MANUFACTURING

NUMBERS:

9700742

9700752

System Tested and Certified by NSF

International and WQA against NSF/ANSI

Standard 42 and 53 for the reduction of:

Standard No. 42: Aesthetic Effects

Nominal Particulate Reduction Class I

Standard No. 53: Health Effects

Cyst Reduction & Turbidity Reduction as

verified and substantiated by test data.

System Tested and Certified by WQA

against NSF/ANSI Standard 372

for lead-free compliance

P/N 1011106 Rev. G 12/13

VZN V SERIES

WATER FILTRATION

VZN-441V, VZN-441V-T5

Owner’s Manual

VZN V SERIES

TABLE OF CONTENTS

Owner Information ...............................................................2

General............................................................................... 2

Warranty Information .......................................................... 2

Service/Technical Assistance ............................................. 3

Important Safety Information ..............................................4

Specifications .......................................................................6

Dimensions......................................................................... 6

Electrical Ratings and Plug Configurations ........................ 6

Replacement Cartridges .................................................... 6

Electrical Cord & Plug Configurations ................................ 6

Performance Data Sheet ......................................................7

Filter Cartridge Capacities.................................................. 7

Performance Claims for Percent Reduction....................... 7

Operation ...............................................................................8

Overview ............................................................................ 8

Manual Flushing ................................................................. 8

Installation .............................................................................9

Unpacking .......................................................................... 9

Equipment Setup ................................................................ 9

Mounting the System ....................................................... 10

Drain Valve Connection .....................................................11

Rinse Valve Connection ................................................... 12

System Inlet Connection .................................................. 12

Filtered Water Permeate Outlet Connection .................... 12

Inlet Water Plumbing ........................................................ 12

Installing a Bypass ........................................................... 13

Starting the Controller ...................................................... 13

Rinsing the Ultra Filter Cartridge...................................... 13

Sanitizing the System and Lines ...................................... 14

Rinsing the Carbon Element and TAC Cartridge ............. 14

Maintenance ........................................................................15

Replacing the Ultra Filter Cartridge.................................. 15

Rinsing and Replacing the Carbon Element .................... 16

Rinsing and Replacing the TAC Cartridge ...................... 17

System Sanitization .......................................................... 17

Changing the Interval Setting ........................................... 18

Resetting the Timer Program ........................................... 18

Check Permeate Tank Air Pre-Charge ............................. 18

Troubleshooting .................................................................19

Replacement Parts .............................................................20

Notes....................................................................................23

Limited Warranty ................................................................24

OWNER INFORMATION

General

The VZN system is an innovative filtration system that uses

proprietary multi-bore hollow fiber membranes as well as a

carbon element to provide the latest innovation in filtration

technology.

This manual provides the safety, installation, and

operating procedures for the VZN water filtration system. All

information contained in this manual should be read prior

to installing and operating the system. Your VZN system

is manufactured from the finest materials available and is

assembled to strict quality standards. This system has been

tested at the factory to ensure dependable trouble-free operation.

Warranty Information

Please read the full text of the Limited Warranty in this

manual.

If the system arrives damaged, contact the carrier immediately and file a damage claim with them. Save all packing

materials when filing a claim. Freight damage claims are the

responsibility of the purchaser and are not covered under

warranty.

The warranty does NOT extend to:

• Damages caused in shipment or damage as result of

improper use.

• Installation of electrical service.

• Normal maintenance as outlined in this manual.

• Malfunction resulting from improper maintenance.

• Damage from moisture leaking into electrical

components.

• Damage from tampering with, removal of, or changing

any preset control or safety device.

IMPORTANT! Keep these instructions for future reference. If the system changes

ownership, be sure this manual accompanies the equipment.

2

P/N 1011106 Rev. H 12/13

OWNER INFORMATION (continued)

Service/Technical Assistance

If you experience any problems with the installation or operation of your system, contact A.J. Antunes & Co. at 1-630-784-

1000, or toll free in the United States at 1-800-253-2991.

Fill in the information in the next column and have it handy

when calling for assistance. The serial number is on the

specification plate located on the system.

Purchased From:

Date of Purchase:

Model No.:

Serial No.:

Mfg. No.:

VZN V SERIES

Suggested replacement period for the Ultra Filter Cartridge is

approximately 3 years.

For sales in the state of Iowa:

Seller: Date:

Buyer: Date:

IMPORTANT

A.J. Antunes and Company reserves the right to change specifications and product

design without notice. Such revisions do NOT entitle the buyer to corresponding

changes, improvements, additions, or replacements for previously purchased equipment.

P/N 1011106 Rev. H 12/13

3

VZN V SERIES

IMPORTANT SAFETY INFORMATION

In addition to the warnings and cautions in this manual, use

the following guidelines to safely operate the system:

• Read all instructions before using equipment.

• Install or locate the equipment only for its intended use

as described in this manual.

• Do NOT use corrosive chemicals in this equipment.

• Do NOT operate this equipment if it has a damaged

cord or plug; if it is not working properly, or if it has

been damaged or dropped.

• This equipment should be serviced by qualified personnel only. Contact A.J. Antunes & Co. for repair.

• Do NOT immerse cord or plug in water.

• Keep cord away from heated surfaces.

• This equipment should be supplied with only cold

water.

• For installations in Massachusetts, the Commonwealth

of Massachusetts Plumbing Code 248 CMR shall be

adhered to. The use of saddle valves are not permitted.

Please consult your local plumber.

The following warnings and cautions appear throughout this

manual and should be carefully observed.

• Unplug the power cord before performing any

service or maintenance on the unit.

• All electrical connections must be in accordance with

local electrical codes and any other applicable codes.

• WARNING ELECTRICAL SHOCK HAZARD. FAILURE

TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS INJURY OR DEATH.

- Do NOT modify the power supply cord plug. If it

does not fit the outlet, have a proper outlet installed

by a qualified electrician.

- Do NOT use an extension cord with this unit.

• If the supply cord is damaged, it must be replaced by

the manufacturer, its service agent, or a similarly qualified person.

• This equipment is to be installed to comply with the

local plumbing code and any other applicable code.

• Water pressure must not exceed 100 psig (690 kPa).

To reduce water pressure, install a water pressure

regulator and set to suit the application.

• The trans membrane pressure (inlet pressure minus

the permeate water pressure) must not exceed 45 psi

(310 kPa).

• A ground fault circuit interrupter (GFCI) must be

installed on the circuit to this system.

• When installed on metallic plumbing, a properly sized

electrical bonding jumper must be installed across the

inlet and outlet pipes serving this unit.

NOTE: If the inlet water pressure is less than 50 psig (345

kPa), it is recommended that a suitably-sized booster

system (outlet pressure 60 psig - 100 psig max (414 kPa 690 kPa max) be installed.

4

P/N 1011106 Rev. H 12/13

VZN V SERIES

IMPORTANT SAFETY INFORMATION (continued)

Protect from becoming dry

If the membrane dries out, irreversible damage to the Ultra

Filter membrane may result. Protect the filter from becoming

dry by keeping it wet and sealed at all times.

Protect from freezing

If the Ultra Filter membrane freezes during operation or storage, irreversible damage to the membrane and brittle cracking

of the cartridge or housing may result.

Protect from direct sunlight or other UV sources

Avoid long-term exposure to direct sunlight or other UV

sources. The Ultra Filter should be stored in a dark location.

Protect from high temperatures or abrupt variation in

temperature

The maximum operating temperature is 100°F (38°C). Avoid

abrupt variations in temperature. Any temperature variation

should be made slowly.

Protect from rough handling or dropping

Mechanical damage, external breakage, and/or internal breakage of the filter can result if the system is dropped or bumped.

Handle with care at all times during transportation and installation.

Protect from organic solvents and concentrated acids

Prevent any and all contact of the membrane with strong solvents, solvents containing chlorine, or concentrated acids. Do

NOT use strong solvents or concentrated acids on any plastic

parts of the filter system. Examples of some solvents to avoid:

acetone, methyl acetate (nail polish remover); hexane (spot

removers); turpentine, toluene (paint thinners); dry cleaning

solutions, insecticides.

CAUTION

This equipment is to be installed to comply with the

basic plumbing code of the Building Officials and Code

Administrators, Inc. (BOCA) and the Food Service

Sanitation Manual of the Food and Drug Administration

(FDA).

CAUTION

Water Flow Regulator Assemblies are NOT interchangeable. Operating the system with the wrong Water Flow

Regulator or without a regulator can damage the system, cause personal injury, and voids the warranty!

CAUTION

All electrical connections must be in accordance with

local electrical codes and any other applicable codes.

A ground fault circuit interrupter (GFCI) must be

installed on the circuit to this system.

When installed on metallic plumbing, a properly sized

electrical bonding jumper must be installed across the

inlet and outlet pipes serving this unit.

Protect from abrasive material

The membranes must be protected from abrasive materials

like shavings left in a pipe. Abrasive materials in contact with

the membrane can cause irreversible damage to the membrane. All pipes must be flushed clean before installing the filter. All plastic parts of the filter system must be protected from

sharp objects like knives, sand paper, or other tools. Cutting

or nicking a plastic part can weaken it and cause a leak. Do

NOT use abrasive cleansers on any plastic parts.

Protect from water hammer

The system must be protected from shock, pressure surges,

or pulsation that may occur inside water pipes. Water hammer occurs in pipes when a valve or faucet shuts quickly.

Install a water hammer arrestor (pressure vessel containing

compressed air separated from the water by a diaphragm) to

reduce pressure shock.

P/N 1011106 Rev. H 12/13

5

VZN V SERIES

MAY VA RY

SPECIFICATIONS

Dimensions

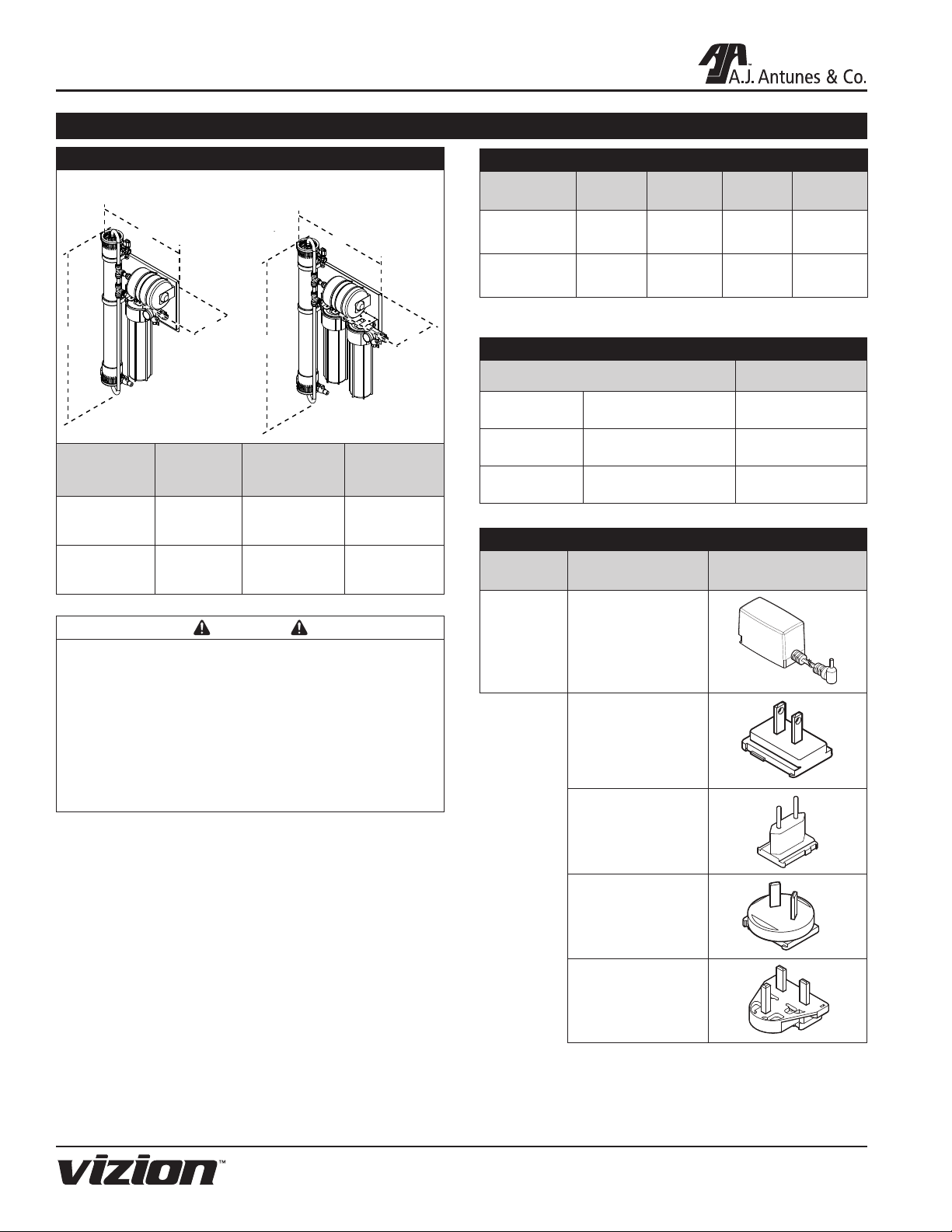

VZN-441V-T5VZN-441V

C

Model &

Mfg. No.

VZN-441V

9700742

VZN-441V-T5

9700752

A

B

C

Width

(A)

24"

(61 cm)

32 3/4"

(83 cm)

Depth

(B)

10 1/8"

(26 cm)

10 1/8"

(26 cm)

A

B

Height

(C)

49 5/16"

(125 cm)

49 5/16"

(125 cm)

CAUTION

All electrical connections must be in accordance with

local electrical codes and any other

applicable codes.

Electrical Ratings and Plug Configurations

Model &

Mfg. No.

VZN-441V

9700742

VZN-441V-T5

9700752

NOTE: Includes plug adaptors for US, Europe, Australia, and UK.

Volts Watts Amps Hertz

100–240 10 .08 50/60

100–240 10 .08 50/60

Replacement Cartridges

Replacement Part Number

VZN-441V

VZN-441V-T5

VZN-441V

VZN-441V-T5

VZN-441V-T5 TAC-05 Cartridge 7000554

L-440 Ultra Filter 7000412

Carbon Element 7000669

Electrical Cord & Plug Configurations

Kit Model

Number

Description Configuration

DC Power Supply

100 - 240 VAC

0012146

Includes the

4 plug adaptors

below

NOTE: PLUG STYLE

A ground fault circuit interrupter (GFCI) must be

installed on the circuit to this system.

When installed on metallic plumbing, a properly sized

electrical bonding jumper must be installed across the

inlet and outlet pipes serving this device.

US

NEMA 1-15 (2 pin)

or NEMA 5-15

(3 Pin)

Euro

CEE 7/16

AS/NZS

3112

AUS

(2 Pin)

UK

BS 136 3

6

P/N 1011106 Rev. H 12/13

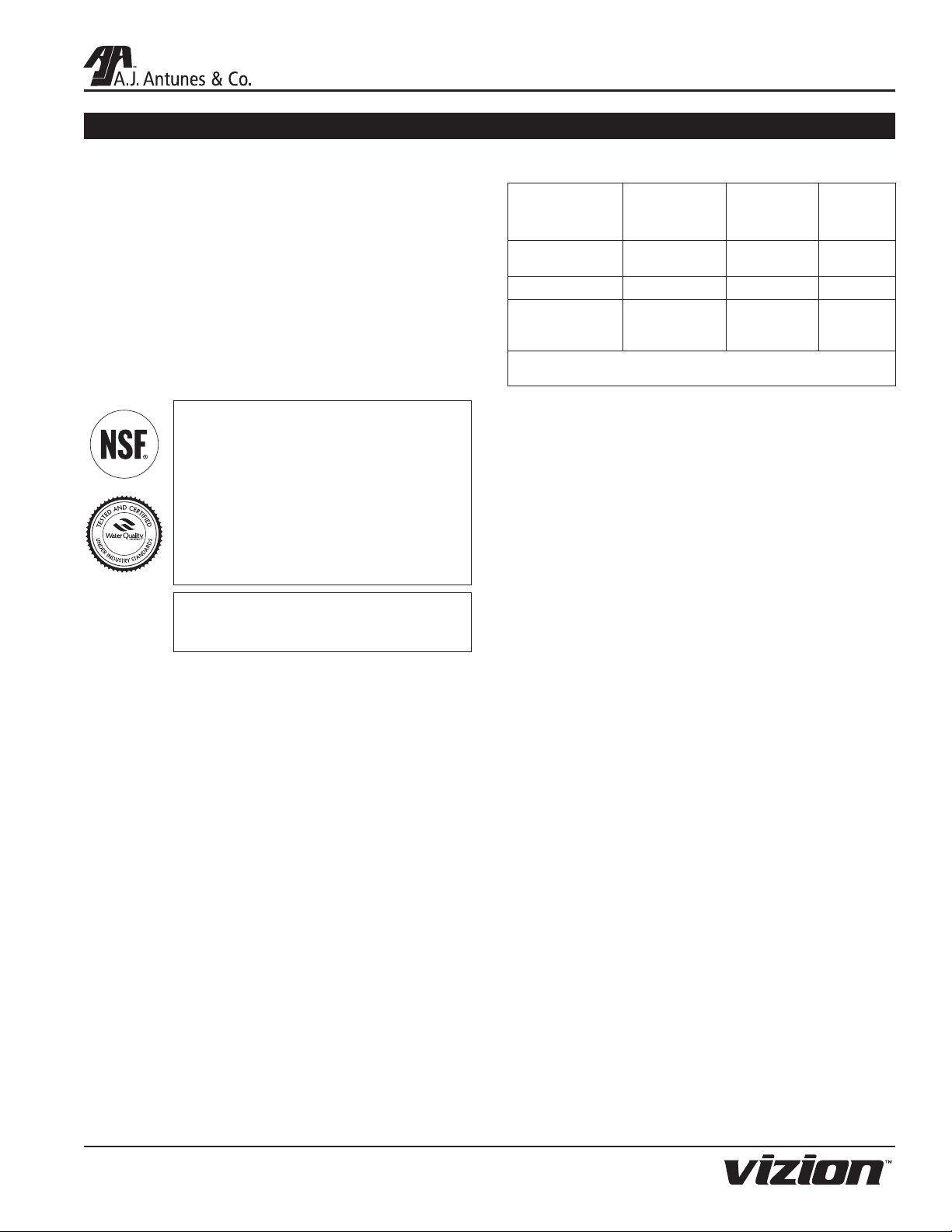

PERFORMANCE DATA SHEET

VZN V SERIES

Filter Cartridge Capacities

Maximum Operating Pressure 100 psig (690 kPa)

Maximum Operating Temperature 100°F (38°C)

Minimum Operating Temperature 40°F (4°C)

Maximum Trans Membrane Pressure 45 PSI (3.1 Bar)

pH Range 3-10

MWCO 100 kD

NSF/WQA Certified Rated Service

Flow:

VZN-441V & VZN-441V-T5 13 gpm (49 l/m)

System Tested and Certified by NSF

International and WQA against NSF/ANSI

Standard 42 and 53 for the reduction of:

Standard No. 42: Aesthetic Effects

Nominal Particulate Reduction Class I

Standard No. 53: Health Effects

Cyst Reduction & Turbidity Reduction

as verified and substantiated by test data.

System Tested and Certified by WQA

against NSF/ANSI Standard 372

for lead-free compliance

Performance Claims for Percent Reduction

Substance Influent

1

cyst

Turbidity 11 ± 1 NTU ≤ 0.5 NTU 99.1%

Particulate Class I

Particles 0.5 to <

1µm

1

based on the use of microspheres or Cryptosporium parvum oocysts

Challenge

Concentration

minimum

50,000/L

at least 10,000

particles /mL

Reduction

Requirement

99.95% 99.95%

≥ 85% N/A

Minimum

Reduction

%

This system has been tested according to NSF/ANSI

Standard 42 and 53 for reduction of the substances listed

below. The concentration of the indicated substances in water

entering the system was reduced to a concentration less than

or equal to the permissible limit for water leaving the system,

as specified in NSF/ANSI 42 or 53. While testing was performed under standard laboratory conditions, actual performance may vary.

NOTE: The NSF/WQA information provided applies to the

Ultra Filter cartridge.

Do not use with water that is microbiologically unsafe or

of unknown quality without adequate disinfection before

or after the system. Systems certified for cyst reduction

may be used on disinfected waters that may contain filterable cysts.

P/N 1011106 Rev. H 12/13

7

VZN V SERIES

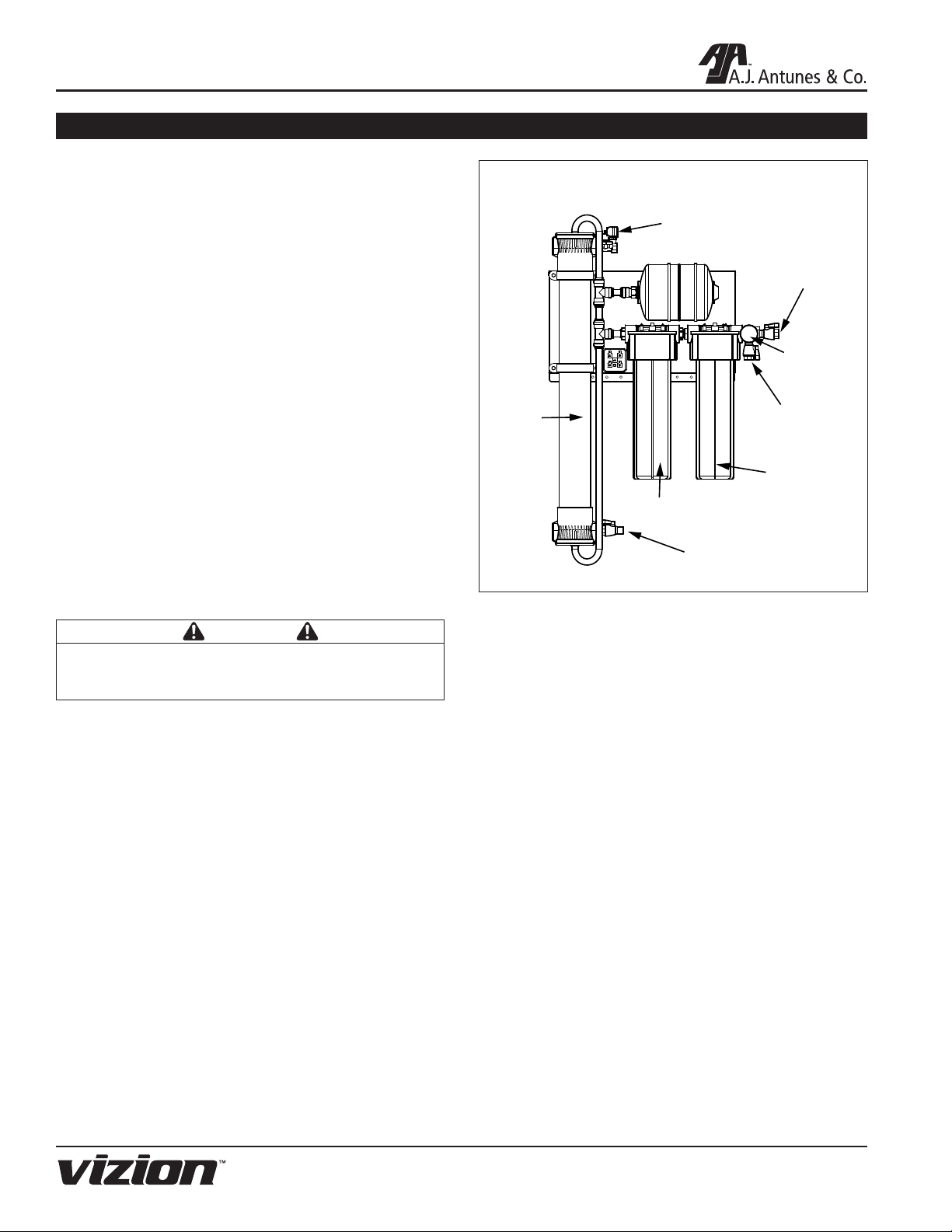

Overview

OPERATION

The VZN system operates in two modes:

• Normal Operation Mode

• Flush Mode

During Normal Operation Mode, water enters the Inlet and

flows through the Ultra Filter before exiting the Permeate

Outlet as usable product water.

During Flush Mode, the Drain Valve opens and water entering the Inlet flushes and cleans the Ultra Filter membrane by

removing any debris collecting on the membrane wall.

The Drain Valve is only powered during Flush Mode.

NOTE: Do NOT unplug the power cord or turn off the system during Flush Mode. If there is a power outage or the

system is unplugged, water will continue to be filtered

but the system will NOT flush. This could cause the Ultra

Filter to plug prematurely and may reduce the life of the

filter.

The flush is automated by the Universal Pulse Controller to

last 10 seconds and take place in one-hour intervals. This

interval can be changed (see Changing the Interval Setting

in the Maintenance section of this manual).

CAUTION

Changing the flush interval may cause the Ultra Filter

to plug prematurely and may reduce the life of the filter.

Consult the factory for more information.

Ultra Filtration

Cartridge

System

Flush

Solenoid

Valve

(Automatic)

Carbon Element

Housing

Inlet

Ball Valve

(Manual)

(VZN-441V-T5 only)

Figure 1. System Components

Rinse

Ball Valve

(Manual)

Check Valve

Assembly

with Outlet

Pressure Gauge

Outlet

Ball Valve

(Manual)

TAC Cartridge

Housing

Manual Flushing

A manual flush can be activated at any time by pressing the

FLUSH button on the Universal Pulse Controller.

When the FLUSH button is pressed, the Flush LED on the

controller flashes and the Drain Valve opens for 10 seconds.

After flushing is complete, the Drain Valve will close, the Flush

LED will stop flashing and the unit will automatically return to

Normal Operation Mode.

NOTE: A manual flush will not affect the interval flush

setting.

8

P/N 1011106 Rev. H 12/13

Loading...

Loading...