EDS Series

Indoor Units Outdoor Units

EDS25 GCN9

EDS35 GCN12

EDS52 ONG3-18

EDS73 GCZ22

EDS100 GC10-34

EDS120 GC45

EDS25X2 GC9+9

EDS35X2 GC12+12

EDS52X2 GC17+17

EDS25X2+EDS35 GC9+9+12

EDS25X2+EDS52 GC9+9+17

EDS25+EDS35+EDS52 GC9+12+17

EDS35X3 GC12+12+12

REFRIGERANT

R22

COOLING ONLY

COOLINGONLYWITHHEATER

HEAT PUMP

HEAT PUMP WITH HEATER

REV: 0 FEB 2009

A

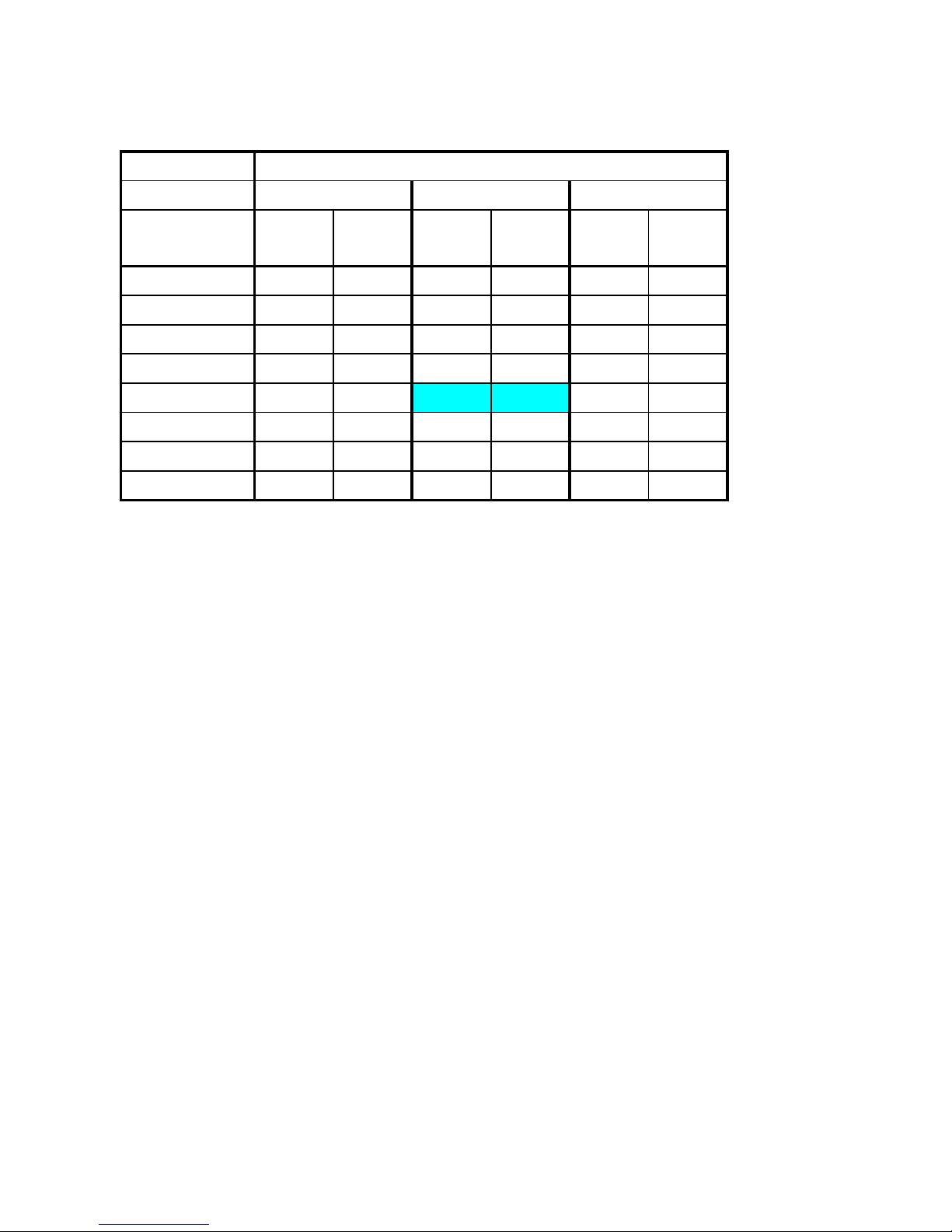

LIST OF EFFECTIVE PAGES

Revision 0

Service Manual - EDS

LIST OF EFFECTIVE PAGES

Note: Changes in the pages are indicated by a “Revision#” in the footer of each effected page

(when none indicates no changes in the relevant page). All pages in the following list represent

effected/ non effected pages divided by chapters.

Dates of issue for original and changed pages are:

Original ....... 1 ........ FEB 2009

Total number of pages in this publication is 137 consisting of the following:

Page

No.

Revision

No. #

Page

No.

Revision

No. #

Page

No.

Revision

No. #

Title....................... 0

A ........................... 0

i............................. 0

1-1 - 1-3 ................ 0

2-1 - 2-6 ................ 0

3-1 ........................ 0

4-1 - 4-4 ................ 0

5-1 - 5-12 .............. 0

6-1 - 6-6 ................ 0

7-2 ........................ 0

8-1 - 8-6 ................ 0

9-1 - 9-4........................ 0

10-1-10-2 .............. 0

11-1....................... 0

12-1-12-31 ............ 0

13-1-13-2 .............. 0

14-1-14-24 ............ 0

Installation manual

.0

=HURLQWKLVFROXPQLQGLFDWHVDQRULJLQDOSDJH

*Due to constant improvements please note that the data on thisVHUYLFHPDQXDOFDQEHPRGL¿HGZLWKRXWQRWLFH

**Photos are not contractual

i

TABLE OF CONTENTS

Revision Y07-00Service Manual - EDS

Table of Contents

1. INTRODUCTION ...................................................................................................1-1

2. PRODUCT DATA SHEET......................................................................................2-1

3. RATING CONDITIONS ..........................................................................................3-1

4. OUTLINE DIMENSIONS .......................................................................................4-1

5. PERFORMANCE DATA & PRESSURE CURVES ................................................5-1

6. SOUND LEVEL CHARACTERISTICS ..................................................................6-1

7. ELECTRICAL DATA..............................................................................................7-1

8. WIRING DIAGRAMS .............................................................................................8-1

9. ELECTRICAL CONNECTIONS.............................................................................9-1

10. REFRIGERATION DIAGRAMS.............................................................................10-1

11. TUBING CONNECTIONS......................................................................................11-1

12. CONTROL SYSTEM .............................................................................................12-1

13. TROUBLESHOOTING ..........................................................................................13-1

14. EXPLODED VIEWS AND SPARE PARTS LISTS.................................................14-1

15.

INSTALLATION MANUAL

..................

................................................................15-1

1-1

INTRODUCTION

Revision 0Service Manual - EDS

1. INTRODUCTION

1.1 General

The new EDS ductable pressurized system basic on comapct indoor and outdoor unit, it range

comprise the A (cooling only) ,B(cooling only with supplementart heater) ,H (heat pump) ,D(heat

pump with supplementare heater),Dual and Trio, models as follows:

Cooling Only:

EDS25A/GCN9 R22 ST; EDS35A/GCN12 R22 ST;EDS52A/ONG3-17 R22 ST;

EDS73A/GCZ R22 ST; EDS100A/GC10-34 R22 ST;EDS120A/GC45 R22 ST;

EDS25A/GCN9 R22 ST; EDS35A/GCN12 R22 ST;EDS52A/ONG3-17 R22 ST;

EDS73A/GCZ R22 ST; EDS100A/GC10-34 R22 ST;EDS120A/GC45 R22 ST;

Cooling Only with supplementary heater:

1.2 Main Features

The EDS VHULHVEHQH¿WVIURPWKHPRVWDGYDQFHGWHFKQRORJLFDOLQQRYDWLRQs,

namely:

R22 models.

Microprocessor control.

Infrared remote control with liquid crystal display.

Supports Indoor Air Quality features, such as –.

,QGRRUODUJHGLDPHWHUFURVVÀRZIDQ, allowing low noise level operation.

Bended indoor coil with treated alumLQXP¿QVDQGFRDWLQJIRULPSURYHGHI¿FLHQFy.

Easy access to the interconnecting tubing and wiring connections, so that removing

the front grill or casing is not necessary.

Refrigerant pipes can be connected to the indoor unit from 5 different optional

directions.

Low indoor and outdoor noise levels.

Easy installation and service.

New package design for indoor unit, it should be based on open sleeve and open

sides

Installation manual to be printed on one page with back and front printing

One RC simply manual printing on two side as the standard

EDS25H/GCN9 R22 RC; EDS35H/GCN12 R22 RC;EDS52H/ONG3-17 R22 RC;

EDS73H/GCZ R22 RC; EDS100H/GC10-34 R22 RC;EDS120H/GC45 R22 RC;

Heat pump:

EDS25D/GCN9 R22 RC; EDS35D/GCN12 R22 RC;EDS52D/ONG3-17 R22 RC;

EDS73D/GCZ R22 RC; EDS100D/GC10-34 R22 RC;EDS120D/GC45 R22 RC;

Heat pump with supplementary heater:

EDS25x2 A(B,D,H)/GC9+9 ST(RC); EDS35x2 A(B,D,H)/GC12+12 ST(RC);

EDS52x2 A(B,D,H)/GC17+17 ST(RC);

Dual:

EDS25x2+35A(B,D,H)/GC9+9+12 ST(RC);EDS25x2+52A(B,D,H)/GC9+9+17 ST(RC);

EDS25+35+52A(B,D,H)/GC9+12+17 ST(RC);EDS35x3A(B,D,H)/GC12+12+12 ST(RC)

Trio:

1-2

INTRODUCTION

Revision 0 Service Manual - EDS

1.3 Indoor Unit

The indoor unit is ductable pressurized VSOLWV\VWHPDQGFDQEHHDVLO\¿WWHGWRPDQ\W\SHVRI

residential and commercials applications.

It includes:

Casing with air inlet and outlet grills.

AODUJHGLDPHWHUWDQJHQWLDOIDQ

Bended coil with treated aluminum ¿ns.

0RWRUL]HGÀDSV

Multi-speed motor with internal protection

Advanced electronic control box assembly

Interconnecting wiring terminal block

Mounting plate

1.4 Filtration

The EDS VHULHVSUHVHQWVRQO\RQHW\SHRIDLU¿OWHUV

Easily accessible, and re-usable pre¿OWHUVPHVK

1.5 Control

The microprocessor indoor controller, and wire controller with remote controller, supplied as

VWDQGDUGSURYLGHFRPSOHWHRSHUDWLQJIuQFWLRQDQGSURJUDPPLQJ)RUIXUWKHUGHWDLOV

SOHDVHUHIHUWRWKH2SHUDWLRQ0DQXDO Appendix A.

1.6 Outdoor Unit

The EDS outdoor units can be insWDOOHGDVÀRRURUZDOOPRXQWHGXQLWVE\XVLQJD

wall supporting bracket. The metal sheets are protected by anti- corrosion paint work

DOORZLQJORQJOLIHUHVLVWDQFH All outdoor XQLWVDUHSUHFKDUJHG)RUIXUWKHULQIRUPDWLRQ

SOHDVHUHIHUWRWKH3URGXFW'DWD6KHHW, Chapter 2.

It includes :

Compressor mounted in a soundprooIHGFRPSDUWPHQW

Rotary –IRU*&15675&*&15675&21*5675&*&=5675&

Scroll –IRU*&5675&*&5675&

$[LDOIDQ

2XWGRRUFRLOZLWKK\GURSKLOLFORXYHU¿nVIRU5&XQLWV

2XWOHWDLUIDQJULOO

Interconnecting wiring terminal block.

1-3

INTRODUCTION

Revision 0 Service Manual - EDS

1.7 Tubing Connections

Flare type interconnecting tubing to be produced on site.

For further details please refer to the Installation Manual, Outdoor Chapter 3.

1.8 Inbox Documentation

Each unit is supplied with its own installation and operation manuals, one simply

remote control manual Matching Table

Indoor unit

Type Outdoor unit

Unit 1 Unit 2 Unit 3

EDS25EDS35EDS

52

EDS73 EDS100 EDS120

GCN 9 EDS25 A/B

GCN 12 EDS35 A/C

ONG 3-18 EDS52 A/C

GCZ 22 EDS73 A/C

GC 10-34 EDS100 B/D

Single

GC 45 EDS120 B/E

GC9+9 EDS25 EDS25 A/B

GC12+12 EDS35 EDS35 A/C

Dual

GC17+17 EDS52 EDS52 A/C

GC9+9+12 EDS25 EDS25 EDS35 A/B A/C

GC9+9+17 EDS25 EDS25 EDS52 A/B A/C

GC9+12+17 EDS25 EDS35 EDS52 A/B A/C A/C

Trio

GC12+12+12 EDS35 EDS35 EDS35 A/C

1.9 Matching Table

1.9.1 R22

A-1/4’’ B-3/8’’ C-1/2’’ D-5/8’’ E-3/4’’ Liquid / Suction

Model Indoor Unit

EDS 25

Model Outdoor Unit GCN 9

Installation Method of Pipe Flared

Characteristics

Units Cooling only

Cooling Heating

Capacity (4)

Btu/hr 9380

9380 9550

kW 2.75

2.75 2.80

Power input (4)

kW 0.932

0.932 0.80

EER (Cooling) or COP(Heating) (4)

W/W 2.95

2.95 3.50

Energy efficiency class

C

CB

Power supply

V

220-240

Ph

1

Hz

50

Rated current

A 4.3

4.3 3.7

Power factor

0.95

0.95 0.95

Prated (IDU)

W

80

Prated (IDU+ODU)

W

1370

Starting current

A

18.2

Circuit breaker rating

A

10

INDOOR

Fan type & quantity DirectX1

Fan speeds

H/M/L RPM

1210/1020/860

Air flow (1)

H/M/L m3/hr

588/409/-

External static pressure

Min Pa

30Pa

Sound power level (2)

H/M/L dB(A)

59/54/50

Sound pressure level(3)

H/M/L dB(A)

46/41/37

Moisture removal

l/hr

0.58

Condenstate drain tube I.D

mm

19.05

Dimensions

WxHxD mm

690x250x611

Net Weight

kg

20

Package dimensions

WxHxD mm

820x280x628

Packaged weight

kg

23

Units per pallet

units

10

Stacking height

units

5 levels

OUTDOOR

Refrigerant control Capillary tube

Compressor type,model Rotary,Meizhi PH170G1C-4DZDE1

Fan type & quantity Propeller(direct) x 1

Fan speeds

H RPM

750

Air flow

H m3/hr

1370

Sound power level

H dB(A) 60

61

Sound pressure level(3)

H dB(A) 50.5

51.1

Dimensions

WxHxD mm

760x545x245

Net Weight

kg 30

30.5

Package dimensions

WxHxD mm

880x310x610

Packaged weight

kg 33

33.5

Units per pallet

Units

9

Stacking height

units

3 Levels

Refrigerant type R22

Standard charge

kg(4m)

0.83

Additional charge

4mİLinİ10m:0g/m; 10m<Linİ15m:+130g

Connections

between units

Liquid line

In.(mm)

1/4"(6.35)

Suction line

In.(mm)

3/8"(9.52)

Max.tubing length

m.

Max.15

Max.height difference

m.

Max.7

Operation control type Remote control

Heating elements (Option)

kW

Others

(1)Airflow in ducted units;at nominal external static pressure 30Pa.

(2)Sound power in ducted units is measured at air discharge.

(3)Sound pressure level measured at 1-meter distance from unit.

(4)Rating conditions in accordance to ISO 5151 and ISO 13253 (for ducted units).

(5)The declared value's tolerance is in accordance with EN14511.

PRODUCT DATA SHEET

2. PRODUCT DATA SHEET

2-1Revision 0Service Manual - EDS

Model Indoor Unit

EDS 35

Model Outdoor Unit GCN12

Installation Method of Pipe Flared

Characteristics

Units Cooling only

Cooling Heating

Capacity (4)

Btu/hr 12620

12620 12110

kW 3.70

3.70 3.55

Power input (4)

kW 1.175

1.175 0.98

EER (Cooling) or COP(Heating) (4)

W/W 3.15

3.15 3.62

Energy efficiency class

B

BA

Power supply

V

220-240

Ph

1

Hz

50

Rated current

A 5.4

5.4 4.5

Power factor

0.95

0.95 0.95

Prated (IDU)

W

90

Prated (IDU+ODU)

W

1660

Starting current

A

25

Circuit breaker rating

A

15

INDOOR

Fan type & quantity DirectX1

Fan speeds

H/M/L RPM

900/730/660

Air flow (1)

H/M/L m3/hr

830/500/-

External static pressure

Min Pa

30

Sound power level (2)

H/M/L dB(A)

59/55/51

Sound pressure level(3)

H/M/L dB(A)

46/42/38

Moisture removal

l/hr

0.6

Condenstate drain tube I.D

mm

19.05

Dimensions

WxHxD mm

945x250x611

Net Weight

kg

27

Package dimensions

WxHxD mm

1095x280x628

Packaged weight

kg

30

Units per pallet

units

5

Stacking height

units

5 levels

OUTDOOR

Refrigerant control Capillary tube

Compressor type,model Rotary,Sanyo C-RV212HC2CB

Fan type & quantity Propeller(direct) x 1

Fan speeds

H RPM

830

Air flow

H m3/hr

1500

Sound power level

H dB(A) 64

64.5

Sound pressure level(3)

H dB(A) 55

56

Dimensions

WxHxD mm

760x545x245

Net Weight

kg 33

33.5

Package dimensions

WxHxD mm

880x310x610

Packaged weight

kg 35.5

36

Units per pallet

Units

9

Stacking height

units

3 Levels

Refrigerant type R22

Standard charge

kg(4m)

0.99

Additional charge

4mİLinİ10m:0g/m; 10m<Linİ15m:+170g

Connections

between units

Liquid line

In.(mm)

1/4"(6.35)

Suction line

In.(mm)

1/2"(12.7)

Max.tubing length

m.

Max.15

Max.height difference

m.

Max.7

Operation control type Remote control

Heating elements (Option)

kW

Others

(1)Airflow in ducted units;at nominal external static pressure 30Pa.

(2)Sound power in ducted units is measured at air discharge.

(3)Sound pressure level measured at 1-meter distance from unit.

(4)Rating conditions in accordance to ISO 5151 and ISO 13253 (for ducted units).

(5)The declared value's tolerance is in accordance with EN14511.

PRODUCT DATA SHEET

2-2

Revision 0Service Manual - EDS

Model Indoor Unit

EDS 52

Model Outdoor Unit ONG3-17

Installation Method of Pipe Flared

Characteristics

Units Cooling only

Cooling Heating

Capacity (4)

Btu/hr 19790

19790 18940

kW 5.80

5.80 5.55

Power input (4)

kW 1.92

1.92 1.61

EER (Cooling) or COP(Heating) (4)

W/W 3.02

3.02 3.45

Energy efficiency class

B

BB

Power supply

V

220-240

Ph

1

Hz

50

Rated current

A 8.8

8.8 7.4

Power factor

0.95

0.95 0.95

Prated (IDU)

W

154

Prated (IDU+ODU)

W

2460

Starting current

A

46.8

Circuit breaker rating

A

15

INDOOR

Fan type & quantity DirectX1

Fan speeds

H/M/L RPM

1210/1038/986

Air flow (1)

H/M/L m3/hr

1100/805/706

External static pressure

Min Pa

30

Sound power level (2)

H/M/L dB(A)

64/60/58

Sound pressure level(3)

H/M/L dB(A)

51/47/45

Moisture removal

l/hr

1.32

Condenstate drain tube I.D

mm

19.05

Dimensions

WxHxD mm

1080X611X250

Net Weight

kg

29

Package dimensions

WxHxD mm

1165X628X280

Packaged weight

kg

33

Units per pallet

units

5

Stacking height

units

5 levels

OUTDOOR

Refrigerant control Capillary tube

Compressor type,model Rotary,Panasonic 2V34S225BUC

Fan type & quantity Propeller(direct) x 1

Fan speeds

H RPM

920

Air flow

H m3/hr

2160

Sound power level

H dB(A) 65

65

Sound pressure level(3)

H dB(A) 54

55

Dimensions

WxHxD mm

795x610x290

Net Weight

kg 43

44

Package dimensions

WxHxD mm

970x650x394

Packaged weight

kg 46

47

Units per pallet

Units

9

Stacking height

units

3 Levels

Refrigerant type R22

Standard charge

kg(7.5m)

1.45

Additional charge

4mİLinİ10m:0g; 10m<Linİ15m:+100g

Connections

between units

Liquid line

In.(mm)

1/4"(6.35)

Suction line

In.(mm)

1/2"(12.7)

Max.tubing length

m.

Max.15

Max.height difference

m.

Max.7

Operation control type Remote control

Heating elements (Option)

kW

Others

(1)Airflow in ducted units;at nominal external static pressure 30Pa.

(2)Sound power in ducted units is measured at air discharge.

(3)Sound pressure level measured at 1-meter distance from unit.

(4)Rating conditions in accordance to ISO 5151 and ISO 13253 (for ducted units).

(5)The declared value's tolerance is in accordance with EN14511.

PRODUCT DATA SHEET

2-3Revision 0Service Manual - EDS

Model Indoor Unit EDS 73

Model Outdoor Unit GC-22

Installation Method of Pipe Flared

Characteristics

Units Cooling only

Cooling Heating

Capacity (4)

Btu/hr 23710

23710 25250

kW 6.95

6.95 7.40

Power input (4)

kW 2.31

2.31 2.05

EER (Cooling) or COP(Heating) (4)

W/W 3.01

3.01 3.61

Energy efficiency class

B

BA

Power supply

V

220-240

Ph

1

Hz

50

Rated current

A 10.6

10.6 9.4

Power factor

0.95

0.95 0.95

Prated (IDU)

W

242

Prated (IDU+ODU)

W

3250

Starting current

A

52

Circuit breaker rating

A

20

INDOOR

Fan type & quantity DirectX1

Fan speeds

H/M/L RPM

1206/1079/967

Air flow (1)

H/M/L m3/hr

1350/1134/909

External static pressure

Min Pa

30

Sound power level (2)

H/M/L dB(A)

64/61/59

Sound pressure level(3)

H/M/L dB(A)

51/48/46

Moisture removal

l/hr

1.45

Condenstate drain tube I.D

mm

19.05

Dimensions

WxHxD mm

1365X611X250

Net Weight

kg

35

Package dimensions

WxHxD mm

1515X628X280

Packaged weight

kg

39

Units per pallet

units

5

Stacking height

units

5 levels

OUTDOOR

Refrigerant control Capillary tube

Compressor type,model Rotary,Panasonic,2V40S225AUA

Fan type & quantity Propeller(direct) x 1

Fan speeds

H RPM

850

Air flow

H m3/hr

2480

Sound power level

H dB(A)

70

Sound pressure level(3)

H dB(A)

59

Dimensions

WxHxD mm

846x690x302

Net Weight

kg 53

55.5

Package dimensions

WxHxD mm

990x770x430

Packaged weight

kg 56.5

59

Units per pallet

Units

6

Stacking height

units

2 levels

Refrigerant type R22

Standard charge

kg(7.5m)

2.05

Additional charge

4mİLİ10m:+0g 10m<Lİ15m:+280g

Connections

between units

Liquid line

In.(mm)

ĭ9.53(3/8")

Suction line

In.(mm)

ĭ15.88(5/8")

Max.tubing length

m.

Max.15

Max.height difference

m.

Max.7

Operation control type Remote control

Heating elements (Option)

kW

Others

(1)Airflow in ducted units;at nominal external static pressure 30Pa.

(2)Sound power in ducted units is measured at air discharge.

(3)Sound pressure level measured at 1-meter distance from unit.

(4)Rating conditions in accordance to ISO 5151 and ISO 13253 (for ducted units).

(5)The declared value's tolerance is in accordance with EN14511.

PRODUCT DATA SHEET

2-4

Revision 0Service Manual - EDS

e

Model Indoor Unit

EDS 100

Model Outdoor Unit

GC 10-34

Installation Method of Pipe Flared

Characteristics

Units

Cooling Heating

Capacity (4)

Btu/hr

33440 37530

kW

9.80 11.00

Power input (4)

kW

3.9 3.50

EER (Cooling) or COP(Heating) (4)

W/W

2.51 3.14

Energy efficiency class 5 N/

A

Power supply

V

380-415

Ph

3

Hz

50

Rated current

A

8.7 7.8

Power factor 0.85 0.85

Prated (IDU)

W

308

Prated (IDU+ODU)

W

6500

Starting current

A

45

Circuit breaker rating

A

15

INDOOR

Fan type & quantit

y

DirectX2

Fan speeds

H/M/L RPM

1100/960/880

A

ir flow (1)

H/M/L m3/hr

1750/1515/1193

External static pressure

Min Pa

30

Sound power level (2)

H/M/L dB(A)

62/59/57

Sound pressure level(3)

H/M/L dB(A)

49/46/44

Moisture removal

l/hr

3.08

Condenstate drain tube I.D

mm

19.05

Dimensions

WxHxD mm

1535x250x611

N

et Wei

g

ht

kg

43

Package dimensions

WxHxD mm

1682x280x628

Packaged weight

kg

47

Units per pallet

units

5

Stacking height

units

5

OUTDOOR

Refrigerant control Capillary Tube

Compressor type,model Srcoll C-SB303H8A

Fan type & quantit

y

Propeller (direct) * 2

Fan speeds

H RPM

780

A

ir flow

H m3/hr

4680

Sound power level

H dB(A)

64

Sound pressure level(3)

H dB(A)

56

Dimensions

WxHxD mm

950X1270X340

N

et Wei

g

ht

kg

115

Package dimensions

WxHxD mm

1108X1286X473

Packaged weight

kg

134

Units per pallet

Units

1

Stacking height

units

1

Refrigerant type R22

Standard charge

kg(7.5m)

2.77

A

dditional charge

7.5m˘Lin İ 50m: +35g/m

Connections

between units

Liquid line

In.(mm)

3/8"(9.53)

Suction line

In.(mm)

3/4"(19.05)

Max.tubing length

m.

Max. 50m

Max.height differenc

m.

Max. 10m

Operation control type Remote control

Heating elements (Option)

kW

Others

(1)Airflow in ducted units;at nominal external static pressure 30Pa.

(2)Sound power in ducted units is measured at air discharge.

(3)Sound pressure level measured at 1-meter distance from unit.

(4)Rating conditions in accordance to ISO 5151 and ISO 13253 (for ducted units).

(5)The declared value's tolerance is in accordance with EN14511.

PRODUCT DATA SHEET

2-5Revision 0Service Manual - EDS

Model Indoor Unit EDS 120

Model Outdoor Unit GC 45

Installation Method of Pipe Flared

Characteristics

Units

Cooling Heating

Capacity (4)

Btu/hr

43670 54590

kW

12.80 16.00

Power input (4)

kW

4.56 4.98

EER (Cooling) or COP(Heating) (4)

W/W

2.81 3.21

Energy efficiency class C C

Power supply

V

380-415

Ph

3

Hz

50

Rated current

A

9.2 8.7

Power factor 0.85 0.85

Prated (IDU)

W

308

Prated (IDU+ODU)

W

5800

Starting current

A

65.8

Circuit breaker rating

A

15

INDOOR

Fan type & quantity DirectX2

Fan speeds

H/M/L RPM

1257/1056/1021

Air flow (1)

H/M/L m3/hr

2000/1692/1452

External static pressure

Min Pa

0

Sound power level (2)

H/M/L dB(A)

64/61/59

Sound pressure level(3)

H/M/L dB(A)

51/48/46

Moisture removal

l/hr

3.7

Condenstate drain tube I.D

mm

19.05

Dimensions

WxHxD mm

1785X611X250

N

et Weight

kg

50

Package dimensions

WxHxD mm

1935X628X280

Packaged weight

kg

55

Units per pallet

units

5

Stacking height

units

5

OUTDOOR

Refrigerant control Capillary Tube

Compressor type,model Srcoll JT160BCBY1L

Fan type & quantity Propeller (direct) * 2

Fan speeds

H RPM

780

Air flow

H m3/hr

4680

Sound power level

H dB(A)

64

Sound pressure level(3)

H dB(A)

56

Dimensions

WxHxD mm

950X1270X340

N

et Weight

kg

120

Package dimensions

WxHxD mm

1108X1286X473

Packaged weight

kg

139

Units per pallet

Units

1

Stacking height

units

1

Refrigerant type R22

Standard charge

kg(7.5m)

3.97

Additional charge

7.5m˘Lin İ 50m: +35g/m

Connections

between units

Liquid line

In.(mm)

3/8"(9.53)

Suction line

In.(mm)

3/4"(19.05)

Max.tubing length

m.

Max. 50m

Max.height difference

m.

Max. 10m

Operation control type Remote control

Heating elements (Option)

kW

Others

(1)Airflow in ducted units;at nominal external static pressure 30Pa.

(2)Sound power in ducted units is measured at air discharge.

(3)Sound pressure level measured at 1-meter distance from unit.

(4)Rating conditions in accordance to ISO 5151 and ISO 13253 (for ducted units).

(5)The declared value's tolerance is in accordance with EN14511.

(5)The declared value's tolerance is in accordance with EN14511.

PRODUCT DATA SHEET

2-6Revision 0Service Manual - EDS

3-1

RATING CONDITIONS

Revision 0Service Manual - EDS

3. RATING CONDITIONS

Standard conditions in accordance with ISO 5151, ISO 13253 (for ducted units)

and EN 14511.

Cooling:

Indoor: 27

o

C DB 19oC WB

Outdoor: 35

o

C DB

Heating:

Indoor: 20

o

C DB

Outdoor: 7

o

C DB 6oC WB

3.1 Operating Limits

3.1.1 R22

Indoor Outdoor

Cooling

Upper limit

32

o

C DB 23oC WB 46oC DB

Lower limit 21

o

C DB 15oC WB 10oC DB

Heating

Upper limit 27

o

C DB 24oC DB 18oC WB

Lower limit 10

o

C DB -5oC DB -6oC WB

Voltage 198 – 264 V

Unit:mm

MODEL EDS 25 EDS 73

EDS 35 EDS 100

EDS 52 EDS 120

18

61

11

Hanging hole

Model

A

480

730

865

1150

1320

1570

B

530

780

915

1200

1370

1620

D

533

783

918

1203

1373

1623

Fan

1

2

2

2

3

4

Moter

1

1

1

1

2

2

EDS25

EDS35

EDS52

EDS73

EDS100

EDS120

Dimensions(mm)

Quantity

C

665

915

1050

1335

1505

1755

Electrical Box

Water Drain Port

3/4"OD G

Hanging

hole

4-1Revision 0Service Manual - EDS

OUTLINE DIMENSIONS

4. OUTLINE DIMENSIONS

4.1

Unit mm

OUTDOOR MODEL GCN 9

GCN 12

290

016

308

500

74

795

OUTDOOR MODEL ONG3-17

260

245

830

760

545

472

50

732

4-2Revision 0Service Manual - EDS

OUTLINE DIMENSIONS

1270

950

112 .5

65.4

378

187.5572

340

80.8

81

OUTDOOR MODEL GC 10-34 GC45

Unit mm

OUTDOOR MODEL GC 22

Unit mm

Different configuration in different model

GC 9+9

GC 12+12

846

302

096

153

540

330

4-3Revision 0Service Manual - EDS

OUTLINE DIMENSIONS

OUTDOOR MODEL

GC 17+17

Different configuration

in different model

Unit mm

1270

950

112 .5

65.4

130.8

378

187.5572

340

80.8

81

GC 9+9+12

GC 9+9+17

GC 9+12+17

GC 12+12+12

4-4Revision 0Service Manual - EDS

OUTLINE DIMENSIONS

Cooling Capacity(KW)

Data

Entering Air WB/DB ID Coil(

o

C)

15/21 17/24 19/27 21/29 23/32

TC

2.72 2.88 3.023.15 3.26

15 SC

2.19 2.33 2.45 2.40 2.44

PI

0.700.700.700.700.70

TC

2.70 2.86 2.99 3.12 3.23

20 SC

1.92 2.042.16 2.10 2.14

PI

0.75 0.760.760.760.77

TC

2.59 2.78 2.94 3.073.18

25 SC

2

.13 2.29 2.42 2.37 2.43

PI

0.81 0.82 0.83 0.83 0.83

TC

2.43 2.622.832.94 3.04

30 SC

2.032.19 2.36 2.32 2.41

PI

0.88 0.89 0.900.91 0.91

TC

2.24 2.43

2.67

2.80 2.91

35 SC

1.91 2.08

2.27

2.24 2.34

PI

0.95 0.96

0.98

0.99 0.99

TC

2.0

32.22 2.46 2.59 2.70

40 SC

1.77 1.95 2.15 2.11 2.22

PI

1.021.041.06 1.071.08

TC

1.76 1.95 2.19 2.32 2.43

46 SC

1.611.79 2.011.97 2.07

PI

1.12 1.14 1.16 1.18 1.19

LEGEND

TC - Total Cooling Capacity,KW

SC - Sensi

ble Capacity,KW

Pl - Power Input

WB - Wet Bulb Temp(oC)

DB - Dry Bulb Temp(oC)

ID - Indoor

OU - Outdoor

Data Field

Filled the nominal data in the cells which font is RED

Entering Air DB

OD Coil(

o

C)

EDS25H / GCN9 R22

Heating Capacity (KW)

ENTERING AIR DB ID COIL(Oc)

15 20 25

ENTERING WB

OD COIL(

o

C)

TH Pl TH Pl TH Pl

-10 1.500.72 1.44 0.77 1.38 0.81

-71.61 0.74 1.55 0.78 1.50 0.82

-21.71 0.75 1.65 0.79 1.60 0.84

22.08 0.78 2.00 0.831.91 0.88

6 2.94 0.84

2.85 0.90

2.75 0.96

10 3.19 0.893.11 0.95 3.021.02

15 3.45 0.93 3.

36 1.00 3.28 1.06

20 3.63 0.95 3.55 1.043.45 1.12

LEGEND

TH - Total Heating Capacity,KW

Pl - Power Input

WB - Wet Bulb Temp(oC)

DB - Dry Bulb Temp(oC)

ID - Indoor

OU - Outdoor

Data Field

Filled the nominal data in the sheet which font is RED

EDS25H / GCN9 R22

Cooling Capacity(KW)

Data

Entering Air WB/DB ID Coil(

o

C)

15/21 17/24 19/27 21/29 23/32

TC

3.56 3.77 3.94 4.12 4.26

15 SC

3.013.19 3.36 3.28 3.34

PI

0.85 0.85 0.85 0.86 0.86

TC

3.52 3.73 3.91 4.08 4.22

20 SC

2.51 2.672.822.74 2.80

PI

0.92 0.93 0.93 0.94 0.94

TC

3.39 3.633.844.014.15

25 SC

2.92 3.13 3.31 3.25 3.34

PI

0.99 1.00 1.011.021.02

TC

3.18 3.42 3.70 3.843.98

30 SC

2.78 3.00 3.24 3.17 3.30

PI

1.08 1.091.10 1.11 1.11

TC

2.93 3.18

3.49

3.66 3.80

35 SC

2.622.85

3.11

3.073.20

PI

1.16 1.18

1.20

1.21 1.21

TC

2.652.90 3.21 3.39 3.52

40 SC

2.43 2.672.94 2.90 3.04

PI

1.25 1.27 1.29 1.31 1.32

TC

2.30 2.55 2.86 3.043.18

46 SC

2.21 2.45 2.76 2.71 2.83

PI

1.37 1.40 1.42 1.44 1.45

LEGEND

TC - Total

Cooling Capacity,KW

SC - Sensible Capacity,KW

Pl - Power Input

WB - Wet Bulb Temp(oC)

DB - Dry Bulb Temp(oC)

ID - Indoor

OU - Outdoor

Data Field

Filled the nominal data in the cells which font is RED

Entering Air DB

OD Coil(

o

C)

EDS35H / GCN12 R22

Heating Capacity (KW)

ENTERING AIR DB ID COIL(Oc)

15 20 25

ENTERING WB

OD COIL(

o

C)

TH Pl TH Pl TH Pl

-10 1.81 0.811.74 0.86 1.67 0.90

-71.95 0.831.88 0.871.81 0.92

-22.07 0.842.00 0.891.93 0.94

22.52 0.88 2.42 0.93 2.31 0.99

6 3.55 0.94

3.45 1.01

3.33 1.07

10 3.86 1.00 3.76 1.073.66 1.14

15 4.17 1.044.0

71.12 3.97 1.19

20 4.40 1.074.30 1.16 4.17 1.25

LEGEND

TH - Total Heating Capacity,KW

Pl - Power Input

WB - Wet Bulb Temp(oC)

DB - Dry Bulb Temp(oC)

ID - Indoor

OU - Outdoor

Data Field

Filled the nominal data in the sheet which font is RED

EDS35H / GCN12 R22

Cooling Capacity(KW)

Data

Entering Air WB/DB ID Coil(

o

C)

15/21 17/24 19/27 21/29 23/32

TC

5.77 6.11 6.40 6.68 6.91

15 SC

4.56 4.845.10 4.98 5.07

PI

1.46 1.46 1.46 1.47 1.47

TC

5.72 6.06 6.34 6.62 6.85

20 SC

4.08 4.33 4.58 4.44 4.54

PI

1.57 1.58 1.59 1.60 1.60

TC

5.49 5.89 6.23 6.51 6.74

25 SC

4

.44 4.75 5.034.94 5.06

PI

1.70 1.71 1.73 1.74 1.74

TC

5.15 5.55 6.00 6.23 6.45

30 SC

4.21 4.55 4.92 4.825.01

PI

1.841.86 1.88 1.90 1.90

TC

4.75 5.15

5.66

5.94 6.17

35 SC

3.97 4.32

4.72

4.66 4.86

PI

1.99 2.02

2.05

2.072.0

7

TC

4.30 4.70 5.21 5.49 5.72

40 SC

3.694.06 4.46 4.40 4.61

PI

2.14 2.17 2.21 2.23 2.25

TC

3.74 4.13 4.644.92 5.15

46 SC

3.35 3.72 4.19 4.11 4.30

PI

2.35 2.39 2.43 2.46 2.48

LEGEND

TC - Total Cooling

Capacity,KW

SC - Sensible Capacity,KW

Pl - Power Input

WB - Wet Bulb Temp(oC)

DB - Dry Bulb Temp(oC)

ID - Indoor

OU - Outdoor

Data Field

Filled the nominal data in the cells which font is RED

Entering Air DB

OD Coil(

o

C)

EDS52H /ONG3-17 R22

Heating Capacity (KW)

ENTERING AIR DB ID COIL(Oc)

15 20 25

ENTERING WB

OD COIL(

o

C)

TH Pl TH Pl TH Pl

-10 2.811.33 2.70 1.41 2.59 1.49

-73.021.36 2.92 1.44 2.811.51

-23.21 1.38 3.10 1.46 3.00 1.54

23.91 1.44 3.75 1.54 3.58 1.63

6 5.51 1.55

5.35 1.66

5.16 1.76

10 5.99 1.6

45.831.75 5.671.87

15 6.47 1.71 6.31 1.84 6.15 1.96

20 6.821.76 6.66 1.91 6.47 2.06

LEGEND

TH - Total Heating Capacity,KW

Pl - Power Input

WB - Wet Bulb Temp(oC)

DB - Dry Bulb Temp(oC)

ID - Indoor

OU - Outdoor

Data Field

Filled the nominal data in the sheet which font is RED

EDS52H /ONG3-17 R22

Cooling Capacity(KW)

Data

Entering Air WB/DB ID Coil(

o

C)

15/21 17/24 19/27 21/29 23/32

TC

6.57 6.96 7.28 7.60 7.86

15 SC

5.34 5.66 5.96 5.835.93

PI

1.70 1.71 1.71 1.72 1.72

TC

6.50 6.897.21 7.53 7.79

20 SC

4.644.93 5.21 5.06 5.17

PI

1.841.851.86 1.871.88

TC

6.25 6.70 7.08 7.41 7.66

25 SC

5.19 5.56 5.88

5.77 5.92

PI

1.99 2.00 2.022.042.04

TC

5.86 6.31 6.837.08 7.34

30 SC

4.93 5.32 5.75 5.635.86

PI

2.15 2.18 2.21 2.22 2.23

TC

5.41 5.86

6.44

6.76 7.02

35 SC

4.645.05

5.52

5.46 5.68

PI

2.33 2.36

2.40

2.42 2.43

TC

4.8

95.35 5.92 6.25 6.50

40 SC

4.31 4.75 5.22 5.14 5.39

PI

2.51 2.54 2.59 2.622.64

TC

4.25 4.70 5.28 5.60 5.86

46 SC

3.92 4.35 4.90 4.80 5.03

PI

2.75 2.79 2.842.88 2.91

LEGEND

TC - Total Cooling Capacity,KW

SC - Sensible

Capacity,KW

Pl - Power Input

WB - Wet Bulb Temp(oC)

DB - Dry Bulb Temp(oC)

ID - Indoor

OU - Outdoor

Data Field

Filled the nominal data in the cells which font is RED

Entering Air DB

OD Coil(

o

C)

EDS73H /GCZ22 R22

Heating Capacity (KW)

ENTERING AIR DB ID COIL(Oc)

15 20 25

ENTERING WB

OD COIL(

o

C)

TH Pl TH Pl TH Pl

-10 3.611.693.47 1.80 3.34 1.89

-73.891.73 3.75 1.833.611.92

-24.13 1.75 3.99 1.86 3.851.96

25.021.844.821.95 4.612.07

6 7.091.97

6.88 2.11

6.642.24

10 7.71 2.08 7.50 2.23 7.29 2.38

15 8.32 2

.17 8.12 2.34 7.91 2.49

208.77 2.24 8.57 2.43 8.32 2.62

LEGEND

TH - Total Heating Capacity,KW

Pl - Power Input

WB - Wet Bulb Temp(oC)

DB - Dry Bulb Temp(oC)

ID - Indoor

OU - Outdoor

Data Field

Filled the nominal data in the sheet which font is RED

EDS73H /GCZ22 R22

Cooling Capacity(KW)

Data

Entering Air WB/DB ID Coil(

o

C)

15/21 17/24 19/27 21/29 23/32

TC

9.68 10.25 10.72 11.20 11.58

15 SC

7.19 7.63 8.047.857.99

PI

2.75 2.76 2.76 2.78 2.79

TC

9.58 10.15 10.6311.10 11.48

20 SC

6.837.26 7.677.45 7.61

PI

2.98 2.99 3.013.033.03

TC

9.21 9.8710.44 1

0.91 11.29

25 SC

7.00 7.49 7.92 7.78 7.98

PI

3.21 3.24 3.27 3.29 3.30

TC

8.649.30 10.06 10.44 10.82

30 SC

6.647.17 7.75 7.59 7.90

PI

3.48 3.52 3.57 3.59 3.60

TC

7.97 8.64

9.49

9.96 10.34

35 SC

6.26 6.81

7.44

7.35 7.65

PI

3.76 3.82

3.88

3.91 3.93

TC

7.21 7.88 8.73 9.21 9.58

40 SC

5.81 6.40 7.04 6.93 7.26

PI

4.054.11 4.19 4.23 4.26

TC

6.266.93 7.788.26 8.64

46 SC

5.28 5.86 6.60 6.47 6.78

PI

4.44 4.52 4.59 4.66 4.70

LEGEND

TC -

Total Cooling Capacity,KW

SC - Sensible Capacity,KW

Pl - Power Input

WB - Wet Bulb Temp(oC)

DB - Dry Bulb Temp(oC)

ID - Indoor

OU - Outdoor

Data Field

Filled the nominal data in the cells which font is RED

Entering Air DB

OD Coil(

o

C)

EDS100H /GC10-34 R22

Heating Capacity (KW)

ENTERING AIR DB ID COIL(Oc)

15 20 25

ENTERING WB

OD COIL(

o

C)

TH Pl TH Pl TH Pl

-10 5.822.815.60 2.99 5.38 3.14

-7 6.27 2.88 6.043.045.823.20

-2 6.652.91 6.43 3.09 6.21 3.26

2 8.10 3.057.76 3.25 7.43 3.44

6 11.42 3.28

11.093.51

10.70 3.73

10 12.42 3.46 12.093

.70 11.76 3.96

15 13.42 3.6213.093.90 12.75 4.14

20 14.14 3.72 13.814.0413.42 4.35

LEGEND

TH - Total Heating Capacity,KW

Pl - Power Input

WB - Wet Bulb Temp(oC)

DB - Dry Bulb Temp(oC)

ID - Indoor

OU - Outdoor

Data Field

Filled the nominal data in the sheet which font is RED

EDS100H /GC10-34 R22

Cooling Capacity(KW)

Data

Entering Air WB/DB ID Coil(

o

C)

15/21 17/24 19/27 21/29 23/32

TC

11.88 12.58 13.16 13.75 14.21

15 SC

7.86 8.33 8.788.588.73

PI

3.39 3.40 3.40 3.42 3.43

TC

11.77 12.47 13.0513.6314.10

20 SC

8.39 8.91 9.42 9.15 9.35

PI

3.673.693.70 3.73 3.74

TC

11.30 12.12 12.8213.40 13.86

25 SC

7

.64 8.18 8.66 8.508.72

PI

3.96 3.99 4.034.06 4.07

TC

10.60 11.42 12.35 12.8213.28

30 SC

7.26 7.84 8.47 8.30 8.64

PI

4.28 4.34 4.39 4.43 4.44

TC

9.79 10.60

11.65

12.23 12.70

35 SC

6.847.44

8.13

8.04 8.36

PI

4.634.70

4.7

8

4.824.84

TC

8.859.6710.72 11.30 11.77

40 SC

6.35 6.99 7.697.57 7.94

PI

4.99 5.075.16 5.21 5.25

TC

7.69 8.50 9.55 10.14 10.60

46 SC

5.77 6.40 7.21 7.077.41

PI

5.47 5.56 5.66 5.74 5.79

LEGEND

TC - Total Cooling

Capacity,KW

SC - Sensible Capacity,KW

Pl - Power Input

WB - Wet Bulb Temp(oC)

DB - Dry Bulb Temp(oC)

ID - Indoor

OU - Outdoor

Data Field

Filled the nominal data in the cells which font is RED

Entering Air DB

OD Coil(

o

C)

EDS120H /GC45 R22

Heating Capacity (KW)

ENTERING AIR DB ID COIL(Oc)

15 20 25

ENTERING WB

OD COIL(

o

C)

TH Pl TH Pl TH Pl

-10 7.60 4.027.31 4.28 7.024.49

-7 8.18 4.12 7.894.34 7.60 4.58

-2 8.68 4.17 8.39 4.42 8.10 4.67

210.56 4.37 10.13 4.649.694.92

6 14.90 4.69

14.47 5.02

13.96 5.33

10 16.21 4.95 15

.77 5.30 15.34 5.66

15 17.51 5.17 17.075.57 16.645.92

20 18.45 5.32 18.025.77 17.51 6.22

LEGEND

TH - Total Heating Capacity,KW

Pl - Power Input

WB - Wet Bulb Temp(oC)

DB - Dry Bulb Temp(oC)

ID - Indoor

OU - Outdoor

Data Field

Filled the nominal data in the sheet which font is RED

EDS120H /GC45 R22

Outdoor

25.1

RPM 747

Octave

Band

Cooling Heating

635556

125 56 56

250 52 53

500 49 49

1000 45 46

2000 39 40

4000 35 36

8000 27 29

50.5

60.9

51.1

60.8

Cooling

SEND TO

Outdoor Sound Power

(heating),

dB(A)

Outdooor

Outdoor Sound Power

(cooling)

, dB(A)

Outdoor Sound Pressure

(heating)

, dB(A)

Outdoor Sound Pressure

(cooling)

, dB(A)

Heating

Drawing of microphon position

Outdoor

Outdoor Octave Band Sound Pressure Level, dB

Background Noise,dB(A):

Outdoor Unit Noise Data Report - Fix RPM

Model:

Type:

GCN9RC(R22)

PILOT

Noise spectrum & NC Curves

NC15

NC20

NC25

NC30

NC35

NC40

NC45

NC50

NC55

NC60

NC65

0

10

20

30

40

50

60

70

80

90

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequencies [Hz]

Octave Band Sound Pressure Level [dB re 20 mPa]

Noise spectrum & NC Curves

NC15

NC20

NC25

NC30

NC35

NC40

NC45

NC50

NC55

NC60

NC65

0

10

20

30

40

50

60

70

80

90

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequencies [Hz]

Octave Band Sound Pressure Level [dB re 20 mPa]

Mic.

Unit

Ground

Outdoor

25.1

RPM 833

Octave

Band

Cooling Heating

635756

125 57 56

250 55 55

500 55 56

1000 48 50

2000 43 44

4000 39 40

8000 32 35

54.9

64.0

56.2

64.5

Cooling

SEND TO

Outdoor Sound Power

(heating),

dB(A)

Outdooor

Outdoor Sound Power

(cooling)

, dB(A)

Outdoor Sound Pressure

(heating)

, dB(A)

Outdoor Sound Pressure

(cooling)

, dB(A)

Heating

Drawing of microphon position

Outdoor

Outdoor Octave Band Sound Pressure Level, dB

Background Noise,dB(A):

Outdoor Unit Noise Data Report - Fix RPM

Model:

Type:

GCN12RC(R22)

Pilot

Noise spectrum & NC Curves

NC15

NC20

NC25

NC30

NC35

NC40

NC45

NC50

NC55

NC60

NC65

0

10

20

30

40

50

60

70

80

90

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequencies [Hz]

Octave Band Sound Pressure Level [dB re 20 mPa]

Noise spectrum & NC Curves

NC15

NC20

NC25

NC30

NC35

NC40

NC45

NC50

NC55

NC60

NC65

0

10

20

30

40

50

60

70

80

90

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequencies [Hz]

Octave Band Sound Pressure Level [dB re 20 mPa]

Mic.

Unit

Ground

Outdoor

25.1

RPM 906

Octave

Band

Cooling Heating

63 60 61

125 5860

250 5860

500 50 52

1000 47 49

2000 44 45

4000 41 42

8000 35 39

53.3

64.4

55.2

66.1

Cooling

SEND TO

Outdoor Unit Noise Data Report - Fix RPM

Model:

Type:

ONG3-17

Polit

Outdoor Octave Band Sound Pressure Level, dB

Background Noise,dB(A):

Drawing of microphone position

Outdoor

Heating

Outdoor Sound Power level

(heating),

dB(A)

Outdooor

Outdoor Sound Power level

(cooling)

, dB(A)

Outdoor Sound Pressure level

(heating)

,dB(A

)

Outdoor Sound Pressure level

(cooling)

,dB(A)

Noise spectrum & NC Curves

NC15

NC20

NC25

NC30

NC35

NC40

NC45

NC50

NC55

NC60

NC65

0

10

20

30

40

50

60

70

80

90

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequencies [Hz]

Octave Band Sound Pressure Level [dB re 20 mPa]

Noise spectrum & NC Curves

NC15

NC20

NC25

NC30

NC35

NC40

NC45

NC50

NC55

NC60

NC65

0

10

20

30

40

50

60

70

80

90

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequencies [Hz]

Octave Band Sound Pressure Level [dB re 20 mPa]

Mic.

Unit

Ground

Outdoor

24.1

RPM 830

Octave

Band

Cooling Heating

6356 58

125 57 59

250 59 60

500 55 56

1000 51 54

2000 49 50

4000 45 47

8000 35 39

58.2

68.7

59.7

69.7

Cooling

SEND TO

Outdoor Sound Power

(heating),

dB(A)

Outdooor

Outdoor Sound Power

(cooling)

, dB(A)

Outdoor Sound Pressure

(heating)

, dB(A)

Outdoor Sound Pressure

(cooling)

, dB(A)

Heating

Drawing of microphon position

Outdoor

Outdoor Octave Band Sound Pressure Level, dB

Background Noise,dB(A):

Outdoor Unit Noise Data Report - Fix RPM

Model:

Type:

GC22RC(R22)

AUDIT

Noise spectrum & NC Curves

NC15

NC20

NC25

NC30

NC35

NC40

NC45

NC50

NC55

NC60

NC65

0

10

20

30

40

50

60

70

80

90

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequencies [Hz]

Octave Band Sound Pressure Level [dB re 20 mPa]

Noise spectrum & NC Curves

NC15

NC20

NC25

NC30

NC35

NC40

NC45

NC50

NC55

NC60

NC65

0

10

20

30

40

50

60

70

80

90

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequencies [Hz]

Octave Band Sound Pressure Level [dB re 20 mPa]

Mic.

Unit

Ground

Noise Data Report

Cooling/Heating

2009-2-13

Outdoor

23.9

RPM 840

Octave

Band

Cooling Heating

63 68 68

125 68 69

25060 59

500 58 57

1000 55 53

2000 51 49

4000 46 43

8000 39 36

60.2

72.35

61.6

73.83

Cooling

SEND TO

Outdoor Unit Noise Data Report - Fix RPM

Model:

Type:

GC34RC(R22)

AUDIT

Outdoor Octave Band Sound Pressure Level, dB

Background Noise,dB(A):

Drawing of microphon position

Outdoor

Heating

Outdoor Sound Power

(heating),

dB(A)

Outdooor

Outdoor Sound Power

(cooling)

, dB(A)

Outdoor Sound Pressure

(heating)

, dB(A)

Outdoor Sound Pressure

(cooling)

, dB(A)

Noise spectrum & NC Curves

NC15

NC20

NC25

NC30

NC35

NC40

NC45

NC50

NC55

NC60

NC65

0

10

20

30

40

50

60

70

80

90

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequencies [Hz]

Octave Band Sound Pressure Level [dB re 20 mPa]

Noise spectrum & NC Curves

NC15

NC20

NC25

NC30

NC35

NC40

NC45

NC50

NC55

NC60

NC65

0

10

20

30

40

50

60

70

80

90

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequencies [Hz]

Octave Band Sound Pressure Level [dB re 20 mPa]

Mic.

Unit

Ground

Noise Data Report

Cooling/Heating

2009-2-13

Outdoor

23.9

RPM 784

Octave

Band

Cooling Heating

63 67 68

125 68 69

250 58 59

500 56 57

1000 53 53

2000 48 49

4000 43 43

8000 35 36

58.6

69.48

58.7

70.13

Cooling

SEND TO

Outdoor Sound Power

(heating),

dB(A)

Outdooor

Outdoor Sound Power

(cooling)

, dB(A)

Outdoor Sound Pressure

(heating)

, dB(A)

Outdoor Sound Pressure

(cooling)

, dB(A)

Heating

Drawing of microphon position

Outdoor

Outdoor Octave Band Sound Pressure Level, dB

Background Noise,dB(A):

Outdoor Unit Noise Data Report - Fix RPM

Model:

Type:

GC45RC(R22)

AUDIT

Noise spectrum & NC Curves

NC15

NC20

NC25

NC30

NC35

NC40

NC45

NC50

NC55

NC60

NC65

0

10

20

30

40

50

60

70

80

90

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequencies [Hz]

Octave Band Sound Pressure Level [dB re 20 mPa]

Noise spectrum & NC Curves

NC15

NC20

NC25

NC30

NC35

NC40

NC45

NC50

NC55

NC60

NC65

0

10

20

30

40

50

60

70

80

90

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequencies [Hz]

Octave Band Sound Pressure Level [dB re 20 mPa]

Mic.

Unit

Ground

1. If there is a additional electric-heater, the cable must be thicked one grade.

2. Use supply wire sizes as per local electrical codes and regulations.

MODEL

EDS 25/ GCN9

EDS 73/ G 22C

EDS 35/ GCN12 EDS 52/ ONG3-17

Model

Indoor And Outdoor Unit

Connections

Power Supply

Indoor Unit

Outdoor Unit

EDS25

Power Supply

1N~230V-50Hz

GCN9

Max. Current

A

7.1 8.2 12.9 18.7

3G, 1.0

EDS35 EDS52 EDS73

3G, 1.5 3G, 1.5 3G, 2.5

Connections cable

6G, 1.0 6G, 1.5 6G, 1.5 6G, 2.5

GCN12 ONG3-17 22

MODEL EDS100/GC10-34 EDS120/ G 45C

Model

Power Supply

Indoor Unit

Outdoor Unit

EDS120

Power Supply

3N~400V-50Hz

Max. Current A

11.3

5G, 4.0

Connections cable

6G, 2.5

7-2

Use supply wire sizes as per local electrical codes and regulations.

45

Indoor And Outdoor Unit

Connections

EDS100

11.0

5G, 4.0

6G, 2.5

10-34

7-1

ELECTRICAL DATA

Revision 0Service Manual - EDS

7. ELECTRICAL DATA

7-1

7-2

ELECTRICAL DATA

Revision 0Service Manual - EDS

7. ELECTRICAL DATA

Model

Power Supply

Indoor Unit

Outdoor Unit

Power Supply

1N~230V-50Hz

Max. Current

A

12.8

3G,1.5

2EDS25

GC9+9

2EDS35

GC12+12

17.6

3G, 2.5

Connections cable

6G, 1.0 6G, 1.5

7-3 Model:2xEDS25/GC9+9 2xEDS35/GC12+12

1. If there is a additional electric-heater, the cable must be thicken one grade.

2. Use supply wire sizes as per local electrical codes and regulations.

Indoor And Outdoor Unit

Connections

7-4

EDS25X2+EDS35 / GC9+9+12

EDS25 2+EDS52 / GC9+9+17

EDS25+EDS35+EDS52/ GC9+12+17

EDS35X3 / GC12+12+12

Model: EDS 52+52 / GC17+17

Model

Power Supply

Indoor Unit

Outdoor Unit

mm

2

Power Supply

1N~230V-50Hz

Max. Current A

23.7

19.5 24.1 27.3 24.7

3G, 4.0 3G, 2.5 3G, 4.0 3G, 4.0 3G, 4.0

Connections cable

mm

2

6G, 1.5 6G, 1.5 6G, 1.5 6G, 1.5 6G, 1.5

2 EDS25 +EDS35

GC9+9+12 GC9+9+17

2

EDS52

GC17+17 GC9+12+17 GC12+12+12

1. If there is a additional electric-heater, the cable must thicken one grade.

2. Use supply wire sizes as per local electrical codes and regulations.

2 EDS25 +EDS52

EDS25+EDS35+EDS52

3 EDS35

Indoor And Outdoor Unit

Connections

8-1

WIRING DIAGRAMS

Revision 0Service Manual - EDS

8. WIRING DIAGRAMS

8.1 Indoor Unit : EDS25 EDS35 EDS52 EDS73

8-2

WIRING DIAGRAMS

Revision 0Service Manual - EDS

8.2 Indoor Unit : EDS100 EDS120

8-3

WIRING DIAGRAMS

Revision 0Service Manual - EDS

8.3 Outdoor unit : GCN9 GCN12

8-4

WIRING DIAGRAMS

Revision 0Service Manual - EDS

8.4

Outdoor unit : GC10-34 GC45

8-5

WIRING DIAGRAMS

Revision 0Service Manual - EDS

8.5

Outdoor unit : ONG3-17

8-6

WIRING DIAGRAMS

Revision 0Service Manual - EDS

8.6

Outdoor unit : GCZ22

ELECTRICAL CONNECTIONS

9. ELECTRICAL CONNECTIONS

9.1 Model: EDS25/GCN9 EDS35/GCN12 EDS52/ONG3-17

EDS73/GCZ22

9-1Revision 0Service Manual - EDS

LN

4

6

5

N/3

Indoor Unit

connection cable

Outdoor Unit

Power Supply

400V/3N~/50Hz

L1

L2

L3

N

E

N

4

5

6

N

/3

1L2L

3L

L

sensor connection wires

(only for heatpump)

Electrical protection to be provided

during installation

9-2Revision 0Service Manual - EDS

ELECTRICAL CONNECTIONS

9.2 Model: EDS100/GC10-34 EDS120/GC45

RES

230V

50Hz

Power supply

N

L

E

1DI2DI

RES

1elbaC2elbaC

Cable C

Outdoor Unit

NOTICE:

Defrost cable have to be disabled and

resistors have to be used in two indoor

units when unit is cooling only model.

Electrical protection to be

provided during installation

-------

Only for heatpump unit

RES 4.7k

9-2Revision 0Service Manual - EDS

ELECTRICAL CONNECTIONS

9.3 Model: 2xEDS25/GC9+9 2xEDS/GC12+12

Power cable C2

230V/1N~/50Hz

C3

1

L2L3

LLN

ONLY FOR HEATPUMP UNIT

Outdoor Unit

Electrical protection to be

provided during installation

LN45 6

1.N 1.4 1.5 1.6L1

ID 1

LN45 6

L2 2N 2.4 2.5 2.6

ID 2

Switch

Power Cable

OPTIONAL

LN45 6

L3 3N 3.4 3.5 3.6

ID 3

C1

400V/3Ph/50Hz

Power Cable

NOTICE

1. Power optional: 3-phase power 400V/3Ph/5OHz or 1 - phase

power 230V/1Ph/5OHz.

2. The current cable is connected by 1-phase power, if you want

to use 3-phase power, "Power Switch C1" must be connected

according to the wire diagram.

3. If the outdoor is dual unit, you must cancel unit 3 and its cables.

4. Power supply plugs must be disable if you find it in indoor unit.

3DO2DO1DO

9-4Revision 0Service Manual - EDS

ELECTRICAL CONNECTIONS

9.4 Model: EDS 52+52 / GC 17+17

EDS 25x2+EDS 35 / GC 9+9+12

EDS 25x2+EDS 52 / GC 9+9+17

EDS 25+EDS 35+EDS52 / GC 9+12+17

EDS 35x3 / GC 12+12+12

REFRIGERATION DIAGRAMS

10. REFRIGERATION DIAGRAMS

10.1 Heat Pump Models

10.1.1 EDS25H / GCN 9 RC EDS35H / GCN 12 RC EDS52H / ONG3-18 RC

EDS73H/GCZ22 RC EDS100H/GC10-34 RC EDS120H/GC45 RC

HEATING MODE

Service

COOLING MODE

Service

Outdoor coil

Sensor

Capillary

tube

Strainer

Check

valve

OUTDOOR UNIT

valve

Reverse

tube

Capillary

Compressor

Outdoor coil

Sensor

tube

Capillary

Reverse

Strainer

valve

Compressor

tube

Capillary

Check

valve

OUTDOOR UNIT

INDOOR UNIT

Flared

connection

Valves

port

Indoor coil

Sensor

INDOOR UNIT

connection

Flared

Valves

port

Indoor coil

Sensor

10-1Revision 0Service Manual - EDS

REFRIGERATION DIAGRAMS

10.2 Cooling Only Models

10.2.1 EDS25A/GCN9 ST EDS35A/GCN12 ST EDS52A/ONG3-18 ST

EDS73A/GCZ22 ST EDS100A/GC10-34 ST EDS120A/GC45 ST

Outdoor coil

Strainer

Capillary

tube

rosserpmoC

Service

port

OUTDOOR UNIT

connection

Valves

Flared

Indoor coil

Sensor

INDOOR UNIT

10-2Revision 0Service Manual - EDS

11-1

TUBING CONNECTIONS

Revision 0Service Manual - EDS

11. TUBING CONNECTIONS

TUBE (Inch)

TORQUE (Nm)

¼” Ǫ”½”ǫ”¾”

Flare Nuts 11-13 40-45 60-65 70-75 80-85

Valve Cap 13-20 13-20 18-25 18-25 40-50

Service Port Cap 11-13 11-13 11-13 11-13 11-13

1. Valve Protection Cap-end

2. Refrigerant Valve Port (use Allen wrench to open/close)

3. Valve Protection Cap

4. Refrigerant Valve

5. Service Port Cap

6. Flare Nut

7. Unit Back Side

8. Copper Tube

When the outdoor unit is installed above the indoor unit an oil trap is required every 5m along

the suction line at the lowest point of the riser. Incase the indoor unit is installed above the

outdoor, no trap is required.

12-1

CONTROL SYSTEM

Revision 0Service Manual - EDS

12. CONTROL SYSTEM EDS Series

12.1 Electronic Control

12.1.1 Introduction

The electronic control information is designed for service applications, and is common

to the following groups of air-conditioners:

Ɣ ST/ RC group -Cooling only / cooling and heating by heat pump.

Ɣ SH group -Cooling and heating by heat pump and supplementary

heater.

Ɣ RH group -Cooling, heating by heaters only.

12.1.2 Jumpers Settings

GROUP J6 Setting J2 Setting

ST / RC Open Open

SH Closed Open

RH Closed Closed

12-2

CONTROL SYSTEM

Revision 0 Service Manual - EDS

12.2 Legend

AC - Alternate Current

A/C - Air-Conditioner

ANY - ON or OFF status

CLOCK - ON/OFF Operation Input, (dry contact)

COMP - Compressor

CPU - Central Processing Unit

ELUM - Extended Louver Upward Movement (Software Jumper)

E²PROM, EEP - Erase Enable Programmable Read Only Memory

HE - Heating Element

HPC - High Pressure Control

H/W - Hardware

ICP - Indoor Condensation Pump

ICT - Indoor Coil Temperature (RT2) sensor

IF, IFAN - Indoor Fan

IR - Infra Red

LEVEL1 - Normal Water Level

LEVEL2/3 - Medium/High Water Level

LEVEL4 2YHUÀRZ/HYHO

Max - Maximum

Min - Minimum

min - Minute (time)

NA - Not Applicable

OCP - Outdoor Condensation Pump

OCT - Outdoor Coil Temperature (RT3) sensor

OF, OFAN - Outdoor Fan

OPER - Operate

Para. - Paragraph

RAT - Return Air Temperature (RT1) sensor

RC - Reverse Cycle (Heat Pump)

R/C - Remote Control

RCT - Remote Control Temperature

RH - Resistance Heater

RT - Room Temperature (i.e. RCT in IFEEL mode, RAT otherwise)

RV - Reversing Valve

SB, STBY - Stand-By

sec - Second (time)

Sect - Section

SH - Supplementary Heater

SPT - Set Point Temperature

ST - Standard (a Model with Cooling Only)

S/W - Software

TEMP - Temperature

W/O - Without

WVL - Water Valve

'T - The difference between SPT and RT.

in Heat Mode: 'T = SPT-RT

in Cool/Dry/Fan Mode: 'T = RT-SPT

12-3

CONTROL SYSTEM

Revision 0Service Manual - EDS

12.3 General functions

12.3.1 COMP operation

For each Mode including POWER OFF & SB, a Min time delay of 3 min

before COMP restarting, excluding DEICING Mode

The Min operation time of COMP under different operating conditions is

Operation Mode

Min operation time of

COMP

.nim3sedoMotuArolooC,taeH

Fan, Dry2YHUÀRw, Protection modes, or mode change ignored

12.3.2 IFAN operation

x Min time interval between IFAN speed change in AUTOFAN Mode, is 30 sec.

x Min time interval between IFAN speed change in H/M/L Mode is 1 sec.

x IFAN speed in Heat/Cool Autofan Mode is determined according to the following table:

' deepSNAFIT

'T t HGIH2

2 t'T t DEM1

1 t' WOLT

where in Heat Mode: 'T = SPT-RT

in Cool Mode: 'T = RT-SPT

Note:

x In Heat Mode, the rules in section 4.0.3 have the higher priority.

x The table above can be represent by a hysteresis curve which

will minimize the switching of the IFAN relay and will minimize the

change in IFAN speed:

T [oc]

L

M

H

IFAN speed

321

12.3.3 OFAN operation

x Min time interval between OFAN ON/OFF state change is 30 sec.

x In general, OFAN starts together with COMP.

12.3.4 HE operation

x Minimum Heaters ON or OFF time is 30 sec.

x Heaters can be activated only if IFAN is on.

12-4

CONTROL SYSTEM

Revision 0 Service Manual - EDS

12.3.5 Protections

x High pressure protection is applicable to all operating modes.

x Deicing control is valid in Heat and Auto Heat Mode only.

x Defrosting control is valid in Dry, Cool, Heat and Auto Modes.

x No reset after protection modes.

12.3.6 Thermistors operation

x Return air Temp. is detected by RAT (RT1) in normal Mode, or by RCT (R/C sensor)

in I-FEEL Mode.

x Indoor Coil Temp. is detected by ICT (RT2).

12.3.6.1 'H¿QLWLRQRIWKHUPLVWRUIDXOWV

a. Thermistor is disconnected -

The thermistor reading is below -30

o

c.

b. Thermistor is shorted -

The thermistor reading is over 75

o

c.

c. Thermistor Temp reading doesn’t change (irrelevant for RT1) -

(i) This test is performed only once after a unit is switched from

OFF/STBY to operation. $WWKH¿UVWRFFXUUHQFHRIPLQ

continuous COMP operation, the current ICT & OCT are

compared with those when the COMP was switched from OFF

to ON 10 min before. If the 'T is less than 3

o

c, the thermistor is

regarded as defective.

(ii) The ICT and OCT no-change error can be disabled together by

connecting a4.7 kohm resistor (5%) to the OCT connector. These

resistors are equivalent to a thermistor at 43+/-1

o

c and 48+/-1oc

respectively.

(iii) Connecting a 4.7k resistor to the ICT connector will disable the

ICT no-change error only.

12-5

CONTROL SYSTEM

Revision 0Service Manual - EDS

12.3.6.2 Handling the thermistor faults in a COMP unit

i. ICT/OCT thermistor is disconnected or shorted -

The invalid thermistor temperature is replaced by 43oc, so that the unit

can continue the normal operation. All protections related to that faulty

thermistor will be disabled. For example, in case of any ICT fault, the ICT

high pressure protection in Heat Mode and ICT defrost protection in Cool

Mode will not operate anymore. The same is also applied to the OCT fault.

ii. RAT thermistor is disconnected or shorted –

The RAT will be derived from the ICT by using the equations :

Heat Mode: RAT=ICT/2.3

Cool Mode RAT=ICT*4

Notes:

x In case of any thermistor failure, the STBY LED will be blinking until the

fault condition is corrected.

x 8VHUFDQXVHWKHV\VWHPGLDJQRVWLFVIXQFWLRQWR¿QGRXWWKHQDWXUHRI

the thermistor faults.

i. RAT thermistor is disconnected or shorted –

System will operate continuously in the last IFAN & WVL status when

turned ON.

Notes:

x As in the COMP unit, the STBY LED will be blinking to indicate a

thermistor fault. And, the user can use the system diagnostics function

WR¿QGRXWWKHQDWXUHRIWKHIDXOW

12-6

CONTROL SYSTEM

Revision 0 Service Manual - EDS

12.4 Cooling Mode - General

1) Room Temperature, RT, is detected by

x RAT in normal operation, or

x RCT (R/C sensor) in I-FEEL mode.

2) The resolution of RT is 1

o

c.

x RT is activating COMP/WVL if (RT > SPT), and

x RT is stopping COMP/WVL if (RT =< SPT).

3) Indoor Coil Temp is detected by ICT (RT2).

4) Outdoor Coil Temp is detected by OCT (RT3).

5) OFAN OPERATIONS

x OFAN starts together with COMP in general.

12-7

CONTROL SYSTEM

Revision 0Service Manual - EDS

12.4.1 Cooling

Mode: Cool, Auto (at Cooling)

Temp: Selected desired temperature.

Fan: HIGH, MED, LOW

Timer: Any

I Feel: On or Off

Control function

Maintains room temp at desired level by comparing RT and SPT.

(RT - SPT) [oc]

+3

+2

+1

0

-1

-2

ON

OFF

ON

OFF

USER FAN SPEED

ON

OFF

COMP

(WVL)

OFAN

IFAN

RV

Note:

1) IFAN is always running at High, Medium or Low speed selected by user.

2) In IFEEL mode, the Room Temperature (RT) is the RCT from a R/C. Otherwise, the

RT is the RAT from the Room Thermistor.

12-8

CONTROL SYSTEM

Revision 0 Service Manual - EDS

12.4.2 Cooling with Autofan

Mode: Cool, Auto (at cooling)

Temp: Selected desired temperature

Fan: Auto

Timer: Any

I Feel: On or Off

Control function

Maintains room temp at desired level and controls the IFAN speed for optimal comfort.

(RT - SPT) [oc]

+3

+2

+1

0

-1

-2

ON

OFF

ON

OFF

H

L

M

ON

OFF

COMP

(WVL)

OFAN

IFAN

RV

12-9

CONTROL SYSTEM

Revision 0Service Manual - EDS

12.5 Heating Mode

12.5.1 Heating Mode - General

x In heating Mode, temp. compensation schedule will be activated for wall mounted

units.

SPT [oc]

Add to SPT

I-FEEL ON I-FEEL OFF

18 d SPT d 27 0

o

c+2

o

c

27 < SPT d 30 0

o

c+3

o

c

Notes :

x No compensation will be activated in Forced operation modes

12.5.2 IF operating rules

x As a general rule for RC and SH groups, when COMP is ON, excluding

protection modes, IFAN will be switched ON if

x ICT > 35

o

c or

at the IFTC 30 sec after the COMP is switched ON. In

this case, the IFAN will be started at low speed.

Notes :

1) In SH or RC group, if HE is set to OFF due to low ICT, IFAN will be

switched to LOW and will be turned OFF after 30 sec.

2) An exception to this rule (4.0.3.a) is the Back-up mode for SH.

x In RC and SH groups, whenever COMP & HE are both

OFF, excluding protection modes, IFAN operation will be according

to the following:

In other models IFAN will operate in low speed for 30 sec and then stop. If

COMP is OFF for more than 3 minutes and IFEEL Mode is inactive, IFAN will

operate in low speed according to the following graph:

IFAN Speed

Any

Low

Stop

30 35 40

EMD/ELD

EMD/ELD

ICT [oc]

15 20 25

General :

For WAX :

SPT+4 SPT+6 ICT

[

o

c

]

ON

OFF

IFAN (Low Speed)

12-10

CONTROL SYSTEM

Revision 0 Service Manual - EDS

12.5.3 HE operation

x For all Groups, HE can be ON only when IFAN is ON.

x For all Groups, HE switches to OFF when ICT > 50

o

c, and is activated

again when ICT d 45

o

c.

x In SH or RC group, HE operation is limited by the following graph:

x Back-up mode for SH group

After COMP has been working for 5 minutes, HE & IFAN are activated even

if the ICT is still below 35

o

c. This situation is called Back-up Mode. Both

HE & IFAN will work in Back-up Mode until the ICT reaches 35

o

c. Then, the

operation goes on in the usual mode .

HE

ON

OFF

30

45 50

ICT [oc]

15

General :

For WAX :

35

20

40

12-11

CONTROL SYSTEM

Revision 0Service Manual - EDS

12.5.4 Heating, RC or SH Group

Mode: Heat, Auto (at heating)

Temp: Selected desired temperature

Fan: HIGH, MED, LOW

Timer: Any

I Feel: On or Off

Control function

Maintains room temp. at desired level by comparing RAT or RCT to SPT.

(RT - SPT) [oc]

+2

+1

0

-1

-2

-3

ON

OFF

ON

OFF

H/M/L

OFF

L

ON

OFF

Note 1 Note 2

COMP

(WVL)

HE1

HE2

IFAN

ON

OFF

RV

12-12

CONTROL SYSTEM

Revision 0 Service Manual - EDS

12.5.5 Heating, RC or SH Group with Autofan

Mode: Heat, Auto (at heating)

Temp: Selected desired temperature

Fan: Auto

Timer: Any

I Feel: On or Off

Control function

Maintains room temp at desired level by controlling COMP, IFAN and OFAN.

(RT - SPT) [oc]

+2

+1

0

-1

-2

-3

ON

OFF

ON

OFF

H

OFF

L

M

ON

OFF

Note 1 Note 2

COMP

(WVL)

HE1

HE2

IFAN

RV

ON

OFF

12-13

CONTROL SYSTEM

Revision 0Service Manual - EDS

12.5.6 OFAN operation is controlled by the graph below when

1. (RAT t SPT – 2oc), AND

2. (ICT t 45

o

c), AND

3. (COMP is ON)

Otherwise, OFAN runs together with COMP.

OCT [oc]

+3

+2

+1

0

-1

OFAN

ON

OFF

12-14

CONTROL SYSTEM

Revision 0 Service Manual - EDS

12.6 Automatic Cooling or Heating

12.6.1 Automatic Cooling or Heating - General

x Switching-temperature between Cooling and Heating is SPT ± 3oc.

x Autofan in Automatic Cooling and Heating Mode will activate “Cooling

with Autofan Mode” and “Heating with Autofan Mode” respectively.

x When the Auto Mode is started with SPT +/-0

o

c, the unit will not select

Auto Heat or Auto Cool mode immediately. Instead, the unit will be in

a temporary Fan Mode with IFAN operating at low speed.

The proper Auto Heat mode or Auto Cool will be started whenever the RT

reaches SPT-1

o

c or SPT+1oc respectively.

x For RC & SH units, Mode change between Auto Heat & Auto Cool

Modes is possible only after the COMP has been OFF during the

last T minutes.

Mode Change time, T

Auto Cool to Auto Heat 3 min

Auto Heat to Auto Cool 4 min

x When unit is changed form Cool/Dry mode to Auto Mode, the unit

will continue to operate at (Auto) Cool Mode until the conditions for

switching from Auto Cool to $XWR+HDWDUHVDWLV¿HG

Similarly, when unit is changed from Heat Mode to Auto Mode, the

unit will continue to operate at (Auto) Heat Mode until the conditions

for switching from Auto Heat to $XWR&RRODUHVDWLV¿HG

12-15

CONTROL SYSTEM

Revision 0Service Manual - EDS

12.6.2 Auto Cooling or Heating, RC or SH Groups

Mode: Auto

Temp: Selected desired temperature

Fan: Any

Timer: Any

I Feel: On or Off

Control function

Maintains room temp at desired level by selecting between cooling and heating modes.

(RT - SPT) [oc]

+3

+2

+1

0

-1

-2

-3

ON

OFF

ON

OFF

H/M/L/OFF

L/OFF

ON

OFF

ON

OFF

COMP

& OFAN

HE1

HE2

IFAN

RV

H/M/L/OFF

L/OFF

FFO/L/M/HDEEPSNAFRESU

L/OFF

Auto Cool Mode Auto Heat Mode

nim3>nim4>

nim2>nim3>

)3()3(

(4)

(4)

(5)

Auto Heat Mode

12-16

CONTROL SYSTEM

Revision 0 Service Manual - EDS

12.7 Dry Mode

12.7.1 Dry, ST or RC group

Mode: Dry

Temp: Selected desired temp

Fan: Low (automatically selected by software)

Timer: Any

I FEEL: Any

Control function

5HGXFHURRPKXPLGLW\ZLWKPLQLPXPWHPSÀXFWXDWLRQVE\RSHUDWLQJLQ&RRO0RGHZLWK

low speed IFAN.

Notes :

x When Dry is ON, the COMPLVIRUFHG2))IRUPLQORQJHUWKDQWKH

3 min Min COMP-Off time) after every 15 min of continuous COMP

operation.

x When Dry is OFF, the COMPLVIRUFHG21IRUPLQORQJHUWKDQWKH

min Min COMP-On time) after every 15 min of continuous COMP OFF

time.

x :KHQ'U\LVFKDQJHGIURP21WR2))RUYLFHYHUVDWKHOLPLWV

PHQWLRQHGLQDUHLJQRUHG The COMP operation is only

controlled by the 3 min Min OFF time and 1 min Min ON time.

x In Dry Mode, IFAN is LOW when COMP is ON, and is OFF when

COMP is OFF.

DRY

(RT - SPT) [oc]

+2

+1

0

-1

-2

ON

OFF

ON

OFF

LOW

OFF

DRY-ON

DRY-OFF

ON

OFF

Time [min]

10

20

30

40 50

Max 15 minutes

3.5

min

Note1

6 min

Note 2

COMP

& OFAN

HE1

& HE2

IFAN

RV

Max 15 minutes

5 minutes COMP

ON time

12-17

CONTROL SYSTEM

Revision 0Service Manual - EDS

12.8 Protection

12.8.1 Cooling Mode Protections

Indoor Coil Defrost

Mode: Cooling, Dry, Auto

Temp: Selected desired temp.

Fan: Any

Timer: Any

I Feel: On or Off

Control Function

Protect the indoor coil from ice formation at low ambient temperature.

t1 = 5 min minimum for each COMP starting

t2 = OFAN cycling (alternate between ON and OFF every 30 sec) for 20 min

maximum

t3 = COMP and OFAN stop for 10 min minimum

Notes:

x When J7 is closed (connected), OFAN cycling is cancelled and the

set temperature for COMP & OFAN cut-out and cut-in are changed.

COMP & OFAN are forced OFF when ICT =< -6

o

c, and are kept OFF

until ICT > 14

o

c.

x For WAX model, the defrost processes is simpler. When J7 is open,

COMP & OFAN are forced OFF when ICT =< -1

o

c, and are kept OFF

until ICT > 5

o

c. When J7 is closed, the WAX defrosting process is the

same as that of the other models (R.H.S. of the graph above). In both

cases, the ICT checking in t2 and t3 are not applied.

ICT [oc]

+2

ON

OFF

ON

OFF

t1 t2 t3

COMP

OFAN

+1

+5

+14

0

-1

-6

ON

OFF

IFAN

J7 OPEN J7 CLOSED

t1 t1

12-18

CONTROL SYSTEM

Revision 0 Service Manual - EDS

12.8.2 High Pressure Protection

Mode: (Auto) Cooling or Dry

Temp: Selected desired temp.

Fan: Any

Timer: Any

I Feel: On or Off