Aiwa CXBK-7 Service manual

CX-BK7

SERVICE MANUAL

Ver 1.1 2004.02

• CX-BK7 is the amplifier, disc player, tape

deck and tuner section in BMZ-K7D.

This system incorporates Dolby* Digital, Dolby Pro

Logic (II) adaptive matrix surround decoder, and the

DTS** Digital Surround System.

*Manufactured under license from Dolby

Laboratories.

“Dolby”, “Pro Logic” and the double-D symbol are

trademarks of Dolby Laboratories.

**Manufactured under license from Digital Theater

Systems, Inc. “DTS” and “DTS Dig ita l S ur round”

are registered trademarks of Digital Theater

Systems, Inc.

US and foreign patents licensed from Dolby

Laboratories.

DVD

Section

Tape deck

Section

Model Name Using Similar Mechanism NEW

DVD Mechanism Type CDM69DV-DVBU16V

Optical Traverse Unit Name DBU-1

Model Name Using Similar Mechanism NEW

Tape Transport Mechanism Type CMAL1Z241A

SPECIFICATIONS

AEP Model

UK Model

E Model

Australian Model

Amplifier section

The following measured at AC 120, 127, 220, 240 V,

50/60 Hz

Rated Power Output at Stereo mode

Continuous RMS power output (reference)

Front speaker:

Center speaker: 50 watts (8 ohms at 1 kHz,

Surround speaker: 50 watts (8 ohms at 1 kHz,

Inputs

LINE IN AUDIO (phono jacks):

LINE IN VIDEO (phono jack):

MD (AUX) IN (phono jacks):

MIC (phone jack): sensitivity 1 mV,

150 + 150 watts

(6 ohms at 1 kHz, 10%

THD)

10% THD)

10% THD)

voltage 1.1V, impedance

47 kilohms

max. input level 1Vp-p,

unbalanced, Sync

negative, impedance

75 ohms

voltage 1.1V, impedance

47 kilohms

impedance 10 kilohms

Outputs

MD (AUX) OUT (phono jacks):

VIDEO OUT (phono jack):

S-VIDEO OUT (4-pin/mini-DIN jack):

COMPONENT VIDEO OUT:

PHONES (stereo mini jack):

Front spea ker: Use only the supplie d

Surround speaker: Use only the supplied

Center speaker: Use only the supplied

SUB WOOFER OUT: voltage 1 V,

voltage 500 mV,

impedance 4.7 kilohms

max. output level

1 Vp-p, unbalanced, Sync

negative, load impedance

75 ohms

Y: 1 Vp-p, unbalanced,

Sync negative,

C: 0.286 Vp-p, load

impedance 75 ohms

Y: 1 Vp-p, 75 ohm s

B

, PR: 0.7 Vp-p, 75 ohms

P

accepts headphones of

32 ohms or more

speaker SX-BK7

speaker SX-BK7R

speaker SX-BK7C

impedance 1 kilohm

Disc player section

System Compact disc and digital

audio and video system

Laser Semiconductor laser

(DVD: λ=657 nm,

CD: λ=793 nm)

Emission duration:

continuous

Frequency response DVD (PCM 48 kHz):

2 Hz − 22 kHz (±1 dB)

CD: 2 Hz − 20 kHz (±1 dB)

Video color system format

NTSC, PAL

OPTICAL DIGITAL OUT (Euro/UK, Russian models

only)

(Square optical connector jack, rear panel)

Wavelength 660 nm

Tape deck section

Recording system 4-track 2-channel stereo

Frequency response 100 − 10,000 Hz (±3 dB) ,

using Sony TYPE I ca ssette

– Continued on next page –

DVD DECK RECEIVER

9-961-333-02 Sony Corporation

2004B05-1 Home Audio Company

C 2004.02 Published by Sony Engineering Corporation

CX-BK7

Tune r se ction

FM stereo, FM/AM superheterodyne tu ner

FM tuner section

Tuning range

Russian model: 65.0 - 74.0 MHz

Other models: 87.5 -108.0 MHz

Antenna FM lead antenna

Antenna terminals 75 ohm unba la nc e d

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range

Latin American models: 530 − 1,710 kHz

Saudi Arabian model: 531− 1,602 kHz (with the

Other models: 531 − 1,602 kHz (with the

Antenna AM loop antenna

Antenna terminals External antenna terminal

Intermediate frequency 450 kHz

General

Power requirements

Euro/UK, Russian models: 230 V AC, 50/60 Hz

Australian model: 230 − 240 V AC, 50/60 Hz

Saudi Arabian model: 120 − 127 V, 220 V AC,

Other models: 120 V, 220 V or 230 −

Power consumption

Dimensions (w/h/d)

Mass

87.5 - 108.0 MHz

(with the interval set at

10 kHz)

531 − 1,710 kHz

(with the interval set at

9k Hz)

interval set at 9 kH

interval set at 9 kHz)

530 − 1,710 kHz (with the

interval set at 10 kHz)

50/60 Hz

Adjustable with voltage

selector

240 V A C , 50/60 Hz

Adjustable with voltage

selector

250 watts

0.4 watts (in ECO MODE)

Approx. 211 × 379 ×

419 mm

Approx. 10.8 kg

z)

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

This appliance is

classified as a CLASS 1

LASER product. This

label is located on the

rear exterior.

The following caution label is located inside the

apparatus.

Design and specifications are subject to change

without notice.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 ˚C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 ˚C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

2

CX-BK7

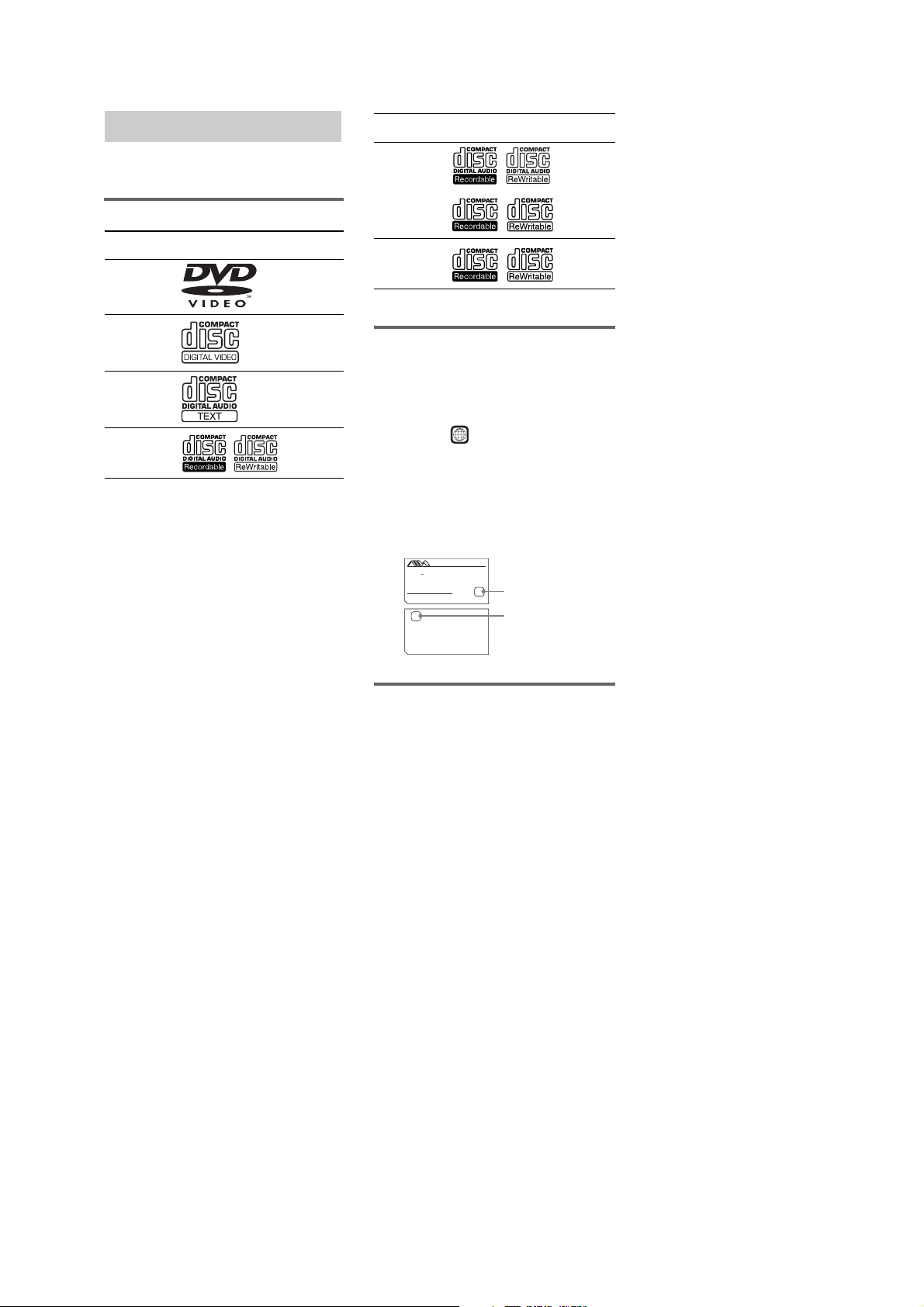

Playable discs

You can play back the following discs on this

system. Other discs cannot be played back.

List of playable discs

Format of

discs

DVD VIDEOs Audio +

VIDEO CDs Audio +

Audio CDs Audio

CD-R/CD-RW

(audio data)

Disc logo Contents

Video

Video

Audio

Format of

discs

CD-R/CD-RW

(MP3 files)

CD-R/CD-RW

(JPEG files)

The “DVD VIDEO” logo is a trademark.

Disc logo Contents

Audio

Video

Region code of DVDs you can

play on this system

Your system has a region code printed on the

back of the unit and will only play DVDs labeled

with identical region code.

DVDs labeled will also be played on this

ALL

system.

If you try to play any other DVD, the message

“Playback prohibited by area limitations.” will

appear on the TV screen. Depending on the

DVD, no region code indication may be labeled

even though playing the DVD is prohibited by

area restrictions.

MODEL NO. CX-BK7

DVD DECK RECEIVER

AC:230V 50/60Hz W

SERIAL NO.AREA

SERIAL NO.

Sony Corporation

X

4-249-187-2 CEL/CEK

Region code

X

(Euro/UK, Russian models)

Region code

(except Euro/UK, Russian

models)

Discs that this system cannot

play

•CD-ROMs (except for extension “.MP3,”

“.JPG,” or “.JPEG”)

•CD-Rs/CD-RWs other than those recorded in

the following formats:

–music CD format

–video CD format

–MP3/JPEG format that conforms to

ISO9660*

Session*

1

Level 1/Level 2, Joliet or Multi

2

•Data part of CD-Extras

•Super Audio CDs

•Progressive JPEG format files cannot be

played on this system.

• DVD-RWs in VR mode (DVD-RWs created

in VR (Video Recording) mode allow the

contents to be programed or edited.)

• DVD-ROMs

• DVD Audio discs

•A DVD with a different region code.

•Audio tracks in MP3PRO format.

•A disc that has a non-standard shape (e.g.,

card, heart).

•A disc with paper or stickers on it.

•A disc that has the adhesive, cellophane tape,

or a sticker still left on it.

*1

ISO9660 Format

The most common international standard for the

logical format of files and folders on a CD-ROM.

There are severa l specification levels. In Leve l 1, file

names must be in the 8.3 format (no more than eight

characters in the name, no more than three characters

in the extension “.MP3” or “.JPG”) and in capital

letters. Folder names can be no longer than eight

characters. There can be no more than eight nested

folder levels. Level 2 sp ecifications allow file names

and folder names up to 31 characters long. Each

folder can have up to 8 trees.

For Joliet in the expansion format (file and folder

names can have up to 64 characters) m ake sure of the

contents of the writing software, etc.

*2

Multi Session

This is a recording method that enables adding of

data using the Trac k-At-Once method. Conventional

CDs begin at a CD control area called the Lead-in

and end at an area called Lead-out. A Multi Session

CD is a CD having multiple sessions, with each

segment from Lead-in to Lead-out regarded as a

single session.

CD-Extra: This format records audio (audio CD

data) on the tracks in se ssion 1 and data on the tracks

in session 2.

3

CX-BK7

Note on playback operations

of DVDs and VIDEO CDs

Some playback operations of DVDs and VIDEO

CDs may be intentionally set by software

producers. Since this system plays DVDs and

VIDEO CDs according to the disc contents the

software producers designed, some playback

features may not be available. Also, refer to the

instructions supplied with the DVDs or VIDEO

CDs.

Copyrights

This product incorporates copyright protection

technology that is protected by U.S. patents and

other intellectual property rights. Use of this

copyright protection technology must be

authorized by Macrovision, and is intended for

home and other limited viewing uses only unless

otherwise authorized by Macrovision. Reverse

engineering or disassembly is prohibited.

Music discs encoded with

copyright prot ec ti on

technologies

This product is designed to playback discs that

conform to the Compact Disc (CD) standard.

Recently, various music discs encoded with

copyright protection technologies are marketed

by some record companies. Please be aware that

among those discs, there are some that do not

conform to the CD standard and may not be

playable by this product.

Cautions when playing a disc

that is recorded in Multi

Session

•This system can play Multi Session CDs when

an MP3 audio track is contained in the first

session. Any subsequent MP3 audio tracks

recorded in later sessions can also be played

back.

•This system can play Multi Session CDs when

a JPEG image file is contained in the first

session. Any subsequent JPEG image files

recorded in later sessions can also be played

back.

•If audio tracks and images in music CD

format or video CD format are recorded in the

first session, only the first session will be

played back.

Notes on discs

•This system can play CD-R/CD-RW discs

edited by the user. However, note that

playback of some discs may not be possible

depending on the recording device used for

recording or the disc condition.

•Discs recorded on CD-R/CD-RW drives may

not be played back because of scratches, dirt,

recording condition or the driver’s

characteristics.

•CD-R and CD-RW discs that have not been

correctly finalized (processing to allow play

by a normal CD player) cannot be played.

•CD-R and CD-RW discs recorded in multisession that have not ended by “closing the

session” are not supported.

•The system may be unable to play MP3/JPEG

format files that do not have the extender

“.MP3,” “.JPG,” or “.JPEG.”

•Attempting to play non-MP3/JPEG format

files that have the extender “.MP3,” “.JPG,”

or “.JPEG” may result in noise or

malfunction. Playback is possible up to 8

levels.

•With formats other than ISO9660 level 1 and

2, folder names or file names may not be

displayed correctly.

•The following discs take a longer time to start

playback:

–a disc recorded with a complicated tree

structure.

–a disc recorded in Multi Session.

–a disc to which data can be added (non-

finalized disc).

•Some CD-Rs, CD-RWs, DVD-Rs or DVDRWs (in video mode) (DVD-RWs created in

video mode have the same format as a DVD

VIDEO) cannot be played on this system

depending upon the recording quality or

physical condition of the disc, or the

characteristics of the recording device.

Furthermore, the disc will not play if it has not

been correctly finalized. For more

information, see the operating instructions for

the recording device.

•A disc recorded in packet write format cannot

be played.

4

TABLE OF CONTENTS

CX-BK7

1. SERVICING NOTES ................................................ 6

2. GENERAL ................................................................... 8

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 9

3-2. Panel ................................................................................ 10

3-3. Top Panel Block .............................................................. 10

3-4. Front Panel Assy ............................................................. 11

3-5. Shield Plate...................................................................... 11

3-6. MAIN Board ................................................................... 12

3-7. Rear Cover....................................................................... 12

3-8. Tuner (FM/AM) .............................................................. 13

3-9. SP Board.......................................................................... 13

3-10. ACDC Board, Power Transformer.................................. 14

3-11. FRONT AMP/SUR AMP Board ..................................... 14

3-12. DVD Mechanism Deck (CDM69DV-DVBU16V)......... 15

3-13. Signal Cassette Mechanism ............................................ 15

3-14. Optical Pick-Up Section (DVBU16V) ........................... 16

3-15. Optical Traverse Unit (Service Assy , DBU-1) ............... 16

3-16. SW (1) Board, SW (2) Board, SW (3) Board,

SW (4) Board, Bracket (TOP) Assy ............................... 17

3-17. RELAY Board ................................................................. 17

3-18. Motor (Stocker) Assy (Stocker) (M761) ........................ 18

3-19. Motor (Roller) Assy (Roller) (M781)............................. 18

3-20. Motor (Mode) Assy (Mode) (M771) .............................. 19

3-21. Rubber Roller (Slider) Assy ........................................... 19

3-22. Timing Belt (Front/Rear) ................................................ 20

3-23. Cam (Gear) ...................................................................... 20

3-24. SENSOR Board ............................................................... 21

4. ASSEMBLY

4-1. How to Install the Cam (Eject Lock).............................. 22

4-2. How to Install the Cam (Gear)........................................ 22

4-3. How to Install the Gear (Mode 2)................................... 23

4-4. How to Install the Gear (Mode Cam) ............................. 23

4-5. How to Install the Rotary Encorder (S702),

Gear (Stocker Communication) ...................................... 24

4-6. How to Install the Cam (Stocker U/D) ........................... 24

4-7. How to Install the Stocker Assy ..................................... 25

4-8. Phase Adjustment Between Pinions (Slider)

and Slider-1 to 5 (L/R).................................................... 26

5. TEST MODE.............................................................. 27

6. ELECTRICAL ADJUSTMENTS

DVD Section ................................................................... 37

DECK Section ................................................................. 37

7. DIAGRAMS

7-1. Block Diagram – RF SERVO Section – ......................... 38

7-2. Block Diagram – CHANGER/VIDEO Section – .......... 39

7-3. Block Diagram – TUNER/TAPE/USB Section – .......... 40

7-4. Block Diagram – AMP Section – ................................... 41

7-5. Block Diagram

– PANEL/POWER SUPPLY Section – .......................... 42

7-6. Note for Printed Wiring Boards

and Schematic Diagrams ................................................ 43

7-7. Printed Wiring Board – RF Board – ............................... 44

7-8. Schematic Diagram – RF Board –.................................. 45

7-9. Printed Wiring Boards – CHANGER Section –............. 46

7-10. Schematic Diagram – CHANGER Section – ................. 47

7-11. Printed Wiring Board

– MB03 Board (Side A) –............................................... 48

7-12. Printed Wiring Board

– MB03 Board (Side B) – ............................................... 49

7-13. Schematic Diagram – MB03 Board (1/8) – ................... 50

7-14. Schematic Diagram – MB03 Board (2/8) – ................... 51

7-15. Schematic Diagram – MB03 Board (3/8) – ................... 52

7-16. Schematic Diagram – MB03 Board (4/8) – ................... 53

7-17. Schematic Diagram – MB03 Board (5/8) – ................... 54

7-18. Schematic Diagram – MB03 Board (6/8) – ................... 55

7-19. Schematic Diagram – MB03 Board (7/8) – ................... 56

7-20. Schematic Diagram – MB03 Board (8/8) – ................... 57

7-21. Printed Wiring Board – VIDEO Board – ........................ 58

7-22. Schematic Diagr am – VIDEO Board – .......................... 59

7-23. Printed Wiring Board – DECK Board – ......................... 60

7-24. Schematic Diagram – DECK Board – ............................ 61

7-25. Printed Wiring Board – USB AUX Board –................... 62

7-26. Schematic Diagr am – USB AUX Board –...................... 63

7-27. Printed Wiring Board – MIC Board – ............................ 64

7-28. Schematic Diagram – MIC Board – ............................... 65

7-29. Schematic Diagram – MAIN Board (1/4) – ................... 66

7-30. Schematic Diagram – MAIN Board (2/4) – ................... 67

7-31. Schematic Diagram – MAIN Board (3/4) – ................... 68

7-32. Schematic Diagram – MAIN Board (4/4) – ................... 69

7-33. Printed Wiring Board – MAIN Board – ......................... 70

7-34. Printed Wiring Board – FRONT AMP Board – ............. 71

7-35. Schematic Diagr am – FRONT AMP Board (1/2) – ....... 72

7-36. Schematic Diagr am – FRONT AMP Board (2/2) – ....... 73

7-37. Printed Wiring Board – SURAMP Board – ................... 74

7-38. Schematic Diagram – SURAMP Board – ...................... 75

7-39. Printed Wiring Boards

– HEADPHONE/SP Boards – ........................................ 76

7-40. Schematic Diagrams

– HEADPHONE/SP Boards – ........................................ 77

7-41. Printed Wiring Boards – PANEL Section (1/2) – .......... 78

7-42. Schematic Diagr am – PANEL Section (1/2) –............... 79

7-43. Printed Wiring Boards – PANEL Section (2/2) – .......... 80

7-44. Schematic Diagr am – PANEL Section (2/2) –............... 81

7-45. Printed Wiring Boards

– ACDC Board (Except Saudi Arabia model) –............. 82

7-46. Schematic Diagram

– ACDC Board (Except Saudi Arabia model) –............. 83

7-47. Printed Wiring Board

– ACDC Board (Saudi Arabia model) –......................... 84

7-48. Schematic Diagram

– ACDC Board (Saudi Arabia model) –......................... 85

7-49. Printed Wiring Board – PT96 Board – ........................... 86

7-50. Schematic Diagram – PT96 Board – .............................. 87

7-51. IC Pin Function Description ........................................... 98

8. EXPLODED VIEWS

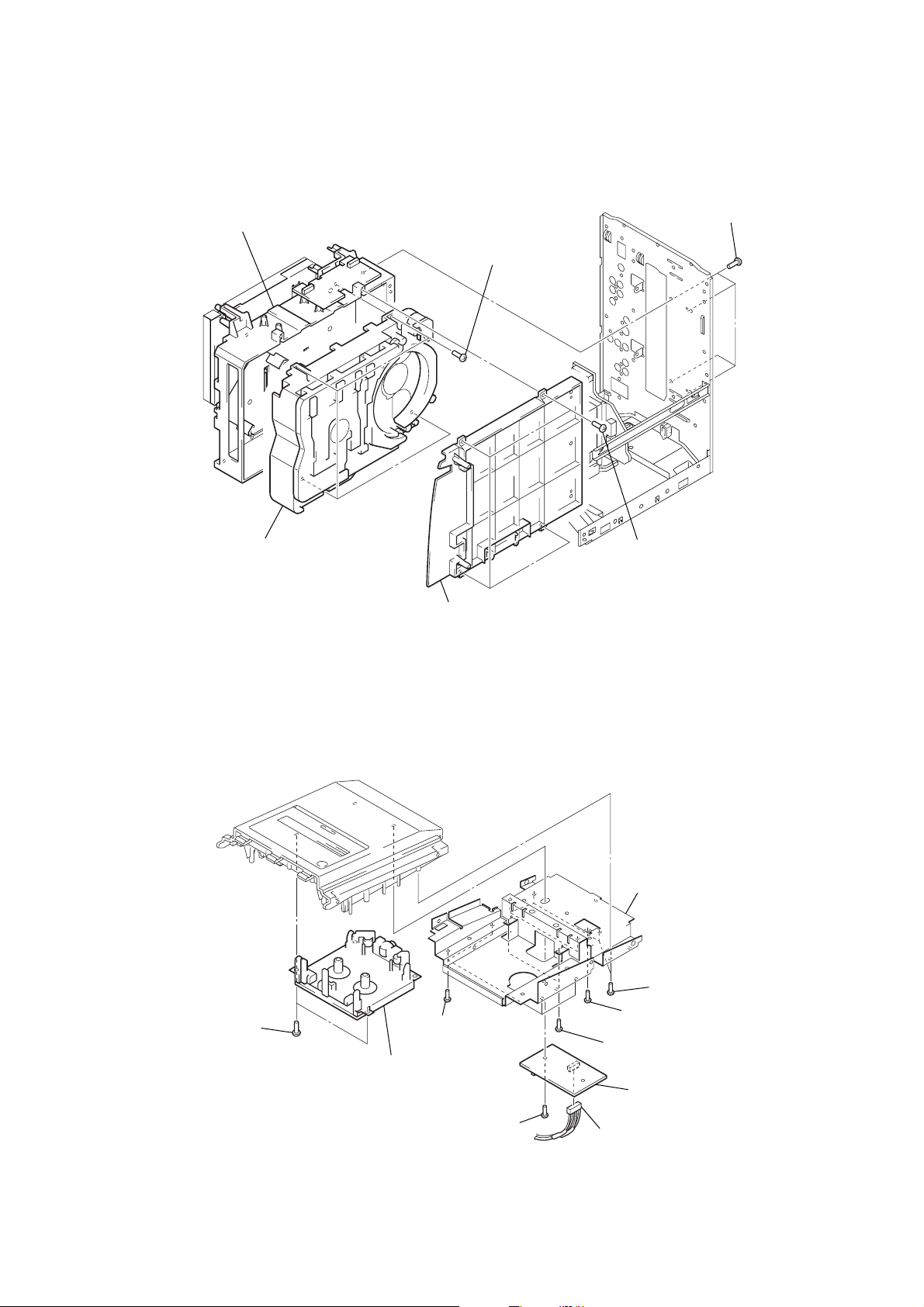

8-1. Side Panel Section.......................................................... 114

8-2. Top Panel Section...........................................................115

8-3. Front Block-1

(KEY LED RMC/USB AUX Board Section)................ 116

8-4. Front Block-2

(LCD VOL Board Section) ............................................ 117

8-5. Front Block-3

(Cabinet Front Assy Section)......................................... 118

8-6. MAIN/ACDC Board Section .........................................119

8-7. MB03 Board Section...................................................... 120

8-8. Power Transformer Section ........................................... 121

8-9. FR ONT AMP/SUR AMP Board Section....................... 122

8-10. DVD Mechanism Deck Section-1

(CDM69DV-DVBU16V) ............................................... 123

8-11. DVD Mechanism Deck Section-2

(CDM69DV-DVBU16V) ............................................... 124

8-12. DVD Mechanism Deck Section-3

(CDM69DV-DVBU16V) ............................................... 125

8-13. DVD Mechanism Deck Section-4

(CDM69DV-DVBU16V) ............................................... 126

8-14. DVD Mechanism Deck Section-5

(CDM69DV-DVBU16V) ............................................... 127

8-15. DVD Mechanism Deck Section-6

(CDM69DV-DVBU16V) ............................................... 128

8-16. Optical Traverse Unit Section (DVBU16V).................. 129

9. ELECTRICAL PARTS LIST .............................. 130

5

CX-BK7

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objectiv e lens.

RELEASING THE DISC LOCK

The disc lock function for the antitheft of an demonstration

disc in the store is equipped.

Releasing Procedure :

While pressing the [ENTER] key , press the Z key for 5 seconds.

The message “UNLOCKED” is displayed and the disc is unlocked.

Note: When “LOCKED” is displayed, the disc lock is not released by

turning power on/off with the I/1 key.

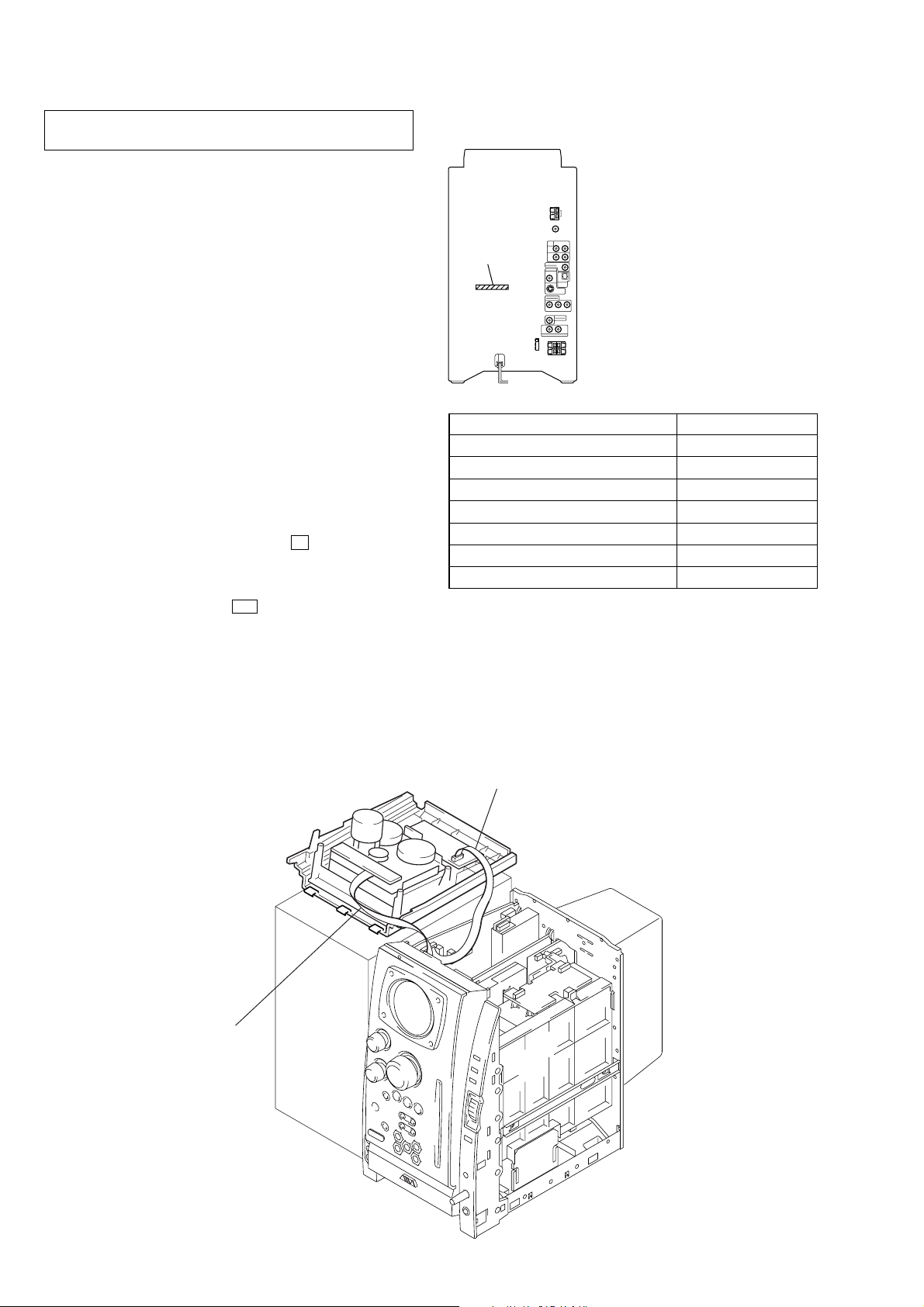

• MODEL IDENTIFICATION

– Rear Cover –

PART No.

MODEL PART No.

Chilean and Peruvian models 4-249-187-1

AEP and UK models 4-249-187-2

Mexican model 4-249-187-3

Saudi Arabia model 4-249-187-4

Singapore and Malaysia models 4-249-187-5

Australian model 4-249-187-6

CIS model 4-249-187-7

[]

[]

[]

[]

[]

[]

[]

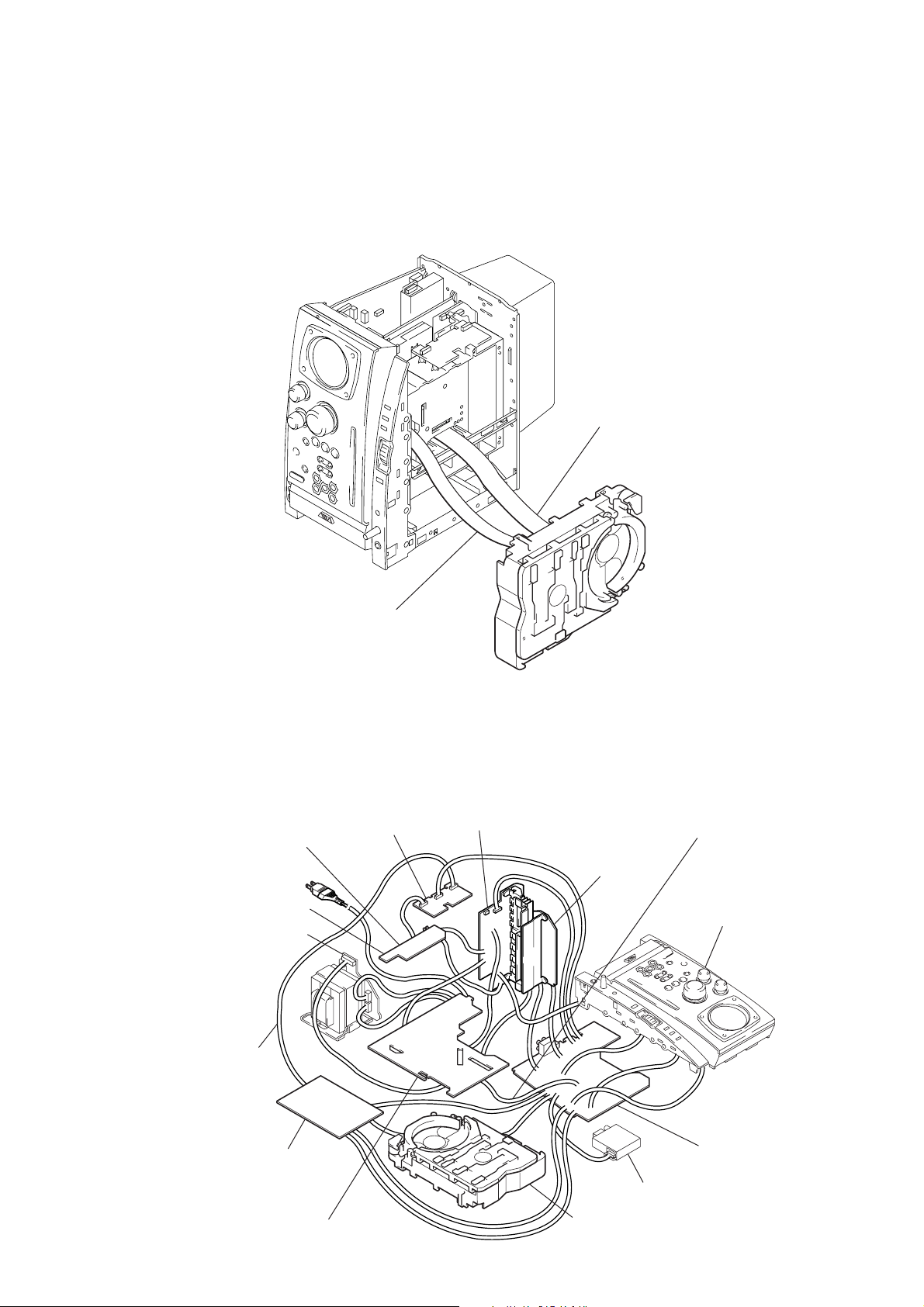

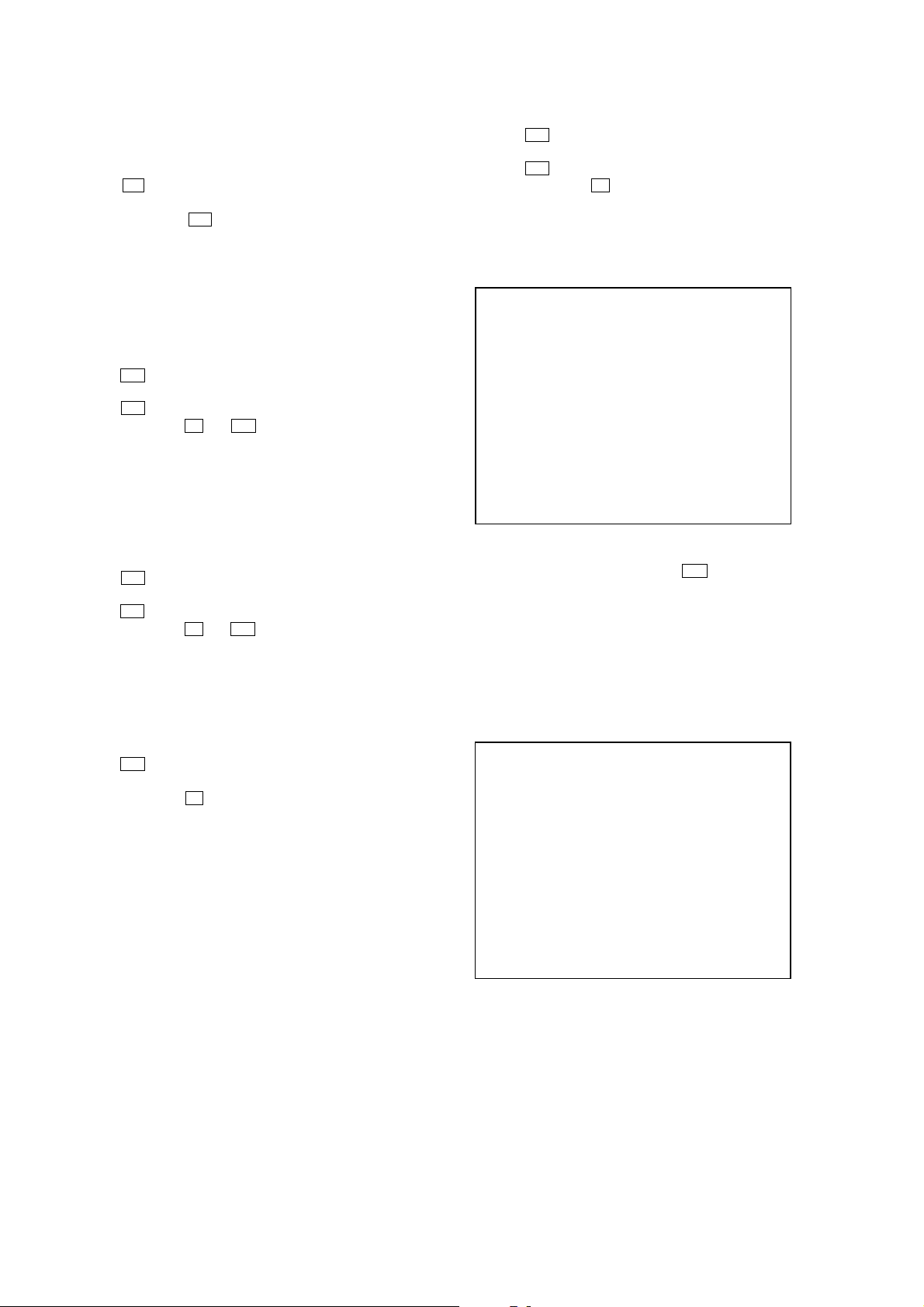

SERVICE POSITION

– Tape mechanism deck –

Connect the wire (flat type) (8 core)

to the main board (CN903) and

the mechanism deck.

Connect the wire (flat type) (11 core)

to the deck board (CN008) and the main board (CN009).

6

CX-BK7

– DVD mechanism deck –

• In checking the DVD mechanism deck section, prepare two extension jigs (Part No. J-2501-103-A: 1mm Pitch, 29 cores, Length

300mm/Part No. J-2501-248-A: 1mm Pitch, 27 cores, Length 300mm).

Note: The DVD mechanism deck of this model is a vertical type and putting it vertically as shown in the figure is the standard position.

When checking signals such as RF waveforms, operate it with the DVD mechanism deck in the standard position as shown below.

Connect the extension jig (J-2501-248-A)

to the relay board (CN201) and

the main board (CN901).

Connect the extension jig (J-2501-103-A)

to the RF board (CN002) and

the MBO3 board (CN501).

– MAIN board, ACDC board and MB03 board –

• For connecting the DVD mechanism deck, prepare three extension jigs. (Refer to “– DVD mechanism deck –”)

• In checking the MAIN/ACDC/MB03 boards, prepare three e xtension jigs (Part No. J-2501-231-A: 1mm Pitch, 15 cores, Length 300mm/

Part No. J-2501-243-A: 1mm Pitch, 17 cores, Length 300mm/Part No. J-2501-265-A: 4 pin, Length 300mm).

Connect the extension jig

(J-2501-231-A) to the video

board (CN802) and the SP

board (CN312).

SP board

PT96 board

Connect the extension jig

(J-2501-243-A) to the video

board (CN801) and the MB03

board (CN105).

video board

front AMP board

SURAMP board

Connect the extension jig

(J-2501-265-A) to the ACDC

board (CN004) and the main

board (CN007).

front panel section

MB03 board

ACDC board

main board

tuner unit

DVD mechanism deck

7

CX-BK7

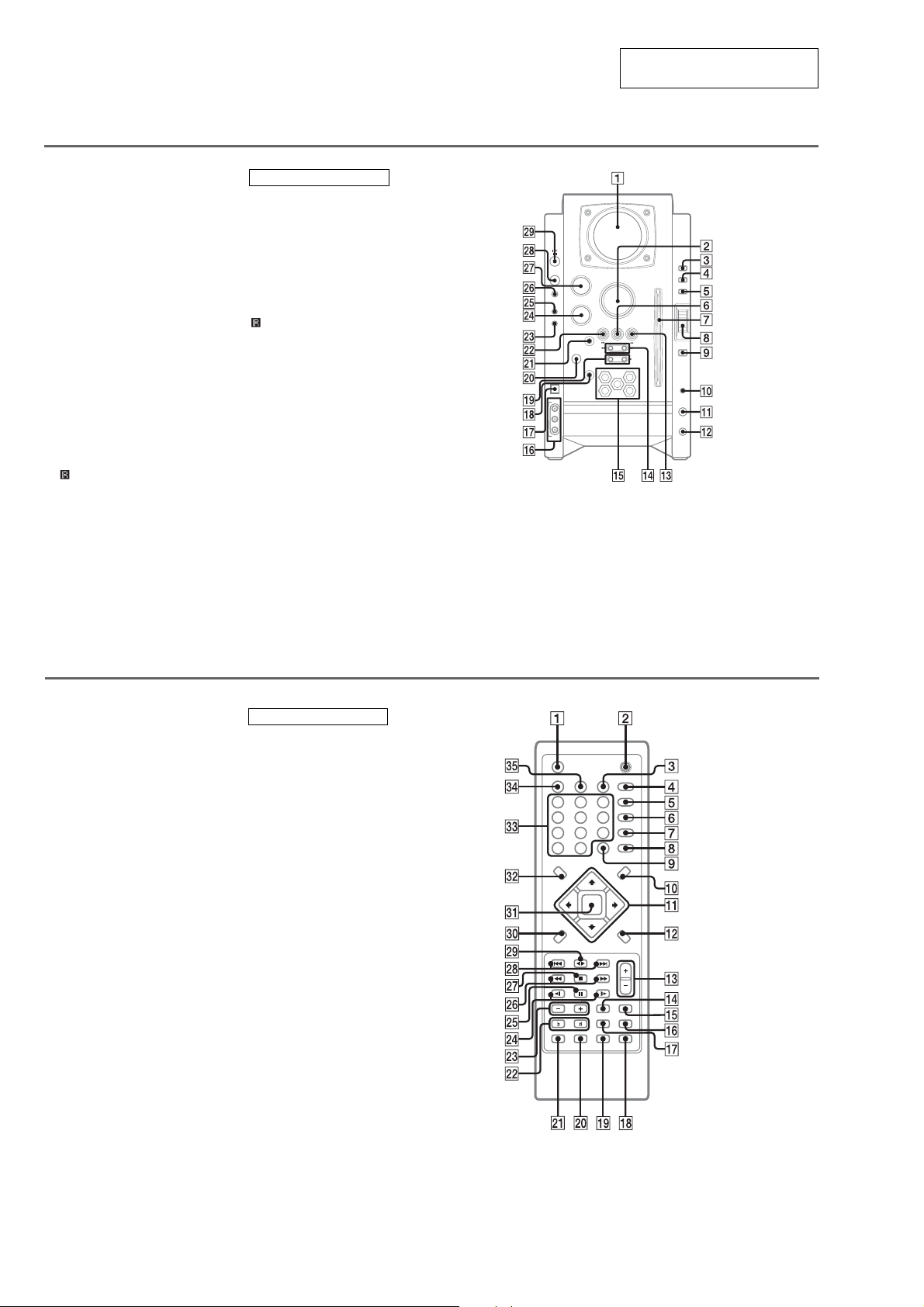

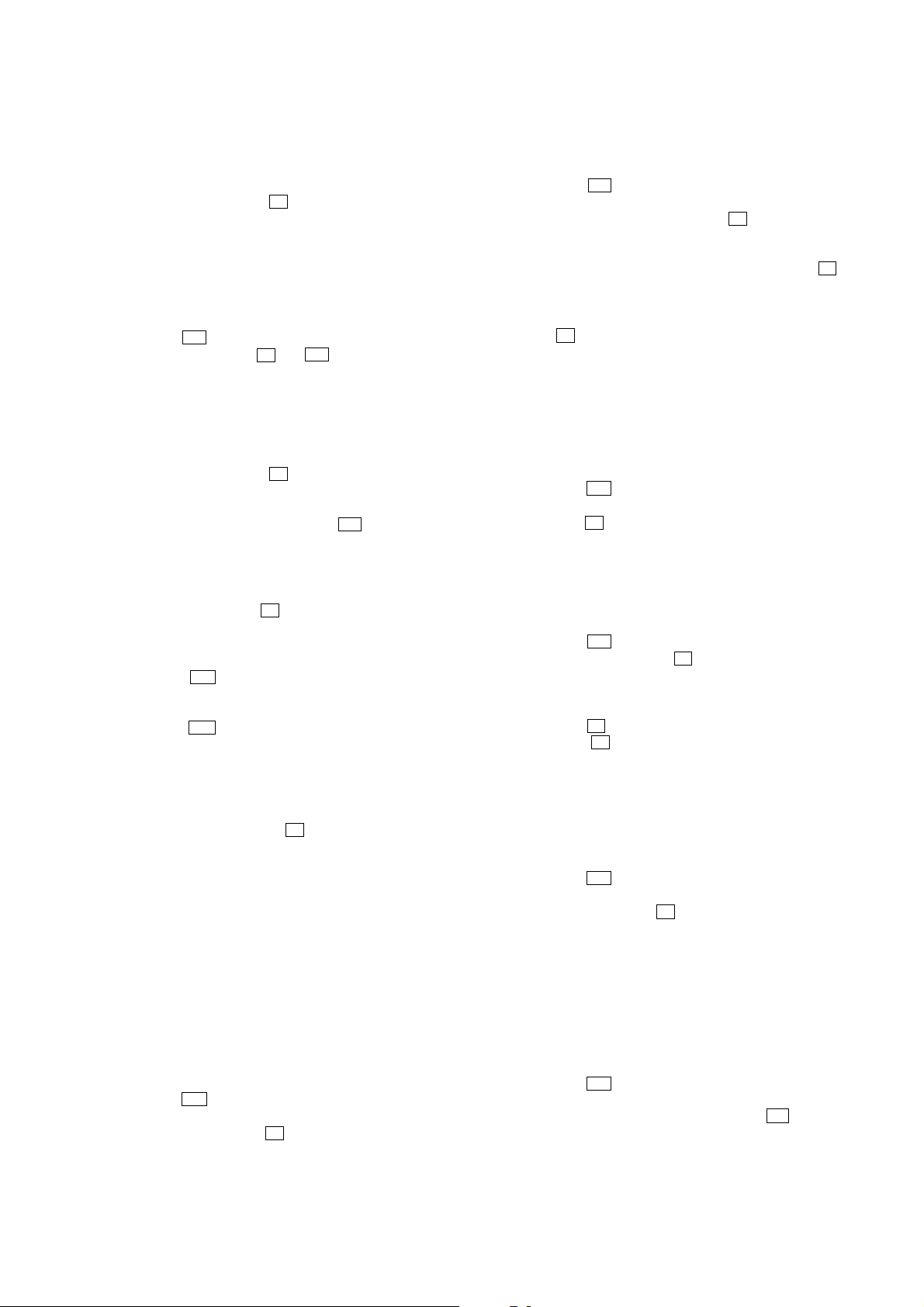

SOUND FIELD

• LOCATION OF CONTROLS

Main unit

1 Display window

2 VOLUME control

3 PLAY MODE

4 DISPLAY

4 RDS

5 MODE

6 TUNER PRESET CLEAR

7 Disc slot

8 MULTI JOG

9 ENTER

q; PHONES jack

qa MIC LEVEL

qs MIC jack

qd SELECT DIRECTION

nN

qf TUNING − ./m

qf TUNING + M/>

qg DISC SELECT

qh LINE IN

qj USB jack

qk Z EJECT/DISC CHANGE

ql ALBUM/PLAY LIST +/−

w;

wa CD SYNC

wa REC PAUSE/START

ws TUNER PRESET SET

wd i-Bass

wf BASS

wg SOUND FIELD

wh TUNER/BAND

wj TREBLE/MIDDLE

wk FUNCTION

wl [/1 (power)

*1

*1

(Remote sensor)

BUTTON DESCRIPTIONS

[/1 (power) wl

X (pause) ws

Z (eject) qk

x (stop) 6

M/> (fast forward/

TUNING +) qf

nN SELECT DIRECTION

qd

./m (rewind/TUNING −)

qf

(Remote sensor) w;

*1

(except Euro/UK models):

DISPLAY

(Euro/UK models):

RDS function

SECTION 2

GENERAL

This section is extracted from

instruction manual.

TREBLE /

MIDDLE

FUNCTION

TUNER/BAND

LINE IN

VIDEO

L

R

AUDIO

VOLUME

BASS

TUNER PRESET

CLEAR

SELECT

SET

DIRECTION

CD SYNC

TUNING

REC PAUSE/

START

ALUBAM/PLAY LIST

Z EJECT

DISC SELECT

1

4

DISC CHANGE

3

2

5

PLAY MODE

DISPLAY

MODE

ENTER

PHONES

MIC LEVEL

MIN

XAM

MIC

Remote control

1 FUNCTION

2 [/1

3 REPEAT

4 SOUND FIELD

5 AUDIO

6 SUBTITLE

7 ANGLE

8 DVD SETUP

9 DISC SKIP

q; DVD MENU

qa M/m/</,

qs DVD DISPLAY

qd VOL +/−

qf FM MODE

qg TUNER/BAND

qh ECHO

qj KARAOKE

qk CLEAR)

ql AMP MENU

w; CLOCK/TIMER SELECT

wa CLOCK/TIMER SET

ws KEY CONTROL

wd ALBUM +/−

wf SLOW −/+

wg X (pause)

wh TUNING −/+

wj x (stop)

wk PRESET −/PREV .

wk PRESET +/NEXT >

wl SELECT bB

e; O RETURN

ea ENTER

es DVD TOP MENU

ed Number buttons

ef DISPLAY

eg PLAY MODE

*

#/2

BUTTON DESCRIPTIONS

[/1 2

x (stop) wj

bB (SELECT) wl

X (pause) wg

M/m/</, qa

m (TUNING −) wh

M (TUNING +) wh

. (PRESET −/PREV) wk

> (PRESET +/NEXT) wk

t (SLOW —) wf

T (SLOW +) wf

#

(KEY CONTROL) ws

2

(KEY CONTROL) ws

*

Switches the active function: DVD,

USB, TAPE, TUNER, VIDEO, MD.

8

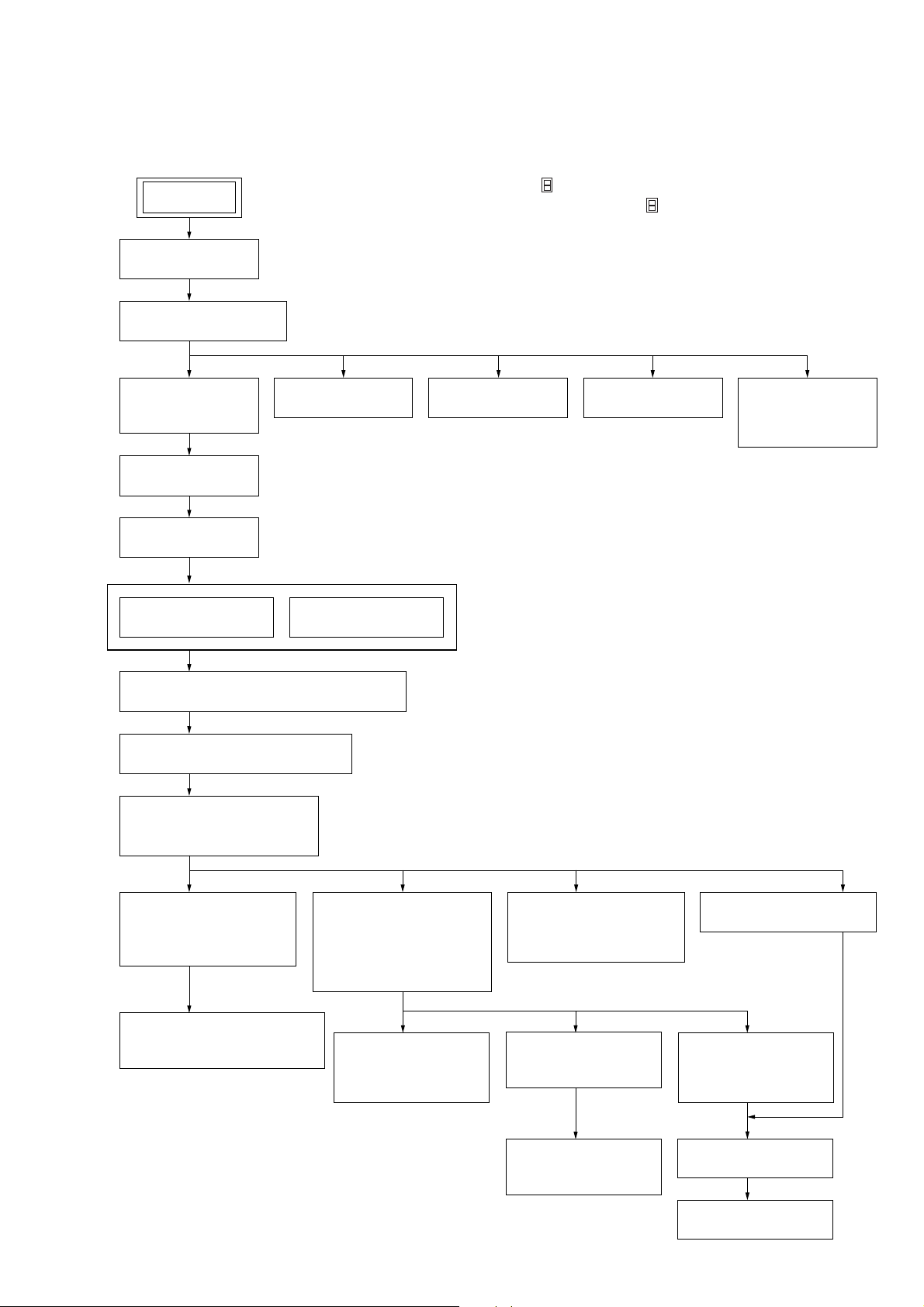

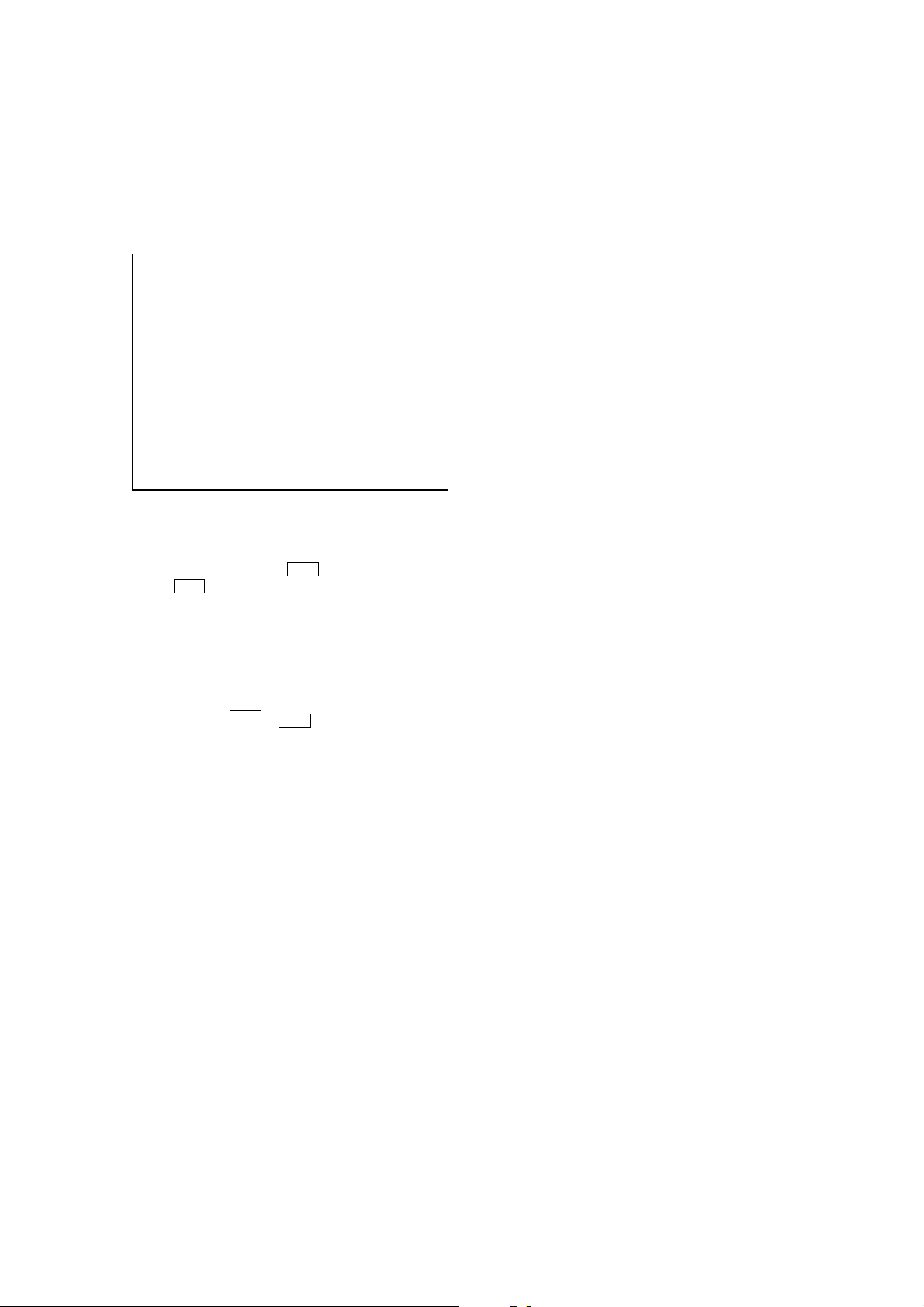

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

CX-BK7

SECTION 3

DISASSEMBLY

SET

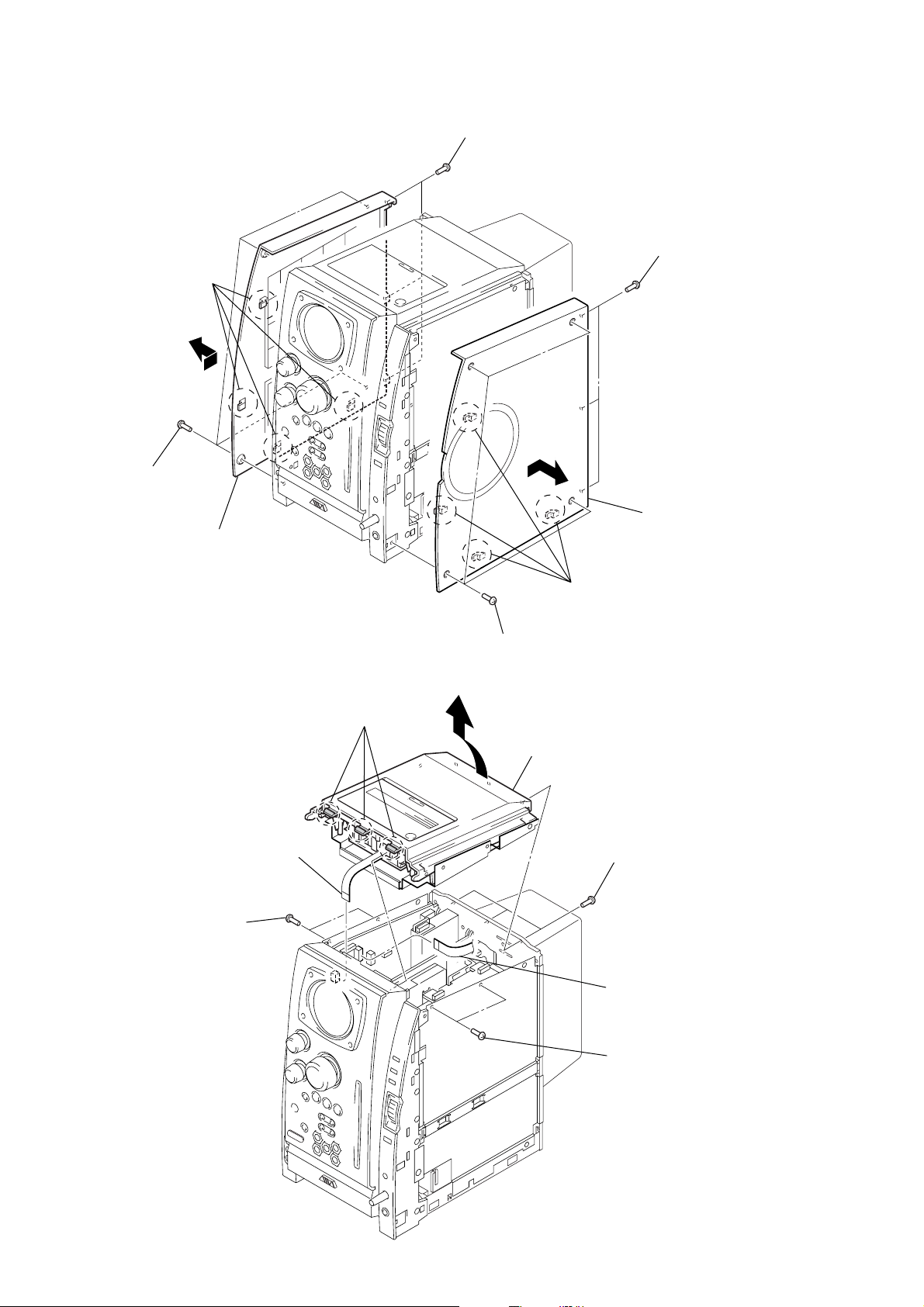

3-2. PANEL

(Page 10)

3-3. TOP PANEL BLOCK

(Page 10)

3-4. FRONT PANEL

ASSY

(Page 11)

3-5. SHIELD PLATE

(Page 11)

3-6. MAIN BOARD

(Page 12)

3-8. TUNER (FM/AM)

(Page 13)

Note 1: The process described in can be performed in any order.

Note 2: Without completing the process described in , the next process can not be performed.

Note 3: Tape deck is not loaded in US model.

3-7. REAR COVER

(Page 12)

3-9. SP BOARD

(Page 13)

3-8. TUNER (FM/AM)

(Page 13)

3-9. SP BOARD

(Page 13)

3-13. SIGNAL

CASSETTE

MECHANISM

(Page 15)

3-10. ACDC BOARD, POWER TRANSFORMER

(Page 14)

3-11. FRONT AMP/SURAMP BOARD

(Page 14)

3-12. DVD MECHANISM DECK

(CDM69DV-DVBU16V)

(Page 15)

3-14. OPTICAL PICK-UP

SECTION

(DVBU16V)

(Page 16)

3-15. OPTICAL TRAVERSE UNIT

(SERVICE ASSY, DBU-1)

(Page 16)

3-16. SW (1) BOARD,

SW (2) BOARD,

SW (3) BOARD,

SW (4) BOARD,

BRACKET (TOP) ASSY

(Page 17)

3-19. MOTOR (ROLLER)

ASSY (ROLLER)

(M781)

(Page 18)

3-18. MOTOR (STOCKER)

ASSY (STOCKER)

(M761)

(Page 18)

3-21. RUBBER ROLLER

(SLIDER) ASSY

(Page 19)

3-17. RELAY BOARD

(Page 17)

3-20. MOTOR (MODE)

ASSY (MODE)

(M771)

(Page 19)

3-22. TIMING BELT

(FRONT/REAR)

(Page 20)

3-23. CAM (GEAR)

(Page 20)

3-24. SENSOR BOARD

(Page 21)

9

CX-BK7

Note: Follow the disassembly procedure in the numerical order given.

3-2. PANEL

3

four claws

4

2

four screws

(BVTP3

×

10)

1

three screws

(BVTP3

×

10)

9

6

three screws

(BVTP3

right panel

0

×

10)

5

panel (left)

3-3. TOP PANEL BLOCK

4

wire (flat type) (8core)

(CN903)

1

two screws

×

(BVTP3

10)

2

three claws

3

7

four screws

(BVTP3

6

8

four claws

×

10)

top panel block

1

5

three screws

(BVTP3

wire (flat type) (11core)

(CN009)

×

10)

10

1

two screws

(BVTP3

×

10)

CX-BK7

)

3-4. FRONT PANEL ASSY

1

q;

front panel assy

6

two screws

(QT2+3-10)

2

wire (flat type) (17core)

(CN004)

wire (flat type) (19core)

(CN905)

8

two claws

9

connector (CN530)

3

wire (flat type) (5core)

(CN503)

4

two lead with connectors

5

five screws

(BVTP3

3-5. SHIELD PLATE

4

left shield plate

3

four screws

(BVTP3

×

10)

×

10)

7

four screws

(QT2+3-10)

2

shield plate (right

1

four screws

(BVTP3 × 10)

11

CX-BK7

)

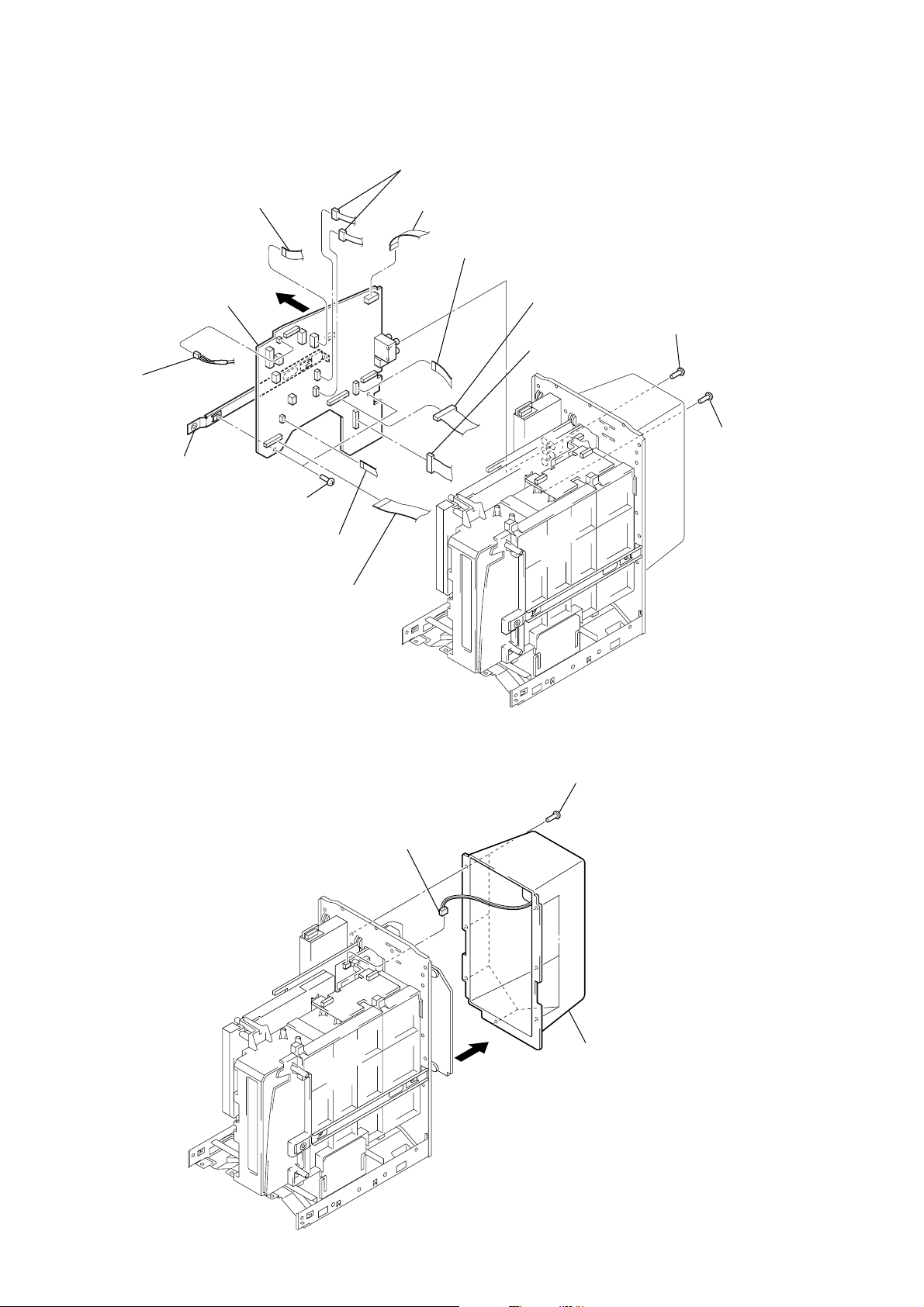

3-6. MAIN BOARD

2

wire (flat type)

(11core: EXCEPT AEP, UK) (CN509)

(15core: AEP, UK) (CN508)

qf

q;

connector

(CN602)

qg

PC board

holder (main)

main board

qd

5

two screws

(BVTP3

×

6)

9

two connectors

(CN007, CN507)

1

wire (flat type) (11core)

(CN502)

6

wire (flat type) (11core)

(CN501)

7

connector

(CN007)

8

connector

(CN006)

3

two screws

(BVTP3

4

×

10)

screw

(BVTP3

×

10

3-7. REAR COVER

qs

wire (flat type) (7core)

(CN904)

wire (flat type) (27core)

qa

(CN901)

3

connector

(CN303)

1

seven screws

(BVTP3

×

10)

12

2

rear cover

4

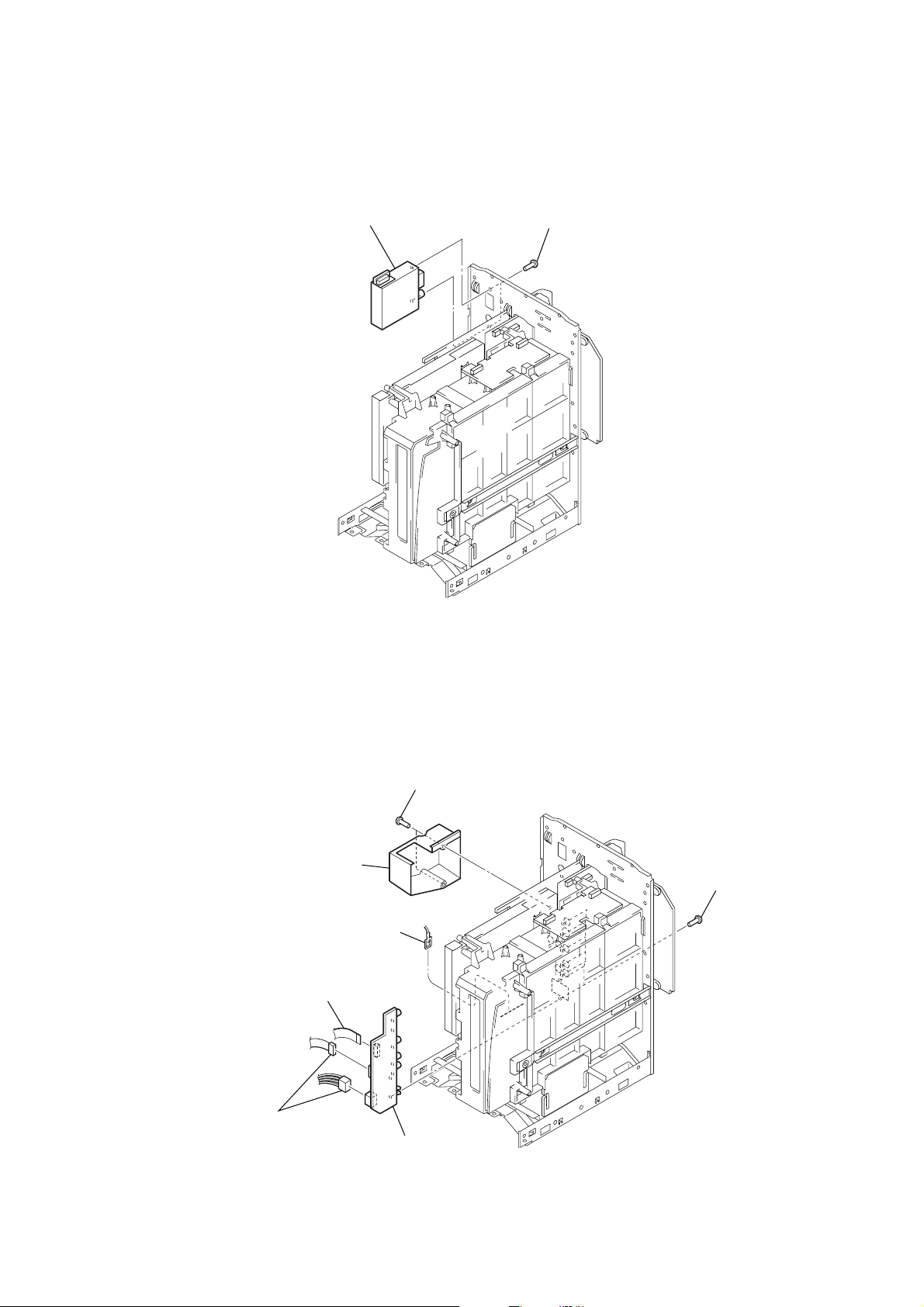

3-8. TUNER (FM/AM)

)

2

tuner (FM/AM)

1

two screws

(BVTP3

CX-BK7

×

8)

3-9. SP BOARD

5

two connectors

(CN503, CN511)

2

condenser cover

3

lead with connector

4

wire (flat type) (15core)

(CN512)

1

two screws

(BVTP3 × 12)

7

SP board

6

seven screws

(BVTP3 × 10

13

CX-BK7

)

3-10. ACDC BOARD, POWER TRANSFORMER

1

two connectors

(CN003, CN005)

2

connector (CN006)

5

9

four screws

(ITC+4-8)

five screws

(BVTP3

3

connector (CN011)

7

connector

(CN014)

×

10)

8

connector

(CN008)

4

two screws

(BVTP3

×

10)

6

ACDC board

0

power transformer

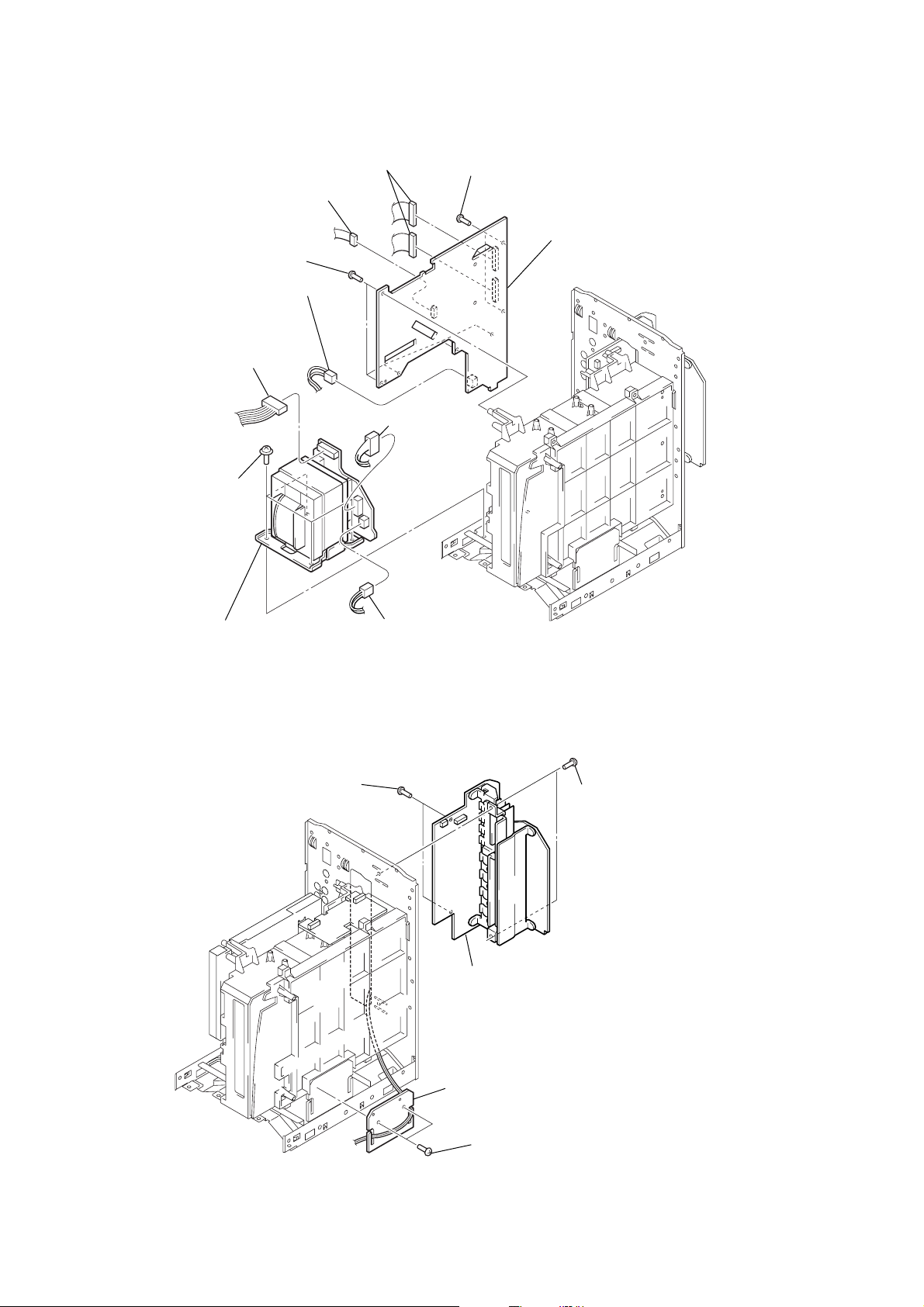

3-11. FRONT AMP/SURAMP BOARD

4

two screws

(BVTP3 × 10)

8

connector

(CN007)

3

5

front AMP/SURAMP board

two screws

(BVTP3 × 10

14

2

CD support board

1

two screws

(BVTP3 × 10)

3-12. DVD MECHANISM DECK (CDM69DV-DVBU16V)

)

5

mecanical holder (disk)

4

four screws

(BVTP3

×

10)

1

four screws

(BVTP3

CX-BK7

×

10

6

DVD mechanism deck (CDM69DV-DVBU16V)

3-13. SIGNAL CASSETTE MECHANISM

9

two screws

(BVTP3

×

10)

q;

3

mechanical cover (disk)

7

four screws

(BVTP2.6

signal cassette mechanism

2

screw

(BVTP3

×

10)

2

four screws

(BVTP3

×

10)

8

shield plate (top)

5

five screws (BVTP3 × 10)

3

screw (BVTP3 × 10)

×

8)

6

two screws (BVTP3 × 10)

4

deck board

1

connector

(CN302)

15

CX-BK7

)

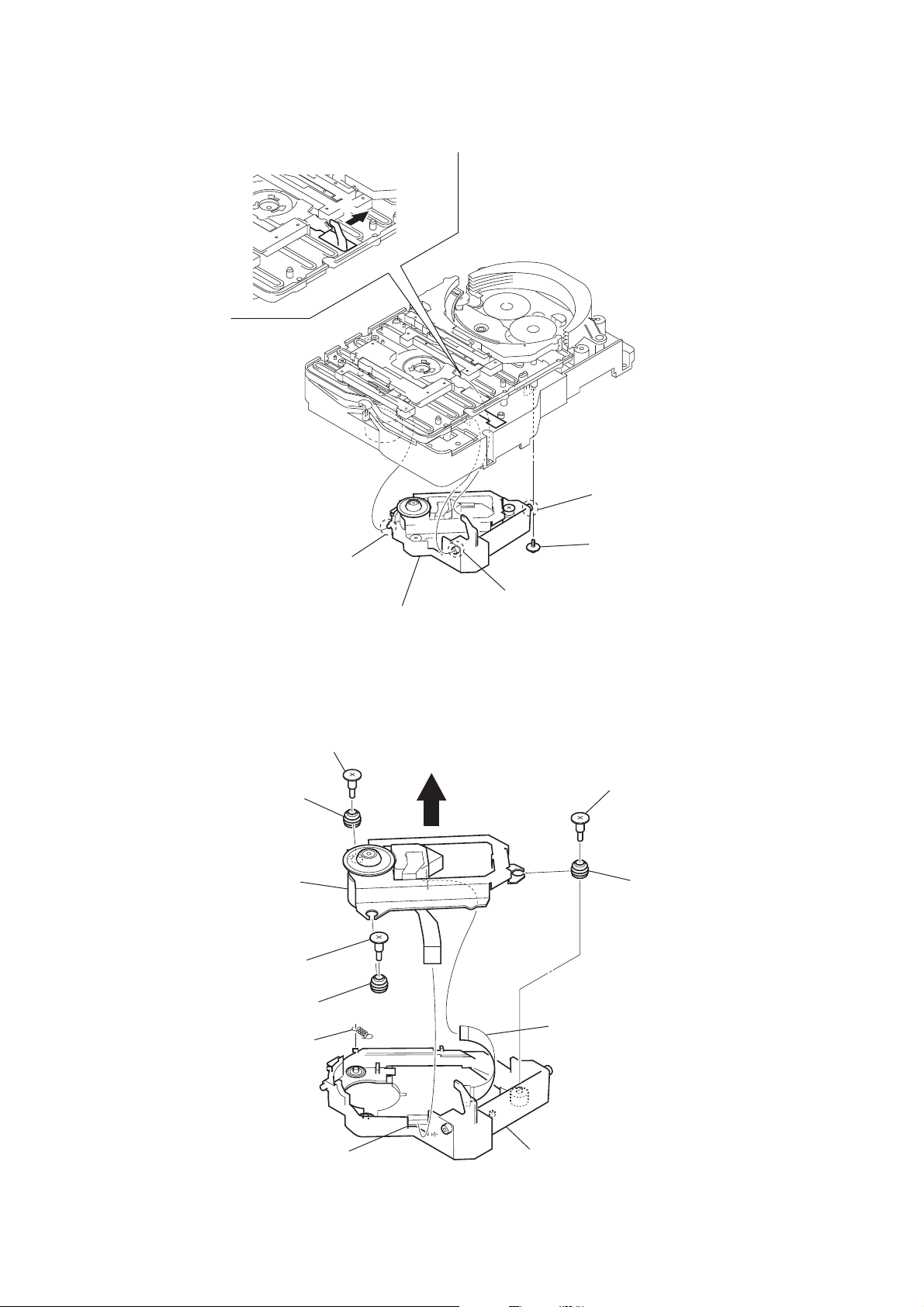

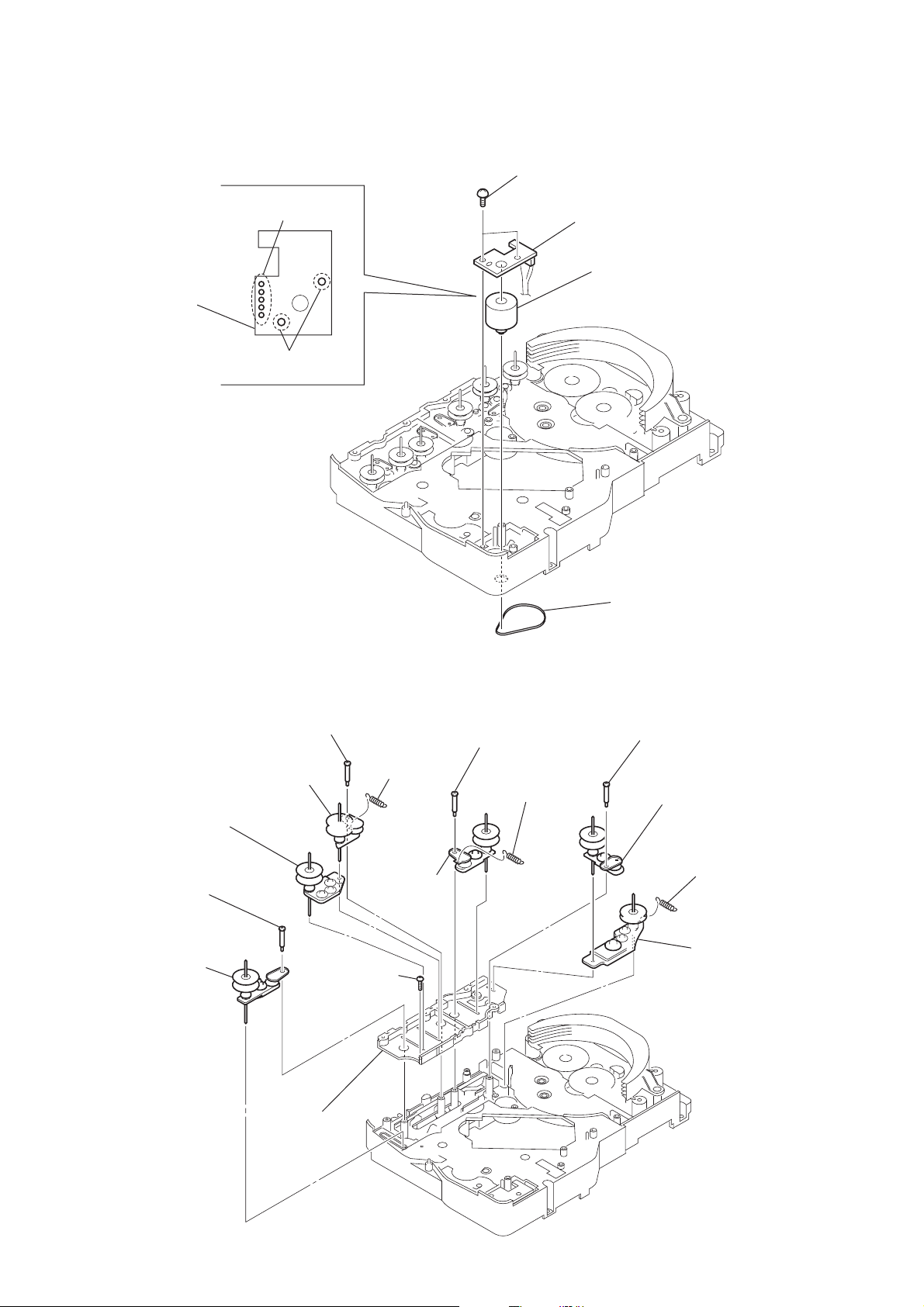

3-14. OPTICAL PICK-UP SECTION (DVBU16V)

2

5

boss

6

optical

pick-up section

(DVBU16V)

3-15. OPTICAL TRAVERSE UNIT (SERVICE ASSY, DBU-1)

1

step screw (M)

8

insulator

5

qa

optical traverse unit (service assy, DBU-1)

4

boss

3

boss

1

screw

(PTPWHM2.6

2

step screw (M)

9

insulator (RB)

16

3

4

tension spring

step screw (M)

q;

insulator

(DBU1)

6

connector

(CN003)

7

flexible board

holder (DBU1) section

CX-BK7

)

)

3-16. SW (1) BOARD, SW (2) BOARD, SW (3) BOARD, SW (4) BOARD, BRACKET (TOP) ASSY

4

SW (3) board

5

SW (4) board

6

six screws

(BVTP2.6

×

8

1

four

(BTP2.6

2

SW (1) board

7

3

SW (2) board

screws

×

6)

bracket (top) assy

3-17. RELAY BOARD

relay board

– bottom view –

5

connector

(CN703)

4

connector

(CN710)

3

6

relay board

2

four screws

(BVTP2.6

×

8

1

Remove five solders.

17

CX-BK7

)

3-18. MOTOR (STOCKER) ASSY (STOCKER) (M761)

3

two screws

(BVTP2.6

5

stocker motor board

×

4

8)

2

Remove two solders.

6

motor (stocker) assy (stocker) (M761)

1

belt (stocker)

3-19. MOTOR (ROLLER) ASSY (ROLLER) (M781)

3

two screws

5

motor (roller) assy

(roller)(M781)

2

Remove two solders.

4

roller motor

1

board

belt (roller V

18

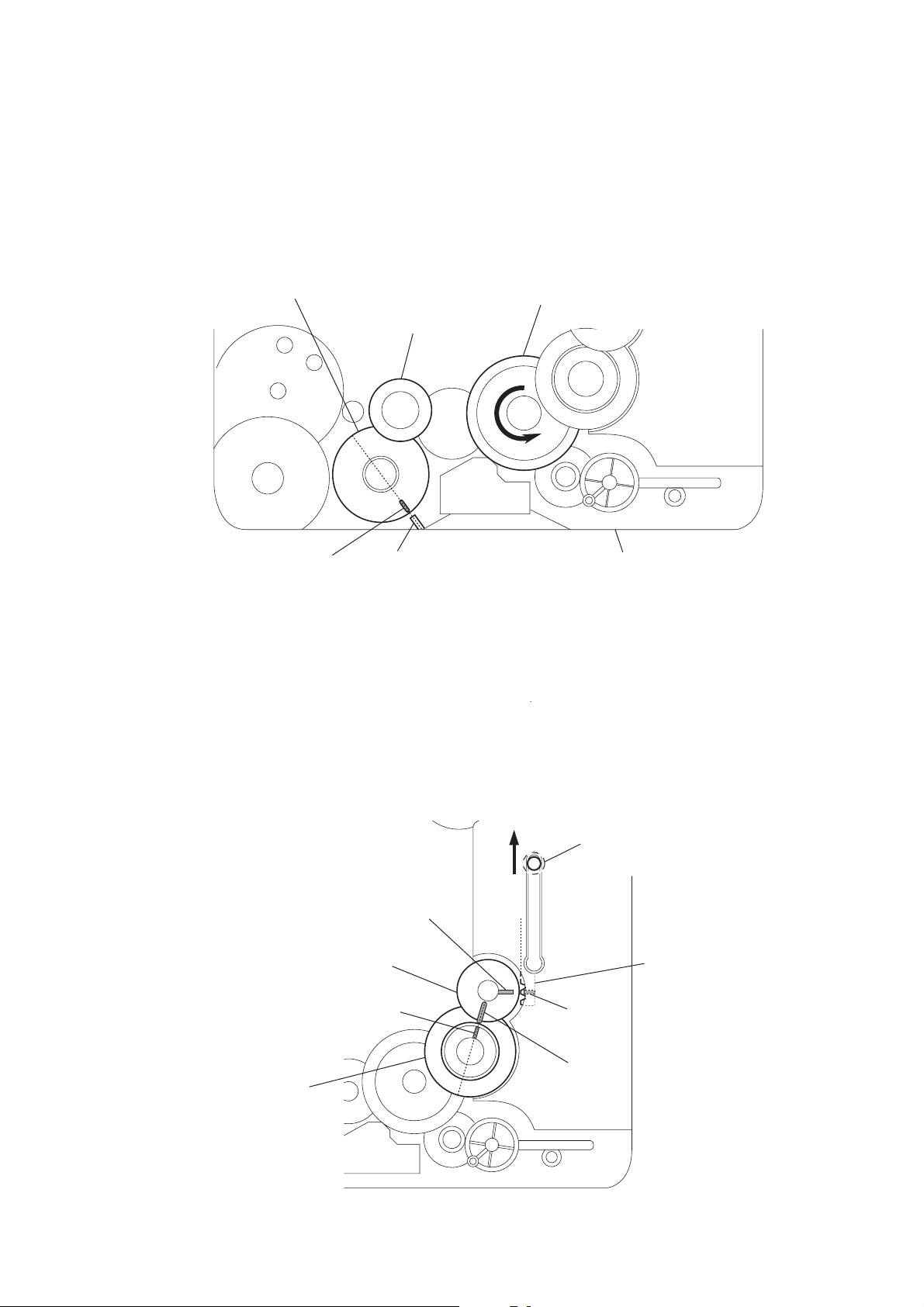

3-20. MOTOR (MODE) ASSY (MODE) (M771)

)

1

Remove five solders

of rotary encoder.

MODE MOTOR

board

2

Remove two solders

of motor (M771)

3

two screws

(BVTP2.6

×

8)

4

mode motor board

6

motor (mode) assy (mode) (M771)

CX-BK7

3-21. RUBBER ROLLER (SLIDER) ASSY

8

step screw

9

tension spring

(slider 2)

7

rubber roller

(slider 1) assy

×

8)

qs

qd

rubber roller

(slider 1) assy

qa

rubber roller

(slider 2) assy

step screw

0

rubber roller

(slider 4) assy

qf

screw

(BVTP2.6

5

step screw

6

tension spring

(base slider 4)

5

belt (mode V)

1

step screw

2

rubber roller

(slider S) assy

3

4

tension spring

(base slider 5

rubber roller

(slider 5) assy

qg

sub chassis

19

CX-BK7

)

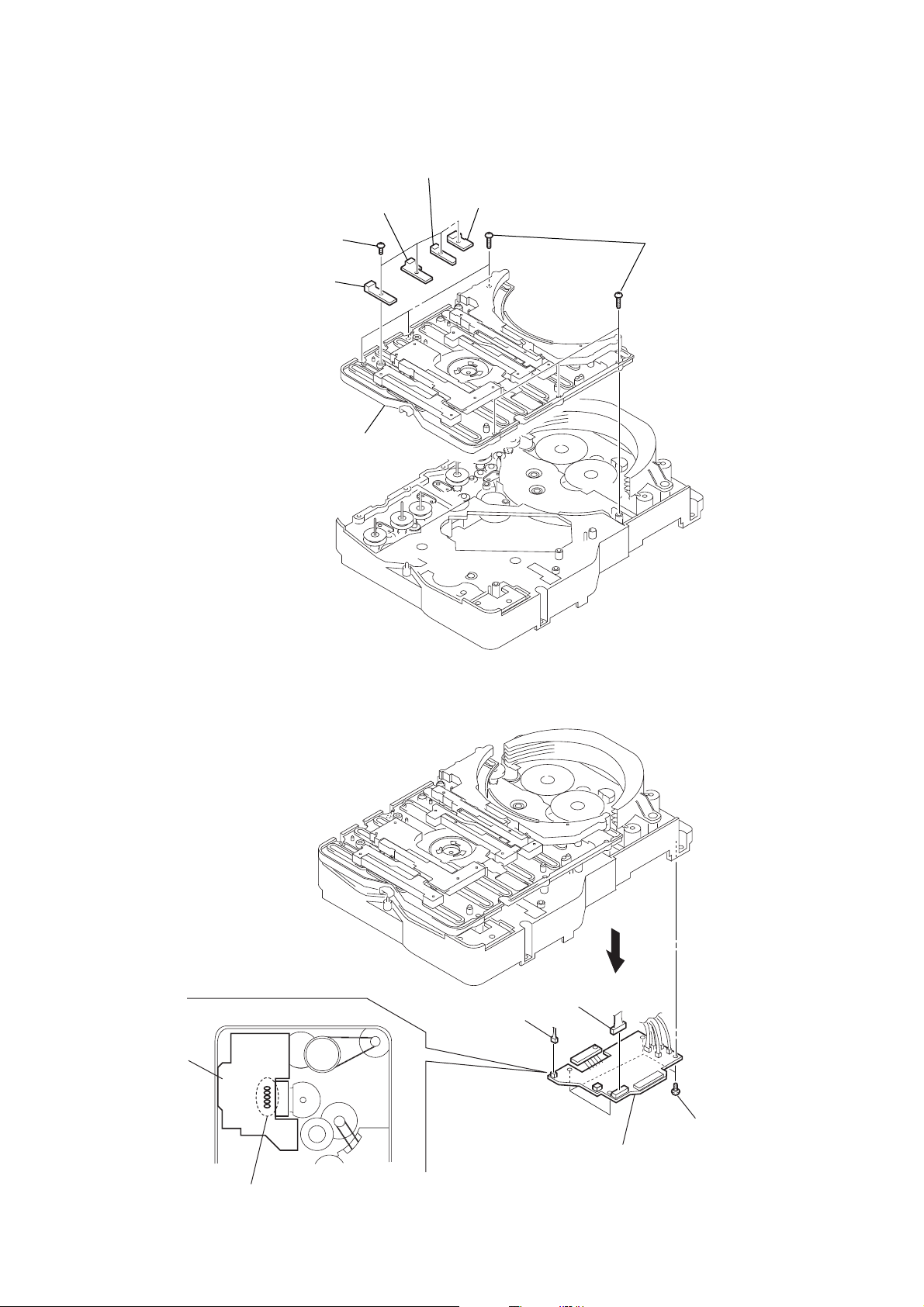

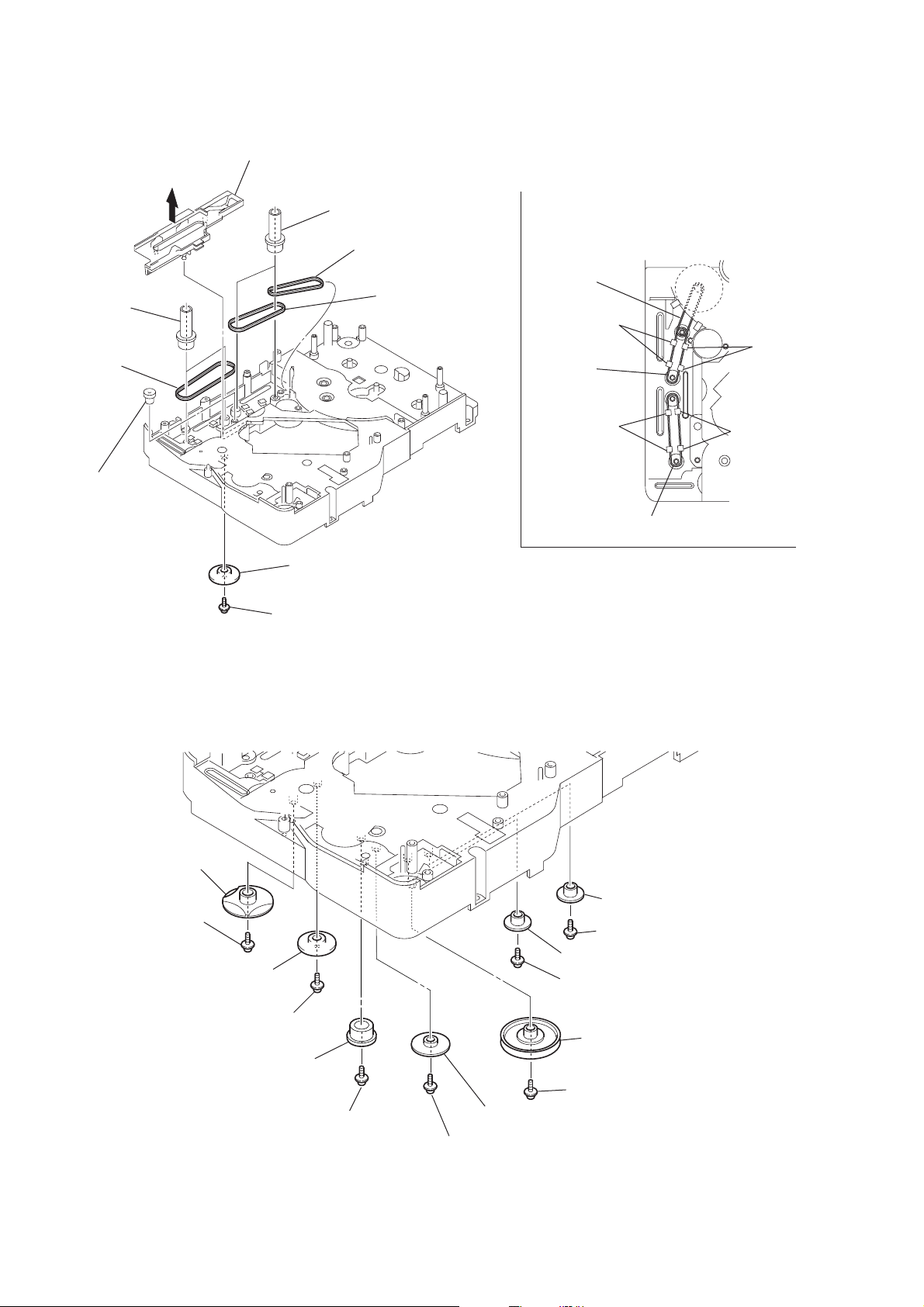

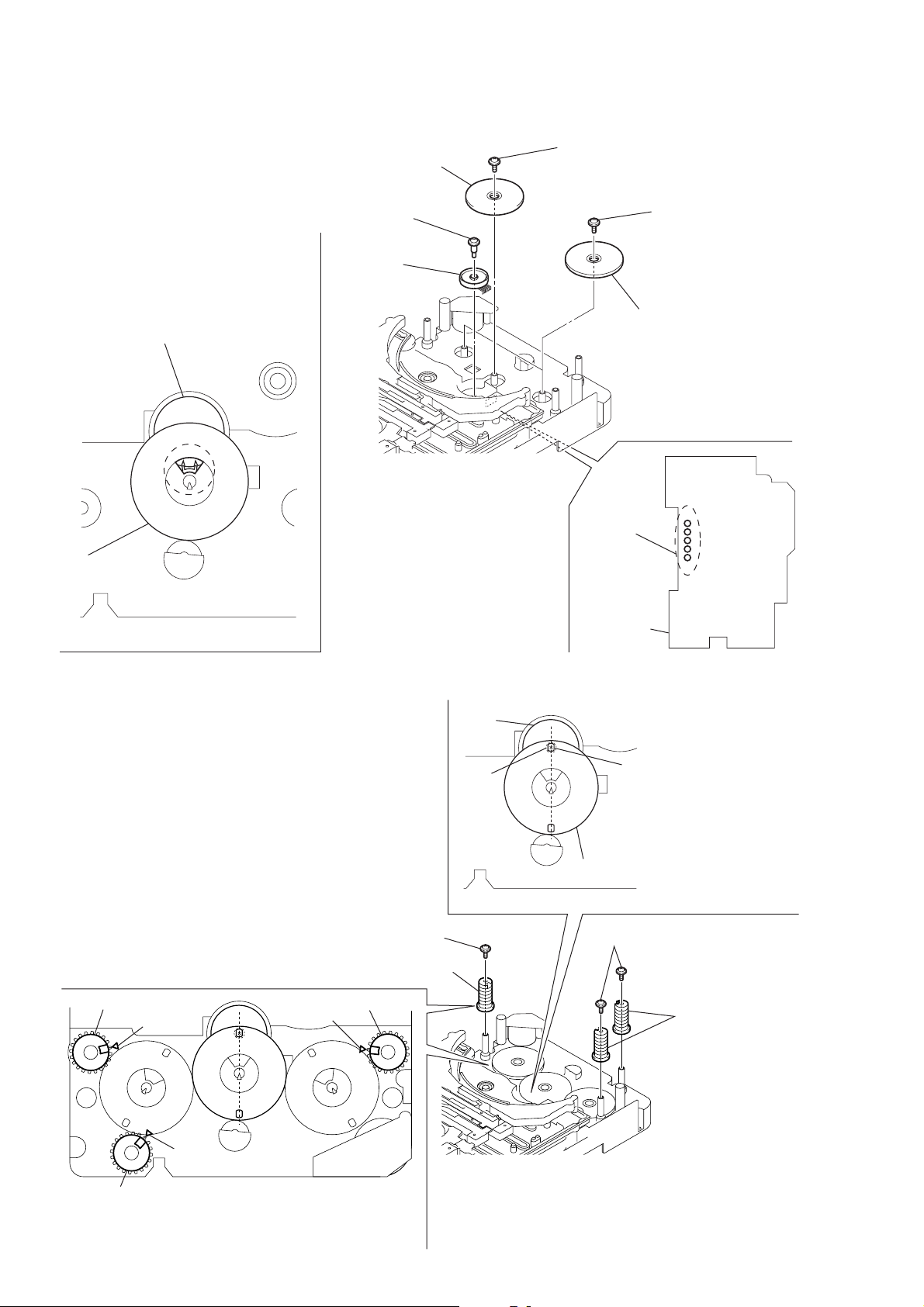

3-22. TIMING BELT (FRONT/REAR)

3

slider (mode cam) assy

5

two gears

(center)

6

timing belt

(front)

7

two gears (center)

8

timing belt (rear)

9

timing belt (rear)

When install three timing belts,

its pass under each claws.

timing belt

(rear)

claw

timing belt

(rear)

claw

4

gear

(timing)

3-23. CAM (GEAR)

qf

cam (gear)

: Note

2

gear (mode cam)

: Note

1

screw

(PTPWH2.6

×

claw

timing belt (front)

Note: Refer to assembly (Section 4)

8)

claw

20

qd

screw

qs

gear(mode cam)

qa

screw

(PTPWH2.6

0

Note: Refer to assembly

(Section 4).

×

8)

gear (mode C)

:Note

9

screw

(PTPWH2.6

6

gear (mode 5)

5

screw (PTPWH2.6 × 8

4

gear (mode 5)

3

screw (PTPWH2.6 × 8)

2

pulley

(mode deceleration)

1

screw(PTPWH2.6 × 8)

8

gear (mode D)

×

8)

7

screw (PTPWH2.6 × 8)

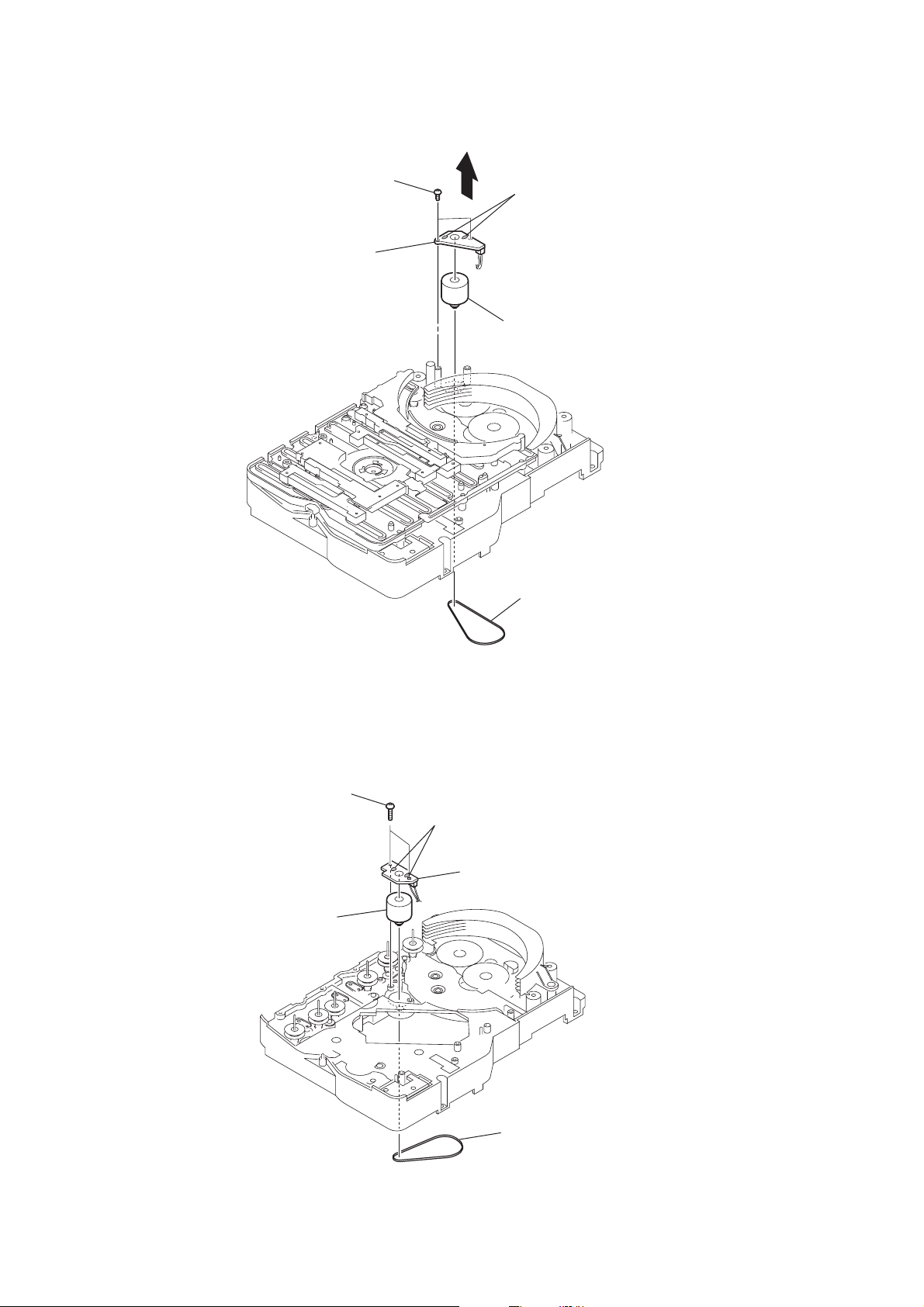

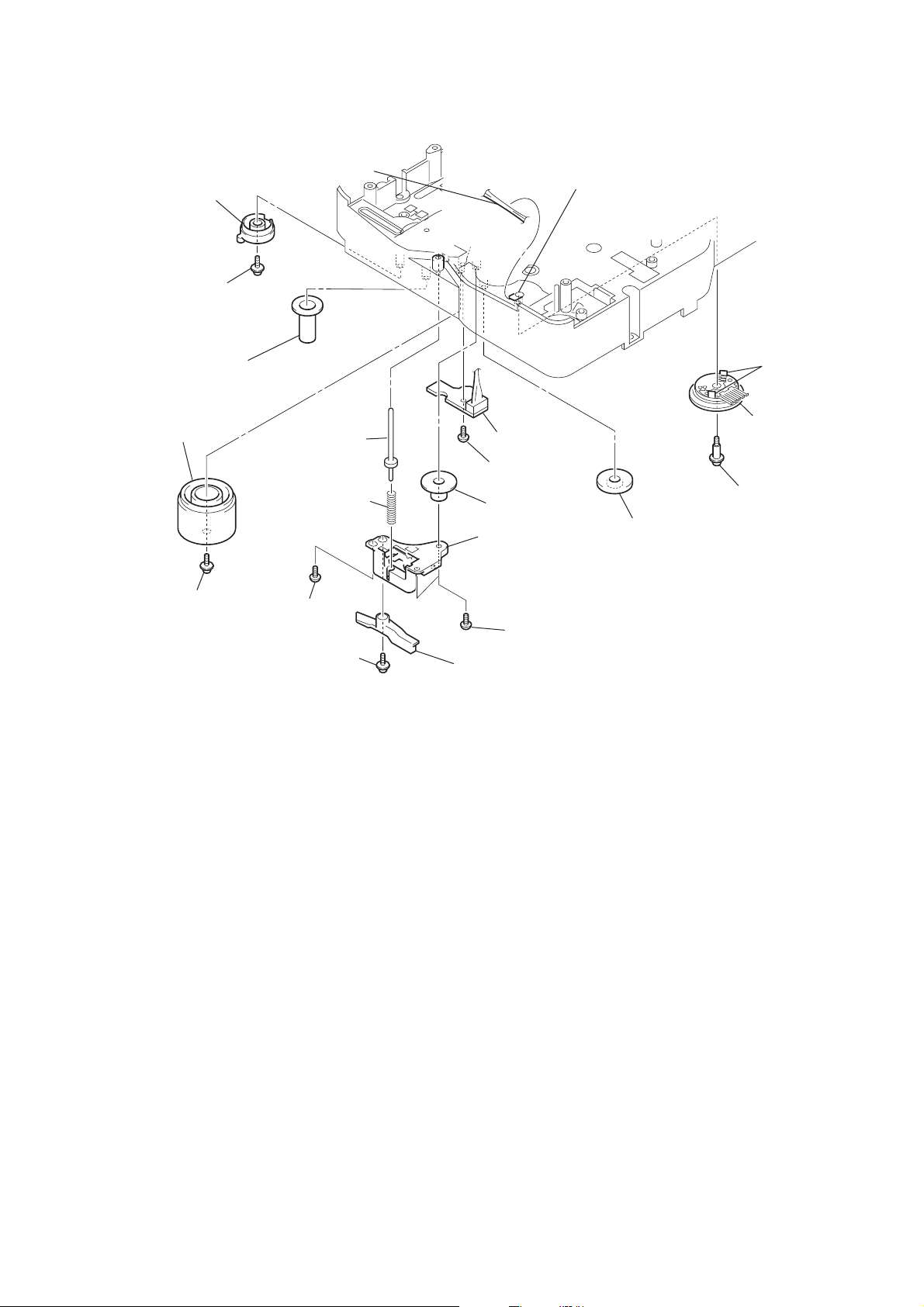

3-24. SENSOR BOARD

ql

harness

qd

gear (eject lock)

q;

cam (eject lock)

: Note

qh

two claws

qj

rotary encoder

(S771)

qf

gear

(mode B)

w;

screw

(BVTP2.6

×

8)

qg

screw

(PTPWH2.6

×

8)

wa

sensor board

8

shaft

(shutter)

7

compression spring

(shutter)

qs

cam (BU U/D)

qa

screw

(PTPWH2.6

×

8)

3

screw

(BVTP2.6

×

8)

1

screw

(PTPWH2.6

×

8)

4

two screws

(BVTP2.6

×

8)

2

lever shutter (A)

5

base (shutter) block

6

gear (mode A)

9

screw

(PTPWH2.6

×

8)

qk

claw

Note: Refer to assembly (Section 4).

CX-BK7

21

CX-BK7

SECTION 4

ASSEMBLY

• This set can be assembled in the order shown below.

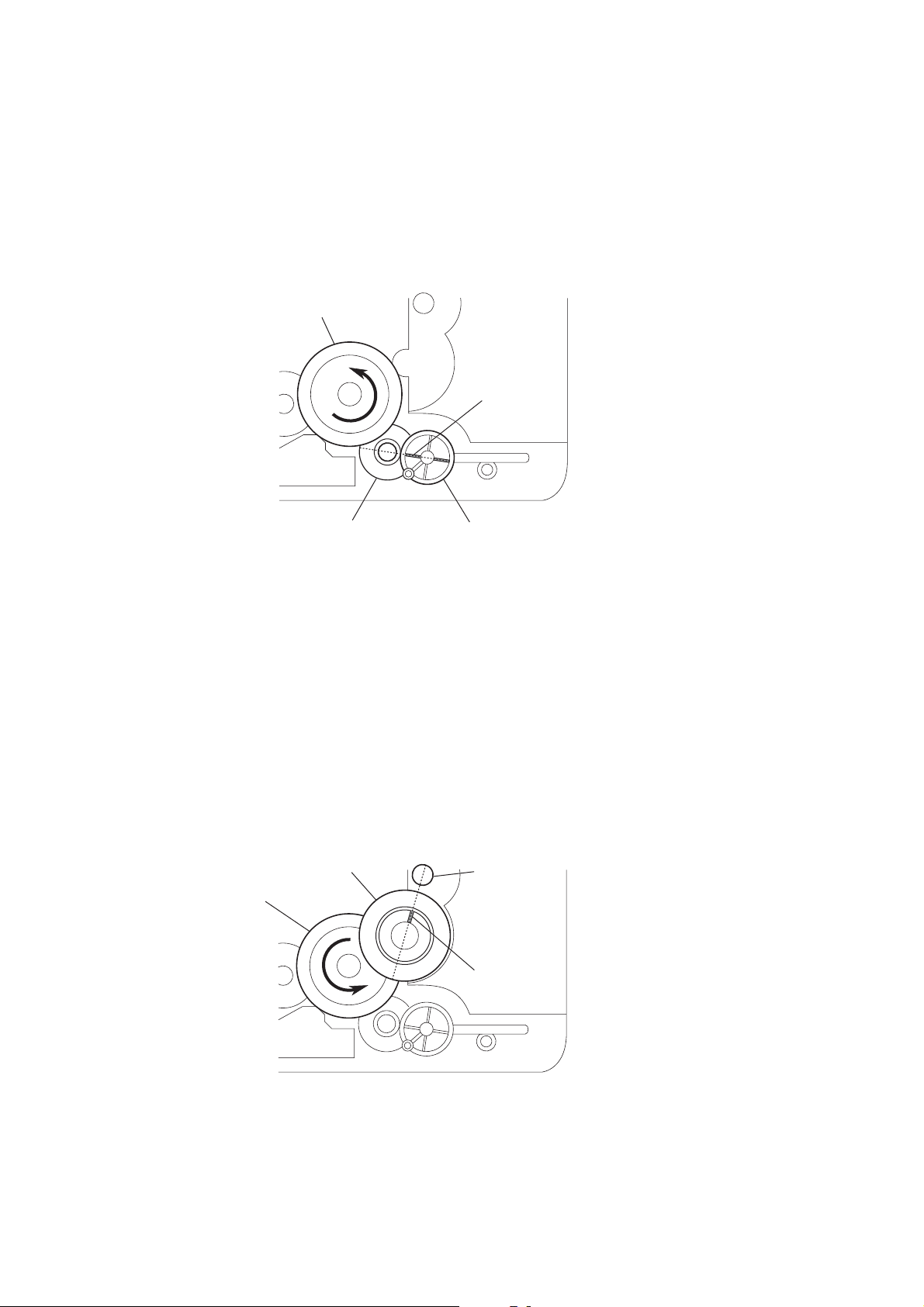

4-1. HOW TO INSTALL THE CAM (EJECT LOCK)

1

Rotate the cam (BU U/D) fully in the direction of arrow.

2

Engage the gear (eject lock) and the gear of the cam (eject lock)

aligning the mark with the center of the gear (eject lock).

cam (BU U/D)

mark

gear (eject lock)

– bottom view • front –

4-2. HOW TO INSTALL THE CAM (GEAR)

1

Check that the cam (BU U/D) can not be rotated in the direction of arrow.

2

Align the mark on the cam (gear) with the boss as shown in the figure

and install the cam (gear).

cam (gear)

cam (BU U/D)

cam (eject lock)

boss

mark

22

– bottom view • front –

4-3. HOW TO INSTALL THE GEAR (MODE 2)

1

Align the mark on the rotary encoder (S701) with the projection of the assy.

2

Check that the cam (BU U/D) can not be rotated in the direction of arrow.

3

Install the gear (mode 2).

rotary encoder

(S701)

gear

(mode 2)

CX-BK7

cam (BU U/D)

mark projection chassis

– bottom view • front –

4-4. HOW TO INSTALL THE GEAR (MODE CAM)

1

Slide the shaft in the direction of arrow.

2

Align mark A on the gear (mode cam) with mark B on the slider (mode cam) assy,

then install the gear (mode cam).

3

Check that mark C on the gear (mode cam) is in alignment with mark D on the cam (gear).

mark

A

gear (mode cam)

shaft

slider (mode cam) assy

cam (gear)

mark

D

– bottom view • front –

mark

mark

B

C

23

CX-BK7

4-5. HOW TO INSTALL THE ROTARY ENCODER (S702), GEAR (STOCKER COMMUNICATION)

4

Engage the rotary encoder (S702)

and the gear (stocker communication)

as shown below in the figure.

rotary encoder

(S702)

gear

(stocker communication)

3

screw

(PWH2

×

6)

1

rotary encoder

(S702)

5

screw

(PTPWH2.6

×

8)

7

two screws

(PTPWH2.6

6

two gears

(stocker communication)

×

8)

gear

(stocker

communication)

– rear –

4-6. HOW TO INSTALL THE CAM (STOCKER U/D)

3

screw

(PTPWH2.6

2

cam (stocker U/D)

×

rotary encoder

(S702)

screw

8)

2

five

solders

relay board

1

Position the hole on the gear

(stocker communication) on the

screw of the rotary encoder (S702).

gear

(stocker communication)

– rear –

3

hole

two screws

(PTPWH2.6

×

8)

24

cam (stocker U/D)

f

mark

f

mark

cam (stocker U/D)

To install three cams (stocker U/D), align each groove

of the cam (stocker U/D) with each f mark on the

chassis as shown in the figure.

cam (stocker U/D)

f

mark

2

two cams

(stocker U/D)

4-7. HOW TO INSTALL THE STOCKER ASSY

1

Fit three shafts of the stocker assy in respective slits

of the cams (stocker U/D).

CX-BK7

cam (stocker U/D)

cam (stocker U/D)

cam (stocker U/D)

Note: For the location of slits of the cams (stocker U/D),

see 4-6. HOW TO INSTALL CAM (STOCKER U/D).

cam (stocker U/D)

shaft shaftstocker assy

cam (stocker U/D)

shaft

pulley (stocker)

stocker assy

pulley (stocker)

A

2

Making sure that three shafts of the stocker assy fit in

respective slits of the cams (stocker U/D), rotate the

pulley (stocker) in the direction of arrow A by hand to

store the stocker assy.

25

CX-BK7

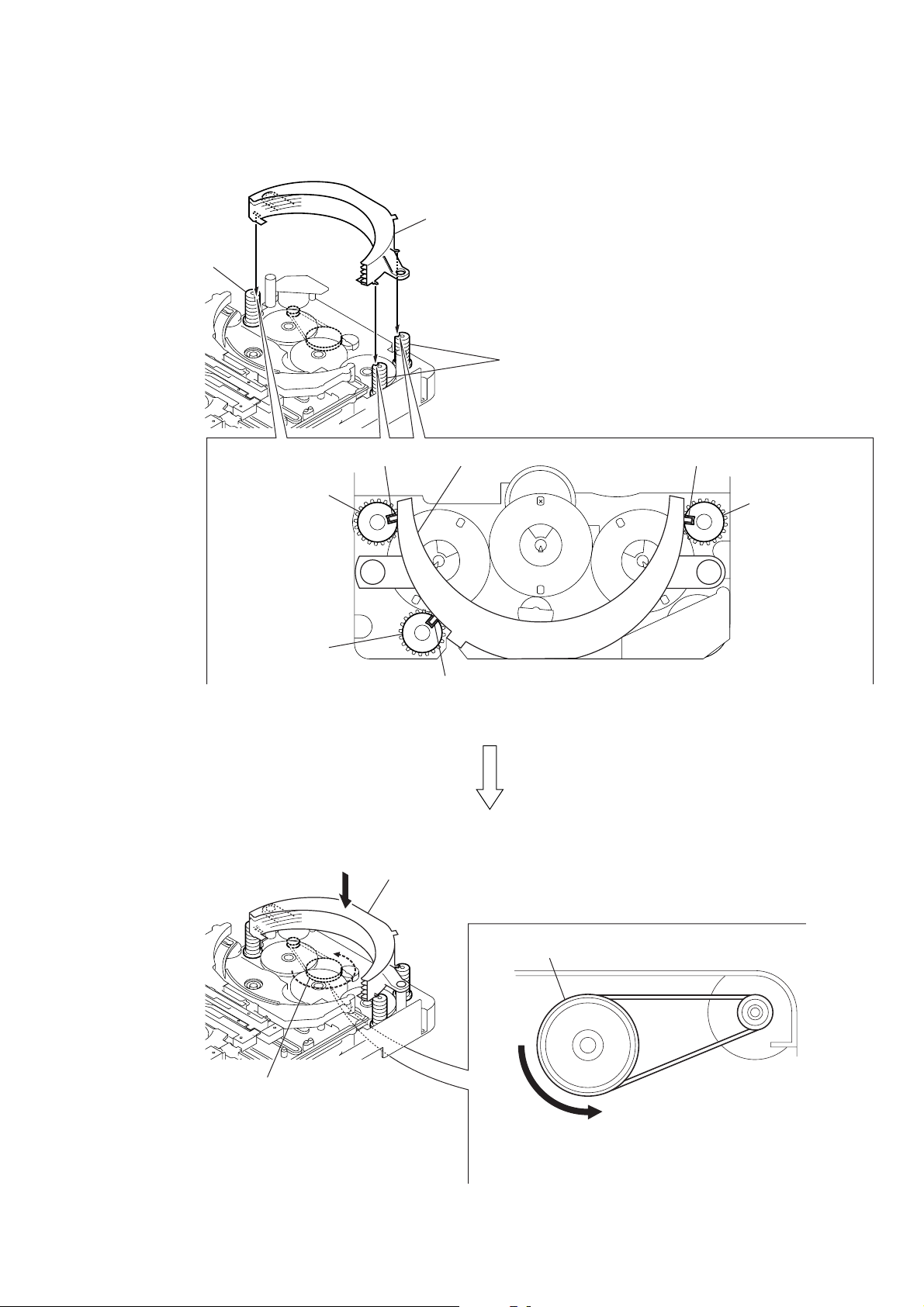

4-8. PHASE ADJUSTMENT BETWEEN PINIONS (SLIDER) AND SLIDER-1 TO 5 (L/R)

As shown in the following figure, adjust the portion A of each slider to the boss with the

1

slider-1 to 5 (L) and the slider-1 to 5 (R) pushed in the arrow directions respectively (see Fig. 1).

2

Paying attention to the up/down direction of the pinion (slider) (see Fig. 2), install each pinion (slider)

so that the portion

Note: Push in the pinion (slider) until the claw of the boss comes out above the pinion (slider) to lock.

B

of each pinion (slider) meshes with the portion A of each slider (see Fig. 3).

A

slider-5 (L)

slider-4 (L)

slider-3 (L)

slider-2 (L)

slider-1 (L)

(Fig. 1)

boss

claw

slider-5 (R)

slider-4 (R)

slider-3 (R)

slider-2 (R)

slider-1 (R)

boss

boss

boss

boss

A

A

A

A

A

A

pinion (slider)

pinion (slider)

A

pinion (slider)

pinion (slider)

26

pinion (slider)

pinion (slider) portion

slider portion

A

B

(Fig. 2)

boss

(Fig. 3)

pinion (slider) portion

slider portion

claw

A

boss

pinion (slider)

A

B

A

SECTION 5

TEST MODE

CX-BK7

[COLD RESET]

• The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning

the set to the customer.

Procedure:

1. Press the three buttons x , [ENTER], and [FUNCTION]

simultaneously.

2. The fluorescent indicator tube becomes blank for a while, and

the set is reset, then becomes demonstration mode.

[VERSION DISPLAY]

• This mode is used to check the model and software version.

Procedure:

1. Press the I/1 button to turn the power ON.

2. Press two buttons of x and I/1 simultaneously for five

seconds. The model name is displayed, then the software

version is displayed.

[LCD TEST]

• This mode is used to check the liquid crystal display.

Procedure:

1. Press three buttons of x , [MODE], and [FUNCTION]

simultaneously.

2. All segments of liquid crystal display are turned ON.

3. To release from this mode, press the I/1 button.

[TUNER TEST]

• This mode is used to check the change of frequency.

Procedure:

1. Press three buttons of x , [MODE], and [TUNER/BAND]

simultaneously.

2. The message “TUN TEST” is displayed on the liquid crystal

display.

3. Each time

FM frequency.

4. Press the [TUNER/BAND] button to set AM.

5. Each time Y button is pressed, the display changes preset

AM frequency.

Y button is pressed, the display changes preset

[AMP TEST]

• This mode is used to check the function of the amplifier.

Procedure:

1. Press three buttons of x , [MODE], and [i-Bass]

simultaneously.

2. The message “AMP TEST” is displayed on the liquid crystal

display.

3. When the [VOLUME] knob is turned clockwise, the message

“VOLUME MAX” is displayed on the liquid crystal display.

When the [VOLUME] knob is tur ned counterclockwise. The

message “VOLUME 0” is displayed on the liquid crystal

display.

4. Each time the [BASE] or [TREBLE/MIDDLE] knob is turned,

the message “EQ MAX”, “EQ MIN” or “EQ FLAT” is

displayed in this order on the liquid crystal display.

[USB TEST]

• This mode is used to display the status of comunication.

Procedure:

1. Press the I/1 button to turn the power ON.

2. Press the [FUNCTION] button to select “USB”.

3. Press three buttons of x , [PLAY MODE], and [i-Bass]

simultaneously.

4. The message “WINAMP3” is displayed on the liquid crystal

display at first.

[ROBBERY PREVENTION LOCK]

• This mode is used to unable to take sample disc out of set in the

shop.

Procedure:

1. Press the I/1 button to turn the power ON.

2. Press the [FUNCTION] button to select “DVD”.

3. Press two buttons of [ENTER] and Z simultaneously for five

seconds.

4. The message “LOCKED” is displayed on the liquid crystal

display and the disc is locked. (Even if pressing the Z button,

the message “LOCKED” is displayed on the liquid crystal

display and the disc is locked)

5. To release from this mode, press two buttons of [ENTER]

and Z simultaneously for five seconds again.

6. The message “UNLOCKED” is displayed on the liquid crystal

display and the disc is unlocked.

[SHIP MODE]

• This mode moves the optical pick-up to the position durable to

vibration. Use this mode when returning the set to the customer

after repair.

Procedure:

1. Press the I/1 button to turn the power ON.

2. Press the [FUNCTION] button to select “DVD”.

3. Press the x button for five seconds.

4. The message “MECHA LOCK” is displayed on the liquid crystal

display and the ship mode is set, then becomes power off.

[DECK TEST]

• This mode is used to check the tape deck operation.

Procedure:

1. Press the I/1 button to turn the power ON.

2. Press three buttons of

simultaneously.

3. The message “TC TEST” is displayed on the liquid crystal

display.

4. Press the z button to start recording.

5. When the x button is pressed during recording, the tape is

rewound back to the beginning of recording, then playback starts.

z , [MODE], and [FUNCTION]

[REPEAT 5 TIMES CANCEL]

• The number of repeat for DVD playback is 5 times when the

repeat mode is “REPEAT”. This mode enables DVD to repeat

playback for limitless times.

Procedure:

1. Press the I/1 button to turn the power ON.

2. Press the [FUNCTION] button to select “DVD”.

3. Press three buttons of x , [PLAY MODE], and [FUNCTION]

simultaneously.

4. Repeat 5 times limit is canceled.

[AM STEP CHANGE-OVER]

(Except Saudi Arabia model)

•A step of AM channels can be changed ov er between 9 kHz and

10 kHz.

Procedure:

1. Press the I/1 button to turn the power ON.

2. Press the [FUNCTION] button to select “TUNER”.

3. Press two buttons of [TUNER/BAND] and I/1 simultaneously.

27

CX-BK7

[ZIVA DEBUG MODE]

• This mode is used to unable to reset for performing the debug of

ziva.

Procedure:

1. Press the I/1 button to turn the power ON.

2. Press the [FUNCTION] button to select “DVD”.

3. Press three buttons of Y , [PLAY MODE], and [FUNCTION]

simultaneously.

4. Ziva debug mode is set.

[COLOR SYSTEM CHANGE-OVER]

(Saudi Arabia, Singapore, Malaysia and Australian

model)

• This mode is used to changed over color system.

Procedure:

1. Press the I/1 button to turn the power ON.

2. Press the [FUNCTION] button to select “DVD”.

3. Press the I/1 button to turn the power OFF.

4. Press two buttons of X and I/1 simultaneously.

5. The message “COLOR NTSC” or “COLOR P AL” is displayed

on the liquid crystal display, and the color system is changed

over NTSC or PAL.

[DVD POWER MANAGER CHANGE-OVER]

• This mode is used to changed over DVD power ON/OFF for

decreasing of reception noise in the tuner mode.

Procedure:

1. Press the I/1 button to turn the power ON.

2. Press the [FUNCTION] button to select “DVD”.

3. Press the I/1 button to turn the power OFF.

4. Press two buttons of x and I/1 simultaneously.

5. The message “DVD POWER ON” or “DVD POWER OFF”

will be displayed on the liquid crystal display, and DVD power

ON/OFF changed over in the tuner mode.

[COMPULSION INTERLACE]

• This mode is used to changed over video output into interlace.

Procedure:

1. Press the I/1 button to turn the power ON.

2. Press the [FUNCTION] button to select “DVD”.

3. Press two buttons of X and [FUNCTION] simultaneously.

4. Video output is changed over interlace.

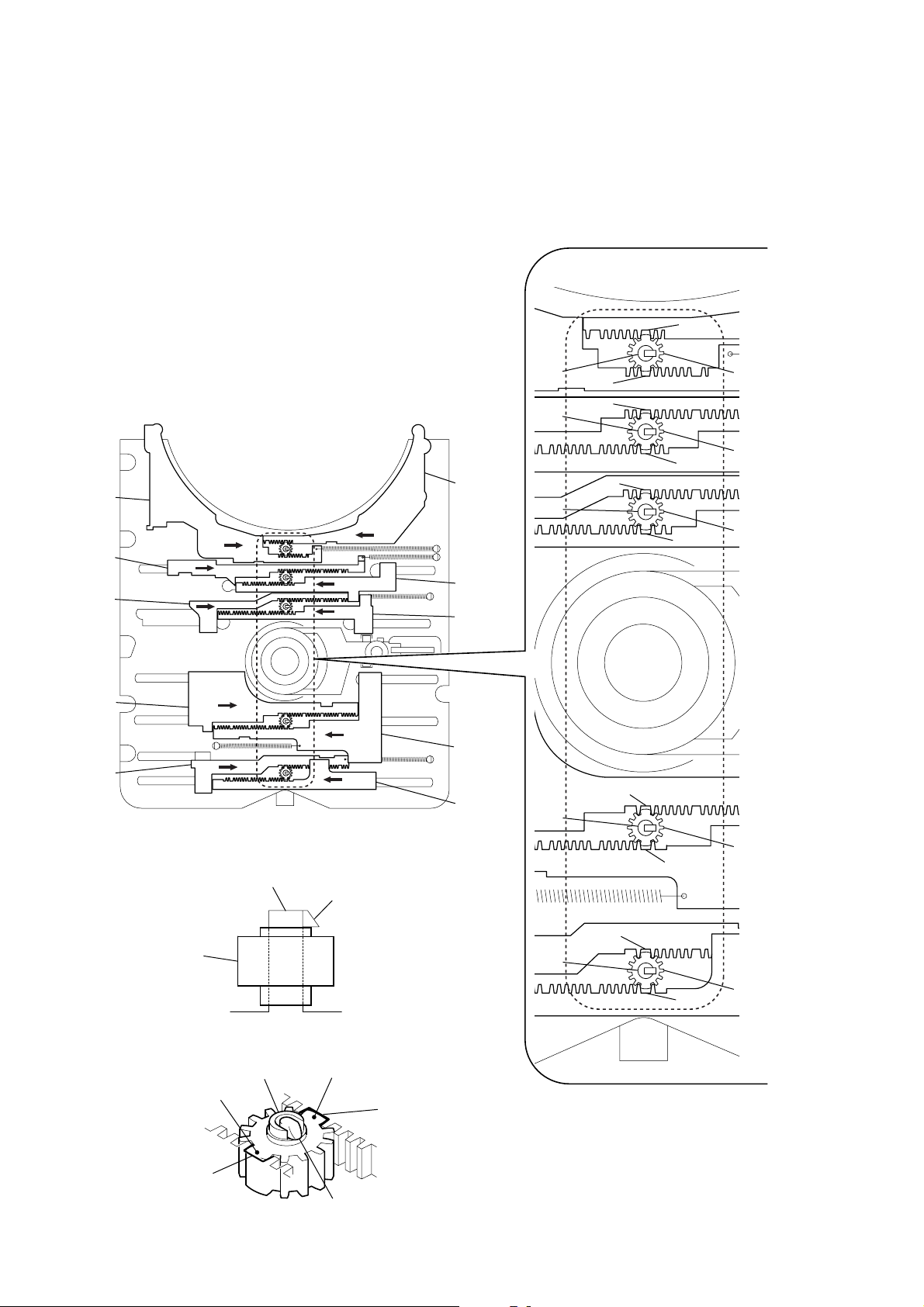

[DVD TEST MODE GENERAL DESCRIPTION]

The T est Mode allows you to make dia gnosis and adjustment easily

using the remote commander and monitor TV. The instructions,

diagnostic results, etc. are given on the on-screen display (OSD).

[TEST DISC LIST]

Use the following test disc on test mode.

TDV-520CSO (DVD-SL): PART No. J-2501-236-A

LUV-P01 (CD): PART No. 4-999-032-01

TDV-540C (DVD-DL): PART No. J-2501-235-A

Note: Do not use existing test disc for DVD.

[STARTING DVD TEST MODE]

1. Press the I/1 button to turn the power ON.

2. Press the [FUNCTION] button to select “DVD”.

3. Press the I/1 button to turn the power OFF.

4. Press two buttons of x and [PLAY MODE] simultaneously,

and [VOLUME] knob is turned clockwise.

5. The message “SERVICE IN” is displayed on the liquid crystal display, and the Test Mode Menu is displayed on the monitor screen as follows. (At the bottom of the menu screen, the

model name and revision number are displayed)

Test Mode Menu

0. Syscon Diagnosis

1. Drive Auto Adjustment

2. Drive Manual Operation

3. Mecha Aging

4. Emergency History

5. Mecha Error History

6. Version Information

7. Video Level Adjustment

Exit: POWER Key

Model :BMZ-K7D

Revision :x.xx

6. T o execute each function, select the desired menu and press its

number on the remote commander (RM-Z20016).

7. To release from test mode, press the I/1 button and turn the

power off.

[OPERATING DVD TEST MODE]

0. SYSCON DIAGNOSIS

The same contents as board detail check by serial interface can be

checked from the remote commander operation.

On the Test Mode Menu screen, press [10/0] key on the remote

commander, and the following Check Menu will be displayed.

### Syscon Diagnosis ###

Check Menu

0. Quit

1. All

2. Version

3. EEPROM

4. GPIO

5. SD Bus

6. Video

0-0. Quit

Quit the Syscon Diagnosis and return to the Test Mode Menu.

28

CX-BK7

0-1. All (All items continuous check)

This menu checks all diagnostic items continuously. Normally, all

items are checked successively one after another automatically

unless an error is found, but at a certain item that requires judgment

through a visual check to the result, the following screen is displayed

for the key entry.

• Example display

### Syscon Diagnosis ###

Diag All Check

No.2 Version

2-2. Version

ROM Reversion = X.XX

Press NEXT Key to Continue

Press PREV Key to Repeat

For the ROM check, the check sum calculated by the syscon is

output, and therefore you must compare it with the specified value

for confirmation.

Following the message, press the > button to go to the next item,

or press the . button to repeat the same operation again.

To quit the diagnosis and return to Check Menu screen, press the

[RETURN] key on the remote commander to display Check Menu.

• Error occurred

If an error occurred, the diagnosis is suspended and error is displayed.

Press the

diagnosis, or press the . button to repeat the same check where

an error occurred, or press the > button to continue the check

from the item next to faulty item.

[RETURN] key on the remote commander to quit the

0-2. Version

0-2-2. Version

The revision number of ROM IC204 that the program for

the DVD system processor (IC207) is stored.

(4 digits hexadecimal number)

0-2-3. ROM Check Sum

The revision number of ROM IC204 that the program for

the DVD system processor (IC207) is stored.

0-2-4. Model Type

Model name is displayed. (BMZ-K7D)

0-2-5. Region

Model destination code is displayed. (2 digits number)

0-3. EEPROM Check

0-3-1. Sampling Check

EEPROM check at every 64 words.

It compares read data with write data of each address. When

there are discrepancies between two data, it displays error.

0-3-2. Detail Check

EEPROM check at every 1 word.

It compares read data with write data of each address. When

there are discrepancies between two data, it displays error.

0-4. GP I/O Check

Pull up/down setting check of the DVD system processor (IC207)

pin 150, 151 and 154 (for clock setting port).

0-5. SD Bus Check

SD bus data check between DVD decoder (IC701) and MPEG

decoder (IC207).

0-6. Video Check

Output the color bars for video level adjustment.

General Description of Checking Method

Selecting 2 and subsequent items calls the submenu screen of each

item. And selecting 2 and subsequent items executes respective

menus and outputs the results.

For the contents of each submenu, see “Check Items List” as below.

Check Items List:

0-2. Version

0-2-1. All

0-2-2. Version

0-2-3. ROM Check Sum

0-2-4. Model Type

0-2-5. Region

0-3. EEPROM Check

0-3-1. Sampling Check

0-3-2. Detail Check

0-4. GP I/O Check

0-5. SD Bus Check

0-6. Video Check

29

CX-BK7

1. DRIVE AUTO ADJUSTMENT

On the Test Mode Menu screen, press the [1] key on the remote

commander, and the Adjustment Menu will be displayed.

## Drive Auto Adjustment ##

Adjustment Menu

0. ALL

1. DVD-SL

2. CD

3. DVD-DL

Exit: RETURN

Normally, [10/0] is selected to adjust DVD (single layer), CD and

DVD (dual layer) in this order . But, individual items can be adjusted

for the case where adjustment is suspended due to an error. In this

mode, the adjustment can be made easily through the operation

following the message displayed on the screen.

The disc used for adjustment must be the one specified for

adjustment.

1-0. ALL

Press the [10/0] key on the remote commander, and the servo set

data in EEPROM will be initialized. Then, 1. DVD-SL disc, 2. CD

disc and 3. DVD-DL disc are adjusted in this order.

Each time one disc was adjusted, it is ejected. Replace it with the

specified disc following the message. You can f inish the adjustment

by pressing the

[RETURN] button on the remote commander.

1-1. DVD-SL (single layer)

Press the [1] ke y on the remote commander and insert a DVD single

layer disc following the message. Then the adjustment will be made

through the steps, then adjusted values will be written to the

EEPROM.

DVD Single Layer Disc Adjustment Steps:

1. Sled reset

2. Disc check memory SL

3. Wait 300 msec

4. Set disc type SL

5. LD on

6. Spindle start

7. Wait 1 sec

8. Focus servo on 0

9. Auto track offset adjust

10. CLVA on

11. Wait 500 msec

12. Tracking on

13. Wait 1 sec

14. Sled on

15. Check CLV on

16. Auto focus offset adjust

17. Auto focus gain adjust

18. Auto focus offset adjust

19. EQ boost adjust

20. Auto track gain adjust

21.All servo stop

22.EEP copy loop filter offset

1-2. CD

Press the [2] key on the remote commander and insert a CD disc

following the message. Then the adjustment will be made through

the steps, then adjusted values will be written to the EEPROM.

Note: During adjustment of each disc, the measurement for disc type judg-

ment is made. As automatic adjustment does not judge the disc

type unlike conventional models, take care not to insert wrong type

discs. Also, do not give a shock during adjustment.

CD Adjustment Steps

1. Sled rest

2. Disc check memory CD

3. Wait 500 msec

4. Set disc type CD

5. LD on

6. Spindle start

7. Wait 500 msec

8. Focus servo on 0

9. Auto track offset adjust

10. CLVA on

11. Wait 500 msec

12. Tracking on

13. (TC display start)

14. Wait 1 sec

15. Sled ON

16. Check CLV on

17. Auto focus offset adjust

18. Auto focus gain adjust

19. Auto focus offset adjust

20. EQ boost adjust

21. Auto track gain adjust

22. All servo stop

30

Loading...

Loading...