Air Taema NEFTIS ICU User manual

NEFTIS ICU

Taema

Maintenance Manual

YM027300 / Rev 0 / April 2006

Software Version V1.xx

www.airliquide.com

www.taema.com

2

Taema

NEFTIS ICU

CONTENTS

Preface.............................................................................................................................................................................. 5

Terminology .................................................................................................................................................................... 6

Typography ..................................................................................................................................................................... 7

General safety instructions......................................................................................................................................... 8

1. operation/description.......................................................................................................................................... 10

1.1. Operating Principle...................................................................................................................................... 10

1.2. Functional Description ............................................................................................................................... 10

1.2.1. Block Diagram of Operation .................................................................................................................10

Electronics........................................................................................................................................................... 11

Power supply ...................................................................................................................................................... 11

Front panel (indicator lights, screen, etc.) ...................................................................................................... 11

Pneumatic Mechanism...................................................................................................................................... 12

Pneumatic Operation......................................................................................................................................... 13

1.2.2. Pneumatic Cabling Diagram................................................................................................................. 15

1.3. Description .................................................................................................................................................... 16

1.3.1. Front View ............................................................................................................................................... 16

1.3.2. View of the expiratory unit..................................................................................................................... 16

1.3.3. Rear View................................................................................................................................................ 17

1.3.4. View from Above .................................................................................................................................... 17

1.3.5. Blower View ............................................................................................................................................18

1.3.6. Inside View of Rear Cover .................................................................................................................... 18

2. Maintenance .......................................................................................................................................................... 19

2.1. Special Tools................................................................................................................................................. 19

2.2. Preventive Maintenance............................................................................................................................. 20

2.2.1. Annual Maintenance.............................................................................................................................. 20

Required spare parts ......................................................................................................................................... 20

2.2.2. 20,000-Hourly Maintenance*................................................................................................................ 21

Required spare parts ......................................................................................................................................... 21

Recommended additional spare parts ............................................................................................................ 21

2.3. Disassembly/reassembly protocol.......................................................................................................... 22

Notes on how to avoid damaging the connections ....................................................................................... 22

2.3.1. Removing the Rear Cover .................................................................................................................... 23

2.3.2. Removing the Battery ............................................................................................................................ 25

2.3.3. Removing the Top Cover ...................................................................................................................... 26

2.3.4. Removing the Metal Frame .................................................................................................................. 28

2.3.5. Removing the Front ............................................................................................................................... 29

2.3.6. Replacing the Actuator Board .............................................................................................................. 33

2.3.7. Replacing the Power Supply Board..................................................................................................... 34

2.3.8. Replacing the Inspiratory Valve ........................................................................................................... 37

2.3.9. Replacing the Solenoid Valve Assembly............................................................................................ 38

2.3.10. Replacing the O2 Proportional Valve ................................................................................................... 39

2.3.11. Replacing the Flow Rate Sensor Assembly....................................................................................... 40

2.3.12. Replacing the Mixer ............................................................................................................................... 40

2.3.13. Replacing the Touch Screen ................................................................................................................ 41

2.3.14. Replacing the Microprocessor Board.................................................................................................. 44

2.3.15. Replacing the Blower Outlet Filter ....................................................................................................... 45

2.3.16. Removing the Blower ............................................................................................................................ 46

2.3.17. Replacing the O2 Connector Filter ....................................................................................................... 47

2.4. Corrective Maintenance ............................................................................................................................. 48

2.4.1. Alarm Messages..................................................................................................................................... 48

Troubleshooting for alarms 002 and 004........................................................................................................ 52

Troubleshooting for alarm 033 ......................................................................................................................... 52

2.5. Operation Monitoring and Calibration Protocols ................................................................................ 54

YM027300 / Revision 0 / April 2006

3

Taema

2.5.1. Preface..................................................................................................................................................... 54

2.5.2. Operation Check .................................................................................................................................... 54

2.5.3. Additional Checks .................................................................................................................................. 56

Mixer Airtightness............................................................................................................................................... 56

Inspiratory valve airtightness............................................................................................................................ 57

Blower .................................................................................................................................................................. 58

O2 Cell................................................................................................................................................................. 58

Nebulizer ............................................................................................................................................................. 58

2.5.4. Maintenance Mode ................................................................................................................................59

Accessing maintenance mode (Calibration) .................................................................................................. 59

Using Maintenance Mode ................................................................................................................................. 59

Calibrating the machine .................................................................................................................................... 59

Pressure sensor calibration.............................................................................................................................. 60

Calibrating the Low-Pressure Sensors (around 100 mbar) ......................................................................... 60

Calibrating the High-Pressure Sensor (approx. 3.5 bar).............................................................................. 62

Calibrating the NEFTIS ICU Flow Rate Sensors........................................................................................... 63

Calibrating the ventilation flow rate sensors ..................................................................................................64

Calibrating the actuators ................................................................................................................................... 67

Predictive Maintenance (under development) ............................................................................................... 68

2.5.5. Advanced Maintenance Mode.............................................................................................................. 69

Accessing Advanced maintenance mode ...................................................................................................... 69

Using Advanced Maintenance Mode .............................................................................................................. 69

2.5.6. Expert Mode............................................................................................................................................ 72

Introduction .........................................................................................................................................................72

Access ................................................................................................................................................................. 72

Use ....................................................................................................................................................................... 72

Description .......................................................................................................................................................... 74

NEFTIS ICU

3. Bill of Material....................................................................................................................................................... 75

3.1. Main Components........................................................................................................................................ 75

3.2. Kits and Miscellaneous Parts ................................................................................................................... 80

4. NEFTIS ICU Recommissioning Sheet............................................................................................................. 81

YM027300 / Revision 0 / April 2006

4

Taema

NEFTIS ICU

PREFACE

This document is a maintenance manual and is not intended to replace the user manual in any

way.

The objective of this document is to provide additional information to trained individuals who are

both competent and qualified to carry out preventive and/or corrective maintenance on NEFTIS

ICU KC023000 units.

It contains technical information that is the property of Taema and that may not be divulged without

the prior agreement of Taema.

YM027300 / Revision 0 / April 2006

5

Taema

NEFTIS ICU

TERMINOLOGY

Warning

Notifies the user of the possibility of a minor or serious injury that could arise when handling the ventilator,

whether correctly or incorrectly.

Attention

Notifies the user of the possibility of a technical problem or malfunction of the ventilator that could arise

when handling the ventilator, whether correctly or incorrectly.

Note

Highlights a piece of information.

YM027300 / Revision 0 / April 2006

6

Taema

TYPOGRAPHY

Font Example Function

NEFTIS ICU

Lucida Console, bold excessive pressure

See Section 3.1

Italic

Solenoid valve

Bold, italic

monitoring patient exhalation

Text from the screen

Text referring to another section of

the manual.

Text in the index

Highlights an important point in a

sentence.

YM027300 / Revision 0 / April 2006

7

Taema

NEFTIS ICU

GENERAL SAFETY INSTRUCTIONS

P

RECAUTIONS FOR OXYGEN USE

− No incandescent source nearby

− No fatty substances.

P

RECAUTIONS IN THE EVENT OF AN OXYGEN LEAK

− No smoking

− Avoid all sources of flame or spark

− Close the oxygen supply valve

− Air the room while there is a leak and for at least 20 minutes afterwards

− Air one's own clothing.

ELECTRICAL SUPPLY

− Check that the voltage in the mains plug used correctly corresponds to the electrical

characteristics of NEFTIS

− As NEFTIS

ICU has an internal battery, it is preferable to leave the unit plugged into the

electrical power supply, with the On/Off switch in the On position in STANDBY mode, to keep

the battery charged.

− If it is stored, the NEFTIS ICU should be charged regularly with the On/Off switch in On

position, connected to the electrical power supply, in STANDBY mode, for at least 10 hours, to

keep the battery charged. The interval between two recharges must not exceed three weeks

(batteries charged),

− In the event of prolonged storage (more than three weeks), keep the battery disconnected.

When returning the unit to service, perform a test of battery characteristics (see Section 2.5.5).

P

UTTING NEFTIS ICU IN SERVICE

− Before each use, check that the audible and visual alarms (red indicator on keyboard) are

operative, and carry out checks as listed in the 'recommissioning' sheet.

E

LECTROMAGNETIC COMPATIBILITY

− NEFTIS

− NEFTIS

ICU conforms to the protection requirements of Directive 93/42/CEE.

ICU operation can be affected by the use of appliances in its immediate proximity,

such as diathermic, high frequency electro-surgery units, defibrillators, cell phones or, more

generally, by electromagnetic interference that exceeds the levels set by standard EN 60 6011-2.

A

T HIGH AMBIENT TEMPERATURE

− The NEFTIS

ICU ventilator heats the respiratory gas by 4 to 6°C above the ambient

temperature according to the parameters selected. At ambient temperatures over 35°C, the

respiratory gas temperature can exceed 40°C. In this case, the ventilator will trigger an alarm.

I

N THE EVENT OF OXYGEN SUPPLY FAILURE

− In normal operation, the NEFTIS

coming from the central supply or a cylinder, at ratios depending on the FiO

supply fails, the NEFTIS ICU replaces the unavailable oxygen with ambient air. All ventilation

parameters are maintained, except for the FiO

informs you of the situation.

ICU (indicated on the manufacturer's plate on the rear panel).

ICU delivers a mixture composed of ambient air and oxygen

setting. If the O

2

, which becomes equal to 21%. An alarm

2

2

YM027300 / Revision 0 / April 2006

8

Taema

NEFTIS ICU

USING THE NEFTIS ICU

In compliance with standard EN 60 601-1 (Appendix A Para. 6.8.2.b):

"The manufacturer, assembler, installer or importer only consider themselves responsible for the

safety, reliability and characteristics of a unit if the:

Assembly, extensions, settings, changes or repairs were carried out by personnel authorized by

them,

− Electrical installation of the corresponding area is compliant with IEC recommendations,

− Unit is used in compliance with the instructions for use.

If the accessories used by a user do not conform to the manufacturer’s instructions, the

manufacturer is relieved of all responsibility in the event of an incident.

If spare parts used during scheduled maintenance do not conform to the manufacturer’s

specification, the manufacturer is relieved of all responsibility in the event of an incident.

− Ventilation must not be started immediately after storage or transportation under conditions

that differ from the recommended operating conditions.

− NEFTIS

ICU must not be used with inflammable anaesthetic agents or explosive products.

− Do not use anti-static or electrically conductive ducts or tubes.

− NEFTIS

− For correct operation of the NEFTIS

ICU must not be used exposed to direct sunlight.

ICU, maintain free circulation of air, keeping rear and

underneath air inlets completely unobstructed.

The manufacturer has anticipated the majority of possible malfunctioning cases for NEFTIS and

these are normally covered by the internal monitoring system. It is nevertheless recommended, in

case of complete patient dependence, to provide an additional system that is completely

autonomous, and which can be used to check the effectiveness of the ventilation, as well as an

emergency device, such as a manual IM5 insufflator.

C

LEANING AND MAINTENANCE OF NEFTIS

− Do not use abrasive powders, alcohol, acetone or other easily flammable solvents.

− NEFTIS

ICU must be checked on a regular basis. To schedule and record maintenance

operations, refer to the maintenance sheet in the user manual.

YM027300 / Revision 0 / April 2006

9

Taema

NEFTIS ICU

1. OPERATION/DESCRIPTION

1.1. OPERATING PRINCIPLE

The blower is controlled by a microprocessor and is slaved to a volume control unit or a pressure

control unit according to the selected ventilation mode.

NEFTIS

The mixer provides a precise and variable concentration between 21% and 100% oxygen.

The O

The expiratory circuit includes:

The expired gas flow rates are measured by the hot wire sensor whose signal is processed by the

electronics to obtain spirometry data.

ICU does not generate negative pressure during the expiratory phase.

concentration of the insufflated mixture is measured by the FiO2 sensor.

2

• a two-way patient valve,

• an expired gas flow rate sensor (hot wire);

• a special trap.

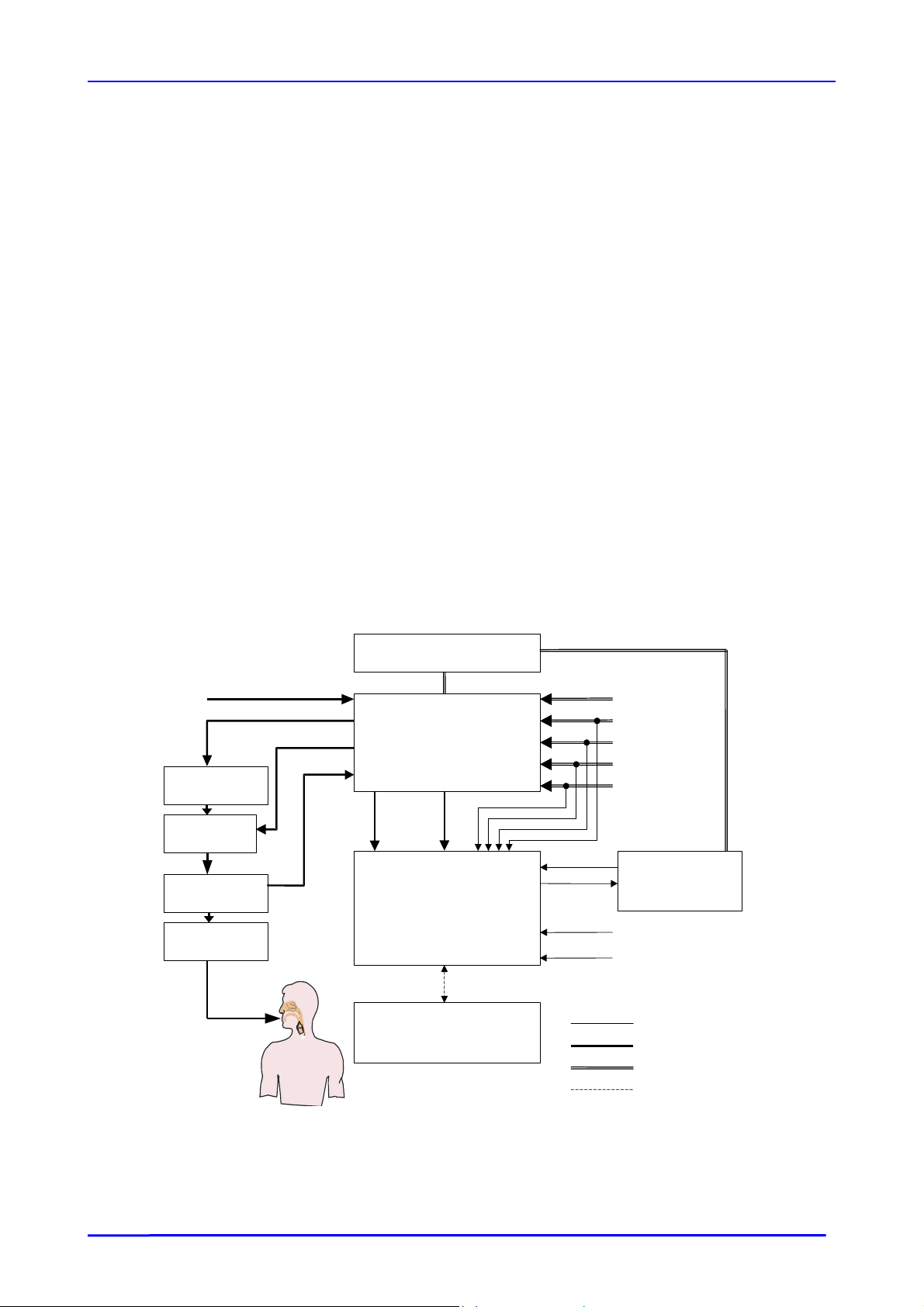

1.2. FUNCTIONAL DESCRIPTION

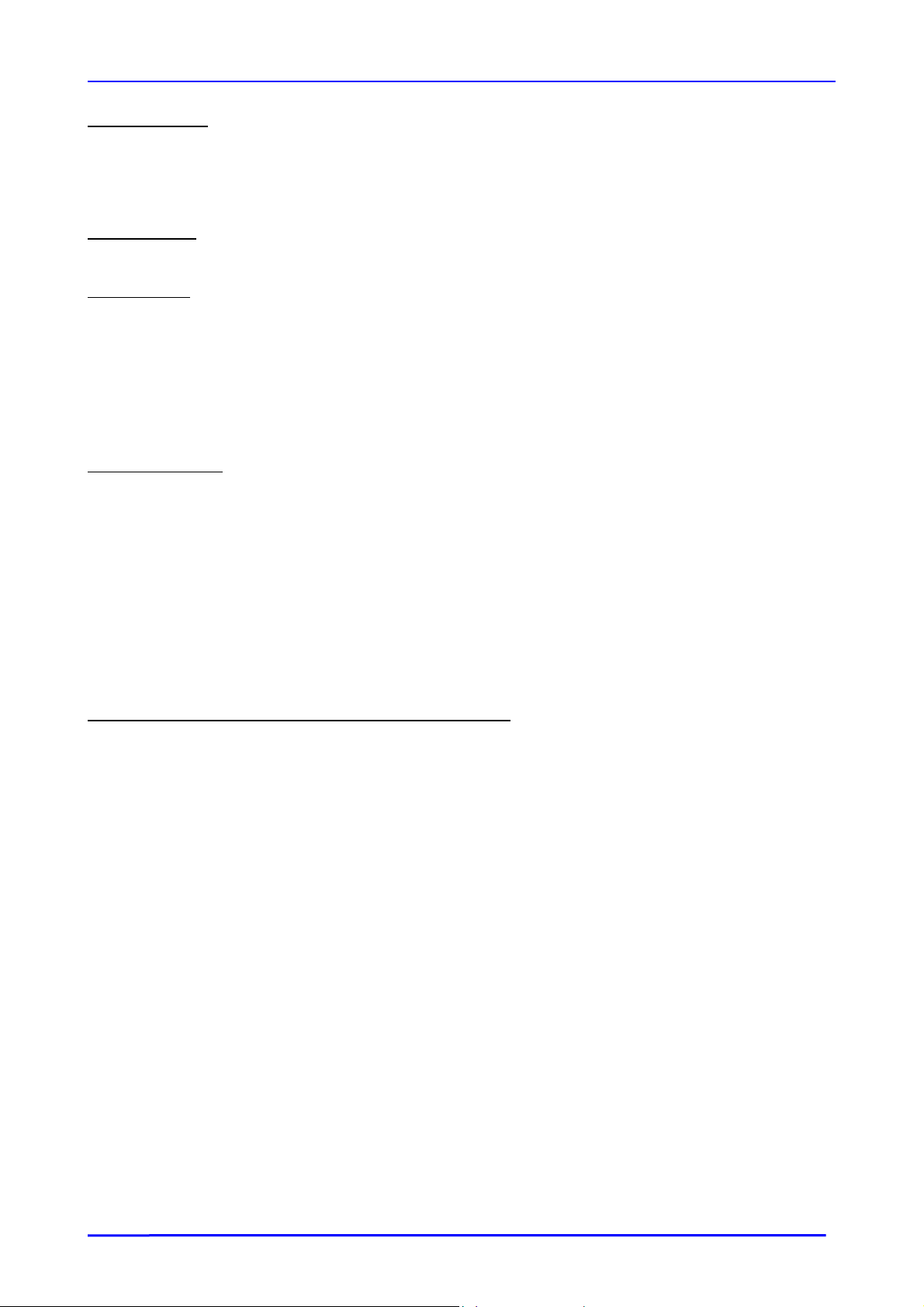

1.2.1. BLOCK DIAGRAM OF OPERATION

O2 supply

Gaseous mixture

Patient tube

V. exp

Flow ctrl

Mask or

probe

PEEP control

Pressure

measure

Flow measurement

Mechanism (housing)

Ventilation/pneumatic unit

measure

ment

Microprocessor board

Flow

ment

Electronics

Ventilator µP

Monitor µP

Inputs/Outputs

Settings:

PEEP,

Vt,

Freq,

Alarms, etc.

Touch screen

Front panel

LEDS

Mains power supply

Battery

Patient

Software:

Ventilator

Monitor

Electrical connection

Pneumatic connection

Mechanical connection

Logic connection

YM027300 / Revision 0 / April 2006

10

Taema

NEFTIS ICU

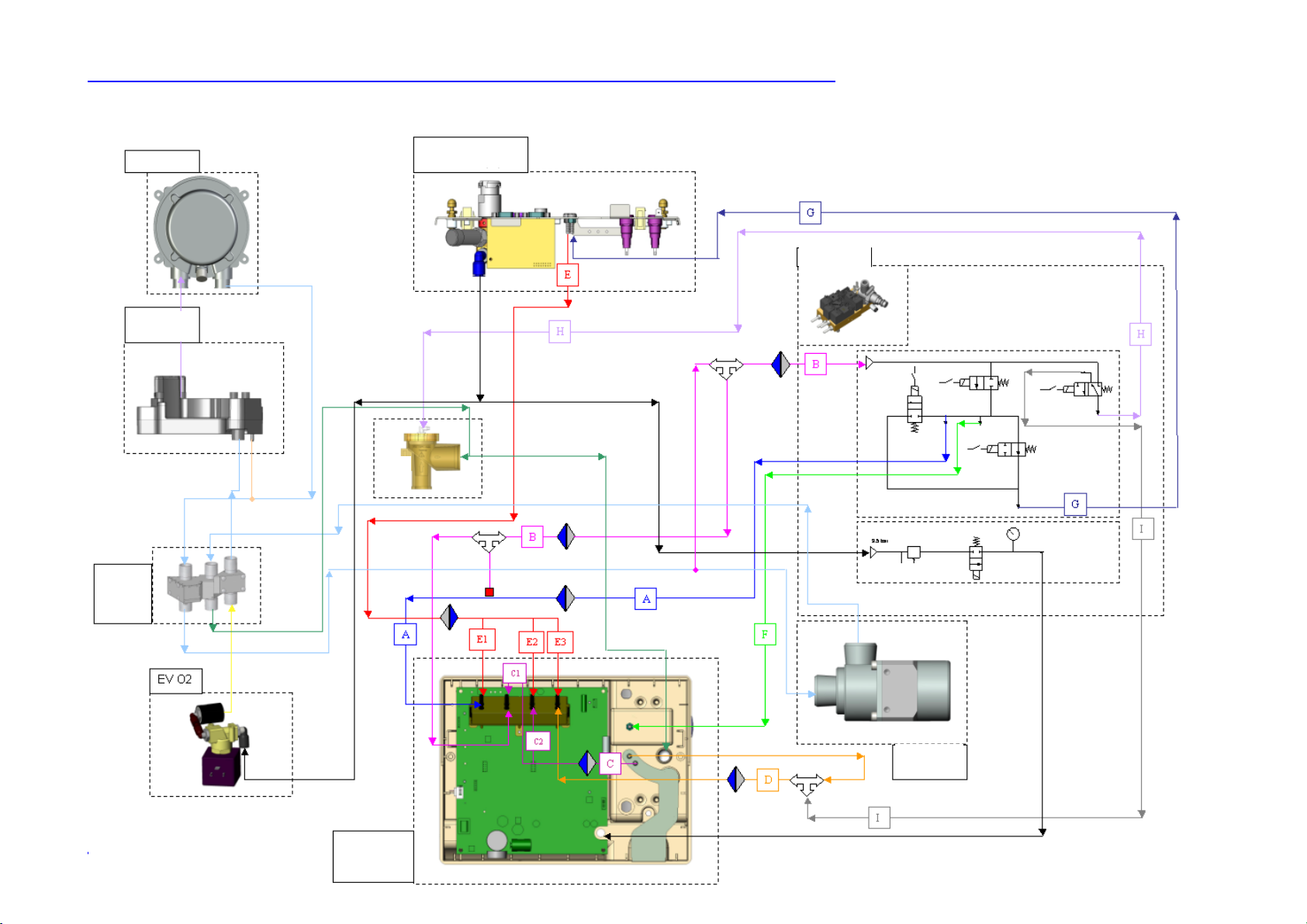

ELECTRONICS

HE MICROPROCESSOR BOARD

T

The microprocessor board consists of two identical central processor units from Motorola, split into

two sub-systems:

The ventilator:

This sub-system is the processor dedicated to ventilation. It integrates the electronic

conditioning stages associated with the sensors and the control of the electro-pneumatic

components, the audible alarms, a dialog link and the exchanges with the monitor.

The monitor:

integrates a screen, the information exchange medium between the user and the NEFTIS

This sub-system is the MMI (Man Machine Interface) dedicated processor. It

ICU and

the electronic stages associated with the safety and the redundancy of the controls for certain

components and alarms, as a link to the ventilator.

T

HE ACTUATOR BOARD

The actuator board includes all the actuator power controls (solenoid valve, valves, blowers, etc.).

POWER SUPPLY

The board power supply supplies power to the microprocessor board and to all the pneumatic

actuators. This power can be supplied from the mains, from a direct current source connected to

the NEFTIS

device. The power supply board performs automatic switching between these different power

sources and informs the microprocessor board of the power sources available.

Linked to this sub-assembly, the internal battery provides a back-up power supply if the two other

power sources are lost.

However, the microprocessor board has a power supply cut-off command via the internal battery,

in case battery protection is necessary.

ICU, known as an external DC source, or from the internal backup battery built into the

FRONT PANEL (INDICATOR LIGHTS, SCREEN, ETC.)

The NEFTIS

controlled by the processor board. This screen is only visible thanks to its backlighting.

The front panel is also equipped with LEDs indicating functions such as alarms and operational

modes in NIV (Non-Invasive Ventilation). These displays are implemented on the microprocessor

board.

The front panel, at MMI level, has an interface with touch keys (touch-screen), a navigation coding

wheel allowing the user to set and confirm parameters. Access is also possible by selecting the

configuration zone from the touch-screen (dual access).

ICU screen consists of an LCD colour display equipped with CCFL back-lighting

YM027300 / Revision 0 / April 2006

11

Taema

NEFTIS ICU

PNEUMATIC MECHANISM

ECHANICS

M

The pcb supports all the pneumatic components (solenoid valve, valve, flow rate sensor etc.). The

pcb is mechanically decoupled from the housing.

The blower enclosure unit

plate of the housing.

The rear cover

: covers the blower/mixer assembly and the internal battery unit. The NEFTIS ICU

access and interface assembly is located on the rear plate (mains power, external DC, RS232, O2

inlet, etc.).

T

HE COMPLETE PNEUMATIC CIRCUIT

The complete pneumatic circuit consists of an assembly of components performing the pneumatic

function of the NEFTIS

Mixer

: The principle of this sub-system is to provide a precise and variable concentration between

21% and 100% oxygen.

Blower

: This sub-system facilitates the supply of a gas flow at a given pressure.

The inspiratory assembly

pressure from an assisted valve.

The expiratory assembly:

control of the pressure level (PEEP).

The electro-pneumatic components

: The blower associated with an air/O2 mixer is integrated in the rear

ICU. This simple system is sub-divided into five sub-systems:

: This sub-system allows the control of a flow rate or an inspiratory

This sub-system facilitates the evacuation of an expiratory flow rate with

(sensors and actuators).

YM027300 / Revision 0 / April 2006

12

Taema

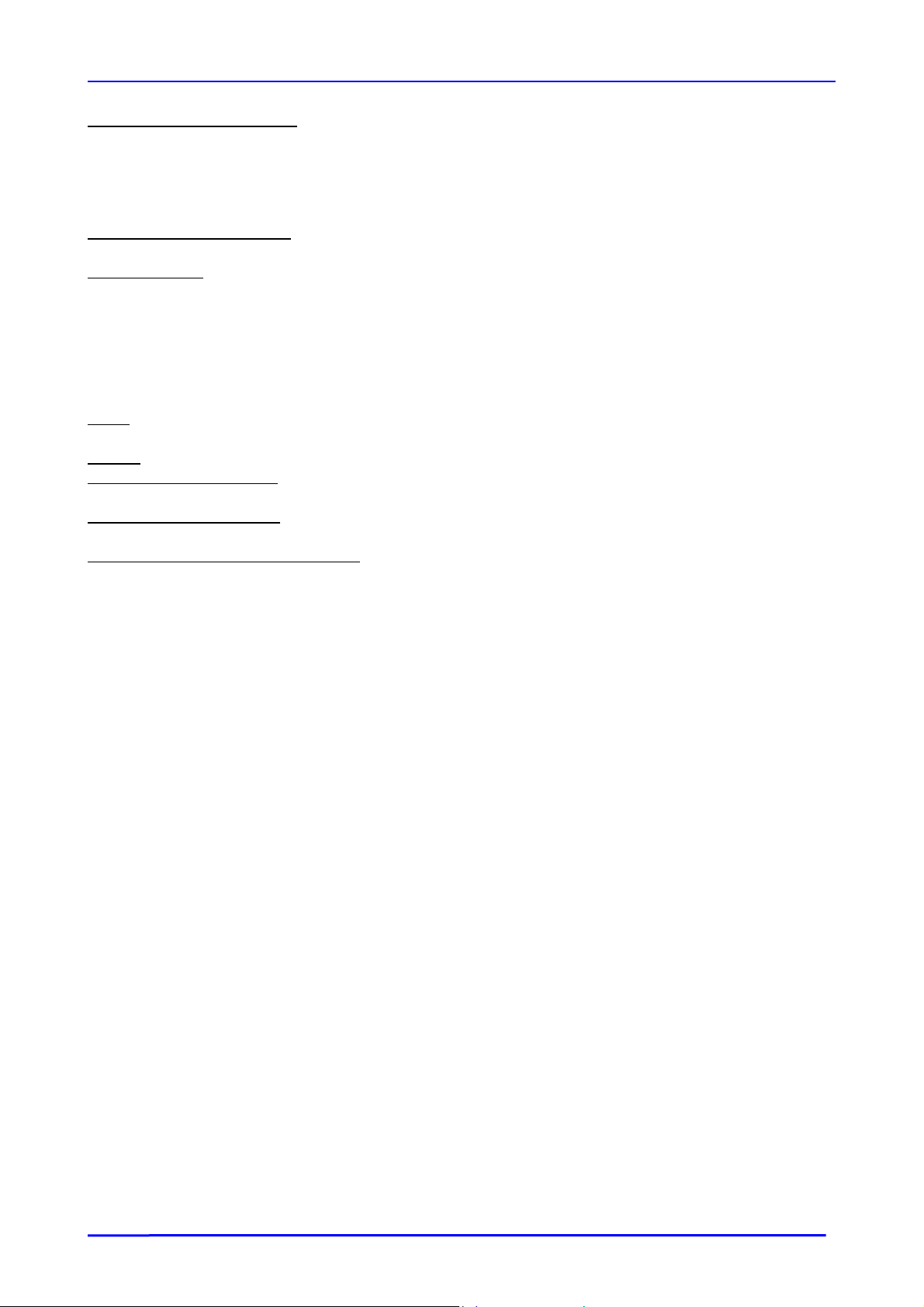

A

e

NEFTIS ICU

PNEUMATIC OPERATION

1 : Inspiratory valve

4 : PEEP proportional solenoid valve

5 : Blower

6 : Enclosure/Mixer

7 : Expiratory valve

8 : O

proportional solenoid valve

2

9 : Expiratory flow sensor (hot wire)

10 : Inspiratory flow sensor (Honeywell)

11 :

O

flow sensor

2

12a,12b: Pressure sensors

13 : Balloon pressure sensor

14 : Ambient air inlet/safety valve

15 : Air intake

15 b: Air inlet filter

16 : O2 CELL

17 : I/E cycle management solenoid valve

18 : Solenoid drain valve

19 : Blower outlet flow sensor

20 : Blower outlet particle filter

21 : Insp ∆P pressure sensor

22 : O

pressure sensor

2

23 : Nebulizer reducer

24 : Nebulizer solenoid valve

25 : O

connector

2

26 : Bacteriological filter

27 : Patient gas temperature sensor

28 : Laminar filter

29 : Blower inlet filter

30 : Ambient air connector 3/2 solenoid valve

O2

30

25

22

IR

15

15 B

8

N.F

28

23

11

6

29

24

5

20

19

1

10

4

17

Nebulizer circuit

21

27

T

12a

18

PEEPcircuit

12b

13

14

26

O2

16

7

9

The administering of ventilation cycles to a patient by NEFTIS ICU is the result of action involving

three essential components: the pressure generator (the blower), the inspiratory valv

(electro-pneumatic) and the PEEP solenoid valve (proportional solenoid valve).

Patient

YM027300 / Revision 0 / April 2006

13

Taema

NEFTIS ICU

THE PRESSURE GENERATOR

The role of blower (5) is to guarantee the pressurisation required to deliver a ventilation cycle that

conforms to the settings.

This blower draws the gaseous mixture from enclosure/mixer (6). Via O

proportional solenoid

2

valve (8) – connected to the network – this mixture can contain a variable rate of oxygen, from

21% to 100%.

For the following description of the inspiratory and expiratory phases, it is assumed that blower 5a

has pressurized the circuit sufficiently.

NSPIRATORY PHASE

I

PEEP proportional solenoid valve (4) is kept open and both I/O solenoid valves (17) and (18)

(position open or closed) are closed.

The output pressure from the blower is therefore at the level of the expiratory valve and thus

seals the part of the circuit located between the patient and the expiratory valve.

In other words, the gaseous flow is forced to focus on the patient only and cannot escape into the

atmosphere.

The inspiratory cycle delivered to the patient is a result of the setting of inspiratory valve (1). If the

mode selected is barometric, the inspiratory valve regulates in relation to the pressure sensor

which indicates the highest value (12b if 12a is inoperative or inversely). If the mode selected is

volumetric, the inspiratory valve regulates in relation to the flow rate sensor which indicates the

highest value (10) (19 if 10 is inoperative or inversely).

E

XPIRATORY PHASE

In this phase, a PEEP level must be set. To do this, open at least one of the I/O solenoid valves

(17 and 18) in order to lower the pressure applied to the expiratory valve membrane (this same

pressure guarantees the leak-tightness of the inspiratory phase) and proportional solenoid valve

4 controls the PEEP level required via pressure sensor P12a.

During this time, the inspiratory valve guarantees the flow rate regulation function via sensor (10).

This flow rate allows rinsing of the circuit and easier detection of any inspiratory call by the patient.

Note

During NIV ventilation (thus leakage ventilation), the inspiratory valve can fulfil the additional role

of an on-demand valve by adjusting the set pressure level if the leaks are too great.

UNCTION OF THE EXPIRATORY UNIT

F

The expiratory valve is integrated into this unit and a hot wire flow-rate sensor is added to

measure the flow-rate exhaled by the patient. The restriction allows a reduction of the sound

produced by the expiratory bag in the presence of PEEP.

A silicone disc is inserted in the bag to absorb vibrations.

The ambient air plug valve enables the patient to breathe through the machine when it is switched

off, with a resistance less than 6 hPa.

YM027300 / Revision 0 / April 2006

14

Taema

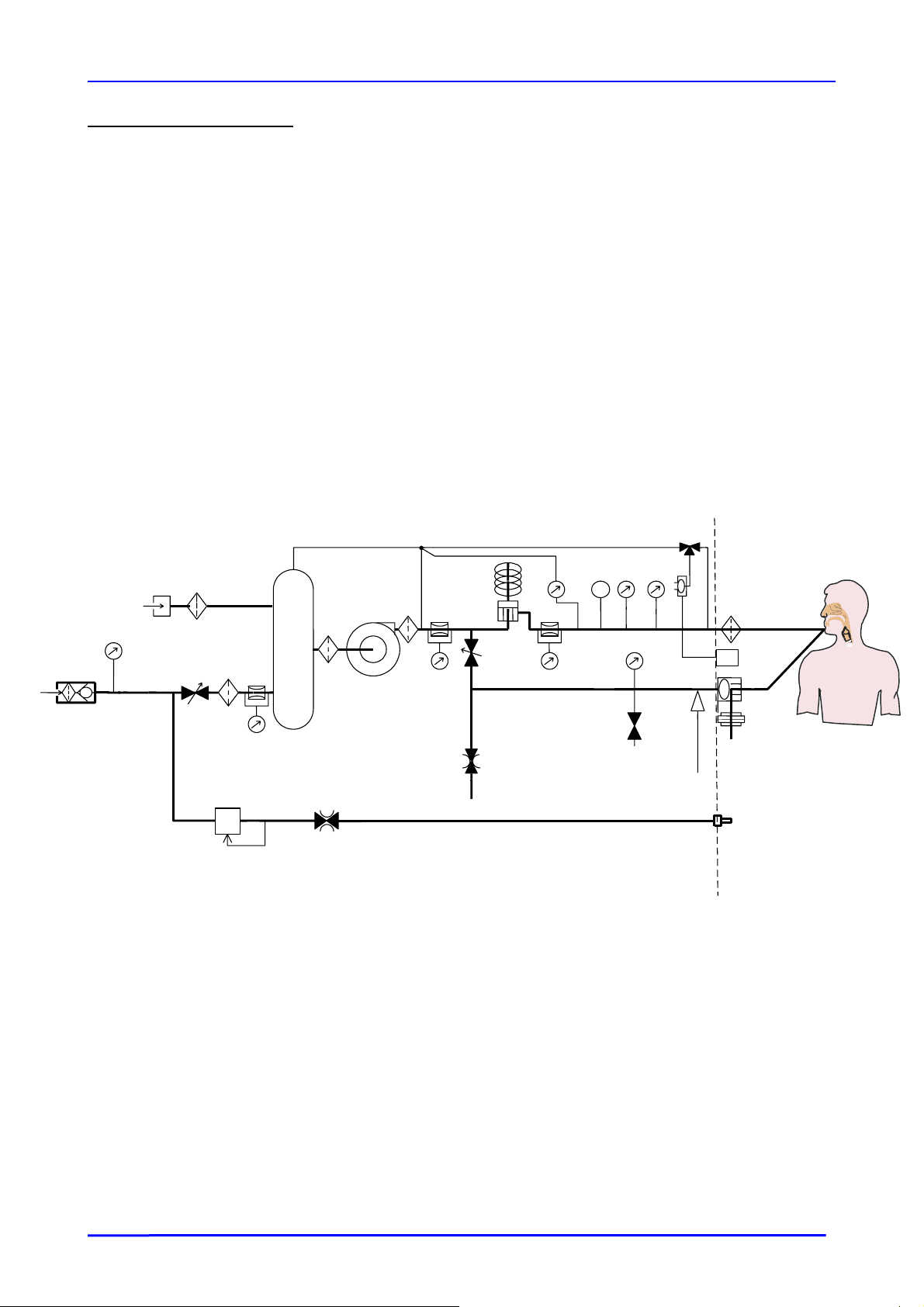

1.2.2. PNEUMATIC CABLING DIAGRAM

Blower

NEFTIS ICU

Rear sheet assembly

5

25

Flow

sensors

Block

Enclosure

6

mixer

19

10

11

Safety

valve

22

4

PEEP unit

18

Reducer

23

4

24

17

30

Nebulizer

output

8

12a

12b

Front panel

assembly

13

21

YM027300 / Revision 0 / April 2006

1

Inspiratory

valve

15

Taema

1.3. DESCRIPTION

NEFTIS ICU

Mounting

knob

Expiratory

valve trap

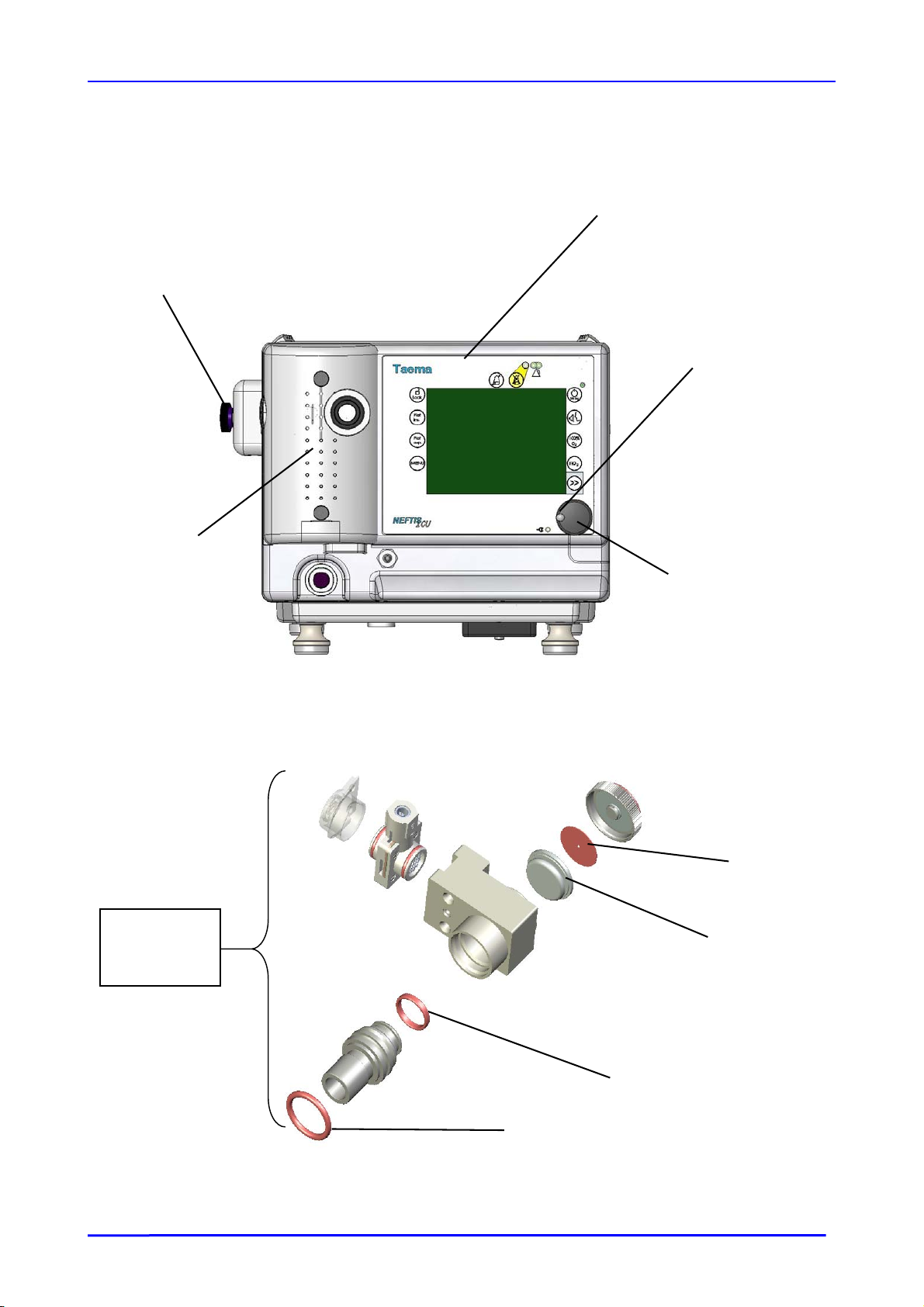

1.3.1. FRONT VIEW

Touch screen

Milled screw

spherical end

Milled screw

Expiratory

1.3.2. VIEW OF THE EXPIRATORY UNIT

valve

assembly

Exp valve disc

Expiratory

valve

membrane

O-ring

O-ring

YM027300 / Revision 0 / April 2006

16

Taema

r

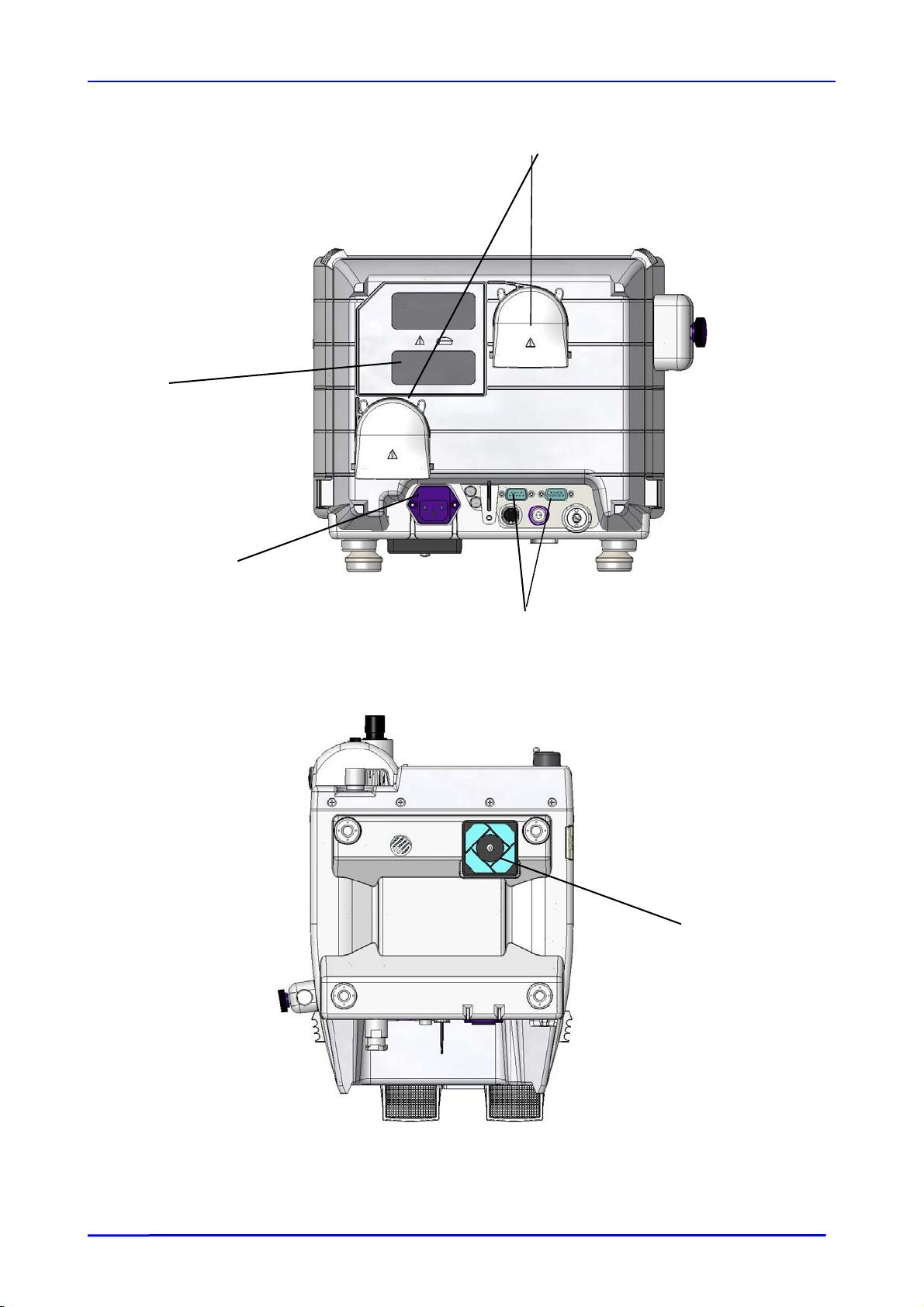

1.3.3. REAR VIEW

Rear cover

filte

NEFTIS ICU

Deflector

Power supply

connector

fuses

1.3.4. VIEW FROM ABOVE

Sub D board RS232

connectors

Base fan filter

YM027300 / Revision 0 / April 2006

17

Taema

r

r

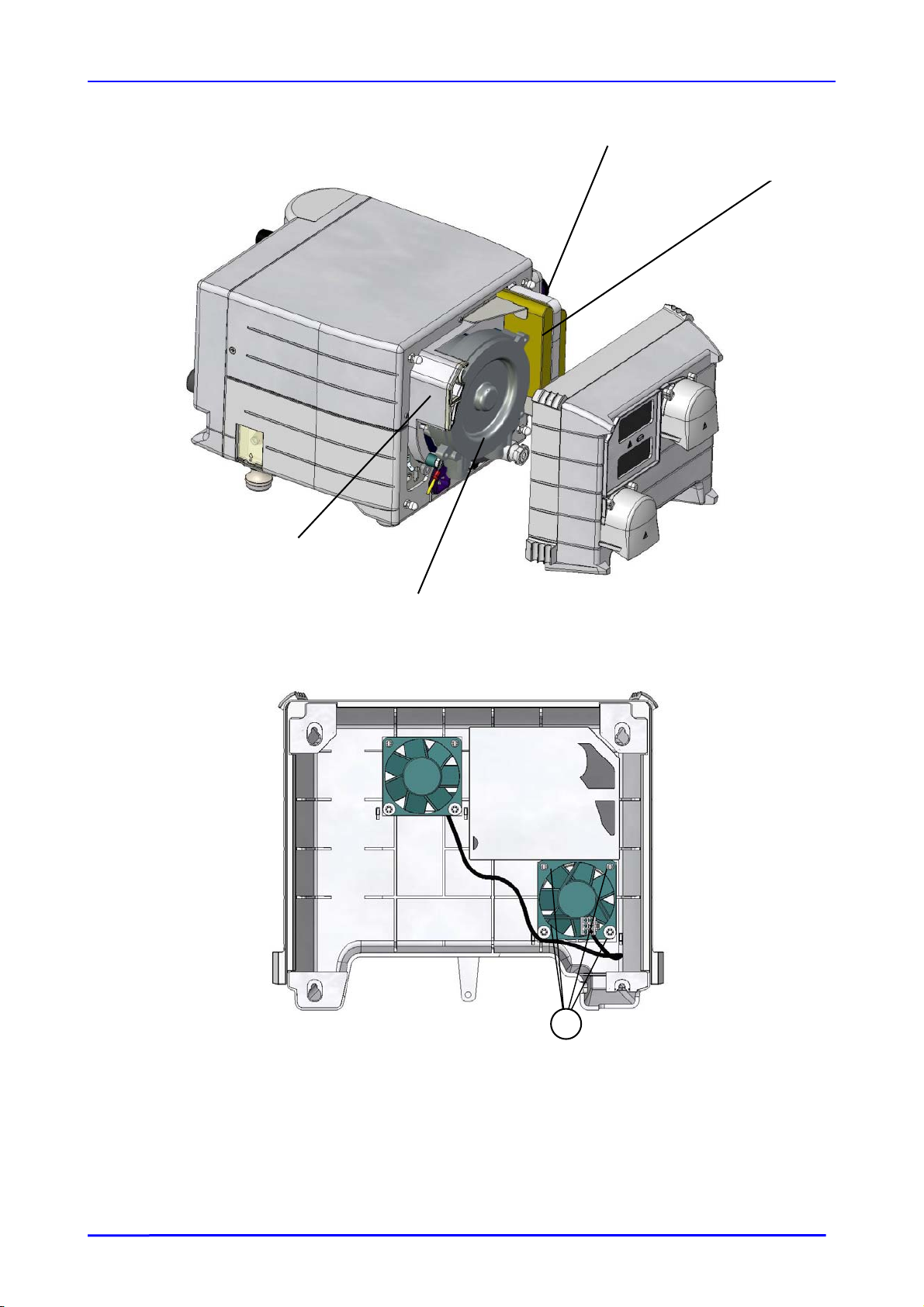

1.3.5. BLOWER VIEW

NEFTIS ICU

Battery mounting

blade

Battery

Mixe

enclosure

Blowe

1.3.6. INSIDE VIEW OF REAR COVER

23

YM027300 / Revision 0 / April 2006

18

Taema

2. MAINTENANCE

NEFTIS ICU

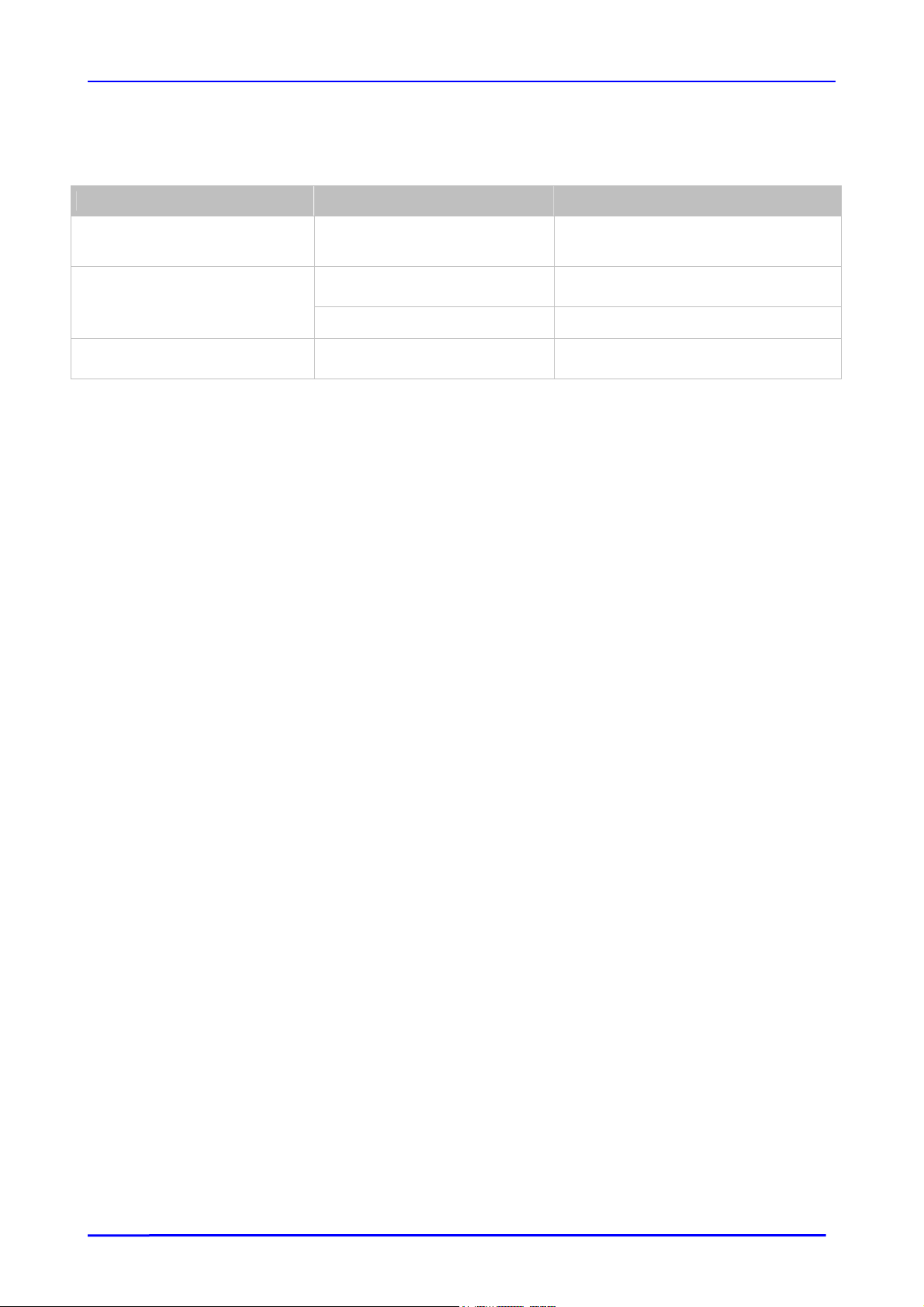

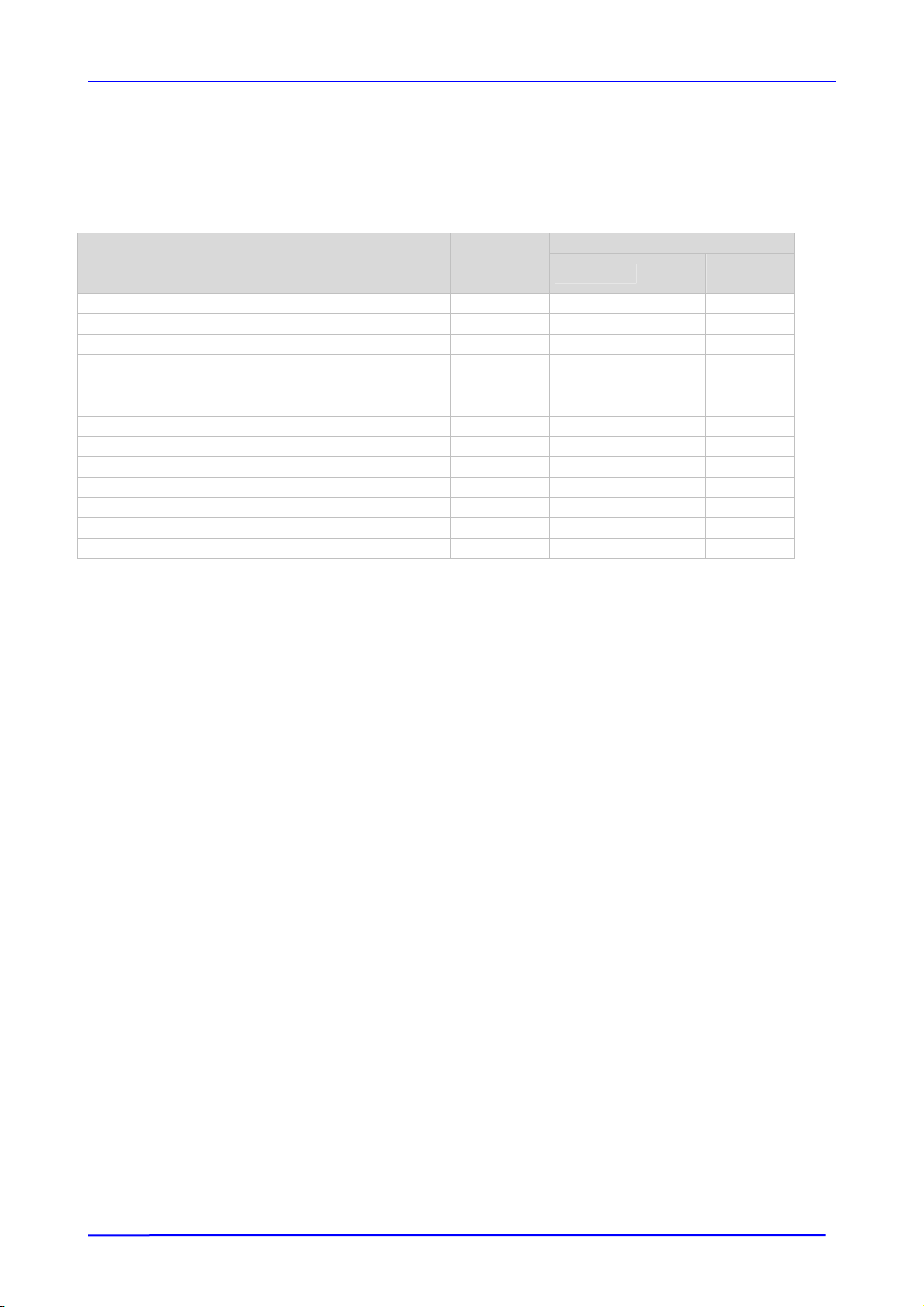

2.1. S

Pressure gauge, 0 – 5 bar Class 1 X X X

O2 connector disassembly key YA004400 X X X

Siemens test lung VS206103 X X X

Integrator test lung KY000600 X X X

Red restriction for integrator test lung KY241800 X X X

Pressure connector T-fitting X X X

Syringe X X X

Digital voltmeter X X

External oxygen meter X X

Pressure gauge, 0 – 100 mbar Class 1 X X X

3-gas connector monitoring pressure gauge BJ060900 X X

Mixer blanking plate YA017200 X X

Battery maintenance cable YA017300 X X X

PECIAL TOOLS

Type of unit Part No.

Type of maintenance

Annual

4

yearly

Correctiv

e

YM027300 / Revision 0 / April 2006

19

Taema

NEFTIS ICU

2.2. PREVENTIVE MAINTENANCE

2.2.1. ANNUAL MAINTENANCE

1- Internal dusting of device

2- Replace the four blue pressure sensor filters

3- Replace the blower output filter

4- Replace the blower dust filters located at the back of the unit

5- Replace the ventilator dust filter underneath the device

6- Replace the oxygen connector check valve end guide

7- Replace the O-rings of the black sleeve on the expiratory unit

8- Replace the expiratory valve membrane and disc

9- Replace the O-ring on the expiratory valve control pressure connector

10- Carry out a check on machine performance

Note

Whenever an internal component of the NEFTIS ICU is replaced (pressure sensor, flow rate

sensors, microprocessor board, blower, etc.) the full adjustment and checking procedure should be

carried out.

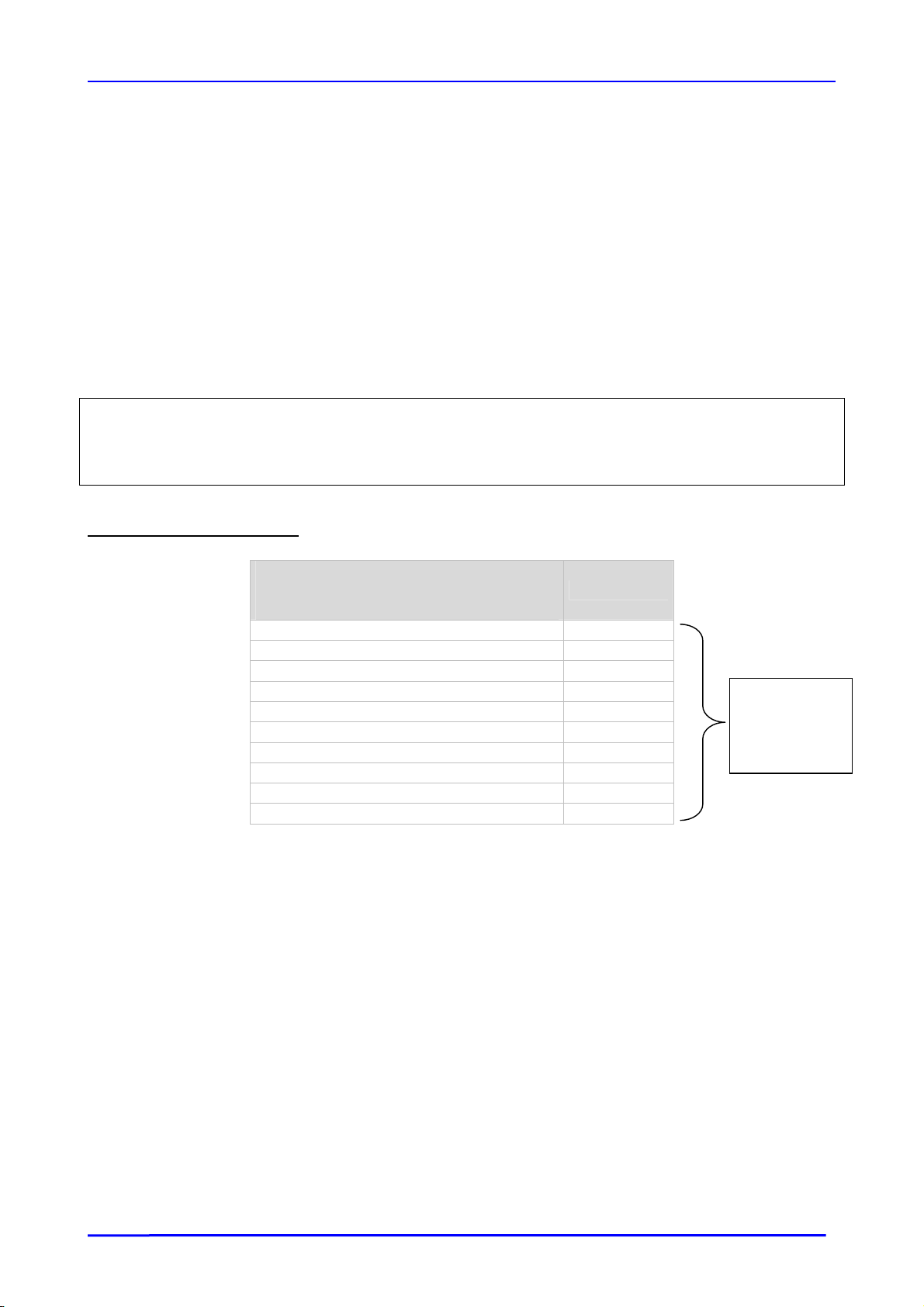

REQUIRED SPARE PARTS

DESCRIPTION

Acrodisc filters 5

Blower outlet filter 1

Rear cover filter 1

Base fan filter 1

Check valve end guide 1

Sleeve O-ring 1

Sleeve O-ring 1

Exp valve membrane 1

Exp valve disc 1

Exp valve connector O-ring 1

Standard maintenance time: 3 hours.

Equipment downtime: 12 hours.

QUANTITY

NEFTIS ICU

ANNUAL

MAINT. KIT

KC026300

YM027300 / Revision 0 / April 2006

20

Taema

2.2.2. 20,000-HOURLY MAINTENANCE*

1- Internal dusting of device

2- Replace the four blue pressure sensor filters

3- Replace the blower outlet filter

4- Replace the blower dust filter located at the back of the unit

5- Replace the fan dust filter underneath the device

6- Replace the oxygen connector check valve end guide

7- Replace the O-rings of the black sleeve on the expiratory unit

8- Replace the expiratory valve membrane and disc

9- Replace the O-ring on the expiratory valve control pressure connector

10- Replace the blower

11- Carry out a check on machine performance

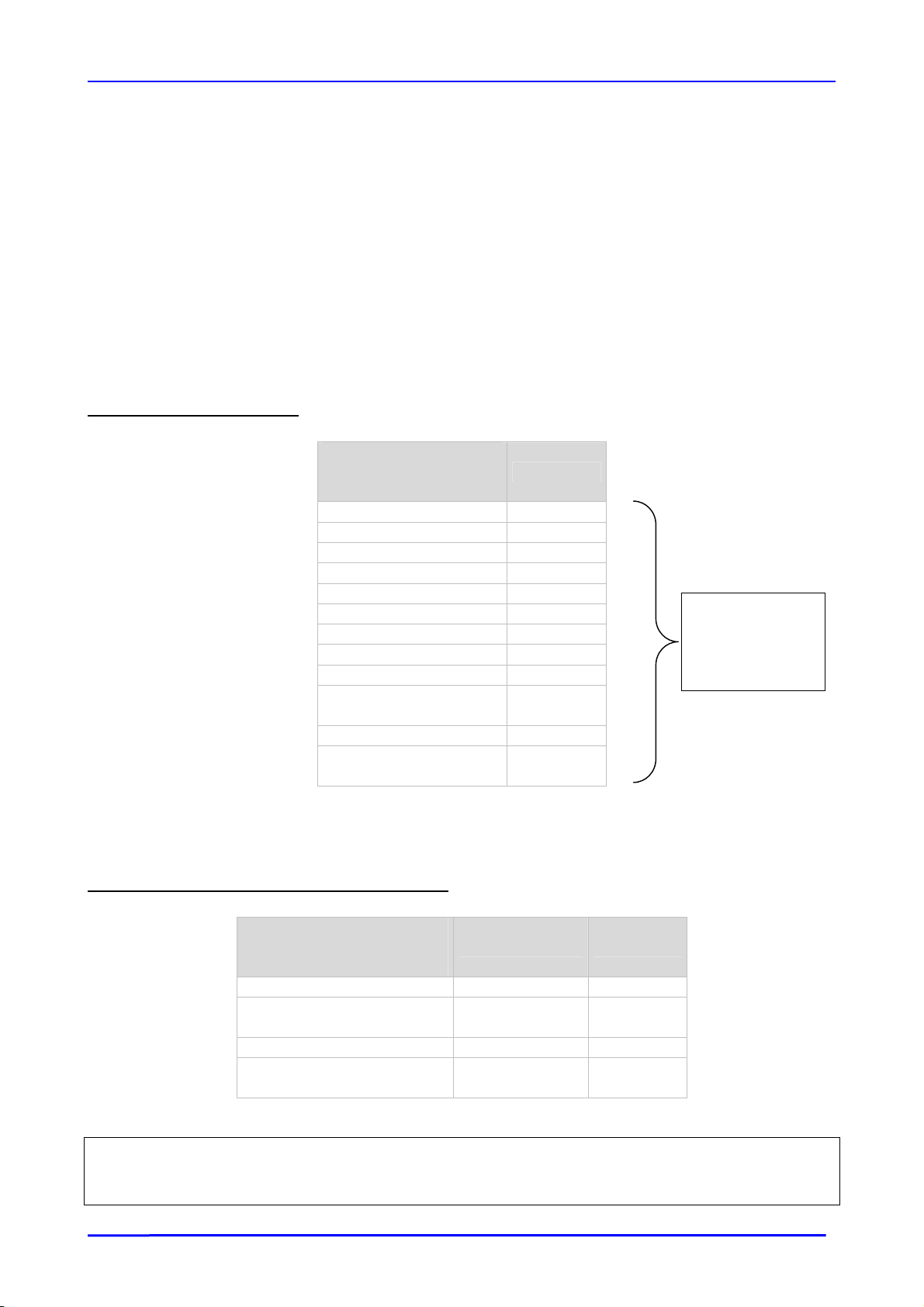

REQUIRED SPARE PARTS

DESCRIPTION

Acrodisc filters 5

Blower outlet filter 1

Rear cover filter 1

Fan filter 1

Check valve end guide 1

Sleeve O-ring 1

Sleeve O-ring 1

Exp valve membrane 1

Exp valve disc 1

Exp valve connector Oring

Blower 1

MOLEX housing for

female contact

Standard maintenance time: 4 hours.

Equipment downtime: 12 hours.

QUANTITY

1

1

NEFTIS ICU

NEFTIS ICU

20,000-HR

MAINT. KIT

KC026400

RECOMMENDED ADDITIONAL SPARE PARTS

DESCRIPTION

INTERNAL BATTERY KY569400 1

LITHIUM BATTERY, 3.6V

½ AA

OXYGEN CELL YR049700 1

LCD CCFL

FLUORESCENT TUBE

Note

Required spare parts are not include in the maintenance kit. However these parts could be replace

in maintenance. Therefore it’s recommended to have them during an intervention.

YM027300 / Revision 0 / April 2006

REFERENCE QUANTITY

VS106125 1

KY620500 1

21

Taema

NEFTIS ICU

2.3. DISASSEMBLY/REASSEMBLY PROTOCOL

Any removal of a component part of the NEFTIS

always requires a full check of the device (see level 2 recommissioning sheet).

NOTES ON HOW TO AVOID DAMAGING THE CONNECTIONS

YPE ELECTRICAL CONNECTORS

KK-T

These connectors should normally be removed by lifting the plastic clips and then pulling on the

cable.

H

OSES ON THE ELECTRONIC PRESSURE SENSORS

The hoses should be removed from the electronic pressure sensors by pulling the hose with

moderate force whilst working the hose clear of the sensor cable support sleeve.

Avoid placing any mechanical stress on the sensor itself. Mechanical stress could sever the

electrical tabs of these sensors.

If possible, do not disconnect the hose from the sensor olive connector side, but from the Y-

piece connector side. Handle the olive connectors with care.

Avoid the application of any sudden depressurising or overpressure to the sensor. To do this, do

not clamp the tube fully when connecting and de-connecting.

P

OLYURETHANE TUBE

®

A Polyurethane

− Firstly, perform the same action as when connecting the pipe in the quick-fit connector.

− When it is at the bottom of its housing, press on the black bushing, hold it down, and

Reinstallation is not difficult, but it is advisable to ensure that the tube is sufficiently lodged in its

housing (5 to 8 mm) to avoid any leakage.

H

ANDLING OF COMPONENTS (AND ELECTRICAL CONTACTS IN GENERAL)

The tabs of components (e.g.: EPROM) and all the components intended to go in electrical

contacts (e.g. connector base) should not be touched, because they are affected by the acidity of

the skin.

E

LECTRONIC BOARDS

Use an anti-static apron when handling an electronic board.

If you remove the board, place the soldered side on an antistatic apron (code VS206001).

Handle with care and without applying any mechanical stress. Be aware of the relative mechanical

fragility of the SMDs (surface mount devices).

The disassembly/reassembly of the microprocessor board must be performed with care. In particular,

tools must not be allowed to slip, in case they damage the surrounding components or tracks.

E

LECTROSTATIC CHARGES

Before touching a component, touch an earthing connection to ensure that you are free of

electrostatic charges.

tube is removed in two steps.

pull on the pipe. The tube comes out easily.

ICU, except the rear cover and the top cover,

YM027300 / Revision 0 / April 2006

22

Taema

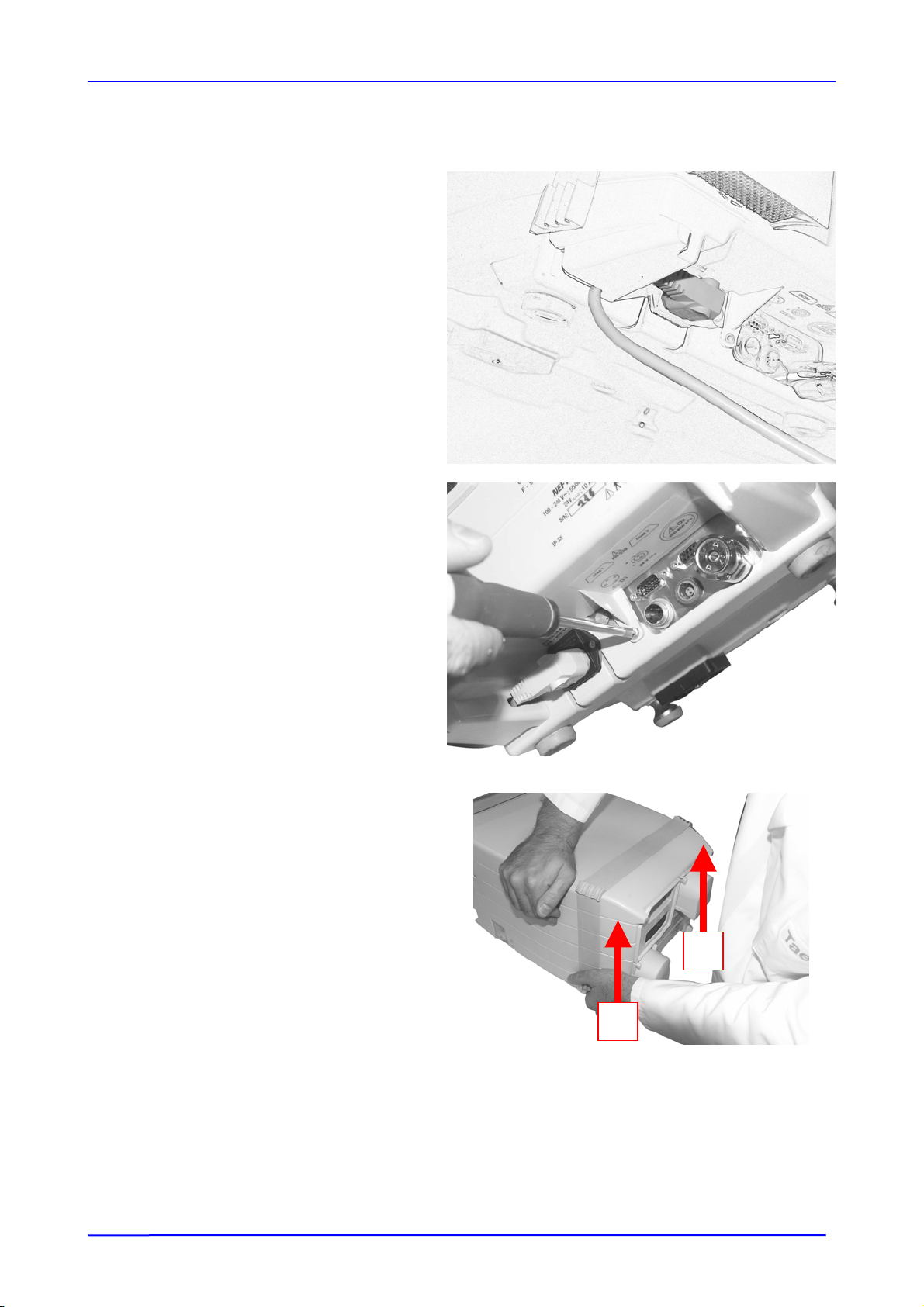

2.3.1. REMOVING THE REAR COVER

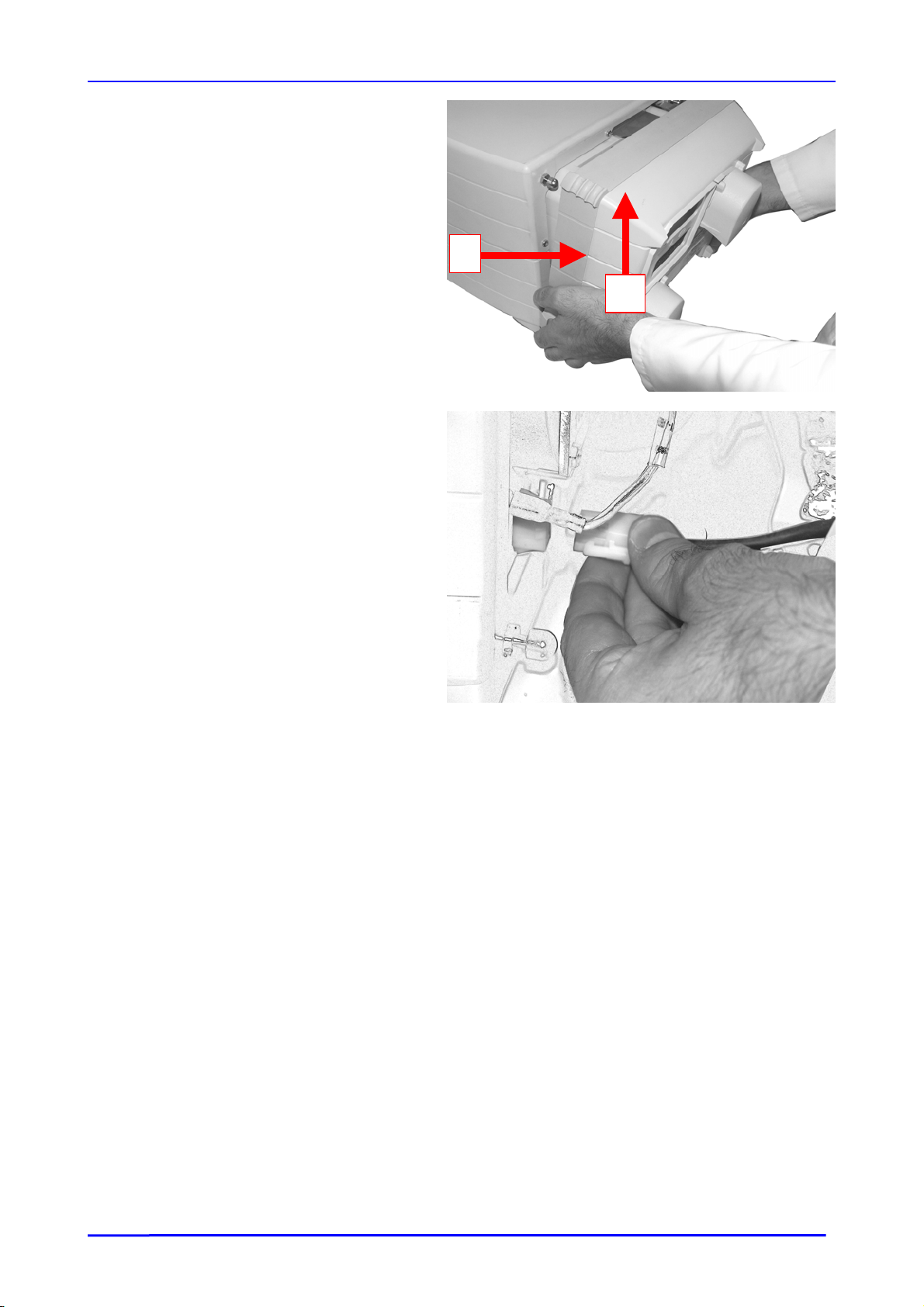

• Position the mains cable as follows

NEFTIS ICU

• Remove the screw from the rear cover

• Disconnect the mains cable

• Lift the rear cover by the left side (1) and

then by the right side (2)

2

1

YM027300 / Revision 0 / April 2006

23

Taema

1

• Pull (1) and then lift (2) the cover clear.

NEFTIS ICU

2

• Disconnect the strand from the fans.

• Remove the rear cover

YM027300 / Revision 0 / April 2006

24

Taema

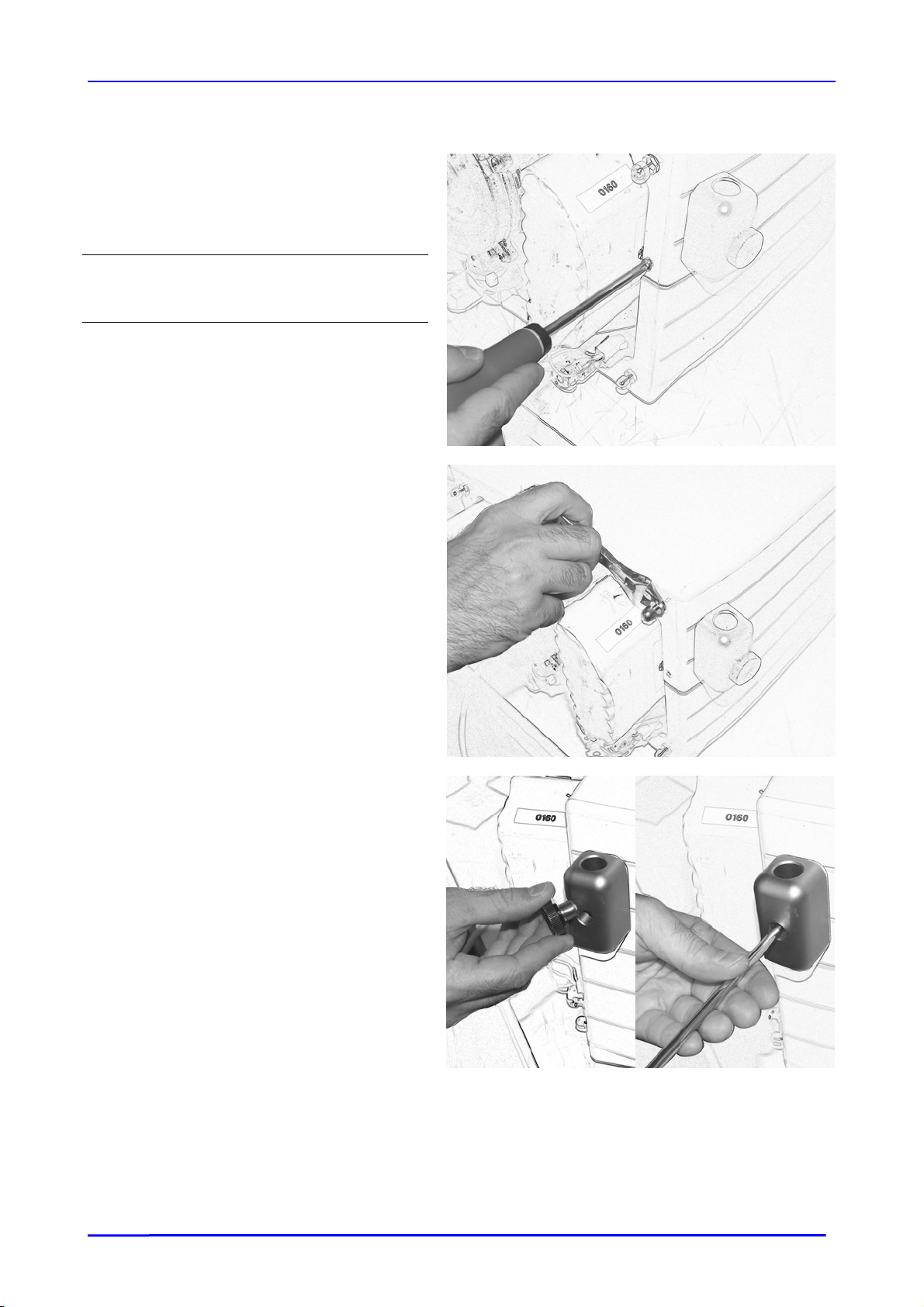

2.3.2. REMOVING THE BATTERY

Remove the rear cover (See Section

•

2.3.1)

Warning

The battery blade must be handled with

care.

• Unclip the lower blade using your middle

finger, whilst holding it with your thumb (see

photo).

NEFTIS ICU

• Disconnect the battery strand.

• Remove the battery.

YM027300 / Revision 0 / April 2006

25

Taema

2.3.3. REMOVING THE TOP COVER

• Remove the rear cover and the battery

blade (See Sections 2.3.1 and 2.3.2)

Note

Leave the battery connected to avoid being

subjected to a loud noise.

• Remove the three M4 Phillips head

screws at the rear of the upper cover.

NEFTIS ICU

• Remove the mounting lugs at the rear of

the upper cover.

• Remove the milled screw and the arm

support screw.

YM027300 / Revision 0 / April 2006

26

Loading...

Loading...