Page 1

CX-JD5

SERVICE MANUAL

Ver. 1.2 2005.05

• CX-JD5 is the amplifier, DVD player, tape

deck and tuner section in JAX-D5.

This system incorporates Dolby* Digital, Dolby Pro

Logic (II) adaptive matrix surround decoder, and the

DTS** Digital Surround System.

*Manufactured under license from Dolby

Laboratories.

“Dolby”, “Pro Logic” and the double-D symbol are

trademarks of Dolby Laboratories.

** Manufactured under license from Digital Theater

Systems, Inc. “DTS” and “DTS Digital Surround”

are registered trademarks of Digital Theater

Systems, Inc.

US and foreign patents licensed from Dolby

Laboratories.

DVD

Section

Tape deck

Section

Model Name Using Similar Mechanism NEW

DVD Mechanism Type CDM74-DVBU23

Optical Traverse Unit Name DBU-1

Model Name Using Similar Mechanism NEW

Tape Transport Mechanism Type CWM43FR16/CWM43FR26

AEP Model

E Model

Australian Model

Amplifier section

The following measured at AC 120, 127, 220, 240 V,

50/60 Hz

Rated Power Output at Stereo mode

Continuous RMS power output (reference)

Front speaker: 90 + 90 watts

(6 ohms at 1 kHz, 10%

THD)

Center speaker: 30 watts (8 ohms at 1 kHz,

10% THD)

Surround speaker: 30 watts

(8 ohms at 1 kHz, 10%

THD)

Inputs

MD/VIDEO (AUDIO) IN (phono jacks):

voltage 450/250 mV,

impedance 47 kilohms

MIC (phone jack): sensitivity 1 mV,

impedance 10 kilohms

Outputs

MD/VIDEO (AUDIO) OUT (phono jacks):

voltage 250 mV,

impedance 1 kilohm

SPECIFICATIONS

VIDEO OUT (phono jack):

S-VIDEO OUT (4-pin/mini-DIN jack):

COMPONENT VIDEO OUT:

PHONES (stereo mini jack):

Front speaker: Use only the supplied

Surround speaker: Use only the supplied

Center speaker: Use only the supplied

SUB WOOFER OUT: voltage 1 V,

max. output level

1 Vp-p, unbalanced, Sync

negative, load impedance

75 ohms

Y: 1 Vp-p, unbalanced,

Sync negative,

C: 0.286 Vp-p, load

impedance 75 ohms

Y: 1 Vp-p, 75 ohms

B

, PR: 0.7 Vp-p, 75 ohms

P

accepts headphones of

8ohms or more

speaker SX-JD5

speaker SX-JD5R

speaker SX-JD5C

impedance 1 kilohm

Disc player section

System Compact disc and digital

audio and video system

Laser Semiconductor laser

(DVD: λ=657 nm,

CD: λ=793 nm)

Emission duration:

continuous

Frequency response DVD (PCM 48 kHz):

2 Hz – 22 kHz (±1 dB)

CD: 2 Hz – 20 kHz (±1 dB)

Video color system format

NTSC, PAL

Tape deck section

Recording system 4-track 2-channel stereo

Frequency response 40 – 13,000 Hz (±3 dB),

using Sony TYPE I

cassette

– Continued on next page –

DVD DECK RECEIVER

9-961-039-03 Sony Corporation

2005E05-1 Personal Audio Group

© 2005.05 Published by Sony Engineering Corporation

Page 2

CX-JD5

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 – 108.0 MHz

Antenna FM lead antenna

Antenna terminals 75 ohm unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range

Latin American models: 530 – 1,710 kHz

Saudi Arabian model: 531– 1,602 kHz (with the

Other models: 531 – 1,602 kHz (with the

Antenna AM loop antenna

Antenna terminals External antenna terminal

Intermediate frequency 450 kHz

General

Power requirements

European model: 230 V AC, 50/60 Hz

Australian model: 230 – 240 V AC, 50/60 Hz

Saudi Arabian model: 120 – 127 V, 220 V or

Other models: 120 V, 220 V or 230 –

Power consumption

(with the interval set at

10 kHz)

531 – 1,710 kHz

(with the interval set at

9kHz)

interval set at 9 kHz)

interval set at 9 kHz)

530 – 1,710 kHz (with the

interval set at 10 kHz)

230 – 240V AC,

50/60 Hz

Adjustable with voltage

selector

240 V AC, 50/60 Hz

Adjustable with voltage

selector

255 watts

0.4 watts (in Power Saving

Mode, European Model

Only)

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

The following caution label is located inside the unit.

This appliance is classified

CLASS 1 LASER PRODUCT

LUOKAN 1 LASER LAITE

KLASS 1 LASER APPARAT

as a CLASS 1 LASER

product.

This label is located on the

rear exterior.

The following caution label is located inside the apparatus.

Dimensions (w/h/d)

Mass

Design and specifications are subject to change

without notice.

Approx. 280 × 330 ×

405 mm

Approx. 11.75 kg

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 ˚C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 ˚C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

2

Page 3

CX-JD5

• DVD-RWs in VR mode (DVD-RWs created

in VR (Video Recording) mode allow the

contents to be programed or edited.)

• DVD-ROMs

• DVD Audio discs

•A DVD with a different region code.

•Audio tracks in MP3PRO format.

•A disc that has a non-standard shape (e.g.,

card, heart).

•A disc with paper or stickers on it.

•A disc that has the adhesive, cellophane tape,

or a sticker still left on it.

*1

ISO9660 Format

The most common international standard for the

logical format of files and folders on a CD-ROM.

There are severa l specification levels. In Leve l 1, file

names must be in the 8.3 format (no more than eight

characters in the name, no more than three characters

in the extension “.MP3” or “.JPG”) and in capital

letters. Folder names can be no longer than eight

characters. There can be no more than eight nested

folder levels. Level 2 sp ecifications allow file names

and folder names up to 31 characters long. Each

folder can have up to 8 trees.

For Joliet in the expansion format (file and folder

names can have up to 64 characters) m ake sure of the

contents of the writing software, etc.

*2

Multi Session

This is a recording method that enables adding of

data using the Track -At-Once method. Conventional

CDs begin at a CD control area called the Lead-in

and end at an area called Lead-out. A Multi Session

CD is a CD having multiple sessions, with each

segment from Lead-in to Lead-out regarded as a

single session.

CD-Extra: This format records audio (audio CD

data) on the tracks in se ssion 1 and data on the tracks

in session 2.

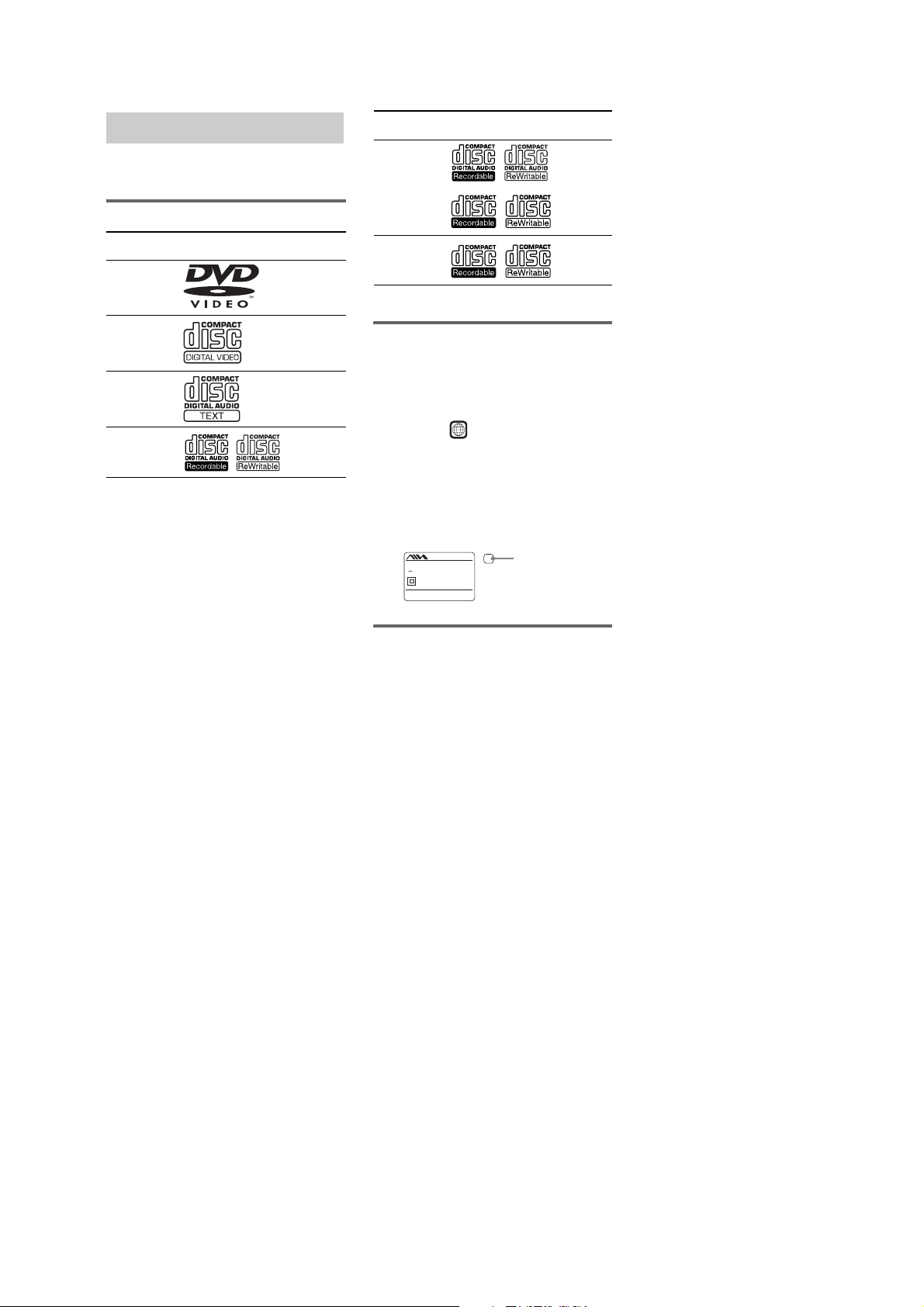

Playable discs

You can play back the following discs on this

system. Other discs cannot be played back.

List of playable discs

Format of

discs

DVD VIDEOs Audio +

VIDEO CDs Audio +

Audio CDs Audio

CD-R/CD-RW

(audio data)

Disc logo Contents

Video

Video

Audio

Format of

discs

CD-R/CD-RW

(MP3 files)

CD-R/CD-RW

(JPEG files)

The “DVD VIDEO” logo is a trademark.

Disc logo Contents

Audio

Video

Region code of DVDs you can

play on this system

Your system has a region code printed on the

back of the unit and will only play DVDs labeled

with identical region code.

DVDs labeled will also be played on this

ALL

system.

If you try to play any other DVD, the message

“Playback prohibited by area limitations.” will

appear on the TV screen. Depending on the

DVD, no region code indication may be labeled

even though playing the DVD is prohibited by

area restrictions.

MODEL NO.

CX-JD5

X

DVD DECK RECEIVER

AC: 120V/220V/230-240V

50/60Hz XXXW

SERIAL NO.

Sony Corporation

Region code

Discs that this system cannot

play

•CD-ROMs (except for extension “.MP3,”

“.JPG,” or “.JPEG”)

•CD-Rs/CD-RWs other than those recorded in

the following formats:

–music CD format

–video CD format

–MP3/JPEG format that conforms to

ISO9660*

Session*

•Data part of CD-Extras

•Super Audio CDs

•Progressive JPEG format files cannot be

played on this system.

1

Level 1/Level 2, Joliet or Multi

2

3

Page 4

CX-JD5

Notes on discs

•This system can play CD-R/CD-RW discs

edited by the user. However, note that

playback of some discs may not be possible

depending on the recording device used for

recording or the disc condition.

•Discs recorded on CD-R/CD-RW drives may

not be played back because of scratches, dirt,

recording condition or the driver’s

characteristics.

•CD-R and CD-RW discs that have not been

correctly finalized (processing to allow play

by a normal CD player) cannot be played.

•CD-R and CD-RW discs recorded in multisession that have not ended by “closing the

session” are not supported.

•The system may be unable to play MP3/JPEG

format files that do not have the extender

“.MP3”, “.JPG”, or “.JPEG”.

•Attempting to play non-MP3/JPEG format

files that have the extender “.MP3”, “.JPG”,

or “.JPEG” may result in noise or

malfunction. Playback is possible up to 8

levels.

•With formats other than ISO9660 level 1 and

2, folder names or file names may not be

displayed correctly.

•The following discs take a longer time to start

playback.

–a disc recorded with complicated tree

structure.

–a disc recorded in Multi Session.

–a disc to which data can be added (non-

finalized disc).

•Some CD-Rs, CD-RWs, DVD-Rs or DVDRWs (in video mode) (DVD-RWs created in

video mode have the same format as a DVD

VIDEO) cannot be played on this system

depending upon the recording quality or

physical condition of the disc, or the

characteristics of the recording device.

Furthermore, the disc will not play if it has not

been correctly finalized. For more

information, see the operating instructions for

the recording device.

•A disc recorded in packet write format cannot

be played.

Note on playback operations

of DVDs and VIDEO CDs

Some playback operations of DVDs and VIDEO

CDs may be intentionally set by software

producers. Since this system plays DVDs and

VIDEO CDs according to the disc contents the

software producers designed, some playback

features may not be available. Also, refer to the

instructions supplied with the DVDs or VIDEO

CDs.

Copyrights

This product incorporates copyright protection

technology that is protected by U.S. patents and

other intellectual property rights. Use of this

copyright protection technology must be

authorized by Macrovision, and is intended for

home and other limited viewing uses only unless

otherwise authorized by Macrovision. Reverse

engineering or disassembly is prohibited.

Music discs encoded w ith

copyright prote ction

technologies

This product is designed to playback discs that

conform to the Compact Disc (CD) standard.

Recently, various music discs encoded with

copyright protection technologies are marketed

by some record companies. Please be aware that

among those discs, there are some that do not

conform to the CD standard and may not be

playable by this product.

Cautions w hen pla ying a disc

that is recorded in Multi

Session

•This system can play Multi Session CDs when

an MP3 audio track is contained in the first

session. Any subsequent MP3 audio tracks

recorded in later sessions can also be played

back.

•This system can play Multi Session CDs when

a JPEG image file is contained in the first

session. Any subsequent JPEG image files

recorded in later sessions can also be played

back.

•If audio tracks and images in music CD

format or video CD format are recorded in the

first session, only the first session will be

played back.

4

Page 5

TABLE OF CONTENTS

CX-JD5

1. SERVICING NOTES ................................................ 6

2. GENERAL

Location of Controls ....................................................... 8

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 9

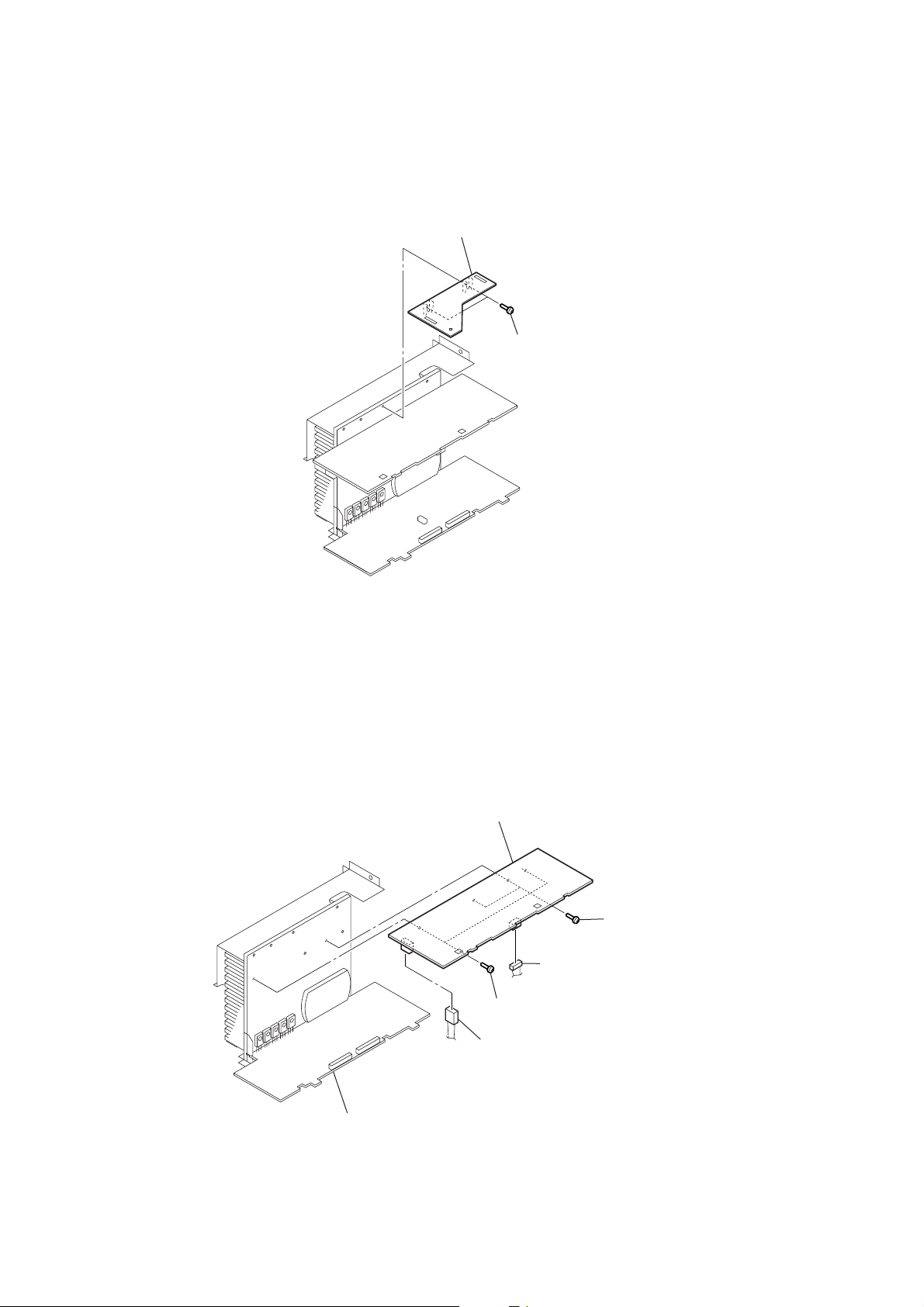

3-2. Steel Cabinet Case .......................................................... 10

3-3. Tray Panel........................................................................ 10

3-4. DVD Mechanism Deck (CDM74-DVBU23) ................. 11

3-5. Front Panel Section ......................................................... 11

3-6. Mechanism Deck (CWM43FR16/CWM43FR26) ......... 12

3-7. Back Panel Section.......................................................... 12

3-8. MAIN Board Section ...................................................... 13

3-9. MAIN Board ................................................................... 13

3-10. I-BASS Board ................................................................. 14

3-11. FRONT AMP Board, SURROUND AMP Board........... 14

3-12. TRANS Board ................................................................. 15

3-13. MB03 Board .................................................................... 15

3-14. VIDEO Board.................................................................. 16

3-15. DRIVER Board, SW Board ............................................ 16

3-16. Table Assy ....................................................................... 17

3-17. MOTOR (TB) Board ....................................................... 17

3-18. MOTOR (LD) Board....................................................... 18

3-19. RF Board ......................................................................... 18

3-20. Optical Traverse Unit (DBU-1) ...................................... 19

4. TEST MODE.............................................................. 20

5. ELECTRICAL ADJUSTMENTS......................... 30

6. DIAGRAMS

6-1. Block Diagram – DVD DSP (1/2) Section –................. 31

6-2. Block Diagram – DVD DSP (2/2) Section –................. 32

6-3. Block Diagram – TUNER/TAPE DECK Section – ...... 33

6-4. Block Diagram – MAIN Section – ................................ 34

6-5. Block Diagram – AMP Section – .................................. 35

6-6. Block Diagram

– DISPLAY/POWER SUPPLY Section – ...................... 36

6-7. Note for Printed Wiring Boards

and Schematic Diagrams ................................................ 37

6-8. Printed Wiring Board – RF Section –............................ 38

6-9. Schematic Diagram – RF Section –............................... 39

6-10. Printed Wiring Boards – CHANGER Section – ............ 40

6-11. Schematic Diagram – CHANGER Section – ................ 41

6-12. Printed Wiring Board

– MB Section (Component Side) – ................................ 42

6-13. Printed Wiring Board

– MB Section (Conductor Side) – .................................. 43

6-14. Schematic Diagram – MB Section (1/8) – .................... 44

6-15. Schematic Diagram – MB Section (2/8) – .................... 45

6-16. Schematic Diagram – MB Section (3/8) – .................... 46

6-17. Schematic Diagram – MB Section (4/8) – .................... 47

6-18. Schematic Diagram – MB Section (5/8) – .................... 48

6-19. Schematic Diagram – MB Section (6/8) – .................... 49

6-20. Schematic Diagram – MB Section (7/8) – .................... 50

6-21. Schematic Diagram – MB Section (8/8) – .................... 51

6-22. Printed Wiring Board – MAIN Section – ...................... 53

6-23. Schematic Diagram – MAIN Section (1/4) – ................ 54

6-24. Schematic Diagram – MAIN Section (2/4) – ................ 55

6-25. Schematic Diagram – MAIN Section (3/4) – ................ 56

6-26. Schematic Diagram – MAIN Section (4/4) – ................ 57

6-27. Printed Wiring Board – I-BASS Section – .................... 58

6-28. Schematic Diagram – I-BASS Section – ....................... 59

6-29. Printed Wiring Board – FRONT AMP Section – .......... 60

6-30. Schematic Diagram – FRONT AMP Section –............. 61

6-31. Printed Wiring Board

– SURROUND AMP Section – ...................................... 62

6-32. Schematic Diagram – SURROUND AMP Section –.... 63

6-33. Printed Wiring Boards – PANEL Section – .................. 64

6-34. Schematic Diagram – PANEL Section –....................... 65

6-35. Printed Wiring Boards – KEY Section – ....................... 66

6-36. Schematic Diagram – KEY Section – ........................... 67

6-37. Printed Wiring Board – VIDEO Section – .................... 68

6-38. Schematic Diagram – VIDEO Section – ....................... 69

6-39. Printed Wiring Board – TRANS Section – ................... 70

6-40. Schematic Diagram – TRANS Section – ...................... 71

6-41. Printed Wiring Board – SUB TRANS Section –........... 72

6-42. Schematic Diagram – SUB TRANS Section – ............. 73

6-43. IC Pin Function Description ........................................... 78

7. EXPLODED VIEWS

7-1. Case Section .................................................................... 92

7-2. Front Panel Section-1...................................................... 93

7-3. Front Panel Section-2...................................................... 94

7-4. Front Panel Section-3...................................................... 95

7-5. Front Panel Section-4...................................................... 96

7-6. Chassis Section-1 ............................................................ 97

7-7. Chassis Section-2 ............................................................ 98

7-8. DVD Mechanism Deck Section-1

(CDM74-DVBU23) ........................................................ 99

7-9. DVD Mechanism Deck Section-2

(CDM74-DVBU23) ....................................................... 100

7-10. DVD Mechanism Deck Section-3

(CDM74-DVBU23) ....................................................... 101

7-11. DVD Mechanism Deck Section-4

(CDM74-DVBU23) ....................................................... 102

8. ELECTRICAL PARTS LIST .............................. 103

5

Page 6

CX-JD5

Ver 1.1

SECTION 1

SER VICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objectiv e lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and

check that the S curve waveforms is output three times.

DVD TRAY LOCK MODE

•This mode let you lock the disc trays. When this mode is activated, the disc tray will not open when

or [DISC CHANGE] button is pressed. The message “LOCKED”

will be displayed in the will be displayed on the fluorescent

indicator tube.

Z OPEN/CLOSE button

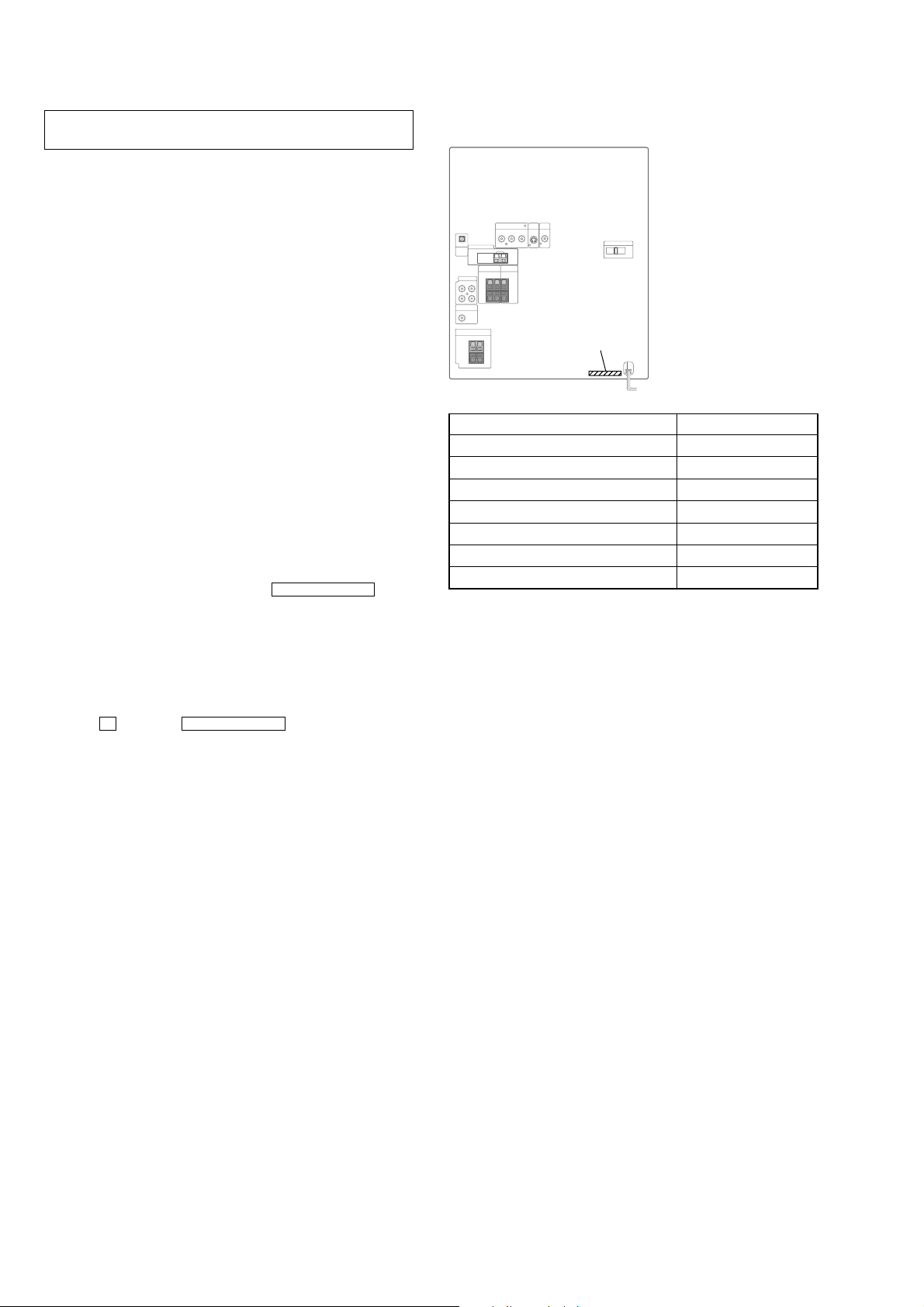

• MODEL IDENTIFICATION

– Rear Cover –

PART No.

MODEL PART No.

Singapore and Malaysia models 4-247-797-0

E model 4-247-797-1

Thai model 4-247-797-5

AEP and CIS models 4-247-797-7

Chilean and Peruvian models 4-247-797-8

Australian model 4-247-797-9

Saudi Arabia model 4-247-798-4

[]

[]

[]

[]

[]

[]

[]

Procedure:

1. Press [POWER] button to turn the set ON.

2. Select DVD function.

3. Press x button and Z OPEN/CLOSE button simultaneously

and hold down until “LOCKED” or “UNLOCKED” displayed

on the fluorescent indicator tube (around 5 seconds).

6

Page 7

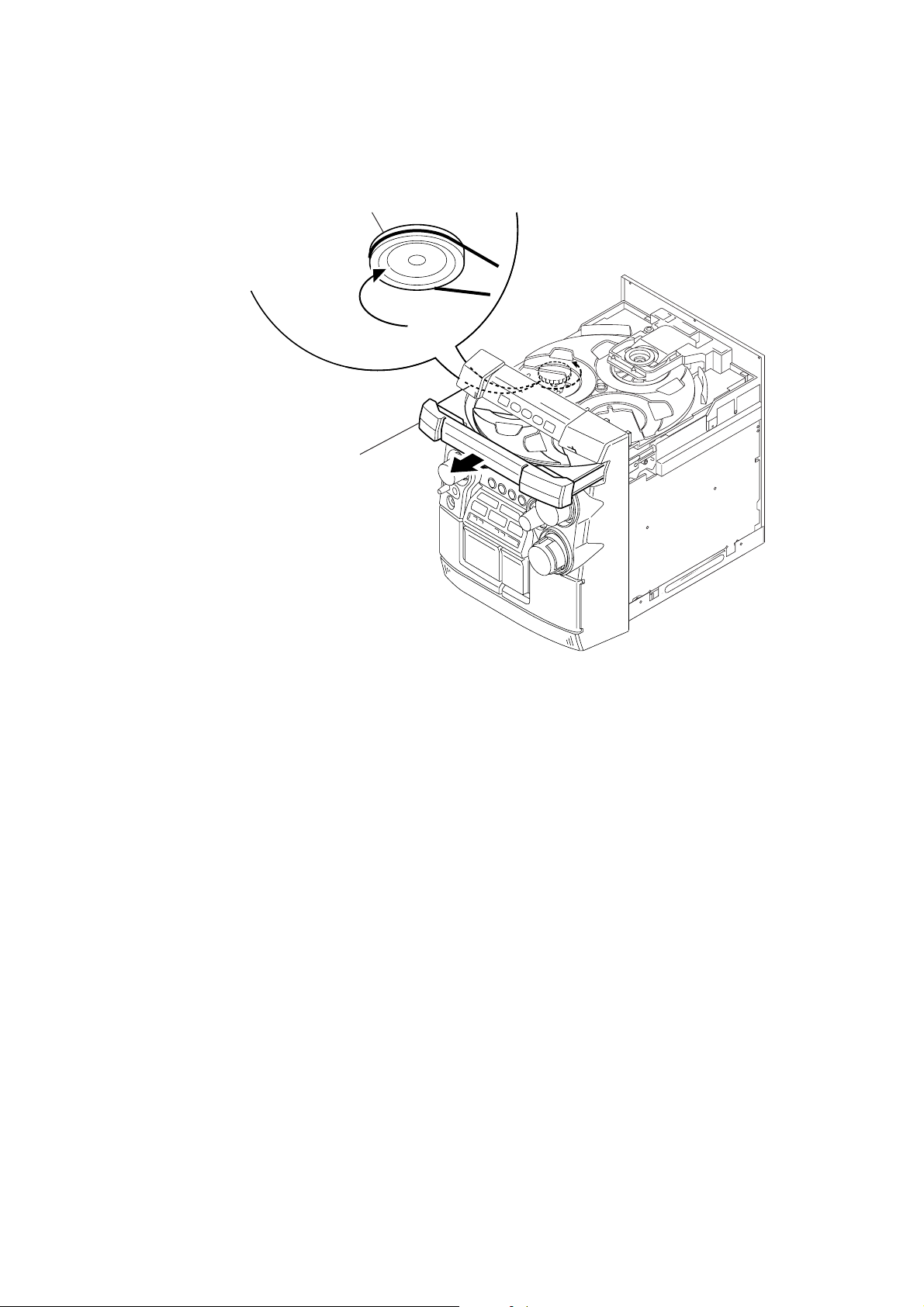

HOW TO OPEN THE DISC TRAY WHEN POWER SWITCH TURNS OFF.

1 Remove the steel cabinet case.

2 Turn the loading gear

in the direction of arrow A.

A

3 Pull-out the disc tray.

CX-JD5

7

Page 8

CX-JD5

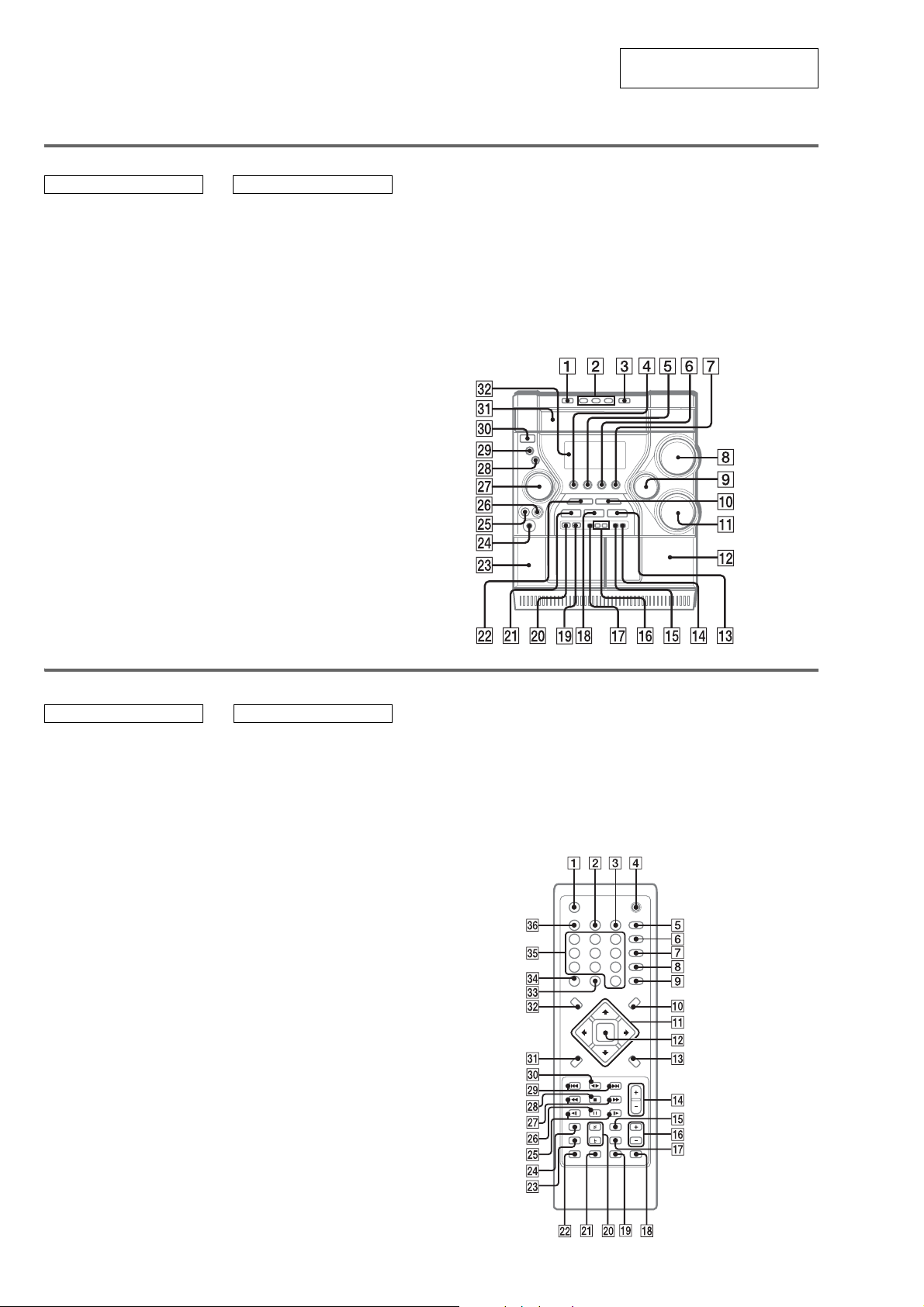

• LOCATION OF CONTROLS

Main unit

ALPHABETICAL ORDER

ALBUM +/– qh

BASS qa

CD SYNC qg

Deck A wd

Deck B qs

DIR (TAPE B) bB ws

DISC DIRECT PLAY 1/2/3 2

DISC SKIP/EX-CHANGE 1

Disc tray ea

DISPLAY qj

Display window es

DVD 7

ENTER wk

i-Bass ql

MD (VIDEO) 6

MIC jack wh

MIC LEVEL wg

MODE wl

MULTI JOG wj

OPEN/CLOSE Z 3

PHONES jack wf

REC PAUSE/START qf

SOUND FIELD w;

TAPE A/B 4

TREBLE/MIDDLE 9

TUNER/BAND 5

TUNING – ./m wa

TUNING + M/> qd

VOLUME control 8

BUTTON DESCRIPTIONS

[/1 (power) e;

X (pause) qk

Z (OPEN/CLOSE) 3

x (stop) q;

M/> (fast forward/

TUNING +) qd

nN DIRECTION ws

./m (rewind/TUNING –)

wa

SECTION 2

GENERAL

This section is extracted from

instruction manual.

Remote control

ALPHABETICAL ORDER BUTTON DESCRIPTIONS

ALBUM +/– qh

AMP MENU qg

CLEAR 9

CLOCK/TIMER SELECT 3

CLOCK/TIMER SET 2

DISPLAY 1

D.SKIP qk

DVD DISPLAY qd

DVD MENU q;

DVD SETUP qj

DVD TOP MENU es

ECHO wd

ENTER qs

FM MODE ql

FUNCTION*

KARAOKE wf

KEY CONTROL

i-Bass 6

Number buttons eg

PLAY MODE 7

PRESET –/PREV . wl

PRESET +/NEXT > wl

REPEAT 8

O RETURN ea

SELECT nN e;

SLOW –/+ wg

SHIFT*

SLEEP eh

SOUND FIELD 5

TUNER/BAND ed

TUNER MEMORY wa

TUNING –/+ wj

VOL +/– qf

1

ef

#/2 w;

2

ws

[/1 4

x (stop) wk

nN (SELECT) e;

X (pause) wh

M/m/</, qa

m (TUNING –) wj

M (TUNING +) wj

. (PRESET –/PREV) wl

> (PRESET +/NEXT) wl

t (SLOW –) wg

T (SLOW +) wg

# (KEY CONTROL) w;

2 (KEY CONTROL) w;

*1

Switches the active function among

CD, TAPE, TUNER, MD (VIDEO)

and DVD.

*2

Press and hold SHIFT and press m ,

, or < to do the following;

SHIFT + m = SUBTITLE

SHIFT + , = ANGLE

SHIFT + < = AUDIO

e.g.)Press and hold SHIFT, and

press m to active the subtitle menu.

8

Page 9

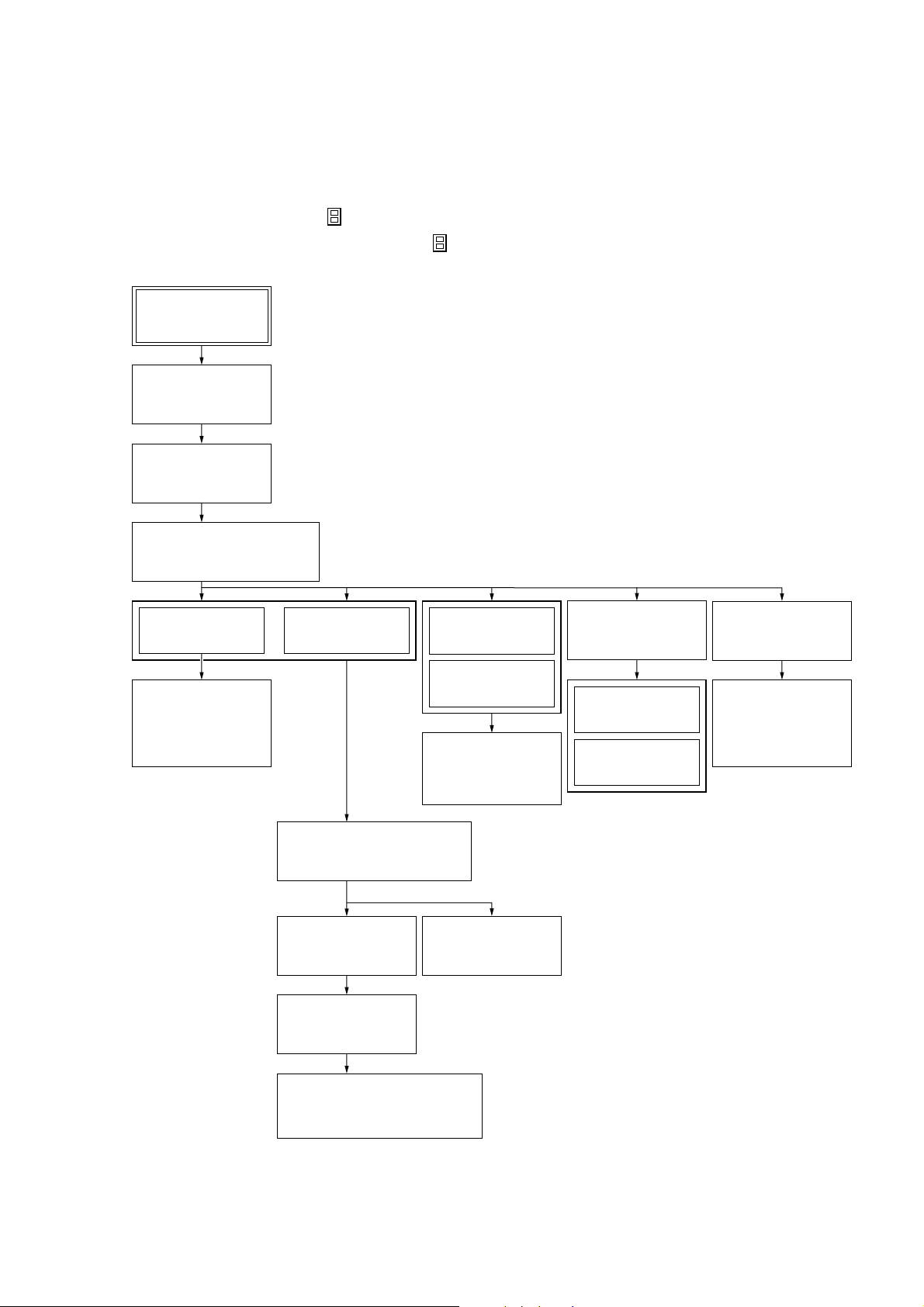

SECTION 3

DISASSEMBLY

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

Note 1: The process described in can be performed in any order.

Note 2: Without completing the process described in , the next process can not be performed.

Set

3-2. STEEL

CABINET CASE

(Page 10)

3-3. TRAY PANEL

(Page 10)

CX-JD5

3-4. DVD MECHANISM DECK

(CDM74-DVBU23)

(Page 11)

3-5. FRONT PANEL

SECTION

(Page 11)

3-6. MECHANICAL

DECK

(CWM43FR16/

CWM43FR26)

(Page 12)

3-7. BACK PANEL

3-8. MAIN BOARD SECTION

3-9. MAIN BOARD

SECTION

(Page 12)

(Page 13)

(Page 13)

3-13. MB03

BOARD

(Page 15)

3-14. VIDEO

BOARD

(Page 16)

3-15. DRIVER

BOARD,

SW BOARD

(Page 16)

3-12. TRANS

BOARD

(Page 15)

3-16. TABLE ASSY

(Page 17)

3-17. MOTOR (TB)

BOARD

(Page 17)

3-18. MOTOR (LD)

BOARD

(Page 18)

3-19. RF BOARD

(Page 18)

3-20. OPTICAL

TRAVERSE

UNIT

(DBU-1)

(Page 19)

3-10. I-BASS BOARD

(Page 14)

3-11. FRONT AMP BOARD,

SURROUND AMP BOARD

(Page 14)

9

Page 10

CX-JD5

)

Note: Follow the disassembly procedure in the numerical order given.

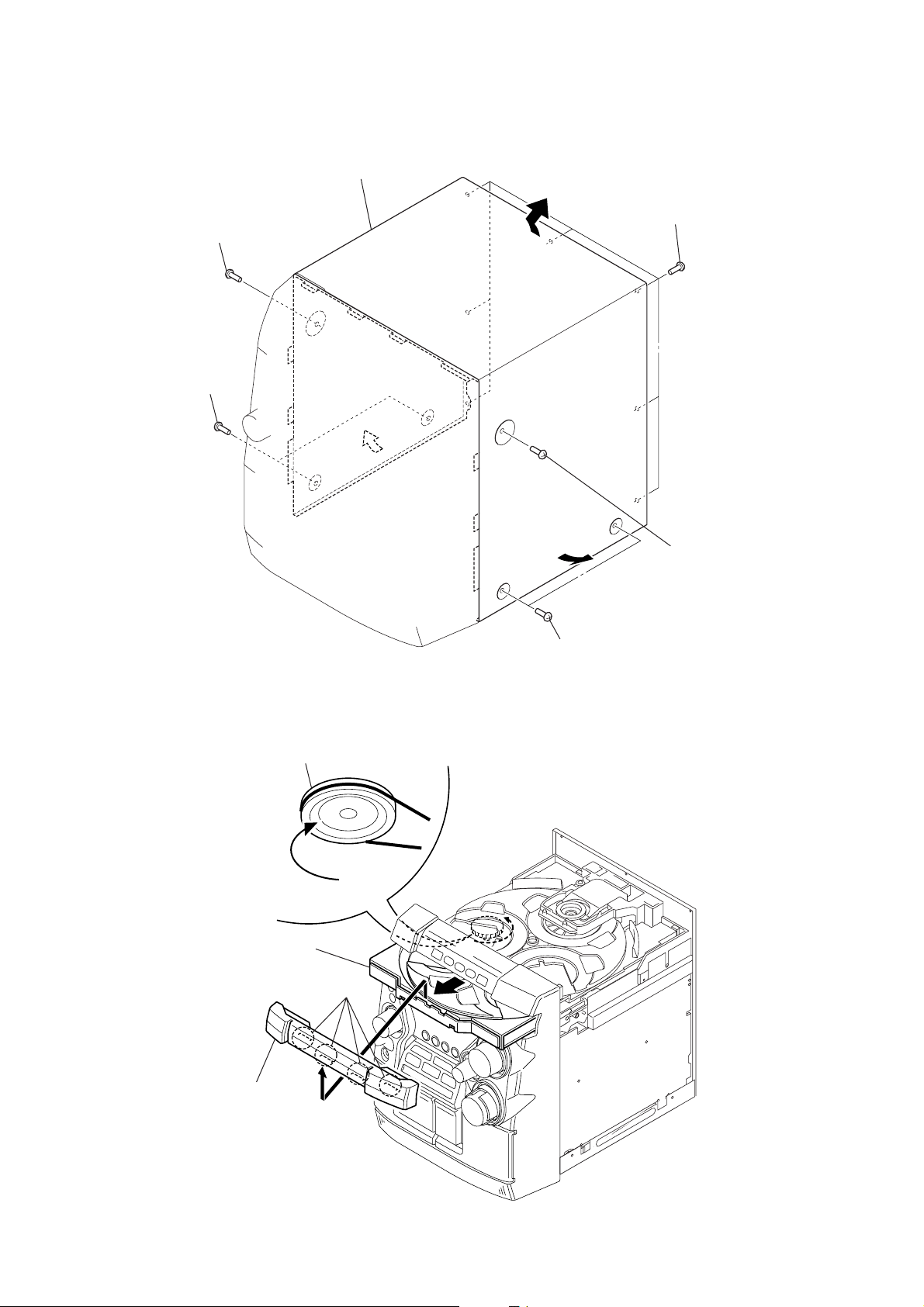

3-2. STEEL CABINET CASE

4

steel cabinet case

3

screw

(case3 TP2)

3

two screws

(case3 TP2)

1

seven screws

(BVTT3

×

6)

3-3. TRAY PANEL

1

2

Turn the loading gear

in the direction of arrow A.

A

Pull-out the disc table.

3

four claws

2

two screws

(case3 TP2)

2

screw

(case3 TP2

10

4

tray panel

Page 11

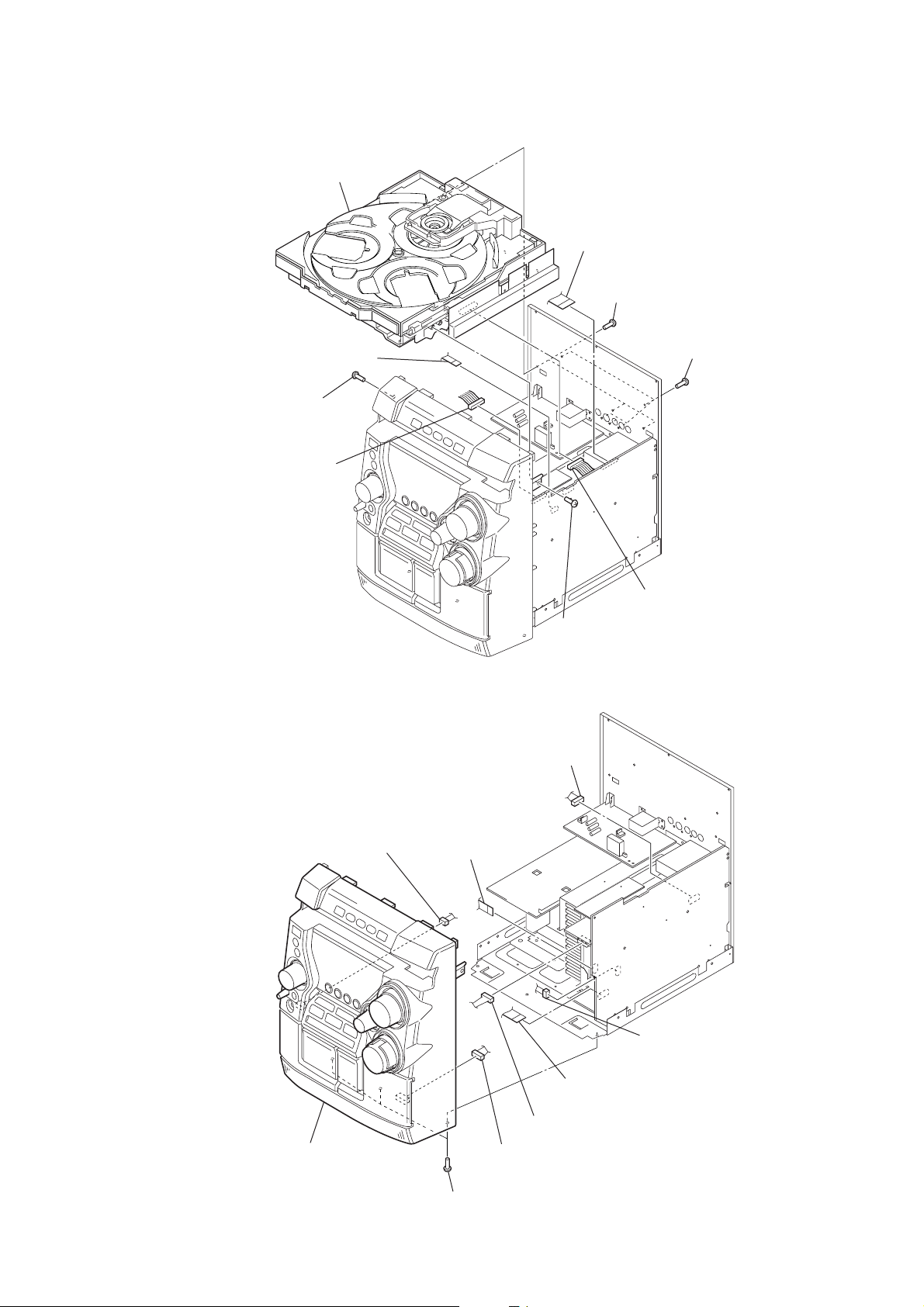

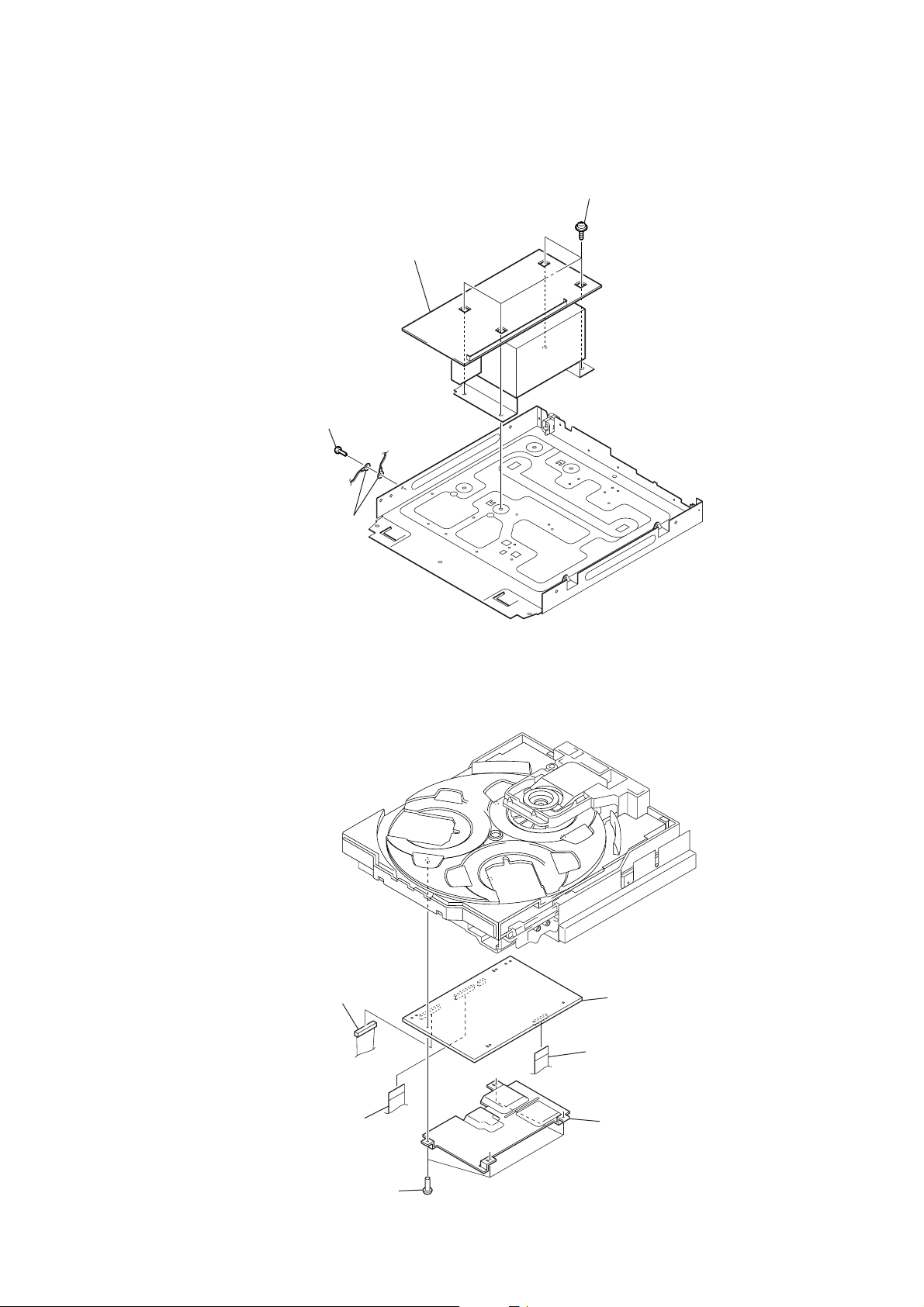

3-4. DVD MECHANISM DECK (CDM74-DVBU23)

)

)

5

DVD mechanism deck

(CDM74-DVBU23)

7

wire (flat type) (6 core)

(CN101)

2

screw

(BVTP3 × 10)

6

connector (CN543)

9

wire (flat type) (25 core)

(CN301)

4

three screws

(BVTT3 × 6)

3

five screws

(BVTP3 × 8

CX-JD5

3-5. FRONT PANEL SECTION

1

connector (CN503)

4

connector (CN902)

2

wire (flat type) (9 core)

(CN706)

1

screw

(BVTP3 × 10)

8

connector (CN804)

6

connector (CN802

8

front panel section

7

three screws

(BVTP3 × 10)

3

wire (flat type) (12 core)

(CN805)

5

connector (CN304)

9

connector (mechanical deck)

11

Page 12

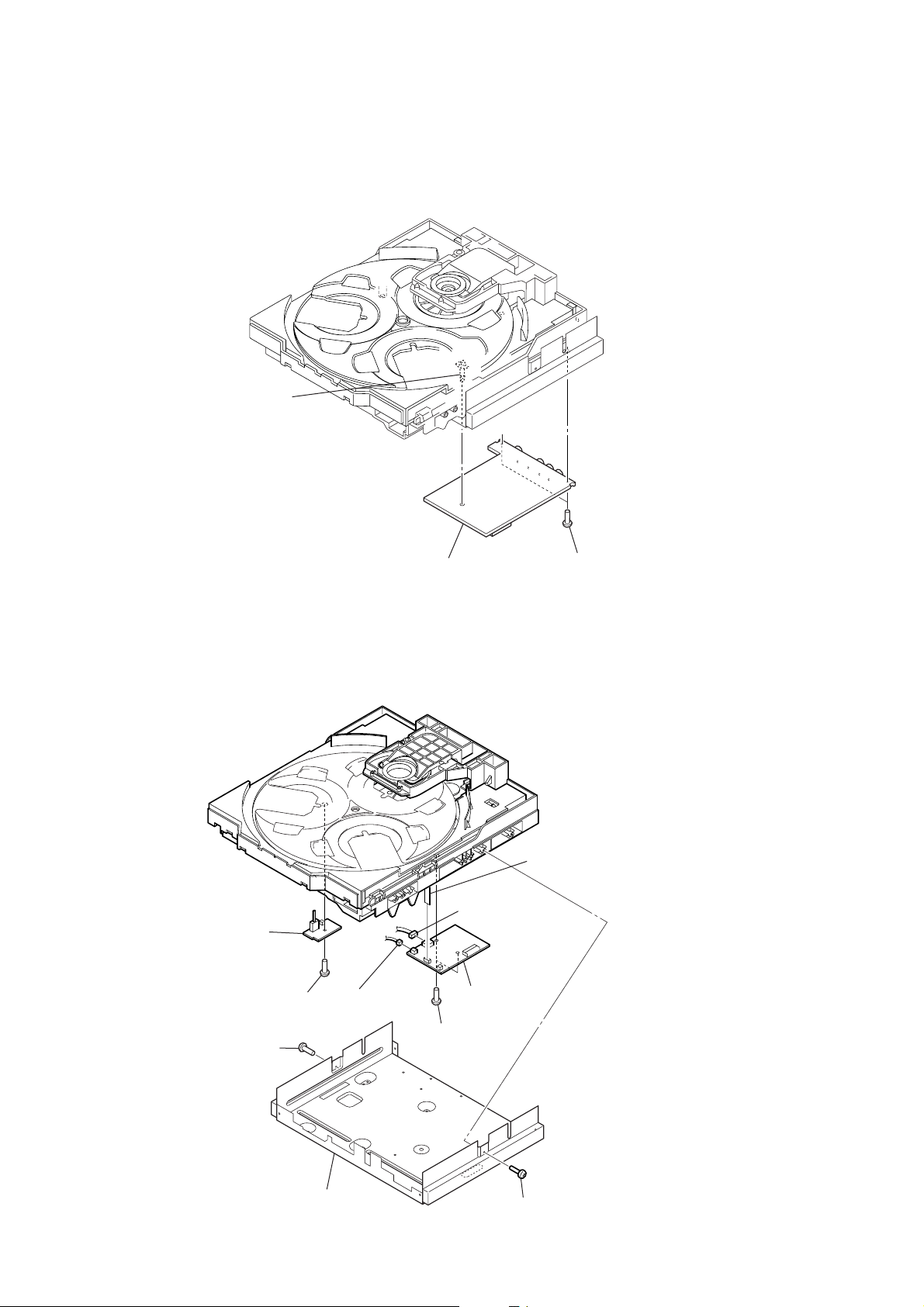

CX-JD5

)

)

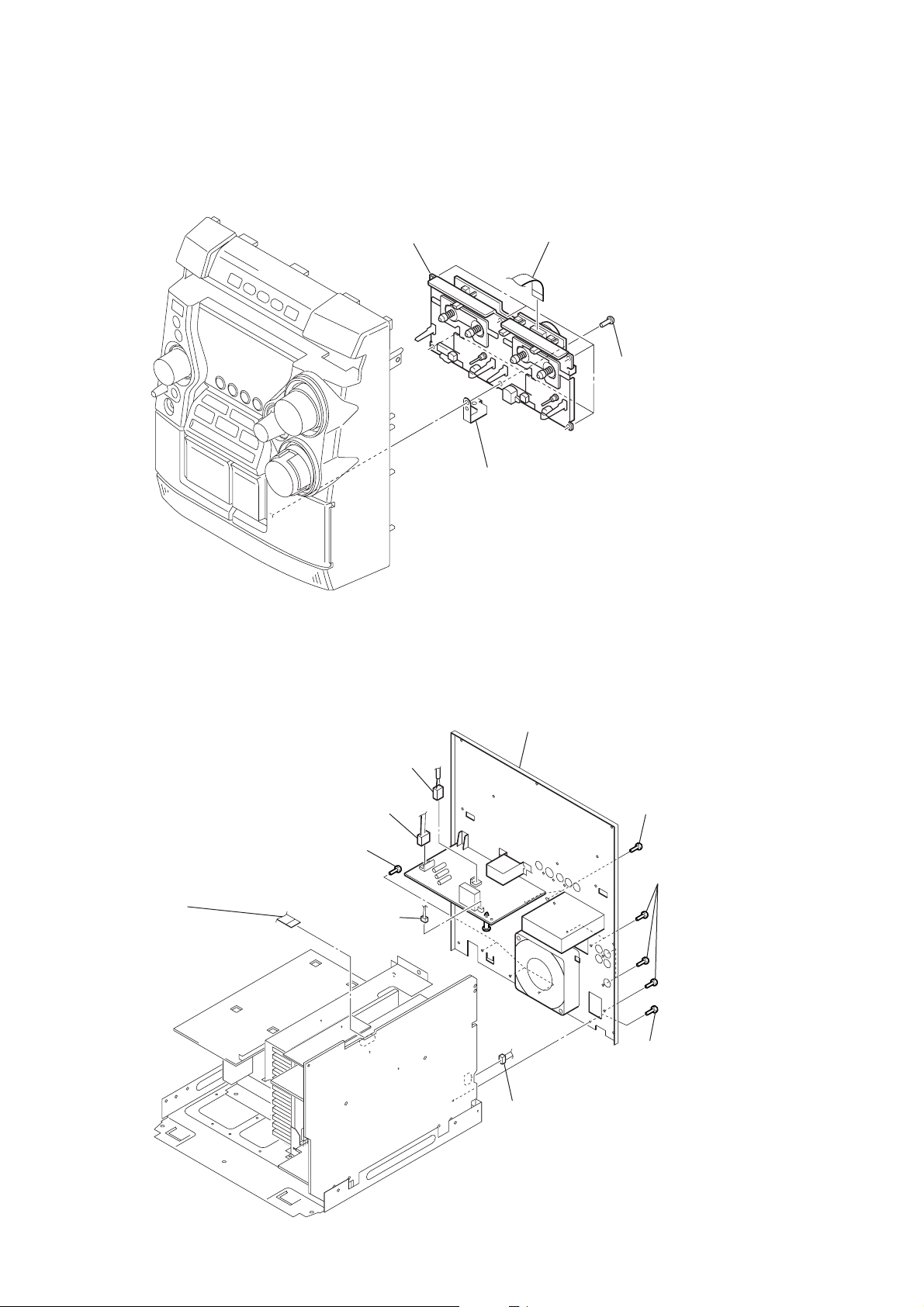

3-6. MECHANICAL DECK (CWM43FR16/CWM43FR26)

3

mechanical deck

(CWM43FR16/CWM43FR26)

4

1

wire (flat type) (13 core)

ground mechanical plate

2

six screws

(BVTP3

×

10

3-7. BACK PANEL SECTION

4

wire (flat type)

(11 core) (except AEP)

(15 core) (AEP)

(CN102)

8

three screws

(BVTT3

1

2

connector

(CN902)

×

3

connector

(CN901)

6)

connector

(CN903)

9

back panel section

0

connector

(CN704)

5

two screws

(BVTT3

7

×

6

five screws

(BVTP3

screw

(BVTT3

6)

×

8

×

6)

12

Page 13

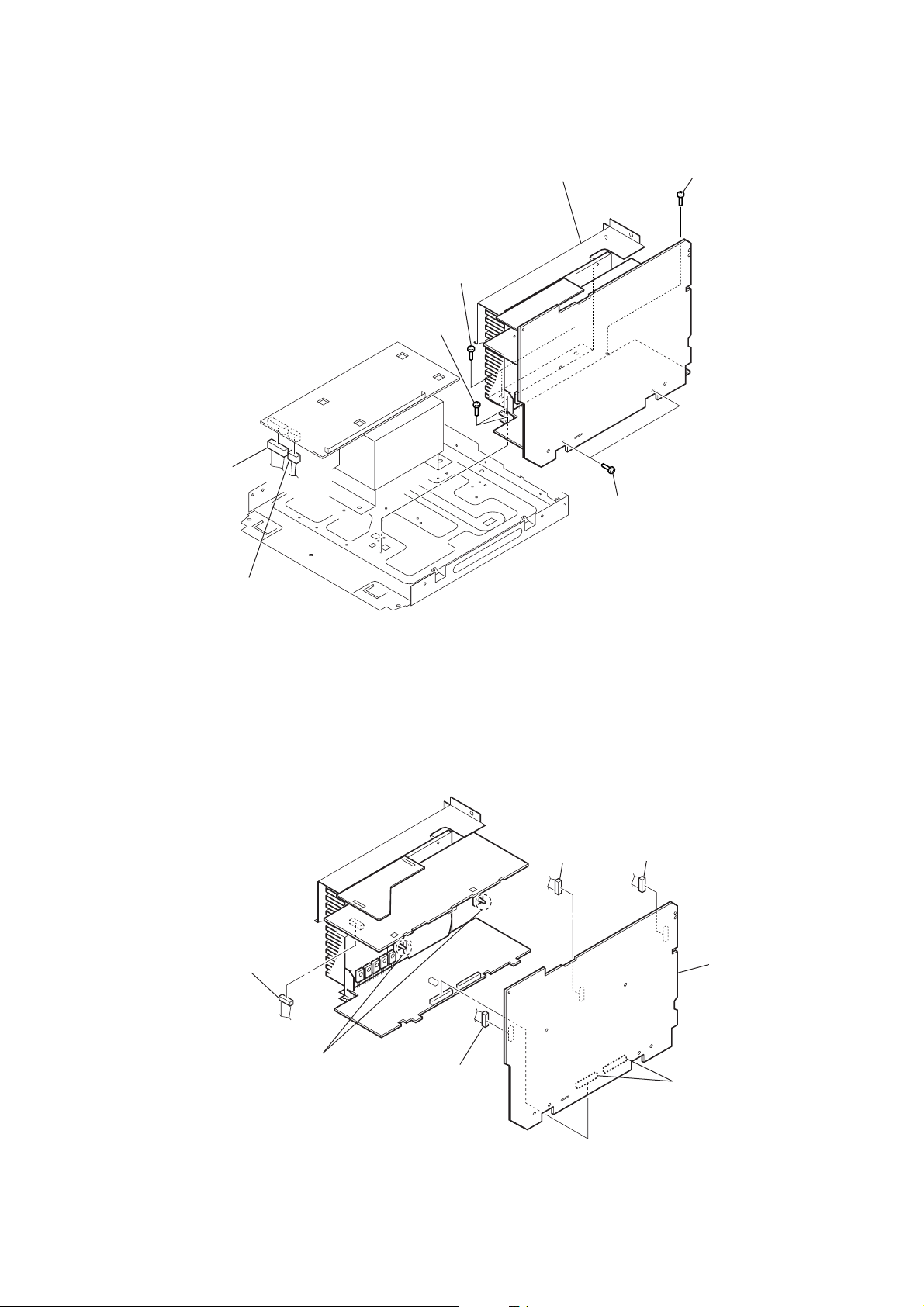

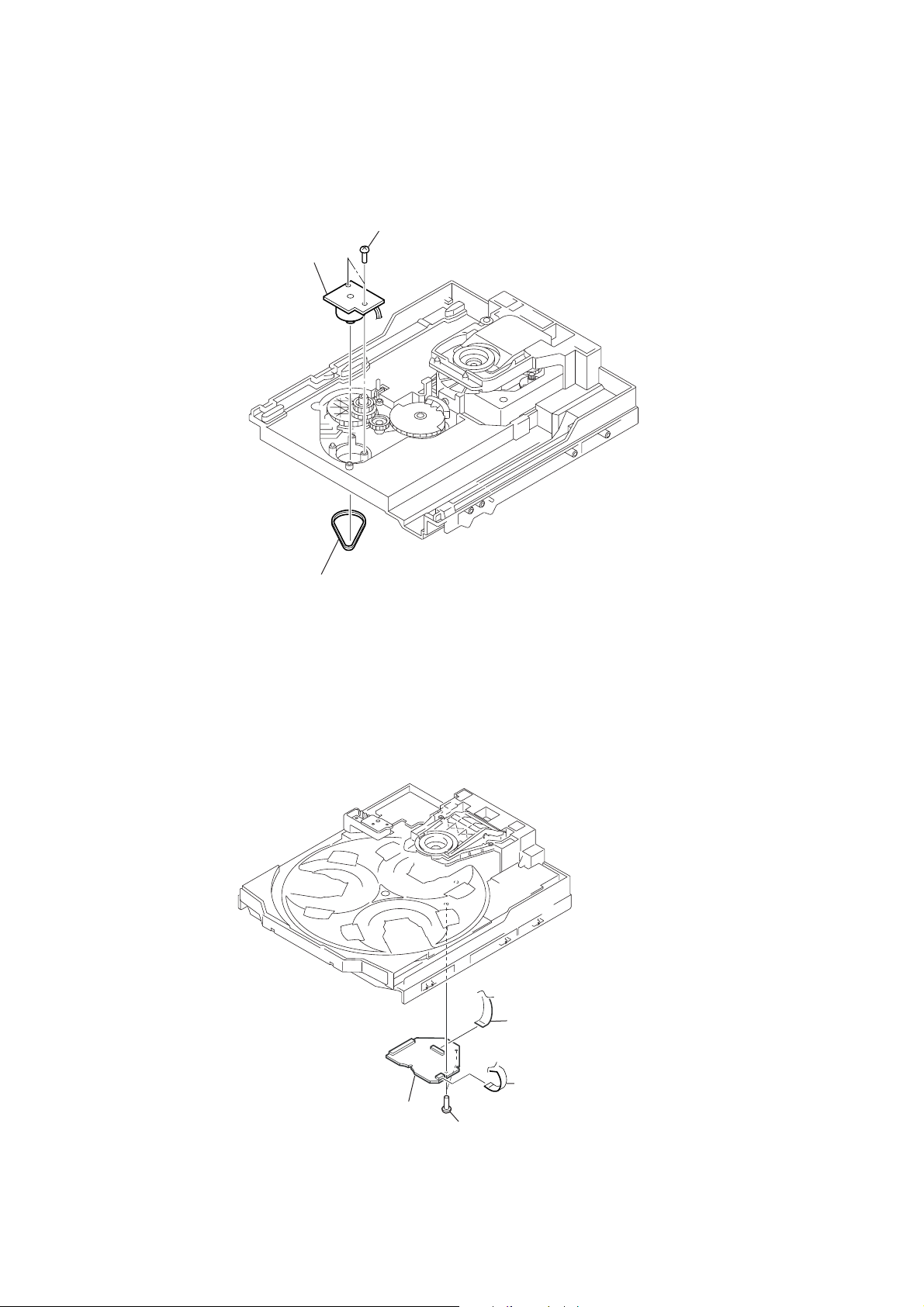

3-8. MAIN BOARD SECTION

d

1

connector

(CN914)

4

two screws

(BVTT3

3

two screws

(BVTT3

×

6)

CX-JD5

7

main board section

×

6)

6

two screws

(BVTP3

×

5

8)

screw

(BVTT3

×

6)

2

connector

(CN915)

3-9. MAIN BOARD

1

connector

(CN303)

3

connector

(CN901)

4

connector

(CN104)

7

main boar

5

two PC board holders

2

connector

(CN103)

6

two connectors

(CN705, CN707)

13

Page 14

CX-JD5

)

)

3-10. I-BASS BOARD

2

I-bass board

1

two screws

(BVTP3 × 8

3-11. FRONT AMP BOARD, SURROUND AMP BOARD

5

6

front amp board

surround amp board

2

3

two screws

(BVTP3

×

1

connector (CN305)

4

two screws

(BVTP3

connector (CN302)

10)

×

16

14

Page 15

3-12. TRANS BOARD

1

screw

(BVTT3 × 6)

4

trans board

3

four screws

(ITC+4-8R)

CX-JD5

3-13. MB03 BOARD

2

two earth lugs

3

connector

(CN102)

2

wire (flat type)

(17 core)(CN105)

4

four screws

(BVTT3 × 6)

6

MB03 board

1

wire (flat type) (29 core)

(CN501)

5

heat sink

15

Page 16

CX-JD5

)

)

3-14. VIDEO BOARD

2

PWB holder

3-15. DRIVER BOARD, SW BOARD

0

SW board

9

screw

(BVTP2.6)

2

screw

(BVTP3

×

8)

4

connector

(CN704)

3

video board

5

7

6

two screws

(BVTP2.6)

connector

(CN704)

driver board

1

two screws

(BVTT3 × 6

8

wire (flat type) (5 core

(CN702)

16

3

bracket (DVD)

1

screw

(BVTP3

×

8)

Page 17

3-16. TABLE ASSY

)

6

table assy

5

two claws

CX-JD5

Ver. 1.2

3-17. MOTOR (TB) BOARD

2

Pull-out the table assy.

1

screw

(PTPWH M2.6)

2

tray

A

1

Turn the loading gear

in the direction of arrow A.

3

belt (table)

4

hook

3

wire (flat type) (5 core

(CN702)

4

connector

(CN731)

6

5

two screws

(BTTP M2.6)

motor (TB) board

17

Page 18

CX-JD5

)

3-18. MOTOR (LD) BOARD

3

motor (LD) board

2

two screws

(BTTP M2.6)

3-19. RF BOARD

1

belt (loading)

3

flexible flat cable

(24 core) (CN001

18

2

RF board

1

two screws

(BTTP 2.6)

4

flexible board

(CN003)

Page 19

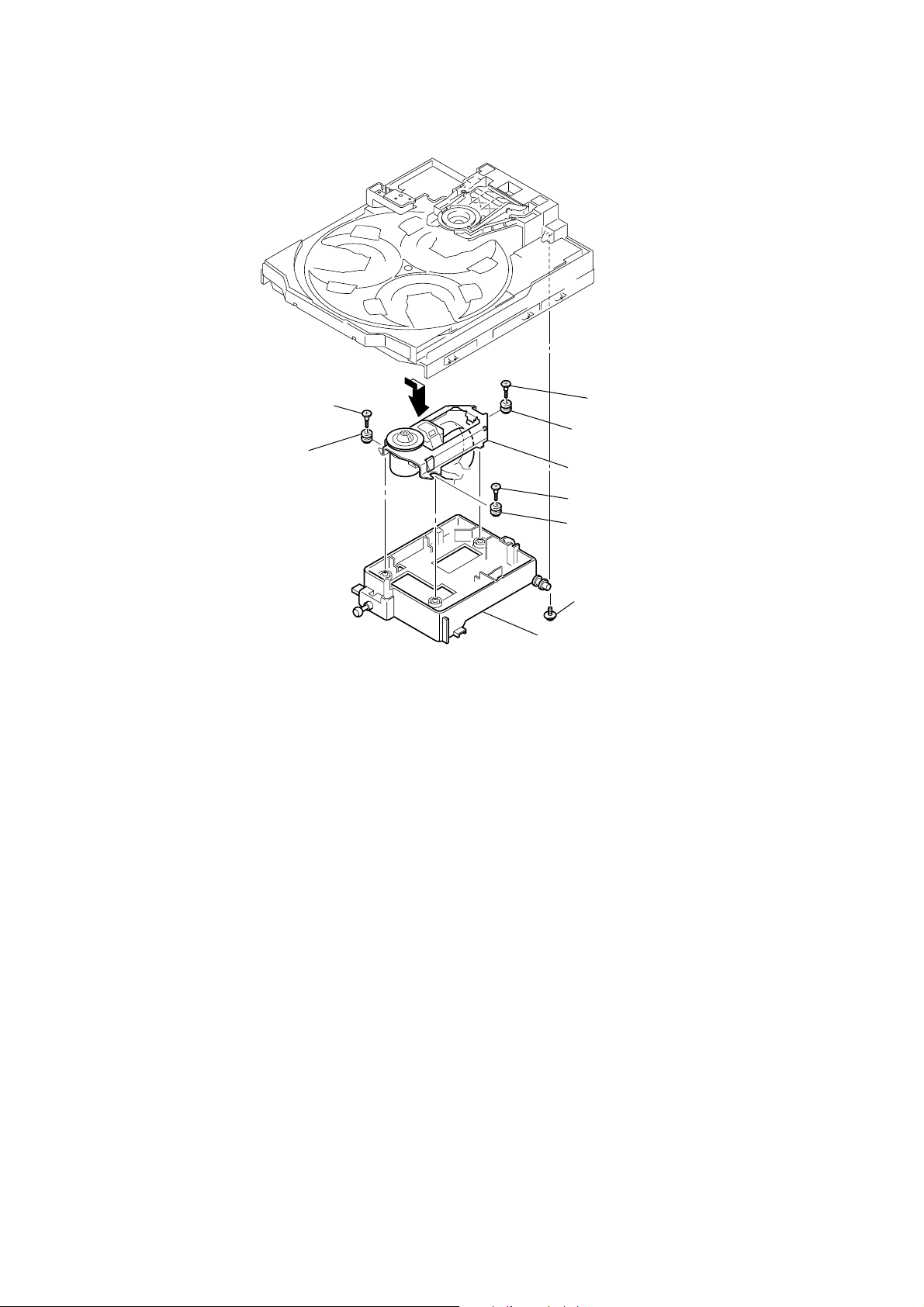

3-20. OPTICAL TRAVERSE UNIT (DBU-1)

CX-JD5

3

step

6

insulator

(HRC)

screw (M)

2

4

step

screw (M)

7

insulator

9

optical traverse unit (DBU-1)

5

step

screw (M)

8

insulator (HRC)

1

floating

0

holder (DBU) assy

screw (PTPWH M2.6)

19

Page 20

CX-JD5

SECTION 4

TEST MODE

[MC TEST MODE]

• This mode is used to check operations of the respective sections

of Amplifier, Tuner , and Tape.

Procedure:

* To enter MC Test Mode

1. P ress x button, [ENTER] but t on and [DISC 3] button

simultaneously, the message “TEST MODE” will be displayed

on the fluorescent indicator tube.

* Check of Amplifier

1. When [BASS] knob is turned clockwise, GEQ increases to its

maximum and a message “GEQ MAX” appears on the

fluorescent indicator tube.

2. When [BASS] knob is turned counter clockwise, GEQ

decreases to its minimum and a message “GEQ MIN” appears

on the fluorescent indicator tube.

3. When [SOUND FIELD] button is pressed, GEQ is set to flat

and a message “GEQ FLAT” appears on the fluorescent

indicator tube.

4. When the [VOLUME] knob is turned clockwise even slightly,

the sound volume increases to its maximum and a message

“VOL MAX” appears for two seconds, then the display returns

to the original display.

5. When the [VOLUME] knob is turned counter-clockwise even

slightly, the sound volume decreases to its minimum and a

message “VOL 0” appears for two seconds, then the display

returns to the original display.

* VACS ON/OFF Change Over

1. Press [i-Bass] button. The message “VACS OFF” or “VACS

ON” appears.

* Tape function

1. When a tape is inserted in Deck B and recording is started, the

function is changed to VIDEO automatically.

2. After recording is stopped by pressing

button will change the function to TAPE B and rewind Tape B

until the recording start position and playback of Tape B is

started. If the [REC PAUSE/ START] button is pressed for a

pause and pressed again to resume recording during recording

time, when tape deck B is rewind, tape deck B will be rewind

until the position where the pause is applied.

* AMS Test Mode

1. Select the function “TAPE A” or “TAPE B”.

2. Insert a test tape AMS-110A or AMS-120 to selected tape deck.

3. Press the [CD STNC] button to enter the AMS test mode.

4. After the test tape is rewind to the beginning of the tape, the

AMS+ is checked, and the mechanism is shut off after detecting

the AMS signal twice.

5. Then the AMS- is checked and the mechanism is shut off after

detecting the AMS signal twice.

6. When the check is complete, a message of either OK or NG

appears.

* To release MC Test mode.

1. To release this mode, press [POWER] button.

2. The cold reset is enforced at the same time.

x button, press – m

[AMP TEST MODE ]

• This mode is used in order to set up each section of amplifier.

Procedure:

1. Press x button, [ENTER] button and [DISC2] button

simultaneously, the message “AMP TEST” will be displayed

on the fluorescent indicator tube.

2. Press [ENTER] button and [DISC1] button simultaneously,

VACS display/amplifier regulation display is switched.

3. Press [SOUND FIELD] button, SURROUND ON/OFF is

switched.

4. Press [i-Bass] button, i-Bass ON/OFF is switched.

5. Turn the [BASS] knob, BASS (i-Bass) volume adjustment is

performed.

6. Press [ENTER] button, i-Bass f0 adjustment is performed.

7. To release this mode, pull out the A C cord. Then insert the AC

code, and press [POWER] button to turn the set ON. The cold

reset is enforced at the same time.

[PANEL TEST MODE ]

• This mode is used check operation of the front panel.

Procedure:

1. Press X button, [ENTER] button and [DISC2] button

simultaneously, all LED and se gments in fluorescent indicator

tube are lighted up.

2. Press [ENTER] button and [DISC2] button simultaneously,

the key check mode is activated. In the key check mode, the

fluorescent indicator tube displays “KEY 0 0 0”. While pressing

the key, the number corresponding to each key is displayed.

Example: When [ENTER] button is pressed “KEY 0 2 0”

3. Press [ENTER] button and [DISC2] button simultaneously

again, the key control mode is activated. In the key control

mode, the fluorescent indicator tube displays “KEYCONT 0”.

4. Press

5. Press [ENTER] button and [DISC2] button simultaneously

[ENTER] button and [DISC2] button simultaneously

again, “VOLUME FLR” will be displayed.

When the [VOLUME] knob is turned clockwise, the message

“VOLUME UP” appears for two seconds, then the message

“VOLUME FLR” is displayed again.

When the [VOLUME] knob is turned counter-clockwise, the

message “VOLUME DO W” appears for two seconds, then the

message “VOLUME FLR” is displayed again.

again, release from this mode.

[VERSION DISPLAY]

• This mode is used check the model, destination, software version.

Procedure:

1. Press X button, [ENTER] button and [DISC3] button

simultaneously, the model and destination are displayed.

2. Each time [ENTER] button and [DISC2] button is pressed

simultaneously, the display changes from MC version, GC

version and DVD version in this order, and release from this

mode.

3. When [ENTER] button and [DISC2] button is pressed

simultaneously while the version numbers are being displayed

except model and destination, the date of the software creation

appear. When [ENTER] button and [DISC2] button is pressed

simultaneously again, the display returns to the software

version display.

20

[COLD RESET]

• The cold reset clears all data stored in the RAM to initial condi-

tions. Execute this mode when returning the set to the customer .

Procedure:

1. Press x button, [ENTER] button, and [DISC1] button

simultaneously.

2. The fluorescent indicator tube becomes blank for a while, and

the set is reset.

Page 21

CX-JD5

[HOT RESET]

• The hot reset clears data except BUCKUP stored in the RAM.

Procedure:

1. Press X button, [ENTER] button, and [DISC1] button

simultaneously.

2. The fluorescent indicator tube becomes blank for a while, and

the set is reset.

[TUNER STEP CHANGE]

• The step interval of AM channels can be toggled between 9 kHz

and 10 kHz.

Procedure:

1. Press [POWER] button to turn the set ON.

2. Press [TUNER/BAND] button to select the “AM”.

3. Press [POWER] button to turn the set OFF.

4. Press [ENTER] button and [POWER] button simultaneously .

The system will turn ON automatically. The message “AM 9k

STEP” or AM 10k STEP” appears and thus the channel step is

changed.

[DVD REPEAT 5 LIMIT OFF MODE]

• The number of repeat for DVD playback is 5 times when the

repeat mode is “REPEAT ALL”. This mode enables DVD to

repeat playback for limitless times.

Procedure:

1. Press [POWER] button to turn the set ON.

2. Select DVD function.

3. Press X button, [ENTER] button, and [DVD] button

simultaneously to enter the DVD repeat 5 limit off mode.

4. To release this mode, operate the cold reset. (Refer to the “MC

COLD RESET”)

[DVD SHIP MODE (LOCK)]

• This mode moves the optical pick-up to the position durable to

vibration. Use this mode when returning the set to the customer

after repair.

Procedure:

1. Press [POWER] button to turn the set ON.

2. Select DVD function.

3. Press [DVD] button and [POWER] button simultaneously . T he

set will power off automatically.

4. After the “SEE YOU” blinking display finish, a message

“LOCK” is displayed on the fluorescent indicator tube and the

DVD ship mode is set.

[DVD POWER MANAGE]

• This mode let you switch on or off power supply to the BU

during TUNER function.

• When DVD POWER is set to OFF, the power supply to the B U

is cut off during TUNER function. It will increase the time taken

to access DVD when function change from TUNER to DVD

but it will improve tuner reception.

•When DVD POWER is set to ON, the power supply to the BU

is not cut off during TUNER function. It will reduce the time

taken to access DVD when function change from TUNER to

DVD but it will decrease tuner reception performance.

Procedure:

1. Press [POWER] button to turn the set ON.

2. Select DVD function.

3. Press [POWER] button to turn the set OFF.

4. Press x button, [POWER] button simultaneously . The set will

power on automatically.

5. The message “DVD POWER” will be displayed on the

fluorescent indicator tube.

[DVD COLOR SYSTEM CHANGE OVER]

• The color system can be changed over NTSC or PAL.

Procedure:

1. Press [POWER] button to turn the set ON.

2. Select DVD function.

3. Press [POWER] button to turn the set OFF.

4. Press X button, [POWER] button simultaneously. The set will

power on automatically.

5. The message “COLOR PAL” or “COLOR NTSC” will be

displayed on the fluorescent indicator tube. The color system is

changed over.

[DVD TRAY LOCK MODE]

• This mode let you lock the disc trays. When this mode is acti-

vated, the disc tray will not open when Z OPEN/CLOSE button

or [DISC CHANGE] button is pressed. The message “LOCKED”

will be displayed in the will be displayed on the fluorescent

indicator tube.

Procedure:

1. Press [POWER] button, to turn the set ON.

2. Select DVD function.

3. Press x button and Z OPEN/CLOSE button, simultaneously

and hold down until “LOCKED” or “UNLOCKED” displayed

on the fluorescent indicator tube (around 5 seconds).

[MD/VIDEO SWITCHING]

• This mode let you switch from MD to VIDEO and vice-versa.

Procedure:

1. Press [POWER] button, to turn the set ON.

2. Select MD function.

3. Press [VIDEO/AUX] and [POWER] button simultaneously.

The function will change to VIDEO. Press the same buttons

again to change from VIDEO to MD.

[DVD TEST MODE GENERAL DESCRIPTION]

The T est Mode allows you to make diagnosis and adjustment easily

using the remote commander and monitor TV. The instructions,

diagnostic results, etc. are given on the on-screen display (OSD).

[STARTING DVD TEST MODE]

1. Press the [POWER] button to turn the power on.

2. Select the function “DVD”.

3. Press the [POWER] button to turn the power off.

4. Press two buttons of x and Z OPEN/CLOSE for more than

1 second simultaneously, and [VOLUME] knob is turned clockwise.

5. It displays “SERVICE IN” on the fluorescent indicator tube,

and displays the Test Mode Menu on the monitor screen as

follows. (At the bottom of the menu screen, the model name

and revision number are displayed)

Test Mode Menu

0. Syscon Diagnosis

1. Drive Auto Adjustment

2. Drive Manual Operation

3. Mecha Aging

4. Emergency History

5. Mecha Error History

6. Version Information

7. Video Level Adjustment

Exit: POWER Key

Model :JAX-Dxxxx

Revision :x.xx

6. T o execute each function, select the desired menu and press its

number on the remote commander (RM-Z20013).

7. T o release from test mode, press the [POWER] button and turn

the power off.

21

Page 22

CX-JD5

[OPERATING DVD TEST MODE]

0. SYSCON DIAGNOSIS

The same contents as board detail check by serial interface can be

checked from the remote commander operation.

On the Test Mode Menu screen, press [10/0] key on the remote

commander, and the following Check Menu will be displayed.

### Syscon Diagnosis ###

Check Menu

0. Quit

1. All

2. Version

3. EEPROM

4. GPIO

5. SD Bus

6. Video

0-0. Quit

Quit the Syscon Diagnosis and return to the Test Mode Menu.

0-1. All (All items continuous check)

This menu checks all diagnostic items continuously. Normally, all

items are checked successively one after another automatically

unless an error is found, but at a certain item that requires judgment

through a visual check to the result, the following screen is displayed

for the key entry.

• Example display

### Syscon Diagnosis ###

General Description of Checking Method

Selecting 2 and subsequent items calls the submenu screen of each

item. And selecting 2 and subsequent items executes respective

menus and outputs the results.

For the contents of each submenu, see “Check Items List” as below.

Check Items List:

0-2. Version

0-2-1. All

0-2-2. Revision

0-2-3. ROM Check Sum

0-2-4. Model T ype

0-2-5. Region

0-3. EEPROM Check

0-3-1. Sampling Check

0-3-2. Detail Check

0-4. GP I/O Check

0-5. SD Bus Check

0-6. Video Check

0-7. Audio Check

0-2. Version

0-2-2. Revision

The revision number of ROM IC204 that the program for

the DVD system processor (IC207) is stored.

(4 digits hexadecimal number)

0-2-3. ROM Check Sum

The revision number of ROM IC204 that the program for

the DVD system processor (IC207) is stored.

0-2-4. Model Type

Model name is displayed. (JAX-D5)

0-2-5. Region

Model destination code is displayed. (2 digits number)

Diag All Check

No.2 Version

2-2. Version

ROM Reversion = 1.06

Press NEXT Key to Continue

Press PREV Key to Repeat

For the ROM Check, the check sum calculated by the Syscon is

output, and therefore you must compare it with the specified value

for confirmation.

Following the message, press the NEXT > button to go to the

next item, or press the PREV . button to repeat the same

operation again.

To quit the diagnosis and return to Check Menu screen, press the

[RETURN] key on the remote commander to display Check Menu.

• Error occurred

If an error occurred, the diagnosis is suspended and error is displayed.

Press the [RETURN] key on the remote commander to quit the

diagnosis, or press the PREV . button to repeat the same check

where an error occurred, or press the NEXT > button to continue

the check from the item next to faulty item.

0-3. EEPROM Check

0-3-1. Sampling Check

EEPROM check at every 64 words.

It compares read data with write data of each address. When

there are discrepancies between two data, it displays error.

0-3-2. Detail Check

EEPROM check at every 1 word.

It compares read data with write data of each address. When

there are discrepancies between two data, it displays error.

0-4. GP I/O Check

Pull up/down setting check of the DVD system processor (IC207)

pin 150, 151 and 154 (for clock setting port).

0-5. SD Bus Check

SD bus data check between DVD decoder (IC701) and MPEG

DECODER (IC207).

0-6. Video Check

Output the color bars for video level adjustment.

22

Page 23

CX-JD5

1. DRIVE AUTO ADJUSTMENT

On the Test Mode Menu screen, press the [1] key on the remote

commander, and the Adjustment Menu will be displayed.

## Drive Auto Adjustment ##

Adjustment Menu

0. ALL

1. DVD-SL

2. CD

3. DVD-DL

Exit: RETURN

Normally, [10/0] is selected to adjust DVD (single layer), CD and

DVD (dual layer) in this order . But, individual items can be adjusted

for the case where adjustment is suspended due to an error. In this

mode, the adjustment can be made easily through the operation

following the message displayed on the screen.

The disc used for adjustment must be the one specified for

adjustment.

1-0. ALL

Press the [10/0] key on the remote commander, and the servo set

data in EEPROM will be initialized. Then, 1. DVD-SL disc, 2. CD

disc and 3. DVD-DL disc are adjusted in this order.

Each time one disc was adjusted, it is ejected. Replace it with the

specified disc following the message. You can f inish the adjustment

by pressing the

[RETURN] button on the remote commander.

1-1. DVD-SL (single layer)

Press the [1] ke y on the remote commander and insert a DVD single

layer disc following the message. Then the adjustment will be made

through the steps, then adjusted values will be written to the

EEPROM.

DVD Single Layer Disc Adjustment Steps:

1. Sled reset

2. Disc check memory SL

3. Wait 300 msec

4. Set disc type SL

5. LD on

6. Spindle start

7. Wait 1 sec

8. Focus servo on 0

9. Auto track offset adjust

10. CLVA on

11. Wait 500 msec

12. Tracking on

13. Wait 1 sec

14. Sled on

15. Check CLV on

16. Auto focus offset adjust

17. Auto focus gain adjust

18. Auto focus offset adjust

19. EQ boost adjust

20. Auto track gain adjust

21. All servo stop

22. EEP copy loop filter offset

1-2. CD

Press the [2] key on the remote commander and insert a CD disc

following the message. Then the adjustment will be made through

the steps, then adjusted values will be written to the EEPROM.

Note: During adjustment of each disc, the measurement for disc type judg-

ment is made. As automatic adjustment does not judge the disc

type unlike conventional models, take care not to insert wrong type

discs. Also, do not give a shock during adjustment.

CD Adjustment Steps

1. Sled rest

2. Disc check memory CD

3. Wait 500 msec

4. Set disc type CD

5. LD on

6. Spindle start

7. Wait 500 msec

8. Focus servo on 0

9. Auto track offset adjust

10. CLVA on

11. Wait 500 msec

12. Tracking on

13. (TC display start)

14. Wait 1 sec

15. Sled ON

16. Check CLV on

17. Auto focus offset adjust

18. Auto focus gain adjust

19. Auto focus offset adjust

20. EQ boost adjust

21. Auto track gain adjust

22. All servo stop

23

Page 24

CX-JD5

1-3. DVD-DL (dual layer)

Press the [3] key on the remote commander and insert a DVD dual

layer disc following the message. Then the adjustment will be made

through the steps, then adjusted values will be written to the

EEPROM.

DVD Dual Layer Disc Adjustment Steps:

1. Sled reset

2. Disc check memory DL

3. Wait 500 msec

4. Set disc type DL

5. LD on

6. Spindle start

7. Wait 1 sec

Layer 1 Adjust

8. Focus servo on 0

9. Auto track offset adjust

10. CLVA on

11. Wait 500 msec

12. Tracking on

13. Wait 500 msec

14. Sled on

15. Check CLV lock

16. Auto focus adjust

17. Auto focus gain adjust

18. Auto focus offset adjust

19. EQ boost adjust

20. Auto Track Gain Adjust

Layer 0 Adjust

21. Focus jump (L1 t L0)

22. Auto track offset adjust L0

23. CLVA on

24. Wait 500 msec

25. Tracking on

26. Wait 500 msec

27. Sled on

28. Check CLV lock

29. Auto Focus Adjust

30. Auto focus gain adjust

33. Auto focus offset adjust

34. EQ boost adjust

35. Auto track gain adjust

37. All servo stop

2. DRIVE MANUAL OPERATION

Note: This mode is used for design, and not used in service fundamen-

tally.

On the Test Mode Menu screen, press the [2] key on the r emote

commander, and the Operation Menu will be displayed. For the

manual operation, each servo on/off control and adjustment can be

executed manually.

## Drive Manual Operation ##

Operation Menu

1. Disc Type

2. Servo Control

3. Track/Layer Jump

4. Non EEPROM Write Adjust

5. EEPROM Write Adjust

6. Memory Check

7. Disc Check Memory

8. Error Rate Display

9. SACD Water Mark

Exit: RETURN

In using the manual operation menu, take care of the following

points. These commands do not provide protection, thus requiring

correct operation. The sector address or time code field is displayed

when a disc is loaded.

Note:

1. Set correctly the disc type to be used on the Disc Type screen.

2. In case of an alarm, exit the manual operation menu immediately to stop the servo operation, and press the [POWER] button

to turn the power off.

Basic operation:

(controllable from front panel or remote commander)

[POWER] :Power OFF (release the Test Mode)

Z OPEN/CLOSE : Stop and eject/Loading

[RETURN] : Return to Operation Menu or Test

Mode Menu

PREV . , NEXT > :Transition between sub modes of menu

[1] to [9], [10/0] : Selection of menu items

Cursor o/

O

: Increase/Decrease in manually

adjusted value

24

Page 25

CX-JD5

2-1. Disc Type

Disc Type

Disc Type Select

1. Disc Type Auto Check

2. Set Disc Type DVD

3. Set Disc Type CD

4. Set Disc Type Hybrid

Exit: RETURN

2-1-1. Disc Type Auto Check

1) Press the [1] key on the remote commander to display the Disc

Type Auto Check screen.

2) Insert a disc and press the [ENTER] key on the remote

commander.

3) It judges the type of inserted disc automatically and displays

the disc type and so on as below.

Disc Type Auto Check

Disc Type xx

Layer xx

Mirr Time xx

Mirr Count xx

FZC Count xx

PI Reference xx

PI Peak xx

2-1-3. Disc Type CD

It sets up so that it may judge as a disc type of specification of the

disc with which the set was inserted.

[1]: CD disc (normal speed, 12 cm)

[2]: CD disc (double speed, 12 cm)

[3]: CD disc (normal speed, 8 cm)

[4]: CD disc (double speed, 8 cm)

[5]: CD-RW disc (normal speed, 12 cm)

[6]: CD-RW disc (double speed, 12 cm)

[7]: CD-RW disc (normal speed, 8 cm)

[8]: CD-RW disc (double speed, 8 cm)

2-1-4. Disc Type Hybrid

It sets up so that it may judge as a disc type of specification of the

disc with which the set was inserted.

[1]: SACD Hybrid disc (SACD layer, 12 cm)

[2]: SACD Hybrid disc (CD layer, normal speed, 12 cm)

[3]: SACD Hybrid disc (CD layer, double speed, 12 cm)

[4]: SACD Hybrid disc (SACD layer, 8 cm)

[5]: SACD Hybrid disc (CD layer, normal speed, 8 cm)

[6]: SACD Hybrid disc (CD layer, double speed, 8 cm)

2-2. Servo Control

Note: Be sure to perform the disc type setup before performing this item.

Servo Control

1.LD off R.Sled FWD

2.Focus off L.Sled REV

3.SPDL off U.Sled Reset

4.CLVA off D.Sled Limit

5.Trk. off

6.Sled off

7.Fcs.Srch off

ENTER.Execute

Exit: RETURN

Disc T ype : CD or DVD

Layer : SINGLE or DUAL

Mirr Time : Mirror time of between disc surface and record

surface when disc type judgment. (hexadecimal

number)

Mirr Count : The number of times which mirror counts between

disc surface and record surface when disc type

judging.

FZC Count : The number of times which focus zero cross points

of each layer when lens down.

PI Reference : The average of PI reference voltage. (hexadecimal

number)

PI Peak : PI peak level voltage. It performs only when disc

type judgment is successful. (hexadecimal number)

2-1-2. Disc Type DVD

It sets up so that it may judge as a disc type of specification of the

disc with which the set was inserted.

[1]: DVD single layer disc (12 cm)

[2]: DVD dual layer disc (0 layer, 12 cm)

[3]: DVD dual layer disc (1 layer, 12 cm)

[4]: DVD-RW disc (12 cm)

[5]: DVD single layer disc (8 cm)

[6]: DVD dual layer disc (0 layer, 8 cm)

[7]: DVD dual layer disc (1 layer, 8 cm)

[8]: DVD-RW disc (8 cm)

0.All Servo Off

Exit: RETURN

On this screen, the servo on/off control necessary for replay is

executed. Normally, turn on each servo from 1 sequentially and

when CLVA is turned on, the usual trace mode becomes active. In

the trace mode, DVD sector address or CD time code is displayed.

This is not displayed where the spindle is not locked.

The spindle could run overriding the control if the spindle system is

faulty or RF is not present. In such a case, do not operate CLVA.

[1] LD :Turn on/off the laser.

[2] Focus : Search the focus and turn on the focus.

[3] SPDL :Turn on/off the spindle.

[4] CLVA : Turn on/off normal servo of spindle servo.

[5] Trk. : Turn on/off the tracking servo.

[6] Sled : Turn on/off the sled servo.

[7] FCS. Srch :Turn on/off the focus search.

[10/0] : All servo off.

[R] Sled FWD (right cursor) :Move the sled forward.

[L] Sled REV (left cursor) : Move the sled reverse.

[U] Sled FWD (up cursor) : Reset the sled.

[D] Sled REV (down cursor): Limit in the sled.

25

Page 26

CX-JD5

2-3. Track/Layer Jump

Track/Layer Jump

1. 1Tj FWD

2. 1Tj REV

3.500Tj Fine FWD

4.500Tj Fine REV

5.10kTj Dirc FWD

6.10kTj Dirc REV

7.20kTj Dirc FWD

8.20kTj Dirc REV

0. All Servo Off

Exit: RETURN

On this screen, track jump, etc. can be performed. Only for the DVD

dual layer disc, the focus jump and layer jump are displayed in the

right field

[1] 1Tj FWD : 1 track jump forward.

[2] 1Tj REV : 1 track jump reverse.

[3] 500Tj FWD : 500 track jump (fine search)forward.

[4] 500Tj REV :500 track jump (fine search) reverse.

[5] 10kTj FWD : 10k track jump (direct search) forward.

[6] 10kTj REV :10k track jump (direct search) reverse.

[7] 20kTj FWD : 20k track jump (direct search) forward.

[8] 20kTj REV :20k track jump (direct search) reverse.

[10/0] : All servo off.

2-5. EEPROM Write Adjust

EEPROM Write Adjust

1. Focus Offset

2. Focus Gain

3. Trk. Offset Coarse

4. ——————

5. Trk. Gain

6. EQ Boost

0.All Servo Off

Exit: RETURN

On this screen, each item can be adjusted automatically. Select the

desired number

selected item is adjusted automatically. Thus value is stored in the

EEPROM.

[1] to [10/0] from the remote commander, and

[1] Focus Offset : Adjusts focus offset.

[2] Focus Gain : Adjusts focus gain.

[3] TRK. Offset Coarse : Adjusts tracking offset of the RF

amp (IC001) side.

[5] TRK. Gain : Adjusts track gain.

[6] EQ Boost : Adjusts amount of boost of

equalizer.

[10/0] : All servo off.

2-4. Non EEPROM Write Adjust

Non EEPROM Write Adjust

1. Focus Offset

2. Focus Gain

3. Trk. Offset Coarse

4. Trk. Offset Fine

5. Trk. Gain

6. EQ Boost

0.All Servo Off

Exit: RETURN

On this screen, each item can be adjusted automatically. Select the

desired number

current setting for the selected item will be displayed, then increase

or decrease numeric value with theOkey orokey. If CLV has

been applied, the jitter is displayed for reference for the adjustment.

[1] to [10/0] from the remote commander, and

[1] Focus Offset : Adjusts focus offset.

[2] Focus Gain : Adjusts focus gain.

[3] TRK. Offset Coarse : Adjusts tracking offset of the RF

amp (IC001) side.

[4] TRK. Offset Fine : Adjusts tracking offset of the DSP

(IC401) side.

[5] TRK. Gain : Adjusts track gain.

[6] EQ Boost : Adjusts amount of boost of

equalizer.

[10/0] : All servo off.

2-6. Memory Check

Display images are shown as follows, and all two screens are able

to switch by theOkey (UP) orokey (DW).

EEPROM Data 1/2 CD SL L0 L1

Focus Gain xx xx xx xx

Trk. Gain xx xx xx xx

Focus Offset xx xx xx xx

Trk. Offset xx xx xx xx

EQ. Boost xx xx xx xx

PI Level xx xx -- -Fcs. Balance -- xx -- -Jitter xx xx xx xx

Mirror Time xx xx xx -FE Level -- xx -- -Traverse Lv1. -- xx -- -Next:DW Default:CLR Exit:RET

EEPROM Data 2/2 CDRW DVDRW

Focus Gain xx xx

Trk. Gain xx xx

Focus Offset xx xx

Trk. Offset xx xx

EQ. Boost xx xx

Next:UP Default:CLR Exit:RET

26

On this screen, current servo adjusted data stored in the EEPROM

are displayed. The adjusted data are initialized by pressing the

[CLEAR] key, but be careful that they are not recoverable after

initialization.

Before clearing the adjusted data, make a note of the set data.

Page 27

CX-JD5

2-7. Disc Check Memory

Disc Check Memory

1. SL Disc check

2. SL Disc check

3. SL Disc check

Exit: RETURN

On this screen, measure the mirror time of chucked disc, and write

to the EEPROM.

2-8. Error Rate Display

Error Rate Display

UC CR Address

PI1 Err Now xx xxxx xxxxxxxx

Max xx xxxx xxxxxxxx

Avg xx xxxx

PI2 Err Now xx xxxx xxxxxxxx

Max xx xxxx xxxxxxxx

Avg xx xxxx

PO Err Now xx xxxx xxxxxxxx

Max xx xxxx xxxxxxxx

Avg xx xxxx

3. MECHA AGING

On the T est Mode Menu screen, selecting [3] executes the aging of

the mechanism deck.

### Aging Test MENU ###

** Pls use over 40 min.CD **

Operation Menu

1. Open/Close Test

Exit: RETURN

1) Set over-40-min. CDs in Disc 1 to 3.

2) On the Aging Test MENU screen, press the [1] key on the

remote commander to display the Open/Close Test screen.

3) Insert discs and press the [ENTER] key on the remote

commander.

4) Is starts the aging.

During aging, the disc number, operating status and repeat cyc le

are displayed. Aging can be aborted at any time by pressing

the [RETURN] key. After the oper ation is stopped, press the

[RETURN] key to return to the Aging Test MENU.

Exit: RETURN

On this screen, measure and display the error rate.

UC : Incorrect value

CR : Correct value

Add: Address

2-9. SACD Water Mark Check

SACD Water Mark Check

PSP AMP

PSN

Start: ENTER Exit: RETURN

On this screen, measure the PSP AMP v alue and PSN value of SACD

water mark.

27

Page 28

CX-JD5

4. EMERGENCY HISTORY

On the Test Mode Menu screen, selecting [4] displays the

information such as servo emergency history.

The history information from last 1 up to 10 can be scrolled with

theOkey orokey. Also, specific information can be displayed

by directly entering that number with ten keys.

### EMG. History ###

Laser Hours CD xxxxhxxm

DVD xxxxhxxm

a. bb xx xx xx xx xx xx xx

xx xx xx xx xx xx xx xx

a. bb xx xx xx xx xx xx xx

xx xx xx xx xx xx xx xx

Select:1-9 Scroll:UP/DOWN

(1.Latest EMG.) Exit: RETURN

xxxxhxxm: The laser on total hours. Data below minutes are

omitted.

a. : Error number.

bb :Error code.

xx :Not used.

• Clearing History Information

Clearing laser hours:

Press the [DVD DISPLAY] and [CLEAR] keys in this order.

Then both CD and DVD data are cleared.

Clearing emergency history:

Press the

Initializing EEPROM data:

Press [DVD MENU] and [CLEAR] keys in this order.

The data have been initialized when “EEPROM Initialize

Finished” message is displayed, press the [RETURN] key to

return to the EMG. History screen.

• Code list of Emergency History

10: Communication to RF AMP (IC001) failed.

11: Each servo for focus, tracking, and spindle is unlocked.

12: Check sum error of EEPROM (IC204).

14: Communication to servo DSP (IC509) failed, or servo DSP

15: Communication to DVD decoder (IC701) failed, or DVD

16: Communication to DSD decoder (IC801) failed, or DSD

20: Initialization of sled servo failed. It is not placed in the ini-

23: Sled servo operation error.

24: Made a request to move the sled servo to wrong position.

30: Tracking balance adjustment error.

31: Tracking gain adjustment error.

33: Focus bias adjustment error.

34: Focus gain adjustment error.

35: Equalizer adjustment error.

40: Focus servo does not operate.

41: With a DVD dual layer disc, focus jump failed.

50: CLV (spindle) servo does not operate.

51: Spindle does not stop.

60: Made a request to seek nonexistent address.

61: Seek error of retry more than regulated times.

70: Control data could not be read.

80: Disc reading failed.

[DVD TOP MENU] and [CLEAR] keys in this order.

(IC509) is faulty.

decoder (IC701) is faulty.

decoder (IC801) is faulty.

tial position.

5. MECHA ERROR HISTORY

On the T est Mode Menu screen, selecting [5] displays the information

of mechanism deck error history.

The history information from last 1 up to 8 can be scrolled with

theOkey orokey.

### Mecha Error History ###

1. aa bb cc dd ee xx xx xx

2. aa bb cc dd ee xx xx xx

3. aa bb cc dd ee xx xx xx

4. aa bb cc dd ee xx xx xx

5. aa bb cc dd ee xx xx xx

6. aa bb cc dd ee xx xx xx

7. aa bb cc dd ee xx xx xx

8. aa bb cc dd ee xx xx xx

Scroll:UP/DOWN

(1.Latest Err.) Exit: RETURN

aa : Initialization is completed or not.

FF : Complete.

other number : Not complete.

bb : Operating status of mechanism deck at an error occurred.

(lod sq jcp)

00 : Initializing.

10 to 15 : Open operating.

16 to 19 : Kicking cause open failed.

1A to 1F : Open operating.

20 to 27 : Complete the open operation.

28 : No disc and complete the open operation.

29 to 2F : Complete the open operation.

30 to 3F : Close requesting.

40 to 4F : Open requesting.

50 to 5F : Close operating.

60 to 6F : Complete the chucking operation.

80 to 8F : Complete the release operation.

(BU is home position)

90 to 9F :BU down operating.

A0 to AF: Opening/closing the shutter. Or stationary state in

open/close the shutter is enablement.

B0 to BF : BU up requesting.

C0 to CF : BU down requesting.

D0 to DF: BU upping.

E0 to EF : No disc checking in disc loading.

cc : Operating status of table at an error occurred.

(tbl sq jcp)

13 : The rotation stop position determination error of a

table.

11 to 12 : The loading position determination error of a table.

dd : Operating status of mechanism deck at an error occurred.

(lod op jcp)

00 : Complete the operation.

10 to 1F : Open operating.

20 to 2F : Close operating.

30 to 3F : Release operating.

60 to 6F : Chucking operating.

70 to 7F : Kicking operating.

80 to 8F : Returning the BU to home position. (after kicking)

ee : The status of table operation. (“n” is unfixed)

(tbl op cp)

1n : Rotating in the direction of a forward.

2n : Rotating in the direction of a reverse.

28

Page 29

6. VERSION INFORMATION

On the Test Mode Menu screen, selecting [6] displa ys the ROM

version and region code.

The parenthesized hexadecimal number in version field is checksum

value of ROM.

## Version Information ##

IF con. Ver.x. xxx

SYScon. Ver.x. xx (xxxx)

Model JAX-Dxx

Region xx

Config xxxxxxxx

Front End Ver.x.xx

Exit: RETURN

IF con. : The version of system controller (IC101).

SYScon. : The version of DVD system processor (IC207).

Front End: The version of mechanism controller (IC901).

CX-JD5

7. VIDEO LEVEL ADJUSTMENT

On the Test Mode Menu screen, selecting [7] displays color bars

for video level adjustment. During display of color bars, OSD

disappears but the menu screen will be restored if pressing the

[RETURN] key.

29

Page 30

CX-JD5

SECTION 5

ELECTRICAL ADJUSTMENTS

Note:

1. VIDEO board is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use DVD reference disc unless othermise indicated.

[DVD reference disc]

TDV-520CSO (DVD-SL): PART No. J-2501-236-A

LUV-P01 (CD): PART No. 4-999-032-01

TDV-540C (DVD-DL): PART No. J-2501-235-A

Note: Do not use exiting test disc for DVD.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent when the

signal level is low than specified value with the following checks.

AUTO SERVO ADJUSTMENT

After parts related to the servo circuit (RF amplifier (IC001), DSP

(IC401), motor driver (IC501), EEPROM (IC302) so on) are

replaced, re-adjusting the servo circuit is necessary. Select “ALL”

at “1. DRIVE AUTO ADJUSTMENT” (Refer to page 23 in TEST

MODE) and adjust DVD-SL (single layer), CD and D VD-DL (dual

layer).

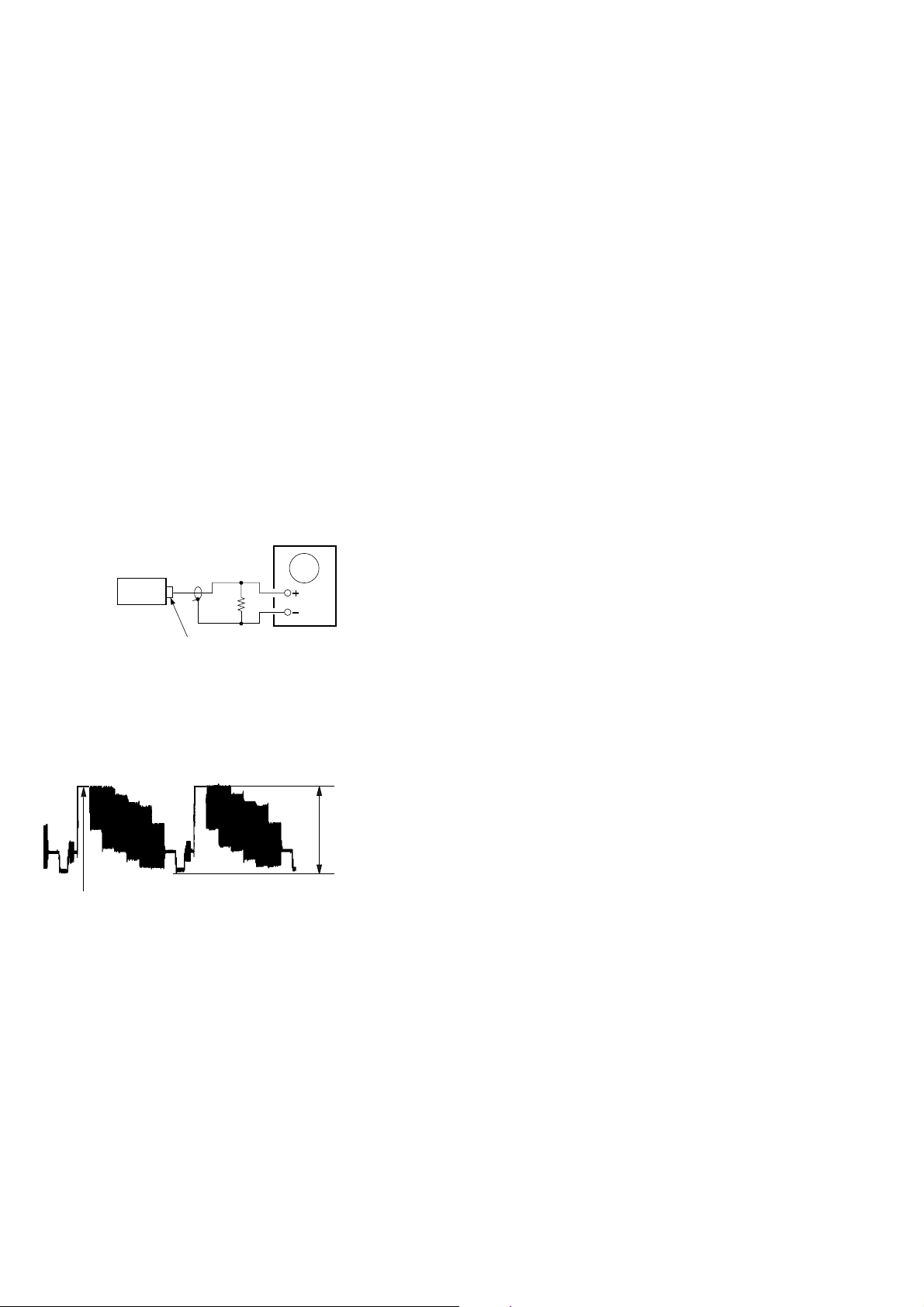

Video Level Check (VIDEO BOARD)

Purpose

This adjustment is made to satisfy the NTSC standard, and if not

adjusted correctly, the brightness will be too large or small.

Oscilloscope

75

Ω

set

J802

VIDEO OUTPUT

Procedure:

1. Connect oscilloscope to VIDEO output.

2. Load a DVD reference disc playback.

3. Check the video signal level is 1.00±0.05Vp-p.

(WHITE 100%)

1.00 ± 0.05 Vp-p

30

Page 31

SECTION 6

DIAGRAMS

6-1. BLOCK DIAGRAM – DVD DSP (1/2) Section –

OPTICAL TRAVERSE

UNIT

(DBU-1)

IC001

CD/DVD RF AMP

CX-JD5

DOUT

SPINDLE

MOTOR

SLED

MOTOR

DVDLD

CDLD

LD GND

VCC

GND

FCS+

FCS-

TRK+

TRK-

M

M

INLIM

SW

64

SCLK

GFS

13

19

71

30

GFS_CD

SCLK_CD

DOUT

LRCK

PCMD

BCK

EXCK

C2PO

SCOR

WDCK

XTAI

COUT22FOK24LOCK

74

75

FOK_CD

LOCK_CD

COUT_CD

RFIN

117

SPIN

SCK_DSD

LRCK

163

MDAT

160

BCLK

158

SBIN

148

EXCK

147

WFCK

151

C2PO

155

SCOR

150

GSCOR

146

MDIN2

137

SPO

135

APE0

109

D0-D7 A0-A7

172-176

1,2,4

8 8

14-21

D0-D7

65

66

67

79SBSO

80

10WFCK

14

15

17

IC703(1/2)

AMP

25MDP

71

768FS

IC703(2/2)

AMP

26

64

SCOR

JIT

45

IC503

AMP

5

6

50 RFAC

20 MIRR

39 FE

40 SE

41 TE

RFDC

43

CE

42

VC

38

33

FFDR

34 FRDR

31

TFDR

32

TRDR

SFDR

29

30 SRDR

26

31

SSTP

76

52

INLIM

SQSO77SQCK

SQSO

XRST

MD2

2

63

98

54

3

SQCK

XDRST

DOCTRL/ISBTEST

IC509

CD DECODER

SERVO DSP

DATA5XLAT6CLOK7SENS

MUTE

4

3

49 27 50 9 72

59

LAT_CD

DATA_CD

MUTE_CD

8

CLOK_CD

SENS_CD

RF

B

A

D

C

E

F

VC

AUTOMATIC

POWER

CONTROL (FOR DVD)

Q001

AUTOMATIC

POWER

CONTROL (FOR CD)

Q002

PD

A +5V

SPDL+

SPDL-

SLEDA+

SLEDASLEDB+

SLEDB-

Q901

X901

20MHz

40 XTAL

41 EXTAL

1

DVDRFP

A23

B2

4

C25

6

D2

A12

B

11

C10

9

D

CD A16

CD B

15

14

CD C

13

CD D

17

CD F

18

CD E

VC

20

21

DVD LD

22

CD LD

23

DVDPD

24

CDPD

DO1+

36

DRV

DO1-

37

DO2+

34

DRV

DO2-

35

IC501

MOTOR/COIL DRIVE

DO5+

27

DRV

DO5-

28

IN6+

47

IN6-

46

DO3+

32

DO3-

31

DRV

DO4+

30

DO4-

29

TSD-M

76

73

63

LDSEL

TSD-M

57RFAC

27MIRR

40FE

39TE

MNTR

42

VI25

36

48SDEN

47SDATA

46SCLK

26LDON

42

40

IN1+

48

IN1-

1

IN2+

3

IN2-

4

43

VC VC

IN5-

13

OUT6

45

IN3-

10

IN4-

7

MUTE12

MUTE34

MUTE5

19202122

60

SP_ON

MUTE_2D

MIRR

PI/CE

SDEN

DATA RF

CLK RF

LDON

FFDR

FRDR

TFDR

TRDR

43

44

SLED_B

VC

62

FG

SLED_A

28

82

LDON

SDCLK_RF

2

83

SDATA_RF

7

8

SDEN

FCS_JMP_2

66

65TE67FE29

PI

FCS_JMP_1

61

MIRR

7

SLED

IC701

DVD DECODER

HDB0-HDB8

XRD17XWR18XCS19XINT020XINT1

5,7,

9-14

85

89-96

A0-A7

XRD

44,41,39,35

32,30,27,24,26

XHWR

XHRD NC

66-69,71,

MD0-MD9,

MDA-MDF

84

XWR

96,97,99,

101,102,

104-106

MA0-MA9

XMWR

XRAS RAS

XOE OE

XCAS

MA11/MNT2

XTL1

MA10/MNT1

GFS

164

21

XRST

22

12

25

XCS_DVD

INIT0_DVD23INIT1_DVD

XSAK

46HDRQ

XDCK

48

49

XSRQ

53XHAC

73-75,

79,80,

12

82-87,

89,91

76

95

93

171

92

107

XRST

58

XRST_1882

2-5,

16

7-10,

41-44,

46-49

21-24,

27-32,

20,19

6

MNT1

GFS_DVD

16Mbit D-RAM

I/O0-I/O15

WE

17

1878

3394

UCAS

34

LCAS

35

MECHANISM

CONTROLLER

IC706

A0-A11

IC901(1/2)

SDA_EEP

SCL_EEP

WP_EEP

HDB-DATA

XSAK

XSDCK

XSRQ

• Signal Path

5

100

99

: DVD

: DIGITAL OUT

768FS-2

768FS-1

5 SDA

6

7

(Page 32)

(Page 32)

IC903

EEPROM

SCL

WP

A

B

3131

Page 32

CX-JD5

6-2. BLOCK DIAGRAM – DVD DSP (2/2) Section –

DOUT

IC207

DVD SYSTEM PROCESSOR

A

(Page 31)

AUDIO

+5V

D +5V

ZIVA

D +3.3V

(Page 31)

B

HDB-DATA

X SAK

X DCK

X SRQ

A0-A9,A10/AP,NC

IC392

+3.3V

1 3

REGULATOR

IC907

+3.3V

1 3

REGULATOR

IC211

+1.8V

1 3

REGULATOR

768FS-2

768FS-1

IC203

SDRAM

DQ0-DQ31

8

2,4,5,7,

8,10,11,13,

74,76,77,79,

80,82,83,85,

31,33,34,36,

37,39,40,42,

45,47,48,50,

51,53,54,56

25-27

60-66

24,21

16,71,28,59

WE

17

18 52

19 51

20 49

22 48

23

D+3.3V

A3V-2

ZIVA

D +1.8V

IC901 (2/2)

MECHANISM

CONTROLLER

177-174

171-168,182

32

12

4

62,73,86,97

IC204

EEPROM

WC

DO

IC904

FF

CKQ

3 1

CLR

6

4

SDDATA0-SDDATA7,

SDEN

179

SDCLK

183

SDREQ

178

57-60

64-71

75-78

MD0-MD31

81-84

88-95

99-102

42-33

MA0-MA11

45,46

MDQM0-MDQM3DQM0-DQM3

53

MWE

MCASCAS

MRASRAS

MCS0CS

BA0BS0

47

BA1BS1

188 DRVRDY

162 CS (ZIVA_E2P)