onditioning

R410A

aintenance and

Downflow – Precision Air C

SmartCool™

Installation, M

Commissioning

Precision Air Conditioning

Warranty

Warranty is only valid in

Spares

Training

Customer Services

Legal Notices

ã

SmartCoolTM - D

Precision Air Conditioning

About Airedale Products & Customer Services

the event that

CAUTION

All AIAC products or parts (non consumable) supplied for installation within the UK mainland and

commissioned by an AIAC engineer, carry a full Parts & Labour warranty for a period of 12 months

from the date of commissioning or 18 months from the date of despatch, whichever is the sooner.

Parts or Equipment supplied by AIAC for installation within the UK or for Export that are properly

commissioned in accordance with AIAC standards and specification, not commissioned by an AIAC

engineer; carry a 12 month warranty on non consumable Parts only from the date of commissioning

or 18 months from the date of despatch, whichever is the sooner.

Parts or equipment installed or commissioned not to acceptable AIAC standards or specification

invalidate all warranty.

In the period between delivery and commissioning the equipment: is properly protected & serviced as

per the AIAC installation & maintenance manual provided where applicable the glycol content is

maintained to the correct level.

In the event of a problem being reported and once warranty is confirmed as valid under the given

installation and operating conditions, the Company will provide the appropriate warranty coverage

(as detailed above) attributable to the rectification of any affected Airedale equipment supplied

(excluding costs for any specialist access or lifting equipment that must be ordered by the customer).

Any spare part supplied by Airedale under warranty shall be warranted for the unexpired period of

the warranty or 3 months from delivery, whichever period is the longer.

To be read in conjunction with the Airedale Conditions of Sale - Warranty and Warranty Procedure,

available upon request.

Warranty cover is not a substitute for maintenance. Warranty cover is conditional to maintenance

being carried out in accordance with the recommendations provided during the warranty period.

Failure to have the maintenance procedures carried out will invalidate the warranty and any liabilities

by Airedale International Air Conditioning Ltd.

A spares list for 1 3 and 5 years will be supplied with every unit and is also available from our Spares

department on request.

As well as our comprehensive range of products, Airedale offers a modular range of Refrigeration

and Air Conditioning Training courses, for further information please contact Airedale.

For further assistance, please e-mail: enquiries@airedale.com or telephone:

UK Sales Enquiries + 44 (0) 113 239 1000 enquiries@airedale.com

International Enquiries + 44 (0) 113 239 1000 enquiries@airedale.com

Spares Hot Line + 44 (0) 113 238 7878 spares@airedale.com

Airedale Service + 44 (0) 113 239 1000 service@airedale.com

Technical Support + 44 (0) 113 239 1000 tech.support@airedale.com

Training Enquiries + 44 (0) 113 239 1000 marketing@airedale.com

For information, visit us at our Web Site: www.airedale.com

AIAC Ltd endeavours to ensure that the information in this document is correct and fairly stated, but

none of the statements are to be relied upon as a statement or representation of fact. AIAC Ltd does

not accept liability for any error or omission, or for any reliance placed on the information contained

in this document.

The development of Airedale products and services is continuous and the information in this

document may not be up to date. It is important to check the current position with AIAC Ltd at the

address stated. This document is not part of a contract or licence unless expressly agreed.

No part of this document may be reproduced or transmitted in any form or by any means, electronic

or mechanical, including photocopying, recording, or information storage and retrieval systems, for

any purpose other than the purchaser’s personal use, without the express written permission of

AIAC Ltd.

Cover image is the SC25D100-X2X2-0; Controller display is for illustration only.

2013 Airedale International Air Conditioning Limited. All rights reserved. Printed in the UK.

2

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Precision Air Conditioning

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Precision Air Conditioning

SmartCoolTM – D

About Airedale Products & Customer Services ...................................................................... 2

Warranty ................................................................................................................................. 2

Spares .................................................................................................................................... 2

Training .................................................................................................................................. 2

Health and Safety ....................................................................................................................... 6

Specifier’s Guide Indoor Unit ................................................................................................... 7

Nomenclature ......................................................................................................................... 7

Introduction ............................................................................................................................ 8

System Configurations .............................................................................................................. 9

Dual Circuit ............................................................................................................................. 9

Dual Cool ............................................................................................................................. 10

Chilled Water ........................................................................................................................ 11

Installation Data ....................................................................................................................... 12

Dimensions .......................................................................................................................... 12

Positioning ............................................................................................................................ 13

Minimum Unit Clearance ...................................................................................................... 13

Electrical Services Incoming Cable ...................................................................................... 14

Incoming Mains Gland Plate ................................................................................................ 14

Weights ................................................................................................................................ 15

Refrigerant Pipe Sizing Guide .............................................................................................. 18

Refrigerant Charging Guide ................................................................................................. 19

Packaged Unit Pre-Charged Refrigerant Volumes ............................................................... 21

Design Data – Water Cooled & Free Cooling ....................................................................... 22

System Pressure Strength Test ........................................................................................... 23

System Leak Test ................................................................................................................ 23

Evacuation ........................................................................................................................... 24

Refrigerant Handling ............................................................................................................ 25

Oil Charging Guide ............................................................................................................... 26

Pressure switch settings....................................................................................................... 26

Compressor Oil Information ................................................................................................. 27

Chilled Water System ........................................................................................................... 29

Humidification ....................................................................................................................... 29

Condensate Drain Pipework ................................................................................................. 32

Fitting Instructions ................................................................................................................ 33

Pipe Clips ............................................................................................................................. 33

Condensate Drain Priming ................................................................................................... 33

Checking for Leaks .............................................................................................................. 33

Condensate Pump Operation ............................................................................................... 33

Fan Speeds .......................................................................................................................... 35

Pipework Schematics .............................................................................................................. 47

X2X2 .................................................................................................................................... 48

X2C0 .................................................................................................................................... 49

W2W2 .................................................................................................................................. 50

W2C0 ................................................................................................................................... 51

W2F0.................................................................................................................................... 52

C000..................................................................................................................................... 53

C0C0 .................................................................................................................................... 54

Controls .................................................................................................................................... 55

PCO3 CONTROLLER .......................................................................................................... 55

DISPLAY KEYPAD CONNECTIONS ................................................................................... 56

Addressing the Display Keypad ........................................................................................... 57

Use Of Extra Functions Buttons ........................................................................................... 59

Navigation ............................................................................................................................ 59

EVD EVO Driver Setup ........................................................................................................ 60

Removable Plug and Play Display ....................................................................................... 60

Driver Initialization (Driver Reset Function) .......................................................................... 61

3

Precision Air Conditioning

SmartCoolTM - D

Input / Outputs ...................................................................................................................... 63

Technical Data .......................................................................................................................... 64

System Operating Limits ......................................................................................................... 64

Air Cooled Models (X2X2) ....................................................................................................... 65

Performance Data – Air Cooled Models ............................................................................... 65

Mechanical Data- X2X2 ........................................................................................................ 67

Electrical Data – X2X2 .......................................................................................................... 70

Sound Data – X2X2 .............................................................................................................. 73

Interconnecting Wiring –X2X2 .............................................................................................. 74

Air Cooled and Chilled Water Models (X2C0) ........................................................................ 76

Performance Data – Air Cooled & Chilled Water Models ..................................................... 76

Mechanical Data –X2C0 ....................................................................................................... 78

Electrical Data –X2C0 .......................................................................................................... 84

Sound Data – X2C0.............................................................................................................. 90

Waterside pressure drops – X2C0 ....................................................................................... 91

Interconnecting Wiring – X2C0 ............................................................................................. 92

Water Cooled Models (W2W2)................................................................................................. 94

Performance Data – Water Cooled Models .......................................................................... 94

Mechanical Data – W2W2 .................................................................................................... 95

Electrical Data – W2W2 ........................................................................................................ 98

Sound Data - Water Cooled Models ................................................................................... 101

Waterside pressure drop - W2W2 ...................................................................................... 102

Interconnecting Wiring – W2W2 ......................................................................................... 103

Water Cooled and Chilled Water models (W2C0) ................................................................ 105

Performance Data –Water Cooled & Chilled Water Models ............................................... 105

Mechanical Data – W2C0 ................................................................................................... 107

Electrical Data- W2C0 ........................................................................................................ 113

Sound Data – W2C0........................................................................................................... 119

Waterside Pressure Drops W2C0 ...................................................................................... 120

Interconnecting Wiring – W2C0 .......................................................................................... 122

Water Cooled and Free Cooling (W2F0) ............................................................................... 124

Performance Data – Water Cooled & Free Cooling ............................................................ 124

Mechanical Data – W2F0 ................................................................................................... 126

Electrical Data – W2F0 ....................................................................................................... 132

Sound Data – W2F0 ........................................................................................................... 138

Waterside Pressure Drops W2F0 ....................................................................................... 139

Interconnecting Wiring – W2F0 .......................................................................................... 141

Chilled Water Single Circuit (C000) ...................................................................................... 143

Performance Data – Chilled Water – Single Circuit ............................................................ 143

Mechanical Data – C000 .................................................................................................... 144

Electrical Data - C000......................................................................................................... 147

Sound Data – C000 ............................................................................................................ 149

Waterside Pressure Drop C000 .......................................................................................... 150

Interconnecting Wiring – C000 ........................................................................................... 151

Chilled Water Dual Circuit (C0C0) ......................................................................................... 152

Performance Data – Chilled Water – Dual Circuit .............................................................. 152

Mechanical Data – C0C0 .................................................................................................... 153

Electrical Data - C0C0 ........................................................................................................ 156

Sound Data- C0C0 ............................................................................................................. 158

Waterside pressure drop - C0C0 ........................................................................................ 159

Interconnecting Wiring – C0C0 ........................................................................................... 160

Commissioning Data ............................................................................................................. 161

Humidifier ........................................................................................................................... 162

Head Pressure Control ....................................................................................................... 164

Precision Air Conditioning

4

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Precision Air Conditioning

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Precision Air Conditioning

SmartCoolTM – D

Electronically Commutated (EC) Fan Motor ....................................................................... 165

EC Fan interrogation .......................................................................................................... 165

Suction Throttle Valve ........................................................................................................ 166

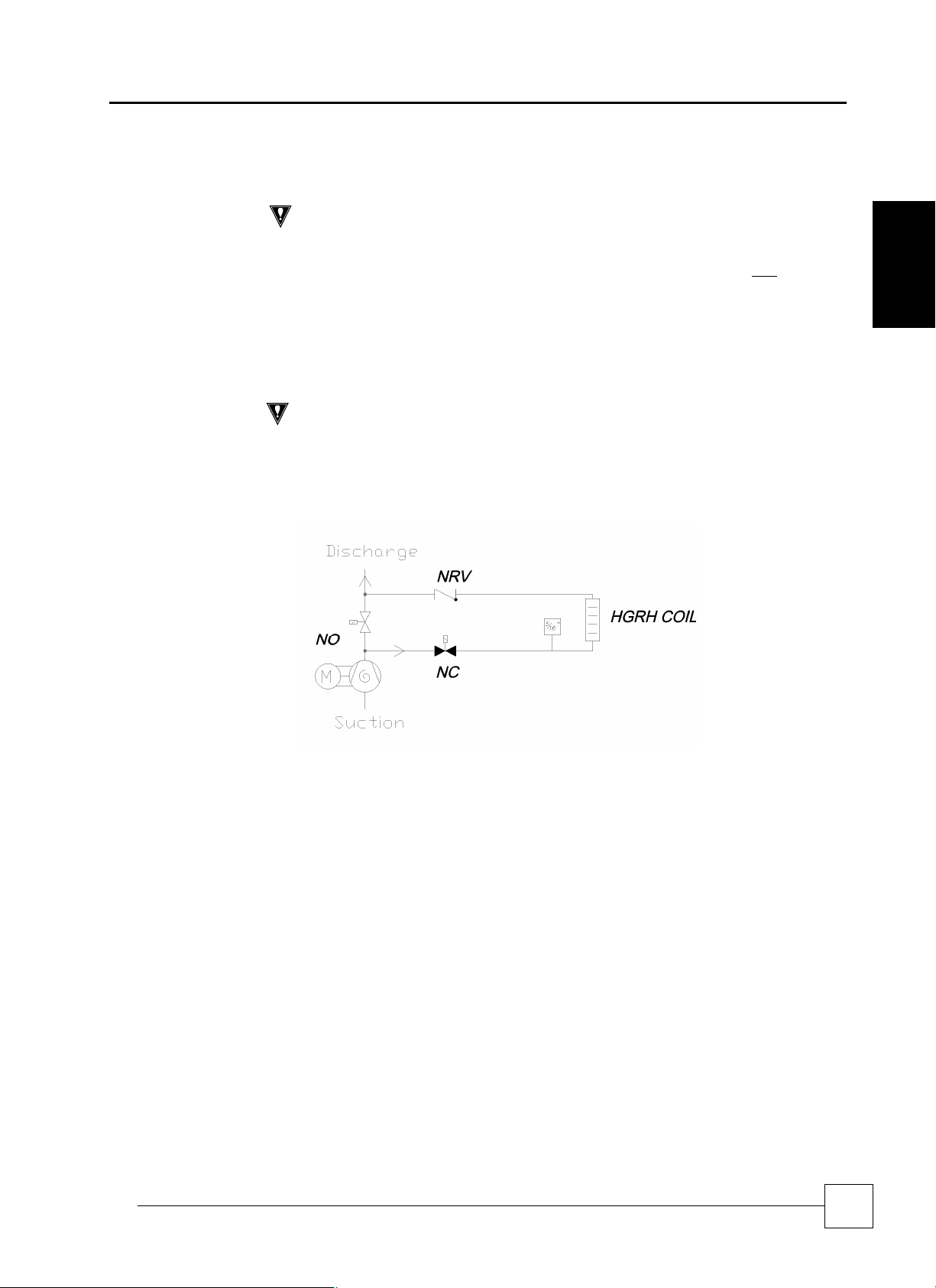

Hot Gas Re-Heat (HGRH) .................................................................................................. 166

Commissioning procedure ................................................................................................... 167

Commissioning Checklist ................................................................................................... 167

Pre Commissioning checks ................................................................................................ 167

Fan Section ........................................................................................................................ 168

Chiller /Glycol units ............................................................................................................ 169

Heating ............................................................................................................................... 169

Humidification ..................................................................................................................... 170

Condenser .......................................................................................................................... 170

Water cooled condenser .................................................................................................... 170

Refrigeration circuit ............................................................................................................ 171

Indoor unit optional extras .................................................................................................. 173

Controls .............................................................................................................................. 174

Maintenance ........................................................................................................................... 175

Filter Changing ................................................................................................................... 175

3 Monthly ............................................................................................................................ 176

6 Monthly ............................................................................................................................ 176

12 Monthly .......................................................................................................................... 176

Humidifier Bottle Change ................................................................................................... 177

Evaporator Fan removal ..................................................................................................... 178

Troubleshooting Indoor Unit................................................................................................. 179

Suction throttle valve (STV) ................................................................................................ 181

Hot Gas Re-heat (HGRH) .................................................................................................. 181

Humidifier ........................................................................................................................... 181

Unit Alarms: ........................................................................................................................ 182

Specifier’s Guide Outdoor unit ............................................................................................. 190

Unit Identification ................................................................................................................ 190

Standard Features ............................................................................................................. 191

Optional Extras - Energy Saving ........................................................................................ 193

Installation data...................................................................................................................... 194

Dimensions / Weights / Positioning .................................................................................... 194

Unit Lifting .......................................................................................................................... 199

Re-orientation to Vertical Discharge ................................................................................... 200

Positioning .......................................................................................................................... 201

Siting Recommendations ................................................................................................... 201

Pipework Connections........................................................................................................ 201

Holding Charge .................................................................................................................. 201

Pipework Installation - Good Practices ............................................................................... 201

Performance Data – Condensers ....................................................................................... 202

Performance Data – Dry Coolers ....................................................................................... 204

Sound Data ........................................................................................................................ 206

Mechanical Data – Condensers and Dry Coolers .............................................................. 208

Dry Cooler Waterside Pressure Drop ................................................................................. 212

Electrical Data .................................................................................................................... 213

Interconnecting Wiring........................................................................................................ 213

Troubleshooting..................................................................................................................... 214

Unmatched Outdoor Units .................................................................................................. 214

Airedale Matched Outdoor Units ........................................................................................ 215

Maintenance ........................................................................................................................... 216

5

Precision Air Conditioning

IMPORTANT

S

afety

CAUTION

1 Installation, service and maintenance of Airedale equipment should only be

CAUTION

2 When working with any air conditioning units ensure that the electrical i

solator

Protective personal

Refrigerant Warning

Manual Handling

Environmental Policy

SmartCoolTM - D

Health and Safety

General

Precision Air Conditioning

The information contained in this manual is critical to the correct operation and

maintenance of the unit and should be read by all persons responsible for the installation,

commissioning and maintenance of this Airedale unit.

The equipment has been designed and manufactured to meet international safety

standards but, like any mechanical/electrical equipment, care must be taken if you are to

obtain the best results.

carried out by technically trained competent personnel.

is switched off prior to servicing or repair work and that there is no power to

any part of the equipment.

3 Also ensure that there are no other power feeds to the unit such as fire alarm

circuits, BMS circuits etc.

4 Electrical installation commissioning and maintenance work on this equipment

should be undertaken by competent and trained personnel in accordance with local

relevant standards and codes of practice.

5 The refrigerant used in this range of products is classified under the COSHH

regulations as an irritant, with set Workplace Exposure Levels (WEL) for

consideration if this plant is installed in confined or poorly ventilated areas.

6 A full hazard data sheet in accordance with COSHH regulations is available should

this be required.

equipment

Airedale recommends that personal protective equipment is used whilst installing,

maintaining and commissioning equipment.

The Airedale SmartCool uses R410A refrigerant which is a high pressure refrigerant. It

requires careful attention to proper storage and handling procedures.

Use on manifold gauge sets designed for use with R410A refrigerant. Use only refrigerant

recovery units and cylinders designed for high pressure refrigerants.

R410A must only be charged in the liquid state.

The refrigerant must be stored in a clean, dry area away from sunlight. The refrigerant

must never be stored above 50°C.

Some operations when servicing or maintaining the unit may require additional assistance

with regard to manual handling. This requirement is down to the discretion of the

engineer. Remember do not perform a lift that exceeds your ability.

It is our policy to:

· Take a proactive approach to resolve environmental issues and ensure

compliance with regulatory requirements.

· Train personnel in sound environmental practices.

· Pursue opportunities to conserve resources, prevent pollution and eliminate

waste.

· Manufacture products in a responsible manner with minimum impact on the

environment.

· Reduce our use of chemicals and minimise their release to the environment.

· Measure, control and verify environmental performance through internal and

external audits.

· Continually improve our environmental performance.

6

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Precision Air Conditioning

Installation, Maintenance and Commissioning Manual :6877419 02/2013

International Example

SC19D065 - C000 -0

SC19D

065 - C000 -0Dual Cool Example

SC31D065 - X2C0 -0

SC31D

065 - X2C0 -0Mono Cool Example

SC25D100 - X2X2 -0

SC25D

100 - X2X2 -

0

19 - 31

Mono / Dual

(Circuit 1)

Mono / Dual

(Circuit 2)

Precision Air Conditioning

Specifier’s Guide Indoor Unit

Nomenclature

è

è

è

SmartCool SC

Decimetre Case Width (dm)

Upflow U

Downflow D

Nominal Capacity (kW)033-150

Separator -

Air Cooled (Comp Indoor) X

Water Cooled (Comp Indoor) W

Chilled Water C

No Compressor 0

Single Compressor 1

Tandem Compressor 2

Inverter Compressor V

No Option 0

Air Cooled (Comp Indoor) X

Water Cooled (Comp Indoor) W

Free Cooling F

Chilled Water C

No Compressor 0

Single Compressor 1

Tandem Compressor 2

Inverter Compressor V

Seperator -

400V 3PH 50Hz 0

SmartCoolTM – D

General

Voltage

Note

Dual Cool units are defined as those having 2 different cooling mediums (i.e. R410A and Chilled Water [X2C0]).

Dual Circuit units are defined as those having 2 independent cooling circuits (i.e. X2X2 or C0C0).

7

Precision Air Conditioning

Introduction

CE Directive

SmartCoolTM - D

General

Precision Air Conditioning

Designed to provide environmental precision air conditioning for applications such as

telecommunication facilities, data centers, computer rooms, clean rooms and

laboratories.

Description Capacity kW (1)

X2X2 Dual circuit direct expansion air cooled 55 -122

X2C0 Dual cool direct expansion air cooled and

chilled water

W2W2 Dual circuit direct expansion water cooled 54 -123

W2C0 Dual cool direct expansion water cooled and

chilled water

W2F0 Dual cool water cooled and glycol free cooling (W2) 30 - 86

C000 Single circuit chilled water 69 -149

C0C0 Dual circuit chilled water 20 -102

(1) Based on nominal unit capacities

Full function units provide full control of temperature, humidity and filtration.

The modular design of the SmartCool allows grouping of differing model types and

capacities to be installed side by side. The flexibility of this type of installation provides for

multi-circuit functionality.

A full range of air cooled condensers is available with the direct expansion indoor units to

provide a matched system with optional performance upgrade, refer to Outdoor Unit

A full range of Dry coolers is available to complement the free cooling indoor units. Dry

coolers are a cost effective and safe solution against legionella.

Also available is a full range of Airedale water chillers to complement the chilled water

indoor units.

The range has been designed and optimised for operation with ozone benign refrigerant

R410A.

Airedale certify that the equipment detailed in this manual conforms with the following

EC Directives:

Electromagnetic Compatibility Directive (EMC) 2004/108/EC

Low Voltage Directive (LVD) 2006/95/EC

Machinery Directive (MD) 89/392/EEC in the version

2006/427/EC

Pressure Equipment Directive (PED) 97/23/EC

To comply with these directives appropriate national & harmonised standards have been

applied. These are listed on the Declaration of Conformity, supplied with each product.

(X2) 30 – 82.5

(C0) 50 - 102

(W2) 30 - 85

(C0) 50 - 102

(F0) 50 - 102

8

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Precision Air Conditioning

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Precision Air Conditioning

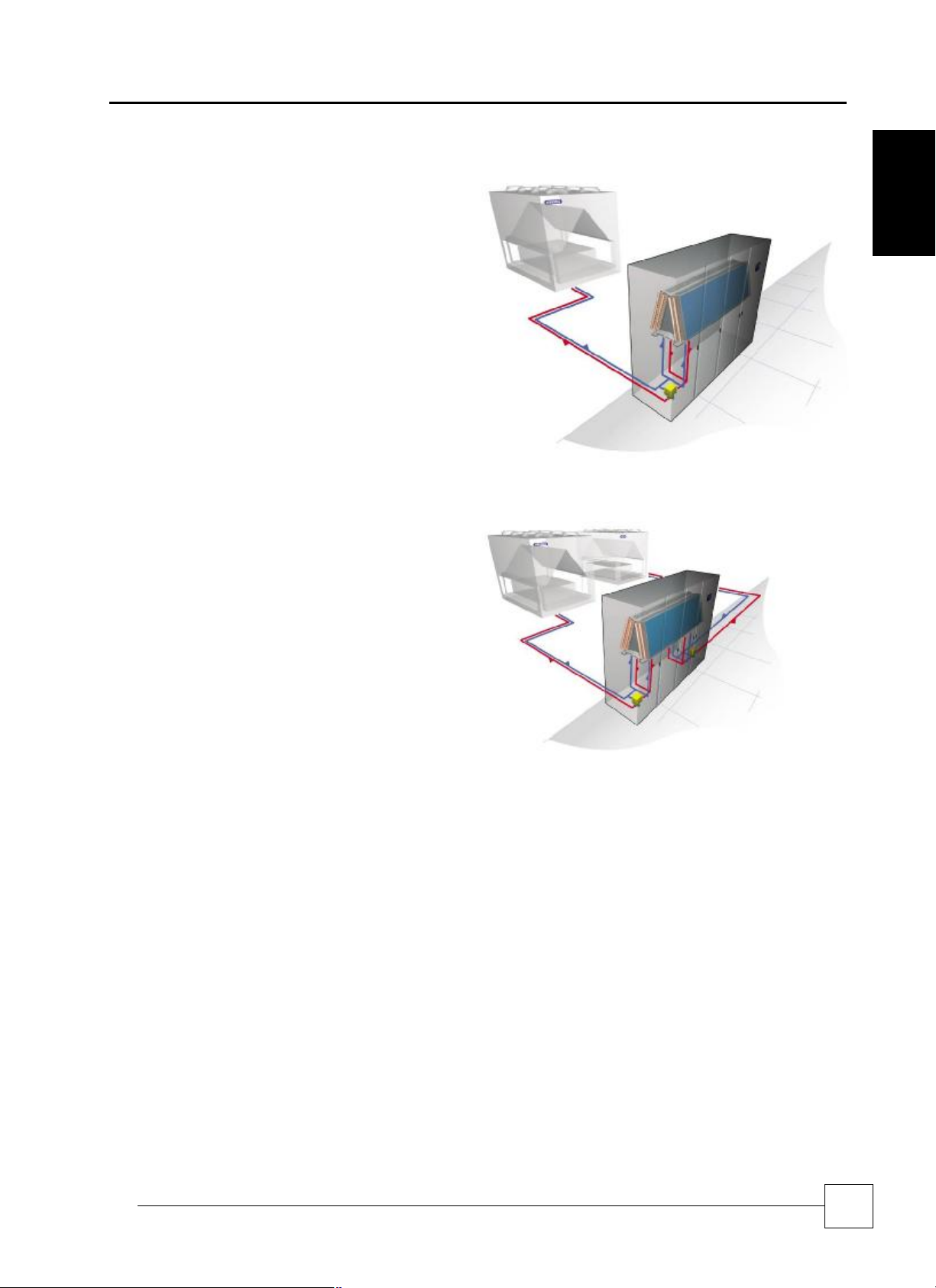

System Configurations

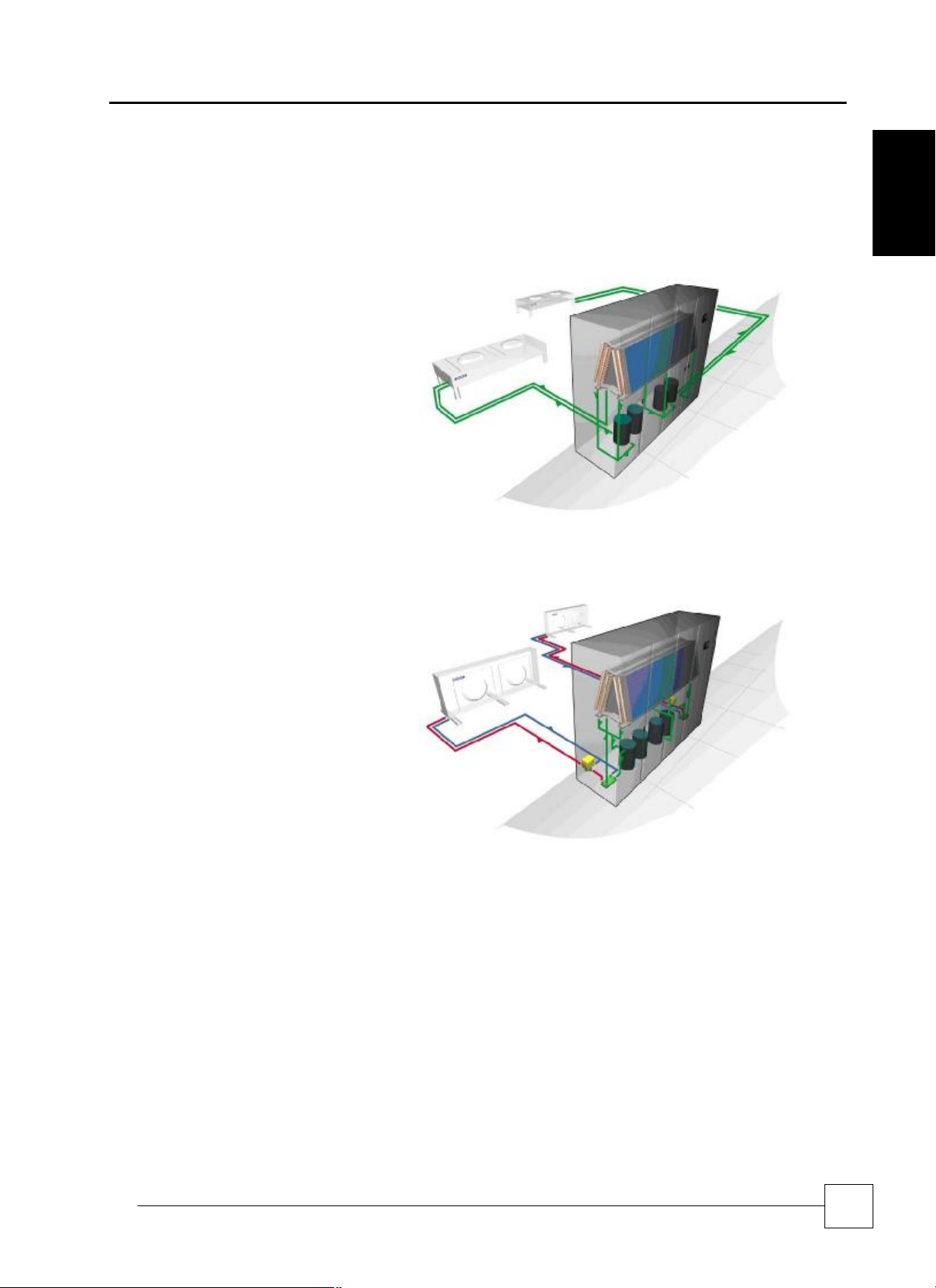

Dual Circuit

X2X2

The SmartCool X2X2 is an air cooled, direct

expansion (DX), double circuit system linked

to two separate, remotely mounted air cooled

condensers.

Optimised for heat transfer using energy

efficient refrigerant R410A in each circuit, the

X2X2 system is located within the conditioned

space, absorbing room heat and transferring it

outside to the condensers.

By using one or more same/dissimilar sized

scroll compressors across the X2X2 double

circuit, part load efficiency can be maximised

and capacity more precisely matched to

application.

SmartCoolTM – D

General

W2W2

Suitable for applications favouring reduced

refrigerant charges, the SmartCool W2W2 is a

double circuit system featuring, DX cooling

within the case and dry coolers outside.

Warm room air is passed through two

completely independent evaporator coils and

an integral plate condenser transfers the heat

load to the glycol solution which is then

channelled outside to two air cooled dry

coolers.

9

Precision Air Conditioning

SmartCoolTM - D

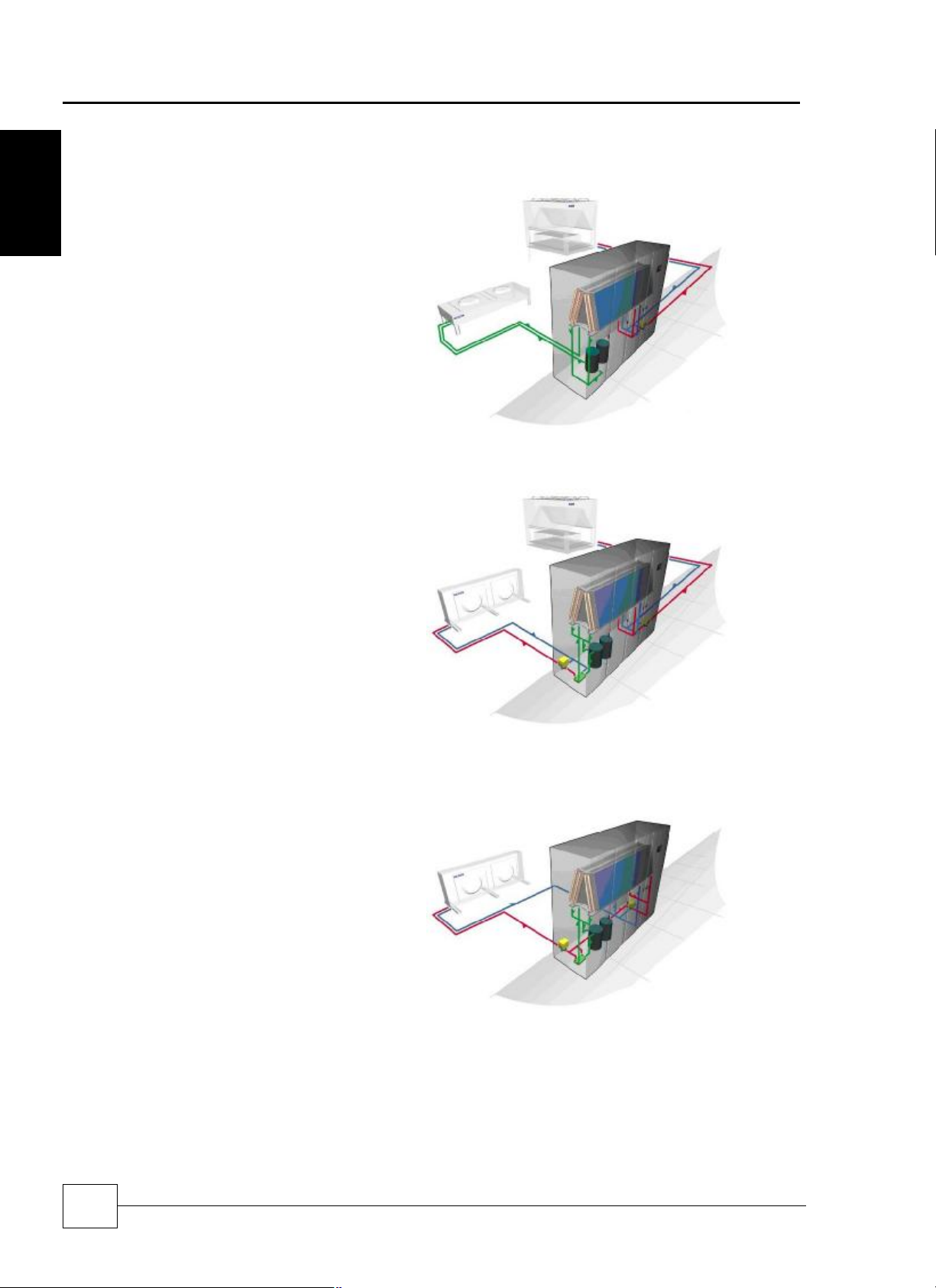

Dual Cool

General

X2C0

For redundancy in critical applications, the SmartCool

dual cool X2C0 offers two different cooling mediums,

air cooled DX and chilled water, within the same case.

The X2C0 system is managed by the Airetronix

microprocessor to select which medium acts as the

primary source of cooling or which acts as back-up,

should the primary source fail or is unable to cope with

the heat load.

Precision Air Conditioning

W2C0

For applications where a water cooled system is

preferred over air cooled, the SmartCool W2C0

comprises two different cooling mediums within the

same case: DX water cooled, as in the W2W2 system,

and chilled water, as in the C000 system.

The Airetronix microprocessor elects which medium

acts as the primary source of cooling and which as

back-up, if the primary source fails or is unable to cope

with the heat load.

W2F0

The W2F0 system includes a free-cooling coil in

conjunction with the evaporator. In low ambient

conditions, particularly in relation to the high

temperatures and continuous system operation of a

server environment, the W2F0 system will run with

minimum energy. At times of higher ambient,

sophisticated Airetronix controls technology will

modulate the 3-way water regulating valves to

transition from free cooling back to mechanical cooling.

Typically the SmartCool W2F0 single circuit freecooling system uses 46%* less energy than a standard

air cooled DX system.

10

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Precision Air Conditioning

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Chilled Water

Precision Air Conditioning

C000

Where a chilled water single circuit system is preferred,

warm room air is blown across the efficient cooling coils

of the SmartCool C000 and the heat transferred to a

chilled water system such as Airedale’s high efficiency

TurboChill.

By controlling the 3-way water regulating valve, the

intelligent Airetronix microprocessor can achieve precise

control of temperature and humidity.

SmartCoolTM – D

General

C0C0

In the SmartCool C0C0 unit, the cooling coils are split

into two independent systems, each with a 3-way water

regulating valve, and cooled by chilled water from two

separate chillers.

For extra security, the dual circuit configuration of

SmartCool C0C0 offers 2N redundancy.

11

Precision Air Conditioning

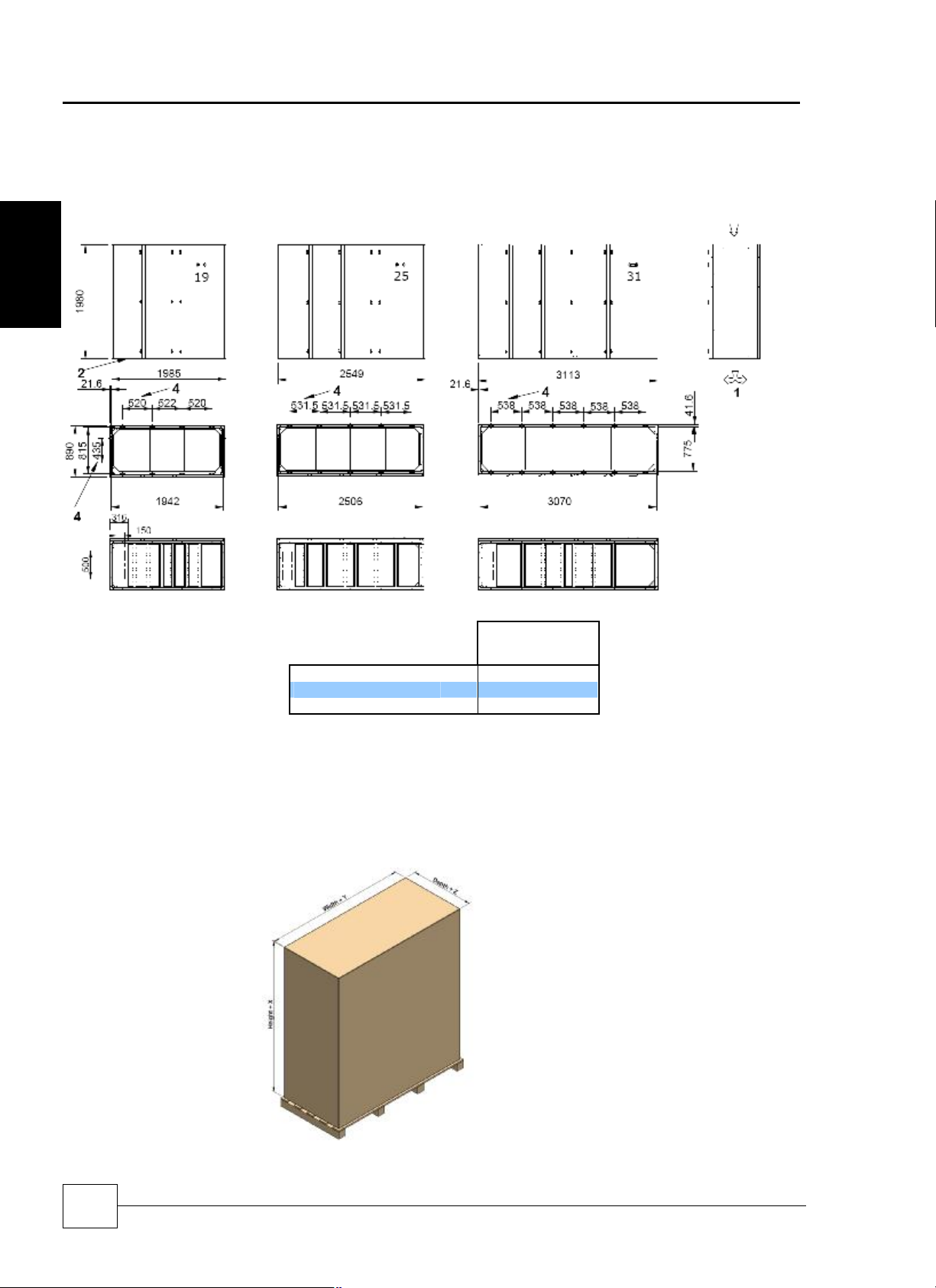

Dimensions

Stan

dard Airflow Configuration (mm)

Packed Dimensions

SmartCoolTM - D

Installation Data

Installation

Precision Air Conditioning

SC19D

SC25D

SC31D

(1)

(2)

(3)

(4)

Forward or reversed air discharge available as standard on all products. Does not require configuring.

Area denotes services entry location. For specific details please contact Airedale.

Open base. Shaded area denotes air discharge.

M6 fixing holes positions for mounting ceiling duct extensions or plenums.

For specific markets units shall be shipped, mounted on wooden pallet and covered with

polythene. The pallet shall be mechanically fixed to the unit for transportation only

(Please contact Airedale for this option)

mm 1980 x 890 x 1985

mm 1980 x 890 x 2549

mm 1980 x 890 x 3113

H x D x W

X = 160mm

Y = 50mm

Z = 50mm

12

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Precision Air Conditioning

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Po

sitioning

Minimum

U

nit Clearance

Open & Enclosed Floorstand Option

SC19D

SC25D

Minim

um Ceiling Clearance

- (D)

SC19D

SC25D

SC31D

Precision Air Conditioning

SmartCoolTM – D

(D)

Installation

(2)

(1)

SC31D

mm 1985 800

mm 2549 800

mm 3113 800

A B C - Floorstand(3)

Min 200 – Max 750

(+ 50mm Feet Adjustable +/-

20mm) (4)

Forward Only Forward and 1 Side Forward and 2 Sides All Faces

mm

mm

mm

720 500 380 250

740 550 440 280

750 590 480 300

Notes

(1) Shown with optional open floor stand.

(2) Shaded area indicates minimum service and maintenance requirements. The unit must be installed with allowance for carpet tile clearance.

(3) Dimension C denotes recommended minimum/maximum floor stand height, refer to Airedale for special applications, please specify at order.

(4) Min = Threaded foot at minimum extension (additional to “C” dimension).

Max = Threaded foot at maximum extension (additional to “C” dimension).

13

Precision Air Conditioning

SmartCoolTM - D

Precision Air Conditioning

Electrical Services Incoming Cable

Service connections to the smartcool unit are from the left hand side. Provision must be made when sizing cable lengths.

Installation

Mains Electrical Incoming Isolator Termination

Electrical Services Entry Option 2

The Floorstand provided by Airedale however has provision for cable entry via the right hand side should it be required,

adjacent to the condensate drain.

Mechanical Services Entry + Electrical Option 1

Option 1

Option 2

Electrical services through floor stand

(Next to condensate drain)

Incoming Mains Gland Plate

1

2

4 hole centres are punched in the gland plate for

location of cable glands. The plate is removable for

drilling to required size.

3

4

Holes1 and 2 for interconnecting wiring to Outdoor unit.

Holes 3 and 4 for Mains incoming Supply A and B

14

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Precision Air Conditioning

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Precision Air Conditioning

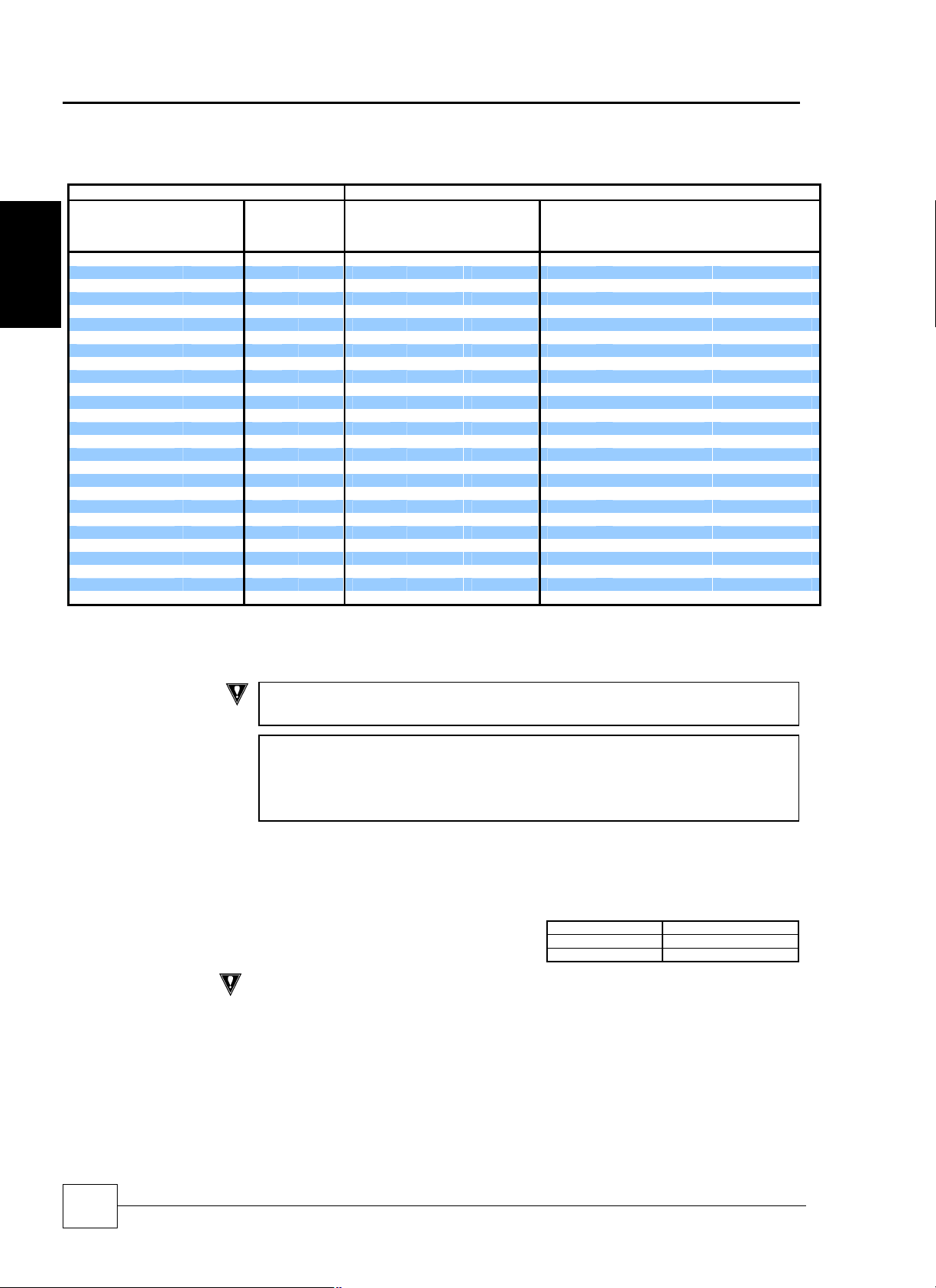

Weights

SmartCoolTM – D

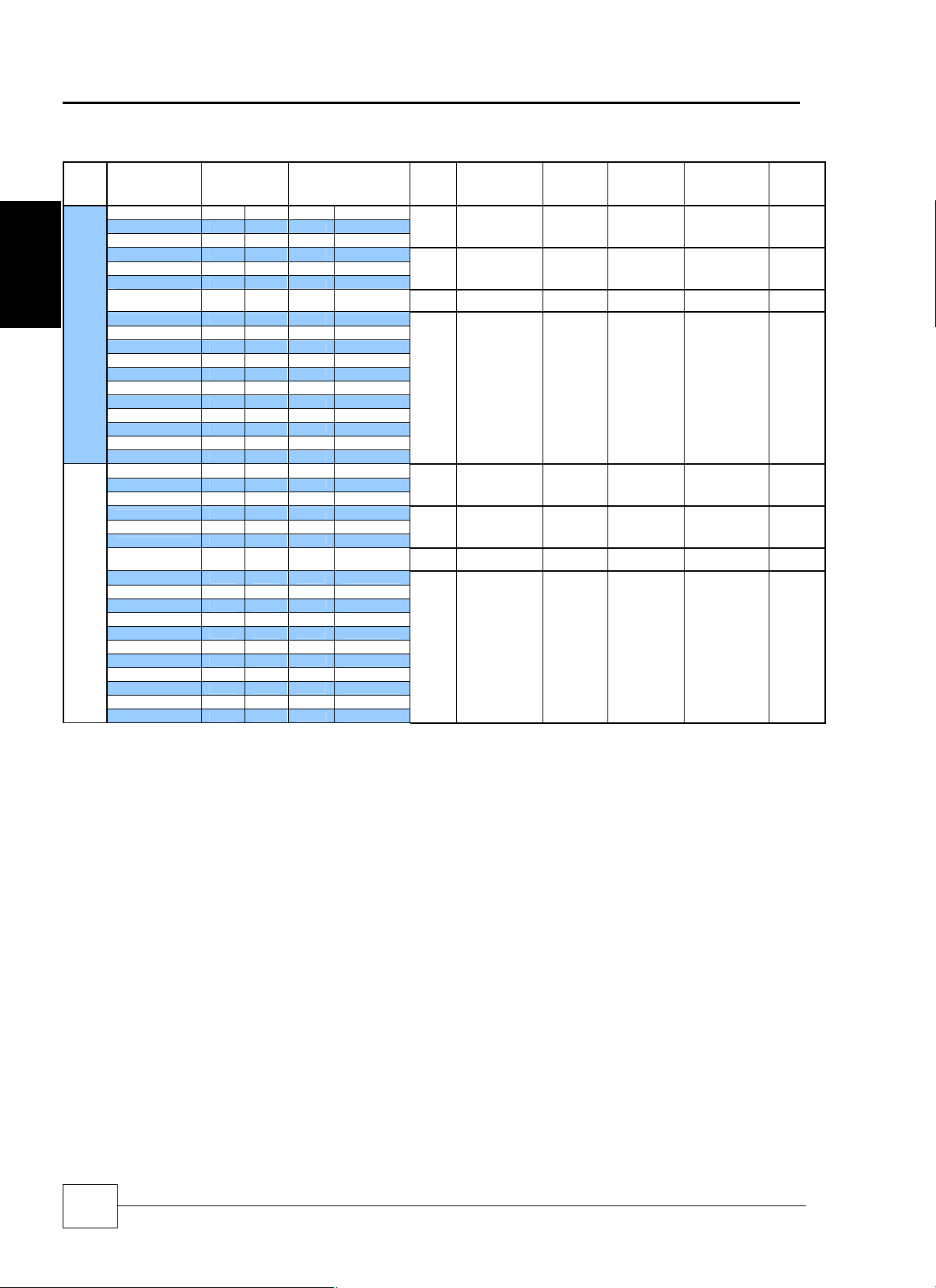

Unit Shipped Weight (kg) Installed Weight (kg)

SC19D055-X2X2-0 900 900

SC19D070-X2X2-0 900 910

SC19D080-X2X2-0 900 910

X2X2

X2C0

Note

(1) Shipped weights

(2) Installed weight includes refrigerant charges/ internal water volume.

SC25D080-X2X2-0 1020 1020

SC25D090-X2X2-0 1110 1120

SC25D100-X2X2-0 1130 1130

SC31D100-X2X2-0 1280 1290

SC31D120-X2X2-0 1300 1310

SC31D130-X2X2-0 1300 1310

Unit Shipped Weight (kg) Installed Weight (kg)

SC19D033-X2C0-0 820 860

SC19D038-X2C0-0 820 860

SC19D045-X2C0-0 820 860

SC19D064-X2C0-0 890 920

SC19D070-X2C0-0 900 930

SC19D076-X2C0-0 900 930

SC25D045-X2C0-0 940 980

SC25D050-X2C0-0 990 1030

SC25D055-X2C0-0 1000 1040

SC25D067-X2C0-0 1010 1050

SC25D073-X2C0-0 1010 1060

SC25D080-X2C0-0 1020 1060

SC31D055-X2C0-0 1150 1200

SC31D065-X2C0-0 1150 1210

SC31D075-X2C0-0 1160 1210

SC31D077-X2C0-0 1170 1220

SC31D080-X2C0-0 1170 1220

SC31D083-X2C0-0 1170 1220

Installation

15

Precision Air Conditioning

SmartCoolTM - D

Weights

Unit Shipped Weight (kg) Installed Weight (kg)

SC19D055-W2W2-0 940 940

SC19D070-W2W2-0 970 980

SC19D080-W2W2-0 970 980

Installation

W2W2

W2C0

Note

(1) Shipped weights

(2) Installed weight includes refrigerant charges/ internal water volume.

SC25D080-W2W2-0 1090 1110

SC25D090-W2W2-0 1220 1230

SC25D100-W2W2-0 1230 1250

SC31D100-W2W2-0 1390 1400

SC31D120-W2W2-0 1400 1410

SC31D130-W2W2-0 1400 1420

Unit Shipped Weight (kg) Installed Weight (kg)

SC19D033-W2C0-0 850 880

SC19D038-W2C0-0 860 890

SC19D045-W2C0-0 860 890

SC19D064-W2C0-0 950 980

SC19D070-W2C0-0 950 980

SC19D076-W2C0-0 960 990

SC25D045-W2C0-0 980 1020

SC25D050-W2C0-0 1050 1090

SC25D055-W2C0-0 1050 1100

SC25D067-W2C0-0 1070 1110

SC25D073-W2C0-0 1070 1120

SC25D080-W2C0-0 1080 1120

SC31D055-W2C0-0 1210 1260

SC31D065-W2C0-0 1220 1270

SC31D075-W2C0-0 1220 1270

SC31D077-W2C0-0 1230 1280

SC31D080-W2C0-0 1230 1280

SC31D083-W2C0-0 1230 1290

Precision Air Conditioning

16

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Precision Air Conditioning

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Precision Air Conditioning

Weights

Unit Shipped Weight (kg) Installed Weight (kg)

SmartCoolTM – D

SC19D033-W2F0-0 850 880

SC19D038-W2F0-0 860 890

SC19D045-W2F0-0 860 890

SC19D064-W2F0-0 950 980

SC19D070-W2F0-0 950 980

SC19D076-W2F0-0 960 990

SC25D045-W2F0-0 980 1020

SC25D050-W2F0-0 1050 1090

W2F0

C000

SC25D055-W2F0-0 1050 1100

SC25D067-W2F0-0 1070 1110

SC25D073-W2F0-0 1070 1120

SC25D080-W2F0-0 1080 1120

SC31D055-W2F0-0 1210 1260

SC31D065-W2F0-0 1220 1270

SC31D075-W2F0-0 1220 1270

SC31D077-W2F0-0 1230 1280

SC31D080-W2F0-0 1230 1280

SC31D083-W2F0-0 1230 1290

Unit Shipped Weight (kg) Installed Weight (kg)

SC19D065-C000-0 725 780

SC19D075-C000-0 725 780

SC19D090-C000-0 730 780

SC25D090-C000-0 840 920

SC25D100-C000-0 840 920

SC25D110-C000-0 840 920

SC31D110-C000-0 1000 1080

SC31D130-C000-0 1000 1080

SC31D150-C000-0 1000 1080

Installation

Unit Shipped Weight (kg) Installed Weight (kg)

SC19D033-C0C0-0 730 790

SC19D038-C0C0-0 730 790

SC19D045-C0C0-0 730 790

C0C0

Note

(1) Shipped weights

(2) Installed weight includes refrigerant charges/ internal water volumes.

SC25D045-C0C0-0 850 930

SC25D050-C0C0-0 850 930

SC25D055-C0C0-0 850 930

SC31D055-C0C0-0 1010 1100

SC31D065-C0C0-0 1010 1100

SC31D075-C0C0-0 1010 1100

17

Precision Air Conditioning

IMPORTANT

Tandem Compressor and suction throttle valve applications:

REMEM

BER excessive pressure loss in interconnecting pipework will impair system

Oil Traps

Pipe Supports

CAUTION

All pipework should be clamped prior to insulation being applied. Clamping over

Horizontal Sections

SmartCoolTM - D

Precision Air Conditioning

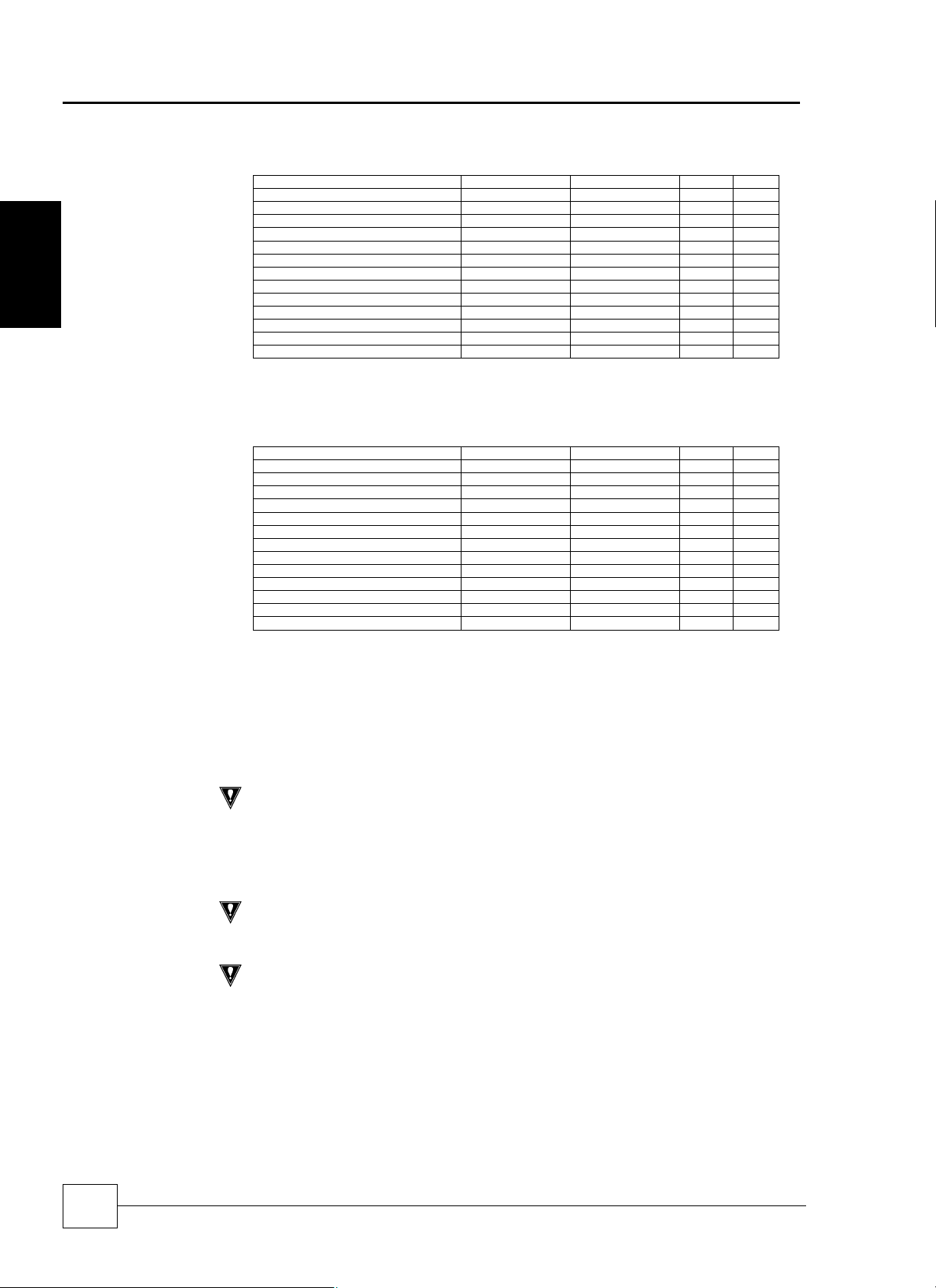

Refrigerant Pipe Sizing Guide

The refrigerant pipe sizing information below is for a guide only. Pipe sizes based on 100% load.

Liquid Disch

SC19D055-X2X2-0 CR50 1/2" 7/8" 5/8" 7/8" 3/4" 5/8" 7/8" 7/8"

SC19D070-X2X2-0 CR65 5/8" 7/8" 5/8" 7/8" 7/8" 5/8" 7/8" 7/8"

SC19D080-X2X2-0 CR65 5/8" 7/8" 5/8" 7/8" 7/8" 3/4" 7/8" 7/8"

SC25D080-X2X2-0 CR65 5/8" 7/8" 5/8" 7/8" 7/8" 3/4" 7/8" 7/8"

Installation

SC25D090-X2X2-0 CR65 7/8" 1 1/8" 5/8" 7/8" 7/8" 3/4" 7/8" 7/8"

SC25D100-X2X2-0 CR80 7/8" 1 1/8" 3/4" 1 1/8" 1 1/8" 3/4" 1 1/8" 1 1/8"

SC31D100-X2X2-0 CR80 7/8" 1 1/8" 3/4" 1 1/8" 1 1/8" 3/4" 1 1/8" 1 1/8"

SC31D120-X2X2-0 CR105 7/8" 1 1/8" 3/4" 1 1/8" 1 1/8" 3/4" 1 1/8" 1 1/8"

SC31D130-X2X2-0 CR105 7/8" 1 1/8" 3/4" 1 1/8" 1 1/8" 7/8" 1 1/8" 1 1/8"

SC19D033-X2C0-0 CR50 1/2" 7/8" 5/8" 7/8" 3/4" 5/8" 7/8" 7/8"

SC19D038-X2C0-0 CR65 5/8" 7/8" 5/8" 7/8" 7/8" 5/8" 7/8" 7/8"

SC19D045-X2C0-0 CR65 5/8" 7/8" 5/8" 7/8" 7/8" 3/4" 7/8" 7/8"

SC19D064-X2C0-0 CR105 5/8" 7/8" 3/4” 1 1/8” 1 1/8” 7/8” 1 3/8” 1 1/8”

SC19D070-X2C0-0 CR105 7/8" 1 1/8" 3/4” 1 1/8” 1 1/8” 7/8” 1 3/8” 1 1/8”

SC19D076-X2C0-0 CR105 7/8" 1 1/8" 3/4” 1 1/8” 1 1/8” 7/8” 1 3/8” 1 1/8”

SC25D045-X2C0-0 CR65 7/8" 1 1/8" 5/8" 7/8" 7/8" 3/4" 7/8" 7/8"

SC25D050-X2C0-0 CR65 7/8" 1 1/8" 5/8" 7/8" 7/8" 3/4" 7/8" 7/8"

SC25D055-X2C0-0 CR80 7/8" 1 1/8" 3/4" 1 1/8" 1 1/8" 3/4" 1 1/8" 1 1/8"

SC25D067-X2C0-0 CR105 7/8" 1 3/8" 3/4” 1 1/8” 1 1/8” 7/8” 1 3/8” 1 1/8”

SC25D073-X2C0-0 CR105 7/8" 1 3/8" 3/4” 1 1/8” 1 1/8” 7/8” 1 3/8” 1 1/8”

SC25D080-X2C0-0 CR105 7/8" 1 3/8" 3/4” 1 1/8” 1 1/8” 7/8” 1 3/8” 1 1/8”

SC31D055-X2C0-0 CR80 7/8" 1 3/8" 3/4" 1 1/8" 1 1/8" 3/4" 1 1/8" 1 1/8"

SC31D065-X2C0-0 CR105 7/8" 1 3/8" 3/4" 1 1/8" 1 1/8" 3/4" 1 1/8" 1 1/8"

SC31D075-X2C0-0 CR105 7/8" 1 3/8" 3/4" 1 1/8" 1 1/8" 7/8" 1 1/8" 1 1/8"

SC31D077-X2C0-0 CR105 7/8" 1 3/8" 3/4” 1 1/8” 1 1/8” 7/8” 1 3/8” 1 1/8”

SC31D080-X2C0-0 CR105 7/8" 1 3/8" 3/4” 1 1/8” 1 1/8” 7/8” 1 3/8” 1 1/8”

SC31D083-X2C0-0 CR105 7/8" 1 3/8" 3/4” 1 1/8” 1 1/8” 7/8” 1 3/8” 1 1/8”

(1) For interconnecting pipework with a predominantly horizontal layout.

(2) For interconnecting pipework with a predominantly vertical layout.

(3) Careful pipework selection must be done if the liquid line rises. Additional system sub cooling may be required to overcome friction losses.

Equivalent Pipe Lengths with R410A

Indoor

Unit

Outdoor

Unit

Indoor Unit

Connection Size 0-15m Discharge 15-40m Discharge

Liquid

(3)

Horizontal

(1)

Vertical

(2)

Liquid

(3)

Horizontal

(1)

Vertical

(2)

In part load, gas velocity should be taken into account when selecting and commissioning

pipework to ensure full oil return.

performance; this should be factored in during the design of the system and where

necessary oil separators employed.

Excessive pressure drop in liquid lines can cause poor refrigerant distribution to

expansion devices and can cause malfunction of the system (especially with condensers

lower than the evaporator)

For long vertical rises in both liquid and discharge lines, it is essential that oil traps are

located every 4m to ensure proper oil movement / entrapment. In addition there should be

an oil trap at the exit of the air handling unit before a vertical riser is applied (refer to

example below).

The following table identifies the maximum

distance between pipe supports on vertical

and horizontal pipe runs.

insulation is not acceptable.

Pipe O/D (inches) Support distance (m)

3/8 - 7/8 1.0

1 1/8 - 2 1/8 2.0

It is good practice to ensure a slight gradient toward the compressor in the direction of the

refrigerant flow for suction lines running horizontal. This assists oil return to the

compressor. A gradient of approximately 1:200 (0.5%) shall be used.

18

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Precision Air Conditioning

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Liquid Line

Pipe Insulation

Condenser above Air Handling Unit

Condenser below Air Handling Unit

4m

Refrigerant

C

harging Guide

Unit Refrigerant

Charge

(1)

excessive.

Precision Air Conditioning

If the system is configured with the SmartCool higher than the condenser unit h it may

be required to increase the degree of sub cooling to prevent flashing gas. This flashing is

caused by excess pressure drop caused by the static head of refrigerant and can cause

poor operation of the evaporator and metering device.

Careful pipe sizing is recommended to ensure that the liquid does not form gas due to

excess pressure drop

Increasing the liquid line size minimizes pipe friction and flashing due to friction pressure

drop.

However as a fail safe it is recommended that the condenser is installed below the

indoor unit to allow for correct liquid drain.

The liquid line of the system must be insulated if passing through extremely warm places

(Boiler houses etc). Ensuring that the refrigerant does not become flash gas.

t

SmartCoolTM – D

Installation

Discharge Line

The following information can be used to estimate the refrigerant quantity required in a

typical split system installation.

The following table shows the refrigerant charge / circuit for the indoor and outdoor units.

(kg/Circuit)

(Indoor Unit) kg/Circuit

SC19D055-X2X2

SC19D070-X2X2

SC19D080-X2X2

SC25D080-X2X2

SC25D090-X2X2

SC25D100-X2X2

SC31D100-X2X2

SC31D120-X2X2

SC31D130-X2X2

SC19D033-X2C0

SC19D038-X2C0

SC19D045-X2C0

SC19D064-X2C0

SC19D070-X2C0

SC19D076-X2C0

SC25D045-X2C0

SC25D050-X2C0

SC25D055-X2C0

SC25D067-X2C0

SC25D073-X2C0

SC25D080-X2C0

SC31D055-X2C0

SC31D065-X2C0

SC31D075-X2C0

SC31D077-X2C0

SC31D080-X2C0

SC31D083-X2C0

(1)Fitted with optional hot gas re-heat

t

Warning: May have flash gas occurring

in liquid line if riser friction losses are

Liquid Diagrams above for illustration only

Indoor Unit Standard Condenser Larger Condenser

4.41 4.56

4.66 4.81

4.66 4.81

5.84 6.04

6.37 6.60

6.38 6.60

7.56 7.83

7.57 7.83

7.67 7.94

4.34 4.49

4.59 4.74

4.59 4.74

5.13 5.33

5.13 5.34

5.14 5.34

5.77 5.97

6.31 6.53

6.31 6.53

6.31 6.56

6.32 6.57

6.32 6.57

7.49 7.75

7.49 7.76

7.49 7.76

7.50 7.79

7.50 7.79

7.50 7.79

HGRH

kg/Circuit (Outdoor Unit) kg/Circuit (Outdoor Unit) kg/Circuit

CR50

CR65

CR65

CR65

CR65

CR80

CR80

CR105

CR105

CR50

CR65

CR65

CR105

CR105

CR105

CR65

CR65

CR80

CR105

CR105

CR105

CR80

CR105

CR105

CR105

CR105

CR105

4.9

9.78

9.78

9.78

9.78

8.37

8.37

16.72

16.72

4.9

9.78

9.78

16.72

16.72

16.72

9.78

8.37

8.37

16.72

16.72

16.72

8.37

16.72

16.72

16.72

16.72

16.72

CR65

CR80

CR80

CR80

CR80

CR105

CR105

CR130

CR130

CR65

CR80

CR80

CR130

CR130

CR130

CR80

CR80

CR105

CR130

CR130

CR130

CR105

CR130

CR130

CR130

CR130

CR130

9.78

8.37

8.37

8.37

8.37

16.72

16.72

22.05

22.05

9.78

8.37

8.37

22.05

22.05

22.05

8.37

8.37

16.72

22.05

22.05

22.05

16.72

22.05

22.05

22.05

22.05

22.05

19

Precision Air Conditioning

Liquid

Line Refrigerant

IMPORTANT

The pipe

sizes/refrigerant charges quoted are for guidance only. It is the responsibility of

Split systems may require additional oil which should be added to the low side of

Design should be in accordance with accepted refrigeration prac

tice to ensure good oil

Calculation of

Liquid Line

Calculation of

System

Example

Selecting The Liquid Line Size

Liquid Line Refrigerant

System Refrigerant Charge

SmartCoolTM - D

Charge (kg/m)

Installation

Refrigerant Charge (kg)

Refrigerant Charge (kg)

Precision Air Conditioning

The following table shows the refrigerant charge / metre for the liquid line, using R410A

and assuming a liquid line temperature of 40°C.

Liquid Line (m) kg/m

3/8” 0.05

1/2” 0.09

5/8” 0.15

3/4” 0.21

7/8” 0.30

1 1/8” 0.53

the installing contractor/site engineer to check the pipe sizes/refrigerant charges are correct

for each system installation and application. Excess pressure drop on a system may require

additional refrigerant charges to ensure correct unit operation.

each compressor.

return to the compressor(s) under all normal operating conditions.

The liquid line refrigerant charge can be calculated using the following equation:

LR = L x m

The system refrigerant charge can be calculated using the following equation:

SR = LR + IR + OR

Where:

LR = Total Liquid Line Refrigerant charge (kg)

L = Length of Interconnecting pipework (metres)

m = Liquid Line Refrigerant charge / metre. Refer to

Liquid Line Refrigerant

Charge (kg/m), above.

Where:

SR = Total System Refrigerant charge (kg)

LR = Total Liquid Line Refrigerant charge. (As calculated from above)

IR = Indoor Unit Refrigerant Charge.

OR = Outdoor Unit Refrigerant Charge.

Indoor Unit Model Ref. = SC19D055-X2X2-0

Outdoor Unit Model Ref. = CR50 Condenser

Interconnecting Pipework = 10 metres

From the Refrigerant Pipe Sizing Guide, the liquid line size given for pipework length of 10 metres

is:

Liquid Line Size = 5/8”

LR = L x m

Charge

LR = 10 x 0.15

SR = LR + IR + OR

SR = 1.5 + 5.57 + 4.9 System Refrigerant Charge = 10.81kg / Circuit

Where:

L = 10 metres

m = 0.15 kg/m

Liquid Line Charge = 1.5 kg

Where:

LR = 1.5 kg. (As calculated from above)

IR = 4.41 kg

OR = 4.9 kg

20

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Precision Air Conditioning

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Liquid Sub Cooling

Precision Air Conditioning

The degree of liquid sub cooling required to prevent flashing of liquid refrigerant can be calculated by

the following method.

Given the following as an example:

· Refrigerant R410A

· Condensing temperature (54.4°C)

· Liquid lift 20m

· Piping friction loss 0.21 bar

· Losses through valves and fittings 0.5 Bar

1. Determine the pressure drop due to pipe friction = 0.21 Bar

2. Pressure drop due to valves and fittings = 0.5 Bar

3. Pressure loss due to liquid lift = height x 0.115 = 20 x 0.115 = 2.3 bar

Note:- At normal liquid temperatures the static pressure loss due to elevation at the top of a liquid lift

0.115 bar/m

Therefore:- Total pressure loss in liquid line = 3.01bar

Condensing pressure @ Condensing temperature (54.4°C) = 34 Bar

Total pressure loss in liquid line = 3.01 Bar

Nett pressure at Expansion valve = 34 - 3.01 = 30.99 bar

Saturation temperature at the Nett pressure at expansion valve (30.99 bar) = 52°C

(from Refrigerant tables)

SmartCoolTM – D

Installation

Sub cooling required

= Condensing temperature — Saturation temperature at the Nett pressure at expansion valve

= 54.4 - 52 = 2.4 °C

Therefore liquid sub cooling required to prevent liquid flashing = 2.4 °C

Packaged Unit Pre-Charged Refrigerant Volumes

Indoor unit kg / circuit HGRH kg / circuit Indoor unit kg / circuit HGRH kg / circuit

SC19D055-W2W2 5.75 5.90 SC19D033-W2F0 5.68 5.83

SC19D070-W2W2 7.32 7.47 SC19D038-W2F0 7.25 7.40

SC19D080-W2W2 7.32 7.47 SC19D045-W2F0 7.25 7.40

SC25D080-W2W2 8.51 8.70 SC19D064-W2F0 9.60 9.81

SC25D090-W2W2 10.85 11.07 SC19D070-W2F0 9.61 9.81

SC25D100-W2W2 10.85 11.07 SC19D076-W2F0 9.61 9.82

SC31D100-W2W2 12.04 12.30 SC25D045-W2F0 8.44 8.63

SC31D120-W2W2 12.04 12.30 SC25D050-W2F0 10.78 11.00

SC31D130-W2W2 12.04 12.31 SC25D055-W2F0 10.78 11.00

SC19D033-W2C0 5.68 5.83 SC25D067-W2F0 10.79 11.04

SC19D038-W2C0 7.25 7.40 SC25D073-W2F0 10.79 11.04

SC19D045-W2C0 7.25 7.40 SC25D080-W2F0 10.80 11.04

SC19D064-W2C0 9.60 9.81 SC31D055-W2F0 11.96 12.23

SC19D070-W2C0 9.61 9.81 SC31D065-W2F0 11.97 12.23

SC19D076-W2C0 9.61 9.82 SC31D075-W2F0 11.97 12.23

SC25D045-W2C0 8.44 8.63 SC31D077-W2F0 11.97 12.26

SC25D050-W2C0 10.78 11.00 SC31D080-W2F0 11.98 12.27

SC25D055-W2C0 10.78 11.00 SC31D083-W2F0 11.98 12.27

SC25D067-W2C0 10.79 11.04

SC25D073-W2C0 10.79 11.04

SC25D080-W2C0 10.80 11.04

SC31D055-W2C0 11.96 12.23

SC31D065-W2C0 11.97 12.23

SC31D075-W2C0 11.97 12.23

SC31D077-W2C0 11.97 12.26

SC31D080-W2C0 11.98 12.27

SC31D083-W2C0 11.98 12.27

(1)Fitted with optional hot gas re-heat

21

Precision Air Conditioning

Dry

Cooler (kW)

Calculation of

Design

V

r

D

r

Ca

lculation of

Indoor Unit

D

D

This will typically occur when the water/glycol temperature is approximately 20°C and the

The indoor unit pressure drop will reduce at other operating conditions.

Specific Heat Capacity (Cp)

Pressure Drop Correction

SmartCoolTM - D

Design Data – Water Cooled & Free Cooling

Installation

Volumetric Flow Rate (l/s)

Pressure Drop (DPs)

The dry cooler design duty is equivalent to the Total Heat of Rejection (THR) from the indoor unit.

This value can be taken from the performance data in the technical manual using the following.

Parameters required are:

· Ambient conditions (°C dB) Airedale recommend a 10°C lower than the EWT.

· Glycol content (%)

· Entering & leaving water/glycol temperatures (°C) (EWT and LWT)

· Mean condensing temperature (°C) Based on 5°C above leaving water/glycol temperature

The maximum design volumetric flow rate can be calculated using the following equation:

&

=

x Cp

Where:

Q = Total Heat Rejection (kW).

T = Temperature Difference between Water/Glycol Entering/ Leaving (°C).

= Density. Refer to table below.

Cp = Specific heat capacity. Refer to table below.

The maximum indoor unit pressure drop can be calculated using the following equation:

DPs= DPw x Pc

Using the volumetric flow rate calculated above, the pressure drop (DPw) can be taken from the

relevant pressure drop graph..

Where:

Ps = Maximum Water/Glycol Pressure Drop for the indoor unit (kPa).

Pw = Equivalent Water Pressure Drop for indoor unit (kPa).

Pc = % Glycol Pressure Drop Correction Factor @ 20°C Water Temperature.

The resultant pressure drop (DPs) is the maximum pressure drop based on the indoor unit

running at the prescribed conditions.

Precision Air Conditioning

Q

x ΔT

Refer to table below.

Density (r)

Factor (Pc)

water/glycol is being circulated through the free cooling coil and through the water cooled

condenser.

Water/Glycol Temperature °C

20 4.183 3.972 3.815 3.645 3.468

25 4.181 3.981 3.826 3.660 3.485

30 4.179 3.989 3.838 3.674 3.502

35 4.178 3.998 3.849 3.688 3.518

40 4.179 4.007 3.861 3.702 3.535

45 4.181 4.015 3.872 3.716 3.552

Water/Glycol Temperature °C

20 998 1013 1030 1045 1060

25 997 1012 1028 1043 1058

30 996 1010 1026 1041 1055

35 994 1008 1024 1039 1053

40 992 1006 1022 1036 1050

45 990 1003 1020 1035 1048

Water/Glycol Temperature °C

20 0.983 1.0125 1.054 1.0958 1.15

0% / 0°C 10% / -4°C 20% / -9°C 30% / -15°C 40% / -23°C

Fc Fc Fc Fc Fc

0% / 0°C 10% / -4°C 20% / -9°C 30% / -15°C 40% / -23°C

Fc Fc Fc Fc Fc

0% 10% 20% 30% 40%

Pc Pc Pc Pc Pc

Ethylene Glycol (Volume) / Freezing Point °C

Ethylene Glycol (Volume) / Freezing Point °C

Ethylene Glycol (Volume)

22

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Precision Air Conditioning

Installation, Maintenance and Commissioning Manual :6877419 02/2013

System Pressure

IMPORTANT

Low pressure transducers and switches must be removed whilst the high pressure

CAUTION

Before carrying out the pressure test, precautions shall be taken to evacuate

all

System Leak Test

RECORD

Record on commissioning sheet provided once completed.

IMP

ORTANT

Filter Drier

IMPORTANT

Failure to correctly fit a filter drier can cause malfunction of the system.

They are

Precision Air Conditioning

Installation Data

The system must be pressure tested to ensure that the pipework is installed satisfactory.

Strength Test

Nitrogen (Oxygen free) should only be used.

Strength Pressure Test is the pressure applied to a refrigeration system for its integral

strength and it is usually defined as maximum working pressure (MWP) x factor of 1.43.

The pressure test ideally should be carried out for a period of one hour.

strength test is carried out.

personnel from the area of risk and post notices advising that the system or

equipment is under pressure.

The test pressure in the system should be held for at least one hour. A longer period may

be appropriate for larger systems or a fall in pressure due to leaks may not be detected.

Any fall in pressure indicates a leak which should be traced.

SmartCoolTM – D

Installation

The system leak test is carried out with the low pressure transducers and switches fitted.

Leak Pressure Test is the pressure applied to a refrigeration system or part of a system to

test for leakage. This test pressure is defined as Maximum Working Pressure of the

particular system x factor of 1.1.

It is important that solenoid valves are energised correctly to ensure that the Hot Gas

Reheat coil is fully pressure tested (the normally closed (NC) valve should be energised).

The use of a magnetic coil lifter is recommended.

The filter drier must be installed as close to the expansion valve as possible. It should be

the last component within the system to be installed.

however no substitute to good refrigeration practices with regard to system

cleanliness.

23

Precision Air Conditioning

Evacuation

RECORD

Record on commissioning sheet provided once completed.

IMPORTANT

CAUTION

Ensure that the

e

vacuation gauge is isolated before introduc

ing any pressure. The

SmartCoolTM - D

Installation Data

Installation

Precision Air Conditioning

Evacuation for systems operating on R410A refrigerant should be carried out as follows

1 The procedure should be carried out using a high vacuum pump. The pump should

be connected to the high and low pressure sides of the system via a gauge manifold

fitted with compound gauges. A high vacuum gauge should be fitted to the system at

the furthest point from the vacuum pump.

2 Triple evacuation should be used to ensure that all contaminants are removed or at

least reduced to significantly low proportions.

3 The vacuum pump should be operated until a pressure of 1.5 Torr (200 Pa) absolute

pressure is reached, at which time the vacuum pump should be stopped and the

vacuum broken with oxygen free nitrogen until the pressure rises above zero.

4 The above operation should be repeated a second time.

5 The system should then be evacuated a third time but this time to 0.5 Torr (absolute

pressure and broken with the correct refrigerant, until pressures equalise between

the charging bottle and the system.

It is important that solenoid valves are energises correctly to ensure that the Hot Gas

Reheat Coil is fully evacuated. (The Normally Closed (NC) valve should be energised).

The use of a magnetic coil lifter is recommended.

24

gauge may become dangerous when exposed to any positive pressure.

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Precision Air Conditioning

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Refrigerant Handling

CAUTION

P

ersonal

p

rotective equipment must be worn

when handling refrigerants.

Charging Gauges

Refrigerant Quality

Refrigerant Charge

RECORD

Record on commissioning sheet provided once completed.

IMPORTANT

Schrader Caps

Final Leak Test

Precision Air Conditioning

Installation Data

Only certified personnel must charge the systems with refrigerant

The refrigerant Schrader connections on the SmartCool units are 5/16” to allow for the

increase working pressures of R410A. Gauges designed for R410A must only be used.

The system must be charged with clean virgin refrigerant R410A only.

The exact refrigerant charge is dependant on site circumstances and operating

Weights

temperatures. Pipework runs must be taken into consideration. The refrigerant charge

must be weighed into the system and recorded within your F-Gas record.

It is important that solenoid valves are energised correctly to ensure that the Hot Gas

ReHeat coil is broken of vacuum (the Normally Closed (NC) valve should be energised).

The use of a magnetic coil lifter is recommended.

SmartCoolTM – D

Installation

The valve must also be energised when charging the system with refrigerant.

The solenoid valve head must be put back on the body before unit operation.

Schrader caps must be replaced following connection of service gauges to the unit.

A final leak test must be carried out following removal of service gauges prior to leaving

site ensuring that the system complies with F-Gas regulations.

25

Precision Air Conditioning

Oil Charging Guide

Compressors

The compressor oil sight glass (where fitted)

should indicate a level of between 1/

3

IMPORTANT

IMPORTANT

For applications with pipework in excess of 20m, long vertical run

s, special

REMEMBER, TOO MUCH or TOO LITTLE OIL can cause compressor damage. As a

ALWAYS use the oil specified by the compressor manufacturer.

Polyolester oil is extremely hygroscopic and will rapidly absorb moisture from the

Pressure switch settings

SmartCoolTM - D

Installation Data

Installation

Precision Air Conditioning

The compressor(s) is supplied with oil for up to approximately 20m of interconnecting

pipework.

and 2/3 to ensure correct operation.

Run the compressor(s) for a minimum of 1 hour to check oil return and motor function. For

tandem or trio sets, checks should be performed in part load operation.

1. Use a temperature metering device on each circuit:

2. Check operation and superheat readings are within acceptable limits.

3. Check suction and discharge pressure are within acceptable limits.

4. Check there is NO foaming in the compressor sight glass. This would indicate the

presence of liquid returning to the compressor.

5. Check sight glass following commissioning and top oil up if level has fallen below

minimum.

6. If oil has been added to allow for long pipe runs, large number of oil traps, etc,

and the level in the compressors keep decreasing; the oil return in the system is

insufficient. A pipework design check is required.

It is possible to check the oil level of a compressor a few moments after it is turned off.

However the oil level must not be observed when the compressor is turned off. The

refrigerant in the system can give a false indication of this level.

In this case the oil level should be at about 1/3.

operating conditions etc, ensure good oil return is guaranteed AND add sufficient

oil to the system.

rule NO MORE than 10% additional oil should be added to any system.

air. The oil must therefore not be left open to the atmosphere for long periods of

time. The system must be correctly evacuated to ensure all moisture is removed.

High pressure switch cut-out 40.3 bar (583psi)

High pressure switch cut-in 30.0 bar (435psi)

High pressure switch differential 10.3 bar (148psi)

Low pressure switch cut-out 1.0 bar (14psi)

Low pressure cut-in 3.0 bar (43psi)

Low pressure differential 2.0 bar (29psi)

26

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Precision Air Conditioning

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Recommended

Precision Air Conditioning

Compressor Oil Information

Oil

Sight

Glass

Yes

Yes POE 160SZ Internal

Yes

Yes POE 160SZ Internal

Yes POE 160SZ Internal

Yes

Yes POE 160SZ Internal

X2X2

X2C0

W2W2

Unit

CP1 CP2 CP1 CP2

SC19D055-X2X2

SC19D070-X2X2

SC19D080-X2X2

SC25D080-X2X2

SC25D090-X2X2

SC25D100-X2X2

SC31D100-X2X2

SC31D120-X2X2

SC31D130-X2X2

SC19D033-X2C0

SC19D038-X2C0

SC19D045-X2C0

SC19D064-X2C0

SC19D070-X2C0

SC19D076-X2C0

SC25D045-X2C0

SC25D050-X2C0

SC25D055-X2C0

SC25D067-X2C0

SC25D073-X2C0

SC25D080-X2C0

SC31D055-X2C0

SC31D065-X2C0

SC31D075-X2C0

SC31D077-X2C0

SC31D080-X2C0

SC31D083-X2C0

SC19D055-W2W2

SC19D070-W2W2

SC19D080-W2W2

SC25D080-W2W2

SC25D090-W2W2

SC25D100-W2W2

SC31D100-W2W2

SC31D120-W2W2

SC31D130-W2W2

Total oil

charge (l)

1.57 1.57 37.2 37.2

1.57 1.57 37.2 37.2

1.57 1.57 37.2 37.2

1.57 1.57 37.2 37.2

3 3 58 58

3 3 58 58

3 3 58 58

3.3 3.3 64.2 64.2

3.3 3.3 64.2 64.2

1.57 1.57 37.2 37.2

1.57 1.57 37.2 37.2

1.57 1.57 37.2 37.2

3.3 3.3 67 67

3.3 3.3 69 69

3.6 3.3 72 72

1.57 1.57 37.2 37.2 Yes

3 3 58 58

3 3 58 58

3.3 3.3 67 67

3.3 3.3 69 69

3.6 3.6 72 72

3 3 58 58

3.3 3.3 64.2 64.2

3.3 3.3 64.2 64.2

3.3 3.3 69 69

3.3 3.3 69 72

3.6 3.8 72 72

1.57 1.57 37.2 37.2

1.57 1.57 37.2 37.2

1.57 1.57 37.2 37.2

1.57 1.57 37.2 37.2

3 3 58 58

3 3 58 58

3.3 3.3 64.2 64.2

3.3 3.3 64.2 64.2

3.3 3.3 64.2 64.2

Compressor

Weight (kg)

oil

replacement

variant

PVE Lubricant

320HV

PVE Lubricant

320HV

PVE Lubricant

320HV

PVE Lubricant

320HV

SmartCoolTM – D

Motor

Protection

Type

Internal Thermodisc No

Internal Thermodisc No

Internal Thermodisc No

Internal Thermodisc No

Discharge Gas

Temperature

Protection

Discharge

Gas

Thermostat

Discharge

Gas

Thermostat

Discharge

Gas

Thermostat

Discharge

Gas

Thermostat

Temperature

Range

Opens

@135°C

Opens

@135°C

Opens

@135°C

Opens

@135°C

Oil

sump

heater

Yes

Yes

Yes

Yes

Installation

27

Precision Air Conditioning

Discharge

SmartCoolTM - D

Compressor Oil Information

Total Oil

Charge (l)

1.57 1.57 37.2

1.57 1.57 37.2

1.57 1.57 37.2

3.3 3.3 67 67

3.3 3.3 69 69

3.6 3.6 72 72

1.57 1.57 37.2 37.2 Yes

3 3 58 58

3 3 58 58

3.3 3.3 69 69

3.3 3.3 69 69

3.6 3.6 72 72

3 3 58 58

3.3 3.3 64.2 64.2

3.3 3.3 64.2 64.2

3.3 3.3 69 69

3.3 3.6 69 72

3.6 3.6 72 72

1.57 1.57 37.2

1.57 1.57 37.2

1.57 1.57 37.2

3.3 3.3 67 67

3.3 3.3 69 69

3.6 3.6 72 72

3 3 58 58

3 3 58 58

3.3 3.3 67 67

3.3 3.3 69 69

3.6 3.6 72 72

3 3 58 58

3.3 3.3 64.2 64.2

3.3 3.3 64.2 64.2

3.3 3.3 69 69

3.3 3.6 69 72

3.6 3.6 72 72

Installation

Unit

SC19D033-W2C0

SC19D038-W2C0

SC19D045-W2C0

SC19D064-W2C0

SC19D070-W2C0

SC19D076-W2C0

SC25D045-W2C0

SC25D050-W2C0

SC25D055-W2C0

SC25D067-W2C0

W2C0

SC25D073-W2C0

SC25D080-W2C0

SC31D055-W2C0

SC31D065-W2C0

SC31D075-W2C0

SC31D077-W2C0

SC31D080-W2C0

SC31D083-W2C0

SC19D033-W2F0

SC19D038-W2F0

SC19D045-W2F0

SC19D064-W2F0

SC19D070-W2F0

Sc19D076-W2F0

SC25D045-W2F0 1.57 1.57 37.2 37.2 Yes

SC25D050-W2F0

SC25D055-W2F0

SC25D067-W2F0

W2F0

SC25D073-W2F0

SC25D080-W2F0

SC31D055-W2F0

SC31D065-W2F0

SC31D075-W2F0

SC31D077-W2F0

SC31D080-W2F0

SC31D083-W2F0

Compressor Weight

(kG)

37.2

37.2

37.2

37.2

37.2

37.2

Precision Air Conditioning

Oil

Recommended

Sight

Glass

oil replacement

variant

PVE Lubricant

Yes

Yes POE 160SZ Internal

Yes POE 160SZ Internal

Yes

yes POE 160SZ Internal

yes POE 160SZ Internal

320HV

PVE Lubricant

320HV

PVE Lubricant

320HV

PVE Lubricant

320HV

Motor

Protection

Type

Internal Thermodisc No

Internal Thermodisc No

Internal Thermodisc No

Internal Thermodisc No

Gas

Temperature

Protection

Discharge

Gas

Thermostat

Discharge

Gas

Thermostat

Discharge

Gas

Thermostat

Discharge

Gas

Thermostat

Temperature

Range

Opens

@135°C

Opens

@135°C

Opens

@135°C

Opens

@135°C

Oil sump

heater

Yes

Yes

Yes

Yes

28

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Precision Air Conditioning

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Chilled Water System

IMPORTANT

Humidifi

cation

Humidifier

-

Intelligent

Precision Air Conditioning

Installation Data

The chilled water coil is factory pressure tested to 20 barg. The chilled water system

Modulation

maximum operating pressure is 10 barg.

The chilled water pipework external to the unit is required to be pressure tested to ensure

water tightness.

The chilled water coils need to be bled of air prior to unit operation. The bleed valve is