Page 1

INSTALLATION INSTRUCTIONSOWNER’ S GUIDE &

External-Mount, 2 -3kW

Depth Transducer

Models: R99, R109LH, R109LM, R109LH-W, R209, R309,

R509LH, R509LM, R509LH-W, R609LH, R609LM

U.S. Patent No. 7,369,45; 8,582,393. UK Patent No. 2 414 077

Follow the precautions below for optimal

product performance and to reduce the risk of

property damage, personal injury, and/or death.

WARNING: Boats capable of speeds above 25kn

(29MPH)—You must follow these instructions for a

17-335-01 rev. 10 01/09/14

safe installation. For boats exceeding 35 kn. (40MPH)

or when the instructions cannot be met, mount an inhull transducer. At high speeds, the fairing and/or

transducer may break away from the boat.

WARNING: A stuffing tube is required. The stuffing tube

seals the hull forming a water-tight conduit for the cable.

WARNING: Always wear safety goggles and a dust

mask when installing.

WARNING: The fairing must be installed parallel to the

keel to ensure proper boat handling and water flow

under the transducer.

WARNING: Immediately check for leaks when the boat

is placed in the water. Do not leave the boat in the water

unchecked for more than three hours. Even a small leak

may allow considerable water to accumulate.

WARNING: Fiberglass hull—The transducer and stuffing

tube must be installed in solid fiberglass, not in coring

CAUTION: Aluminum hull—The stainless steel

hardware must be isolated from an aluminum hull to

prevent electrolytic corrosion.

CAUTION: Steel hull—Follow generally accepted

installation practices.

CAUTION: Never install a metal fitting on a vessel with

a positive ground system.

CAUTION: External mount only. The transducer will

overheat if it is mounted in a hull pocket.

CAUTION: Never pull, carry, or hold the transducer by

its cable. This may sever internal connections.

CAUTION: Never strike the transducer.

CAUTION: Tighten the nylon locking nuts with a torque

wrench using a force not exceeding 27N-m (20ft.-lb.).

Do not over tighten. It may crack the transducer and/or

crush the fairing.

CAUTION: Never use solvents. Cleaner, fuel, sealant,

paint, and other products may contain solvents that can

damage plastic parts, especially the transducer’s face.

with Temperature Sensor

Record the information found on the cable tag for future reference.

Part No.:_________________Date___________Frequency________kHz

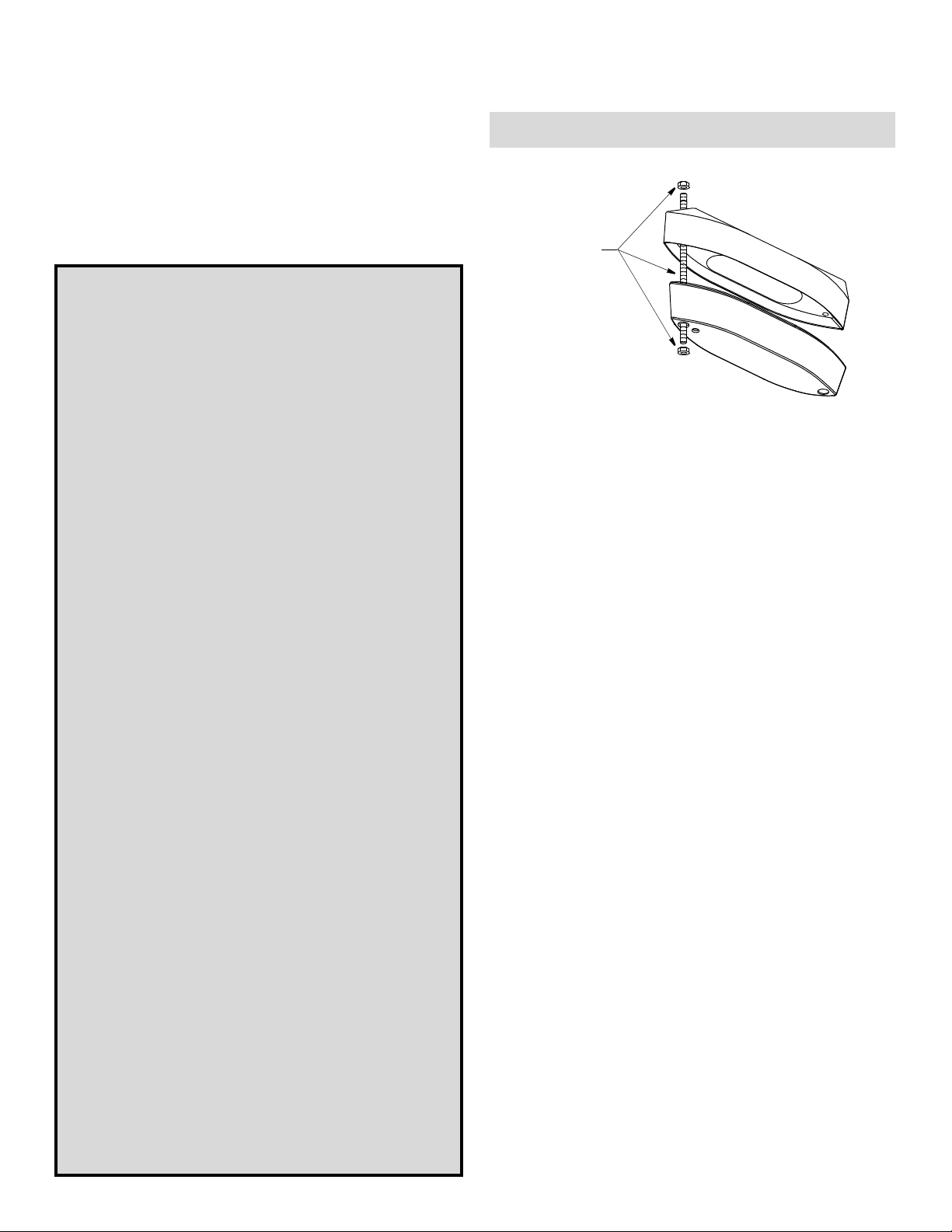

Remove

and discard

the packing

hardware.

Figure 1. Packing hardware

Copyright © 2007 Airmar Technology Cor p.

IMPORTANT: Please read the instructions completely

fairing

transducer

before proceeding with the installation. These instructions

supersede any other instructions in your instrument manual

if they differ.

Applications

• Recommended for all hull materials

• Not recommended for hulls less than 9m (30') long

• Not recommended for stepped hulls. Mount an in-hull transducer

• Accommodates a deadrise angle up to 22

°

Unpacking & Pretest

Remove and discard the packing hardware (rod and 2 nuts) (see

Figure 1). Connect the temperature function to the instrument and

check for the approximate air temperature. If there is no reading

or it is inaccurate, check the connections and test again. If there is

still a problem, return the product to your place of purchase.

Tools & Materials

Safety goggles

Dust mask

Angle finder

Band saw (blade must be very sharp)

Rasp or power tool

Electric drill

Drill bits:

pilot hole 3mm or 1/8"

fiberglass, wood, or steel hull 14mm or 9/16"

aluminum hull 15mm or 9/16"

Permanent marker

Mild household detergent or weak solvent (such as alcohol)

Sandpaper

File (installation in a metal hull)

Marine sealant (suitable for below waterline)

Wrenches

Torque wrench

Grommet(s) (some installations)

Cable ties

Water-based anti-fouling paint (mandatory in salt water)

Page 2

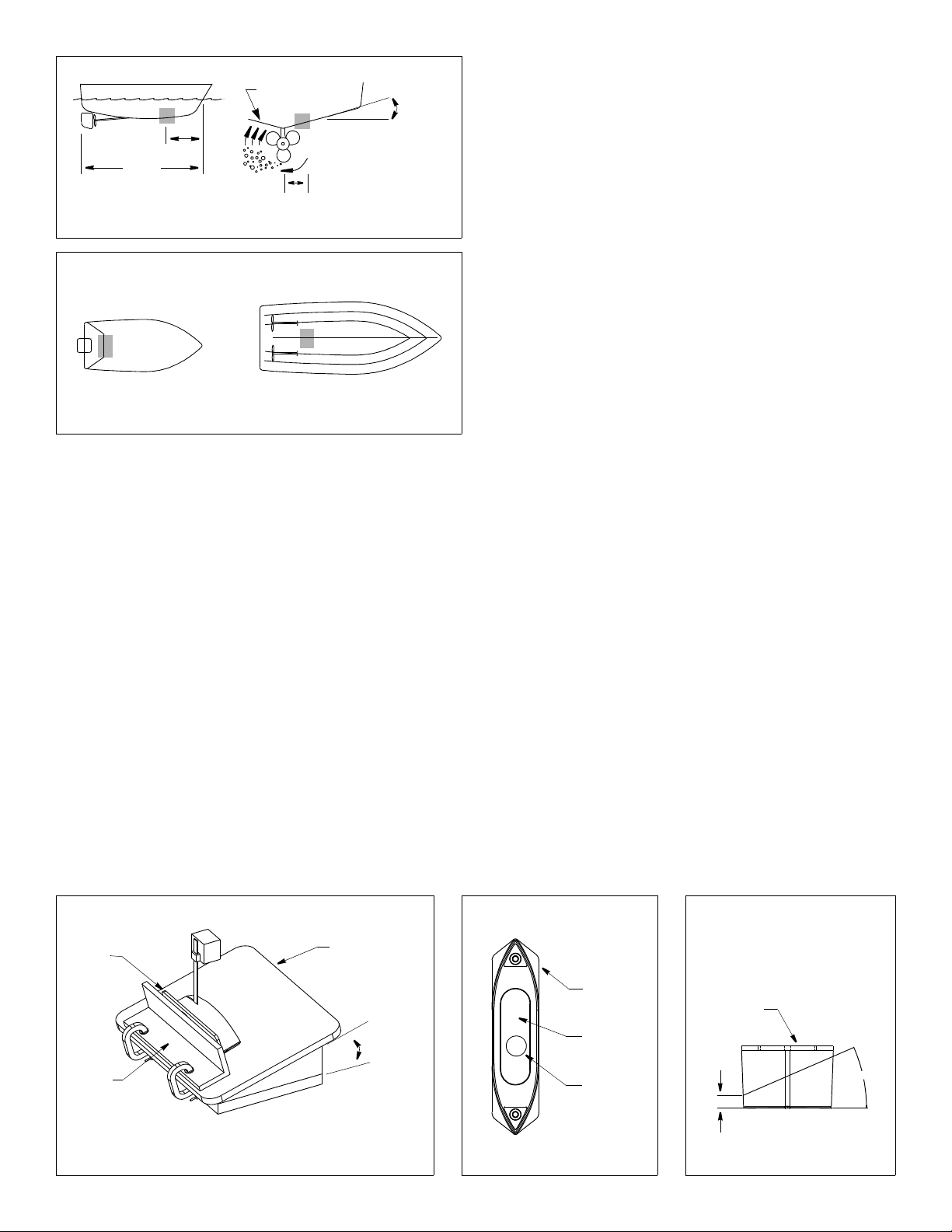

pressure waves

1/3

LWL

(Load Waterline Length)

Figure 2. Transducer location on displacement hull

NOTE: Mount within the

aft 1/3 of the hull, as far

back as possible.

outboard and I/O

Figure 3. Transducer location on planing hull

Copyright © 2005 Airmar Technology Cor p.

Copyright © 2005, 2009 Airmar Techn ology Corp.

200- 600mm

(8 – 24")

inboard

slope of hull

deadrise

angle

parallel to

waterline

Mounting Location

Guidelines

CAUTION: Do not mount in line with or near water intake or

discharge openings or behind strakes, fittings, or hull irregularities

that will disturb the water flow.

CAUTION: Do not mount the sensor where the boat may be

supported during trailering, launching, hauling, or storage to avoid

damaging the transducer’s face.

• The water flowing under the hull must be smooth with a

minimum of bubbles and turbulence (especially at high speeds).

• The transducer must be continuously immersed in water.

• The transducer beam must be unobstructed by the keel or

propeller shaft(s).

• Choose a location away from interference caused by power and

radiation sources such as: the propeller(s) and shaft(s), other

machinery, other echosounders, and other cables. The lower

the noise level, the higher the echosounder gain setting that

can be used.

• Choose a location with a minimal deadrise angle, not to

exceed 22

• Choose an accessible spot inside the vessel with adequate space

for the height of the stuffing tube and tightening the nuts.

°.

Hull Types

• Displacement hull powerboat—Locate about 1/3 of the way

along the LWL and 200– 600mm (8– 24") off the centerline (see

Figure 2). The starboard side of the hull where the propeller

blades are moving downward is preferred.

• Planing hull powerboat— (see Figure 3)

• Mount within the aft 1/3 of the hull, as far back as possible.

Outboard and I/O—Mount just forward of the engine(s).

Inboard—Mount ahead of the propeller(s) and shaft(s).

• Mount on or as close to the centerline as possible, and well

inboard of the first set of lifting strakes to ensure that the

transducer is in contact with the water at high speeds.

• Mounting on the starboard side of the hull where the

propeller blades are moving downward is preferred.

Stuffing Tube

After determining the best mounting location for the transducer,

install the stuffing tube. Follow the installation instructions

packaged with the stuffing tube.

Fairing: Cutting, Bedding & Installing

Cutting the Fairing

CAUTION: Shape the fairing to the hull as precisely as possible. If

there are gaps between the fairing and the hull near the ends, cut

a new fairing. Over tightening the rods to minimize gaps may

crack the transducer and/or crush the fairing.

1. Measure the deadrise angle of the hull at the stuffing tube using

an angle finder or digital level (see Figure 2).

2. Tilt the band saw table to the measured angle and secure the

cutting fence (see Figure 4). Do not exceed 22°.

3. Place the fairing on the table so the cutting guide rests against

the fence (see Figures 4 and 5). Note the fairing is symmetrical.

4. Adjust the fence so the fairing will be cut in about two equal parts.

The section that will become the fairing must be a minimum of

20mm (3/4") at its thinnest dimension (see Figure 6).

5. Recheck steps 1 through 4; then cut the fairing.

6. Check the fit by placing the fairing against the hull. Be sure the

fairing is parallel to the centerline of the boat (keel), and the

stuffing tube is about 2/3 of the way back in the cavity (see

Figure 5). Hold the fairing on the ends and try to rock it back

and forth. Shape the fairing to the hull as precisely as possible

with a rasp or power tool until it no longer rocks.

2

cutting

guide

fence

Figure 4. Cutting the fairing

Copyright © 2005 Airmar Technolog y Corp.

band saw

table

deadrise

angle

bottom view aft view

Bow

location

of stuffing

tube

Figure 5. Fairing

Copyright © 2007 - 2011 Airmar Techno logy Corp. Copyright © 2005 Airmar Technology Corp.

cutting

guide

cavity for

stuffing

tube

>

NOTE

: After the fairing is cut,

the section with the cutting guide

becomes the backing block.

cutting

guide

20mm

(3/4")

min.

22

Figure 6. Fairing

max

°

Page 3

threaded

rod (2)

(uncolored)

backing

block

hull

fairing

stuffing

tube

A

Bow >

marine

sealant on

washers (2),

backing block,

rods (2)

marine

sealant on

fairing,

recess

70mm

(2-3/4")

102mm

(4")

sleeve for

installation

in aluminum

hull only

metal nut

& washer

color this

section of

rod with

permanent

marker

Figure 7. Bedding and installing the fairing and backing block (non-metal hull shown)

Copyright © 2007 Airmar Technology Corp.

7. The remaining section of the fairing with the cutting guide will

be used as the backing block inside the hull. It will provide a

level surface for tightening the nuts on the threaded rods.

Dry Fitting the Fairing

1. To locate the hole for the forward threaded rod (nearest the bow),

measure the distance between the cable exit and the forward hole

in the transducer, center to center. (The rounded bottom is

forward and the temperature sensor is aft.) Being sure the

fairing will be parallel to the centerline of the boat (keel),

measure this distance A on hull and mark the hole (see Figure 7).

2. Drill a pilot hole at the marked location. Using the appropriate

size drill bit, drill the hole through the hull for one threaded rod.

Do not drill the second hole at this time.

3. Prepare the threaded rods (see Figure 8). Using a permanent

marker, draw a line on each threaded rod 102mm (4") from the

end and color this section. (The colored section will be used to

fasten the transducer to the fairing.) Screw a nut onto the colored

section of each threaded rod above the 102mm (4") line drawn.

4. Place the fairing against the hull. Push the uncolored end of the

threaded rod through the fairing and the hull until the nut rests

inside the recess in the fairing (see Figure 7). With a person

stationed inside the vessel, slide the backing block onto the rod.

Temporarily secure the rod with a stainless steel washer and nut.

5. Align the fairing parallel to the centerline of the boat (keel).

Using the aft hole in the fairing as a guide, drill a pilot hole.

Then drill the hole using the appropriate size drill bit.

6. Remove the fairing from the hull. Clean and sand the area

around the holes, inside and outside, to ensure that the marine

Figure 8. Threaded rod

Copyright © 2007 Airmar Technolog y Corp.

sealant will adhere properly. Remove any petroleum residue with

a mild household detergent or a weak solvent such as alcohol.

Metal hull—Remove all burrs with a file and sandpaper.

Bedding & Installing the Fairing

CAUTION: Be sure the surfaces to be bedded are clean and dry.

1. If there is any residue on the fairing and transducer, remove it

with a mild household detergent to ensure the marine sealant

will adhere properly.

2. Apply a 2mm (1/16") thick layer of marine sealant: (see Figure 7)

• To the surface of the backing block that will contact the hull

• To the surface of the fairing that will contact the hull

• To the recesses in the fairing for the washers and nuts

• To the threaded rods

• To the surface of the washers that will contact the backing block

NOTE: Be sure the rods have marine sealant on the threads under

the nuts. Back each nut off 13mm (1/2") and apply sealant to the

threads. Then return each nut to the marked location on the rod.

3. Slide a washer along the uncolored section of each threaded

rod until it rests against the nut (see Figure 8).

Aluminum hull—The stainless steel rods must be isolated from

an aluminum hull to prevent electrolytic corrosion. Cut the

sleeving 70mm (2-3/4"). Slide the isolation sleeve over the

uncolored section of each bedded rod as far down as possible.

Apply a 2mm (1/16") thick layer of the marine sealant to the

outside of the sleeving.

threaded

rod (2)

metal nut (4)

and washer (2)

backing block

hull

fairing

washer (2)

metal nut (2)

transducer

washer (2)

nylon locking nut (2)

foam plug (2)

temperature

sensor

cable

stuffing

tube

Figure 9. Bedding and installing the transducer

Copyright © 2007 Airmar Technology Corp.

(non-metal hull shown)

marine sealant on

transducer that contacts

fairing and recess

rounded bottom

marine sealant

flush with hull

Bow >

3

Page 4

4. Push the uncolored section of each threaded rod through the

fairing, the hull, and the backing block until the washer rests inside

the recess in the fairing (see Figure 7). With a person stationed

inside the vessel, secure each rod with a washer (bedded side

against the backing block) and double stainless steel nuts. Use

a wrench to hold the lower nut while tightening the top nut

against it.

Aluminum hull—The top of the isolation sleeve must be below

the top of the backing block to prevent the sleeving from

interfering with tightening the nuts.

Wood hull—Allow the wood to swell before tightening the nuts.

Transducer: Bedding & Installing

1. Apply a 2mm (1/16") thick layer of marine sealant to the surface

of the transducer that will contact the fairing including the

recesses for the washers and nuts (see Figure 9).

2. Thread the transducer cable through the stuffing tube.

3. Slide the transducer onto the threaded rods being sure the

rounded bottom is facing forward toward the bow and the

temperature sensor is aft. Seat the transducer firmly within the

recess in the fairing. Secure the transducer in place by applying

a washer and a nylon locking nut to each threaded rod.

Tighten each nut with a torque wrench using a force not

exceeding 12N-m (10ft.-lb.). Then tighten each nut again using

a force not exceeding 27N-m (20ft.-lb.). Do not over tighten as it

may crack the transducer and/or crush the fairing. Be sure the

rods extend a minimum of 3 threads beyond the nut after

being tightened.

4. Plug the mounting holes to minimize turbulence on the surface

of the transducer. Be sure there is marine sealant on the

exposed threads of the rods. Cut the white foam plugs to length

so that when installed, each plug is recessed 5mm (3/16")

below the surface of the transducer. Push the foam plugs into

the holes. Use marine sealant to fill the remaining recess flush

with the transducer’s surface.

5. Remove excess marine sealant on the outside of the hull to

ensure smooth water flow under the transducer.

Sealing & Routing the Cable

To form a watertight seal inside the stuffing tube, follow the

installation instructions that came with your stuffing tube. The

completed installation will look like Figure 10.

Route the cable to the echosounder being careful not to tear the

cable jacket when passing it through the bulkhead and other parts

of the boat. Use grommet(s) to prevent chafing. To reduce

electrical interference separate the transducer cable from other

electrical wiring and the engine. Coil any excess cable and secure

it in place with cable ties to prevent damage.

Refer to your echosounder owners manual to connect the cable to

the instrument.

cable

aft view

stuffing tube

backing block

hull

fairing

transducer

Figure 10. Completed installation (non-metal hull shown)

Copyright © 2005 Airmar Technolog y Corp.

boat in the water unattended for more than 3 hours before

rechecking. If there is a small leak, there may be considerable

bilge water accumulation after 24 hours. If a leak is observed,

repeat the bedding and installing procedures beginning on page 3

immediately.

Maintenance, Repair & Replacement

Anti-fouling Paint

Surfaces exposed to salt water must be coated with anti-fouling

paint. Use water-based anti-fouling paint only. Never use ketonebased paint since ketones can attack many types of plastic

possibly damaging the transducer. Reapply anti-fouling paint

every 6 months or at the beginning of each boating season.

Cleaning

Aquatic growth can accumulate rapidly on the transducer’s

surface reducing its performance within weeks. Clean it using a

Scotch-Brite® scour pad and mild household detergent, being

careful to avoid making scratches. In severe cases, lightly wet

sand the surface with fine grade wet/dry paper.

Replacement Transducer & Parts

The information needed to order a replacement Airmar transducer is

printed on the cable tag. Do not remove this tag. When ordering,

specify the part number, date, and frequency in kHz. For convenient

reference, record this information on the top of page one.

Lost, broken, and worn parts should be replaced immediately.

Fairing & Stuffing Tube 33-439-01

Obtain parts from your instrument manufacturer or marine dealer.

Gemeco Tel: 803-693-0777

(USA) Fax: 803-693-0477

Checking for Leaks

When the boat is placed in the water, immediately check around

the threaded rods and the stuffing tube for leaks. Note that very

small leaks may not be readily observed. It is best not to leave the

35 Meadowbrook Drive, Milford, New Hampshire 03055-4613, USA

4

Copyright © 2005 - 2014 Airmar Technology Corp. All rights reserved.

•

www.airmar.com

Loading...

Loading...