Page 1

CSD-A110

U(S)

CSD-A170

LH(S)

SERVICE MANUAL

COMPACT DISC RADIO

CASSETTE RECORDER

This Service Manual is the “Revision Publishing” and replaces “Simple Manual”

CSD-A110 U(S)/A170 LH(S)(S/M Code No. 09-003-342-2T1).

• BASIC TAPE MECHANISM : ZZM-1 YR2NF

• BASIC CD MECHANISM : DA11T3C

S/M Code No. 09-003-342-2R1

REVISION

DATA

Page 2

SPECIFICATIONS

U MODEL LH MODEL

Design and specifications are subject to change

•

without notice

.

Design and specifications are subject to change

•

without notice

.

2

Page 3

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING

This set employs laser. Therefore, be sure to follow carefully the

instructions below when servicing.

WARNING!

WHEN SERVICING, DO NOT APPROACH THE LASER EXIT

WITH THE EYE TOO CLOSELY. IN CASE IT IS NECESSARY TO

CONFIRM LASER BEAM EMISSION. BE SURE TO OBSERVE

FROM A DISTANCE OF MORE THAN 30cm FROM THE

SURFACE OF THE OBJECTIVE LENS ON THE OPTICAL

PICK-UP BLOCK.

Caution: Invisible laser radiation when

open and interlocks defeated avoid exposure to beam.

Advarsel:Usynling laserståling ved åbning,

når sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling.

VAROITUS!

Laiteen Käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saattaa altistaa käyt-täjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle.

VARNING!

Om apparaten används på annat sätt än vad som specificeras i

denna bruksanvising, kan användaren utsättas för osynling

laserstrålning, som överskrider gränsen för laserklass 1.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

ATTENTION

L'utilisation de commandes, réglages ou procédures autres que

ceux spécifiés peut entraîner une dangereuse exposition aux

radiations.

ADVARSEL!

Usynlig laserståling ved åbning, når sikkerhedsafbrydereer ude

af funktion. Undgå udsættelse for stråling.

This Compact Disc player is classified as a CLASS 1 LASER

product.

The CLASS 1 LASER PRODUCT label is located on the rear

exterior.

CLASS 1

KLASSE 1

LUOKAN 1

KLASS 1

LASER PRODUCT

LASER PRODUKT

LASER LAITE

LASER APPARAT

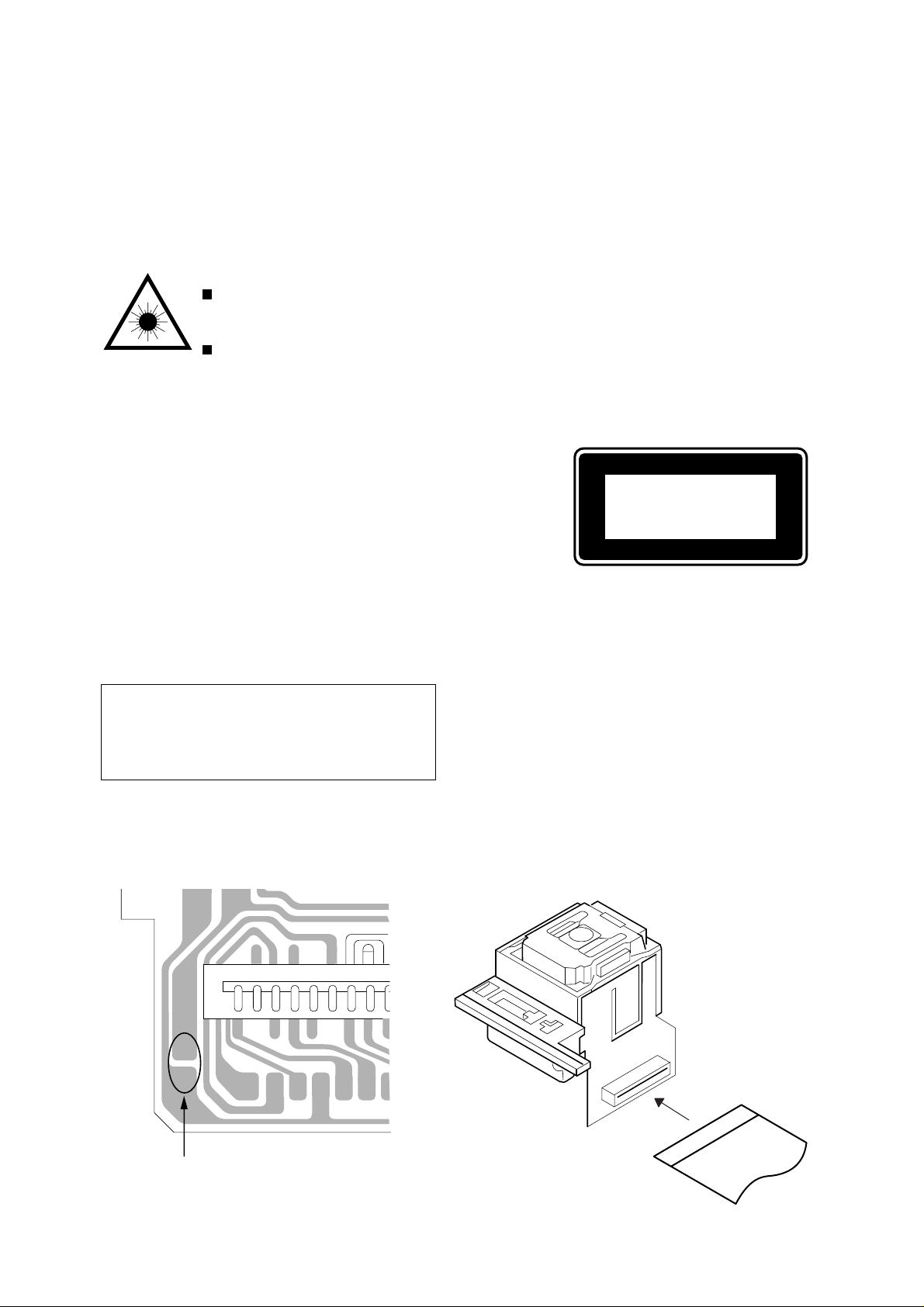

Precaution to replace Optical block

(SF-P101NR)

Body or clothes electrostatic potential could ruin

laser diode in the optical block. Be sure ground

body and workbench, and use care the clothes

do not touch the diode.

1) After the connection, remove solder shown in

the right figure.

PICK UP ASSY

SF-P101NR

Solder

1

16

TO/FROM CD C.B

3

Page 4

ELECTRICAL MAIN PARTS LIST

REF. NO PART NO. KANRI DESCRIPTION

NO.

IC

87-A20-955-010 IC,LA1828

87-A21-064-010 IC,LA4227

87-A21-520-040 C-IC,M61509FP

87-A20-446-010 C-IC,LA9241ML

87-A20-459-010 C-IC,LC78622ED

87-A21-093-010 IC,LA6541D

8A-CD9-610-010 C-IC,LC865516A-5P16

87-A20-650-010 IC,RPM6938-V11<A170 LH<S>>

87-A21-431-010 IC,BA4560N

TRANSISTOR

89-327-143-080 TR,2SC2714 (0.1W)

87-026-447-080 TR,2SC1740S R

87-026-463-080 TR,2SA933S (0.3W)

87-026-213-080 CHIP-TR,DTC114YK

89-112-965-080 TR,2SA1296 (0.75W)

87-026-291-080 TR,DTC124XS

89-213-702-010 TR,2SB1370 (1.8W)

87-026-462-080 TR,2SC1740 S(RS 0.3W)

89-318-154-080 TR,2SC1815 (0.4W)

89-109-332-380 TR,2SA933RS

89-113-187-080 TR,2SA1318TU

87-026-295-080 TR,DTC144TK

87-026-237-080 CHIP-TR,DTC124XK<A170 LH<S>>

89-317-403-080 TR,2SC1740S

87-026-239-080 TR,DTC114TK (0.2W)

87-026-464-080 TR,DTC114TS (0.3W)

REF. NO PART NO. KANRI DESCRIPTION

NO.

C809 87-010-405-080 CAP, ELECT 10-50V

C810 87-010-401-080 CAP, ELECT 1-50V

C811 87-010-178-080 CHIP CAP 1000P

C812 87-010-178-080 CHIP CAP 1000P

C816 87-010-180-080 C-CER 1500P

C817 87-010-180-080 C-CER 1500P

C821 87-010-401-080 CAP, ELECT 1-50V

C822 87-010-401-080 CAP, ELECT 1-50V

C823 87-010-178-080 CHIP CAP 1000P

C824 87-010-178-080 CHIP CAP 1000P

C829 87-010-178-080 CHIP CAP 1000P

C830 87-010-178-080 CHIP CAP 1000P

C833 87-018-195-080 CAP, CER 1200P-16V

C834 87-010-248-080 CAP, ELECT 220-10V

C835 87-010-322-080 C-CAP,S 100P-50 CH

C836 87-010-322-080 C-CAP,S 100P-50 CH

C843 87-010-197-080 CAP, CHIP 0.01 DM

C844 87-018-124-080 CAP, CER 270P-50V

C845 87-010-178-080 CHIP CAP 1000P

C846 87-010-263-080 CAP, ELECT 100-10V

C851 87-010-186-080 CAP,CHIP 4700P

C852 87-010-178-080 CHIP CAP 1000P

C853 87-018-211-080 CAP, CER 0.01-50<A170 LH<S>>

C853 87-A11-145-080 CAP,TC U 0.01-50 Z F<A110 U<S>>

CN201 87-099-018-010 CONN,16P

CN801 87-A60-110-010 CONN,4P V S2M-4W

CNA302 8A-CDA-629-010 CONN ASSY,6P MA-TU

CNA801 8A-CD9-630-010 CONN ASSY, 4P RPH

L801 87-007-342-010 COIL,OSC 85K BIAS

SW801 8Z-CD9-609-010 SW,SL 1-6-2 PS62D01

DIODE

87-020-465-080 DIODE,1SS133 (110MA)

87-A40-128-080 C-VARI-CAP,HVU202A

87-027-399-080 ZENER,HZ7A3L (200MA)<A170 LH<S>>

87-A40-509-080 ZENER,MTZJ6.8C<A110 U<S>>

87-070-345-080 DIODE,IN4148

87-A40-648-080 ZENER,MTZJ8.2A

87-017-978-080 DIODE,1N4003

87-017-932-080 ZENER,MTJ6.2B<A110 U<S>>

87-A40-465-010 DIODE,FR202

MAIN C.B

C211 87-A11-603-080 CAP, S 0.15-16<A170 LH<S>>

C212 87-A11-603-080 CAP, S 0.15-16<A170 LH<S>>

C215 87-016-460-080 C-CAP,S 0.22-16 B

C216 87-016-460-080 C-CAP,S 0.22-16 B

C231 87-010-213-080 C-CAP,S 0.015-50 B

C232 87-010-213-080 C-CAP,S 0.015-50 B

C233 87-A10-201-080 C-CAP,S0.33-16 KB

C234 87-A10-201-080 C-CAP,S0.33-16 KB

C235 87-016-669-080 C-CAP,S 0.1-25 K B

C236 87-016-669-080 C-CAP,S 0.1-25 K B

C237 87-010-371-080 CAP, ELECT 470-6.3V

C239 87-010-197-080 CAP, CHIP 0.01 DM

C239 87-010-805-080 CAP, S 1-16<A110 U<S>>

C240 87-010-197-080 CAP, CHIP 0.01 DM

C240 87-010-805-080 CAP, S 1-16<A110 U<S>>

C247 87-010-401-080 CAP, ELECT 1-50V

C248 87-010-401-080 CAP, ELECT 1-50V

C310 87-010-248-080 CAP, ELECT 220-10V

C316 87-010-263-080 CAP,E 100-10

C317 87-010-197-080 CAP, CHIP 0.01 DM

C801 87-010-248-080 CAP, ELECT 220-10V

C805 87-012-365-080 C-CAP,S 0.027-25VBK

C806 87-012-365-080 C-CAP,S 0.027-25VBK

C807 87-010-405-080 CAP, ELECT 10-50V

C808 87-010-405-080 CAP, ELECT 10-50V

CD C.B

C30 87-010-260-080 CAP, ELECT 47-25V

C261 87-010-402-080 CAP, ELECT 2.2-50V

C262 87-010-402-080 CAP, ELECT 2.2-50V

C263 87-010-178-080 CHIP CAP 1000P

C264 87-010-178-080 CHIP CAP 1000P

C265 87-010-263-080 CAP, ELECT 100-10V

C266 87-010-263-080 CAP, ELECT 100-10V

C267 87-010-112-080 CAP, ELECT 100-16V

C268 87-010-112-080 CAP, ELECT 100-16V

C271 87-010-237-080 CAP, ELECT 1000-16V

C272 87-010-237-080 CAP, ELECT 1000-16V

C278 87-010-405-080 CAP, ELECT 10-50V

C279 87-010-385-080 CAP, ELECT 220-25V

!C301 87-016-495-000 CAP,E 3300-25 M SMG

C306 87-010-404-080 CAP, ELECT 4.7-50V

C307 87-010-401-080 CAP, ELECT 1-50V

C308 87-010-221-080 CAP, ELECT 470-10V

C311 87-010-263-080 CAP, ELECT 100-10V

C312 87-010-385-080 CAP, ELECT 220-25V

C321 87-010-197-080 CAP, CHIP 0.01 DM

C322 87-010-263-080 CAP, ELECT 100-10V

C325 87-010-405-080 CAP, ELECT 10-50V

C401 87-010-403-080 CAP, ELECT 3.3-50V

C402 87-010-197-080 CAP, CHIP 0.01 DM

C403 87-010-263-080 CAP, ELECT 100-10V

C404 87-010-248-080 CAP, ELECT 220-10V

C406 87-010-374-080 CAP, ELECT 47-10V

C407 87-010-178-080 CHIP CAP 1000P

C408 87-010-198-080 CAP, CHIP 0.022

C409 87-010-248-080 CAP, ELECT 220-10V

C410 87-010-263-080 CAP, ELECT 100-10V

C411 87-A11-177-080 C-CAP,S 0.15-16 K B

C412 87-010-401-080 CAP, ELECT 1-50V

C413 87-016-369-080 C-CAP,S 0.033-25 B K

C414 87-010-405-080 CAP, ELECT 10-50V

C416 87-010-545-080 CAP, ELECT 0.22-50V

C417 87-012-157-080 C-CAP,S 330P-50 CH

4

Page 5

REF. NO PART NO. KANRI DESCRIPTION

NO.

C418 87-010-213-080 C-CAP,S 0.015-50 B

C419 87-A11-608-080 C-CAP,S 0.33-25 K B

C420 87-016-369-080 C-CAP,S 0.033-25 B K

C421 87-A11-177-080 C-CAP,S 0.15-16 K B

C422 87-010-184-080 CHIP CAPACITOR 3300P(K)

C423 87-010-992-080 C-CAP,S 0.047-25 B

C424 87-A11-606-080 C-CAP,S 0.22-25 K B

C425 87-010-176-080 C-CAP,S 680P-50 SL

C426 87-A11-608-080 C-CAP,S 0.33-25 K B

C428 87-010-197-080 CAP, CHIP 0.01 DM

C429 87-010-186-080 CAP,CHIP 4700P

C430 87-012-156-080 C-CAP,S 220P-50 CH

C431 87-010-545-080 CAP, ELECT 0.22-50V

C432 87-010-374-080 CAP, ELECT 47-10V

C433 87-010-401-080 CAP, ELECT 1-50V

C434 87-010-184-080 CHIP CAPACITOR 3300P(K)

C435 87-010-197-080 CAP, CHIP 0.01 DM

C436 87-010-374-080 CAP, ELECT 47-10V

C437 87-010-404-080 CAP, ELECT 4.7-50V

C438 87-016-669-080 C-CAP,S 0.1-25 K B

C439 87-010-178-080 CHIP CAP 1000P

C441 87-010-197-080 CAP, CHIP 0.01 DM

C442 87-010-313-080 CAP, CHIP 18P

C445 87-012-368-080 C-CAP,S 0.1-50 F

C446 87-012-368-080 C-CAP,S 0.1-50 F

C447 87-012-368-080 C-CAP,S 0.1-50 F

C448 87-010-315-080 C-CAP,S 27P-50 CH

C450 87-012-140-080 CAP 470P

C451 87-012-156-080 C-CAP,S 220P-50 CH

C455 87-010-247-080 CAP, ELECT 100-50V

C457 87-010-312-080 C-CAP,S 15P-50 CH

C458 87-010-312-080 C-CAP,S 15P-50 CH

C459 87-010-263-080 CAP, ELECT 100-10V

C460 87-015-819-080 CAPACITOR,0.01

C461 87-010-197-080 CAP, CHIP 0.01 DM

C462 87-010-248-080 CAP, ELECT 220-10V

C463 87-010-197-080 CAP, CHIP 0.01 DM

C465 87-010-404-080 CAP, ELECT 4.7-50V

C466 87-012-368-080 C-CAP,S 0.1-50 F

C467 87-010-263-080 CAP, ELECT 100-10V

C469 87-012-154-080 C-CAP,S 150P-50 CH

C470 87-010-544-080 CAP, ELECT 0.1-50V

C471 87-015-785-080 CHIP CAPACITOR, 0.1FZ-25Z

C472 87-015-785-080 CHIP CAPACITOR, 0.1FZ-25Z

C473 87-015-785-080 CHIP CAPACITOR, 0.1FZ-25Z

C474 87-015-785-080 CHIP CAPACITOR, 0.1FZ-25Z

C475 87-010-197-080 CAP, CHIP 0.01 DM

C476 87-010-236-080 CAP,E 1000-10 SME

C477 87-010-197-080 CAP, CHIP 0.01 DM

C478 87-010-263-080 CAP, ELECT 100-10V

C479 87-010-197-080 CAP, CHIP 0.01 DM

C480 87-010-221-080 CAP, ELECT 470-10V

C481 87-010-405-080 CAP, ELECT 10-50V

C482 87-010-405-080 CAP, ELECT 10-50V

C489 87-012-368-080 C-CAP,S 0.1-50 F

C490 87-012-368-080 C-CAP,S 0.1-50 F

C491 87-010-197-080 CAP, CHIP 0.01 DM

C492 87-010-221-080 CAP, ELECT 470-10V

C494 87-010-197-080 CAP, CHIP 0.01 DM

C501 87-012-368-080 C-CAP,S 0.1-50 F

C502 87-010-322-080 C-CAP,S 100P-50 CH

C503 87-010-322-080 C-CAP,S 100P-50 CH

C504 87-010-322-080 C-CAP,S 100P-50 CH

C505 87-010-322-080 C-CAP,S 100P-50 CH

C506 87-010-322-080 C-CAP,S 100P-50 CH

C510 87-016-669-080 C-CAP,S 0.1-25 K B

C831 87-010-198-080 CAP, CHIP 0.022

CN202 8A-CH4-689-010 CONN,3P V 2.5

CN205 87-A60-109-010 CONN,2P V S2M-2W

CN301 8A-CH4-689-010 CONN,3P V 2.5

REF. NO PART NO. KANRI DESCRIPTION

NO.

CN401 87-A60-424-010 CONN,16P V TOC-B

CN403 87-099-201-010 CONN,8P 6216 H

CN802 8A-CH4-687-010 CONN,4P V 2.5

CNA205 8A-CD9-626-010 CONN ASSY, 2P DOOR

CNA402 8A-CDA-625-010 CONN ASSY,6P CD-ME

CNA802 8A-CD9-631-010 CONN ASSY, 4P TP-ME

L401 87-003-102-080 COIL, 10UH

L404 87-003-152-080 COIL, 100UH

R840 87-029-124-010 RES,FUSE 2.2-1/4

SFR430 87-024-437-080 SFR100K,RH063EC

X401 8Z-CD5-633-010 VIB, CER16.93MHZ FCR16.93M2

FRONT C.B

C601 87-010-313-080 CAP, CHIP 18P

C602 87-010-315-080 C-CAP,S 27P-50 CH

C603 87-010-319-080 C-CAP,S 56P-50 CH

C604 87-010-317-010 CHIP CAP,S 39P CH

C605 87-010-264-040 CAP,E 100-10 5L

C606 87-012-368-080 C-CAP,S 0.1-50 F

C607 87-015-779-010 CHIP CAPACITOR, 0.01

C608 87-010-415-080 CAP ELE SRE 10-50V<A110 U<S>>

C608 87-010-405-080 CAP, ELECT 10-50V<A170 LH<S>>

C609 87-010-400-080 CAP, ELECT 0.47-50V<A170 LH<S>>

C609 87-010-493-080 CAP,E 0.47-50 GAS<A110 U<S>>

C610 87-010-178-010 CAP, S 1000P-50<A170 LH<S>>

C611 87-A10-189-040 CAP,E 220-10

C612 87-010-405-080 CAP, ELECT 10-50V<A170 LH<S>>

C613 87-012-368-080 C-CAP,S 0.1-50 F

C614 87-010-312-080 C-CAP,S 15P-50 CH

CN601 87-099-033-010 16P 6216 H<A170 LH<S>>

CN601 87-099-757-010 CONN,16P 9604S F<A110 U<S>>

CN602 87-A60-079-010 CONN,08P H 9604S-08F<A110 U<S>>

CN602 87-099-201-010 CONN,8P 6216 H<A170 LH<S>>

CNA604 8A-CDA-623-010 CONN ASSY,7P KEY

L601 87-003-102-080 COIL, 10UH

LED602 88-CD6-630-010 LED,934ID RED

LED608 88-CD6-630-010 LED,934ID RED

LED610 88-CD6-631-010 LED,934GD GRN

LED611 87-CD8-616-010 LED,SA36-11 HWA-11.0

S601 87-A91-704-080 SW,TACT EVQ 214 05R<A110 U<S>>

S601 87-A90-696-080 SW,TACT TS2103-03-430<A170 LH<S>>

S602 87-A91-704-080 SW,TACT EVQ 214 05R<A110 U<S>>

S602 87-A90-696-080 SW,TACT TS2103-03-430<A170 LH<S>>

S603 87-A91-704-080 SW,TACT EVQ 214 05R<A110 U<S>>

S603 87-A90-696-080 SW,TACT TS2103-03-430<A170 LH<S>>

S604 87-A91-704-080 SW,TACT EVQ 214 05R<A110 U<S>>

S604 87-A90-696-080 SW,TACT TS2103-03-430<A170 LH<S>>

S605 87-A91-704-080 SW,TACT EVQ 214 05R<A110 U<S>>

S605 87-A90-696-080 SW,TACT TS2103-03-430<A170 LH<S>>

S609 87-A91-704-080 SW,TACT EVQ 214 05R<A110 U<S>>

S609 87-A90-696-080 SW,TACT TS2103-03-430<A170 LH<S>>

S611 87-A91-704-080 SW,TACT EVQ 214 05R<A110 U<S>>

S611 87-A90-696-080 SW,TACT TS2103-03-430<A170 LH<S>>

X601 87-030-273-010 VIB,XTAL 32.768K5PPM

X602 87-030-376-080 VIB,CER CSA5.76MG200

TUNER C.B

C1 87-010-314-080 C-CAP,S 22P-50V

C2 87-010-316-080 C-CAP,S 33P-50 CH

C3 87-010-314-080 C-CAP,S 22P-50V

C4 87-010-148-080 CAP, CHIP S 75P SL

C5 87-010-378-080 CAP, ELECT 10-16V

C7 87-012-156-080 C-CAP,S 220P-50 CH

C9 87-010-311-080 CAP 12P

C11 87-010-152-080 C-CAP,S 8P-50 CH

C12 87-010-314-080 C-CAP,S 22P-50V

C13 87-010-322-080 C-CAP,S 100P-50 CH

5

Page 6

REF. NO PART NO. KANRI DESCRIPTION

NO.

C15 87-016-669-080 C-CAP,S 0.1-25 K B

C16 87-010-178-080 CHIP CAP 1000P

C17 87-016-669-080 C-CAP,S 0.1-25 K B

C18 87-010-198-080 CAP, CHIP 0.022

C19 87-016-669-080 C-CAP,S 0.1-25 K B

C20 87-010-400-080 CAP, ELECT 0.47-50V

C21 87-010-403-080 CAP, ELECT 3.3-50V

C26 87-012-358-080 C-CAP,S 0.47-10 F Z

C27 87-012-358-080 C-CAP,S 0.47-10 F Z

C28 87-010-992-080 C-CAP,S 0.047-25 B

C29 87-010-992-080 C-CAP,S 0.047-25 B

C30 87-010-248-080 CAP, ELECT 220-10V

C31 87-010-379-080 CAP, ELECT 22-16V

C36 87-010-263-080 CAP, ELECT 100-10V

C38 87-010-197-080 CAP, CHIP 0.01 DM

C51 87-010-197-080 CAP, CHIP 0.01 DM

CF1 87-A90-128-010 FLTR,AM IF CFAL-455

CF2 87-008-261-010 FILTER, SFE10.7MA5-A

CF3 87-008-261-010 FILTER, SFE10.7MA5-A

CN2 87-A60-116-010 CONN,6P H S2M-6WR

L2 87-A50-560-010 COIL,FM BPF(ACD)

L3 8A-CD9-660-010 BAR-ANT,MW 2B-ACD(COI)

L4 87-A50-562-010 COIL,FM RF EX(ACD)

L6 87-A50-337-010 COIL,AM OSC (TOKO)

L7 87-A50-579-010 COIL,AM IFT(ACD)

L8 87-A50-335-010 COIL,FM IFT (TOKO)

L9 87-A50-577-010 COIL,FM DET(ACD)

L10 87-005-849-080 COIL,10UH(CECS)

S1 87-A91-548-010 SW,SL-2-3 SK23E01G06

VC1 87-A91-167-010 TUN-CAP,20P-160P FA-22125 N000

REF. NO PART NO. KANRI DESCRIPTION

VOLSEL C.B<A170 LH<S>>

!

!

!

NO.

FC901 87-033-213-010 CLAMP,FUSE SMK<A170 LH<S>>

FC902 87-033-213-010 CLAMP,FUSE SMK<A170 LH<S>>

F901 87-035-347-010 FUSE,2.5A 250V T<A170 LH<S>>

HP C.B

CN204 87-A60-685-010 CONN,4P H WHT EH

CN605 87-A60-117-010 CONN,7P H S2M-7WR

CNA203 8A-CDA-628-010 CONN ASSY,4P MA-HP

J251 87-A60-569-010 JACK,HTJ-035-18

LED606 88-CD6-630-010 LED,934ID RED

LED607 88-CD6-630-010 LED,934ID RED

S606 87-A90-696-080 SW,TACT TS2103-03-430<A170 LH<S>>

S607 87-A90-696-080 SW,TACT TS2103-03-430<A170 LH<S>>

S608 87-A90-696-080 SW,TACT TS2103-03-430<A170 LH<S>>

S614 87-A90-696-080 SW,TACT TS2103-03-430<A170 LH<S>>

S615 87-A90-696-080 SW,TACT TS2103-03-430<A170 LH<S>>

BATT1 C.B

C901 87-010-192-080 C-CAP,S 0.022-50 F

C902 87-010-192-080 C-CAP,S 0.022-50 F

C903 87-010-192-080 C-CAP,S 0.022-50 F

C904 87-010-192-080 C-CAP,S 0.022-50 F

CNA901 8A-CDA-627-010 CONN ASSY,3P PWR

!

PR901 87-A90-092-080 PROTECTOR,2.5A 491<A170 LH<S>>

SP901 87-CD6-213-010 SPR-C,BATT (-)

SP902 87-CD6-213-010 SPR-C,BATT (-)

BATT2 C.B

SP903 87-CD6-213-010 SPR-C,BATT (-)

SP904 87-CD6-213-010 SPR-C,BATT (-)

MOTOR C.B

M2 9X-262-576-910 MOTOR GEAR ASSY

PIN3 91-564-722-110 CONNECTOR 6P

SW1 91-572-085-120 LEAF SW

6

Page 7

IC BLOCK DIAGRAM

IC, LA6541D IC, M61509FP

• Regarding connectors, they are not stocked as they are not the initial order items.

The connectors are available after they are supplied from connector manufacturers upon the order is received.

CHIP RESISTOR PART CODE

Chip Resistor Part Coding

88

A

Resistor Code

Chip resistor

Wattage Type Tolerance

1/16W 1005 5% CJ

1/16W

1/10W

1/8W

1608

2125

3216

5%

5%

5%

Symbol

Figure

Value of resistor

CJ

CJ

CJ

Form

L

W

Dimensions (mm)

LW t

1.0 0.5 0.35 104

t

1.6 0.8 0.45

2 1.25 0.45

1.6

0.55

3.2

Resistor Code

108

118

128

mono. SW

: A

: A

Control logic

IC, LA1828 IC, BA4560N

87

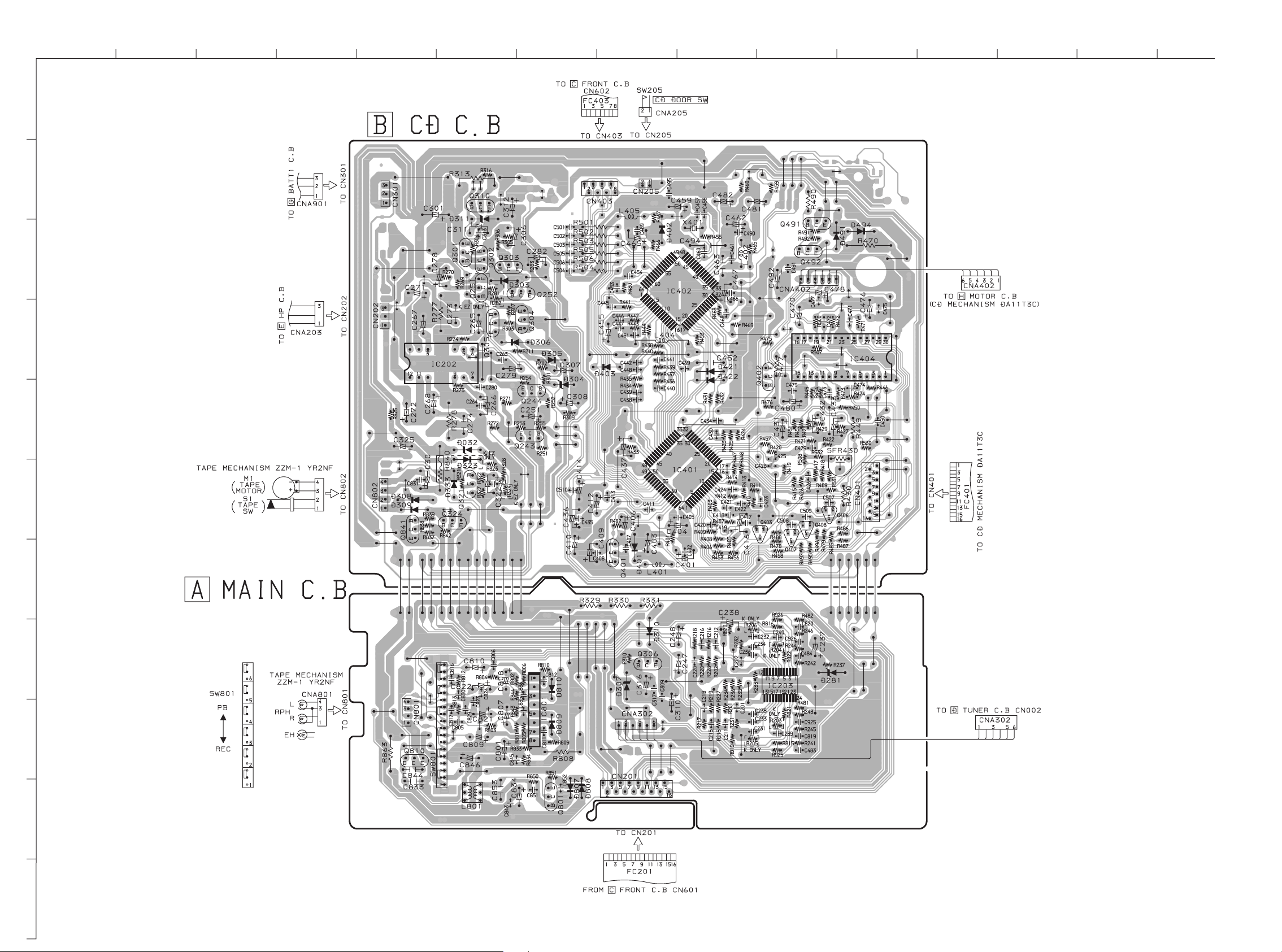

Page 8

WIRING-1 (MAIN/CD)

1

A

B

C

D

234567

8

9

10

11 12 13

14

E

F

G

H

I

J

K

109

Page 9

SCHEMATIC DIAGRAM-1 (MAIN)

DRY BATTERY

R14X8

DC 12V

1211

J90

Page 10

SCHEMATIC DIAGRAM-2 (CD)

1413

Page 11

WIRING-2 (MOTOR)

1

A

B

H MOTOR C.B

C

234567

M2

TRANSISTOR ILLUSTRATION

ECB ECB ECB

2SA1296

2SC1815

2SA933

2SC1740

DTC114TS

DTC124XS

2SA1318

D

E

F

G

TO B CD C.B CNA402

_

PIN3

+

M2

(SLED MOTOR)

SW1

(INSIDE LIMIT SW)

(SPINDLE MOTOR)

SW1

_

M3

M3

+

C

B

E

2SC2714

DTC114TK

DTC114YK

DTC124XK

DTC144TK

BCE

2SB1370

H

I

J

K

1615

Page 12

WIRING-3 (FRONT/HP/BATT1/BATT2)

1

A

B

C

D

234567

8

9

10

11 12 13

14

E

F

G

H

I

J

K

1817

Page 13

SCHEMATIC DIAGRAM-3 (FRONT)

CN602

CONN, 8P H 9604S-08F

2019

Page 14

SCHEMATIC DIAGRAM-4 (TUNER)

L005, TC001

FM FREQ. RANGE

ADJ.

2221

Page 15

WIRING-4 (TUNER)

1

A

B

C

D

234567

E

F

G

H

I

J

K

23

Page 16

ELECTRICAL ADJUSTMENT

D

TUNER C.B

5

L003 (MW BAR ANT)

B

CD C.B

TC001

L005

3

2

1

L006

L004

TP1(DET)

16

IC001

1

L007

1

2

IC002

TP2(VT)

+

C039

21

1

5

IC404

SFR430

CN401

A

MAIN C.B

E

H.P. C.B

9

IC801

1

CN201

M1 (TAPE MOTOR)

CN801

L801

8

RPH

67

J251

PHONES

24

6

7

Page 17

PRACTICAL SERVICE FIGURE

< TUNER SECTION >

1. FM VT Adjustment

Settings : • Test point : TP2(VT)

• Adjustment location : L006

Method : Set to FM 108.0MHz and adjust L006 so that the

test point voltage becomes 6.0V ± 0.05V.

2. MW VT Adjustment

Settings : • Test point : TP2(VT)

• Adjustment location : L004

Method : Set to MW 1000kHz (U), and adjust L004 so that

the test point voltage becomes 3.75V ± 0.05V.

3. FM Tracking Adjustment

L005.........................................................................98.0MHz

4. MW Tracking Adjustment

L003...........................................................................600kHz

TC001.......................................................................1400kHz

5. AM IF Adjustment

Settings : • Test point : TP1(DET)

• Adjustment location : L007

Method : Adjust L007 so that the output level at 1400kHz

becomes maximum.

< DECK SECTION >

6. Tape Speed Adjustment

Settings : • Test tape : TTA–100

• Test point : J251 (PHONES jack)

• Adjustment location : SFR of deck motor

Method : Play back the test tape and adjust SFR so that

the frequency counter reads 3000Hz ± 30Hz.

< TUNER SECTION >

< FM SECTION >

Sensitivity: Less than 19dB (88.0MHz)

(THD 3%) Less than 18dB (98.0MHz)

Less than 18dB (108.0MHz)

Signal to Noise Ratio: More than 60dB (at 98.0MHz)

(Input 60dB)

Distortion: Less than 1.5% (at 98.0MHz)

(Input 60dB)

Intermediate frequency: 10.7MHz ±0.1MHz

Stereo separation: More than 22dB

< AM SECTION >

Sensitivity: Less than 45dB (at 600kHz)

(S/N 10dB) Less than 45dB (at 1000kHz)

Less than 45dB (at 1400kHz)

Distortion: Less than 1.5%

(Input 74dB)

Intermediate frequency: 455kHz±3.5kHz

< CASSETTE SECTION >

Tape speed: 3000Hz+3%-2%

Wow & flutter: Less than 0.35% (JIS RMS)

S/N ratio: More than 35dB

Distortion: Less than 3.0% (PB)

Noise (PB): Less than 1mV

(DC, MIN)

Less than 1.2mV (AC, MIN)

Erasing Ratio (W/O FILTER): More than 45dB

7. Head Azimuth Adjustment

Settings : • Test tape : TTA–320

• Test point : J251 (PHONES jack)

• Adjustment location : Azimuth adjustment

screw

Method : Play back the 8kHz signal of the test tape and

adjust screw so that the output becomes

maximum.

8. Bias frequncy Adjustment

L801..................................................................85kHz±0.5kHz

< CD SECTION >

9. FE Balance Adjustment

Settings : • Test point : IC401 PIN58 (VR), IC401 PIN 20

(FE)

• Adjustment location : SFR430

Method : Playback the disc and adjust SFR430 so that the

test point voltage becomes 0V.

25

Page 18

IC DESCRIPTION

IC, LA9241ML

Pin No. Pin Name I/O Description

Pin to which external pickup photo diode is connected. RF signal is created by adding

1

FIN2

I

with the FIN1 pin signal. FE signal is created by subtracting from the FIN1 pin signal.

10

11

12

13

14

15

2

3

4

5

6

7

8

9

FIN1

E

F

TB

TE-

TE

TESI

SCI

TH

TA

TD-

TD

JP

TO

I

Pin to which external pickup photo diode is connected.

Pin to which external pickup photo diode is connected. TE signal is created by

I

subtracting from the F pin signal.

I

Pin to which external pickup photo diode is connected.

I

DC component of the TE signal is input.

Pin to which external resistor setting the TE signal gain is connected between the TE

I

pin.

O

TE signal output pin.

TES “Track Error Sense” comparator input pin. TE signal is passed through a band-

I

pass filter then input.

I

Shock detection signal input pin.

I

Tracking gain time constant setting pin.

O

TA amplifier output pin.

Pin to which external tracking phase compensation constants are connected between

I

the TD and VR pins.

I

Tracking phase compensation setting pin.

I

Tracking jump signal (kick pulse) amplitude setting pin.

O

Tracking control signal output pin.

16

17

18

19

20

21

22

23

24

25

26

27

28

29

FD

FD-

FA

FA-

FE

FE-

AGND

SP

SPI

SPG

SP-

SPD

SLEQ

SLD

—

O

Focusing control signal output pin.

Pin to which external focusing phase compensation constants are connected between

I

the FD and FA pins.

Pin to which external focusing phase compensation constants are connected between

I

the FD– and FA– pins.

Pin to which external focusing phase compensation constants are connected between

I

the FA and FE pins.

O

FE signal output pin.

I

Pin to which external FE signal gain setting resistor is connected between the FE pin.

Analog signal GND.

O

Signal ended output of the CV+and CV- pin input signal.

I

Spndle amp input.

I

Pin to which external spindle gain setting resistor in 12 cm mode is connected.

Pin to which external spindle phase compensation constants are connected together

I

with SPD pin.

O

Spindle control signal output pin.

I

Pin to which external sled phase compensation constants are connected.

O

Sled control signal output pin.

30, 31

32, 33

34

35

SL-, SL+

JP-, JP+

TGL

TOFF

I

Sled advance signal input pin from microprocessor.

I

Tracking jump signal input pin from DSP.

I

Tracking gain control signal input from DSP. Low gain when TGL = H.

I

Tracking off control signal input pin from DSP. Off when TOFF = H.

26

Page 19

Pin No. Pin Name I/O Description

36

TES

O

Pin from which TES signal is output to DSP.

37

38

39, 40

41

42

43

44

45

46

47

48

49

50

51

52

HFL

SLOF

CV–, CV+

RFSM

RFS-

SLC

SLI

DGND

FSC

TBC

NC

DEF

CLK

CL

DAT

O

O

O

—

O

—

O

“High Frequency Level” is used to judge whether the main beam position is on top of

bit or on top of mirror.

I

Sled servo off control input pin.

I

CLV error signal input pin from DSP.

RF output pin.

RF gain setting and EFM signal 3T compensation constant setting pin together with

I

RFSM pin.

“Slice Level Control” is the output pin which controls the RF signal data slice level by

DSP.

I

Input pin which control the data slice level by the DSP.

Digital system GND.

Output pin to which external focus search smoothing capacitor is connected.

I

“Tracking Balance Control” EF balance variable range setting pin.

No connection.

Disc defect detector output pin.

I

Reference clock input pin. 4.23 MHz of the DSP is input.

I

Microprocessor command clock input pin.

I

Microprocessor command data input pin.

53

54

55

56

57

58

59

60

61

62

63

64

CE

DRF

FSS

VCC2

REFI

VR

LF2

PH1

BH1

LDD

LDS

VCC1

—

—

—

I

Microprocessor command chip enable input pin.

O

“Detect RF” RF level detector output.

I

“Focus Search Select” focus search mode (± search/+ search) select pin.

Servo system and digital system Vcc pin.

Pin to which external bypass capacitor for reference voltage is connected.

O

Reference voltage output pin.

I

Disc defect detector time constant setting pin.

I

Pin to which external capacitor for RF signal peak holding is connected.

I

Pin to which external capacitor for RF signal bottom holding is connected.

O

APC circuit output pin.

I

APC circuit input pin.

RF system Vcc pin.

27

Page 20

IC, LC78622ED

Pin No. Pin Name I/O Description

1

DEFI

I

Defect sense signal (DEF) input pin. (Connect to 0V when not used).

2

3

4

5

6

7

8

9

10

11

12, 13

14

15

16

17

18

TAI

PDO

VVSS

ISET

VVDD

FR

VSS

EFMO

EFMIN

T2

CLV+, CLK-

___

V/P

HFL

TES

TOFF

TGL

—

—

—

I

O

For PLL.

I

Test signal input pin with built-in pull-down resistor. Be sure to connect to 0V.

Phase comparator output pin to control external VCO.

GND pin for built-in VCO. Be sure to connect to 0V.

Pin to which external resistor adjusting the PD0 output current.

Power supply pin for built-in VCO.

I

Pin for VCO frequency range adjustment.

Digital system GND. Be sure to connect to 0V.

O

For slice level control.

I

I

Test signal input pin with built-in pull-down resistor. Be sure to connect to 0V.

O

Disc motor control output. Three level output is possible using command.

Rough servo or phase control automatic selection monitoring output pin. Rough servo

O

EFM signal output pin.

EFM signal input pin.

at H. Phase servo at L.

I

Track detect signal input pin. Schmidt input.

I

Tracking error signal input pin. Schmidt input.

O

Tracking OFF output pin.

O

Tracking gain selection output pin. Gain boost at L.

19, 20

21

22

23

24

25

26

27

28

29

30

31

32, 33

34

35

36

37

JP+, JP-

PCK

FSEQ

VDD

SL+

SL-

—

PUIN

_______

RW

EMPH

C2F

DOUT

T3, T4

N.C.

MUTEL

LVDD

LCHO

—

—

—

—

O

Track jump control signal output pin. Three level output is possible using command.

O

EFM data playback clock monitoring pin 4.3218 MHz when phase is locked in.

Sync signal detection output pin. H when the sync signal which is detected from EFM

O

signal and thesync signal which is internally generated agree.

Digital system power supply pin.

O

Moves the sled to outer circumference.

O

Moves the sled to inner circumference.

Not connected.

I

CD pickup inner switch detection.

O

Read, wright signal.

O

De-emphasis monitor output pin. De-emphasis disc is being played back at H.

O

C2 flag output pin.

O

DIGITAL OUT output pin. (EIAJ format).

I

Test signal input pin with built-in pull-down resistor. Be sure to connect to 0V.

Not used. Set the pin to open.

O

L-channel 1-bit DAC.

O

L-channel mute output pin.

L-channel power supply pin.

L-channel output pin.

38

39

40

41

42

LVSS

RVSS

RCHO

RVDD

MUTER

—

—

—

O

R-channel 1-bit DAC.

O

L-channel GND. Be sure to connect to 0V.

R-channel GND. Be sure to connect to 0V.

R-channel output pin.

R-channel power supply pin.

R-channel mute output pin.

28

Page 21

Pin No. Pin Name I/O Description

43

XVDD

—

Crystal oscillator power supply pin.

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

XOUT

XIN

XVSS

SBSY

EFLG

PW

SFSY

SBCK

FSX

WRQ

RWC

SQOUT

COIN

___________

CQCK

RES

T11

—

O

Pin to which external 16.9344 MHz crystal oscillator is connected.

I

Crystal oscillator GND pin. Be sure to connect to 0V.

O

Subcode block sync signal output pin.

O

C1, C2, single and dual correction monitoring pin.

O

Subcode P, Q, R, S, T, U and W output pin.

O

Subcode frame sync signal output pin. Falls down when subcode enters standby.

Subcode read clock input pin. Schmidt input. (Be sure to connected to 0V when not

I

in use.)

Pin outputting the 7.35 kHz sync signal which is generated by dividing frequency of

O

crystal oscillator.

O

Subcode Q output standby output pin.

I

Read/write control input pin. Schmidt input.

O

Subcode Q output pin.

I

Command input pin from microprocessor.

I

Command input read clock or subcode read input clock from SQOUT pin

I

LC78622 reset input pin. Set this pin to L once when the main power is turned on.

O

Test signal output pin. Use this pin as open (normally L output).

60

61

62

63

64

16M

4.2M

T5

______

CS

T1

O

16.9344 MHz output pin.

O

4.2336 MHz output pin.

I

Test signal input pin with built-in pull-down resistor. Be sure to connect to 0V.

Chip select signal input pin with built-in pull-down resistor. Be sure to connect to 0V

I

while it is not controlling.

I

Test signal input pin without built-in pull-down resistor. Be sure to connect to 0V.

29

Page 22

IC, LC865516A-5P16

Pin No. Pin Name I/O Description

1

2

3

4

5

SEG E

SEG F

SEG G

NC

I-RES

O

SEG E control.

O

SEG F control.

O

SEG G control.

—

Not connected.

I

Micro processor reset input

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

6

7

8

9

XT(IN)

NC

XT2(OUT)

VSS

CF1(IN)

CF2(OUT)

VDD

I-KEY0

I-KEY1

I-MOTOR

I-CD SW

O-SHIFT

NC

O-BASS LED

O-QS LED

O-SFT LED

I-DRF

I-WRQ

NC

I

Connected to an external 32.768 kHz crystal oscillator.

—

Not connected.

O

Connected to an external 32.768 kHz crystal oscillator.

—

GND.

I

Connected to an external 5.76 MHz ceramic filter.

O

Connected to an external 5.76 MHz ceramic filter.

—

Microprocessor power supply (+5V).

I

Key AD input. (AD)

I

Key AD input. (AD)

I

Deck status input. (AD)

I

CD door switch status input.

O

Main clock shift output.

—

Not connected.

O

BASS LED ON/OFF control output. (Not connected)

O

Q sound LED ON/OFF control output. (Not connected)

—

Not connected.

I

CD RF level detection input.

I

CD subcode Q standby input.

—

Not connected.

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

I-REM

O-CD ON

O-TU ON

O-P.CONT

NC

O-BEAT

O-MUTE

O-DIGIT

O-SEG RPEAT

O-COIN

I-SQOUT

O-CQCK

O-WRC

O-DATA

O-CD LED

O-TU LED

O-TA LED

—

Remote control input.

O

CD power control output.

O

TU power control output.

O

The main power supply control output.

—

Not connected.

O

Beat control.

O

Main mute output.

O

7-segment LED power supply control output.

O

REPEAT LED ON/OFF control output.

O

CD command output.

I

CD subcode Q input.

O

CD command/CLK for subcode.

O

CD read/write control output.

O

Data output to M62349FP.

O

LED ON/OFF control output for the CD function.

O

LED ON/OFF control output for the TU function.

O

LED ON/OFF control output for the TA function. (Not connected)

30

Page 23

Pin No. Pin Name I/O Description

42

NC

—

Not connected.

43

44

45

46

47

48

SEG DP

SEG A

SEG B

SEG C

SEG D

NC

—

O

O

O

O

O

SEG DP control.

SEG A control.

SEG B control.

SEG C control.

SEG D control.

Not connected.

31

Page 24

MECHANICAL PARTS LIST 1/1

REF. NO PART NO. KANRI DESCRIPTION

NO.

1 8A-CDA-006-010 WINDOW,CASS

2 87-B00-010-010 BADGE,AIWA 30.5-5.2 S 2.5L

3 8A-CDA-003-010 LID,CASS

4 8A-CDA-212-010 SPR-T,CASS

5 8A-CDA-008-010 WINDOW,LED<A110 U<S>>

5 8A-CDL-031-010 WINDOW,LED<A170 LH<S>>

6 8A-CDA-028-010 CABI ASSY,FRONT

7 8A-CDA-206-010 HLDR,SPKR

8 8A-CDA-020-010 KNOB,SL BAND

9 8A-CDA-009-010 WINDOW,TU

10 8A-CDA-007-010 LENS,LED

11 8A-CDA-019-010 KEY,VOL

12 8A-CDA-004-010 LID,CD

13 8A-CDA-213-010 COVER, CHUCK

14 87-036-368-010 MAGNET

15 8A-CDA-207-010 HLDR,CHUCK

16 8Z-CDB-170-010 BASE,CHUCK

17 88-CD9-211-210 RING,CHUCK

18 8A-CDA-620-010 FF-CABLE,16P FR-MAIN

19 8A-CDA-208-010 HLDR,LED

20 8A-CDA-622-010 FF-CABLE,8P CD-FR

21 8A-CDA-016-010 KEY,CD

22 87-063-165-010 OIL-DMPR 150

23 8A-CDA-017-010 KEY,MODE

24 88-CH6-220-010 CUSHION,CD A

25 8A-CDA-621-010 FF-CABLE,16P CD-RF

26 8A-CDA-012-010 CHAS,CD

27 87-036-389-010 SW,PUSH LOCK

28 8A-CDA-211-010 SPR-T,CD

29 8A-CDA-010-010 HANDL,ARM

30 8A-CDA-011-010 HANDL,COVER

31 87-NF8-220-010 DMPR,150<A110 U<S>>

32 8Z-CH4-640-010 ANT,ROD

33 8Z-CDB-169-010 PANEL,CD SANYO

34 8A-CDA-027-010 KEY,PAUSE

35 8A-CDA-026-010 KEY,STOP

36 8A-CDA-025-010 KEY,FF

37 8A-CDA-024-010 KEY,REW

38 8A-CDA-023-010 KEY,PLAY

39 8A-CDA-022-010 KEY,REC

REF. NO PART NO. KANRI DESCRIPTION

40 8A-CDA-221-010 SPR-P,REC

41 8A-CDA-220-010 PLATE,REC

42 8A-CDA-021-010 KNOB,RTRY TU

43 8A-CDA-013-010 POINTER,TU

44 8A-CDA-201-010 HLDR,TU

45 8A-CDA-216-010 GEAR,TU B

46 8A-CDA-203-010 GUIDE,GEAR

47 8A-CDA-202-010 GEAR,RELAY

48 8A-CDA-215-010 DRUM,TU

49 8A-CDA-002-010 CABI,REAR<A110 U<S>>

49 8A-CDA-030-010 CABI,REAR LH<A170 LH<S>>

49 8A-CDL-030-010 CABI,REAR LH<A170 LH<S>>

50 8A-CDA-005-010 LID,BATT

51 8Z-CD5-634-010 COVER,AC SOCKET

52 8A-CDA-626-010 CONN ASSY,2P DOOR

53 8A-CDA-630-010 CONN ASSY,4P RPH

54 8A-CDA-633-010 CONN ASSY,4P SP

55 8A-CDA-631-010 CONN ASSY,4P TA-ME

56 8A-CDA-204-010 HLDR,VOL<A170 LH<S>>

!

57 87-A60-178-010 JACK,AC E W/SW<A170 LH<S>>

!

57 87-A60-177-010 JACK,AC U W/SW<A110 U<S>>

58 8A-CDA-018-010 KEY,QSOUND

!

59 8A-CDA-612-010 PT,E 2.5W<A170 LH<S>>

!

59 8A-CDA-611-010 PT,U 2.5W<A110 U<S>>

60 8A-CH4-682-010 SPKR,10- 7OHM<A110 U<S>>

60 88-CD9-626-010 SPKR,100 7OHM 3W<A170 LH<S>>

61 88-CD6-661-010 HLDR,BAR ANT.<A110 U<S>>

62 87-A91-369-010 SW,AC SL 2 2 2 SDKGA41700<A170

A 87-721-096-410 QT2+3-10 GLD

B 87-753-104-410 VT2+3-30 W/0 BLK<A170 LH<S>>

C 8A-CK4-223-010 S-SCREW,CD

D 87-067-566-010 TAPPING SCREW, VFTT+3-6<A170

E 87-352-075-210 VT2+2.6-10<A170 LH<S>>

F 8A-CDA-222-010 S-SCREW,CASS+2.6-4<A110 U<S>>

H 87-253-097-410 U+3-12 BLK<A110 U<S>>

I 87-261-073-410 V+2.6-6<A110 U<S>>

J 87-751-096-410 VT2+3-10 GLD

NO.

LH<S>>

LH<S>>

COLOR NAME TABLE

Basic color symbol Color Basic color symbol Color Basic color symbol Color

B Black C Cream D Orange

G Green H Gray L Blue

LT Transparent Blue N Gold P Pink

R Red S Silver ST Titan Silver

T Brown V Violet W White

WT Transparent White Y Yellow YT Transparent Yellow

LM Metallic Blue LL Light Blue GT Transparent Green

LD Dark Blue DT Transparent Orange

32

Page 25

MECHANICAL EXPLODED VIEW 1/1

60

12

A

A

11

10

P.C. B

A

G

7

A

7

A

7

A

18

13

14

15

19

16

17

P.C. B

A

26

25

20

21

9

27

C

24

23

28

C

34

A

33

DA11T3C

A

54

35

36

31

30

P.C. B

37

38

29

B

57

E

51

62

A

40

E

P.C. B

A

A

A

41

59

K

PLATE,ANT

PLATE,PT

A

P.C. B

50

A

32

H

B

49

8

22

7

3

2

4

5

6

1

A

7

A

A

7

60

39

ZZM-1

D

F

J

43

42

44

P.C. B

46

45

A

D

P.C. B

P.C. B

A

A

61

I

P.C. B

47

48

3433

Page 26

TAPE MECHANISM EXPLODED VIEW 1/1

12

TAPE MECHANISM PARTS LIST 1/1

REF. NO PART NO. KANRI DESCRIPTION

1 8Z-ZM1-254-210 SPR-C,REEL R

11

A

TERMINAL,LB1

10

22

9

21

4

8

14

20

23

7

55

3

56

15

19

LEVER,E OPEN

31

6

2

1

5

13

18

54

17

27

28

30

26

2 8Z-ZM1-225-110 GEAR,REEL R

3 8Z-ZM1-253-110 SPR-C,AUTO SENSOR

4 8Z-ZM1-217-110 LEVER,AUTO SENSOR

5 8Z-ZM1-212-110 LEVER,T-UP

6 8Z-ZM1-245-010 SPR-T,AUTO

7 8Z-ZM1-236-010 CLR,SLIP FF/REW

8 8Z-ZM1-252-010 SPR-C,FF/REW

9 8Z-ZM1-230-010 GEAR,SLIP FF/REW A

10 8Z-ZM1-266-010 FELT,FF/REW

11 8Z-ZM1-231-010 GEAR,SLIP FF/REW B

12 8Z-ZM1-213-010 LEVER,FF/REW

13 8Z-ZM1-209-110 LEVER,PAUSE

14 8Z-ZM1-222-010 LEVER,E-LOCK M

15 8Z-ZM1-256-010 SPR-P,PAUSE

16 8Z-ZM1-244-010 SPR-T,T-UP

17 8Z-ZM1-247-210 SPR-T,PINCH

18 8Z-ZM1-261-110 ROLLER ASSY,PINCH

19 8Z-ZM1-221-010 LEVER,PINCH

20 8Z-ZM1-205-210 LEVER,PLAY

21 8Z-ZM1-248-010 SPR-T,BRG

22 87-A90-403-110 HEAD,RPH MS15R

23 84-ZM2-227-310 SPR-C,AZIMUTH

24 8Z-ZM1-216-010 LEVER,AUTO

25 8Z-ZM1-246-010 SPR-T,AUTO 2

26 8Z-ZM1-233-010 GEAR,IDL REW

27 8Z-ZM1-208-010 LEVER,STOP

28 8Z-ZM1-207-010 LEVER,FF

29 8Z-ZM1-206-010 LEVER,REW

30 8Z-ZM1-211-110 LEVER,REC 2

NO.

REF. NO PART NO. KANRI DESCRIPTION

31 87-A91-533-010 HEAD,EH PH-K380

32 8Z-ZM1-215-010 LEVER,REC LOCK

33 87-A91-492-010 SW,LEAF MSW18560

34 8Z-ZM1-226-010 GEAR,REEL L

35 8Z-ZM1-241-010 SPR-T,PLAY

36 8Z-ZM1-220-010 LEVER,REC SENSOR

37 8Z-ZM1-249-010 SPR-T,FR

38 8Z-ZM1-242-110 SPR-T,FF/REW

39 8Z-ZM1-229-010 GEAR,CAM

40 8Z-ZM1-232-010 GEAR,IDL FF/REW

41 8Z-ZM1-234-010 FLY-WHL,ZZM-1

42 8Z-ZM1-267-010 SHAFT,CAPSTAN 2

43 8Z-ZM1-228-010 GEAR,SLIP T-UP B

44 8Z-ZM1-265-010 FELT,T-UP

45 8Z-ZM1-227-010 GEAR,SLIP T-UP A

46 8Z-ZM1-251-110 SPR-C,T-UP SLIP

47 8Z-ZM1-243-210 SPR-T,STOP/PAUSE

48 87-A91-531-010 MOT,MS15C2L

49 8Z-ZM1-271-010 PULLEY,MOT ZZM-1

50 8Z-ZM1-264-010 BELT,MAIN S

51 8Z-ZM1-260-010 SPR-P,CASETTE

52 8Z-ZM1-201-310 CHAS ASSY,ZZM-1

53 8Z-ZM1-255-110 SPR-T,E-LOCK

54 8Z-ZM1-214-010 LEVER,LOCK

55 8Z-ZM1-257-110 SPR-C,F/R

56 8Z-ZM1-275-010 W-L,1.47-4-0.25

A 84-ZM2-242-010 S-SCREW,AZ1-2-6.4

B 8Z-ZM1-270-110 V+2.6 ZZM-1

NO.

48

50

51

53

52

49

47

16

24

25

29

B

32

33

34

1

35

36

37

46

45

44

38

42

43

40

41

39

3635

Page 27

CD MECHANISM EXPLODED VIEW 1/1

SHAFT,SLIDE

B

CD MECHANISM PARTS LIST 1/1

SF-P101NR

CHASSIS

B

1

2

REF. NO PART NO. KANRI DESCRIPTION

NO.

1 S2-121-A28-400 COVER GEAR

2 S2-511-A21-000 GEAR MIDDLE

3 S2-511-A21-100 GEAR,DRIVE

A S1-PN2-03R-OSE SCR PAN PCS 2-3

B 87-261-073-410 SCR S-TPG FLT 2.6-6

ALL M8-ZZK-E90-070 DA11T3C

A

A

3

SPINDLE

MOTOR(M3)

MOTOR C,B

3837

Page 28

ACCESSORIES/PACKAGE LIST

REF. NO PART NO. KANRI DESCRIPTION

1 8A-CDL-902-010 IB,LH(ESP)FM<A170 LH<S>>

1 8A-CDA-903-010 IB,U(ESF)FM<A110 U<S>>

2 8Z-CDK-962-010 RC UNIT,RC-ZAT02(VS)<A170 LH<S>>

!

3 87-A80-036-010 AC CORD SET ASSY,E W/FLTR VOL

!

3 87-A80-109-010 AC CORD,HK7281 BLK U<A110 U<S>>

!

4 87-A90-312-010 PLUG,CONVERSION WTN-1157R1

NO.

<A170 LH<S>>

<A170 LH<S>>

39

931196

2–11, IKENOHATA 1–CHOME, TAITO-KU , TOKY O 110, J APAN TEL:03 (3827) 3111

Printed in Singapore

Loading...

Loading...