AIWA CX-LEM550 Service Manual

CX-LEM550

SERVICE MANUAL

Ver 1.0 2004.06

CX-LEM550 is the Amplifier, CD player,

Tape Deck and T uner section in XR-EM550.

CD

Section

Tape deck Model Name Using Similar Mechanism HCD-GP5

Section T ape Transport Mechanism Type CMAL1Z240A

AEP Model

UK Model

E Model

Model Name Using Similar Mechanism HCD-NE5

Base Unit Name BU-K7BD81B

Optical Pick-up Name KSM-213EDP/C2NP

Main unit

Amplifier section

European model:

DIN power output (rated): 20 + 20 W

(6 ohms at 1 kHz, DIN)

Continuous RMS power output (reference):

25 + 25 W

(6 ohms at 1 kHz, 10%

THD)

Music power output (reference):

38 + 38 W

Other models:

The following measured at AC 2 30 V or AC 120 V, 5 0/

60 Hz

DIN power output (rated): 20 + 20 W

(6 ohms at 1 kHz, DIN)

Continuous RMS power output (reference):

25 + 25 W

(6 ohms at 1 kHz, 10%

THD)

Inputs

MD (phono jacks): Sensitivity 450 mV,

impedance 47 kilohms

Outputs

PHONES: Accepts headphones with

an impedance of 8 ohms or

more

SPEAKER: Accepts impedance of 6 to

16 ohms.

SPECIFICATIONS

CD player section

Laser Semiconductor laser

(λ=780 nm)

Emission duration:

continuous

Frequency response 20 Hz – 20 kHz

Tape deck section

Recording system 4-track 2-channel, stereo

Frequency response 50 – 13,000 Hz (±3 dB),

using Sony TYPE I

cassettes

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 – 108.0 MHz

Antenna FM lead antenna

Antenna terminals 75 ohms unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

European model: 531 – 1,602 kHz

(with the tuning interval

set at 9 kHz)

Other models: 530 – 1,710 kHz

Antenna AM loop antenna, external

Intermediate frequency 450 kHz

General

Power requirements

European model: 230 V AC, 50/60 Hz

Korean model: 220 V AC, 60 Hz

Taiwanese model: 120 V AC, 50/60 Hz

Other models: 110 – 120 V or 220 – 240 V

Power consumption

— Continued on next page —

(with the tuning interval

set at 10 kHz)

531 – 1,602 kHz

(with the tuning interval

set at 9 kHz)

antenna terminal

AC, 50/60 Hz

Adjustable with voltage

selector

67 W

0.3 W (in Power Saving

Mode)

9-877-819-01

2004F1678-1

© 2004.06

COMPACT DISC DECK RECEIVER

Sony Corporation

Home Audio Company

Published by Sony Engineering Corporation

CX-LEM550

Dimensions (w/h/d) Approx. 164 × 230.5 × 266

mm incl. projecting parts

and controls

Mass Approx. 4.1 kg

Design and specifications are subject to change

without notice.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

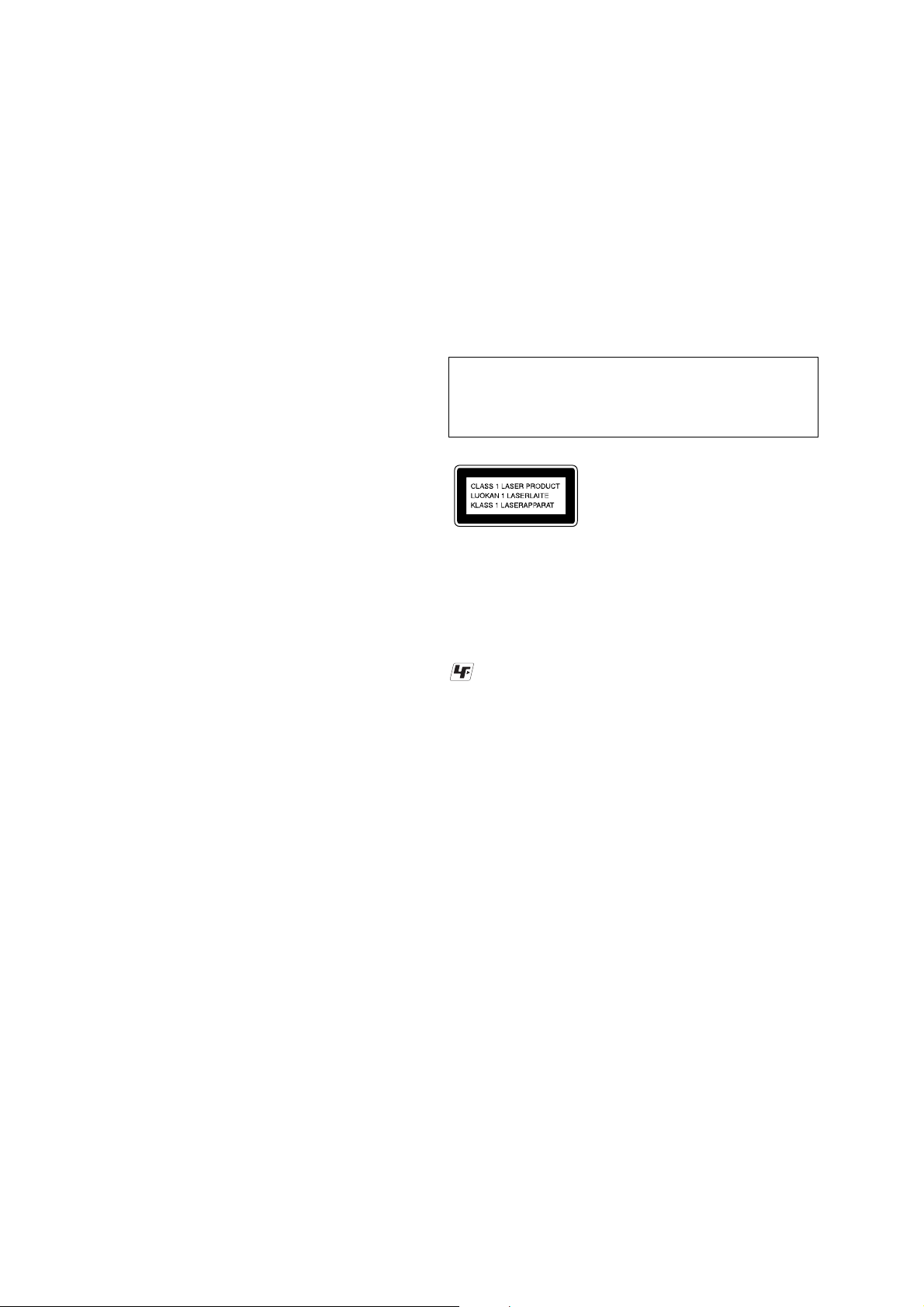

This appliance is

classified as a CLASS 1

LASER product. This

label is located on the

rear exterior.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

TABLE OF CONTENTS

CX-LEM550

1. SERVICING NOTES ................................................ 4

2. GENERAL ................................................................... 6

3. DISASSEMBLY

3-1. Rear Cabinet .................................................................... 8

3-2. Top Panel Assy ................................................................ 9

3-3. Front Panel Assy .............................................................. 9

3-4. Base Unit (BU-K7BD81B) ............................................. 10

3-5. Tape Cassette Mechanism Deck ...................................... 10

3-6. MAIN Board.................................................................... 11

3-7. AMP Board...................................................................... 11

4. TEST MODE ............................................................... 12

5. MECHANICAL ADJUSTMENTS......................... 13

6. ELECTRICAL ADJUSTMENTS

Deck Section.................................................................... 13

CD Section ...................................................................... 14

7. DIAGRAMS

7-1. Block Diagram – CD Servo Section –............................ 16

– MAIN Section – ........................................................... 17

7-2. Printed Wiring Board – CD Board – .............................. 18

7-3. Schematic Diagram – CD Board – ................................. 19

7-4. Printed Wiring Board – MAIN Board – ......................... 20

7-5. Schematic Diagram – MAIN Board –............................ 21

7-6. Printed Wiring Board – AMP Section – ......................... 22

7-7. Schematic Diagram – AMP Section – ............................ 23

7-8. Printed Wiring Board – CONTROL Board – .................. 24

7-9. Schematic Diagram – CONTROL Board –.................... 25

7-10. Printed Wiring Board – POWER Board – ....................... 26

7-11. Schematic Diagram – POWER Board –.......................... 27

8. EXPLODED VIEWS

8-1. Overall Section ................................................................ 34

8-2. Front Panel Assy-1 .......................................................... 35

8-3. Front Panel Assy-2 .......................................................... 36

8-4. Top Panel Assy ................................................................ 37

9. ELECTRICAL PARTS LIST .................................. 38

3

CX-LEM550

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveforms is output three times.

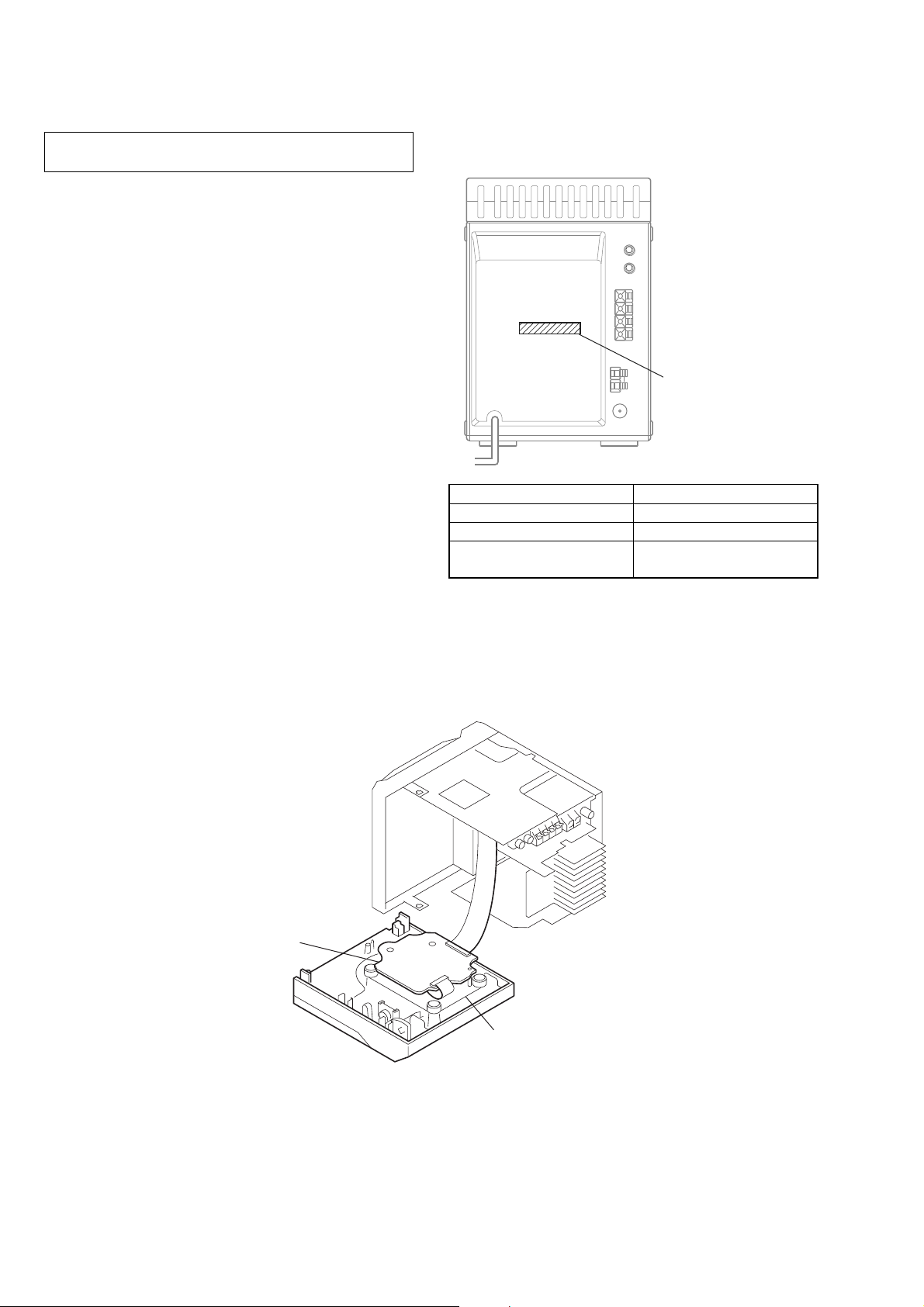

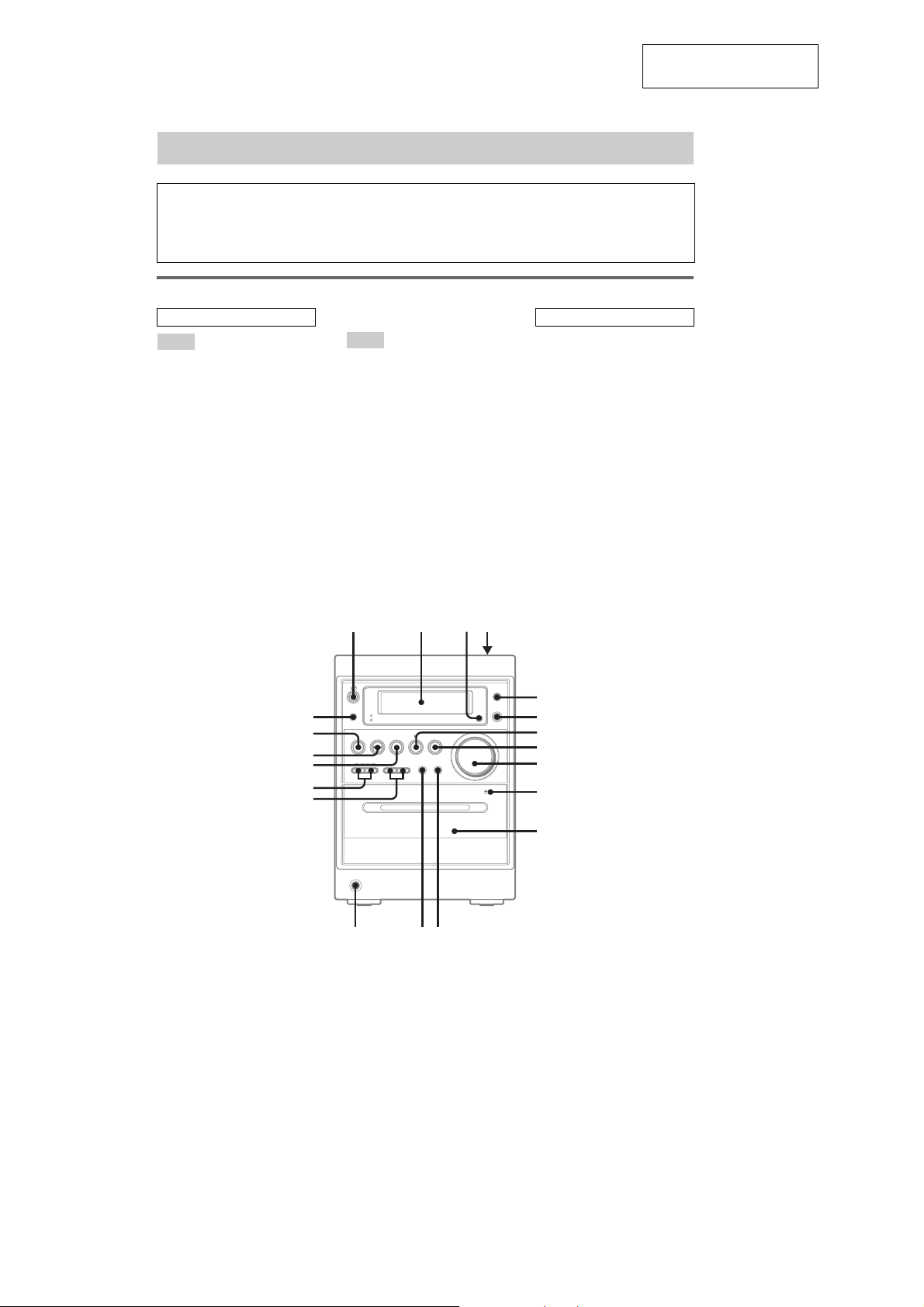

MODEL IDENTIFICATION

– Back Panel –

Power Voltage Indication

Model Name Power Voltage Indication

AEP and UK models 230 V AC, 50/60 Hz 67W

Korean model 220 V AC, 50/60 Hz 67W

Other models (Singapore, 110 – 120 V or

Chilean and peruvian models) 220 – 240 V AC, 50/60Hz 67W

SERVICE POSITION OF THE CD MECHANISM DECK

CD board

CD Mechanism Deck

4

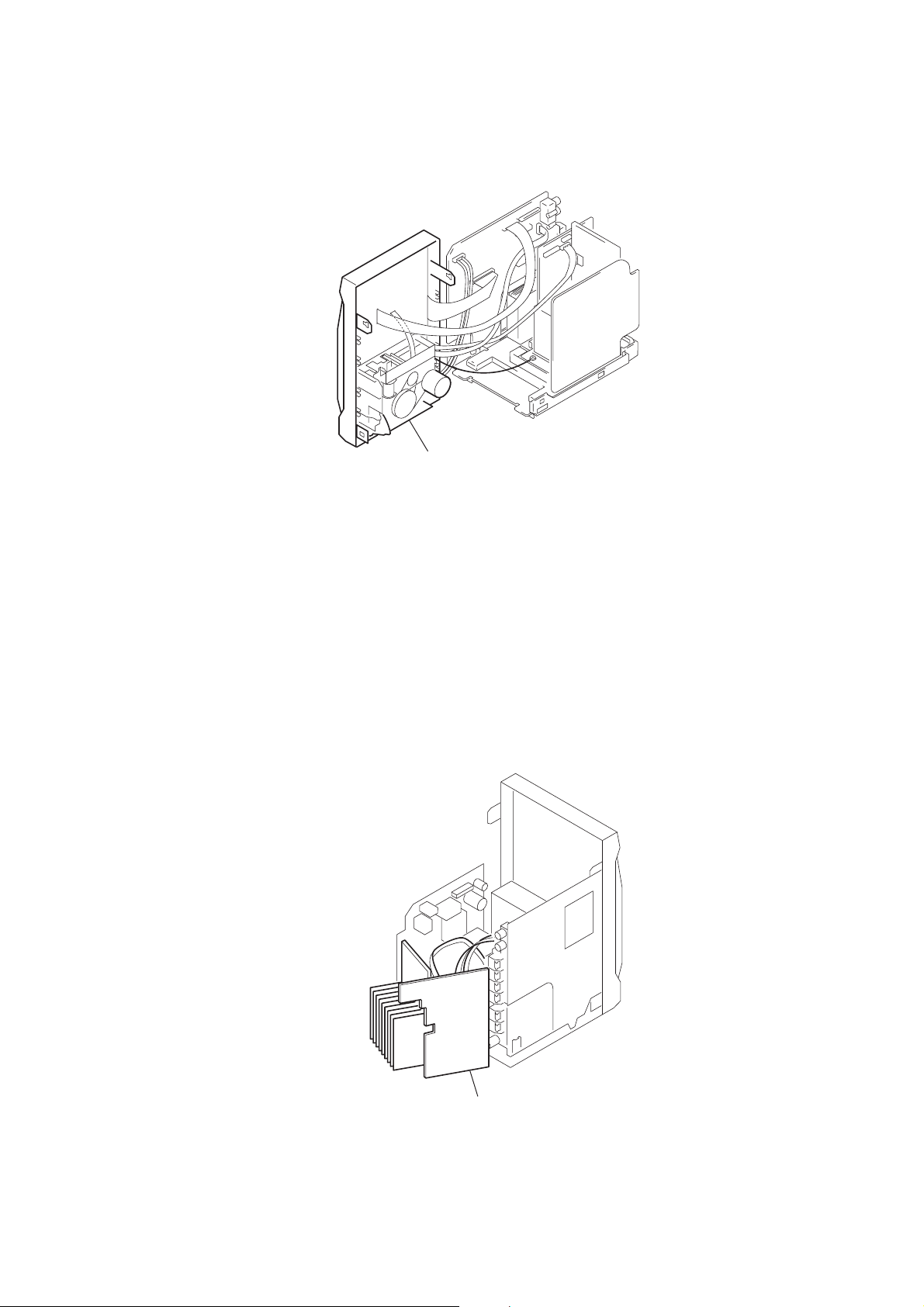

SERVICE POSITION OF THE TAPE CASSETTE MECHANISM DECK

Tape Cassette Mechanism Deck

(CMAL1Z240A)

CX-LEM550

SERVICE POSITION OF THE AMP BOARD

AMP board

5

CX-LEM550

SECTION 2

GENERAL

List of button locations and reference pages

This section is extracted

from instruction manual.

How to use this page

Use this page to find the location of buttons and other

parts of the system that are mentioned in the text.

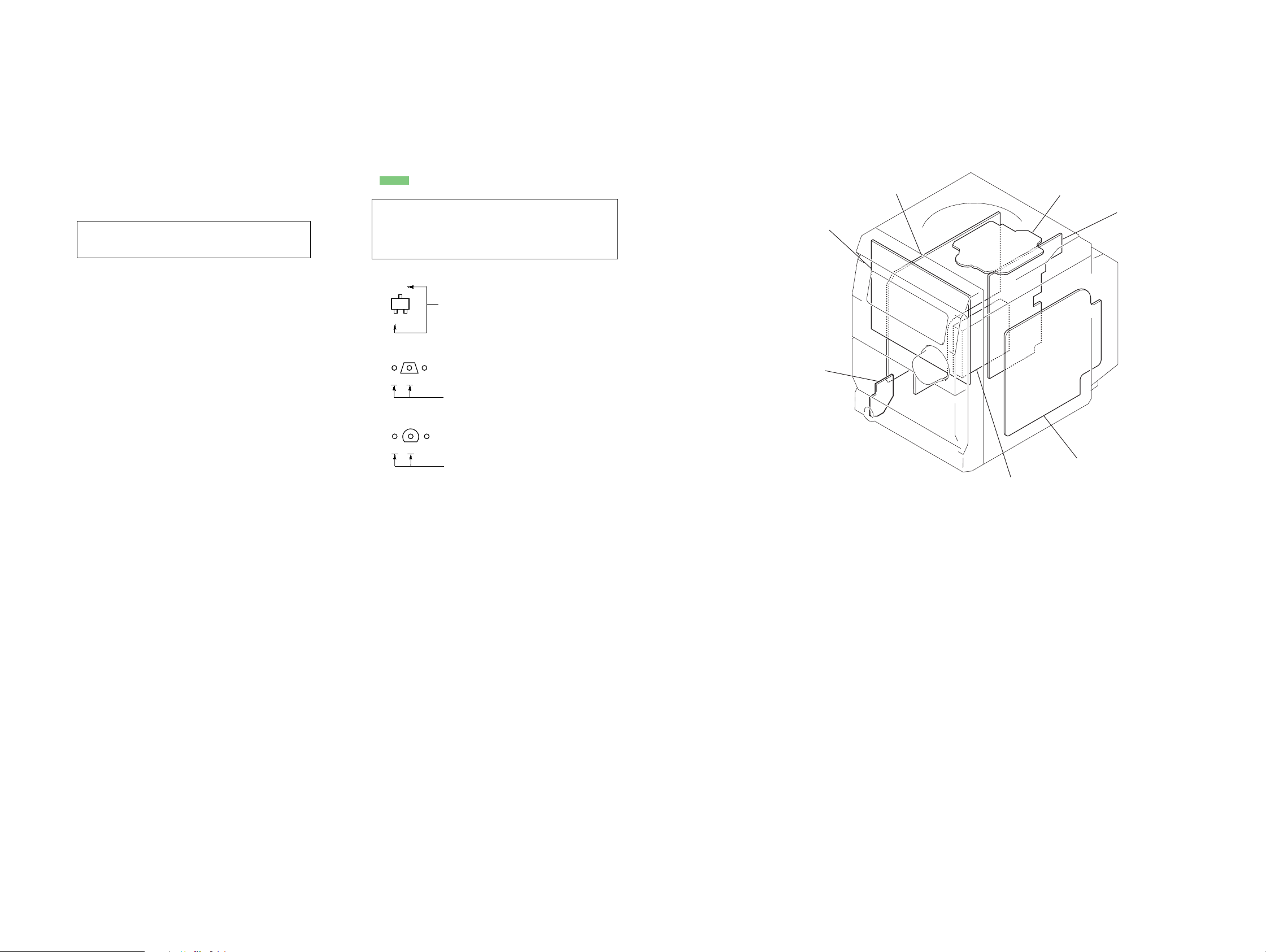

Main unit

ALPHABETICAL ORDER

A – O

ALBUM +/– qg (10, 11, 16)

BASS/TREBLE 5 (18)

Cassette compartment qa

CD SYNCHRO qd (16)

DIRECTION 8 (15, 16, 17)

DISPLAY w; (14, 21)

Display window 2

i-Bass 6 (18)

OPEN (CD open/close) 4 (10)

P – Z

PHONES jack qf

PLAY MODE 8 (9, 11, 16)

Remote sensor 3

TUNER/BAND qj (12, 13)

TUNING +/– qh (12, 13, 18)

TUNING MODE 8 (12, 13)

VOLUME 9 (19, 23, 25)

1234

Illustration number

DISPLAY

Name of button/part Reference page

r

wa (14, 21)

RR

BUTTON DESCRIPTIONS

?/1 (power) 1 (7, 19, 20, 25)

.m/M> (skip back/

skip forward, rewind/fast

forward) qh (10, 11, 15)

x (stop) 7 (10, 16, 17, 25)

z REC PAUSE/START qs (16,

17)

CD/NX (play/pause) qk (10,

11, 23)

TAPE/nN (play) ql (15, 16,

17, 20)

Z PUSH (tape open/close) q;

(15)

w;

ql

qk

qj

qh

qg

5

6

7

8

9

0

qa

qs

qdqf

6

Remote control

CX-LEM550

ALPHABETICAL ORDER

A – O P – Z

ALBUM +/– qa (10, 11, 16)

CD qh (9, 11)

CLEAR qd (11)

CLOCK/TIMER SELECT 2

(19, 20, 23)

CLOCK/TIMER SET 3 (8, 19,

20)

DISPLAY ql (14, 21)

ENTER 9 (8, 11, 12, 19, 20)

EQ qs (18)

FM MODE 4 (13, 24)

FUNCTION 6 (22, 24)

PLAY MODE qk (9, 11, 24)

REPEAT 4 (10)

SLEEP w; (18)

TAPE qg (15)

TUNER/BAND 5 (12, 13)

TUNER MEMORY qj (12)

TUNING MODE qk (12, 13)

VOLUME +/– 0 (19, 23)

ql

qk

qj

qh

qg

qf

BUTTON DESCRIPTIONS

?/1 (power) 1 (7, 19, 20, 25)

m/M (rewind/fast forward)

7 (10, 15)

./> (go back/go forward)

qf (8, 10, 11, 19, 20)

x (stop) 8 (10, 16, 17, 25)

X (pause) 8 (10, 15)

N (play) 8 (9, 11, 20)

+/– (tuning) qf (12, 13)

w; 1

2

3

4

5

6

7

8

qd

qs

qa

Setting the clock

Use buttons on the remote for the operation.

1 Press ?/1 to turn on the system.

2 Press CLOCK/TIMER SET.

3 Press ./> repeatedly to set the

hour.

4 Press ENTER.

5 Press ./> repeatedly to set the

minute.

6 Press ENTER.

The clock starts working.

To adjust the clock

1 Press CLOCK/TIMER SET.

2 Press ./> until “CLOCK” appears,

then press ENTER.

3 Do the same procedures as step 3 to 6

above.

Note

The clock is not displayed in Power Saving Mode

(page 21).

9

*

0

7

CX-LEM550

•This set can be disassembled in the order shown below.

SET

3-1. REAR CABINET

(Page 8)

3-2. TOP PANEL ASSY

(Page 9)

SECTION 3

DISASSEMBLY

3-3. FRONT PANEL ASSY

(Page 9)

3-5. TAPE CASSETTE

MECHANISM DECK

(Page 10)

Note: Follow the disassembly procedure in the numerical order given.

3-4. BASE UNIT

3-6. MAIN BOARD

3-1. REAR CABINET

1

four screws

×

(BTP3

12)

(BU-K7BD81B)

(Page 10)

(Page 11)

3-7. AMP BOARD

(Page 11)

4

five screws

(BVTP3 × 10)

3

two screws

(BVTP3 × 10)

8

rear cabinet

5

6

7

connector

(CN310)

2

four screws

(BTP3 × 12)

two screws

(BVTP3

×

10)

8

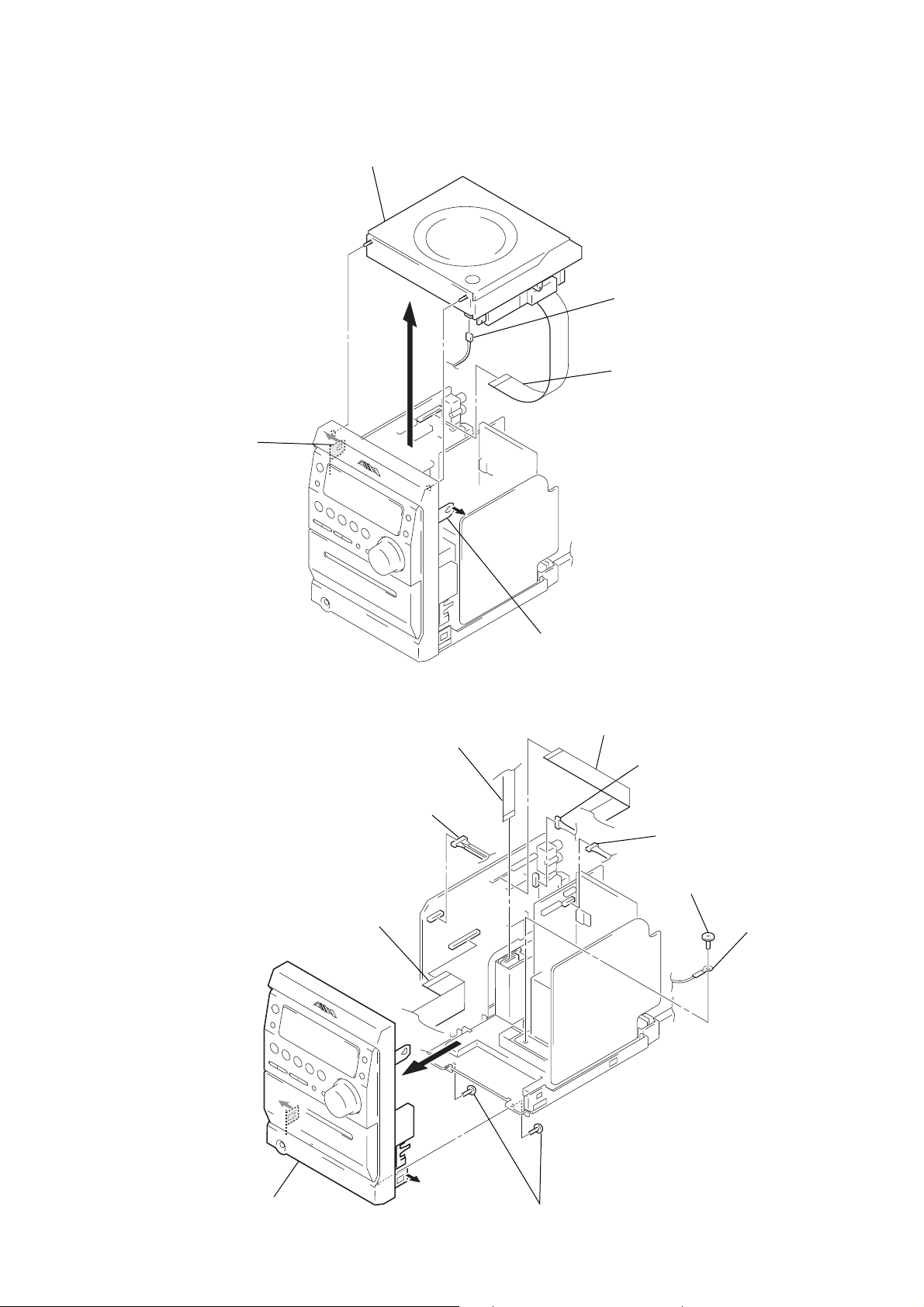

3-2. TOP PANEL ASSY

6

top panel assy

5

connector

(S820)

CX-LEM550

2

claw

3-3. FRONT PANEL ASSY

3

q;

wire (flat type) (11 core)

5

connector

(CN301)

4

1

claw

2

wire (flat type) (16 core)

(CN303)

wire (flat type) (27 core)

(CN305)

3

connector

(CN501B)

4

connector

(CN501A)

1

wire (flat type) (24 core)

(CN302)

8

qd

flont panel assy

7

9

6

two screws

(BVTP3 × 10)

qa

screw

(BVTP4 × 8)

qs

harness

9

CX-LEM550

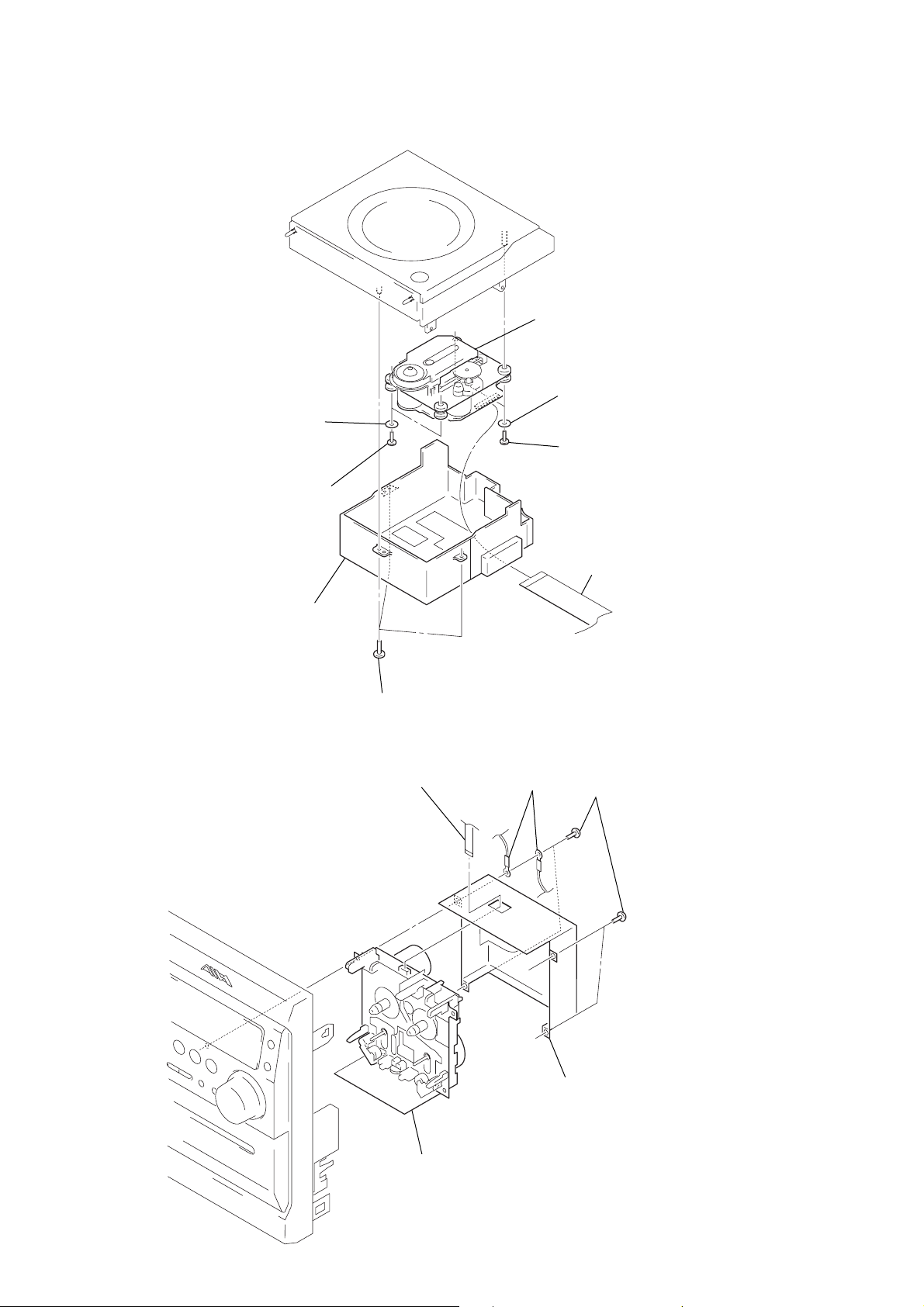

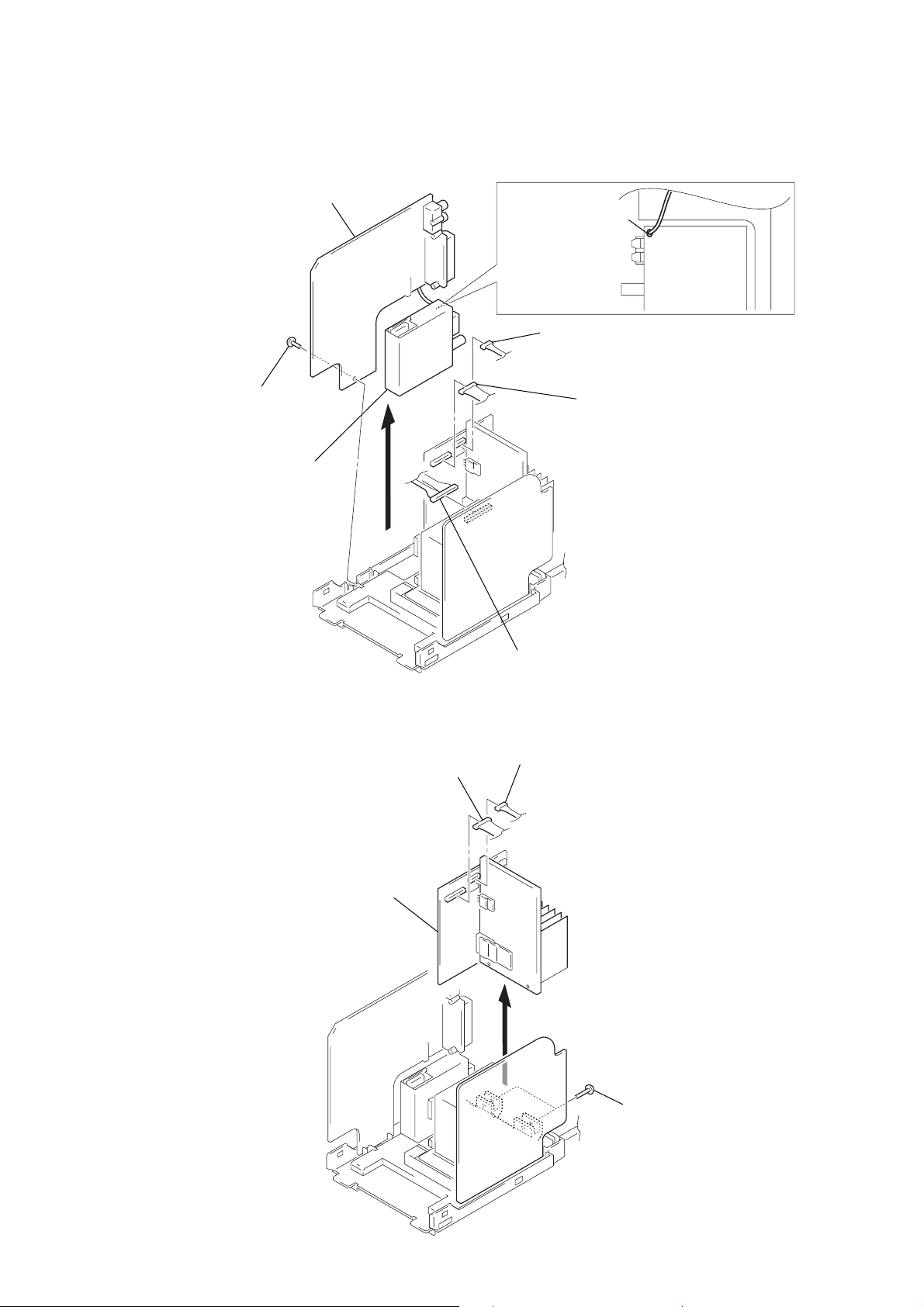

3-4. BASE UNIT (BU-K7BD81B)

7

two washers

8

base unit

(BU-K7BD81B)

5

two washers

4

two screws

6

two screws

2

CD cover

1

3-5. TAPE CASSETTE MECHANISM DECK

1

wire (flat type) (7 core)

three screws

(BTP2.6

×

8)

3

two harness

3

wire (flat type) (27core)

(CN201)

2

four screws

(BVTP3

×

10)

10

5

tape cassette mechanism deck

(CMAL1Z240A)

4

plate (shield cassette)

3-6. MAIN BOARD

4

7

8

MAIN board

screw

(BVTP3

×

10)

tuner (FM/AM)

5

6

Remove the solder.

1

connector (CN307)

2

connector (CN308)

CX-LEM550

3-7. AMP BOARD

4

AMP board

2

connector

(CN308)

3

connector (CN903)

1

connector

(CN307)

3

two screws

(BVTP3

×

14)

11

CX-LEM550

SECTION 4

TEST MODE

COLD RESET

• The cold reset clears all data including preset data stored in

the RAM to initial conditions. Execute this mode when

returning the set to the customer.

Procedure:

1. Press the ?/1 button to turn the power on.

2. While pressing the x button, press the ?/1 button and turn

the [VOLUME] knob in the counter-clock wise.

3. The message “RESET” is displayed and the set is reset.

PANEL TEST

• All se gments of liquid crystal display are tested, and the version

and released date of the micro computer are displayed.

Procedure:

1. Press the ?/1 button to turn the power on.

2. While pressing the [DISPLAY] button, press the ?/1 button

and turn the [VOLUME] knob in the counter-clock wise.

Then all segments of liquid crystal display are turned on.

3. Press the [i-BASS] button, the v ersion and released date of the

micro computer are displayed.

example of display:

0116 V202

Version of micro computer

(In this case, version 202)

released date of micro computer

(In this case, released of January 16)

4. Press the [BASS/TREBLE] button, the model name and

distination are displayed.

example of display:

A20 CE2

distination

(In this case, UK model)

model name

(In this case, CX-LEM550)

5. To exit from this mode, perform the “COLD RESET”.

TUNER STEP CHANGE-OVER

(EXCEPT FOR AEP, UK MODEL)

• Either the 9 kHz step or 10 kHz step can be selected for the

AM channel step.

Procedure:

1. Set the FUNCTION to AM, and press the ?/1 button to turn

the power off.

2. While depressing the [TUNING + ] button, press the

?/1 button.

3. The message “9K STEP” or “10K STEP” is displayed on the

liquid crystal display, and thus the channel step is changed

over.

M >

12

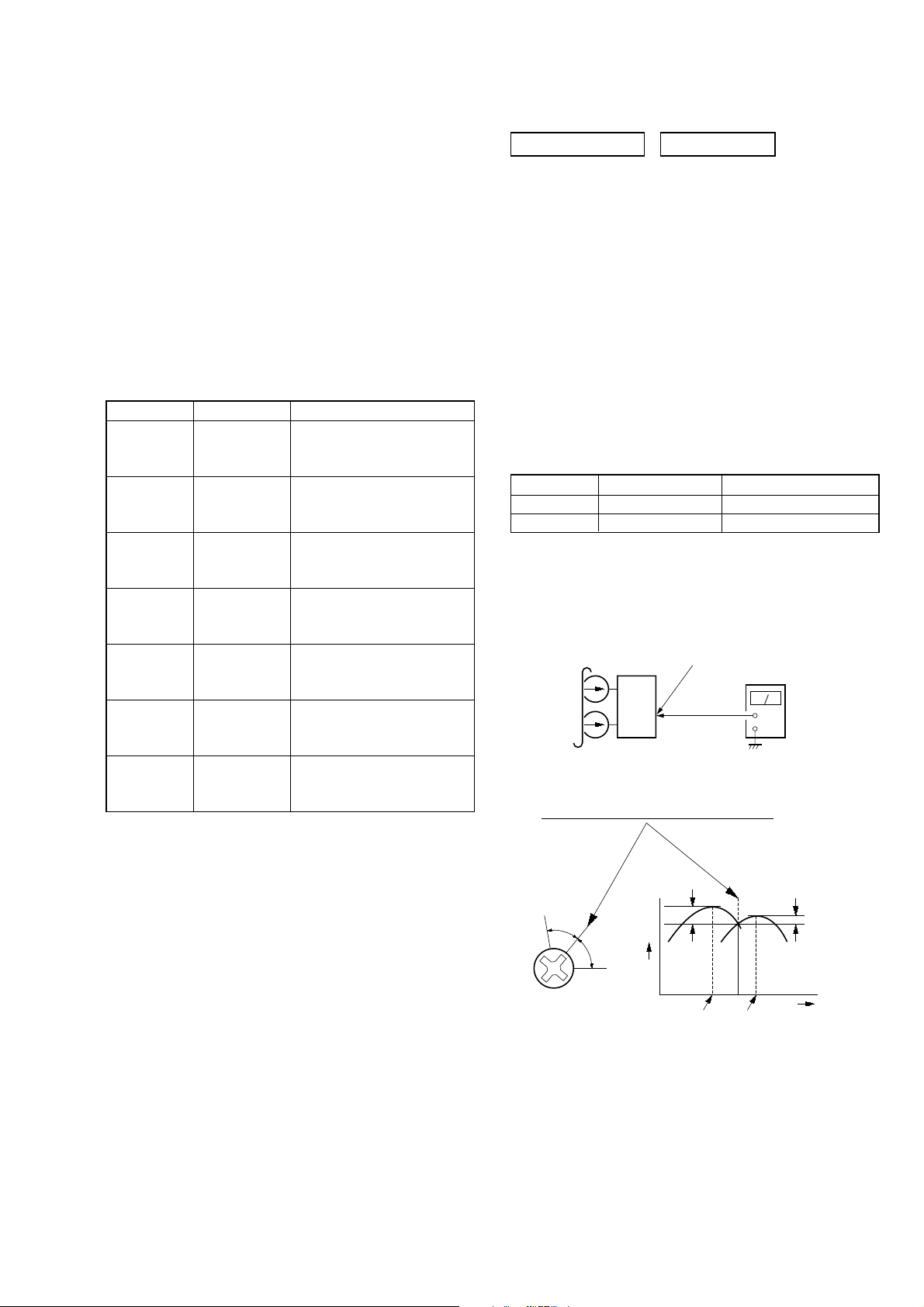

SECTION 5

set

MAIN board

SPEAKER terminal (J302)

L-CH, R-CH

+

–

level meter

test tape

P-4-A100

(10 kHz, – 10 dB)

MECHANICAL ADJUSTMENTS

CX-LEM550

SECTION 6

ELECTRICAL ADJUSTMENTS

TAPE MECHANISM DECK SECTION

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback heads pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to

the parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

Torque Measurement

Mode Torque meter Meter reading

3.04 mN • m to 6.96 mN • m

FWD CQ-102C 31 to 71 g • cm

(0.43 – 0.98 oz • inch)

FWD

back tension

REV CQ-102RC 31 to 71 g • cm

REV

back tension

FF/REW CQ-201B 71 to 143 g • cm

FWD tension CQ-403A 100 g • cm or more

REV tension CQ-403R 100 g • cm or more

CQ-102C 2 to 6 g • cm

CQ-102RC 2 to 6 g • cm

0.20 mN • m to 0.58 mN • m

(0.02 – 0.08 oz • inch)

3.04 mN • m to 6.96 mN • m

(0.43 – 0.98 oz • inch)

0.20 mN • m to 0.58 mN • m

(0.02 – 0.08 oz • inch)

6.97 mN • m to 14.02 mN • m

(0.98 – 1.99 oz • inch)

9.8 mN • m or more

(1.4 oz • inch or more)

9.8 mN • m or more

(1.4 oz • inch or more)

DECK SECTION 0 dB = 0.775 V

Precaution

1. Demagnetize the record/playback head with a head demagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to

the parts adjusted.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in

this service manual. (As a general rule, playback circuit

adjustment should be completed before performing recording

circuit adjustment.)

6. The adjustments should be performed for both L-CH and RCH.

7. Switches and controls should be set as follows unless otherwise

specified.

Test T ape

Tape Signal Used for

P-4-A100 10 kHz, –10 dB Azimuth Adjustment

WS-48B 3 kHz, 0 dB Tape Speed Check

Record/Playback Head Azimuth Adjustment

Procedure:

1. Mode: Playback

2. Turn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 1dB of peak.

L-CH

peak

Screw

position

R-CH

peak

Output

level

within

1dB

L-CH

peak

R-CH

peak

within

1dB

Screw

position

13

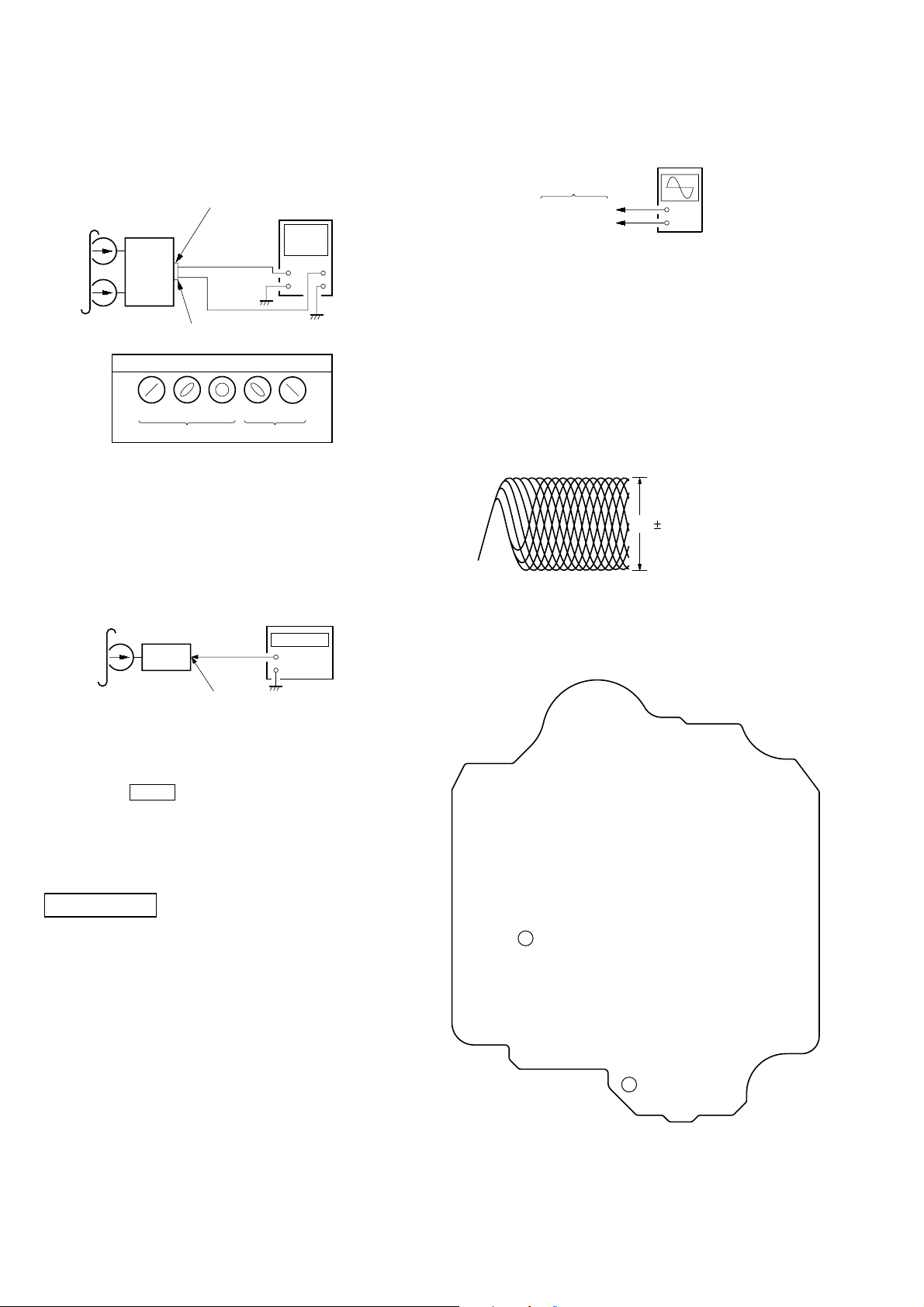

CX-LEM550

3. Mode: Playback

MAIN board

test tape

P-4-A100

(10 kHz, – 10 dB)

L-CH

set

R-CH

in phase 45°90°135°180

SPEAKER terminal (J302)

L-CH

R-CH

waveform of oscilloscope

good

oscilloscope

wrong

H

V

°

4. After the adjustments, apply suitable locking compound to

the parts adjusted.

Adjustment Location:Record/Playback/Erase Head

Tape Speed Check

Mode: Playback

test tape

WS-48B

(3 kHz, 0 dB)

set

frequency counter

+

–

FOCUS BIAS CHECK

CD board

TP (RFACO)

TP (VC)

oscilloscope

(DC range)

+

–

Procedure :

1. Connect the oscilloscope to TP (RF ACO) and TP (VC) on the

CD board.

2. Insert the disc (YEDS-18). (Part No. : 3-702-101-01)

3. Press the [CD ] button.

NX

4. Confirm that the oscilloscope waveform is as shown in the

figure below. (eye pattern)

A good eye pattern means that the diamond shape (◊) in the

center of the waveform can be clearly distinguished.

• RF signal reference waveform (eye pattern)

VOLT/DIV: 0.2 V (with the 10: 1 probe in use.)

TIME/DIV: 500 ns

1.1

0.2 Vp-p

When observing the eye pattern, set the oscilloscope

for AC range and raise vertical sensitivity.

Checking Location:

– CD BOARD (Conductor Side) –

MAIN board

SPEAKER terminal (J302)

L-CH, R-CH

1. Turn the power on.

1. Insert the WS-48B into the deck.

2. Press the nN button on the deck.

3. Confirm that the frequency counter reads 3,000 ± 90 Hz.

Sample value of Wow and Flutter: 0.3% or less W.RMS (JIS)

(WS-48B)

CD SECTION

Note:

1. CD Block is basically constructed to operate without

adjustment.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indica ted.

3. Use an oscilloscope with more than 10 MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the

following checks.

5. Check the focus bias check when optical block is replaced.

TP (VC)

TP

(RFACO)

14

SECTION 7

DIAGRAMS

CX-LEM550

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

For Schematic Diagrams.

Note:

• All capacitors are in µF unless otherwise noted. (p: pF).

50 WV or less are not indicated except f or electrolytics and

tantalums.

• All resistors are in Ω and 1/

specified.

• f : internal component.

• 5 : fusible resistor.

• C : panel designation.

Note: The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

• A : B+ Line.

• B : B– Line.

• H : adjustment for repair.

•Voltages and waveforms are dc with respect to ground under no-signal (detuned) conditions.

no mark: TUNER (FM)

( ): CD PLAY

〈 〉: TAPE REC

•Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production

tolerances.

•Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production

tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : TUNER (FM/AM)

J : CD PLAY

E : TAPE PLAY

a : TAPE REC

j : MD (AUX) IN

•Abbreviation

E51 : Chilean and peruvian models

KR : Korea model

SP : Singapore model

4

W or less unless otherwise

For Printed Wiring Boards.

Note:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• W : indicates side identified with part number.

• f : internal component.

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side : Parts on the pattern face side seen from

(Conductor side) the pattern face are indicated.

Parts face side : Parts on the parts face side seen from

(Component side) the parts face are indicated.

• Indication of transistor.

C

Q

B

E

B

B

These are omitted.

Q

CE

These are omitted.

Q

CE

These are omitted.

• Circuit Boards Location

CONTROL board

HP board

MAIN board

CD board

AMP board

POWER board

TUNER unit

1515

Loading...

Loading...