Page 1

CSD-A120

U(S),K(S)

HS(S),HRJ(S)

EZ(S),LH(S)

HRJ(L),HRJ(P)

CSD-A140

LH(S)

SERVICE MANUAL

COMPACT DISC STEREO

CASSETTE RECEIVER

BASIC TAPE MECHANISM : TN-9ZR-219

BASIC CD MECHANISM : DA11T3C

S/M Code No. 09-014-356-0N1

DATA

Page 2

120HR, K, E, HS MODEL

SPECIFICATIONS

120LH, 140LH MODEL

Design and specifications are subject to change without

•

notice

.

120U MODEL

Design and specifications are subject to change without

•

notice

.

-2-

Design and specifications are subject to change without

•

notice

.

Page 3

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING

This set employs laser. Therefore, be sure to follow carefully the

instructions below when servicing.

WARNING!

WHEN SERVICING, DO NOT APPROACH THE LASER EXIT

WITH THE EYE TOO CLOSELY. IN CASE IT IS NECESSARY TO

CONFIRM LASER BEAM EMISSION. BE SURE TO OBSERVE

FROM A DISTANCE OF MORE THAN 30cm FROM THE

SURFACE OF THE OBJECTIVE LENS ON THE OPTICAL

PICK-UP BLOCK.

Caution: Invisible laser radiation when

open and interlocks defeated avoid exposure to beam.

Advarsel:Usynling laserståling ved åbning,

når sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling.

VAROITUS!

Laiteen Käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saattaa altistaa käyt-täjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle.

VARNING!

Om apparaten används på annat sätt än vad som specificeras i

denna bruksanvising, kan användaren utsättas för osynling

laserstrålning, som överskrider gränsen för laserklass 1.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

ATTENTION

L'utilisation de commandes, réglages ou procédures autres que

ceux spécifiés peut entraîner une dangereuse exposition aux

radiations.

ADVARSEL!

Usynlig laserståling ved åbning, når sikkerhedsafbrydereer ude

af funktion. Undgå udsættelse for stråling.

This Compact Disc player is classified as a CLASS 1 LASER

product.

The CLASS 1 LASER PRODUCT label is located on the rear

exterior.

CLASS 1

KLASSE 1

LUOKAN 1

KLASS 1

LASER PRODUCT

LASER PRODUKT

LASER LAITE

LASER APPARAT

-3-

Page 4

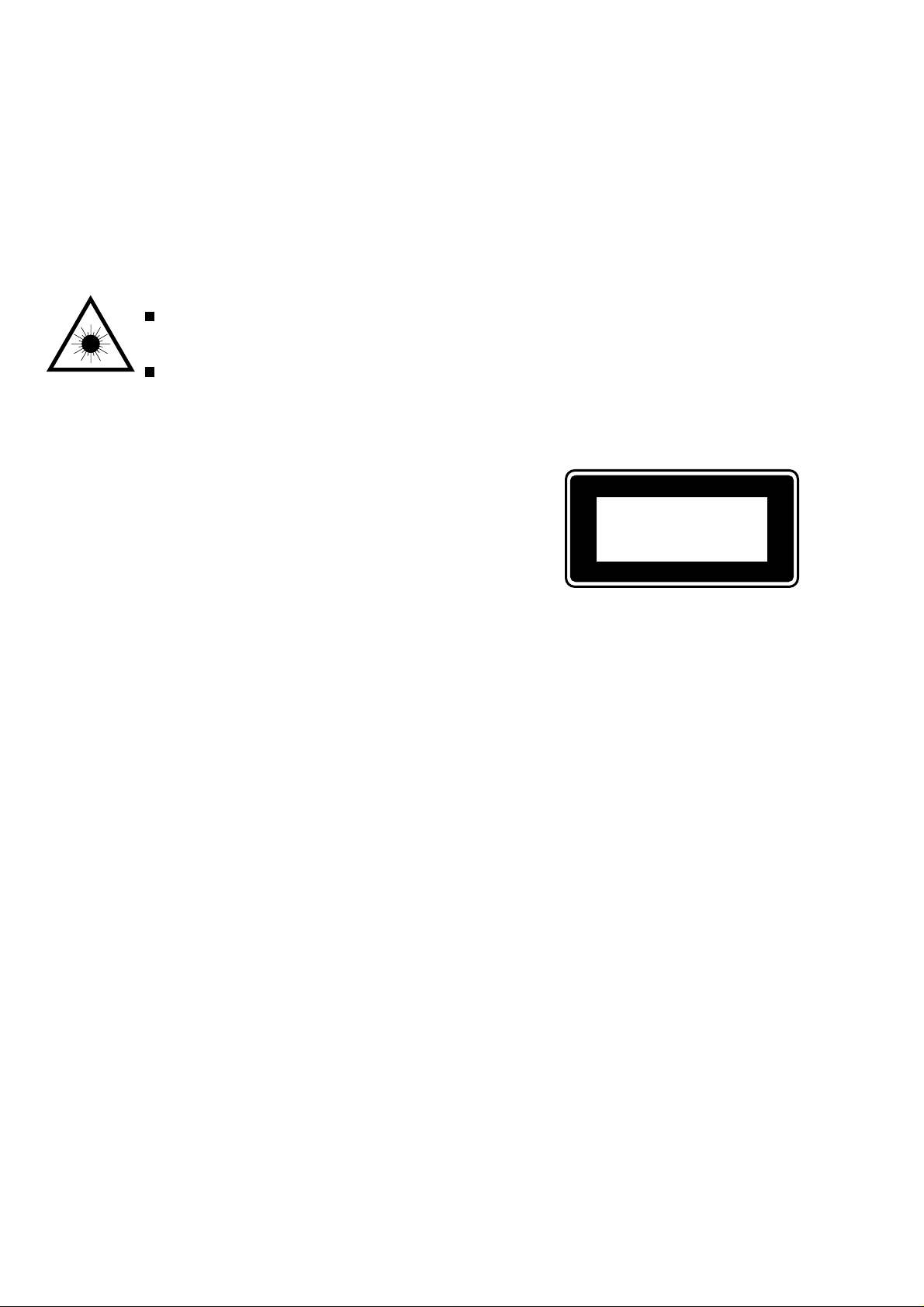

Precaution to replace Optical block

(SF-P101NR)

Body or clothes electrostatic potential could ruin

laser diode in the optical block. Be sure ground

body and workbench, and use care the clothes

do not touch the diode.

1) After the connection, remove solder shown in

the right figure.

PICK UP ASSY

SF-P101NR

Solder

1

16

TO/FROM MAIN C.B

-4-

Page 5

ELECTRICAL MAIN PARTS LIST-1/3

REF. NO PART NO. KANRI DESCRIPTION

NO.

IC

87-A21-271-010 IC,TA2111N<USC>

87-A20-212-010 IC,TA8127N<EXCEPT USC>

87-A20-569-010 IC,BA3308

8B-CDC-618-010 C-IC,LA9250ML

8B-CDC-619-010 C-IC,LC78602E

8B-CDC-636-010 C-IC,MM1469XH

8B-CDC-621-010 IC,UTC6650

87-A21-193-010 IC,TA8227P

87-A21-241-010 IC,MC14551BCP<140LHSC>

TRANSISTOR

8B-CDC-616-010 TR,3CG9012

8B-CDC-611-010 TR,2SD1936

8B-CDC-617-010 TR,3DG9013

89-318-155-080 TR,2SC1815GR

8A-RU2-602-010 TR,3DA8050

87-A30-015-080 TR,2SA1317(T/U)

87-026-215-080 TR,DTC114YS

8B-CDC-613-010 TR,2SA1346

8B-CDC-614-010 TR,2SB764

8A-RU2-604-010 TR,3CA8550

8B-RD3-607-010 TR,2SB562B

87-A30-090-080 FET,2SK2541

87-A30-168-010 TR,2SB1566F

DIODE

87-070-345-080 DIODE,IN4148

8Z-CA3-615-010 DIODE,1S2638<EXCEPT USC>

8B-CDC-631-010 ZENER,BZX55C6V8CECCL

8B-CDC-622-010 DIODE,GMB01

87-020-465-080 DIODE,1SS133(T-72)<USC>

8B-CDC-630-010 ZENER,WZ-033

87-A40-398-010 DIODE,1N4001

MAIN C.B

C101 87-A11-875-010 CAP,CER 24P-50 J SL<USC>

C101 87-A11-849-080 CAP,CER 27P-50 J CH<EXCEPT USC>

C103 87-A11-875-010 CAP,CER 24P-50 J SL

C104 88-254-242-010 CAP,CER 30P-50 J CH HE50S JCH

C105 87-A10-577-010 CAP,CER 0.022-50 Z YF

C106 87-A10-139-010 CAP,CER 18P-50 K CH<EXCEPT USC>

C106 88-RU7-634-010 CAP,CER 20P-50 J CH<USC>

C107 87-A10-577-010 CAP,CER 0.022-50 Z YF<USC>

C108 88-RU7-634-010 CAP,CER 20P-50 J CH

<EXCEPT 120LHSC,140LHSC>

C108 87-A11-847-080 CAP,CER 22P-50 J CH<140LHSC>

C108 87-A11-848-080 CAP,CER 24P-50 J CH<120LHSC>

C109 87-A10-129-010 CAP,CER 3P-50 K CH

C110 87-A10-577-010 CAP,CER 0.022-50 Z YF<120LHSC,140LHSC>

C113 87-010-265-080 CAP, ELECT 33-16V

C114 87-010-400-010 CAP, ELECT 0.47-50SME<EXCEPT USC>

C115 87-010-400-010 CAP, ELECT 0.47-50SME

C116 87-A10-176-010 CAP,CER 1000P-50 M D<EXCEPT USC>

C116 87-A11-146-080 CAP,TC U 0.022-50 Z F<USC>

C117 87-010-401-080 CAP, ELECT 1-50V<EXCEPT USC>

C118 87-010-401-080 CAP, ELECT 1-50V<USC>

C118 87-010-403-080 CAP, ELECT 3.3-50V<EXCEPT USC>

C119 87-010-400-010 CAP, ELECT 0.47-50SME<USC>

C119 87-010-401-080 CAP, ELECT 1-50V<EXCEPT USC>

C120 87-A10-176-010 CAP,CER 1000P-50 M D

C121 87-A10-577-010 CAP,CER 0.022-50 Z YF<EXCEPT USC>

C122 87-A10-577-010 CAP,CER 0.022-50 Z YF<EXCEPT USC>

C123 87-A12-366-080 CAP,M 0.015-100 J CP

C124 87-A12-366-080 CAP,M 0.015-100 J CP

C125 87-010-545-080 CAP, ELECT 0.22-50V

C126 87-010-545-080 CAP, ELECT 0.22-50V<USC,140LHSC>

REF. NO PART NO. KANRI DESCRIPTION

C127 87-A12-365-080 CAP,M 0.012-100 J CP<EXCEPT KSC,EZSC>

C127 87-A12-362-080 CAP,M 6800P-100 J CP<KSC,EZSC>

C128 87-A12-365-080 CAP,M 0.012-100 J CP

C128 87-A12-362-080 CAP,M 6800P-100 J CP<KSC,EZSC>

C129 87-A10-577-010 CAP,CER 0.022-50 Z YF

C130 87-A10-577-010 CAP,CER 0.022-50 Z YF<EXCEPT USC>

C140 87-A11-145-080 CAP,TC U 0.01-50 Z F<EXCEPT 140LHSC>

C141 87-A11-148-080 CAP,TC U 0.1-50 Z F<EXCEPT USC,140LHSC>

C142 87-A11-145-080 CAP,TC U 0.01-50 Z F<EXCEPT 140LHSC>

C143 87-A10-176-010 CAP,CER 1000P-50 M D<USC>

C144 87-A11-145-080 CAP,TC U 0.01-50 Z F<USC>

C145 87-A11-145-080 CAP,TC U 0.01-50 Z F<USC>

C152 87-A11-145-080 CAP,TC U 0.01-50 Z F<USC>

C155 87-A10-176-010 CAP,CER 1000P-50 M D

C180 87-010-248-010 CAP, ELECT 220-10V

C313 87-010-401-080 CAP, ELECT 1-50V

C314 87-010-401-080 CAP, ELECT 1-50V

C361 87-010-248-010 CAP, ELECT 220-10V

C362 87-010-263-080 CAP, ELECT 100-10V

C401 87-010-405-080 CAP, ELECT 10-50V

C402 87-A10-182-010 CAP,CER 0.01-50 Z F

C403 87-010-248-080 CAP, ELECT 220-10V

C403 87-010-248-080 CAP, ELECT 220-10V

C404 87-010-260-080 CAP, ELECT 47-25V

C405 87-A10-182-010 CAP,CER 0.01-50 Z F

C406 87-010-263-080 CAP, ELECT 100-10V

C407 87-010-546-080 CAP, ELECT 0.33-50V

C408 87-A10-182-010 CAP,CER 0.01-50 Z F

C409 87-010-263-080 CAP, ELECT 100-10V

C410 87-A12-370-080 CAP,M 0.033-100 J CP

C411 87-010-405-080 CAP, ELECT 10-50V

C413 87-010-263-080 CAP, ELECT 100-10V

C414 87-010-402-080 CAP, ELECT 2.2-50V

C415 87-A12-370-080 CAP,M 0.033-100 J CP

C419 87-A10-182-010 CAP,CER 0.01-50 Z F

C420 87-010-402-080 CAP, ELECT 2.2-50V

C424 87-A12-370-080 CAP,M 0.033-100 J CP

C426 87-010-544-080 CAP, ELECT 0.1-50V

C427 87-A10-179-010 CAP,CER 3300P-50 M E

C428 87-A12-371-080 CAP,M 0.039-100 J CP

C429 87-A11-782-080 CAP,M 0.1-100 J

C430 87-A11-782-080 CAP,M 0.1-100 J

C431 87-A10-176-010 CAP,CER 1000P-50 M D

C432 87-A11-782-080 CAP,M 0.1-100 J

C433 87-A12-370-080 CAP,M 0.033-100 J CP

C434 87-A10-179-010 CAP,CER 3300P-50 M E

C436 87-010-545-080 CAP, ELECT 0.22-50V

C437 87-010-401-080 CAP, ELECT 1-50V

C438 87-A10-179-010 CAP,CER 3300P-50 M E

C439 87-010-260-080 CAP, ELECT 47-25V

C440 87-A11-782-080 CAP,M 0.1-100 J

C441 87-A10-577-010 CAP,CER 0.022-50 Z YF

C442 87-010-221-080 CAP, ELECT 470-10V

C443 87-A10-182-010 CAP,CER 0.01-50 Z F

C444 87-010-263-080 CAP, ELECT 100-10V

C445 87-A10-577-010 CAP,CER 0.022-50 Z YF

C448 87-010-544-080 CAP, ELECT 0.1-50V

C453 87-A10-577-010 CAP,CER 0.022-50 Z YF

C454 87-010-263-080 CAP, ELECT 100-10V

C456 87-010-370-040 CAP,E 330-6.3 SME

C457 87-010-221-080 CAP, ELECT 470-10V

C459 87-010-263-080 CAP, ELECT 100-10V

C460 87-010-236-080 CAP,E 1000-10 SME

C461 87-010-403-080 CAP, ELECT 3.3-50V

C462 87-010-403-080 CAP, ELECT 3.3-50V

C465 87-A10-210-010 CAP,CER 0.047-50 M

C466 87-A10-176-010 CAP,CER 1000P-50 M D

C467 87-A10-182-010 CAP,CER 0.01-50 Z F

NO.

<EXCEPT KSC,EZSC,140LHSC>

<EXCEPT USC,140LHSC>

-5-

Page 6

ELECTRICAL MAIN PARTS LIST-2/3

REF. NO PART NO. KANRI DESCRIPTION

NO.

C481 87-A11-145-080 CAP,TC U 0.01-50 Z F<USC>

C484 87-A10-176-010 CAP,CER 1000P-50 M D

<EXCEPT USC,EZSC,140LHSC>

C485 87-A11-145-080 CAP,TC U 0.01-50 Z F

<EXCEPT 120LHSC,USC,140LHSC>

C486 87-010-263-080 CAP, ELECT 100-10V<EXCEPT KSC,EZSC>

C487 87-A11-148-080 CAP,TC U 0.1-50 Z F

<HRJSC,HRJPC,HRJLC,KSC,HSSC>

C488 87-A11-145-080 CAP,TC U 0.01-50 Z F

<EXCEPT 120LHSC,140LHSC>

C502 87-010-248-080 CAP, ELECT 220-10V

C503 87-A10-176-010 CAP,CER 1000P-50 M D

C505 87-010-263-080 CAP, ELECT 100-10V

C801 87-A11-891-080 CAP,CER 470P-50 J SL

C802 87-A11-891-080 CAP,CER 470P-50 J SL

C805 87-010-545-080 CAP, ELECT 0.22-50V

C806 87-010-545-080 CAP, ELECT 0.22-50V

C807 87-A10-176-010 CAP,CER 1000P-50 M D

C808 87-A10-176-010 CAP,CER 1000P-50 M D

C809 87-010-405-080 CAP, ELECT 10-50V

C810 87-010-405-080 CAP, ELECT 10-50V

C811 87-010-263-080 CAP, ELECT 100-10V

C812 87-010-263-080 CAP, ELECT 100-10V

C813 87-010-386-080 CAP,E 330-25 M SME

C814 87-010-386-080 CAP,E 330-25 M SME

C817 87-A12-380-080 CAP,M 0.22-100 J CP

C818 87-A12-380-080 CAP,M 0.22-100 J CP

C819 87-010-101-080 CAP, ELECT 220-16

C820 87-010-386-080 CAP,E 330-25 M SME

C821 87-010-401-080 CAP, ELECT 1-50V

C856 87-010-405-080 CAP, ELECT 10-50V

C857 87-010-237-080 CAP,E 1000-16 M SME

C858 87-010-388-080 CAP,E 1000-25 M SME

CF101 87-008-582-010 FLTR,SFU455B

CF102 87-008-261-010 FILTER, SFE10.7MA5-A<EXCEPT USC>

CF102 87-008-582-010 FLTR,SFU455B<USC>

CF103 87-A90-420-010 FLTR,CF CDA10.7MG1<USC>

CN310 8B-CDC-677-010 F-CABLE ASSY,7P 2 93MM

CN401 8B-CDC-660-010 CONN,16P V TOC-B

CN402 8B-CDC-661-010 CONN ASSY,6P CD-ME

CN403 8B-CDC-663-010 F-CABLE ASSY,5P 2 153MM

CN404 8B-CDC-664-010 F-CABLE ASSY,8P 2 153MM

CN801 8B-CDC-657-010 CONN,4P V SPK-0UT

CN851 8B-CDC-658-010 CONN,3P V BATT

CNH401 8B-CDC-665-010 FF-CABLE,16P 1 200MM

HP801 8B-CDC-629-010 JACK,HTJ035-08D

L101 8B-CDC-640-010 COIL,FMRF4T5MM

L102 8B-CDC-639-010 COIL,FMOSC3T5MM

L103 8B-CDC-640-010 COIL,FMRF4T5MM

L104 8B-CDC-673-010 COIL,AM IFT

L105 87-005-849-080 COIL,10UH(CECS)<EXCEPT USC>

L402 87-005-684-080 COIL,10UH J LF0.5S

L803 87-005-680-080 COIL,4.7UH J LF5.0S<EXCEPT 140LHSC>

LF401 87-A90-133-010 SW LEAF LSA1120JAU

R475 87-029-366-090 FUSING RESISTOR, 1/2W-4.7 F

SW101 8B-CDC-644-010 SW,SL 2-2-2 SK22F03G9AA

SW102 8B-CDC-644-010 SW,SL 2-2-2 SK22F03G9AA

SW801 8B-CDC-643-010 SW,SL 2-4-3 SK43D01G9AA

T101 8B-CDC-672-010 COIL,AM OSC

T102 8B-CDC-674-010 COIL,FM IFT1<EXCEPT USC>

T103 8B-CDC-673-010 COIL,AM IFT<EXCEPT USC>

T103 8B-CDC-688-010 IFT, 4A-224R<USC>

T105 8B-CDC-675-010 COIL,FM DET<EXCEPT USC>

VC101 8B-CDC-671-010 TUN-CAP,20P-126P DF443DF02-A04

VR101 8B-CDC-634-010 SFR,10K<EXCEPT USC>

VR501 8B-CDC-633-010 SFR,500 H

VR801 8A-RU2-661-010 VR,50KC

WH401 8B-CDC-662-010 F-CABLE ASSY,2P 2 253MM

X401 8Z-CD5-633-010 VIB, CER16.93MHZ FCR16.93M2

REF. NO PART NO. KANRI DESCRIPTION

RECTIFIER C.B

C851 87-A10-182-010 CAP,CER 0.01-50 Z F

C852 87-A10-182-010 CAP,CER 0.01-50 Z F

C853 87-A10-182-010 CAP,CER 0.01-50 Z F

C854 87-A10-182-010 CAP,CER 0.01-50 Z F

C855 87-010-388-080 CAP,E1000-25 M SME

CASETTE C.B

C216 87-010-248-080 CAP, ELECT 220-10V

C219 87-A10-176-010 CAP,CER 1000P-50 M D

C301 87-010-405-080 CAP, ELECT 10-50V

C302 87-010-405-080 CAP, ELECT 10-50V

C303 87-A10-179-010 CAP,CER 3300P-50 M E

C304 87-A10-179-010 CAP,CER 3300P-50 M E

C305 87-010-382-080 CAP,E 22-25 M 11L SME

C306 87-010-382-080 CAP,E 22-25 M 11L SME

C307 87-A12-369-080 CAP,M 0.027-100 J CP

C308 87-A12-369-080 CAP,M 0.027-100 J CP

C309 87-010-404-080 CAP, ELECT 4.7-50V

C310 87-010-404-080 CAP, ELECT 4.7-50V

C311 87-A12-356-080 CAP,M 2200P-100 J CP

C312 87-A12-356-080 CAP,M 2200P-100 J CP

C315 87-010-221-080 CAP, ELECT 470-10V

C316 87-010-405-080 CAP, ELECT 10-50V

C317 87-A10-182-010 CAP,CER 0.01-50 Z F

C318 87-A10-182-010 CAP,CER 0.01-50 Z F

C323 87-A10-182-010 CAP,CER 0.01-50 Z F

C351 87-A11-112-080 CAP,TC U 1000P-50 J CH<140LHSC>

C352 87-A10-182-010 CAP,CER 0.01-50 Z F

C353 87-A10-182-010 CAP,CER 0.01-50 Z F

CN301 8B-CDC-659-010 CONN,4P V T-HEAD

SW301 8B-CDC-635-010 SW,SL 1-9-2 PS92D01

T351 87-CD8-605-010 COIL,OSC BIAS 4A363R

VR351 8B-CDC-634-010 SFR,10K

CD KEY&DISPLAY C.B

DP401 8B-CDC-624-010 LED,A505RDD

LED401 87-070-106-010 LED,SE3001DT R

SW401 8B-CDC-623-010 SW,TACT 1102B160G

SW402 8B-CDC-623-010 SW,TACT 1102B160G

SW403 8B-CDC-623-010 SW,TACT 1102B160G

SW404 8B-CDC-623-010 SW,TACT 1102B160G

SW405 8B-CDC-623-010 SW,TACT 1102B160G

SW406 8B-CDC-623-010 SW,TACT 1102B160G

BATTERY C.B

SENSOR C.B<140LHSC>

C201 87-010-378-080 CAP,E 10-16M 11L SME<140LHSC>

CN201 8B-CDN-601-010 CONN,3P REMOTE<140LHSC>

MOTOR C.B

M2 S0-M10-A09-700 MOTOR SLED ASSY

PIN3 S2-369-750-000 PLUG,6P

SW1 S4-S13-A01-600 SW,LEAF

NO.

-6-

Page 7

ELECTRICAL MAIN PARTS LIST-3/3

• Regarding connectors, they are not stocked as they are not the initial order items.

The connectors are available after they are supplied from connector manufacturers upon the order is received.

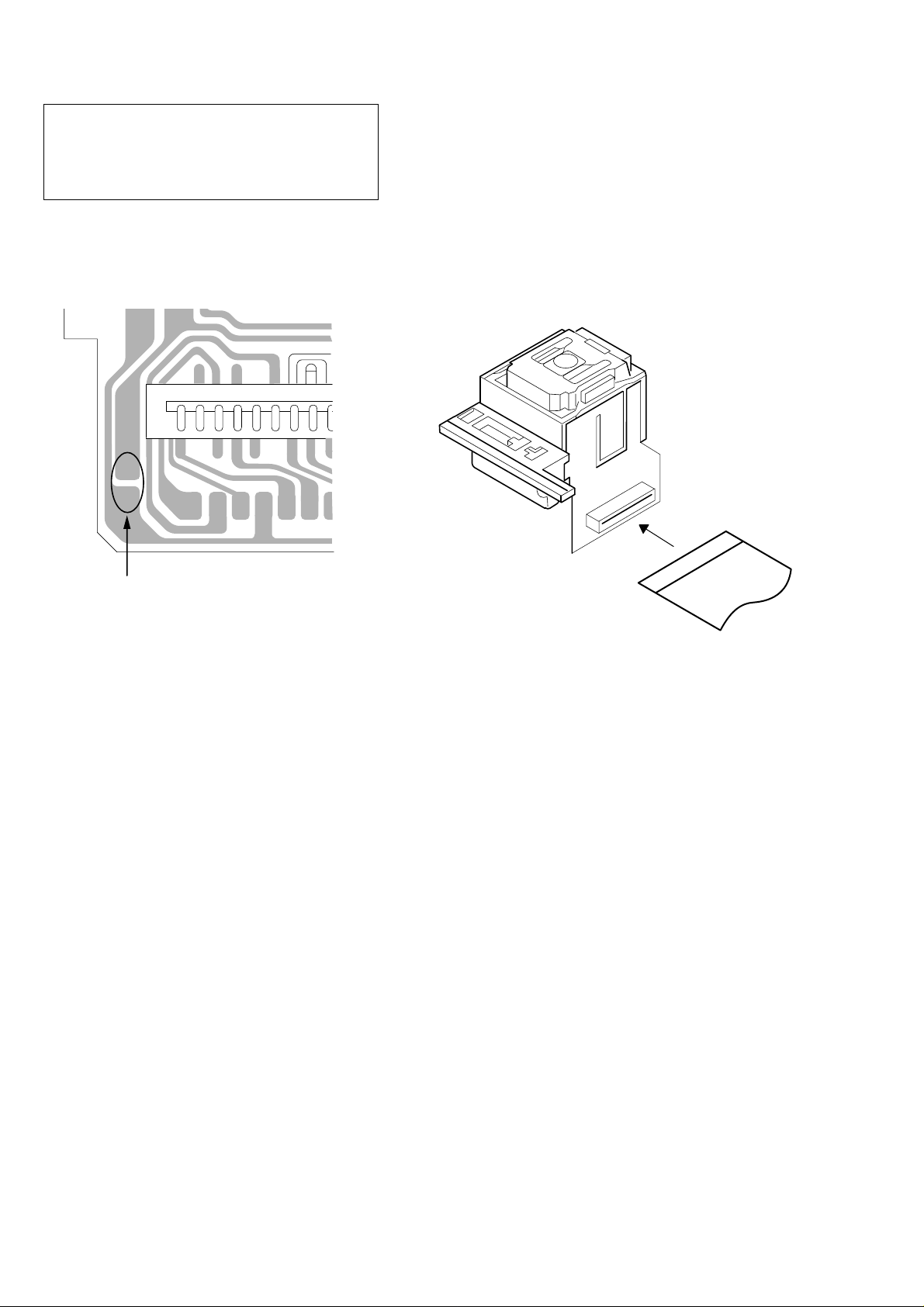

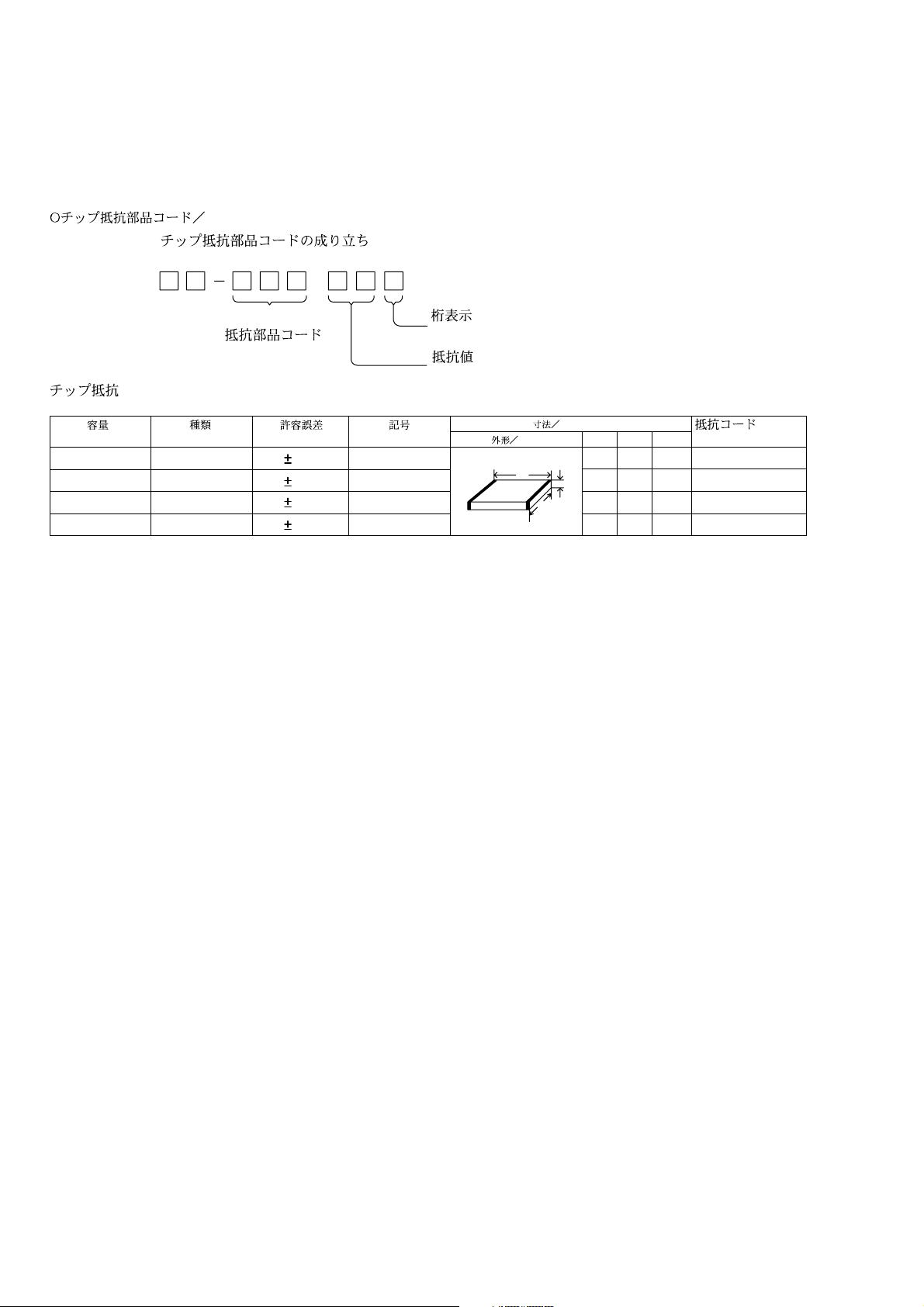

CHIP RESISTOR PART CODE

Chip Resistor Part Coding

88

A

Resistor Code

Chip resistor

Wattage Type Tolerance

1/16W 1005 5% CJ

1/16W

1/10W

1/8W

1608

2125

3216

5%

5%

5%

Symbol

CJ

CJ

CJ

Figure

Value of resistor

Form

L

Dimensions (mm)

t

W

0.55

Resistor Code

108

118

128

LW t

1.0 0.5 0.35 104

1.6 0.8 0.45

2 1.25 0.45

3.2

1.6

: A

: A

-7-

Page 8

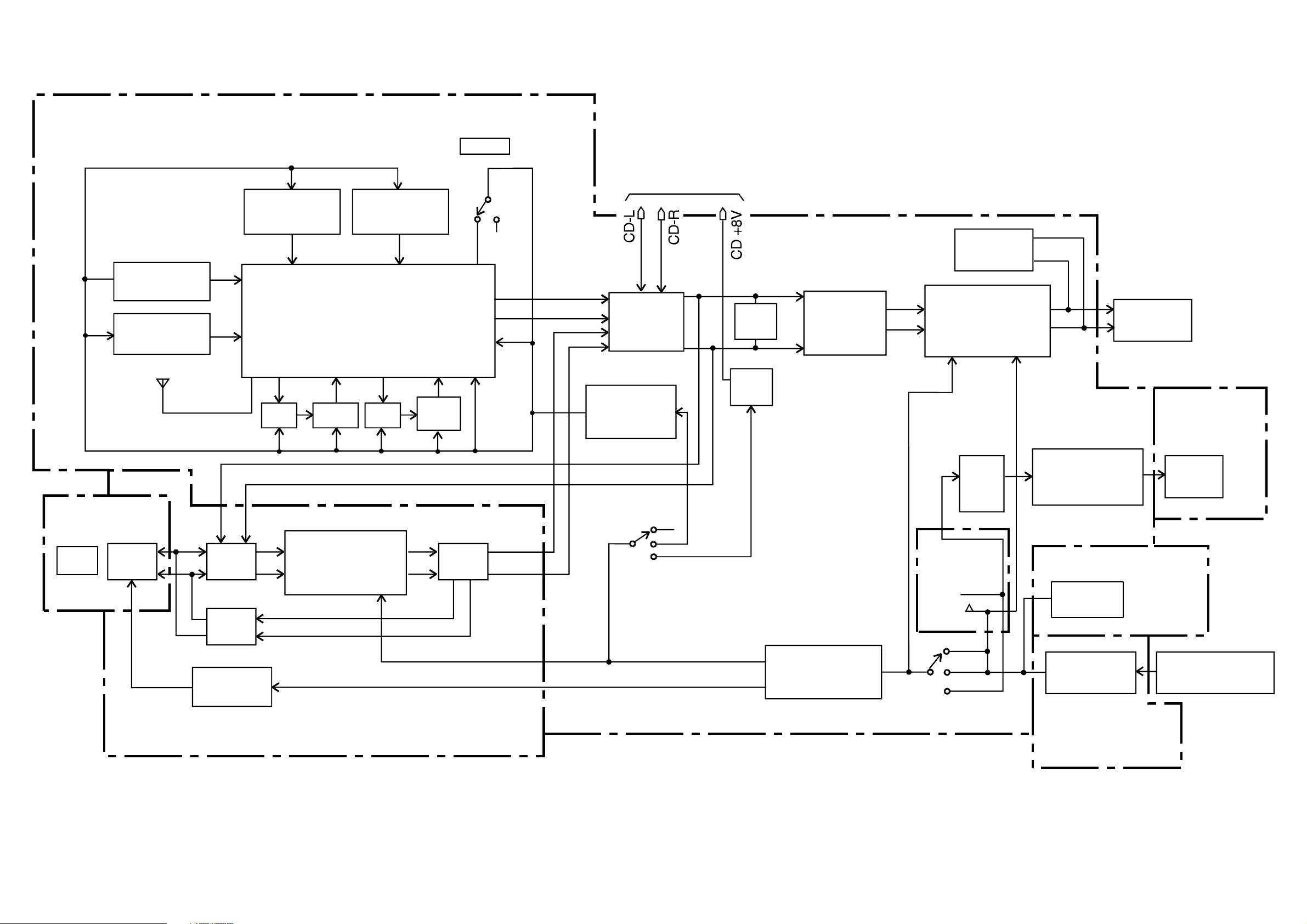

BLOCK DIAGRAM-1/2 (TUNER, CASETTE&POWER AMP)

MAIN C.B (1/2)

AMRF

L104,VC101B

FM RF

L103,VC101D

FM

ANT

MECHANISM

TN-9ZR-219 (1/3)

R/EHP

HEAD

T351,Q352

T101,VC101A

24

23

1

SW301

A.G

SW301

B.C

AC BIAS

AM OSC

20

MIX. IF AMP & DET

3

T102

2

IC301,BA3308

8

FM OS

L102, VC101C

21

IC101TA8127

8

CF102

PRE AMP

4

T103

6

VCC

3

7

C

7

CF101

455K

SW301

SW101

BAND

AM

16

13

14

22

6

D.E

FM

R-CH

L-CH

R-CH

L-CH

TO MAIN C.B (2/2)

SW802

B,D

REGULATOR

Q161,Q163

TAPE

SW801C

CD

RADIO

Q801

Q802

Q851

Q852

VOLUME

VR801

A,B

REGULA TOR

Q362,Q361,D363

PHONES

6

POWER AMP

IC801,TA8227

7

1

VCC2

Q502

Q501

D503

MECHANISM

TN-9ZR-219

(3/3)

SW501

LEAFSW

TAPE

RADIO

CD

SW801A

HP801

2

11

12

VCC1

MOTOR

3

REGULATOR

IC501,UT6650

BATTERY C.B

DC 12V

RECTIFIER

D851~D854

SPEAKER

MECHANISM

TN-9ZR-219 (2/3)

M501

2222

DECK

MOTOR

TRANSFORMER

CASETTE C.B

RECTIFIER

C.B

-8-

Page 9

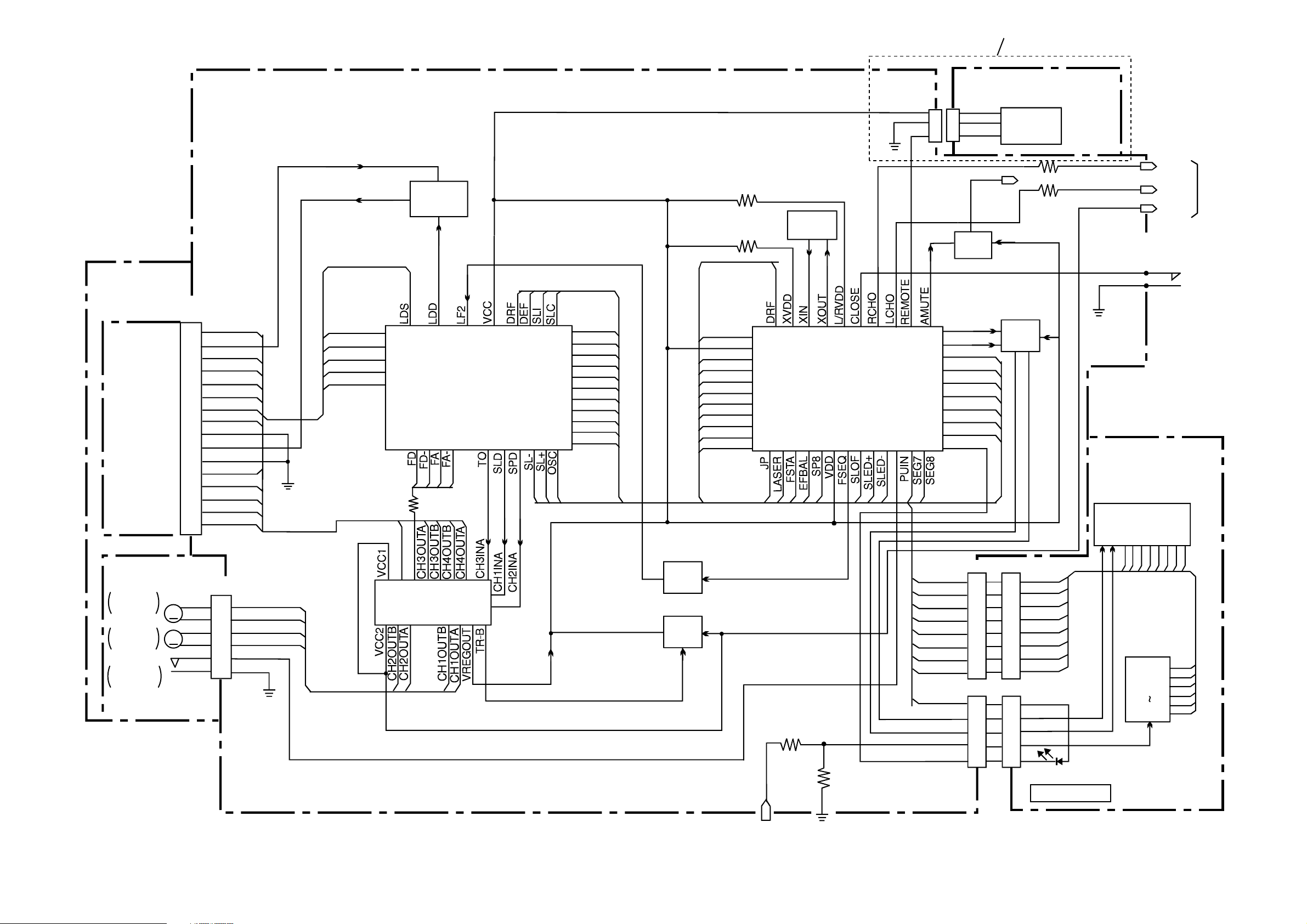

BLOCK DIAGRAM-2/2 (CD)

140LH

CD MECHANISM

DA11T3C

CN401

OPTIGAL

PICK UP

SF-P101NR

MAIN C.B (2/2)

VREF

1

COM

2

E

3

D

4

A

5

B

6

C

7

F

8

GND

9

LD

10

VR

11

MO

12

F+

13

T-

14

T+

15

F-

16

FIN2

FIN1

E

F

1

2

3

4

Q401

63

62

LA9250M

1718191520

59

ASP

IC401

56

525150

2826293031

LF2

45

49

44

43

42

41

40

38

37

36

35

33

CLV

HFL

TES

TOFF

TGL

TJP

LASER

FSTA

EFBAL

SP8

SLOF

DEF

VVDD

FR

VSS

EFMO

EFMIN

CLV

HFL

TES

TOFF

TGL

X40

1

16.934M

64

62

61

1

6

7

8

9

10

12

13

14

15

171819202122232526

16

60

DSP

IC402

LC78602E

55

58

575452

REM401

27

283231

SENSOR C.B

SENSOR

CN201

MUTE

Q407

42

51

41

44

38

37

36

35

34

33

43

DIG1

DIG2

KEYIN

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

PROG

Q405

Q406

RCH

LCH

+8V

LF401

LFSW

CD KEY &

DISPLAY C.B

LED DISPLAY

DP401

TO MAIN C.B (1/2)

MOTOR C.B

M3

SPINDLE

MOTOR

M2

SLED

MOTOR

SW1

INSIDE

LIMIT SW

M

M

CN402

SPIN+

1

SPIN-

2

SM+

3

SM-

4

PU-IN-SW

5

GND

6

CH4INA

BIAS IN

23

25

21

IC403

MM1469XH

22

11

12

17

18

216

26

27

3

10

19

5

IC403

DRIVER

+5V

-9-

Q403

Q404

+8V

+8V

TO MAIN C.B

(1/2)

CN404

DISP08

DISP07

DISP06

DISP05

DISP04

DISP03

DISP02

DISP01

CN403

KEYIN

DIG1

DIG2

PROG

8

7

6

5

4

3

2

1

1

2

3

4

5

CN4404

8

7

6

5

4

3

2

1

CN4403

1

2

3

4

5

KEY

MATRIX

SW401

SW406

LED401

PROGRAM

Page 10

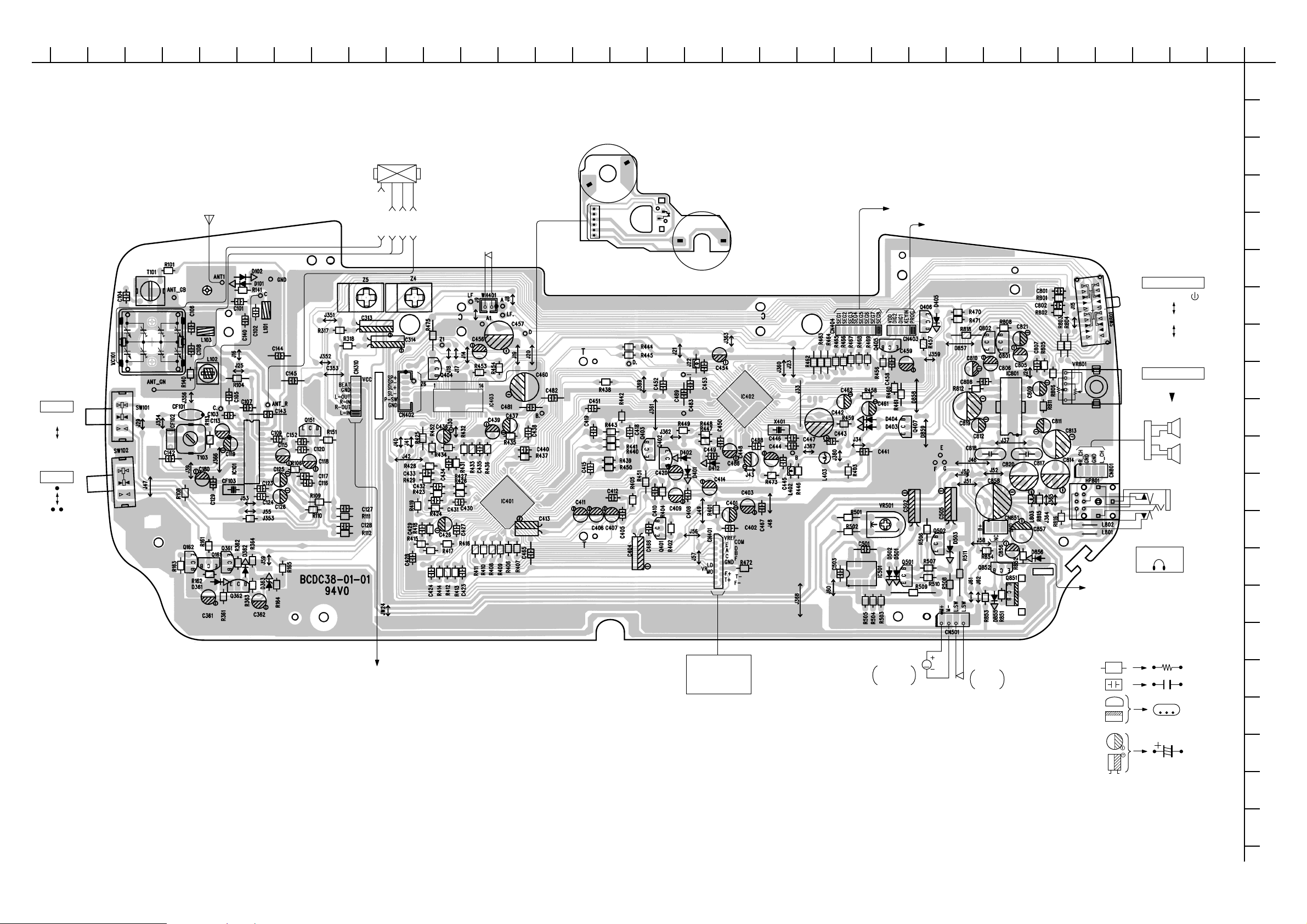

WIRING-1/4 (MAIN/U MODEL, MOTOR)

MAIN C.B

(INSERTED PARTS)

FM ANT.

L104

MW COIL

GRN

VIO

NATURAL

RED

LF401

LF SW

MOTOR C.B

(CONDUCTOR SIDE)

M2

+

_

6

PIN3

1

M2

(SLED MOTOR)

SW1

(INSIDE LIMIT SW)

SW1

(SPINDLE MOTOR)

_

M3

101112131415161718192021222324

1234567892526272829303132

A

B

C

D

TO CD KEY&DISPLAY C.B CN4404

+

TO CD KEY&DISPLAY C.B CN4403

E

SW101

BAND

AM

FM

SW102

OSC

M3

SW801

F

FUNCTION

TAPE

STANDBY

G

RADIO

A

B

D

C

1

5

1

24

13

12

1

6

778

15212228

32 33

17

16

48

49

1

64

32 33

17

16

1

1

2

16

15

48

49

64

85

1

11

CD

H

VR801

6

7

4

9

VOLUME

MAX

I

MIN

3

10

12

1

4

1

1

2

3

4

CNH801

SPK1

2W

(LCH)

SPK2

2W

(RCH)

J

K

L

3

1

M

HP801

PHONES

N

4

1

4

TO RECTIFIER C.B

CNH851

O

TO CASETTE C.B

CN302

-10-

OPTICAL

PICK UP

SF-P101NR

M501

DECK

MOTOR

M

SW501

LEAF

SW

TATE MECHANISM

TN-9ZR-219 (2/2)

NOTE

Rxx

E C B

E C B

P

Q

E C B

R

S

T

U

Page 11

WIRING-2/4 (MAIN/EXCEPT U MODEL, MOTOR)

MAIN C.B

(INSERTED PARTS)

FM ANT.

L104

MW COIL

GRN

VIO

NATURAL

RED

LF401

LF SW

MOTOR C.B

(CONDUCTOR SIDE)

M2

+

_

6

PIN3

1

M2

(SLED MOTOR)

SW1

(INSIDE LIMIT SW)

SW1

(SPINDLE MOTOR)

_

M3

101112131415161718192021222324

1234567892526272829303132

A

140LH

SENSOR C.B

B

(INSERTED PARTS)

C

1

D

TO CD KEY&DISPLAY C.B CN4404

TO CD KEY&DISPLAY C.B CN4403

+

E

F

SW101

BAND

AM

FM

SW102

OSC

M3

except

EZ,K

except

A

B

D

C

140LH

140LH

except

140LH

except

1

5

1

12

LH

except

140LH

24

13

except

140LH

1

6

778

15212228

32 33

17

16

1

64

LH

except

140LH

48

49

16

17

16

except

LH,EZ

2

1

15

32 33

1

except

EZ,K

except LH

64

except LH

48

49

140LH

1

58

1

4

6

7

4

9

3

10

1

12

4

1

3

TO RECTIFIER C.B

SW801

FUNCTION

TAPE

RADIO

CD

VR801

VOLUME

MAX

MIN

1

2

3

4

CNH801

HP801

PHONES

STANDBY

SPK1

2W

(LCH)

SPK2

2W

(RCH)

G

H

I

J

K

L

M

N

O

CNH851

TO CASETTE C.B

CN302

-11-

OPTICAL

PICK UP

SF-P101NR

M501

DECK

MOTOR

1

4

M

SW501

LEAF

SW

TATE MECHANISM

TN-9ZR-219 (2/2)

NOTE

Rxx

E C B

E C B

P

Q

R

E C B

S

T

U

Page 12

WIRING-3/4 (CASETTE, CD KEY&DISPLAY)

101112131415161718192021222324

1234567892526272829303132

CASETTE C. B

(R/PH)

1234

CNH301

14

E CGH F A DB

EHL CH R CH

ME CHANISM

TN-9ZR-219 (1/2)

19

A

B

C

D

E

F

1

7

CN310

TO MAIN C. B

G

H

I

DP401

CD TRACK

CD KEY&DISPLAY C. B

SW401 SW406 SW402

PROGRAM

NOTE

Rxx

J

K

L

M

N

O

P

Q

R

LED401

PROGRAM

11

TO MAIN C. B

CN404

TO MAIN C. B

CN403

-12-

SW405 SW404 SW403

REPEAT

E C B

E C B

S

E C B

T

U

Page 13

WIRING-4/4 (RECTIFIER, BATTERY)

123456789101112131415

BATTERY C. B

(INSERTED PARTS)

RECTIFIER C. B

(INSERTED PARTS)

DRT BATTERY

R20 X 8

DC 12V

A

B

C

D

E

F

G

H

I

U,EZ,K,HS

MODEL

LH,HRJ

MODEL

TU (U,EZ,K,HS)

TU

SW901

CNH851

AC

U : 120V 60Hz

HS : 220V 60Hz

EZ, K : 230V 50Hz

AC

110 - 120V

220 - 240V

50/60Hz

J

K

L

M

3

1

CN851

TO MAIN C. B

N

O

P

Q

NOTE

Rxx

R

S

E C B

E C B

E C B

T

SW901

VOLT AGE

SELECT

220 - 240V

110 - 120V

-13-

U

Page 14

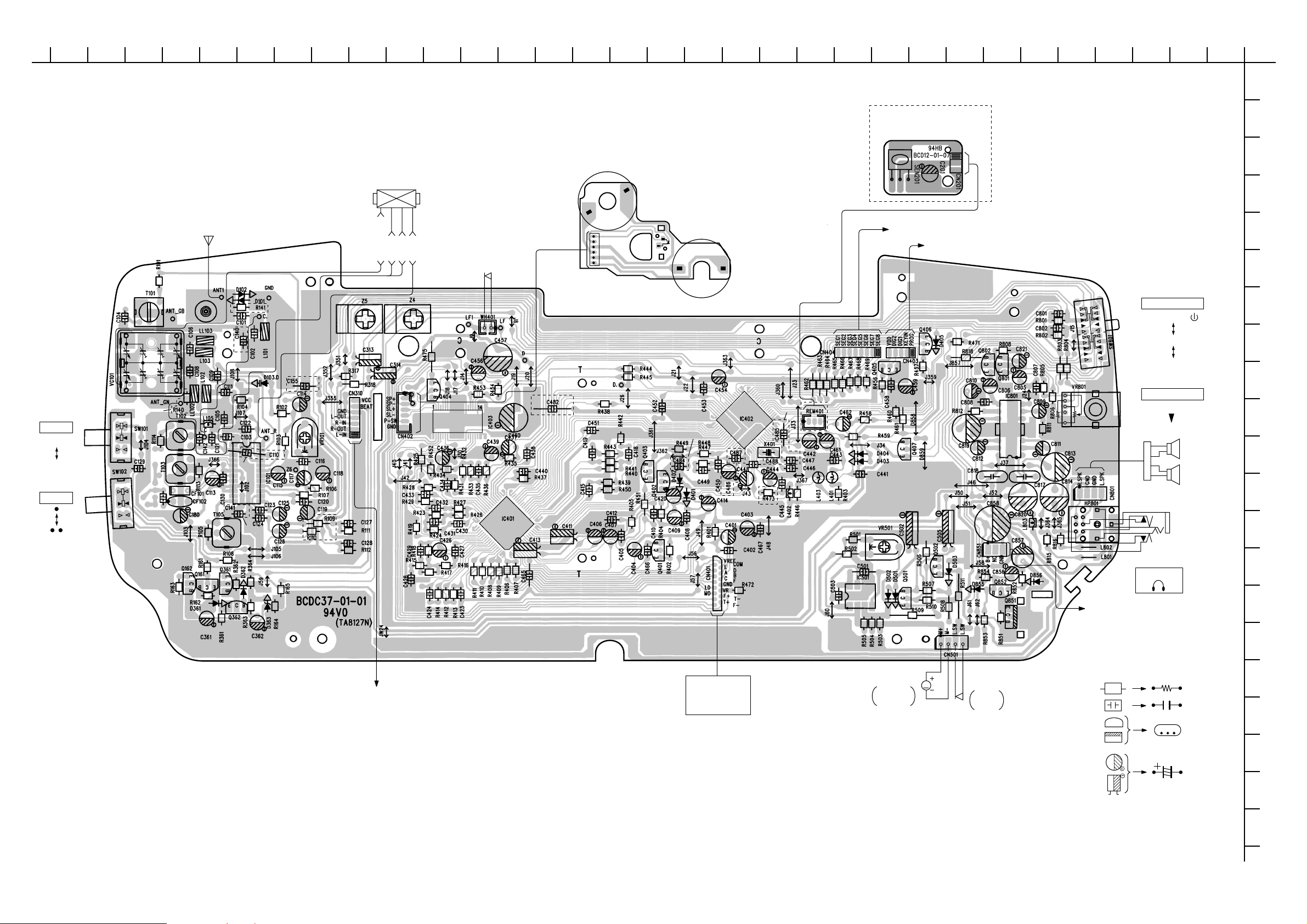

SCHEMATIC DIAGRAM-1/3 (TUNER U MODEL)

MAIN C.B (1/2)

T101,VC101A

AM FREQ. ADJ.

AM OSC

0.001 0.002

L104,VC101B

AM TRACKING ADJ.

0.01

0.01

50V

C322

100P

R

P

R

P

P

R

R

L103,VC101D

FM TRACKING ADJ.

FM RF

0.01

25V

47uF

0.027

6.8K

2200P

2200P

50V

4.7K

P

AM IFT

L102,VC101C

FM FREG. ADJ.

T103

AM IFT ADJ.

50V

4.7K

R

0.01

0.01

6.8K

MIX IF & DET

PRE AMP

R

4.7K

FM OSC

33uF

16V

P

SW301A-H

(REC/PB SW)

47uF

50V

P

R

C107

0.022

0.027

4.7K

25V

6.8K

1000P

P

0.47uF

50V

0.01

50V

FM SW

0.01

3300P

0.01

R

50V

0.022

3.3K

10V

50V

0.022

0.1

1.5K

1.5K

BAND

0.0150.015

CN302

CN310

F-CABLE

50V

50V

5.6K

OSC

5.6K

0.012

8.2K

0.012

REG

REG

STANDBY

50V

FUNCTION

FUNCTION

FUNCTION

STANDBY

50V

STANDBY

6.8K

3.3K

3.3K

50V

VOLUME

VOLUME

WZ-033

4.7K

MUTE

MUTE

50V

50V

REG

50V

1000P

1000P

REG

REG

REG

10uF 50V

10uF 50V

TO MAIN C.B (2/2)

POWER

AMP

MOTOR

REG

1000P

0.022

100V

0.1

0.022

100V

9.1K

VR501

NORMAL TAPE

SPEED ADJ.

JW

JW

PHONES

(LCH)

(RCH)

MECHANISM

TN-9ZR-219(2/2)

L

MECHANISM

TN-9ZR-219(1/2)

3.3K

0.047uF

100V

FREQ. ADJ.

T351

AC BIAS

0.01

BEAT

SW

CASETTE C.B

AC BIAS LEVEL

0.01

0.01

AC BIAS

R

P

ADJ.

10V

REG

1.8K

10V

REG

FUNCTION

SIGNAL :

STANDBY

: PB/FM

RECTIFIER C.B

BATTERY C.B

R20X8

DC 12V

TU

D857

1N4001

AC 120V,60Hz

AC~

: REC/AM

-14-

Page 15

SCHEMATIC DIAGRAM-2/3 (TUNER EXCEPT U MODEL)

X : NO MOUNT

Ref. No.

HRJ

50V

STANDBY

25V

C108

C110

C127,128

C140

C141

C155

C351

R109,110

R111,112

R140

R141

L803

20P

X

0.012 0.0126800P

50V

6.8K

3.3K

VOLUME

VOLUME

50V

3.3K

WZ-033

MAIN C.B (1/2)

T101,VC101A

AM FREG. RANGE ADJ.

L103,VC101D

FM FREQ.TRACKING ADJ.

VC101

TUNING

L104,VC101B

AM TRACKING ADJ.

50V

C322

100P

R

C

P

R

P

P

R

R

25V

0.027

6.8K

2200P

2200P

4.7uF

50V

P

4.7K

AM OSC

0.022

0.022

R

0.01

0.01

50V

4.7K

AM IFT

FM IF ADJ.

PRE AMP

P

R

4.7K

(REC/PB SW)

L102,VC101C

FM FREG. RANGE ADJ.

R140

C142

0.01

4.7uF

50V

0.027

4.7K

P

R

SW301A-H

6.8K

25V

VR101

VCO FREQ.ADJ.

BAND

OSC

REG

REG

0.022

STANDBY

STANDBY

50V

FUNCTION

SW801

SW801

FUNCTION

FUNCTION

3.3uF

1000P

50V50V

50V

50V

30P

15

AM IF ADJ.

0.01

50V

3300P

C

R

P

16V

1000P

50V

MIX IF & DET

1.5K

1.5K

50V

0.015

77

1

CN302

4.7K

1

F-CABLE

0.015

FM DET

CN310

C351

50V

FM IF ADJ.

0.022

0.022

120 LH

24P

0.022

0.01

0.1

1000P

X

2.7K

X

4.7µH

K

10V

EZ HS

20P

X

X

4.7K

MUTE

MUTE

50V

140 LH

22P

0.022

X

X

X

1000P

X

8.2K8.2K 15K

33K

1K1K

Jamper

REG

REG

1000P

1000P 10uF 50V

REG

REG

50V

50V

10uF 50V

TO MAIN C.B (2/2)

123 4

876 5

POWER

AMP

MOTOR

REGULATOR

0.022

100V

0.022

100V

1000P

10V

10V

9.1K

0.1

VR501

NORMAL TAPE

SPEED ADJ.

L803

PHONES

MECHANISM

TN-9ZR-219(2/2)

(LCH)

(RCH)

DECK

L

MECHANISM

TN-9ZR-219(1/2)

3.3K

0.047uF

50V

T351

AC BIAS

FREQ. ADJ.

0.001

BEAT

SW

CASETTE C.B

AC BIAS LEVEL

0.01

0.01

AC

BIAS

R

P

ADJ.

10V

REG

1.8K

10V

REG

STANDBY

FUNCTION

SIGNAL :

: PB/FM

: REC/AM

BATTERY

C.B

R20X8

DC 12V

D857 1N4001

RECTIFIER C.B

VCD139ENFN

VBCD12DSFN

TU (EZ,K)

TU (HS)

THERMAL FUSE

EZ, K: 230V 50Hz

HS: 220V 60Hz

AC~

TU (LH,HRJ)

VBCD12DSFN

110V/220V SW

SW901

THERMAL FUSE

SW901

VOLTAGE

SELECT

110-120V

220-240V

50/60Hz

AC~

-15-

Page 16

SCHEMATIC DIAGRAM-3/3 (CD)

MAIN C.B (2/2)

OPTIGAL

PICK UP

SF-P101NR

50V

0.01

0.01

10V

25V

10V

LD CONT

0.033 100V

0.1

2.2K

0.1 100V

1000P

3300P

0.01

50V

50V

6.8K

10V

0.033

100V

50V

ASP

4.7K

2.2uF

50V

10V

0.01

REG

0.033

2.2uF

50V

C487

C484

U

D412

1SS133

0.1

0.1

U

10V

0.022

10V

R473

50V

1.2K

0.01

L402

10uH

C445

0.022

4.7K

C485

J34

100

1

1

2

2

3

3

CN201REM401

C488

0.01

EXCEPT LH

MUTE SW

3.3uF 50V

3.3uF 50V

SEN201

MC14551

BCP

C201

10uF

16V

2.2K

2.2K

X : NO MOUNT

Ref.No.

HRJ

R473

150

C486

C485

C484

C487

X

E 100/10V E 100/10V

0.01 0.01

0.001 0.001

0.1 0.1 0.1

SENSOR

C.B

K

EZ HS

U

220

150

X

X

X

X

140 LH

TO MAIN C.B (1/2)

140 LH120 LH

X

X

X

XX

WH401

CD

MECHANISM

DA11T3C

MOTOR

C.B

M3

SPINDLE

MOTOR

SLED

M2

MOTOR

INSIDE

SW1

LIMIT SW

10V

C489

5V REG

0.1

U

EQ SW

0.022

10V

10V

C483

0.1

EXCEPT

U,LH

U

TO MAIN C.B (1/2)

3.9K

3.9K

Q405,406

DRIVER

SW401

SW402

SW403

SW404

SW405

PROGRAM

LED401

LHU

A505

RDD

CD TRACK

SW406

REPEAT

PROGRAM

CD KEY &

C482 0.1

C482 0.1

DISPLAY

0.1 100V

0.1

100V

1000P

IC403

MOTOR COIL

DRIVER

PIN3

M

M

100V

8.2K

0.033

100V

1.5K

0.1

3300P

2.7K

5.6K

50V

50V

1.8K

10V

25V

3300P

IN4148

J363

2.2µH

0.1

C481

0.01

U

6.3V

C.B

-16-

SIGNAL :

: PB

Page 17

TRANSISTOR ILLUSTRATION-1/1

ECB ECB ECB

2SC1815

BCE

2SB1566

DTC114YS

2SD1936

ECB ECB

3CA8550

3CG9012

2SB764

2SA1317

2SA1346

3DA8050

3DG9013

SDG

2SK25412SB562

-17-

Page 18

IC BLOCK DIAGRAM-1/1

IC, BA3308

IC, MM1469XH

IC, TA8127N

28 27 26 25 24 23 22

10k

13k

Level shift

10k

T.S .D

10k

Level shift

13k

10k

1 2 3 4 5 6 7

Vcc

21 20 19 18 17 16 15

10k

Vcc

13k

Level shift

50k

DRIVER MUTE

50k

Level shift

13k

10k

8 9 10 11 12 13 14

IC, TA2111N

MPX IN

AGC

DET OUT

AF

BUFF

FM

MUTE

AM

DET

AM

IF

AM

IF INFMIF IN

AF

VCO

DIVIDE

LEVEL

FM

DET

DET

FM

IF

TUN

LEDSTLED

AM RF IN FM RF OUT FM OSC AM OSC AFC LPF2 LPF1 L-OUT R-OUTRF VCC

24 23 22 21 20 19 18 17 16 15 14

AM

FM

OSC

OSC

AM

MIX

FM

RF

FM RF IN RF GND MIX OUT AGC VCC GND TUN LED ST LED QUADAM

LOW CUT

FM

MIX

-18-

DECODE

ST/MO

FM/AM

1110987654321 12

13

Page 19

VOLTAGE CHART-1/2

THE MEASURED VALUE IS DC VOLTAGE

UNIT: V

TUNER SECTION

TEST CONDITION: SET AM/FM TUNER ON ONE FREQUENCY

IC101 (TA8127N)

PIN'S NUMBER 123456789101112

AM 0.74 0 3.19 3.19 0 3.19 3.19 3.19 0 0 2.77 3.20

FM 0 0 4.39 4.43 0.84 4.38 4.11 4.38 0 0 4.20 4.34

PIN'S NUMBER 13 14 15 16 17 18 19 20 21 22 23 24

AM 1.03 1.01 2.82 2.48 2.48 0.64 0.99 3.19 3.14 3.19 3.19 3.19

FM 1.05 1.03 3.77 4.22 3.87 0.70 1.37 4.34 4.41 4.41 4.41 4.41

TRANSISTOR Q161(9012) Q162(2SD1936)

EBCEBC

FM 7.03 6.34 6.95 0.33 0.88 6.34

CASSETTE & POWER SECTION

TEST CONDITION: TAPE PLAY

IC801 (TA8227P)

PIN'S NUMBER 123456789101112

PLAY 12.50 6.36 12.10 0 0.58 0 0 0.58 6.62 12.10 6.37 12.50

IC501 (UTC6650)

PIN'S NUMBER 12345678

2.03 3.31 3.37 3.17 0 0 1.45 0.69

IC301 (BA3308)

PIN'S NUMBER 123456789

1.84 0 1.85 0 0 6.71 1.88 0 1.85

TRANSISTOR Q352(8050C) Q362(2SD1936) Q361(9012)

EBCEBCEBC

TAPE PLAY 6.63 7.02 7.03 6.38 6.91 11.20 11.90 11.20 7.03

TAPE REC 0.06 7.00 0.65 6.36 6.91 10.80 11.50 10.90 7.00

TRANSISTOR Q501(9013G) Q502(2SB562)

EBCEBC

11.20 10.70 4.08 2.86 10.60 3.43

CD SECTION

TEST CONDITION: CD PLAY

IC402 (LC78602E)

PIN'S NUMBER 123456789101112

CD PLAY 0.02 0 1.60 0 1.59 4.93 0.36 0 2.46 2.40 0 2.60

PIN'S NUMBER 13 14 15 16 17 18 19 20 21 22 23 24

CD PLAY 0 1.56 0 4.93 2.50 4.90 0.43 0.43 0.03 4.93 4.93 0.03

PIN'S NUMBER 25 26 27 28 29 30 31 32 33 34 35 36

CD PLAY 0.03 0.05 0.06 4.90 2.50 1.78 2.93 2.93 4.88 2.93 2.93 0.95

PIN'S NUMBER 37 38 39 40 41 42 43 44 45 46 47 48

CD PLAY 3.00 0 0 2.80 2.75 4.91 4.91 0 0 0 0 0

PIN'S NUMBER 49 50 51 52 53 54 55 56 57 58 59 60

CD PLAY 0 0 4.93 2.00 0 1.74 4.20 0 1.76 0 0 1.80

PIN'S NUMBER 61 62 63 64

CD PLAY 2.00 4.92 4.92 4.85

-19-

Page 20

VOLTAGE CHART-2/2

IC401 (LA9250ML)

PIN'S NUMBER 123456789101112

CD PLAY 2.43 2.43 2.48 2.48 2.48 2.43 2.46 2.45 2.46 2.46 2.45 2.45

PIN'S NUMBER 13 14 15 16 17 18 19 20 21 22 23 24

CD PLAY 2.45 2.40 2.46 0 2.55 2.40 2.33 2.47 2.49 2.47 2.40 2.40

PIN'S NUMBER 25 26 27 28 29 30 31 32 33 34 35 36

CD PLAY 2.47 2.80 2.47 2.53 2.20 2.20 1.58 0.09 0 0.25 0.04 0.43

PIN'S NUMBER 37 38 39 40 41 42 43 44 45 46 47 48

CD PLAY 0.43 4.93 0.30 2.40 4.93 0.15 1.50 0 2.65 0 2.18 2.45

PIN'S NUMBER 49 50 51 52 53 54 55 56 57 58 59 60

CD PLAY 2.40 2.49 0 4.85 2.45 2.45 0 4.93 2.40 2.45 2.25 2.25

PIN'S NUMBER 61 62 63 64

CD PLAY 2.20 3.47 0.18 0.80

IC403 (MM1469XH)

PIN'S NUMBER 123456789101112

CD PLAY 2.89 2.95 2.53 2.48 5.33 5.08 4.73 0 2.48 2.78 3.36 2.56

PIN'S NUMBER 13 14 15 16 17 18 19 20 21 22 23 24

CD PLAY 0 6.06 0.81 0.83 2.93 3.00 2.48 2.46 6.56 6.56 2.47 2.47

PIN'S NUMBER 25 26 27 28

CD PLAY 2.49 2.96 2.93 0

TRANSISTOR Q404(2SB764) Q405(A8550) Q406(8550)

ECBECBECB

7.60 4.93 6.97 4.20 2.00 4.30 4.20 2.00 4.30

TRANSISTOR Q403(A1346) Q407(A1346)

ECBECB

4.90 2.20 4.90 4.90 4.90 0

-20-

Page 21

ELECTRICAL ADJUSTMENT-1/2 (U MODEL)

U MODEL

MAIN C.B

T101

2

L103

A

D

C

L102

IC101

T103

18

3

MW

COIL

L104

B

VC101

1

< TUNER SECTION >

1. AM IF Adjustment

Test point: IC101 (TA2111N) 18PIN

Adjustment location: T103

T103 ....................................................................... 455kHz

2. AM Frequency Range Adjustment

Test point: IC101 (TA2111N) 18PIN

Adjustment location: T101, VC101A

T101 ....................................................................... 517kHz

VC101A ............................................................... 1750kHz

3. AM Tracking Adjustment

Test point: IC101 (TA2111N) 18PIN

Adjustment location: L104, VC101B

L104 ............................................. 600kHz waveform max.

VC101B...................................... 1400kHz waveform max.

5

4

test

point

4. FM Frequency Range Adjustment

Test point: IC101 (TA2111N) 18PIN

Adjustment location: L102, VC101C

L102 ........................................................................87MHz

VC101C.................................................................109MHz

5. FM Tracking Adjustment

Test point: IC101 (TA2111N) 18PIN

Adjustment location: L103, VC101D

L103 ..............................................88MHz waveform max.

VC101D ......................................108MHz waveform max.

< DECK SECTION >

6. AC BIAS Frequency Adjustment

Test point: CN301 4PIN

Adjustment location: T351

T351 ................................................................ 60±0.5MHz

7. AC BIAS Level Adjustment

Test point: CN301 4PIN

Adjustment location: VR351

VR351 ................................................................... 14±0.5V

8. Normal Tape Speed Adjustment

Test point: HP801 (Headphone Jack)

Test Tape: B-111LNA

Adjustment location: VR501

VR501 .................................................................... 3000Hz

-21-

67

test point

6

7

T351

VR351

CASETTE C.B

CN301

4

MAIN C.B

HP801

VR501

8

Page 22

ELECTRICAL ADJUSTMENT-2/2 (EXCEPT U MODEL)

T351

VR351

CN301

4

67

6

7

test point

CASETTE C.B

8

VR501

HP801

MAIN C.B

EXCEPT U MODEL

MAIN C.B

T101

2

L104

MW

COIL

3

1

B

VC101

T102

T103

A

D

C

T105

L103

L102

11

IC101

19

VR101

4

< TUNER SECTION >

1. AM IF Adjustment

Test point: IC101 (TA8127N) 19PIN

Adjustment location: T103

(LH, HR, HS MODEL)

T103 ....................................................................... 455kHz

(EZ, K MODEL)

T103 ....................................................................... 465kHz

2. AM Frequency Range Adjustment

Test point: IC101 (TA8127N) 19PIN

Adjustment location: T101, VC101A

(LH MODEL)

T101 ....................................................................... 517kHz

VC101A ............................................................... 1750kHz

(HR, HS, K, EZ MODEL)

T101 ....................................................................... 513kHz

VC101A ............................................................... 1635kHz

3. AM Tracking Adjustment

Test point: IC101 (TA8127N) 19PIN

Adjustment location: L104, VC101B

L104 ............................................. 600kHz waveform max.

VC101B...................................... 1400kHz waveform max.

5. FM Frequency Range Adjustment

6. FM Tracking Adjustment

7. VCO Frequency Adjustment

6

5

7

~

6

7

test

point

test

point

1

Test point: IC101 (TA8127N) 19PIN

Adjustment location: L102, VC101C

(LH, HR, HS MODEL)

L102 ........................................................................87MHz

VC101C.................................................................109MHz

(K, EZ MODEL)

L102 .....................................................................87.3MHz

VC101C..............................................................108.3MHz

Test point: IC101 (TA8127N) 19PIN

Adjustment location: L103, VC101D

L103 ..............................................88MHz waveform max.

VC101D ......................................108MHz waveform max.

Test point: IC101 (TA8127N) 11PIN

Adjustment location: VR101

VR101 ........................................................... 76±0.05MHz

4. FM IF Adjustment

Test point: IC101 (TA8127N) 19PIN

Adjustment location: T102, T105

T102, T105 ...........................................................10.7MHz

< DECK SECTION >

6. AC BIAS Frequency Adjustment

Test point: CN301 4PIN

Adjustment location: T351

T351 ................................................................ 60±0.5MHz

7. AC BIAS Level Adjustment

Test point: CN301 4PIN

Adjustment location: VR351

VR351 ................................................................... 14±0.5V

8. Normal Tape Speed Adjustment

Test point: HP801 (Headphone Jack)

Test Tape: B-111LNA

Adjustment location: VR501

VR501 .................................................................... 3000Hz

-22-

Page 23

IC DESCRIPTION-1/2 (LA9250M)-1/2

Pin No. Pin Name I/O Description

1, 2

FIN2, 1

Pickup photodiode (focus, RF) connection.

I

10

11

12

13

14

15

16

17

18

3

4

5

6

7

8

9

E

F

TB

TE-

TE

TESI

SCI

TH

TA

TD-

TD

JP

TO

(NC)

FD

FD-

—

—

—

—

—

Pickup photodiode (tracking) connection.

I

TE signal DC component input. Pickup photodiode (tracking) connection.

I

TE signal gain setting resistor connection. A resistor is connected between this pin and TE.

TE signal output.

O

TES comparator input. Takes the bandpass filtered TE signal as its input.

I

Shock detection input.

I

Tracking gain time constant setting.

TA amplifier output.

O

In conjunction with the TD and VR pins, used to form the tracking phase compensation circuit

—

constant.

Tracking phase compensation setting.

Track jump signal amplitude setting.

Tracking control signal output.

O

No connection.

Focusing control signal output.

O

In conjunction with the FD and FA pins, used to form the focusing phase compensation circuit

I

constant.

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

FA

FA-

FE

FE-

SP

SPG

SP-

SPD

SLEQ

SLD

SLSL+

OSC

(NC)

SLOF

—

—

—

—

—

—

In conjunction with the FD- and FA- pins, used to form the focusing phase compensation circuit

O

constant.

In conjunction with the FA and FE pins, used to form the focusing phase compensation circuit

I

constant.

FE signal output.

O

FE signal gain setting resistor connection. A resistor is connected between this pin and FE.

I

CLV pin input signal inverted output.

Gain setting resistor connection. (12 cm spindle mode)

In conjunction with the SPD pin, spindle phase compensation time constant connection.

Spindle control signal output.

O

Sled phase compensation time constant connection.

Sled control signal output.

O

I

Sled feed signal input from the microcontroller.

I

Oscillator frequency setting.

No connection.

Sled servo off control input.

I

34

35

36

37

38

TGRF

SP8

EFBAL

FSTA

LASER

—

—

Tracking servo gain RF level follower function setting.

Spindle 8 cm/12 cm mode switching control from the DSP.

E/F balance adjustment signal input from the DSP.

I

Focus search control signal input from the DSP.

I

Laser on/off control from the DSP.

I

-23-

Page 24

IC DESCRIPTION-1/2 (LA9250M)-2/2

Pin No. Pin Name I/O Description

39

(NC)

—

No connection.

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

TJP

TGL

TOFF

TES

HFL

CLV

GND

RF

RF-

SLC

SLI

DEF

DRF

FSC

TBC

FSS

VCC

—

—

—

—

—

Track jump signal input from the DSP.

I

Tracking gain control signal input from the DSP.

I

Tracking off control signal input from the DSP.

I

TES signal output to the DSP.

O

Output for the HFL signal that indicates whether the main beam is positioned over pits or mirror.

O

CLV error signal input from the DSP.

I

GND.

RF output.

O

In conjunction with the RF pin, sets the RF gain and sets the EFM 3T compensation.

Output for control of the RF waveform data slice level according to the DSP.

O

Input for control of the RF waveform data slice level according to the DSP.

I

Disc defect detection output.

O

RF level detection output.

O

Focus search smoothing capacitor output.

O

E/F balance variation range setting.

Focus search mode setting.

VCC.

57

58

59

60

61

62

63

64

REFI

VR

LF2

PH1

BH1

LDD

LDS

(NC)

—

—

—

—

—

Reference voltage bypass capacitor connection.

Reference voltage output.

O

Disc defect detection time constant setting.

RF signal peak hold capacitor connection.

RF signal bottom hold capacitor connection.

APC circuit output.

O

APC circuit input.

I

No connection.

-24-

Page 25

IC DESCRIPTION-2/2 (LC78602E)-1/2

Pin No. Pin Name I/O Description

1

DEFI

I

Defect detection signal (DEF) input. (Must be connected to 0V if unused)

10

11

12

13

14

15

16

17

18

2

3

4

5

6

7

8

9

3 V/*5 V

PDO

VVSS

ISET

VVDD

FR

VSS

EFMO

EFMIN

TMOD

CLV

HFL

TES

TOFF

TGL

JP

LASER

—

—

—

—

—

I

Supply voltage selection input. (High: 3V operation, low: 5V operation)

O

PLL circuit pins PDO output current adjustment resistor connection.

Digital system ground. This pin must be connected to 0V.

O

Slice level control pins

I

I

Test input. This pin must be connected to 0V.

O

Disc motor control output. This is a 3-value output.

I

Track detection signal input. This is a Schmitt input.

I

Tracking error signal input. This is a Schmitt input.

O

Tracking off output.

O

Tracking gain switching output. A low level output raises the gain.

O

Track jump control output. This is a 3-value output.

O

Laser control. A pull-down resistor is built in.

Internal VCO control phase comparator output.

Internal VCO ground. This pin must be connected to 0V.

Internal VCO power supply.

VCO frequency range adjustment.

EFM signal output.

EFM signal input.

19

20

21

22

23

24

25

26

27

28

29

30

31-38

39

FSTA

EFBAL

SP8

VDD

FSEQ

PCK

SLOF

SLED+

SLED-

PUIN

DOUT

NC

*SEG8-1

VSS

—

—

—

O

FSTA control. A pull-down resistor is built in.

O

EFBAL control. A pull-down resistor is built in.

O

SP8 control. A pull-down resistor is built in.

Digital system power supply.

Synchronizing signal detection output. Outputs a high level if the synchronizing signal detected

O

from the EFM signal and the internally generated synchronizing signal match.

EFM data playback clock monitor. 4.3218 MHz when the phase is locked.

O

(Note that this output is only provided in test mode. This pin outputs a low level during normal

mode operation) (No connection)

O

Sled off control output.

O

Sled feed output.

I

Limit switch detection input. A pull-up resistor is built in. (No connection)

O

Digital output. (EIAJ format)

Unused pin. This pin must be left open.

O

Segment output (8)-(1). A pull-up resistor is built in.

Digital system ground. This pin must be connected to 0V.

40

41, 42

43

44

45, 46

47

NC

*DIG2, 1

*PROG

*KEYI1

NC

*RANDOM

—

—

Unused pin. This pin must be left open.

O

Common driver output (2), (1). A pull-up resistor is built in.

O

Program operation monitor. A pull-up resistor is built in.

I

Key matrix input (1). A pull-up resistor is built in.

Unused pin. This pin must be left open.

O

Random mode indicator output. (Low: random mode, high: modes other than random mode)

-25-

Page 26

IC DESCRIPTION-2/2 (LC78602E)-2/2

Pin No. Pin Name I/O Description

Remote controller identifier input (3). This pin functions as an output pin set to the low level

48

49

50

51

52

53

54

RMTSL3

EFLG

FSX

*AMUTE

REMOTE

RMTSL2

LCHO

I/O

O

O

O

I/O

O

during resets (when the *RES pin is low) and for a few milliseconds after the *RES pin switches

to the high level. Therefore, applications that will set this pin high must connect an external pullup resistor to this pin.

Monitor for C1, C2, single, and double error corrections.

(Note that this output is only provided in test mode. This pin outputs a low level during normal

mode operation) (No connection)

Outputs a 7.35 kHz synchronizing signal that is generated by dividing the crystal oscillator

output.

(Note that this output is only provided in test mode. This pin outputs a low level during

normal mode operation) (No connection)

Audio mute output signal.

I

Remote controller signal input.

Remote controller identifier input (2). This pin functions as an output pin set to the low level

during resets (when the *RES pin is low) and for a few milliseconds after the *RES pin switches

to the high level. Therefore, applications that will set this pin high must connect an external pullup resistor to this pin.

Left channel D/A converter output.

55

56

57

58

59

60

61

62

63

64

L/RVDD

L/RVSS

RCHO

CLOSE

RMTSL1

XOUT

XIN

XVDD

*RES

DRF

—

—

—

D/A converter power supply.

D/A converter ground. This pin must be connected to 0V.

O

Right channel D/A converter output.

I

Close switch detection input. A pull-up resistor is built in.

I

Remote controller identifier input (1). A pull-up resistor is built in.

O

Connections for a 16.9344 crystal element.

I

Crystal oscillator circuit power supply.

I

IC reset input. Applications must set this pin low temporarily when power is first applied.

I

DRF input.

-26-

Page 27

MECHANICAL EXPLODED VIEW-1/1

43

PWB

PWB

44

14

WIRE,

BINDER

41

40

J

42

D

D

M

C

C

D

S

D

38

34

C

HT-SINK

AMP

HT-SINK

REG.

P

33

O

O

39

H

47

46

J

37

O

O

C

C

C

K

C

J

WIRE,

JP1-25-313

D

27

PLATE,ANT

35

C

30

36

C

P

26

25

A

F

20

PWB

32

28

P

C

31

13

12

11

I

K

PWB

29

31

C

13

TN-9ZR-219

16

B

L

15

18

16

16

E

9

24

23

22

21

N

LF401

LEAF SWITCH

C

19

C

17

16

G

B

6

T

L

7

8

5

A140LHSC

4

45

PWB

R

3

2

33

PLA TE TRANS

A120HRJ

P

Q

P

Q

PWB

N

10

L

1

-27-

Page 28

MECHANICAL PARTS LIST-1/1

REF. NO PART NO. KANRI DESCRIPTION

NO.

1 8B-CDC-004-010 LENS,CASS<EXCEPT A120HRJPC,A120HRJLC>

1 8B-CDC-065-010 LENS,CASS BLUE<A120HRJLC>

1 8B-CDC-095-010 LENS,CASS PINK<A120HRJPC>

2 8B-CDC-003-010 LID,CASS<EXCEPT A120HRJPC,A120HRJLC>

2 8B-CDC-064-010 LID,CASS BLUE<A120HRJLC>

2 8B-CDC-094-010 LID,CASS PINK<A120HRJPC>

3 8B-CDC-007-010 BOX,CASS<EXCEPT A120HRJPC,A120HRJLC>

3 8B-CDC-068-010 BOX,CASS BLUE<A120HRJLC>

3 8B-CDC-098-010 BOX,CASS PINK<A120HRJPC>

4 8B-CDN-002-010 CABI,FR ASSY<A140LHSC>

4 8B-CDC-033-010 CABI,FR ASSY EX

<A120HRJSC,A120LHSC,A120USC,A120HSSC>

4 8B-CDC-061-010 CABI,FR ASSY EX BLUE<A120HRJLC>

4 8B-CDC-091-010 CABI,FR ASSY EX PINK<A120HRJPC>

4 8B-CDC-035-010 CABI,FR ASSY EZ<A120KSC,A120EZSC>

5 8B-CDC-022-010 PLATE,TU EZ<A120KSC,A120EZSC>

5 8B-CDC-023-010 PLATE,TU HR<A120HRJSC,A120HSSC>

5 8B-CDC-079-010 PLATE,TU HR BLUE<A120HRJLC>

5 8B-CDC-108-010 PLATE,TU HR PINK<A120HRJPC>

5 8B-CDC-020-010 PLATE,TU U<A120LHSC,A120USC,A140LHSC>

6 8B-CDC-217-010 SPR-P,REC

7 8B-CDC-216-010 SPR-T,CASS

8 8B-CDC-213-010 PLATE,CASS

9 8A-CM3-211-010 SPR-P,CASS

10 8B-CDC-204-010 HLDR,CD KEY

11 8B-CDC-006-010 KEY,CD<EXCEPT A120HRJPC,A120HRJLC>

11 8B-CDC-067-010 KEY,CD BLUE<A120HRJPC,A120HRJLC>

12 8B-CDC-018-010 PLATE,CD EX<EXCEPT A120HRJPC,A120HRJLC>

12 8B-CDC-077-010 PLATE,CD EX BLUE<A120HRJLC>

12 8B-CDC-107-010 PLATE,CD EX PINK<A120HRJPC>

13 8B-CDC-625-010 SPKR, 8OHM BCD-C

14 8B-CDC-030-010 PLATE,AC VOLTAGE<EXCEPT A120USC,

A120KSC,A120EZSC,A120HSSC>

15 8B-CDC-005-010 KEY,CASS SET

<EXCEPT A120HRJPC,A120HRJLC>

15 8B-CDC-066-010 KEY,CASS SET BLUE<A120HRJLC>

15 8B-CDC-096-010 KEY,CASS SET PINK<A120HRJPC>

16 8B-CDC-210-010 CUSHION,CD

17 M8-ZZK-E90-070 DA11T3C

18 8B-CDC-038-010 PANEL,CD(SANYO)

19 8B-CDC-203-010 HLDR,CD

20 8B-CDC-012-010 CHAS,CD<EXCEPT A120HRJPC,A120HRJLC>

20 8B-CDC-073-010 CHAS,CD BLUE<A120HRJLC>

20 8B-CDC-103-010 CHAS,CD PINK<A120HRJPC>

21 8B-CDC-207-010 BASE,CHUCK<EXCEPT A140LHSC>

21 8B-CDC-220-010 BASE,CHUCK (SANYO)<A140LHSC>

22 8B-CDC-206-010 HLDR,CHUCK

23 87-036-368-010 MAGNET

24 8B-CDC-208-010 PLATE,CHUCK

25 87-CD9-211-010 GEAR,

26 8B-CDC-215-010 SPR-T,CD

27 8B-CDN-004-010 LID,CD<A140LHSC>

27 8B-CDC-002-010 LID,CD

<EXCEPT A120HRJPC,A120HRJLC,A140LHSC>

27 8B-CDC-063-010 LID,CD BLUE<A120HRJLC>

27 8B-CDC-093-010 LID,CD PINK<A120HRJPC>

28 8B-CDC-014-010 POINTER,

29 8B-CDC-201-010 HLDR,TU

30 8B-CDC-205-010 HLDR,PWB

REF. NO PART NO. KANRI DESCRIPTION

31 8B-CDC-212-010 PLATE,SPKR

32 8B-CDC-016-010 KNOB,RTRY TU

32 8B-CDC-076-010 KNOB,RTRY TU BLUE<A120HRJLC>

32 8B-CDC-106-010 KNOB,RTRY TU PINK<A120HRJPC>

!

33 8B-CDC-610-010 PT,E<A120KSC,A120EZSC>

!

33 8B-CDC-609-010 PT,H<EXCEPT A120USC,A120KSC,A120EZSC>

!

33 8B-CDC-607-010 PT,U<A120USC>

34 8B-CDC-015-010 KNOB,RTRY VOL

34 8B-CDC-075-010 KNOB,RTRY VOL BLUE<A120HRJLC>

34 8B-CDC-105-010 KNOB,RTRY VOL PINK<A120HRJPC>

35 86-CS3-216-010 HLDR,BAR ANT

36 8B-CDC-642-010 BAR-ANT,AM

37 86-CS3-211-010 COVER, AC SOCKET

!

38 87-A60-178-010 JACK,AC E W/SW<EXCEPT A120USC>

!

38 8B-CDC-626-010 JACK,AC U<A120USC>

39 8B-CDC-010-010 CABI,REAR<EXCEPT A120HRJPC,A120HRJLC>

39 8B-CDC-071-010 CABI,REAR BLUE<A120HRJLC>

39 8B-CDC-101-010 CABI,REAR PINK<A120HRJPC>

40 8B-CDC-013-010 HANDL,<EXCEPT A120HRJPC,A120HRJLC>

40 8B-CDC-074-010 HANDL,BLUE<A120HRJLC>

40 8B-CDC-104-010 HANDL,PINK<A120HRJPC>

41 8B-CDC-679-010 ANT,ROD FM

42 8B-CDC-218-010 SPR,BATT (+/-)

43 8B-CDC-219-010 SPR,BATT (-)

44 8B-CDC-011-010 LID,BATT<EXCEPT A120HRJPC,A120HRJLC>

44 8B-CDC-072-010 LID,BATT BLUE<A120HRJLC>

44 8B-CDC-102-010 LID,BATT PINK<A120HRJPC>

45 8B-CDN-001-010 LENS,REMOTE CONTROL<A140LHSC>

46 86-CS3-210-010 COVER, VOLTAGE<EXCEPT A120USC,

!

47 87-A90-146-010 SW,SL 1-1-2<EXCEPT A120USC,

A 87-621-072-410 QT1+2.6-5

B 8B-CDC-211-010 S-SCREW,CD

C 87-745-095-410 SCREW UT2+3-8

D 87-651-103-410 SCREW VT1+3-25

E 87-571-033-410 TAPPING SCREW, VIT+2-4

F 87-251-033-410 U+2-4

G 87-641-038-410 UT1+2-12

H 87-741-094-410 UT2+3-6

I 87-261-072-410 V+2.6-5

J 87-265-095-410 V+3-8 NI

K 87-651-075-410 VT1 +2.6-10

L 87-651-036-410 VT1+2-8

M 87-651-073-410 VT1+2.6-6

N 87-751-035-410 VT2+2-6W/0 SLOT

O 86-CS3-218-010 W,3.5-14-0.5

P 86-CS3-217-010 NUT, M3X0.5P NI

Q 87-651-099-410 VT1+3-15<A120HRJSC,A120HRJPC,A120HRJLC>

R 87-751-096-410 VT2+3-10 GLD<A140LHSC>

S 87-581-096-410 UIT +3-10

T S9-C01-201-530 CAMERA SCREW M2-1.5

NO.

<EXCEPT A120HRJPC,A120HRJLC>

<EXCEPT A120HRJPC,A120HRJLC>

A120KSC,A120EZSC,A120HSSC>

A120KSC,A120EZSC>

<A120HRJSC,A120HRJPC,A120HRJLC>

-28-

Page 29

COLOR NAME TABLE

Basic color symbol Color Basic color symbol Color Basic color symbol Color

B Black C Cream D Orange

G Green H Gray L Blue

LT Transparent Blue N Gold P Pink

R Red S Silver ST Titan Silver

T Brown V Violet W White

WT Transparent White Y Yellow YT Transparent Yellow

LM Metallic Blue LL Light Blue GT Transparent Green

LD Dark Blue DT Transparent Orange GM Metallic Green

YM Metallic Yellow DM Metallic Orange PT Transparent Pink

LA Aqua Blue GL Light Green

-29-

Page 30

TAPE MECHANISM EXPLODED VIEW-1/1 (TN-9ZR-219)

42

H

-30-

Page 31

TAPE MECHANISM PARTS LIST-1/1 (TN-9ZR-219)

REF. NO PART NO. KANRI DESCRIPTION

NO.

1 S1-877-013-120 CHASSIS ASSY

2 S1-877-120-010 MOTOR PULLEY

3 S6-002-070-100 MOTOR FR-410CA-12250T

4 S1-877-010-170 AUTO LEVER

5 S1-877-010-190 AUTO LEVER SPR

6 S1-877-030-090 SPR,EARTH

7 S1-877-010-370 SPR,LEVER BTN STOP

8 S1-867-050-040 BELT,RF

9 S1-877-093-050 FLYWHEEL ASSY

10 S1-877-090-070 BELT,MAIN

11 S1-877-070-060 SPR,ARM PULLEY RF

12 S1-877-073-030 RF PULLEY ARM ASSY

13 S1-877-010-110 FR BUTTON LEVER SPR

14 S1-877-010-520 BTN,ACTUATOR

15 S1-877-010-060 STOP BUTTON LEVER

16 S1-877-010-230 LEVER,BTN FF

17 S1-877-010-240 LEVER,BTN RWD

18 S1-877-010-320 SPR,PLATE T GEAR

19 S1-877-010-250 LEVER,BTN REC

20 S1-877-040-010 PINCH ROLLER ARM

21 S1-877-040-070 PINCH ROLLER ASSY

22 S1-877-010-270 PLATE,SW

23 S1-877-010-310 SPR,ACTUATOR

24 S1-877-053-040 TAKE UP REEL ASSY

25 S1-821-103-4A0 GEAR T ROLLER

REF. NO PART NO. KANRI DESCRIPTION

NO.

26 S1-821-100-460 BACK TENSION SPR

27 S1-877-030-030 PANEL,HEAD

28 S1-877-040-080 PINCH ROLLER ARM SPR

29 S1-877-030-070 SPR,PANEL HEAD

30 S6-401-011-490 SW,LEAF MSW-1541T

31 S1-867-020-040 RPH COLLAR

32 S1-877-033-010 SENSING PLATE ASSY

33 S9-400-312-000 SPR,HEAD

34 S6-201-011-170 HEAD,RP-7442FS-1251

35 S1-877-030-050 ARM MG

36 S6-207-100-020 HEAD E TC-230AN(SL)

37 S1-877-020-010 LEVER,SAFETY REC

38 S1-821-100-700 GEAR,FF

39 S1-877-015-030 T ROLLER GEAR PLATE ASSY

40 S1-877-060-020 BACK TENSION SPR

41 S1-877-060-010 S REEL

42 8B-CDC-217-010 SPR-P,REC

A S9-817-000-000 SCREW AZIMUTH M2-4.3

B S9-210-000-000 SCREW,+/- M2-5

C S9-C33-172-030 CAMERA(SPECIAL) SCREW M2-1.7

D S9-999-000-010 P.WASHER 1.85-3.2-0.2

E S9-888-000-000 P.WASHER CUT 1.2-3-0.4

F S9-999-030-010 P.WASHER CUT 1.5-3.2-0.5

G S9-316-000-000 FH WASHER 2.1-5-0.2

H S9-C01-201-530 CAMERA SCREW M2-1.5

-31-

Page 32

CD MECHANISM EXPLODED VIEW-1/1 (DA-11T3C)

1

SW1

A

2

3

4

MOTOR C.B

M2

PIN 3

-32-

Page 33

CD MECHANISM PARTS LIST-1/1 (DA-11T3C)

REF. NO PART NO. KANRI DESCRIPTION

1 M8-ZZK-E90-070 DA11T3C

2 S2-121-A28-400 COVER GEAR

3 S2-511-A21-000 GEAR MIDDLE

4 S2-511-A21-100 GEAR,DRIVE

A S1-PN2-03R-OSE SCR PAN PCS 2-3

NO.

-33-

Page 34

ACCESSORIES/PACKAGE LIST-1/1

REF. NO PART NO. KANRI DESCRIPTION

1 8B-CDC-906-010 IB,EZ(9L)AL<A120EZSC>

1 8B-CDC-901-010 IB,H(ECA)AL

1 8B-CDC-931-010 IB,HS(K)AL<A120HSSC>

1 8B-CDC-905-010 IB,K(E)AL<A120KSC>

1 8B-CDN-902-010 IB,LH(ESP)AL<A140LHSC>

1 8B-CDC-902-010 IB,LH(ESP)AL<A120LHSC>

1 8B-CDC-903-010 IB,U(ESF)AL<A120USC>

!

2 87-A80-036-010 AC CORD SET ASSY,E W/FLTR VOL

!

2 87-A80-081-010 AC CORD SET ASSY,EZ BLK

!

2 87-A80-154-010 AC CORD SET,HS 250V 3A<A120HSSC>

!

2 87-A80-109-010 AC CORD,HK7281 BLK U<A120USC>

!

3 87-099-726-010 PLUG,ADPTR CONV(K)<A120KSC>

!

3 87-099-789-010 PLUG,ADPTR IR44<A140LHSC>

!

3 87-099-789-010 PLUG,ADPTR IR44<A120HRJSC,A120HRJPC,

4 8B-CDN-961-010 RC UNIT,RC-BAT01<A140LHSC>

NO.

<A120HRJSC,A120HRJPC,A120HRJLC>

<A140LHSC>

<EXCEPT A120USC,A120HSSC,A140LHSC>

A120HRJLC,A120LHSC>

-34-

Page 35

2–11, IKENOHATA 1–CHOME, TAITO-KU, TOKYO 110-8710, JAPAN TEL:03 (3827) 3111

H251701

Printed in Singapore

Loading...

Loading...