Air M5A User manual

PUBLICATION

NO.

88119-C

tions

TECHNICAL

COMPRESSOR-DEHYDRATOR,

NSN

6520-00-139-1246

(COMPRESSO-DRI,

Serial

(Contract

Number

No.

DLA

2700

MANUAL

DENTAL

MODEL

and

120-88-C-8536)

EQUIPMENT

M5B)

above

Air

P.O.

Techniques,

70

CANTIAGUE

BOX

870

TEL.

HICKSVILLE,

(516)

ROCK

433-7676

ROAD

Inc.

N.Y.

11802

October

1988

Section/Paragraph

I

INTRODUCTION

TABLE

OF

CONTENTS

1

2

3

-4

5

6

II

INSTALLATION

2-1

2-2

2-3

2-4

III

THEORY

3-1

3-2

3-3

IV

OPERATING

4-1

4-2

General

Description

Leading

Eguipment

Tools

and

Storage

AND

General

Installation

Preparation

Operational

OF

OPERATION

General

Pumping

Purging

INSTRUCTIONS

Operator's

Operating

and

Purpose.

Particulars

Supplied

Test

Eguipment

Data

PREPARATION

for Use

Checkout

Cycle

Cycle

Controls

Procedures

FOR

and

Indicators

USE

Uy

Uy

0

>

>

ヒュ

!

Rh

J

ta

1

papa

V

MAINTENANCE

1

2

3

-4

5

6

4-3

4-4

4-5

4-6

4-7

Intermittent

Restarting

Normal

Expedient

Turn-0ff

INSTRUCTIONS

General

Cleaning

Inspection

Performance

Verification

Troubleshooting

Removal

-7

-8

-9

-1

0101010

01

-1

O1

-1

O

№

Removal

Removal

Removal

Removal

Removal

Removal

Load

Load

Procedure

of

Compressor

of

Dryer

of

Pressure

of

Motor

of

Run

of

Start

Operation

and

Switch

and

Capacitor

Capacitor

Assembly

Cooling

Coil

and

Compressor

from

Transit

Assembly

Bracket

Assembly

Case

Assembly

で で >

1

や

や

や

1

a

On

oO

i

On

On

!

onan

oo

on

' !

on

non

ma

0

O

E

pa

A

A

A

Die

B

hammer

TABLE

OF

CONTENTS

(Cont'd.)

Section/Paragraph

5-13

Disassembly

5-14

5-15

5-16

5-17

5-18

VI

PREPARATION

6-1

6-2

VII

PARTS

LIST

Flow

Pilot

Dryness

Motor

Replacement

RESHIPMENT

FOR

General]

Reshipment

Compressor

Pumping

Purging

and

Repair

Control

Operated

Indicator

and

LIST

Cycle,

Cycle,

Valve

Pressure

Compressor

OF

ILLUSTRATIONS

Title

Setup

for

Schematic

Schematic

Switch

Assembly

Operation

Diagram

Diagram

Unloader

—

Valve

Operator's

Compressor

Compressor

Dryer

and

Pressure

P/N

88009

Flow

Control

Unloader

Motor

Leading

and

Particulars

Equipment

Tools

and

Operator's

Load

Factors

Compressor

Controls

Wiring

and

Diagram

Assembly

Cooling

Switch,

Valve,

Valve,

Coil

Capacitor

P/N

P/N

80325

Compressor

LIST

OF

TABLES

Supplied

Test

Equipment

Controls

and

Troubleshooting

Indicators

Assembly,

and

88076

Assembly,

Indicators

P/N

88008

Bracket

P/N

88202

Assembly

Parts

List

11

SECTION

I

INTRODUCTION

1.1

This

manual

Compressor-Dehydrator,

Model

Hicksville,

1.2

The

compressor

which

air,

and

free

Treatment

cover

during

and

is

1.3

The

leading

1.4

Table

Section

GENERAL

contains complete

M5-B)

manufactured

New

York

DESCRIPTION

is a completely

automatically

of

oil,

Unit.

of

which

normal

readily

is

operation.

maintained.

LEADING

particulars

EQUIPMENT

1-2

lists

VII,

the

Parts

Dental

by

11801.

AND

PURPOSE

regenerates

moisture,

A

transit

designed

to

The

PARTICULARS

of

the

SUPPLIED

separate

List,

for a complete

operating

Equipment,

Air

Techniques,

portable

the

and

particulate

case

serve

compressor

compressor

items

and

NSN

unit

drying

is

an

agent.

integral

as a sound

can

are

supplied

list

maintenance

6520-00-139-1246,

Inc.,

with

70

an

matter,

instructions

Cantiague

integral

The

unit

to

operate a Dental

part

supressor

be

rapidly

contained

with

the

of

components.

placed

in

compressor.

supplies

of

the

and

protective

Table

for

(COMPRESSO-DRI,

Rock

Road,

drying

section

compressed

Operating

compressor,

device

into

operation

1.1.

Refer

to

the

1.5

The

tools

in

Table

1.6

There

are

TOOLS

and

test

1-3.

STORAGE

no

special

AND

TEST

equipment

DATA

EQUIPMENT

storage

required

to

requirements

1-1

maintain

for

the

the

compressor

compressor.

are

listed

Table

1-1.

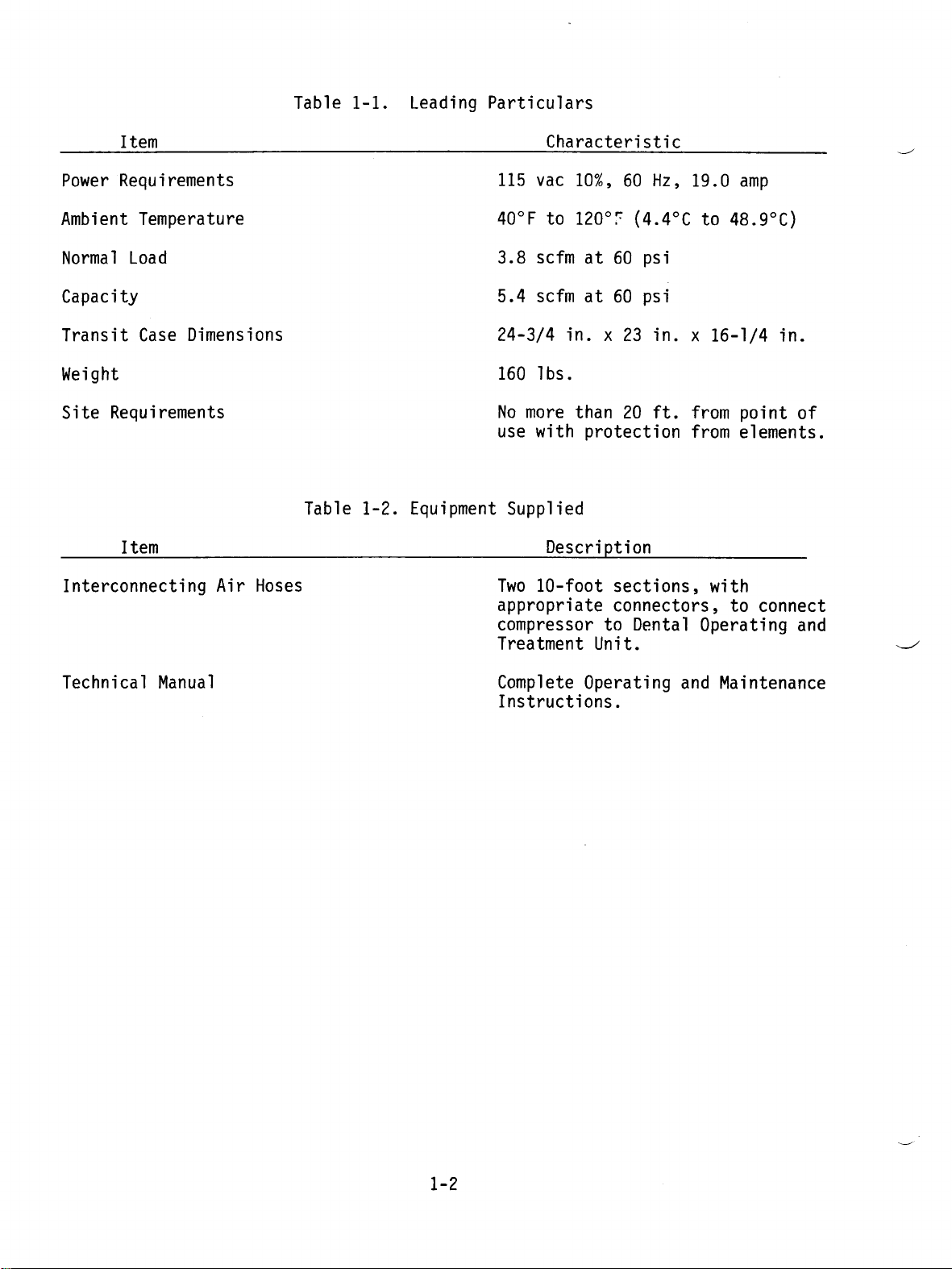

Leading

Particulars

Item

Power

Ambient

Normal

Requirements

Temperature

Load

Capacity

Transit

Case

Weight

Site

Requirements

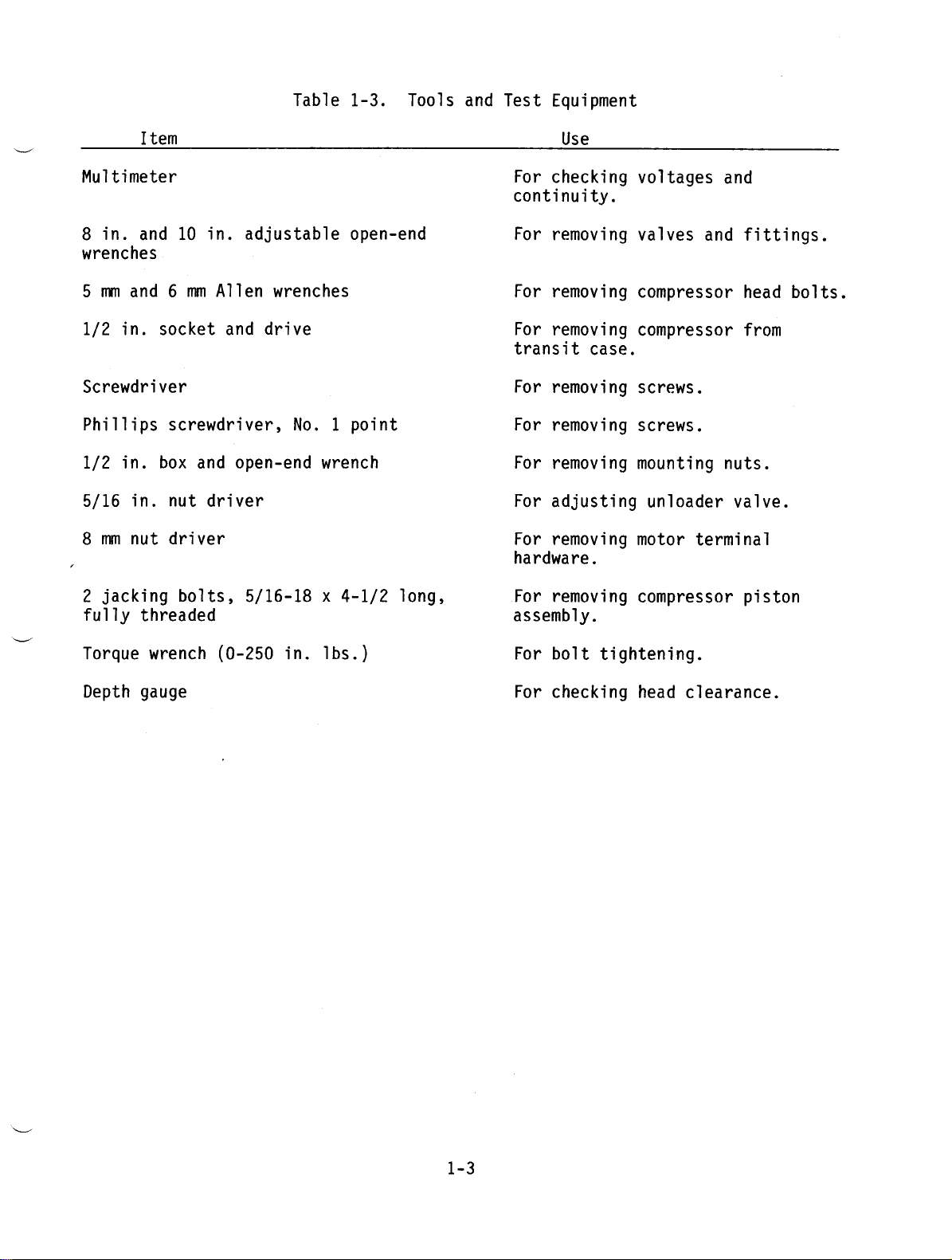

Item

Interconnecting

Dimensions

Air

Hoses

Table

1-2.

Equipment

Characteristic

115

vac

10%,

40°F

3.8

5.4

24-3/4

No

use

160

to

scfm

scfm

Ibs.

more

with

120°F

in. x 23

than

Supplied

Description

Two

10-foot

appropriate

compressor

Treatment

60

Hz,

(4.4°C

at

60

psi

at

60

psi

in. x 16-1/4

20

ft.

protection

sections,

connectors,

to

Dental

Unit.

19.0

amp

to

48.9°C)

from

from

point

elements.

with

to

Operating

in.

of

connect

and

Technical

Manual

Complete

Instructions.

Operating

and

Maintenance

1-2

Table

1-3.

Tools

and

Test

Equipment

Item

Multimeter

8

in.

and

wrenches

5

mm

and 6 mm

1/2

in.

socket

Screwdriver

Phillips

1/2

5/16

8

mm

2

jacking

fully

screwdriver,

in.

box

in.

nut

nut

driver

threaded

10

in.

Allen

and

and

driver

bolts,

adjustable

wrenches

drive

No. 1 point

open-end

open-end

wrench

5/16-18 x 4-1/2

long,

Use

For

checking

continuity.

For

removing

For

removing

For

removing

transit

For

For

For

For

For

case.

removing

removing

removing

adjusting

removing

hardware.

For

removing

assembly.

voltages

valves

and

compressor

compressor

screws.

screws.

mounting

unloader

motor

terminal

compressor

and

fittings.

head

from

nuts.

valve.

piston

bolts.

Torque

wrench

Depth gauge

(0-250

in.

Ibs.)

For

For

bolt

tightening.

checking

head

clearance.

1-3

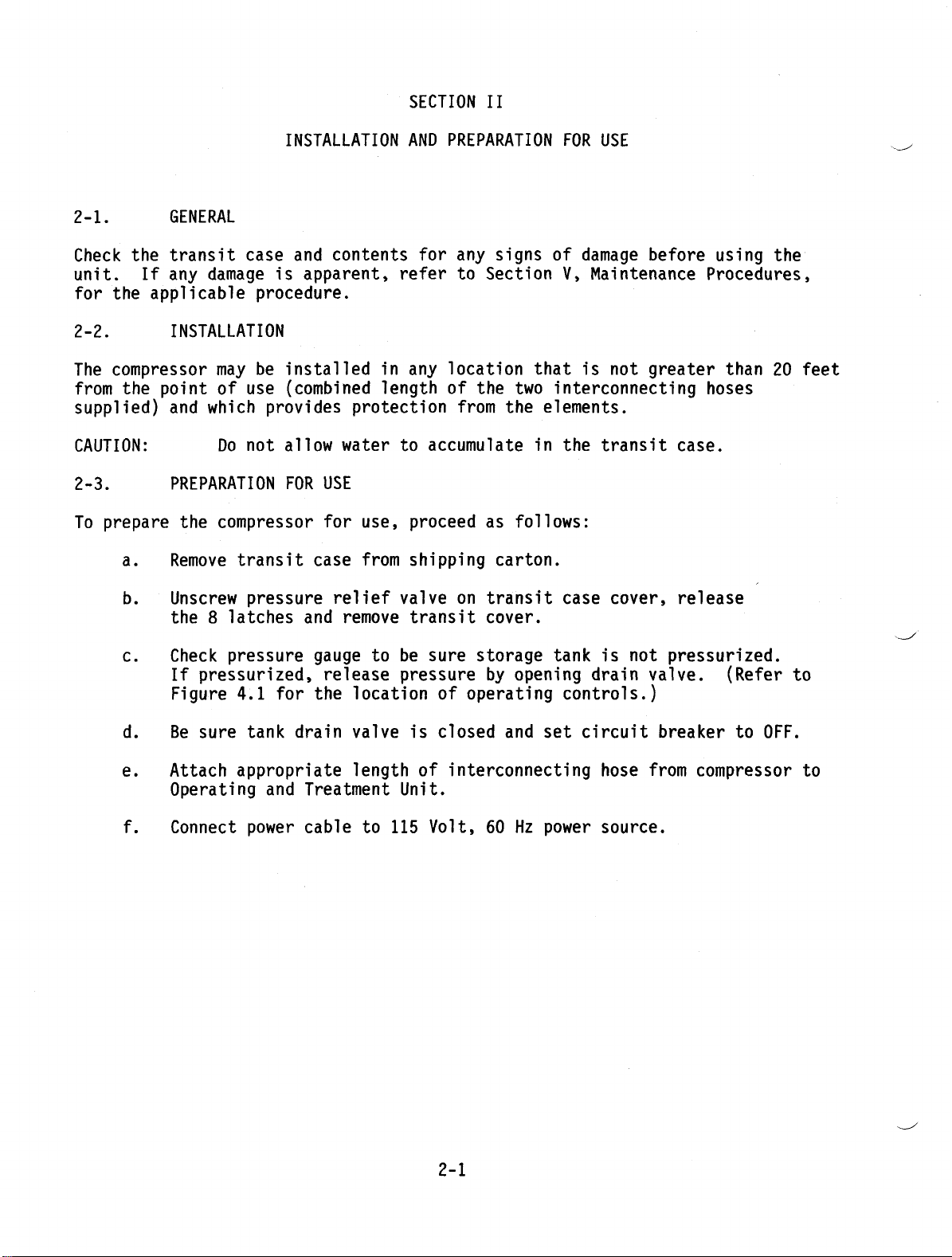

SECTION

II

2-1.

Check

unit.

for

the

If

the

2-2.

The

compressor

from

the

supplied)

CAUTION:

2-3.

To

prepare

a.

b.

GENERAL

transit

any

damage

applicable

INSTALLATION

may

point

and

of

which

Do

PREPARATION

the

compressor

Remove

transit

Unscrew

the 8 latches

INSTALLATION

case

and

is

apparent,

procedure.

be

installed

use

(combined

provides

not

allow

FOR

case

pressure

and

contents

in

length

protection

water

USE

for

use,

from

relief

remove

AND

PREPARATION

for

refer

any

location

of

to

accumulate

proceed

shipping

valve

transit

any

to

Section

the

from

as

on

transit

cover.

signs

of

that

two

the

elements.

in

follows:

carton.

FOR

USE

damage

V,

Maintenance

is

not

before

greater

interconnecting

the

case

transit

cover,

case.

release

using

the

Procedures,

than

20

hoses

feet

c.

d.

e.

f.

Check

If

Figure

Be

Attach

pressure

pressurized,

4.1

sure

appropriate

Operating

Connect

gauge

release

for the

tank

power cable

drain valve

and

Treatment

to be

pressure

location

is

length

to

of

Unit.

115

sure

storage

by

of

operating

closed

opening

and

interconnecting

Volt,

60

Hz

tank

is

drain

controls.)

set

circuit

hose

power

source.

not

pressurized.

valve.

breaker

from

(Refer

to

OFF.

compressor

to

to

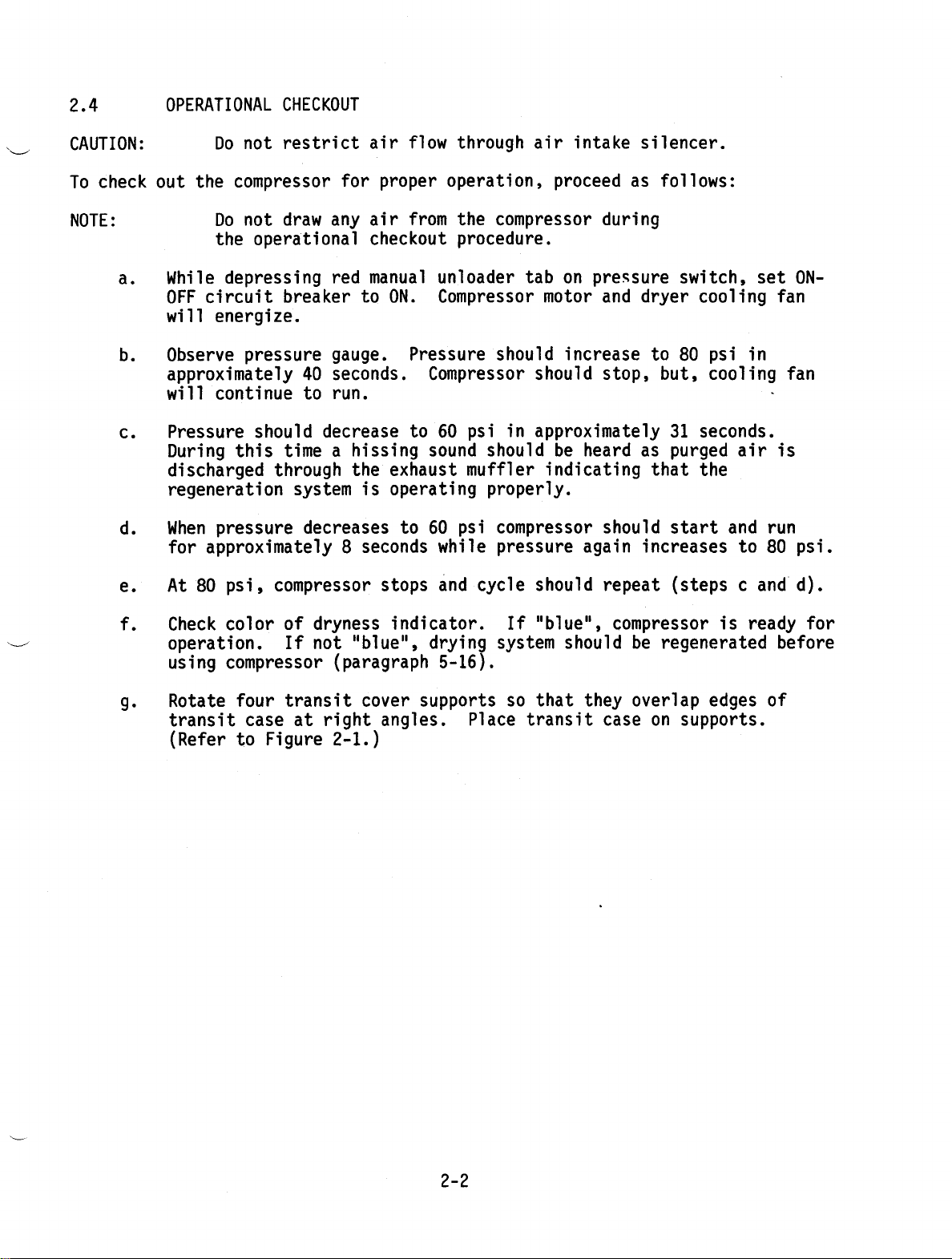

2.4

OPERATIONAL

CHECKOUT

CAUTION:

To

check

NOTE:

a.

b.

c.

d.

e.

Do

not

out

the

compressor

Do

not

the

operational

While

OFF

will

Observe

approximately

will

Pressure

During

discharged

regeneration

When

for

At

depressing

circuit breaker

energize.

pressure

continue

this

pressure

approximately

80

psi,

restrict

for

draw

any air

red

gauge.

40

seconds.

to

run.

should

through

compressor

decrease

time a hissing

system

decreases

8

air

proper

checkout

manual

to

ON.

the

exhaust

is

operating

seconds

stops

flow

operation,

from

unloader

Compressor

Pressure

Compressor

to

60

sound

to 60

while

and

through

the

procedure.

psi

muffler

psi

cycle

air

compressor

tab

should

should

in

approximately

should

properly.

compressor

pressure

should repeat

intake

proceed

during

on

pressure

motor

indicating

and

increase

stop,

be

heard

should

again

silencer.

as

follows:

switch,

dryer

to

80

but,

31

as

purged

that

start

increases

(steps c and

set

cooling

psi

in

cooling

seconds.

air

the

and

to

fan

fan

、

is

run

80

d).

ON-

psi.

f.

g.

Check

operation.

using

Rotate

transit

(Refer

color

compressor

four

case

to

of

dryness

If

not

transit

at

Figure

indicator.

"blue",

(paragraph

cover

right

angles.

2-1.)

drying

5-16).

supports

Place

If

"blue",

system

so

that

transit

compressor

should

they

case

be

regenerated

overlap

on

supports.

is

ready

edges

for

before

of

2-2

RELIEF

VALVE

AU

AAA

Pret

DIG

AFTER

LOC

Figure

2-1.

Compressor

273

Setup

for

Operation

SECTION

III

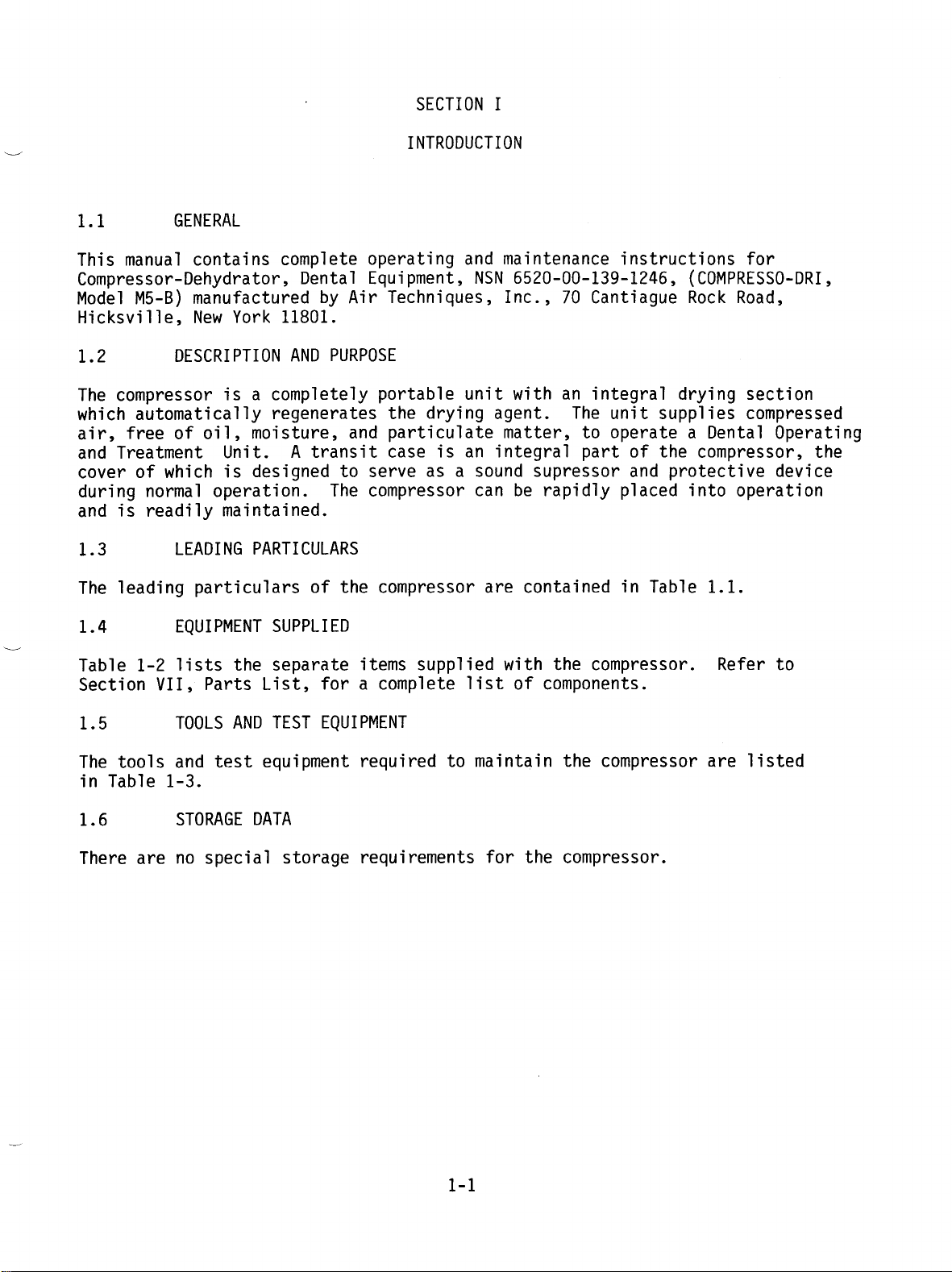

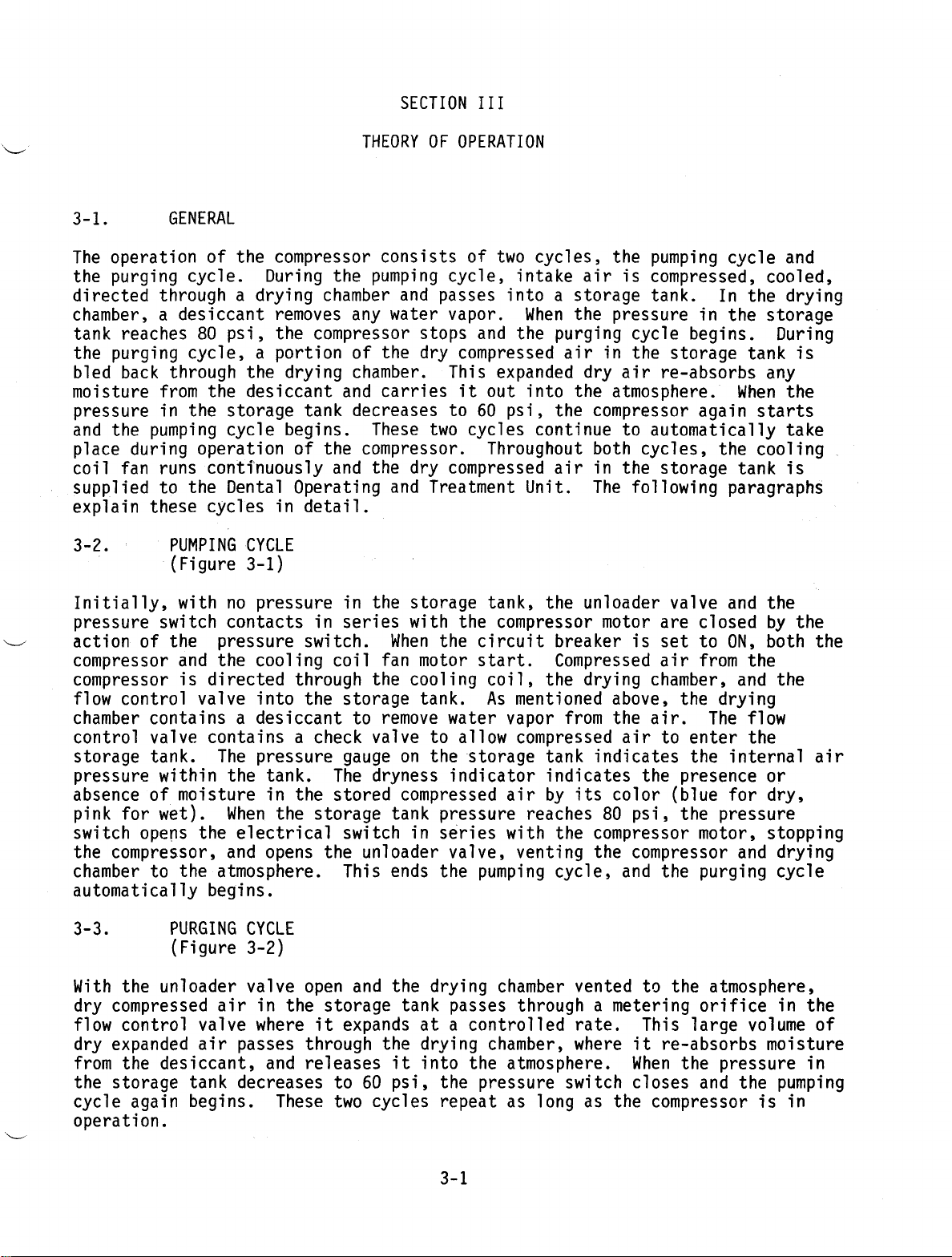

3-1.

The

operation

the

purging

directed

chamber,

tank

the

purging

bled back

moisture

pressure

and

the

place

coil

supplied

explain

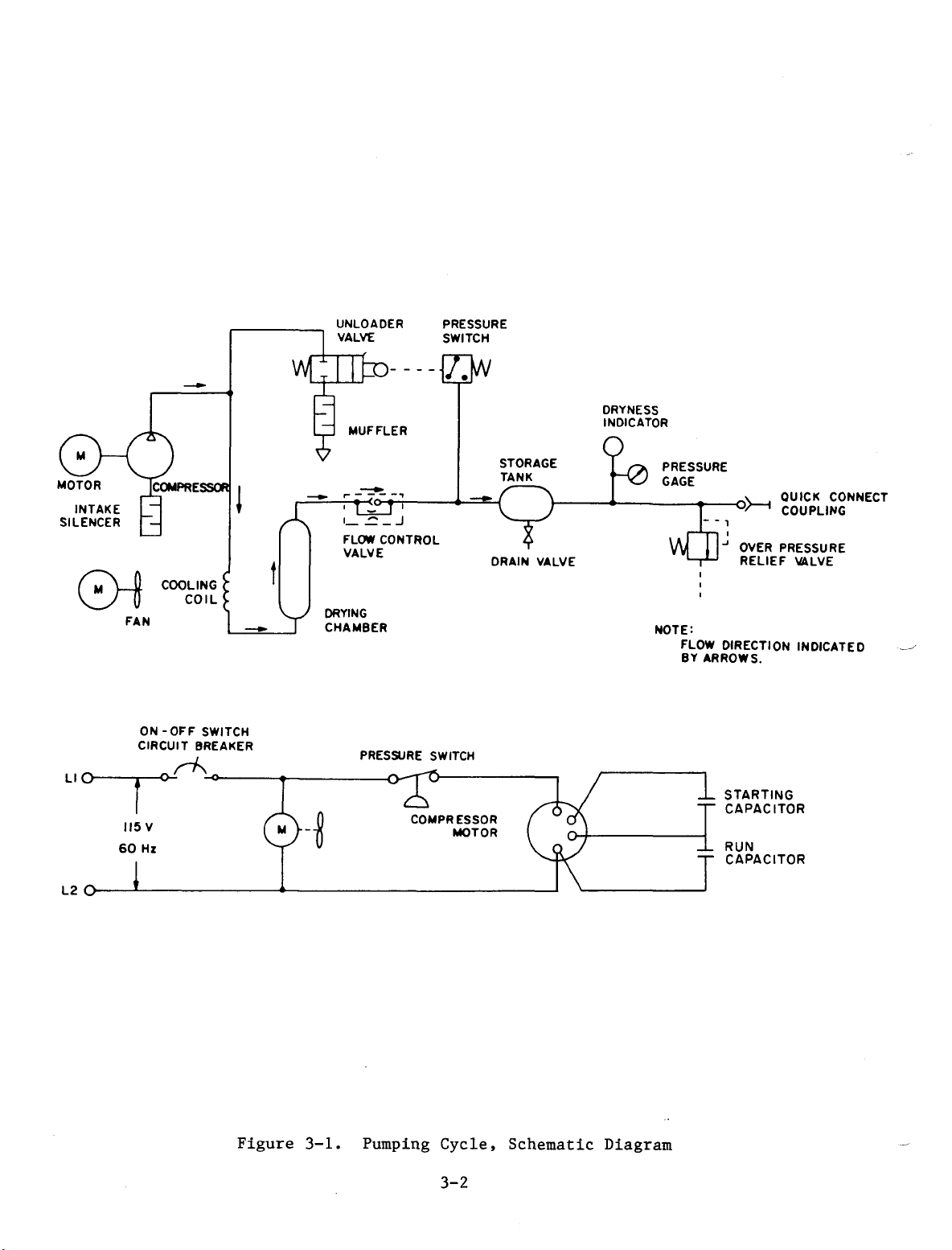

3-2.

GENERAL

through a drying

a

desiccant

reaches

through

from

in

pumping

during

fan

runs

to

these

PUMPING

(Figure

Initially,

pressure

action

compressor

compressor

flow

control

chamber

control

storage

pressure

absence

pink

for

switch

the

compressor,

chamber

with

switch

of

the

and

is

contains a desiccant

valve

tank.

within

of

moisture

wet).

opens

to

the

automatically

of

the

compressor

cycle.

During

the

chamber

removes

80

psi,

the

compressor

cycle, a portion

the

drying

the

desiccant

the

storage

cycle

operation

continuously

the

Dental

cycles

tank

begins.

of

the

and

Operating

in

detail.

CYCLE

3-1)

no

pressure

contacts

pressure

the

cooling

directed

valve

into

contains a check

The

pressure

the

tank.

in

When

the

electrical

and

opens

atmosphere.

begins.

in

switch.

through

the

the

the

storage

the

THEORY

consists

pumping

any

water

of

the

chamber.

and

carries

decreases

These

compressor.

the

and

in

the

series

When

coil

fan

the

storage

to

remove

valve

gauge

The

dryness

stored

tank

switch

unloader

This

ends

OF

OPERATION

of

cycle,

and

passes

vapor.

stops

dry

and

compressed

This

it

to

60

two

cycles

dry

compressed

Treatment

storage

with

the

the

motor

circuit breaker

start.

cooling

tank.

water

to

allow

on

the

storage

indicator

compressed

pressure

in

series

valve,

the

pumping

two

cycles,

intake

air

into a storage

When

the

the

purging

air

expanded

out

into

psi,

dry

the

the

continue

Throughout

air

Unit.

tank,

the

unloader

compressor

Compressed

coil,

As

the

mentioned

vapor

from

drying

compressed

tank

indicates

air

by

its

reaches

with

the

venting

cycle,

the

pumping

is

compressed,

tank.

pressure

cycle

in

the

storage

air

re-absorbs

atmosphere.

compressor

to

automatically

both

in

The

cycles,

the

storage

following

valve

motor

is

are

set

air

chamber,

above,

the

air.

air

to

indicates

the

color

80

(blue

psi,

compressor

the

compressor

and

the

cycle

In

in

the

begins.

When

again

the

tank

paragraphs

and

closed

to

ON,

from

and

the

drying

The

enter

the

internal

presence

for

the

pressure

motor,

and

purging

and

cooled,

the

drying

storage

During

tank

is

any

the

starts

take

cooling..

is

the

by

the

both

the

the

flow

the

or

dry,

stopping

drying

cycle

the

air

3-3.

With

the

dry

compressed

flow

control

dry

expanded

from

the

the

storage

cycle

again

operation.

PURGING

(Figure

unloader

air

valve

air

passes

desiccant,

tank

decreases

begins.

CYCLE

3-2)

valve

in

the

where

and

These

open

and

storage

it

expands

through

releases

to

60

two

the

tank

at a controlled

the

drying

it

psi,

cycles

drying

passes

into

the

repeat

3-1

chamber

through a metering

chamber,

the

atmosphere.

pressure

as

switch

long

vented

rate.

where

as

the

to

the

This

large

it

re-absorbs

When

the

closes

compressor

atmosphere,

orifice

in

volume

moisture

pressure

and

the

pumping

is in

the

of

in

UNLOADER

VALVE

MUFFLER

PRESSURE

SWITCH

ORYNESS

INDICATOR

MOTOR

INTAKE

SILENCER

COMPRESSORI

|

COOLING

COIL

FAN

To

δν

60

L2

O-

ON-OFF

MN

Hz

|

—

SWITCH

I

ee,

TOT

ALI

FLOW

VALVE

DRYING

CHAMBER

PRESSURE

CONTROL

SWITCH

COMPRESSOR

ORAIN

MOTOR

STORAGE

TANK

VALVE

PRESS

GAGE

NOTE:

FLOW

BY

URE

———O

771

|-

一

一

一

一

ARROWS.

QUICK

A

COUPLING

1

OVER

PRESSURE

RELIEF

DIRECTION

VALVE

INDICATED

STARTING

CAPACITOR

RUN

CAPACITOR

CONNECT

-一

Figure

3-1.

Pumping

Cycle,

3-2

Schematic

Diagram

Loading...

Loading...