Page 1

Agilent U1583B Current Clamp

Operating Instructions

The U1583B current clamp is a dual range 40 A and 400 A clamp-on AC current clamp. This U1583B current

clamp is designed for Agilent handheld digital multimeter (DMM) and Agilent handheld oscilloscope. The

BNC-to-banana plug is required to connect the current clamp with DMM. While for handheld oscilloscope,

it needs to use with BNC connector.

Assistance

For technical assistance, contact your nearest Agilent Sales Offi ce or visit the Agilent website at

www.agilent.com/fi nd/assist for further information.

Regulatory Markings

The CE mark is a registered trademark of the European Community.This CE mark

shows that the product complies with all the relevant European Legal Directives. If

it was accompanied by a year, it indicates the year the design was approved. This

ISM device complies with Canadian ICES-001.

Product contains restricted substance(s) above the maximum value, with 40 yr

Environmental Protection Use Period.

The CSA mark is a registered trademark of the Canadian Standards Association.

The C-tick mark is a registered trademark of the Spectrum Management Agency of

Australia. This signifi es compliance with the Australia EMC Framework regulations

under the terms of the Radio Communication Act of 1992.

This instrument complies with the WEEE Directive (2002/96/EC) marking

requirement. This affi xed product label indicates that you must not discard this

electrical/electronic product in domestic household waste.

Safety Information

Please use the Agilent U1583A current clamp only as specifi ed in this manual. Otherwise, the protection

provided may be impaired. A WARNING identifi es conditions and actions that pose hazards to the user. A

CAUTION identifi es conditions and actions that may be damaging to the equipment under test. To avoid

possible electric shock, personal injury or damage to this instrument, ensure that you use the adapter

safely, and refer to the guidelines below.

400A MAX

CAT III 600V

AC - Alternating Current

Caution, risk of danger (Refer to the

user’s and service guide for details)

Maximum allowable current

measurement is 400 A

Category III 600V over-voltage protection Double Insulation

Range button in lock mode.

Range ~ 40 A, Output ~ 10 mV/A

To be applied around or removed from

un-insulated hazardous live conductors

- Do not use the adapter if it is damaged. Inspect the case before you use the adapter.

Look for cracks or missing plastic. Pay particular attention to the insulation

surrounding the connectors.

- Inspect the clamp jaw before each use. It shall not have cracks or missing parts,

loose or weakened components. Be sure there is insulation surrounding the jaw.

Range button in release mode.

Range ~ 400 A, Output ~ 1 mV/A

DC - Direct Current

Ground

Caution, risk of electric shock (Refer to

the user’s and service guide for detail)

Page 2

- Inspect output cable without exposing the metal to ensure insulation.

- Do not operate the adapter around explosive gas, vapor or dust.

- Do not exceed the rated voltage/current as marked on the adapter.

- Use with extreme caution when working around bare conductors or bus bars. It could

results in electric shock if have accidentally contact to the conductors.

- Always keep your hand behind the fi nger guard of clamp jaw.

- When servicing the adapter, use only specifi ed replacement parts.

- Use with caution when working above 30 V ac rms, 42 V peak or 60 V dc. Such

voltage poses a shock hazard.

- Avoid working alone.

- Do not operate the adapter if the cover is removed or loosened.

- Do not connect to BNC output or banana plug to any power sources.

- Use the proper terminals, function, and range for your measurements.

Standard Item Purchased Checklist

The following items are included when you make a purchase:

• U1583B current clamp

• BNC-to-banana plug

• Operating Instructions sheet (this sheet)

General Specifi cations

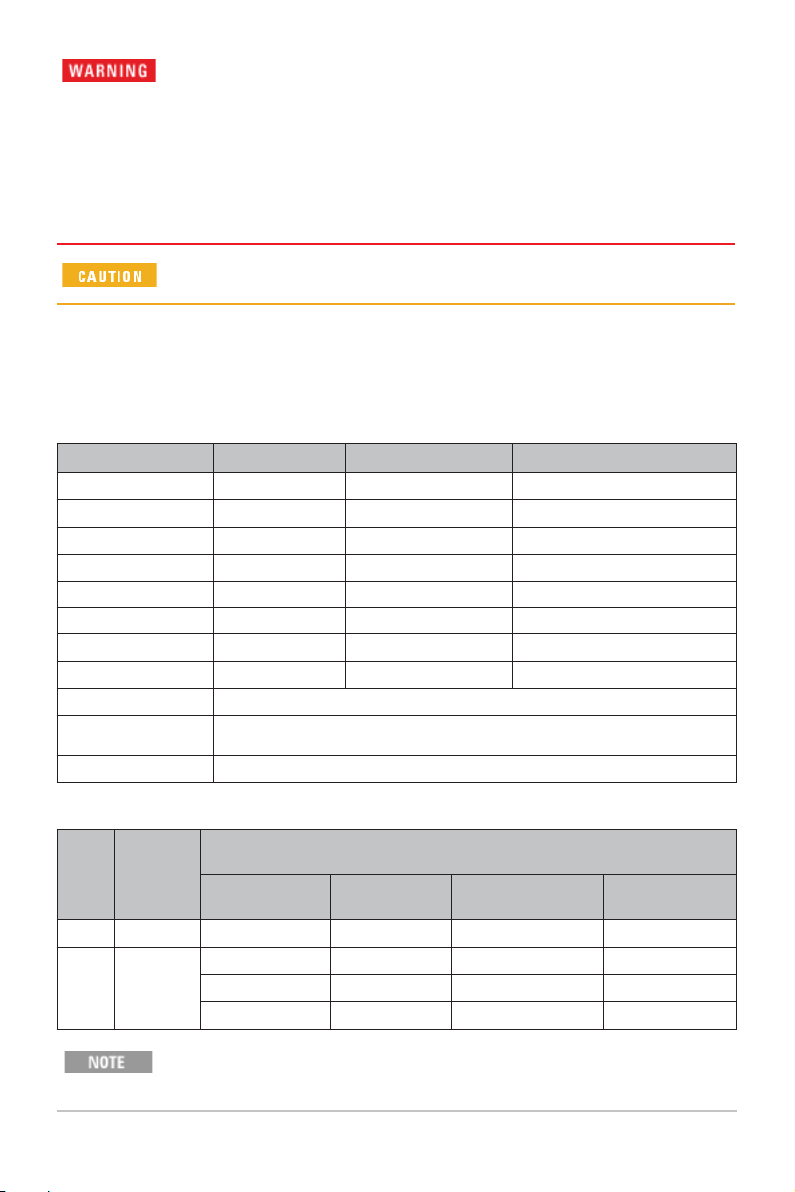

Specifi cations Current Clamp Specifi cations Current Clamp

Specifi ed Current Range 1 A to 400 A ac Load impedance > 1 M ohm, < 100 pF

Usable Current Range 0.5 A to 400 A Operating Temperature –10 °C to 55 °C (14 °F to 131 °F)

AC crest factor < 3 Storage Temperature –20 °C to 70 °C (–4 °F to 158 °F)

Bandwidth 10 kHz Measurement Category CAT III 600 V; Pollution degree II

Weight 294 grams Dimensions (HxWxD) 44 mm (H) x 92 mm (W) x 188 mm (L)

Cable length 1500 +/– 20 mm Maximum conductor size 30 mm or 16 mm x 2

Maximum Jaw Opening 32 mm Warm-up time Immediately upon power on

Altitude Up to 2000 meters Warranty One year

Relative Humidity Max 80% RH for temperature up to 35 °C decreasing linearly to 50% RH at 55 °C

Safety Compliance Safety Compliance Certifi ed by CSA (Canada & USA) for IEC/EN/UL 61010-1 2nd Edition &

EMC Compliance Certifi ed to IEC/EN 61326:2002, CISPR 11, and equivalents for Group 1, Class A

EN/IEC 61010-2-032

Electrical Accuracy Specifi cations

Range

40 A 10 mV/A 0.5 A ~ 40 A 2 % + 0.5 A 5 % + 0.5 A 10 % + 0.5 A

400 A 1 mV/A 0.5 A ~ 40 A 2.5 % + 0.5 A 4.5 % + 0.5 A 12.5 % + 0.5 A

Output

Resolution

± (% of reading + digit) at 23 °C ±5 °C, with relative humidity less than 80% R.H.

Span 48 Hz ~ 65 Hz

40 A ~ 200 A 2 % + 0.5 A 4 % + 0.5 A 12 % + 0.5 A

200 A ~ 400 A 1.5 % + 0.5 A 3.5 % + 0.5 A 11.5 % + 0.5 A

• The current conductor must be centered within the jaw aperture and no infl uence from adjacent

currents.

• Connect to load impedance > 1 MW ||100 pF.

• Crest factor < 3.

Accuracy

40 ~ 48 Hz/

65 Hz ~ 1 kHz

1 kHz ~ 10 kHz

Page 3

Current Clamp with

BNC connector

BNC-to-banana

plug

Handheld Digital

Multimeter (DMM)

Current Clamp with

BNC connector

Handheld

Oscilloscope

Figure 1: Connection Diagram

Alignment Marks

Put one conductor only within the jaws on inside section of the

indicated marks as much as possible in order to meet the accuracy of

specifi cations. Make sure the clamp is vertical to the conductor.

Current Range Selection

To push and release the yellow button for 40 A range and lock the button for 400 A range.

Button Range Output

Release

Lock

~ 40 A ~ 10 mV/A

~ 400 A ~ 1 mV/A

Operation

AC current can be measured without removing the conductor out of the circuit by following the procedures

as shown below:

1. Plug the BNC of cable to the BNC with dual banana plugs, and then plug into the V/COM terminals on

multimeter. For oscilloscope, plug the BNC connector directly to oscilloscope.

2. Set the ACV measurement and range on multimeter you used.

3. Position the jaw to a single conductor and center it accordingly to alignment marks.

4. Ensure that the arrow marked on the clamp jaw point towards the load of phase measurements or

away from the load (toward the source) for neutral measurements.

5. Observe the AC value on a multimeter or the waveform on an oscilloscope which is proportional to the

current.

6. Select a lower range on the Clamp-on adapter and set the corresponding sensitivity (mV/ A setting)

on the oscilloscope if required.

Calibration Equipment

The pre-calibration guidelines are shown as follows:

• Be sure you are a qualifi ed person to perform the calibration

• The environment should be 23 °C ±2 °C and the relative humidity (RH) shall be < 80%.

The test equipment requirements listed in table below or equivalents are required to perform the calibration

and performance verifi cation test procedures. Alternative equipment may be used as long as the accuracy is

as good as or better than the specifi cations listed.

Standard Source Operating Range

AC Current Calibrator 33 mA – 329.99 mA at 10 Hz to 3 kHz

Multimeter AC 500.0 mV or 1000.0 mV

50 Turns Current Coil 0.2 A – 20.5 A

0.33 A – 2.99999 A at 10 Hz to 3 kHz

3 A – 20.5 A at 10 Hz to 3 kHz

Accuracy

Required

≤ ± 0.2 %

≤ ± 0.6 %

≤ ± 3.0 %

≤ ± 1.5 %

≤ ± 1.0 %

Wavetek 9100 or Fluke 5520A or 5101B

or equivalent

Agilent U1251A or U1252A or

Agilent-34405A or equivalent

Fluke 5500A Coil or Wavetek 9100

Option 200 or equivalent

Recommended

Equipment

Page 4

Adjustment Procedures

AC 40 A range

1. Lock RANGE button of U1583B current clamp to 40 A mode.

2. Connect the output BNC of U1583B to a BNC-to-dual banana converter plug and proceed to

connect it to the output of the V (HI) and COM (LO) terminals of the multi-meter.

3. Set multi-meter to AC 500.0 mV or 1000.0 mV.

4. Open the jaws of the current clamp and centrally place it around the 50 turns coil.

5. Set the calibrator output to 50 turns coil. Confi gure the calibrator to generate a current 20 A with

60 Hz frequency for adjustment of the current clamp.

6. Remove two Phillips screws on the back of the current clamp and proceed to adjust the VR1

until the display on multimeter indicates AC 200 mV ± 0.2 mV. Please refer to below fi gure for

the position of VR1.

VR1 for AC 40 A

adjustment

VR2 for AC 400 A

adjustment

Figure 2: U1583B Current Clamp Circuit Board Diagram

AC 400 A range

1. Release the Range button of U1583B current clamp to 400 A mode.

2. Connect the output BNC of U1583B to a BNC-to-dual banana converter plug and proceed to

connect it to the output of the V (HI) and COM (LO) terminals of the multi-meter.

3. Set Multi-meter to AC 500.0 mV or 1000.0 mV.

4. Open the jaws of the current clamp and centrally place it around the 50 turns coil.

5. Set the calibrator output to 50 turns coil. Confi gure the calibrator to generate a current 20 A with

60 Hz frequency for adjustment of the current clamp.

6. Remove two Phillips screws on the back of the current clamp and proceed to adjust the VR2

until the display on multimeter indicates AC 200 mV ± 0.2 mV. Please refer to Figure 2 for the

position of VR2.

Remember to replace the screws to its original position after performing the calibration

adjustments.

Maintenance

Repair or service not cover in this sheet should be performed only by qualifi ed personnel.

To avoid electrical shock or damage to the Clamp-on adapter, do not get water inside

the case .

Cleaning

• Periodically wipe the case with a damp cloth and mild detergent. Do not use abrasive or solvents.

• Open the jaws and wipe the metal of jaw with a lightly oiled cloth, and then wipe the oil with dry

cloth. Do not allow rust or corrosion to form on the metal ends of jaw.

Troubleshooting

If the current clamp does not perform properly, follow the steps below to identify the problem:

1. Inspect the mating surface of jaw for cleanliness. If any external material is present, the jaws

may not close properly and affects the result.

2. Verify that the function selection and range on the multimeter or oscilloscope are correct and

the range is adjusted on current clamp.

©Agilent Technologies, Inc., 2009, 2010

Printed in Malaysia

March 29, 2010

U1583-90107

Loading...

Loading...