Page 1

®

®

SWITCH BLADE

5 ft. & 6 ft. Sickle Bar Mower

Model With Spring Break-A-Way

Rev 08-11

Part No. 02974374P

PART'S MANUAL

An Operator's Manual was shipped with the equipment in the Manual Canister.

This Operator's Manual is an integral part of the safe operation of this machine

and must be maintained with the unit at all times. READ, UNDERSTAND, and

FOLLOW the Safety and Operation Instructions contained in this manual before

operating the equipment. If the Operator's Manual is not with the equipment,

contact your dealer or Alamo Industrial (800-356-6286) to obtain a Free copy

before operating the equipment.

ALAMO INDUSTRIAL

1502 E. Walnut

Seguin, Texas 78155

210-372-3551

© 2011 Alamo Group Inc.

Page 2

Page 3

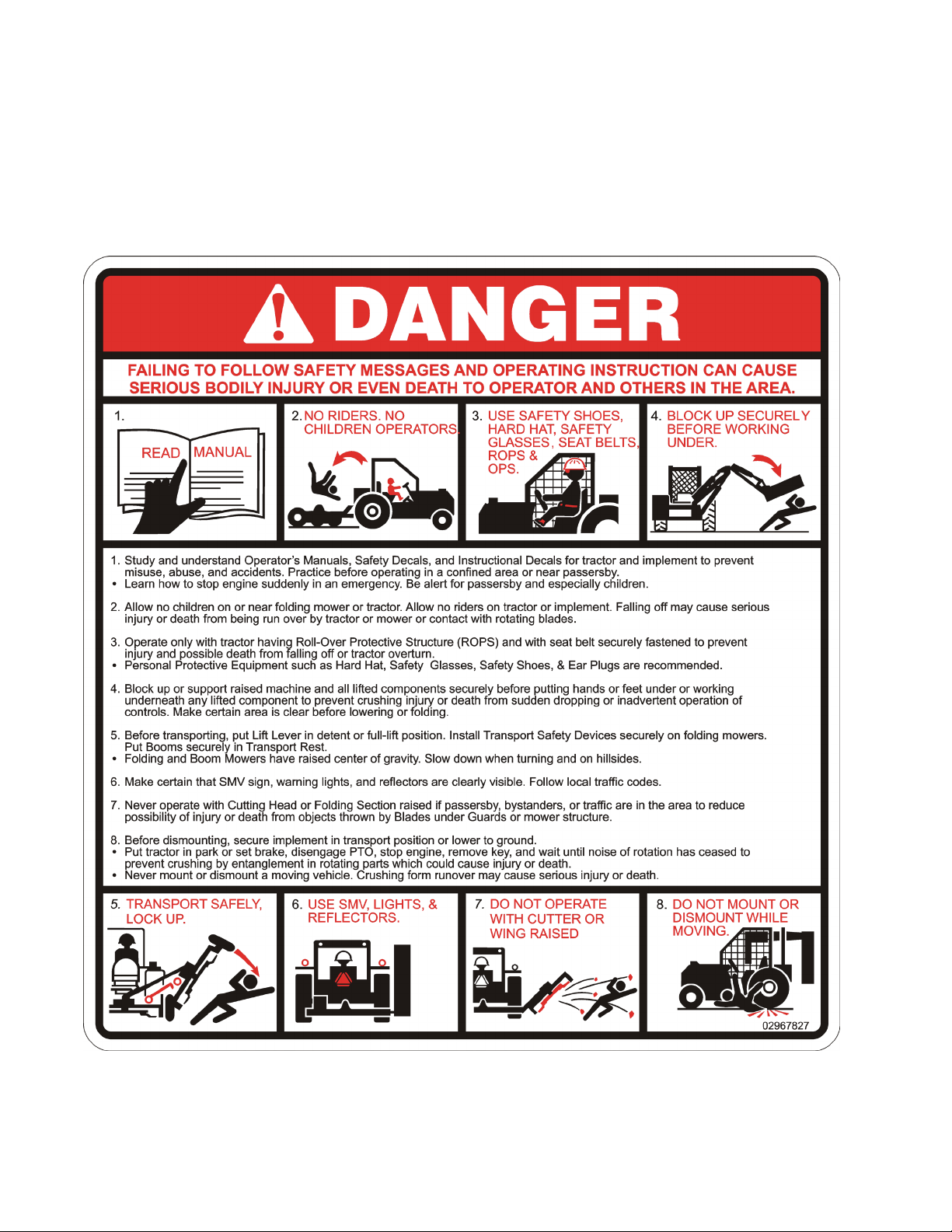

TO THE OWNER/OPERATOR/DEALER

All implements with moving parts are potentially hazardous. There is no substitute for a cautious, safe-minded operator who recognizes the potential hazards and follows reasonable safety practices. The manufacturer has designed this implement to be used with

all its safety equipment properly attached to minimize the chance of accidents.

BEFORE YOU START!! Read the safety messages on the implement and shown in your manual.

Observe the rules of safety and common sense!

WARRANTY INFORMATION:

Read and understand the complete Warranty Statement found in this Manual. Fill out the Warranty Registration Form in full and return

it within 30 Days. Make certain the Serial Number of the Machine is recorded on the Warranty Card and on the Warranty Form that

you retain. The use of "will-t" parts will void your warranty and can cause catastrophic failure with possible injury or death.

Page 4

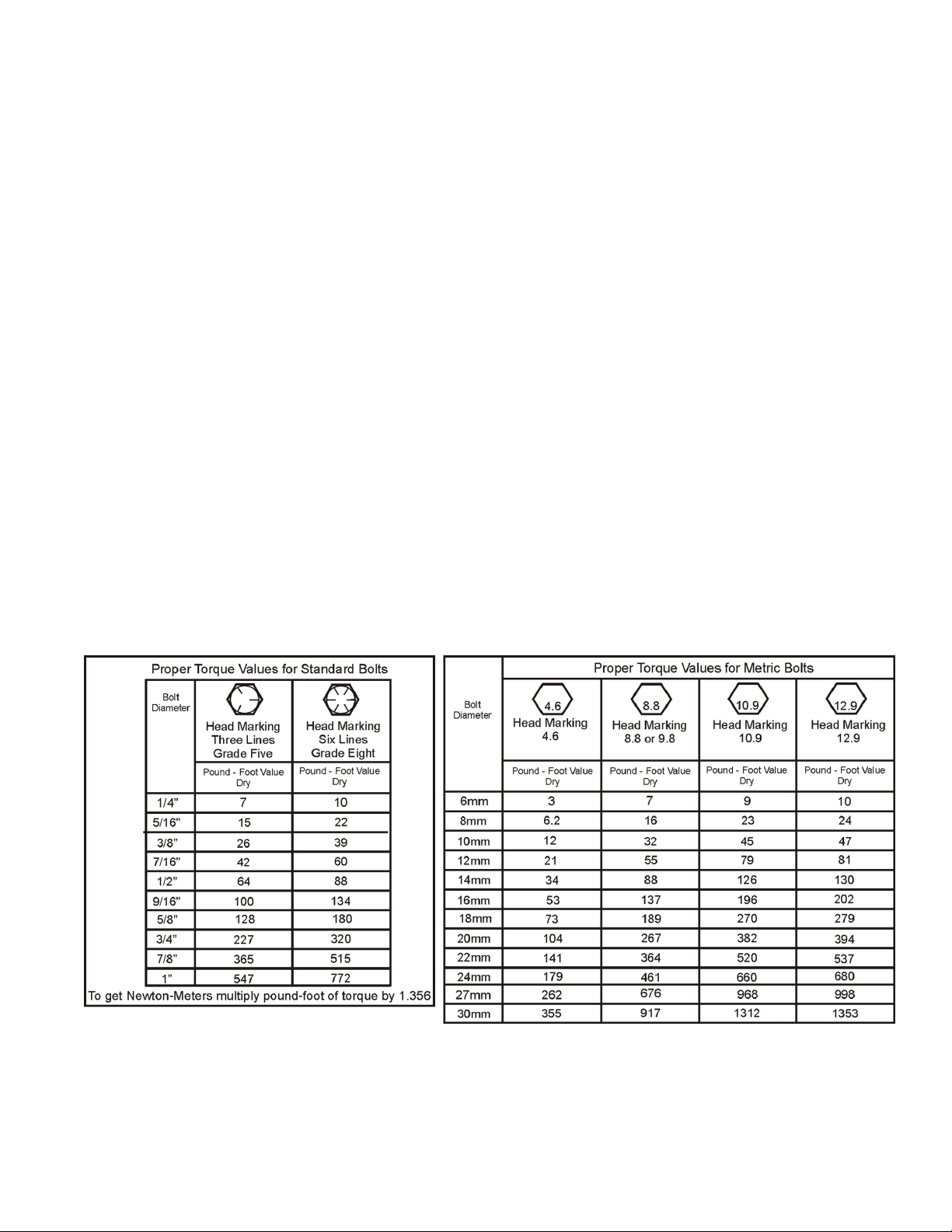

BOLT TORQUE

Mounting procedures for mowers will require a signicant amount of bolt nut and washer installation.

Frame and structure mounting bolts should be installed using Red Loctite, and torqued to the dry values

listed in the torque chart based on the bolt size and hardness.

Other structures such as pump mounting bolts should be installed with Blue Loctite and torqued to the dry

values indicated in the chart.

Bolt tightness should be completed with and checked with a suitable torque wrench.

Torque checks should be completed throughout the life of the mower in accordance with the maintenance

chart provided in this manual.

Loose bolts on a frame or in a casting may be a result of:

● Vibration from the mower due to imbalance of the mower blades

● Pulled threads due to over tightening

● Distortion of the hole due to under tightening during installation

Bolts broken or sheared in the mounting structure or tractor may be the result of:

● Improper alignment of the Mounting Plate or Structure such that it is not sitting at on the mating

surface

● Distortion of the bolt due to over-tightening

● Under tightening of the bolts

Check the bolt torque during installation and prior to delivery with a suitable torque wrench.

Page 5

PARTS

SECTION

Parts Section – 1

Page 6

PARTS ORDERING GUIDE

®

®

The following instructions are offered to help eliminate needless delay and error in processing

purchase orders for the equipment in this section.

1. The Parts Section is prepared in logical sequence and grouping of parts that belong to the

basic machine featured in this manual. Part Numbers and Descriptions are given to help locate

the parts and quantities required.

2. The Purchase Order must include the name and address of the person or organization ordering

the parts, who should be charged, and if possible, the serial number of the machine for which

the parts are ordered.

3. The Purchase Order must clearly list the quantity of each part, the complete and correct part

number (be sure to include all periods), and the basic name of the part.

4. The Manufacturer reserves the right to substitute parts where applicable.

5. Some parts are unlisted items which are special production items not normally stocked and

are subject to special handling. Request a quotation for such parts before sending a Purchase

Order.

6. The Manufacturer reserves the right to change prices without prior notice.

Note: Please refer to The Safety Section in the front of this Manual for the proper part number

when ordering replacement safety decals.

For maximum safety and to guarantee optimum product reliability, always use

genuine Alamo Industrial Parts. The use of inferior replacement parts may cause

premature or catastrophic failure which could result in serious injury or death.

Direct any questions regarding parts to:

ALAMO INDUSTRIAL

1502 E. Walnut

Seguin, Texas 78155

830-379-1480

©2011 Alamo Group Inc.

Parts Section – 2

Page 7

PART NAME INDEX

CARRIAGE ARM ASY - LH WG - PN 02977721........................................................................................................................................ 4

CARRIAGE ARM ASY - RH WG - PN 02974362....................................................................................................................................... 6

COMMON COMPONENT BOX - PN 02974368......................................................................................................................................... 8

CUTTER BAR ASY - 5 FT LH WG - PN 02977715.................................................................................................................................... 9

CUTTER BAR ASY - 5 FT RH WG - PN 02974360.................................................................................................................................. 11

CUTTER BAR ASY - 6 FT LH WG - PN 02977717.................................................................................................................................. 13

CUTTER BAR ASY - 6 FT RH WG - PN 02974372.................................................................................................................................. 15

HYD CYL ASY - BAR TILT - PN 0693500A............................................................................................................................................ 17

HYD CYL ASY - CURB LIFT - PN 0693400A......................................................................................................................................... 18

HYD DIVERTER VALVE - CYL CONTROL - PN 02977622................................................................................................................. 19

HYD DIVERTER VALVE - MOTOR CONTROL - PN 02977621........................................................................................................... 20

HYD DIVERTER VALVES - PN 02977621 & PN 02977622................................................................................................................... 21

HYD FILTER ASY - PN 02974309............................................................................................................................................................ 22

HYD MOTOR ASY - PN 02974301 & PN 02974301A............................................................................................................................. 23

HYD MOTOR DRIVE ASY - PN 02974300 & PN 02974300A................................................................................................................ 25

HYD PUMP ASY - PN 02974302 (SN 10361 09-04 & DOWN)............................................................................................................... 26

HYD PUMP ASY - PN 02974302A (SN 10362 10-04 TO 10770)............................................................................................................. 27

HYD PUMP ASY - PN 02974302B (SN 10771 09-08 & UP).................................................................................................................... 29

HYD PUMP ASY - TANDEM PN 02974303B.......................................................................................................................................... 31

HYD SCHEMATIC - SINGLE WG............................................................................................................................................................ 33

HYD TANK ASY - PN 02981705............................................................................................................................................................... 35

HYD VALVE ASY W-FITTINGS - PN 02982077..................................................................................................................................... 37

HYD VALVE ASY W-O FITTINGS - PN 02974306................................................................................................................................. 39

HYD VALVE REMOTE CONTROL CABLES......................................................................................................................................... 41

HYD VALVE SOLENOID ASY - PN 02988789....................................................................................................................................... 43

KNIFE BAR - 5 FT RH WG - PN 02974361 - W/ SERRATED KNIVES................................................................................................. 44

KNIFE BAR - 6 FT RH WG - PN 02974373 - W/ SERRATED KNIVES................................................................................................. 45

KNIFE BAR - 5 FT LH WG - PN 02977716 - W/ SERRATED KNIVES................................................................................................. 46

KNIFE BAR - 6 FT LH WG - PN 02977718 - W/ SERRATED KNIVES................................................................................................. 47

SHOE & BRK-A-WAY PRE-ASY RH MOUNT - PN 02975986.............................................................................................................. 49

SHOE & BRK-A-WAY PRE-ASY LH MOUNT - PN 02977726.............................................................................................................. 51

SHOE, DRIVE & BRK-A-WAY ASY RH MOUNT - PN 02975194........................................................................................................ 53

SHOE, DRIVE & BRK-A-WAY ASY LH MOUNT - PN 02977727......................................................................................................... 55

WIRING HARNESS - DUAL WG - PN 02977754.................................................................................................................................... 57

WIRING HARNESS - SINGLE WG - PN 02974318................................................................................................................................. 58

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -3

Page 8

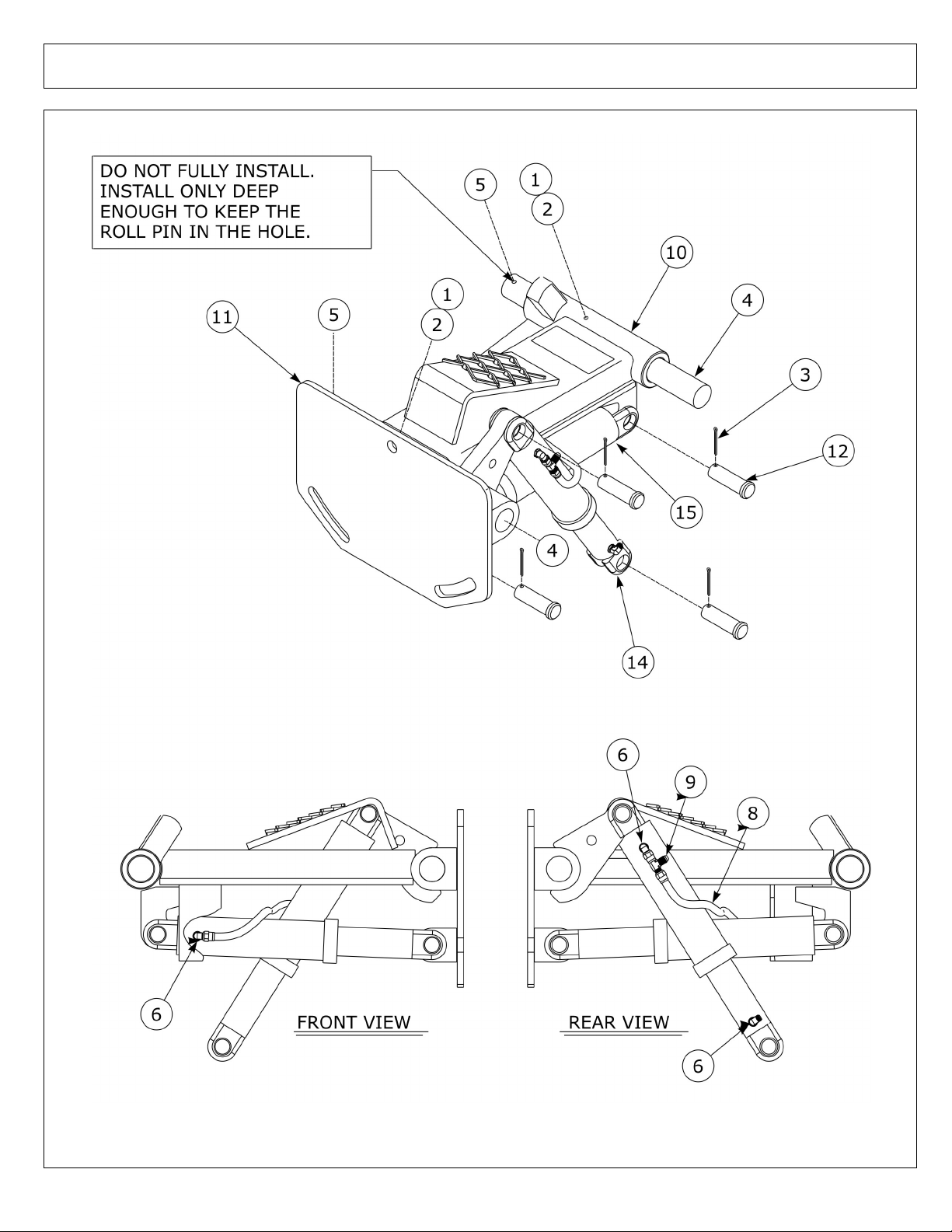

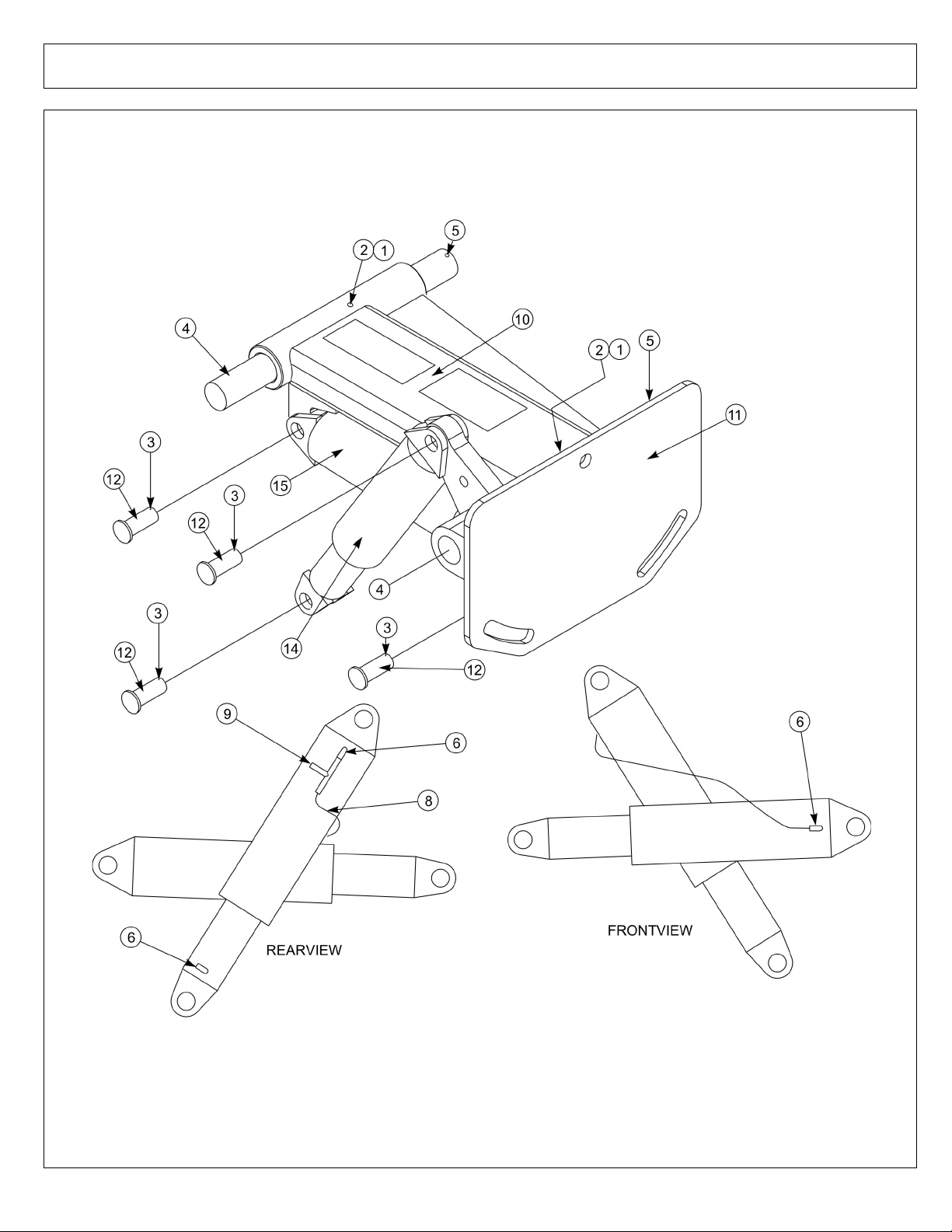

CARRIAGE ARM ASY - LH WG - PN 02977721

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -4

Page 9

CARRIAGE ARM ASY - LH WG - PN 02977721

Continued...

ITEM PART NO. QTY. DESCRIPTION

02977721 1 CARRIAGE ARM ASY, LH WING

1 000206 2 RED LUBRICAPS

2 00752670 2 GREASE FITTING

3 00755153 4 COTTER PIN

4 0112700 2 CARRIAGE PIN

5 0113400 2 PIN ROLL

6 02045200 3 ELBOW

8 02965475 1 HOSE, # 4 - 18" LG

9 02970702 1 HYD. ADAPTER

10 02977719 1 CARRIAGE ARM WLD’MT, LH

11 02977720 4 PIVOT MOUNT WLD’MT

12 0424200 1 PIN FOR CYLINDER LUGS

14 0693400A 1 CURB STOP CYLINDER ASY

15 0693500A 1 BAR LIFT CYLINDER ASY

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -5

Page 10

CARRIAGE ARM ASY - RH WG - PN 02974362

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -6

Page 11

CARRIAGE ARM ASY - RH WG - PN 02974362

Continued...

ITEM PART NO. QTY. DESCRIPTION

02974362 1 CARRIAGE ARM ASY.

1 000206 2 NO. 2 RED LUBRICAPS<

2 00752670 2 FITTING,GREASE STRAIGHT 1/4-28

3 00755153 4 PIN,COTTER 3/16 X 1-1/2 PLATED

4 0112700 2 CARRIAGE PIN

5 0113400 2 PIN ROLL 3/8 X2-1/2

6 02045200 3 ADP HYD ELBOW 4MP-4MJ90

8 02965475 1 HOSE #4 - 4FJX - 4FJX - 18LG

9 02970702 1 ADP HYD TEE 4MJ-4MJ-4FJX

10 02974324 1 CARRIAGE ARM CASTING

11 02974329 1 PIVOT MOUNT CASTING

12 0424200 4 PIN CLEVIS 7/8 X2-3/4

14 0693400A 1 CURB STOP CYLINDER

15 0693500A 1 BAR LIFT CYLINDER

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -7

Page 12

COMMON COMPONENT BOX - PN 02974368

ITEM PART NO. QTY. DESCRIPTION

02974368 1 COMMON COMPONENT BOX SINGLE

2 02964028 1 PUSH PULL SWITCH

3 02982367 1 SWITCH KNOB

6 02974310 1 FILTER ELEMENT

7 02974318 1 WIRE HARNESS

8 02974321 1 DECAL, VALVE & SWITCH OPERATION

9 02974322 1 3 - POSITION TOGGLE SWITCH

10 02974348 1 HYDRAULIC TANK ASY.

11 02974364 1 VALVE ASY.

12 02974962 1 TOGGLE SWITCH BOOT COVER

13 02975270 1 DECAL, REVERSING SWITCH INSTRUCTION

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -8

Page 13

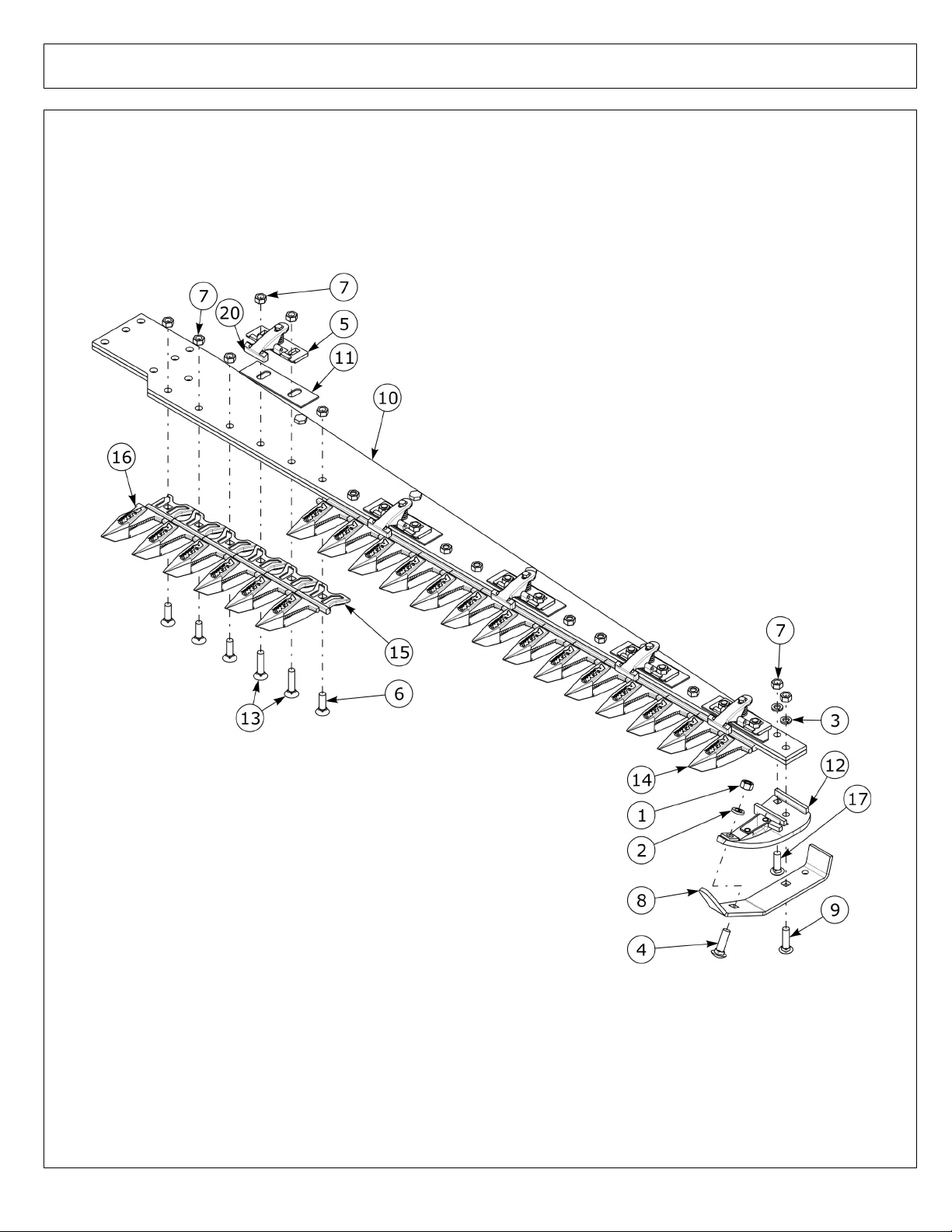

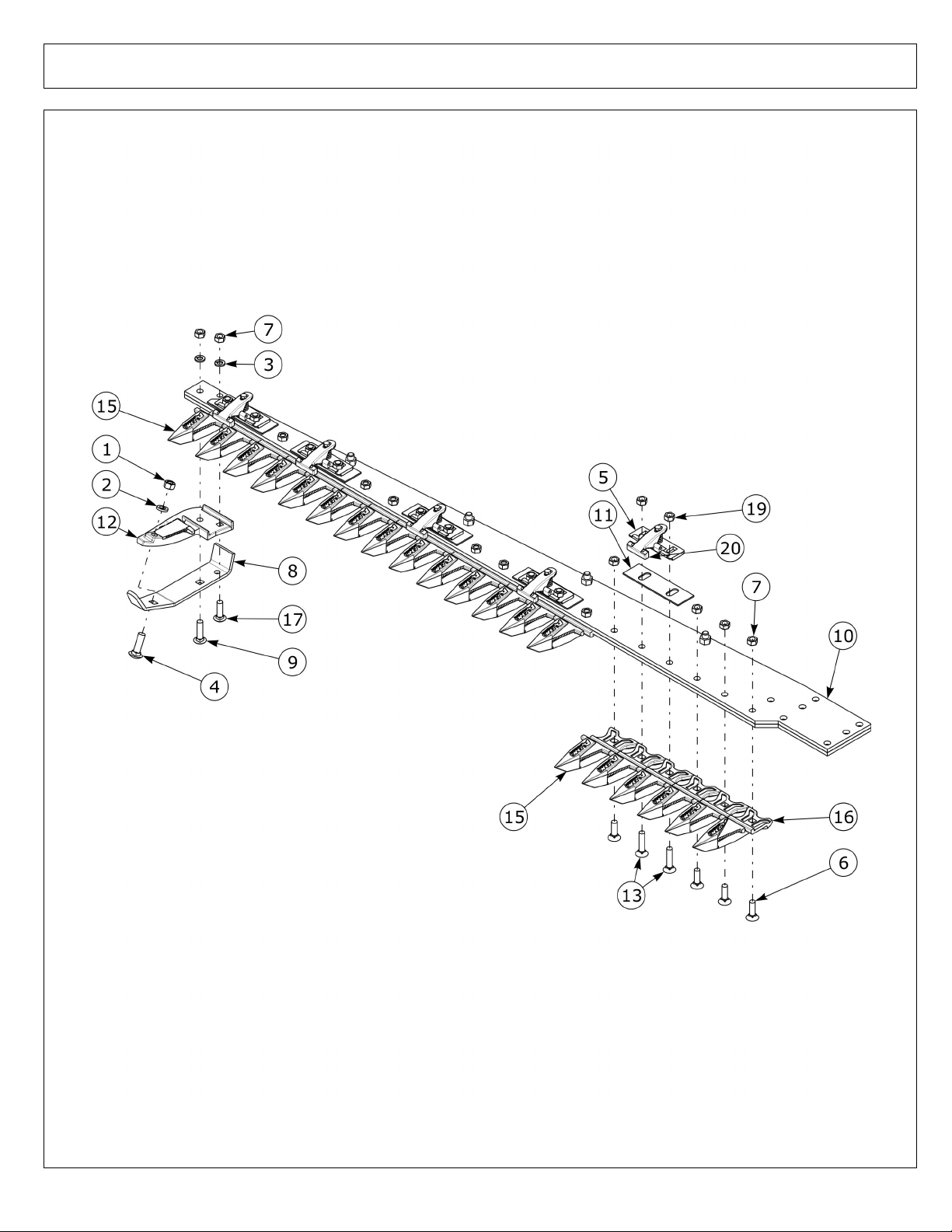

CUTTER BAR ASY - 5 FT LH WG - PN 02977715

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -9

Page 14

CUTTER BAR ASY - 5 FT LH WG - PN 02977715

Continued...

ITEM PART NO. QTY. DESCRIPTION

02977715 1 5 FT CUTTER BAR ASY LH WING

1 00001200 1 NUT

2 00019600 1 LOCKWASHER

3 00022200 2 LOCKWASHER

4 000516 1 CARRIAGE BOLT

5 02983841 5 LOW ARCH HOLD DOWN CLIP

6 0046400 10 PLOW BOLT

7 00999316 22 NUT

8 0569500 1 OUTER SHOE SOLE, LH

9 0129000 1 CARRIAGE BOLT

10 02983841 4 LOW ARCH HOLD DOWN CLIP

11 02974345 1 CUTTER BAR, 5 FT

12 0532600 4 WEAR PLATE

13 0571100 1 OUTER SHOE ASSEMBLY

14 0571800 10 PLOW BOLT

15 0571900 1 WEAR PLATE

16 0593500 1 OUTER ROCK GUARD

17 0593700 18 CENTER ROCK GUARD

18 0596200 1 INNER ROCK GUARD, LH

19 12666000 1 CARRIAGE BOLT

20 02983843 5 PLASTIC WEAR STRIP .188 THICK

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -10

Page 15

CUTTER BAR ASY - 5 FT RH WG - PN 02974360

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -11

Page 16

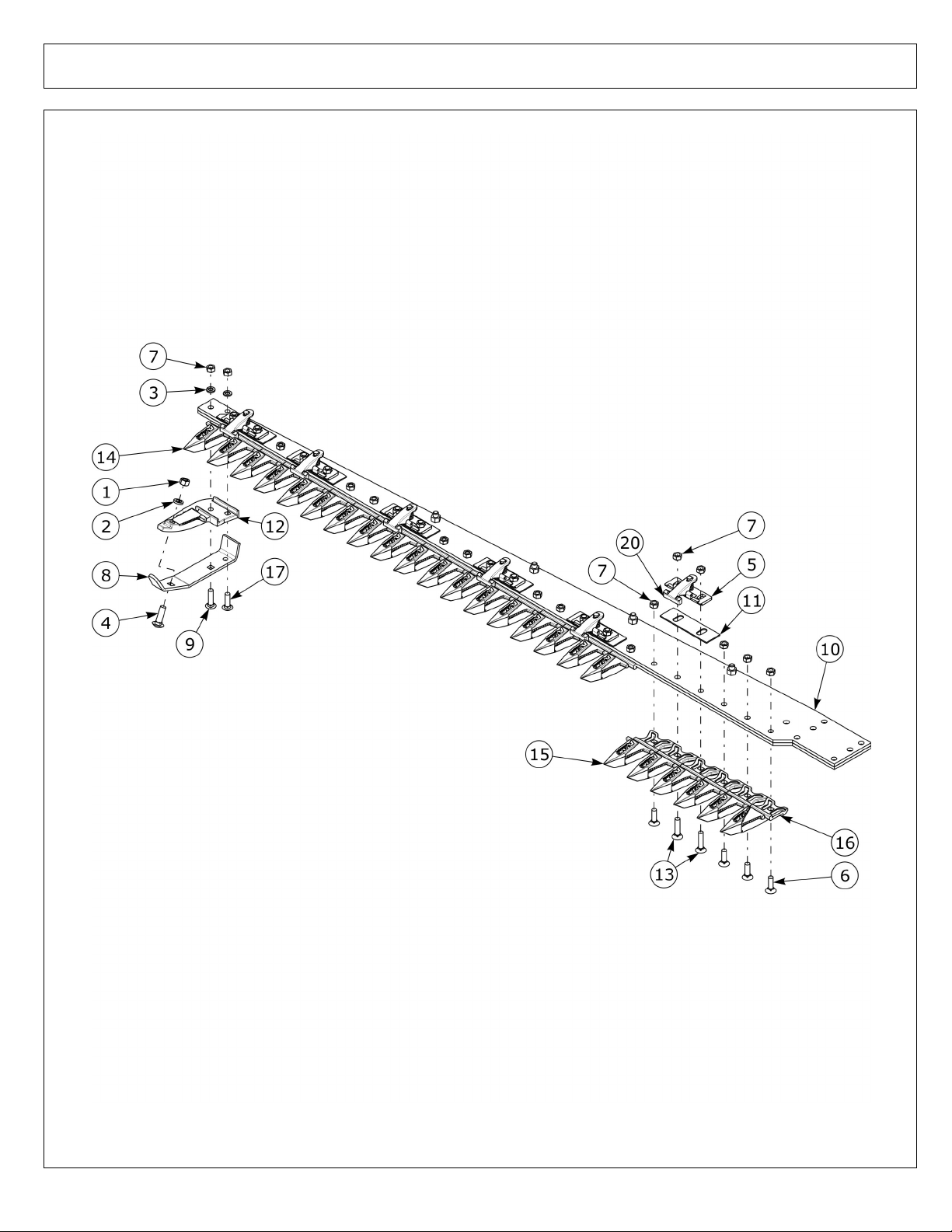

CUTTER BAR ASY - 5 FT RH WG - PN 02974360

Continued...

ITEM PART NO. QTY. DESCRIPTION

02974360 1 5 FT CUTTER BAR ASY. RH WING

1 00001200 1 NUT

2 00019600 1 LOCKWASHER

3 00022200 2 LOCKWASHER

4 000516 1 CARRIAGE BOLT

5 02983841 5 LOW ARCH HOLD DOWN CLIP

6 0046400 10 PLOW BOLT

7 00999316 12 NUT

8 0123800 1 OUTER SHOE SOLE, RH

9 0129000 1 CARRIAGE BOLT

10 02974345 4 CUTTERBAR 5 FT

11 0532600 4 WEAR PLATE

12 0570900 1 OUTER SHOE ASSEMBLY, RH

13 0571800 10 PLOW BOLT

14 0571900 1 WEAR PLATE

15 0593600 1 OUTER ROCK GUARD, RH

16 0593700 18 CENTER ROCK GUARD

17 0593800 1 INNER ROCK GUARD, RH

18 12666000 1 CARRIAGE BOLT

19 4527 10 NUT,LOCK FLG WHIZ 7/16-14NC PL

20 02983843 5 PLASTIC WEAR STRIP .188 THICK

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -12

Page 17

CUTTER BAR ASY - 6 FT LH WG - PN 02977717

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -13

Page 18

CUTTER BAR ASY - 6 FT LH WG - PN 02977717

Continued...

ITEM PART NO. QTY. DESCRIPTION

02977717 1 6 FT CUTTER BAR ASY. LH WING

1 00001200 1 NUT

2 00019600 1 LOCKWASHER

3 00022200 2 LOCKWASHER

4 000516 1 CARRIAGE BOLT

5 02983841 6 LOW ARCH HOLD DOWN CLIP

6 0046400 12 PLOW BOLT

7 00999316 14 NUT

8 0569500 1 OUTER SHOE SOLE, LH

9 0129000 1 CARRIAGE BOLT

10 02974346 1 CUTTER BAR, 6 FT

11 0571900 1 WEAR PLATE

12 0571100 1 OUTER SHOE ASSEMBLY, LH

13 0571800 12 PLOW BOLT

14 0593500 1 OUTER ROCK GUARD

15 0593700 22 CENTER ROCK GUARD

16 0596200 1 INNER ROCK GUARD

17 12666000 1 CARRIAGE BOLT

18 4527 12 FLANGE NUT

19 0532600 5 PLASTIC WEAR INSERTS

20 02983843 6 PLASTIC WEAR STRIP .188 THICK

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -14

Page 19

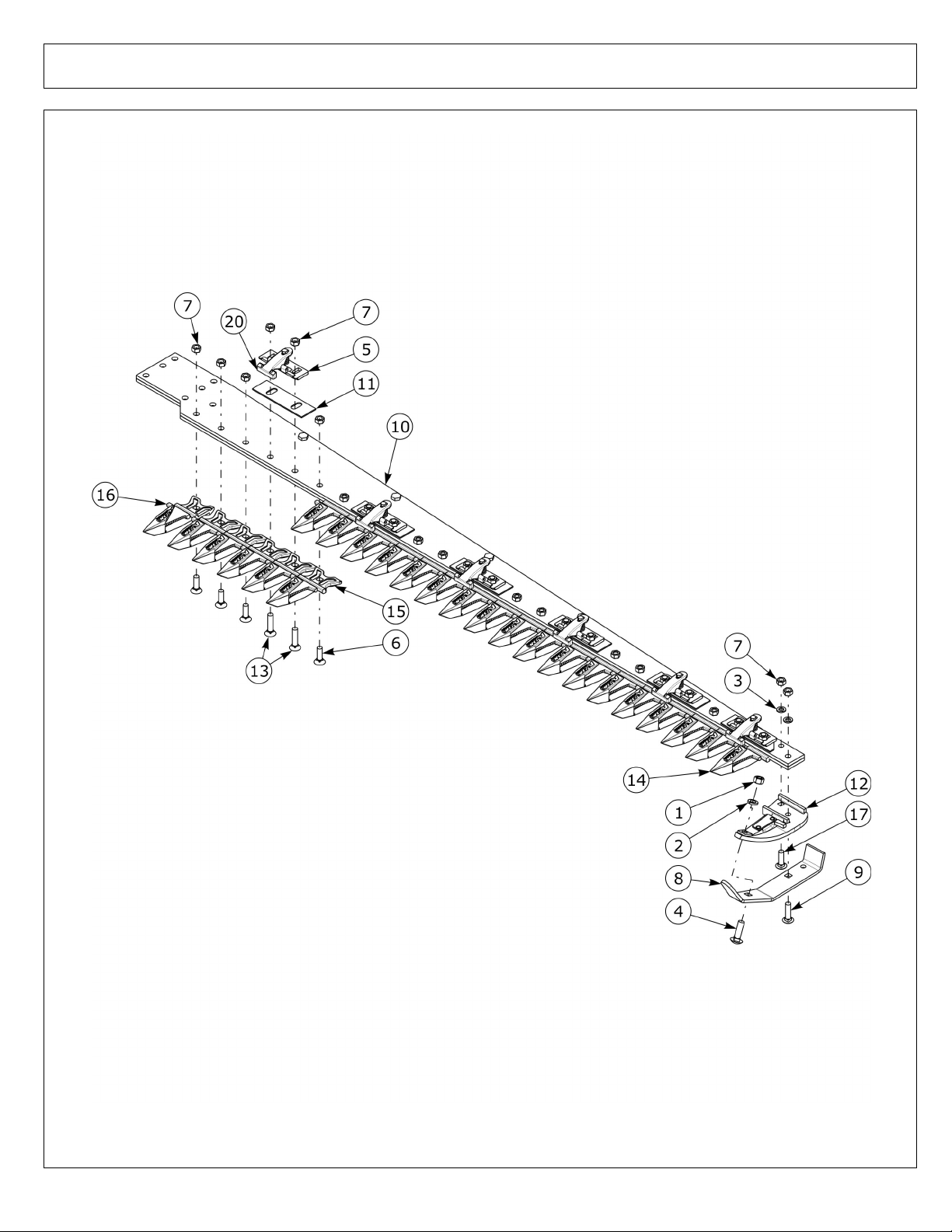

CUTTER BAR ASY - 6 FT RH WG - PN 02974372

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -15

Page 20

CUTTER BAR ASY - 6 FT RH WG - PN 02974372

Continued...

ITEM PART NO. QTY. DESCRIPTION

02974372 1 6 FT CUTTER BAR ASY. RH WING

1 00001200 1 NUT

2 00019600 1 LOCKWASHER

3 00022200 2 LOCKWASHER

4 000516 1 CARRIAGE BOLT

5 02983841 6 LOW ARCH HOLD DOWN CLIP

6 0046400 12 PLOW BOLT

7 00999316 14 NUT

8 0123800 1 OUTER SHOE SOLE, RH

9 0129000 1 CARRIAGE BOLT

10 02974346 1 CUTTER BAR, 6 FT

11 0571900 1 WEAR PLATE

12 0570900 1 OUTER SHOE ASSEMBLY, RH

13 0571800 12 PLOW BOLT

14 0593600 1 OUTER ROCK GUARD, RH

15 0593700 22 CENTER ROCK GUARD

16 0593800 1 INNER ROCK GUARD, RH

17 12666000 1 CARRIAGE BOLT

18 4527 12 FLANGE NUT

19 0532600 5 PLASTIC WEAR INSERTS

20 02983843 6 PLASTIC WEAR STRIP .188 THICK

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -16

Page 21

HYD CYL ASY - BAR TILT - PN 0693500A

ITEM PART NO. QTY. DESCRIPTION

0693500A 1 BAR LIFT CYLINDER ASY.

1 02977114 1 TUBE WLD’MT

2 02977116 1 CYL HEAD

3 02977115 1 ROD WLD’MT

4 --------------- 1 * O-RING

5 --------------- 1 * BACK-UP SEAL RING

6 --------------- 1 * ROD SEAL

7 --------------- 1 * ROD WIPER

8 --------------- 1 * WIRE RING

9 02977121 1 SEAL KIT, ( * INCLUDES ITEMS 4, 5, 6, 7 & 8 )

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -17

Page 22

HYD CYL ASY - CURB LIFT - PN 0693400A

ITEM PART NO. QTY. DESCRIPTION

0693400A 1 CURB STOP CYLINDER ASY.

1 02977114 1 TUBE WLD’MT

2 02977116 1 CYLINDER HEAD

3 02977118 1 PISTON

4 02977122 1 ROD WLDMT

5 02977123 1 CYLINDER ROD

6 02716500 1 LOCKNUT

7 --------------- 1 * PSP SEAL

8 --------------- 1 * O-RING

9 --------------- 1 * BACK-UP RING

10 --------------- 1 * ROD SEAL

11 --------------- 1 * NYLON WEAR RING

12 --------------- 1 * SNAP IN ROD SEAL

13 --------------- 1 * WIRE RING

14 02977121 1 SEAL KIT, ( * INCLUDES ITEMS 7, 8, 9, 10, 11, 12 & 13 )

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -18

Page 23

HYD DIVERTER VALVE - CYL CONTROL - PN 02977622

ITEM PART NO. QTY. DESCRIPTION

1 02977622 1 VALVE SOLENOID DIVERTER

02988755 1 SELECTOR, 6WAY, 6GPM SAE-4

02988756 1 COIL, 12 VDC, 6 WAY VS125

02988819 1 SOLENOID, VALVE, SELECTOR

02988820 1 CONNECTOR, DIN, STANDARD

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -19

Page 24

HYD DIVERTER VALVE - MOTOR CONTROL - PN 02977621

ITEM PART NO. QTY. DESCRIPTION

1 02977621 1 VALVE, SOLENOID DIVERTER (USE W/ DUAL WINGS)

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -20

Page 25

HYD DIVERTER VALVES - PN 02977621 & PN 02977622

ITEM PART NO. QTY. DESCRIPTION

1 02974962 1 BOOT, TOGGLE SWITCH COVER

2 02977825 1 DECAL, INSTUCT. LEFT & RIGHT SWITCH

3 02977826 1 SWITCH, 2-POSITION "ON" & "OFF"

4 02977622 1 DIVERTER VALVE & SOLENOID, # 4 PORTS

5 02962181 4 HYD. ADAPTER STRAIGHT

6 02977915 2 HYD. ADAPTER ELBOW

7 02977621 1 DIVERTER VALVE & SOLENOID DIVERTER, # 8 PORTS

8 02962214 2 HYD. ADAPTER ELBOW

9 00696800 4 HYD. ADAPTER STRAIGHT

10 02761100 2 HYD. ADAPTER ELBOW

11 02977754 1 WIRE HARNESS, LH DUAL WINGS

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -21

Page 26

HYD FILTER ASY - PN 02974309

ITEM PART NO. QTY. DESCRIPTION

1 02976906 1 BOWL

2 02976907 1 FILTER CONDITION GAUGE

3 02976908 1 FILTER RETAINER SPRING

4 02974319 1 AIR BREATHER ELEMENT

5 02976909 1 AIR BREATHER KIT

6 02974310 1 FILTER ELEMENT

7 02976910 1 SEAL KIT

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -22

Page 27

HYD MOTOR ASY - PN 02974301 & PN 02974301A

ITEM PART NO. QTY. DESCRIPTION

02974301 1 HORIZONTAL KNIFE DRIVE ASY (W/ 5/16" KEY WAY) SWB6-10672 & DOWN

02974301A 1 HORIZONTAL KNIFE DRIVE ASY (W/ 1/4" KEY WAY) SWB5-10673 & UP

1 02976883 1 INTERNAL DRIVE SHAFT

2 02976884 1 STAR & HOUSING SET

3 02976885 7 HOUSING TIE SCREW

4 02976886 4 FLANGE ATTACHMENT SCREW

5 02976887 1 FLANGE MOUNT

6 02976888 1 THRUST BEARING RACE

7 02976889 1 THRUST BEARING

8 02976890 1 OUTPUT SHAFT, (W/ 5/16" KEY WAY) SWB6-10672 & DOWN

02976890A 1 OUTPUT SHAFT, (W/ 1/4" KEY WAY) SWB5-10673 & UP

9 02976891 1 MOTOR HOUSING

10 02976892 1 PLUG

11 02976893 1 SPACER PLATE

12 02976894 1 END CAP

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -23

Page 28

HYD MOTOR ASY - PN 02974301 & PN 02974301A

Continued...

ITEM PART NO. QTY. DESCRIPTION

13 MA000229 1 KEY, 5/16" X 5/16" X 1" LG KEY SWB6-10672 & DOWN

102268 1 KEY, 1/4" X 1/4" X 1" LG KEY SWB5-10673 & UP

03200521 1 KEY, STEPPED 1/4" X 5/16" X 1" LG KEY (AS NEEDED)

14 02976895 1 SEAL KIT, GEROTOR MOTOR

NOTE:THERE WERE TWO DIFFERENT SIZE KEYS USED, A 1/4 INCH AND A 5/16 INCH. TO MIX THESE COMPONENTS THERE IS A STEPPED KEY

AVAILABLE THAT IS 1/4 AND 5/16 INCH. CHECK WHICH IS NEEDED.

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -24

Page 29

HYD MOTOR DRIVE ASY - PN 02974300 & PN 02974300A

ITEM PART NO. QTY. DESCRIPTION

02974300 1 HORIZONTAL KNIFE DRIVE ASY (W/ 5/16" KEY WAY) SWB6-10672 & DOWN

02974300A 1 HORIZONTAL KNIFE DRIVE ASY (W/ 1/4" KEY WAY) SWB5-10168 & DOWN

1 02974311 1 FLYWHEEL

2 02974315 1 HUB ADAPTER (W/ 5/16" KEY WAY) SWB5-10673 & UP

02974315A 1 HUB ADAPTER (W/ 1/4" KEY WAY) SWB6-10169 & UP

3 02974317 1 KNIFE DRIVE STUD ASY.

4* 02977820 2 SOCKET HEAD CAPSCREW, (TORQUE TO 35 FT. LBS)

5 02980453 1 SUPPORT HORIZONTAL KNIFE DRIVE

6 02967570 2 HEX BOLT

NOTE:TORQUE BOLTS ITEM #4 TO 35 FT. LBS.

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -25

Page 30

HYD PUMP ASY - PN 02974302 (SN 10361 09-04 & DOWN)

ITEM PART NO. QTY. DESCRIPTION

02974302 1 PUMP ASY, 1.16/0.49 CID/REV (STEEL MOUNTING FLANGE & END CAP)

1 02976923 1 CONNECTING SHAFT

2 02976922 1 GEAR SET

3 02976921 1 GEAR SET

4 02976920 1 END CAP (STEEL END CAP)

5 02976919 1 MOUNTING FLANGE (STEEL MOUNTING FLANGE)

6 02976918 1 GEAR HOUSING

7 02976917 1 GEAR HOUSING

8 02976916 4 HOUSING TIE BOLT

9 02976915 2 DOWEL PIN

10 02976914 2 DOWEL PIN

11 02976913 1 MID SPACER PLATE

12 02976912 4 THRUST BLOCK

13 02976911 4 WASHER

* 02976924 1 SEAL KIT ( INCLUDES ITEMS W / * )

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -26

Page 31

HYD PUMP ASY - PN 02974302A (SN 10362 10-04 TO 10770)

ITEM PART NO. QTY. DESCRIPTION

02974302A 1 PUMP ASY, 1.16/0.49 CID/REV (ALUMINUM MOUNTING FLANGE & END CAP)

1 02980846 1 MOUNTING FLANGE, (ALUMINUM MOUNTING FLANGE)

2 02980847 1 END CAP, (ALUMINUM END CAP)

3 02980848 1 HOUSING, (F/ LARGE GEAR SECTION)

4 02976913 1 MID SECTION SPACER PLATE

5 02980849 1 HOUSING, (F/ SMALL GEAR SECTION)

6 -------------- 4 SEAL, BACK UP (INCLUDED N SEAL KIT)

7 02980850 1 DRIVE GEAR, (LARGE GEAR)

8 02980851 1 DRIVEN GEAR, (LARGE GEAR)

9 02980852 1 DRIVE GEAR, (SMALL GEAR)

10 02980853 1 DRIVEN GEAR, (SMALL GEAR)

11 -------------- 1 SHAFT SEAL, (INCLUDED IN SEAL KIT)

12 02980856 1 SNAP RING

13 02980857 4 THRUST BLOCK, (F/ LARGE OR SMALL GEAR SECTION)

14 ------------- 4 CHANNEL SEAL, (INCLUDED IN SEAL KIT)

15 02976911 4 WASHER

16 02980854 4 FASTENER, (173MM)

17 02980855 4 NUT

18 -------------- 4 SECTIONAL SEAL, (INCLUDED IN SEAL KIT)

19 02976915 2 PIN, DOWEL, (SHORT PIN)

20 02976914 2 PIN, DOWEL, (LONG PIN)

21 02976923 1 CONNECTING, SHAFT

22 02980858 1 SEAL KIT, (F/ LARGE GEAR SECTION)

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -27

Page 32

HYD PUMP ASY - PN 02974302A (SN 10362 10-04 TO 10770)

Continued...

ITEM PART NO. QTY. DESCRIPTION

23 02980859 1 SEAL KIT, (F/ SMALL GEAR SECTION)

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -28

Page 33

HYD PUMP ASY - PN 02974302B (SN 10771 09-08 & UP)

ITEM PART NO. QTY. DESCRIPTION

02974302B 1 PUMP TANDEM GEAR 1.16/.50 CID

1 02985005 1 PUMP FLANGE

2 02985006 1 REAR COVER

3 02988046 4 THRUST PLATE

4 02988047 1 DRIVE GEAR

5 02988048 1 SHAFT, DRIVE GEAR

6 02988049 1 DRIVEN GEAR

7 02988050 1 SHAFT, DRIVEN GEAR

8 02988051 1 KIT, M10 BOLT & WASHER, 4 EA.

9 02985014 1 RETAINING RING

10 02985015 1 MID-PLATE SPACER

11 02985016 1 SPLINED CONNECTING SHAFT

12 02985017 8 PIN, DOWEL

02988051 1 BOLTS AND WASHERS KIT

02985018 1 SEAL KIT

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -29

Page 34

THIS PAGE INTENTIONAL LEFT BLANK

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -30

Page 35

HYD PUMP ASY - TANDEM PN 02974303B

ITEM PART NO. QTY. DESCRIPTION

02974303B 1 TANDEM PUMP ASSEMBLY

1 02985003 1 BODY, (.38 CID SECTION)

2 02985004 1 BODY, (.98 CID SECTION)

3 02985005 1 PUMP FLANGE

4 02985006 1 REAP COVER

5 02985007 4 THRUST PLATE (NOT INCLUDED IN SEAL KIT)

6 02985008 1 DRIVE GEAR, (.38 CID SECTION)

7 02985009 1 DRIVE GEAR, (.98 CID SECTION)

8 02985010 1 DRIVEN GEAR, (.38 CID SECTION)

9 02985011 1 DRIVEN GEAR, (.98 CID SECTION)

10 02985012 4 BOLT, HEX HEAD M10 X 165MM

11 02985013 4 WASHER, M10

12 02985017 8 DOWEL PIN

13 02985015 1 MID PLATE SPACER

14 02985014 1 RETAINING RING

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -31

Page 36

HYD PUMP ASY - TANDEM PN 02974303B

Continued...

ITEM PART NO. QTY. DESCRIPTION

15 02985016 1 SPLINED CONNECTING SHAFT

16 02985018 1 SEAL KIT

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -32

Page 37

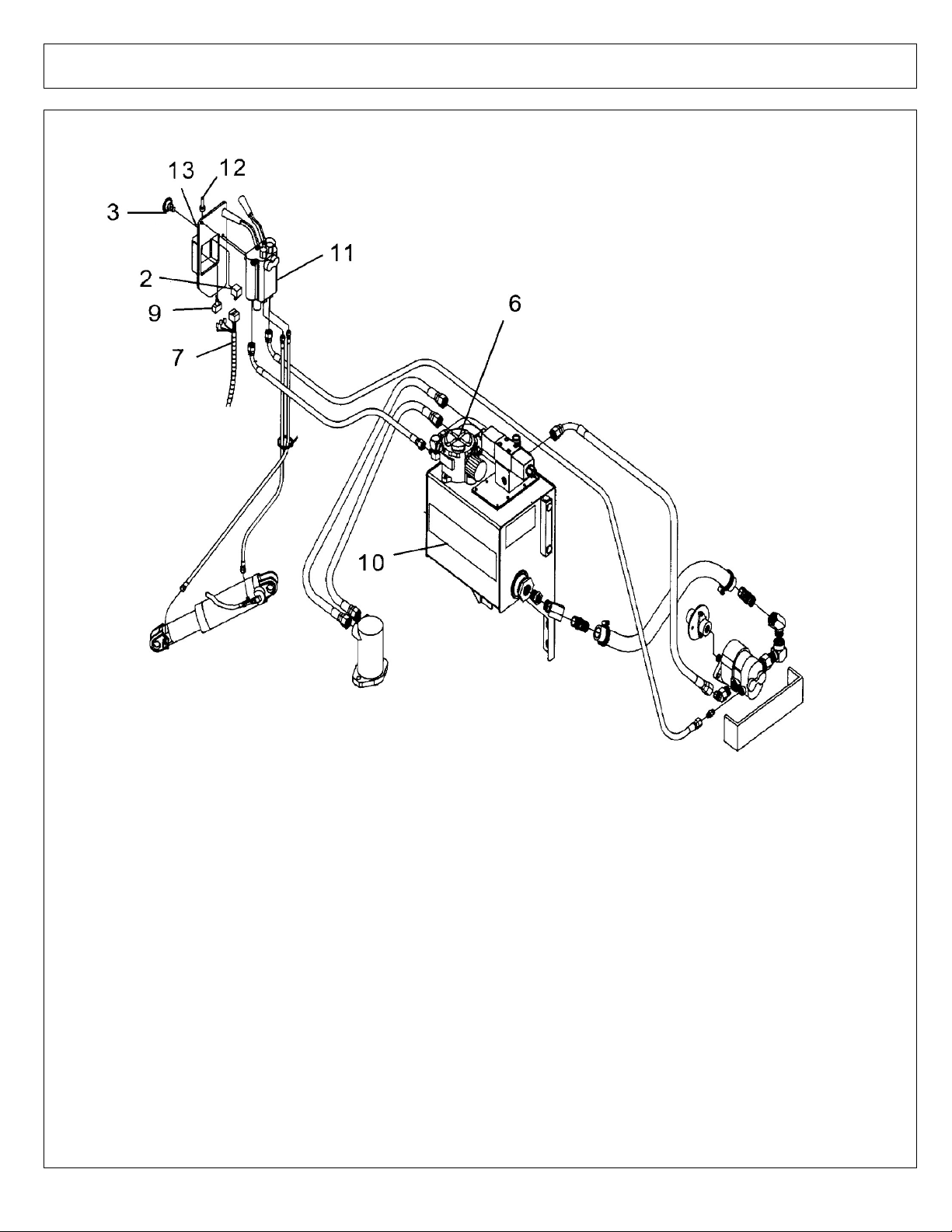

HYD SCHEMATIC - SINGLE WG

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -33

Page 38

HYD SCHEMATIC - SINGLE WG

Continued...

ITEM PART NO. QTY. DESCRIPTION

1 02974302 1 PUMP TANDEM GEAR, 1.16/0.49 CID

02974303 1 PUMP TANDEM GEAR, 0.98/0.37 CID

2 02981705 1 HYDRAULIC TANK ASY. ( NCLUDES NEXT 4 ITEMS )

02974309 1 FILTER ASY.

02974312 1 SUCTION STRAINER

02988789 1 CONTROL VALVE SOLENOID

02981527 1 TANK WLDMT

3 0693400A 1 CURB STOP CYLINDER ASY

4 0693500A 1 BAR LIFT CYLINDER ASY

5 02982296 1 BREAK-A-WAY VALVE ASY ( CONSIST OF THE FOLLOWING 6 ITEMS )

02965521 1 VALVE BODY ONLY

00751003 1 PIPE PLUG

02823100 2 HYD. ADAPTER ELBOW

00016200 2 BOLT

00750940 2 LOCKNUT

02982478 1 RELIEF CARTRIDGE ( 1550 PSI SETTING )

6 02981979 1 ROTARY ACTUATOR ASY.

7 02974301 1 MOTOR, 2.8 CID

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -34

Page 39

HYD TANK ASY - PN 02981705

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -35

Page 40

HYD TANK ASY - PN 02981705

Continued...

ITEM PART NO. QTY. DESCRIPTION

02981705 1 ASSEMBLY HYDRAULIC TANK

1 00017000 8 LOCKWASHER 1/4 PL STD

2 001891 1 ADP HYD ELBOW 4MP-6MJ90

3 00696800 3 ADP HYD STGHT 8MJ-8MB

4 10119000 2 HHCS 5/16 NC 1 PL5

5 0117100 1 MAGNETIC DRAIN PLUG

6 02959924 5 NUT TOPLOCK 1/4 NC PLB

7 02962213 1 ADP HYD ELBOW 8MB-8MJ 90

10 02968880 1 GAUGE SIGHT TEMPERATURE

11 02988789 1 VALVE SOLENOID CONTROL

12 02974309 1 FILTER HOUSING W/FILTER GUAGE

13 02974312 1 SUCTION STRAINER

14 02974320 1 HOSE #8-8FJX-8FJX-15LG "

15 02981527 1 WELDMENT HYDRAULIC TANK

16 02974369 1 COVER TANK ACCESS

17 02974370 1 ADP HYD ELBOW SPCL 8MJ-12MB 90 W/4FP

18 064600D 1 COVER GASKET

19 00002100 8 HHCS 1/4 NC 1/2 PL5

20 10074000 2 HHCS 1/4 NC 3 PL5

21 02974997 1 DECAL,NAME SWITCH BLADE

22 000752 1 ELBOW 2MP-2FP 90

23 000752 2 SEAL WASHER 1/4

24 00011700 2 5/16 LOCKWASHER

25 00024100 3 1/4 FLATWASHER

26 10058000 3 HHCS 1/4 NC 1 PL5

27 00776031 1 CANISTER, PARTS MANUAL

28 02974374CA 1 MANUAL OPERATORS, SWITCH BLADE

29 02977417 1 DECAL, OPERTOR`S MANUAL INSIDE

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -36

Page 41

HYD VALVE ASY W-FITTINGS - PN 02982077

ITEM PART NO. QTY. DESCRIPTION

02982077 1 VALVE ASY, W/ FITTINGS ( 2-SPOOL )

1 02974306 1 VALVE, DIRECTIONAL CONTROL

2 02968850 2 HYD. ADAPTER STRAIGHT

3 03200284 2 HYD. ADAPTER STRAIGHT

4 02965166 2 HYD. TEE ADAPTER

5 02981896 2 HYD. ADAPTER

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -37

Page 42

THIS PAGE INTENTIONAL LEFT BLANK

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -38

Page 43

HYD VALVE ASY W-O FITTINGS - PN 02974306

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -39

Page 44

HYD VALVE ASY W-O FITTINGS - PN 02974306

Continued...

ITEM PART NO. QTY. DESCRIPTION

02974306 1 VALVE ASY, 2 SPOOL W/O FITTINGS

1 02976934 2 UNLOAD PLUNGER

2 02966645 2 POPPET ASY.

3 02966646 1 SPACER

4 02976933 2 SPOOL

5 02966648 4 SEAT ASY.

6 02966649 2 PLUG ASY.

7 02966650 2 PLUG ASY.

8 02966651 2 BUSHING

9 02966652 2 LOCKOUT SPRING

10 02966653 1 CAP ASY.

11 02966654 1 PLUG ASY.

12 02976932 1 BODY

13 02976931 1 POPPET

14 02976930 1 SEAT

15 02966657 4 O-RING

16 02966658 2 RETAINING RING

17 02966659 1 WASHER

18 02966660 1 WASHER

19 02966661 1 WASHER

20 02966662 1 WASHER

21 02976946 1 CAP ASY.

22 02976945 1 SPRING

23 02966669 1 SPRING

24 02976944 2 PLUG ASY.

25 02976943 1 WASHER

26 02976942 1 WASHER

27 02976941 3 BALL

28 02976940 1 SPRING

29 02976939 1 SPRING

30 02976938 1 CONE

31 02976937 1 SPACER

32 02976936 1 ADAPTER CAP

33 02976935 1 WASHER

34 02966671 2 WIPER SEAL

35 02976957 2 HANDLE KIT

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -40

Page 45

HYD VALVE REMOTE CONTROL CABLES

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -41

Page 46

HYD VALVE REMOTE CONTROL CABLES

Continued...

ITEM PART NO. QTY. DESCRIPTION

1 00015800 2 LOCKNUT

2 000354 2 BOLT

3 001636 2 BOLT

4 00750940 3 LOCKNUT

5 02959924 2 LOCKNUT

6 02966687 2 ADJUSTING YOKE END

7 02966688 2 CLEVIS PIN

8 02968698 2 COTTER PIN

9 02971200 1 CABLE, REMOTE CONTROL - 48" LG

02971201 1 CABLE, REMOTE CONTROL - 60" LG

02971202 1 CABLE, REMOTE CONTROL - 72" LG

02971203 1 CABLE, REMOTE CONTROL - 102" LG

10 02974296 1 SWITCH MOUNT WLD’MT

11 02974299 1 ANGLE, MOUNT

12 02974323 2 ANGLED SINGLE AXIS CONTROL ASY.

13 02964028 1 SWITCH, PUSH PULL ( W/ ITEMS 14 )

14 02982367 1 KNOB ( REPLACEMENT KNOB F/ ITEM # 13 )

02982366 1 JAM NUT ( REPLACEMENT F/ ITEM # 13 )

02982365 1 NUT ( REPLACEMNT F/ ITEM # 13 )

15 02964318 1 RELIEF VALVE ( SET @ 2500 PSI )

16 02974321 1 DECAL INSTRUCT VALVE & SWITCH

17 02974322 1 3 - POSITION TOGGLE SWITCH

18 02982077 1 VALVE ASY, W/ FITTINGS

19 02974962 1 BOOT, TOGGLE SWITCH COVER

20 00023500 6 FLATWASHER

21 02733700 3 BOLT

22 02975270 1 DECAL INSTRUCTIONS, REVERSING SWITCH

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -42

Page 47

HYD VALVE SOLENOID ASY - PN 02988789

ITEM PART NO. QTY. DESCRIPTION

02988789 1 VALVE SOLENOID ASY.

1 02979345 1 BODY

2 02979346 1 RELIEF CARTRIDGE

3 02979190 1 BOLT KIT

4 02989041 1 *SOLENOID ASY.

5 02988802 1 STEM TUBE ASY.

6 02988803 1 COIL SOLENOID

7 02988804 1 COIL NUT

* * 1 CONSISTS OF REPLACEMENT PARTS - STEM TUBE, COIL SOLENOID, COIL NUT

02988805 1 SEAL KIT (NOT SHOWN)

02979191 1 SEAL KIT/RELIEF CARTRIDGE (NOT SHOWN)

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -43

Page 48

KNIFE BAR - 5 FT RH WG - PN 02974361 - W/ SERRATED KNIVES

ITEM PART NO. QTY. DESCRIPTION

02974361 1 5’ CUTTER BAR, ASY, SERRATED KNIFE

1 02982752 21 SERRATED KNIFE SECTION

2 0189900 1 KNIFE PROTECTOR,CARDBOARD 63"

3 02974316 1 INSERT NYLON DRIVE BRG CLAMP

4 02974349 1 KNIFE HEAD WLD’MT

00756328 1 BOLT

5 02976270 35 SECTION BOLT

6 02976271 7 HEAD BOLT

7 02976272 42 LOCKNUT

8 0530100M 1 BACKING STRIP 5’

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -44

Page 49

KNIFE BAR - 6 FT RH WG - PN 02974373 - W/ SERRATED KNIVES

ITEM PART NO. QTY. DESCRIPTION

02974373 1 ASSEMBLY 6`SERR KNIFE BAR

1 02982752 25 KNIFE SECTION TOP SER CHRM PLT

2 0687800 1 ANGLE, BOARD 84"

3 02974316 1 INSERT NYLON DRIVE BRG CLAMP

4 02974349 1 WELDMENT KNIFE HEAD

5 02976270 43 SECTION BOLT 5/8 LONG

6 02976271 7 HEAD BOLT 1-1/64 LONG

7 02976272 50 SECTION LOCKNUT (CONE)

8 0531900 1 BACKING STRIP 6`

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -45

Page 50

KNIFE BAR - 5 FT LH WG - PN 02977716 - W/ SERRATED KNIVES

ITEM PART NO. QTY. DESCRIPTION

02977716 1 5’ KNIFE BAR ASY, LH WING

1 02982752 21 SERRATED KNIFE SECTION

2 0189900 1 KNIFE PROTECTOR, CARDBOARD 63"

3 02974316 1 INSERT NYLON DRIVE BRG CLAMP

4 02974349 1 KNIFE HEAD WLD’MT

00756328 1 BOLT

5 02976270 35 SECTION BOLT

6 02976271 7 HEAD BOLT

7 02976272 42 LOCKNUT

8 0530100M 1 BACKING STRIP, 5’

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -46

Page 51

KNIFE BAR - 6 FT LH WG - PN 02977718 - W/ SERRATED KNIVES

ITEM PART NO. QTY. DESCRIPTION

02977718 1 6’ KNIFE BAR ASY, LH WING

1 02982752 25 SERRATED KNIFE SECTION

2 0189900 1 KNIFE PROTECTOR, CARDBOARD 63"

3 02974316 1 INSERT NYLON DRIVE BRG CLAMP

4 02974349 1 KNIFE HEAD WLD’MT

00756328 1 BOLT

5 02976270 43 SECTION BOLT

6 02976271 7 HEAD BOLT

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -47

Page 52

KNIFE BAR - 6 FT LH WG - PN 02977718 - W/ SERRATED KNIVES

Continued...

ITEM PART NO. QTY. DESCRIPTION

7 02976272 50 LOCKNUT

8 0531900 1 BACKING STRIP, 6’

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -48

Page 53

SHOE & BRK-A-WAY PRE-ASY RH MOUNT - PN 02975986

ITEM PART NO. QTY. DESCRIPTION

02975986 1 SHOE & BRK-A-WAY PRE-ASY RH MOUNT

1 00011100 1 FLATWASHER

2 03101646 1 LOCKWASHER

3 00002000 1 BOLT

5 03200250 1 RUBBER BUMPER PAD

6 02974363 6 WASHER

7 00019600 1 LOCKWASHER

8 00019300 1 BOLT

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -49

Page 54

SHOE & BRK-A-WAY PRE-ASY RH MOUNT - PN 02975986

Continued...

NOTE:THIS ITEM IS SPRING LOADED AT THE FACTORY. ALL OTHER PARTS NOT LISTED ARE NOT AVAILABLE FOR INDIVIDUAL SALE. DO NOT

ATTEMPT TO REMOVE ANY PART FROM THIS ASSEMBLY OTHER THAN THE SHOWN LISTED PARTS.

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -50

Page 55

SHOE & BRK-A-WAY PRE-ASY LH MOUNT - PN 02977726

ITEM PART NO. QTY. DESCRIPTION

02977726 1 SHOE & BRK-A-WAY PRE-ASY LH MOUNT

1 00011100 1 FLATWASHER

2 03101646 1 LOCKWASHER

3 00002000 1 BOLT

5 03200250 1 RUBBER BUMPER PAD

6 02974363 6 WASHER

7 00019600 1 LOCKWASHER

8 00019300 1 BOLT

NOTE:THIS ITEM IS SPRING LOADED AT THE FACTORY. ALL OTHER PARTS NOT LISTED ARE NOT AVAILABLE FOR INDIVIDUAL SALE. DO NOT

ATTEMPT TO REMOVE ANY PART FROM THIS ASSEMBLY OTHER THAN THE SHOWN LISTED PARTS.

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -51

Page 56

THIS PAGE INTENTIONAL LEFT BLANK

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -52

Page 57

SHOE, DRIVE & BRK-A-WAY ASY RH MOUNT - PN 02975194

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -53

Page 58

SHOE, DRIVE & BRK-A-WAY ASY RH MOUNT - PN 02975194

Continued...

ITEM PART NO. QTY. DESCRIPTION

02975194 1 ASY SHOE DRIVE SPRING BRKWY

1 00000200 5 NUT 3/4 NC HEX PL

2 00001200 1 NUT 1/2 NC HEX PL

3 00001800 8 LOCKNUT TLM 1/2 NC PLB

5 00002701 2 FLATWASHER,3/4,TYPE AW,ZP

6 00011100 2 FLATWASHER STD 3/8

7 00015800 2 LOCKNUT TLM 3/8-NC PLC

8 5C8130 1 HEXNUT 1/2 JAM ZP

9 000206 3 NO. 2 RED LUBRICAPS<

11 02974343 2 TUBE 1-1/4 OD X 9/16 ID X3-3/4

12 00749130 2 HHCS 1/2-13UNC 1-3/4 PL5

13 02974344 1 SOLE SKID SHOE

14 00752670 1 FITTING,GREASE STRAIGHT 1/4-28

15 00753642 2 HEXB 3/8 NC X 1-1/4 PL5

16 02974354 1 SPACER CUTTER BAR

17 02974358 1 ROD DEFLECTOR

18 02042300 2 ADP HYD STGHT 10MB-8MJ

19 02931300 3 HHCS,3/4NC X 2,ZP,GRD5

20 02972570 3 LOCKWASHER 3/4 PL STD

21 02974300A 1 ASY HORIZ KNIFE DRV 1"X1/4"KEY

22 02974301A 1 MOTOR GEROTOR 2.8CID 1"X1/4"KY

23 02976853 4 PLOW BOLT #3 1/2 NC 2-1/2 PL8

24 02976854 4 PLOW BOLT #3 1/2 NC 7 PL8

25 02974313 1 BRACKET HYDRAULIC MOTOR ADAPTR

26 02974342 2 TUBE 1-1/4 OD X 9/16 ID X4-5/8

27 02975986 1 PREASY SKIDSHOE & BREAKAWAY

28 02988071 2 FLANGE NUT, 1/2" NC

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -54

Page 59

SHOE, DRIVE & BRK-A-WAY ASY LH MOUNT - PN 02977727

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -55

Page 60

SHOE, DRIVE & BRK-A-WAY ASY LH MOUNT - PN 02977727

Continued...

ITEM PART NO. QTY. DESCRIPTION

02977727 1 ASY LH SHOE DRIVE SPRING BRKWY

1 00000200 5 NUT 3/4 NC HEX PL

2 00001200 1 NUT 1/2 NC HEX PL

3 00001800 8 LOCKNUT TLM 1/2 NC PLB

5 00002701 2 FLATWASHER,3/4,TYPE AW,ZP

6 00011100 2 FLATWASHER STD 3/8

7 00015800 2 LOCKNUT TLM 3/8-NC PLC

8 5C8130 1 HEXNUT 1/2 JAM ZP

9 000206 3 NO. 2 RED LUBRICAPS<

11 02974343 2 TUBE 1-1/4 OD X 9/16 ID X3-3/4

12 00749130 2 HHCS 1/2-13UNC 1-3/4 PL5

13 02974344 1 SOLE SKID SHOE

14 00752670 1 FITTING,GREASE STRAIGHT 1/4-28

15 00753642 2 HEXB 3/8 NC X 1-1/4 PL5

16 02974354 1 SPACER CUTTER BAR

17 02977740 1 ROD LH DEFLECTOR

18 02042300 2 ADP HYD STGHT 10MB-8MJ

19 02931300 3 HHCS,3/4NC X 2,ZP,GRD5

20 02972570 3 LOCKWASHER 3/4 PL STD

21 02974300A 1 ASY HORIZ KNIFE DRV 1"X1/4"KEY

22 02974301A 1 MOTOR GEROTOR 2.8CID 1"X1/4"KY

23 02976853 4 PLOW BOLT #3 1/2 NC 2-1/2 PL8

24 02976854 4 PLOW BOLT #3 1/2 NC 7 PL8

25 02974313 1 BRACKET HYDRAULIC MOTOR ADAPTR

26 02974342 2 TUBE 1-1/4 OD X 9/16 ID X4-5/8

27 02977726 1 PREASY LH SKID SHOE & BREAKAWY

28 02988071 2 FLANGE NUT, 1/2" NC

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -56

Page 61

WIRING HARNESS - DUAL WG - PN 02977754

ITEM PART NO. QTY. DESCRIPTION

02977754 1 WIRE HARNESS LH DUAL WING

2 02965731 1 FUSE 10 AMP, TYPE ATO

NOTE:TOGGLE SWITCH IS SHOWN FOR ILLUSTRATION ONLY AND IS NOT INCLUDED WITH WIRE HARNESS. THIS WIRE HARNESS IS ONLY USED

WHEN LH WING IS MOUNTED. IT DOES NOT REPLACE THE RH HARNESS BUT IS USED WITH IT.

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -57

Page 62

WIRING HARNESS - SINGLE WG - PN 02974318

ITEM PART NO. QTY. DESCRIPTION

02974318 1 WIRE HARNESS SINGLE WING

1 002504 2 CONNECTOR, COIL-HRSCHMANN TYPE

2 02965731 1 FUSE 10 AMP, TYPE ATO

NOTE:THIS WIRE HARNESS IS USED WITH A RH WING MOWER, WIRE HARNESS WILL NOT INCLUDE PUSH PULL SWITCH OR TOGGLE SWITCH. IF

LH WING IS USED THIS WIRE HARNESS WILL STILL BE USED AND THE LH WING HARNESS WILL ALSO BE USED.

Switchblade 5`and 6` Spring-Brk-a-way (11-06) Rev 08-11

©2011 Alamo Group Inc. Parts Section -58

Page 63

Page 64

TO THE OWNER/OPERATOR/DEALER

To keep your implement running efciently and safely, read your manuals thoroughly and follow these directions and

the Safety Messages in this Manual. The Table of Contents clearly identies each section where you can easily nd the

information you need.

The OCCUPATIONAL SAFETY AND HEALTH ACT (1928.51 Subpart C) makes these minimum safety requirements of

tractor operators:

REQUIRED OF THE OWNER

1. Provide a Roll-Over-Protective Structure that meets the requirements of this standard.

2. Provide seat belts that meet the requirements of this paragraph of this standard and SAE J4C.

3. Ensure that each employee uses such seat belt while the tractor is moving.

4. Ensure that each employee tightens the seat belt sufciently to conne the employee to the

protected area provided by the ROPS.

REQUIRED OF THE OPERATOR

1. Securely fasten seat belt if the tractor has a ROPS.

2. Where possible, avoid operating the tractor near ditches, embankments, and holes.

3. Reduce speed when turning, crossing slopes, and on rough, slick, or muddy surfaces.

4. Stay off slopes too steep for safe operation.

5. Watch where you are going, especially at row ends, on roads, and around trees.

6. Do not permit others to ride.

7. Operate the tractor smoothly, no jerky turns, starts, or stops.

8. Hitch only to the draw bar and hitch points recommended by the tractor manufacturer.

9. When the tractor is stopped, set brakes securely and use park lock, if available.

Keep children away from danger all day, every day...

Equip tractors with rollover protection (ROPS) and keep all machinery guards

in place...

Please work, drive, play and live each day with care and concern for your safety

and that of your family and fellow citizens.

Page 65

ALAMO INDUSTRIAL

Limited Warranty

1. Limited Warranties

1.01. Alamo industrial warrants for one year from the purchase date to the original non-commercial, governmental, or municipal purchaser

(“purchaser”) and warrants for six months to the original commercial or industrial purchaser (“purchaser”) that the goods purchased

are free from defects in material or workmanship.

1.02. Manufacturer will replace for the purchaser any part or parts found, upon examination at one of its factories, to be defective under

normal use and service due to defects in material or workmanship.

1.03. This limited warranty does not apply to any part of the goods which has been subjected to improper or abnormal use, negligence,

alteration, modication, or accident, damaged due to lack of maintenance or use of wrong fuel, oil, or lubricants, or which has served

its normal life. This limited warranty does not apply to any part of any internal combustion engine, or expendable items such as blades,

shields, guards, or pneumatic tires except as specically found in your operator’s manual.

1.04. Except as provided herein, no employee, agent, dealer, or other person is authorized to give any warranties of any nature on behalf

of manufacturer.

2. Remedies And Procedures

2.01. This limited warranty is not effective unless the purchaser returns the registration and warranty form to manufacturer within 30 days of

purchase.

2.02. Purchaser claims must be made in writing to the authorized dealer (“dealer”) from whom purchaser purchased the goods or an approved

authorized dealer (“dealer”) within 30 days after purchaser learns of the facts on which the claim is based.

2.03. Purchaser is responsible for returning the goods in question to the dealer.

2.04. If after examining the goods and/or parts in question, manufacturer nds them to be defective under normal use and service due to

defects in material or workmanship, manufacturer will:

(A) repair or replace the defective goods or part(s) or

(B) reimburse purchaser for the cost of the part(s) and reasonable labor charges (as determined by manufacturer) if purchaser

paid for the repair and/or replacement prior to the nal determination of applicability of the warranty by manufacturer. The choice of

remedy shall belong to manufacturer.

2.05. Purchaser is responsible for any labor charges exceeding a reasonable amount as determined by manufacturer and for returning the

goods to the dealer, whether or not the claim is approved. Purchaser is responsible for the transportation cost for the goods or part(s)

from the dealer to the designated factory.

3. Limitation Of Liability

3.01. Manufacturer disclaims any express (except as set forth herein) and implied warranties with respect to the goods including, but not

limited to, merchantability and tness for a particular purpose.

3.02. Manufacturer makes no warranty as to the design, capability, capacity, or suitability for use of the goods.

3.03. Except as provided herein, manufacturer shall have no liability or responsibility to purchaser or any other person or entity with respect

to any liability, loss, or damage caused or alleged to be caused directly or indirectly by the goods including, but not limited to, any

indirect, special, consequential, or incidental damages resulting from the use or operation of the goods or any breach of this warranty.

Not withstanding the above limitations and warranties, manufacturer’s liability hereunder for damages incurred by purchaser or others

shall not exceed the price of the goods.

3.04. No action arising out of any claimed breach of this warranty or transactions under this warranty may be brought more than two (2)

years after the cause of action has occurred.

4. Miscellaneous

4.01. Proper venue for any lawsuits arising from or related to this limited warranty shall be only in Guadalupe county, Texas.

4.02. Manufacturer may waive compliance with any of the terms of this limited warranty, but no waiver of any terms shall be deemed to be

a waiver of any other term.

4.03. If any provision of this limited warranty shall violate any applicable law and is held to be unenforceable, then the invalidity of such

provision shall not invalidate any other provisions herein.

4.04. Applicable law may provide rights and benets to purchaser in addition to those provided herein.

Keep for your records

Attention: Purchaser should ll in the blanks below for his reference when buying repair parts and/or for proper machine identication

Alamo Industrial Implement Model ____________________________ Serial Number ________________________________

Date Purchased __________________________________________ Dealer ______________________________________

Attention:

Read your operator’s manual

when applying for warranty.

ALAMO INDUSTRIAL

1502 E. Walnut

Seguin, Texas 78155

830-379-1480

Page 66

Switch Blade 5 ft. & 6 ft (02/05) P/N 02974374P

Loading...

Loading...