Agria 400P Operating Instructions Manual

4235

Before commissioning the machine, read operating

instructions and observe warnings and safety instructions.

Operating Instructions No. 998 745 04.15

Multi-Purpose MachineMulti-Purpose Machine

Multi-Purpose MachineMulti-Purpose Machine

Multi-Purpose Machine

400P400P

400P400P

400P

Operating InstructionsOperating Instructions

Operating InstructionsOperating Instructions

Operating Instructions

Translation of the original operating instructionsTranslation of the original operating instructions

Translation of the original operating instructionsTranslation of the original operating instructions

Translation of the original operating instructions

2 agria Multi-Purpose Machine 400P

Symbols, Name Plate

Please complete:

Machine Type No.........................

Identification No.

....................................................

Engine Type:................................

Engine No....................................

Date of Purchase: .......................

For name plate, refer to p3/fig. A/9.

For engine type and number, ref er to

p3/fig. B/6.

Please state these data when order-

ing spare parts to avoid wrong deliveries.

Only use original agria spare parts!

Specifications, figures and dimensions stated in these instructions are

not binding. No claims can be deriv ed

from them. We reserve the right for

improvements without changing these

instructions.

This delivery comprises:

l

Operating instructions

l

Multi-purpose base machine

l

Tool kit

Symbols:

Warning – Danger

Important information

Fuel

Choke

Oil

Mowing drive

Travelling drive

Forward

Reverse

Open (unlocked)

Closed (locked)

PTO

è - Serviceç= please contact Your specialised agria-workshop

agria Multi-Purpose Machine 400P 3

A

B

Designation of Parts

4 agria Multi-Purpose Machine 400P

Designation of Parts

Figure A

1 Pto speed engagement lever

2 Linkage for front attachments

3 Transmission oil plug (filling and checking oil level)

4 Linkage for rear attachments

5 Grooves on wheel shaft

6 Wheel shaft

7 Gearbox cover/Transmission oil drain opening

8 Pto/pto guard

9 Name plate (machine identification no.)

10 Handlebar

11 V-belt guard (V-belt clutch)

12 Drive wheel

13 Drive-wheel detent spring

14 Guard

Figure B

1 Air filter

2 Carburetor

3 Fuel tank cap

4 Fuel tank

5 Choke lever

6 Engine type no.

7 Starter handle

8 Cooling air-screen

9 Exhaust with guard

10 Spark plug/spark plug connector

11 Engine oil filler plug and dip-stick

12 Engine oil drain plug

13 Fuel tap

agria Multi-Purpose Machine 400P 5

Index

Amount of Delivery ..........................2

Symbols, Name Plate......................2

Designation

of Parts.............................. 3, 54

Recommendations

Lubricants, Anti-Corrosive Agents ..6

Fuel ..................................................6

Maintenance and Repair .................6

Unpacking and Assembly ..... 7

1. Safety Instructions....... 8–12

2. Specifications

Multi-purpose Machine ..................13

Noise Level ....................................13

Vibration Acceleration Value..........13

Engine............................................14

Operation on Slopes......................14

3. Devices and Operating

Elements

Engine............................................15

Speed Control Lever......................16

Safety circuit ..................................16

Choke .............................................16

Fuel Tap .........................................17

Clutch.............................................17

Main Gearbox ................................18

Drive Wheels .................................20

PTO................................................25

Stand .............................................25

Steering Handle .............................26

Attachments...................................27

Hoeing, Ridging ....................... 30-32

4. Commissioning and

Operation

Commissioning the Machine .........33

Starting the Engine ........................34

Shutting off the Engine ..................35

Working..........................................36

5. Maintenance

Engine............................................37

Air Filter .........................................38

Fuel System...................................39

Spark Plug .....................................40

Cooling System .............................40

Governor........................................41

Exhaust..........................................41

Speed Control................................41

Carburetor Settings .......................41

Machine .........................................42

Drive-wheels .................................. 42

Safety circuit ..................................43

Clutch Play.....................................43

General ..........................................45

Cleaning.........................................45

Storage ..........................................46

6. Troubleshooting.......... 48–49

Electrical Wiring ................... 50

Lubrication Chart ................. 50

Varnishes, Wear Parts.......... 51

Inspection and

Maintenance Chart............... 52

Conformity Declaration ....... 55

Note fold-out pages!

Fig. A and B ............................ 3

Fig. C and D .......................... 54

1

2

3

4

5

6

6 agria Multi-Purpose Machine 400P

Recommendations

Lubricants and

Anti-Corrosive Agents:

Use the lubricants specified for engine

and gearbox (see “Specifications”).

We recommend using Bio-lubricating

oil or Bio-lubricating grease for “open”

lubrication points or nipples (as specified in the operating instructions).

We recommend using Bio-slushing oil

to preserve machines and attachments

(do not apply on painted covers). You

can brush or spray the oil.

Anti-corrosive agents are environmentally friendly and degrade fast.

Using ecologically safe Bio-lubricants

and Bio-anti-corrosives, you contribute

to environmental protection and to the

wellbeing of humans, animals and

plants.

Fuel:

This engine runs smoothly on commercial unleaded regular and supergrade

petrol (including E10).

Do not add oil to petrol.

If, for environmental reasons, you use

unleaded petrol, make sure the fuel is

drained completely when shutting down

the engine for more than 30 days. This

is to prevent resin residue from depositing in the caburetor , fuel filter, and tank.

Or add a fuel stabilizer to the fuel.

For further instructions see “Engine

Preservation”.

Maintenance and Repair:

The trained mechanics of your agria

workshop expertly carr y out any maintenance and repair work.

You should only carry out major maintenance work and repairs on your own,

if you have the proper tools and knowledge of machines and internal combustion engines.

Do not hammer against the flywheel with

a hard object or metal tools as it might

crack and shatter in operation, causing

injuries and damage. Only use suitable

tools to pull off the flywheel.

agria Multi-Purpose Machine 400P 7

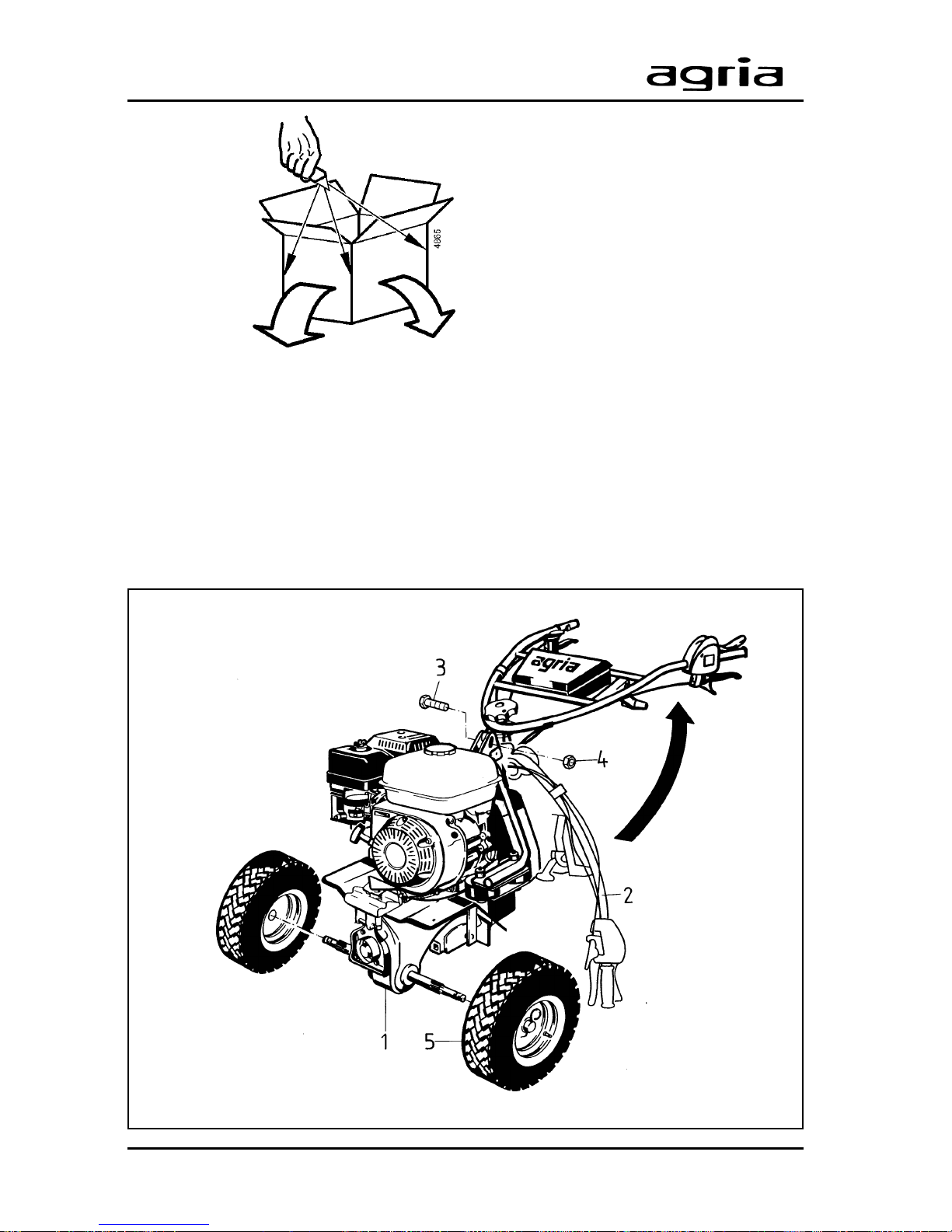

Unpacking and Assembl y

E

1 Base machine

2 Steering handle

3 Steering handle attachment bolt

4 Hex nut

5 Drive wheels (accessory items)

l

Open the box top.

l

Cut the two rear corners open and

fold down the side.

l

Remove the steering handle attach-

ment bolt (3 + 4).

l

Pivot the steering handle (2) upwards. Then attach and tighten the bolt

(3 + 4).

l

Attach the drive wheels (see instructions on page 20).

l

Starting-up

See instructions on page 33.

8 agria Multi-Purpose Machine 400P

1. Safety Instructions

1

Before starting the engine, read the operating instructions and note:

Warning

This symbol marks all paragraphs in

these operating instructions which affect

your safety. Pass all safety instructions

on to other users and operators.

Due Use

The multi-purpose machine is a handcontrolled automatic single-axle machine which can power and/or pull various implements approved by the manufacturer . Areas of application are for such

as turning over the ground, mowing

grass and meadowland, snow clear ance

and sweeping (due use).

Any other type of operation is considered undue. The manufacturer is not liable for any damages resulting from

undue use, for which the risk lies with

the user alone.

When the multi-purpose machine is

used on public roads, the local national

road traffic rules must be observed, e.g.

reflectors, lights.

The multi-purpose machine is not intended for use with a trailer on public

roads or as as a tractor unit without implements.

Due use includes compliance with

manufacturer’s instructions on operation, maintenance and repair.

Any unauthorized changes to the machine render manufacturer liability null

and void.

General Instructions on

Safety and Accident

Prevention

Basic Rule:

The respective national accident prev ention regulations have to be adhered to,

as well as all other generally accepted

rules governing operational safety, occupational health and road traffic regulations.

When driving on public roads, you hav e

to observe the current traffic code.

Accordingly, check the machine f or road

and operational safety each time you

take up operation.

Only persons familiar with the tractor and

instructed on the hazards of operation

are allowed to use, maintain and repair

the tractor.

Teenagers younger than 16 years are

not allowed to operate the machine!

Only work in good light and visibility.

Operator’s clothes should fit tight. Avoid

wearing loose fitting clothes. Wear solid

shoes.

Note the warning and instruction signs

on the tractor for safe operation. Comply for your own safety.

When transporting the tractor on vehicles or trailers outside the area to be

cultivated, ensure that the engine is

turned off.

Careful with rotating tools – keep at a

safe distance!

Foreign powered parts shear and crush!

Riding on the attachment during opera-

tion is not permitted.

agria Multi-Purpose Machine 400P 9

1. Safety Instructions

1

Mounted or trailed attachments affect

the tractor’s driving, steering, braking,

and tipping characteristics. Therefore,

ensure that steering and braking functions are sufficient. Match operating

speed to conditions.

Do not change settings of governor . High

engine speed increases risk of accidents.

Working Area and

Dangerous Area

The user is liable to third parties working within the tractor’s working range.

Staying in hazardous area is not permitted.

Check the immediate surroundings of

the tractor before y ou start it. W atch out

for children and animals.

Before you start work, clear the area

from any foreign object. During operation, always w atch out for further objects

and remove them in time.

For operation in enclosed areas , ensure

that a safety distance is kept to enclosures to prevent damage to tools.

Operation and

Safety Devices

Before you start the engine

Become familiar with the devices and

operating elements and their functions.

Above all, learn how to turn the engine

off quickly and safely in an emergency.

Ensure that all guards in place.

With no attachment mounted, make

sure PTO-shaft is cov ered with the protective cap.

Starting the engine

Do not start the engine in closed rooms.

The carbon monoxide contained in the

exhaust fume is extremely toxic when

inhaled.

Before you start the engine set all controls to neutral or idling position.

When starting the engine, do not step

in front of the machine and the attachment.

Do not use assist-starting liquids when

using electrical assist-starting devices

(jumper cable). Danger of explosion.

Operation

Never leave the oper ator’s position at the

steering handle while tractor is at work.

Nev er adjust the handles during work danger!

For any operation do not leave the operator’s position as defined by the steering handle, especially not when you turn

the machine.

Riding on the attachment during operation or in transport is not permitted.

If blockages occur in the attachment,

turn off the engine and clean the attachment with an appropriate tool.

In case of damage to the multi-purpose

machine or to the attachment, immediately turn off the engine and have it repaired.

If steering causes problems, immediately bring the machine to a halt and

turn it off.

Have the malfunction removed without

delay.

10 agria Multi-Purpose Machine 400P

1. Safety Instructions

1

To prevent the machine from sliding on

slopes make sure it is secured by another person using a bar or a rope. This

person must be located at a higher position than the vehicle at a saf e distance

from the attachment at work.

If possible, always work horizontally to

the slope.

End of Operation

Never lea v e the multi-purpose machine

unattended with the engine running.

Before you leave the machine, turn off

the engine. Then close fuel taps.

Secure the machine against unauthorized use. If tractor is equipped with an

ignition key, remove the ke y . For all other

versions, remov e the spark plug connector to secure the tractor.

Attachments

Only mount attachments with the engine

and PTO switched off.

Always use appropriate tools and wear

gloves when changing attachments and

parts thereof.

To fit and remove attachments, bring the

support leg into proper position and ensure stability.

Secure the machine and attachments

against rolling off (parking brake, wheel

chocks).

Beware of injuries while coupling attachments.

Couple the attachments as specified

and only couple at specified points.

Secure the machine and attachment

against unauthorized use and rolling off

when you leave the machine. If necessary, install transport or safety devices

to provide protection.

Hoeing Attachment

Adjust the guards in such a way that only

the sets of blades penetrating the soil

are not covered.

When hoeing, make sure the depth bar

is adjusted properly.

Mowing Attachment

Handle with care! Sharp blades of the

cutter bar may cause injuries when handled improperly! Remove knife guards

only for mowing and refit immediately

after work has finished.

For transport and storage alwa ys fit the

knife guards. Secure finger bars additionally with tension springs.

Do not transport the removed cutter bar

without knife guards.

When fitting/removing the cutter bar,

make sure all blades are protected by

the knife guards.

To exchange the knife and to fit/remove

the knife driver , mak e sure that you turn

screws and bolts away from the cutting

blades to remove them.

To grind the mowing knives, always wear

safety goggles and gloves.

Weights

Always fit weights properly and at specified points.

Maintenance

Never carry out any maintenance or

cleaning while the engine is running.

Before you work on the engine, always

remove spark plug connector (petrol

engine only).

agria Multi-Purpose Machine 400P 11

1. Safety Instructions

1

Check regularly and, if necessary, replace all guards and tools subject to

wear and tear.

Replace damaged cutting tools.

Always wear safety gloves and use

proper tools when exchanging cutting

tools.

Do not carry out repairs like welding,

grinding, drilling, etc. on structural and

safety-relevant parts (e.g. coupling devices)!

Keep the machine and the attachment

clean to avoid risk of fire.

Check nuts and bolts regularly for tight

fit and re-tighten, if necessary.

Ensure that you re-install all safety and

guards and adjust them properly after

maintenance and cleaning.

Only use original agria spare parts. All

other conventional spare parts must correspond to quality and technical requirements specified by agria.

Storage

It is not allowed to store the machine in

rooms with open heating.

Never park the machine in closed rooms

with fuel left in tank. Fuel vapours are

hazardous.

Engine, Fuel, and Oil

Never let the engine run in closed rooms.

Extreme danger of intoxication! For the

same reason, also replace damaged

exhaust pipes immediately.

Be careful when dealing with fuel. Great

danger of fire! Never refill fuel close to

open fire, inflammable sparks or hot engine parts. Do not refill fuel in closed

rooms. Do not smoke when refilling!

Refill only with the engine switched off

and cooled down.

Do not spill any fuel, use a proper filling

device.

In case of fuel-spillage, pull the machine

awa y from the spillage before you start

the engine.

Make sure fuel is of specified quality.

Store fuel in approved cans only.

Store anti-corrosive agents and stabi-

lizing liquids out of reach of children. If

sickness and vomiting occur , see a doctor. If fuel has contacted ey es, rinse them

thoroughly , avoid inhaling of vapours.

Read and observe enclosed instructions.

Before you dispose of opened and

seemingly empty pressurised tins (e.g.

of assist-starting liquids) make sure they

are completely empty. Empty them in

ventilated places saf e from spark formation or flames. If necessary, dispose of

tins in hazardous waste deposits.

Be careful when draining hot oil, danger of burns.

Make sure oil used is of specified quality. Storage is in approved cans only.

Dispose of oil, greases, and filters

seperately and properly.

Tyres and Tyre Pressure

When working on the tyres, make sure

the machine is parked properly and secured against rolling off.

Any repairs are to be carried out by

trained mechanics only and with the appropriate tools.

Regularly check air pressure in the tyres.

Excessive pressure may cause bursts.

12 agria Multi-Purpose Machine 400P

1. Safety Instructions

1

When adding weight, make sure the tyre

pressure is correct.

Re-tighten bolts of drive-wheels or check

tightness when doing maintenance

work.

Electrical System and Battery

When working on the electrical system,

make sure the battery is disconnected

(negative terminal) (for tractors

equipped with battery).

Make sure to connect the battery properly – first connect the positive terminal

and then negative terminal. Disconnect

in reverse order.

Be careful with battery gases – explosive!

Avoid spark discharge and open flames

near batteries.

Remove plastic cover (if equipped) to

recharge battery and to prevent highly

explosive gases from building up.

Careful when handling battery acid!

Only use specified circuit breakers. If the

circuit breakers are to strong, they will

destroy the electrical system – danger

of fire.

Always cover positive terminal with the

specified cover or terminal cap.

Persons having a pacemaker may not

touch live parts of the ignition system

when the engine is running.

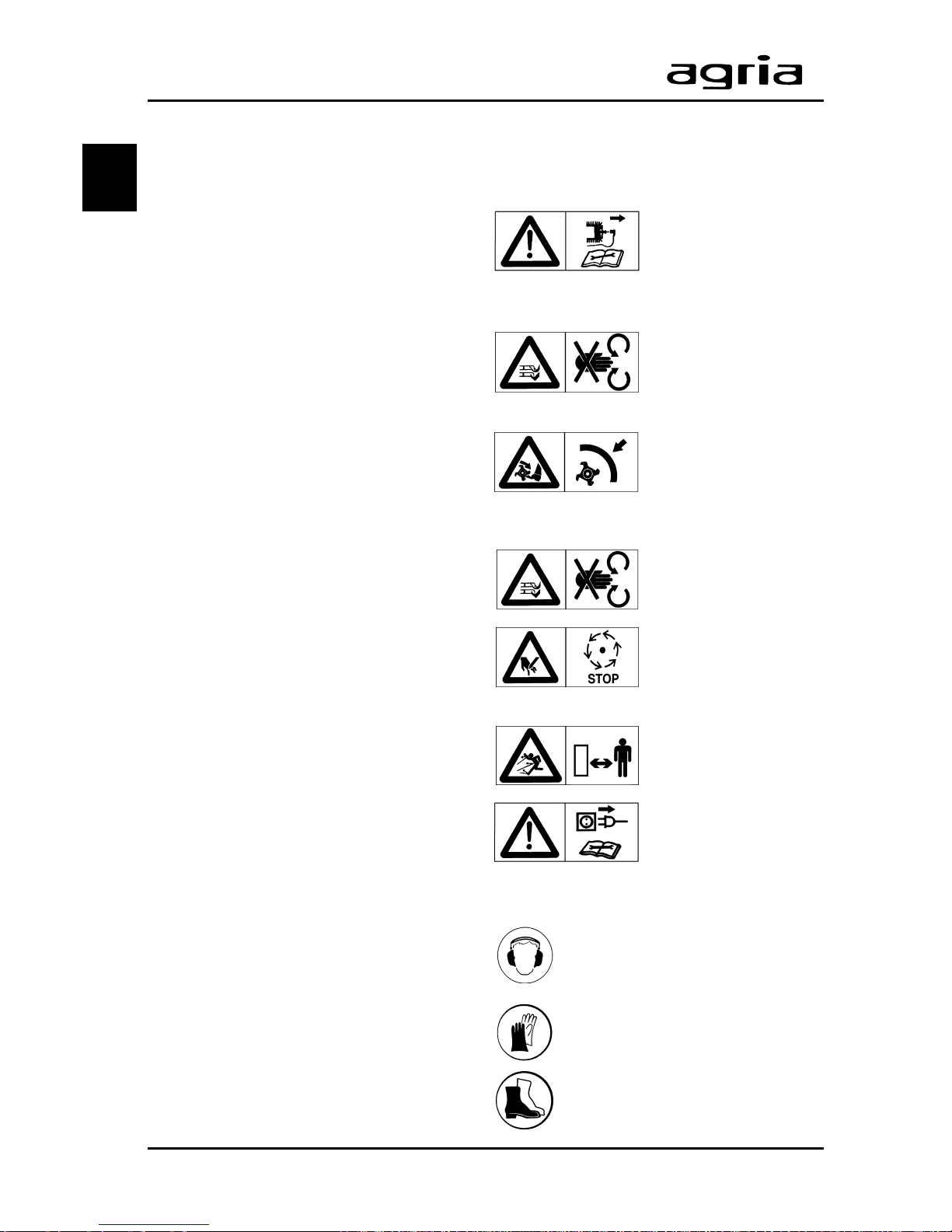

Explanation of

Warning Signs

Before any cleaning,

maintenance, and repair work switch off the

engine and pull spark

plug connector .

With the engine running, keep at a safe

distance from hoeing

or cutting tools.

Do not work without

guards in place. Before starting the engine, bring guards in

proper position.

With the engine running, keep at a safe

distance from knife.

Do not touch moving

machinery parts. W ait

until they have come

to a complete stop.

With the engine running, keep at a safe

distance.

Only drive the attachment at speed “I”.

Signs

When working with the

machine,wear individual protective ear plugs.

Wear protective gloves.

Wear solid shoes.

agria Multi-Purpose Machine 400P 13

2. Specifications

2

1

Dimensions:

a ........................................ 100 mm

b ........................................ 630 mm

c......................................... 160 mm

d ........................................ 380 mm

e ........................................ 700 mm

h .............................. 860–1080 mm

l........................................ 1200 mm

A .............. (13x5.00 - 6) 525 mm

A ..................... (3.50 - 6) 440 mm

A (Twin tyres 3.50 - 6) ..... 857 mm

A ..................... (4.00 - 8) 640 mm

A Hoeing tools........... 450–650 mm

Clutch: ............................. V-belt clutch

with idler pulleys

between engine and gearbox

Friction clutch for reverse speed

Only use original agria V-belts!

(List of wear parts p49)

Transmission:...................Worm gear

with free-wheel drive mechanism on

drive wheels

Transmission oil SAE 90-API GL5

Filling quantity approx. 0.5 l

Speeds: ...................3 forward speeds

(moving V-belt to another pulley)

1 reverse speed (friction wheel)

see table below

Steering handle:...vibration damping,

height-adjustable,

side-adjustable without tools

Weight: ......................... Approx. 50 kg

Noise level:

Noise level ....................... Lp = 84 dBA

in accordance with EN 11201 (at

operator’s ear)

Acoustic power level LWA = 96,1 dB(A)

in accordance with EN ISO 3744

Vibration acceleration value:

on handlebar:................ ahw < 2.5 m/s

2

in accordance with ISO 5349 at 85% of rated

engine speed with tool at work.

Speed Revolutions [rpm] Ground speed [km/h]

Wheel shaft

Pto Tyres

i

tot

n

dw

n

pto

13x5.00-6 3.50-6 4.00-8

I 67.5 55 1650 3.2 3.6 4.4

II 42.7 85 2550 5.0 5.6 6.9

III 28.1 125 3750 7.3 8.3 10.1

R 61.7 58 1740 3.4 3.8 4.7

Tyres: (Accessory) .............................

................ 13x5.00-6 (Grassland tyre)

....... 3.50 - 6 und 4.00 - 8 (Field tyre)

Tyre pressure: ........................ 1.0 bar

Multi-purpose machine

14

agria Multi-Pur pose Machine 400P

2. Specifications

2

Engine

Manufacturer: ..........................Honda

Engine type: .............. GX 200 QHQ4

Version: ....................... Fan-air cooled

1-cylinder, 4-stroke

petrol ohv engine

Bore:........................................ 68 mm

Stroke:..................................... 54 mm

Cubic capacity: ................... 196 ccm

Compression ratio:................. 8.5 : 1

Output: .................................... 4.8 kW

at 3,600 rpm

Max. torque:.......................... 13.2 Nm

at 3,000 rpm

Spark plug: ................NGK BPR6 ES

Spark plug gap: ............... 0.7–0.8 mm

Ignition system:

Contactless solenoid ignition, ignition

point is pre-set, radio remote

screened according to VDE 0879

Valve lash (engine cold):

Intake: ................ 0.15 mm ± 0.02 mm

Outlet: ................ 0.20 mm ± 0.02 mm

Starter:

Soft-pull recoil starter with mechanical

decompression facility

Fuel tank capacity: .................... 3.6 l

Fuel: Standard regular grade petrol for

motor vehicles, octane number see

engine operating instructions

Air filter: ..................Dr y element filter

with foamed preliminary filter

Carburetor: .......... Throttle valve type

Mixture control screw:

opened approx. 2 1/8 turns in base

setting

Rated speed: .....................3,600 rpm

Top no-load speed:...........3,850 rpm

Idling speed:...........1,250–1,600 r pm

Engine oil:

Filling quantity..................approx. 0.6 l

Multi-grade oil SAE 10 W-40

SJ or higher quality grade

Operability on Slopes:

Continuous operation possible

up to ..................20° inclination (37 %)

Temporar y operation possible

up to ..................25° inclination (47 %)

(with oil level at “max” = upper level

mark)

agria Multi-Purpose Machine 400P 15

3. Devices and Operating Elements

3

The agria multi-purpose machine type

400 is a base power machine and is always operated with an attachment

mounted. Therefore, the machine is

suited for horticultural, agricultural,

forestal operations , as well as for g rassland and park maintenance and for winter service work.

Available attachments are:

l

hoeing and tilling

l

mowing

l

turf and grounds care

l

ploughing

l

sweeping

l

gravel and salt spreading

l

snow dozing and rotory snow

cleaning

l

transporting

Engine

The four-stroke petrol engine runs on

conventional petrol (ref er to fuel recommendations p6). During the first 20 operating hours (break-in period) do not

use engine to maximum power. Even

after the break-in period never use

engine at higher speed than necessary

for the work in hand.

I

High engine speed is harm-

ful to any engine and considerably affects its longevity. This applies especially for no load operation.

Any over speed (have the engine roar)

can result in immediate damage.

Cooling System

The engine is fan-cooled. Therefore

keep screen at recoil starter and cooling fins of the cylinder clean and free

from sucked-in plant trash.

Idling Speed

Always ensure that idling speed is adjusted correctly. At low speeds and with

the speed control lever set to idle, the

engine is supposed to run smoothly and

without run-out.

Air Filter

The air filter purifies the air intake. A

blocked filter reduces engine output.

Ignition System

The engine is equipped with a maintenance-free, contactless electronic ignition system.

We recommend to have necessary

check-ups done by an expert only.

16 agria Multi-Purpose Machine 400P

3. Devices and Operating Elements

3

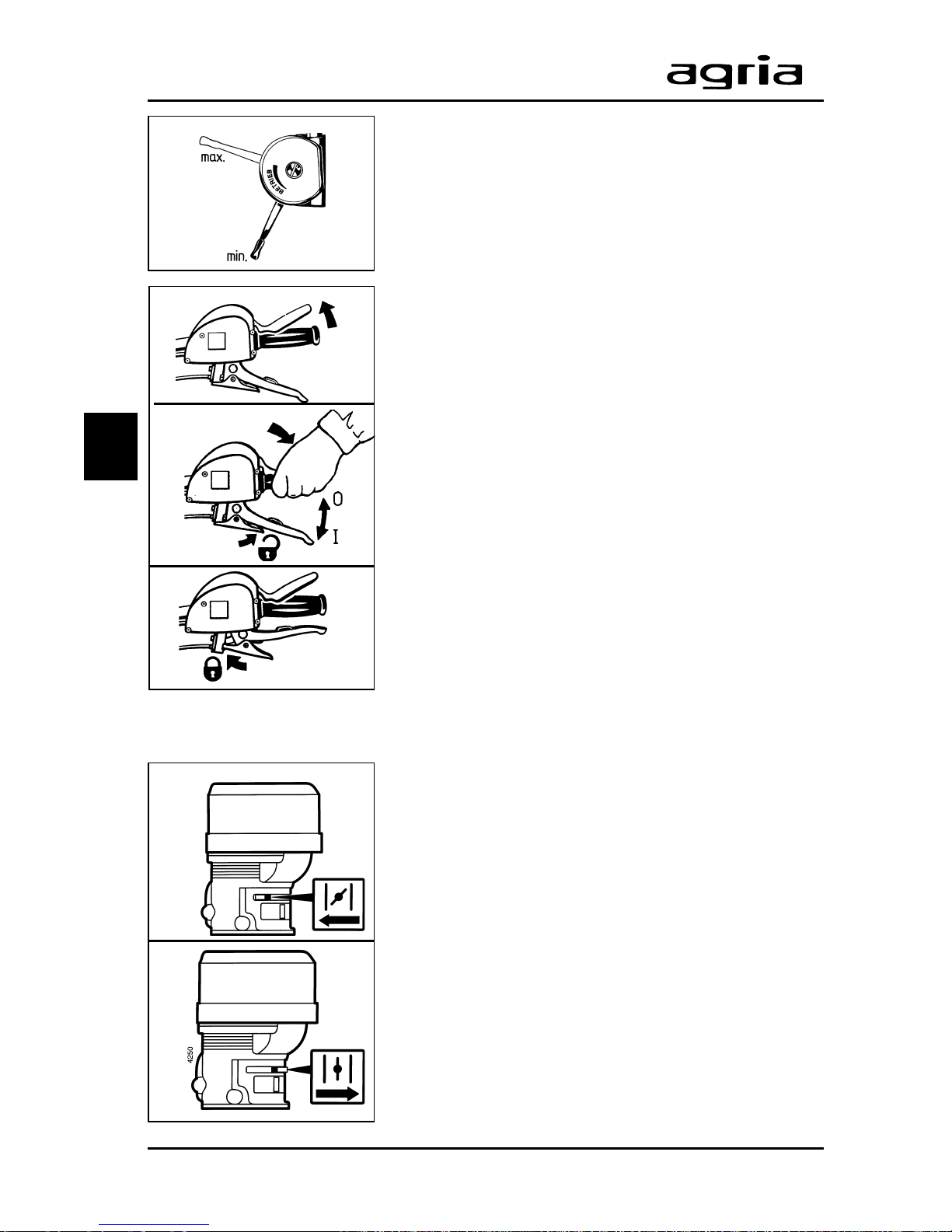

Speed Control Lever

The speed control lever (C/9) on the steering handle is for stepless setting of engine speed from min.

= idle to max. = full throttle.

Safety circuit

The multi-purpose machine is equipped with a safety

circuit lev er .

Stop position: When releasing the le ver (C/4)

the ignition system is switched off (engine is shut

off). Beware – engine keeps running due to centrifugal mass.

Start position: For starting the engine and

for short breaks, pull the clutch lev er (C/5) and lock

with pawl (C/6).

Operating position: To operate the machine,

press down the safety circuit lever (E/3 or G/3).

W

Do not tie down the safety circuit lever.

I

The safety circuit lever also serves as engine

safety circuit in an emergency. Upon release,

the lever will automatically go to STOP position.

Choke

The choke lever (B/5) is on the carburetor.

Close the choke f or cold starts. To do this, move

the lever to the left.

Open the choke for w arm starts and operation.

To do this, move the lever to the right.

agria Multi-Purpose Machine 400P 17

3. Devices and Operating Elements

3

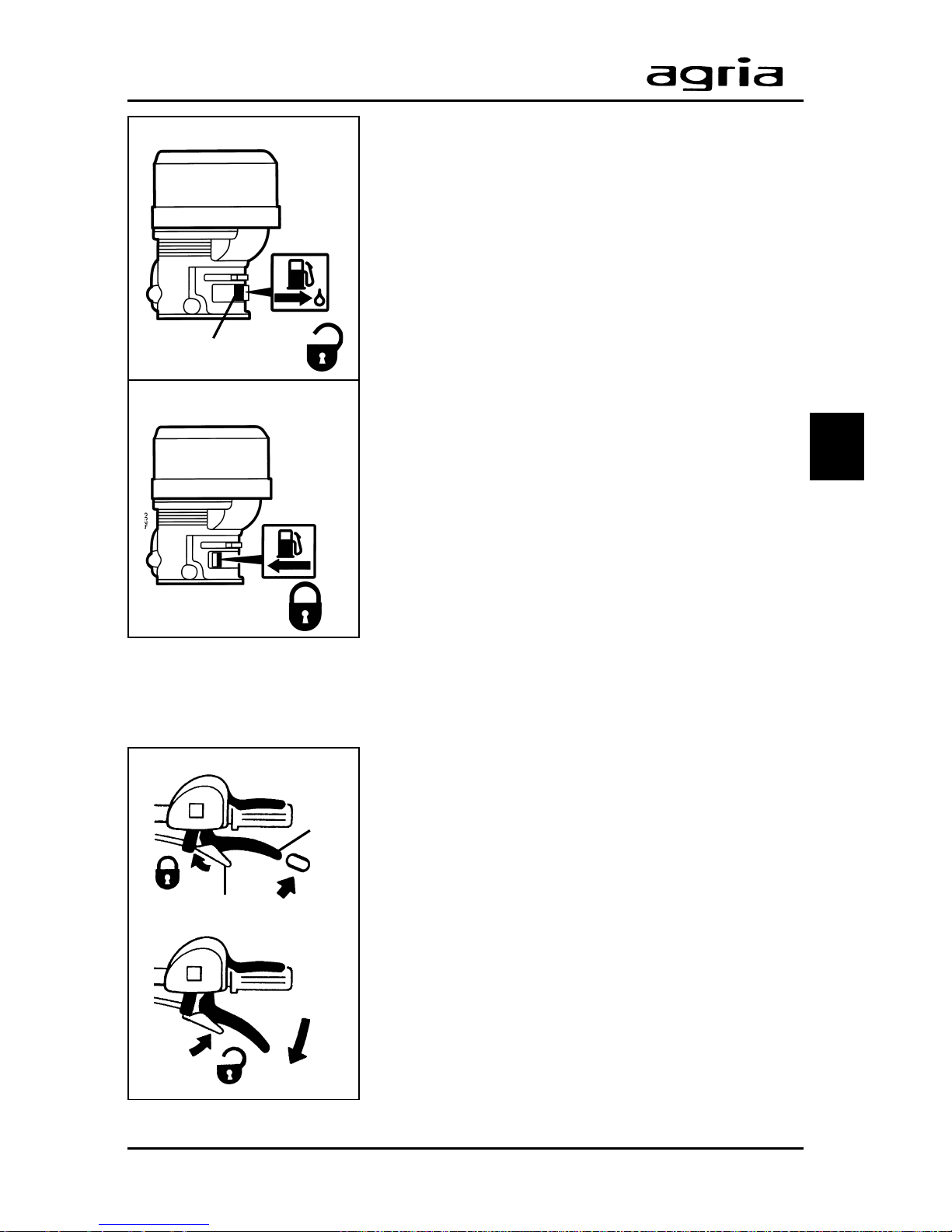

Fuel tap

The fuel tap (B/13) is on the carburetor.

Move the tap to the right to open it.

Move the tap to the left to close it.

Clutch

The multi-purpose machine is equipped with a Vbelt clutch with integrated reverse shift. Operation

is via the clutch lever (C/5).

The machine is decoupled when you pull the clutch

lev er until pawl locks into place. Now, the engine

stops driving the machine. The clutch lever can be

locked with pawl (C/6) when the machine is

decoupled.

To avoid clutch slipping away during operation, a

clutch play is factory-set at the clutch le v er (refer to

“Maintenance”).

After the first operating hour, the clutch play has to

be checked and, if necessary, re-adjusted (refer to

“Maintenance”).

B/13

C/5

C/6

Loading...

Loading...