Air Vent WHSP2000 Users Manual

CONTENTS

1 Safety Information

1 Tools and Materials Needed

1 Optional Tools & Materials

1 FCC Requirements

1 Operating Information

2 What Comes in the Carton

2 Step-by-Step Installation

3 Attic Ventilation Requirements

3 Electrical Requirements

3 5-Year Limited Warranty

4 Replacement Plus™ Protection

4 Operating Instructions

4 WHSP2000 Specifications

4 WHSP2000 Troubleshooting Guide

READ AND SAVE

THESE INSTRUCTIONS

SAFETY INFORMATION

Read the following safety information

before installing this Whole House Attic

Fan. Failure to follow these instructions

could result in personal injury or property

damage. If you need assistance in understanding these instructions or have

questions or comments, please call

309-692-6969.

WARNING – TO REDUCE THE RISK OF

FIRE OR ELECTRIC SHOCK, DO NOT USE

THIS FAN WITH ANY SOLID-STATE SPEED

CONTROL DEVICE OTHER THAN THOSE

INCLUDED WITH THE PRODUCT OR AVAILABLE AS AN OPTIONAL CONTROLLER

SPECIFICALLY MANUFACTURED FOR THIS

PRODUCT.

Whisper Aire

™

WHSP2000

Whole House Attic Fan

Installation

Instructions

WARNING – TO REDUCE THE RISK OF

FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

•

Use this unit only in the manner intended

by the manufacturer. If you have questions,

contact the manufacturer.

•

Before servicing or cleaning the unit, switch

power off at service panel and lock the service disconnecting means to prevent power

from being switched on accidentally. When

the service disconnecting means cannot be

locked, securely fasten a prominent warning

device, such as a tag, to the service panel.

CAUTION – FOR GENERAL VENTILATING

USE ONLY. DO NOT USE TO EXHAUST

HAZARDOUS OR EXPLOSIVE MATERIALS

AND VAPORS.

CAUTION – THIS UNIT HAS AN UNGUARD-

ED IMPELLER DURING OPERATION. DO NOT

USE IN LOCATIONS READILY ACCESSIBLE

TO PEOPLE OR ANIMALS.

WARNING – TO REDUCE THE RISK OF

FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

•

Qualified person(s) in accordance with all

applicable codes and standards, including

fire-rated construction, must do installation

work and electrical wiring.

•

Sufficient air is needed for proper combustion

and exhausting of gases through the flue

(chimney) of fuel burning equipment to

prevent back drafting. Follow the heating

equipment manufacturer’s guideline and

safety standards such as those published by

the National Fire Protection Association

(NFPA), and the American Society for Heating,

Refrigeration, and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

•

When cutting or drilling into wall or ceiling,

do not damage electrical wiring and other

hidden utilities.

•

Ducted fans must always be vented to the

outdoors.

•

DO NOT install this unit over a tub or shower.

•

NEVER place a switch where it can be

reached from a tub or shower.

TOOLS AND MATERIALS NEEDED

•

Safety goggles

•

Tape measure or folding ruler

•

Pencil

•

Portable electric drill

•

Small drill bit (1/8-, 3/16-inch, etc.)

•

Heavy gauge (bailing) wire or wire hanger

•

Utility knife or Keyhole saw – for cutting

sheet rock

•

Saw for cutting lumber

•

2X framing lumber (length depends on

Step 5) to match cross section dimensions

of existing joist

•

Wood screws or nails for framing

(minimum 8, see Step 5)

•

1/4-inch nut driver bit

•

(3) Twist-on electrical wire connectors

•

Screwdriver with Phillips bit

•

(2) 1.5V (AA) batteries

Optional Tools and Materials–

•

Code required electrical materials

Note: Before you begin the step-by-step

installation, read the sections on “Attic

Ventilation Requirements” and

“Electrical Requirements” on page 3.

FCC REQUIREMENTS

THIS DEVICE COMPLIES WITH PART 15 OF THE

FCC RULES.

FCC ID: NGQGLD001

Operation is subject to the following two

conditions:

•

This device may cause harmful interference.

•

This device must accept any interference

received, including interference that may

cause undesired operation.

OPERATING INFORMATION

•

Keep screened windows and/or doors open

when the fan is operating to avoid drawing

carbon monoxide from furnace and water

heater flues and extinguishing pilot lights

of appliances.

•

During hot weather requiring air conditioning,

when outside air is cooler than indoors, cool

the house quicker by first operating the

whole house fan for approximately 10

minutes. Then turn off the fan and turn on

the air conditioner.

•

For operation during mild weather conditions

(when the use of air conditioning is not

required) use “Exhaust” modes to evacuate

warm air quickly.Then reduce the speed to

lower settings for maintaining whole house

ventilation.

WHAT COMES IN THE CARTON

To make sure you have everything you need

to install your new whole house attic fan,

unpack the carton and take inventory. The

carton should contain:

(1) Fan assembly

(1) Return grill with (6) fasteners

(1) 1-inch wide x 84-inch long roll of

adhesive-backed foam

(1) Remote controller (Batteries not

included)

(6) Hex head screws for mounting fan

unit to ceiling joists

Step-by-step

installation

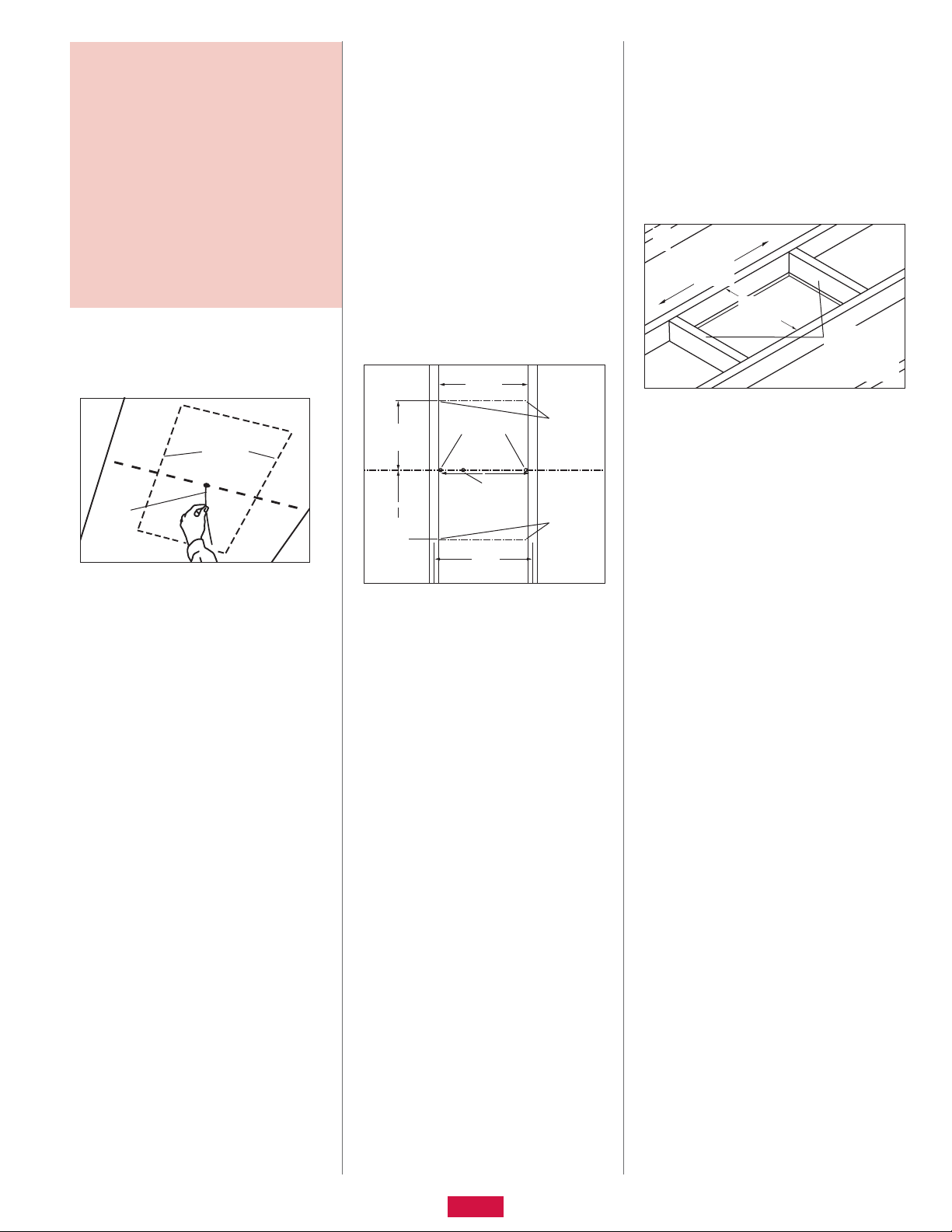

A

Proposed fan

location

Center

of

hallway

ceiling

Step 1: Select a central

location for the fan

•

Your whole house attic fan is designed for

horizontal mounting on the floor of your attic,

usually above a centrally located hallway.

Note: For vertical installations, the fan should

be mounted between 16-inch OC wall studs

only. For 24-inch OC wall studs, framing will

have to be installed to simulate a 16-inch OC

wall stud situation at the desired fan location.

Installation procedures are essentially the

same as those for a horizontal installation.

•

In the hallway, find the center of the ceiling

by measuring half the distance between the

walls. Mark the spot with a pencil.

•

Drill a hole with a small bit on the ceiling

mark, and push a straight length of wire

through the hole so you can locate it in

the attic. (Illustration A)

Step 2: Investigate

the attic location

•

Go to the attic and find the hole you’ve made

in the ceiling from below.

•

Locate the joist nearest to the hole.

•

Clear the insulation between the joists at

the location of the hole (approximately 1

feet on each side of hole). Wear work

gloves to avoid skin irritation from the

insulation.

•

Check for electrical and other wires or pipes.

If any wires or pipes are in the way, you can

have them moved by a professional or pick

another location to mount the fan.

•

Check the clearance above the fan location.

There must be at least 24 inches between

the top of the fan and the roof. Providing

enough air space above the fan helps

prevent the motors from overheating and

keeps them running efficiently.

•

In addition, make sure that enough clearance

exists for the path of the shutter. To ensure

proper operation, a minimum of 4 inches

clearance is required on the hinged side

of the unit. No framing lumber, truss mem-

bers, utilities, etc. should impede the path

of the shutter.

Warning: Failure to provide sufficient shutter

clearance could result in damage to the

product.

1

/

14

B

1

/

11

4"

1

/

4")

(7

1

/

11

4"

1

/

4")

(7

2"

1

/

2")

(22

Holes at

center of

cutout sides

Hole at

center of

hallway

16"

(24")

Corner

marks for

cutout

Corner

marks for

cutout

Step 4: Cut the hole

•

Using a keyhole saw or utility knife, cut

between the four corner locations.

Note: If you are cutting from inside the attic,

you may first want to cut a hand-sized hole

at the center to allow for a place to secure

the sheet rock while cutting between the four

corners. This should help prevent the face of

the sheet rock from tearing below.

C

1

/

22

2"

1

/

2")

(14

1

/

14

2"

1

/

2")

(22

Install framing

2x’s flush with

sheet rock

cutout edges

Step 5: Install the

framing members

•

Depending on the ceiling joist spacing, cut

2X lumber to (2) 14 1/2-inch lengths for

16-inch OC joists or (2) 22 1/2-inch lengths

for 24-inch OC joists.

Note: Verify these lengths with a tape mea-

sure before cutting lumber.

•

Using nails or wood screws (not provided),

install the framing members between the

Step 3: Establish cut-out

location inside attic

Note: If the whole house fan fits through

your attic access opening, the remaining

installation steps can be performed from

inside the attic except the grill installation

(Step 8) and possibly the cutting of framing

lumber. (Step 5)

•

Select the joist bay that has the “centering”

hole which was created in Step 1, provided

that the criteria established in Step 2 are

satisfied.

Note: If ceiling joists are parallel to the length

of the hallway, it is possible that the whole

house fan will not be centered in the hallway

ceiling. Another location may need to be considered depending on personal preferences.

•

Drill two holes at the edges of the joists in

perpendicular line with “centering” hole.

(Illustration B)

Note: Make sure that the perpendicular

distance between joists is approximately

14 1/2 inches for 16-inch OC joists or

22 1/2 inches for 24-inch OC joists.

•

1

/

For 16-inch OC joists, measure 11 1/4 inches

2

(or for 24-inch OC joists, measure 7 1/4

inches) from both sides of both holes along

edges of joists and mark. This locates the

four corners of the cut-out as shown.

(Illustration B)

joists with the inside edge flush with the

exposed sheet rock edges. (Illustration C)

•

Optional Step: To help reduce the noise level

of the fan in the “Exhaust Mode” (higher

speeds), install additional 2X framing lumber

above the ceiling joists and framing members

to create a box that extends the fan further

away from the plane of the ceiling and the

grill.

Warning: It is critical to ensure that enough

clearance is available for the fan (Step 2).

In addition, the framed box should be sealed

so that attic air can not be drawn into it

through the joints.

Note: This optional step should help minimize

the possibility of blown-in insulation from

being carried by the airflow and should also

help prevent the insulation from impeding the

path of the shutter. If after this step has been

implemented and the insulation is still moved

by the flow of air, an air dam can easily be

created around the three, non-hinged sides

of the unit using either cardboard or lumber.

This air dam will force the flow of air to travel

up and over the top of the insulation.

Step 6: Mount the fan assembly

•

Using the 1-inch rolled adhesive-backed

foam, cut and apply to the underside of the

flange around perimeter of housing wall. (For

positioning: Edge of foam can be butted

against wall of housing.) Application of the

2

foam minimizes vibration and seals possible

air passages between the living space and

the attic.

•

Using the six pre-drilled holes in the whole

house fan flange, secure the fan assembly to

the ceiling joists and framing using fasteners

provided.

Note: Orientation of the whole house fan

should allow clearance for a fully-open shutter (not only vertical distance above the fan,

but also horizontal clearance at hinged

side of the fan as described in Step 2).

Step 7: Make electrical

wiring connections

•

Refer to “Electrical Requirements” section,

page 3, for information on bringing electric

power to fan location.

•

At your home’s breaker box, turn off the electrical power to the circuit associated with the

fan. Do not turn on the power to this circuit

until you have completely finished the fan

installation.

•

From the attic, remove the cover from the

electrical wiring box on the side of the fan

housing.

•

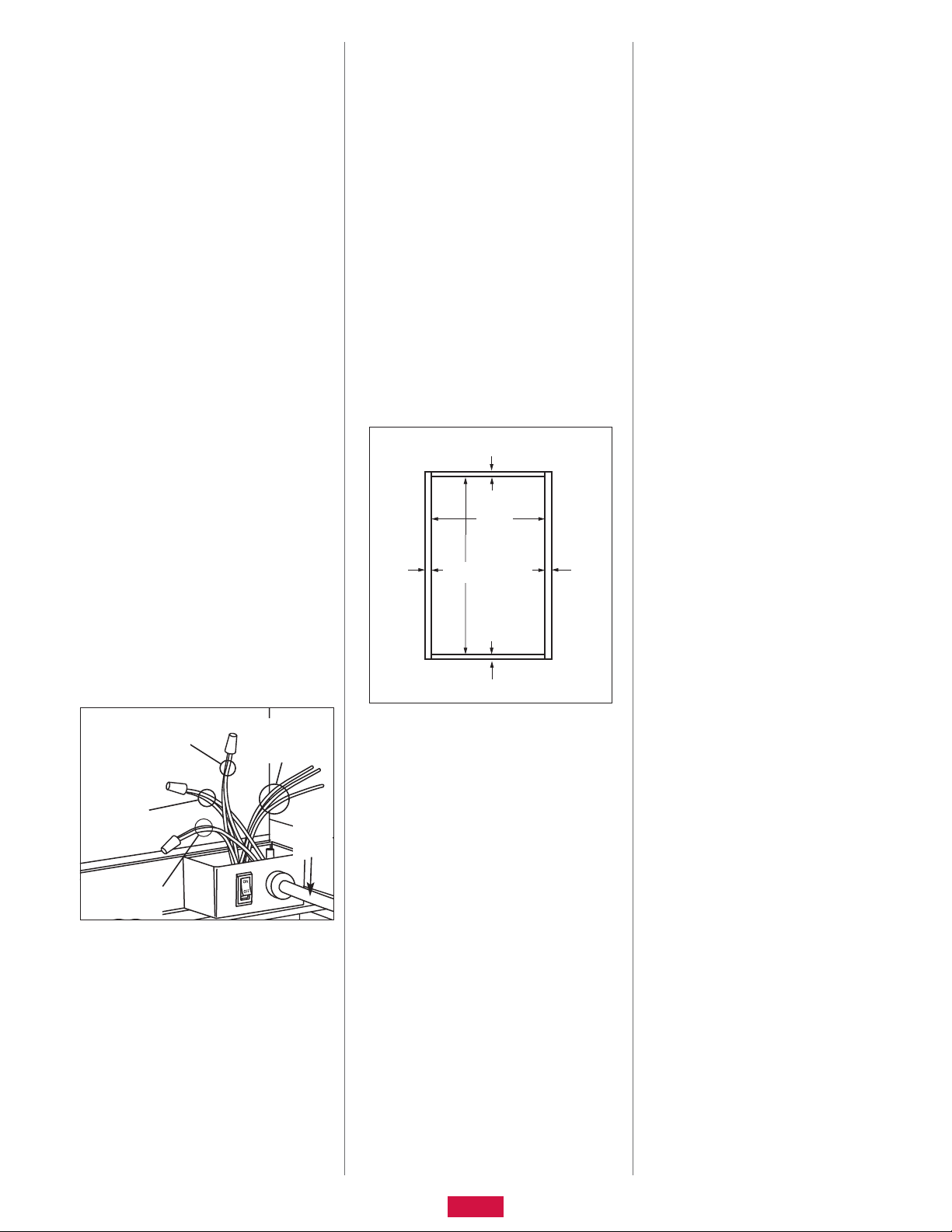

Using wire nuts make the following electrical

connections (Illustration D):

•

Hot wire from power supply (typically

black) to the fan’s black wire

•

Common (neutral) wire from power

supply (typically white) to the fan’s

white wire

•

Ground wire from power supply

(typically bare copper) to the fan’s

green wire

D

White lead &

neutral wire

from service

Black lead

& hot wire

from service

Green lead &

ground wire

from service

•

Leads (blue, red, & yellow) other than those

previously specified are only to be used for

an optional wall-mounted control. Do not remove insulation from these lead ends unless

installing the optional controller.

Warning: Failure to isolate these leads (blue,

red, & yellow) from each other and from

other conductors, including the metal wiring

box, could result in erroneous unit operation

or possibly damage to the unit.

Note: For more information about the option-

al wall-mounted controller and availability,

call 309-692-6969.

Three leads

for optional

wall controller

Power

service

from

panel

•

Push the wire connections into the unit’s

wiring box. Secure the cover to the electrical

wiring box.

•

Turn on the switch mounted to the electrical

wiring box.

•

Before leaving the attic, place the attic insulation around the whole house fan.

Step 8: Install the grill

•

Using the six fasteners provided, center and

install the grill over the opening from the

hallway. The fasteners should penetrate the

joists and framing added in Step 5.

Note: It may be necessary to trim the sheet-

rock around the perimeter of the opening to

allow for a flush installation of the grill. If so,

trim 3/4-inch from the edges of the long

sides of the sheet rock opening and 5/8-inch

from the edges of the short sides of the sheet

rock opening using a utility knife.

(Illustration E)

5

/

E

3

/

4"

8"

1

/

14

4"

1

/

22

2"

5

/

8"

3

/

4"

Step 9: Operate the fan

•

Open windows and interior doors of rooms to

be ventilated by the fan.

•

If you have a fireplace, make sure the flue

is closed.

•

At your home’s breaker box, switch on the

circuit breaker associated with the fan.

•

Insert batteries into remote.

•

Refer to the section entitled WHSP2000

Operating Instructions (page 4) for information on the functionality of the unit. A

condensed version of the operating instructions is located on the back of the remote.

ATTIC VENTILATION REQUIREMENTS

In order for the whole house fan to work properly, adequate ventilation is needed to exhaust

the hot air from the attic that the fan pulls into

the attic from your home’s living space. If your

attic is not adequately vented, the whole house

fan will shut off automatically as a result of fan

motor overload.

•

The WHSP2000 whole house fan requires a

minimum of 2.6 square feet, or approximately 384 square inches, of open attic vent area.

•

Check your attic ventilation system to make

sure that it provides at least this minimum

amount of open vent area. Typically, undereave or soffit vents are installed near the

floor of the attic, and roof louvers, gable

vents, or ridge vents are installed high in

the attic to allow air to escape. These vents

are installed to provide attic ventilation year

round, and when the whole house fan is on,

these vents provide the net free area to

exhaust it.

Remember: When measuring your vents,

obstructions such as louvers and screens

need to be factored into the open area. A

good rule of the thumb is to divide the

vent’s size in half.

ELECTRICAL REQUIREMENTS

Your whole house attic fan runs on standard

115-volt house current. Electrical installation

and wiring of the fan must adhere to the

National Electrical Code and all local codes

that apply, including fire-rated construction.

Wiring the whole house attic fan itself is a

simple procedure that most homeowners can

accomplish (see Step 7, page 3). However,

bringing the electrical power supply to the fan

requires a higher level of electrical knowledge

and skill. If you are not experienced at installing residential electrical wiring and/or are not

familiar with all national and local electrical

codes, you should hire a qualified electrician

to do the wiring for you.

5-YEAR LIMITED WARRANTY

The WHSP2000 is warranted for five (5) years

from date of purchase against defects in workmanship and materials. This warranty covers

the fan blades and motors.

If you believe any part is defective, call

1-800-527-1924 for Customer Service. If it

is determined that the product needs to be

returned to Air Vent, it must be shipped freight

prepaid to Air Vent, Inc., 3000 West Commerce

Street, Dallas, Texas 75212. If found to be defective following examination by Air Vent, Inc.,

any defective part will be replaced free of

charge and returned freight prepaid. This warranty does not cover any labor costs, including

those required for field repair or replacement

3

or removal of any allegedly defective part. This

warranty gives you specific legal rights and

you may also have other rights, which vary,

from state to state.

REPLACEMENT PLUS PROTECTION

™

The product to which this warranty applies is

covered by Replacement Plus protection for a

period of two (2) years, provided that the product has been installed in strict accordance with

written installation instructions and in accordance with all local codes and standards,

including those pertaining to fire-rated construction. Under this warranty feature, Air Vent,

Inc., at no charge, will replace any part covered by this warranty and found to be defective

during the Replacement Plus period (The

Replacement Plus period begins when the

whole house attic fan installation is completed). Maximum liability under Replacement Plus

will be equal to the reasonable cost of the replacement part, including labor to remove the

defective part and install the replacement part.

In instances in which Air Vent, Inc., according

to the terms of this warranty has agreed to pay

the cost of labor required to replace a defective

part, Air Vent, Inc. will provide reimbursement

only upon receipt of a copy of the contractor’s

invoice or other written evidence of the completion of the work which Air Vent, Inc., at its

sole discretion, deems acceptable.

OPERATING INSTRUCTIONS

•

To start the unit, press “START.” The fan will

resume the speed setting that was last selec-

ted as indicated by the corresponding LED

which lights up momentarily when the

“START” button is depressed.

Note: Upon startup, it will take approximately

15 seconds (time for shutter to completely

open) before the processor is capable of

accepting signals from the remote control

transmitter.

•

To change speeds, press the “START” button

until the desired speed is selected as indicated by the corresponding LED on the

remote control.

Remember: It will only be possible to change

speeds after the shutter (inside of the attic)

has reached the fully open position.

•

To use the timer feature, depress the “SET

RUN HOURS” button until the desired run

time is selected as indicated by the corresponding LED which lights up momentarily

when the button is depressed. When the unit

is turned off and then back on, the timer feature defaults to manual mode.

Note: The unit must be running and the shut-

ter must be fully open before the timer feature can be activated.

•

To stop the unit at any time, depress the

“STOP” button. This interrupts power to the

fan motors and sends power to the shutter

drive motor. It will take approximately 15

seconds for the shutter to completely close

and for the processor to recognize signal

transmission from the remote control.

•

In order to conserve battery power, an 8-second timeout feature has been integrated into

the remote control software. After 8 seconds

has elapsed from the last signal transmission, any subsequent signal transmitted (by

depressing either the “START” button to

change speeds or the “SET RUN HOURS” button to change the timer selection) will be a

duplicate of the current setting. The button

used to activate the desired setting change

will need to be depressed consecutive times

until the corresponding LED of the desired

setting momentarily lights up.

WHSP2000

Troubleshooting Guide

Go to step 2.

If No

If Yes

•

Go to step 7 if fans run, but a control problem exists.

Go to step 10 if communication interference occurs.

•

•

A) Flip the switch to the ON position.

Go to step 3.

Go to step 11 for all other inquiries.

•

•

B) Repeat step 1.

Go to step 4.

•

Go to step 7.

•

power off at the circuit breaker.

A) Make the correct wiring connections with

B) Turn the appropriate circuit breaker ON.

C) Turn the junction box mounted switch ON.

D) Repeat step 1.

Go to step 5.

•

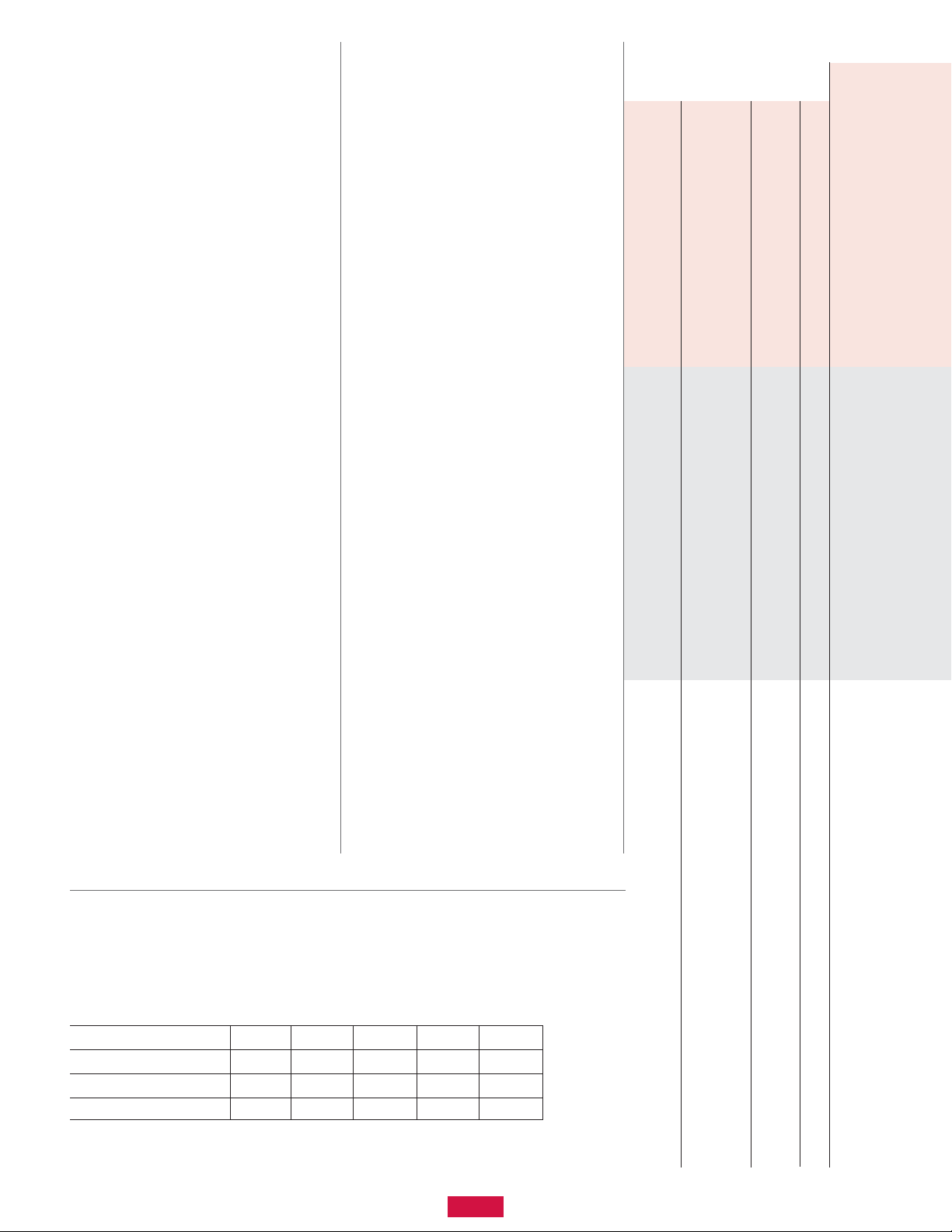

WHSP2000 SPECIFICATIONS

General Electrical Ratings 115 VAC 60 Hz

Startup Current Approx. 4.0 A

R-Value of Shutter R-25

Weight 25 lbs. (without grill)

Remote Batteries (2) 1.5 V – AA (Alkaline Recommended) NOT INCLUDED

Airflow (CFM @ 0.0" S.P.) 1290 1410 1600 1700 2200

Current Draw (A) 2.0 2.1 2.3 2.4 3.1

Power Consumption (W) 220 240 270 290 370

Fan Speed (RPM) 1665 1835 2040 2215 2830

4

Step Troubleshooting Question

1 Does the unit run?

2 Is the junction box switch in the “ON” position?

Black lead to hot leg {typically black}

White lead to common (neutral) leg {typically white}

Green lead to ground {typically bare or green}

•

•

•

electrical service?

4 Are the leads from the WHSP2000 connected correctly to the

3 Is the red LED on the side of the housing lit?

Loading...

Loading...