Page 1

Agilent

N8201A Performance

Downconverter

Synthetic Instrument

Module, 3 Hz to 26.5 GHz

User’s Guide

Edition, January 22, 2008

N8201-90006

Agilent Technologies

Page 2

Notices

CAUTION

WARNING

© Agilent Technologies, Inc. 2006 - 2008

No part of this manual may be reproduced

in any form or by any means (including

electronic storage and retrieval or translation into a foreign language) without prior

agreement and written consent from Agilent Technologies, Inc. as governed by

United States and international copyright

laws.

Windows

Adobe Acrobat Reader

®

®

Manual Part Number

N8201-90006

Edition

Edition, January 22, 2008

Printed in USA

Agilent Technologies, Inc.

1400 Fountaingrove Pkwy

Santa Rosa, CA 95403

Warranty

The material contained in this document is provided “as is,” and is subject to being changed, without notice,

in future editions. Further, to the maximum extent permitted by applicable

law, Agilent disclaims all warranties,

either express or implied, with regard

to this manual and any information

contained herein, including but not

limited to the implied warranties of

merchantability and fitness for a particular purpose. Agilent shall not be

liable for errors or for incidental or

consequential damages in connection

with the furnishing, use, or performance of this document or of any

information contained herein. Should

Agilent and the user have a separate

written agreement with warranty

terms covering the material in this

document that conflict with these

terms, the warranty terms in the separate agreement shall control.

Technology Licenses

The hardware and/or software described in

this document are furnished under a

license and may be used or copied only in

accordance with the terms of such license.

Restricted Rights Legend

computer software” as defined in FAR

52.227-19 (June 1987) or any equivalent

agency regulation or contract clause. Use,

duplication or disclosure of Software is

subject to Agilent Technologies’ standard

commercial license terms, and non-DOD

Departments and Agencies of the U.S. Government will receive no greater than

Restricted Rights as defined in FAR

52.227-19(c)(1-2) (June 1987). U.S. Government users will receive no greater than

Limited Rights as defined in FAR 52.227-14

(June 1987) or DFAR 252.227-7015 (b)(2)

(November 1995), as applicable in any

technical data.

Safety Notices

A CAUTION notice denotes a hazard. It calls attention to an operating procedure, practice, or the like

that, if not correctly performed or

adhered to, could result in damage

to the product or loss of important

data. Do not proceed beyond a

CAUTION notice until the indicated

conditions are fully understood and

met.

A WARNING notice denotes a

hazard. It calls attention to an

operating procedure, practice, or

the like that, if not correctly performed or adhered to, could result

in personal injury or death. Do not

proceed beyond a WARNING

notice until the indicated conditions are fully understood and met.

If software is for use in the performance of

a U.S. Government prime contract or subcontract, Software is delivered and

licensed as “Commercial computer software” as defined in DFAR 252.227-7014

(June 1995), or as a “commercial item” as

defined in FAR 2.101(a) or as “Restricted

Page 3

Introducing the N8201A Performance Downconverter

The Agilent Technologies N8201A performance downconverter down converts a microwave

signal to an IF signal providing IF output frequencies of 7.5, 21.4, and 321.4 MHz to offer

three different signal bandwidth capabilities. External mixing can be utilized to down

convert microwave signals up to 110 GHz. The N8201A is based upon the industry’s most

accurate spectrum analyzer, the PSA Series.

Agilent's synthetic instrument family offers the highest-performing RF/MW LAN-based

modular instrumentation and the smallest footprint for automated test systems; providing

the maximum flexibility and minimizing the cost of an ATS over its lifetime.

Agilent’s synthetic instrument modules use LAN eXtension for Instrumentation (LXI)

modular format. LXI differs from other modular formats (such as VXI and PXI) by using an

external computer and local area network (LAN), rather than embedded computers, for

control.

The LXI standard supports the IEEE 1588 time synchronization and protocol standard, which

allows synchronous triggering of different instruments, even with different-length LAN

cables. The IEEE 1588 precision time protocol (PTP) enables a common sense of time over a

distributed system.

Synthetic instrument modules offered by Agilent Technologies include the following:

• N8201A performance downconverter, 3 Hz to 26.5 GHz

• N8211A performance analog upconverter, 250 kHz to 20 / 40 GHz

• N8212A performance vector upconverter, 250 kHz to 20 GHz

• N8221A IF digitizer, 30 MS/s

• N8241A arbitrary waveform generator, 15-Bit, 1.25 GS/s or 625 MS/s

• N8242A arbitrary waveform generator, 10-Bit, 1.25 GS/s or 625 MS/s

For further information, refer to:

http://www.agilent.com/find/synthetic

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 3

Page 4

4 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 5

Contents

1 Software Installation

2 Hardware Setup and Configuration

Introducing the N8201A Performance Downconverter 3

Installing Software and Instrument Drivers 6

Step 1. Install Microsoft .NET Version 1.1 7

Step 2. Install the Agilent I/O Libraries 8

Step 3. Install the IVI Shared Components 9

Step 4. Install the Agilent Synthetic Instrument Finder 11

Step 5. Install the Agilent Synthetic Instrument GUI 12

Step 6. Install the IVI-COM Drivers 13

Step 7. Install the Agilent N8201A Performance Downconverter User Interface 15

Installing Optional Software and Instrument Drivers 16

(Optional) Step 8. Install the Agilent N8201A Option H02 Spectrum Analyzer GUI 17

(Optional) Step 9. Install the Microsoft Virtual Machine (VM) 19

(Optional) Step 10. Install the Apache HTTP Server 21

(Optional) Step 11. Install the SA Remote Web Server 24

Step 1. Unpack the N8201A Performance Downconverter 28

Verify the Shipment 28

(Optional) Prepare the Instrument for Rack Mounting 28

Step 2. Connect LAN Cables and Turn On Power 29

(Optional) Connect to a LAN with a Cross-Over LAN Cable 31

Step 3. Verify Connection with Synthetic Instrument Finder 32

(Optional) Step 4. Connect to the Agilent N8201A Option H02 Spectrum Analyzer GUI 34

(Optional) Step 5. Connect to an SA Remote Web Server 36

(Optional) Step 6. Verify Operation < 3 GHz 43

Performing a Self-Test 43

(Optional) Step 7. Verify Operation > 3 GHz 47

Performing a Self-Test 47

Troubleshooting 50

Alternative Ways to Verify Connectivity to the PC 50

How to Use the Synthetic Instrument Finder 51

How to Reset the LAN Configuration 55

How to Set a Static IP Address 56

How to Troubleshoot Connectivity Problems on the Network 60

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 1

Page 6

How to Determine a PCs Configuration Settings 60

If the Instrument was Unable to Join the LAN 62

If the LAN LED is Red 62

If the Instrument’s IP Address or Hostname Cannot be Found with Ping 63

If the Instrument is Not Found by the Synthetic Instrument Finder 63

If the Instrument’s Hostname and PC Cannot Communicate 63

If the Instrument Web Page is Not Visible 64

If the Software Driver Will Not Open the Connection 64

3 Using the Agilent Synthetic Instrument GUI

Starting the Agilent Synthetic Instrument GUI 67

Left Pane 68

Right Pane 68

Features of the Agilent Synthetic Instrument GUI 69

File Menu 69

Help 70

Left Pane 71

Right Pane 72

Settings on the Agilent Synthetic Instrument GUI 74

Frequency 74

Frequency List 74

Level 76

Input RF 76

IF Output 76

Reference Oscillator 76

Preselector (Option 123) 77

External Mixer 77

Calibration 78

Events (Settling Events and Event Logging) 78

Event Logging 79

Preset 80

Refresh All Values 80

4 Front and Rear Panel Features

N8201A Performance Downconverter Front Panel Features 82

RF INPUT 82

Power 82

Line Power LED 83

LAN LED 83

1588 LED 84

2 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 7

COHERENT CARRIERS 84

EXT MIXER 85

IF OUTPUTS 85

TRIGGERS 85

REFERENCES 85

IF LOG VIDEO (Option V7L) 86

NOISE SOURCE +28 V (PULSED) (Option 219) 86

VGA OUT 86

N8201A Performance Downconverter Rear Panel Features 87

AC Power Receptacle 87

LAN 87

LXI Trigger Bus 88

Interconnect Cabling 89

Operational Considerations 90

Agilent 89601A Vector Signal Analysis Software 90

Configuring the Local Area Network (LAN) Interface 90

5 Preventive Maintenance

Using, Inspecting, and Cleaning RF Connectors 92

Repeatability 92

RF Cable and Connector Care 92

Proper Connector Torque 93

Connector Wear and Damage 93

SMA Connector Precautions 93

Cleaning Procedure 94

General Procedures and Techniques 95

Connector Removal 96

Instrument Removal 98

Standard instrument 98

Half-Rack-Width Instrument 99

Bench Top Instrument 99

Instrument Installation 100

Standard rack instrument 100

Half-Rack-Width Instrument 101

Bench Top Instrument 101

6 Service, Support, and Safety Information

Safety and Regulatory Information 104

EMC 104

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 3

Page 8

7Glossary

Safety 104

Safety Summary 104

Equipment Installation 105

Environmental Conditions 106

Before Applying Power 106

Magnetic Susceptibility 107

Vibration 107

Ground the Instrument or System 107

Fuses and Circuit Breakers 108

Maintenance 108

Safety symbols and Instrument Markings 108

Service and Support 111

Agilent on the Web 111

Return Procedure 112

Shipping the Instrument 112

4 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 9

User’s Guide

1

Software Installation

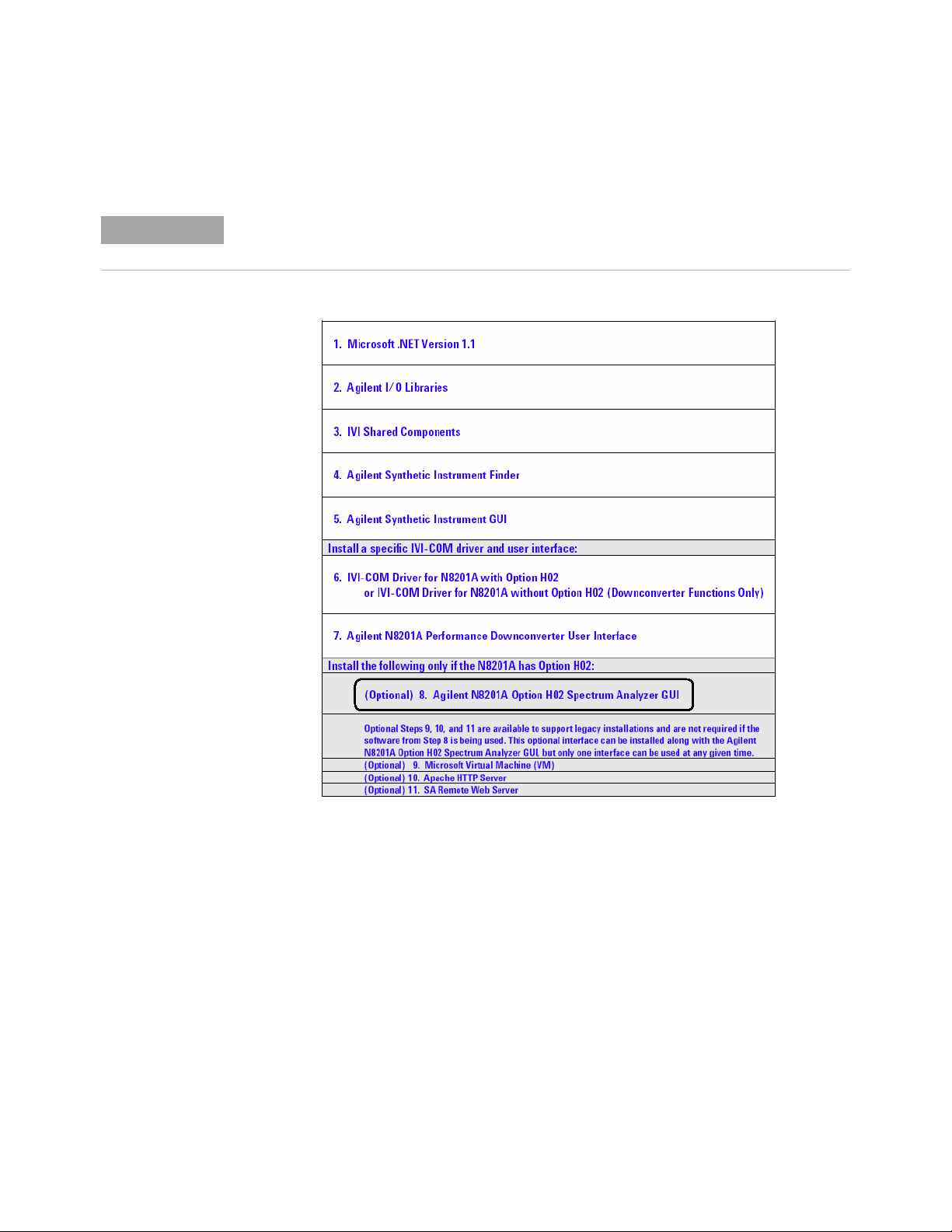

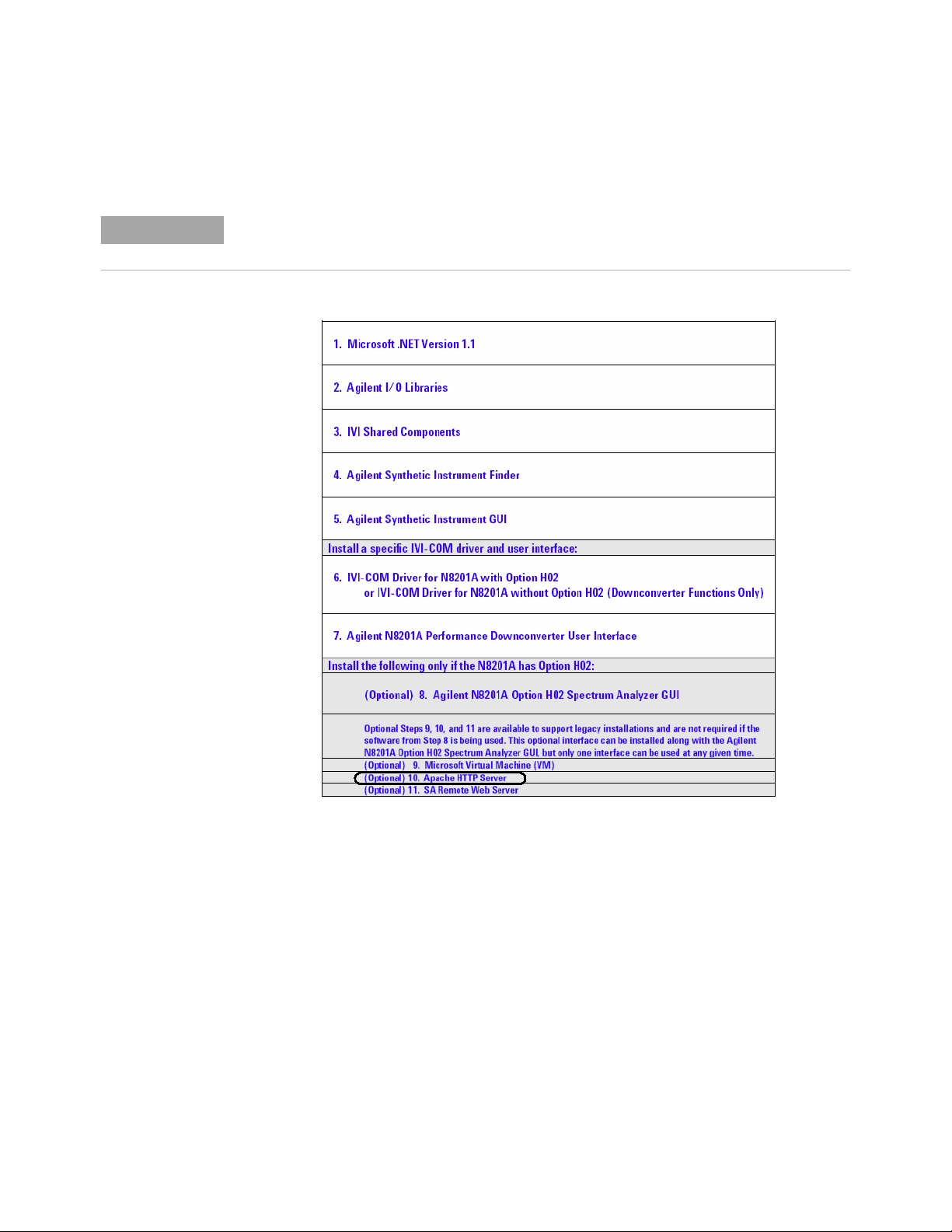

This installation process installs the required software and instrument drivers used by the

N8201A performance downconverter:

“Verify the PC Meets Minimum Requirements" on page 6

“Step 1. Install Microsoft .NET Version 1.1" on page 7

“Step 2. Install the Agilent I/O Libraries" on page 8

“Step 3. Install the IVI Shared Components" on page 9

“Step 4. Install the Agilent Synthetic Instrument Finder" on page 11

“Step 5. Install the Agilent Synthetic Instrument GUI" on page 12

“Step 6. Install the IVI-COM Drivers" on page 13

“Step 7. Install the Agilent N8201A Performance Downconverter

User Interface" on page 15

Install the following only if the N8201A performance downconverter has Option H02

“(Optional) Step 8. Install the Agilent N8201A Option H02

Spectrum Analyzer GUI" on page 17

Install the following only if the N8201A performance downconverter has Option H02

(Optional Steps 9, 10, and 11 are available to support legacy installations and are not

required if the software from Step 8 is being used. This interface can be installed

along with the Agilent N8201A Option H02 Spectrum Analyzer GUI, but only one

interface can be used at any given time.)

“(Optional) Step 9. Install the Microsoft Virtual Machine (VM)" on page 19

“(Optional) Step 10. Install the Apache HTTP Server" on page 21

“(Optional) Step 11. Install the SA Remote Web Server" on page 24

Agilent Technologies

5

Page 10

1 Software Installation

NOTE

CAUTION

Installing Software and Instrument Drivers

1 Verify the PC Meets Minimum Requirements

• 1 GHz Intel Pentium processor

• Microsoft Windows XP Professional or Home Edition (Service Pack 1

or 2), Windows 2000 (Service Pack 2)

• 512 MB of RAM

• Up to 40 MB of available hard- disk space

• Microsoft Internet Explorer 6.0 (or higher), or Netscape 7.1 or 8.0

2 Place the CD with the Instrument Drivers and Documentation in the CD-ROM drive.

a Adobe Acrobat Reader 5.0 or later is used during this installation process and can be

installed from the CD described above.

b Click Adobe Acrobat Reader 5.0 to install the software, if needed.

3 Click Instrument Drivers.

If the following software or instrument drivers are installed on the PC to be used, uninstall

them and install the software and instrument drivers shipped on the CD described above:

Step 1. Microsoft .NET 1.1

Step 2. Agilent I/O Libraries

Step 3. IVI Shared Components

Step 4. Agilent Synthetic Instrument Finder

Step 5. Agilent Synthetic Instrument GUI

Step 6. IVI-COM Drivers (for N8201A with Option H02 and without Option H02)

Step 7. Agilent N8201A Performance Downconverter User Interface

(Optional) Install the following only if the downconverter has Option H02

Step 8. Agilent N8201A Option H02 Spectrum Analyzer GUI

(Optional) Steps 9, 10, and 11 are available to support legacy installations and are not

required if the software from Step 8 is being used. This interface can be installed along with

the Agilent N8201A Option H02 Spectrum Analyzer GUI, but only one interface can be used

at any given time.

Step 9. Microsoft Virtual Machine (VM)

Step 10. Apache HTTP Server

Step 11. SA Remote Web Server

6 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 11

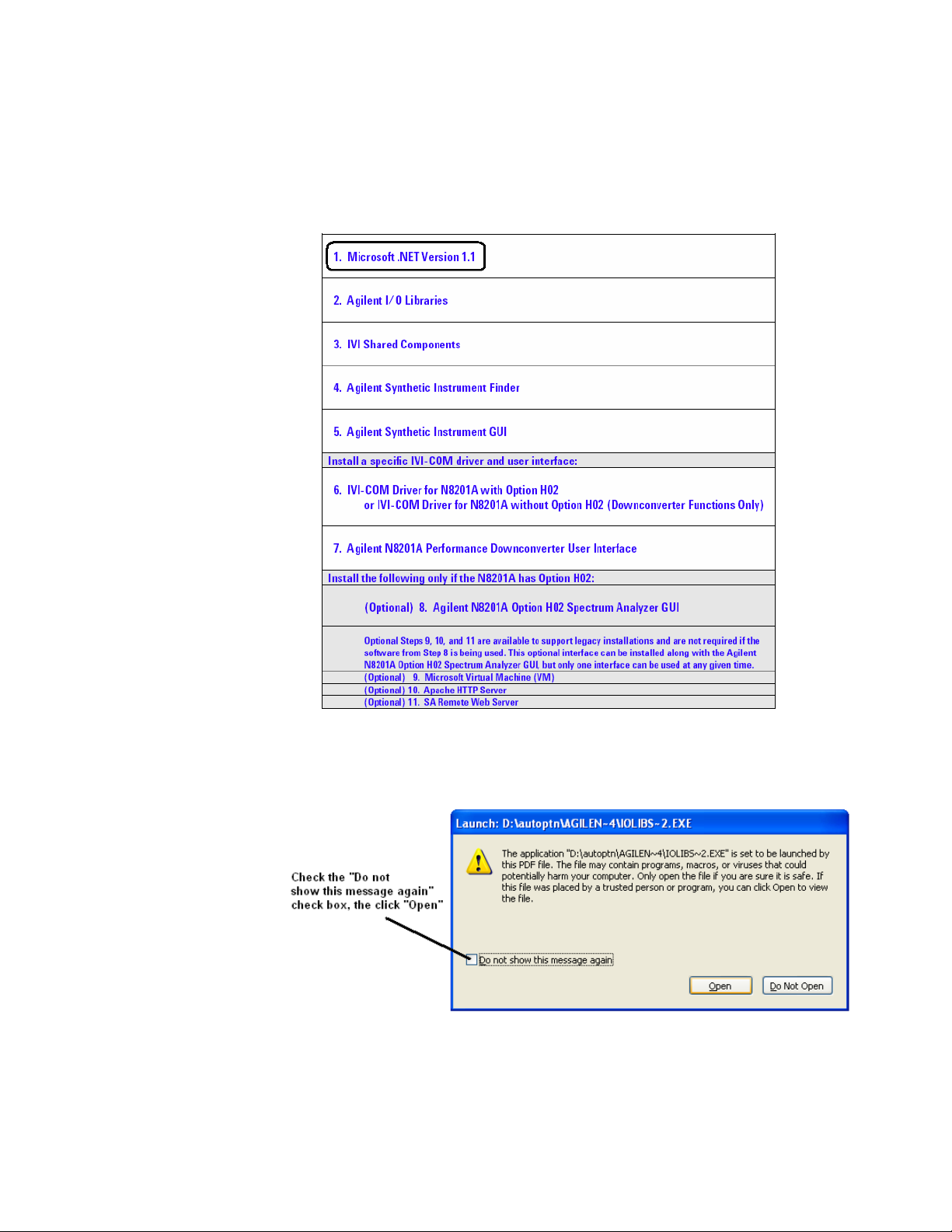

Step 1. Install Microsoft .NET Version 1.1

1 Select Microsoft Version 1.1.

Software Installation 1

2 Click the check box, “Do not show this message again” so that the check box is

selected. This will stop the message from displaying each time a selection is made from

the Software and Driver Installation menu.

3 Click Open.

4 Follow the installation instructions and accept the default settings.

5 Click Finish.

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 7

Page 12

1 Software Installation

Step 2. Install the Agilent I/O Libraries

1 Select Agilent I/O Libraries.

2 Follow the instructions and accept the default settings.

3 Click Finish.

8 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 13

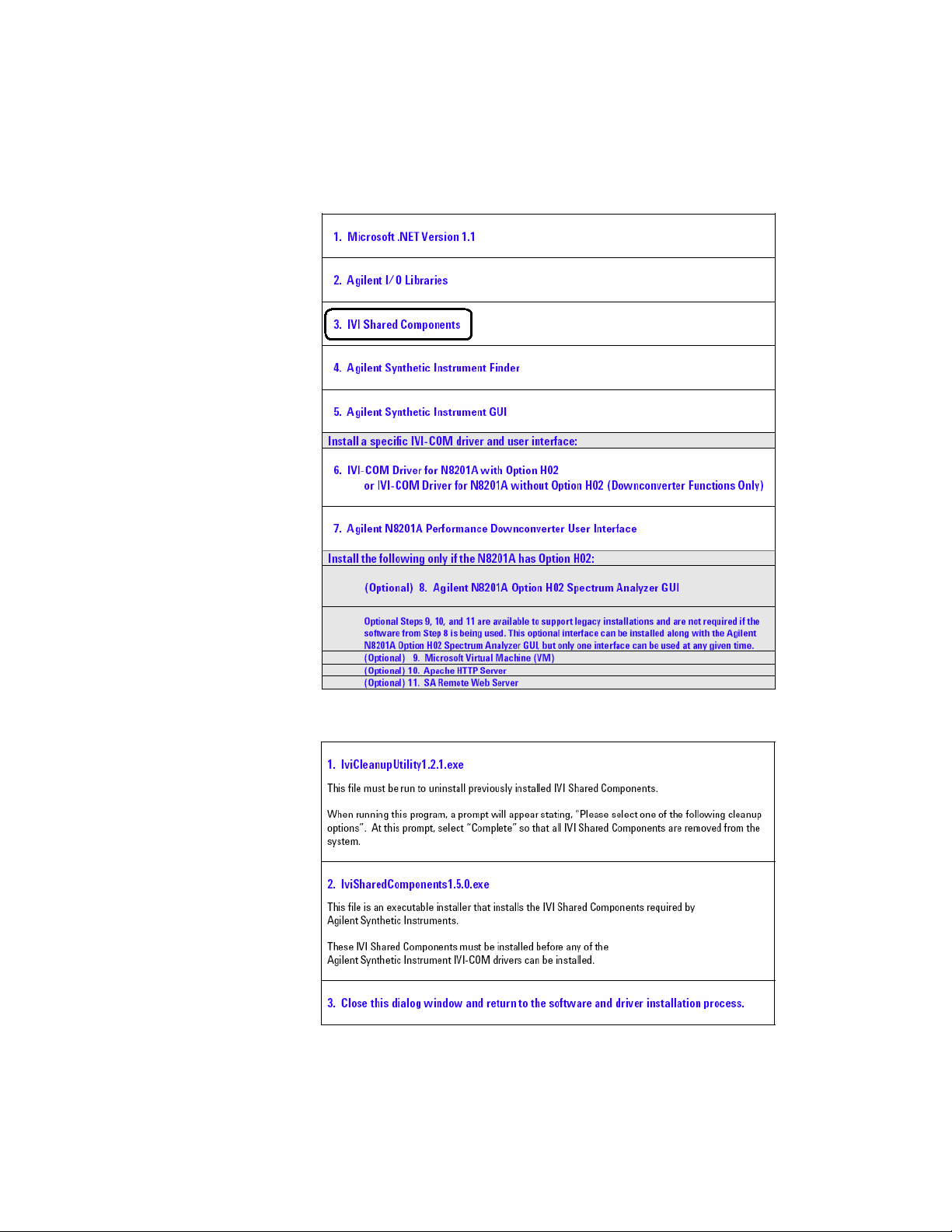

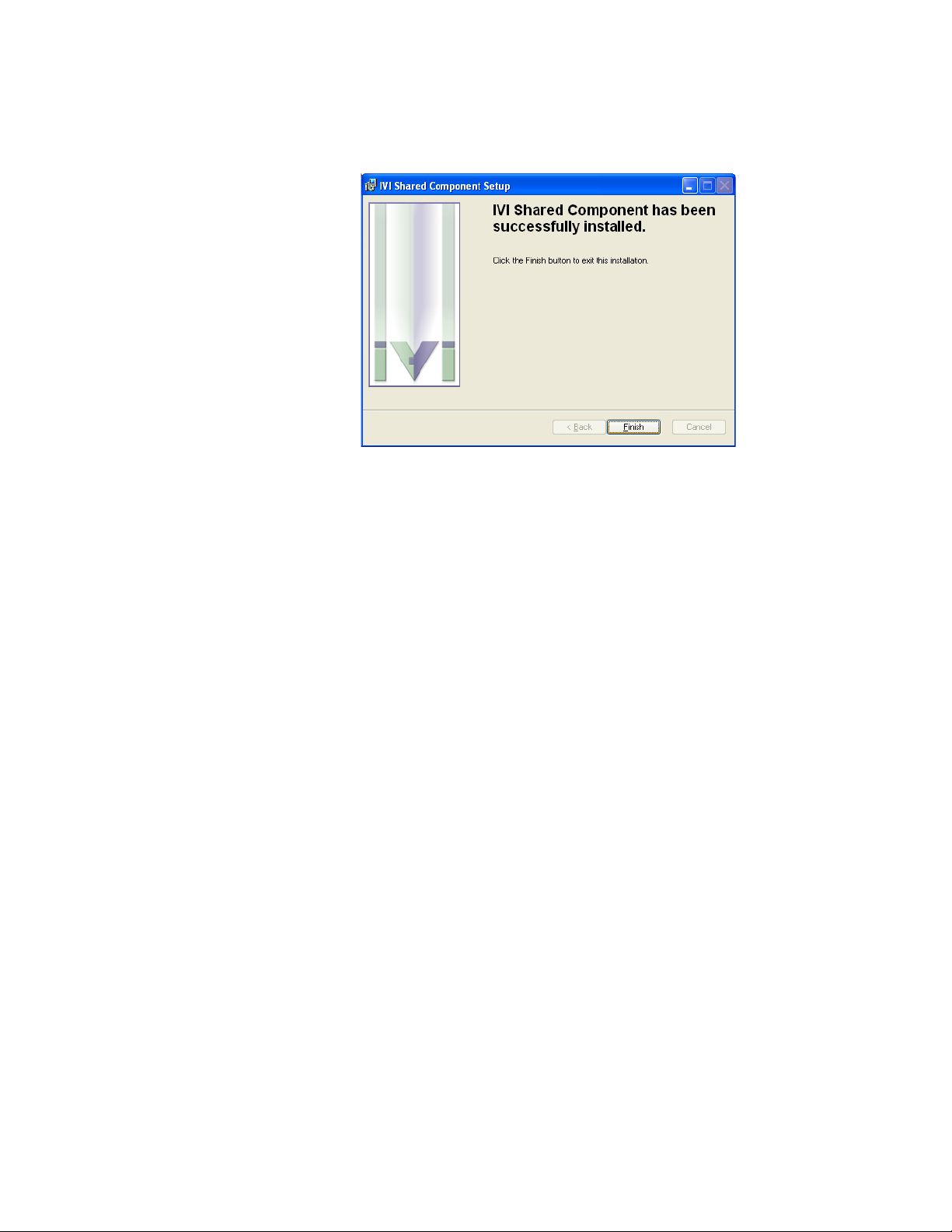

Step 3. Install the IVI Shared Components

1 Select IVI Shared Components.

Software Installation 1

2 Run the IviCleanupUtility before running the IviSharedComponents or a network access

error may occur during installation of the IviSharedComponents.

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 9

Page 14

1 Software Installation

3

4 Click Finish.

Follow the installation instructions and accept the default settings.

10 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 15

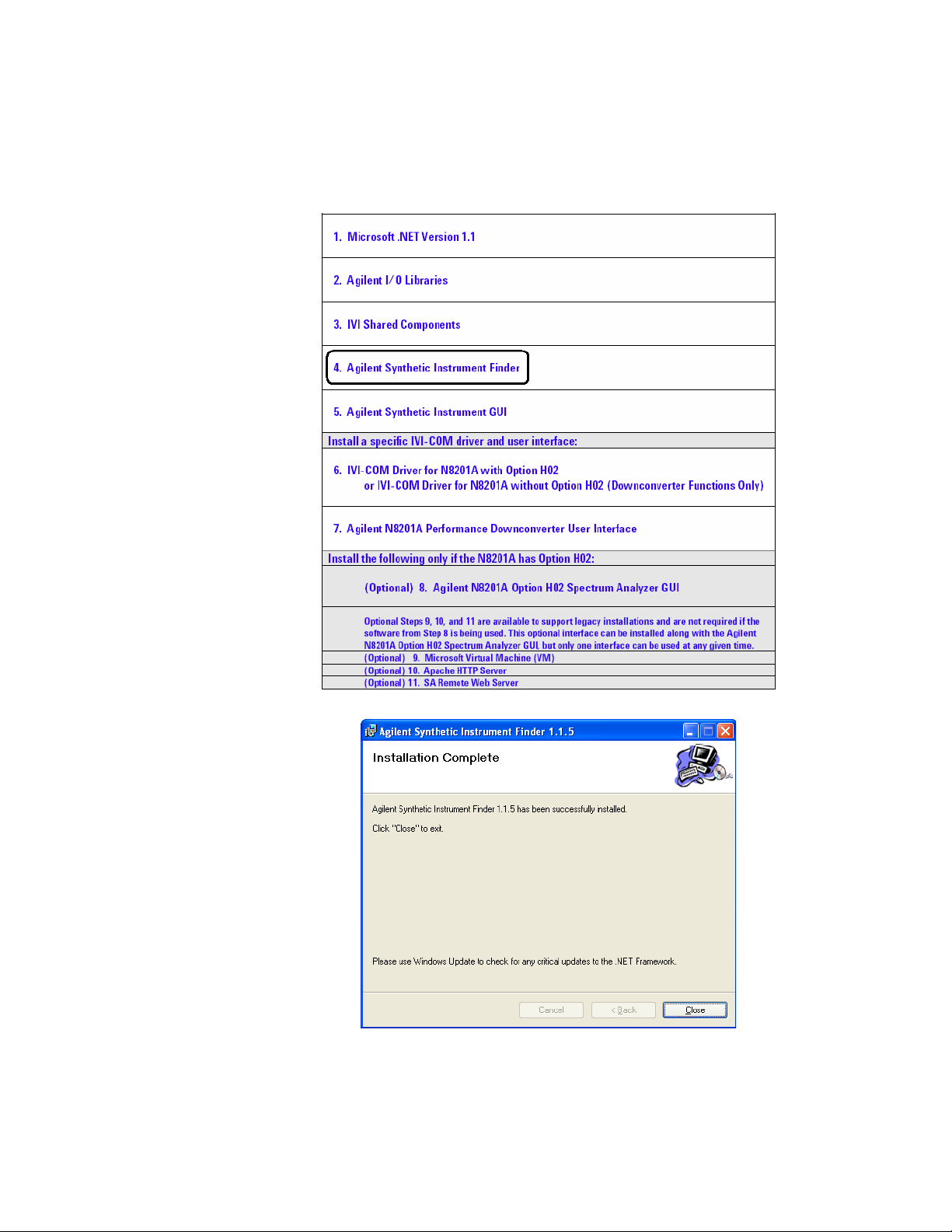

Step 4. Install the Agilent Synthetic Instrument Finder

1 Select Agilent Synthetic Instrument Finder.

Software Installation 1

2 Follow the installation instructions and accept the default settings.

3 Click Close.

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 11

Page 16

1 Software Installation

Step 5. Install the Agilent Synthetic Instrument GUI

1 Select Agilent Synthetic Instrument GUI.

2 Follow the installation instructions and accept the default settings.

Click Close.

12 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 17

Step 6. Install the IVI-COM Drivers

There are two different IVI-COM drivers available for the N8201A performance

downconverter.

• If the N8201A performance downconverter is equipped with Option H02, a different

IVI-COM driver is available that enables functionality similar to a PSA spectrum analyzer.

• If the N8201A performance downconverter is not equipped with Option H02, only

downconverter functions are available.

1 Select one of the IVI-COM Drivers.

Software Installation 1

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 13

Page 18

1 Software Installation

2

You should see the above dialog when the installation is complete for IVI-COM that

supports Option H02 and the below dialog when the installation is complete for IVI-COM

that supports N8201A performance downconverters that are not equipped with Option H02.

Follow the installation instructions and accept the default settings.

3 Click Finish.

14 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 19

Software Installation 1

Step 7. Install the Agilent N8201A Performance Downconverter User Interface

1 Select Agilent N8201A Performance Downconverter User Interface.

2 Follow the installation instructions and accept the default settings.

3 Click Close.

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 15

Page 20

1 Software Installation

Installing Optional Software and Instrument Drivers

Software for steps 8, 9, 10, and 11 can be installed on your PC, but Option H02 is required to

use these software applications with the N8201A performance downconverter; prior to

continuing, verify that Option H02 is installed.

To Verify that Option H02 is Installed

1 Start the Synthetic Instrument Finder (from the Windows Desktop,

click Start > All Programs > Agilent SI Tools > Synthetic Instrument Finder).

2 Select an instrument, from the left-hand pane of the Synthetic Instrument Finder, and

right-click on the instrument with the mouse.

3 Select Interactive IO.

4 Type *OPT? at the Command prompt and click Send & Read.

5 Read the response in the Instrument Session History box; the required option should be

listed as H02.

If Option H02 is Installed

• If Option H02 is installed, proceed to “(Optional) Step 8. Install the Agilent N8201A

Option H02 Spectrum Analyzer GUI" on page 17.

• If Option H02 is installed, you can also use the SA Remote Web Server. To use this

optional interface, you must perform “(Optional) Step 9. Install the Microsoft Virtual

Machine (VM)" on page 19, “(Optional) Step 10. Install the Apache HTTP Server" on

page 21, and “(Optional) Step 11. Install the SA Remote Web Server" on page 24; this

interface can be installed along with the Agilent N8201A Option H02 Spectrum Analyzer

GUI, but only one interface can be used at any given time.

If Option H02 is Not Installed

• If Option H02 is not installed, software installation is complete!

The N8201A performance downconverter can be manually controlled on instruments

without Option H02 by using the Agilent Synthetic Instrument GUI.

(Refer to “Starting the Agilent Synthetic Instrument GUI" on page 67.)

• Without Option H02, the Agilent N8201A Option H02 Spectrum Analyzer GUI cannot

be used and does not need the software installed.

• Without Option H02, the N8201A performance downconverter cannot be used with

the SA Remote Web Server and does not need software installed for the Microsoft

Virtual Machine (VM), the Apache HTTP Server, or the SA Remote Web Server.

a Close the Interactive IO dialog box.

b Close the Synthetic Instrument Finder dialog box.

c Click Exit CD-ROM. The software and driver installation is complete!

d Restart the computer and continue to “Hardware Setup and Configuration" on

page 27.

16 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 21

Software Installation 1

NOTE

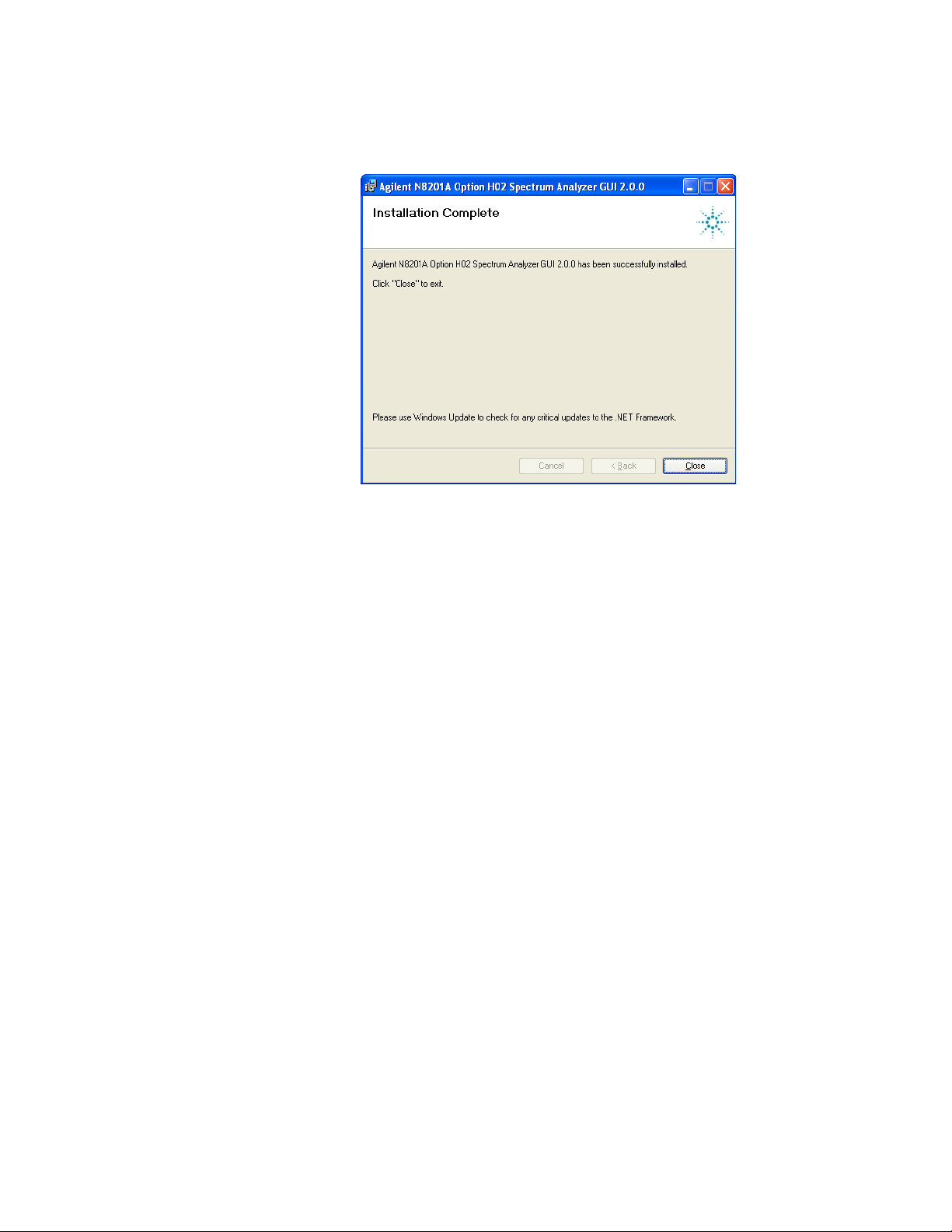

(Optional) Step 8. Install the Agilent N8201A Option H02 Spectrum Analyzer GUI

Before performing this optional installation step, read about

“Installing Optional Software and Instrument Drivers" on page 16.

1 Select Agilent N8201A Option H02 Spectrum Analyzer GUI.

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 17

Page 22

1 Software Installation

2

3 Click Close.

Follow the installation instructions and accept the default settings.

18 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 23

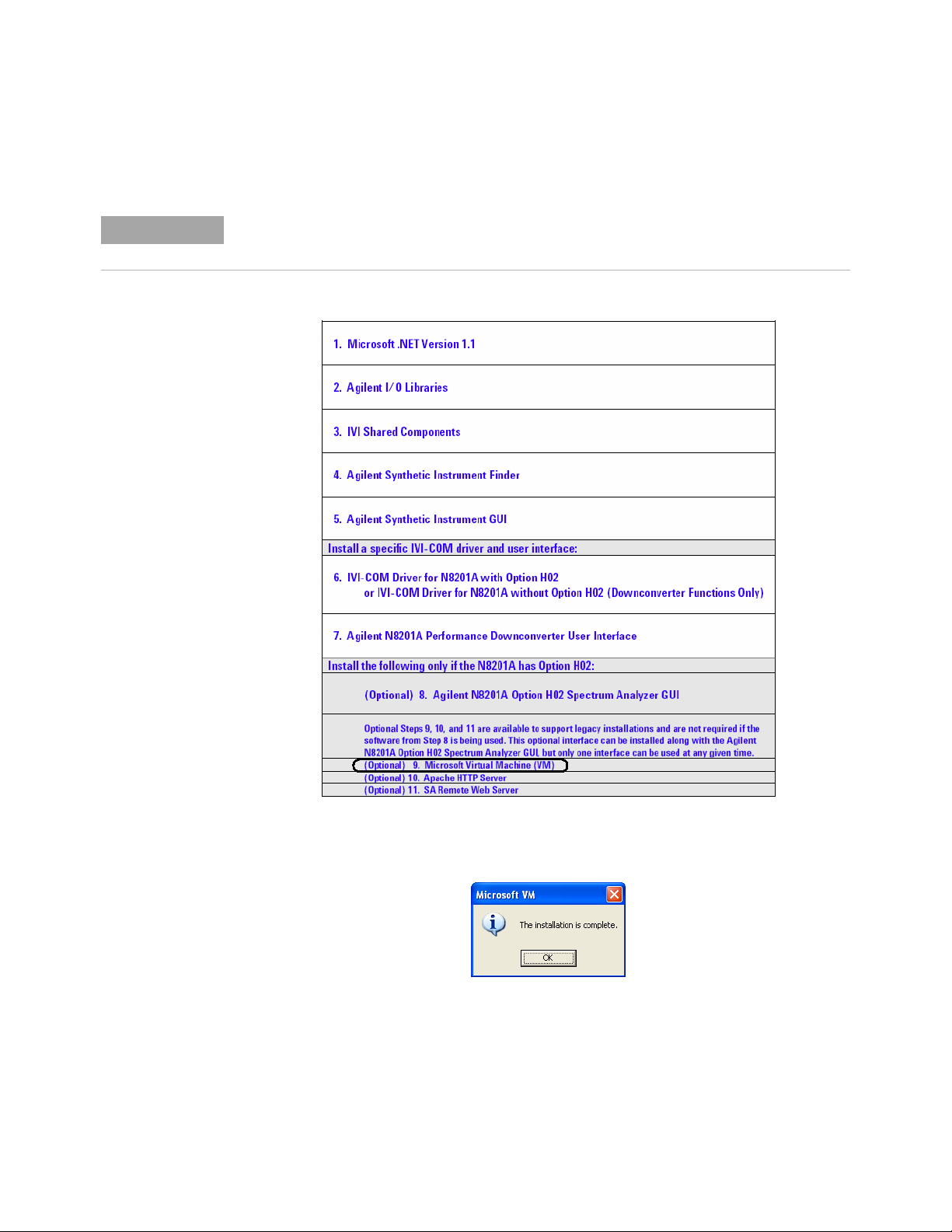

(Optional) Step 9. Install the Microsoft Virtual Machine (VM)

NOTE

Before performing this optional installation step, read about

“Installing Optional Software and Instrument Drivers" on page 16.

1 Select Microsoft Virtual Machine (VM).

Software Installation 1

2 Follow the installation instructions and accept the default settings.

3 Click OK.

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 19

Page 24

1 Software Installation

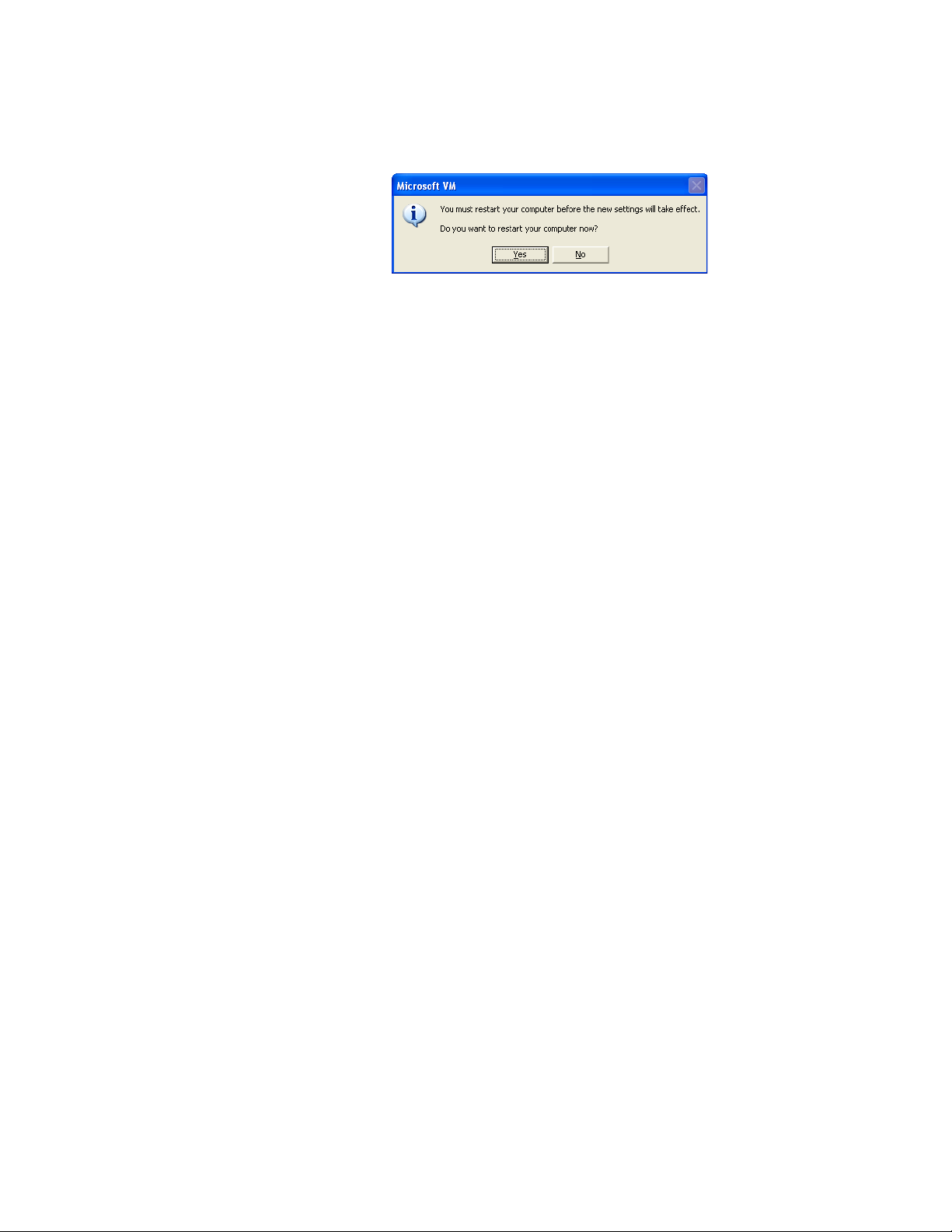

4

Click No on the Microsoft VM dialog box. This step will be completed later in the

process after the SA Remote Web Server is installed.

20 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 25

(Optional) Step 10. Install the Apache HTTP Server

NOTE

Before performing this optional installation step, read about

“Installing Optional Software and Instrument Drivers" on page 16.

1 Select Apache HTTP Server.

Software Installation 1

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 21

Page 26

1 Software Installation

2

3 Click Next.

Follow the installation instructions and accept the default settings

4 Click Next.

22 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 27

Click Finish.

5

Software Installation 1

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 23

Page 28

1 Software Installation

NOTE

(Optional) Step 11. Install the SA Remote Web Server

Before performing this optional installation step, read about

“Installing Optional Software and Instrument Drivers" on page 16.

1 Select SA Remote Web Server.

24 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 29

Software Installation 1

NOTE

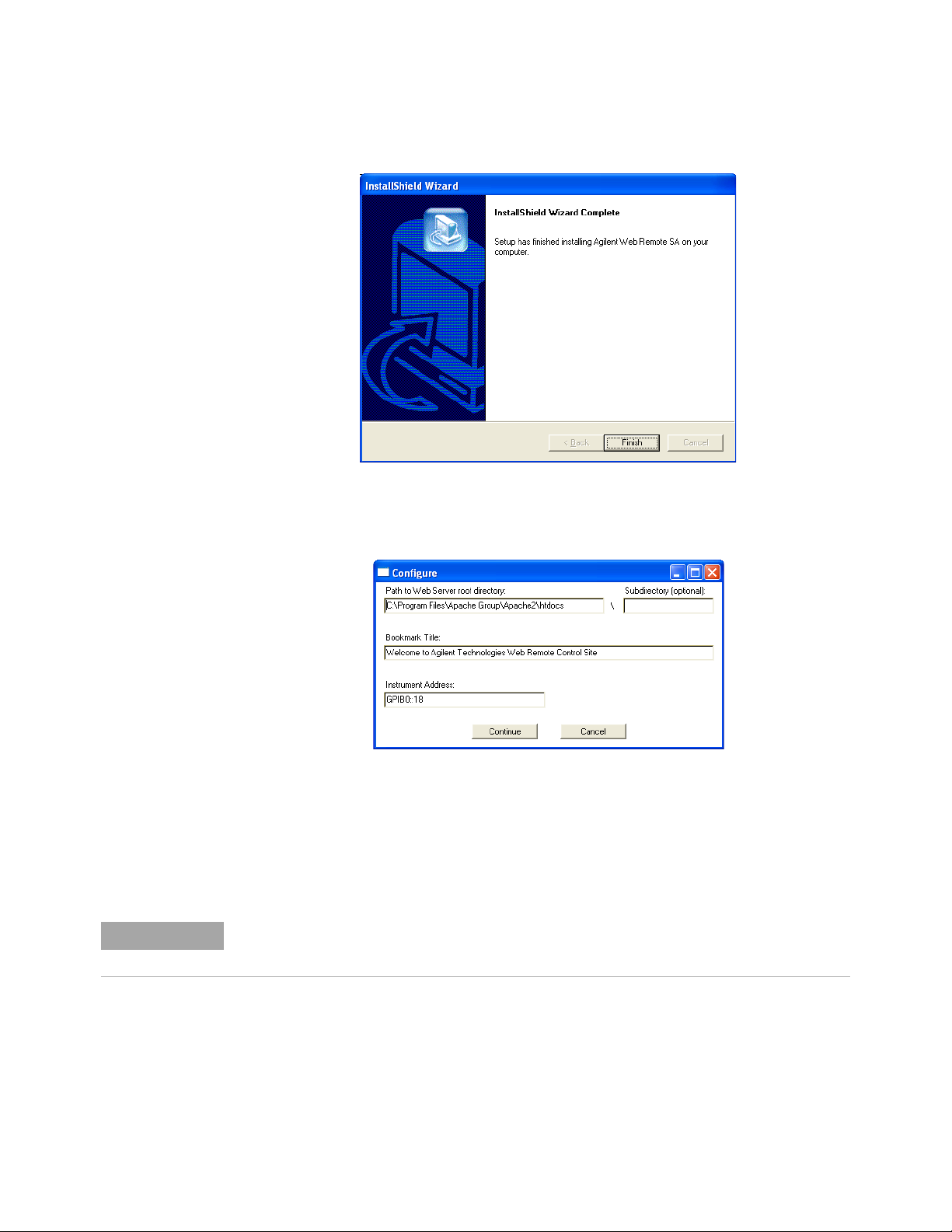

Follow the installation instructions and accept the default settings.

2

3 Click Finish.

4 Click Cancel on the Configure dialog box. This step will be completed later in the

process after restarting the computer.

5 Close the Agilent N8201A Performance Downconverter Software and Driver Installation

menu (driver_installation_list.pdf dialog box).

6 Click Exit CD-ROM. The software and driver installation is complete.

7 Restart the computer and continue to “Hardware Setup and Configuration" on page 27.

Restart the computer!

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 25

Page 30

1 Software Installation

26 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 31

User’s Guide

2

Hardware Setup and Configuration

“Step 1. Unpack the N8201A Performance Downconverter" on page 28

“Step 2. Connect LAN Cables and Turn On Power" on page 29

“Step 3. Verify Connection with Synthetic Instrument Finder" on page 32

“(Optional) Step 4. Connect to the Agilent N8201A Option H02

Spectrum Analyzer GUI" on page 34

“(Optional) Step 5. Connect to an SA Remote Web Server" on page 36

“(Optional) Step 6. Verify Operation < 3 GHz" on page 43

“(Optional) Step 7. Verify Operation > 3 GHz" on page 47

“Troubleshooting" on page 50

• “Alternative Ways to Verify Connectivity to the PC" on page 50

• “How to Reset the LAN Configuration" on page 55

• “How to Set a Static IP Address" on page 56

• “How to Troubleshoot Connectivity Problems on the Network" on page 60

• “How to Determine a PCs Configuration Settings" on page 60

• “If the Instrument was Unable to Join the LAN" on page 62

• “If the LAN LED is Red" on page 62”

• “If the Instrument’s IP Address or Hostname Cannot be Found with Ping" on page 63

• “If the Instrument is Not Found by the Synthetic Instrument Finder" on page 63”

• “If the Instrument’s Hostname and PC Cannot Communicate" on page 63”

• “If the Instrument Web Page is Not Visible" on page 64”

• “If the Software Driver Will Not Open the Connection" on page 64”

Agilent Technologies

27

Page 32

2 Hardware Setup and Configuration

WARNING

NOTE

CAUTION

Step 1. Unpack the N8201A Performance Downconverter

The unique shape of the N8201A performance downconverter was intended to allow

multiple instruments to reside in a compact system that is both modular and

transportable. With instruments adjacent to each other, handles could not be installed on

the respective instruments. Exercise caution when lifting and carrying the instrument to

avoid personal injury. At 25.9 kilograms (57 pounds) shipping weight and 19 kilograms

(42 pounds) net weight, it is recommended that two people be utilized for instrument

lifting and transport.

Verify that any options ordered are included with the shipment by checking the packing

literature included with the shipment.

The serial number label on the N8201A performance downconverter only verifies

hardware/firmware options. The packing literature verifies all items shipped.

Verify the Shipment

1 Inspect the shipping container for damage.

Signs of damage may include a dented or torn shipping container or cushioning material

that shows signs of unusual stress or compacting.

2 Carefully remove the contents from the shipping container and verify that the order is

complete.

The following items are shipped standard with each N8201A performance

downconverter:

• instrument drivers, synthetic graphical user interface, and documentation CD-ROM

(p/n N8200-90004)

• three-prong AC power cord specific to geographic location

(Optional) Prepare the Instrument for Rack Mounting

If the N8201A performance downconverter is to be placed in a system rack, the feet

currently attached can be replaced with the rack mount feet (part number

W1312-40032) supplied with the accessories. Failure to do so can result in a safety

issue. For further information, refer to the Agilent N8200A Series Synthetic

Instrument Modules, Rack Configuration Guide, N8200-90003.

28 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 33

Step 2. Connect LAN Cables and Turn On Power

NOTE

Install the N8201A performance downconverter so that the detachable power cord is

readily identifiable and is easily reached by the operator. The detachable power cord is the

instrument disconnecting device. It disconnects the mains circuits from the mains supply

before other parts of the instrument. The front panel switch is only a standby switch and is

not a LINE switch. Alternatively, an externally installed switch or circuit breaker (which is

readily identifiable and is easily reached by the operator) may be used as a disconnecting

device.

Before connecting to a LAN, verify your local policy by contacting the system administrator

in your Information Technology (IT) department and inquire about connecting instruments

to the LAN.

Hardware Setup and Configuration 2

• If the network uses DHCP [

assigned to the device automatically. If you need to know what the IP address is, it can

be determined using the Synthetic Instrument Finder. (Refer to “Step 3. Verify

Connection with Synthetic Instrument Finder" on page 32.)

• If DHCP is not present, but the instrument is set to use DHCP (the default), the

instrument waits two minutes for its DHCP request to time out. When the

N8201A performance downconverter is used in this situation, there is a time delay of

approximately three minutes between the time of when the N8201A performance

downconverter’s power is turned on and when it is available for use.

• If the network does not use DHCP, you can use Auto IP or configure your LAN

settings manually. Although you can also manually configure LAN settings in a

network with DHCP, it is recommended that you do so with the assistance of your

system administrator.

• If the network uses Auto IP (does not use DHCP), the N8201A performance

downconverter acquires a 169.254.xxx.xxx address. (Refer to “How to Set a Static IP

Address" on page 56.)

If you wish to communicate directly between the N8201A performance downconverter and

your PC without the use of a LAN hub, you can connect directly to your PC. (Refer to

“(Optional) Connect to a LAN with a Cross-Over LAN Cable" on page 31.)

Dynamic Host Configuration Protocol], an address is

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 29

Page 34

2 Hardware Setup and Configuration

1

Connect a LAN cable from the LAN connector on your PC to an empty connector on your

internal local area network or LAN hub.

2 Connect a LAN cable from the LAN connector on the rear panel of the

N8201A performance downconverter to an empty connector on your internal local area

network or LAN hub.

3 Turn on power to the PC.

4 Turn on power to the N8201A performance downconverter and wait until the LAN LED

turns solid green or until you hear an attenuator click from within the

N8201A performance downconverter; this can take up to four minutes depending on

whether the instrument is using DHCP or Auto IP.

30 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 35

Hardware Setup and Configuration 2

(Optional) Connect to a LAN with a Cross-Over LAN Cable

If you wish to communicate directly between the N8201A performance downconverter and

your PC without the use of a LAN hub, you can connect directly to your PC.

1 Connect a cross-over LAN cable from the LAN connector on your PC to the LAN

connector on the rear panel of the N8201A performance downconverter.

2 Turn on power to the PC.

3 Turn on power to the N8201A performance downconverter and wait until the LAN LED

turns solid green or until you hear an attenuator click from within the

N8201A performance downconverter; this can take up to four minutes depending on

whether the instrument is using DHCP or Auto IP.

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 31

Page 36

2 Hardware Setup and Configuration

Step 3. Verify Connection with Synthetic Instrument Finder

Agilent supplies a program named the Synthetic Instrument Finder that enables

connection between a PC and instruments that are connected on a LAN [Local Area

Network].

1 From the Windows Desktop,

click Start > All Programs > Agilent SI Tools > Synthetic Instrument Finder.

The Synthetic Instrument Finder should appear and look similar to the following.

2 Select an instrument, from the left-hand pane of the Synthetic Instrument Finder, and

right-click on an instrument with the mouse.

32 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 37

Hardware Setup and Configuration 2

Select Open Webpage and a Web browser should appear that allows viewing and

3

modifying settings for instruments on the network.

• If this Web page does not open or you experience an error, refer to

“Troubleshooting" on page 50.

• If this Web page opens, you have verified connectivity and can continue

on to one of the following:

• With Option H02 not installed, refer to

“Using the Agilent Synthetic Instrument GUI" on page 65

• With Option H02 installed, refer to

“(Optional) Step 4. Connect to the Agilent N8201A Option H02 Spectrum Analyzer

GUI" on page 34

• With Option H02 installed, refer to

“(Optional) Step 5. Connect to an SA Remote Web Server" on page 36.

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 33

Page 38

2 Hardware Setup and Configuration

NOTE

(Optional) Step 4. Connect to the Agilent N8201A Option H02

Spectrum

Analyzer GUI

If Option H02 is not installed, the Agilent N8201A Option H02 Spectrum Analyzer GUI

software cannot be used!

In addition to Option H02, you must have performed “(Optional) Step 8. Install the Agilent

N8201A Option H02 Spectrum Analyzer GUI" on page 17; this interface can be installed

along with the SA Web Remote Server, but only one interface can be used at any given time.

(For further software installation information, refer to “Installing Optional Software and

Instrument Drivers" on page 16.)

The N8201A performance downconverter can be manually controlled on instruments

without Option H02 by using the Agilent Synthetic Instrument GUI.

(Refer to “Starting the Agilent Synthetic Instrument GUI" on page 67.)

34 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 39

Hardware Setup and Configuration 2

This section describes how to access and use the Agilent N8201A Option H02

Spectrum Analyzer GUI.

1 From the Windows Desktop, click

Start > All Programs > Agilent SI Tools > N8201A Option H02 Spectrum Analyzer GUI.

2 Click File > Connect (upper-left corner)

on the Agilent N8201A Option H02 Spectrum Analyzer GUI.

3 Enter the VISA Address (for example, TCPIP0::141.121.87.18::inst0::instr) of the

instrument being connected to and click OK.

• If you don’t know the IP address of the instrument, that is used as part of the

VISA Address connection string, refer to the Default IP Address that is displayed

when verifying connection with the Synthetic Instrument Finder. (Refer to “Step 3.

Verify Connection with Synthetic Instrument Finder" on page 32.)

The Agilent N8201A Option H02 Spectrum Analyzer GUI controls the N8201A performance

downconverter that is equipped with Option H02 and simulates the functionality of an

Agilent PSA spectrum analyzer. To learn how to use the controls of this GUI interface, refer

to the PSA documentation.

PSA documentation is available from the Agilent N8201A Performance Downconverter

Synthetic Instrument Module, 3 Hz to 26.5 GHz, Instrument Drivers and Documentation CD

(refer to “Installing Software and Instrument Drivers" on page 6) or from the Web at:

http://www.agilent.com/find/psa

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 35

Page 40

2 Hardware Setup and Configuration

NOTE

(Optional) Step 5. Connect to an SA Remote Web Server

If Option H02 is not installed, the SA Remote Web Server software cannot be used!

In addition to Option H02, you must have installed the Microsoft Virtual Machine (VM), the

Apache HTTP Server, and the SA Remote Web Server software; this interface can be

installed along with the Agilent N8201A Option H02 Spectrum Analyzer GUI, but only one

interface can be used at any given time. (For further software installation information, refer

to “Installing Optional Software and Instrument Drivers" on page 16.)

The N8201A performance downconverter can be manually controlled on instruments

without Option H02 by using the Agilent Synthetic Instrument GUI.

(Refer to “Starting the Agilent Synthetic Instrument GUI" on page 67.)

1 From the Windows Desktop,

select Start > All Programs > Agilent I/O Libraries Suite > Agilent Connection Expert.

2 Click Add Interface.

36 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 41

Select Remote GPIB (via E5810 or Remote IO Server).

IP Address

3

Hardware Setup and Configuration 2

4 Click Add.

5 Enter the N8201A performance downconverter’s IP address.

If you do not know the IP address, use the Synthetic Instrument Finder.

a From the Windows Desktop,

select Start > All Programs > Agilent SI Tools> Synthetic Instrument Finder.

b Select an instrument from the list of instruments shown to see its IP address.

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 37

Page 42

2 Hardware Setup and Configuration

The Remote GPIB interface dialog box should look similar to the following:

6 Select IP address and enter the IP Address of the N8201A performance downconverter

in the Remote GPIB Interface dialog box.

7 Enter gpib7 for the Interface Name on Remote Host.

8 Click Test connection. If the connection was successful, text stating “The interface was

successfully opened“ should appear.

9 Click OK.

38 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 43

Hardware Setup and Configuration 2

From the Windows Desktop,

10

select Start > All Programs > Agilent Web Remote > SA > Configure and a

Configure dialog box similar to the following should appear.

11 Click Continue and a dialog box similar to the following should appear.

12 Click Yes on the Instrument Information dialog box.

13 Click OK.

14 From the Windows Desktop, select Start > Run.

15 Enter CMD in the Run dialog box to select the Command Window.

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 39

Page 44

2 Hardware Setup and Configuration

16

From the command window prompt, type ipconfig to get the IP Address of your

computer.

17 Write down your computer's IP address.

IP Address: __ __ __ . __ __ __ . __ __ __ . __ __ __

This IP address is needed in the following steps.

If you are attempting to access the web server from another machine, you need to make

sure to use the hostname or IP Address of the adapter that is on the same network as

the machine you are using. (In regards to the example above, if you are trying to access

the webpage from a machine on the network that is connected to the adapter with the

169.254.241.150 address, you need to use 169.254.241.150 and not 141.121.83.141 as the

IP Address.)

40 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 45

Hardware Setup and Configuration 2

From the Windows Desktop,

18

select Start > All Programs > Agilent Web Remote > SA > Start Server to start the

Spectrum Analyzer Instrument Server.

19 From the Windows Desktop, select Microsoft’s Internet Explorer.

20 Insert your PC’s IP address (from the command window above).

Use the following syntax: http://141.121.83.141/index.html and a

display similar to the following should appear.

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 41

Page 46

2 Hardware Setup and Configuration

21

Select Web Control SA on the left of the web page.

• If one of the following dialog boxes appears, click Run or Install and accept the

installation.

If the following display appears, the SA Remote Web Server configuration is complete!

42 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 47

(Optional) Step 6. Verify Operation < 3 GHz

CAUTION

NOTE

Operation verification is a test that, when completed, will ensure that the downconverter is

operating correctly in the low band (< 3 GHz).

Make sure that the total power of all signals at the downconverter input does not

exceed +30 dBm (1 watt).

Performing a Self-Test

Instrument Connections

• Downconverter: 7.5 MHz Out

• Spectrum Analyzer: RF Input

Hardware Setup and Configuration 2

The N8201A performance downconverter can be controlled with either the

SA Remote Web Server or the Agilent Synthetic Instrument GUI, but only one interface can

be used at any given time.

• If Option H02 is not installed, the N8201A performance downconverter can be manually

controlled using the Agilent Synthetic Instrument GUI.

• If Option H02 is installed, you can use either the SA Remote Web Server or the

Agilent Synthetic Instrument GUI.

(For information on using these different interfaces, refer to “(Optional) Step 4. Connect

to the Agilent N8201A Option H02 Spectrum Analyzer GUI" on page 34 or “Starting the

Agilent Synthetic Instrument GUI" on page 67.)

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 43

Page 48

2 Hardware Setup and Configuration

Perform the following procedure to run a self-test:

1 Close SA Remote Web Server.

2 From the Windows Desktop,

select Start > All Programs > Agilent SI Tools > Agilent Synthetic Instrument GUI.

3 Click the listed downconverter in the “Agilent Synthetic Instrument GUI,

Recent Connections” dialog box.

44 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 49

The following dialog box should appear.

4

Hardware Setup and Configuration 2

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 45

Page 50

2 Hardware Setup and Configuration

Measurement Procedure

5 Tune the Spectrum Analyzer to the following:

• Frequency: 7.5 MHz

• Amplitude: 10 dBm

• Span: 100 kHz

6 Tune the downconverter to the following:

• Level: Attenuator: 20 dBm

• RF Enabled: Enabled

• Input RF: Signal Source: 50 MHz Cal

• Frequency: 50 MHz

7 Verify that a 7.5 MHz signal is present on the spectrum analyzer.

46 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 51

(Optional) Step 7. Verify Operation > 3 GHz

CAUTION

Operation verification is a test that, when completed, will ensure that the

N8201A performance downconverter is operating correctly in the high band (> 3 GHz).

Make sure that the total power of all signals at the N8201A performance

downconverter

Performing a Self-Test

Downconverter to Spectrum Analyzer Connections

• Downconverter: 7.5 MHz Out

• Spectrum Analyzer: RF Input

Downconverter to Source Connections

input does not exceed +30 dBm (1 watt).

Hardware Setup and Configuration 2

• Downconverter: RF Input

• Source: RF Output

Perform the following procedure to run a self-test:

1 From the Windows Desktop,

select Start > All Programs > Agilent SI Tools > Agilent Synthetic Instrument GUI.

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 47

Page 52

2 Hardware Setup and Configuration

2

Click the downconverter in the Agilent Synthetic Instrument GUI dialog box listed under

Recent Connections.

3 The following dialog box should appear.

48 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 53

Measurement Procedure

4 Tune the Spectrum Analyzer to the following:

• Frequency: 7.5 MHz

• Amplitude: 10 dBm

• Span: 100 kHz

5 Tune the downconverter to the following:

• Center Frequency: 3.5 GHz

• Attenuator: 20 dBm

• RF Enabled: Enabled

• Source: Internal

6 Tune the Source to the following:

• Frequency: 3.5 GHz

• Amplitude: 0 dBm

• RF On

Hardware Setup and Configuration 2

Verify that a 7.5 MHz signal is present on the spectrum analyzer.

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 49

Page 54

2 Hardware Setup and Configuration

Troubleshooting

Alternative Ways to Verify Connectivity to the PC

In addition to using “Step 3. Verify Connection with Synthetic Instrument Finder" on

page 32 and “(Optional) Step 4. Connect to the Agilent N8201A Option H02

Spectrum Analyzer GUI" on page 34, connectivity can be verified between the

N8201A performance downconverter and the PC with the following:

• Verify that the LAN LED on the N8201A performance downconverter’s rear panel is

green or blinking green. This indicates a good connection.

If the LED is off, there is a problem with your LAN connection.

• Verify that the LAN LED on the N8201A performance downconverter’s front panel (next

to the LAN port) is solid green.

If the LED turns red, this indicates a problem with your LAN connection. This takes

approximately 60 seconds.

• Ping the N8201A performance downconverter from the PC.

a From the Windows Desktop, select Start > Run.

b At the Open prompt, type CMD and press Enter to open a command window.

c At the command prompt, type Ping and the instrument’s IP address (for example,

Ping 141.121.84.108.) or type Ping and the instruments hostname (for

example, Ping a-n8201a-00179).

50 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 55

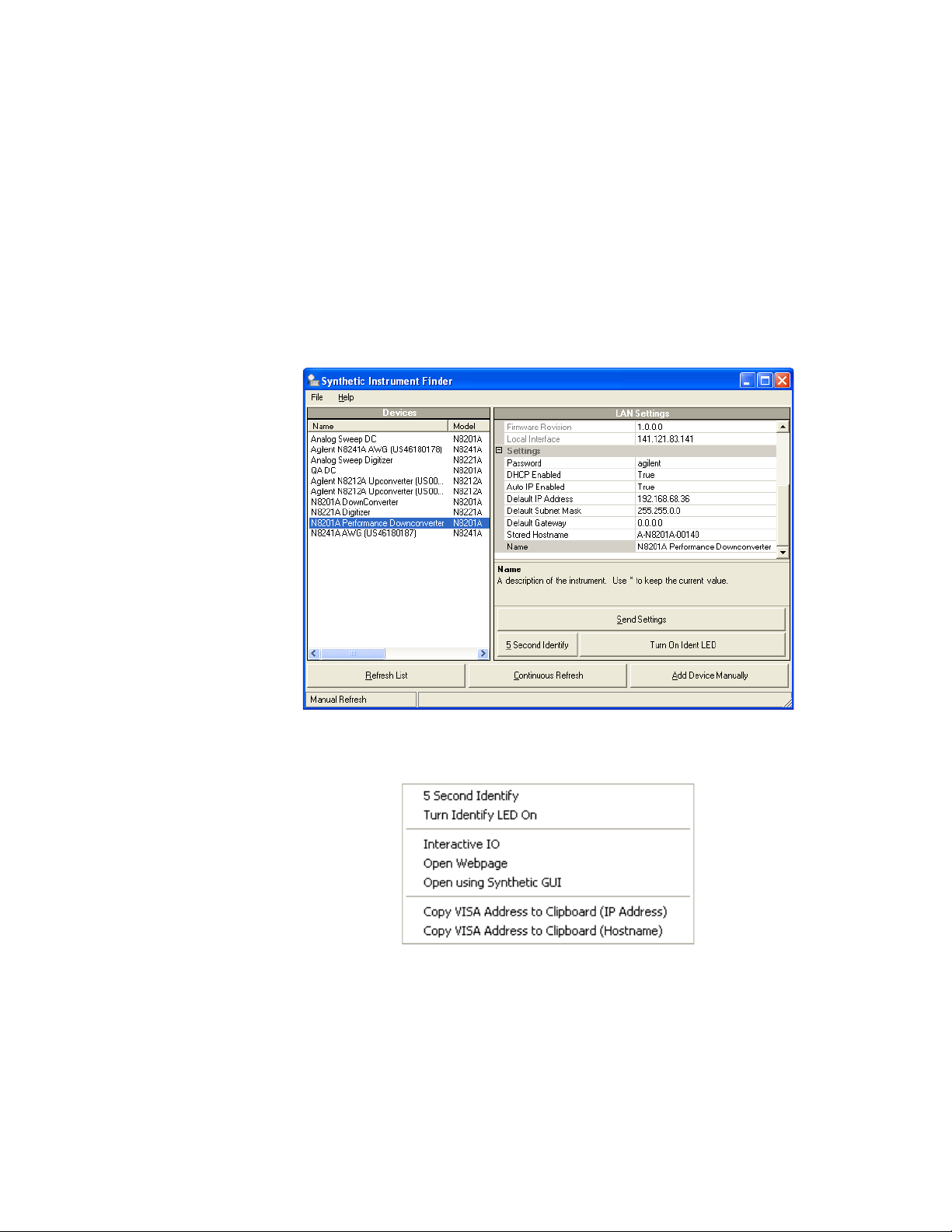

How to Use the Synthetic Instrument Finder

Agilent supplies a program named the Synthetic Instrument Finder that enables

connection between a PC and instruments that are connected on a LAN [Local Area

Network].

1 From the Windows Desktop,

click Start > All Programs > Agilent SI Tools > Synthetic Instrument Finder.

The Synthetic Instrument Finder should appear and look similar to the following.

Hardware Setup and Configuration 2

2 Select an instrument, from left-hand pane of the Synthetic Instrument Finder, and

right-click on an instrument with the mouse.

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 51

Page 56

2 Hardware Setup and Configuration

The Synthetic Instrument Finder window is divided into two main sections:

• right pane contains information specific to the instrument highlighted in the left pane.

• left pane contains a list of equipment available on your LAN for connection.

Right-Pane Functions

Send Settings Sends the current instrument settings to the N8201A performance

downconverter. Use this function if you modified the settings in Instrument Finder.

5 Second Identify Flashes the LAN LED for five seconds.

Turn On Ident LED When On, the LAN LED continuously flashes on and off. Once the

Turn On Ident LED button is pressed, the button name changes to Turn Off Ident LED.

Refresh List Updates the device’s list.

Continuous Refresh Updates the device’s list every one minute.

Add Device Manually Allows you to add a device for connection. Use this feature

only if your instrument does not appear in the Devices list.

a Click Add Device Manually. The Devices area will display a new listing titled

“Unknown”.

b In the Manual settings area, enter in the MAC address, serial number, and model

number of the device.

c In the LAN settings area, enter in the information for the new device. (Make sure

that you scroll down the list to get to the editable settings area.)

d Click Send Settings to enter this information in the Devices area.

e Double-click the new listing to open the webpage, or right-click and select Open

using Synthetic GUI to use the virtual interface.

52 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 57

Hardware Setup and Configuration 2

Left-Pane Functions

In the left pane, right-click on the N8201A performance downconverter and the

following menu should appear.

Interactive IO Opens the Agilent Interactive IO application which allows SCPI

commands to be sent to the instrument. (The Interactive IO option is only available if the

Agilent Connection Expert has been installed on the PC.)

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 53

Page 58

2 Hardware Setup and Configuration

Open Webpage Opens the Web page associated with the currently selected instrument.

From this Web page, settings for the instrument can be viewed and modified.

Tip: There are two other ways to access the device’s Web page:

• By double-clicking on the Device listing in the Synthetic Instrument Finder.

• By typing in the device’s hostname or IP address in your Internet browser.

Open using Synthetic GUI Opens the Synthetic Instrument GUI.

Copy VISA Address to Clipboard (IP Address) Copies the VISA IP address to the

clipboard for use in other applications.

Copy VISA Address to Clipboard (Hostname) Copies the VISA hostname to the

clipboard for use in other applications. It is recommended that you use this address on

networks with DHCP and DNS network capability.

54 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 59

How to Reset the LAN Configuration

NOTE

Recessed

LAN RST

Button

On the instrument front panel, near the power switch, is a recessed button labeled

“RESET”. This button enables you to place the LAN configuration of the instrument

into a known state.

When this button is pressed (a straightened paper clip will do the job) the following

settings are made and the system reboots.

• Subnet Mask is set to 255.255.0.0

• DHCP is set to on

• Auto IP is set to on

• If DHCP and Auto IP are set to off, the IP address will be set to 192.168.EE.FF,

where EE and FF are the last two parts of the MAC address (AA.BB.CC.DD.EE.FF).

This is designed to prevent multiple instruments from using the same default IP

address (refer to the instrument label).

If you had manually configured LAN settings before, you may have to reconfigure your

instrument to reset DHCP and Auto IP to OFF. Refer to “How to Set a Static IP Address" on

page 56.

Hardware Setup and Configuration 2

• The instrument hostname is set to A-N82XXA-NNNNN, where N82XXA is the

instrument model number (such as N8201A) and NNNNN represents the last five

digits of the instrument serial number.

If the instrument is in an environment with a DHCP server, it is assigned an IP address

through DHCP. The IP address can be found by using the instrument hostname as the

URL in a web browser.

Without DHCP, the instrument will use Auto IP and acquire a 169.254.X.X address. If

no DHCP is present, but the instrument is set to use DHCP (the default), the instrument

will wait two minutes for its DHCP request to time out. In this case, there is a time delay

of approximately three minutes between when the instrument is powered on and when it

is usable.

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 55

Page 60

2 Hardware Setup and Configuration

NOTE

How to Set a Static IP Address

The DHCP server automates the process of setting up the IP addresses on your network

by default. When the N8201A performance downconverter is turned on, it searches for a

DHCP server on the network and selects a “dynamic IP address”. Each time the

N8201A performance downconverter is rebooted, the N8201A performance

downconverter may get a different IP address. To set the N8201A performance

downconverter to a static IP address, rather than allowing the DHCP server to select an

auto IP address:

1 Assign a N8201A performance downconverter instrument IP address that will work with

your computer.

F

For a company wide network, your system administrator will have to assign an IP address

that is compatible with your PC. If you have a private LAN network or a direct connection

from your PC to the instrument, you can assign the IP address. Refer to “Step 1. Unpack the

N8201A Performance Downconverter" on page 28.

2 Connect the N8201A performance downconverter in one of the following two

configurations:

• Connect a LAN cable from the LAN connector on your PC to an empty connector on

your internal local area network or LAN hub. Connect a LAN cable from the LAN

connector on the rear panel of the N8201A performance downconverter to an empty

connector on your internal local area network or LAN hub.

Figure 1 Connecting the PC LAN cable to a company/private LAN to the instrument LAN

• Connect a cross-over cable from the LAN connector on your PC to the LAN

connector on the rear panel of the N8201A performance downconverter.

56 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 61

Hardware Setup and Configuration 2

Figure 2 Connecting the PC LAN cable to the instrument LAN (cross-over cable)

3 Turn on power to the PC.

4 Turn on power to the N8201A performance downconverter and wait until the LAN LED

turns solid green; this takes about 60 seconds.

5 From the Windows Desktop,

click Start > All Programs > Agilent SI Tools > Synthetic Instrument Finder.

The following Synthetic Instrument Finder dialog box should appear.

6 Select the N8201A performance downconverter listed in the Agilent Synthetic

Instrument Finder dialog box to access the N8201A performance downconverter Web

page.

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 57

Page 62

2 Hardware Setup and Configuration

7

Click View & Modify LAN Config in the left-pane of the Web page. The following dialog

box should appear.

8 Click Modify Configuration to access the Password dialog.

9 Click Submit (accept the default password) and the following dialog box should appear.

The default password is set to “agilent”.

Tip: You can change the password from the View & Modify LAN Connections. (Scroll

down the Parameter column until you locate the Change Password parameter.)

58 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 63

Hardware Setup and Configuration 2

NOTE

10

Change the DHCP and Auto IP radio-buttons to Off. Change the IP address, Subnet

Mask, and Default Gateway values to meet your network requirements.

11 Click Save to save the new settings. Parameters marked with an asterisk (*) also require

that you click "Renew LAN settings" before changes take effect.

For the new settings to become effective, you may first cycle the power of the instrument

and then cycle the power of the PC.

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 59

Page 64

2 Hardware Setup and Configuration

How to Troubleshoot Connectivity Problems on the Network

The Synthetic Instrument Finder program is used to find instruments on a network when

the N8201A performance downconverter is connected through a router or cross-over

cable. There are three possible configurations:

• connecting the PC through a company wide site LAN connection to the

N8201A performance downconverter

• connecting the PC to the same private LAN network as the instrument

• connecting the PC directly to the instrument using a cross-over cable - this would

typically be used for troubleshooting and is not normally used to control an

instrument directly

The N8201A performance downconverter is shipped with a default IP address. This

default IP address is 192.168.EE.FF, where EE and FF are the last two parts of the

Media Access Control (MAC) address (AA.BB.CC.DD.EE.FF).

How to Determine a PCs Configuration Settings

From a DOS Window

1 From the Windows Desktop, click Start > Run.

2 At the Open: prompt, type CMD and press Enter to open a DOS window.

3 At the command prompt, type ipconfig/all to display the PCs network connection

details.

Or,

From the PCs Control Panel

1 From the Windows Desktop, click Start > Settings > Control Panel > Network and

Internet Connections.

2 From the Network and Internet Connections window, double-click the Local Area

Connection.

3 In the Local Area Connection Status dialog, click the Support tab and click Details to

display the PCs Network Connection Details.

The Network Connection Details include:

• Physical Address

• DHCP status, enabled or disabled (displayed when using the DOS window ipconfig

command only)

• Auto configuration enabled or disabled (displayed when using the DOS window

ipconfig command only)

• IP Address

• Subnet Mask

60 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 65

• Default Gateway

• DHCP Server Address

• Lease Obtained

• Lease Expired

• Primary WINS Servers

• Secondary WINS Servers

Hardware Setup and Configuration 2

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 61

Page 66

2 Hardware Setup and Configuration

If the Instrument was Unable to Join the LAN

or

If the LAN LED is Red

Symptom

Possible Causes Possible Solutions

The instrument is not connected to a LAN. If connecting the instrument to a switch or hub, verify

that the instrument is connected with a standard LAN

cable.

An incorrect LAN cable is being used.

• If connecting the instrument directly to a PC, verify

that the instrument is connected with a cross-over

cable.

• If connecting the instrument to a switch or hub,

verify that the instrument is connected with a

standard LAN cable.

The device’s LAN port is not active. Connect the instrument to a known working LAN

port.

The device is configured to use DHCP, but no DHCP

server is available.

• Disable DHCP. Refer to “How to Set a Static IP

Address" on page 56.

• Connect the device to a LAN that uses a DHCP

server.

The instrument is configured to use a duplicate static

IP address.

• Make sure that no other device is using the same

IP address as your instrument.

• Configure your instrument to use a different IP

address. Refer to “How to Set a Static IP

Address" on page 56.

62 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 67

Hardware Setup and Configuration 2

If the Instrument’s IP Address or Hostname Cannot be Found with Ping

Possible Causes Possible Solutions

The instrument was unable to join the LAN. See “If the Instrument was Unable to Join the

LAN" on page 62.

The instrument’s LAN settings are incorrect. Verify that the instrument’s settings are appropriate

for your LAN.

A firewall is preventing communication between your

PC and your instrument.

The instrument is using Auto-IP (That is, the

instrument assigned itself a 169.254.x.x IP address)

and your PC is not using Auto IP (That is, PC does not

have a 169.254.x.x IP address.)

Make sure that your firewall settings allow

communication between your PC and other devices.

• Disable Auto-IP on the instrument.

• Configure your PC to use Auto-IP.

If the Instrument is Not Found by the Synthetic Instrument Finder

Possible Causes Possible Solutions

The instrument was unable to join the LAN. See “If the Instrument was Unable to Join the

LAN" on page 62.

The instrument and PC are on different

switches/hubs and different subnets.

• Put the instrument on the same switch or hub as

your PC.

• If the instrument is using DHCP, make sure that the

instrument and the PC are put on the same subnet.

• If the instrument is using a static IP address, make

sure that the instrument IP address and subnet

mask put the instrument on the same subnet as

your PC.

If the Instrument’s Hostname and PC Cannot Communicate

Possible Causes Possible Solutions

No DNS server is available. Communicate with the instrument using the

instrument’s IP address.

The DNS server has not been updated. Wait several minutes.

The PC cannot communicate with the device over

LAN.

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 63

See “If the Instrument’s IP Address or Hostname

Cannot be Found with Ping" on page 63.

Page 68

2 Hardware Setup and Configuration

If the Instrument Web Page is Not Visible

Possible Causes Possible Solutions

• The instrument has not yet joined the LAN.

See “If the LAN LED is Red" on page 62.

• The instrument is unable to join the LAN.

Your PC cannot communicate with the device over

your LAN.

You are attempting to use the device’s hostname and

the hostname is not working.

Your browser is configured to use a proxy, and the

proxy does not allow communication with

instruments on the LAN.

See “If the Instrument was Unable to Join the

LAN" on page 62.

See “If the Instrument’s Hostname and PC Cannot

Communicate" on page 63.

Disable or reconfigure the proxy settings. Open

Internet Explorer and select Tools > Internet Options

> Connections > LAN Settings…

If the Software Driver Will Not Open the Connection

Possible Causes Possible Solutions

Your PC cannot communicate with the device over

your LAN.

Someone else is currently connected to the

instrument.

See “If the Instrument’s IP Address or Hostname

Cannot be Found with Ping" on page 63.

Make sure that no one else is connected to the

instrument.

64 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 69

User’s Guide

3

Using the

Agilent

“Starting the Agilent Synthetic Instrument GUI" on page 67

“Features of the Agilent Synthetic Instrument GUI" on page 69

“Settings on the Agilent Synthetic Instrument GUI" on page 74

Synthetic Instrument GUI

Agilent Technologies

65

Page 70

3 Using the Agilent Synthetic Instrument GUI

NOTE

Although only one interface can be used at any given time, the N8201A performance

downconverter can be controlled with any of the following:

• Agilent N8201A Option H02 Spectrum Analyzer GUI

• SA Remote Web Server

• Agilent Synthetic Instrument GUI

Which interface should be used:

• If Option H02 is not installed, the N8201A performance downconverter can be manually

controlled using the Agilent Synthetic Instrument GUI; without Option H02, the

N8201A performance downconverter cannot be controlled with SCPI commands.

• If Option H02 is installed, you can use either the Agilent N8201A Option H02 Spectrum

Analyzer GUI, the SA Remote Web Server, or the Agilent Synthetic Instrument GUI.

(For information on using these different interfaces, refer to “(Optional) Step 4. Connect

to the Agilent N8201A Option H02 Spectrum Analyzer GUI" on page 34, “(Optional) Step

5. Connect to an SA Remote Web Server" on page 36, or “Starting the Agilent Synthetic

Instrument GUI" on page 67.)

To verify that Option H02 is installed:

1 Start the Synthetic Instrument Finder (from the Windows Desktop,

click Start > All Programs > Agilent SI Tools > Synthetic Instrument Finder).

2 Select an instrument, from the left-hand pane of the Synthetic Instrument Finder, and

right-click on the instrument with the mouse.

3 Select Interactive IO.

4 Ty p e *OPT? at the Command prompt and click Send & Read.

5 Read the response in the Instrument Session History box; the required option should be

listed as H02.

66 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 71

Starting the Agilent Synthetic Instrument GUI

This section describes how to access and use the Agilent Synthetic Instrument GUI.

1 From the Windows Desktop,

click Start > All Programs > Agilent SI Tools > Agilent Synthetic Instrument GUI.

2 Click Connection Manager (lower-left corner)

on the Agilent Synthetic Instrument GUI dialog box.

Using the Agilent Synthetic Instrument GUI 3

3 Click Find Instruments (lower-left corner) on the Connect to Instrument dialog box.

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 67

Page 72

3 Using the Agilent Synthetic Instrument GUI

4

Select an N8201A performance downconverter and click Tes t (lower-left corner) on the

Connect to Instrument dialog box.

• If the bottom of the dialog box displays the message “Connection Succeeded“, the

instrument was found and communication has been established.

• If the bottom of the dialog box displays the message “N8201A is not supported”, the

instrument is not communicating. Refer to “Troubleshooting" on page 50.

5 Click Connect (lower-right corner) on the Connect to Instrument dialog box and the

following dialog box should appear.

If the Agilent Synthetic Instrument GUI appears, the N8201A performance downconverter

has successfully connected using a LAN connection!

Left Pane

The lower portion of the left pane displays the settings available for adjustment on the

N8201A performance downconverter. Click a function button to activate that function and

the related functions are displayed in the Properties area. For example, Center Frequency is

the active function and all settings associated with Center Frequency are available for

modification.

Right Pane

The upper portion of the right pane always displays the functions that are most commonly

used for a measurement. These functions are also accessible from the left pane. Changing

one of these parameters changes the setting in the left pane as well.

The lower portion of the right pane can have three tabs: Dynamic Help, Instrument

Information, and the Event Log. For more information on theses areas, refer to “Dynamic

Help" on page 72, “Instrument Information" on page 73, and “Event Log" on page 73.

68 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 73

Using the Agilent Synthetic Instrument GUI 3

Features of the Agilent Synthetic Instrument GUI

File Menu

The File menu accesses options for instrument connection, save and recall settings, and

exiting the application. Theses tasks are also available by clicking the icons on the tool bar.

Figure 3 File sub menu

Connect

Accesses the Connect to Instrument dialog box which is used to connect to an instrument

on the LAN hub.

Figure 4 Connect to Instrument Window

Reconnect

Re-establishes the connection to the instrument if the instrument has been disconnected.

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 69

Page 74

3 Using the Agilent Synthetic Instrument GUI

Disconnect

Terminates the connection to the active instrument that is using the

Synthetic Instrument GUI.

Load Settings

Accesses the Load Instrument Properties dialog box where you can recall user-definable

instrument settings.

Save Settings

Accesses the Save Instrument Properties dialog box where you can save instrument

settings for use at a later time.

Exit

Closes the Agilent Synthetic Instrument GUI application.

Help

The Help menu displays the current versions of the GUI and drivers.

Figure 5 Help About Synthetic GUI

70 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 75

Left Pane

Using the Agilent Synthetic Instrument GUI 3

Start Page

The Start Page lists the instruments previously connected to the Agilent Synthetic

Instrument GUI.

Error Log

Displays a history of all instrument and GUI related errors and messages.

Figure 6 Error Log

Connection Manager Accesses the Connect to Instrument dialog box.

Table 1 Controls available from the Connect to Instrument Dialog Box

Saved Connections Accesses user defined connections.

Recent Connections Displays a list of instruments that have recently been controlled by the

Agilent Synthetic Instrument GUI.

Connection Expert Accesses Agilent Connections Expert.

Find Instruments Lists the instruments found in Instrument Finder.

Test Tests the connection between the PC and the highlighted instrument.

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 71

Page 76

3 Using the Agilent Synthetic Instrument GUI

Right Pane

The upper portion of the right pane always displays the functions that are most commonly

used for a measurement. These functions are also accessible from the left pane. Changing

one of these parameters changes the setting in the left pane as well.

The lower portion of the right pane can have the following tabs: Dynamic Help, Instrument

Information, and Event Log.

Dynamic Help

Provides information about the function currently selected in the left pane.

Figure 7 Dynamic Help

72 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 77

Using the Agilent Synthetic Instrument GUI 3

Instrument Information

Provides information about your N8201A performance downconverter such as the serial

number, IP address, software revision used, and so on.

Figure 8 Instrument Information Page

Event Log

When enabled in the Events parameters area, displays the event log history.

Figure 9 Event Log History

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 73

Page 78

3 Using the Agilent Synthetic Instrument GUI

Settings on the Agilent Synthetic Instrument GUI

Frequency

Sets the center frequency or frequency offset of the N8201A performance downconverter.

Center Frequency

Sets the center frequency while the span remains constant. The frequency range of the

N8201A performance downconverter is 3 Hz to 26.5 GHz plus the frequency offset. If the

External Mixer Enabled equals External, the frequency range is 3 Hz to 335 GHz.

Frequency Offset

Enables you to input a frequency offset value to account for external frequency

conversions. This value is added to the display readout of the marker frequency, center

frequency, start frequency, stop frequency, and all other absolute frequency settings. Limits

are

−500 THz to 500 THz.

Frequency List

Sets up a list of frequencies for the instrument to step through. The list begins with Start

Frequency, and adds the Step Frequency until the Stop Frequency is reached. The next

trigger causes the list to be repeated.

Disabled Prevents a frequency step sequence from being initiated.

Start Sets the first frequency that will be swept on a list sweep.

Stop Sets the last frequency that will be swept before the list is repeated.

Step Sets the difference between successive swept frequencies.

Trigger Se t u p Sets up the trigger that will be used to step through the frequency list.

Trigger Source

Sets the source of triggers. When the specified trigger occurs, the instrument will move to

the next frequency in its frequency list. Possible values are:

EXT - TTLLX10LX11LX12LX13

LX14 LX15 LX16 LX17 LAN0

LAN1 LAN2 LAN3 LAN4 LAN5

LAN6 LAN7 ALARM0

74 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 79

Using the Agilent Synthetic Instrument GUI 3

Trigger Source (set to ALARM0)

Table 2 Controls available when Trigger Source is set to ALARM0

Alarm Mode Defines the way that Alarm Time will be interpreted. In absolute mode,

the alarm will begin firing at the time of day specified in Absolute Alarm

Time. In relative mode, the alarm will begin firing at a time relative to

when the alarm is set up.

Relative Alarm Time Defines the number of seconds after pressing Execute Trigger that the

first alarm will occur.

Absolute Alarm Time Defines the time that the first alarm will occur.

Alarm Period Defines the time between successive alarms.

Alarm Repeat Defines the number of times the alarm will be repeated.

A value of 1 means that the alarm will occur once and will not be

repeated. A value of 2 means that the alarm will occur twice.

A value of 0 means that the alarm will be repeated until the alarm is

disabled.

Trigger Detection

Controls the trigger polarity. It is Positive to trigger on a rising edge and Negative to trigger

on a falling edge.

Execute Trigger

Sends the new trigger settings to the instrument

Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz 75

Page 80

3 Using the Agilent Synthetic Instrument GUI

Level

Sets the input attenuation. The input attenuation can be set from 0 to 70 dB in 2 dB

steps.The input impedance is set to 50 ohms. Input attenuation is used to minimize

compression caused by a signal level that is too high in amplitude.

Input RF

Accesses the functions to select the input signal source (choices are RF, 50 MHz Cal, or

External Mixer), enable a preamplifier, and to set the coupling to either AC or DC.

IF Output

Accesses the functions to set the IF Bandwidth and IF Frequency.

Table 3 Grouped Values

IF Output IF Bandwidth

IF Output 1 0 to 3 MHz 21.4 MHz 50 Ohm

IF Output 2 100 MHz 321.4 MHz 50 Ohm

IF Output 3 10 MHz 7.5 MHz 50 Ohm

Reference Oscillator

Allows you to use either the internal or an external reference oscillator for making

measurements.

Reference Output

Switches the 10 MHz out signal on the front panel of the N8201A performance

downconverter On and Off.

Reference Input Source

Specifies whether to use an External or Internal source for the reference oscillator. If set to

External, a value must be specified for External Frequency with limits from 1 MHz to

30 MHz.

Limits

IF Frequency

Limits

Input Impedance

Limits

76 Agilent N8201A Performance Downconverter Synthetic Instrument Module, 3 Hz to 26.5 GHz

Page 81

Preselector (Option 123)

Adjust

Allows you to manually adjust the preselector filter center frequency to optimize its

response on the signal of interest. When enabled, the center frequency must be set to

3.045 GHz or greater.

Limits are: –250 MHz to 250 MHz.

PreSelector Enabled

Enables or disables the preselector.

Enabled: Can be set if the Center Frequency is greater than 3.045000000 GHz.

Possible Values: Enabled, Disabled

Peak

Using the Agilent Synthetic Instrument GUI 3

Performs a peak search.

Enabled: Can run if Center Frequency is greater than 3.045000000 GHz.

Instrument Functions: A - L

External Mixer

Selects either the internal mixer or an external mm-wave mixer.

• When Internal mixing is selected, normal operation and all other external mixing

functions are unavailable.

• When External mixing is selected, you can analyze high frequency signals (that is,

higher than the spectrum analyzer’s maximum frequency) by using an appropriate

external mixer.

Band Selects a band, or sets the frequency band to be user defined.

User Defined values: