Page 1

®

®

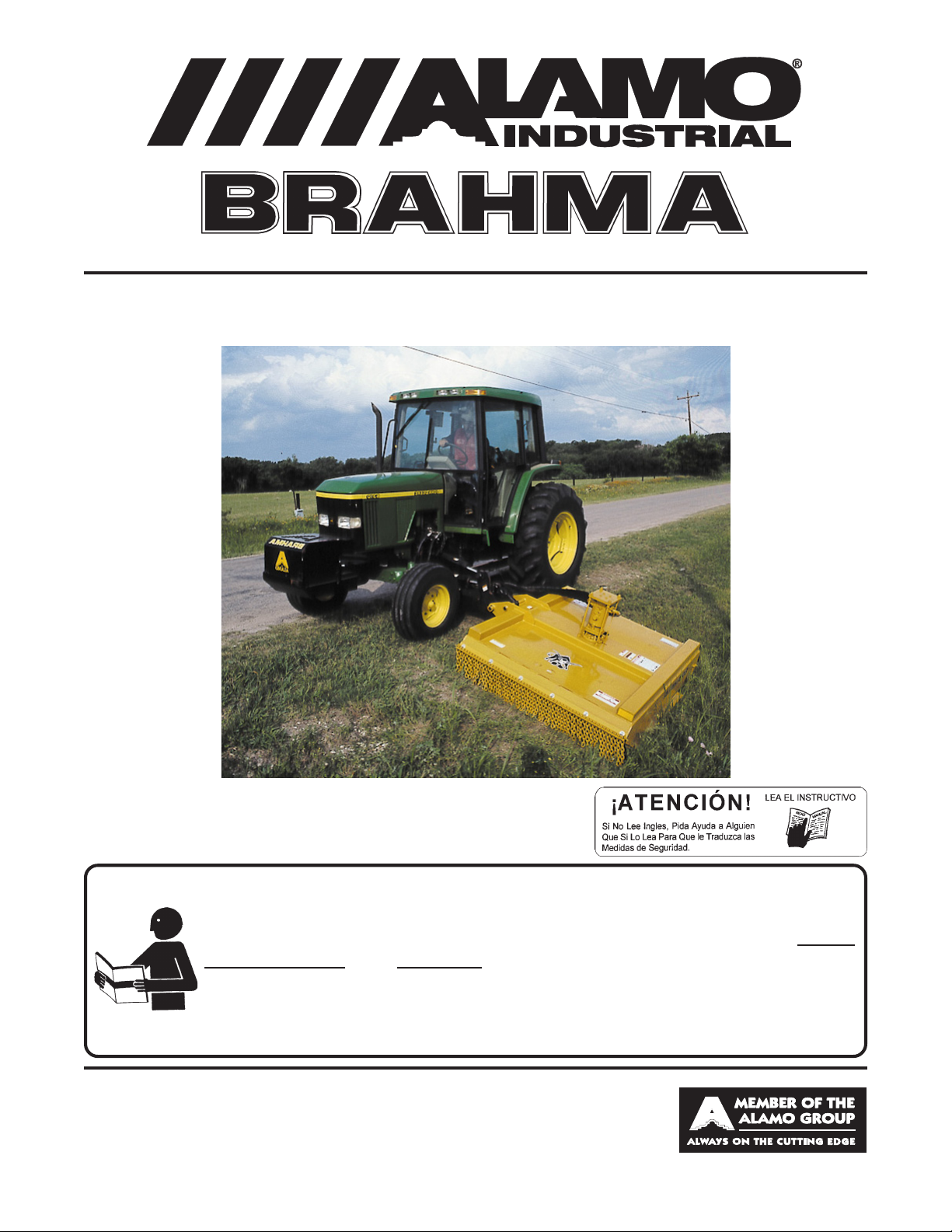

BOOM ARM MOWER

Rev 08-07 Part No. 02968822P

PART'S MANUAL

An Operator's Manual was shipped with the equipment in the Manual

Canister. This Operator's Manual is an integral part of the safe operation of

this machine and must be maintained with the unit at all times. READ,

UNDERSTAND, and FOLLOW the Safety and Operation Instructions

contained in this manual before operating the equipment. If the Operator's

Manual is not with the equipment, contact your dealer or Servis-Rhino (800446-5158) to obtain a Free copy before operating the equipment.

ALAMO INDUSTRIAL

1502 E. Walnut

Seguin, Texas 78155

210-372-3551

© 2007 Alamo Group Inc.

Page 2

TO THE OWNER/OPERATOR/DEALER

RED

RED

002369

*

*

LOCK UP.

5. TRANSPORT SAFELY,

6. USE SMV, LIGHTS, &

REFLECTORS.

7. DO NOT OPERATE WITH

MOWER OR WING RAISED.

8. DO NOT MOUNT OR

DISMOUNT WHILE MOVING.

4. BLOCK UP SECURELY

BEFORE WORKING UNDER.

3. USE SAFETY SHOES,HARD

HAT, SAFETY GLASSES,

SEAT BELTS, & ROPS.

2. NO RIDERS, NO CHILDREN

OPERATORS.

1.

MANUAL

READ

Never mount or dismount a moving vehicle. Crushing from runover may cause injury or death.

Put tractor in park or set brake, disengage PTO, stop engine, remove key, and wait until noise of rotation has ceased

to prevent entanglement in rotating parts which may cause injury or death.

8. Before dismounting, secure flail mower in transport position or lower to ground.

7. Never operate with Flail Mower or Folding Section raised if passersby, bystandards or traffic are in the area to reduce

possibility of injury or death from objects thrown by Blades under Shields or implement structure.

6. Make certain that SMV sign, Warning Lights, and Reflectors are clearly visible. Follow local traffic codes.

Install Restrictor in folding circuit to slow down lowering and unfolding if action is faster than is desirable.

5. Before transporting, put Lift Lever in detent or full-lift position. Install Transport Safety Devices securely on folding

implements. Slowdown when turning and on hillsides.

4. Block up or support raised machine and all lifted components securely before putting hands or feet under or working

underneath any lifted component to prevent crushing injury or death from sudden dropping or inadvertent operation of

controls. Make certain that area is clear before lowering or folding.

3. Operate only with tractor having Roll-Over Protective Structure (ROPS) and with seatbelt fastened securely and

snugly to prevent injury and possible death from falling off or tractor overturn. Personal Protective Equipment such as

Hard Hat, Safety Glasses, Safety Shoes, and Ear Plugs are recommended.

2. Allow no children on or near implement of tractor. Allow no riders on tractor or implement. Falling off can cause

serious injury or death from being runover by tractor or mower or contact with Flail Mower Blades.

Learn how to stop engine suddenly in an emergency. Be alert for passersby and especially children.

1. Study and understand Operator's Manuals, Safety Signs, and Instructional Decals for tractor & flail mower to prevent

misuse, abuse, & accidents. Practice before operating mower in a confined area or near passersby.

FAILING TO FOLLOW SAFETY MESSAGES AND OPERATING INSTRUCTIONS CAN CAUSE

SERIOUS BODILY INJURY OR EVEN DEATH TO OPERATOR AND OTHERS IN THE AREA.

DANGER

All implements with moving parts are potentially hazardous. There is no substitute for a cautious, safe-minded operator who

recognizes the potential hazards and follows reasonable safety practices. The manufacturer has designed this implement to

be used with all its safety equipment properly attached to minimize the chance of accidents.

BEFORE YOU START!! Read the safety messages on the implement and shown in your manual.

Observe the rules of safety and common sense!

FAILING TO FOLLOW SAFETY MESSAGES AND OPERATING INSTRUCTIONS CAN CAUSE

SERIOUS BODILY INJURY OR EVEN DEATH TO OPERATOR AND OTHERS IN THE AREA.

2. NO RIDERS, NO CHILDREN

3. USE SAFETY SHOES,HARD

HAT, SAFETY GLASSES,

SEAT BELTS, & ROPS.

4. BLOCK UP SECURELY

BEFORE WORKING UNDER.

1. Study and understand Operator's Manuals, Safety Signs, and Instructional Decals for tractor & flail mower to prevent

misuse, abuse, & accidents. Practice before operating mower in a confined area or near passersby.

Learn how to stop engine suddenly in an emergency. Be alert for passersby and especially children.

2. Allow no children on or near implement of tractor. Allow no riders on tractor or implement. Falling off can cause

serious injury or death from being runover by tractor or mower or contact with Flail Mower Blades.

3. Operate only with tractor having Roll-Over Protective Structure (ROPS) and with seatbelt fastened securely and

snugly to prevent injury and possible death from falling off or tractor overturn. Personal Protective Equipment such as

Hard Hat, Safety Glasses, Safety Shoes, and Ear Plugs are recommended.

4. Block up or support raised machine and all lifted components securely before putting hands or feet under or working

underneath any lifted component to prevent crushing injury or death from sudden dropping or inadvertent operation of

controls. Make certain that area is clear before lowering or folding.

5. Before transporting, put Lift Lever in detent or full-lift position. Install Transport Safety Devices securely on folding

implements. Slowdown when turning and on hillsides.

Install Restrictor in folding circuit to slow down lowering and unfolding if action is faster than is desirable.

6. Make certain that SMV sign, Warning Lights, and Reflectors are clearly visible. Follow local traffic codes.

7. Never operate with Flail Mower or Folding Section raised if passersby, bystandards or traffic are in the area to reduce

possibility of injury or death from objects thrown by Blades under Shields or implement structure.

8. Before dismounting, secure flail mower in transport position or lower to ground.

Put tractor in park or set brake, disengage PTO, stop engine, remove key, and wait until noise of rotation has ceased

to prevent entanglement in rotating parts which may cause injury or death.

Never mount or dismount a moving vehicle. Crushing from runover may cause injury or death.

5. TRANSPORT SAFELY,

6. USE SMV, LIGHTS, &

LOCK UP.

7. DO NOT OPERATE WITH

MOWER OR WING RAISED.

8. DO NOT MOUNT OR

DISMOUNT WHILE MOVING.

WARRANTY INFORMATION:

Read and understand the complete Warranty Statement found in this Manual. Fill out the Warranty Registration Form

in full and return it within 30 Days. Make certain the Serial Number of the Machine is recorded on the Warranty Card

and on the Warranty Form that you retain. The use of "will-fit" parts will void your warranty and can cause

catastrophic failure with possible injury or death.

Page 3

PARTS

SECTION

Parts Section – 1

Page 4

PARTS ORDERING GUIDE

®

®

The following instructions are offered to help eliminate needless delay and error in

processing purchase orders for the equipment in this section.

1. The Parts Section is prepared in logical sequence and grouping of parts that belong to

the basic machine featured in this manual. Part Numbers and Descriptions are given to

help locate the parts and quantities required.

2. The Purchase Order must include the name and address of the person or organization

ordering the parts, who should be charged, and if possible, the serial number of the machine

for which the parts are ordered.

3. The Purchase Order must clearly list the quantity of each part, the complete and correct

part number (be sure to include all periods), and the basic name of the part.

4. The Manufacturer reserves the right to substitute parts where applicable.

5. Some parts are unlisted items which are special production items not normally stocked

and are subject to special handling. Request a quotation for such parts before sending a

Purchase Order.

6. The Manufacturer reserves the right to change prices without prior notice.

NOTE: Please refer to The Safety Section in the front of this Manual for the proper

Part Number when ordering Replacement Safety Decals.

For maximum safety and to guarantee optimum product reliability, always use

genuine Servis-Rhino Parts. The use of inferior replacement parts may cause

premature or catastrophic failure which could result in serious injury or death.

Direct any questions regarding parts to:

ALAMO INDUSTRIAL

1502 E. Walnut

Seguin, Texas 78155

830-379-1480

©2007 Alamo Group Inc.

Parts Section – 2

Page 5

PART NAME INDEX

BEARING ASY - 1500 FLAIL HEAD......................................................................................................................................................... 4

BEARING ASY - 2000 FLAIL HEAD......................................................................................................................................................... 5

BLADE CARRIER ASY - BAR PN 02965737............................................................................................................................................ 6

BLADE CARRIER ASY - PAN PN 02964456............................................................................................................................................ 7

CHAIN GUARD ASY - FRONT (DEEP DECK) PN 02965797................................................................................................................. 8

COMMON BOX PARTS PN 02969093..................................................................................................................................................... 10

CONTROL VALVE ASY PN 02969613 SN 01241 (05-06) & DOWN.................................................................................................... 12

CONTROL VALVE ASY PN 02981363 SN 01242 (06-06) & UP........................................................................................................... 14

CYLINDER ASY - LIFT............................................................................................................................................................................ 16

CYLINDER ASY - TILT............................................................................................................................................................................ 17

FLAIL HEAD ASY PN 02968984 - 60 INCH PART 1 ............................................................................................................................ 18

FLAIL HEAD ASY PN 02968984 - 60 INCH PART 2............................................................................................................................. 20

FLAIL HEAD SUB-ASY 1500................................................................................................................................................................... 22

FLAIL HEAD SUB-ASY 2000................................................................................................................................................................... 24

GAUGE WHEEL - SIDE PN 02966070 (OPTIONAL)............................................................................................................................. 26

HYDRAULIC TANK SUB-ASY PN 02981211........................................................................................................................................ 27

MOTOR & SPINDLE ASY PN 02969096................................................................................................................................................. 28

MOTOR ASY - FLAIL HEAD................................................................................................................................................................... 30

MOUNTING ARM ASY PN 02979631..................................................................................................................................................... 32

OIL RESERVOIR ASY PN 02968168....................................................................................................................................................... 34

PULLEY ASY - FLAIL HEAD 1500 & 2000............................................................................................................................................ 36

ROLLER ASY - FLAIL HEAD 1500 & 2000............................................................................................................................................ 37

ROLLER ASY - ROTARY HEAD (OPTION) .......................................................................................................................................... 38

ROTARY HEAD - MOTOR ASY (PARTS) - PN 02979881 PART 1...................................................................................................... 40

ROTARY HEAD - MOTOR ASY (PARTS) - PN 02979881 PART 2...................................................................................................... 42

ROTARY HEAD ASY................................................................................................................................................................................ 44

ROTARY HEAD ASY (NEW STYLE) ..................................................................................................................................................... 46

ROTARY HEAD PRE-ASY (NEW STYLE)............................................................................................................................................. 48

ROTARY HEAD SUB-ASY ...................................................................................................................................................................... 50

ROTOR SHAFT ASY - FLAIL HEAD 60 INCH ...................................................................................................................................... 52

ROTOR SHAFT ASY - FLAIL HEAD 80 INCH ...................................................................................................................................... 53

SERVO CONTROLLED PISTON PUMP ASY PN 02969527A PART 1................................................................................................ 54

SERVO CONTROLLED PISTON PUMP ASY PN 02969527A PART 2................................................................................................ 56

SPINDLE & HOUSING ASY PN 02960553B........................................................................................................................................... 58

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -3

Page 6

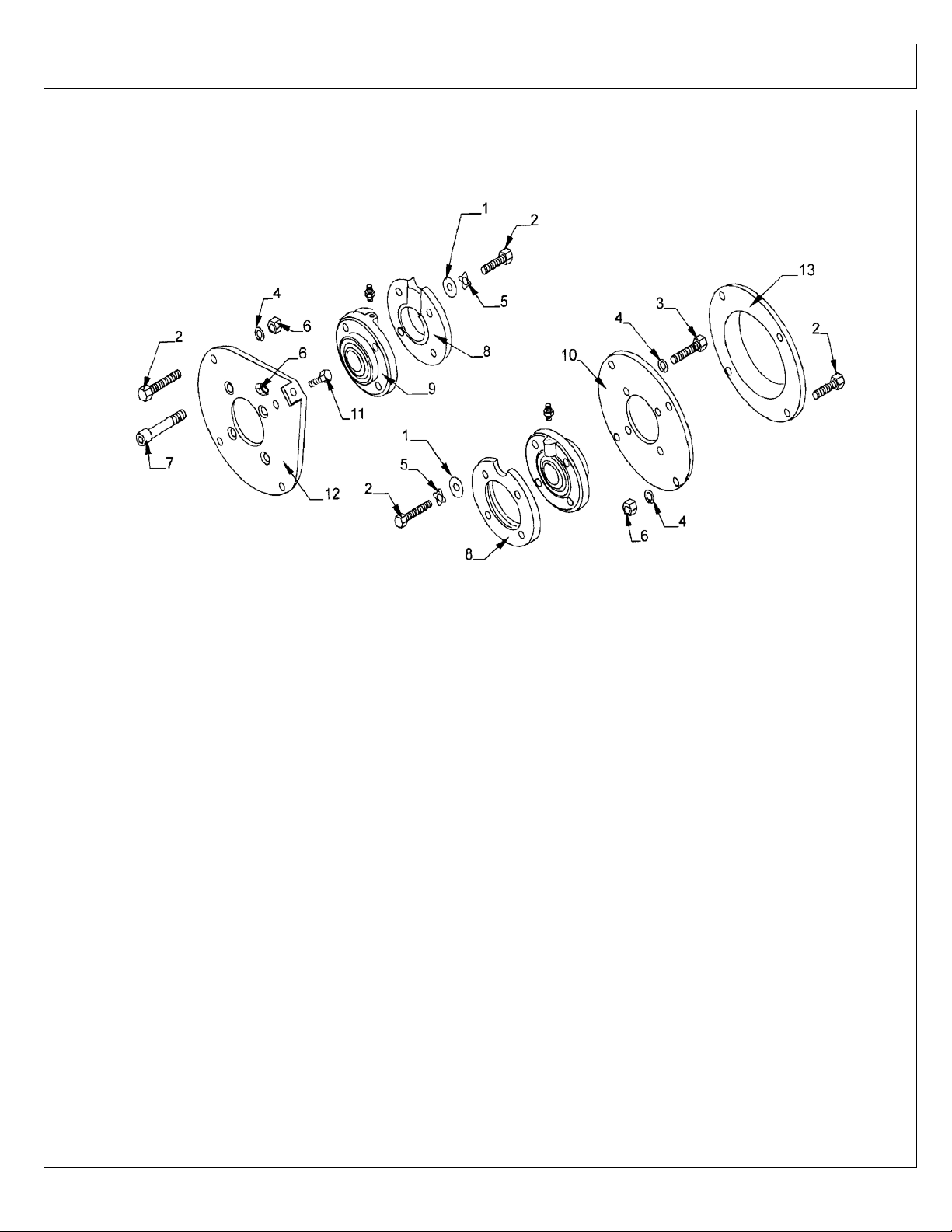

BEARING ASY - 1500 FLAIL HEAD

ITEM PART NO. QTY. DESCRIPTIONITEM PART NO. QTY. DESCRIPTION

1 02.824.01 2 WASHER

2 05.264.23 10 SETSCREW

3 05.264.25 4 SETSCREW

4 05.282.03 12 SPRING WASHER

5 05.283.03 2 SHAKEPROOF WASHER

6 05.286.03 10 NUT

7 05.345.05 4 SOCKET CSK SCREW

8 06.219.01 2 DISC-SHIELD

9 06.221.01 2 BEARING ASY. ( DRIVE OR NON-DRIVE END )

10 09.584.01 1 BEARING PLATE-NON DRIVE

11 09.585.01 1 ADJUSTING-BOLT

12 09.586.01 1 BEARING PLATE-DRIVE END

13 09.588.01 1 GUARD - NON DRIVE

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -4

Page 7

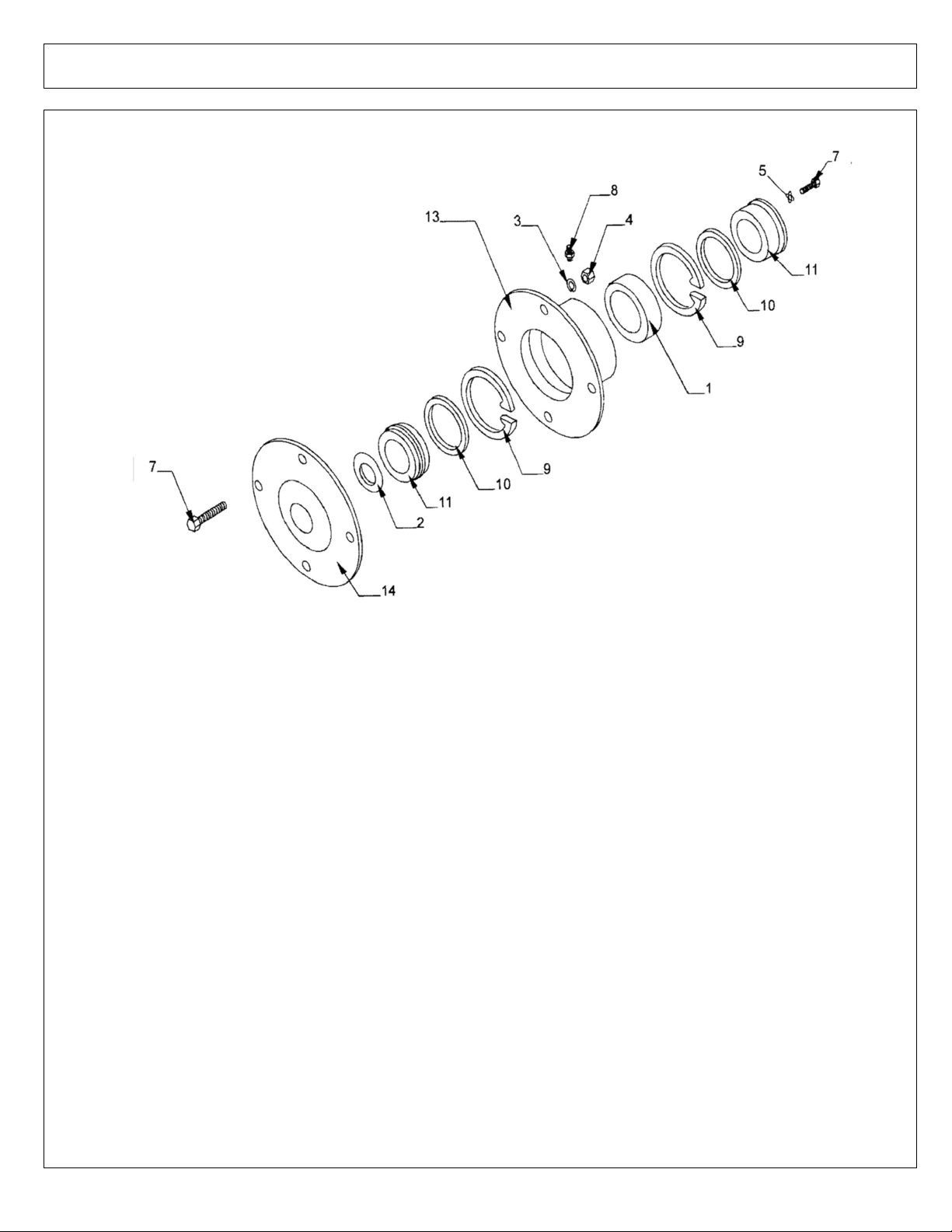

BEARING ASY - 2000 FLAIL HEAD

ITEM PART NO. QTY. DESCRIPTIONITEM PART NO. QTY. DESCRIPTION

1 04.163.04 2 BEARING

2 04.252.01 2 WASHER

3 05.282.03 8 SPRING WASHER

4 05.286.03 10 NUT

5 05.283.04 2 WASHER

6 05.264.23 4 SETSCREW

05.264.24 4 SETSCREW

7 05.264.33 2 SETSCREW

8 05.953.03 2 GREASE NIPPLE

9 05.959.07 4 CIRCLIP

10 06.909.01 4 SEAL

11 06.910.01 4 COLLAR

12 09.585.01 1 ADJUSTING BOLT

13 41456.01 1 HOUSING

41457.01 1 HOUSING

14 41461.01 1 GUARD

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -5

Page 8

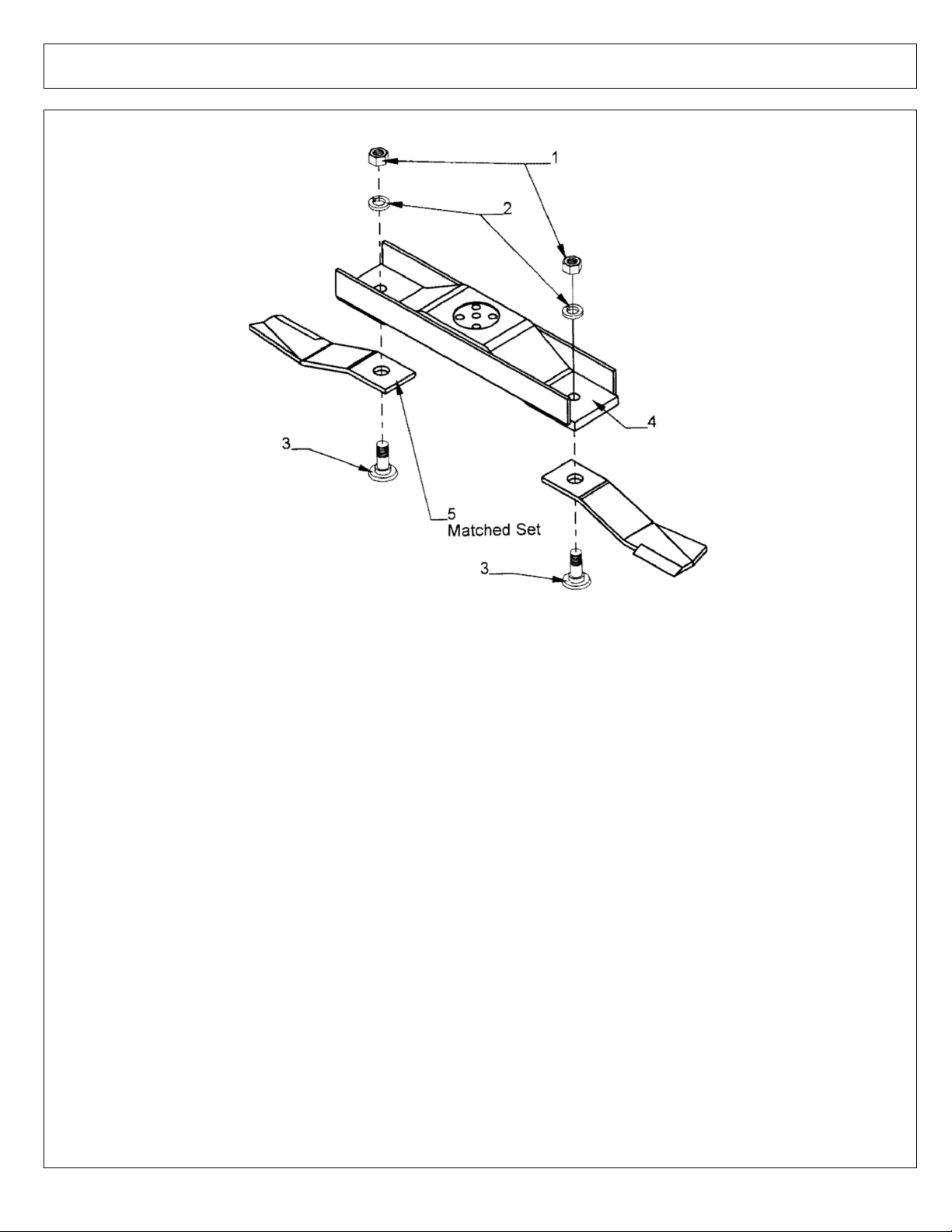

BLADE CARRIER ASY - BAR PN 02965737

ITEM PART NO. QTY. DESCRIPTIONITEM PART NO. QTY. DESCRIPTION

02965737 1 BLADE BAR ASY

1 00747900 2 HEX NUT

2 00748000 2 HEAVY LOCKWASHER

3 00752827 2 BLADE BOLT ( TORQUE TO 600 FT LBS )

4 02965579 1 BLADE BAR WLD’MT

5 02966262 1 BLADES ( MATCHED SET )

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -6

Page 9

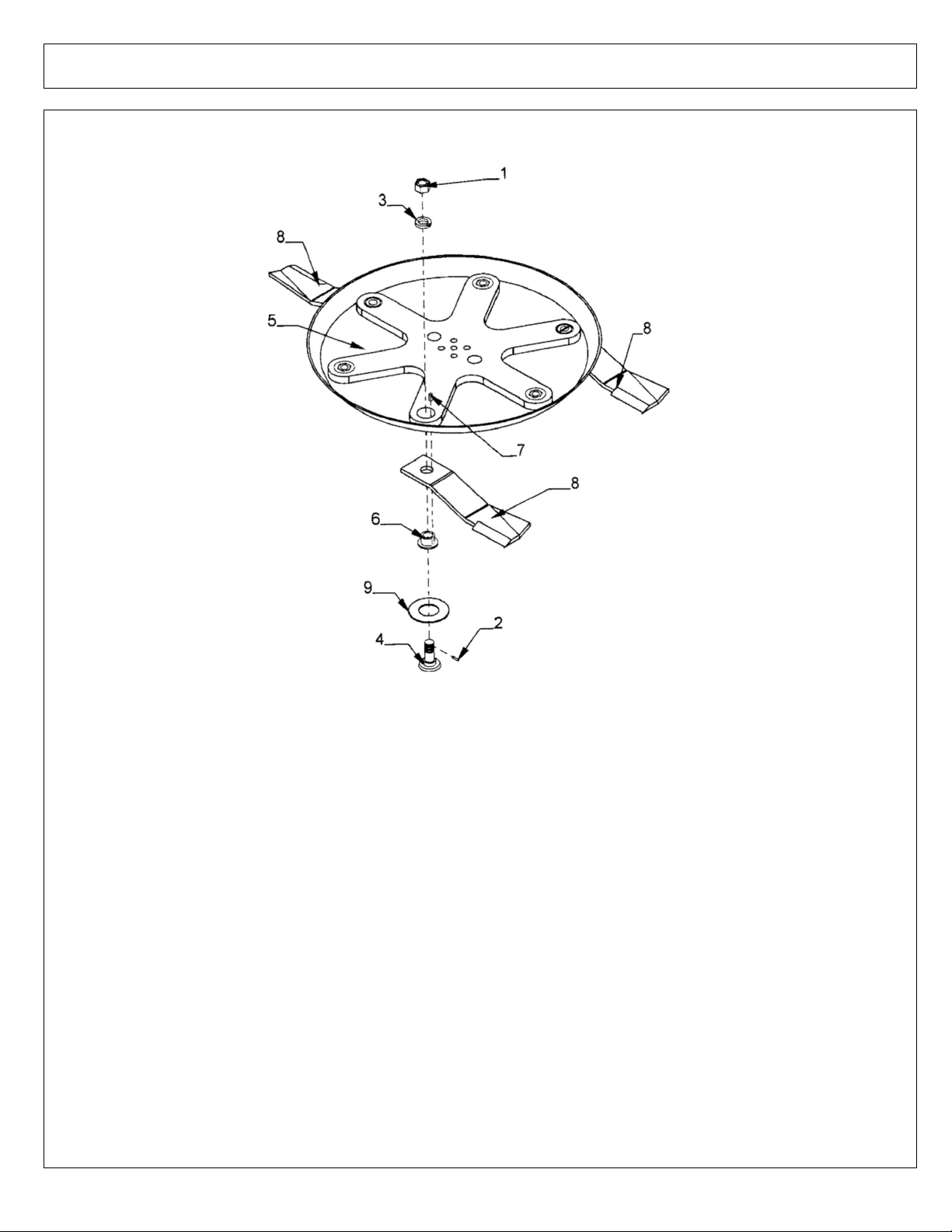

BLADE CARRIER ASY - PAN PN 02964456

ITEM PART NO. QTY. DESCRIPTIONITEM PART NO. QTY. DESCRIPTION

02964456 1 BLADE PAN ASY. W/ BLADES

1 00020900 3 SLOTTED NUT

2 00023200 3 ROLL PIN

3 00755623 3 WASHER

4 02964330 3 KEYED BLADE BOLT ( TORQUE TO 600 FT LBS )

5 02964804 1 BLADE PAN ASY. W/O BLADES

6 02964815 3 BLADE BOLT BUSHING

7 02964954 3 KEY

8 02964960 1 BLADES ( MATCHED SET )

9 02965229 3 WEAR WASHER

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -7

Page 10

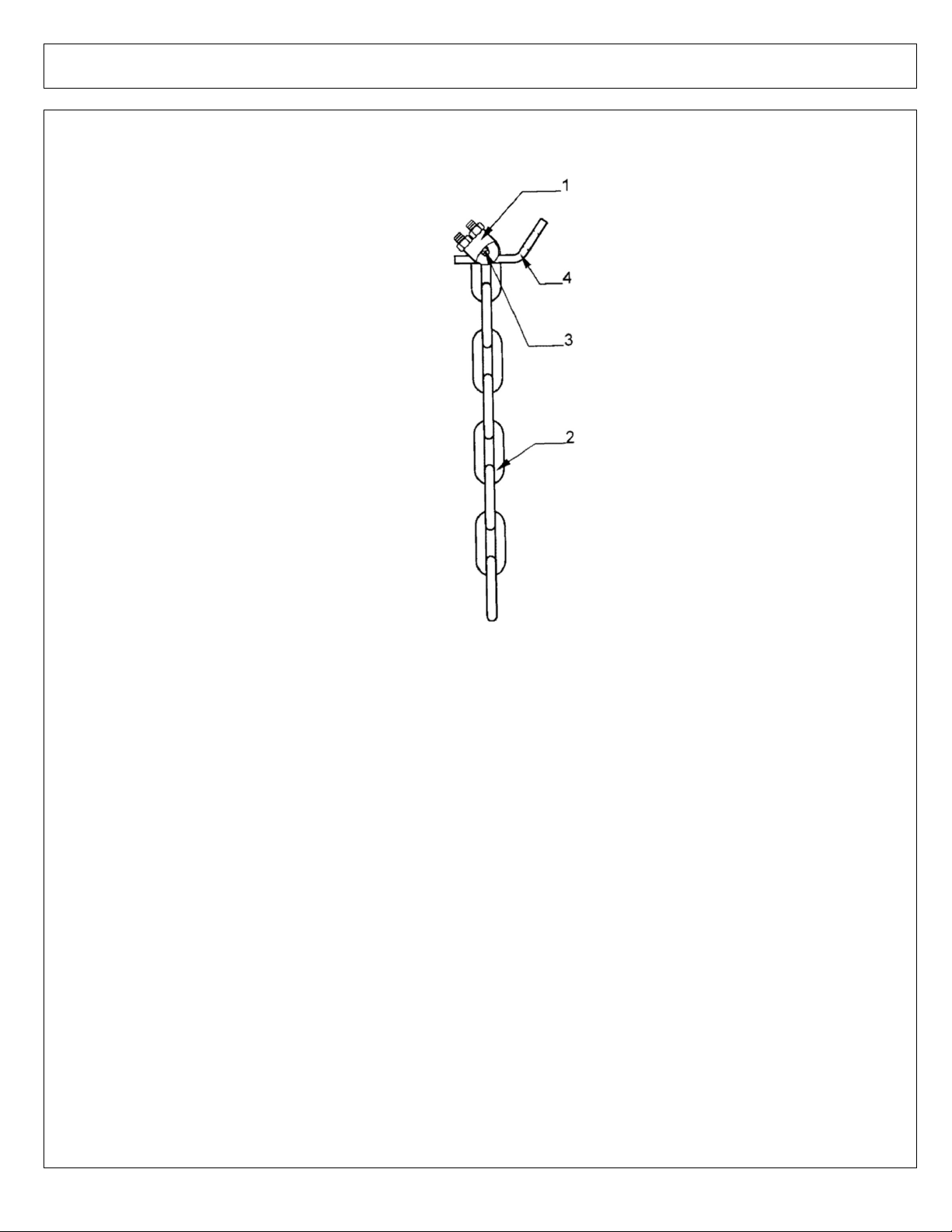

CHAIN GUARD ASY - FRONT (DEEP DECK) PN 02965797

ITEM PART NO. QTY. DESCRIPTIONITEM PART NO. QTY. DESCRIPTION

1 00001000 4 CABLE CLAMP

2 00751127 71 CHAIN 5/16 WLD 8 LINK ZINC PL

3 00992000 11 CABLE, 1/4 GA AIRCRAFT (7X19)

4 02979119 1 BRKT,CHAIN GUARD DEEP DECK

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -8

Page 11

THIS PAGE INTENTIONAL LEFT BLANK

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -9

Page 12

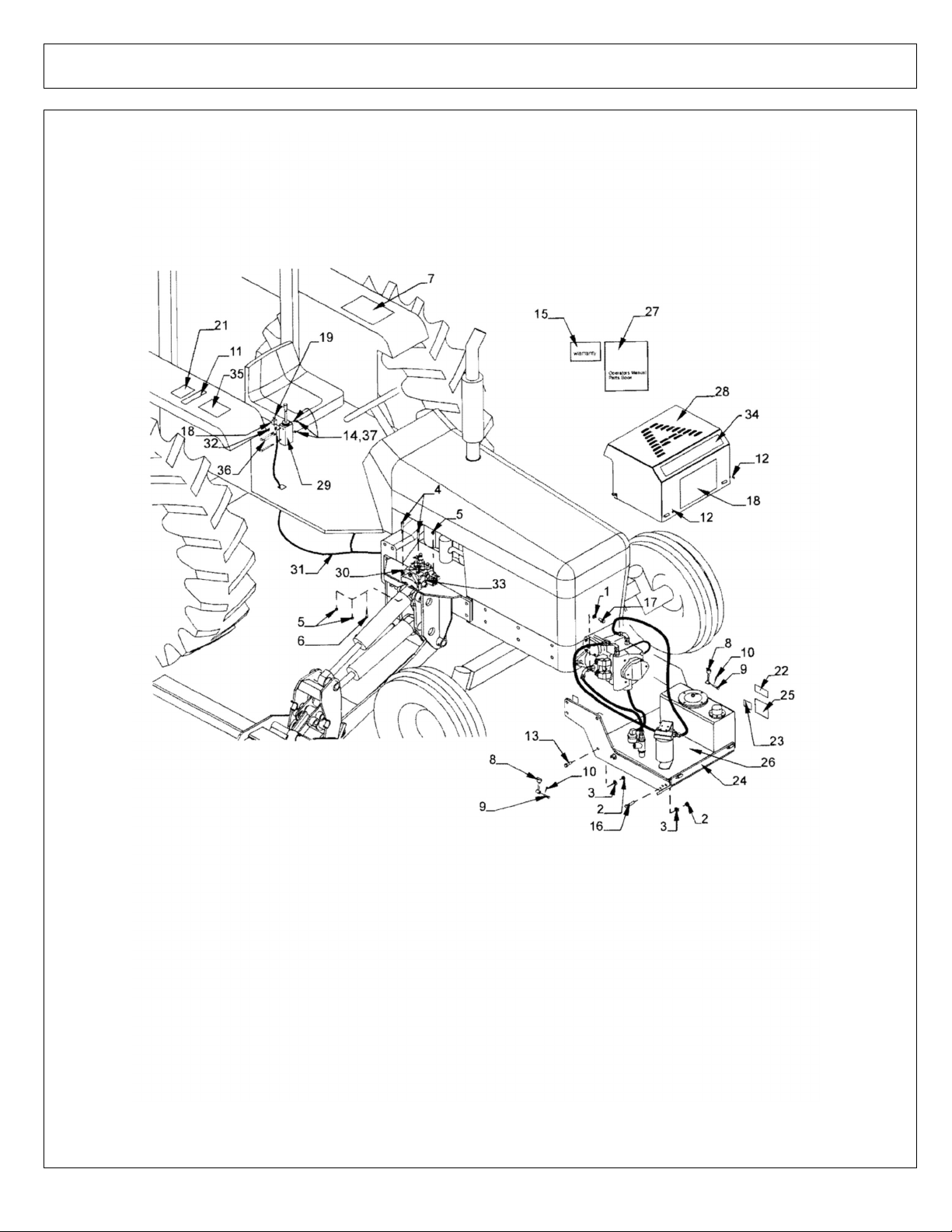

COMMON BOX PARTS PN 02969093

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -10

Page 13

COMMON BOX PARTS PN 02969093

ITEM PART NO. QTY. DESCRIPTION

02969093 1 COMMON BOX, BRAHMA

1 00001300 2 LOCKWASHER

2 00001800 8 LOCKNUT

3 00002700 8 FLATWASHER

5 00750940 3 NUT

6 00016300 3 BOLT

7 002369 1 DECAL, DANGER MULTI-HAZARD - FLAIL

02967827 1 DECAL, DANGER MULTI-HAZARD - ROTARY

8 00725336 2 STRAP

9 00725337 2 PIN

10 00725338 2 COTTER PIN

11 00725746 1 DECAL, SPANISH TRANSLATION

12 00726119 2 BRASS WASHER, SPECIAL

13 00748823 2 BOLT

14 00750940 6 LOCKNUT

15 00763504 1 ALAMO, WARRANTY CARD

16 02027400 6 BOLT

17 02776600 2 BOLT

18 02963201 1 DECAL, AG LOGO

19 02964028 1 PUSH-PULL SWITCH

20 02964063 1 SWITCH KNOB

21 02965093 1 DECAL, PROPER ENGINE RPM

22 02965262 1 DECAL, WARNING HOSE BURST

23 02979473 1 DECAL, AW ISO VG100 TRACTER HYD.FLUID

24 02966634 1 BUMPER WLD’MT

25 03200437 1 DECAL, PRESSURIZED TANK

26 02981212 1 OIL RESERVOIR ASY - BRAHMA

27 02968822 1 PARTS & OPERATORS MANUAL

28 02969032 1 TANK & PUMP COVER WLD’MT

29 02969128 1 DUAL AXIS - JOYSTICK

29A 02974119 1 BALL JOINT PIVOT - PLASTIC BALL (NOT SHOWN ))

29B 02974120 1 BALL JOINT PIVOT - DIE CAST METAL (NOT SHOWN )

30 02971274 2 CABLE CONNECTION KIT

31 02970204 1 PUMP SOLENOID - WIRE HARNESS (INCLUDES ITEM 32)

32 02969741 1 FUSE (REFERENCE ONLY)

33 02981363 1 2 SPOOL VALVE ASY - BRAHMA

34 02969646 1 DECAL, NAME BRAHMA

35 02969666 1 DECAL, JOYSTICK INSTRUCTIONS

36 02733700 3 BOLT

37 00023500 9 FLATWASHER

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -11

Page 14

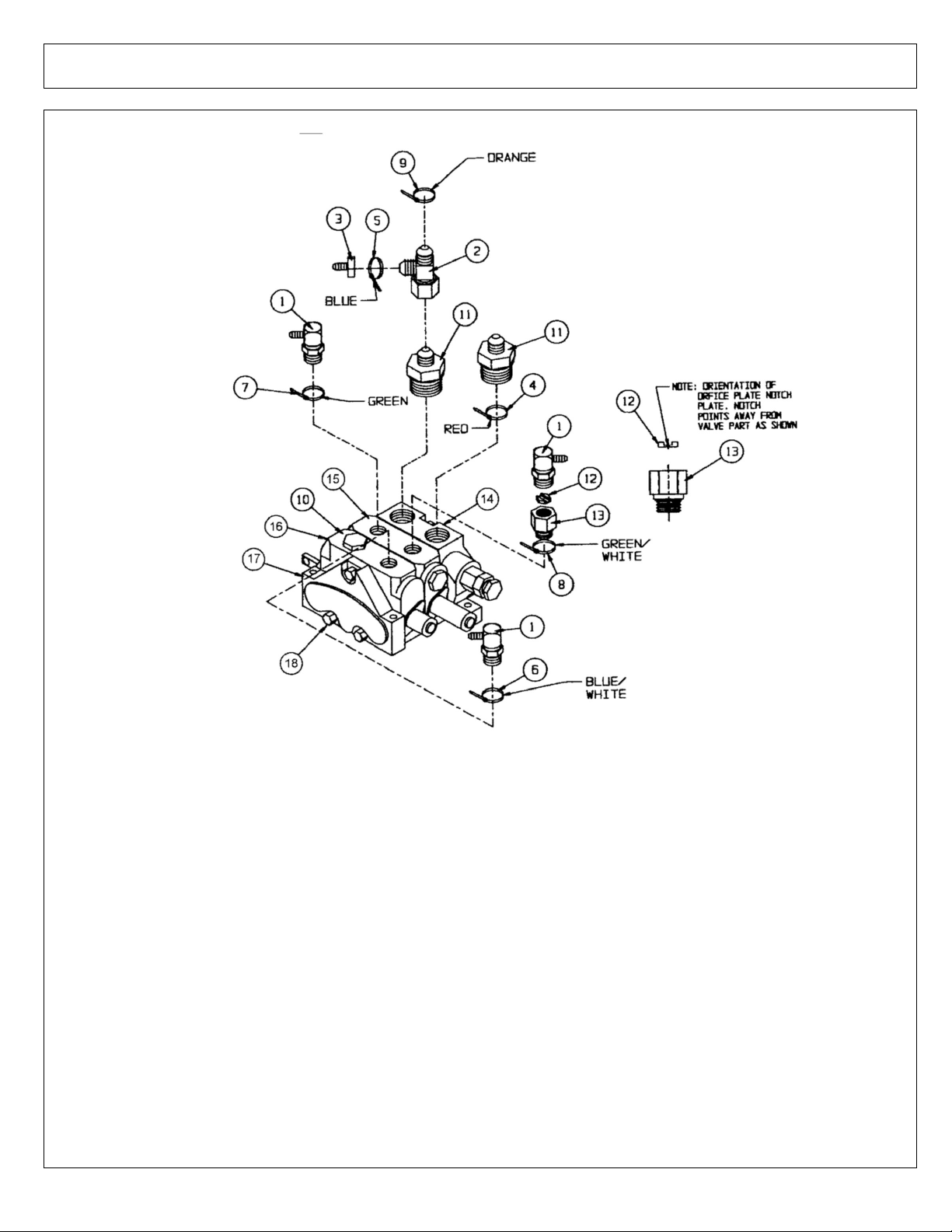

CONTROL VALVE ASY PN 02969613 SN 01241 (05-06) & DOWN

ITEM PART NO. QTY. DESCRIPTIONITEM PART NO. QTY. DESCRIPTION

02981363 1 CONTROL VALVE ASY

1 02962249 3 ADAPTER, HYD ELBOW

2 02967150 1 ADAPTER, HYD TEE

3 02967151 1 ADAPTER, HYD STRAIGHT

4 02968828 1 TIE, PLASTIC 4"LG - RED

5 02968830 1 TIE, PLASTIC 4"LG - BLUE

6 02968831 1 TIE, PLASTIC 4"LG - BLUE/WHITE

7 02968832 1 TIE, PLASTIC 4"LG - GREEN

8 02968833 1 TIE, PLASTIC 4"LG - GREEN/WHITE

9 02968834 1 TIE, PLASTIC 4"LG - ORANGE

10 02969131 1 DIRECTIONAL CONTROL VALVE

11 63042700 2 ADAPTER, HYD STRAIGHT

12 02969399 1 RESTRICTOR-ORFICE, ONE WAY

13 02972159 1 ADAPTER, HYD ELBOW

14 02979336 1 INLET

15 02979337 1 DOUBLE ACTION FLOAT

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -12

Page 15

CONTROL VALVE ASY PN 02969613 SN 01241 (05-06) & DOWN

Continued...

ITEM PART NO. QTY. DESCRIPTION

16 02979338 1 SINGLE ACTION

17 02979339 1 OUTLET COVER

18 02979340 3 STUD ASY.

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -13

Page 16

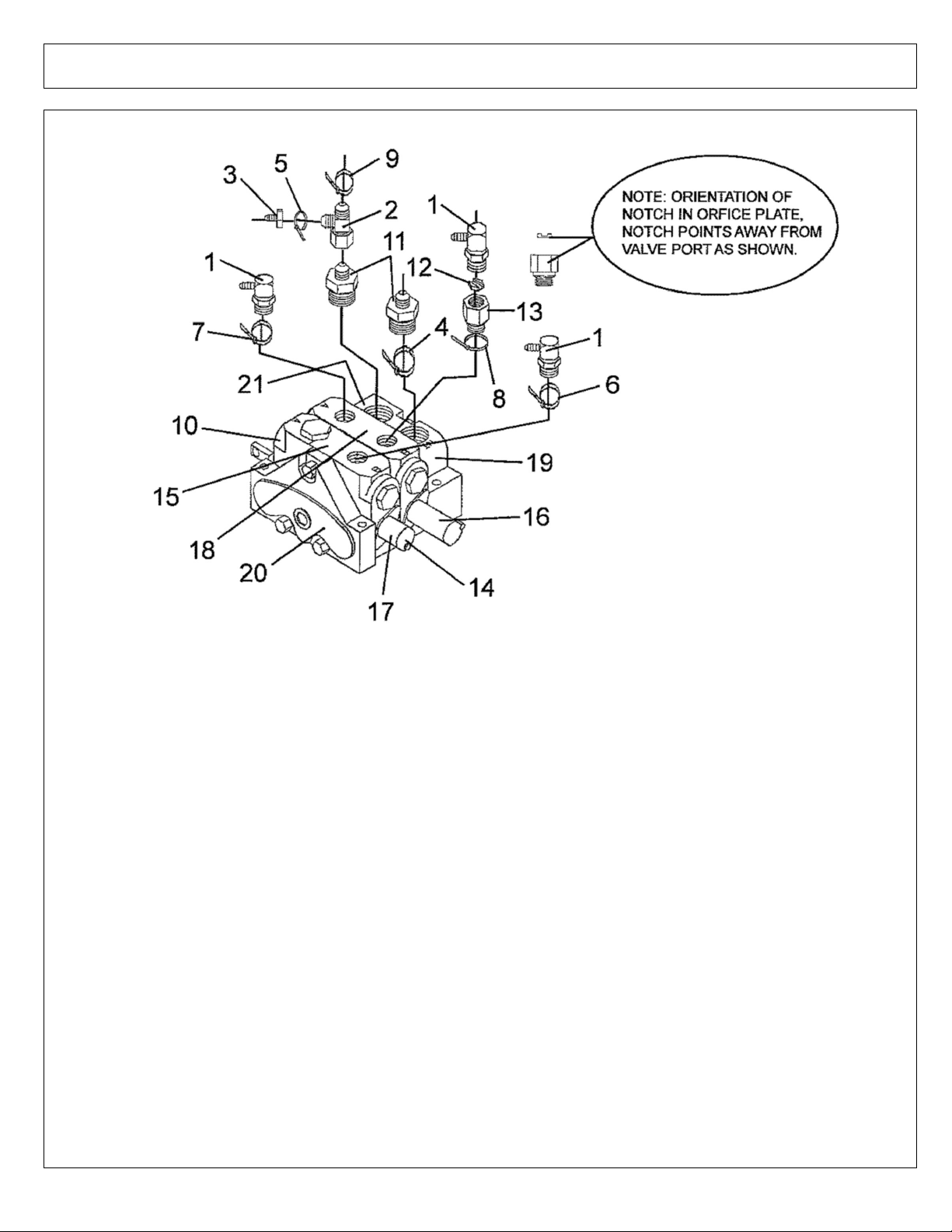

CONTROL VALVE ASY PN 02981363 SN 01242 (06-06) & UP

ITEM PART NO. QTY. DESCRIPTIONITEM PART NO. QTY. DESCRIPTION

02981363 1 CONTROL VALVE ASY.

1 02962249 3 HYD. ADAPTER ELBOW

2 02967150 1 HYD. ADAPTER TEE

3 02967151 1 HYD. ADAPTER STRAIGHT

4 02968828 1 PLASTIC TIE 4"LG - RED

5 02968830 1 PLASTIC TIE 4"LG - BLUE

6 02968831 1 PLASTIC TIE 4"LG - BLUE/WHITE

7 02968832 1 PLASTIC TIE 4"LG - GREEN

8 02968833 1 PLASTIC TIE 4"LG - GREEN/WHITE

9 02968834 1 PLASTIC TIE 4"LG - ORANGE

10 02980906 1 DIRECTIONAL CONTROL VALVE

11 63042700 2 HYD. ADAPTER STRAIGHT

12 02969399 1 ONE WAY RESTRICTOR-ORFICE

13 02972159 1 HYD. ADAPTER ELBOW

14 02962596 1 DETENT CAP 02908600 VALVE

15 02984398 1 VALVE SECTION TILT

16 02958734 1 SPOOL POSITIONER KIT 4-POS DET

17 02750100 1 DETENT KIT

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -14

Page 17

CONTROL VALVE ASY PN 02981363 SN 01242 (06-06) & UP

Continued...

ITEM PART NO. QTY. DESCRIPTION

18 02984421 1 VALVE SECTION LIFT

19 02046700 1 VALVE END PLATE

20 02884397 1 MAIN RELIEF - 3000 PSI

21 02984396 1 VALVE SECTION-INLET COVER

22 02918400 2 VALVE HANDLE FROM 02908600

23 02966875 2 VALVE HANDLE CONNECTION KIT

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -15

Page 18

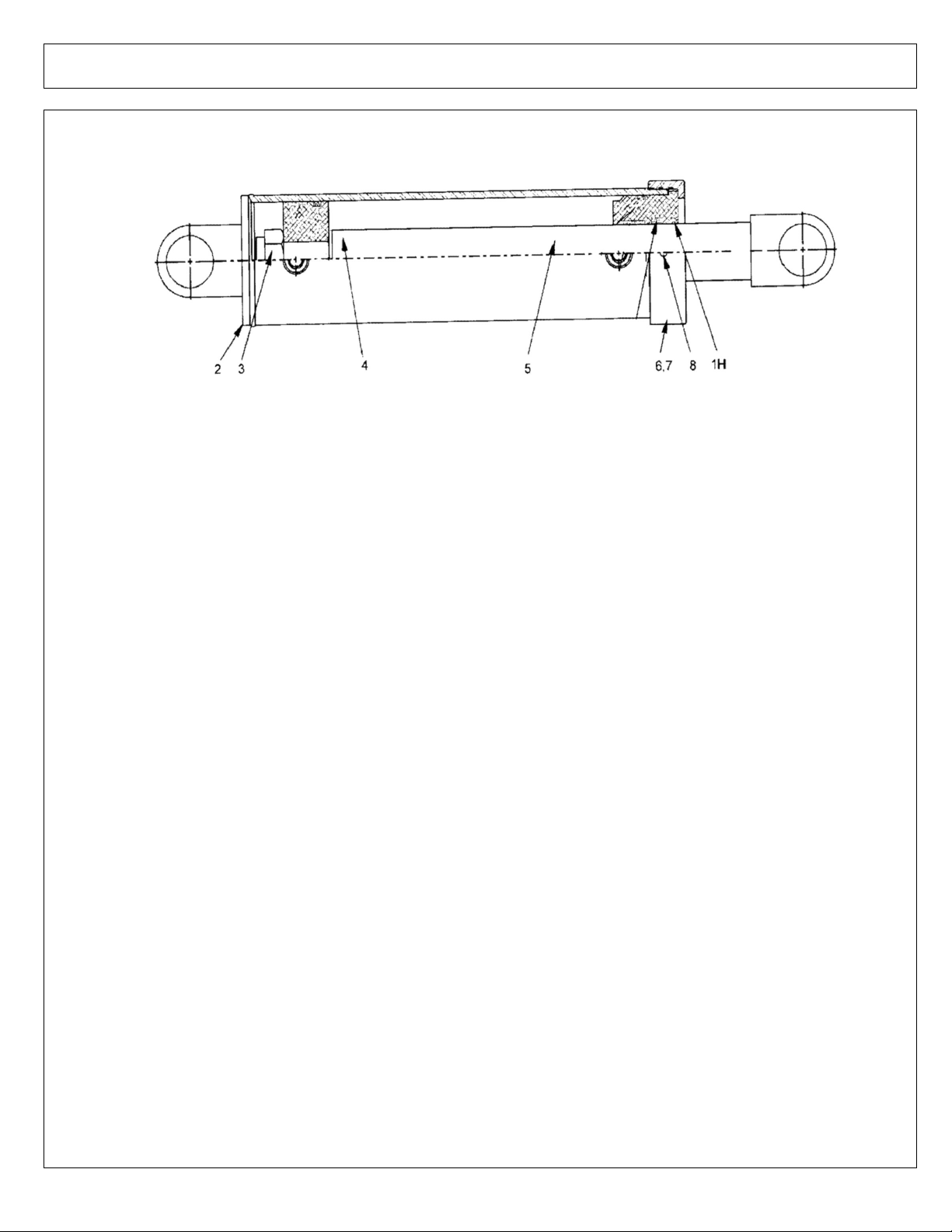

CYLINDER ASY - LIFT

ITEM PART NO. QTY. DESCRIPTIONITEM PART NO. QTY. DESCRIPTION

02968032A 1 HYD. LIFT CYL.( 10-1/2" STROKE )

1 02975531 1 SEAL KIT

2 02975464 1 TUBE WLD’MT ( LIFT CYL. )

3 1917155 1 LOCKNUT

4 02975456 1 PISTON

5 02975458 1 ROD WLD’MT ( LIFT CYL. )

6 02975449 1 HEAD GLAND ( LIFT CYL. )

7 02968803 2 BUSHINGS

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -16

Page 19

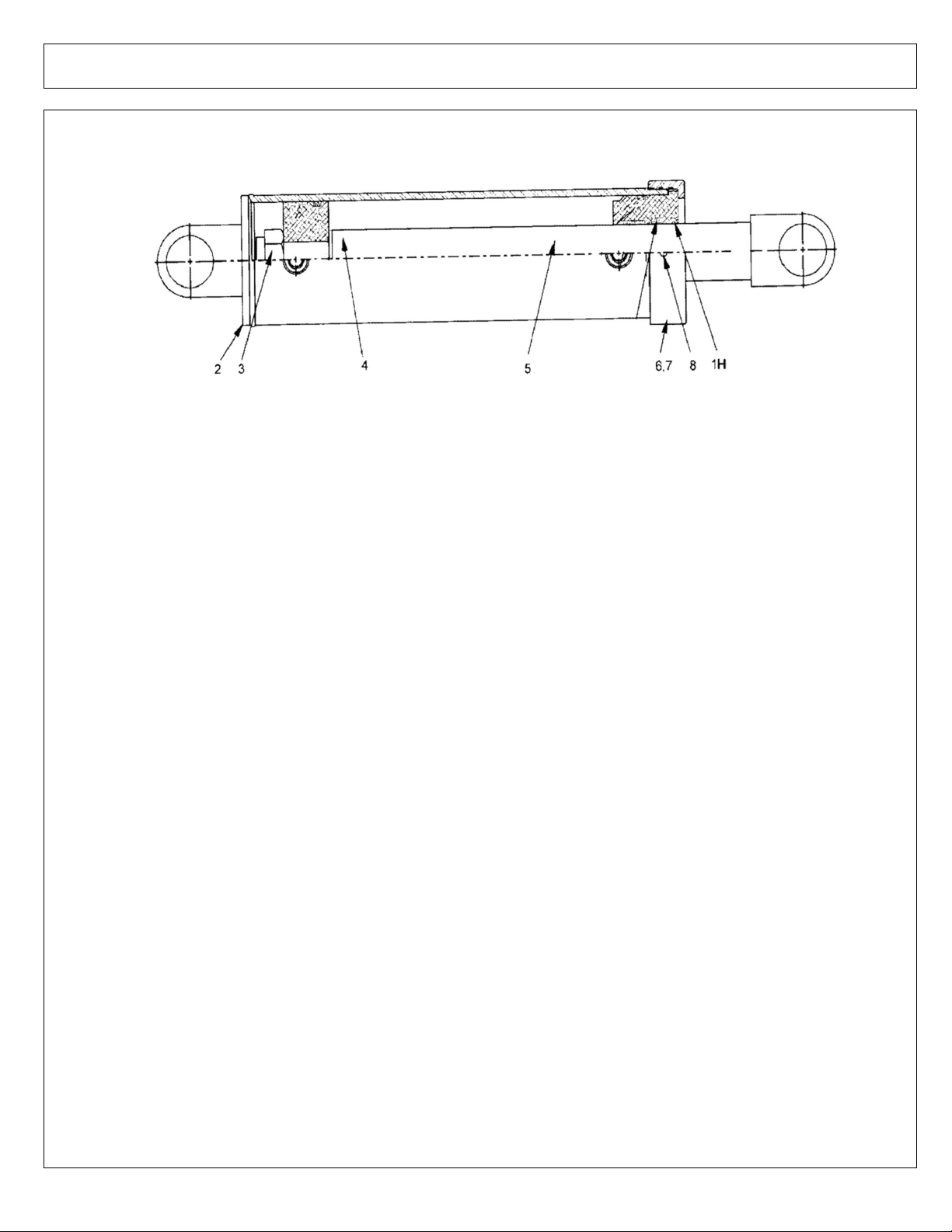

CYLINDER ASY - TILT

ITEM PART NO. QTY. DESCRIPTIONITEM PART NO. QTY. DESCRIPTION

02968024A 1 HYD. TILT CYL. ( 12-13/16" STROKE )

1 02975531 1 SEAL KIT

2 02975550 1 TUBE WLD’MT ( TILT CYL. )

3 1917155 1 LOCKNUT

4 02975456 1 PISTON

5 02975549 1 ROD WLD’MT ( TILT CYL. )

6 02975459 1 HEAD GLAND ( TILT CYL. )

7 02968803 2 BUSHINGS

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -17

Page 20

FLAIL HEAD ASY PN 02968984 - 60 INCH PART 1

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -18

Page 21

FLAIL HEAD ASY PN 02968984 - 60 INCH PART 1

ITEM PART NO. QTY. DESCRIPTION

02968984 1 HEAD ASY, 60" FLAIL ( 1500 HEAD )

02968985 1 HEAD ASY, 80" FLAIL ( 2000 HEAD )

1 NFS 1 SERIAL PLATE - BRAHMA

2 000108 1 DECAL, OPERATING INSTRUCTIONS , FLAIL

3 02969464 1 ADAPTER REDUCER

4 02979128 1 PRESSURE HOSE ( RED )

5 02979127 1 RETURN HOSE, W/90 DEG ELBOW ( ORANGE )

6 02970705 1 CASE DRAIN HOSE ( BLUE )

7 002369 1 DECAL, MULTI-HAZARD FLAIL

8 00015800 2 LOCKNUT

9 00059900 2 BOLT

10 00695100 10 LOCKNUT

11 00725739 1 DECAL, USE REPAIR SHIELDS / GUARDS

12 00725746 1 DECAL, SPANISH, TRANSLATE SAFETY MATERIAL

13 00756059 1 DECAL, DANGER OIL LEAK

14 00757139 1 DECAL, ALAMO GROUP ( 5X19 )

15 00758194 1 DECAL, PINCH POINT V-BELT

16 02845500 10 HEX BOLT

17 02962764 2 DECAL, PINCH POINT SCISSORS

18 02967668 1 DECAL, CUTTING BLADES / THROWN OBJECTS , FLAIL

19 02976663 1 CLAMP PLATE

20 02968274 1 MOWER HEAD MOUNT PIN

21 02976694 1 MOWER HEAD MOUNT WLD’MT

22 02968561 1 HEAD LINK PIN WLD’MT

23 02968896 3 PLASTIC TIE - ORANGE

24 02968894 3 PLASTIC TIE - RED

25 02968895 3 PLASTIC TIE - BLUE

26 02969647 1 DECAL, BRAHMA 30"

27 02969648 1 DECAL, BRAHMA PICTURE

28 03200432 1 DECAL, USE GENUINE PARTS FLAIL

29 3710151 4 METAL TACK

30 8301295 1 PISTON MOTOR - INCLUDES THE FOLLOWING :

30A 02964954 1 MOTOR KEY (REFERENCE ONLY)

31 90.162.12 1 FLAIL HEAD - INCLUDESTHE FOLLOWING (5 ITEMS)

72.736.01 1 BEARING ASY.

72.740.02 1 ROLLER ASY. 1500

72.753.01 1 ROTOR SHAFT ASY. 1500

76.114.01 1 COWL ASY. 1500

76.154.01 1 MOTOR,PULLEY & BELT ASY.

31A 90.282.12 1 FLAIL HEAD 2000 * - INCLUDES THE FOLLOWING ( 5 ITEMS )

76.115.01 1 MOTOR,PULLEY & BELT ASY.

76.117.01 1 COWL ASY 2000

76.118.01 1 BEARING ASY

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -19

Page 22

FLAIL HEAD ASY PN 02968984 - 60 INCH PART 2

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -20

Page 23

FLAIL HEAD ASY PN 02968984 - 60 INCH PART 2

ITEM PART NO. QTY. DESCRIPTION

76.119.01 1 ASY,ROTOR SHAFT 4934

76.155.01 1 ASY,ROLLER 2000 4934

32 02957622 1 ADP HYD STGHT 16MB-16MJ

33 02962213 1 ADP HYD ELBOW 8MB - 8MJ 90°

34 02090900 1 ADP HYD ELBOW 16MB-16MJ90

35 02961085 1 CORDURA SLEEVING-54 LG

36 02775500 3 PLASTIC TIE 21 LG.

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -21

Page 24

FLAIL HEAD SUB-ASY 1500

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -22

Page 25

FLAIL HEAD SUB-ASY 1500

ITEM PART NO. QTY. DESCRIPTION

1 05.201.17 2 TENSION PIN

2 05.264.21 3 SETSCREW

3 05.264.23 10 SETSCREW

4 05.264.24 6 SETSCREW

5 05.281.03 5 FLATWASHER - PLATED

6 05.281.04 6 FLATWASHER - PLATED

7 05.282.01 12 SPRING WASHER - PLATED

8 05.282.03 20 SPRING WASHER - PLATED

9 05.286.01 16 PLATED NUT

10 05.286.03 17 PLATED NUT

11 05.287.02 6 SELF - LOCKING NUT

12 05.839.24 6 BOLT CUP SQUARE

13 09.589.01 1 TOP DRIVE, GUARD

14 09.590.01 1 BOTTOM DRIVE, GUARD

15 09.594.02 2 BACKING STRIP - 1500

16 09.595.02 1 FLEXIBLE GUARD - 1500

17 41418.01 2 CLAMP GUARD

18 41424.01 1 FLEXIBLE GUARD - 1500

19 41425.01 1 COWL - 1500

20 41429.01 1 FRT FIXED GUARD - 1500

21 41430.01 1 FRT ADJ GUARD - 1500

22 41436.01 2 FRT GUARD - PIVOT SPACER

23 41438.01 1 FRT GUARD - PIVOT PIN

24 9293054 12 BOLT CUP SQUARE

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -23

Page 26

FLAIL HEAD SUB-ASY 2000

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -24

Page 27

FLAIL HEAD SUB-ASY 2000

ITEM PART NO. QTY. DESCRIPTION

1 05.201.17 2 TENSION PIN

2 05.264.21 3 SETSCREW

3 05.264.23 10 SETSCREW

4 05.264.24 6 SETSCREW

5 05.281.03 5 FLATWASHER - PLATED

6 05.281.04 8 FLATWASHER - PLATED

7 05.282.01 16 SPRING WASHER - PLATED

8 05.282.03 20 SPRING WASHER - PLATED

9 05.286.01 16 PLATED NUT

10 05.286.03 17 PLATED NUT

11 05.287.02 8 SELF - LOCKING NUT

12 05.839.24 8 BOLT CUP SQUARE

13 09.589.01 1 TOP DRIVE, GUARD

14 09.590.01 1 BOTTOM DRIVE, GUARD

15 41.237.01 2 BACKING STRIP - 2000

16 41.063.01 1 FLEXIBLE GUARD - 2000

17 41418.01 2 CLAMP GUARD

18 41452.01 1 FLEXIBLE GUARD - 2000

19 41445.01 1 COWL - 2000

20 41453.01 1 FRT FIXED GUARD - 2000

21 41454.01 1 FRT ADJ GUARD - 2000

22 41436.01 2 FRT GUARD - PIVOT SPACER

23 41444.01 1 FRT GUARD - PIVOT PIN

24 9293054 16 BOLT CUP SQUARE

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -25

Page 28

GAUGE WHEEL - SIDE PN 02966070 (OPTIONAL)

ITEM PART NO. QTY. DESCRIPTIONITEM PART NO. QTY. DESCRIPTION

02966070 1 GUAGE WHEEL, SIDE MOUNT, DEEP DECK

1 00001800 8 LOCKNUT

2 00606000 1 COTTERPIN

3 02892000 8 BOLT, HEX HEAD

4 02965675 1 PIN WLEDMENT

5 02966238 1 WHEEL MOUNTING WLEDMENT

6 373024D 1 HUB ASY.

7 373024H 1 WHEEL & TIRE ASY.

8 37302C2C 2 BUSHING

9 5DR12160 1 NUT, SLOTTED

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -26

Page 29

HYDRAULIC TANK SUB-ASY PN 02981211

ITEM PART NO. QTY. DESCRIPTIONITEM PART NO. QTY. DESCRIPTION

02981211 1 HYDRAULIC TANK SUB-ASY.

1 00001300 4 LOCKWASHER

3 00011800 4 BOLT

4 00751984 6 STARWASHER

5 02275700 1 PIPE TEE

6 02963659 1 MAGNETIC PLUG

7 02977040 1 TANK WLD’MT

8 02968166 1 SUCTION STRAINER

9 02968879 1 FILLER/BREATHER CAP ASY.

10 02968880 1 GAUGE, SIGHT & TEMP.

11 02969377 6 MACHINE SCREW, SLOTTED HEX

12 63081000 1 REDUCER BUSHING

13 00011700 2 LOCKWASHER

14 10119000 2 LOCKWASHER

15 00023500 4 FLATWASHER

16 00750940 2 LOCKNUT

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -27

Page 30

MOTOR & SPINDLE ASY PN 02969096

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -28

Page 31

MOTOR & SPINDLE ASY PN 02969096

ITEM PART NO. QTY. DESCRIPTION

02969096 1 MOTOR & SPINDLE ASY.

1 00019600 4 LOCKWASHER

2 00750316 2 HYD. ADAPTER ELBOW

3 00750317 2 SPLIT FLANGE KIT

4 -------------- 1 GREASE NLGI "000" ( NOT SHOWN , SEE MAINTENCE SECTION ) (REFERENCE ONLY)

5 02776600 4 BOLT

6 02958782 1 HYD. ADAPTER STRAIGHT

7 02960553B 1 SPINDLE HOUSING - SPINDLE ASY.(SEE SPINDLE HOUSING & SPINDLE ASY.)

8 02961038 1 SPINDLE / MOTOR - GASKET

9 02967193B 1 PISTON MOTOR ASY

02967193RB 1 PISTON MOTOR ASY ( REBUILT UNIT ) (REFERENCE ONLY)

02972094 1 SEAL KIT, VALVE BLOCK TO MOTOR

02971574 1 RELIEF CARTRIDGE, 4000 PSI

02981685 1 O-RING ( F/ 02971574 )

02981686 1 O-RING ( F/ 02971574 )

02981687 1 O-RING ( F/ 02971574 )

02981688 2 BACK-UP RING ( F/ 02971574 )

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -29

Page 32

MOTOR ASY - FLAIL HEAD

ITEM PART NO. QTY. DESCRIPTIONITEM PART NO. QTY. DESCRIPTION

1 8301295 1 PISTON MOTOR, 2.48 CU.IN./REV W/O FITTINGS

2 05.960.16 1 KEY

3 8600908 1 O-RING GASKET

4 03.198.01 1 HYD. ADAPTER

5 8581338 1 HYD. ADAPTER

6 05.835.02 2 HYD. ADAPTER

7 08.955.25 2 HYD. ADAPTER

8 8600916 2 O-RING GASKET

9 8699238 1 SEAL KIT ( FOR P/N 8301295 MOTOR )

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -30

Page 33

THIS PAGE INTENTIONAL LEFT BLANK

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -31

Page 34

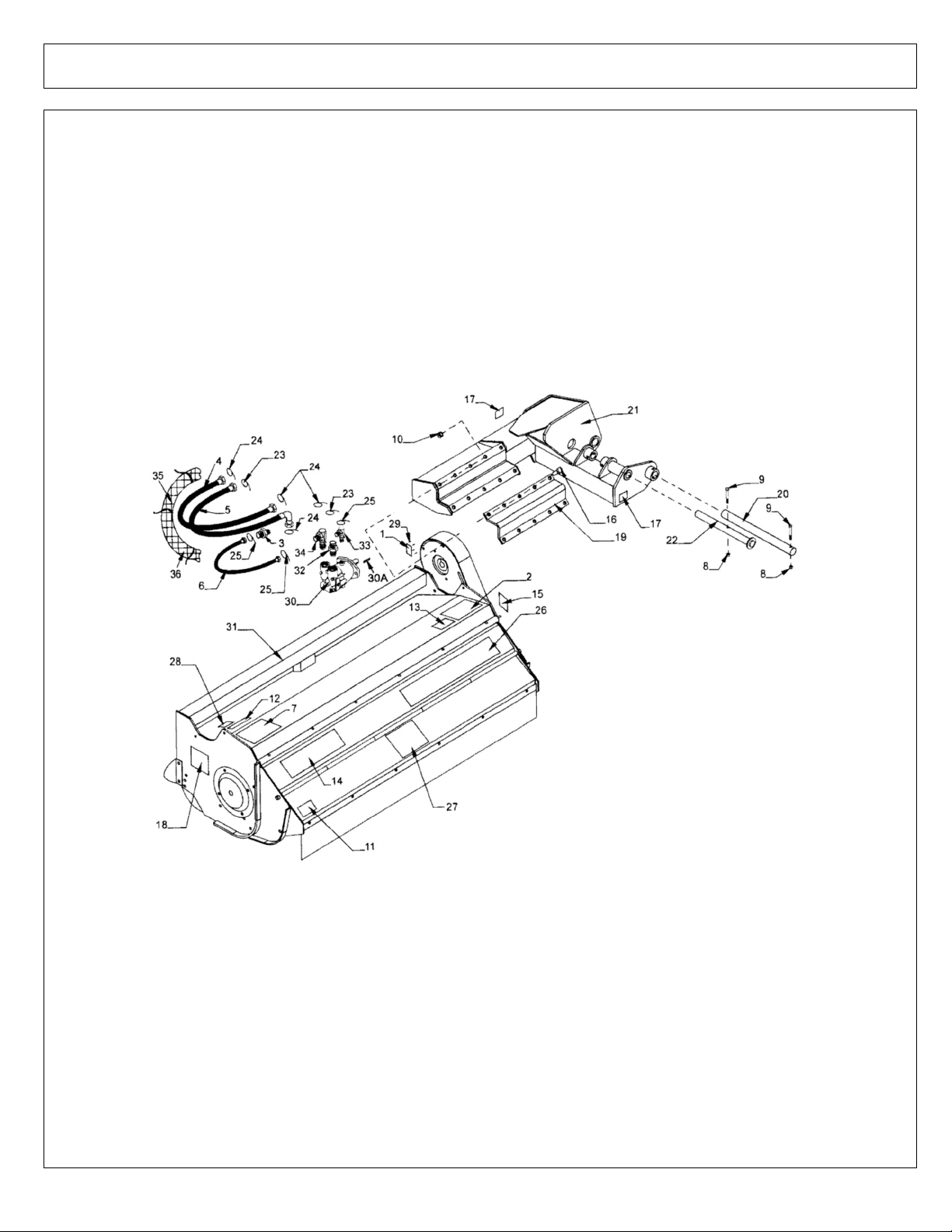

MOUNTING ARM ASY PN 02979631

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -32

Page 35

MOUNTING ARM ASY PN 02979631

ITEM PART NO. QTY. DESCRIPTION

02979631 1 MOUNTING ARM ASY, BRAHMA

1 00013900 1 BOLT

2 00059900 5 BOLT

3 00015800 5 LOCKNUT

4 02968803 8 TEFLON BEARING

5 00764656 2 TEFLON BEARING

6 02890900 4 HOSE - 47"LG

7 02919400 3 BULKHEAD FITTING - 45 DEG

8 02960018 4 FITTING - 90 DEG

9 02962764 3 DECAL, PINCH POINTS

10 02965262 1 DECAL, HOSE BURST

11 02966791 2 TEFLON BEARING IMPREG

12 02968023A 1 HYD. TILT CYL.( SEE LIFT &TILT CYL.)

13 02968024A 1 HYD. LIFT CYL.( SEE LIFT &TILT CYL.)

14 02985235 1 WLDMT, HEAD PIVOT

15 02968101 1 ARM BASE PIN

16 02968103 1 LINK BASE CYLINDER PIN

17 02979612 1 MACHINED ARM , BRAHMA

18 02979628 1 CYLINDER ROD PIN

19 02979620 1 MACHINED , CYLINDER LINK

20 02968197 1 CYLINDER ROD PIN

21 02979614 1 MACHINED , CYLINDER LINK

22 02979627 1 CYLINDER BASE PIN

23 02968830 3 PLASTIC TIE - BLUE

24 02968831 3 PLASTIC TIE - BLUE/WHITE

25 02968832 3 PLASTIC TIE - GREEN

26 02968833 3 PLASTIC TIE - GREEN/WHITE

27 02968896 1 PLASTIC TIE - ORANGE

28 02968895 1 PLASTIC TIE - BLUE

29 02968894 1 PLASTIC TIE - RED

30 3710151 4 METAL TACK

31 02960692 1 SERIAL PLATE - BRAHMA ARM

32 02275800 2 DOUBLE CLEVIS

33 00751685 1 HAIRPIN

34 02973792 1 CHAIN

35 15C2000 2 HARDENED WASHER 1-1/4"

36 02968274 1 PIN- MOWER HEAD MT.

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -33

Page 36

OIL RESERVOIR ASY PN 02968168

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -34

Page 37

OIL RESERVOIR ASY PN 02968168

ITEM PART NO. QTY. DESCRIPTION

02968168 1 OIL RESERVOIR ASY.

1 00002000 4 BOLT

2 00752067 1 STRAIGHT ADAPTER

3 02041800 1 ELBOW - 90DEG

4 02042300 1 STRAIGHT ADAPTER

5 02042400 1 STRAIGHT ADAPTER

6 02043600 2 ADAPTER - 45DEG

7 02822700 1 ELBOW - 90DEG

8 02969527 1 PUMP, FRONT-SERVO ( INCLUDES 02970206 SOLENOID SERVO CONTROL )

02969527RB 1 PUMP, FRONT-SERVO REBUILT (REFERENCE ONLY)

9 02968164 3 HOSE

10 02968165 1 HOSE

11 02968167 1 STRAIGHT ADAPTER

12 02968169 1 TANK SUB-ASY.

13 02968896 1 PLASTIC TIE - 11"LG ( ORANGE )

14 02968895 1 PLASTIC TIE - 11"LG ( BLUE )

15 02968894 1 PLASTIC TIE - 11"LG ( RED )

16 02968922 1 PRESSURE FILTER HEAD ASY.

17 02968923 1 PRESS FILTER ASY.

03101646 4 LOCKWASHER

18 03200587 1 PLUG

19 63042700 3 ADAPTER

20 02972836 1 COIL ASSY.

21 02972835 1 ASSY, CARTRIDGE VALVE W/O COIL

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -35

Page 38

PULLEY ASY - FLAIL HEAD 1500 & 2000

ITEM PART NO. QTY. DESCRIPTIONITEM PART NO. QTY. DESCRIPTION

76.154.01 1 PULLEY ASY. F/ 60" ( 1500 ) HEAD

76.115.01 1 PULLEY ASY. F/ 80" ( 2000 ) HEAD

1 03.795.02 2 PULLEY

2 04.282.17 2 STUD

3 05.281.03 2 WASHER

4 05.282.03 4 SPRING WASHER

5 05.286.03 4 NUT

6 05.424.02 1 TAPERLOCK

7 05.424.18 1 TAPERLOCK F/ 60" ( 1500 ) HEAD

05.424.17 1 TAPERLOCK F/ 80" ( 2000 ) HEAD

8 05.625.12 2 SCREW

9 05.960.16 1 BELT

10 05.960.16 1 KEY

11 09.587.01 1 COVER PLATE

12 41342.01 1 PLATE

13 02964954 1 MOTOR KEY (REFERENCE ONLY)

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -36

Page 39

ROLLER ASY - FLAIL HEAD 1500 & 2000

ITEM PART NO. QTY. DESCRIPTIONITEM PART NO. QTY. DESCRIPTION

1 09.898.01 1 LEFT BRKT ( NOT SHOWN )

09.898.02 1 RIGHT BRKT

2 05.959.05 4 CIRCLIP

3 03.007.02 2 BEARING ( CAN USE BRG P/N 42954.01 )

09.714.01 1 BEARING KIT COMPLETE ( BOTH SIDES ), ITEMS 3,4,5,6,7,8 & 9 (AS REQUIRED)

4 04.164.04 2 SEAL

5 41851.01 2 CAP

6 05.953.01 4 GREASE NIPPLE

7 05.234.01 2 WASHER

8 05.625.10 2 SOCKET HEAD BOLT

9 05.282.03 2 SPRING WASHER

10 42955.05 1 ROLLER - 60" ( 1500 ) HEAD

42955.07 1 ROLLER - 80" ( 2000 ) HEAD

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -37

Page 40

ROLLER ASY - ROTARY HEAD (OPTION)

ITEM PART NO. QTY. DESCRIPTIONITEM PART NO. QTY. DESCRIPTION

703262 1 ROLLER KIT, 62"

1 00001800 8 LOCKNUT

2 000516 8 CARRIAGE BOLT

3 107784 1 ROLLER

4 107380 1 RIGHT ROLLER MOUNT - WLD’MT

107182 1 LEFT ROLLER MOUNT - WLD’MT

5 002037 2 SEAL

6 703976 2 BEARING

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -38

Page 41

THIS PAGE INTENTIONAL LEFT BLANK

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -39

Page 42

ROTARY HEAD - MOTOR ASY (PARTS) - PN 02979881 PART 1

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -40

Page 43

ROTARY HEAD - MOTOR ASY (PARTS) - PN 02979881 PART 1

ITEM PART NO. QTY. DESCRIPTION

02979881 1 MOTOR ASY, PISTON TYPE 4.91 CID

1 02980529 1 BARREL HOUSING ASY

2 02980530 1 VALVE PLATE

4 02980536 1 NOZZLE, 2.5

5 02980537 1 PLUG ASY, 7/8" HEXAGON

6 02980538 1 BEARING HOUSING

7 02980539 1 O-RING, 132 X 3

8 02980540 1 O-RING, 104.5 X 3

9 02980541 1 SEAL CARRIER

10 02980542 1 SHAFT SEAL

11 02980543 1 SPACER WASHER

12 02980544 1 RETAINING RING

13 02980545 1 RETAINING RING

14 02980546 1 SHAFT ASY, TYPE U

15 02980548 1 CYLINDER BARREL

16 02980549 1 BARREL SUPPORT

17 02980550 7 PISTON ASY

18 02980551 21 PISTON RING

19 02980552 1 RING GEAR

20 02980553 1 TAP ROL BEARING

21 02980554 1 BEARING, TAPERED ROLLER

22 02980555 1 SPACER WASHER (AS REQUIRED)

23 02980556 1 RETAINING RING

24 02980557 1 SHIM, 0.5 (AS REQUIRED)

02980558 1 SHIM, 0.2 (AS REQUIRED)

02980559 1 SHIM, 0.4 (AS REQUIRED)

02980560 1 SHIM, 0.6 (AS REQUIRED)

02980561 1 SHIM, 0.8 (AS REQUIRED)

02980562 1 SHIM, 1.0 (AS REQUIRED)

02980563 1 SHIM, 0.7 (AS REQUIRED)

25 02980564 4 BOLT, SOCKET HEAD M12 X 50 10.9

26 02980565 1 LOCKWASHER, M13 X 19.5

27 02980547 1 GUIDE PIN

28 02980571 1 RELIEF MANIFOLD

02980570 1 RELIEF VALVE, SEAL KIT (AS REQUIRED)

29 02980568 1 RELIEF VALVE, 280 BAR

30 02980569 1 RELIEF VALVE, 330 BAR

31 02980237 2 O-RING

32 02980531 1 KEY, FLAT

33 02980532 2 STEEL BALL

34 02980533 2 PLUG, HEXAGON

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -41

Page 44

ROTARY HEAD - MOTOR ASY (PARTS) - PN 02979881 PART 2

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -42

Page 45

ROTARY HEAD - MOTOR ASY (PARTS) - PN 02979881 PART 2

ITEM PART NO. QTY. DESCRIPTION

35 02980534 2 O-RING

36 02980535 2 PLUG ASY, HEX SOCKET

37 02980572 2 PLUG ASY

38 02980573 1 PLUG ASY

39 02980566 1 REBUILD KIT

40 02980567 1 SEAL KIT FOR 02979881 MTR

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -43

Page 46

ROTARY HEAD ASY

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -44

Page 47

ROTARY HEAD ASY

ITEM PART NO. QTY. DESCRIPTION

02969091 1 HEAD, ASY, 60 PAN DEP DEK

02969090 1 HEAD, ASY, BAR DEP DEK

1 00001800 6 LOCKNUT TLM 1/2 NC PLB

2 00002700 6 FLATWASHER 1/2 PL STD

3 00011100 22 FLATWASHER STD 3/8

4 00013900 1 HHCS 3/8 NC 2-1/2 PL5

5 00015800 13 LOCKNUT TLM 3/8-NC PLC

6 00023100 11 HHCS 3/8 -16UNC 1-1/2 PL5

7 00059900 1 HEXB 3/8 NC 3 PL5

8 001650 1 DECAL-ALAMO IND. LOGO

9 00725746 1 DECAL, PELIGRO

10 00756059 1 DECAL-WARNING OIL LEAK

11 00757140 1 DECAL,ALAMO INDUSTRIAL LOGO

12 00769736 1 DECAL,USE/REPAIR GUARDS

13 00769737 2 DECAL-BLADES THROWN OBJECTS

14 02030700 6 HHCS 1/2-13UNC 1-1/4 PL5

15 02753400 3 PLASTIC TIE-ON 15 LG

16 02885700 1 REAR FLAP 10 X 63 X 3/8 THK

17 02885800 1 REAR CLAMP BAR

18 02925100 1 DECAL-REPLACEMENT PARTS

19 02961085 1 CORDURA SLEEVING-54 LG

20 02962764 1 DECAL - PINCH POINTS

21 02965797 1 ASY,FRT CNGD 60VM DP DK

22 02967827 1 DECAL-MULTI HAZ

23 02968274 1 PIN- MOWER HEAD MT.

24 02984760 1 PIN 1-1/4

25 02969094 1 PRE-ASSEMBLY-60ROTARY /BAR

02969095 1 PRE-ASSEMBLY-60ROTARY /PAN

26 02969645 1 PLATE,S/N - BRAHMA ROTARY

27 02969647 1 DECAL,NAME--BRAHMA 30(BLACK)

28 02969648 1 DECAL,PICTURE - BRAHMA (BLACK)

29 02969677 1 HOSE #16-16FJX -16FJX - 68LG

30 02969678 1 HOSE #16-16FJX -16FJX45- 74LG

31 02969679 1 HOSE #16-16FJX -16FJX45- 69LG

32 3710151 4 METAL TACK

33 02968896 1 PLASTIC TIE 11LG

34 02968895 1 PLASTIC TIE 11LG

35 02968894 1 PLASTIC TIE 11LG

36 1458392 1 DECAL,RED REFLECTOR

37 1458393 1 DECAL,YELLOW REFLECTOR

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -45

Page 48

ROTARY HEAD ASY (NEW STYLE)

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -46

Page 49

ROTARY HEAD ASY (NEW STYLE)

ITEM PART NO. QTY. DESCRIPTION

02969091 1 HEAD, ASY, 60" PAN DEEP DECK

02969090 1 HEAD, ASY, 60" BAR DEEP DECK

1 00001800 6 LOCKNUT, 1/2" NC PLB

2 00002700 6 FLATWASHER, 1/2" PL STD

3 00011100 22 FLATWASHER, 3/8" NC STD

4 00013900 1 HHCS 3/8" NC 2-1/2" PL5

5 00015800 13 LOCKNUT, 3/8"-NC PLC

6 00023100 11 HHCS 3/8" -16UNC 1-1/2" PL5

7 00059900 1 HEXB 3/8" NC 3" PL5

8 001650 1 DECAL, ALAMO IND. LOGO

9 00725746 1 DECAL, PELIGRO

10 00756059 1 DECAL, WARNING OIL LEAK

11 00757140 1 DECAL, ALAMO INDUSTRIAL LOGO

12 00769736 1 DECAL, USE/REPAIR GUARDS

13 00769737 2 DECAL, BLADES THROWN OBJECTS

14 02030700 6 HHCS 1/2"-13UNC 1-1/4" PL5

15 02753400 3 PLASTIC TIE, 15" LG

16 02885700 1 REAR FLAP, 10" X 63" X 3/8" THK

17 02885800 1 REAR CLAMP BAR

18 02925100 1 DECAL, REPLACEMENT PARTS

19 02961085 1 CORDURA SLEEVING, 54" LG

20 02962764 1 DECAL, PINCH POINTS

21 02965797 1 ASY,FRT CNGD 60VM DP DK

22 02967827 1 DECAL, MULTI HAZ

23 02968274 1 PIN, MOWER HEAD MT

24 02984760 1 PIN, 1-1/4" X 15-3/4"LG CHR PLT

25 02969094 1 PRE-ASSEMBLY - 60" ROTARY /BAR

02969095 1 PRE-ASSEMBLY - 60" ROTARY /PAN

27 02969647 1 DECAL, NAME--BRAHMA 30(BLACK)

28 02969648 1 DECAL, PICTURE - BRAHMA (BLACK)

29 02969677 1 HOSE #16-16FJX -16FJX - 68" LG

30 02969678 1 HOSE #16-16FJX -16FJX45 - 74" LG

31 02969679 1 HOSE #16-16FJX -16FJX45 - 69" LG

33 02968896 1 PLASTIC TIE, 11" LG

34 02968895 1 PLASTIC TIE, 11" LG

35 02968894 1 PLASTIC TIE, 11" LG

36 1458392 1 DECAL, RED REFLECTOR

37 1458393 1 DECAL, YELLOW REFLECTOR

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -47

Page 50

ROTARY HEAD PRE-ASY (NEW STYLE)

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -48

Page 51

ROTARY HEAD PRE-ASY (NEW STYLE)

ITEM PART NO. QTY. DESCRIPTION

02969094 1 PRE-ASSEMBLY - 60 ROTARY / BAR

02969095 1 PRE-ASSEMBLY - 60 ROTARY / PAN

1 02966618 1 WLDMT.-MOWER DP. DK. BRAHMA

2 00011100 8 FLATWASHER, STD 3/8"

3 00015800 8 LOCKNUT, 3/8" NC PLC

4 00037200 6 LOCKNUT, 3/4" NC GRC PL

5 02960521 6 HEX HEAD BOLT, 3/4" NC 2-3/4" PL8

6 02965737 1 BLADE BAR ASY (OPTIONAL)

7 02964456 1 PAN ASSEMBLY, 60 V/M STUMP (OPTIONAL)

8 02965751 2 SKID SHOE ROTARY

9 02965808 1 SPACER, 3-1/8" BLADE BAR

10 00003901 4 LOCKWASHER, 3/4" PL HEAVY

11 02708700 4 SOCKET HEAD BOLT, 3/4" NC 2" PL8

12 02967089 4 SOCKET HEAD BOLT, 3/4" NC 6" PL8

13 2A361612 8 PLOW BOLT, 3/8" X 1 1/2"

14 02969096 1 MOTOR ASY, W/ SPINDLE

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -49

Page 52

ROTARY HEAD SUB-ASY

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -50

Page 53

ROTARY HEAD SUB-ASY

ITEM PART NO. QTY. DESCRIPTION

02969094 1 ROTARY HEAD SUB-ASY, 60" W/BAR CARRIER

02969095 1 ROTARY HEAD SUB-ASY, 60" W/PAN CARRIER

1 00003901 4 LOCKWASHER

2 00011100 8 FLATWASHER

3 00015800 8 LOCKNUT

4 00037200 6 LOCKNUT

5 00900265 1 TEXAS YELLOW PAINT (REFERENCE ONLY)

6 02960521 6 BOLT

7 02964456 1 BLADE PAN ASY. 60" STUMP JUMPER

02965737 1 BLADE BAR ASY.

8 02965751 2 SKID SHOE

9 02965808 1 SPACER, 3-1/8 F/ BLADE PAN ONLY

10 02966618 1 DECK WLD’MT - DP. DK. BRAHMA

11 02967007 4 BOLT, SOCKET HEAD USE W/ PAN ONLY (TORQUE TO 400 FT. LBS.)

02708700 4 BOLT, SOCKET HEAD USE W/ BAR ONLY (TORQUE TO 400 FT. LBS.)

12 02969096 1 MOTOR ASY. - W/ SPINDLE

13 2A361612 8 PLOW BOLT

14 00012101 4 LOCKWASHER

15 00036300 16 NUT

16 00749136 8 LOCKNUT

17 02970752 4 TIE ROD

18 02970753 1 MOTOR SUPPORT PLATE

19 02970755 4 BOLT

20 W67 16 HARDENED WASHER

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -51

Page 54

ROTOR SHAFT ASY - FLAIL HEAD 60 INCH

ITEM PART NO. QTY. DESCRIPTIONITEM PART NO. QTY. DESCRIPTION

09.666.01 1 ROTOR SHAFTASY, 60"( 1500 MM )

1 09.597.01 1 ROTOR SHAFT WLD’MT, 60" ( 1500 MM )

2 05.775.10 40 BOLT

3 05.282.08 40 SPRING WASHER

4 05.968.06 40 LOCKNUT

5 09.517.01 40 D-RING SHACKLE

6 09.528.01 80 FLAIL KNIFE, ( STANDARD )

7 02975613 80 FLAIL KNIFE, SERRATED ( OPTIONAL )

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -52

Page 55

ROTOR SHAFT ASY - FLAIL HEAD 80 INCH

ITEM PART NO. QTY. DESCRIPTIONITEM PART NO. QTY. DESCRIPTION

41458.01 1 ROTOR SHAFT ASY, 80"( 2000 MM )

1 41.299.01 1 ROTOR SHAFT WLD’MT, 80" ( 2000 MM )

2 05.775.10 54 BOLT

3 05.282.08 54 SPRING WASHER

4 05.968.06 54 LOCKNUT

5 09.517.01 54 D-RING SHACKLE

6 09.528.01 108 FLAIL KNIFE, ( STANDARD )

7 02975613 108 FLAIL KNIFE, SERRATED ( OPTIONAL )

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -53

Page 56

SERVO CONTROLLED PISTON PUMP ASY PN 02969527A PART 1

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -54

Page 57

SERVO CONTROLLED PISTON PUMP ASY PN 02969527A PART 1

ITEM PART NO. QTY. DESCRIPTION

02969527A 1 PISTON PUMP - SOLENOID CONTROL

2 02977418 1 JAM NUT

3 02977419 1 RETAINING RING

4 02977420 2 RETAINING RING

6 02977421 1 SEAL WASHER

7 02977422 8 CAP SCREW

8 02977423 1 ROTATING KIT, SUB-ASY

9 02977424 1 SERVO PISTON SUB-ASY

10 02977425 1 FOLLOWER, SERVO PISTON

11 02977426 1 PLATE, COVER

12 02977427 2 GASKET, COVER PLATE

14 02977428 1 GASKET, HOUSING

16 02970209 1 GASKET, CONTROL HOUSING

17 02977430 1 PLATE, COVER

18 02977431 1 CAMPLATE, SUB-ASY

19 02977432 2 RACE, THRUST

20 02977433 1 BEARING, THRUST

21 02977434 2 RELIEF VALVE SUB-ASY

22 02977525 2 O-RING

24 02977436 2 BOLT

25 02977437 2 BOLT

26 02970208 6 SOCKET HEAD BOLT

27 02977439 1 VALVE PLATE

28 02977440 1 HOUSING SUB-ASY.

29 02977526 1 HOUSING

30 02977527 1 BEARING ( PRESS FIT )

31 02977528 1 PLUG SUB-ASY.

32 02977529 1 O-RING

33 02977530 1 CRADLE SUB-ASY.

34 02977531 2 BUSHING, DOWEL

35 02977532 1 BUSHING

36 02977533 1 BUTTON HEAD BOLT

37 02977534 2 BOLT

38 02977535 2 SEAL SUB-ASY.

39 02977441 1 BACKPLATE SUB-ASY.

40 02977536 1 BEARING, PRESS FIT

41 02977537 1 ROLL PIN

42 02977325 1 SHAFT, PISTON PUMP

43 02977551 1 COVER PLATE KIT

44 02977442 1 O-RING

45 02977444 2 BOLT

46 02977449 1 PLATE, COVER

47 02977443 1 MOLDED O-RING

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -55

Page 58

SERVO CONTROLLED PISTON PUMP ASY PN 02969527A PART 2

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -56

Page 59

SERVO CONTROLLED PISTON PUMP ASY PN 02969527A PART 2

ITEM PART NO. QTY. DESCRIPTION

48 02977445 1 WASHER

49 02977446 1 PLUG, SUBASSY

50 02977538 1 O-RING .087 DIA X .644INSIDE

51 02977540 1 USE 02977446

52 02977541 1 USE 02977538

53 02977447 2 PLUG, SUBASSY

54 02977539 2 O-RING .116 DIA X .924INSIDE

58 02977199 1 SEAL PUMP SHAFT

59 02977450 1 CHARGE PUMP ASSEMBLY

60 02977543 1 BUSHING, PRESS FIT W/11 TOOTH

61 02977544 1 PLUG

62 02977545 1 O-RING

63 02977546 1 SHIM (1)NOTE: MAY REQUIRE MORE

64 02977547 1 SPRING

65 02977548 1 POPPET

66 02970207 1 ASY,SOLENOID SERVO CONTROL

67 02977451 1 GEROTOR, INNER RING

68 02977452 1 GEROTOR, OUTER RING

69 02977453 3 ORIFICE, CONTROL VALVE

72 02977456 1 COUPLER

73 02977457 2 RING, RETAINING

74 02977458 1 PLUG SUBASSY

75 02977459 1 WASHER

76 02977460 8 WASHER

77 02977461 4 WASHER

78 02977462 1 RING LOCK

79 02972835 1 ASY CARTRIDGE VALVE W/O COIL

80 02972836 1 ASY COIL

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -57

Page 60

SPINDLE & HOUSING ASY PN 02960553B

ITEM PART NO. QTY. DESCRIPTIONITEM PART NO. QTY. DESCRIPTION

02960553B 1 SPINDLE & HOUSING ASY, SPLINED

1 00999612 1 GREASE, NLGI 000 EP (AS REQUIRED)

2 02963815 1 HOUSING, MACHINED SPINDLE

3 02960561 1 SPINDLE -SPLINED

4 02960558 1 BEARING RING

5 02960559 1 SEAL

6 00754627 1 SNAP RING

7 02960557 1 BEARING CUP & CONE ASY.

8 00755628 1 BEARING CUP & CONE ASY, (USE 00769938)

9 02964269 1 LOCKWASHER, MODIFIED

10 02962030 1 LOCKNUT, SPINDLE BEARING

11 02959018 1 GREASE RELIEF FITTING

Brahma (07-06) Rev 07-07

Brahma (07-06) Rev 07-07

©2007 Alamo Group Inc. Parts Section -58

©2007 Alamo Group Inc. Parts Section -58

Page 61

Page 62

ALAMO INDUSTRIAL

Limited Warranty

1. LIMITED WARRANTIES

1.01. Alamo Industrial warrants for one year from the purchase date to the original non-commercial, governmental, or

1.02. Manufacturer will replace for the Purchaser any part or parts found, upon examination at one of its factories, to be

1.03. This limited warranty does not apply to any part of the goods which has been subjected to improper or abnormal use,

1.04. Except as provided herein, no employee, agent, Dealer, or other person is authorized to give any warranties of any

2. REMEDIES AND PROCEDURES.

2.01. This limited warranty is not effective unless the Purchaser returns the Registration and Warranty Form to Manufacturer

2.02. Purchaser claims must be made in writing to the Authorized Dealer (“Dealer”) from whom Purchaser purchased the

2.03. Purchaser is responsible for returning the goods in question to the Dealer.

2.04. If after examining the goods and/or parts in question, Manufacturer finds them to be defective under normal use and

2.05. Purchaser is responsible for any labor charges exceeding a reasonable amount as determined by Manufacturer and

3. LIMITATION OF LIABILITY.

3.01. MANUFACTURER DISCLAIMS ANY EXPRESS (EXCEPT AS SET FORTH HEREIN) AND IMPLIED WARRANTIES

3.02. MANUFACTURER MAKES NO WARRANTY AS TO THE DESIGN, CAPABILITY, CAPACITY, OR SUITABILITY FOR

3.03. EXCEPT AS PROVIDED HEREIN, MANUFACTURER SHALL HAVE NO LIABILITY OR RESPONSIBILITY TO

3.04. NO ACTION ARISING OUT OF ANY CLAIMED BREACH OF THIS WARRANTY OR TRANSACTIONS UNDER

4. MISCELLANEOUS.

4.01. Proper Venue for any lawsuits arising from or related to this limited warranty shall be only in Guadalupe County,

4.02. Manufacturer may waive compliance with any of the terms of this limited warranty, but no waiver of any terms shall

4.03. If any provision of this limited warranty shall violate any applicable law and is held to be unenforceable, then the

4.04. Applicable law may provide rights and benefits to purchaser in addition to those provided herein.

municipal purchaser (“Purchaser”) and warrants for six months to the original commercial or industrial purchaser

(“Purchaser”) that the goods purchased are free from defects in material or workmanship.

defective under normal use and service due to defects in material or workmanship.

negligence, alteration, modification, or accident, damaged due to lack of maintenance or use of wrong fuel, oil, or

lubricants, or which has served its normal life. This limited warranty does not apply to any part of any internal

combustion engine, or expendable items such as blades, shields, guards, or pneumatic tires except as specifically found

in your Operator’s Manual.

nature on behalf of Manufacturer.

within 30 days of purchase.

goods or an approved Authorized Dealer (“Dealer”) within 30 days after Purchaser learns of the facts on which the

claim is based.

service due to defects in material or workmanship, Manufacturer will:

(a) Repair or replace the defective goods or part(s) or

(b) Reimburse Purchaser for the cost of the part(s) and reasonable labor charges (as determined by Manufacturer)

if Purchaser paid for the repair and/or replacement prior to the final determination of applicability of the warranty

by Manufacturer.

The choice of remedy shall belong to Manufacturer.

for returning the goods to the Dealer, whether or not the claim is approved. Purchaser is responsible for the transportation

cost for the goods or part(s) from the Dealer to the designated factory.

WITH RESPECT TO THE GOODS INCLUDING, BUT NOT LIMITED TO, MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE.

USE OF THE GOODS.

PURCHASER OR ANY OTHER PERSON OR ENTITY WITH RESPECT TO ANY LIABILITY, LOSS, OR DAMAGE

CAUSED OR ALLEGED TO BE CAUSED DIRECTLY OR INDIRECTLY BY THE GOODS INCLUDING, BUT NOT

LIMITED TO, ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL DAMAGES RESULTING FROM

THE USE OR OPERATION OF THE GOODS OR ANY BREACH OF THIS WARRANTY. NOT WITHSTANDING THE

ABOVE LIMITATIONS AND WARRANTIES, MANUFACTURER’S LIABILITY HEREUNDER FOR DAMAGES

INCURRED BY PURCHASER OR OTHERS SHALL NOT EXCEED THE PRICE OF THE GOODS.

THIS WARRANTY MAY BE BROUGHT MORE THAN TWO (2) YEARS AFTER THE CAUSE OF ACTION HAS

OCCURRED.

Texas.

be deemed to be a waiver of any other term.

invalidity of such provision shall not invalidate any other provisions herein.

KEEP FOR YOUR RECORDS

ATTENTION: Purchaser should fill in the blanks below for his reference when buying repair parts and/or for proper machine

identification when applying for warranty.

Alamo Industrial Implement Model ____________________________ Serial Number ________________________________

Date Purchased __________________________________________ Dealer ______________________________________

ATTENTION:

READ YOUR OPERATOR’S MANUAL

ALAMO INDUSTRIAL

1502 E. Walnut

Seguin, Texas 78155

830-379-1480

Page 63

TO THE OWNER/OPERATOR/DEALER

To keep your implement running efficiently and safely, read your manual thoroughly and follow these directions and

the Safety Messages in this Manual. The Table of Contents clearly identifies each section where you can easily find

the information you need.

The OCCUPATIONAL SAFETY AND HEALTH ACT (1928.51 Subpart C) makes these minimum safety

requirements of tractor operators:

REQUIRED OF THE OWNER:

1. Provide a Roll-Over-Protective Structure that meets the requirements of this Standard; and

2. Provide Seatbelts that meet the requirements of this paragraph of this Standard and SAE J4C; and

3. Ensure that each employee uses such Seatbelt while the tractor is moving; and

4. Ensure that each employee tightens the Seatbelt sufficiently to confine the employee to the protected

area provided by the ROPS.

REQUIRED OF THE OPERATOR

1. Securely fasten seatbelt if the tractor has a ROPS.

2. Where possible, avoid operating the tractor near ditches, embankments, and holes.

3. Reduce speed when turning, crossing slopes, and on rough, slick, or muddy surfaces.

4. Stay off slopes too steep for safe operation.

5. Watch where you are going - especially at row ends, on roads, and around trees.

6. Do not permit others to ride.

7. Operate the tractor smoothly - no jerky turns, starts, or stops.

8. Hitch only to the drawbar and hitch points recommended by the tractor manufacturer.

9. When the tractor is stopped, set brakes securely and use park lock, if available.

Keep children away from danger all day, every day...

Equip tractors with rollover protection (ROPS) and keep all machinery

guards in place...

Please work, drive, play and live each day with care and concern for your

safety and that of your family and fellow citizens.

Page 64

Brahma Mower Pub 04-04 P/N 02968822P

Printed U.S.A

Loading...

Loading...