Page 1

NSX-AJ800

U

NSX-SZ800

LH

SERVICE MANUAL

BASIC CD MECHANISM : BZG-5 ZD3N1M

COMPACT DISC STEREO SYSTEM

SYSTEM

NSX–AJ800

NSX–SZ800

• This Service Manual is the “Revision Publishing” and replace “Simple Manual”

NSX-AJ800/SZ800<U,LH>, (S/M Code No. 09-012-443-5T1).

• If requiring information about the CD mechanism, see Service Manual of

BZG-5 (S/M Code No. 09-00C-353-3N2).

CD

CASSEIVER

TAPE

MECHANISM

6ZM–3 PR4NM

2ZM–3MK2

PR4NM

BASIC TAPE MECHANISM: 2ZM-3MK2 PR4NM/

6ZM-3 PR4NM

FRONT

SPEAKER

SX–NAJ801CX–NAJ800

SX–WNSZ800CX–NSZ800

SATELLITE

SPEAKER

SX–S85

REMOTE

CONTROLLER

RC–BAS01

S/M Code No. 09-013-443-5R1

REVISION

DATA

Page 2

SPECIFICATIONS

TUNER

FM tuning range: 87.5 MHz to 108 MHz

FM usable Sensitivity(IHF):

FM antenna terminals: 75 ohms (unbalanced)

AM tuning range: 530 kHz to 1710 kHz (10 kHz step)

AM usable sensitivity: 350

AM antenna: Loop antenna

AMPLIFIER

Main amplifier<U>

Power output: 125 W + 125 W (50 Hz - 20 kHz,

Total

harmonic distortion:

Main amplifier<LH>

Power output: Rated: 120 W + 120 W (6 ohms,

Total

harmonic distortion:

Satellite amplifier<U>

Power output: 15 W + 15 W (50 Hz - 20 kHz, THD

Total

harmonic distortion:

Satellite amplifier<LH>

Power output: Rated: 16 W + 16 W (8 ohms, T.H.D.

Total

harmonic distortion:

Input: VIDEO/AUX: 700 mV

Output: FRONT SPEAKERS: 6 ohms or more

CASSETTE DECK<U>

Track format: 4 tracks, 2 channels stereo

Frequency response: 50 Hz - 15 kHz

Recording system: AC bias

Heads: DECK 1: playback x 1

13.2 dBf

531 kHz to 1602 kHz (9 kHz step)

mV/m

THD less than 1%, 6 ohms)

156 W + 156 W (1 kHz, THD less

than 10%, 6 ohms)

0.08% (70 W, 1 kHz, 6 ohms, DIN AUDIO)

T.H.D. 1%, 1kHz)

Reference: 150 W + 150 W (6 ohms,

T.H.D. 10%, 1kHz)

0.08% (70 W, 1 kHz, 6 ohms, DIN AUDIO)

less than 1%, 8 ohms)

18 W + 18 W (1 kHz, THD less than

10%, 8 ohms)

0.2% (7 W, 1 kHz, 8 ohms, DIN AUDIO)

1%, 1kHz)

Reference: 20 W + 20 W (8 ohms,

T.H.D. 10%, 1kHz)

0.2% (7 W, 1 kHz, 8 ohms, DIN AUDIO)

MIC: 1.7 mV (10 kohms)<LH>

STAELLITE SPEAKERS: 8 ohms or more

PHONES: 32 ohms or more

DECK 2: recording/playback x 1,

erase x 1

CD PLAYER

Laser: Semiconductor laser (

D/A converter: 1 bit dual

Signal-to-noise ratio: 85 dB (1 kHz, 0 dB)

Harmonic distortion: 0.05 % (1 kHz, 0 dB)

FRONT SPEAKERS SX-NAJ801 ( only for NSX-AJ800)

Speaker system: 3 way, bass reflex (magnetic shielded)

Speaker units: Woofer: 160 mm (63/8 in.) cone

Tweeter: 60 mm (2

Super tweeter: 20 mm (

Impedance: 6 ohms

Dimensions (W x H x D): 230 x 324 x 224 mm

( 91/8 x 127/8 x 87/8 in.)

Weight: 3.8 kg (8 lbs 6 oz)

FRONT SPEAKERS SX-WNSZ800 ( only for NSX-SZ800)

Speaker system: 3 way, Built-in subwoofer (magnetic

shielded type)

Speaker units: Subwoofer: 160 mm cone type

Full range: 100 mm cone type

Super tweeter: 20 mm ceramic type

Impedance: 6 ohms

Dimensions (W x H x D): 230 x 324 x 257 mm

Weight: 4.8 kg

SATELLITE SPEAKERS SX-S85

Speaker system: Full range (magnetic shielded type)

Speaker units: 80 mm cone type

Impedance: 8 ohms

Sensitivity: 87 dB/W/m

Dimensions (W x H x D): 100 x 325 x 95 mm

( 4 x 127/8 x 33/4 in.)(with pedestal)

100 x 186 x 84 mm

( 4 x 73/8 x 33/8 in.)(without pedestal)

Weight: 0.6 kg (1 lbs 5 oz)

GENERAL

Power requirements: 120 V AC, 60 Hz<U>

120 V/220 - 230 V/240 V AC

(Switchable), 50 Hz/60 Hz<LH>

Power consumption: 140 W<U>, 180 W<LH>

Power consumption

in standby mode: With ECO mode on: 0.6 W

With ECO mode off: 24 W<U>, 26 W<LH>

Dimensions ( W x H x D): 260 x 326 x 345 mm

(101/4 x 127/8 x 135/8 in.)

Weight: 8.4 kg (18 lbs 8 oz)<U>, 8.9 kg<LH>

• Design and specifications are subject to change without notice.

l = 780 nm)

3

/8 in.) cone

13

/16 in.) ceramic

CASSETTE DECK<LH>

Track format: 4 tracks, 2 channels stereo

Frequency response: CrO2 tape: 50 Hz – 15000 Hz

Normal tape: 50 Hz – 15000 Hz

Recording system: AC bias

Heads: DECK 1: playback x 1

DECK 2: recording/playback x 1,

erase x 1

• The word "BBE"and the "BBE symbol" are trademarks of BBE

Sound, Inc.

Under license from BBE Sound,Inc.

– 2 –

Page 3

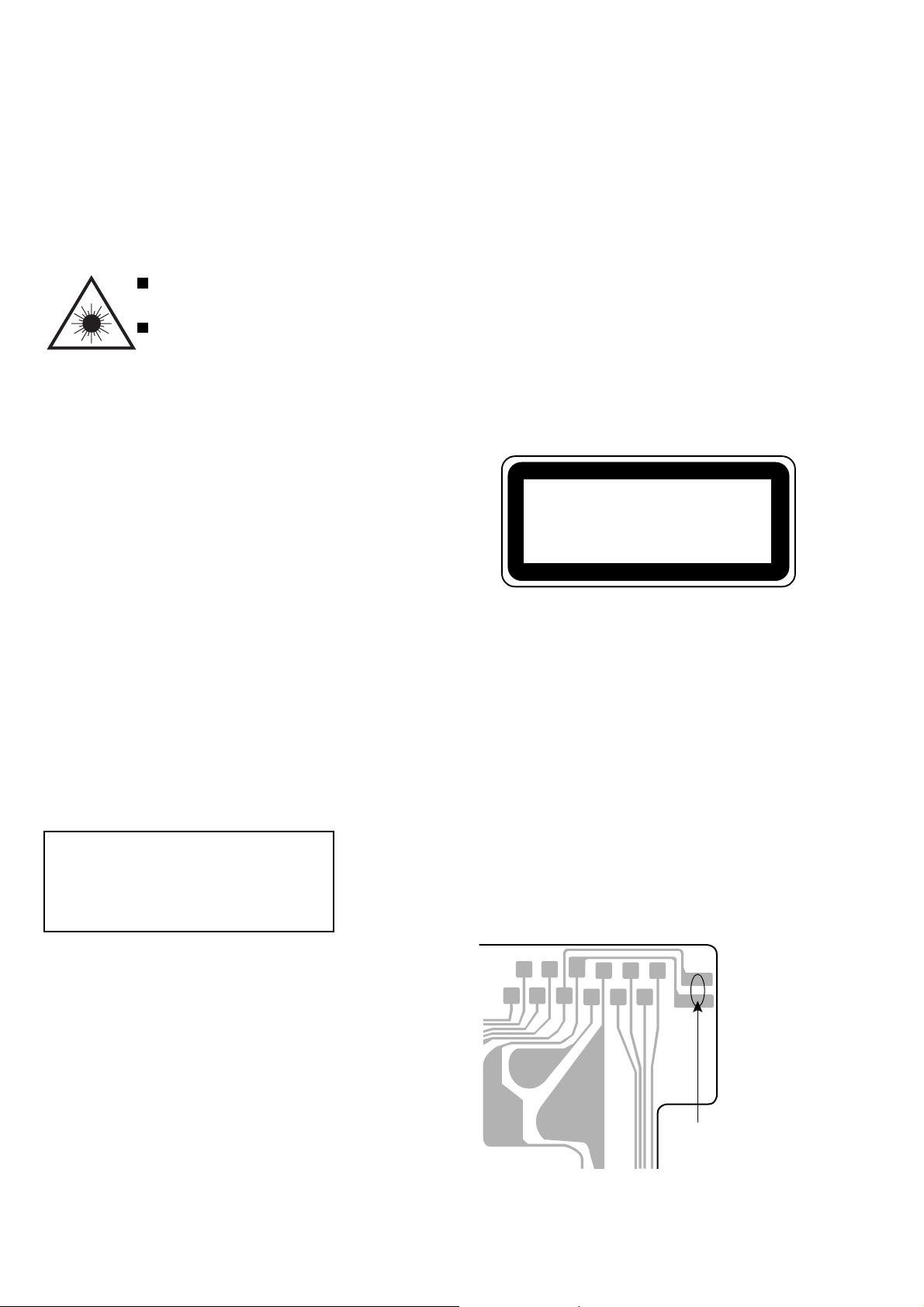

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING

This set employs laser. Therefore, be sure to follow carefully

the instructions below when servicing.

WARNING!!

WHEN SERVICING, DO NOT APPROACH THE LASER

EXIT WITH THE EYE TOO CLOSELY. IN CASE IT IS

NECESSARY TO CONFIRM LASER BEAM EMISSION.

BE SURE TO OBSERVE FROM A DISTANCE OF MORE

THAN 30cm FROM THE SURFACE OF THE OBJECTIVE

LENS ON THE OPTICAL PICK-UP BLOCK.

Caution: Invisible laser radiation when

open and interlocks defeated avoid

exposure to beam.

s Advarsel: Usynlig laserståling ved åbning,

når sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling.

VAROITUS!

Laiteen Käyttäminen muulla kuin tässä käyttöohjeessa

mainitulla tavalla saataa altistaa käyt-täjän

turvallisuusluokan 1 ylittävälle näkymättömälle

lasersäteilylle.

VARNING!

Om apparaten används på annat sätt än vad som

specificeras i denna bruksanvising, kan användaren

utsättas för osynling laserstrålning, som överskrider

gränsen för laserklass 1.

CAUTION

Use of controls or adjustments or performance of procedures other than those specified herin may result in

hazardous radiation exposure.

ATTENTION

L’utillisation de commandes, réglages ou procédures

autres que ceux spécifiés peut entraîner une dangereuse

exposition aux radiations.

ADVARSEL

Usynlig laserståling ved åbning, når sikkerhedsafbrydereer

ude af funktion. Undgå udsættelse for stråling.

This Compact Disc player is classified as a CLASS 1

LASER product.

The CLASS 1 LASER PRODUCT label is located on the

rear exterior.

CLASS 1 LASER PRODUCT

KLASSE 1 LASER PRODUKT

LUOKAN 1 LASER LAITE

KLASS 1 LASER APPARAT

Precaution to replace Optical block

(KSS-213F)

Body or clothes electrostatic potential could

ruin laser diode in the optical block. Be sure

ground body and workbench, and use care the

clothes do not touch the diode.

1) After the connection, remove solder shown in

right figure.

PICK-UP ASSY PWB

Solder

– 3 –

Page 4

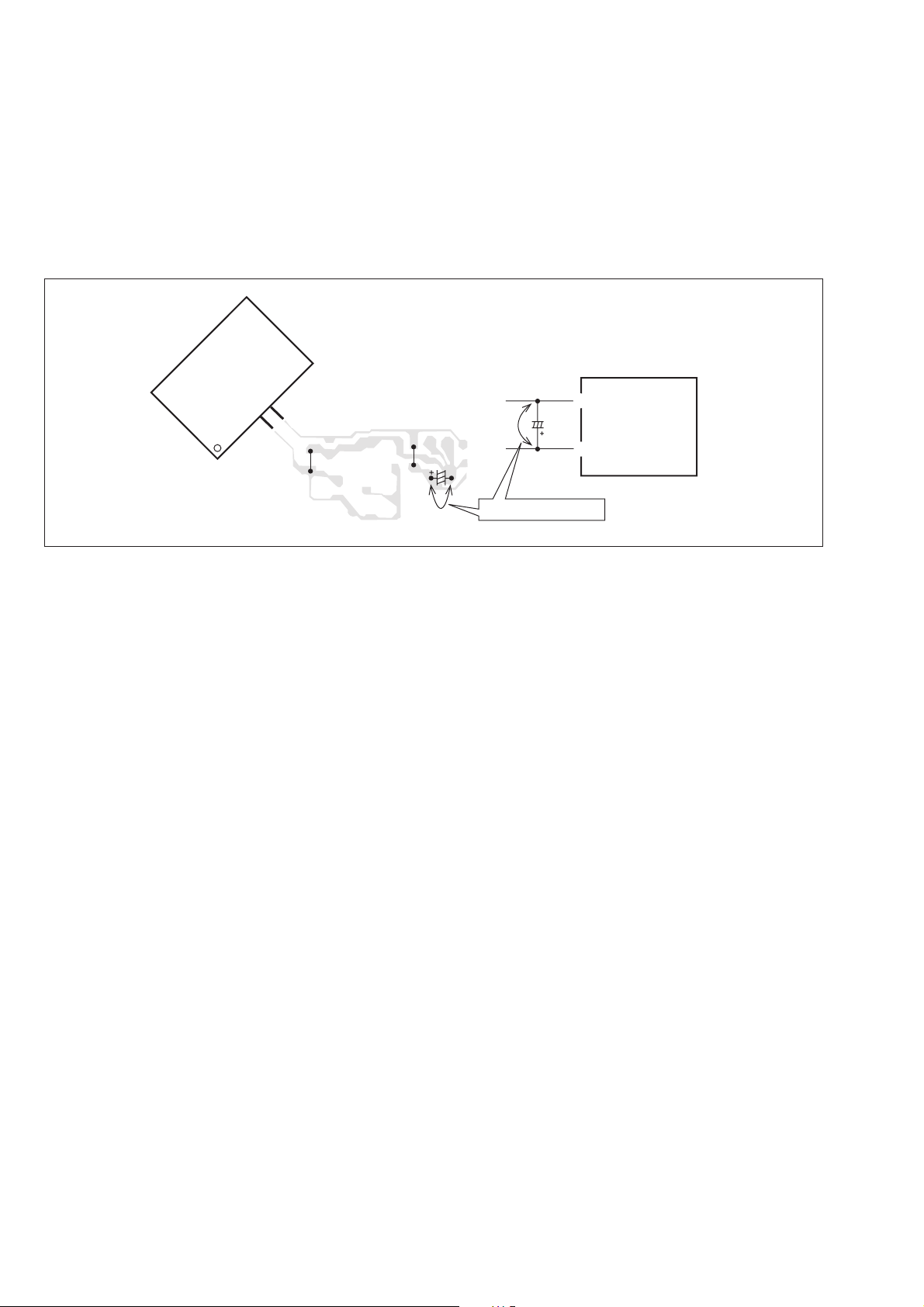

NOTE ON BEFORE STARTING REPAIR

1. Forced discharge of electrolytic capacitor of power supply block

When repair is going to be attempted in the set that uses relay circuit in the power supply block, electric potential is kept charged across

the electrolytic capacitors (C101, 102) even though AC power cord is removed. If repair is attempted in this condition, secondary defect

can occur.

In order to prevent the secondary trouble, perform the following measures before starting repair work.

Discharge procedure

11

1 Remove the AC power cord.

11

22

2 Connect a discharging resistor at an end of lead wire that

22

has clips at both ends. Connect the other end of the lead

wire to metal chassis.

33

3 Contact the other end of the discharging resistor to the

33

positive (+) side (+VH) of C101. (For two seconds)

44

4 Contact the same end of the discharging resistor as step

44

33

3 to the negative (-) side (-VH) of C102 in the same way.

33

(For two seconds)

55

5 Check that voltage across C101 and C102 has decreased

55

to 1 V or less using a multimeter or an oscilloscope.

Select a discharging resistor referring to the following table.

Charging voltage (V) Discharging

(C101, 102) resistor (Ω)

25-48 100 3 87-A00-247-090

49-140 220 5 87-A00-232-090

Note: The reference numbers (C101, C102) of the electrolytic capacitors can change depending on the models. Be sure to check the

reference numbers of the charging capacitors on schematic diagram before starting the discharging work.

Rated power (W) Parts number

MAIN C.B

D101

3

C101 C102

22

Fig-1

4

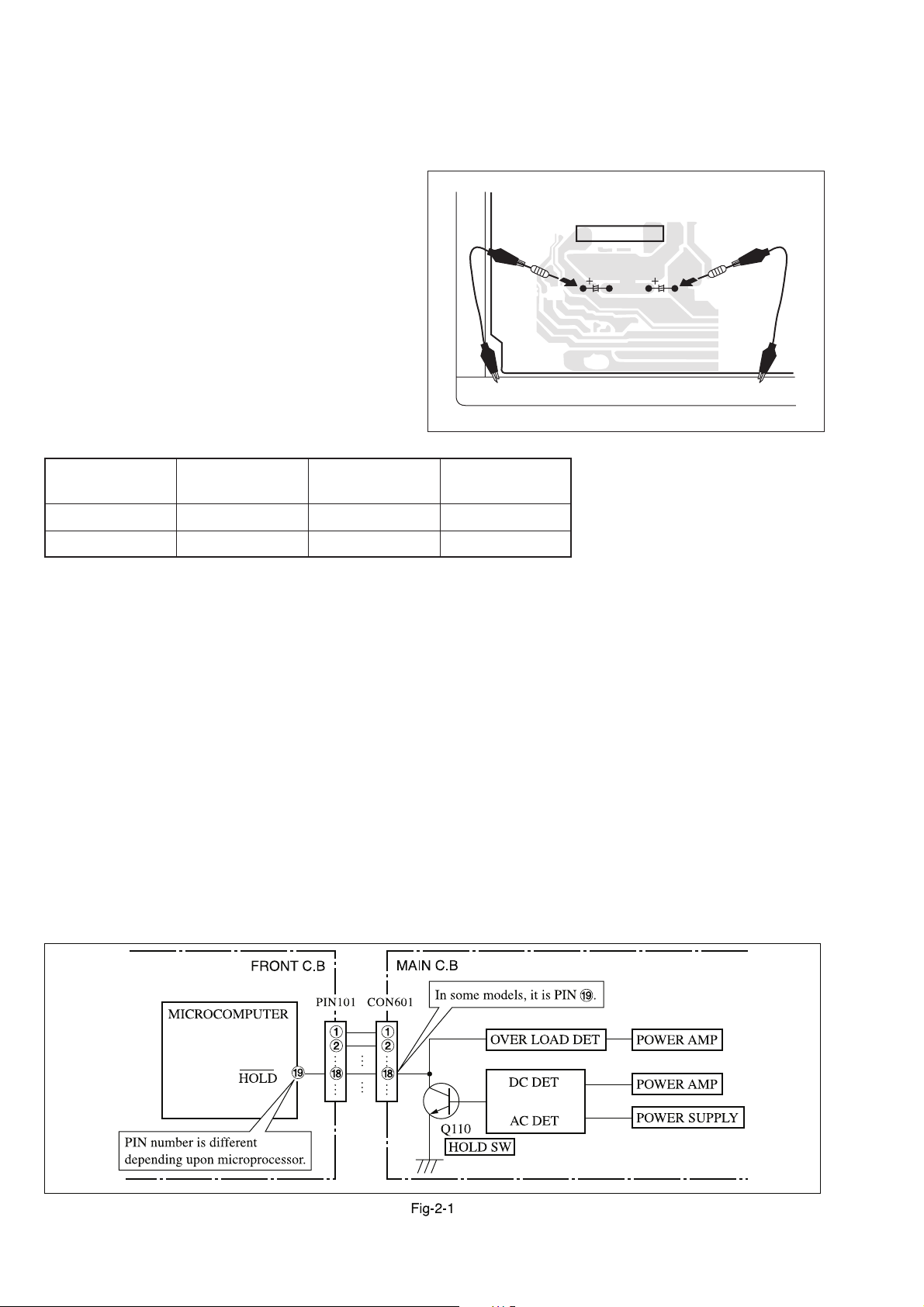

2. Check items before exchanging the MICROCOMPUTER

Be sure to check the following items before exchanging the MICROCOMPUTER. Exchange the MICROCOMPUTER after confirming

that the MICROCOMPUTER is surely defective.

2-1. Regarding the HOLD terminal of the MICROCOMPUTER

When the HOLD terminal (INPUT) of the MICROCOMPUTER is “H”, the MICROCOMPUTER is judged to be operating correctly.

When this terminal is “L”, the main power cannot be turned on. Therefore, be sure to check the terminal voltage of the HOLD

terminal before exchange.

When the MICROCOMPUTER is not defective, the HOLD terminal can also go “L” when the POWER AMPLIFIER has any

abnormalities that triggers the abnormality detection circuit on the MAIN C. B. that sets the HOLD terminal to “L”.

• Good or no good judgement of the MICROCOMPUTER

11

1 Turn on the AC main power.

11

22

2 Confirm that the main power is turned on and the HOLD terminal of the MICROCOMPUTER keeps the “H” level or not.

22

33

3 When the HOLD terminal is “L” level, the abnormality detection circuit is judged to be working correctly and the

33

MICROCOMPUTER is judged to be good.

– 4 –

Page 5

In such a case, check also if the POWER AMPLIFIER circuit or power supply circuit has any abnormalities or not.

2-2. Regarding reset

There are cases that the machine does not work correctly because the MICROCOMPUTER is not reset even though the AC power

cord is re-inserted, or the software reset (pressing the STOP key + POWER key) is performed.

When the above described phenomenon occurs, it can lead to wrong judgement as if the MICROCOMPUTER is defective and to

exchange the MICROCOMPUTER. In such a case, perform the forced-reset by the following procedure and check good or no

good of the MICROCOMPUTER.

11

1 Remove the AC power cord.

11

FRONT C.B

18

MICROCOMPUTER

FRONT C.B

22

2 Short both ends of the electrolytic capacitor C113 that is connected to VDD of the MICROCOMPUTER with tweezers.

22

33

3 Connect the AC power cord again. If the MICROCOMPUTER returns to the normal operation, the MICROCOMPUTER is

33

good.

Note: The reference number or MICROCOMPUTER pin number of transistor (Q110) and electrolytic capacitor (C113) can change depending

on the models. Be sure to check the reference numbers on schematic diagram before starting the discharging work.

15

C113

Short with tweezers.

Fig-2-2

C113

%

*

VSS

VDD

MICROCOMPUTER

2-3. Confirmation of soldering state of MICROCOMPUTER

Check the soldering state of the MICROCOMPUTER in addition to the above described procedures. Be sure to exchange the

MICROCOMPUTER after surely confirming that the trouble is not caused by poor soldering but the MICROCOMPUTER itself.

– 5 –

Page 6

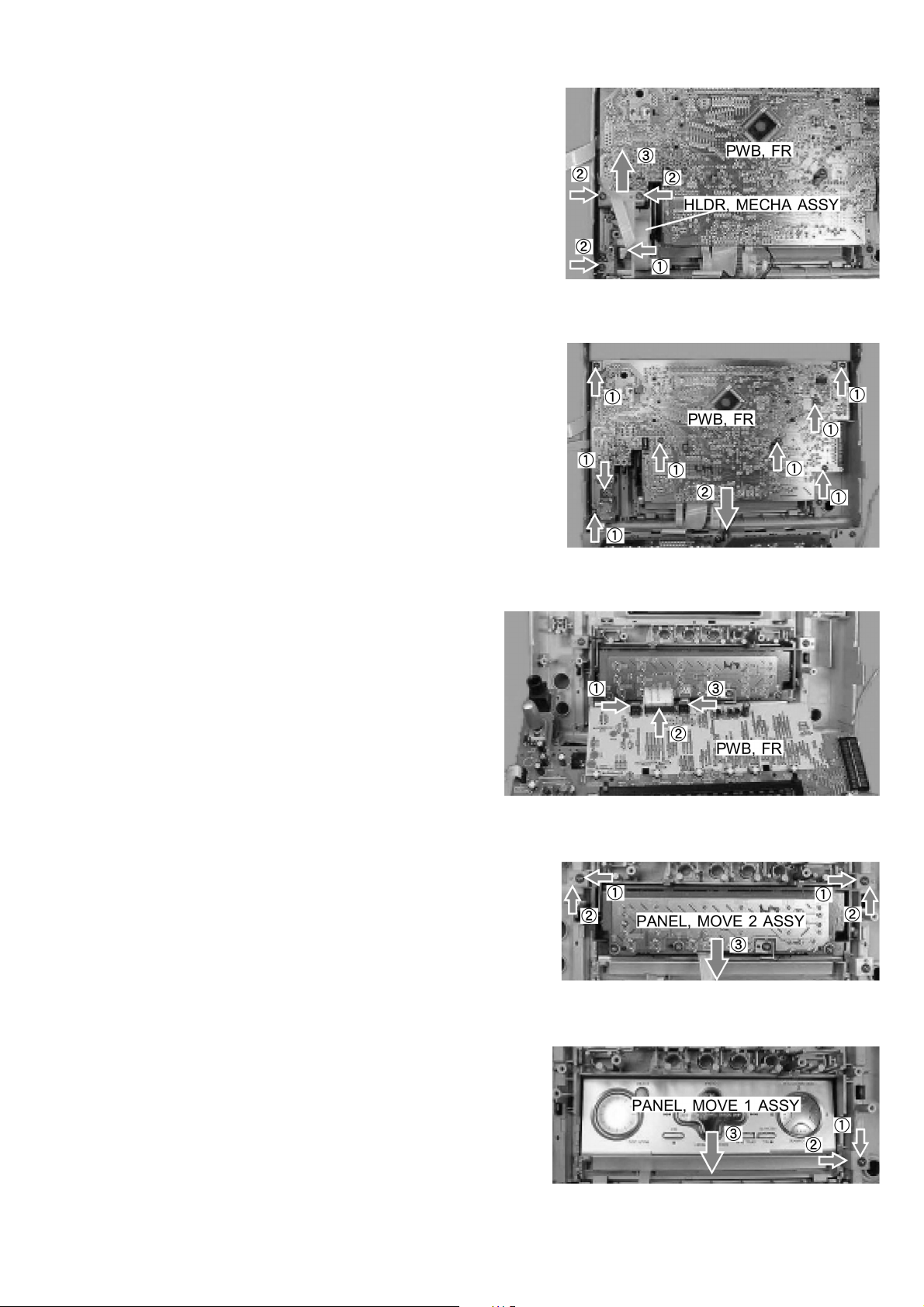

DISASSEMBLY INSTRUCTIONS

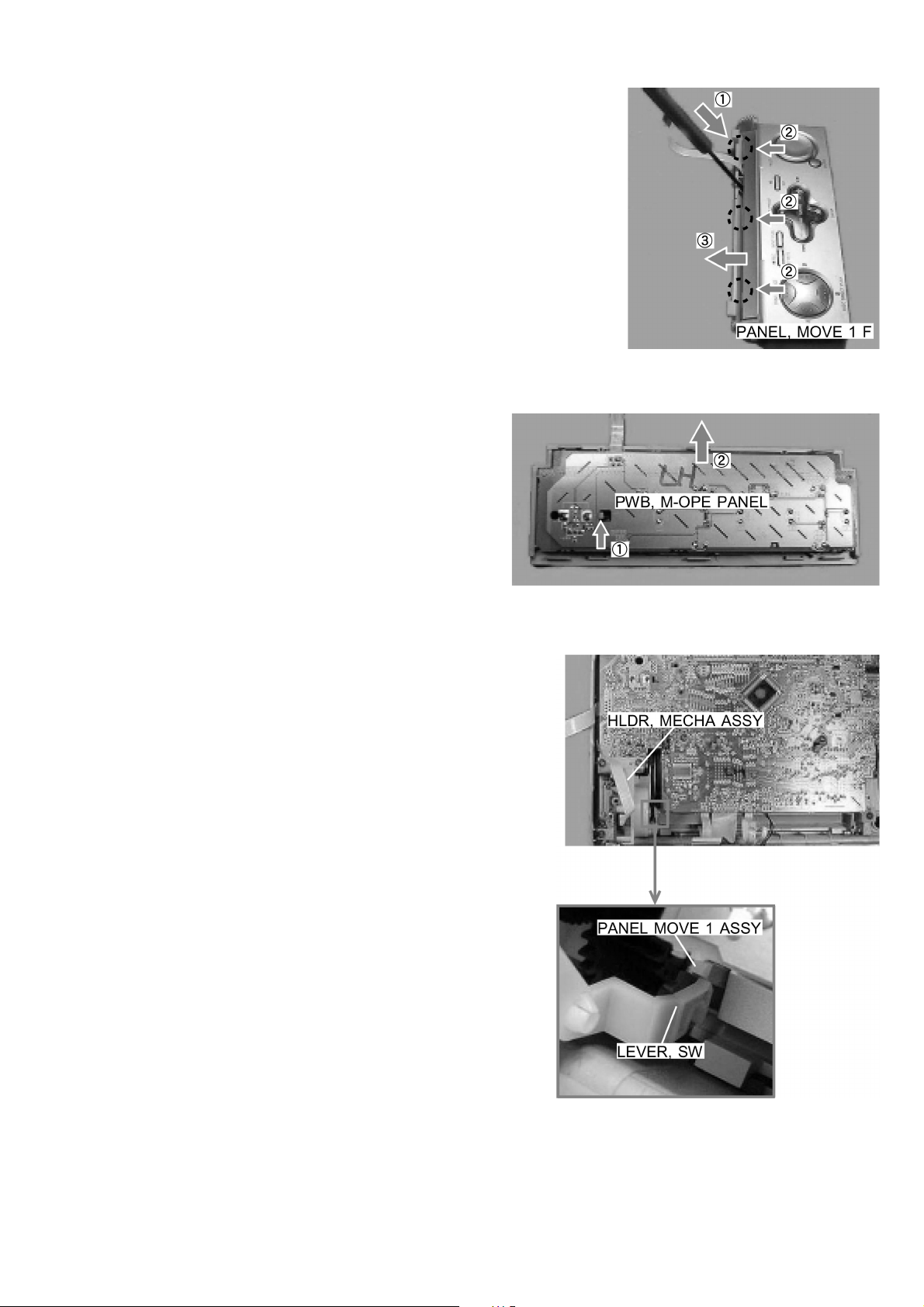

1. How to Remove PANEL, MOVE ASSY

Remove the outside ornamental parts, CD mechanism,

CABI. FR before starting the following procedure.

1) Remove the FFC (1) and the three screws (2). Then

remove HLDR, MECHA ASSY.

2) Remove the eight screws (1) and remove the PWB. FR (2).

3) Remove the three FFC (1), (2), (3).

4) Remove the two screws (1) and remove the HLDR,

PANEL 2 (2). Then remove PANEL, MOVE 2 ASSY (3).

5) Remove the screw (1) and the HLDR, PANEL (2). Then

remove PANEL, MOVE 1 ASSY (3).

– 6 –

Page 7

2. How to Disassemble PANEL, MOVE 1 ASSY

1) Insert a screwdriver tip into the clearance on top of the

PANEL, MOVE 1 ASSY (1) and remove the PANEL,

MOVE 1 F (3).

2) Remove the claw (1) and remove the PWB, M-OPE

PANEL (2).

3. Note when Re-installing the HLDR, MECHA ASSY

Re-installing the HLDR, MECHA ASSY after the PANEL,

MOVE is closed.

Re-install it in a way that the LEVER SW of the HLDR,

MECHA ASSY is located beneath the PANEL, MOVE 1

ASSY.

– 7 –

Page 8

ELECTRICAL MAIN PARTS LIST

REF. NO. DESCRIPTIONPART NO. KANRI

IC

87-020-454-010 IC,DN6851<U>

87-A21-269-010 IC,EW732<LH>

8B-NF7-631-130 C-IC,LC866560W-5V19

87-A21-831-010 IC,SPS-422-1-F1

87-A21-911-040 C-IC,M61515FP

87-A21-419-040 C-IC,NJM14558MD-TE2

87-A21-893-040 C-IC,NJM4558V-TE2

87-A21-023-040 C-IC,BA3835F

87-A21-401-040 C-IC,M61503FP

87-A21-695-010 IC,LA1845L

87-A21-928-010 IC,LC72131D-N

TRANSISTOR

87-A30-494-080 TR,2SA1980G

87-026-463-080 TR,2SA933S (0.3W)

87-A30-559-010 TR,CSB1370EF

87-A30-492-080 TR,2SC5343G

87-A30-107-070 C-TR,CMBT5401

87-A30-484-080 C-TR,KRA102S

87-A30-190-080 TR,CC5551

87-A30-106-040 C-TR,CMBT5551

87-A30-098-010 TR,FP 1016

87-026-609-080 TR,KTA1266GR

87-A30-087-080 C-FET,2SK2158

87-A30-490-080 C-TR,KRC107S

87-A30-076-080 C-TR,2SC3052F

87-026-610-080 TR,KTC3198GR

87-A30-074-080 C-TR,RT1P 141C

87-A30-162-010 FET,2SK2937

87-A30-582-080 TR,CDA1585BC

87-A30-495-080 TR,2SA1981Y

87-A30-091-080 FET,2SJ460

87-A30-090-080 FET,2SK2541

87-A30-063-080 C-TR,KRA104S

87-A30-256-010 TR,2SD1933

87-A30-255-010 TR,2SB1342

87-A30-075-080 C-TR,2SA1235F

89-327-143-080 C-TR,2SC2714 (0.1W)

87-A30-489-080 C-TR,KRA107S

87-A30-520-080 TR,2SC5342Y

87-A30-515-080 TR,2SA1979O/Y

87-A30-234-080 TR,CSC4115BC

DIODE

87-A40-393-090 DIODE,1N5402GW(F20)

87-A40-839-090 DIODE,G5SBA60L-6088

87-A40-781-080 ZENER,UZ36BSA

87-A40-764-080 ZENER,UZ10BSC

87-A40-553-080 DIODE,1N4003 LES

87-A40-270-080 C-DIODE,MC2838

87-A40-269-080 C-DIODE,MC2836

87-A40-291-080 DIODE,1N4148 (CPT)

87-A40-488-080 DIODE,1SS244

87-A40-748-080 ZENER,UZ5.6BSA

87-A40-747-080 ZENER,UZ5.1BSB

87-A40-749-080 ZENER,UZ5.6BSB

87-A40-768-080 ZENER,UZ16BSA

87-A40-802-080 ZENER,UZ5.1BSC

87-A40-739-080 ZENER,UZ2.7BSA

87-A40-128-080 C-VARI-CAP,HVU202A

87-017-149-080 ZENER,HZS6A2L

MAIN C.B

C1 87-A12-383-000 CAP,E 3300-65 M 85 IV LELON<U>

C1 87-016-657-090 CAP,E 3300-71<LH>

KANRI

NO.

REF. NO. DESCRIPTIONPART NO.

NO.

C2 87-A12-383-000 CAP,E 3300-65 M 85 IV LELON<U>

C2 87-016-657-090 CAP,E 3300-71<LH>

C3 87-A12-317-080 C-CAP,U 0.1-50 Z F

C4 87-A12-317-080 C-CAP,U 0.1-50 Z F

C5 87-A12-317-080 C-CAP,U 0.1-50 Z F

C6 87-A12-317-080 C-CAP,U 0.1-50 Z F

C9 87-010-759-080 C-CAP,U, 0.1-25F

C10 87-010-759-080 C-CAP,U, 0.1-25F

C11 87-010-759-080 C-CAP,U, 0.1-25F

C12 87-010-759-080 C-CAP,U, 0.1-25F

C21 87-A12-780-090 CAP,E 4700-35 M 85 SKR

C22 87-A12-780-090 CAP,E 4700-35 M 85 SKR

C31 87-A12-091-080 CAP,E 10-50 SMG

C32 87-012-286-080 CAP, U 0.01-25

C33 87-A12-062-080 CAP,E 100-10 SMG<U>

C34 87-A12-072-080 CAP,E 100-25 SMG

C35 87-A12-071-080 CAP,E 47-25 SMG

C36 87-010-381-080 CAP, ELECT 330-16V

C38 87-012-286-080 CAP, U 0.01-25

C60 87-A12-089-080 CAP,E 3.3-50 SMG

C61 87-A12-071-080 CAP,E 47-25 SMG

C83 87-A12-074-080 CAP,E 470-25 SMG

C97 87-010-831-080 C-CAP,U,0.1-16F

C101 87-012-279-080 C-CAP,U 2700P-50 B

C102 87-012-279-080 C-CAP,U 2700P-50 B

C103 87-A12-084-080 CAP,E 0.22-50 SMG

C104 87-A12-084-080 CAP,E 0.22-50 SMG

C107 87-A12-089-080 CAP,E 3.3-50 SMG

C108 87-A12-089-080 CAP,E 3.3-50 SMG

C111 87-A12-077-080 CAP,E 33-35 SMG

C112 87-A12-077-080 CAP,E 33-35 SMG

C113 87-A10-596-080 C-CAP,S 100P-100 J CH

C114 87-A10-596-080 C-CAP,S 100P-100 J CH

C117 87-A12-317-080 C-CAP,U 0.1-50 Z F

C118 87-A12-317-080 C-CAP,U 0.1-50 Z F

C119 87-012-286-080 CAP, U 0.01-25

C120 87-012-286-080 CAP, U 0.01-25

C123 87-010-177-080 C-CAP,S 820P-50 SL

C124 87-010-177-080 C-CAP,S 820P-50 SL

C133 87-012-282-080 CAP, U 4700P-50

C140 87-012-278-080 C-CAP,U 2200P-50 B

C186 87-010-759-080 C-CAP,U, 0.1-25F

C187 87-A12-180-080 CAP,E 10-63 M 105 KME

C188 87-A12-180-080 CAP,E 10-63 M 105 KME

C201 87-010-759-080 C-CAP,U, 0.1-25F

C202 87-010-759-080 C-CAP,U, 0.1-25F

C203 87-010-759-080 C-CAP,U, 0.1-25F

C204 87-010-759-080 C-CAP,U, 0.1-25F

C220 87-012-274-080 CHIP CAP,U 1000P-50B

C225 87-A12-317-080 C-CAP,U 0.1-50 Z F

C226 87-A12-317-080 C-CAP,U 0.1-50 Z F

C227 87-A12-317-080 C-CAP,U 0.1-50 Z F

C228 87-A12-317-080 C-CAP,U 0.1-50 Z F

C241 87-010-831-080 C-CAP,U,0.1-16F

C301 87-012-274-080 CHIP CAP,U 1000P-50B

C302 87-012-274-080 CHIP CAP,U 1000P-50B

C303 87-012-275-080 C-CAP,U 1200P-50 B

C304 87-012-275-080 C-CAP,U 1200P-50 B

C307 87-A12-062-080 CAP,E 100-10 SMG

C308 87-A12-062-080 CAP,E 100-10 SMG

C309 87-012-188-080 C-CAP,U 47P-50 CH

C310 87-012-188-080 C-CAP,U 47P-50 CH

C313 87-012-284-080 CAP, U 6800P-50

C314 87-012-284-080 CAP, U 6800P-50

C315 87-A12-062-080 CAP,E 100-10 SMG

C317 87-A12-085-080 CAP,E 0.33-50 SMG

C318 87-A12-085-080 CAP,E 0.33-50 SMG

C326 87-010-787-080 CAP, U 0.022-25

C327 87-010-831-080 C-CAP,U,0.1-16F

C360 87-A12-087-080 CAP,E 1-50 SMG

– 8 –

Page 9

REF. NO. DESCRIPTIONPART NO. KANRI

C399 87-A10-039-080 C-CAP,U 470P-50 J CH

C401 87-A12-083-080 CAP,E 0.1-50 SMG

C402 87-A12-083-080 CAP,E 0.1-50 SMG

C403 87-012-193-080 C-CAP,U 82P-50 CH

C404 87-012-193-080 C-CAP,U 82P-50 CH

C405 87-012-283-080 C-CAP,U 5600P-50 B<LH>

C405 87-012-286-080 CAP, U 0.01-25<U>

C406 87-012-283-080 C-CAP,U 5600P-50 B<LH>

C406 87-012-286-080 CAP, U 0.01-25<U>

C407 87-012-281-080 C-CAP,U 3900P-50 B<LH>

C407 87-012-286-080 CAP, U 0.01-25<U>

C408 87-012-281-080 C-CAP,U 3900P-50 B<LH>

C408 87-012-286-080 CAP, U 0.01-25<U>

C409 87-012-278-080 C-CAP,U 2200P-50 B

C410 87-012-278-080 C-CAP,U 2200P-50 B

C411 87-A12-091-080 CAP,E 10-50 SMG

C412 87-A12-091-080 CAP,E 10-50 SMG

C452 87-A12-069-080 CAP,E 22-25 SMG

C453 87-012-279-080 C-CAP,U 2700P-50 B

C454 87-012-279-080 C-CAP,U 2700P-50 B

C455 87-012-279-080 C-CAP,U 2700P-50 B

C456 87-012-286-080 CAP, U 0.01-25

C457 87-A12-361-080 CAP,M 5600P-100 J CP

C458 87-012-274-080 CHIP CAP,U 1000P-50B

C459 87-012-271-080 CAP, U 560P-50

C460 87-010-831-080 C-CAP,U,0.1-16F

C461 87-012-158-080 C-CAP,S 390P-50 CH

C462 87-012-158-080 C-CAP,S 390P-50 CH

C470 87-018-127-080 CAP, CER 470P-50V

C605 87-012-280-080 CAP, U 3300P-50

C606 87-012-280-080 CAP, U 3300P-50

C609 87-010-785-080 C-CAP,U0.015-25BK

C610 87-010-785-080 C-CAP,U0.015-25BK

C611 87-A12-084-080 CAP,E 0.22-50 SMG

C612 87-A12-084-080 CAP,E 0.22-50 SMG

C613 87-A12-084-080 CAP,E 0.22-50 SMG

C614 87-A12-084-080 CAP,E 0.22-50 SMG

C615 87-012-172-080 CAPACITOR CHIP U 10P CH

C616 87-016-455-080 CAP,E 470-6.3 SMG

C617 87-016-455-080 CAP,E 470-6.3 SMG

C618 87-A12-091-080 CAP,E 10-50 SMG

C620 87-A12-062-080 CAP,E 100-10 SMG

C623 87-A12-084-080 CAP,E 0.22-50 SMG

C624 87-A12-084-080 CAP,E 0.22-50 SMG

C630 87-A10-260-080 C-CAP,U 0.1-16 K B

C631 87-012-281-080 C-CAP,U 3900P-50 B

C632 87-012-281-080 C-CAP,U 3900P-50 B

C633 87-A11-070-080 C-CAP,U 0.033-16 K B

C634 87-A11-070-080 C-CAP,U 0.033-16 K B

C661 87-012-336-080 CAP, CHIP SS 3300 SL

C662 87-012-336-080 CAP, CHIP SS 3300 SL

C671 87-010-831-080 C-CAP,U,0.1-16F<LH>

C672 87-010-831-080 C-CAP,U,0.1-16F<LH>

C673 87-012-278-080 C-CAP,U 2200P-50 B<LH>

C677 87-012-286-080 CAP, U 0.01-25

C771 87-A12-062-080 CAP,E 100-10 SMG

C772 87-012-286-080 CAP, U 0.01-25

C782 87-012-286-080 CAP, U 0.01-25

C783 87-012-286-080 CAP, U 0.01-25

C784 87-012-286-080 CAP, U 0.01-25

C785 87-012-286-080 CAP, U 0.01-25

C786 87-012-286-080 CAP, U 0.01-25

C788 87-012-167-080 C-CAP,U 5P-50 CH

C789 87-A12-052-080 C-CAP,S 0.033-25 J B

C790 87-A12-052-080 C-CAP,S 0.033-25 J B

C791 87-010-831-080 C-CAP,U,0.1-16F

C792 87-012-286-080 CAP, U 0.01-25

C793 87-A12-090-080 CAP,E 4.7-50 SMG

C795 87-012-286-080 CAP, U 0.01-25

C796 87-012-286-080 CAP, U 0.01-25

KANRI

NO.

REF. NO. DESCRIPTIONPART NO.

NO.

C797 87-A12-091-080 CAP,E 10-50 SMG

C798 87-012-286-080 CAP, U 0.01-25

C799 87-A12-077-080 CAP,E 33-35 SMG

C800 87-010-829-080 CAP, U 0.047-16

C801 87-A12-089-080 CAP,E 3.3-50 SMG

C802 87-010-829-080 CAP, U 0.047-16

C803 87-010-787-080 CAP, U 0.022-25

C804 87-A12-062-080 CAP,E 100-10 SMG

C807 87-A12-086-080 CAP,E 0.47-50 SMG

C808 87-A12-087-080 CAP,E 1-50 SMG

C809 87-A12-087-080 CAP,E 1-50 SMG

C810 87-010-831-080 C-CAP,U,0.1-16F

C814 87-012-286-080 CAP, U 0.01-25

C815 87-A12-086-080 CAP,E 0.47-50 SMG

C816 87-A12-086-080 CAP,E 0.47-50 SMG

C821 87-A12-091-080 CAP,E 10-50 SMG

C823 87-010-177-080 C-CAP,S 820P-50 SL

C824 87-A12-090-080 CAP,E 4.7-50 SMG

C825 87-010-596-080 CAP, S 0.047-16

C842 87-012-286-080 CAP, U 0.01-25

C844 87-012-286-080 CAP, U 0.01-25

C850 87-A12-071-080 CAP,E 47-25 SMG

C851 87-012-286-080 CAP, U 0.01-25

C852 87-012-286-080 CAP, U 0.01-25

C853 87-012-286-080 CAP, U 0.01-25

C858 87-010-831-080 C-CAP,U,0.1-16F

C901 87-018-145-080 CAP,TC-U 6.8P-50 CH

C904 87-012-286-080 CAP, U 0.01-25

C905 87-012-286-080 CAP, U 0.01-25

C907 87-012-286-080 CAP, U 0.01-25

C908 87-A10-915-080 C-CAP,U 1000P-25 J CH

C909 87-012-286-080 CAP, U 0.01-25

C910 87-012-174-080 CAP CHIP CERA SS 12P CHJ

C911 87-012-170-080 C-CAP,U 8P-50 CH

C912 87-012-195-080 C-CAP,U 100P-50CH

C913 87-012-286-080 CAP, U 0.01-25

C914 87-012-166-080 C-CAP,U 4P-50 CH

C915 87-012-174-080 CAP CHIP CERA SS 12P CHJ

C916 87-012-180-080 C-CAP,U 22P-50 CH

C917 87-012-186-080 C-CAP,U 39P-50 CH

C918 87-A10-039-080 C-CAP,U 470P-50 J CH

C921 87-012-195-080 C-CAP,U 100P-50CH

C922 87-012-174-080 CAP CHIP CERA SS 12P CHJ

C959 87-010-831-080 C-CAP,U,0.1-16F

C960 87-010-831-080 C-CAP,U,0.1-16F

C961 87-012-167-080 C-CAP,U 5P-50 CH

C963 87-015-785-080 CHIP CAPACITOR, 0.1FZ-25Z

C971 87-A12-067-080 CAP,E 330-16 SMG

C972 87-A12-090-080 CAP,E 4.7-50 SMG

C973 87-012-286-080 CAP, U 0.01-25

C974 87-012-286-080 CAP, U 0.01-25

C979 87-012-195-080 C-CAP,U 100P-50CH

C981 87-A12-071-080 CAP,E 47-25 SMG

C982 87-010-831-080 C-CAP,U,0.1-16F

C983 87-012-286-080 CAP, U 0.01-25

C984 87-012-286-080 CAP, U 0.01-25

C987 87-012-286-080 CAP, U 0.01-25

C991 87-012-176-080 CAP 15P

C992 87-012-176-080 CAP 15P

C993 87-012-274-080 CHIP CAP,U 1000P-50B

C995 87-012-274-080 CHIP CAP,U 1000P-50B

C997 87-010-831-080 C-CAP,U,0.1-16F

C998 87-A12-071-080 CAP,E 47-25 SMG

C999 87-A11-155-080 CAP,TC U 0.01-16 Z F

CF831 87-008-261-010 FILTER, SFE10.7MA5-A

CF832 87-008-261-010 FILTER, SFE10.7MA5-A

CN3 8B-NF7-619-010 CONN ASSY,2P V PANO

CN101 87-099-197-010 CONN, 9P 6216 V

CN301 87-A60-620-010 CONN,3P V 2MM JMT

CN351 87-A60-625-010 CONN,8P V 2MM JMT

– 9 –

Page 10

REF. NO. DESCRIPTIONPART NO. KANRI

CN501 87-099-564-010 CONN,4P TUC-P4P-B1

CN601 87-099-719-010 CONN,30P TYK-B(X)

CN602 87-A60-131-010 CONN,6P V FE

CNA1 8A-NF8-653-010 CONN ASSY,9P TID-A(480)<LH>

CNA2 8B-NF7-618-010 CONN ASSY,3P V PANO

CON351 86-ZM3-605-110 CONN ASSY,8P -RPB<U>

FC602 88-906-251-110 FF-CABLE,6P 1.25(RVS-FACE)

FC605 88-909-101-110 FF-CABLE, 9P 1.25 100MM

J201 87-A60-929-010 JACK,DIA6.3 BLK ST W/S TAI

J203 87-A60-238-010 TERMINAL,SP 4P (MSC)

J207 87-A60-881-010 JACK,PIN 2P MSP 242V05 PBSN

J602 87-A60-881-010 JACK,PIN 2P MSP 242V05 PBSN

J831 87-A60-202-010 TERMINAL,ANT 4P MSP-154V-02

JR123 87-A10-596-080 C-CAP,S 100P-100 J CH

JR124 87-A10-596-080 C-CAP,S 100P-100 J CH

L201 87-A50-610-010 COIL,1UH K(MDEC)

L202 87-A50-610-010 COIL,1UH K(MDEC)

L203 87-A50-610-010 COIL,1UH K(MDEC)

L204 87-A50-610-010 COIL,1UH K(MDEC)

L401 87-A50-625-010 COIL,TRAP 85KHZ (SANWA)<LH>

L402 87-A50-625-010 COIL,TRAP 85KHZ (SANWA)<LH>

L451 87-007-342-010 COIL,OSC 85K BIAS

L801 87-A50-608-010 COIL,FM DET-N(TOK)

L802 87-A91-551-010 FLTR,PCFJZH-450 L(TOK)

L811 87-005-847-080 COIL,2.2UH(CECS)

L832 87-005-847-080 COIL,2.2UH(CECS)

L902 88-ZA1-602-110 COIL,FM-RF-U2 2G

L903 88-ZA1-601-010 COIL,FM-RF-U1 2G

L904 87-005-847-080 COIL,2.2UH(CECS)

L905 88-ZA1-624-010 COIL,FM IFT 7-6.2 (COILS)

L906 88-ZA1-603-010 COIL,FM-OSC-U 2G

L951 8A-NF8-667-010 COIL,AM PACK 4(TOK)

R129 87-A00-262-080 RES,M/F 0.15-2W J

R130 87-A00-262-080 RES,M/F 0.15-2W J

R131 87-A00-262-080 RES,M/F 0.15-2W J

R132 87-A00-262-080 RES,M/F 0.15-2W J

R243 87-A00-440-050 RES,220-1/2W J RP

R244 87-A00-440-050 RES,220-1/2W J RP

R245 87-A00-440-050 RES,220-1/2W J RP

R246 87-A00-440-050 RES,220-1/2W J RP

R790 87-012-286-080 CAP, U 0.01-25

R991 87-012-195-080 C-CAP,U 100P-50CH

R993 87-012-195-080 C-CAP,U 100P-50CH

R995 87-012-195-080 C-CAP,U 100P-50CH

SFR451 87-024-435-080 SFR 33K RH 063EC

SFR452 87-024-435-080 SFR 33K RH 063EC

TH101 87-A91-042-080 C-THMS,100K 55001

TH102 87-A91-042-080 C-THMS,100K 55001

W99 8B-NFJ-620-010 F-CABLE,9P 2.5 280MM<U>

WH1 87-A90-510-010 HLDR,WIRE 2.5-9P

X992 87-A70-306-010 VIB,XTAL 4.500MHZ CSA-309ST

FRONT C.B

C39 87-A10-039-080 C-CAP,U 470P-50 J CH

C40 87-012-195-080 C-CAP,U 100P-50CH

C41 87-012-195-080 C-CAP,U 100P-50CH

C42 87-012-195-080 C-CAP,U 100P-50CH

C43 87-012-195-080 C-CAP,U 100P-50CH

C44 87-012-195-080 C-CAP,U 100P-50CH

C45 87-012-195-080 C-CAP,U 100P-50CH

C46 87-012-195-080 C-CAP,U 100P-50CH

C47 87-012-195-080 C-CAP,U 100P-50CH

C48 87-012-199-080 C-CAP,U 220P-50 J CH

C49 87-012-267-080 C-CAP,U 270P-50 B

C50 87-012-267-080 C-CAP,U 270P-50 B

C141 87-012-278-080 C-CAP,U 2200P-50 B

C142 87-010-785-080 C-CAP,U0.015-25BK

C153 87-A11-058-080 C-CAP,U 0.22-10 K B

KANRI

NO.

REF. NO. DESCRIPTIONPART NO.

NO.

C154 87-A10-189-040 CAP,E 220-10

C155 87-012-176-080 CAP 15P

C156 87-012-198-080 CAP 180P

C158 87-A10-039-080 C-CAP,U 470P-50 J CH

C161 87-012-274-080 CHIP CAP,U 1000P-50B

C162 87-012-274-080 CHIP CAP,U 1000P-50B

C165 87-012-268-080 C-CAP,U 330P-50 B

C166 87-010-552-040 CAP,E 22-16 GAS

C171 87-012-369-080 C-CAP,S 0.047-50F

C172 87-010-408-040 CAP,E 47-50 M 11L SME

C173 87-010-421-040 CAP,E 4.7-50 5L

C174 87-010-421-040 CAP,E 4.7-50 5L

C180 87-010-759-080 C-CAP,U, 0.1-25F

C185 87-010-759-080 C-CAP,U, 0.1-25F

C186 87-012-274-080 CHIP CAP,U 1000P-50B

C188 87-012-369-080 C-CAP,S 0.047-50F

C191 87-012-286-080 CAP, U 0.01-25

C192 87-010-759-080 C-CAP,U, 0.1-25F

C251 87-010-260-040 CAP,E 47-25 M 11L SME

C315 87-010-759-080 C-CAP,U, 0.1-25F

C391 87-012-274-080 CHIP CAP,U 1000P-50B

C392 87-012-199-080 C-CAP,U 220P-50 J CH

C451 87-010-759-080 C-CAP,U, 0.1-25F

C452 87-010-759-080 C-CAP,U, 0.1-25F

C453 87-010-759-080 C-CAP,U, 0.1-25F

C454 87-010-759-080 C-CAP,U, 0.1-25F

C455 87-010-759-080 C-CAP,U, 0.1-25F

C502 87-012-282-080 CAP, U 4700P-50<LH>

C503 87-010-112-040 CAP,E 100-16 M 11L SME<LH>

C505 87-010-492-040 CAP,E 0.33-50 M 5L SRE<LH>

C506 87-012-191-080 CHIP CAP 68 PF<LH>

C507 87-010-545-040 CAP,E 0.22-50 M 11L SME<LH>

C508 87-010-544-040 CAP,E 0.1-50 M 11L SME<LH>

C510 87-012-195-080 C-CAP,U 100P-50CH<LH>

C511 87-A12-065-080 CAP,E 33-16 SMG<LH>

C512 87-012-274-080 CHIP CAP,U 1000P-50B<LH>

C514 87-010-759-080 C-CAP,U, 0.1-25F<LH>

C515 87-012-274-080 CHIP CAP,U 1000P-50B<LH>

C517 87-012-274-080 CHIP CAP,U 1000P-50B<LH>

C518 87-010-759-080 C-CAP,U, 0.1-25F<LH>

C520 87-012-273-080 C-CAP,U 820P-50 B<LH>

C531 87-010-805-080 CAP, S 1-16<LH>

CN101 87-099-720-010 CONN,30P TYK-B(P)

CN103 87-099-196-010 CONN,8P 6216 V

CN201 87-099-017-010 CONN, 15P 6216 V<LH>

CN202 87-099-013-010 CONN,11P 6216 V<U>

CN301 87-099-209-010 CONN,4P 6216H

CN303 87-099-209-010 CONN,4P 6216H

CN911 87-099-212-010 CONN,5P 6216 V

FB501 87-A90-896-080 F-BEAD, 035600STY7<LH>

FC103 88-908-301-110 FF-CABLE,8P 1.25

FC201 88-915-101-110 FF-CABLE, 15P 1.25 100MM<LH>

FC202 88-911-101-110 FF-CABLE,11P 1.25<U>

FC301 88-904-091-110 FF-CABLE,4P 1.25 90MM

FC303 88-904-091-110 FF-CABLE,4P 1.25 90MM

FC911 88-905-151-110 FF-CABLE, 5P 1.25 150MM

FL401 8B-NF7-621-010 FL,BJ815GNK

J502 87-A61-242-010 JACK,6.3 BLK MONO W/SW V KM<LH>

L151 87-A50-656-010 COIL,CLK 5.76MHZ (TOKO)7KLY

LED401 87-A40-791-040 LED,LTL-307E RED

LED402 87-017-756-040 LED,SLR-342DCT31 ORN

S162 87-A91-645-010 SW,RTRY EC12E24304NON-CLICK

S301 87-A90-095-080 SW,TACT EVQ11G04M

S302 87-A90-095-080 SW,TACT EVQ11G04M

S321 87-A90-095-080 SW,TACT EVQ11G04M

S322 87-A90-095-080 SW,TACT EVQ11G04M

S323 87-A90-095-080 SW,TACT EVQ11G04M

S324 87-A90-095-080 SW,TACT EVQ11G04M

S326 87-A90-095-080 SW,TACT EVQ11G04M

S327 87-A90-095-080 SW,TACT EVQ11G04M

– 10 –

Page 11

REF. NO. DESCRIPTIONPART NO. KANRI

KANRI

REF. NO. DESCRIPTIONPART NO.

NO.

S328 87-A90-095-080 SW,TACT EVQ11G04M

S335 87-A90-095-080 SW,TACT EVQ11G04M

VR501 87-NB7-602-010 VR,RTRY 10KAX1 1 V<LH>

CN302 87-A60-083-010 CONN,04P H 9604S-04F

S303 87-A90-095-080 SW,TACT EVQ11G04M

S304 87-A90-095-080 SW,TACT EVQ11G04M

S305 87-A90-095-080 SW,TACT EVQ11G04M<LH>

S306 87-A90-095-080 SW,TACT EVQ11G04M<LH>

PANORAMA AMP C.B

S307 87-A90-095-080 SW,TACT EVQ11G04M

C201 87-A12-088-080 CAP,E 2.2-50 SMG

C202 87-A12-088-080 CAP,E 2.2-50 SMG

C204 87-016-459-080 CAP,E 470-10 M SMG

C207 87-012-286-080 CAP, U 0.01-25

S308 87-A90-095-080 SW,TACT EVQ11G04M

S329 87-A90-095-080 SW,TACT EVQ11G04M

S330 87-A90-095-080 SW,TACT EVQ11G04M

S332 87-A90-095-080 SW,TACT EVQ11G04M

C208 87-012-286-080 CAP, U 0.01-25

S333 87-A90-095-080 SW,TACT EVQ11G04M

C213 87-012-172-080 CAPACITOR CHIP U 10P CH

C215 87-010-831-080 C-CAP,U,0.1-16F

C216 87-010-831-080 C-CAP,U,0.1-16F

MOTOR C.B

C301 87-012-274-080 CHIP CAP,U 1000P-50B

C302 87-012-274-080 CHIP CAP,U 1000P-50B

CN912 87-099-210-010 CONN,5P 6216 H

M900 87-045-305-010 MOT,RF-500 TB

C303 87-A12-084-080 CAP,E 0.22-50 SMG

C304 87-A12-084-080 CAP,E 0.22-50 SMG

S911 87-036-109-010 PUSH SWITCH

S912 87-036-109-010 PUSH SWITCH

C309 87-A12-089-080 CAP,E 3.3-50 SMG

C310 87-A12-089-080 CAP,E 3.3-50 SMG

C311 87-A12-092-080 CAP,E 22-50 SMG

C312 87-A12-092-080 CAP,E 22-50 SMG

C315 87-012-199-080 CAP 220P

C316 87-012-199-080 CAP 220P

BOX SW C.B

CNA901 8B-NF7-620-010 CONN ASSY,3P V 120MM

S901 87-036-252-010 SW,PUSH SPPB 51

S902 87-036-252-010 SW,PUSH SPPB 51

C317 87-012-286-080 CAP, U 0.01-25

C318 87-012-286-080 CAP, U 0.01-25

FAN C.B

C401 87-010-831-080 C-CAP,U,0.1-16F

C402 87-010-831-080 C-CAP,U,0.1-16F

C403 87-A12-091-080 CAP,E 10-50 SMG

C404 87-A12-091-080 CAP,E 10-50 SMG

CN101 87-A60-134-010 CONN,9P V FE

C501 87-A12-087-080 CAP,E 1-50 SMG

C502 87-A12-071-080 CAP,E 47-25 SMG

C503 87-A12-071-080 CAP,E 47-25 SMG

CN502 87-A60-688-010 CONN,4P H GRY TUC-P04X-C1

CN503 87-A60-619-010 CONN,2P V 2MM JMT

CN102 87-099-043-010 CONN 2P EH

CN104 87-049-919-010 CONN,3P EH V WHT

R333 87-A00-258-080 RES,M/F 0.22-1W J

DECK C.B<U>

R334 87-A00-258-080 RES,M/F 0.22-1W J

CON105 87-099-753-010 CONN,11P H 9604

SFR1 87-024-581-010 SFR,3.3K DIA6V K0A

PT C.B

SOL1 82-ZM3-628-010 SOL ASSY 23 SO

SOL2 82-ZM3-628-010 SOL ASSY 23 SO

CN1 87-A61-110-010 CONN,9P V TID-A<LH>

!

PT1 8B-NF7-612-010 PT,BNF-7LH<LH>

!

PT1 8B-NF7-611-010 PT,BNF-7U<U>

!

PT2 8B-MA6-673-010 PT,SUB BMA H (VRK)<LH>

PT81 8B-MA6-671-010 PT,SUB BMA U (VRK)<U>

!

!

RY1 87-A91-339-010 RELAY,AC DC12V G5PA-2<LH>

!

RY81 87-A91-418-010 RELAY,AC12V G5PA-1-M<U>

S1 87-A90-165-010 SW,SL 1-2-3 SWS2301<LH>

!

T1 87-A60-317-010 TERMINAL, 1P MSC<LH>

!

T2 87-A60-317-010 TERMINAL, 1P MSC<LH>

!

!

T81 87-A60-317-010 TERMINAL, 1P MSC<U>

!

T82 87-A60-317-010 TERMINAL, 1P MSC<U>

WH81 87-A90-510-010 HLDR,WIRE 2.5-9P<U>

SW1 87-A90-248-010 SW,MICRO ESE11SH2CXQ

SW2 87-A90-248-010 SW,MICRO ESE11SH2CXQ

SW3 87-A90-248-010 SW,MICRO ESE11SH2CXQ

SW4 87-A90-248-010 SW,MICRO ESE11SH2CXQ

SW5 87-A90-248-010 SW,MICRO ESE11SH2CXQ

M1 87-045-347-010 MOT,SHU2L 70

DECK C.B<LH>

CON1 87-099-756-010 CONN,15P 9604S F

SFR1 87-024-581-010 SFR,3.3K DIA6V K0A

SOL1 82-ZM3-627-010 SOL ASSY 27 SO

SOL2 82-ZM3-627-010 SOL ASSY 27 SO

SW1 87-A90-248-010 SW,MICRO ESE11SH2CXQ

M-0P-PANEL C.B

SW2 87-A90-248-010 SW,MICRO ESE11SH2CXQ

SW3 87-A90-248-010 SW,MICRO ESE11SH2CXQ

CN304 87-099-209-010 CONN,4P 6216H

S341 87-A90-095-080 SW,TACT EVQ11G04M

S342 87-A90-095-080 SW,TACT EVQ11G04M

SW4 87-036-110-010 PUSH SWITCH

SW5 87-036-110-010 PUSH SWITCH

SW6 87-036-110-010 PUSH SWITCH

S343 87-A90-095-080 SW,TACT EVQ11G04M

S344 87-A90-095-080 SW,TACT EVQ11G04M

SW8 87-A90-248-010 SW,MICRO ESE11SH2CXQ

SW9 87-A90-248-010 SW,MICRO ESE11SH2CXQ

S345 87-A90-095-080 SW,TACT EVQ11G04M

M1 87-045-347-010 MOT,SHU2L 70

S346 87-A90-095-080 SW,TACT EVQ11G04M

S347 87-A90-095-080 SW,TACT EVQ11G04M

S348 87-A90-095-080 SW,TACT EVQ11G04M

HEAD-1 C.B

S349 87-A90-095-080 SW,TACT EVQ11G04M

85-ZM3-602-010 PWB,FLEX A

S350 87-A90-095-080 SW,TACT EVQ11G04M

S351 87-A90-095-080 SW,TACT EVQ11G04M

CON301 85-MA2-615-010 CONN ASSY 3P-PB<U>

CON301 87-NF6-615-010 CONN ASSY,3P PB<LH>

S352 87-A90-095-080 SW,TACT EVQ11G04M

S371 87-A91-991-010 SW,RTRY REO12303PVB8H

HEAD-2 C.B<LH>

S-OP-PANEL C.B

85-ZM3-602-010 PWB,FLEX A

CON351 87-NF6-616-010 CONN ASSY,8P-RPB

– 11 –

NO.

Page 12

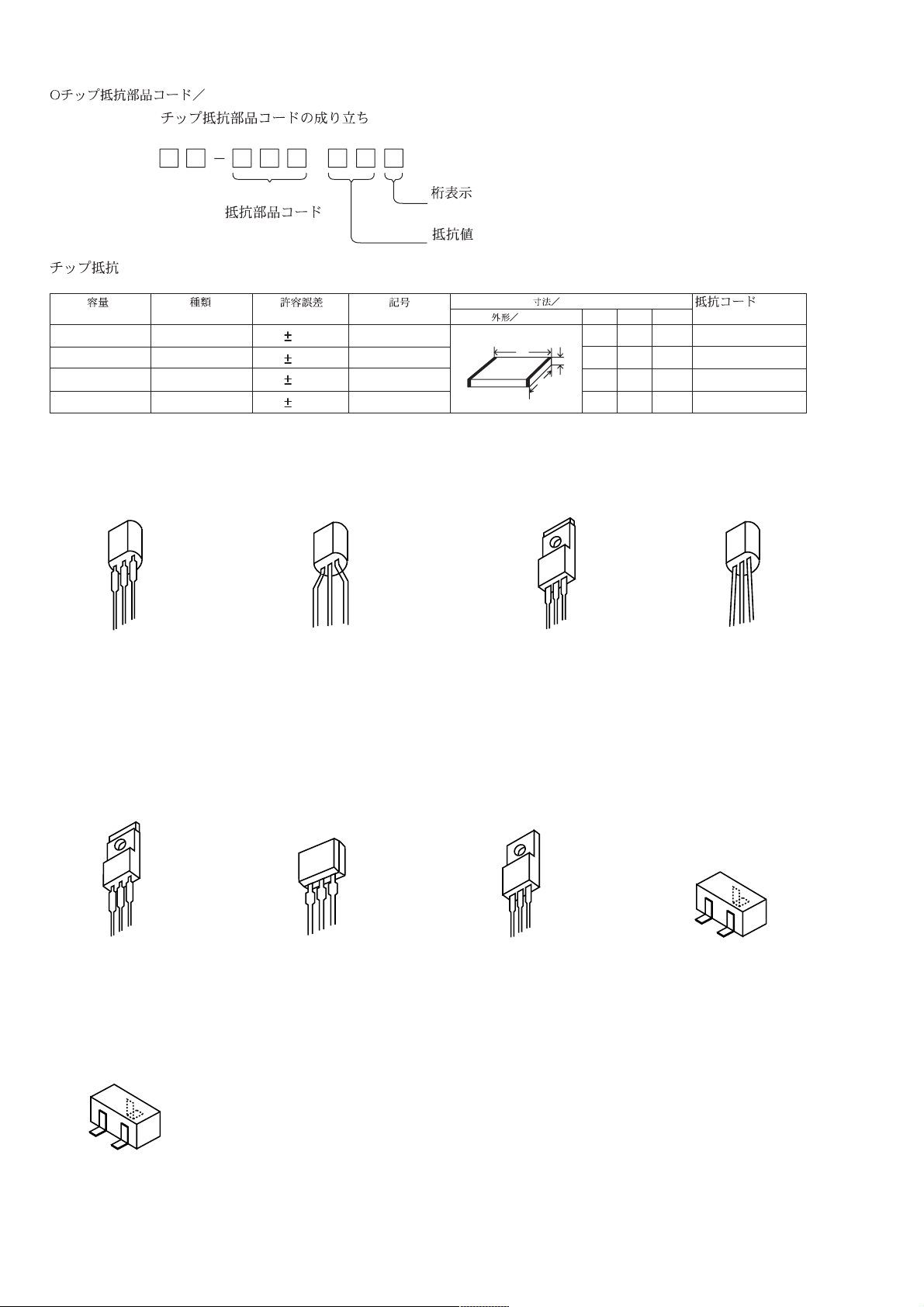

CHIP RESISTOR PART CODE

Chip Resistor Part Coding

88

A

Resistor Code

Chip resistor

Wattage Type Tolerance

1/16W 1005 5% CJ

1/16W

1/10W

1/8W

1608

2125

3216

5%

5%

5%

TRANSISTOR ILLUSTRATION

E C B

B C E

Symbol

CJ

CJ

CJ

Figure

Value of resistor

Form

L

Dimensions (mm)

t

W

B C E

0.55

Resistor Code

108

118

128

E C B

LW t

1.0 0.5 0.35 104

1.6 0.8 0.45

2 1.25 0.45

3.2

1.6

: A

: A

2SA1980G

2SA933S

CDA1585BC

CSC4115BC

KTA1266GR

KTC3198GR

G D S

2SK2937

D

2SA1979O/Y

2SA1981Y

2SC5342Y

2SC5343G

S D G

2SJ460

2SK2541

2SB1342

2SD1933

FP1016

B C E

CSB1370EF

B

2SA1235F

2SC2714O

2SC3052F

CMBT5551

CMBT5401

CC5551

C

E

KRA102S

KRA104S

KRA107S

KRC107S

RT1P141C

G

S

2SK2158

– 12 –

Page 13

WIRING 1 (MAIN / FAN)

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

13

R

S

T

U

Page 14

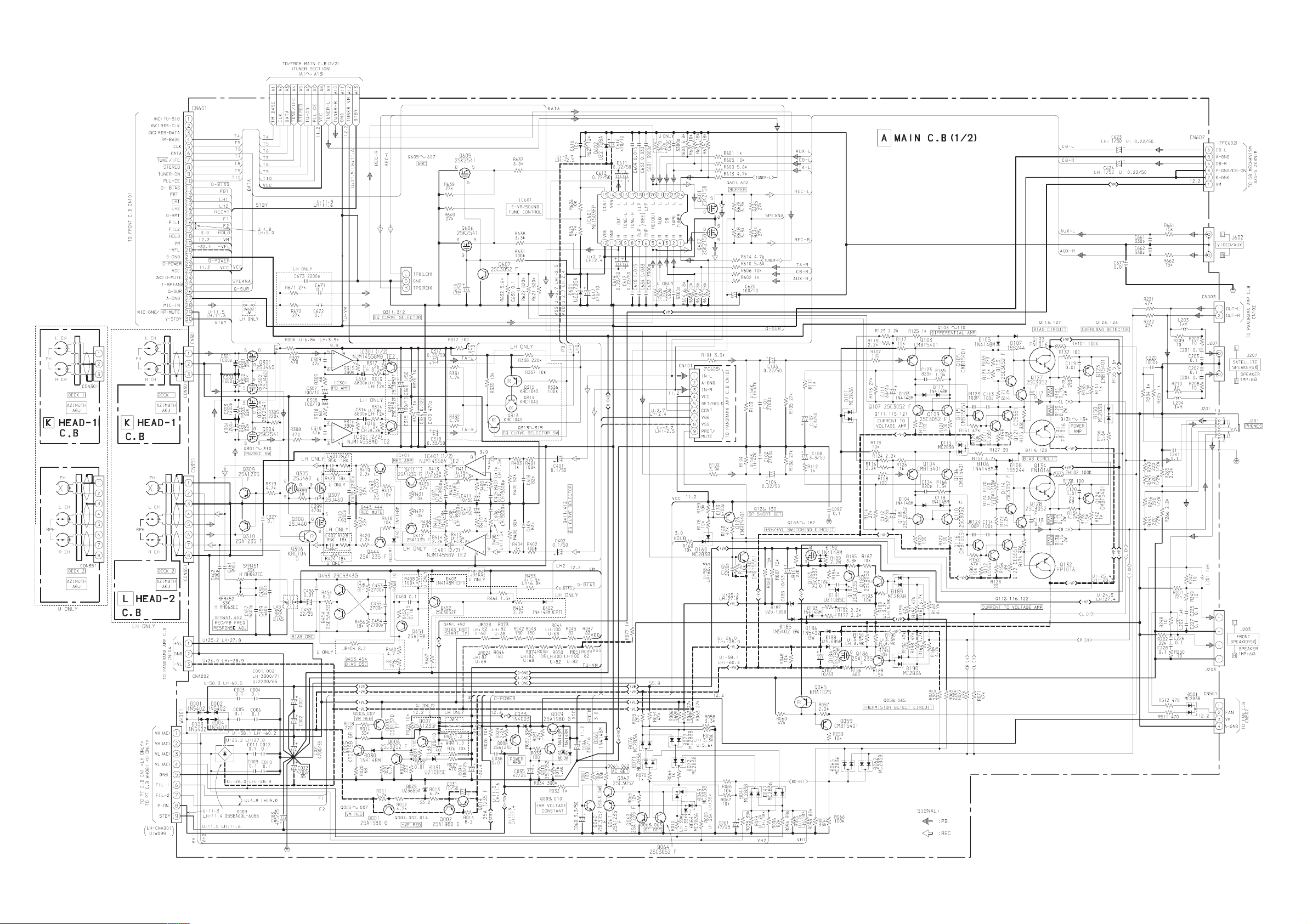

SCHEMATIC DIAGRAM – 1 (MAIN 1 / 2)

– 14 –

Page 15

SCHEMATIC DIAGRAM – 2 (MAIN 2 / 2: TUNER)

– 15 –

Page 16

SCHEMATIC DIAGRAM – 3 (FAN)

– 16 –

Page 17

WIRING 2 (FRONT / MOTOR / BOX SW)

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

17

R

S

T

U

Page 18

WIRING 3 (M OP PANEL)

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

18

R

S

T

U

Page 19

WIRING 4 (S OP PANEL)

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

19

R

S

T

U

Page 20

SCHEMATIC DIAGRAM – 4 (FRONT)

– 20 –

Page 21

WIRING 5 (PANORAMA AMP)

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

21

R

S

T

U

Page 22

SCHEMATIC DIAGRAM – 5 (PANORAMA AMP)

– 22 –

Page 23

WIRING 6 (PT : U)

151413121110987654321

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

23

R

S

T

U

Page 24

SCHEMATIC DIAGRAM – 6 (PT: U)

– 24 –

Page 25

WIRING 7 (PT : LH)

151413121110987654321

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

25

R

S

T

U

Page 26

SCHEMATIC DIAGRAM – 7 (PT: LH)

– 26 –

Page 27

WIRING 8 (DECK: U)

151413121110987654321

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

27

R

S

T

U

Page 28

WIRING 9 (DECK: LH)

151413121110987654321

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

28

R

S

T

U

Page 29

IC BLOCK DIAGRAM

– 29 –

Page 30

FL (BJ815GNK) GRID ASSIGNMENT AND ANODE CONNECTION

GRID ASSIGNMENT

– 30 –

Page 31

ANODE CONNECTION

– 31 –

Page 32

IC DESCRIPTION

IC, LC866560W-5V19

DescriptionPin No. Pin Name I/O

1 O-C-SHIFT O Clock shift output for micro computer when tuner receiving broadcast.

2 O-POWER O Power control ON/OFF output.

3 O-2PB O DECK 2 / DECK 1 play output.

4 O-PANE-LED O Moving PANEL LED ON/OFF output (Not used).

5 O-DATA O Data output.

6 O-RMT O REC MUTE output.

7 O-BIAS O Bias ON/OFF output.

8 O-MUTE O System MUTE ON/OFF.

9

10 O-PANO-LED O Panorama LED ON/OFF output.

11 HP-MUTE I Head phone jack detection. "L" : MUTE

12 RESET I Reset input for MICON.

13 I-DISH I CD turnable photo sensor input.

14 I-SUBQ I SUB-Q data input.

O-TU-ON/

O-STB-SHIFT-VCD

O Tuner power supply ON/OFF output/MICON standby shift VCD output.

15 VSS1 - Connected to ground.

16 CF1 I Oscillator circuit input (5.76 MHz).

17 CF2 O Oscillator circuit output (5.76 MHz).

18 VDD1 - Digital power supply pin.

19 I-HOLD I Power failure detected input.

20 I-KEY1 I Key A/D input 1.

21 I-KEY2 I Key A/D input 2.

22 I-KEY3 I Key A/D input 3.

23 I-PANEL-SW I Panel OPEN/CLOSE detect switch AD input.

24 I-JOG I Dial jog rotary encoder input.

25 I-SPEANA I Spectrum analyser level detection.

26 I-CDSW I CD mehca switch input.

27 I-WRQ I CD WRQ input.

28 I-TM-BASE I Reference clock input for timer switch.

29 I-RMC I System remote control signal input. "L" : ACTIVE

30 ~ 41 G12 ~ G1 O FL grid G12 ~ G1 output.

42 ~ 45 P35 ~ P32 O FL segment P35 ~ P32 output.

46 VDD3 - Digital power supply pin.

47 P31 O FL segment P31 output.

48 SPEANA-A/P30 O Spectrum analyser BPF switching control A output/FL segment P30 output.

49 SPEANA-B/P29 O Spectrum analyser BPF switching control B output/FL segment P29 output.

50 SPEANA-C/P28 O Spectrum analyser BPF switching control C output/FL segment P28 output.

51 VP - Power supply for FL.

52 ~ 53 P27 ~ P26 O FL segment P27 ~ P26 output.

54 ECO-OFF/P25 I/O ECO-OFF data input<LH only>/FL segment P25 output.

55 LW/P24 I/O LW diode input (Not used)/FL segment P24 output.

– 32 –

Page 33

DescriptionPin No. Pin Name I/O

56 KARAOKE/P23 I/O Karaoke input to diode<LH only>/FL segment P23 output.

57 DEMO/P22 I/O Demo (on the stop) diode input (Not used)/FL segment P22 output.

58 DOLBY/P21 I/O DECK DOLBYdiode input (Not used)/FL segment P21 output.

59 AM-ST/P20 I/O AM-ST select diode (Not used)/FL segment P20 output.

60 SOFT/P19 I/O DECK SOFT diode input (Not used)/FL segment P19 output.

61 SW/P18 I/O SW diode input (Not used)/FL segment P18 output.

62 FM1/P17 I/O FM1 diode input (Not used)/FL segment P17 output.

63

64 AM-9K/10K/P15 I/O AM-9K/10Kselect diode input/FL segment P15 output.

65 CASINO/P14 I/O Initial casino diode input<LH only>/FL segment P14 output.

66 REA/P13 I/O DECK2 side A recordable switch. "L" : REC<LH only>/FL segment P13 output.

67 CST1/P12 I/O DECK1 cassette detection switch data input. "L" : ON/FL segment P12 output.

68 CAM1/P11 I/O DECK1 CAM STOP switch data input. "L" : ON/FL segment P11 output.

69 AUTO2/P10 I/O DECK2 AUTO STOP switch data input/FL segment P10 output.

70 AUTO1/P9 I/O DECK1 AUTO STOP switch data input/FL segment P9 output.

71 CAM2/P8 I/O DECK2 CAM switch data input. "L" : ON/FL segment P8 output.

72 VDD4 - Digital power supply pin.

73 REB/P7 I/O DECK2 side B recordable switch. "L" : REC<LH only>/FL segment P7 output.

74 CST2/P6 I/O DECK2 cassette detection switch data input. "L" : ON/FL segment P6 output.

75 M-GEQ/P5 I/O Manual GEQ diode input<LH only>/FL segment P5 output.

76 R+1/P4 I/O DECK R+1 diode input<U only>/FL segment P4 output.

77 1+1/P3 I/O DECK 1+1 diode input (Not used)/FL segment P3 output.

78 P-CL/P2 I/O (Not used)/FL segment P2 output.

79 P-OP/P1 I/O (Not used)/FL segment P1 output.

80 BOX1 I Cassette BOX1 open/close detect input.

PANO/P16 I/O Panorama diode input/FL segment P16 output.

81 BOX2 I Cassette BOX1 open/close detect input.

82 I-VOL2 I Volume rotary encoder input 2.

83 I-VOL1 I Volume rotary encoder input 1.

84 I-IFC I Tuner IF count input.

85 O-MP-CL O Moving panel close output.

86 O-MP-OP O Moving panel open output.

87 O-PLL CE O Tuner PLL IC chip enable output.

88 O-KSCAN O Initial scan output.

89 VSS2 - Connected to ground.

90 VDD2 - Digital power supply pin.

91 STBY-LED O Standby LED ON/OFF output. "L" : ON

92 O-MOTOR O Cassette deck motor control output.

93 O-SOL1 O DECK1 solenoid output.

94 O-SOL2 O DECK2 solenoid output.

95 O-CD-DATA O CD IC control data output.

96 O-CD-CLK O CD IC control clock output.

– 33 –

Page 34

DescriptionPin No. Pin Name I/O

97 O-CD-CE O CD data chip enable output.

98 I-STEREO/I-DRF I Tuner stereo detect input/RF (radio frequency) detect.

99 O-P-DATA O Panorama IC data output.

100 O-CLK O PLL IC clock output.

– 34 –

Page 35

ADJUSTMENT – 1 <TUNER / FRONT>

< TUNER SECTION >

1. Clock Frequency Check

Settings : • Test point : TP2 (CLK)

Method : Set to AM 1710 kHz and check that the test point is

2160 kHz ± 45 Hz.

2. AM VT Check

Settings : • Test point : TP1 (VT)

Method : Set to AM 1710 kHz and check that the test point is less

than 8.5 V. Then set to AM 530 kHz and check that the

test point is more than 0.6 V.

3. AM Tracking Adjustment

Settings : • Test point : TP8 (Lch), TP9 (Rch)

• Adjustment location : L951(1/3)

Method : Set to AM 1000 kHz and adjust L951(1/3) so that the

test point becomes maximum.

4. AM IF Adjustment

Settings : • Test point : TP8 (Lch), TP9 (Rch)

• Adjustment location :

L802 ................................................... 450 kHz

5. FM VT Adjustment

Settings : • Test point : TP1 (VT)

• Adjustment location: L906

Method : Set to FM 87.5 MHz check that the test point is more

than 0.4 V. Then set to FM 108.0 MHz and adjust L906

so that the test point becomes 7.0 V ± 0.1 V.

< FRONT SECTION >

10. µ-CON OSC Adjustment

Settings : • Test point : TP5 (KEY-SCAN)

TP6 (GND)

• Adjustment location : L151

Method : Insert AC plug while pressing of "POWER" key and

"TUNER" function key.

Connect a frequency counter across TP5 and TP6.

Then adjust L501 so that the test point becomes

141.67 Hz ± 0.14 Hz.

[ Manual Reset ]

Make up for RESET after adjustment.

* Reset is to press "POWER" key while pressing of

"CLEAR (STOP)" key.

6. FM Tracking Adjustment

Settings : • Test point : TP8 (Lch), TP9 (Rch)

• Adjustment location: L903

Method : Set to FM 87.5 MHz and adjust L903 so that the

test point is less than 9 dBµV.

7. DC Balance / Mono Distortion Adjustment

Settings : • Test point : TP3, TP4 (DC Balance)

TP8 (LCH), TP9 (RCH)

(Mono Distortion)

• Adjustment location : L801

• Input level : 60 dBµV

Method : Set to FM 98.0 MHz and adjust L801 so that the voltage

between TP3 and TP4 becomes 0 V ± 500 mV with

minimum distortion.

8. Output Level Check

<AM>

Settings : • Test point : TP8 (Lch), TP9 (Rch)

• Input level : 74 dBµV

Method : Set to AM 1000 kHz and check that the test point is

40 mV ± 3 dB.

<FM>

Settings : • Test point : TP8 (Lch), TP9 (Rch)

• Input level : 60 dBµV

Method : Set to FM 98.0 MHz and check that the test point is

150 mV ± 3 dB.

9. FM Separation Check

Settings : • Test point : TP8 (Lch), TP9 (Rch)

• Input level : 60 dBµV

Method : Set to FM 98.0 MHz and check that the test point is

more than 25 dB.

– 35 –

Page 36

ADJUSTMENT – 2 <DECK>

< DECK SECTION >

1. Tape Speed Adjustment (DECK 2)

Settings : • Test tape : TTA–100

• Test point : TP8 (Lch), TP9 (Rch)

• Adjustment location : SFR1

Method : Play back the test tape and adjust SFR1 so that the

test point becomes 3000 Hz ± 5 Hz (FWD) and FWD

SPEED ± 45Hz (REV) with respect to forward speed.

2. Head Azimuth Adjustment (DECK 1, DECK 2)

Settings : • Test tape : TTA–330

• Test point : TP8 (Lch), TP9 (Rch)

• Adjustment location : Head azimuth

adjustment screw

Method : Play back (FWD) the 8 kHz signal of the test tape and

adjust screw so that the output becomes maximum.

Next, perform on REV PLAY mode.

3. PB Frequency Response Check (DECK 1, DECK 2)

Settings : • Test tape : TTA–330

• Test point : TP8 (Lch), TP9 (Rch)

Method : Play back the 315 Hz and 10 kHz signals of the test

tape and check that the output ratio of the 10 kHz

signal with respect to that of the 315 Hz signal is

0 dB ± 5 dB.

4. PB Sensitivity Check (DECK 1, DECK 2)

Settings : • Test tape : TTA–200

• Test point : TP8 (Lch), TP9 (Rch)

Method : Play back the test tape and check that the output level

of the test point is 110 mV ± 3 dB.

5. REC/PB Frequency Response Check (DECK 2)

Settings : • Test tape : TTA–602

• Test point : TP8 (Lch), TP9 (Rch)

• Input signal : 8 kHz/1 kHz (-26 dB)

• Adjustment location: SFR451 (Lch)

SFR452 (Rch)

Method : Apply a 1 kHz signal and REC mode. Then adjust

OSC attenuator so that the output level at TP8, TP9

becomes 10 mV. Record and play back

the 1 kHz and 8 kHz signals and adjust SFRs so that

the output of 8 kHz signals becomes 0 dB ± 1 dB with

respect to that of the 1 kHz signal.

6. REC/PB Frequency Response Check (DECK 2)

Settings : • Test tape : TTA–602

• Test point : TP8 (Lch), TP9 (Rch)

• Input signal : 8 kHz/1 kHz (-26 dB)

Method : Apply a 1 kHz signal and REC mode. Then adjust

OSC attenuator so that the output level at TP8, TP9

becomes 10 mV. Record and play back

the 1 kHz signals and check that the output is

0 dB ± 2.5 dB.

7. REC/PB Sensitivity Check (DECK 2)

Settings : • Test tape : TTA–602

• Test point : TP8 (Lch), TP9 (Rch)

• Input signal : 1 kHz (0VU / -8.0 dB)

Method : Apply a 1 kHz signal and REC mode. Then adjust

OSC attenuator so that the output level at TP8, TP9

becomes 80 mV. Record and play back

the 1 kHz signals and check that the output is

–1 dB ± 3.5 dB.

– 36 –

Page 37

CD TEST MODE

1. How to Start the CD Test Mode

While pressing the FUNCTION button, insert the AC plug to the power outlet.

When the test mode is started, the message [CD TEST] is displayed.

2. How to Exit the CD Test Mode

Press the POWER button or disconnect the AC plug.

*When any key other than PLAY is pressed during play mode, the machine exits the test mode.

3. Function Descriptions and Application of the CD Test Mode

No

1

2

3

4

5

6

Mode

Start mode

Search

mode

Play mode

Traverse

mode

Sled mode

Spindle

mode

Operation

STOP button

Play button

PAUSE

button

FF button

RWD button

REC/REC

MUTE button

Display

All indicators light

READING

Normal

Normal

CD TEST

CD TEST

All indicators light

Function

• All FL indicators light

• LD illuminates all the time

• Focus search continuous

operations *1

• Spindle motor continuous kick

• Normal playback

• If TOC cannot be read, focus

search is continued

• Tracking servo OFF/ON

• Each time PAUSE button is

pressed, the tracking servo

repeats turning OFF/ON

• Pickup moves to the inner

circumference *2

At the same time, lens kicks to

the inner circumference

• Pickup moves to the outer

circumference *2

At the same time, lens kicks to

the outer circumference

• The spindle motor rotates

forward (rough speed) by

pressing the button and rotates

backward by pressing one more

time and stops by pressing again

Checking item

• FL check

• Microprocessor check

• APC circuit check

• Laser current measurement

• Focus search waveform check

• Focus error waveform check

(DRF in the search mode is

ignored)

• Each servo circuit is checked

• DRF check

• Tracking balance check

• Sled circuit check

• Tracking circuit check

• Mechanism operation check

• Pickup check

• Spindle circuit

• Spindle motor

*1: The driver IC heats up and the protection circuit starts working when the focus search is continued for 10 minutes or longer. There can be a

case that operations cannot be performed correctly.

In such a case, turn off the main power. After cooling down the machine, restart the machine.

*2: Be careful not to damage the gear because the sled motor rotates while the FF or RWD button is being pressed even if the pick-up is located

in the innermost track or the outermost track.

– 37 –

Page 38

MECHANICAL EXPLODED VIEW 1 / 1

A

BZG-5

A

A

G

51

52

A

54

A

U

G

50

A

H

H

A

PLATE,PT 85 U

A

53

G

22

45

I

46

A

FL401

PWB

14

44

27

21

A

41

A

FC301

26

25

20

PLATE,EARTH MIC

A

30

21

31

32

36

40

37

38

37

47

CON351

A

FC103

A

FC201<LH>

FC202<U>

28

b

38

E

FC911

29

39

PWB

CON301

E

FC605

A

b

A

PWB

B

34

35

B

49

PLATE,EARTH MECH

60

33

PWB

A

A

2ZM-3MK2<LH>

6ZM-3<U>

FC602

48

C

57

A

PWB

J

C

A

WIRE,BINDER

58

F

61

J

62

F

CHAS,MAIN

A

59

50

A

A

F

PLATE,PT 85

c

HT-SINK,

ASSY LH

A

G

H

H

c

C

43

U

42

56

10

43

a

16

12

55

I

15

A

C

14

a

17

LH

4

18

19 23

24

D

A

PWB

11

8

9

PWB

7

3

1

FC303

13

5

2

6

– 38 –

Page 39

MECHANICAL PARTS LIST 1 / 1

REF. NO. DESCRIPTIONPART NO. KANRI

1 8B-NF7-007-010 WINDOW,CASS 1

2 8B-NF7-008-010 WINDOW,CASS 2

3 8B-NF7-003-010 BOX,CASS 1 REV

4 8B-NF7-042-010 BOX,CASS 2 1WAY<U>

4 8B-NF7-004-010 BOX,CASS 2 REV<LH>

5 8A-NF8-281-010 SPR-T,EJECT 1

6 8A-NF8-282-010 SPR-T,EJECT 2

7 8B-NF7-083-010 PANEL,MOVE 1F LH<LH>

7 8B-NF7-009-010 PANEL,MOVE 1F U<U>

8 8B-NF7-030-010 KEY,CD

9 8B-NF7-022-010 KEY,ASSY OPE REV

10 8B-NF7-031-010 KEY,ENTER

11 8B-NF7-045-010 PANEL,MOVE 1R H<LH>

11 8B-NF7-010-010 PANEL,MOVE 1R U<U>

12 8B-NF7-013-010 KNOB,RTRY JOG

13 8B-NF7-068-010 WINDOW,DISP LH<LH>

13 8B-NF7-006-010 WINDOW,DISP U<U>

14 8Z-NF6-210-010 DMPR,150 N

15 8B-NF7-221-010 HLDR,PANEL

16 8B-NF7-015-010 KEY,ASSY POWER

17 8B-NF7-014-010 KNOB,RTRY MIC<LH>

18 8B-NF7-052-010 RING,FUN 4

19 8B-NF7-048-010 KEY,ASSY FUN 4

20 8B-NF7-037-010 KEY,PANEL

21 8B-NF7-223-010 HLDR,PANEL 2

22 8B-NF7-061-010 CABI,FR H<LH>

22 8B-NF7-001-010 CABI,FR U<U>

23 8B-NF7-029-010 KEY,BBE

24 8B-NF7-055-010 KEY,TIMER H<LH>

24 8B-NF7-032-010 KEY,TIMER U<U>

25 8B-NF7-086-010 PANEL,MOVE 2 LH<LH>

25 8B-NF7-011-010 PANEL,MOVE 2U<U>

26 8B-NF7-220-010 SPR-T,OPEN

27 8A-NF6-201-010 GUIDE,FL

28 8B-NF7-214-010 BELT,SQ 1.8-113.5

29 8B-NF7-213-010 PULLEY,RELAY

30 8B-NF7-212-010 GEAR,RELAY

31 8B-NF7-211-010 GEAR,PANEL

32 8B-NF7-217-010 LEVER,SW

33 8B-NF7-210-010 HLDR,MECHA

34 84-ZG1-267-010 PULLEY,LOAD MO 8

35 87-045-305-010 MOTOR, RF-500TB DC-5V (2MA)

36 87-NF4-216-010 HLDR,LOCK 1

37 86-NF9-224-010 SPR-C,LOCK

38 82-NF5-229-010 PLATE,LOCK

KANRI

NO.

REF. NO. DESCRIPTIONPART NO.

39 87-NF4-217-110 HLDR,LOCK 2

40 8B-NF7-012-010 KNOB,RTRY VOL

41 8B-NF7-222-010 HLDR,STOP

42 8A-NF8-007-010 PANEL,LEFT V-2

43 8B-NF7-040-010 PANEL,TOP V-2 ANF8<LH>

43 8B-NF7-039-010 PANEL,TOP V-2 BNFK<U>

44 87-CE3-023-010 BADGE,AIWA 30N SILV

45 8B-NF7-035-010 WINDOW,TRAY

46 8B-NF7-005-010 PANEL,TRAY

47 8A-NF8-206-010 HLDR,PWB M

48 8B-NF7-239-010 HLDR,TR U

49 87-064-185-010 HLDR,WIRE

50 8B-NF7-209-010 HLDR,PT(85-58)<U>

50 8A-NF7-225-010 HLDR,PWB PT 85S<LH>

51 87-085-185-010 BUSHING, AC CORD (E)<LH>

51 87-A91-422-010 BUSHING,AC CORD(U)<U>

!

52 87-A80-157-010 AC CORD ASSY,E BLK CC<LH>

!

52 87-A80-149-010 AC CORD ASSY,U BLK<U>

53 8A-NF8-008-010 PANEL,RIGHT V-2

54 8B-NF7-071-010 CABI,REAR LHSM<LH>

54 8B-NF7-002-010 CABI,REAR USM<U>

55 8B-NF7-026-010 KEY,ASSY PANORAMA

56 8A-NF8-006-010 WINDOW,TOP<LH>

57 8B-NF7-225-010 HLDR,TR PNRM ST

58 8B-NF7-237-010 HLDR,TR PNRM

59 8B-NF7-236-010 HLDR,PWB PNRM R

60 8B-NF7-235-010 HLDR,PWB PNRM F

61 8B-NF7-238-010 HLDR,FAN LOW

62 87-A91-751-010 FAN,DSB0812M-S382 -400MM

A 87-067-703-010 TAPPING SCREW, BVT2+3-10

B 87-067-758-010 BVT2+3-12 W/O SLOT

C 87-721-096-410 QT2+3-10 GLD

D 87-067-688-010 BVTT+3-6

E 87-NF4-224-010 S-SCREW,IT3B+3-8 CU

F 87-067-579-010 TAPPING SCREW, BVT2+3-8

G 87-067-641-010 UTT2+3-8(W/O SLOT)BL

H 87-078-199-010 S-SCREW,ITC+4-10 R

I 87-721-097-410 QT2+3-12 GLD

J 87-B10-315-010 BVIT3B+3-8 R W/O

NO.

COLOR NAME TABLE

Basic color symbol Color Basic color symbol Color Basic color symbol Color

B Black C Cream D Orange

G Green H Gray L Blue

LT Transparent Blue N Gold P Pink

R Red S Silver ST Titan Silver

T Brown V Violet W White

WT Transparent White Y Yellow YT Transparent Yellow

LM Metallic Blue LL Light Blue GT Transparent Green

LD Dark Blue DT Transparent Orange GM Metallic Green

YM Metallic Yellow DM Metallic Orange PT Transparent Pink

LA Aqua Blue GL Light Green HT Transparent Gray

– 39 –

Page 40

TAPE MECHANISM EXPLODED VIEW 1 / 1 <U>

PWB

e

38

56

25

24

23

PLATE, SHLD

M3

22

26

27

29

LVR EJECT L

SH, 1.63-3.2

-0.5 SLT

28

30

J

31

45

G

44

35

32

34

e

33

M

36

37

L

30

33

J

b

32

34

43

58

42

41

35

36

31

H

47

48

40

46

F

B

A

51

A

52

14

53

47

55

41

58

GEAR PLAY

13

38

57

a

LVR EJECT R

39

4

60

10

8

N

d

c

GEAR

11

PLAY

16

12

17

c

d

9

4

13

49

E

18

54

3

2

4

15

7

6

11

54

a

b

27

9

10

12

21

K

7

4

1

2

6

3

5

I

19

MOTOR

20

PWB

8

50

I

– 40 –

Page 41

TAPE MECHANISM PARTS LIST 1 / 1 <U>

REF. NO. DESCRIPTIONPART NO. KANRI

1 82-ZM1-234-310 FLY-WHL,L ASSY

2 82-ZM3-305-310 GEAR,CAM M2(*)

3 82-ZM1-226-010 GEAR,REW

4 82-ZM1-216-510 GEAR,REEL

5 09-001-420-010 FLY-WHL,R ASSY

6 82-ZM1-225-210 GEAR,FR

7 82-ZM3-306-110 LVR,FR M2

8 82-ZM3-333-310 SLIP DISK ASSY 2

9 82-ZM1-322-010 SPR-T,FR 60

10 82-ZM1-220-210 GEAR,IDLER

11 82-ZM3-616-010 RING MAGNET 4

12 82-ZM1-227-310 LVR,TRIG

13 82-ZM1-265-310 SPR-E,TRIG

14 86-ZM3-219-010 PLATE,SPACER 0.1

15 82-ZM1-237-610 FLY-WHL ASSY,RW

16 86-ZM3-210-010 BELT,PS

17 82-ZM3-221-210 PULLEY,MOT 2M 3

18 86-ZM3-203-010 HLDR,MOT S

19 86-ZM1-206-010 BELT,MAIN L

20 82-ZM3-628-010 SOL ASSY,23 SO

21 82-ZM3-335-310 PULLEY,COUPLER M3

22 86-ZM3-215-110 CHAS ASSY,RS

23 82-ZM1-258-210 SPR-T,PINCH L

24 82-ZM1-341-210 LVR ASSY,PINCH L2

25 82-ZM1-266-310 LVR,DIR

26 82-ZM1-214-010 SPR-T,DIR

27 82-ZM1-333-210 PLATE,LINK2

28 82-ZM3-339-110 SHAFT,COUPLER N3

29 82-ZM1-255-310 SPR-E,LVR DIR

30 82-ZM1-285-410 SPR-C,BT L

31 82-ZM1-222-310 LVR,PLAY

32 82-ZM1-217-410 REEL TABLE

33 82-ZM1-244-510 SPR-C,BT

34 82-ZM1-257-010 SPR-T,CAS

35 82-ZM1-242-010 LVR,CAS

36 82-ZM1-243-010 LVR,STOP

37 82-ZM1-240-110 LVR,REC(*)

38 82-ZM1-344-110 LVR ASSY,PINCH R2

39 86-ZM3-204-010 SPR-T,PINCH S

40 82-ZM1-208-310 HLDR,HEAD

KANRI

NO.

REF. NO. DESCRIPTIONPART NO.

NO.

41 82-ZM1-219-110 SPR-T,LINK

42 82-ZM1-210-110 GEAR,H T

43 82-ZM3-353-010 SPR-T,HEAD

44 82-ZM1-207-910 GUIDE,TAPE

45 82-ZM1-314-110 PLATE,HEAD

46 87-A92-196-010 HEAD,PH HADKH2604A FPC

47 82-ZM1-218-010 SPR-E,HB

48 82-ZM1-206-910 CHAS,HEAD

49 86-ZM3-214-110 BELT,SBU RR

50 82-ZM1-338-110 BELT,FR 4

51 87-A92-195-010 HEAD,RPH HASVH5507A

52 86-ZM3-205-110 SPR-C,RPH S

53 86-ZM3-202-210 BASE,HEAD S

54 82-ZM1-245-210 HLDR,IC

55 86-ZM3-605-110 CONN ASSY,8P -RPB

56 82-ZM1-259-210 SPR-T,PINCH R

57 86-ZM3-201-010 CHAS,HEAD S

58 82-ZM1-269-210 SPR-T,BRG

A 86-ZM3-207-010 S-SCREW,RPH

B 86-ZM3-209-010 S-SCREW,AZIMUTH S

C 86-ZM3-218-110 S-SCREW,EH 2

D 86-ZM3-208-110 S-SCREW,EH

E 87-251-071-410 U+2.6-4

F 80-ZM6-207-010 V+1.6-7

G 86-ZM4-206-010 S-SCREW,AZIMUTH L

H 85-ZM3-202-010 S-SCREW,TG

I 82-ZM3-334-010 PW 2.16-6-0.4

J 80-ZM6-243-010 SH 1.75-3.6-0.5 SLT

K 87-B10-043-010 W-P,0.99-4-0.25 SLT

L 86-ZM3-213-010 S-SCREW,HLDR MOT S

M 87-761-073-410 VFT2+2.6-8 W/O SLOT

N 82-ZM3-222-010 S-SCREW,SHILD PLATE

– 41 –

Page 42

TAPE MECHANISM EXPLODED VIEW 1 / 1 <LH>

50

A

48

51

49

47

44

B

C

46

52

53

a

54

A

9

B

47

48

49

50

29

31

60

35

38

29

58

a

37

32

29

30

39

51

43

40

43

37

39

35

36

7

27

38

32

31

58

b

PWB

8

1

2

3

PLATE

SHLD,M3

4

5

6

60

29

30

E

44

C

45

46

52

53

b

54

55

40

25

12

13

14

11

15

16

33

10

56

59

33

25

18

D

20

17

19

24

11

GEAR

PLAY

21

57

23

PWB

7

8

28

19

42

26

13

15

14

16

17

18

20

4

GEAR

PLAY

PLATE

SHLD,M3

D

5

6

21

19

28

23

41

24

42

22

PWB

55

34

– 42 –

Page 43

TAPE MECHANISM PARTS LIST 1 / 1 <LH>

REF. NO. DESCRIPTIONPART NO. KANRI

1 82-ZM3-335-310 PULLEY,COUPLER M3

2 87-B10-043-010 W-P,0.99-4-0.25 SLT

3 86-ZM1-206-010 BELT,MAIN L

4 82-ZM1-322-010 SPR-T,FR 60

5 82-ZM1-220-210 GEAR,IDLER

6 82-ZM3-616-010 RING MAGNET 4

7 82-ZM1-341-210 LVR ASSY,PINCH L2

8 82-ZM1-258-210 SPR-T,PINCH L

9 87-A90-821-110 HEAD,RPH HADKH56 FPC

10 82-ZM3-342-010 BELT,SBU MOT 3

11 82-ZM1-338-110 BELT,FR 4

12 09-001-420-010 FLY-WHL,R ASSY

13 82-ZM3-333-310 SLIP DISK ASSY 2

14 82-ZM3-334-010 PW 2.16-6-0.4

15 82-ZM3-306-110 LVR,FR M2

16 82-ZM1-225-210 GEAR,FR

17 82-ZM3-305-310 GEAR,CAM M2(*)

18 82-ZM1-226-010 GEAR,REW

19 82-ZM1-216-510 GEAR,REEL

20 82-ZM1-227-310 LVR,TRIG

21 82-ZM1-265-310 SPR-E,TRIG

22 82-ZM3-351-010 HLDR,IC 2

23 82-ZM1-344-210 LVR ASSY,PINCH R2

24 82-ZM1-259-210 SPR-T,PINCH R

25 82-ZM1-234-310 FLY-WHL,L ASSY

26 82-ZM1-237-610 FLY-WHL,R ASSY

27 82-ZM3-339-110 SHAFT,COUPLER N3

28 82-ZM1-255-310 SPR-E,LVR DIR

29 82-ZM1-217-410 REEL TABLE

30 82-ZM1-285-410 SPR-C,BT L

31 82-ZM1-333-210 PLATE,LINK2

32 82-ZM1-222-310 LVR,PLAY(*)

33 82-ZM3-307-010 CUSH-G,DIA3.7-8-3.2

34 87-045-347-010 MOT,SHU2L 70

35 82-ZM1-257-010 SPR-T,CAS

KANRI

NO.

REF. NO. DESCRIPTIONPART NO.

NO.

36 82-ZM3-340-010 SH,BELT D2

37 82-ZM1-242-010 LVR,CAS

38 82-ZM1-244-510 SPR-C,BT

39 82-ZM1-243-010 LVR,STOP

40 82-ZM1-240-110 LVR,REC(*)

41 82-ZM1-264-010 LVR,EJECT R

42 82-ZM3-627-010 SOL ASSY 27 SO

43 82-ZM1-241-310 LVR,MC

44 82-ZM1-208-310 HLDR,HEAD

45 87-A90-820-110 HEAD,PH HADKH25 FPC

46 82-ZM1-314-110 PLATE,HEAD

47 82-ZM1-207-910 GUIDE,TAPE

48 82-ZM3-353-010 SPR-T,HEAD 2

49 82-ZM1-210-110 GEAR,H T

50 82-ZM1-219-110 SPR-T,LINK

51 82-ZM1-269-210 SPR-T,BRG

52 82-ZM1-218-010 SPR-E,HB

53 82-ZM1-206-910 CHAS,HEAD

54 82-ZM1-266-310 LVR,DIR

55 82-ZM1-214-010 SPR-T,DIR

56 82-ZM3-221-210 PULLEY,MOT 2M

57 82-ZM3-301-610 CHAS ASSY,M2

58 80-ZM6-243-010 SH 1.75-3.6-0.5 SLT

59 82-ZM3-329-410 BELT,SBU R2

60 82-ZM1-288-010 SH,1.63-3.2-0.5 SLT

A 80-ZM6-207-010 V+1.6-7

B 86-ZM4-206-110 S-SCREW,AZIMUTH L

C 85-ZM3-202-010 S-SCREW,TG

D 82-ZM3-222-010 S-SCREW,SHILD PLATE

E 82-ZM3-318-110 S-SCREW W,MOTOR M2

– 43 –

Page 44

GENERAL SPEAKER DISASSEMBLY INSTRUCTIONS (FOR REFERENCE)

Type.1

Insert a flat-bladed screwdriver into the position indicated by the

arrows and remove the panel. Remove the screws of each speaker

unit and then remove the speaker units.

Type.2

Remove the grill frame and four pieces of rubber caps by pulling

out with a flat-bladed screwdriver. Remove the screws from hole

where installed rubber caps. Insert a flat-bladed screwdriver into

the position indicated by the arrows and remove the panel. Remove the screws of each speaker unit and then remove the speaker

units.

Type.4

TOOLS

1 Plastic head hammer

2 (() flat head screwdriver

3 Cut chisel

12 3

How to Remove the PANEL, FR

1. Insert the (() flat head screwdriver tip into the gap

between the PANEL, FR and the PANEL, SPKR. Tap the

head of the (() flat head screwdriver with the plastic

hammer head, and create the clearance as shown in Fig-1.

2. Insert the cut chisel in the clearance, and tap the head of

the cut chisel with plastic hammer as shown in Fig-2, to

remove the PANEL, FR.

Type.3

Insert a flat-bladed screwdriver into the position indicated by the

arrows and remove the panel. Turn the speaker unit to counterclockwise direction while inserting a flat-bladed screwdriver into

one of the hollows around speaker unit, and then remove the speaker

unit. After replacing the speaker unit, install it turning to clockwise

direction until "click" sound comes out.

3. Place the speaker horizontally. Tap head of the cut chisel

with plastic hammer as shown in Fig-3, and remove the

PANEL, FR completely.

Fig-1 Fig-2

How to Attach the PANEL, FR

Attach the PANEL, FR to the PANEL, SPKR. Tap the four

corners of the PANEL, FR with the plastic hammer to fit the

PANEL, FR into the PANEL, SPKR completely.

– 44 –

Fig-3

Page 45

SPEAKER PARTS LIST (SX-NAJ801<YUSC / YUSC9>)

REF. NO. DESCRIPTIONPART NO. KANRI

1 8B-NSH-001-010 PANER,FR

2 8A-NSJ-006-010 BADGE,AIWA S35

3 8B-NSH-007-010 PANEL,DUCT

4 8B-NSH-008-010 PROTECTOR,

5 8B-NSH-602-010 SPKR, W 160 35/4

6 8B-NSK-604-010 SPKR, T 60

KANRI

NO.

REF. NO. DESCRIPTIONPART NO.

NO.

SPEAKER PARTS LIST (SX-WNSZ800<YLSL>)

REF. NO. DESCRIPTIONPART NO.

1 8B-NS7-001-010 PANEL,FR

2 8B-NS7-002-010 PANEL,SP A

3 8B-NS7-003-010 PANEL,SP B

4 8B-NS7-004-010 PANEL,DUCT

5 8B-NS7-005-010 PANEL,BA A

6 8B-NS8-007-010 PROTECTOR,M

7 8B-NS7-602-010 SPKR, W 200R 35/4

8 8B-NS8-604-010 SPKR, M 100W

9 88-NSK-610-010 SPKR, CERAMIC ASSY

10 88-NS5-610-010 CORD,SPKR

11 8B-NS7-016-010 RING,TW

KANRI

NO.

SPEAKER PARTS LIST (SX-S85)

REF. NO. DESCRIPTIONPART NO.

1 8B-NS7-009-010 PANEL,FR

2 8B-NS7-011-010 GRILLE,FRAME ASSY

3 8B-NS7-606-010 SPKR, 80

4 8B-NS7-610-010 CORD,5.0

KANRI

NO.

ACCESSORIES / PACKAGE LIST

REF. NO. DESCRIPTIONPART NO.

1 8B-NF7-902-010 IB,LH(ESP)M<LH>

1 8B-NF7-903-010 IB,U(ESF)M<U>

2 87-A92-150-010 ANT,LOOP AM NO-CONT

3 8B-NF7-701-010 RC UNIT,RC-BAS01

4 87-043-115-010 ANT,FEEDER FM

5 87-A91-017-010 PLUG,CONVERSION JT-0476<LH>

!

KANRI

NO.

– 45 –

Page 46

2–11, IKENOHATA 1–CHOME, TAITO-KU, TOKYO 110, JAPAN TEL:03 (3827) 3111

Printed in Singapore9820572 0251431

Loading...

Loading...