Page 1

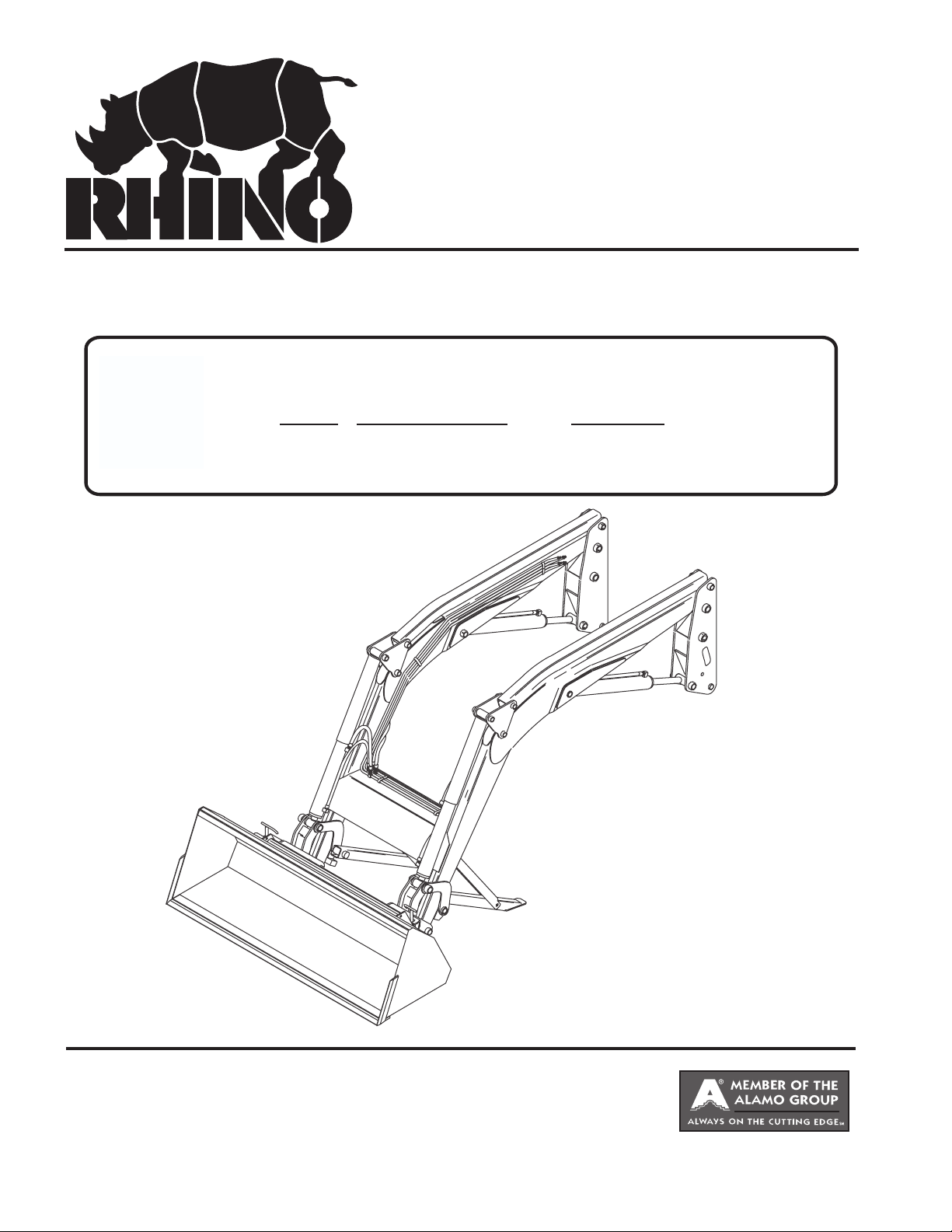

7214 MSL

®

Loader

Published 12/04 Part No. F-3778

OPERATOR’S MANUAL

This Operator’s Manual is an integral part of the safe operation

of this machine and must be maintained with the unit at all

times. READ, UNDERSTAND, and FOLLOW the safety and

Operation Instructions contained in this manual before

operating the equipment.

RHINO

®

1020 S. Sangamon Ave.

Gibson City, IL, 60936

800-446-5158

Email: parts@servis-rhino.com

© 2004 Alamo Group, Inc.

Page 2

TO THE OWNER/OPERATOR/DEALER

All implements with moving parts are potentially hazardous. There is no substitute for a cautious, safe-minded

operator who recognizes the potential hazards and follows reasonable safety practices. The manufacturer has

designed this implement to be used with all its safety equipment properly attached to minimize the chance of

accidents.

BEFORE YOU START!!

SAFETY HAZARD SIGNAL WORDS

There arethree levels of hazard intensity identified by signal words

DANGER, WARNING and CAUTION. The level of hazard

intensity is identified by the following definitions.

Read the safety messages on the implement and shown in your manual. Observe

the rules of safety and common sense!

DANGER

DANGER-Immediate hazards which will result in severe

injury or death.

WARNING

WARNING-Hazards or unsafe practices which could result in

minor personal injury or death.

THIS SAFETY SYMBOL MEANS

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS

CAUTION

CAUTION-Hazards or unsafe practices which could result in

minor personal injury or property damage.

INVOLVED!

PELIGRO

LEA EL INSTRUCTIVO

Si No Lee Ingles, Pida Ayuda a Alguien Que

Si Lo Lea Que le Traduzca las Medidas de

Seguridad.

Read and understand the complete Warranty Statement found in this Manual. Fill out the Warranty Registration Form in full

and return it within 30 Days. Make certain the Serial Number of the Machine is recorded on the Warranty Card and on the

Warranty Form that you retain. The use of will-fit parts will void your warranty and can cause catastrophic failure with

possible injury or death.

Page 3

TABLE OF CONTENTS

SAFETY SECTION

Safety Precautions

Safety Hazard Signal Words

Decal Locations

Safety Decals

INTRODUCTION SECTION

Introduction

Specifications

ASSEMBLY SECTION

Dismounting and Mounting Loader to Tractor

Mounting Attachment To Loader, Dismounting Attachment From Loader

OPERATION SECTION

Preparing Tractor, Operating Loader, Filling Bucket

Lifting Load, Carrying Load, Dumping Bucket, Lowering Bucket..............4-3

Operating Float Control, Loading From Bank .......................4-4

Peeling & Scraping, Loading Truck & Spreaders From Pile, Backfilling ..........4-5

Handling Large Heavy Objects ...............................4-6

Operating Grapple Fork ..................................4-7

Operating Bale Spear ...................................4-10

Operation of MSL......................................4-11

.........................................

......................................

........................................

.........................................

........................................

.......................................

.......................................

.....................................

................................

....................................

.......................

.........

....................

1-1

1-2

1-7

1-8

1-10

2-1

2-2

2-3

3-1

3-2

3-3

4-1

4-2

MAINTENANCE SECTION .....................................5-1

Daily Maintenance

Lift Cylinder Service

Tilt Cylinder Service

Replacing Wear Bushings

Adjusting Bucket Level Indicator

Hydraulic Trouble Shooting

Torque Chart

.....................................

....................................

....................................

.................................

..............................

.................................

........................................

5-2

5-3

5-4

5-5

5-5

5-6

5-7

F-3778-12-04 Rhino is a registered trademark of Alamo Group Inc.

© 2004 Alamo Group Inc.

Page 4

SAFETY

SECTION

© 2004 Alamo Group Inc.

Safety Section 1-1

Page 5

SAFETY

SAFETY PRECAUTIONS

A careful operator operates best. Most accidents can be

avoided by observing certain precautions. Read all

precautions that follow before operating your tractor and

loader to help prevent accidents. Equipment should be

operated only by those who are responsible and instructed to

do so.

GENERAL

1. Read your Operator's Manuals carefully before using tractor

SAFETY

or loader. Lack of operating knowledge can lead to accidents.

2. Replace damaged or illegible safety decals. See pages 1-10

& 1-11 for required decals.

3. Operate tractor and loader only from operator's seat.

TRACTOR

1. Use an approved roll bar and seat belt for safe operation.

Overturning a tractor without a rollbar can result in death or

injury. If your tractor is not equipped with a rollbar and seat

belt, see your Tractor Dealer.

2. Equip your tractor with FOPS (Falling Object Protective

Structure) before installing or operating loader.

3. Always use seat belt when rollbar is installed. Do not use seat

belt if rollbar is removed from tractor.

4. Add recommended wheel ballast and/or rear weight as

recommended in owner's manual to provide good stability.

5. Move rear wheels to widest settings recommended to

increase stability.

6. Move and turn tractor at low speeds.

LOADER

1. Improper use of a loader can cause serious injury or death.

2. Do not lift or carry anybody on loader, in bucket or on

attachment.

3. Never allow anyone to get under loader bucket or reach

through lift arms when bucket is raised.

4. Do not walk or work under a raised loader or bucket or

attachment unless it is securely blocked or held in position.

5. Avoid overhead wires and obstacles when loader is raised.

Contacting electric lines can cause electrocution.

6. Make sure all parked loaders are on a hard, level surface.

Engage all safety devices.

OPERATING LOADER

1. As owner of this loader, it is your responsibility to be certain

anyone operating this loader has read this manual first to be

aware of safe operation of your tractor and loader.

2. Exercise caution when operating any loader with a raised

loaded bucket or fork.

3. Avoid loose fill, rocks and holes. They can be dangerous for

loader operation or movement.

4. Use care when operating on steep grades to maintain proper

stability. Always carry bucket or attachment as low as

possible.

5. Allow for loader length when making turns.

6. Stop loader arms gradually when lowering or lifting.

7. Use caution when handling loose or shiftable loads.

8. Carry bucket or attachment at a low position during transport

for better visibility.

9. When parking or servicing, lower bucket to ground, stop

engine and set park brakes before leaving tractor seat.

10. Operate loader controls only when properly seated at

controls.

11. Using front end loaders without special attachments for

handling large heavy objects such as large round or

rectangular bales, logs and oil drums is NOT

RECOMMENDED.

12. Handling large heavy objects can be extremely dangerous

due to:

Danger of rolling tractor over.

Danger of upending tractor.

Danger of objects rolling or sliding down loader arms onto

operator.

13. If you must perform this sort of work (see 12 above), protect

yourself by:

Use proper attachments only.

Never lift load higher than necessary to clear ground when

moving.

Ballast tractor rear to compensate for load.

Never lift large objects with equipment that does not have

an anti-rollback device.

Move slowly and carefully, avoiding rough terrain.

MAINTENANCE

1. When servicing or replacing pins in cylinder ends, buckets,

etc., always use a drift and hammer of non-sparking material.

Failure to do so could result in injury from flying metal

fragments.

2. Do not modify or alter or permit anyone else to modify or alter

loader or any of its components or any loader function without

first consulting your Dealer. If you have any questions

regarding loader modifications contact your Rhino Dealer.

3. Always wear safety goggles when servicing or repairing

tractor or loader.

4. Escaping hydraulic/diesel fluid under pressure can penetrate

skin causing serious personal injury.

DO NOT use your hand to check for leaks. Use a piece of

cardboard or paper to search for leaks.

Stop engine and relieve pressure before connecting or

disconnecting hydraulic or diesel lines.

Tighten all connections before starting engine or

pressurizing lines.

If any fluid is injected into skin, obtain medical attention

immediately or gangrene may result.

5. Do not tamper with relief valve setting. Valve relief is factory-

set. Changing relief setting can cause overloading of your

tractor or loader and serious operator injury may result.

Whenever you see this symbol

It means:

F-3778-12-04 Safety Section 1-2

© 2004 Alamo Group Inc.

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

Page 6

SAFETY

PELIGRO!

DANGER!

WARNING!

WARNING!

Si no lee Ingles, pida ayuda a alguien que si Io

lea para que Ie traduzca las medidas de

seguridad.

SAFETY

Never operate the Power Unit or Implement until you have read

and completely understand this Manual, the Power Unit Operators

Manual, and each of the Safety Messages found in the Manual or

on the Power Unit and Implement. Learn how to stop the Power

Unit engine suddenly in an emergency. Never allow inexperienced

or untrained personnel too operate the Power Unit and Implement

without supervision. Make sure the operator has fully read and

understood the manuals prior to operation.

Always maintain the safety decals in good readable condition. If

the decals are missing, damaged, or unreadable, obtain and install

replacement decals immediately.

Make certain that the Slow Moving Vehicle (SMV) sign is installed in such a way as to be clearly

visible and legible. When transporting the Equipment use the Power Unit flashing warning lights and

follow all local traffic regulations.

WARNING!

WARNING!

DANGER!

Operate this Equipment only with a Tractor equipped with an

approved roll-over-protective system (ROPS). Always wear seat

belts. Serious injury or even death could result from falling off the

tractorparticularly during a turnover when the operator could be

pinned under the Operator Protective Structure.

Do not modify or alter this Implement. Do not permit anyone to

modify or alter this Implement, any of its components or any

Implement function.

BEFORE leaving the Power Unit seat, always engage the brake and/or set the Power Unit

transmission in parking gear, disengage the auxiliary hydraulics, stop the engine, remove the key, and

wait for all moving parts to stop. Place the Power Unit shift lever into a low range or parking gear to

prevent the tractor from rolling. Never dismount a Power Unit that is moving or while the engine is

running. Operate the Power Unit controls from the operator seat only.

F-3778-12-04 Safety Section 1-3

© 2004 Alamo Group Inc.

Page 7

SAFETY

DANGER!

SAFETY

DANGER!

DANGER!

Never allow children to operate or ride on the Power Unit or Implement.

Do not mount the Power Unit while the Power Unit is moving. Mount the

Power Unit only when the Power Unit and all moving parts are completely

stopped.

Start the Power Unit only when properly seated in the Power Unit seat.

Starting a Power Unit in gear can result in injury or death. Read the Power

Unit operator's manual for proper starting instructions.

DANGER!

WARNING!

WARNING!

Never work under the Implement, the framework, or any lifted component

unless the Implement is securely supported or blocked up to prevent

sudden or inadvertent falling which could cause serious injury or even

death.

The operator and all support personnel should wear hard hats, safety

shoes, safety glasses, and proper hearing protection at all times for

protection from injury including injury from items thrown by the

equipment.

PROLONGED EXPOSURE TO LOUD NOISE MAY CAUSE

PERMANENT HEARING LOSS!

attached can often be noisy enough to cause permanent hearing loss.

We recommend that you always wear hearing protection if the noise in

the Operators position exceeds 80db. Noise over 85db over an extended

period of time will cause severe hearing loss. Noise over 90db adjacent to

the Operator over an extended period of time will cause permanent or

total hearing loss.

saws, radios, and other such sources close to the ear] is cumulative over

a lifetime without hope of natural recovery

Note: Hearing loss from loud noise [from tractors, chain

Tractors with or without an Implement

F-3778-12-04 Safety Section 1-4

© 2004 Alamo Group Inc.

Page 8

SAFETY

DANGER!

DANGER!

Do not operate this Equipment with hydraulic oil leaking. Oil is expensive

and its presence could present a hazard. Do not check for leaks with your

hand! Use a piece of heavy paper or cardboard. High- pressure oil streams

from breaks in the line could penetrate the skin and cause tissue damage

including gangrene. If oil does penetrate the skin, have the injury treated

immediately by a physician knowledgeable and skilled in this procedure.

Transport only at safe speeds. Serious accidents and injuries can result

from operating this equipment at unsafe speeds. Understand the Power

Unit and Implement and how it handles before transporting on streets and

highways. Make sure the Power Unit steering and brakes are in good

condition and operate properly.

Before transporting the Power Unit and Implement, determine the safe

transport speeds for you and the equipment. Make sure you abide by the

following rules:

1. Test the Power Unit at a slow speed and increase the speed slowly.

Apply the Brakes smoothly to determine the stopping characteristics of

the Power Unit and Implement.

As you increase the speed of the Power Unit the stopping distance

increases. Determine the maximum safe transport speed for you and

this Equipment.

2. Test the equipment at a slow speed in turns. Increase the speed

through the turn only after you determine that it is safe to operate at a

higher speed. Use extreme care and reduce your speed when turning

sharply to prevent the Power Unit and Implement from turning over.

Determine the maximum safe turning speed for you and this equipment

before operating on roads or uneven ground.

SAFETY

WARNING!

WARNING!

3. Only transport the Power Unit and Implement at the speeds that you

have determined are safe and which allow you to properly control the

equipment.

Be aware of the operating conditions. Do not operate the Power Unit with

weak or faulty brakes. When operating down a hill or on wet or rain slick

roads, the braking distance increases: Use extreme care and reduce your

speed. When operating in traffic always use the Power Unit's flashing

warning lights and reduce your speed. Be aware of the traffic around you

and watch out for the other guy.

Never attempt to lubricate, adjust, or remove material from the Implement

while it is in motion or while Power Unit engine is running. Make sure the

Power Unit engine is off before working on the Implement!

Periodically inspect all moving parts for wear and replace when necessary

with authorized service parts. Look for loose fasteners, worn or broken

parts, and leaky or loose fittings. Make sure all pins have cotter pins and

washers. Serious injury may occur from not maintaining this machine in

good working order.

F-3778-12-04 Safety Section 1-5

© 2004 Alamo Group Inc.

Page 9

SAFETY

WARNING!

SAFETY

DANGER!

DANGER!

DANGER!

Always read carefully and comply fully with the manufacturers

instructions when handling oil, solvents, cleansers, and any other

chemical agent.

Never run the Power Unit engine in a closed building or without adequate

ventilation. The exhaust fumes can be hazardous to your health.

KEEP AWAY FROM ROTATING ELEMENTS

and possible serious injury or death.

Never allow children to play on or around Power Unit or Implement.

Children can slip or fall off the Equipment and be injured or killed.

Children can cause the Implement to shift or fall crushing themselves or

others.

to prevent entanglement

WARNING!

DANGER!

DANGER!

Do not exceed the rated PTO speed for the Implement. Excessive PTO

speeds can cause Implement driveline failures resulting in serious injury.

NEVER use drugs or alcohol

Power Unit and Implement. Drugs and alcohol will affect an operators

alertness and coordination and therefore affect the operators ability to

operate the equipment safely. Before operating the Power Unit or

Implement, an operator on prescription or over-the-counter medication

must consult a medical professional regarding any side effects of the

medication that would hinder their ability to operate the Equipment

safely.

NEVER

their alertness or coordination is impaired. Serious injury or death to the

operator or others could result if the operator is under the influence of

drugs or alcohol.

Operate the Power Unit and/or Implement controls only while properly

seated in the operator's seat with the seat belt securely fastened around

you. Inadvertent movement of the Power Unit or Implement may cause

serious injury or death.

knowingly allow anyone to operate this equipment when

immediately before or while operating the

F-3778-12-04 Safety Section 1-6

© 2004 Alamo Group Inc.

Page 10

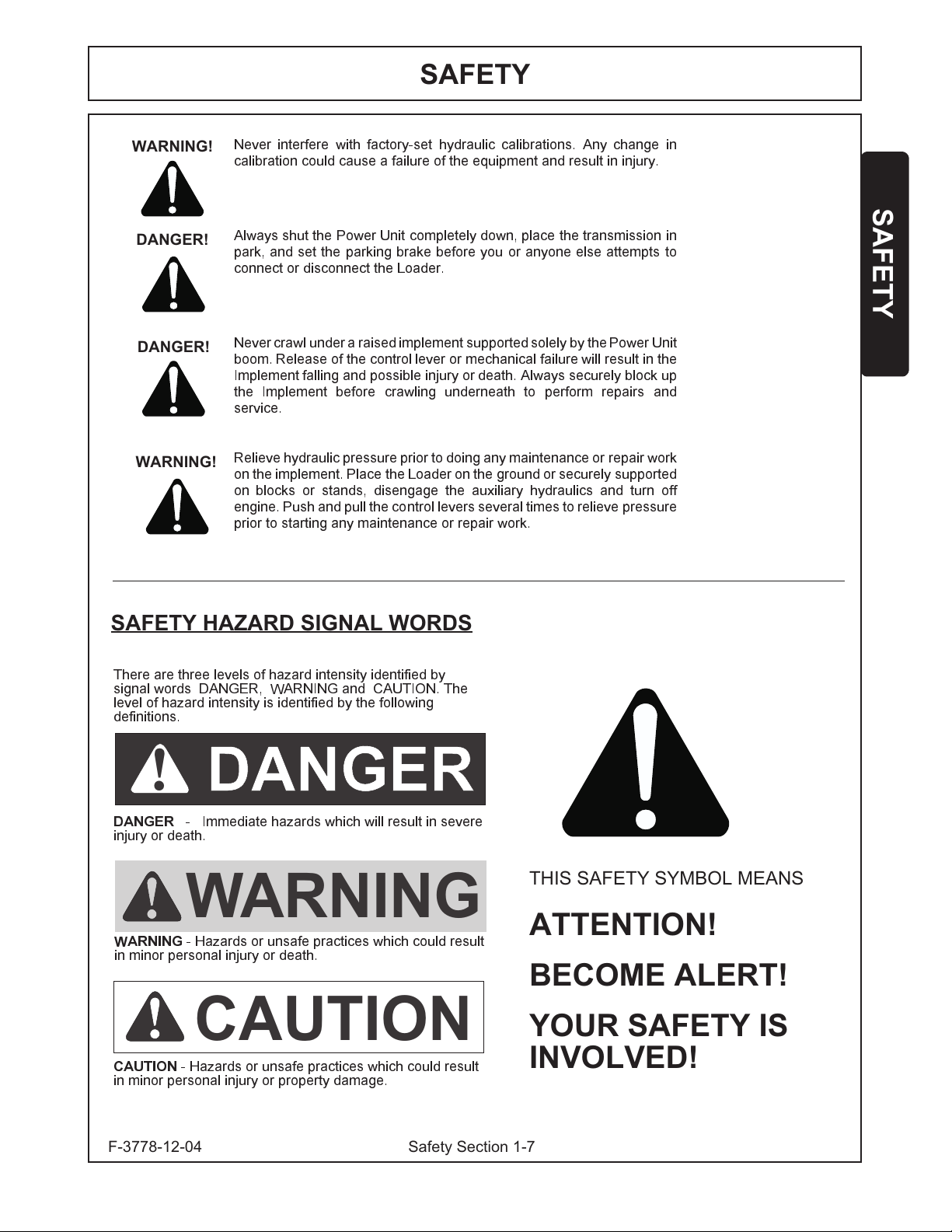

SAFETY

WARNING!

DANGER!

DANGER!

WARNING!

Never interfere with factory-set hydraulic calibrations. Any change in

calibration could cause a failure of the equipment and result in injury.

SAFETY

Always shut the Power Unit completely down, place the transmission in

park, and set the parking brake before you or anyone else attempts to

connect or disconnect the Loader.

Never crawl under a raised implement supported solely by the Power Unit

boom. Release of the control lever or mechanical failure will result in the

Implement falling and possible injury or death. Always securely block up

the Implement before crawling underneath to perform repairs and

service.

Relieve hydraulic pressure prior to doing any maintenance or repair work

on the implement. Place the Loader on the ground or securely supported

on blocks or stands, disengage the auxiliary hydraulics and turn off

engine. Push and pull the control levers several times to relieve pressure

prior to starting any maintenance or repair work.

SAFETY HAZARD SIGNAL WORDS

There are three levels of hazard intensity identified by

signal words DANGER, WARNING and CAUTION. The

level of hazard intensity is identified by the following

definitions.

!

DANGER

injury or death.

- Immediate hazards which will result in severe

WARNING

WARNING

in minor personal injury or death.

- Hazards or unsafe practices which could result

CAUTION

CAUTION

in minor personal injury or property damage.

- Hazards or unsafe practices which could result

THIS SAFETY SYMBOL MEANS

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS

INVOLVED!

F-3778-12-04 Safety Section 1-7

© 2004 Alamo Group Inc.

Page 11

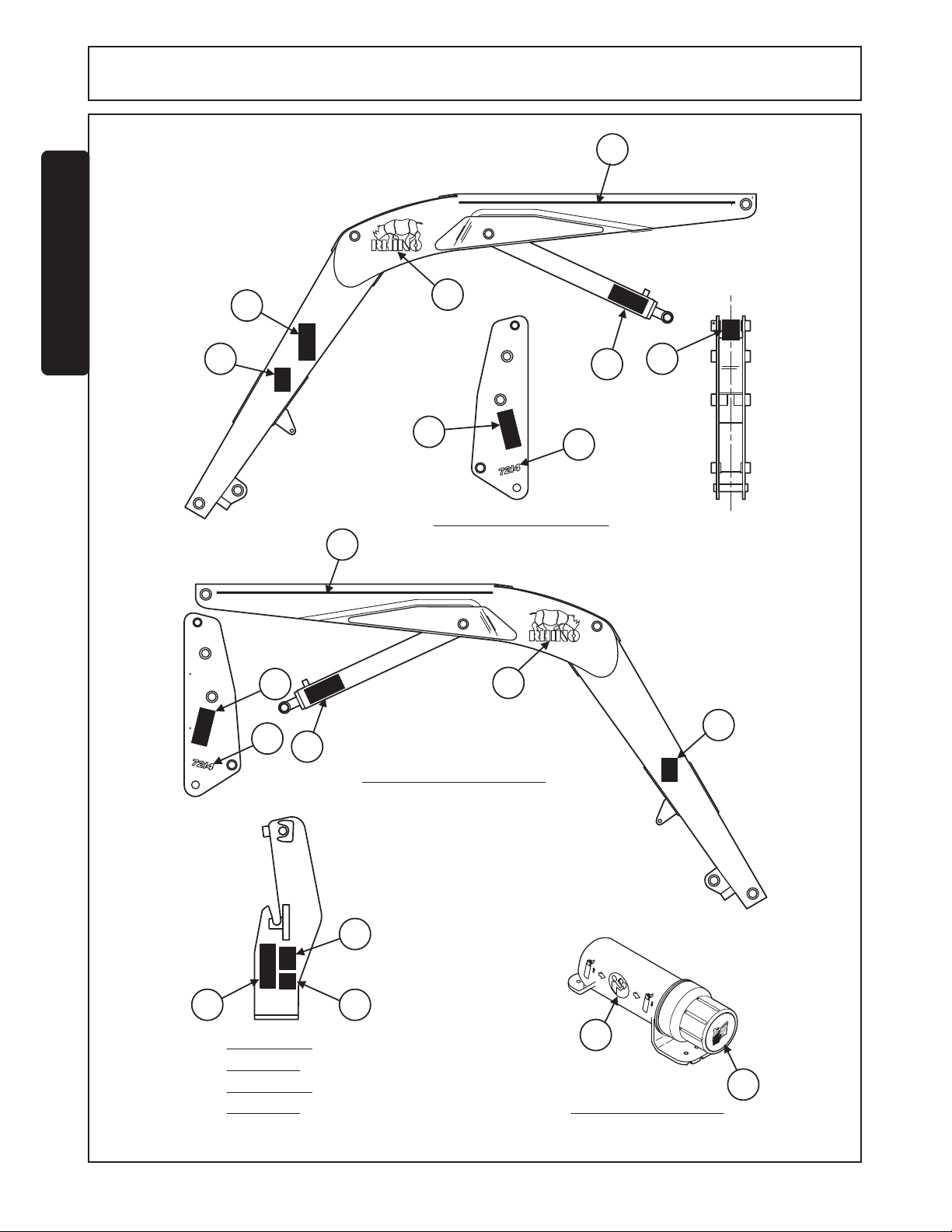

SAFETY

8

SAFETY

5

3

1

9

7

C

L

4

6

LEFT SIDE OF LOADER

8

5

2

3

6

9

RIGHT SIDE OF LOADER

11

10 12

LEFT SIDE

LEFT MID

MOUNTING

BRACKET

F-3778-12-04 Safety Section 1-8

© 2004 Alamo Group Inc.

13

MANUAL CANISTER

M

A

N

S

’

U

R

A

O

L

T

A

R

E

P

O

INSIDE

13

Page 12

SAFETY

ITEM PART NO. QTY. TYPE DESCRIPTION

1 49695 1 LOGO Rhino, Left

2 51447 1 LOGO Rhino, Right

3 48434 2 DANGER Loader Safety

4 46776 1 WARNING Loader Safety

5 51902 2 WARNING Loader Removal/Reinstallation Safety

6 49703 2 MODEL 7214

7 48858 1 DANGER Electric Shock

8 35674-5 2 STRIPE White, 54"

9 48322 2 DANGER Support Loader

10 47730 1 WARNING Handling Bales/Do Not Carry People

11 48921 1 DANGER Use ROPS, Seatbelt, Rear Ballast

12 46779 1 WARNING Bucket Shift (Suspended Front Axle Only)

13 00776031 1 MANUAL CANISTER Read Operator’s Manual

SAFETY

F-3778-12-04 Safety Section 1-9

© 2004 Alamo Group Inc.

Page 13

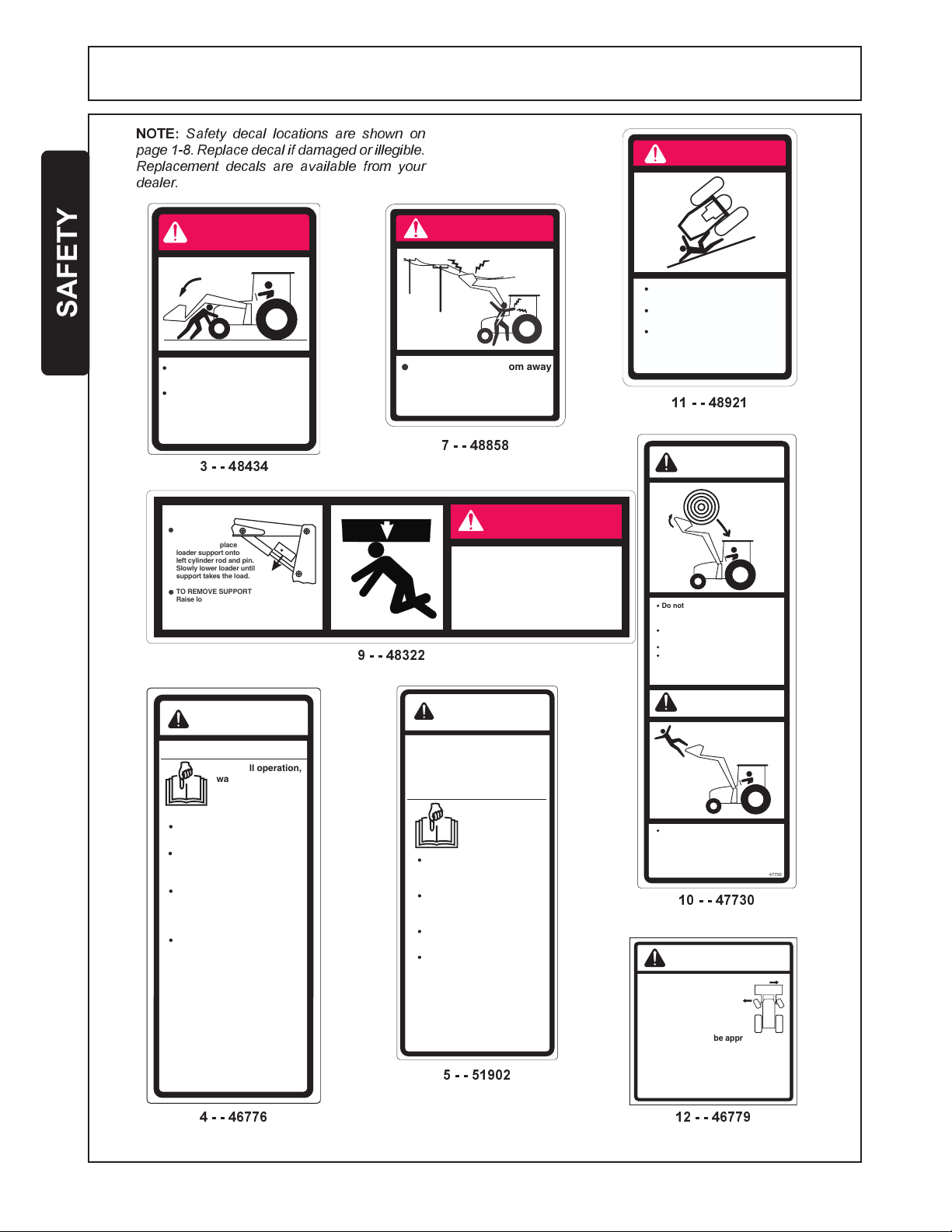

SAFETY

NOTE:

page 1-8. Replace decal if damaged or illegible.

Replacement decals are available from your

dealer.

SAFETY

Do not walk or work under a

raised loader.

Lower loader to ground

when parked.

Failure to comply may result

in serious injury and/or death.

Safety decal locations are shown on

DANGER

48434

3 - - 48434

TO SUPPORT

LOADER ARMS

Raise loader, place

loader support onto

left cylinder rod and pin.

Slowly lower loader until

support takes the load.

TO REMOVE SUPPORT

Raise loader, remove pin, and

support, then store.

9 - - 48322

DANGER

Keep bucket and boom away

from overhead electric lines.

Failure to comply will result in

serious injury or death.

48858

7 - - 48858

DANGER

Loader support must be

installed prior to working

under raised loader. Failure

to comply may result in

serious injury or death.

DANGER

Use ROPS and seatbelt at

all times.

Add recommended rear

ballast.

Operate tractor at low speeds.

Failure to comply may result in

serious injury or death.

11 - - 48921

WARNING

Do not handle round bales or large

48322

objects unless loader is equipped

with proper attachments.

Operate loader only with approved

hydraulic valves.

Handle raised loads with caution.

Carry loads low.

Failure to comply may result in

serious injury and/or death.

48921

WARNING

LOADER SAFETY

Know all operation,

warning and safety

instructions in the

operator’s manual

before operating the loader.

Operate loader only from

operator’s seat.

Carry bucket low during

transport for better visibility

and to avoid overturns.

Use wheel ballast and / or

rear weight for stability as

recommended in the

operator’s manual.

When parking or servicing

unit, lower the bucket to the

ground, stop engine, and

set the parking brake to

avoid tractor movement.

Failure to follow any of

the instructions above

can cause serious injury

to the operator or other

WARNING

TO AVOID INJURY

DURING REMOVAL

OR REINSTALLATION

OF LOADER

Read and

understand

instructions in

operator’s manual

Make sure detached loader

is parked on hard, level

ground.

Always have a bucket

mounted to loader when it

is removed from tractor.

Do not permit bystanders

within 10 feet of loader.

Do not remove bucket or

repair loader if it is not

mounted on tractor.

Failure to comply could

cause loader to collapse.

Failure to follow above

instructions can cause

serious injury.

persons in are.

(Replacement manuals are

available from your dealer.)

46776

5 - - 51902

4 - - 46776

F-3778-12-04 Safety Section 1-10

WARNING

Do not lift or carry anybody in

loader or work from bucker or any

other attachment.

Failure to comply may result

in serious injury or death.

47730

10 - - 47730

WARNING

When the loader is mounted to

a tractor with SuperSteer™,

the bucket will shift in

the opposite direction

from which the

front wheels are turned.

Maximum shift will be approximately

51902

8 inches and most noticeable when the

tractor is stationary.

Failure to heed this warning can result

in serious injury to the operator or

other persons.

46779

12 - - 46779

© 2004 Alamo Group Inc.

Page 14

SAFETY

SAFETY

®

1 - - 49695

2 - - 51447

6 - - 49703 8 - - 35674-5

®

13 - - 00776031

F-3778-12-04 Safety Section 1-11

© 2004 Alamo Group Inc.

A

M

N

S

U

’

A

R

L

O

T

A

R

E

P

O

INSIDE

Page 15

SAFETY

FEDERAL LAWS AND REGULATIONS

This section is intended to explain in broad terms the concept and effect of federal laws and regulations

concerning employer and employee equipment operators. This section is not intended as a legal

interpretation of the law and should not be considered as such.

Employer-Employee Operator Regulations

U.S. Public Law 91-596 (The Williams-Steiger Occupational and Health Act of 1970) OSHA

SAFETY

Employer Responsibilities:

To ensure employee safety during Tractor and Implement operation, it is the employer’s responsibility to:

1. Train the employee in the proper and safe operation of the Tractor and Implement.

2. Require that the employee read and fully understand the Tractor and Implement Operator’s manual.

This Act Seeks:

“...to assure so far as possible every working man and woman in the nation safe and healthful

working conditions and to preserve our human resources...”

DUTIES

Sec. 5 (a) Each employer(1) shall furnish to each of his employees employment and a place of employment which are free

from recognized hazards that are causing or are likely to cause death or serious physical harm to

his employees;

(2) shall comply with occupational safety and health standards promulgated under this Act.

(b) Each employee shall comply with occupational safety and health standards and all rules,

regulations and orders issued pursuant to this Act which are applicable to his own actions and

conduct.

OSHA Regulations

OSHA regulations state in part: “At the time of initial assignment and at least annually thereafter,

the employer shall instruct every employee in the safe operation and servicing of all equipment

with which the employee is, or will be involved.”

3. Permit only qualified and properly trained employees to operate the Tractor and Implement.

4. Maintain the Tractor and Implement in a safe operational condition and maintain all shields and guards

on the equipment.

5. Ensure the Tractor is equipped with a functional ROPS and seat belt and require that the employee

operator securely fasten the safety belt and operate with the ROPS in the raised position at all times.

6. Forbid the employee operator to carry additional riders on the Tractor or Implement.

7. Provide the required tools to maintain the Tractor and Implement in a good safe working condition and

provide the necessary support devices to secure the equipment safely while performing repairs and

service.

8. Require that the employee operator stop digging if bystanders or passersby come within 10 yards.

Child Labor Under 16 Years of Age

Some regulations specify that no one under the age of 16 may operate power machinery. It is your

responsibility to know what these regulations are in your own area or situation. (Refer to U.S. Dept. of

Labor, Employment Standard Administration, Wage & Home Division, Child Labor Bulletin #102.)

F-3778-12-04 Safety Section 1-12

© 2004 Alamo Group Inc.

Page 16

INTRODUCTION

SECTION

© 2004 Alamo Group Inc.

Introduction Section 2-1

Page 17

INTRODUCTION

INTRODUCTION

INTRODUCTION

This manual provides operation, maintenance, assembly and parts identification for your new loader.

Your loader has been designed to give many years of satisfactory service. Successful operation and long life of the

loader depends on proper maintenance and operation. Please read this manual carefully and follow all instructions.

Correct assembly, operation and maintenance will save you much time and expense. Also follow instructions included

with loader mounting and hydraulic kits to insure that loader is installed correctly to tractor.

NOTE: This safety alert symbol identifies important safety messages in this manual.

Observe and follow all safety messages to prevent personal injury.

Reference to left-hand and right-hand used in this manual refers to position of operator when seated in the operating

position of loader.

If at any time you have a service problem with your loader or need new parts, contact your local dealer.

Your dealer will need your loader model number and serial number to give you prompt efficient service.

Parts orders must give complete description, correct part number, total amount required, model number,

all necessary serial numbers, method of shipment and shipping address.

F-3778-12-04 Introduction Section 2-2

© 2004 Alamo Group Inc.

Page 18

INTRODUCTION

7214 SPECIFICATIONS

Specifications will vary with tractor, tire size, hydraulic system and bucket used. The specifications are given for a loader

equipped with 96" H.D. material bucket, quick attach device and 4-bar linkage, operated with an average tractor hydraulic

system of 25 GPM with engine operating at 2300 RPM, and control valve relief setting of 2750 PSI.

Break-away Capacity

At Pivot Point

800mm Forward of Pivot Point

. .... .... .... .... .... .... ....

. .... .... .... .... ....

Lift capacity at Full Height

At Pivot Point

800mm Forward of Pivot Point

Raising Time

. .... .... .... .... .... .... .... ....

Lowering Time

Attachment Dumping Time

Attachment Rollback Time

Weight w/ Average Mounting Kit, Hose Kit, and 96" HD Material Bucket

. .... .... .... .... .... .... ....

. .... .... .... .... ....

.... .... .... .... .... .... .... ....

... .... .... .... .... .... ....

... .... .... .... .... .... ....

. ....

Lift Cylinder:

Stroke .... .... .... .... .... .... .... ....28.88 in.

Piston Diameter .... .... .... .... .... .... ....3.50 in.

Rod Diameter . .... .... .... .... .... .... ....1.75 in.

Bucket Cylinder:

Stroke .... .... .... .... .... .... .... ....16.00 in.

Piston Diameter .... .... .... .... .... .... ....3.50 in.

Rod Diameter . .... .... .... .... .... .... ....1.75 in.

(A) Maximum Lift Height at Pivot Pin . . .... .... .... .... ....169in.

(B) Maximum Height Under Bucket

(C) Clearance with Bucket Dumped

(D) Reach at Maximum Height

(E) Maximum Dump Angle

... .... .... .... .... .... ....

(F) Reach with Attachment on ground

(G) Attachment Rollback Angle

(H) Digging Depth

.... .... .... .... .... .... ....

(J) Overall Height in Carry Position

... .... .... .... .... ....

.. .... .... .... .... ....

. .... .... .... .... .... ....

. .... .... .... .... ....

.... .... .... .... .... ....

.. .... .... .... .... ....

9260 #

8540 #

5840 #

5140 #

6.6 sec.

4.6 sec.

3.0 sec.

2.9 sec.

3603 #

159 in.

133 in.

44 in.

71°

103 in.

39°

4 in.

89 in.

INTRODUCTION

E

D

G

F

(Manufacturers estimated specifications and design subject to change without notice.)

A

B

C

J

H

F-3778-12-04 Introduction Section 2-3

© 2004 Alamo Group Inc.

Page 19

ASSEMBLY

SECTION

© 2004 Alamo Group Inc.

Assembly Section 3-1

Page 20

ASSEMBLY

DISMOUNTING LOADER AND MOUNTING LOADER TO TRACTOR

Figure B

Figure A

STORAGE

POSITION

Remove linch

pin and hitch pin

to fold down

parking stand

OPERATION

POSITION

Secure parking

stand down

with hitch pin

and linch pin

DISMOUNTING LOADER

WARNING:

installation or removal of loader, do not allow

bystanders within 10 feet of loader and

bucket or optional attachment.

ASSEMBLY

WARNING:

attachment, such as a bucket, mounted to

loader when it is removed from tractor. Pallet

fork, bale spear, or similar attachments are

too light to safely counterbalance loader

boom arms when loader is dismounted from

tractor.

1. Locate tractor and loader on firm level ground.

2. With bucket raised above ground, tilt down

approximately 30 degrees from level.

3. Lower boom by retracting lift cylinders to lift tractor

front end (tires can be off ground).

To avoid injury during

Always have a heavy

Figure C

loader

upright

pin

1"

Figure D

Linch Pin

Hitch Pin

CAUTION:

Right Side View

mount vertical

stop surface

mount pin

saddle

Keep clear of dropping parking

stands. Dropping parking stands could cause

injury.

6. Remove linch pins and 1-1/2" hitch pins from loader

upright. Remove tarp strap securing loader hoses

from tractor handrail.

7. Start tractor engine and release brakes. Retract

bucket cylinders to allow parking stands to contact

ground.

WARNING:

It is important not to put excessive

weight on parking stands by retracting lift

cylinders. Damage may result.

8. Extend lift cylinders 10" to 12" to rotate top of loader

uprights forward, out of mid mounting brackets,

allowing tractor to be pushed rearward. Retract

bucket cylinders until lower loader upright pins clear

mount pin saddles and front tires and/or fenders (see

Figure D).

4. Stop engine. Allow tractor front end to lower by

relaxing ONLY lift cylinders with control lever. This will

remove pressure on hitch pins (see Figure C).

NOTE:

Do not relax bucket cylinders.

9. Move tractor rearward approximately 6", taking care

not to stretch hydraulic hoses.

10.Stop tractor engine and set parking brake. Relax lift

cylinders and bucket cylinders by moving each control

lever in both directions. Disconnect hydraulic hoses at

5. Set parking brake. Rotate parking stands from

storage position to operation position by removing

mid mounting couplers on right side of loader. Install

plastic dust plugs and caps on couplers.

linch pins and hitch pins. Reinstall hitch pin and linch

pin when parking stands are in operation position (see

Figure B).

11.Start tractor engine and release brakes. Slowly back

tractor out of and away from loader.

F-3778-12-04 Assembly Section 3-2

© 2004 Alamo Group Inc.

Page 21

ASSEMBLY

MOUNTING LOADER

WARNING:

installation or removal of loader or

attachment, do not allow bystanders within

10 feet of loader and bucket or optional

attachment.

1. Slowly drive tractor into loader and stop approximately

6" from mid mounting brackets. Shut off tractor engine

and set parking brake.

2. Connect male couplers of hydraulic hoses to female

quick couplers, matching corresponding colors. Make

sure couplers are clean before connecting together.

3. Start engine and release parking brake. Make sure lift

cylinders are extended 10" to 12". Stroke bucket

cylinders to raise or lower uprights for loader upright

pin to clear each mount pin saddle by approximately 1"

(see Figure D on previous page).

4. Drive tractor forward until loader upright pins contact

mount vertical stop surfaces just above mount pin

saddles (see Figure D). Extend tilt cylinders to FULLY

seat both loader upright pins into mount pin saddles

and raise parking stands off ground. Retract lift

cylinders, allowing tractor to move forward. Continue

until loader uprights have fully seated into back of

mount saddles by retracting lift cylinders to raise

tractor front end (tires can be off ground).

To avoid injury during

5. Stop engine. Allow tractor front end to lower by

relaxing ONLY lift cylinders with control lever.

NOTE:

6. Set parking brake. Insert two 1-1/2 x 8" pins and linch

pins.

7. Remove linch pins and hitch pins from parking stands,

rotate parking stands into storage position, and secure

stands in storage position with hitch pins and linch pins

(Figure B on previous page).

8. Use tarp strap to secure hoses to tractor handrail away

from moving parts.

Do not relax tilt cylinders.

CAUTION:

when rotating up into storage position.

Shearing action of parking stands when

rotating into storage position could cause

injury.

Keep clear of parking stands

ASSEMBLY

F-3778-12-04 Assembly Section 3-3

© 2004 Alamo Group Inc.

Page 22

ASSEMBLY

DISMOUNTING AND MOUNTING BUCKET OR ATTACHMENT TO LOADER

MOUNTING QUICK ATTACH BUCKET OR OPTIONAL

ATTACHMENT TO LOADER

WARNING:

of bucket or attachment do not allow

bystanders within 10 feet of loader and bucket

or attachment.

1. Locate tractor and attachment on level ground. Lower

boom to three to five inches off ground.

2. Disengage latch pins by lifting handles and pulling

toward rear so pins are held out of attachment ears.

Lift Handle

Extend bucket cylinders slightly, making sure loader

3.

quick attach bar is parallel to attachment. Continue

driving very slowly toward attachment. Continue

driving tractor forward, positioning quick attach bar so

it touches attachment or bucket just below attachment

channel.

4. Activate bucket rollback while moving tractor slightly

ASSEMBLY

ahead so quick attach bar catches underneath

channel of attachment. Continue to roll attachment

back completely so latch pins engage in bracket ears.

To avoid injury during installation

Pull Back

DISMOUNTING QUICK ATTACH BUCKET OR

OPTIONAL ATTACHMENT FROM LOADER

WARNING:

bucket or attachment, do not allow

bystanders within 10 feet of loader and bucket

or attachment.

1. Locate tractor and loader on level ground.

2. Lower boom arms until bucket or attachment is level

and approximately 3 inches off ground. Shut off tractor

engine and engage tractor brakes.

3. Disengage latch pins by lifting handles and pulling

toward rear so pins are held out of attachment ears.

Lift Handle

Start tractor engine, release tractor brakes and extend

4.

bucket cylinders while slowly backing tractor away

from bucket or attachment, until quick attach bar

disengages from attachment channel.

To avoid injury during removal of

Pull Back

5. Activate lift cylinders to raise attachment and extend tilt

cylinders to tilt attachment at a slight downward angle,

so quick attachment mechanism is visible. Visually

inspect mechanism to verify pins are engaged in ears

on back of attachment.

NOTE:

follow instructions for detaching, then repeat above

procedure.

ADJUSTING ATTACHMENT LEVEL INDICATOR

With various tractor tire options or attachments, it may be

necessary to adjust attachment level indicator bracket up

or down tilt cylinder tube. Tractor must be on level surface

with attachment flat on surface. Loosen u-bolt to adjust.

Offset on bucket level indicator rod should be at slotted

hole when attachment is level.

If bucket or attachment is not securely attached,

F-3778-12-04 Assembly Section 3-4

© 2004 Alamo Group Inc.

Level indicator

bracket

Level Indicator

Rod

Page 23

OPERATION

SECTION

© 2004 Alamo Group Inc.

Operation Section 4-1

Page 24

OPERATION

PREPARING TRACTOR PRIOR TO OPERATION

WARNING:

before inspecting, servicing or operating

loader and tractor.

INSPECTION

Thoroughly inspect your fully assembled tractor and

loader prior to operation.

1. Check all hardware to be sure that it has been properly

installed and tightened. Retighten all hardware after 10

hours of initial operation.

2. Check tire pressure. Refer to tractor operator's manual

for recommended pressures.

3. With tractor on level surface, compare tractor rear axle

height from left to right, measuring from axle center to

ground. Adjust air pressure in rear tires until axle

height measures same for both sides.

NOTE:

side, cutting edge on loader bucket will not sit flat on

ground.

4. Review tractor lubrication schedule and consult

MAINTENANCE section of this manual to be certain all

pivot points have been properly lubricated.

If rear axle on tractor is not level from side to

Read all operator's manuals

FILLING THE BUCKET

Approach and enter the pile with a level bucket.

Loaders with 1-lever control, ease lever back and away

from you to lift and roll back bucket.

Loaders with 2-lever controls, ease both levers back to lift

and roll back bucket.

5. Use instructions listed in MAINTENANCE section of

this manual to check all hose and tubing connections

to insure no leaks are present.

INSTALL COUNTERBALANCE

WARNING:

loader, add sufficient counterweight so a

minimum of 25% of total weight of tractor,

loader and rated load is on rear wheels when

bucket contains rated load and is in maximum

forward position.

Sufficient weight can be added to tractor by filling rear

OPERATION

wheels with liquid ballast, installing wheel weights or 3-

point hitch counterweight. If 3-point hitch counterweights

are used, they should be carried as low as possible at all

times to maximize stability.

Effective counterbalance weight of mounted rear

equipment is determined by multiplying actual weight of

equipment by 1.50.

EXAMPLE:

to rear of tractor, multiplied by 1.50, equals 1200 pounds

of effective counterbalance weight.

After adding recommended counterweight, weigh tractor

at rear axle to be sure counterbalance is adequate.

Equipment weighing 800 pounds, attached

Before operating tractor and

Lift and roll back of bucket will increase efficiency

because...

... A level bucket throughout the lifting cycle resists bucket

lift and increases breakaway effort.

NOTE:

completely filled during each pass. Maximum productivity

is determined by the amount of material loaded in a given

period of time. Time is lost if two or more attempts are

made to fill the bucket on each pass.

Do not be concerned if the bucket is not

F-3778-12-04 Operation Section 4-2

© 2004 Alamo Group Inc.

Page 25

OPERATION

LIFTING THE LOAD

When lifting the load, keep the bucket positioned to avoid

spillage. Loader has mechanical self leveling of

attachment in both raise and lower cycle. Attachment can

be adjusted by using bucket cylinders.

CAUTION:

excess of loader capacity.

CARRYING THE LOAD

Position bucket just below tractor hood for maximum

stability and visibility, whether bucket is loaded or empty.

Do not attempt to lift loads in

When transporting the load, keep bucket as low as

possible, to avoid tipping, in case a wheel drops in a rut.

DUMPING THE BUCKET

Lift bucket high enough to clear side of vehicle. Move

tractor in as close as possible to side of vehicle, then

dump bucket.

LOWERING THE BUCKET

After bucket is dumped, back away from vehicle while

lowering and rolling back bucket.

OPERATION

Use extreme care when operating loader on a slope, keep

bucket as low as possible. This keeps center of gravity low

and will provide maximum stability.

CAUTION:

dangerous. Extreme care is recommended.

Keep bucket as low as possible.

Operating loader on a hillside is

F-3778-12-04 Operation Section 4-3

© 2004 Alamo Group Inc.

Page 26

OPERATION

OPERATING WITH FLOAT CONTROL

During hard surface operation, keep bucket level and put

lift control in float position to permit bucket to float on

working surface. If hydraulic down pressure is exerted on

bucket, it will wear faster than normal.

Float will also prevent mixing of surface material with

stockpile material. Float position will reduce the chance of

surface gouging when removing snow or other material,

or when working with a blade.

Sidecutting is a good technique for cutting down a big pile.

LOADING FROM A BANK

Choose a forward gear that provides sufficient ground

speed for loading.

OPERATION

Exercise caution when undercutting high banks. Dirt

slides can be dangerous. Load from as low as possible for

maximum efficiency. Loader lift and breakaway capacity

diminish as loading height is increased.

If the pile sides are too high and liable to cause cave-in,

use loader to break down the sides until a slot can be cut

over the top.

Another method for large dirt piles is to build a ramp

approach to the pile.

It is important to keep the bucket level when approaching

a bank or pile. This will help prevent gouging the work

area.

F-3778-12-04 Operation Section 4-4

© 2004 Alamo Group Inc.

Page 27

OPERATION

PEELING AND SCRAPING

Use a slight bucket angle, travel forward and hold lift

control forward to start the cut. Make a short 5 to 8 foot

angle cut and break out cleanly.

With bucket level, start a cut at notch approximately 2

inches deep. Hold depth by feathering bucket control to

adjust cutting lip up or down. When front tires enter the

notch, adjust lift cylinders to maintain proper depth.

Do not roll bucket over and attempt to backgrade. This

type of use can cause severe overloading of bucket

cylinders when fully extended, possibly causing bucket

cylinder rods to become bent.

BACKFILLING

Approach pile with a level bucket.

Make additional passes until desired depth is reached.

During each pass, use only bucket control while working

depth. This will allow you to concentrate on controlling

bucket angle to maintain a precise cut.

LOADING LOW TRUCKS OR SPREADERS FROM A

PILE

For faster loading, minimize angle of turn and length of run

between pile and spreader.

Backgrade occasionally with a loaded bucket to keep

working surface free of ruts and holes. Also, hold lift

control forward so full weight of bucket is scraping ground.

OPERATION

Poor methods actually move no more dirt and make it

more difficult to hold a level grade.

Do not use bucket in dumped position for bulldozing. This

method, shown above, will impose severe shock loadings

on dump linkage, bucket cylinder and tractor.

F-3778-12-04 Operation Section 4-5

© 2004 Alamo Group Inc.

Page 28

OPERATION

Leave dirt in bucket. Dumping on each pass wastes time.

Operate tractor at right angles to ditch. Take as big a bite

as tractor can handle without lugging down.

OPERATION

Leave dirt which drifts over side of bucket for final cleanup.

Pile dirt on high side for easier backfilling on a slope.

HANDLING LARGE HEAVY OBJECTS

DANGER

1. Using front end loaders for handling large heavy

objects such as large round or rectangular bales, logs

and oil drums is not recommended.

2. Handling large heavy objects can be extremely

dangerous due to:

•

Danger of tractor rolling over.

•

Danger of up-ending tractor.

•

Danger of object rolling or sliding down loader

arms onto operator.

3. If you must perform above work, protect yourself by:

•

Never lifting load higher than necessary to clear

ground when moving.

•

Ballasting tractor rear to compensate for load.

•

Never lifting large objects with equipment that

does not have an anti-rollback device.

•

Moving slowly and carefully, avoiding rough

terrain.

SAFE OPERATION

IS YOUR BEST PROTECTION

AGAINST ACCIDENTS

F-3778-12-04 Operation Section 4-6

© 2004 Alamo Group Inc.

Page 29

OPERATION

OPERATING GRAPPLE FORK

Operation of your tractor and loader with grapple fork

option requires some same basic considerations as

operation with a bucket, plus two new requirements: you

now have to operate a grapple fork while already

operating your tractor and loader; and you must also take

into account additional space requirements (added length

and height) needed because of attached grapple fork.

INTENDED USE

Use of this loader without special attachments for

handling large heavy objects such as large round or

rectangular bales, logs and oil drums is NOT

RECOMMENDED.

Handling large heavy objects can be extremely

dangerous due to:

Danger of rolling tractor over.

•

Danger of upending tractor.

•

Danger of objects rolling or sliding down loader

•

arms onto operator.

If you must perform any work listed above, protect

yourself by:

Never lift load higher than necessary to clear

•

ground when moving.

Ballast tractor rear to compensate for load.

•

•

Never lift large objects with equipment that does

not have an anti-rollback device.

•

Move slowly and carefully, avoiding rough

terrain.

GRASPING ROUND BALES

Approach bale with grapple fork open and bucket level.

Use loader float position if bale is on ground.

Ease valve control lever for grapple fork forward to close

grapple fork around bale.

NOTE:

shown above, they may also be grasped from either side if

necessary. DO NOT ATTEMPT TO LIFT MORE THAN

ONE LARGE ROUND BALE AT A TIME as this can cause

overloading of loader or tractor or cause unstable

conditions.

While large round bales are best grasped as

OPERATION

Using special attachments as shown, and exercising

caution, your loader can be used to handle large round or

rectangular bales and loose bulky materials like hay and

silage. Do not attempt to use loader to handle logs,

fertilizer bags or liquid containers since such use is NOT

RECOMMENDED.

LIFTING AND CARRYING LOAD

Ease both loader control levers back to lift and roll bucket

back.

F-3778-12-04 Operation Section 4-7

© 2004 Alamo Group Inc.

Page 30

OPERATION

Position bucket just below level of tractor hood for

maximum stability and visibility whether bucket is loaded

or empty.

Use extreme care when operating loader on a slope.

Carry load as low as possible. This keeps center of gravity

for bale, tractor and loader low and will provide maximum

tractor stability.

CAUTION:

dangerous. Extreme care is recommended to

avoid overturns.

Operating a loader on a hillside is

Gradually open grapple fork tines, allowing material to

drop into tub grinder. For round bales it may be necessary

to gradually set bale into tub grinder to avoid shock

loading tub grinder due to bale weight and to avoid

sudden load on grinder mechanism.

Even on level ground, transport bucket and load as low as

possible to avoid tipping in case a wheel drops in a rut and

to avoid power lines.

OPERATION

WARNING:

loader boom clear of overhead lines. Allowing

loader boom or any attachments to contact

overhead power lines may electrify entire

tractor and electrocute (kill) operator.

LOADING INTO TUB GRINDER

Lift bucket high enough to clear tub grinder sides. Move

tractor toward tub grinder to position load near center.

Extend bucket cylinders to position bucket in dump

attitude.

Keep bucket, grapple fork and

Roll bucket back, close grapple fork and back tractor away

from tub grinder, then lower loader boom after dumping.

STACKING BALES

WARNING:

large bales, extreme care must be taken in

handling them. Be aware of forces acting on

stacked bales due to gravity and keep workers

far from zones of potential hazard from shifting

or falling bales. DO NOT ALLOW

BYSTANDERS!

Use loader and grapple fork to gently position bale on

stack, then release bale while removing bucket and fork.

Because of size and weight of

F-3778-12-04 Operation Section 4-8

© 2004 Alamo Group Inc.

Page 31

OPERATION

Slowly back tractor away from stack.

LOADING FROM A STACK, BUNKER SILO OR PIT

SILO

Choose a forward gear that provides sufficient ground

speed for loading.

Exercise caution when undercutting a high pile.

Avalanching material can be dangerous.

When loading material from ground, keep a level bucket

and use lift control float position. If hydraulic down

pressure is exerted on a bucket, it will wear faster than

normal. Keep bucket level when approaching pile.

Touch pile as near as possible to top with bucket

positioned in dump attitude and grapple fork open. Close

grapple fork while maneuvering bucket to grasp loose

material.

CAUTION:

capacity diminish as loader height is

increased. Care must be taken not to grasp

more material than your loader can safely

support.

An alternative method is to use your loader and grapple

fork to knock material down from top of pile so it can be

loaded from ground.

Loader lift and break-away

OPERATION

Keeping a level bucket and using loader float will reduce

surface gouging and mixing surface material with

stockpile material.

When a sufficient amount of material has accumulated in

front of bucket, close grapple fork to grasp material and

curl bucket.

F-3778-12-04 Operation Section 4-9

© 2004 Alamo Group Inc.

Page 32

OPERATION

OPERATING BALE SPEAR

Loader equipped with bale spear is designed to handle

round bales up to 2000 pounds.

WARNING:

extreme caution. Sharp points on bale spear

can cause serious injury or death.

Load bale spear by approaching from round end to

prevent cutting strings or puncturing plastic or net wrap.

Tilt bale spear upward to prevent bale from falling off of

spear.

Operate bale spear using

WARNING:

large bales, extreme care must be taken in

handling them. Be aware of forces acting on

stacked bales due to gravity and keep

workers far from zones of potential hazard

from shifting or falling bales. DO NOT

ALLOW BYSTANDERS!

WARNING:

boom clear of overhead lines. Allowing

loader boom or any attachments to contact

overhead power lines may electrify entire

tractor and electrocute (kill) operator.

Because of size and weight of

Keep bale spear and loader

Carry bales as low to the ground as possible to allow

maximum visibility and avoid tipping.

OPERATION

F-3778-12-04 Operation Section 4-10

© 2004 Alamo Group Inc.

Page 33

OPERATION

MSL

Linkage

Boom

MSL Triangular

Pivot Plate

Tilt

Cylinder

Four-Bar

Linkage

Attachment

Link

Guide

Link

Tilt Dump

Stop

Quick-Attach

Bracket

Relief

Cartridge

Loader

Upright

Lift Cylinder

Tilt Cylinder

Base End

Tilt Cylinder

Rod End

Relief Valve

Cartridge

OPERATION AND NOMENCLATURE OF MSL

(Mechanical Self Leveling) LOADER

MSL maintains the attitude of loader bucket or attachment

relative to ground as set by the operator using the tilt

cylinders. Constant attitude is maintained when lift

cylinders raise or lower boom, as long as no tilt

adjustment is made.

MSL consists of linkages connected to loader uprights

and extending forward to triangular pivot plates. Equal

displacement tilt cylinder base ends are attached to the

pivot plates and rod ends are attached to another linkage

commonly referred to as a four-bar linkage. The four-bar

linkage, which allows increased dump and rollback

rotation connects to bucket or attachment.

Hydraulic relief for tilt cylinders is required when raising

the boom with attachment fully dumped. The attachment

contacts dump stops on underside of front ends of boom.

While raising boom, MSL system pushes attachment

tighter against dump stops and tilt cylinder base end

pressure increases. A hydraulic relief valve cartridge

allows the pressurized oil to transfer to rod end of tilt

cylinder, eliminating excessive loads on MSL system.

Hydraulic relief is not necessary when lowering boom.

IMPORTANT:

tubes and hoses are correctly plumbed for proper

operation of MSL relief valve. Refer to diagram below.

Pressure setting for relief valve is set at 210 bar (3,045

psi) and MUST

is stamped with required 210 bar setting.

It is important that the tilt cylinder oil line

be maintained at that level. The cartridge

OPERATION

F-3778-12-04 Operation Section 4-11

© 2004 Alamo Group Inc.

Page 34

MAINTENANCE

SECTION

© 2004 Alamo Group Inc.

Maintenance Section 5-1

Page 35

MAINTENANCE

Regular maintenance of your loader and hydraulic system

will ensure maximum loader efficiency and long life.

WARNING:

beneath a raised loader unless loader is

properly supported to prevent accidental

lowering.

NEVER

perform maintenance

DAILY MAINTENANCE

Check fluid level of tractor hydraulic system

•

before starting each day's operation. If

necessary, add hydraulic oil as recommended

in your tractor operator's manual.

Every four hours of operation, lubricate all

•

twenty-two grease fittings. One grease fitting on

the end of each pin, accessible from outside the

loader.

Repair hydraulic oil leaks promptly to avoid loss

•

of oil and serious personal injury from escaping

oil.

Replace hoses immediately if they are damaged

•

by a cut or scrape, extruded at the fittings, or

leaking.

After every ten hours of operation, check all

•

hardware and tighten where required.

WARNING:

pressure can penetrate skin, causing serious

personal injury.

DO NOT use your hand to check for leaks. Use

•

a piece of wood or cardboard and wear eye

protection to search for leaks.

Stop engine and relieve pressure before

•

connecting or disconnecting lines.

Tighten all connections before starting engine or

•

pressurizing lines.

If any fluid is injected into skin, obtain medical attention

immediately or gangrene may result.

Escaping hydraulic fluid under

Grease Fitting Locations

MAINTENANCE

GREASE

POINTS

F-3778-12-04 Maintenance Section 5-2

© 2004 Alamo Group Inc.

Page 36

MAINTENANCE

13

5

2

14

4

677

3

1

4

3

2

LIFT CYLINDER

15

CYLINDER SERVICE

Loader cylinders are designed to be reliable and easy to

service. If a cylinder should malfunction during warranty

period, return complete cylinder assembly, without

disassembling, to your authorized service department or

contact your authorized service department for

instructions. Unauthorized disassembly of a cylinder in

warranty period will

Following is an outline procedure for disassembling and

reassembling cylinders.

LIFT CYLINDER DISASSEMBLY

1. Remove cylinder from loader.

2. Hold cylinder tube (13) stationary and pull wire ring

(14) out through slot.

3. Pull shaft (1), with all assembled parts, out of cylinder

tube (13).

NOTE:

Resistance will be felt until piston seal (8)

slides over wire retaining ring groove.

4. Remove elastic lock nut (12) from end of shaft and

slide cylinder piston (10) and cylinder head (4) off

shaft.

5. Remove piston wear ring (11), piston seal (8), and o-

ring (9) from outside grooves on piston (10).

6. Remove wiper seal (2), rod seal (3), and wear ring (5)

from inside of cylinder head (4) and o-ring (7) with

backup washer (6) from groove on outside of head.

7. Clean all parts, including cylinder tube, in a suitable

cleaning solvent, then use air pressure to blow any dirt

or excess solvent from all parts.

8. Examine all parts for wear or damage and replace, if

necessary.

VOID WARRANTY

.

Lips of seal

(3) must face

inward.

4

8

6

5

13

12

11

10

9

14

9

8

LIFT CYLINDER REASSEMBLY

NOTE:

Be careful not to damage seals and o-rings on

edges or holes in cylinder tube. Inspect and remove burrs

and sharp edges if necessary before reassembly.

1. Place rod seal (3) into groove inside cylinder head (4).

NOTE:

Lips of seal (3) must face inward and seal must

be firmly seated in groove.

2. Install wiper seal (2) with lip of seal facing out and flush

with top of cylinder head (4). Install wear ring (5) inside

other end of head (4).

3. Place o-ring (7) with backup washer (6) in groove on

outside of head (4). Backup washer must be to rod

side.

4. Remove sharp edges on outer edge of threaded end of

shaft (1). Lubricate wiper seal (2) and rod seal (3) in

head (4) and carefully slide head (4) onto shaft.

5. Place o-ring (9), piston seal (8), and piston wear ring

(11) in grooves on outside of piston (10).

NOTE:

For easier installation, place piston seal (8) in

120°F water to warm seal.

6. Slide piston (10) onto threaded end of shaft and install

elastic lock nut (12). Tighten elastic lock nut to 575

ft.·lbs. torque.

7. Lubricate piston wear ring (11) and piston seal (8) on

piston (10), o-ring (9) on head (4) and inside of cylinder

tube (13), then carefully slide piston and head into

cylinder tube (13).

8. Insert wire retaining ring (14) into slot in cylinder tube

(13). Apply pressure to wire ring to thread it into groove

while turning cylinder head.

15

10

11

MAINTENANCE

F-3778-12-04 Maintenance Section 5-3

© 2004 Alamo Group Inc.

Page 37

MAINTENANCE

Lips of seal

(7) must face

inward.

4

7

6

22

5

21

9

1

3

20

5

4

16

15

TILT CYLINDER

TILT CYLINDER DISASSEMBLY

1. Remove cylinder from loader.

2. Secure cylinder in a vise and manually extend and

retract cylinder rod to remove oil in cylinder.

3. With cylinder rod fully extended, remove set screws

(21) from cylinder. Remove plug (20) and apply air

pressure into hole where plug was removed. This will

unseat internal head (8) and move it along cylinder

rod.

4. Hold cylinder tube (1) stationary and pull retaining wire

(2) out through slot while turning head (17) in same

direction.

5. Pull shaft (19) with all assembled parts out of cylinder

tube (1).

6. Remove internal head (8) from cylinder shaft.

7. To remove piston from rod assembly, hold shaft

MAINTENANCE

assembly by placing a rod through hole in shaft (3) and

a shaft through cross head shaft (19) and turn

counterclockwise.

8. Remove wiper seal (6), rod seal (7), and wear ring (9)

from inside cylinder head (8), and backup ring (4) and

o-ring (5) from groove on outside of head (17).

9. Remove wiper seal (18), rod seal (7), and wear ring (9)

from inside cylinder head (17), and o-ring (15) with

backup ring (16) from groove on outside of head (17).

2

14

11

12

13

12

11

10

9

8

7

6

19

18

7

9

17

16

15

9

7

18

23

12

11

Lips of seal

(7) must face

inward.

13

12

11

14

10.Remove piston wear rings (11), support rings (12), and

seal (13) from outside groove of piston (10).

11.Clean all parts, including cylinder tube, in suitable

cleaning solvent, then use air pressure to blow away

any dirt or excess solvent from all parts.

12.Examine all parts for wear or damage and replace, if

necessary.

TILT CYLINDER REASSEMBLY

NOTE:

Be careful not to damage seals and o-rings on

edges or holes in cylinder tube. Inspect and remove burrs

and sharp edges if necessary before reassembly.

1. Place rod seal (7) into groove inside cylinder heads (8

& 17).

NOTE:

Lips of seal (7) must face pressure side of

cylinder as shown in cutout illustrations of head

assemblies and seal must be firmly seated in grooves.

2. Install wiper seal (6) with lip of seal facing out into

groove on cylinder head (8).

3. Install wiper seal (18) with lip facing out and flush with

top of cylinder head (17).

4. Install wear ring (9) inside other end of cylinder heads

(8 & 17).

5. Place backup ring (16) and o-ring (15) in groove on

outside of head (17). Make sure o-ring and backup ring

are installed as shown in cutout illustration for head

(17).

F-3778-12-04 Maintenance Section 5-4

© 2004 Alamo Group Inc.

Page 38

MAINTENANCE

TILT CYLINDER REASSEMBLY CONTINUED

6. Place o-ring (5) and backup ring (4) in groove in

outside of head (8). Make sure o-ring and backup ring

are installed as shown in cutout illustration for head

(8).

7. Remove sharp edges on outer edge of threaded end of

shaft (19). Lubricate wiper seal (18) and rod seal (7) in

head (17) and carefully slide head onto shaft in

orientation shown.

8. Place o-ring (14) into groove inside piston, and seal

components (11-13) into groove on outside of piston.

Lubricate o-ring (14) and slide piston onto threaded

shaft (19) in orientation shown.

9. Clean internal and external threads on shafts (19 & 3)

with parts cleaner, dry and apply Loctite

threads on shaft (19), then assemble shaft (3) to cross

head shaft (19). Tighten to 450-500 ft.·lbs. torque.

REPLACING WEAR BUSHINGS

Loader lift and tilt cylinders are manufactured with

replaceable wear bushings at each end. (Refer to

cylinder illustrations on previous pages.) Wear bushings

are designed to be easily replaced using tools ordinarily

available.

®

271 to

10.Lubricate o-ring (5), backup ring (4), wiper seal (6),

and rod seal (7). Carefully slide cylinder head (8) into

cylinder tube (1), then into inner tube. Turn tube (1)

with open end facing up and use a shaft or tube to seat

head into tube. Be careful not to score cylinder wall.

Install plug (20), apply Loctite and install set screws

(21) in place. Seat set screws equally from each side.

11.Apply a light coating of oil to shaft and piston seals.

Turn tube (1) horizontal and secure in vise. Turn shaft,

piston, and head assembly so hole in shaft (3) is

horizontal and slide into cylinder, guiding rod into head

(8).

12.Lubricate o-ring (15) and backup ring (16), then

carefully slide piston and head into cylinder tube (1).

13.Insert wire retaining ring (2) into slot in cylinder tube

(1). Apply pressure to wire ring to thread it into groove

while turning cylinder head.

1. Use a drift pin to remove wear bushing.

2. Press replacement bushing in place using mallet and

block of wood, or similar method.

Level indicator

bracket

Level Indicator

Rod

ADJUSTING ATTACHMENT LEVEL INDICATOR

With various tractor tire options or attachments, it may be

necessary to adjust attachment level indicator bracket up

or down tilt cylinder tube. Tractor must be on level surface

with attachment flat on surface. Loosen u-bolt to adjust.

Offset on bucket level indicator rod should be at slotted

hole when attachment is level.

MAINTENANCE

THIS SAFETY SYMBOL MEANS

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS

INVOLVED!

F-3778-12-04 Maintenance Section 5-5

© 2004 Alamo Group Inc.

Page 39

MAINTENANCE

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE REMEDY

1. Loader slow or will

not lift and/or dump.

2. Loader chatters or

vibrates when raising

or lowering.

3. Loaded bucket

dumps or uncurls

when control valve is

in neutral.

1. Hydraulic oil too heavy. 1. Change to proper oil.

2. Oil filter plugged. 2. Clean or replace filter.

3. Hydraulic pump worn. 3. Repair or replace pump.

4. Oil line restricted or leaking. 4. Check all hoses and tubes for

5. Control valve does not shift

properly.

6. Air in hydraulic system. 6. Cycle lift cylinders and bucket

7. Cylinder leaks internally. 7. Replace seals.

8. Faulty relief valve (tractor). 8. Clean or replace relief valve.

1. Air leak in pump inlet line. 1. Check, tighten or replace inlet

2. Air in hydraulic system. 2. Cycle lift and bucket cylinders.

3. Oil level too low. 3. Add oil as required.

4. Faulty relief valve (tractor). 4. Replace relief valve.

1. Control valve spool is leaking. 1. Contact your Dealer.

2. Control linkage binding. 2. Inspect, adjust or repair linkage.

leaks, damage or restrictions.

Replace damaged or restricted

hoses or tube oil lines.

5. Inspect, clean, repair or replace

valve.

cylinders several times to free

system of air.

line.

3. Cylinder seals bypassing oil. 3. Repair or replace cylinders.

4. External leakage. 1. Damaged seals. 1. Remove leaking component and

5. Pump noisy. 1. Inlet line restricted or leaking. 1. Check for air leaks, restrictions or

2. Oil level too low. 2. Add oil as required.

3. Pump worn or damaged 3. Repair or replace pump.

6. Excessive wear on

bucket cutting edge.

MAINTENANCE

7. Loader raises when

bucket is rolled back.

8. Bucket cutting edge

not flat on the

ground.

1. Bucket is riding on cutting edge

instead of wear pads.

1. Air in lift cylinder lines. 1. Slowly cycle all cylinders to purge

1. Rear axle on tractor not level from

side to side.

F-3778-12-04 Maintenance Section 5-6

replace seals.

collapsed hose. Tighten or

replace hose. Clean filter if

necessary.

1. Use boom FLOAT position or

bucket level indicator to ensure

bucket rides on wear pads.

system

of air. Replenish hydraulic

system.

1. With tractor on level surface,

compare rear axle height from left

to right, measuring from axle

center to ground. Adjust air

pressure in rear tires until axle

height measures the same for

both sides.

© 2004 Alamo Group Inc.

Page 40

MAINTENANCE

GENERAL TORQUE SPECIFICATIONS

USE THE FOLLOWING TORQUES WHEN SPECIAL TORQUES ARE NOT GIVEN

AMERICAN STANDARD CAP SCREWS METRIC CAP SCREWS

SAE

Grade

Typical

Grade ID

Markings

on Head

Cap

Screw

Size

Inches MIN MINMINMINMINMAX MAXMAXMAXMAXMIN MAX MIN MINMAX MAX

1/4-20 6.25 129867.25 15111188.5 10 8.25 119.5 13 M6 x 1.00

1/4-28 8 312321.5169 36.527272011 12 10.5 1412 16 M8 x 1.25

5/16-18 14 5742392915 7052473519 20 18.5 2520 27 M10 x 1.50

5/16-24 17.5 10275705219 12391846223 26 23 3125 34 M12 x 1.75

3/8-16 26 1631201158528 19814613910335 38 35 47.537 50 M14 x 2.00

3/8-24 31 23817617613034 29321621415842 46 41 55.545 61 M16 x 2.50

7/16-14 41 32524023317245 39829428421055.5 61 55 74.560 81 M18 x 2.50

7/16-20 51 46534333524755 57742640830169 74.5 68 9275 102 M20 x 2.50

1/2-13 65 63947245033272 78057654740488 97.5 86 11696 130 M22 x 2.50

1/2-20 76 81259957342384 992732700517103 114 102 138112 152 M24 x 3.00

9/16-12 95 1217898863637105 148810981055779129 142 127 172140 190 M27 x 3.00

9/16-18 111 165812241181872123 2027149614441066150 167 148 200164 222

5/8-11 126 139 171 188 168 228185 251

5/8-18 152 168 206 228 203 275224 304

3/4-10 238 262 322 355 318 431350 474

3/4-16 274 305 371 409 365 495402 544

7/8-9 350 386 474 523 466 631515 698

7/8-14 407 448 551 607 543 736597 809

1-8 537 592 728 802 716 970790 1070

1-14 670 740 908 1003 894 1211987 1337

TORQUE TORQUETORQUETORQUE

85

Typical

Grade ID

Markings

on Head

Cap Screw

Millimeters

M30 x 3.00

FT-LBSFT-LBS N·mFT-LBS N·mN·m FT-LBS N·m Size

NOTE: These values apply to fasteners as

received from supplier, dry or when lubricated

with normal engine oil. They do not apply if

special graphite or molydisulphide greases or

other extreme pressure lubricants are used.

10.98.8Metric Class

O-Ring Face Seal Hose/

Tube Swivel Nut

Metric

Tube

O.D.

(mm)

5

6

8

10

12

16

20

22

25

32

38

50.8

Dash

Size

-3

-4

-5

-6

-8

-10

-12

-14

-16

-20

-24

-32

Thread

9/16 - 18

11/16 - 16

13/16 - 16

1 - 14

1-3/16 - 12

1-3/16 - 12

1-7/16 - 12

1-11/16 - 12

2 - 12

Size

(in.)

--

--

--

Swivel

Nut Hex

Size

(in.)

--

11/16

-13/16

15/16

1-1/8

1-3/8

-1-5/8

1-7/8

2-1/4

--

Torque

N·mlb

--

16

-24

50

69

102

102

142

190

217

--

Swivel Nut

Torque Specifications for

37° JIC Fittings

Assembly Torque

Thread

Size

Size

-4 140 ± 10 12 ± 1 2 27/16-20