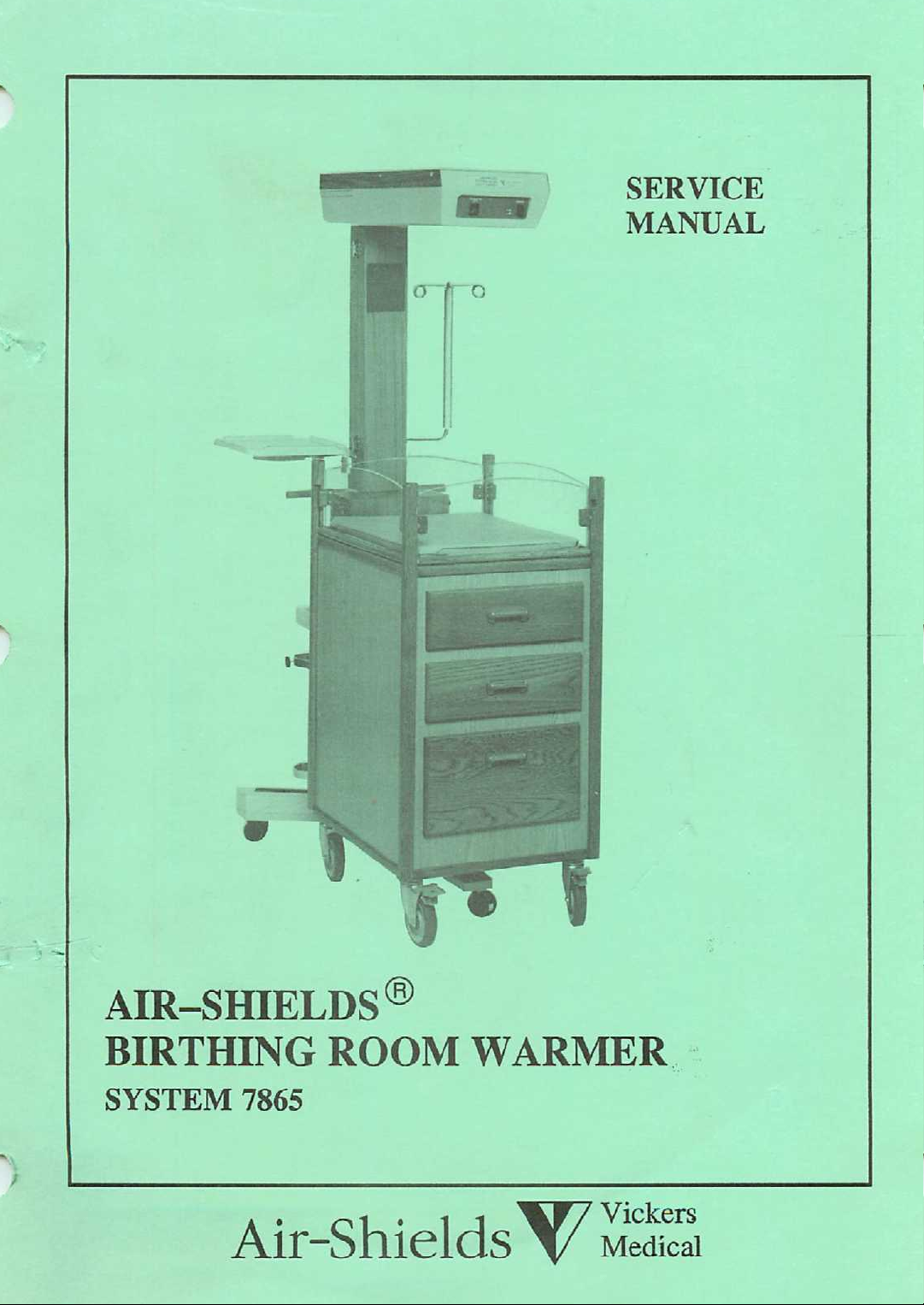

Air Shields 7865 Service manual

SERVICE

MANUAL

AIR-SHIELDS

BIRTHING

SYSTEM

7865

Air-ShieldsV

®

ROOM

WARMER

Vickers

Medical

The

productbeing

workmanshipfor

the

following exceptions.

All

consumable

upon

shipment

described

one

year

and

disposable

only.

LIMITED

WARRANTY

inthis manual iswarranted

from

the

date

of shipment from Air-Shields, Hatboro, with

products

are

guaranteedtobe

against

defects

free from

in materialsor

defects

Calibrations

1

year

During the warranty period

placed at no charge to the customer. There

parts

within

are

warranty.*

the

continental U.S

considered

normal

any

defective parts

maintenance

other

will

and

are

not

than

those

included

listed

above

in

the

willbere

be no labor charge for replacing the

1. Damage to the unit is incurred as a result of mishandling.

2. The customer fails to maintain the unit in a proper manner.

3. The customer

by

Air-Shields.

uses

any parts, accessories, or fittings not specifiedor sold

4. Sale or service is performed by a non-certified service/dealer agency.

This warranty is inlieu of all other warranties, expressed or implied,and Air-Shields

shall innoeventbe liableforincidentalorconsequential damagesincludinglossofuse,

property damage, or personal

The

AccreditationManualforHospitalsrequireseach piece ofequipmentto be tested

initial

priorto

use and at least annually thereafter. To comply withthis standard, we

injury

resultingfrombreach of warranty.

recommend that you participateinourAccreditation TestingCompliance Program dur

ingthewarrantyperiod.Thisservicecan be performed bycertified technicians through

our

Product

Service

Group

and

authorized

dealers.

.

Foroptimal performance, productservice should be performed onlybyqualifiedserv

icepersonnel. ProductServiceGroupinstrumentation specialistsare locatedthrough

out the United States and are dispatched for required maintenance by calling

800-523-2404.

ized

Air-Shields

Cat.

No.78991

EX£A4

5 6 7 8 9

[lM3)4 5 6 7 8 9

SERVICE

Customersoutsidethe U.S. should contacttheir local factory-author

distributor

51-6

for

service.

Air-Shields \

330

Jacksonville

^S»7

Vickers

Medical

Rd.,Hatboro,PA19040

Printed

(Change 1)

(Change 2)

(Change

(Change

(Change

in

U.S.A.

3)

4)

5)

9/87

3/88

8/89

1/91

10/91

6/92

PLEASE

READ

Please check the A page

Since

Air-Shields

improvements

the

printed

rear

ofthe

manualorunder

oneach

shown on the right.

THIS

MODIFICATIONS SHOULD BEPERFORMEDONLY BY

TO

CANNOTASSUME RESPONSIBILITYFORANY CONDITIONS AFFECTING THE PROPER

OPERATION OF THIS

REPAIR

page

MANUAL

MAINTAIN

OR

conductsacontinuous

are

sometimes

manuals.

oftextis

CONTAINS PROPRIETARY

YOUR WARRANTY AND TO

MODIFICATION.

NOTE

Some

parts

usedinyour

this

manual.

function

Thissometimes

ofthe equipment.

When

indicated

ON

equipment

for

change

incorporated

this

separate

EQUIPMENT

information.

occurs,

coverinthe

bya

vertical

product

into

equipment

changed

barinthe

INFORMATION.

AVOID

WHICH

improvement

materialisprovidedonseparate

form

ofa

margin

QUALIFIED

CREATING SAFETY HAZARDS. WE

MAY RESULT

REPLACEMENT

occurs

Order

maybedifferent

dueto

difficultyinparts

the

part

listedinthe

NOTE:

ALSO

SEE

than

Parts

PAGE

those

program,

before

circuit

and

they

canbeincorporated

sheetsat

change

package.

nexttothe

REPAIRS AND AUTHORIZED

FROM

Changed

changed

SERVICE PERSONNEL

material,

UNAUTHORIZED

PARTS

which

appearinthe

procurement,

List.

2.

butdoes not

Parts

component

into

the

material

as

List

alter

the

of

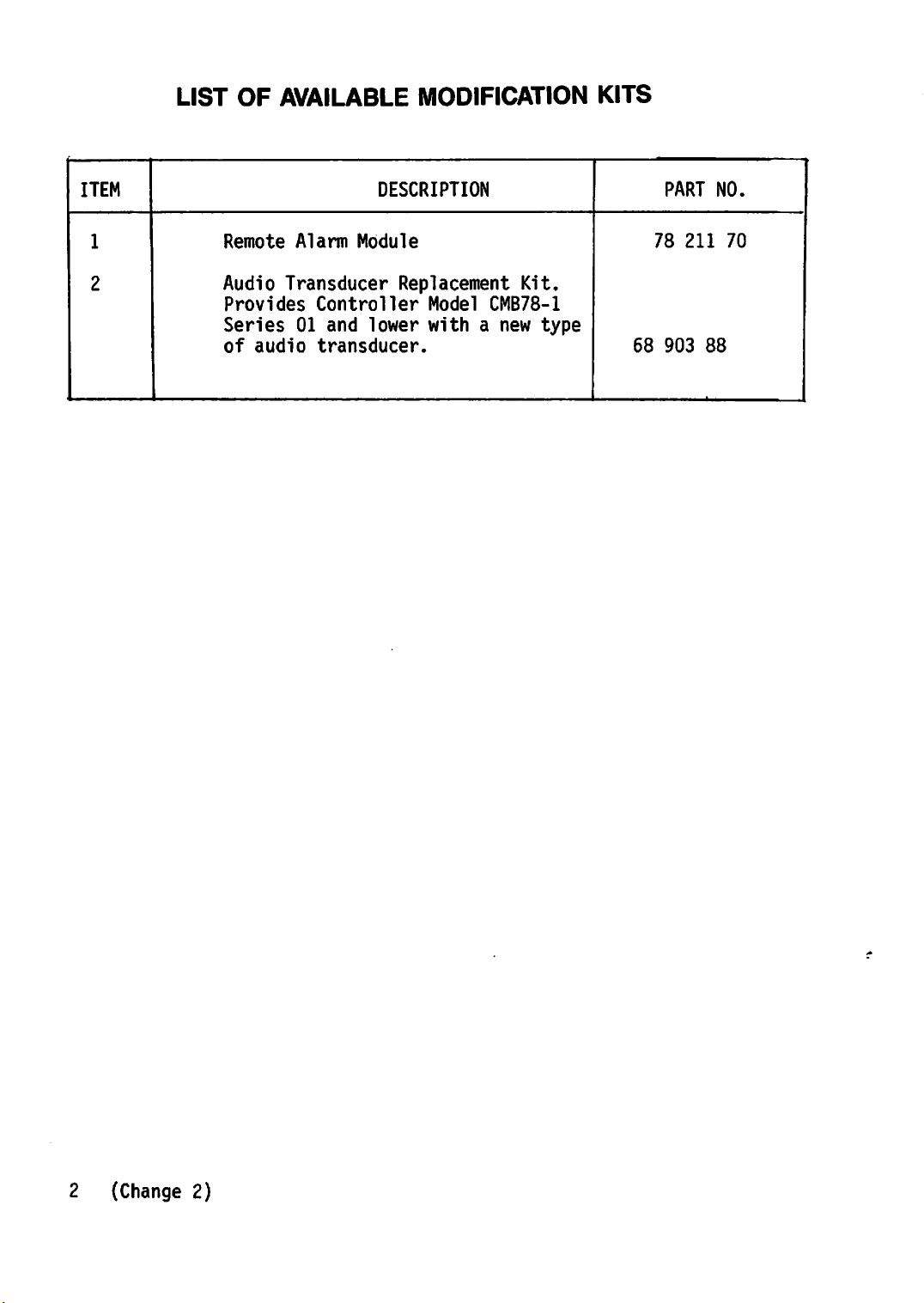

LIST

OF

AVAILABLE

MODIFICATION

KITS

ITEM

1

2

Remote

Audio

Provides

Transducer

Series

of

audio

Alarm

01 and

Module

Controller

lower

transducer.

DESCRIPTION

Replacement

Model

with

Kit.

CMB78-1

a new

type

68

PART

78

903

211

NO.

70

88

2 (Change 2)

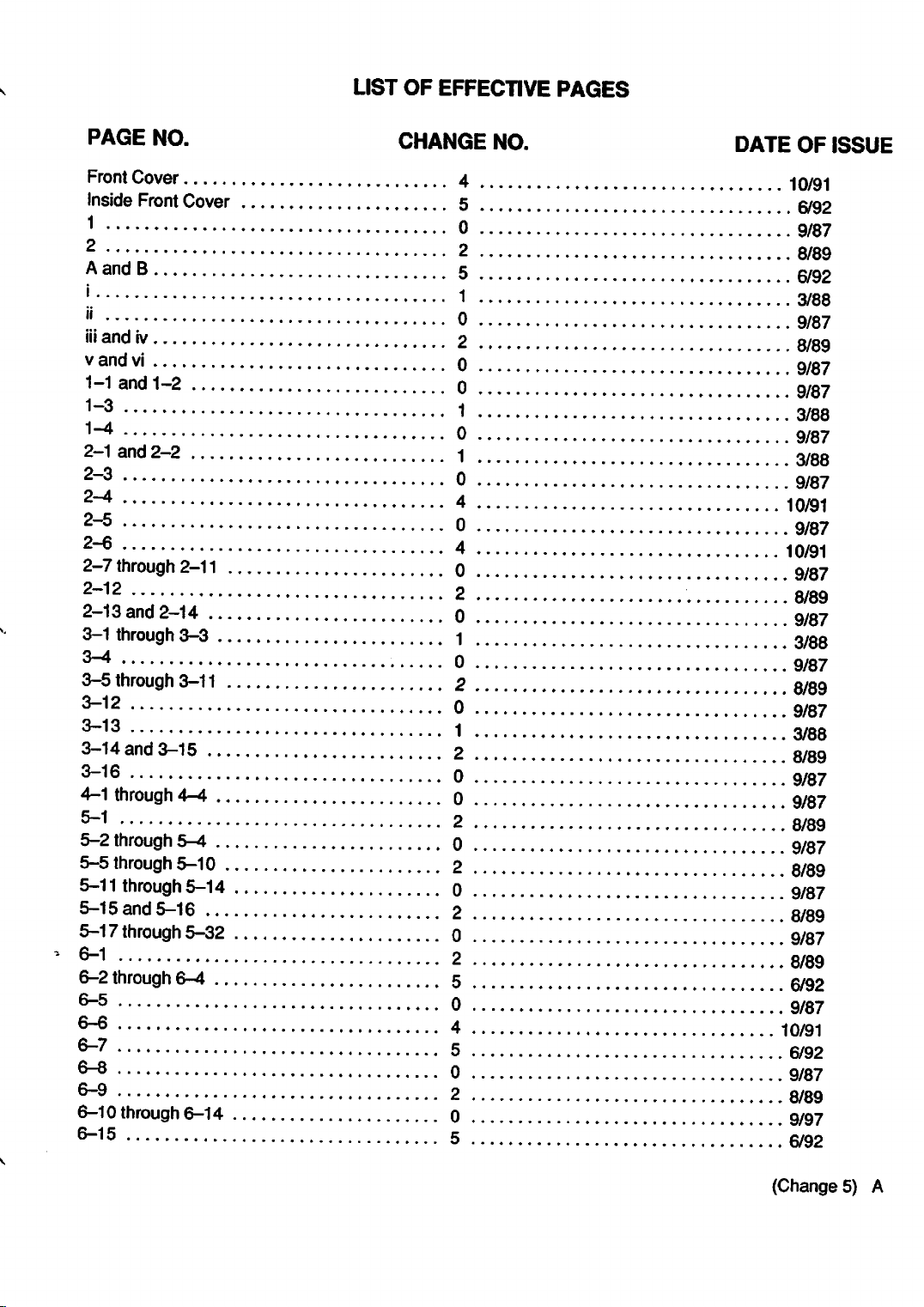

LIST

OF

EFFECTIVE

PAGES

PAGE

Front

Inside

1 0

2 2

A

!.

" 0 9/87

iij

vandvi 0

1"1

1-3 1

1-4 0

2-1 and2-2

2-3 0

2-4 4

2-5 0

2-6 4

2-7

2-12 2

2-13

3-1

3-4 • 0

3-5

3-12 0

3-13 1

3-14

3-16 0

4-1

5-1 2

5-2

5-5

5-11

5-15 and5-16 2

5-17

6-1

6-2

6-5 0

6-6 4

6-7 5

6-8 0

6-9 2

6-10

6-15 5

NO.

Cover

Front

Cover

and

B 5

and

iv

and

1"2 0

through

and

through

through

and

through

through

through

through

through

through

through

2-11

2-14 0

3-3 1

3-11

3-15 2

4-4 0

5-4 0

5-10 2

5-14 0

5-32 0

6-4 5

6-14 0 9/97

CHANGE

4

5

1

2

-,

0

2

2

NO.

DATE

OF

10/91

6/92

9/87

8/89

6/92

3/88

8/89

9/87

9/87

3/88

9/87

3/88

9/87

10/91

9/87

10/91

9/87

8/89

9/87

3/q8

9/87

8/89

9/87

3/88

8/89

9/87

9/87

8/89

9/87

8/89

9/87

8/89

9/87

8/89

6/92

9/87

10/91

6/92

9/87

8/89

6/92

ISSUE

(Change5)

A

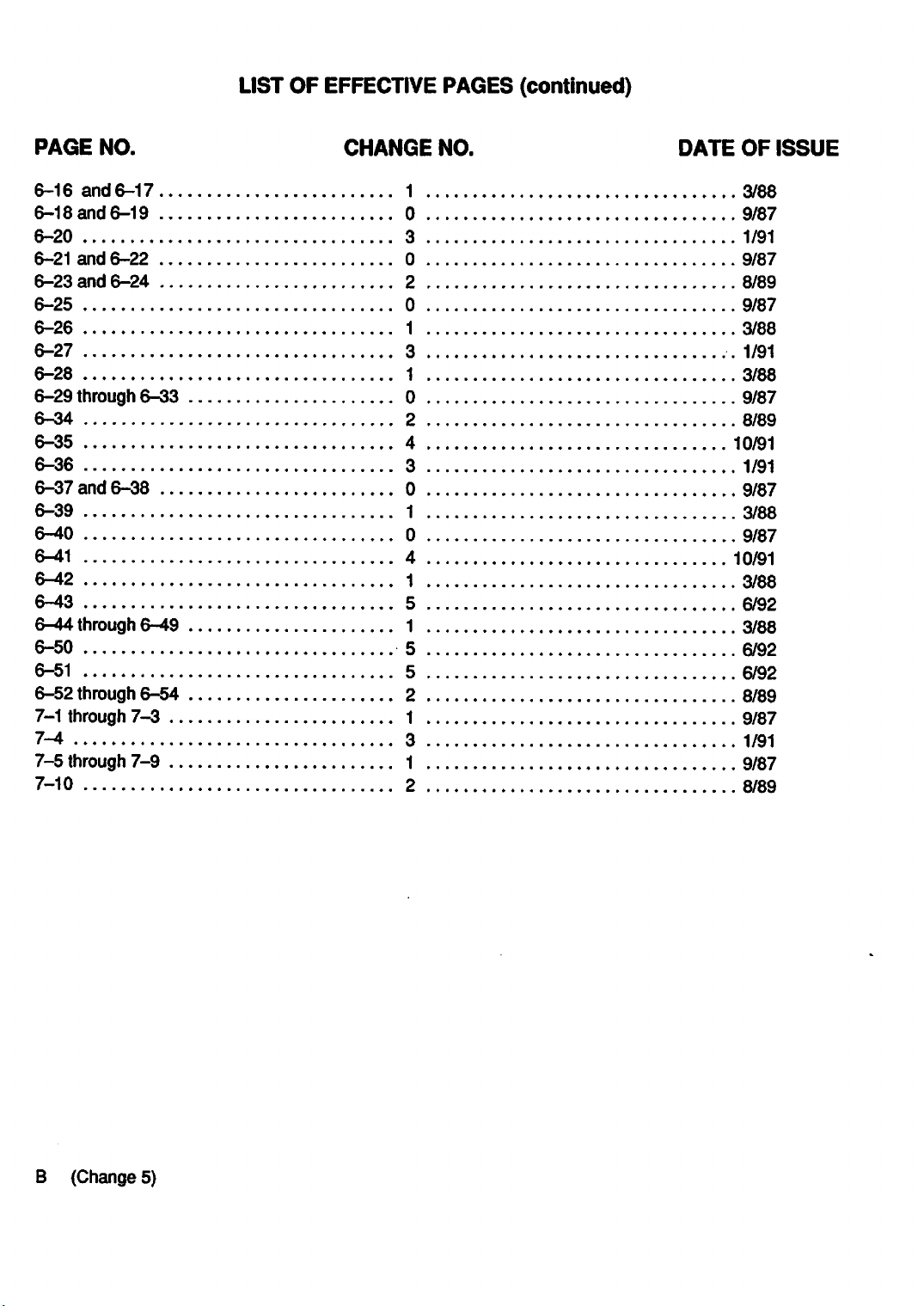

LIST

OF EFFECTIVE

PAGES

(continued)

PAGE

6-16

6-18

6-20

6-21

6-23

6-25

6-26

6-27

6-28

6-29

6-34

6-35

6-36

6-37

6-39

6-40

6-41

6-42

6-43

6-44

6-50

6-51

6-52

7-1

through

7-4

7-5

through

7-10

NO.

and

6-17

and

6-19

and

6-22

and

6-24

through

and

6-38

through

through

6-33

6-49

6-54

7-3

7-9

CHANGE

1

0

3

0

2

0

1

3

1

0 9/87

2

4

3 1/91

0

1

0

4 10/91

1

5

1 3/88

5

5

2 8/89

1 9/87

3 1/91

1 9/87

2

NO.

DATE

OF

3/88

9/87

1/91

9/87

8/89

9/87

3/88

1/91

3/88

8/89

10/91

9/87

3/88

9/87

3/88

6/92

6/92

6/92

8/89

ISSUE

B (Change 5)

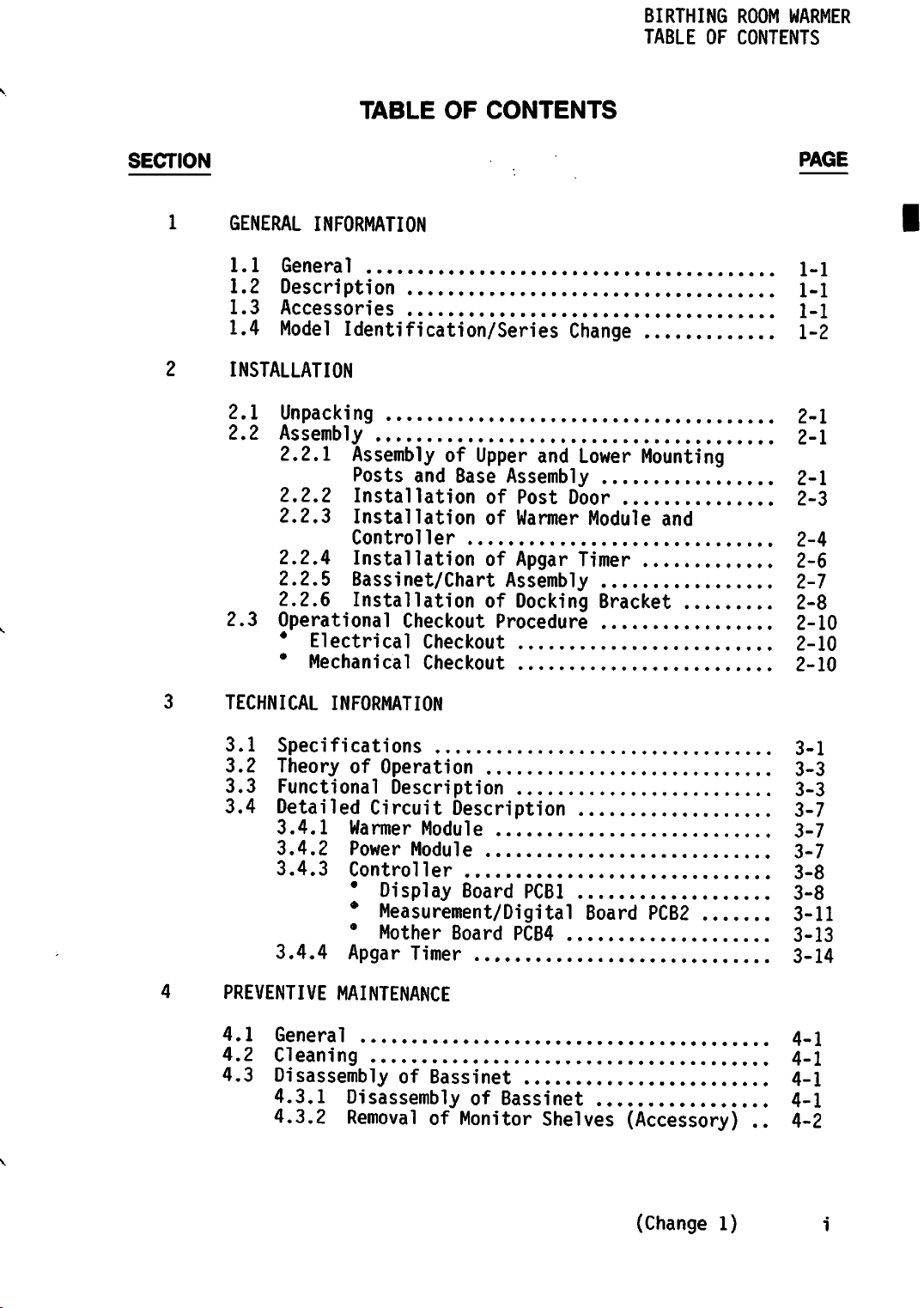

BIRTHING

TABLE OF CONTENTS

ROOM WARMER

SECTION

1 GENERAL INFORMATION

1.1

General

1.2

Description

1.3

Accessories

1.4

Model

2 INSTALLATION

2.1

2.2

Unpacking

Assembly

2.2.1

2.2.2

2.2.3

2.2.4

2.2.5

2.2.6

2.3

Operational

*

Electrical

•

Mechanical

TABLE

Identification/Series

AssemblyofUpper

Posts

Installation

Installation

Control

InstallationofApgar

Bassinet/Chart

OF

CONTENTS

Change

and

Lower

and

Base

Assembly

of

Post

of Warmer

ler 2-4

Assembly

Door

Timer

InstallationofDocking

Checkout

Checkout

Checkout

Procedure

Mounting

Module

Bracket

PAGE

1-1

1-1

1-1

1-2

2-1

2-1

2-1

2-3

and

2-6

2-7

2-8

2-10

2-10

2-10

3 TECHNICAL INFORMATION

3.1

3.2

3.3

3.4

4 PREVENTIVE MAINTENANCE

4.1

4.2

4.3

Specifications

Theory

Functional

Detailed

3.4.1

3.4.2

3.4.3

3.4.4

of

Operation

Description

Circuit

Warmer

Power

Controller

*

*

*

Apgar

Module

Module

Display

Measurement/Digital

Mother

Timer

General

Cleaning

DisassemblyofBassinet

4.3.1

4.3.2

DisassemblyofBassinet

RemovalofMonitor

Description

Board

Board

PCB1

PCB4

Shelves

Board

PCB2

(Accessory)..4-2

3-1

3-3

3-3

3-7

3-7

3-7

3-8

3-8

3-11

3-13

3-14

4-1

4-1

4-1

4-1

(Change

1)

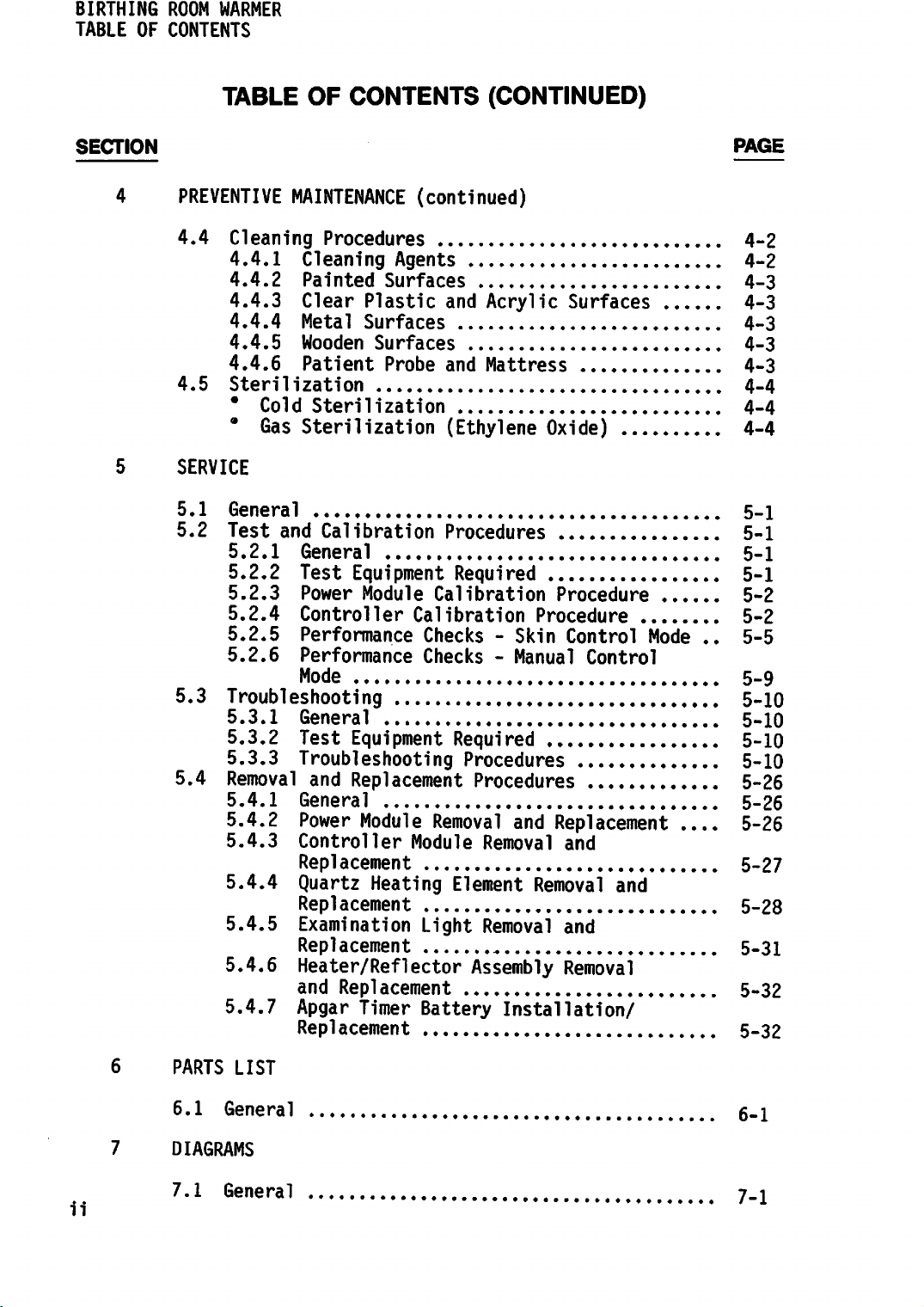

BIRTHING ROOM

TABLE OF CONTENTS

WARMER

SECTION

4

5 SERVICE

TABLE

PREVENTIVE

4.4

4.5 Sterilization 4-4

5.1

5.2

5.3

5.4

Cleaning

4.4.1

4.4.2

4.4.3

4.4.4

4.4.5 Wooden

4.4.6

•

•

General

Test

5.2.1

5.2.2

5.2.3 Power Module Calibration Procedure 5-2

5.2.4

5.2.5

5.2.6

Troubleshooting

5.3.1

5.3.2

5.3.3

Removal

5.4.1

5.4.2

5.4.3 Controller

5.4.4

5.4.5

5.4.6

5.4.7

OF

CONTENTS

MAINTENANCE

Procedures

Cleaning

Painted

Clear

Metal

Patient

Cold

Gas

Sterilization

Sterilization

and

Calibration

General

Test

Controller

Performance

Performance

Mode

General

Test

Agents

Surfaces

Plastic

Surfaces

Surfaces

Probe

Equipment

Equipment

Troubleshooting

and

Replacement

General

Power

Replacement

Quartz

Repl

Module

Heating

acement

Examination

Replacement

Heater/Reflector

and

Repl

acement

Apgar

Repl

Timer

acement

(CONTINUED)

(continued)

and

Acrylic

and

Mattress

(Ethylene

Procedures

Required

Calibration

Checks-Skin

Checks-Manual

Required

Procedures

Procedures

Removal

Module

Removal

Element

Light

Removal

Assembly

Battery

Procedure

and

Removal

Installation/

Surfaces

Oxide)

Control

Control

Mode

Replacement

and

and

and

Removal

..

PAGE

4-2

4-2

4-3

4-3

4-3

4-3

4-3

4-4

4-4

5-1

5-1

5-1

5-1

5-2

5-5

5-9

5-10

5-10

5-10

5-10

5-26

5-26

5-26

5-27

5-28

5-31

5-32

5-32

6 PARTS LIST

6.1

7 DIAGRAMS

7.1

ii

General

General

6-1

7_1

BIRTHING

TABLE

OF CONTENTS

ROOM

WARMER

FIGURE

2.

.1

.2

2,

2.

.3

2,

.4

2.

.5

.6

2.

2.

.7

.8

2,

2,

.9

3.

.1

4,

,1

5,

.1

5,

.2

5.

.3

,4

5,

5.

,5

,6

5,

6,

,1

6.

,2

6.

.3

,4

6.

6.5

6.6

6.7

6.8

6.9

6.10

6.11

6.12

6.13

6.14

6.15

6.16

6.17

6.18

LIST

Assembly

Base

Mounting

Installation

Installation

Installation

Bassinet/Cart

Installation

Checking

Checking

System

Removing

Duty

Power

Controller

Adjustment

Quartz

Examination

Installation/ReplacementofApgar

Birthing

Bassinet/Cart,

Controller

Controller

Diagram

Controller

Diagram

Controller

Diagram

Controller

Diagram

Power

Power

Parts

Warmer

Warmer

Heater/Reflector

Apgar

Monitor

AC

Receptacle

Diagram

I.V.

Diagram 6-48

Resuscitation

Controller

Model

of

Assembly

Post

Side

Mattress

Block

Side

Cycle

Module

Heating

Room

Module

Module

Location

Module

Module

Timer,

Shelf

Pole-1-inch

CMB78-1

OF

ILLUSTRATIONS

TITLE

Upper

of

of

of

Docking

Diagram

Adjustment

Module

Light

Assembly,

Display

Display

Display

Display

Assembly,

Assembly,

Parts

Motherboard/Speaker

and

Lower

Mounting

Door

Warmer

Apgar

Side Panels 2-7

Module and

Timer

Assembly

Bracket

and

End

Panels

Tilt

and

End

Panels

Removal

Element

Warmer,

Parts

Diagram

Assembly,

Subassembly,

Unit,

Box

Box,

and

Replacement

Removal

Removal

Removal

Parts

Location

Parts

Board

Board

Board

Board

PCB1,

PCB2,

PCB3,

PCB4,

Parts

Power

Parts

Assembly,

Location

Parts

Assembly,

Diameter,

Parts

Location

and

Replacement

and

and

Replacement

Location

Diagram

Location

Parts

Parts

Parts

Parts

Location

Supply

Location

Parts

Parts

Diagram

Location

Parts

Parts

Assy

Series

02,

Parts

Location

Posts

Controller

Replacement

Timer

Batteries

Diagram

Diagram

Location

Location

Location

Location

Diagram

Board

Diagram

Location

Location

Diagram

Location

Location

Diagram

PCB4,

Diagram

and

and

PCB1,

Diagram

Diagram

..

..

..

PAGE

2-2

2-3

2-5

2-6

2-8

2-9

2-13

2-14

3-4

4-2

5-5

5-26

5-27

5-30

5-31

5-32

6-2

6-6

6-8

6-10

6-14

6-18

6-22

6-26

6-30

6-34

6-38

6-40

6-42

6-44

6-46

6-50

6-52

(Change

2)

iii

LIST

OF ILLUSTRATIONS (CONT.)

17.7

I

FIGURE

7.1

7.2

7.3

7.4

7.5

7.6

7.8

TABLE

1.1

1.2

1.3

1.4

1.5

3.1

6.1

6.2

6.3

6.4

6.5

6.6

6.7

6.8

6.9

6.10

6.11

6.12

6.13

6.14

6.15

6.16

6.17

6.18

TITLE

Schematic

Schematic

Controller

Schematic

Schematic

Schematic

Schematic

Wiring

Schematic

Assy,

Series

Series

Series

Series

Series

Specifications

Birthing

Bassinet/Cart,

Controller

Controller

Controller

List 6-15

Controller

Controller

Power

Power

Power

Warmer

Warmer

Heater/Reflector

Apgar

Monitor

AC

Receptacle

I.V.

Resuscitation

Controller

Controller

Diagram,

Diagram,

Display

Diagram,

Diagram,

Diagram,

Diagram,

Diagram,

Diagram,

PCB4

for

Change-Bassinet/Cart,

Change-Warmer

Change-Power

Change-Controller

Change-Apgar

Room

Assembly,

Display

Controller

Measurement/Digital

Board

PCB2

Controller

Controller

Apgar

Power

Power

Timer

Module

Module

Controller

Model

LIST

Warmer,

Parts

CMB78-1

OF

TITLE

Module,

Module,

Timer,

Parts

List

Parts

Board

TABLES

PCBl,

Measurement/Digital

Control

Mother

Module

Module

Module),

Module

Module

Timer,

Shelf

Pole,

1-Inch

Assembly,

Power

Parts

Board

Board

PCB3,

PCB4,

Parts

Supply

Parts

Assembly,

List

Parts

Subassembly,

Assembly,

List

Unit,

Box

Box,

Parts

Assembly,

Diameter,

Parts

List

Motherboard/Speaker

Model

CMB78-1

Series

Display

Board

Mother

and

Warmer

Board

PCB3

Board

Motherboard/Speaker

Series

Model

Model

Model

Module,

Model

List

List

Parts

List

Board,

List

Parts

Parts

List

Parts

Parts

Assy,

Model

AT78-1

Parts

Board

Parts

PCBl

List

List

List

List

02,

02

CBB78-1

WBR78-1

PM78-1

CMB78-1

List

PCB2,

List

List

(Series

PCB4

Parts

PCBl

PCB4

and

Parts

List

....

IE

01

...

..

...

PAGE

7-3

7-4

7-5

7-6

7-7

7-8

7-9

7-10

PAGE

1-2

1-2

1-3

1-3

1-3

3-1

6-3

6-7

6-9

6-11

6-19

6-23

6-27

6-31

6-35

6-39

6-41

6-43

6-45

6-47

6-49

6-51

6-53

iv

(Change

2)

BIRTHING

TABLE

OF CONTENTS

ROOM

WARMER

CHART

5.1

5.2

5.3

Controller

Warmer

Power

Module

Module

LIST

OF

FLOWCHARTS

TITLE

Module

Troubleshooting

Troubleshooting

Troubleshooting

PAGE

5-12

5-21

5-23

BIRTHING

TABLE

OF

ROOM

WARMER

CONTENTS

vi

(This

pageisintentionally

left

blank.)

BIRTHING

GENERAL

ROOM

WARMER

INFORMATION

1.1

GENERAL

This

The

care

manual

provides

repairofthe

1.2

DESCRIPTION

Air-Shields®

integrated

of

system

the

newborn.

Air-Shields®

Bassinet/Cart,

manual

temperature

Accessories

and

The

the

heat

storage

Birthing

infant

can

control,

control.

are

of

Room

SECTION

GENERAL

instructions

Birthing

Birthing

that

Warmer

Room

may

be

The

Birthing

Module

Warmerisdesignedtoprovide

used

andaController

monitoringofskin

available

equipment.

Warmer

be

transportedtoanother

for

resuscitation,

Interlocking

1

INFORMATION

for

installation,

Room

Warmer,

immediately

Room

Warmer

Module

temperature

oxygen

after

consistsofa

maintenance

System

birth

which

and

delivery,

Bassinet/Cartisdetachable

area

in

the

hospital.

7865.

an

for

provides

skin

and

the

mounting

so

1.3

ACCESSORIES

WARMER

s

Resuscitation

•

Oxygen

•

Airway

e

Oxygen

«

Twin-0-Vac™,

•

Flowmeter,

t

Oxygen

9

Oxygen

•

Oxygen

•

Monitor

• I.V.

0

AC

§ Positive Pressure Pediatric Resuscitator

• Remote Alarm Module

Delivery

Air

Hose

Hose

Shelf

Pole

Receptacle

Box

Delivery

Pressure

System,

Pediatric

Without

Tank

Holder,DandECylinders

Assembly

Assembly

Unit

Box

(includes)

Manifold

Gauge

Yoke

Oxygen

(Six

Take-Off

(3

ft.)

(10

ft.)

Outlets)

and

Gauge

1-1

BIRTHING ROOM WARMER

GENERAL INFORMATION

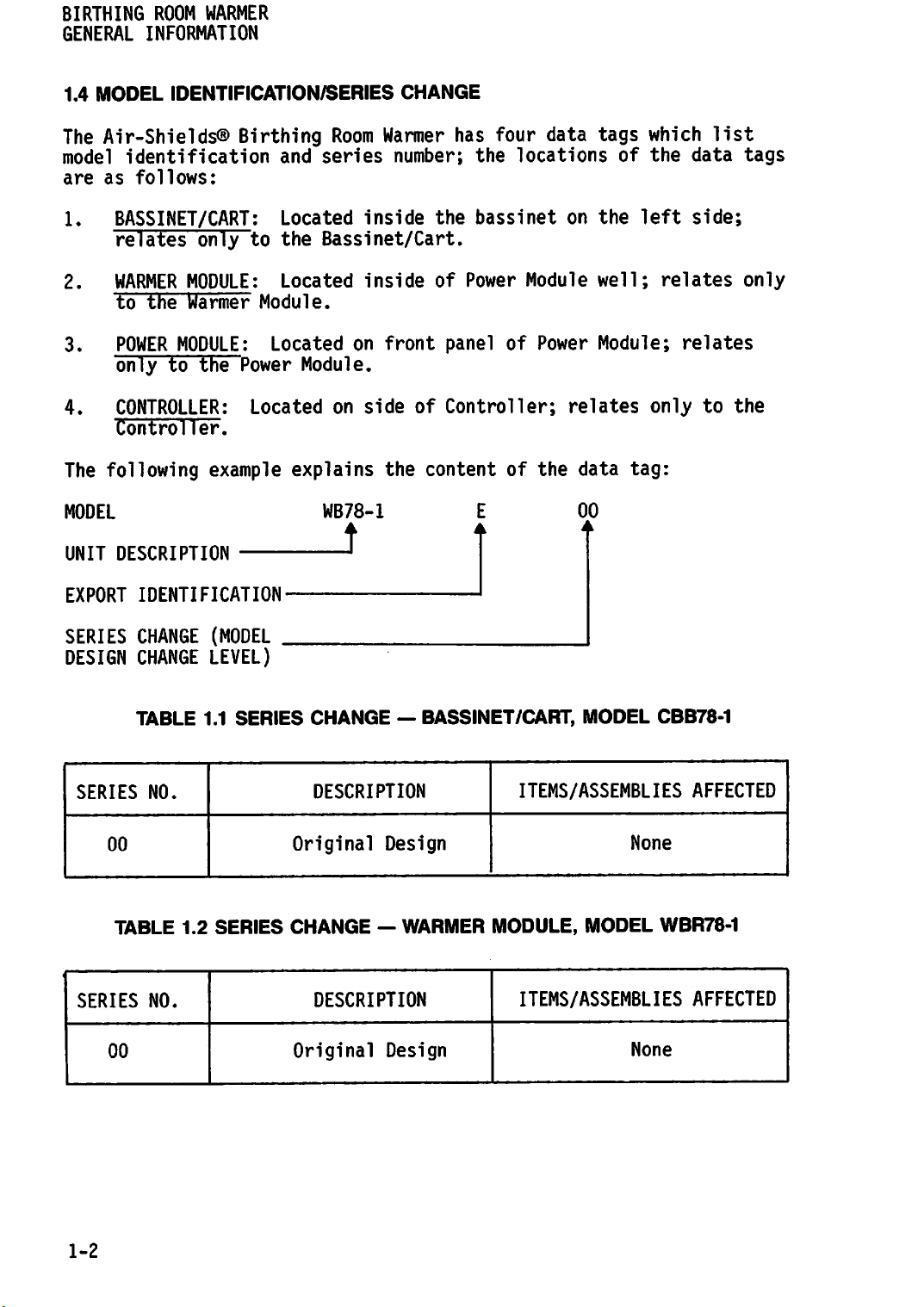

1.4

MODEL

The

Air-Shields®

model

are

as

1.

BASSINET/CART:

relates

2.

WARMER

to the

3.

POWER

only

4.

CONTROLLER:

Controller.

The

following

IDENTIFICATION/SERIES

Birthing

identification

follows:

only

MODULE:

Warmer

to

MODULE:

to

the

Power

Located

example

and

Located

the

Located

Module.

Located

Module.

explains

CHANGE

Room

series

inside

Warmer

number;

has

the

Bassinet/Cart.

on

inside

on

side

of

front

the

panel

of

Controller;

contentofthe

four

the

locations

bassinet

Power

Module

of

data

on

Power

relates

tags

of the

the

well;

Module;

data

which

left

only

tag:

list

data

side;

relates

relates

to

tags

only

the

MODEL

UNIT

DESCRIPTION

EXPORT IDENTIFICATION

SERIES

DESIGN

SERIES

SERIES

CHANGE

CHANGE

TABLE

00

TABLE

NO.

NO.

1.1

1.2

(MODEL

LEVEL)

SERIES

SERIES

WB78-1

.J

.

CHANGE

DESCRIPTION

Original

CHANGE-WARMER

DESCRIPTION

—

BASSINET/CART,

Design

00

•

MODEL

ITEMS/ASSEMBLIES

None

MODULE, MODEL

ITEMS/ASSEMBLIES

CBB78-1

AFFECTED

WBR78-1

AFFECTED

1-2

00

Original

Design

None

BIRTHING

GENERAL

ROOM

WARMER

INFORMATION

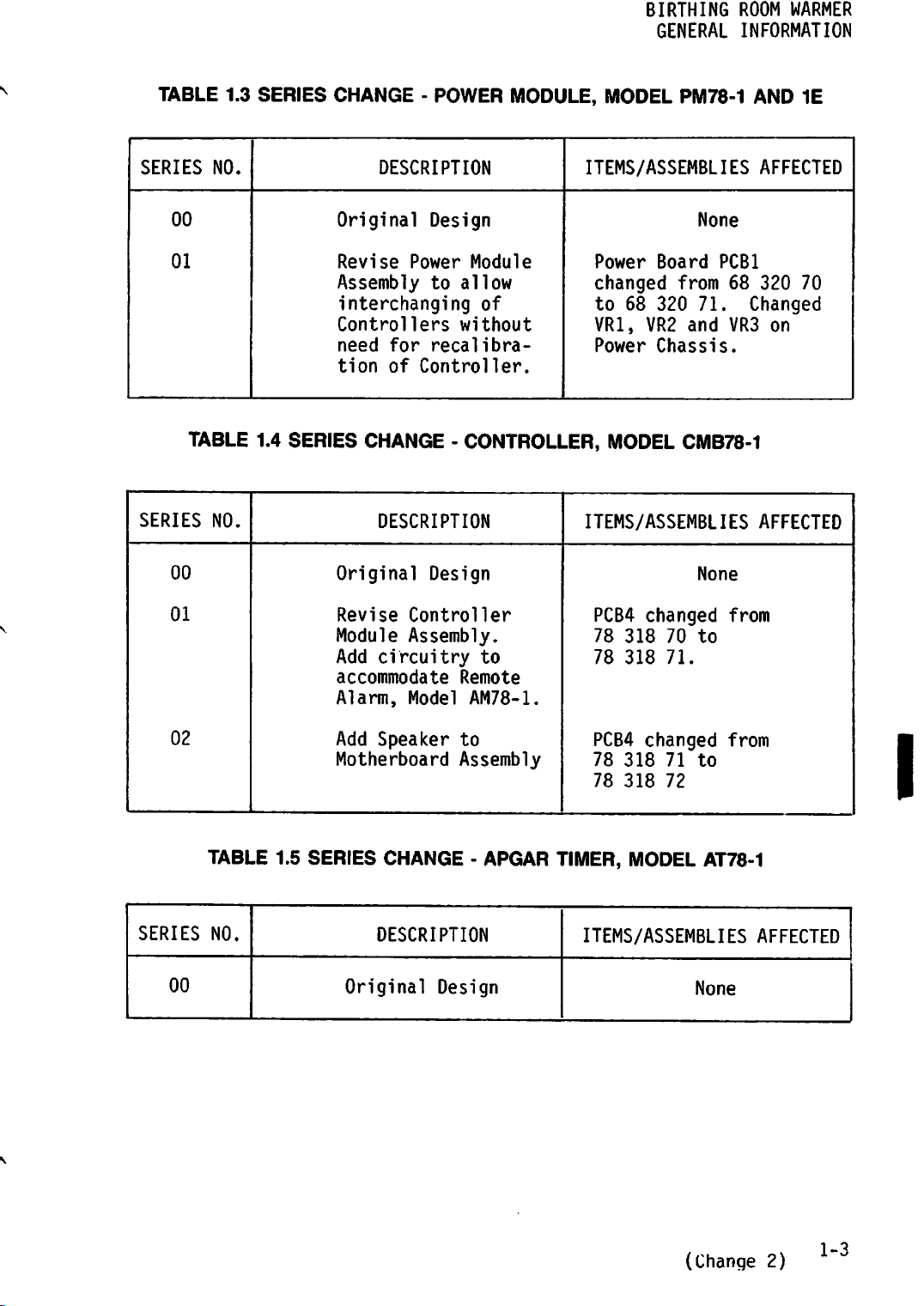

TABLE 1.3

SERIES

00

01

TABLE 1.4

SERIES

00

NO.

NO.

SERIES

SERIES

CHANGE - POWER MODULE, MODEL PM78-1 AND 1E

DESCRIPTION

Original

Revise

Assembly

interchanging

Controllers

need

tion of Controller.

Design

Power

to allow

for

recalibra-

Module

of

without

ITEMS/ASSEMBLIES AFFECTED

None

Power

changed

to 68 320

VR1, VR2 and VR3 on

Power

Board

PCBl

from

71.

Chassis.

68

320

Changed

70

CHANGE - CONTROLLER, MODEL CMB78-1

DESCRIPTION

Original

Design

ITEMS/ASSEMBLIES AFFECTED

None

01

02

SERIES

00

TABLE 1.5

NO.

Revise

Module

Add

circuitry

accommodate

Alarm,

Add

Speaker

Motherboard

SERIES

CHANGE -

DESCRIPTION

Original

Controller

Assembly.

to

Remote

Model

AM78-1.

to

Assembly

APGAR

Design

PCB4

78

78

PCB4

78

78

changed

318

70 to

318

71.

changed

318

71 to

318

72

from

from

TIMER, MODEL AT78-1

ITEMS/ASSEMBLIES AFFECTED

None

I

(Change 2)

1-3

BIRTHING

GENERAL

ROOM

WARMER

INFORMATION

1-4

(This

pageisintentionally

left

blank.)

BIRTHING

ROOM

WARMER

INSTALLATION

2.1

UNPACKING

When

or

materials.

The

following

removing

otherwise

Birthing

items:

Warmer

Upper

Lower

Base

Docking

Controller

Bassinet/Cart

Mattress

Mattress

Ballast

Casters

Patient

Handle

Apgar

Post

Bumpers

End and Side Panels

Module

Mounting

Mounting

Assembly

Timer

Door

the

equipment

damage

Room

Warmer

Bracket

Assembly

Tray

for

Cart

Probe

INSTALLATION

from

unprotected

is

shippedincartons

Assembly

Post

Post

and

SECTION

the

surfaces;

Power

Module

2

cartons,

remove

use

all

which

care

packing

contain

not

to

scratch

the

2.2

ASSEMBLY

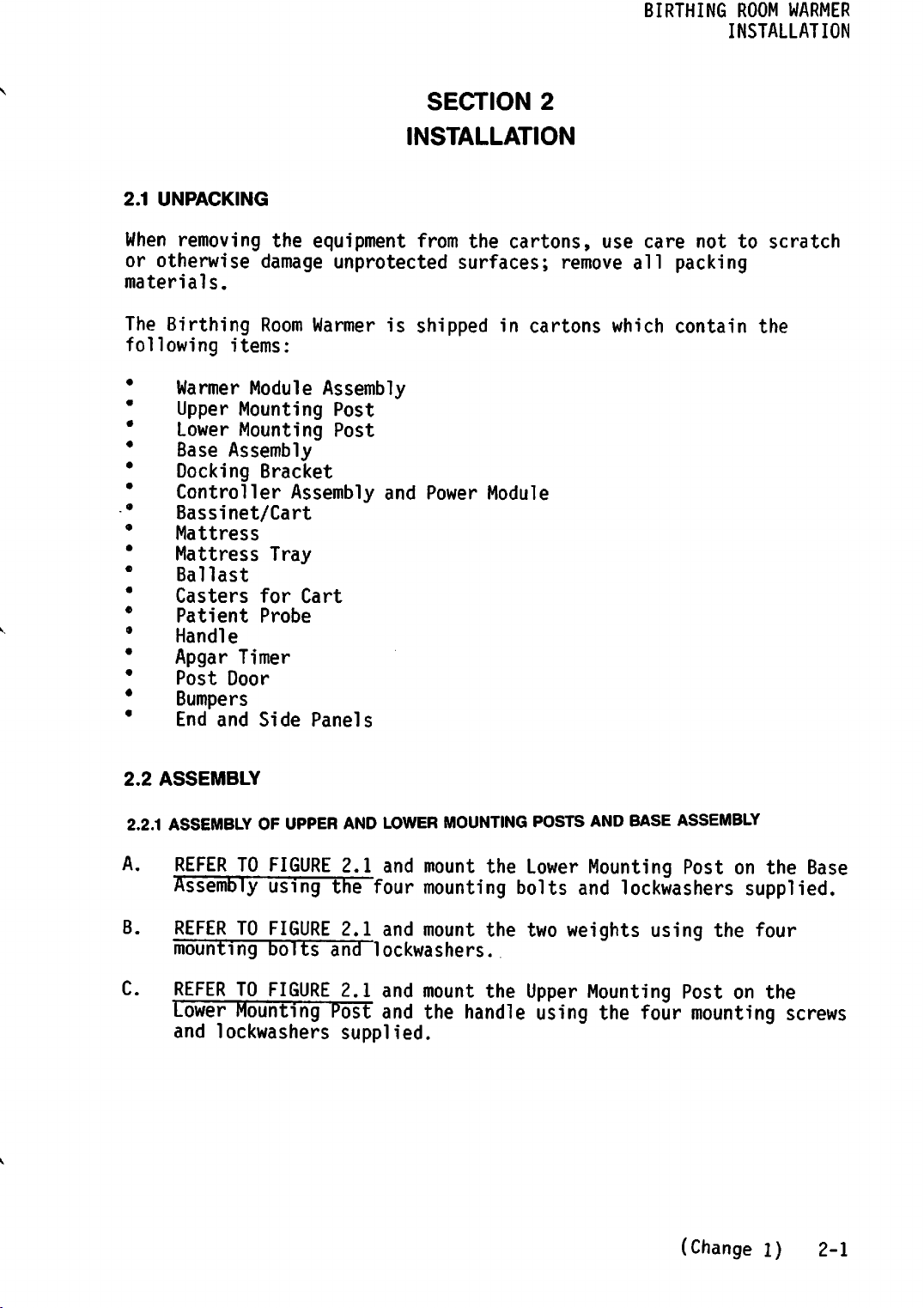

2.2.1 ASSEMBLY OF UPPER AND LOWER

A.

B.

C

REFERTOFIGURE

Assembly

REFER

mounting bolts and

TO

using

FIGURE

REFERTOFIGURE

Lower

and

Mounting

lockwashers

2.1

the

2.1

2.1

Post

supplied.

and

four

and

lockwashers.

and

and

MOUNTING

mount

the

mounting

mount

mount

the

the two

the

handle

POSTS AND BASE ASSEMBLY

Lower

bolts

Upper

using

Mounting

and

lockwashers

weights

Mounting

the

Postonthe

using

Post

four

mounting

(Change

supplied.

the

four

on

the

1)

Base

screws

2-1

BIRTHING

ROOM

INSTALLATION

UPPER

WARMER

MOUNTING

POST

HANDLE

BALLAST

1/2"X1/4-20

1/4"

SPLIT

LOCK

5/16"-18

5/16"

SPLIT

HEX HEAD

WASHER

1

3/8"x1/4-20

1/4"

SPLIT

1/4"

I.D. x 1" O.D. x

x 1

3/4"

LOCK

WASHER

LOCK

HEX

1

5/8"x1/4-20

1/4"

HEX

HEAD

WASHER

.09

HEAD

SPLIT

THK.

LOCK

FLAT

HEX HEAD

WASHER

WASHER

2-2

FIGURE

(Change 1)

2.1

ASSEMBLY

OF

AND

UPPER

BASE

AND

LOWER

ASSEMBLY

MOUNTING

POSTS

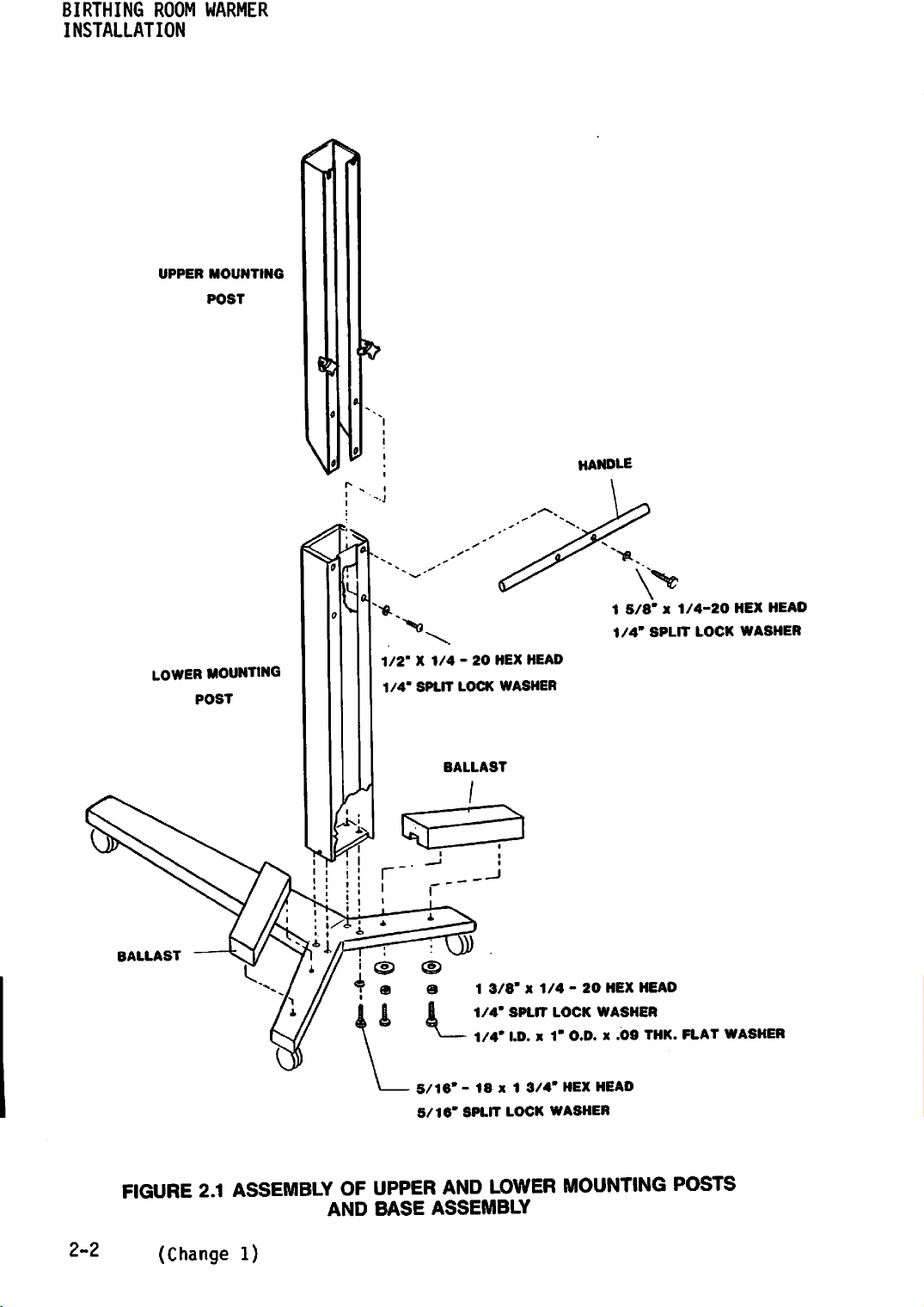

2.2.2

To

install

A.

B.

INSTALLATION

the

MOUNT

Front

MOUNT

hinges.

THE

of

THE

OF

Post

POST

the

TWO

POST

DOOR

Door,

DOOR

Post.

BUMPERS

refertoFigure

(1)

with

the

hardware

(3)

on

the

post

^Sl

2.2

and

provided

directly

BIRTHING

ROOM

WARMER

INSTALLATION

proceedasfollows:

(2)

on

the

across

from

the

FIGURE

2.2

MOUNTING

POST

DOOR

2-3

BIRTHING

INSTALLATION

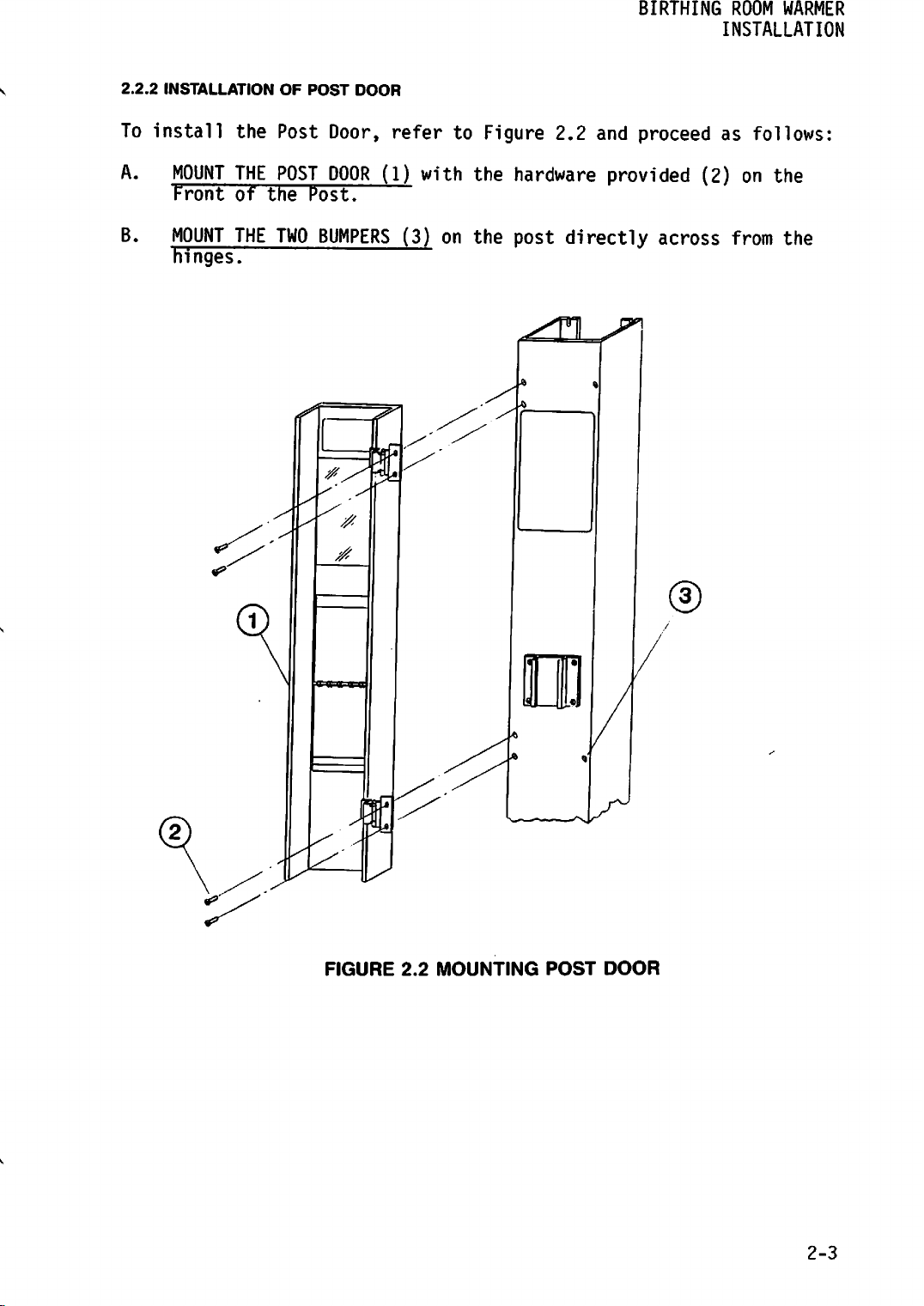

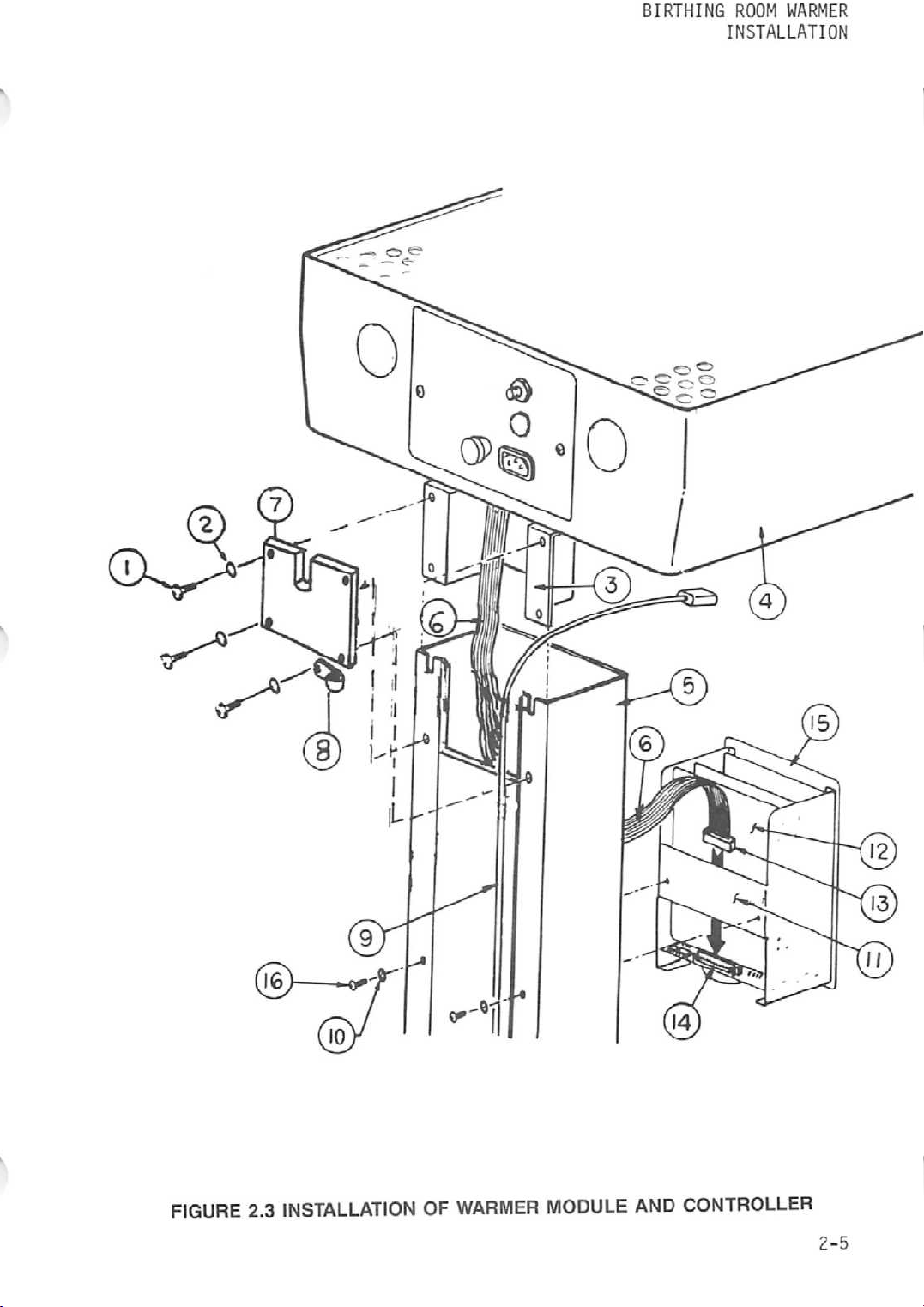

2.2.3

INSTALLATION

ROOM

WARMER

OF

WARMER

MODULE

AND

CONTROLLER

To install

proceed

A.

CAUTION:

when

B.

IMPORTANT: Make

heads

Post.

the

Warmer

as

follows:

RAISE

(5)

SLOWLY

end

THE

and

insert

Use

Installing

LOWER THE WARMER

of

the

WARMER

the

interconnecting ribbon

caretoprevent

the

Warmer

Mounting Post. Refer to the illustration below

reinforcing plate (7)

and

no 10 lock

and

are

washers

between

Module on

MODULE (4)

and

the

(2) in the

sure

that

the

screw

the

Mounting Post, refer to Figure

above

damagetothe

Module.

MODULE

the

open

endofthe

cable

(6) into

the

open

interconnecting

MOUNTING flange intothe open

Warmer Module using the 10 - 32 X

the

upper-most

lock

washers

heads

and

the

holes.

(2)

outer

are

directly

surfaceofthe

2.3

Mounting

endofthe

ribbon

and

secure

112"

under

and

cable

screws

the

screw

Mounting

C. INSTALL THE POWER CORD CLAMP (8) on the Power Cord (9); position

clamp

11

inches

from

the

endofthe

Power

Cord.

">

Post

post.

the

(1)

the

D. SECURE THE POWER CORD CLAMP AND POWER CLAMP to the Mounting

Post and reinforcing bracket when installing the two lower-most Warmer

Module mounting screws (1) as shown in figure 2.3 and the illustration below.

Tighten all mounting

screws

securely.

NOTE: Raise the frontofthe Warmer Moduleslightlywhen tightening the topmost

mounting screws. This

will

relieve

the

pressure

on

the

screws

and

ease

the

tightening procedure.

E. OPEN THE DOOR that covers the mounting post.

F. CAREFULLY THREAD THE INTERCONNECTING CABLE (6) out through the

Controller opening at

CAUTION:

•

•

When

that

Make

circuit

connecting

the

cableIsnot

sure

that

board

and

the

front of the Warmer Module mounting post.

the

Interconneding

twisted

the

Interconnecting

the

back

or

crimped.

crossmember

cabletothe

cableIsdressed

of

the

Controller

Controller,

down

chassis.

make

between

sure

the

2-4

(Change

4)

BIRTHING

ROOM

WARMER

INSTALLATION

FIGURE

2.3

INSTALLATIONOFWARMER

MODULE

AND

CONTROLLER

2-5

BIRTHING

INSTALLATION

ROOM

WARMER

I • When connecting the interconnecting cable to the Controller,

that

the

key

on

the

cable

G.

CAREFULLY

the

back

connect

THREAD

cross-member

the

cable plug (13) to

plug is inserted into the slot on the connector

CAUTION:

nottotwist,

H.

CAREFULLY

When

crimp,

Installing

pinch,orotherwise

DRESS

opening in the Mounting Post, insert the Controller (15) into the opening, and

install the Controller mounting screws (16) and lock

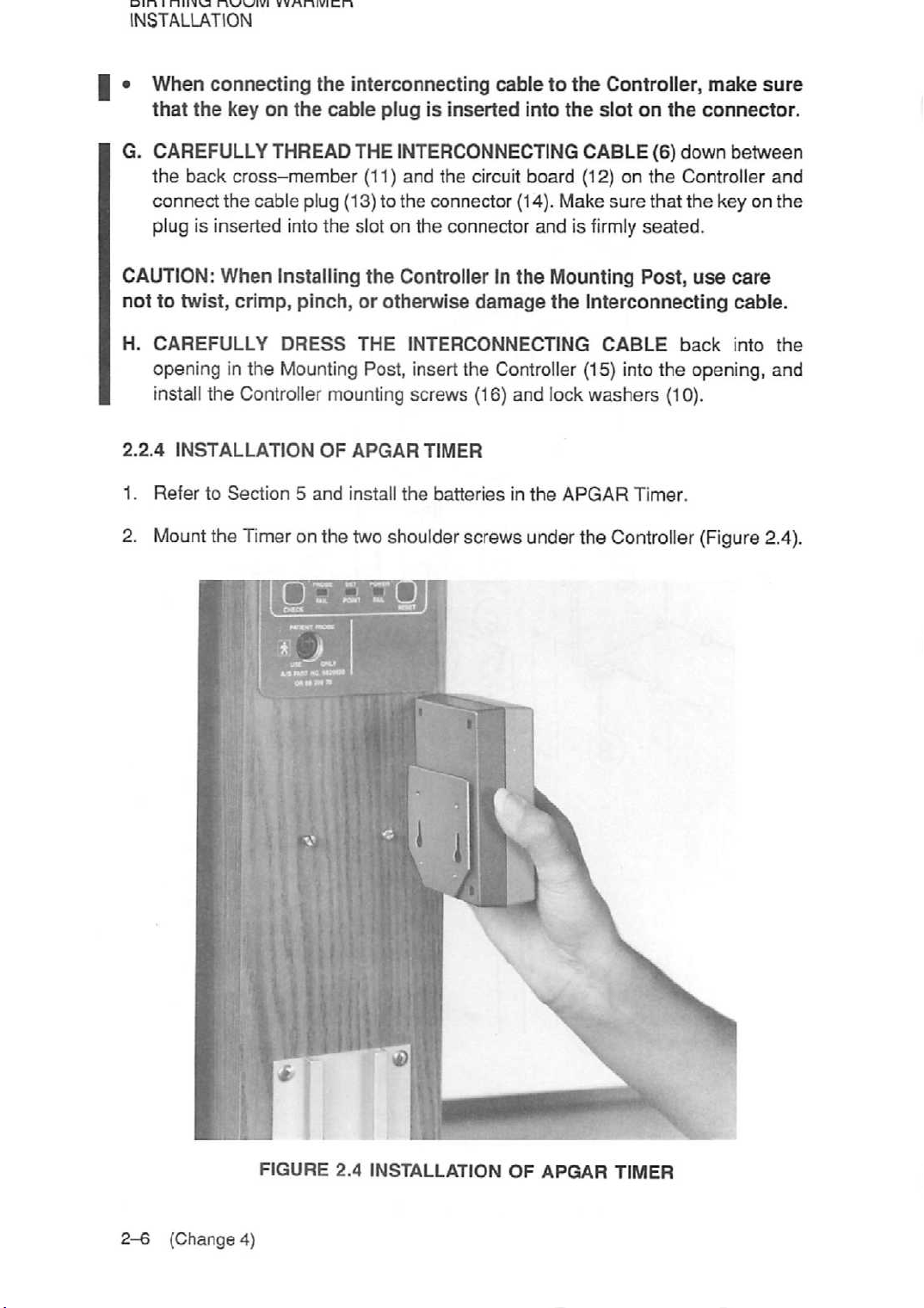

2.2.4

1.

2.

INSTALLATION

RefertoSection5and

Mount

the Timer on the two shoulder screws under the Controller (Figure 2.4).

OF

plugisinserted

THE

INTERCONNECTING

into

the

CABLE

(11) and the circuit board (12) on

the

connector (14). Make

andisfirmly

the

Controller In

THE

INTERCONNECTING

the

damage

Mounting

the

Interconnecting

washers

APGAR

install

TIMER

the

batteriesinthe

APGAR

slot

sure

CABLE

Timer.

on

the

(6)

down

the

that

seated.

Post,

back

(10).

Controller

the

make

connector.

between

key on

use

care

cable.

into

sure

and

the

the

2-6

(Change

FIGURE

4)

2.4

INSTALLATION

OF

APGAR

TIMER

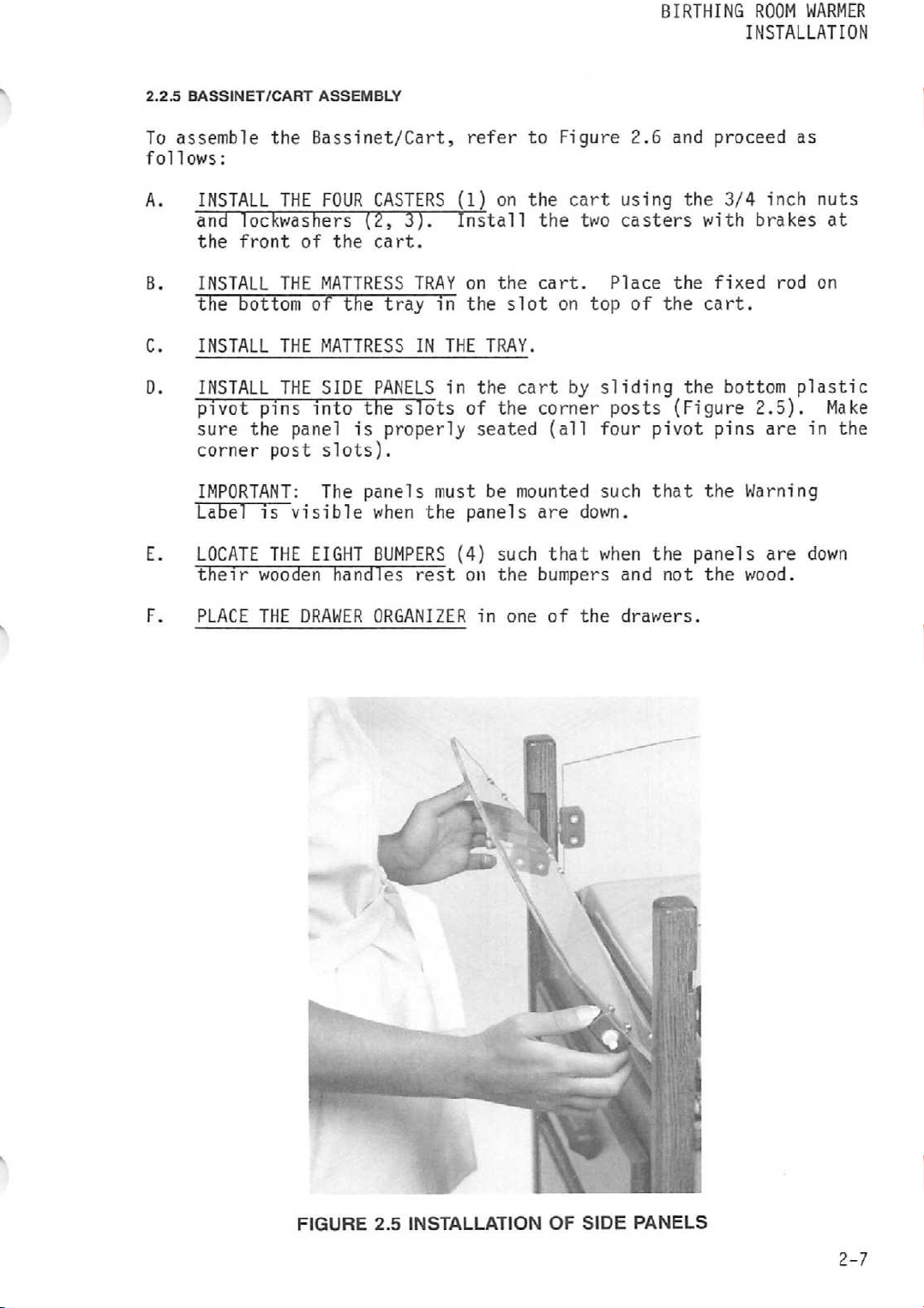

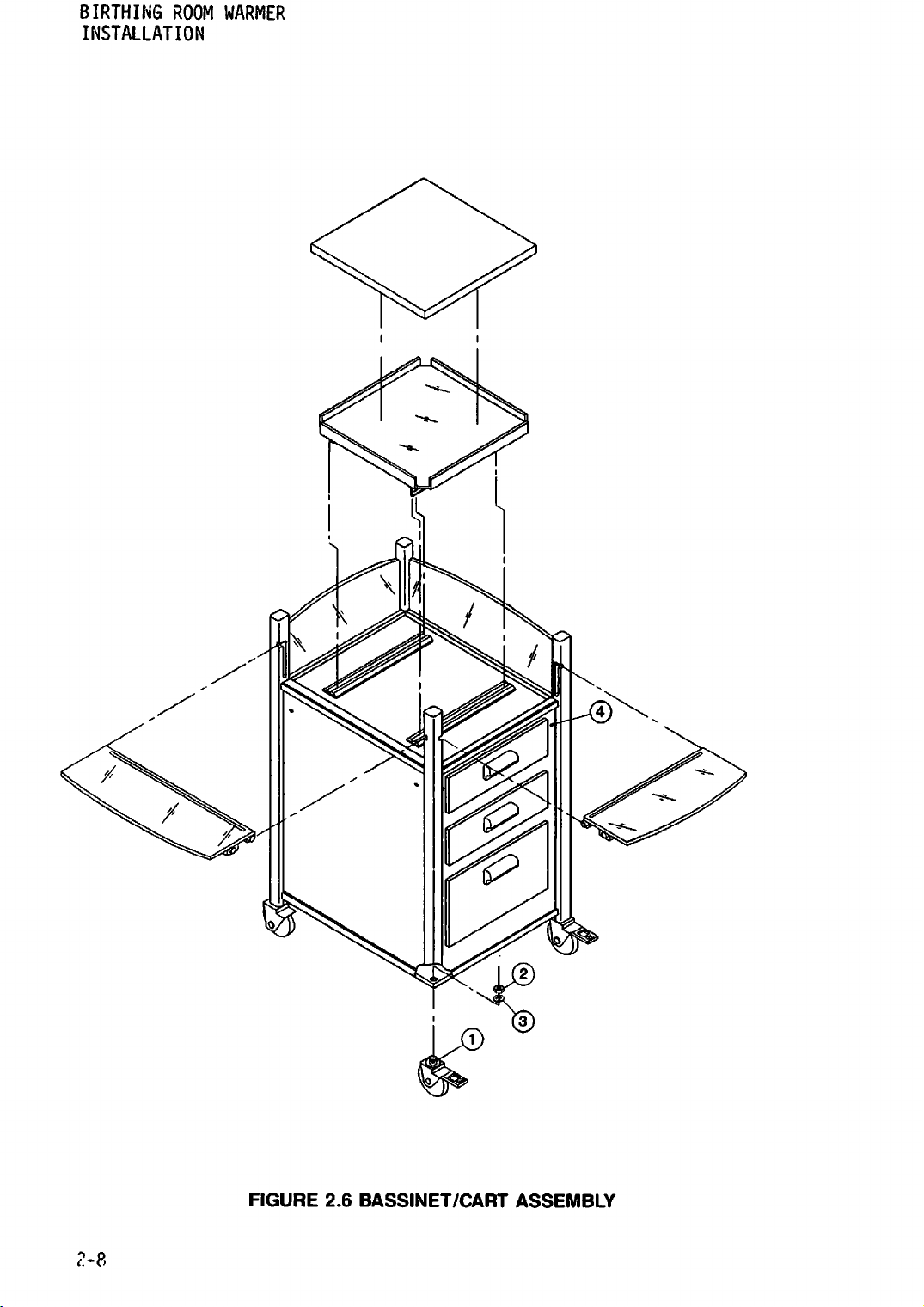

2.2.5

BASSINET/CART

To

assemble

follows:

ASSEMBLY

the

Bassinet/Cart,

refer

to

Figure

BIRTHING

2.6 and

ROOM WARMER

INSTALLATION

proceed

as

A.

B.

C.

D.

E.

F.

INSTALL

and

the

INSTALL

THE

FOUR

lockwashers

front

of

THE

the

MATTRESS

the bottom of the

INSTALL

INSTALL

pivot

sure

corner

IMPORTANT:

Label

LOCATE

their

PLACE

THE

THE

pins

the

post

is

THE

wooden

THE

MATTRESS

SIDE

into

panel

slots).

The

visible

EIGHT

handles

DRAWER

is

CASTERS

(2,

3).

cart.

TRAY

tray

IN

PANELS

the

slots

properly

panels

when the

BUMPERS

rest

ORGANIZER

(1)

on

Install

on the cart.

in

the

slot

THE

TRAY.

in

the

of

the

seated

must

be

panels

(4)

such

on

the

in

one

the

cart

the

two

on top of the

cart

by

corner

(all

mounted

are

down.

that

bumpers

of

the

using

casters

Place

sliding

posts

four

such

when

and not the

drawers.

the

(Figure

pivot

that

the

the

with

fixed

cart.

the

pins

the

panels

3/4

inch

brakes

bottom

2.5).

are

Warning

are

wood.

nuts

rod on

plastic

in

down

at

Make

the

FIGURE

2.5

INSTALLATION

OF

SIDE

PANELS

2-7

BIRTHING

INSTALLATION

ROOM

WARMER

FIGURE

2.6

BASSINET/CART

ASSEMBLY

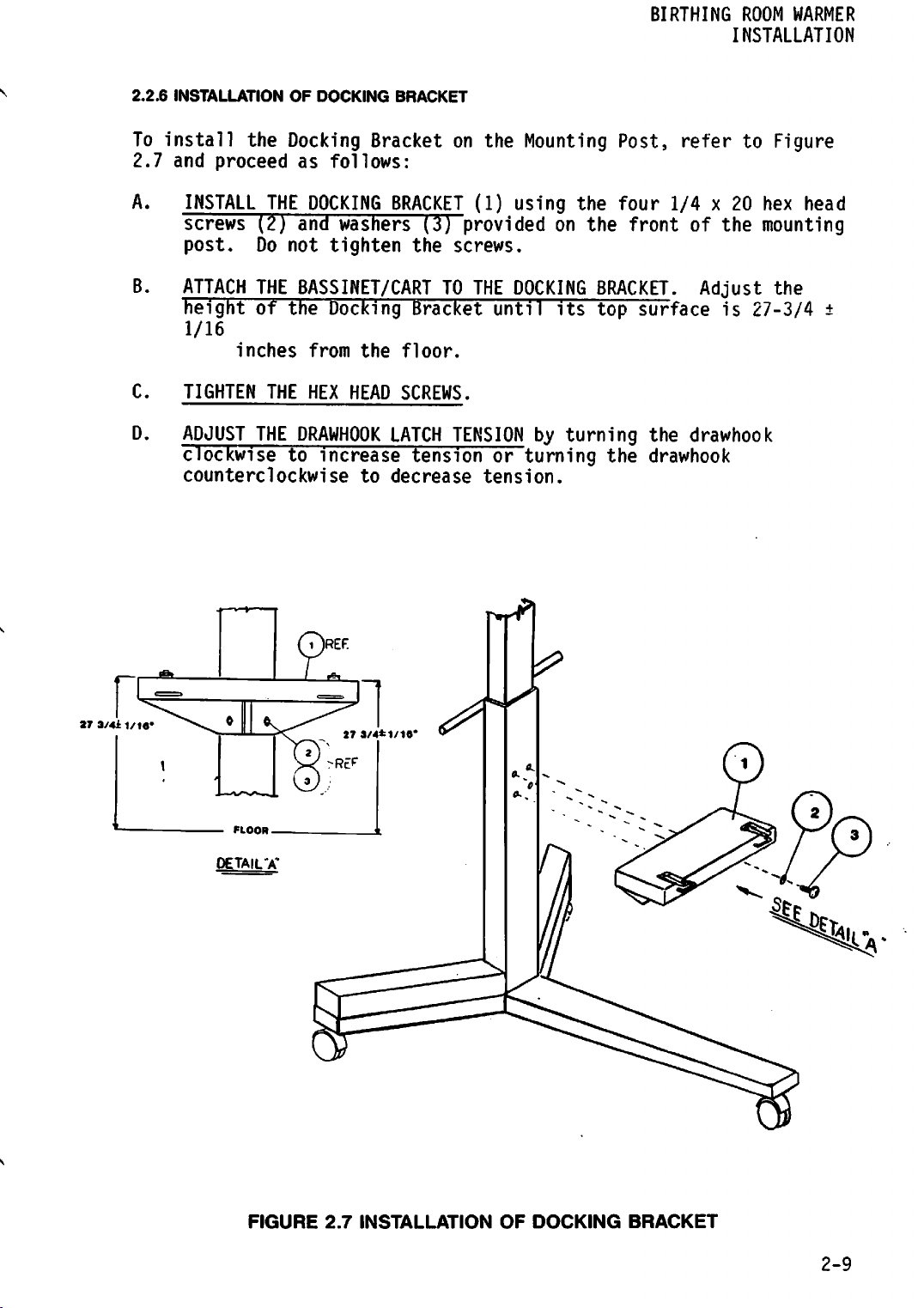

2.2.6

To

install

2.7

INSTALLATION

the

and

proceed

OF

DOCKING

Docking

as

follows:

BRACKET

Bracketonthe

Mounting

BIRTHING

Post,

ROOM

WARMER

INSTALLATION

refertoFigure

A.

B.

C.

D.

INSTALL

screws

post.

ATTACH

height

1/16

TIGHTEN THE HEX HEAD SCREWS.

ADJUST

clockwise

counterclockwise to decrease tension.

THE

DOCKING

(2)

and

washers

Do

not

tighten

THE

BASSINET/CARTTOTHE

of

the

Docking

inches from the floor.

THE

DRAWHOOK

to

increase

BRACKET

(3)

the

Bracket

LATCH

tension

(1)

using

providedonthe

the

four

front

screws.

DOCKING

until

its

BRACKET.

top

TENSIONbyturning

or

turning

r»rr

the

1/4x20

of

Adjust

surface

the

drawhook

drawhook

the

is

27-3/4

hex

head

mounting

the

±

27

3/4il/1««

FIGURE

2.7

INSTALLATION

OF

DOCKING

BRACKET

2-9

BIRTHING

INSTALLATION

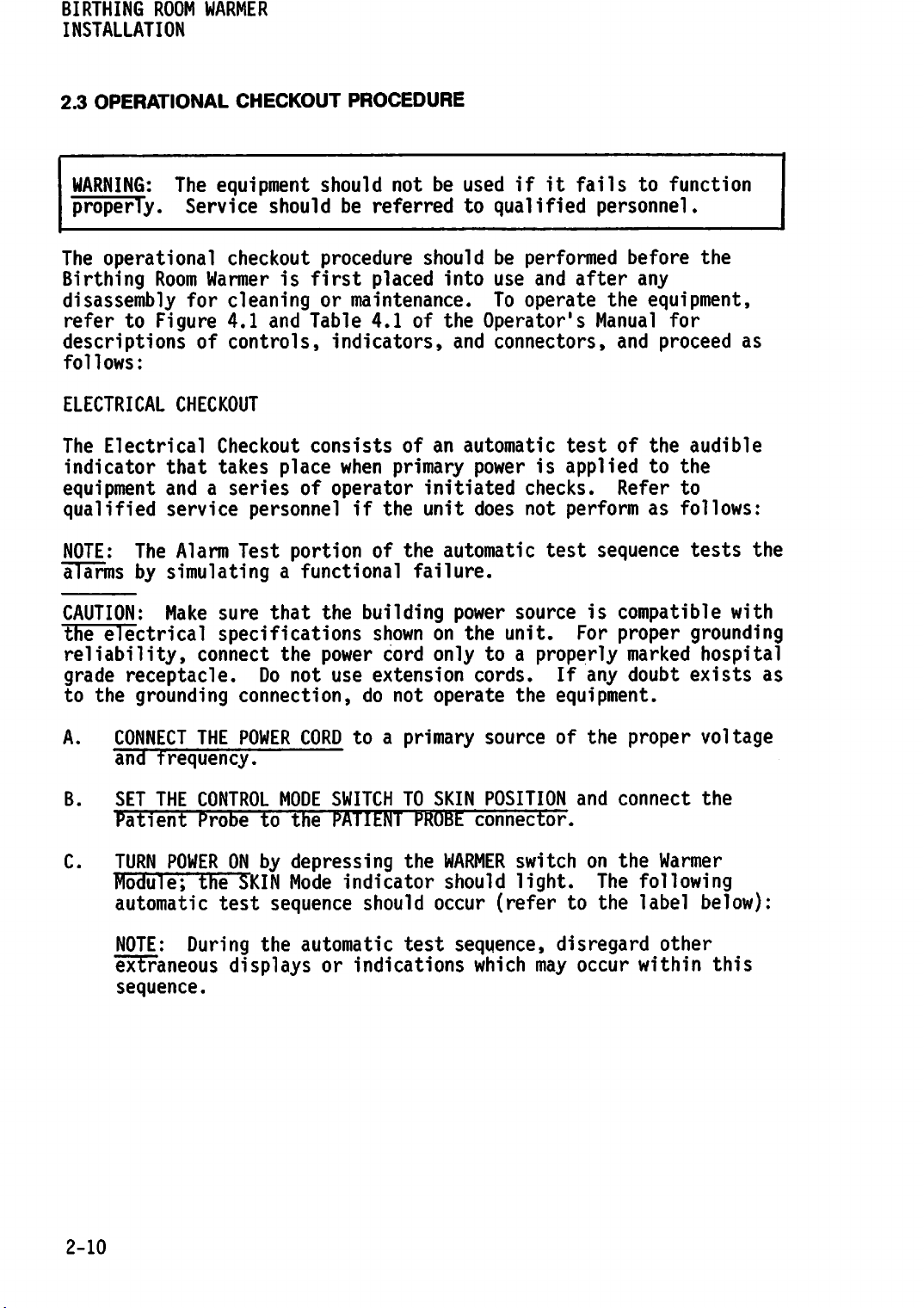

2.3

OPERATIONAL

ROOM

WARMER

CHECKOUT

PROCEDURE

WARNING:

properly.

The

operational

Birthing

disassembly

refer

descriptions

follows:

ELECTRICAL

The Electrical

indicator

equipment

qualified

NOTE:

alarms

CAUTION:

the

electrical

reliability,

grade

to

the

The

Service

Room

for

to

Figure

CHECKOUT

that

andaseries

service

The

Alarm

by

simulatingafunctional

Make

receptacle.

grounding

equipment

should

should

checkout

Warmer

cleaning

4.1

of

controls,

Checkout

takes

procedure

is

first

or

and

Table

consists of an automatic test

place

of

personnelifthe

Test

sure

portionofthe

that

the

specifications

connect

the

power

Do

not

connection,

not

be

used

be

referredtoqualified

should

placed

maintenance.

4.1

of

indicators,

when

operator

primary

initiated

unit

be

into

use

To

the

Operator's

and

connectors,

power

does

automatic

failure.

building

shown

use

extension

do

cord

not

power

on

the

only

to a

cords.

operate

if

it

performed

and

operate

is

applied

checks.

not

performasfollows:

test

source

unit.

properly

If

the

equipment.

fails

to

personnel.

before

after

any

the

equipment,

Manual

and

of

the

to

Refer

sequence

is

compatible

For

proper

marked

any

doubt

function

the

for

proceed

audible

the

to

tests

grounding

hospital

exists

as

the

with

as

A.

CONNECT

and frequency.

B. SET THE CONTROL MODE SWITCH TO SKIN POSITION and connect the

Patient

c-

TURN

Module;

automatic

NOTE:

extraneous

sequence.

THE

Probe

POWER

the

During

POWER

ON

SKIN

test

CORD

to

the

by

depressing

Mode

sequence

the

automatic

toaprimary

PATIENT

PROBE

the

indicator

should

test

occur

displaysorindications

source

connector.

WARMER

should

switch

light.

(refertothe

sequence,

which

of

the

on

The

disregard

may

occur

proper

the

Warmer

following

label

other

within

voltage

below):

this

2-10

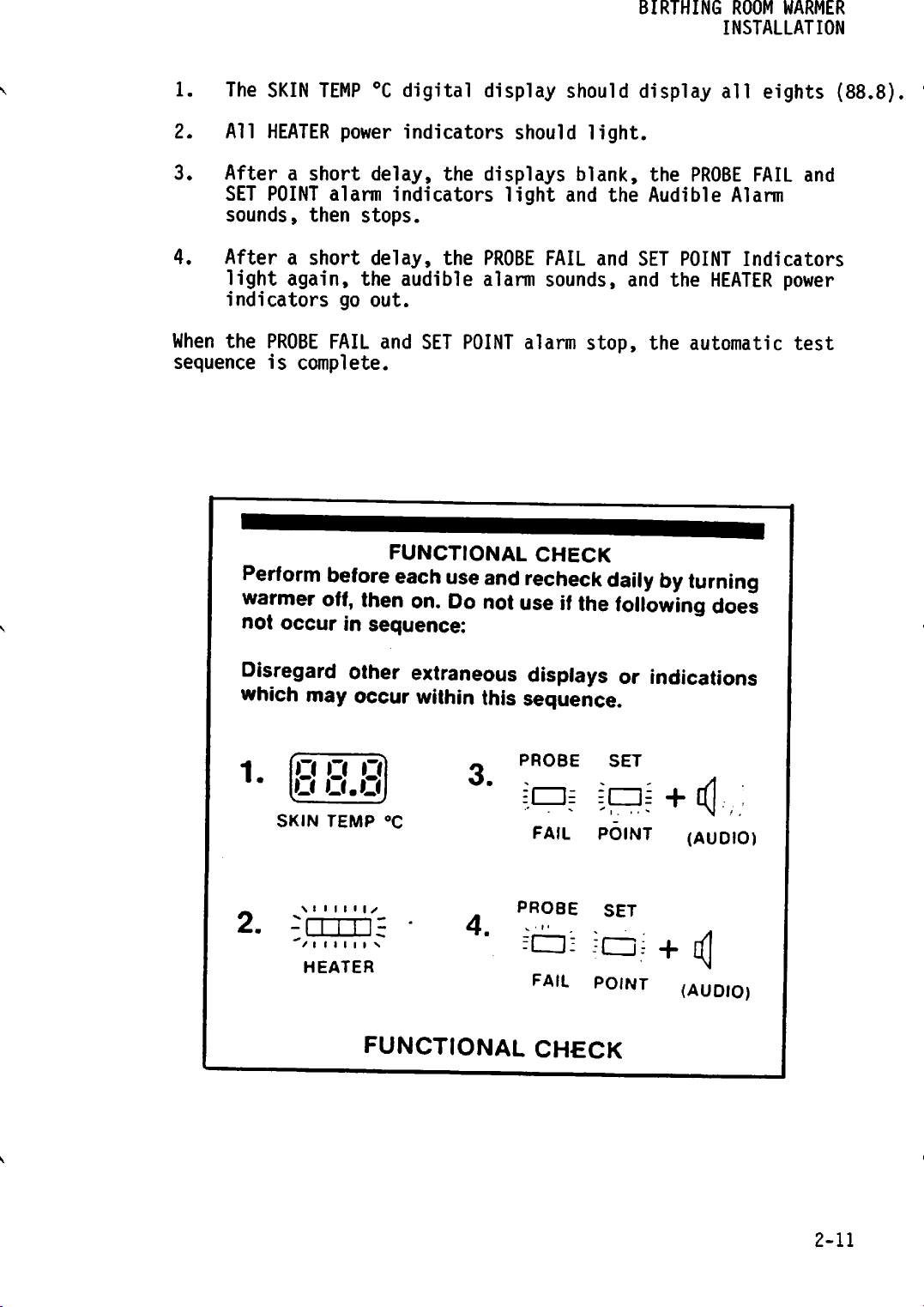

1.

The

SKIN

TEMP

°C

digital

display

should

BIRTHING

display

ROOM

INSTALLATION

all

WARMER

eights

(88.8).

2.

3.

4.

All

Afterashort

SET

sounds,

Afterashort

light

indicators

When

the

sequence

Perform

warmer

not

HEATER

POINT

then

again,

PROBE

is

complete.

occur

power

alarm

go

FAIL

before

indicators

delay,

indicators

stops.

delay,

the

audible

out.

and

SET

FUNCTIONAL

each

off, then on.

in

sequence:

the

displays

light

the

PROBE

alarm

POINT

use

and

Do

notuse ifthe

should

and

FAIL

sounds,

alarm

CHECK

recheck

light.

blank,

and

stop,

the

and

the

Audible

SET

POINT

the

the

automatic

dailybyturning

following

PROBE

Alarm

HEATER

does

FAIL

and

Indicators

power

test

Disregard

other extraneous displays or indications

which may occur within this sequence.

PROBE

fcU

FAIL

PROBE

=• =

FAIL

CHECK

S +4,:

POINT

-=c±i+i<|

P0INT

2.

o o o

U

SKIN

\ i i i i i i •

/I

HEATER

U.U

TEMP

I I I I I s

°C

FUNCTIONAL

3.

4.

SET

(AUDIO)

SET

(AUDIO)

2-11

BIRTHING

INSTALLATION

ROOM

WARMER

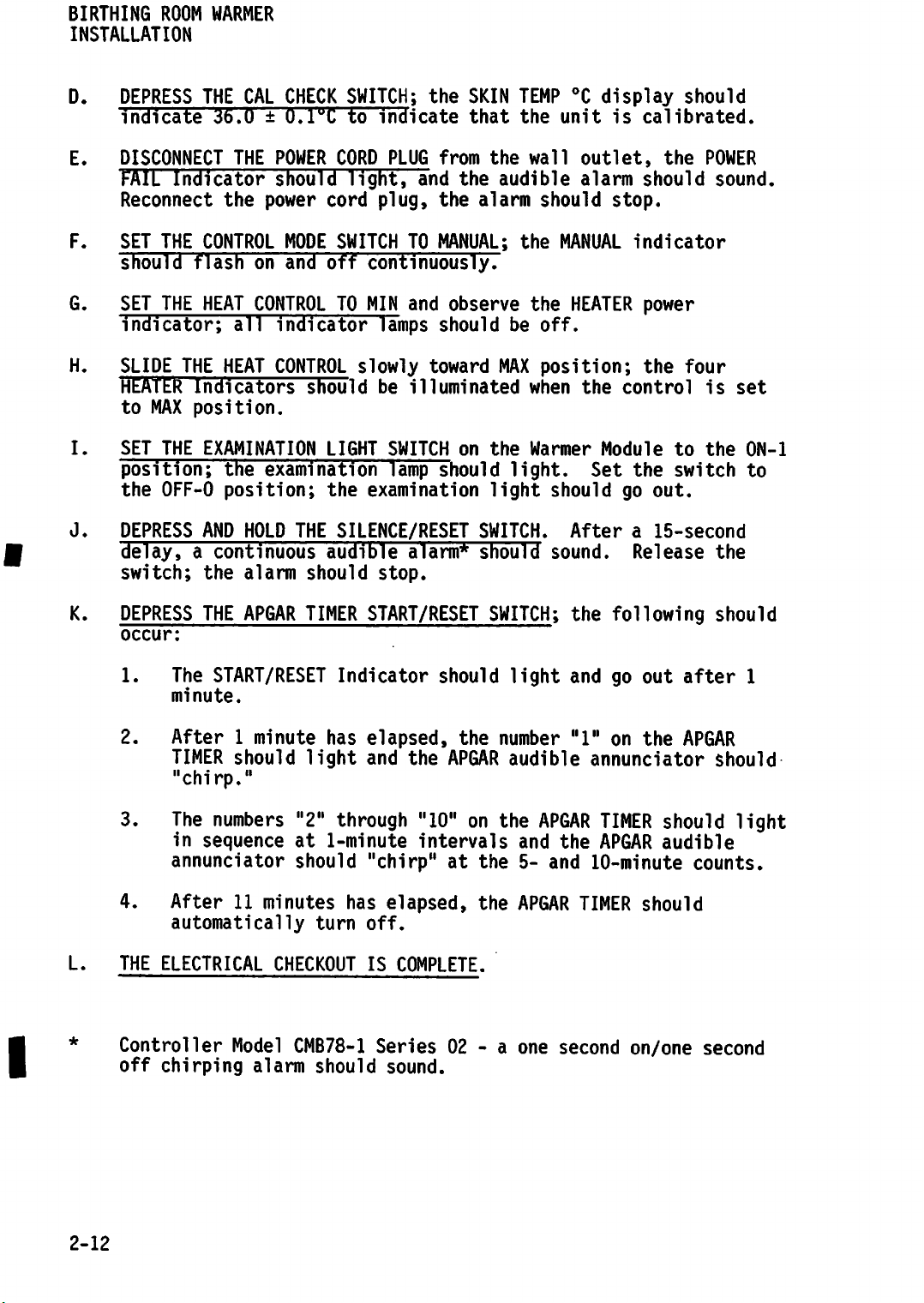

D.

E.

F.

G.

H.

I.

J.

DEPRESS

indicate

DISCONNECT

FAIL

Reconnect

SET THE

should flash on and off continuously.

SET

indicator;

SLIDE

HEATER Indicators should be illuminated when the control is set

to

SET THE EXAMINATION LIGHT SWITCH on the Warmer Module to the ON-1

position;

the

DEPRESS

delay,acontinuous

switch;

THE

36.0±0.1°C

Indicator

CONTROL

THE

HEAT

THE

MAX

position.

OFF-0

AND

the

CAL

CHECK

THE

POWER

should

the

power

MODE

CONTROL

all

indicator

HEAT

the

CONTROL

examination

position;

HOLD

THE

alarm

should

SWITCH;

to

CORD

light,

cord

SWITCH

TO

MIN

slowly

the

examination

SILENCE/RESET

audible

the

indicate

PLUG

and

plug,

TO

and

lamps

toward

lamp

alarm*

stop.

SKIN

that

from

the

the

the

alarm

MANUAL;

observe

should

should

light

SWITCH.

should

TEMP

the

wall

audible

should

the

the

be

off.

MAX

position;

light.

should

sound.

°C

display

unit

outlet,

alarm

MANUAL

HEATER

Set

After a

is

calibrated.

the

should

stop.

indicator

power

the

the

switch

go

out.

15-second

Release

should

POWER

sound.

four

to

the

I

K.

DEPRESS

occur:

1.

2.

THE

The

START/RESET

minute.

APGAR

TIMER

After1minute

TIMER

should

Indicator

has

light

START/RESET

elapsed,

and

"chirp."

3.

4.

L.

THE ELECTRICAL CHECKOUT IS COMPLETE.

Controller

off

The

numbers

in

sequence

annunciator

After

11

minutes

automatically

Model

chirping

alarm

"2"

through

at

1-minute

should

has

turn

CMB78-1

should

"chirp"

off.

SWITCH;

should

the

the

APGAR

"10"onthe

intervals

at

the

elapsed,

Series02- a

sound.

the

light

number

audible

APGAR

and

5-

and

APGAR

one

the

following

and

go

"1"

on

annunciator

TIMER

the

APGAR

10-minute

TIMER

second

on/one

out

after

the

APGAR

should

audible

counts.

should

should

1

should

light

second

2-12

BIRTHING

ROOM

WARMER

INSTALLATION

MECHANICAL

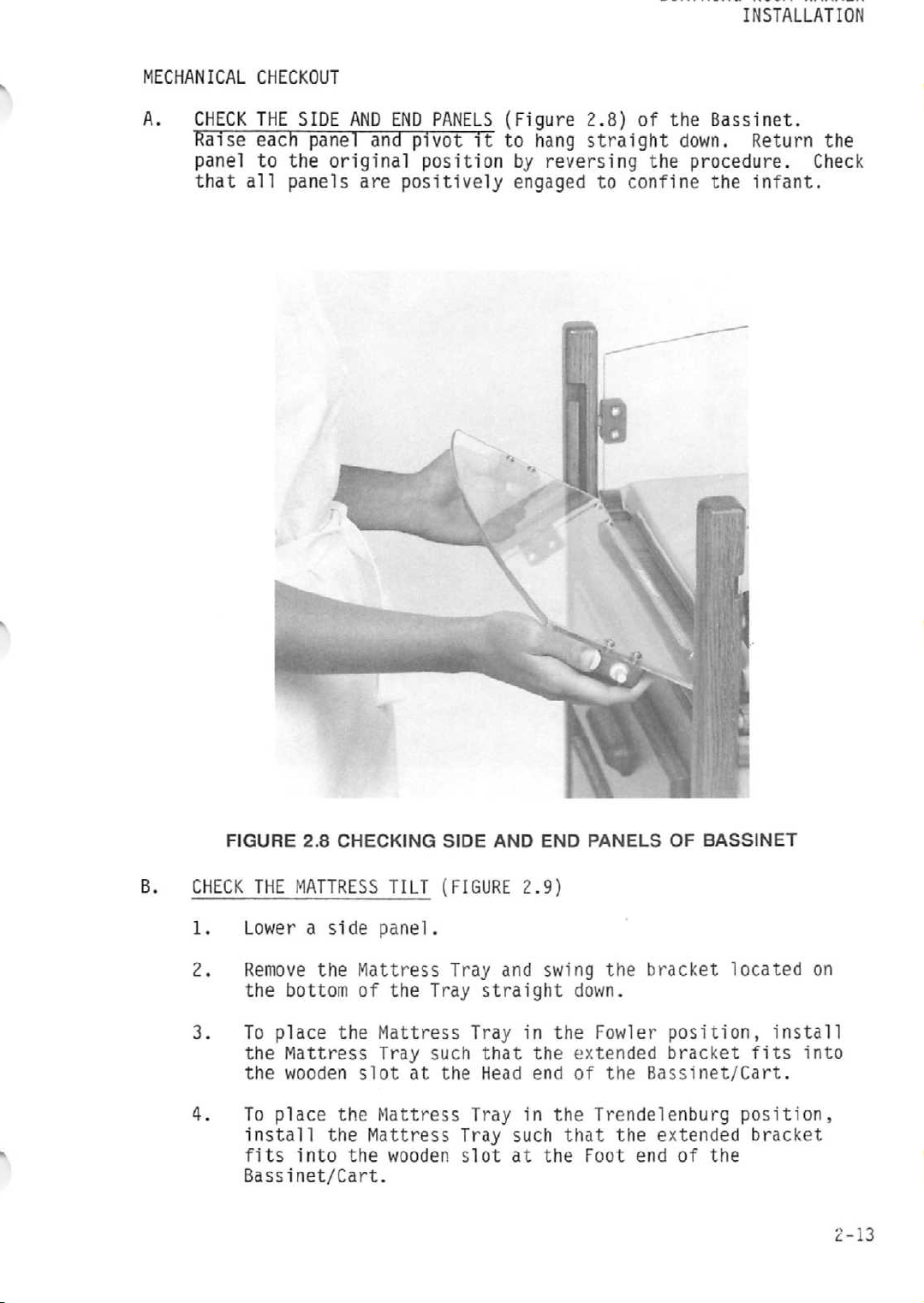

A.

CHECK

Raise

panel

that

CHECKOUT

THE

each

to

the

all

panels

SIDE

panel

original

AND

are

END

PANELS

and

pivot

position

positively

(Figure

it

to

hang

by

reversing

engaged

2.8)

of

straight

the

to

confine

the

Bassinet.

down.

procedure.

the

Return

infant.

the

Check

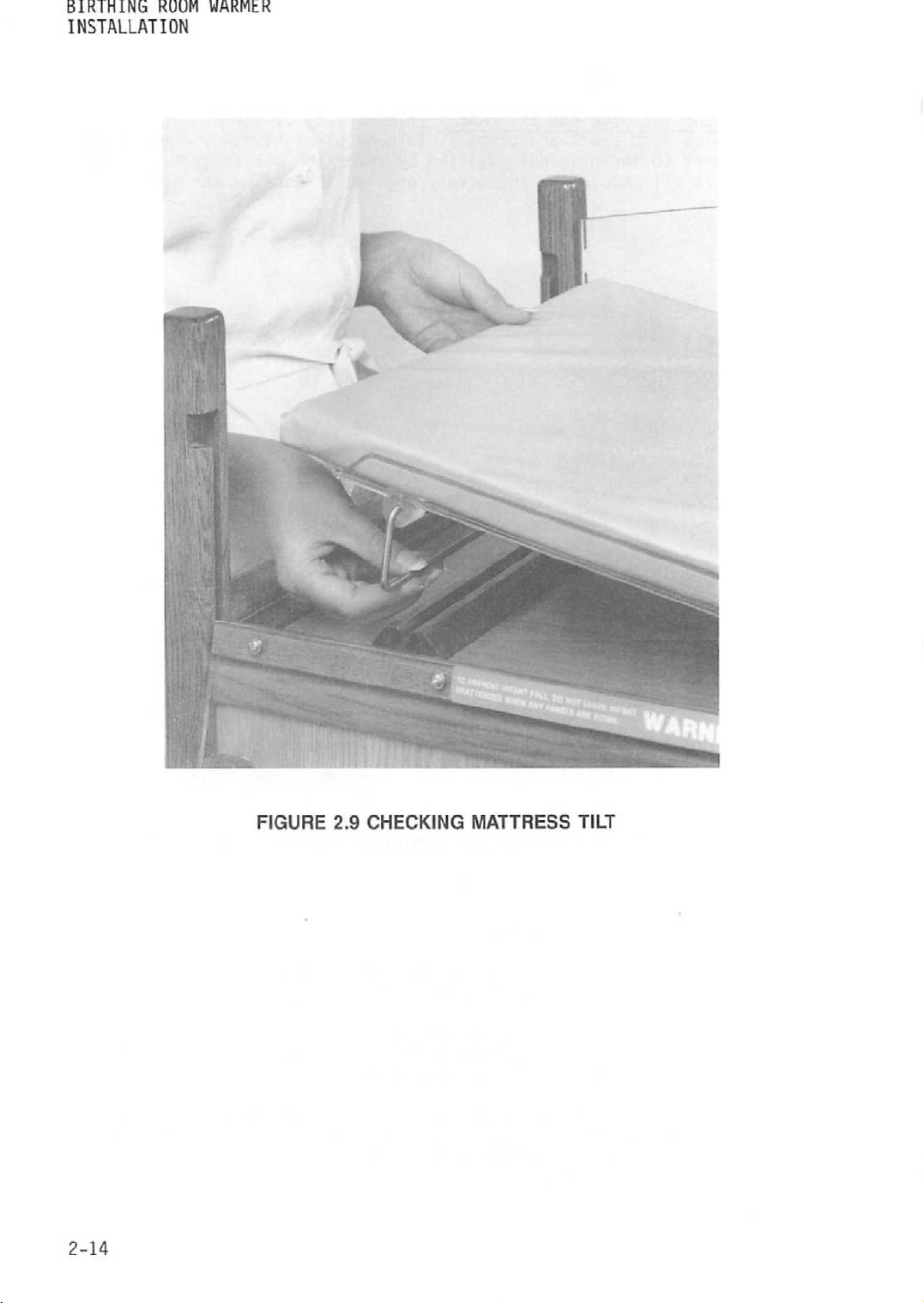

B.

FIGURE

CHECK

1.

2.

3.

4.

2.8

CHECKING

THE

MATTRESS

Lower a

Remove

the

To

place

the

the wooden slot at the Head end of the Bassinet/Cart.

To

place

install

fits

Bassinet/Cart.

side

the

bottom

Mattress

the

into

TILT

panel.

Mattress

of the Tray

the

Mattress

Tray

the

Mattress

Mattress

the

wooden

SIDE

(FIGURE

Tray

Tray

such

Tray

Tray

slot

AND

END

2.9)

and

swing

straight

in

that

the

in

such

at

the

PANELS

the

down.

the

Fowler

extended

the

Trendelenburg

that

the

Foot

OF

bracket

position,

bracket

extended

end

of

BASSINET

located

install

fits

position,

bracket

the

on

into

2-13

BIRTHING

ROOM

INSTALLATION

WARMER

2-14

FIGURE

2.9

CHECKING

MATTRESS

TILT

Loading...

Loading...