Page 1

Agilent

3.125 Gb/s Serial BERT

N5980A

User Guide

Page 2

Notices

© Agilent Technologies, Inc. 2006

No part of this manual may be reproduced in

any form or by any means (including electronic

storage and retrieval or translation into a

foreign language) without prior agreement and

written consent from Agilent Technologies,

Inc. as governed by United States and

international copyright laws.

Manual Part Number

N5980-91010

Edition

Revision 1.0 May 2006

Printed in Germany

Agilent Technologies, Deutschland GmbH

Herrenberger Str. 130

71034 Böblingen, Germany

For Assistance and Support

http://www.agilent.com/find/assist

For Product Updates

http://www.agilent.com/find/manufa

cturing_BERT

Warranty

The material contained in this document is

provided “as is,” and is subject to being

changed, without notice, in future editions.

Further, to the maximum extent permitted by

applicable law, Agilent disclaims all

warranties, either express or implied, with

regard to this manual and any information

contained herein, including but not limited to

the implied warranties of merchantability and

fitness for a particular purpose. Agilent shall

not be liable for errors or for incidental or

consequential damages in connection with

the furnishing, use, or performance of this

document or of any information contained

herein. Should Agilent and the user have a

separate written agreement with warranty

terms covering the material in this document

that conflict with these terms, the warranty

terms in the separate agreement shall

control.

Technology Licenses

The hardware and/or software described in

this document are furnished under a license

and may be used or copied only in accordance

with the terms of such license.

Restricted Rights Legend

If software is for use in the performance of a

U.S. Government prime contract or

subcontract, Software is delivered and licensed

as “Commercial computer software” as

defined in DFAR 252.227-7014 (June 1995), or

as a “commercial item” as defined in FAR

2.101(a) or as “Restricted computer software”

as defined in FAR 52.227-19 (June 1987) or any

equivalent agency regulation or contract

clause. Use, duplication or disclosure of

Software is subject to Agilent Technologies’

standard commercial license terms, and nonDOD Departments and Agencies of the U.S.

Government will receive no greater than

Limited Rights as defined in FAR 52.22719(c)(1-2) (June 1987). U.S. Government users

will receive no greater than Limited Rights as

defined in FAR 52.227-14 (June 1987) or DFAR

252.227-7015 (b)(2) (November 1995), as

applicable in any technical data.

Safety Notices

CAUTION

A CAUTION notice denotes a hazard.

It calls attention to an operating

procedure, practice, or the like that, if

not correctly performed or adhered to,

could result in damage to the product

or loss of important data. Do not

proceed beyond a CAUTION notice

until the indicated conditions are fully

understood and met.

WARNING

A WARNING notice denotes a

hazard. It calls attention to an

operating procedure, practice, or the

like that, if not correctly performed

or adhered to, could result in

personal injury or death. Do not

proceed beyond a WARNING notice

until the indicated conditions are

fully understood and met.

2 N5980A User Guide

Page 3

Safety Summary

General Safety Precautions

The following general safety

precautions must be observed during

all phases of operation of this

instrument. Failure to comply with

these precautions or with specific

warnings elsewhere in this manual

violates safety standards of design,

manufacture, and inte nded use of the

instrument.

Agilent Technologies Inc. assumes

no liability for the customer's failure

to comply with these requirements.

Before operation, review the

instrument and manual for safety

markings and instructions. You must

follow these to ensure safe operation

and to maintain the instrument in

safe condition.

General

This product is a Safety Class 1

instrument (provided with a

protective earth terminal). The

protective features of this product

may be impaired if it is used in a

manner not specified in the

operation instructions.

All Light Emitting Diodes (LEDs)

used in this product are Class 1

LEDs as per IEC 60825-1.

Environment Conditions

This instrument is intended for

indoor use in an installation category

II, pollution degree 2 environment. It

is designed to operate at a maximum

relative humidity of 95% and at

altitudes of up to 2000 meters.

Refer to the specifications tables for

the ac mains voltage requirements

and ambient operating temperature

range.

Before Applying Power

Verify that all safety precautions are

taken. The power cable inlet of the

instrument serves as a device to

disconnect from the mains in case of

hazard. The instrument must be

positioned so that the operator can

easily access the power cable inlet.

When the instrument is rack

mounted the rack must be provided

with an easily accessible mains

switch.

Ground the Instrument

To minimize shock hazard, the

instrument chassis and cover must

be connected to an electrical

protective earth ground. The

instrument must be connected to the

ac power mains through a grounded

power cable, with the ground wire

firmly connected to an electrical

ground (safety ground) at the power

outlet. Any interruption of the

protective (grounding) conductor or

disconnection of the protective earth

terminal will cause a potential shock

hazard that could result in personal

injury.

Do Not Operate in an Explosive

Atmosphere

Do not operate the instrument in the

presence of flammable gases or

fumes.

Do Not Remove the Instrument

Cover

Operating personnel must not

remove instrument covers.

Component replacement and internal

adjustments must be made only by

qualified personnel.

Instruments that appear damaged or

defective should be made

inoperative and secured against

unintended operation until they can

be repaired by qualified service

personnel.

Page 4

Safety Symbols on

Instruments

Indicates warning or caution. If

you see this symbol on a product,

you must refer to the manuals for

specific Warning or Caution

information to avoid personal

injury or damage to the product.

Safety requirements for electrical

equipment for measurement,

control, and laboratory use

CAN/CSA C22.2 No. 1010.1

Notice for European Community:

This product complies with the

relevant European legal

Directives: EMC Directive

89/336/EEC and Low Voltage

Directive 73/23/EEC.

Conformity Mark of the

Australian ACA for EMC

compliance.

(1993) UL 3101, 3111 (First

Editions). This equipment has

also been evaluated to IEC 61010

edition 1 including amendments

1 and 2.

Environmental Information

General Recycling Mark for

plastic parts used in the product.

4 N5980A User Guide

Page 5

Contents

Contents

1 Introduction 7

2 Getting Started 8

Inspect Shipment 8

Connect the Instrument 9

Front Panel 9

Rear Panel 10

Install User Software for N5980A 11

To Install the User Software for N5980A 12

To Access N5980A 14

3 Operating N5980A with the User Interface 16

Introduction 16

Running the BER Test 17

Setting the Instrument Parameters 18

Setup 18

Advanced 19

Viewing the Results 20

4 Reference for the User Interface 21

File Menu 21

Advanced Mode 21

Store Setting 21

Store Setting As 22

Recall Setting 22

Factory Default Setting 22

Instrument Default Setting 22

Exit 22

Connection Menu 22

Connect 23

Info 24

Help Menu 24

Error Indicators 24

BER Bar 25

N5980A User Guide 5

Page 6

Contents

Error 25

Sync Loss 25

Setup and Advanced Tab 26

Setup 26

Advanced 27

BER and Advanced BER Tab 28

BER 28

Advanced BER 29

5 Programming Reference 30

Introduction 30

Common Command Summary 30

Agilent N5980A Command Summary 30

SCPI Instrument Command List- Reference 31

Common Commands 31

All Channels 33

SMA Output (Electrical Generator) 34

SFP Output (Optical Generator) 36

Trigger Output 38

Synchronization mode 39

Sample Code 42

6 N5980A User Guide

Page 7

Introduction

1 Introduction

This chapter introduces you to the Serial BERT User Guide, and it

provides information on the various chapters and topics covered.

1 Getting Started

Inspect Shipment

Connect the Instrument

Install User Software for N5980A

2 Operating N5980A with the User Interface

Introduction

Running the BER Test

Setting the Instrument Parameters

Viewing the Results

3 Reference for the User Interface

4 Programming through SCPI

Introduction

Common Command Summary

SCPI Instrument Command List

Sample Code

N5980A User Guide 7

Page 8

Getting Started

2 Getting Started

Inspect Shipment

Agilent N5980A 3.125 GB/s

Serial BERT

Before you get started with the Serial BERT check if the shipment

package contains the following standard deliverables:

If the content is incomplete, if there is

mechanical damage, or if the

instrument does not work within its

specifications, notify the nearest Agilent

office. The Agilent office will arrange

for repair or replacement without

awaiting settlement.

SFP Loopback connector

Local Power Cord

USB Cable

(see CD content below).

CD

The CD content is:

Autorun.inf – If your PC supports autorun, this file starts the

installation.

dotnetfx.exe - This installs the latest Microsoft .Net Framework

2.0. This should be done in case .Net Framework 2.0 is not

already installed, and internet access is not available.

N5980A.msi – The Serial BERT installer package

Setup.exe – If your PC doesn’t support autorun, execute this file

to run the installation.

DoC.pdf - Declaration of Conformity

DataSheet.pdf – This document contains the product

specifications.

Presales_Presentation.pdf – Describes typical applications.

UserGuide.pdf – This document contains the details about how

to use the Serial BERT.

8 N5980A User Guide

Page 9

Getting Started

Connect the Instrument

In order to connect the Serial BERT let’s have a look at the Front and

the Rear Panels:

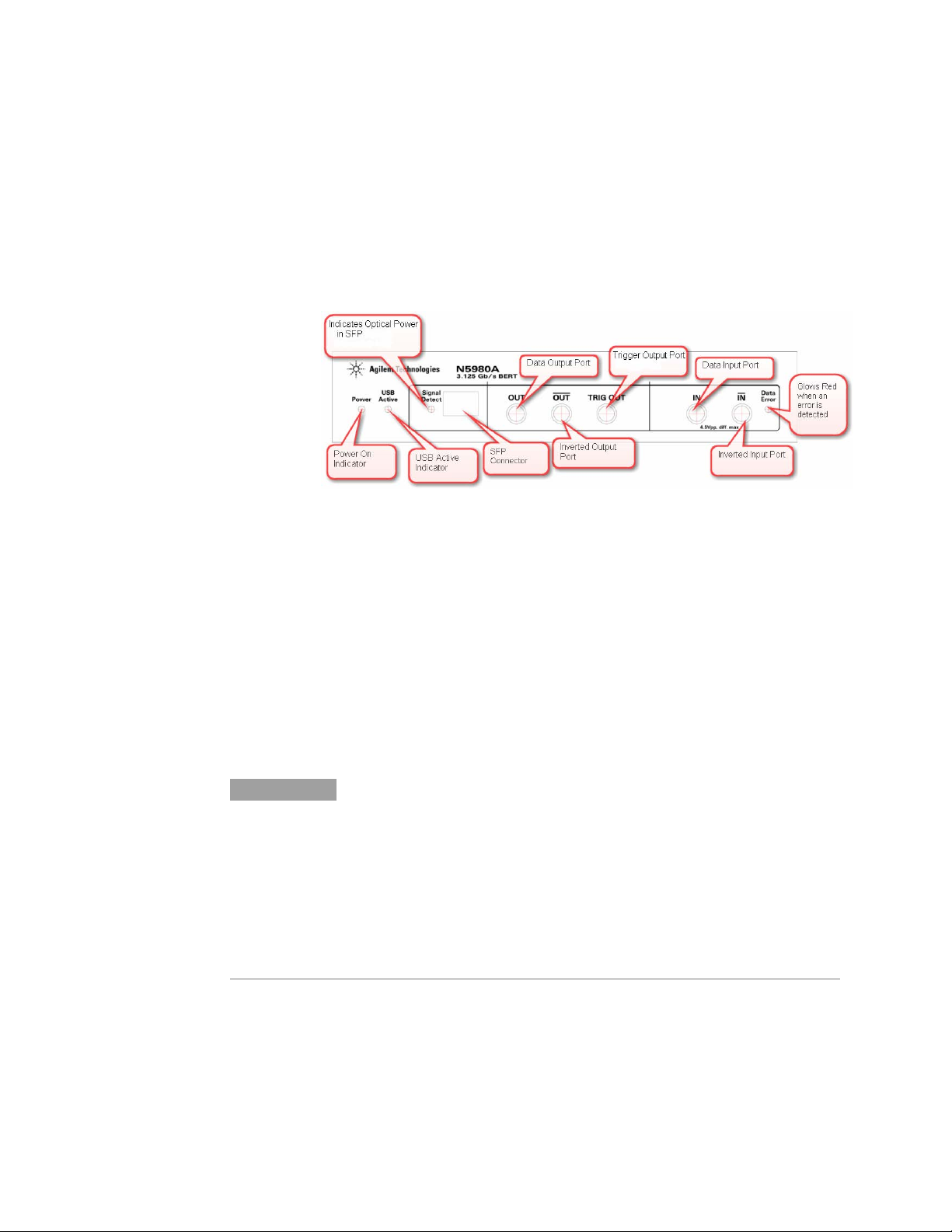

Front Panel

The Front Panel has LEDs, Data In/Out ports, and an SFP connector.

Figure 1 Front Panel

SFP

The Small Form Factor Pluggable interface (SFP) is an industry

standard daughter card used in networking devices. It interfaces a

network device with a networking cable. Typically SFP modules are

optical transceivers using multimode (850 nm), or single-mode (1310

nm, 1550nm) cabling.

An SFP loopback connector is part of the N5980A shipment delivery.

This connector is used for functional verification of the SFP port. It

has an internal loop from the SFP output to the SFP input signal.

NOTE

SFP compliant modules can be inserted into the SFP slot. While selecting

golden SFP modules observe the specifications of the selected device. Make

sure that the supported maximum PRBS length, and the maximum data rate

matches with the N5980A settings. Make sure that the wavelength of the SFP

module, and the cabling are identical, and that the optical power is within the

specified limit. To measure BER at the SFP input, select the Input “SFP

(Optical)” in the user interface.

N5980A User Guide 9

Page 10

Getting Started

LED

LEDs Function

Power LED

USB Active

Signal Detect

Data Error

Indicates power-on

Indicates that the instrument is currently being

used/controlled by the user software

Indicates the status of the Signal Detect line when the

inserted SFP module supports a Signal Detect Control line.

Usually this pin indicates whether the optical input power

is above or within the specified range.

Indicates that the error detector has detected bit errors

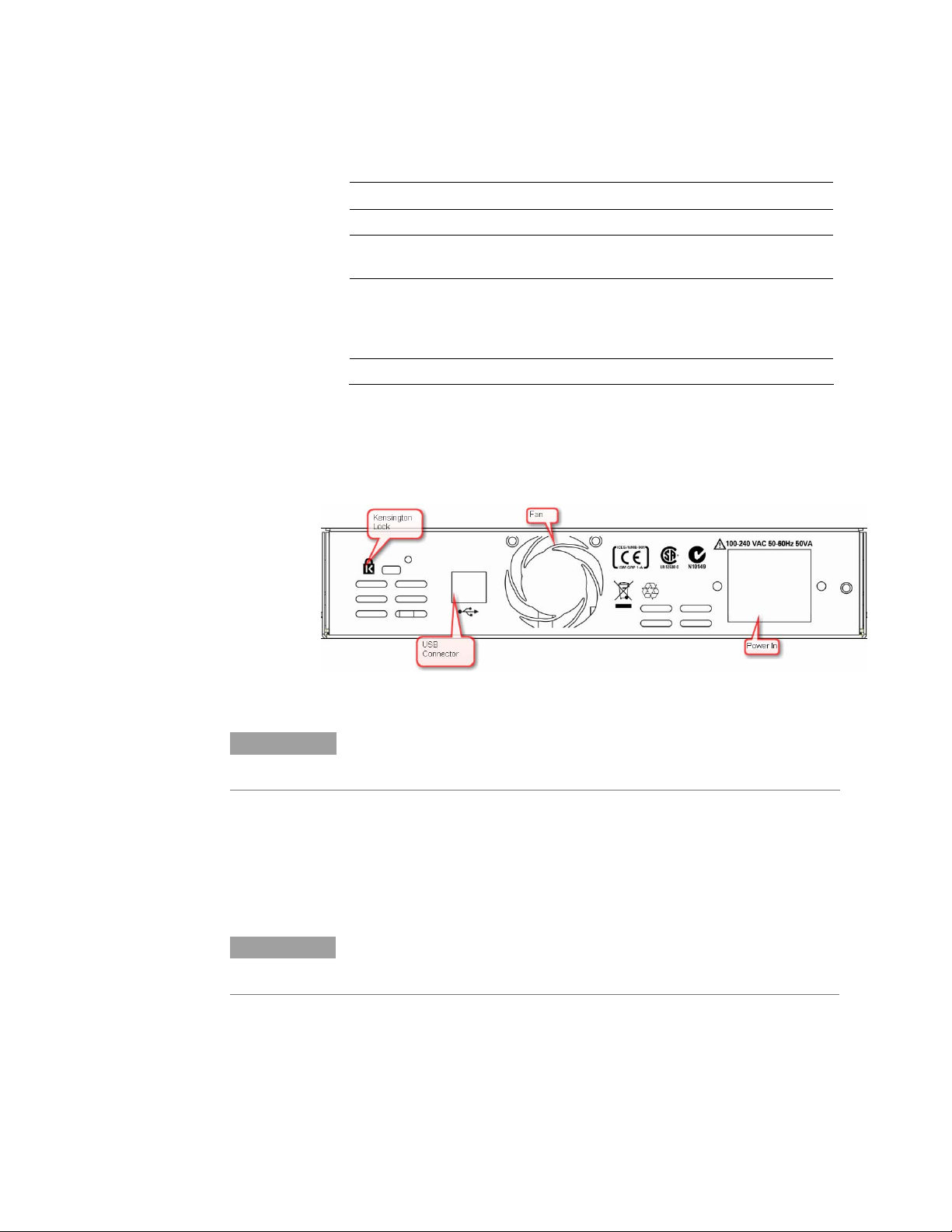

Rear Panel

The Rear Panel has the USB connector,the Power in, and the safety

symbols.

Figure 2 Rear Panel

NOTE

For proper ventilation keep the Serial BERT at a distance of 2 cm on both sides,

and 10 cm at the back.

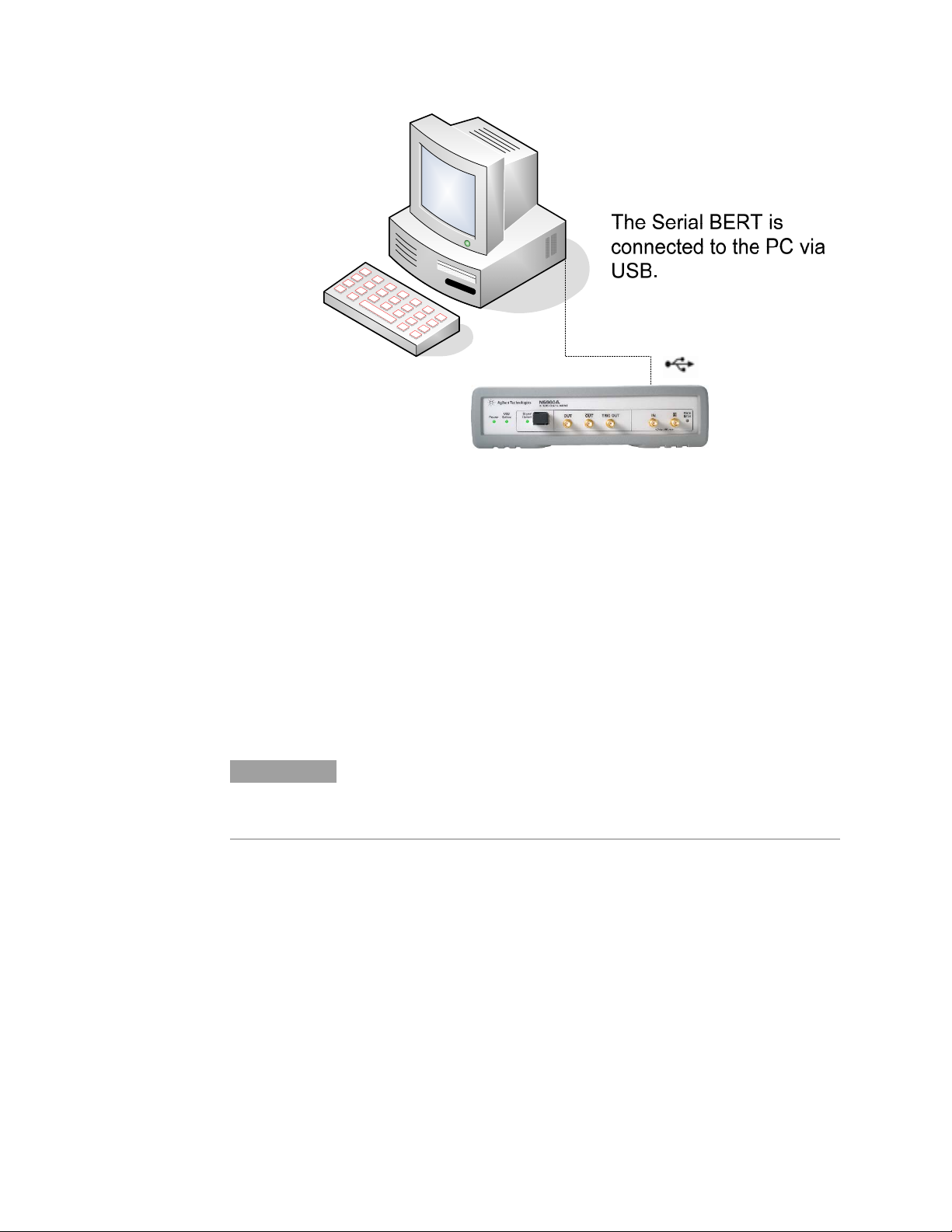

To Connect N5980A

1 Connect the N5980A power cord at the rear panel Power In.

2 Connect the instrument, via USB, to the PC on which the User

Interface will be installed.

NOTE

Some USB hubs might decrease performance. If possible, directly connect the

N5980A to your PC.

10 N5980A User Guide

Page 11

Getting Started

Figure 3 Serial BERT setup diagram

Install User Software for N5980A

The requirements for software installation:

Either Windows 2000 Service Pack 4, or Windows XP Service

Pack 2

Microsoft .NET Framework 2.0 is automatically downloaded from

the Microsoft download center during installation. Alternatively

dotnetfx.exe may be run from the installation CD in order to

install the Microsoft .Net Framework 2.0. This step should be

executed in case .Net Framework 2.0 is not already installed on

the computer, or the available internet connection is slow.

NOTE

To execute the User Software, Microsoft .NET Framework 2.0 is required.

N5980A User Guide 11

Page 12

Getting Started

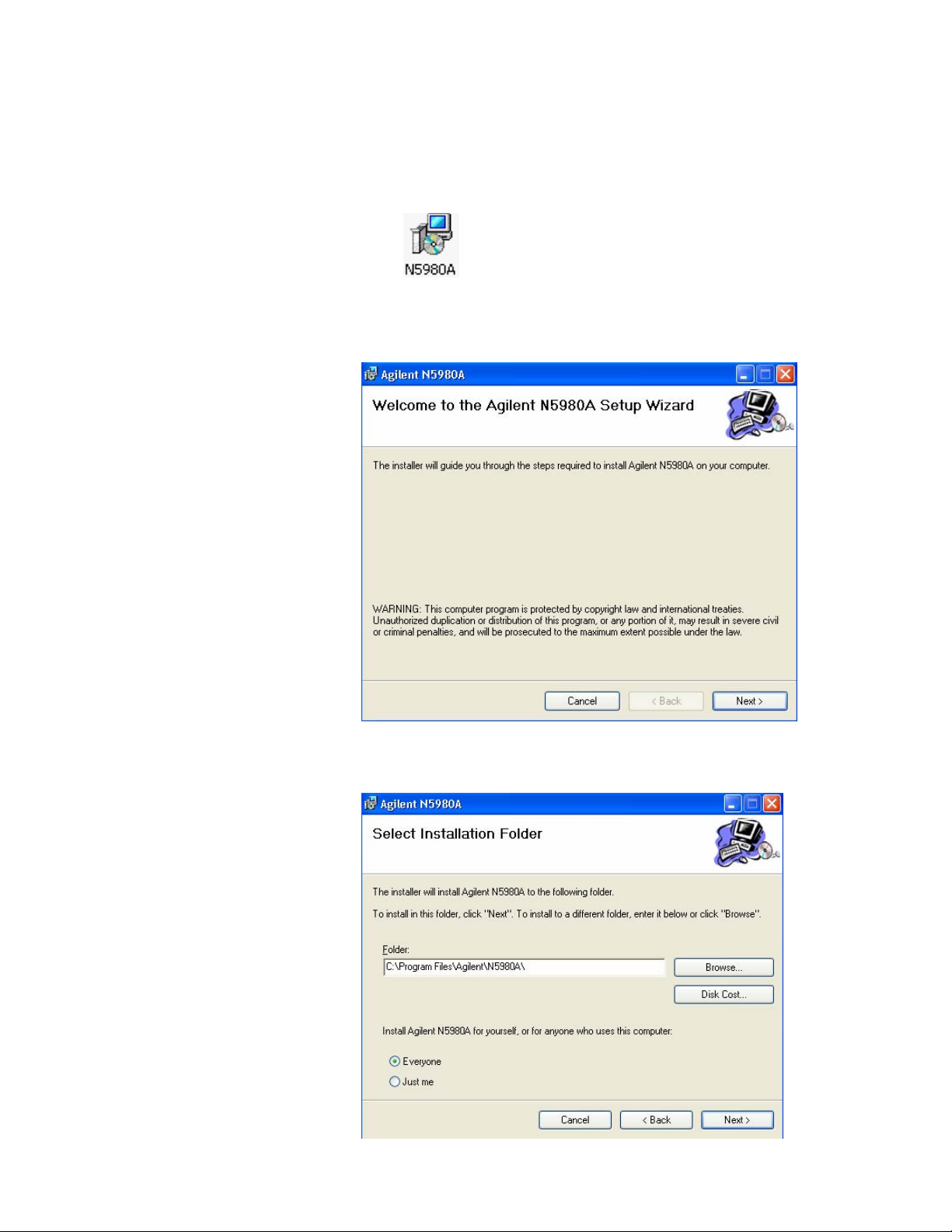

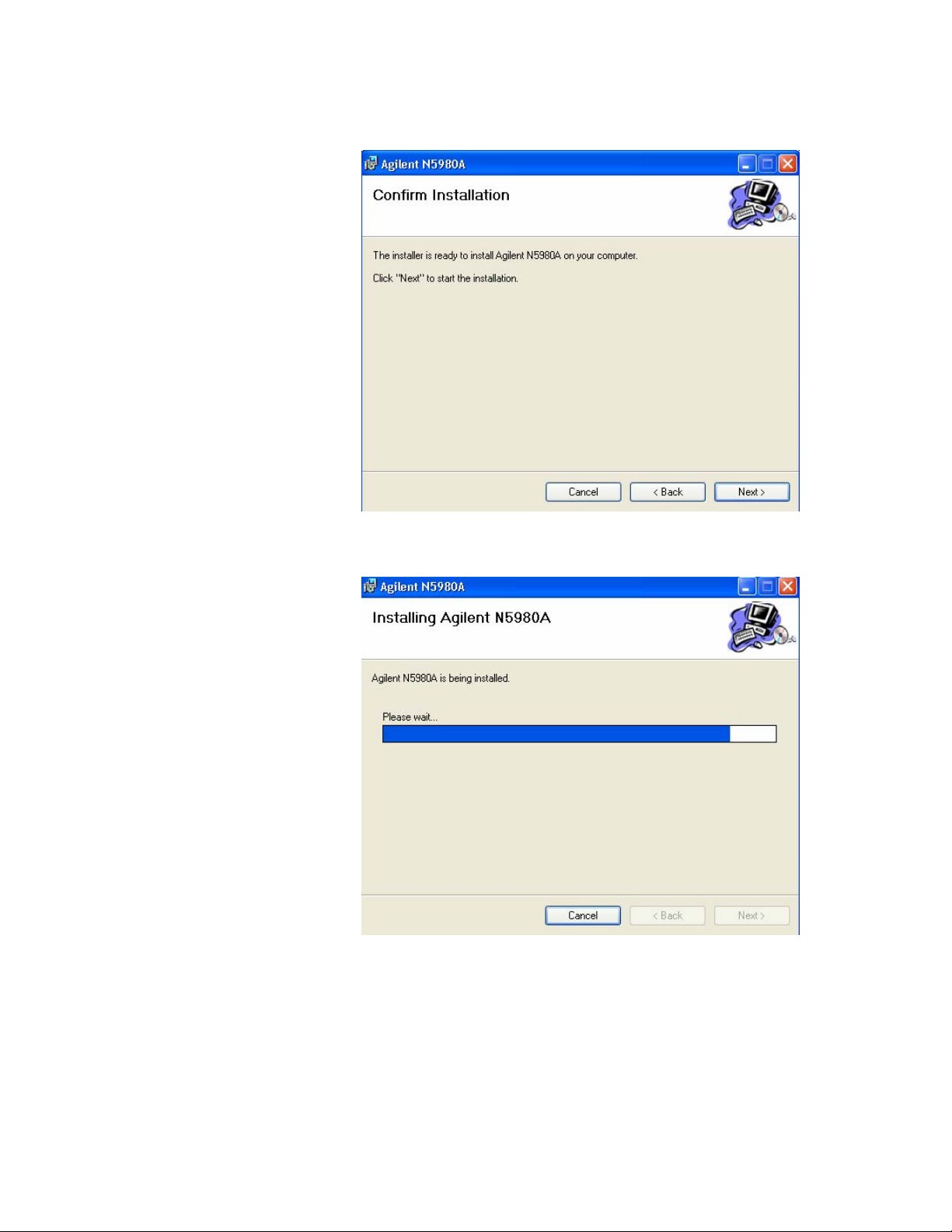

To Install the User Software for N5980A

1 Insert the CD in the PC’s CD Drive.

2 Double-click

Displays the Welcome screen.

3 The Installer guides you through the installation process.

12 N5980A User Guide

Page 13

Getting Started

Select the folder in which N5980A will be saved.

N5980A User Guide 13

Page 14

Getting Started

After the installation is completed, click Finish to close the installer.

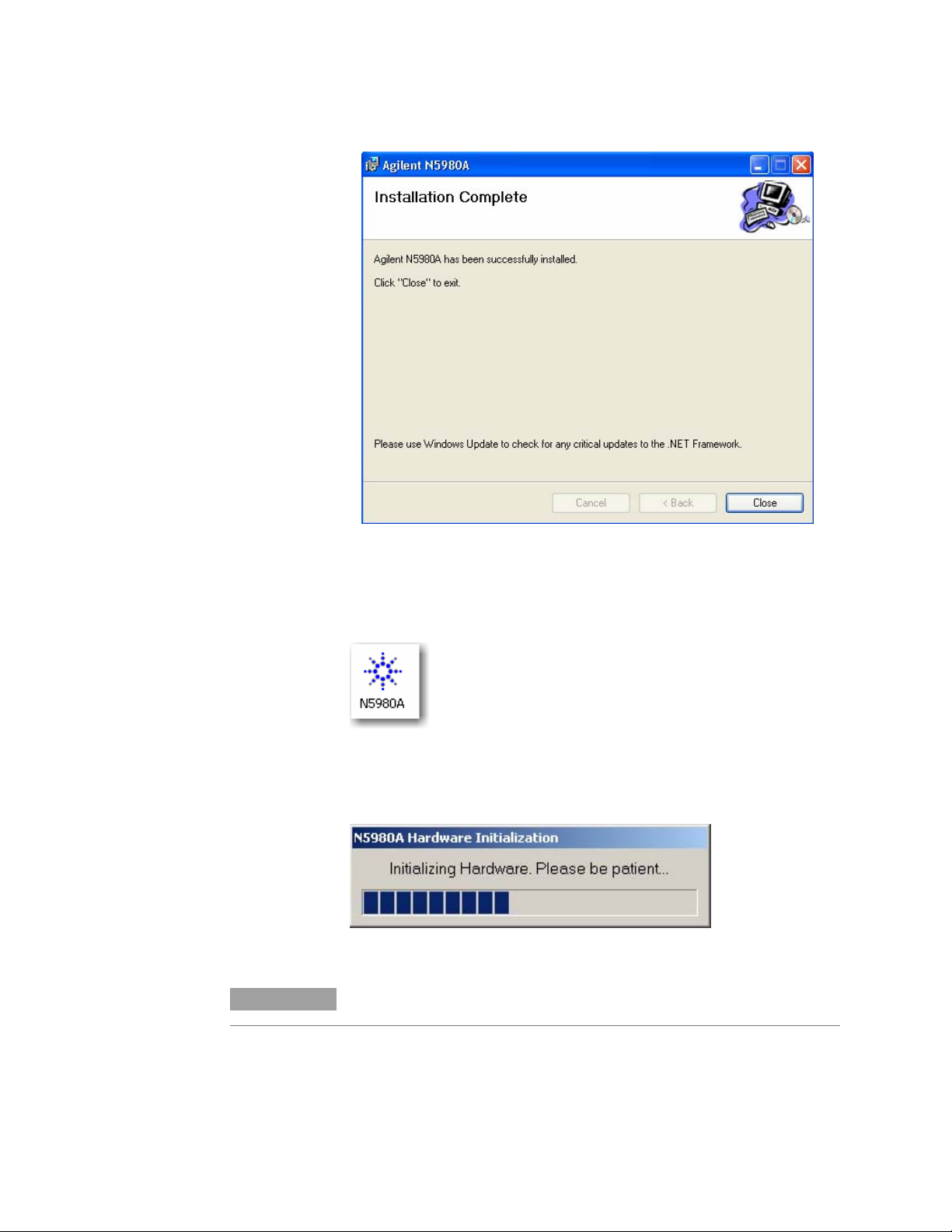

To Access N5980A

To launch N5980A, go to Program File and click on:

If there is a N5980A connected to the PC via USB, and the User

Software is installed, then the following screen appears:

NOTE

Typical Hardware Initialization duration is between 3 to 5 minutes.

14 N5980A User Guide

Page 15

Getting Started

Upon completion of Hardware Initialization, the User Interface starts

and the following window appears.

Demo Offline

In Demo Offline mode N5980A need not be connected to the PC. The

connection dialog looks like the screen below.

Click Demo (Offline) to start the offline version of the GUI.

NOTE

Before disconnecting the USB cable, or powering down the instrument, make

sure you have closed the User Software.

.

N5980A User Guide 15

Page 16

Operating N5980A with the User Interface

3 Operating N5980A with the User Interface

Introduction

The graphical user interface runs on the PC, and the screen is

divided into two areas; one for setting parameters, and the other for

viewing results.

The Setting Parameters area of the screen has options for setting

parameters like Data Rate, Data Pattern and so on. The Viewing

Results area of the screen runs the test, and displays the results.

The User Software operates in two modes, Standard Mode and

Advanced Mode.

In Standard Mode you can modify the basic instrument setting,

and view the results.

In Advaced Mode you can modify the detailed instrument

settings, and view all the results.

NOTE

For more details check the Reference for the User Interface

.

16 N5980A User Guide

Page 17

Operating N5980A with the User Interface

Running the BER Test

The User Software supports a quick pass/fail measurement, which is

generally used for testing the DUT in manufacturing. This

measurement allows you to count the number of bit errors during a

user specified gating time. The result of the measurement is

displayed as Gating Errors, Gating BER, and by a simple red (=fail)

/ green (=pass) color coding of the Gating BER bar.

1 To run the basic measurement, click on Start Gating Period or

F12.

2 In case you want to stop the running measurement, click on:

3 Once the measurement is complete, the results would appear as

follows:

NOTE

N5980A User Guide 17

The Gating Time can be modified in Advanced Mode.

Page 18

Operating N5980A with the User Interface

Setting the Instrument Parameters

N5980A has two (SFP and SMA) integrated Pattern Generators,

which can be adjusted to different parameters, for example, different

patterns or different error insertion rates.

The N5980A Error Detector has two (SFP and SMA) different

physical input ports, while only one input port can be analyzed at a

given time. The analyzed input can be selected with the User

Software.

There are two setting pages, Setup and Advanced.

Setup

In the Setup page you can change, the Data Rate, which applies for

the Pattern Generator, and the Error Detector ; Data Pattern and

Logic Level for the Pattern Generator; and Data Pattern and the

analyzed Input of the Error Detector.

1 The following options are under Data Rate; and XAUI

[3,125.00Mb/s] is the default data rate:

2 The Data Pattern of the Pattern Generator supports PRBS

polynoms, clock patterns, and K28.5 pattern. PRBS 2^23-1 is

the default pattern:

NOTE

Use the scroll bar to see the complete list of patterns provided.

3 Logic Level has two options, ECL [850mV], and LVDS [400mV].

ECL [850mV] is the default level.

4 Error Detector Pattern. For details refer to

5 Error Detector Input has two options, SMA [Electrical], and

SFP [Optical]. SMA [Electrical] is the default input for the

Error Detector.

Error Detector.

18 N5980A User Guide

Page 19

Operating N5980A with the User Interface

Advanced

To view the Advanced page, click on the File menu and enable the

Advanced Mode:

The Advanced page has the following settings:

In this page you can set SFP and SMA Data Patterns, Error Insertion

Rate, and also select Clock Trigger Output for the Generator. It also

gives the option for setting the Gating Time for the Error Detector.

N5980A User Guide 19

Page 20

Operating N5980A with the User Interface

Viewing the Results

There are two options for viewing the results, BER and Advanced

BER, as shown below.

BER displays Gating BER and the Elapsed Gating Time.

The Advanced BER page can be opened only when Advanced Mode

is enabled. See below:

In this page you can see the Gating Errors, Actual Errors , and the

Pattern that is currently being used by the Error Detector.

20 N5980A User Guide

Page 21

Reference for the User Interface

4 Reference for the User Interface

This section explains the measured parameters, and the display

options that are specific to these measurements. Additionally, some

information is provided to explain the theoretical background to

these measurements.

When N5980A is launched the following screen is displayed:

File Menu

The File menu has the following options.

Advanced Mode

The Advanced Mode allows you to change the settings, and view the

results in the Advanced, and the Advanced BER pages.

Store Setting

This saves the changes made to the setting. To enable this menu

option you need to store a setting first.

N5980A User Guide 21

Page 22

Reference for the User Interface

Store Setting As

This is used to store/recall any setting with a user selected filename.

The user selects a specific location, and file name to save the settings.

Recall Setting

This recalls the saved settings.

Factory Default Setting

Restores the factory default settings, and is useful when the user has

problems finding a defined instrument state.

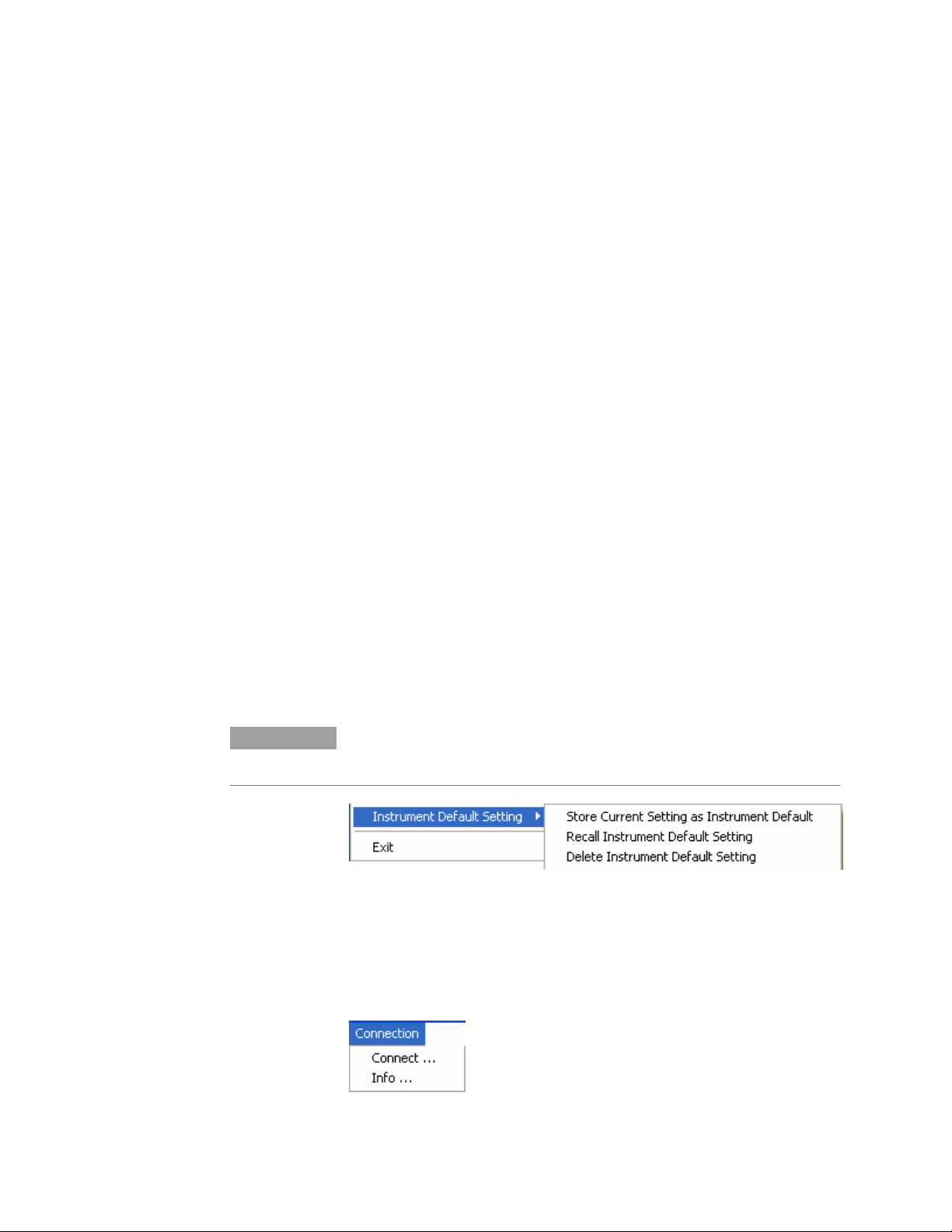

Instrument Default Setting

This is enabled only when Advanced Mode is on. The Instrument

Default Setting has three options related to the default setting.

Store Current Setting As Instrument Default, stores the

instruments current setting as default for this instrument. The

instrument default setting will be automatically applied whenever the

user software connects to the instrument. The instrument default

setting is stored individually for each instrument based on the

instrument's serial number.

Recall Instrument Default Setting, recalls the instrument's default

setting.

Delete Instrument Default Setting, deletes the instrument's default

setting.

If no User Setting exists, the factory default setting will be applied

when the User Software connects to the instrument.

NOTE

This setting is stored individually for each instrument by storing the instrument

serial number in the file name.

.

Exit

This closes the session with N5980A.

Connection Menu

This has the following options:

22 N5980A User Guide

Page 23

Reference for the User Interface

Connect

The Connect… option shows the Connection Dialog box.

NOTE

NOTE

If there are no instruments connected to the PC, then Connect button will be

disabled. If an instrument is connected, the user can connect to that

instrument.

In the Available Devices, the list of connected device will appear,

and the Connect button will be enabled.

Each PC can control only one N5980A.

In Remote Programming Setup, a port number can be selected for the

remote programming interface. The instrument will then be accessed

via a socket that connects the PC’s IP address and the chosen port

number.

Refresh updates the list of Available Devices.

Selecting the connection launches the GUI, as shown below.

N5980A User Guide 23

Page 24

Reference for the User Interface

Help Menu

Info

This option provides the following information.

Error Indicators

The Help Menu has the following information.

About gives you the Software details.

The GUI screen contains the Error Indicator:

There are two indicators and a BER bar, see the screen above. These

indicators inform you about the following errors:

• Bit error in the data stream

• Loss of pattern synchronization

• Complete loss of data

24 N5980A User Guide

Page 25

Reference for the User Interface

BER Bar

The BER bar displays the BER calculated during a period of 200 ms.

Error

This indicator turns red when errors are detected.

Stable errors are caused by the error add function: it turns

SFP/SMA Error Insertion Rate off.

Variable and high errors may be caused by faulty

connectors/cables. BERT connected to your device shows:

Stable or variable errors caused by your device. Correct the

problems with your device.

If the problems are not clear, then accumulate measurement

data and analyze the results.

Sync Loss

This indicator turns red when the measured BER is higher than the

sync threshold of 0.1.

The ED pattern does not match the incoming data pattern.

Patterns have lost sync.

The device connected to the BERT has inverted the data pattern.

The device has changed the data pattern.

NOTE

Error Detector can sync only PRBS patterns. Clock patterns cannot be measured

by the error detector, and will result in loss of synchronization.

N5980A User Guide 25

Page 26

Reference for the User Interface

Setup and Advanced Tab

Setup

General

Data Rate:

There are different data rates in the drop down list. These rates are

common to the Generator, and the Error Detector.

The following screen lists the available Data Rates.

Generator

Data Pattern:

There are different patterns available, for example, PRBS patterns,

Clock patterns, and K28.5 pattern.

NOTE

The drop down screen below lists the available patterns. To view all the

patterns use the scroll bar.

Level:

There are two levels provided, the ECL and the LVDS.

26 N5980A User Guide

Page 27

Reference for the User Interface

Error Detector

Data Pattern:

The Error Detector (ED) has a built in CDR for automatic clock

recovery, and phase alignment. The ED also performs automatic

polarity correction when required. Additionally it can detect the

incoming PRBS. The input for the Data Pattern has two options, SMA

[Electrical], and SFP [Optical]. SMA [Electrical] is the default input

for the Error Detector.

Automatic

SFP (Optical

Generator)

SMA (Electrical

Generator)

PRBS 2^7-1

PRBS 2^15-1

PRBS 2^23-1

PRBS 2^31-1

Error Detector determines the incoming data stream

automatically. The supported data streams are:

PRBS 2^7-1

PRBS 2^15-1

PRBS 2^23-1

PRBS 2^31-1

The data pattern is taken from the current setting on the SFP

generator output.

The data pattern is taken from the current setting on the SMA

generator output.

A PRBS 2^7-1 is used for pattern synchronization.

A PRBS 2^15-1 is used for pattern synchronization.

A PRBS 2^23-1 is used for pattern synchronization.

A PRBS 2^31-1 is used for pattern synchronization.

Input:

There are two inputs to the Error Detector, the SMA (Electrical),

and the SFP (Optical).

Advanced

In the Advanced tab you can separately set the Data Patterns, and

Error insertion for the SFP and SMA generator outputs.

Generator

SFP Data Pattern:

In this drop down list you have the same set of patterns, as in the

setup page, to select from. The selected pattern will affect the SFP

output.

SMA Data Pattern:

In this drop down list you have the same set of patterns to select

from. The selected pattern will affect the SMA output.

N5980A User Guide 27

Page 28

Reference for the User Interface

NOTE

NOTE

On the advanced page the SFP and the SMA Data pattern can be adjusted

independently.

SFP Error Insertion Rate:

This drop down list gives a set of Error Insertion Rates that can be

inserted for the SFP output.

SMA Error Insertion Rate:

This drop down list gives a set of Error Insertion Rates that can be

inserted for the SFP output.

Both the lists contain the same set of Error Insertion Rates. The following

screen shows this list.

Trigger Out:

The Trigger Out lists a set of clock triggers. The list is shown below:

Error Detector

Gating Time:

The Gating Time can be set in terms of hour, minute, and seconds.

The maximum gating time is 168 hours 59 minutes and 59 seconds.

BER and Advanced BER Tab

BER

Gating BER Bar

This BER Bar indicates the Bit Error during the Gating Period. Once

the Gating Period is complete this Bar turns green if the test passes

(Gating BER is 0.0), and turns red if the test fails (Gating BER > 0.0).

28 N5980A User Guide

Page 29

Reference for the User Interface

The screenshot below shows the Gating BER Bar.

Elapsed Gating Time

This bar shows the gating time while the test runs.

Before the test begins this bar is empty as shown below:

And after the gating time is complete this bar appears as shown

below:

Advanced BER

This page contains Gating Error, Actual Error, Error Detector Pattern

Gating BER Bar, and Elapsed Gating Time.

Gating Errors

This indicates the number of Errors that occurred during the gating

time.

Actual Errors

This indicates the number of errors that occurred during the last

update interval of 200ms.

Error Detector Pattern

This displays the pattern that is currently being used by the Error

Detector.

N5980A User Guide 29

Page 30

Programming Reference

5 Programming Reference

Introduction

The SCPI commands represent the instrument’s advanced analysis,

and pattern generation features that can be controlled from within

the remote programs.

Programming can only be done using raw Windows Sockets. The

remote programming language is close to SCPI, but it’s without a full

featured SCPI parser.

Thus N5980A is not SCPI1997 compliant.

The missing standard SCPI features:

Status handling/registers

Support of short and long form of SCPI commands (the

commands must be sent exactly like noted below)

No default suffixes.

Only a few of the standard commands (e.g. *OPC is missing)

The commands must always be complete, even for the second

parameter that belongs to the same root node inside a transaction.

Example:

SCPI allows: :SOUR1:PATT PRBS7;EADD ONCE

N5980A needs: :SOUR1:PATT PRBS7; :SOUR1:PATT:EADD

ONCE

See

Sample Code

as an example to control the N5980A from within a remote program.

Common Command Summary

*TST?

*OPC?

*RST

*IDN?

*OPT?

Agilent N5980A Command Summary

:FREQ?

:FREQ

:MMEM:STOR:STAT

:MMEM:LOAD:STAT

:SYST:ERR?

:SOUR1:PATT

:SOUR1:PATT?

:SOUR1:PATT:EADD

:SOUR1:PATT:EADD:RATE?

:SOUR1:PATT:EADD:RATE

30 N5980A User Guide

Page 31

Programming Reference

:SOUR1:VOLT

:SOUR1:VOLT?

:SOUR2:PATT

:SOUR2:PATT?

:SOUR2:PATT:EADD

:SOUR2:PATT:EADD:RATE

:SOUR2:PATT:EADD:RATE?

:SOUR3:PATT?

:SOUR3:PATT

:SENS1:SYNC:TYPE

:SENS1:SYNC:TYPE?

:SENS1:PATT?

:SENS1:GATE:PER

:SENS1:GATE:PER?

:SENS1:FETC:ECO?

:SENS1:FETC:ECO:DELT?

:SENS1:FETC:ERAT?

:SENS1:FETC:ERAT:DELT?

:SENS1:INP

:SENS1:INP?

:SENS1:GATE:STAT

:SENS1:GATE:STAT?

SCPI Instrument Command List- Reference

The following reference section lists the instrument commands. The

commands are described, and in addition the available attributes for

certain commands are also described.

Common Commands

ID Query

Syntax *IDN?

Description Reads the identification string from the instrument. The

*IDN?

format of the identification string is:

Agilent Technologies,Product Number,Serial

Number,Revision Info

Product Number is currently N5980A.

Serial Number is read from the instrument hardware (0 if

offline).

Revision Info consists of:

Application Revision (Microsoft w.x.y.z format)

Instruments Firmware Revision (Major.Minor, 0 if

offline)

Hardware Revision (0 if offline)

N5980A User Guide 31

Page 32

Programming Reference

Read error queue

Syntax :SYST:ERR?

Description Reads one error from the instruments error queue.

Load factory default setting

Syntax *RST

Description Discards the current instrument setting, and loads the

Operation complete

Syntax *OPC?

Description Returns 1 when all pending commands have been

Option Query

Syntax *OPT?

Description Reports all instrument options. Currently the instrument

:SYST:ERR?

*RST

reset/default setting.

*OPC?

executed. Blocks until all pending commands are executed.

*OPT?

does not have any option, so this query reports 0.

Output: always return 0

Self test

Syntax *TST?

Description Performs the instrument selftest. Returns 0 in case of

*TST?

success and 1 in case of errors during the selftest. Error

messages that are discovered during the selftest will be

stored in the instrument’s error queue.

32 N5980A User Guide

Page 33

Programming Reference

Store current setting

Syntax :MMEM:STOR:STAT “filename”

Description Stores the current setting into the specified file. If a file

Recall setting

Syntax :MMEM:LOAD:STAT “filename”

Description Loads stored instrument setting from the given file.

All Channels

Datarate

Syntax :FREQ?

Description Either sets or gets the instrument’s datarate. The datarate

Available Data Rates

:MMEM:STOR:STAT “filename”

with the same name already exists, then this file will be

overwritten.

:MMEM:LOAD:STAT “filename”

:FREQ

:FREQ FE

OC3|OC12|OC48|OC48FEC|FC1|FC2|GBE1|XAUI

always applies to all the channels (electrical out, optical out,

clock out, and error detector input).

Name Frequency Parameter

Fast Ethernet 125.00Mb/s FE

OC-3 155.52Mb/s OC3

OC-12 622.08Mb/s OC12

OC-48 2.48832Gb/s OC48

OC-48 with

FEC

1 x FC 1.0625Gb/s FC1

2 x FC 2.125Gb/s FC2

Gigabit

Ethernet

XAUI 3.125Gb/s XAUI

2.666Gb/s OC48FEC

1.25Gb/s GBE1

N5980A User Guide 33

Page 34

Programming Reference

SMA Output (Electrical Generator)

The SMA output is accessed via the root node :SOUR1

Pattern

:SOUR1:PATT

Syntax :SOUR1:PATT?

:SOUR1:PATT

PRBS7|PRBS15|PRBS23|PRBS31|CLK2|CLK4|CLK8|CLK10|CLK16

|CLK20|K28_5

Description Either sets or gets the pattern of the SMA output.

Available

Patterns

Name Parameter

PRBS 2^7-1 PRBS7

PRBS 2^15-1 PRBS15

PRBS 2^23-1 PRBS23

PRBS 2^31-1 PRBS31

Clock / 2 CLK2

Clock / 4 CLK4

Clock / 8 CLK8

Clock / 10 CLK10

Clock / 16 CLK16

Clock / 20 CLK20

K28.5 K28_5

34 N5980A User Guide

Page 35

Programming Reference

Error Insertion

The error insertion is capable to enforce a given error ratio, and to

add single errors into the data stream. Both are available in parallel.

Insertion Rate

Description Either sets or gets the error insertion rate. Only the listed

Available Insertion

Add Single Error

Description Adds a single error to the generated data stream. This is

:SOUR1:PATT:EADD:RATE

Syntax :SOUR1:PATT:EADD:RATE?

:SOUR1:PATT:EADD:RATE NR3

error rates are available. If another value is specified while

sending the command, the error rate will be rounded to the

next available value.

Rate

Inserted error rate Parameter

None 0

1e-3 1e-3

1e-4 1e-4

1e-5 1e-5

1e-6 1e-6

1e-7 1e-7

1e-8 1e-8

1e-9 1e-9

:SOUR1:PATT:EADD

Syntax :SOUR1:PATT:EADD ONCE

available even if the cyclic error insertion is active.

Output Level

Syntax :SOUR1:VOLT?

Description This either sets or gets the output level. The output is

Available Output

Levels

:SOUR1:VOLT

:SOUR1:VOLT ECL|LVDS

always AC. Specifying the output level actually changes

only the amplitude of the generated electrical signal.

Parameter Level

ECL 850mV

LVDS 400mV

N5980A User Guide 35

Page 36

Programming Reference

SFP Output (Optical Generator)

The SFP output is accessed via the root node :SOUR2

Pattern

:SOUR2:PATT

Syntax :SOUR2:PATT?

:SOUR2:PATT

PRBS7|PRBS15|PRBS23|PRBS31|CLK2|CLK4|CLK8|CLK10|CLK16

|CLK20|K28_5

Description Either sets or gets the pattern of the SFP output.

Available

Patterns

Name Parameter

PRBS 2^7-1 PRBS7

PRBS 2^15-1 PRBS15

PRBS 2^23-1 PRBS23

PRBS 2^31-1 PRBS31

Clock / 2 CLK2

Clock / 4 CLK4

Clock / 8 CLK8

Clock / 10 CLK10

Clock / 16 CLK16

Clock / 20 CLK20

K28.5 K28_5

36 N5980A User Guide

Page 37

Programming Reference

Error Insertion

The error insertion is capable to enforce a given error ratio, and to

add single errors into the data stream. Both are available in parallel.

Insertion Rate

Description Either sets or gets the error insertion rate. Only the listed

Available Insertion

Add Single Error

Description Adds a single error to the generated data stream. This is

:SOUR2:PATT:EADD:RATE

Syntax :SOUR2:PATT:EADD:RATE?

:SOUR2:PATT:EADD:RATE NR3

error rates are available. If another value is specified while

sending the command, the error rate will be rounded to the

next available value.

Rate

Syntax :SOUR2:PATT:EADD ONCE

Inserted error rate Parameter

None 0

1e-3 1e-3

1e-4 1e-4

1e-5 1e-5

1e-6 1e-6

1e-7 1e-7

1e-8 1e-8

1e-9 1e-9

:SOUR2:PATT:EADD ONCE

available even if the cyclic error insertion is active.

N5980A User Guide 37

Page 38

Programming Reference

Trigger Output

The trigger output is accessible via the root node :SOUR3

Pattern

:SOUR3:PATT

Syntax :SOUR3:PATT?

:SOUR3:PATT CLK2|CLK4|CLK8|CLK10|CLK16|CLK20

Description Either sets or gets the pattern of the trigger output.

Available Patterns

Name Parameter

Clock / 2 CLK2

Clock / 4 CLK4

Clock / 8 CLK8

Clock / 10 CLK10

Clock / 16 CLK16

Clock / 20 CLK20

Error Detector

The Error Detector channel is accessed via the root node :SENS1

Detected Pattern

Syntax :SENS1:PATT?

Description Gets the pattern that is currently used on the Error

Response

:SENS1:PATT?

Detector to compare it with the incoming data stream. This

might change when the Error Detector detects a very high

error ratio, and tries to synchronize with the incoming data.

Error Detector Pattern Response

PRBS 2^7-1 PRBS7

PRBS 2^15-1 PRBS15

PRBS 2^23-1 PRBS23

PRBS 2^31-1 PRBS31

Error Detector has lost pattern

synchronization.

UNKNOWN

38 N5980A User Guide

Page 39

Programming Reference

Synchronization mode

Synchronization

:SENS1:SYNC:TYPE

Syntax :SENS1:SYNC:TYPE

Description Either sets or gets the synchronization type. The

Available

Types

AUTO|SFP|SMA|PRBS7|PRBS15|PEBS23|PRBS31

:SENS1:SYNC:TYPE?

synchronization type defines which patterns will be used to

synchronize when a synchronization loss is detected by the

Error Detector.

Parameter Synchronization behavior

AUTO The Error Detector will use all available

patterns to synchronize with the incoming

data stream.

SFP The Error Detector will use only the

pattern that is set for the SFP output.

SMA The Error Detector will only use the

pattern that is set for the SMA output.

PRBS7 The Error Detector will only use a PRBS

2^7-1 data stream.

PRBS15 The Error Detector will only use a PRBS

2^15-1 data stream.

PRBS23 The Error Detector will only use a PRBS

2^23-1 data stream.

PRBS31 The Error Detector will only use a PRBS

2^31-1 data stream.

Actual Bit Error Rate

Syntax :SENS1:FETC:ERAT:DELT?

Description Gets the bit error ratio of the last update interval (approx

:SENS1:FETC:ERAT:DELT

200ms).

Actual Number of Errors

Syntax :SENS1:FETC:ECO:DELT?

Description Gets the number of errors that have been counted during

:SENS1:FETC:ECO:DELT

the last update interval (approx. 200ms).

N5980A User Guide 39

Page 40

Programming Reference

Gating Time

Syntax :SENS1:GATE:PER?

Description Either gets or sets the duration of the gating interval. The

Gating Bit Error Rate

Syntax :SENS1:FETC:ERAT?

Description Gets the bit error ration that is captured during the gating

Gating Number of Errors

Syntax :SENS1:FETC:ECO?

Description Gets the number of errors that have been counted during

:SENS1:GATE:PER

:SENS1:GATE:PER integer

allowed range for the gating time is 1s to 608399s (168

hours, 59 minutes, 59 seconds). The gating time is always

in seconds. Fractional seconds are not supported, and will

be rounded to the closest time in seconds.

:SENS1:FETC:ERAT

interval. This value might/will change while the gating is in

progress, and will freeze at the end of the gating interval.

:SENS1:FETC:ECO

the gating interval. This value might/will change while

gating is in progress, and will freeze at the end of the

gating interval.

Start Gating

Abort Gating

:SENS1:GATE:STAT 1

Syntax :SENS1:GATE:STAT 1|ON

Description Starts a new gating period. This command will be ignored if

a gating period is already in progress.

:SENS1:GATE:STAT 0

Syntax :SENS1:GATE:STAT 0|OFF

Description This command aborts the currently active gating period

immediately. It will be ignored if the gating is not in

progress.

40 N5980A User Guide

Page 41

Programming Reference

Gating Progress

Input Selection

:SENS1:GATE:STAT

Syntax :SENS1:GATE:STAT?

Description Requests the current state of the gating interval. It will

return 1 while the gating is in progress and 0 if the gating

is finished/ inactive. It is guaranteed that the very first

:SENS1:GATE:STAT? query after the start of the gating

period will report a valid state of the gating progress. There

is no need to capture 0-1-0 transitions of the gating

progress.

SENS1:INP

Syntax SENS1:INP SFP|SMA

Description Selects the input for the error detector.

N5980A User Guide 41

Page 42

Programming Reference

Sample Code

The following example code shows how to control the N5980A from

within a remote program. The example code is implemented in C#.

The code snippets show the required code that needs to be added to a

user program.

It implements a class N5980A in the namespace N5980AExample that

allows communication with the N5980A user software.

using System;

using System.Collections.Generic;

using System.Text;

using System.Net;

using System.Net.Sockets;

using System.Windows.Forms;

namespace TBertExample

{

class N5980A

{

/// <summary>

/// Holds the input buffer when reading from the socket.

/// </summary>

byte[] bufferin = new byte[64 * 1024];

/// <summary>

/// Holds the TcpClient that is used to establish the

/// remote connection.

/// </summary>

TcpClient m_Client = null;

/// <summary>

/// Holds the NetworkStream that provides the communication

link.

/// </summary>

NetworkStream m_Stream = null;

/// <summary>

/// Connect to the instrument with the given hostname and

/// port number. Both values can be retrieved by the

/// Connection -> Info... menu item in the N5980A software

/// </summary>

/// <param name="host">Hostname of the PC that executes

/// the N5980A software.</param>

/// <param name="port">Port number of the software instance

/// to communicate with.</param>

public void Connect(string host, int port)

{

try

{

// resolve address of the given hostname

IPHostEntry ipHostEntry = Dns.Resolve(host);

IPAddress ipAddress = ipHostEntry.AddressList[0];

// create TcpClient and connect it to the instrument

m_Client = new TcpClient();

m_Client.Connect(new IPEndPoint(ipAddress, port));

m_Stream = m_Client.GetStream();

}

catch (Exception e)

{

MessageBox.Show(e.Message, "Connect");

}

}

/// <summary>

/// Close the connection with the N5980A software.

42 N5980A User Guide

Page 43

Programming Reference

/// </summary>

public void Disconnect()

{

if (m_Client != null)

m_Client.Close();

}

/// <summary>

/// Write to a SCPI command to a network socket and return

the

/// response if it was a query.

/// </summary>

/// <param name="s">SCPI command to be written to the

socket</param>

/// <returns>Response of the instrument or an empty string

/// if there is no response.</returns>

public string Send(string s)

{

string response = "";

int i;

// Write the string to the network socket

byte[] bufferout = new byte[s.Length + 1];

for (i = 0; i < s.Length; i++)

bufferout[i] = (byte)s[i];

bufferout[s.Length] = (byte)'\n';

m_Stream.Write(bufferout, 0, bufferout.Length);

// If the string containes a '?', then it is a query and

// the response nneds to be read from the instrument

if (s.IndexOf('?') != -1)

{

// Read resonse from network stream

int numRead = m_Stream.Read(bufferin, 0,

bufferin.Length);

// if the response contained any bytes, then convert

them

// to a valid string

if (numRead > 0)

{

StringBuilder sb = new StringBuilder();

for (i = 0; i < numRead; i++)

sb.Append((char)bufferin[i]);

// make sure that all kind of terminators are

// reported as \r\n

sb.Append("\r\n");

response = sb.ToString().Trim(new char[] { '\r', '\n'

});

if (response.IndexOf("\r\n") != -1)

response = response.Replace("\r\n", "\n");

if (response.IndexOf("\r") != -1)

response = response.Replace("\r", "\r");

if (response.IndexOf("\n") != -1)

response = response.Replace("\n", "\r\n");

}

}

return response;

}

}

}

Communicate with the instrument

Given the class above, the communication with the instrument

can be done like this:

using System;

using System.Collections.Generic;

namespace TBertExample

{

static class Program

N5980A User Guide 43

Page 44

Programming Reference

{

/// <summary>

/// The main entry point for the application.

/// </summary>

[STAThread]

static void Main()

{

N5980A instrument = new N5980A();

// Connect to the N5980A software running on the same

// PC as this program and that is using port number 5025

instrument.Connect("localhost", 5025);

// set the data rate to OC-3

instrument.Send(":freq OC3");

// read the data rate

string response = instrument.Send(":freq?");

// Close the socket => disconnect from the instrument

instrument.Disconnect();

// From here on, it is no longer possible to communicate

with the

// instrument.

}

}

}

44 N5980A User Guide

Loading...

Loading...