BluCube

Heat Pump Condensing Unit

Installation and Maintenance Manual

BluCube™

Condensing Unit

2

Condensing Units

Installation and Maintenance Manual : 7222094 11/2013

Warranty, Commissioning &

Maintenance

As standard, Airedale guarantees all non consumable parts only for a period of 12 months, variations

tailored to suit product and application are also available; please contact Airedale for full terms and

details.

To further protect your investment in Airedale products, Airedale Service can provide full commissioning

services, comprehensive maintenance packages and service cover 24 hours a day, 365 days a year

(UK mainland). For a free quotation contact Airedale Service or your local Sales Engineer.

All Airedale products are designed in accordance with EU Directives regarding prevention of build up of

water, associated with the risk of contaminants such as Legionella.

Where applicable, effective removal of condensate is achieved by gradient drainage to outlets and

where used, humidification systems produce sterile, non-toxic steam during normal operation.

For effective prevention of such risk it is necessary that the equipment is maintained in accordance with

Airedale recommendations.

CAUTION

Warranty cover is not a substitute for Maintenance. Warranty cover is conditional to maintenance being

carried out in accordance with the recommendations provided during the warranty period. Failure to

have the maintenance procedures carried out will invalidate the warranty and any liabilities by Airedale

International Air Conditioning Ltd.

Spares

A spares list for 1 3 and 5 years will be supplied with every unit and is also available from our Spares

department on request.

Training

As well as our comprehensive range of products, Airedale offers a modular range of Refrigeration and

Air Conditioning Training courses, for further information please contact Airedale.

Customer Services

For further assistance, please e-mail: enquiries@airedale.com or telephone:

UK Sales Enquiries

+ 44 (0) 113 238 7789

enquiries@airedale.com

International Enquiries

+ 44 (0) 113 239 1000

enquiries@airedale.com

Spares Hot Line

+ 44 (0) 113 238 7878

spares@airedale.com

Airedale Service

+ 44 (0) 113 239 1000

service@airedale.com

Technical Support

+ 44 (0) 113 239 1000

tech.support@airedale.com

Training Enquiries

+ 44 (0) 113 239 1000

marketing@airedale.com

For information, visit us at our Web Site: www.airedale.com

Legal Notices

AIAC Ltd endeavours to ensure that the information in this document is correct and fairly stated, but none

of the statements are to be relied upon as a statement or representation of fact. AIAC Ltd does not

accept liability for any error or omission, or for any reliance placed on the information contained in this

document.

The development of Airedale products and services is continuous and the information in this document

may not be up to date. It is important to check the current position with AIAC Ltd at the address stated.

This document is not part of a contract or licence unless expressly agreed.

No part of this document may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying, recording, or information storage and retrieval systems, for any

purpose other than the purchaser’s personal use, without the express written permission of AIAC Ltd.

2013 Airedale International Air Conditioning Limited. All rights reserved. Printed in the UK.

About Airedale Products & Customer Services

Condensing Units

BluCube™

Condensing Units

3

Installation and Maintenance Manual 7222094: 11/2013

Health and Safety ......................................................................................... 5

Refrigerant Warning ................................................................................................................................ 5

Manual Handling ...................................................................................................................................... 5

Environmental Considerations .................................................................... 6

Environmental Policy ............................................................................................................................... 6

CE Directive............................................................................................................................................. 6

General Specification ................................................................................... 7

Nomenclature .......................................................................................................................................... 7

Introduction .............................................................................................................................................. 7

Capacity Range Cooling Only Unit .......................................................................................................... 8

Capacity Range Heat Pump Unit ............................................................................................................. 8

Installation Data ............................................................................................ 9

Lifting ....................................................................................................................................................... 9

Positioning ............................................................................................................................................. 10

Dimensional Data .................................................................................................................................. 11

Incoming Services ................................................................................................................................. 17

Refrigeration Information ........................................................................... 19

Pressure Testing ................................................................................................................................... 19

Evacuation ............................................................................................................................................. 19

Refrigeration Pipework Installation - Good Practices ............................................................................. 20

Pipework Schematics .............................................................................. Error! Bookmark not defined.

Technical Data Cooling Only ..................................................................... 27

Operational Limits .................................................................................................................................. 27

Cooling Only Fixed Capacities............................................................................................................... 28

Cooling Only Modulating Capacities ...................................................................................................... 29

Mechanical Data Cooling Only Fixed Capacities ................................................................................... 30

Mechanical Data Cooling Only Modulating Capacities .......................................................................... 32

Electrical Data – Cooling Only ............................................................................................................... 34

Interconnecting Wiring ........................................................................................................................... 38

Technical Data Heat Pump ......................................................................... 39

Operational Limits .................................................................................................................................. 39

Heat Pump Cooling Fixed Capacities .................................................................................................... 41

Heat Pump Cooling Modulating Capacities ........................................................................................... 42

Heat Pump Heating Fixed Capacities .................................................................................................... 43

Heat Pump Heating Modulating Capacities ........................................................................................... 44

Mechanical Data - Heat Pump Fixed Capacities ................................................................................... 45

Mechanical Data - Heat Pump Modulating Capacities ........................................................................... 47

Electrical Data – Heat Pump.................................................................................................................. 49

Interconnecting Wiring - Heat Pump ...................................................................................................... 53

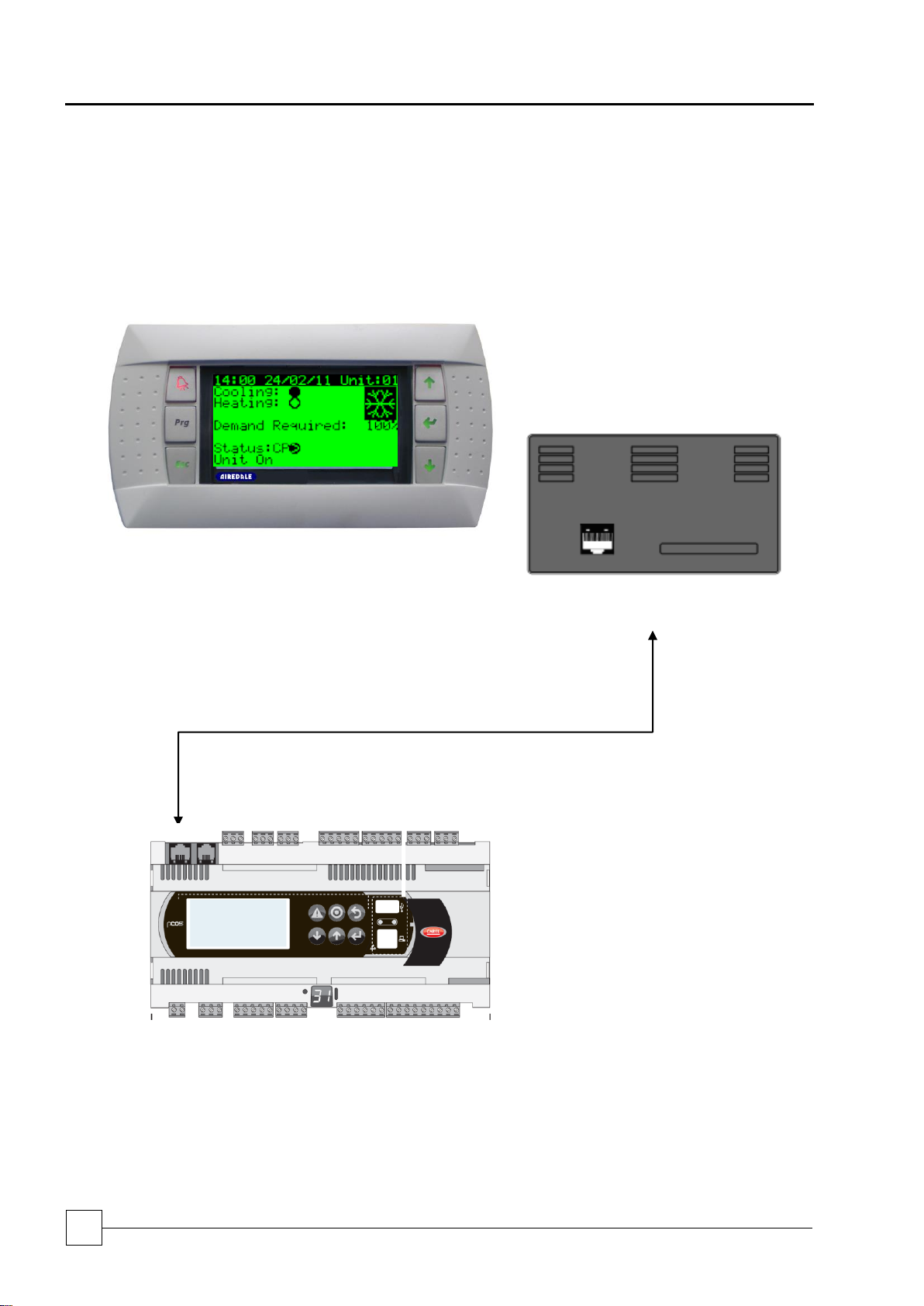

Controls ....................................................................................................... 54

Display Keypad ................................................................................................................................ ...... 54

Display Keypad Connections ................................................................................................................. 54

Use of Display Keypad Buttons ............................................................................................................. 55

Navigation.............................................................................................................................................. 56

Password Protection .............................................................................................................................. 56

Adjusting Customer Control Settings ..................................................................................................... 56

Network Display ................................................................ ..................................................................... 57

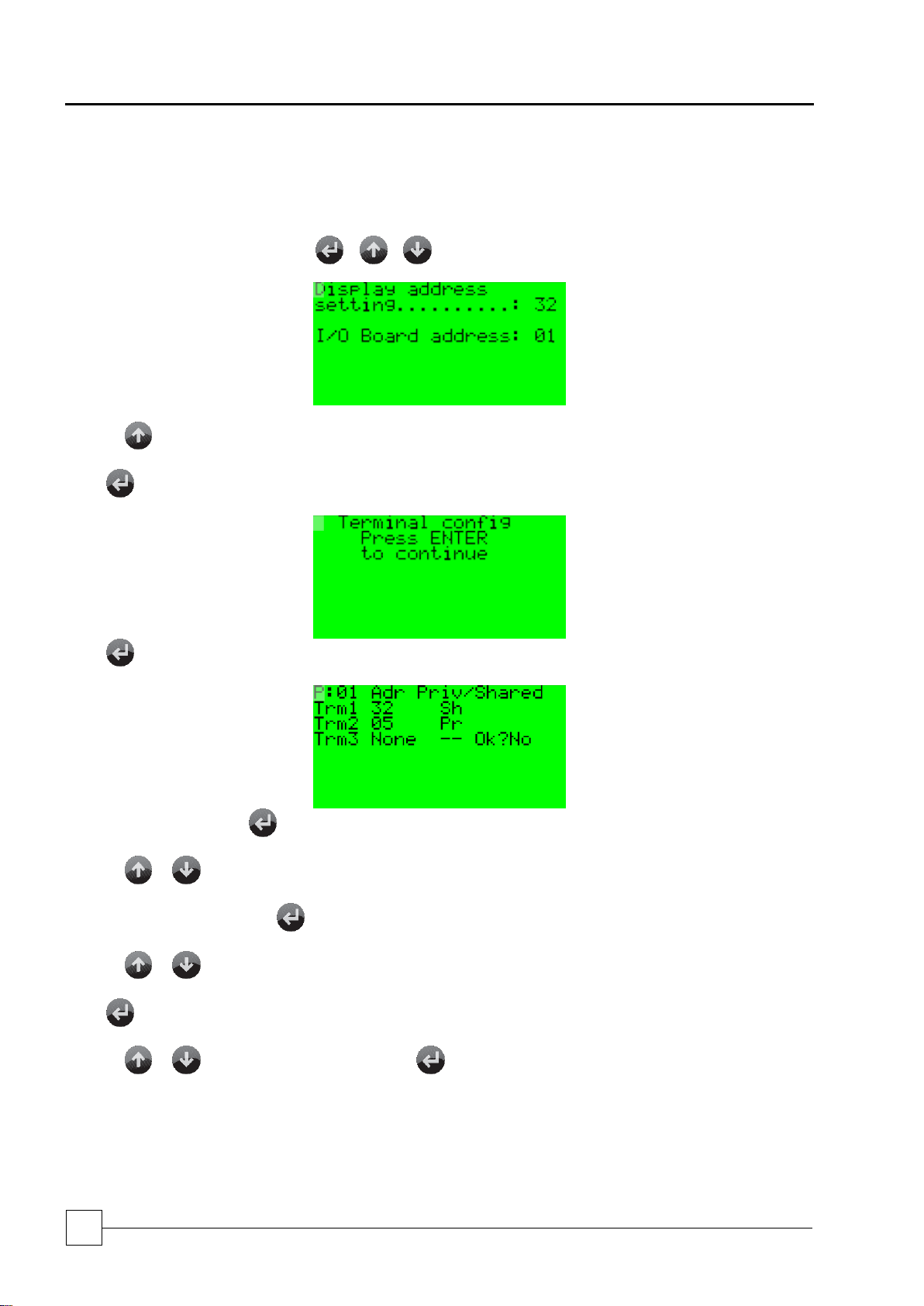

Addressing the Display Keypad ............................................................................................................. 57

Addressing the pCO Controller .............................................................................................................. 58

Remote Display Keypad ........................................................................................................................ 59

Programming the Remote Display Keypad to the Controller ................................................................. 60

Addressing the pCO5 Controller ............................................................................................................ 61

BluCube Operational Icons .................................................................................................................... 62

Compressor ........................................................................................................................................... 62

BluCube™

Condensing Unit

4

Condensing Units

Installation and Maintenance Manual : 7222094 11/2013

Unit Status ............................................................................................................................................. 62

Cooling/Heating Indication ..................................................................................................................... 62

Network Wiring ...................................................................................................................................... 63

Commissioning ........................................................................................... 64

Pre-Start Checks ................................................................................................................................... 64

Control Circuit Checks ........................................................................................................................... 65

Cooling Only & Heat Pump .................................................................................................................... 65

Heat Pump Units .................................................................................................................................... 65

Refrigerant Charging ............................................................................................................................. 66

Adding Oil .............................................................................................................................................. 66

Running Checks .................................................................................................................................... 67

Troubleshooting .......................................................................................... 68

Operational Maintenance Checks .............................................................. 71

Maintenance Schedule .......................................................................................................................... 71

General Inspections ............................................................................................................................... 71

Coil Guard Cleaning .............................................................................................................................. 71

Electrical Inspection ............................................................................................................................... 71

Controls Alarm Log ................................................................................................................................ 71

Condensing Units

BluCube™

Condensing Units

5

Installation and Maintenance Manual 7222094: 11/2013

IMPORTANT

The information contained in this manual is critical to the correct operation and

maintenance of the unit and should be read by all persons responsible for the

installation, commissioning and maintenance of this Airedale unit.

Safety

The equipment has been designed and manufactured to meet international safety

standards but, like any mechanical/electrical equipment, care must be taken if you are to

obtain the best results.

CAUTION

1 Installation, service and maintenance of Airedale equipment should only be carried

out by technically trained competent personnel.

CAUTION

2 When working with any air conditioning units ensure that the electrical isolator is

switched off prior to servicing or repair work and that there is no power to any part of

the equipment.

3 Also ensure that there are no other power feeds to the unit such as fire alarm

circuits, BMS circuits etc.

4 Electrical installation commissioning and maintenance work on this equipment

should be undertaken by competent and trained personnel in accordance with local

relevant standards and codes of practice.

5 The refrigerant used in this range of products is classified under the COSHH

regulations as an irritant, with set Workplace Exposure Levels (WEL) for

consideration if this plant is installed in confined or poorly ventilated areas.

6 A full hazard data sheet in accordance with COSHH regulations is available should

this be required.

Protective Personal

Equipment

Airedale recommends that personal protective equipment is used whilst installing,

maintaining and commissioning equipment.

Refrigerant Warning

The Airedale BluCube uses R410A refrigerant which is a high pressure refrigerant. It

requires careful attention to proper storage and handling procedures.

Use only manifold gauge sets designed for use with R410A refrigerant. Use only

refrigerant recovery units and cylinders designed for high pressure refrigerants.

R410A must only be charged in the liquid state to ensure correct blend makeup.

The refrigerant must be stored in a clean, dry area away from sunlight. The refrigerant

must never be stored above 50°C.

Manual Handling

Some operations when servicing or maintaining the unit may require additional

assistance with regard to manual handling. This requirement is down to the discretion of

the engineer. Remember do not perform a lift that exceeds your ability.

Health and Safety

BluCube™

Condensing Unit

6

Condensing Units

Installation and Maintenance Manual : 7222094 11/2013

Environmental

Policy

It is our policy to:

Take a proactive approach to resolve environmental issues and ensure

compliance with regulatory requirements.

Train personnel in sound environmental practices.

Pursue opportunities to conserve resources, prevent pollution and eliminate

waste.

Manufacture products in a responsible manner with minimum impact on the

environment.

Reduce our use of chemicals and minimise their release to the environment.

Measure, control and verify environmental performance through internal and

external audits.

Continually improve our environmental performance.

CE Directive

Airedale certify that the equipment detailed in this manual conforms with the following

EC Directives:

Electromagnetic Compatibility Directive (EMC)

2004/108/EC

Low Voltage Directive (LVD)

2006/95/EC

Machinery Directive (MD)

89/392/EEC version 2006/42/EC

Pressure Equipment Directive (PED)

97/23/EC

To comply with these directives appropriate national & harmonised standards have been

applied. These are listed on the Declaration of Conformity, supplied with each product.

Environmental Considerations

Condensing Units

BluCube™

Condensing Units

7

Installation and Maintenance Manual 7222094: 11/2013

CUR

092 V 25 - V CO - 0

R410A Condensing Units

Case size

092 - 920mm Case

122 - 1220mm Case

Airflow Configuration

V - Vertical Airflow

Nominal Capacity (kW)

@ 7°C evaporating & 35°C ambient

Compressor type

1 - Fixed Capacity Compressor

V - Variable Capacity Compressor

Mode of operation

CO - Cooling Only

HP - Heat Pump

Power supply

0 - 400V/3~/50Hz

Introduction

The BluCube is Airedale’s high efficiency R410A condensing unit with heat pump variant that can be

universally matched with a variety of industry standard air handling units.

Its latest technology features include EC fans, variable capacity control and modulating head

pressure control.

Benefiting from an extremely compact and modular design, the BluCube will fit into a standard lift.

The BluCube’s small footprint ensures minimal space claim on rooftops or in plant rooms.

Capacity range from

Cooling Only Unit

14 to 43kW (EER 2.9 to 3.4)

Heat Pump units

Cooling Mode

14 to 44kW (EER 2.6 to 3.4)

Heating Mode

14 to 40kW (EER 2.5 to 2.7)

General Specification

Nomenclature

BluCube™

Condensing Unit

8

Condensing Units

Installation and Maintenance Manual : 7222094 11/2013

Model No.

Nominal Cooling

Capacity (kW)

Nominal Unit Input

Power (kW)

EER

Dimensions

(H x W x L) mm

CUR092V16-1CO-0

13.8

4.1

3.37

1750 x 764 x 922

CUR092V20-1CO-0

20.3

6.2

3.26

1750 x 764 x 922

CUR092V25-1CO-0

26.0

8.4

3.10

1750 x 764 x 922

CUR092V29-1CO-0

28.6

9.5

3.01

1750 x 764 x 922

CUR122V35-1CO-0

38.8

12.5

3.10

1750 x 764 x 1222

CUR122V40-1CO-0

43.4

14.5

3.00

1750 x 764 x 1222

CUR092V16-VCO-0

15.6

4.5

3.48

1750 x 764 x 922

CUR092V20-VCO-0

20.3

6.2

3.27

1750 x 764 x 922

CUR092V25-VCO-0

24.8

7.6

3.26

1750 x 764 x 922

CUR092V29-VCO-0

28.4

9.2

3.08

1750 x 764 x 922

CUR122V35-VCO-0

37.1

12.0

3.09

1750 x 764 x 1222

CUR122V40-VCO-0

42.6

14.3

2.98

1750 x 764 x 1222

Model No.

Nominal Cooling

Capacity (kW)

Nominal Unit Input

Power (kW)

EER

Nominal

Heating

Capacity (kW)

Nominal Unit Input

Power (kW)

EER

Dimensions

(H x W x L) mm

CUR092V16-1HP-0

14.6

4.4

3.32

13.7

5.1

2.69

1750 x 764 x 922

CUR092V20-1HP-0

21.1

6.7

3.15

19.4

7.2

2.69

1750 x 764 x 922

CUR092V25-1HP-0

26.5

9.3

2.85

24.2

9.1

2.66

1750 x 764 x 922

CUR092V29-1HP-0

28.7

10.6

2.71

26.4

10.2

2.59

1750 x 764 x 922

CUR122V35-1HP-0

39.7

13.7

2.90

35.5

14.3

2.48

1750 x 764 x 1222

CUR122V40-1HP-0

44.1

15.9

2.77

39.2

15.6

2.51

1750 x 764 x 1222

CUR092V16-VHP-0

16.4

4.9

3.35

15.0

5.5

2.73

1750 x 764 x 922

CUR092V20-VHP-0

21.0

6.8

3.09

19.4

7.2

2.69

1750 x 764 x 922

CUR092V25-VHP-0

25.3

8.4

3.01

23.2

8.8

2.64

1750 x 764 x 922

CUR092V29-VHP-0

28.4

10.4

2.73

26.5

10.3

2.57

1750 x 764 x 922

CUR122V35-VHP-0

38.1

13.1

2.91

34.4

13.6

2.53

1750 x 764 x 1222

CUR122V40-VHP-0

43.5

15.7

2.77

40.0

15.7

2.55

1750 x 764 x 1222

In cooling, 7°C evaporating, 35°C ambient (standard AC axial fan at maximum speed)

In heating, 50°C condensing, 5°C ambient (standard AC axial fan at maximum speed)

Input power includes compressor and fan

Capacity Range Cooling Only Unit

Capacity Range Heat Pump Unit

Condensing Units

BluCube™

Condensing Units

9

Installation and Maintenance Manual 7222094: 11/2013

Lifting

Whenever a condensing unit is lifted, it should be from the base and, where possible, with

all packing and protection in position. If slings are used care should be taken to ensure

that the slings do not crush the casework or coil. The slings are to be located into the

recess within the unit frame to ensure safe lifting.

Due note should also be made of the fact that the compressor is at one end of the unit,

and therefore the centre of gravity will also be towards that end.

If the unit is dropped, it should immediately be checked for damage.

Employ lifting specialists

Local codes and regulations relating to the lifting of this type of equipment should

be observed

Use the appropriate spreader bars/lifting slings with the holes/lugs provided

Chains/slings MUST NOT interfere with the casing of fan assembly to avoid damage

Lift the unit slowly and evenly

IMPORTANT

If the unit is dropped, it should immediately be checked for damage and reported

to Airedale.

CAUTION

Only use lifting points provided.

Ensure drip tray is removed before lifting (Heat Pump units only)

Cut-out size ???mm x ???mm

Minimum lifting chain

length of 1500mm

Sling Length 4500mm

Installation Data

BluCube™

Condensing Unit

10

Condensing Units

Installation and Maintenance Manual : 7222094 11/2013

Positioning

The installation position should be selected with the following points in mind:

Position on a stable and even base, levelled to ensure that the compressor

operates correctly.

Levelling should be to +/- 5mm.

Where vibration transmission to the building structure is possible, fit pad anti-

vibration mounts.

Observe airflow and maintenance clearances.

Pipework and electrical connections are readily accessible.

Where multiple units are installed, due care should be taken to avoid the

discharge air from each unit adversely affecting other units in the vicinity.

Within a side enclosed installation, the fan MUST be higher than the

enclosing structure.

Ensure there are no obstructions directly above the fans.

Allow free space above the fans to prevent air recirculation.

CAUTION

Prior to connecting services, ensure that the equipment is installed and

completely level.

REAR

092 Models

LEFT

RIGHT

(1) Airflow clearance minimum 300 (mm),

(2) Maintenance clearance minimum:

Single unit minimum 750mm

FRONT

REAR

122 Models

LEFT

RIGHT

(1) Airflow clearance minimum 300 (mm),

(2) Maintenance clearance minimum:

Single unit minimum 750mm

FRONT

Condensing Units

BluCube™

Condensing Units

11

Installation and Maintenance Manual 7222094: 11/2013

092 Models

AC Fans

EC Fans

X

mm

123.5

137.2

Dimensional Data

BluCube™

Condensing Unit

12

Condensing Units

Installation and Maintenance Manual : 7222094 11/2013

Condensing Units

BluCube™

Condensing Units

13

Installation and Maintenance Manual 7222094: 11/2013

092 Short Case Axial Fan

BluCube™

Condensing Unit

14

Condensing Units

Installation and Maintenance Manual : 7222094 11/2013

SCAF Fans

X

mm

140.2

Y

mm

8 Hole 11.5mm diameter 605mm PCD

Condensing Units

BluCube™

Condensing Units

15

Installation and Maintenance Manual 7222094: 11/2013

122 Models

BluCube™

Condensing Unit

16

Condensing Units

Installation and Maintenance Manual : 7222094 11/2013

AC Fans

EC Fans

X

mm

123.5

137.2

Condensing Units

BluCube™

Condensing Units

17

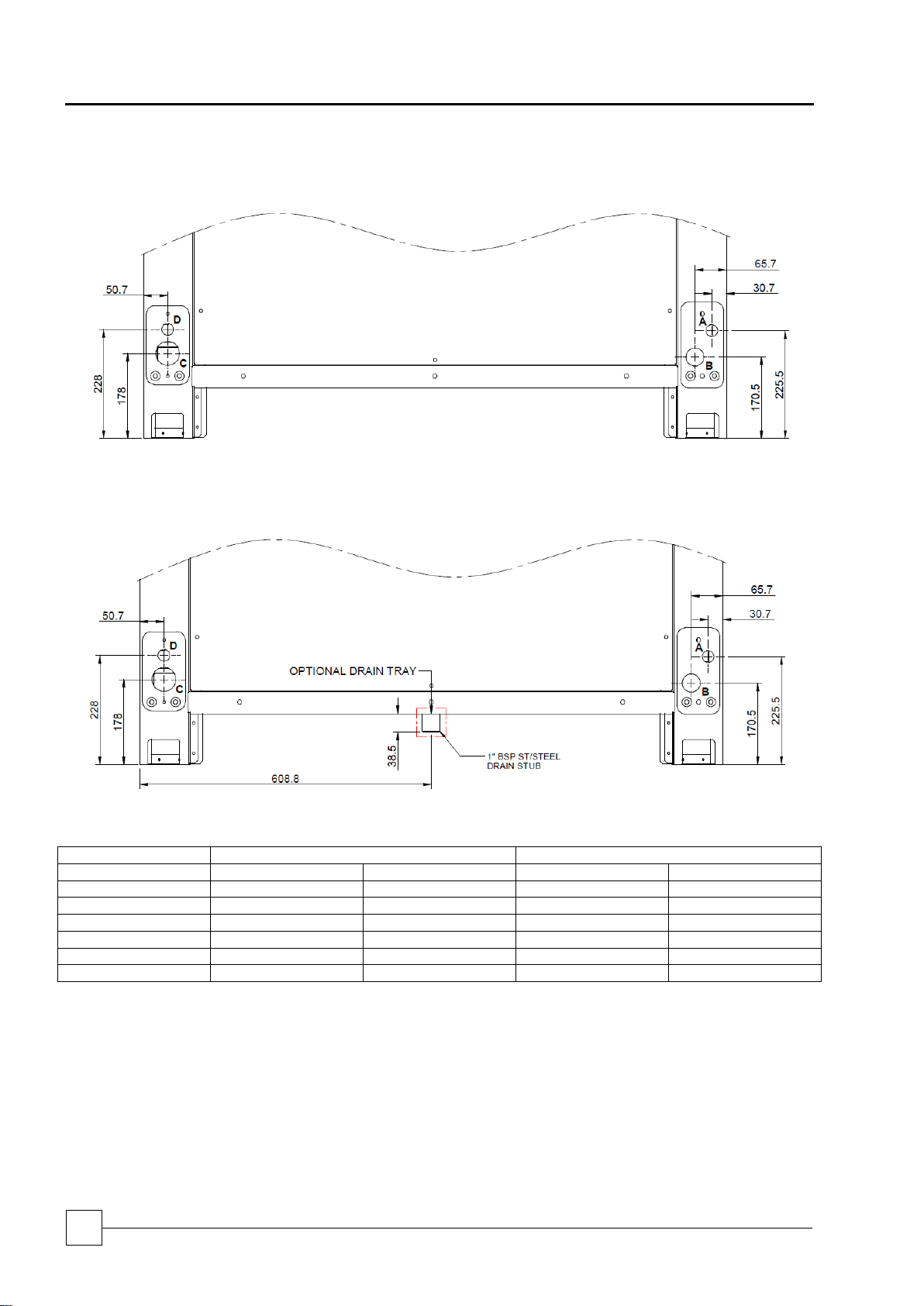

Installation and Maintenance Manual 7222094: 11/2013

Wiring Access Holes (mm)

Pipe Work Hole Sizes (mm)

Cooling Only A B C D

CUR092V16

25

38

50

25

CUR092V20

25

38

50

25

CUR092V25

25

38

50

25

CUR092V29

25

38

50

25

Heat Pump

CUR092V16

25

38

38

25

CUR092V20

25

38

38

25

CUR092V25

25

38

38

25

CUR092V29

25

38

38

25

Incoming Services

Cooling only 092

Heat Pump 092

BluCube™

Condensing Unit

18

Condensing Units

Installation and Maintenance Manual : 7222094 11/2013

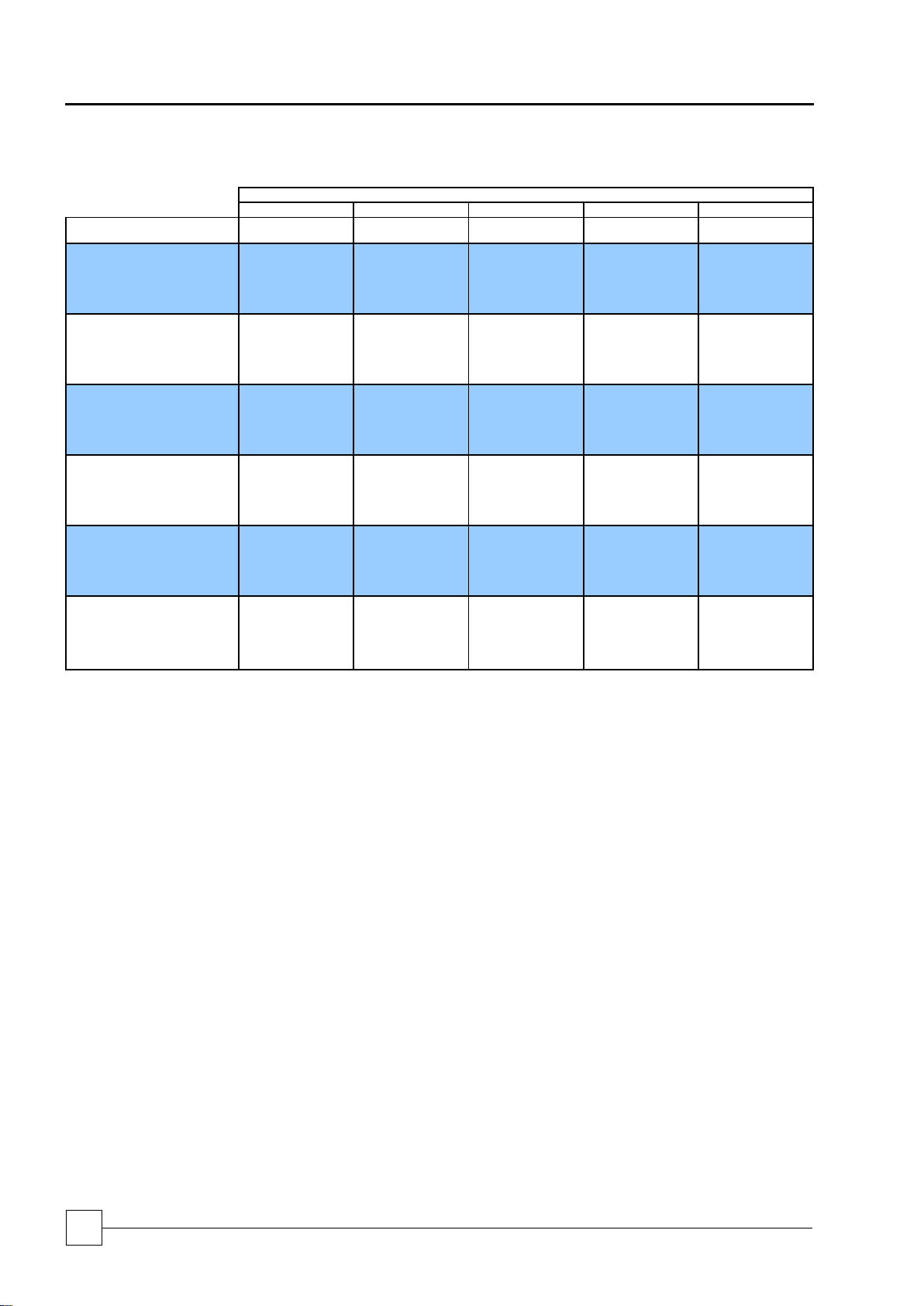

Wiring Access Holes (mm)

Pipe Work Hole Sizes (mm)

Cooling Only A B C D

CUR122V35

25

38

50

25

CUR122V40

25

38

50

25

Heat Pump

CUR122V35

25

38

50

25

CUR122V40

25

38

50

25

Cooling Only 122

Heat Pump 122

Condensing Units

BluCube™

Condensing Units

19

Installation and Maintenance Manual 7222094: 11/2013

Refrigeration Information

Pipework Installation

General

Special consideration should be given to vertical pipe runs and heat pump installation.

When insulating refrigerant lines, cut approximately 30 - 50cm longer than the distance

between the units to ensure the insulation goes right up to the unit. Leave connections

uncovered for leak testing.

Remove burrs to the ends of the copper tube, holding the tube downward to avoid

allowing dirt to contaminate the tube.

The installation of a sight glass close to the indoor unit is recommended.

Pressure Testing

When installation is complete, the system should be pressure tested.

Fill the system with dry nitrogen to a pressure of between 17 bar/250psig and 34bar/

500 psig.

NOTE: The LP switch must be disconnected for pressures above 17bar/250 psig.

Record the pressure over a minimum of 60 minutes to detect major leaks (a 24 hour

period should preferably be allowed).

If a reduction in pressure is detected, trace the leak and repair before conducting a further

pressure test and charging.

Evacuation

Evacuation for systems operating with R410A refrigerant to be carried out as follows.

Use a high vacuum pump and connect to the high and low pressure sides of the system

via a gauge manifold fitted with compound gauges. A high vacuum gauge should be fitted

to the system at the furthest point from the vacuum pump.

Triple evacuation should be used to ensure that all contaminants are removed.

Operate the vacuum pump until a pressure of 1.5 torr (200 Pa) absolute pressure is

reached, then stop the vacuum pump to break the vacuum using Nitrogen (Oxygen free)

until the pressure rises above zero.

The above operation should be repeated a second time.

The system should then be evacuated a third time but this time to 0.5 torr absolute

pressure.

Break with the correct refrigerant, until pressures equalise between the charging bottle

and the system.

IMPORTANT

Ensure all valves within the system are open during pressure testing / evacuation.

BluCube™

Condensing Unit

20

Condensing Units

Installation and Maintenance Manual : 7222094 11/2013

Refrigeration Pipework Installation - Good Practices

Oil Traps

For long vertical rises in both suction and discharge lines, it is essential that oil traps are

located every 4m to ensure proper oil movement / entrapment. In addition there should

be an oil trap at the exit of the air handling unit before a vertical riser is applied (refer to

example below).

Pipe Supports

The following table identifies the maximum

distance between pipe supports on vertical

and horizontal pipe runs.

Pipe O/D (inches)

Support distance (m)

3/8 - 7/8

1.0

1 1/8 - 2 1/8

2.0

CAUTION

All pipework should be clamped prior to insulation being applied (Suction Line).

Clamping over insulation is not acceptable.

Horizontal Sections

It is good practice to ensure a slight gradient toward the compressor in the direction of

the refrigerant flow for suction lines running horizontal. This assists oil return to the

compressor. A gradient of approximately 1:200 (0.5%) shall be used.

Condensing Unit Above Air Handling Unit

Condensing Unit Below Air Handling Unit

- - - - -Suction Line ……….. Liquid

Note the diagram above is for illustration only.

IMPORTANT

The pipe sizes and refrigerant charges quoted are for guidance only. It is the responsibility of the installing

contractor/site engineer to check the pipe size/refrigerant charge is correct for each system installation

and application.

Split systems may require additional oil which should be added to the low pressure side of each compressor.

Design should be in accordance with accepted refrigeration practice to ensure good oil return to the

compressor(s) under all normal operating conditions.

REMEMBER excessive pressure loss in interconnecting pipework will impair system performance; this should

be factored in during the design of the system and where necessary oil traps employed.

Traps are required every

4m of vertical rise.

Installation Data

Condensing Units

BluCube™

Condensing Units

21

Installation and Maintenance Manual 7222094: 11/2013

Pipework Schematics

Cooling Only – Fixed Capacity

BluCube™

Condensing Unit

22

Condensing Units

Installation and Maintenance Manual : 7222094 11/2013

Pipework Schematics

Cooling Only – Digital Scroll

Condensing Units

BluCube™

Condensing Units

23

Installation and Maintenance Manual 7222094: 11/2013

Pipework Schematics

Heat Pump

BluCube™

Condensing Unit

24

Condensing Units

Installation and Maintenance Manual : 7222094 11/2013

Pipework Schematics

Heat Pump

Condensing Units

BluCube™

Condensing Units

25

Installation and Maintenance Manual 7222094: 11/2013

Pipework Schematics

Heat Pump

BluCube™

Condensing Unit

26

Condensing Units

Installation and Maintenance Manual : 7222094 11/2013

Equivalent Pipe Lengths with R410A

Outdoor

Unit

0-20m

Suction

20-40m

Suction

40-60m

Suction

60-80m

Suction

Connection Size

Liquid

Suction

Liquid H V

Liquid H V

Liquid H V

Liquid H V

(3)

(1)

(2)

(3)

(1)

(2)

(3)

(1)

(2)

(3)

(1)

(2)

CUR092V16-1CO-0

3/8

7/8

1/2

1 1/8

7/8

1/2

1 1/8

7/8

1/2

1 1/8

7/8

1/2

1 1/8

7/8

CUR092V20-1CO-0

1/2

1 1/8

1/2

1 3/8

7/8

5/8

1 3/8

1 1/8

5/8

1 3/8

1 1/8

5/8

1 3/8

1 1/8

CUR092V25-1CO-0

1/2

1 3/8

1/2

1 3/8

1 1/8

5/8

1 3/8

1 1/8

5/8

1 3/8

1 1/8

5/8

1 3/8

1 1/8

CUR092V29-1CO-0

1/2

1 3/8

5/8

1 5/8

1 3/8

5/8

1 5/8

1 3/8

3/4

1 5/8

1 3/8

3/4

1 5/8

1 3/8

CUR122V35-1CO-0

5/8

1 3/8

3/4

1 5/8

1 3/8

3/4

1 5/8

1 3/8

3/4

1 5/8

1 5/8

3/4

1 5/8

1 5/8

CUR122V40-1CO-0

5/8

1 5/8

3/4

1 5/8

1 5/8

3/4

1 5/8

1 5/8

3/4

1 5/8

1 5/8

3/4

1 5/8

1 5/8

CUR092V16-VCO-0

3/8

7/8

1/2

1 1/8

7/8

1/2

1 1/8

7/8

1/2

1 1/8

7/8

1/2

1 1/8

7/8

CUR092V20-VCO-0

1/2

1 1/8

1/2

1 3/8

1 1/8

1/2

1 3/8

1 1/8

5/8

1 3/8

1 1/8

5/8

1 3/8

1 1/8

CUR092V25-VCO-0

1/2

1 3/8

1/2

1 3/8

1 1/8

5/8

1 3/8

1 1/8

5/8

1 3/8

1 1/8

5/8

1 3/8

1 1/8

CUR092V29-VCO-0

1/2

1 3/8

5/8

1 5/8

1 3/8

5/8

1 5/8

1 3/8

5/8

1 5/8

1 3/8

5/8

1 5/8

1 3/8

CUR122V35-VCO-0

5/8

1 3/8

3/4

1 5/8

1 3/8

3/4

1 5/8

1 3/8

3/4

1 5/8

1 3/8

3/4

1 5/8

1 3/8

CUR122V40-VCO-0

5/8

1 5/8

3/4

1 5/8

1 5/8

3/4

1 5/8

1 5/8

3/4

1 5/8

1 5/8

7/8

1 5/8

1 5/8

Equivalent Pipe Lengths with R410A

Outdoor

Unit

Connection Size

0-

20m Suction /

Disch

20-

40m

Suction /

Disch

40-

60m

Suction /

Disch

60-

80m

Suction /

Disch

Liquid

Suction

Disch

Liq

H V Liquid H V

Liquid H V

Liquid H V

(3)

(1)

(2)

(3)

(1)

(2)

(3)

(1)

(2)

(3)

(1)

(2)

CUR092V16-1HP-

3/8

1/2

1/2

3/4

1/2

1/2

3/4

5/8

1/2

3/4

5/8

1/2

3/4

5/8

CUR092V20-1HP-

3/8

5/8

1/2

7/8

5/8

5/8

7/8

5/8

5/8

7/8

5/8

5/8

7/8

5/8

CUR092V25-1HP-

1/2

7/8

1/2

1 1/8

5/8

5/8

1 1/8

3/4

5/8

1 1/8

3/4

5/8

1 1/8

3/4

CUR092V29-1HP-

1/2

7/8

5/8

1 1/8

3/4

5/8

1 1/8

3/4

3/4

1 1/8

3/4

3/4

1 1/8

3/4

CUR122V35-1HP-

1/2

7/8

3/4

1 3/8

7/8

3/4

1 3/8

7/8

3/4

1 3/8

7/8

3/4

1 3/8

7/8

CUR122V40-1HP-

5/8

1 1/8

3/4

1 3/8

7/8

3/4

1 3/8

7/8

3/4

1 3/8

7/8

3/4

1 3/8

7/8

CUR092V16-VHP-

3/8

1/2

1/2

7/8

1/2

1/2

7/8

1/2

1/2

7/8

1/2

1/2

7/8

1/2

CUR092V20-VHP-

3/8

5/8

1/2

7/8

5/8

1/2

7/8

5/8

5/8

7/8

5/8

5/8

7/8

5/8

CUR092V25-VHP-

1/2

7/8

1/2

1 1/8

5/8

5/8

1 1/8

5/8

5/8

1 1/8

5/8

5/8

1 1/8

5/8

CUR092V29-VHP-

1/2

7/8

5/8

1 1/8

3/4

5/8

1 1/8

3/4

5/8

1 1/8

3/4

5/8

1 1/8

3/4

CUR122V35-VHP-

1/2

7/8

3/4

1 3/8

3/4

3/4

1 3/8

3/4

3/4

1 3/8

3/4

3/4

1 3/8

3/4

CUR122V40-VHP-

5/8

1 1/8

3/4

1 3/8

7/8

3/4

1 3/8

7/8

3/4

1 3/8

7/8

7/8

1 3/8

7/8 (1) For interconnecting pipework with a predominantly horizontal layout.

(2) For interconnecting pipework with a predominantly vertical layout.

(3) Careful pipework selection must be done if the liquid line rises. Additional system sub cooling may be required to overcome friction losses.

All pipe sizes have been calculated based on a nominal condition 7°C evaporating and 50°C condensing

Suction and discharge double risers may be required for modulating capacity units at part load.

Refrigeration Pipe Sizing Guide

Cooling Only

Heat Pump

Condensing Units

BluCube™

Condensing Units

27

Installation and Maintenance Manual 7222094: 11/2013

Typical Cooling Application Envelope

12, -20

12, 42

15, 45

28, 45

28, -20

-30

-20

-10

0

10

20

30

40

50

0 5 10 15 20 25 30

Return Air Temperature (°C)

Ambient Temperature (°C)

Operating Limits - Cooling Only

3, 48

15, -20

15, 48

-23, 23

-23, -20

-30

-20

-10

0

10

20

30

40

50

60

-25 -20 -15 -10 -5 0 5 10 15 20

Evaporating temperature (°C)

Ambient temperature (°C)

Technical Data Cooling Only

Operational Limits

Data based upon a 12°C T across the indoor heat exchanger.

BluCube™

Condensing Unit

28

Condensing Units

Installation and Maintenance Manual : 7222094 11/2013

Ambient (°C)

25

30

35

40

45

Unit

TEvap

(°C)

Output

(kW)

Input

(kW)

Output

(kW)

Input

(kW)

Output

(kW)

Input

(kW)

Output

(kW)

Input

(kW)

Output

(kW)

Input

(kW)

CUR092V16-1CO-0

-5

9.6

3.8

9.6

3.8

9.2

4.0

8.6

4.4

8.0

4.8 0 11.5

3.8

11.5

3.8

11.0

4.0

10.3

4.4

9.6

4.9 5 13.8

3.8

13.7

3.7

13.0

4.1

12.2

4.5

11.5

4.9 7 14.8

3.8

14.7

3.7

13.8

4.1

13.0

4.5

12.2

4.9

10

16.4

3.8

16.2

3.7

15.2

4.1

14.3

4.5

13.5

5.0

CUR092V20-1CO-0

-5

14.7

5.5

14.5

5.5

13.7

5.9

12.7

6.4

11.7

6.9 0 17.6

5.4

17.2

5.6

16.2

6.0

15.2

6.5

14.1

7.0 5 21.1

5.3

20.2

5.6

19.1

6.1

17.9

6.6

16.8

7.2 7 22.6

5.3

21.5

5.7

20.3

6.2

19.1

6.7

17.9

7.2

10

25.0

5.3

23.6

5.7

22.2

6.2

20.9

6.7

19.6

7.3

CUR092V25-1CO-0

-5

19.2

6.8

18.6

7.1

17.5

7.7

16.4

8.4

N/A

N/A 0 23.2

6.9

22.1

7.4

20.9

8.0

19.5

8.7

18.0

9.5 5 27.6

7.1

26.1

7.7

24.5

8.3

22.8

9.0

21.0

9.8 7 29.4

7.2

27.7

7.8

26.0

8.4

24.2

9.1

22.3

9.9

10

32.1

7.5

30.3

8.0

28.4

8.7

26.5

9.3

24.3

10.1

CUR092V29-1CO-0

-5

21.8

7.5

20.7

8.0

19.3

8.7

17.9

9.5

N/A

N/A 0 26.1

7.6

24.5

8.3

22.9

9.0

21.2

9.9

19.4

10.8 5 30.6

8.0

28.8

8.6

26.9

9.4

24.9

10.2

22.8

11.1 7 32.5

8.1

30.6

8.8

28.6

9.5

26.5

10.4

24.3

11.3

10

35.4

8.3

33.4

9.0

31.2

9.8

28.9

10.6

26.5

11.5

CUR122V35-1CO-0

-5

28.5

9.4

27.9

12.0

26.1

13.0

24.2

14.1

22.2

15.3 0 34.3

9.8

33.1

12.3

31.0

13.3

28.8

14.4

26.4

15.6 5 41.0

11.2

38.9

12.7

36.5

13.6

33.9

14.7

31.1

15.9 7 43.7

11.9

41.3

12.8

38.8

13.8

36.1

14.8

33.1

16.1

10

47.8

12.2

45.2

13.0

42.4

14.0

39.5

15.1

36.3

16.3

CUR122V40-1CO-0

-5

32.7

11.0

31.6

13.6

29.6

14.5

27.6

15.6

N/A

N/A 0 39.3

12.5

37.3

14.0

35.0

15.0

32.6

16.1

30.0

17.3 5 46.2

13.6

43.6

14.5

40.9

15.5

38.1

16.6

35.0

17.9 7 49.0

13.8

46.3

14.8

43.4

15.7

40.4

16.9

37.2

18.1

10

53.5

14.2

50.5

15.1

47.4

16.1

44.1

17.2

40.6

18.5

Cooling Only Fixed Capacities

Notes:

1 Output kW refers to the compressor duty.

2 Input kW refers to the compressor and fan input power only.

Condensing Units

BluCube™

Condensing Units

29

Installation and Maintenance Manual 7222094: 11/2013

Ambient (°C)

25

30

35

40

45

Unit

TEvap

(°C)

Output

(kW)

Input

(kW)

Output

(kW)

Input

(kW)

Output

(kW)

Input

(kW)

Output

(kW)

Input

(kW)

Output

(kW)

Input

(kW)

CUR092V16-VCO-0

-5

10.9

4.0

10.9

4.1

10.4

4.2

9.7

4.7

9.0

5.1

0

13.1

4.1

13.1

4.1

12.4

4.4

11.6

4.8

10.7

5.2 5 15.7

4.2

15.6

4.1

14.7

4.5

13.7

4.9

12.7

5.4 7 16.8

4.2

16.6

4.1

15.6

4.5

14.6

5.0

13.5

5.5

10

18.6

4.2

18.3

4.2

17.2

4.6

16.0

5.1

14.8

5.6

CUR092V20-VCO-0

-5

14.9

5.3

14.8

5.2

13.9

5.8

12.9

6.3

12.0

6.9

0

17.8

5.4

17.4

5.4

16.4

5.9

15.3

6.5

14.1

7.1

5

21.1

5.4

20.3

5.6

19.1

6.1

17.8

6.7

16.5

7.4 7 22.5

5.4

21.6

5.7

20.3

6.2

18.9

6.8

17.5

7.5

10

24.7

5.4

23.5

5.8

22.1

6.4

20.6

7.0

19.1

7.6

CUR092V25-VCO-0

-5

18.5

6.2

18.0

6.4

16.9

7.1

15.6

7.9

N/A

N/A 0 22.2

6.2

21.3

6.6

20.0

7.2

18.6

8.0

17.1

8.9

5

26.3

6.2

24.9

6.8

23.4

7.5

21.8

8.2

20.0

9.1

7

28.0

6.3

26.4

6.9

24.8

7.6

23.1

8.3

21.3

9.1

10

30.5

6.5

28.7

7.1

27.0

7.7

25.1

8.5

23.2

9.3

CUR092V29-VCO-0

-5

21.9

7.2

20.8

7.7

19.4

8.6

17.8

9.6

N/A

N/A 0 26.1

7.2

24.6

8.0

22.9

8.8

21.1

9.8

19.2

10.9 5 30.4

7.5

28.7

8.2

26.8

9.1

24.7

10.0

22.5

11.1

7

32.3

7.6

30.4

8.3

28.4

9.2

26.2

10.1

23.9

11.2

10

35.1

7.8

33.1

8.5

30.9

9.4

28.5

10.3

26.0

11.4

CUR122V35-VCO-0

-5

27.5

9.0

27.0

11.5

25.5

12.4

23.8

13.4

21.9

14.6 0 32.8

9.2

31.9

11.8

30.0

12.7

28.0

13.7

25.8

14.9 5 39.0

10.2

37.2

12.2

35.0

13.1

32.6

14.1

30.0

15.2 7 41.7

11.1

39.5

12.3

37.1

13.2

34.5

14.2

31.8

15.4

10

45.7

11.7

43.1

12.6

40.5

13.5

37.6

14.5

34.6

15.6

CUR122V40-VCO-0

-5

32.9

10.9

31.9

13.5

30.2

14.5

28.3

15.7

N/A

N/A 0 38.8

12.1

37.1

13.9

35.0

14.9

32.8

16.1

30.4

17.4 5 45.2

13.4

42.8

14.3

40.3

15.4

37.7

16.5

34.8

17.8 7 47.9

13.5

45.3

14.5

42.6

15.5

39.8

16.7

36.7

18.0

10

52.1

13.8

49.2

14.8

46.2

15.8

43.0

17.0

39.7

18.3

Cooling Only Modulating Capacities

Notes:

1 Output kW refers to the compressor duty.

2 Input kW refers to the compressor and fan input power only.

BluCube™

Condensing Unit

30

Condensing Units

Installation and Maintenance Manual : 7222094 11/2013

CUR092V16-1CO-0

CUR092V20-1CO-0

CUR092V25-1CO-0

Capacity

Nominal Cooling Capacity

(1)

kW

13.8

20.3

26.0

Capacity Steps

1 1 1

Dimensions – W x D x H

(2)

mm

922 x 764 x 1736

922 x 764 x 1736

922 x 764 x 1736

Masses – Machine / Operating

(3)

kg

212

213

241

Construction

Panels: Galvanised Sheet Steel, Epoxy Baked Powder Paint – Light Grey (RAL 7035)

Material/Colour

Condenser

Rifled Copper Tube/Louvered Hydrophilic Coated Aluminium Fins

Fan Motor

Axial

Motor Type

AC 1ph

AC 1ph

AC 1ph

Quantity x Motor Size

kW

1 x 0.6

1 x 0.6

1 x 0.6

Diameter

mm

630

630

630

Maximum Fan Speed

RPM

860

860

860

Maximum Airflow

m³/s

2.0

2.0

2.0

Compressor

Compressor Type

Fixed Capacity Scroll

Quantity

1 1 1

Oil Charge Volume

l

1.57

1.57

3.3

Oil Type

Polyolester

Refrigeration

Single Circuit - 2 pipe configuration

Refrigerant control and type

Optional REEV package

Refrigerant type

R410A

Holding Charge

Inert Gas

Coil Volume

l

9.9

9.9

9.9

Refrigerant Charge

(4)

kg

5.7

5.8

5.8

Connections

Liquid (sweat)

in

3/8

1/2

1/2

Suction (sweat)

in

7/8

1 1/8

1 3/8

Optional Extras

EC Fan

Quantity x Motor Size

kW

1 x 0.72

1 x 0.72

1 x 0.72

Diameter

mm

630

630

630

Maximum Fan Speed

RPM

1000

1000

1000

Maximum Airflow

m³/s

2.3

2.3

2.3

Dimensions – W x D x H

(2)

mm

922 x 764 x 1750

922 x 764 x 1750

922 x 764 x 1750

Masses – Machine / Operating

(3)

kg

204

205

232

Short Case Axial Fan

Designed to 75Pa ESP

Quantity x Motor Size

kW

1 x 1.4

1 x 1.4

1 x 1.4

Diameter

mm

560

560

560

Maximum Fan Speed

RPM

1330

1330

1330

Maximum Airflow

m³/s

2.8

2.8

2.8

Dimensions – W x D x H

(2)

mm

922 x 764 x 1753

922 x 764 x 1753

922 x 764 x 1753

Masses – Machine / Operating

(3)

kg

218

219

247

REEV Selection

E²V -24

E²V – 35

E²V - 35

(1) Evaporating temperature 7°C, Ambient 35°C with an AC fan matched with a REEV package

(2) Overall dimensions for clearance

(3) Unit mass excludes a refrigerant charge

(4) For guidance only

Mechanical Data Cooling Only Fixed Capacities

Condensing Units

BluCube™

Condensing Units

31

Installation and Maintenance Manual 7222094: 11/2013

CUR092V29-1CO-0

CUR122V35-1CO-0

CUR122V40-1CO-0

Capacity

Nominal Cooling Capacity

(1)

kW

28.6

38.8

43.4

Capacity Steps

1 1 1

Dimensions – W x D x H

(2)

mm

922 x 764 x 1736

1222 x 764 x 1736

1222 x 764 x 1736

Masses – Machine / Operating

(3)

kg

241

292

296

Construction

Panels: Galvanised Sheet Steel, Epoxy Baked Powder Paint – Light Grey (RAL 7035)

Material/Colour

Condenser

Rifled Copper Tube/Louvered Hydrophilic Coated Aluminium Fins

Fan Motor

Axial

Motor Type

AC 1ph

AC 3ph

AC 3ph

Quantity x Motor Size

kW

1 x 0.6

1 x 1.97

1 x 1.97

Diameter

mm

630

630

630

Maximum Fan Speed

RPM

860

1330

1330

Maximum Airflow

m³/s

2.0

3.5

3.5

Compressor

Compressor Type

Fixed Capacity Scroll

Quantity

1 1 1

Oil Charge Volume

l

3.3

3.3

3.6

Oil Type

Polyolester

Refrigeration

Single Circuit - 2 pipe configuration

Refrigerant control and type

Optional REEV package

Refrigerant type

R410A

Holding Charge

Inert Gas

Coil Volume

l

9.9

12.4

12.4

Refrigerant Charge

(4)

kg

5.8

7.3

7.4

Connections

Liquid (sweat)

in

1/2

5/8

5/8

Suction (sweat)

in

1 3/8

1 3/8

1 5/8

Optional Extras

EC Fan

Quantity x Motor Size

kW

1 x 0.72

1 x 1.85

1 x 1.85

Diameter

mm

630

630

630

Maximum Fan Speed

RPM

1000

1230

1230

Maximum Airflow

m³/s

2.3

3.5

3.5

Dimensions – W x D x H

(2)

mm

922 x 764 x 1750

1222 x 764 x 1750

1222 x 764 x 1750

Masses – Machine / Operating

(3)

kg

233

284

287

Short Case Axial Fan

Designed to 75Pa ESP

Quantity x Motor Size

kW

1 x 1.4

N/A

N/A

Diameter

mm

560

N/A

N/A

Maximum Fan Speed

RPM

1330

N/A

N/A

Maximum Airflow

m³/s

2.8

N/A

N/A

Dimensions – W x D x H

(2)

mm

922 x 764 x 1753

N/A

N/A

Masses – Machine / Operating

(3)

kg

247

N/A

N/A

REEV Selection

E²V – 35

E²V - 45

E²V - 45

(1) Evaporating temperature 7°C, Ambient 35°C with an AC fan matched with a REEV package

(2) Overall dimensions for clearance

(3) Unit mass excludes a refrigerant charge

(4) For guidance only

Mechanical Data Cooling Only Fixed Capacities Continued

BluCube™

Condensing Unit

32

Condensing Units

Installation and Maintenance Manual : 7222094 11/2013

CUR092V16-VCO-0

CUR092V20-VCO-0

CUR092V25-VCO-0

Capacity

Nominal Cooling Capacity

(1)

kW

15.6

20.3

24.8

Capacity Steps

16-100%

16-100%

16-100%

Dimensions – W x D x H

(2)

mm

922 x 764 x 1736

922 x 764 x 1736

922 x 764 x 1736

Masses – Machine / Operating

(3)

kg

219

220

241

Construction

Panels: Galvanised Sheet Steel, Epoxy Baked Powder Paint – Light Grey (RAL 7035)

Material/Colour

Condenser

Rifled Copper Tube/Louvered Hydrophilic Coated Aluminium Fins

Fan Motor

Axial

Motor Type

AC 1ph

AC 1ph

AC 1ph

Quantity x Motor Size

kW

1 x 0.6

1 x 0.6

1 x 0.6

Diameter

mm

630

630

630

Maximum Fan Speed

RPM

860

860

860

Maximum Airflow

m³/s

2.0

2.0

2.0

Compressor

Compressor Type

Modulating Capacity Scroll

Quantity

1 1 1

Oil Charge Volume

l

1.9

1.9

3.2

Oil Type

Polyolester

Refrigeration

Single Circuit - 2 pipe configuration

Refrigerant control and type

Optional REEV package

Refrigerant type

R410A

Holding Charge

Inert Gas

Coil Volume

l

9.9

9.9

9.9

Refrigerant Charge

(4)

kg

5.7

5.7

5.8

Connections

Liquid (sweat)

in

3/8

1/2

1/2

Suction (sweat)

in

7/8

1 1/8

1 3/8

Optional Extras

EC Fan

Quantity x Motor Size

kW

1 x 0.72

1 x 0.72

1 x 0.72

Diameter

mm

630

630

630

Maximum Fan Speed

RPM

1000

1000

1000

Maximum Airflow

m³/s

2.3

2.3

2.3

Dimensions – W x D x H

(2)

mm

922 x 764 x 1750

922 x 764 x 1750

922 x 764 x 1750

Masses – Machine / Operating

(3)

kg

211

212

233

Short Case Axial Fan

Designed to 75Pa ESP

Quantity x Motor Size

kW

1 x 1.4

1 x 1.4

1 x 1.4

Diameter

mm

560

560

560

Maximum Fan Speed

RPM

1330

1330

1330

Maximum Airflow

m³/s

2.8

2.8

2.8

Dimensions – W x D x H

(2)

mm

922 x 764 x 1753

922 x 764 x 1753

922 x 764 x 1753

Masses – Machine / Operating

(3)

kg

218

219

247

REEV Selection

E²V – 24

E²V - 35

E²V - 35

(1) Evaporating temperature 7°C, Ambient 35°C with an AC fan matched with a REEV package

(2) Overall dimensions for clearance

(3) Unit mass excludes a refrigerant charge

(4) For guidance only

Mechanical Data Cooling Only Modulating Capacities

Condensing Units

BluCube™

Condensing Units

33

Installation and Maintenance Manual 7222094: 11/2013

CUR092V29-VCO-0

CUR122V35-VCO-0

CUR122V40-VCO-0

Capacity

Nominal Cooling Capacity

(1)

kW

28.4

37.1

42.6

Capacity Steps

16-100%

16-100%

16-100%

Dimensions – W x D x H

(2)

mm

922 x 764 x 1736

1222 x 764 x 1736

1222 x 764 x 1736

Masses – Machine / Operating

(3)

kg

243

293

295

Construction

Panels: Galvanised Sheet Steel, Epoxy Baked Powder Paint – Light Grey (RAL 7035)

Material/Colour

Condenser

Rifled Copper Tube/Louvered Hydrophilic Coated Aluminium Fins

Fan Motor

Axial

Motor Type

AC 1ph

AC 3ph

AC 3ph

Quantity x Motor Size

kW

1 x 0.6

1 x 1.97

1 x 1.97

Diameter

mm

630

630

630

Maximum Fan Speed

RPM

860

1330

1330

Maximum Airflow

m³/s

2.0

3.5

3.5

Compressor

Compressor Type

Modulating Capacity Scroll

Quantity

1 1 1

Oil Charge Volume

l

3.2

3.2

3.2

Oil Type

Polyolester

Refrigeration

Single Circuit - 2 pipe configuration

Refrigerant control and type

Optional REEV package

Refrigerant type

R410A

Holding Charge

Inert Gas

Coil Volume

l

9.9

12.4

12.4

Refrigerant Charge

(4)

kg

5.8

7.3

7.4

Connections

Liquid (sweat)

in

1/2

5/8

5/8

Suction (sweat)

in

1 3/8

1 3/8

1 5/8

Optional Extras

EC Fan

Quantity x Motor Size

kW

1 x 0.72

1 x 1.85

1 x 1.85

Diameter

mm

630

630

630

Maximum Fan Speed

RPM

1000

1230

1230

Maximum Airflow

m³/s

2.3

3.5

3.5

Dimensions – W x D x H

(2)

mm

922 x 764 x 1750

1222 x 764 x 1750

1222 x 764 x 1750

Masses – Machine / Operating

(3)

kg

234

285

287

Short Case Axial Fan

Designed to 75Pa ESP

Quantity x Motor Size

kW

1 x 1.4

N/A

N/A

Diameter

mm

560

N/A

N/A

Maximum Fan Speed

RPM

1330

N/A

N/A

Maximum Airflow

m³/s

2.8

N/A

N/A

Dimensions – W x D x H

(2)

mm

922 x 764 x 1753

N/A

N/A

Masses – Machine / Operating

(3)

kg

247

N/A

N/A

REEV Selection

E²V – 35

E²V - 45

E²V - 45

(1) Evaporating temperature 7°C, Ambient 35°C with an AC fan matched with a REEV package

(2) Overall dimensions for clearance

(3) Unit mass excludes a refrigerant charge

(4) For guidance only

Mechanical Data Cooling Only Variable Capacities Continued

BluCube™

Condensing Unit

34

Condensing Units

Installation and Maintenance Manual : 7222094 11/2013

CUR092V16-1CO-0

CUR092V20-1CO-0

CUR092V25-1CO-0

Unit Data

(1)

Nominal Run Amps

A

11.5

16.9

19.4

Maximum Start Amps

A

73.7

103.7

145.7

Recommended Mains Fuse Size

A

20

32

32

Max Mains Incoming Cable Size

mm²

35

35

35

Mains Supply

V

400V / 3PH + N / 50Hz

Control circuit

VAC

24

24

24

Condenser Fan - Motor

Motor Type

AC

AC

AC

1~

1~

1~

Quantity x Motor Size

kW

1 x 0.6

1 x 0.6

1 x 0.6

Full Load Amps

A

2.7

2.7

2.7

Locked Rotor Amps

A

9.2

9.2

9.2

Compressor

Motor Size

kW

4.6

6.4

8.5

Nominal Run Amps

A

7.9

13.3

15.8

Locked Rotor Amps

A

70

100

142

Type of Start

Direct On Line

OPTIONAL EXTRAS

Electronic Soft-start

Nominal Run Amps

A

11.5

16.9

19.4

Maximum Start Amps

A

45.7

63.7

88.9

Recommended Mains Fuse Size

A

16

25

32

Power Factor Correction

Nominal Run Amps

A

11.2

16.5

18.6

Maximum Start Amps

A

73.7

103.7

145.7

Recommended Mains Fuse Size

A

20

32

32

Compressor Nominal Run Amps

A

7.5

12.8

14.9

First upgrade EC Motor

1~

1~

1~

Quantity x Motor Size

kW

1 x 0.72

1 x 0.72

1 x 0.72

Full Load Amps

A

3.3

3.3

3.3

Locked Rotor Amps

A

N/A

N/A

N/A

Second upgrade SCAF

1~

1~

1~

Quantity x Motor Size

kW

1 x 1.4

1 x 1.4

1 x 1.4

Full Load Amps

A

6 6 6

Locked Rotor Amps

A

18

18

18

Electrical Data – Cooling Only

(1) Based upon ARI conditions, Evaporating at 7°C, Condensing at 54.4°C.

Condensing Units

BluCube™

Condensing Units

35

Installation and Maintenance Manual 7222094: 11/2013

CUR092V29-1CO-0

CUR122V35-1CO-0

CUR122V40-1CO-0

Unit Data

(1)

Nominal Run Amps

A

20.6

25.1

29

Maximum Start Amps

A

145.7

162.4

201.4

Recommended Mains Fuse Size

A

32

40

50

Max Mains Incoming Cable Size

mm²

35

35

35

Mains Supply

V

400V / 3PH + N / 50Hz

Control circuit

VAC

24

24

24

Condenser Fan - Motor

Motor Type

AC

AC

AC

1~

3~

3~

Quantity x Motor Size

kW

1 x 0.6

1 x 1.97

1 x 1.97

Full Load Amps

A

2.7

3.4

3.4

Locked Rotor Amps

A

9.2

11.9

11.9

Compressor

Motor Size

kW

9.5

12.2

13.8

Nominal Run Amps

A

17

20.7

24.6

Locked Rotor Amps

A

142

158

197

Type of Start

Direct On Line

OPTIONAL EXTRAS

Electronic Soft-start

Nominal Run Amps

A

20.6

23.8

27.5

Maximum Start Amps

A

88.9

99.2

122.6

Recommended Mains Fuse Size

A

32

40

50

Power Factor Correction

Nominal Run Amps

A

19.8

23.8

29

Maximum Start Amps

A

145.7

162.4

201.4

Recommended Mains Fuse Size

A

32

40

50

Compressor Nominal Run Amps

A

16.2

19.4

23.1

First upgrade EC Motor

1~

3~

3~

Quantity x Motor Size

kW

1 x 0.72

1 x 1.85

1 x 1.85

Full Load Amps

A

3.3

2.9

2.9

Locked Rotor Amps

A

N/A

N/A

N/A

Second upgrade SCAF

1~

N/A

N/A

Quantity x Motor Size

kW

1 x 1.4

N/A

N/A

Full Load Amps

A

6

N/A

N/A

Locked Rotor Amps

A

18

N/A

N/A

Electrical Data – Cooling Only Continued

(1) Based upon ARI conditions, Evaporating at 7°C, Condensing at 54.4°C.

BluCube™

Condensing Unit

36

Condensing Units

Installation and Maintenance Manual : 7222094 11/2013

CUR092V16-VCO-0

CUR092V20-VCO-0

CUR092V25-VCO-0

Unit Data

(1)

Nominal Run Amps

A

12.2

15.7

18.2

Maximum Start Amps

A

67.7

104.7

114.7

Recommended Mains Fuse Size

A

20

25

25

Max Mains Incoming Cable Size

mm²

35

35

35

Mains Supply

V

400V / 3PH + N / 50Hz

Control circuit

VAC

24

24

24

Condenser Fan - Motor

Motor Type

AC

AC

AC

1~

1~

1~

Quantity x Motor Size

kW

1 x 0.6

1 x 0.6

1 x 0.6

Full Load Amps

A

2.7

2.7

2.7

Locked Rotor Amps

A

9.2

9.2

9.2

Compressor

Motor Size

kW

5 7 8

Nominal Run Amps

A

8.6

12.1

14.5

Locked Rotor Amps

A

64

101

111

Type of Start

Direct On Line

OPTIONAL EXTRAS

Electronic Soft-start

Nominal Run Amps

A

12.2

15.7

18.2

Maximum Start Amps

A

42.1

64.3

70.3

Recommended Mains Fuse Size

A

20

25

32

Power Factor Correction

N/A

N/A

N/A

Nominal Run Amps

A

N/A

N/A

N/A

Maximum Start Amps

A

N/A

N/A

N/A

Recommended Mains Fuse Size

A

N/A

N/A

N/A

Compressor Nominal Run Amps

A

N/A

N/A

N/A

First upgrade EC Motor

1~

1~

1~

Quantity x Motor Size

kW

1 x 0.72

1 x 0.72

1 x 0.72

Full Load Amps

A

3.3

3.3

3.3

Locked Rotor Amps

A

N/A

N/A

N/A

Second upgrade SCAF

1~

1~

1~

Quantity x Motor Size

kW

1 x 1.4

1 x 1.4

1 x 1.4

Full Load Amps

A

6 6 6

Locked Rotor Amps

A

18

18

18

Electrical Data – Cooling Only Continued

(1) Based upon ARI conditions, Evaporating at 7°C, Condensing at 54.4°C.

Condensing Units

BluCube™

Condensing Units

37

Installation and Maintenance Manual 7222094: 11/2013

CUR092V29-VCO-0

CUR122V35-VCO-0

CUR122V40-VCO-0

Unit Data

(1)

Nominal Run Amps

A

20.4

25.5

30.8

Maximum Start Amps

A

121.7

144.4

177.4

Recommended Mains Fuse Size

A

32

40

50

Max Mains Incoming Cable Size

mm²

35

35

35

Mains Supply

V

400V / 3PH + N / 50Hz

Control circuit

VAC

24

24

24

Condenser Fan - Motor

Motor Type

AC

AC

AC

1~

3~

3~

Quantity x Motor Size

kW

1 x 0.6

1 x 1.97

1 x 1.97

Full Load Amps

A

2.7

3.4

3.4

Locked Rotor Amps

A

9.2

11.9

11.9

Compressor

Motor Size

kW

9.4

11.8

13.9

Nominal Run Amps

A

16.8

21.1

26.4

Locked Rotor Amps

A

118

140

173

Type of Start

Direct On Line

OPTIONAL EXTRAS

Electronic Soft-start

Nominal Run Amps

A

20.4

25.5

30.8

Maximum Start Amps

A

74.5

88.4

108.2

Recommended Mains Fuse Size

A

32

40

50

Power Factor Correction

N/A

N/A

N/A

Nominal Run Amps

A

N/A

N/A

N/A

Maximum Start Amps

N/A

N/A

N/A

N/A

Recommended Mains Fuse Size

A

N/A

N/A

N/A

Compressor Nominal Run Amps

A

N/A

N/A

N/A

First upgrade EC Motor

1~

3~

3~

Quantity x Motor Size

kW

1 x 0.72

1 x 1.85

1 x 1.85

Full Load Amps

A

3.3

2.9

2.9

Locked Rotor Amps

A

N/A

N/A

N/A

Second upgrade SCAF

1~

N/A

N/A

Quantity x Motor Size

kW

1 x 1.4

N/A

N/A

Full Load Amps

A

6.0

N/A

N/A

Locked Rotor Amps

A

18

N/A

N/A

Electrical Data – Cooling Only Continued

(1) Based upon ARI conditions, Evaporating at 7°C, Condensing at 54.4°C.

BluCube™

Condensing Unit

38

Condensing Units

Installation and Maintenance Manual : 7222094 11/2013

BluCube

L1

Mains incoming supply 400V/3PH/50Hz

L2

L3

N

PE

502

24 Volts AC

551

Cooling Signal

845

Variable Capacity Compressor Only

0-10Volts Compressor demand

500

0 Volts

561

NO

Critical alarm Normally Open

562

Common

GND 563

NC

Critical alarm Normally Closed

Rx-Tx-

Use Awg20/22 twisted pair (with overall shield) cable,

Belden ref. 8762 (Airedale ref: 6110316), or equivalent,

for

network

Network Connections

(Inward connection)

Rx+Tx+

GND

Rx-Tx-

Use Awg20/22 twisted pair (with overall shield) cable,

Belden ref. 8762 (Airedale ref: 6110316), or equivalent,

for

network

Network Connections

(Outward connection)

Rx+Tx+

GND

Interconnecting Wiring

Condensing Units

BluCube™

Condensing Units

39

Installation and Maintenance Manual 7222094: 11/2013

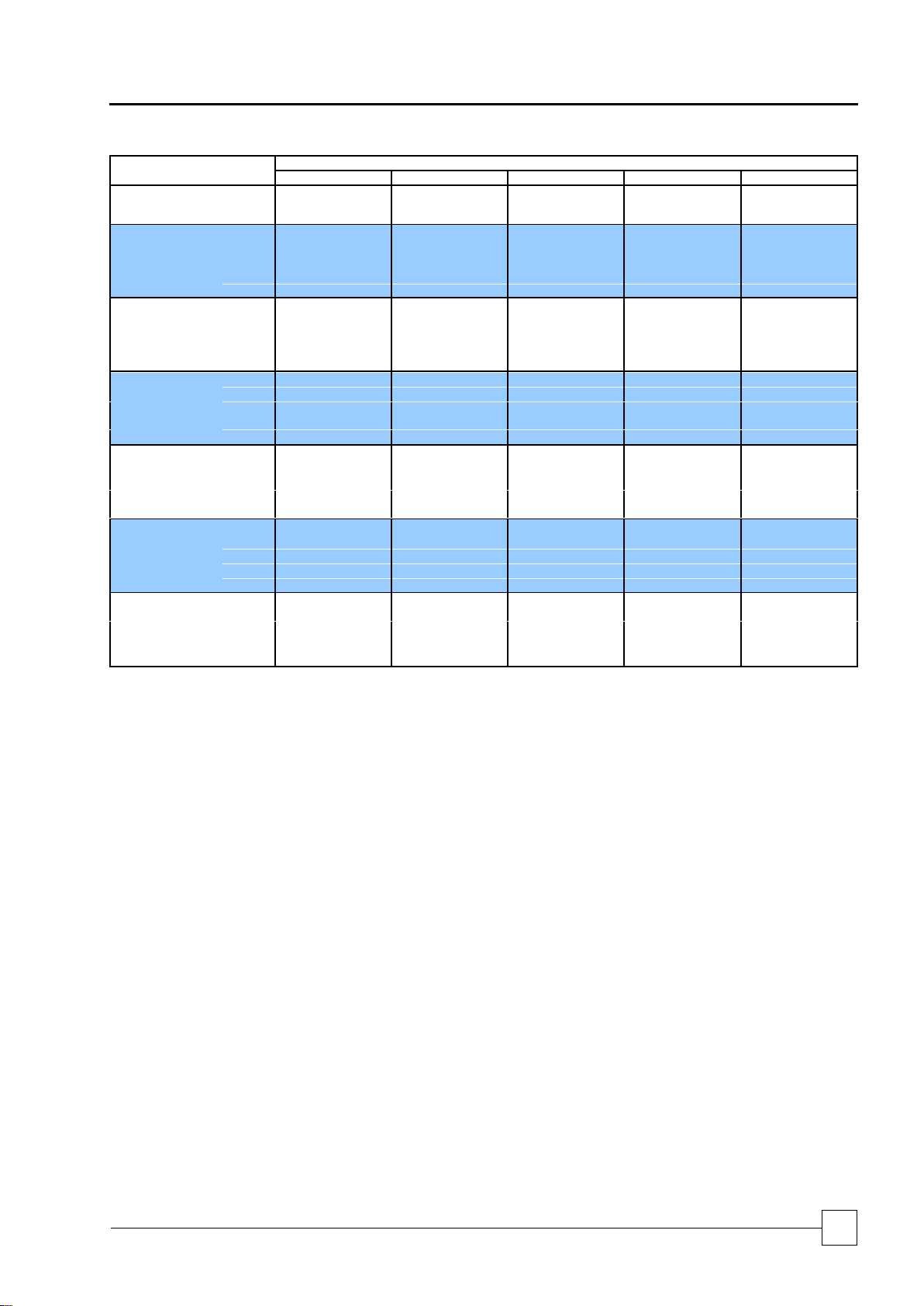

Typical Heating Application Envelope

28, -13

26, -15

28, 25

12, 25

12, -15

-20

-15

-10

-5

0

5

10

15

20

25

30

0 5 10 15 20 25 30

Return Air Temperature (°C)

Ambient Temperature (°C)

CAUTION

A minimum air on temperature limit of 12°C must be adhered to ensure correct unit

operation.

Any fresh air introduced to the unit must have pre-heaters to maintain this

minimum temperature.

Operating Limits - Heat Pump Heating Cycle

-15, 25

-15, 38

25, 60

25, 25

13, 60

-20, 25

-20, 38

0

10

20

30

40

50

60

70

-25 -20 -15 -10 -5 0 5 10 15 20 25 30

Ambient temperature (°C)

Condensing temperature (°C)

Fixed Capacity Modulated Capacity

Technical Data Heat Pump

Operational Limits

Data Based on a 12°C T across coil.

BluCube™

Condensing Unit

40

Condensing Units

Installation and Maintenance Manual : 7222094 11/2013

Operating Limits - Heat Pump Cooling Cycle

-23, -20

-23, 23

15, 42

15, -20

3, 42

15, 48

3, 48

-30

-20

-10

0

10

20

30

40

50

60

-25 -20 -15 -10 -5 0 5 10 15 20

Evaporating temperature (°C)

Ambient temperature (°C)

Fixed Capacity Modulated Capacity

Condensing Units

BluCube™

Condensing Units

41

Installation and Maintenance Manual 7222094: 11/2013

Summer Ambient (°C)

25

30

35

40

45

Unit

Evap

Temp

(°C)

Output

(kW)

Input

(kW)

Output

(kW)

Input

(kW)

Output

(kW)

Input

(kW)

Output

(kW)

Input

(kW)

Output

(kW)

Input

(kW)

CUR092V16-1HP-0

-5

10.3

3.9

10.3

3.8

9.8

4.2

9.2

4.6

8.5

5.0 0 12.4

3.9

12.2

3.9

11.6

4.3

11.0

4.7

10.3

5.2 5 14.8

3.9

14.4

4.0

13.7

4.4

13.0

4.8

12.2

5.3 7 15.9

3.8

15.4

4.0

14.6

4.4

13.8

4.8

13.0

5.3

10

17.6

3.7

16.9

4.0

16.0

4.4

15.2

4.9

14.3

5.3

CUR092V20-1HP-0

-5

15.8

5.5

15.1

5.8

14.3

6.3

13.3

6.8

N/A

N/A 0 18.7

5.5

17.9

6.0

17.0

6.5

15.9

7.0

14.8

7.6 5 21.9

5.7

20.9

6.1

19.8

6.6

18.7

7.2

17.5

7.7 7 23.3

5.7

22.2

6.2

21.1

6.7

19.9

7.2

18.7

7.8

10

25.4

5.8

24.2

6.3

23.0

6.8

21.8

7.3

21.1

6.7

CUR092V25-1HP-0

-5

20.3

7.0

19.3

7.7

18.3

8.4

17.1

9.1

N/A

N/A 0 24.0

7.4

22.8

8.0

21.5

8.7

20.1

9.5

N/A

N/A 5 28.1

7.8

26.6

8.4

25.0

9.1

23.3

9.9

N/A

N/A 7 29.8

8.0

28.2

8.6

26.5

9.3

24.6

10.1

N/A

N/A

10

32.4

8.2

30.6

8.9

28.8

9.6

26.7

10.3

N/A

N/A

CUR092V29-1HP-0

-5

22.5

8.0

21.2

8.7

19.9

9.5

28.7

10.6

N/A

N/A 0 26.5

8.4

25.0

9.1

23.4

10.0

21.6

10.9

N/A

N/A 5 30.8

8.9

29.0

9.6

27.1

10.4

25.1

11.4

N/A

N/A 7 32.6

9.0

30.7

9.8

28.7

10.6

26.6

11.6

N/A

N/A

10

35.4

9.3

33.3

10.1

31.1

11.0

28.7

10.6

N/A

N/A

CUR122V35-1HP-0

-5

30.5

11.8

29.0

12.9

27.2

13.9

25.3

15.1

N/A

N/A 0 36.1

12.3

34.2

13.2

32.1

14.3

29.8

15.5

N/A

N/A 5 42.1

12.7

39.9

13.7

37.4

14.8

34.8

15.9

31.9

17.3 7 44.6

12.9

42.3

13.9

39.7

14.9

36.9

16.1

33.9

17.5

10

48.6

13.2

46.0

14.2

43.2

15.3

40.2

16.4

39.7

14.9

CUR122V40-1HP-0

-5

34.5

13.5

32.7

14.5

30.7

15.6

28.6

16.8

N/A

N/A 0 40.4

14.1

38.3

15.1

36.0

16.2

33.5

17.4

N/A

N/A 5 46.9

14.8

44.4

15.7

41.7

16.8

38.8

18.1

N/A

N/A 7 49.6

15.0

47.0

16.0

44.1

17.1

41.0

18.4

N/A

N/A

10

53.9

15.4

51.0

16.5

47.8

17.6

44.5

18.8

N/A

N/A

Heat Pump Cooling Fixed Capacities

Notes:

1 Output kW refers to the compressor duty.

2 Input kW refers to the compressor and fan input power only.

BluCube™

Condensing Unit

42

Condensing Units

Installation and Maintenance Manual : 7222094 11/2013

Summer Ambient (°C)

25

30

35

40