Page 1

Switchbox with Remote Switch

Models: SB260, SB264

WARNING: Always wear safety goggles and a dust

mask when installing to prevent personal injury.

WARNING: The power must be “OFF” before

proceeding with the installation.

17-498-01 rev.02 12/14/10

WARNING: A safe installation requires a 0.5 amp fastblow fuse or circuit breaker. Failure to do so may

damage the product and /or result in fire, damage to

the boat, and/or personal injury.

CAUTION: To reduce electrical interference from

other electrical wiring and any on-board equipment with

strong magnetic fields such as radar equipment, radio

transmitters, boat engines, generators, etc., separate

the cables by at least 1m (3').

CAUTION: Be careful not to tear the cable jackets

when passing them through bulkheads and other

parts of the boat. Use grommets to prevent chaffing.

Use deck glands to prevent water seepage into the

boat.

CAUTION: Use a multimeter to check the polarity and

the connections to the 10 - 32 VDC power supply

before applying power to the transducer(s).

IMPORTANT: Please read the instructions completely

before proceeding with the installation. These

instructions supersede any other instructions in your

instrument manual if they differ.

INSTALLATION INSTRUCTIONSOWNER’S GUIDE &

Figure 1. SB264 Switchbox and remote switch

Tools & Materials

Safety glasses

Dust mask

Grommets (some installations)

Deck glands (some installations)

Cutting pliers

Phillips screwdrivers

Pencil

Electric drill

Drill bits:

Switchbox 3mm or 1/8"

Remote switch 11mm or 1/2" spade bit

Sandpaper

Weak solvent (such as alcohol)

Wire strippers

Heat shrink tubing

Blade screwdriver

Pliers

Adjustable wrench

Cable ties (some installations)

Copyright © 2008 Airmar Technolog y Corp.

Applications

• Single transmission line transducers and echosounders only

• 1kW echosounders only. Do not use with 2 kW echosounders.

• SB260 switches between:

- Two depth transducers connected to one echosounder. The

transducers must use C32 or C332 cable.

- Two echosounders connected to one depth transducer. The

echosounder must be dual-frequency with a single

transmission-line. The transducer must use C32 or C332

cable.

• SB264

Switches between a wide-beam and a narrow-beam depth

transducer connected to one echosounder. Pair a wide-beam

SS264W with one of the narrow-beam models such as: B258,

B260, or M260. Both transducers must have C32 or C332

cable.

Locating Switchbox, Remote Switch & Cables

IMPORTANT: Be sure to allow an extra 25 cm (10") of cable to

make the connections within the switchbox.

Switchbox—Select a convenient dry mounting location for the

water-resistant switchbox about 1–2m (3' – 5') from the echosounder(s).

• Retrofit—If the transducer(s) and echosounder(s) are already

installed, select a location with easy access to the cable(s). Be

sure the cable(s) will be long enough to make the necessary

connections. Allow an extra 25 cm (10") for wiring ease.

• New installation—Install the transducer(s) and echosounder(s)

before connecting the switchbox. Plan the cable runs.

Remote Switch—Locate the remote switch on the dash panel or

other convenient location near the echosounder. Check the backside for any obstructions such as cables and wires.

• Minimum clearance on backside 36mm (1-1/2")

• Maximum panel thickness6mm (1/4”)

Page 2

Running the Cables

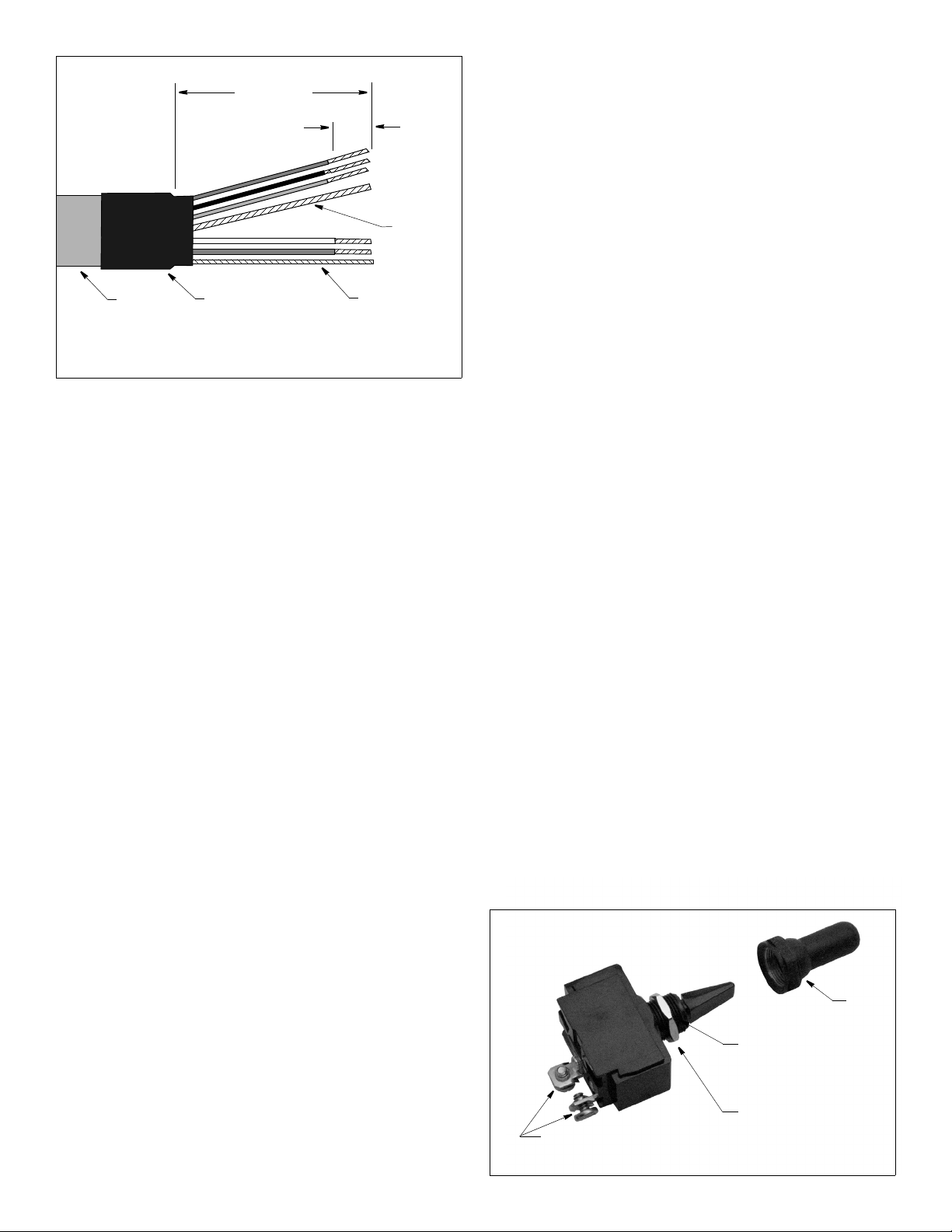

Figure 2. Preparing the cable (SS264W cable shown)

64mm (2 1/2")

remove cable jacket and

10mm

(3/8")

cable

jacket

inner bare

(depth)

outer bare

(shield)

remove

insulation

foil shielding

heat-shrink

tubing

Copyright © 2008 Airmar Technolog y Corp.

If new equipment is being installed, route the transducer cable(s),

the echosounder cable(s), the power cable, and the remote switch

cable to the proposed location of the switchbox before beginning

the installation.

• To reduce electrical interference from other electrical wiring

and any on-board equipment with strong magnetic fields such

as radar equipment, radio transmitters, boat engines,

generators, etc., separate the cables by at least 1m (3').

• Use grommets when passing cables through bulkheads and

other parts of the boat to prevent chafing.

• Use deck glands where necessary to prevent water seepage

into the boat.

• Allow an extra 25 cm (10") of cable for wiring ease.

• Do not fasten the cables in place at this time.

Hole Drilling

1. Remove the switchbox cover and set aside along with the four

screws. Hold the switchbox at the selected location and mark the

position of the screw holes.

NOTE: If the switchbox will be mounted on a vertical surface,

face the compression fittings downward to avoid any possibility

of water seeping into the box.

Installing the Remote Switch

IMPORTANT: It may be easier to wire the remote switch before

installing it in the mounting surface.

1. Strip 60mm (2-1/2") of the cable jacket and foil shielding from

one end of the C2 cable (see Figure 2).

2. Strip 10mm (3/8") of conductor insulation from the end of each

insulated wire in each cable.

3. Protect the cable’s foil shielding from causing a short by using

heat shrink tubing around the jacket where the wires emerge

from the cable. The tubing must overlap the wires a minimum of

6mm (1/4").

4. On the switch, unscrew the plastic ring and discard. It will not be

used. Unscrew the hexagonal nut and set aside.

5. Connect the blue wire to one of the screw terminals on the back

of the remote switch and the black wire to the other terminal

(see Figure 3). Either wire can be connected to either screw

terminal. It will not affect the performance of the switch.

Connect each wire by loosening a screw. Wrap the striped end

of the wire around the threads of the screw and tighten it again.

6. From the backside of the mounting surface, push the toggle

through the mounting hole. With the notch on the threaded stem

facing the word “Wide-Beam” or “A” on the label, screw the nut

against the surface. Tighten it with an adjustable wrench.

7. Screw the water-resistant boot onto the toggle switch.

Preparing the Cables

1. Allowing an extra 25 cm (10") for wiring ease, cut each cable to

length. Do not fasten the cables in place at this time.

2. Push approximately 200mm (8") of each cable through the

appropriate compression fitting. Follow the diagram on the

switchbox cover (see Figure 1). Be careful not to damage the

circuit board.

3. Strip 60mm (2-1/2") of the cable jacket and foil shielding from

the cut end of each cable (see Figure 2).

4. Strip 10mm (3/8") of conductor insulation from the end of each

colored wire in each cable.

5. Protect each cable’s foil shielding from causing a short inside

the switchbox by using heat shrink tubing around the jacket

where the wires emerge from the cable. The tubing must

overlap the wires a minimum of 6mm (1/4").

2. At the marked locations, drill 3mm or 1/8" holes to a depth of

10mm (3/8"). Do not fasten the switchbox in place at this time.

3. At the planned location for the switch, use the label as a

template to mark the hole (see Figure 1).

4. Drill a 3mm or 1/8" pilot hole. Using a 11mm or 1/2" drill bit, drill

the hole for the switch.

5. Sand the area around the hole, inside and out. Clean the

surface with a weak solvent such as alcohol to ensure the label

will adhere properly.

6. Apply the switch label by removing the backing from the

adhesive and pressing the label firmly into place.

2

screw terminals

Figure 3. Installing the switch

boot

notch

faces word

“widebeam”

or “A” on label

hexagonal nut

Copyright © 2008 Airmar Technol ogy Corp.

Page 3

terminal (25)

A

A or

B

B or

compression

fitting

power

supply

Figure 4. Connecting the switchbox

Copyright © 2008 Airmar Technolog y Corp.

Connecting the Switchbox

CAUTION: Be sure to connect each wire to the correct terminal in

the correct terminal block.

Wire each cable to its corresponding terminal block (see Figure 4).

Follow the color code on the PC board. Insert the stripped end of

each colored wire into the square hole in the correspondingly

labeled terminal. Using a small Phillips screwdriver, tighten the

terminal screw to lock the wire into place. Be sure the stripped

end of the wire is inserted up to the insulation only. Do not include

any insulation inside the terminal. Gently tug on the wire to ensure

it is firmly held in place. Repeat this process until all the wires are

connected.

NOTE: Some echosounder cables contain wire colors that differ

from those listed on the PC board. And some cables do not

contain all the wire colors listed on the PC board. If a wire color

(not to scale)

differs, match the wire’s function to the function listed on the PC

board. Check the table on page 4.

NOTE: It may be easiest to connect the cables in the following

order:

• SB264

Echosounder

Wide-beam transducer SS264W

Narrow-beam transducer A: B256, B258, B260, or M260

Power

Remote switch

• SB260

Echosounder or transducer

Transducer B or Echosounder B

Transducer A or Echosounder A

Power

Remote switch

3

Page 4

Echosounder

Brand

Furuno brown white T-

Lowrance no orange wire orange not used

Navman/

Northstar

Raymarine green follow instructions below rsense

Wire Color Terminal label Wire Function

white brown T+

no orange wire orange not used

Raymarine Echosounder Only

If you are connecting a Raymarine echosounder(s), the cable

contains a green wire. Since there is no terminal on the PC board

labelled green, you will need to use the supplies in the plastic bag

marked Raymarine to connect the green wire. If you are connecting two echosounders, follow the steps below with both cables.

1. Strip an additional 10mm (3/8") of insulation from the brown wire.

2. Connect the green wire and one resistor by inserting the end of

each into separate holes in the butt connector (see Figure 5).

With the wires pushed tightly against the far inside wall of the

connector, lightly squeeze the button with pliers until it

depresses. Gently tug on the wire and the resistor to ensure

that they are securely connected.

3. Cover the resistor with a sleeve. While holding the sleeve tightly

against the butt connector, twist the free end of the resistor

together with the brown wire. Be sure the resistor is completely

covered by the sleeve to prevent a short circuit inside the

switch.

4. The twisted pair will be connected to the terminal labeled

“brown”. Follow the instructions “Connecting the Switchbox” on

page 3.

Completing the Installation

1. From outside the switchbox, carefully pull each of the cables in

turn until 100 - 150mm (4 - 6") of the cable jacket remains inside

the box (see Figure 4).

2. Use a wrench to tighten the nut on each compression fitting to

make a water-resistant seal.

3. Arrange the wires neatly inside the switchbox. Be sure that no

bare wires are touching.

4. Using the screws supplied, attach the switchbox to the selected

mounting surface at the holes previously drilled.

5. Attach the switchbox cover with the screws provided for a

water-resistant seal.

6. If they are not connected already, connect the power cable to

the power source and the echosounder(s) cable(s) to the

instrument(s).

7. Fasten all the cables in place. Coil any excess cable and

secure with cable ties to prevent damage.

Parts

Lost, broken, or worn parts should be replaced immediately.

Obtain parts from your instrument manufacturer or marine dealer.

Gemeco Tel: 803.693.0777

(USA) Fax: 803.693.0477

Email: sales@gemeco.com

Airmar EMEA Tel: 33.(0)2.23.52.06.48

(Europe, Middle East, Africa) Fax: 33.(0)2.23.52.06.49

Email: sales@airmar-emea.com

butt connector

resistor

sleeve

Figure 5. Connecting a Raymarine echosounder

Copyright © 2008 Airmar Technology Cor p.

green wire

brown wire

butt connector

resistor covered

by sleeve

twisted connection

®

AIRMAR

TECHNOLOGY CORPORATION

4

Copyright © 2008 - 2010 Airmar Technology Corporation. All rights reserved.

35 Meadowbrook Drive, Milford, New Hampshire 03055-4613, USA

www.airmar.com

Loading...

Loading...