Page 1

YIELD MONITOR 2000

Operators Manual

Manual written with assistance from:

Tri-Tech Communications & Publications, 1636 13th St., Boone, IA 50036

Page 2

Page 3

Yield Monitor 2000

Ag Leader Technology

General

Welcome

System Upgrades

Welcome to the Ag Leader Technology family. Ag Leader Technology is

dedicated to developing advanced, yet practical and cost-effective tools for

grain production. Above all, however, we are dedicated to meeting your

needs for support of existing products and development of product

improvements.

We want to hear from you! Feel free to call any time to discuss:

• Operational problems with your system

• Features you don’t like about your system

• Features you would like added to your system

We will do our best to ensure that you are happy with your current system

and that it is upgraded in the future to better meet your needs.

Ag Leader Technology will periodically mail to you a program chip that

replaces the existing chip in your monitor console. The new chip will

upgrade your monitor, make it easier to use, and may add new features.

To receive an upgrade chip and new product news, you must send in or

fax (515-232-3595) the Registration Form that is at the beginning of the

operator’s manual. Our mailing address is:

Limited Warranty

Ag Leader Technology

1203A Airport Road

P.O. Box 2348

Ames, IA 50010

Ag Leader Technology will repair or replace at no charge any component of

the Yield Monitor 2000 system that fails during normal service on the

combine model for which the system is intended to be used within two years

from the date of first use.

Warranty is not provided for damage resulting from abuse, neglect,

accidents, vandalism, acts of nature, or any other causes that are outside the

normal, intended use of the Yield Monitor 2000 system.

June 1997

1-1

Page 4

General

Yield Monitor 2000

Ag Leader Technology

Ag Leader Technology shall not be liable for indirect, incidental, or

consequential damages to the dealer, end user, or third parties arising from

the sale, installation, or use of the Yield Monitor 2000 system.

Service

Copyright Notice

If you have a problem with your system, call us directly at the phone number

below. If we determine you have a hardware failure, we will ship

replacement hardware immediately. Our mailing address and phone numbers

are:

Ag Leader Technology

1203A Airport Road

P.O. Box 2348

Ames, IA 50010

Phone: 515-232-5363

Fax: 515-232-3595

Note: Return failed hardware to us by UPS (preferred) or US mail..

Ag Leader Technology has copyrighted (1996) the contents of this manual

and the operating program for the Yield Monitor 2000 system. No

reproductions of this material may be made without first obtaining the

consent of Ag Leader Technology.

Proprietary

Technology Notice

1-2

The Yield Monitor 2000 system has patents on its design and operational

features. Copying features of this system relating to measurement and

calculation of grain flow and weight or organization of field and load data

may result in patent infringement.

* * *

June 1997

Page 5

Yield Monitor 2000

Ag Leader Technology

Setup Overview

Important Notices

Section Contents

The yield monitor must be set up before field operation, but before you begin

the setup procedures, read the following notices:

• You can upgrade the Yield Monitor 2000 console by replacing a

computer chip inside the box. To receive the free upgrade chip, you

must send in the registration form at the beginning of the operator’s

manual.

• If you plan to make yield maps on your own computer, you will need to

use Precision Map 2000 (or another mapping program that can process

memory cards from the Yield Monitor 2000) to process the memory

cards when they get full. You can also purchase memory cards from Ag

Leader Technology. Precision Map 2000 comes with your Yield

Monitor 2000 kit.

The following subjects are detailed in this section:

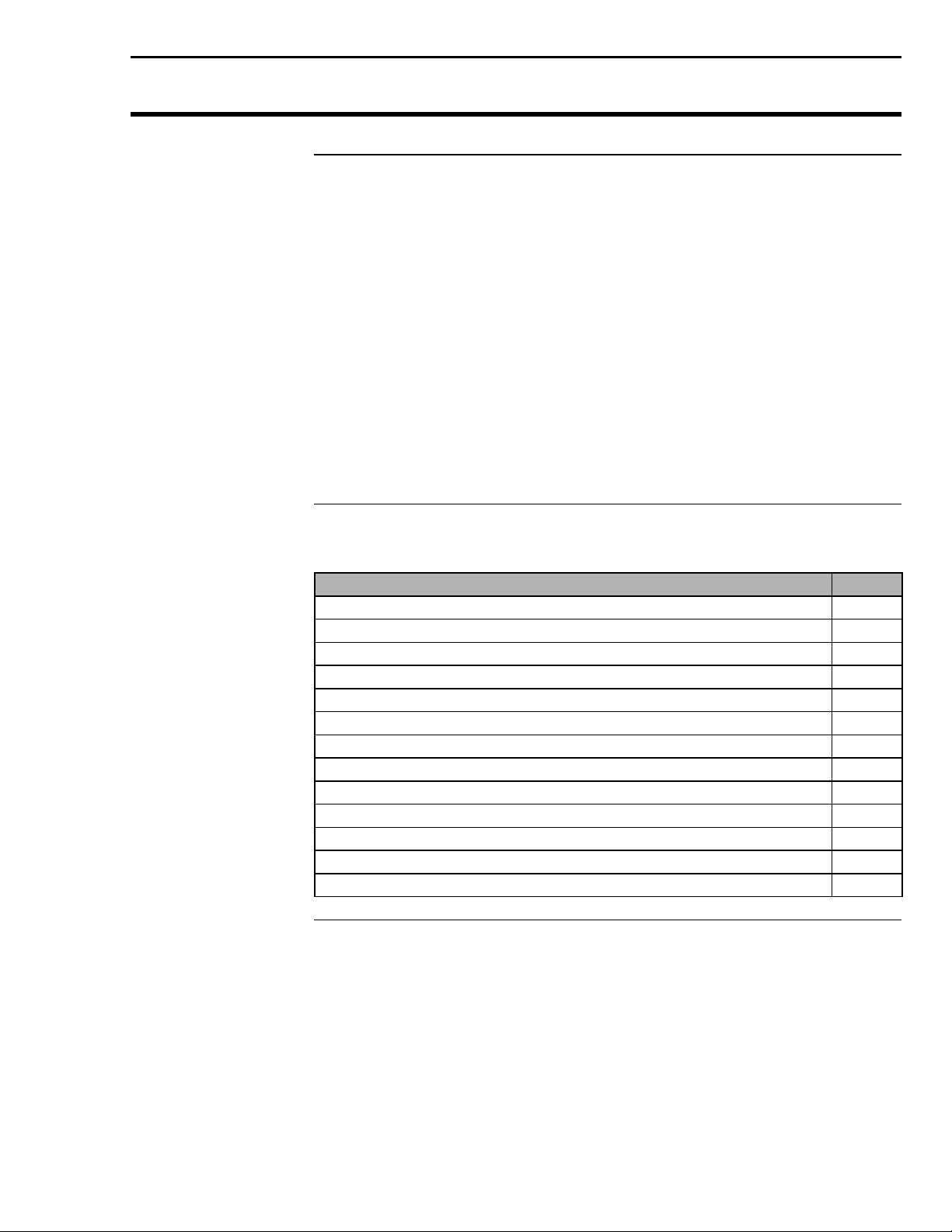

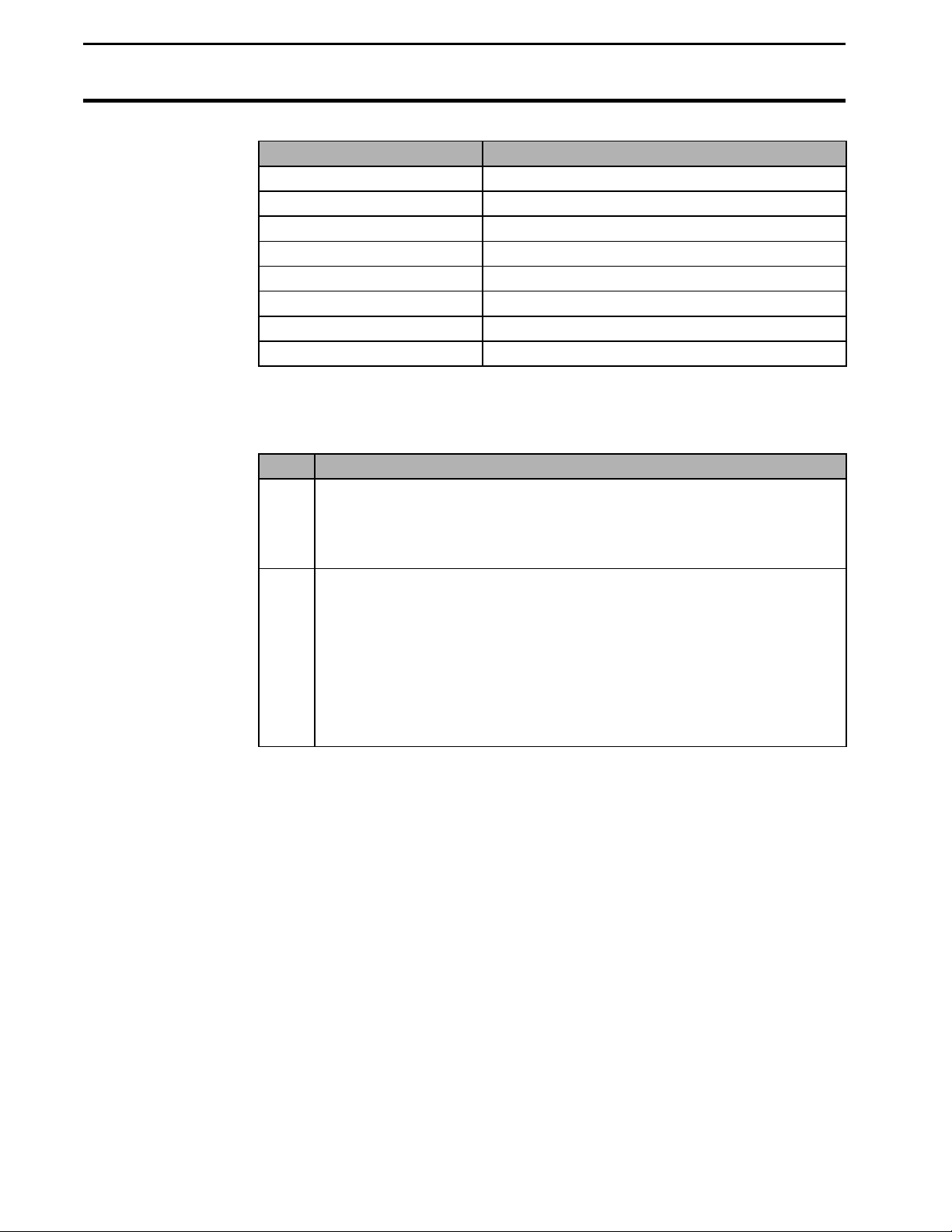

Subject Page

General Description 2-2

Before Setup 2-9

Setting Date and Time 2-10

Logging Settings 2-11

Settings Under SETUP Key 2-14

Setting Swath 2-17

Speed Setting 2-19

Setting Moisture 2-21

Setting Dry % Moisture, Dry Lbs/Bu 2-22

Setting Initial Calibration Numbers 2-23

Starting, Naming Fields/Loads 2-25

Setting Stop Height 2-31

Copying Memory to Backup 2-32

June 1997

* * *

2-1

Page 6

General Description

Yield Monitor 2000

Ag Leader Technology

Introduction

Monitor

Organization

The yield monitor is designed to accurately measure and record acres,

moisture, grain weight, bushels, and yield in bu/ac on-the-go. It is GPS

compatible and can log yield mapping data on memory cards. The yield

monitor must be calibrated to be accurate.

If you are using the monitor with a GPS receiver, you must use a

memory card to save GPS information. If you do not have a GPS

receiver, you do not need a memory card; the monitor has enough internal

memory for 976 total loads and 255 total fields which should last the entire

season.

The monitor is organized by fields and loads. A load subdivides a field into

smaller sections. A monitor load can be smaller or larger than a combine

tank, wagon, or truck load. It is recommended to use different loads for

different hybrids or varieties or field conditions (like a wet hole). The

operator manually changes the load when it is appropriate to do so while

harvesting.

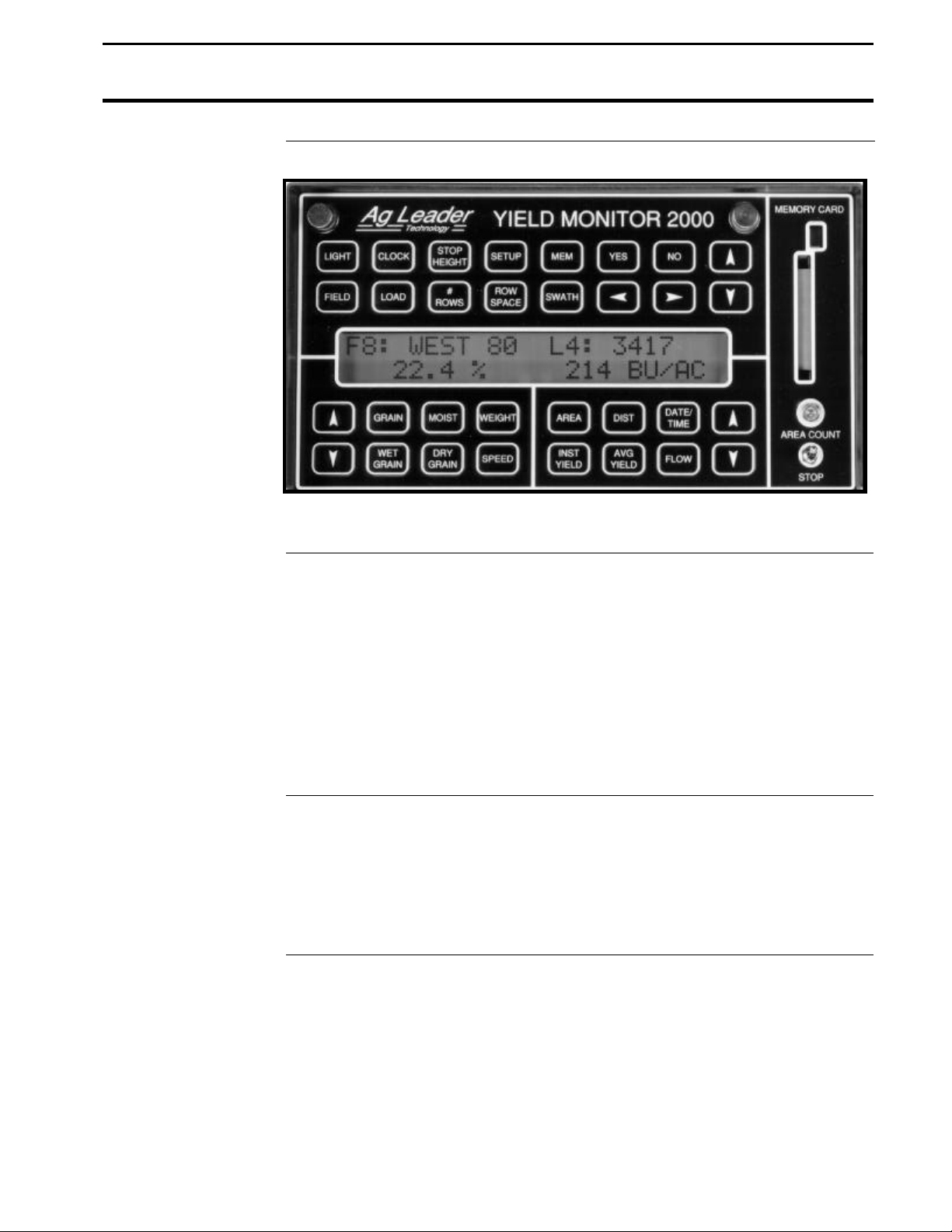

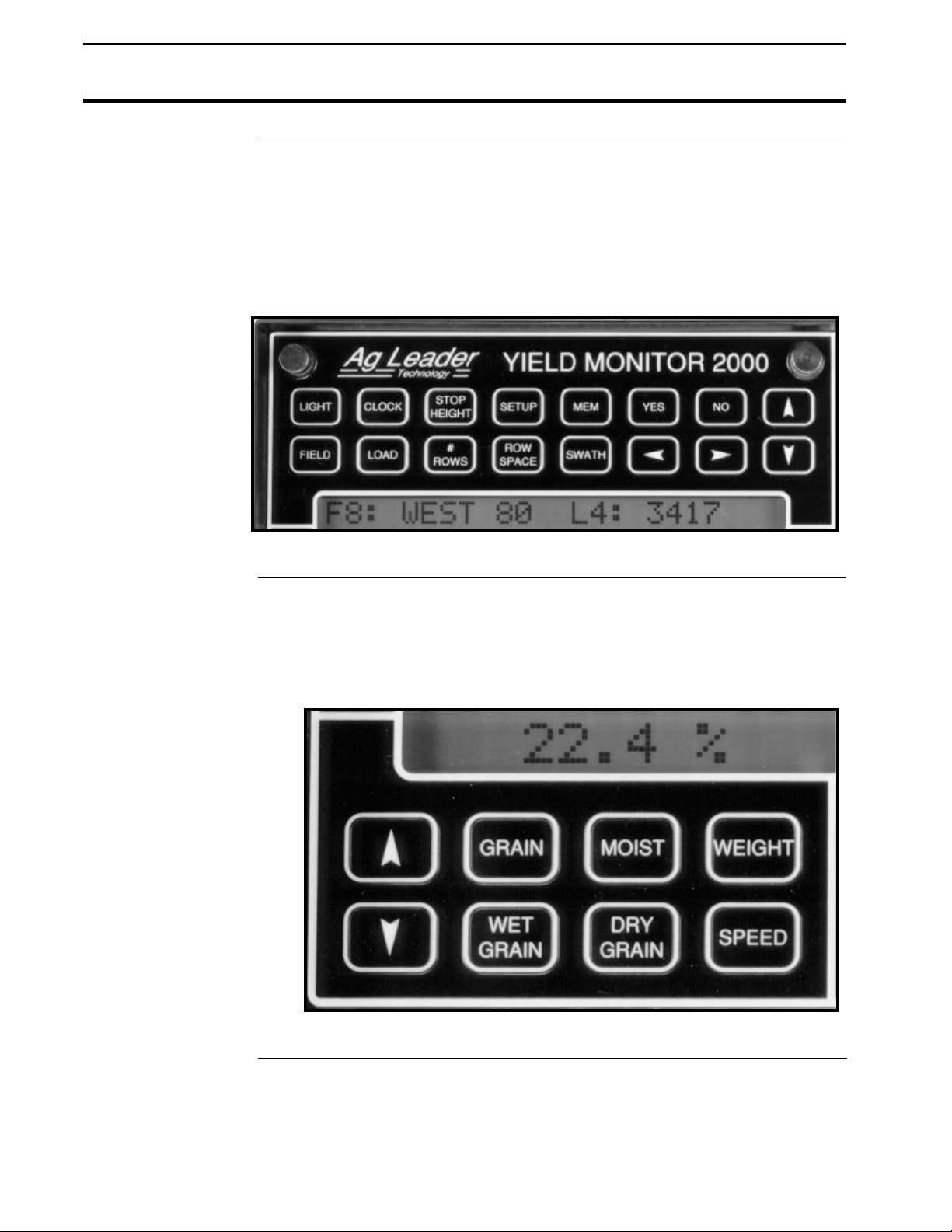

Keypad

The monitor has three groups of keys: a top group, a bottom-left group, and

a bottom-right group. When you press a key, the monitor beeps. Each key

(particularly the SETUP and MEM keys) have menu items to scroll through

by continually pressing the key to advance to the next menu item under that

key.

2-2

June 1997

Page 7

Yield Monitor 2000

Ag Leader Technology

General Description

Arrow Keys

Yes/No Keys

Figure 1: Front panel of the yield monitor 2000

When you press a key and a menu item appears, you must use the arrow

keys to scroll through a list of settings to select the appropriate setting.

Example: If you pressed the SETUP key to access “LOGGING

DEVICE=”, you must use the UP or DOWN ARROW key to set the

LOGGING DEVICE = NONE, EXT, or ?M CARD.

Note: After selecting a setting, you need not press another key to save it;

the monitor automatically remembers your selection.

When you press a key and the monitor asks you a question, press the YES

or NO key to answer the question.

Example: If you pressed the MEM key to access “COPY MEMORY TO

BACKUP?”, press the YES or NO key.

June 1997

2-3

Page 8

General Description

Yield Monitor 2000

Ag Leader Technology

Top Keys

Bottom-Left Keys

The top group of keys is the top two rows of keys (refer to Figure 2 below).

The menu items for these keys appear only on the top line of the display,

except for two menu items accessed through the MEM key. These items

appear on the bottom line of the display. You must use the UP and DOWN

ARROW keys in the top two rows of keys to change a setting for the top

group of keys.

Figure 2: Top group of keys

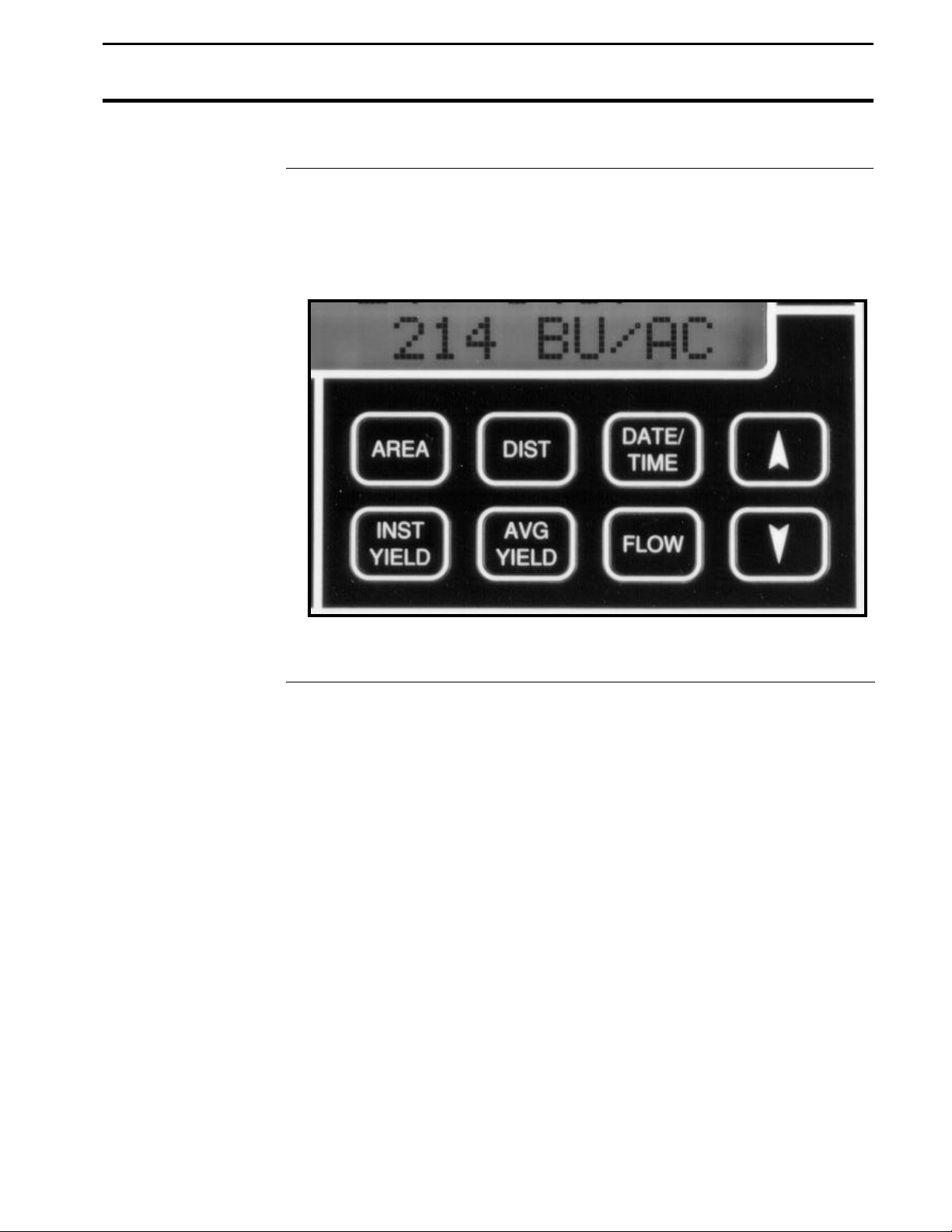

The eight keys on the bottom-left of the monitor compose the bottom-left

key group. The menu items accessed through these keys appear only at the

bottom-left of the display. Use the UP and DOWN ARROW keys in the

bottom-left group to change a setting for this group of keys.

2-4

Figure 3: Bottom-left key group

June 1997

Page 9

Yield Monitor 2000

Ag Leader Technology

General Description

Bottom-Right Keys

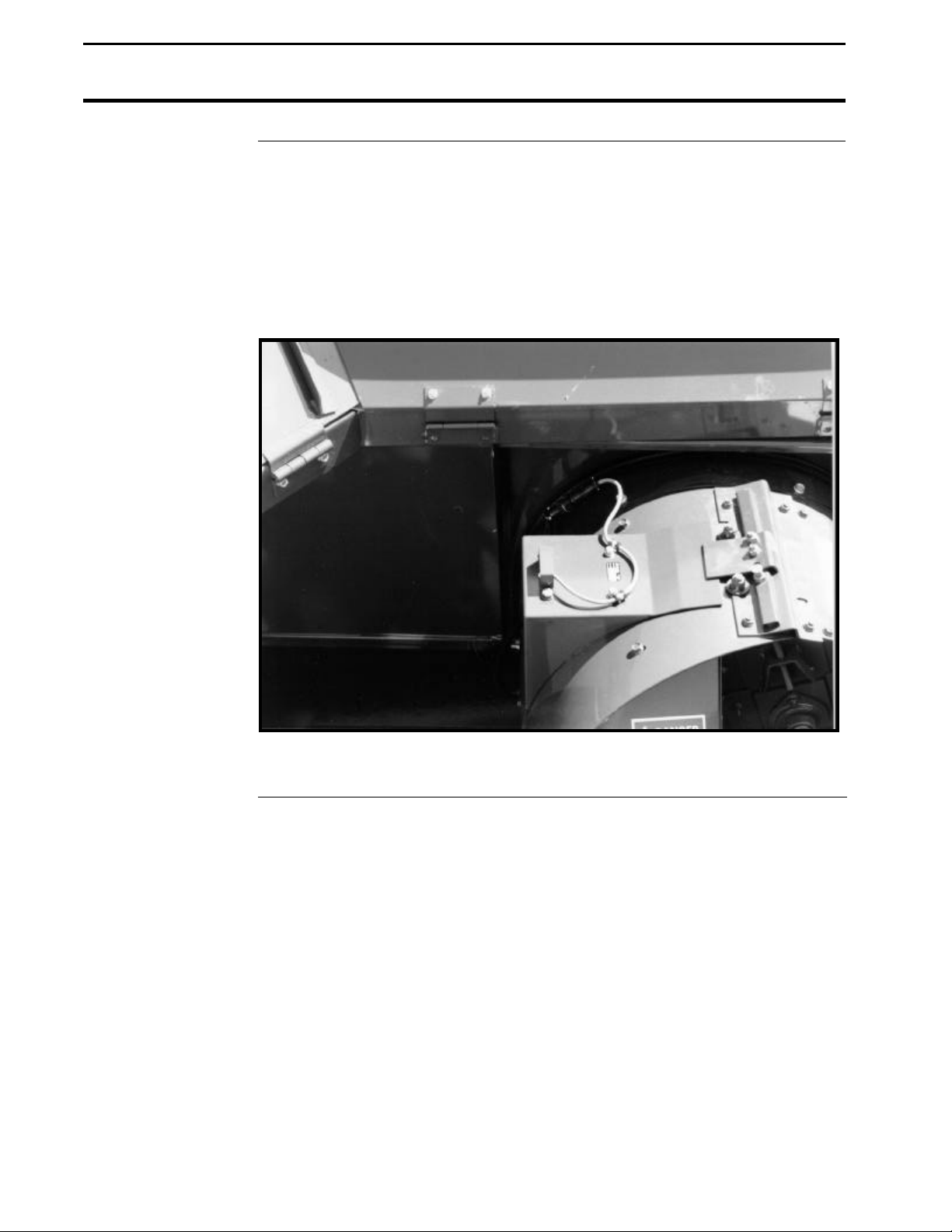

The eight keys on the bottom-right of the monitor compose the bottom-right

key group. The menu items accessed through these keys appear only at the

bottom-right of the display. Use the UP and DOWN ARROW keys in the

bottom-right group to change a setting for this group of keys.

Figure 4: Bottom-right key group

June 1997

2-5

Page 10

General Description

Yield Monitor 2000

Ag Leader Technology

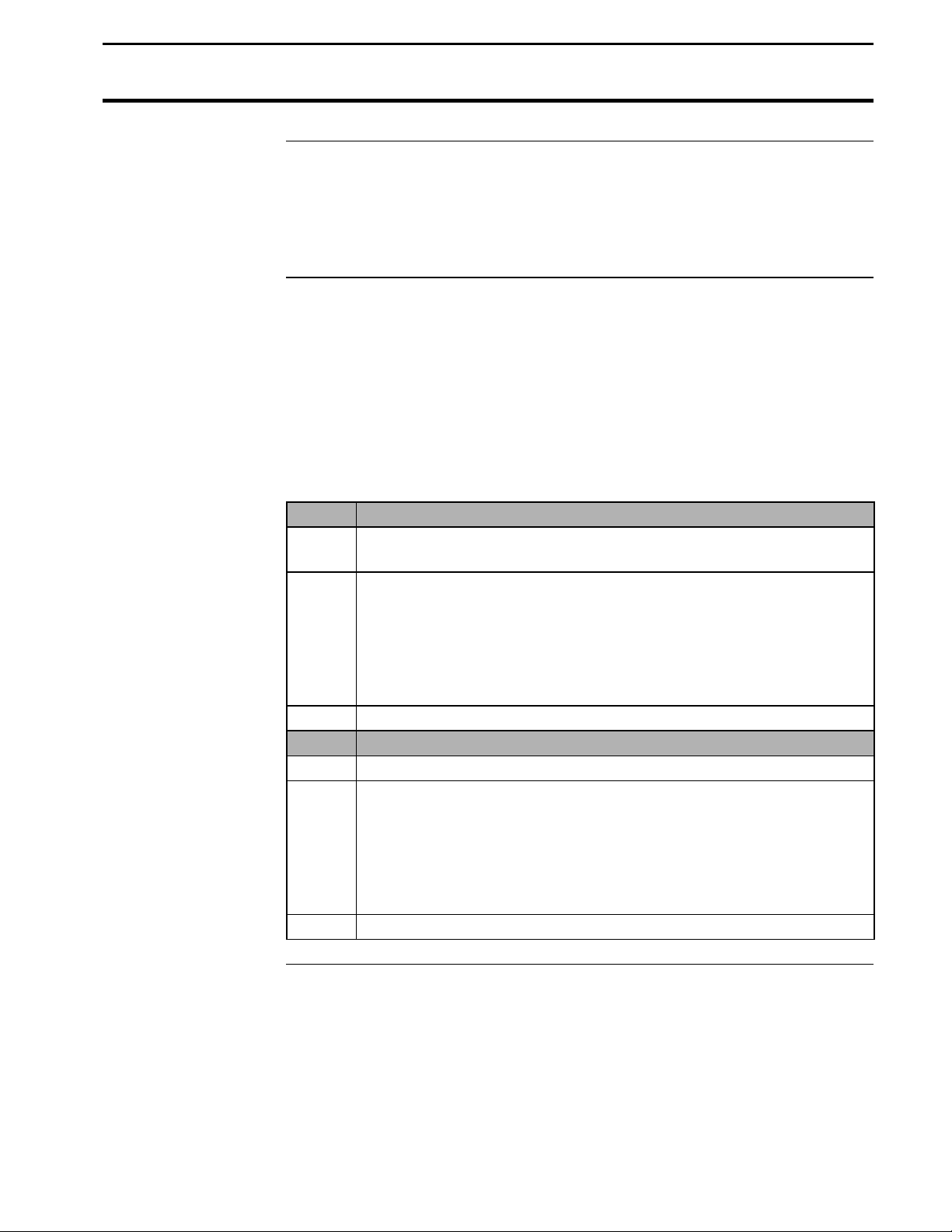

Grain Flow Sensor

Below is an example of a grain flow sensor. Your grain flow sensor may

look different, depending on which combine model you have. On all

combines, the grain flow sensor installs on top of the clean grain elevator.

The grain flow sensor measures the grain weight in pounds as you harvest.

The clean grain paddles throw the grain, as the paddles rotate around the top

sprocket, toward the grain flow sensor. The flow sensor measures the grain

weight when the grain strikes the flow sensor impact plate.

2-6

Figure 5: Grain flow sensor

June 1997

Page 11

Yield Monitor 2000

Ag Leader Technology

General Description

Moisture Sensor

Below is an example of a moisture sensor installed on the auger that fills the

combine grain tank.

Figure 6: Moisture sensor

June 1997

2-7

Page 12

General Description

Yield Monitor 2000

Ag Leader Technology

Header Height

Sensor

Below is an example of a header height sensor installed underneath a

combine cab. The header height sensor tells the monitor the position of the

combine head so that when the head is raised on the row ends as the

combine turns around, the monitor stops counting acres.

2-8

Figure 7: Header height sensor

* * *

June 1997

Page 13

Yield Monitor 2000

Ag Leader Technology

Before Setup

Using Power

Supply

Setting the

Monitor on Field,

Load

Other than for setting the stop height and calibrating the distance, the yield

monitor console does not need to be in the combine to set it up. You can use

the provided power supply (plugs into 120 v outlet) to power up the monitor

console inside your home or shop.

When going through the setup procedures, take note of which settings can

be set differently for each load. You should setup the monitor with it set to

Field 1, Load 1, because any new loads you create will use the settings for

the previously created load in that field. The monitor should come from the

factory with only Field 1, Load 1 created. Follow the procedure below to

try to change to a different field and load to verify that only Field 1, Load 1

has been created. If there is more than one field and load already created in

the monitor, you will have to change the settings for each one of those loads.

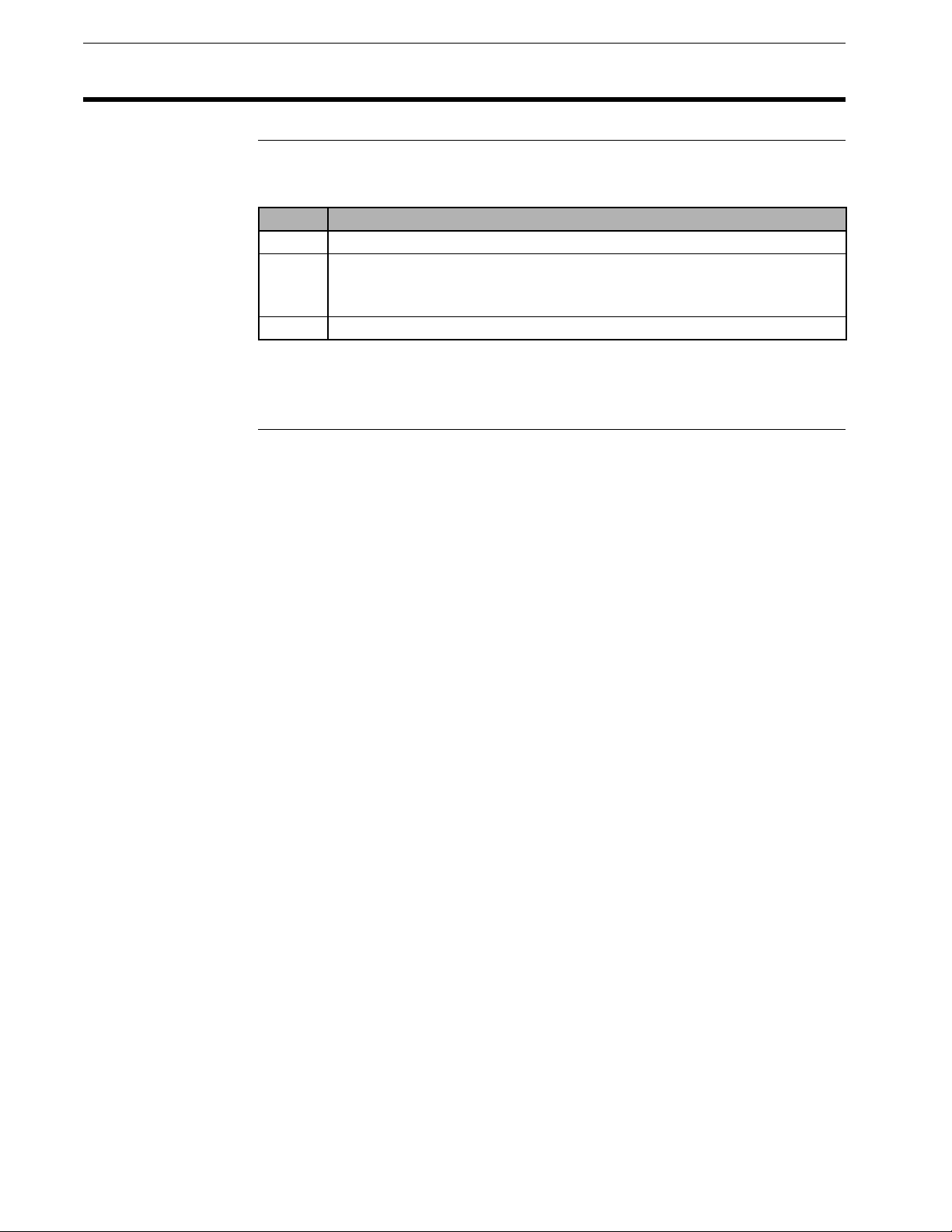

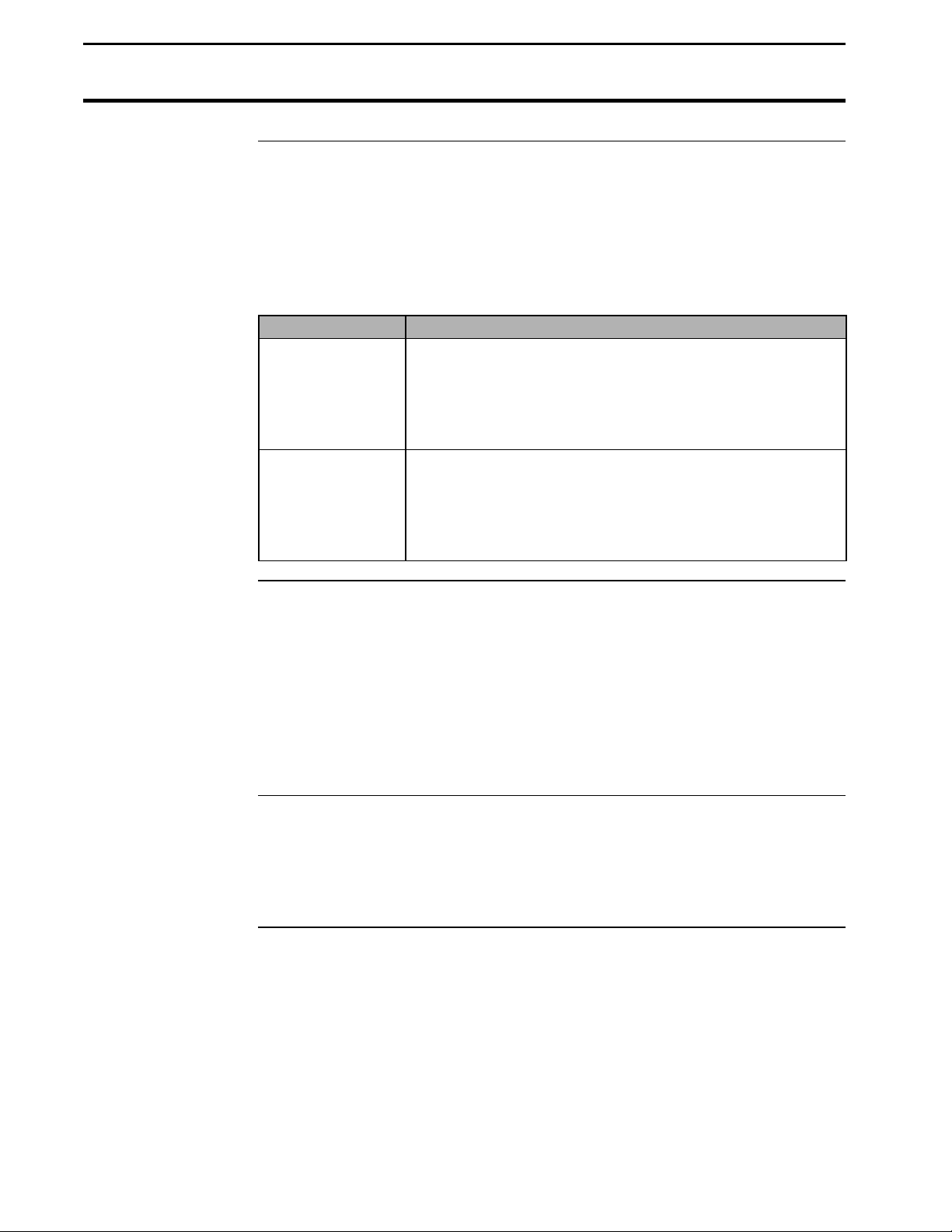

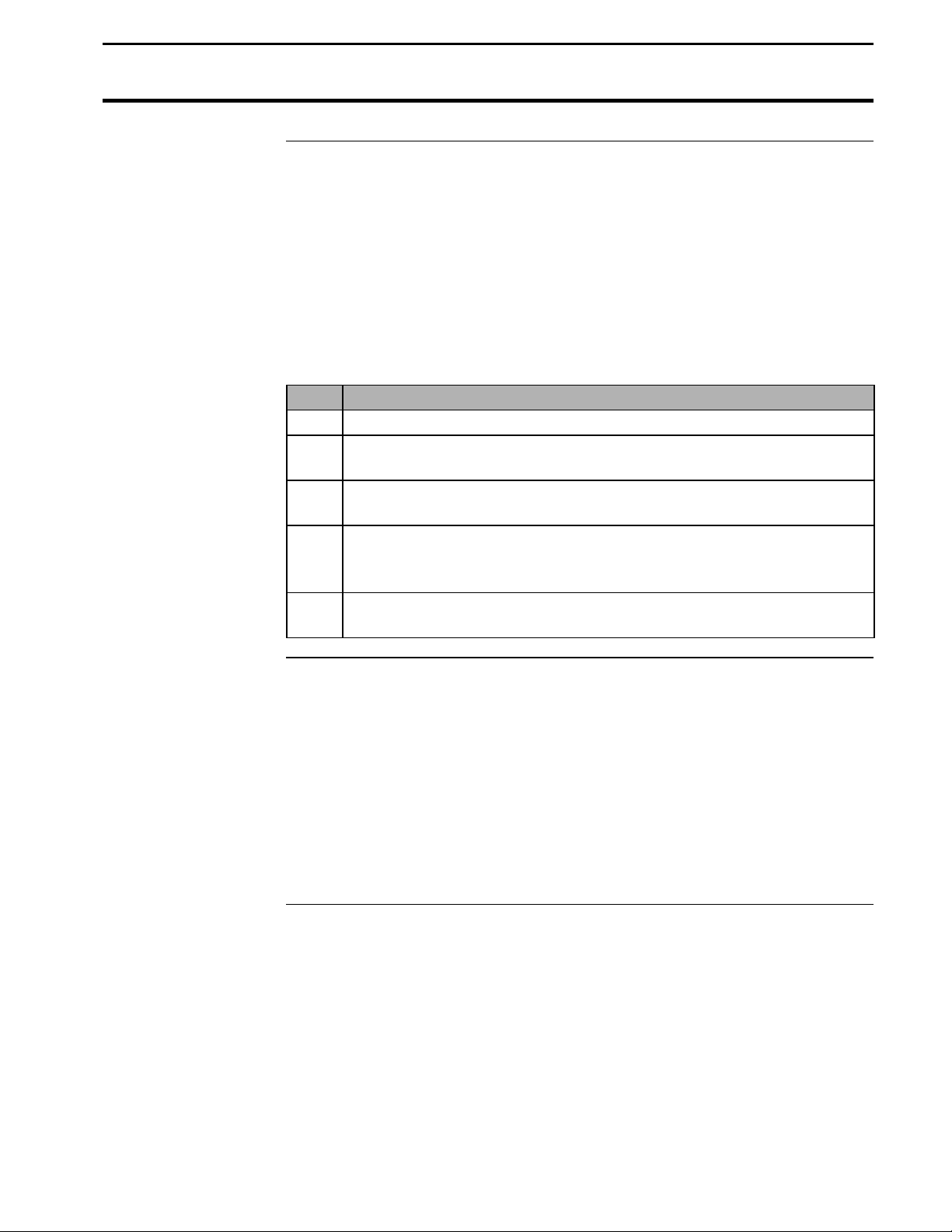

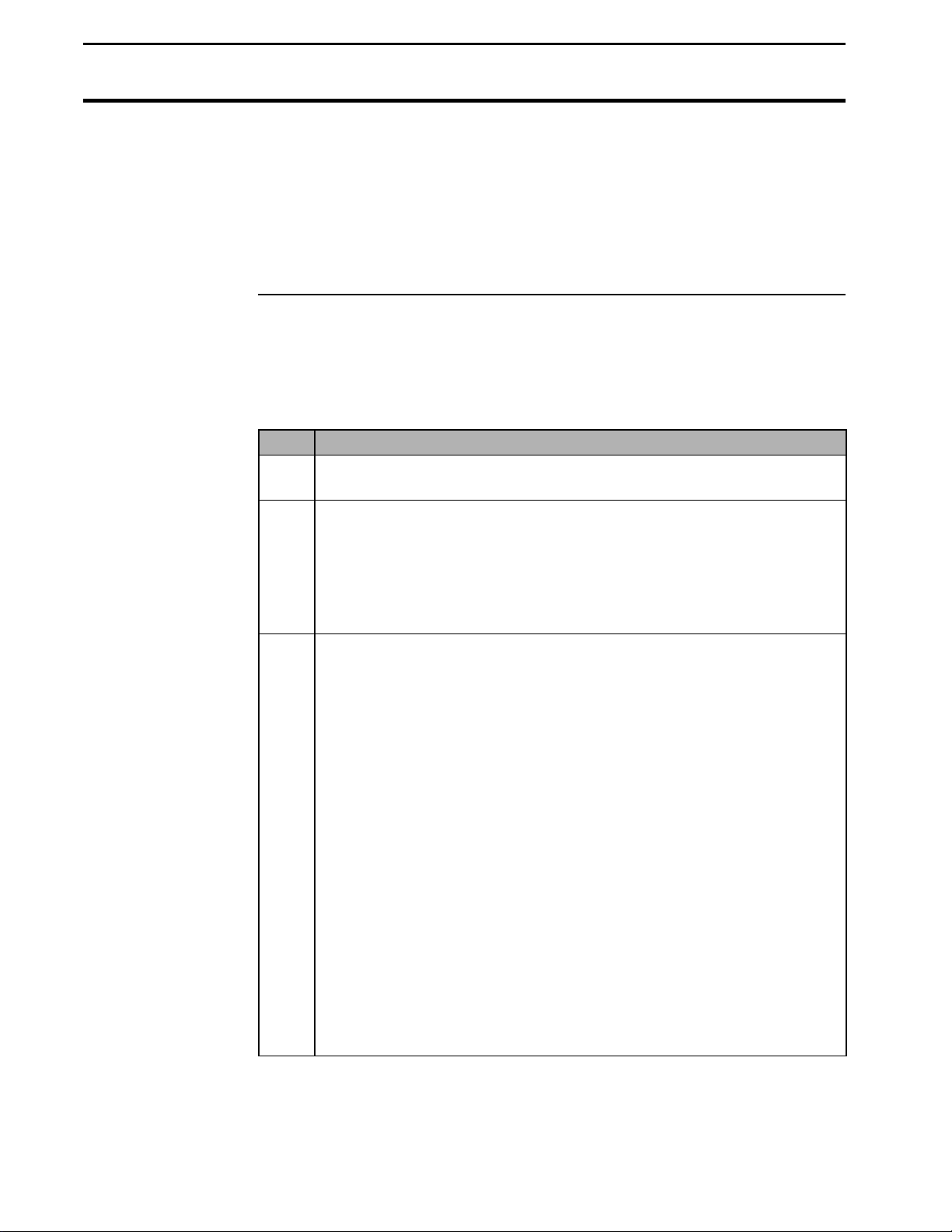

Step Action

1 Press the FIELD key to display the field only to find the last field

and created.

2 Press the top UP ARROW key until “START NEW FIELD?”

appears on the display.

Note: You can see how many fields are already created by

scrolling through the fields until START NEW FIELD? is

displayed.

3 Press the NO key.

Step Action

4 Press the LOAD key to display the field and load.

5 Press the top UP ARROW key until “START NEW LOAD?”

appears on the display.

Note: You can see how many loads are already created by

scrolling through the loads until START NEW LOAD? is

displayed.

6 Press the NO key.

* * *

June 1997

2-9

Page 14

Setting Date and Time

Yield Monitor 2000

Ag Leader Technology

Setting the Date

and Time

Follow these procedures to set the time and date:

Step

1

2

3

Press the CLOCK key to display the time and date.

Use the RIGHT ARROW key to move the cursor under the time or date

value that needs to be changed.

Use the top UP and DOWN ARROW keys to set the value.

Action

Note: The DATE/TIME key displays the date and time that the load was

created.

* * *

2-10

June 1997

Page 15

Yield Monitor 2000

Ag Leader Technology

Logging Settings

Selecting a

Logging Device

The instantaneous yield and GPS data are not recorded in the monitor’s

internal memory, but are logged to a separate device; either a memory card

or an external datalogger, which connects to the nine-pin serial port on the

monitor.

To select a logging device, press the SETUP key until “LOGGING DEVICE

=NONE or ?M CARD or EXT” appears on the display. Use the top UP or

DOWN ARROW keys to select the correct setting from the menu choices:

• NONE: Select this setting if you do not have a GPS receiver and

therefore are not logging instantaneous yield and GPS information on

either a memory card or a datalogger.

• ?M CARD: Select this setting if you have a GPS receiver and will be

logging instantaneous yield and GPS information to a memory card in

the yield monitor. The ? changes to the size of the card that was last

formatted in the monitor.

• EXT: Select this setting if you have a GPS receiver and will be logging

instantaneous yield and GPS information to an external datalogger.

Notes:

• The monitor will not log to a memory card and datalogger at the same

time.

• The LOGGING DEVICE must be set on ?M CARD for the monitor to

receive a GPS signal.

• When the monitor is turned on with the logging device set for a card, the

monitor beeps and asks you to “INSTALL CARD OR PRESS NO”

before it advances to the normal operating mode. Press the NO key if

you do not have a card and want to advance to the next operating mode.

June 1997

2-11

Page 16

Logging Settings

Yield Monitor 2000

Ag Leader Technology

Setting a Logging

Interval

To set a logging interval, press the SETUP key until “1 or 2 or 3 SEC

LOGGING INTERVAL” is displayed. Use the top UP or DOWN ARROW

keys to select 1, 2, or 3.

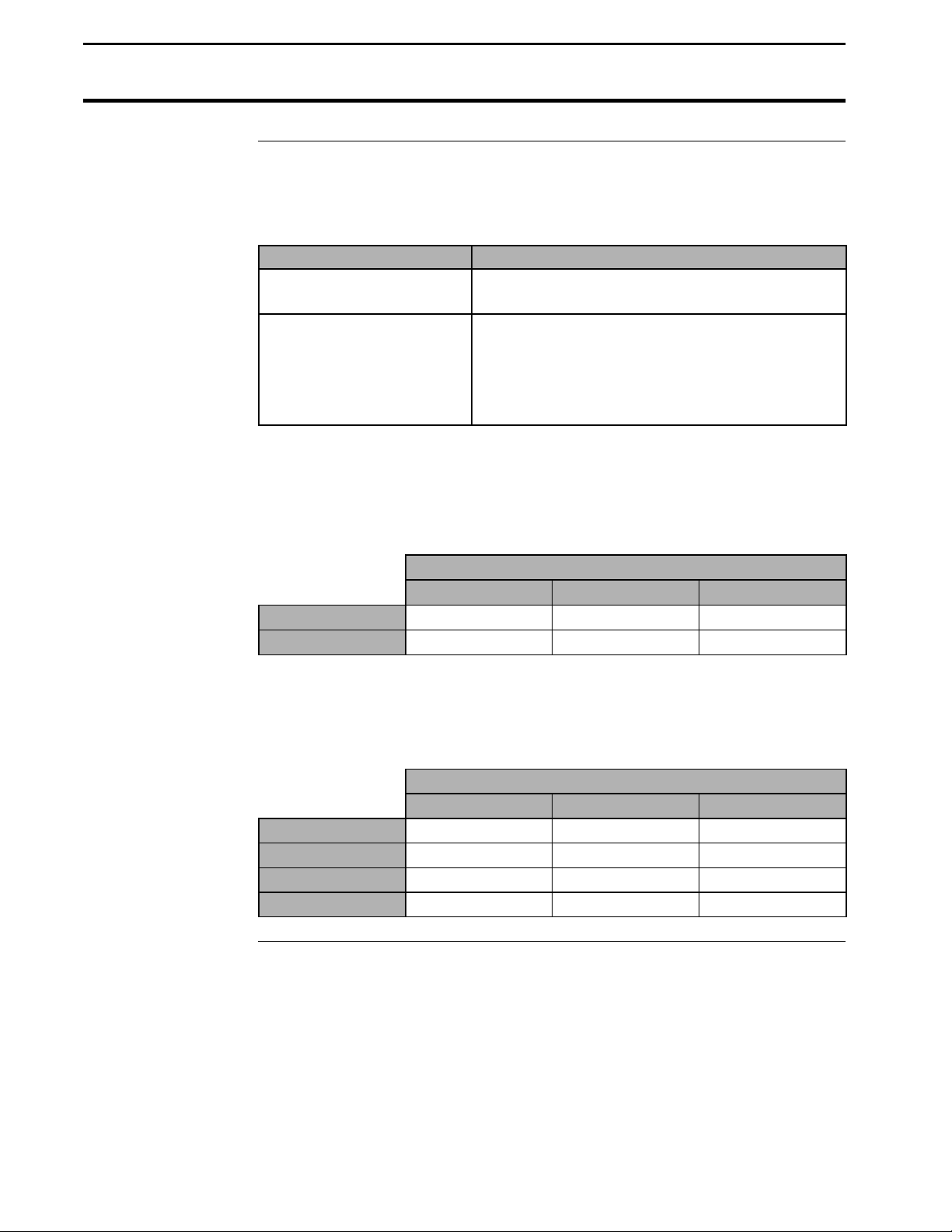

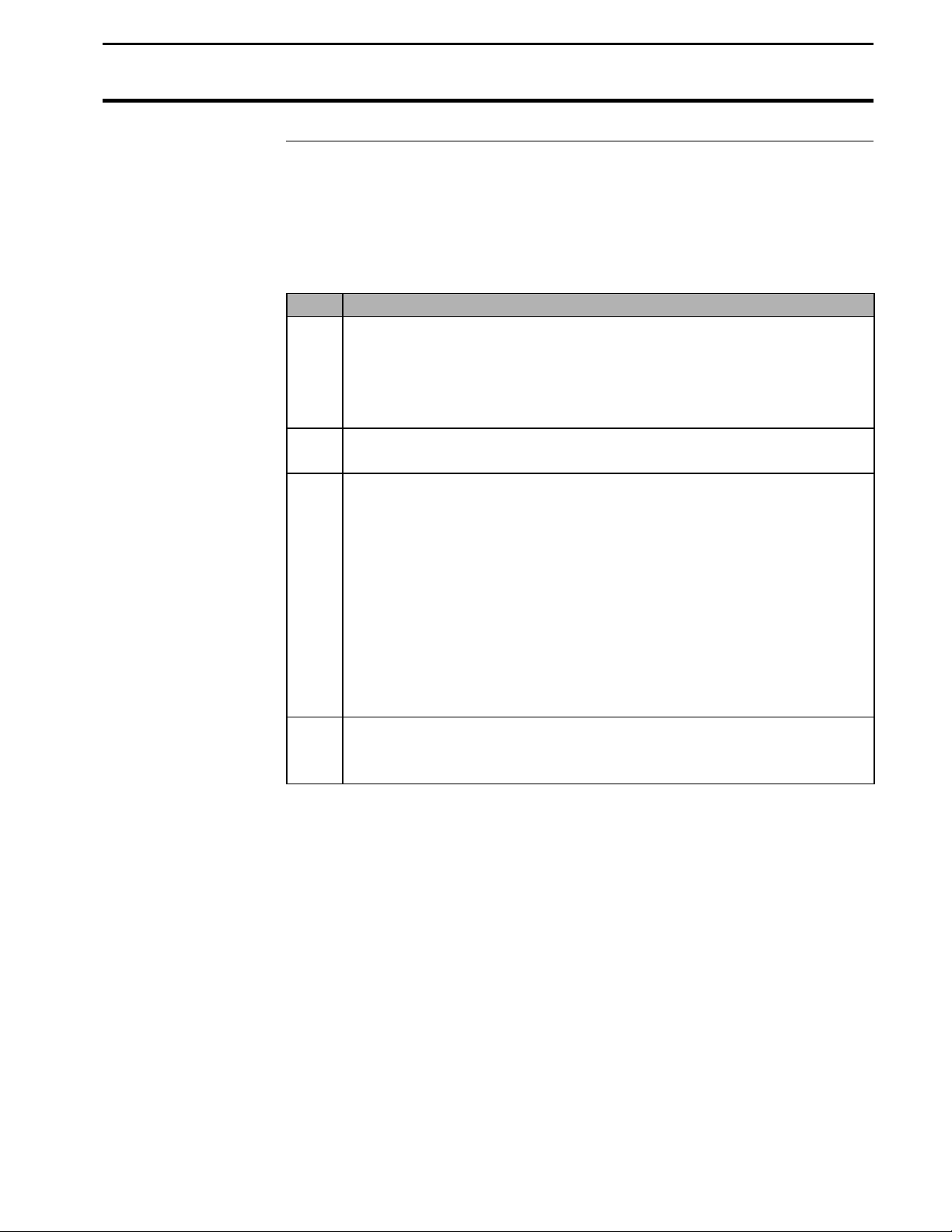

If you are . . . Then . . .

Not logging data to a

memory card,

Logging data to a card, This setting determines how often the yield and

The recommended setting is either two or three seconds. A 1-second logging

interval probably will record more yield points than you need for yield

mapping purposes.

Example:

3 mph

5 mph

Ignore this selection.

GPS information is saved to the card. It also

affects how large an area each GPS record will

represent on a map and how many hours can be

logged to a memory card before it is full.

Distance Traveled (ft)

1 sec 2 sec 3 sec

4.4 8.8 13.2

7.3 14.6 21.9

Also, a longer logging interval will allow you to log more hours of data to a

memory card. Refer to the table below to compare card space and logging

intervals:

Logging Hours Available/Logging Interval

1 sec 2 sec 3 sec

.5 M Card

1 M Card

2 M Card

4 M Card

6.7 13.5 20.3

15.7 31.5 47.3

33.8 67.6 101.4

69.8 139.7 209.5

2-12

June 1997

Page 17

Yield Monitor 2000

Ag Leader Technology

Logging Settings

Setting Log

Without Grain

Flow

To set the log without grain flow, press the SETUP key until “LOG W/O

GRAIN FLOW =NO or YES “ appears on the display.

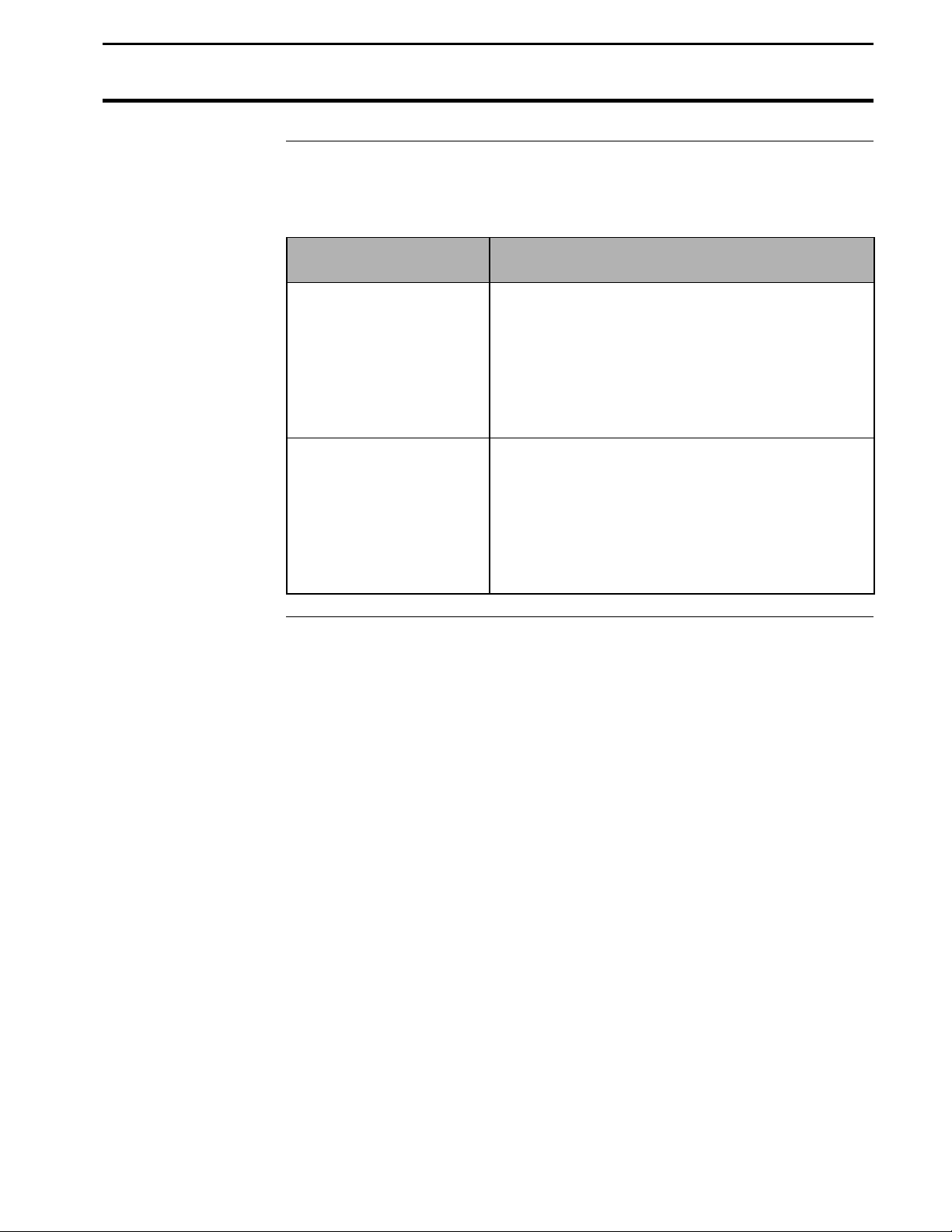

If you are operating

the Monitor . . . Then . . .

In a combine, Set this to NO, using the top UP or DOWN

ARROW keys.

Note: The yield and GPS information is logged

only when the elevator speed is more than 250

rpm and acres are counting, or the grain flow is

more than 0 BU/HR.

On vehicles other than

combines,

Set this to YES using the top UP or DOWN

ARROW keys.

Note: GPS information is logged only when the

area count light is off (counting acres). This

allows you to perform site verification (refer to

the Options section for more information).

* * *

June 1997

2-13

Page 18

Settings Under SETUP Key

Yield Monitor 2000

Ag Leader Technology

Expand Bu Below

Std%

Number of Beeps

When Acre

Counting Stops

Press the SETUP key until “EXPAND BU BELOW STD%=NO or YES”

appears on the display. Use the top UP or DOWN ARROW keys to select

NO or YES.

Note: This setting applies to all loads and grains in the monitor. It can be

changed from NO to YES and vice-versa at any time.

If you select . . . Then . . .

No, You prevent the monitor from adding bushels to grain

that is dryer than the dry percent moisture by which dry

bushels are calculated. This calculates all yields in terms

of actual bushels available for you to sell.

(Recommended setting).

Yes, The monitor shows a yield comparison of all loads at the

dry percent moisture. This increases the bushels of the

grain harvested below the dry percent moisture to

account for moisture lost because of excessive dryness of

the grain.

To set the number of times the monitor beeps when the head is raised and

the acres are not being counted at the end of a pass, press the SETUP key

until “MAX AC STOP BEEPS=x” appears on the display. Use the top UP

or DOWN ARROW keys to set this number from 5 to 100+.

Serial Number

2-14

Suggestion: The recommended setting is 20. Set this number high enough

so that the beeps continue until the head is lowered to give the operator an

audible signal that the head is lowered enough to begin counting acres again.

Press the SETUP key until “MONITOR SER# = xxxxxx” appears on the

display. Use the top UP or DOWN ARROW keys to set the serial number,

which is on the bottom of the monitor. The monitor serial number should be

set correctly from the factory.

June 1997

Page 19

Yield Monitor 2000

Ag Leader Technology

Settings Under SETUP Key

Other Settings

Box Calibration Press the SETUP key until “xxx BOX CAL” appears on the display, then use

Voltage Calibration Press the SETUP key until “xxx VOLTAGE CAL” appears on the display,

Sensor Calibration Press the SETUP key until “xxxx SENSOR CAL” appears on the display,

To set the remaining settings under the SETUP key, refer to the Yield

Monitor Initial Calibration Sheet in this section for the correct values.

the top UP or DOWN ARROW keys to set the number equal to the Initial

Calibration Sheet if needed. The Box calibration number should have been

set correctly at the factory.

then use the top UP or DOWN ARROW keys to set the number equal to the

number on the Initial Calibration Sheet if needed. The Voltage calibration

number should have been set correctly at the factory.

then use the top UP or DOWN ARROW keys to set the number equal to the

Initial Calibration Sheet if needed. The Sensor calibration number should

have been set correctly at the factory.

Note: If you replace the flow sensor, you must change this setting to the

value of the new sensor calibration number of the new flow sensor.

Scale Factor Press the SETUP key until “SCALE FACTOR=x.x” is displayed.

Press the top Up and DOWN ARROW key to change the scale factor to the

value on the Initial Calibration Sheet.

Important:

• Never change the scale factor during harvest. Doing so will cause the

monitor to lose calibration accuracy and you will have to set the monitor

on different grain types and recalibrate every grain type.

• If you have cleared the fields in the monitor, but have a good

calibration and will save the old calibration loads, do not adjust the

scale factor number, even if it is not set to the value on the initial

calibration sheet. If you do adjust the scale factor after saving the old

calibration loads, you will have to erase the old calibration loads and

enter new calibration loads for every grain type.

EL Pulse/Rev Press the SETUP key until “x EL PULSE/REV” appears on the display, then

use the top UP or DOWN ARROW keys to set the number equal to the

Initial Calibration Sheet if needed. EL Pulse/Rev should have been set

correctly at the factory.

June 1997

2-15

Page 20

Settings Under SETUP Key

Yield Monitor 2000

Ag Leader Technology

Tooth Sprocket Press the SETUP key until “x TOOTH SPROCKET” appears on the display,

then use the top UP or DOWN ARROW keys to set the number equal to the

Initial Calibration Sheet if needed. This number should have been set

correctly at the factory.

Note: This sprocket is at the top of the clean grain elevator and the elevator

paddles rotate around it.

TI, T2, and T3 Press the SETUP key three additional times until “T1=10,” “T2=5,” and

“T3=8” appear on the display, then check these numbers against the Initial

Calibration Sheet. If they are not set correctly, change them using the top UP

or DOWN ARROW keys. These numbers should have been set correctly at

the factory.

* * *

2-16

June 1997

Page 21

Yield Monitor 2000

Ag Leader Technology

Setting Swath

Setting Swath

Follow these procedures to set the swath.

Note: The number of rows and row space needs to be set for each grain

type. The monitor calculates swath by multiplying the number of rows by

row space.

Step Action

1 Press the GRAIN key and use the bottom-left UP or DOWN

ARROW keys to change to the grain type of which you want to set

the swath.

Note: You must have a load displayed to change the grain type.

2 Press the # ROWS key to display “x ROW CUT, x ROW HEAD”

for the selected grain type.

3 Use the RIGHT or LEFT ARROW keys to move the cursor under

the “Row Head” value. Use the top UP or DOWN ARROW keys to

set the Row Head value to the correct number of rows for the

selected grain type.

Note: The Row Head value is the permanent number of rows; do

not change it after it is set. The Row Cut value is used to calculate

acres, and it can be used to reduce the number of rows in partial

swath situations (point rows). Whenever you change the value for

the Row Head, the value for the Row Cut automatically adjusts to

equal the Row Head value.

4 Press the ROW SPACE key to display “x INCH ROWS” for the

selected grain type, then use the top UP or DOWN ARROW keys to

set the correct value.

June 1997

2-17

Page 22

Setting Swath

Yield Monitor 2000

Ag Leader Technology

Step Action

5 Repeat the above steps for each grain type that will be harvested.

Make sure to set the grain type back to the original setting for the

load after you have finished setting the swath.

Recommendations for Row Crop Heads:

• For row crops, set your row space to the planted row spacing

and your number of rows to the number of total rows of your

combine head.

Recommendations for Cutting Platform Heads:

• Set the swath in the monitor to one foot less than the actual

swath width of the head because you can rarely maintain a

constant full swath while harvesting.

• Set the monitor on a row space of 12 inches and a number of

rows that adds up to the correct swath.

Example: If your cutting platform head is 20 actual feet, set the

monitor’s swath to 19 feet by setting the row space to 12 inches and

the number of rows to 19. Setting the row space to 12 inches for

cutting platforms allows you to reduce the cutting swath by easierto-see one-foot increments when you are harvesting a partial swath.

Refer to the Swath Setting document in the operation section for

more information about partial swath.

* * *

2-18

June 1997

Page 23

Yield Monitor 2000

Ag Leader Technology

Speed Setting

Speed Setting

The monitor can record its ground speed from three different sources:

• Ground speed sensor on combine

• Radar gun

• GPS (only with Ag Leader Technology GPS 2000, Trimble AgGPS 120,

122 receivers, must have VTG data string)

The monitor has six different speed settings. The speed settings are set for

each load. With a load displayed press the DIST key until “SPD=” is

displayed. Use the bottom right UP or DOWN ARROW keys to select:

• WHL (wheels)

• TRK (tracks)

• RAD (radar)

• GPS/WHL

• GPS/TRK

• GPS/RAD

If you are getting ground speed from… Select

The combine speed sensor WHL

The combine speed sensor on combine tracks TRK

A radar gun RAD

Compatible GPS receiver and backup sensor is combine

speed sensor

Compatible GPS receiver and backup sensor is combine

speed sensor on tracks

Compatible GPS receiver and backup sensor is a radar gun GPS/RAD

GPS/WHL

GPS/TRK

Note: If you want to use a radar gun, contact Ag Leader Technology and

purchase a special adapter cable for your radar gun.

Since the speed setting is set for each load, the monitor will set the speed

setting of any newly created loads to the same setting as the previous load in

that field. Make sure that all the loads in the monitor are set to the correct

speed setting before you create new loads.

June 1997

2-19

Page 24

Speed Setting

Yield Monitor 2000

Ag Leader Technology

You have to calibrate distance for wheels, tracks, or radar speed settings,

depending on which one you use. Refer to the calibrating distance

instructions in the Calibration section.

If you are getting your ground speed from a GPS receiver, you

probably will have to change a setting on the GPS receiver to “turn on”

the ground speed feature. Even using a GPS receiver for ground speed,

you still must select either wheels, tracks, or radar as a backup speed sensor

and calibrate distance for that setting. If the GPS signal is lost, the monitor

will take readings from the backup speed sensor.

* * *

2-20

June 1997

Page 25

Yield Monitor 2000

Ag Leader Technology

Moisture Setting

Setting/Changing

Moisture

The monitor can be set on automatic moisture to receive readings from the

moisture sensor or manual moisture to use an average moisture for each

load. The monitor comes from the factory set on automatic moisture.

Follow these steps to set the moisture setting.

Note: Any new loads you create will have the same moisture setting as that

of the last load in the same field. Make sure all of the existing loads are set

on automatic moisture.

Step Action

1 Press the LOAD key to display a load on the top line of the display.

2 Press the MOIST key until “MOIST=AUTO or MAN” appears on

the display.

3 Use the bottom-left UP or DOWN ARROW key to select AUTO or

MAN.

4 If you set MOIST=MAN, you must enter an average moisture value

for that load. Press the MOIST key until “xx.x AVG %” appears on

the display.

5 Use the bottom-left UP or DOWN ARROW keys to set an average

moisture value for that load.

Buildup on the

Sensor

The moisture sensor can give readings that are too high if sticky material

from weeds or green stems buildup on the moisture sensor. This is normally

only a problem in soybeans with a lot of weeds or green stems. If you have

high moisture readings from buildup, remove the moisture sensor and clean

it. After cleaning, continue harvesting. If the buildup condition is severe,

you may not be able to keep the moisture sensor clean. In such conditions,

set the moisture for the load on manual and enter the average moisture for

that load as instructed above. After buildup conditions cease, set the

moisture back to automatic.

* * *

June 1997

2-21

Page 26

Setting DRY % Moisture,

Dry Lbs/Bu

Yield Monitor 2000

Ag Leader Technology

Setting Dry %

Moisture

Setting Dry Lbs/Bu

Follow these procedures to set dry % moisture:

Step Action

1 Press the GRAIN key until a grain type appears on the display and

use the bottom-left UP or DOWN ARROW keys to set a grain type

you will harvest.

Note: You must have the load displayed to change the grain type.

2 Press the GRAIN key until “xx.x DRY %” appears on the display,

then use the bottom-left UP or DOWN ARROW keys to set Dry %

to the moisture level you want the monitor to use to calculate dry

bushels (example: 15%-corn, 13%-soybeans). Typically, this value

is the same moisture your elevator uses to calculate the bushels for

which you are paid.

3 Repeat steps 1-2 and set DRY % for each grain type you will

harvest.

Use DRY LB/B to change the pounds/bushel value that the monitor uses to

calculate bushels.

Step Action

1 Press the GRAIN key until a grain type appears on the display and

use the bottom-left UP or DOWN ARROW keys to select a grain

type you will harvest.

Note: You must have a load displayed to change the grain type.

2 Press the GRAIN key until “xx DRY LB/B” appears on the display,

then use the bottom-left UP or DOWN ARROW keys to set the

correct value for the grain type.

Note: This value can be changed for all grain types except corn (56

lbs/bu), soybeans (60 lbs/bu), and wheat (60 lbs/bu).

3 Repeat steps 1-2 and set dry lbs/bu for each grain type you will use.

* * *

2-22

June 1997

Page 27

Yield Monitor 2000

Ag Leader Technology

Setting Initial Calibration

Numbers

Setting Initial

Calibration

Numbers

Refer to the Yield Monitor Initial Calibration Sheet in this section to set the

calibration numbers for each grain type.

Follow these procedures to set the calibration numbers for each grain type:

Step Action

1 Press the GRAIN key and use the bottom-left UP or DOWN

ARROW keys to select a grain type that you will harvest.

Note: You must have a load displayed to change the grain type.

2 Press the GRAIN key until “M1=xxx” appears on the display.

3 Check the value shown for this grain type against that on the Initial

Calibration Sheet. If the value is not correct, use the bottom-left

UP or DOWN ARROW keys to set it.

4 Press the GRAIN key again to advance to the S1 value.

5 Check the value shown for this grain type against that on the Initial

Calibration Sheet. If this value is not correct, use the bottom-left

UP or DOWN ARROW keys to set it.

6 If grain weight (pounds) has never been calibrated for this grain

type, press the GRAIN key to advance to the C11 value.

7 Check the value shown for this grain type against that on the Initial

Calibration Sheet. If this value is not correct, use the bottom-left

UP or DOWN ARROW keys to set it.

Notes:

• You may not be able to set C11 to the exact number as on the

Initial Calibration Sheet. Set it as close to the initial number as

you can.

• When you change C11, the C2 through C10 values change

proportionally (they may not agree with the numbers on the

Initial Calibration Sheet, but they will be close enough).

• If pounds has been calibrated previously for this grain type, do

not change C11.

8 Press the GRAIN key until the grain type appears on the display.

June 1997

2-23

Page 28

Setting Initial Calibration

Numbers

Step Action

9 Press the bottom-left UP or DOWN ARROW keys to change the

10 Repeat Step 9 for every grain type you will harvest. When you

Yield Monitor 2000

Ag Leader Technology

grain type displayed to another grain that you will harvest, then set

the calibration numbers for this grain type as described above.

have set these values for every grain type, press the LOAD key to

display field and load on the top line, and set the grain type for this

field and load.

Copy Memory to

Backup

To ensure that you do not lose the grain calibration settings, immediately

copy the memory to backup. Press the MEM key until “COPY MEMORY

TO BACKUP” appears on the top line of the display, then press the YES

key.

* * *

2-24

June 1997

Page 29

Yield Monitor 2000

Ag Leader Technology

Starting, Naming Fields, Loads

Recommendations

Starting, Naming

Fields and Loads

Follow these guidelines when starting and naming the fields and loads:

• It is strongly recommended that you create and name the fields and loads

before harvest because this will save you time during harvest.

• Select field names that you can use year after year; do not try to use the

field numbers of the monitor to keep track of the fields from year to year.

The monitor’s data recording system works best if you select a name for

a field and reuse the same name in successive years for that field’s yield

data.

There are two ways to start and name your fields and loads:

• Connect the monitor to a computer that runs Windows 3.1 or

Windows 95

• Start and name fields and loads on the monitor

Note: You may want to start and name the fields only because you may not

know how many loads you want to create until harvest. You can always

create and name fields and loads or change field and load names on the

monitor during harvest.

Starting, Naming

Fields and Loads

With a Computer

To create and name the fields and loads with a computer, you must first

connect the yield monitor to the computer and establish communication.

Refer to the “Connecting the Monitor to Your PC” instructions in the

Printing Field/Load Summary document in the Operation section for

information about establishing communication between your computer and

yield monitor. If you have Windows 95 you will use the HyperTerminal

program. If you have Windows 3.1 you will use the Terminal program.

After you have established communication, “Type PRINT, NAME, or

START & press Enter” will appear on the computer display, and the monitor

will be set to READY TO PRINT.

You must enter commands on the computer to start and name fields and

loads and to select a grain type. When you enter a command on the

computer, the display on the monitor will change accordingly. After you

enter a command on the computer, “Type PRINT, NAME, or START &

press Enter” is displayed again on the computer indicating you can enter

another command. Refer to the commands and instructions below.

June 1997

2-25

Page 30

Starting, Naming Fields, Loads

On computer press… To…

Follow the procedures below to start and name fields and loads and to select

a grain type for each field from the computer.

Step Action

1 With the monitor set “READY TO PRINT” and “Type PRINT,

NAME, or START & press Enter” displayed on the computer, press

the F key on the computer and press the Enter key. This will

display a field and its grain type on the monitor.

2 To change to the field or to create the field you want to name, press

the U key to increase or the D key to decrease the field number and

press the Enter key.

Yield Monitor 2000

Ag Leader Technology

F Display Field

L Display Load

U Increase Field or Load

D Decrease Field or Load

GU Increase Grain Type

GD Decrease Grain Type

Y Answer Yes to question

N Answer No to question

When you increase the field to a field that has not been created yet,

the monitor will display “START NEW FIELD?”. Press the Y key

on the computer and press the Enter key. Refer to step 3 to change

the grain type.

2-26

June 1997

Page 31

Yield Monitor 2000

Ag Leader Technology

Step Action

3 Set the grain type for the field by pressing the GU keys to increase

Starting, Naming Fields, Loads

the grain type or the GD keys to decrease the grain type and press

the Enter key. The grain types are listed below in order.

• SOYBEANS

• CORN

• WHEAT

• OATS

• RYE

• BARLEY

• SORGHUM

• POPCORN

• EDIBL BEANS

• CORN 2

• CANOLA

• RICE

• SUNFLOWERS

• CORN 3

• CORN 3

• OPT GRAIN 1

Note: You can only have one grain type per field. When you set

the grain type for the field, the monitor is actually setting the grain

type for the load (will be load one if no loads have been created yet).

When you create more loads in that field, the grain type of the new

loads will be the same as the grain type of the previous load. If loads

have already been created in the field, and you are setting the grain

type with the field only displayed, you actually will be setting the

grain type for only load one in the field. You will have to display

each load previously created in the field and change the grain type for

each load.

4

To name the field, type name and press the Enter key and then enter

a name up to eight characters long at the “New Name:” prompt on

the computer screen. Press the Enter key to accept the new name.

Note: Choose a name for each field that you will use year after year

for that field.

5 Repeat steps 1-4 and create and name all your fields.

6 Once you have named all of the fields, set the monitor on the first

field by pressing the F key and then the D key on the computer to

scroll to the very first field.

June 1997

2-27

Page 32

Starting, Naming Fields, Loads

Step Action

7

Press the L key on the computer and then hit the Enter key to

display the load. Press the U key to increase or the D key to

decrease the load to the first load to name and press the Enter key.

When you increase the load to a load that has not been created yet,

the monitor will display “START NEW LOAD?”. Press the Y key

on the computer and press the Enter key to start a new load.

8

Type “name” on the computer and press the Enter key. Type a

name up to 8 characters long at the “New Name:” prompt on the

computer and press the Enter key. You will see the name appear.

Suggestions:

It is common to use Load 1 for the end rows, so you might want to

name it ENDROWS. Other loads could be designated for varieties or

hybrids.

Example: “L2:P3417” “L3:P3489”

9 Repeat steps 7-8 and name all the loads in that field.

10

Change to the next field by pressing the F key and press the Enter

key and the press the U key to increase or the D key to decrease the

field to the next field you want to name the loads and press the Enter

key.

11 Repeat step 10 and start and name all the loads in every field.

Yield Monitor 2000

Ag Leader Technology

2-28

June 1997

Page 33

Yield Monitor 2000

Ag Leader Technology

Starting, Naming Fields, Loads

Starting, Naming

Fields With the

Monitor

Follow these steps to create and name fields with the monitor:

Step Action

1 Press the FIELD key to display field only on the top line.

2 Use the RIGHT ARROW key to move the cursor (the line under the

arrow or colon just to the right of the field number) to the right one

or more spaces.

3 Press the top UP or DOWN ARROW key scroll through symbols,

numbers, or letters you can use to name the field. Move the cursor to

the right one space to enter another character. You can enter up to

eight characters for a name. To remove a character, scroll to the

space located between the 9 and A.

Example:

F1:WEST8

CORN 0.0 AV B/A

Note:

• The monitor beeps each time the character changes. If you hold

down the top UP or DOWN ARROW key, you will notice that

the characters change slowly for the first few, but then begin

changing very rapidly. This allows you to easily make a change of

one or two characters while allowing you to scroll through all the

available characters rapidly.

• Choose a name for each field that you will use year after year for

that field.

4 Press the top UP ARROW key to try to advance to the next field. If

the next field has not been created, the top line displays “START

NEW FIELD?”

5 Press the YES key to start a new field. The monitor beeps four times

quickly, displays the field number and “SET GRAIN/PRESS YES”

on the top line, and displays the grain type set for the previous field

on the bottom left.

6 If the grain type displayed is not correct for this field, use the

bottom-left UP or DOWN ARROW keys to change it.

7 When the grain type is set correctly, press the YES key.

8 Name the field and repeat steps 1 through 7 for each field you want

to create.

When you have created all the fields you need, scroll back to the first field

that you expect to harvest.

June 1997

2-29

Page 34

Starting, Naming Fields, Loads

Yield Monitor 2000

Ag Leader Technology

Starting, Naming

Loads With the

Monitor

The next step is to create and name the loads within the fields. You need to

consider how you want to logically subdivide the fields into loads.

Note: It is common to designate Load 1 for the end rows and name it

“ENDROWS”. The other loads could be designated for a certain variety or

hybrid. Name these loads the hybrid or variety name (example:

“L2:P3417”). Because you may not know how many loads you want to

create until harvest, you can create and name more loads any time.

Step Action

1 Press the LOAD key to display field and load on the top line.

2 With the cursor under the load, use the RIGHT ARROW key to

move the cursor to the right one space.

3 Press the top-right UP ARROW key to change the blank space to

either a symbol, number, or letter. You can enter up to eight

characters for a load name.

Example:

F1:WEST8 L1:HYBRID

CORN 0.0 AV B/A

4 Press the LOAD key to display field and load on the top line to

create a load.

5 Press the top-right UP ARROW key to scroll to the next load. If

the next load has not already been created, the monitor displays

“START NEW LOAD?” on the top line.

6 Press the YES key to start a new load.

7 Name the new load and create and name loads for all the fields you

have created.

8 Repeat steps 1 through 7 for each field you want to create.

Settings Performed

in the Combine

2-30

All the settings up to this point could be completed with the monitor out of

the combine and plugged into a wall outlet. The stop height setting and the

distance calibration must be completed with the monitor in the combine cab.

* * *

June 1997

Page 35

Yield Monitor 2000

Ag Leader Technology

Setting Stop Height

Setting Area Count

Stop Height

The monitor automatically takes readings from the header sensor so that

when you lift the combine’s head at the end of the rows to turn around, and

stops counting area if the head is raised high enough. The stop height

number setting determines how high the head must be raised at the ends of

the rows to stop counting area. The stop height can be set differently for

each grain type.

Follow these procedures to set the stop height:

Step Action

1 Set the monitor on a data load (load with an arrow to the right of the

load number (L1->).

2 Press the GRAIN key to display the grain type. Use the bottom-left

UP or DOWN ARROW keys to change the grain type.

Note: You must have a load displayed to change the grain type.

3 Press the STOP HEIGHT key to display the stop height value

(typically, the value is between 55 and 75).

4 Position the head at the height at which you want to stop counting

acres (this must be slightly higher than the height at which you run

the head while harvesting).

5 Put the area count switch in the up position. If the AREA COUNT

LIGHT is off, use the top DOWN ARROW key to decrease the stop

height value until the light turns on.

Note: When the light is off, you are counting acres. When it is on,

you are not counting acres.

6 If the AREA COUNT LIGHT is on, use the top UP ARROW key to

increase the stop height value until the light turns off. Then decrease

the value by one, which should make the light turn on.

7 Change the grain type to a different grain and set the stop height

value for that grain type.

8 Repeat steps 1 through 7 for all grain types you will harvest. Make

sure you change the grain type for the load back to its original

setting.

Note: You may want to fine-tune the stop height when you begin

harvesting.

* * *

June 1997

2-31

Page 36

Copying Memory to Backup

Yield Monitor 2000

Ag Leader Technology

Copy Memory to

Backup

Calibrating

Distance,

Temperature and

for Vibration

Once you have finished setting up the monitor you should backup the

settings in the main memory to the backup memory. When you start

harvesting you should back up the monitor at lease once a day. Refer to the

procedures below.

Step Action

1 Press the MEM key until “COPY MEMORY TO BACKUP?” is

displayed.

2 Press YES key.

-or-

3 Shut the monitor off and “COPY MEMORY TO BACKUP

BEFORE POWER OFF?” is displayed.

4 Press YES key.

You should put the monitor back in the cab if you have not already done so

and refer to the Calibration Section and calibrate for distance, temperature

and vibration to complete the setup of the monitor. You can not calibrate

for moisture or grain weight until you start harvesting.

* * *

2-32

June 1997

Page 37

Yield Monitor 2000

Ag Leader Technology

Calibration Overview

Introduction

Before you begin using the monitor, you must calibrate its settings so that it

may provide accurate data. These subjects will provide directions for

calibration:

Subject Page

Calibrating Distance 3-2

Calibrating Temperature 3-5

Calibrating for Vibration (C1) 3-6

Calibrating Moisture 3-8

Calibrating Grain Weight 3-11

* * *

June 1997

3-1

Page 38

Calibrating Distance

Yield Monitor 2000

Ag Leader Technology

Preparing to

Calibrate Distance

You must do the following before you begin calibrating distance:

• Accurately measure a known distance, setting flags or making a mark at

each end

Notes:

• A distance of at least 200 feet is desired to obtain an accurate

calibration.

• For maximum accuracy, calibrate on a ground surface that is at least

somewhat similar to field conditions (you can also calibrate while

harvesting if you know or measure a precise distance in the field).

• Change to a data load (load with arrow to right of load number L1->)

with no distance.

Follow these procedures to change to a data load.:

Step Action

1

• Start a new load by pressing the top UP ARROW key with the

load displayed and scroll past the last load.

or

• Make an existing load the data load by pressing the MEM key

until “CHANGE TO THIS LOAD?” appears on the display, then

press the YES key.

2 Press the DIST key to display “x FT,” and check that 0 feet are in the

data load. If there are feet in the load, start a new load according to

step 1.

3-2

June 1997

Page 39

Yield Monitor 2000

Ag Leader Technology

Calibrating Distance

Calibrating

Distance

Follow these procedures to calibrate the monitor for distance:

Step Action

1 Press the DIST key until “SPD=WHL or TRK or RAD or

GPS/WHL or GPS/TRK or GPS/RAD” is displayed. Use the

lower right UP or DOWN ARROW keys to change “SPD=” to:

WHL if you are using the wheel speed sensor on the combine for

ground speed

TRK if you are using the track speed sensor on the combine for

ground speed

RAD if you are using a radar gun for ground speed

Note:

If you are using a GPS receiver for ground speed (monitor set on

SPD=GPS/WHL, GPS/TRK or GPS/RAD) you still need to set

speed equal to either WHL, TRK or RAD and do a distance

calibration for the backup speed sensor. The monitor will start

using the selected backup speed sensor if the GPS signal is lost.

Do not set “SPD=” to anyone of the three GPS settings when

calibrating distance.

Example:

If you are using your GPS receiver as the ground speed sensor and

you are using the wheel speed sensor on the combine as the backup

speed sensor, you must calibrate distance for the wheel speed

sensor by setting SPD=WHL. However, the speed setting you

should leave the monitor set on for field operation is

SPD=GPS/WHL.

2 With the AREA COUNT SWITCH down and the red light on

(distance and area counting stopped), pick a spot on the combine

and align it with the marking at one end of the measured distance.

3 Flip the AREA COUNT SWITCH up, and, if necessary, lower the

head enough to make the red light turn off.

4 Press the DIST key until “x FT” is displayed.

5 Drive the measured distance, stopping at the end mark.

6 Flip the AREA COUNT SWITCH down (red light turns on).

June 1997

3-3

Page 40

Calibrating Distance

Yield Monitor 2000

Ag Leader Technology

Step Action

7 Use the lower-right UP or DOWN ARROW key to increase or

decrease the number of feet displayed so that it is equal to the

distance measured.

Notes:

• When you change the feet measurement on the display, you are

changing the distance calibration number. You can see the

number if you press the DIST key until “xxxxpls/100’ “ appears

on the display.

• It may take several increment or decrement cycles to go from

where the measured distance is 1 foot under to 1 foot over the

measured distance. Count the number of beeps and set it in the

middle of this range.

Clearing Feet Out

of the Load

Calibrating

Distance

Accurately

Follow these procedures to clear the feet out of the load:

Step Action

1 Press the MEM key until “CLEAR DATA IN THIS LOAD?”

appears on the display.

2 Press the YES key.

3 After the Monitor beeps four times and “ARE YOU REALLY

SURE? YOU WILL LOSE DATA” appears on the display, press

the YES key again.

4 If you are using a GPS receiver for ground speed, change the

“SPD=” setting back to the correct GPS setting for that load.

Turn the combine around and repeat the above steps for calibrating distance

and clearing feet out of the load until you are confident that you have set the

distance calibration as accurately as you can.

Note: Perform this check while traveling forward only because combine

tires roll slightly differently in forward than they do in reverse.

3-4

* * *

June 1997

Page 41

Yield Monitor 2000

Ag Leader Technology

Calibrating Temperature

Introduction

Calibrating

Temperature

The moisture sensor contains a temperature sensor, which measures the

grain temperature for use in adjusting the measured grain moisture.

Follow these procedures to calibrate temperature:

Step Action

1 Press the MOIST key until the temperature reading “xx DEG F”

appears at the bottom-left of the display.

2 Use the bottom-left UP or DOWN ARROW keys to set the

temperature to the ambient air temperature, which automatically

changes “x T OFFSET”. (You can press the MOIST key to display

“x T OFFSET”).

Notes:

• For accurate moisture readings, it is more important that you not change

the temperature offset while harvesting than it is to have it set exactly

right. Therefore, after you set it, leave it at that setting.

• To calibrate temperature accurately, you must obtain an accurate

ambient air temperature after the temperature has been relatively stable

for several hours.

• If the combine has sat overnight, the moisture sensor may be cooler than

ambient air temperature because the air can warm much more quickly

than the sheet metal of the combine. If you are adjusting temperature

without harvesting grain, it is best to do it when the combine has been

sitting in a constant ambient temperature for several hours.

• If you set temperature while harvesting grain, the sensor measures grain

temperature, which will be close to ambient if the air temperature has

been constant for several hours.

• To get the most accurate setting, check grain temperature at the combine

with a thermometer.

* * *

June 1997

3-5

Page 42

Calibrating for Vibration (C1)

Yield Monitor 2000

Ag Leader Technology

Introduction

Calibration

Procedure

The yield monitor must be calibrated to eliminate false grain flow readings

that are caused by vibration forces when the combine runs empty. Press the

GRAIN key to set the C1 number to eliminate the false grain flow readings.

C1 must be set for each grain type you harvest.

Follow these procedures to calibrate for vibration (C1):

Step Action

1 Set the monitor on a data load (load with an arrow to the right of the

load number, L1->) that has no data in it and is set for the correct

grain type.

Note: To set the monitor on a data load, follow these steps:

Step Action

1 Either start a new load or display a load that was already

created.

2 Press the MEM key until “CHANGE TO THIS LOAD?”

appears on the display.

3 Press the YES key.

2 Press the GRAIN key until “C1=x” appears on the display.

3 Use the bottom-left DOWN ARROW key to set C1=0.

4 Press the FLOW key to display “x BU/HR”.

5 Engage the separator and run the combine empty and at full throttle

and watch the flow in bu/hr.

6 With the separator running, increase the C1 number using the

bottom-left UP or DOWN ARROW keys until the flow in bu/hr is

reduced to a zero reading. Because the vibration forces are not

constant, it may be hard to adjust C1 so that there is always a zero

flow. You should adjust C1 high enough, so that there is only one

flow reading over zero in a 10 second period.

3-6

Note:

• You should have the head on the combine when you perform

steps 5 and 6. A head adds to the combine vibration, particularly

cutting platform heads.

• The final C1 value should be between 0 and 250.

June 1997

Page 43

Yield Monitor 2000

Ag Leader Technology

Step Action

7 Press the MEM key until “CLEAR DATA IN THIS LOAD?”

8 Press the YES key twice to erase the data in the load so that the load

9 Repeat the above steps for every grain type you harvest.

Calibrating for Vibration (C1)

appears on the display.

can be used for yield data.

* * *

June 1997

3-7

Page 44

Calibrating Moisture

Yield Monitor 2000

Ag Leader Technology

Important Notes

Grain Moisture

Calibration

Procedure

• You must calibrate the monitor for grain moisture for each grain type

before the monitor can accurately measure grain moisture and dry

bushels. Moisture is calibrated on one load only.

• Make sure the temperature has been properly calibrated before

calibrating moisture. Refer to the instructions in this section for

calibrating temperature.

• You do not have to calibrate for grain moisture at the beginning of the

season to get accurate results, although it is recommended. You can wait

for a more convenient time in the season to calibrate moisture. The

monitor will automatically correct all grain moistures for all the loads

that were previously harvested of that grain type.

Follow these procedures to calibrate the monitor for grain moisture:

Step Action

1 Set the monitor on a data load (arrow to the right of load number,

i.e., L1à) of the correct grain type that has no data in it, and harvest

a load of grain into the monitor. Ideally, the load should be only one

to two combine hoppers of grain that varies little in moisture content.

Calibrating moisture using a smaller load will make it less likely for

the moisture to vary within the load which will give a more accurate

calibration.

3-8

Notes:

• To set the monitor on a data load:

• Either start a new load

-or-

• Display a load already created.

• Press the MEM key.

• Press the YES key when the message “CHANGE TO

THIS LOAD?” appears at the bottom of the display.

• Press the MOIST key to check that the data load the monitor is

set on is set to MOIST=AUTO”.

2 Use a reference moisture sensor and take readings from several grain

samples from that load.

Caution: Do NOT enter the grain tank when the separator is

running.

June 1997

Page 45

Yield Monitor 2000

Ag Leader Technology

Step Action

3 Make sure the moisture readings do not vary more than 4 to 5

4 Calculate the average actual moisture from the readings taken from

5 Make sure the load for which the moisture samples were taken is

6 Press the MOIST key until “xx.x AVG %” is displayed on the

7 To calibrate for moisture, use the lower left UP or DOWN ARROW

Calibrating Moisture

percentage points from the different grain samples. If they do, you

may not be able to accurately calculate the actual average moisture.

If this is the case, harvest another load.

the grain samples.

displayed on the top line.

bottom left line.

keys to change the displayed moisture reading on the monitor to the

actual average moisture obtained from the reference moisture tester.

This automatically adjusts the moisture of every previous load in the

monitor for that grain type.

Buildup on the

Moisture Sensor

that cause high

readings

Note: When you change the displayed moisture with the arrow keys,

the monitor automatically changes the “x.x% OFFSET” value under

the MOIST key and vice versachanging the offset value

automatically changes the displayed moisture readings. Typical offset

values are 0.0corn, +2.0wheat, +4.5soybeans.

Make sure the moisture sensor does not have a buildup of sticky material on

it (this can be a problem with soybeans) when you are harvesting the

moisture calibration load. You will know there is buildup if your moisture is

reading 8-10 or more percentage points too high. If you calibrate moisture

when the moisture sensor has a sticky buildup, your calibration will be

inaccurate.

If you have a severe buildup problem on the moisture sensor, follow these

procedures to set those loads to manual moisture. Refer to the Operation

section for more details.

Step Action

1 Press the MOIST key.

2 Use the lower left UP or DOWN ARROW keys to set

“MOIST=MAN”.

June 1997

3-9

Page 46

Calibrating Moisture

Yield Monitor 2000

Ag Leader Technology

Step Action

3 Press the MOIST key again to display “xx.x AVG %”.

4 Use the lower left UP or DOWN ARROW keys to change the “xx.x

AVG %” value to the average actual moisture.

Press the GRAIN key to check “xx.x DRY %” for the grain type. Verify that

it is set to the moisture you want the monitor to use to calculate dry bushels.

* * *

3-10

June 1997

Page 47

Yield Monitor 2000

Ag Leader Technology

Calibrating Grain Weight

Before You Begin

Calibrate the moisture before calibrating grain weight. Refer to the

instructions in this section for moisture calibration.

You must calibrate the monitor for grain weight (lbs) for each grain type

before the monitor will accurately measure bushels. You should be able to

calibrate your yield monitor for grain weight to an average error of 1 percent

to 3 percent.

IMPORTANT: Before calibrating, it is extremely important that you

check the clearance between the tip of the clean grain elevator paddles

and the inside of the elevator housing at the top of the clean grain

elevator. There must be ½ inch or less clearance as the paddle rotates

around the top sprocket. If your clearance is more than ½ inch, your

calibration will likely be inaccurate.

You do not have to calibrate grain weight at the beginning of the season to

get accurate results, although it is recommended. Each time you calibrate the

monitor, it will automatically correct all grain weights for all the loads of that

grain type that were previously harvested.

Note: Because the monitor measures the weight, not the volume, of the

grain hitting the flow sensor, test weight and different varieties do not cause

calibration inaccuracies.

C Numbers

The 11 C Numbers, C1 through C11 determine the pounds that the monitor

calculates from the data that it records into your loads as you harvest. You

can display the C numbers under the GRAIN key. Changing the C numbers

changes the pounds in every load set on that grain type for which the C

numbers were changed. Anytime you calibrate the monitor it adjusts the C

numbers automatically.

The C numbers initially should be set to the same values that appear on

your initial calibration sheet. (Refer to the Setup section). With the C

numbers set at their initial value, your accuracy of grain weight measurement

may be only in the +/- 20 percent range.

Note: After the monitor adjusts the C numbers when calibration is complete,

do not set them back to the initial values from the machine calibration sheet.

If you do, you will change calibration accuracy.

June 1997

3-11

Page 48

Calibrating Grain Weight

The C1 number is set to eliminate extra pounds that would be recorded from

vibration when the separator is engaged and the combine is running empty.

The C1 number is set by the operator manually and will not automatically

change when the monitor is calibrated. Refer to the instructions on setting

C1 in the Vibration calibration section.

Yield Monitor 2000

Ag Leader Technology

Calibration Loads

Grain Flow Rate

The Monitor calibrates itself on the basis of actual load weights you enter

into the monitor. You obtain actual load weights by weighing the grain of a

load in the monitor on accurate scales (elevator, calibrated weigh wagon).

When you enter an actual weight for a load into the monitor, that load

becomes a calibration load. Any load (that has pounds of grain in it) in any

field in the monitor can be a calibration load at anytime.

The monitor’s calibration can be very accurate because the monitor

calibrates a specific calibration value for virtually every level of grain flow

rate or amount of grain that goes through your combine that the flow sensor

is measuring. The grain flow rate that your flow sensor measures changes as

the travel speed of the combine changes or the crop yield changes.

Note: The monitor, however, can calibrate only for the grain flow rates that

were moving through your combine at the time the calibration loads were

harvested. You must change your grain flow rates (by varying travel speed

or swath width) from one calibration load to the next or grain weight will

not be measured accurately.

Calibration

Accuracy

3-12

For accurate calibration results, you must obtain at least six calibration

loads (loads with actual weights). Each calibration load must be

harvested under a different grain flow rate by varying either your

travel speed or your swath width. You should achieve accurate calibration

results with no more than 10 to 15 calibration loads; if you do not,

something is wrong and you need to troubleshoot grain weight calibration.

* * *

June 1997

Page 49

Yield Monitor 2000

Ag Leader Technology

Calibrating Grain Weight

Harvesting

Calibration Loads

Carefully follow these directions to calibrate your monitor for grain weight:

Step Action

1 With the combine stopped, the combine grain tank empty, and a

hauling vehicle empty, set the monitor on a data load (arrow to the

right of the load number L1-> on the display) that has no data in it. If

desired, name the load for future reference. Make sure the load is set

on the correct grain type by pressing the GRAIN key.

Note: Follow these procedures to set the monitor on a data load:

Step Action

1 Either start a new load or display a load already created and:

2 Press the MEM key until “CHANGE TO THIS LOAD?” is

displayed.

3 Press the YES key.

2 Decide the speed at which you will drive or the swath width you will

use for this load to vary the grain flow rate going through your

combine. Try to keep your speed or swath width as consistent as

possible for the entire load.

Example Calibration loads (Ld) with varying speed (S) or swath

width (SW):

Ld 1 Ld 2 Ld 3 Ld 4 Ld 5 Ld 6

S (mph)

SW (rows)

3 Harvest grain into the calibration load in the monitor. The moisture

content of the grain does not matter.

Recommendation: Harvest 3,000 or more lbs for calibration loads.

5.0 4.5 4.0 3.5 3.0 2.5

6 5 4 3 2 1

June 1997

3-13

Page 50

Calibrating Grain Weight

Step Action

4 Unload one or more times into the hauling vehicle, finishing with the

5 Immediately change data loads in the monitor to ensure that you do

6 Weigh the grain on the hauling vehicle and record the actual load

7 Repeat the above steps and harvest another calibration load.

Yield Monitor 2000

Ag Leader Technology

following:

• Combine grain tank again empty

• All the grain from the calibration load on the hauling vehicle

• No grain from any other combine on the hauling vehicle

not inadvertently add grain after you have unloaded into the hauling

vehicle.

weight on a log sheet in the back of this section of the manual.

Notes:

• If you are using a weigh wagon to weigh the grain, make sure the

wagon has been calibrated properly.

• Be absolutely sure that the measured and actual weights

correspond, which means that:

• The combine’s grain tank was completely empty when the

load was started

• The grain tank was completely empty when the load was

finished

• All the grain from that monitor load went into the same

vehicle

• No other grain, such as from another combine, was loaded

into the vehicle

Entering Actual

Load Weights

3-14

As you obtain actual weights from the calibration loads, you can either enter

the weights in the monitor one at a time and calibrate after entering each

load or wait until you obtain them all, enter them all at once, and then

calibrate. Both methods produce the same calibration accuracy. Enter the

actual load weights as follows:

Step Action

1 Display a load for which you have an actual weight (lbs).

2 Press the WEIGHT key to display the measured lbs the monitor

calculated.

3 Press the WEIGHT key again to display “0 ACT LB”.

June 1997

Page 51

Yield Monitor 2000

Ag Leader Technology

Step Action

4 Press the lower-left UP ARROW key once, which will cause actual

5 Use the lower-left UP or DOWN ARROW key to change the initial

Calibrating Grain Weight

lbs to jump to measured lbs (rounded off to the nearest 10 lbs).

actual lbs value to equal the scales weight obtained for that load.

Note: You may repeat steps one through five and enter all your

actual weights at once and then proceed with the next steps, or you

can proceed with the next steps now and calibrate each time you

enter an actual weight. Either method produces the same results.

Calibration

Procedure

Follow these steps to calibrate the yield monitor:

Step Action

1

Set the monitor to any load that is of the grain type you want to

calibrate. Press the GRAIN key to verify the correct grain type.

2 Press the GRAIN key until “CAL LBS NOW?” appears on the

display.

Note: Because the monitor does not record data while it is

calibrating, stop the combine before pressing the YES key in the next

step.

3 Press the YES Key. The message “CALIBRATING” appears on the

top line of the monitor for a few seconds, then the message changes

to “x.x% MAX, x.x% AVG ERR”, and finally, the monitor beeps

and the message “PRESS ANY KEY TO CONTINUE” appears or

“CONTINUE WITH LBS CAL?” appears (if you have entered four

or more actual weights) on the bottom line of the display.

Note: The average and maximum errors tell you the accuracy of

your grain weight calibration. It is extremely important to look

for a high average and maximum error for every time you

perform a calibration.

June 1997

3-15

Page 52

Calibrating Grain Weight

Step Action

4

Yield Monitor 2000

Ag Leader Technology

If the… Then…

Maximum error is +/- 15

percent or higher and

“CONTINUE WITH LBS

CAL?” is displayed

Maximum error is +/- 15

percent or higher and

“PRESS ANY KEY TO

CONTINUE” is displayed

Maximum error is less than

+/- 15 percent

Notes:

• If you do not want to scroll through all the calibration loads, you

can press the NO key and the monitor returns to its normal

display.

Press the NO key and then hit any key

to advance through each calibration

load and its calibration error. Write

down the calibration loads and errors

of loads with errors of +/- 15 percent

or higher.

Press any key to advance through each

calibration load and its calibration

error. Write down the calibration loads

and errors of loads with errors of +/15 percent or higher.

If you have 4 or more actual weights,

CONTINUE WITH LBS CAL? will be

displayed. Press the YES key to

continue with the full calibration and

go to step 8, otherwise PRESS ANY

KEY TO CONTINUE will be

displayed and the errors you have are

your final errors until you can enter 4

or more actual weights and fully

complete the calibration.

3-16

Example:

An example of a calibration load and its error is “F2/L1 +1.0%

ERROR”. This means that the weight of the grain that the monitor

measured in field 2 load 1 is +1.0% higher than the actual weight that

was entered for that load.

5 If you find calibration loads with calibration errors of higher than +/-

15 percent, display those loads, one at a time, on the top line and

check the following:

• Is the grain type correct for this load?

• Is the moisture reasonable for this grain type and field?

• Is the actual lbs value correct for this load?

June 1997

Page 53

Yield Monitor 2000

Ag Leader Technology

Step Action

6 If you find errors, follow these steps:

7 If you do not find errors, follow these steps to eliminate the actual

8

Calibrating Grain Weight

Step Action

1 Correct the errors.

2 Perform another calibration.

3 Check the calibration errors.

weight:

Step Action

1 Display the calibration load that has the highest % error

above +/- 15 percent.

2 Eliminate this load as a calibration load by removing the

actual lbs for that load. Press the WEIGHT key until “xxxx

ACT LB” appears on the display.

3 Use the bottom-left DOWN ARROW key to set actual

weight to 0.

4 Press the GRAIN key to display “CAL LBS NOW?”

5 Press the YES key to perform another calibration.

6 Verify that the maximum error is less than +/- 15 percent. If it

is not, zero out the actual weight in the calibration load with

the next highest error.

Your goal after completing a full calibration should be to

achieve an average error of 1 percent to 3 percent and a

maximum error of 3 percent to 5 percent. Once the full

calibration is complete, the monitor displays the final average and

maximum error.

Recalibrating the

Monitor

Note: The monitor takes 1 to 2 minutes to complete a full

calibration.

9 If you have high final average and maximum errors, press any key to

scroll through each calibration load and its error. Write down each

error and then zero out the actual weight in the load with the highest

error as mentioned in the above steps. Perform another calibration

and observe your new average and maximum errors.

You can add or delete a calibration load and recalibrate the monitor any time

during the season to improve the monitor’s calibration accuracy. If you have

not achieved satisfactory calibration results after entering 10 to 15

calibration loads (with varied flow rates) something is wrong. Refer to the

Troubleshooting section instead of adding more actual weights.

June 1997

3-17

Page 54

Calibrating Grain Weight

Yield Monitor 2000

Ag Leader Technology

Periodic Checks

for Accuracy

Adjusting for

Chain Slack

Check the monitor for calibration accuracy periodically throughout the

season by weighing a monitor load of grain. If you find the monitor is not

accurate, enter that actual weight into the monitor and calibrate the monitor

again.

Note: If you do not vary your flow rates while harvesting your initial

calibration loads, later in the season you may find the monitor is not accurate

because you are harvesting at a different grain flow rate than for what you

have calibrated. Entering one or two more calibration loads at that grain

flow rate will improve your accuracy greatly.

If you adjust for slack in your clean grain elevator chain during the season,

make sure that you use the lower adjuster. If you move the top shaft of the

grain elevator, your calibration will be inaccurate and you will have to enter

all new calibration loads.

* * *

3-18

June 1997

Page 55

Field Load Actual % Indicated Dry Dry

# Name # Name Crop Variety Date Lbs Moist Lbs Bu Acres Yield Comments

Page 56

Page 57

Page 58

Field Load Actual % Indicated Dry Dry

# Name # Name Crop Variety Date Lbs Moist Lbs Bu Acres Yield Comments

Page 59

Page 60

Field Load Actual % Indicated Dry Dry

# Name # Name Crop Variety Date Lbs Moist Lbs Bu Acres Yield Comments

Page 61

Page 62

Field Load Actual % Indicated Dry Dry

# Name # Name Crop Variety Date Lbs Moist Lbs Bu Acres Yield Comments

Page 63

Page 64

Page 65

Yield Monitor 2000

Ag Leader Technology

Operation Overview

Important Notices

Section Contents

The yield monitor must be calibrated so that it provides accurate yield

information. Carefully read and follow the directions in the calibration

section of the manual.

Because you will keep an entire harvest season’s records in the monitor’s

memory, you should back up the monitor’s memory at least once a day.

When you turn off the monitor, press the YES key when the message

“COPY MEMORY TO BACKUP OR PRESS NO?” appears on the display.

You can back up the memory more frequently. Press the MEM key until

“COPY MEMORY TO BACKUP?” appears on the display, then press the

YES key.