Page 1

Agilent U2300A Series USB Multifunction Data Acquisition Devices

Service Guide

Agilent Technologies

Page 2

Notices

© Agilent Technologies, Inc. 2007 - 2010

No p art o f this manu al may be re produce d in

any form or by any means (including electronic storage and retrieval or translation

into a foreign language) without prior agreement and written consent from Agilent

Technologies, Inc. as governed by United

States and international copyright laws.

Manual Part Number

U2351-90203

Edition

Second Edition, August 23, 2010

Printed in Malaysia

Agilent Technologies, Inc.

Bayan Lepas Free Industrial Zone,

11900 Penang, Malaysia

Warranty

The material contained in this document is provided “as is,” and is subject to being changed, without notice,

in future editions. Further, to the maximum extent permitted by applicable

law, Agilent disclaims all warranties,

either express or implied, with regard

to this manual and any information

contained herein, including but not

limited to the implied warranties of

merchantability and fitness for a particular purpose. Agilent shall not be

liable for errors or for incidental or

consequential damages in connection with the furnishing, use, or performance of this document or of any

information contained herein. Should

Agilent and the user have a separate

written agreement with warranty

terms covering the material in this

document that conflict with these

terms, the warranty terms in the separate agreement shall control.

Technology Licenses

The hardware and/or software described in

this document are furnished under a license

and may be used or copied only in accordance with the terms of such license.

Restricted Rights Legend

U.S. Government Restricted Rights. Software and technical data rights granted to

the federal government include only those

rights customarily provided to end user customers. Agilent provides this customary

commercial license in Software and technical data pursuant to FAR 12.211 (Technical

Data) and 12.212 (Computer Software) and,

for the Department of Defense, DFARS

252.227-7015 (Technical Data - Commercial

Items) and DFARS 227.7202-3 (Rights in

Commercial Computer Software or Computer Software Documentation).

Safety Notices

CAUTION

A CAUTION notice denotes a hazard. It calls attention to an operating procedure, practice, or the like

that, if not correctly performed or

adhered to, could result in damage

to the product or loss of important

data. Do not proceed beyond a

CAUTION notice until the indicated

conditions are fully understood and

met.

WARNING

A WARNING notice denotes a

hazard. It calls attention to an

operating procedure, practice, or

the like that, if not correctly performed or adhered to, could result

in personal injury or death. Do not

proceed beyond a WARNING

notice until the indicated conditions are fully understood and

met.

II U2300A Series DAQ Service Guide

Page 3

Safety Information

The following general safety precautions must be observed during all phases of this instrument. Failure to comply

with these precautions or with specific warnings elsewhere in this manual violates safety standards of design,

manufacture, and intended use of the instrument. Agilent Technologies, Inc. assumes no liability for the

customer’s failure to comply with these requirements.

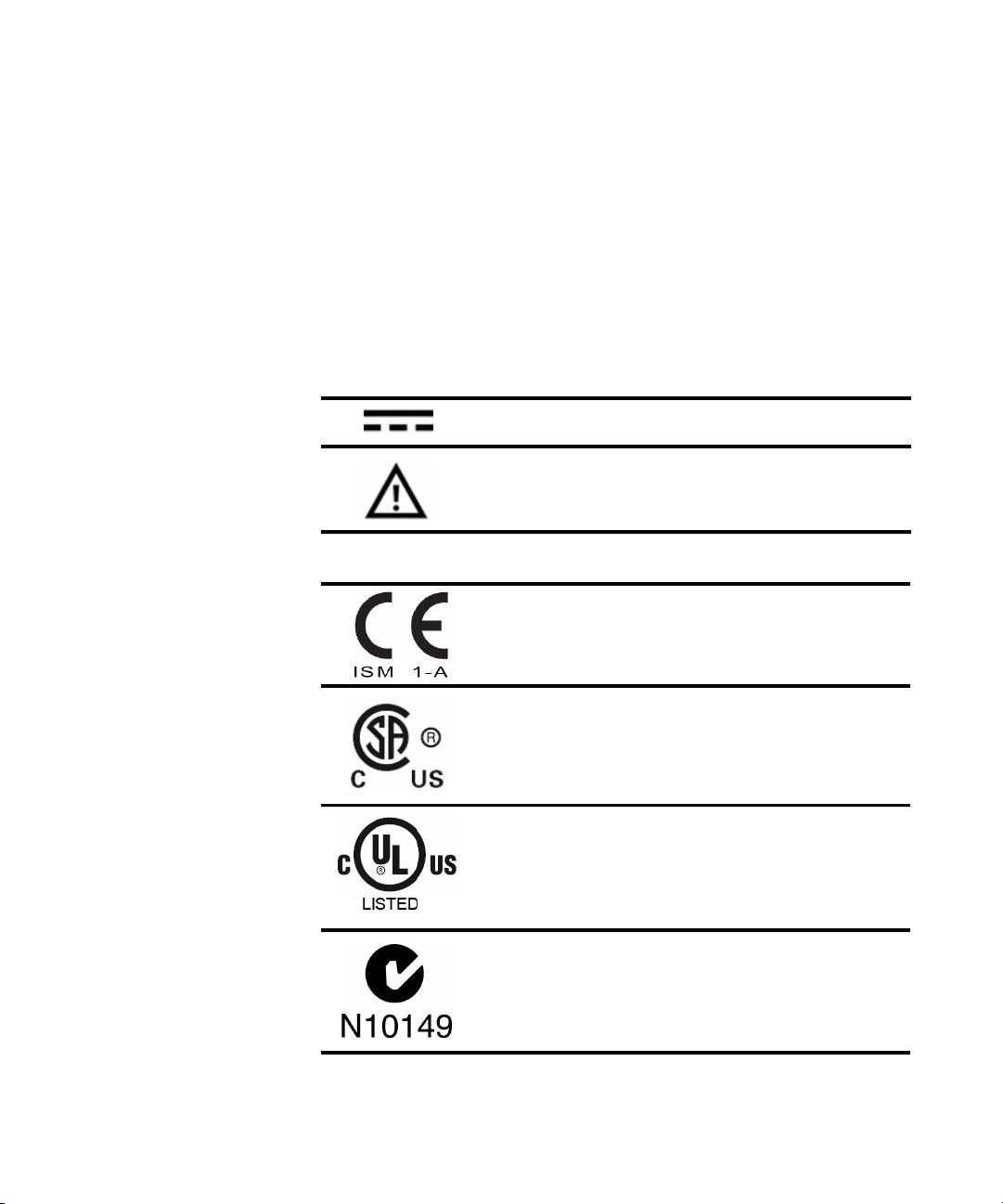

Safety Symbols

The following symbols indicate that precautions must be taken to maintain safe

operation of the instrument.

Direct current

Warni ng

Regulatory Markings

The CE mark shows that the product complies with all the

relevant European Legal Directives (if accompanied by a year, it

signifies when the design was proven).

The CSA mark is a registered trademark of the Canadian Standards Association. A CSA mark with the indicators "C" and "US"

means that the product is certified for both the U.S. and Canadian

markets, to the applicable American and Canadian standards.

The UL Mark is a registered trademark of Underwriters Laboratories Inc. UL listing mark with the indicators "C" and "US” indicates the product compliance with both Canadian and U.S.

requirements.

The C-tick mark is a registered trademark of the Spectrum Management Agency of Australia. This signifies compliance with the

Australian EMC Framework regulations under the terms of the

Radio Communications Act of 1992.

U2300A Series DAQ Service Guide III

Page 4

General Safety Information

WARNING

CAUTION

• Do not use the device if it is damaged.Before you use the device,

inspect the case. Look for cracks or missing plastic. Do not operate the

device around explosive gas, vapor or dust.

• Do not apply more than the rated voltage (as marked on the device)

between terminals, or between terminal and external ground.

• Always use the device with the cables provided.

• Observe all markings on the device before connecting to the device.

• Turn off the device and application system power before connecting to

the I/O terminals.

• When servicing the device, use only specified replacement parts.

• Do not operate the device with the removable cover removed or

loosened.

• Do not connect any cables and terminal block prior to performing

self-test process.

• Use only the power adapter supplied by the manufacturer to avoid any

unexpected hazards.

• Do not load the output terminals above the specified current limits.

Applying excessive voltage or overloading the device will cause

irreversible damage to the circuitry.

• Applying excessive voltage or overloading the input terminal will

damage the device permanently.

• If the device is used in a manner not specified by the manufacturer, the

protection provided by the device may be impaired.

• Always use dry cloth to clean the device. Do not use ethyl alcohol or

any other volatile liquid to clean the device.

• Do not permit any blockage of the ventilation holes of the device.

IV U2300A Series DAQ Service Guide

Page 5

Waste Electrical and Electronic Equipment (WEEE) Directive 2002/96/EC

This instrument complies with the WEEE Directive (2002/96/EC) marking

requirement. This affixed product label indicates that you must not discard this

electrical/electronic product in domestic household waste.

Product Category:

With reference to the equipment types in the WEEE directive Annex 1, this

instrument is classified as a “Monitoring and Control Instrument” product.

The affixed product label is shown as below:

Do not dispose in domestic household waste

To return this unwanted instrument, contact your nearest Agilent office, or visit:

http://www.agilent.com/environment/product

for more information.

U2300A Series DAQ Service Guide V

Page 6

In This Guide...

1 Characteristics and Specifications 1

This chapter specifies the product specifications and electrical

measurement specifications of the U2300A Series USB

Multifunction DAQ devices.

2 Calibration 15

This chapter describes the step- by- step calibration procedures that

covers hardware setup, self calibration, performance verification

procedures and adjustment procedures.

3 Dismantle Procedures 41

This chapter shows the step- by- step disassemble procedures and

list the available replacement parts together with its part number

for U2300A Series USB Multifunction DAQ devices.

4 Troubleshooting and Self-Test Procedures 47

This chapter includes the information on general troubleshooting

hints and self test procedures for the U2300A Series USB

Multifunction DAQ devices.

A Connector Pins Configuration 51

All the U2300A Series USB Multifunction DAQ devices pins

configuration are provided in the appendix.

B Test Limits 57

This appendix provides the test limits of analog input and analog

output for the U2300A Series USB Multifunction DAQ devices.

VI U2300A Series DAQ Service Guide

Page 7

Contents

Contents

1 Characteristics and Specifications 1

Product Specifications 2

Electrical Measurement Specifications 10

2 Calibration 15

Introduction 16

Types Of Signal Sources 17

Input Configurations 18

Hardware Connection 22

Self-Calibration 26

Adjustment Procedures 32

Performance Verification Procedure 34

A/D Data Conversion 38

3 Dismantle Procedures 41

General Disassemble 42

Replacement Parts 46

4 Troubleshooting and Self-Test Procedures 47

Troubleshooting 48

Self-Test Procedures 49

A Connector Pins Configuration 51

Pins Configuration for U2331A, U2355A and U2356A 52

Pins Configuration for U2351A, U2352A, U2353A and U2354A 53

B Tes t L im it s 57

Analog Input 58

U2300A Series DAQ Service Guide VII

Page 8

Contents

Analog Output 62

VIII U2300A Series DAQ Service Guide

Page 9

Agilent U2300A Series Multifunction USB DAQ

Service Guide

1

Characteristics and Specifications

Product Specifications 2

Electrical Measurement Specifications 10

This chapter specifies the specifications of the U2300A DAQ

devices.

Agilent Technologies

1

Page 10

1 Characteristics and Specifications

Product Specifications

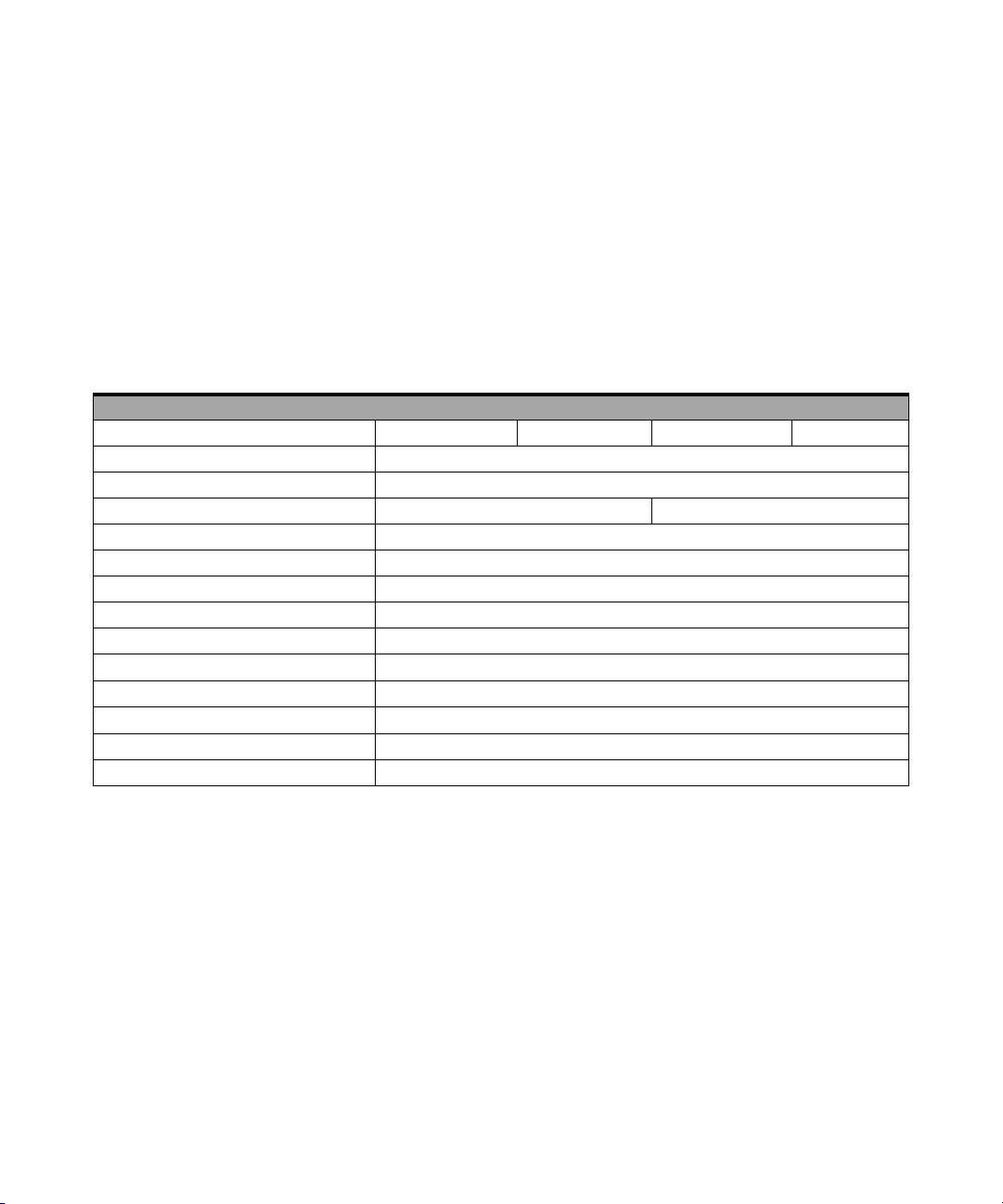

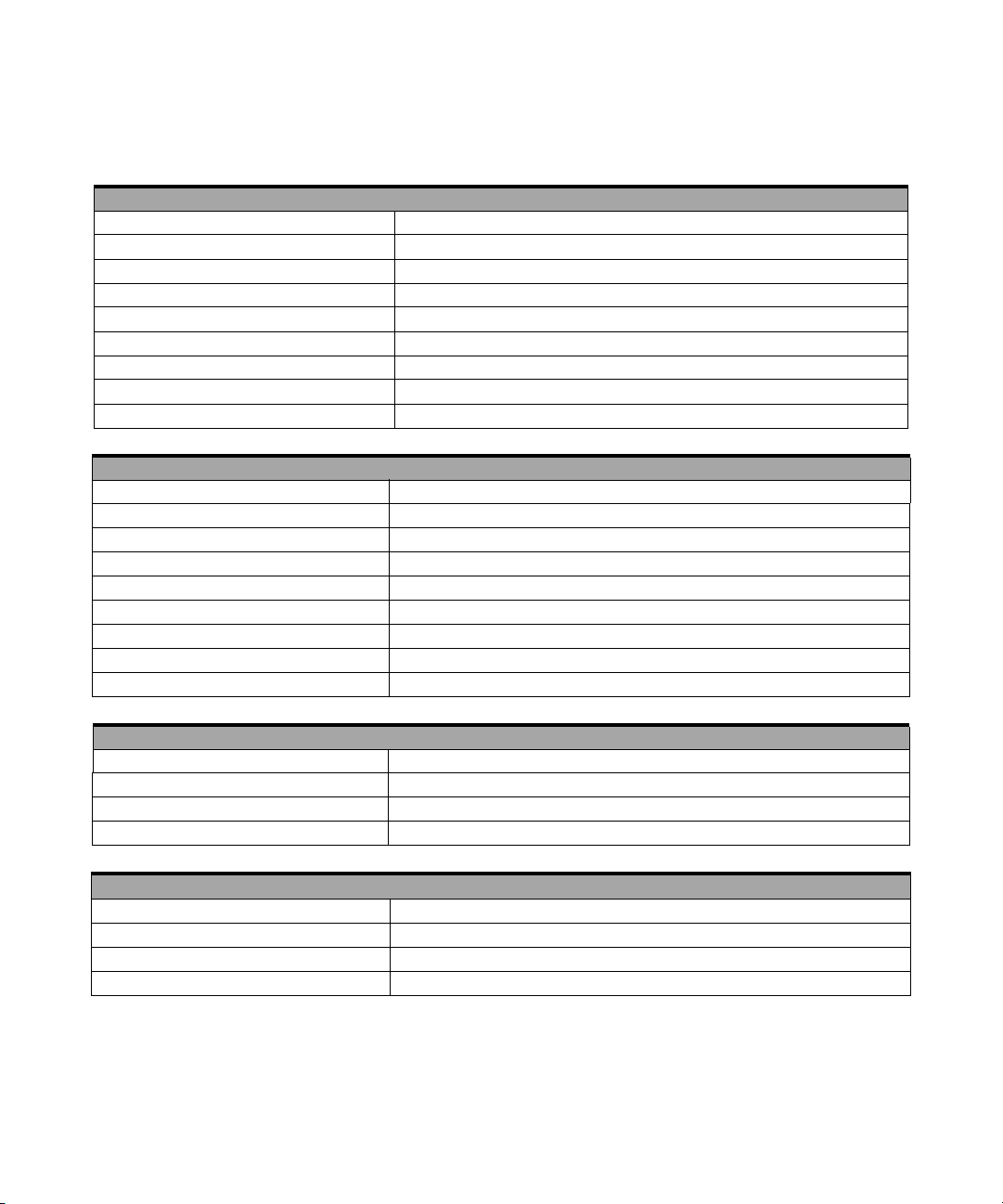

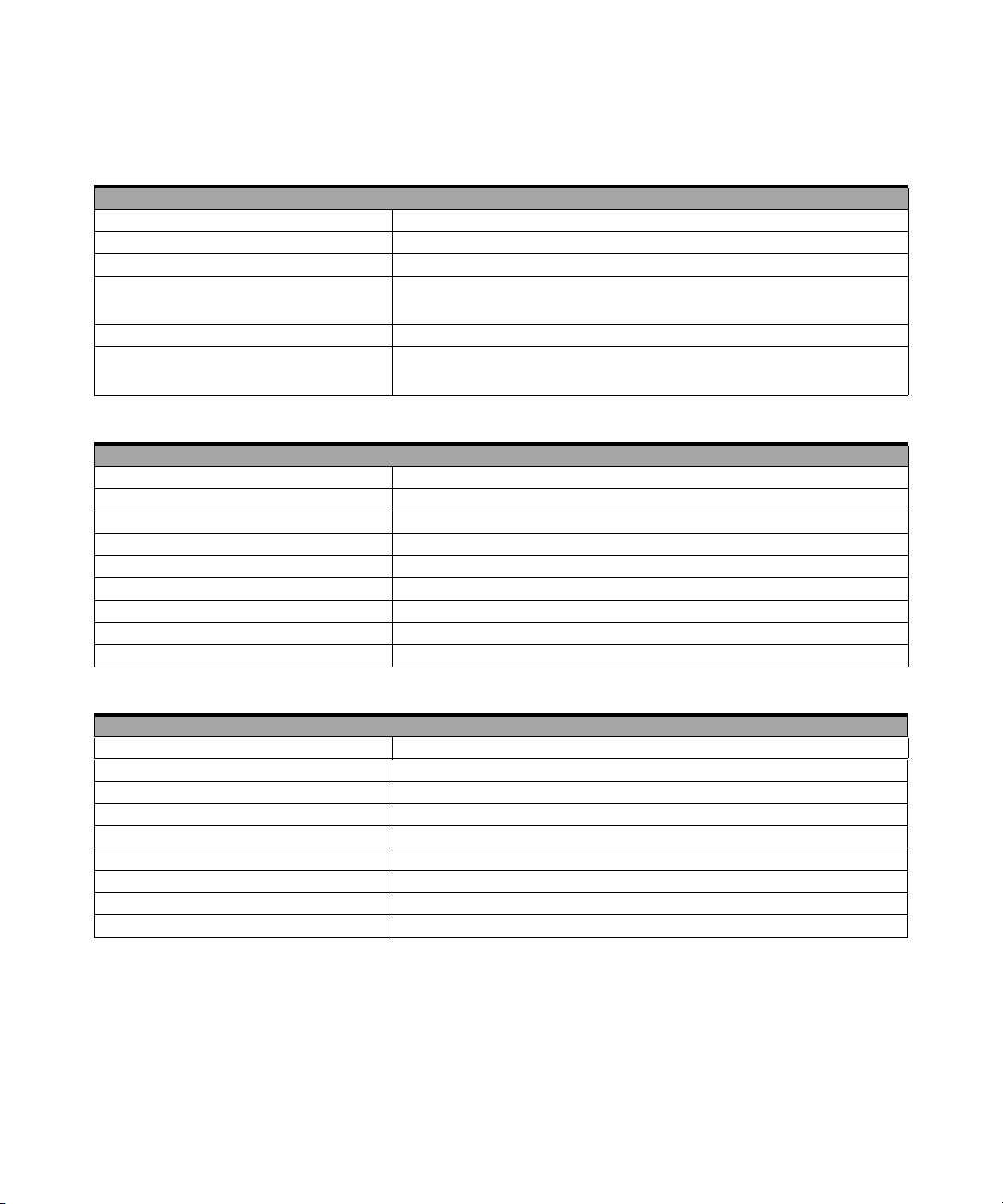

Basic Multifunction DAQ Device Specifications

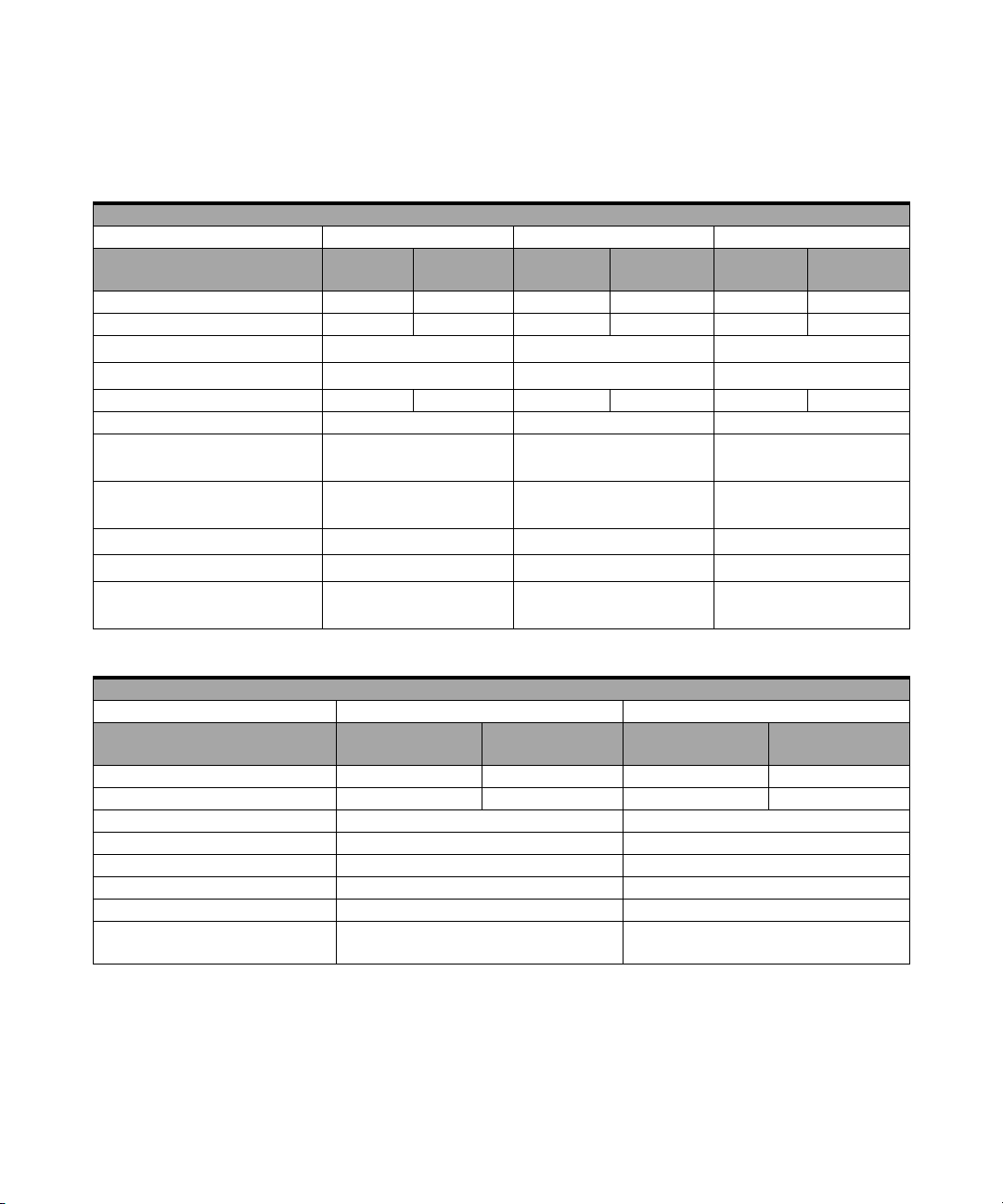

Tab l e 1 - 1 Product specifications for basic multifunction DAQ device (U2351A,

U2352A, U2353A, and U2354A)

Analog Input

Model Number U2351A U2352A U2353A U2354A

Resolution 16 bits, no missing codes

Number of channels 16 SE/8 DI (software selectable/channel)

Maximum sampling rate 250 kSa/s 500 kSa/s

Scan list memory Up to 100 selectable channels entries

Programmable bipolar input range ±10 V, ±5 V, ±2.5 V, ±1.25 V

Programmable unipolar input range 0 to 10 V, 0 to 5 V, 0 to 2.5 V, 0 to 1.25 V

Input coupling DC

Input impedance 1 GΩ / 100 pF

Operational common mode voltage range

Overvoltage protection Power on: Continuous ±30 V, Power off: Continuous ±15 V

Trig g e r s o u rc e s

Trigger modes Pre- trigger, delay-trigger, post-trigger and middle-trigger

FIFO buffer size Up to 8 MSa

External analog/digital trigger, SSI/star trigger

±7.5 V maximum

[4]

[1]

2 U2300A Series DAQ Service Guide

Page 11

Characteristics and Specifications 1

Analog Output

Model Number U2351A U2352A U2353A U2354A

Resolution 16 bits N/A 16 bits N/A

Number of channels 2 N/A 2 N/A

Maximum update rate 1 MSa/s N/A 1 MSa/s N/A

Output ranges 0 to 10 V, ±10 V,

0 to AO_EXT_REF,

±AO_EXT_REF

[2]

N/A 0 to 10 V, ±10 V,

0 to AO_EXT_REF,

±AO_EXT_REF

[2]

Output coupling DC N/A DC N/A

Output impedance 0.1 Ω Typical N/A 0.1 Ω Typical N/A

Stability Any passive load

up to 1500 pF

N/A Any passive load

up to 1500 pF

Power-on state 0 V steady state N/A 0 V steady state N/A

Trigger sources External

analog/digital trigger,

SSI/star trigger

[1]

Trigger modes Post-trigger and

delay-trigger

FIFO buffer size 1 channel: Maximum 8 MSa

2 channels: Maximum 4 MSa/ch

Function generation mode Sine-wave, square-wave, triangle,

sawtooth and noise waveform

N/A External

analog/digital trigger,

SSI/star trigger

[1]

N/A Post-trigger and

delay-trigger

N/A 1 channel: Maximum 8 MSa

2 channels: Maximum 4 MSa/ch

N/A Sine-wave, square-wave, triangle,

sawtooth and noise waveform

N/A

N/A

N/A

N/A

N/A

N/A

Digital I/O

Model Number U2351A | U2352A | U2353A | U2354A

Number of bits 24-bit programmable input/output

Compatibility TTL

Input voltage V

= 0.7 V maximum, IIL = 10 µA maximum

IL

VIH = 2.0 V minimum, IIH = 10 µA maximum

Input voltage range –0.5 V to +5.5 V

Output voltage V

= 0.45 V maximum, IOL = 8 mA maximum

OL

= 2.4 V minimum, IOH = 400 µA maximum

V

OH

U2300A Series DAQ Service Guide 3

Page 12

1 Characteristics and Specifications

General Purpose Digital Counter

Model Number U2351A | U2352A | U2353A | U2354A

Maximum count (2³¹-1) bits

Number of channels Two independent up/down counter

Compatibility TTL

Clock source Internal or external

Base clock available 48 MHz

Maximum clock source frequency 12 MHz

Input frequency range 0.1 Hz to 6 MHz at 50% duty cycle

Pulse width measurement range 0.167 µs to 178.956 s

Analog Trigger

Model Number U2351A | U2352A | U2353A | U2354A

Trigger source All analog input channels, External analog trigger (EXTA_TRIG)

Trigger level ±Full Scale for internal; ±10 V for external

Trigger conditions Above high, below low and window (software selectable)

Trigger level resolution 8 bits

Bandwidth 400 kHz

Input Impedance for EXTA_TRIG 20 kΩ

Coupling DC

Overvoltage Protection Continuous for ± 35 V maximum

Digital Trigger

Model Number U2351A | U2352A | U2353A | U2354A

Compatibility TTL/CMOS

Response Rising or falling edge

Pulse width 20 ns minimum

Calibration

[3]

Model Number U2351A | U2352A | U2353A | U2354A

On board reference voltage 5 V

Temperature drift ±2 ppm/°C

Stability ±6 ppm/1000 hours

4 U2300A Series DAQ Service Guide

Page 13

Characteristics and Specifications 1

General

Model Number U2351A | U2352A | U2353A | U2354A

Remote interface Hi-Speed USB 2.0

Device class USBTMC Class Device

Programmable interface Standard Commands for Programmable Instruments (SCPI) and IVI-COM

[1] System Synchronous Interface (SSI) and Star-trigger commands are used when

modular devices are used in instrument chassis.

[2] Maximum external reference voltage for analog output (AO_EXT_REF) is ±10 V.

[3] 20 minutes warm-up time is recommended.

[4] Refer to Figure 1-1 for more information.

U2300A Series DAQ Service Guide 5

Page 14

1 Characteristics and Specifications

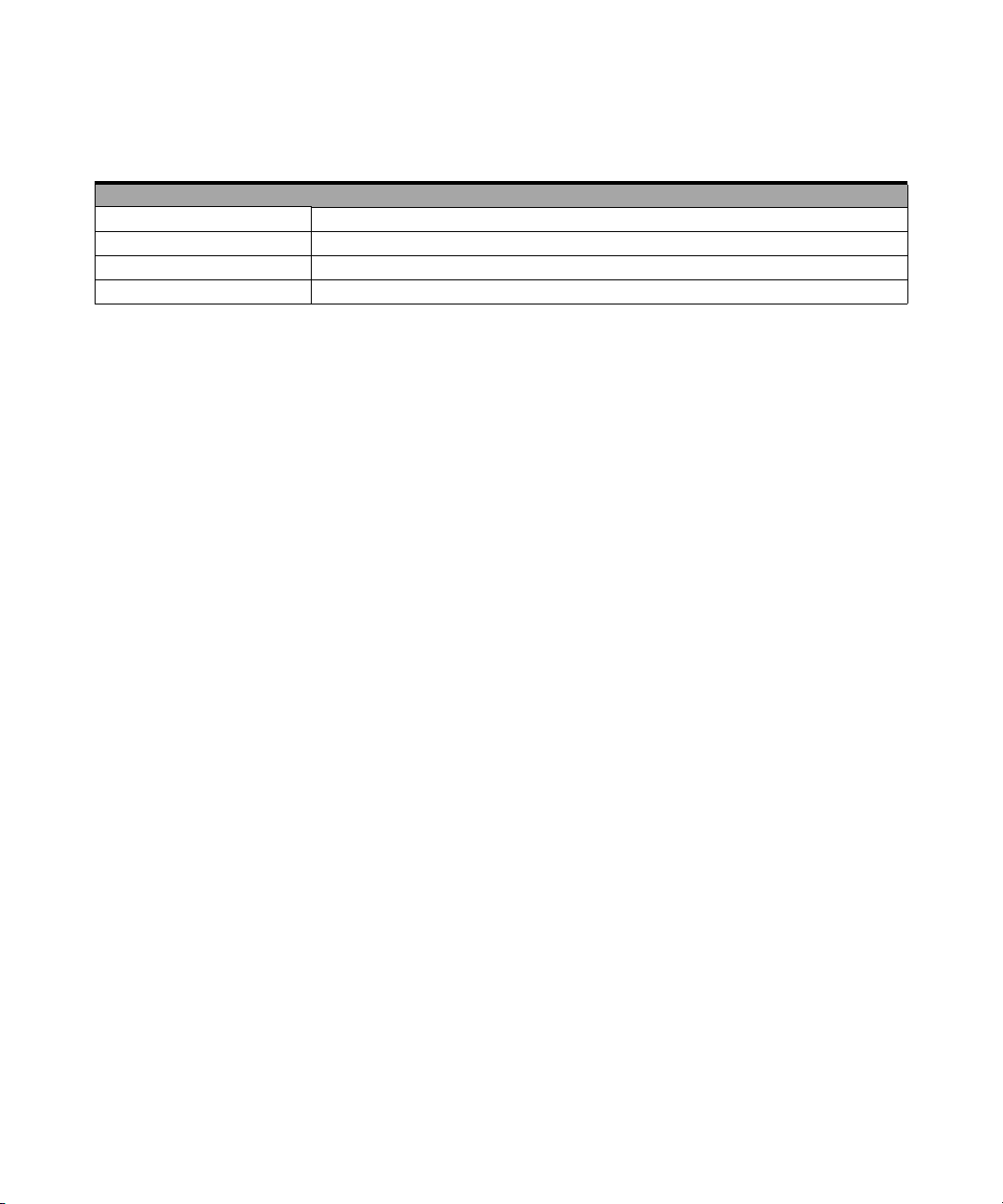

7.5

-7.5

Figure 1-1 Operational common mode voltage range

This graph shows that the common mode voltage range is tightly

linked with the output voltage. The output voltage range of the

DAQ devices is ±10 V. Therefore, the common mode voltage range

is ±7.5 V. Any operation beyond these voltage ranges may produce

unexpected and unreliable results, and should be avoided.

6 U2300A Series DAQ Service Guide

Page 15

Characteristics and Specifications 1

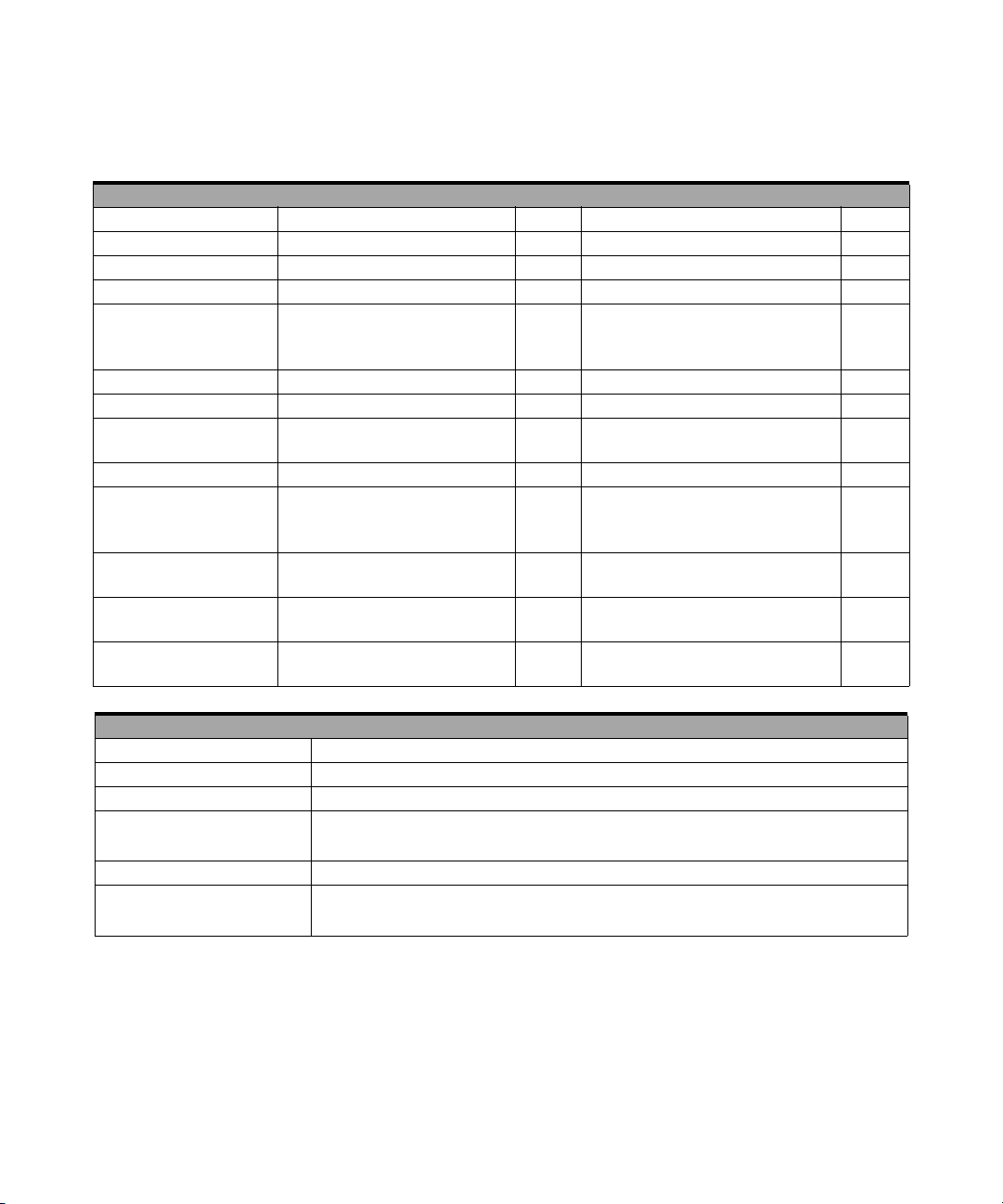

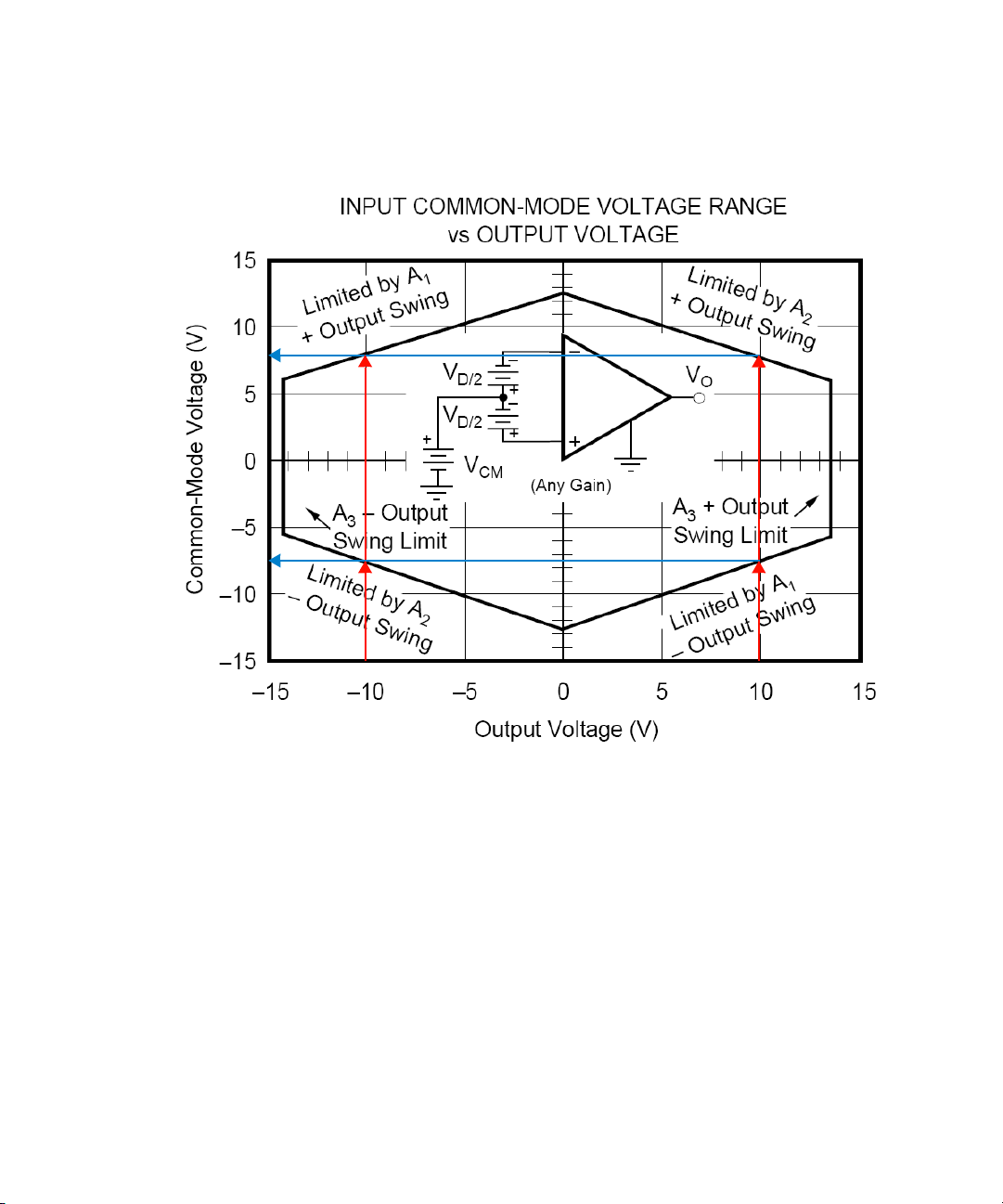

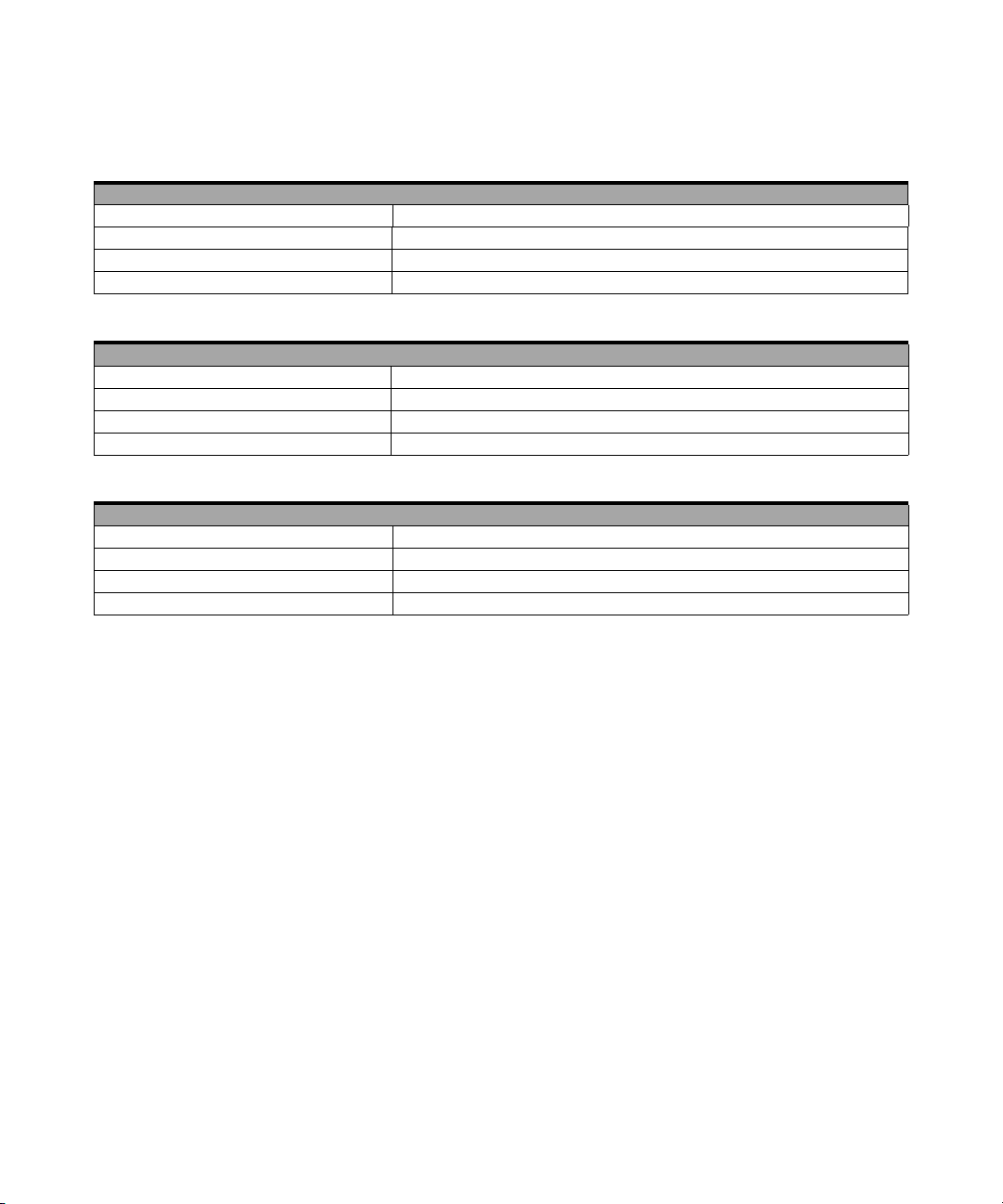

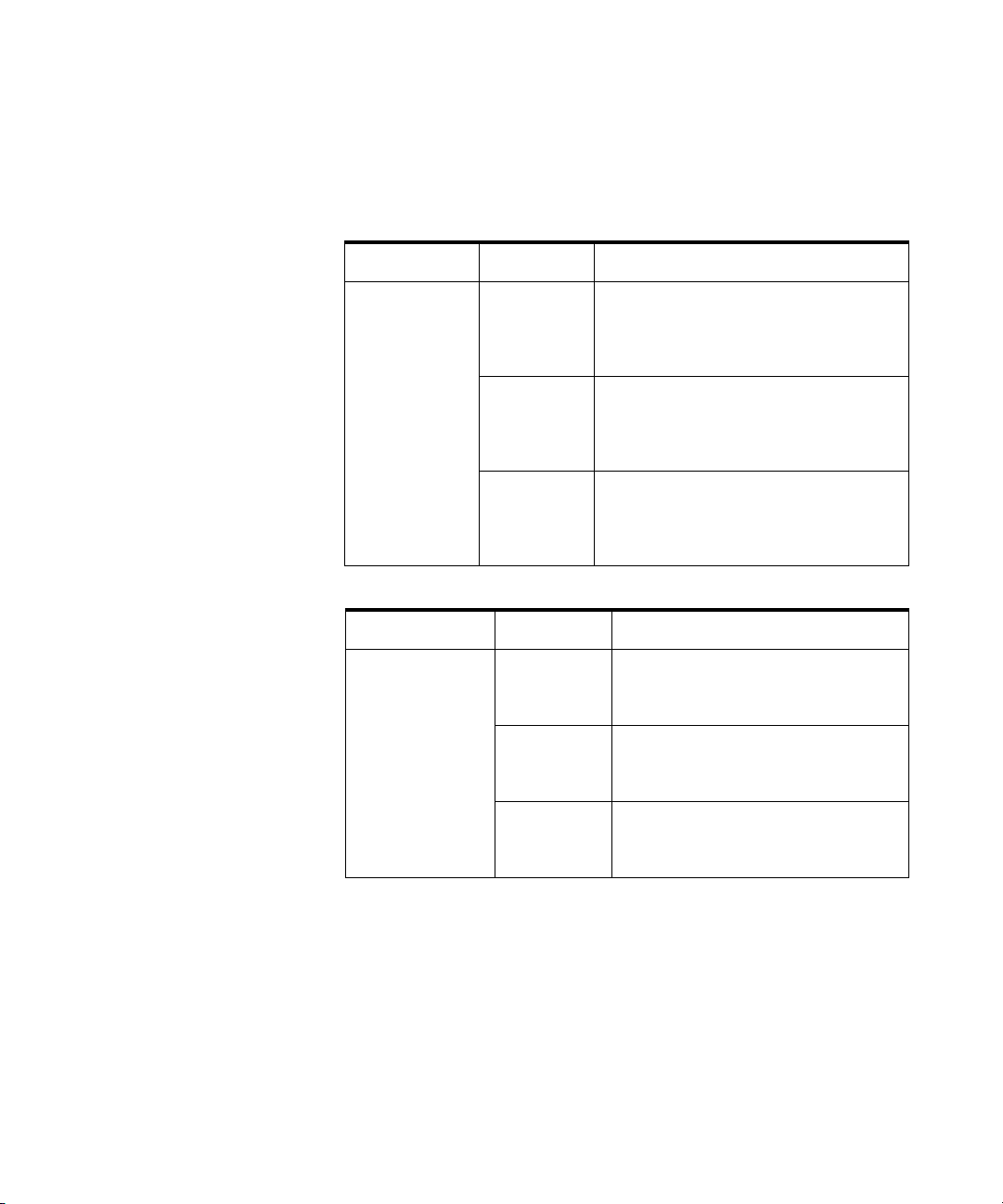

High Density Multifunction DAQ Device Specifications

Tab l e 1 - 2 Product specifications for high density multifunction DAQ device

(U2355A, U2356A and U2331A)

Analog Input

Model Number U2355A U2356A U2331A

Resolution 16 bits, no missing codes 12 bits, no missing codes

Number of channels 64 SE/32 DI (software selectable/channel)

Maximum sampling rate 250 kSa/s 500 kSa/s 3 MSa/s (single channel)

1 MSa/s (multi channels)

Scan list memory Up to 100 selectable channels entries

Programmable bipolar input range ±10 V, ±5 V, ±2.5 V, ±1.25 V ±10 V, ±5 V, ±2.5 V,

±1.25 V, ±1 V, ±0.5 V,

±0 .25 V, ±0.2 V, ±0.0 5 V

Programmable unipolar input range 0 to 10 V, 0-5 V, 0-2.5 V, 0-1.25 V 0-10 V, 0-5 V, 0-4 V, 0-2.5 V, 0-2 V,

0-1 V, 0-0.5 V, 0-0.4 V, 0-0.1V

Input coupling DC

Input impedance 1 GΩ / 100 pF

Operational common mode voltage range ±7.5 V maximum

Overvoltage protection Power on: Continuous ±30 V, Power off: Continuous ±15 V

Trig g e r s o u rc e s

External analog/digital trigger, SSI/star trigger

Trigger modes Pre-trigger, delay-trigger, post-trigger and middle-trigger

FIFO buffer size Up to 8 MSa

[1]

Analog Output

Model Number U2355A U2356A U2331A

Resolution 12 bits

Number of channels 2

Maximum update rate 1 MSa/s

Output ranges

0 to 10 V, ±10 V, 0 to AO_EXT_REF, ±AO_EXT_REF

[2]

Output coupling DC

Output impedance 0.1 Ω Typical

Stability Any passive load up to 1500 pF

Power on state 0 V steady state

Trigger sources

External analog/digital trigger, SSI/star trigger

[1]

Trigger modes Post-trigger and delay-trigger

FIFO buffer size 1 channel: Maximum 8 MSa, 2 channels: Maximum 4 MSa/ch

Function generation mode Sine-wave, square-wave, triangle, sawtooth and noise waveform

U2300A Series DAQ Service Guide 7

Page 16

1 Characteristics and Specifications

Digital I/O

Model Number U2355A | U2356A | U2331A

Number of bits 24-bit programmable input/output

Compatibility TTL

Input voltage V

Input voltage range –0.5 V to +5.5 V

Output voltage V

General Purpose Digital Counter

Model Number U2355A | U2356A | U2331A

Maximum count (2³¹-1) bits

Number of channels Two independent up/down counter

Compatibility TTL

Clock source Internal or external

Base clock available 48 MHz

Maximum clock source frequency 12 MHz

Input frequency range 0.1 Hz to 6 MHz at 50% duty cycle

Pulse width measurement range 0.167 µs to 178.956 s

= 0.7 V max, IIL = 10 µA max

IL

= 2.0 V min, IIH = 10 µA max

V

IH

= 0.45 V max, I

OL

= 2.4 V min, IOH = 400 µA max

V

OH

= 8 mA max

OL

Analog trigger

Model Number U2355A | U2356A | U2331A

Trigger source All analog input channels, External analog trigger (EXTA_TRIG)

Trigger level ±Full Scale for internal; ±10 V for external

Trigger conditions Above high, below low and window (software selectable)

Trigger level resolution 8 Bits

Bandwidth 400 kHz

Input Impedance for EXTA_TRIG 20 kΩ

Coupling DC

Overvoltage Protection Continuous for ±35 V maximum

8 U2300A Series DAQ Service Guide

Page 17

Characteristics and Specifications 1

Digital Trigger

Model Number U2355A | U2356A | U2331A

Compatibility TTL/CMOS

Response Rising or falling edge

Pulse width 20 ns minimum

Calibration

[3]

Model Number U2355A | U2356A | U2331A

On board reference 5 V

Temperature drift ±2 ppm/°C

Stability ±6 ppm/1000 hours

General

Model Number U2355A | U2356A | U2331A

Remote interface Hi-Speed USB 2.0

Device class USBTMC Class Device

Programmable interface Standard Commands for Programmable Instruments (SCPI) and IVI-COM

[1] System Synchronous Interface (SSI) and Star-trigger commands are used when

modular devices are used in instrument chassis.

[2] Maximum external reference voltage for analog output (AO_EXT_REF) is ±10 V.

[3] 20 minutes warm-up time is recommended.

U2300A Series DAQ Service Guide 9

Page 18

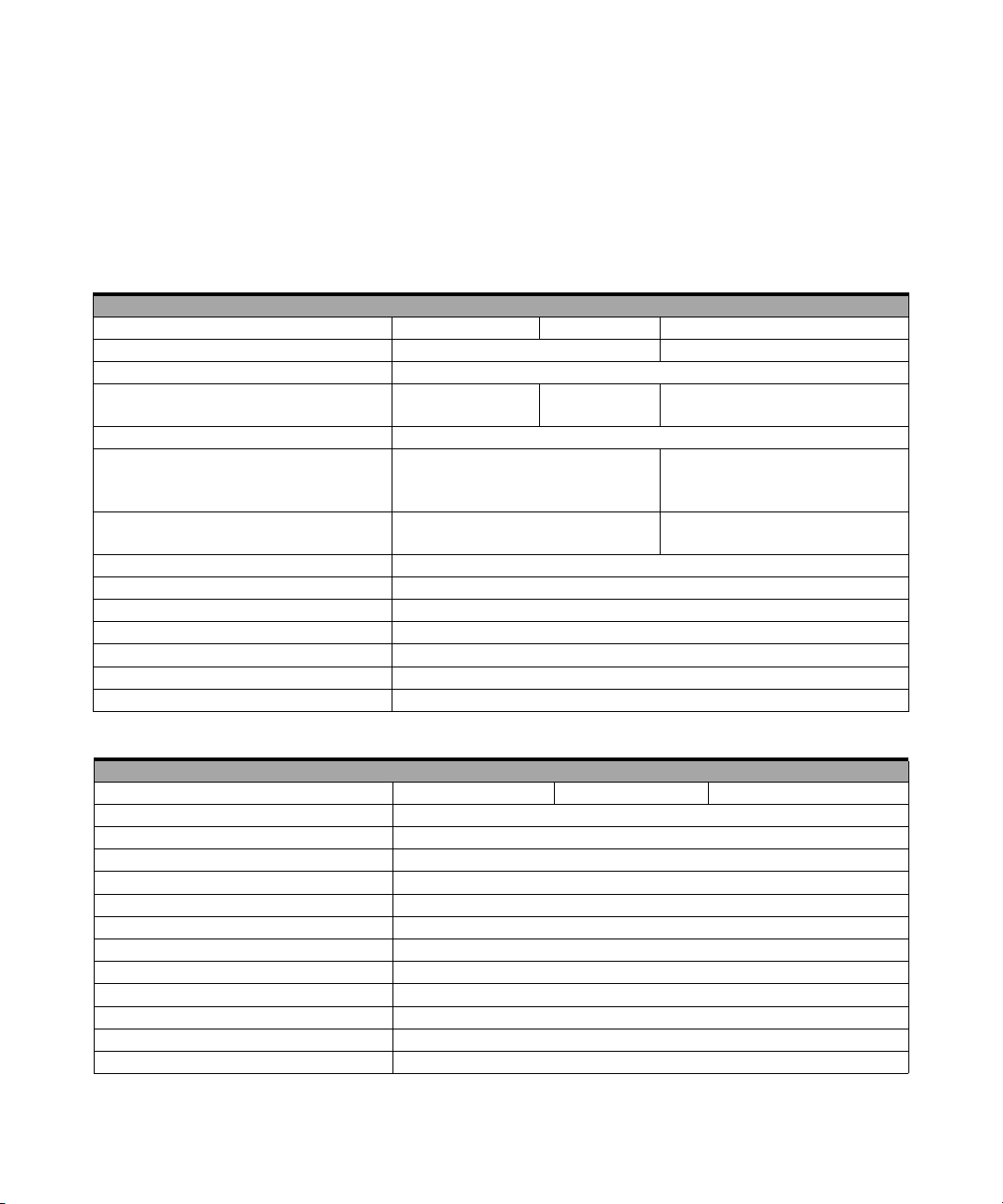

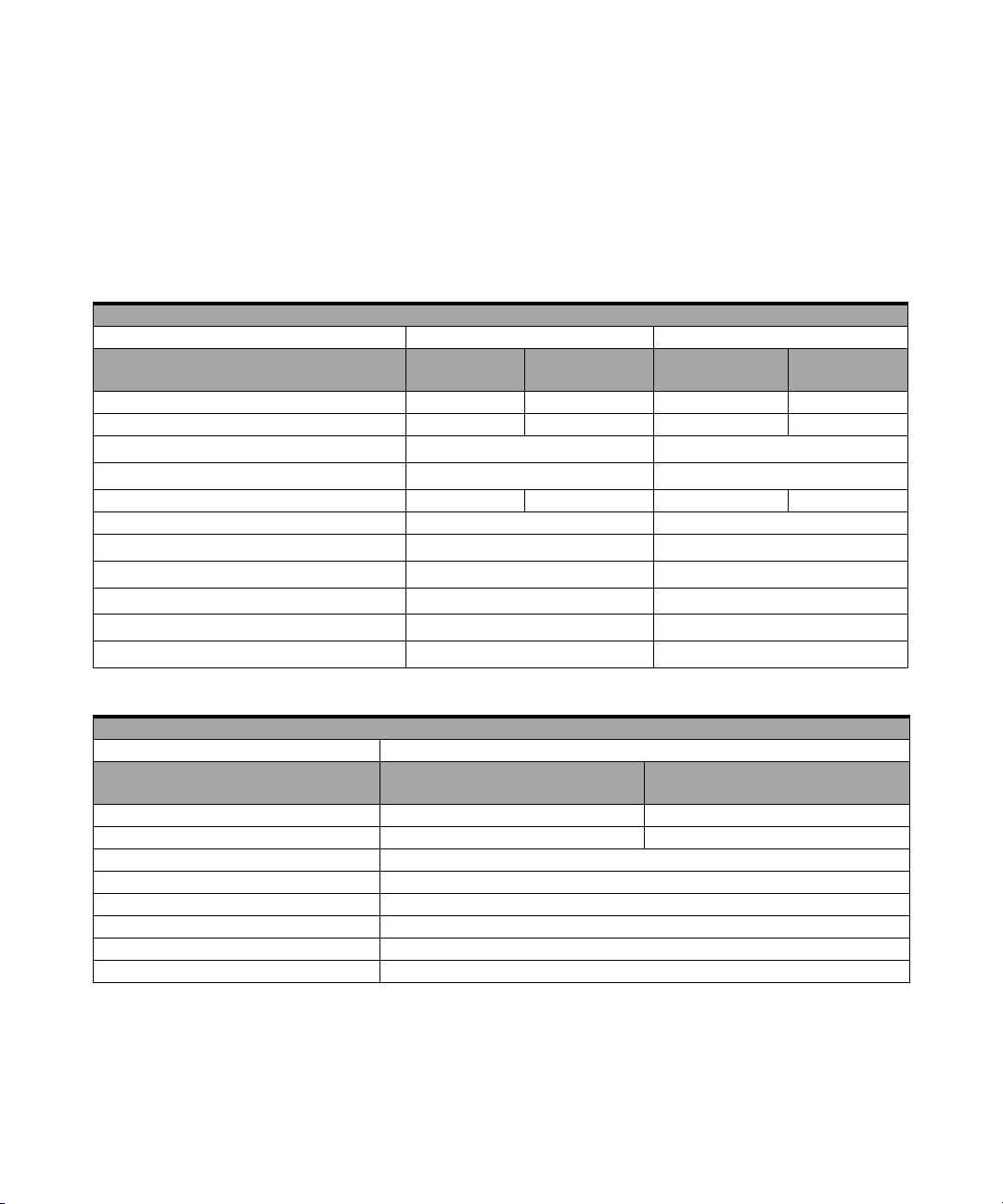

1 Characteristics and Specifications

Electrical Measurement Specifications

Basic Multifunction USB DAQ Device

Analog Input Measurement

[1]

Model Number U2351A | U2352A U2353A | U2354A

Function 23 °C ± 5 °C

0 °C to 18 °C

28 °C to 45 °C

23°C ± 5°C

0°C to 18°C

28°C to 45°C

Offset Error ±1 mV ±5 mV ±1 mV ±5 mV

Gain Error ±2 mV ±5 mV ±2 mV ±5 mV

–3 dB small signal bandwidth

1% THD large signal bandwidth

[2]

[2]

760 kHz 1.5 MHz

300 kHz 300 kHz

System noise 1 mVrms 2 mVrms 1 mVrms 2.5 mVrms

CMRR 62 dB 62 dB

Spurious-free dynamic range (SFDR)

[3]

Signal-to-noise and distortion ratio (SINAD)

Total harmonic distortion (THD)

Signal-to-noise ratio (SNR)

Effective number of bits (ENOB)

Analog Output Measurement

[3]

[3]

[3]

[1]

[3]

88 dB 82 dB

80 dB 78 dB

–90 dB –82 dB

80 dB 78 dB

13 12.6

Model Number U2351A | U2353A

0 °C to 18 °C

Function 23 °C ± 5 °C

28 °C to 45 °C

Offset Error ±1 mV ±4 mV

Gain Error ±4 mV ±5 mV

Slew rate 19 V/µs

Rise time 0.9 µs

Fall time 0.9 µs

Settling time to 1% output error 4 µs

Driving capability 5 mA

Glitch energy 5 ns-V (Typical), 80 ns-V (Maximum)

10 U2300A Series DAQ Service Guide

Page 19

Characteristics and Specifications 1

[1] Specifications are for 20 minutes of warm-up time, calibration temperature at 23 °C and

input range of ±10 V.

[2] Specifications are based on the following test conditions

Bandwidth Test Model Number Test Conditions

• –3 dB small

signal bandwidth

• 1% THD large

signal bandwidth

U2351A

U2352A

U2353A

U2354A

(DUT setting at ±10 V bipolar)

Sampling Rate:

Input voltage:

• –3 dB small signal bandwidth

• 1% THD large signal

bandwidth

Sampling Rate:

Input voltage:

• –3 dB small signal bandwidth

• 1% THD large signal

bandwidth

[3] Specifications are based on the following test conditions.

Dynamic Range Test Model Number Test Conditions

(DUT setting at ±10 V bipolar)

SFDR, THD, SINAD,

SNR, ENOB

U2351A

U2352A

U2353A

U2354A

Sampling Rate:

Fundamental Frequency:

Number of points:

Fundamental input voltage:

Sampling Rate:

Fundamental Frequency:

Number of points:

Fundamental input voltage:

.

250 kSa/s

10% FSR

FSR –1 dB FS

500 kSa/s

10% FSR

FSR –1 dB FS

250 kSa/s

2.4109 kHz

8192

FSR –1 dB FS

500 kSa/s

4.974 kHz

16384

FSR –1 dB FS

U2300A Series DAQ Service Guide 11

Page 20

1 Characteristics and Specifications

High Density Multifunction USB DAQ Device

Analog Input Measurement

[1]

Model Number U2355A U2356A U2331A

Function 23 °C ± 5 °C

0 °C - 18 °C

28 °C - 45 °C

23 °C ± 5 °C

0 °C to 18 °C

28 °C to 45 °C

23 °C ± 5 °C

0 °C to 18 °C

28 °C to 45 °C

Offset Error ±1 mV ±2 mV ±1 mV ±2 mV ±2 mV ±3 mV

Gain Error ±2 mV ±3 mV ±2 mV ±6 mV ±6 mV ±7.5 mV

–3 dB small signal bandwidth

1% THD large signal bandwidth

[2]

[2]

760 kHz 1.3 MHz 1.2 MHz

400 kHz 400 kHz N/A

System noise 1 mVrms 2 mVrms 1 mVrms 4 mVrms 3 mVrms 5 mVrms

CMRR 64 dB 61 dB 62 dB

Spurious-free dynamic range

[3]

(SFDR)

Signal-to-noise and distortion

ratio (SINAD)

[3]

Total harmonic distortion (THD)

Signal-to-noise ratio (SNR)

[3]

Effective number of bits

[3]

(ENOB)

Analog Output Measurement

[3]

[1]

88 dB 86 dB 71 dB

80 dB 78 dB 72 dB

–90 dB –84 dB –76 dB

80 dB 78 dB 72 dB

13 12.6 11.6

Model Number U2355A | U2356A U2331A

Function 23 °C ± 5 °C

0 °C to 18 °C

28 °C to 45 °C 23 °C ± 5 °C

0 °C to 18 °C

28 °C to 45 °C

Offset Error ±1 mV ±4 mV ±1.5 mV ±3mV

Gain Error ±4 mV ±5 mV ±4 mV ±5 mV

Slew rate 19 V/µs 19 V/µs

Rise time 0.9 µs 0.9 µs

Fall time 0.9 µs 0.9 µs

Settling time to 1% output error 4 µs 4 µs

Driving capability 5 mA 5 mA

Glitch energy 5 ns-V (Typical),

80 ns-V (Maximum)

5 ns-V (Typical),

80 ns-V (Maximum)

12 U2300A Series DAQ Service Guide

Page 21

Characteristics and Specifications 1

[1] Specifications are for 20 minutes of warm-up time, calibration temperature at 23 °C and

input range of ±10 V.

[2] Specifications are based on the following test conditions

Bandwidth Test Model Number Test Conditions

• –3 dB small

signal bandwidth

• 1% THD large

signal bandwidth

U2355A Sampling Rate:

U2356A Sampling Rate:

U2331A Sampling Rate:

(DUT setting at ±10 V bipolar)

Input voltage:

• –3 dB small signal bandwidth

• 1% THD large signal

bandwidth

Input voltage:

• –3 dB small signal bandwidth

• 1% THD large signal

bandwidth

Input voltage:

• –3 dB small signal bandwidth

• 1% THD large signal

bandwidth

[3] Specifications are based on the following test conditions.

Dynamic Range Test Model Number Test Conditions

(DUT setting at ±10 V bipolar)

SFDR, THD, SINAD,

SNR, ENOB

U2355A Sampling Rate:

Fundamental Frequency:

Number of points:

Fundamental input voltage:

U2356A Sampling Rate:

Fundamental Frequency:

Number of points:

Fundamental input voltage:

U2331A Sampling Rate:

Fundamental Frequency:

Number of points:

Fundamental input voltage:

.

250 kSa/s

10% FSR

FSR –1 dB FS

500 kSa/s

10% FSR

FSR –1 dB FS

3 MSa/s

10% FSR

FSR –1 dB FS

250 kSa/s

2.4109 kHz

8192

FSR –1 dB FS

500 kSa/s

4.974 kHz

16384

FSR –1 dB FS

3 MSa/s

29.892 kHz

65536

FSR –1 dB FS

U2300A Series DAQ Service Guide 13

Page 22

1 Characteristics and Specifications

14 U2300A Series DAQ Service Guide

Page 23

Agilent U2300A Series USB Multifunction DAQ

Service Guide

2

Calibration

Introduction 16

Types Of Signal Sources 17

Ground-referenced signal sources 17

Floating signal sources 17

Input Configurations 18

Single-ended connections 18

Differential Input Mode 20

Hardware Connection 22

Self-Calibration 26

Adjustment Procedures 32

Performance Verification Procedure 34

A/D Data Conversion 38

This chapter includes the equipments required for the

calibration procedure and describe the hardware connection

for analog input and analog output. The self- calibration

procedure, performance verification procdure and adjustment

procedure are also included.

Agilent Technologies

15

Page 24

2 Calibration

Introduction

Prior to checking the performace of the instrument, ensure

that you have all the equipments listed in the following to

perform the verification procedure for analog input and

analog output.

Equipment Checklist

✔ Agilent U2300A Series USB Multifunction DAQ devices

✔ Agilent Digital Multimeter (DMM) 34401A/34410A

✔ Fluke Calibrator 5520A/5720A

✔ Computer with Agilent IO Library Suites installed

✔ U2901A Terminal Block

✔ USB Mini- B Cable

✔ U2901A SCSI Cable

Follow the following steps to ensure the instrument gives

accurate analog input readings and analog outputs.

1 Perform the self- calibration procedure. See

“Self- Calibration”.

2 Perform the performance verification procedure. See

“Performance Verification Procedure”, “Analog Input

Connection” for information on analog input connection

and “Analog Output Connection” for information on

analog output connection.

3 If the instrument gives accurate readings or accurate

outputs, adjustment procedure is not necessary. If the

instrument does not give accurate readings or accurate

outputs, perform the adjustment procedure. See

“Adjustment Procedures”.

4 After perform the adjustment procedure, repeat the

self- calibration procedure and then perform the

verification procedure.

5 If the instrument still does not give accurate readings or

accurate outputs, repeat step 3 and step 4.

16 U2300A Series DAQ Service Guide

Page 25

Types Of Signal Sources

Ground-referenced signal sources

A ground- referenced signal source is defined as a signal

source that is connected in some way to the building’s

grounding system. This means that the signal source is

connected to a common ground point with respect to the

U2300A series DAQ (assume the host PC which is connected

with DAQ is in the same power ground).

Floating signal sources

A floating signal source is a signal that is not connected to

the building’s grounding system. It is also a device with an

isolated output. Example of floating signal sources are

optical isolator output, transformer output, and

thermocouple.

Calibration 2

U2300A Series DAQ Service Guide 17

Page 26

2 Calibration

Input Configurations

Single-ended connections

A single- ended connection is applicable when the analog

input signal is referenced to a ground and can be shared

with other analog input signals. There are two different

types of single- ended connections, which are RSE and NRSE

configuration.

• Referenced Single- Ended (RSE) mode

In referenced single- ended mode, all the input signals are

connected to the ground provided by the U2300A series

DAQ and suitable for connections with floating signal

sources. The following figure illustrates the RSE mode.

Figure 2-1 Floating source and RSE input connections

NOTE

18 U2300A Series DAQ Service Guide

When more than two floating sources are connected, these sources are

referenced to the same common ground.

Page 27

Calibration 2

• Non- Referenced Single- Ended (NRSE) Mode

In NRSE mode, the DAQ device does not provide the

grounding point. The ground reference point is provided

by the external analog input signal. You can connect the

signals in NRSE mode to measure ground- referenced

signal sources, which are connected to the same

grounding point. The following figure illustrates the

connection. The signal local ground reference is connected

to the negative input of the instrumentation Amplifier

(AI_SENSE pin on connector1). Hence, any potential

difference of the common mode ground between signal

ground and the signal ground on DAQ board will be

rejected by the instrumentation amplifier.

Figure 2-2 Ground-referenced sources and NRSE input connections

U2300A Series DAQ Service Guide 19

Page 28

2 Calibration

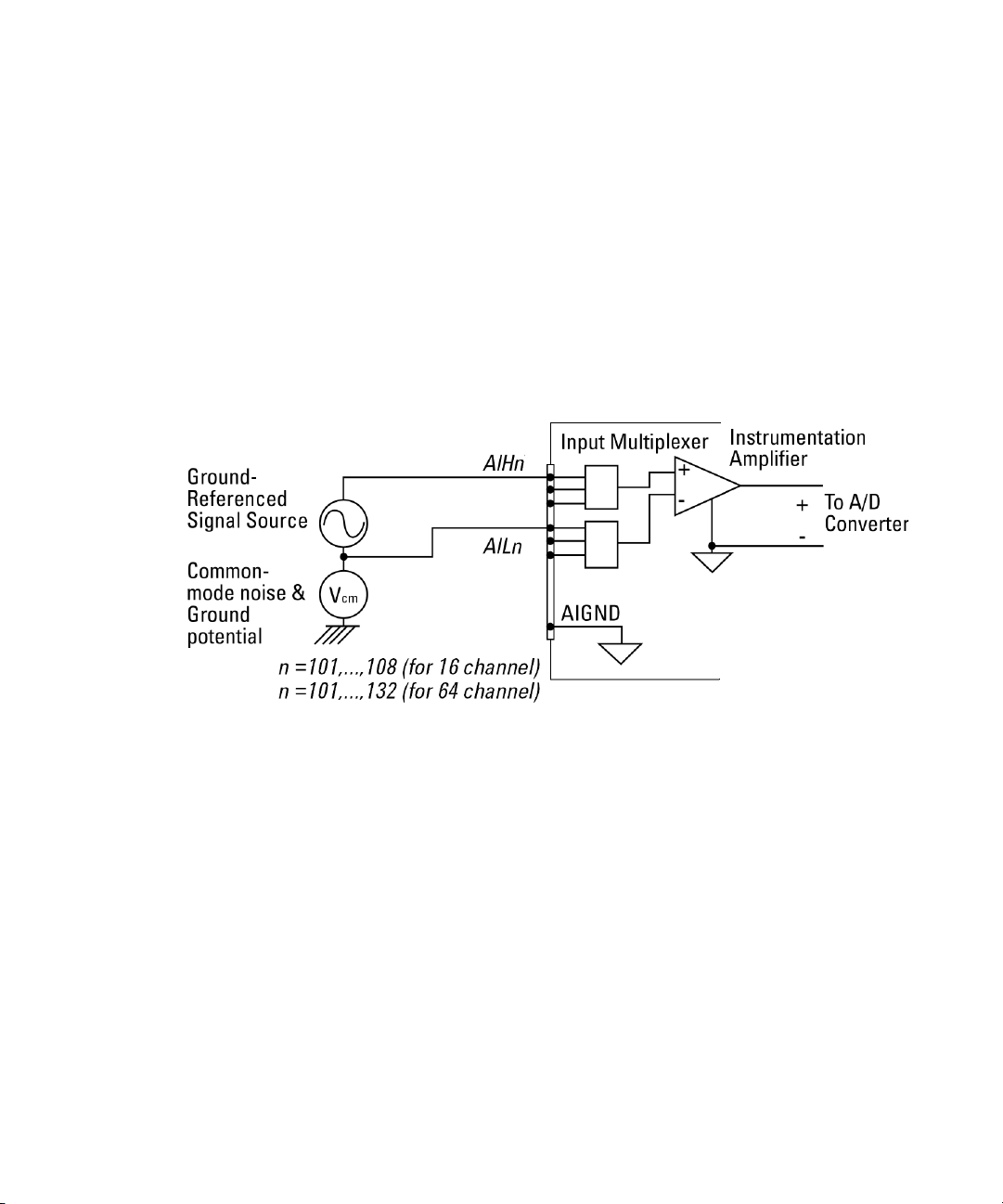

Differential Input Mode

The differential input mode provides two inputs that respond

to the difference of the signal voltage. The analog input of

the U2300A series DAQ has its own reference ground or

signal return path. The differential mode can be used for the

common- mode noise rejection if the signal source is

ground- referenced. The following figure shows the

connection of ground- referenced signal sources under

differential input mode.

Figure 2-3 Ground-referenced source and differential input mode

20 U2300A Series DAQ Service Guide

Page 29

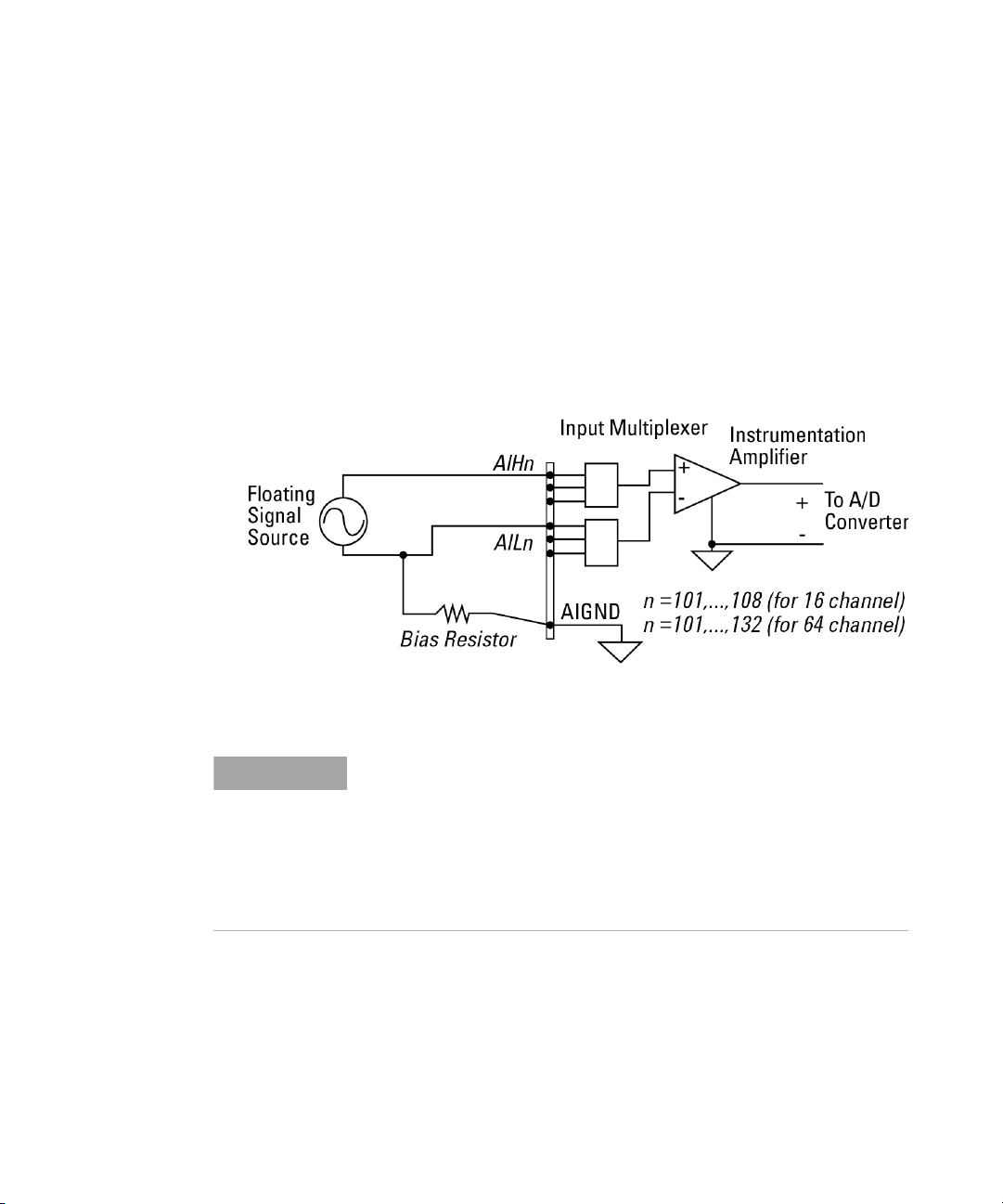

Calibration 2

The following figure illustrates the connection of a floating

signal source to the U2300A series DAQ in differential input

mode. For floating signal sources, additional resistor is

needed at each channel to provide a bias return path. The

resistor value is equivalent to about 100 times the source

impedance. If the source impedance is less than 100 W, you

can connect the negative polarity of the signal directly to

AI_GND, as well as the negative input of the Instrumentation

Amplifier. The noise couples in differential input mode are

less compared to the single- ended mode.

Figure 2-4 Floating source and differential input

NOTE

U2300A Series DAQ Service Guide 21

• Agilent U2300A series DAQ is designed with high input impedance.

Please ensure that all the connection are connected properly before

acquiring any data. Failing to do so may cause data fluctuation or

erroneous readings.

• Unused pins at multiplexing DAQ inputs can be treated as floating

source with infinite output impedance. Therefore, necessary grounding

system is required in user application system.

Page 30

2 Calibration

Hardware Connection

The connection to verify the analog input readings and

analog outputs are different. To verify the analog input

readings, see “Analog Input Connection” for descriptions on

the way to connect the instruments. To verify the analog

outputs, see “Analog Output Connection” for descriptions on

hardware setup.

Analog Input Connection

The equipments required for analog input connection are the

DAQ device, Fluke calibrator, terminal block, USB mini- B

cable and SCSI cable. Follow the follwing step- by- step

instruction for analog input connection.

1 Connect the DAQ device to a PC with a USB mini- B cable

and connect the DAQ device to a U2901A terminal block

using the U2901A SCSI cable.

NOTE

22 U2300A Series DAQ Service Guide

• Ensure that the PC has the DAQ device’s driver and the Agilent IO

Libraries 14.2 or higher installed. Note that the Agilent Measurement

Manager software comes with the standard purchase of the U2300A

Series DAQ devices.

• If you do not have the DAQ device’s driver and the Agilent IO Libraries

14.2 or higher installed, refer to the Agilent U2300A Series Data

Acquisition Devices and Agilent Measurement Manager Quick Start

Guide, for more information on the installation.

2 Short all the DAQ device’s analog input channels. Refer to

“Connector Pins Configuration” for the pins assignment.

3 Connect the DAQ device’s analog input channels to the

calibrator output.

4 Connect the DAQ device’s analog input ground (AI_GND)

to the calibrator ground. See Figure 2- 1. Note that the

analog inputs shown in the figure uses U2351A as an

example.

Page 31

Calibration 2

DAQ

AI101

...

AI164

AIGND

Calibrator

Output

GND

Figure 2-5 The analog input and calibrator connection

Setup diagram

DAQ

SCSI Cable

Mini-B

USB Cable

Terminal Block

(e.g. AI101 to AI164

Analog Input

for U2351A)

PC

Calibrator

Figure 2-6 The analog input and calibrator connection

U2300A Series DAQ Service Guide 23

Page 32

2 Calibration

Analog Output Connection

The equipments required for analog output connection are

the DAQ device, DMM, terminal block, USB mini- B cable and

SCSI cable. Follow the follwing step- by- step instruction for

analog input connection.

1 Connect the DAQ device to a PC with a USB mini- B cable

and connect the DAQ device to a U2901A terminal block

using the U2901A SCSI cable.

NOTE

• Ensure that the PC has the DAQ device’s driver and the Agilent IO

Libraries 14.2 or higher installed. Note that the Agilent Measurement

Manager software comes with the standard purchase of the U2300A

Series DAQ devices.

• If you do not have the DAQ device’s driver and the Agilent IO Libraries

14.2 or higher installed, refer to the Agilent U2300A Series Data

Acquisition Devices and Agilent Measurement Manager Quick Start

Guide, for more information on the installation.

2 Connect a wire at each pin you would like to test on the

U2901A terminal block. (Refer to “Connector Pins

Configuration” for the pins assignment)

3 Connect the DAQ device’s analog output channel 1

(AO201) to the DMM input.

4 Connect the DAQ device’s analog output ground

(AO_GND) to DMM GND.

5 Repeat steps 3 and 4 for analog output channel 2

(AO202).

24 U2300A Series DAQ Service Guide

Page 33

Calibration 2

DAQ

AO201

AOGND

DMM

Input

GND

Figure 2-7 The analog input and DMM connection

Setup diagram

DAQ

SCSI Cable

Mini-B

USB Cable

Terminal Block

Analog Output

(e.g. AO201 to AO202

for U2351A)

PC DMM

Figure 2-8 The analog output and DMM connection

U2300A Series DAQ Service Guide 25

Page 34

2 Calibration

Self-Calibration

Self- calibration can be operated using the following SCPI

command via Agilent Connection Expert.

CALibration:BEGin

In calibration mode, the command will initiate a voltage

adjustment in sequence for the specified Digital Analog

Converter (DAC) channel. This sequence sets a zero and gain

adjustment constant for each DAC output.

The function of DAQ device will not carry on until the

self- calibration has completed. You can query the status of

the self- calibration performed using the following SCPI

command.

*OPC?

Two ways of performing the self- calibration will be

introduced in this section. The first option is to use the

Agilent Connection Expert to send the SCPI commands and

the second option is to use the Agilent Measurement

Manager application software.

Option 1: Self-calibration with Agilent Connection Expert

WARNING

• Unplug all cables that are connected to the DAQ device before

performing self-calibration.

• Any cables connected to the DAQ device may cause the failure of

the self-calibration process.

1 Power on the DAQ and disconnect all connections from

DAQ device. Warm it up for 30 minutes to ensure that it

is operating at stable condition.

2 Go to Start > All Programs > Agilent IO Libraries Suite > Agilent

Connection Expert to launch the Agilent Connection Expert.

26 U2300A Series DAQ Service Guide

Page 35

Calibration 2

3 Connect the DAQ device to the PC with mini- B type USB

cable. The connected DAQ device will be visible in the

Instrument I/O on this PC panel as illustrated in Figure 2- 5.

4 Select the DAQ device that you wish to send the SCPI

commands to and then click the Interactive IO icon on the

toolbar to launch the Agilent Interactive IO. See Figure

2- 5.

Step 2: Click the Interactive IO icon

Step 1:

Select the instrument

Figure 2-9 Launch the Interactive IO in Agilent Connection Expert

5 The Agilent Interactive IO dialog box will appear as shown in

Figure 2- 6. Click Send & Read to send the “*IDN?” default

command. This instrument’s response should appear in

the Instrument Session History panel.

U2300A Series DAQ Service Guide 27

Page 36

2 Calibration

6 Successful communication between the Agilent Connection

Expert and the connected hardware will be shown in the

Instrument Session History panel. The users may now send

other SCPI commands to the instrument.

Figure 2-10 Interactive IO dialog box

7 Ensure that the DAQ device has been warmed up for 30

minutes. Send the SCPI commands “*RST” and “*CLS” to

clear the register in DAQ device.

8 Send “CAL:BEG” to start the self- calibration process. This

process may take a few minutes to complete.

9 Send “*OPC?” to check the operation complete status.

10 If “*OPC?” return 1, send “SYST:ERR?” to check if any

system error has occurred during the self- calibration

process. If there is no system error, the self- calibration

process is done. Otherwise, the self- calibration process is

failed.

28 U2300A Series DAQ Service Guide

Page 37

Calibration 2

Option 2: Self-calibration with Agilent Measurement Manager

WARNING

• Unplug all cables that are connected to the DAQ device before

performing self-calibration.

• Any cables connected to the DAQ device may cause the failure of

the self-calibration process.

1 Power on the DAQ device and disconnect all connections

from it. Warm it up for 30 minutes to ensure that it is

operating at stable condition.

2 Connect the DAQ device to the PC with mini- B type USB

cable. Launch the Agilent Measurement Manager and

select the DAQ device you wish to do the self-calibration

process.

3 Go to Tools and select Self Calibration.

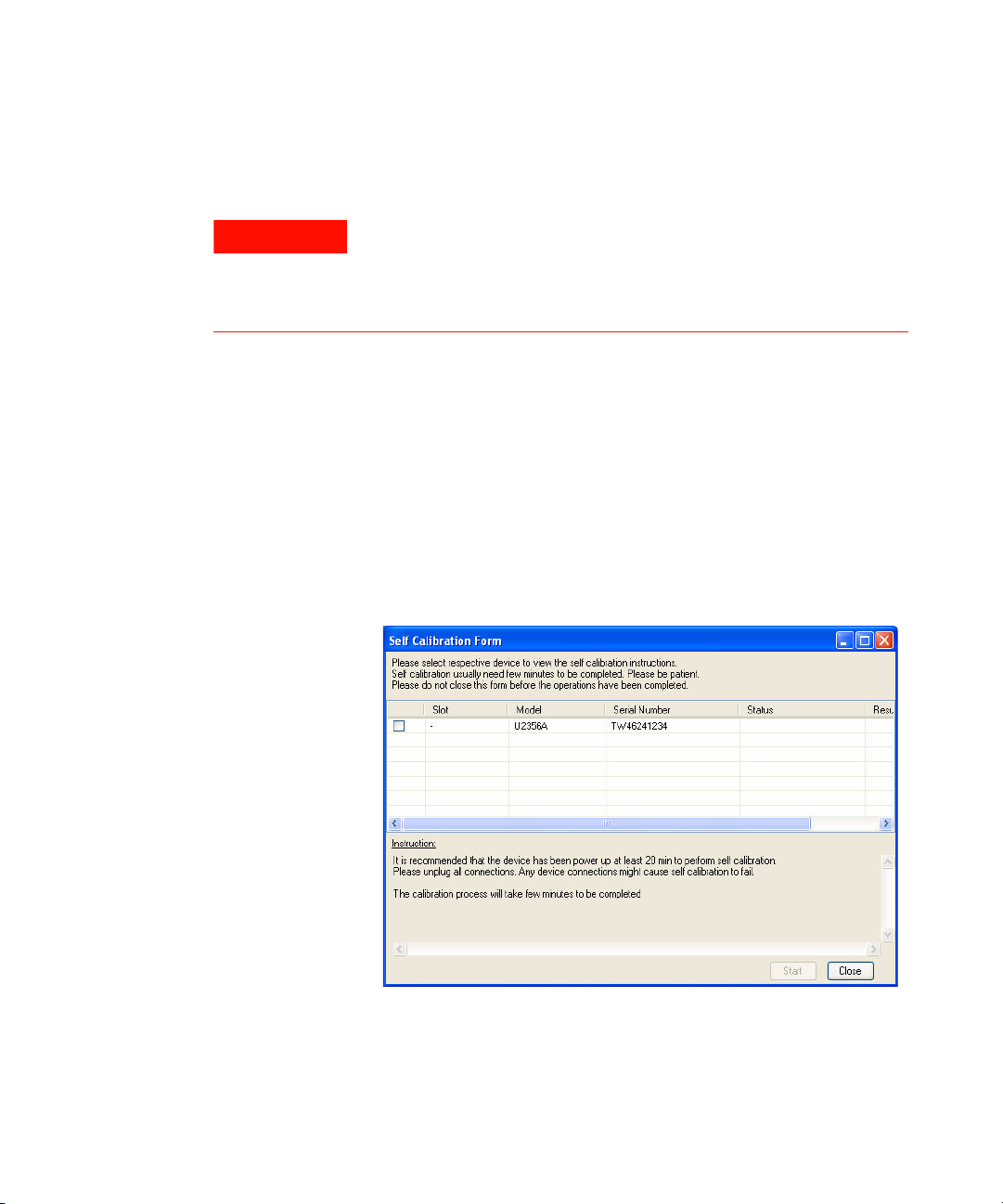

4 The Self Calibration Form dialog box will appear as shown

below.

Figure 2-11 Self Calibration Form dialog box in Agilent Measurement

Manager

U2300A Series DAQ Service Guide 29

Page 38

2 Calibration

5 Select the instrument that you would like to perform

self- calibration and the Start button will be enabled. Click

Start to proceed. See Figure 2- 8.

6 The calibration process will take a few minutes to be

completed. Once done, the status and results of the

process will be displayed as shown in Figure 2- 9.

Figure 2-12 Self Calibration Form dialog box in Agilent Measurement

Manager with a device being selected

30 U2300A Series DAQ Service Guide

Page 39

Calibration 2

Figure 2-13 Self Calibration Form dialog box in Agilent Measurement Ma-

naer showing the status and resultof the self-calibration process

U2300A Series DAQ Service Guide 31

Page 40

2 Calibration

Adjustment Procedures

DAQ on- board 5 V calibration

If in the performance verification procedure is not accurate,

adjustment procedure is required. The following flowchart

shows the steps for 5 V calibration.

Step 1:

Open the DAQ device metal casing.

Power on DAQ device and warm up for 30 minutes.

Connect the DMM to U37 on the daughter board.

Step 2: 5 V calibration

Connect the DAQ device to the computer with USB cable.

Monitor the DMM readings.

Tune the 5 V until you get the voltage in between 4.9999 to 5.0001 V.

Send “CAL:VREF:TUNE MINUS” (to decrease voltage),

Send “CAL:VREF:TUNE PLUS” (to increase voltage),

Send “CAL:VREF” (to save to EPROM)

Step 3:

After save to EPROM,

power cycle the unit.

Step 4:

Reconfirm the 5 V

reading.

Figure 2-14 The flowchart showing the steps for 5 V calibration

32 U2300A Series DAQ Service Guide

Page 41

Calibration 2

Tab l e 2 - 3 Step-by-step descriptions for Figure 2-10

Step Descriptions

Step 1 Before power on the DAQ device, open the DAQ device’s metal casing. Refer to “Dismantle Procedures” for

more information to disassemble the unit. Then, power on the DAQ device and warm it up for approximately 30

minutes. Connect the DMM to U37 on the daughter board. The following images shows the location of U37 and

the way to connect it.

U37

Step 2 Ensure that the DAQ device’s driver is installed in the computer before connecting it to the computer. The driver

can be obtained from the Agilent USB Modular Instrument U2300A & U2700A Series Product Reference

CD-ROM. Measure the voltage difference at U37 with the DMM. If the measured voltage is more than 5 V, send

the command “

CAL:VREF:TUNE MINUS” to decrease the voltage, otherwise if the measured

voltage is less than 5 V, send the command “CAL:VREF:TUNE PLUS” to increase the voltage.

Tune the voltage until the measured voltage is in the range of 4.9999 V and 5.0001 V. When the

tuning process is done, send “CAL:VREF” to save it in the EPROM.

Step 3 Power cycle the DAQ device by turning on and off the DAQ device.

Step 4 Measure the voltage at U37 again to ensure the measured voltage is in the range of 4.9999V to 5.0001 V. If there

is any problem occurs, the DMM will not measure the voltage in the specified range.

Proceed to self calibration procedure.

U2300A Series DAQ Service Guide 33

Page 42

2 Calibration

Performance Verification Procedure

Prior to calibrate the instrument, check the performance of

the instrument to see if any adjustment is required, “Step 2:

DAQ configuration and verification test”.

This is to ensure that the DAQ device gives accurate

readings or outputs. The performance verification procedure

for analog input and analog output are automated and are

verify using the Automated Calibration software.

The performance verification procedure involve two steps:

Step 1: DAQ self- calibration

Step 2: DAQ configuration and verification test

Analog Output

34 U2300A Series DAQ Service Guide

Page 43

Calibration 2

Step 1: DAQ self- calibration

Step 1:

Power on DAQ device and disconnect all connections from DAQ.

Warm up for 30 minutes.

Step 2: Reset DAQ

Send “*RST”

Step 3: Clear DAQ

Send “*CLS”

Step 4:

Wait: 1 second

Step 5: Start self-calibration

Send “CAL:BEG”

Wait: 60 seconds

Step 6: Check operation complete status

Send “*OPC?”

No

U2300A Series DAQ Service Guide 35

OPC status = 1?

Ye s

Step 7: Read system error

“SYST:ERR?”

System error?

No

Calibration DONE!

Ye s

Calibration FAIL!

Page 44

2 Calibration

Step 2: DAQ configuration and verification test

Step 1:

Step 1:

Power on DAQ device and connect the calibrator to DAQ. Warm up for

Power on DAQ device and connect the calibrator to DAQ. Warm up for

30 minutes.

30 minutes.

Step 2: DAQ configuration

Step 2: DAQ configuration

Send “ROUT:SCAN(@Channel))”, Send “ROUT:CHAN:RANG

Send “ROUT:SCAN(@Channel)”, Send “ROUT:CHAN:RANG

Range,(Channel))”, Send “ROUT:CHAN:RANG Range,((@Channel))”,

Range,(@Channel)”, Send “ROUT:CHAN:POL Polarity,(@Channel)”,

Send “ACQ:SRAT MaxSamplingRate”

Send “ACQ:SRAT MaxSamplingRate”

Step 3: Calibrator

Step 3: Calibrator

Source the desired test voltage to DAQ

Source the desired test voltage to DAQ

Step 4: DAQ data acquisition

Send “ACQ:POIN 100”, Send “DIG”

Wait: 0.2 second

Step 5: Check waveform complete status

Send “WAV:COMP?”

No

Step 6: DAQ fetch data

Send “WAV:DATA?” Read data as int 16 array

Step 7: Data conversion

Convert the data into voltage and get the average value for 100

points (please see Data conversion section for the formula)

Repeat steps above for all channels, polarities and ranges The

test points are shown as table

36 U2300A Series DAQ Service Guide

WAV complete status = YES?

Ye s

Compare the reading with the test specification

Page 45

Calibration 2

NOTE

Byte ordering must use LSB first.

Analog Output

Step 1:

Power on DAQ device and conenct the DMM

to DAQ. Warm up for 30 minutes

Step 2: DAQ configuration

Send “SOUR:VOLT:POL Polarity,(@Channel)”,

Send “SOUR:VOLT”RSRC INT,(@Channel)”,

Send “SOUR:VOLT Voltage,(@Channel)”

Step 3: DMM

Measure the output voltage of DAQ

Repeat steps above for all channels and

polarities. The test points are shown as table

Compare the reading with

the test specification

U2300A Series DAQ Service Guide 37

Page 46

2 Calibration

A/D Data Conversion

A/D data conversion converts analog voltage into digital

information. The following section illustrates the format of

acquired raw data for the A/D conversion.

Below is the illustrated example of the acquired raw data

scan list for CH 101, CH 102, and CH 103.

#800000200 <byte> <byte> <byte> <byte> <byte> <byte> <byte> <byte> ...

Data length indicator, The

next 8 bytes (0000 0200)

specifying the actual data

length only, not actual data.

Data length (200 bytes long)

1st data

LSB

1st data

MSB

CH 101 CH 102 CH 103 CH 101 ...

1st data

LSB

1st data

MSB

1st data

LSB

1st data

MSB

2nd data

LSB

16-bit Data Format

LSB MSB

DDDD DDDD DDDD DDDD

2nd data

MSB

...

12-bit Data Format

LSB MSB

DDDD XXXX DDDD DDDD

D - Data bits

X - Unused bits

Raw data conversion

To convert the data into an actual float number, we need

the voltage range and polarity information. Below are the

calculations on the raw data conversion for both bipolar and

unipolar.

To perform a sample calculation of the conversion, take

the U2356A as an example. The resolution of U2356A is

16 bits and the range is taken as 10 V. The Int16b value

calculated using conversion algorithm is 12768.

38 U2300A Series DAQ Service Guide

Page 47

Calibration 2

Hence, the 16 bits binary read back calculation will be as

follows.

LSB MSB

<11100000> <00110001>

= 12768

NOTE

NOTE

The raw data provided by U2300A series DAQ devices is in the byte order

of LSB first.

Bipolar:

2 Int16 value×

⎛⎞

Converted value

Example of converted value

--------------------------------------

⎝⎠

resolution

2

⎛⎞

⎝⎠

Range×=

2 12768×

------------------------

16

2

10× 3.896 V==

Unipolar:

Int16 value

⎛⎞

Converted value

----------------------------

⎝⎠

resolution

2

Example of converted value

The converted value is of float type. As such, you may need to type cast

the Int16 value to float in your programming environment.

0.5+

Range×=

12768

⎛⎞

---------------

⎝⎠

2

16

0.5+

10× 6.948 V==

To perform a sample calculation of the conversion, take

the U2331A as an example. The resolution of U2331A is

12 bits and the range is taken as 10 V. The Int12b value

calculated using conversion algorithm is 12768.

LSB MSB

<11100000> <00110001>

= 12768

U2300A Series DAQ Service Guide 39

Page 48

2 Calibration

There are unused bits in the 12- bit data format.

Therefore, there is a need to perform a 4- bit right shift

operation. Hence, the 12 bits binary read back calculation

will be as follows.

LSB MSB

<00011110> <00000011>

= 798

NOTE

NOTE

The raw data provided by U2300A series DAQ devices is in the byte order

of LSB first.

Bipolar:

2 Int16 value×

⎛⎞

Converted value

Example of converted value

--------------------------------------

⎝⎠

resolution

2

Range×=

2798×

⎛⎞

------------------

⎝⎠

12

2

10× 3.896 V==

Unipolar:

Int16 value

⎛⎞

Converted value

----------------------------

⎝⎠

resolution

2

Example of converted value

• The converted value is of float type. As such, you may need to type cast

the Int12 value to float in your programming environment.

0.5+

Range×=

798

⎛⎞

---------

0.5+

⎝⎠

12

2

10× 6.948 V==

• For the U2331A, there is a need to perform a 4-bit right shift operation.

This is because it is equipped with 12-bit ADC, and the last 4 bits are

truncated.

40 U2300A Series DAQ Service Guide

Page 49

Agilent U2300A Series USB Multifunction DAQ

Service Guide

3

Dismantle Procedures

General Disassemble 42

Mechanical Disassemble 42

Replacement Parts 46

This chapter describes the step- by- step disassemble

procedures and list the available replacement parts for

U2300A Series DAQ devices,

Agilent Technologies

41

Page 50

3 Dismantle Procedures

General Disassemble

NOTE

This chapter provides the step- by- step guides on how to

dismantle the module and install the replacement assembly. To

assemble back the module, follow the instructions in reverse

order.

The parts shown in the following figures are representative and

may look different than what you have in your module.

The removable assemblies include:

• Plastic casing

• Metal casing

• Rear metal casing

• Front metal casing, which is attached to the carrier board

and measurement board

Mechanical Disassemble

Follow the instructions in this section for the instrument

disassemble process.

Step 1: Pull the bumper out to remove the plastic casing.

Plastic casing

42 U2300A Series DAQ Service Guide

Page 51

Dismantle Procedures 3

Step 2: Flip the plastic casing open.

Step 3: Slide the metal casing out of the plastic casing.

Metal casing

U2300A Series DAQ Service Guide 43

Page 52

3 Dismantle Procedures

Front metal piece

Step 4: Unscrew all the following indicated screws from metal

casing.

Step 5: Gently pull the front metal piece out, which is attached to

the carrier and measurement boards.

Step 6: Unscrew all the following indicated screws from the

metal casing and remove the rear metal piece.

Rear metal casing

44 U2300A Series DAQ Service Guide

Page 53

Metal casing

Rear metal casing

Carrier board and

measurement board

Dismantle Procedures 3

Disassembled parts:

Front

metal casing

U2300A Series DAQ Service Guide 45

Page 54

3 Dismantle Procedures

Replacement Parts

This section provides the information of orderable replacement

parts for U2300A Series DAQ devices. The parts availabled for

replacement are listed in the table below with the reference

part numbers and the respective part names.

You can order the replacement parts from Agilent using the part

number provided in the table below. To order replacement parts

from Agilent, do the following:

1 Identify the Agilent part number of the required parts as

shown in the replacement parts list.

2 Contact your nearest Agilent Sales Office or Service Center.

3 Provide the instrument model number and serial number.

Tab l e 3 - 4 Replacement parts list

Part Number Part Name

U2351-60002 Metal Casing

5190-0013 Plastic Cover

U2351-00201 Rear Metal Piece

U2351-61201 L-shape Mount

46 U2300A Series DAQ Service Guide

Page 55

Agilent U2300A Series USB Multifunction DAQ

Service Guide

4

Troubleshooting and Self-Test

Procedures

Troubleshooting 48

Self-Test Procedures 49

This chapter provides the information on general troubleshooting and

self-test procedures.

Agilent Technologies

47

Page 56

4 Troubleshooting and Self-Test Procedures

Troubleshooting

This section provides suggestions for solving general problems that

you may encounter with the instrument. It guides you on what to

check in the following situations:

1. Power Indicator LED is not lit

Verify that the ac power cord is connected to the power inlet in

the DAQ device.

2. Power Indicator LED is lit but the AO/ AI Indicator LED is not lit

Verify that the USB cable is connected to the PC and the USB

inlet in the DAQ device.

3. Power Indicator LED is lit and AO/ AI Indicator LED is lit

Verify if the SCPI commands are correct with “SYSTem:ERRor?”

command.

Refer to U2300A Series USB Multifunction Programming Guide for

SCPI error messages.

NOTE

48 U2300A Series DAQ Service Guide

If there are no response from the instrument, contact the nearest Agilent

Service Center to obtain further assistance.

Page 57

Self-Test Procedures

Troubleshooting and Self-Test Procedures 4

WARNING

4 Go to Start > All Programs > Agilent IO Libraries Suite > Agilent

5 Go to Start > All Programs > Agilent T&M Toolkit > Agilent Interactive IO

6 Send the SCPI command “*TST?” to the instrument to start

7 The command will return either "+0" to indicate all tests passes

8 If the command returns "+1" , apply SCPI command

NOTE

Do not connect any cables and terminal block prior to performing

self-test procedures.

Connection Expert to launch the Agilent Connection Expert.

to launch the Interactive I/O dialog box.

perform the self- test of the instrument.

or "+1" to indicate one or more tests failed.

“SYSTem:ERRor?” to enquire the error message.

Refer to Agilent U2300A Series USB Multifunction Data Acquisition

Programming Guide for SCPI error messages.

U2300A Series DAQ Service Guide 49

Page 58

4 Troubleshooting and Self-Test Procedures

50 U2300A Series DAQ Service Guide

Page 59

Agilent U2300A Series USB Multifunction DAQ

Service Guide

A

Connector Pins Configuration

Pins Configuration for U2331A, U2355A and U2356A 52

Pins Configuration for U2351A, U2352A, U2353A and U2354A 53

This appendix attached the pins configuration for all the

U2300A Series DAQ devices.

Agilent Technologies

51

Page 60

A Connector Pins Configuration

Pins Configuration for U2331A, U2355A and U2356A

The U2300A Series DAQ is equipped with 68–pin very high

density cable interconnect (VHDCI) type connectors.

Figure A-1 Pins Configuration of Connector 1 for

U2331A, U2355A, U2356A

NOTE

52 U2300A Series DAQ Service Guide

(AIH101..132) and (AIL101..132) are for differential mode connection pair.

Figure A-2 Pins Configuration of Connector 2

for U2331A, U2355A, U2356A

Page 61

Connector Pins Configuration A

Pins Configuration for U2351A, U2352A, U2353A and U2354A

Figure A-3 Pins Configuration for U2352A,

U2354A

NOTE

U2300A Series DAQ Service Guide 53

(AIH101..108) and (AIL101..108) are for differential mode connection pair.

Figure A-4 Pins Configuration for U2351A,

U2353A

Page 62

A Connector Pins Configuration

Tab l e A- 5 68-pin VHDCI connector pins descriptions

Signal Name Direction Reference

Ground

AI_GND N/A N/A Analog input (AI) ground. All three ground

For 16 Channels:

AI<101..116>

For 64 Channels:

AI<101..164>

AI_SENSE Input AI_GND Analog input sense. The reference pin for any

EXTA_TRIG Input AI_GND External AI analog trigger

AO201 Output AO_GND Analog output channel 1

AO202 Output AO_GND Analog output channel 2

AO_EXT_REF Input AO_GND External reference for AO channels

AO_GND N/A N/A Analog ground for AO

EXTD_AO_TRIG Input D_GND External AO waveform trigger

EXTD_AI_TRIG Input D_GND External AI digital trigger

RESERVED Output N/A Reserved pins. Do not connect them to any signal.

COUNT<301,302>_CLK Input D_GND Source of counter <301,302>

COUNT<301,302>_GATE Input D_GND Gate of counter <301,302>

COUNT<301,302>_OUT Input D_GND Output of counter <301,302>

COUNT<301,302>_UPDOWN Input D_GND Up/Down of counter <301,302>

EXT_TIMEBASE Input D_GND External Timebase

D_GND N/A N/A Digital ground

DIO501<7,0> PIO D_GND Programmable DIO of Channel 501

DIO502<7,0> PIO D_GND Programmable DIO of Channel 502

DIO503<4,0> PIO D_GND Programmable DIO of Channel 503

DIO504<4,0> PIO D_GND Programmable DIO of Channel 504

Input AI_GND U2351A/U2352A/U2353A/U2354A

Description

references (AI_GND, AO_GND, and D_GND) are

connected together on board.

Analog input channels 101~116. Each channel pair, AI<i,

i+8>(i = 101..108), can be configured either as two

single-ended inputs or one differential input (marked as

AIH<101..108> and AIL<101..108>).

U2331A/U2356A/U2355A

Analog input channels 101~164). Each channel pair, AI<i,

i+32> (i = 101..132), is configured either as two

single-ended inputs or one differential input (marked as

AIH<101..132> and AIL<101..132>)

AI<101..116> or AI<101..164> channels in NRSE input

configuration.

54 U2300A Series DAQ Service Guide

Page 63

Connector Pins Configuration A

U2300A Series DAQ Service Guide 55

Page 64

A Connector Pins Configuration

56 U2300A Series DAQ Service Guide

Page 65

Agilent U2300A Series USB Multifunction DAQ

Service Guide

B

Test Limits

Analog Input 58

Analog Output 62

This appendix provides the test limits for analog input and analog output

when performing the verification procedure.

Agilent Technologies

57

Page 66

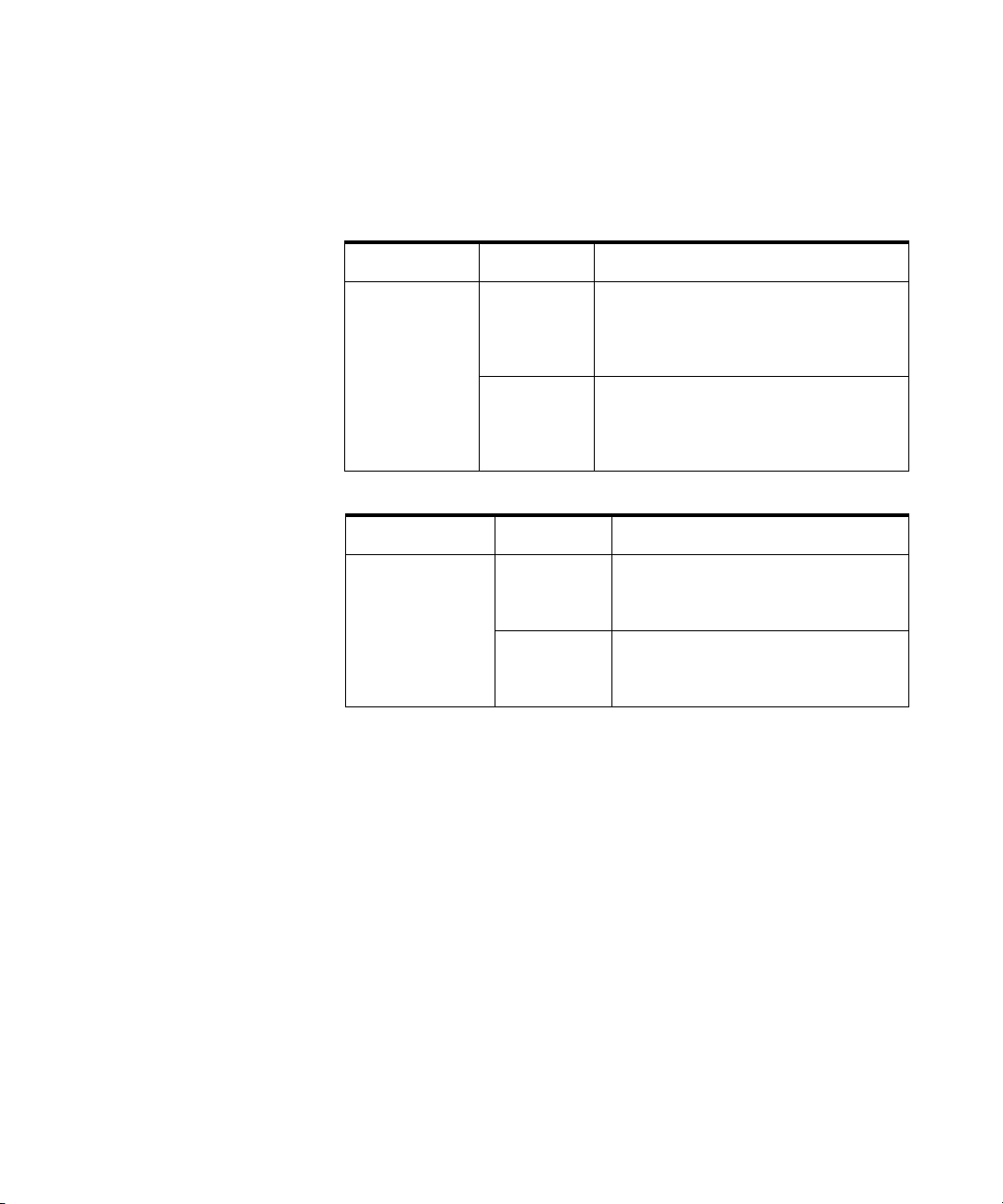

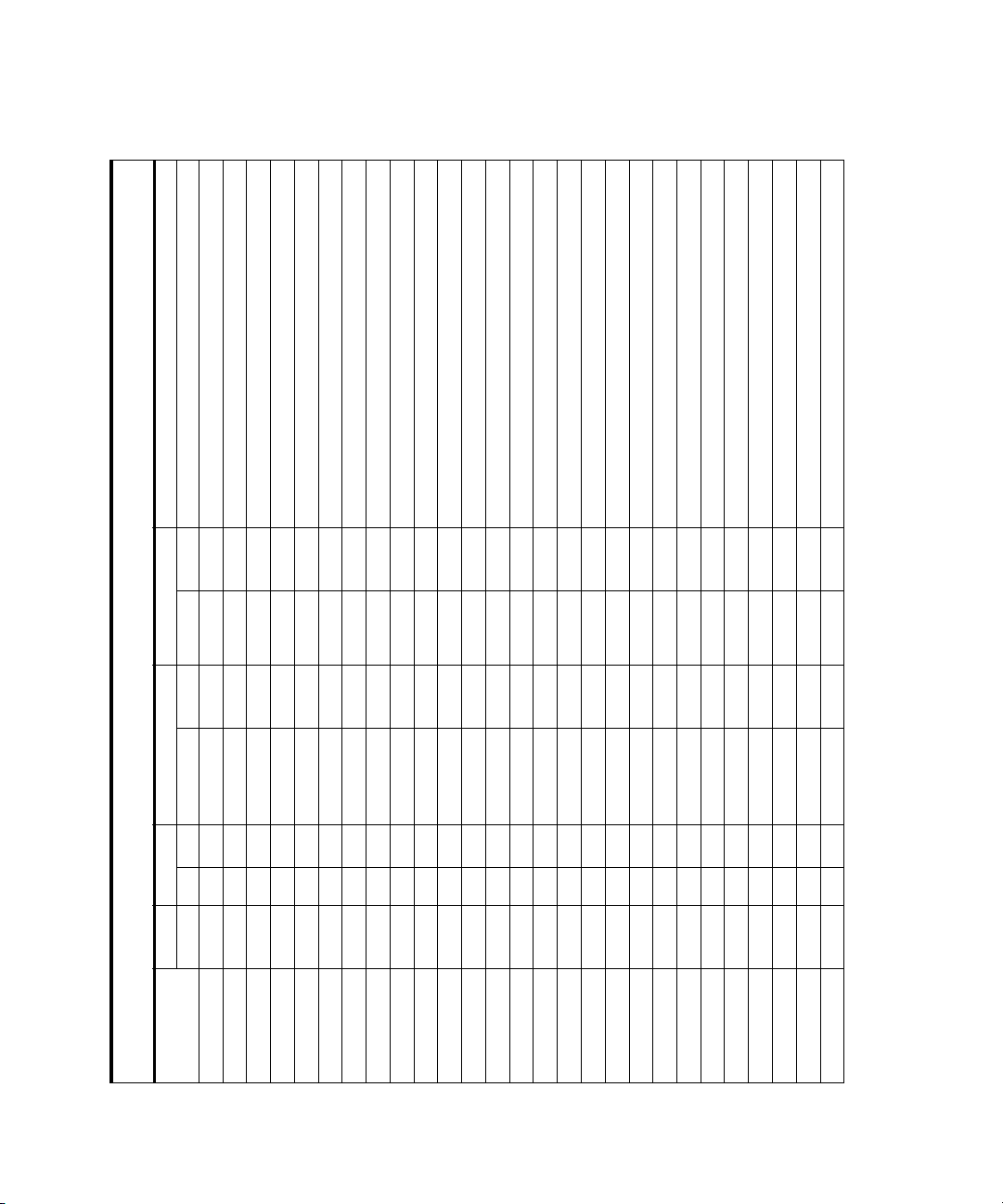

BTest Limits

Setting Range (V) Test Point (V) Te st L im i t ( V ) Tes t Re s ul t

Polarity Min Max Location Val ue Lower Upper Reading

0.001 BIP –10 10 Center FS 0.00000 –0.00100 0.00100 Offset = DAQ reading – Calibrator source voltage

0.002 BIP –10 10 Positive FS 9.98779 9.98579 9.98979 DAQ reading – Offset

0.002 BIP –10 10 Negative FS –9.98779 –9.98979 –9.98579 DAQ reading – Offset

0.001 BIP –5 5 Center FS 0.00000 –0.00100 0.00100 Offset = DAQ reading – Calibrator source voltage

0.002 BIP –5 5 Positive FS 4.99390 4.99190 4.99590 DAQ reading – Offset

0.002 BIP –5 5 Negative FS –4.99390 –4.99590 –4.99190 DAQ reading – Offset

Offset/

Analog Input

Analog Input

Gain Error (V)

U2351A, U2352A, U2353A, U2354A:

0.001 BIP –2.5 2.5 Center FS 0.00000 –0.00100 0.00100 Offset = DAQ reading – Calibrator source voltage

0.001 BIP –1.25 1.25 Center FS 0.00000 –0.00100 0.00100 Offset = DAQ reading – Calibrator source voltage

0.0015 BIP –2.5 2.5 Positive FS 2.49695 2.49545 2.49845 DAQ reading – Offset

0.0015 BIP –2.5 2.5 Negative FS –2.49695 –2.49845 –2.49545 DAQ reading – Offset

0.0015 BIP –1.25 1.25 Positive FS 1.24847 1.24697 1.24997 DAQ reading – Offset

0.0015 BIP –1.25 1.25 Negative FS –1.24847 –1.24997 –1.24697 DAQ reading – Offset

0.002 UNIP 0 10 Positive FS 9.99390 9.99190 9.99590 DAQ reading – Offset

0.002 UNIP 0 10 Negative FS 0.00610 0.00410 0.00810 DAQ reading – Offset

0.002 UNIP 0 5 Positive FS 4.99695 4.99495 4.99895 DAQ reading – Offset

0.002 UNIP 0 5 Negative FS 0.00305 0.00105 0.00505 DAQ reading – Offset

0.001 UNIP 0 2.5 Center FS 1.25000 1.24900 1.25100 Offset = DAQ reading – Calibrator source voltage

0.001 UNIP 0 2.5 Positive FS 2.49847 2.49747 2.49947 DAQ reading – Offset

0.001 UNIP 0 2.5 Negative FS 0.00153 0.00053 0.00253 DAQ reading – Offset

0.001 UNIP 0 1.25 Center FS 0.62500 0.62400 0.62600 Offset = DAQ reading – Calibrator source voltage

0.001 UNIP 0 1.25 Positive FS 1.24924 1.24824 1.25024 DAQ reading – Offset

0.0015 UNIP 0 10 Center FS 5.00000 4.99850 5.00150 Offset = DAQ reading – Calibrator source voltage

0.0015 UNIP 0 5 Center FS 2.50000 2.49850 2.50150 Offset = DAQ reading – Calibrator source voltage

0.001 UNIP 0 1.25 Negative FS 0.00076 –0.00024 0.00176 DAQ reading – Offset

58 U2300A Series DAQ Service Guide

Page 67

Test Limits B

Setting Range (V) Test Point (V) Te st L im i t ( V ) Tes t Re s ul t

Polarity Min Max Location Val ue Lower Upper Reading

0.001 BIP –10 10 Center FS 0.00000 –0.00100 0.00100 Offset = DAQ reading – Calibrator source voltage

0.002 BIP –10 10 Positive FS 9.98779 9.98579 9.98979 DAQ reading – Offset

0.002 BIP –10 10 Negative FS –9.98779 –9.98979 –9.98579 DAQ reading – Offset

0.001 BIP –5 5 Center FS 0.00000 –0.00100 0.00100 Offset = DAQ reading – Calibrator source voltage

0.002 BIP –5 5 Positive FS 4.99390 4.99190 4.99590 DAQ reading – Offset

0.002 BIP –5 5 Negative FS –4.99390 –4.99590 –4.99190 DAQ reading – Offset

Analog Input

U2355A, U2356A:

Offset/

Gain Error (V)

0.001 BIP –2.5 2.5 Center FS 0.00000 –0.00100 0.00100 Offset = DAQ reading – Calibrator source voltage

0.001 BIP –1.25 1.25 Center FS 0.00000 –0.00100 0.00100 Offset = DAQ reading – Calibrator source voltage

0.0015 BIP –2.5 2.5 Positive FS 2.49695 2.49545 2.49845 DAQ reading – Offset

0.0015 BIP –2.5 2.5 Negative FS –2.49695 –2.49845 –2.49545 DAQ reading – Offset

0.0015 BIP –1.25 1.25 Positive FS 1.24847 1.24697 1.24997 DAQ reading – Offset

0.001 UNIP 0 10 Center FS 5.00000 4.99900 5.00100 Offset = DAQ reading – Calibrator source voltage

0.0015 BIP –1.25 1.25 Negative FS –1.24847 –1.24997 –1.24697 DAQ reading – Offset

0.001 UNIP 0 5 Center FS 2.50000 2.49900 2.50100 Offset = DAQ reading – Calibrator source voltage

0.0015 UNIP 0 10 Positive FS 9.99390 9.99240 9.99540 DAQ reading – Offset

0.0015 UNIP 0 10 Negative FS 0.00610 0.00460 0.00760 DAQ reading – Offset

0.001 UNIP 0 2.5 Center FS 1.25000 1.24900 1.25100 Offset = DAQ reading – Calibrator source voltage

0.001 UNIP 0 2.5 Positive FS 2.49847 2.49747 2.49947 DAQ reading – Offset

0.001 UNIP 0 2.5 Negative FS 0.00153 0.00053 0.00253 DAQ reading – Offset

0.001 UNIP 0 1.25 Center FS 0.62500 0.62400 0.62600 Offset = DAQ reading – Calibrator source voltage

0.001 UNIP 0 1.25 Positive FS 1.24924 1.24824 1.25024 DAQ reading – Offset

0.0015 UNIP 0 5 Positive FS 4.99695 4.99545 4.99845 DAQ reading – Offset

0.0015 UNIP 0 5 Negative FS 0.00305 0.00155 0.00455 DAQ reading – Offset

0.001 UNIP 0 1.25 Negative FS 0.00076 –0.00024 0.00176 DAQ reading – Offset

U2300A Series DAQ Service Guide 59

Page 68

BTest Limits

Setting Range (V) Test Point (V) Te st L im i t ( V ) Tes t Re s ul t

Polarity Min Max Location Val ue Lower Upper Reading

0.002 BIP –10 10 Center FS 0.00000 -0.00200 0.00200 Offset = DAQ reading – Calibrator source voltage

0.006 BIP –10 10 Positive FS 9.80469 9.79869 9.81069 DAQ reading – Offset

0.006 BIP –10 10 Negative FS –9.80469 –9.81069 –9.79869 DAQ reading – Offset

0.004 BIP –5 5 Positive FS 4.90234 4.89834 4.90634 DAQ reading – Offset

0.004 BIP –5 5 Negative FS –4.90234 –4.90634 –4.89834 DAQ reading – Offset

0.002 BIP –2.5 2.5 Positive FS 2.45117 2.44917 2.45317 DAQ reading – Offset

0.002 BIP –2.5 2.5 Negative FS –2.45117 –2.45317 –2.44917 DAQ reading – Offset

Analog Input

U2331A:

Offset/

Gain Error (V)

0.0015 BIP –5 5 Center FS 0.00000 –0.00150 0.00150 Offset = DAQ reading – Calibrator source voltage

0.0015 BIP –2.5 2.5 Center FS 0.00000 –0.00150 0.00150 Offset = DAQ reading – Calibrator source voltage

0.001 BIP –1.25 1.25 Center FS 0.00000 –0.00100 0.00100 Offset = DAQ reading – Calibrator source voltage

0.001 BIP –1 1 Center FS 0.00000 –0.00100 0.00100 Offset = DAQ reading – Calibrator source voltage

0.001 BIP –1 1 Positive FS 0.98047 0.97947 0.98147 DAQ reading – Offset

0.001 BIP –1 1 Negative FS –0.98047 –0.98147 –0.97947 DAQ reading – Offset

0.001 BIP –0.5 0.5 Center FS 0.00000 –0.00100 0.00100 Offset = DAQ reading – Calibrator source voltage

0.001 BIP –0.5 0.5 Positive FS 0.49023 0.48923 0.49123 DAQ reading – Offset

0.001 BIP –0.5 0.5 Negative FS –0.49023 –0.49123 –0.48923 DAQ reading – Offset

0.001 BIP –0.25 0.25 Center FS 0.00000 –0.00100 0.00100 Offset = DAQ reading – Calibrator source voltage

0.001 BIP –0.25 0.25 Positive FS 0.24512 0.24412 0.24612 DAQ reading – Offset

0.001 BIP –0.25 0.25 Negative FS –0.24512 –0.24612 –0.24412 DAQ reading – Offset

0.001 BIP –0.2 0.2 Center FS 0.00000 –0.00100 0.00100 Offset = DAQ reading – Calibrator source voltage

0.001 BIP –0.2 0.2 Positive FS 0.19609 0.19509 0.19709 DAQ reading – Offset

0.001 BIP –0.2 0.2 Negative FS –0.19609 –0.19709 –0.19509 DAQ reading – Offset

0.001 BIP –0.05 0.05 Center FS 0.00000 –0.00100 0.00100 Offset = DAQ reading – Calibrator source voltage

0.001 BIP –0.05 0.05 Positive FS 0.04902 0.04802 0.05002 DAQ reading – Offset

0.0015 BIP –1.25 1.25 Positive FS 1.22559 1.22409 1.22709 DAQ reading – Offset

0.0015 BIP –1.25 1.25 Negative FS –1.22559 –1.22709 –1.22409 DAQ reading – Offset

0.001 BIP –0.05 0.05 Negative FS –0.04902 –0.05002 –0.04802 DAQ reading – Offset

60 U2300A Series DAQ Service Guide

Page 69

Test Limits B

Setting Range (V) Test Point (V) Tes t Li m it ( V) Test Result

Polarity Min Max Location Val ue Lower Upper Reading

0.004 UNIP 0 10 Positive FS 9.90234 9.89834 9.90634 DAQ reading – Offset

0.004 UNIP 0 10 Negative FS 0.09766 0.09366 0.10166 DAQ reading – Offset

0.002 UNIP 0 5 Positive FS 4.95117 4.94917 4.95317 DAQ reading – Offset

0.002 UNIP 0 5 Negative FS 0.04883 0.04683 0.05083 DAQ reading – Offset

Analog Input

U2331A:

0.0015 UNIP 0 10 Center FS 5.00000 4.99850 5.00150 Offset = DAQ reading – Calibrator source voltage

Offset/

Gain Error (V)

0.0015 UNIP 0 5 Center FS 2.50000 2.49850 2.50150 Offset = DAQ reading – Calibrator source voltage

0.001 UNIP 0 4 Center FS 2.00000 1.99850 2.00150 Offset = DAQ reading – Calibrator source voltage

0.001 UNIP 0 2.5 Center FS 1.25000 1.24900 1.25100 Offset = DAQ reading – Calibrator source voltage

0.001 UNIP 0 2.5 Positive FS 2.47559 2.47409 2.47709 DAQ reading – Offset

0.001 UNIP 0 2.5 Negative FS 0.02441 0.02291 0.02591 DAQ reading – Offset

0.001 UNIP 0 2 Center FS 1.0000 0.99900 1.00100 Offset = DAQ reading – Calibrator source voltage

0.001 UNIP 0 2 Positive FS 1.98047 1.97947 1.98147 DAQ reading – Offset

0.001 UNIP 0 2 Negative FS 0.01953 0.01853 0.02053 DAQ reading – Offset

0.001 UNIP 0 1 Center FS 0.50000 0.49900 0.50100 Offset = DAQ reading – Calibrator source voltage

0.001 UNIP 0 1 Positive FS 0.99023 0.98923 0.99123 DAQ reading – Offset

0.001 UNIP 0 1 Negative FS 0.00977 0.00877 0.01077 DAQ reading – Offset

0.001 UNIP 0 0.5 Center FS 0.25000 0.24900 0.25100 Offset = DAQ reading – Calibrator source voltage

0.001 UNIP 0 0.5 Positive FS 0.49512 0.49412 0.49612 DAQ reading – Offset

0.001 UNIP 0 0.5 Negative FS 0.00488 0.00388 0.00588 DAQ reading – Offset

0.001 UNIP 0 0.4 Center FS 0.20000 0.19900 0.20100 Offset = DAQ reading – Calibrator source voltage

0.001 UNIP 0 0.4 Positive FS 0.39609 0.39509 0.39709 DAQ reading – Offset

0.001 UNIP 0 0.4 Negative FS 0.00391 0.00291 0.00491 DAQ reading – Offset

0.001 UNIP 0 0.1 Center FS 0.05000 0.04900 0.05100 Offset = DAQ reading – Calibrator source voltage

0.001 UNIP 0 0.1 Positive FS 0.09902 0.09802 0.10002 DAQ reading – Offset

0.0015 UNIP 0 4 Positive FS 3.96094 3.95894 3.96294 DAQ reading – Offset

0.0015 UNIP 0 4 Negative FS 0.03906 0.03706 0.04106 DAQ reading – Offset

0.001 UNIP 0 0.1 Negative FS 0.00098 –0.00002 0.00198 DAQ reading – Offset

U2300A Series DAQ Service Guide 61

Page 70

BTest Limits

Setting Range (V) Test Point (V) Tes t L im i t ( V ) Tes t R esu l t

Polarity Min Max Location Val ue Lower Upper Reading

0.001 BIP –10 10 0 0.0000 –0.0010 0.0010 Offset = DMM reading – DAQ source voltage

Offset/

Analog Output

Analog Output

Gain Error (V)

U2351A, U2353A:

0.004 BIP –10 10 Positive FS 9.9997 9.9957 10.0037 DMM reading – Offset

0.004 BIP –10 10 Negative FS –10.0000 –10.0040 –9.9960 DMM reading – Offset

0.001 UNIP 0 10 0 0.0000 –0.0010 0.0010 Offset = DMM reading – DAQ source voltage

0.002 UNIP 0 10 Positive FS 9.9998 9.9978 10.0018 DMM reading – Offset

Setting Range (V) Test Point (V) Tes t L im i t ( V ) Tes t R esu l t

Polarity Min Max Location Val ue Lower Upper Reading

Offset/

Analog Output

Gain Error (V)

U2355A, U2356A:

0.001 BIP –10 10 0 0.0000 –0.0010 0.0010 Offset = DMM reading – DAQ source voltage

0.004 BIP –10 10 Positive FS 9.9951 9.9911 9.9991 DMM reading – Offset

0.004 BIP –10 10 Negative FS –10.0000 –10.0040 –9.9960 DMM reading – Offset

0.001 UNIP 0 10 0 0.0000 –0.0010 0.0010 Offset = DMM reading – DAQ source voltage

0.002 UNIP 0 10 Positive FS 9.9976 9.9956 9.9996 DMM – Offset

Setting Range (V) Test Point (V) Tes t L im i t ( V ) Tes t R esu l t

Polarity Min Max Location Val ue Lower Upper Reading

Offset/

Analog Output

Gain Error (V)

U2331A:

0.004 BIP –10 10 Positive FS 9.9951 9.9911 9.9991 DMM reading – Offset

0.004 BIP –10 10 Negative FS –10.0000 –10.0040 –9.9960 DMM reading – Offset

0.0015 BIP –10 10 0 0.0000 –0.0015 0.0015 Offset = DMM reading – DAQ source voltage

62 U2300A Series DAQ Service Guide

0.004 UNIP 0 10 Positive FS 9.9976 9.9936 10.0016 DMM reading – Offset

0.0025 UNIP 0 10 0 0.0000 –0.0025 0.0025 Offset = DMM reading – DAQ source voltage

Page 71

www.agilent.com

Contact us

o obtain service, warranty or technical

T

support assistance, contact us at the following

phone numbers:

United States:

(tel) 800 829 4444 (fax) 800 829 4433

Canada:

(tel) 877 894 4414 (fax) 800 746 4866

China:

(tel) 800 810 0189 (fax) 800 820 2816

Europe:

(tel) 31 20 547 2111

Japan:

(tel) (81) 426 56 7832 (fax) (81) 426 56

7840

Korea:

(tel) (080) 769 0800 (fax) (080) 769 0900

Latin America:

(tel) (305) 269 7500

Ta i w a n :

(tel) 0800 047 866 (fax) 0800 286 331

Other Asia Pacific Countries:

(tel) (65) 6375 8100 (fax) (65) 6755 0042

Or visit Agilent worlwide web at:

www.agilent.com/find/assist

Product specifications and descriptions in

this document subject to change without notice.

© Agilent Technologies, Inc. 2007 - 2010

Printed in Malaysia

Second Edition, August 23, 2010

U2351-90203

Agilent Technologies

Loading...

Loading...