Page 1

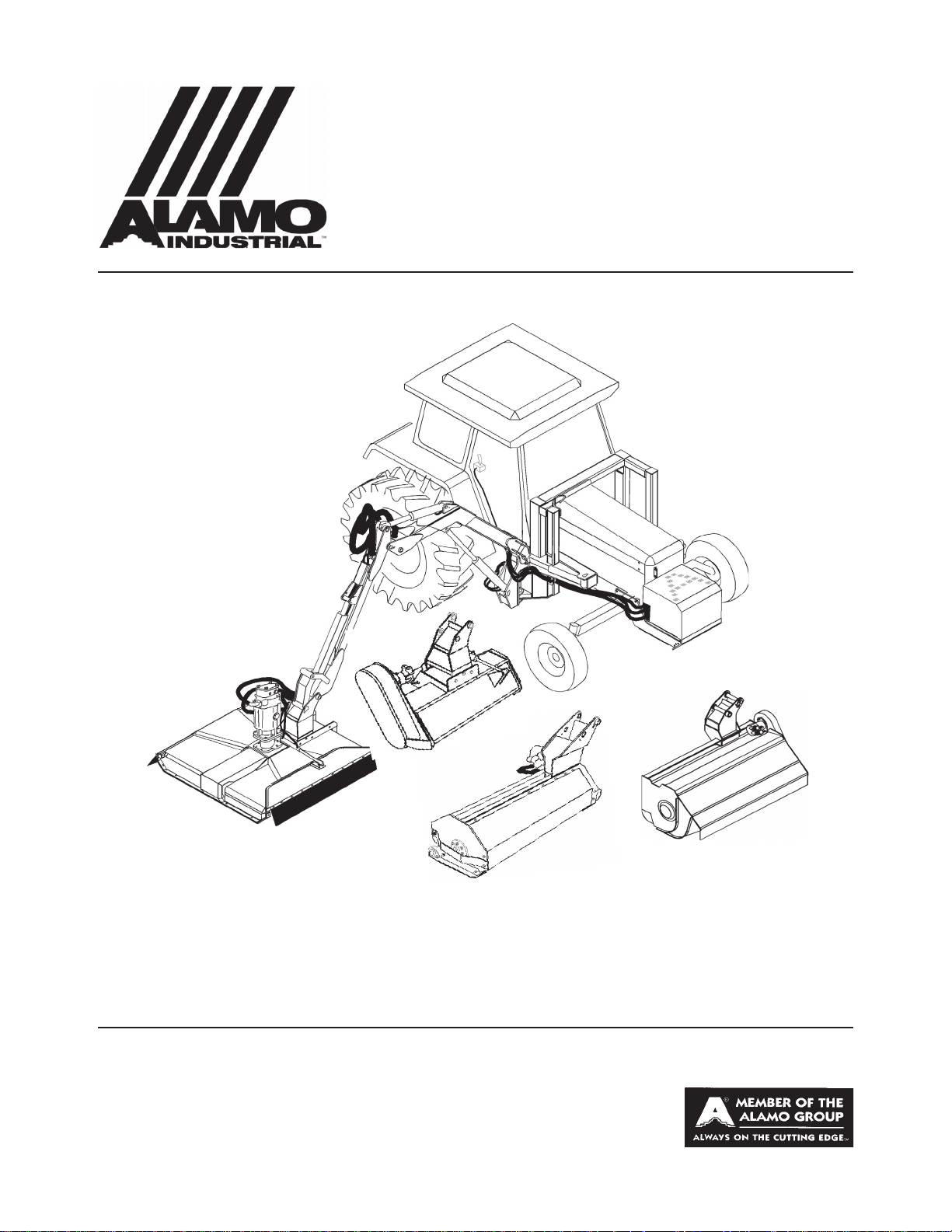

A-BOOM

Assembly Instruction Manual

John Deere 6615 and 7615

Tractors equipped with additional options, special equipment, tractor manufacturer modifications,

new tractor models, or Customer alterations may prevent this Mount Kit from being properly

mounted to the tractor. Alamo Group is not responsible for modifications to the MountKit to

accommodate these differences.

ALAMO INDUSTRIAL

1502 E. Walnut

Seguin, Texas 78155

210-372-3551

© 2003 Alamo Group Inc.

Part No. 02980169

Page 2

TO THE OWNER/OPERATOR/DEALER

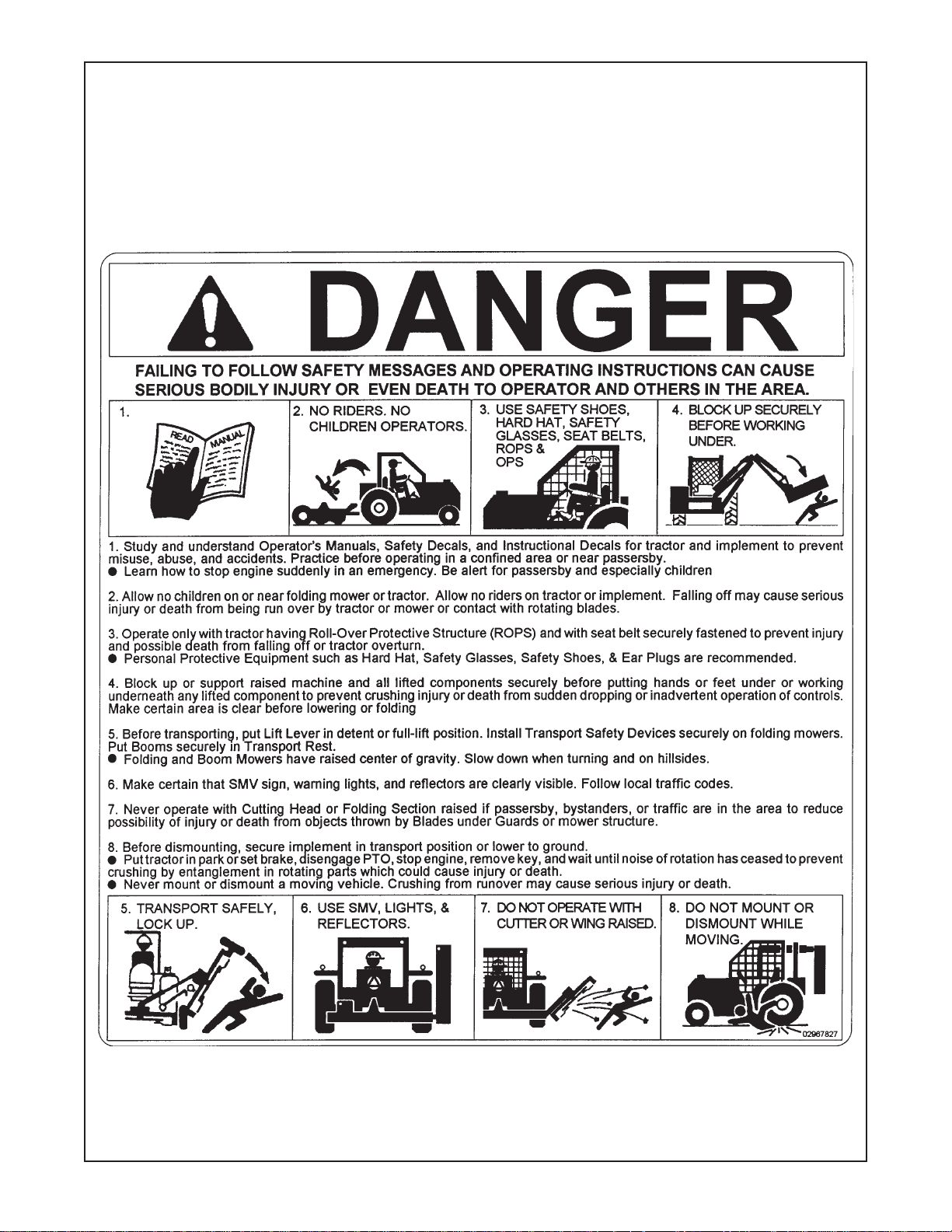

All implements with moving parts are potentially hazardous. There is no substitute for a cautious,

safe-minded operator who recognizes the potential hazards and follows reasonable safety

practices. The manufacturer has designed this implement to be used with all its safety equipment

properly attached to minimize the chance of accidents.

BEFORE YOU START!! Read the safety messages on the implement and shown in your

manual. Observe the rules of safety and common sense!

WARRANTY INFORMATION:

Read and understand the complete Warranty Statement found in this Manual. Fill out the Warranty

Registration Form in full and return it within 30 Days. Make certain the Serial Number of the Machine

is recorded on the Warranty Card and on the Warranty Form that you retain. The use of "will-fit"

parts will void your warranty and can cause catastrophic failure with possible injury or death.

Page 3

INTRODUCTION

ABOUT THIS MANUAL:

The intent of this publication to provide the competent technician with the information necessary

to perform the CORRECT Assembly to the Alamo Industrial Product. This will, in turn provide for

complete customer satisfaction

It is hoped that the information contained in this and other Manuals will provide enough detail to

eliminate the need for contact of the Alamo Industrial Technical Service Dept. However, it should be

understood that many instances may arrive where correspondence with the Manufacturer is necessary.

CONTACTING MANUFACTURER: (Please help us Help You! Before You Call! )

Alamo Industrial Service Staff Members are dedicated to helping you solve your problem, or

your customer’s service problem as quickly and efficiently as possible. Unfortunately, we receive

entirely to many calls with only a minimum amount of information. In some cases, the correspondent

has never gone out to look at the equipment and merely calls inquiring of the problems described to him

by the operator or customer.

Most calls received by Alamo Industrial Service can be classified into approx. 6 general categories.

1. Hydraulic or Mechanical Trouble Shooting.

2. Request for Technical Information or Specifications.

3. Mounting or Fitting Problem.

4. Special Service Problem.

5. Equipment Application Problems.

6. Tractor Problem Inquiries.

HOW YOU CAN HELP:

Make sure the call is necessary! Most of the calls received may not be necessary if the Dealer

Service Technician would do the following.

1. Check the Service Information at your Dealership provided by Alamo Industrial, This

would include, Service Bulletins, Information Bulletins, Parts Manuals, Operators Manuals, Assembly

Manual or Service Manual, many of these are available via the Alamo Industrial Internet site (www.AlamoIndustrial.Com). Attempt to diagnose or repair problem before calling.

2. If a call to Alamo Industrial is needed, Certain Information should be available and ready

for the Alamo Industrial Service Staff. Such information as, Machine Model, Serial Number, Your Dealer

Name, Your Account Number and Any other information that will be useful. This information is vital for

the development of a prompt and correct solution to the problem. This will also help to develop a

database of problems and related solutions, which will expedite a solution to future problems of a similar

nature.

3. The technician may be asked to provide detailed information about the problem

including the results of any required trouble shooting techniques. If the information is not available, The

technician may be asked to get the information and call back. Most recommendations for repairs will

be based on the procedures listed in the Service Manual / Trouble Shooting Guide and Information

provided by customer.

CONTACT ALAMO INDUSTRIAL:

Alamo Industrial, 1502 E. Walnut St. Seguin TX. 78155, Technical Service Dept. PH: 830-372-2708

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Index -3

Page 4

INDEX - ASSEMBLY INSTRUCTION

Safety Section

Operation Safety............................................................................. 1

Section 1

Tools and Supplies Needed f/ Assembly.................................. 1-2

Pre-Dilivery Check List...................................................................... 1-3 to 1-5

Section 2

Fill Left rear Wheel w/ calcium Cloride............................................. 2-2

Wheel Counter Weight Parts.............................................................2-2

Wheel Counter Weight Installation.................................................... 2-3

Section 3

Front Pump Drive Parts.....................................................................3-2

Crankshaft Pulley Preparation...........................................................3-3

Pump Driveshaft Assembly...............................................................3-3

Pump Driveshaft Half, Shaft End.......................................................3-4

Pump Mount Plate..............................................................................3-4 to 3-5

Pump Drive Shaft, Tube End.............................................................3-5

Pump Installation................................................................................3-5 to 3-6

Frame Rail Support Installation......................................................... 3-7

Page

Section 4

Frame Rail Pre- Assembly................................................................ 4-2 to 4-6

High Frame Parts...............................................................................4-7

Frame Rail Pre-Installation................................................................ 4-8 to 4-11

High Frame Pre-Installation............................................................... 4-12 to 4-16

Tack Welding Frame Assembly........................................................ 4-17 to 4-21

Remove Frame for Final Welding......................................................4-21 to 4-23

Section 5

Frame Rails Final Installation.............................................................5-2

Boom Rest Installation.......................................................................5-3

Axle Strap Installation.........................................................................5-4

Stabilizer Kit Installation.....................................................................5-4

High Frame Installation...................................................................... 5-5 to 5-8

Tie Up Hoses to Tractor Frame (Stack valve Hoses)....................... 5-8

Section 6

Hydraulic Tank Installation................................................................. 6-2

Hydraulic Tank Counter Weight Installation...................................... 6-2

Hydraulic Tank Oil Level Sight Gauge............................................... 6-3

Hydraulic Tank Decal Installation.......................................................6-3

Cab Decal Installation........................................................................6-4

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Index -4

Page 5

INDEX - ASSEMBLY INSTRUCTION

Section 7

Cutter Motor Control Valve................................................................ 7-2

Boom Installation / Boom Hoses....................................................... 7-2 to 7-3

Pump / Tank Hose Installation...........................................................7-4 to 7-5

Section 8

Control Handle Asy Installation (Mechanical Valve).......................... 8-2

"ON" "OFF" Switch Schematic (Standard Mechanical).................... 8-3

"ON" "OFF" Switch Installation (Standard Mechanical).................... 8-4

Control Valve Operation (Standard Mechanical)............................... 8-5

Hydraulic Hose Schematic (Standard Mechanical)...........................8-6

Hydraulic Hose Control Circuit (Standard Mechanical).....................8-7 to 8-8

Remote Control Cable Installation (Standard Mechanical)............... 8-8 to 8-11

Section 9

Joystick Mount Parts......................................................................... 9-2

Install Joystick Mount to Seat............................................................ 9-3

Install Joystick Controler to Seat Bracket..........................................9-4

Tractor Floor Mat Removal................................................................9-4

Wire Harness to Tractor Connections...............................................9-5 to 9-6

Tractor Ignition Wire Connection.......................................................9-6

Connect Wire Harness to Joystick....................................................9-6

Tractor Floor Mat re-Install.................................................................9-6

Tractor Cab Decal Installation........................................................... 9-7

Connect Wire Harness to Control Valve........................................... 9-8 to 9-13

Page

Section 10

Attaching Flail Axe Head.................................................................... 10-2 to 10-3

Attaching Ditcher Head......................................................................10-4

Attaching Timbercat Head................................................................. 10-5

Attaching X-Frame Square Head...................................................... 10-6

Section 11

Filling Hydraulic Tank w/Oil................................................................11-2 to 11-3

Section 12

Hydraulic Start Up Instructions.......................................................... 12-2

Post Assembly Check List................................................................ 12-3

Section 13

Boom Rest Plate Installation............................................................ 13-2 to 13-3

Boom Swing Stop Installation........................................................... 13-4

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Index -5

Page 6

NOTES

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Index -6

Page 7

SAFETY

SECTION

© 2003 Alamo Group Inc.

Safety Section 1-1

Page 8

SAFETY

Read these assembly instructions through completely and understand them

before proceeding with the assembly of the equipement.

A safe and careful operator is the best operator . Safety is of primary importance to the manufacturer and should be to the owner/operator . Most accidents can be avoided by being aware of

your equipment, your surroundings, and observing certain precautions. The first section of this

manual includes a list of Safety Messages that, if followed, will help protect the operator and

bystanders from injury or death. Read and understand these Safety Messages before assembling, operating or servicing this Implement. This equipment should only be operated by those

persons who have read the Manual, who are responsible and trained, and who know how to do

so safely and responsibly .

The Safety Alert Symbol combined with a Signal Word, as seen below, is used throughout this

manual and on decals which are attached to the equipment. The Safety Alert Symbol means:

“ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!” The Symbol and Signal

Word are intended to warn the owner/operator of impending hazards and the degree of possible

injury faced when operating this equipment..

Practice all usual and customary safe working precautions and

above all---remember safety is up to YOU. Only YOU can prevent

serious injury or death from unsafe practices.

CAUTION! The lowest level of Safety Message; warns of possible injury. Decals

located on the Equipment with this Signal Word are Black and Yellow.

WARNING! Serious injury or possible death! Decals are Black and Orange.

DANGER! Imminent death/critical injury. Decals are Red and White. (SG-1)

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Safety Section - 2

Page 9

SAFETY

PELIGRO!

Si no lee Ingles, pida ayuda a alguien que si lo lea para que le

traduzca las medidas de seguridad. (SG-3)

READ, UNDERSTAND, and FOLLOW the following Safety

Messages. Serious injury or death may occur unless care is

taken to follow the warnings and instructions stated in the Safety

Messages. Always use good common sense to avoid hazards.

(SG-2)

PELIGRO!

Si no lee Ingles, pida ayuda a alguien que

si lo lea para que le traduzca las medidas

de seguridad. (SG-3)

INSTRUCTIVO!

!LEA EL INSTRUCTIVO!

!

LEA EL

WARNING!

WARNING!

DANGER!

WARNING!

Perform service, repairs and lubrication according to the maintenance section. Ensure the unit

is properly lubricated as specified in the lubrication schedule and all bolts and nuts are properly

torqued. Failure to properly service, repair and maintain this Implement in good operating

condition could cause component failure and possible serious injury or even death. (SG-35)

Operate this Equipment only with a Tractor equipped with an

approved roll-over-protective system (ROPS). Always wear seat

belts. Serious injury or even death could result from falling off the

tractor--particularly during a turnover when the operator could be

pinned under the ROPS. (SG-7)

Never work under the Implement, the framework, or any lifted component unless the Implement is securely supported or blocked up to

prevent sudden or inadvertent falling which could cause serious injury

or even death. (SG-14)

Use caution and wear protective gloves when handling sharp objects such as blades, knives,

and other cutting edges. Be alert to worn component surfaces which have sharp edges. Sharp

surfaces can inflict severe laceration injuries if proper hand protection is not worn. (SG-37)

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003Alamo Group Inc.

Safety Section - 3

Page 10

SAFETY

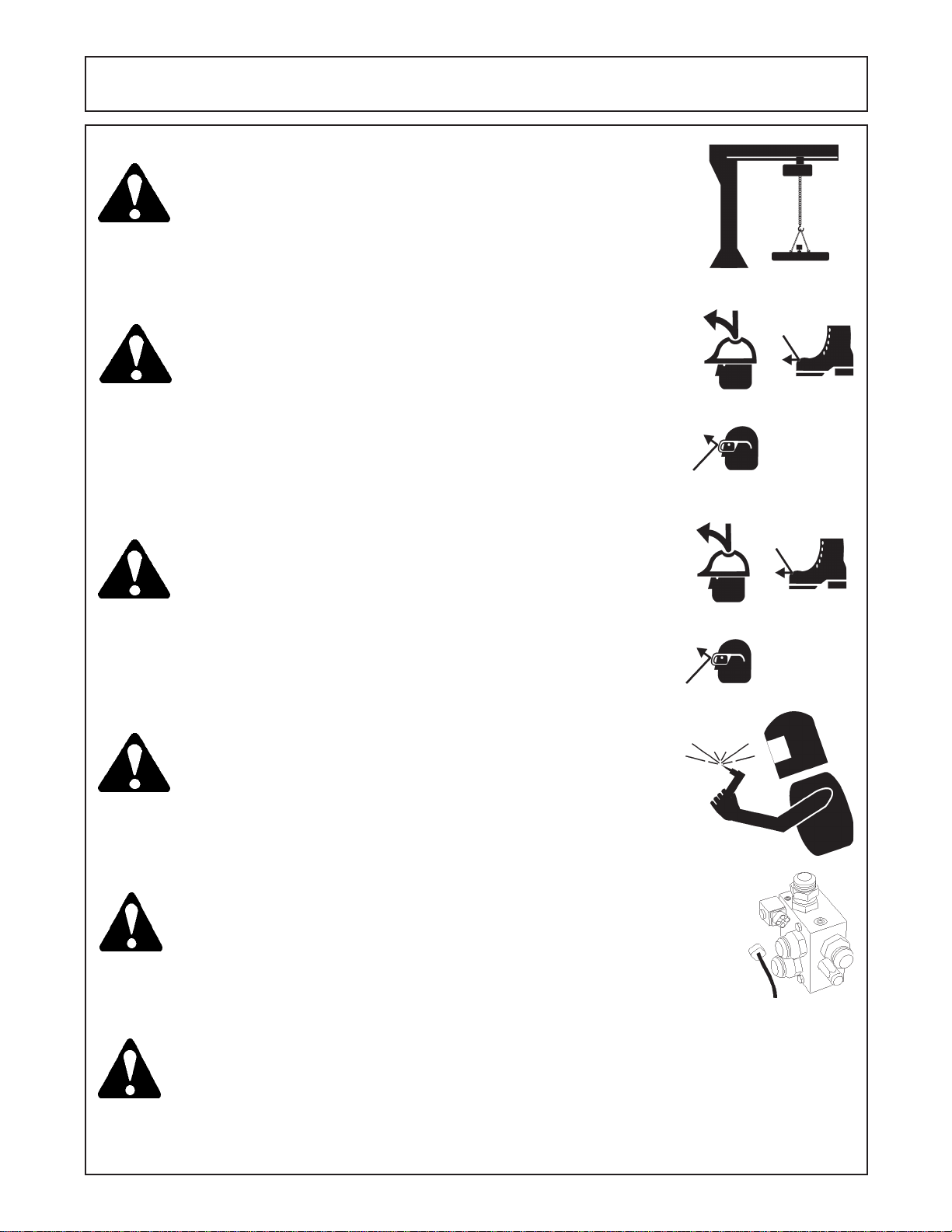

WARNING!

WARNING!

WARNING!

Many of the parts are heavy and require lifting assistance. Do not try to

lift the heavy parts by yourself. Get help from another employee or from

an overhead crane.

The operator and all support personnel should wear hard hats,

safety shoes, safety glasses, and proper hearing protection at all

times for protection from injury including injury from items thrown by

the equipment. (SG-16)

Always wear safety shoes with steel toes when working on this equipment.

It is recommended that the safety shoes have metatarsal guards.

WARNING!

DANGER! Always disconnect the wire leads from the mower valve solenoid before

DANGER!

When welding use Welding hood with the appropriate OSHA required

protective lens, welding apron, and welding gloves.

performing service on the Tractor or Mower. Use caution when working

on the Tractor or Mower. Tractor engine must be stopped before

working on Mower or Tractor. The Mower Blades could inadvertently be

turned on without warning and cause immediate dismemberment, injury

or death. (SBM-12)

Never run the tractor engine in a closed building or without adequate

ventilation. The exhaust fumes can be hazardous to your health.

(SG-23)

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Safety Section - 4

Page 11

SAFETY

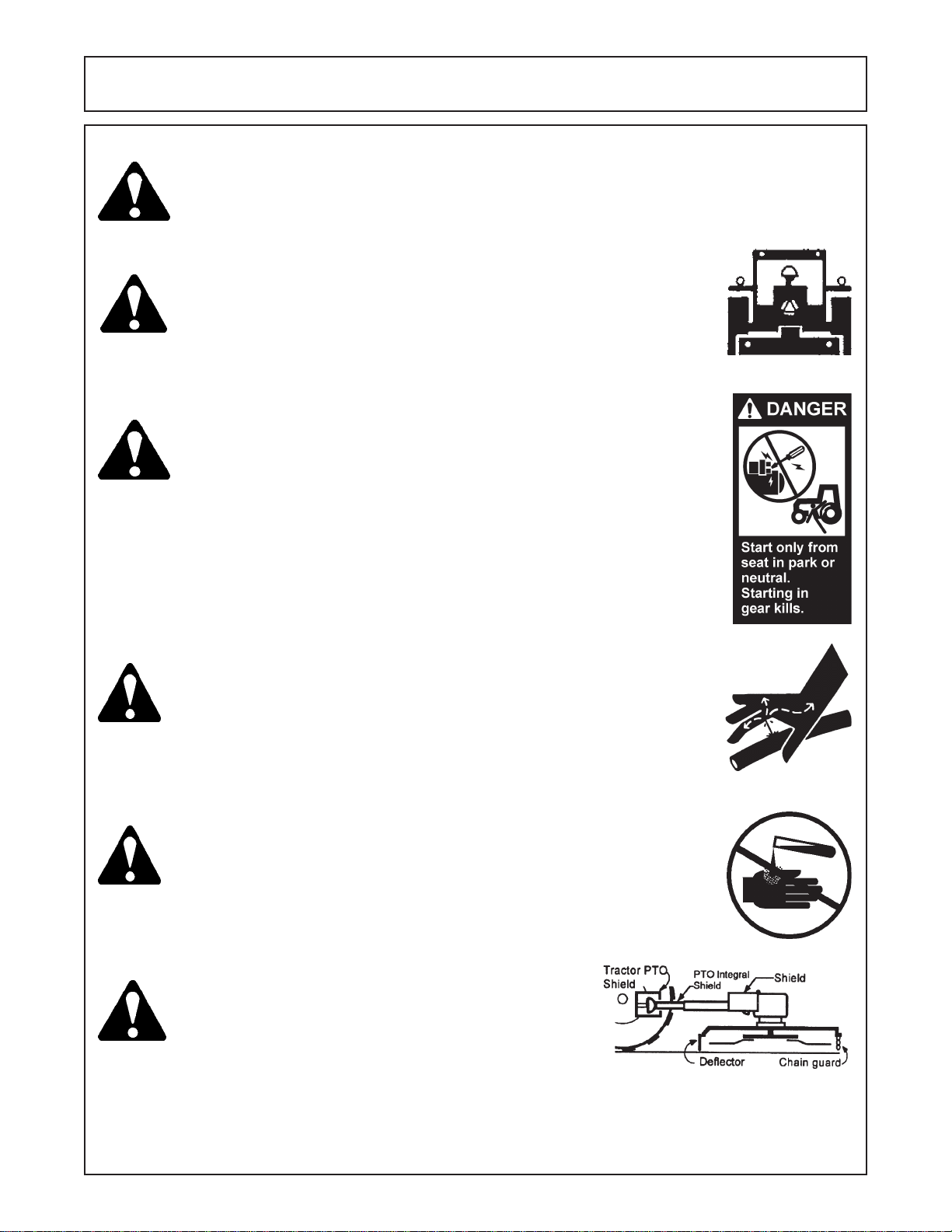

DANGER!

WARNING!

DANGER!

Before starting the mower make sure the area is clear and the floor has

been swept. The mower blade can throw objects several hundred feet.

Thrown objects could damge property or cause severe bodily injuries even

death.

Make certain that the “Slow Moving Vehicle” (SMV) sign is installed in

such a way as to be clearly visible and legible. When transporting the

Equipment use the Tractor flashing warning lights and follow all local traffic

regulations. (SG-6)

Start tractor only when properly seated in the Tractor seat. Starting a

tractor in gear can result in injury or death. Read the Tractor operators

manual for proper starting instructions. (SG-13)

DANGER!

WARNING!

DANGER! All Safety Shields, Guards and Safety devices including

Do not operate this Equipment with hydraulic oil leaking. Oil is

expensive and its presence could present a hazard. Do not check for

leaks with your hand! Use a piece of heavy paper or cardboard. Highpressure oil streams from breaks in the line could penetrate the skin

and cause tissue damage including gangrene. If oil does penetrate the

skin, have the injury treated immediately by a physician knowledgeable and skilled in this procedure. (SG-15)

Always read carefully and comply fully with the manufacturers instructions when handling oil, solvents, cleansers, and any other chemical

agent. (SG-22)

(but not limited to) - the Deflectors, Chain Guards, Steel

Guards, Gearbox Shields, PTO integral shields , and

Retractable Door Shields should be used and maintained in good working condition. All safety devices

should be inspected carefully at least daily for missing

or broken components. Missing, broken, or worn items

must be replaced at once to reduce the possibility of

injury or death from thrown objects, entanglement, or

blade contact. (SGM-3)

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003Alamo Group Inc.

Safety Section - 5

Page 12

SAFETY

DANGER!

DANGER! Operate the Tractor and/or Implement controls only while properly seated

WARNING!

NEVER use drugs or alcohol immediately before or while operating the

Tractor and Implement. Drugs and alcohol will affect an operator’s

alertness and coordination and therefore affect the operator’s ability to

operate the equipment safely. Before operating the Tractor or Implement, an operator on prescription or over-the-counter medication must

consult a medical professional regarding any side effects of the medication that would hinder their ability to operate the Equipment safely.

NEVER knowingly allow anyone to operate this equipment when their

alertness or coordination is impaired. Serious injury or death to the

operator or others could result if the operator is under the influence of

drugs or alcohol. (SG-27)

in the Tractor seat with the seat belt securely fastened around you.

Inadvertent movement of the Tractor or Implement may cause serious

injury or death. (SG-29)

Engine Exhaust, some of its constituents, and certain vehicle

components contain or emit chemicals known to the state of

California to cause cancer and birth defects or other

reproductive harm. (SG-30)

WARNING!

WARNING!

WARNING!

WARNING!

Battery posts, terminals and related accessories contain lead

and lead compounds, chemicals known to the state of California to cause cancer and birth defects or other reproductive

harm. W ash Hands after handling. (SG-31)

Use extreme caution when getting onto the Implement to perform repairs, maintenance and

when removing accumulated material. Only stand on solid flat surfaces to ensure good footing.

Use a ladder or raised stand to access high spots which cannot be reached from gound level.

Slipping and falling can cause serious injury or death. (SG-33)

Avoid contact with hot surfaces including hydraulic oil tanks, pumps, motors, valves and hose

connections. Relieve hydraulic pressure before performing maintenance or repairs. Use

gloves and eye protection when servicing hot components. Contact with a hot surface or fluid

can cause serious injury from burns or scalding. (SG-34)

Avoid contact with hot surfaces of the engine or muffler. Use gloves and eye protection when

servicing hot components. Contact with a hot surface or fluid can cause serious injury from

burns or scalding. (SG-38)

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Safety Section - 6

Page 13

Section 1

A-BOOM

TOOL REQUIREMENTS

AND

PRE-DELIVER Y INSPECTION

CHECKLIST

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section1 - 1

Page 14

Assembly

Tools, Supplies and Equipment Needed

Tools that are recommended to complete this assembly. There are number of different ways

to do things, some items are recommended to make assembly easier but may not be

required.

1. An over Head Hoist, the hoist (or Lift) should be a 2-1/2 ton capacity minimum. Hoist should

be able to move and stop within fractions of an inch. Hoist should also have a 12 foot lift

(Required).

2. Compressed Air, Air must be filtered and dry. A Safety air nozzle for blowing out Hoses and

Fitting prior to assembly. (Required).

3. Complete Air Impact Sockets, 1/2" Drive and 3/4” drive (Recommended).

4. Torque Wrench, 400-ft lb. rating, can use a Torque Amplifier Wrench. (Required)

5. Complete Set of Hand Wrenches from 7/16" to 2" (Recommended).

6. Assortment of Screwdrivers, (Short ones and Long ones). (Required)

7. Electric Grinder or Air Grinder, Size according to needs (Required).

8. Burr Grinder, Electric or Air optional, for resizing Holes and removing Burrs from stamped

metal or stamped holes. (Required)

9. Welder, capable of welding up to 3/8" material, Use experienced Welder Personel. (Required)

10. Flame Proof or flame retardant Material to Cover and protect Tractor finish and components

during assembly. (Required)

11. A good fire Extinguisher on hand before any welding or grinding begins. (Required)

12. Clean dust free work area, clean Lint Free towels or wipes. Do not do any welding, use

compressed Air or lay out any component unless area is clean. Material the size of a human

hair can contaminate the Hydraulic System (Required).

13. A place to keep all Components separate and clean untill ready for them (Recommended)

14. Electrical Butt connectors and Electrical Pliers. (Required)

15. Paint Scraper to remove Paint before welding. (Recommended)

16. Floor Jack, 2-1/2 Ton capacity (Required)

17. An asortment of large C-Clamps (Required)

A-Boom (JD 6615/ 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section 1 - 2

Page 15

A-BOOM PRE-DELIVERY INSPECTION CHECKLIST

Pre-Operation Inspection: After Assembly is complete. Check the following items

before operating the unit to assure that they are properly assembled. (See following page 1-4

for component location)

Saftey Equipment:

----- Operators Manual is with Unit.

----- The Safety Decals are installed as listed in the Assembly Manual.

----- Valve operation plate is installed.

----- Operators cage or Tractor Cab is in place. (Item 1 page 1-5)

----- Deflectors are installed on the Mower Head. (Item 2 page 1-5)

----- Tractor Rops or Cab with seatbels installed properly.

Frame and Boom:

----- Axle Plate Bolts are torqued to 240 ft. lbs. (Item 3 page 1-5)

----- Boom Rest Axle Plate Bolts are torqued to 240 ft. lbs.

----- Front Rail Bolts are torqued to 170 ft. lbs. (Item 17 page 1-5)

----- Front Support Bolts are torqued to 240 ft. lbs. (Item 4 page 1-5)

----- Hydraulic Tank mounting Pins / Bolts in place correctly.

----- Boom Main Pins are torqued to 170 ft. lbs.

----- King Pin Retaining Nut is properly locked in place.

----- All Welds inspected toinsure proper welds and locations.

Hydraulic System:

----- Oil Level in Hydraulic Tank is within the sight gauge. (Item 5 page 1-5)

----- Hose connections are tightented according to specifications.

----- Hoses do not have any kinks or twist in them.

----- Front Pump Shaft adapter bolts are tight. (Item 6 page 1-5)

----- Front Pump Shaft Coupler / Drive Shaft is lubricated and has an anti-seize compound

on the Splines of Pump and Shafts. (Item 7 page 1-5)

----- The Pump Drive Shaft has correct alignment.

----- Suction Hose has no leaks or kinks.

Rotary Mower Head:

----- Skid Shoe Bolts are torqued to 120 ft. lbs. (Item 8 page 1-5)

----- Spindle Housing Bolts are torqued to 400 ft. lbs. (Item 9 page 1-5)

----- The Spindle Housing is properly lubricated. (item 10 page 1-5)

----- Motor Bolts are torqued to 120 ft. lbs. (Item 11 page 1-5)

----- Blade Carrier (Bar) Bolts torque to 400 ft. lbs. (Item 12 page 1-5)

----- All Blade Bolts are torqued, the retainings Pins are in place. (item 13 page 1-5)

----- Blades Swing freely. (Item 14 page 1-5)

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section1 - 3

Page 16

A-BOOM PRE-DELIVERY INSPECTION CHECKLIST

Pre-Operation Inspection: Check the following items before operating the unit to assure

that they are properly assembled. (See following page 1-4 for component location)

Flail Mower Head:

___ Skid Shoe Bolts are torqued to 120 ft-lbs (Item 15 page 5)

___ Motor Bolts are torqued to 120 ft-lbs

___ Belt Alignment& tension adjustment is correct

___ Cutter shaft bearings are properly lubricated

___ Roller bearings are properly lubricated (Item 16 Page 5)

___ Blades swing freely

Tractor Mower Operation Inspection:

___ Using all Safety precautions, operate the Tractor and Mower unit for 30 minutes and

while the unit is running check the following items: Note! Only make adjustments after

the mower has been turned off and all motion has stopped and all hydraulic pressure

has been relieved.

___ No Hydraulic oil leaks at the hose connections

___ Operate the boom and mower head throughout its full range of motion and check

for hose's rubbing, pinching, or kinking.

___ Make sure the Return Filter Gauge is reading in the Green after Oil is warm.

___ Check the function of the Mower Head On-Off Valve and switch for proper function

___ Make sure that the tractor will not start with the mower on-off switch in the on

position.

___ Check the Blade Rotation for the Rotary Mower Head to make sure it is turning

Clockwise looking from the top of the mower deck.

___ Make sure the control valve boom movements agree with the valve operation decal.

___ Make Sure Boom Movement operates as expected and is smooth and under control

(no air in the control system)

___ Look for any unusual or excessive noise or vibrations.

___ Make sure all Wheel Weights are installed, Tires are Filled with liquid and Counter

Weight is installed

___ Make sure the left rear wheel of the tractor stays on the ground when the boom is

fully extended horizontally with 200 lbs. placed on the outside of the mower head.

Post-Operation Inspection:

___ Check that the oil in the hydraulic tank has not turned milky in color or has foam on top.

___ Check that there are no loose fasteners or hardware.

A-Boom (JD 6615/ 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section 1 - 4

Page 17

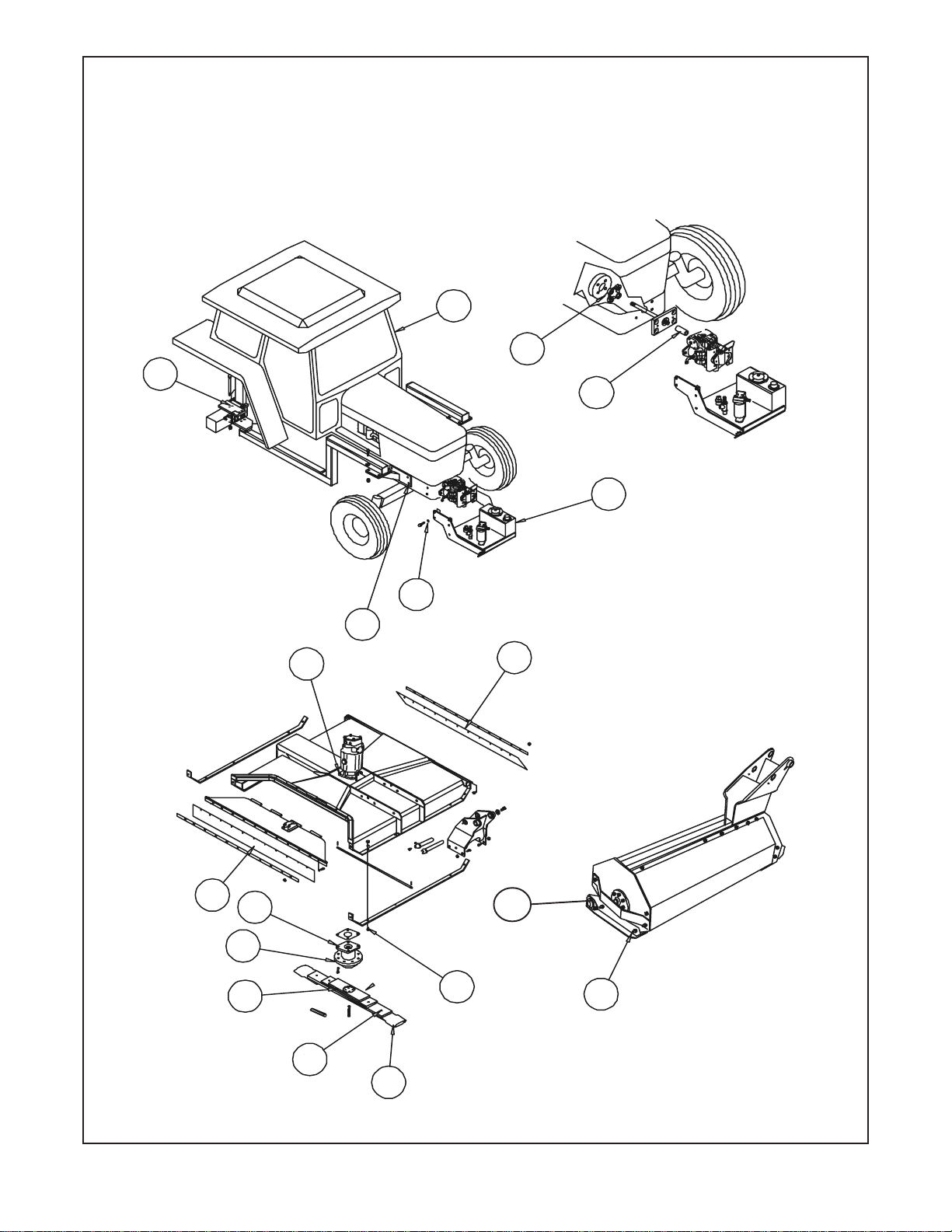

Tractor - Mower Component Location

For Check List

1

6

3

7

5

17

4

11

2

10

9

12

8

2

16

15

13

14

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section1 - 5

Page 18

Section 2

A-BOOM

Wheel Weight

Inst allation

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section 2 - 1

Page 19

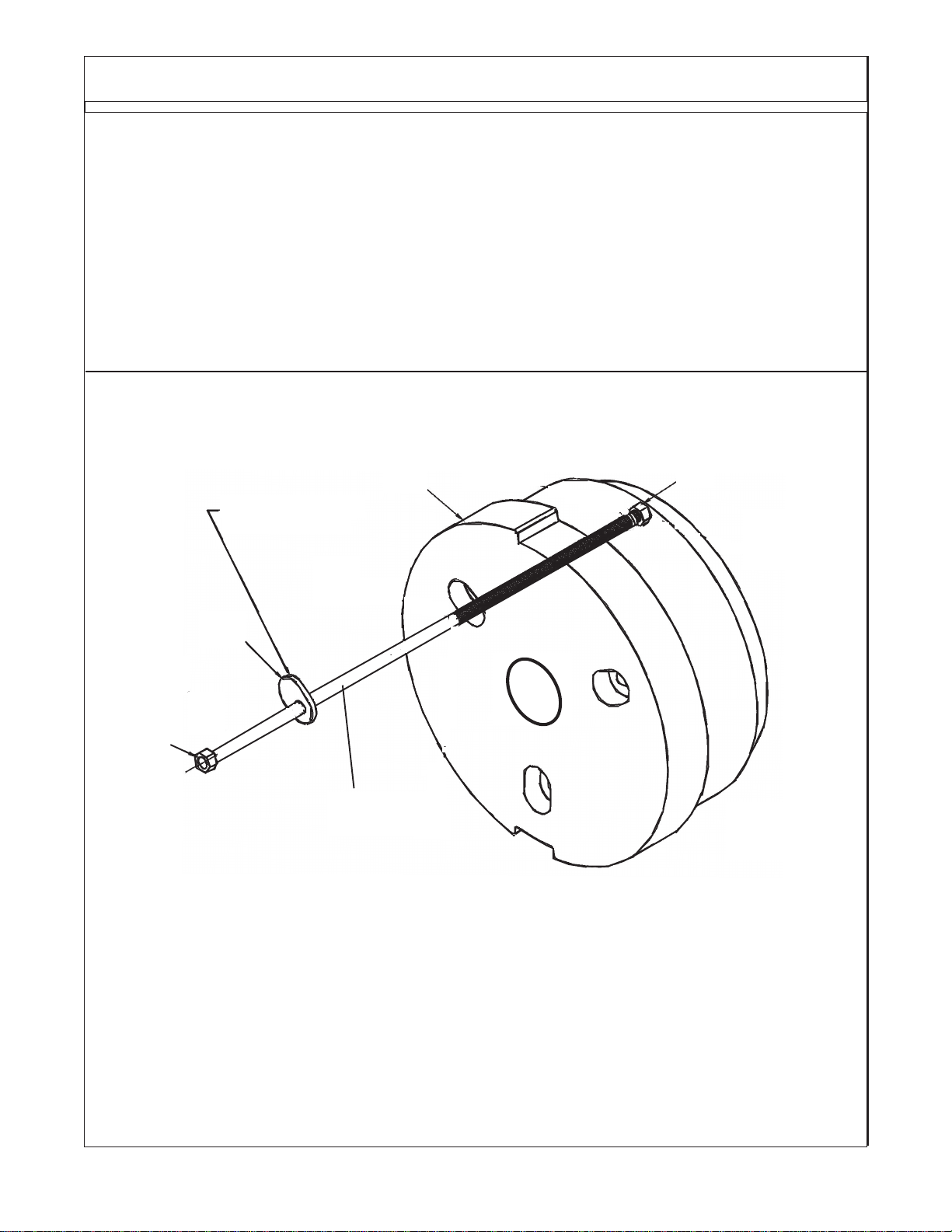

Rear Wheel Counter Weight

Fill Left Rear Wheel with Liquid:

The Left Rear Wheel must be filled with liguid. Alamo Industrial recommends a Calcium Cloride

Water Mixture. The recommended Ratio of a 30 / 70 mix (30% Calcium Cloride and 70% Water), this

mixture will add weight at about 10.5 lbs per gallon. Follow the Mixture procedures furnished by the

Manufactured of the Brand of Calcium Cloride that you are useing. It is also recommended that a trained

person installs the calcium Cloride. Calcium Cloride must be added in addition to the Steel Wheel

Wieght and the Counter Weight that hangs on the Left Side. It is Not recommended to use straight

Water in the Wheel as this would not provide protection against freezing. A 30/70 Calcium Cloride

Water mixture provides anti-freeze to approx -50 deg. F. below 0.

Rotate Washer to Match Bolt

Circle dia. and Washer fits into

Wheel Weight Slot.

3

4

2

1

Bolt is shown extra long in

drawing for illustration only

Figure 1

Item Part No. Qty Description

1 02979603 3 Hex Head Bolt, 7/8" NC X 16"

2 02971569 3 Wheel Weight Washer, Special

3 02970758 1 Wheel Weight Casting, 1400 lbs.

4 5JRC1490 3 Locknut, Top Lock 7/8" NC

Note: some Older Units used a All Thread Rod with Hex Nuts Lock Nuts, with Flat Washer

and Lock washer. This was replaced with the Bolt Type shown above. These Bolt and Nut

combinations will replace the old All Thread type.

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section 2 - 2

Page 20

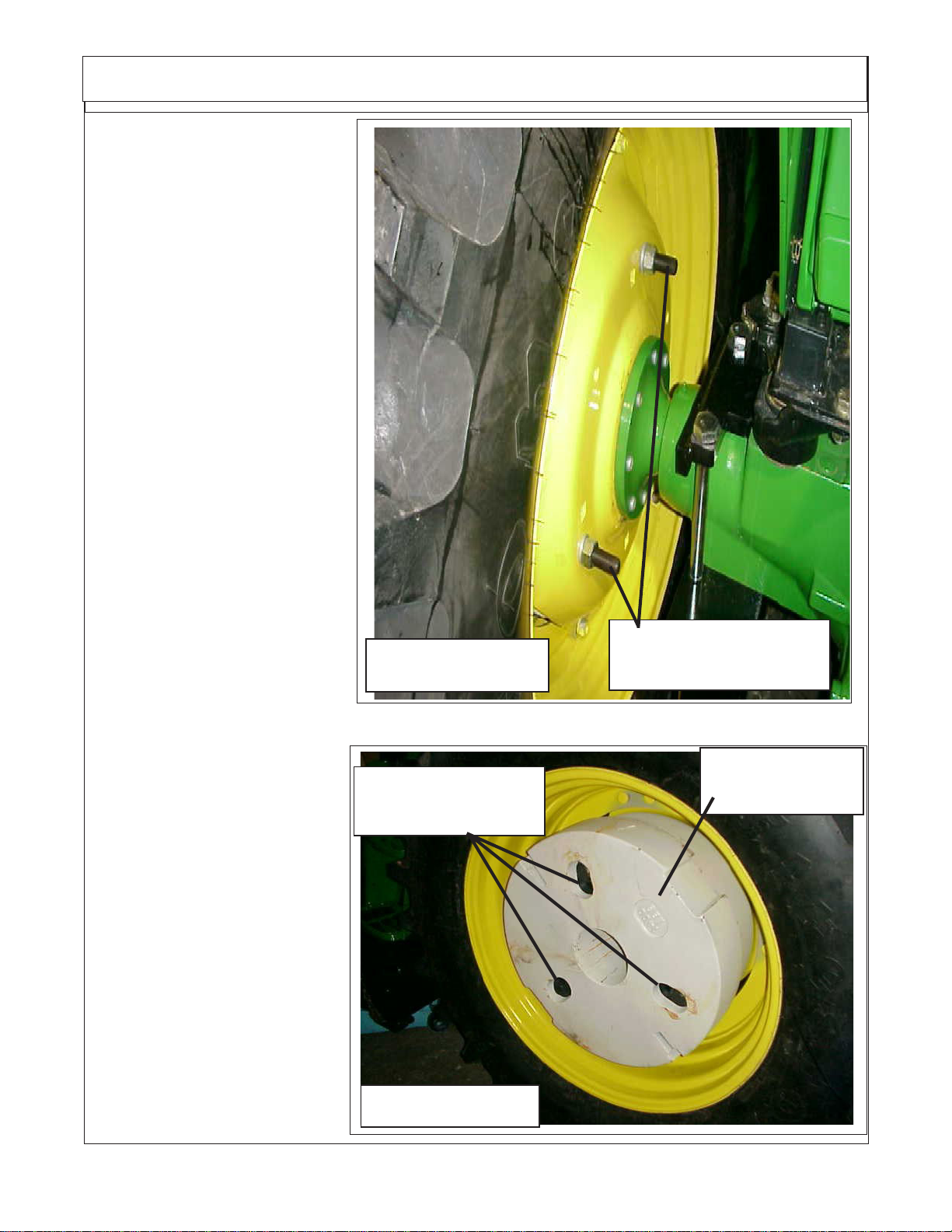

Rear Wheel Counter Weight

Installing Wheel Weight

1. This Wheel Weight is 1400

lbs. Always use caution when

working with it.

2. Locate the three Holes in

LH Rear Wheel. Make sure these

holes are 15/16" dia. if not, they

must be reamed out.

3. Lift Left Rear Tractor

Wheel till it just clears the ground.

This will allow the Wheel to be

rotated when aligning mounting

holes for Weight.

4. Using a forklift, lift Wheel

Weight into Wheel. When Wheel

Weight is centered in Wheel Secure Forklift and Set Parking Brake

on Forklift. Insert one of the three

bolts through Weight and Wheel

(Rotate Wheel to align holes if

needed). Install a Hex Lock Nut on

inside. Insert the other two Bolts

through Weight and Wheel and

start the other two Locknuts. Do

not tighten yet. (See Figure 2)

Figure 2

Wheel Weight Mntg

Lock Nut

5. Looking at the outside

make sure the three special Washers (Figure 1 Item 2) are aligned

with the Slots in the Wheel Weight.

Tighten the three Bolts now. You

will need an assistant to hold the

other Side while you are tightening

the Bolts. While tightening Bolts,

check to make sure the three special washers are seated correctly.

If these Bolts are tightened and

washer are not seated into the

recess on Wheel Weight, damage will occur. (See Figure 3)

Wheel Weight

Special Washers

Mounting Bolts

Part # 02971569

(3)

6. Remove forklift away from

Wheel and Weight. Re-check

tightness of Wheel Weight retaining Bolts. Bolts should torque to

500 ft. lbs.

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

Figure 3

Wheel Weight

1400 lbs.

© 2003 Alamo Group Inc.

Section 2 - 3

Page 21

NOTES

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section 2 - 4

Page 22

Section 3

A-Boom

Front Pump &

Drive Shaft

Inst allation

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section 3 - 1

Page 23

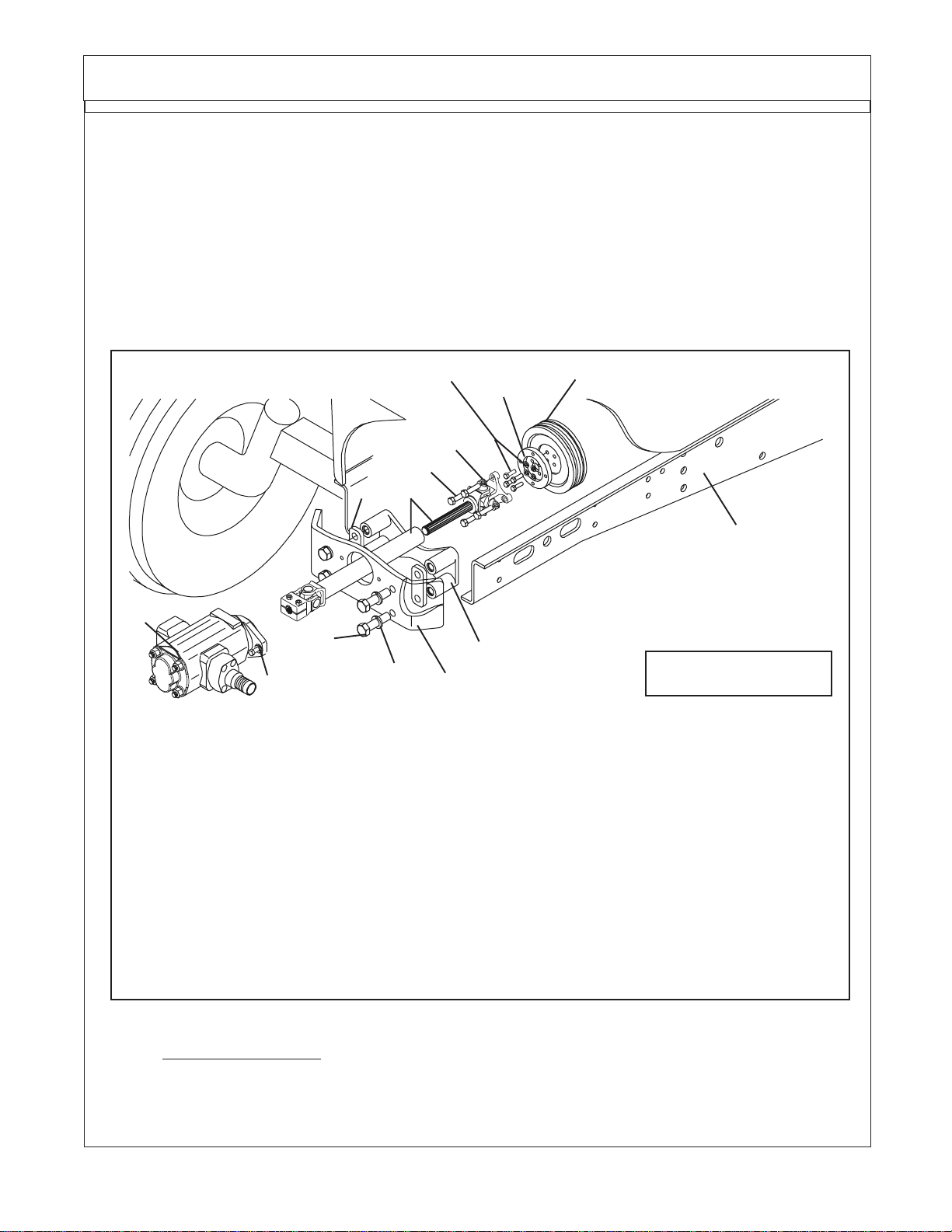

Pump / Drive Assembly Instructions

Installing Pump, Pump Drive Components and Hydraulic Tank:

This Section covers the installation of Pump Drive Components, Pump Assembly and the

Hydraulic Tank. Some precautions must be followed during the Assembly Process and before unit is

ever started for the first time.

1. Tractor must be disabled to prevent accidental engine start and prevent daamge to components.

2. All Fittings, Hose, Cylinders, Tank must be kept plugged at all times, No part of the Hydraulic

System can be left open at any time

3. All Tools, Work Area, Components and Workers Hands must remain Clean when working on

any part of the Hydraulic System.

4. All components should be rechecked for tightness at least twice, Hose routing also double

checked.

Existing JD Bolts & Washers

2

JD Tractor Crankshaft Pulley

7

6

3

10

JD Tractor Frame Rails

Pump

4

8,9

Item Part No. Qty Description

1 02976087 ar Front Pump Plate (Standard) Shown

02979080 ar Front Pump Plate (Optional w/ Pump Guard)

2 02979790 1 Pulley Adapter

3 02973712A 1 Driveline Assembly

4 02975669 4 Bolt, 20 mm 2.5P X 60 mm GR 10.9

5 02971158 4 Lockwasher, 20 mm

6 02976344 4 Bolt, 7/16" NC X 1-1/4" GR 8

7 00022200 4 Lockwasher, 7/16"

8 02892000 2 Bolt, 1/2" NC X 1-1/2" GR8

9 00001300 2 Lockwasher, 1/2"

10 02978480 2 Spacer, Pump Plate (JD 6615 Series)

5

JD Tractor Front Casting

1

Figure 1

Installing Pump Drive Components:

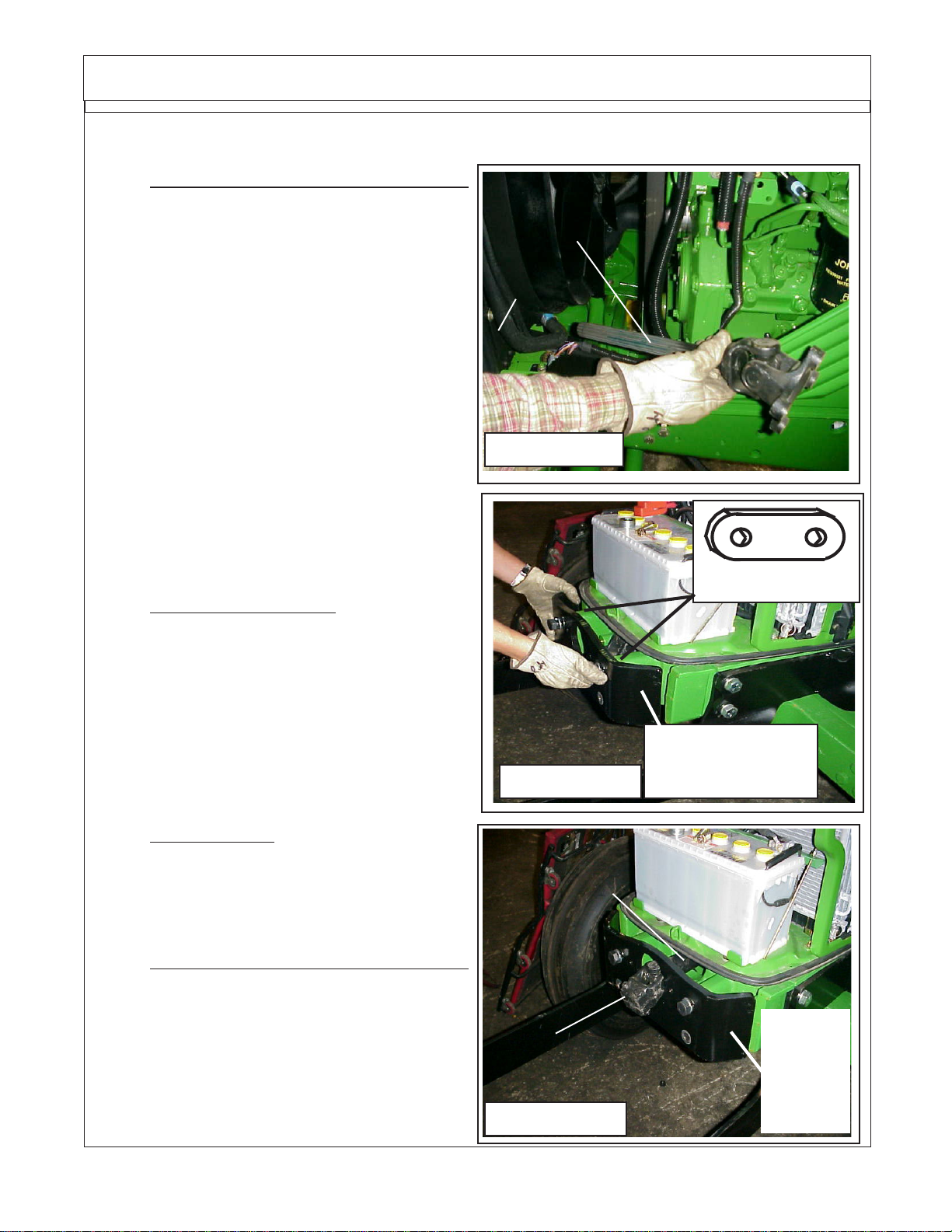

1. Remove Front Cover (See Figure 2), Remove the 4 plastic plugs shown in figure 1 and discard

them, they will not be needed. Remove the 2 Allen Head Cover Retaining Bolts. After removal, this front

cover will not be used. The front Casting will have a Driveline Hole in it. (See Figure 3). This will be the

same on 2 WD or 4 WD.

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section 3 - 2

Page 24

Pump / Drive Assembly Instructions

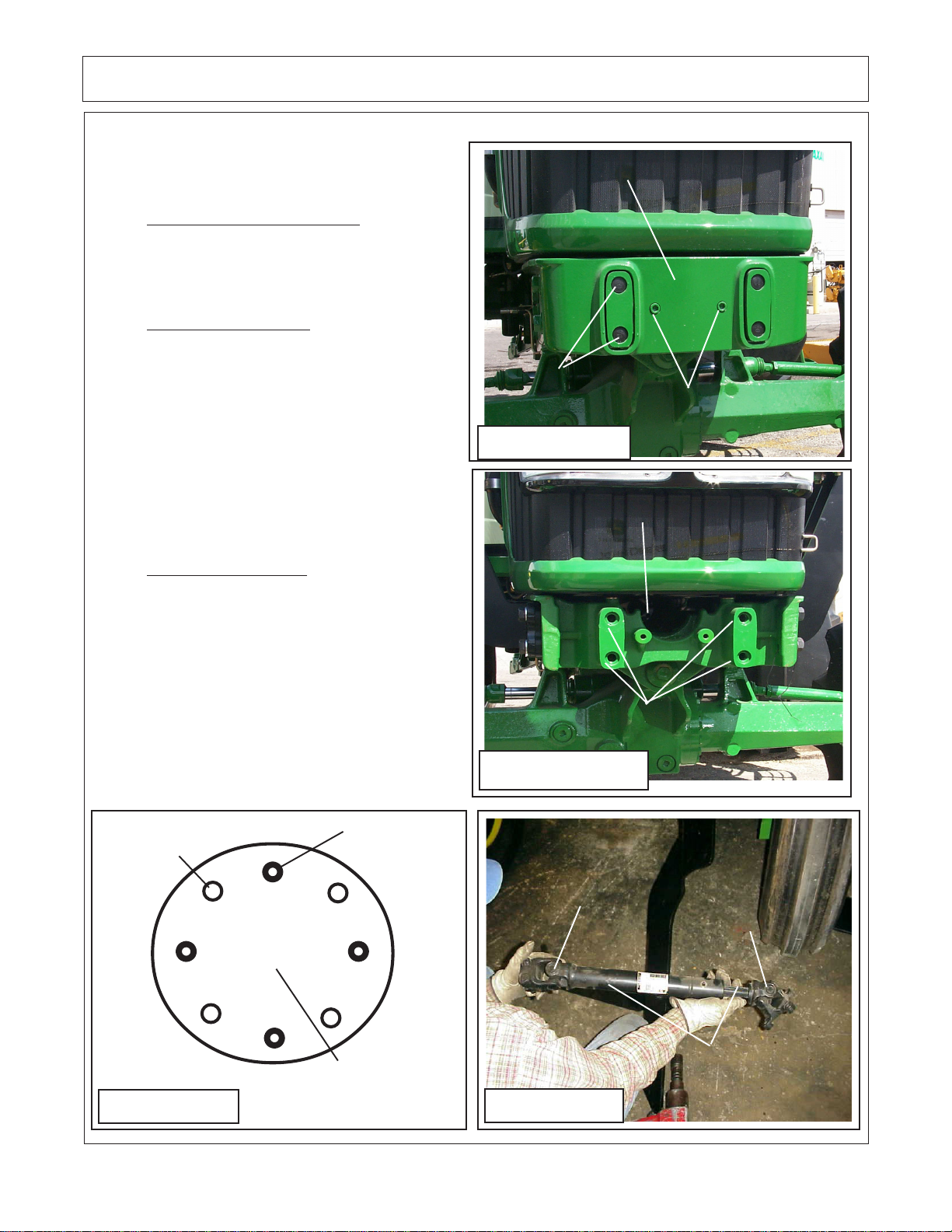

Installing Pump Drive

Components:

2. Access to Crankshaft Pulley. The Factory

Crankshaft Pulley will not need to be removed. The

Pulley Adapter will be bolted to the Factory Crankshaft Pulley.

3. Install Pulley Adapter. The Pulley adapter

to be used is a round plate with 4 threaded

holes and four non-threaded holes in it. Notice

this pulley adapter will not have a center hole in

it (See Figure 4). The Non-treaded holes are

used to mount the Adapter to the Pulley using

bolts # 02979791 (10mm 1.5 P X 35mm

Gr.10.9) & Lockwasher # 00755954 (10 mm).

Do not use longer bolts to mount Pulley Adapter

to Pulley than is supplied with mounting kit.

4. Driveshaft Assembly. The drive shaft is a

two piece Assembly, an inner and outer shaft

assembly (See Figure 5). The Shaft End has a

four bolt flange yokes on it that connect to the

Crankshaft Pulley Adapter. The Tube end has a

splined clamp yoke on it that connects to the

Pump. This Drive Shaft connects to the Pulley

Adapter. Note that the Universals of the Driveshaft

are in time. When installed in tractor they should be

in time as shown, both Yokes the same.

Plastic Plugs

Figure 2

Front Cover Removed

Pump Plate Mounting Holes

Figure 3

Front Cover

Cover

Retaining

Bolts (2)

4

Non-Threaded

Holes

Figure 4

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

4 Threaded

Holes

Pulley Adapter

Part # 02979790

Figure 5

Section 3 - 3

Splined Clamp Yoke

/ Tube End

Flange Yoke

/ Shaft End

Drive Shaft

Assembly

Page 25

Pump / Drive Assembly Instructions

Installing Pump Drive Components: (continued)

6. Install Shaft End of Driveline / Engine end.

Install the Shaft 1/2 Assembly w/ Flanged Yoke into

the Engine compartment of Tractor, install it from

the LH front Side down and under radiator. (See

Figure 6). This needs to be installed this way

because the Flange Yoke will not go through the

Crankshaft access hole in the front of the Tractor

(See Figure 3). Bolt the Flange Yoke to the Pulley

Adapter using the four 7/16" X 1-1/4" Bolts (Part #

02976344), use the four Lock Washers (Part #

00022200), put Locktite on the threads of the Bolts

and install them into Pulley Adapter. To Tighten

these four Bolts, use a long extension and go

through the front Crankshaft Pulley access hole in

front of Tractor. Do Not use bolts longer than 1-1/4"

long, longer bolts will damage

Crankshaft Pulley.

Shaft 1/2 Assembly

w/ Flanged Yoke

Tractor

Radiator

Figure 6

Tractor Engine

Left Hand front side

of Tractor

Installing Pump Mount Plate & Tube

End of Driveshaft:

1. Install Pump Mount Plate. Install Front Pump

Plate # 02976087 standard mount plate (See

Figure 7) or # 02979080 optional Pump Mount

Plate w/ Pump Guard built on. (Not Shown) use

the 2 Spacers on the JD 6615 Series, Do not install

Pump Mount Plate without using these Spacers.

The Spacers are for Tractor Hood Clearance. Insert

the 4 bolts and lock washers into Pump Mount Plate

and spacers (See Figure 7), tighten them to re-

quired Torque (See Bolt Torque Chart).

2. Driveline timeing means the universal joints

are both the same position when driveline half is slid

together. If they are not timed, it will decrease the life

of the universal joint and in some cases could cause

a vibration. (See Figure 5 on previous page)

3. Install Tube End of Driveline / Pump End.

Slide the Tube half of driveshaft through Pump

Mount Plate and Tractor Crankshaft Access Hole

(See Figure 8). You will have to align the Universals

when doing this (time the Driveshaft). Slide the two

together where the Universal are in time (See

Figure 5 on previous page), this will help the

driveshaft to operate smoothly.

Figure 7

Tube End of

Driveshaft

Splined

Clamp Yoke

Figure 8

Spacer (2)

Standard Pump

Mount Plate

Shown

Standard

Pump

Mount

Plate

Shown

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section 3 - 4

Page 26

Pump / Drive Assembly Instructions

Installing Pump Mount Plate & Tube End of Driveshaft: (continued)

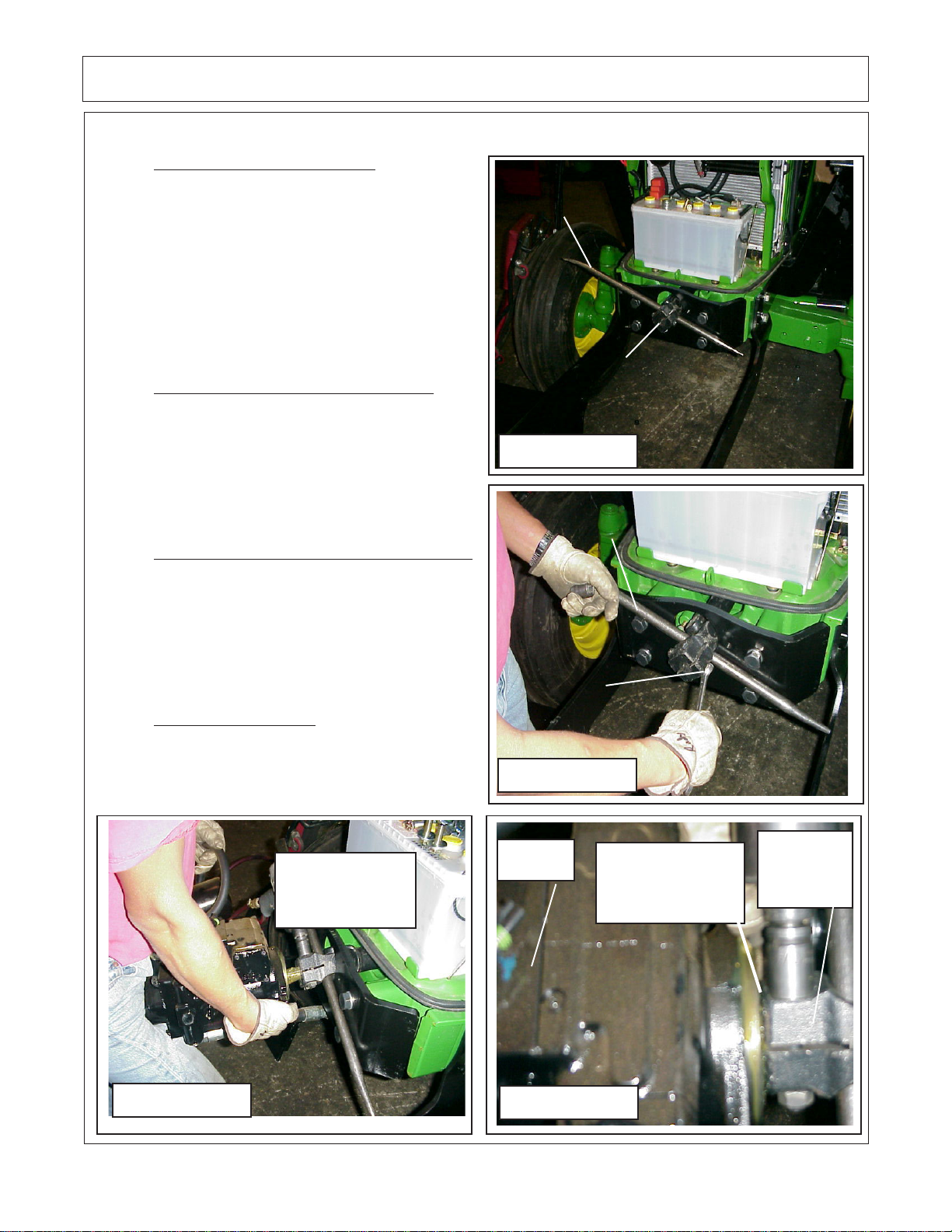

4. Loosen Splined Clamp Yoke. Insert a bar

through the Yoke to hold Driveshaft up and to help

loosen the Bolts in the clamp Yoke (See Figure 10).

This can be loosened with a hand Wrench or a

Socket whichever is easier for you (See Figure 10).

Some times it is easier to test fit the Tube End of

Driveshaft to the Pump while the Pump is on the

bench.

Bar to Hold

Drive Shaft

Installing Pump:

1. Install Pump into Splined Clamp Yoke. Slide

the Pump Splined Shaft into the Spline Clamp Yoke

(See Figure 11). Leave the Bar stuck in through the

Yoke as shown, this helps to stabilize the Yoke as

you slide Shaft into the Yoke. Once Pump is slid into

the Splined Yoke, keep the Pump supported; DO

NOT let the Pump hang on the Yoke unsupported.

2. Pump / Driveshaft Yoke Gap Adjustment.

After sliding Pump Shaft into Splined Clamp Yoke,

the Pump and Yoke must be slid apart far enough to

allow for a 1/16" to 1/8" Gap between them. The Yoke

edge cannot touch the Pump Housing; it will damage

the Housing and the Yoke if it does. This is a very

critical adjustment (See Figure 12).

3. Tighten Clamp Yoke. After Gap between

Yoke and Pump has been adjusted tighten the Bolts

& Nuts on the Clamp Yoke (See Figure 12 & 13).

Check Pump to Yoke Gap once more. Keep Pump

Supported do not let it hang on Yoke.

Driveshaft, Spline

Clamp Yoke End

Figure 9

Bar to Hold

Driveshaft

Loosen

Clamp

Yoke Bolt

Figure 10

Align Splines of

Pump Shaft w/

Splines of Yoke

Bar to Hold

Figure 11

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Driveshaft

Section 3 - 5

Pump

Assembly

1/16" to 1/8" Gap

between Pump &

Figure 12

Yoke (must)

Splined

Clamp

Yoke

Page 27

Pump / Drive Assembly Instructions

Installing Pump: (continued)

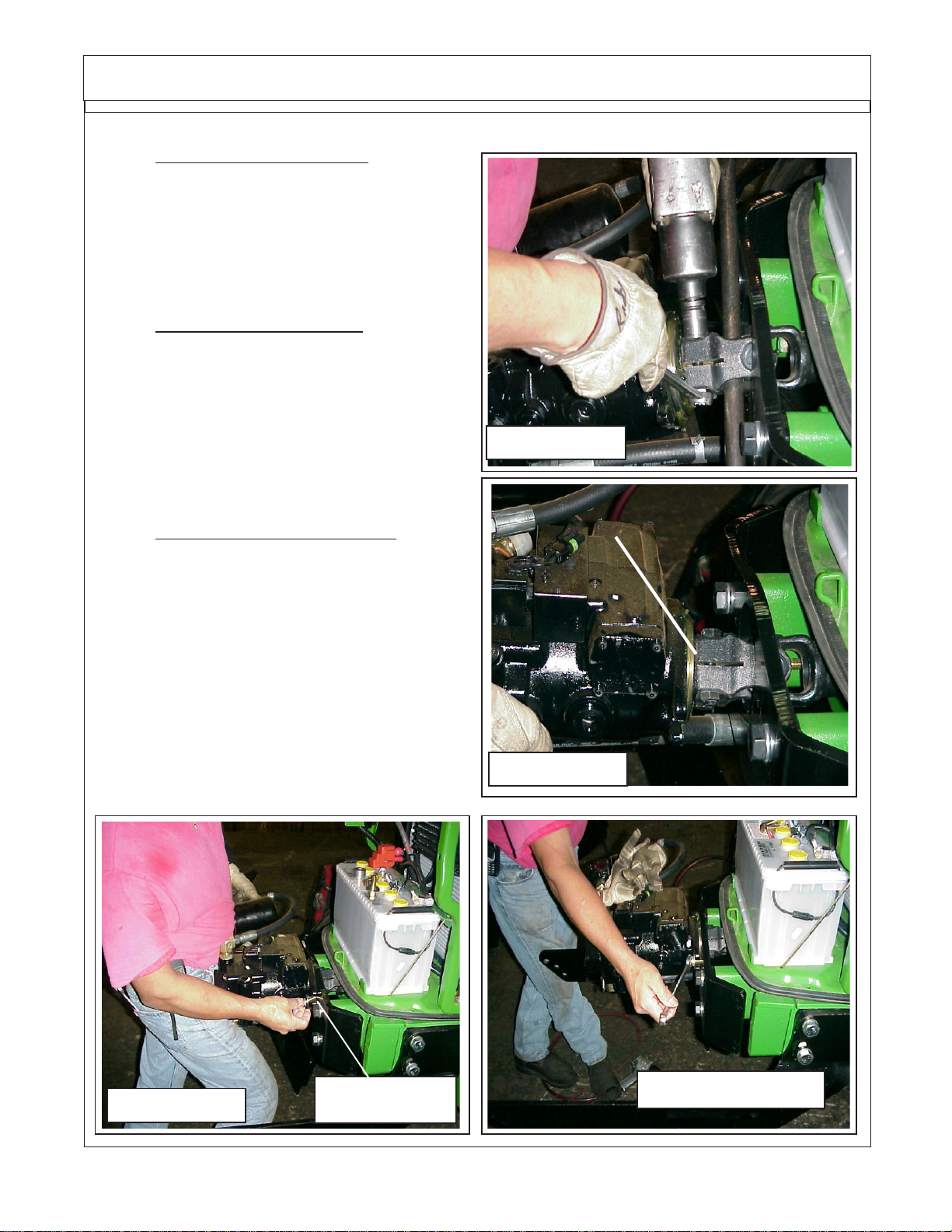

5. Mount Pump to Pump Plate. Remove the

Bar that is slid through the Driveshaft Yoke and

push the Pump inward (See Figure 14). This will

make the two piece Driveshaft slide together allowing the Pump to be pushed towards the tractor.

Do this untill the Pump is against the Pump Plate

(See Figure 15).

6. Install Pump Mounting Bolts. While holding

in on the Pump (See Figure 15) start the two

Pump Retaining Bolts. Make sure both Bolts are

started well before you stop supporting pump. The

Bolts should be snugged untill pump sits level

before you stop supporting it (See Figure 16). Let

go of the Pump, it may slide back some and leave

a slight gap between Pump and Mounting Plate

(See Figure 16).

7. Tightening Pump Mounting Bolts. There is

a shoulder on Pump Flange that must line up

through hole in Pump Mounting Plate (See Figure

14), if the Pump is slid back as in figure 14 try to

push it inward untill it is against Pump Mount Plate

as shown (See Figure 15). Slowly and alternating

from Left to the Right side, tighten the Pump

mounting bolts untill they are tight. DO NOT FORCE

Pump through Pump Mount Plate, if it will not freely

slide in check for a problem of some kind. Excess

force could damage Pump Housing. (See Figure

16). Do Not remove any Plastic caps from Pump

inlet or outlet at this time, keep all openings plugged

and sealed to keep them clean.

Figure 13

Gap ? Check, this must have a gap

between Pump & drivesahft

Figure 14

Pump Retaining

Figure 15

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Bolts (2)

Section 3 - 6

Figure 16

Page 28

Pump / Drive Assembly Instructions

Install Front frame Rail Support s:

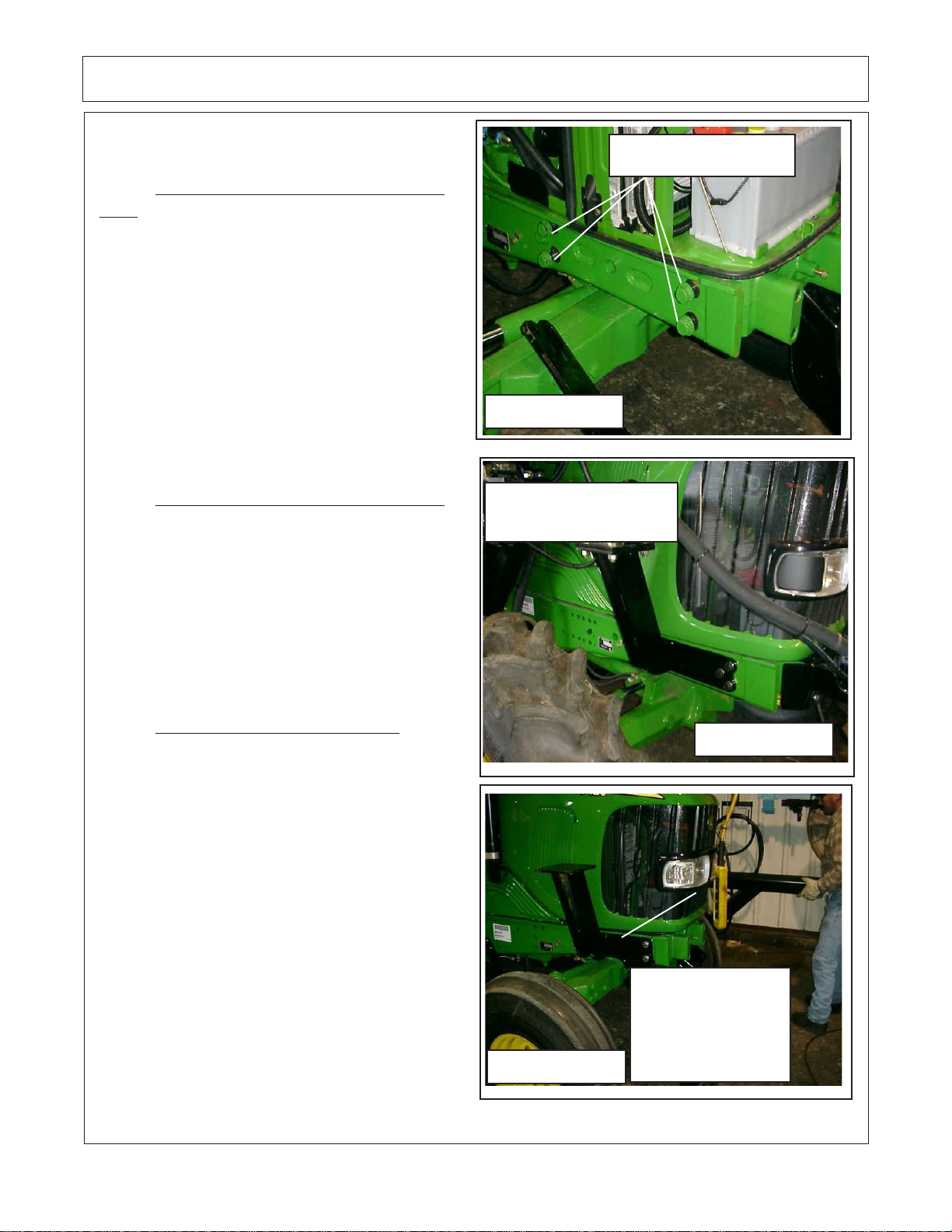

1. Remove Bolts from Tractor Frame

Rails. Find the front most 4 Bolts in the Tractor

Frame Rail, There are 4 on the RH side and 4 on

the LH Side. DO NOT REMOVE THE BOLTS

FROM BOTH SIDES AT THE SAME TIME,

ONLY do one side at a time the RH or the LH.

For illustration start with the RH Side (See

Figure 17). The RH & LH Frame Rail Supports

have a Right and a Left. They will not interchange and must be mounted on the correct

side. Notice the way they are built, the Plate part

that bolts to Tractor is longer in the front on both

LH & RH. Make sure the longest part is to the

front (See Figure 18).

2. Install Frame Rail Support RH Side.

This works best with a 2 man team. The RH

Frame Rail Support the is held on with the 5

bolts that Bolts that are supplied w/ mounting

kit. Start all 5 bolts with Lockwasher before any

of the 4 are tightened (See Figure 18). When

tightened down it will look like the picture in

Figure 18. Tighten the four retaining bolts for the

RH Frame Rail Support before lossening or

removeing the bolts on the LH side.

Tractor Frame Rail

Bolts(5)

Figure 17

Right Hand Frame rail

Support Shown

3. Install Frame Rail Support LH Side. Make

sure that the bolts on the RH side have been

tightened before removing the four bolts on the

LH side. The LH Frame Rail Support will install

the same as the RH side did. Remove the 4

bolts; Install the Front Frame Rail Support.

Tighten the 4 bolts through Tractor Frame Rail.

(See Figure 19).

Figure 19

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

Figure 18

Mounting Plates on

Front Frame Rail

Support, the longer

part toward front on

RH and LH side

RH Frame

Rail Support

RH Tank

Mount Bracket

© 2003 Alamo Group Inc.

Section 3 - 7

Page 29

NOTES

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section 3 - 8

Page 30

Section 4

A-Boom

Frame Rail / High Frame

Setup / Pre- Assembly

Inst allation

A-Boom(JD 6615/ 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section 4 - 1

Page 31

Frame Rail Set Up

Frame Rail Pre-Assembly:

The Frame Rail Set UP. The Frame Rails for the Machete will be set up on the tractor,

positioned, measured but not welded. The Machete High frame is set on to Frame Rails,

positioned and leveled. After all is set up and positioned it will be Tack Welded in Place on Tractor.

Then it will be dis-assembled and welded up on the Shop floor. This is done to ensure better welds

and to enable the parts to be turned so the components can be Flat Welded. It has been found

that this will make the components stronger. This also gives a chance for all frame components

to be test fitted and broken loose during this trial if when another component makes the previous

one interferes.

The Tractor should be covered and protected from Spark from the Welder and Grinder

at all times. It will be your responsibility to protect the Tractor and its components. DO NOT WELD

or GRIND near any Glass or Painted Surface unless it is protected from sparks, these Sparks

will damage any surface.

The purpose for Setting Frame up, tack welding it then removing it, is because with the

amount of Welding that will have to be done these frame components will need to be repainted.

The repainting is easier with frames off. The Frame components are shipped already painted but

this is to protect the metal, plan on repainting them after welding.

DO NOT weld any frame or component untill instructed to do so in the instructions. Read

through this entire instruction book to be familiar with which part goes where and when.

DO NOT try to man handle large components alone, one slip can break a window,

damage a hood or worse. Note the order of assembly of other Assemblies, example the Pump

Drive Shaft, Front Rail Supports, Rear Stack Valve Modifications and Joystick Assembly are

assembled to Tractor before the frame rails. This is because some components will be in the way

of others after they are assembled..

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section 4 - 2

Page 32

Frame Rail Installation

Frame Rail Pre-Assembly: (continued)

RH & LH Frame Rails. Shown below are example of Frame rails, There is a Right and Left Frame

Rail, They will not interchange from side to side. LH must be mounted on the Left and Right on the Right.

To ID which is which, the easiest way is to look for the Counter Weight Mounting Tubes (See Figure

1 Item 2), these are welded on to the LH Frame Rail Only. The Rail Mounting Pad (See Figure 1 Item

4) is loose and not welded to the front of the Frame Rail untill final assembly.

Figure 1

5

1

3

4

Item Part No. Qty Description

1 02979767 1 4 WD Frame Rail Weldment, LH (Shown)

02979768 1 4 WD Frame Rail Weldment, RH (Not Shown)

3 ------------- 2 Rear Mounting Plate (Welded on LH and RH Frame Rail)

4 02725900 2 Front Rail Mounting Pad (not welded to frame rail when recievedl)

5 02974704 2 Stabilizer Strap, (Axle Straps) Fit above Axle.

Note:

Item 3 is welded to both LH and RH Frame Rails from the factory. Item 4 will be welded on

during assembly procedures. Do not weld on any components until instructed to do so, then check

instructions carefully because some components are only to be tack welded then removed to be

welded later.

Actual Tube Design may vary from drawing above. Shown above is a general Frame

Rail Weldment. While Frame Rails may be designed different the mounting process will be the

same.

3 Point Arm Stabilizers on tractor will have to be removed when mounting Frame rails

and will have to be modified to be used again. This modification will be customers responsibility.

A-Boom(JD 6615/ 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section 4 - 3

Page 33

Frame Rail Installation

Frame Rail Pre-Assembly: (continued)

Frame Rail Stiffener Kit (Crossmember). Shown below is the Frame Rail Stiffener Kit. This

mounts under the Tractor and will be added to the Frame Rails during Assembly. Item 5 Rail Support

Gussets are shipped loose and are not part of the Assembly, they will be bolted to the tractor and when

instructed you will need to weld the Frame Rail Support to them (See Figure 2).

Frame Stiiffener Kit

Frame Rail, RH Shown

Frame Rail Stiffener Kit

(Crossmember)

3,4

Item Part No. Qty Description

02970118 -- Frame Rail Stiffener Kit (Item 1 thru 4)

1 02970115 2 Rail Stiffener Weldment

2 02970086 1 Tube, Rail Stiffiner

3 02712500 4 Bolt, 1" NC X 4" GR8

4 5JRC1680 4 Locknut, 1" NC (Toplock)

5 02978499 2 Gusset Rail Support

Figure 2

5

1

2

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section 4 - 4

Page 34

Frame Rail Installation

Frame Rail Pre-Assembly: (continued)

High Frame Mounting Tube Components. (See Figure 3 & 4) These Components are to be laid

out and will be tack welded to frame Rails and High frame during Pre-Assembly Process. Locate and

ID these Parts for later installation. Remember DO NOT Weld any components untill instructed to do

so.

High Frame Mounting Tube Componnets

1

Machete High

Frame

2

2A

RH Frame Rail

Front Shown

2

Figure 3

Item Part No. Qty Description

1 ---Ref----- 2 Mounting Tubes, (Length will Vary with Mount Kit).

02918600 4 Bolt, 3/4" X 2" Long (Not Shown)

00037200 4 Locknut, 3/4" Toplock (Not Shown

2 02966639 7 Bar Mounting Strap

2A 02966639 1 Bar Mounting Strap (Cut In Half)

3 00037200 8 Locknut, Toplock

4 02957039 8 Bolt, 3/4" X 10-1/2" Long

5 02966641 2 Angle Mount

2A

Cut Off

3

6-3/4"

Width of Frame

Rail Tube

1

4

Frame Rail

(to Rear Axle)

5

A-Boom(JD 6615/ 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section 4 - 5

Page 35

High Frame Installation

Frame Rail Pre-Assembly: (continued)

High Frame Mounting Tube Components. (See Figure 4) These Components are Sitting in

approx. position of assembly to illustrate where they are to be when tack welding them. Space is left

between them for Illustration only, they will be closer together when assembled.

Also See Figure 3 on previous Page.

Bolts (3 each side)

Angle Mount (2

each side)

Mounting Tube

Frame

Rail

Rear of

Frame Rail

(1 each side)

Mounting Bolt Holes

(2 each end)

Angle Mount

(2 each side)

Bar Mounting

Strap Cut Off

(2 each side)

Locknuts (3 each side)

Bar Mounting

Figure 4

High Frame and King Post Frame Sub-Assembly. (See Figure 5) The High frame will come

with the King Post Sub-Assembly built to it. The 2 Wheel drive and 4 Wheel Drive High frames are

different and will not interchange between 2 WD and 4 WD Tractors, the 4 Wheel drive High Frame has

the King Post Mounting welded higher up on frame than 2 WD Frame. DO NOT try to use a 2 Wheel

drive Frame on 4 Wheel Drive Tractor or vice versa, it will not work.

Hydraulic Tank, The Hydraulic Tank is mounted on the LH side of High Frame. It will be mounted

by the Mounting tubes that are welded to the High Frame and the Tubes that are welded on to the

Hydraulic Tank. There will be long bolts with Allen Heads that will be inserted down through these tubes.

Tank Mounted Counter Weight. There is a tank mounted counter weight that will be mounted

on to the Hydraulic Tank useing Allen Head Bolts. There will be a cover that bolts on over counter weight.

Straps

Front

of

Frame

Rail

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section 4 - 6

Page 36

High Frame Installation

High Frame & King Post Asy

NOTE: 2 Wheel Drive High

Frame and 4 Wheel Drive

Frame looks the same except King Post and Bracing

is higher up. The 2 Wheel

Drive and the 4 Wheel Drive

High Frames will not interchange.

Hydraulic Tank

King Post

High Frame

Suction Line

to Pump

Oil Return Filter

Hydraulic Tank

Mounting Tube

Counter Weight

Mounting Tube

Oil Suction Filter

Tank Counter Weight Weldment

Figure 5

Counter Weight Cover

NOTE: Shown above is a general view of the High Frame, Counter Weight

and Cover and may not look the same as the one for your application. The

Assembly procedures will be the same even if the shape of Tank and

Weight are different than shown.

A-Boom(JD 6615/ 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section 4 - 7

Page 37

Frame Rail Installation

Pre-Installing Frame Rails:

1. Lay Out Components in Display. It is

helpful to lay out the component in as neat a

display as possible. Lay out the Bolts according to size and length. Lay out the Nuts and

washer by size. This will allow you to see how

many of each part as you use them and help

to identify any missing parts. (See figure 6)

2. Front Frame Rail Supports. These

Frame Rail Support Mounts (part # 02979765

LH & 02979766 RH). These should already

be mounted from previous Assembly of

Front Pump and Drive Shaft Components. It

is easier to mount the Pump Drive Shaft

before these Frame Supports are installed. If

you are mounting the Frame rail supports

now, there are important things to remember. There are 4 bolts that go through Tractor

Frame that will have to be removed before

this can be mounted,

4 bolts from both sides (LH & RH) of the

Tractor at the same time. Remove the 4 from

one side or the other, install the 4 retaining

(New Bolts) that hold the Rail Support

Weldment on and tighten them. Then go to

the other side and remove the 4 Bolts from

Tractor Frame Rail and install Machete Frame

rail Supports using the 4 new Support Retaining Bolts. The Tank Support brackets connect to the Tractor. These will be mounted

when the Frame Rail Supports are installed

(See Figure 7).

DO NOT remove these

Figure 6

Figure 7

Frame Rail

Support Brackets

3. Rail Support Gusset Mount. There

are two Bolts in the Tractor frame rail that will

need to be removed in order to mount this

gusset support. It is easier to do now with the

frame rails off. It will need to be installed now,

as the Frame Stiffener Assembly will line up

with these Gussets. Note the angle on the

Gusset as it is being mounted (See Figure

8) See Figure 2 for drawing of Frame Stiffener Kit and Part numbers for components.

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section 4 - 8

Figure 8

Page 38

Frame Rail Installation

Pre-Installing Frame Rails: (continued)

4. Front Rail Mounting Pad. There are

two of these Pads; one is used on the left and

one on the right. These Pads are the same

so it will not matter which goes on which side.

(See Figure 9). Set the Pad down over the

Front rail Support aligning the four holes in

pad with the four holes Support. Insert the

four Bolts into the mount pad and plates on

front support mount (See Figure 10). Install

a nut on one or two of the Bolts but do not

tighten them, the Bolts are only installed to

prevent the Pad from moving side to side.

5. Locate RH and LH Frame Rail. There

are two different frame rails, RH and LH. Start

with either one you want, for illustration we

started with the RH (See Figure 11). Remember the LH is the one with the Counter

Weight Mount Tubes welded onto it, (See

Figure 1)

6. Prepare Tractor Axle Housing. First

look up under Tractor at the rear axle where

the frame Rails mount you will see holes in

the Axle castings on both LH and RH side that

has plastic plugs in them. The Plastic Plugs

will have to be removed now as they cannot

be removed once the Frame Rails are in

place (See Figure 12).

Front Rail

Mounting Pad

P N. 02725900

Figure 9

Front Frame Rail

Mount Pad

Front Frame Rail

Support Mount

Figure 10

Figure 11

A-Boom(JD 6615/ 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section 4 - 9

Figure 12

Page 39

Frame Rail Installation

Pre-Installing Frame Rails: (continued)

7. Installing Frame Rails. Using a Hoist,

lift the frame rail and slide it into place under the

right rear Axle. Hold the frame rails as shown to

prevent it from moving (See Figure 13). Using

a Floor Jack (See Figure 14) support the

Frame Rail up under the Axle. Note: the RH and

LH Frame rail will install the same so you can

work either side first.

8. Install first Frame Rail to Tractor &

Rear Axle. The Frame Rails Mount to the rear

Axle of Tractor. The RH Side has Longer Bolts

than the LH Side does. This is because the Axle

Mounted Boom Rest will also mount here using

some of the same Bolts. For now use shorter

Bolts to hold Frame Rail up to Axle while you

finish the Pre-Installation. The Bolts that were

removed from the Tractor when you mounted

the Front Frame Rail Supports will work well for

this (See Figure 15).

9. Install the other Frame Rail. The other

frame rail will install the same as the first did.

DO NOT do any welding at this time.

10. Frame Stabilizer Kit. Locate the Frame

Stabilizer Kit (See Figure 16). This should be

bolted together as shown, for fitting under

tractor and to Frame rails it must be bolted

together.

Figure 13

Figure 14

Figure 7

Use Extreme caution so

that Frame Rail will not hit

Cab or Hood & cause

damage

Floor Jack and

Frame Rail

Rear Axle

Mount

Figure 15

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section 4 - 10

Figure 16

Page 40

Frame Rail Installation

Pre-Installing Frame Rails: (continued)

11. Raising Frame Stabilizer Kit Up Under

Tractor. Using a Floor Jack slide Stabilizer Kit

under Tractor right behind the front wheels. (See

Figure 17). Note the Floor Jack used here has

had channel built for it that cradles the square

shape, this is also good for supporting the frame

rails during assembly. Using Jack helps to align

Stabilizer to frame rails. This is shown on a 2 WD

Tractor for illustration and is the same for the 4

WD

12. Align Stabilizer Kit. Raise Stabilizer Kit

with the Floor Jack up untill it is flush up against the

Stabilizer Gusset Support that should already be

bolted to the frame from earlier installation steps

(See Figure 18). This should be this way on the

RH and LH side. DO NOT Weld Gusset to

Stabilizer yet this will be done later. Secure the

Stabilizer kit to the Frame Rails with C-Clamps on

both LH and RH (See Figure 19). You may leave

the Floor Jack or remove it.

Figure 17

Stabilizer Gusset

Machete

Frame Rail

13. Align Frame Rails on Front Mount Pads.

Locate the Front Frame rails on the mount pad so

that there is room for the Bolt heads to clear the

Frame Rail. Here we have wedged a Screwdriver

with a 1/4" shank between the Bolt Head and the

Frame Rail. Anything about that size can be used

to keep enough distance so bolt can be removed

and reinstalled without interference. Use a CClamp to hold it in place when aligned. Do this on

Both the RH and LH side. (See Figure. 20)

Stabilizer up

against Gusset

C-Clamps

Figure 18

Frame Rail

(Front)

Front Rail

Mounting Pad

Stabilizer Kit

C-Clamp

1/4"

Shanked

Screwdriver

Figure 19

A-Boom(JD 6615/ 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section 4 - 11

Figure 20

Page 41

Frame Rail Installation

Pre-Installing High Frame:

1. High Frame Shipping Pallet. The High

frame is shipped bolted to a Pallet, Do not

unbolt this from the Pallet untill the Hoist has

been connected to the High frame. The Hoist

must be supporting the weight of the High

Frame before any of the bolts holding High

frame to pallet are removed.

2. Prepare High Frame for Lifting. There

are two lift lugs welded to the top of the High

frame for lifting it (See Figure 21). These Lugs

will lift the bare High Frame straight without the

King Post Sub-Assembly bolted to it. With the

King Post Sub-Assembly bolted to the High

Frame it will require you to adjust the length of

the lifting chain and lifting point to balance the

load (See Figure 22) and lift High frame level.

High frame must be level when lifted over

Frame rails.

Figure 21

3. Level High Frame. Use two magnetic

Levels as shown. These magnets should be

installed before lifting High frame.

The First Magnetic level is put on the

Top of the High Frame on the Bottom Side

(See Figure 23). This level will allow you to

level the frame from left to right without having

to climb up later to use a Level that you hold.

The Second Magnetic Level is put on

the Kin Post Pivot toward the front of the tractor

so that it will level the High Frame from front to

rear as shown (See Figure 24).

Top of High Frame

Figure 22

King Post

Pivot Pin

Magnetic Level

Front of

Tractor

Magnetic Level

Figure 23

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section 4 - 12

Figure 24

Page 42

Frame Rail Installation

Pre-Installing High Frame: (continued)

4. Lower High frame down over Tractor.

This is a two man job in order to keep control of

High Frame on both sides of tractor (See

Figure 25). Lower the High Frame down over

the Frame rails (See Figure 26) slowly, as it

must straddle the Frame Rails (See Figure

26). Lower High Frame untill the top of the High

Frame is no higher than the cab of The Tractor

max. and no lower than 24-1/2" from frame to

hood as the min. distance (See Figure 25) .

Another mark to look at is the Horizontal tube of

the High frame should be parallel up and down

with the Frame Rail Tube as shown on next

page (See Figure 29).

24-1/2"

Min

height

frame

to

Hood

Figure 25

5. Check High Frame for Level. Check

the two Magnetic Levels that you installed

earlier. The Top Level should be from side to

side of the Tractor (See Figure 27). The level

on the King Post Pivot Pin should be level

making High Frame Level straight up and Down

(See Figure 28). Leave the Magnets on the

High frame, as you will have to check then one

more time later. DO NOT do any welding at this

time.

6. Secure High Frame to Frame Rails.

Secure the High Frame to the Frame rails with

C-Clamps on both sides (See Figure 29). Do

not weld anything at this time.

Level

High Frame

Frame Rail

Figure 26

Level

Figure 27

A-Boom(JD 6615/ 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section 4 - 13

Figure 28

Page 43

Pre-Installing High Frame: (continued)

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

12345678901234567890123456

1

6

12345678901234567890123456

2

2

2

2

2

2

7. Align High frame to Frame Rails. The

High Frame Vertical Tube should be as directly

above the Vertical tube of the frame rails as

possible (See Figure 30). The illustrations in

figure 30 shows the High Frame not directly

over the Frame Rail Vertical Tube, try to get it

as directly over it as you can.

no higher than the Cab of the Tractor. The

horizontal tube of the High Frame should be

just above the height of the horizontal Tube of

the Frame Rail (See Figure 29 & 30)

Rail when aligned and leveled. (See Figure

29). Leave the Hoist connected to the High

frame for safety and additional support.

Support

Plate

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Support

8. Re-check all alignment points. Re-check the alignment of the Frame Rails and High

Frame for level mounting position. These components must be aligned now before any Tack

welding begins.

Frame Rail Installation

The height of the High frame should be

Clamp the High frame to the Frame

Frame Rail

Horizontal Tube

High Frame

Horizontal Tube

Front

Mount

Figure 30

Frame Rail Tube & Frame Rail must be align

parallel with each other up and down here

Figure 29

Machete High Frame

Vertical Tube

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

Frame Rail leading to rear

Axle Housing of Tractor

Section 4 - 14

234567890123456789012345

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

Set High

Frame in

Line with

Frame Rail

Vertical Tube

as shown

Frame Rail

Vertical Tube

Page 44

Frame Rail Installation

Pre-Install Mounting Tubes for High Frame: (continued)

Machete High

1

Frame

1

2A

RH Frame Rail

Front Shown

2

2A

2A

4

6-3/4"

Figure 31

Item Part No. Qty Description

1 ---Ref----- 2 Mounting Tubes, (Length may Vary with Mount Kit).

02918600 4 Bolt, 3/4" X 2" Long (Not Shown)

00037200 4 Locknut, 3/4" Toplock (Not Shown

2 02966639 6 Bar Mounting Strap

2A 02966639 2 Bar Mounting Strap (Cut one end off LH Rail only)

3 00037200 8 Locknut, Toplock

4 02957039 8 Bolt, 3/4" X 10-1/2" Long

5 02966641 2 Angle Mount (Front only)

Cut one end off

Mounting

Tube Width

Frame Rail

(to Rear Axle)

2

5

9. Install Mounting Tubes . Loosely bolt

the Front Angle Mount end of Mounting Tube

(See Figure 32). Slide 1 Mounting Tube in on

top of the Frame Rail on each side, the end

that has the Angle Mount bolted to it goes to

the Front away from the Tractor Cab. The

mounting Tube should be slid back till the end

of mounting tube is about 1/2" from the end of

the Frame Rail. (See Figure 34). Do Not

Tack Weld any components at this time.

Note: in figure 32 note the location of High

Frame Tube Height as compared to Mounting Tube Height, this is the way that it will

appear as looking over the Hood of the Tractor toward LH Side.

High Frame

Figure 32

A-Boom(JD 6615/ 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Section 4 - 15

(LH Side)

Mounting

Tube

Page 45

Frame Rail Installation

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

6

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

123456

1

6

123456

6

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

6

Pre-Install Mounting Tubes for High Frame: (continued)

10. Install Front Angle Mount. Loosely

bolt the Front Angle Mount on the other end

between Plates on Front

Angle Mount end Only

(front) of each Mounting Tube (See Figure

Washer 1/8" thich inserted

33). Notice the washer that is installed be-

Angle Mount

tween the Angle Mount and Mount Tube, This

is there because about a 1/16" Gap is needed

between the Mount Tube Plate and the Angle

Mount Plate. Putting this 1/8" thick washer on

the front Angle Mount end only will allow for

this Gap on both ends. (See Figure 33 & 34)

This should be done on right hand and left

hand side Mounting Tube. This Gap allows

the High Frame with the Mounting Tubes

welded onto it, to be lowered down between

the front and rear Angle Mount, which will be

Figure 33

welded to the Frame rails later. Do not do any

tack welding till instructed to.

Mounting Angle

Washer Here

w/ Bolts & Nuts

Mounting Tube

Frame Rail

2345678901234567890123456789012123456789012345678901234567890121

2345678901234567890123456789012123456789012345678901234567890121

23456789012345678901234567890121

2345678901234567890123456789012123456789012345678901234567890121

23456789012345678901234567890121

2345678901234567890123456789012123456789012345678901234567890121

2345678901234567890123456789012123456789012345678901234567890121

23456789012345678901234567890121

2345678901234567890123456789012123456789012345678901234567890121

23456789012345678901234567890121

2345678901234567890123456789012123456789012345678901234567890121

23456789012345678901234567890121

2345678901234567890123456789012123456789012345678901234567890121

23456789012345678901234567890121

2345678901234567890123456789012123456789012345678901234567890121

234567

234567

Put a Spacer

A-Boom (JD 6615 / 7615 Asy Instruction Manual) 07/03

© 2003 Alamo Group Inc.

Front

Support

Mount

Figure 34

Bar Mounting Straps

with Bolts & Nuts

234567

234567

234567

234567

234567

234567

2345

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

234567

2345678234567890123456789012345

Machete High Frame

Frame

Section 4 - 16

Rail

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

Approx. 1/2"

from end

2345

2345

Set High

Frame in

Line with

Frame Rail

Page 46

Frame Rail Installation

Tack Welding Frame Rails:

1. Tack Weld Frame Rails to Front Mount-

ing Pads. Check to make sure that the Frame

rail is still aligned on front rail Mounting Pad,

Frame Rail should not interfere with the Mounting Pad bolt heads Check the LH and RH

Frame rail (See Figure 35). If alignment is

correct Tack Weld the Frame Rails to the Front

Rail Mounting Pads. (See Figure 32). When

tack Welding use 4 good tack welds per Frame

rail, 2 on each side of Tube. (See Figure 37).

The C- Clamp on The Frame Rail Tube at the

mounting pad can be left on till later.

2. Tack Weld Frame rails to Frame Rail

Stiffener. Tack Weld the frame Stiffener Brackets to the Frame Rails, but be sure you DO

NOT tack Weld the Stabilizer Gusset at this

time (See Figure 38). The reason for not

welding the stabilizer gusset at this time is