Page 1

DC

POWER SUPPLY

HANDBOOK

Application Note 90B

Page 2

TABLE OF CONTENTS

Introduction...........................................................................................................................................................6

Definitions ..............................................................................................................................................................6

Ambient Temperature..........................................................................................................................................6

Automatic (Auto) Parallel Operation ..................................................................................................................6

Automatic (Auto) Series Operation.....................................................................................................................7

Automatic (Auto) Tracking Operation................................................................................................................8

Carryover Time....................................................................................................................................................8

Complementary Tracking....................................................................................................................................8

Compliance Voltage ............................................................................................................................................8

Constant Current Power Supply ..........................................................................................................................8

Constant Voltage Power Supply..........................................................................................................................9

Constant Voltage/Constant Current (CV/CC) Power Supply..............................................................................9

Constant Voltage/Current Limiting (CV/CL) Power Supply............................................................................10

Crowbar Circuit.................................................................................................................................................11

Current Foldback...............................................................................................................................................11

Drift....................................................................................................................................................................11

Efficiency...........................................................................................................................................................11

Electromagnetic Interference (EMI)..................................................................................................................11

Inrush Current....................................................................................................................................................11

Load Effect (Load Regulation)..........................................................................................................................12

Load Effect Transient Recovery Time ..............................................................................................................12

Off-Line Power Supply......................................................................................................................................12

Output Impedance of a Power Supply...............................................................................................................12

PARD (Ripple and Noise).................................................................................................................................13

Programming Speed...........................................................................................................................................14

Remote Programming (Remote Control)...........................................................................................................14

Remote Sensing (Remote Error Sensing)..........................................................................................................15

Resolution..........................................................................................................................................................15

Source Effect (Line Regulation)........................................................................................................................15

Stability (see Drift)............................................................................................................................................16

Temperature Coefficient....................................................................................................................................16

Warm Up Time..................................................................................................................................................16

Principles of Operation.......................................................................................................................................17

Constant Voltage Power Supply........................................................................................................................17

Regulating Techniques...................................................................................................................................18

Series Regulation ...........................................................................................................................................18

Typical Series Regulated Power Supply........................................................................................................19

Pros and Cons of Series Regulated Supplies .................................................................................................19

The Series Regulated Supply - An Operational Amplifier............................................................................20

Series Regulator with Preregulator................................................................................................................23

Switching Regulation.....................................................................................................................................25

Basic Switching Supply.................................................................................................................................26

3

Page 3

Typical Switching Regulated Power Supplies...............................................................................................27

Summary of Basic Switching Regulator Configurations...............................................................................30

SCR Regulation..............................................................................................................................................31

Constant Current Power Supply ........................................................................................................................32

Constant Voltage/Constant Current (CV/CC) Power Supply............................................................................34

Constant Voltage/Current Limiting Supplies....................................................................................................36

Current Limit..................................................................................................................................................36

Current Foldback............................................................................................................................................37

Protection Circuits.............................................................................................................................................38

Protection Circuits for Linear Type Supplies ................................................................................................38

Overvoltage Crowbar Circuit Details ............................................................................................................39

Crowbar Response Time................................................................................................................................41

Special Purpose Power Supplies........................................................................................................................43

High Voltage Power Supply...........................................................................................................................43

High Performance Power Supplies................................................................................................................45

Extended Range Power Supplies ...................................................................................................................50

Advantages of Extended Range.....................................................................................................................50

Example of Extended Range Power Supply..................................................................................................51

Faster Down-Programming Speed .................................................................................................................53

Bipolar Power Supply/Amplifier...................................................................................................................54

Digitally Controlled Power Sources ..............................................................................................................55

AC and Load Connections..................................................................................................................................59

Checklist For AC and Load Connections..........................................................................................................59

AC Power Input Connections.........................................................................................................................59

Load Connections for One Power Supply......................................................................................................59

Load Connections for Two or More Power Supplies ....................................................................................60

AC Power Input Connections............................................................................................................................60

Autotransformers ...........................................................................................................................................61

Line Regulators..............................................................................................................................................61

Input AC Wire Rating....................................................................................................................................61

LOAD CONNECTIONS FOR ONE POWER SUPPLY...................................................................................61

DC Distribution Terminals.............................................................................................................................62

Load Decoupling............................................................................................................................................64

Ground Loops.................................................................................................................................................65

DC Common ..................................................................................................................................................68

DC Ground Point............................................................................................................................................72

Remote Error Sensing (Constant Voltage Operation Only)...........................................................................72

Load Connections For Two or More Power Supplies.......................................................................................78

DC Distribution Terminals.............................................................................................................................78

DC Common ..................................................................................................................................................79

DC Ground Point............................................................................................................................................79

Remote Programming.........................................................................................................................................80

Constant Voltage Remote Programming With Resistance Control...................................................................80

Remote Programming Connections ...............................................................................................................81

Output Drift....................................................................................................................................................81

Protecting Against Momentary Programming Errors....................................................................................82

Backup Protection for Open Programming Source........................................................................................83

4

Page 4

Constant Voltage Remote Programming With Voltage Control.......................................................................84

Programming with Unity Voltage Gain.........................................................................................................84

Programming with Variable Voltage Gain....................................................................................................85

Constant Current Remote Programming............................................................................................................86

Remote Programming Accuracy........................................................................................................................86

Remote Programming Speed .............................................................................................................................88

Output Voltage and Current Ratings................................................................................................................91

Duty Cycle Loading...........................................................................................................................................91

Reverse Current Loading...................................................................................................................................93

Dual Output Using Resistive Divider................................................................................................................94

Parallel Operation..............................................................................................................................................96

Auto Parallel Operation.....................................................................................................................................96

Series Operation ................................................................................................................................................97

Auto-Series Operation.......................................................................................................................................97

Auto Tracking Operation...................................................................................................................................99

Converting a Constant Voltage Power Supply To Constant Current Output....................................................99

PERFORMANCE MEASUREMENTS ..........................................................................................................101

Constant Voltage Power Supply Measurements..............................................................................................101

Precautions...................................................................................................................................................101

CV Source Effect (Line Regulation)............................................................................................................104

CV Load Effect (Load Regulation)..............................................................................................................104

CV PARD (Ripple and Noise).....................................................................................................................105

CV Load Effect Transient Recovery Time (Load Transient Recovery)......................................................109

CV Drift (Stability)......................................................................................................................................111

CV Temperature Coefficient........................................................................................................................111

CV Programming Speed...............................................................................................................................111

CV Output Impedance..................................................................................................................................113

Constant Current Power Supply Measurements..............................................................................................113

Precautions...................................................................................................................................................114

CC Source Effect (Line Regulation)............................................................................................................116

CC Load Effect (Load Regulation)..............................................................................................................116

CC PARD (Ripple and Noise) .....................................................................................................................116

CC Load Effect Transient Recovery Time ..................................................................................................117

CC Drift (Stability)......................................................................................................................................117

CC Temperature Coefficient........................................................................................................................119

Other Constant Current Specifications ........................................................................................................119

Index...................................................................................................................................................................120

5

Page 5

INTRODUCTION

Regulated power supplies employ engineering techniques drawn from the latest advances in many disciplines

such as: low-level, high-power, and wideband amplification techniques; operational amplifier and feedback

principles; pulse circuit techniques; and the constantly expanding frontiers of solid state component

development.

The full benefits of the engineering that has gone into the modern regulated power supply cannot be realized

unless the user first recognizes the inherent versatility and high performance capabilities, and second,

understands how to apply these features. This handbook is designed to aid that understanding by providing

complete information on the operation, performance, and connection of regulated power supplies.

The handbook is divided into six main sections: Definitions, Principles of Operation, AC and Load

Connections, Remote Programming, Output Voltage and Current Ratings, and Performance Measurements.

Each section contains answers to many of the questions commonly asked by users, like:

What is meant by auto-parallel operation?

What are the advantages and disadvantages of switching regulated supplies?

When should remote sensing at the load be used?

How can ground loops in multiple loads be avoided?

What factors affect programming speed?

What are the techniques for measuring power supply performance?

In summary, this is a book written not for the theorist, but for the user attempting to solve both traditional and

unusual application problems with regulated power supplies.

DEFINITIONS

AMBIENT TEMPERATURE

The temperature of the air immediately surrounding the power supply.

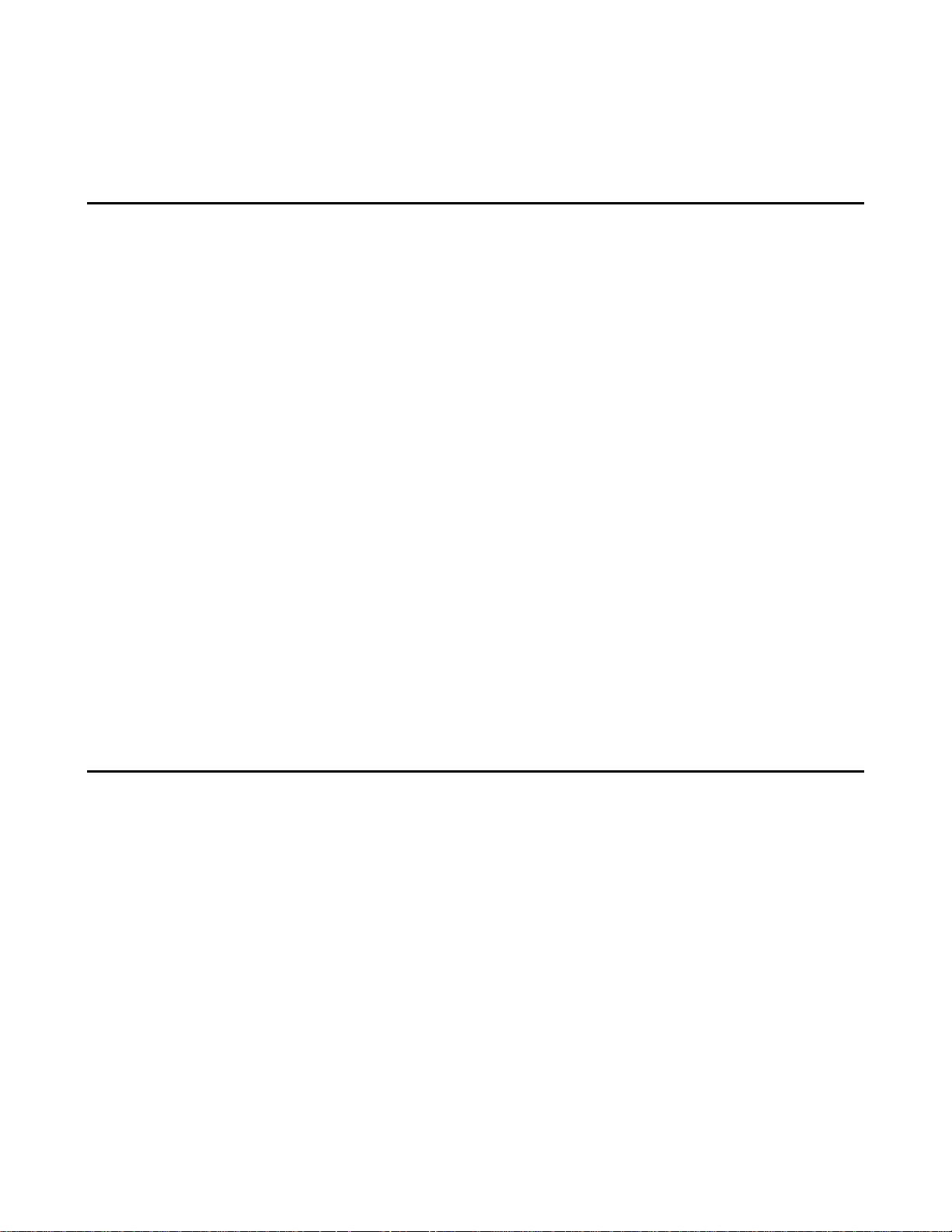

AUTOMATIC (AUTO) PARALLEL OPERATION

A master-slave parallel connection of the outputs of two or more supplies used for obtaining a current output

greater than that obtainable from one supply. Auto-Parallel operation is characterized by one-knob control,

equal current sharing, and no internal wiring changes. Normally only supplies having the same model number

may be connected in Auto-Parallel, since the units must have the same IR drop across the current monitoring

resistors at full current rating.

6

Page 6

AUTO-PARALLEL POWER SUPPLY SYSTEM

AUTOMATIC (AUTO) SERIES OPERATION

A master-slave series connection of the outputs of two or more power supplies used for obtaining a voltage

greater than that obtainable from one supply. Auto-Series operation, which is permissible up to 300 volts off

ground, is characterized by one-knob control, equal or proportional voltage sharing, and no internal wiring

changes. Different model numbers may be connected in Auto-Series without restriction, provided that each

slave is capable of Auto-Series operation.

AUTO-SERIES POWER SUPPLY SYSTEM

7

Page 7

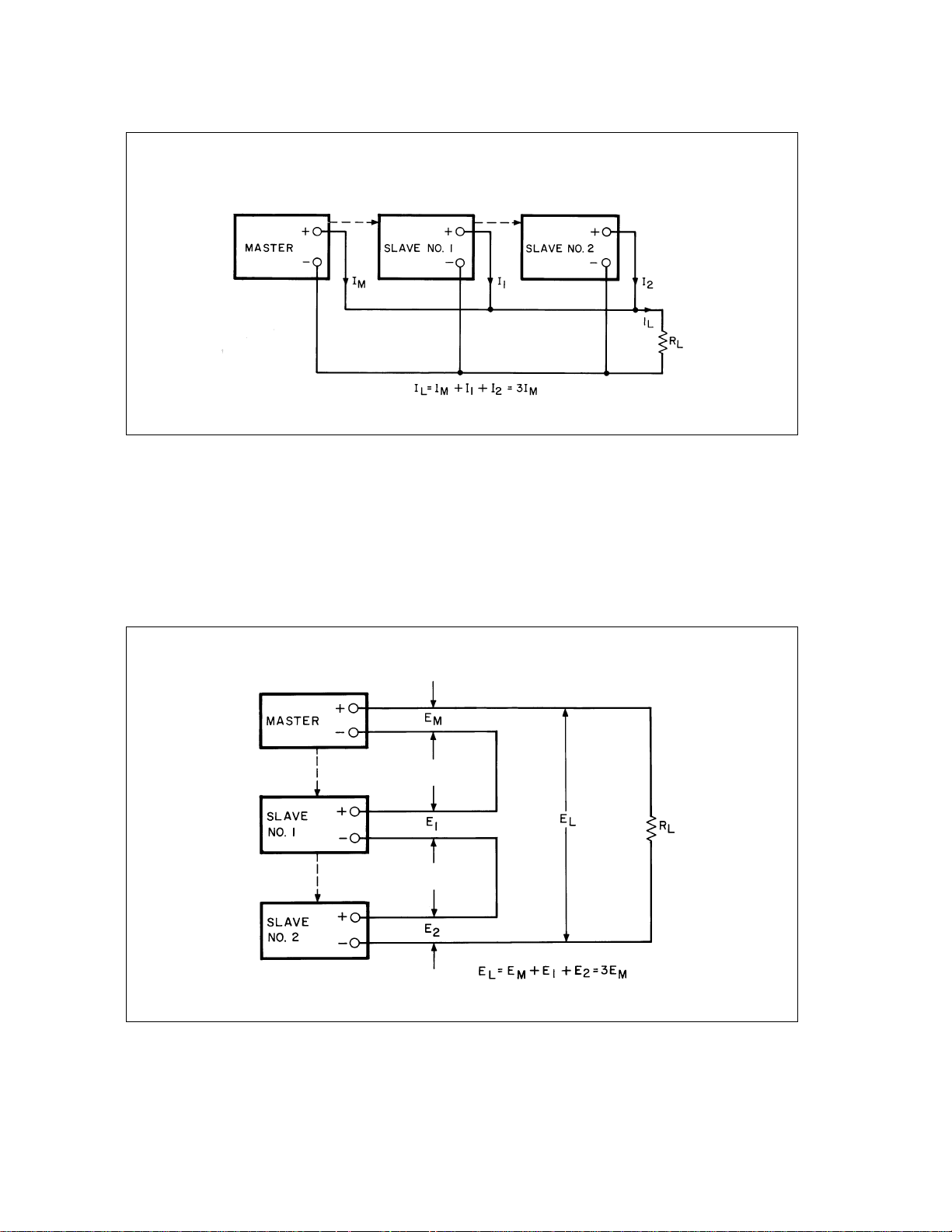

AUTOMATIC (AUTO) TRACKING OPERATION

A master-slave connection of two or more power supplies each of which has one of its output terminals in

common with one of the output terminals of all of the other power supplies. Auto-Tracking operation is

characterized by one-knob control, proportional output voltage from all supplies, and no internal wiring

changes. Useful where simultaneous turn-up, turn-down or proportional control of all power supplies in a

system is required.

AUTO-TRACKING POWER SUPPLY SYSTEM

CARRYOVER TIME

The period of time that a power supply's output will remain within specifications after loss of ac input power. It

is sometimes called holding time.

COMPLEMENTARY TRACKING

A master-slave interconnection similar to Auto-Tracking except that only two supplies are used and the output

voltage of the slave is always of opposite polarity with respect to the master. The amplitude of the slaves' output

voltage is equal to, or proportional to, that of the master. A pair of complementary tracking supplies is often

housed in a single unit.

COMPLIANCE VOLTAGE

The output voltage rating of a power supply operating in the constant current mode (analogous to the output

current rating of a supply operating in the constant voltage mode).

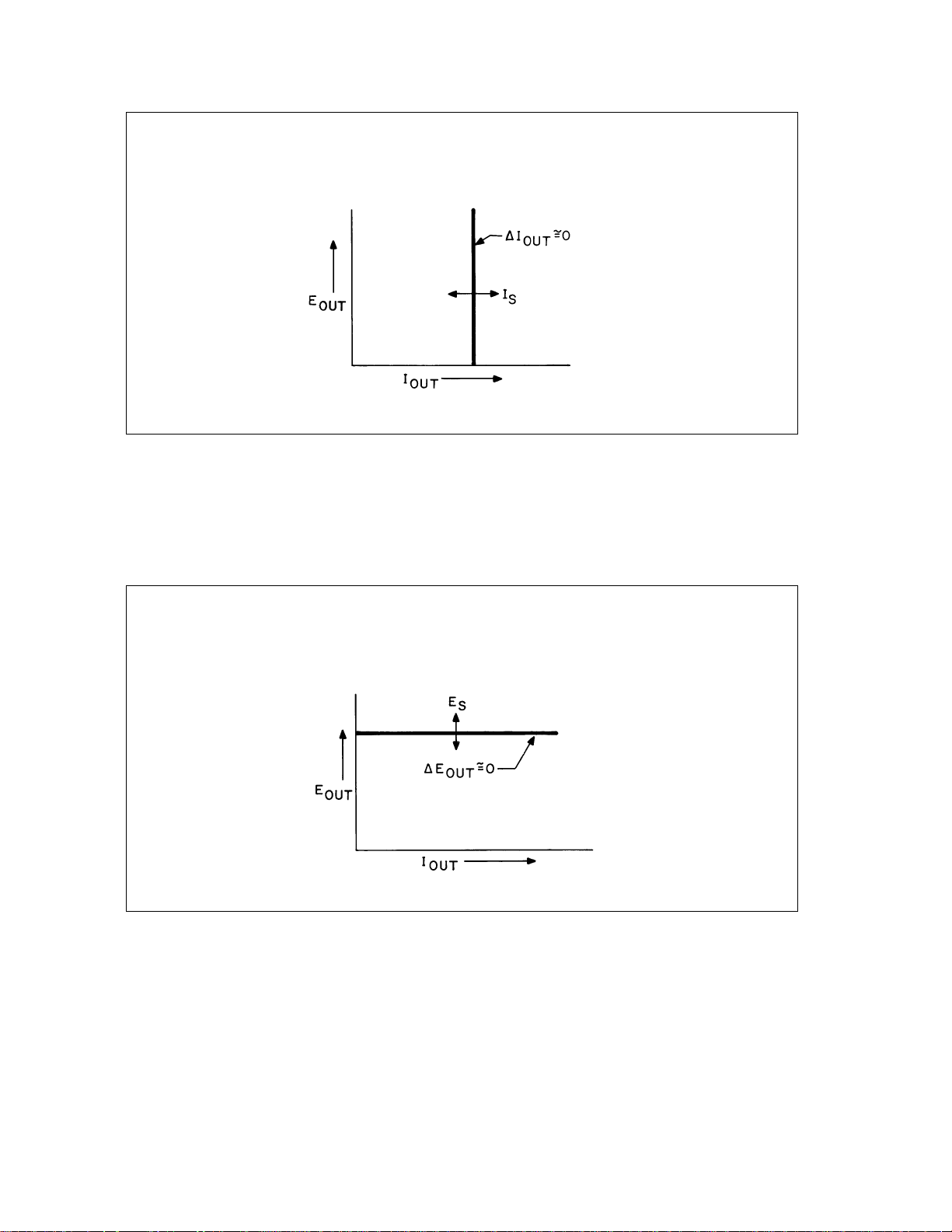

CONSTANT CURRENT POWER SUPPLY

A regulated power supply that acts to maintain its output current constant in spite of changes in load, line,

temperature, etc. Thus, for a change in load resistance, the output current remains constant while the output

voltage changes by whatever amount necessary to accomplish this.

8

Page 8

CONSTANT CURRENT POWER SUPPLY

OUTPUT CHARACTERISTICS

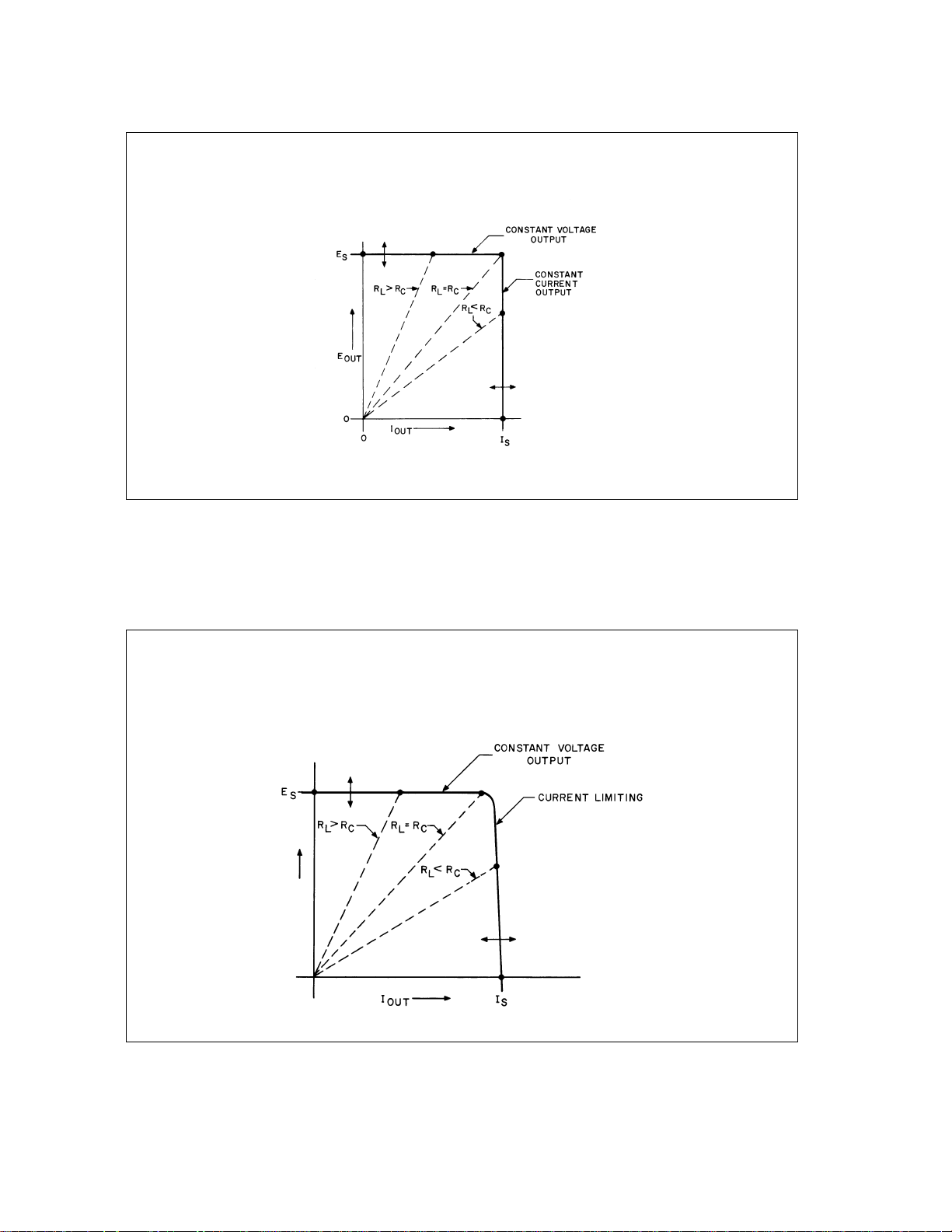

CONSTANT VOLTAGE POWER SUPPLY

A regulated power supply that acts to maintain its output voltage constant in spite of changes in load, line,

temperature, etc. Thus, for a change in load resistance, the output voltage of this type of supply remains

constant while the output current changes by whatever amount necessary to accomplish this.

CONSTANT VOLTAGE POWER SUPPLY

OUTPUT CHARACTERISTIC

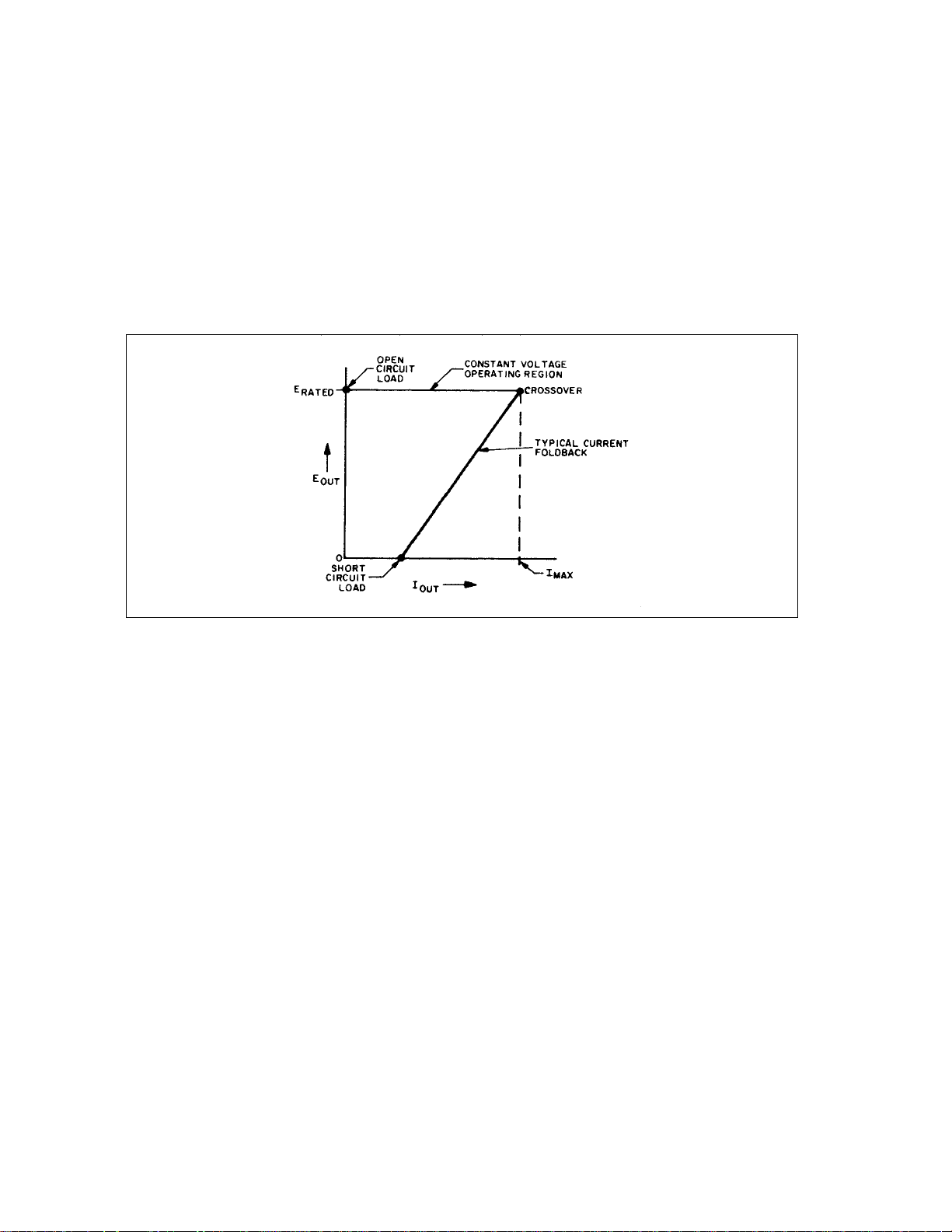

CONSTANT VOLTAGE/CONSTANT CURRENT (CV/CC) POWER SUPPLY

A power supply that acts as a constant voltage source for comparatively large values of load resistance and as a

constant current source for comparatively small values of load resistance. The automatic crossover or transition

between these two modes of operation occurs at a "critical" or "crossover" value of load resistance Rc = Es/Is,

where Es is the front panel voltage control setting and Is is the front panel current control setting.

9

Page 9

CONSTANT VOLTAGE/CONSTANT CURRENT

(CV/CC) OUTPUT CHARACTERISTIC

CONSTANT VOLTAGE/CURRENT LIMITING (CV/CL) POWER SUPPLY

A supply similar to a CV/CC supply except for less precise regulation at low values of load resistance, i.e., in

the current limiting region of operation. One form of current limiting is shown above.

CONSTANT VOLTAGE/ CURRENT LIMITING

(CV/CL) OUTPUT CHARACTERISTIC

10

Page 10

CROWBAR CIRCUIT

An overvoltage protection circuit that monitors the output voltage of the supply and rapidly places a short

circuit (or crowbar) across the output terminals if a preset voltage level is exceeded.

CURRENT FOLDBACK

Another form of current limiting often used in fixed output voltage supplies. For load resistance smaller than

the crossover value, the current, as well as the voltage, decreases along a foldback locus.

DRIFT

The maximum change in power supply output during a stated period of time (usually 8 hours) following a

warm-up period, with all influence and control quantities (such as; load, ac line, and ambient temperature)

maintained constant. Drift includes periodic and random deviations (PARD) over a bandwidth from dc to 20Hz.

(At frequencies above 20Hz, PARD is specified separately.)

EFFICIENCY

Expressed in percent, efficiency is the total output power of the supply divided by the active input power.

Unless otherwise specified, Agilent measures efficiency at maximum rated output power and at worst case

conditions of the ac line voltage.

ELECTROMAGNETIC INTERFERENCE (EMI)

Any type of electromagnetic energy that could degrade the performance of electrical or electronic equipment.

The EMI generated by a power supply can be propagated either by conduction (via the input and output leads)

or by radiation from the units' case. The terms "noise" and "radio-frequency interference" (RFI) are sometimes

used in the same context.

INRUSH CURRENT

The maximum instantaneous value of the input current to a power supply when ac power is first applied.

11

Page 11

LOAD EFFECT (LOAD REGULATION)

Formerly known as load regulation, load effect is the change in the steady-state value of the dc output voltage

or current resulting from a specified change in the load current (of a constant-voltage supply) or the load

voltage (of a constant-current supply), with all other influence quantities maintained constant.

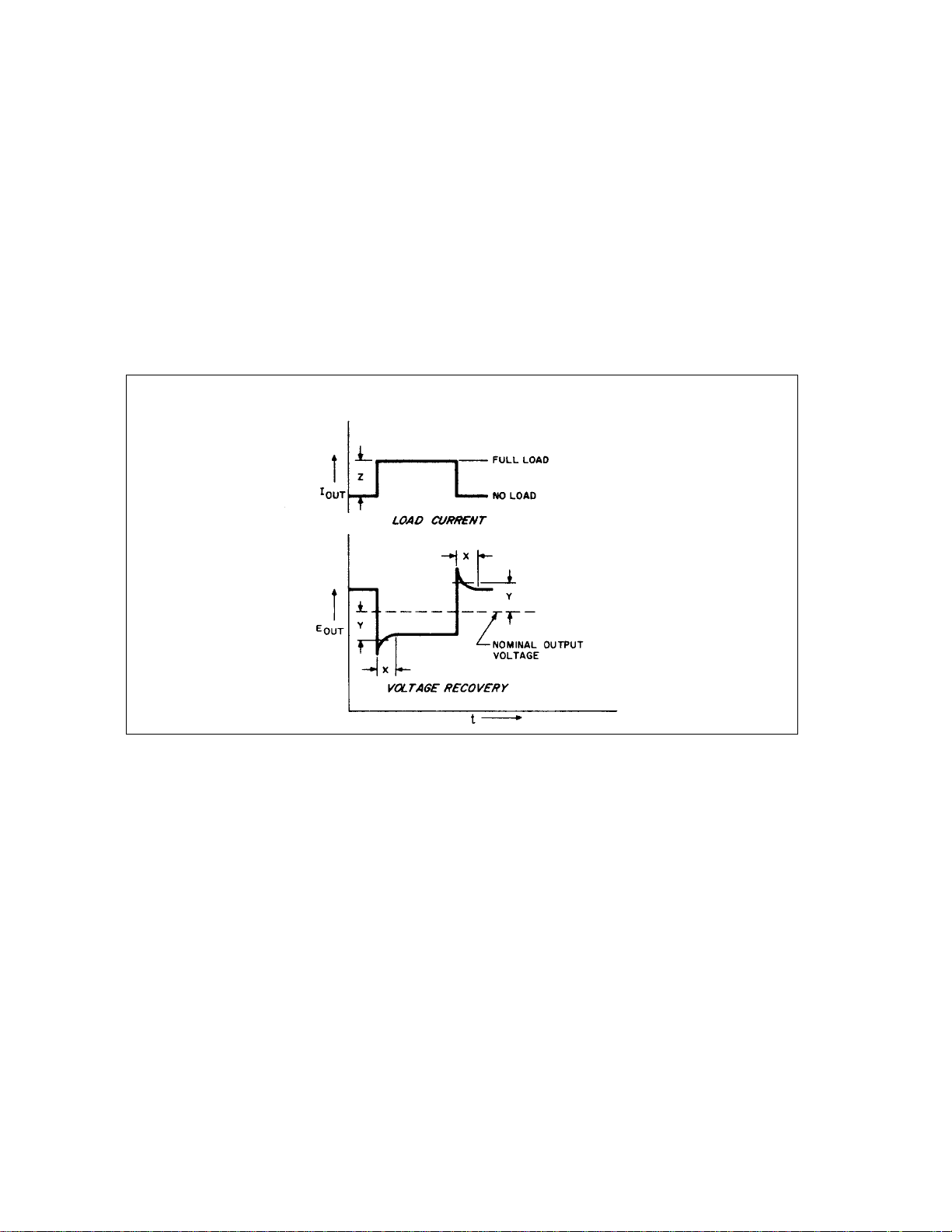

LOAD EFFECT TRANSIENT RECOVERY TIME

Sometimes referred to as transient recovery time or transient response time, it is, loosely speaking, the time

required for the output voltage of a power supply to return to within a level approximating the normal dc output

following a sudden change in load current. More exactly, Load Transient Recovery Time for a CV supply is the

time "X" required for the output voltage to recover to, and stay within "Y" millivolts of the nominal output

voltage following a "Z" amp step change in load current --where:

TRANSIENT REC OVERY TIME

(1) "Y" is specified separately for each model but is generally of the same order as the load regulation

specification.

(2) The nominal output voltage is defined as the dc level halfway between the steady state output voltage

before and after the imposed load change.

(3) "Z" is the specified load current change, typically equal to the full load current rating of the

OFF-LINE POWER SUPPLY

A power supply whose input rectifier circuits operate directly from the ac power line, without transformer

isolation.

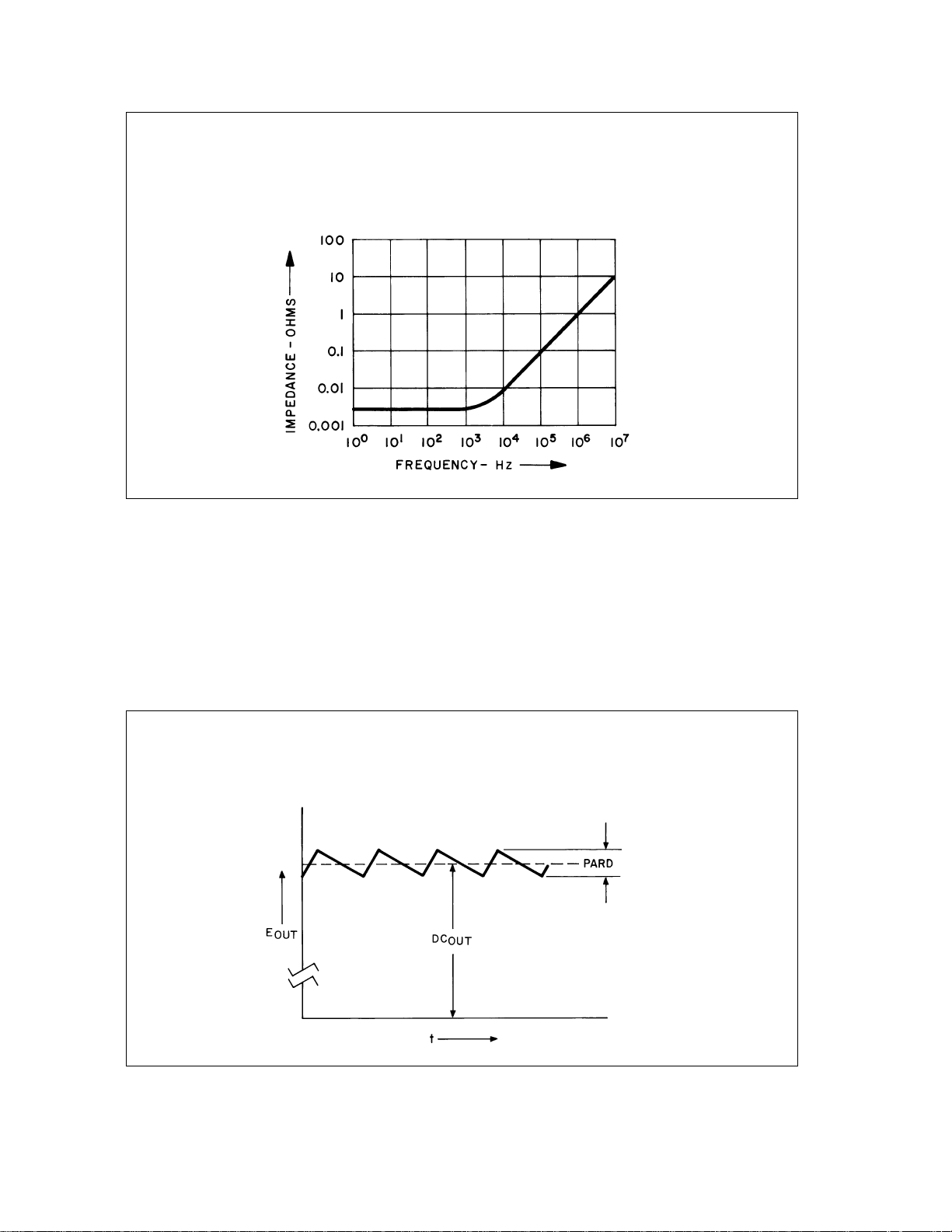

OUTPUT IMPEDANCE OF A POWER SUPPLY

At any frequency of load change, ∆EOUT/∆IOUT. Strictly speaking, the definition applies only for a sinusoidal

load disturbance, unless the measurement is made at zero frequency (dc). The output impedance of an ideal

constant voltage power supply would be zero at all frequencies, while the output impedance for an ideal

constant current power supply would be infinite at all frequencies.

12

Page 12

TYPICAL OUTPUT IMPEDANCE OF A CONSTANT

VOLTAGE POWER SUPPLY

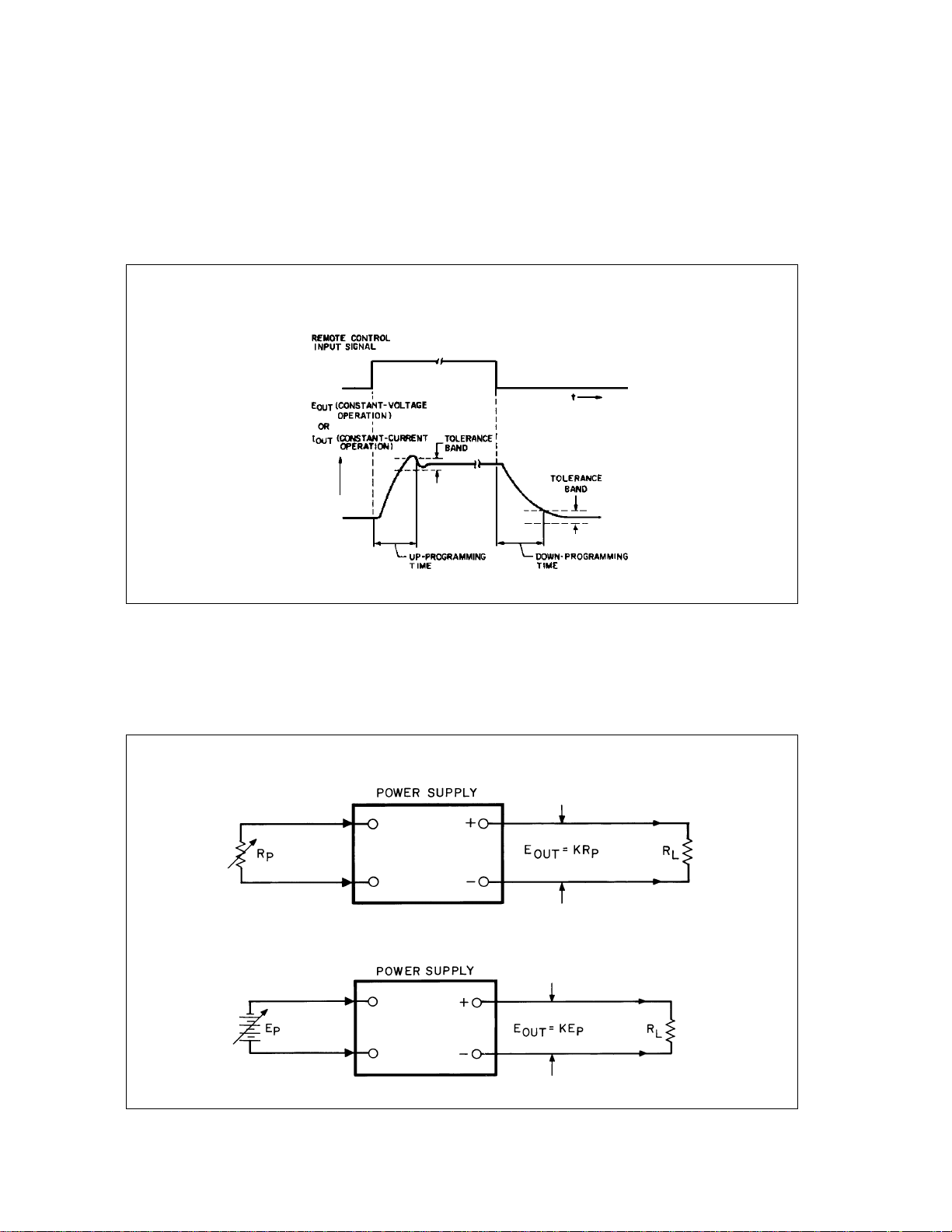

PARD (RIPPLE AND NOISE)

The term PARD is an acronym for "Periodic and Random deviation" and replaces the former term ripple and

noise. PARD is the residual ac component that is superimposed on the dc output voltage or current of a power

supply. It is measured over a specified bandwidth, with all influence and control quantities maintained constant.

PARD is specified in rms and/or peak-to-peak values over a bandwidth of 20Hz to 20MHz. Fluctuations below

20Hz are treated as drift. Attempting to measure PARD with an instrument that has insufficient bandwidth may

conceal high frequency spikes that could be detrimental to a load.

DC OUTPUT OF POWER SUPPLY AND

SUPERIMPOSED PARD COMPONENT

13

Page 13

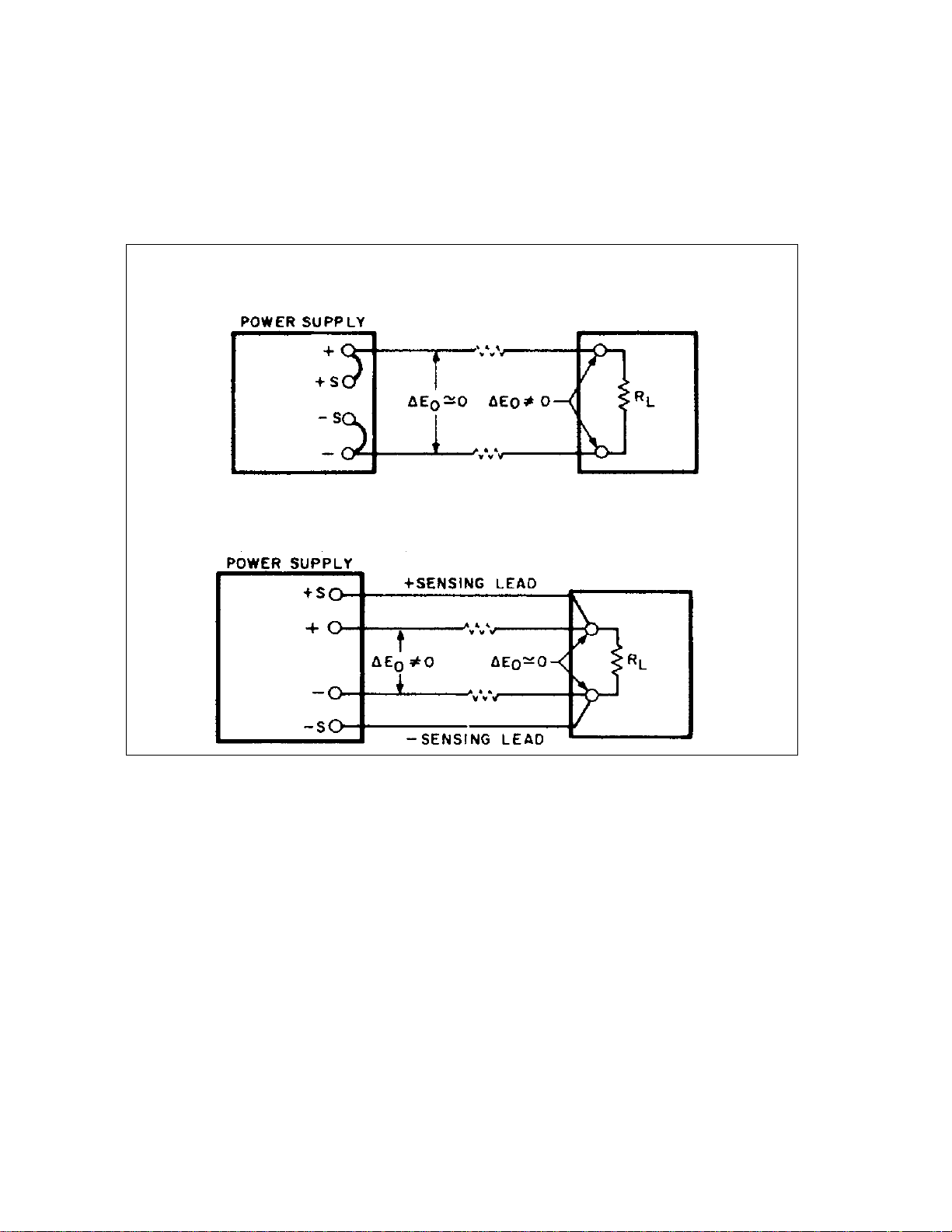

PROGRAMMING SPEED

The maximum time required for the output voltage or current to change from an initial value to within a

tolerance band of the newly programmed value following the onset of a step change in the programming input

signal. Because the programming speed depends on the loading of the supply and on whether the output is being

programmed to a higher or lower value, programming speed is usually specified at no load and full load and in

both the up and down directions.

PROGRAMMING SPEED WAVEFORMS

REMOTE PROGRAMMING (REMOTE CONTROL)

Control of the regulated output voltage or current of a power supply by means of a remotely varied resistance or

voltage. The illustrations below show examples of constant voltage remote programming. CC applications are

similar.

REMOTE PROGRAMMING USING RESISTANCE CONTROL

REMOTE PROGRAMMING USING VOLTAGE CONTROL

14

Page 14

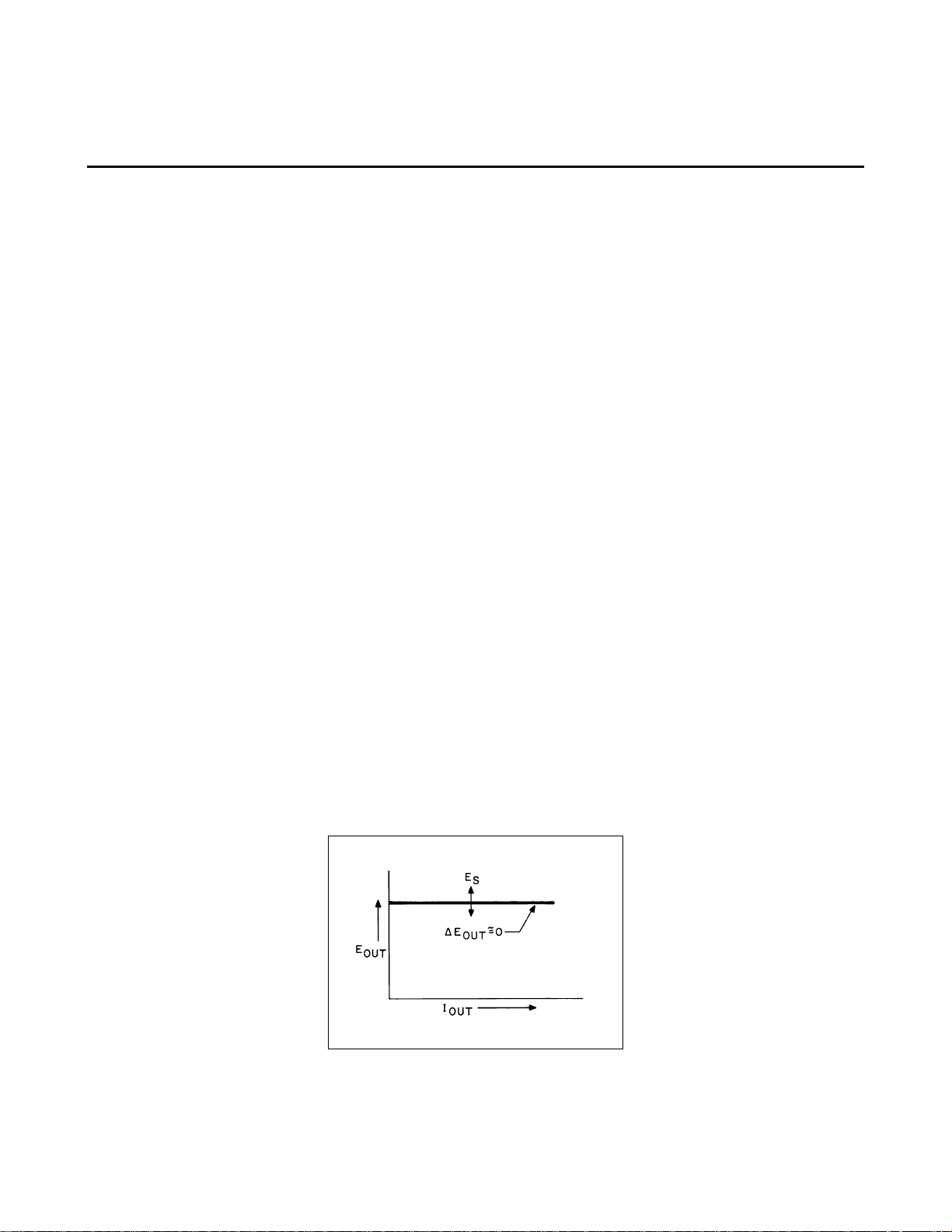

REMOTE SENSING (REMOTE ERROR SENSING)

A means whereby a constant voltage power supply monitors and regulates its output voltage directly at the load

terminals (instead of the power supply output terminals). Two low current sensing leads are connected between

the load terminals and special sensing terminals located on the power supply, permitting the power supply

output voltage to compensate for IR drops in the load leads (up to a specified limit).

POWER SUPPLY AND LOAD CONNECTED NORMALLY

POWER SUPPLY AND LOAD CONNECTED FOR REMOTE SENSING

RESOLUTION

The smallest change in output voltage or current that can be obtained using the front panel controls.

SOURCE EFFECT (LINE REGULATION)

Formerly known as line regulation, source effect is the change in the steady-state value of the dc output voltage

(of a CV supply) or current (of a CC supply) due to a specified change in the source (ac line) voltage, with all

other influence quantities maintained constant. Source effect is usually measured after a "complete" change in

the ac line voltage; from low line to high line or vice-versa.

15

Page 15

STABILITY (SEE DRIFT)

TEMPERATURE COEFFICIENT

For a power supply operated at constant load and constant ac input, the maximum steady-state change in output

voltage (for a constant voltage supply) or output current (for a constant current supply) for each degree change

in the ambient temperature, with all other influence quantities maintained constant.

WARM UP TIME

The time interval required by a power supply to meet all performance specifications after it is first turned on.

16

Page 16

PRINCIPLES OF OPERATION

Electronic power supplies are defined as circuits which transform electrical input power--either ac or dc--into

output power--either ac or dc. This definition thus excludes power supplies based on rotating machine

principles and distinguishes power supplies from the more general category of electrical power sources which

derive electrical power from other energy forms (e. g., batteries, solar cells, fuel cells).

Electronic power supplies can be divided into four broad classifications:

(1) ac in, ac out-line regulators and frequency changers

(2) dc in, dc out-converters and dc regulators

(3) dc in, ac out-inverters

(4) ac in, dc out

This last category is by far the most common of the four and is generally the one referred to when speaking of a

"power supply". Most of this Handbook is devoted to ac in/dc out power supplies, although a brief description

of a dc-to-dc converter is presented later in this section.

Four basic outputs or modes or operation can be provided by dc output power supplies:

• Constant Voltage: The output voltage is maintained constant in spite of changes in load, line, or

temperature.

• Constant Current: The output current is maintained constant in spite of changes in load, line, or

temperature.

• Voltage Limit: Same as Constant Voltage except for less precise regulation characteristics.

• Current Limit: Similar to Constant Current except for less precise regulation.

As explained in this section, power supplies are designed to offer these outputs in various combinations for

different applications.

CONSTANT VOLTAGE POWER SUPPLY

An ideal constant voltage power supply would have zero output impedance at all frequencies. Thus, as shown in

Figure 1, the voltage would remain perfectly constant in spite of any changes in output current demanded by the

load.

Figure 1. Ideal Constant Voltage Power Supply Output Characteristic

17

Page 17

A simple unregulated power supply consisting of only a rectifier and filter is not capable of providing a ripple

free dc output voltage whose value remains reasonably constant. To obtain even a coarse approximation of the

ideal output characteristic of Figure 1, some type of control element (regulator) must be included in the supply.

Regulating Techniques

Most of today's constant voltage power supplies employ one of these four regulating techniques:

a. Series (Linear)

b. Preregulator/Series Regulator

c. Switching

d. SCR

Series Regulation

Series regulated power supplies were introduced many years ago and are still used extensively today. They have

survived the transition from vacuum tubes to transistors, and modern supplies often utilize IC's, the latest in

power semiconductors, and some sophisticated control and protection circuitry.

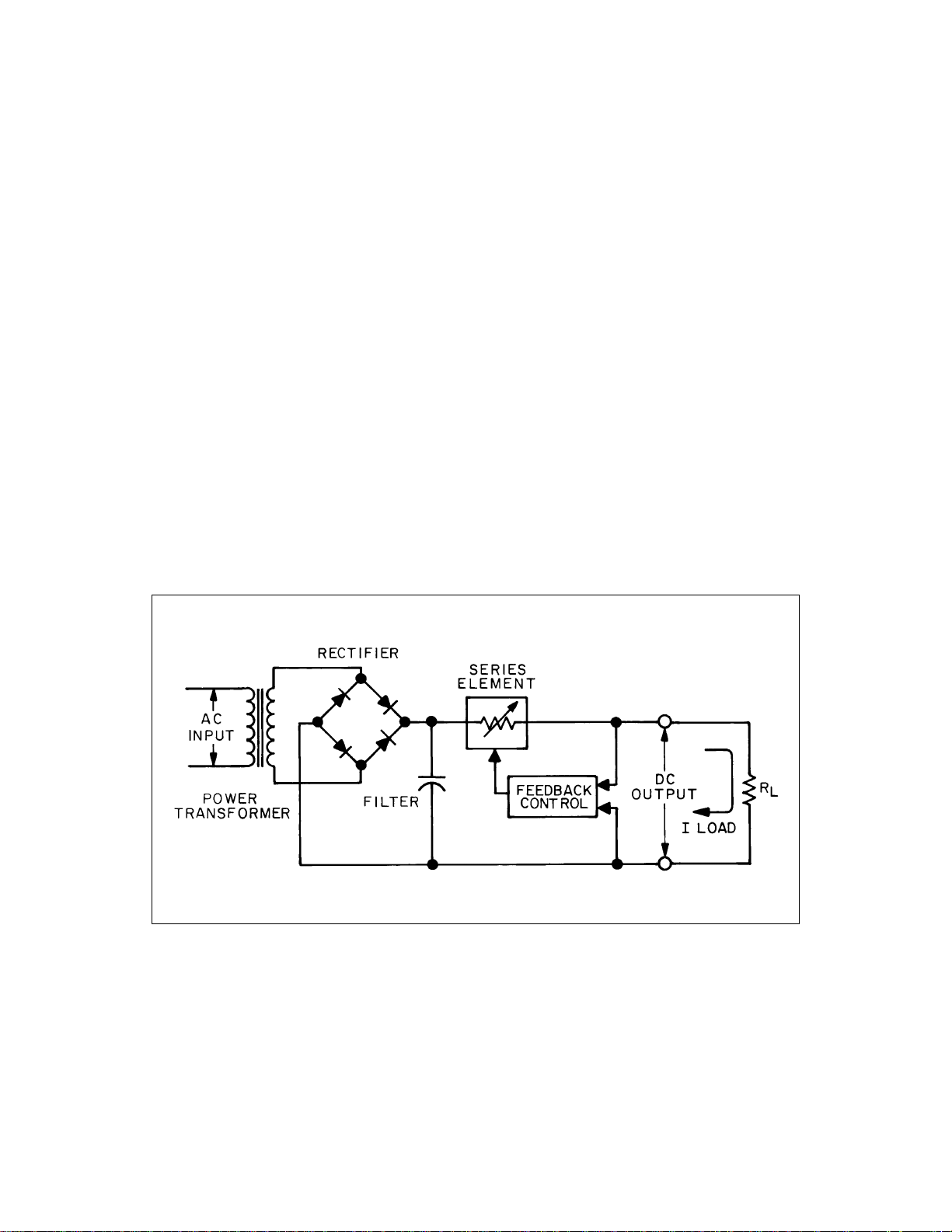

The basic design technique, which has not changed over the years, consists of placing a control element in

series with the rectifier and load device. Figure 2 shows a simplified schematic of a series regulated supply with

the series element depicted as a variable resistor. Feedback control circuits continuously monitor the output and

adjust the series "resistance" to maintain a constant output voltage. Because the variable resistance of Figure 2

is actually one or more power transistors operating in the linear (class A) mode, supplies with this type of

regulator are often called linear power supplies.

Figure 2. Basic Series Regulated Supply

Notice that the variable resistance element can also be connected in parallel with the load to form a shunt

regulator. However, this type of regulator is seldom used because it must withstand full output voltage under

normal operating conditions, making it less efficient for most applications.

18

Page 18

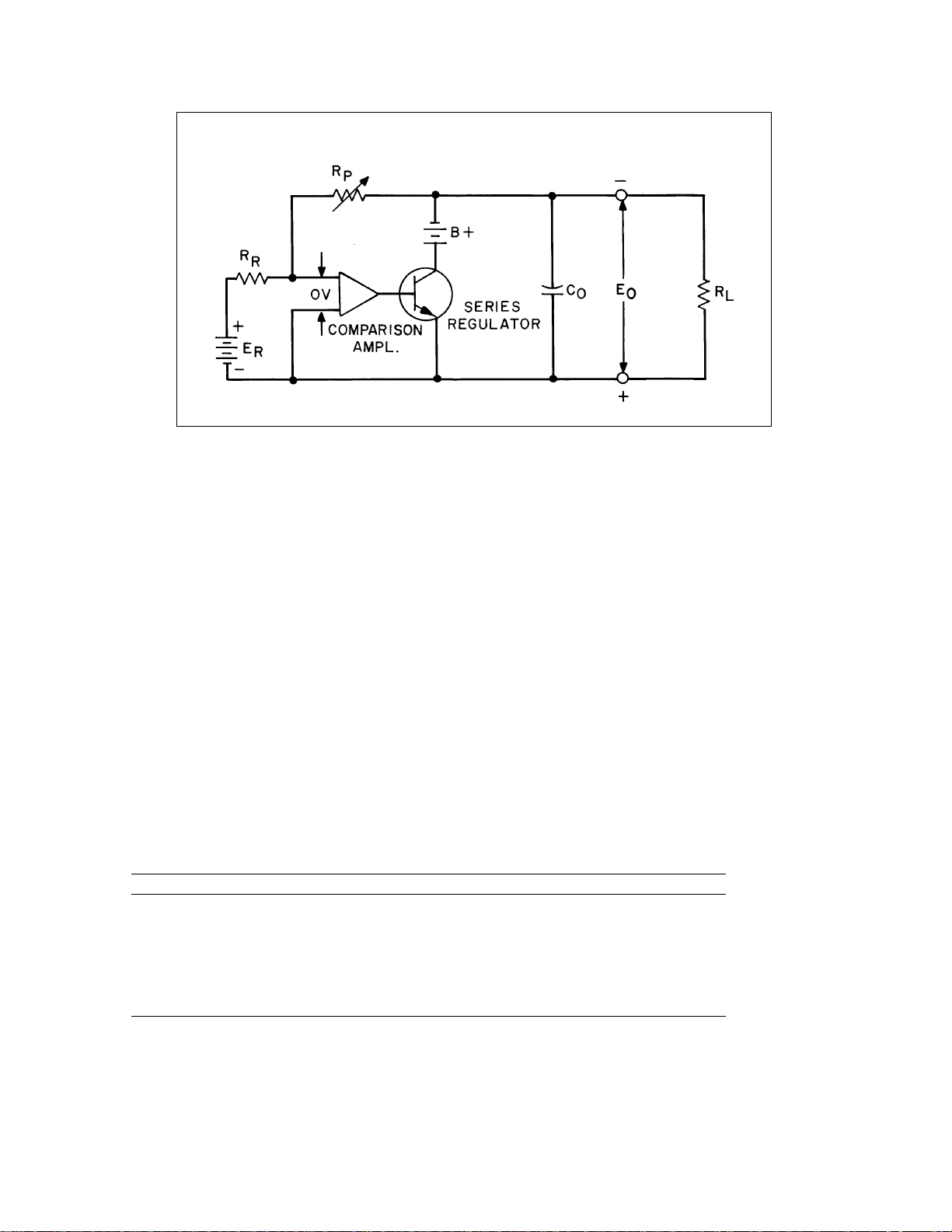

Typical Series Regulated Power Supply

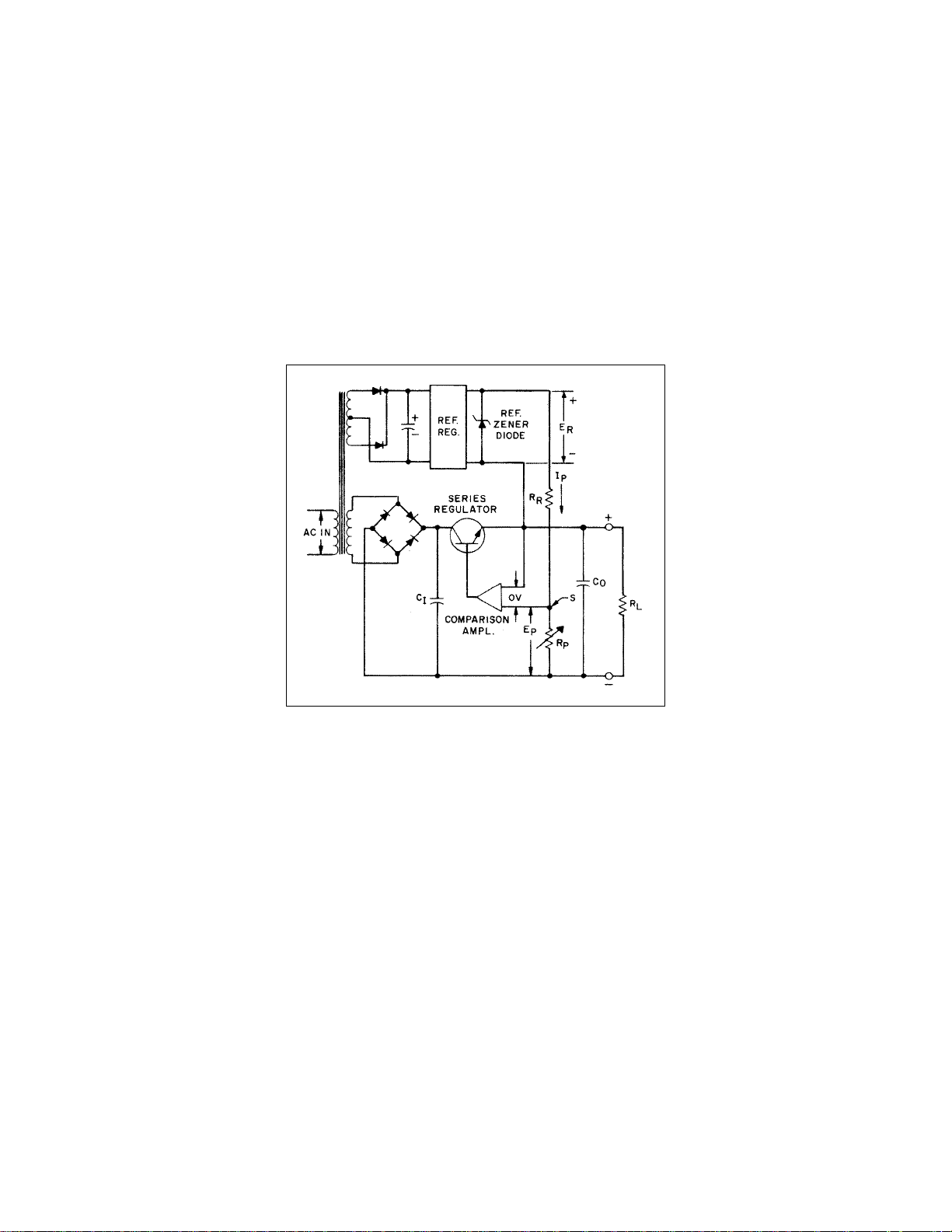

Figure 3 shows the basic feedback circuit principle used in Agilent series regulated power supplies. The ac

input, after passing through a power transformer, is rectified and filtered. By feedback action, the series

regulator alters its voltage drop to keep the regulated dc output voltage constant despite variations in the ac line,

the load, or the ambient temperature.

The comparison amplifier continuously monitors the difference between the voltage across the voltage control

resistor, RP, and the output voltage. If these voltages are not equal, the comparison amplifier produces an

amplified difference (error) signal. This signal is of the magnitude and polarity necessary to change the

conduction of the series regulator which, in turn, changes the current through the load resistor until the output

voltage equals the voltage (EP) across the voltage control.

Figure 3. Series Regulated Constant Voltage Power Supply

Since the net difference between the two voltage inputs to the comparison amplifier is kept at zero by feedback

action, the voltage across resistor R

current I

flowing through RR is constant and equal to ER/RR. The input impedance of the comparison amplifier

P

is very high, so essentially all of the current I

programming current I

is constant, EP (and hence the output voltage) is variable and directly proportional to RP.

P

Thus, the output voltage becomes zero if R

is also held equal to the reference voltage ER. Thus the programming

R

flowing through RR also flows through RP. Because this

P

is reduced to zero ohms.

P

Of course, not all series regulated supplies are continuously adjustable down to zero volts. Those of the OEM

modular type are used in system applications and, thus, their output voltage adjustment is restricted to a narrow

range or slot. However, operation of these supplies is virtually identical to that just described.

Pros and Cons of Series Regulated Supplies

Series regulated supplies have many advantages and usually provide the simplest most effective means of

satisfying high performance and low power requirements.

In terms of performance, series regulated supplies have very precise regulation properties and respond quickly

19

Page 19

to variations of the line and load. Hence, their line and load regulation and transient recovery time* are superior

to supplies using any of the other regulation techniques. These supplies also exhibit the lowest ripple and noise,

are tolerant of ambient temperature changes, and with their circuit simplicity, have a high reliability.

*Power supply performance specifications are described in the Definitions section of this handbook.

The major drawback of the series regulated supply is its relatively low efficiency. This is caused mainly by the

series transistor which, operating in the linear mode, continuously dissipates power in carrying out its

regulation function. Efficiency (defined as the percentage of a supply's input power that it can deliver as useful

output: P

OUT/PIN

), ranges typically between 30 and 45% for series regulated supplies. With the present need for

energy conservation, this inefficiency is being scrutinized very closely.

For many of today's applications, the size and weight of linear supplies constitute another disadvantage. The

power transformer, inductors, and filter capacitors necessary for operation at the 60Hz line frequency tend to be

large and heavy, and the heat sink required for the inherently dissipative series regulator increases the overall

size.

The Series Regulated Supply - An Operational Amplifier

The following analogy views the series regulated power supply as an operational amplifier. Considering the

power supply as an operational amplifier can often give the user a quick insight into power supply behavior and

help in evaluating a power supply for a specific application.

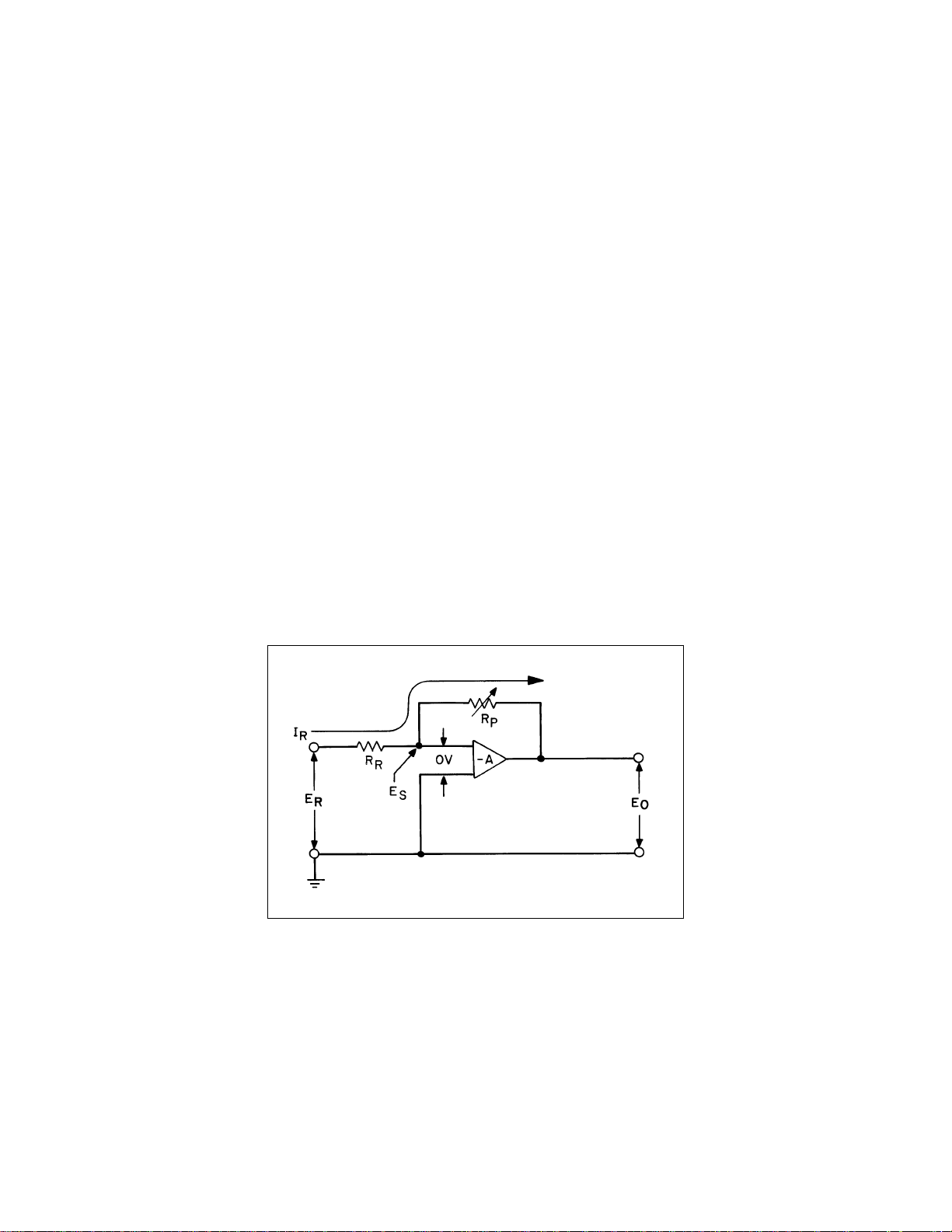

An operational amplifier (Figure 4) is a high gain dc amplifier that employs negative feedback. The power

supply, like an operational amplifier, is also a high gain dc amplifier in which degenerative feedback is

arranged so the operational gain is the ratio of two resistors.

Figure 4. Operational Amplifier

As shown in Figure 4, the input voltage E

voltage is fed back to this same summing point through resistor R

input current to the amplifier can be considered negligibly small, and all of the input current I

both resistors R

and RP. As a result:

R

is connected to the summing point via resistor RR, and the output

R

. Since the input impedance is very high, the

P

flows through

R

20

Page 20

IR =

ER-E

R

S

R

=

ES-E

R

O

P

Then multiplying both sides by RRRP, we obtain

E

= ESRP + ESRR –EORR.(2)

RRP

Figure 4 yields a second equation relating the amplifier output to its gain and voltage input

E

=ES (-A) (3)

O

which when substituted in equation (2) and solved for Es yields

E

R RP

ES =

+ RR (1+A)

R

P

Normally, the operational amplifier gain is very high, commonly 10,000 or more. In equation (4)

If we let A → ∞

Then Es→ O

(1)

(4)

(5)

This important result enables us to say that the two input voltages of the comparison amplifier of Figure 4 (and

Figure 3) are held equal by feedback action.

In modern well-regulated power supplies, the summing point voltage Es is at most a few millivolts. Substituting

Es = 0 into equation (1) yields the standard gain expression for the operational amplifier

R

P

EO = -E

R

R

R

(6)

Notice that from equation 6 and Figure 4, doubling the value of RP doubles the output voltage.

To convert the operational amplifier of Figure 4 into a power supply we must first apply as its input a fixed dc

input reference voltage E

(see Figure 5).

R

21

Page 21

Figure 5. Operational Amplifier w i t h DC I nput Signal

A large electrolytic capacitor is then added across the output terminals of the operational amplifier. The

impedance of this capacitor in the middle range of frequencies (where the overall gain of the amplifier falls off

and becomes less than unity) is much lower than the impedance of any load that might normally be connected to

the amplifier output. Thus, the phase shift through the output terminals is independent of the phase angle of the

load applied and depends only on the impedance of the output capacitor at medium and high frequencies.

Hence, amplifier feedback stability is assured and no oscillation will occur regardless of the type of load

imposed.

In addition, the output stage inside the amplifier block in Figure 4 is removed and shown separately. After these

changes have been carried out, the modified operational amplifier of Figure 5 results.

Replacing the batteries of Figure 5 with rectifiers and a reference zener diode results in the circuit of Figure 6.

A point by point comparison of Figures 3 and 6 reveals that they have identical topology--all connections are

the same, only the position of the components on the diagram differs!

Thus, a series regulated power supply is an operational amplifier. The input signal to this operational amplifier

is the reference voltage. The output signal is regulated dc. The following chart summarizes the corresponding

terms used for an operational amplifier and a power supply.

Operational Amplifier Constant Voltage Power Supply

Input Signal Reference Voltage

Output Signal Regulated DC

Amplifier Regulator

Output Stage Series Regulating Transistor

Bias Power Supply Rectifier/Filter

Gain Control Output Voltage Control

As a result of the specific method used in transforming an operational amplifier into a power supply, some

restrictions are placed on the general behavior of the power supply. The most important of these are:

(1) The large output capacitor Co limits the bandwidth. *

22

Page 22

(2) The use of a fixed dc input voltage means that the output voltage can only be one polarity, the opposite of

the reference polarity.**

(3) The series regulator can conduct current in only one direction. This, together with the fact that the rectifier

has a given polarity, means that the power supply can only deliver current to the load, and cannot absorb

current from the load.

* Special design steps have been added to the design of most Agilent low voltage supplies to permit a

significant reduction in the size of the output capacitor merely by changing straps on the rear terminal strip (see

page 89).

** In Agilent’s line of Bipolar Power Supply/Amplifiers this output capacitor is virtually eliminated by using a

special feedback design. In addition, BPS/A instruments are capable of ac output, conduct current in either

direction, and their outputs are continuously variable through zero (see page 54).

Figure 6. Operational Amplifier Representation of Adjustable CV Power Suppl y

Series Regulator with Preregulator

Adding a preregulator ahead of the series regulator allows the circuit techniques already developed for low

power supplies to be extended readily to medium and higher power designs. The preregulator minimizes the

power dissipated in the series regulating elements by maintaining the voltage drop across the regulator at a low

and constant level. This improves efficiency by 10 to 20% while still retaining the excellent regulation and low

ripple and noise of a series regulated supply. In addition, fewer series regulating transistors are required, thus

23

Page 23

minimizing size increases.

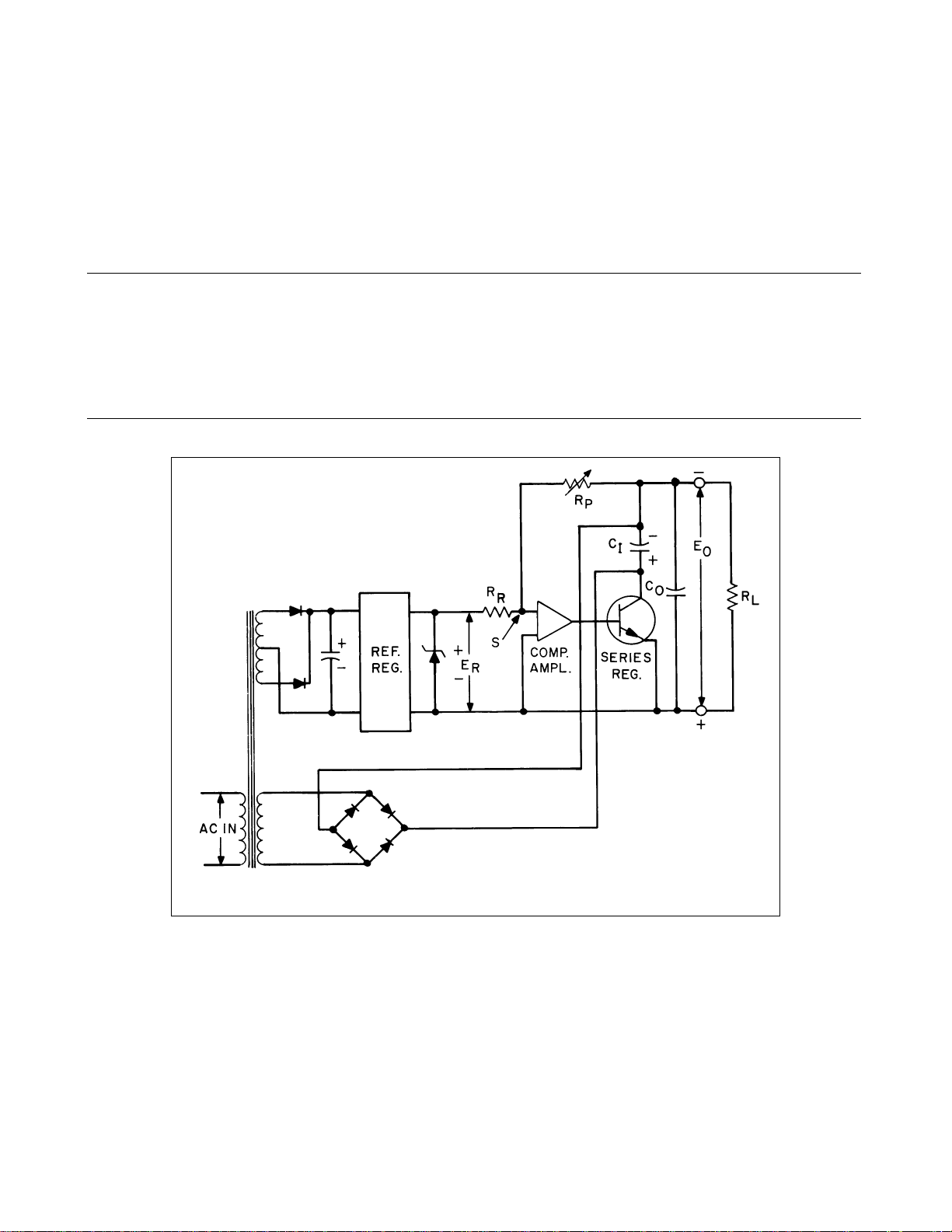

Figure 7 shows an earlier Agilent power supply using SCR's as the preregulating elements. Silicon Controlled

Rectifiers, the semiconductor equivalent of thyratons, are rectifiers which remain in a non-conductive state,

even when forward voltage is provided from anode to cathode, until a positive trigger pulse is applied to a third

terminal (the gate). Then the SCR "fires", conducting current with a very low effective resistance; it remains

conducting after the trigger pulse has been removed until the forward anode voltage is removed or reversed. On

more recent preregulator designs, the SCR's are replaced by a single triac, which is a bidirectional device.

Whenever a gating pulse is received, the triac conducts current in a direction that is dependent on the polarity

of the voltage across it. Triacs are usually connected in series with one side of the input transformer primary,

while SCR's are included in two arms of the bridge rectifier as shown in Figure 7. No matter which type of

element is used, the basic operating principle of the preregulator circuit is the same. During each half cycle of

the input, the firing duration of the SCR's is controlled so that the bridge rectifier output varies in accordance

with the demands imposed by the dc output voltage and current of the supply.

Figure 7. Constant Voltage Power Supply with SCR Preregulator

The function of the preregulator control circuit is to compute the firing time of the SCR trigger pulse for each

24

Page 24

half cycle of input ac and hold the voltage drop across the series regulator constant in spite of changes in load

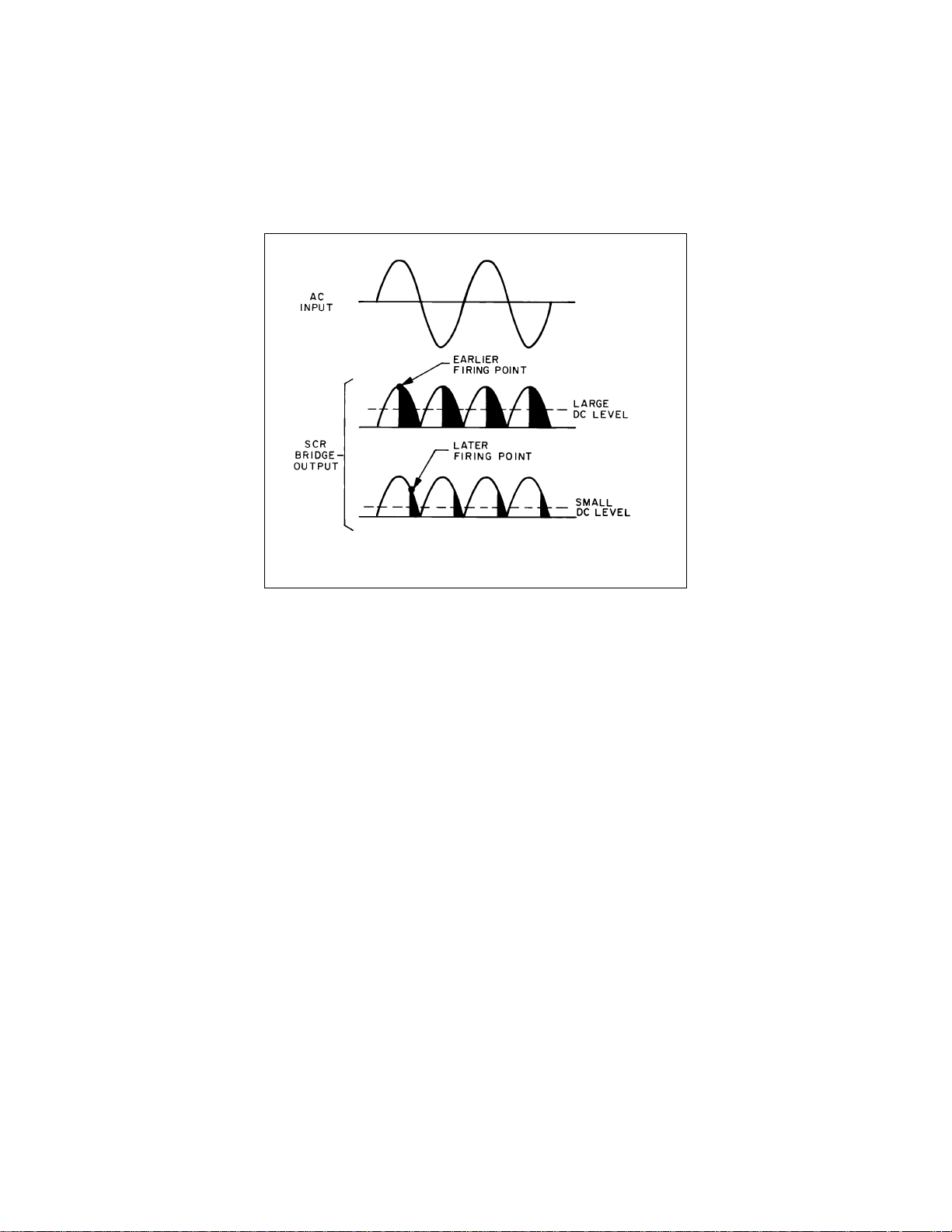

current, output voltage, or input line voltage. Figure 8 shows how varying the conduction angle of the SCR's

affects the amplitude of the output voltage and current delivered by the SCR bridge rectifier of Figure 7. An

earlier firing point results in a greater fraction of halfcycle power from the bridge and a higher dc level across

the input filter capacitance. For later firing times, the dc average is decreased.

Figure 8. SCR Conduction Angle Control of Preregulator Output

The reaction time of an Agilent preregulator control circuit is much faster than earlier SCR or magamp circuits.

Sudden changes in line voltage or load current result in a correction in the timing of the next SCR trigger pulse,

which can be no farther away than one half cycle (approximately 8 milliseconds for a 60Hz input). The large

filter capacitance across the rectifier output allows only a small voltage change to occur during any 8

millisecond interval, avoiding the risk of transient drop-out and loss of regulation due to sudden changes in load

or line. The final burden of providing precise and rapid output voltage regulation rests with the series regulator,

while the preregulator handles the coarser and slower regulation demands.

The preregulator SCRs, together with the leakage inductance of the power transformer, limit high inrush

currents during turn-on. A slow-start circuit allows gradual turn-on of the SCRs while the leakage inductance

acts as a small filter choke in series with the SCRs. Thus, both the supply's input components and other ac

connected instruments are protected from surge currents.

Switching Regulation

The rising cost of electricity and continuous reductions in the size of many electronic devices have stimulated

recent developments in switching regulated power supplies. These supplies are smaller, lighter, and dissipate

less power than equivalent series regulated or series/preregulated supplies.

Although basic switching regulator technology and its advantages have been known for years, a lack of the

necessary switching transistors, rectifier diodes, and filter capacitors caused certain performance problems that

were costly to minimize. As a result, these supplies were used only in airborne, space, or other applications

where cost was a secondary consideration to weight and size. However, the advent of high-voltage, fast

25

Page 25

switching power transistors, fast recovery diodes, and new filter capacitors with lower series resistance and

inductance, have propelled switching supplies to a position of great prominence in the power supply industry.

Presently, switching supplies still have a strong growth potential and are constantly changing as better

components become available and new design techniques emerge. Concurrently, performance is improving,

costs are dropping, and the power level at which switching supplies are competitive with linear supplies

continues to decrease. Before continuing with this discussion, a look at a basic switching supply circuit will

help to explain some of the reasons for its popularity.

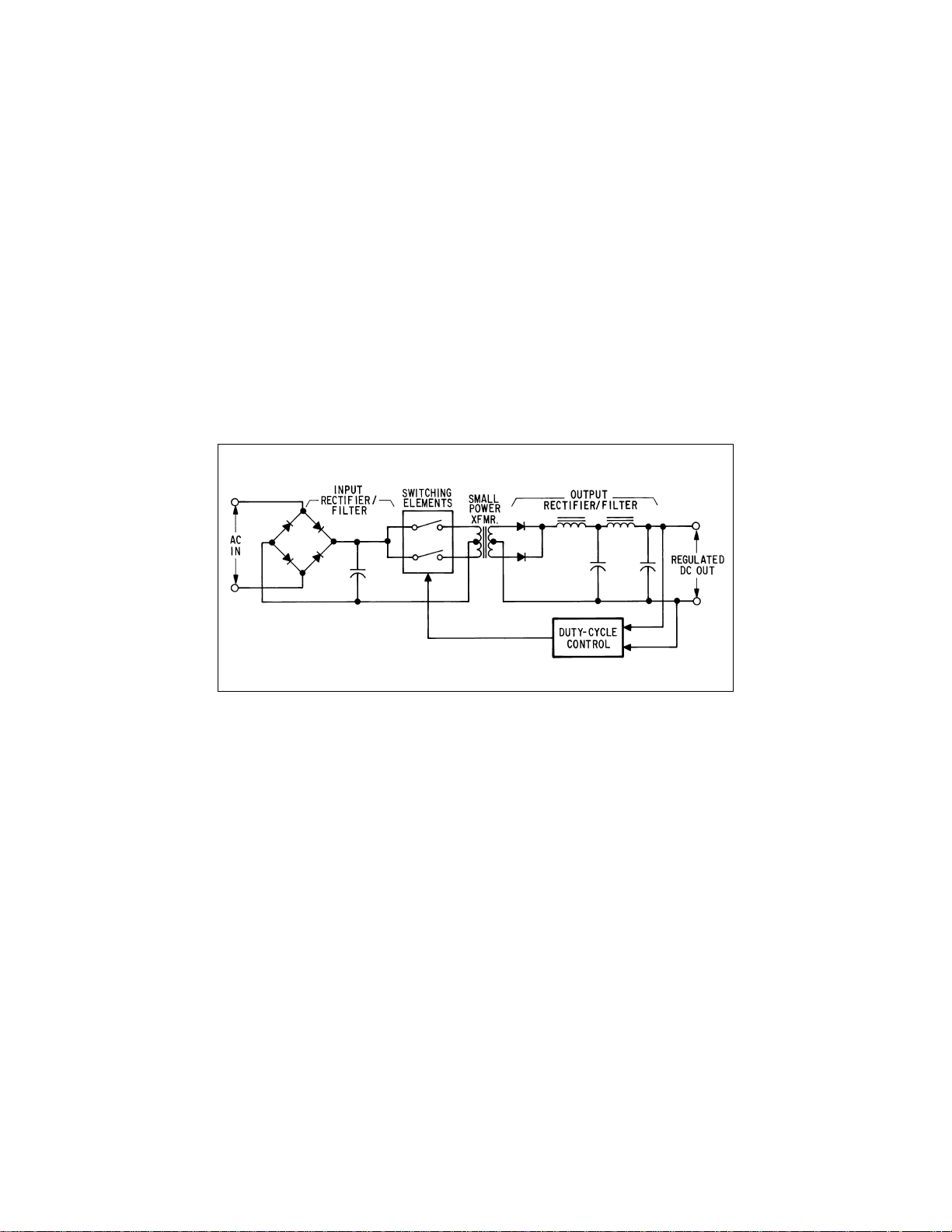

Basic Switching Supply

In a switching supply, the regulating elements consist of series connected transistors that act as rapidly opened

and closed switches (Figure 9). The input ac is first converted to unregulated dc which, in turn, is "chopped" by

the switching element operating at a rapid rate(typically 20KHz). The resultant 20KHz pulse train is

transformer-coupled to an output network which provides final rectification and smoothing of the dc output.

Regulation is accomplished by control circuits that vary the on-off periods (duty cycle) of the switching

elements if the output voltage attempts to chance.

Figure 9. Basic Swit chi ng Supply

Operating Advantages and Disadvantages. Because switching regulators are basically on/off devices, they

avoid the higher power dissipation associated with the rheostat-like action of a series regulator. The switching

transistors dissipate very little power when either saturated (on) or nonconducting (off) and most of the power

losses occur elsewhere in the supply. Efficiencies ranging from 65 to 85% are typical for switching supplies, as

compared to 30 to 45% efficiencies for linear types. With less wasted power, switching supplies run at cooler

temperatures, cost less to operate, and have smaller regulator heat sinks.

Significant size and weight reductions for switching supplies are achieved because of their high switching rate.

The power transformer, inductors, and filter capacitors for 20KHz operation are much smaller and lighter than

those required for operation at power line frequencies. Typically, a switching supply is less than one-third the

size and weight of a comparable series regulated supply.

Besides high efficiency and reduced size and weight, switching supplies have still another benefit that suits the

needs of the modern environment. That is their ability to operate under low ac input voltage (brownout) conditions and a relatively long carryover (or holdup) of their output if input power is lost momentarily. The

switching supply is superior to the linear supply in this regard because more energy can be stored in its input

filter capacitance. To provide the low voltage, high current output required in many of today's applications, the

series regulated supply first steps down the input ac and energy storage must be in a filter capacitor with a low

26

Page 26

voltage across it. In a switching supply, however, the input ac is rectified directly (Figure 9) and the filter

capacitor is allowed to charge to a much higher voltage (the peaks of the ac line). Since the energy stored in a

capacitor = 0.5CV2, while its volume (size) tends to be proportional to CV, storage capability is better in a

switching supply.

Although its advantages are impressive, a switching supply does have some inherent operating characteristics

that could limit its effectiveness in certain applications. One of these is that its transient recovery time (dynamic

load regulation) is slower than that of a series regulated supply. In a linear supply, recovery time is limited only

by the speeds of the semiconductors used in the series regulator and control circuitry. In a switching supply,

however, recovery is limited mainly by the inductance in the output filter. This may or may not be of

significance to the user, depending upon the specific application.

Also, electro-magntic interference (EMI) is a natural byproduct of the on-off switching within

these supplies. This interference can be conducted to the load (resulting in higher output ripple and

noise), it can be conducted back into the ac line, and it can be radiated into the surrounding

atmosphere. For this reason, all Agilent Technologies switching supplies have built-in shields and

filter networks that substantially reduce EMI and control output ripple and noise.

Reliability has been another area of concern with switching supplies. Higher circuit complexity

and the relative newness of switching regulator technology have in the past contributed to a

diminished confidence in switching supply reliability. Since their entry into this market, Agilent

has placed a strong emphasis on the reliability of their switching supplies. Field failures have been

minimized by such factors as careful component evaluation, MTBF life tests, factory "burn-in"

procedures, and sound design practices.

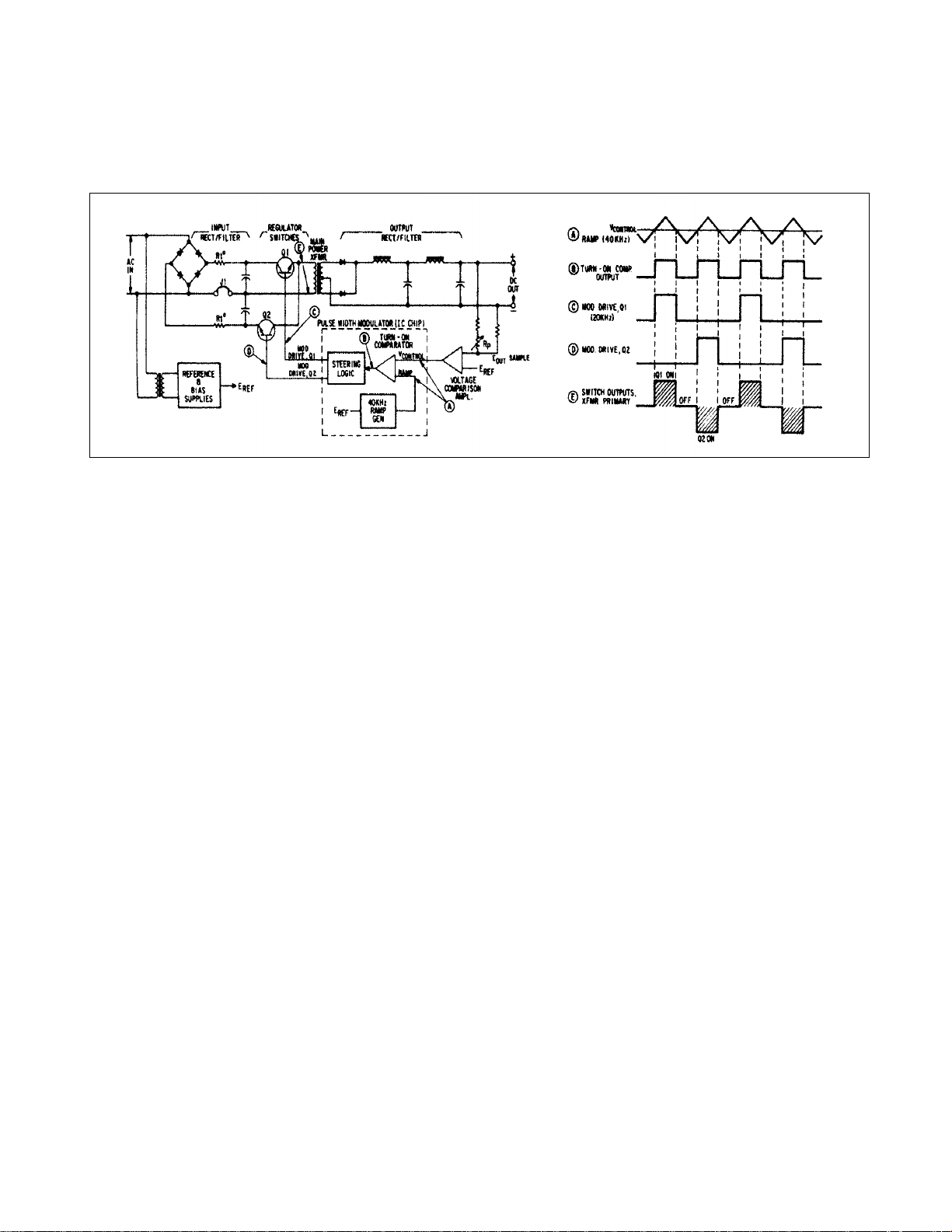

Typical Switching Regulated Power Supplies

Currently, switching supplies are widely used by Original Equipment Manufacturers (OEMs). This class of

switching supply provides a high degree of efficiency and compactness, moderate-to-good regulation and ripple

characteristics, and a semi-fixed constant voltage output.

Figure 10 shows one of Agilent’s higher power, yet less complex, OEM switching supplies. Regulation is

accomplished by a pair of push-pull switching transistors operating under control of a feedback network

consisting of a pulse width modulator and a voltage comparison amplifier. The feedback elements control the

ON periods of the switching transistors to adjust the duty cycle of the bipolar waveform (E) delivered to the

output rectifier/filter. Here the waveform is rectified and averaged to provide a dc output level that is

proportional to the duty cycle of the waveform. Hence, increasing the ON times of the switches increases the

output voltage and vice-versa.

The waveforms of Figure 10 provide a more detailed picture of circuit operation. The voltage comparison

amplifier continuously compares a fraction of the output voltage with a stable reference (EREF) to produce the

VCONTROL level for the turn-on comparator. This device compares the VCONTROL input with a triangular

ramp waveform (A) occurring at a fixed 40KHz rate. When the ramp voltage is more positive than the control

level, a turn-on signal (B) is generated. Notice that an increase or decrease in the VCONTROL voltage varies

the width of the output pulses at B and thus the ON time of the switches.

Steering logic within the modulator chip causes switching transistors Q1 and Q2 to turn on alternately, so that

each switch operates at one-half the ramp frequency (20KHz).

27

Page 27

Included, but not shown, in the modulator chip are additional circuits that establish a minimum "dead time" (off

time) for the switching transistors. This ensures that both switching transistors cannot conduct simultaneously

during maximum duty cycle conditions.

Figure 10. Switchi ng Regul ated Constant Voltage Supply

Ac Inrush Current Protection. Because the input filter capacitors are connected directly across the rectified

line, some form of surge protection must be provided to limit line inrush currents at turn-on. If not controlled,

large inrush surges could trip circuit breakers, weld switch contacts, or affect the operation of other equipment

connected to the same ac line. Protection is provided by a pair of thermistors in the input rectifier circuit. With

their high negative temperature coefficient of resistance, the thermistors present a relatively high resistance

when cold (during the turn-on period), and a very low resistance after they heat up.

A shorting strap (J1) permits the configuration of the input rectifier-filter to be altered for different ac inputs.

For a 174-250Vac input, the strap is removed and the circuit functions as a conventional full-wave bridge. For

87-127Vac inputs, the strap is installed and the input circuit becomes a voltage doubler.

Switching Frequencies, Present and Future. Presently, 20KHz is a popular repetition rate for switching

regulators because it is an effective compromise with respect to size, cost, dissipation, and other factors.

Decreasing the switching frequency would bring about the return of the acoustical noise problems that plagued

earlier switching supplies and would increase the size and cost of the output inductors and filter capacitors.

Increasing the switching frequency, however, would result in certain benefits; including further size reductions

in the output magnetics and capacitors. Furthermore, transient recovery time could be decreased because a

higher operating frequency would allow a proportional decrease in the output inductance, which is the main

constraint in recovery performance.

Unfortunately, higher frequency operation has certain drawbacks. One is that filter capacitors have an

Equivalent Series Resistance and Inductance (ESR and ESL) that limits their effectiveness at high frequencies.

Another disadvantage is that power losses in the switching transistors, inductors, and rectifier diodes increase

with frequency. To counteract these effects, critical components such as filter capacitors with low ESRs, fast

recovery diodes, and high-speed switching transistors are required. Some of these components are already

available, others are not. Switching transistors are improving, but remain one of the major problems at high

frequencies. However, further improvements in high-speed switching devices, such as the new power Field

Effect Transistors (FETs) would make high frequency operation and its associated benefits, a certainty for

28

Page 28

future switching supplies.

Preregulated Switching Supply. Figure 11 shows another higher power switching supply similar to the circuit

of Figure 10 except for the addition of a triac preregulator. Operation of this preregulator is similar to the

previously described circuit of Figure 7. Briefly, the dc input voltage to the switches is held relatively constant

by a control circuit which issues a phase adjusted firing pulse to the triac once during each half-cycle of the

input ac. The control circuit compares a ramp function to a rectified ac sinewave to compute the proper firing

time for the triac.

Although the addition of preregulator circuitry increases complexity, it provides three important benefits. First,

by keeping the input to the switches constant, it permits the use of lower voltage, more readily available

switching transistors. The coarse preregulation it provides also allows the main regulator to achieve a finer

regulation. Finally, through the use of slow-start circuits, the initial conduction of the triac is controlled;

providing an effective means of limiting inrush current.

Note that the preregulator triac is essentially a switching device and, like the main regulator switches, does not

absorb a large amount of power. Hence, the addition of the preregulator does not significantly reduce the

overall efficiency of this supply.

Figure 11. Switching Supply with Preregulator.

Single Transistor Switching Regulator. At lower output power levels, a one transistor switch becomes

practical. The single transistor regulator of Figure 12 can receive a dc input from either one of two sources

without a change in its basic configuration. For ac-to-dc requirements, the regulator is connected to a line

rectifier and SCR preregulator and for dc-to-dc converter applications it is connected directly to an external dc

source.

Like the previous switching supplies, the output voltage is controlled by varying the ON times of the regulator

switch. The switch is turned on by the leading edge of each 20KHz clock pulse and turned off by the pulse

width modulator at a time determined by output load conditions.

While the regulating transistor is conducting, the half-wave rectifier diode is forward biased and power is

transferred to the output filter and the load. When the regulator is turned off, the "flywheel" diode conducts,

sustaining current flow to the load during the off period. A flywheel diode (sometimes called a freewheeling or

29

Page 29

catch diode) was not required in the two transistor regulators of Figures 10 and 11 because of their full-wave

rectifier configuration.

Another item not found in the previous regulators is "flyback" diode CR

transformer winding which is bifilar wound with the primary. During the off periods of the switch, CR

. This diode is connected to a third

F

is

F

forward biased, allowing the return of surplus magnetizing current to the input filter, and thus preventing

saturation of the transformer core. This is an important function because core saturation often leads to the

destruction of switching transistors. In the previously described two transistor push-pull circuits, core saturation

is easier to avoid because magnetizing current is applied to the core in both directions. Nevertheless, matched

switching transistors and balancing capacitors must still be used in these configurations to ensure that core

saturation does not occur.

Figure 12. Single Transistor Sw i t ching Regulator

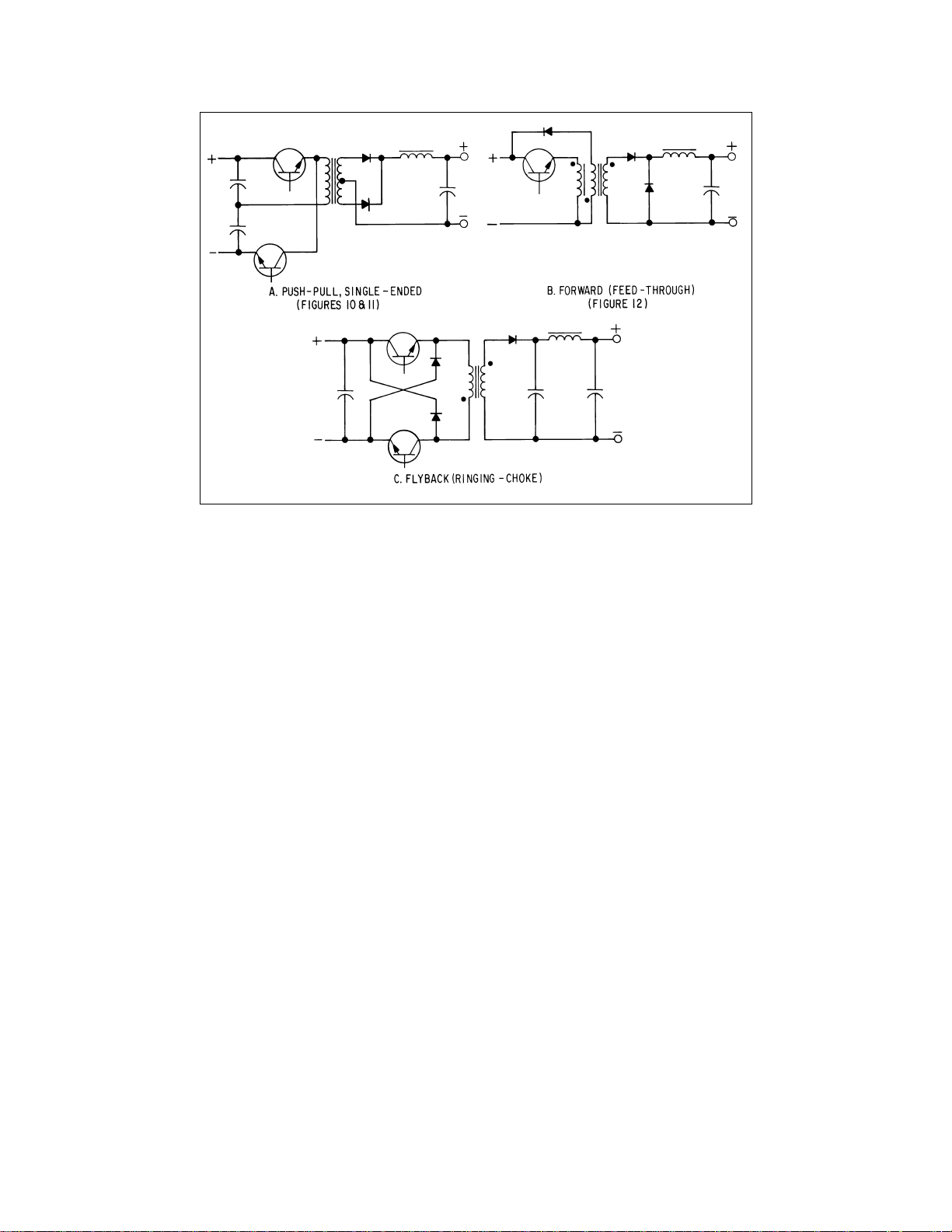

Summary of Basic Switching Regulator Configurations

Figure 13 shows three basic switching regulator configurations that are often used in today’s power supplies.

Configuration A is of the push-pull class and this version was used in the switching supplies shown in Figures

10 and 11. Other variations of this circuit are used also, including two-transistor balanced push-pull and four

transistor bridge circuits.

As a group, push-pull configurations are the most effective for low-voltage, high-power and high performance

applications. Push-pull circuits have the advantage of a ripple frequency that is double that of the other two

basic configurations and, of course, output ripple is inherently lower.

30

Page 30

Figure 13. Basic Swit chi ng Regulator Configurations

Configuration B is a useful alternative to push-pull operation for lower power requirements It is called a

forward, or feed-through, converter because energy is transferred to the power transformer secondary

immediately following turn-on of the switch. Although the ripple frequency is inherently lower, output ripple

amplitude can be effectively controlled by the choke in the output filter. Two-transistor forward converters also

exist wherein both transistors are switched simultaneously. They provide the same output power as the single

transistor versions, but the transistors need handle only half the peak voltage.

Configuration C is known as a flyback, or ringing choke, converter because energy is transferred from primary

to secondary when the switches are off (during flyback). In the example, two transistors are used and both are

switched simultaneously. While the switches are on, the output rectifier is reverse biased and current in the

primary inductance rises in a linear manner. When the switches are turned off, the collapsing magnetic field

reverses the voltage across the primary, and the previously stored energy is transferred to the output filter and

load. The two diodes in the primary protect the transistors from inductive surges that occur at turn-off.

Flyback techniques have long been used as a means of generating high voltages (e. g., the high voltage power

supply in television receivers) and, as you might expect, this configuration is capable of providing higher output

voltages than the other two methods. Also, the flyback regulator provides a greater variation of output voltage

with respect to changes in duty cycle. Hence, the flyback configuration is the most obvious choice for high, and

variable, output voltages while the push-pull and forward configurations are more suitable for providing low,

and fixed, output voltages.

SCR Regulation

SCR regulation techniques permit the design of low cost, compact power supplies with efficiencies of

approximately 70%. Their main disadvantages are a higher ripple and noise, a less precise regulation, and a

slower transient recovery time relative to the other three regulation methods. However, these supplies are

widely used in high power applications where a lower degree of performance can be tolerated.

31

Page 31

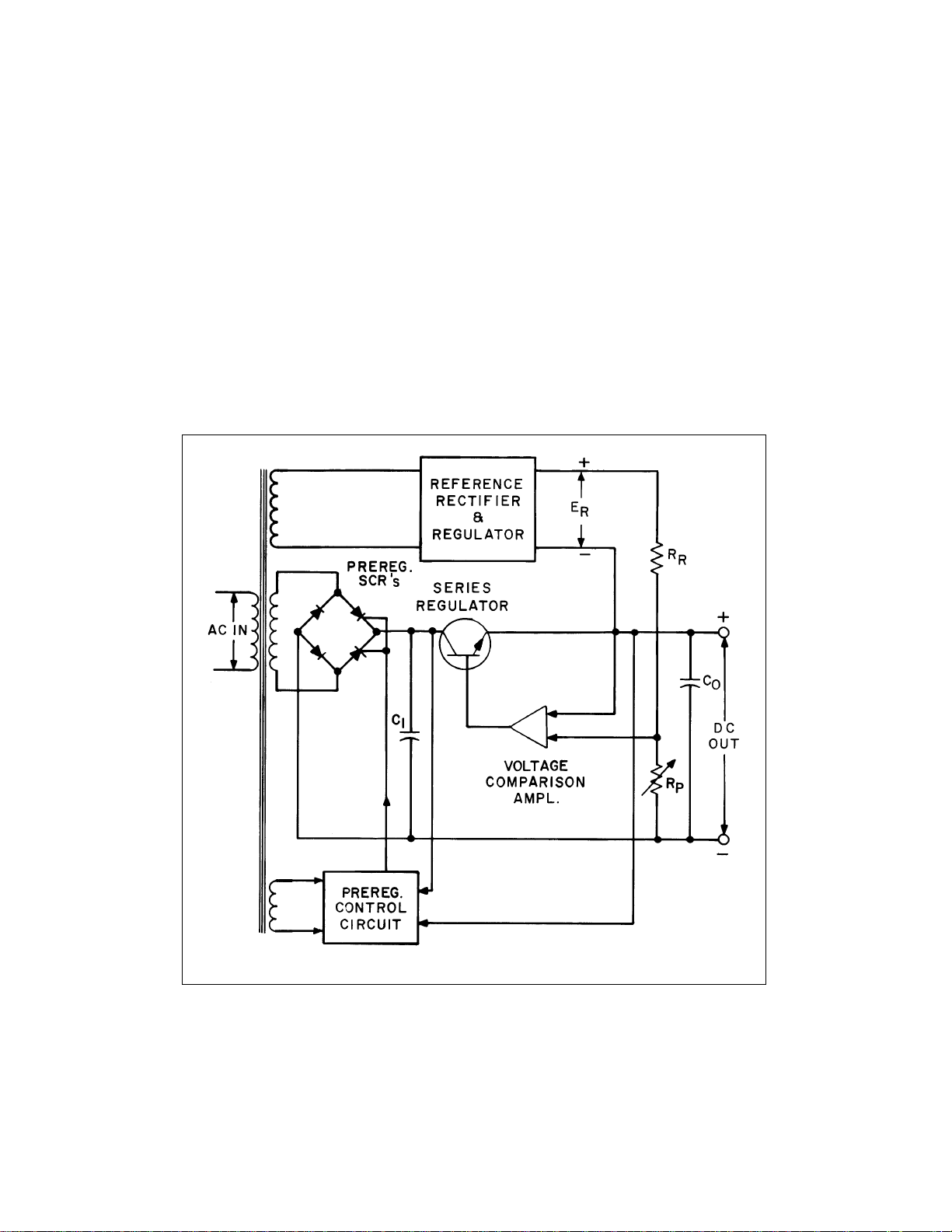

Figure 14 illustrates a typical SCR regulated supply whose output is continuously variable down to near zero

volts. Circuit operation is very similar to the SCR preregulators described previously, except that the SCR

control circuit receives its input from the voltage comparison amplifier. The control circuit computes the firing

time for the SCRs, varying this in a manner which will result in a constant output despite changes in line

voltage or load resistance. The control circuit is capable of making a nearly complete correction within the first

half-cycle (8.3msec) following a disturbance.

Figure 14. SCR Regulated Power Suppl y

CONSTANT CURRENT POWER SUPPLY

The ideal constant current power supply exhibits an infinite output impedance (zero output admittance) at all

frequencies. Thus, as Figure 15 indicates, the ideal constant current power supply would accommodate a load

resistance change by altering its output voltage by just the amount necessary to maintain its output current at a

constant value.

Constant current power supplies find many applications in semiconductor testing and circuit design, and are

also well suited for supplying fixed currents to focus coils or other magnetic circuits, where the current must

remain constant despite temperature-induced changes in the load resistance. Just as loads for constant voltage

power supplies are always connected in parallel (never in series), loads for constant current power supplies

must always be connected in series (never in parallel).

32

Page 32

Figure 15. Ideal Constant Current Power Supply Output Characteristic

Any one of the four basic constant voltage regulators can also furnish a constant current output provided that its

output voltage can be varied down to zero, or at least over the output voltage range required by the load.

Besides the regulator, the reference and control circuits required for constant current operation are nearly

identical to those used for constant voltage operation. As a result of these many common elements, most

constant current configurations are combined with a constant voltage circuit in one Constant Voltage/Constant

Current (CV/CC) power supply.

The following paragraphs describe the current feedback loop generally employed in Agilent Technologies

CV/CC supplies. This particular approach to constant current, while sufficiently effective for most applications,

does have limitations that are caused by its simplified nature. For example, although output capacitor Co

minimizes output ripple and improves feedback stability, it also increases the programming response time and

decreases the output impedance of the supply; a decrease in output impedance inherently results in degradation

of regulation. If precise regulation, rapid programming, and high output impedance are required, improvements

on the basic feedback loop are necessary as described under Precision Constant Current Sources later in this

section.

Figure 16 illustrates the elements constituting a basic constant current power supply using a linear type

regulator. As mentioned previously, many of these elements are identical to those of a constant voltage supply

with the only basic difference being in their output sensing techniques. While the constant voltage supply

monitors the output voltage across its output terminals, the constant current supply monitors the output current

by sensing the voltage drop across a current monitoring resistor (RM) connected in series with the load .

The current feedback loop acts continuously to keep the two inputs to the comparison amplifier equal. These

inputs are the voltage drop across the front panel current control and the IR drop developed by load current I

L

flowing through current monitoring resistor RM. If the two voltages are momentarily unequal, the comparison

amplifier output changes the conduction of the series regulator, which in turn, corrects the load current (voltage

drop across RM) until the error voltage at the comparison amplifier input is reduced to zero. Momentary

unbalances at the comparison amplifier are caused either by adjustment of current control Ra, or by

instantaneous output current changes due to external disturbances. Whatever the cause, the regulator action of

the feedback loop will increase or decrease the load current until the change is corrected.

33

Page 33

Figure 16. Constant Current Power Suppl y

CONSTANT VOLTAGE/CONSTANT CURRENT (CV/CC) POWER SUPPLY

Because of its convenience, versatility, and inherent protection features, many Agilent supplies employ the

CV/CC circuit technique shown in Figure 17. Notice that only low power level circuitry has been added to a

constant voltage supply to make it serve as a dual-purpose source.

Two comparison amplifiers are included in a CV/CC supply for controlling output voltage and current. The

constant voltage amplifier approaches zero output impedance by varying the output current whenever the load

resistance changes, while the constant current amplifier approaches infinite output impedance by varying the

output voltage in response to any load resistance change. It is obvious that the two comparison amplifiers

cannot operate simultaneously. For any given value of load resistance, the power supply must act either as a

constant voltage or a constant current supply--it cannot be both. Transfer between these two modes is

accomplished automatically by suitable decoupling circuitry at a value of load resistance equal to the ratio of

the output voltage control setting to the output current control setting.

34

Page 34

Figure 17. Constant Voltage/Constant Current CV/CC Power Supply

Figure 18 illustrates the output characteristic of an ideal CV/CC power supply. With no load attached (RL= ∞),

I

= 0, and

OUT

= ES, the front panel voltage control setting. When a load resistance is applied to the output

EOUT

terminals of the power supply, the output current increases, while the output voltage remains constant; point D

thus represents a typical constant voltage operating point. Further decreases in load resistance are accompanied

by further increases in I

with no change in the output voltage until the output reaches Is, a value equal to the

OUT

front panel current control setting. At this point the supply automatically changes its mode of operation and

becomes a constant current source; still further decreases in the value of load resistance are accompanied by a

drop in output voltage with no accompanying change in the output current value. Thus, point B represents a

typical constant current operating point. Still further decreases in the load resistance result in output voltage

decreases with no change in output current, until finally, with a short circuit across the output load terminals.

I

= Is and EOUT = 0.

OUT

By gradually changing the load resistance from a short circuit to an open circuit the operating locus of Figure

18 will be traversed in the opposite direction.

35

Page 35

Figure 18. Operating Locus of a CV/CC Power Supply

Full protection against any overload condition is inherent in the Constant Voltage/Constant Current design

principle because all load conditions cause an output that lies somewhere on the operating locus of Figure 18.

For either constant voltage or constant current operation, the proper choice of ES and Is insures optimum protection for the load device as well as full protection for the power supply.

The slope of the line connecting the origin with any operating point on the locus of Figure 18 is proportional to

the value of load resistance connected to the output terminals of the supply. The "critical" or "crossover" value

of load resistance is defined as RC = ES/IS, and adjustment of the front panel voltage and current controls

permits the "crossover" resistance to be set to any desired value from 0 to ∞. If R

is in constant voltage operation, while if R

is less than RC, the supply is in constant current operation.

L

is greater than RC, the supply

L

CONSTANT VOLTAGE/CURRENT LIMITING SUPPLIES

Current limiting supplies provide overcurrent protection for applications where a constant voltage is the only

requirement. There are two basic types of current limiting circuits used today; conventional current limit and

current foldback

Current Limit

Current limiting is similar to constant current except that the current feedback loop uses fewer stages of gain.

Because of this, regulation in the region of current limiting operation is less precise than in constant current

36

Page 36

operation. Thus, the current limiting locus of Figure 19 slopes more than that of Figure 18, and the crossover

“knee" is more rounded.

A sharp knee indicates continuous regulation through the crossover region while a rounded knee denotes loss of

regulation before the crossover value is reached. To avoid any possibility of performance degradation, the

current limit crossover point must be set somewhat higher than the maximum expected operating current when

using a Constant Voltage/Current Limiting (CV/CL) Supply.

Figure 19. Current Limiting Characteristi c

CV/CL supplies employ either a fixed current limit or a continuously variable limit. In either case the change in

the output current of the supply from the point where current limiting action is first incurred to the current value

at short circuit is customarily 3% to 5% of the current rating of the power supply.

By their current limiting action, CV/CL supplies prevent damage to components within the power supply and

will also protect the load provided that the current limiting crossover point is set at a current value that the load

can handle without damage. All of Agilent's current limiting supplies are self restoring; that is, when the

overload is removed or corrected, the output voltage is automatically restored to the previously set value.

Current Foldback