Aiwa CXVX-5 Service manual

CX-VX5

SERVICE MANUAL

Ver 1.0 2004. 03

• CX-VX5 are DVD receiver

in AVJ-X5.

DVD

Section

SPECIFICATIONS

AEP Model

UK Model

Model Name Using Similar Mechanism NEW

DVD Mechanism Type CDM80-DVBU24

Optical Pick-up Name DBU-1

Amplifier section

Stereo mode 60 W + 60 W (5 ohms at

1 kHz, THD 10 %)

Surround mode Front: 60 W + 60 W

Center*: 60 W

Surround*: 60 W + 60 W

(5 ohms at 1 kHz, THD

10 %)

Subwoofer*: 100 W

(3 ohms at 100 Hz, THD

10 %)

* Depending on the sound field settings and the source,

there may be no sound output.

Inputs VIDEO 1:

Sensitivity: 300 mV

Impedance: 50 kilohms

VIDEO 2:

Sensitivity: 300 mV

Impedance: 50 kilohms

MIC 1/MIC 2:

Sensitivity: 1 mV

Impedance: 10 kilohms

Outputs VIDEO 1 (AUDIO

OUT):

Voltage: 1 V

Impedance: 1 kilohm

Phones Accepts low-and high-

impedance headphones.

DVD system

Laser Semiconductor laser

(DVD: λ=650 nm)

(CD: λ=780 nm)

Emission duration:

continuous

Signal format system NTSC or NTSC/PAL

Frequency response (at 2 CH STEREO mode)

DVD (PCM): 2 Hz to 22

kHz (±1.0 dB)

CD: 2 Hz to 20 kHz (±1.0

dB)

Harmonic distortion Less than 0.03 %

– Continued on next page –

9-877-635-01

2004C04-1

© 2004. 03

DVD RECEIVER

Sony Corporation

Home Audio Company

Published by Sony Engineering Corporation

1

CX-VX5

Tuner section

System PLL quartz-locked digital

synthesizer system

FM tuner section

Tuning range 87.5 – 108.0 MHz (50 kHz

step)

Antenna FM wire antenna

Antenna terminals 75 ohms, unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range 531 – 1,602 kHz (with the

interval set at 9 kHz)

Antenna AM loop antenna

Intermediate frequency 450 kHz

Video section (VIDEO 1, 2, EURO AV)

Inputs Video: 1 Vp-p 75 ohms

Outputs Video: 1 Vp-p 75 ohms

Design and specifications are subject to change without

notice.

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the lead

free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to about

350 °C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky , less prone to flo w) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may also

be added to ordinary solder.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY P ARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

CX-VX5

Laser component in this product is capable

of emitting radiation exceeding the limit for

Class 1.

This appliance is

classified as a CLASS 1

LASER product. The

label is located on the

left side of the unit as

viewed from the front.

3

CX-VX5

TABLE OF CONTENTS

1. SERVICE POSITIONS

1-1. DVD Mechanism Block ...................................................... 5

1-2. MICON Board..................................................................... 5

2. GENERAL

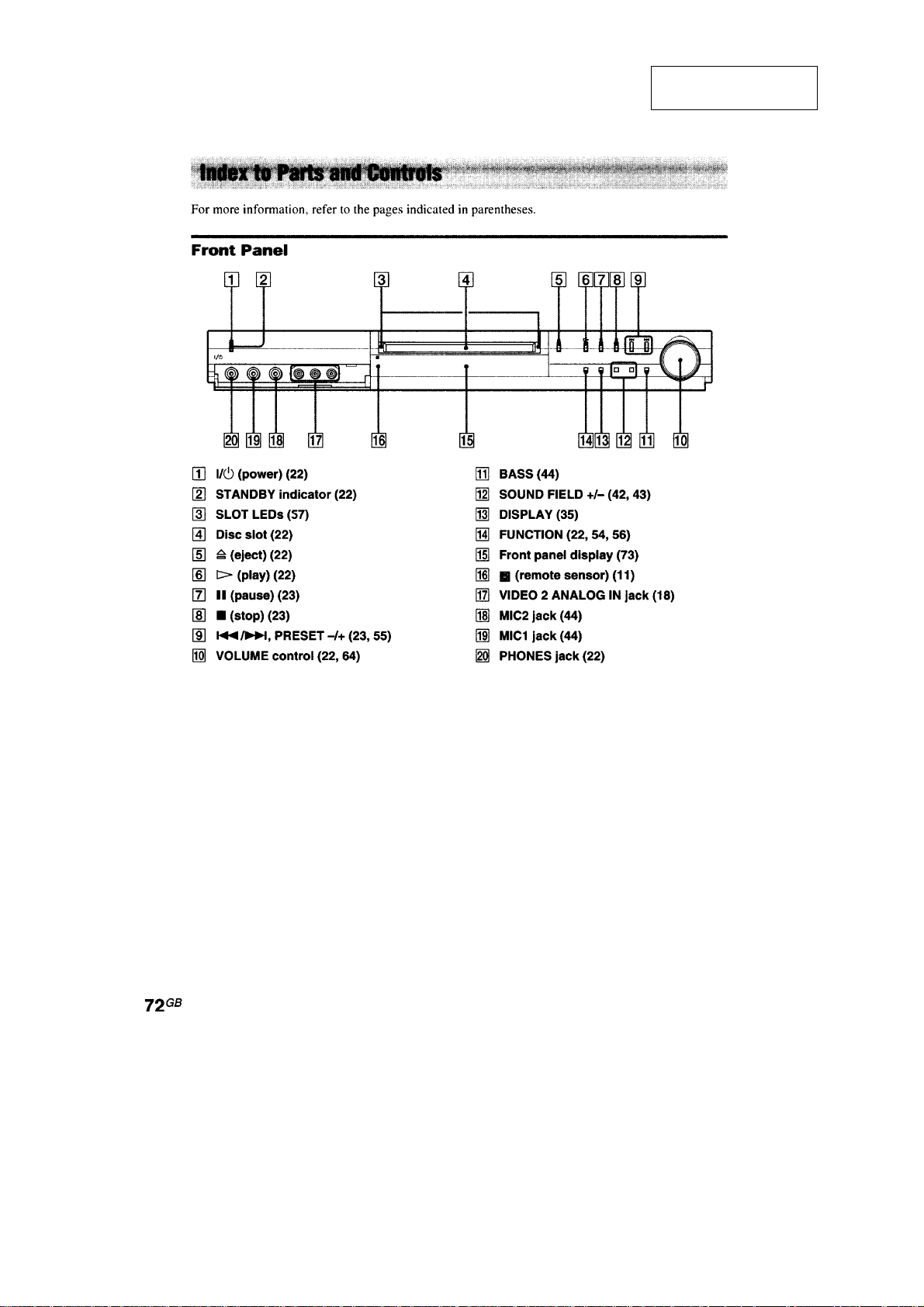

Front Panel............................................................................... 6

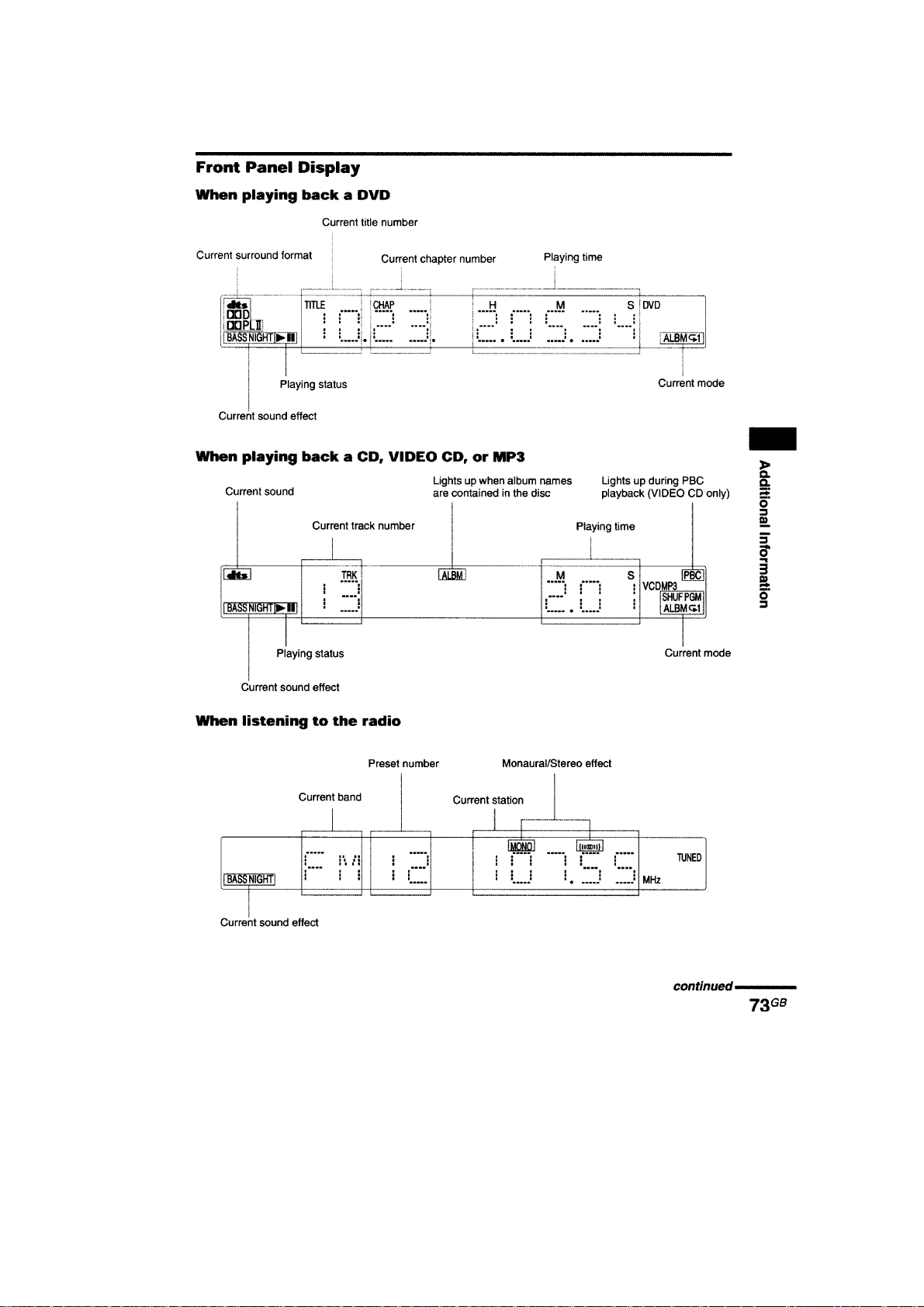

Front Panel Display ................................................................. 7

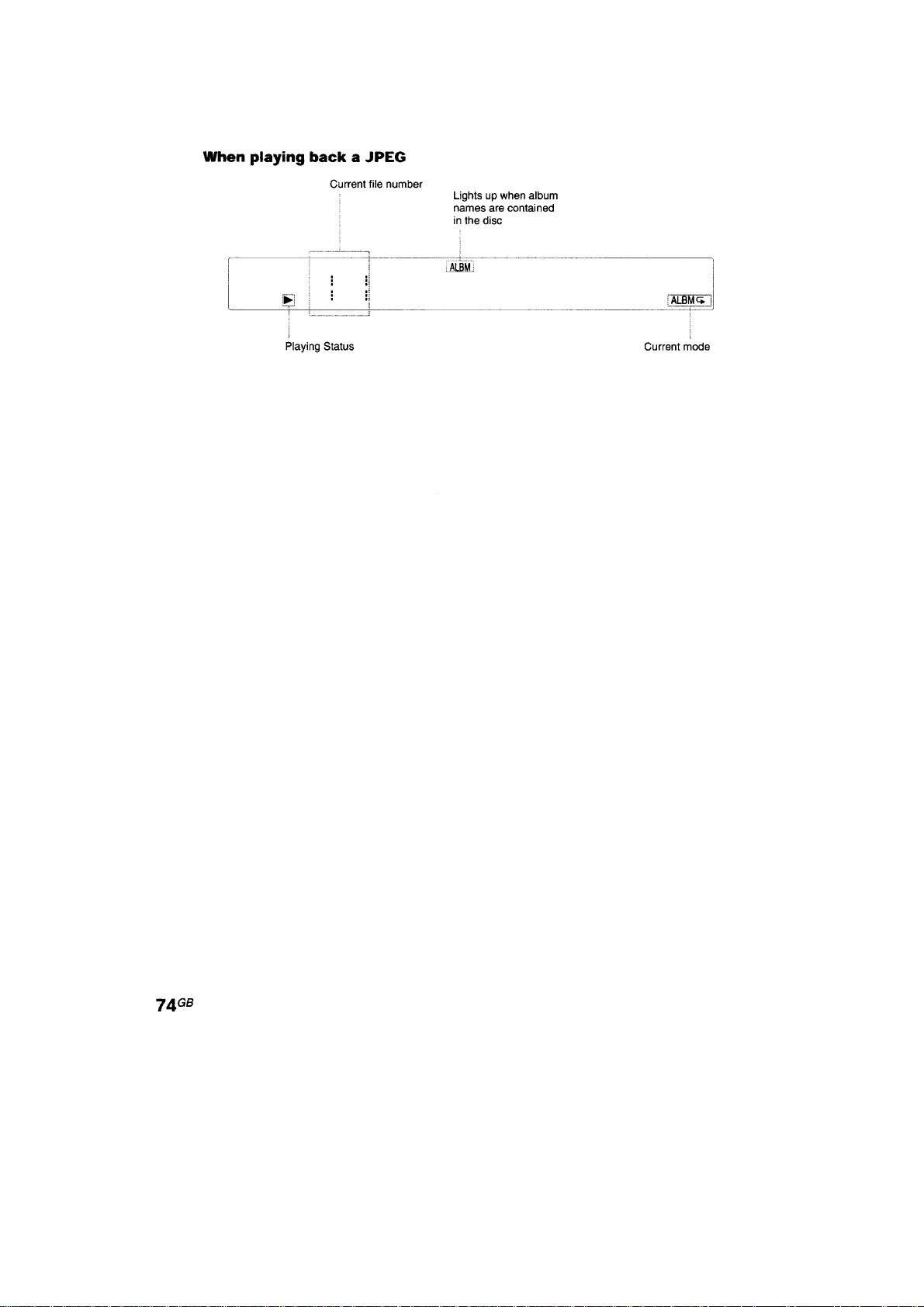

Rear Panel................................................................................ 9

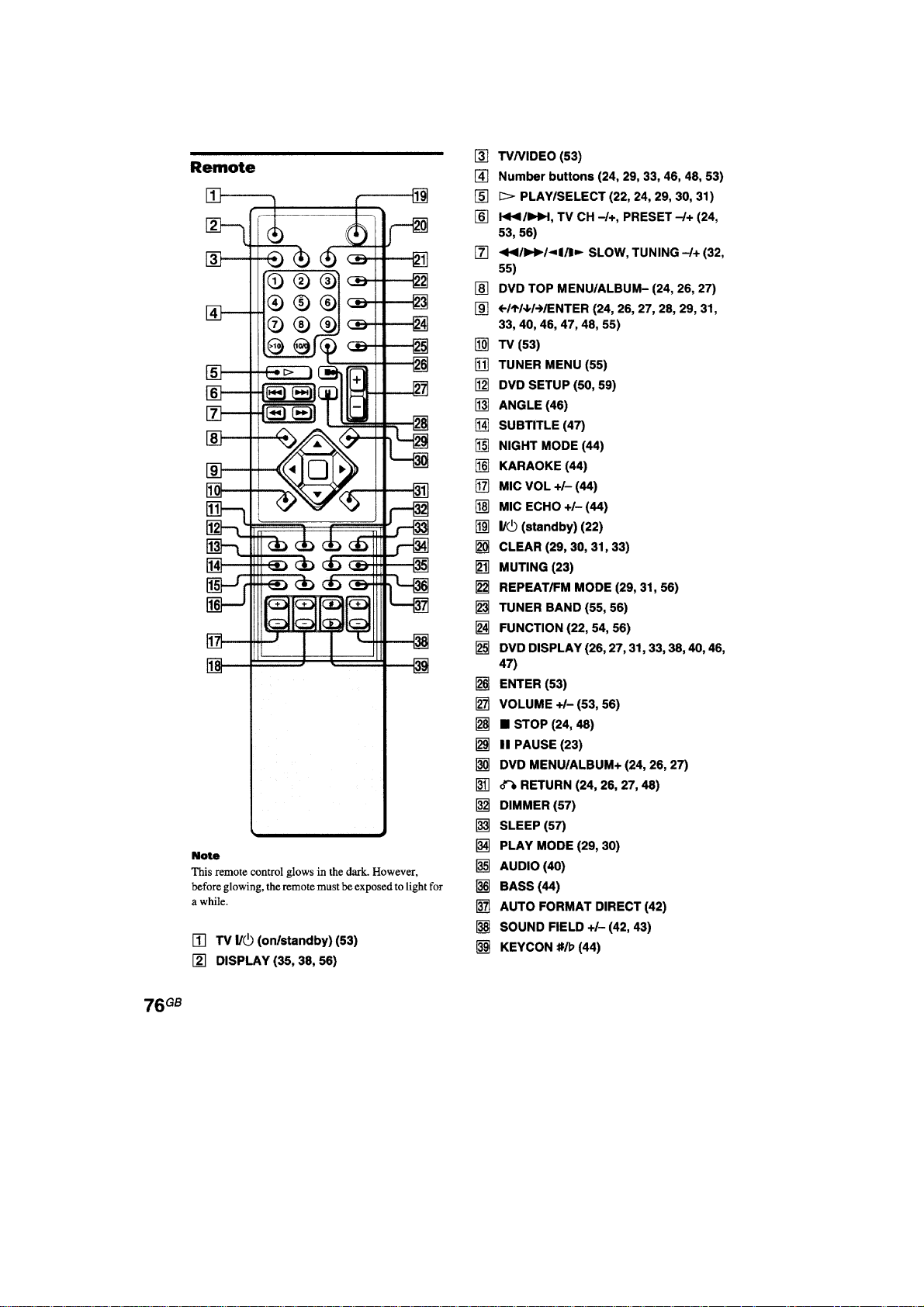

Remote................................................................................... 10

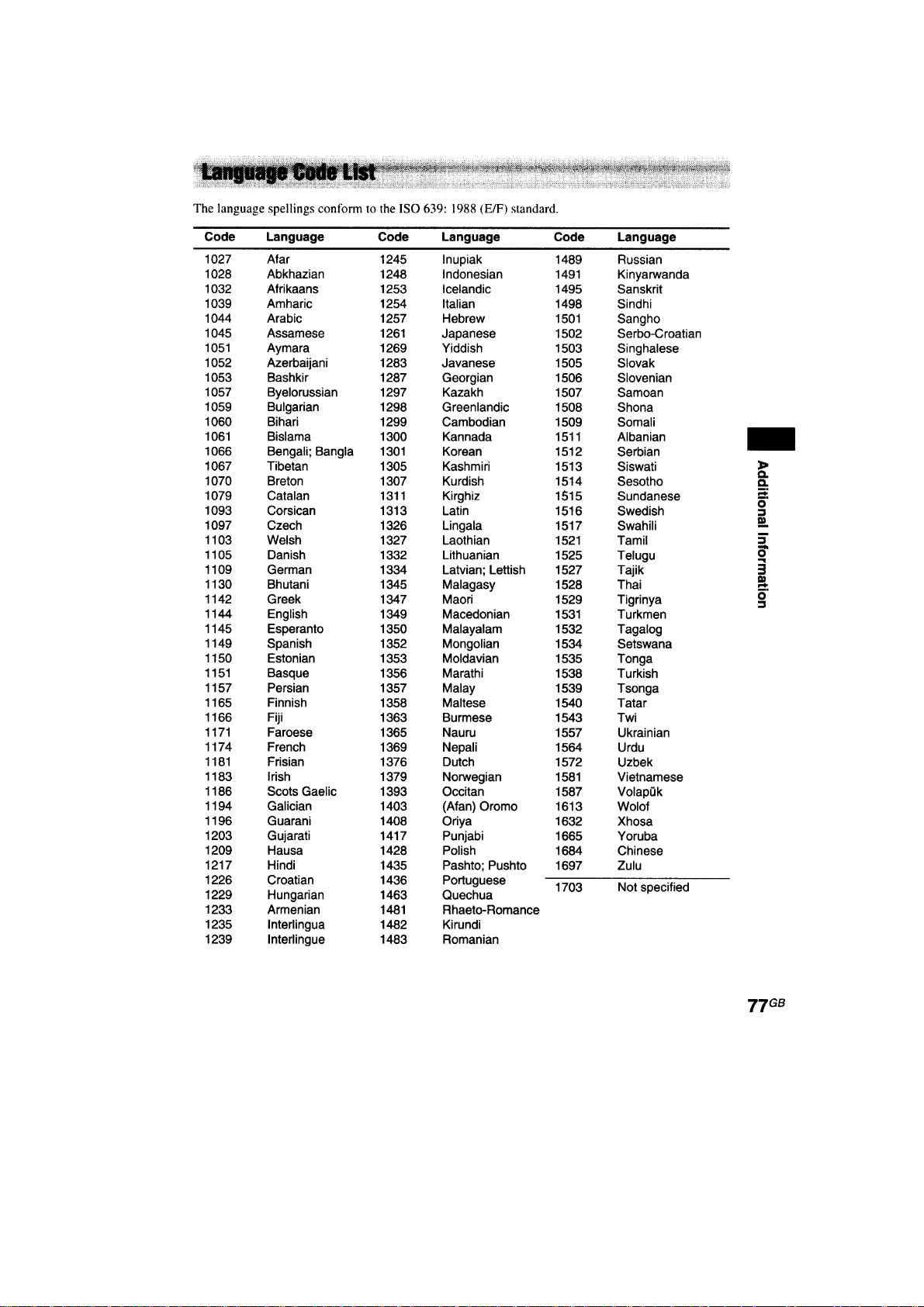

Language Code List............................................................... 11

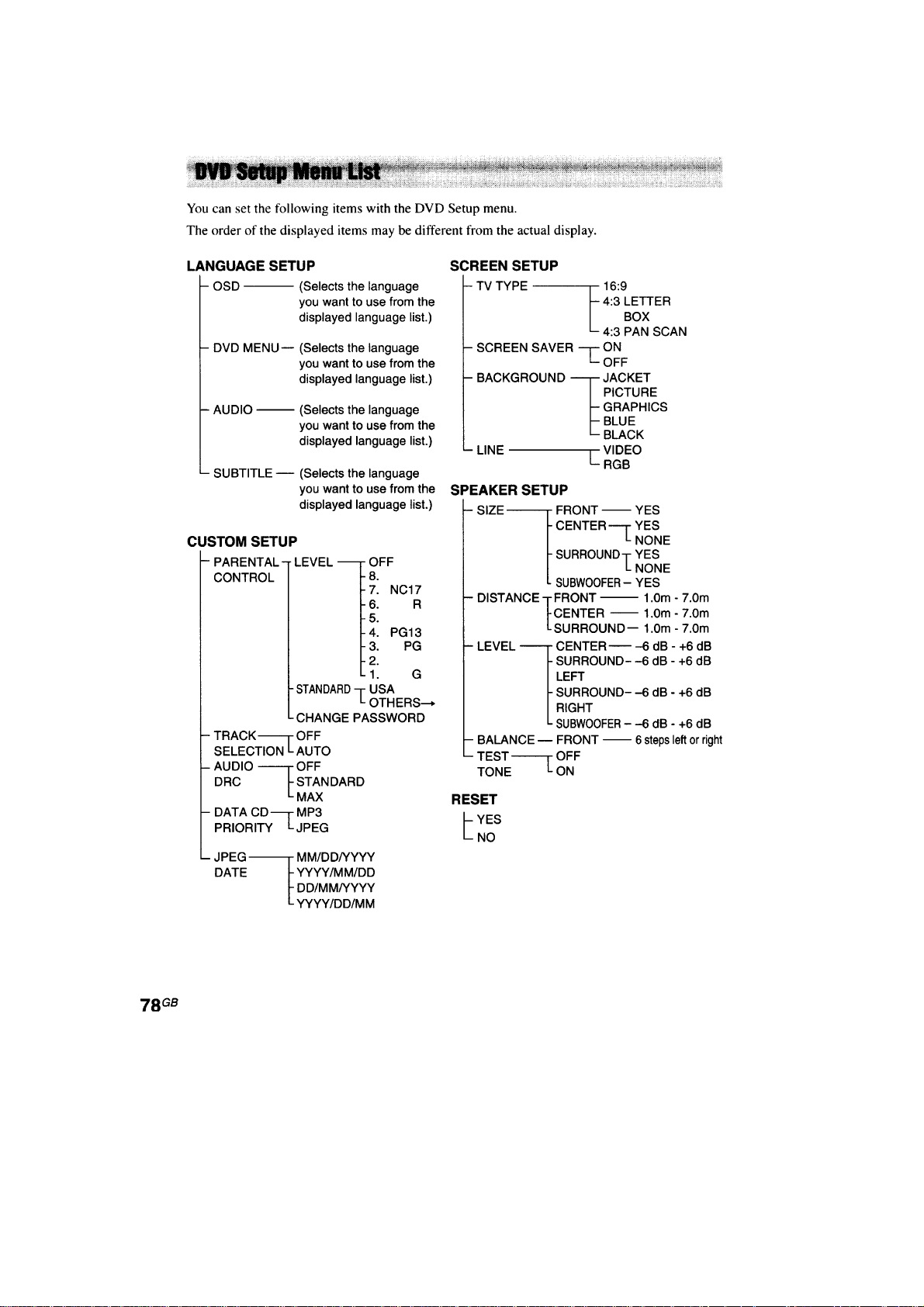

DVD Setup Menu List........................................................... 12

3. DISASSEMBLY

3-1. Top Cover .......................................................................... 14

3-2. Front Panel Assy ............................................................... 15

3-3. FL Board ........................................................................... 16

3-4. P-KEY Board, RM Board .................................................16

3-5. F-AV Board ....................................................................... 17

3-6. Rear Panel Section ............................................................ 17

3-7. MICON Board................................................................... 18

3-8. Mechanism Deck............................................................... 18

3-9. DMB03 Board ................................................................... 19

3-10. AMP Board ....................................................................... 19

3-11. POWER Board .................................................................. 20

3-12. Chassis (Top)..................................................................... 20

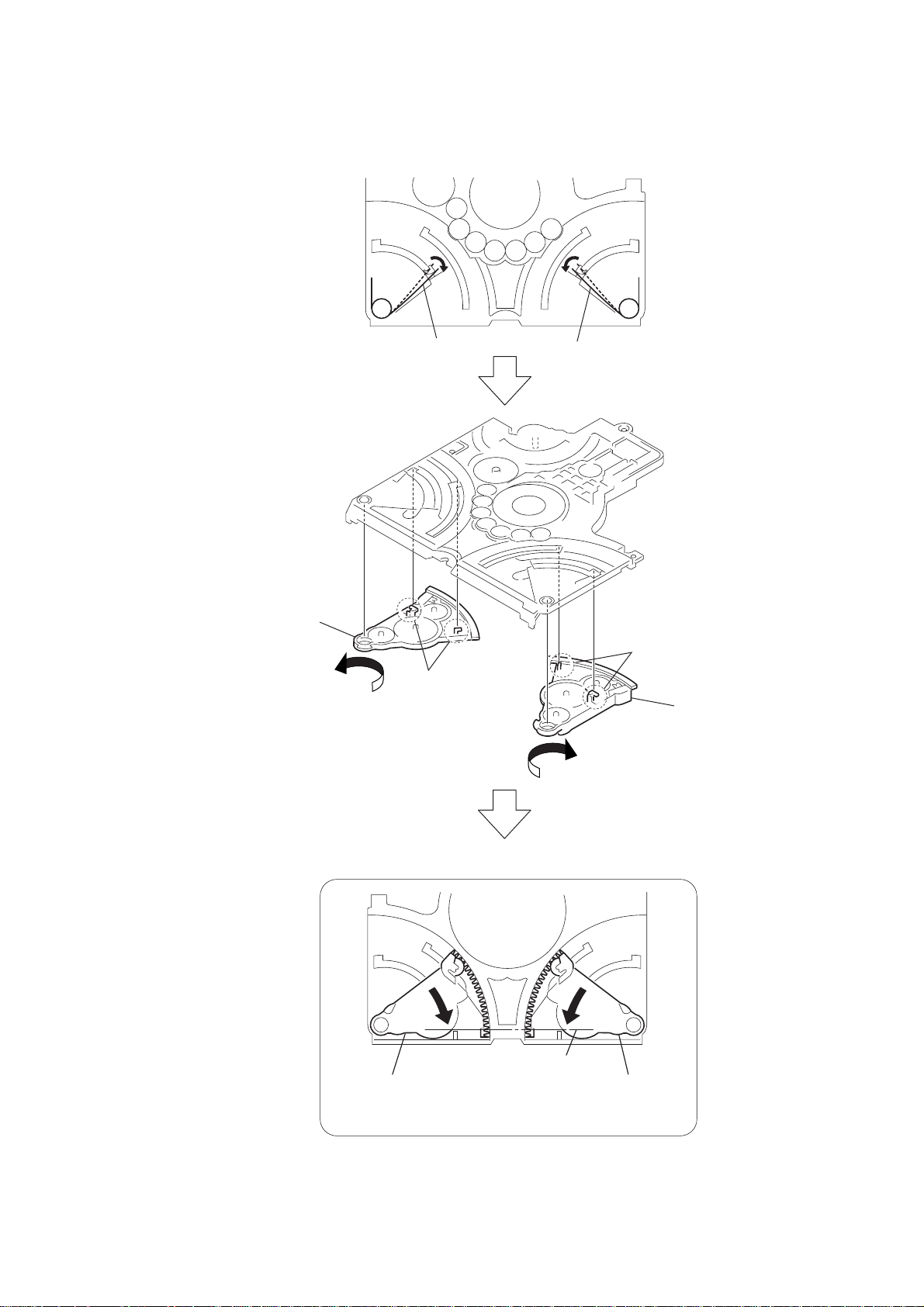

3-13. Lever (Loading-R/L) ......................................................... 21

3-14. Lever (Disc Stop), Disc Sensor Lever ............................... 22

3-15. DRIVER Board ................................................................. 22

3-16. RF Board ........................................................................... 23

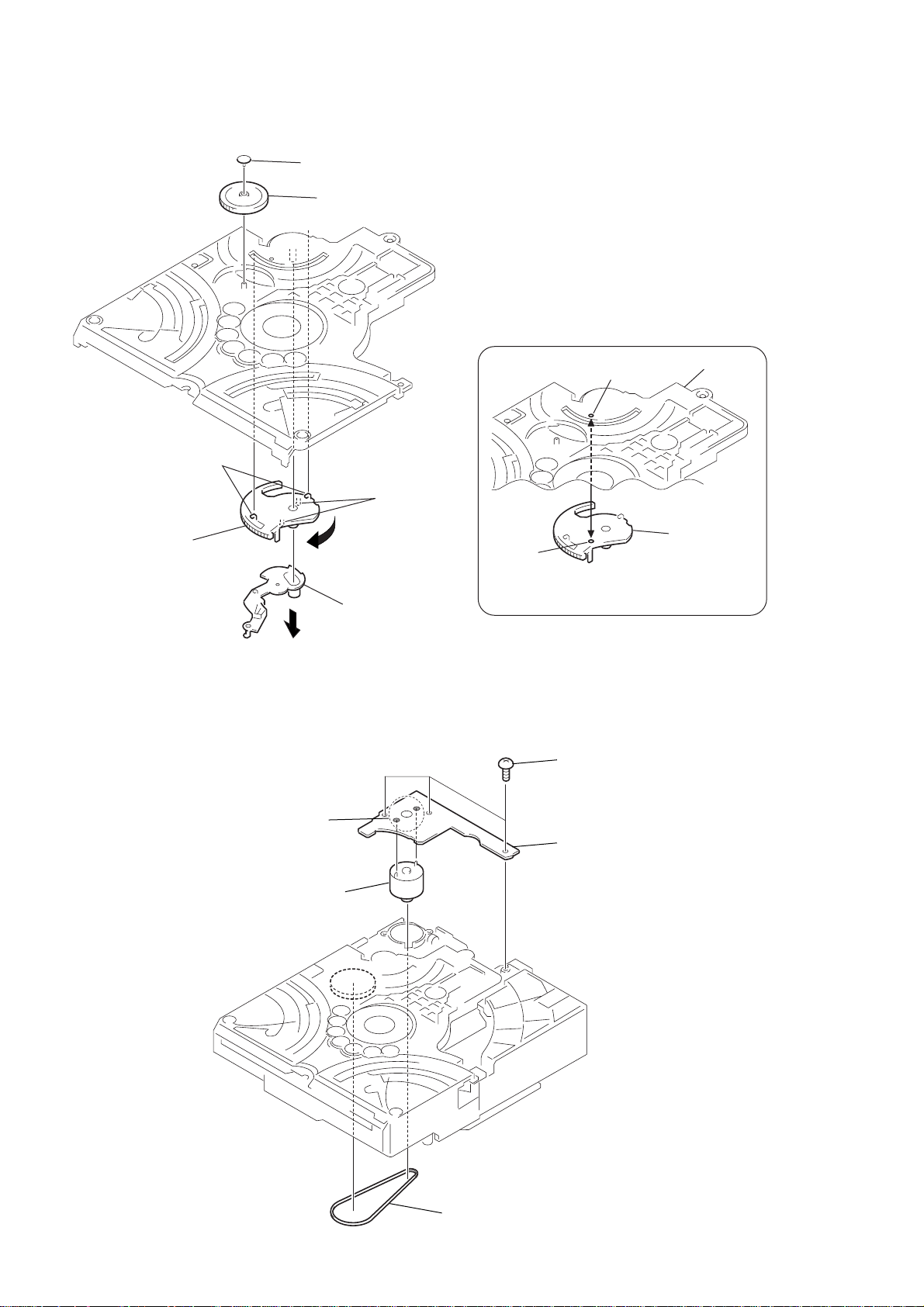

3-17. Optical Pick-up ................................................................. 23

3-18. Base Unit ........................................................................... 24

3-19. Lever (BU Lock) ............................................................... 24

3-20. Close Lever ....................................................................... 25

3-21. Lever (DIR), Gear (IDL-B)............................................... 25

3-22. Gear (IDL-C)..................................................................... 26

4. TEST MODE .....................................................................27

5. ELECTRICAL ADJUSTMENT.................................... 35

6. DIAGRAMS

6-1. Circuit Boards Location .................................................... 36

6-2. Printed Wiring Board

–DVD Mechanism Section (1/2)– ..................................... 39

6-3. Schematic Diagram –DVD Mechanism Section (1/2)– .... 40

6-4. Printed Wiring Board

–DVD Mechanism Section (2/2)– ..................................... 41

6-5. Schematic Diagram –DVD Mechanism Section (2/2)– .... 41

6-6. Printed Wiring Board –DMB03 Section (1/2)– ................ 42

6-7. Printed Wiring Board –DMB03 Section (2/2)– ................ 43

6-8. Schematic Diagram –DMB03 Section (1/8)– ...................44

6-9. Schematic Diagram –DMB03 Section (2/8)– ...................45

6-10. Schematic Diagram –DMB03 Section (3/8)– ...................46

6-11. Schematic Diagram –DMB03 Section (4/8)– ...................47

6-12. Schematic Diagram –DMB03 Section (5/8)– ...................48

6-13. Schematic Diagram –DMB03 Section (6/8)– ...................49

6-14. Schematic Diagram –DMB03 Section (7/8)– ...................50

6-15. Schematic Diagram –DMB03 Section (8/8)– ...................51

6-16. Printed Wiring Boards –I/O Section (1/2)–....................... 52

6-17. Printed Wiring Boards –I/O Section (2/2)–....................... 53

6-18. Schematic Diagram –I/O Section (1/2)– ........................... 54

6-19. Schematic Diagram –I/O Section (2/2)– ........................... 55

6-20. Printed Wiring Board –F-AV Section–.............................. 56

6-21. Schematic Diagram –F-AV Section– ................................ 57

6-22. Printed Wiring Board –Micon Section– ............................ 58

6-23. Schematic Diagram –Micon Section–............................... 59

6-24. Printed Wiring Boards –Key Section– ..............................60

6-25. Schematic Diagram –Key Section–................................... 61

6-26. Printed Wiring Board –FL Section–.................................. 62

6-27. Schematic Diagram –FL Section– .................................... 63

6-28. Printed Wiring Board –AMP Section (1/2)– ..................... 64

6-29. Printed Wiring Board –AMP Section (2/2)– ..................... 65

6-30. Schematic Diagram –AMP Section (1/2)–........................ 66

6-31. Schematic Diagram –AMP Section (2/2)–........................ 67

6-32. Printed Wiring Board –Power Section (1/2)– ................... 68

6-33. Printed Wiring Board –Power Section (2/2)– ................... 69

6-34. Schematic Diagram –Power Section– ............................... 70

7. EXPLODED VIEWS

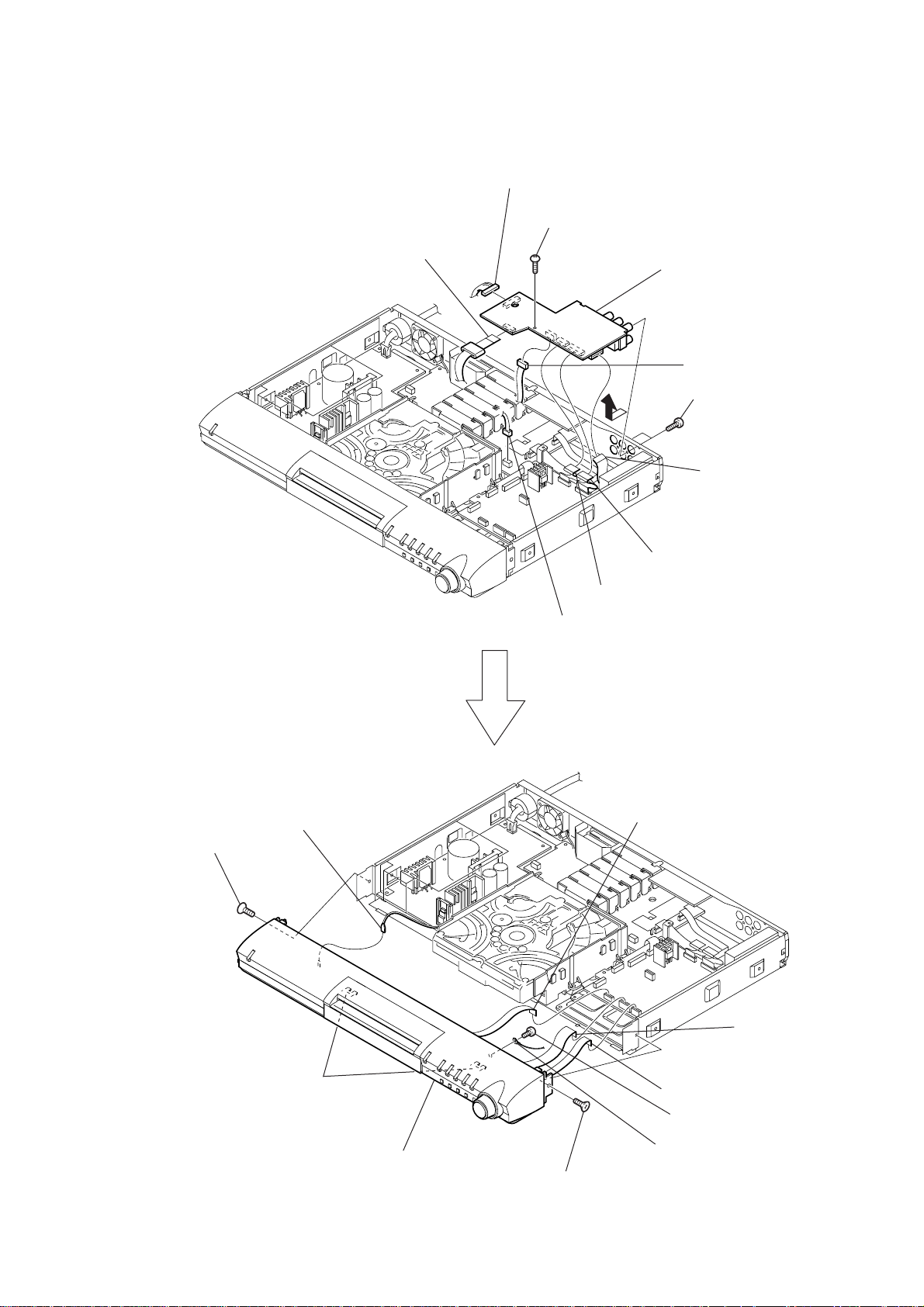

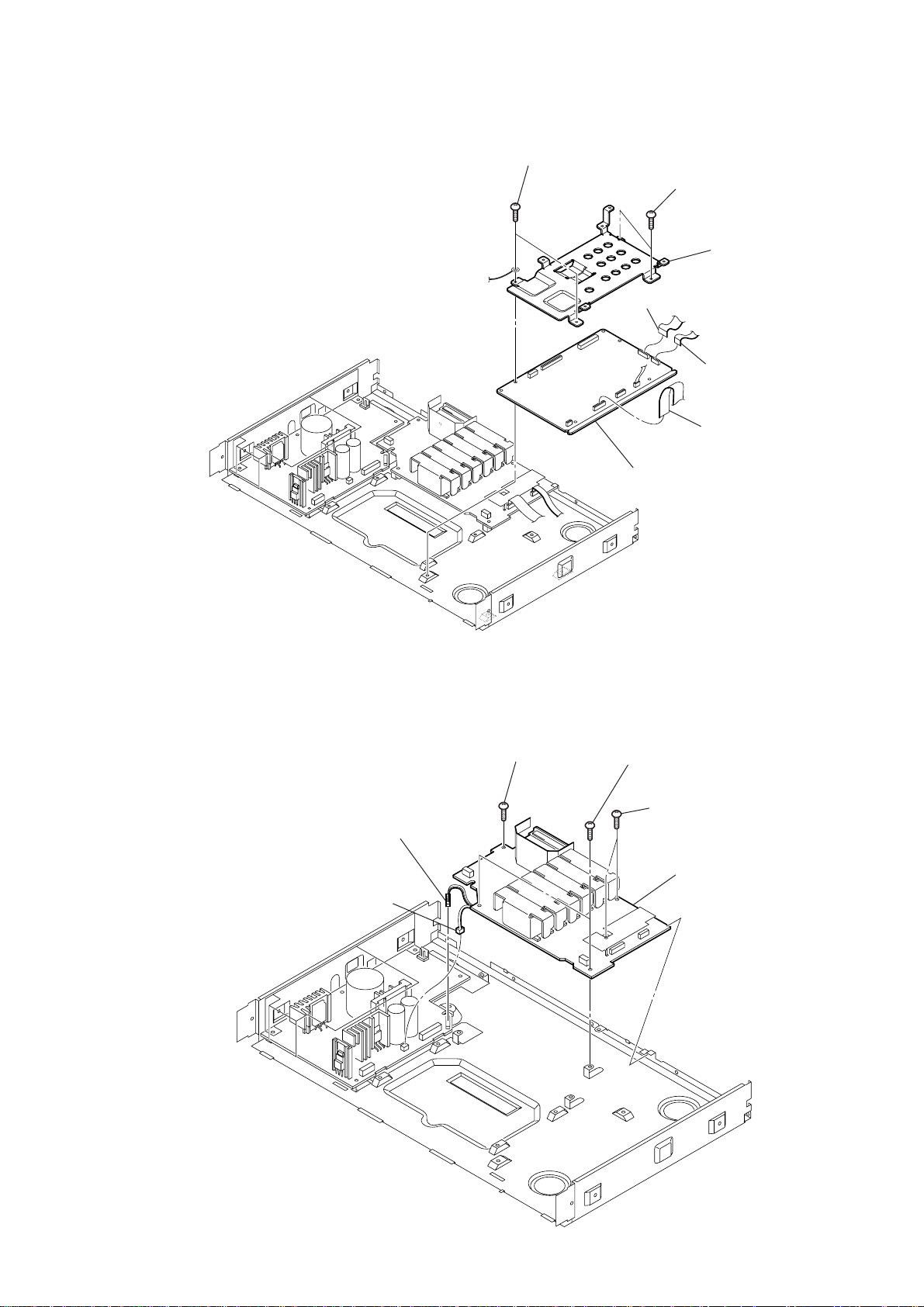

7-1. Main Section .....................................................................71

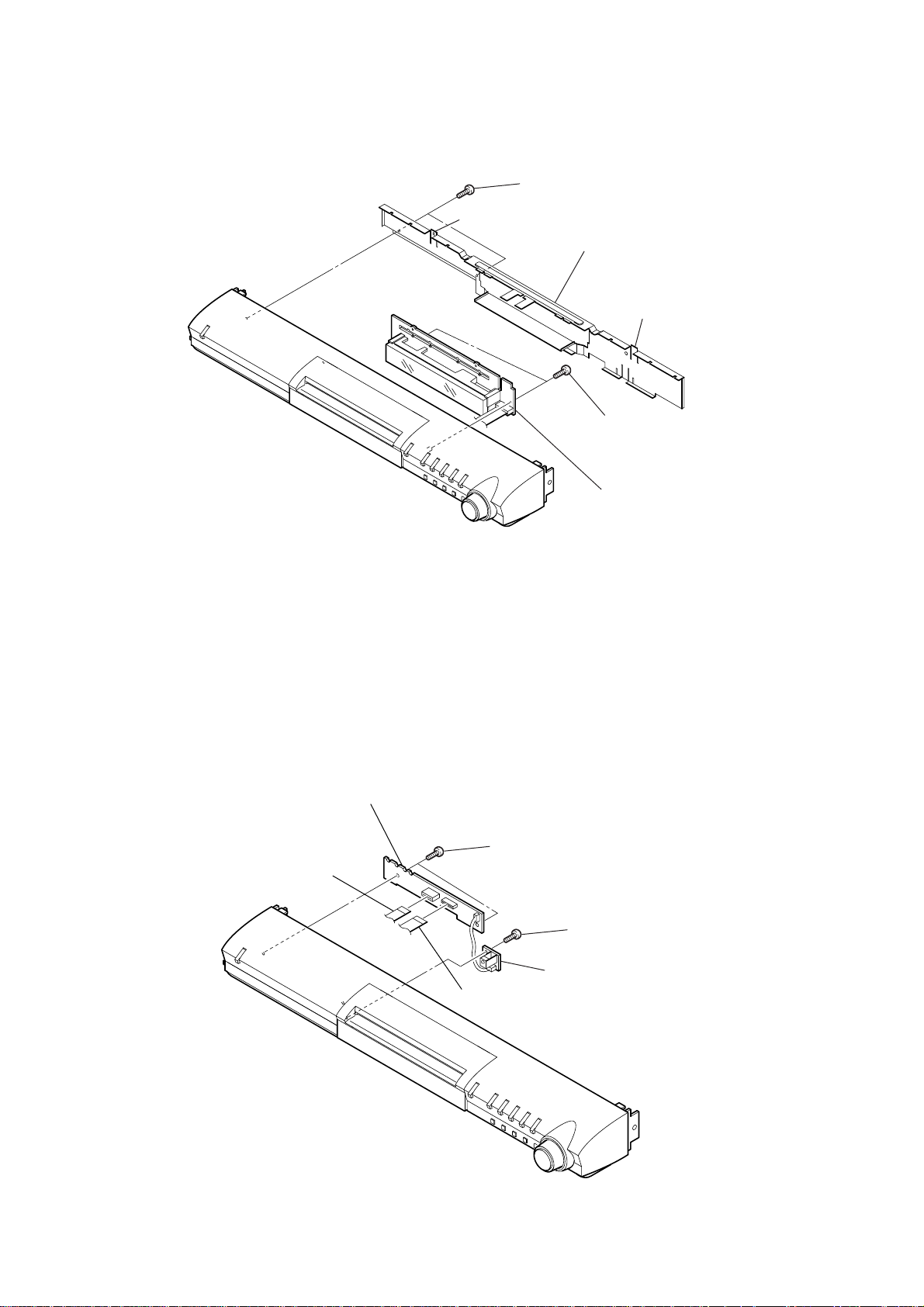

7-2. Front Panel Section ...........................................................72

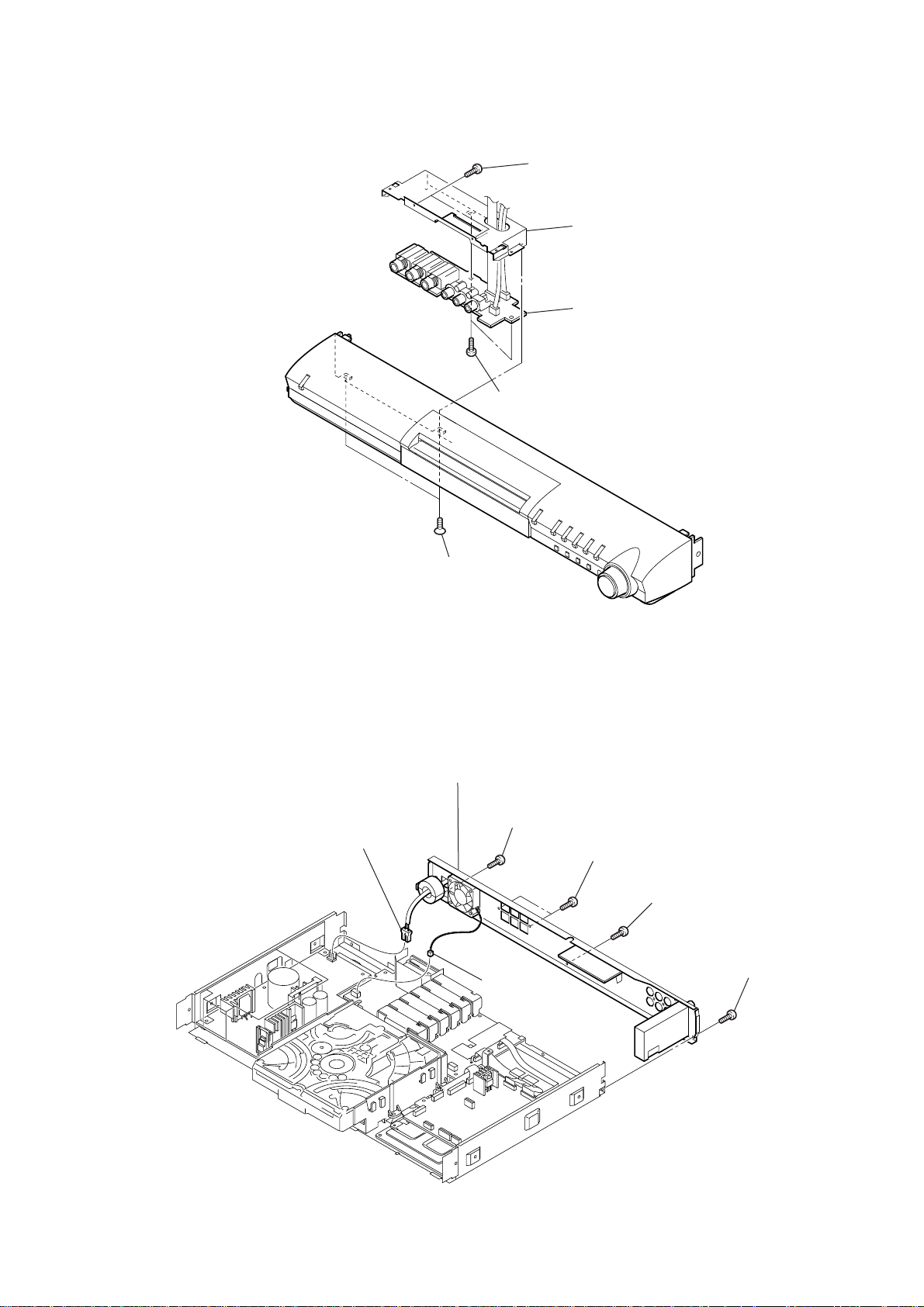

7-3. Rear Panel Section ............................................................ 73

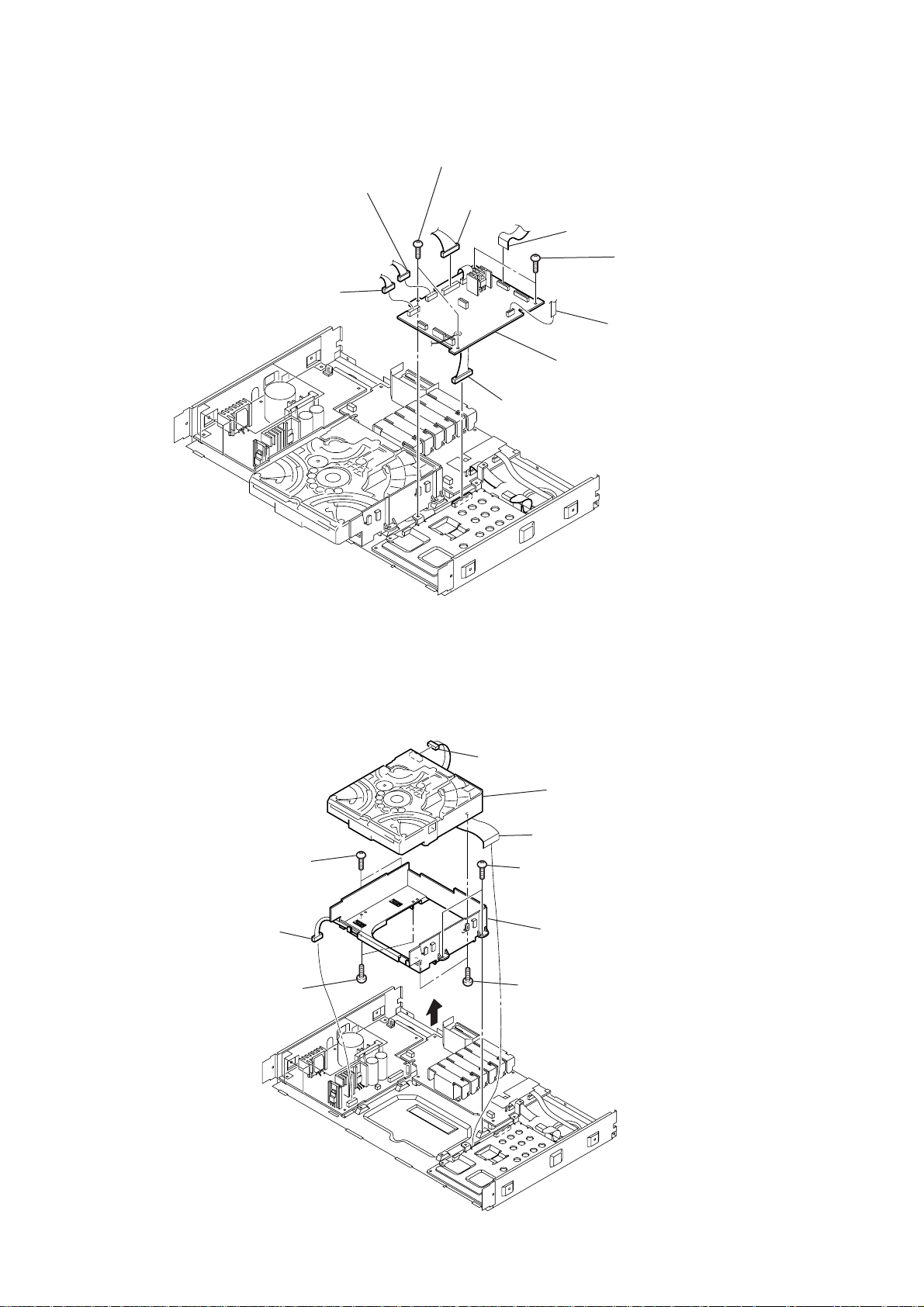

7-4. Chassis Section-1 ..............................................................74

7-5. Chassis Section-2 ..............................................................75

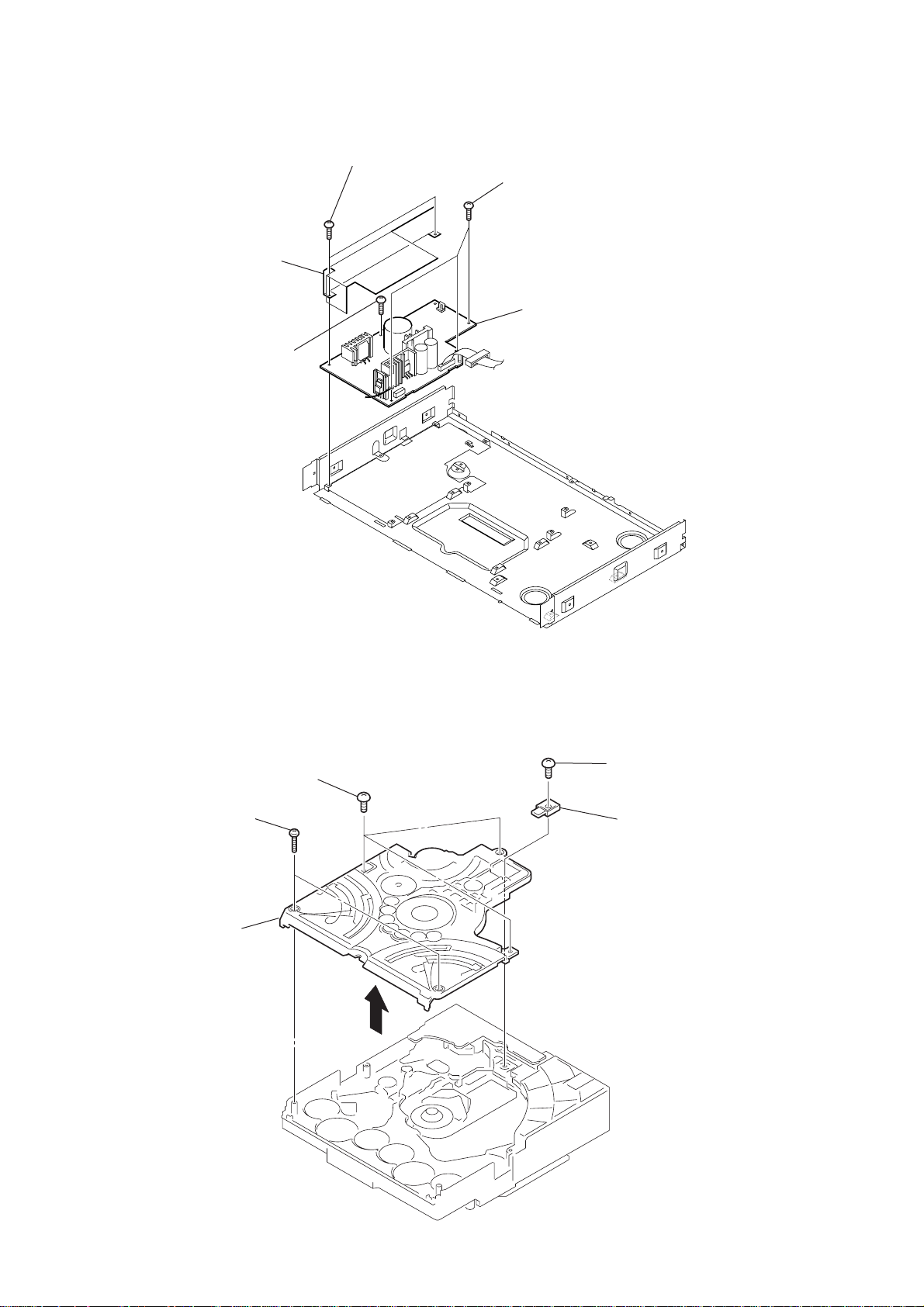

7-6. DVD Mechanism Deck Section-1..................................... 76

7-7. DVD Mechanism Deck Section-2..................................... 77

7-8. DVD Mechanism Deck Section-3..................................... 78

7-9. Base Unit Section .............................................................. 79

8. ELECTRICAL PARTS LIST ........................................80

4

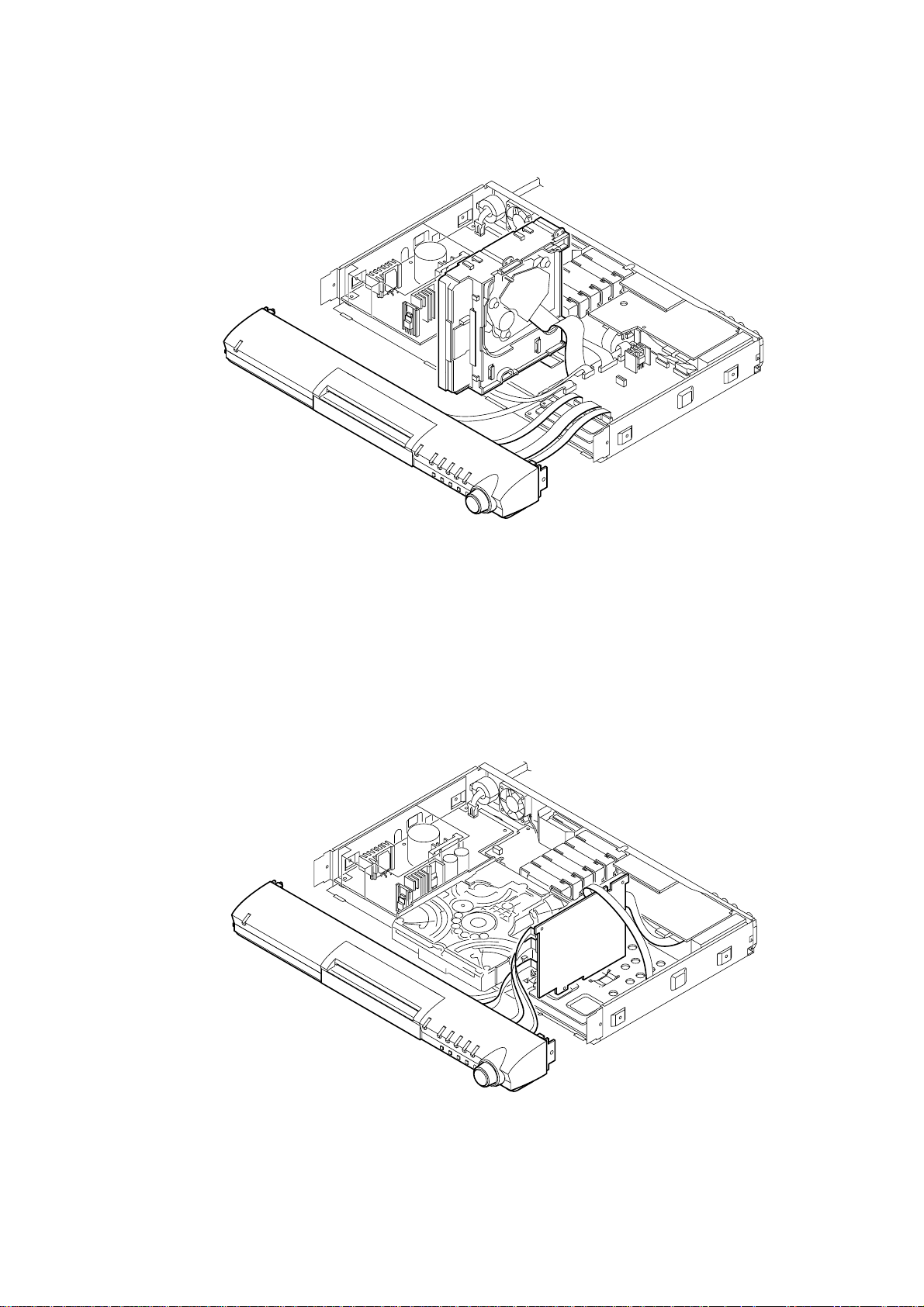

1-1. DVD MECHANISM BLOCK

CX-VX5

SECTION 1

SERVICE POSITIONS

1-2. MICON BOARD

5

CX-VX5

SECTION 2

GENERAL

This section is extracted

from instruction manual.

6

CX-VX5

7

CX-VX5

8

CX-VX5

9

CX-VX5

10

CX-VX5

11

CX-VX5

12

Note : Disassemble the unit in the order as shown below.

SET

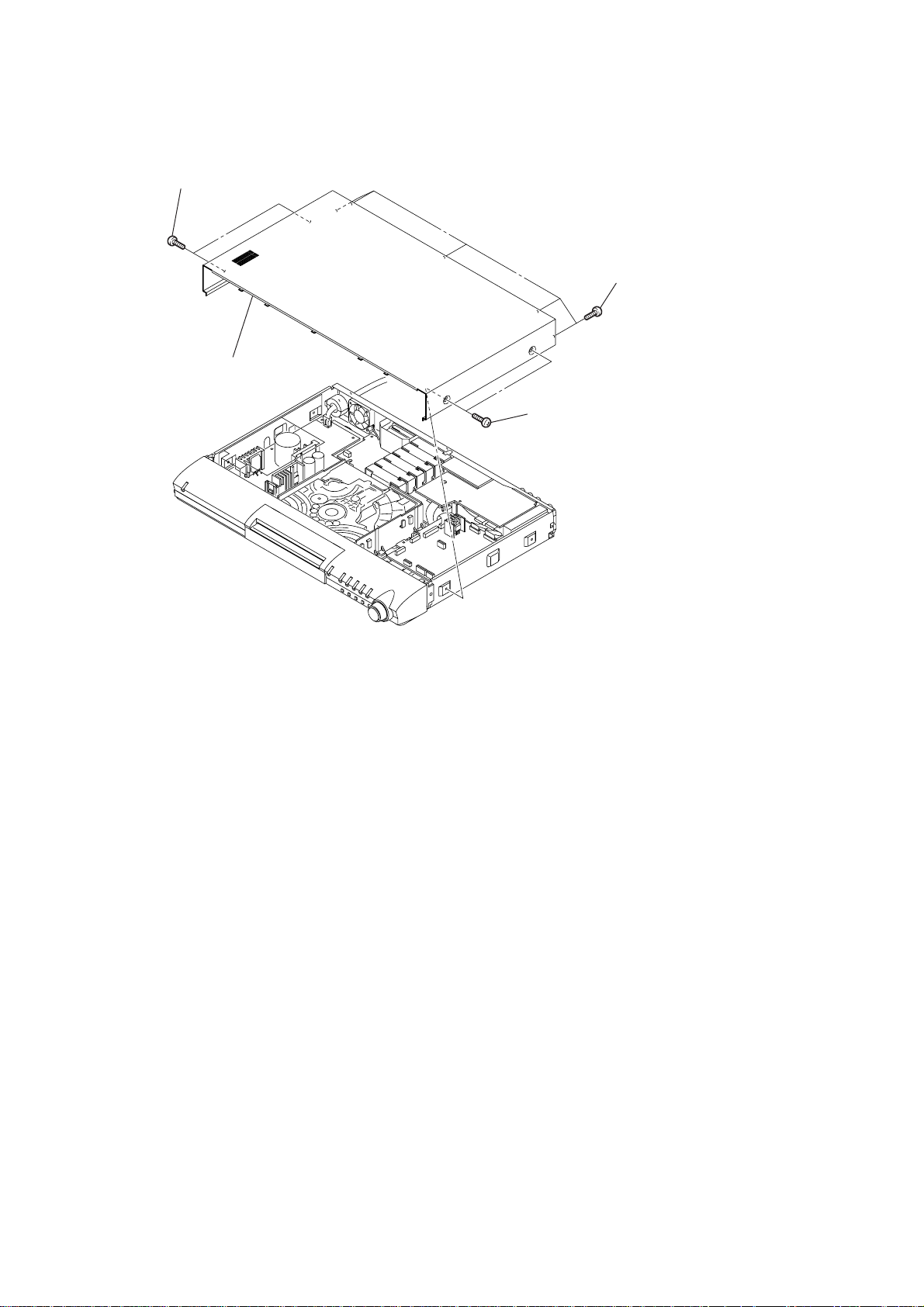

3-1. TOP COVER

(Page 14)

CX-VX5

SECTION 3

DISASSEMBLY

3-2. FRONT PANEL ASSY

(Page 15)

3-3. FL BOARD

(Page 16)

3-4. P-KEY BOARD,

RM BOARD

(Page 16)

3-5. F-AV BOARD

(Page 17)

3-8. MECHANISM DECK

(Page 18)

3-12. CHASSIS (TOP)

(Page 20)

3-11. POWER BOARD

(Page 20)

3-7. MICON BOARD

3-9. DMB03 BOARD

3-15. DRIVER BOARD

(Page 22)

3-6. REAR PANEL SECTION

(Page 17)

3-10. AMP BOARD

(Page 19)

(Page 18)

(Page 19)

3-18. BASE UNIT

(Page 24)

3-13. LEVER (LOADING-R/L)

(Page 21)

3-14. LEVER (DISC STOP),

DISC SENSOR LEVER

(Page 22)

3-16. RF BOARD

(Page 23)

3-17. OPTICAL PICK-UP

(Page 23)

3-19. LEVER (BU LOCK)

(Page 24)

3-20. CLOSE LEVER

(Page 25)

3-21. LEVER (DIR),

GEAR (IDL-B)

(Page 25)

3-22. GEAR (IDL-C)

(Page 26)

13

CX-VX5

Note : Follow the disassembly procedure in the numerical order given.

3-1. TOP COVER

2

two

screws

x

4

top cover

6)

(+BTP 3

1

two

screws

(+BTP 3

3

(+BTP 3

x

6)

five

screws

x

6)

14

3-2. FRONT PANEL ASSY

2

5

CN106

4

CN104

2

screw

(+BVTP 3

3

x

CX-VX5

6)

0

I/O board

9

CN108

1

two

screws

(+P 3

x

8)

8

CN105

qh

screw

(+KTP 3

x

6

CN101

7

CN107

qa

CN400

qf

qg

lug

6)

CN501

qk

two claws

ql

front panel assy

qj

screw

(+KTP 3

x

qs

wa

6)

CN503

w;

screw

(+BVTP 3

lug

qd

x

CN50

6)

15

CX-VX5

)

3-3. FL BOARD

claw

1

two

screws

(+P 2.6

x

6)

2

sub chassis

claw

3

two

screws

(+P 2.6

x

6)

3-4. P-KEY BOARD, RM BOARD

3

CN804

2

P-KEY board

1

two

screws

(+P 2.6

x

6)

5

(+P 2.6

4

screw

FL board

x

6

16

6

RM board

4

CN801

3-5. F-AV BOARD

2

two

screws

(+P 2.6

x

6)

3

two

screws

(+P 2.6

x

6)

5

F-AV board

4

connector bracket

1

two

screws

(+KTP 2.6

x

6)

)

CX-VX5

3-6. REAR PANEL SECTION

1

CN901

7

rear panel section

6

(+P 3

2

CN501

screw

x

8)

5

two

(+P 3

screws

x

8)

4

(+P 3

screw

x

8)

3

screw

(+P 3

x

8

17

CX-VX5

s

r

3-7. MICON BOARD

5

CN506

4

CN509

7

two

(+P 3

3

screws

x

8)

CN508

9

CN102

2

CN510

8

MICON board

6

two

(+P 3

1

CN505

screw

x

8)

3-8. MECHANISM DECK

3

two

screws

(+BVTP 3

CN906

1

8

two

screws

(+P 3

x

x

10)

6

CN701

0

mechanism deck

5

CN501

6)

4

2

two

screws

(+BVTP 3

9

mechanism holde

7

two

screws

(+P 3

x

10)

x

6)

18

3-9. DMB03 BOARD

k

d

5

two

screws

(+BVTP 3

x

6)

7

4

two

(+BVTP 3

3

CN107

DMB03 board

screws

6

2

1

x

heat sin

CN106

CN105

CX-VX5

6)

3-10. AMP BOARD

1

CN905

2

CN902

3

screw

(+BVTP 3

x

6)

4

two

screws

(+BVTP 3

5

two

(+BVTP 3

6

x

6)

screws

x

AMP boar

6)

19

CX-VX5

)

3-11. POWER BOARD

2

sheet (barrier)

3

screw

(+BVTP 3

x

1

two

screws

(+BVTP 3

6)

x

6)

4

three

(+BVTP 3

screws

5

POWER board

x

6)

3-12. CHASSIS (TOP)

3

two screws

(+P 2

5

chassis (top)

4

three screws

(+BVTP 2.6

×

10)

1

×

8)

screw

(+BVTP 2.6

2

lever (CL UP2

×

8)

20

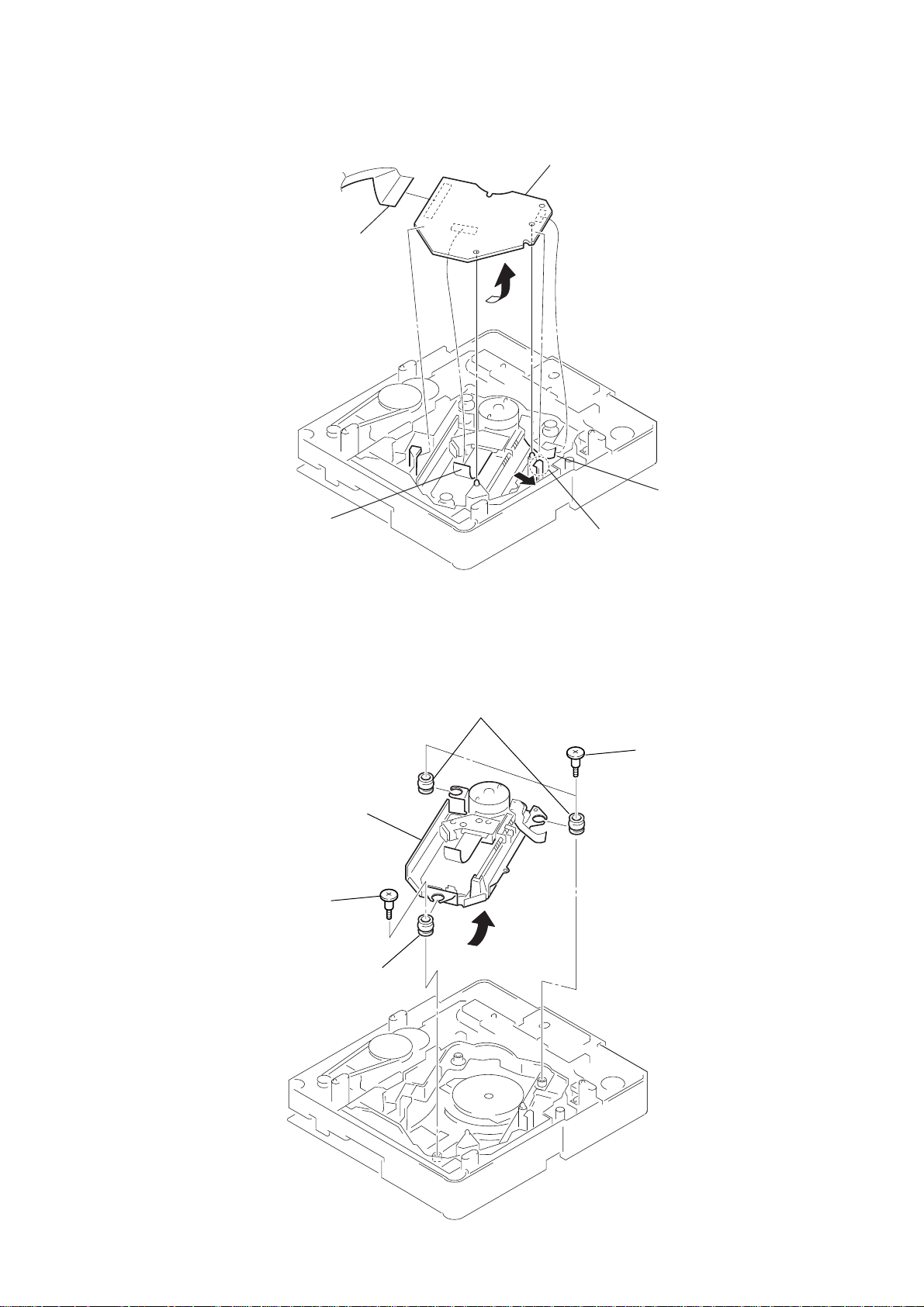

3-13. LEVER (LOADING-R/L)

CX-VX5

5

lever (loading-R)

1

spr-T (loading-L) spr-T (loading-R)

4

two hooks

1

2

two hooks

3

lever (loading-L)

PRECAUTION DURING LEVER (LOADING-R/L) INSTALLATION

Align the horizontal position.

lever (loading-L)

Install the

both levers so that they move symmetrically.

lever (loading-R)

21

CX-VX5

)

3-14. LEVER (DISC STOP), DISC SENSOR LEVER

1

gear (cap)

2

gear (IDL-L)

PRECAUTION DURING LEVER (DISC STOP) INSTALLATION

5

two hooks

6

lever (disc stop)

3-15. DRIVER BOARD

3

two claws

4

lever (disc sensor)

hole

hole

Install the lever (disc stop) so that the both holes

are aligned.

2

three screws

(+BVTP 2.6 × 8

chassis (top)

lever (disc stop)

3

Remove soldering

from the two points.

4

motor (pulley) assy

1

belt (MOT)

5

DRIVER board

22

3-16. RF BOARD

)

4

wire (flat type)

(CN002)

5

RF board

CX-VX5

3

wire (flat type)

(CN001)

3-17. OPTICAL PICK-UP

5

(DBU-1)

2

step screw (M)

optical pick-up

3

two insulators

1

2

(CN003)

claw

1

two step screws (M

wire (flat type)

4

insulator

23

CX-VX5

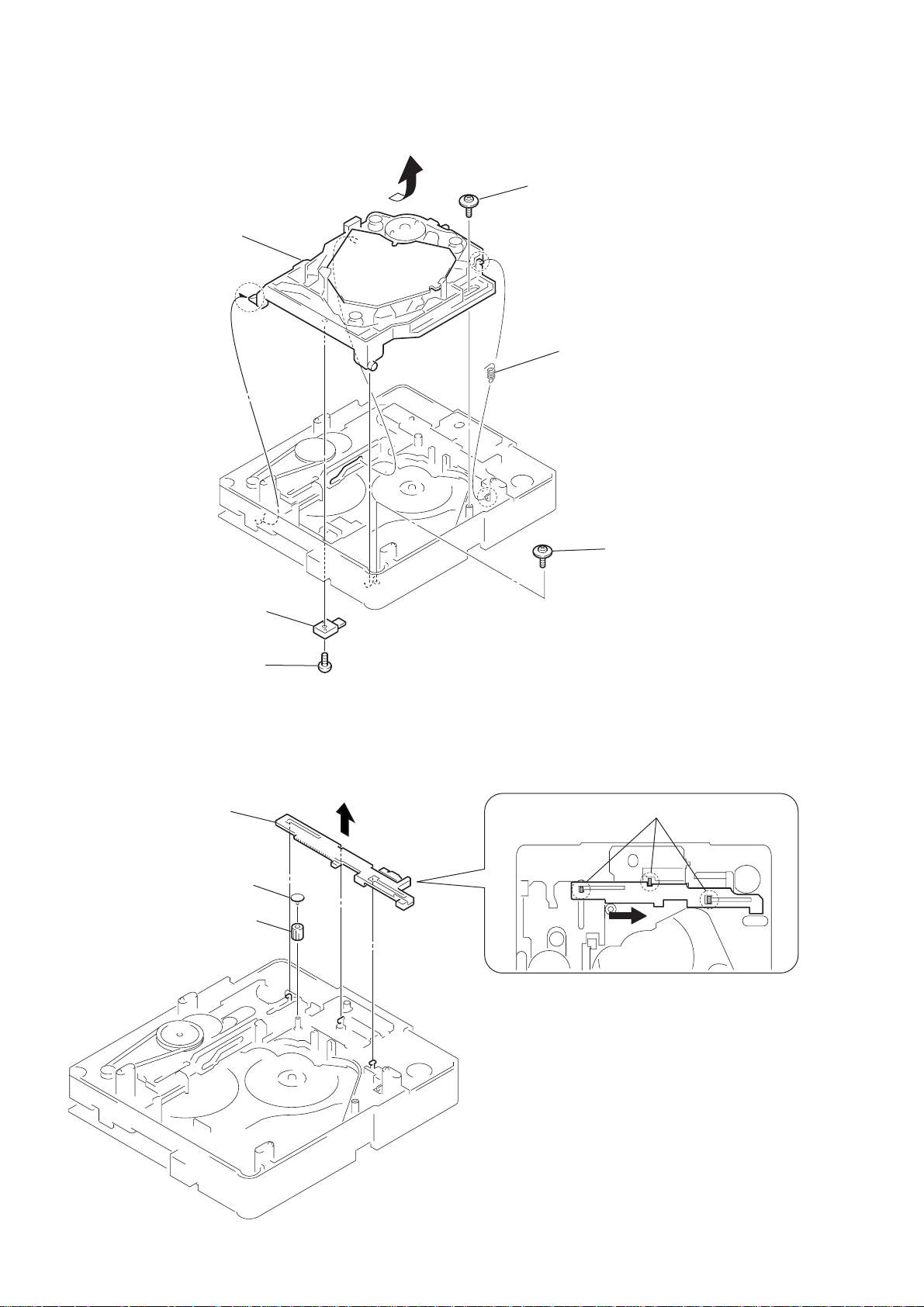

3-18. BASE UNIT

6

base unit

4

floating screw

(+PTPWHM 2.6)

3

spr-E (holder down)

2

lever (CL UP2)

1

screw

(+BVTP 2.6

3-19. LEVER (BU LOCK)

4

lever (BU lock)

1

gear (cap)

2

gear (BU lock)

5

floating screw

(+PTPWHM 2.6)

×

8)

3

three hooks

2

24

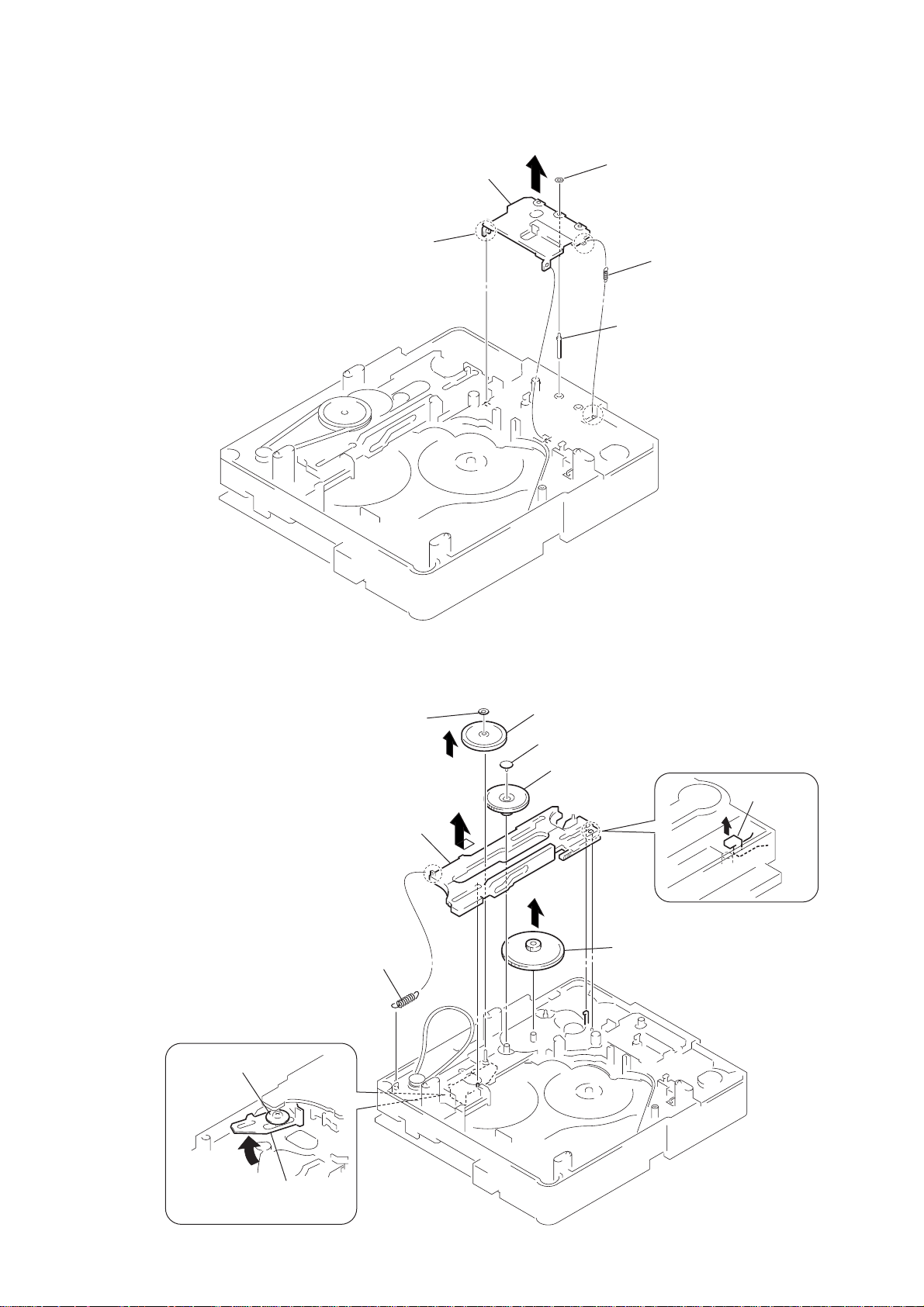

3-20. CLOSE LEVER

3

5

claw

close lever

1

washer (3-1-0.4)

2

spr-E (close lever)

4

shaft (disc stop)

CX-VX5

3-21. LEVER (DIR), GEAR (IDL-B)

2

1

spr-E (DIR)

6

Loosen the screw.

retaining ring

9

lever (DIR)

3

pulley (gear)

4

gear (cap)

5

gear (IDL-A)

q;

gear (IDL-B)

8

stopper

7

Hold the release lever

and change the direction.

25

CX-VX5

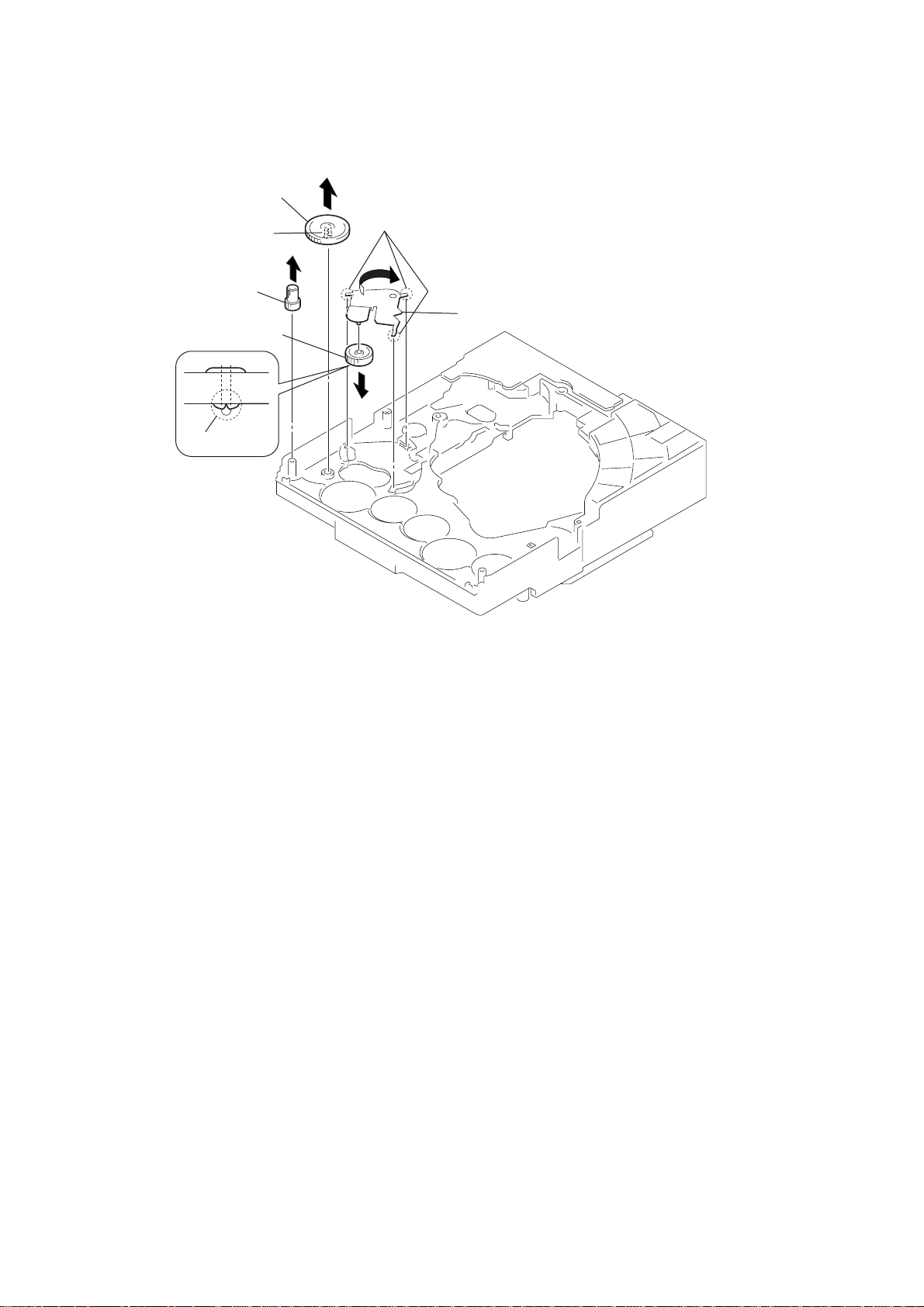

3-22. GEAR (IDL-C)

1

3

gear (IDL-D)

2

two claws

gear (IDL-F)

7

gear (IDL-C)

6

claw

4

three hooks

5

gear (loading lever)

26

SECTION 4

TEST MODE

CX-VX5

[Version Display Mode]

*The software version is displayed.

Procedure:

1. Press three buttons of X , [PRESET +] and [FUNCTION]

simultaneously for two seconds.

2. The message “MODEL NAME & AREA” is displayed. The

version display mode is activated.

3. Press the [DISPLAY] button. “STR ***” is displayed.

4. Each time the [DISPLAY] button is pressed, the display changes

in the order of DVD, MODEL NAME & AREA and STR.

5. To exit from this mode, press the ?/1 button.

[Key T est Mode]

* Button check

Procedure:

1. Press three buttons of x , [FUNCTION] and Z simultaneously.

2. The message “KEY00 V.OL” is displayed.

3. Each time a button is pressed, “KEY00 V.OL” value increases.

However, once a button is pressed, it is no longer taken into

account.

4. When all buttons are pressed, “KEY12 V.OL” appears and the

number blinking is stopped.

5. To exit from this mode, disconnect the power cord.

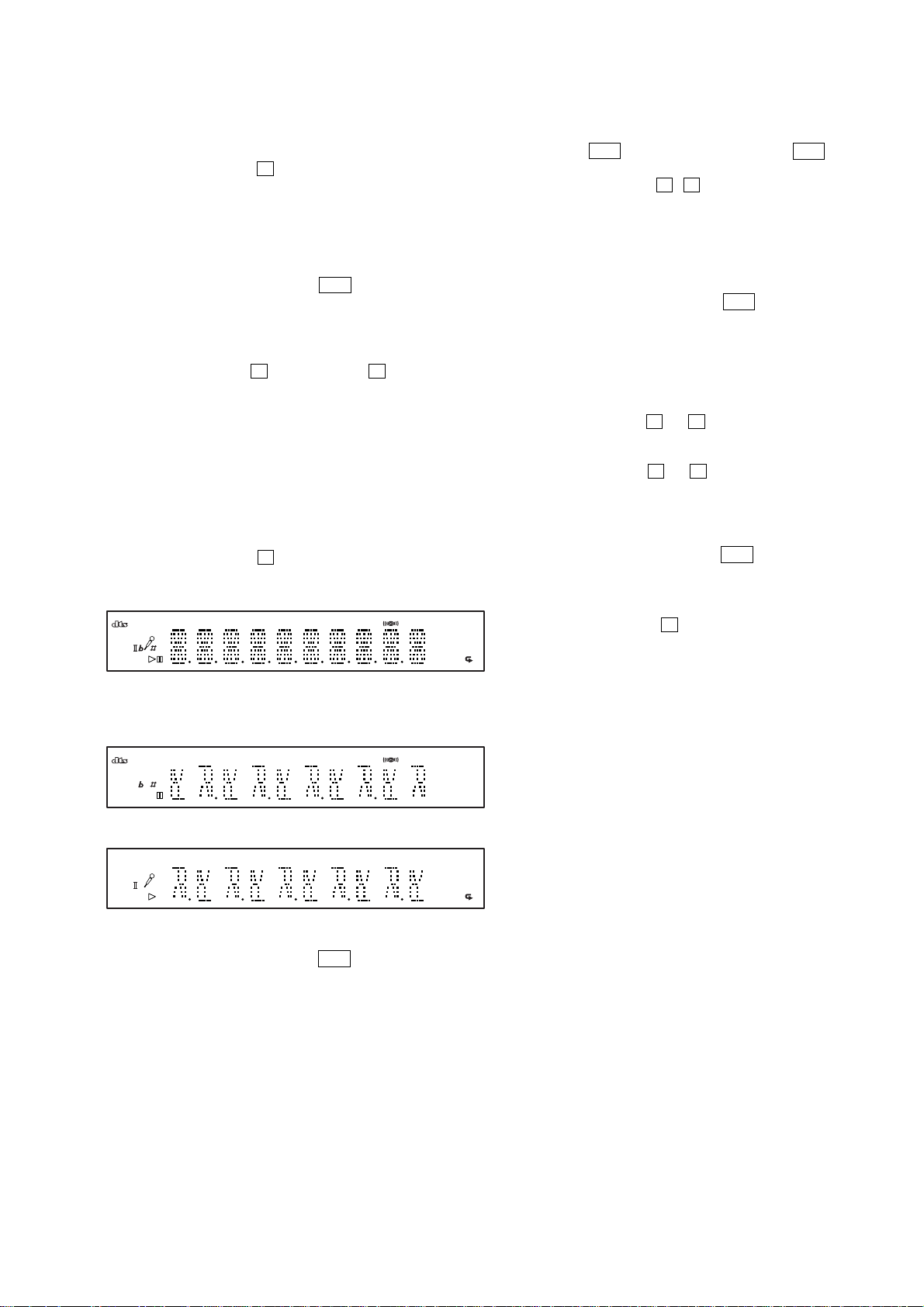

[Display T est Mode]

Procedure:

1. Press three buttons of X , [PRESET --] and [FUNCTION]

simultaneously.

2. All segments are turned on.

D

D

BASS

SLEEP

NTSC VF

D

D

D

PL

NIGHT

TRK CHAP ID3 ALBM MONO

TITLE

HMS

DVD SACD PBC

VCD MP3

kHz SHUF PGM

MHz

ALBM

TUNED

[OSD Test Mode]

Procedure:

1. Press the ?/1 button on the main unit or the ?/1 button on

the remote commander to turn the set on.

2. Press two buttons of Z , x and turn the [VOLUME] control

clockwise simultaneously.

3. The message “SERVICE IN” is displayed on the display. The

Test Mode Menu is displayed on the TV screen.

4. To execute each function, select the number on the remote

commander.

5. See the following section for explanation in detail.

6. To exit from this mode, press the ?/1 button.

[Disc Slot Lock]

The disc slot lock function for the antitheft of an demonstration

disc in the store is equipped.

Setting Procedure:

1. Turn the set on.

2. Press two buttons of x and Z simultaneously for five seconds.

3. The message “LOCKED” is displayed and the slot is locked.

Releasing Procedure:

1. Press two buttons of x and Z simultaneously for f ive seconds

again.

2. The message “UNLOCKED” is displayed and the slot is

unlocked.

Note : When “LOCKED” is displayed, the slot lock is not released

by turning power on/off with the ?/1 button.

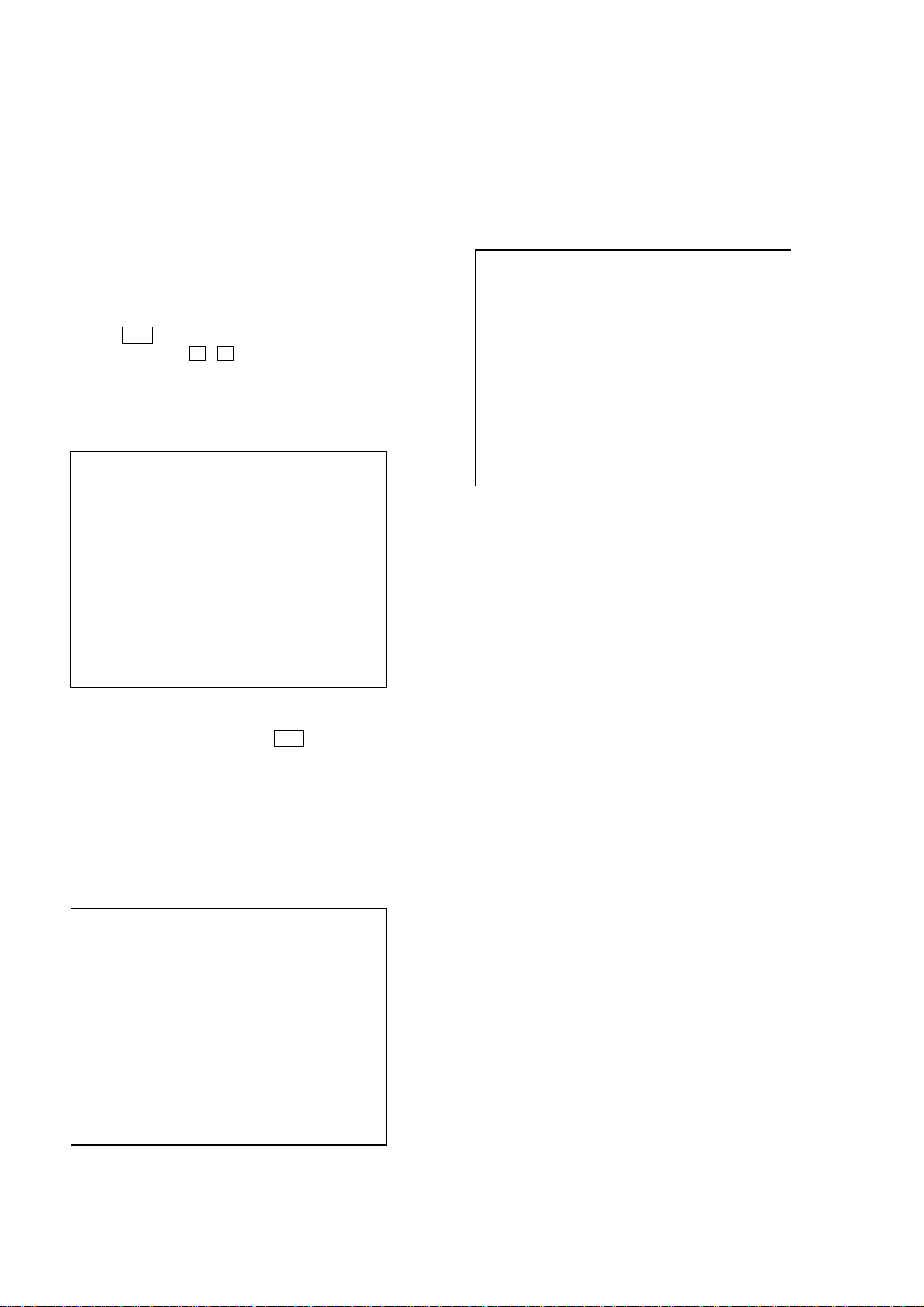

[Repeat Limit Release Mode]

Procedure:

1. Press three buttons of x , [PRESET +] and [FUNCTION]

simultaneously.

1

2. Repeat limit is released.

3. Press the [DISPLAY] button, all segments are turned off.

4. When the [DISPLAY] button is pressed, the display will light

up as follows.

TITLE

NTSC

D

D

PL

NIGHT

CHAP ALBM MONO

DVD PBC

V MP3

SHUF

ALBM

5. Press the [DISPLAY] button and confirm the display.

D

BASS

D

D

SLEEP

VF

TRK ID3

HMS

SACD

CD

kHz PGM

MHz

TUNED

6. Every pressing of the [DISPLAY] button turns on each segments

in the same order.

7. To exit from this mode, press the ?/1 button.

1

27

CX-VX5

[GENERAL DESCRIPTION]

The T est Mode allows you to make dia gnosis and adjustment easily

using the remote commander and monitor TV. The instructions,

diagnostic results, etc. are given on the on-screen display (OSD).

[TEST DISC LIST]

Use the following test disc on test mode.

TDV-520CSO (DVD-SL): PART No. J-2501-236-A

LUV-P01 (CD): PART No. 4-999-032-01

TDV-540C (DVD-DL): PART No. J-2501-235-A

Note: Do not use exiting test disc for DVD.

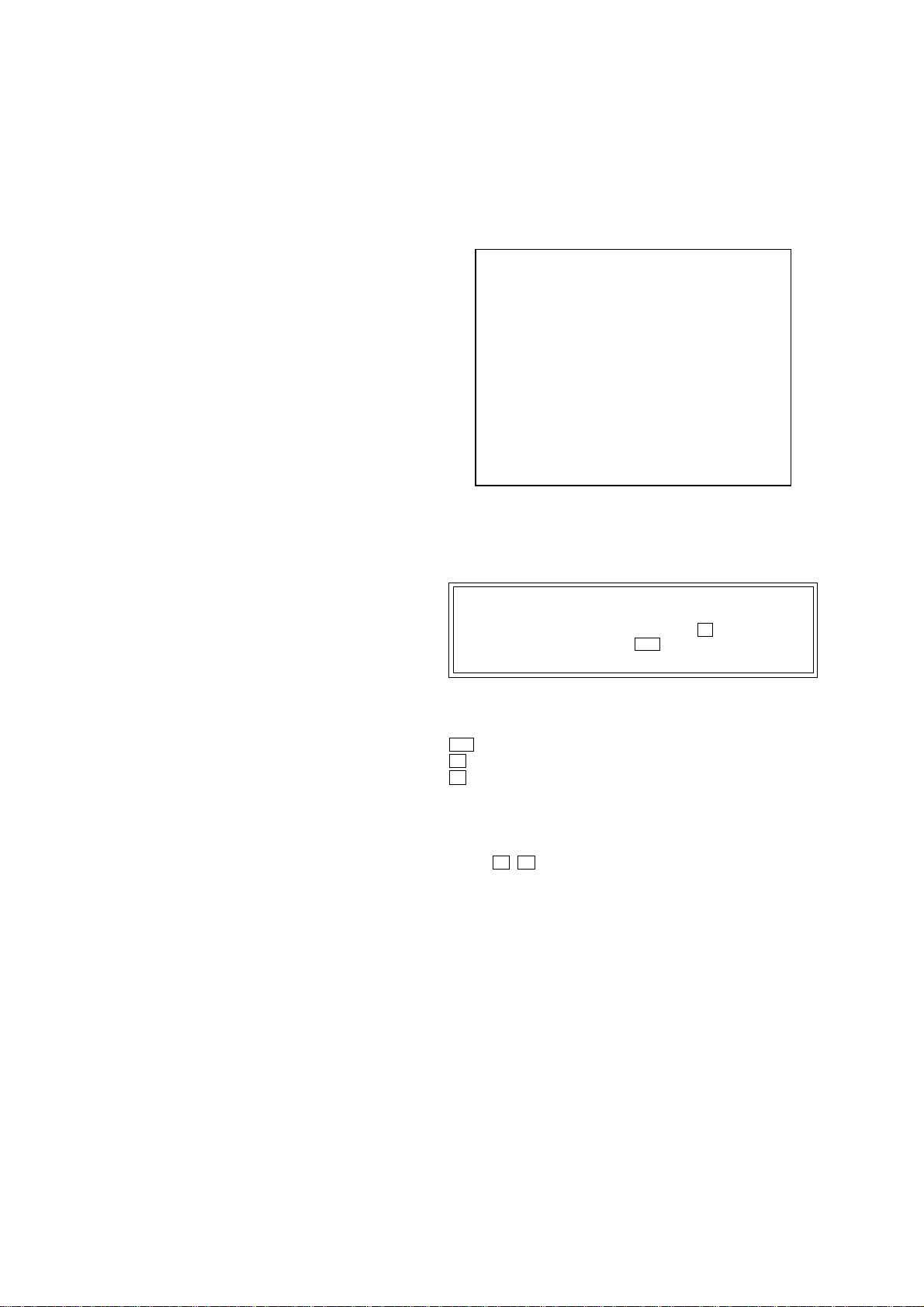

[ST ARTING TEST MODE]

1. Press the @/1 button to turn the power on.

2. Press two buttons of Z , x and turn the [VOLUME] control

clockwise simultaneously to enter the test mode.

3. It displays “SERVICE IN” on the fluorescent indicator tube,

and displays the Test Mode Menu on the monitor screen as

follows. (At the bottom of the menu screen, the model name

and revision number are displayed)

Test Mode Menu

0. Syscon Diagnosis

1. Drive Auto Adjustment

2. Drive Manual Operation

3. Mecha Aging

4. Emergency History

5. Mecha Error History

6. Version Information

7. Video Level Adjustment

Exit: POWER Key

Model :xx

Revision :x.xx

4. To execute each function, select the desired menu and press its

number on the remote commander.

5. To release from test mode, press the

power off.

@/1 button and turn the

0-1. All (All items continuous check)

This menu checks all diagnostic items continuously. Normally, all

items are checked successively one after another automatically

unless an error is found, but at a certain item that requires judgment

through a visual check to the result, the following screen is displayed

for the key entry.

• Example display

### Syscon Diagnosis ###

Diag All Check

No.2 Version

2-3. ROM Check Sum

Check Sum = ****

Press NEXT Key to Continue

Press PREV Key to Repeat

For the ROM Check, the check sum calculated by the Syscon is

output, and therefore you must compare it with the specified value

for confirmation.

Following the message, press the [NEXT ] button to go to the

next item, or press the [ PREV] button to repeat the same

operation again.

To quit the diagnosis and return to Check Menu screen, press the

.

>

[RETURN] key on the remote commander to display Check Menu.

• Error occurred

If an error occurred, the diagnosis is suspended and error is displayed.

Press the

diagnosis, or press the [ PREV] button to repeat the same check

where an error occurred, or press the [NEXT ] button to continue

the check from the item next to faulty item.

[RETURN] key on the remote commander to quit the

.

>

[OPERA TING TEST MODE]

0. SYSCON DIAGNOSIS

The same contents as board detail check by serial interface can be

checked from the remote commander operation.

On the Test Mode Menu screen, press [10/0] key on the remote

commander, and the following Check Menu will be displayed.

### Syscon Diagnosis ###

Check Menu

0. Quit

1. All

2. Version

3. EEPROM

4. GPIO

5. SD Bus

6. Video

0-0. Quit

Quit the Syscon Diagnosis and return to the Test Mode Menu.

General Description of Checking Method

Selecting 2 and subsequent items calls the submenu screen of each

item. And selecting 2 and subsequent items executes respective

menus and outputs the results.

For the contents of each submenu, see “Check Items List” as below .

Check Items List:

0-2. Version

0-2-1. All

0-2-2. Revision

0-2-3. ROM Check Sum

0-2-4. Model Type

0-2-5. Region

0-3. EEPROM Check

0-3-1. Sampling Check

0-3-2. Detail Check

0-4. GP I/O Check

0-5. SD Bus Check

0-6. Video Check

0-2. Version

0-2-2. Revision

The revision number of ROM (IC205) that the program for

the DVD system processor (IC206) is stored.

0-2-3. ROM Check Sum

Check sum is calculated. (4 digits hexadecimal number)

28

CX-VX5

0-2-4. Model Type

Model name is displayed. (DAV-SCX)

0-2-5. Region

Model destination code is displayed. (2 digits number)

0-3. EEPROM Check

0-3-1. Sampling Check

EEPROM check at every 64 words.

It compares read data with write data of each address. When

there are discrepancies between two data, it displays error.

0-3-2. Detail Check

EEPROM check at every 1 word.

It compares read data with write data of each address. When

there are discrepancies between two data, it displays error.

0-4. GP I/O Check

Pull up/down setting check of the DVD system processor (IC206)

pin 150, 151 and 154 (for clock setting port).

0-5. SD Bus Check

SD bus data check between DVD decoder (IC701) and D-RAM

(IC706).

0-6. Video Check

Output the color bars for video level adjustment.

1. DRIVE AUTO ADJUSTMENT

On the Test Mode Menu screen, press the [1] key on the remote

commander, and the Adjustment Menu will be displayed.

## Drive Auto Adjustment ##

Adjustment Menu

0. ALL

1. DVD-SL

2. CD

3. DVD-DL

1-1. DVD-SL (single layer)

Press the 1 ke y on the remote commander and insert a DVD single

layer disc following the message. Then the adjustment will be made

through the steps below, then adjusted values will be written to the

EEPROM.

DVD Single Layer Disc Adjustment Steps:

1. Sled tilt reset

2. Disc check memory SL

3. Wait 300 msec

4. Set disc type SL

5. LD on

6. Spindle start

7. Wait 1 sec

8. Focus servo on 0

9. Auto track offset adjust

10. CLVA on

11. Wait 500 msec

12. Tracking on

13. Wait 1 sec

14. Sled on

15. Check CLV on

16. Auto LFO adjust

17. Auto focus offset adjust

18. Auto tilt position adjust

19. Auto focus gain adjust

20. Auto focus offset adjust

21. EQ boost adjust

22. Auto loop filter offset adjust

23. Auto track gain adjust

Search Check

24. 32 track jump forward

25. 32 track jump reverse

26. 500 track jump forward

27. 500 track jump reverse

28.All servo stop

29.EEP copy loop filter offset

1-2. CD

Press the

following the message. Then the adjustment will be made through

the steps below , then adjusted values will be written to the EEPR OM.

[2] key on the remote commander and insert a CD disc

Exit: RETURN

Normally,

DVD (dual layer) in this order . But, individual items can be adjusted

for the case where adjustment is suspended due to an error. In this

mode, the adjustment can be made easily through the operation

following the message displayed on the screen.

The disc used for adjustment must be the one specified for

adjustment.

1-0. ALL

Press the [10/0] key on the remote commander, and the servo set

data in EEPROM will be initialized. Then, 1. DVD-SL disc, 2. CD

disc and 3. DVD-DL disc are adjusted in this order.

Each time one disc was adjusted, it is ejected. Replace it with the

specified disc following the message. You can f inish the adjustment

by pressing the [RETURN] button on the remote commander.

Note: During adjustment of each disc, the measurement for disc type judg-

[10/0] is selected to adjust DVD (single layer), CD and

ment is made. As automatic adjustment does not judge the disc

type unlike conventional models, take care not to insert wrong type

discs. Also, do not give a shock during adjustment.

CD Adjustment Steps

1. Sled tilt rest

2. Disc check memory CD

3. Wait 500 msec

4. Set disc type CD

5. LD on

6. Spindle start

7. Wait 500 msec

8. Focus servo on 0

9. Auto track offset adjust

10. CLVA on

11. Wait 500 msec

12. Tracking on

13. (TC display start)

14. Wait 1 sec

15. Jitter display start

16. Sled ON

17. Check CLV on

18. Auto loop filter offset adjust

19. Auto focus offset adjust

20. Auto focus gain adjust

21. Auto focus offset adjust

22. EQ boost adjust

23. Auto LFO Adjust

29

CX-VX5

24. Auto track gain adjust

Search Check

25. 32Tj forward

26. 32Tj reverse

27. 500Tj forward

28. 500Tj reverse

29. All servo stop

1-3. DVD-DL (dual layer)

Press the [3] key on the remote commander and insert a DVD dual

layer disc following the message. Then the adjustment will be made

through the steps below, then adjusted values will be written to the

EEPROM.

DVD Dual Layer Disc Adjustment Steps:

1. Sled tilt reset

2. Disc check memory DL

3. Wait 500 msec

4. Set disc type DL

5. LD on

6. Spindle start

7. Wait 1 sec

Layer 1 Adjust

8. Focus servo on 0

9. Auto track offset adjust

10. CLVA on

11. Wait 500 msec

12. Tracking on

13. Wait 500 msec

14. Sled on

15. Check CLV lock

16. Auto loop filter offset adjust, Auto focus adjust

17. Auto focus gain adjust

18. Auto focus offset adjust

19. EQ boost adjust

20. Auto loop filter offset adjust

21. Auto Track Gain Adjust

Search Check

22. 32 track jump forward

23. 32 track jump reverse

24. 500 track jump forward

25. 500 track jump reverse

Layer 0 Adjust

26. Focus jump (L1 t L0)

27. Auto track offset adjust L0

28. CLVA on

29. Wait 500 msec

30. Tracking on

31. Wait 500 msec

32. Sled on

33. Check CLV lock

34. Auto focus filter offset adjust

35. Auto Focus Adjust

36. Auto focus gain adjust

37. Auto focus offset adjust

38. EQ boost adjust

39. Auto Loop Filter Offset

40. Auto track gain adjust

Search Check

41. 32 track jump forward

42. 32 track jump reverse

43. 500 track jump forward

44. 500 track jump reverse

Layer Jump Check

45. Layer jump (L0 ? L1)

46. Layer jump (L1 ? L0)

47. All servo stop

2. DRIVE MANUAL OPERA TION

Note: This mode is used for design, and not used in service fundamen-

tally.

On the Test Mode Menu screen, press the [2] key on the remote

commander, and the Operation Menu will be displayed. For the

manual operation, each servo on/off control and adjustment can be

executed manually.

## Drive Manual Operation ##

Operation Menu

1. Disc Type

2. Servo Control

3. Track/Layer Jump

4. Non EEPROM Write Adjust

5. EEPROM Write Adjust

6. Memory Check

7. Disc Check Memory

8. Error Rate Display

9. SACD Water Mark

Exit: RETURN

In using the manual operation menu, take care of the following

points. These commands do not provide protection, thus requiring

correct operation. The sector address or time code field is displayed

when a disc is loaded.

Note:

1. Set correctly the disc type to be used on the Disc Type screen.

2. In case of an alarm, immediately press the x button to stop the

servo operation, and press the @/1 button to turn the power off.

Basic operation:

(controllable from front panel or remote commander)

@/1 :Power OFF (release the Test Mode)

x : Servo stop

A : Stop and eject

[RETURN] : Return to Operation Menu or Test

Mode Menu

[ PREV], [NEXT ] :Transition between sub modes of menu

>.

[1] to [9], [10/0] : Selection of menu items

Cursor o/

O

: Increase/Decrease in manually

adjusted value

30

Loading...

Loading...