Page 1

CX-LFA660/LFA770

SERVICE MANUAL

Ver. 1.1 2005.10

CX-LFA660/LFA770 are the Amplifier , CD pla yer, Tape

Deck and Tuner section in XR-FA660/FA770.

Photo : CX-LFA660

CD CD Mechanism Type CDM77B-F1BD81A

Section Base Unit Name BU-F1BD81A

TAPE Model Name Using Similar Mechanism NEW

Section Tape Transport Mechanism T ype CMAL1Z240A

AEP Model

UK Model

CX-LFA660/LFA770

Australian Model

CX-LFA660

Model Name Using Similar Mechanism NEW

Optical Pick-up Name KSM-215DCP/C2NP

SPECIFICATIONS

Amplifier section

CX-LFA770 for XR-FA770

DIN power output (rated): 55 + 55 W

(6 ohms at 1 kHz, DIN)

Continuous RMS power output (referen ce):

70 + 70 W

(6 ohms at 1 kHz, 10%

THD)

Music power output (reference):

125 + 125 W

CX-LFA660 for XR-FA660

European model:

DIN power output (rated): 40 + 40 W

(6 ohms at 1 kHz, DIN)

Continuous RMS power output (referen ce):

50 + 50 W

(6 ohms at 1 kHz, 10%

THD)

Music power output (reference):

85 + 85 W

Other models:

The following measured at AC 230 – 240 V, 50/60 Hz

DIN power output (rated): 40 + 40 W

(6 ohms at 1 kHz, DIN)

Continuous RMS power output (referen ce):

50 + 50 W

(6 ohms at 1 kHz, 10%

THD)

Inputs

MD IN (RCA pin jacks): Sensitivity 2 V,

impedance 47 kilohms

Outputs

PHONES (stereo mini jack):

Accepts headphones with

an impedance of 32 ohms

or more

SPEAKER: Accepts impedance of

6ohms

CD player section

Laser Semiconductor laser

(λ=770 – 810 nm)

Emission duration:

continuous

Frequency response 20 Hz – 20 kHz

Tape deck section

Recording system 4-track 2-channel, stereo

— Continued on next page —

9-879-045-02

2005J16-1

© 2005.10

COMPACT DISC DECK RECEIVER

Sony Corporation

Personal Audio Division

Published by Sony Engineering Corporation

Page 2

CX-LFA660/LFA770

Frequency response 50 – 13,000 Hz (±3 dB),

using Sony TYPE I

cassettes

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 – 108.0 MHz

(50-kHz step)

Antenna FM lead antenna

Antenna terminals 75 ohms unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

European model: 531 – 1,602 kHz

(with the tuning interval

set at 9 kHz)

Other models: 530 – 1,710 kHz

(with the tuning interval

set at 10 kHz)

531 – 1,602 kHz

(with the tuning interval

set at 9 kHz)

Antenna AM loop antenna, external

antenna terminal

Intermediate frequency 450 kHz

General

Power requirements

European model: 230 V AC, 50/60 Hz

Australian model: 230 – 240 V AC, 50/60 Hz

Power consumption

XR-FA770: 75 W

0.3 W (in Power Saving

Mode)

XR-FA660

European model: 65 W

0.3 W (in Power Saving

Mode)

Other models: 70 W

Dimensions (w/h/d) Approx. 190 × 250 × 308

mm incl. projecting parts

and controls

Mass

CX-LFA770 for XR-FA770:

Approx. 6.1 kg

CX-LFA660 for XR-FA660:

Approx. 5.8 kg

Design and specifications are subject to change

without notice.

TABLE OF CONTENTS

1. SERVICING NOTES ................................................ 3

2. GENERAL ................................................................... 5

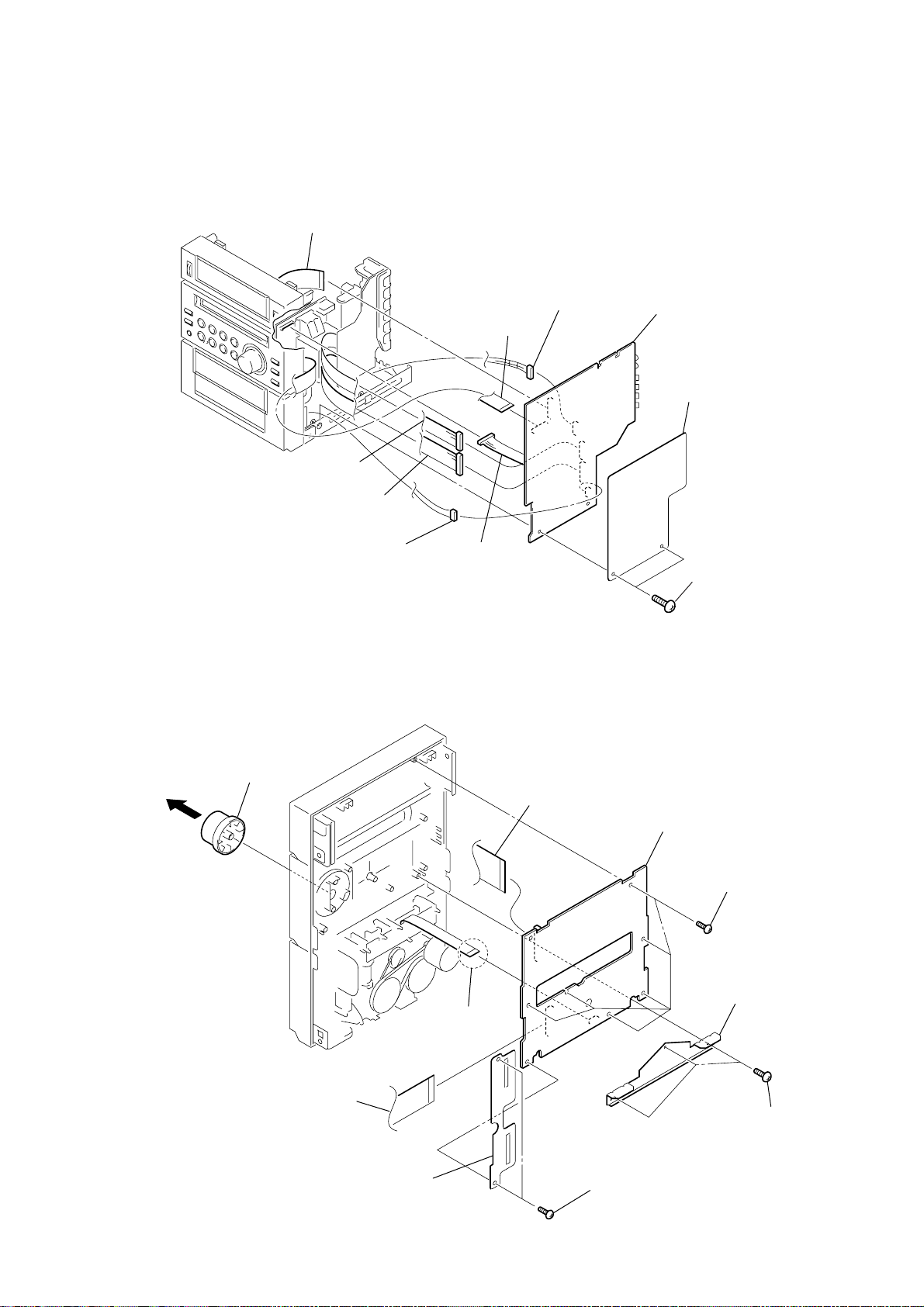

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 8

3-2. Top Cabinet, Tuner (FM/AM), DC Fan.......................... 9

3-3. Panel (DVD) .................................................................... 9

3-4. CD Mechanism Section................................................... 10

3-5. Front Panel Section ......................................................... 10

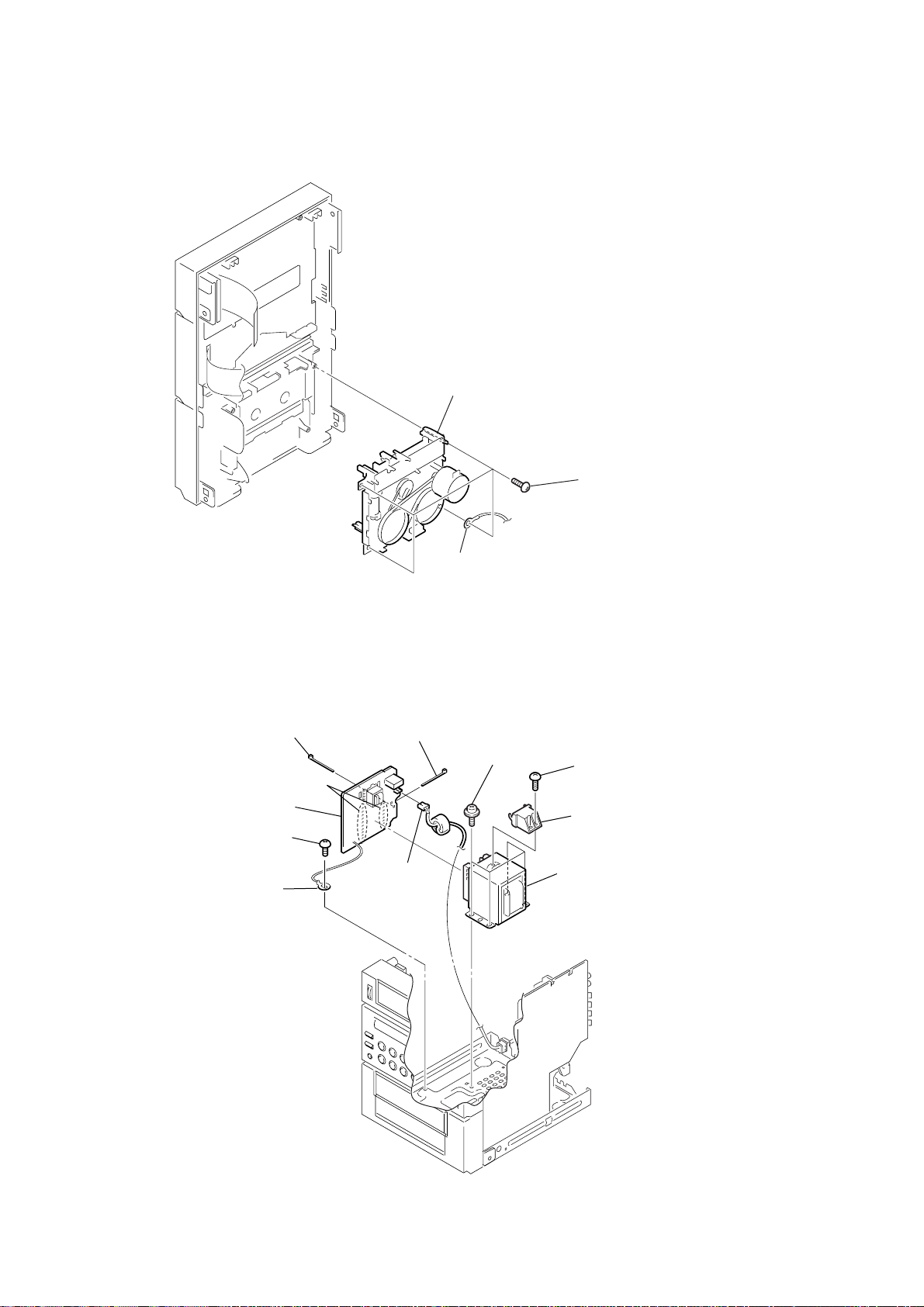

3-6. MAIN Board.................................................................... 11

3-7. FRONT Board ................................................................. 11

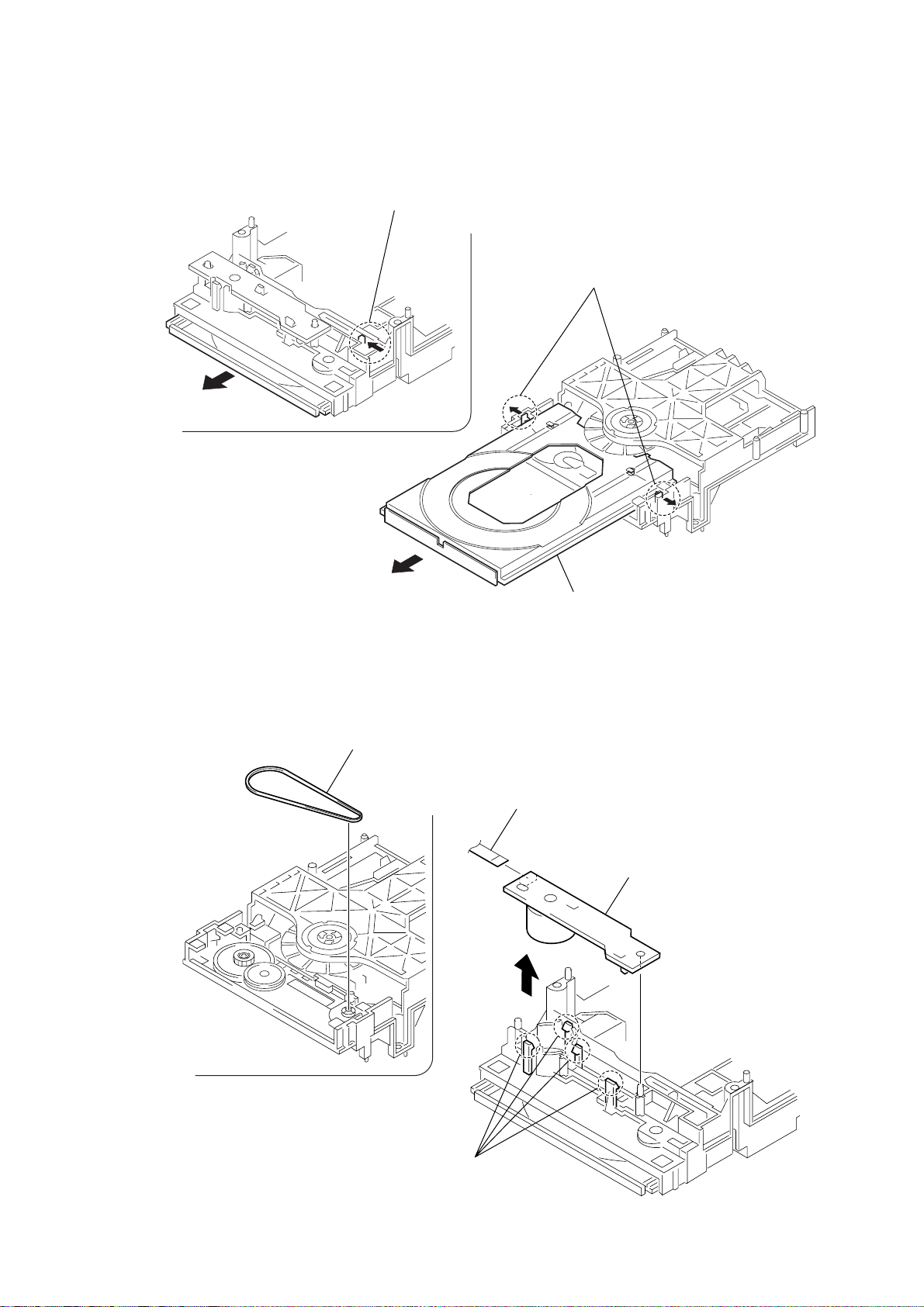

3-8. Cassette Deck Mechanism............................................... 12

3-9. Power Transformer .......................................................... 12

3-10. Tray (AU) ........................................................................ 13

3-11. MS-128 Board ................................................................. 13

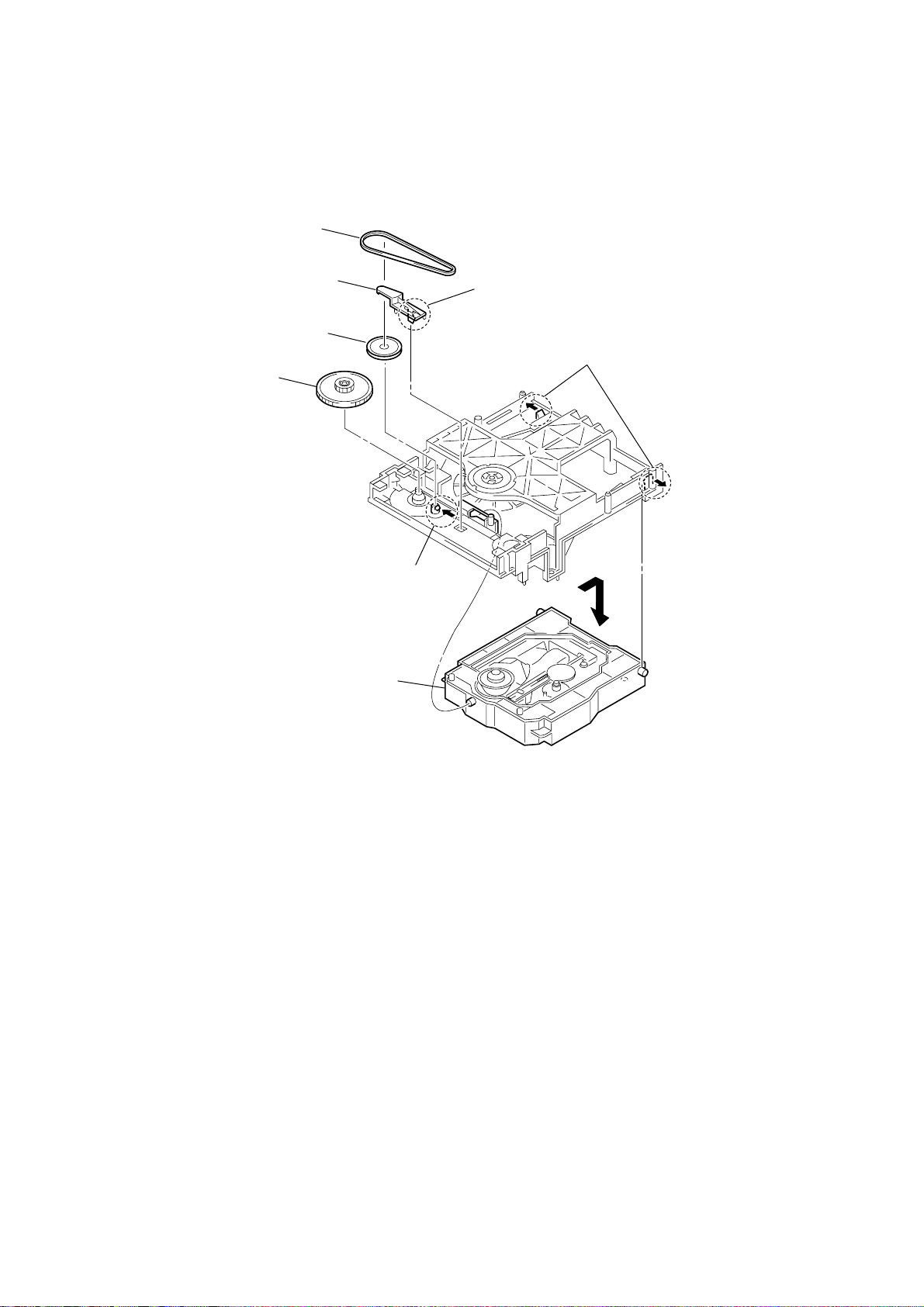

3-12. Base Unit, Belt, Driving Gear ......................................... 14

4. TEST MODE ............................................................... 15

5. MECHANICAL ADJUSTMENTS......................... 16

6. ELECTRICAL ADJUSTMENTS .......................... 17

7. DIAGRAMS

7-1. Block Diagram – BD Section –...................................... 22

– MAIN Section – ........................................................... 23

7-2. Printed Wiring Board – BD81A Section – ..................... 24

7-3. Schematic Diagram – BD81A Section –........................ 25

7-4. Printed Wiring Boards – MAIN Section – ..................... 26

7-5. Schematic Diagram – MAIN Section (1/2) –................. 27

7-6. Schematic Diagram – MAIN Section (2/2) –................. 28

7-7. Printed Wiring Board – FRONT Section –..................... 29

7-8. Schematic Diagram – FRONT Section – ....................... 30

7-9. Printed Wiring Board – AMP Section – ......................... 31

7-10. Schematic Diagram – AMP Section – ............................ 32

7-11. Printed Wiring Board – PT Section – ............................. 33

7-12. Schematic Diagram – PT Section –................................ 33

8. EXPLODED VIEWS

8-1. Overall Section ................................................................ 41

8-2. Front Section ................................................................... 42

8-3. Chassis Section................................................................ 43

8-4. CD Mechanism Deck Section (CDM77B-F1BD81A).... 44

8-5. Base Unit (BU-F1BD81A).............................................. 45

9. ELECTRICAL PARTS LIST .................................. 46

2

Page 3

SECTION 1

SERVICING NOTES

CX-LFA660/LFA770

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on the

rear exterior.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveforms is output three times.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

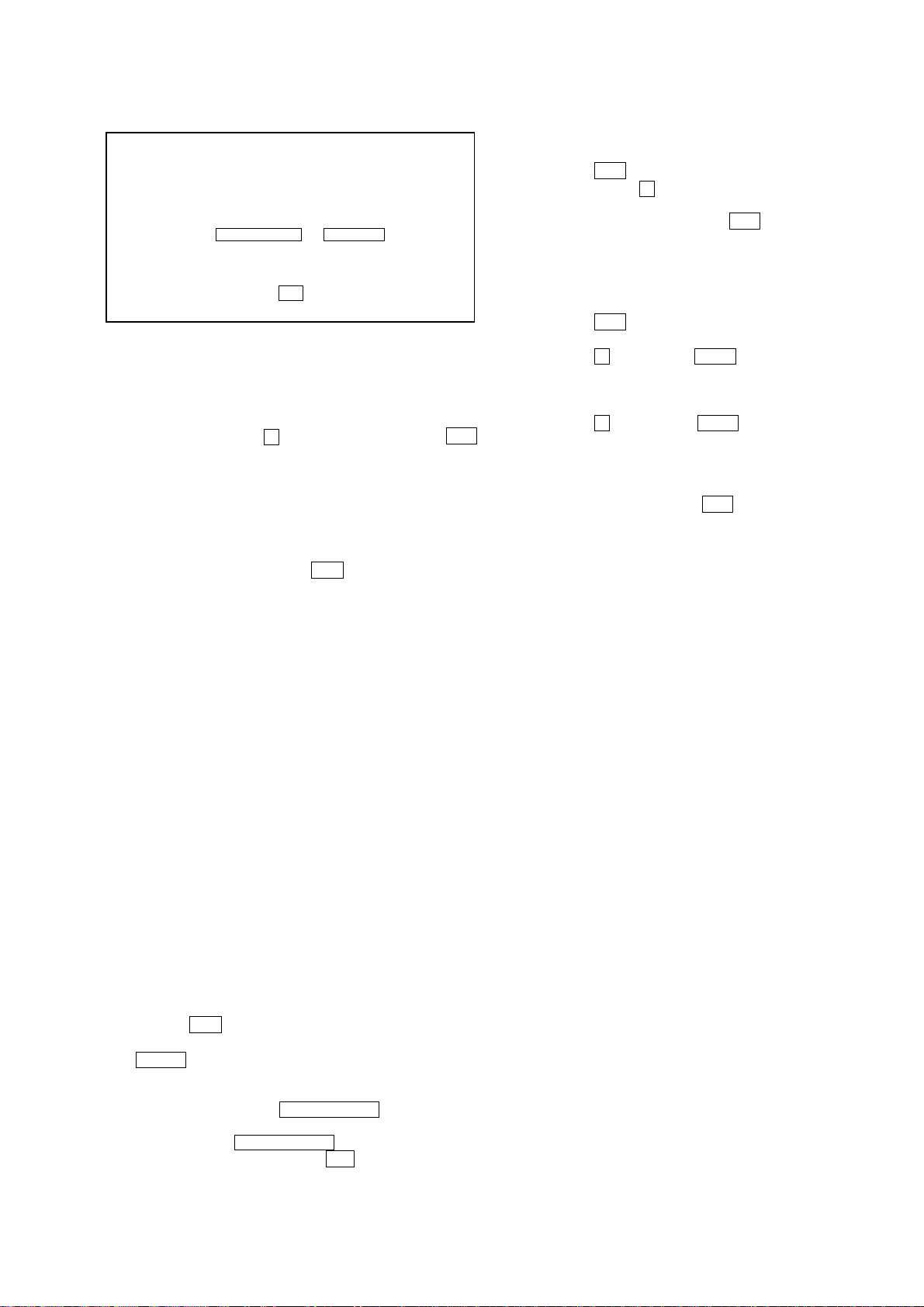

MODEL IDENTIFICATION

– Back Panel –

Part No.

Model Name Part No.

AEP and UK models 2-067-053-0[ ]

Australian model 2-067-053-2[ ]

3

Page 4

CX-LFA660/LFA770

k

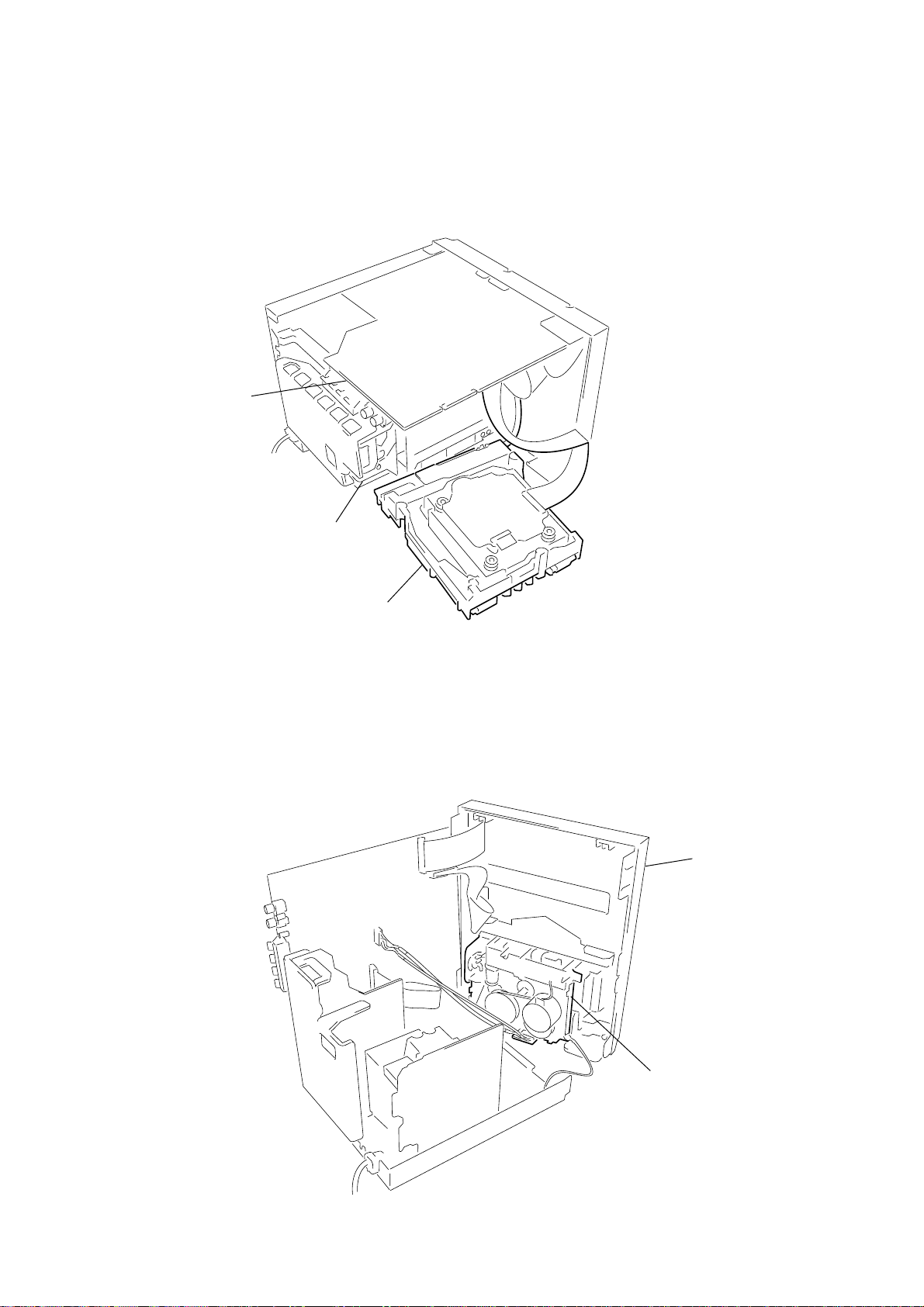

• SERVICE POSITION OF THE CD MECHANISM DECK

*

Lay the CX-LFA660/LFA770 with the left-side facing downward and then check the CD mechanism deck after removing it

from the Holder Mech.

MAIN Board

holder mech

CD mechanism deck

• SERVICE POSITION OF THE TAPE CASSETTE MECHANISM DECK

*

Remove the CD mechanism deck and the Holder mech from the unit and check the tape cassette mechanism deck with

the front panel being open.

front panel

tape cassette mechanism dec

4

Page 5

SECTION 2

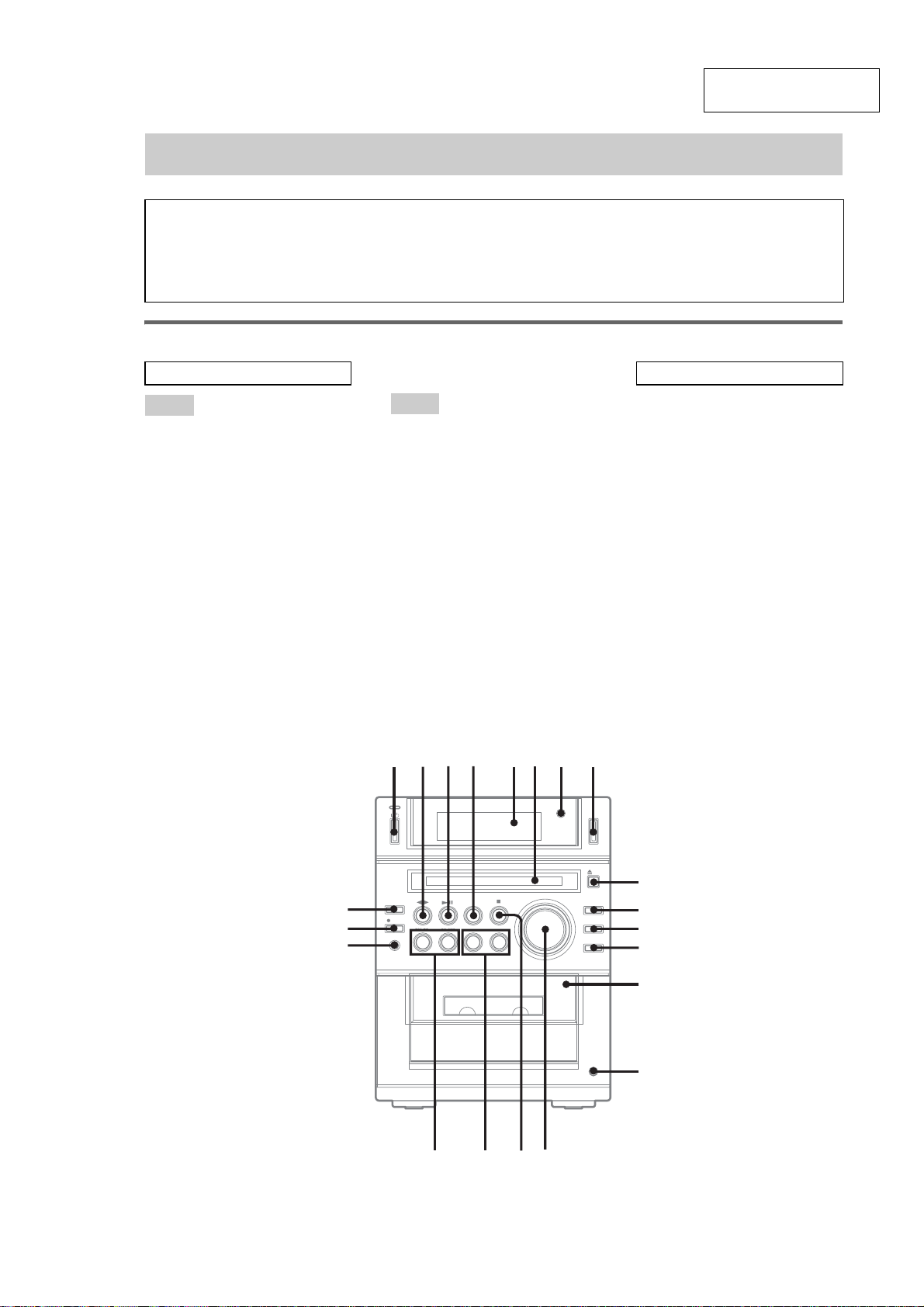

Main unit

ALBUM +/– qj (10, 11, 16)

BASS/TRE qa (18)

Cassette compartment qd

CD SYNC wa (16)

Disc tray 6

DISPLAY 8 (14, 21)

Display window 5

i-Bass q; (18)

MD ql (23)

PHONES jack qf

PLAY MODE qs (9, 11, 15, 16,

17)

Remote sensor 7

TUNER/BAND 4 (12, 13)

TUNING +/– qk (12, 13)

TUNING MODE qs (12, 13)

VOLUME control qg (26)

?/1 (power) 1 (7, 13, 26)

TAPE nN (play) 2 (15, 16)

CD NX (play/pause) 3 (9)

Z CD (open/close) 9 (9)

Z PUSH OPEN (tape open/close)

qd (15)

x (stop) qh (10, 12, 15, 16, 26)

m/M (rewind/fast forward)

qk (10, 15)

l/L (go back/go forward)

qk (10, 17, 18)

z REC PAUSE/START (record)

w; (16)

List of button locations and reference pages

How to use this page

Use this page to find the location of buttons and other

parts of the system that are mentioned in the text.

Illustrati

on number

r

DISPLAY

8 (

14, 21

)

RR

Name of button/ pa r t Reference page

ALPHABETICAL ORDER

A – O

P – Z

BUTTON DESCRIPTIONS

1234 567 8

9

q;

qa

qs

qf

qd

qg

qhqjqk

ql

w;

wa

GENERAL

CX-LFA660/LFA770

This section is extracted

from instruction manual.

5

Page 6

CX-LFA660/LFA770

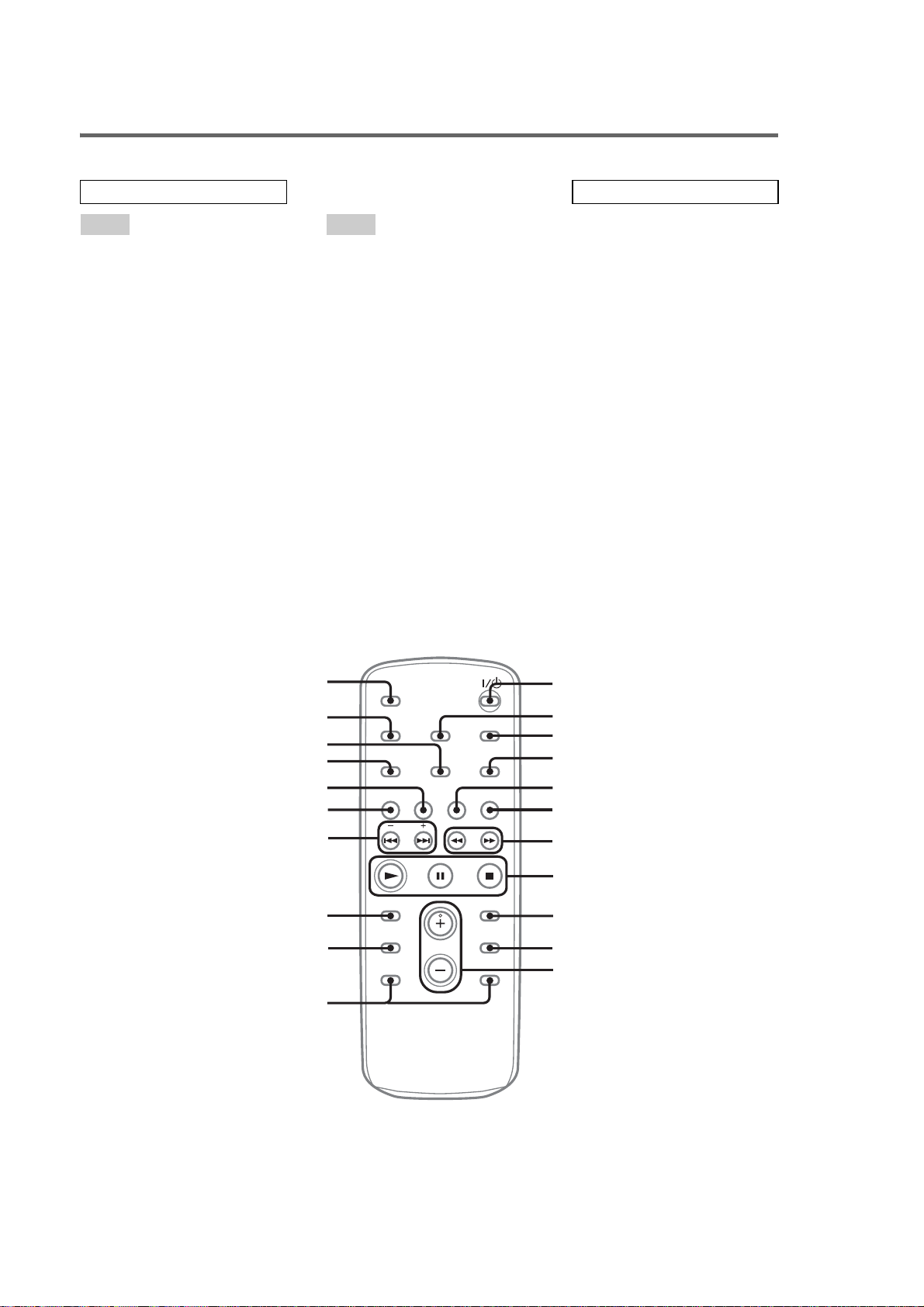

Remote control

ALPHABETICAL ORDER

A – O P – Z

ALBUM +/– qs (10, 11)

CD qj (9, 11)

CLEAR qf (11)

CLOCK/TIMER SELECT 2

(19, 20)

CLOCK/TIMER SET 3 (8, 19,

20)

DISC SKIP* q;

DISPLAY w; (14, 21)

ENTER 9 (8, 11, 12, 19, 20)

EQ qd (18)

FM MODE 4 (14)

FUNCTION 6 (9, 11, 15, 20, 23)

PLAY MODE ql (9, 11, 15, 20)

REPEAT 4 (10)

SLEEP wa (18)

TAPE qh (15, 20)

TUNER BAND 5 (12, 13)

TUNER MEMORY qk (12)

TUNING MODE ql (12, 13)

VOLUME +/– qa (19)

BUTTON DESCRIPTIONS

?/1 (power) 1 (7, 19)

m/M (rewind/fast forward )

7 (10, 15)

x (stop) 8 (10, 12, 15)

X (pause) 8 (10, 15)

N (play) 8 (9, 15, 20)

./> (go back/go forward)

qg (8, 10, 18, 19)

+/– (tuning) qg (12)

*Button does not function with

this model.

wa

w;

ql

qk

qj

qh

qg

qf

qd

qs

1

2

3

4

5

6

7

8

9

0

qa

6

Page 7

Setting the clock

Use buttons on th e remote for the operatio n.

1

Press ?/1 to turn on the system.

2

Press CLOCK/TIMER SET.

3

Press . or > rep eatedly to set the

hour.

4

Press ENTER.

5

Press . or > rep eatedly to set the

minute.

6

Press ENTER.

The clock sta rt s working.

To adjust the clock

CX-LFA660/LFA770

1

Press CLOCK/T IM ER SE T.

2

Press . or > repeatedly until “CLOCK”

appears, then press ENTER.

3

Do the same procedures as step 3 to 6

above.

7

Page 8

CX-LFA660/LFA770

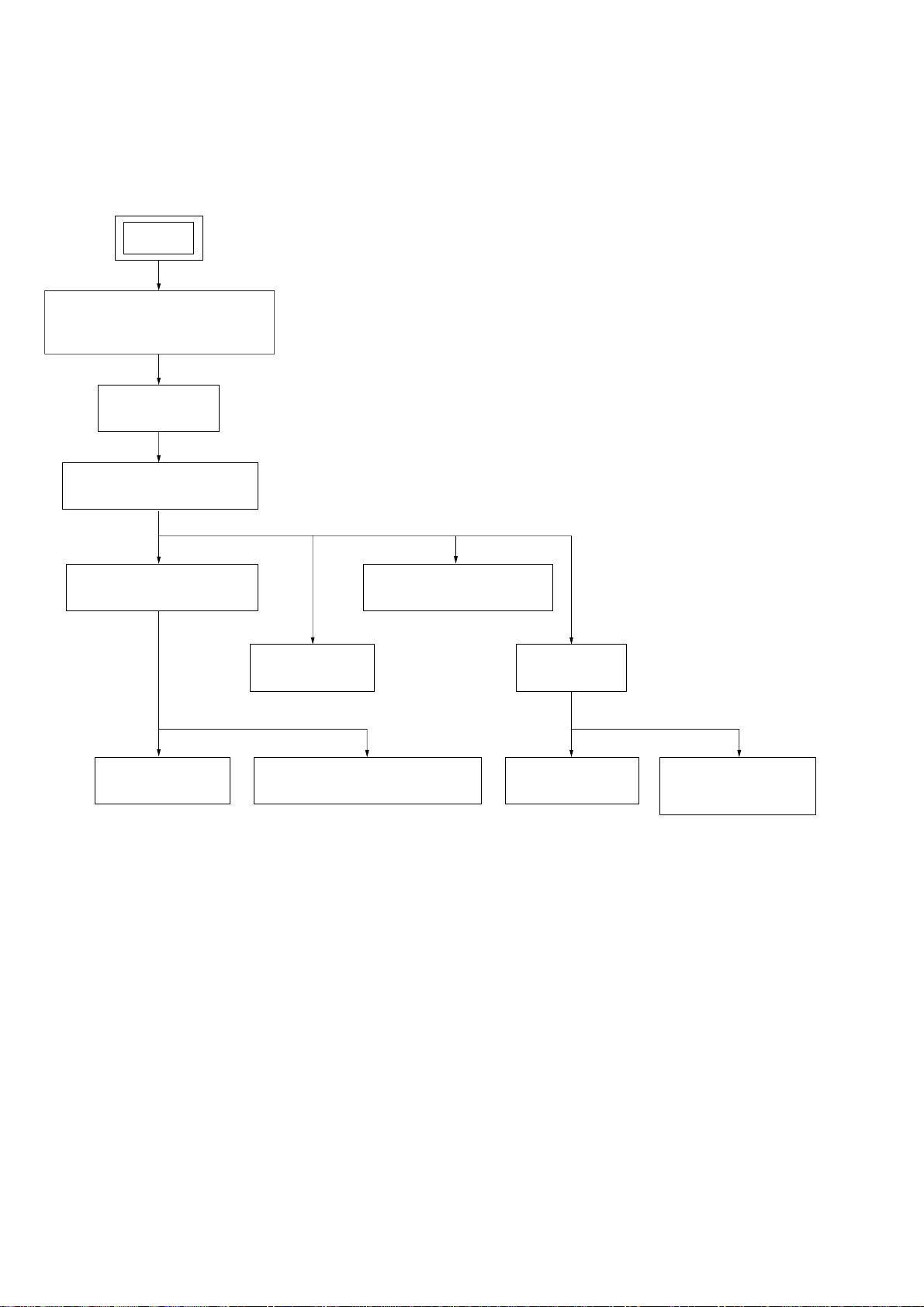

3-1. DISASSEMBLY FLOW

•This set can be disassembled in the order shown below.

SET

SECTION 3

DISASSEMBLY

3-2. T OP CABINET , TUNER (FM/AM),

DC FAN

(Page 9)

3-3. PANEL (DVD)

(Page 9)

3-4. CD MECHANISM SECTION

(Page 10)

3-5. FRONT PANEL SECTION

(Page 10)

3-6. MAIN BOARD

(Page 11)

3-9. POWER TRANSFORMER

(Page 12)

3-10. TRAY (AU)

(Page 13)

3-7. FRONT BOARD

(Page 11)

3-8. CASSETTE DECK MECHANISM

(Page 12)

3-11. MS-128 BOARD

(Page 13)

3-12. BASE UNIT, BELT,

DRIVING GEAR

(Page 14)

8

Page 9

Note: Follow the disassembly procedure in the numerical order given.

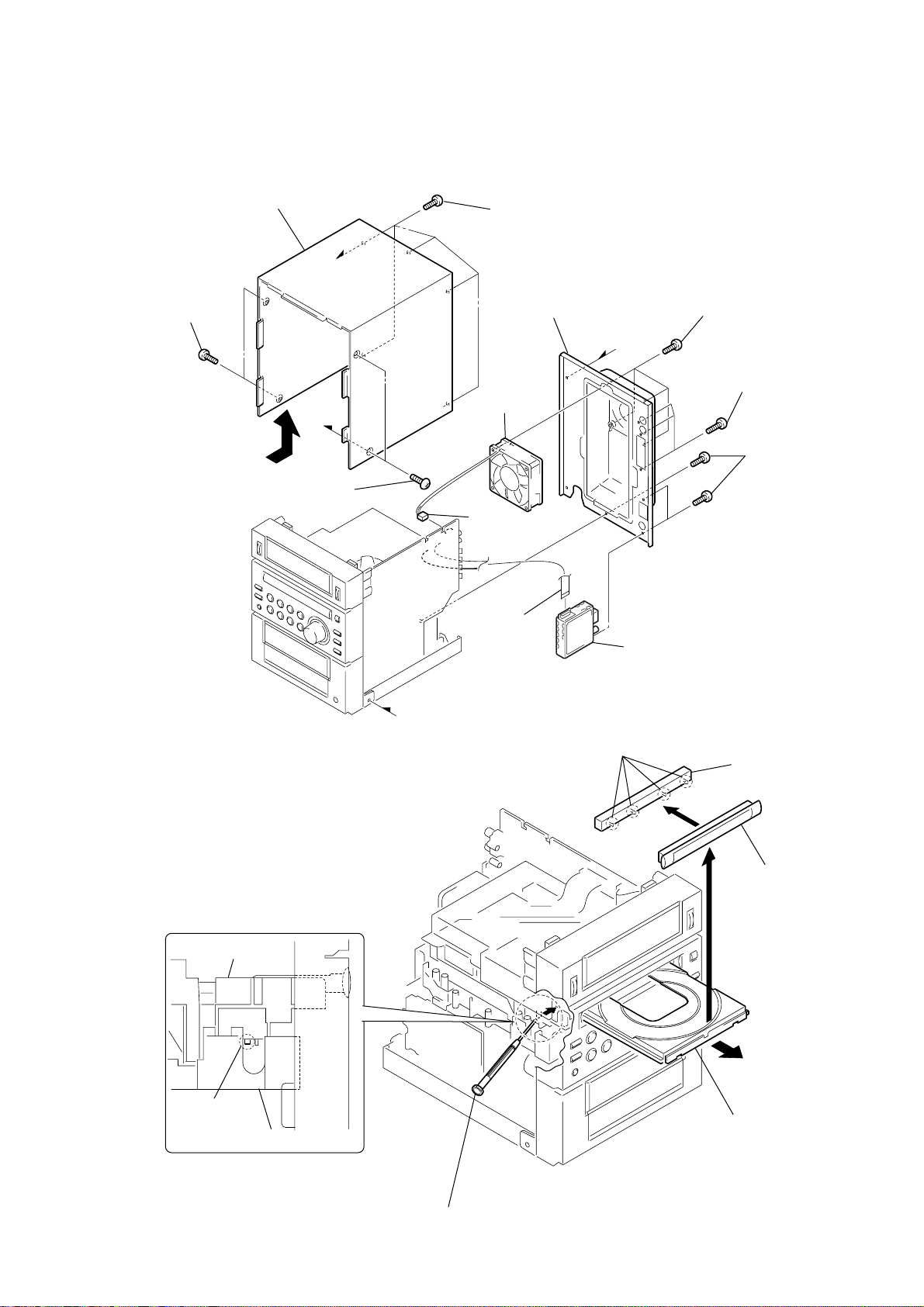

3-2. TOP CABINET, TUNER (FM/AM), DC FAN

5

2

two s

(+BVTP 3

crews

×

8)

top cabinet

b

4

1

two s

(+BVTP 3

crews

a

×

8)

3

five s

qd

DC fan

crews

rear panel

(+BVTP 3

qs

q;

connector

(3P)(CN290)

CX-LFA660/LFA770

×

8)

qa

four s

(+BVTP 3

a

crews

×

8)

6

three s

(+BVTP 3

7

(+BVTP 3

crews

three s

×

10)

crews

×

8)

3-3. PANEL (DVD)

CD mechanism

8

wire (flat type)

(15 core)

b

3

four claws

9

tuner

4

base loading

5

panel (DVD)

chuck cam

2

holder mecha

1

Move the chuck cam located at the bottom of the CD mechanism in the direction of the arrow

using the flathead screwdriver.

Pull-out the disc tray.

9

Page 10

CX-LFA660/LFA770

)

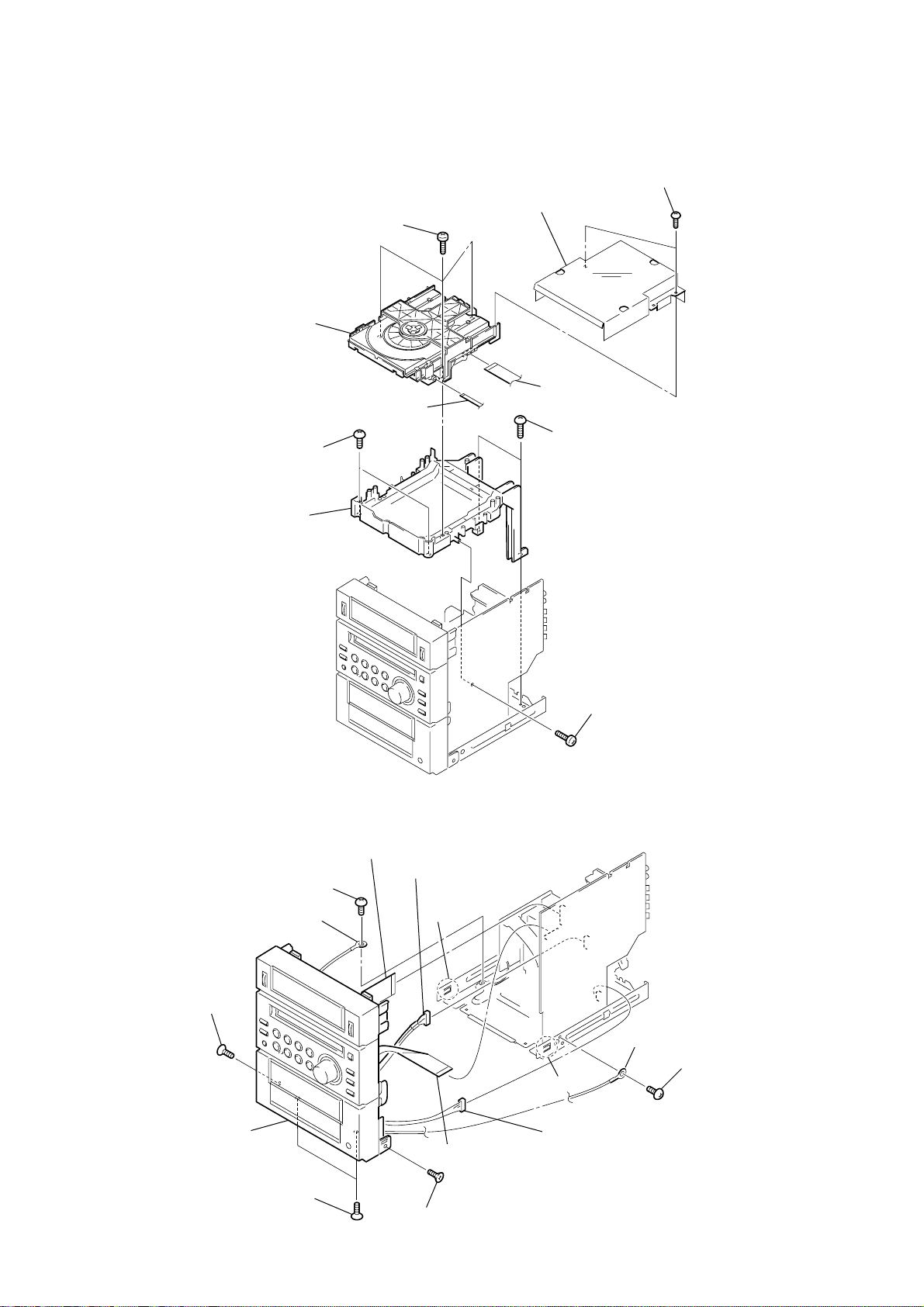

3-4. CD MECHANISM SECTION

6

CD mechanism deck

(CDM77B-F1BD81A)

8

two s

(+BVTP 3

3

three s

(+BVTP 3

5

wire (flat type) (5 core)

crews

×

crews

8)

1

two s

(+BVTP 2.6

2

shield case (mecha)

×

10)

4

wire (flat type)

(27 core)

9

two s

(+BVTP 3

crews

crews

×

10)

×

8)

q;

holder mecha

3-5. FRONT PANEL SECTION

2

1

screw

(+B 3)

earth wire

5

wire (flat type)

(25core) (CN603)

9

connector

(7P) (CN601)

qd

claw

7

s

crew

(+BVTP 3

×

10

10

qa

two screws

(+KTP 3

qf

front panel section

7

×

8)

screw

(+KTP 3

4

earth wire

3

screw

qs

claw

8

connector

6

wire (flat type)

(21core) (CN602)

×

8)

q;

two screws

(+KTP 3

×

8)

(5P) (CN201)

(+B 3)

Page 11

3-6. MAIN BOARD

)

2

wire (flat type)

(25core) (CN603)

7

connector

(9P) (CN002)

8

connector

(11P) (CN003)

3

wire (flat type)

(21core) (CN602)

5

connector

(7P) (CN601)

CX-LFA660/LFA770

q;

MAIN board

9

sheet (PWB MAIN)

3-7. FRONT BOARD

1

knob (VOL)

6

connector

(5P) (CN201)

1

connector

(10P) (CN257)

8

w

ire (flat type)

25core (CN802)

q;

FRONT board

4

two s

six s

crews

crews

3

bracket

(+BVTP 3

4

(+BVTP 2.6

×

10)

×

10)

9

w

ire (flat type)

21core (CN801)

6

sheet (protection)

7

w

ire (flat type)

8core (CN803)

5

two s

(+BVTP 2.6

crews

2

three s

crews

×

(+BVTP 3

×

10)

10

11

Page 12

CX-LFA660/LFA770

)

3-8. CASSETTE DECK MECHANISM

3

cassette deck mechanism

1

four screws

(+BVTP 3

×

10)

3-9. PO WER TRANSFORMER

5

binding band

9

Remove the soldering.

q;

PT board

1

s

(+B 3)

2

earth wire

crew

4

binding band

6

connector

(CN202)

2

earth wire

3

four s

crews

7

(+BVTP 3

8

holder (PWB PT

qa

power transformer

s

crew

×

8)

12

Page 13

3-10. TRAY (AU)

2

1

Move the Chuck cam in the direction of the arrow.

bottom side

two claws

3

CX-LFA660/LFA770

3-11. MS-128 BOARD

1

belt

4

5

tray (AU)

2

wire (flat type)

(5core) (CN001)

4

MS-128 board

3

four claws

13

Page 14

CX-LFA660/LFA770

3-12. BASE UNIT, BELT, DRIVING GEAR

4

belt

6

support

8

pulley gear

9

driving gear

5

claw

1

two claws

3

base unit

(BU-F1BD81A)

7

claw

2

14

Page 15

SECTION 4

TEST MODE

CX-LFA660/LFA770

Note 1: Regarding the notification symbol “R”

Because the number of the operating buttons of this product

are limited, some operations require use of the operating

buttons of the remote commander. When a specific operation

requires use of the operating buttons of the remote commander,

“R” is added to the specific operating procedure in this manual.

Example MENU/NO “R” The MENU/NO button of remote

commander.

Note 2: Incorrect operations may be performed if the test mode is

not entered properly.

In this case, press the ?/1 button to turn the po wer of f, and

retry to enter the test mode.

1. Cold Reset

• The cold reset clears all data including preset data stored in

the RAM to initial conditions. Execute this mode when

returning the set to the customers.

Procedure:

1. Press three buttons x , [VOLUME] (down) and ?/1

simultaneously.

2. When this button is operated, all of the settings are reset.

2. Panel Test Mode

•This mode is used to check the software version, LCD, LED

and keyboard.

Procedure:

1. Press three bottons [DISPLAY], ?/1 and [VOLUME] (down)

simultaneously.

2. When the panel test mode is activated, all se gments are turned

on.

4. Repeat 5 Times Limit Release Mode

Procedure:

1. Press the ?/1 button to turn the power on.

2.

Press three buttons

simultaneously.

3. To exit from this mode, press the ?/1 button.

5. Disc Tray Lock

The disc tray lock function for the antitheft of an demonstration

disc in the store is equipped.

Setting Procedure :

1. Press the ?/1 button to turn the set on.

2. Insert a disc.

3. Press the x button and the Z CD button simultaneously for

five seconds.

4. The message “LOCKED” is displayed and the tray is locked.

Releasing Procedure :

1.

Press the

five seconds again.

2. The message “UNLOCKED” is displayed and the tray is

unlocked.

Note: When “LOCKED” is displayed, the slot lock is not released by

turning power on/off with the ?/1 button.

x , [VOLUME] (down)

x

button and the Z CD button simultaneously

and the [PLAY MODE]

for

2-1. V ersion T est Mode

Procedure:

1. When the panal test mode is activated, press the [BASS/

TREBLE] button and the version is displayed.

2. Press the [i-Bass] button and the date of the software production

is displayed.

3. Press the [BASS/TREBLE] button again and the version is

displayed.

4. To exit from this mode, pull out the AC plug.

2-2. Key Test Mode

Procedure:

1. When the panel test mode is activated, press the [PLAY MODE]

button, to select the key test mode. In the ke y check mode, the

fluorecent indicator displays “KEY 0”. Each time a button is

pressed, “KEY” value increases. However, once a button is

pressed, it is no longer taken into account. When all keys are

pressed correctly, “KEY 19” is displayed.

2. To exit from this mode, pull out the AC plug.

3. Common Test

Procedure:

1. Press the ?/1 button to turn the power on.

2. When the common test mode is activated, each time press the

EQ “R” button, the message “EQ MAX”, “EQ MIN”, “EQ

FLAT” is displayed in this order.

3. The message “Volume MAX” is displayed, when press the

[VOLUME] (up) button or V OLUME + “R” b utton. The message “Volume MIN” is displayed, when press the [VOLUME]

(down) button or VOLUME – “R” button.

4. To exit from this mode, press the ?/1 button to turn off the

main power.

15

Page 16

CX-LFA660/LFA770

SECTION 5

MECHANICAL ADJUSTMENTS

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback heads pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to

the parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

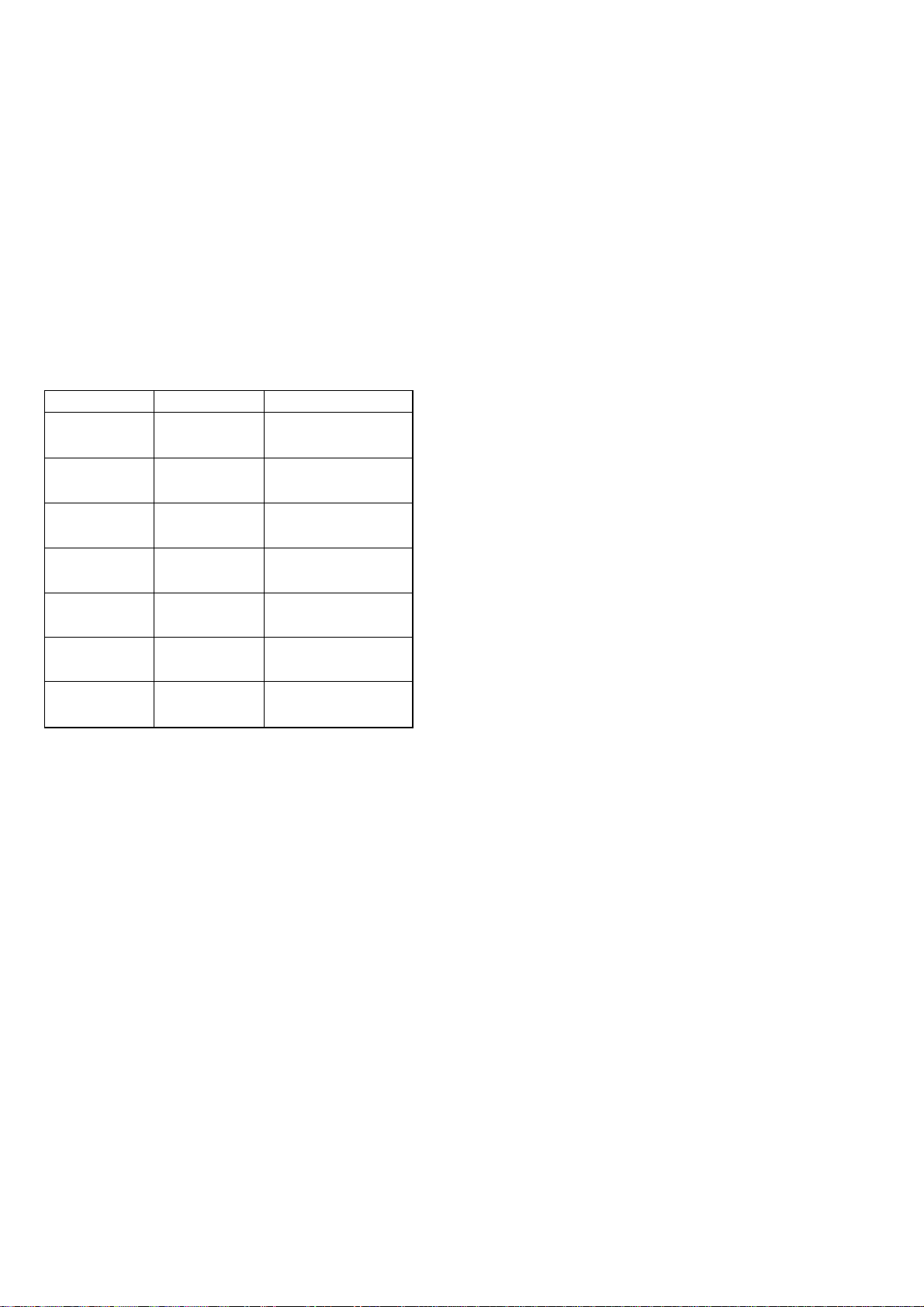

Torque Measurement

Mode

FWD

FWD

back tension

REV

REV

back tension

FF/REW

FWD tension

REV tension

Torque meter Meter reading

2.94 – 7.84 mN • m

CQ-102C

CQ-102C

CQ-102RC

CQ-102RC

CQ-201B

CQ-403A

CQ-403R

(30 to 79 g • cm)

(0.42 – 1.11 oz • inch)

0.15 – 0.59 mN • m

(2 to 6 g • cm)

(0.03 – 0.08 oz • inch)

2.94 – 7.84 mN • m

(30 to 79 g • cm)

(0.42 – 1.11 oz • inch)

0.15 – 0.59 mN • m

(2 to 6 g • cm)

(0.03 – 0.08 oz • inch)

6.86 – 17.64 mN • m

(70 to 179 g • cm)

(0.98 – 2.49 oz • inch)

9.8 mN • m or more

(100 g • cm or more)

(1.4 oz • inch or more)

9.8 mN • m or more

(100 g • cm or more)

(1.4 oz • inch or more)

16

Page 17

SECTION 6

ELECTRICAL ADJUSTMENTS

CX-LFA660/LFA770

DECK SECTION 0 dB=0.775V

1. Demagnetize the record/playback head with a head

demagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to

the parts adjusted.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in

this service manual. (As a general rule, playback circuit

adjustment should be completed before performing recording

circuit adjustment.)

6. The adjustments should be performed for both L-CH and RCH.

7. Switches and controls should be set as follows unless otherwise

specified.

Signal Used forTape

P-4-A100

WS-48B

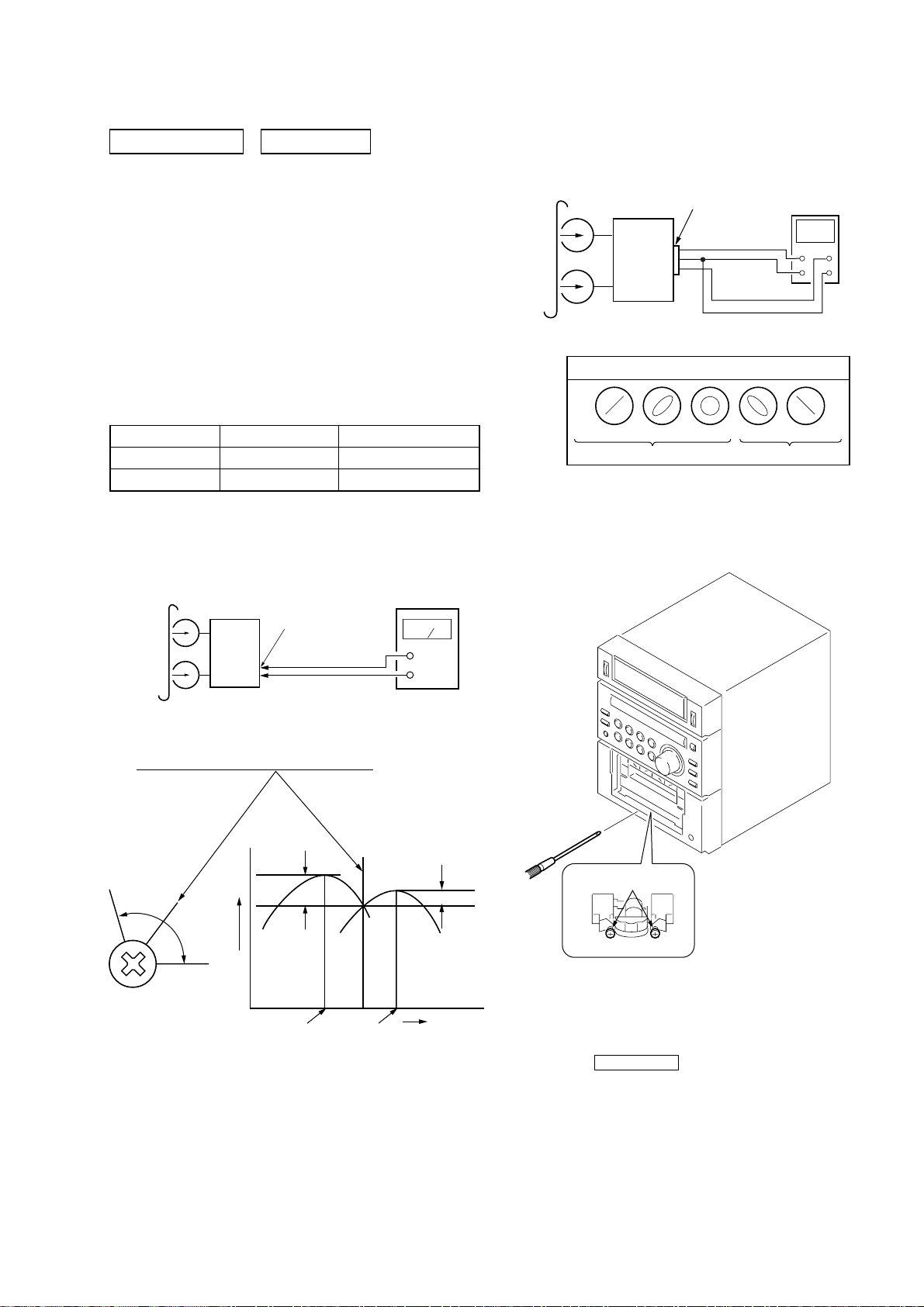

[Record/Playback Head Azimuth Adjustment]

Procedure:

1. Mode : Playback

test tape

P-4-A100

(10kHz, –10dB)

10 kHz, –10 dB

3 kHz, 0 dB

MAIN board

J201

speaker terminal

Azimuth Adjustment

Tape Speed Adjustment

level meter

3. Mode: Playback

test tape

P-4-A100

(10kHz, –10dB)

set

in phase 45

MAIN board

J201

speaker terminal

L

R

Waveform of oscilloscope

°

90

°

good

135

oscilloscope

°

wrong

180

°

4. After the adjustments, apply suitable locking compound to

the parts adjusted.

Adjustment Location: Record/Playback/Erase Head

set

+

–

2. Turn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 1 dB of peak.

L-CH

peak

screw

position

R-CH

peak

output

level

within

1 dB

L-CH

peak

R-CH

peak

within 1dB

screw

position

adjustment screw

[Tape Speed Check]

Procedure:

1. Turn the power on.

2. Insert the WS-48B into deck.

3. Press the TAPE nN button of deck.

4. Check the reading of frequency counter becomes 3000 ± 90

Hz.

Sample Value of Wow and flutter

W.RMS (JIS) less than 0.3%

(test tape: WS-48B)

17

Page 18

CX-LFA660/LFA770

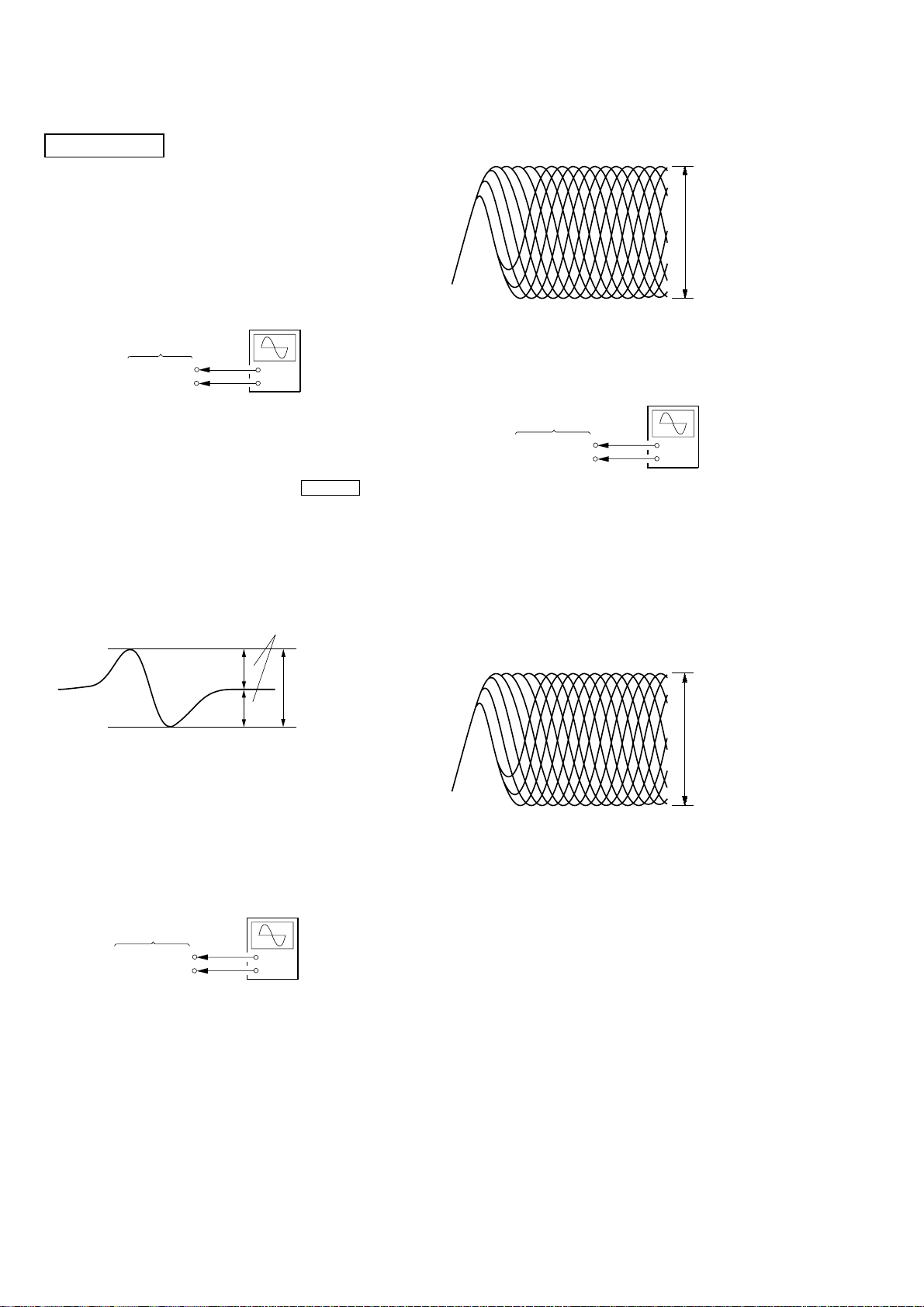

CD SECTION

Note:

1. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

2. Use an oscilloscope with more than 10MΩ impedance.

3. Clean the object lens by an applicator with neutral detergent when the

signal level is low than specified value with the following checks.

S-curve Check

Connection:

oscilloscope

BD81A board

TP (FEO)

TP (VC)

Procedure:

1. Connect an oscilloscope to test point TP (FEO) and TP (VC)

on the BD81A board.

2. Turn the power on.

3. Put the disc (YEDS-18) in and press the button

and actuate the focus search. (actuate the focus search when

disc table is moving in and out)

4. Check the oscilloscope waveform (S-curve) is symmetrical

between A and B. And confirm peak to peak level within 2 ± 1

Vp-p.

S-curve waveform

+

–

symmetry

A

B

CD

NX

within 2

±

1 Vp-p

RFDC signal waveform

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

±

level: 0.6

0.15 Vp-p

Checking Location: BD81A board (Side B)

RFAC Level Check

Connection:

oscilloscope

BD81A board

TP (RFACO)

TP (VC)

+

–

Procedure:

1. Connect an oscilloscope to test point TP (RF ACO) and TP

(VC) on the BD81A board.

2. Turn the power on.

3. Put the disc (YEDS-18) in to playback the number five track.

4. Confirm that oscilloscope waveform is clear and check RFAC

signal level is correct or not.

Note:

A clear RFAC signal waveform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

RFAC signal waveform

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

Note:

•Try to measure several times to make sure than the ratio of A : B

or B : A is more than 10 : 7.

•Take sweep time as long as possible and light up the

brightness to obtain best waveform.

Checking Location: BD81A board (Side B)

RFDC Le

vel Check

Connection:

oscilloscope

BD81A board

TP (RFDCO)

TP (VC)

+

–

Procedure:

1. Connect an oscilloscope to test point (RFDCO) and TP (VC)

on the BD81A board.

2. Turn the power on.

3. Put the disc (YEDS-18) in to playback the number five track.

4. Confirm that oscilloscope wav eform is clear and check RFDC

signal level is correct or not.

A clear RFDC signal waveform means that the shape “◊” can be

Note:

clearly distinguished at the center of the waveform.

Checking Location: BD81A board (Side B)

level: 1.0

±

0.4 Vp-p

18

Page 19

CX-LFA660/LFA770

E-F Balance Adjustment

Connection:

oscilloscope

BD81A board

TP (TEO)

TP (VC)

+

–

Procedure:

1. Connect an oscilloscpe to test point TP (TEO) and TP (VC) on

the BD81A board.

,,

PLAY MODE/TUNING MODE

2. Press three buttons

and simulfaneously enter the CD test mode.

Z

CD

x

3. Put the disc (YEDS-18) in to playback the number five track.

CD

4. Press the button. If it plays, press theCD

NX

NX

button again. (The tracking servo and the sledding servo are

turned OFF)

5. Check the level B of the oscilliscope's waveform and the A

(DC voltage) of the center of the Traverse waveform.

Confirm the following :

A/B x 100 = less than ± 10%

Traverse Wavef orm

0V

Center of

the waveform

B

A (DC

voltage)

level: 1.0 ± 0.5 Vp-p

Checking Location:

– BD81A BOARD (Side B) –

BD81A BOARD

(SideB)

IC251

TP

(VC)

TP

(TEO)

TP

(FEO)

TP

(RFDCO)

IC303

IC301

IC101

TP

(RFACO)

6. Press the button. (The tracking servo and

CD

NX

sledding servo are turned ON)

7. To exit from this mode, turn the power off.

Notes: •Always move the optical pick-up to most inside track when

0V

exiting from this mode. Otherwise, a disc will not be unloaded.

• Do not run the sled motor excessively, otherwise the gear can

be chipped.

Traverse Wavef orm

Tracking servo

Sled servo

OFF

Tracking servo

Sled servo

ON

C (DC

voltage)

Checking Location: BD81A board (Side B)

19

Page 20

CX-LFA660/LFA770

MEMO

20

Page 21

SECTION 7

D

DIAGRAMS

CX-LFA660/LFA770

• Circuit Boards Location

FRONT BOARD

PT BOARD

HP BOARD

BD81A BOARD

MAIN BOARD

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

For Schematic Diagrams.

Note:

• All capacitors are in µF unless otherwise noted. (p: pF)

50 WV or less are not indicated except f or electrolytics and

tantalums.

• All resistors are in Ω and 1/

specified.

• f : internal component.

• C : panel designation.

Note: The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

• A : B+ Line.

• B : B– Line.

•Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

No mark: FM

( ) : CD STOP

•Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage v ariations ma y be noted due to normal production

tolerances.

•Waveforms are taken with a oscilloscope.

Voltage v ariations ma y be noted due to normal production

tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : TUNER

J : CD

d : AUX

E : PB (TAPE)

a : REC (TAPE)

4

W or less unless otherwise

For Printed Wiring Boards.

Note:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• f : internal component.

• : Pattern from the side which enables seeing.

• Indication of transistor.

C

Q

B

E

B

•Abbreviation

AUS: Australian model

These are omitted.

CE

These are omitted.

MS-128 BOARD

AMP BOAR

CX-LFA660/LFA770

2121

Page 22

CX-LFA660/LFA770

7-1. BLOCK DIAGRAM — BD SECTION —

OPTICAL PICK-UP

BLOCK

(KSM-215DCP/C2NP)

DETECTOR

VCC

VC

FOCUS

COIL

TRACKING

COIL

M101

(SPINDLE)

M102

(SLED)

IC301

+1.7V

+3.3V

A

B

C

D

E

F

Q10

VR

LD

GND

PD

F

F+

T+

T

M

M

16

15

17

18

19

20

21

22

LD

DRIVER

IC251

SL/SP MOTOR

DRIVER

CH2OUT-F

CH1FIN

CH2OUT-R

CH1RIN

CH1OUT-R

CH2FIN

CH1OUT-F

CH2RIN

CH4OUT-F

CH4OUT-R

CH3OUT-R

CH3OUT-F

SFDR

SRDR

OPIN+

MUTE

X171

16.9MHz

+3.3V

SW101

5

6

7

8

9

10

3

24

26

27

28

29

19

20

36

77

78

37

7

11

12

13

14

30

29

6

100

A

B

C

D

E

F

LD

XTAO

XTAI

PD

SSTP

TFDR

TRDR

FFDR

FRDR

CH3FIN

CH3RIN

MPD

XRST

IC101

RF AMP

PCMD1

LRCK1

LRCK

PCMD

BCK

BCK1

XTACN

XRST

DATA

XLAT

CLOCK

SENS

SCOR

GFS

C2PO

FOK

AOUT1

AOUT2

DOUT

61

62

63

65

66

60

95

100

102

104

105

107

115

113

114

1

2

3

81

86

71

XTACN

XRST

DATA

XLAT

CLOCK

SENS

SCOR

DIGITAL SIGNAL

11

SDO0

16

LRCKIA

19

SFSY/LRCK1B

14

SDIO

15

BCKIA

18

SBSY/BCK1B

PROCESSOR

STANBY

PO11/BUCK/AD1

SRMSTB

VDD

VDD

VDDM

MIACK

MICK

MIDIO

MILP

MICS

RESET

55

21

40

36

41

IC303

5 1

REG

3.3V

CN201

3

8

7

6

5

4

2

SCOR

SENS

CLOCK

XLT

DATA

XRST

XTACN

• Signal Path

MP3STB

MP3REQ

MIACK

MICK

MIDIO

MILP

MICS

MP3RST

SRMSTB

SCOR

SENS

CLOCK

XLT

DATA

XRST

XTACN

LOUT

ROUT

DOUT

: CD

A

B

MAIN

SECTION

MAIN

SECTION

CX-LFA660/LFA770

2222

Page 23

— MAIN SECTION —

L

MD

R

TUNER UNIT

DECK

L-CH

REC/PB

HEAD

R-CH

ERASE

HEAD

MECHA BLOCK

SW1

PLAY

SW2

R REC

SW3

F REC

SW4

PACK

+SOL

SW5

PEND

M1

DECK

MOTOR

J601

+10V

L-CH

R-CH

TU-DO

TU-DI

TU-CL

TU-CE

TUNED

STEREO

TU-MUTE

FM SOUT

RDS DATA

RDS INT

M

VCC

R-CH

R-CH

R-CH

R-CH

T301

REC BIAS

Q452,453

Q454

Q804,805

SOL

DRIVE

Q806,807

MOTOR

DRIVE

BIAS

OSC

Q450

Q451

Q306

PB

SWITCH

Q301,302,305

REC

SWITCH

+VM

PB/REC EQ AMP

IC601

OUT L

AUX L

19 18

23

2

21

TU L

TAPE L

CD L

OUT R

CONT

REC OUT

CX-LFA660/LFA770

Q101,103,105

Q107,109

Q111,113,127

PRE

R-CH

16

13

28

SYSTEM CONTROLLER

IC801

O- MUTE

SEG1

SEG16

G1

G12

KEY1

KEY0

VOL ENC

RESET

I-RMC

86

43

45

.

47

50

.

52

60

31

42

20

27

22

87

11

23

29

18

FIL1 FIL2-VFL

S801-808

FUCTION

KEY

S809-815.S817,818

FUCTION

KEY

S616

VOLUME

ENCODER

D802

STAND BY

Q803

RESET

SWITCH

X801

32.768kHz

X802

10MHz

28

FUNC-DATA

75

TU-DI

76

TU-DO

74

TU-CLOCK

73

TU-CE

71

TU TUNED

70

TU STELEO

77

TU MUTE

23

RDS SIG

25

RDS DATA

26

RDS CLK

79

TA-R/P

12

XT1

13

XT2

15

X IN

16

X OUT

80

TA-BIAS

68

TA-PLAY SW

24

TA-SW

TA SOL

81

67

TA-END SW

78

TA-MOTOR

STAND-BY LED

I-POWER-DOWN

I-POWER-MONITOR

FL801

FLUORESCENT

DISPLAY

IC803

RESET

1

IC802

REMOTE

CONTROL

RECEIVER

VDD1

MUTE

Q121

31

AMP

Q280-282

THR DET

D807

D806

2

Q809

+3.3V

REG

VDD2

Q117,119

POWER

AMP

+3.9V

D808

Q123,250,251

OVER

CURRENT

DET

R-CH

R-CH

L

R

Q204,206

DC

DET

Q203,205

DC

DET

L

R

R-CH

Q290-293

FAN

DRIVE

-VH

-VP

+VP

FAN

+VH

J702

HEADPHONES

J201

SPEAKER

Q060-065

DC

DET

-VH

Q201

DET

Q202

DET

-VL

+VL

• R-CH is omitted due to same as L-CH.

• Signal Path

: TUNER

: CD

: AUX

: PB (TAPE)

: REC (TAPE)

POWER

TRANSFORMER(MAIN)

D001

+VH

-VH

VF

VF

D002

PT252

CX-LFA660/LFA770

B

BD SECTION

CD OPEN/CLOSE

TRY

MOTOR

OPEN

CLOSE

AOUT1

AOUT2

M

R-CH

MOTOR DRIVE

IC501

FIN

OUT1

4 7

RIN

OUT2

2 9

BD

SECTION

Q009.010

-VFL

REG

IC001

+7V

3

1

REG

VM

Q001-003

FL

REG

+3.9V

Q006,011,012

REG

Q810-812

+3.9V

REG

VL

D251-254

Q008

RELAY

DRIVE

D256

RY251

PT251

POWER

TRANSFORMER(SUB)

D257

AC

IN

+3.3V

REG

Q020,021

VCC

CD-VCC

IC002

+3.3V

REG

CN701

SCOR

XTCN

XRST

XL-T-CD

CD-DATA

SENS

CD-CLK

A

MP3-DO

MP3-DI

MP3-CLK

MP3-CS

MP3-CP

MP3-ACK

MP3-REQ

MP3-RESET

MP3-STB

C1

C2

C3

C4

C5

C6

C7

C8

C9

C10

C11

C12

C13

C14

C15

C16

C16

C15

C14

C13

C12

C11

C10

C9

C8

C7

C6

C5

C4

C3

C2

C1

6

MP3-STB

2

MP3-RST

3

MP3-REC

1

MI-ACK

O-MI-LP

5

O-MI-CS

4

MI

100

MI-DIO-O

98

MI-DIO-I

99

97

O-CD-CLK

O-CD-SENS

96

O-CD-DATA

95

O-CD-XLT

9

O-CD-XRST

8

O-CD-XTCN

7

I-CD-SCOR

10

91

O-TRY-OPN

92

O-TRY-CLS

65

I-SW-TROPN

I-SW-TRCLS

66

POWER ON

DVDD

AVDD

MP3VD

94CD POWER

85

2323

Page 24

CX-LFA660/LFA770

7-2. PRINTED WIRING BOARD — BD81A SECTION —

12

A

B

C

• See page 21 for Circuit Boards Location. :Uses unleaded solder.

3456789

SPINDLE

MOTOR

IC303

1

3

5

4

(LIMIT)

36

1

IC251

9

192728

IC301

16

17

10

18

32

33

1

64

49

48

SLED

MOTOR

D

E

TP

(VC)

TP

(TEO)

MAIN

12

12

E

OPTICAL

PICK-UP

BLOCK

(KSM–215DCP)

TP

(FEO)

TP

(RFDCO)

(RFACO)

IC101

12

12

TP

BOARD

CN604

(Page 26)

• Semiconductor

Location

Ref. No.

IC101 D-7

IC251 C-6

IC301 C-7

IC303 B-7

Location

CX-LFA660/LFA770

Q10 E-4

2424

Page 25

CX-LFA660/LFA770

7-3. SCHEMATIC DIAGRAM — BD81A SECTION —

R307

10k

TP433

MP3VDD

FB301

MAIN

BOARD

(1/2)

CN604

(Page 27)

C308

C309

0.1 F

C307

0.1 F

47

4V

R303

100k

C310

0.1 F

IC303

BH15FB1W

C302

C303

0.1

0.1

F

F

TP422

MP3GND

CN201

27P

C311

0.1 F

TP401

TP402

TP403

TP404

TP405

TP406

TP407

TP408

TP417

TP416

TP415

TP414

TP413

TP412

TP419

TP410

TP411

TP409

TP434

IC301

TC94A34FG-002

C305

TP186

MVDD

TP187

MGND

MP3STB

MP3REQ

MIACK

MICK

MIDIO

MILP

MICS

MP3RST

R205

SCOR

SENS

CLK

XLT

DATA

XRST

XTCN

AVDD

ROUT

LOUT

DOUT

R204

0

TP304

C316

0.0022 B

TP

301

C315

0

306

R

C312

0.1 F

220

4V

0

R411

R410

R409

R408

R407

R406

R412

C213

22p CH

R313

0.1 B

220

100

100

100

100

100

100

100

22p CH

C212

DVDD

TP435

220p CH

C211

• Refer to page 36 for IC Pin Function Description. • See page 34, 35 for IC Block Diagrams. • See page 34 for Waveforms.

B

C134

0.1 F

42

C1

.0015

C151

100

10V

0

5

16

R

0.1 B

1

15

R

C143

0.1 F

2

14

TP

0

C210

R203

0

TP302

TP303

R351

100

10k

R405

R404

R419

R403

R402

R401

R301

C317

0.01 B

0.1 F

47 4V

C306

0.1 F

100

100

100

100

100

100

C318

0.01

B

100k

R305

100k

C320

0

C174

0.1 F

TP436

AVDD

C201

100

0

10V

R201

TP420

AGND

C203

100

10V

B

09

2

C

.01

0

TP421

DGND

TP427

PCMDI

TP103

LRCK

R352

100

R353

100

TP104

PCMD

R354

100

TP105

C162

R182

100

470p CH

C181

0.1 F

BCK

R161

100

0.1 F

R171C171

47022p CH

R172

1M

16.9MHz27p CH

X171C172

CH

22 6.3V

C183

22 6.3V

C184

0.1 F

C182

C194

0.1

F

C161

0.1 F

0

R173

470p

C185

R181

100

C186

R302

C313

C314

0

k

143

3.3

R

B

141

C

0.1

42

k

1

1

R

.7k

4

41

1

R

O

CK

S

148

EX

SB

TP

49

P1

T

C163

0.1

3

0

16

10

R

R162

47k

B

1

0.0

33

C1

133

80k

1

R

32

0k

1

1

R

IC101

CXD3059AR

0.1

196

C

B

7

C132

0.4

CH

4

I

C12

100p

1M

FAC

R

131

131

R

C

TP125

0

191

R

C125

0.1 F

H

C

B

O

C

30p

15k

0.1

3

FA

R

24

1

TP

4

GF

FCK

145

XU

W

TP14

TP

22

B

0.1

C1

121

R

C123

K

3

47

C

1

XP

P15

TP

T

2

12

P

TP123

T

O

C

FD

R

TP121

R111

1k

C111

0.0033 B

R112

15k

C112

470p

C113

JPO102

JPO103

C115

0.1 F

TP167

LOCK

TP178

FOK

TP166

DFCT

TP165

MIRR

O

FS

2P

P146

G

C

T

T

CK

62

U

D

160

O

P1

P

C

W

T

T

R193

NM

0.0033

FEI

R114

15k

R113

1k

TEI

C114

470p B

0.1 F

C195

+

W

425

S

TP

S101

SW

W

426

S

TP

C11

C10

C15

C14

10

10

0.1

0.1

6.3

6.3

F

F

B

B

TP423

IOP1

C16

R11

0

JPO004

0.0068

R13

1

1

F

TP424

IOP2

R10

3.3

Q10

2SB1690K

C18

0.001 B

TP428

FRDR

TP430

TRDR

MDP

C251

B

R253

10k

IC251

BA5947FM

(HSOP28)

C252

0.1 F

C255

0.1 F

C259

0.1

C258

F

0.1

+

SL+

SP

SL-

2

3

251

25

TP25

TP

TP

F

257

C

0.1

C17

R12

220

100k

4V

JPO10

APC

C116

100

10V

TP177

VC

TP429

FFDR

TP431

TFDR

TP432

MDP

R252

R251

22k

10k

C260

220 10V

CN101

16P

E

TP10

D

TP11

A

TP12

B

TP13

C

TP14

F

TP102

PD

TP15

F+

TP16

F-

TP17

T-

TP18

F-

TP19

0

P

25

S

TP

M101

M102

CX-LFA660/LFA770

2525

Page 26

CX-LFA660/LFA770

7-4. PRINTED WIRING BOARD — MAIN SECTION —

12

34567 9

A

B

C

1

10

D

D

PT

BOARD

CN257

(Page 33)

(CHASSIS)

E

E

F

PHONES

G

MS-128

• See page 21 for Circuit Boards Location. :Uses unleaded solder.

770

E

E

E

E

E

E

S

11

S

EE

E

E

E

1

9

F

AMP

BOARD

CNA102

(Page 31)

(CHASSIS)

5

1

E

E

E

E

IC002

1

660

EXCEPT AUS

E

EXCEPT

AUS

7

1

1

E

E

E

3

E

E

E

E

E

E

E

AMP

BOARD

CNA101

(Page 31)

L202

8

10

• Semiconductor

Location

Ref. No.

D001 C-3

D002 C-3

D004 B-2

D005 B-3

D006 B-3

B

FRONT

BOARD

CN801

(Page 29)

D010 A-7

D011 A-7

D012 A-7

D020 E-6

D022 B-5

D023 B-4

9

IC501

1

1

2

4

5

C

FRONT

BOARD

CN802

(Page 29)

D024 B-5

D025 B-4

D026 B-4

D027 B-4

D028 B-4

D029 B-4

D031 B-5

D033 C-6

E

E

E

660

26

660

27

A

660

BD81A

BOARD

CN201

(Page 24)

HEAD

(REC/PB/ERASE)

+

1

2

-

3

-

4

5

+

-

6

7

+

L-CH

REC/PB

R-CH

ERASE

EXCEPT

AUS

IC601

E

660

2

1

660 660

D034 C-5

D035 C-5

D036 B-4

D037 B-5

D038 B-4

D039 C-6

D040 B-6

D041 B-6

D042 B-4

D043 B-4

D064 B-5

D201 D-4

D202 D-4

D203 E-3

D204 D-4

D205 E-3

D206 E-3

D207 E-3

D208 E-3

D209 D-4

D210 D-4

L201

EXCEPT AUS

CN605(15P)

AUS

AUS

CN606(11P)

JW674

JW655

EXCEPT AUS

E

E

TUNER

3

FAN

1

E

D290 G-7

D291 G-7

D301 E-7

D601 E-8

Location

Ref. No.

Location

D602 E-8

D603 F-8

D604 E-9

IC002 E-5

IC501 B-7

IC601 E-7

Q001 B-3

Q002 B-3

Q003 B-4

Q008 D-3

Q009 C-5

Q010 D-5

Q020 E-6

Q021 F-6

Q060 B-5

Q061 A-5

Q062 A-5

Q063 B-5

Q064 A-4

Q065 A-4

Q201 D-3

Q202 D-4

Q203 D-4

Q204 D-4

Q205 D-4

Q206 D-5

Q290 G-9

Q291 G-9

Q292 G-9

Q293 G-9

Q301 E-6

Q302 E-7

Q303 E-6

Q304 E-7

Q305 E-6

Q306 E-7

Q307 E-6

Q450 C-7

Q451 D-6

Q452 C-7

Q453 D-7

Q454 D-7

H

(DISC IN/OUT)

CX-LFA660/LFA770

(LOADING)

M

E

R

SPEAKER

IMPEDANCE

USE 6

L

L

R

IN

M D

2626

Page 27

CX-LFA660/LFA770

7-5. SCHEMATIC DIAGRAM — MAIN SECTION (1/2) —

CN501

5P

2

3

4

5

6

7

8

9

10

11

12

13

JW029

JW655

7

-7

4

T

0

3

6

3

D

1

S

S

1

470

16V

C637

• See page 34 for IC Block Diagrams.

IC501

BA6956AN

k

8

.5

0

0

1

6

5

5

R

7

0

5

R

1

.0

0

5

0

5

k

C

1

0

0

.0

.1

0

0

L501

C506

7

1

0

0.01

5

.0

C

0

R672

15k

1

C503

100

16V

4

5

2

0

0

0

5

5

5

C

C

R

C646

10 50V

C647

10 50V

CN604

27P

k

k

k

1

0

.6

.6

.0

0

5

5

0

1

2

1

4

1

0

0

0

0

5

5

5

5

R

R

C

R

R668

*

R667

*

2

3

2

4

0

0

0

6

6

C

.0

C

0

R602

15k

R601

15k

R606

IC601

BD3881FV

C643

0.0022

7

5

4

0

2

0

6

2

0

C

.0

0

.0

0

k

1

1

1

6

R

7

k

0

6

.2

R

2

C609 C610

180p 180p

2.2k

0

FB665

FB665

.1

0

8

6

6

C

p

p

0

0

0

0

1

1

6

7

6

6

6

6

C

C

0.0022

k

.8

1

3

6

6

R

7

0

6

C

k

1

3

1

6

R

R609

15k

R605

2.2k

.1

0

3

5

6

C

p

p

p

0

0

0

0

0

1

1

4

5

6

6

6

6

C

C

C642

8

6

0

k

.0

.8

0

1

8

4

0

6

6

6

C

R

8

6

0

.0

0

k

1

4

1

6

R

0

k

1

5

6

1

R

1

1

1

0

*

*

*

1

8

3

6

7

5

6

5

5

6

6

6

6

C

C

C

C

4

p

4

0

6

7

C

4

7

6

2

2

4

0

*

0

6

C

.0

8

0

1

6

k

R

1

2

1

6

R

k

k

.2

.2

8

8

5

6

1

1

6

6

R

R

8

k

0

6

.2

2

R

2

2

2

*

*

*

*

7

2

6

1

1

2

2

2

6

6

6

6

R

R

R

R

k

k

k

.6

.7

4

5

4.7

4

0

9

2

2

1

6

6

6

R

R

R

.1

0

0

7

6

C

p

p

p

p

0

0

0

0

1

0

0

0

*

1

10

1

1

8

4

9

5

0

4

5

4

5

5

6

6

6

6

6

C

C

C

C

C

C617

4.7 50V

R665

22k

R666

5

p

4

22k

0

6

7

C

4

R627 R628

C611

2

*

2.2k 2.2k

0.22

50V

5

V

2

0

6

5

3

R

1

6

7

C

.4

0

k

.6

5

3

R629

2

68k

6

R

2

5

.1

6

0

C

C618

4.7

50V

V

0

C614

5

2

0.47

1

6

50V

2

C

.2

0

C615

R630

4.7

50V

68k

C616

4.7

50V

FB661

0

1

.0

0

1

4

6

C

R043

220 1/4W

R042

220 1/4W

R041

220 1/4W

R040

100 1/4W

FB663

FB666

0UH

0

0UH

0

W

/4

1

0

2

2

6

4

0

R

W

/4

1

0

0

1

4

4

0

R

*3

3

*

L660

3

*

L661FB667

3

*

L664

3

*

L665

3

*

L666

3

*

L667

W

/4

1

0

2

2

7

4

0

R

W

/4

1

0

2

2

5

4

0

R

L660,664,666

10uH

JW

D290

1SS133T-77

L661,665,667

10uH

NO MOUNT

FB664

14

15

16

18

19

20

21

22

23

24

25

26

27

28

CNA201

29

J601

0.1

C669

30

31

32

33

34

35

5P

R660

10k

C660

R662

220p

*

0UH

R661

*

FB660

JW

R659

C659

10k

220p

C636

0.01

1

1

5

6

.00

C

0

CN602

21P

CN603

0

V

0

7

R631

C621

100p

470

R632

(660) (770)

1k

R643

JW

1k

R644

JW

1k

R645

JW

1k

R646

JW

1k

R650

JW

1k

R651

JW

(660) (770)

1k

R652

JW

100

R653

JW

100

R654

JW

1k

R655

JW

1k

R656

JW

1k

R657

JW

1k

R658

JR

1k

R669

JR

1k

R670

JW

25P

C451

0.012

100V

R633 R634 R635 R636

C619 C620

0.001 0.001

39k 39k 56 56

Q301

2SK2158-T2B

Q302

2SK2158-T2B

C301C302

0.0010.001

Q303

2SK2158-T2B

R301

R302

18k

18k

T301

BIAS OSC

470

220p

C303

R303

1M

Q450

2SC2001-LK

1/4W

C452

2.2 50V

C622

100p

R638

390k

C625

R637

390k

R639

R641

5.6k

R640

5.6k

C624

C623

Q307

KTA1504

2SC2001-LK

R453R452

5.6

1/4W

47 16V

Q306

KTA1504

D301

1SS133T-77

Q451

47 16V

5.6

V

5

2

8

6

2

C

6

.7

C

4

0.022

150k

C626

0.022

150k

R642

R671

0

KRA303-RTK

R450

C453

18k

0.015

50V

3

3

9

0

0

3

3

2

3

5

0

0

6

6

C

C

.0

.0

0

0

.7

4

4

5

4

C

R647

15k

7

-7

3

T

R648

0

3

47k

6

3

D

p

1

0

S

1

S

.1

1

0

2

8

6

6

5

0

4

C

.0

0

5

3

6

C

C304

100 16V

Q305

KRA303-RTK

C457

0.018

3

6

C

R304

4.7k

R455

6.8k

R649

22k

Q304

8

R451

6

0

18k

.0

0

C

C

.3

V

.3

0

-4

2

4

1

7

-

0

1

7

6

-7

0

0

D

.1

C631

0

330

4

3

10V

6

C

R454

2.2k

C458

10

50V

6

-7

2

-T

D

2

J

-T

Z

J

T

Z

33

T

M

6

M

C

Q453Q452

KTA1266GR-AT2SD13873

C459

47

16V

R456

22k

R457

2.2k

Q454

KRC102M-AT

k

k

0

0

R293

1

1

10k

8

9

9

9

2

2

R

R

Q293

2SC3052F

T1-LF

R296

k

0

47k

0

1

97

R295

2

R

C292

4.7

50V

R294

0

10k

C460

50V

R292

8.2k

2SC3052F

R458

10k

10

D291

1SS133T-77

Q290

KTC3198GR

-AT

Q291

2SC3052F

T1-LF

W

/4

1

0

1

R291

0

1k

C290

25V

CN601

9

2

R

47

7P

Q292

T1-LF

1

1

5

2

R

1

0

2

L

17uH

R253C225C227

10

0.1

0.1

1/4W

50V

50V

10

R252

C226

R250

C228

0.1

L202

17uH

10

0.1 50V

50V

1/4W

CN290

3P

J702

R760

220 1/2W

J201

TERMINAL, 4P SP

R759

220 1/2W

R761

220 1/2W

220 1/2W

C763

0.1 25V

W701

R763

/8W

4

1

2.2k

76

1/8W

R

k

.2

2

CN701

R762

5P

CX-LFA660/LFA770

2727

Page 28

CX-LFA660/LFA770

7-6. SCHEMATIC DIAGRAM — MAIN SECTION (2/2) —

2729282526

3

21

23

4

22

24

1216182014

13

CNA001

10P

*

R066

660: JW

770: 3.3 1/2W

CN002

CN003

5

31

32

9P

11P

33

34

35

2

1

11

19

15

9

10

8

6

7

1SS133T-77

D043

1SS133T-77

R079

8.2k

R095

8.2k

k

.7

2

7

7

0

R

R070

2.7k

MTZJ-T-77-4.3C

IC002

TA78033LS

1SS133T-77

C039

10

50V

D041

D028

4

2

0

D

7

-7

0

T

4

3

0

3

D

1

S

S

1

C008

0.1

C018

100 16V

7

7

-7

-7

T

T

6

7

2

3

3

2

0

3

3

0

1

1

D

D

S

S

S

S

1

1

7

-7

7

2

T

2

3

-7

0

3

3

T

2

D

1

3

0

3

S

D

1

S

S

1

S

1

C033

4.7

50V

k

k

6

2

5

2

1

4

7

8

0

0

R

R

C004C003

100000p

100000p

35V

35V

D001

G5SBA60L-6088

7

Q008

2SC1623-L5L6

R011

4.7k

2

1

0

D

1

1

0

D

7

-7

0

T

1

3

0

3

D

1

S

S

1

C013

0.0047

KTA1266GR-AT

R012

4.7k

MTZJ-T-77-36B

-7

T

3

3

1

R030

S

22k

S

1

7

R031

-7

100

T

3

3

1

S

S

1

C035

100

16V

C083

470

25V

Q001

R037

0

D006

C019

*

R096

82k

R093

82k

k

9

3

8

7

0

R

R094

39k

770

1/2W

1/2W

1/2W

1/2W

1/2W

*

R054

R055

R066

3.3

R001

R002

R003

3.3

3.3

3.3

3.3

C026

100

10E-2 10E-2

50V

C006C005

100000p

100000p

35V

35V

C009

0.1

50V

D002

G5SBA60L-6088

C011

0.1

C025

D004 D005

100

50V

k

k

0

0

R017

0

0

1

100k

*

0

2

0

C

1

7

0

0

1

0

0

R

R

C021

4700

25V

C022

4700

25V

JW

FB001

C037 C038

100

35V

100

35V

R036

47k

2SC1623-L5L6

R034 R076

220k 4.7k

R026

10k

Q010

KTA1266GR-AT

R024

4.7k

R013

Q009

7

-7

4

T

3

3

0

3

D

1

S

S

1

Q002

KTA1266GR-AT

7

-7

5

T

3

3

0

3

D

1

S

S

1

C023

C036

100

470

16V

16V

R014

10 1/4W

Q003

2SA1235-F

C024

100

25V3.3k

R015

100k

C007

0.1

D038

1SS133T-77

C061

47 35V

W

J

2

3

0

D

7

7

-7

-7

5

R027

T

T

2

3

3

22k

0

3

3

D

1

1

S

S

S

S

1

1

7

-7

T

3

3

3

0

3

1

D

S

S

1

k

k

D039

2

6

5

2

MTZJ-T-77-16A

2

2

8

7

0

0

R

R

Q020

2SA952-K2

R035

47k

D018

JW

R033

470

Q021

DTC114YKA-T146

D037

1SS133T-77

D031

1SS133T-77

D036

1SS133T-77

C030

R052

1k

R083

47k

R080

47k

C031

0.1

R051

1k

Q065

2SC1623-L5L6

7

-7

0

T

2

3

0

3

D

1

S

S

1

C027

100

0.1

16V

Q064

2SC1623-L5L6

Q060

DTC114EKA

T146

R063

2SA1235-F

R203

470

R207

8.2k

R208

6.8k

Q063

R065

8.2k

Q205

2SA1235-F

10k

R062

47k

D064

RD3.3ESB2

Q203

2SC1623-L5L6

R211

10k

R209

2.2k

R210

2.2k

R212

10k

7

-7

-77

3

T

0

3

2

3

D

1

S

S

1

7

-7

4

T

0

3

2

3

D

1

S

S

1

D207

5

T

0

3

1SS133T-77

2

3

D

1

S

S

1

5

7

k

k

1

1

2

2

.7

4

4.7

R

R

6

8

k

1

k

1

2

2

.7

.7

R

4

R

4

7

-7

6

T

0

3

D208

2

3

1SS133T-77

D

1

S

S

1

C032

0.1

Q061

2SA1235-F

Q201

2SJ599-Z-E2

C201

47

63V

D201

RK46LF-T2

D202

RK46LF-T2

C202

47

63V

R048

22k

Q206

2SC1623-L5L6

R206

D209

R201

1.5k

100k

Q202

2SK3377-Z-E2

R202

D210

2SA1235-F

1SS133T-77

R205

100k

3

1

2

R

R214

1k

1.5k

Q062

k

1

1SS133T-77

R061

22k

R081

100

2SA1235-F

R204

470

Q204

D029

D042

1SS133T-77

CX-LFA660/LFA770

30

EP001

TERMINAL,EARTH

2828

Page 29

CX-LFA660/LFA770

7-7. PRINTED WIRING BOARD — FRONT SECTION —

12

A

B

C

MAIN

BOARD

CN603

(Page 26)

FRONT BOARD

IC802

DISPLAY

C

• See page 21 for Circuit Boards Location. :Uses unleaded solder.

34567

1

1

3

2

(FLUORESCENT INDICATOR TUBE)

51

50

IC801

31

80

81

100

1

30

EXCEPT AUS

(CHASSIS)

44 45

|

/

u

AUS

AUS

E

3

IC803

E

4

2

1

|

/

u

• Semiconductor

Location

Ref. No.

D802 A-7

D803 C-5

D804 B-6

D807 B-5

D808 B-6

D809 E-4

D810 D-5

D811 D-6

D901 B-6

IC801 B-4

IC802 A-2

IC803 B-6

Q803 C-5

Q804 E-3

Q805 D-3

Q806 E-3

Q807 E-3

Q809 B-6

Q810 D-5

Q811 D-6

Q812 D-6

Location

D

E

B

MAIN

BOARD

CN602

(Page 26)

6

i-Bass

BASS/TRE

PLAY MODE/

TUNING MODE

CD

VOLUME

E

CD SYNC

TUNER/BAND

E

E

E

E

+

ALBUM

-

CD

^

+

TUNING

E

TAPE

4

-

4

E

RECPAUSE/

START

MD

TAPE

MECHANISM

DECK

CX-LFA660/LFA770

2929

Page 30

CX-LFA660/LFA770

7-8. SCHEMATIC DIAGRAM — FRONT SECTION —

CN801

21P

R810

100

R841

100

R849

100

R865

100

R868

100

R934

1k

R939

1k

R940

1k

R941

1k

R942

1k

CN802

25P

• Refer to page 39 for IC Pin Function Description. • See page 34 for Waveforms.

R870

10k

R872 R876

C803

0.1

0

0

1

2

6

R853

10k

R851

10k

10k

R850

R848

100k

R847

100k

R846

100k

R845

R844

100k

R960

1k

C805

100

16V

R936

R935

100k

C806

0.1

1k

1k

R938

100k

8

R

0

0

1

3

6

8

R

10k 10k

k

0

0

1

0

0

1

1

9

6

4

7

8

6

6

R

8

8

R

R

k

1

1

7

8

R

0

9

0

8

R

J

k

k

1

1

4

3

7

7

8

8

R

R

IC801

LC876980B-53L3-E

R878

10k

k

k

k

k

k

k

k

0

0

0

0

0

k

1

k

7

1

0

9

5

R

7

8

R

JR810

0

0

1

1

1

0

9

8

81

8

8

87

R

R

R

k

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

2

4

3

5

6

8

8

8

8

8

8

8

8

8

8

R

R

R

R

R

FL801

HNA-12SS27

C828

0.1

k

k

k

k

k

k

k

0

0

0

0

0

0

1

1

1

8

9

7

8

8

8

8

8

8

R

R

R

k

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

2

4

3

0

1

9

9

9

9

9

8

8

8

8

8

R

R

R

R

R

.1

C841

0

0.1

0

4

8

C

C825

0.1

k

k

k

k

k

k

k

k

k

k

k

0

0

0

0

0

0

0

0

1

1

5

6

9

9

8

8

R

R

0

0

0

0

0

0

1

1

1

1

1

8

0

9

7

9

0

9

01

9

8

9

8

9

8

R

R

R

R

R

k

0

0

0

0

0

0

0

0

0

1

1

1

1

4

2

3

5

0

0

0

0

9

9

9

9

R

R

R

R

D901

RD5.1ESB2

C827

0

4.7 50V

1

6

0

R908

9

R

1

3

9

R

10k

R877

10k

C818

4.7

50V

C809

0

0

0

0

3

0.1

1

0

9

1

R

R943

100

R944

100

R945

100

R946

1k

R947

100

R948

1k

R949

1k

R950

470

R951

1k

R952

470

R953

470

R954

470

R955

1k

C829

10p

TP1

TP2

TP3

TP4

TP5

TP6

R832

R831 R830 R829 R828 R827 R826

2.2k

1.5k 1k 680 470 330 2 20

W

W

W

W

W

W

S

S

S

S

S

8

0

8

S

R932

4.7k

W

S

8

1

8

S

6

7

0

0

8

8

S

S

R925

R838 R837 R836 R835 R834 R833

2.2k

1.5k 1k 680 470 330 220

W

W

S

7

1

8

S

W

S

S

4

5

1

1

8

8

S

S

4

5

0

0

8

8

S

S

W

S

3

1

8

S

W

S

S

2

3

0

0

8

8

S

S

W

W

S

S

2

1

1

1

8

8

S

S

R840

3.3k

W

S

1

0

8

S

W

S

0

1

8

S

1

.0

0

2

0

8

C

R839

3.3k

W

S

C801

9

0

0.01

8

S

R926

100k

Q811

KTC3203Y-AT

C837

100p

100

R860

C846

100p

M

0

1

7

V

0

5

8

2

C845

100p

C842

100p

0

k

1

3

3

9

R

Q810

D811

KTA1271Y

RD3.3ESR

R928

1k

2

2

2

3

0

8

R927

2.2k

C

.0

0

Q812

KTC3203Y-AT

R929

82

C833

220

16V

C804

0.1

C838

0.1

0

7

0

k

1

Q803

KTC3875

k

7

4

8

5

8

R

2

0

8

R

R859

47k