Air MC3 LK, MC3 IR User manual

MC3 LK, IR

Type

Electric dental micromotor MC3 LK and IR

with brushes. Non-sterilisable, compact and

robust, oil-sealed micromotor, adapted to low

speeds. Removable, sterilisable sleeves.

Interchangeable brushes.

• MC3 LK: with light, internal spray

• MC3 IR: without light, internal spray

Technical data and assembly

Coupling

Power supply by multipurpose cable, for turbines, air motors and MC3.

fig. 1

Classification

Class IIa, "active medical devices", as per

section III "Classification", Rule 9 of Annex IX

to Directive 93/42 EEC, namely: "Therapeutic

devices intended to administer or exchange

energy".

Comments

The performance of the motor varies, depending on the type of electronic power supply

used.

Electromagnetism

Corresponds to the electromagnetic compatibility in accordance with CEI 601-1-2.

Safety

According to IEC 601-1 standard (General

safety for Medical Electrical Equipement), the

MC3 motor shall be classified as a class II

type BF device. Associated terminology is

defined in section 2.1.7 & 2.2.5 of the same

document. The following regulations as specified in IEC 601-1 must be observerd :

• "Protection against electrical shock"

• "Leakeage currents"

• "Protection against excessive temperatures and other safety hasard"

Cooling

By compressed air. Place the flow-meter on

the connector and set 10 normliter/min.

fig. 2

Coupling

Connection in accordance with ISO 3964,

with the handpiece retaining ring.

• MC3 LK: Version connector internal spray

and light

• MC3 IR: Version connector internal spray

(without light)

Junction

Power supplied through multifunction tube

with silicon sheath, from the 4VLR, 4VLM,

4VLRB families.

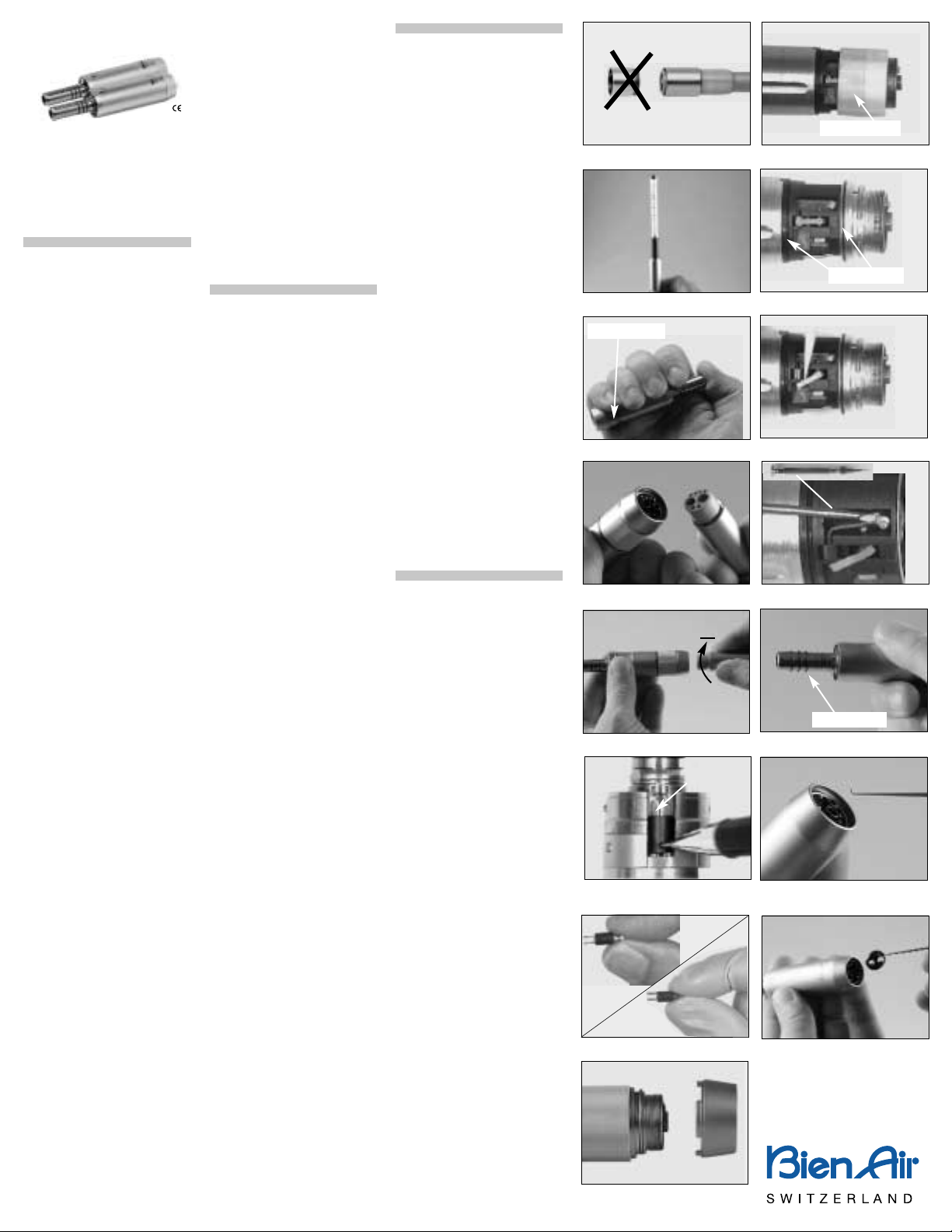

Tube assembly on MC3 LK and IR

Remove the adaptor-sleeve for turbines from

the cable

fig.1

. Remove the sleeve

fig. 3

.

Check that the back of the micromotor and the

plug on the cable are clean, rotate in order to

find the exact position and push right in.

Screw the nut of the cable tightly

fig 4

.

Replace the cover.

Important

Liquid or spray must not be allowed to penetrate inside the motor, due to risk of irreversible damage. Never connect an instrument

with a micromotor that is running.

Changing the bulb

MC3 LK:

figs 3 and 5

. Box of 5 bulbs. Wear

rubber gloves when carrying out this changing operation.

Changing the carbon brushes

Attention: Precision work. Keep the carbon

brushes dry and never let them come into

contact with lubricant, as otherwise they may

be irreversibly damaged. To remove the 2 carbon brushes, follow the procedure shown in

figs 3 and 6

for MC3 LK, IR.

Blow dry, clean air across the apertures at the

rear of the body of the motor.

To reassemble, proceed in the reverse order.

Seals replacement

• To change the o-rings REF 011.35.28-010,

fig. 7

• To change the seal REF 011.75.56-010,

fig. 8

• To change the o-rings REF 705.02.66-010,

fig. 6

Removing seal, place it on the tubes and

remount the attachment

fig. 4

.

Maintenance

Maintenance animations at

www.bienair.com

Only use maintenance products and/or components from Bien-Air. The use of other products and components can lead to annulment

of the guarantee.

Important

After cleaning and disinfecting/sterilizing

the instrument and before using it, operate at moderate speed, with a bur in the

chuck, for 10 to 15 seconds to distribute,

and remove, the excess lubricant.

Overhaul

Never disassemble the device. For all modifications and repairs, we recommend that you

contact your regular supplier or Bien-Air

direct. Bien-Air asks the user to have its

dynamic instruments checked or inspected at

least once a year thereafter.

Sleeves

Removable

figs 3 and 4

, sterilisable at 136°C

±2°C (277°F ± 3,6ºF). The required time for

sterilisation of our products must comply with

the prevailing local regulations for this type of

instrument.

Cleaning and disinfection

Use cleaner Spraynet, Bien-Air. Disinfect with

a clean damp cloth. Products containing acetone, chlorine and bleach are not recommended as disinfectants.

Never immerse in solutions.

Not suitable for ultrasonic bath.

Excess material from products used for maintenance (lubricants, cleaning products and

disinfectants) originating from CA or PM may

penetrate into the electric brush motor and

interfere with its functioning. It is essential to

follow the maintenance instructions accompanying each product. Never lubricate the

electric brush motor.

Environment

Temperature between -40°C (-40°F) and

70°C (158°F), relative humidity between 10%

and 100%, atmospheric pressure 50 kPa to

106 kPa (7,3 to 15,3 psi).

Application

Product intended for professional use only.

Information

The technical specifications, illustrations and

dimensions contained in these instructions

are given only as a guide. They may not be

the subject of any claim. The manufacturer

reserves the right to make technical improvements to its equipment, without amending

these instructions. The French original of this

text conforms to the legal standards. For all

additional information, please contact BienAir at the address indicated on the reverse.

Generalities

The device must be used by a com-petent

person in accordance with the current legal

provisions concerning industrial safety, health

and accident prevention regulations, and

these working instructions. In accordance

with these requirements, the operator:

• must only use working devices that are in

perfect working order; in the event of irregular

functioning, excessive vibration, abnormal

heating or other signs indicating malfunction

of the device, the work must be stopped

immediately; in this case, contact a repair

centre that is approved by Bien-Air;

• must ensure that the device is used only for

the purpose for which it is intended, must

protect himself, his patients and third parties

from any danger, and must avoid contamination through the use of the product.

The device is intended for medical treatment

only; any use other than that for which this

product is intended is not allowed and may

prove to be dangerous. The medical device

meets all the current European legal requirements.

The device is not authorised for use in an

explosive atmosphere. (Anaesthetic gas)

Never immerse in disinfectant solutions.

Recommendations

It is essential to use dry, purified compressed

air in order to ensure the long working life of

the device. Maintain the quality of the air and

the water by regular maintenance of the compressor and the filtration systems. The use of

unfiltered hard water will lead to early blockage of the tubes, connectors and spray cones.

Rest the device on a suitable support in order

to eliminate the risk of injury to you yourself,

to your patient and to third parties.

Guarantee

Terms of guarantee

Bien-Air grants the user a guarantee for its

complete product range, covering any faulty

functioning and defects in material or manufacture, for a period of 18 months from the

date of the invoice. Bien-Air also offers a

24-month guarantee for the glass-bar light

conductors.

In the event of justified claims, Bien-Air or its

authorised representative will fulfil the company’s obligations under this guarantee by

repairing or replacing the product free of

charge.

Any other claims, of whatever nature, in particular in the form of a claim for damages and

interest, are excluded.

Bien-Air shall not be held responsible for

damage or injury and the consequences thereof, resulting from:

• excessive wear and tear

• improper handling

• non-observance of the instructions for

installation, operation and maintenance

• unusual chemical, electrical or electrolytic

influences

• poor connections, whether of the air water

or electricity supply.

The guarantee does not cover flexible “fibre

optic” type conductors, or any parts made of

synthetic materials.

The guarantee shall become null and void if

the damage and its consequences are due to

improper manipulation of the product, or

modifications to the product carried out by

persons not authorised by Bien-Air.

Claims under the terms of the guarantee will

be considered only on presentation, together

with theproduct, of the invoice or the consignment note, on which the date of purchase,

the product reference and the Serial No.

should be clearly indicated.

fig.

1

fig. 3

fig. 2

REF 011.75.43-001

fig. 5a

fig.

4a

fig. 4b

fig. 6a

fig. 6b

fig. 5c

✗

✓

fig. 5b

REF 011.75.46-001

fig. 6c

fig. 6d

fig. 6e

REF 705.02.66-010

fig. 7

fig. 8a

fig. 8b

REF 011.35.28-010

0120

REF Legend

1600077-001 MC3 LK micromotor, E INTRAmatic LUX

1600071-001 MC3 IR micromotor, E INTRAmatic

211.75.08-010 Carbon brushes

705.02.66-010 O-Ring

011.35.28-010 O-Ring

011.75.56-010 Flat seal

011.75.43-001 Sleeves MC3 LK, IR

011.75.46-001 Protective sleeve

1500007-005 Pack of 5 bulbs, for micromotors

1600307-001 Fow-meter for MC2 and MC3 micromotors

1600036-006 Spraynet, cleaning spray 500 ml, box of 6 cans

List of registered trade mark products ®:

Aquilon

®

(Bien-Air)

Gyro Long-Life®(Bien-Air)

Isolite

®

(Bien-Air)

Isolux

®

(Micro-Méga)

Lubrifluid

®

(Bien-Air)

Lubrimed

®

(Bien-Air)

Ondine

®

(Bien-Air)

Symbols

Movement in the direction indicated

In these instructions, “Device” corresponds to the product described in the

heading “Type”. For example, turbine, contra-angle, handpiece, motor, tube,

electronics, connectors, station etc.

Movement fully to the stop, in the

direction indicated

Bien-Air USA, Inc.

Dental

17880 Skypark Circle

Suite 140

Irvine, CA 92614 USA

Phone 1-800-433-BIEN

Phone 949-477-6050

Fax 949-477-6051

ba-usa@bienair.com

Bien-Air on Internet:

www.bienair.com

REF 2100041/02.04

Set supplied

Accessories in option

REF 1600036-006

REF 011.35.28-010

MC3 LK 1600077-001

X

MC3 IR 1600071-001 X

REF 011.75.43-001

REF 011.75.46-001

REF 011.35.28-010

REF 1500007-005

REF 211.75.08-010

Bien-Air SA

Case postale 8

CH-2500 Bienne 6 0120

REF 1500007-005

Ampoules de rechange

Ersatzbirnen

Spare bulbs

Bombillas de recambio

Lampadine di ricambio

5

SWISS MADE

REF 705.02.66-010

REF 011.75.56-010

REF 705.01.06-010

REF 1600307-001

REF 011.75.43-001

Loading...

Loading...