Page 1

AIWA VX-T1480

Recommended Safety Parts

Item Part No. Description

M101 S5-96P-480-010 MOTOR, LOAD(1) 1

M2001 S5-94J-980-040 CAPSTAN DD UNIT SP39BD 1

M2003 S5-89V-110-040 MICRO MOTOR EP14BA 1

R1042 87-029-165-060 RES, FUSE 2.7 - 1W

UN4001 S4-841-1B5-000 CYLINDER UNIT ASS’Y 1

IC1002 S0-7S0-902-9A0 JC, OEC9029A

TU6001 S1-447-070-200 TUNER UHF UE25-B01

R445 87-022-304-010 RES, M/O 1.5K - 3W

R446 87-022-304-010 RES, M/O 1.5K - 3W

R447 56-158-268-0J0 RES, FUSE 68 - 1/2W

R449 S5-K2C-E8R-2K0 RES, CEM 8.2 - 7W

R450 87-029-160-010 RES, FUSE 2.2 - 1W

R452 S6-358-11R-8J0 RES, FUSE 1.8 - 1W

R501 S5-K20-E2R-2K0 RES, CEM 2.2 - 7W

R505 S3-X28-B33-3J0 R, M/O 33K - 3W

R508 S3-X28-D47-3J0 RES, M/O 47K - 5W

R512 S3-U18-182-2J0 RES, M/O 8.2K - 1W

R513 87-022-623-010 RES, M/O 15 - 2W

R517 S6-148-12R-2J0 RES, FUSE 22 - 1W

R531 S3-X18-AR5-6J0 RES, M/O 0.56 OHM

R538 S0-11K-215-5J0 RES, 1.5M - 1/2W

R598 87-029-374-010 RES, FUSE 47 - 1/4W

C502 S0-JBB-07H-3K0 CAP, CER 0.0022 - 2KV

C503 S0-JBB-07H-3K0 CAP, CER 0.0022 - 2KV

C505 S2-222-B22-4K0 CMP, 0.22 - 250V

C506 S2-222-B10-4K0 CMP, 0.1 - 250V

C515 S0-E7T-B01-0M0 CAP, E 1-160V

C529 SB-393-0MH-3M0 CAP, CER 0.0022 - 250V

C530 SB-393-0MQ-2K0 CAP, CER 470PF - 250V

C533 SB-393-0M1-2K0 CAP, CER 100PF - 250V

C546 SB-393-0MH-3M0 CAP, CER 0.0022 - 250V

D411 S2-8T1-0EL-S60 DIODE, 10ELS6TA1

D501 S2-BTR-M11-C00 DIODE, RM11C

D502 S2-BTR-M11-C00 DIODE, RM11C

D503 S2-BTR-M11-C00 DIODE, RM11C

D504 S2-BTR-M11-C00 DIODE, RM11C

D508 S2-8TE-QS0-400 DIODE, 11EQS04TA1

D509 S2-8T1-0EL-S60 DIODE, 10ELS6TA1

D510 S2-811-5DF-600 DIODE,1SDF6-FC

D512 S2-8T1-DQ0-900 DIODE, 21DQ09-TA2B1

D519 S2-8T1-DQ0-900 DIODE, 21DQ09-TA2B1

IC401 S0-5SD-840-300 IC, TA8403K

IC501 S0-ED0-460-500 lC, TDA4605-3

IC502 S0-Q09-780-500 IC, NJM7805FD

IC506 S0-025-004-500 PHOTO, COUPLER TLP621 (GR)

Q406 SD-UQ0-208-900 TR, 2SD2089

Q500 S4-1FK-239-700 TR, 2SK2397 - 01

Q502 SA-3T1-371-A00 TR, 2SA1371

Q503 SC-300-416-000 TR, 2SC4160

Q511 SB-WT0-092-600 TR, 2SB926 (S,T)

Q516 SD-70D-239-600 TR, 2SD2396

L501 S2-9K0-000-010 COIL, LINE FILTER RB-20871

L502 S2-9K0-000-010 COIL, LINE FILTER RB-20871

FB401 S4-321-300-9F0 TR, 3213009

T501 S4-813-502-2W0 TR, 8135022W

F501 S8-0PT-040-020 FUSE, 4A-250V T

F502 S8-0PT-1R6-020 FUSE, 21801.6

RY501 S5-600-101-140 RELAY SDT-SS-109DM

ICP502 S8-3PC-030-020 MICRO FUSE, 251003

ICP503 S8-3PC-050-020 MICRO FUSE, 251005

ICP504 S8-3PC-030-020 MICRO FUSE, 251003

ICP505 S8-3PC-010-020 MICRO FUSE, 251001

R802 87-A00-164-060 R, M/O 12K - 2W

R805 87-A00-164-060 R, M/O 12K - 2W

R810 87-A00-164-060 R, M/O 12K - 2W

Q804 89-314-736-080 TR, 2SC1473A - TA

Q805 89-314-736-080 TR, 2SC1473A - TA

Q806 89-314-736-080 TR, 2SC1473A-TA

J801 S6-6X1-200-140 SOCKET, CRT HPS320

SW501 S5-302-050-010 SW, PLUSSDDFC3O56A

L503 S2-8Q1-400-180 COIL, DEGAUSS 8Q140018

CD501 S2-066-358-070 CORD, AC 1206635807

V801 S9-8Y1-404-640 CRT, W/DY14” A34JXV70X06N

Disassembly Instructions

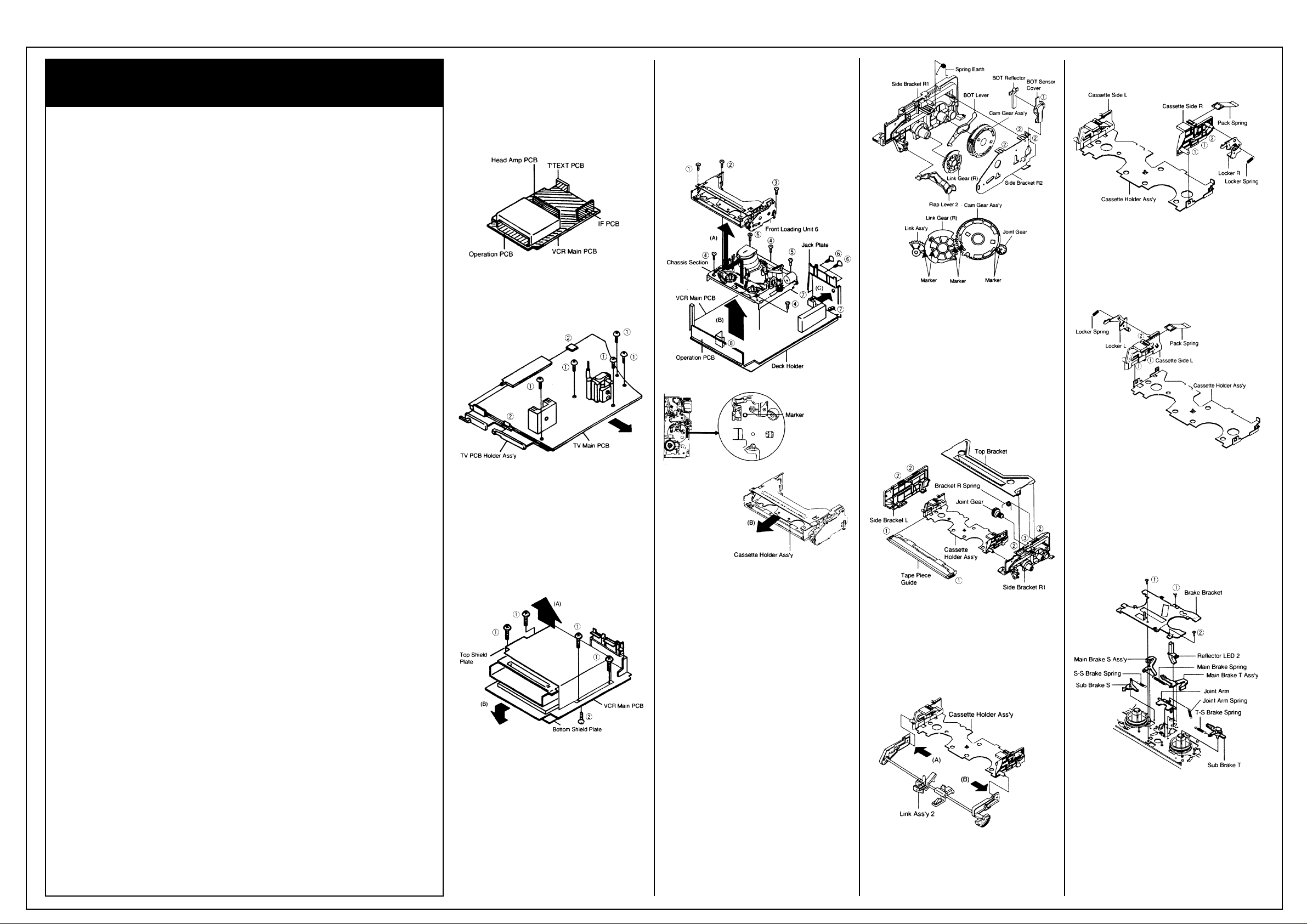

1-4: LOCATION OF PRINTED CIRCUIT

BOARDS

(Refer to Fig. 1-4)

CAUTION: BEFORE ATTEMPTING TO

REMOVE OR REPAIR ANY PCB, UNPLUG

THE POWER CORD FROM THE AC SOURCE.

Fig. 1-4

1-5: MAIN PCB (Refer to Fig. 1-5)

1. Remove the 5 screws (1).

2. Unlock the 2 supports (2) and remove the TV

Main PCB in the direction of the arrow.

Fig. 1-5

1-6: TOP SHIELD PLATE AND BOTTOM

SHIELD PLATE

(Refer to Fig. 1-6)

1. Remove the 4 screws (1).

2. Remove the Top Shield Plate in the direction

of arrow (A).

3. Remove the screw (2).

4. Remove the Bottom Shield Plate in the

direction of arrow (B).

Fig. 1-6

1-7: FRONT LOADING UNIT 6, CHASSIS

SECTION, JACK PLATE AND VCR MAIN PCB

(Refer to Fig. 1-7-A)

1. Remove the screw (1).

2. Remove the screw (2).

3. Remove the screw (3).

4. Remove the Front Loading Unit 6 in the

direction of arrow (A).

5. Remove the 3 screws (4).

6. Remove the 2 screws (5).

7. Remove the Chassis Section in the direction

of arrow (B).

8. Remove the 2 screws (6).

9. Unlock the 2 supports (7) and remove the

Jack Plate in the direction of arrow (C).

10.Unlock the support (8) and remove the VCR

Main PCB.

NOTE

When installing the Front Loading Unit 6, align

the timing marks and pull the Cassette Holder

Ass’y in the direction of arrow (D). (Refer to Fig.

1-7-B)

Fig. 1-7-A

Fig. 1-7-B

2. REMOVAL OF DECK PARTS

2-1: LINK GEAR (R) / CAM GEAR (Refer to

Fig. 2-1)

1. Unlock the support (1).

2. Remove the BOT Sensor Cover and BOT

Reflector.

3. Unlock the 3 supports (2).

4. Remove the Side Bracket R2 and Spring

Earth.

5. Remove the Flap Lever, Link Gear (R), Cam

Gear Ass’y and BOT Lever.

NOTES

When installing the Link Ass’y 2 and Link Gear

(R), align the timing Marks.

Fig. 2-1

2-2: TOP BRACKET / TAPE PIECE GUIDE

(Refer to Fig. 2-2)

1. Unlock the 2 supports (1).

2. Remove the Tape Piece Guide.

3. Unlock the 4 supports (2).

4. Remove the Top Bracket.

5. Remove the Side Bracket R1 and Side

Bracket L.

6. Unlock the support (3).

7. Remove the Joint Gear.

8. Remove the Bracket R Spring.

Fig. 2-2

2-3: LINK ASS’Y 2 (Refer to Fig. 2-3)

1. After removing in the direction (A) of Link

Ass’y 2, remove the Link Ass’y 2 in the

direction (B).

NOTE

Install the (B) first, then install the (A).

Fig. 2-3

2-4: CASSETTE SIDE R (Refer to Fig. 2-4)

1. Unlock the 2 supports (1).

2. Remove the Cassette Side R.

3. Remove the Pack Spring.

4. Remove the Locker Spring.

5. Unlock support (2).

6. Remove the Locker R.

Fig. 2-4

2-5: CASSETTE SIDE L (Refer to Fig. 2-5)

1. Unlock the 2 supports (1).

2. Remove the Cassette Side L.

3. Remove the Pack Spring.

4. Remove the Locker Spring.

5. Unlock the support (2).

6. Remove the Locker L.

Fig. 2-5

2-6: BRAKE BRACKET (Refer to Fig. 2-6)

1. Remove the Main Brake Spring, S-S Brake

Spring, Joint Arm Spring and T-S Brake

Spring.

2. Remove the 2 screws (1).

3. Remove the screw (2).

4. Remove the Brake Bracket.

5. Remove the Sub Brake S, Sub Brake T, Main

Brake S Ass’y and Main Brake T Ass’y.

6. Remove the Joint Arm.

7. Remove the Reflector LED 2.

Fig. 2-6

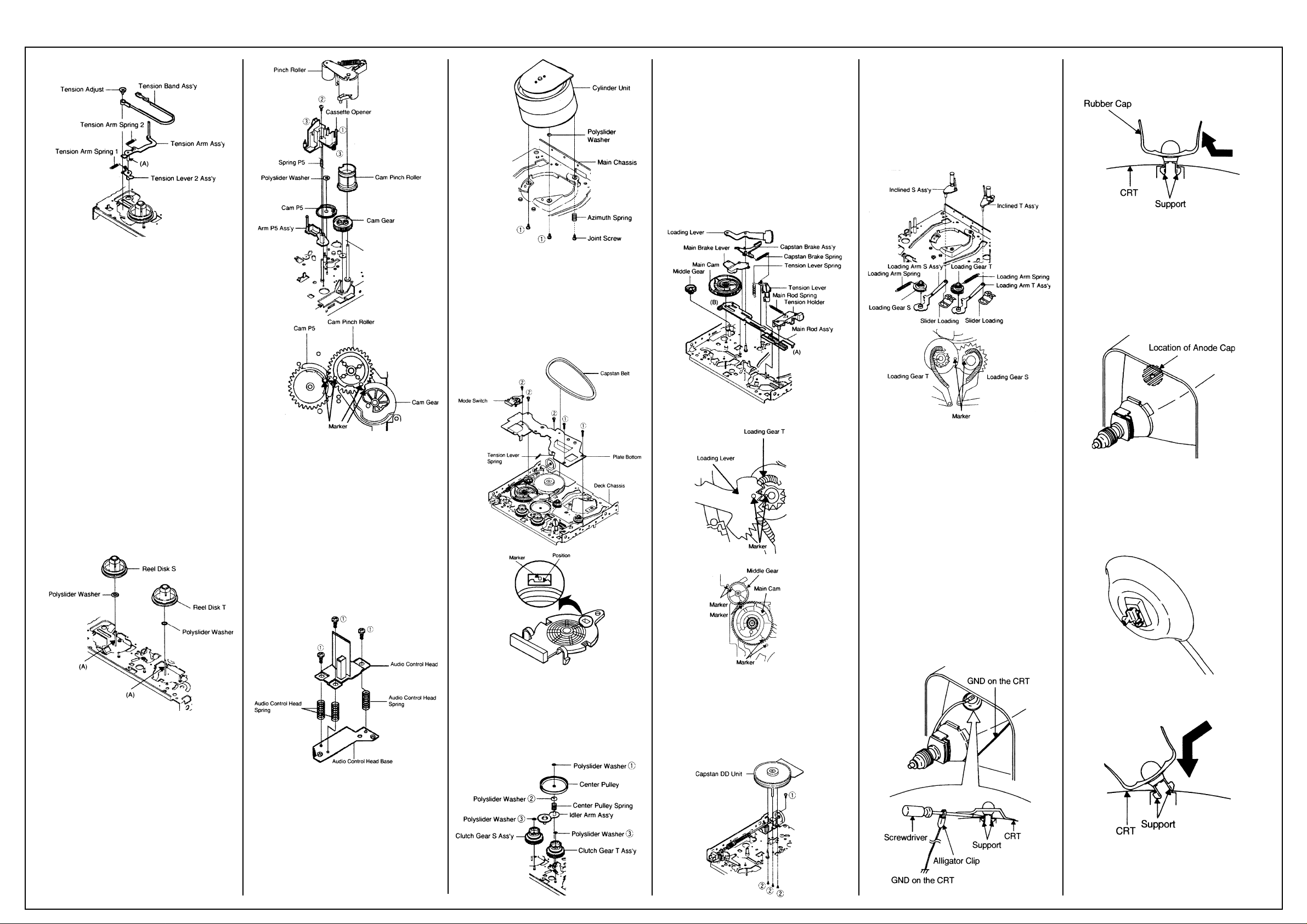

2-7: TENSION BAND (Refer to Fig. 2-7)

1. Remove the Tension Arm Spring 1.

2. Remove the Tension Arm Spring 2.

3. Remove the Tension Adjust.

4. Remove the Tension Arm Ass’y.

5. Remove the Tension Band Ass’y.

6. Remove the Tension Lever 2 Ass’y.

Continues on next page.

Page 2

AIWA VX-T1480

Disassembly Cont’d

Fig. 2-7

NOTES

1. Install the Tension Band Ass’y without twisting it.

2. Oil the area marked with A in Fig. 2-7.

2-8: REEL DISK (Refer to Fig. 2-8)

1. Remove the Reel Disk S and Reel Disk T.

2. Remove the 2 polyslider washers.

NOTES

1. Installation of Reel Disk after performing step

1, 2 and 3 in section 2-7 of DISASSEMBLY

INSTRUCTIONS.

2. The Height Adjustment washers are sometimes attached to the back of the Reel Disk.

3. Clean the Reel Disk Shaft and put in height

adjusting washers.

4. Be careful not to damage the Tension Band

Ass’y at the time of removal and installation.

5. Be careful not to scratch the Reel Disk Shaft

with the polyslider washer or the tool at the

time of removal and installation.

6. After oiling the Reel Disk Shaft, install the

new Reel Disk S and Reel Disk T again.

7. After installation, adjust the height of the Reel

Disk. (Refer to item 1-1 of MECHANICAL

ADJUSTMENTS)

8. After installation, adjust and confirm the

tension post position. (Refer to item 1-2 of

MECHANICAL ADJUSTMENTS)

Fig. 2-8

2-9: PINCH ROLLER / CASSETTE OPENER

(Refer to Fig. 2-9)

1. Unlock the support (1).

2. Remove the Pinch Roller.

3. Remove the screw (2).

4. Unlock the 2 supports (3).

5. Remove the Cassette Opener.

6. Remove the Spring P5 and Arm P5 Ass’y.

7. Remove the Cam Gear, Polyslider Washer 4,

Spring Cam Pinch and Cam Pinch Roller.

8. Remove the Polyslider Washer 5 and Cam

P5.

NOTES

1. Do not touch the Pinch Roller. (Use gloves.)

2. When installing the Cam P5, Cam Pinch

Roller and Cam Gear, align the timing marks.

Fig. 2-9

2-10: AUDIO CONTROL HEAD

(Refer to Fig. 2-10)

1. Disconnect the following connector: (CP4106

6 pins) on the Head Amp PCB.

2. Remove the 3 screws (1).

3. Remove the 3 Audio Control Head Springs.

4. Remove the Audio Control Head.

NOTES

1. Do not touch the head by any means when

replacing the Audio Control Head. (Use

gloves.)

2. After replacement, confirm the following

adjustments.

a. MECHANICAL ADJUSTMENTS: ITEM 2-2

b. MECHANICAL ADJUSTMENTS: ITEM 2-3

Fig. 2-10

2-11: CYLINDER UNIT (Refer to Fig. 2-11)

1. Disconnect the following connectors:

(CP4101 4 pins and CP4102 5 pins) on the

Head Amp PCB.

2. Remove the Joint Screw, then remove the

Azimuth Spring.

3. Remove the 2 screws (1), then remove the

Polyslider Washer and Cylinder Unit from the

Main Chassis.

Fig. 2-11

2-12: PLATE BOTTOM (Refer to Fig. 2-12)

1. Remove the Capstan Belt.

2. Remove the 2 screws (1).

3. Remove the 3 screws (2).

4. Remove the Mode Switch.

5. Remove the Tension Lever Spring.

6. Remove the Plate Bottom.

NOTE

When installing the Mode Switch, align the

timing position.

Fig. 2-12

2-13: CENTER PULLEY (Refer to Fig. 2-13)

1. Remove the Polyslider Washer (1).

2. Remove the Center Pulley.

3. Remove the Polyslider Washer (2).

4. Remove the Center Pulley Spring.

5. Remove the Idler Arm Ass’y.

6. Remove the 2 Polyslider Washers (3).

7. Remove the Clutch Gear T Ass’y and Clutch

Gear S Ass’y.

Fig. 2-13

2-14: MAIN CAM (Refer to Fig. 2-14)

1. Remove the Loading Lever.

2. Remove the Main Brake Lever.

3. Remove the Capstan Brake Spring.

4. Remove the Capstan Brake Ass’y.

5. Remove the Main Rod Spring.

6. Remove the Tension Holder.

7. Remove the Tension Lever.

8. Remove the Main Cam.

9. Remove the Middle Gear.

10. Remove the Main Rod Ass’y.

NOTES

1. When installing the Main Rod Ass’y, install

side (B) first, then install side (A).

2. When installing the Loading Lever, align the

timing marks.

Fig. 2-14

2-15: CAPSTAN DD UNIT (Refer to Fig. 2-15)

1. Remove the screw (1)

2. Disconnect the CP4105 9 pins.

3. Remove the 3 screws (2).

4. Remove the Capstan DD Unit.

NOTE

Use the specified screw to hold the Capstan DD

Unit.

Fig. 2-15

2-16: INCLINED T ASS’Y / INCLINED S ASS’Y

(Refer to Fig. 2-16)

1. Remove the 2 Slider Loadings.

2. Remove the Inclined T Ass’y and Inclined S

Ass’y.

3. Remove the Loading Gear T Ass’y.

4. Remove the Loading Gear S Ass’y.

NOTE

When installing the Inclined T Ass’y and Inclined

S Ass’y, align the timing marks.

Fig. 2-16

3. REMOVAL OF ANODE CAP

Read the following NOTED items before starting

work.

* After turning the power off there might still be a

potential voltage that is very dangerous. When

removing the Anode Cap, make sure to discharge the Anode Cap’s potential voltage.

* Do not use pliers to loosen or tighten the

Anode Cap terminal, this may cause the spring

to be damaged.

REMOVAL

1. Follow the steps as follows to discharge the

Anode Cap. (Refer to Fig. 3-1.) Connect one

end of an Alligator Clip to the metal part of a

flat-blade screwdriver and the other end to

ground. While holding the plastic part of the

insulated Screwdriver, touch the support of

the Anode with the tip of the Screwdriver. A

cracking noise will be heard as the voltage is

discharged.

Fig. 3-1

2. Flip up the sides of the Rubber Cap in the

direction of the arrow and remove one side of

the support. (Refer to Fig. 3-2.)

Fig. 3-2

3. After one side is removed, pull in the opposite

direction to remove the other.

NOTE

Take care not to damage the Rubber Cap.

INSTALLATION

1. Clean the spot where the cap was located

with a small amount of alcohol. (Refer to Fig.

3-3.)

Fig. 3-3

NOTE

Confirm that there is no dirt, dust, etc. at the

spot where the cap was located.

2. Arrange the wire of the Anode Cap and make

sure the wire is not twisted.

3. Turn over the Rubber Cap. (Refer to Fig. 3-4.)

Fig. 3-4

4. Insert one end of the Anode Support into the

anode button, then the other as shown in Fig.

3-5.

Fig. 3-5

5. Confirm that the Support is securely connected.

6. Put on the Rubber Cap without moving any

parts.

Page 3

AIWA VX-T1480

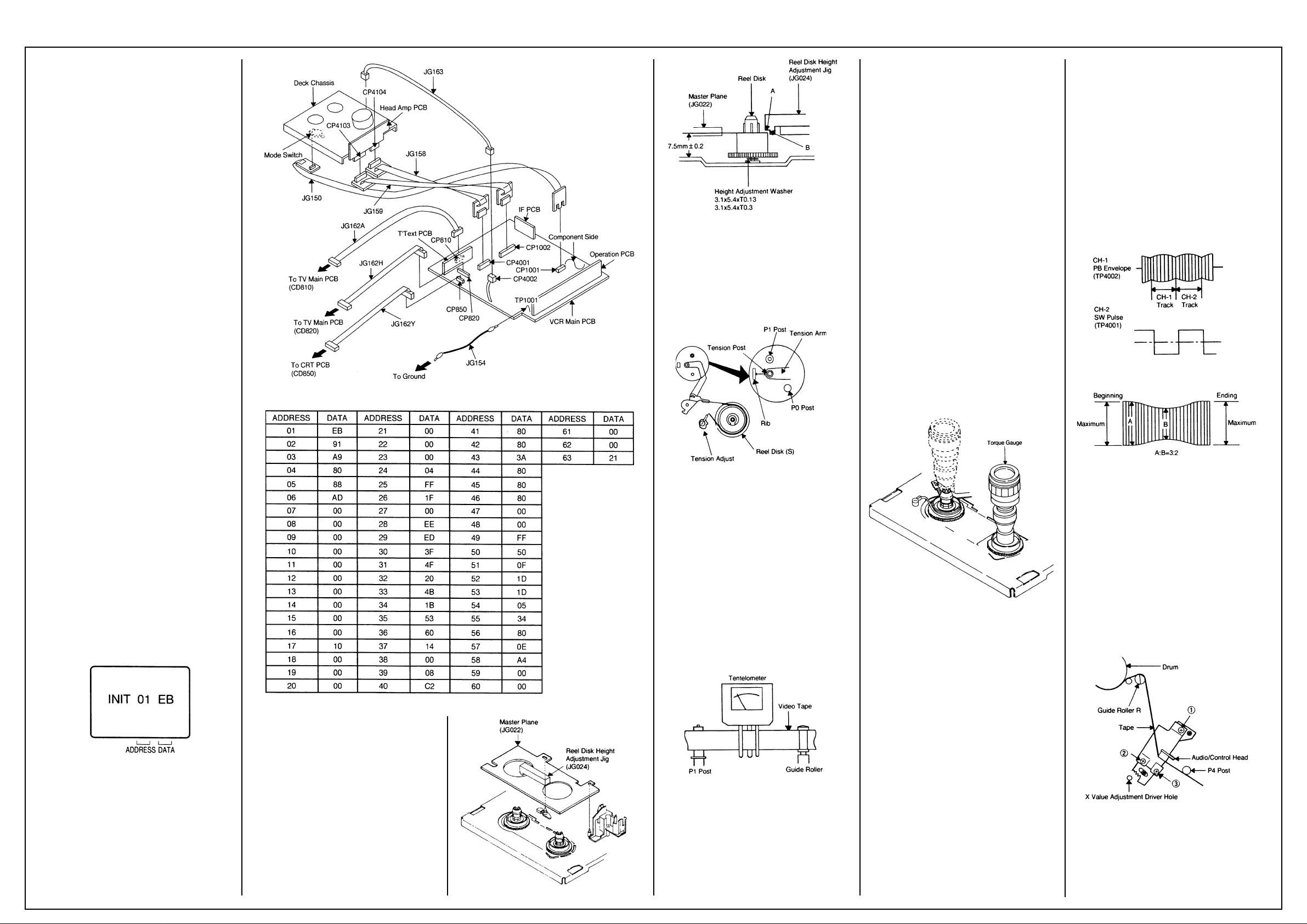

Mechanical Adjustments

SERVICING PREPARATION

How to use the servicing fixture

1. Remove the VCR Main PCB from the Deck

Chassis.

2. Connect as shown in the figure using the

Service Fixture.

• Connect the VCR Main PCB to the Mode

Switch with the cable JG150.

• Connect the VCR Main PCB to the Head Amp

PCB with the cable JG158 and JG159.

• Connect the VCR Main PCB to the TV Main

PCB with the cable JG162A and JG 162H.

• Connect the VCR Main PCB to the CRT PCB

with the cable JG162Y.

• Connect the VCR Main PCB to the FE Head

with the cable JG163.

3. Short circuit between TP1001 and Ground

with the cable JG154. (Refer to MAJOR

COMPONENTS LOCATION GUIDE)

4. The EOT, BOT and Reel Sensor do not work

at this moment.

5. At that time, the STOP/EJECT button is

available to insert and eject the Cassette

Tape.

INSTRUCTIONS

1. Unplug the AC cord once and the clock will be

non-setting.

2. Turn on the POWER and set the VOLUME to

minimum.

NOTE:

If the Auto Set Up Function is working, the unit

cannot be operated. In this case, release the

Function or wait until the Function goes to the

end.

3. Press the VOL. DOWN button on the set and

the Channel button (6) on the remote control

simultaneously. The Fig. 1 appears on the

display.

4. Press the SET +/- button on the remote

control to modify the address and check the

data.

(Refer to Table 1)

5. After checking, turn off the Power.

(If the wrong data is input)

6. Press the SET +/- button on the remote

control to set to the address of the wrong

data, then press the ENTER button. The data

will bink. (Refer to Fig. 1)

7. Press the SET +/- button on the remote

control to set to the correct data, then press

the ENTER button. (Refer to Table 1)

8. Repeat the above steps 6 and 7 and input the

data into the each Address.

9. After the data input, turn off the Power.

Fig. 1

1. CONFIRMATION AND ADJUSTMENT

Read the following NOTED items before starting

work.

• Place an object which weighs between 350g

and 500g on the Cassette Tape to keep it

steady when you want to make the tape run

without the Front Loading Unit 6. (Do not

place an object which weighs over 500g.)

Reel Disk (S)

• When you activate the deck without the Front

Loading Unit 6, short circuit between TP1001

and Ground. In this condition the BOT/EOT/

Reel Sensor will not function.

1-1: CONFIRMATION AND ADJUSTMENT OF

REEL DISK HEIGHT

1. Turn on the power and set to the STOP

mode.

2. Set the master plane (JG022) and reel disk

height adjustment jig (JG024) on mechanism

framework, taking care not to scratch the

drum, as shown in Fig. 1-1-A.

3. Confirm that the reel disk is lower than “A” of

the reel disk height adjustment jig (JG024) on

the master plane and higher than “B” as

shown in Fig. 1-1-B. If it is not, adjust to less

than 7.5mm±0.2mm with the height adjustment washer.

4. Perform the same adjustment for other reel.

Fig. 1-1-A

Fig. 1-1-B

1-2: CONFIRMATION AND ADJUSTMENT OF

TENSION POST POSITION

1. Turn on the power and set to the PLAY mode

adjust the Tension so that the Tension Post is

at the position of 0.3mm~0.5mm from the Rib.

(Refer to Fig. 1-2)

2. Confirm that the video tape is not curling at

the flange of P1 post or is not running on

flanges.

Fig. 1-2

1-3: CONFIRMATION AND ADJUSTMENT OF

BACK TENSION ON PLAYBACK

1. Load a video tape recorded in standard speed

mode. Set the unit to the PLAY mode.

2. Install the tentelometer as shown in Fig. 1-3.

Confirm the value is within 20~27gr/cm at this

time.

IN CASE OF USING A CASSETTE TYPE

TORQUE TAPE.

1. After adjustment, confirm and adjust the

tension post position (Refer to item 1-2) for

the tension arm, install the cassette type

torque tape (JG100A) and set to the PLAY

mode.

2. Confirm that the left hand side tension value

of the torque tape is 25~38gr/cm for the

standard mode tape.

Fig. 1-3

1-4: CONFIRMATION OF FAST FORWARD

TORQUE

1. Set torque gauge (JG002G) on take-up reel

disk, and place unit in FAST FORWARD

mode. (Refer to Fig. 1-4)

2. Confirm that torque is more than 400gr/cm.

NOTE

After setting the torque gauge on the reel disk,

hold the gauge in place. Push the FAST

FORWARD button and the reel disk will begin to

turn.

1-5: CONFIRMATION OF REWIND TORQUE

1. Operate within 4 or 5 seconds after the reel

disk begins to turn.

2. Set torque gauge (JG002G) on supply reel

disk, and place the unit in REWIND mode.

(Refer to Fig 1-4).

3. Confirm that torque is more than 400gr/cm.

NOTE

After setting the torque gauge on the reel disk,

hold the gauge in place.

Push the REWIND button and the reel disk will

begin to turn.

1-6: CONFIRMATION OF REEL BRAKE

TORQUE

(Take-Up Reel Brake) (Refer to Fig. 1-4)

1. Set to STOP mode.

2. Set the torque gauge (JG002G) to the takeup reel and turn it counterclockwise.

3. Confirm that it is more than 200gr/cm at that

time.

(Supply Reel Brake) (Refer to Fig. 1-4)

1. Set to STOP mode.

2. Set the torque gauge (JG002G) to the supply

reel and turn it clockwise.

3. Confirm that it is more than 200gr/cm at that

time.

NOTE

Separate the idler from the reel and confirm the

brake torque.

Fig. 1-4

2-1: GUIDE ROLLER

NOTE

If the torque value checked is out of tolerance,

replace the appropriate parts as follows.

Check Items Replace Parts

1-4 Idler Ass’y or Clutch Ass’y

1-5 Idler Ass’y or Clutch Ass’y

1-6 Main Brake T Ass’y or Main Brake S Ass’y

2. TAPE RUNNING CONFIRMATION AND

ADJUSTMENT

Tape running is adjusted precisely at the factory.

Normally, it is not necessary to make adjustments. It is necessary to confirm and make

adjustments when the parts of the tape running

mechanism are replaced because of extensive

usage or failure.

2-1: GUIDE ROLLER

1. Connect CH-1 on the oscilloscope to TP4002

(PB Envelope) and CH-2 to TP4001 (SW

Pulse).

2. Set the tracking to manual center position in

the following way. Press and hold the tracking

auto button more than 2 seconds to set the

tracking to center position.

3. Trigger with SW pulse and observe the

envelope. (Refer to Fig. 2-1-A)

4. Adjust the guide roller height while observing

the envelope, and make the envelope flat.

Adjust the envelope so that the flatness will

not be affected even when the tracking control

button is pressed. (Use the adjustment

screwdriver JG005).

5. Press and hold the tracking control button

and (at the point that the envelope waveform

starts to reduce) adjust the envelope so that

the A:B ratio is better than 3:2. (Refer to Fig.

2-1-B)

6. Adjust the PG shifter (ELECTRICAL ADJUSTMENTS : ITEM 3-1) in the PLAY mode.

NOTE

After adjustment, confirm and adjust A/C head

tilt. (Refer to item 2-2)

Fig. 2-1-A

Fig. 2-1-B

2-2: CONFIRMATION AND ADJUSTMENT OF

A/C HEAD TILT

When the tape is running abnormally, perform

the following adjustments.

1. Insert a new tape and play it back.

2. Confirm that there is no crease on the tape

between the P4 post and guide roller (R) and

the tape is running smoothly. (It is absolutely

impossible to get satisfactory sound if the

tape is distorted between the A/C head and

P4 post.)

3. If the tape still does not run smoothly, turn the

screw (1) and adjust the tilt of the A/C head.

(Refer to Fig. 2-2)

Fig. 2-2

2-3: ADJUSTMENT OF A/C HEAD HEIGHT

AND AZIMUTH

1. Playback a VHS alignment tape (JG001C)

and observe the waveform at the audio output

terminal.

2. Turn the screw (2) slowly to change the

Page 4

AIWA VX-T1480

Adjustments Cont’d

azimuth of the A/C head. Adjust the height so

that the audio output becomes maximum.

(Refer to Fig. 2-2)

3. Adjust the screw 3, (Refer to Fig. 2-2) until the

height of the A/C head reaches the position

against the tape as shown in Fig. 2-3.

4. When the control head height is not correct.

(When you must turn the screw more than 45

degrees), Turn all of the screws (1), (2) and

(3) to the same degrees. Then confirm the

angle of the audio/control head and adjust

again.

Fig. 2-3

2-4: TAPE RUNNING ADJUSTMENT

1.Adjust the height of reel disk.

(Refer to item 1-1)

2.Confirm and adjust tension post position.

(Refer to item 1-2)

3.Adjust the guide roller.

(Refer to item 2-1)

4.Adjust the A/C head tilt.

(Refer to item 2-2)

5.Adjust the A/C head height and azimuth.

(Refer to item 2-3)

6.Connect CH-1 on the oscilloscope to TP4001

and CH-2 to TP4002. Playback the VHS

alignment tape (JG001E).

Set the tracking to manual center. Adjust X with

the screwdriver for X (JG153) as the Fig. 2-1-A

and Fig. 2-1-B.

(Refer to No. 2 of the item 2-1).

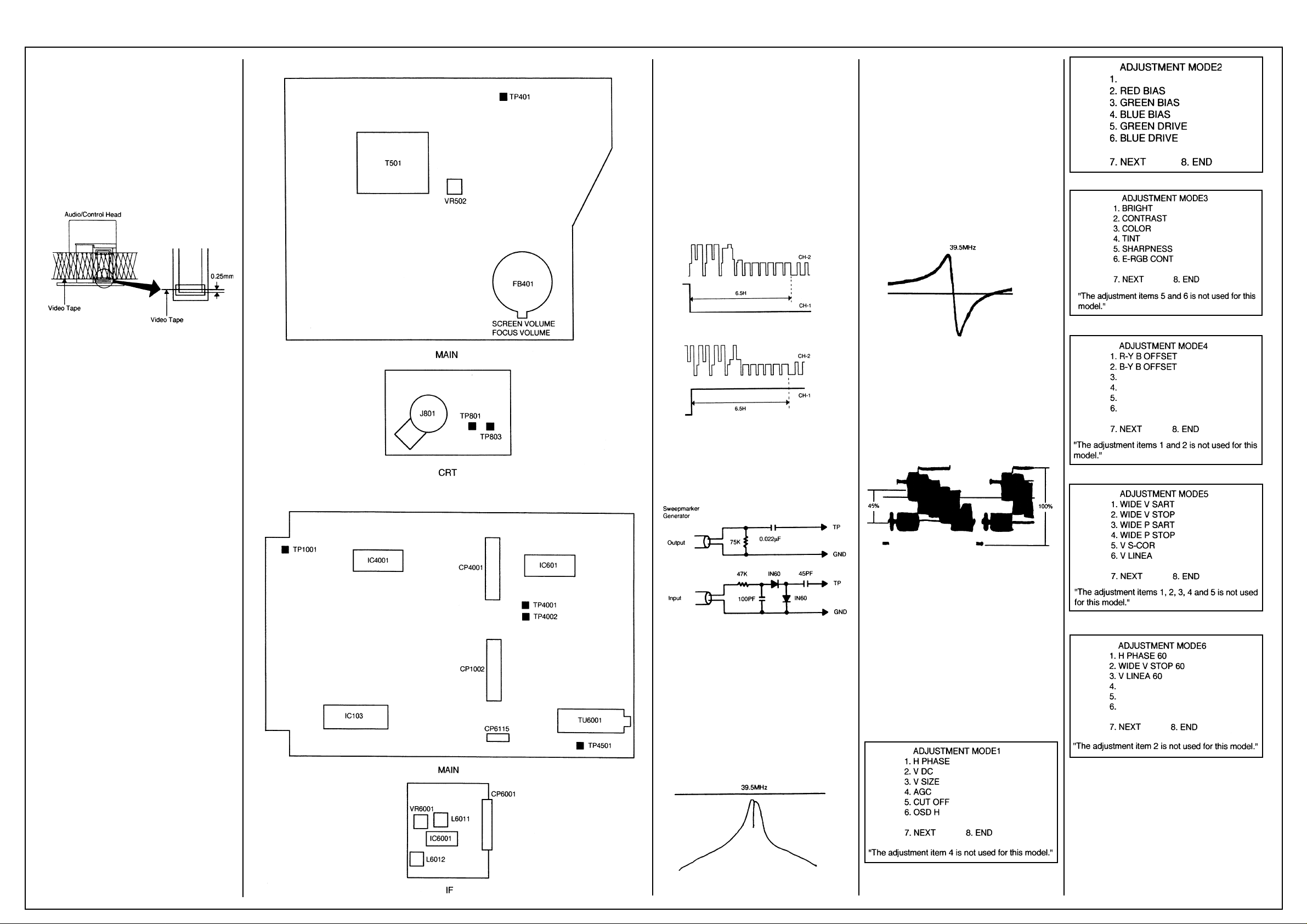

Components Location (TV)

Components Location (VCR)

(If the previous adjustments don’t work well:)

1. Connect CH-1 on the oscilloscope to TP4001

and CH-2 to TP4501.

2. Playback the alignment tape. (JG001F)

3. Set the tracking control to the center position.

(Refer to item 2-1, NO. 2.)

4. Press the VOL. DOWN button on the set and

the channel button (3) on the remote control

simultaneously until the indicator REC

disappears.

5. When the REC indicator is blinking, press

both VOL. DOWN key on the set and the

channel button (4) on the remote control

simultaneously and adjust the Tracking +/button until the arising to the down of the

Head Switching Pulse becomes 6.5 ± 0.5 H.

6. Press the Tracking Auto button.

Fig. 3-1-A

Fig. 3-1-B

3-2: VCO COIL

NOTE

For adjusting of VCO, connect input and output

terminals of sweepmarker generator to the

circuit as shown, then adjust it.

3-3: AFT COIL

CONDITION

MODE-STOP

INSTRUCTIONS

1. Connect the output of sweepmarker generator

to pin 5 of IC6001.

2. Connect the input of sweepmarker generator

to pin 3 of CP6115.

3. Adjust L6012 until the waveform marker

(38.9MHz) becomes as shown in Fig. 3-3.

4. Disconnect the sweepmarker generator and

the oscilloscope.

5. Connect the generator (39.5MHz) to the pin 4

of CP6115 through 2.2K ohm and connect the

DC voltmeter to pin 3 of CP6115.

6. Adjust L6012 until the DC voltage at pin 3 of

CP6115 is 3.8V±0.1V.

Fig. 3-3

3-4: COLOR LEVEL

CONDITIONS

MODE-STOP

INSTRUCTIONS

1. Connect the oscilloscope to TP4501.

2. When the Y-LEVEL is 100%, adjust the

VR6001 until the MAGENTA Section LEVEL

becomes 45± 5%. (Refer to Fig. 3-4)

Fig. 4-2

Fig. 4-3

Fig. 4-4

(VCR SECTION)

Components Location

3. ADJUSTMENT PROCEDURE

Read and perform these adjustments when

repairing the circuits or replacing electrical parts

or PCB assemblies.

CAUTION

When replacing IC’s or transistors, use a silicon

grease. (To prevent the damage to IC’s and

transistors.)

3-1: PG SHIFTER (HEAD SWITCHING)

ADJUSTMENT CONDITIONS

MODE-PLAYBACK

Input Signal-Alignment Tape (JG001F) or Similar

INSTRUCTIONS

1. Unplug the AC plug once to set the clock to

the non-setting state. Then, set the volume

level to minimum.

2. Playback the alignment tape. (JG001F)

3. Set the tracking control to the centre position.

Refer to item 2-1, NO. 2.)

4. Press the VOL. DOWN button on the set and

the channel button (3) on the remote control

simultaneously until the indicator REC

disappears. If the indicator REC disappears,

adjustment is completed.

CONDITION

MODE-STOP

INSTRUCTIONS

1. Connect the output of sweepmarker generator to pin 5 of IC6001.

2. Connect the input of sweepmarker generator

to pin 17 of IC6001.

3. Connect a 10K ohm variable resistor to IF

AGC terminal (pin 4 of IC6001), 9V line and

ground, then adjust to make the waveform of

the oscilloscope readable.

4. Adjust L6011 until the waveform marker

(39.5MHz) becomes as shown in Fig. 3-2.

Fig. 3-2

Fig. 3-4

Electrical Adjustments (TV SECTION)

4. BASIC ADJUSTMENTS

On-Screen Display Adjustment

Do not set the CLOCK, and sound to minimum.

Press the VOL. DOWN key on the set and the

Channel button (9) on the remote control

simultaneously to appear the adjustment mode

on the screen as shown in Fig. 4-1, Fig. 4-2, Fig.

4-3, Fig. 4-4, Fig. 4-5 and Fig. 4-6.

NOTE

Use the 1 - 7 keys on the remote control to

select the options shown in Fig. 4-1, Fig. 4-2,

Fig. 4-3, Fig. 4-4, Fig. 4-5 and Fig. 4-6.

Press the 8 key to end the adjustments.

Fig. 4-1

Fig. 4-5

Fig. 4-6

4-1: CUTOFF

1. Activate the adjustment mode display of Fig.

4-1 and press the channel button (5) on the

remote control.

2. Adjust the Screen Volume until picture is

distinct.

4-2: WHITE BALANCE

1. Receive the color bar pattern.

2. Adjust the adjustment mode display of Fig. 4-2

until the white color is looked like a white.

Page 5

AIWA VX-T1480

Electrical Adjustments

Cont’d

4-3: FOCUS

1. Receive the broadcasting signal.

2. Adjust the Focus Volume until picture is

distinct.

4-4: HORIZONTAL PHASE

1. Receive the color bar pattern.

2. Using the remote control, set the brightness

and contrast to normal position.

3. Activate the adjustment mode display of Fig.

4-1 and press the channel button (1) on the

remote control.

4. Press the VOL. UP/DOWN button on the

remote control until the SHIFT quantity of the

OVER SCAN on right and left becomes

minimum.

4-5: VERTICAL POSITION

1. Receive the color bar pattern.

2. Using the remote control, set the brightness

and contrast to normal position.

3. Activate the adjustment mode display of Fig.

4-1 and press the channel button (2) on the

remote control.

4. Press the VOL. UP/DOWN button on the

remote control until the horizontal line of the

color bar comes to approximate center of the

CRT.

4-6: VERTICAL SIZE

1. Receive the monochrome pattern.

2. Using the remote control, set the brightness

and contrast to normal position.

3. Activate the adjustment mode display of Fig.

4-1 and press the channel button (3) on the

remote control.

4. Press the VOL. UP/DOWN button on the

remote control until the horizontal overscan is

equal to the vertical overscan.

4-7: VERTICAL LINEA

1. Receive the monochrome pattern.

2. Using the remote control, set the brightness

and contrast to normal position.

3. Activate the adjustment mode display of Fig.

4-5 and press the channel button (6) on the

remote control.

4. Press the VOL. UP/DOWN button on the

remote control until the SHIFT quantity of the

OVER SCAN on upside and downside

becomes minimum.

4-8: HORIZONTAL PHASE 60 (AV)

1. Receive the monochrome pattern (Audio

Video Input).

2. Using the remote control, set the brightness

and contrast to normal position.

3. Activate the adjustment mode display of Fig.

4-6 and press the channel button (1) on the

remote control.

4. Press the VOL. UP/DOWN button on the

remote control until the SHIFT quantity of the

OVER SCAN on right and left becomes

minimum.

4-9: VERTICAL LINEA 60 (AV)

1. Receive the monochrome pattern (Audio

Video Input).

2. Using the remote control, set the brightness

and contrast to normal position.

3. Activate the adjustment mode display of Fig.

4-6 and press the channel button (3) on the

remote control.

4. Press the VOL. UP/DOWN button on the

remote control until the SHIFT quantity of the

OVER SCAN on upside and downside

becomes minimum.

4-10: OSD HORIZONTAL

1. Using the remote control, set the brightness

and contrast to normal position.

2. Activate the adjustment mode display of Fig.

4-1 and press the channel button (6) on the

remote control.

3. Press the VOL. UP/DOWN button on the

remote control until the difference of A and B

becomes minimum. (Refer to Fig. 4-7)

Fig. 4-7

4-11: SUB CONTRAST (TV)

1. Receive the monochrome pattern (RF Input).

2. Activate the adjustment mode display of Fig.

4-3 and press the channel button (2) on the

remote control.

3. Press the VOL. UP/DOWN button on the

remote control until the CONTRAST level is

set to the 20”.

4-12: SUB CONTRAST (AV)

1. Receive the monochrome pattern (Audio

Video Input).

2. Activate the adjustment mode display of Fig.

4-3 and press the channel button (2) on the

remote control.

3. Press the VOL. UP/DOWN button on the

remote control until the CONTRAST level is

set to the “20”.

4-13: SUB BRIGHTNESS (TV)

1. Receive the monochrome pattern (RF Input).

2. Using the remote control, set the brightness

and contrast to normal position.

3. Activate the adjustment mode display of Fig.

4-3 and press the channel button (1) on the

remote control.

4. Press the VOL. UP/DOWN button on the

remote control until the white 25% is slightly

brilliant.

4-14: SUB BRIGHTNESS (AV)

1. Receive the monochrome pattern (Audio

Video Input).

2. Using the remote control, set the brightness

and contrast to normal position.

3. Activate the adjustment mode display of Fig.

4-3 and press the channel button (1) on the

remote control.

4. Press the VOL. UP/DOWN button on the

remote control until the white 25% is slightly

brilliant.

4-15: SUB COLOR (TV)

1. Receive the color bar pattern (RF Input).

2. Connect the oscilloscope to TP801.

3. Activate the adjustment mode display of Fig.

4-3 and press the channel button (3) on the

remote control.

4. Adjust the VOLTS RANGE VARIABLE knob of

the oscilloscope until the range between white

100% and 0% is set to 4 scales on the screen

of the oscilloscope.

5. Press the VOL. UP/DOWN button on the

remote control until the red color level is

adjusted to 95% (VX-T1480) or 85% (VXG140) of the white level. (Refer to Fig. 4-8)

Fig. 4-8

4-16: SUB COLOR (AV)

1. Receive the color bar pattern (Audio Video

Input).

2. Connect the oscilloscope to TP801.

3. Activate the adjustment mode display of Fig.

4-3 and press the channel button (3) on the

remote control.

4. Adjust the VOLTS RANGE VARIABLE knob of

the oscilloscope until the range between white

100% and 0% is set to 4 scales on the screen

of the oscilloscope.

5. Press the VOL. UP/DOWN button on the

remote control until the red color level is

adjusted to 95% (VX-T1480) or 85% (VXG140) of the white level. (Refer to Fig. 4-8).

4-17: SUB TINT (AV)

1. Receive the color bar pattern (Audio Video

Input).

2. Connect the oscilloscope to TP803.

3. Activate the adjustment mode display of Fig.

4-3 and press the channel button (4) on the

remote control.

4. Press the VOL. UP/DOWN button on the

remote control until the waveforn becomes as

shown in Fig. 4-9.

Fig. 4-9

4-18: CONSTANT VOLTAGE

1. Receive the monochrome pattern.

2. Using the remote control, set the brightness

and contrast to minimum position.

3. Connect the DC voltmeter to TP401.

4. Adjust the VR502 until the DC voltmeter is

100V ± 0.5V.(VX-T1480) or 103V ± 0.5V (VXG140).

5. PURITY AND CONVERGENCE ADJUST-

MENT

NOTE

1. Turn the unit on and let it warm up for at least

30 minutes before performing the following

adjustments.

2. Place the CRT surface facing east or west to

reduce the terrestrial magnetism.

3. Turn ON the unit and demagnetize with a

Degauss Coil.

5-1: STATIC CONVERGENCE (ROUGH

ADJUSTMENT)

1. Tighten the screw for the magnet. Refer to the

adjusted CRT for the position. (Refer to Fig.

5-1). If the deflection yoke and magnet are in

one body, untighten the screw for the body.

2. Receive the green raster pattern from color

bar generator.

3. Slide the deflection yoke until it touches the

funnel side of the CRT.

4. Adjust center of screen to green, with red and

blue on the sides, using the pair of purity

magnets.

5. Switch the color bar generator from the green

raster pattern to the crosshatch pattern.

6. Combine red and blue of the 3 color crosshatch pattern on the center of the screen by

adjusting the pair of 4 pole magnets.

7. Combine red/blue (magenta) and green by

adjusting the pair of 6 pole magnets.

8. Adjust the crosshatch pattern to change to

white by repeating steps 6 and 7.

5-2: PURITY

NOTE

Adjust after performing adjustments in section 5-1.

1. Receive the green raster pattern from color

bar generator.

2. Adjust the pair of purity magnets to center the

color on the screen. Adjust the pair of purity

magnets so the color at ends are equally

wide.

3. Move the deflection yoke backward (To neck

side) slowly, and stop it at the position when

the whole screen is green.

4. Confirm red and blue colors.

5. Adjust the slant of the deflection yoke while

watching the screen, then tighten the fixing

screw.

Fig. 5-1

5-3: STATIC CONVERGENCE

NOTE

1. Receive the crosshatch pattern from color bar

generator.

2. Combine red and blue of the 3 color crosshatch pattern on the center of the screen by

adjusting the pair of 4 pole magnets.

3. Combine red/blue (magenta) and green by

adjusting the pair of 6 pole magnets.

5-4: DYNAMIC CONVERGENCE

NOTE

Adjust after performing adjustments in section 5-3.

1. Adjust the differences around the screen by

moving the deflection yoke upward/downward

and right/left. (Refer to Fig. 5-2-a)

2. Insert three wedges between the deflection

yoke and CRT funnel to fix the deflection

yoke. (Refer to Fig. 5-2-b)

Fig. 5-2-a

Fig. 5-2-b

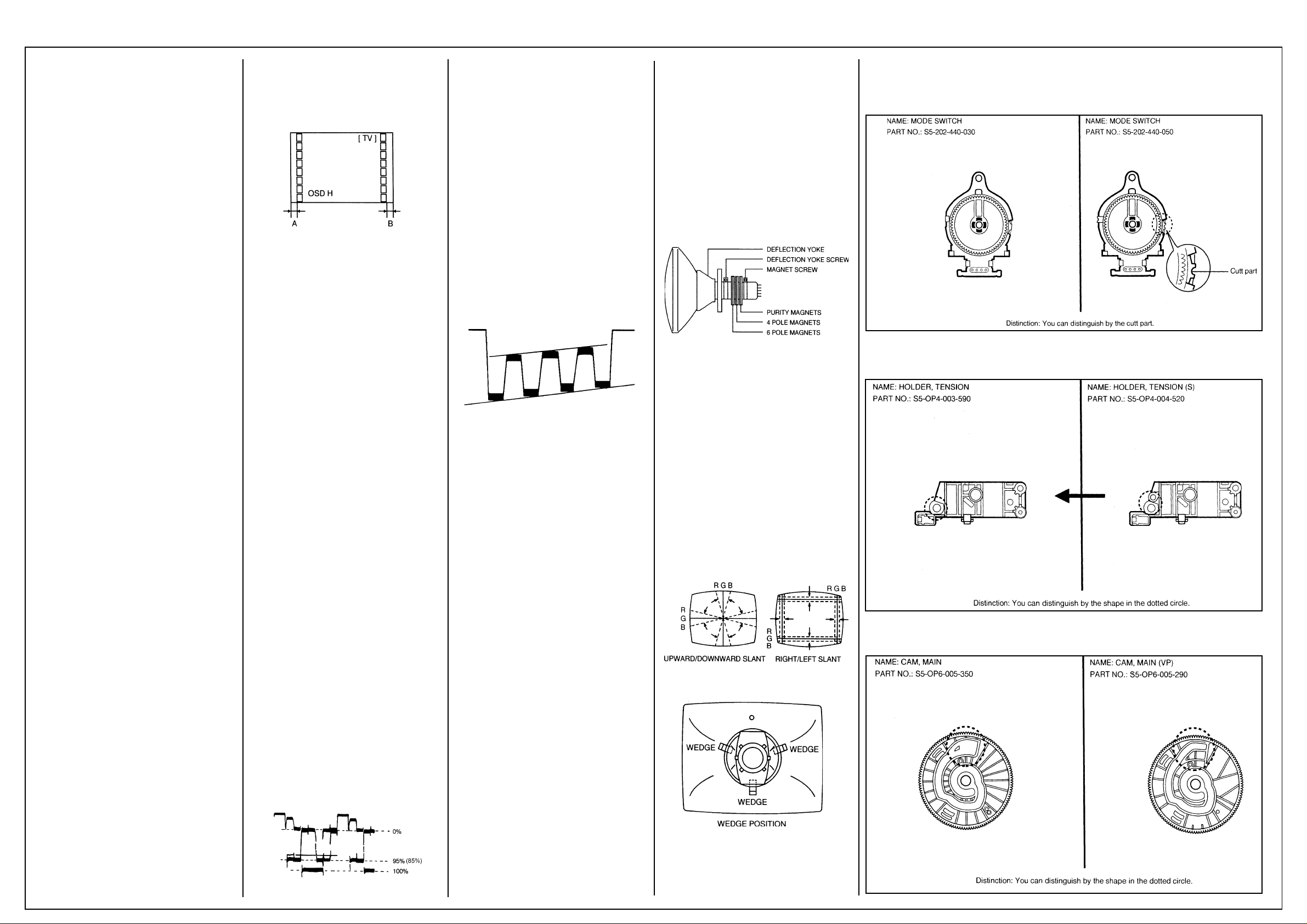

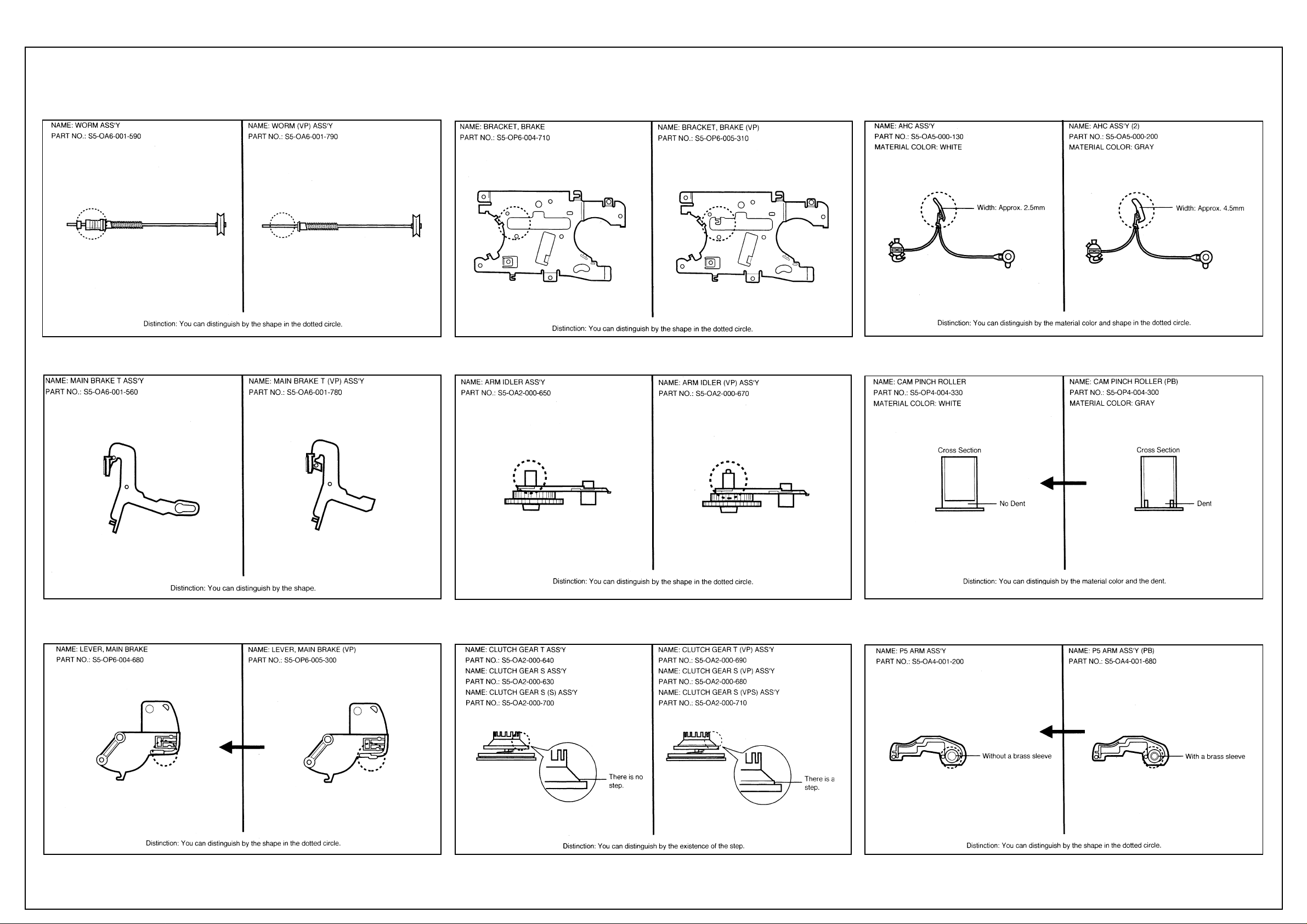

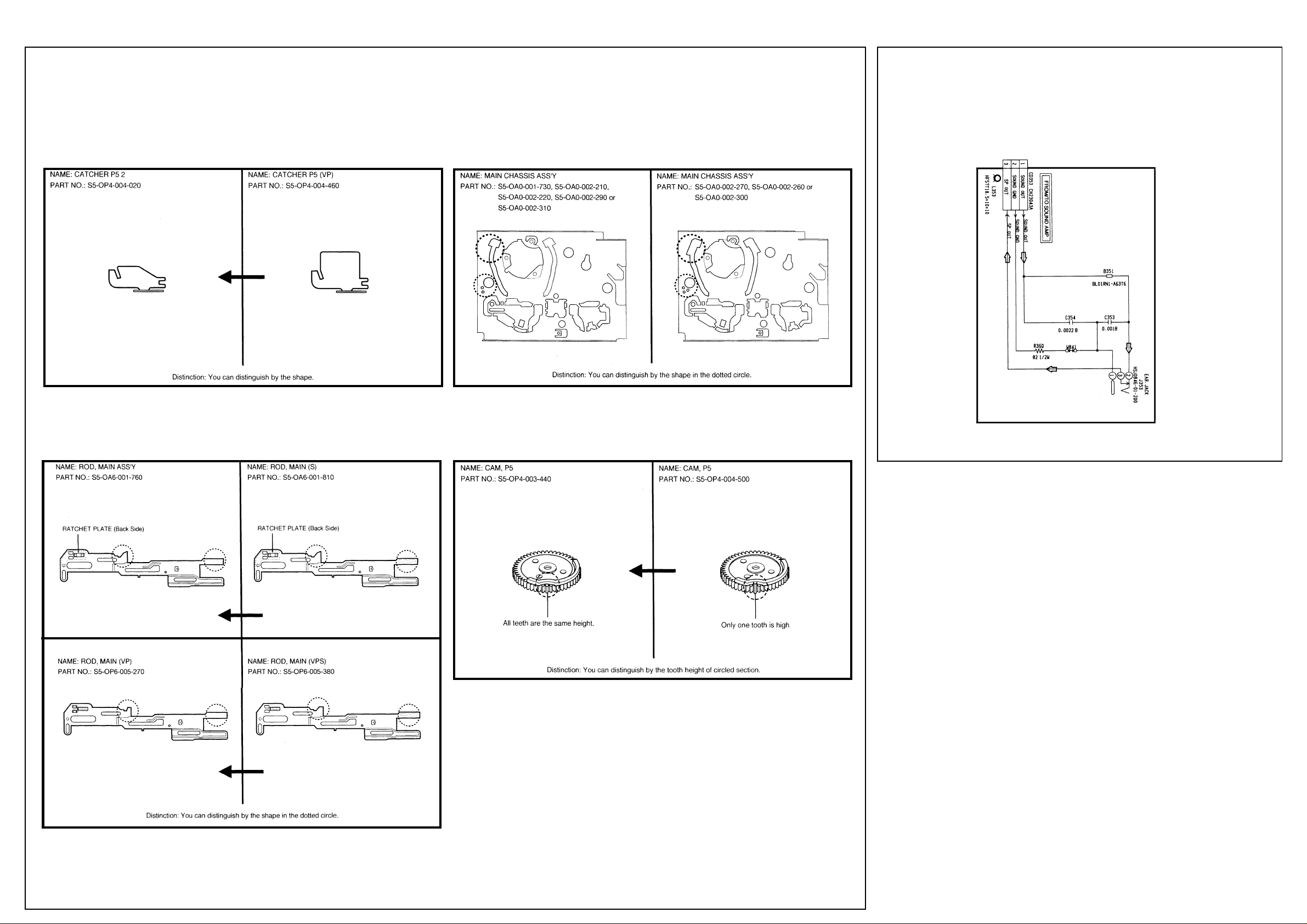

OVD-5 Deck Alternative Parts

Page 6

AIWA VX-T1480

OVD-5 Deck Alternative Parts Cont’d

Page 7

AIWA VX-T1480

OVD-5 Deck Alternative Parts Cont’d

Earphone Diagram

Page 8

AIWA VX-T1480

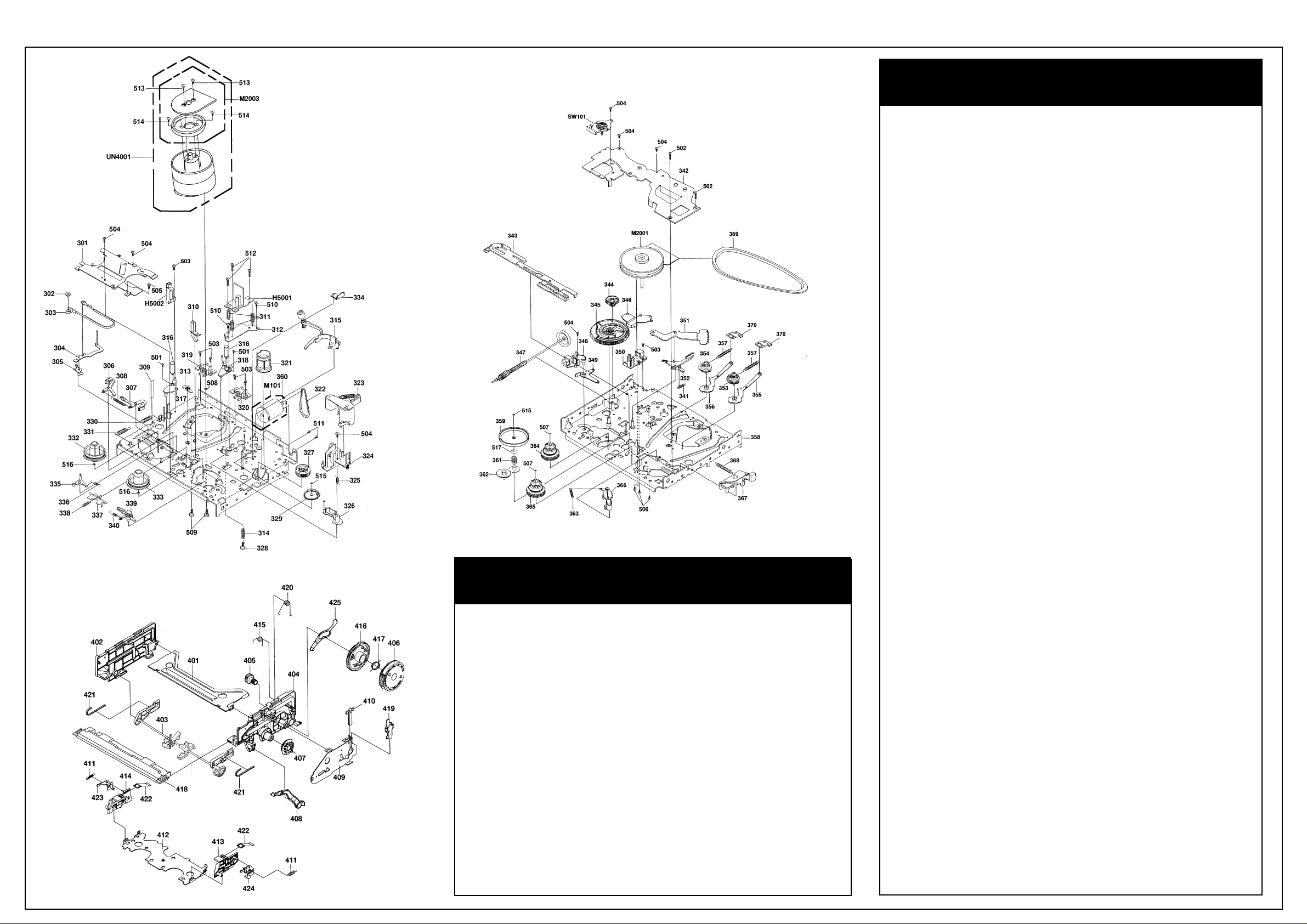

Deck Exploded Parts View

Item Part No. Description

301 S5-OP6-004-710 BRACKET, BRAKE 1

302 S5-OP4-003-580 ADJUST, TENSION 1

303 S5-OA4-001-220 TENSION BAND ASSY 1

304 S5-OA4-001-240 TENSION ARM ASSY

305 S5-OA4-001-230 TENSION LEVER 2 ASSY 1

306 SS-OA6-001-550 MAIN BRAKE S ASSY

307 S5-OA6-001-560 MAIN BRAKE T ASSY 1

308 S5-OP8-002-520 SPR,MAIN BRAKE 1

309 S5-OP9-005-640 REFLECTOR EOT 1

310 SS-OP4-004-110 REFLECTOR, LED 2 1

311 S5-OP8-002-690 SPR, AC HEAD 3

312 S5-OP5-000-600 BASE, AC HEAD 1

313 S5-OP0-003-940 POST, C ASS GUIDE L 1

314 SS-OP8-002-450 SPRING, AZIMUTH 2 1

315 S5-OA5-000-130 AHC ASSY 1

316 S5-OA4-001-020 G-ROLLER ASS’Y 2

317 S5-OA4-001-140 BASE, S INCLINED ASSY 1

318 S5-OA4-001-150 BASE, T INCLINED ASSY 1

319 S5-OP4-003-300 CATCHER S 1

320 S5-OP4-003-320 CATCHER T 1

321 S5-OP4-003-430 CAMPINCH ROLLER 1

322 S5-OP6-004-870 BELT, LOADING 1

323 S5-OA4-001-170 PINCH ROLLER BLOCK 1

324 S5-OP9-005-410 CASS, OPENER 1

325 S5-OP8-002-640 SPR, P5 1

326 S5-OA4-001-200 PS ARM ASSY 1

327 S5-OP4-003-420 CAM, GEAR 1

328 S1-462-30A-140 VT2+3-1 1 1

329 S5-OP4-003-440 CAM, P5 1

330 S5-OP4-003-560 SPR, TENSION ARM 2 1

331 S5-OP4-003-570 SPR, TENSION ARM 1 1

332 S5-OP2-002-160 REEL S 1

Deck Parts List

Deck Parts List Cont’d

Item Part No. Description

333 S5-OP2-002-170 REEL T 1

334 S5-OP4-004-020 CATCHER, P52 1

335 S5-OP6-004-65O SUBBRAKE S 1

336 S5-OP8-002-530 SPR, S-S BRAKE 1

337 S5-OP2-002-470 ARM, JOINT 1

338 S5-OP8-002-620 SPR, JOINT ARM 1

339 S5-OA6-001-570 SUB BRAKE T ASSY 1

340 S5-OP8-002-540 SPR,T-S BRAKE 1

341 S5-OP8-002-550 5PR,CAPBRAKE 1

342 PLATE BOTTOM 1

343 S5-OA6-001-760 ROD MAIN ASSY 1

344 S5-OP4-003-410 GEAR, MIDDLE 1

345 S5-OP6-005-350 CAM MAIN 1

346 S5-OP6-004-680 LEVER MAIN BRAKE 1

347 S5-OA6-001-590 WORM ASSY 1

348 S5-OP6-004-830 BRACKET, WORM F 1

349 S5-OP6-004-740 LEVER, RATCHET 1

350 S5-OP6-004-840 BRACKET, WORM R 1

351 S5-OP3-001-510 LEVER,LOADING 1

352 CAPSTAN BRAKE ASSY (MJ) 1

353 S5-OP3-001-520 GEAR, LOADING S 1

354 S5-OP3-001-530 GEAR, LOADING T 1

355 S5-OA3-000-530 LOADING ARM S ASS’Y 1

356 S5-OA3-000-540 LOADING ARM T ASS’Y 1

357 S5-OP8-002-630 SPR,LOADING GEAR 2

358 MAIN CHASS ASSY 1

359 S5-OP2-002-130 CENTER PULLEY 1

360 S5-OP6-004-860 PULLEY LDM 5 1

361 S5-OP8-002-610 SPR, C-PULLEY 1

362 S5-OA2-000-650 ARM IDLER ASSY 1

363 S5-OP8-002-700 SPR,LEVER TENSION 1

364 S5-OA2-000-640 CLUTCH GEAR T ASSY 1

365 S5-OA2-000-630 CLUTCH GEAR S ASSY 1

366 S5-OP4-003-600 LEVER, TENSION 1

367 S5-OP4-003-590 HOLDER, TENSION 1

368 S5-OP8-002-560 SPR, MAIN ROD 1

369 S5-OP2-002-1S0 BELT,CAPSTAN 1

370 S5-OP3-001-500 SLIDER, LOADING 2

401 S5-OP9-006-170 BRKET , TOP 1

402 S5-OP9-006-070 BRACKET, SIDE L 1

403 S5-OA9-001-710 LINK ASSY 2 1

404 S5-OP9-006-150 BRKET, SIDER 1

405 S5-OP9-006-010 GEAR, JOINT 1

406 S5-OP9-006-020 GEAR, CAM 1

407 S5-OP9-006-090 GEAR, LINK R 1

408 S5-OP9-006-720 LEVER,FLAP 2 1

409 S5-OP9-006-160 BRKET, SIDE R2 1

410 ---- REFLECTOR, EOT 1

411 S5-OP8-002-960 SPR, LOCKER 2

412 S5-OP9-006-110 CASS, HOLDER 1

413 S5-OP9-006-130 CASS, SIDE R 1

414 S5-OP9-006-120 CASS, SIDE L 1

415 S5-OP8-002-980 SPR, BRACKET R 1

416 S5-OP9-006-080 GEAR, CLUTCH 1

417 S5-OP8-002-970 SPR, CLUTCH 1

418 S5-OP9-006-190 TAPE GUIDE PIECE 1

419 S5-OP9-006-200 COVER,SENSOR BOT 1

420 S5-OP8-002-900 SPR, EARTH 1

421 S5-OP8-002-940 SPR, LINK 2

422 S5-OPB-002-990 SPR, PACK 2

423 S5-OP9-006-050 LOCKER, L 1

424 S5-OP9-006-060 LOCKER, R 1

425 S5-OP9-006-100 LEVER, BOT 1

501 87-357-529-310 SCREW TAP(P)BIND 1.7-4.0 2

502 S1-092-26A-640 VT2+2.6-16 2

503 87-751-074-410 VT2+2.6-8 6

504 87-743-073-010 VT2+2.6-6 7

505 S1-071-236-040 SCREW, TAP 23-6 PAN 1

506 87-264-074-410 SCREW, TAP(B)PAN 26-8 3

507 S2-P16-600-5N0 POLY, W(CUT)1.6-6-0.5 2

508 S2-Q31-54B-3N0 PW, 3.1-5.4-T0.13 1

509 S1-0A1-306-040 SCREW, WASHER(A)M3-6 3

510 S1-0B1-266-040 UFT2+M2.6-6 2

511 87-258-091-010 U+M3-3 2

512 87-253-07S-010 U+M2.6-10 3

513 S1-0A1-235-040 SEMS A M2.3-5 2

S14 87-261-093-410 SCREW, M3-5 2

515 87-067-909-010 POLY, W(CUT)2.6-6-0.5 2

516 S2-Q26-471-3N0 POLY, W 2.6-47-0.13 2

517 S2-P26-A00-5N0 POLY, W(CUT)2.6-10-0.5 1

CD1001 S6-872-205-8A0 CORD CONN 8722058A 1

CD2001 ---- JUMPER 2W06080 1

CD5001 ---- CORD, JUMPER 2L05150 1

H5001 S5-23D-910-290 HEAD, AC HVMZA12 1

H5002 S5-43D-020-100 HEAD,FULL ERASE HVFHF00 1

M101* S5-96P-480-010 MOTOR, LOAD(1) 1

M2001* S5-94J-980-040 CAPSTAN DD UNIT SP39BD 1

M2003* S5-89V-110-040 MICRO MOTOR EP14BA 1

SW101 S5-202-440-030 SW, ROTARY SRZZ0B064A 1

UN4001* S4-841-1B5-000 CYLINDER UNIT ASSY 1

* Safety Parts

Page 9

AIWA VX-T1480

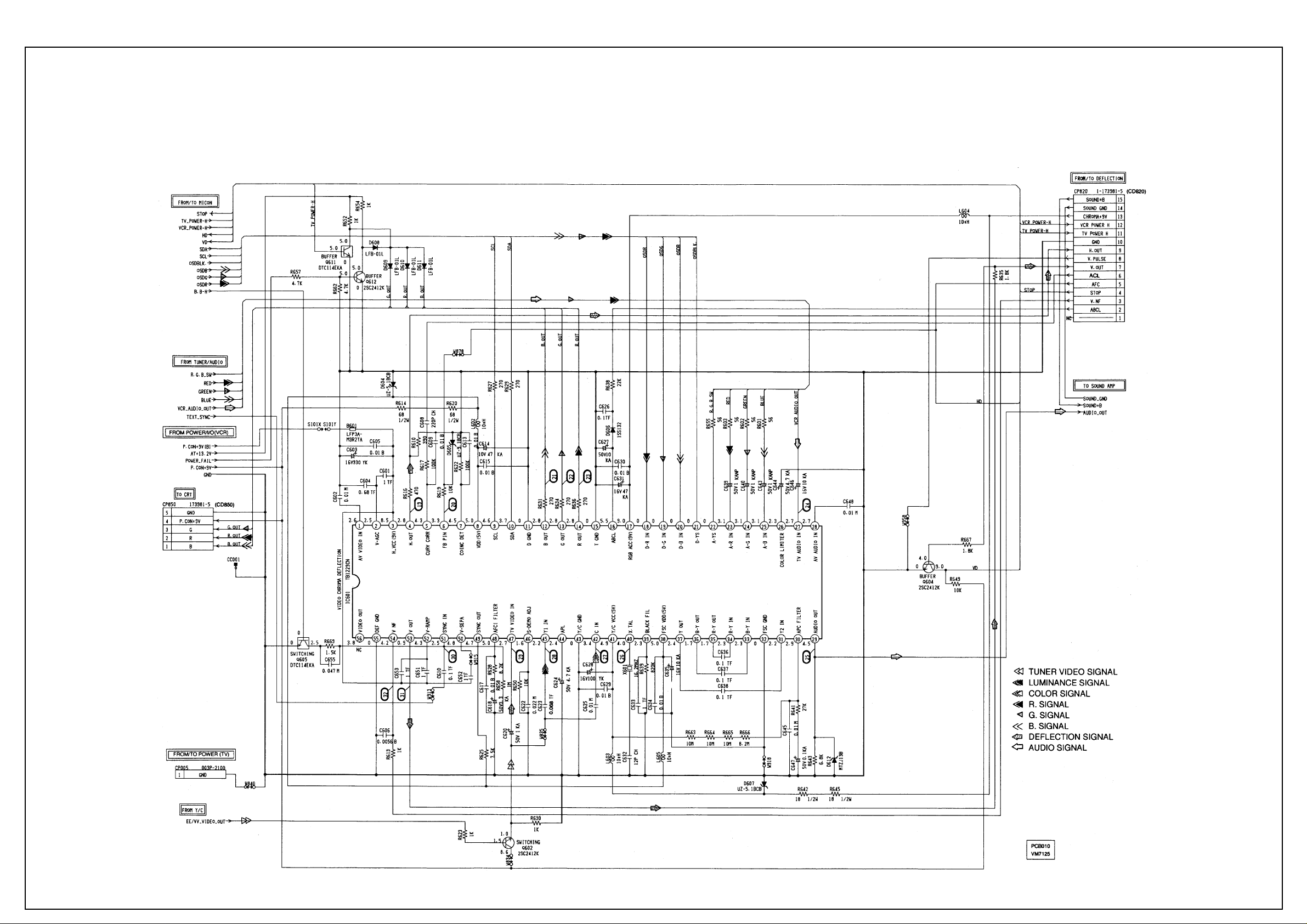

Chroma Diagram

Page 10

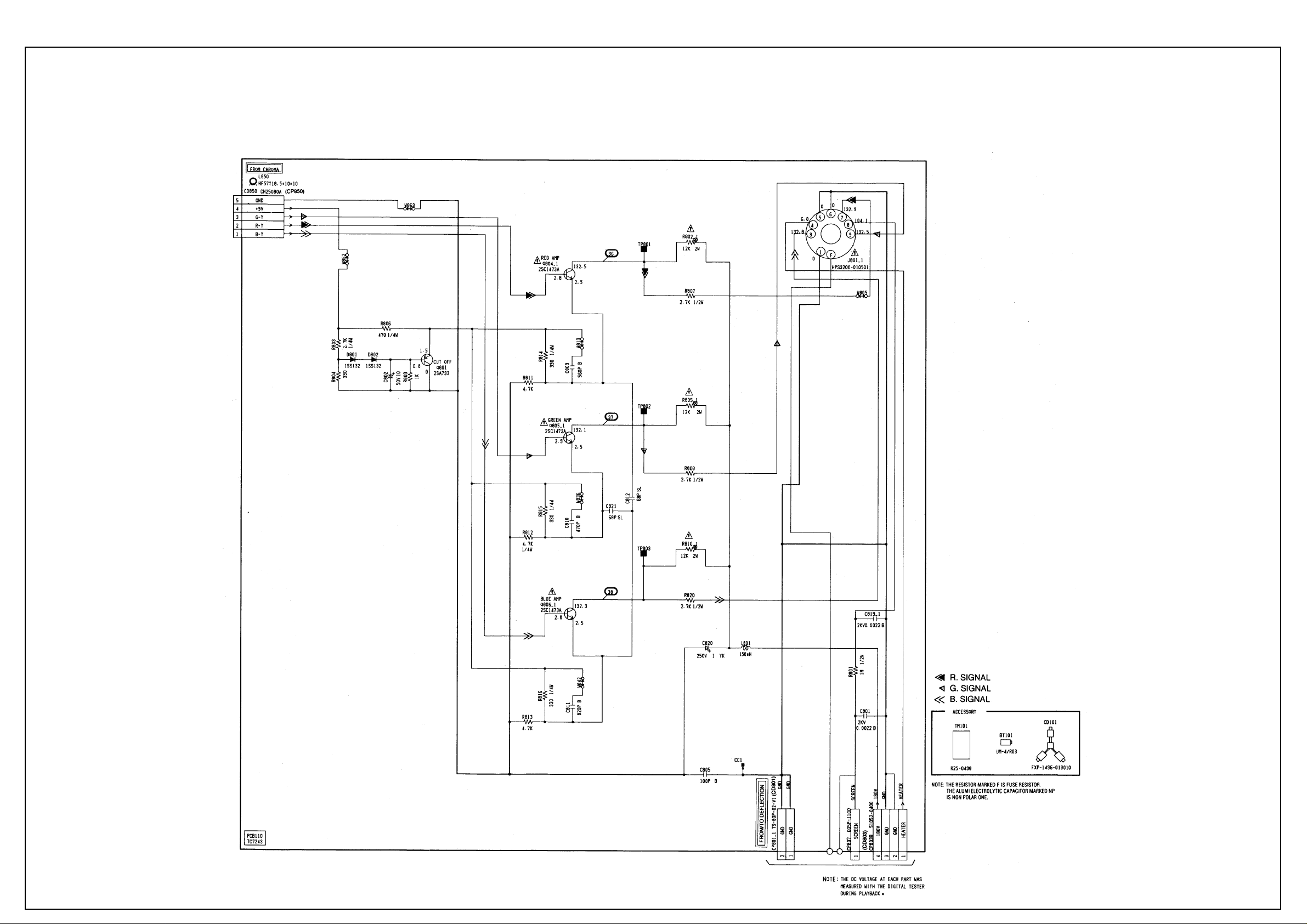

AIWA VX-T1480

CRT Diagram

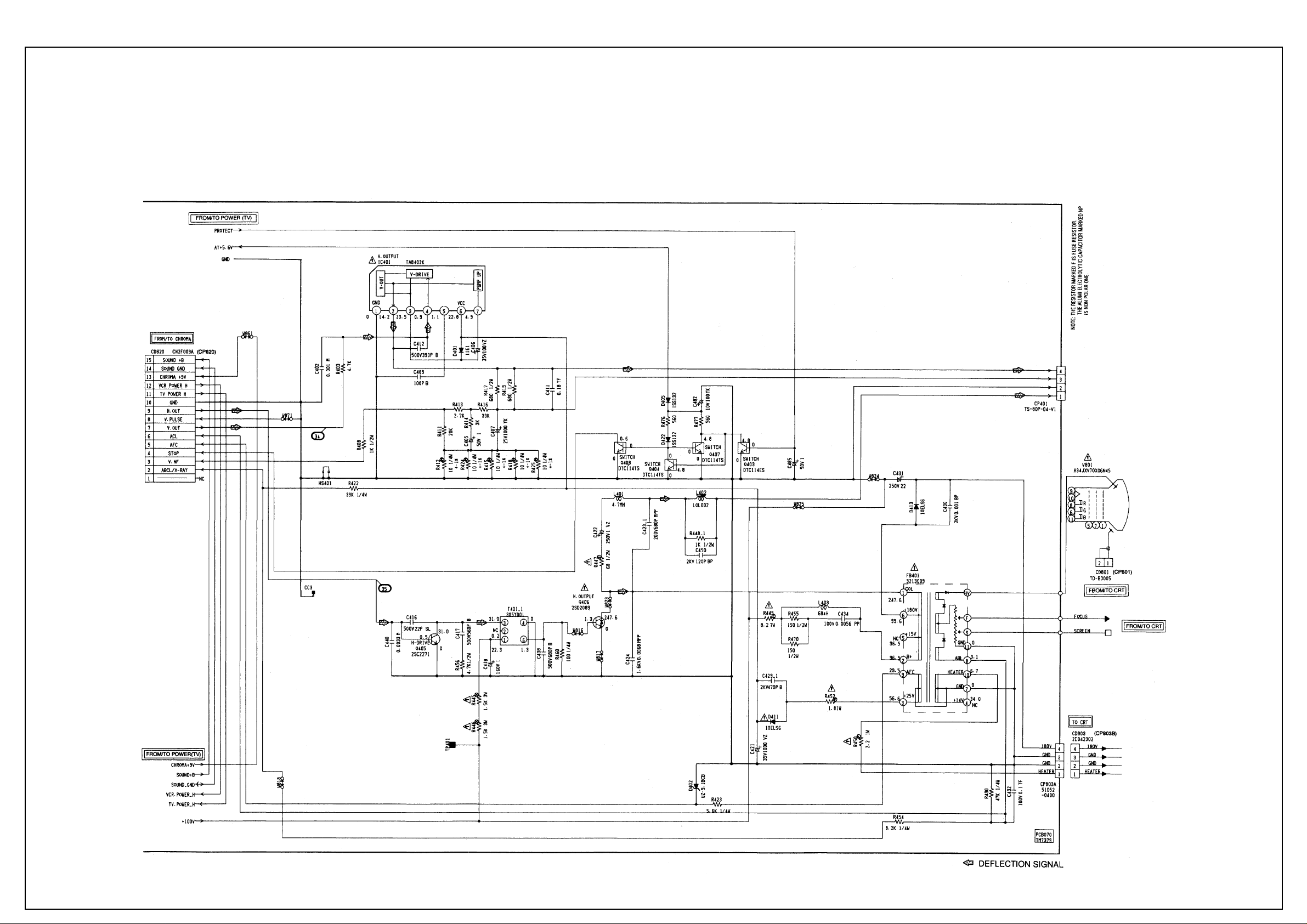

Page 11

AIWA VX-T1480

Deflection Diagram

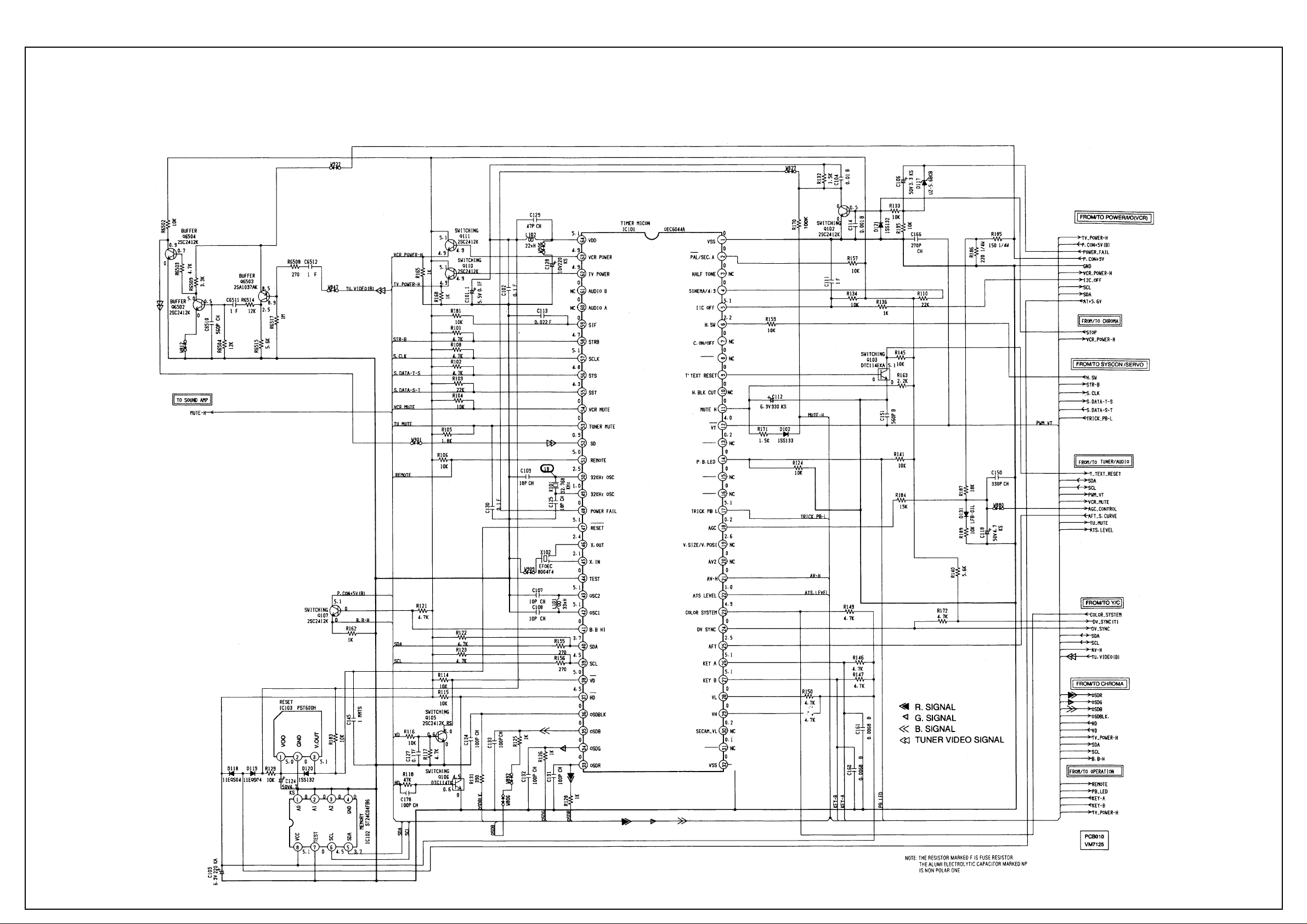

Page 12

AIWA VX-T1480

Microcontroller Diagram

Page 13

AIWA VX-T1480

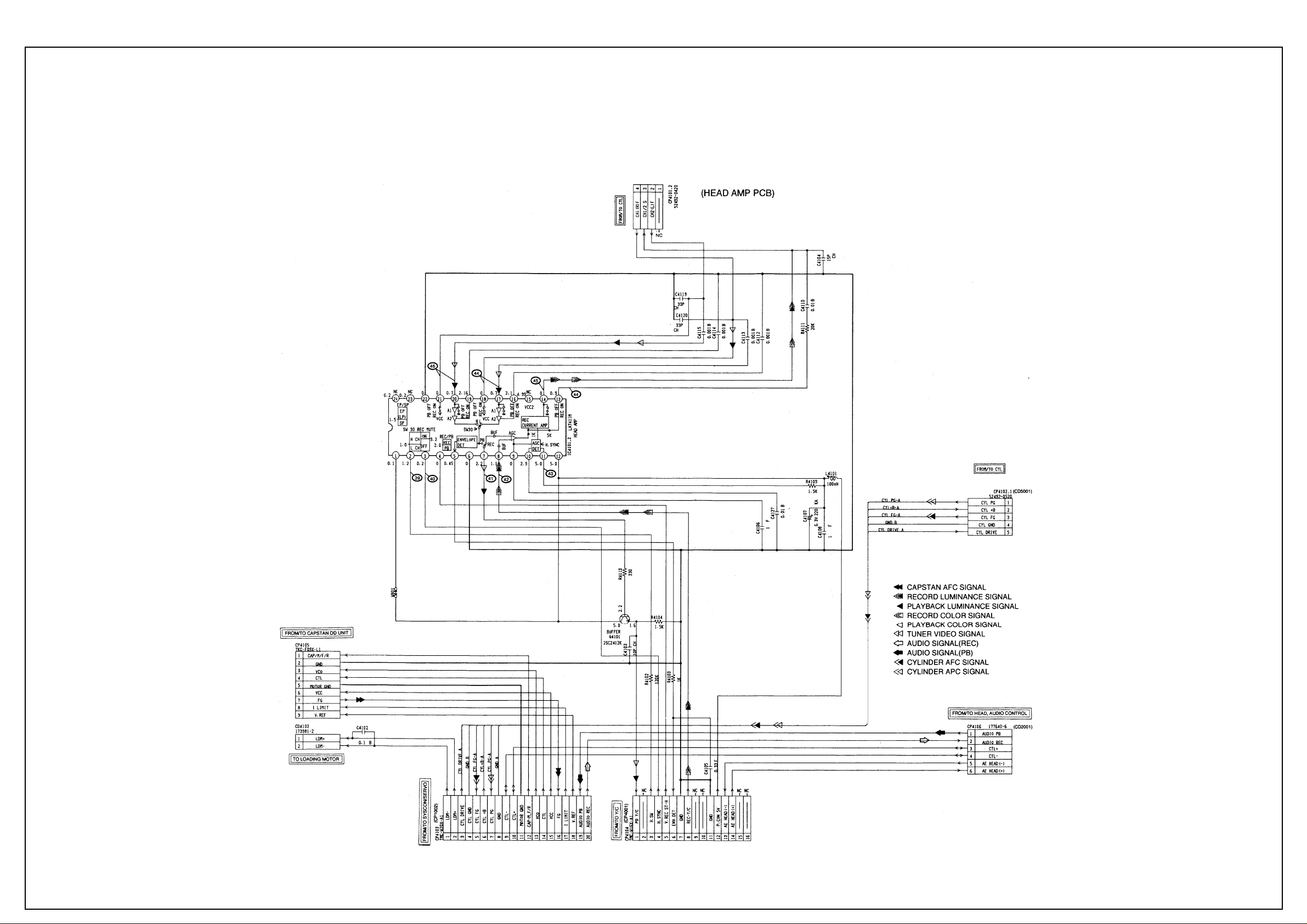

Head Amp Diagram

Page 14

AIWA VX-T1480

IF PCB Diagram

Page 15

AIWA VX-T1480

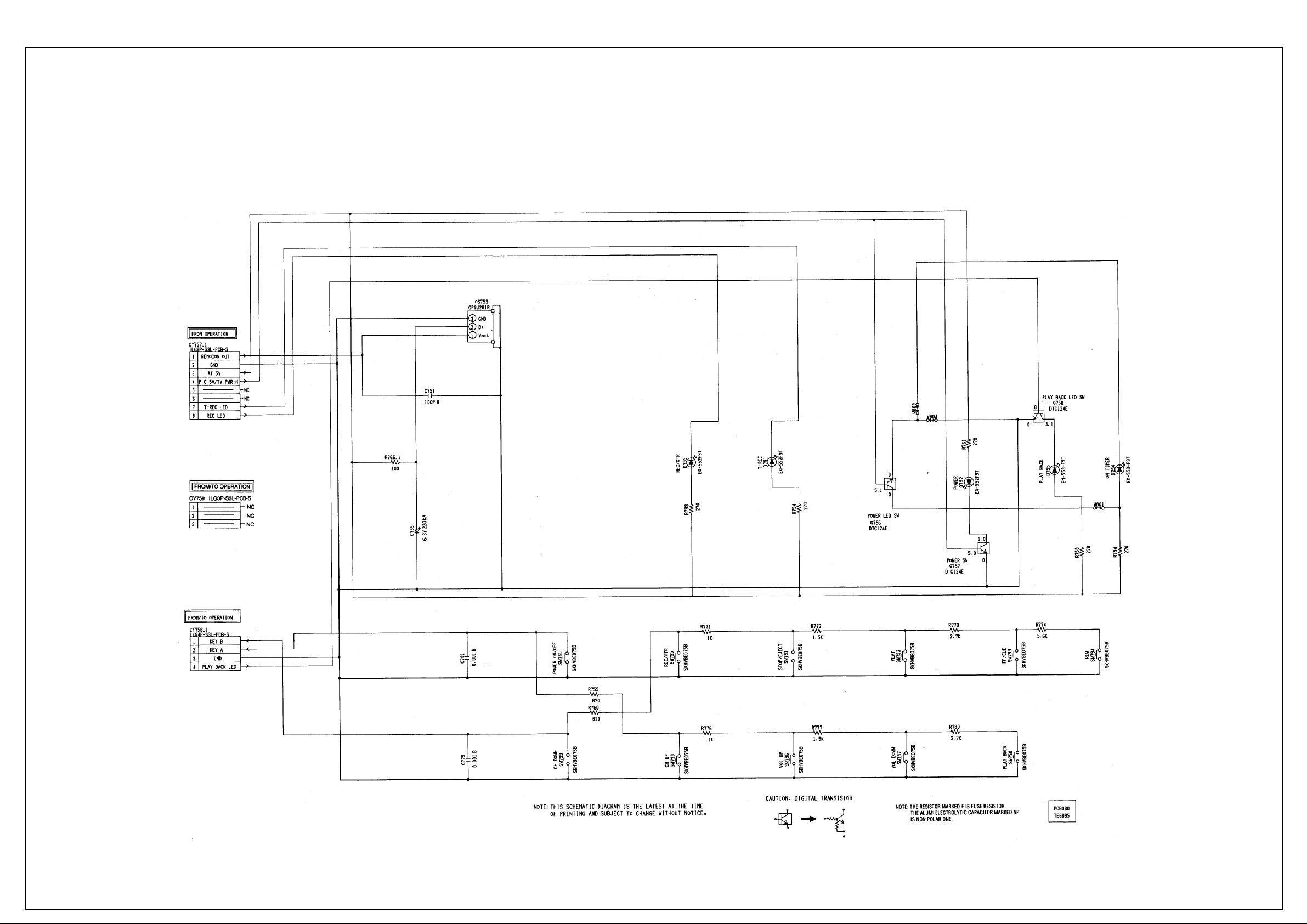

Operations Diagram 1

Page 16

AIWA VX-T1480

Operations Diagram 2

Audio Amp

Diagram

Page 17

AIWA VX-T1480

Power Diagram (TV)

Page 18

AIWA VX-T1480

Power Diagram (VCR)

Page 19

AIWA VX-T1480

Teletext Diagram

Page 20

AIWA VX-T1480

Y/C Diagram

Page 21

AIWA VX-T1480

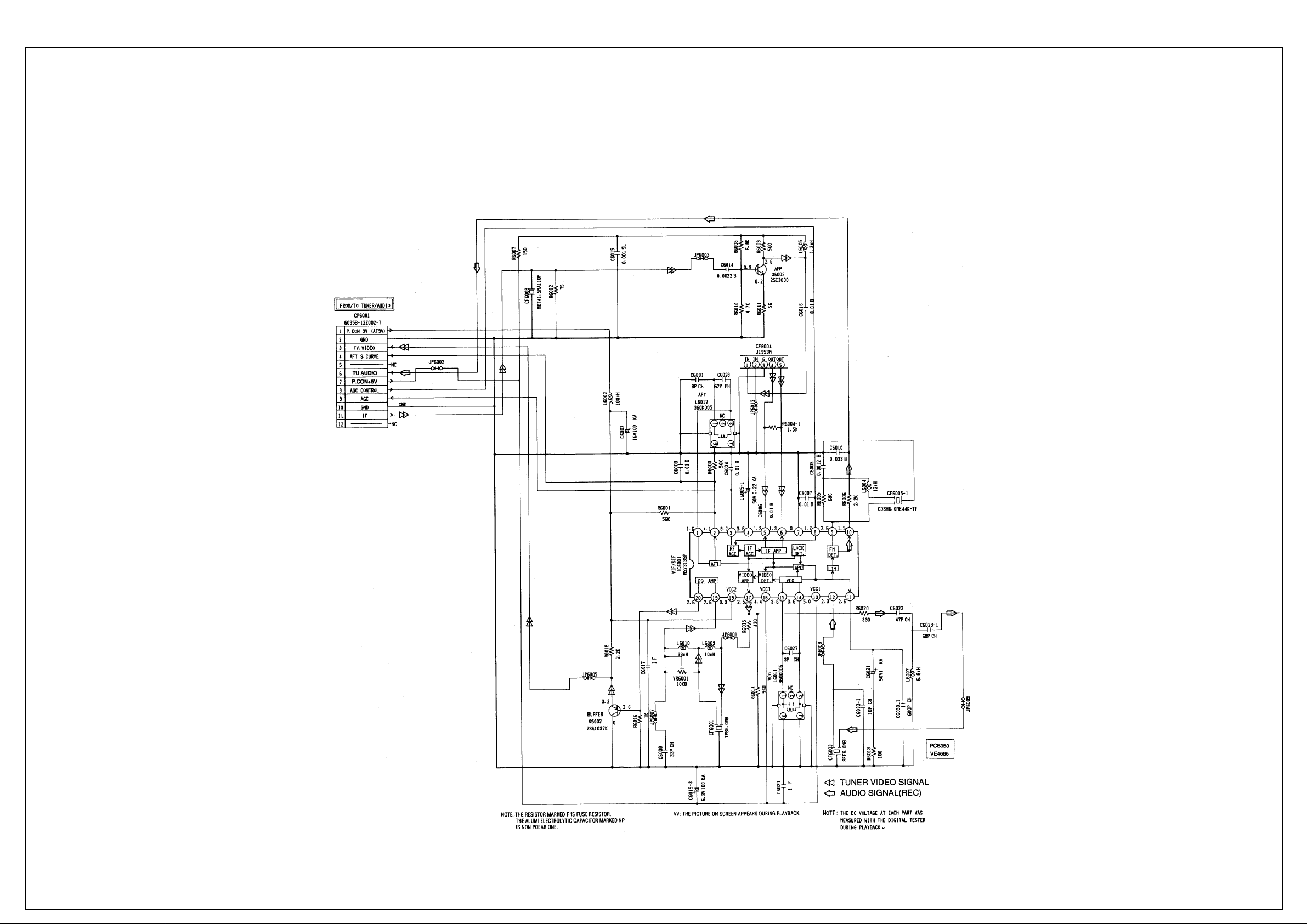

T uner Audio Diagram

Page 22

AIWA VX-T1480

Waveforms

Page 23

AIWA VX-T1480

Wiring Diagram

Page 24

AIWA VX-T1480

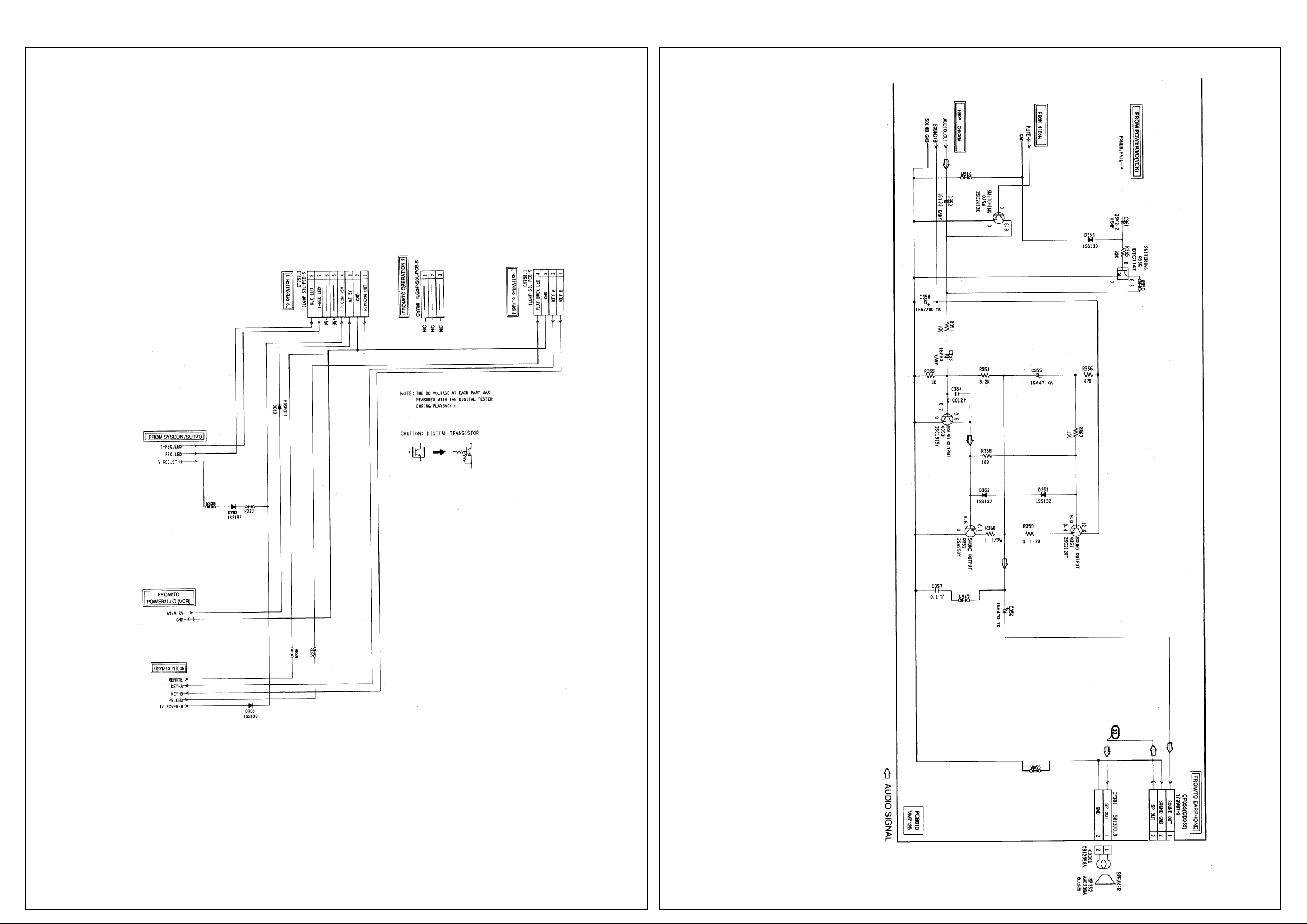

System Control Servo Diagram

Page 25

(TV SECTION)

POWER DOES NOT TURN ON (1)

When turning on the

Power Switch, does the

LED light ?

Yes

Is the voltage at pin 1

of IC502 DC7.7V ?

Yes

Is the voltage at pin 3 of

IC502 DC5.6V ?

Yes

Does RY501 work ?

No

No

No

No No

Does the BASE voltage of

Q501 turn ON or OFF ?

Check P.CON 5V line.

Check IC502, D511 and D512.

Check IC502.

Check pins 62 and 63 of IC101 and

peripheral circuit.

Yes

Check IC506, Q507 and the

peripheral circuit.

Yes

Check Q504, RY501 and the

peripheral circuit.

Page 26

POWER DOES NOT TURN ON (2)

Is CP810 inserted ?

Yes

Is F501 broken ?

Yes

Replace F501.

No

No

Is the voltage at C507

about 160V ?

Yes

Q500 bad ?

Yes

Replace Q500.

No

No

Insert CD810.

Check the circuit between

F501, C507 and R501.

Check IC501 and the

peripheral circuit.

Page 27

GOOD PICTURE BUT NO SOUND

Is the voltage at CP301

changed with the volume

up or down key ?

Yes

Is the voltage at BASE of

Q351 and Q352 DC9V ?

Yes

Is the voltage at pin

1 corrector of Q351

DC9.2V ?

Yes

No

No

No

Is FUSE RESISTOR

(R517) broken ?

Yes

Replace FUSE RESISTOR (R517).

No

Check speaker and

EARPHONE PCB.

Check Sound +B line.

Check Q351 and Q352.

Is the voltage at pin 29

of IC601 changed from

DC10.8V to DC9.9V when

pressing VOLUME UP or

DOWN key ?

Yes

Check Q353 and peripheral circuit.

No

Check pin 28 of IC101, D612

and the peripheral circuit.

Page 28

NO PICTURE

Are the Brightness and

Contrast set to minimum ?

Yes

Is the voltage at pin 3 of

IC601 DC9V ?

Yes

Is the voltage at pin

17 of IC601 DC9V ?

Yes

Is the voltage at pin 41 of

IC601 DC5V ?

Yes

No

No

No

No

Adjust Brightness and Contrast.

Check P.CON 9.6V line.

Check CHROMA 9V line.

Check D607.

Is the voltage at pin 8,

38 of IC601 DC5V ?

Yes

Is the signal at pin 12, 13

and 14 of IC601 output ?

Yes

Is the waveform at TP801,

TP802 and TP803 of CRT

PCB output ?

Yes

Check J801 and CRT.

No

No

No

Is the waveform at pin 47

of IC601 normal ?

Yes

Check IC601.

No

Check D604.

Check Q602 and Video Out Line.

Check Q804, Q805, Q806 and CD850.

Page 29

NO COLOR

Is the color set to

minimum ?

Yes

Is the color signal

received ?

Yes

Is the waveform at pin

40 of IC601 normal ?

Yes

Is the waveform at pin 42

of IC601 normal ?

No

No

No

No

Adjust the color.

Receive the color signal.

Check peripheral circuit of X601.

Check peripheral circuit of VIDEO

out line and Q602.

Yes

Is the waveform 12, 13

and 14 of IC601 normal ?

Yes

Is the waveform at TP801,

TP802 and TP803 of CRT

PCB output.

Yes

Check J801 and CRT.

No

No

Check IC601.

Check Q804, Q805, Q806 and

CD850.

Page 30

ONLY A LINE APPEARS

Is the normal signal at

pin 4 of IC 401 input ?

Yes

Is the normal signal at

pin 38 of IC101 output ?

Yes

Is the voltage at pin 6 of

IC402 DC25V ?

Yes

Check peripheral circuit of IC402

and DY401.

OSD SCREEN DOES NOT APPEAR

No

No

No

Check peripheral circuit of IC601.

Check peripheral circuit of IC101.

Check R452 and FB401.

Is there a waveform at pins

33, 34 and 35 of IC101 ?

Yes

Is there a waveform at

pins 18, 19 and 20 of

IC601 ?

Yes

Check peripheral circuit of IC601.

No

No

Check pin 36 of IC101 and the

peripheral circuit.

Check pins 18, 19 and 20 of

IC601 and the peripheral circuit.

Page 31

(VCR SECTION)

PLAY SHUTS OFF

Insert a cassette and push

PLAY button.

Does it Power off in

about 3 seconds?

No

Does it Power off in

about 6 seconds?

No

Does it Power off

intermittently

No

Yes

Yes

Yes

Check TAPE LOADIG,

LOADING BELT,MODE SWITCH,

DD MOTOR and CYLINDER

MOTOR.

Check REEL SENSOR and

REEL BELT.

Check REEL SENSOR,IC1001

and REEL BELT slack.

Check IC1001.

Page 32

CYLINDER NOT ROTATING DURING PLAYBACK AND RECORDING

Is the voltage at pin 6 of

CP1002 about DC13V ?

Yes

In playback, is the

voltage at pin 3 of

CP1002 about DC1.2V ?

No

In playback, is the

voltage at pin 44 of

IC1001 DC5V Pulse and

is the voltage at pin 46 of

IC1001 about DC1.5V ?

Yes

No

Yes

No

Check UNREG 12V line

of Main PCB.

Replace CYLINDER MOTOR.

Check R1059, R1080 and R1058.

Replace IC1001.

Page 33

AUDIO SHAKES

Is AUDIO HEAD

scratched ?

No

Does pin 15 of IC1001

output a 3.0Vp-p square

wave ? 3.0V

Yes

In playback, is the voltage

at pin 14 of CP1002 2.8V ?

Is the voltage at pin 14 of

CP1002 3.3V when you

stop the CAPSTAN DD

MOTOR manually ?

Yes

Yes

No

No

Replace AUDIO HEAD.

Replace CAPSTAN DD.

Check peripheral components

of IC1001.

In playback, is the

voltage at pin 17 of

CP1002 about DC1.6V ?

Yes

Check AUDIO BLOCK.

No

In playback, is the voltage at

pin 50 of IC1001 3.8V ?

Yes

No

Replace IC1001.

Page 34

CASSETTE TAPE IS NOT ACCEPTED

Does WORM GEAR

of FRONT LOADING

UNIT activate ?

Yes

When cassette is not

inserted, is EOT BOT

PULSE at EMMITTER of

Q1055, Q1056 5V ?

Yes

When a cassette is inserted,

is the voltage between pins

1 and 2 of CP1002 ?

No

When a cassette is

inserted, is the voltage at

pin 49 of IC1001 5V ?

No

No

Yes

No

Does 8 MHz Clock

oscillate ?

No

Check WORM GEAR of

FRONT LOADING UNIT.

Check EOT, BOT, PHOTO

SENSOR, pins 2 and 4 of IC1001.

Replace LOADING MOTOR.

Replace X1001.

Yes

Check circuit of FRONT LOADING

MOTOR.

Yes

Replace IC1001.

Page 35

WHEN INSERTING CASSETTE, IT EJECTS IMMEDIATELY

In another cassette tape

does the same problem

appear ?

Yes

In covering the infrared

sensor, is pin 2 and 3 of

IC1001 5V ?

Yes

When inserting cassette,

is pin 4 of IC1001 low ?

Yes

Is EJECT position of

FRONT LOADING

GEAR OK ?

No

No

No

No

Defective CASSETTE or

FRONT LOADING UNIT.

Replace EOT/BOT PHOTO

TRANSISTORS.

Check R1010.

Check FRONT LOADING GEARS.

Yes

Check IC1001 circuit.

Page 36

FF/REW DO NOT WORK

When the FF/REW is pushed,

does the PULSE appear at

pin 51 of IC1001 ?

Yes

Is the voltage changing at

pin 12 of CP1002 when

you press FF/REW ?

Yes

Is the voltage changing

at pin 14 of CP1002 ?

Yes

Check DECK MECHANISM.

No

No

No

Check pin 74 of IC1001 lines change

IC1001.

Check pin 12 of CP1002 and

peripheal circuit.

Check pin 45 of IC1001 lines change

IC1001.

Page 37

TAPE LOADING IS OK, BUT UNLOADS IMMEDIATELY

Does CYLINDER rotate ?

Yes

Does TP4001 feed HEAD

SWITCHING PULSE

signal ?

30 Hz

No

No

Is the voltage at pin

6 of CP1002 UNREG

12V ?

Yes

In playback, is the

voltage at pin 3 of

CP1002 1.2V ?

Yes

Replace CYLINDER UNIT.

No

Does PG PULSE

signal appear at pin

13 of IC1001 ?

No

No

Check Power circuit.

Does DC5V PULSE signal

appear at pin 44 of IC1001 ?

Is the voltage at pin 46 of

IC1001 DC2.5V ?

Yes

Check R1059, R1080, R1058 and

D1003.

No

Yes

Does REEL SENSOR

PULSE signal appear at

pins 69 and 70 of IC1001 ?

No

Check REEL SENSOR.

Yes

Yes

Replace IC1001.

Page 38

PLAYBACK PICTURE JITTERS HORIZONTALLY

Is FG output level at pin 5

of CP1002 about 5V?

5V

Yes

Is the voltage at pin 3 of

CP1002 1.2V?

Yes

Replace CYLINDER MOTOR.

PLAYBACK PICTURE SHAKES

PLAYBACKPICTURE SHAKES

No

No

Replace CYLINDER MOTOR.

Replace IC1001.

Is FG Pulse output level at

pin 5 of CP1002 about 5V?

5V

Yes

Does pin 11 of IC1001

output a 4.4Vp-p square

wave?

Yes

In playback, is the voltage at

In playback, is the voltage

pin 3 of CP1002 about 1.2V?

at pin 3 of CP1002 about 1.2V?

When slowing CYLINDER, is

When sloeing CYLINDER,is

the voltage 3.8V?

the voltage 3.8V?

Yes

No

No

No

Replace CYLINDER MOTOR.

Replace CYLINDER MOTOR.

Replace IC1001.

Page 39

AUTO TRACKING DOES NOT OPERATE

By manual tracking,

does the DC level at pin 6

of CP4001 change?

Yes

In auto tracking, is the

voltage at pin 5 of IC1001

more than DC1.85V?

Yes Yes

No

No

Does the CTL PULSE

(about 1.0Vp-p) appear

at pin 19 of IC1001?

1.0Vp-p

No

Check IC4101 and

CYLINDER UNIT.

Check CONTROL HEAD.

Replace IC1001.

Page 40

WHEN PLAYBACK,FAST FORWARD OR REWIND MODE IS ACTIVATED, UNIT STOPS IMMEDIATELY

Does CAPSTAN DD

MOTOR rotate?

Yes

Is CAPSTAN BELT OK?

Yes

Does REEL SENSOR PULSE

signal appear at pin 69

of IC1001?

Yes

No

No

No

Refer to section "CAPSTAN

DD MOTOR NOT ROTATING"

Replace CAPSTAN BELT

Check REEL SENSOR and that

the voltage at pin 10 of CX1003

is DC5V.

Does REEL SENSOR PULSE

signal appear at pin 70

of IC1001?

Yes

Replace IC1001.

No

Check around pin 4 of IC1001.

Page 41

PLAYBACK PICTURE JITTERS VERTICALLY

No

Does tracking noise appear

in the picture?

Yes

By adjusting the manual tracking

UP/DOWN buttons,will the

noise disappear in the

picture?

Yes

Are GUIDE POSTS

the right height?

No

No

Check P/B ENVELOPE.

Adjust GUIDE POST height.

Yes

Is PG SHIFTER

Adjustment 6.5H?

Yes

Check PB-Y circuit.

No

Adjust PG SHIFTER.

Page 42

NO PLAYBACK PICTURE

Is E-E appearing on the

Monitor TV?

Yes

Is there PB Y/C signal at

TP4002?

Yes

Is there FM Y signal at

pin 11 of IC4001and there

CHROMA signal at pin

27 of IC4001?

Yes

No

No

No

Is the voltage at pins 12,28

and 54 of IC4001 5V?

Yes

Check 5V line.

No

Check Power circuit.

Check IC4101 and the

connection of the CYLINDER.

Check Q4001,Q4016,Q4004 and

the peripheral circuit.

Is there Y signal at

pin 27 of IC4001 and there

CHROMA signal at pin

31 of IC4001?

Yes

Is there Y signal at

pin 9 of IC4002 and there

CHROMA signal at pin

16 of IC4002?

Yes

Is there VIDEO signal at

pin 2 of IC4001?

Yes

No

No

No

Replace IC4001.

Check IC4002 and the

peripheral cicuit.

Replace IC4001.

Check J4501

Page 43

NO COLOR DURING PLAYBACK

Does FM ENVELOPE

appear at TP4002?

Yes

Does CHROMA signal

appear at pin 27 of IC4001?

Yes

Does COMPOSITE

signal appear at pin 16

of IC4002?

Yes

No

No

No

Check IC4101 and HEAD AMP

BLOCK.

Check C4067 and the peripheral

circuit.

Replace IC4002

Does COLOR BURST

signal appear in the

COMPOSITE signal

at pin 2 of IC4001?

Yes

Check TV Block.

No

Replace IC4001.

Page 44

PLAYBACK PICTURE NOISY (EVEN AFTER CLEANING HEADS)

Is FM signal at TP4002

more than 200mVp-p?

Yes

Is there FM signal at pin 11 of

IC4001 140mVp-p?

Yes

Is VIDEO waveform at

pin 6 of IC4001 over

500mVp-p and are

there any noise?

Yes

No

No

No

Replace CYLINDER MOTOR.

Check Q4001,Q4016,Q4004

and the peripheral circuit.

Check pins 6 and 8 of IC4002

and the peripheral circuit.

Is VIDEO waveform at

pin 37 of IC4001 400mVp-p

are there CHROMA signal

at pins 31 of IC4001 200mVp-p

and are there any noises?

Yes

Is VIDEO waveform at

pin 9 of IC4002 600mVp-p,

are there CHROMA signal

at pin 16 of IC4002 300mVp-p

and are there any noises?

Yes

Check J4501

No

No

Replace IC4001.

Replace IC4002.

Page 45

NO COLOR DURING SELF RECORDING AND PLAYBACK

Does VCR signal

appear at pin 53 of

IC4002 ?

Yes

Does CHROMA

signal appear at pin 29

of IC4001 ?

Yes

Does FM signal

appear at pin 8 of

CP4001 ?

Yes

Does FM signal

appear at pin 8 of

IC4101 ?

No

No

No

No

Replace J4501.

Check VIDEO input circuit.

Replace IC4001

Check Q4005, Q4006 and peripheral

circuit.

Check IC4101 and peripheral circuit.

Yes

Replace IC4101.

Page 46

NO NORMAL AUDIO ON PLAYBACK

Does audio appear on E-E ?

Yes

Is the voltage at pin 17

of IC5001 High ?

Yes

Does AUDIO signal

appear at pin 7 of

IC5001 ?

Yes

Check AUDIO HEAD for debris of

stains.

Check that the connector from AUDIO

HEAD is fully inserted to CP4106.

Replace IC 5001.

No

No

No

Refer to section "NO E-E".

If the pin 52 of IC1001 is not High,

replace the IC1001.

Check R5013, R5014 and peripheral

circuit.

Page 47

CAPSTAN DD MOTOR NOT ROTATION

In playback, is the

voltage at pin 13 of

CP1002 13V ?

Yes

Is the voltage at pin

15 of CP1002 5V ?

Yes

In playback, check the

voltage at pin 17 of

CP1002 is 2V or at pin

50 of IC1001 is 0V ?

Yes

No

No

No

Check POWER circuit.

Replace IC1001.

In playback, is the

voltage at pin 14 of

CP1002 2.5V ?

Yes

Replace IC1001.

Does DD MOTOR rotate now ?

If not, replace DD MOTOR.

No

Check pins between 45 and 47 of

IC1001 and peripheral circuit.

Page 48

AUDIO CAN NOT BE RECORDED

Is BIAS level O.K at

T5001 ? 60V

Yes

Is there AUDIO

signal at pin 10 or 12

of IC5001 ?

Yes

No

No

Is the voltage at pin 20

of IC5001 9.2V ?

Yes

T5001 is broken or shorted.

Check T5001 and peripheral circuit.

No

Check POWER circuit.

Check the circuit between audio

out of Tuner and pin 10 of IC5001.

Is there AUDIO signal

at pin 14 of IC5001 ?

Yes

Is there signal

at pin 22 of IC5001 ?

Yes

Check the lead wire and

connector to A/C HEAD.

No

No

Check IC5001 and peripheral

circuit.

Replace IC5001.

Page 49

CASSETTE IN AND DOWN, UNIT HAS NO FUNCTIONS

Does mode indicator

appear in Display ?

No

Does VCR operate with

the remote control ?

Yes

Check Operation PCB.

Yes

No

Check LOADING MOTOR, MODE

SWITCH and the peripheral parts.

Check IC1001.

Page 50

RECORDING MECHANISM WORKS, BUT NO VIDEO RECORDED FROM INPUT JACK OR TUNER

Does VIDEO signal

appear at pin 51 or 53

of IC4001 ?

Yes

Is there VIDEO signal at

pin 6 of IC4002 and

Does VIDEO signal appear at

pin 8 of IC4001 ?

Yes

Does FM signal appear

at pin 8 to CP4001 ?

Yes

Does the FM current

appear at pin 8 of IC4101

during the REC.

No

No

No

No

Check the circuit from VIDEO input

jack to IC4001, from Tuner Pack to

IC4001.

Check the peripheral circuit of Q4007,

Q4009.

Replace IC4001.

Replace IC4101.

Yes

Check CYLINDER UNIT

and IC4101 circuit.

Page 51

NO E-E (NO VIDEO AND AUDIO FROM TUNER)

Is the voltage at pin 6 of

TU6001 9V ?

Yes

Is defect present when

replacing the IF PCB ?

Yes

Is the voltage at pin 13 of

IC6001 5V and the voltage

at pin 18 of IC6001 9V ?

Yes

No

No

No

Is defect present when

replacing the TU6001.

Yes

Replace TU6001.

No

Check Power PCB.

Check TU6001 and the peripheral

circuit.

Check 9V and 5V line.

Is there VIDEO signal at

pin 20 of IC6001?

Yes

Check Q6002.

No

Replace IC6001 and check peripheral

circuits.

Loading...

Loading...