Page 1

Agilent

U2531A USB Simultaneous Sampling DAQ in

Power Measurement Unit Monitoring

Application Note

Page 2

Introduction

Mobile devices are getting more and

more popular. The mobile phone in

the market now has become a pocket

media center. It contains at least a

digital still camera, video conference

functionality, an MP3 player with

simulated surround sound, and a

color Internet browser coupled with

3-D gaming capability. Mobile phones

are continuously equipped with an

increasing number of functions, and

newer phones will come with higher

resolution cameras, adding various

kinds of storage attachment, mobile

television and personal security

devices such as thumbprint sensors.

Mobile phone power management

thus, becomes one of the most

signifi cant engineering challenges.

Other than mobile phones, the other

portable devices like handheld devices,

Personal Digital Assistants (PDAs),

Smart Phones, Portable Multimedia

Players (PMPs), MP3 players, Gaming,

and Global Positioning System (GPS)

also present increasingly sophisticated

functionality and application

requirements.

To achieve seamless playing of music, gaming, and voice and video call on

the mobile phones, it is necessary that the power outputs from the power

management unit remain stable. This will ensure a good customer experience

arising out of using the mobile devices.

For this reason, it is necessary to have a quick and easy design validation of

the power management unit by monitoring the stability of the power inputs and

outputs while switching between the functions of the PMU. The PMU typically

has an input and a few outputs. The parameters to be measured of each channel

will be both the voltage and current. In this particular application, the PMU

has an input and four output ports. Thus, if both voltage and current are to be

monitored for each port, then a total of ten measurement channels are needed.

PMU Monitoring

In the following sections, this application note focuses on how a PMU (in this

case a PMU with one input port and four output ports) can be monitored. The

purpose of this application is to monitor the channels to determine if the outputs

of the PMU are sending out stable signals when the different functions of the

PMU are executed during design validation. This can be seen easily by detecting

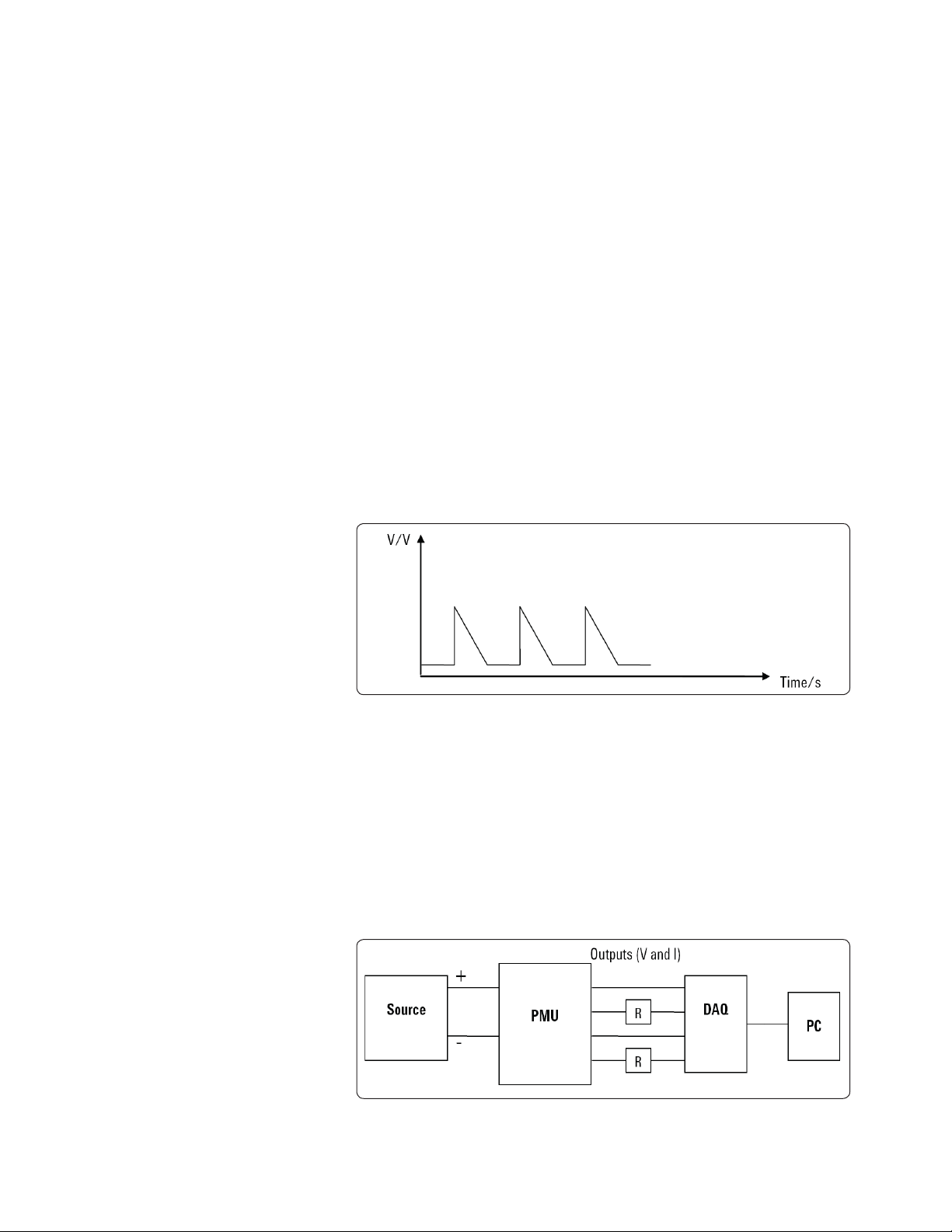

if spikes are present, as shown in Figure 1.

With increasing demands of

functionality and application

requirements, there will also be

an increasing power management

complexity of the overall system.

The drive for these portable device

manufacturers is then moving towards

a power management solution that

is lower in total system cost, and

is fl exible and scalable enough to

manage these demanding power

requirements. The power management

unit (PMU) would be expected to have

different voltage and current outputs

as well to interface to the different

functionality blocks. This voltage

range could range from millivolts to up

to 3.3 V. The current could be in the

range of milliamperes.

Figure 1. Graph indicated a transient signal detected.

To simulate an aging process and to run through all the functionality of the PMU,

the duration of the test will take several hours. Since both voltage and current

measurements need to be made for each port, the total number of channels

needed would be ten. In this particular test, three data acquisition (DAQ) devices

like the U2531A 2 MSa/s, 4-channel simultaneous sampling multifunction DAQ

device and the U2781A 6-Slot USB modular instrument chassis will be most

suitable. Since the maximum voltage output for this particular PMU is 3.3 V, it

can be connected directly to the input of the DAQ device. The current can be

easily measured by measuring the voltage across a resistor. The block diagram

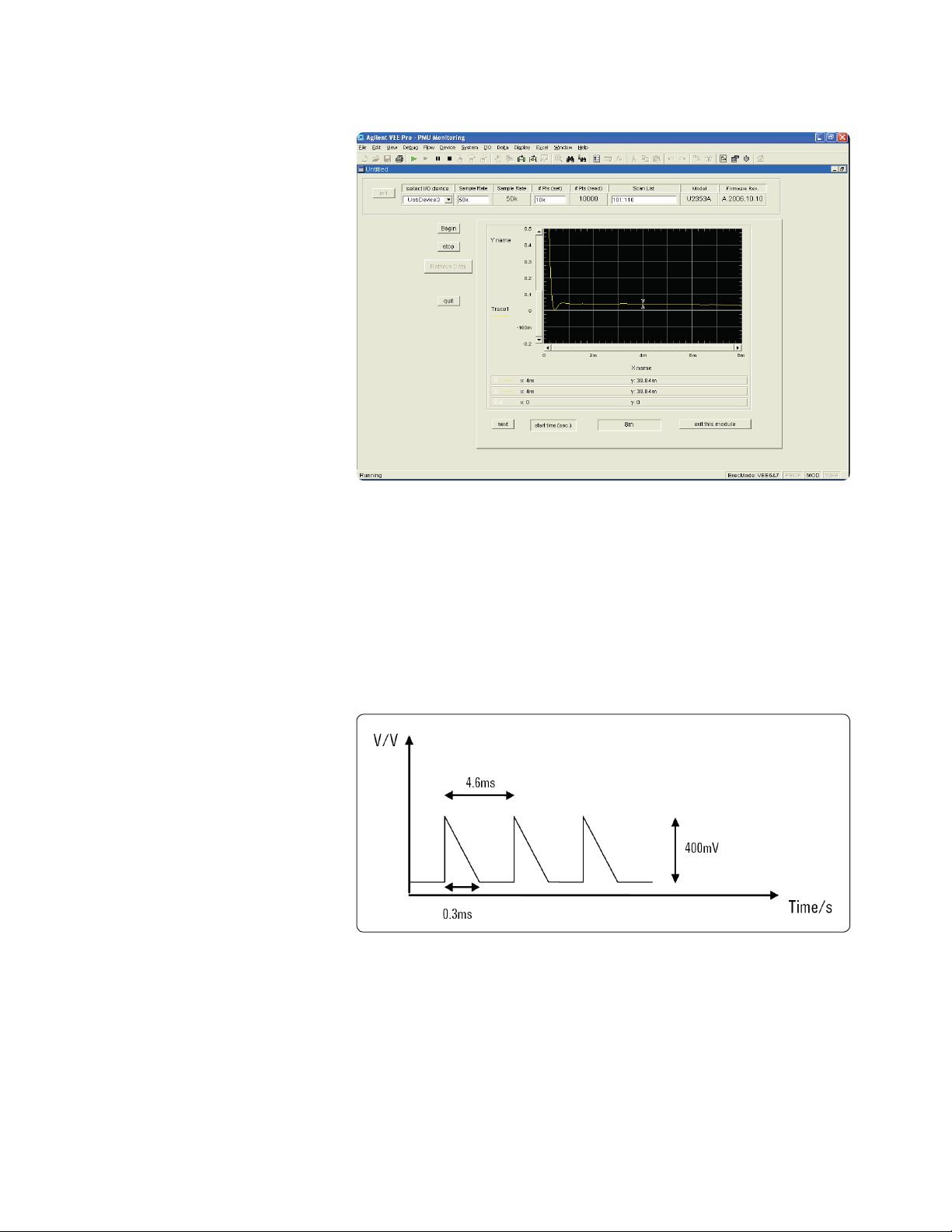

in Figure 2 illustrates how this test is conducted.

Figure 2. Block diagram shows the test setup of PMU monitoring.

2

Page 3

In this application, the program is written in Agilent VEE Pro to control the DAQ

devices in acquiring the voltage and current as shown in Figure 3.

Figure 3. Windows shown is the VEE test program.

The functionality of the PMU is controlled by its fi rmware. In this particular

application, the VEE program is used to control the DAQ devices with regard

to the monitoring of the different channels. In addition, a separate routine is

written to run through the functionality of the PMU. Alternatively, another

routine can be written to control the DAQ and the fi rmware together and to

easily establish a correlation between the DAQ results and the functionality.

During channel monitoring in this particular application a glitch is detected in

one of the channels, as shown in Figure 4.

Figure 4. The graph shows an actual glitch detected by the DAQ.

3

Page 4

The duration of the spike is 0.3 ms. In fact, with the 2 MSa/s sampling rate DAQ,

and the recommendation that the sampling rate employed by the DAQ (or the

test system) should be fi ve times the sampling rate of the signal, the maximum

glitch that can be detected is 2.5 us. In this application, the absolute voltage

is actually not as important since the main purpose of the application is to

monitor the presence of spikes. The DAQ measurements and functionality test

were carried out at the same time, and since it can be determined when a spike

occurs once the data acquisition process has started, it is also possible to easily

and quickly determine the actual status and functionality details of the PMU at

that point in time. Based on this information, the troubleshooting process can be

related to the exact time and situation at which the problem occurred.

Conclusion

With the growing popularity for portable devices, it is necessary to have a quick

and easy design validation of the power management unit. The objective of

monitoring the PMU for stable input and outputs can be achieved using Agilent’s

DAQ. This way it is possible to reduce the time required to resolve the problem.

This is done through a low cost DAQ solution.

References

[1] Agilent U2500A Series USB Simultaneous Multifunction Data Acquisition

Devices User’s Guide, Part Number U2351-90002.

4

Page 5

Agilent Email Updates

t

www.agilent.com/fi nd/emailupdates

Get the latest information on the products and applications you select.

Agilent Direc

www.agilent.com/fi nd/agilentdirect

Quickly choose and use your test

equipment solutions with confi dence.

Agilent

Open

www.agilent.com/fi nd/open

Agilent Open simplifi es the process of connecting and

programming test systems to help engineers design,

validate and manufacture electronic products. Agilent

offers open connectivity for a broad range of systemready instruments, open industry software, PC-standard

I/O and global support, which are combined to more

easily integrate test system development.

Remove all doubt

Our repair and calibration services will get your

equipment back to you, performing like new,

when promised. You will get full value out of your

Agilent equipment throughout its lifetime. Your

equipment will be serviced by Agilent-trained

technicians using the latest factory calibration

procedures, automated repair diagnostics and

genuine parts. You will always have the utmost

confi dence in your measurements.

Agilent offers a wide range of additional expert

test and measurement services for your equipment, including initial start-up assistance onsite

education and training, as well as design, system

integration, and project management.

For more information on repair and

calibration services, go to

www.agilent.com/find/removealldoubt

www.agilent.com

For more information on Agilent Technologies’

products, applications or services, please contact

your local Agilent office. The complete list is

available at:

www.agilent.com/find/contactus

Phone or Fax

United States:

(tel) 800 829 4444

(fax) 800 829 4433

Canada:

(tel) 877 894 4414

(fax) 800 746 4866

China:

(tel) 800 810 0189

(fax) 800 820 2816

Europe:

(tel) 31 20 547 2111

Japan:

(tel) (81) 426 56 7832

(fax) (81) 426 56 7840

Korea:

(tel) (080) 769 0800

(fax) (080) 769 0900

Latin America:

(tel) (305) 269 7500

Taiwan:

(tel) 0800 047 866

(fax) 0800 286 331

Other Asia Pacifi c Countries:

(tel) (65) 6375 8100

(fax) (65) 6755 0042

Email: tm_ap@agilent.com

Revised: 11/08/06

Product specifi cations and descriptions

in this document are subject to change

without notice.

© Agilent Technologies, Inc. 2007

Printed in USA, October 31, 2007

5989-7422EN

Loading...

Loading...