Page 1

NC3600 P4LRH

English

SERVICE MANUAL

VIDEO MECHANISM

S/M Code No. 09-995-333-1N1

DATA

Page 2

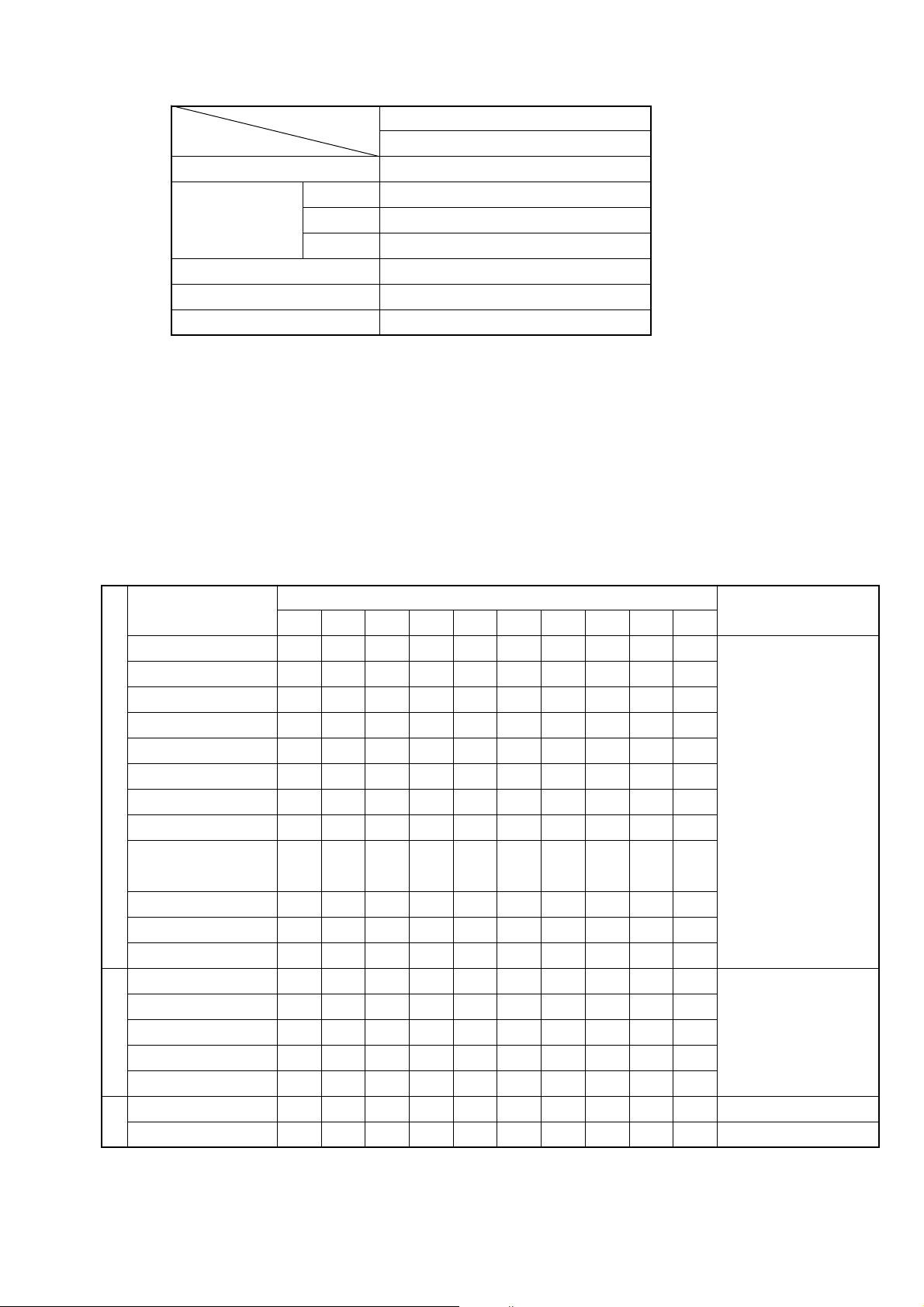

VCR TEST TAPE INTERCHANGEABILITY TABLE

There are two types of the new allgnment tape CH-1B (for NTSC) and CH-2 (for PAL). On each tape four signals (1)-(4)

are recorded for the times and in the order shown below.

(1) : 8min. fi (2) : 2min. fi (3) : 5min. fi (4) : 5min.

The TTV-MP1 (for M-PAL), TTV-MS1 (for MESECAM) and TTV-S1 (for SECAM) allgnment tapes have the same

contents as the previous tapes.

Method

NTSC

Now in use TYPE

Model Contents *1

TTV-N1

TTV-NS1

TTV-N1E

TTV-NS6E

TTV-N2

TTV-N12

(SCV-1998)

TTV-N6

(TTV-N06T)

TTV-N7A

NTSC, Color bar,

1kHz, SP

NTSC, Color bar,

1kHz, SP

NTSC, Color bar,

1kHz, EP

NTSC, Color bar,

No sound, EP

NTSC, Stairsteps,

7kHz, SP

NTSC, Color bar,

1kHz, SP

NTSC, Mono scope,

7kHz, SP

NTSC, Stairsteps,

1kHz, SP, HiFi 400Hz

New TYPE

Model Contents *1

CH-1B(2)

CH-1B(4)

*2

CH-1B(1)

CH-1B(4)

CH-1B(3)

NTSC, Stairsteps,

1kHz, SP

No Changed.

NTSC, Color bar,

1kHz, EP

No Changed.

NTSC, Stairsteps,

7kHz, SP

NTSC, Color bar,

1kHz, EP

No Changed.

NTSC, Color bar,

No sound SP,

HiFi 400Hz

Application

PB-Y Level/General electrical ADJ.

Head ACE Height/Tilt ADJ.

For S-VHS (SQPB) check

Switching position ADJ.

For S-VHS (SQPB) check

Head ACE Azimuth ADJ.

FM Envelope ADJ.

X-V alue ADJ.

For total picture quality check (resolution, etc)

HiFi Audio PB Level ADJ.

Switching position ADJ.

PB-Y Level/General electrical ADJ.

Head ACE Height/Tilt ADJ.

Switching position. (LP Model)

FM Envelope ADJ. (LP Model)

X-Value ADJ. (LP Model)

HEAD ACE Azimuth ADJ.

FM Envelope ADJ. (SP Model)

X-Value ADJ. (SP Model)

For total picture quality check (resolution, etc)

HiFi Audio PB Level ADJ.

FM Filter ADJ.

PAL

TTV-P1

TTV-P1L

TTV-P2

TTV-P6

(TTV-N06T)

TTV-P7

TTV-P16

PAL, Color bar,

1kHz, SP

PAL, Color bar,

1kHz, LP

PAL, Stairsteps,

6kHz, SP

PAL, Monoscope,

6kHz, SP

PAL, Stairsteps,

1kHz, SP,

HiFi 1kHz

PAL, Color bar,

400Hz,

SP, HiFi 1kHz

CH-2(2)

* 3

CH-2(4)

CH-2(1)

CH-2(3)

PAL, Stairsteps,

1kHz, SP

PAL, Color bar,

1kHz, LP

PAL, Stairsteps,

6kHz, SP

No Changed.

PAL, Color bar,

No sound

SP, HiFi400Hz

No Changed.

* 1. Described in the order of color format. video signal. linear audio. tape speed and Hi-Fi audio.

* 2. Use CH-1B (1)-(3) with models used exclusively in the SP mode.

* 3. Use CH-2 (3) and (4) when it is necessary to observe the chroma signal.

2

Page 3

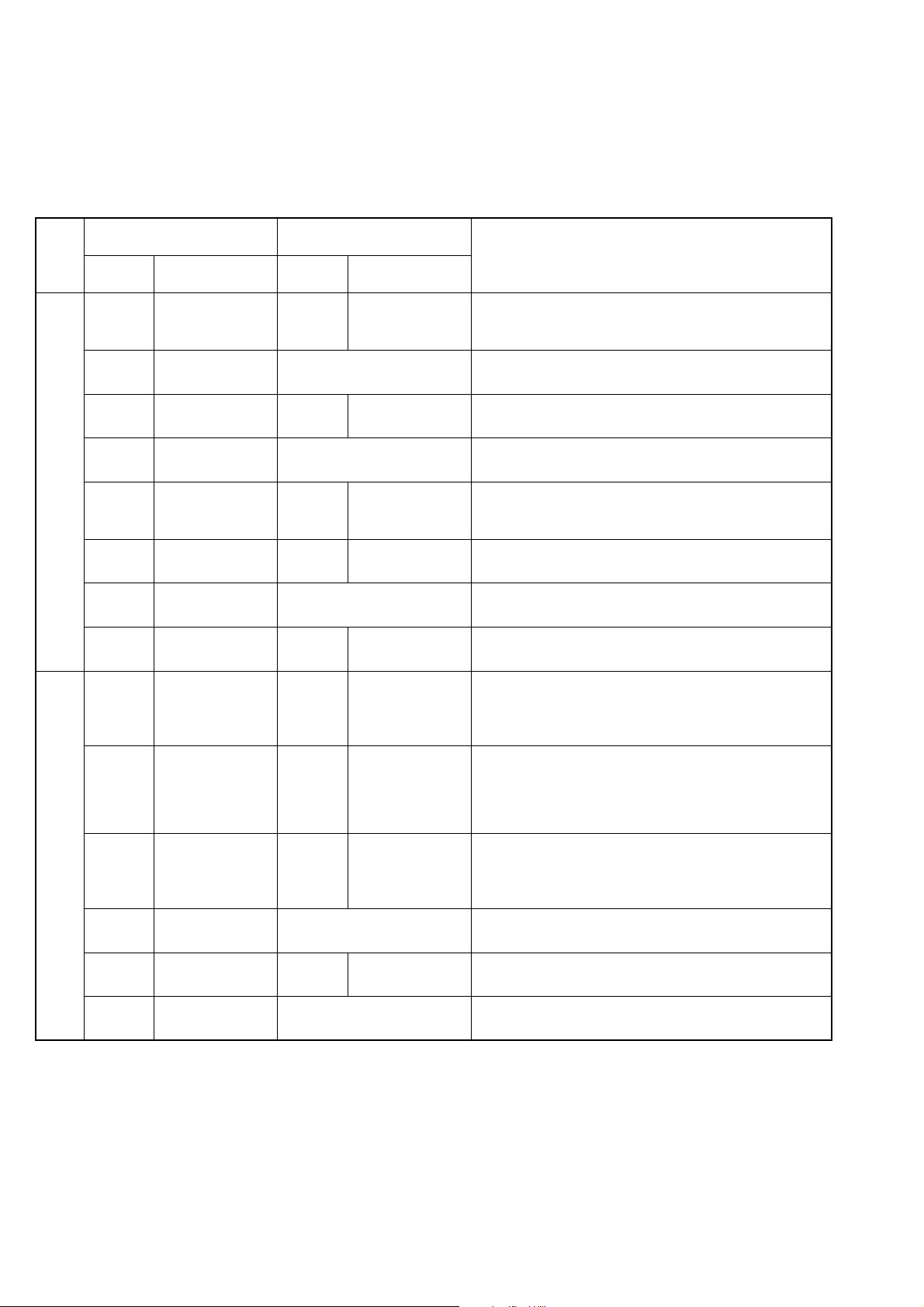

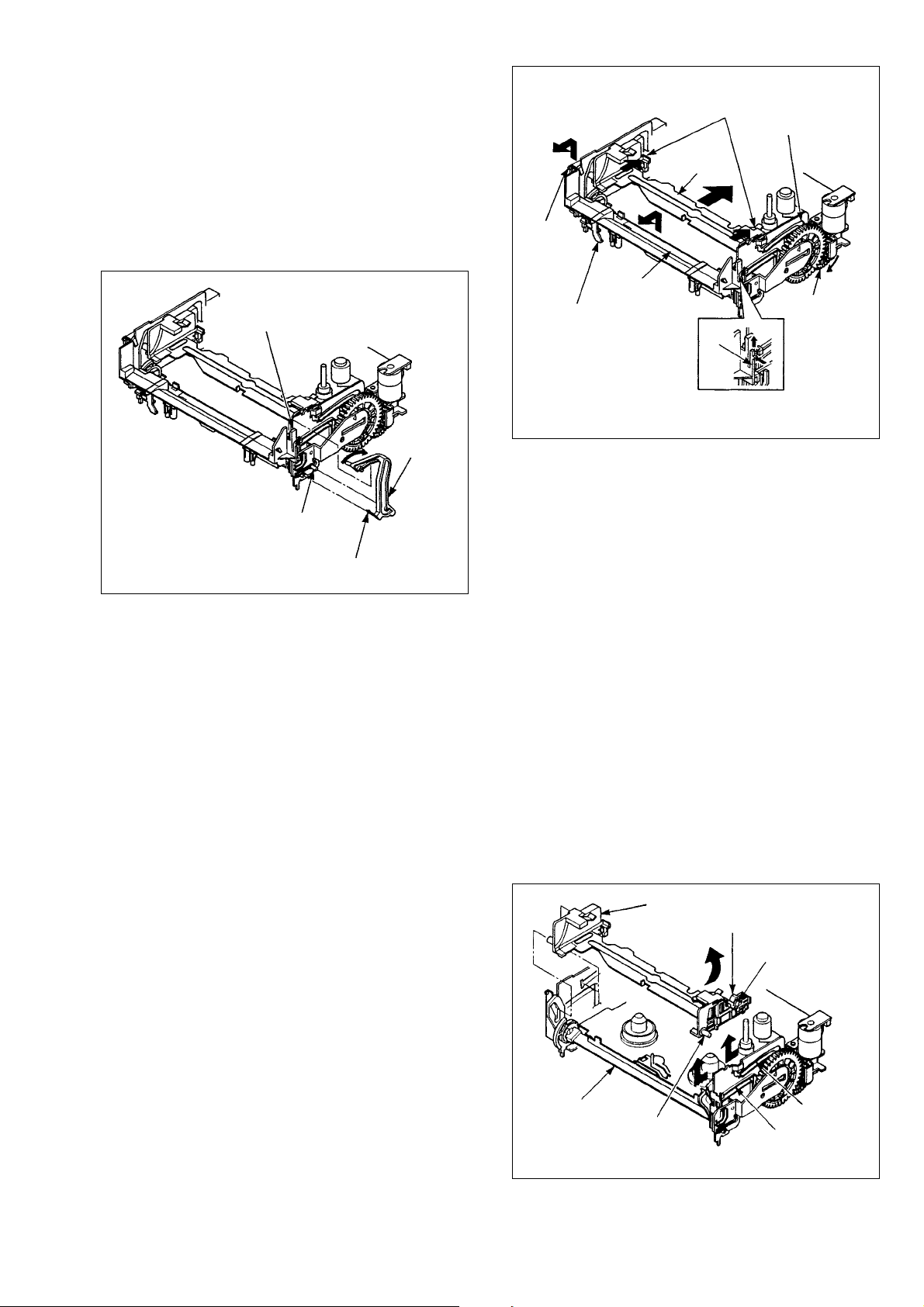

Top bracket

Cassette holder

assembly

Door open lever

FL cassette

guide assembly

2. MECHANICAL ADJUSTMENT

2-1. LOCATION OF MECHANISM PARTS

Head cleaner

Drum brush

Cylinder

assembly

FE head

S slider

Tension lever

S brake

Band brake

ACE head

No. 8 guide cap

Pinch roller

Loading motor

T slider

No. 9 guide lever

FL cam gear

T brake

T real table

S reel table

FL arm lever

Idle lever assembly

FL drive slider

Center gear

assembly

Fig-2-1-1 Upper side

Fig-2-1-2 Upper side

3

Page 4

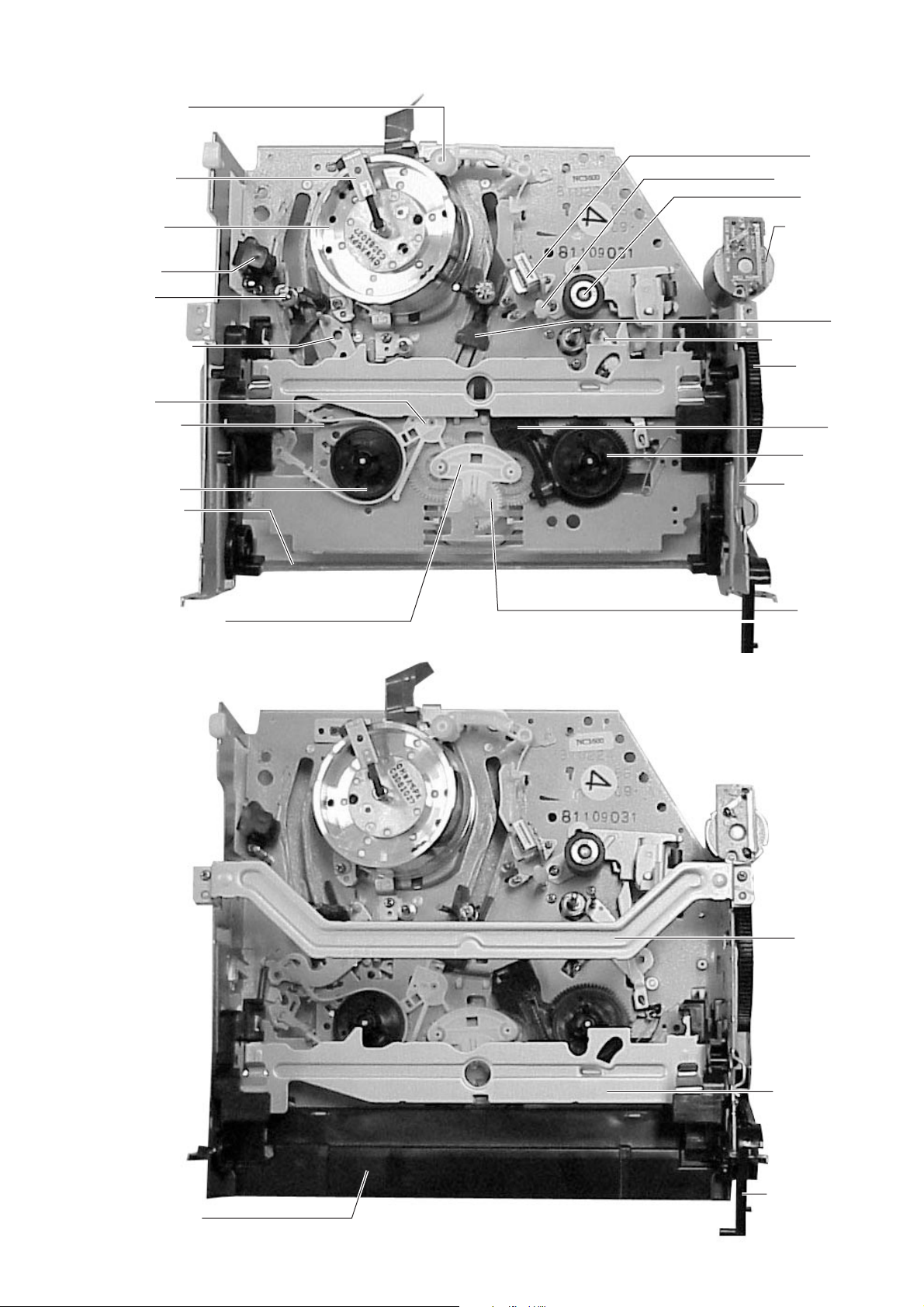

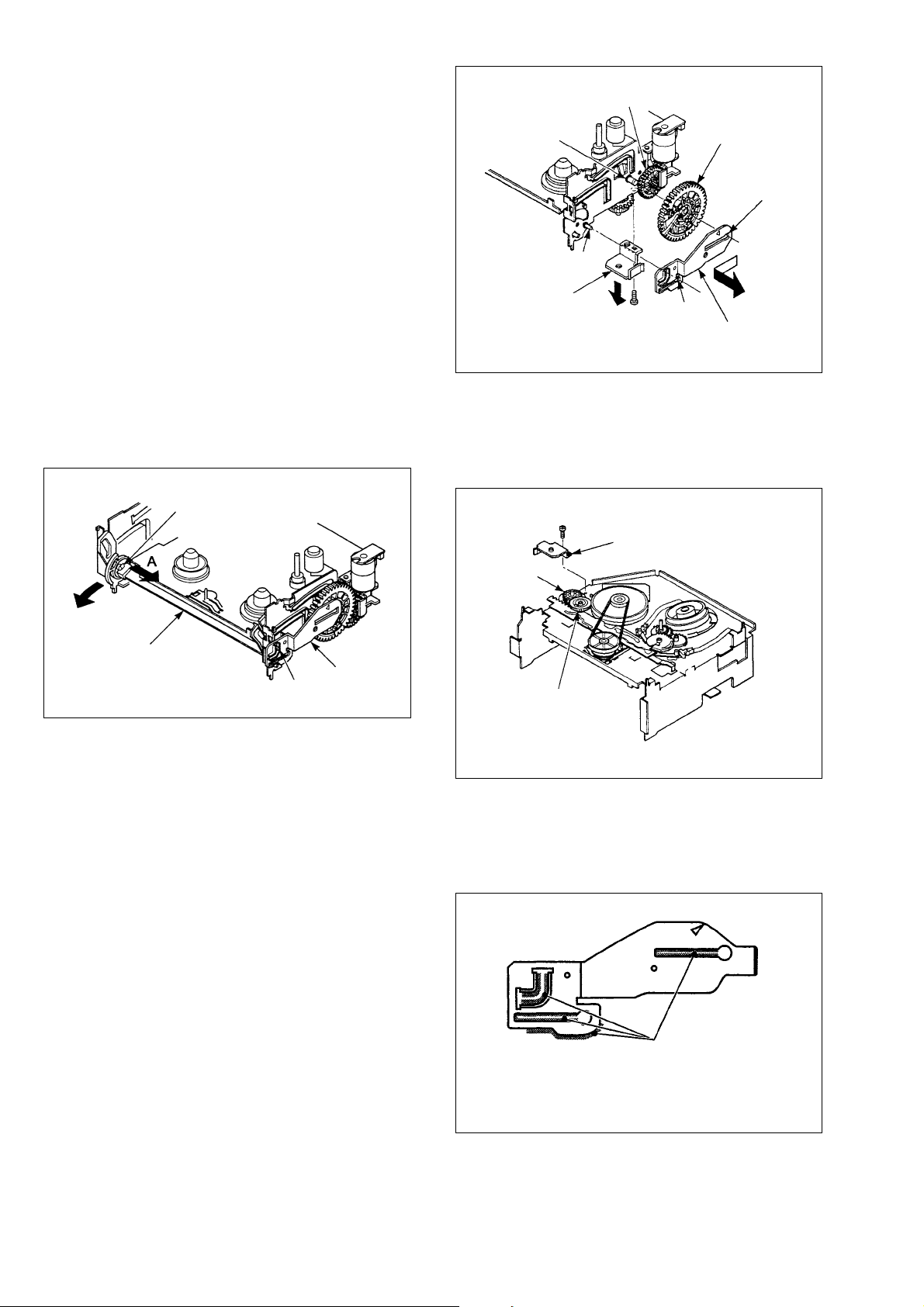

Capstan motor

Worm gear holder

T loading lever

assembly

Worm wheel

Reel belt

Joint gear 1

Joint gear 2

Cam slider

S-VHS switch

Pinch drive lever

2-2. SERVICE TOOL LIST

S loading lever

assembly

Loading drive gear

Tension drive lever

Up/down lever

Holder clutch

assembly

Fig-2-1-3 Rear side

Alignment tape

Torque cassette Post height adjustment screwdriver

(SRK-VHT-103-404) (SV-TG0-030-000)

4

Page 5

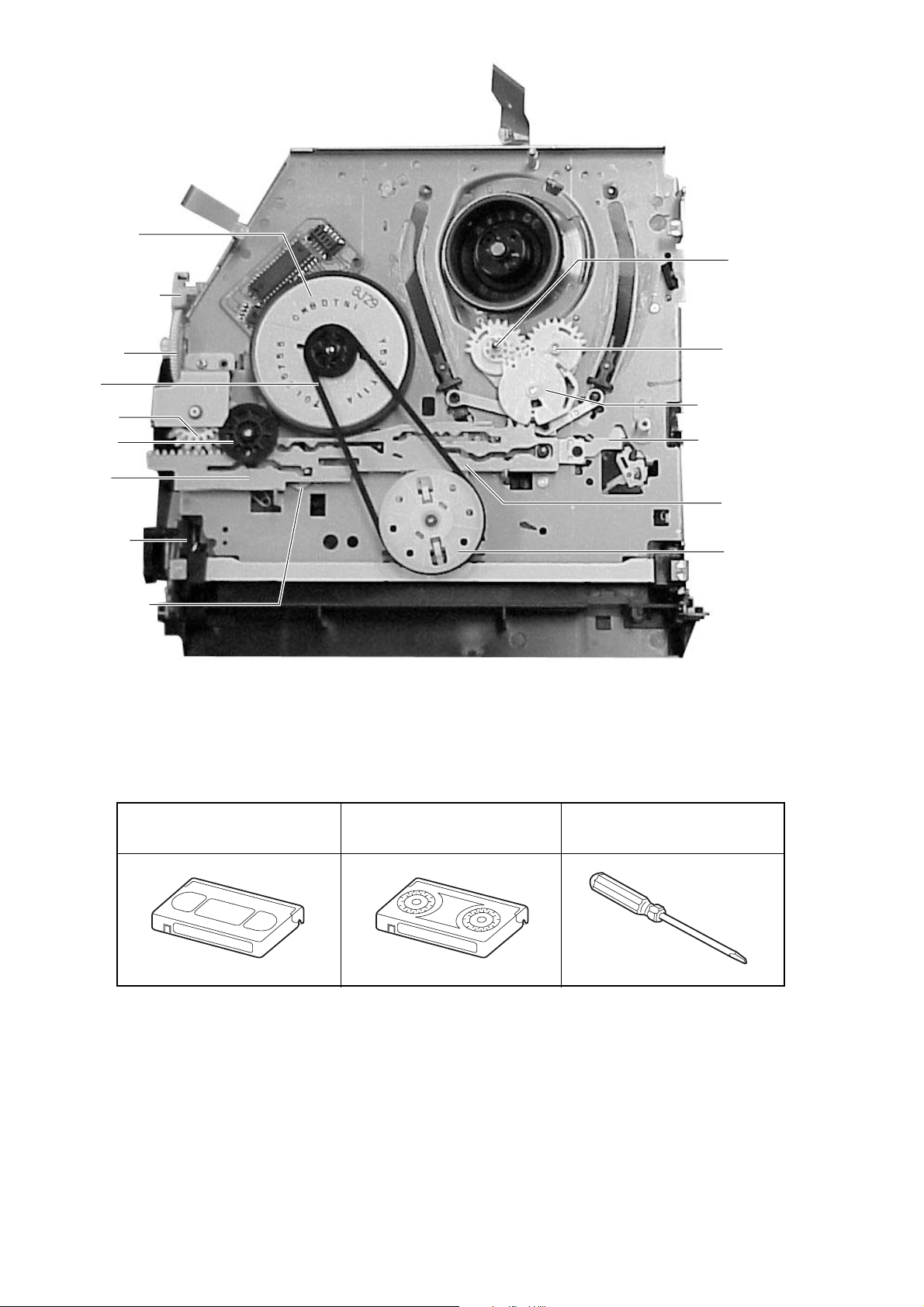

2-3. ALIGNMENT TAPES FOR ADJUSTMENT

Mechanism PAL

Adjustment item SP/LP 2/4 head

FM envelope TTV-P2L

Slant Commercially available tape

A/C head Height TTV-P1 (TTV-P1L)

Azimuth TTV-P2

X value TTV-P2 (TTV-P2L)

RG post slant Commercially available tape

Tape back-tension SRK-VHT-103

2-4. GUIDELINE OF MAJOR PARTS REPLACEMENT

• The replacement periods that are shown below, indicate the guide line only, and are the life of the individual parts.

• The following guideline is compiled on the assumption the mechanism is used under the standard operating conditions

(i.e., normal temperature and normal humidity.) The replacement periods change depending on the operating

environments, method of use and running hours.

• Life of head assembly (cylinder) is especially heavily affected by the operating conditions.

Parts name

Tension post

S/T slant guide post

Impedance roller

Guide post No. 8

Capstan

Guide post No. 9

Guide post No. 3

S/T guide roller

Tape run mechanism

Head assembly

(cylinder)

FE head

ACE head

Pinch roller

Capstan motor

Loading motor

Reel belt

Clutch gear assembly

Drive mechanismOthers

Idle lever assembly

Band brake

Slip ring assembly

500

3

3

3

3

3

3

3

3

1000

3

3

0

3

0

0

3

0

0

0

0

0

1500

3

3

0

3

0

0

3

0

0

0

0

0

Table 2-4-1

Guideline of time

2000

2500

3

3

0

0

0

0

0

0

0

0

0

0

3

3

0

0

0

0

0

0

0

0

0

0

0

0

3000

3

0

0

0

0

0

0

0

0

0

0

0

0

3500

3

0

0

0

0

0

0

0

0

0

0

0

0

4000

3

0

0

0

0

0

0

0

0

0

0

0

0

4500

3

0

0

0

0

0

0

0

0

0

0

0

0

5000

• Cleaning shall be

3

• After cleaning, wait

• Use the specified oil for

0

• When lubricating a part,

0

0

0

0

0

0

0

0

0

0

0

Remarks

performed using a

cotton swab or cotton

cloth moistened with

alcohol.

until the cleaned parts

are dried completely

before using a video

cassette tape.

lubrication.

apply only one or two

drops of oil after

cleaning the part with

alcohol.

3: Cleaning

0: Check the part. Replace when the part needs replacement.

*: Impedance roller is used in some models, but not used in some other models.

5

Page 6

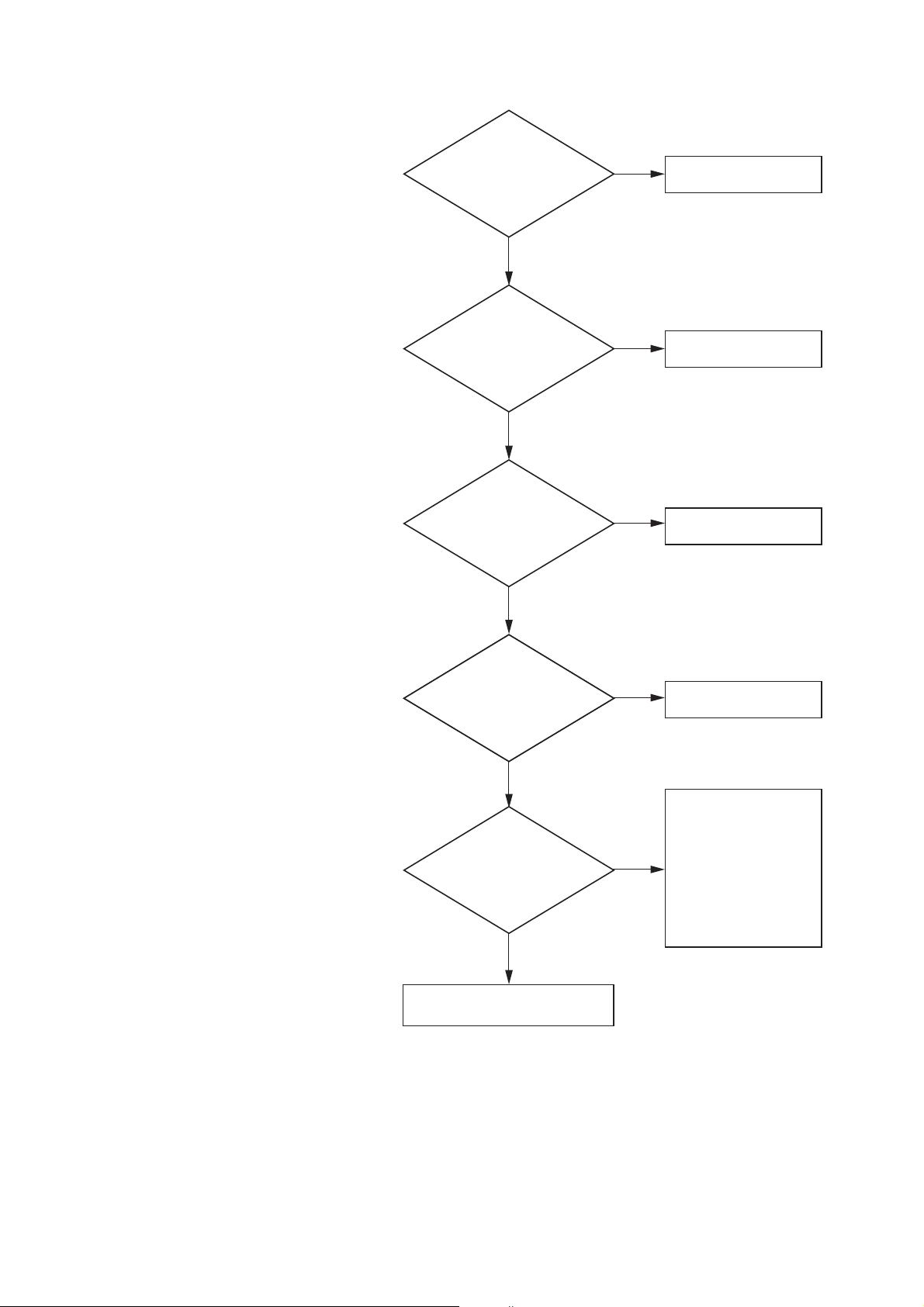

2-5. MECHANISM CHECK PROCEDURE

Do the loading motor rotate

and the worm wheel rotate

when the main power is

turned on without

inserting a cassette?

Does the FL cam gear

rotate clockwise by approx.

15 degrees and return immediately

when the above operation

is performed?

Does the capstan motor

rotate when the cassette holder

is pressed without inserting

a cassette?

Does the T reel table rotate

when the above operation

is performed?

When a cassette whose record

safety tab is not broken, is inserted,

is the tape remaining amount

displayed and is the tape

stopped at the playback

position?

Motor and sensor systems are OK.

Loading motor has

abnormality.

Tape start sensor has

abnormality.

Capstan motor has

abnormality.

Reel belt and reel system

have abnormality.

When a tape is ejected

even though it is wound up

or when tape is stopped

during unloading, the reel

sensor has abnormality.

When the mechanical

operation is found not

normal, the cam switch

has abnormality.

YES

NO

NO

NO

NO

NO

YES

YES

YES

YES

When a trouble is suspected to be caused by mechanism

from the contents of the defect symptoms, follow the

troubleshooting flow chart as shown, and locate the cause

of trouble by the procedure as shown.

2-5-1. Outside Appearance Check

1) Check if there exists any foreign materials or

not inside the VTR.

2) Check if the cylinder and the guides of the

tape run mechanism are stained or not.

2-5-2. Checking Motor and Sensors

Check if motors and sensors (including the control

circuit) have any abnormalities or not, by

following the flow chart.

2-5-3. Trouble Analysis Using the Service Mode

This model has the service mode. The service

mode provides the function to display the status

when trouble occurs. Use the service mode to

analyze cause of trouble.

Refer to the SERVICE MODE section of the

manual for the procedure to display the data and

for the contents of the service mode.

Fig-2-5-1

6

Page 7

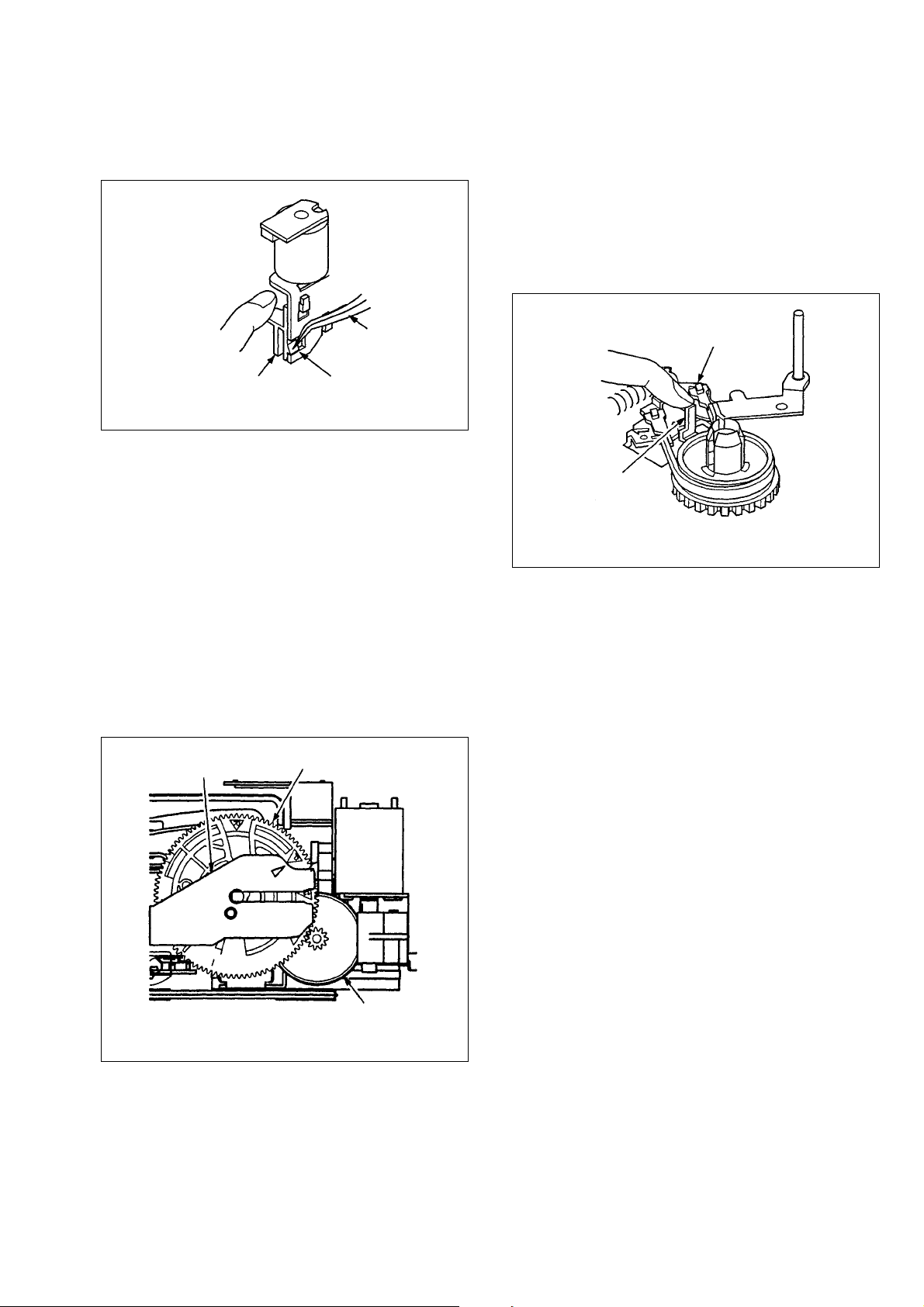

2-5-4. HOW TO OPERATE THE MECHANISM

(MODE TRANSITION) BY MANUAL

OPERATION

1) Remove the worm gear holder using tweezers

and remove the worm gear.

Note: To check the Review, Stop 2, Fast forward/Rewind

modes, rotate the mechanism I the unloading direction

and stop the mechanism where the above described marks

are aligned, and then check the mechanism.

There can be a case that the stop position of a mechanism

by the cam switch and the position where marks are

aligned, can be different due to play and variation of gear.

When you want to operate a mechanism after cassette

holder is removed, be sure to press down the tension drive

lever as shown in Fig-2-5-4 after the S and T sliders start

moving and until the T slider comes to the AC head

position.

Press it down

Worm gear holder

While pressing down the lock levers R and L of the

cassette holder by hand, rotate the worm wheel in the

clockwise direction. Then the mechanism can enter the

loading modes by manual operation.

When the triangle (3) mark of the FL drive slider and the

triangle (3) mark of the FL cam gear are aligned as

shown in Fig-2-5-3, the mechanism can enter the

following mechanism positions.

I

Power OFF

2

R

Review

2

P

Play

2

S1

Stop 1

2

FL drive slider

Press the craw down

Fig-2-5-2

S2

Stop 2

2

FR1

Fast forward/Rewind 1

2

FR2

Fast forward /Rewind 2

2

FL cam gear

Tweezers

Tension lever

Tension drive lever

Fig-2-5-4

2) On replacement of the defective parts

When a specific part is found defective and needs to

be replaced, note the following points.

• Pay special attention when replacing the mechanical

parts that need phase adjustment.

Pay special attention for the parts installation mode

and phase-alignment marks, and others.

• For the parts that need greasing and lubrication, coat

the parts with proper amount of grease or oil as

specified to the specific point. Be careful so that

grease or oil must not splashed to any other parts.

After greasing or lubrication, install the mechanism

into the product, turn on the main power and confirm

proper operation of the mechanism.

Worm wheel

Fig-2-5-3 Position mark (Play position)

Move the mechanism to the status in which the trouble

has occurred, by manual operation as shown above.

Check status of the mechanism in the status in which the

trouble has occurred.

3) Confirmation after repair work is completed.

When the repair work is completed (especially when

replacement and/or adjustment of mechanical parts

are performed), be sure to confirm operation and

movement of mechanical parts and mechanism

before installing the mechanism back into the

machine. Then turn on the main power and operate

the machine to confirm the correct operation of the

machine.

Note: When any repair work is performed and

mechanical parts are replaced in order to

solve the trouble of “Mechanical parts are

broken or phase-adjustment”, and when the

same (or similar) trouble occurs during the

operation check after the main power is

turned on, the main cause (mechanical or

electrical circuit) of the trouble may exist

in other locations. Please check the other

assemblies and blocks too.

7

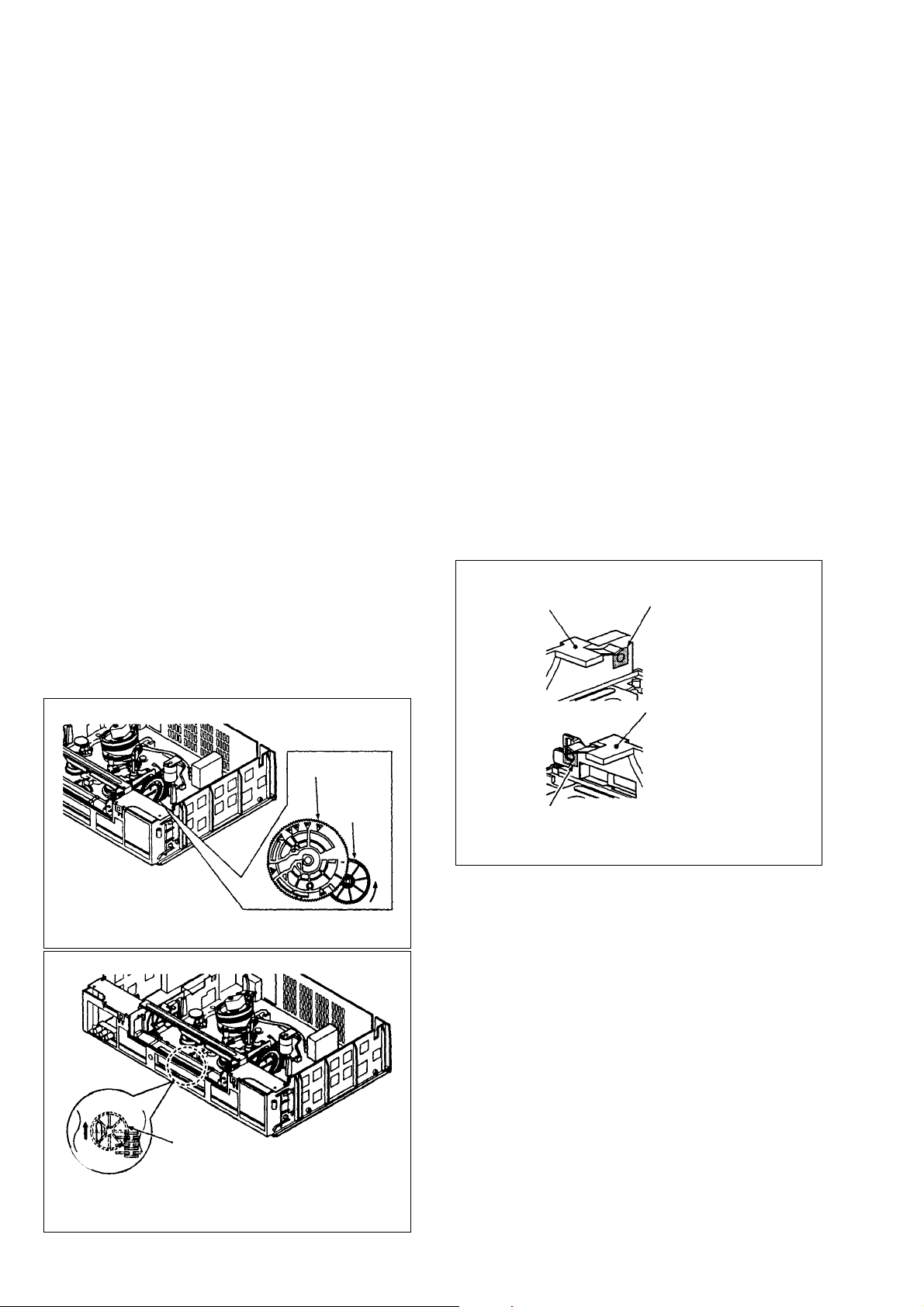

Page 8

2-5-5. How To Eject A Videocassette Manually

Attach an adhesive tape

Attach an adhesive tape

Cassette retainer

block

Cassette retainer

block

Because one of the screws that fix the mechanism

deck to the chassis, is located beneath the cassette,

the mechanism deck cannot be removed while a

videocassette exists inside the mechanism deck.

If a videocassette cannot be ejected even though

the EJECT button is pressed, remove the

videocassette by the following procedure.

1) Remove the work gear holder and the worm

gear by referring to section 2-6-6. Rotate the

worm wheel in the direction of the arrow

(unloading direction, Fig-2-5-5) with a

screwdriver.

2) When the S and T sliders start unloading,

insert a precision (watch) screwdriver into the

long slot on the bottom panel as shown in Fig2-5-6 so that the loosened tape must not get

oily or must not get greasy. Using the

precision (watch) screwdriver, rotate the

pulley of the clutch gear assembly in the

direction of the arrow when viewed from the

bottom. Rotate the worm wheel to take up the

tape onto a reel table.

Note: • Stand the machine in the upright

position when removing a videocassette

manually as shown in Fig-2-5-6 and as

described in this section in order to

protect a tape.

• If a mechanism is locked and if a

videocassette cannot be ejected when

through the worm wheel is rotated,

remove by breaking the cassette

retainer block as shown in Fig-2-5-7.

2-5-6. How To Check Various Mechanism

Modes without Inserting A Videocassette

1) Attach a blind tapes on the right and left of the

cassette holder so that the sensor light should

not reach the start sensor and to the end

sensor. (Fig-2-5-7.)

2) Release both of the right and left lock levers

of the cassette holder so that the cassette

holder can be moved down and slotted in.

3) When cassette down is performed, rotating

speed of the S reel table increases. If rotation

of the S reel table is stopped, the mechanism

starts loading. (If rotation of the S reel table is

not stopped, eject will be activated.)

4) When loading is completed, rotate with hand

the reel table that is opposite side of the

presently rotating reel table.

5) In this state of mechanism, various modes can

be checked now.

Note: When the reel table that is opposite side of

the rotating reel table is turned by hand

during playback, fast forward/rewind

modes so that the reel pulse should not be

sent, the auto eject is activated or the main

power is turned off.

Front side

Rear side

When viewed form the rear side

FL cam gear

Worm

wheel

Fig-2-5-7

Fig-2-5-5

Pulley

Fig-2-5-6

8

Page 9

2-6. REPLACING THE MAIN PARTS

Cassette holder assembly

Lock lever

Boss A

Groove C

Groove D

Boss B

FL arm lever

2-6-1. Door Open Lever

1) Rotate the door open lever in the direction of

the arrow, and remove the claw of the door

open lever that has been inserted in the hole

on the left bottom of the right side of the

mechanism deck.

Then remove the door open lever from the

door open lever shaft and for the door open

lever guide by raising the door open lever.

Door open lever guide

Door open lever shaft

Door open

lever

Claw

FL cassette

guide assembly

Write-protection lever

(Playback only machines

do not have the writeprotection lever)

4) Replace the FL cassette guide assembly with

the new FL cassette guide assembly.

5) After the FL cassette guide assembly is

replaced, assemble the mechanism by

reversing the disassembling procedure.

Lock lever

Guide groove

Worm wheel

Claw

Fig-2-6-2

Claw

Fig-2-6-1

2) Replace the door open lever with a new door

open lever.

3) After the door open lever is replaced,

assemble the mechanism by reversing the

disassembling procedure.

Note: Attach the door open lever in a manner so

that it is located inside the guide.

2-6-2. FL Cassette Guide Assembly

1) Remove the door open lever. (Refer to 2-6-1.)

2) Press the lock levers that are located on both

sides of the cassette holder assembly and

release the lock. Move the cassette holder

assembly until it reaches the vertical shift

position of the guide groove. Remove the

lamp board in the case that your machine has a

lamp board.

Note: When the cassette holder assembly is

cannot be moved smoothly, rotate the

worm wheel clockwise.

2-6-3. Cassette Holder Assembly

1) Remove the door open lever. (Refer to 2-6-1.)

2) Remove the FL cassette guide assembly.

(Refer to Section 2-6-2.)

3) Move the cassette holder assembly to the

front.

4) Remove the cassette holder assembly from the

right side of the mechanism deck as follows:

Pull the right side of the cassette holder

assembly to the front so that the two bosses A

and B on the right side of the cassette holder

assembly, can be removed from the grooves C

and D of the mechanism deck. Then, while

releasing the lock lever in the right, raise the

cassette holder assembly obliquely and

remove the cassette holder assembly from the

right side of the mechanism deck.

3) While pressing in the craws on the both sides

of the FL cassette guide assembly inside,

remove the FL cassette assembly by raising it

up.

Fig-2-6-3

9

Page 10

5) Replace the cassette holder assembly with the

new cassette holder assembly.

6) After the cassette holder assembly is replaced,

assemble the mechanism by reversing the

disassembling procedure.

Boss of mechanism

deck

Worm wheel

FL cam gear

Note: Attach the cassette holder assembly while

releasing the lock lever.

2-6-4. FL Arm Lever

1) Remove the door open lever. (Refer to section

2-6-1.)

2) Remove the FL cassette guide assembly.

(Refer to section 2-6-2.)

3) Remove the cassette holder assembly.

(Refer to section 2-6-3.)

4) Remove the FL arm lever as follows: Pull the

left claw of the FL arm lever in the direction

of the arrow A, and remove the FL arm lever

from the boss of the mechanism deck. Pull

the FL arm lever from its left side to the front

and remove the FL arm lever.

Claw

Boss of mechanism

deck

Joint gear metal bracket

6) Turn the mechanism deck upside down.

7) Remove one screw from the joint gear metal

bracket, and remove the joint gear metal

bracket.

8) Remove the joint gear 2.

Screw

Joint gear 1

Boss hole

Screw

FL drive slider

Fig-2-6-5

Joint gear metal bracket

Boss hole

FL arm lever

FL drive slider

Boss

Fig-2-6-4

5) Replace the FL arm lever with a new FL arm

lever.

6) After the FL arm lever is replaced, assemble

the mechanism by reversing the disassembling

procedure.

Note: Attach the FL arm lever so that boss of the

FL arm lever enters into the groove of the

FL driver slider.

2-6-5. FL Drive Slider, Joint Gear 2, FL Cam

Gear and Joint Gear 1

1) Remove the door open lever. (Refer to section

2-6-1.)

2) Remove the FL cassette assembly. (Refer to

section 2-6-2.)

3) Remove the cassette holder assembly. (Refer

to section 2-6-3.)

4) Remove the FL arm lever. (Refer to section 26-4.)

5) Remove the FL drive slider.

Remove the FL drive slider as follows: Slide

the FL drive slider slightly to the front in order

so that the boss of the mechanism deck is

aligned to the portion where the slider groove

becomes wider (boss hole). Pull the FL drive

slider from the boss and remove the FL slider.

Joint gear 2

Fig-2-6-6

9) Remove the FL cam gear.

10) Remove the joint gear 1.

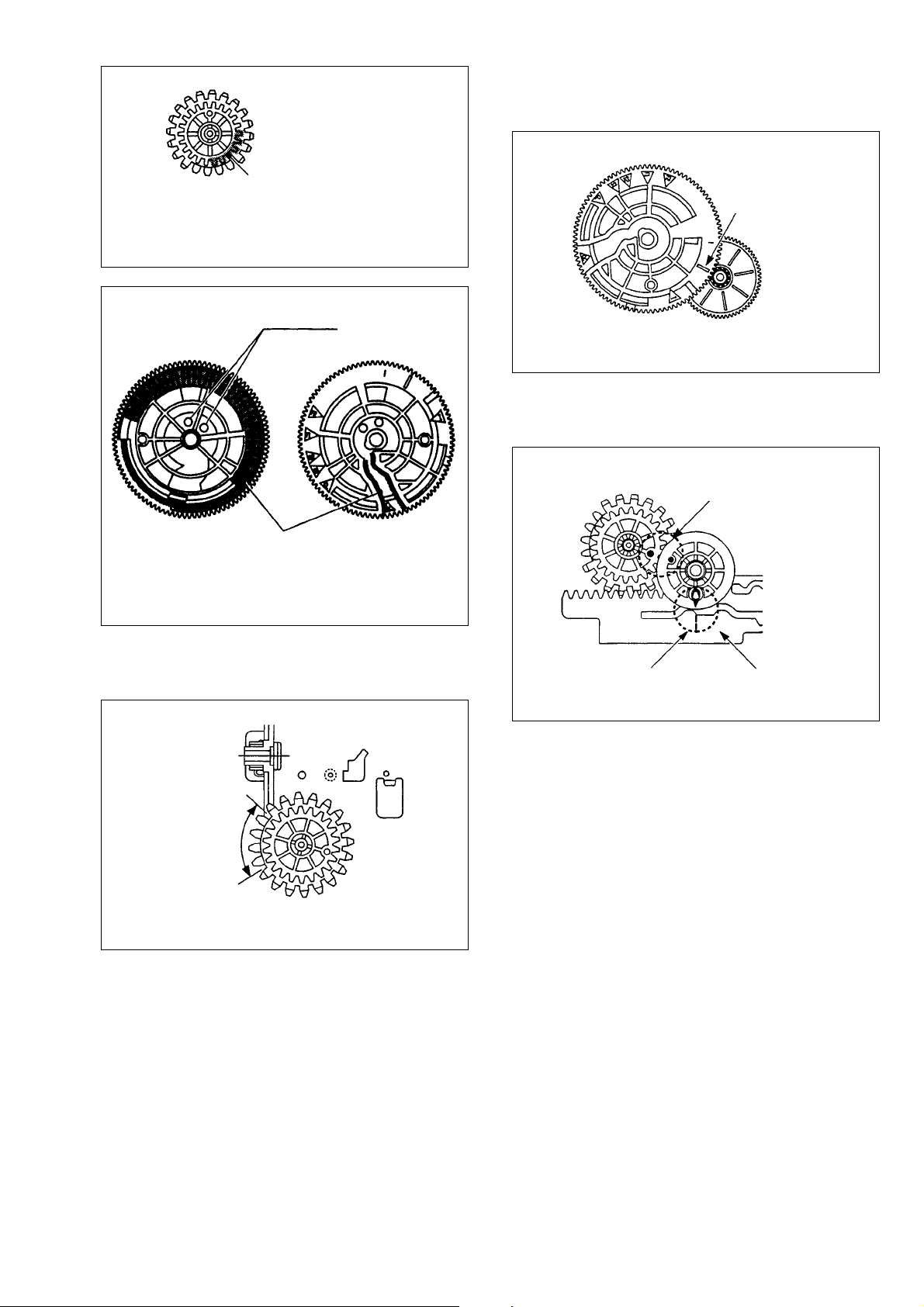

11) Replace the parts with the new parts.

Coat the following area of the new parts with

grease. (Refer to Fig-2-6-7 to Fig-2-6-11.)

The shaded portion should

be coated with grease

Fig-2-6-7 FL drive slider (Super-V dash mechanism)

10

Page 11

The shaded portion should

be coated with grease

13) Attach the FL cam gear so that the marking on

the FL cam gear is aligned to the center of the

worm wheel.

FL cam gear

Marking

Fig-2-6-8 Joint gear 1

Two holes

The shaded portion should

be coated with grease

Fig-2-6-9 FL cam gear (Playback only machines)

12) To attach the joint gear 1, attach it so that cutout of the gear is directed toward the FL cam

gear.

Worm wheel

Fig-2-6-11

14) To attach the joint gear 2, align the marking

on the joint gear 1 with that on the cam slider.

Joint gear 1

Align the markings

Align the markings

Joint gear 2

Cam slider

Fig-2-6-12

Cut-out of the gear

15) After parts are replaced, assemble the

mechanism by reversing the disassembling

procedure.

Joint gear 1

Fig-2-6-10

11

Page 12

2-6-6. Worm Gear, Worm Gear Holder, Loading

Motor and Worm Wheel

1) Remove the claw of the worm gear holder

from the cut-out of the worm wheel in the

direction of the arrow. Remove the worm

gear holder by pulling the worm gear holder

downward.

2) Remove the worm gear.

3) To remove the worm wheel, remove the FL

cam gear first. (Refer to section 2-6-5.)

4) Remove the worm wheel.

5) Remove the screw that fixes the loading

motor, and remove the loading motor.

The shaded portion should be

applied with grease

Fig-2-6-17 Worm wheel

Loading motor

Worm

gear

Screw

Worm wheel

Fig-2-6-13

6) Replace the defective part with the new part.

Apply grease on the following area of the new

parts.

The shaded portion should be applied with grease

Claw

Worm gear

holder

7) After replacement of the part, assemble the

parts by reversing the steps of the removal

procedure.

Note: After attaching the worm gear holder,

check that the claw is caught. (Refer to

Fig-2-6-13.)

2-6-7. Loading Drive Gear, Cam Slider, S/T

Loading Lever Assembly, Pinch Drive

Lever, Tension Drive Lever

1) Put the mechanism deck upside down.

2) Remove the reel belt.

3) Remove the screw that fixes the joint gear

metal bracket, and remove the joint gear metal

bracket. (Refer to section 2-6-5.)

4) Remove the joint gear 2. (Refer to section 2-6-

5.)

5) Remove the claw of the loading drive gear

from the groove of the mechanism deck, and

remove the loading drive gear.

6) Remove the cam slider.

S loading lever

T loading lever assembly

assembly

Fig-2-6-14 Worm gear

The shaded portion should be applied with grease

Fig-2-6-15 Worm gear holder

The shaded portion should be

applied with grease

Fig-2-6-16 Loading motor

Loading drive gear

Joint gear 1

Joint gear 2

Pin of pinch driver lever

Cam slider Pin of tension

drive lever

Claw

Fig-2-6-18

12

Page 13

7) Remove the S/T loading lever assembly.

T loading lever assembly

Align with the

mark

Loading drive gear

Joint gear 1

Joint gear 2

Pin of S brake

assembly

Cam slider

Pin of T brake

assembly

Pin (tension drive lever)

Pin (pinch drive lever)

Align with the

mark

Align with the mark

8) To remove the pinch driver lever, remove the

cassette door guide, pinch assembly, joint

lever, and pinch drive spring first (Refer to

section 2-6-11.). Then, remove the T reel

table. (Refer to section 2-6-9.)

Next, remove the pinch driver lever rotating it

counterclockwise form the rear aide of the

mechanism deck.

Pinch drive lever

The shaded portion should

be applied with grease

Fig-2-6-22 Cam sliding

11) When attaching the S/T loading lever

assembly, align the marks each other.

Fig-2-6-19 (Rear side of the mechanism deck)

9) To remove the tension drive lever, remove the

S reel table first (Refer to section 2-6-9).

Then, rotate the band brake attaching block

counterclockwise, after rotating the tension

driver lever pull it out.

Note: • When the band brake attaching block is

rotated, insert the screwdriver into the

long hole. Be careful not to move the

screwdriver up and down.

• After the parts are attached, check the

tension post and check the adjustment

and back tension. (Refer to section 2-71 and 2-7-2 2).)

Tension drive lever

T loading lever

assembly

12) When attaching the cam slider, loading drive

gear, and joint gear 2, align with the marked

portion.

Align the marks

S loading lever

assembly

Fig-2-6-23

Fig-2-6-20 (Rear side of mechanism deck)

10) Replace to the new part.

Fig-2-6-21 Loading Drive Lever

Long hole

Apply grease on the following area of the new

parts.

Band brake attaching

block

The shaded portion should be

applied with grease

Clearance

Fig-2-6-24

13) Assemble the parts by reversing the steps of

the removal procedure.

13

Page 14

2-6-8. Tension Lever, Band Brake, Tension

Sleeve

1) Remove the S-brake. (Refer to section 2-6-9.)

2) Remove the tension spring.

3) Raise slightly the hole of the tension sleeve to

which the mechanism deck is attached, and

turn it either clockwise or counterclockwise.

Move the tension sleeve until claw of the

tension sleeve agrees with the notch of the

mechanism deck, and remove the tension

sleeve. Remove the tension lever also.

Note: When replacing the tension lever or the

band brake, the tension sleeve does not

need to be removed.

Insert the screwdriver to the rectangular

hole, rotate it clockwise, and remove the

tension lever.

Be careful not to bend the tension lever to

up and down.

4) Rotate the claw of the band brake to right in

order to align the claw with the groove of the

tension lever, and remove the side of the

tension lever of the band brake.

5) Align the claw of the band brake with the

groove of the band brake attaching position of

the mechanism deck side, and remove it.

6) Replace the defective part with the new part.

7) After replacement of the part, attach the part

by reversing the steps of the removal

procedure.

Note: • When replacing the tension lever, apply

oil on the pivot post.

• Be careful not to stain the felt fabric

surface of the band brake, bend, or

damage the band brake.

8) After the parts are attached, check that the

position of the tension post, and adjust the

back tension. (Refer to 2-7-1 and 2-7-2 2).)

9) After replacement of the part, start from the

linearity adjustment of running adjustment

items.

Tension lever

Tension spring

Side of band brake

The shaded portion

should be applied

with oil

Side of band brake

mechanism deck

Tension sleeve

Rear side of mechanism deck

Rectangular

hole

Fig-2-6-25

tension lever

Band brake

Mechanism deck

2-6-9. S Brake Assembly, T Brake Assembly,

Idle Lever Assembly

1) Remove the brake spring between the S brake

assembly and the T brake assembly from the T

side.

2) Remove the claws A and B of the S and T

brake assemblies. When the S and T brake

assemblies cannot be removed smoothly,

release the two claws B of the T brake

assembly.

3) Press the idle lever in the direction of the

cylinder (arrow direction), and remove the idle

lever assembly.

Mechanism deck

Brake spring

Mechanism deck

14

S brake assembly

Band brake

Claw A

Claw B

Compress

spring

T brake assembly

Idle lever assembly

Fig-2-6-26

Page 15

4) Replace the defective part with the new part.

Lumirror

Holder clutch assembly

Spring (Insert it into

the groove A)

Center post

Apply one drop of

oil after cleaning

Groove A

Up/down lever

assembly

Coat the front and rear

sides of the flange with

grease

Claws of up/down lever

assembly

Center gear assembly

Guide

Claw A

Claw C

Claw B

Up/down lever assembly

Flange

Center gear assembly

5) Attach the part by reversing the removing

procedure.

Note: • Check that the pad and the compression

spring of the T brake lever assembly

have not dropped off. Be careful the

pad must not contact with the T reel

table when attaching the T brake.

• Check, before attaching the brake

spring, that the S and T brake

assemblies can rotate smoothly.

• Be careful not to crash the band brake

during replacement of the S brake

assembly.

Idle lever

The hook must be positioned

Center of rotation must be

positioned beneath the base

yet above the flange of the

center post

beneath the base

Fig-2-6-27

2-6-10. Holder Clutch Assembly, Center Gear

Assembly and Up/Down Lever Assembly

1) To remove the center gear assembly and up/

down lever assembly, removal of the S/T

brake assemblies, idle lever assembly (Refer

to section 2-6-9.) and the cam slider. (Refer to

section 2-6-7) is required beforehand.

2) Remove the lumirror that fixes the holder

clutch assembly, and then remove the holder

clutch assembly.

3) Release the two claws of the up/down lever

assembly from the mechanism deck, and

remove the up/down lever assembly together

with the center gear assembly.

Note: • Clean the center post using the cleaning

kit, then apply one drop of oil to the top

of the center post.

(Perform the above describe lubrication

when the center gear assembly, up/

down lever assembly or holder clutch

assembly is replaced.)

• Coat the center gear assembly with

grease. (Perform greasing when the

center gear assembly or the up/down

lever assembly is replaced.)

Fig-2-6-28

4) Replace the defective part with the new part.

5) After replacement of the part, attach the

disassembled parts by reversing the steps of

the removal procedure.

Note: Check the reel torque using the torque

cassette. (Check the reel torque when the

clutch gear assembly or idle lever assembly

is replaced.)

6) Attach the center gear assembly together with

the up/down lever assembly as follows.

Firstly, insert the claw A of the up/down lever

assembly into the base, then insert the center

gear assembly into the center post so that

flange of the center gear assembly is located

beneath the up/down lever assembly guide.

Fig-2-6-29

Finally, push the center gear assembly again

until the claw B of the up/down lever

assembly is locked.

15

Page 16

Note: Check that the spring of the holder clutch

assembly is located at the correct position.

Fig-2-6-30

Note: • Insert the spring of the holder clutch

assembly into any of the six grooves of

the center gear assembly by its own

weight. Confirm that the spring has

entered into any of the six grooves

correctly, then fix the lumirror.

• Do not re-use the lumirror whose slits

have already opened. Be sure to

replace the old lumirror and replace

with the new one.

2-6-11. S and T Reel Tables

1) Remove the S and T brakes. (Refer to section

2-6-9)

2) Remove the band brake. (Refer to section 2-6-

8)

3) Remove the S and T reel tables in the manner

of pulling them out from the reel shafts A and

B.

4) After cleaning the reel shafts A and B using

the cleaning kit, coat the top surface of the

reel shafts A and B, and their bottom surface

with oil.

5) Replace the defective part with the new part.

6) After replacing the new part, attach the

disassembled parts by reversing the steps of

removal procedure.

S reel table

Do not apply

oil to its tip

Reel shaft A

Coat with oil

after cleaning

Spring status in

which the spring

has over-ridden

Spring status when

the spring has

floated

T reel table

Do not apply

oil to its tip

Reel shaft B

Coat with oil

after cleaning

2-6-12. S and T Slider Assemblies

1) Remove the S and T loading lever assemblies.

(Refer to section 2-6-7)

2) Remove the S brake assembly. (Refer to

section 2-6-9.)

3) Remove the tension lever. (Refer to section 26-8.)

4) To replace the T slider assembly, remove the

slider cam first. When it is difficult to remove

the slider cam, remove the holder clutch

assembly and up/down lever. (Refer to section

2-6-10.)

5) Move by sliding, the S and T slider assemblies

to the notches of the S and T loading grooves

of the mechanism deck, and remove the S and

T slider assemblies.

6) Replace the defective part with the new part.

7) After replacement of the part, attach the

disassembled parts by reversing the steps of

removal procedure.

8) After the parts are attached, perform the tape

run system adjustment referring to section 27-3.

S slider assembly

T slider assembly

S loading groove

T loading groove

Fig-2-6-32

2-6-13. Pinch Assembly, Guide Lever No. 9,

Cassette Door Guide

1) Raise the claw of the cassette door guide from

the mechanism deck, rotate the cassette door

guide clockwise, and remove the cassette door

guide.

2) Remove the pinch assembly from the pinch

pivot post in a manner of pulling it up

vertically.

3) Remove the pinch driver lever, the joint lever

that connects the pinch assembly, and remove

the pinch drive spring from the side of the

pinch drive lever.

4) Remove the guide No. 9 spring that is hooked

between the guide No. 9 lever and the

mechanism deck.

5) Remove the guide No. 9 lever.

6) Replace the defective part with the new part.

7) After replacement of the part, attach the

disassembled parts by reversing the steps of

removal procedure.

8) After the parts are attached, perform the tape

run system adjustment referring to 2-7-3.

Fig-2-6-31

16

Page 17

Note: • After the cassette door guide is

Capstan motor shaft

attached, check that the claw is hooked.

• Be careful not to touch the surface of

the pinch roller or grease must not be

attached to surface of the pinch roller.

• Be sure to coat the outer circumference

of the pinch pivot post where it contacts

with the pinch assembly, with grease.

• When replacing the guide No. 9 lever,

be sure to apply oil on the outer

circumference of the pinch pivot and

coat the end surface of the guide post

with grease.

Also, be careful not that grease must

not be attached to the tape running

surface of the guide No. 9 post.

• Check that the guide post end surface

of the guide No. 9 lever touches the top

surface of the mechanism deck.

• Be sure to insert the pinch drive spring

into the small hole of the base.

Guide No. 9

Pinch assembly

Cassette door

guide

Pinch drive spring

Joint lever

Guide No. 9

spring

Small hole

Pinch assembly

The shaded portion

should be coated

with grease

Pinch pivot

post

Guide No. 9 lever

Pinch drive lever

Big hole

Fig-2-6-34

Cassette door

guide

Claw

Guide No. 9 spring

Pinch drive lever

Small hole

Large hole

Fig-2-6-33

Claw

Joint lever

Pinch drive spring

Guide No. 9 lever

Pivot post

The shaded portion

should be lubricated

with oil

2-6-14. FE Head

1) Remove the screw that fixes the FE head and

remove the FE head.

2) Replace the defective part with the new part.

3) After replacement of the part, attach the

disassembled parts by reversing the steps of

removal procedure.

4) After the parts are attached, perform the tape

run system adjustment referring to section 27-3.

Guide post

The shaded portion should

be coated with grease

Fig-2-6-35

17

FE head fixing screw

FE head

Fig-2-6-36

Page 18

2-6-15. ACE Head Assembly

1) Remove FFC from the connector.

2) Remove the ACE head assembly fixing screw

and remove the ACE head assembly.

3) Replace the ACE head with the new ACE

head.

FFC

2-6-16. Head Cleaner Assembly, Head Cleaner

Sleeve

1) Remove the hook of the head cleaner

assembly from the mechanism deck. Remove

the head cleaner assembly by pulling it

upward.

2) To replace the head cleaner sleeve, remove the

head cleaner sleeve by raising the portion A

and by rotating it by 90 degrees.

Roller

ACE head assembly fixing screw

Fig-2-6-37

4) To attach the ACE head assembly to the

mechanism deck, align the boss hole of the

ACE head fixing bracket with the boss of the

mechanism deck. Then align the slit position

of the mechanism deck with the slit position

of the ACE fixing bracket before attaching it.

Slit of ACE head

fixing bracket

ACE head assembly

ACE head assembly

Boss of

mechanism

deck

Head cleaner assembly

Stopper

rib

Hook

Return spring

Stopper

Head cleaner

sleeve

A

Fig-2-6-39

3) Replace the head cleaner assembly with the

new one.

4) Attach the disassembled parts by reversing the

steps of the removal procedure.

Note: • Be careful grease must not be attached

or oil or similar materials to the roller.

• To attach the head cleaner assembly,

attach it to the inside (cylinder side) of

the stopper of the cylinder fixing

bracket.

At the same time, be sure insert the

return spring into the hole of the main

base.

Boss hole

Slit of

mechanism

deck

5) After replacement of the part, attach the

disassembled parts by reversing the steps of

removal procedure.

6) After the parts are attached, perform the tape

run system adjustment referring to 2-7-3.

ACE head assembly

fixing screw

Fig-2-6-38

ACE head

fixing bracket

Head assembly (cylinder)

Head cleaner assembly

FPC

Return spring

Stopper

Stopper rib

Fig-2-6-40

18

Page 19

2-6-17. DRUM AND BRUSH ASSEMBLY

Screw “a”

Cylinder retainer A

Boss of

mechanism

deck

Cylinder retainer C

Screw “c”

Projection

Screw “b”

Cylinder retainer B

Stopper of the post side

Be careful not to contact

Screwdriver

Head assembly

(cylinder)

Screw “c”

Cylinder retainer C

1) Remove the screw fixing the drum brush.

2) Remove the drum brush.

3) Replace with the new drum brush.

Note: Be careful not to apply any force to the

cylinder.

4) After replacing the drum brush, assemble the

mechanism by reversing the removing

procedure.

Drum brush

Coupling

3) Replace the defective part with the new part.

4) After replacement of the part, attach the

disassembled parts by reversing the steps of

the removal procedure.

5) Push the cylinder retainers A and B in the

direction of the arrow until they gently contact

with cylinder, then tighten the screws “a” and

“b”.

Align the boss of the mechanism deck with

the holes of the retainer, then tighten the screw

“c” to fix the cylinder retainer C.

Head assembly (cylinder)

Fig-2-6-41

2-6-18. Cylinder Retainer

1) Remove the head cleaner assembly. (Refer to

section 2-6-16.)

2) Remove the three screws (a, b and c) that fix

the cylinder retainers (A, B and C). Remove

the cylinder retainers by moving them in the

direction of the arrow respectively.

Screw “c”

Cylinder

retainer C

Screw “b”

Cylinder retainer B

Head cleaner

assembly

Cylinder retainer A

Screw “a”

Fig-2-6-43

Note: • The tightening torque for the cylinder

retainer screws a, b and c is 294 to 392

mNm (3 to 4 kg•cm).

• When attaching the cylinder retainer A,

be careful of the position where FPC is

routed through.

(Refer to section 2-6-19.)

• When replacing the cylinder retainer C,

be careful not to damage the cylinder or

the tape guides.

At the same time, be careful so that the

screwdriver must not touch the

cylinder, when loosening or tightening

the screw “c” of the cylinder retainer C.

Stopper of post side

Fig-2-6-42

Fig-2-6-44

19

Page 20

2-6-19. Head Assembly (cylinder)

<Check>

1) Check that the tape running surface of the

head assembly (cylinder) has no scratch.

2) Check that rotation of the head assembly

(cylinder) is normal.

3) Check that the video head is not damaged.

4) Check that the video head is not clogged.

(When clogging cannot be removed by

cleaning.)

5) Check that FPC is not damaged.

It any abnormality is found during the above

steps of 1) to 5), replace the head assembly

(cylinder).

<Replacement>

1) Remove the drum brush. (Refer to section 2-6-

17.)

2) Remove the head cleaner assembly. (Refer to

section 2-6-16.)

3) Remove FPC from the MAIN C.B.

4) Remove the screw that fixes the drum brush,

and remove the drum brush.

5) Remove the cylinder retainer A, cylinder

retainer B, and cylinder retainer C. (Refer to

section 2-6-18.)

6) Remove the head assembly (cylinder).

7) Replace the head assembly with the new head

assembly.

Note: When attaching the new head assembly, be

careful of the direction of the head

assembly.

8) After replacement of the head assembly,

attach the disassembled parts by reversing the

steps of the removal procedure.

When attaching the head assembly (cylinder),

press it in the direction of the arrow “a”, press

the cylinder retainer A in the direction of the

arrow “b”, press the cylinder retainer B in the

direction of “c” gently and fix them with the

respective screws.

(Screw tightening torque: 294 to 392 mNm (3

to 4 kg•cm)

When attaching the drum brush, align the boss

of the mechanism deck with the boss hole of

the metal bracket, and then tighten the screw.

(Screw tightening torque: 294 to 392 mNm (3

to 4 kg•cm)

Head assembly

(cylinder)

Cylinder

retainer C

a

c

Cylinder retainer B

Note: • When attaching the cylinder retainer A,

• Be careful not to touch the video head

Hook it on the groove

(Hook it at the two locations)

Head cleaner assembly

Drum brush

Screw

FPC

Cylinder

retainer A

b

Cylinder pin

Fig-2-6-45

check that FPC is securely hooked on

the groove in the lower side of the head

assembly, and route it under arm.

However, the above described

procedure does not apply to the head

assembly type that does not have the

cylinder window.

directly or not to damage the cylinder.

Head assembly (cylinder)

Cylinder window

Rout it under

the arm

FPC

20

Cylinder retainer A

Fig-2-6-46

10) After the parts are attached, perform the tape

run system adjustment referring to section 27-3.

Page 21

2-6-20. Capstan Motor Assembly, Reel Belt

1) Remove the reel belt.

2) While holding the capstan motor assembly

from the rear of the mechanism deck, remove

the three screws that fix the capstan motor,

from the front of the mechanism deck. Then

remove the capstan motor assembly.

3) Replace to the capstan motor assembly with

the new capstan motor assembly.

4) While being careful not to damage the capstan

motor shaft or the motor itself, insert the

capstan motor assembly from the rear of the

mechanism deck in a way that the positioning

hole of the mechanism deck agrees with the

positioning hole of the capstan motor

assembly.

5) While holding the capstan motor assembly

from the rear of the mechanism deck, attach

the three fixing screws and tighten them with

equal force from the front of the mechanism

deck. When attaching the capstan motor

assembly, the positioning hole of the

mechanism deck must agree with the

positioning hole of the capstan motor

assembly.

Capstan motor shaft

Capstan motor fixing screw

Be sure that the screw does not float

Fig-2-6-48

6) After replacement of the reel belt, attach the

disassembled parts by reversing the steps of

the removal procedure.

Note: Be careful the belt is not twisted or grease

is not attached to the belt.

7) After the parts are attached, perform the tape

run system adjustment referring to section 27-3.

Capstan motor

fixing screw

Poisoning hole

of the capstan motor

assembly

Capstan motor assembly

Reel belt

Fig-2-6-47

Note: • Do not re-use the screw that has been

removed once.

• When attaching the capstan motor

assembly, be careful that it does not

float from the mechanism deck.

2-6-21. Cap of the Guide No. 8

1) Remove the cap from the guide No. 8, and

press-fit the replacement cap to the guide No.

8.

2) Attach the cap to the guide No. 8 with its

inclined surface facing toward the cassette.

Cap of the guide No. 8

Guide No. 8

Fig-2-6-49

21

Page 22

2-7. Check and Adjustment

2-7-1. Checking Position of the Tension Post

1) Remove the cassette holder assembly from the

front loading mechanism, and rotate the worm

wheel clockwise until the cam gear arrives at

the playback mode position. (Refer to Fig-2-52 Cam Position.)

2) Rotate slowly the S reel table clockwise by

two full turns.

3) While rotating the S reel table, insert the flat

head (-) screwdriver tip into the slot of the

adjuster and rotate the screwdriver clockwise

or counter-clockwise until the outer

circumference in the top left of the tension

lever agrees with the inscription mark on the

mechanism deck.

4) Rotate the S reel clockwise again. After

turning the S reel clockwise, check that the

difference between outer circumference in the

top left and the inscription mark is 1 mm or

less.

Note: • The longer inscription mark is located

1.3 mm away from the curved surface

of the mechanism deck. Use the longer

inscription mark as a guide line for

checking step 4).

• When rotating the adjuster, do not

apply force in the vertical (up/down)

direction.

1.3±1mm

Tension lever

Longer inscription

mark

Hole to which the flat head (-)

screwdriver tip shall be inserted

Adjuster

S reel table

2-7-2. Checking Reel Torque

1) Reel torque

1 Reel torque during REV (reverse playback)

..............................supply side

When the reel torque is small, a tape cannot be

wound onto the supply reel table. When the

reel torque is too large, it can damage a tape.

2 Reel torque during REC/PLAY (recording and

playback) .............. take-up side

When the reel torque is small, a tape cannot be

wound onto the take-up reel table. When the

reel torque is too large, an abnormal tension is

applied to a tape that can elongate a tape.

3 Check

Use the torque cassette and check that the

respective torque values are within

specifications.

REV 14.2±3.9 mNm

(145±40g•cm)

REC/PLAY 8.1±2.7 mNm

(82.5±27.5g•cm)

2) Checking the reel torque and the back tension

1 Record the off-the-air TV broadcast signal

over the entire length of a torque cassette in

the SP mode.

2 Insert the torque cassette into the VTR, and

rewind it to the tape end.

3 Enter the REV (reverse playback) mode and

reverse the tape about 15 seconds. Then

check that the winding torque reading which is

shown by the meter on the left side of the

torque cassette, satisfies the winding torque as

described above.

4 Then, rewind the tape to the tape top. Enter

the PLAY mode.

After playing back the tape for about 30

seconds, check that the torque reading shown

by the meter on the right side of the torque

cassette, is in the range of 4.4 to 9.8 mNm (45

to 100g•cm).

At the same time, check that the back tension

reading that is shown by the meter on the left

side of the torque cassette, is in the range of 4

to 7 mNm (41 to 71 g•cm).

5 When the REV mode torque or the PLAY

mode torque is out of the specifications,

replace the clutch gear assembly. (Refer to

section 2-6-10.)

6 When the clutch gear assembly and/or idle

lever assembly is replaced, check the reel

torque.

Fig-2-7-1

22

Page 23

3) Precautions when using the torque cassette

1 Before inserting the torque cassette into a

VTR, remove the tape slack from the torque

cassette. To remove the tape slack, rotate the

reels in a cassette in their tape-winding

directions. (Because the torque cassette does

not have the reel brake, tape slack can easily

occur.)

2 Do not perform FF (fast forward) or REW

(rewind) with the torque cassette.

3 Check the followings when the torque cassette

is inserted into a VTR.

• Tape must not override upon the cap of the

guide No. 8, or tape must not go across the

cap of the guide No. 8.

If the tape is found overridden upon the cap of

the guide No. 8, return the tape gently to the

normal position with utmost care not to

damage the tape.

• Tape must not have any tape slack.

If tape slack is found in the torque cassette,

perform either CUE (fast forward playback) or

REV (reverse playback) and stop the tape.

Check that tape slack has not occurred when

tape is stopped from either CUE (fast forward

playback) or REV (reverse playback).

• After performing the above checks, start any

adjustment and/or check.

4 Precaution when taking out the torque cassette

• Before taking out the torque cassette from a

VTR, be sure enter the STOP mode, wait a

few seconds and then check that there is no

tape slack on the torque cassette tape. Then

press the EJECT button.

5 If the above steps 1) to 4) are not performed,

the torque cassette tape will be damaged and

the correct measurement cannot be performed.

6 When the tape is damaged or become old, the

rotary head of the cylinder can be damaged.

Exchange the tape of a torque cassette with

the new tape by adhering the tape of the

following length.

Use the tape T-120 with length of 10 m.

23

Page 24

2-7-3. Adjustment of tape run system

The tape run system has already been precisely

adjusted before shipment from the factory. Check

and adjustment of the tape run system becomes

necessary only when noise occurs on a monitor

display, or when a tape is damaged by the tape run

system, or a part/component of the tape run system

whose adjustment procedure is shown in the

following paragraph is replaced.

The electric signal output pins that are required for

the tape run system adjustment, are different in the

respective models. Be sure to refer to the test pin

layout diagram that is shown on the Electrical

System Adjustment Procedure of each Service

Manual.

S slant guide T slant guide

S guide roller

FE head

Guide No. 3

Tension lever and

tension post

Review (Review mode

is released by fast

forward/rewind.)

Cylinder

1) Adjustment points

1 Criteria of adjustment

The fundamental concept of the tape run

system adjustment is as follows: The tape run

system adjustment uses the height of the lower

flange of the guide No. 8 as the reference.

Therefore, do not apply any excessive force to

the mechanism deck that can change the

height of the lower flange of the guide No. 8

because this is the reference height of all other

mechanical parts.

T guide roller

ACE head

ACE main base

ACE head, “X” position fixing screw

Pinch roller

Guide No. 9 (It is withdrawn during

review mode.)

Cylinder

S slant guide

Tension post

Guide No. 3

FE head

S guide roller

ACE adjustment screw

Tilt adjustment

Azimuth adjustment

Height adjustment

Capstan

Guide No. 8

ACE head, slit for “X” position adjustment

(Insert the flat screwdriver into the slit for adjustment.)

Fig-2-7-2

T slant guide

ACE head

Capstan

Guide No. 9

Pinch roller

Guide No. 8

T guide roller

The part/component shown in the square ( ), is the adjustment point.

Fig-2-7-3

24

Page 25

2) Adjustment flow chart

Replacement of the complete

cylinder assembly

Replacement of the S and T

sliders

Replacement of the ACE head

assembly

Replacement of the capstan

motor assembly

Replacement of the pinch lever

assembly

Replacement of the impedance

roller

Replacement of the tension

lever assembly

Replacement of the FE head

Replacement of the clutch gear

assembly

Replacement of the reel table

(a) (b) (c) (d) (e) (f) (g) (h) (i)

Coarse adjustment of ACE

assembly

Playback phase adjustment

Linearity adjustment

(S and T guide rollers)

Note 1

Fine adjustment of the ACE

head

Checking the guide No. 9.

(During REV mode)

Checking riseup of envelope

Checking envelope of the self

record-and-playback

Checking for no tape damage

Confirmation of the maximum amplitude

point of the AFM envelope output

1. Height adjustment of audio

head (height adjustment screw)

Play back the pre-recorded SP

tape. Adjust the audio head

height so that top edge of a

tape agrees with the top edge

of the audio head.

Audio head

2. Tilt adjustment of audio head

(tilt adjustment screw)

Keep playing back the SP tape.

Adjust height of the guide

No. 8 so that a tape runs along

with the lower flange of the

guide No. 8.

3. Audio azimuth adjustment

(azimuth adjustment screw)

Play back the alignment tape

TTV-P2, and adjust the azimuth

adjustment screw until audio

output is maximum.

4. “X” adjustment

(head position adjustment)

Play back the alignment tape

TTV-P2. Reset the tracking to

its center.

Adjust the ACE main base

position until envelope

becomes maximum.

Follow the Electrical System Adjustment

Procedure (Servo System).

Tape

Tape

Guide flange No. 8

1. Maximum envelope of

Play back the alignment tape

TTV-P2L. Trigger an

oscilloscope with the switching

pulse. Adjust tracking by

pressing UP/DOWN button

until envelope of the maximum

amplitude is obtained on an

oscilloscope.

3. Adjustment of envelope

Adjust envelope at exit side by

rotating the T guide roller until

the envelope at exit side

becomes as flat as possible.

4. Checking the tracking linearity

Check to see that amplitude of the

envelope increases and decreases as

the TRACKING UP/DOWN buttons

are pressed alternately while the

envelope maintains the flat

waveshape.

c/a > 0.75

b, d/a > 0.63

b, c, d/a > 0.75

Note 1: For the tracking linearity

check of item (c), use the alignment

tape TTV-P2L for adjustment, then

use the alignment tape TTV-P2 for

checking purpose.

the output signal

2. Adjustment of envelope

Adjust envelope at entrance

side by rotating the S guide

roller until the envelope at

entrance side becomes as flat

as possible.

=

=

=

at entrance side

at exit side

{

(Models not supporting

S-VHS)

(Models supporting

S-VHS)

1. Fine adjustment of audio

Play back the alignment tape.

Adjust the height adjustment

screw until the audio signal

envelope becomes flat.

2. Fine adjustment of audio

head tilt. Keep playing back the

alignment tape in the CUE or

in the double-speed playback

mode. Adjust the tilt adjustment

screw until tape runs along

with the lower flange of the

guide No. 8.

3. Checking the audio head

height. Play back the alignment

tape in the same manner as item

“1. Fine adjustment of audio head

height”, and confirm that the audio

signal envelope is flat.

head height

OK

4. Fine adjustment of

audio head azimuth

Play back the alignment tape

TTV-P2 and adjust the audio

head azimuth for the maximum

audio output level by rotating

the azimuth adjustment screw.

NG

5. Rechecking of audio

Same as item “3. Checking

the audio head height.”

head height

NG

1. Checking the tape wrinkle

• Enter the review mode using

a T-160 tape.

• Check the tape wrinkle at the

upper and lower flanges of

the guide No. 8.

2. Adjustment of the guide

No. 9. When the tape runs

exceeding the upper or lower

flange of the guide No. 9 as

shown above, either the pinch

lever or the capstan motor or

the guide No. 9 lever is

defective. Replace the

defective part.

6. “X” position (ACE head position)

• Set the MANUAL TRACKING to

its center.

• Play back the alignment tape

TTV-P2L, and adjust the ACE

main base position so that

amplitude of the envelope

becomes maximum.

• Play back the alignment tape

OK

TTV-P2, and check amplitude of

the envelope is maximum.

• When the envelope is not

maximum, adjust the LP mode

again.

Play back the alignment tape

TTV-P2L,

and enter the REVIEW mode.

2. Switch the mode from

NG

REVIEW to PLAY and check

that the envelope at the

entrance side rises up within 3

seconds.

3. Check that the envelope at

the entrance side rises up

within 3 seconds after a video

cassette is inserted into

cassette compartment.

NG

4. Adjust the S guide roller and

check linearity again.

5. Check the items 2 and 3 again.

When the envelope of the entrance

side does not rise up within 3

seconds, replace the S slider

assembly or the tension lever.

ACE head

Tilt screw

Slit for the “X”

adjustment (Insert the flat

head (-) screwdriver

tip and adjust it.)

c/a > 0.75

b, d/a > 0.63

b, c, d/a > 0.75

OK

Fig-2-7-4

Check the self record-andplayback in the EP mode and

SP mode using the tapes T-120

and T-160.

{

(Models not supporting

=

S-VHS)

=

(Models supporting

=

S-VHS)

Height adjustment screw

“X” position fixing

screw

Azimuth adjustment

screw

Run the T-160 tape in the

various modes of operation.

Check that a tape is not

damaged at any guides.

Playback mode

Frame-by-frame

playback mode

REVIEW

Play back the alignment

tape TTV-P2L.

Check the maximum output of

the video envelope (Ach) is

obtained.

Check that the phase difference

of the control pulse between

the video envelope maximum

point and the AFM envelope

maximum point, is ±3 ms or

less.

Check tape damage at the

guide roller.

Return to item (c) and perform adjustment.

(Or replace the slider assembly.)

Tape damage at the guide

No. 8 brush

Return to item (a) and perform adjustment.

(Or replace the pinch lever.)

Tape damage at the guide

No. 3 lower flange

Return to item (f) and perform adjustment.

(Or replace the pinch lever.)

Tape damage at the guide

No. 8 flange

Return to item (c) and perform adjustment.

Tape damage at the guide

No. 8 flange

Return to item (e) or item (a) and perform adjustment.

(Replace the pinch lever or No. 9 lever or capstan motor.)

Check tape damage at the

guide roller.

Return to item (c) and perform adjustment.

(Or replace the slider assembly.)

2625

Page 26

3) Adjustment of Tape Run System

<Coarse adjustment>

When the parts/components that are listed in table

2-7-1 are replaced, perform the necessary

adjustments referring to the adjustment procedure

of the tape run system.

When the parts/components that are listed in table

2-7-1 are replaced, tape running in the tape run

system can be affected and the alignment tape can

be damaged due to the change of the tape run

system. Therefore, run a T-160 tape and confirm

that extreme wrinkle does not occur at the

respective tape guides before running the

alignment tape.

1 When a tape wrinkle occurs at the S or T

guide roller, adjust the guide rollers so that

tape wrinkle does not occur, by rotating the S

or T guide roller.

2 When a tape wrinkle occurs at the guide No.

8, perform the ACE head tilt adjustment.

3 Rotate the ACE head tilt adjustment screw

counterclockwise until the tape runs along

with the lower flange as shown in Fig-2-7-6

[B].

3) Audio head azimuth adjustment

1 Play back the alignment tape TTV-P2.

2 Connect the AUDIO output connector to a

milli-volt VTVM or to an oscilloscope.

3 Rotate the ACE head azimuth adjustment

screw until the audio output is maximum.

Audio head core

Tape

Table 2-7-1

The replacement parts that require

check and adjustment after

their replacement

• Head assembly (cylinder)

• S and T slider assemblies

• ACE head assembly

• Pinch assembly

• Guide No. 9 lever

• Replacement of the impedance roller

• Tension lever

• FE head

• Clutch gear assembly

• S and T reel assemblies

[Adjustment procedure]

(a) Coarse adjustment of ACE head

1) ACE head height adjustment

1 Play back the pre-recorded SP tape. Check

and adjust the audio head core as follows.

2 Confirm, and adjust if necessary, the ACE

head height so that top edge of the running

tape agrees with the top end of the audio head

core by rotating the height adjustment screw.

(Refer to Fig-2-7-5.)

Adjustment procedure

Perform adjustment

according to item (a)

Perform adjustment

according to item (c)

Perform adjustment

according to item (d)

Control head core

Fig-2-7-5

Fig-2-7-6 Coarse check of the guide No. 8

4) ACE head position adjustment (“X”

adjustment)

1 Play back the alignment tape TTV-P2.

Loosen slightly the “X” position fixing screw.

2 Insert a flat head (-) screwdriver tip into the X

position adjustment slit of the ACE

mechanism deck. Adjust the ACE main base

so that the envelope output is maximum while

the tracking control is set in its center.

(b) Playback phase adjustment

Adjust the playback signal phase according to the

Electrical System Adjustment (Servo system).

2) ACE head tilt adjustment

1 Play back the pre-recorded T-160 SP tape.

Check the tape running conditions at the lower

flange of the guide NO. 8 in the playback

mode.

2 Rotate the ACE head tilt adjustment screw

until tape wrinkle is created at the lower

flange of the guide No. 8 as shown in Fig-2-76 [A].

27

Page 27

Note:

(c) Linearity adjustment

1 Play back the alignment tape TTV-P2L.

Note: • Use the TTV-P2 instead of TTV-P2L

when adjusting a VTR that is equipped

only with the SP mode. Use the TTVP2 instead of TTV-P2L in the same

way throughout the following

procedure when adjusting a VTR that is

equipped only with the SP mode..

• Trigger an oscilloscope externally with

the switching pulse to display an

envelope waveform on an oscilloscope.

• Check that the specifications shown in

Fig-2-7-7 are satisfied when the

maximum amplitude of an envelope

waveform is obtained.

Play back the alignment tape TTV-P2

and check that the following

specifications are satisfied. When the

specifications are not satisfied, adjust as

follows.

6 When the above adjustments are completed,

check that amplitude of the envelope increases

and decreases while it maintains the flat shape

when the TRACKING UP and DOWN

buttons are pressed. Then, play back the

alignment tape TTV-P2 and perform the same

check as described above using the alignment

tape.

7 If shape of the envelope changes as shown in

Fig-2-7-9, the tape run system has

abnormality. Therefore adjust the tape run

system again. The smooth curve of secondorder shape is permissible.

Fig-2-7-9 Abnormal waveform changes

• “a” is the point where the envelope has the maximum

amplitude.

• “b” is the point where the envelope has the minimum

amplitude at the entrance of cylinder.

• “c” is the point where the envelope has the minimum

amplitude at the center of cylinder.

• “d” is the point where the envelope has the minimum

amplitude at the exit of cylinder.

c, b, d/a > 0.75

b, d/a > 0.63

c/a > 0.75

=

=

=

4 When waveform of the zone “A” that is

shown in Fig-2-7-8, does not satisfy the

specification, adjust the S guide roller up and/

or down until the specification is satisfied.

5 When waveform of the zone “B” that is shown

in Fig-2-7-7, does not satisfy the specification,

adjust the T guide roller up and/or down until

the specification is satisfied.

(Models conforming to S-VHS)

{

(Models not conforming to S-VHS)

Fig-2-7-7

(d) Fine adjustment of ACE head

1) Fine adjustment of audio head core height

1 Play back the alignment tape TTV-P1.

2 Adjust the audio head height by rotating the

head height adjustment screw until the signal

envelope becomes flat. (Fig-2-7-10)

Fig-2-7-10

Note: When the alignment tape in which the

audio height adjustment signal of stereo

alternating recording, is not available, omit

the procedure of step 1) and perform the

procedure that is described as (Note) which

is described after step 5) in the following

paragraph.

Fig-2-7-8 Zones of waveform to be adjusted

2) ACE head tilt adjustment

1 Observe the running tape at the lower flange

of the guide No. 8. If a tape wrinkle occurs at

the lower flange of the guide No. 8, turn the

ACE tilt adjustment screw counterclockwise

until tape wrinkle is removed.

2 When a clearance is found between the lower

flange of the guide No. 8 and the lower edge

of a tape, turn the ACE tilt adjustment screw

clockwise so that the tap runs along with the

lower flange.

28

Page 28

Envelope at entrance side

Note: This adjustment can be easily performed in

either SP playback mode, or double-speed

playback or CUE mode.

3) Audio head height check

Play back the tape in the same way as step 1)

and check that the audio envelope is flat. If

the audio envelope is not flat, perform the

adjustment as described in step 1) again.

4) Audio head azimuth adjustment

1 Play back the alignment tape TTV-P2.

2 Adjust the ACE azimuth adjustment screw so

that the audio output becomes maximum.

5) Audio head height re-check

1 Play back the tape in the same way as step 1)

and check that the audio envelope is flat. If

the audio envelope is not flat, perform the

adjustment as described in step 1) again.

Note: • When the alignment tape in which the

audio height adjustment signal of stereo

alternating recording, is not available,

use the conventional alignment and

adjust the head height.

• Play back the alignment tape TTV-P2L.

• Turn the three height adjustment screws

of the ACE head by 45° all in the same

direction so that the audio output is

maximum.

• Re-check the audio head tilt and

azimuth. If necessary, re-adjust them.

6) ACE head position adjustment (“X”

adjustment)

1 Play back the alignment tape TTV-P2L.

2 Press both of the TRACKING UP and DOWN

buttons at the same time to reset the tracking

to the center value.

3 Trigger an oscilloscope externally with the

switching pulse to display an envelope

waveform on an oscilloscope.

4 Adjust position of the ACE main base so that

the maximum amplitude of envelope is

obtained in the same manner as in the “X”

position coarse adjustment.

5 Play back the alignment tape TTV-P2.

6 Check that amplitude of the envelope is

maximum with the tracking in the center.

When maximum amplitude of the envelope

cannot be obtained at the center position of

tracking, re-adjust the ACE “X” position so

that the maximum amplitude of envelope is

obtained in the SP and EP modes with

tracking center.

When the maximum amplitude of envelope is

obtained in the EP mode with the tracking at

center, the error between the tracking position

which produces the maximum amplitude of

envelope in the SP mode and the pre-set

position of tracking center is 3 ms or less.

7 Tighten the “X” position fixing screw and fix

the ACE mechanism deck.

7) When the ACE head fine adjustment is

completed, coat the two screws (tilt and

azimuth adjustment screws) in front of the

ACE head with Neji-lock (screw locking

compound).

(e) Checking the guide lever No. 9

1 Insert a T-160 tape (at tape top) and enter the

CUE mode. When a sufficient amount of tape

is wound onto the T reel table, switch the

mode to the REVIEW 3 mode.

2 Check the running tape at the top and bottom

flanges of the guide No. 8.

Check that the tape runs at the top and bottom

flanges of the guide No. 8 without overriding

the top and bottom flanges. If a tape overrides

either top or bottom flange of the guide No. 8,

either pinch lever, or the capstan motor, or the

guide lever No. 9 is defective. Replace the

defective part.

Note: The adjustment can be performed easier if a

T-160 video cassette is modified (i.e., the

upper case of a video cassette is removed)

for adjustment.

(f) Checking rise-up of an envelope waveform

1 Play back the alignment tape TTV-P2L in the

REV mode. Observe an envelope on an

oscilloscope.

2 Change the mode from REV to PLAY. Check

to see that an envelope of the entrance side as

shown in Fig-2-7-11, rises up within 3 seconds

after the mode is switched to the PLAY mode.

If an envelope of the entrance side does not

rises up within 3 seconds, proceed to step 4.,

and the subsequent steps for adjustment.

3 Remove the video cassette once. Check to see

that an envelope of the entrance side rises up

within 3 seconds after a video cassette is

inserted and the PLAY mode is entered.

Fig-2-7-11 Rise-up of envelope when mode is

switched from REV to PLAY

4 Re-adjust linearity by adjusting the S guide

roller.

5 Perform steps 2 and 3 again to check that

the envelope at entrance side rises up within 3

seconds after entering the PLAY mode. If the

envelope does not rise up, the S slider

assembly or the tension lever may be

defective. Make an attempt to replace them.

29

Page 29

Note: If an envelope does not rise up in the REV

mode, it can cause picture noise on monitor

in the continuous START-and-STOP

repetition recordings.

(g) Checking the envelope waveform

1 Make a self record-and-playback using a T-

120 tape and a T-160 tape. Check that the

envelope waveform satisfies the specifications

shown in Fig-2-7-7.

2 Make a self record-and-playback using a T-

120 tape. Check that the envelope waveform

satisfies the specifications shown in Fig-2-7-

12.

Note: Check the envelope waveform using both

SP and EP tapes.

B/A > 0.55

B > 120 mV

Fig-2-7-12 Envelope output waveform and difference

of waveform between the channels

3 If the specifications of the above described

steps 1 and 2 are not satisfied, replace the

head assembly (slider).

4 Enter the EP mode at the tape top of a T-120

tape. Check the playback picture that is

recorded by the continuous START-andSTOP repetition recordings.

5 When noise appears in the playback picture

which is recorded by the continuous STARTand-STOP repetition recordings, perform item