CNC Retrots

Centroid Fanuc CNC Retrot Installation Manual

Models: AC/DC-30, AC/DC-60

Appendix C - Understanding Fanuc Motor Labels

www.centroidcnc.com

CENTROID_fanuc_retrot_manual.pdf rev4-21-14 Copyright © 2014 CENTROID

Fanuc is a registered trademark of Fanuc LTD

Motor Compatibility Tables

Encoder Upgrade - DC Motors

Encoder Upgrade - AC Motors

Software Setup

AC Encoder Alignment

Fanuc Motor Tuning

Appendix A - Drill Template

Appendix B - Cable Drawings and Pinouts

Appendix D - Torque, HP, and Wattage

7

14

29

40

47

52

60

62

73

79

Fanuc Retrofits

DRIVE WARRANTY DOES NOT COVER DAMAGE BY FAULTY MOTORS OR WIRING.

READ YOUR CNC11 OPERATORS MANUAL AND AC/DC USERS GUIDE BEFORE PERFORMING A FANUC RETROFIT.

FAILURE TO FOLLOW THE INSTRUCTIONS AND SAFETY PRECAUSTIONS IN THOSE MANUALS COULD RESULT IN

SERIOUS INJURY OR DEATH.

The information provided by CENTROID relating to wiring, installation, and operation of CNC components is intended only

as a guide, and in all cases a qualified technician and all applicable local codes and laws must be consulted. CENTROID makes

no claims about the completeness or accuracy of the information provided, as it may apply to an infinite number of field conditions.

As CNC control products from CENTROID can be installed on a wide variety of machine tools NOT sold or support by

CENTROID, you MUST consult and follow all safety instructions provided by your machine tool manufacture regarding

the safe operation of your machine and unique application.

The procedures detailed in this manual are designed to be used by someone familiar with the AC/DC drive and MPU11

software. This documentation is designed to be used in correlation with the available manuals and technical bulletins, and is not

intended to replace any pre-existing documentation.

Only Fanuc motor handling safety procedures are described in this procedure. Additional safety information can be found

in the CNC 11 Operators Manual and the AC/DC Users guide.

Servo Motor Handling

When working with servo motors:

• NEVER pick up or carry the motor by the cables or the shaft. (Always carry by the frame.) Use a crane or lift to

move the motor when necessary.

• NEVER drop or subject the motor to impact. The servo motor is a precision device.

• NEVER set heavy or sharp objects on the motor or cables. Do not step or sit on the motor or cables.

• NEVER use a metal hammer on any part of the motor. If it is absolutely necessary to use a hammer, use a plastic

hammer.

Keep the motor properly secured and away from the edge of the work area when servicing the motor, as a dropped motor could

cause personal injury or destroy the motor.

Page 2 of 80

Fanuc Retrofits

Failure to do so could void your warranty.

Complete the Following Checklist BEFORE powering on your drive.

To be performed with motors disconnected from drive:

□ Check for >100 MΩ between the motor chassis and motor power terminals.

To be performed with motors connected to drive:

□ Confirm continuity between the drive chassis and the motor chassis.

□ On the drive terminals, check for >100 MΩ between motor shield and power terminals.

□ Check VM wiring for correct polarity.

□ Check motor wiring for correct polarity/phase.

□ Check that all screws are tightened down properly. Driving a motor with a terminal loosened

could result in the terminal block overheating and causing a fire.

□ If you are unsure of the condition of a motor, have it inspected by a qualified professional.

Refer to TB155 for further details.

Page 3 of 80

Fanuc Retrofits

Basic Motor Safety, Procedures, and Best Practices

• Be safely dressed when handling a motor. Wear safety shoes and gloves. Avoid loose clothing which can get caught

on the motor. Be careful not to let hair get caught in the rotary section of the motor. Do not handle the motor with wet hands.

• Shut off the power before working on a motor. Wait at least 5 minutes after the motor is shut off before touching any

power terminals.

• Always use the correct cables. Centroid cables are shown in the motor compatibility table. Wiring diagrams and pin outs

for motors are provided in Appendix B.

• Ensure that the motor and motor related components are mounted securely. Ensure that the base or frame to which the

motor is mounted to is strong enough.

• Do not touch the rotary section of the motor when it is running unless instructed to.

• When attaching a component having inertia to the motor, ensure any imbalance between the motor and component is

minimized.

• Be sure to attach a key to a motor with a keyed shaft.

• Use the motor in appropriate environmental conditions. Do not store flammables in close proximity to the motor. When

not in use, store the motor in a dry location between 0° to 40° C.

• Do not remove the nameplate from a motor.

Page 4 of 80

Getting Started

Introduction.................................................................................................................................................................... 7

Motor Compatibility Tables

AC Motors......................................................................................................................................................... 8

DC Motors....................................................................................................................................................... 10

Spindles Motors.............................................................................................................................................. 12

Encoder Upgrade Kit Installation

DC Motors

Black End Cap (Fanuc ● Gettys) with Tachogenerator...................................................................................15

DC Motors with Stock Encoders..................................................................................................................... 22

AC motors

Early red cap and S Series............................................................................................................................. 30

α and αC Series.............................................................................................................................................. 31

Software Setup

Software Setup

Control Configuration...................................................................................................................................... 41

Motor Parameters........................................................................................................................................... 42

Temperature Coefficients................................................................................................................................43

PID and Motor Setup....................................................................................................................................... 44

AC Encoder Alignment

Introduction..................................................................................................................................................... 48

Procedure........................................................................................................................................................ 49

Tuning the Fanuc Motor on a AC/DC

Maximum Feed Rate....................................................................................................................................... 53

Introduction to PID.......................................................................................................................................... 54

PID Tuning Setup............................................................................................................................................ 55

Acceleration Tuning.........................................................................................................................................56

Inertia Tuning.................................................................................................................................................. 57

Position Kp Tuning..........................................................................................................................................58

Position Kd Tuning..........................................................................................................................................59

Performing a System Test............................................................................................................................... 60

Fanuc Retrofits

Table of Contents

Appendices

Appendix A - Drill Template........................................................................................................................................ 61

Appendix B - Cable Drawings and Pinouts

Appendix C - Understanding Fanuc Motor Labels

Appendix D - Torque, HP, and Wattage

Centroid Encoder Cable.................................................................................................................................. 63

Fanuc Encoder Cable..................................................................................................................................... 64

QD200 Pigtail for Black Cap Motors............................................................................................................... 65

QR12 Pigtail for AC Motors............................................................................................................................. 66

QD200 Pigtail for Yellow Cap Motors.............................................................................................................. 67

Extra Large AC Power Cable.......................................................................................................................... 68

Large AC Power Cable....................................................................................................................................69

Large DC Power Cable................................................................................................................................... 70

Medium AC/DC Power Cable.......................................................................................................................... 71

Motor Pinouts..................................................................................................................................................72

Black Caps......................................................................................................................................................74

Yellow Caps..................................................................................................................................................... 75

AC Motors....................................................................................................................................................... 76

Spindle Motors................................................................................................................................................ 78

DC Motors....................................................................................................................................................... 80

AC Motors....................................................................................................................................................... 81

Page 5 of 80

Fanuc Retrofits

Introduction

With the large number of aging FANUC equipped CNC machine tools in the world, CENTROID has answered the call for

an affordable and reliable upgrade! Directly control FANUC servo motors with CENTROID's MPU11 based AC/DC drive.

Retaining the Fanuc servo motor while eliminating the Fanuc user interface and motion control provides savings in time and

money.

This manual covers:

• How to install, align, configure, and tune Fanuc AC and DC motors using Centroid encoders.

• How configure and tune DC Fanuc motors re-using original Fanuc pulse coders

• The basics needed to connect a Fanuc spindle motor to a GPIO4D

Motor series supported:

• Gettys ● Fanuc (Black Cap)

• M Series (Yellow Cap)

• Early red caps

• S Series

If the Fanuc motor has a yellow or black end cap, it is a DC motor. If the Fanuc motor has a red cap, it is an AC motor.

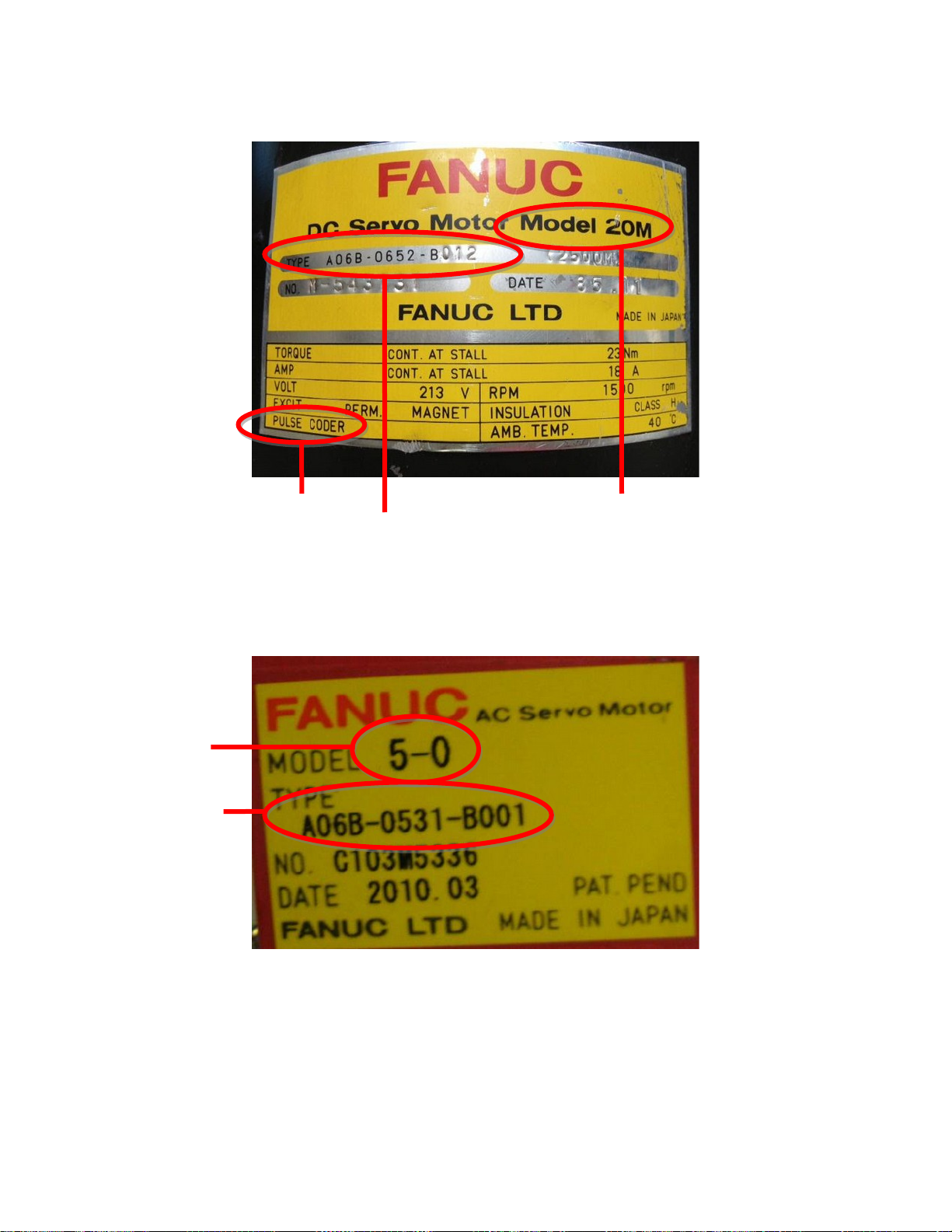

The first step in retrofitting a motor to find your motor in our Motor Compatibility Tables listed on the following pages. Samples of

Fanuc motor labels are shown in Appendix to help identify your motor.

• α Series

• αC Series

• β Series

• Three models of spindle servo motors.

Page 6 of 80

Fanuc Retrofits

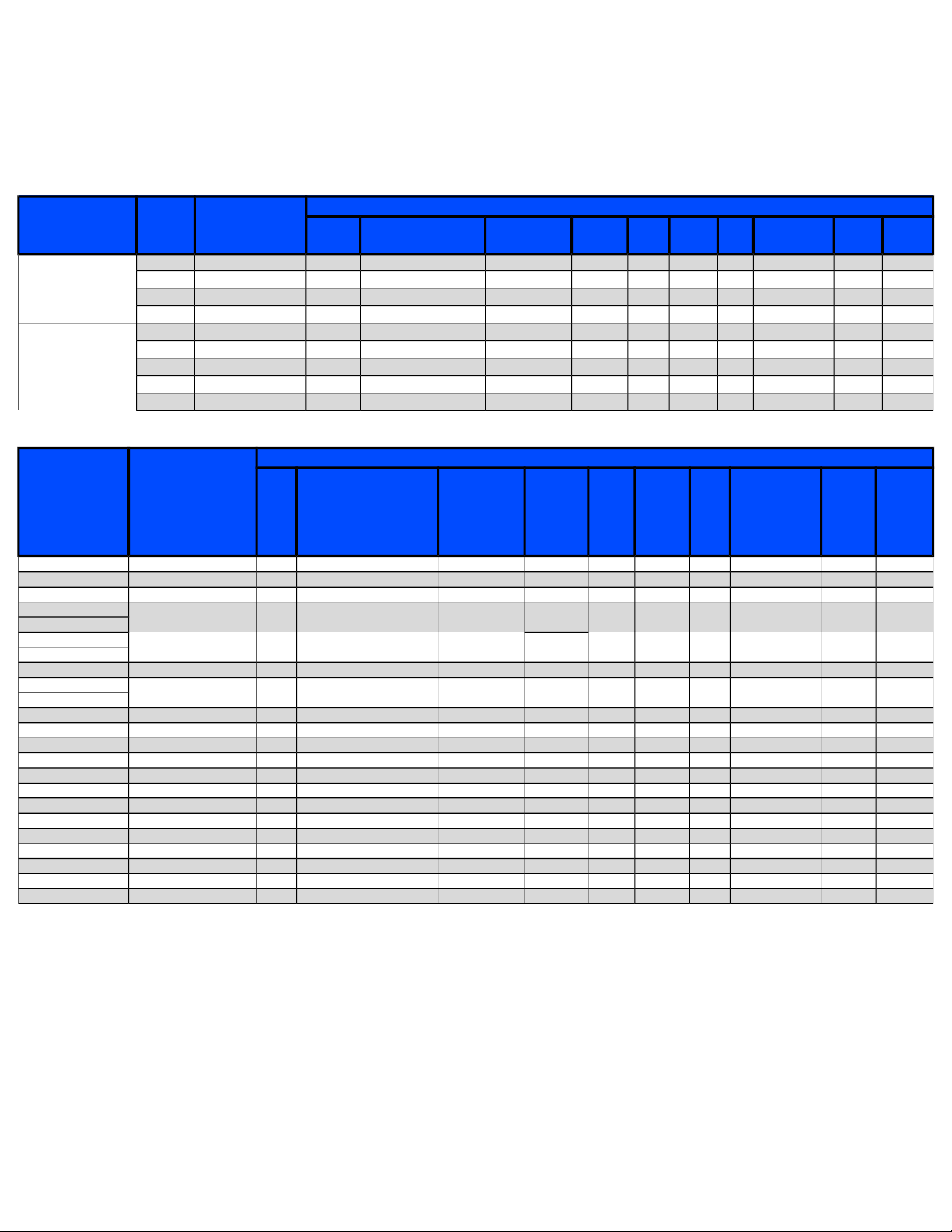

Fanuc AC Motor Compatibility Table

[1]

Fanuc Motor

Series

Early Red Caps

S Series

α (Alpha) Series

&

αC Series

[6]

β (Beta) Series

&

βis Series

1. This table is not a complete list of all Fanuc AC motors, just motors we have verified.

2. An AC/DC-60 may be substituted for an AC/DC-30.

3. Motors with a continuous stall current of above 30A or below 5A are not recommended with the AC/DC. (This gives the AC/DC an approximate range of 500

watts to 6,000 watts or 0.7 hp to 7.8 hp.)

4. You may reuse the existing power cables from your Fanuc with the AC/DC. Cable information is provided for ordering replacement cables and troubleshooting.

5. Encoder retrofit kit currently not available, Centroid can provide engineering to develop or installer to mount encoder.

6. Most Fanuc documentation lists the αC Series as a member of the α Series, while some Fanuc documentation lists the αC Series as a member of the β series.

7. Not to be confused with the yellow-capped DC motor also designated "20M".

Cable drawings and pinouts can be found in Appendix B, Motor RPM, torque, hp, and wattage can be found in Appendix D

Motor

Model

0 A06B-0511-Bxxx

5 A06B-0512-Bxxx

10 A06B-0501-Bxxx

20 A06B-0502-Bxxx

30 A06B-0503-Bxxx

0-0SP A06B-0374-Bxxx

0S A06B-0313-Bxxx

5S A06B-0314-Bxxx

5S/3000 A06B-0514-Bxxx

6S A06B-0316-Bxxx

6S/3000 A06B-0320-Bxxx

10S A06B-0315-Bxxx

10S/3000 A06B-0317-Bxxx

20S A06B-0502-Bxxx

20S/1500

20M

30S A06B-0590-Bxxx

30R

30/2000

40 A06B-0581-Bxxx

20S/3000 A06B-0318-Bxxx

30S/3000 A06B-0319-Bxxx

40S/2000 A06B-0583-Bxxx

α3/3000 A06B-0123-Bxxx

α6/2000 A06B-0127-Bxxx

α6/3000 A06B-0128-Bxxx

αC12/2000 A06B-0141-Bxxx

α12/2000 A06B-0142-Bxxx

α12/3000 A06B-0143-Bxxx

αC22/1500 A06B-0145-Bxxx

α22/1500 A06B-0145-Bxxx

α22/1500 A06B-0146-Bxxx

α30/1200 A06B-0151-Bxxx

α22/2000 A06B-0147-Bxxx

α30/2000 A06B-0152-Bxxx

α40/2000

αC3/2000 A06B-0121-Bxxx

αC6/2000 A06B-0126-Bxxx

α22/3000 A06B-0148-Bxxx

α30/3000 A06B-0153-Bxxx

α40/2000

α1/3000 A06B-0371-Bxxx

α2/2000 A06B-0372-Bxxx

α2/3000 A06B-0373-Bxxx

β3/3000

β6/2000

β4/4000is

β8/3000is

β12/300is

β22/2000is

β0.5/3000

β1/3000

β2/3000

Motor Type

A06B-0505-Bxxx

[7]

A06B-0506-Bxxx

A06B-0157-Bxxx

(Without fan)

A06B-0158-Bxxx

A06B-0033-Bxxx

A06B-0034-Bxxx

A06B-0063-Bx0x

A06B-0075-B203

A06B-0078-Bx0x

A06B-0085-Bx0x

A06B-0113-Bxxx

A06B-0031-Bxxx

A06B-0032-Bxxx

(With fan)

Extra Large AC Power Cable

Extra Large AC Power Cable

Power

Cable

Medium AC or DC Cable

Drawing #. S13370

Large AC Power Cable

Drawing # S13362

Medium AC or DC Cable

Drawing # S13370

Large AC Power Cable

Sub assembly # 12894

Drawing # S13362

Drawing # S13371

Medium AC or DC Cable

Drawing # S13370

Large AC Power Cable

Sub assembly # 12894

Drawing # S13362

Drawing # S13371

[4]

Not Recommended

Not Recommended

Please contact Centroid for a retrofit solution.

Not Recommended

AC/DC

Drive

Model

AC/DC–30

AC/DC - 60

AC/DC – 30

AC/DC - 60

AC/DC – 30

AC/DC - 60

[5]

TBD

Encoder

Retrofit Kit

Retrofit Kit # 12859

[2]

Installation

Instructions

Page 31

[2]

Retrofit Kit # 12859

or # 12876

See next page to

choose a kit for your

application.

[3]

[2]

Retrofit Kit # 12876

Installation

Instructions

Page 28

[3]

[3]

Encoder

Cable

AC/DC Encoder Cable

Sub assembly #12912

Drawing # S13369

Page 7 of 80

Fanuc Retrofits

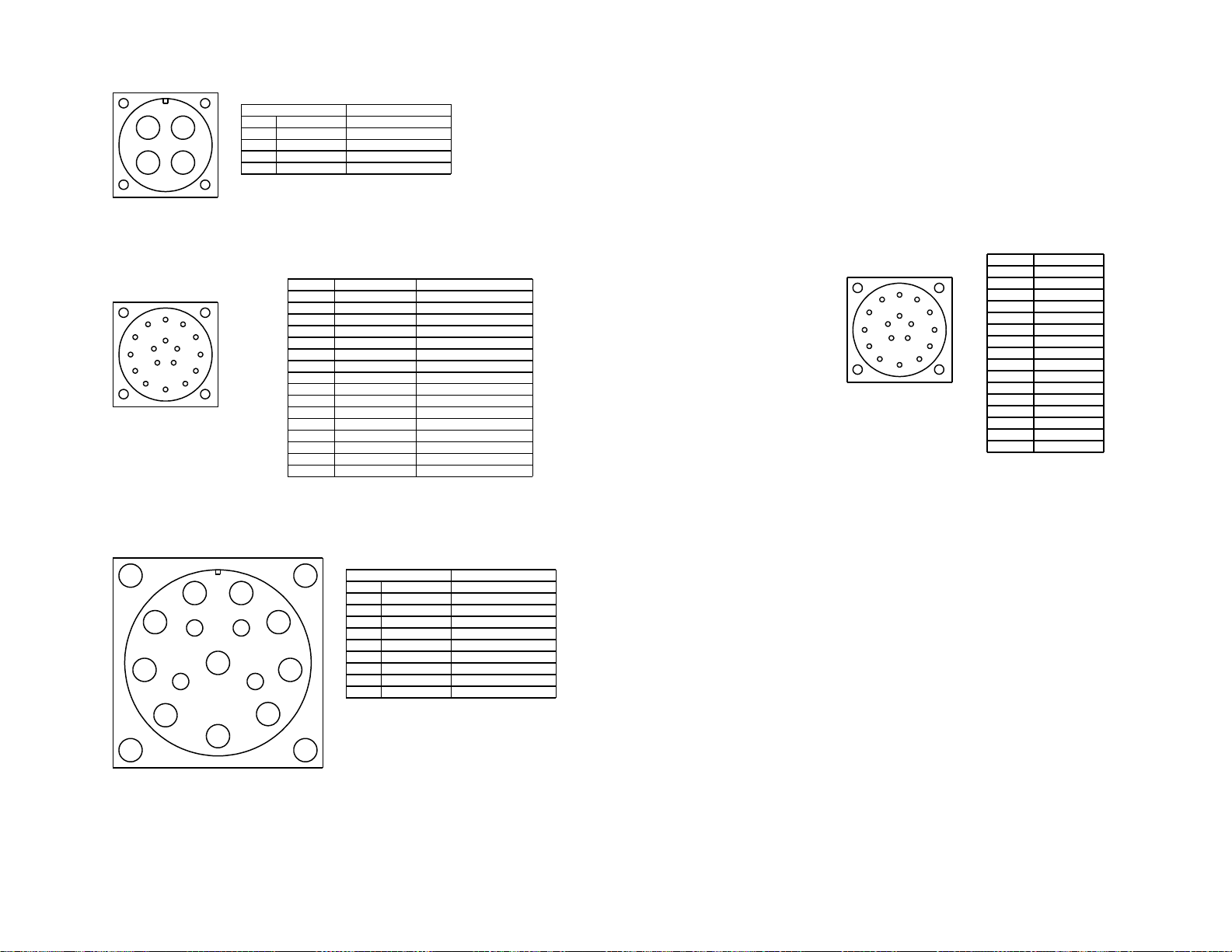

Choosing a Retrofit Kit for Your Fanuc “S” Series AC Servo Motor

In order to differentiate between the two different styles of encoder used on Fanuc's “S” series motors, it is necessary to

remove the red motor end caps and visually inspect the pulse coders.

If your servo motor's encoder resembles this one, you will need assembly #12859. Instructions found in section “AC

Motors: Early and S Series Models” on page 31.

If your servo motor's encoder resembles this one, you will need assembly #12876. Instructions found in section “AC

Motors: α (Alpha) Series Models” on page 37.

Page 8 of 80

Fanuc Retrofits

Black End Cap (Fanuc ● Gettys)

DC Motor Compatibility Table

[1]

Fanuc

Measurement

Motor

Model

Technology

00 A06B-0631-B0xxx TBD

0 A06B-0613-B0xx

Tachogenerator

where xxx is 001 - 028

Pulse Coder

where xxx is 031 or 032

1. This is not a list of all Fanuc DC motors, just the motors we have verified.

2. An AC/DC-60 servo drive may be substituted for an AC/DC-30 servo drive.

5 A06B-0614-Bxxx

10 A06B-0601-Bxxx

30 A06B-0603-Bxxx

00 A06B-0631-B0xx TBD

0 A06B-0613-B0xx

5 A06B-0614-Bxxx

10 A06B-0601-Bxxx

30 A06B-0603-Bxxx

Motor

Type

Power

Cable

Medium AC or DC Cable

Drawing # S13370

Large DC Power Cable

Sub assembly # 12895

Drawing # S13361

Medium AC or DC Cable

Drawing # S13370

Large DC Power Cable

Sub assembly # 12895

Drawing # S13361

[3]

AC/DC

Drive

Model

AC/DC – 30

AC/DC - 6020 A06B-0602-Bxxx

AC/DC – 30

AC/DC - 6020 A06B-0602-Bxxx

Encoder

Retrofit Kit

[4]

[2]

Encoder Retrofit

Kit # 12903

Installation Instructions

Page 15

[4]

[2]

Reuse stock Fanuc

encoder OR replace

with Centroid Encoder

Retrofit

Kit # 12896

Installation Instructions

Page 22

Encoder

Cable

AC/DC Encoder Cable

Sub assembly #12912

Drawing #S13369

Fanuc Coder Cable

Sub assembly # 12893

Drawing # S13357

3. You may reuse the existing power cables from your Fanuc with the AC/DC. Cable information is provided for ordering replacement cables and troubleshooting.

4. CENTROID Encoder retrofit kit has not been developed yet. Centroid can provide engineering services to develop an encoder kit or adapt your own.

Motors with a continuous stall current of above 30A or below 5A are not recommended with the AC/DC servo drive.

(This gives the AC/DC servo drive an approximate range of 500 watts to 6,000 watts or 0.7 hp to 7.8 hp.)

Cable drawings and pinouts can be found in Appendix B

Motor RPM, torque, hp, and wattage can be found in Appendix D

Page 9 of 80

Fanuc Retrofits

Yellow End Cap (M Series)

DC Motor Compatibility Table

[1]

Fanuc

Measurement

Technology

Tachogenerator

or

Resolver

where xxx is 001 or 005

Pulse Coder

where xxx is 011, 012, or 005

Motor

Model

00M A06B-0632-Bxxx

0M A06B-0641-Bxxx

5M A06B-0642-Bxxx

10M A06B-0651-Bxxx

20M A06B-0652-Bxxx

30M A06B-6053-Bxxx

0M A06B-0641-Bxxx

5M A06B-0642-Bxxx

10M A06B-0651-Bxxx

20M A06B-6052-Bxxx

30M A06B-6053-Bxxx

Motor

Type

Power

Cable

Medium AC or DC Cable

Drawing # S13370

Large DC Power Cable

Sub assembly # 12895

Drawing # S13361

Large DC Power Cable

Sub assembly # 12895

Drawing # S13361

Medium AC or DC Cable

Drawing # S13370

Large DC Power Cable

Sub assembly # 12895

Drawing # S13361

Large DC Power Cable

Sub assembly # 12895

Drawing # S13361

[3]

AC/DC

Drive

Model

AC/DC – 30

AC/DC – 60

AC/DC – 30

AC/DC – 60

Encoder

Retrofit Kit

[2]

Reuse stock Fanuc

[2]

encoder OR replace with

Centroid Encoder

Installation Instructions

[4]

TBD

Retrofit

Kit # 12896

Page 22

Encoder Cable

AC/DC Encoder Cable

Sub assembly #12912

Drawing # S13369

AC/DC Encoder Cable

( Use with Retrofit

Encoder )

Sub assembly #12912

Drawing # S13369

Fanuc Coder Cable

( Use with Existing

Encoder)

Sub assembly # 12893

Drawing # S13357

1. This is not a list of all Fanuc DC motors, just the motors we have verified.

2. An AC/DC-60 servo drive may be substituted for an AC/DC-30 servo drive.

3. You may use the existing power cables from your Fanuc with the AC/DC servo drive . Cable information is provided for ordering replacement cables and

troubleshooting.

4. CENTROID Encoder retrofit kit has not been developed yet. Centroid can provide engineering services to develop an encoder kit or adapt your own.

Motors with a continuous stall current of above 30A or below 5A are not recommended with the AC/DC servo drive.

(This gives the AC/DC servo drive an approximate range of 500 watts to 6,000 watts or 0.7 hp to 7.8 hp.)

Cable drawings and pinouts can be found in Appendix B

Motor RPM, torque, hp, and wattage can be found in Appendix D

Page 10 of 80

Fanuc Retrofits

Fanuc Spindle Inverter

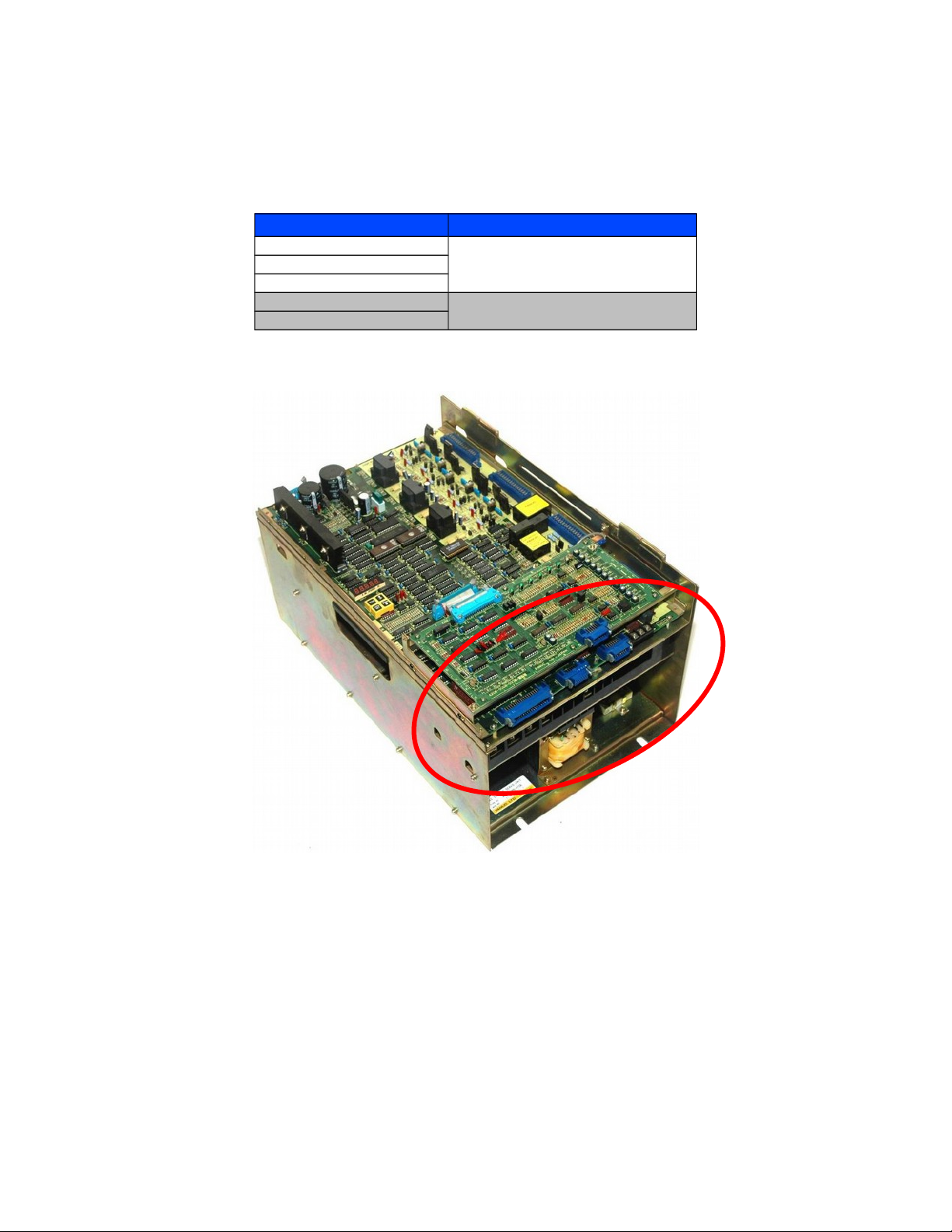

If your spindle is a 6044, 6055, or 5059 and does NOT use optical fiber inputs, then it is compatible with the Centroid

GPIO4D Drive Interface and PLC. Supported spindles require a 0 to +10 VDC input with forward and reverse commands. Mills

with the orient function contain an extra circuit board on the spindle control as shown below.

Spindle Inverter Compatibility Table

Spindle Motor Type Support

A06B-6044-xxxx

Models Without Fibers SupportedA06B-6055-xxxx

A06B-6059-xxxx

A06B-6064-xxxx

α## / #### (Alpha Series)

1. This is not a list of all Fanuc spindle motors, just the motors we have verified.

Not Supported

[1]

Spindle Control with the ORIENT function.

For more reading on AC spindle inverters, read Tech Bulletin #008 “AC Inverter Spindle Motors” and Tech Bulletin

#152 “Inverter Control”.

If connecting the spindle encoder output directly to a Centroid system (unnecessary in most situations), a Motrona Si 251

Sine/Cosine Inerpolater with Adjustable Multiplication Rate Interface is available from Centroid.

The following pages contain I/O information and an example schematic.

Page 11 of 80

I/O Information for a Fanuc Spindle Drive

CN1-22

CN1-26 Common

Stopped

CN1-32

If the spindle driv e has the ORIENT function, it w ill have a ORIENT card on top of the main card.

CN1-14 Common

CN1-6 Common

CN1-12

CN1-21 TLMH (Torque Limit High Gear)

CN1-46 Rev erse

CN1-4

CN1-16

CN1-31

CN1-1

CN1-17 High Gear (Used If ORIENT)

CN1-45 Forward

Spindle Speed

Common

Speed Arrival

A20B-0009-0520

CN1-24 Low Gear (Used If ORIENT)

CN1- 48 Common

CN1-23

Alarm

CN1-7 Ready

CN1-20 Common

CN1-25 Orient

Torque Limit

Spindle Drive Outputs

CN1-9

CN1-49 Load Meter

ORIENT Complete

CN1-19 Alarm Reset

A20B-0008-0240 (0241)

CN1-50 Speed Meter

A20B-0008-0030 (0031)

CN1-15

CN1-5 TLML (Torque Limit Low Gear)

CN2 connector has feedback from motor, and MUST be left on.

CN1-18 Common

CN1-18 Common

Speed Detect

0 V - 10 V Signal

CN1-10

Spindle Drive Inputs

CN1-2

CN1-11

CN1-3

CN1- 47 E-Stop

* The D/A chip on the board needs

pulled out. It w ill be in a socket on the

spindle control board labeled CBI or

CCD. Only one socket w ill have a

chip.

CN1-8 Common

Fanuc Retrofits

Page 12 of 80

Fanuc Retrofits

Example of a Schematic for a Fanuc Spindle Drive

Page 13 of 80

Fanuc Retrofits

DC Motors

Yellow (M Series) and Black (Fanuc●Gettys) end caps are used on DC motors. At the time of this publication, black cap

motors with resolvers and yellow cap motors with tachogenerators/resolvers are not supported.

If the motor has a functioning encoder, it can be used without any modification. Skip to Software Setup section.

DC Motors: Black End Cap Tachogenerator

` This guide is for upgrading the tachogenerator on a black end cap motor. To retrofit a black end cap DC motor, use the

Fanuc Encoder Retrofit Kit 12903 as shown below.

1. 1 Encoder (PN 7546)

2. 1 Pigtail Gasket (PN 4602)

3. 1 Encoder Drill Template (PN 12906)

Waiting on a new picture!

4. 2 Encoder Mounting Bolts (PN 7485)

5. 2 Encoder Mounting Nuts (PN 7571)

6. 1 Encoder Pigtail (PN 12890)

Page 14 of 80

Fanuc Retrofits

1

1

22334

4

Encoder Installation

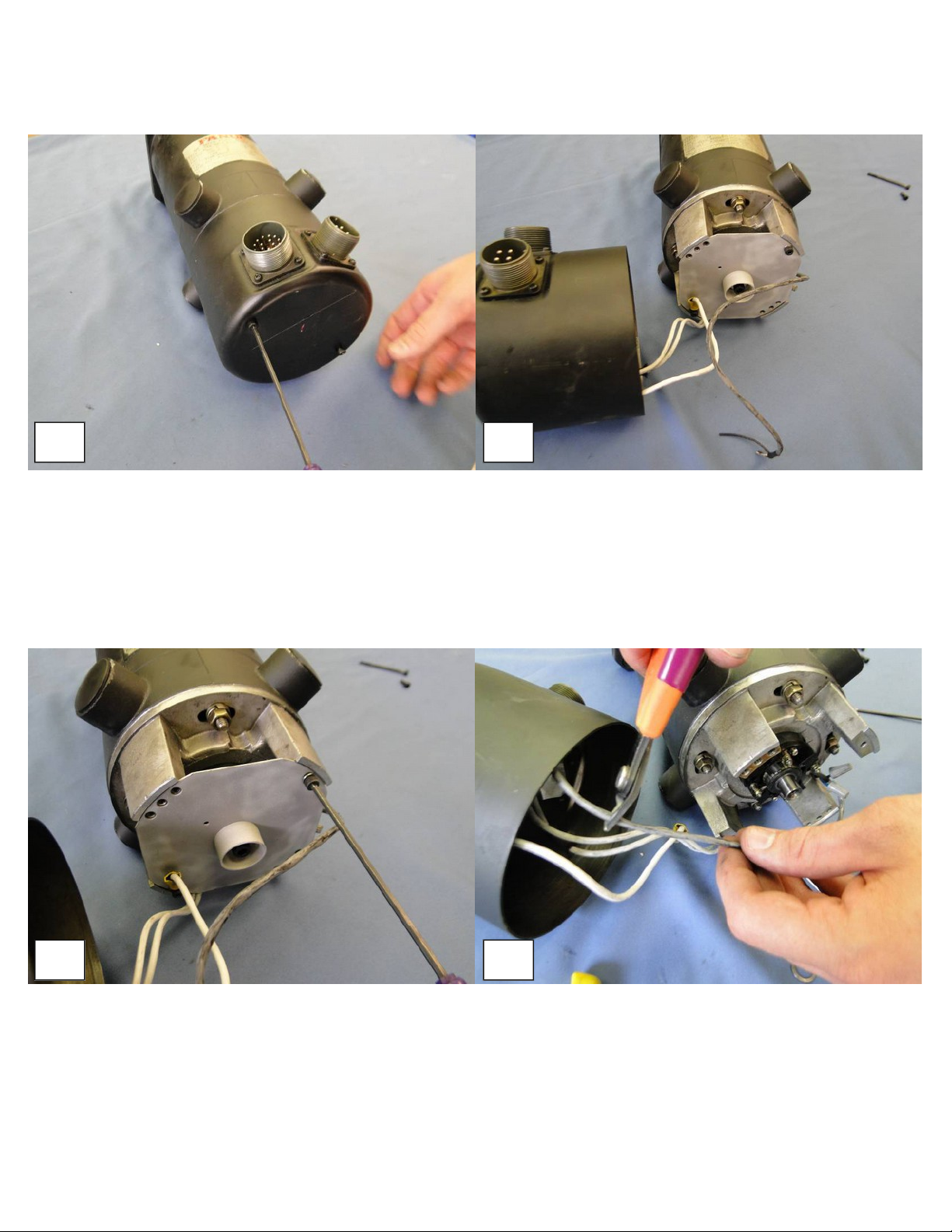

Remove the two bolts holding the black end cap in place using a

3mm hex key. Set aside the end cap bolts. You will use them

again in a later step.

Remove the end cap to expose the tachogenerator assembly.

Remove the mounting plate bolts using a 3mm hex key. Pull off

the mounting plate. Set aside both the mounting plate and

mounting plate bolts, you will use them again in a later step.

.

Disconnect the temperature sensor wires and the

tachogenerator wires. Cut the wires to the tachogenerator.

Unscrew the wire nuts to remove the wire for the temperature

sensor. DO NOT CUT THE POWER WIRES GOING TO THE

MOTOR!

Page 15 of 80

Fanuc Retrofits

556

6

778

8

Remove the center bolt using a 5mm hex key. Remove the retaining screws on the outer stator with a Phillips

screwdriver.

Remove the rotor of the stator of the tachogenerator. Remove the retaining screws on the inner stator with a screw

driver.

Page 16 of 80

.

Fanuc Retrofits

9910

10

11

11

12

12

Remove the remaining piece of the tachogenerator. The motor

should look like this.

Remove the four encoder connector screws. Set aside the

connector screws. You will use them again in a later step.

Acquire the mounting plate you removed in Step 3. If the

mounting plate is dirty or greasy, clean it with some isopropyl

alcohol. Cut out the 1-inch hole on the center of the sticker and

apply to the mounting plate. If your sticker gets lost or damaged,

a template to make a new one is included in Appendix A.

.

Use a center punch to mark the holes on the mounting plate.

Page 17 of 80

Fanuc Retrofits

13

13

14

14

15

15

16

16

Place the encoder on the mounting plate. Insert the encoder

mounting bolts through the mounting plate.

Use a drill press and a #30 drill bit to make both holes in

the mounting plate.

Loosely mount the encoder using the nuts included in the retrofit

kit. The bolts should be loose enough that the encoder can

slide slightly in each direction.

.

Check to make sure the encoder collar screws are backed out.

Slide the encoder assembly onto the back of the motor.

Page 18 of 80

Fanuc Retrofits

17

17

18

18

19

19

20

20

Re-insert the mounting plate bolts that were removed in step 3

with a 3mm hex key.

Tighten the encoder set screws and mounting bolts.

Slide the gasket with the encoder pigtail into the black end cap. Tighten the encoder pigtail using the bolts you removed in Step

10.

Page 19 of 80

.

Fanuc Retrofits

21

21

22

Connect the encoder pigtail connector to the encoder. Apply a bead of non-corrosive RTV sealant (such as Dow

Corning 3165 or 748) onto the end cap mounting surface.

Reinstall the end cap with the bolts removed in step 1.

You are done installing the encoder!

Jump to the Software Setup section.

.

Page 20 of 80

Fanuc Retrofits

DC Motors

DC Motors: Black and Yellow End Cap with Stock Encoder

This guide is for upgrading the relatively low-resolution Fanuc pulse to a high-resolution encoder. To retrofit a black end

cap DC motor, use the Fanuc Encoder Retrofit Kit 12896 as shown below.

Waiting on a new picture!

1. 1 Encoder and MS Connector (PN 12892)

2. 1 Encoder Drill Template (PN 12983)

3. 2 Encoder Standoffs (PN 3636)

.

4. 2 Encoder Mounting Screws (PN 887)

5. 1 Pigtail Gasket (PN 4602)

Page 21 of 80

Fanuc Retrofits

1

1

22334

4

Encoder Installation

Remove the two bolts holding the black end cap in place

using a 3mm hex key. Set aside the end cap bolts. You will

use them again in a later step.

Remove the end cap to expose the pulse coder assembly.

Cut the pulse coder signal cable as well as the two temperature

sensor wires. DO NOT CUT THE GROUND WIRE!

.

Using a Phillips screwdriver, remove the three pulse coder

mounting screws. Set them aside. They will be used again in

step 21.

Page 22 of 80

Fanuc Retrofits

556

6

778

8

Remove the pulse coder. A brass coupling will remain on either

the motor or pulse coder side.

Remove and inspect the coupler. It should fit snugly into the

encoder and the motor. If the coupler is worn or damaged, order

a new one from Fanuc.

Size 0 and 5 motors: Part# A290-0611-x532

Size 10, 20, 30 motors: Part# A290-0501-x503

Using a hex key, remove the two encoder cover bolts. Remove the encoder cover.

Page 23 of 80

.

Fanuc Retrofits

9910

10

11

11

12

12

Remove all the electronics and optics found within the

encoder. Be careful, as the encoder contains a glass disk

which may shatter during removal. Clean off all dirt and glue

residue.

Cut out the center circle on the template, peel off the backing,

and apply it to the encoder base. If you wish, you may also cut

along the outer circle on the template and use it as an

additional reference when aligning it. Position the template

such that the 6-32 hole locations will not interfere with any of

the existing holes on the encoder base. The template MUST

BE CENTERED on the encoder base. Improper alignment

could cause unstable operation as well as cause damage to

your equipment.

Using a sprung center punch, mark the two hole centers on

the base through the template.

.

Refer to drawing D00327 in appendix A of this manual and

double check the center mark locations against the drawing.

Again, THE HOLE LOCATIONS ARE CRITICAL. Ensure that

the actual locations of the center marks are within 0.005” from

their specified locations.

Page 24 of 80

Fanuc Retrofits

Clean the holes of burrs and shavings.

13

13

14

14

15

15

16

16

Using a drill press with a #35 (or 7/64”) drill bit, drill holes on

the center marks approx 0.5” deep. The exact hole depth will

vary depending on the clearance required for your tap. Once

again, check the hole locations against drawing D00327.

Using a 6-32 tap, a tap handle, and some cutting fluid, carefully

thread the holes you just drilled to a minimum depth of 0.3”

Using a nut driver, screw the standoffs from your kit into the

holes you just tapped. Tighten to approximately 8 In-Lb or 0.9

Nm. Do not over-tighten.

.

Slide the encoder onto the shaft.

Page 25 of 80

Fanuc Retrofits

17

17

18

18

19

19

20

20

Using a Phillips screw driver and the crews from the retrofit

kit, secure the encoder flex mount to the standoffs. Tighten to

approximately 8 In-Lb or 0.9 Nm.

Using a hex key, tighten the two set screws on the encoder

collar.

.

Re-insert the brass coupler removed in step 6. Line up the coupling and place the encoder base back into its

original location on the motor.

Page 26 of 80

Fanuc Retrofits

21

21

18

18

19

19

20

20

Re-insert the screws that were removed in step 4. If the

ground wire was originally held down by one of the mounting

screws, re-attach it now. Alternately, the ground wire may be

bolted to one of the unused holes in the motor chassis with a

m4 bolt or screw.

Using a Phillips screw driver, remove the four MS connector

mounting screws. Set them aside. They will be used again in

step 24.

Remove the original MS connector, wiring, and gasket. Clean

the mounting area.

.

Install the pigtail connector and gasket from your kit using the

screws removed in step 22.

Page 27 of 80

Fanuc Retrofits

21

21

22

Connect the pigtail to the encoder. Apply a bead of non-corrosive RTV sealant (such as Dow

Corning 3165 or 748) onto the end cap mounting surface.

Reinstall the end cap with the bolts removed in step 1.

You are done installing the encoder!

Jump to the Software Setup section.

.

Page 28 of 80

Fanuc Retrofits

AC Motors

Red end caps are used on Fanuc AC motors. The Fanuc AC motors have coders/encoders that use a physically different

connector and a proprietary continuation protocol and must be retrofitted to use a Centroid encoder.

AC Motors: Early Red Caps and Some S Series Models

To retrofit a non-S or early S series motor, use the Fanuc Encoder Retrofit Kit 12859 as shown below

Waiting on a new picture!

1. 1 Adapter Plate (PN 12879)

2. 1 Adapter Shaft (PN 12880)

3. 1 Encoder, 40,000 Count (PN 7480)

4. 1 Encoder Pigtail (PN 12821)

5. 3 M4 standoffs (PN 7486)

.

6. 3 Plate Mounting Bolts (PN 6685)

7. 3 Lock Washers (PN 7484)

8. 2 Encoder Mounting Bolts (PN 2762)

9. 1 Pigtail Gasket (PN 4602)

Page 29 of 80

Fanuc Retrofits

3

4

1

2

Encoder Installation

4mm hex key. Set aside the end cap bolts, you will use them

again in a later step.

Remove the end cap and expose the pulse coder assembly.Remove the four bolts holding the red end cap in place using a

Remove the four coder connector screws with a Phillips

screwdriver. Set aside the connector screws. You will use them

again in a later step.

.

On two-piece connectors, remove the connector by prying the

connector apart with a flat blade screwdriver. Then remove the

connector from the end cap. On single-piece connectors, cut the

wires to remove the connector from the end cap.

Page 30 of 80

Fanuc Retrofits

785

6

Cut the temperature sensor wires going from the motor to the

pigtail connector.

Remove the encoder mounting bolts.

Remove the rubber dust cover on the pulse encoder. Loosen

the center bolt using a 4mm hex key while holding the motor

shaft.

.

Gently pull the encoder off the motor. If the encoder is stuck,

Use two allen wrenches to get under the encoder and pry up

and out on the encoder NEVER use a metal hammer or any

type of impact to remove an encoder! Once the encoder is

out then the center bolt can be removed.

Page 31 of 80

Fanuc Retrofits

11

12

9

10

Using a 7mm nut driver, screw the M4 standoffs from the

upgrade kit into the inside of the motor chassis. Tighten to

approximately 8 Lb-In or 0.9 Nm. DO NOT OVER-TIGHTEN!

Use the three plate mounting bolts with lock washers to attach

the adapter plate to the M4 standoffs inside the motor chassis.

Use a 3 mm hex key to attach the plate mounting bolts. Tighten

to approximately 8 In-Lb or 0.9 Nm.

Place the adapter shaft from the kit onto the motor’s encoder

mounting shaft.

.

Check to make sure the encoder collar screws are backed out.

Gently slide the encoder from the kit onto the adapter shaft.

Page 32 of 80

Fanuc Retrofits

15

16

13

14

Install the encoder mounting screws using a 2mm hex key.

Leave the screws loose, as you will need the encoder to be

moveable during the alignment.

Reuse the center bolt that was removed from the old encoder in

step 7. Using a 4mm hex key, tighten the bolt into the encoder

mounting shaft.

Slide the gasket with the encoder pigtail into the red end cap. Reusing the screws from step 3, tighten down the pigtail and

gasket into the red end cap.

Page 33 of 80

.

Fanuc Retrofits

17

18

Plug the pigtail connector firmly into the encoder.

You are done installing the encoder!

Jump to the Software Setup section.

Use zip-ties to hold the temperature sensor wire (and any other

loose wires inside the end cap) neatly in place.

.

Page 34 of 80

Fanuc Retrofits

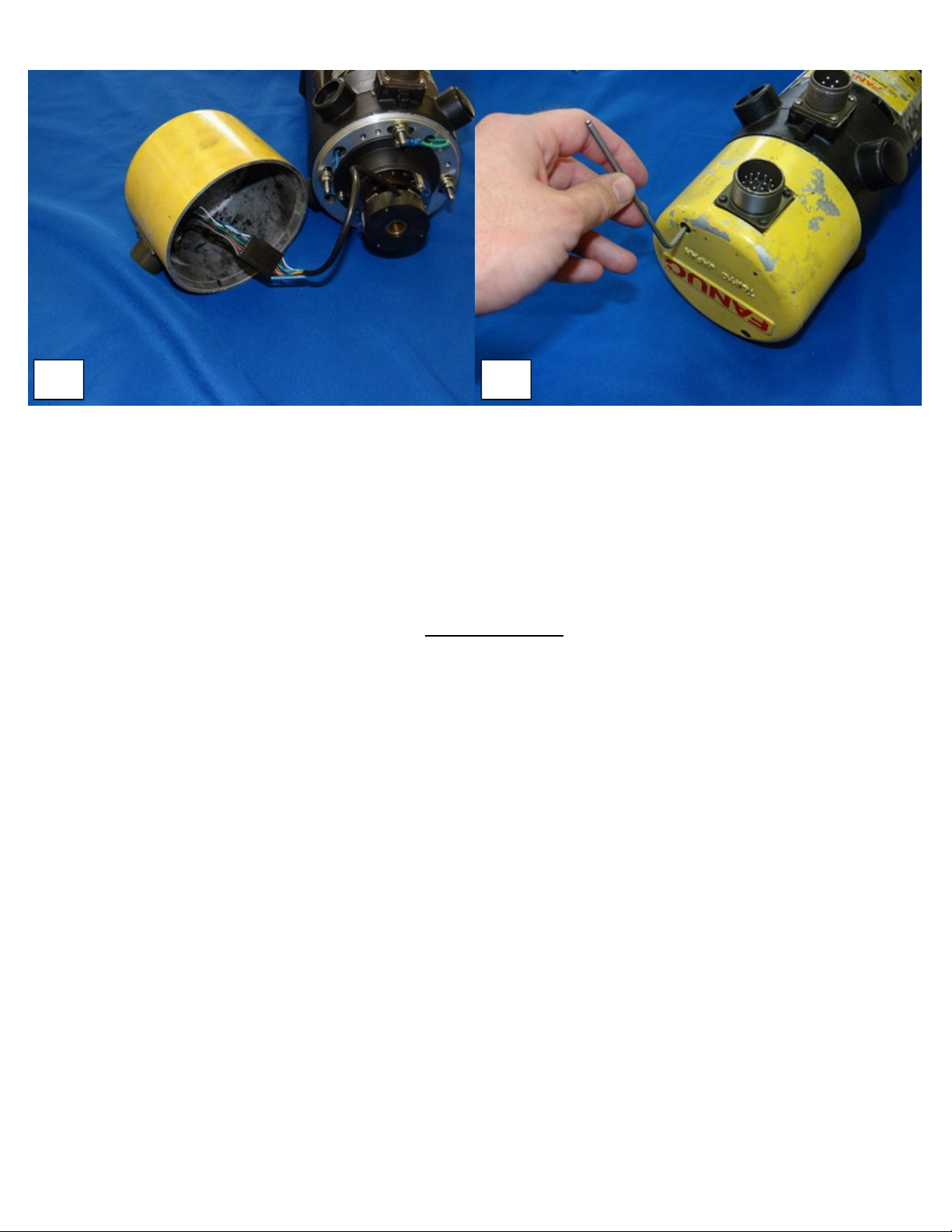

AC Motors: α (Alpha) Series and some S Series Models

To retrofit an α (alpha) series AC motor and late S series motors, use the Fanuc Encoder Retrofit Kit 12876 as shown below

1. 1 Adapter plate assembly (PN 12986)

2. 1 Encoder, 40,000 Count (PN 7480)

3. 1 Encoder Pigtail (PN 12892)

.

4. 4 Plate Mounting Bolts (PN 6417)

5. 4 Lock Washers (PN 7484)

6. 1 Pigtail Gasket (PN 4602)

Page 35 of 80

Fanuc Retrofits

123

4

Encoder Installation

hex key. Set the end cap bolts aside. You will use them again in

a later step.

Remove the end cap and expose the pulse coder assembly.Remove the four bolts holding the red end cap in place using a

Cut the temperature sensor wire going from the motor to the

pigtail connector.

Page 36 of 80

.

Unplug the pigtail connector from the pulse coder.

Fanuc Retrofits

7

8

5

6

Remove the four bolts holding the pulse coder in place using a

3mm hex key.

Remove the pulse coder. A black plastic coupling will remain on

either the motor or pulse coder side. It will be used in the next

step.

Fit the plastic coupling to the shaft of the adapter plate from

the retrofit kit. It must be a snug fit. If the coupling is heavily

worn or damaged, a replacement should be ordered

(Fanuc part# A290-0501-V535)

Page 37 of 80

.

Fit the retrofit assembly onto your motor, making sure that the

black coupler mates with both the encoder shaft and the motor.

Line up the four bolt holes on the adapter plate with the

threaded holes on the motor.

Fanuc Retrofits

11

12

9

10

Using a hex key, secure the retrofit assembly in place with

the four mounting screws and lock washers supplied with

your kit.

Use zip-ties to hold the temperature sensor wires (and any other

loose wires inside the end cap) neatly in place.

Using a Phillips head screwdriver, remove the four MS

connector mounting screws and set them aside. You will need

them again in step 13.

.

Remove the original MS connector and wiring.

Page 38 of 80

Fanuc Retrofits

13

14

Slide the encoder pigtail with the gasket into the end cap and

secure them in place with the four screws removed in step 11.

Plug the pigtail connector firmly into the encoder.

.

You are done installing the encoder!

Jump to the Software Setup section.

Page 39 of 80

Fanuc Retrofits

Software Setup

The AC/DC needs the CNC11 software configured correctly to use the servo motor. The software configuration

procedure(s) described in this manual are intended for someone familiar with the CNC11 software, the AC/DC drive, and available

technical bulletins. This documentation is designed to be used in correlation with the manuals and technical bulletins, and is not

intended to replace any pre-existing documentation.

Control Configuration

The machine parameters need to be adjusted for your Fanuc drive before you can use it. Heating coefficients as well as

temperature warning and error levels are calculated in imperial units. The machine units must be set to inches from the Control

Configuration menu before entering or changing temperature parameters! After saving temperature parameters, the control may

be set back to millimeters if desired. Changing the machine units from inches to millimeters will “automatically” convert

temperature values.

NOTE: Cooling parameters do not change when switching from inches to millimeters because cooling parameters are

calculated as a unit-less value.

To get to the control configuration menu, press F1-Setup. Next, press F3 – Config (The default password is 137), then

F1 – Contrl. Press F10-Save when finished.

Control Configuration Menu

Page 40 of 80

.

Fanuc Retrofits

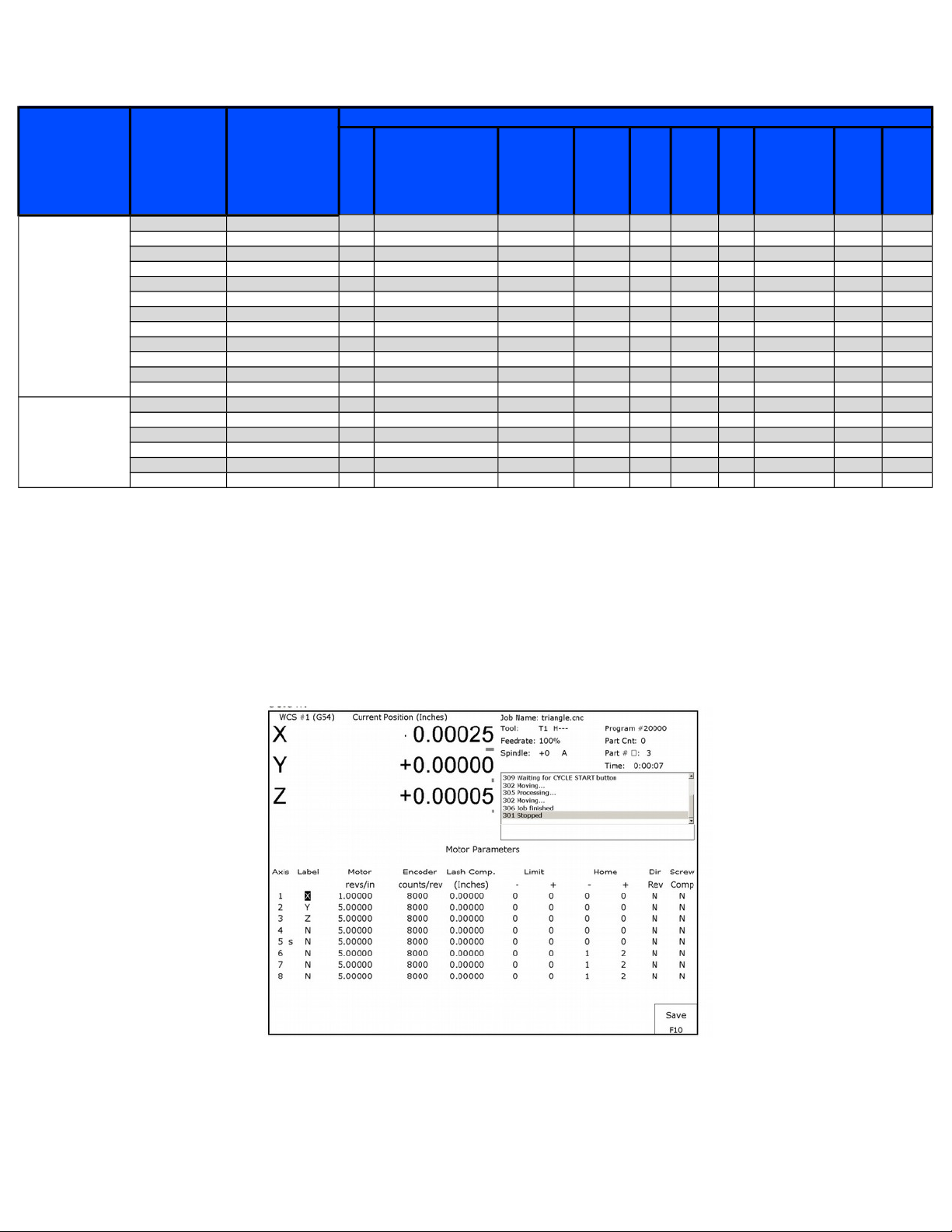

Motor Parameters

In the CNC11 software, access the machine parameters menu by pressing F1 – Setup, F3 – Config, and then F3 - Parms.

Machine Parameters Menu

The table below contains the most important parameters for configuring the AC/DC drive. Set up the control to match your

motor combination. (note: consult the CNC11 manual for a more complete listing of all machine parameters and their uses.)

Recommended Fanuc Parameters

Parameter Number Setting Setting Description

21-24 Motor dependent

25-28 Motor dependent

29 212 (°F) Motor temperature warning

30 260 (°F) Motor temperature error

132-135 Motor dependent

236-239 Motor dependent

256 2 Drive mode

284-291 Dependent on brake resistor Brake resistor wattage (300 w typical)

300-307 1- 8, Depending on Machine Drive axis mapping

308-315 7 -14, Depending on Machine Encoder assignments

340-347 1.75 Precision mode delay

357-364 Motor Dependent

374 255 Debug log axis inclustion (bitwise)

375 4000 Debug log size (samples) 0 to 32768

376 1 Data Log collection type: 1= current data, 2=position data

[1]

[1]

[1]

[1]

[1]

Maximum RPM, may also be set from drive PID screen

Motor heating coefficients axes 1-4

Motor cooling coefficients axes 1-4

Motor heating coefficients axes 5-8

Motor cooling coefficients axes 5-8

1. Tables containing temperature information and maximum RPMs are provided later in this section of the document.

Page 41 of 80

.

Fanuc Retrofits

Recommended Temperature Coefficients for DC Drives

(Measured in Imperial Units)

Series

Black End Cap

( Fanuc ● Gettys )

Yellow End Cap

( M Series )

S Series Red Cap

&

Early Red Cap

(Alpha) Series Red Capα

&

C Series Red Capα

(Beta) Series Red Capβ

&

βis Series Red Cap

[1]

Drive

Model

0 A06B-0613-B0xx 4.0135 3.3333

5 A06B-0614-Bxxx 3.6486 3.0303

10 A06B-0601-Bxxx 0.5017 1.6667

20 A06B-0602-Bxxx 0.2527 1.5873

0M A06B-0641-Bxxx 12.3874 0.0574

5M A06B-0642-Bxxx 7.1351 0.0517

10M A06B-0651-Bxxx 2.8668 0.0369

20M A06B-0652-Bxxx 1.1149 0.0323

30M A06B-0653-Bxxx 0.5902 0.0304

0 A06B-0511-Bxxx 11.7374 3.7037

5 A06B-0512-Bxxx 10.8766 3.3333

10 A06B-0501-Bxxx 3.4637 2.7778

20M

20S/1500

20

20S

30 A06B-0503-Bxxx 0.7993 2.5641

30R

30/2000

40 A06B-0581-Bxxx 0.2965 1.8519

0-0SP A06B-0374-Bxxx 16.6116 8.3333

0S A06B-0313-Bxxx 26.4090 3.7037

5S A06B-0314-Bxxx 14.9505 3.3333

5S/3000 A06B-0514-Bxxx 4.8340 3.3333

6S A06B-0316-Bxxx 6.3282 3.0303

6S/3000 A06B-0320-Bxxx 4.0692 3.0303

10S A06B-0315-Bxxx 7.2561 2.7778

10S/3000 A06B-0317-Bxxx 1.7904 2.7778

20S A06B-0502-B065 0.9969 2.5641

20S/1500 A06B-0505-Bxxx 1.4384 2.5641

30S A06B-0590-Bxxx 1.5897 2.5641

30/2000 A06B-0506-Bxxx 0.4730 2.5641

α3/3000 A06B-0123-Bxxx 26.4090 3.7037

α6/2000 A06B-0127-Bxxx 16.0374 3.3333

α6/3000 A06B-0128-Bx77 5.0293 3.3333

α12/2000 A06B-0142-Bxxx 5.4121 2.7778

α12/3000 A06B-0143-Bx75 1.7445 2.7778

α22/1500 A06B-0146-Bxxx 2.4760 2.5641

α22/2000 A06B-0147-Bx75 1.1063 2.5641

α30/1200 A06B-0151-Bxxx 2.2628 2.3810

α30/2000 A06B-0152-Bxxx 0.8804 2.3810

α40/2000 A06B-0157-Bx75 0.4599 2.2222

αC12/2000 A06B-0141-Bx75 12.0400 2.7778

αC22/1500 A06B-0145-Bxxx 2.4760 2.5641

β3/3000 A06B-0033-Bxxx 22.3805 4.1667

β6/2000 A06B-0034-Bxxx 20.0468 4.1667

β4/4000is A06B-0063-Bx0x 56.9187 8.3333

β8/3000is A06B-0075-B203 34.9260 8.3333

β12/300is A06B-0078-Bx0x 9.6681 6.6667

β22/2000is A06B-0085-Bx0x 6.5645 5.5556

Drive Type

A06B-0505-Bxxx 1.7194 2.5641

A06B-0502-Bxxx 0.9672 2.5641

A06B-0506-Bxxx 0.4600 2.5641

Heating

Coefficients

Cooling

Coefficients

1. Most Fanuc documentation lists the αC Series as a member of the α Series, while some Fanuc documentation lists the αC

Series as a member of the β series.

Page 42 of 80

.

Fanuc Retrofits

PID Menu Setup

From the main menu, Press F1 - Setup, F3 - Config, then F4 – PID to enter the PID Menu as shown below.

Press F1 – PID Config to edit the configuration. Enter the settings for the PID loop from the tables below. The tables are

intended to be used as a baseline of sample values to get started. The PID values shown need some fine tuning and adjusting

before your motor can be used in a machine, which is covered in later sections. Press F10-Save & Exit when you are done.

α and β Motors

Series

α (Alpha)

Series

&

αC Series

β (Beta) Series

βis Series

Black End Cap

( Fanuc ●

Yellow End Cap

( M Series )

[2]

&

Series

Gettys )

Drive

Model

α3/3000 A06B-0123-Bxxx 1 0.02 1

α6/2000 A06B-0127-Bxxx 2 0.02 3

α6/3000 A06B-0128-Bxxx 3 0.02 5

α12/2000 A06B-0142-Bxxx 3 0.02 5

α12/3000 A06B-0143-Bxxx 5 0.02 7

α22/1500 A06B-0146-Bxxx 10 0.02 12

α22/2000 A06B-0147-Bxxx 10 0.02 12

α30/1200 A06B-0151-Bxxx 10 0.02 12

α30/2000 A06B-0152-Bxxx 10 0.02 12

α40/2000 A06B-0157-Bxxx 10 0.02 12

αC12/2000 A06B-0141-Bxxx 7 0.02 9

αC22/2000 A06B-0145-Bxxx 10 0.02 12

β3/3000 A06B-0033-Bxxx 1 0.02 1

β6/2000 A06B-0034-Bxxx 2 0.02 1.8

β4/4000is A06B-0063-Bx0x 1 0.02 1

β8/3000is A06B-0075-B203 2 0.02 1.8

β12/300is A06B-0078-Bx0x 5 0.02 7

β22/2000is A06B-0085-Bx0x 10 0.02 12

Drive Type

Position PID

Kp Ki Kd

DC Motors

Drive

Model

00 A06B-0631-B0xx 1 0.02 1

0 A06B-0613-B0xx 1.25 0.02 2

5 A06B-0614-Bxxx 1 0.02 3

10 A06B-0601-Bxxx 9 0.02 10

20 A06B-0602-Bxxx 10 0.02 12

00M A06B-0632-Bxxx 0.35 0.005 0.35

0M A06B-0641-Bxxx 1 0.02 1

5M A06B-0642-Bxxx 2 0.02 1.8

10M A06B-0651-Bxxx 9 0.02 7.5

20M A06B-0652-Bxxx 10 0.02 12

30M A06B-0653-Bxxx 10 0.02 12

Drive Type

Position PID

Kp Ki Kd

S Series & Early Red Caps

Drive Model Drive Type

0 A06B-0511-Bxxx 2 0.02 3

5 A06B-0512-Bxxx 2 0.02 5

10 A06B-0501-Bxxx 5 0.02 7

20M

20S/1500

20

20S

30 A06B-0503-Bxxx 10 0.02 12

30R

30/2000

40 A06B-0581-Bxxx 10 0.02 12

0-0SP A06B-0374-Bxxx 2 0.02 3

0S A06B-0313-Bxxx 2 0.02 3

5S A06B-0314-Bxxx 2 0.02 3

5S/3000 A06B-0514-Bxxx 2 0.02 3

6S A06B-0316-Bxxx 3 0.02 5

6S/3000 A06B-0320-Bxxx 3 0.02 5

10S A06B-0315-Bxxx 5 0.02 7

10S/3000 A06B-0317-Bxxx 5 0.02 7

20S A06B-0502-B065 10 0.02 12

20S/1500 A06B-0505-Bxxx 10 0.02 12

30S A06B-0590-Bxxx 10 0.02 12

30/2000 A06B-0506-Bxxx 10 0.02 12

A06B-0505-Bxxx 10 0.02 12

A06B-0502-Bxxx 10 0.02 12

A06B-0506-Bxxx 10 0.02 12

Position PID

Kp Ki Kd

PID Menu

Page 43 of 80

.

Fanuc Retrofits

Drive Configuration Setup

From the main menu, press F1 - Setup, F3 - Config, F4 - PID, and then F8 – Drive to enter the Drive Configuration

menu. Press F1 – Drive PID to edit the configuration. Enter the settings for the current feedback PID loop from the tables below.

Press F10-Accept when you are done.

DC Motors

End Cap

Color

Black

( Fanuc ● Gettys )

Yellow

( M Series )

Drive

Model Drive Type

0 A06B-0613-B0xx 0 80% 40% 0 0.75 0.075 0 0.0252 2.12 2,000

5 A06B-0614-Bxxx 0 80% 40% 0 2.00 0.100 0 0.0434 4.23 2,000

10 A06B-0601-Bxxx 0 Not Recommended 60% 0 3.50 0.100 0 0.1736 4.72 1,500

20 A06B-0602-Bxxx 0 Not Recommended 80% 0 3.50 0.100 0 0.2864 6.74 1,500

0M A06B-0641-Bxxx 0 Not Recommended 100% 0 2.00 0.100 0 0.0220 3.73 2,000

5M A06B-0642-Bxxx 0 60% 30% 0 6.00 0.100 0 0.0320 5.80 2,000

10M A06B-0651-Bxxx 0 80% 40% 0 3.50 0.100 0 0.1130 8.85 1,500

20M A06B-0652-Bxxx 0 Not Recommended 60% 0 3.50 0.100 0 0.1649 11.28 1,500

30M A06B-0653-Bxxx 0 Not Recommended 80% 0 3.50 0.100 0 0.3211 13.89 1,200

Poles (ACDC-30)

Current

(ACDC-60)

Current

Current PID

Angle Kp Ki Kd

Inertia

In-lb sec

2

RPM

Max

Kt

S Series & Early Red Caps

Current PID

Drive Model Drive Type

Poles

0 A06B-0511-Bxxx 8 70% 35% 0.000 2.00 0.100 0 0.0174 3.73 2,000

5 A06B-0512-Bxxx 8 70% 35% 0.006 2.00 0.100 0 0.0570 7.64 2,000

10 A06B-0501-Bxxx 8 100% 55% 0.000 2.20 0.100 0 0.0330 9.55 2,000

20M

20S/1500

20

20S

30 A06B-0503-Bxxx 8 Not Recommended 100% 0.000 2.50 0.080 0 0.2083 14.76 1,200

30R

30/2000

40 A06B-0581-Bxxx 8 Not Recommended 100% 0.000 2.50 0.080 0 0.2691 16.11 1,200

0-0SP A06B-0374-Bxxx 8 80% 40% 0.000 2.00 0.100 0 0.0074 3.01 3,000

0S A06B-0313-Bxxx 8 40% 20% 0.000 2.20 0.100 0 0.0174 5.66 3,000

5S A06B-0314-Bxxx 8 50% 25% 0.000 2.20 0.100 0 0.0330 8.94 2,000

5S/3000 A06B-0514-Bxxx 8 100% 50% 0.000 2.20 0.100 0 0.0330 5.04 3,000

6S A06B-0316-Bxxx 8 80% 40% 0.000 2.20 0.100 0 0.0486 9.20 2,000

6S/3000 A06B-0320-Bxxx 8 100% 50% 0.000 2.20 0.100 0 0.0486 7.38 3,000

10S A06B-0315-Bxxx 8 70% 35% 0.000 2.20 0.100 0 0.0868 13.63 2,000

10S/3000 A06B-0317-Bxxx 8 Not Recommended 75% 0.000 2.20 0.100 0 0.0868 6.82 3,000

20S A06B-0502-B065 8 Not Recommended 100% 0.003 2.50 0.080 0 0.1800 10.09 2,000

20S/1500 A06B-0505-Bxxx 8 Not Recommended 80% 0.003 2.50 0.080 0 0.1476 12.13 1,500

30S A06B-0590-Bxxx 8 Not Recommended 75% 0.000 2.50 0.080 0 0.2083 21.15 1,200

30/2000 A06B-0506-Bxxx 8 Not Recommended 100% 0.000 1.50 0.050 0 0.2083 9.12 2,000

A06B-0505-Bxxx 8 Not Recommended 75% 0.000 2.50 0.080 0 0.1476 13.45 1,500

A06B-0502-Bxxx 8 Not Recommended 100% 0.000 2.50 0.080 0 0.1476 10.42 2,000

A06B-0506-Bxxx 8 Not Recommended 100% 0.000 2.50 0.080 0 0.2083 9.11 2,000

ACDC-30

Current

ACDC-60

Current

Angle Kp Ki Kd

Inertia

In-lb sec

Kt

2

Max

RPM

Page 44 of 80

Fanuc Retrofits

α and β Motors

Current PID

Series Drive Model Drive Type

α3/3000 A06B-0123-Bxxx 8 40% 20% 0.00 1.50 0.050 0 0.0122 5.75 3000

α6/2000 A06B-0127-Bxxx 8 56% 28% 0.000 1.50 0.050 0 0.0234 9.56 2000

α6/3000 A06B-0128-Bxxx 8 100% 50% 0.003 1.50 0.050 0 0.0234 5.31 4000

α (Alpha) Series

&

αC Series

β (Beta) Series

βis Series

[2]

&

α12/2000 A06B-0142-Bxxx 8 88% 44% 0.000 2.00 0.100 0 0.0555 12.04 2000

α12/3000 A06B-0143-Bxxx 8 Not Recommended 75% 0.000 2.00 0.100 0 0.0555 6.82 3000

α22/1500 A06B-0146-Bxxx 8 Not Recommended 62% 0.000 2.50 0.100 0 0.1042 15.58 1500

α22/2000 A06B-0147-Bxxx 8 Not Recommended 90% 0.000 2.50 0.100 0 0.1042 10.36 2000

α30/1200 A06B-0151-Bxxx 8 Not Recommended 63% 0.000 2.50 0.100 0 0.1476 20.98 1200

α30/2000 A06B-0152-Bxxx 8 Not Recommended 100% 0.000 2.50 0.100 0 0.1476 13.10 2000

α40/2000 A06B-0157-Bxxx 8 Not Recommended 100% 0.000 2.50 0.100 0 0.1996 12.39 2000

αC12/2000 A06B-0141-Bxxx 8 60% 30% 0.010 4.00 0.075 0 0.0555 18.06 2000

αC22/1500 A06B-0145-Bxxx 8 Not Recommended 62% 0.000 4.00 0.075 0 0.1042 15.58 1500

β3/3000 A06B-0033-Bxxx 8 50% 25% 0.000 2.00 0.100 0 0.0174 4.96 3,000

β6/2000 A06B-0034-Bxxx 8 50% 25% 0.000 2.00 0.100 0 0.0347 9.29 3,000

β4/4000is A06B-0063-Bx0x 8 40% 20% 0.000 2.50 0.100 0 0.0046 6.64 4,000

β8/3000is A06B-0075-B203 8 60% 30% 0.001 2.50 0.100 0 0.0103 10.27 3,000

β12/300is A06B-0078-Bx0x 8 100% 50% 0.000 2.50 0.100 0 0.0208 9.56 3,000

β22/2000is A06B-0085-Bx0x 8 100% 50% 0.000 2.50 0.100 0 0.0520 15.67 2,000

Poles

ACDC-30

Current

ACDC-60

Current

Angle Kp Ki Kd

Inertia

In-lb sec

2

RPM

Max

Kt

Motor Encoder Count Setup

From the main menu, Press F1 - Setup, F3 - Config, F2 – Mach., then F2 – Motor to access the motor parameters

menu. Navigate using the arrow keys. Fanuc motors with Centroid encoders have a 40,000 counts per revolution encoder. For

motors with the original Fanuc coder, CPR varies by model and options.

Set motor direction using the procedure described in Tech Bulletin # 137, “Setting Direction Reversal”.

Set motor revolutions per inch using the procedure described in Tech Bulletin # 036, “Measuring Revs. Per Inch”.

Motor Parameters Menu

Page 45 of 80

Fanuc Retrofits

Other Misc Setup Procedures

Set up the home file using the procedure described in Tech Bulletin #022, “Modifying the “HOM” file”.

You are done configuring software!

Jump to the AC Encoder Alignment on section if you have an AC servo.

Jump to the Calculating and Testing Maximum Feed Rate section if you have a DC servo.

Page 46 of 80

Fanuc Retrofits

AC Encoder Alignment

Introduction

AC drives rely on knowing the motor position in order to stay synchronized while driving the motor. Before the motor is mounted

on a machine, the motors encoder commutation tracks are aligned with the motor phases. The drive applies sinusoidal voltages

to the three-phase input to rotate the motor shaft to a starting position. Typically, there will be four poles in a full rotation of the

shaft. In Centroid software, the index pulse can be aligned with any one of these.

The drive also looks at the commutation lines from the encoder to give it a coarse position of the shaft for smooth

movement on power up. These commutation signals are interpreted by the drive as zones 1 through 6. As the motor turns

clockwise looking at the output shaft the encoder counts should increase. Centroid AC motors use a differential, 8 pole, 5V,

quadrature encoder with an index pulse. The encoder resolution depends on the motor and the drive (see below).

This procedure can also be repeated if you suspect the encoder alignment is incorrect. An incorrect alignment will

show the following symptoms:

1. Axis is jumping.

2. Motor is running roughly.

3. Motor runs better in one direction than the other.

4. Motor has an uneven amount of current draw in one direction than the other.

5. Large current draw with a light load.

Prerequisites

• If connecting a motor to a drive for the first time, please completed the following steps:

◦ Check for >100 MΩ between the motor chassis and power terminals.

◦ With the motor connected to drive, confirm continuity between the drive chassis and motor chassis.

◦ On the drive terminal, check for >100 MΩ between your power and shield terminals.

◦ Check VM wiring for correct polarity

◦ Additional information on motor testing can be found in your installation manual and Technical Bulletin 155.

Tools and Equipment for Encoder Alignment

◦ A set of metric and SAE hex keys.

◦ A small Philips head screw driver set.

◦ Loctite Blue 242 (Optional)

◦ If removing the motor from the machine, a set of clamps such as Irwin Quick Grips.

◦ If there is any contamination or debris inside the end cap, basic cleaning supplies such as a paper towel and all-

purpose cleaner.

◦ If there is not have a rubber O-ring or gasket between the end cap and motor, a non-corrosive RTV sealant (such as

Dow Corning 3165) is needed.

◦ If changing the encoder, you will need a Quantum Devices QR12-10000-8-A-B-E-A-A. This is a 10,000 line, 8 pole,

5V, 8mm shaft encoder. Encoder pigtail pinouts are listed in Appendix B.

Page 47 of 80

Alignment Setup

The motor must be disconnected from the machine or have the machine drive belt removed for the alignment process.

This procedure is best performed on a sturdy bench where you have good lighting and easy access to the encoder. If the motor is

removed from the machine, the motor frame must be firmly secured to the bench using clamps or some other attachment method.

The motor may try to jump around during the procedure (especially if something goes wrong during the alignment). Before

starting the alignment procedure, the drive software must be configured correctly.

Alignment Procedure

DANGER: Do not jog the axis until instructed!

1. Remove the motor end cap.

1. NOTICE: Any dust, dirt, coolant, or other contamination inside the motor end cap can get inside the sensitive internal

components of the optical encoder and cause a premature failure. Make sure the inside of the motor end cap and

encoder mounting plate are clean before continuing with encoder alignment.

If there is a large amount of contamination inside the end cap, there is a high probability that the existing encoder will

work unreliably and need to be replaced. If there is liquid inside the end cap, there may also be liquid inside the

motor. A motor with liquid inside is a serious safety hazard, and will have to be replaced.

2. If installing a new encoder, remove the old encoder. Attach the new encoder. Loosely tighten the encoder ears and

encoder set screws so the encoder spins when the shaft moves.

3. Connect power cable and encoder cable from the drive to the motor.

4. Power up your drive and control system running Centroid CNC software

5. In your CNC software, access the PID menu by pressing F1-Setup, F3-Config, F4-PID as shown below in

Figure 1. Homing the motor is not necessary.

6. Looking at the motor mounting flange, manually rotate the motor shaft clockwise. The “absolute position” on the PID

screen should increase as circled in the picture above. If the position does not increase check the drive communication,

encoder cable, and encoder pigtail.

Fanuc Retrofits

1. NOTICE: The AC/DC servo drive needs the encoder correctly connected/wired before starting up the CNC11

software or drive. If the encoder is not detected upon start up, you will need to restart both the AC/DC drive and the

CNC11 software before trying to test the encoder again. Users can troubleshoot drive errors through the HSC bit

screen definitions as described in the AC/DC servo drive manual.

7. Go to the drive configuration menu by pressing F8-Drive as shown below in Figure 2.

Figure 2. Drive Configuration Menu

Figure 3. Move Sync

8. Press F2-Move Sync as circled in Figure 2. The axis selected is shown underneath PWM Kp as circled in Figure 3. If

you are not on the correct axis, press F1-Toggle Axis until the correct axis label is on the screen. Finally press F10-

GO. The shaft should rotate. The first move sync rotation may cause the motor to jerk or move roughly. Move sync a few

more times by pressing F2-Move Sync then F10-GO repeatedly. All move syncs after the first sync should cause the shaft

to rotate smoothly. If the motor oscillates wildly, moves erratically, or makes loud unusual noises, kill the motor

power immediately!

1. DANGER: An incorrectly wired or configured motor may move violently or unpredictably when attempting move sync.

Keep your body (and others) away from the motor when move syncing for the first time, and be prepared to hit the

emergency stop.

2. DANGER: Large motors may have a tendency to oscillate violently during a move sync due to nature of the current

feedback loop. It is recommended for 3KW and larger motors that you adjust the motor current to half of the

recommended value in the current feedback menu while move syncing. After the encoder alignment process is

complete, set the current back to the recommended setting.

3. NOTICE: If the motor slightly oscillates after move syncing or continues to move a little rough while move syncing,

grab the motor on the shaft carefully with your hand. Move sync the motor while gently squeezing the motor shaft. If

the oscillations and/or jerky movements go away after applying a small amount of load to the shaft, this is normal.

This problem will not occur during normal motor operation.

4. NOTICE: If no motor movement occurs, an error was encountered. AC/DC users can troubleshoot drive errors

through the HSC bit screen definitions as described in the AC/DC manual.

Page 49 of 80

Fanuc Retrofits

Figure 4. Encoder Alignment

Figure 5. Encoder Collar Set Screws

9. Keep running the move sync operation until the point where the encoder reading is closest to 0 or its maximum encoder

count. The “Encoder Reading” is circled in Figure 4.

10.Loosen the encoder collar set screws as shown in Figure 5.

11. Move the encoder until the encoder reading is as close to zero as reasonably possible.

12.Tighten the encoder collar set screws. The encoder collar usually has two set screws on most encoders; make sure both

are tight if applicable.

13. Loosen up the encoder ears and use them to fine tune the adjustment. When the encoder is within specifications, a red

message will appear on the control saying “*** Tighten Encoder Now ***” as circled in Figure 4. For a 40,000 count

encoder, it needs to be aligned with +/- 25 counts of zero. Tighten the encoder ears. The encoder mounting plate is

usually made out of aluminum, so DO NOT OVERTIGHTEN! If the screws do not fit tightly in the encoder mounting

plate, Loctite blue (242) or similar may be used.

14. Press F2-Move Sync and F10 - Go to rotate the motor shaft several full revolutions. Verify that the software still displays

“*** Tighten Encoder Now ***” when closest to the zero position. Some encoder re-adjustment may be needed. Observe

the commutation count goes 1 through 6 consecutively. The commutation count is displayed below encoder reading as

circled in Figure 4. At rest position the commutation zone should be either a 1 or a 6 only. A 0 or a 7 as the commutation

value indicates a bad encoder or wiring problem.

15.Loosely tighten the end cap onto the motor. Be careful placing the encoder cable in the end cap. If the cable is causing

any strain or pushing on the encoder, it will twist the encoder out of alignment.

16.Reboot the drive and control system.

Page 50 of 80

Fanuc Retrofits

17.After a reboot, fast jog the motor in each direction to verify correct operation.

18.In the drive configuration menu, do a final move-sync check to verify that the motor is still aligned correctly. Look for the

red message saying “*** Tighten Encoder Now ***” when the motor is closest to zero.

19.If there is not a rubber O-ring or gasket between the motor and the end cap, remove the end cap again. Apply a bead of

non-corrosive RTV sealant (such as Dow Corning 3165) onto the end cap mounting surface as shown below. Reinstall

the end cap.

20.The motor is ready for normal operation after the system has been rebooted again.

You are done aligning the encoder!

Continue to Calculating and Testing Maximum Feed Rate on the next page.

Page 51 of 80

Fanuc Retrofits

Calculating and Testing Maximum Feed Rate

In past Centroid products the maximum feed rate and acceleration was determined by autotune. At the time of this writing,

the AC/DC does not support auto tune. Maximum feed rate will have to be manually calculated. To perform this calculation you

will need to know the motor revolutions per inch as described in Tech Bulletin # 036, “Measuring Revs. Per Inch”.

Use the following equation: (maximum motor rpm / motor revolutions per inch) * 0.85 = maximum feed rate.

Enter the maximum feed rate in the Jog Parameters menu (F1 - Setup, F3 - Config, F2 – Mach., and then F1-Jog.).

Upon saving your jog parameters a message will appear that says “The # axis accel time should be changed to #.#### in the PID

menu”. Write this number down, it will be used later. This number is not an ideal acceleration rate, but how much the current

acceleration rate needs to change to keep machine performance the same.

Use MDI commands to test the calculated machine maximum feed rate. If the machine is displaying the following

symptoms the calculated feed rate is too fast and should be decreased:

• The load bar graph in the DRO display of the main menu is red, indicating excessive load on the motors

• The software is giving errors such as position errors.

Deadstart

Deadstart located in the jog parameters menu has to do with direction reversal of an axis. The deadstart usually never has

to be changed from the default value on a Milling machine. Sometimes very light wood routing tables with very low resistance and

low inertia can benefit with a deadstart change along with other "hand tuning." Call in if you have this case.

Backlash

Set backlash compensation using the procedure described in Tech Bullion #037, “Measuring Backlash”.

Page 52 of 80

Fanuc Retrofits

A Basic Introduction to Tuning and PID

AC/DC uses a PID loop to control motor movement. PID stands for Proportional, Integral, and Derivative. A PID

controller calculates an "error" value as the difference between a measured process variable (motor velocity) and a desired set

point (expected motor velocity). The controller attempts to minimize the error by adjusting the power to the motor. The PID

controller’s calculation algorithm involves three separate parameters: the proportional, the integral and derivative values, denoted

in the software as Kp, Ki, and Kd. Additionally, the motors inertia constant plays a large value in how the PID loop behaves.

The general idea of the tuning process is to minimize the Absolute Error (ErrAbs), which is measured in encoder counts.

The inertia of the motor varies from machine to machine, and the ideal PID values vary from motor to motor. To achieve optimal

performance out of your Fanuc motor, the inertia, position Kp, and position Kd values will have to be manually adjusted. Under

most circumstances, the position Ki values usually do not need any adjustment. The current feedback Kp, Ki, and Kd (different

from the position feedback Kp, Ki and Kd) should be left alone unless otherwise instructed.

Altering the PID values incorrectly could cause DRAMATIC changes in the way the servo system operates, leading to

possible machine damage. Be cautious when adjusting the PID values, and be prepared to hit the E-stop as the motor may

become unstable or move unpredictably if adjusted incorrectly.

Finally, PID tuning is not a black and white process. What is “good enough” of a value will depend on your accuracy

needs and the capabilities of your system. Some experimentation is always required to find the ideal settings.

Page 53 of 80

Fanuc Retrofits

Tuning Software Setup

Tuning should be done last once everything else is set up and the motor is connected to the machine. Before tuning,

configure the software (and align the encoder if necessary) as discussed in the earlier sections of this manual.

First, home the motor. Go to the PID configuration menu by pressing F1 - Setup, F3 - Config, F4 – PID, and then F1 –

PID Config from the main menu (as shown below). Press F1-Edit Program to bring up PID_Collection_Moves.txt in the default

.txt editor. Edit the G-code so that the motor axis matches the axis of the motor to be tuned. For example, changing the line “G1

w0.0” to “G1 x0.0” will change the program to modify the X-axis instead of the W-axis. Now you should be looking at the PID

configuration menu.

The colors of the text on the top left match the colors of the graphs on the right. For example, if you have a V abs value

written in blue in the top left, the graph for V abs will be displayed on blue in the top right. For the rest of the tuning procedure

when referring to motor velocity, we are referring to the V Abs value and the corresponding graph. When referring to position

error, we are referring to the Err Abs value and the corresponding graph

The graph can be manipulated with a mouse by clicking, dragging, and scrolling. The graph can be manipulated with the

keyboard by using the F3, F4, F5, F6, and F7 keys. This menu and these settings are covered in more detail in the CNC11

manual. Pressing F8 – Change Axis will toggle the axis being graphed and will change the error information displayed in the top

left of the screen. If necessary, press F8 until the selected axis matches the motor to be tuned.

Press F2-Run Program to start the tuning process. The motor should run in a continuous loop and not stop until

manually stopped the motor or the values are adjust with the keyboard. If “finished running program” is immediately displayed,

an error was encountered. Go back to the main menu, and check the message window for errors. Advanced AC/DC users can

troubleshoot drive errors through the HSC bit screen definitions as described in the AC/DC manual.

Note: When viewing the live tuning scope (graphs) be mindful of the scale. You can adjust the scale of the graphic. The

encoder counts and the overall turns ratio of the machine will determine the counts per inch. Adjust the scale of the graph to a

resonable encoder count amount for the given encoder counts per inch of that axis. In other words on a high count per inch

system you may have errors as high as 100 counts, but 100 counts would only be representing .00005” on the machine.

Page 54 of 80

Fanuc Retrofits

Acceleration Tuning

Accel is the time for the axis to reach maximum velocity. An accel rate of 0.1 second is very fast, where an accel rate of

1.0 will be considered very slow.

Record the acceleration rate suggested by the software when the maximum feed rate was saved in the jog parameters

menu. Entered this acceleration rate into the position PID menu (Press F1 - Setup, F3 - Config, F4 – PID, and then F1 – PID

Config.) The rate provided is not the ideal acceleration rate, but a baseline number.

Press F1-Edit Program; adjust PID_Collection_Moves.txt so that it runs at the maximum feed rate. Save changes.

Press F2-Run Program. Slowly decrease the acceleration time in 0.05 increments, testing the value in-between each change. If

you see any of the following symptoms the acceleration rate is too fast and needs to be slowed down:

• The acceleration rate is causing shock or vibration as the machine moves.

• The machine movement becomes bumpy, rough, or jerky.

• The machine creates unusual or loud noises such as thunks or rapping noises.

• The software is giving errors such as position errors.

Page 55 of 80

Fanuc Retrofits

Inertia Tuning

For Inertia, Kp, Ki, and Kd tuning adjust the feed rate in PID_Collection_Moves.txt to the average rate during a typical

machine operation.

The parameters in this menu, with the exception of inertia, do not change based on machine type, and can therefore be

set once from the provided charts. Inertia is set to the motor inertia as a starting point. Once the motor is mounted to a machine,

the inertia value will need to be increased to compensate for the additional inertia of the mechanical drive components.

Inertia is adjusted in the drive configuration menu. From the PID configuration menu press F10 – Save and exit, F8 –

Drive, and then F1 – PID. Throughout the tuning process make changes in the Drive configuration menu, and then go back to the

PID configuration menu and run the collection moves program to see how those changes affect the graph. Repeat this process

until results are acceptable.

The following plots demonstrate the effect of the inertia setting. The dark blue line is the motor velocity (V abs) and the

red line is position error (Err Abs). In the first example, inertia is set to the motor inertia, but a load has been added, so the setting

is too low. The error plot shows that the motor is behind the expected position on acceleration. In the second example, the inertia

value has been increased too much. The motor moves ahead of its expected position during acceleration. In the third example,

inertia has been set to a reasonably accurate value. The motor follows closely at the beginning of the move.

It is best practice to focus on the error around the rising edge of the motor velocity graph. Start adjusting the inertia in

increments of 0.05 at a time, later switching to smaller increments as you approach your final value. Your graph will look slightly

different than the graphs displayed below due to factors such as motor velocity, encoder count, other PID values being off, etc.

The final inertia value should fall in the range of 0.5 to 0.005.

Low Inertia

High Inertia

Inertia Set Correctly

Page 56 of 80

Fanuc Retrofits

KP Tuning

The PID Config menu (F1 - Setup, F3 - Config, F4 – PID, then F1 – PID Config) is used to tune the remainder of the

motor control parameters. To adjust either type in a new value, or use the “Page Up” and “Page Down” keys of your keyboard to

increment or decrement the existing value. Increase Kp until some oscillation is heard or seen on the PID tuning graph. Reduce

the setting below the oscillation point to give some headroom for stability.

The following examples show the effect of Kp. The dark blue line is the motor velocity (V abs) and the red line is position

error (Err Abs). In the first example, Kp is set too low. Large error peaks show where the motor is not following the requested

path. Increasing Kp leads to the second example, where error is low throughout the move. However, there is an increasing

oscillation in the error plot, indicating that the motor will soon become unstable. The third example demonstrates a Kp reduction

to improve stability. The error plot has nearly minimal error achieved during tuning and does not have signs of instability.

Start adjusting the Kp in increments of 1.0 at a time, later switching to smaller increments as you approach your final

value. Your graph will look slightly different than the graphs displayed below due to factors such as motor velocity, encoder count,

motor performance, etc. The final Kp value should fall in the range of 1 to 12.

Low KP High KP

(Unstable)

Kp Set Correctly

Page 57 of 80

Fanuc Retrofits

KD Tuning

After Kp has been adjusted, continue to tuning Kd. The Kd term adds stability to the effects of Kp. If Kp or Kd have been

adjusted far from the default values, a second iteration of the tuning procedure is recommended. Because the two terms are