Air M5A Maintenance Instructions

TM

8-6520-003-24&P

UNIT,

COMPRESSOR-DEHYDRATOR,

DIRECT

MAINTENANCE

(INCLUDING

TECHNICAL

SUPPORT,

REPAIR

SPECIAL

AND

TOOLS

MANUAL

GENERAL

MANUAL

PARTS

LIST)

SUPPORT

AND

(SERIAL

APPROVED

HEADQUARTERS,

DENTAL,

NUMBERS

6520-00-139-1246

FOR

PUBLIC

MODEL

2700

RELEASE;

DEPARTMENT

DISTRIBUTION

M5B

AND

OF

ABOVE)

IS

UNLIMITED

THE

ARMY

1991

SAFETY

STEPS

TO

FOLLOW

IF

SOMEONE

IS

THE

|

DO

IF

IF

NOT

POSSIBLE,

YOU

PULL,

DRY

PUSH,

WOODEN

TRY

CANNOT

INSULATING

VICTIM

TO

PULL

TURN

TURN

OR

LIFT

POLE

MATERIAL.

OF

ELECTRICAL

OR

OFF

GRAB

THE

OFF

THE

OR

A

THE

ELECTRICAL

THE

ELECTRICAL

PERSON

DRY

ROPE,

SHOCK

INDIVIDUAL.

POWER.

TO

SAFETY

OR

SOME

POWER,

USING

OTHER

A

SEND

FOR

AFTER

WITH

THE

PERSONA

START

HELP

THE

INJURED

SOURCE

SHORT

ARTIFICIAL

AS

SOON

AS

PERSON

OF

ELECTRICAL

DISTANCE

RESUSCITATION.

POSSIBLE.

IS

FREE

SHOCK,

AWAY

AND

OF

CONTACT

MOVE

IMMEDIATELY

THE

TM

8-6520-003-24&P

Throughout

to

time

read

Procedures

this

manual

these.

They

which

are

must

are

WARNINGS,

there

be

observed

CAUTIONS,

to

protect

WARNING

to

avoid

you

and

personal

and

the

equipment.

injury,

NOTES.

and

even

loss

Please

of

life.

take

|

Procedures

which

must

be

Essential

observed

or

information

CAUTION

to

avoid

long-term

damage

health

NOTE

that

should

to

equipment,

hazards.

be

remembered.

destruction

of

equipment,

|

a/b

blank

>

TM

8-6520-003-24&P

TECHNICAL

NO.

8-6520-003-24&P

MANUAL

(INCLUDING

You

can

prove

procedures,

mended

Changes

Commander,

5001. A reply

UNIT,

DIRECT

SUPPORT,

MAINTENANCE

REPAIR

PARTS

COMPRESSOR-DEHYDRATOR,

(SERIAL

NUMBERS

6520-00-139-1246

help

improve

Changes

to

Equipment

U.S.

will

this

please

to

Army

be

let

Publications

Technical

Medical

furnished

manual.

us

know.

Materiel

directly

If

you

Mail

and

Blank

Publications)

to

-

AND

AND

find

any

your

Forms),

Agency,

you.

GENERAL

MANUAL

SPECIAL

DENTAL,

2700

located

AND

mistakes

memorandum,

or

DA

in

ATTN:

WASHINGTON,

MODEL

ABOVE)

or

if

you

DA

Form

2028-2

the

back

SGMMA-M,

HEADQUARTERS

DEPARTMENT

DC

SUPPORT

TOOLS

know a way

Form

2028

(Recommended

of

this

manual,

Frederick,

OF

LIST)

M5B

to

im-

(Recom-

to:

MD

THI

siasi

21702-

CHAPTER

Section

CHAPTER

Section

Approved

HOW

TO

USE

1.

INTRODUCTION

I.

General

Il

Equipment

lll.

Principles

2.

OPERATINGINSTRUCTIONS

1

“Operating

II.

UnitOperation

Ill.

Operation

IV.

Operation

Information

for

public

release;

TABLE

TRISIMANHAE

Description

of

Operation .........

Controls

................

of

Auxiliary

Under

and

Equipment

Unusual

Data

is

Conditions

OF

oo

e

ss

distribution

is

unlimited.

CONTENTS

っ

μάς

.

>

seere

...

........................................

Ed

δώ

ναι.

eee

616/016 9 0804

cree

ala

ler

ao

ee

ο

Page

ele 5 iv

e

21

„21

>

2-3

-

TM

8-6520-003-24&P

CHAPTER

Section

CHAPTER

Section

APPENDIX

GLOSSARY

INDEX

3.

L

Il

ИИ.

м.

V.

Vi.

Vil.

Vill.

IX.

4.

1.

Il

A

B.

C.

D.

Е,

UNIT

LEVEL

General

Service

Lubrication

Preventive

Functional

Troubleshooting

Maintenance

Cleaning

Storage

DIRECT

General

Troubleshooting

REFERENCES

MAINTENANCE

COMPONENTS

EXPENDABLE

REPAIR

MAINTENANCE

Information

Upon

Receipt

Instructions

Maintenance

Testing

Instructions

Procedures

and

Shipment

SUPPORT

Information

AND

PARTS

of

Equipment

............

Checks

...

.....

.

Procedures

AND

GENERAL

..

ALLOCATION

OF

END

ITEM

DURABLE

AND SPECIAL

and

Services

.

SUPPORT

CHART

AND

BASIC ISSUE

SUPPLIES

TOOLS

LIST

MAINTENANCE

AND

MATERIALS

ITEMS

LIST

LIST

.

Figure

1-1

1-2

1-3

1-4

15

16

17

18

31

32

E-1

E-2

E-4

ES

ES

No.

Case

data

plate

Air

relief

valve

data

plate

Storage

Tank

Pressure

Unloader

Electrical

Motor-compressor

Motor-compressor

Electrical

Regeneration

Compressor-dehydrator . .

Drying

Electrical

Flow

Unloadervalve

Motor-compressor

tank decal

drain

decal

switch

valve

power

wiring

chamber

assemblies

control

valve

decal

instructional

cable

tag

pumping

purging

diagram

diagram

and

....

...

cooling

..

decal

....

cycle

cycle

26

coil

Title

.........................................

sees

assemblies

rei

iii

Page

Table

No.

LIST

OF

Title

TABLES

TM

8-6520-003-24&P

Page

11

12

13

21

31

32

Nomenclature

Specifications

Physical

Operating

PMCS

General

cross-reference

characteristics

load

troubleshooting

list

factors

....

TM

8-6520-003-24&P

Lİ

This

manual

functions,

operate,

manual

Lİ

The

manual

appendixes,

to

help

index

O

Multiple

Words

ponents

test,

before

locate

will

help

figures

gui

that

or

HOW

provides

and

characteristics

and

repair

operating

is

arranged

a

glossary,

the

chapter

locate

and

are

both

words

that

TO

USE

all

the

information

of

the

item.

or

beginning

by

chapters,

an

index,

or

more

tables

capitalized

you

will

and

section

specific

are

actually

THIS

this

equipment.

You

must

a

maintenance

sections,

DA

Forms

for

subjects.

provided

and

in

see

MANUAL

needed

the

for

quotation

on

to

familiarize

and

2028-2.

general

your

y

the

equipment.

understand

It

describes

yourself

task.

paragraphs

Use

the

subject

ease

in

using

marks

are

the

how

with

table

area

g

names

capabilities,

to

set

up,

the

entire

followed

of

contents

needed.

this

manual.

of

by

The

com-

O

Chapter 3 provides a systematic

ment.

problem

the

detected

O

Only

chart

levels

and

In this

checks

way,

causing

and

quickly.

perform

for

your

of

maintenance

diagnostic

small

the

services

maintenance

level

equipment;

defects can

unit

in

of

maintenance.

frequently

to

the

method

be

fail to

same

functions

or

complete

order

require

tools.

of

inspecting

detected

specified

Maintenance

additional

its

each

early

mission.

time

and

before

Make a habit

and

anything

in

the

maintenance

functions

training;

servicing

they

become a major

wrong

specified

test,

measurement,

the

equip-

of

doing

will

be

allocation

for

higher

TM

8-6520-003-24&P

Scope.

1-1.

This

manual

installation

manual

and

above).

and

1-2.

Special

applies

a.

Type

special

b.

Model

c.

Purpose

treatment

Explanation

or

describes

procedures;

only

to

of

manual.

list).

tools

number

of

equipment.

unit.

The

unique

abbreviations,

CHAPTER

INTRODUCTION

Section

the

compressor-dehydrator;

and

provides

serial

numbers

Unit,

direct

and

equipment

To

provide

compressor-dehydrator

of

abbreviations

acronyms,

I.

GENERAL

operational

2700

and

support

(DS),

name.

processed,

and

INFORMATION

provides

and

maintenance

above.

and

general

M5B,

Compressor-Dehydrator,

compressed

may

also

and

terms

unit

Additional

support

be

used

terms.

used

within

air

1

personnel

functions,

information

for

to

operate

this

with

(GS)

maintenance

the

operation

manual

equipment

services,

follows:

Dental

patient

(serial

ventilators.

are

explained

of

technical

and

actions.

(including

numbers

a

field

dental

in

the

data

and

This

repair

parts

2700

and

operating

glossary.

1-3.

Maintenance

TB

38-750-2

1-4.

Destruction

AR

40-61

publications

ardous.

1-5.

Administrative

a.

of

maintenance

factors

b.

equipment

operational

c.

1-6.

Procedures

prescribes

contains

provide

Place

the

determined

Perform

in

administrative

readiness.

Inside

storage

Preparation

to

prepare

forms,

forms,

of

Army

instructions

periodic

information

records,

records,

materiel

for

destruction

storage.

compressor-dehydrator

effort

exists.

by

the

preventive

is

Items

should

directing

maintenance

preferred

for

the

compressor-dehydrator

authority.

storage.

When

for

equipment

storage

and

reports,

and

to

and

disposal

and/or

in

checks

instructions

administrative

be

in

mission

During

and

equipment

selected

or

shipment.

for

reports.

procedures.

prevent

of

Army

on

storage

readiness

the

storage

services

is

removed

for

administrative

storage

or

enemy

medical

the

disposal

for

only

condition

period,

(PMCS)

shipment

short

keep

listed

from

use.

materiel.

of

medical

periods

within

appropriate

in

table

storage,

storage.

are

listed

Also,

materiel

of

time

24

hours

maintenance

3-1

perform

in

chapter

the

SB

8-75

series

that

are

when a shortage

or

within

the

records,

before

PMCS

3,

placing

to

section

haz-

time

Army

ensure

IX.

1-7.

Quality

TB

740-10/DLAM

assurance

4155.5/AFR

67-43

or

quality

contains

control

QA

or

QC

requirements

(QA

or

QC).

and

procedures.

1-1

TM

8-6520-003-24&P

1-8.

Nomenclature

Table

1-1

identifies

Case

1-9.

Reporting

improvement

AR

40-61

prescribes

reports

for

the

compressor-dehydrator.

cross-reference

official

Common

Compressor-dehydrator

Drying

Fan Dryer

Female

Male

Power

versus

name

chamber

quick-disconnect

commonly

Table

quick-disconnect

switch

and

processing

used

1-1.

Nomenclature

list.

nomenclatures.

cross-reference

medical

Official

Storage

Compressor-dehydrator,

Dehydrator

cooling

Coupling,

Coupling,

*ON'POFF"

materiel

reports.

procedures

for

submitting

medical

materiel

complaints

list.

nomenclature

and

shipping

case

dental

fan

half,

quick-disconnect,

half,

quick-disconnect,

circuit

breaker

complaints

and/or

quality

female

male

and/or

improvement

quality

1-10.

A

1-11.

compressed

protective

air

1-12.

An

as

circuit

switch

to

processed

Warranty

warranty

is

Equipment

a.

The

compressor-dehydrator

b.

The

unit

c.

The

compressor-dehydrator

cover

d.

The

compressor-dehydrator,

to

multiple

Description

a.

Motor-compressor.

intake

silencer

b.

Fan.

The

the

power

с.

Unloader

for

air

d.

Pressure

opens

e.

Storage

operate

f.

Humidity

g.

Pressure

attached

air.

information.

not

applicable.

Section

air

free

of

oil,

contains

during

patient

switch

to

and

ventilators.

is

mounted

fan

provides a steady

is in

valve.

The

flow

from

switch.

closes

tank.

The

equipment. A drain

indicator.

gauge.

Il.

EQUIPMENT

characteristics,

is a compact,

moisture,

an integral

operation.

of

The

the

"ON"

unloader

the

drying

The

pressure

the

unloader

storage

This indicator

This

gauge

and

particulate

moisture

includes a case

when

drying

used

significant

motor-compressor

on the

motor-compressor.

flow

of

position.

valve

is

chamber

switch

valve

and

tank

holds

the

valve

varies

displays

air

to

the

DESCRIPTION

capabilities,

portable,

matter.

assembly

and

its

lid

with a manifold

components.

produces

through

used

to

the

atmosphere.

is

mechanically

opens

processed,

is

located

from

pink

pressure

compressed

the

cooling

vent

the

and

closes

compressed

on

the

to

blue

of

the

and

and

self-contained

which

automatically

is

designed

assembly,

coil.

pressure

operated

bottom

processed

by

the

electrical

air

of

which

AND

features.

unit

to

serve

will

provide

air

that

requires

The

fan

operates

from

the

pressure

circuit

and

provides

the

tank

to

denotes

the

air.

DATA

that

provides

regenerates

as a sound

processed,

additional

continuously

compressor

in

the

air

storage

for

the

motor-compressor.

relatively

drain

the

air

amount

of

processed,

the

drying

suppressor

compressed

processing.

as

and

to

provide

tank.

stable

pressure

or

water.

moisture

agent.

and

long

a

The

in

the

1-2

h.

Safety

valve.

This

i.

Drying

chamber.

air.

j.

Flow

the

storage

the

atmosphere

k.

Case.

container.

control

The

tank

The

lid

valve.

during

during

case

of

operation.

1

Power

switch.

motor-compressor.

The

the

is

the

The

valve

the

used

case

vents

drying

chamber

The

flow

pumping

purging

to

store

is

designed

electrical

excessive

control

cycle

air

is

used

valve

and

provides

pressure

to

controls

cycle.

the

compressor-dehydrator

to

serve

as

power

switch

if

the

hold

desiccant

the

flow

a

metering

a

sound

includes

primary

that

of

compressed

orifice

when

suppressor

a

circuit

pressure

removes

to

expand

itis

notin

and

breaker

TM

switch

fails

moisture

air

from

the

processed

use

and

protective

as

a

protective

8-6520-003-24&P

to

from

drying

to

serve

cover

operate

the

air

properly.

compressed

chamber

as

it

flows

as

a

shipping

during

device

normal

for

to

to

the

1-13.

The

Tabulated

tabulated

data

sor-dehydrator.

a.

Specifications

physical

characteristics.

Electrical

Dimensions

Hoses

data.

provides

and

power

Voltage...

Frequency.

Current

Ambient

Normal

Maximum

(interconnecting

the

physical

...

temperature

operating

operating

specifications,

physical

characteristics.

Table

range

Table

1-3.

load

loa:

to

equipment

characteristics,

Tables

1-2.

Physical

1-2

Specifications.

characteristics.

and

1-3

provide

and

other

information

a

broad

range

for

the

compres-

of

specifications

and

b.

Identification,

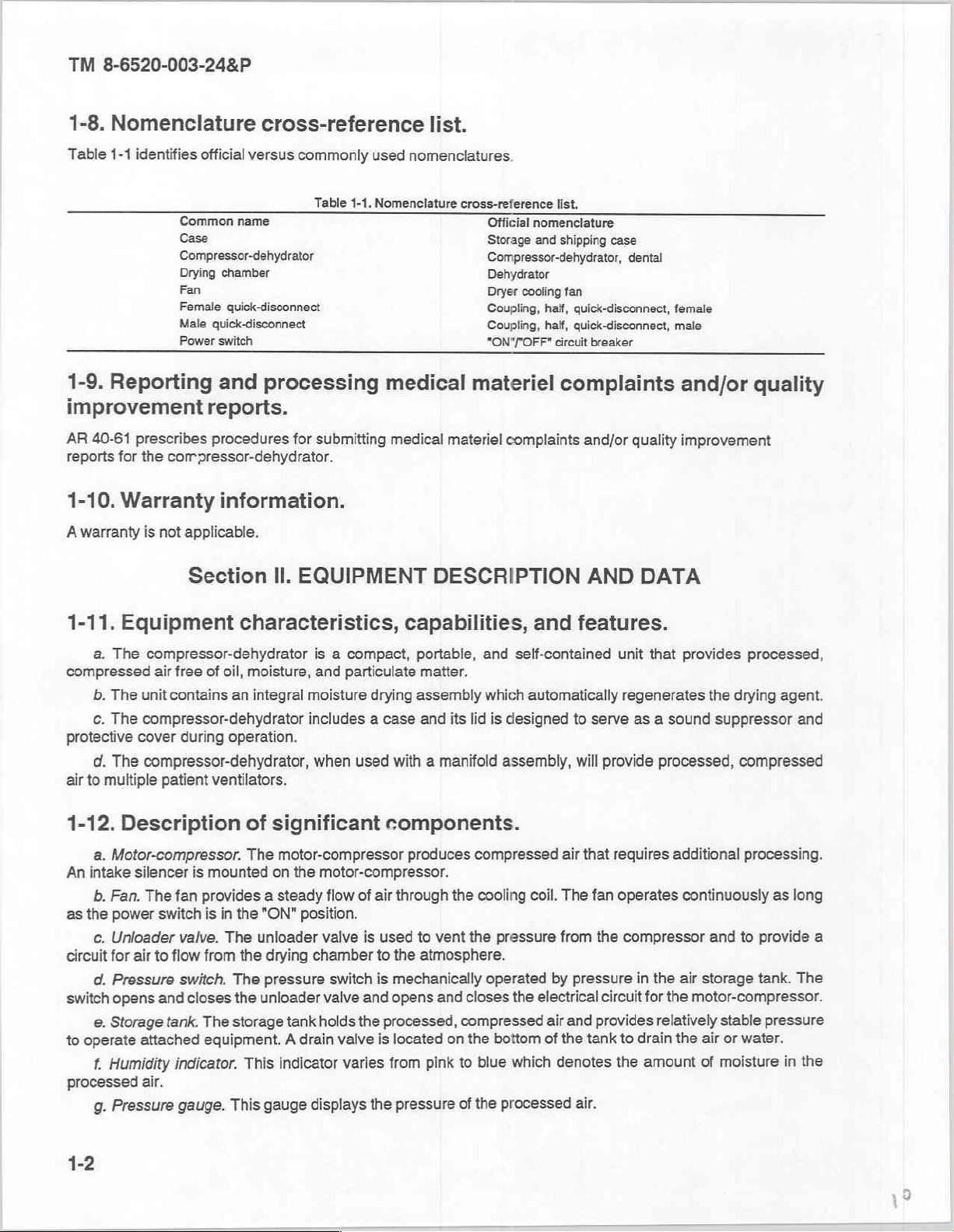

(1)

(2)

to

the

cylindrical

is

shown

is

shown

in

in

instruction,

Case.

(a)

Identification

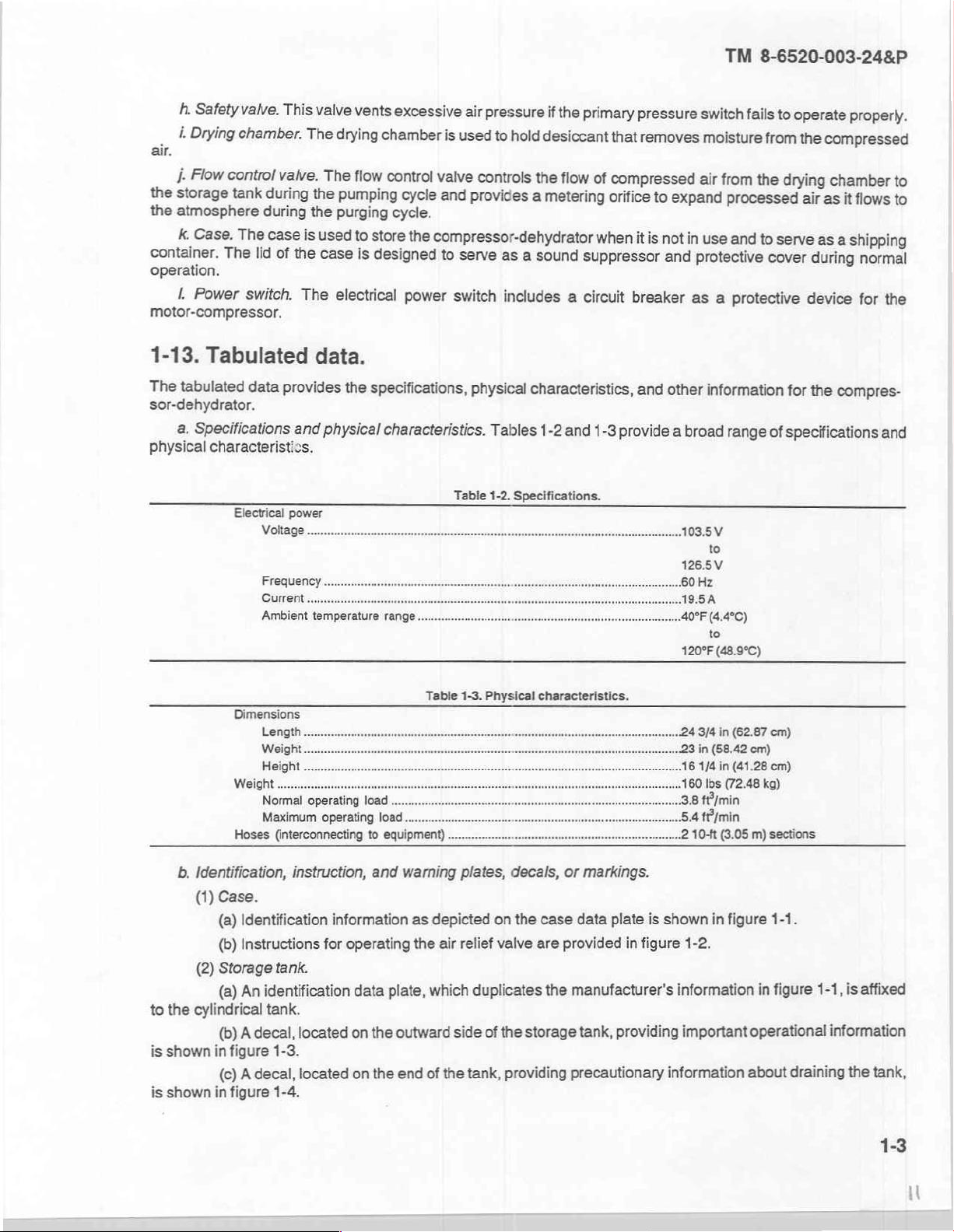

(b)

Instructions

Storage

(a)

tank.

An

identification

tank.

(b) A decal,

figure

located

1-3.

(0) A decal,

figure

1-4.

information

for

operating

located

and

data

plate,

on

the

on the

warning

as

depicted

the

air

which

outward

end

of

the

plates,

on

relief

valve

duplicates

side

of

the

tank,

providing

decals,

the

case

are

the

storage

or

markings.

data

plate

is

provided

in

figure

manufacturer's

tank,

providing

precautionary

shown

in

figure

1-2.

information

important

information

1-1.

in

figure

1-1,

operational

about

draining

is

affixed

information

the

tank,

1-3

TM

8-6520-003-24&P

Figure

1-1.

A)

Use

B)

Check

‘off

C)

To

on

D)

Do

operation

E)

Allow

humid

F)

Check

compressor

G)

Hf

cant

Case

data

115

VAC/60

Hertz

system

operation:

(purges

assure proper

all

not

moisture

moisture)

four

swivel

turn

"off'

compressor

provides

compressor

work

day.

system

moisture

to

operate

monitor

dryer.

plate.

ATTENTION

power

source

Compressor

at

80

psig.

unit

ventilation,

posts.

during

for

the

purging

to

operate

monitor

at

no-load

turns

“white”,

OPERATOR

only.

turns

check

that

the

course

of

system

up

to

24

hours

daily.

If

monitor

until

indicator returns

discontinue

Figure

"on"

(pumps-up)

raised

transit

of a normal

moisture.

at

no-load

indicates

use and

install

1-2.

at

60

case

top rests

work

day.

upon

termination

"pink"

(wet

to

"blue"

(dry

replacement

Air

relief

psig

and

securely

No-load

of

air),

air).

valve

turns

hot

and

allow

desic-

data

plate.

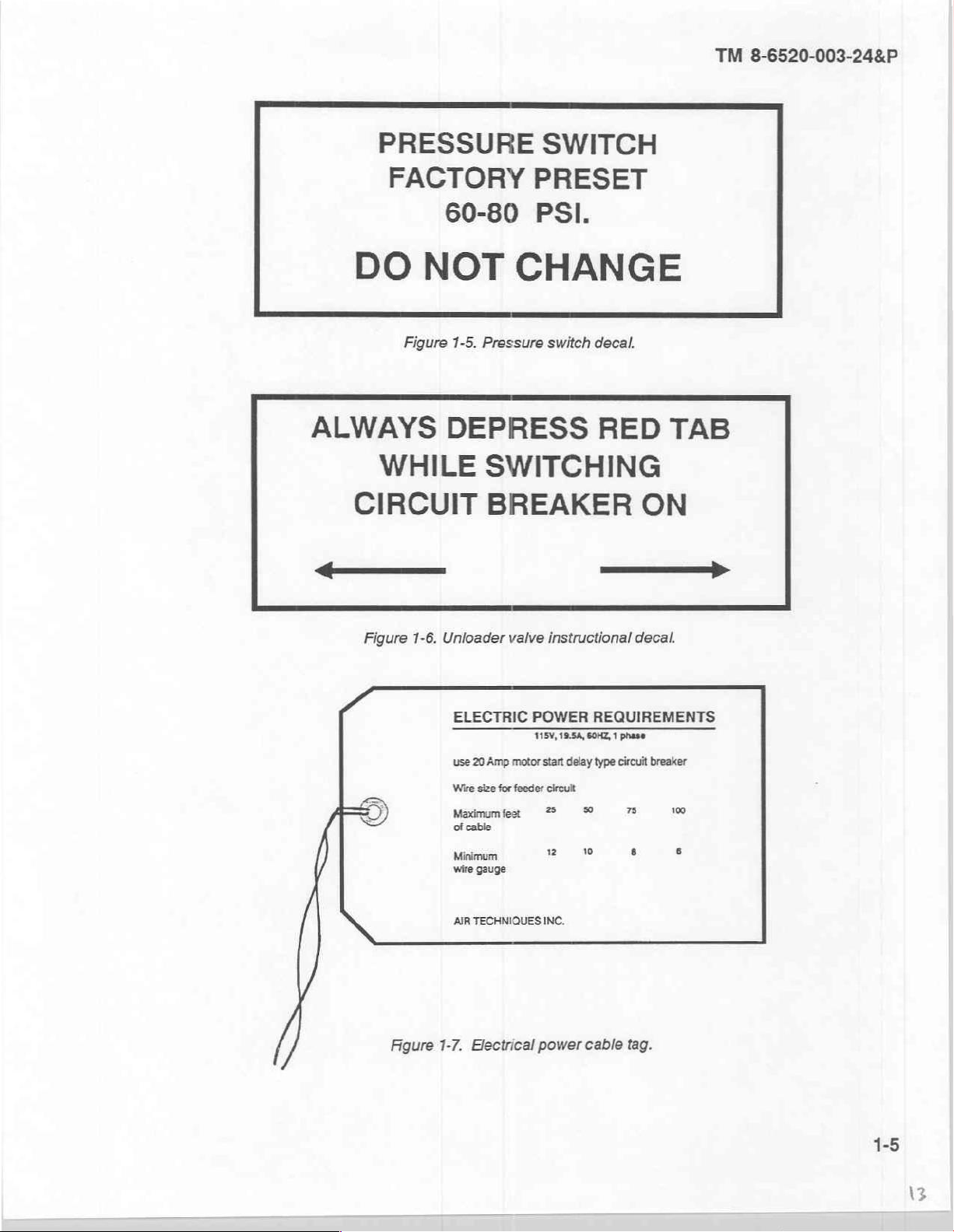

(3)

Pressure

critical

operational

(4)

Electrical

information

is

switch.

information,

power

illustrated

in

Figure

|

Decals,

are

cable. A cardboard

figure

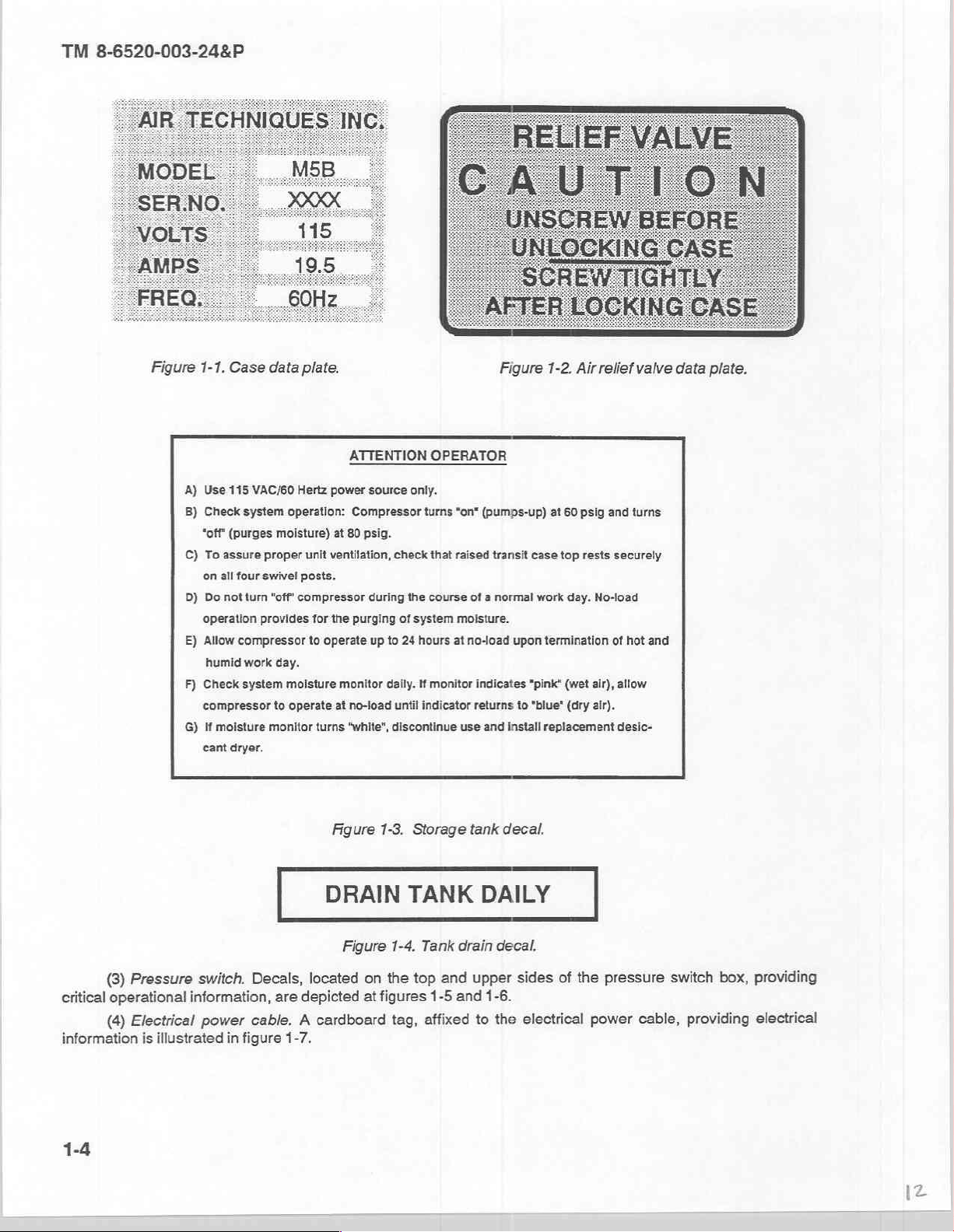

DRAIN

located

depicted

1-7.

Figure

at

1-3.

Storage

TANK

1-4.

Tank

on the top

figures

tag,

1-5

affixed

drain

and

and

tank

decal.

DAILY

decal.

upper

sides

1-6.

to

the

of

the

electrical

power

pressure

cable,

switch

providing

box,

providing

electrical

TM

8-6520-003-24&P

PRESSURE

FACTORY

DO

ALWAYS

WHILE

CIRCUIT

—

60-80

NOT

Figure

1-5.

DEPRESS

SWITCH

PRESET

PSI.

CHANGE

Pressure

SWITCHING

BREAKER

switch

decal.

RED TAB

ON

Figure

A

ミノ

ミ

1-6.

Figure

Unloader

ELECTRIC

use

Wire

Maximumfet

of

Mina

wire

AIR

1-7.

valve

20

Amp

size

for

feeder

cable

gauge

TECHNIQUES

Electrical

instructional

POWER

motor

start

delay

circult

7%

2

INC.

power

decal.

REQUIREMENTS

type

circuit

breaker

©

ze

vw

cable

8

tag.

o,

1-5

TM

8-6520-003-24&P

1-14.

Model

differences

However,

such

engineering

1-15.

8.

Observe

pressure

b.

Ensure

c.

Refer

1-16.

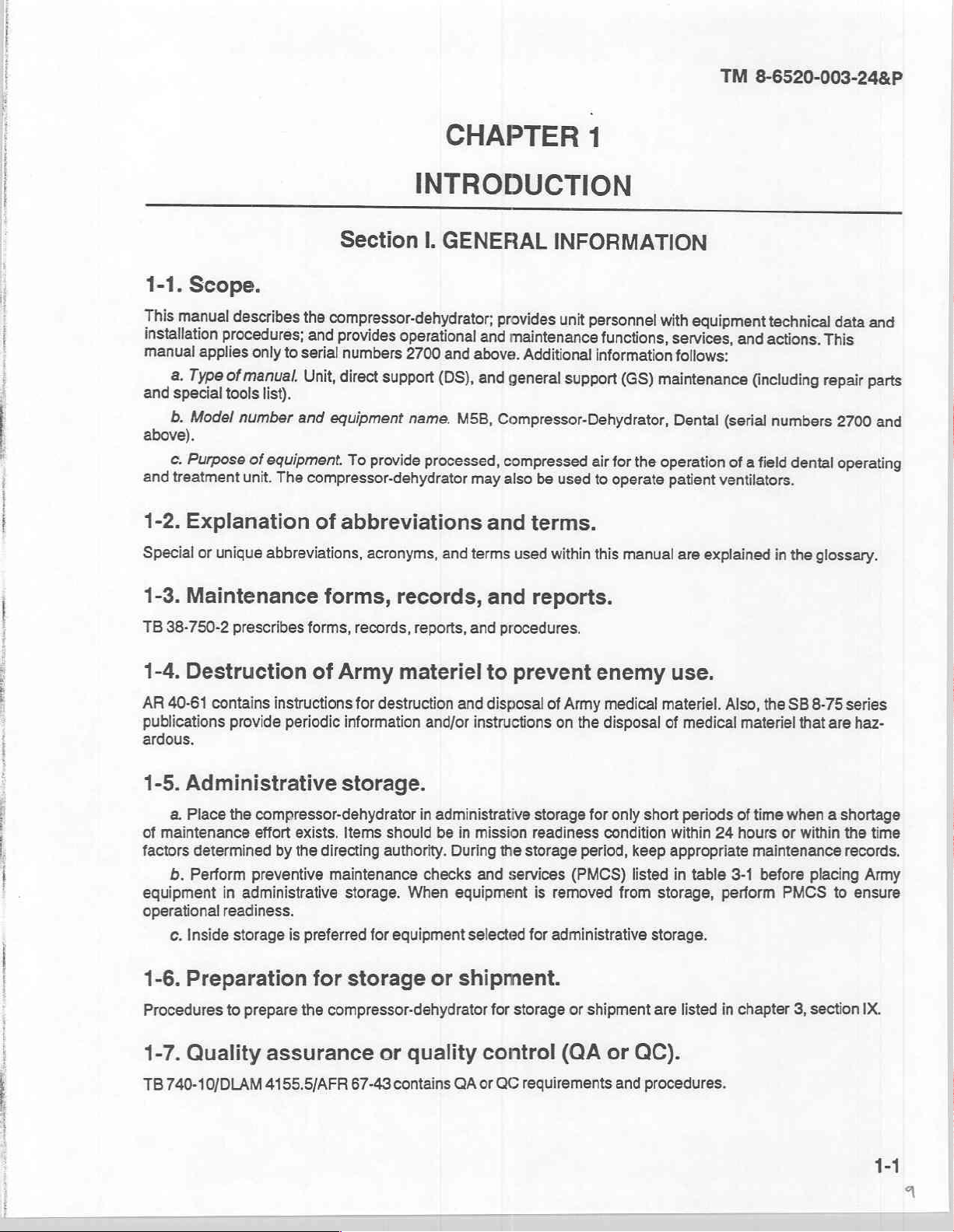

The

operation

pumping

tion

of

the

tinue

to

fan

runs

1-17.

Model

design

Safety,

compressed

differences.

are

not

changes

changes

care,

each

WARNING,

air

that the

to

paragraph

compressor-dehydrator

applicable

in

assemblies,

will

be

and

be

may

3-22

for

Section

General.

of

the

compressor-dehydrator

cycle,

intake

air

is

compressed,

processed

automatically

continuously

Motor-compressor

air

in

occur

and

the

storage

during

the

processed

since

this

subassemblies,

published

in

handling.

CAUTION,

hazardous

guidance

the

on

III.

PRINCIPLES

cooled,

tank

is

operation

air

in

pumping

manual

supply

and

NOTE

personnel.

to

is

turned

cleaning

consists

dried,

vented

of

the

the

storage

cycle

covers

bulletins

of a pumping

back

a

single

model

or

components

and

in

this

manual.

off

when

it

the

intake

silencer

OF

and stored

through

compressor-dehydrator.

tank

is

supplied

(fig

1-8).

occur

subsequent

The

is

not

used

element.

OPERATION

cycle

and a purging

in

the

tank.

the

drying

as

and

serial

number

periodically.

changes

use

for

over

During a purging

chamber.

Throughout

needed.

to

of

electrical

24

hours.

cycle.

These

this

grouping.

Information

manual.

power

During

two

both

and

the

cycle, a por-

cycles

cycles,

on

high

con-

the

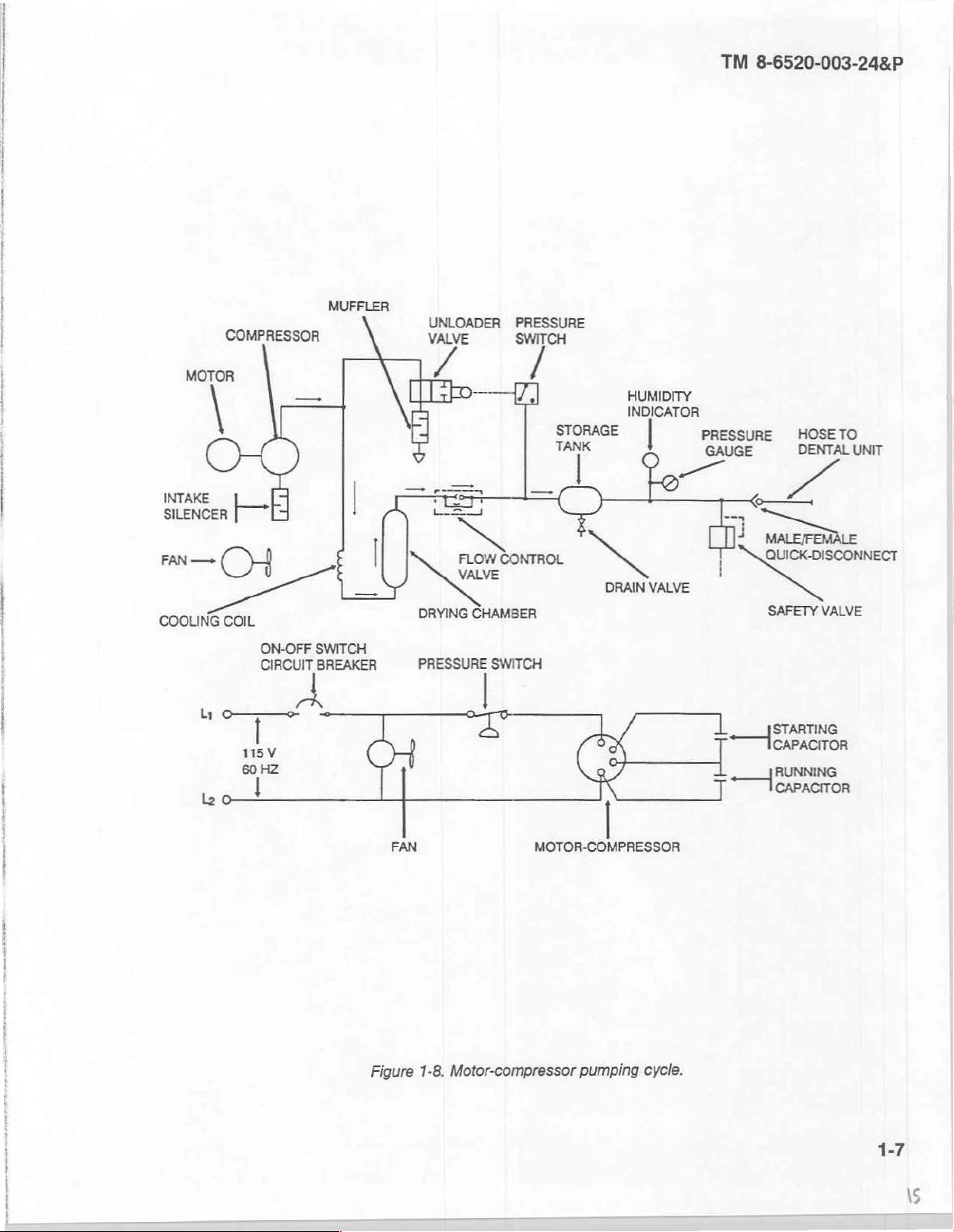

Initially,

closed.

from

into

The

tank.

the

sure

opened

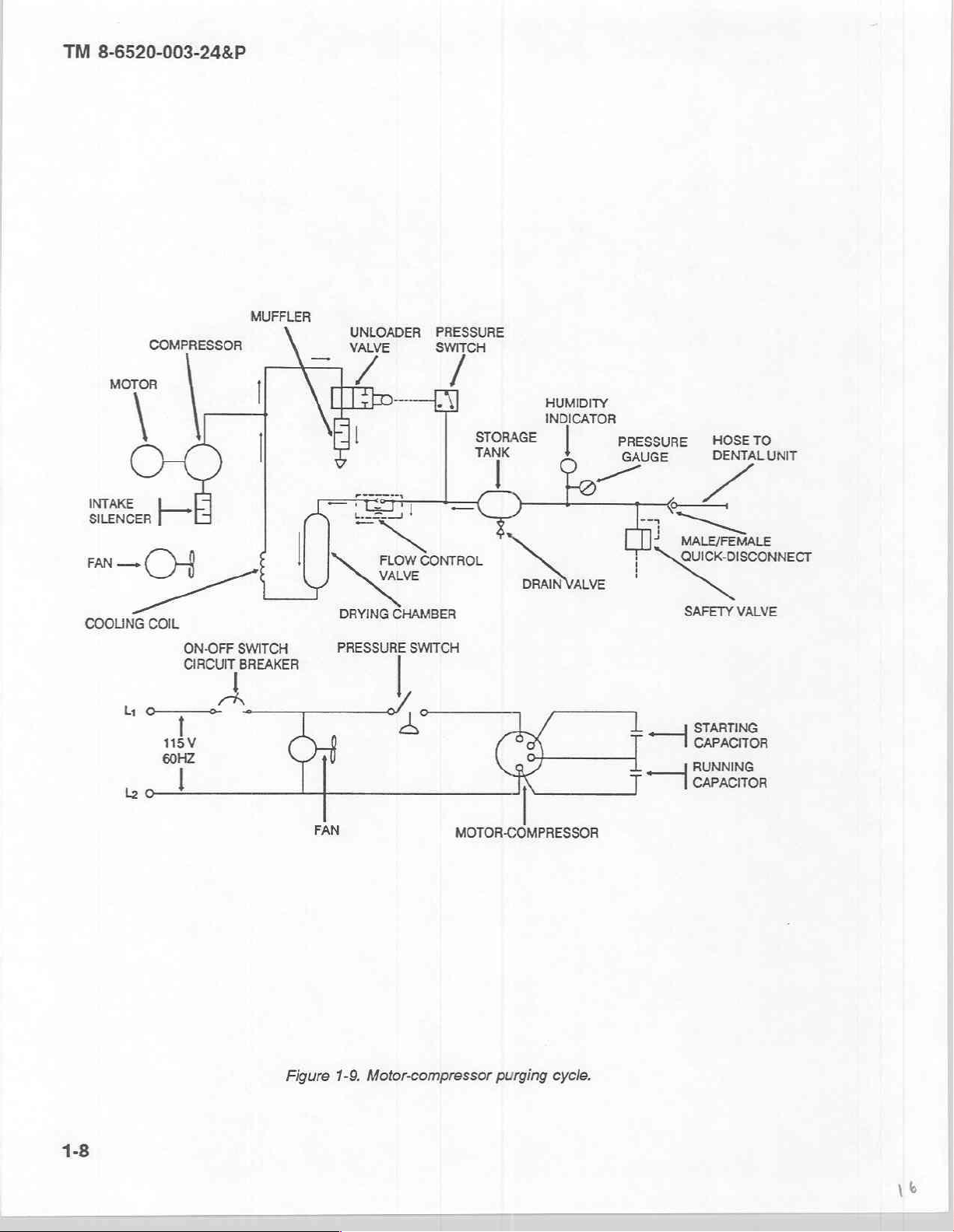

1-18.

The

chamber

orifice

passes

the

the

with

When

the

motor-compressor

the

storage

flow

control

The

gauge

amount

reaches

to

vent

Motor-compressor

purging

vented

in

the

through

atmosphere.

pumping

no

pressure

the

tank.

The

drying

valve

on the

of

moisture

80

psi,

the

cycle

to

flow

control

the

When

cycle

in

the

power

switch

is

chamber

contains a check

storage

in

the

the

pressure

compressor

begins

automatically

the

atmosphere,

valve

drying

the

begins

again.

chamber

air

storage

is

directed

tank

stored

and

tank,

the

turned

contains a desiccant

switch

on,

both

through

valve

indicates

air

by

its

opens

drying

chamber

to

the

color (blue

purging

when

the

and

the

processed

where

it

expands

and

absorbs

pressure

in

the

storage

unloader

the

the

allow

air

and

cycle

pumping

at a controlled

moisture

valve

motor-compressor

cooling

NOTE

stops

coil,

to

remove

the

processed,

pressure

for

dry

the

to

the

atmosphere.

motor-compressor.

(fig

cycle

air

in

the

from

tank

decreases

and

the

the

drying

moisture

within

and

1-9).

ends

storage

rate.

This

the

desiccant.

pressure

and

the

chamber,

from

compressed

the

tank.

The

pink

for

wet).

This

ends

with

the

unloader

tank

passing through a metering

large

This

to

60

psi,

switch

fan

start.

flow

the

compressed

air

to

humidity

When

The

the

volume

moisture

the

pressure

electrical

Compressed

control

enter

the

indicator

the

storage

unloader

pumping

valve

open,

of

dry,

expanded

is

switch

contacts

valve,

air.

storage

valve

cycle.

then

vented

closes

are

air

and

displays

tank

pres-

is

also

the

drying

air

to

and

1-6

M

COMPRESSOR

MOTOR

ーー

MUFFLER

[

UNLOADER

VALVE

ПЕР

PRESSURE

SWITCH

STORAGE

了

HUMIDITY

INDICATOR

PRESSURE

和

GAUGE

TM

8-6520-003-24&P

HOSE

DENTAL

TO

UNIT

—

<

т

QUIGK

DISCONNECT

INTAKE

SILENCER

CH

FAN

|

|

—

e

=

SS

—

CONTROL

FLOW

İM

5

Ke

VALVE

—

COOLING

CoIL

lei

ON-OFF

CIRCUIT

Î

SWITCH

BREAKER

n

DRYING

PRESSURE

CHAMBER

SWITCH

“a

1tsv

HZ

60

wo!

i

|

i

|

FAN

MOTOR-COMPRESSOR

N

VALVE

SAFETY

VALVE

L__yjsrarming

CAPACITOR

RUNNING

一

村

capacron

Figure

1-8.

Motor-compressor

pumping

cycle.

1-7

TM

8-6520-003-24&P

COMPRESSOR

MUFFLER

\

UNLOADER

VALVE

PRESSURE

SWITCH

mre

INTAKE

SILENCER

CH

—

FAN

μα.

En

y

o

115V

ve

ON-OFF

CIRCUIT

—

|

|

|

\

SWITCH

BREAKER

В

|

DRYING

PRESSURE

FAN

<

CONTROL

e

ANE

CHAMBER

SWITCH

ola

a

INDICATOR:

STORAGE

TANK

A

©

MOTOR-COMPRESSOR

Te

DRAIN

VALVE

PRESSURE

GAUGE

=

e

1

J

HOSETO

DENTAL

>

MALE/FEMALE

UNIT

QUICK-DISCONNECT

SAFETY

VALVE

STARTING

CAPACITOR

RUNNING

CAPACITOR

Figure

1-9.

Motor-compressor

purging

cycle.

TM

8-6520-003-24&P

2-1.

Controls

a.

Operating

Paragraph

b.

for a description

(‘ON"/"OFF")

2-2.

The

the

interconnecting

1-12

Operating

Initial

initial

start-up

a.

Remove

b.

Ensure

for a description

indicators include

and

start-up

the

that

OPERATING

Section

and

indicators.

controls consist

of

of

these

indicators.

the

hissing

procedures

lid

of

equipment

hose

sound

procedures.

for

the

case

and

supplied

is

temporarily

CHAPTER

I.

OPERATING

of

the

power

these

controls.

the

pressure

Additional

of

air

venting

Section

each

day

of

setitaside.

with

processed

disconnected

2

INSTRUCTIONS

CONTROLS

switch,

gauge

Il.

compressor-dehydrator

the

and

operating

through

UNIT

the

OPERATION

air

from

from

unloader

the

humidity

indicators

muffler

the

compressor-dehydrator

the

storage

valve,

during a motor-compressor

and

indicator.

include

operation

tank.

the

the

drain

Refer

position

are

as

valve.

back

to

of

the

follows:

is

either

Refer

back

paragraph

power

purging

switch

cycle.

turned

to

1-12

off

or

Do

not

c.

Ensure

d.

Check

e.

Set

motor-compressor

£

Observe

operate.

g.

Listen

again

start

Check

h.

procedures.

Connect

i.

Replace

j.

that the

and/or

the

power

the

for a hissing

operation

Pumping

the

that

not

Do

will

damage

the

the

use any

pressure

close

the

switch

and

the

pressure

sound

at

60

psi.

and

purging

humidity

the

use

the

hose(s)

the

on

lid

air

from

the

storage

gauge

drain

"ON"

fan

will

gauge.

indicator

compressor-dehydrator

handpieces

disconnected

if

four

begin

as

air

cycles

case

is

indicating

valve.

while

to

The

is

automatically

is

of

supports

tank

simultaneously

operate.

motor-compressor

will

continue

the

If

blue.

the

dental

preceding

the

in

to

NOTE

during

the

initial

"0."

depressing

should

vented

NOTE

indicator

through

to

alternate.

is

shut

pink, refer

WARNING

shows

pink

when

operating

suppress

and

treatment

paragraph

noise

the

start-up

the red tab

the

in

2-2b.

of

procedures.

off

at

80

muffler.

to

the

the

The

paragraph

humidity

unit.

motor-compressor.

on

the

unloader

psi.

The

fan

will

motor-compressor

the

for

3-20

indicator.

This

valve.

continue

regeneration

The

to

should

=

TM

8-6520-003-24&P

Do

not

2-3.

Intermittent

The

compressor-dehydrator

energy

valve.

and

minimize

a.

Stopping

(1)

Remove

(2)

Push

(8)

Replace

b.

Restarting

(1)

Remove

(2)

Ensure

(3)

Push

(4)

Replace

flip

procedures.

the

procedures.

that the

the

Failure

the

allow

noise

the

lid

power

the

lid

the

lid

power

the

lid

to

depress

power

liquid

to

accumulate

use

procedures.

may

be

by

using

of

the

case

switch

to

on

the

four

of

the

case

humidity

switch

to

on the

supports.

the

red tab on the

switch

to

stopped

the

following

and

set

the

"OFF"

case

supports.

and

set

indicator

the

"ON"

position

the

"OFF"

CAUTION

in

the

and

restarted

procedures.

it

aside.

position.

it

aside.

is

blue.

CAUTION

unloader

position.

case.

after

while

simultaneously

valve

the

may

initial

daily

depressing

activate

the

start

up

the red

circuit

to

conserve

tab

breaker

electrical

on

the

and

unloader

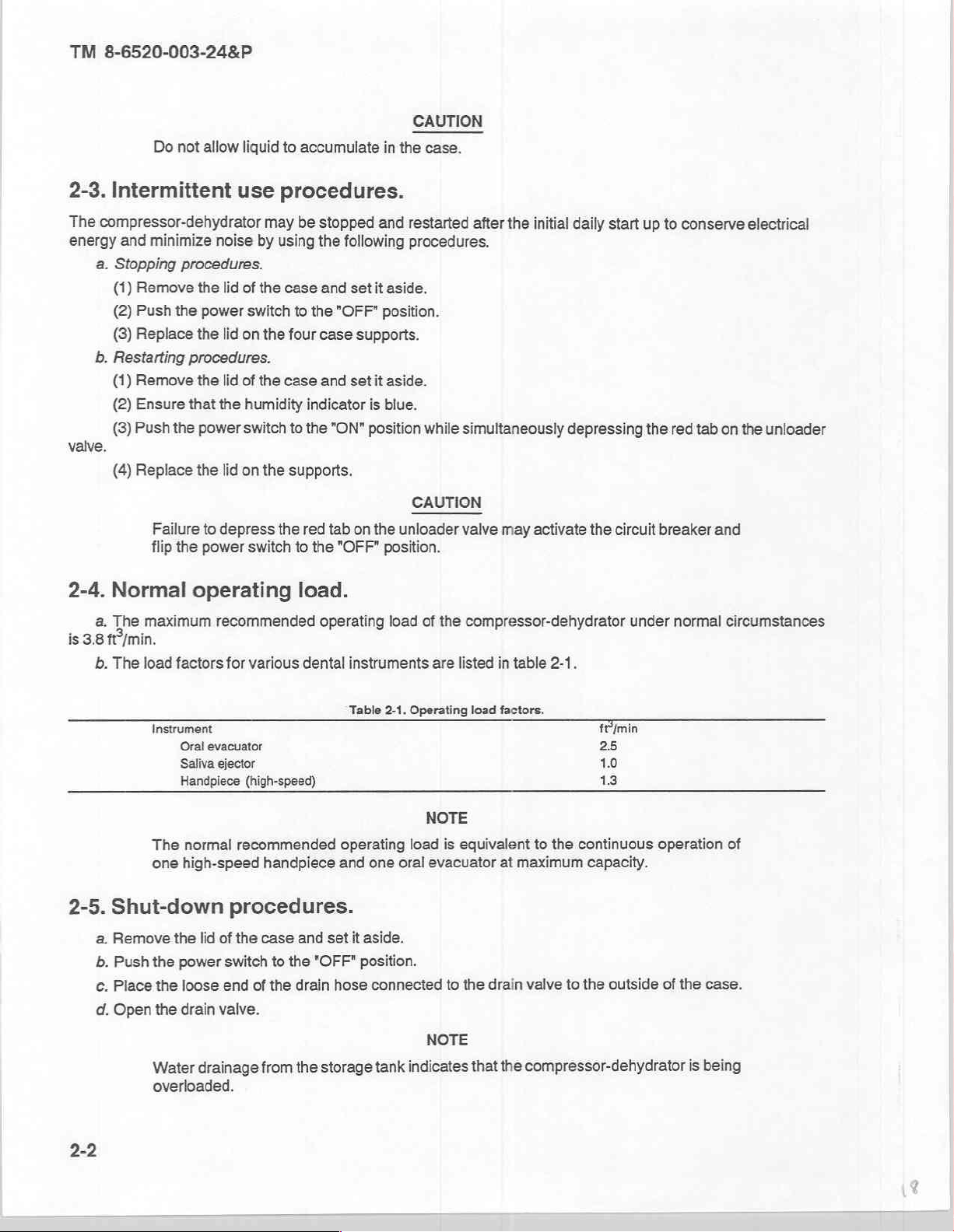

2-4.

are

is

3.8

b.

2-5.

a.

b.

c.

d.

Normal

maximum

fť/min.

The

load

operating

factors

Instrument

Oral

Saliva

Handpiece

The

normal

one

high-speed

Shut-down

Remove

Push

Place

Open

the

lid

the

power

the

loose

the

drain

Water

drainage

overloaded.

recommended

for

various

evacuator

ejector

(high-speed)

recommended

handpiece

procedures.

of

the

case

switch

end

valve.

of

the

from

to

the

load.

operating

dental

operating

and

and

setit

"OFF"

drain

hose

the

storage

load

of

instruments

Table

2-1.

Operating

NOTE

load

one

oral

evacuator

aside.

position.

connected

NOTE

tank

indicates

the

compressor-dehydrator

are

listed

in

table

2-1.

load

factors.

is

equivalent

to

the

that

to

the

at

maximum

drain

valve

the

compressor-dehydrator

ft/min

25

1.0

13

continuous

capacity.

to

the

outside

under

operation

of

normal

the

case.

is

being

circumstances

of

2-2

e.

When

f.

Replace

the

pressure

the

lid

on

gauge

the

supports.

indicates

"0,"

close

the

drain

valve

and

place

the

TM

drain

8-6520-003-24&P

hose

back

inside

the

case.

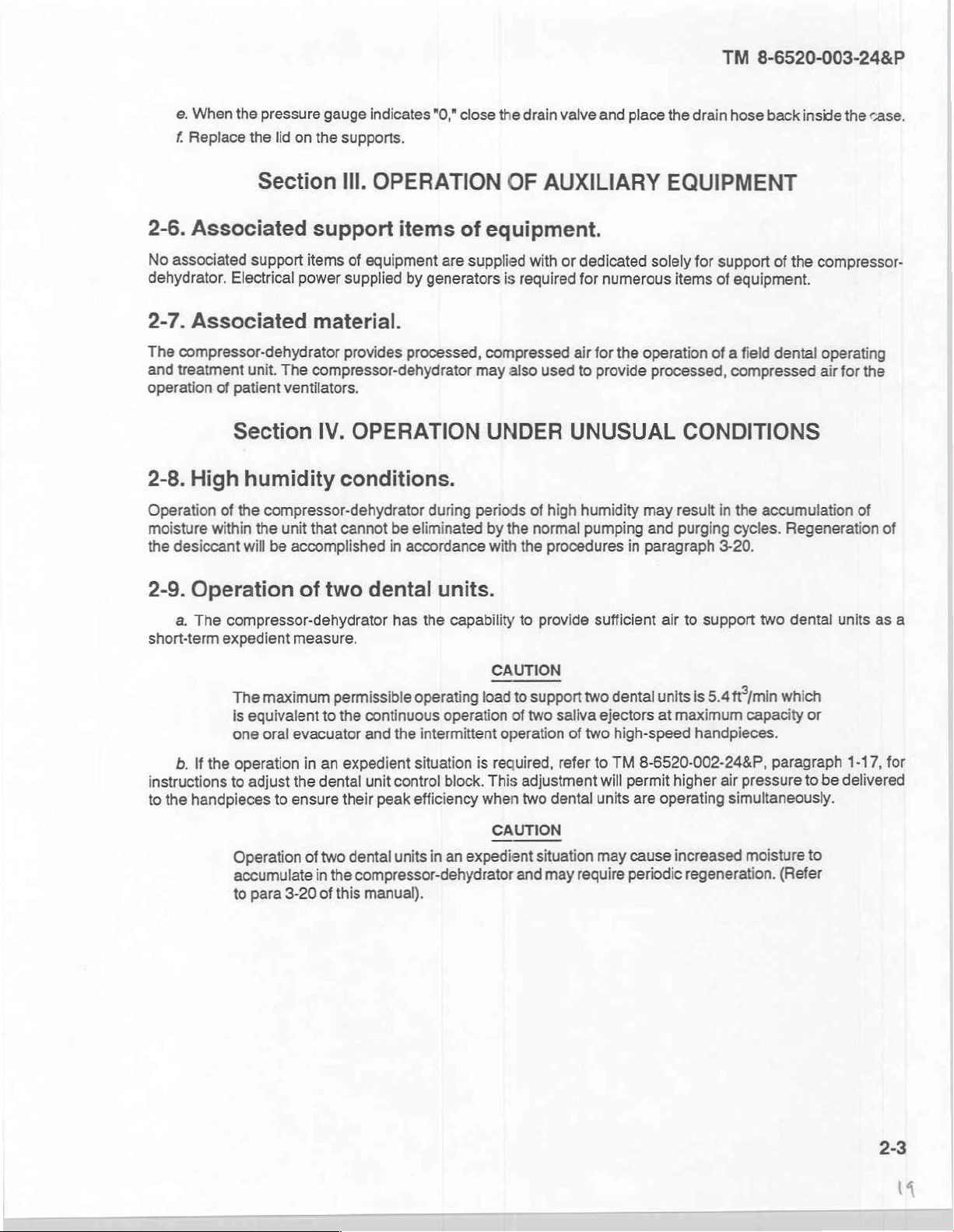

Section

2-6.

Associated

No

associated

dehydrator,

2-7.

Associated

The

compressor-dehydrator

and

treatment

operation

support

Electrical

unit.

of

patient

Section

2-8.

High

Operation

moisture

the

desiccant

2-9.

Operation

a.

The

short-term

humidity

of

the

compressor-dehydrator

within

the

will

be

compressor-dehydrator

expedient

III.

OPERATION

support

items

of

power

supplied

items

equipment

by

material.

provides

The

compressor-dehydrator

ventilators.

IV.

OPERATION

processed,

conditions.

unit

that

cannot

accomplished

of

two

measure,

be

in

accordance

dental

has

of

are

supplied

generators

may

during

eliminated

periods

units.

the

capability

OF

AUXILIARY

equipment.

with

or

dedicated

is

required

compressed

also

UNDER

of

by

the

normal

with the

to

for

air

used

to

UNUSUAL

high

humidity

pumping

procedures

provide

EQUIPMENT

solely

numerous

for

the

operation

provide

sufficient

processed,

may

and

in

paragraph

air

for

items

support

of

of a field

of

equipment.

dental

compressed

CONDITIONS

result

in

the

accumulation

purging

to

cycles.

3-20.

support

two dental

the

compressor-

operating

air

for

the

of

Regeneration

units

as

of

a

The

is

one

b.

If

the

operation

instructions

to

the

to

handpieces

Operation

accumulate

to

maximum

eguivalent

oral

evacuator

in

adjust

the

dental

to

ensure

of

in

para

3-20

of

permissible

to

the

continuous

and

an

expedient

unit

their

two

dental

the

compressor-dehydrator

this

manual).

operating

the

intermittent

situation

control

peak

efficiency

units

operation

block.

in

an

CAUTION

load

to

support

of

two

operation

is

required,

This

adjustment

when

two

CAUTION

expedient

and

two

saliva

ejectors

of

two

refer

to

will

dental

units

situation

may

may

require

dental

units

is

at

maximum

high-speed

TM

8-6520-002-24&P,

permit higher

are

cause

periodic

handpieces.

operating

increased

regeneration.

5.4

ftÓ/min

air

simultaneously.

which

capacity

paragraph

pressure

moisture

(Refer

or

to

to

be

1-17,

for

delivered

TM

8-6520-003-24&P

|

3-1.

Overview.

Maintenance

unit

level

medical

quired

chapter

3-2.

Common

111.

3-3.

Components

3-4.

for

the

provides

Tools

tools

Refer

to

Components

Expendabie

Expendable

functions,

eguipment

equipment

instructions

and

and

test

your

unit's

of

end

and

durable

UNIT

both

except

test

equipment

modified

of

item

and

supplies.

supplies

CHAPTER

LEVEL

Section

preventive

repairer

for

and

information

equipment.

table

end

basic issue

and

I.

and

personnel.

some

tasks

required

of

organization

item

items

materials

GENERAL

corrective,

for

MAINTENANCE

These

involving

to

aid

in

maintenance

and

and

basic issue

are

listed

required

3

INFORMATION

that

are

beyond

personnel

the

performing

equipment

in

for

will

motor-compressor,

the

of

the

appendix

maintenance

the

scope

perform

required

equipment

(MTOE)

items.

C,

sections

are

of

the

majority

storage

tasks.

are

listed

for

authorized

II

and

listed

in

the

user

of

tank,

in

appendix

items.

III.

appendix

are

assigned

maintenance

and

case.

This

B,

section

D,

section

to

re-

II.

|

ㅣ

3-5.

Repair

Repair

3-6.

Special

Special

3-7.

Unpacking

a.

Unpacking

(1)

(2)

(3)

(4)

(5)

by

opening

(6)

parts

tools

Remove

Place

Loosen

Release

Ensure

the

Ensure

parts.

required

for

unit

level

tools.

maintenance

required

Section

The

for

II.

and

installing

the

unit.

compressor-dehydrator

the

compressor-dehydrator

the

compressor-dehydrator

the

screw

in

the

latches

eight

the

pressure

the

that

drain

valve.

that

the

drain

maintenance

the

of

SERVICE

is

air

relief

remove

and

is

gauge

valve

is

closed.

are

listed

in

appendix

compressor-dehydrator

UPON

the

from

further

no

designed

valve

on

the

indicating

RECEIPT

compressor-dehydrator.

shipping

the

feet

20

than

NOTE

outside

use

for

the

lid

of

the

case.

the

of

lid

storage

the

If

"0."

E,

are

carton

from

patient

case.

Set

section

listed

EQUIPMENT

OF

and/or

equipment

the

treatment

aside.

it

pressurized,

is

tank

Il.

appendix

in

crate.

E,

are

you

areas.

release

section

using.

the

III.

pressure

3-1

TM

8-6520-003-24&P

(7)

Ensure

(8)

Check

b.

Installing

(1)

Connect

More

compressor-dehydrator.

Refer

dehydrator

(2)

Connect

(3)

Provide

(4)

Rotate

right

at

case

the

(5)

Place

that

the

power

switch

the

compressor-dehydrator

the

unit.

either

one

or

two

than

two

interconnecting

to

TM

8-6520-002-248P

dental

a

to

the

electrical

environmental

the

four

case

angles.

the

lid

on

lid

the

supports.

power

protection

supports

is in

the

"OFF"

for

any

interconnecting

hoses

for

additional

unit.

cable

to

a

115-volt,

for

the

mounted

position.

damage

hoses

CAUTION

(a

combined

NOTE

compressor-dehydrator.

on

from

storage

to

a

dental

length

information

60-Hz

source

the

motor-compressor

operating

of

20

on

connecting

of

or

shipment.

and

feet)

may

power.

so that

treatment

damage

the

compressor-

they

overlap

unit.

the

the

edges

of

3-8.

General.

No

lubrication

Section

3-9.

General.

a.

The

compressor-dehydrator

for

operation

damage

b.

are

things

observing

©.

area

on

Operation, A -

at

or

failure.

Preventive

you

for

The

following

(1)

Item

the

Equipment

(2)

Interval.

of

the

unit

IV.

all

times.

Table

maintenance

should

improper

is a list

No.

This

This

After

Operation,

Section

is

required.

Ill.

PREVENTIVE

must

Inspection

3-1

contains

do

any

operational

of

column

Inspection

column

will

is

not

limited

time

you see

indicators,

the

PMCS

shows

and

shows

and S -

PMCS

the

when

Semi-annually.

LUBRICATION

MAINTENANCE

be

inspected

allow

defects

to

be

performed

to

performing

they

need

and

maintaining

table

headings

sequence

Maintenance

each

in

Worksheet,

PMCS

INSTRUCTIONS

and

serviced

to

be

discovered

the

to

be

with a description

which

to

item

B, D,

and A should

NOTE

systematically

by

unit

checks

done,

the

proper

do

the

DA

is

to

be

CHECKS

and

corrected

level

maintenance

and

services

such

as

checking

quantities

of

the

PMCS,

Form

and

2404.

serviced; B -

be

performed

AND

to

listed

information

is

used

Before

SERVICES

ensure

before

of

that

they

personnel.

in

the

for

general

operating

to

identify

Operation, D -

with

daily

the

result

PMCS

supplies.

in

each

the

use

unit

is

ready

in

serious

table.

There

cleanliness,

column:

equipment

During

of

the

unit.

(3)

Item

checked

orunusable.

or

serviced.

(4)

Equipment

3-2

When

items

when

to

the

eguipment

that

will

the

eguipment

be

Inspected

is

not

must

be

kept

not

disrupt

Ready/Available

operation.

can

be

and

Procedure.

shut

in

continuous

Perform

down.

This

If:.

This

column

column

operation,

the

complete

identifies

lists

conditions

check

daily

the

that

and

service

checks

general

make

only

and

services

area

or

the

equipment

those

specific

part

unavailable

to

be

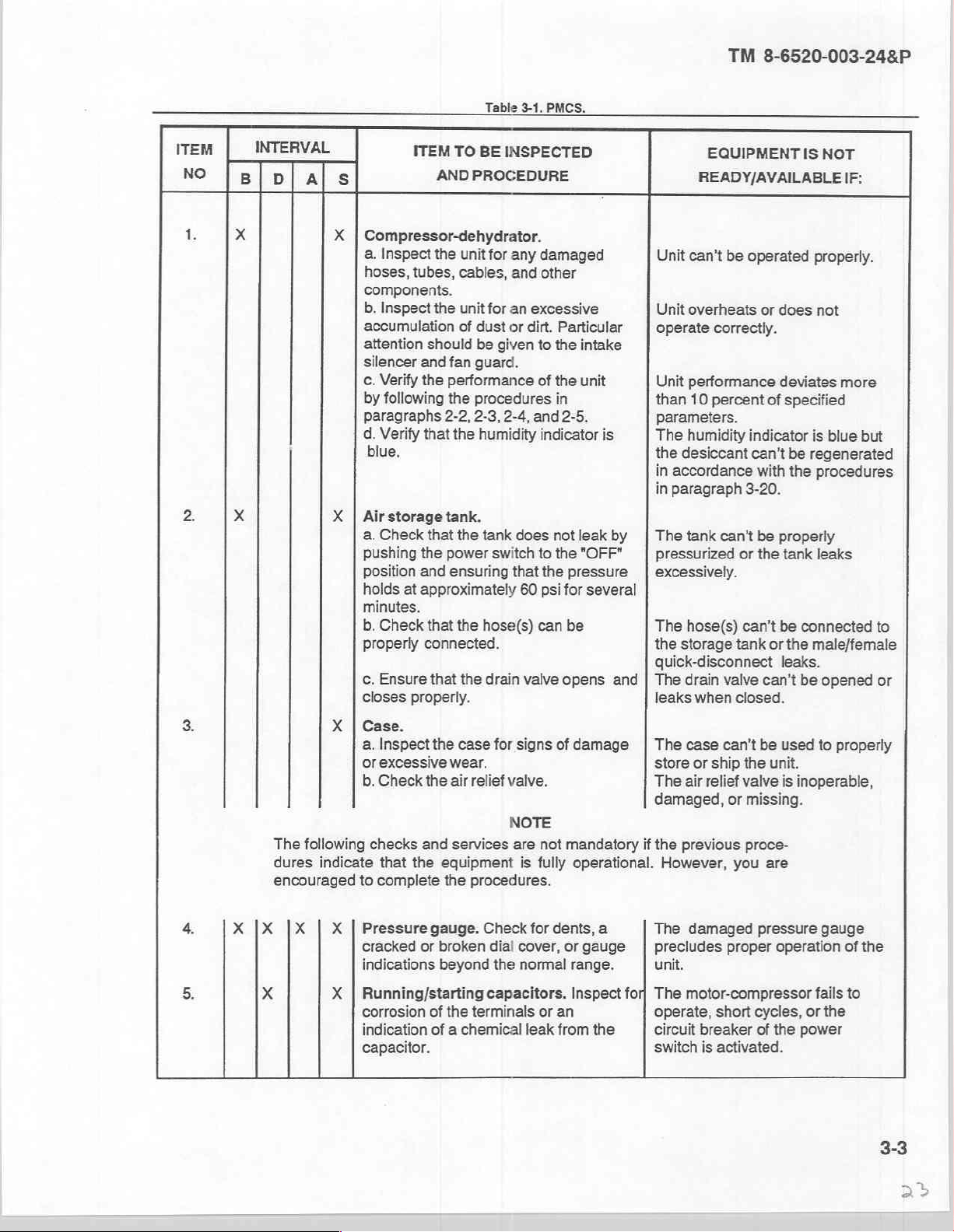

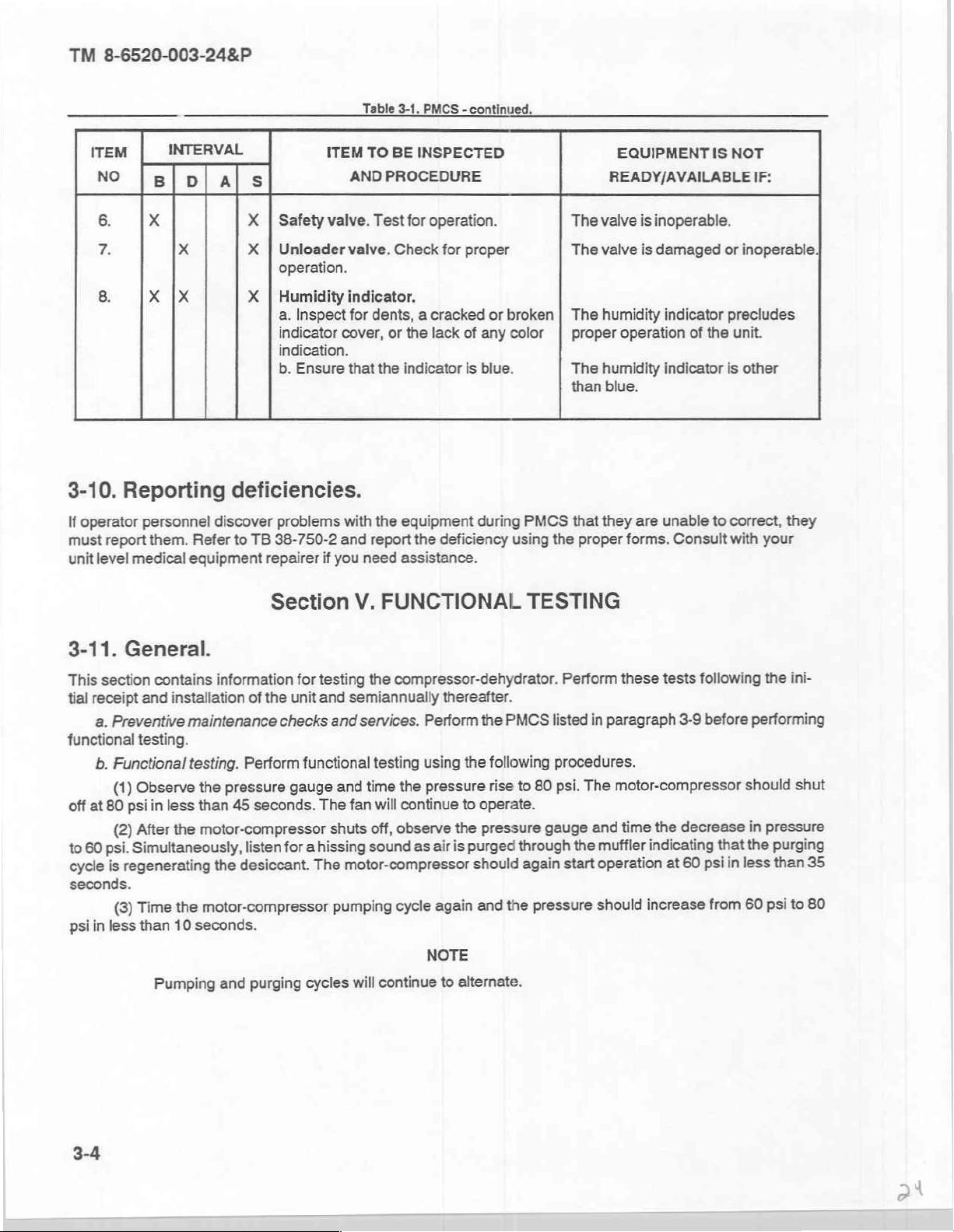

ITEM

νο

INTERVAL

|

el

pl

als

ITEM

AND

Table

3-1.

TO

BE

INSPECTED

PROCEDURE

PMCS.

TM

8-6520-003-24&P

EQUIPMENT

READY/AVAILABLE

IS

NOT

IF:

te

2:

x

X

X

|

Compressor-dehydrator.

a.

Inspect

hoses,

components.

b.

Inspect

accumulation

attention

silencer

c.

Verify

by

following

paragraphs

d.

Verify

blue,

X | Airstorage

a.

Check

pushing

position

holds

minutes.

b.

Check

properly

с.

Ensure

closes

the

unit

tubes,

cables,

the

unit

of

should

and

fan

the

performance

the

2-2, 2-3,

that

the

tank.

that

the

the

power

and

ensuring

at

approximately

that

the

connected.

that

the

properly.

for

any

damaged

and

other

for

an

excessive

dust

or

dirt.

be

given

to

guard.

of

procedures

2-4,

and

humidity

tank

switch

hose(s)

drain

indicator

does

to

that

the

60

psi

can

valve

Unit

can’t

Unit

overheats

Particular

the

intake

the

unit

in

2-5.

is

not

leakby | The

the

"OFF"

pressure | excessively.

for

several

be

opens

operate

Unit

performance

than

parameters.

The

humidity

the

desiccant

in

accordance

in

paragraph

tank

pressurized

The

hose(s)

the

storage

quick-disconnect

and | The

drain

leaks

10

percent

when

be

operated

or

does

correctly.

deviates

of

specified

indicator

can't

with

3-20.

can't be

valve

properly

or

the

can't

tank

or

can’t

closed.

tank

be

leaks.

properly.

not

more

is

blue

be

regenerated

the

procedures

leaks

connected

the

male/female

be

opened

but

to

or

3.

The

dures

encouraged

4.

5.

X

|X |X | X | Pressure

x X | Running/starting

X | Case.

a.

Inspect

or

excessive

b.

Check

following

checks

indicate

that

to

complete

cracked

indications

corrosion

indication

capacitor.

the

case

wear.

the

air

relief

and

services

the

equipment

the

procedures.

gauge.

or

broken

beyond

of

the

terminals

of a chemical

for

signs

of

valve.

NOTE

are

not

is

fully

Check

for

dents,

dial

cover,

the

normal

capacitors.

or

an

leak

from

damage | The

mandatory

operational.

or

gauge

range.

Inspect

the

if

a

for,

case

can't

store

or

ship

The

air

relief

valve

damaged,

the

However,

The

precludes

unit.

The

operate,

circuit

switch

or

previous

you

damaged

proper

motor-compressor

short

breaker

is

activated.

be

used

the

unit.

is

inoperable,

missing.

proce-

are

pressure

operation

cycles,

of

the

power

to

gauge

fails

or

the

properly

of

the

to

TM

8-6520-003-24&P

ITEM

NO

INTERVAL

Bl pl

als

ITEM

AND

Table

TO

BE

PROCEDURE

3-1.

PMCS - continued.

INSPECTED

EQUIPMENT

READY/AVAILABLE

IS

NOT

IF:

x

x X | Unloader

8.

3-10.

If

operator

must

unit

level

3-11.

хх

Reporting

personnel

report

them.

Refer

medical

General.

equipment

X | Safety

operation.

X | Humidity

a.

Inspect

indicator

indication.

b.

Ensure

deficiencies.

discover

to

TB

problems

38-750-2

repairer

Section

valve.

valve.

indicator.

for

dents, a cracked

cover,

that the

with

and

report

if

you

need

V.

Test

for

operation.

Check

or

the

for

proper

the

lack

of

indicator

equipment

the

assistance.

is

deficiency

FUNCTIONAL

or

broken | The

any

color | proper

blue.

during

PMCS

using

TESTING

The

valve

The

valve

humidity

The

humidity

than

blue.

that

they

the

proper

is

inoperable.

is

damaged

indicator

operation

indicator

are

unable

forms.

Consult

of

the

to

or

inoperable,

precludes

unit.

is

other

correct,

with

they

your

This

section

tial

receipt

a.

Preventive

functional

off

at

60

to

cycle

seconds.

psi

testing.

b.

Functional

Observe

(1)

80

psi

After

(2)

Simultaneously,

psi.

regenerating

is

Time

(3)

in

less

than

contains

and

installation

maintenance

testing.

in

less

the

the

10

Pumping

information

of

Perform

pressure

the

than

45

motor-compressor

listen

desiccant.

the

motor-compressor

seconds.

and

for

the

unit

checks

functional

gauge

seconds.

for

purging

a

cycles

testing

and

The

hissing

The

the

compressor-dehydrator.

semiannually

and

services.

testing

the

time

and

fan

will

observe

off,

shuts

sound

motor-compressor

will

continue

cycle

pumping

thereafter.

Perform

using

pressure

continue

the

is

air

as

again

NOTE

to

alternate.

the

PMCS

the

following

rise

to

operate.

pressure

purged

should

the

and

Perform

listed

procedures.

psi.

80

to

gauge

through

start

again

pressure

these

in

paragraph

motor-compressor

The

time

and

muffler

the

operation

should

indicating

increase

tests

3-9

decrease

the

60

at

following

before

psi

that

in

from

performing

should

in

the

less

60

the

ini-

shut

pressure

purging

35

than

80

to

psi

3-4

TM

8-6520-003-24&P

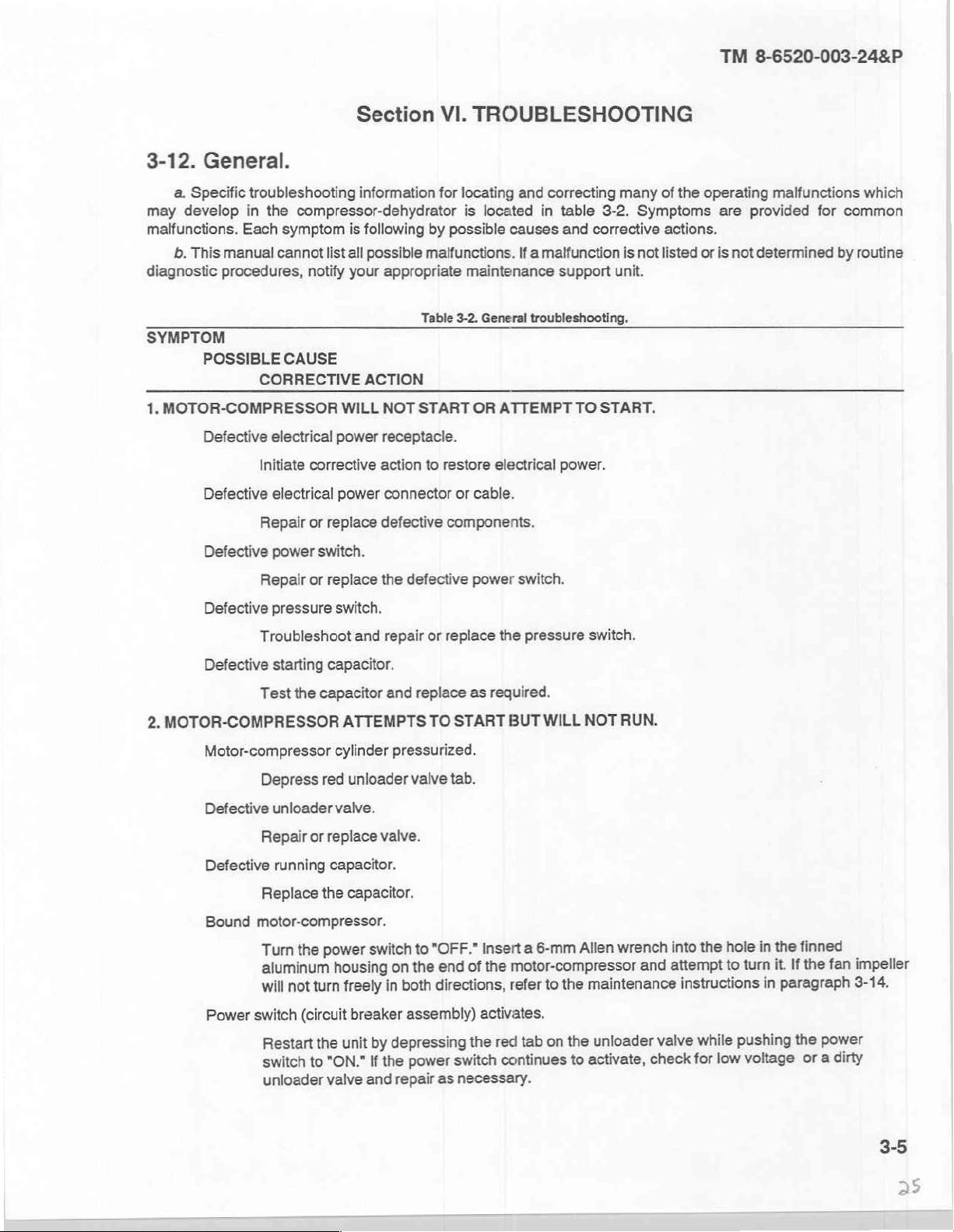

3-12.

may

malfunctions.

diagnostic

SYMPTOM

1.

General.

a.

Specific

develop

b.

This

MOTOR-COMPRESSOR

troubleshooting

in

Each

manual

procedures,

POSSIBLE

Defective

Defective

Defective

Section

information

the

compressor-dehydrator

symptom

cannot

CAUSE

CORRECTIVE

electrical

Initiate

electrical

Repair

power

is

following

list

all

possible

notify

your

ACTION

WILL

power

corrective

power

or

replace

switch.

action

defective

VI.

for

locating

by

possible

malfunctions.

appropriate

Table

3-2.

NOT

START

receptacle.

to

restore

connector

or

components.

TROUBLESHOOTING

and

is

located

maintenance

General

OR

electrical

cable.

in

causes

If a malfunction

troubleshooting.

ATTEMPT

correcting

table

and

support

power.

many

3-2.

corrective

unit.

TO

START.

of

Symptoms

actions.

is

not

listed

the

operating

or

are

is

not

provided

malfunctions

for

determined

which

common

by

routine

Defective

Defective

2.

MOTOR-COMPRESSOR

Motor-compressor

Defective

Defective

Bound

Power

Repair

Troubleshoot

Test

Depress

Repair

Replace

or

replace

pressure

starting

unloader

running

capacitor.

the

capacitor

red

or

replace

capacitor.

the

the

switch.

and

repair

and

ATTEMPTS

cylinder

unloader

valve.

valve.

capacitor.

pressurized.

motor-compressor.

switch

power

the

Turn

aluminum

not

will

switch

(circuit

Restart

switch

unloader

housing

turn

the

"ON."

to

valve

freely

unit

on

in

breaker

depressing

by

the

If

and

repair

defective

or

replace

replace

TO

START

valve

tab.

"OFF."

to

end

the

directions,

both

assembly)

switch

power

as

necessary.

power

switch.

the

pressure

as

required.

BUT

WILL

6-mm

a

Insert

motor-compressor

the

of

to

refer

activates.

tab on the

red

the

continues

switch.

NOT

Allen

maintenance

the

unioader

activate,

to

RUN.

wrench

and

valve

check

hole

the

into

turn

attempt

to

instructions

pushing

while

voltage

low

for

finned

the

in

If

it.

paragraph

in

the

the

power

a

or

impeller

fan

3-14.

dirty

3-5

D

un

TM

8-6520-003-24&P

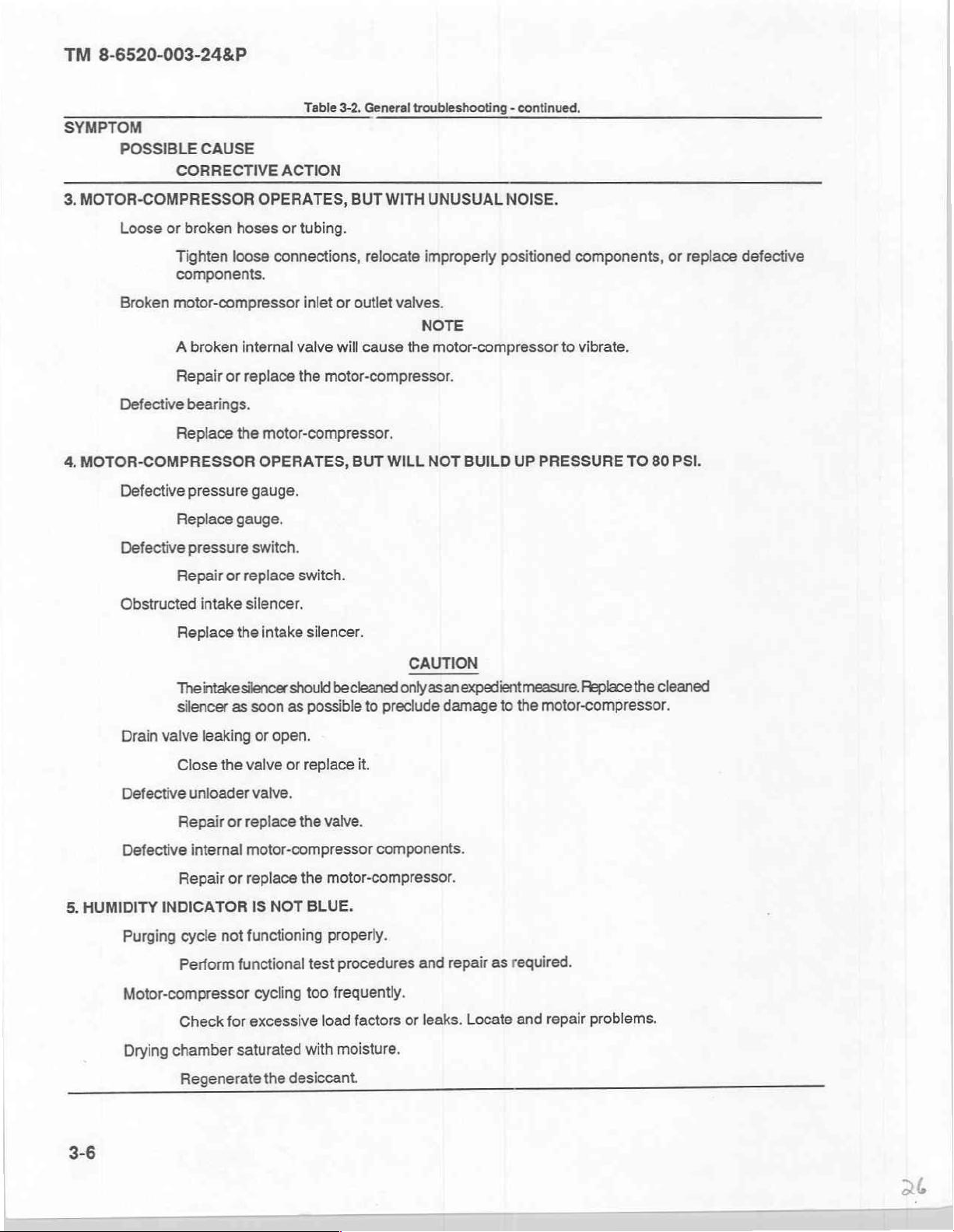

SYMPTOM

POSSIBLE

3.

MOTOR-COMPRESSOR

Loose

or

CAUSE

CORRECTIVE

broken

hoses

Table

ACTION

OPERATES,

or

tubing.

3-2.

BUT

General

WITH

troubleshooting - continued.

UNUSUAL

NOISE.

Broken

Defective

4.

MOTOR-COMPRESSOR

Defective

Defective

Obstructed

Tighten

loose

connections,

components.

motor-compressor

A

broken

Repair

bearings.

Replace

pressure

Replace

pressure

Repair

Replace

Theintakesilencer

silencer

internal

or

replace

the

gauge.

or

replace

intake

silencer.

the

as

motor-compressor.

OPERATES,

gauge.

switch.

intake

should

soon

as

relocate

inlet

or

outlet

valve

will

cause

the

motor-compressor.

BUT

WILL

switch.

silencer.

be

cleaned

possible

to

preclude

improperly

positioned

valves.

NOTE

the

motor-compressor

NOT

BUILD

UP

CAUTION

only

asanexpedientmeasure.

damage

to

the

components,

to

vibrate.

PRESSURE

Replace

TO

the

80

cleaned

motor-compressor.

or

replace

PSI.

defective

5.

HUMIDITY

3-6

Drain

valve

leaking

Close

the

Defective

Defective

unloader

Repair

internal

Repair

or

or

INDICATOR

Purging

cycle

not

Perform

functional

Motor-compressor

for

saturated

Drying

Check

chamber

Regenerate

or

open.

valve

or

replace

it.

valve.

replace

the

valve.

motor-compressor

replace

IS

functioning

excessive

the

NOT

cycling

the

desiccant.

motor-compressor.

BLUE.

properly.

test

procedures

too

frequently.

factors

load

with

moisture.

components.

and

repair

leaks.

or

as

Locate

required.

repair

and

problems.

Loading...

Loading...