION

Page 67

MAINTENANCE

SECTION 6

Page 68

Page 69

MAINTENANCE

MAINTENANCE

HDE-2 ZT 04/18 Maintenance Section 6-1

© 2018 Alamo Group Inc.

Maintenance Service Maintenance Procedure

Interval

After the first 8 hours • Change the engine oil and oil filter.

• Check the torque on the wheel lug nuts.

After the first 50 hours • Change the hydraulic system filter and oil.

Before each use or daily • Check the safety system.

• Check the engine oil level.

• Check the seat belt.

• Check the rollover protection system (ROPS) knobs.

• Clean the engine screen.

• Inspect the blades.

• Clean the Zero Turn Mower deck.

Every 25 hours • Check the hydraulic oil level in the expansion tank.

Every 50 hours • Grease the Zero Turn Mower deck idler arm.

• Grease Blade Spindles. (5 Shots)

• Grease Idler Pivot Point.

• Inspect the mower belt and hydrostat drive belt for cracks and wear.

• Lubricate the deck lift pivots.

Every 100 hours • Change the engine oil (more often in dirty or dusty conditions).

• Check, clean and gap the spark plug.

• Check and clean engine cooling fins and shrouds.

• Grease the front caster pivots (more often in dirty or dusty conditions).

• Lubricate the caster wheel hubs.

• Check and Clean Spark Arrestor.

Every 200 hours • Change the engine oil filter.

Every 250 hours • Replace the primary air filter (more often in dusty or sandy conditions).

• Check the safety air filter.

Every 400 hours • Change the hydraulic system filter and oil.

Every 500 hours • Replace the safety air filter.

• Replace the fuel filter (more often in dirty or dusty conditions).

• Adjust the caster pivot bearing.

• Check the electric clutch.

Monthly • Check the battery charge.

Yearly • Check the torque on the wheel lug nuts.

Before placing in storage • Paint chipped surfaces.

• Check all maintenance procedures listed above before storage.

• Clean The Underside of the mowing deck.

Recommended Regular Maintenance Schedule

Page 70

MAINTENANCE

MAINTENANCE

HDE-2 ZT 04/18 Maintenance Section 6-2

© 2018 Alamo Group Inc.

Lubrication

Proper lubrication at specified intervals will increase the

life of the Zero Turn Mower. Greasing more frequently

where conditions are extremely dusty or sandy is rec-

ommended.

Lubrication Points on the Zero Turn Mower

Power Unit

The Zero Turn Mower Power Unit has 9 grease point locations, 4 on the left side and 4 on the right side (Left Side

Shown, corresponding points are on the Right Side) and

1 on the Pump Idler Pivot.

GREASE TYPE: No 2 Lithium or Molybdenum

1. Grease the Front Caster Pivots every 100 hours and

more frequently in dusty or sandy conditions.

2. Grease the Caster Wheels at the hubs (2 fittings on

each hub) every 50 Hours and more frequently in dusty

or sandy conditions.

3.Grease the Deck Lift Pivot points every 50 hours and

more frequently in dusty or sandy conditions.

4. 2 shots grease at 50 hours to the Pump Idler Pivot.

1

2

3

Lubrication Points on the Zero Turn Mower

Deck

The Zero Turn Mower Deck has 4 grease points. 3 points

on the Blade Spindles and 1 on the Idler pivot.

GREASE TYPE: No 2 Lithium or Molybdenum

1. 5 shots of grease every 50 hours at the Blade Spindles.

2. 2 shots of grease every 50 hours in the Idler Pivot

tube and more frequently in dusty or sandy condi-

tions.

Engine Maintenance

The Bush Hog Series HDE Zero Turn Mowers are offered with 3 different engine manufactures. Briggs &

Stratton, Kawasaki and Kohler. Maintenance procedures

vary from each manufacturer.

Operator / Maintenance manuals are available online

as a free download from each engine manufacturer.

Bush Hog recommends following the Engine manufacturers maintenance schedules for each manufacturer’s

engine model.

See links listed on next page for downloading the

Engine Manual for your Zero Turn Mower.

1

2

4 Pump

Idler

Pivot

Page 71

MAINTENANCE

MAINTENANCE

HDE-2 ZT 04/18 Maintenance Section 6-3

© 2018 Alamo Group Inc.

Mower Model ....Engine Series

Number

HDE2549PS2 ..........Briggs & Stratton Pro Series

HDE2555PS2 ..........Briggs & Stratton Pro Series

HDE2561PS2 ..........Briggs & Stratton Pro Series

HDE2249FS2...........Kawasaki FS651

HDE2255FS2...........Kawasaki FS651

HDE2261FS2...........Kawasaki FS651

HDE2049KT2...........Kohler KT715

HDE2555KP2 ..........Kohler KT745

HDE2561KP2 ..........Kohler KT745

Locate your Mower Model Number and then go to the

Engine Manufacturer’s website and navigate to the manual needed. Follow links listed below, listing the engine

series when prompted.

BRIGGS and STRATTON ENGINES:

www.briggsandstratton.com

go to Support tab

go to Download Manuals in drop down

go to Riding Mowers

enter the engine series number listed for your Zero

Turn Mower model above in the dropdown.

KAWASAKI ENGINES:

www.kawaskienginesusa.com

go to Parts and Support tab

go to Manuals in dropdown

go to Series and choose FS Series

choose either the FS651V Manual

Manual from dropdown.

KOHLER ENGINES

www.kohlerengines.com/manuals

go to Manuals and Maintenance

go to Owners & Service Manuals

enter engine model number under I know my model

number

(KT715 or KT745)

Under Manuals select Owners

Select Language (English)

Checking Engine Oil Level

NOTE: Check oil level when engine is cold.

Engine oil should be checked before each use or daily.

Follow the procedures for checking oil as instructed by

the engine manufacturers manual which applies to your

Zero Turn Mower.

Changing the Engine Oil and Oil Filter

NOTE: It is recommended after the first 8 hours of

usage the oil and filter be changed.

Follow the procedures for changing oil and oil filter as

instructed by the engine manufacturers manual which applies to your Zero Turn Mower.

The engine manufacturers manual will provide the recommended service intervals, oils, amount required and

filters required when changing oil.

Dispose of the used oil at a recycling center.

Servicing the Air Cleaner

Service Intervals:

Every 250 hours replace the primary Air Filter (more often

in dusty or sandy conditions).

Check the Safety Filter every 250 hours and replace

every 500 hours of usage.

Follow the procedures for changing air filter as instructed

by the engine manufacturers manual which applies to

your engine.

Page 72

MAINTENANCE

MAINTENANCE

HDE-2 ZT 04/18 Maintenance Section 6-4

© 2018 Alamo Group Inc.

Servicing the Battery

This Zero Turn Mower is equipped from the factory with

a maintenance free battery that does not need servicing.

However, if the Zero Turn Mower is not being used for an

extended period or placed in storage, disconnect the

Black (ground) cable from the battery. Periodic charging

with automotive battery charger is recommended and will

extend the battery life.

Always wear eye protection when

working with batteries!

The battery is located on the right hand side behind the

seat.

DO NOT short across battery termi-

nals by allowing a wrench or any

other metal object to come in contact with both terminals

at the same time.

DO NOT allow a wrench to come in

contact with any part of the Zero

Turn Mowers frame when working with the POSITIVE (+)

terminal of the battery.

• Keep Battery and Terminals Clean.

Cleaning battery and terminals