Aitecs SP-12S Pro, SEP-12S Plus, SEP-10S Plus User manual

SP-12S Pro, SEP-12S Plus,

SEP-10S Plus

SYRINGE INFUSION PUMPS

SERVICE MANUAL

BS037016EN-P02

CONTENTS

1. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. EXTERNAL VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4. KEYBOARD DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5. TECHNICAL DESCRIPTION

5.1. PRINCIPLE OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2. ELECTRICAL SCHEMATIC DIAGRAM OF THE PUMP . . . . . . . . . . . . . . 9

5.3. ELECTRICAL SCHEMATIC DIAGRAM

OF ELECTRONIC BOARD B7043 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6. SETUP MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7. CHECKING PARAMETERS

7.1. MEANS REQUIRED FOR PARAMETERS CHECKING . . . . . . . . . . . . . 19

7.2. CHECKING INFUSION VOLUME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.3. CHECKING INFUSION RATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.4. CHECKING BOLUS VOLUME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.5. CHECKING OCCLUSION PRESSURE . . . . . . . . . . . . . . . . . . . . . . . . . 21

8. CHECKING ALARM SIGNALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

9. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

10. PUMP REPAIR

10.1. DISASSEMBLING THE PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10.2. REPLACING INTERNAL BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10.3. REPLACING RUBBER BELLOWS . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10.4. REPLACING OPTICAL SENSOR TAX1 . . . . . . . . . . . . . . . . . . . . . . . . 33

10.5. REPLACING END SWITCH S1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10.6. REPLACING PRE-ALARM SWITCH S2 . . . . . . . . . . . . . . . . . . . . . . . . 33

10.7. REPLACING SYRINGE SENSOR S3 . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.8. REPLACING ELECTRONIC BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.9. REPLACING KEYBOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.10. REPLACING MICROCONTROLLER . . . . . . . . . . . . . . . . . . . . . . . . . 35

2

SP-12S Pro, SEP-12S Plus and SEP-10S Plus syringe infusion pumps

10.11. REPLACING SYRINGE SIZE SENSOR . . . . . . . . . . . . . . . . . . . . . . . 35

10.12. REPLACING BUZZER UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.13. REPLACING POWER SUPPLY INLET . . . . . . . . . . . . . . . . . . . . . . . . 36

10.14. REPLACING SUPPLY UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

ANNEX A

ELECTRICAL SCHEMATIC DIAGRAM

OF THE PUMPS SP-12S Pro and SEP-12S Plus . . . . . . . . . . . . . . . . . . . . . . . . . . 40

ANNEX B

ELECTRICAL SCHEMATIC DIAGRAM OF THE PUMP SEP-10S Plus . . . . . . . . . 42

ANNEX C

INTERCONNECTION DIAGRAM OF THE PUMPS . . . . . . . . . . . . . . . . . . . . . . . . 44

ANNEX D

ELECTRICAL SCHEMATIC DIAGRAM OF ELECTRONIC BOARD B7043 . . . 46

ANNEX E

ASSEMBLY DRAWING OF ELECTRONIC BOARD B7043 . . . . . . . . . . . . . . . . . . 52

ANNEX F

DRAWING OF CABLES FOR MULTIFUNCTIONAL CONNECTOR (MFC) . . . . . . 54

ANNEX G

DESCRIPTION OF ERRORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

ANNEX H

PREVENTIVE MAINTENANCE CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

ANNEX I

COMPONENT LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

ANNEX J

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

ANNEX K

COMMUNICATION PROTOCOL. TECHNICAL DESCRIPTION . . . . . . . . . . . . . . 59

Service manual

3

1. INTRODUCTION

u This SERVICE MANUAL describes how to check,

troubleshoot and repair SP-12S Pro, SEP-12S Plus and

SEP-10S Plus syringe infusion pumps. The purpose and

maintenance of the pumps are described in the appropriate OPERATING INSTRUCTIONS.

If when repairing your pump you have encountered problems, which you cannot solve, or the pump parameters are

changed after the repair, please, in all these cases contact

the manufacturer.

NOTE:

The manufacturer’s authorized personnel may carry

out the technical servicing of the pump only!

4

SP-12S Pro, SEP-12S Plus and SEP-10S Plus syringe infusion pumps

2. TECHNICAL DATA

Power supply:

220–230 VAC ±10%, 50/60 Hz, or 115 VAC ±10%, 50/60 Hz,

or internal rechargeable battery

Fuses:

T80 mA/L250 V – for 220–230 VAC

T160 mA/L250 V – for 115 VAC

Power consumption:

10 VA (max)

Internal battery:

9.6 V 1300 mAh NiMH battery

Cordless work time:

8 h (minimum) at 5 ml/h infusion rate;

2 h (minimum) at 100 ml/h infusion rate.

Battery recharging time: 24 hours.

Classification: Class II, CF, splash proof.

RS232 (optional)

12 VDC supply connection (optional)

Nurse Call connection (optional)

Operating temperature range:

+5 to +40 °C.

Storage temperature range:

-20 to +40 °C.

Air pressure:

60 to 106 kPa.

Relative humidity:

90% max., no condensation (operation and storage).

Dimensions:

135 x 305 x 195 mm

Weight:

2.6 kg.

Service manual

5

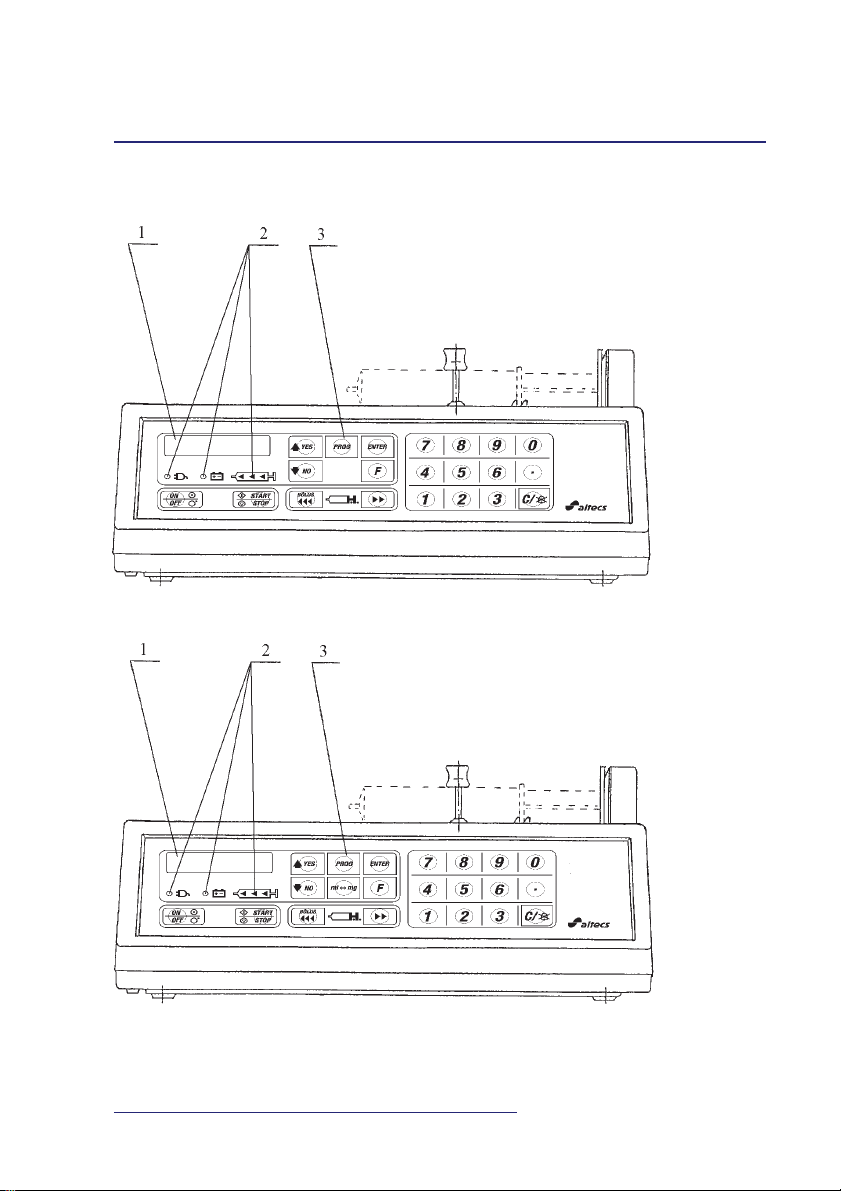

3. EXTERNAL VIEW

Fig. 1.

Front view of the pump SEP-10S Plus

Front view of the pumps SP-12S Pro, SEP-12S Plus

1 – display 2 – indicators 3 – keypad

6

SP-12S Pro, SEP-12S Plus and SEP-10S Plus syringe infusion pumps

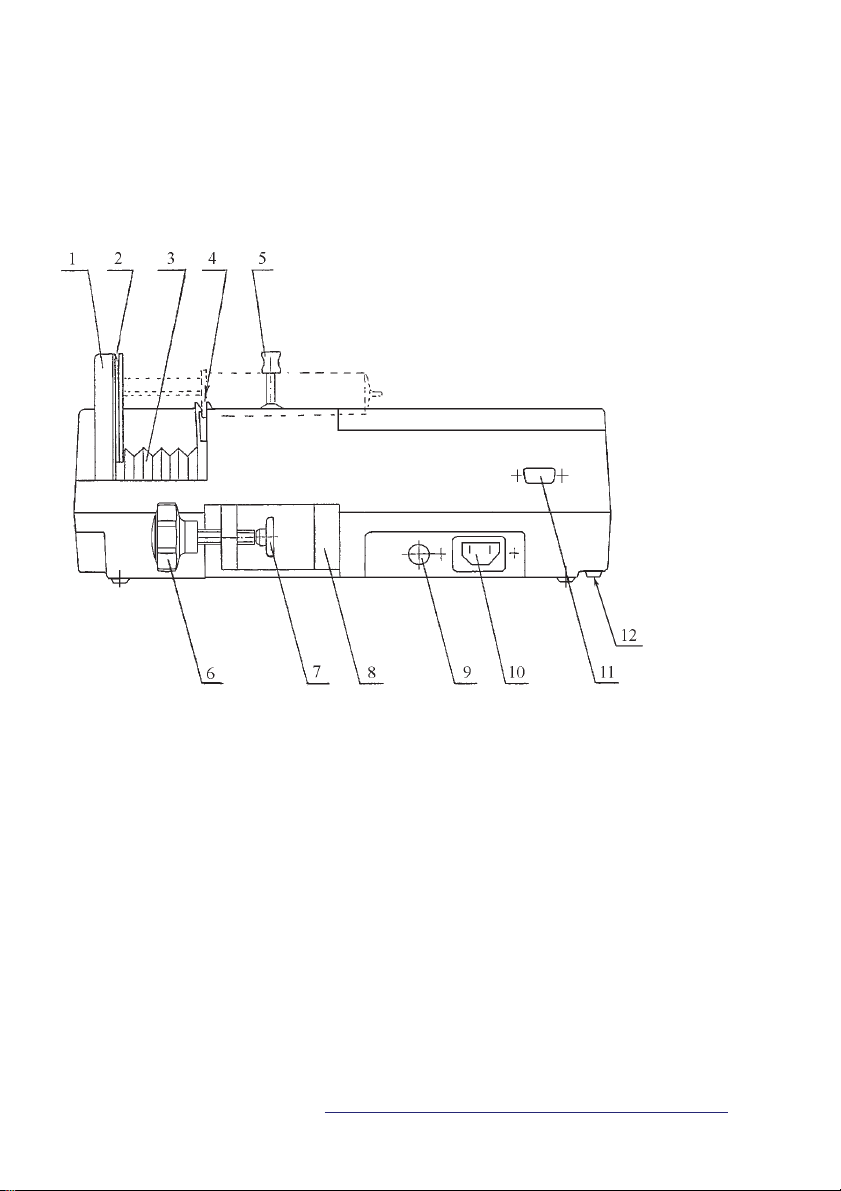

Fig. 2.

Rear view of the pumps SP-12S Pro, SEP-12S Plus and SEP-10S Plus

1 – syringe driver arm

2 – slot for inserting the push-

button of the syringe

plunger

3 – rubber bellows

4 – slot for inserting the finger

grips of the syringe barrel

5 – syringe clamp

6 – handle

7 – cap

8 – mounting pole clamp

9 – fuse holder

10 – mains inlet

11 – MFC*

12 – Audio volume control*

* – optional

7

Service manual

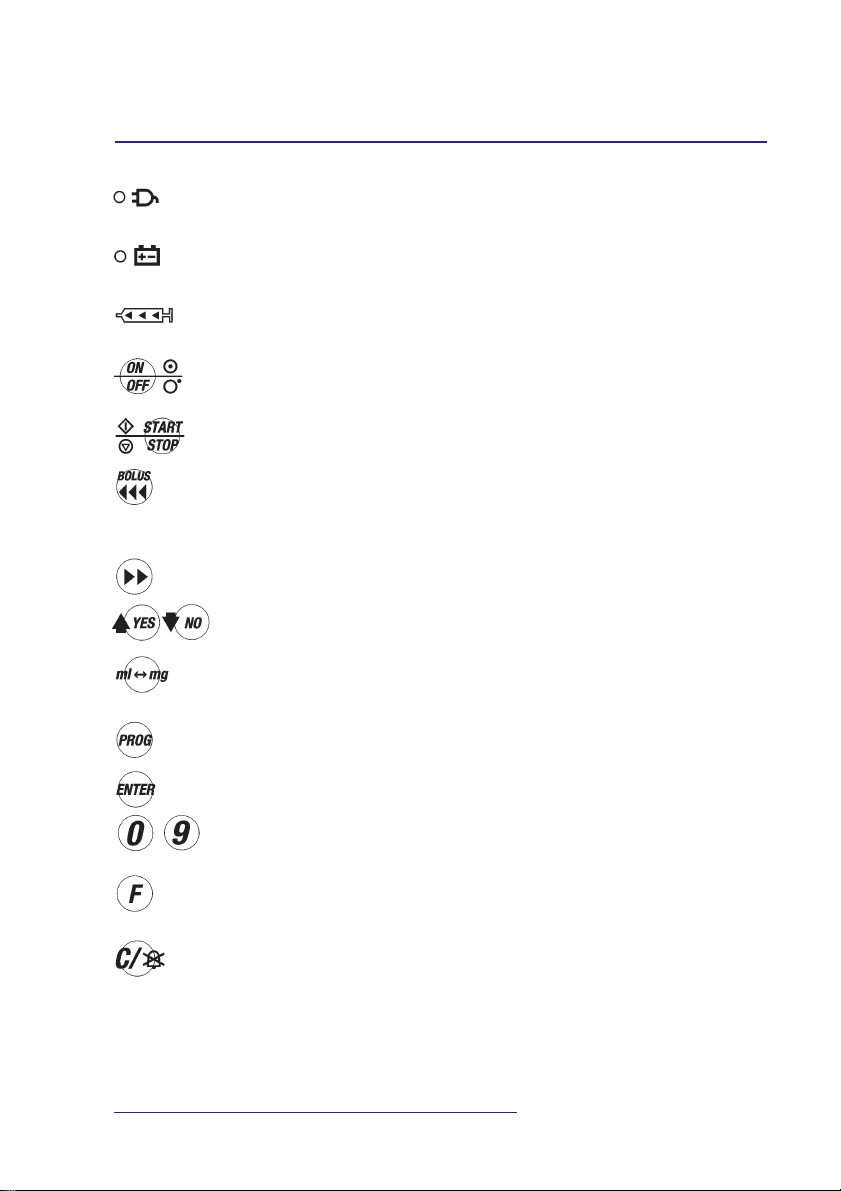

4. KEYBOARD DESCRIPTION

– green indicator, indicating pump connected to the AC line 220–

230V and battery charging.

– green LED is on when pump runs on internal battery; flashing

if LOW BATTERY alarm condition occurs.

– during infusion, three yellow LEDs are sequentially flashing. If

the rightmost LED is on permanently – the infusion is stopped.

– key to switch the pump on/off; keep it pressed for several sec-

onds in order to switch off.

– key to start/stop the infusion.

– key to move the syringe driver arm rapidly to the left-hand side

during syringe insertion or to initiate the Bolus mode; it is also

intended for air removal from the extension set after syringe in-

sertion.

– key to move the syringe driver arm to the right-hand side.

– keys to scroll up/down the list of parameters and syringe brands

or answer positively or negatively the dialog questions.

– key to select dimensions of parameters when programming (only

in SP-12S Pro and SEP-12S Plus).

– key to program (modify) parameters. Pressing it once more re-

stores previous values.

– key to confirm the selected parameter.

...

– numerical keys to enter digits of the parameter being pro-

grammed.

– key to select additional functions or to review programmed pa-

rameters.

– key to cancel the numerical value or the meaning of the param-

eter or silence the alarm signal. It deletes TOTAL INFUSED

and INFUSED DOSE values and clears the numerical value on

display when programming.

8

SP-12S Pro, SEP-12S Plus and SEP-10S Plus syringe infusion pumps

5. TECHNICAL DESCRIPTION

5.1. PRINCIPLE OF OPERATION

u The pump is intended for precise dosing of medicine at the

rate programmed by the operator. The speed of syringe

driver arm is set by the microcontroller, which evaluates the

syringe volume and features of the syringe model. The

microcontroller controls the step motor, which transfers

movement to the syringe driver arm via the helical gear.

The microcontroller monitors also voltage of the internal

battery, mains voltage, occlusion pressure, Bolus volume

and rate. Data on pump status and programming data are

outputted to the alphanumeric 2x16 symbol display. Operation of the microcontroller is monitored by the special

circuit (watch-dog), which unconditionally switches off the

motor in case of failure of the microcontroller.

In case of mains voltage failure, the pump automatically

continues its operation being powered from the internal

rechargeable battery and warns the operator on this by

means of audible and visual signals.

5.2. ELECTRICAL SCHEMATIC DIAGRAM OF THE PUMP

5.2.1. Principle of operation

u The electrical schematic diagram of the pumps are pre-

sented in theAnnex A, B. The interconnection diagram of

the pump is presented in Annex C. Diagrams of the pump

are composed of the following main parts:

w power supply;

w keyboard;

w drive;

w syringe size sensor;

w electronic board B7043.

Service manual

9

5.2.2. Power supply

u 220-230 VAC (or 115 VAC) voltages via the mains filter

MF1 and fuse F1 is fed to the primary winding of the

step-down transformer TR1. Voltage from the secondary

winding of the transformer TR1 reduced to 10-11 VAC is

rectified by the diode bridge D1 and capacitor C1 (1113,5 VDC) and via the fuse F1(A2) is fed to the remaining part of the circuit. The resistor R1 sets the charging

current for the rechargeable batteries GB1, GB2 which

shall be in range of (70-130) mA. When the pump is

powered from the internal battery, power supply current

goes via the diode D2. The fuse F2(A2) protects batteries

by limiting charging and load currents. There is fed a signal to the electronic board B7043 via the diode D3 and

the resistor R2 informing the pump is powered from the

external mains of 50/60 Hz, 220-230 VAC (or 115 VAC).

The electronic board B7043 controls the buzzer Z1.

5.2.3. Keyboard

u The keyboard is composed of 21 keys (SEP-10S Plus

20 keys) in form of a matrix having 7 inputs and 3 outputs. Electronic board B7043 performs scanning of the

keyboard and reading of information from it. The key

ON/OFF controls the circuit of electronic power supply

switch located on the electronic board B7043.

5.2.4. Drive

u The stepper motor SM1 rotates the lead screw with a nut

on it converting rotating movement of the motor to linear movement of the tube. The tube supported by four

guiding bearings is connected to the syringe driver arm.

Marginal positions of the tube with syringe driver arm

are limited by:

w limit switch S1 at the right extreme position which is

actuated by the end of the tube;

10

SP-12S Pro, SEP-12S Plus and SEP-10S Plus syringe infusion pumps

w rotational optical sensor TAX1 at the left extreme position when the tube covers the raster of rotating coupling of the optical sensor TAX1.

In case of occlusion when pressure in the syringe increases to the prohibited level, it stops movement of the

syringe driver arm and at the same rotation of the stepper motor SM1.

Rotation of the stepper motor is controlled by the optical

sensor TAX1 which reads a signal, reflected from the raster

of rotational coupling. This signal is fed to the microcontroller U18 located on the electronic board B7043, and

this signal switches on the emergency signal. There is some

delay between beginning of occlusion on one hand and

stepper motor SM1 stopping and emergency signal actuation on the other hand depending on infusion rate, length,

thickness and elasticity of extension tube.

u The pre-alarm switch S2 is activated when the distance

between syringe finger flange and syringe thumb rest is

equal to 45 mm. When this distance is equal to 27 mm,

the end switch S1 is activated, which in this case acts as

the second pre-alarm switch. When the pre-alarm switch

has been activated, the pump calculates distance to the

end of appropriate syringe. Based on this there are calculated and activated the following warning messages:

Xmin. PREALARM!Xmin. PREALARM!

Xmin. PREALARM!

Xmin. PREALARM!Xmin. PREALARM!

where X ≤ 5 min., and

SYRINGE EMPTY!SYRINGE EMPTY!

SYRINGE EMPTY!

SYRINGE EMPTY!SYRINGE EMPTY!

u In case of occlusion the stepper motor SM1 executes

some number of steps back depending on syringe type.

This reduced pressure in the syringe and extension tube

and at the same time reduces unwanted Bolus volume

injected to the patient when the cause of occlusion is removed.

Service manual

11

5.2.5. Syringe size sensor

u Syringe size sensor is implemented as a sliding poten-

tiometer R1. Depending on syringe diameter, potentiometer slider position is changed and its output voltage at

the same time, which is linearly proportional to the output resistance of the potentiometer R1. This output voltage is fed to the electronic board B7043.

5.3. ELECTRICAL SCHEMATIC DIAGRAM

OF ELECTRONIC BOARD B7043

u The electrical schematic diagram of electronic board

B7043 is shown in the annex C.

It is composed of the following main parts:

w microcontroller circuit;

w display circuit;

w „watch-dog” circuit;

w stabilized power supply;

w electronic power-supply switch circuit;

w syringe size sensor signal processing circuit;

w DAC;

w pulse current stabilizers;

w switches.

5.3.1. Microcontroller circuit

u There is used the T89C51RD2 microcontroller U18 having

internal RAM of 256 bytes for data, internal flash memory

of 64 kB and external EEPROM of 32 kB for software and

external time keeper SRAM U14 with clock for log.

The quartz resonator Q2 of 12,288 MHz sets clock frequency for microcontroller. The microcontroller U18 selects addresses of the SRAM U14 (lower addresses from

port P0 via register U13, higher addresses from port P2

directly). The microcontroller U18 via port P0 and register U11 generates instructions for step motor control,

12

SP-12S Pro, SEP-12S Plus and SEP-10S Plus syringe infusion pumps

writes information to display MD1, writes and reads information to/from SRAM U14, controls the buzzer, LEDs

D26, D27, D28 „RUN”. Also via port P0 and register

U13, it scans the keyboard. Information from the keyboard is read via register U12 to port P0.

u The microcontroller U8 AT89C2051 receives informa-

tion from the microcontroller U18 T89C51RD2 to its

inputs P3.0 and P3.2 on step motor rotation direction,

period between steps and power. The restart signal for the

microcontroller U8 (pin 1) is generated by means of elements C46 and R51 in time of power switching on.

When master „watch-dog” circuit is activated, a high-level

signal is applied to the restart input of the microcontroller U8 interrupting its operation.

5.3.2. Display circuit

u Information to display MD1 (addresses and data) is writ-

ten from the port P0 of microcontroller U18. The resistors R88—R91 sets current via transistor T15 and at that

same time current for backlighting LED of display MD1.

This current shall be equal to 70 ± 10 mA when backlighting is switched on and 10 ± 5 mA when backlighting

is switched off. The backlighting current is controlled by

the signal from microcontroller U18 via register U10. Resistor R93 defines brightness of the display MD1.

5.3.3. “Watch-dog” circuit

u The special „Watch-dog” circuit monitors operation of

the microcontroller U18. In case of disturbances in

microcontroller U18 operation, this circuit prevents functioning of the pump, stops the motor and activates audible alarm. The basis of master „Watch-dog” circuit is

monostable multivibrator U5A, U5B and the trigger

U3A. They compose the frequency discriminator with

pass-band of 500 Hz to 2 kHz.

Service manual

13

u The slave watch-dog circuit is composed of elements

U17A, D25, C61, C74. When for some reason the pulses

cease to arrive to capacitor C61, 0.5 sec later a low-level

signal is generated at the output 6 of the Schmitt trigger

U17A initiating actuation of the master watch-dog circuit.

5.3.4. Stabilized power supply

u There are used two stabilized +5VDC voltages Vcc1 and

Vcc2. The voltage Vcc1 is supplied to the microcontroller

U18, „Watch-dog” circuit and electronic power supply

switch. When powering of the pump is switched off by

means of the key ON/OFF, voltage Vcc1 goes down to 2V

(voltage Vcc2 becomes equal to 0V).

The IC U1 is the voltage stabilizer. The transistor T1 is a

current amplifier and the transistor T2 is a power supply

switch.

Adjustable resistor R13 sets threshold for emergency signal actuation on discharge of batteries GB1, GB2 (voltage on pin 7 of the IC U1 shall go down from +5V to

0V when battery voltage drops to 9.2V).

u DC/DC converter U2 generates necessary negative volt-

age of —(4,7÷5,0)V at its output (pin 5).

5.3.5. Electronic power-supply switch

u When the pump is switched on by pressing the key

ON/OFF, there is set at the same time inhibition to

switch it off, i.e. the low-level signal is applied to pin

13 of the trigger U3B. This inhibition may be removed

either by the microcontroller U18 having received an appropriate request or by the „watch-dog” activated. The

microcontroller U18 via the input T0 receives information on depressed key ON/OFF. Then when the key

ON/OFF is kept depressed for 3 sec the microcontroller

U18 switches off the pump by applying high-level pulse

to the pin 10 of the trigger U3B.

14

SP-12S Pro, SEP-12S Plus and SEP-10S Plus syringe infusion pumps

Electronic power-supply switch output signals control the

power supply stabilizer and switch the microcontroller

U18 to mode of low power consumption or to normal

mode. These signals via capacitor C67 generate start (reset) pulse for microcontroller U18.

5.3.6. Syringe size sensor signal

processing circuit

u The voltage taken from the potentiometer for syringe di-

ameter and proportional to the syringe diameter is fed to

ADC U7. Information on syringe diameter in digital

form from U7 is transferred via the serial port to the input P1.0 of the microcontroller U18.

5.3.7. DAC (digital to analog converter)

u The DAC is composed of resistor network, amplifier U6A

and inverter U6B. Depending on the code at the port P1

of the microcontroller U8, voltage at the output 7 of the

operational amplifier U6A is changing in the range 0 to -

0.4V. The inverter is based on the operational amplifier

U6B and converts this voltage to positive one. The voltage from the output 1 of U4B is fed to two (separate for

each phase of the motor) sample-and-hold units for

analogous signal, implemented on elements T6, C55 and

T7, C57 accordingly. There are generated two independent voltages on capacitors C11, C12 being proportional

to currents flowing through motor phases.

5.3.8. Pulse current stabilizers

u The pulse current stabilizer for the 1st phase is composed

of elements U15A, T5, R56, D18, D19, L4, R61, R60, and

that for the 2nd phase - of elements U15B, T4, R57, D15,

D20, L5, R67, R69. Further is described operation of the

pulse current stabilizer for the 1st phase only. The voltage

from the capacitor C55 is fed to the inverting input 2 of

Service manual

15

the comparator U15A. The non-inverting input of the

comparator receives the signal equal to voltage drop across

the resistors R61, R60 and proportional to current flowing through them. When this voltage is lower than that on

the capacitor C55, then transistor T5 becomes open. Then

the power source VCC-NS is connected to the inductor

L4 and the current through it starts to increase. When voltage drop across resistors R61, R60 exceeds voltage from the

capacitor C55, the transistor T5 becomes closed and current through the reactor L4 starts to decrease. The new cycle is started, and its frequency depends on inductance of

the reactor L4, phase current value and comparator hysteresis.

5.3.9. Switches

u Currents for both phases flow to the common conductors

of motor phase coils via accumulating reactors L4 and L5.

Direction of motor rotation is defined by appropriate order of current switching in both phase coils. This switching is implemented by current switches T8, T9 and T10,

T13 for the 1st and the 2nd phases accordingly.

16

SP-12S Pro, SEP-12S Plus and SEP-10S Plus syringe infusion pumps

6. SETUP MENU

u In order to access optional functions or certain param-

eters, keep the START/STOP key in pressed position and

switch the pump on by pressing the ON/OFF key. When

short beep is heard, release the START/STOP key, enter

appropriate code with the numerical keys and confirm it

by pressing the ENTER key.

The total list of optional functions/parameters and their

access codes are presented in the Table 1:

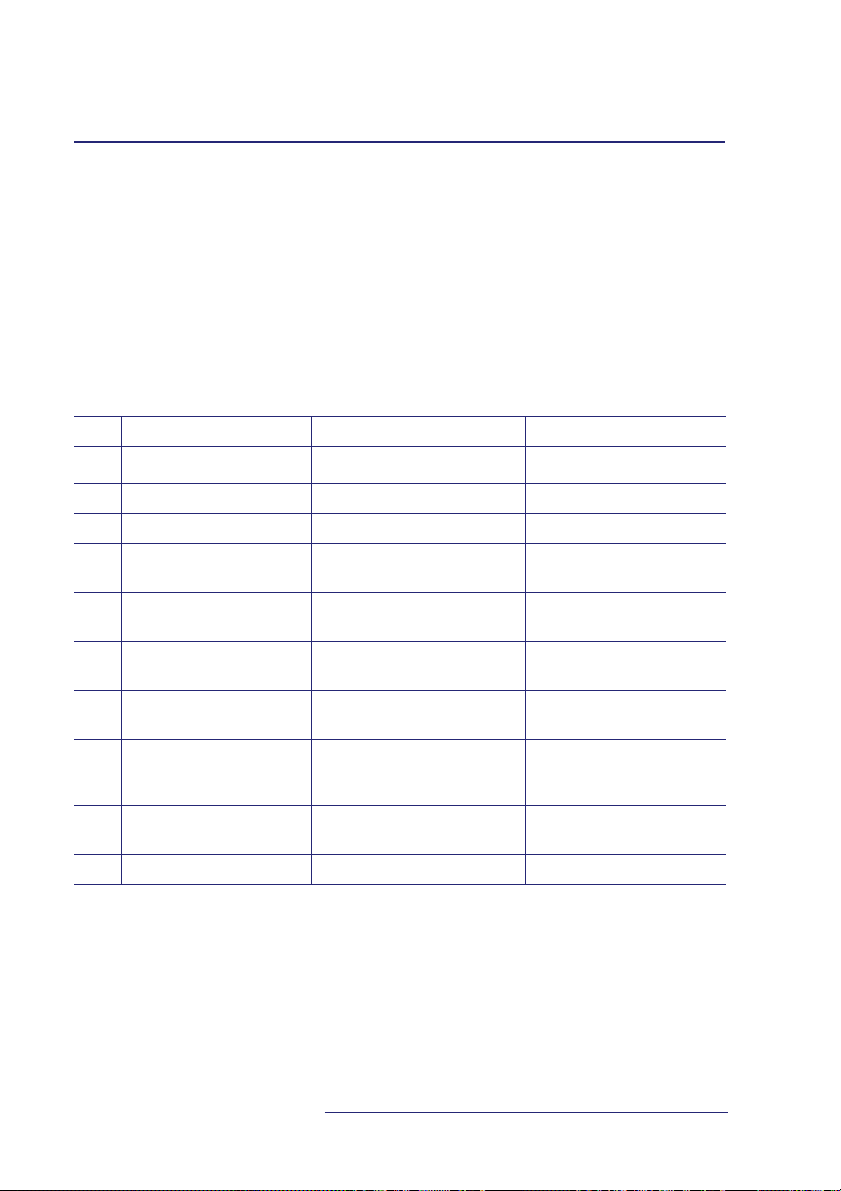

Table 1

CODE NAME DESCRIPTION NOTE

100 Pump modes

137 Syringe list

147 Drug list

157 DEFAULT GRUG SET restoring default

237 Functions Configurable

257 DEFAULT restoring default

PARAMETERS SET (manufacturer’s) parameters

337 LANGUAGE SET:

ENGLISH and other installation of dialog language

537 SYRINGE SIZE to calibrate syringe sensor for calibration needs spacers:

CALIBRATION B8640027, B8640027-01,

547 OCCLUSION calibration of occlusion level

CALIBRATION

637 DATE, TIME setting of date and time

(manufacturer’s) jist of drug

functions/parameters

B8640027-02, B8640027-03,

u List of optional functions may be reviewed using the

scroll keys. If displayed name is marked with the asterisk,

it means that function is active. To activate an inactive

function press the ENTER key, and the asterisk will appear in front of the item name.

To deactivate a function, press the C key. The asterisk

shall disappear.

Service manual

17

u To change flow rate upper limit select appropriate item, press the

PROG key, enter the new value using the numeric keys and confirm

it by pressing the ENTER key.

u To enter a new drug name open the drug list and select the drug name

to be replaced by the new one. Press the PROG key, and enter the new

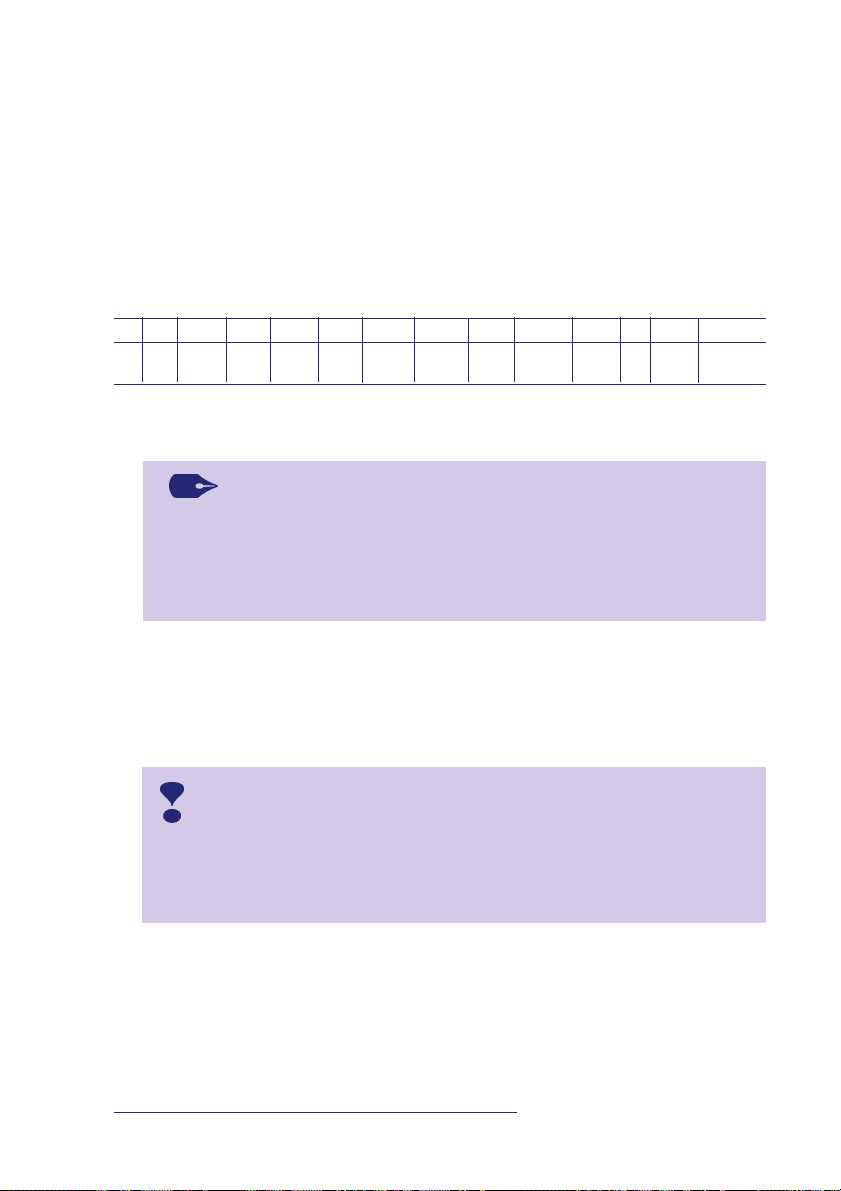

drug name using keys in accordance with the table below (e.g. to enter letter Z press the 9 key four times):

Key 1 2 3 4 5 6 7 8 9 0 . YES NO, C

Cha-

1 A,B, D,E, G,H, J, K, M, N, P,Q, T, U, W, X, %, 0, . Space Backspace

racter

C,2 F, 3 I, 4 L, 5 O, 6 R, S, 7 V, 8 Y, Z, 9 /, -

Confirm the new drug name by pressing the ENTER key.

NOTES:

1. Entered character can be reset by means of the C or NO

keys.

2. Old drug name can be restored by means of the PROG key

until new name is confirmed.

u To exit setup menu press the START/STOP key.

u To change date and time settings enter new values when appropriate

demand is displayed and press the ENTER key to confirm them and

exit setup menu.

ATTENTION !

It is recommended to minimize number of parameters, types

of syringes, drug names and other functions leaving only that

necessary for work. It will help to avoid errors in parameters

programming and thereby decrease patient’s risk.

u If the high occlusion level value after actions specified in section 7.5 are

performed is beyond specified limits, occlusion level shall be calibrated.

For this sake factual value of high occlusion level pressure obtained during testing is entered into pump.

Typical value for CORRECT END is 60 kPa.

18

SP-12S Pro, SEP-12S Plus and SEP-10S Plus syringe infusion pumps

Loading...

Loading...