Page 1

OPTIC4 090311 User Guide

Updated 6/9/10

Overview

to +10 VDC current or velocity requests. OPTIC4 may also be specially configured for legacy DC protocol

compatibility to emulate the OPTIC1 board.

The OPTIC4 allows MPU11 based control systems to interface to third party servo drives that accept -10

OPTIC4 Features

Application: Third Party Drive Interface

Number of Axes: 4

Maximum number of Axes: 8 with two OPTIC4 cards in series

DAC resolution: 16 bits

Analog Output Voltage: -10 to +10 Volts

Control Interface: 2 fiber optics to MPU11

motion control card

Dimensions (W*D*H): 12 * 5 * 0.75 inches

OPTIC4 Connection Overview

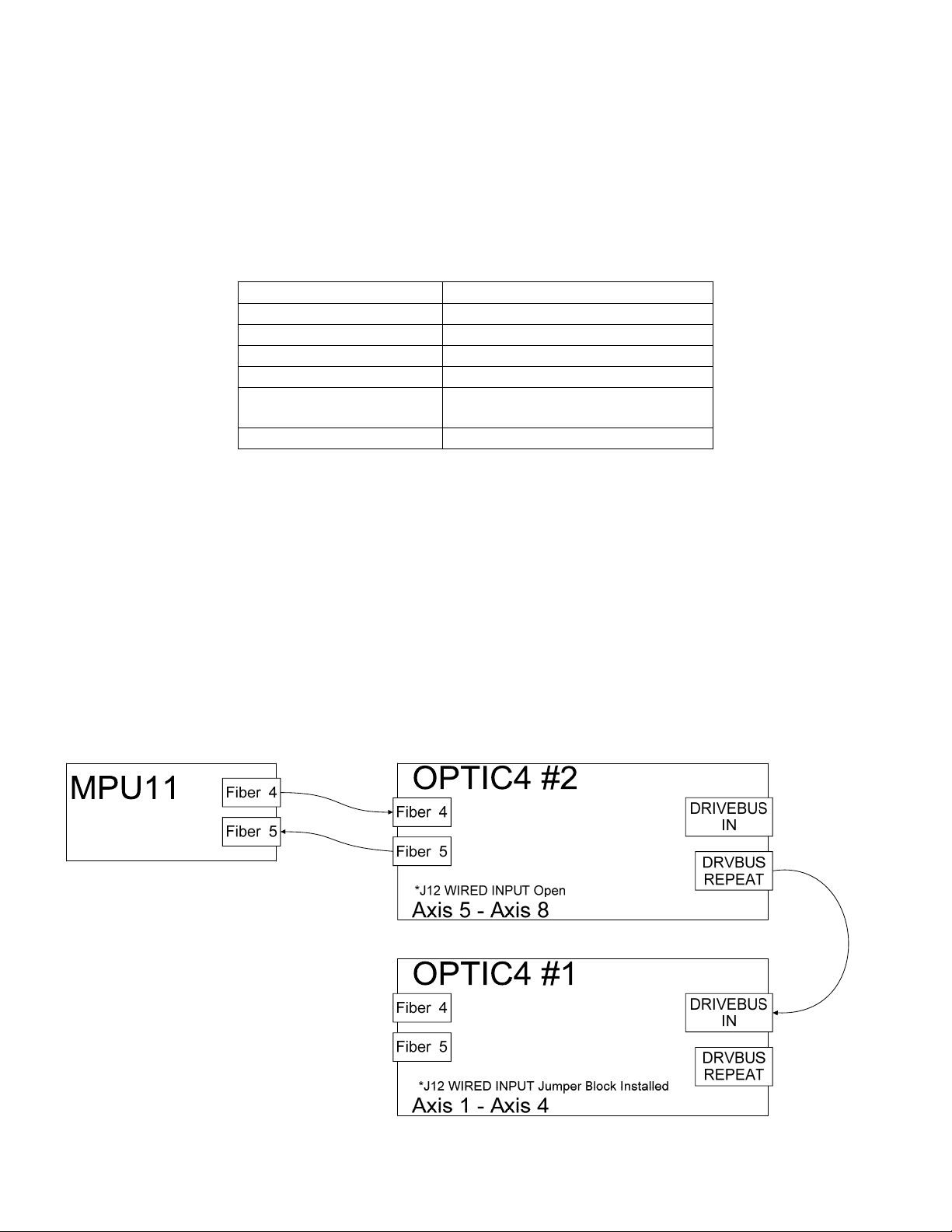

Two OPTIC4 interface cards can be connected to a MPU11 motion control card. The OPTIC4s will

negotiate their axis numbers based on the order they are connected. The last OPTIC4 in the communication

chain will initiate communication and start numbering axes at 1. LED1 will flash one segment at a time during

startup while the OPTIC4s determine their location in the communication chain. After about 10 seconds the

OPTIC4 for axes 1 - 4 will indicate 1 on LED1, and the OPTIC4 for axes 5 - 8 will show 5 on LED1. Once

LED1 stops blinking, startup negotiation is complete and normal operation begins.

LED1 normally indicates the base, or first, axis number on the OPTIC4. If the decimal point is lit, and a

number is flashing on LED1, this indicates an error condition that can be found in the “LED1 Error Codes”

section.

svn://software/optic4/trunk/docs/OPTIC4_MAN.flo MRR Page 1 of 6 8/6/2010

Page 2

Jumper Functions

Designator Jumper Name Function with jumper block in place Function with jumper block removed

J13 Enable Active

High

J12 Wired Input Communicate with another OPTIC4 over

J8 Fiber Repeat Drivebus out to another drive connects with

J10 Config Offset and gain trim - NEVER INSTALL

J9 Aux 1 Spare Spare

J11 Aux 2 Spare Spare

Enable outputs will pull down when axis is

released

wires (this OPTIC4 is not connected to

MPU11)

fiber optics (factory hardwired if all 4 fiber

connectors are installed)

THIS JUMPER

Enable outputs will pull down when axis is enabled

Communicate with MPU11 through fiber connectors

Drivebus out connects to another drive over wires

Normal operation

svn://software/optic4/trunk/docs/OPTIC4_MAN.flo MRR Page 2 of 6 8/6/2010

Page 3

Motor Brake Outputs

Open collector brake driver outputs are provided for each axis. These outputs may be used to

drive a relay to release axis brake solenoids. Note that the OPTIC4 has a built in diode to suppress transients

that should be connected to the relay coil positive supply. This feature does not eliminate the need for noise

suppression devices located close to the relay coil. Motor brake mechanisms may also require noise

suppression, such as a resistor and capacitor network for AC solenoids or a diode for DC solenoids.

Typical Brake Wiring Example

OPTIC4 Internal Circuitry

Brake Relay Driver Output

OPTIC4

RET URN

OPTIC4 Internal Circuitry

Enable and Auxiliary Outputs

5 to 24VDC

Output

Output

External Power Supply

5 VDC

5 COM

OPTIC4 Internal Ci rcuitry

E-stop / Fault Relay Output

External Power Supply

24 VDC

24 COM

Brake Release

Solenoid

E-st op Contact 1

E-st op Contact 2

OPTIC4

RET URN

svn://software/optic4/trunk/docs/OPTIC4_MAN.flo MRR Page 3 of 6 8/6/2010

Page 4

Fault Inputs

Fault inputs are provided for each axis. The input voltage may be from 5 VDC to 24 VDC, but all four

faults must operate from the same voltage. The SIP resistor pack (R69) must be appropriate for the input

voltage.

Typical Fault Input Wiring Example

Servo Drive Internal Circuitry

Fault or Alarm Relay

24 VDC

FAULT COMMON

OPTIC4 Internal Circuitry

Fa ult Input

SIP

24 COM

SIP Identification - XXX Indicates Value

4308R-102

-XXX

SIP Value Marking

471 470 5

122 1.2k 12

222 2.2k 24

SIP Input Voltage Selection

Resistor Value (Ohms) Input Voltage

FAULT IN

SIP Internal Wiring / Pinout

svn://software/optic4/trunk/docs/OPTIC4_MAN.flo MRR Page 4 of 6 8/6/2010

Page 5

OPTIC4 Specifications

Characteristic Min. Typ. Max. Unit

5 Volt Supply Current 0.5 - - A

12 Volt Supply Current 0.25 - - A

Open Collector Output Current - 10 90 mA

Open Collector Output Voltage - 5 25 V

Relay Output Current 0.1 - 10 A @ 125VAC

Relay Output Current 0.1 - 5 A @ 30VDC

Input Operating current 9 11 15 mA

Analog Output Resolution - 16 - bits

Analog Output Voltage -10 - 10 V

Analog Output Current 0 1 20 mA

Fiber 4 and 5 Length - - 100 feet

Size: 12 * 5 * 0.75 (W*D*H) Inches

OPTIC4 Troubleshooting

Symptom Possible Cause Corrective Action

+5V, +12V, or -12V LED not

lit

ENABLE LED not lit and no

error on LED1

Tach output is not stable and

has a square wave shape when

viewed on an oscilloscope

power connection to H1 is

faulty

power not applied to board see +5V, +12V, or -12V LEDs FPGA OK LED not lit

damaged OPTIC4 return for repair

Main enable off Check for errors in software

Encoder is bad - 'A'

channel duty cycle is not

50% at constant velocity

correct wiring or power supply

problem

preventing MPU11 from enabling

drives

Adjust encoder if possible, or replace

encoder

LED1 Error Codes

Error

Number

1 Communication

2 Not Used

3 Not Used

4 Not Used

5 Not Used

6 Not Used

7 Not Used

8 Not Used

9 Not Used

svn://software/optic4/trunk/docs/OPTIC4_MAN.flo MRR Page 5 of 6 8/6/2010

Meaning Cause Corrective Action

Failure

The OPTIC has lost

communication from the

MPU11

Make sure MPU11 is connected and

running. Check fiber 4 or wired

connection. Make sure "WIRED

INPUT" jumper is set properly.

Page 6

12.0"

(305mm)

(152mm)

11.4"

(290mm)

6.0"

OPTIC4 Connections and Mounting Footprint

5.0"

AUX 1 LED

FPGA OK LED

R69 SIP

RESISTOR

(127mm)

ENABLE LED

-12V LED

+12V LED

4.4"

(112mm)

LED1

+5V LED

POWER

Chassis Ground

BRAKE / E-STOP

AXIS 1

AXIS 2 AXIS 3

AXIS 4

DRIVEBUS

IN

E-stop Relay Contact 1

E-stop Relay Contact 2

Brake Relay Driver 1

Brake Relay Driver 2

Brake Relay Driver 3

Brake Relay Driver 4

Relay +5 to +24VDC

Tach Analog

Drive Analog

Tach Analog

Drive Analog

Tach Analog

Drive Analog

Tach Analog

Drive Analog

+5V

Return

Return

Enable

Return

Enable

Return

Enable

Return

Enable

+12V

Return

-12V

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

Return

Auxiliary Output

Fault In

Fault Common

Chassis Ground

Auxiliary Output

Fault In

Fault Common

Chassis Ground

Auxiliary Output

Fault In

Fault Common

Chassis Ground

Auxiliary Output

Fault In

Fault Common

Chassis Ground

Return

Receive +

Receive Transmit Transmit +

HIGH

WIRED

INPUT

ENABLE

ACTIVE

Configuration

Jumpers

ENCODER 4

N/C

Return

-Index

-A

-B

ENCODER 3

+Index

+A

+B

+5V

Fiber 4 to MPU11

Fiber 5 from MPU11

DRIVEBUS

OUT

ENCODER 1

ENCODER 2

N/C

Return

-Index

-A

-B

N/C

Return

-Index

-A

-B

Return

Receive +

Receive Transmit Transmit +

+Index

+A

+B

+5V

+Index

+A

+B

+5V

svn://software/optic4/trunk/docs/OPTIC4_MAN.flo MRR Page 6 of 6 8/6/2010

Loading...

Loading...